Sealed lubricator of enameling machine

A sealed and enamelled machine technology, applied to electrical components, circuits, conductor/cable insulation, etc., can solve the problems of uneven liquid level, small and large oil absorption of oiled felt 13, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

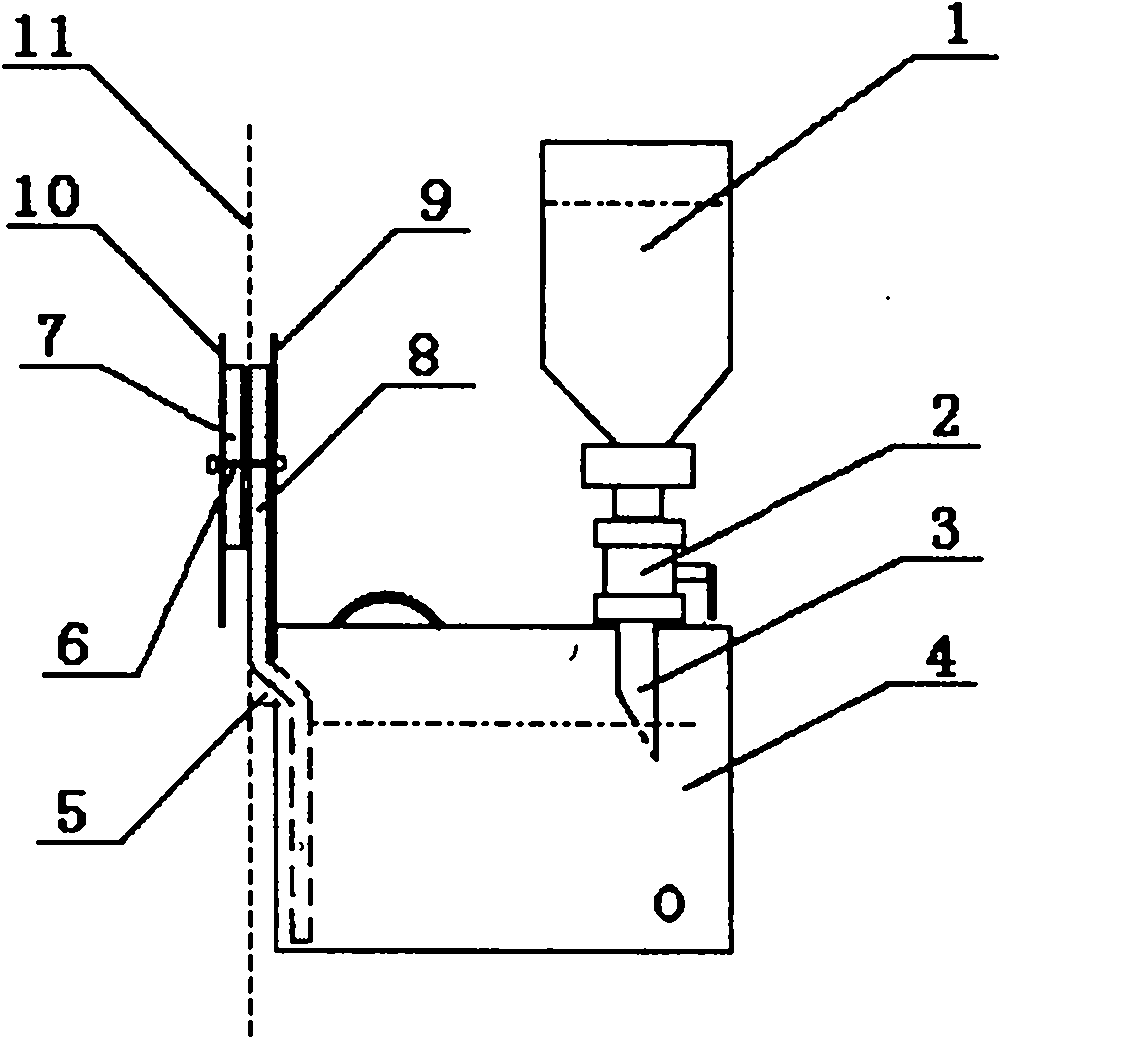

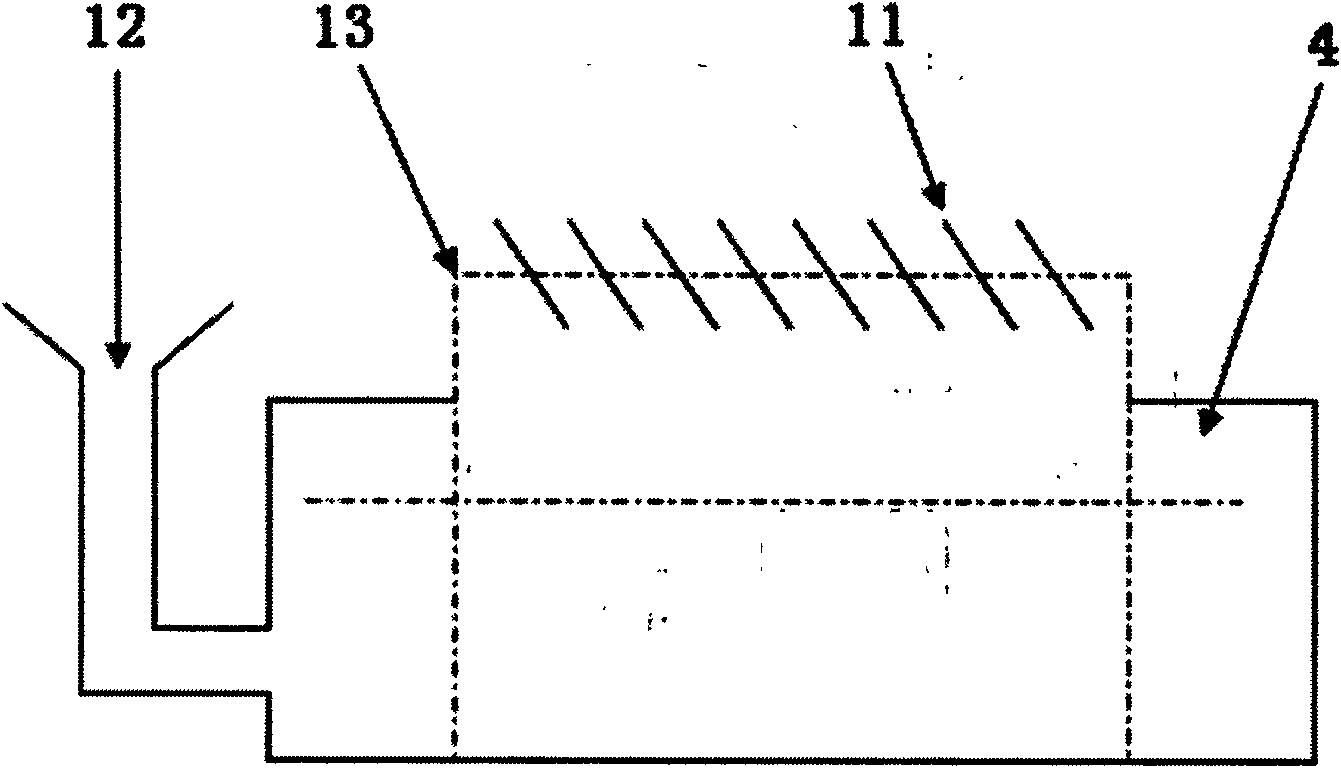

[0017] The sealed oiler of enamelling machine has a structural feature that a control valve 2 is installed on the mouth of the oil cup 1, and the other end of the control valve 2 is connected with an oil outlet pipe 3, and the oil outlet pipe 3 is inserted into the oil inlet opened on the oil box 4, Oil box 4 is refueled from oil cup 1 on the top, and the oil level of oil box 4 can automatically control the liquid level height due to the combined action of gravity and atmospheric pressure; one side of oil box 4 is equipped with a felt fixing splint 9, and the felt fixing splint 9 There is a felt hole 5 on the side of the oil box 4 at the lower end, the lower edge of the felt hole 5 is higher than the outlet of the oil outlet pipe 3, and a part of the first felt 7 and the second felt 8 are installed on the surface of the first felt 7 and a part of the second felt 8 and fixed on the felt fixing splint through the fixing column 6 Between 9 and the pressure plate 10, a felt groove ...

Embodiment 2

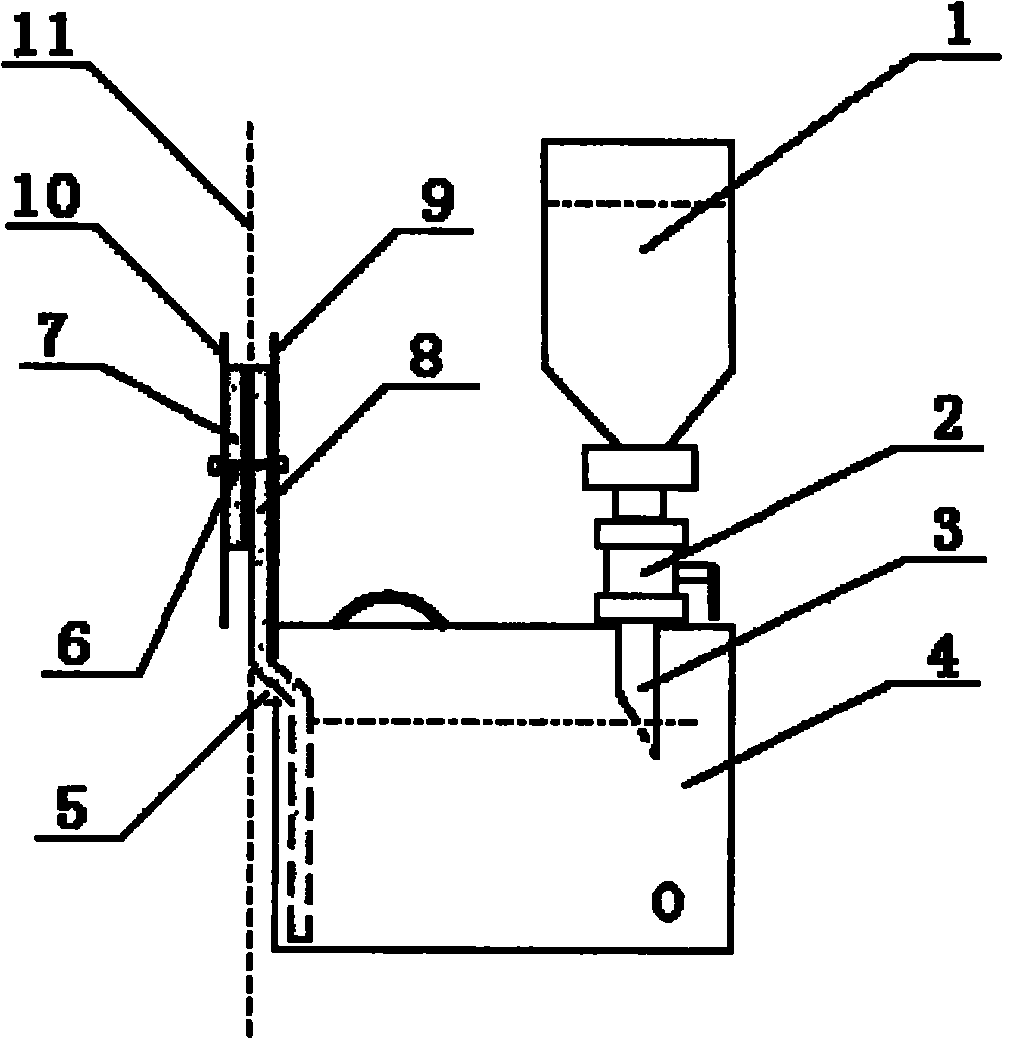

[0019] The difference between this embodiment and embodiment 1 is that

[0020] The outlet of the oil outlet pipe 3 is an oblique opening, and the lower edge of the felt hole 5 is higher than the upper edge of the oblique opening of the oil outlet pipe 3 .

[0021] The function of the control valve 2 installed on the mouth of the oil cup 1 is to close the control valve 2 to limit the flow of lubricating oil in the oil cup 1 when the oil cup 1 is refueled or inserted into the oil inlet of the oil box 4.

[0022] When adding lubricating oil to the sealed oiler of the enamelling machine, first close the control valve 2, take out the oil cup 1, control valve 2, and oil outlet pipe 3 from the oil box 4, separate the oil cup 1 from the control valve 2, and lubricate Put the oil into the oil cup 1, then connect the control valve 2 to the interface of the oil cup 1, then insert it into the oil inlet on the oil box 4, and open the control valve 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com