Patents

Literature

798 results about "Shot peening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites. It entails impacting a surface with shot (round metallic, glass, or ceramic particles) with force sufficient to create plastic deformation.

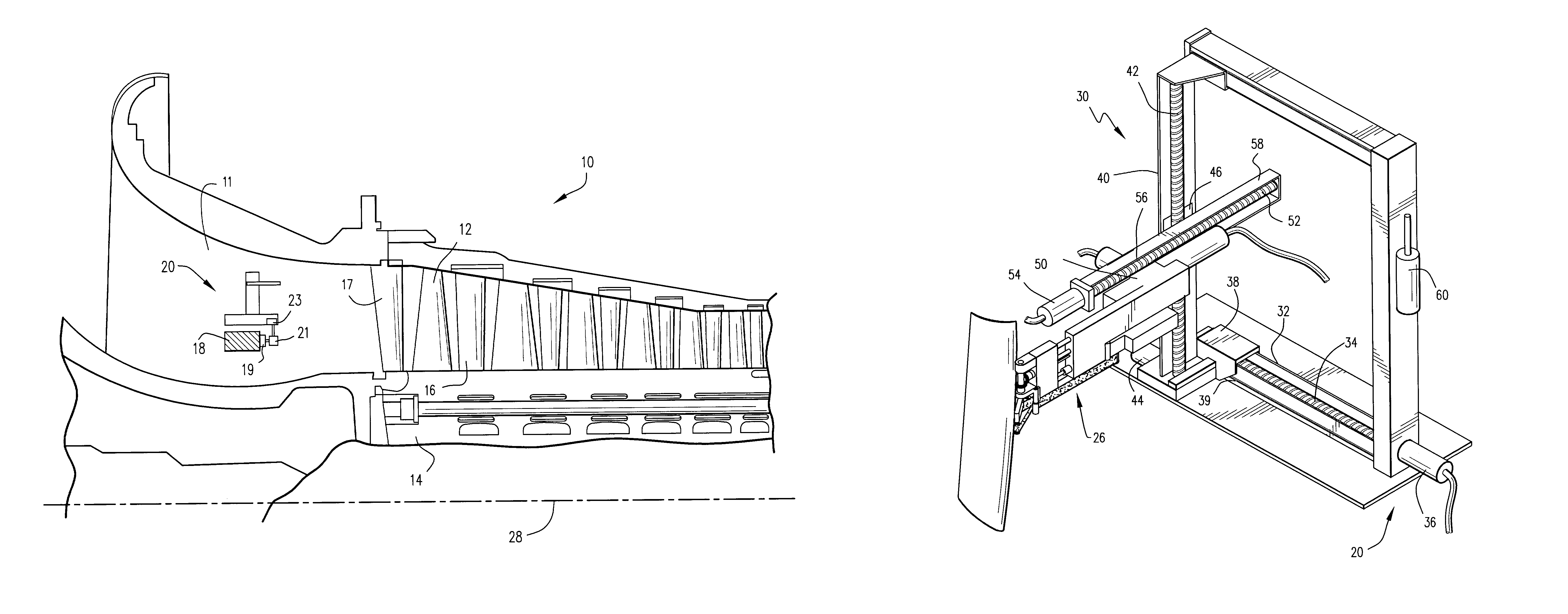

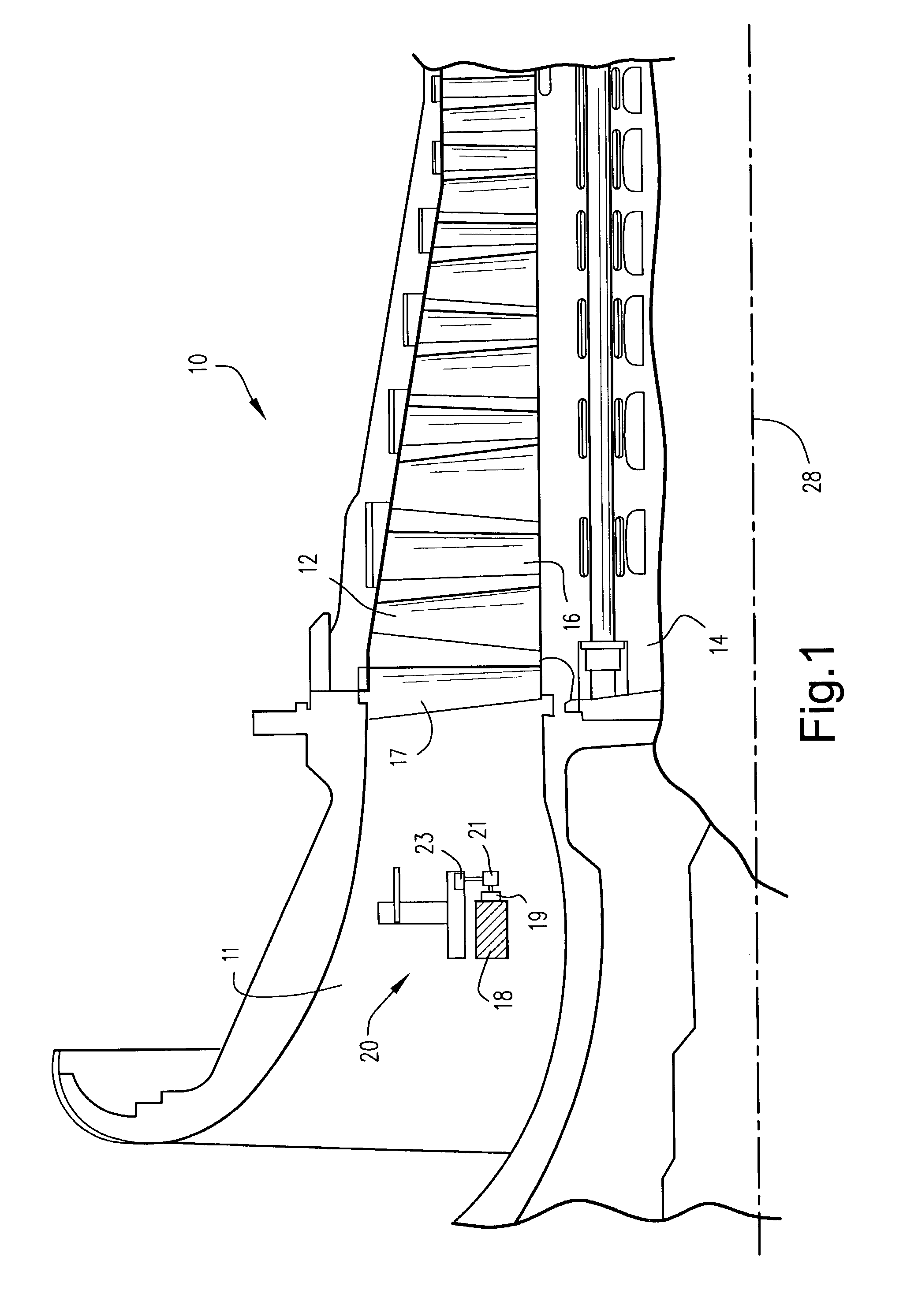

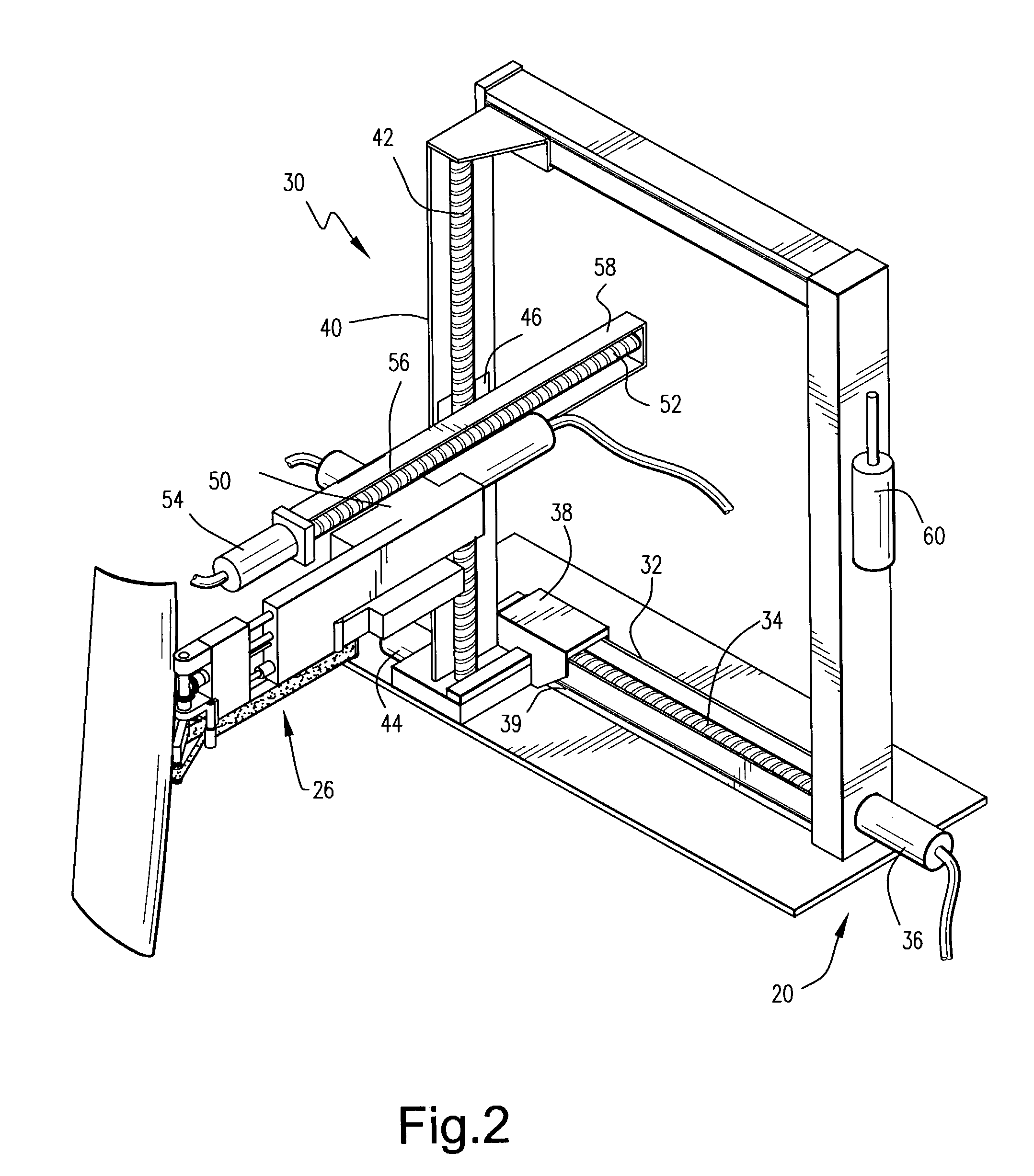

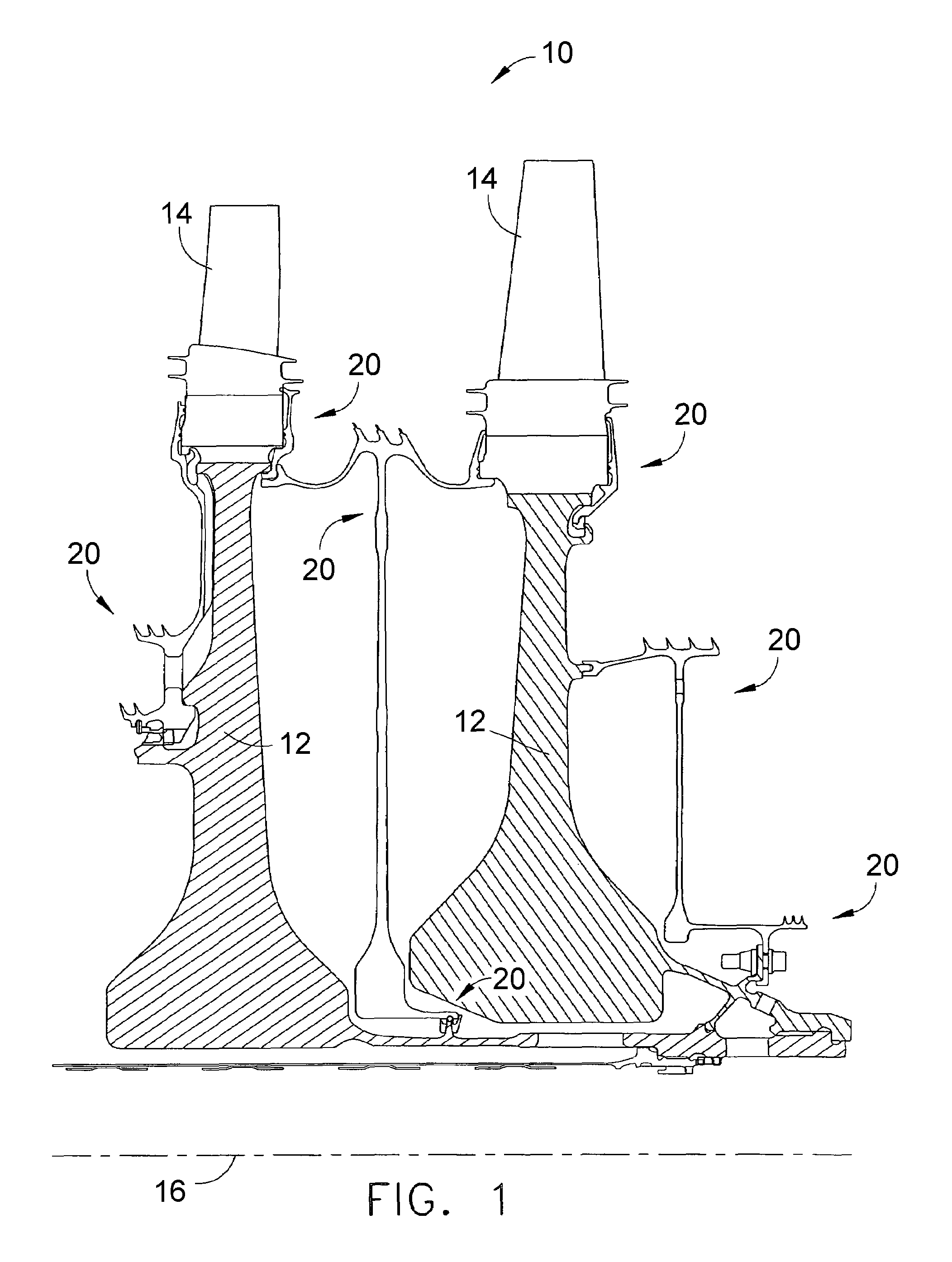

Apparatus and methods for repairing compressor airfoils in situ

InactiveUS7032279B2Maximize impactFine surfacePump componentsAssembly machinesEngineeringManipulator

The apparatus includes a track mounted in the inlet of a compressor. A manipulator is mounted for movement about the track and carries three modules, the last of which mounts a tool head for movement in a Cartesian coordinate system and about the track. A measuring head measures the location of the airfoil surface. An abrading tool mounted on the third module removes surface material from the airfoil. Subsequently, a shot-peening device, either a flapper with embedded shot or free shot is impacted against the abraded surface to strengthen the surface. Final inspection is performed by a light and camera head mounted on the third module.

Owner:GENERAL ELECTRIC CO

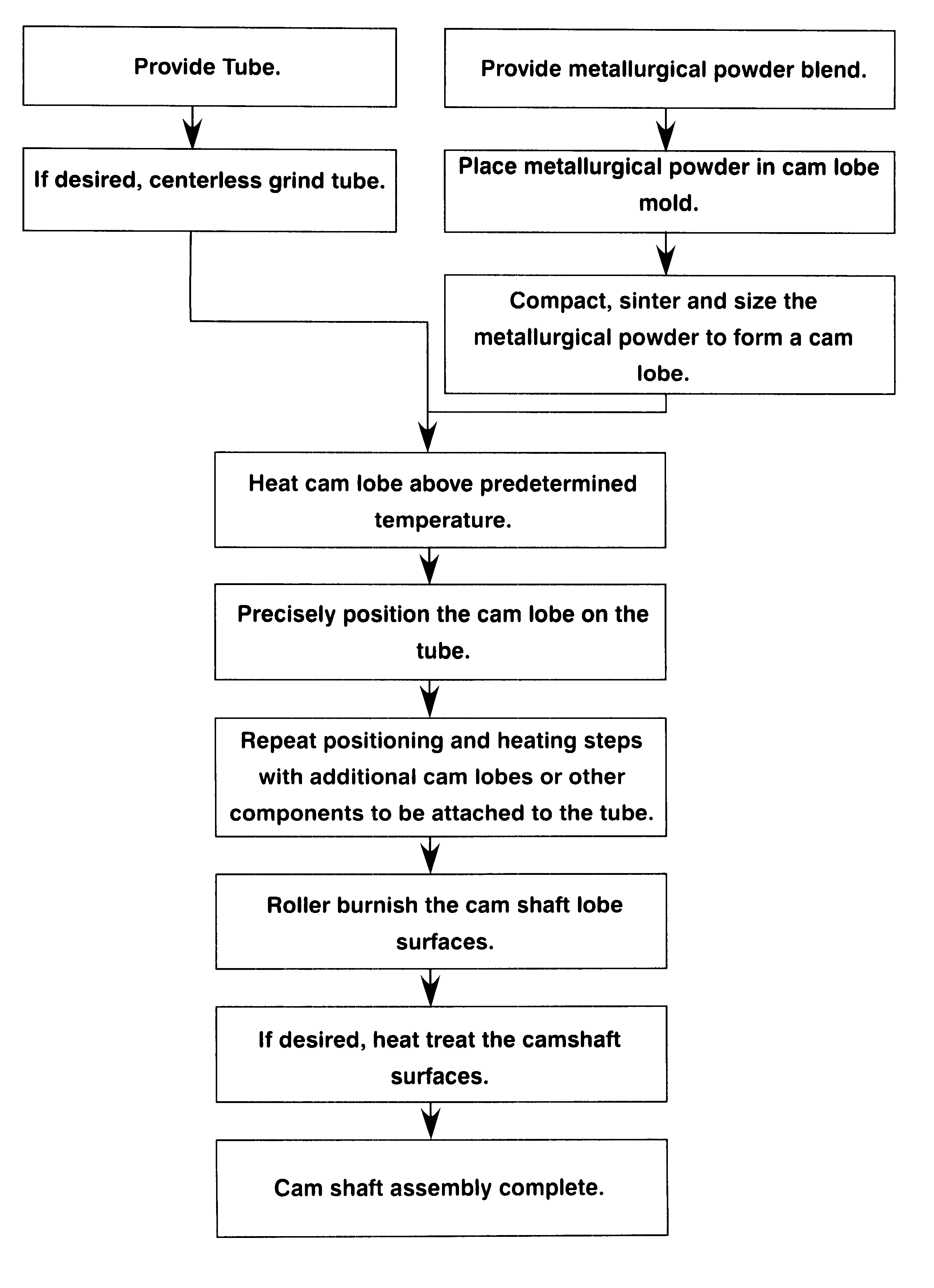

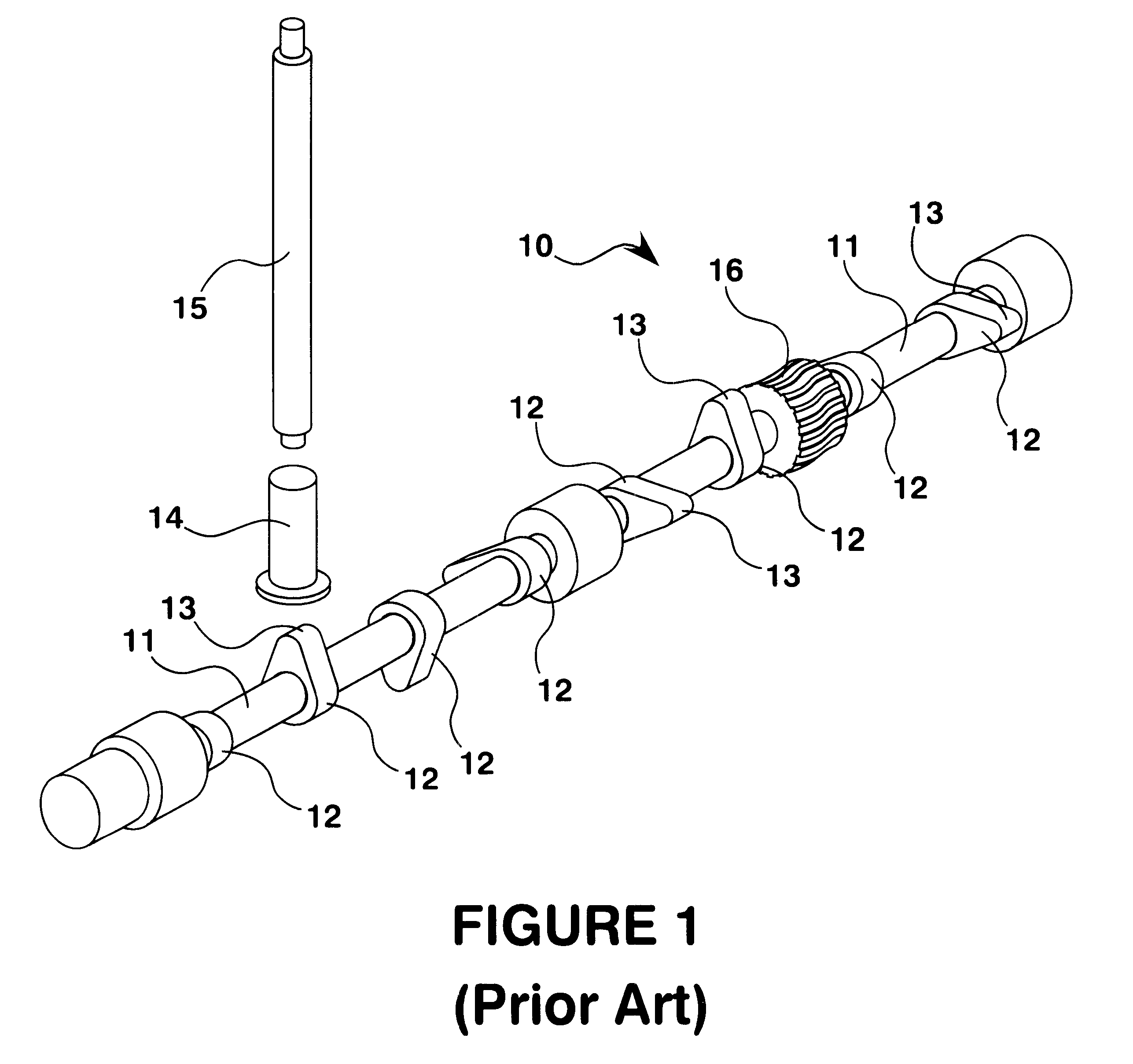

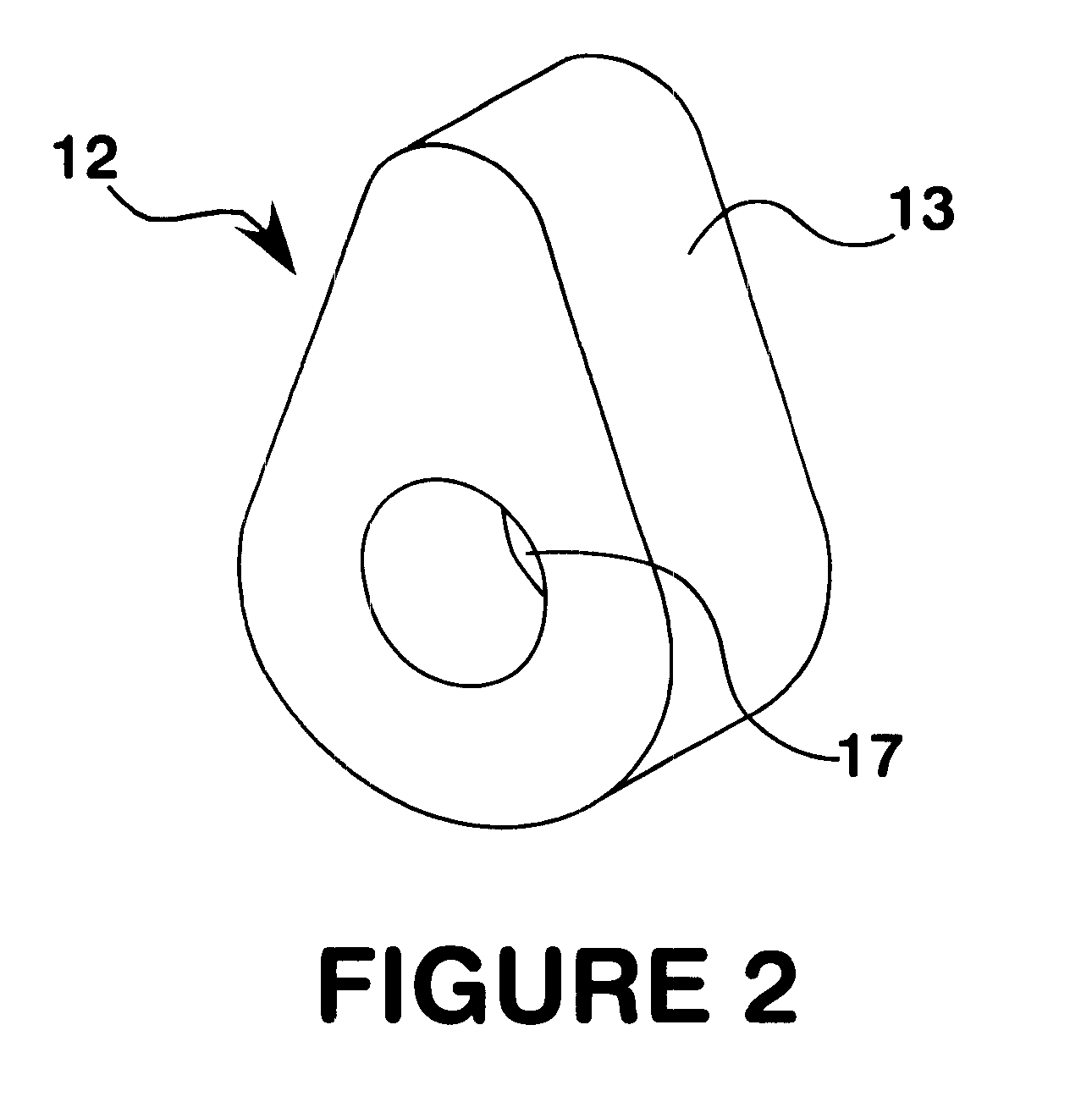

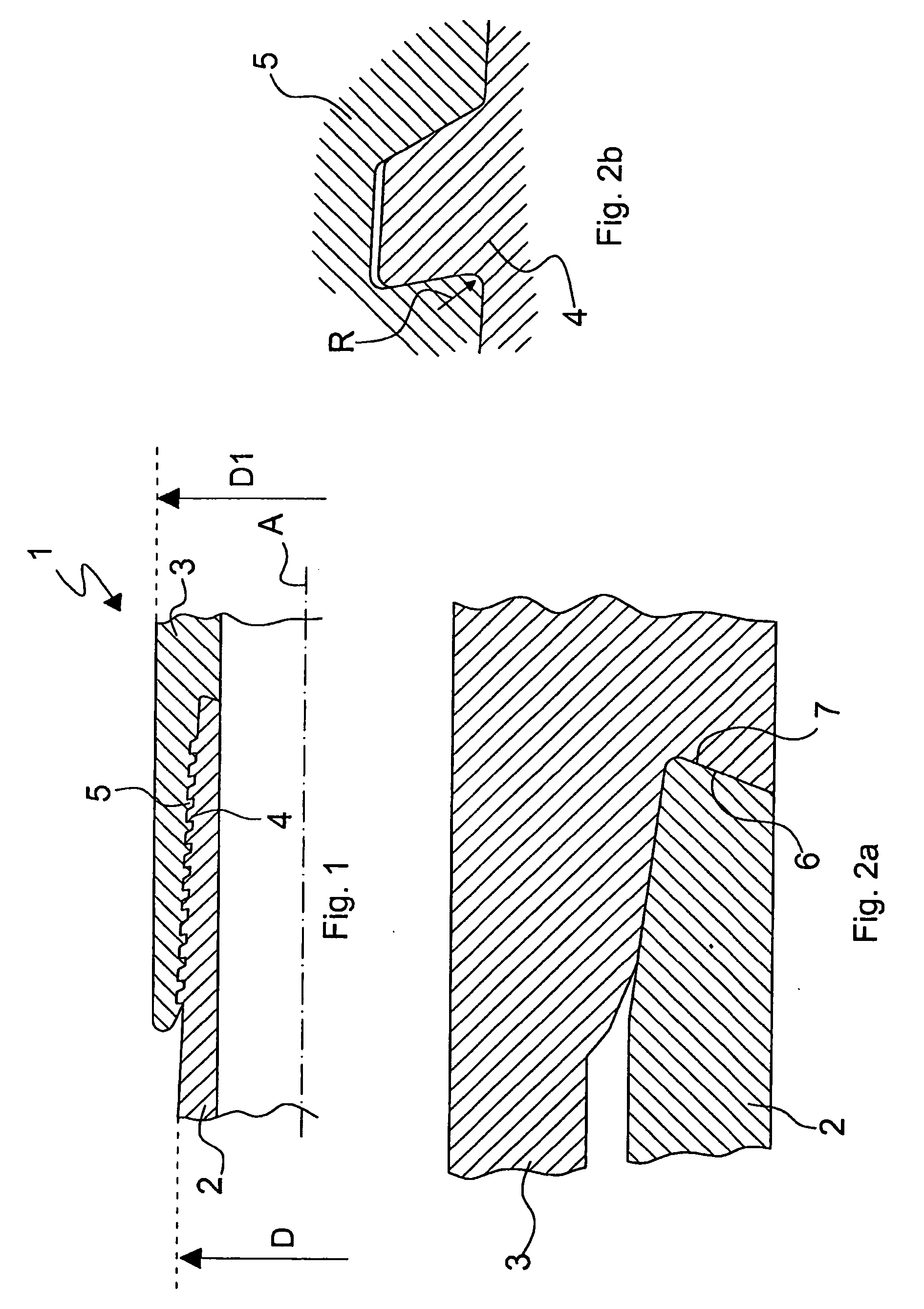

Method of fabricating camshafts

InactiveUS6473964B1Good flexibilitySmall sizeValve drivesMachines/enginesCombustionVolumetric Mass Density

A method of attaching and adjusting first and second members includes providing a first member having an outer surface and a second member. The second member is affixed to the outer surface of the first member at a desired axial position along the length of the first member and in a desired angular orientation. Subsequent to affixing the second member to the first member, the shape and / or dimensions of the second member is adjusted by increasing the density of at least a region of the second member. The densification may be accomplished by, for example, a mechanical working technique such roller burnishing, coining, sizing, shot peening, or laser impacting. In one embodiment of the invention, the method may is adapted to the production of combustion engine camshafts from separately provided camshaft tubes and cam lobes.

Owner:KEYSTONE INVESTMENT CORP

Turbine component protected with environmental coating

ActiveUS7364801B1Suitable for useReliable long-term protection from oxidation and hot corrosionMolten spray coatingPropellersSolid solutionCobalt

An environmental coating suitable for use on turbine components, such as turbine disks and turbine seal elements, formed of alloys susceptible to oxidation and hot corrosion. The environmental coating is predominantly a solid solution phase of nickel, iron, and / or cobalt. The coating contains about 18 weight percent to about 60 weight percent chromium, which ensures the formation of a protective chromia (Cr2O3) scale while also exhibiting high ductility. The coating may further contain up to about 8 weight percent aluminum, as well as other optional additives. The environmental coating is preferably sufficiently thin and ductile to enable compressive stresses to be induced in the underlying substrate through shot peening without cracking the coating.

Owner:GENERAL ELECTRIC CO

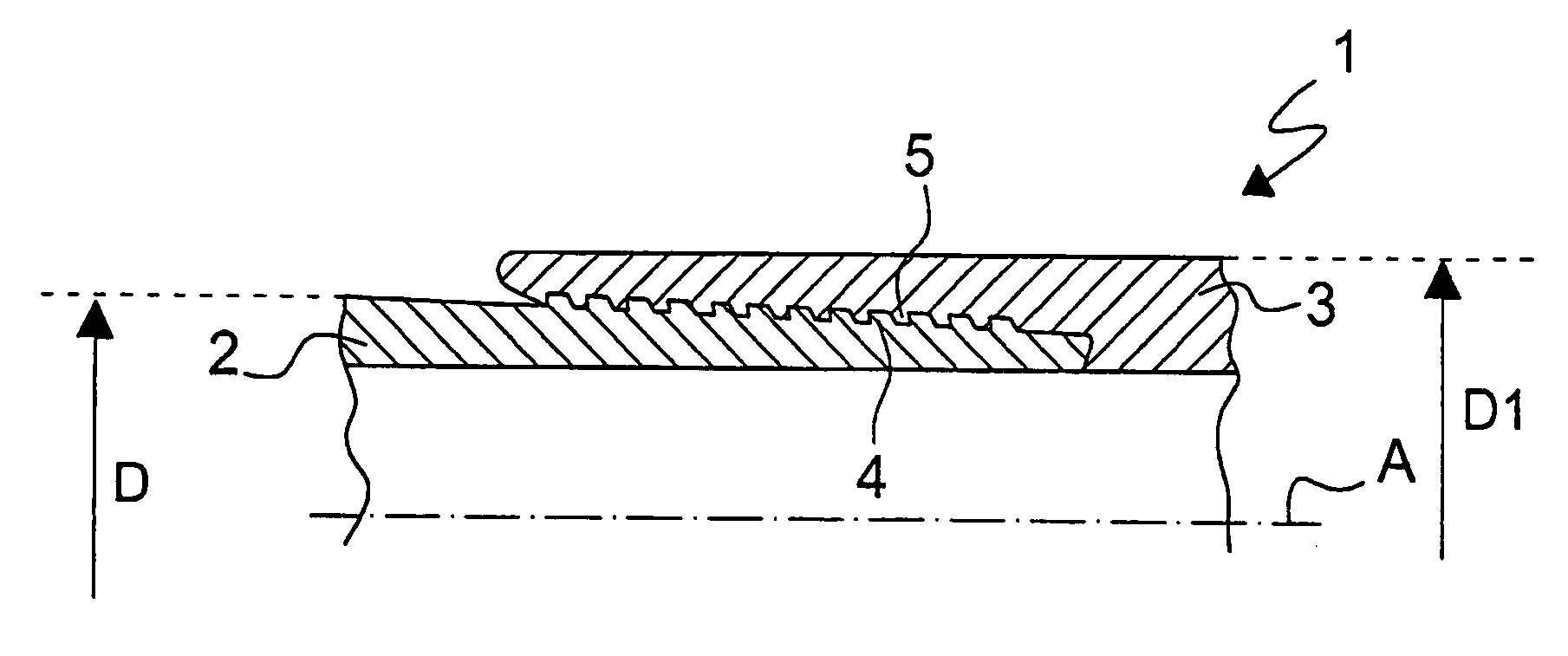

Threaded joint with high radial loads and differentially treated surfaces

ActiveUS20110042946A1Improve fatigue lifeImprove fatigue resistanceDrilling rodsPipe elementsEngineeringScrew thread

A threaded joint has an interference between thread roots of pin and thread crests of the box of value comprised between 1% and 5% of the average thickness of the connection, and a root to load flank radius R comprised in the range of 0.2 mm and 0.4 mm and a surface treatment comprising shot peening applied to the beginning and end of the threaded zone of the pin. In other embodiments the interference can be between thread roots of box and thread crests of the pin.

Owner:TENARIS CONNECTIONS

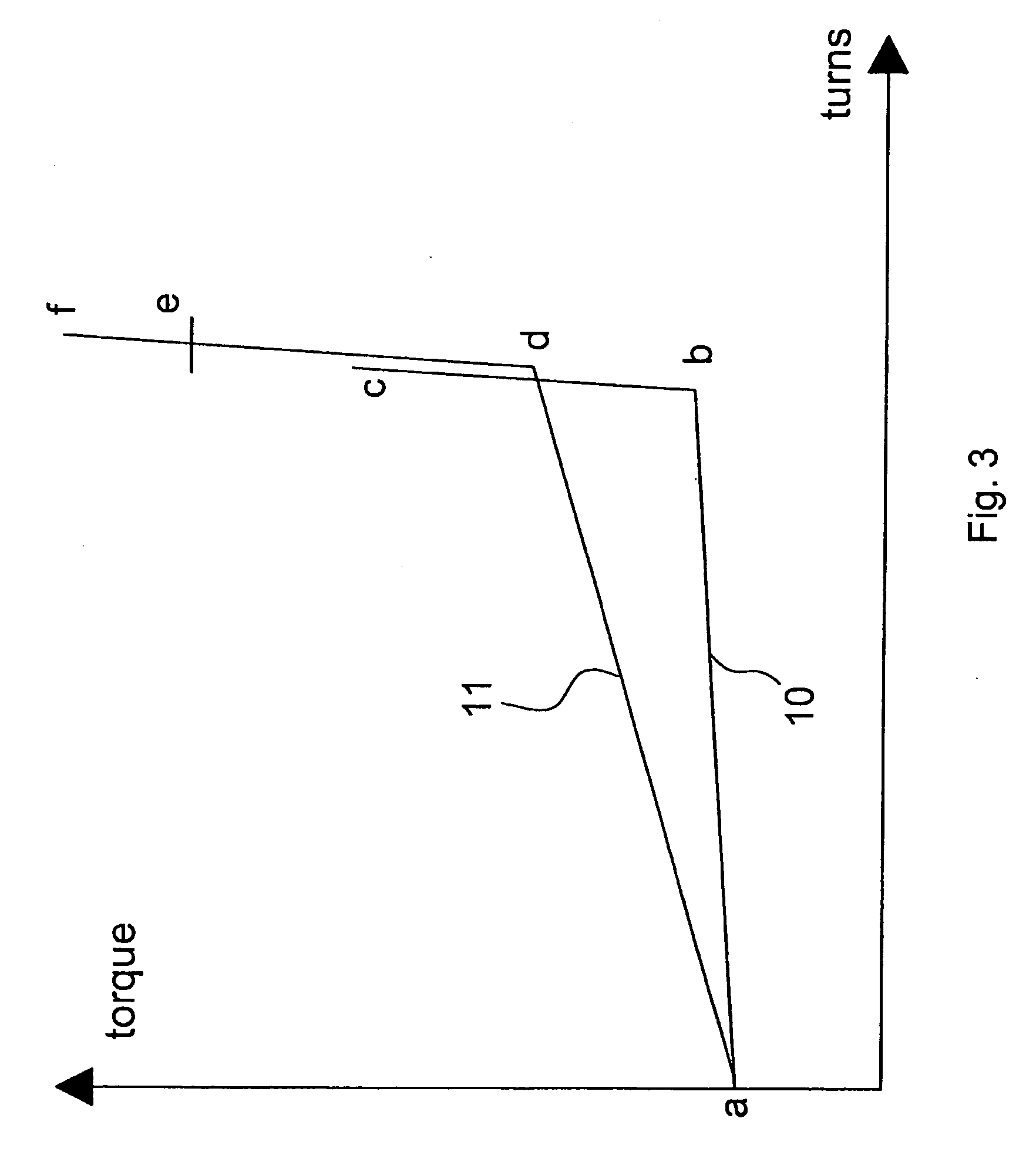

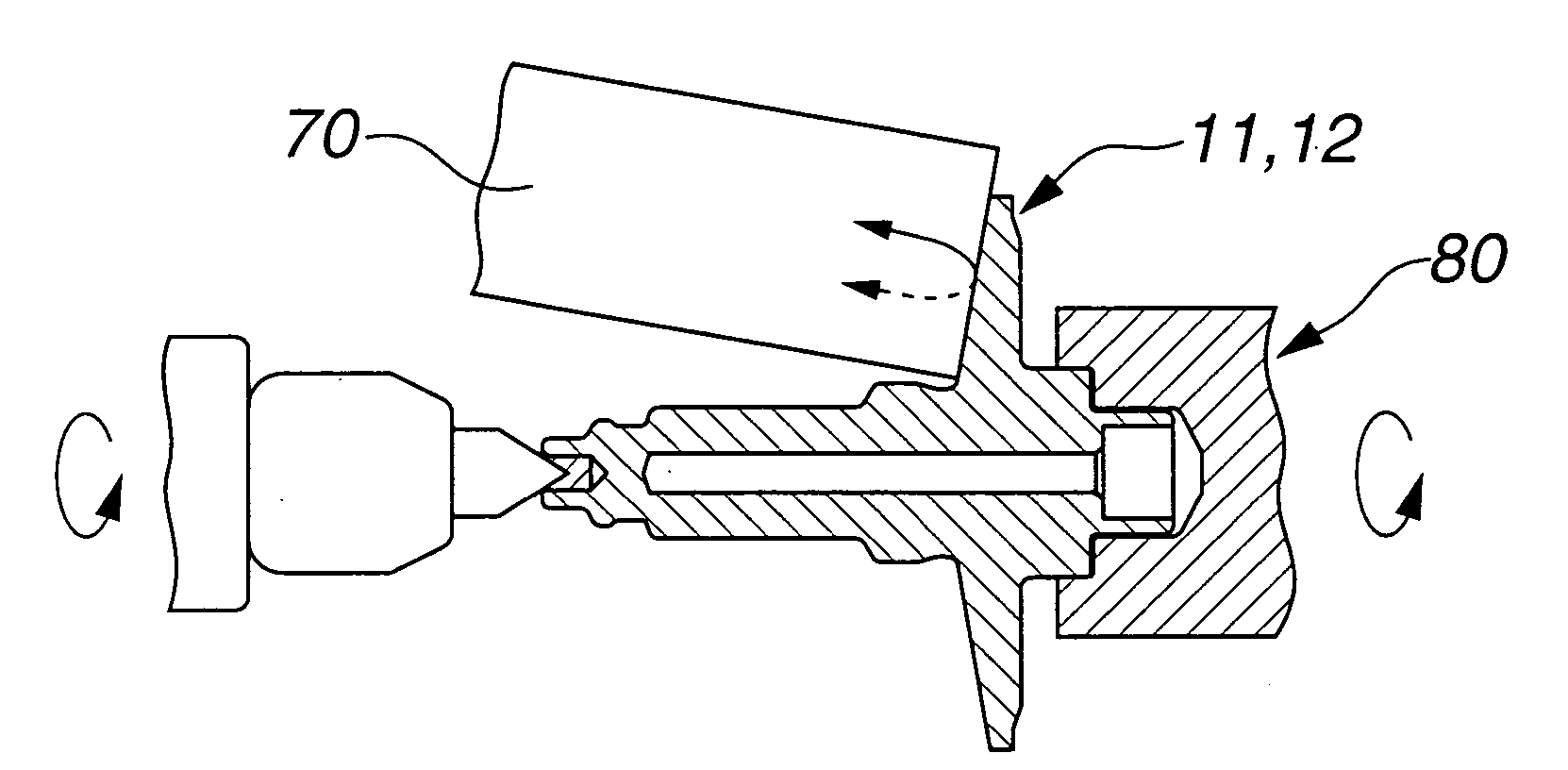

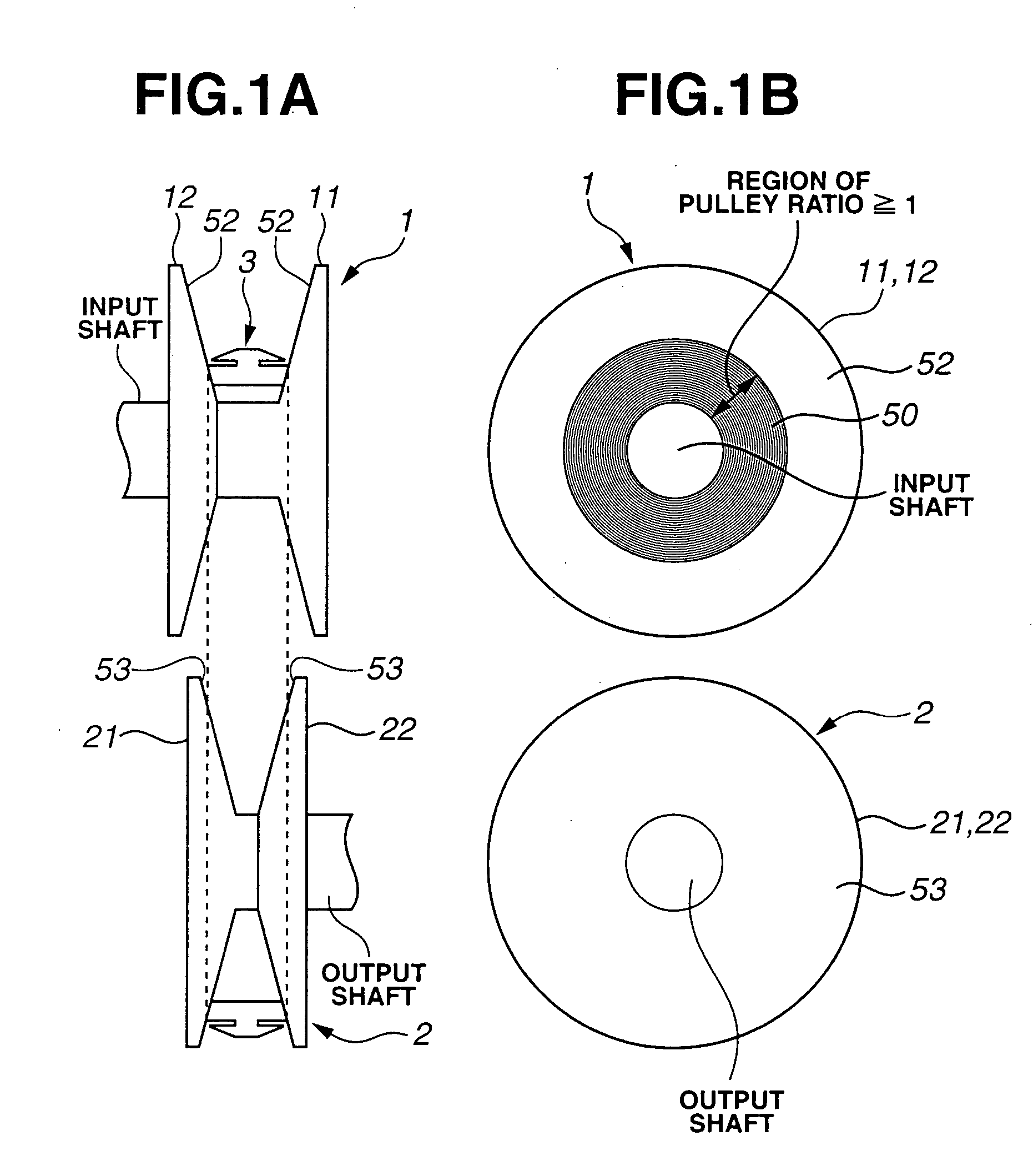

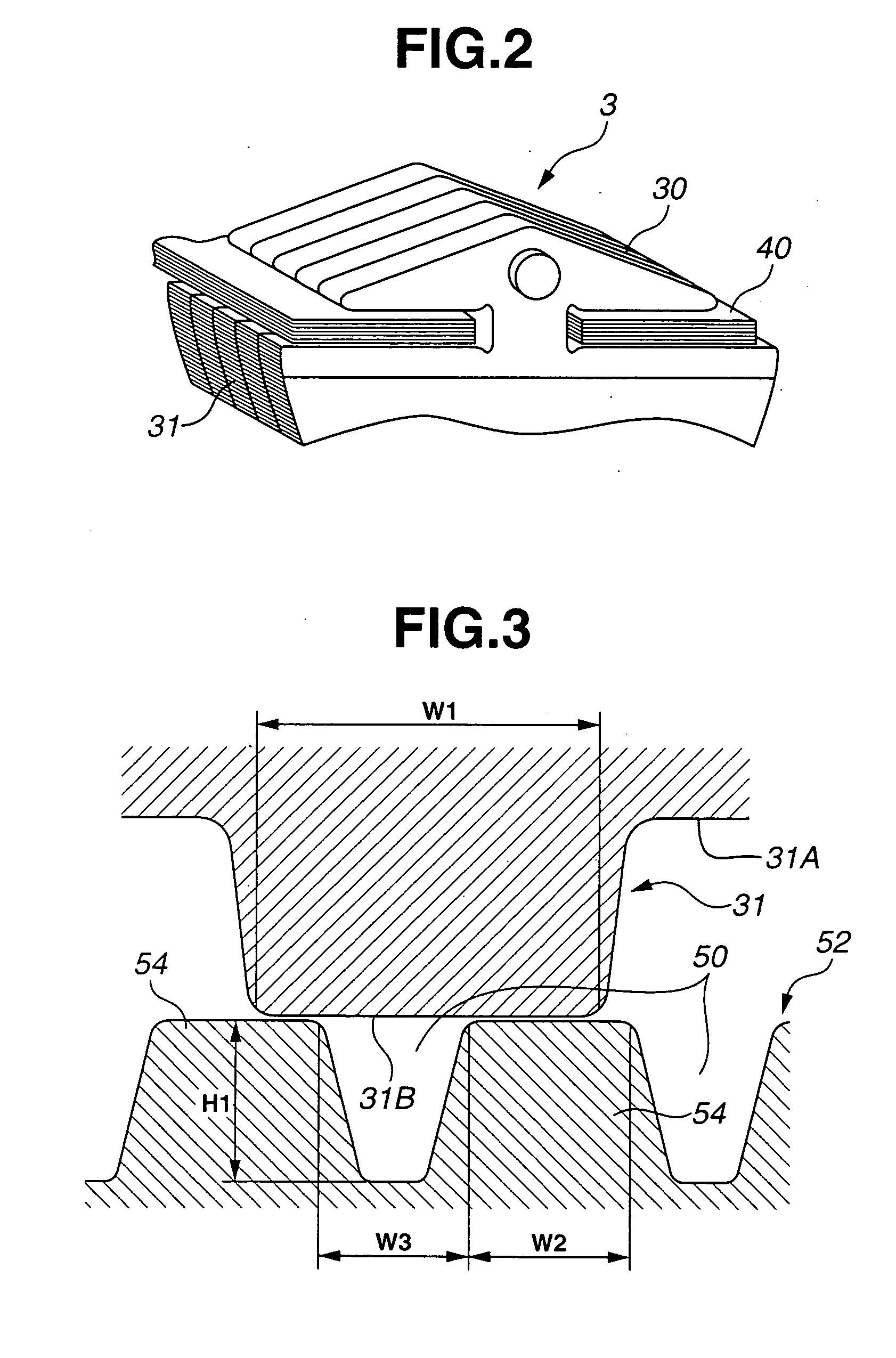

Process for producing a pulley for a continuously variable belt drive transmission

InactiveUS20050217111A1Increase frictionHigh dimensional accuracyGearingPortable liftingPeeningPulley

A process for producing a pulley for a belt drive CVT, including subjecting tapered surfaces of a preform of at least one of input and output pulleys to surface hardening, subjecting the surface-hardened tapered surfaces of the preform to hard turning to form microgrooves radially spaced from one another thereon, between which microprojections are formed, and reducing a height of the microprojections. Alternatively, a process for producing a pulley for a belt drive CVT, including subjecting tapered surfaces of a preform of at least one of input and output pulleys to surface hardening, subjecting the surface-hardened tapered surfaces of the preform to shot peening, and subjecting the shot-peened tapered surfaces of the preform to finishing to form microgrooves having a substantially equal pitch thereon.

Owner:JATCO LTD

High Durability Structures of Amorphous Alloy and a Method of Forming

Articles of bulk-solidifying amorphous alloys with improved durability and fatigue resistance, and more specifically articles of bulk-solidifying amorphous alloys subjected to a surface treatment, such as shot-peening, which creates deformations in the exterior surface, and methods of improving the durability and fatigue resistance of bulk-solidifying amorphous alloys using a surface treatment, such as shot-peening.

Owner:CRUCIBLE INTPROP LLC

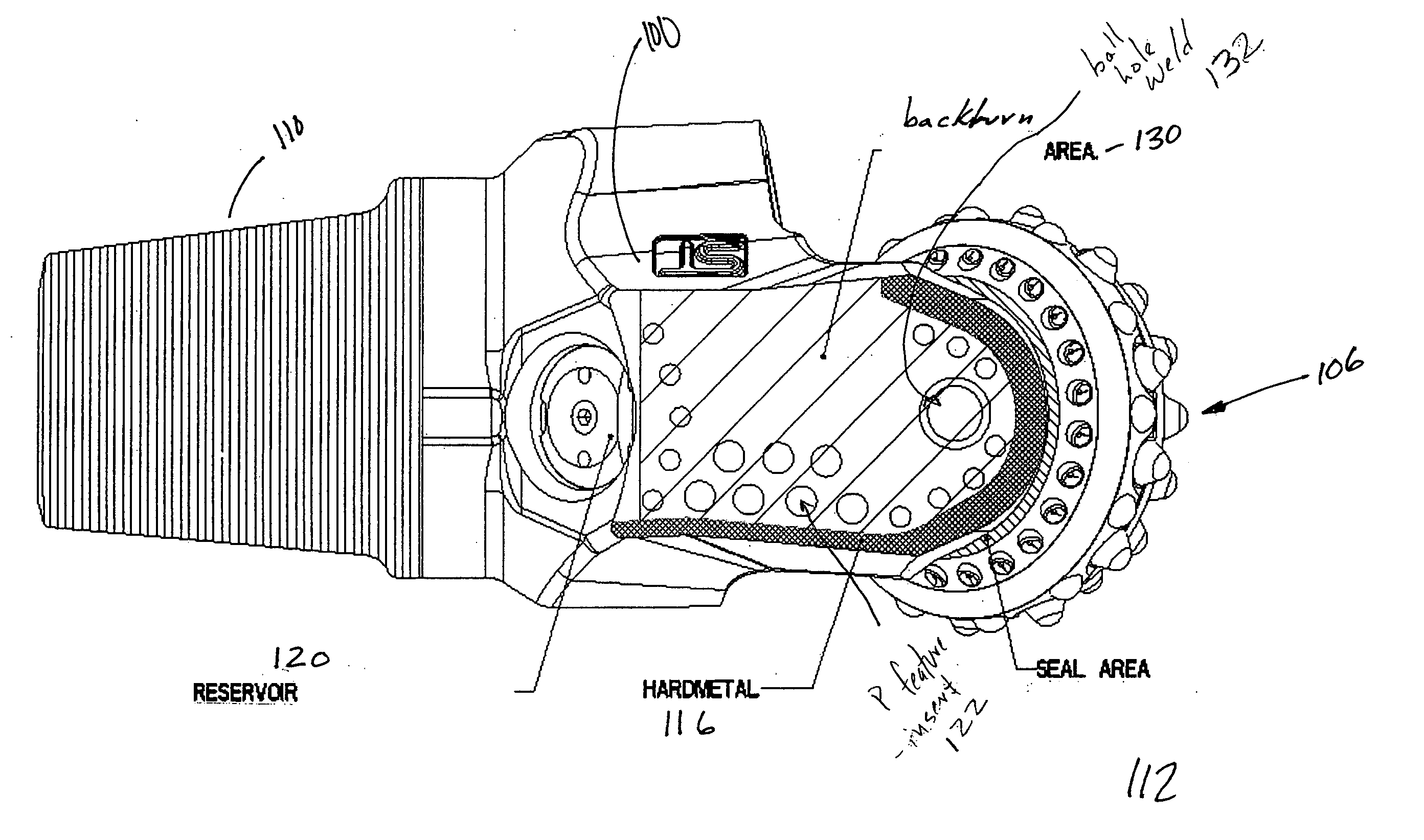

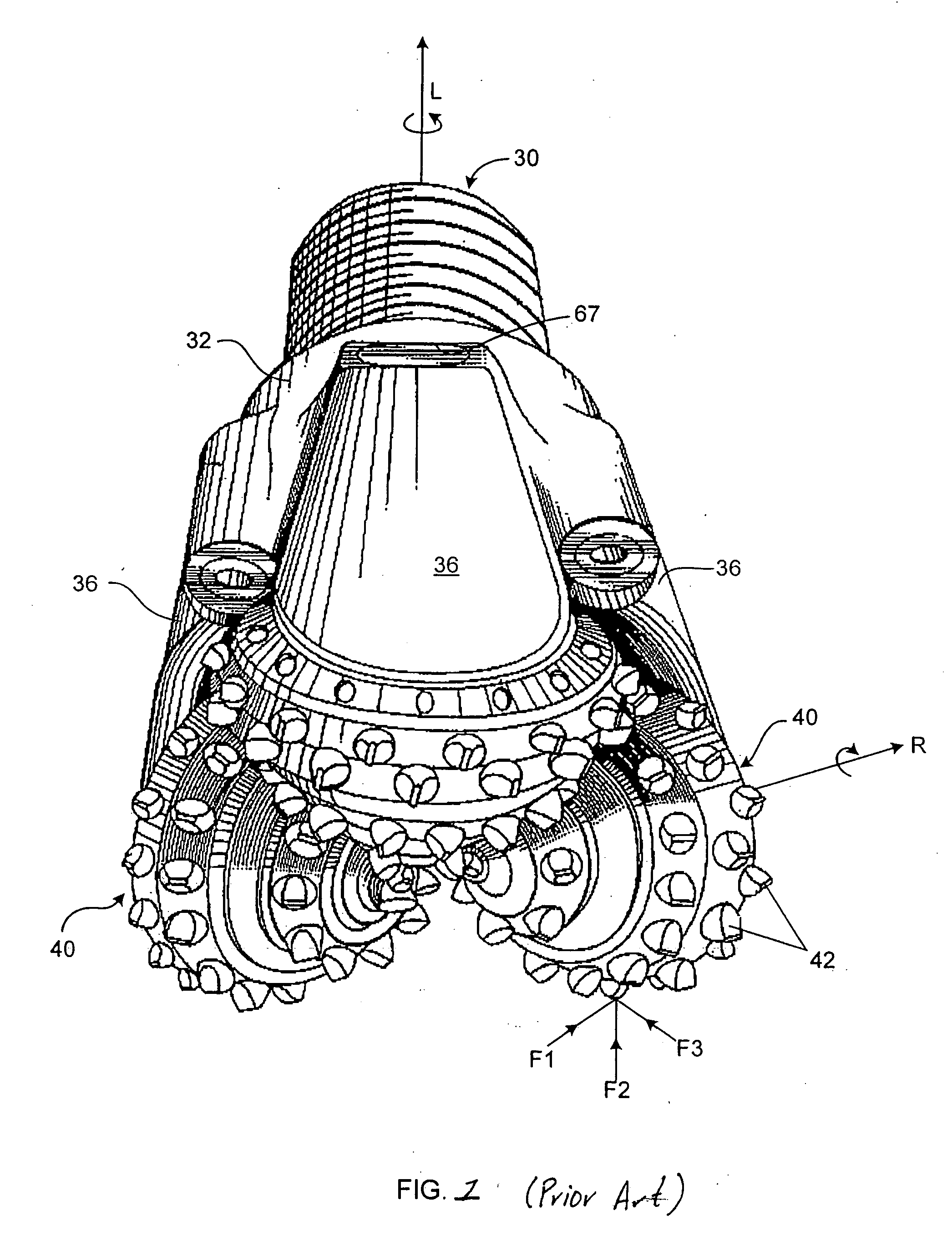

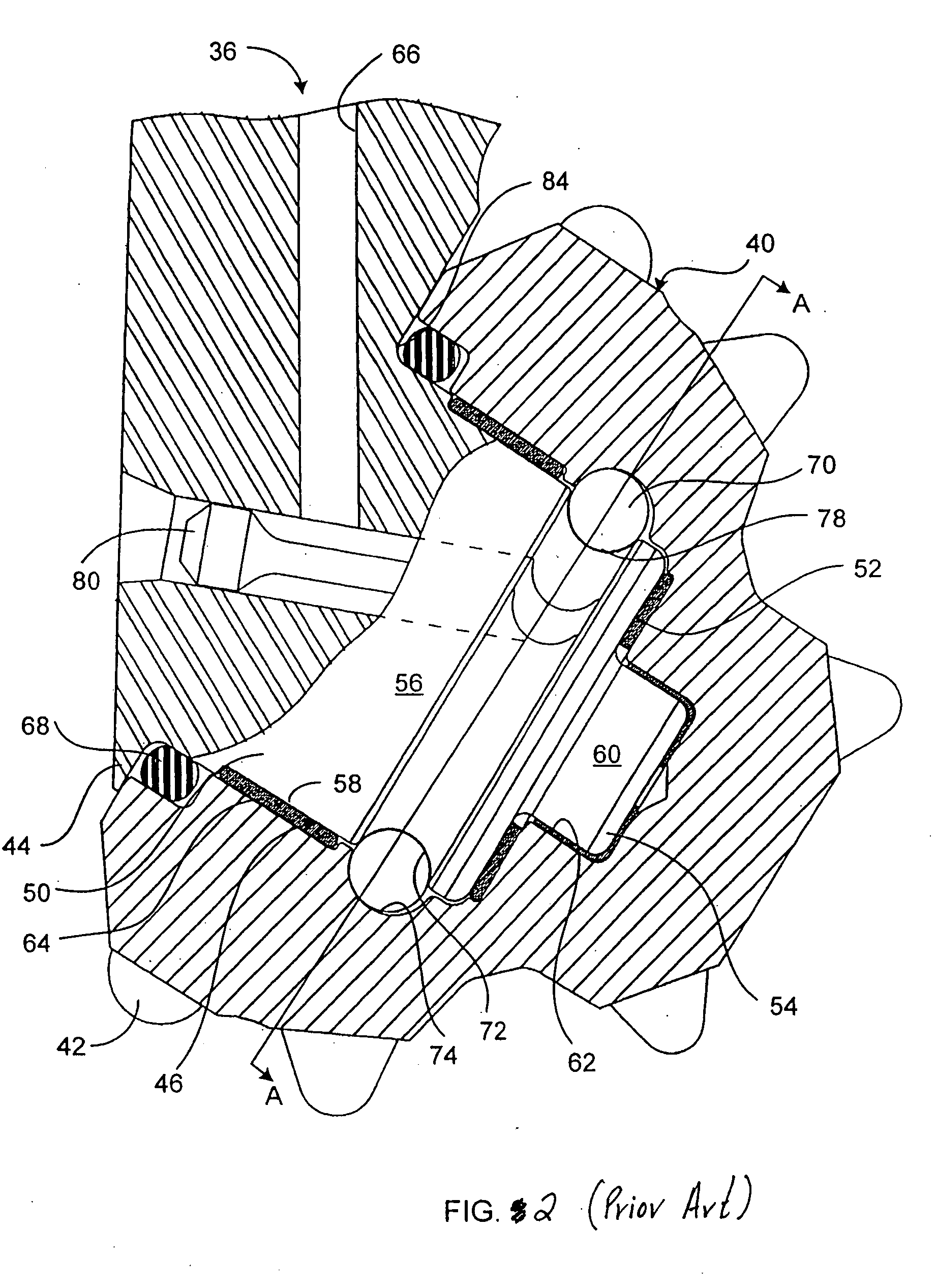

Drill bit having increased resistance to fatigue cracking and method of producing same

The present invention relates to a roller cone drill bit that includes a bit body adapted to be rotated about a longitudinal axis, where the bit body has at least one leg depending therefrom, wherein the leg comprises a treated portion that provides a residual compressive stress, and a roller cone rotatably mounted on a journal. The treated portion treatment may comprise one selected from shot peening, laser-shock peening, and hammer peening. Further, the present invention relates to a method of manufacturing a roller cone drill bit that includes inducing a compressive stress, through plastic deformation, in at least a portion of at least one leg depending from a bit body. The inducing a compressive stress may comprise one selected from shot peening, laser-shock peening, and hammer peening.

Owner:SMITH INT INC

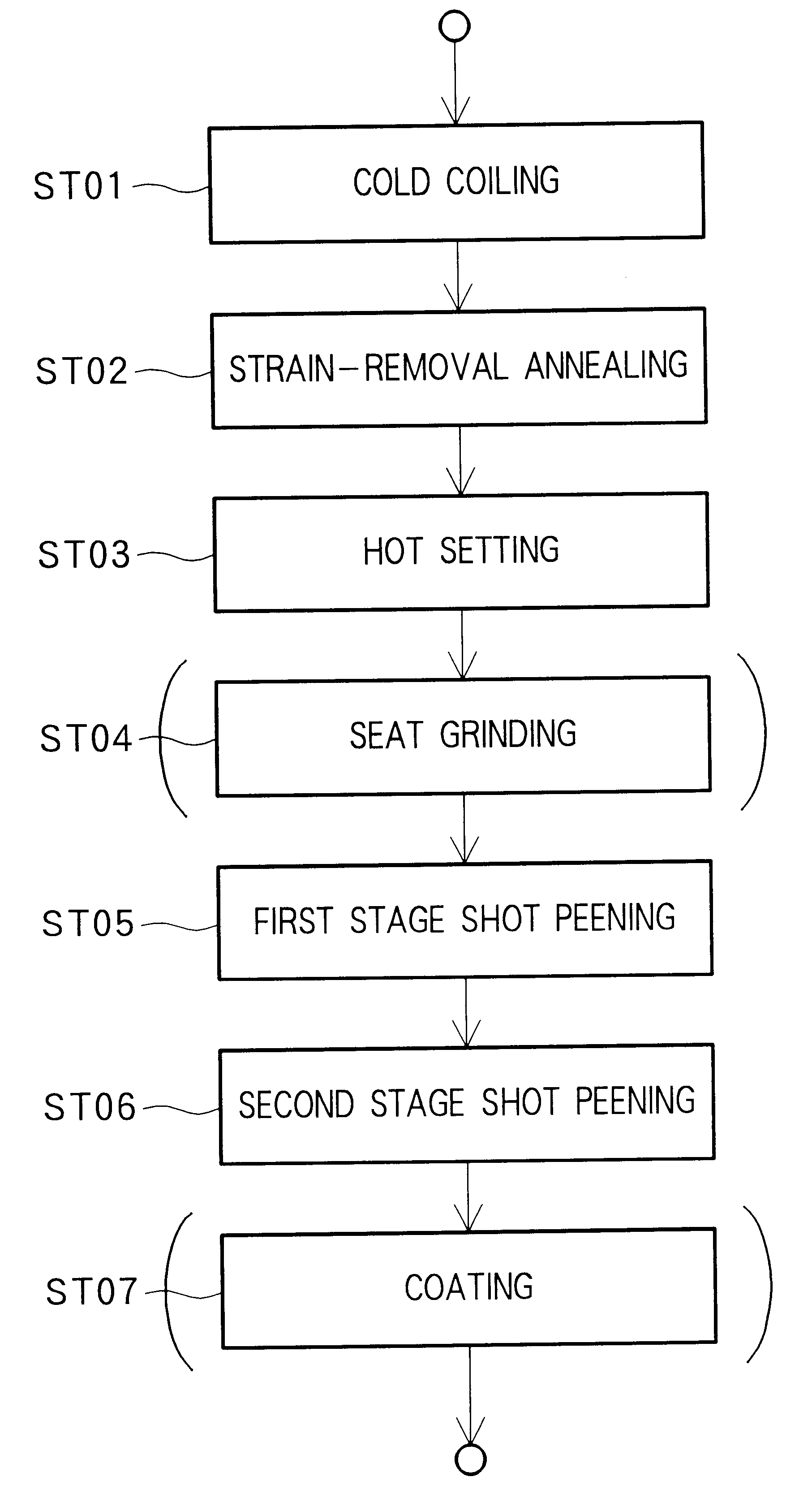

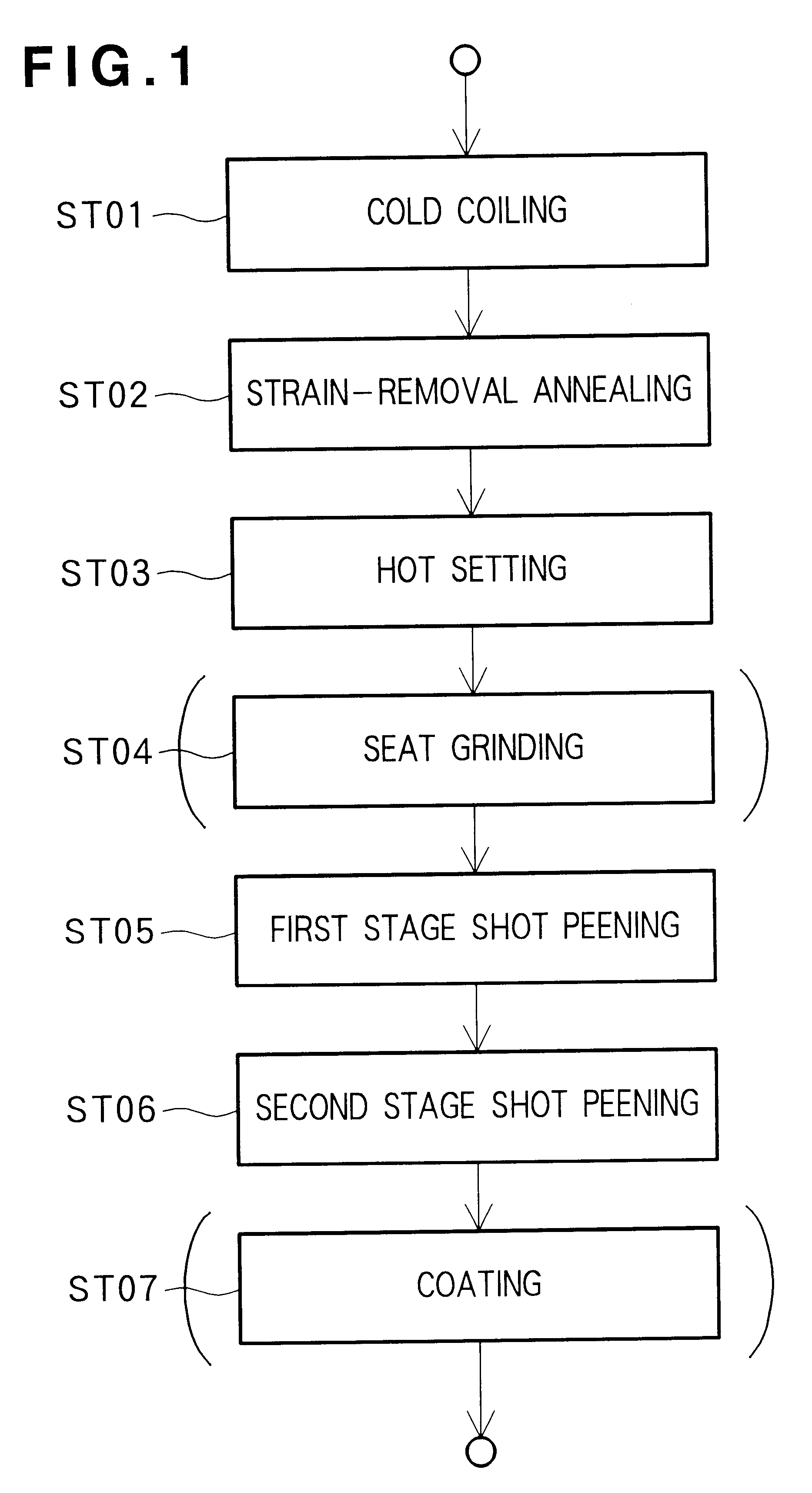

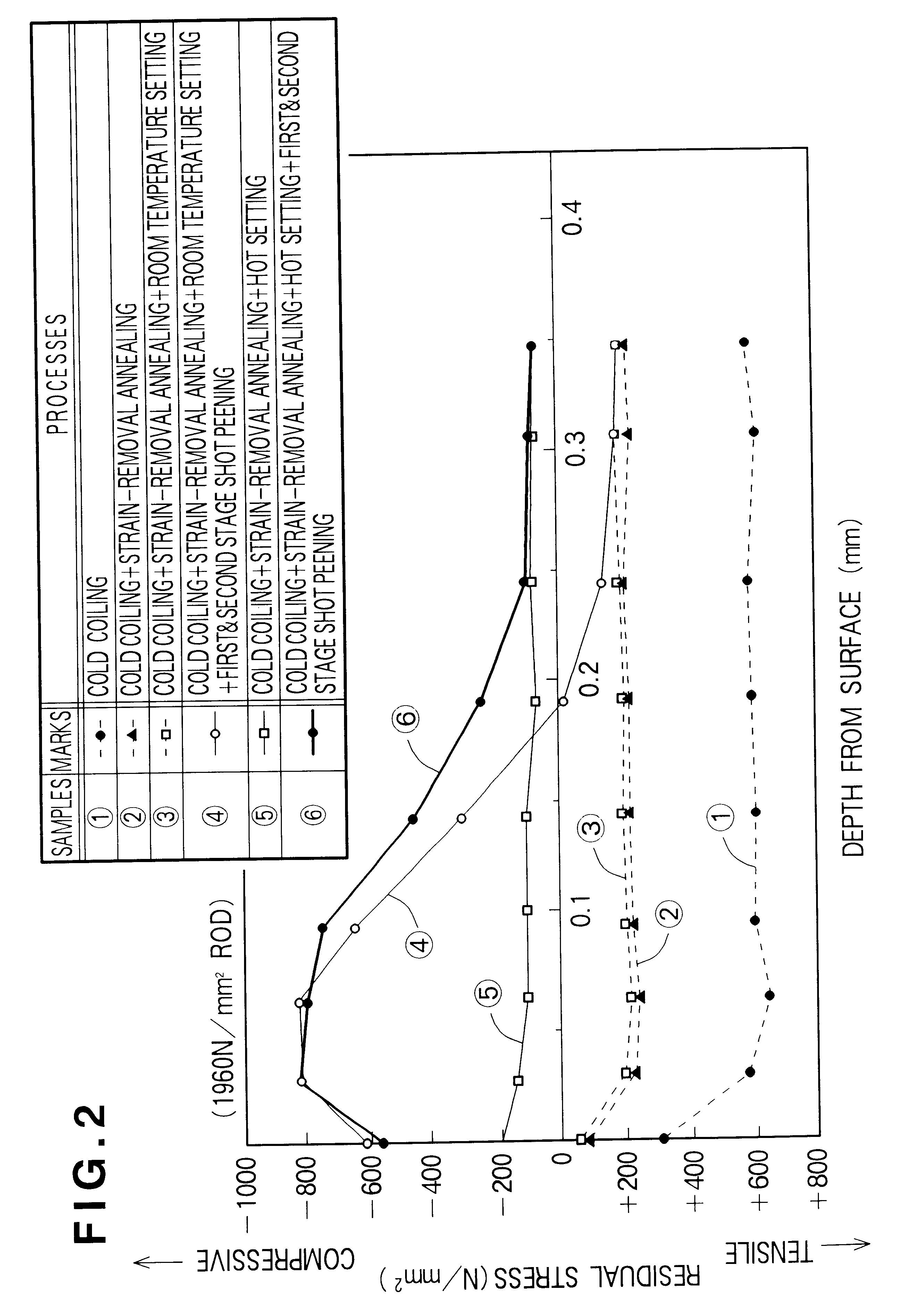

Manufacturing method of suspension spring for car

A method for manufacturing a coiled spring having a high fatigue strength to be used for example as a suspension spring of a car using a rod of tensile strength 1910 to 2020 N / mm2 and diameter 8 to 17 mm. In a cold coiling step, the rod is formed into a coil. Annealing is then carried out to remove strains having arisen inside the coil during the coiling step. A hot setting step of utilizing surplus heat from the annealing step and applying a predetermined load to the coil to compress it for a predetermined time is then carried out. After that, multi-stage shot peening is carried out on the coil.

Owner:SHOWA CORP

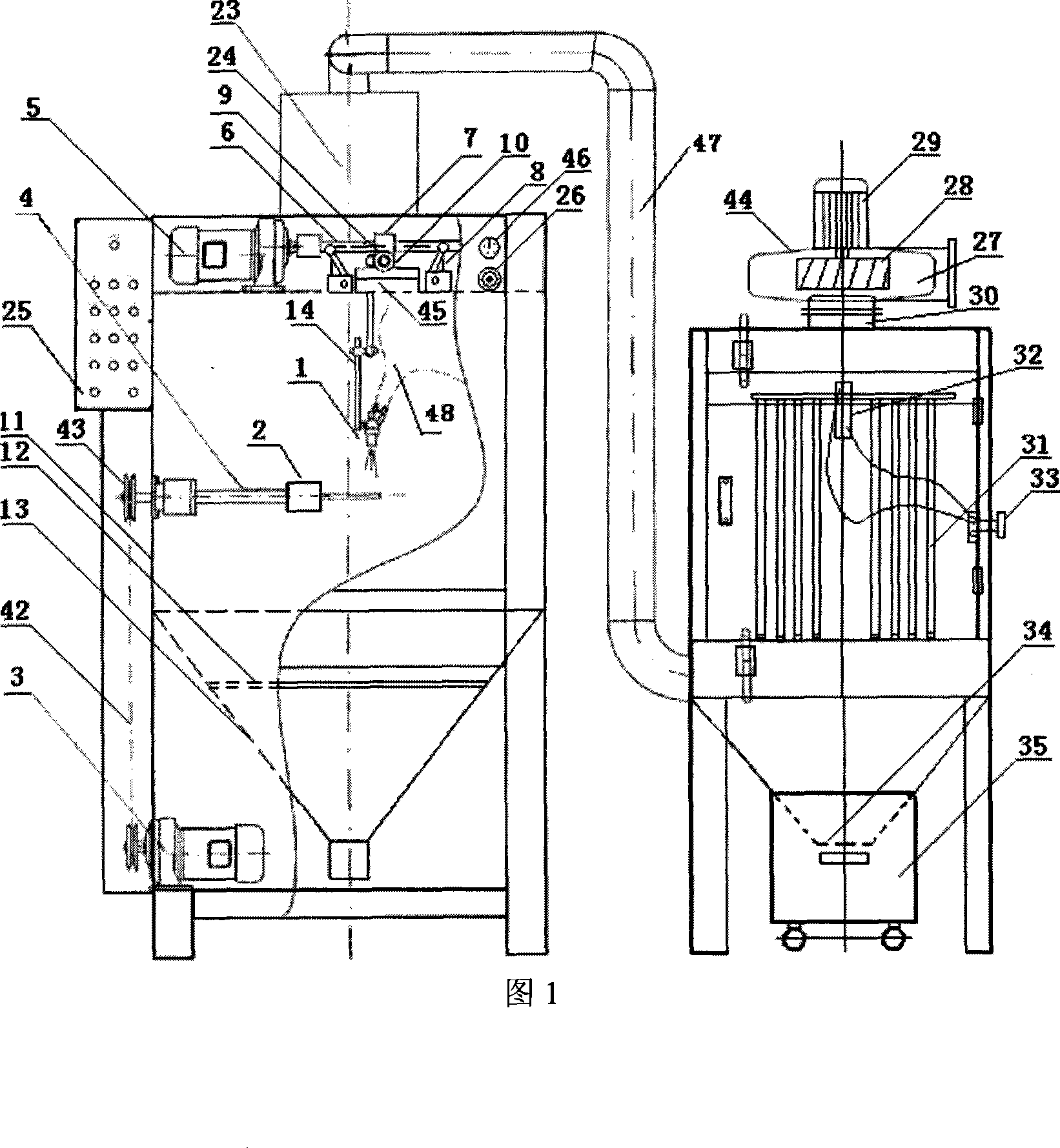

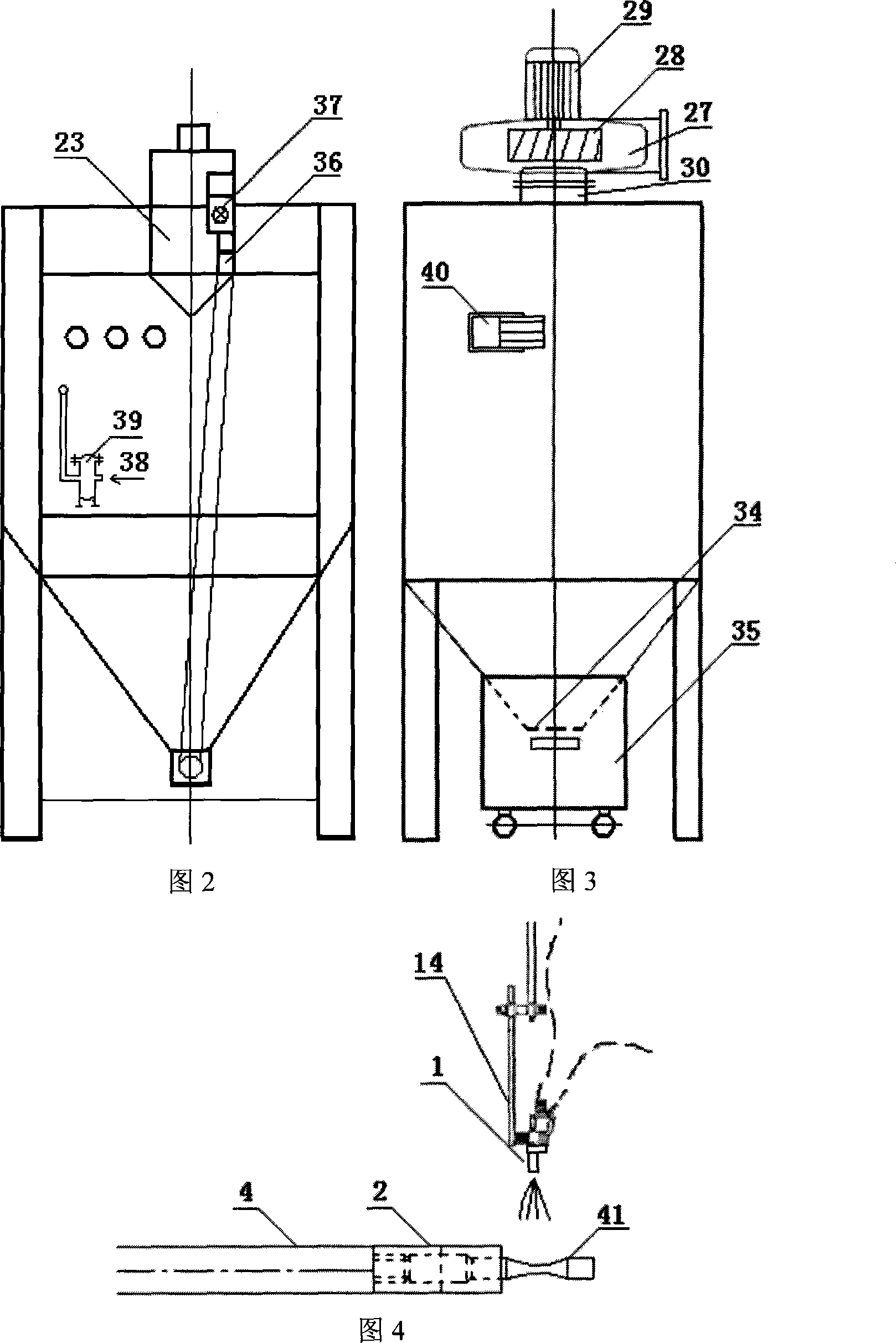

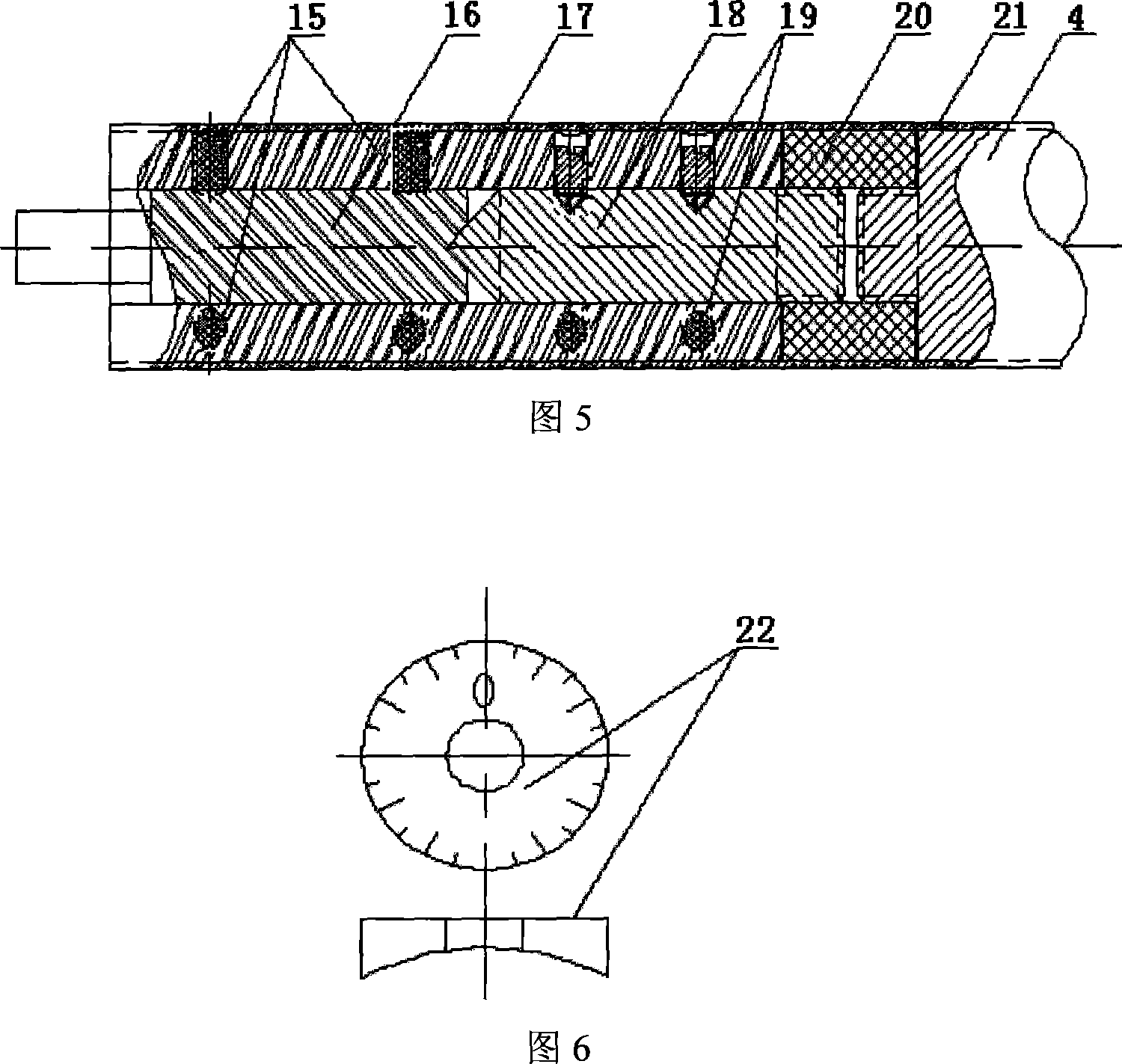

Shot peening machine for processing surface deformation strengthening treatment to magnesium alloy sample

InactiveCN101214633AGuaranteed concentricityGuaranteed parallelismImpeller wheelsBlast gunsAir compressionAbrasive blasting

The present invention relates to a device in the technical field of material processing, in particular to a peener which carries out the surface deformation strengthening process on magnesium alloy samples. The present invention comprises a main peening system, an upper whirlwind separation system, a dedusting system, an air compression system and an electric system, wherein, the upper whirlwind separation system is positioned on the upper end of the main peening system, the lower part of the upper whirlwind separation system is communicated with the main peening system, the upper part is connected with the dedusting system, which is positioned outside the main peening system, the air inlets of both the dedusting system and the main peening system are connected with the air compression system, and the electric system is connected with the main peening system, the upper whirlwind separation system, the dedusting system and the air compression system. The present invention can conveniently assemble and disassemble the samples of the shaft class, the range of the generated peening strenghth is wide, the effect and uniformity of peening is good, and moreover, pollution can be prevented.

Owner:SHANGHAI AIERSI LIGHT ALLOY

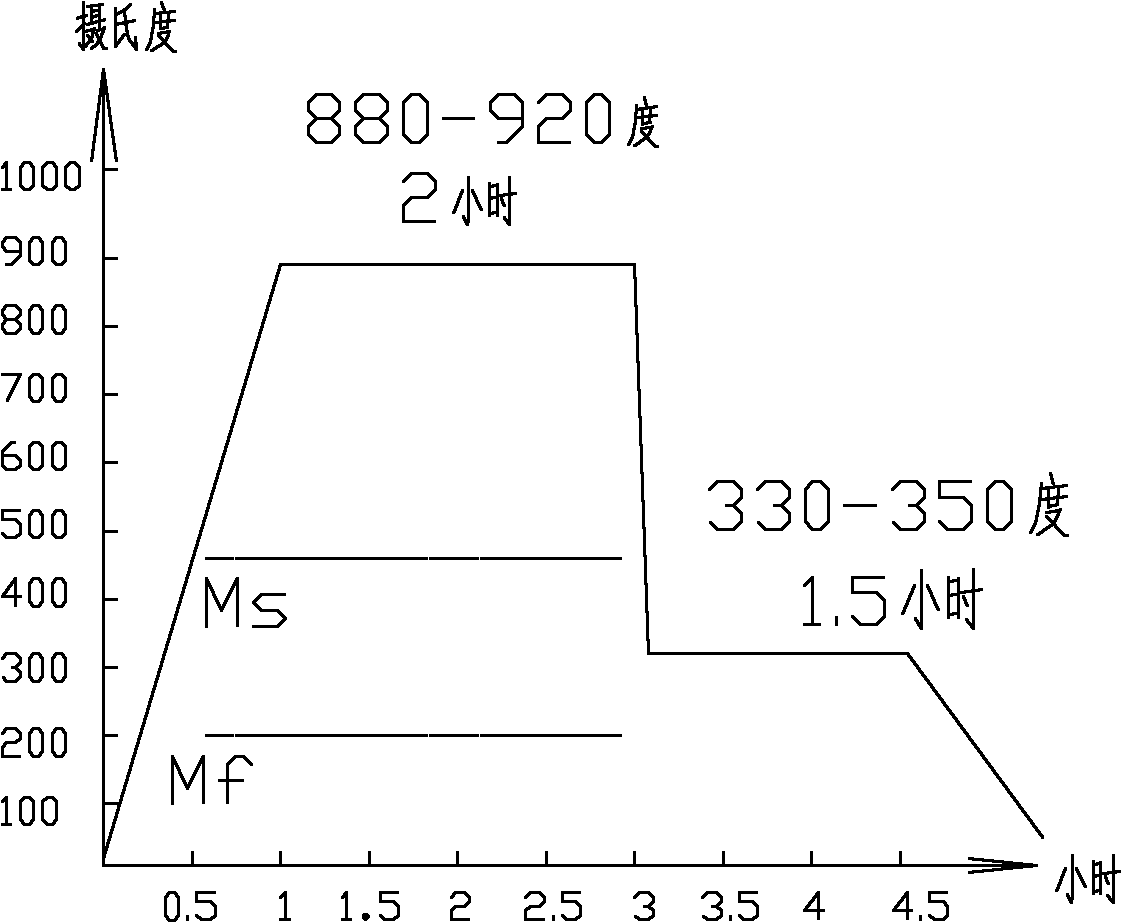

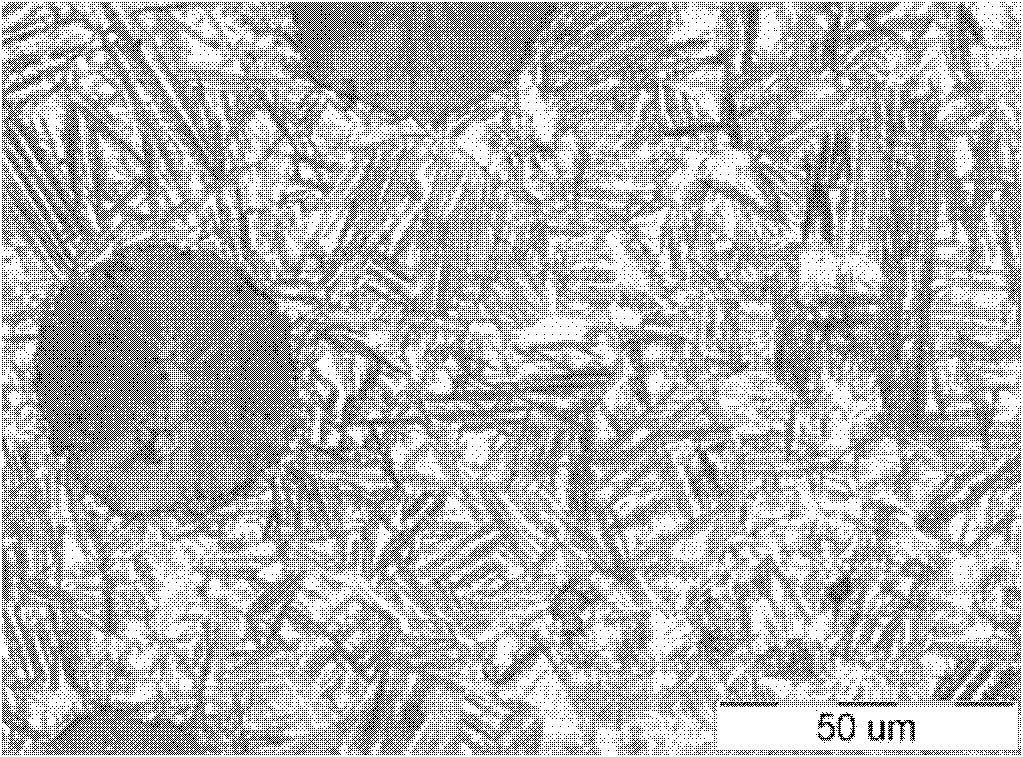

Method for manufacturing austempered ductile iron (ADI) front axle of heavy truck by sand casting

InactiveCN102218504AImprove integrityImprove fatigue lifeFoundry mouldsFurnace typesVolumetric Mass DensityQuenching

The invention discloses a method for manufacturing an austempered ductile iron (ADI) front axle of a heavy truck by sand casting. By the method, nickel molybdenum copper austempered ductile iron (ADI) front axle of the heavy truck is produced by a furane resin sand molding process, and the problems that the internal density and the performance reliability of ADI products are difficult to guarantee and the mechanical properties of the ADI products are low are solved. The method has the following steps of: firstly, casting a blank of the nickel molybdenum copper alloyed spheroidal graphite cast iron front axle by the furane resin sand molding process; secondly, performing the surface shot peening strengthening and isothermal quenching heat treatment; and finally machining the front axle parts. By the method, casting is replaced by forging, and the iron is replaced by steel, the comprehensive mechanical properties are obviously higher than those of common spheroidal graphite cast iron and forged steel, the weight of truck parts is reduced, the investment of heavy forging equipment and dies is saved, the cost is reduced, the production cycle is shortened, energy is saved, the emission is reduced, and the economic benefit and the social benefit are obvious.

Owner:DALIAN XINZHONG GRP +1

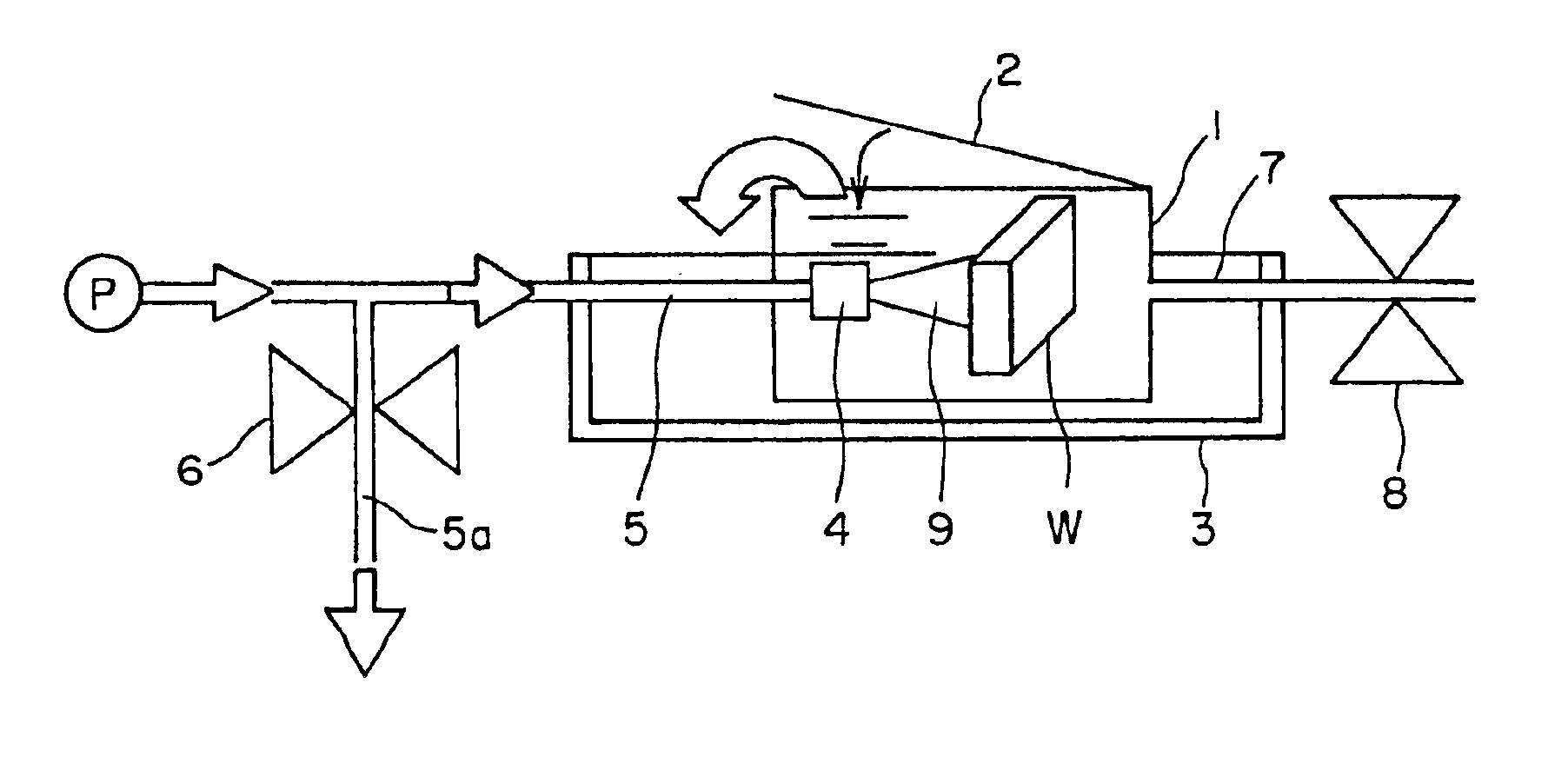

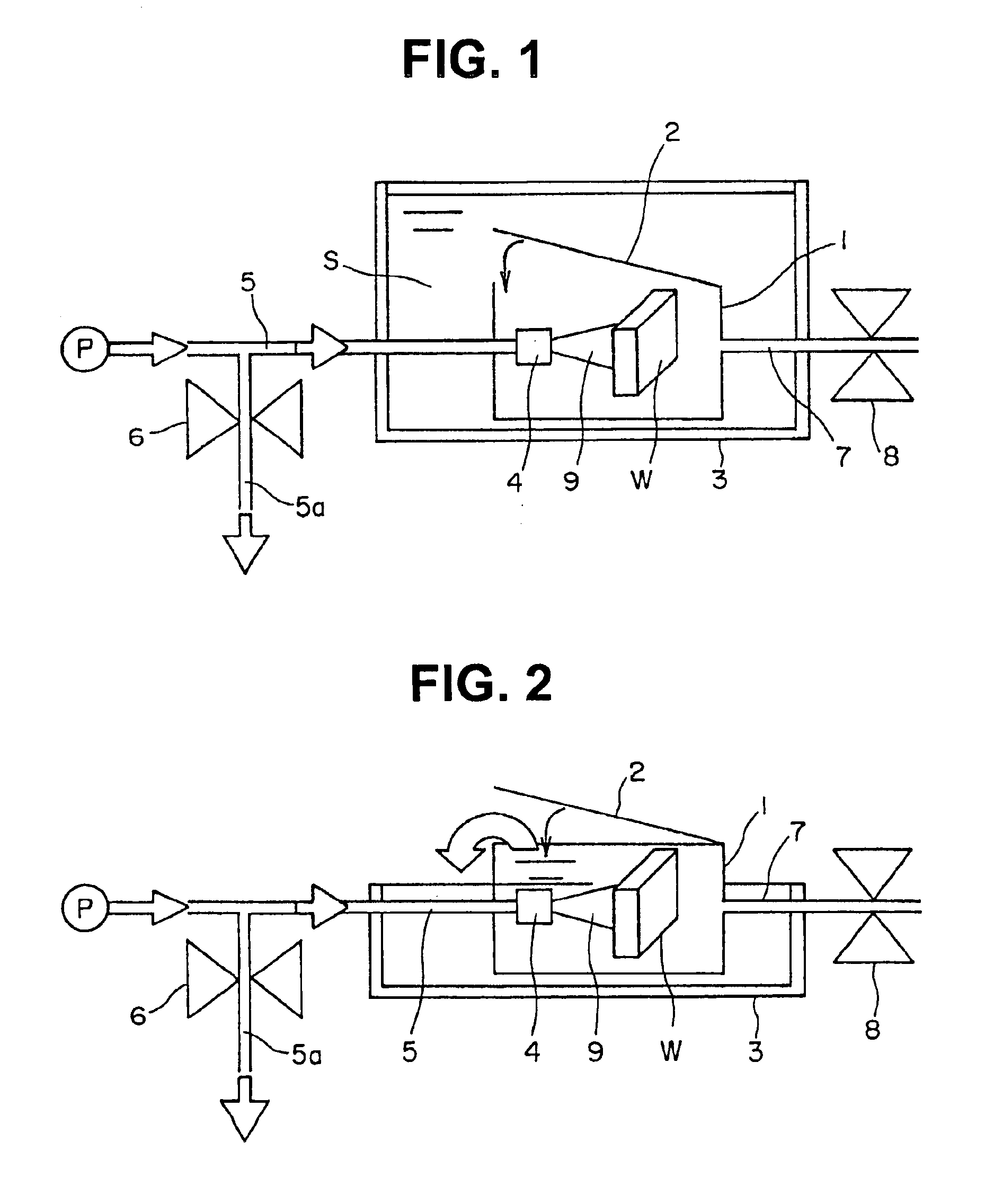

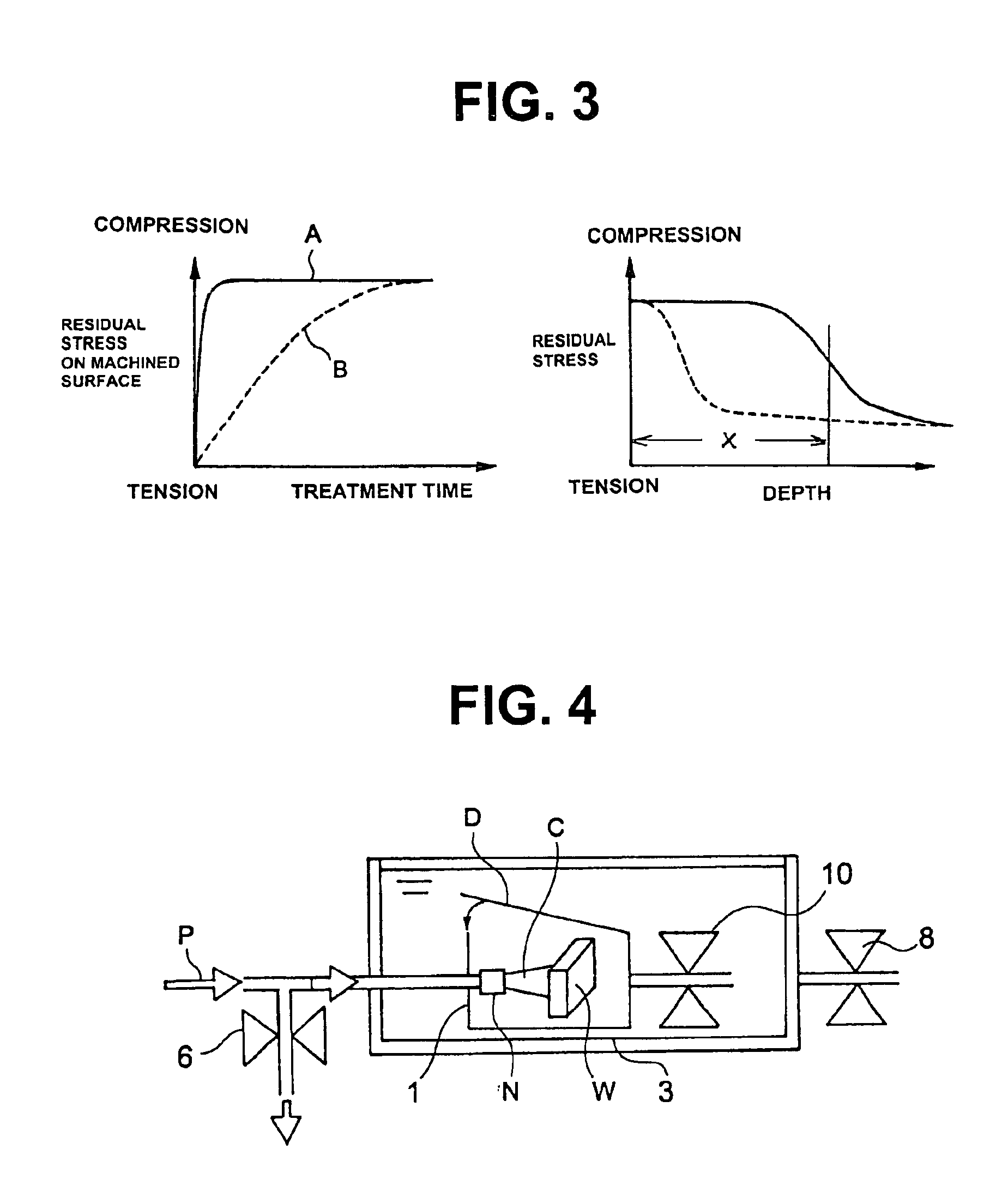

Method and devices for peening and cleaning metal surfaces

InactiveUS6855208B1Improve residual stressHardening workpieceLighting and heating apparatusElectrostatic cleaningMachine partsCavitation bubble

This invention relates to a metal part and other surface modification method suitable for the machining industry in which shot peening is typically used to refine the surface of a metal part (to introduce compressive residual stresses, to enhance fatigue strength, to harden the workpiece) and for fields in which parts need be cleaned. According to the present invention, workpiece W is placed within a first vessel which is filled with a fluid. The first vessel is pressurized by controlling the flow rate of the fluid flowing in the first vessel from nozzle 4 distant from said workpiece on the surface and of the fluid flowing from first vessel. Thus, the collapsing impact force of cavitation bubbles is increased so that the machined part will have its surface strengthened and cleaned by applying a peening effect to the surface of the part with said impact force.

Owner:JAPAN SCI & TECH CORP

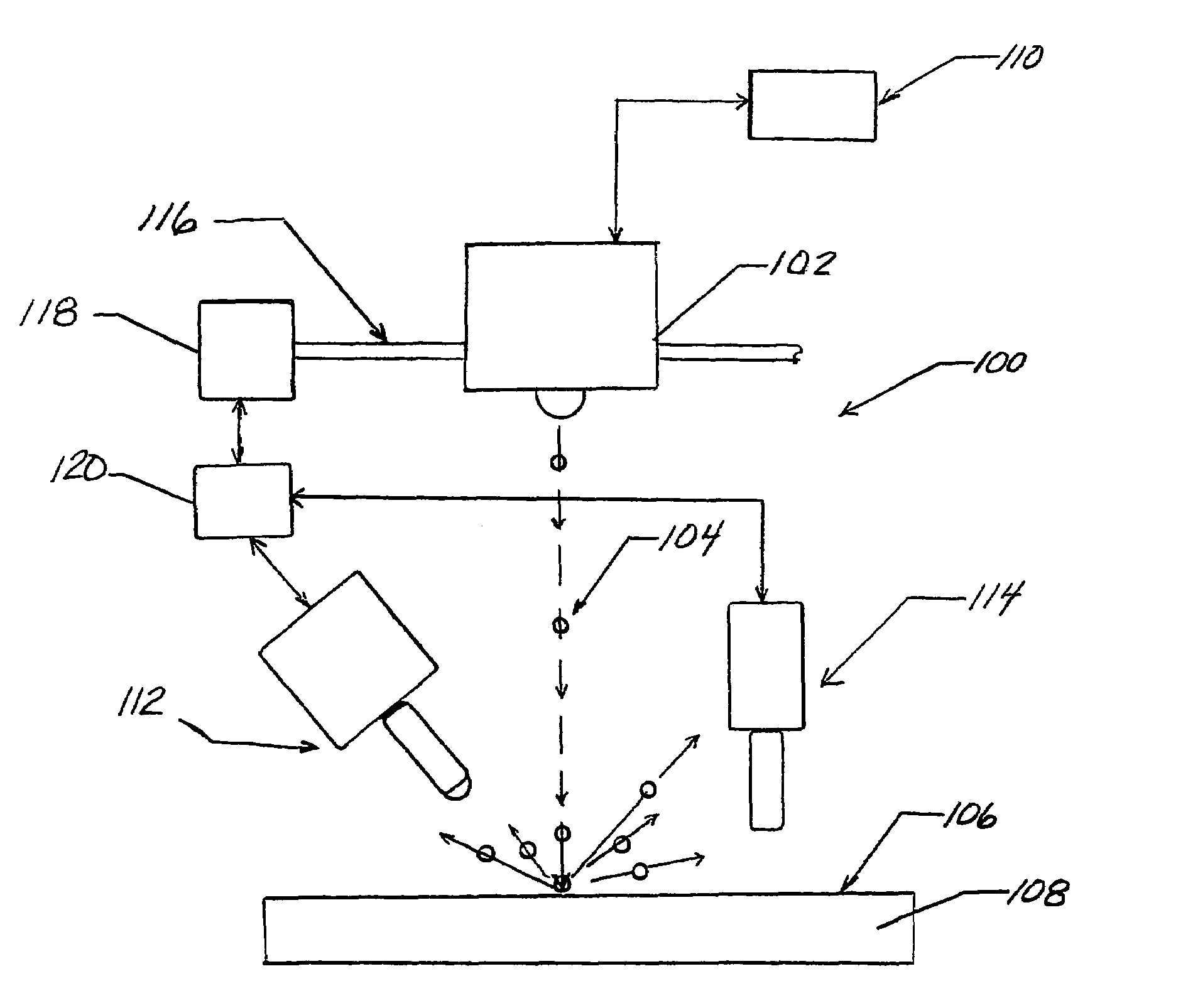

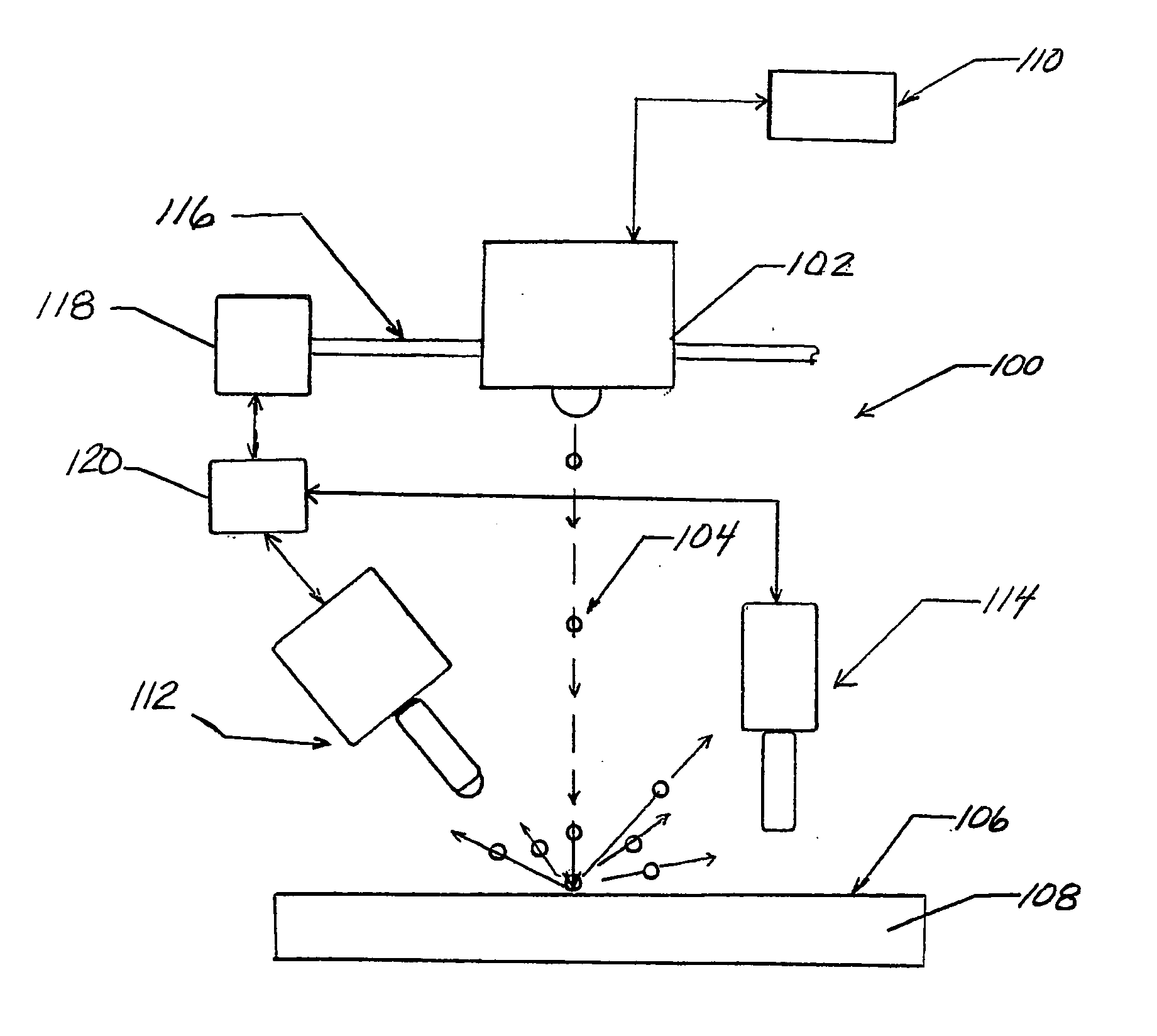

Method and apparatus for providing a layer of compressive residual stress in the surface of a part

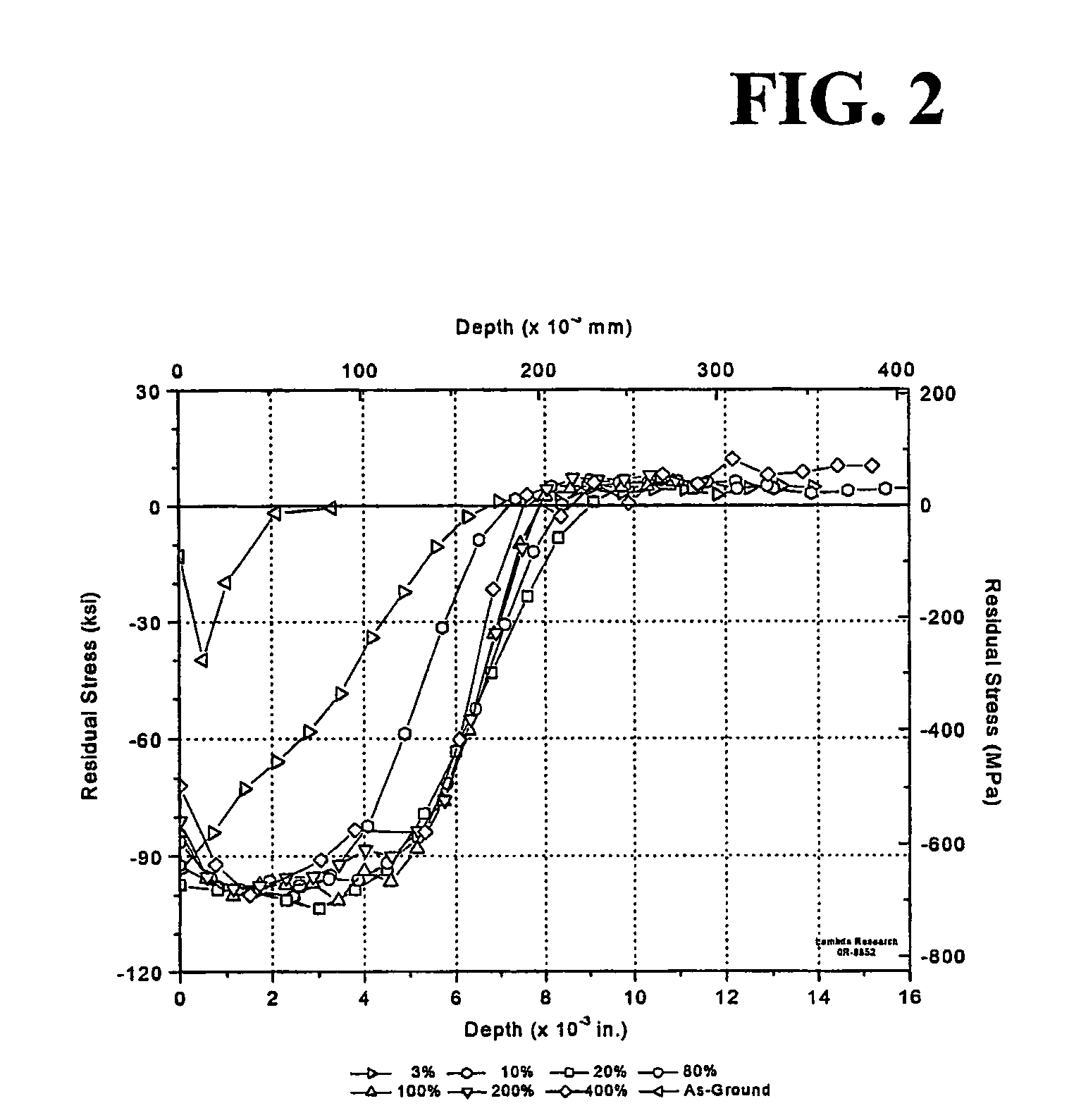

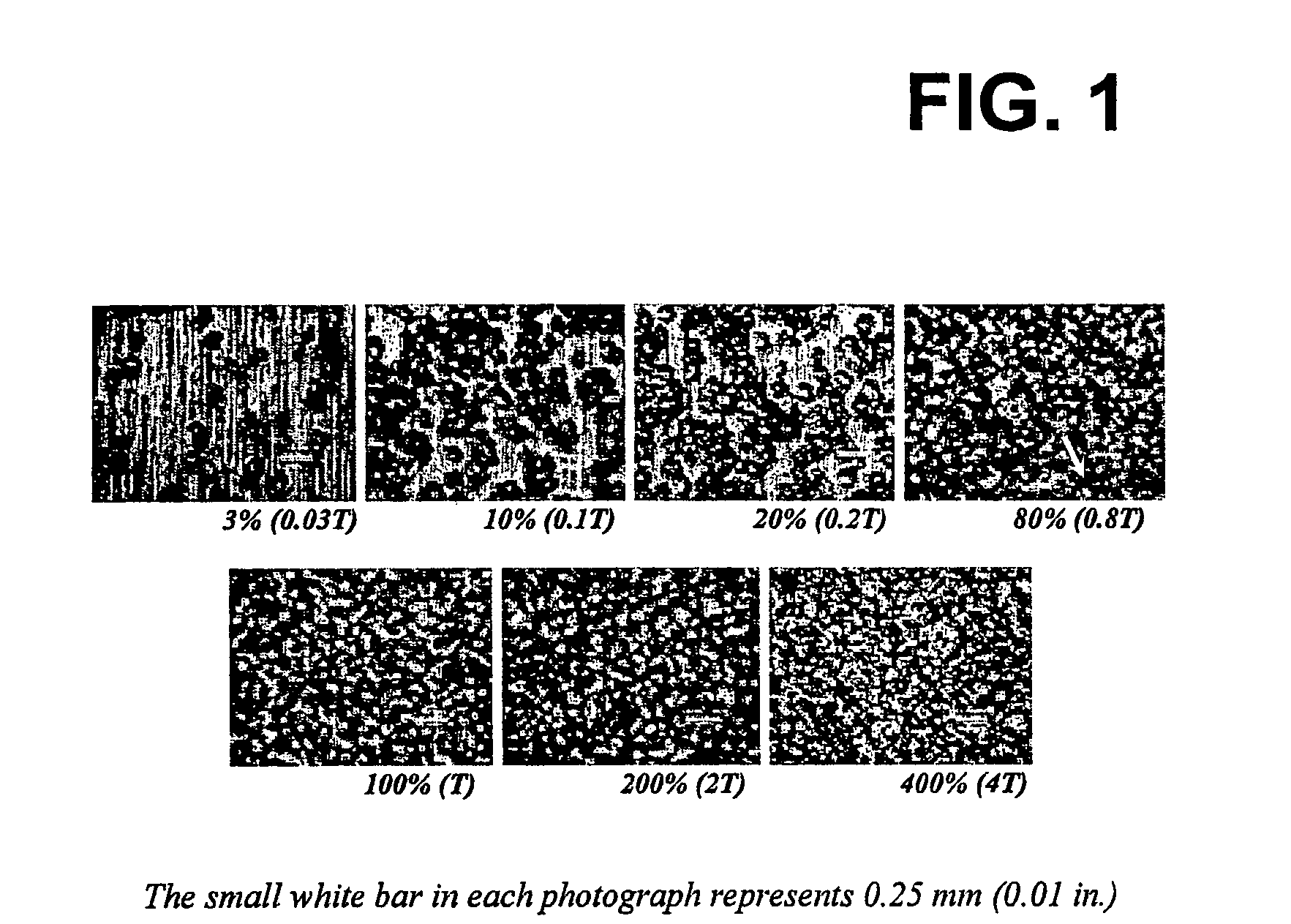

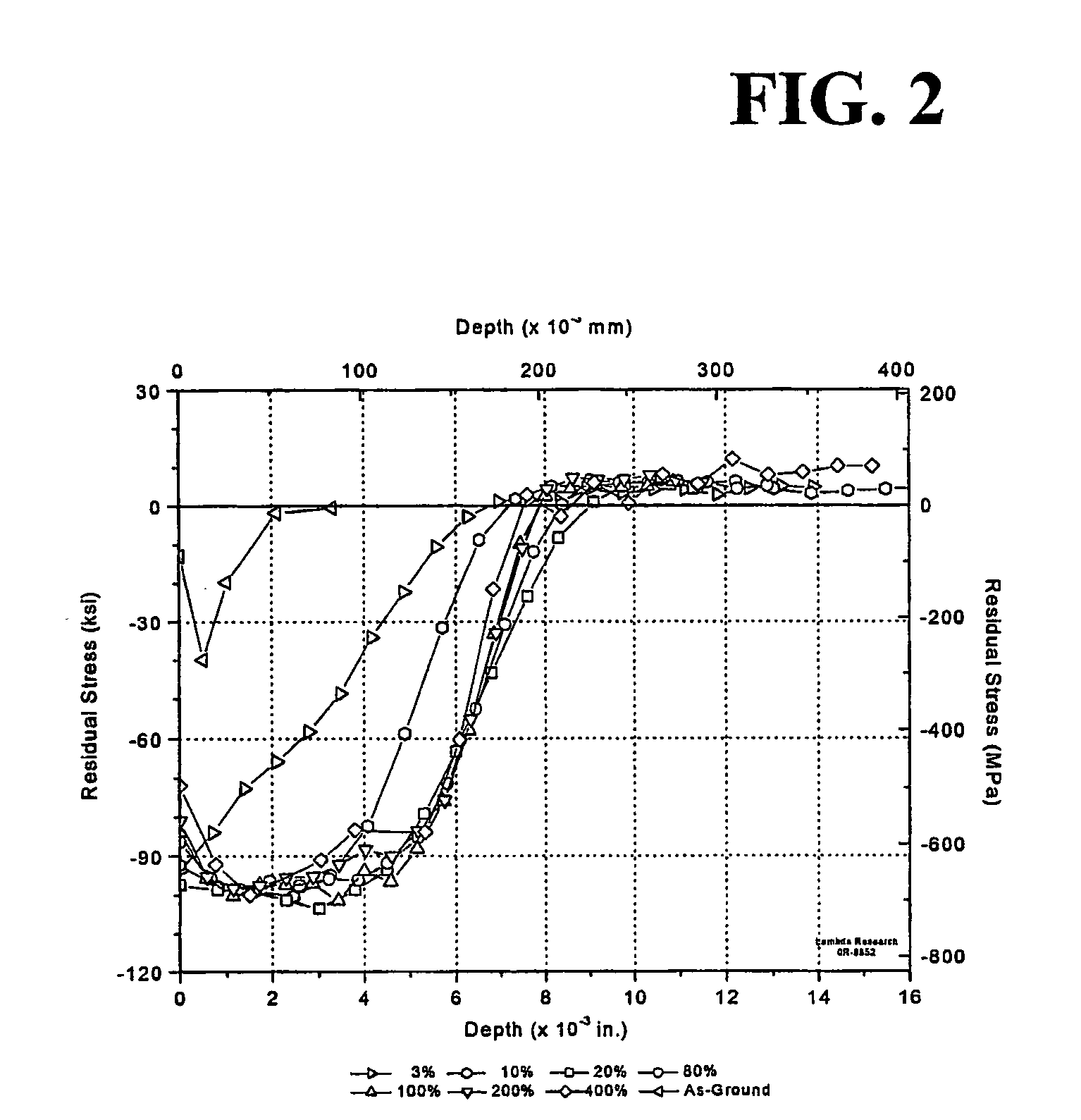

ActiveUS7159425B2Reduce processing timeWork lessBurnishing machinesHeat treatment process controlX-rayHigh surface

The shot peening method and apparatus (FIG. 13) of the present invention utilizes control of the shot peening coverage to provide higher surface compression and comparable depth of compression to conventional 100% coverage peening but with reduced cold working providing improved thermal stability and reduction in shot peening time and cost. A preferred embodiment of this invention employs x-ray diffraction (FIG. 13) residual stress and percent cold work determinated by line broadening to establish the optimal degree of coverage for a given material and shot peening intensity.

Owner:SURFACE TECH HLDG

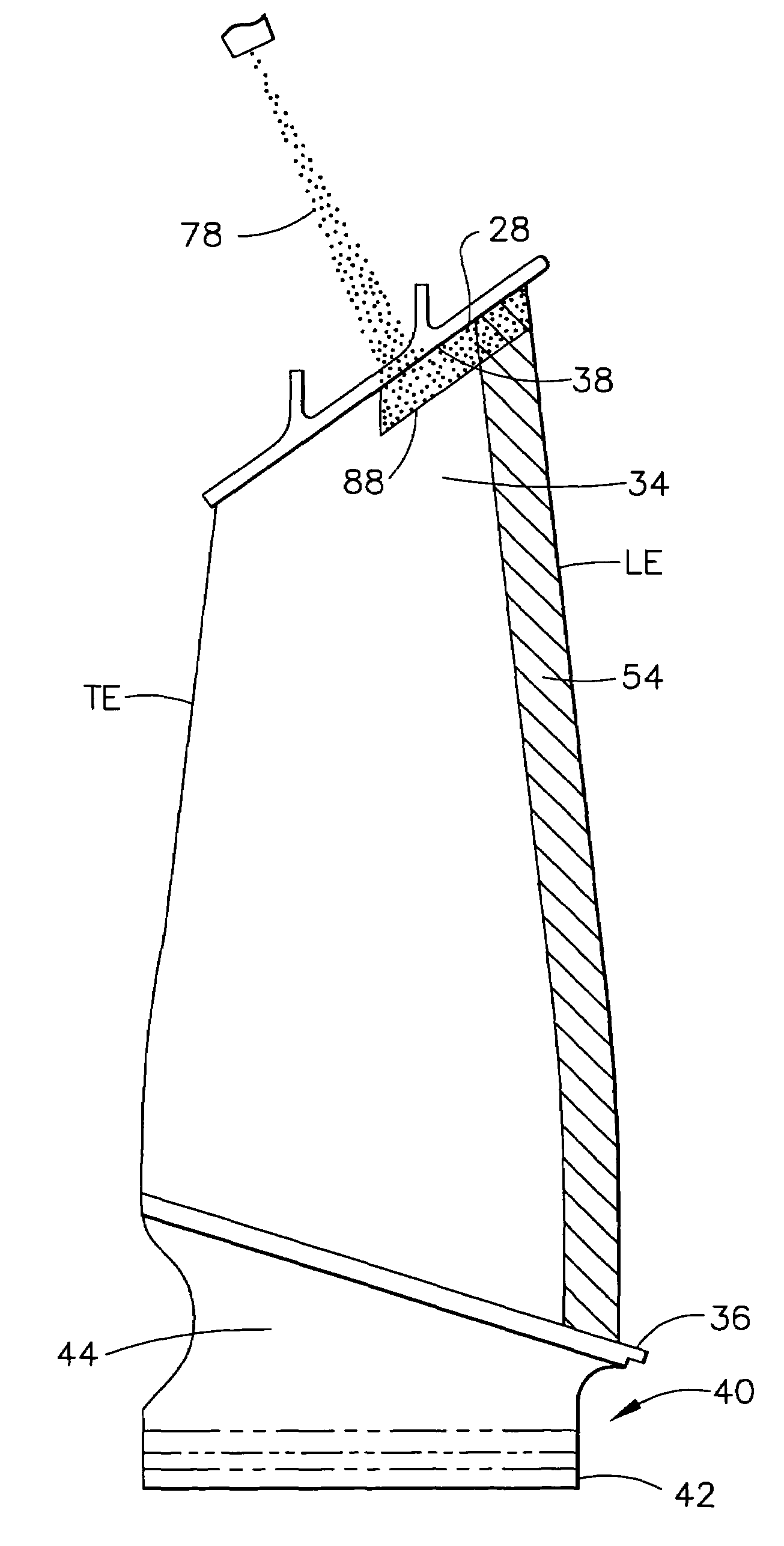

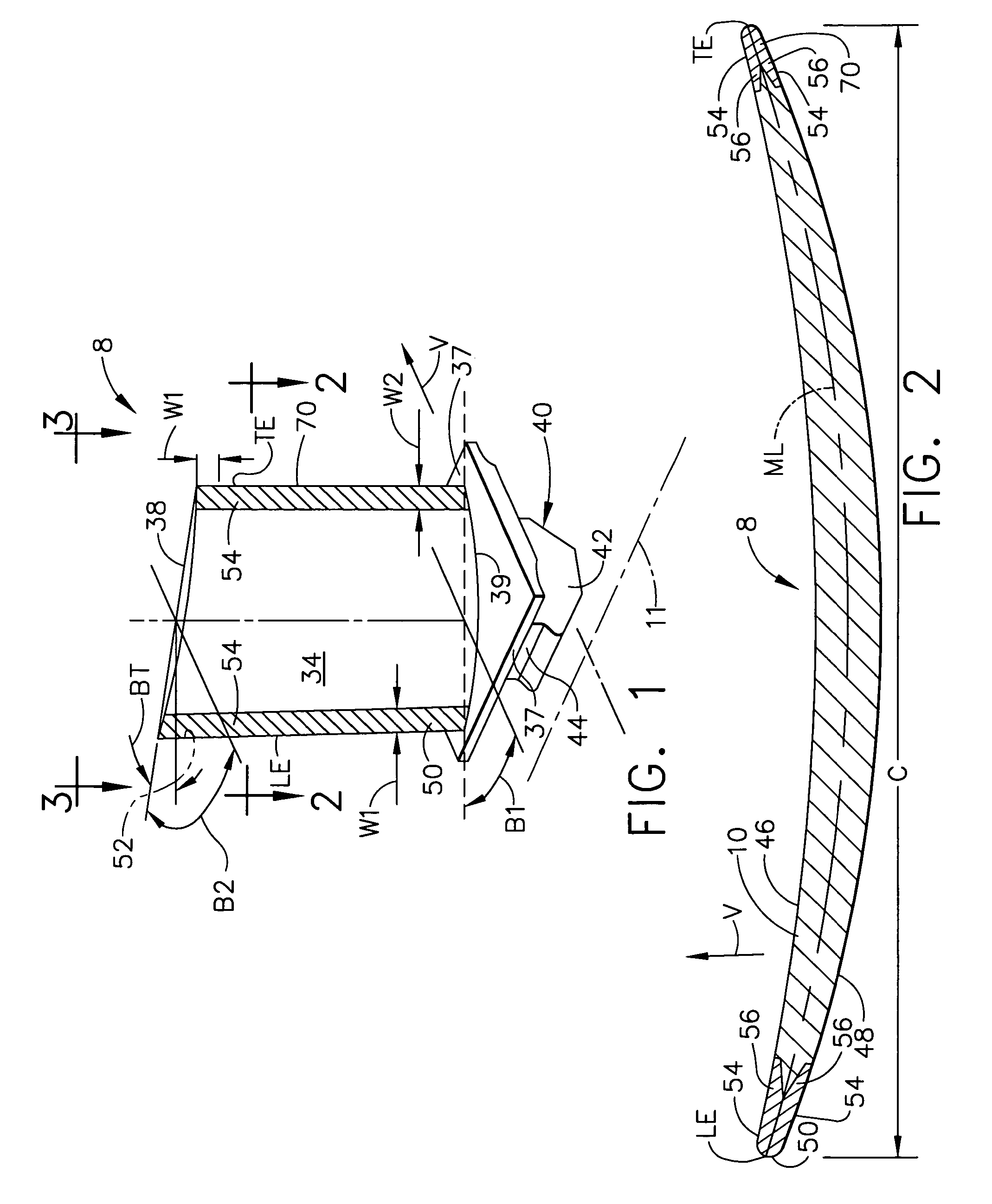

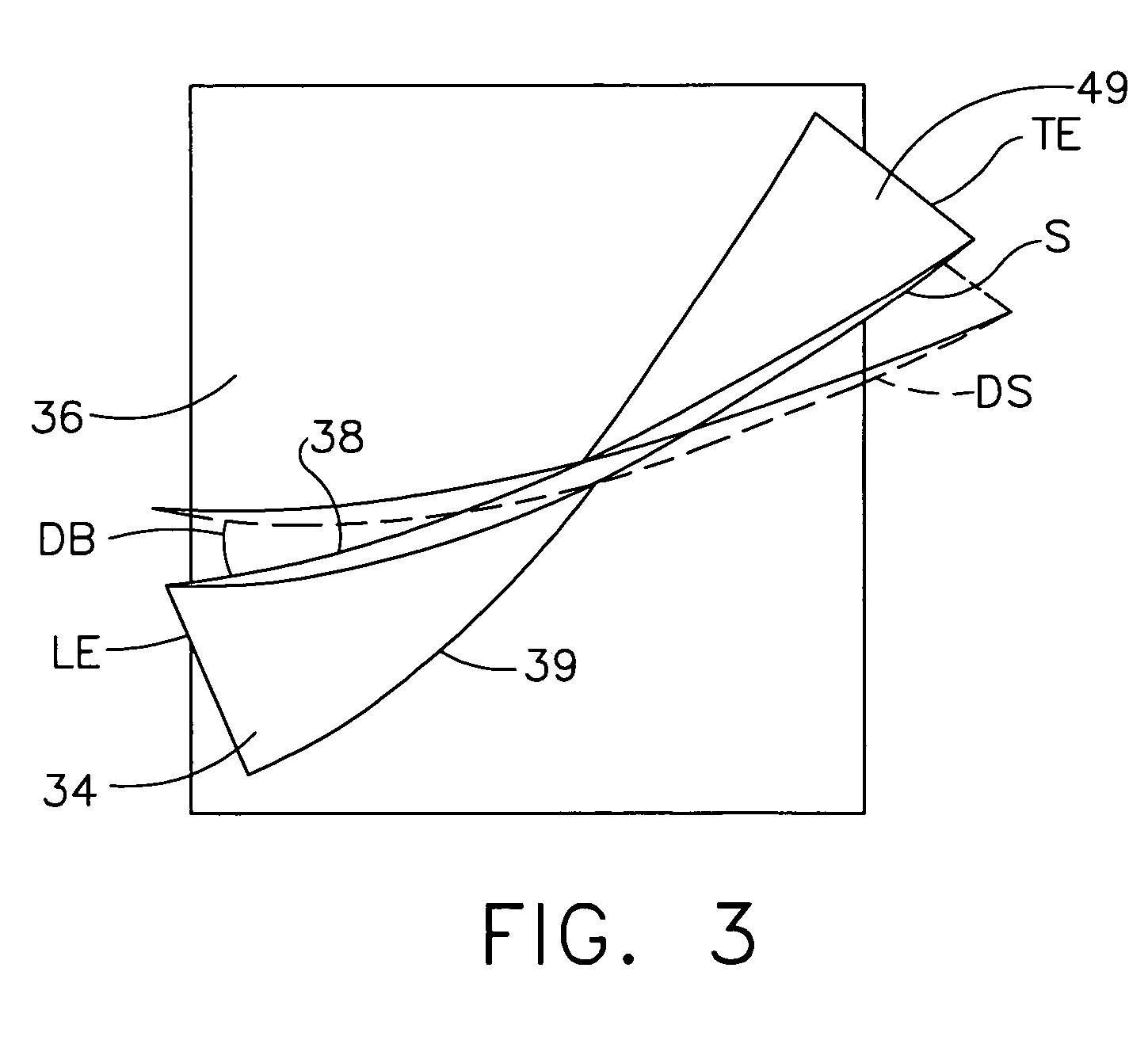

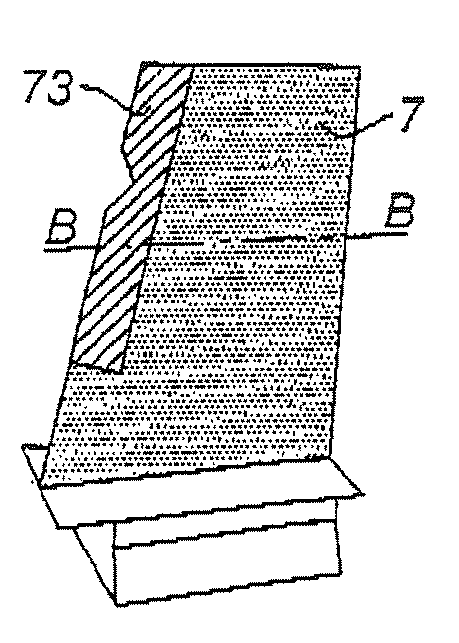

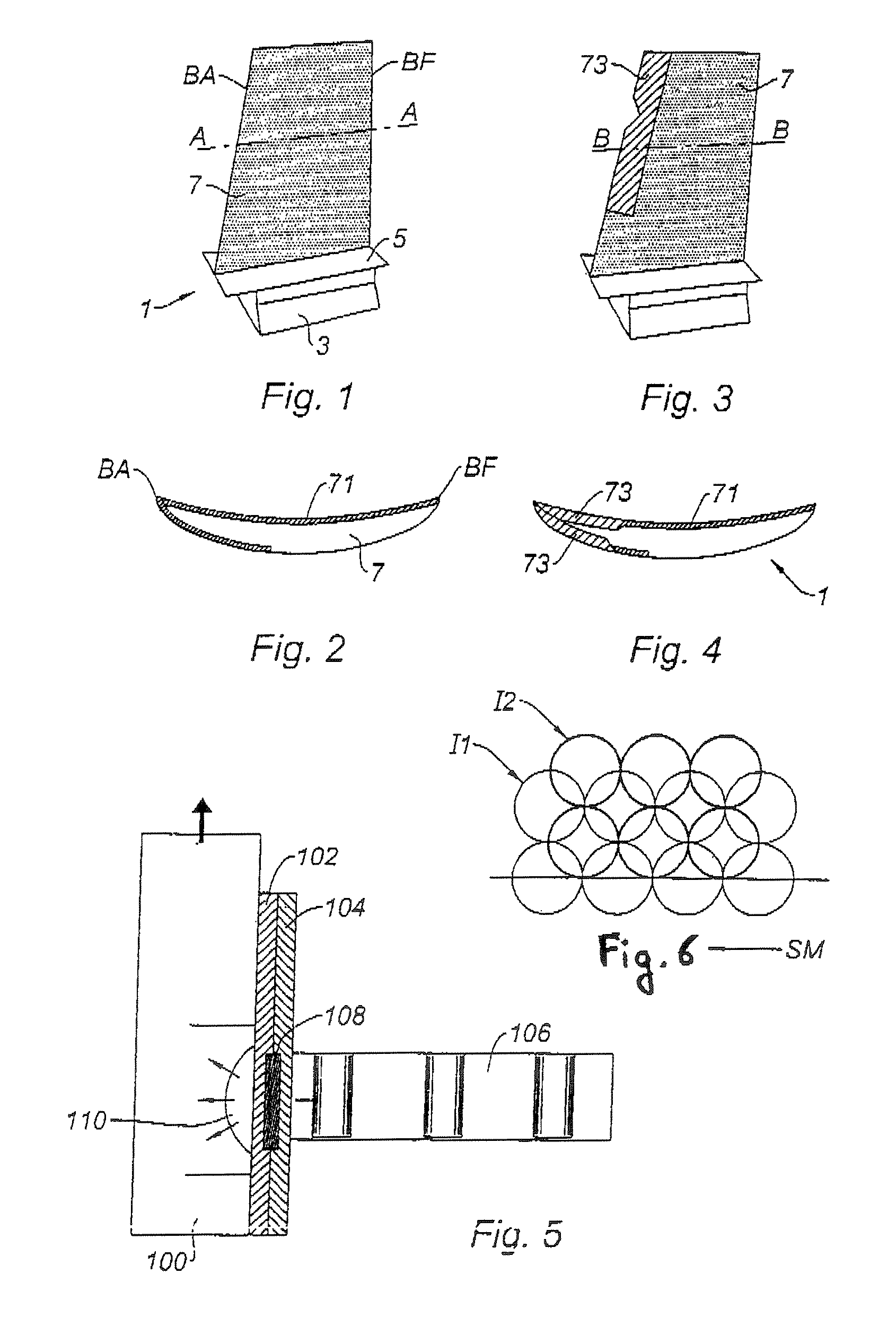

Countering laser shock peening induced airfoil twist using shot peening

A gas turbine engine blade is laser shock peened by laser shock peening a thin airfoil of the blade, forming a laser shock induced twist in the airfoil, and shot peening a portion of the airfoil to counter the laser shock induced twist in the airfoil. The shot peening may be performed before or after the laser shock peening. The shot peening may be applied over a laser shock peened surface formed by the laser shock peening. The shot peening may be performed asymmetrically on asymmetrically shot peened pressure and suction side areas of pressure and suction sides, respectively, of the airfoil. A shot peened patch near a blade tip may be formed on one of pressure and suction sides of the airfoil wherein the airfoil extends radially outwardly from a blade platform to the blade tip of the blade.

Owner:GENERAL ELECTRIC CO

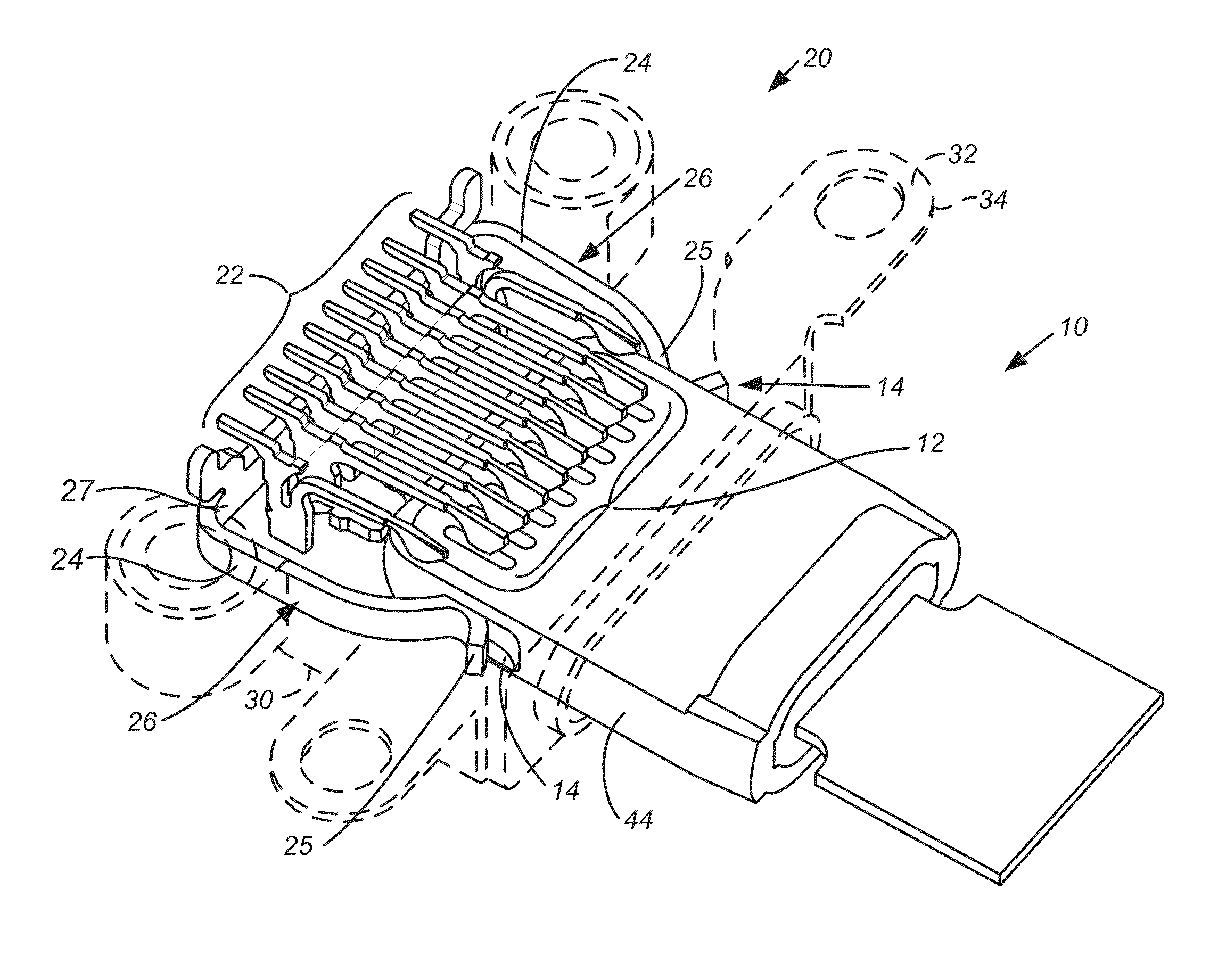

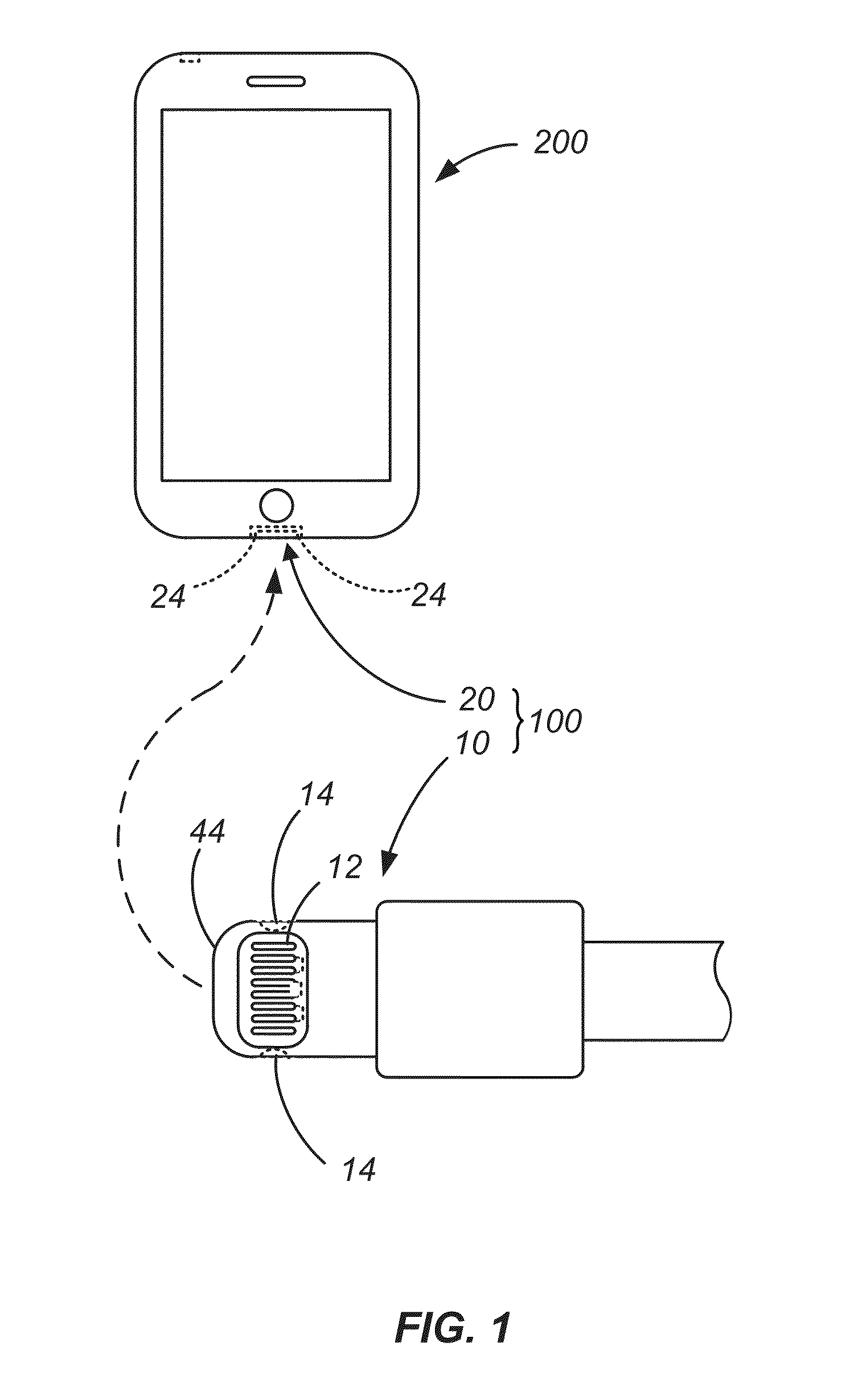

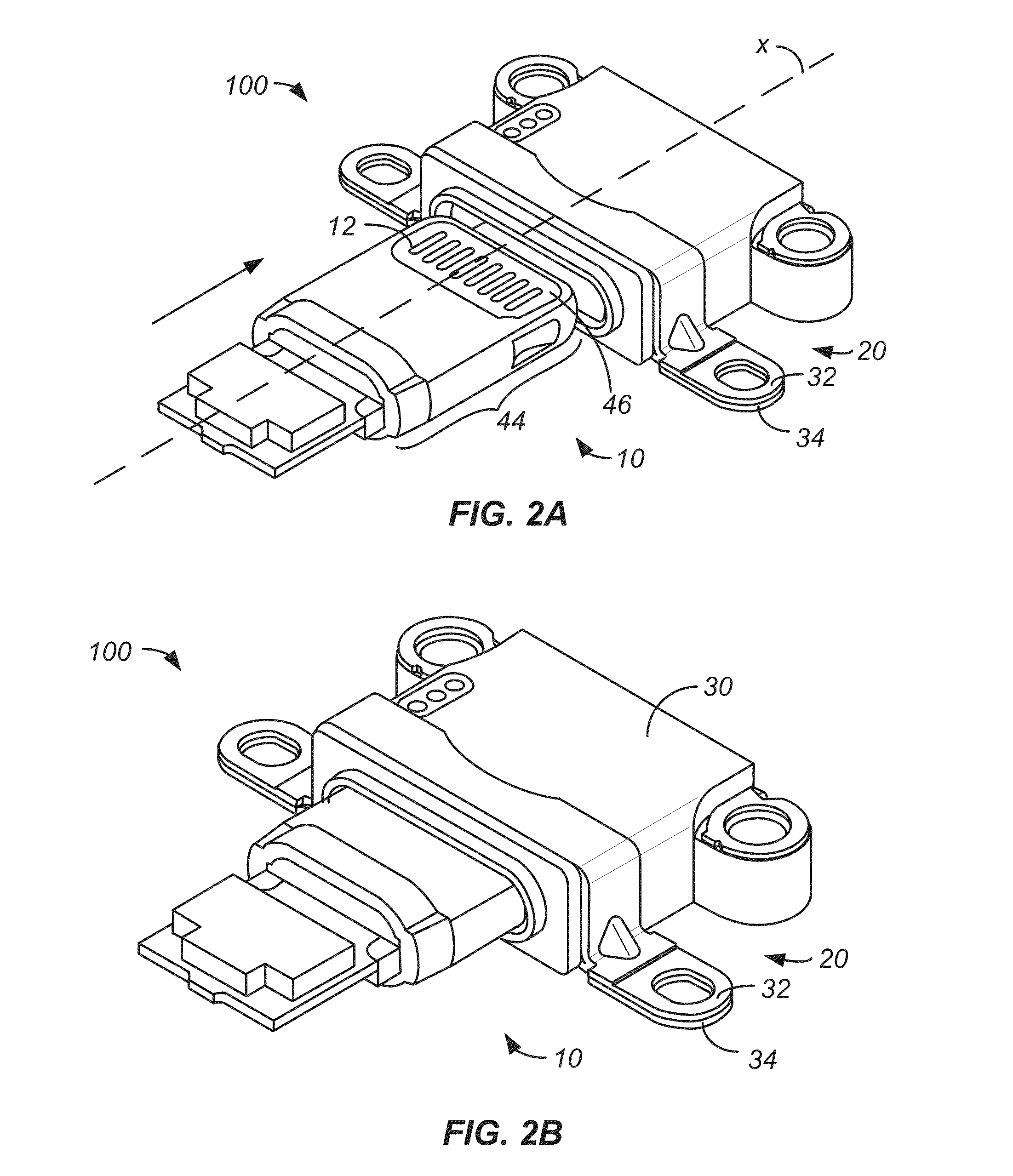

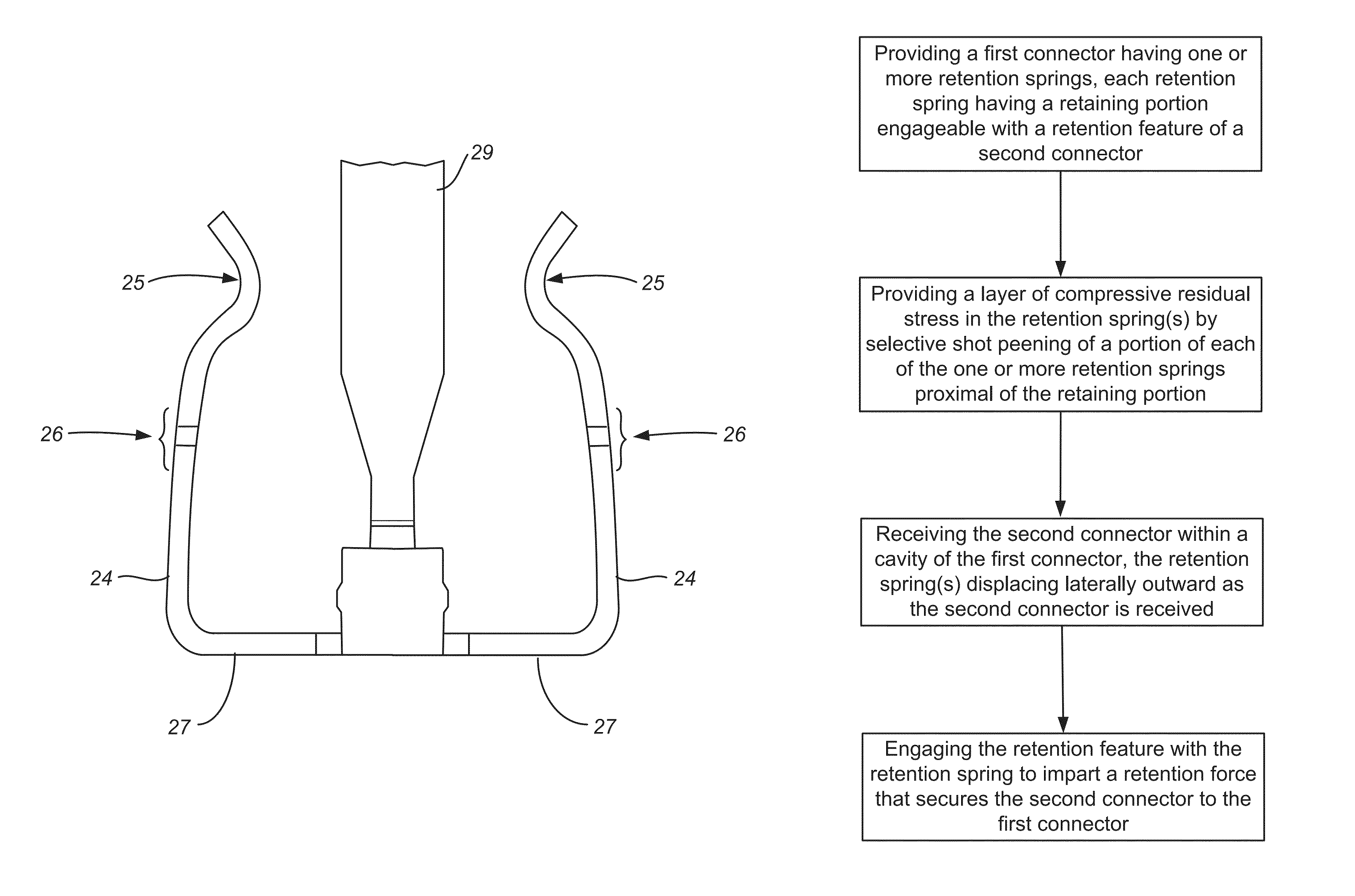

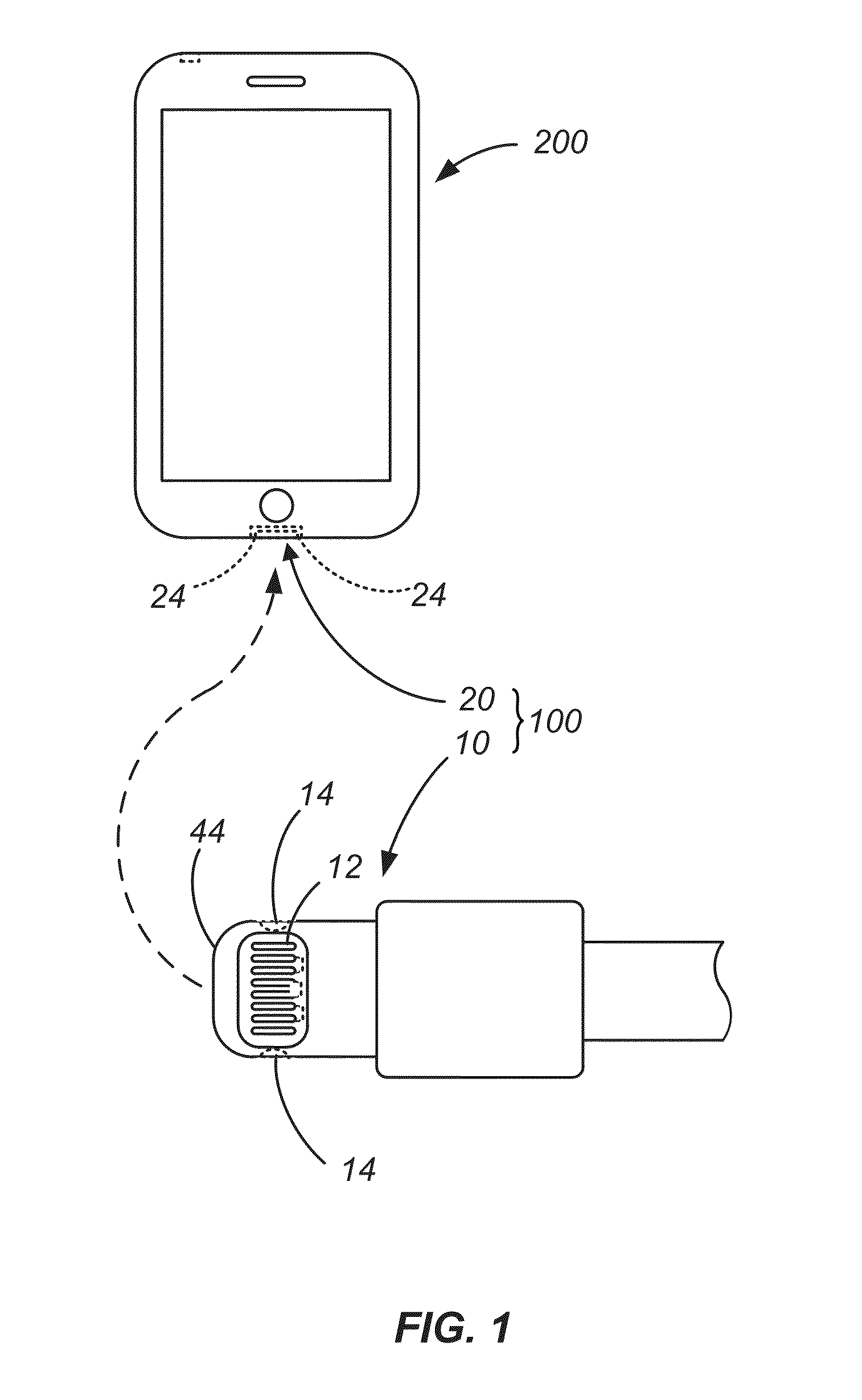

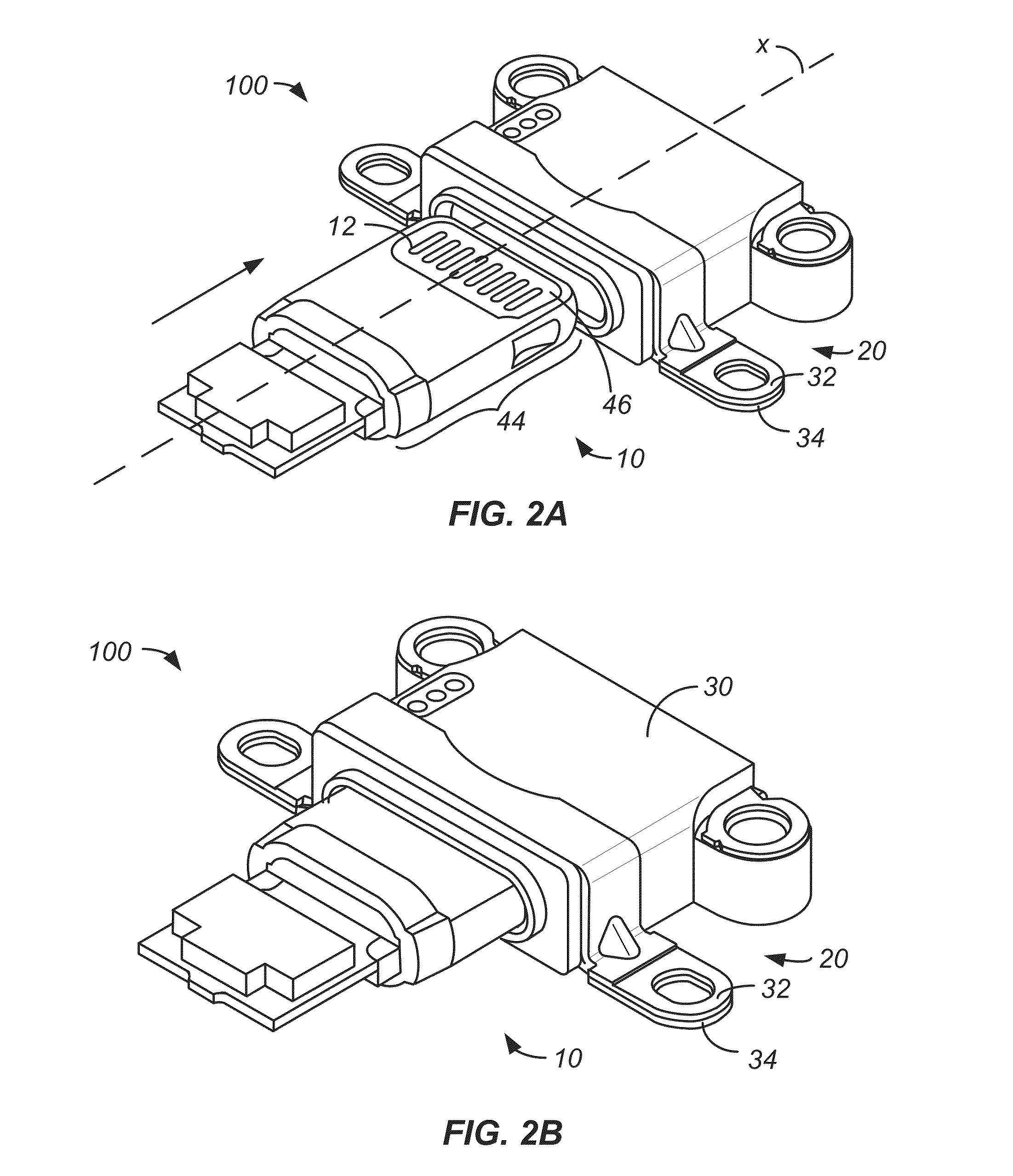

Retention mechanism having improved fatigue strength

InactiveUS20140057479A1Improved retention mechanismIncreased normal forceContact member cases/bases manufactureContact member assembly/disassemblyEngineeringUltimate tensile strength

A retention latch mechanism having a retention spring of a first connector engageable with a retention feature of a second connector. The retention spring may include a spring arm having a distal, curved retaining portion that is resiliently received within the retention feature and a reinforced portion that is proximal of the distal retaining portion. The reinforced portion includes a layer having residual compressive stress to inhibit fatigue failure during repeated cycling of the latch mechanism. The reinforced portion may be formed by a cold working method, such as shot peening a select region of the spring arm. The reinforced portion is formed to inhibit fatigue failure during repeated cycling of the latch mechanism. Methods of forming a retention mechanism having a retention spring with a reinforced portion are provided herein.

Owner:APPLE INC

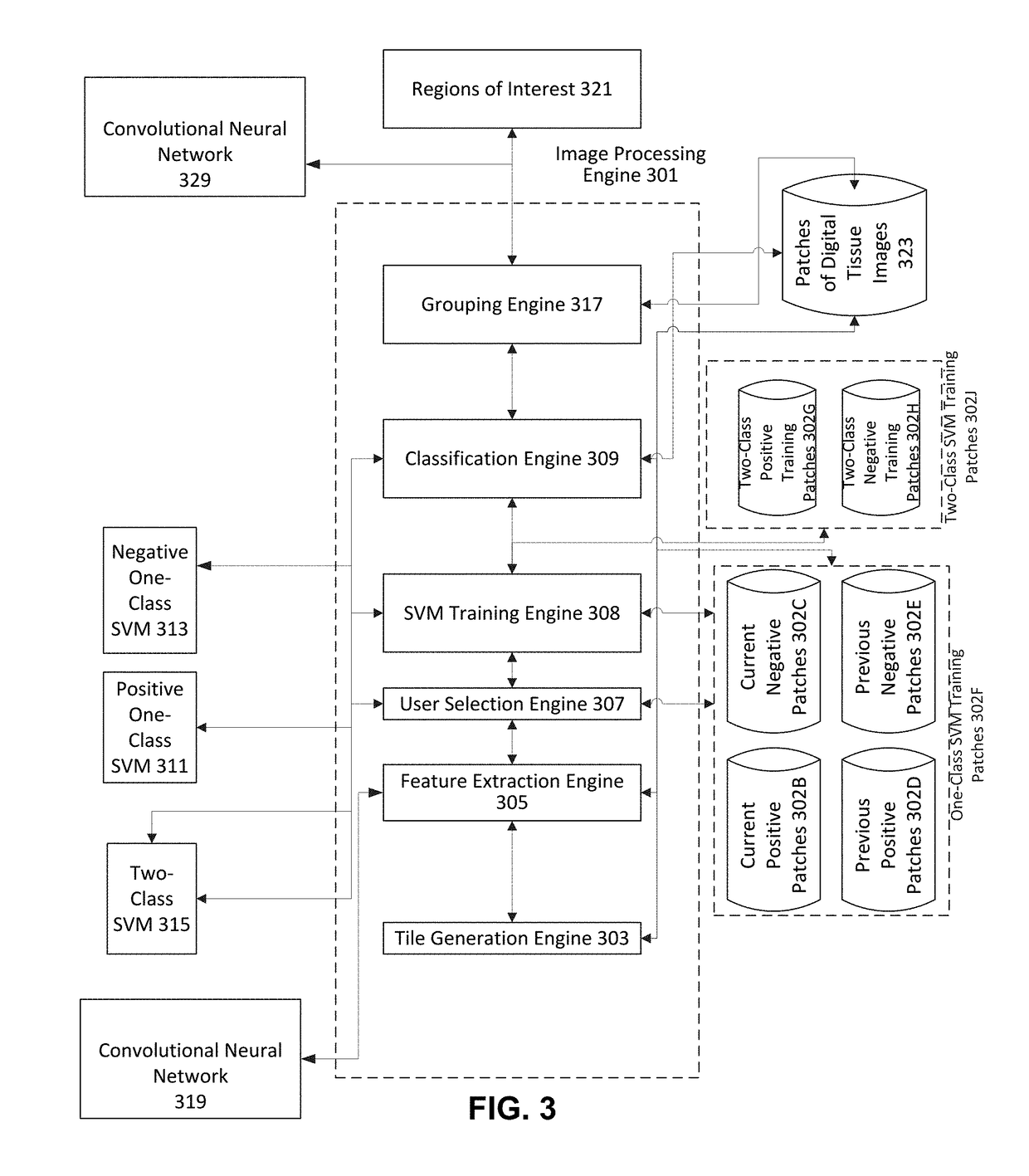

Few-shot learning based image recognition of whole slide image at tissue level

A computer implemented method of generating at least one shape of a region of interest in a digital image is provided. The method includes obtaining, by an image processing engine, access to a digital tissue image of a biological sample; tiling, by the image processing engine, the digital tissue image into a collection of image patches; obtaining, by the image processing engine, a plurality of features from each patch in the collection of image patches, the plurality of features defining a patch feature vector in a multidimensional feature space including the plurality of features as dimensions; determining, by the image processing engine, a user selection of a user selected subset of patches in the collection of image patches; classifying, by applying a trained classifier to patch vectors of other patches in the collection of patches, the other patches as belonging or not belonging to a same class of interest as the user selected subset of patches; and identifying one or more regions of interest based at least in part on the results of the classifying.

Owner:NANTOMICS LLC

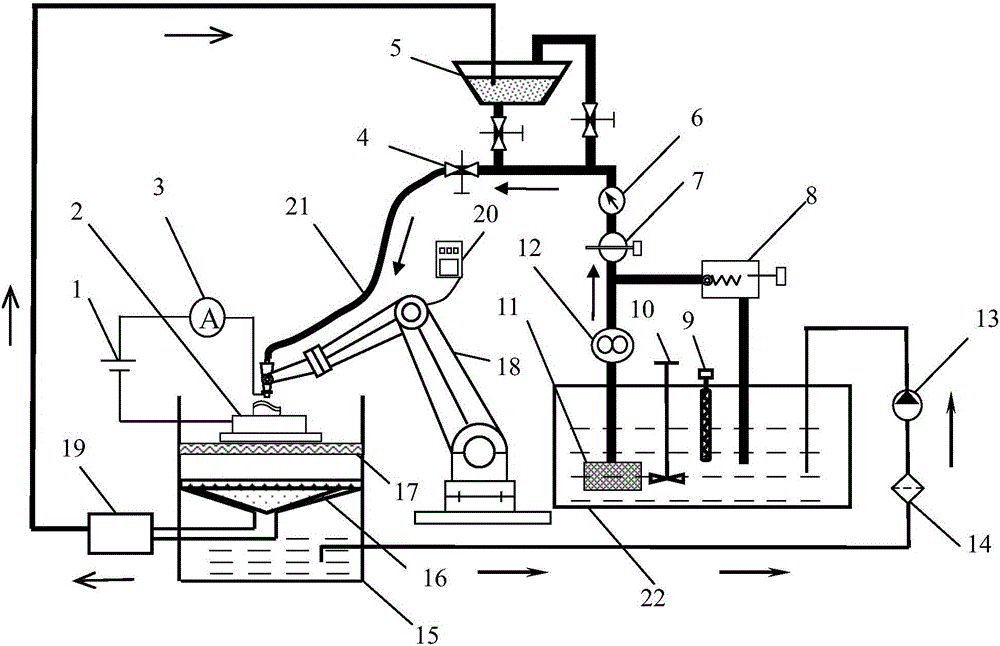

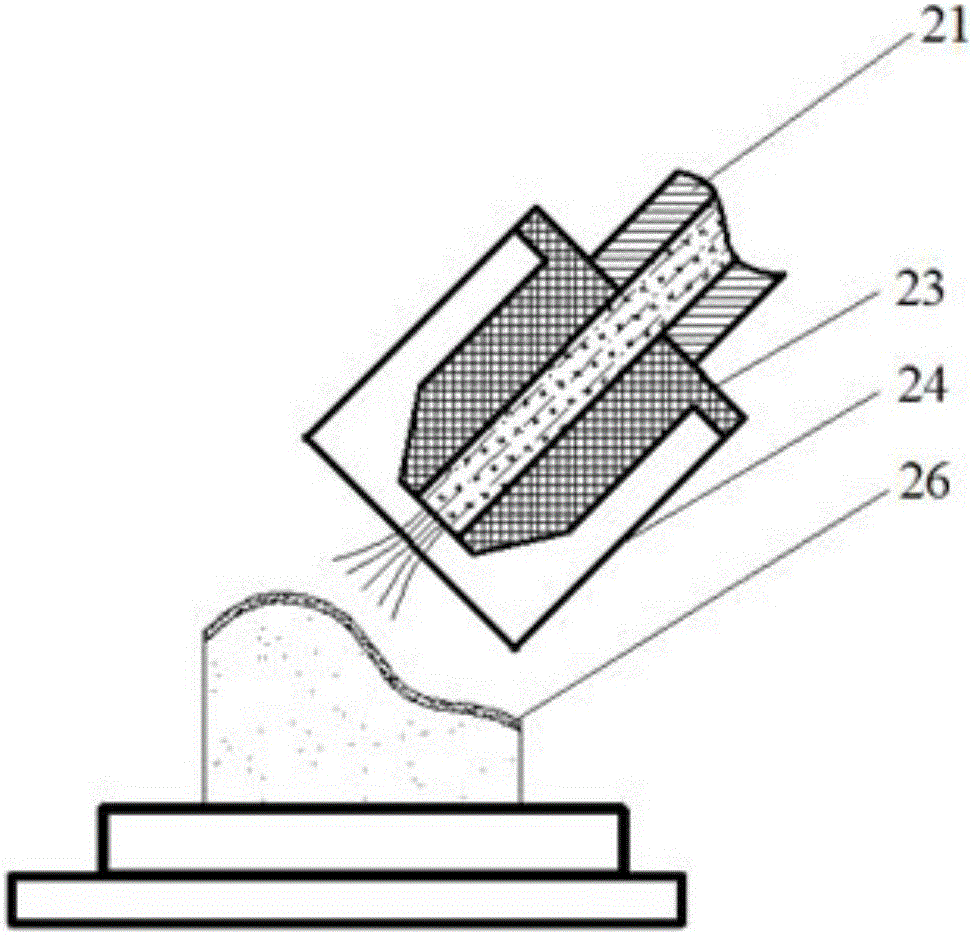

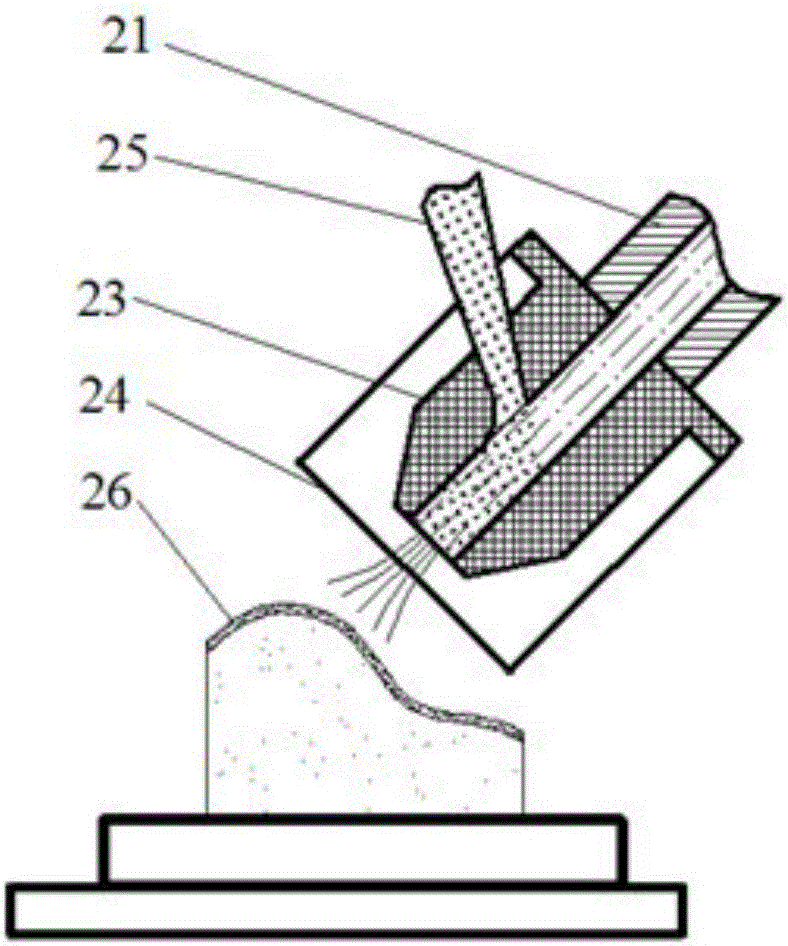

Three-dimensional surface shot peening jet electrodeposition manufacturing method and device

InactiveCN105951141ARemove in timeInhibit nodulationElectrolysis componentsElectrolytic coatingsNumerical controlImpurity

The invention provides a three-dimensional surface shot peening jet electrodeposition manufacturing method and device. According to the manufacturing method and device, a deposition solution and hard particles are mixed and deposit on a conductive substrate in a spraying manner, so that the rapid manufacturing technology of electrodeposition is realized, the growth rate of grains in the electrodeposition process is slowed down, the purpose of refining the grains is reached, and the quality of a deposition layer is dramatically improved; with combination of the shot peening strengthening technology and the electrodeposition technology, the defects of loose texture, pockmarks, pits and the like of the deposition layer caused by single electrodeposited cathode hydrogen evolution and impurity adhesion can be effectively overcome, and the hardness and the compactness of the deposition layer are improved; meanwhile, by introducing a five-axis linkage numerical control machining system, processing formation of a three-dimensional space can be realized, and the uniformity and the shape accuracy of the deposition layer are improved; and the technology can be widely applied to production of noble metal devices and parts in complex shapes and can also be used for surface rapid coat-plating, a strengthening technology and the like.

Owner:JIANGSU UNIV

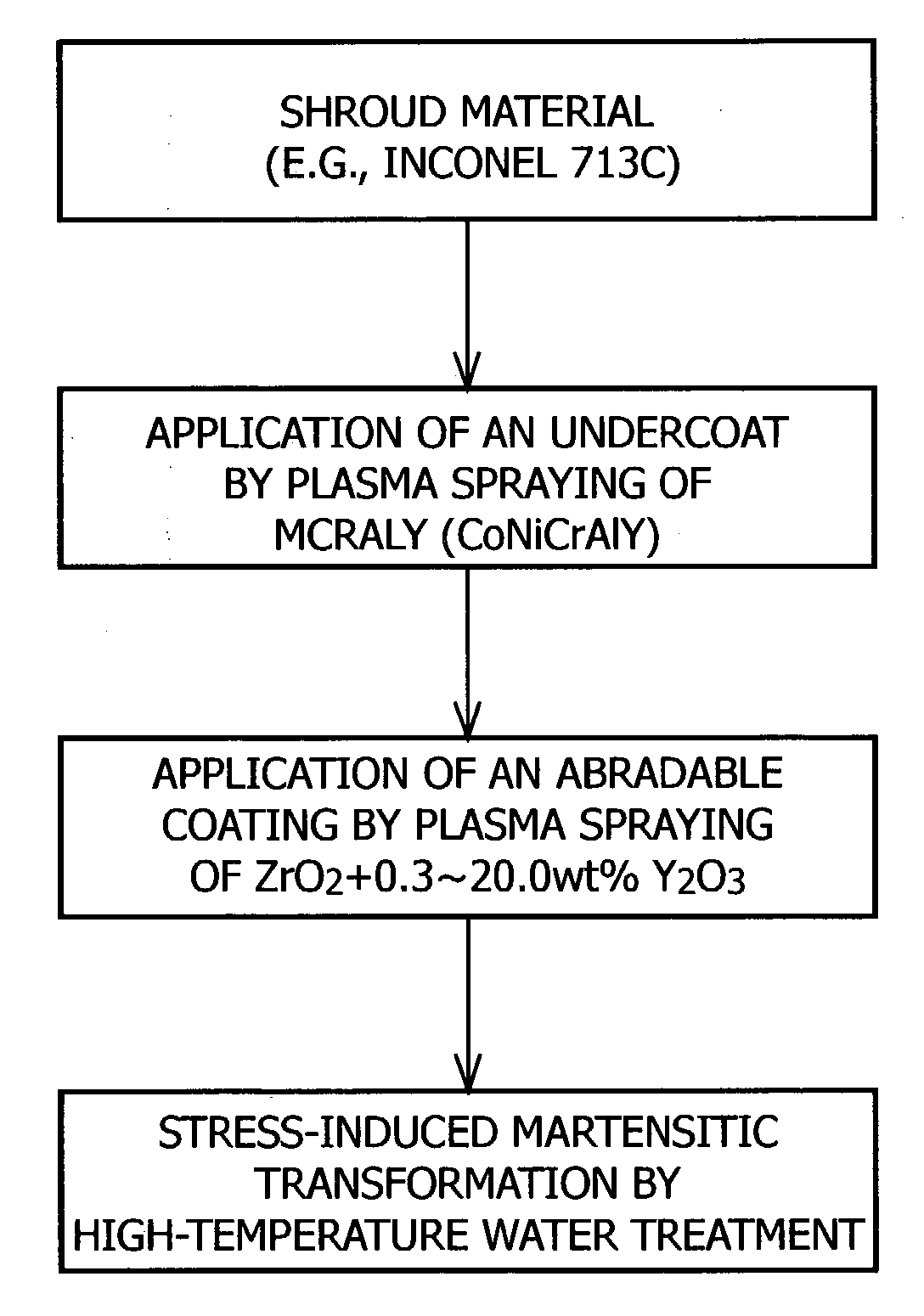

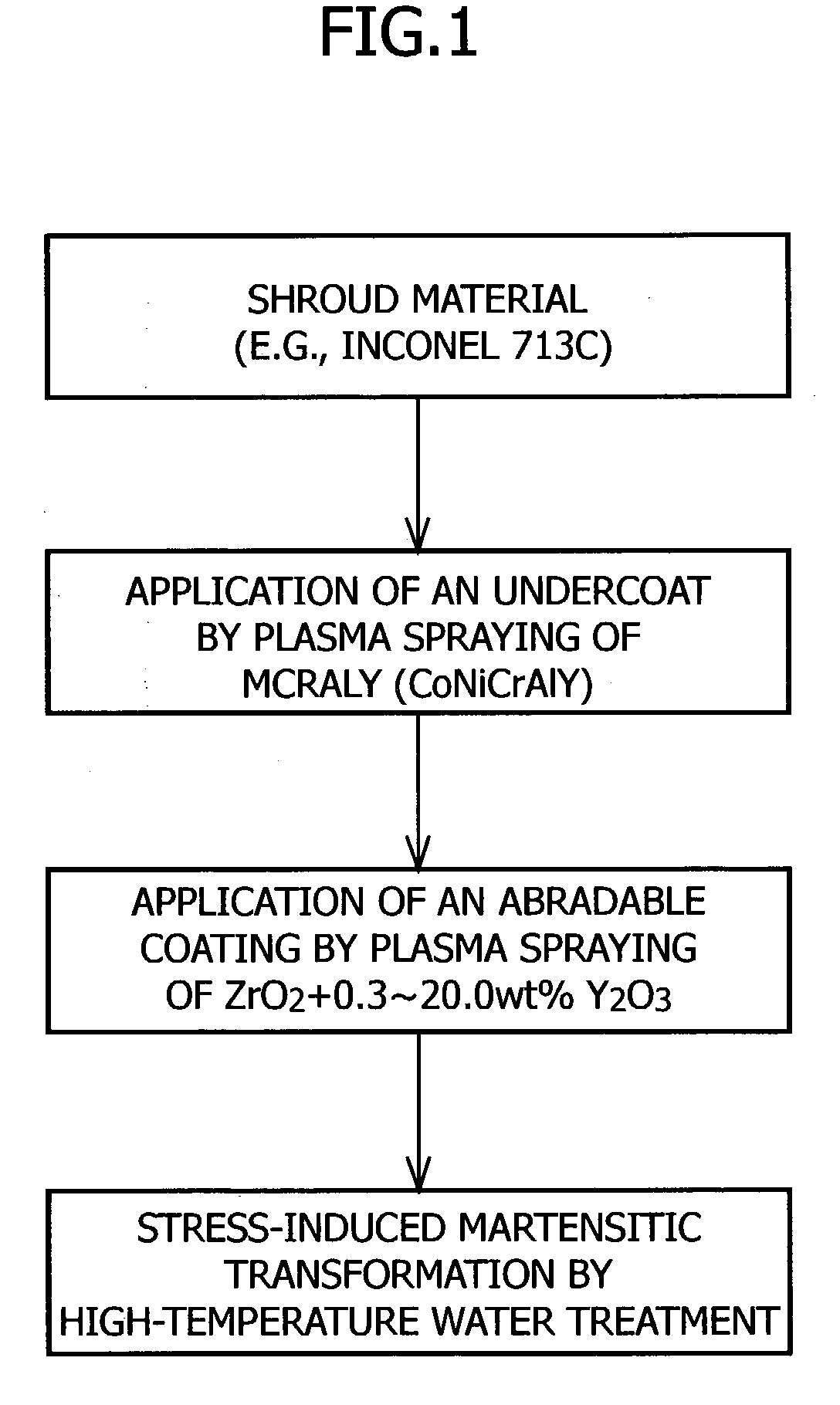

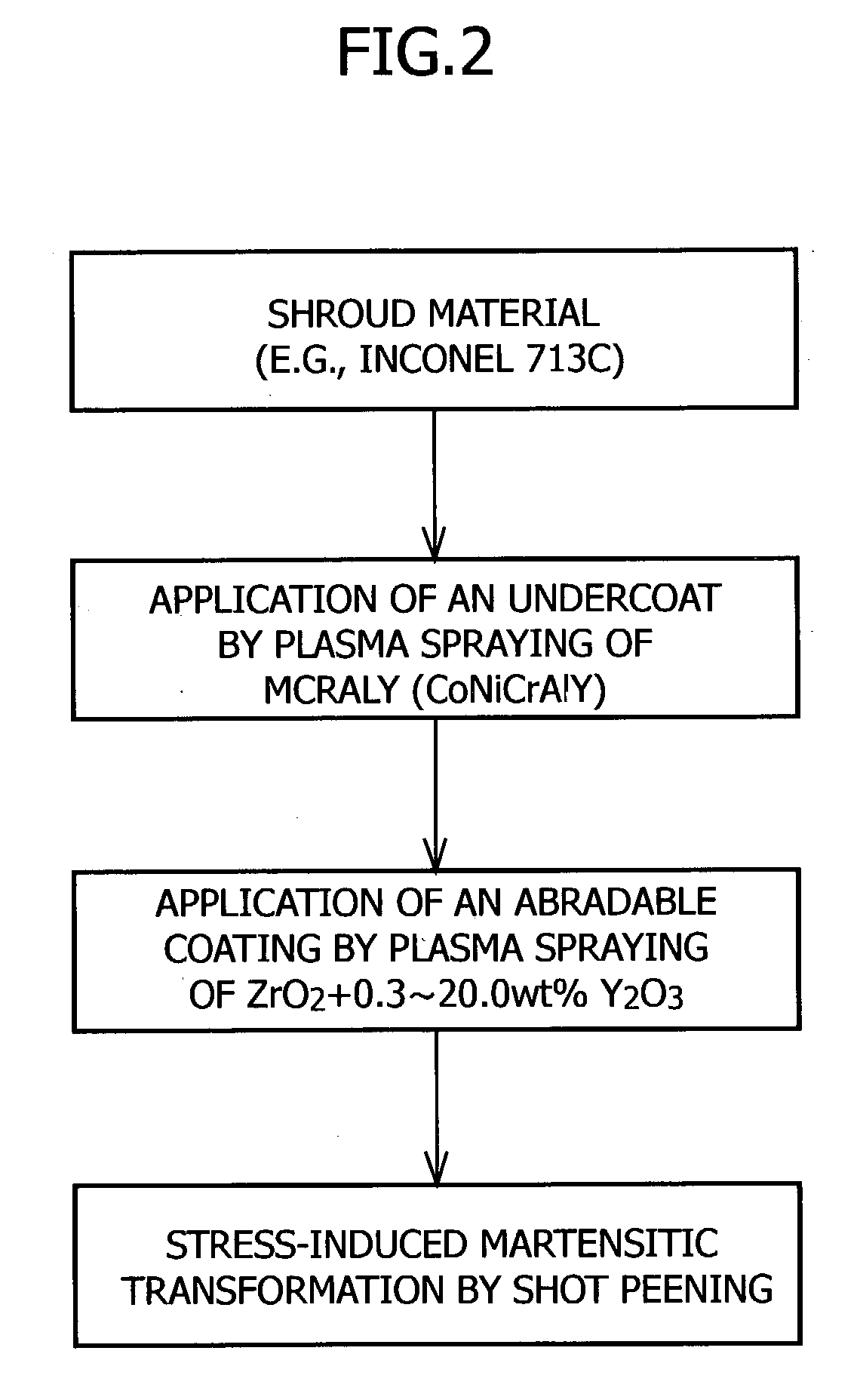

Abradable coating and method for forming same

InactiveUS20040022949A1Excellent cuttabilityImprove performanceMolten spray coatingPretreated surfacesMetallurgyCrystal structure

The present invention provides an abradable coating which is applied to the surfaces of stationary parts in rotary machinery such as gas turbines and does not cause damage or other trouble to the blades, as well as a method for forming the same. This method for forming an abradable coating comprises the steps of coating a shroud material with a partially stabilized zirconia ceramic material to form a zirconia ceramic layer having a cubic or tetragonal crystal structure on the surface of the shroud material; and subjecting the shroud material having the zirconia ceramic layer formed thereon to high-temperature water treatment at a temperature of 100 to 450° C. for 1 to 300 hours and thereby transforming the crystal structure of the zirconia ceramic layer into a monoclinic crystal structure. Alternatively, shot peening may be employed in place of the high-temperature water treatment.

Owner:HASEZAKI KAZUHIRO +2

Latch assembly having spring arms each with a retaining portion and a reinforced portion

InactiveUS8882529B2Increased normal forceAvoid fatigue failureContact member cases/bases manufactureCoupling device engaging/disengagingMechanical engineeringResidual compressive stress

A retention latch mechanism having a retention spring of a first connector engageable with a retention feature of a second connector. The retention spring may include a spring arm having a distal, curved retaining portion that is resiliently received within the retention feature and a reinforced portion that is proximal of the distal retaining portion. The reinforced portion includes a layer having residual compressive stress to inhibit fatigue failure during repeated cycling of the latch mechanism. The reinforced portion may be formed by a cold working method, such as shot peening a select region of the spring arm. The reinforced portion is formed to inhibit fatigue failure during repeated cycling of the latch mechanism. Methods of forming a retention mechanism having a retention spring with a reinforced portion are provided herein.

Owner:APPLE INC

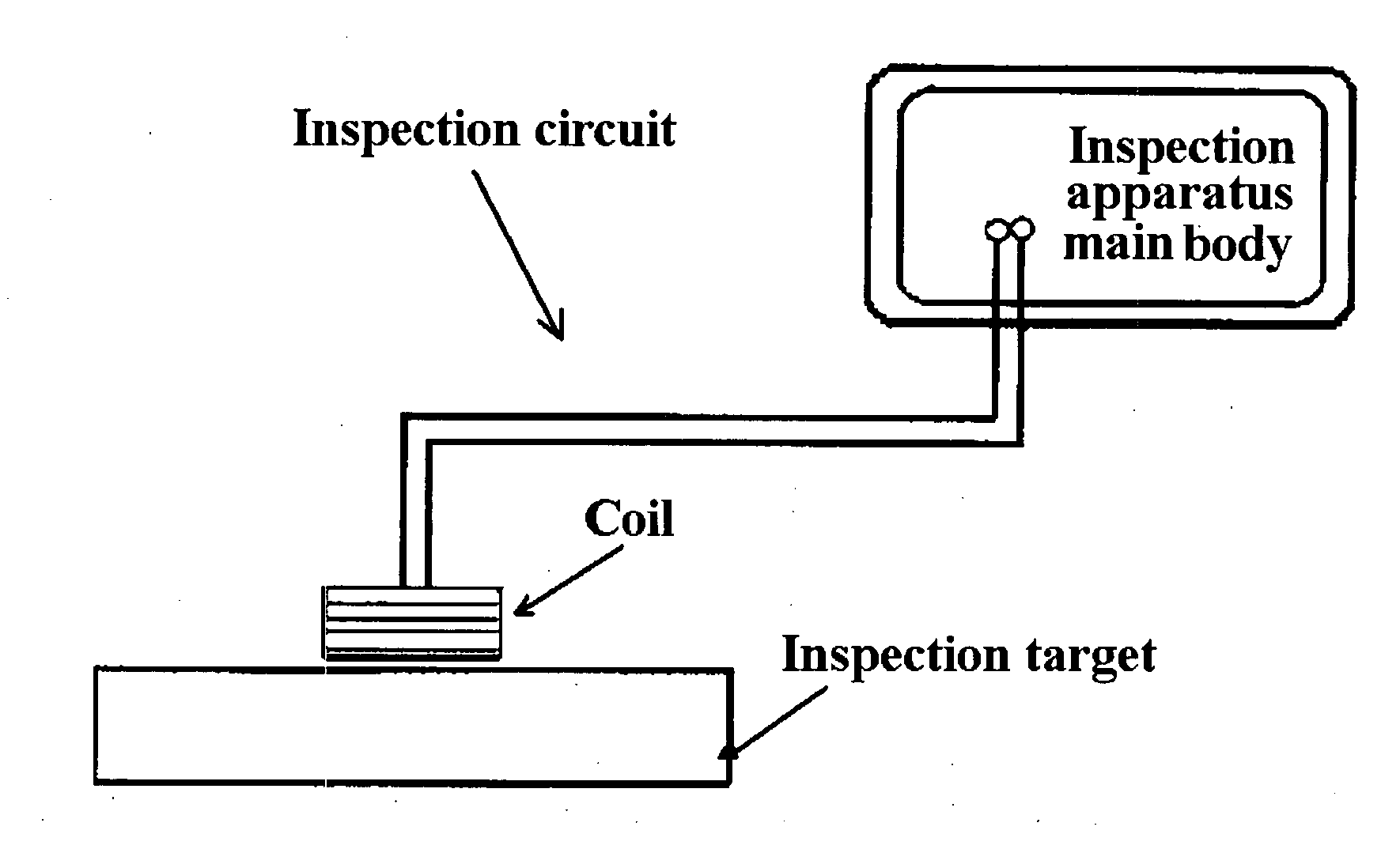

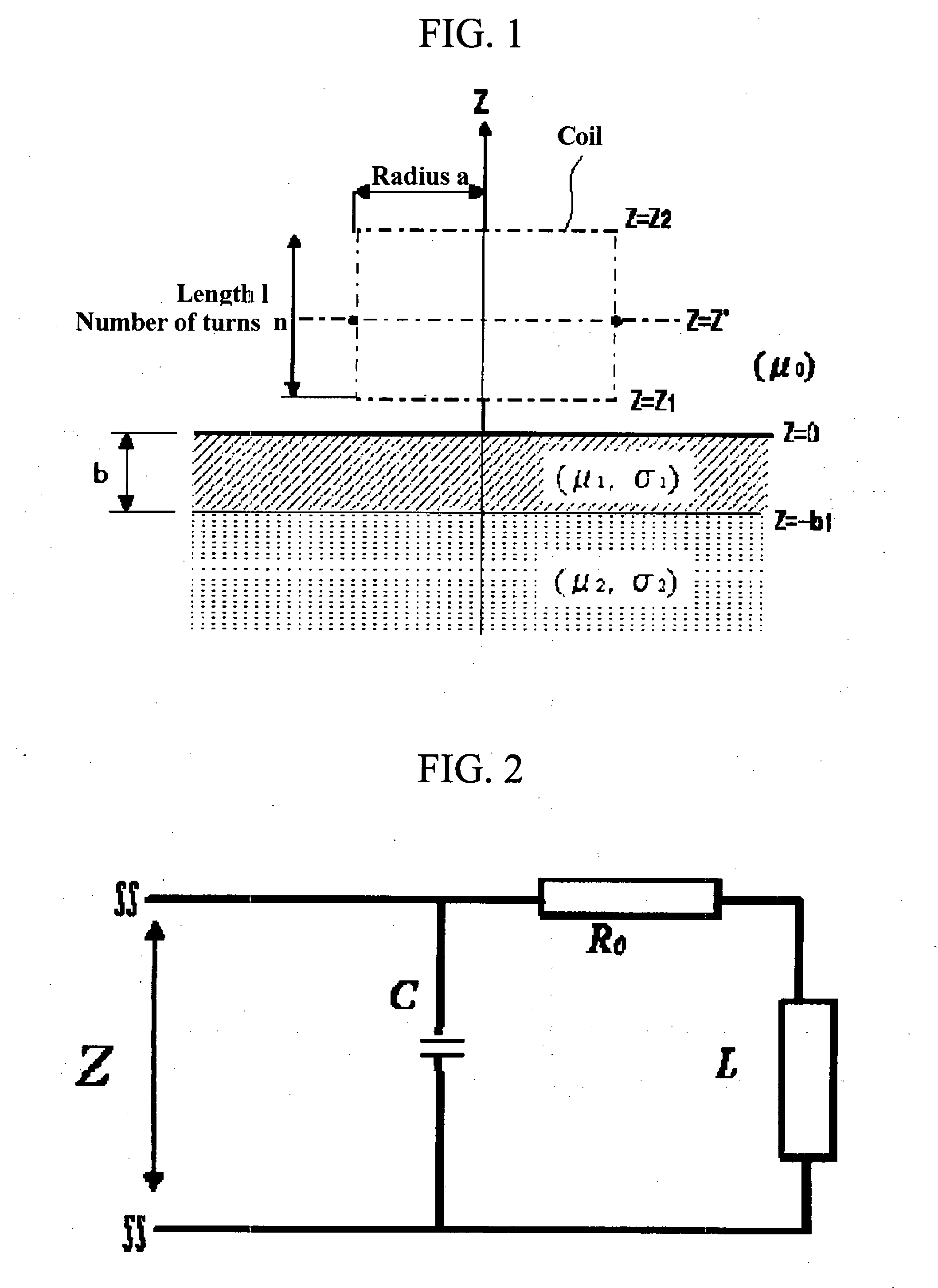

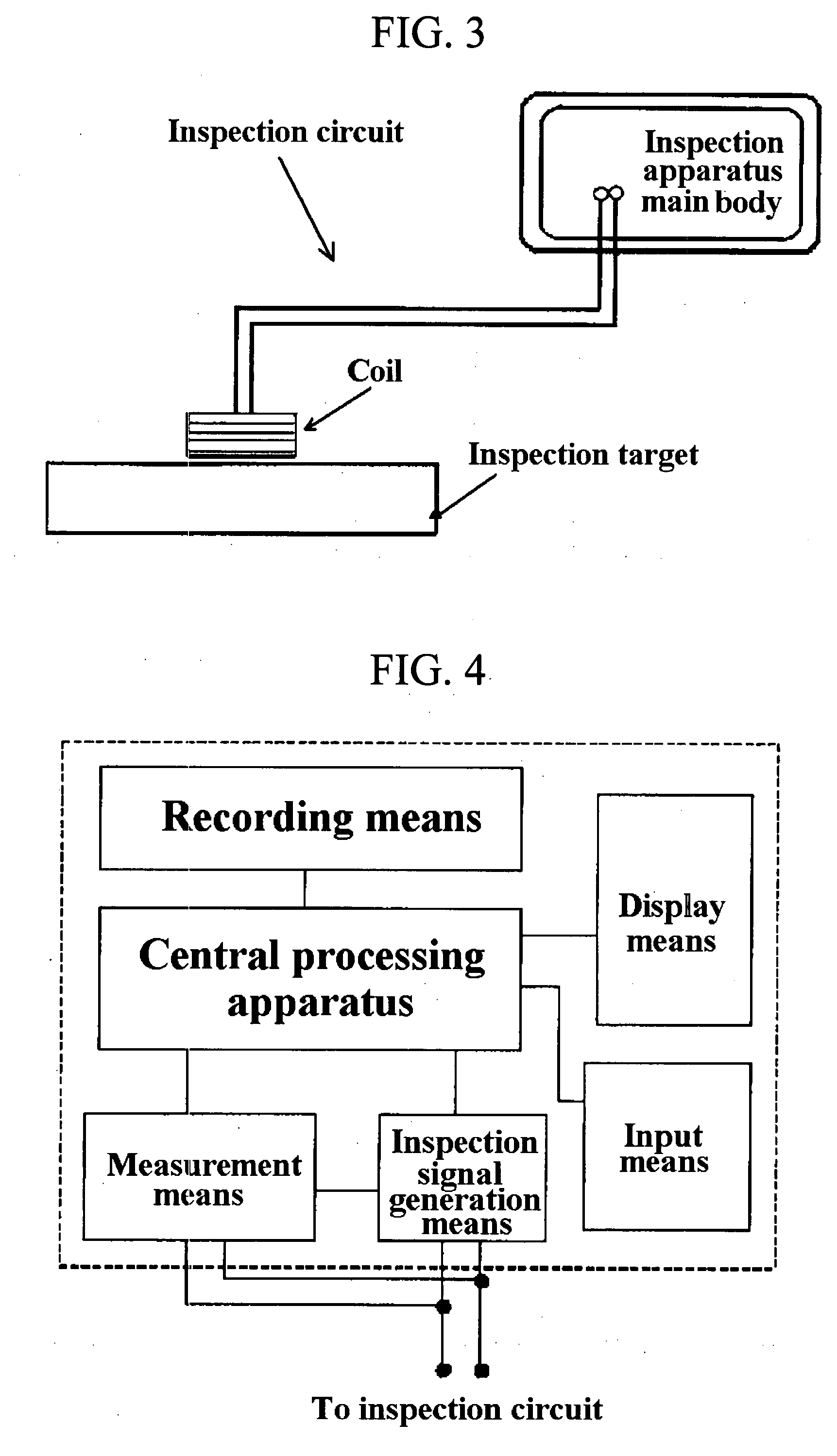

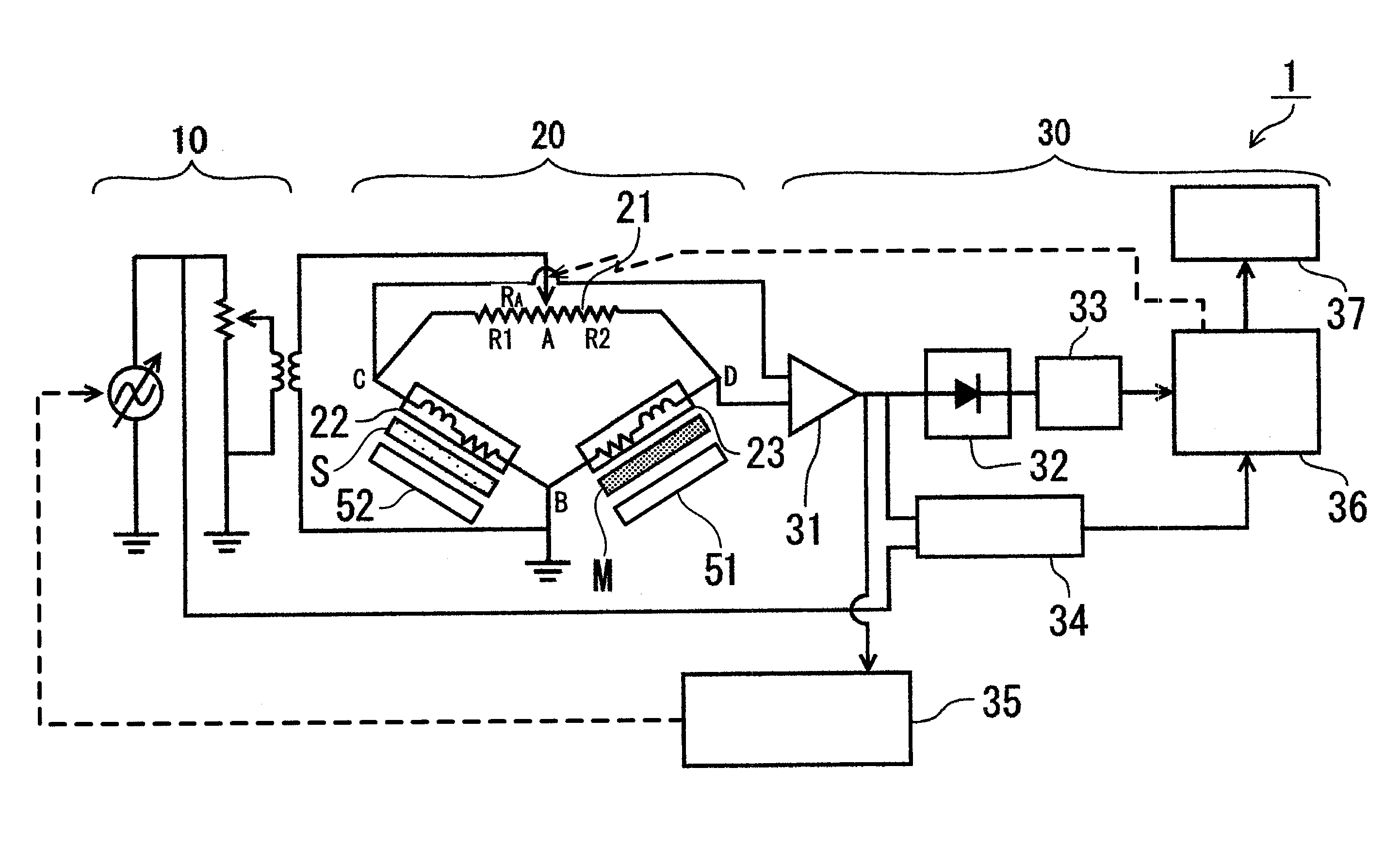

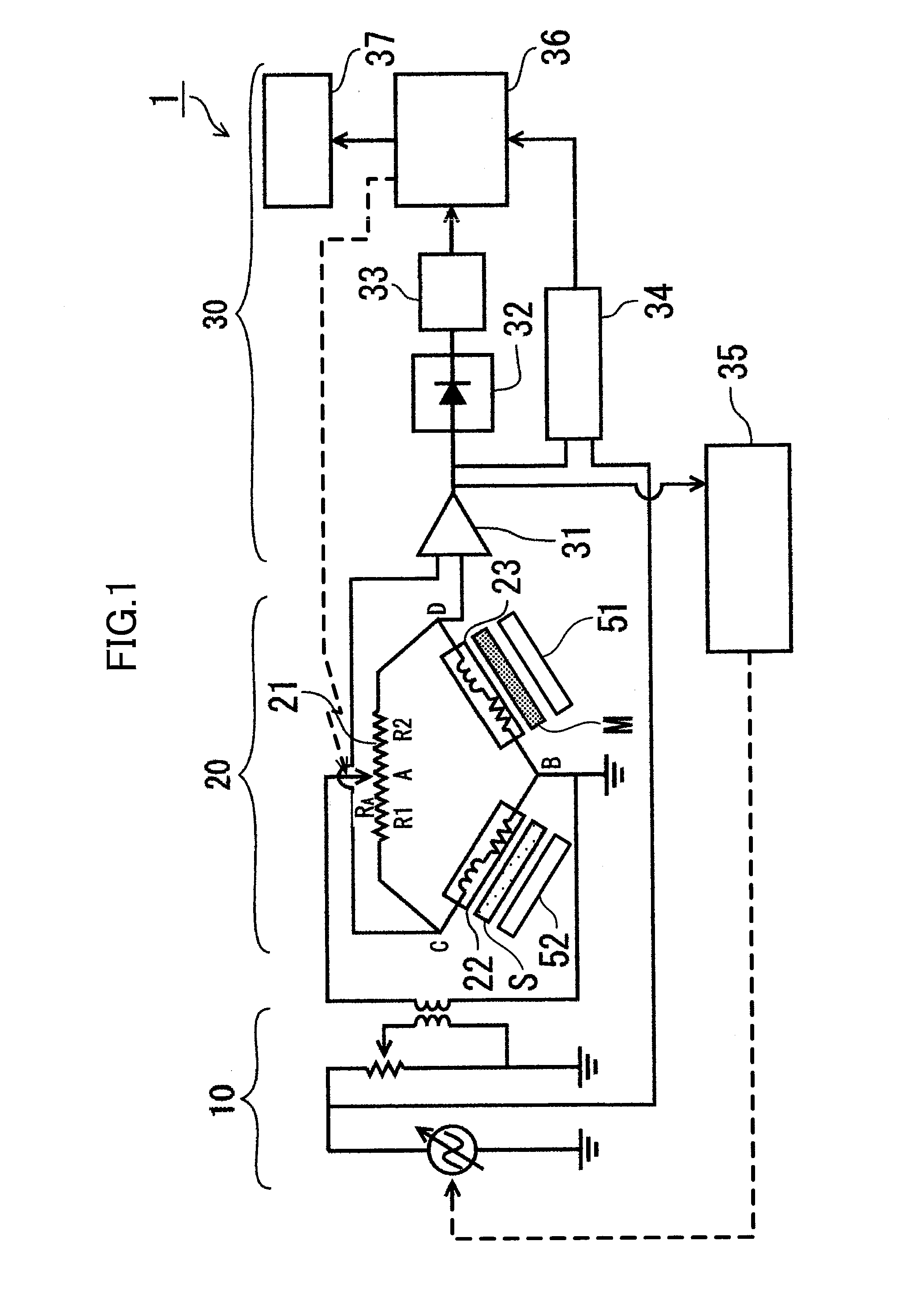

Nondestructive inspection method and apparatus for a surface processed by shot peening

InactiveUS20080001609A1Short timeEasy to measureForce measurementMagnetic property measurementsNon destructiveEngineering

To provide an inspection method and an inspection apparatus that can easily measure a distribution of residual stress on a surface processed by shot peening, including a state of distribution in a depth direction of a material to be treated in a relatively short time without destroying the material to be treated.A coil provided in the inspection circuit is arranged on a surface processed by shot peening of the inspection target, an alternating current signal is input to the inspection circuit with changing a frequency so that frequency response characteristics of impedance of the inspection circuit is measured and acquired as inspection target data, and the inspection target data is compared to frequency response characteristics of impedance acquired from a sample of which a state of generation of residual stress is found.

Owner:FUJI MFG CO LTD

Self-monitoring metals, alloys and materials

ActiveUS20050083032A1Good curative effectImprove assessmentForce measurementMagnetic property measurementsTest materialObservability

Observability of damage precursor, damage and usage states, or event occurrence may be enhanced by modifying component materials to include self-monitoring materials or by processing test material to alter the surface properties. The properties of the self monitoring materials, such as magnetic permeability or electrical conductivity, are monitored with electromagnetic sensors and provide greater property variations with component condition than the original component material. Processing includes shot peening or laser welding.

Owner:JENTEK SENSORS

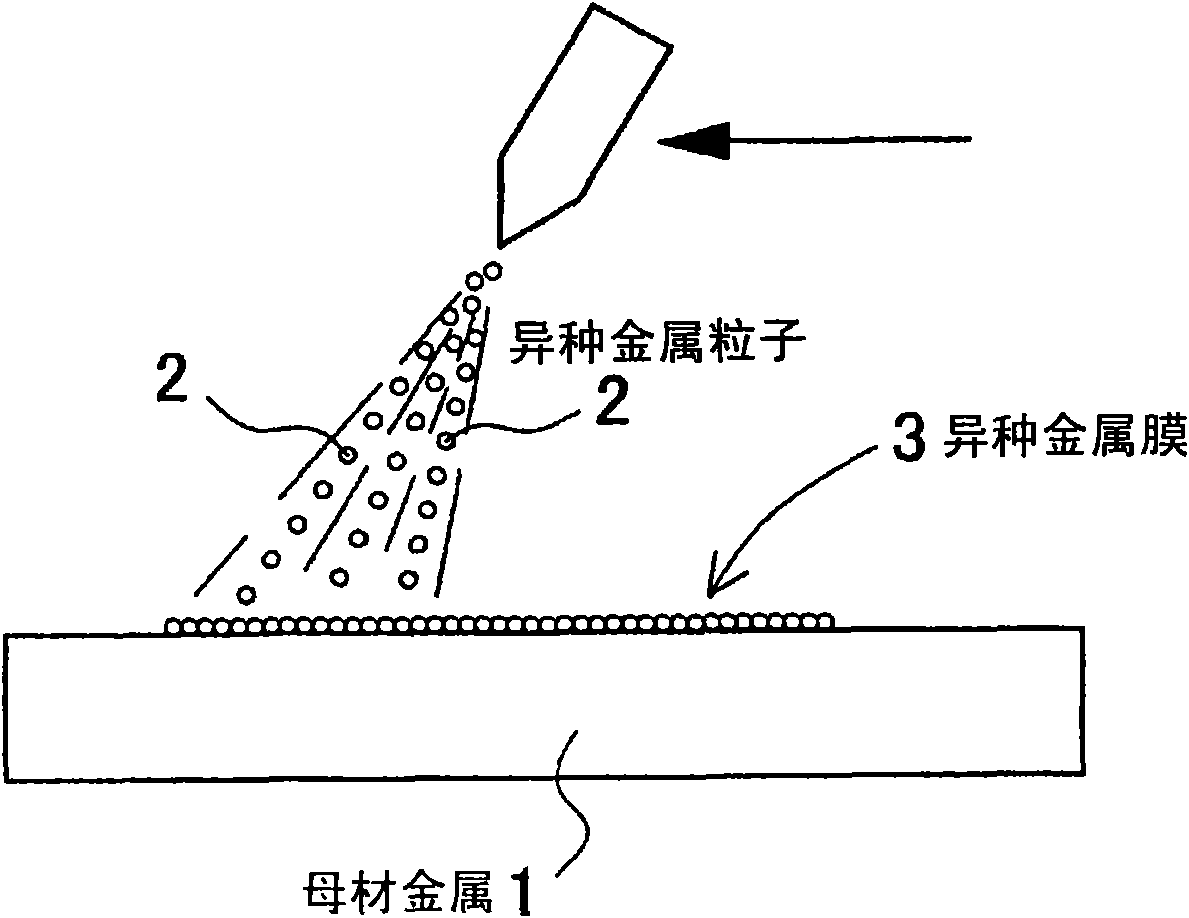

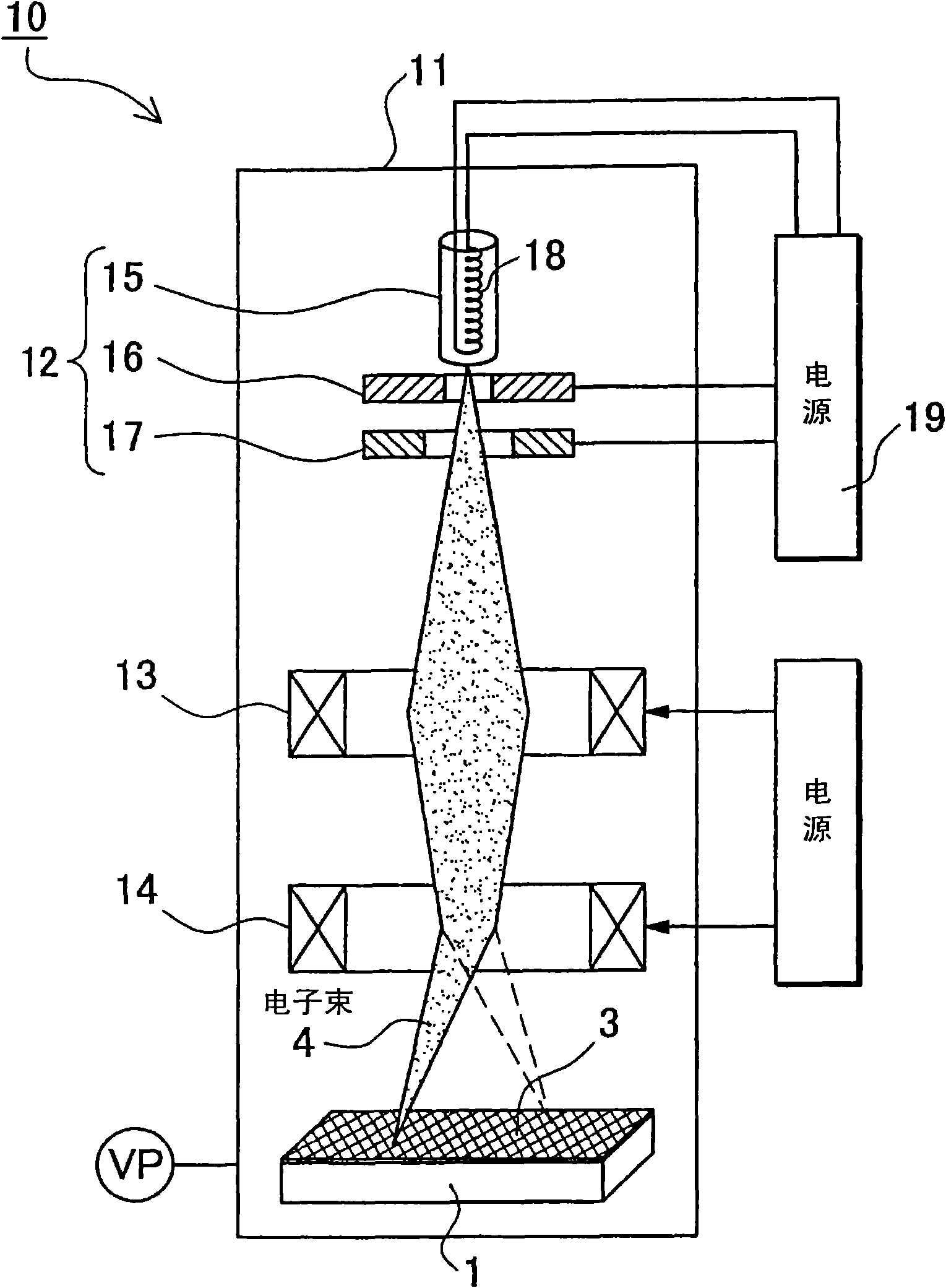

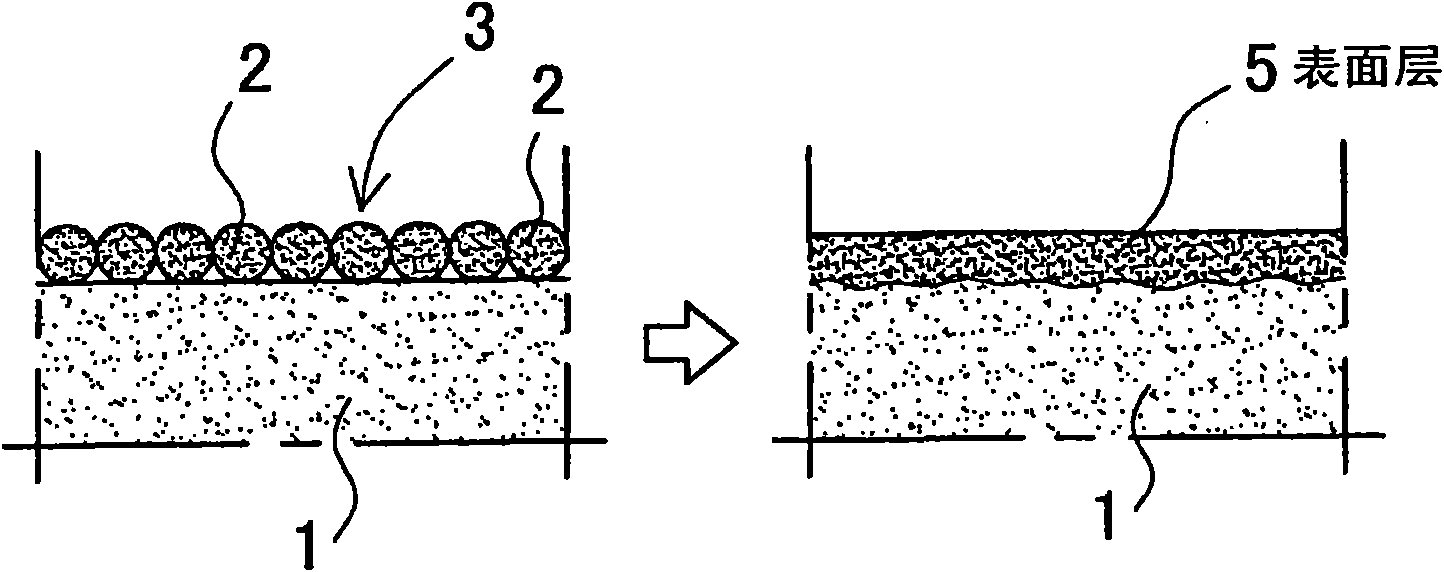

Metal surface treatment method

To reliably bond various metals onto a surface of various parent metals in an alloyed state in a simple, easy and efficient manner. [MEANS FOR SOLVING PROBLEMS] A metal surface treatment method comprising a shot peening step of shot peening dissimilar metal particles (2), which are different from a parent metal (1), on the surface of the parent metal (1) to provide a dissimilar metal film (3) on the surface of the parent metal (1), and an electron beam irradiation step of applying electron beams (4) to the surface of the parent metal (1) with the dissimilar metal film (3) provided thereon by the shot peening step to bond the dissimilar metal film (3) and the parent metal (1).

Owner:LTT BIO PHARMA

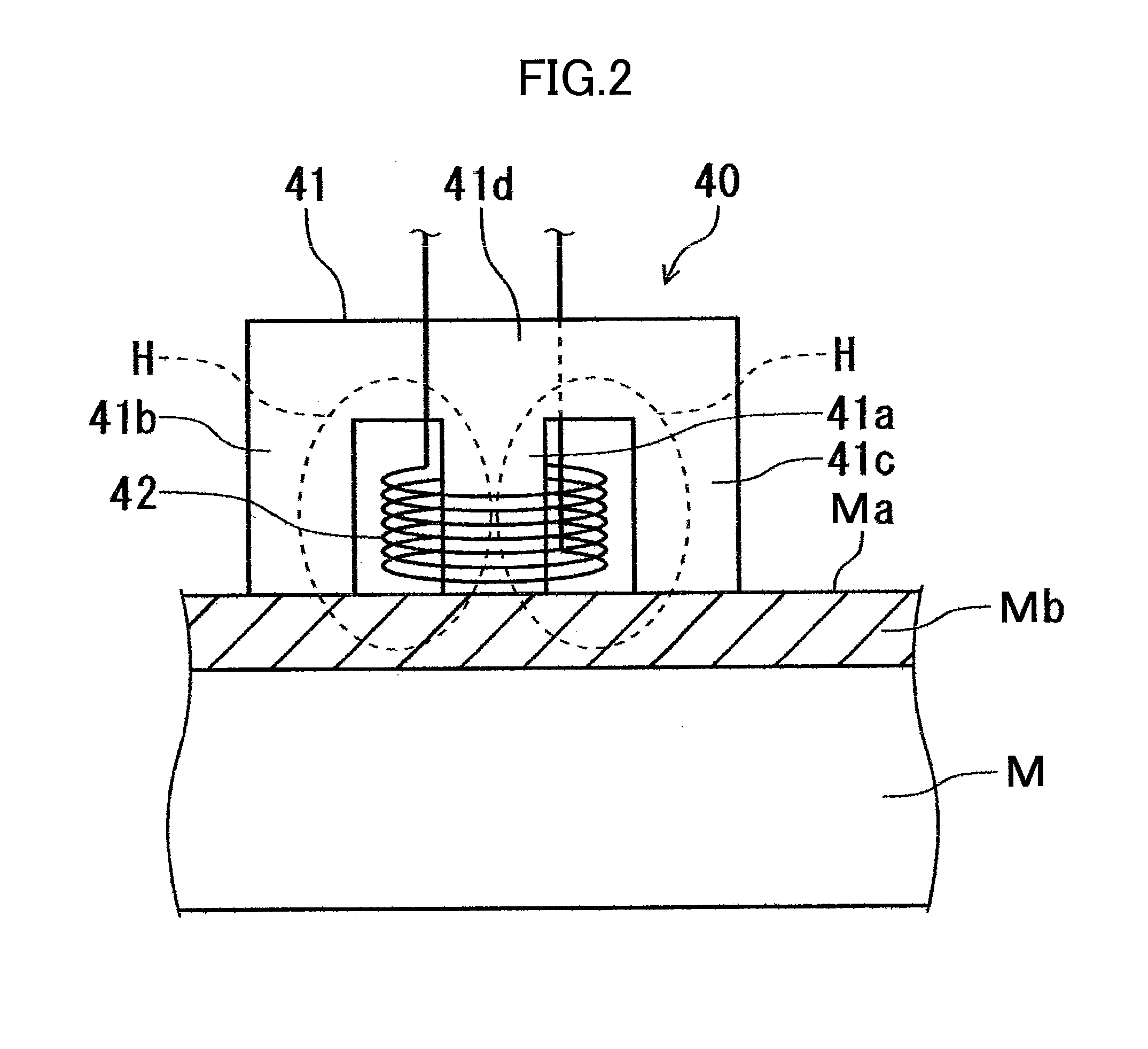

Surface property inspection device and surface property inspection method

ActiveUS20140084910A1Improve detection accuracyHighly accurate inspection of surface stateUsing electrical meansElectrical/magnetic thickness measurementsValue setPeening

To provide a surface property inspection device and surface property inspection method with which the surface treatment condition of treated material such as steel subjected to such surface treatments as shot-peening treatment or heat treatment, nitriding, and the like can be non-destructively and precisely inspected, and which offers a high degree of general purpose application. A surface property inspection device 1 includes an AC power supply, an AC bridge circuit, and a judgment device, and the AC bridge circuit has a variable resistor with a variable split ratio γ, a benchmark detector, and an inspection detector. In variable resistor setting step S1, the split ratio γ of a variable resistor is adjusted and set so that the output from the AC bridge circuit is increased; after setting a frequency at which the output from the AC bridge circuit is maximized using a frequency setting step S2, in pass / fail judgment step S4, a benchmark sample S is brought into contact with the benchmark detector, the sample under inspection M is brought into contact with the inspection detector, and the output from the LPF 33 and the threshold value set in the threshold value setting step S3 are compared and a pass / fail judgment is made of the surface condition of the sample under inspection M.

Owner:SINTOKOGIO LTD

Shape maintenance shot peening strengthening and calibration method for preventing in-plane bending of wall panel

The invention belongs to the forming technique of aerospace wall panels, relating to a shape maintenance shot peening strengthening and calibration method for preventing the in-plane bending of a wall panel. The method comprises the following steps of: firstly carrying out regional division on the spare parts of the wall panel, then inputting data in a shot peening device, and finally carrying out shot peening strengthening in a double opposite spraying manner; when in-plane bending occurs for the shot peening, calibrating thin-gauge skins, firstly choosing a calibration region, and then inputting the data into the shot peening device; and carrying out double opposite spraying on the inner and the outer thin-gauge skins in the deformed region with in-plane bending. According to the invention, aiming at the complicated structural shape, shot peening strengthening is carried out on the wall panel under the condition of guaranteeing that the space shapes of the spare parts are not changed after deformation, and the calibration method for forming the in-plane bending after the shot peening strengthening reduces the rejection rate of the spare parts, avoids severe economic lost and has good technological and economic benefits.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

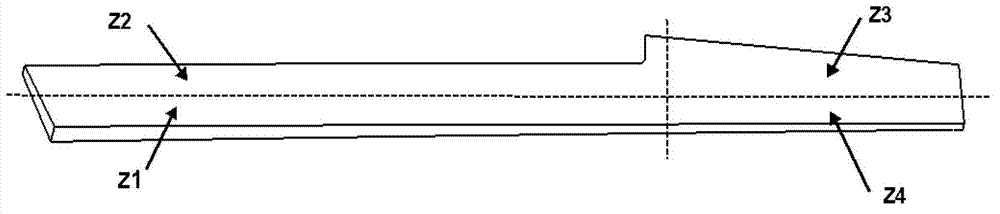

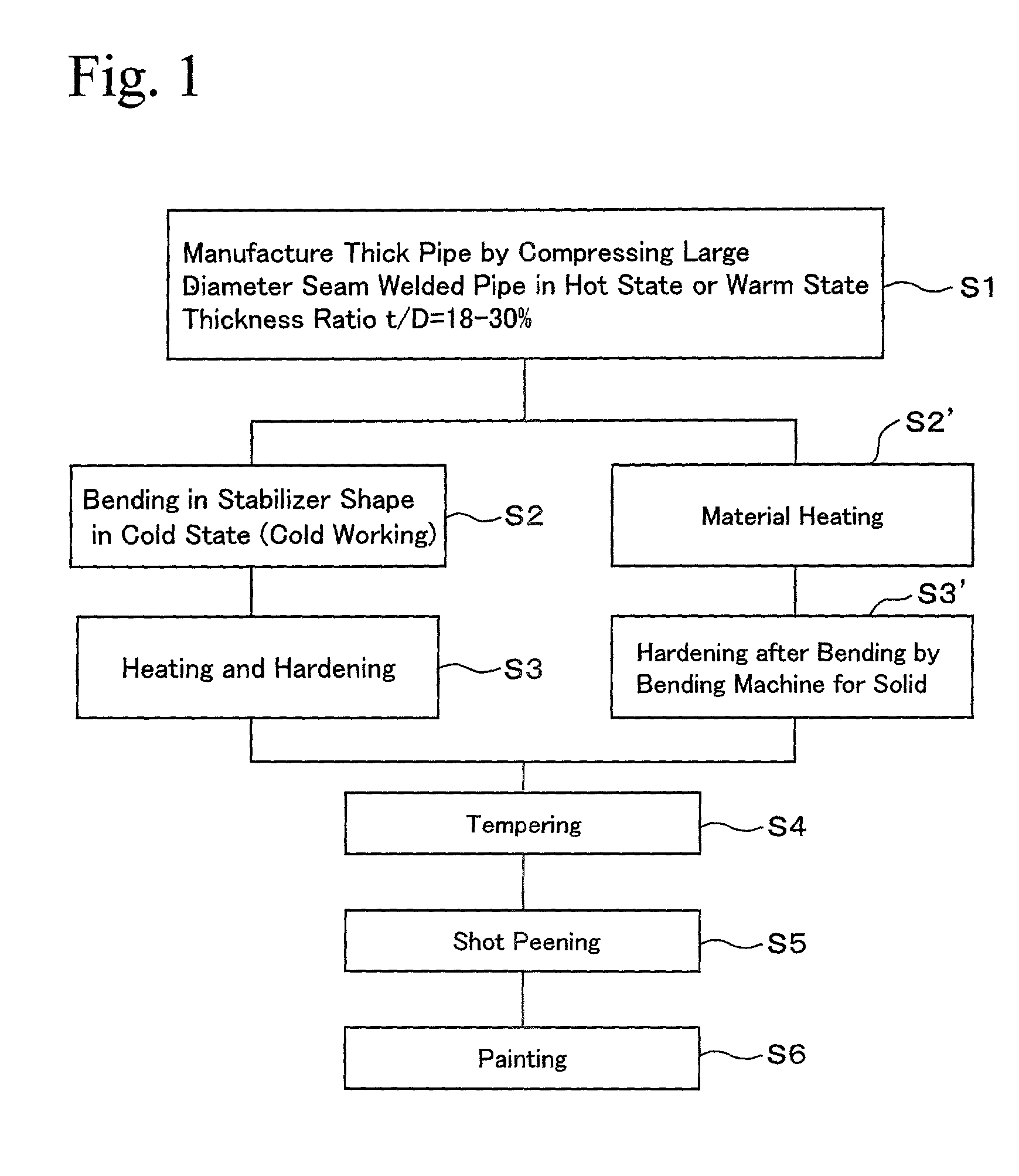

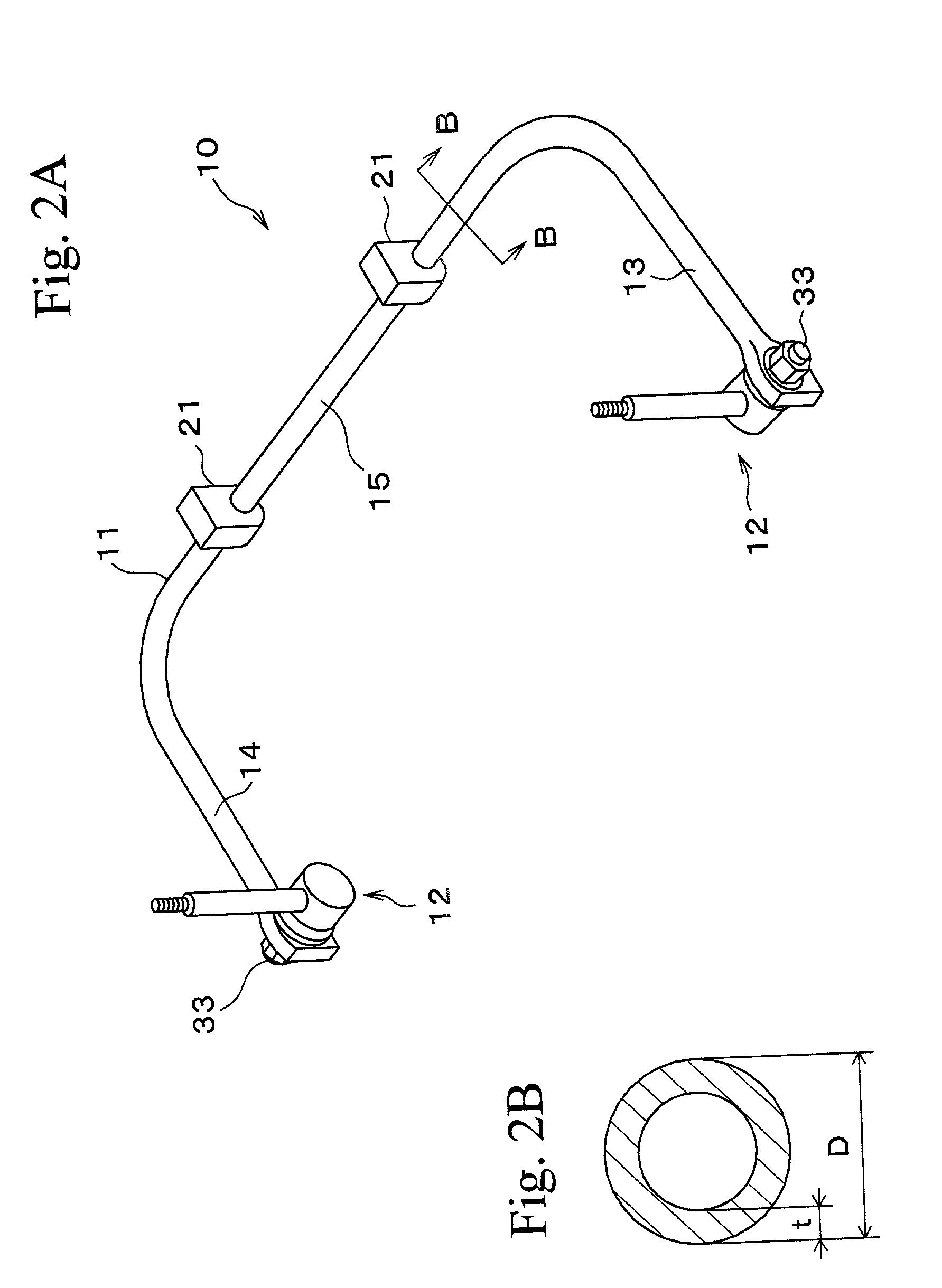

Hollow stabilizer and method of manufacturing the same

In a method of manufacturing a hollow stabilizer, a pipe compressing step of compressing an electroseamed pipe in a temperature range of a hot state or a warm state so as to make a rate of a thickness with respect to an outer diameter between 18 and 35% is performed, and a forming step of forming the compressed electroseamed pipe in a stabilizer shape in a cold state is executed. Next, a step of applying a heat treatment to a half-finished stabilizer is performed, a shot peening step of impacting a shot on the half-finished stabilizer is performed, and a step of coating the half-finished stabilizer is performed.

Owner:NHK SPRING CO LTD

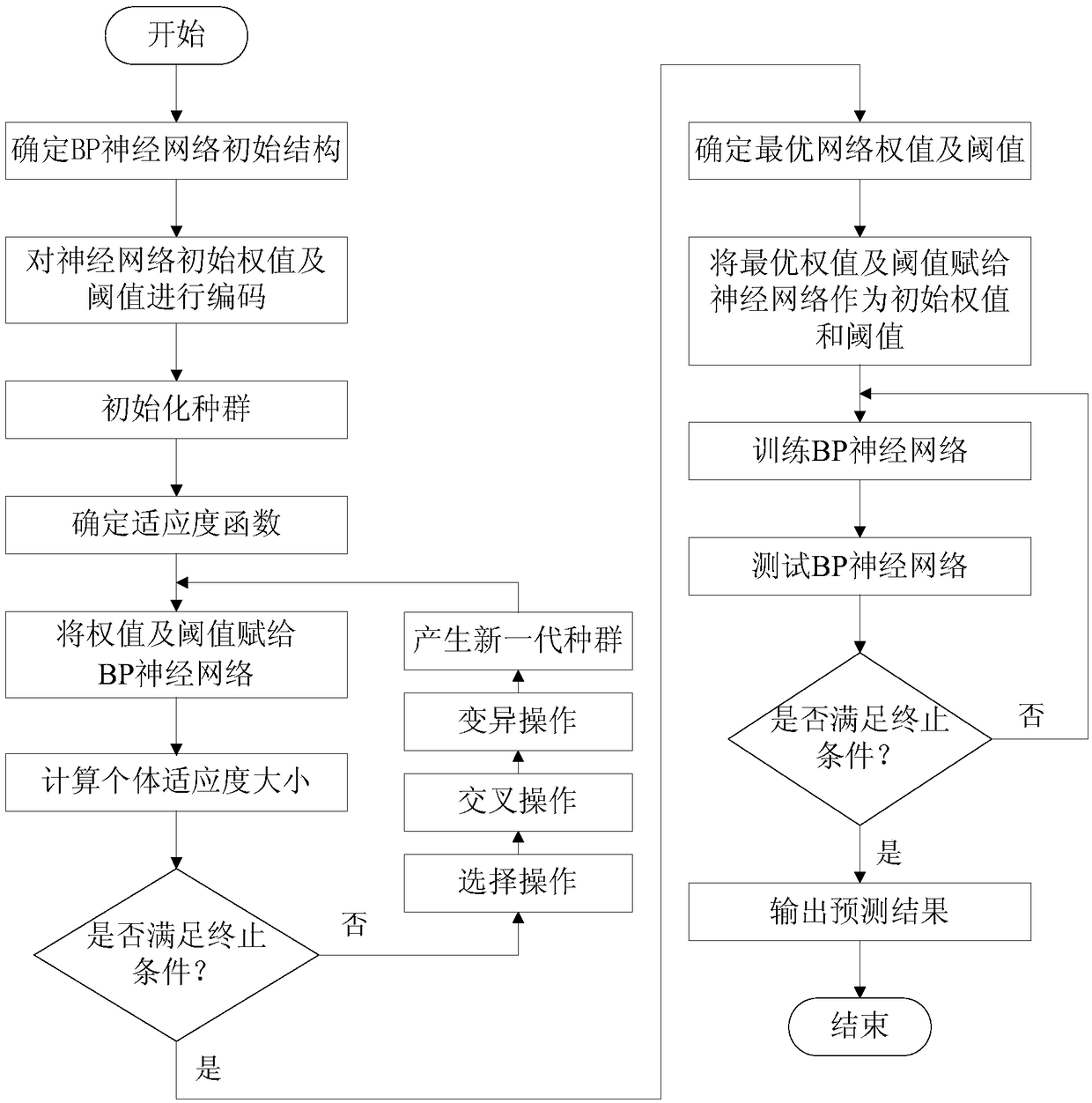

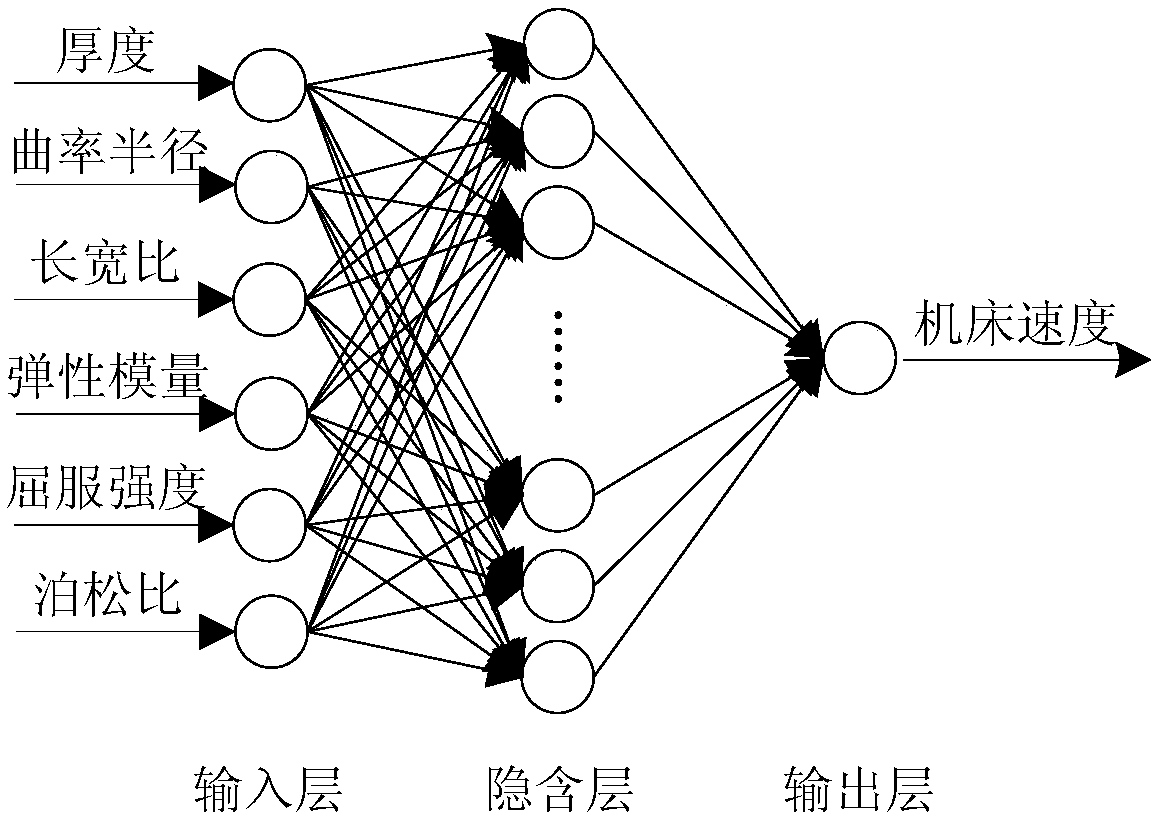

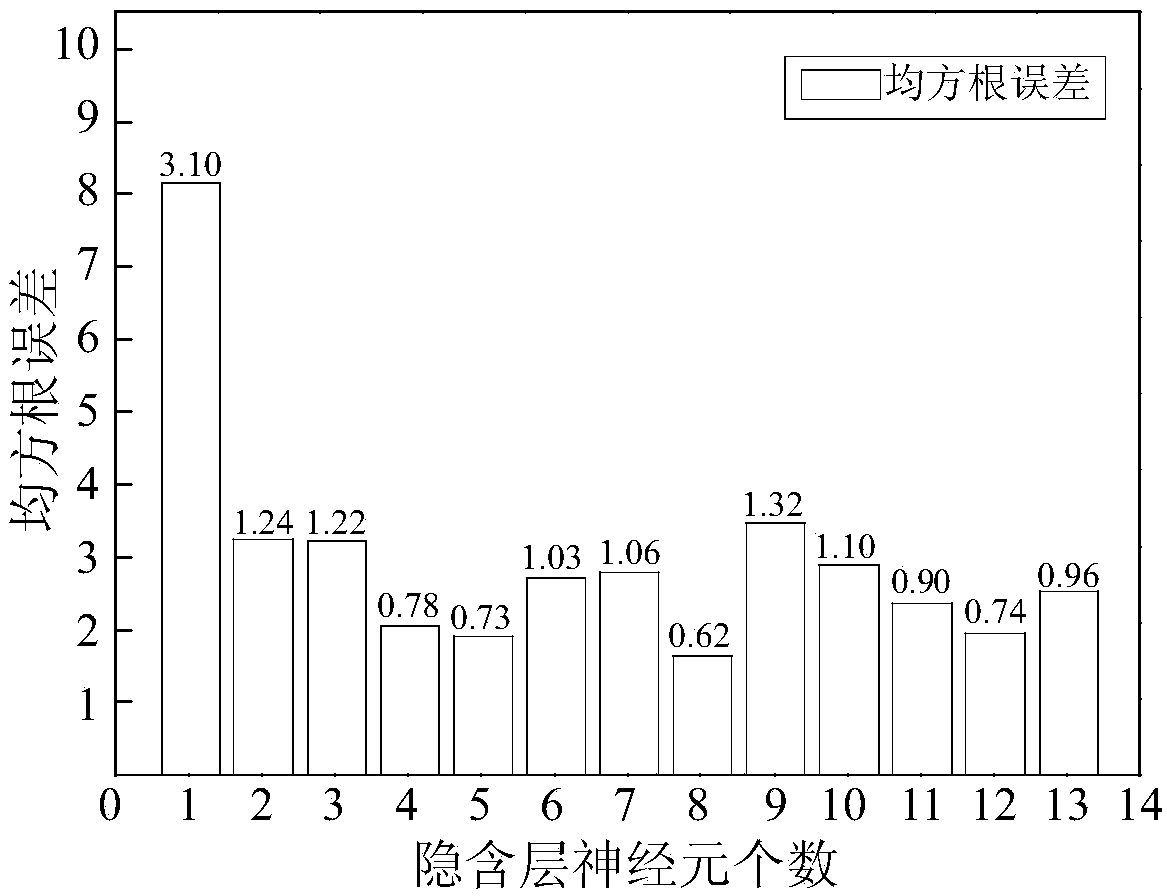

Prediction method of shot peening process parameters based on genetic algorithm optimized BP neural network

ActiveCN109508488AImprove forecast accuracyImprove design efficiencyGeometric CADNeural architecturesAlgorithmPredictive methods

The invention discloses a Prediction method of shot peening process parameters based on genetic algorithm optimized BP neural network, which is used for solving the technical problem of poor practicability of the existing shot peening forming method. The technical scheme is firstly to establish the complex nonlinear mapping relationship between the shape characteristics of parts, mechanical properties of materials and shot peening process parameters by using BP neural network, and then to optimize the structure and parameters of BP neural network by using genetic algorithm, which can be used for the auxiliary design of shot peening process parameters. The BP neural network is adopted to construct the outline features of the part, the complex nonlinear mapping relationship between the mechanical properties of materials and the process parameters of shot peening, The prediction model of shot peening process parameters can be established without fully understanding the internal mechanismof shot peening, and the structure and parameters of BP neural network are optimized by using genetic algorithm, which reduces the prediction time, improves the prediction accuracy, effectively improves the efficiency of the design of shot peening process parameters, and has good practicability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

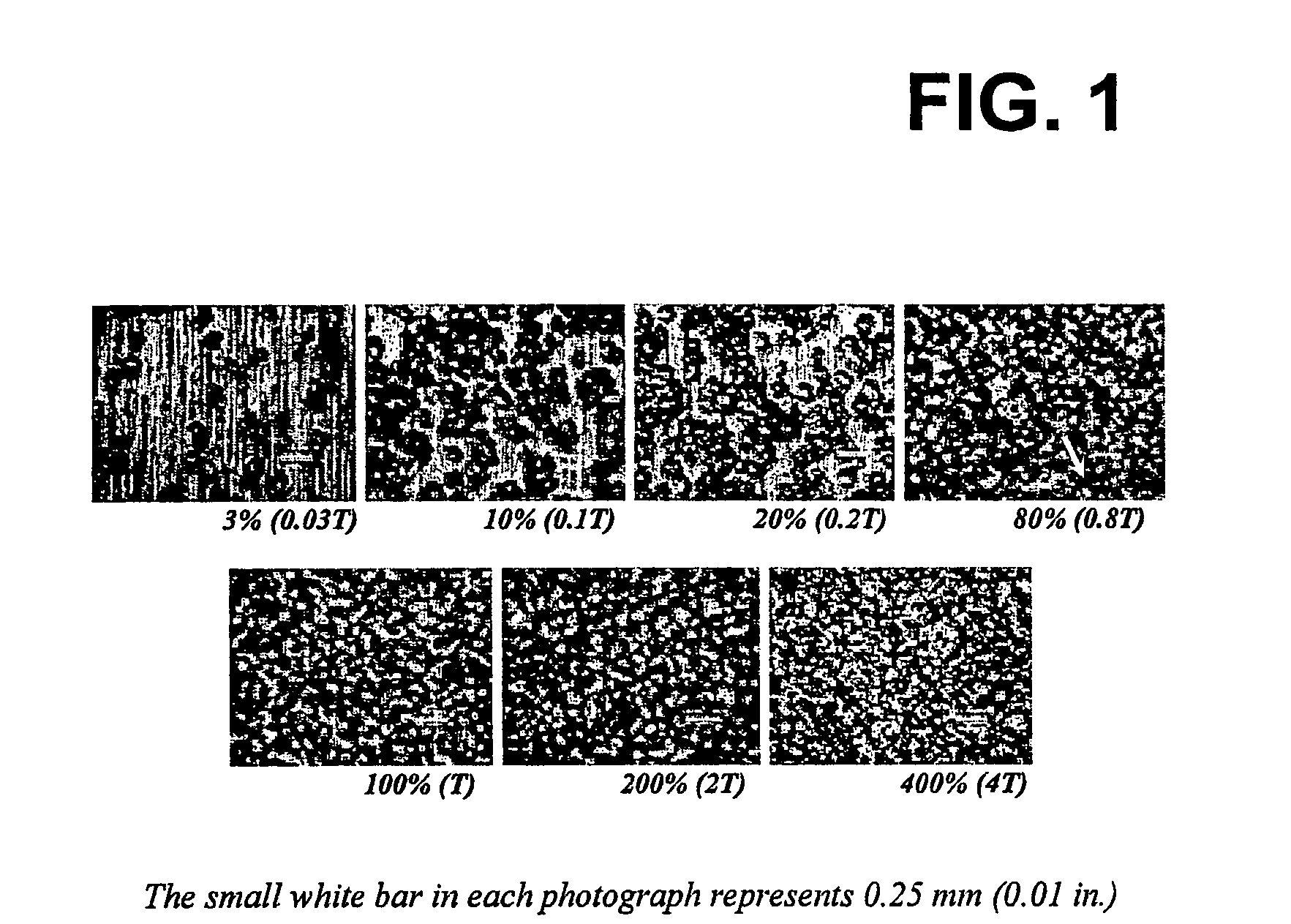

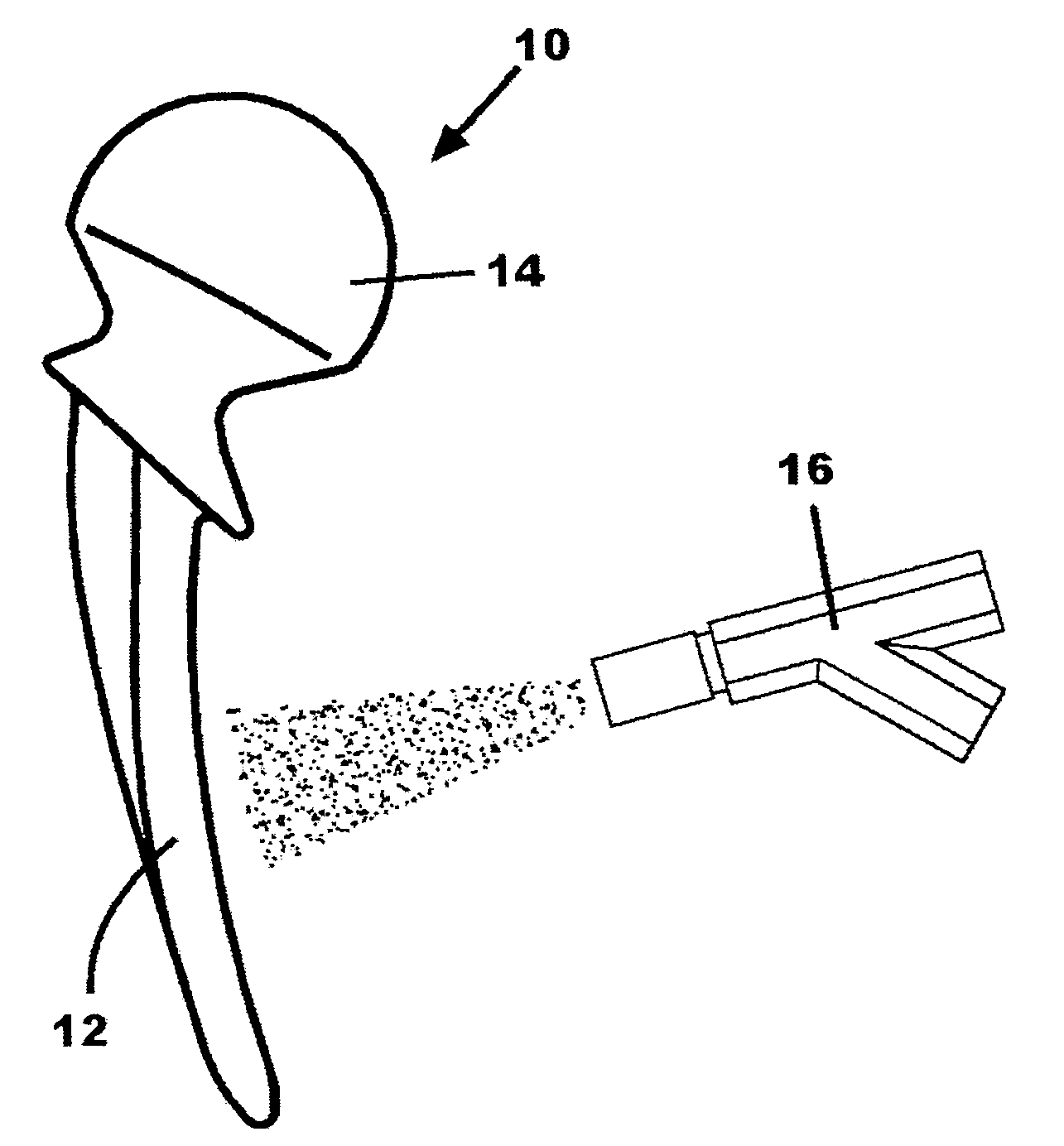

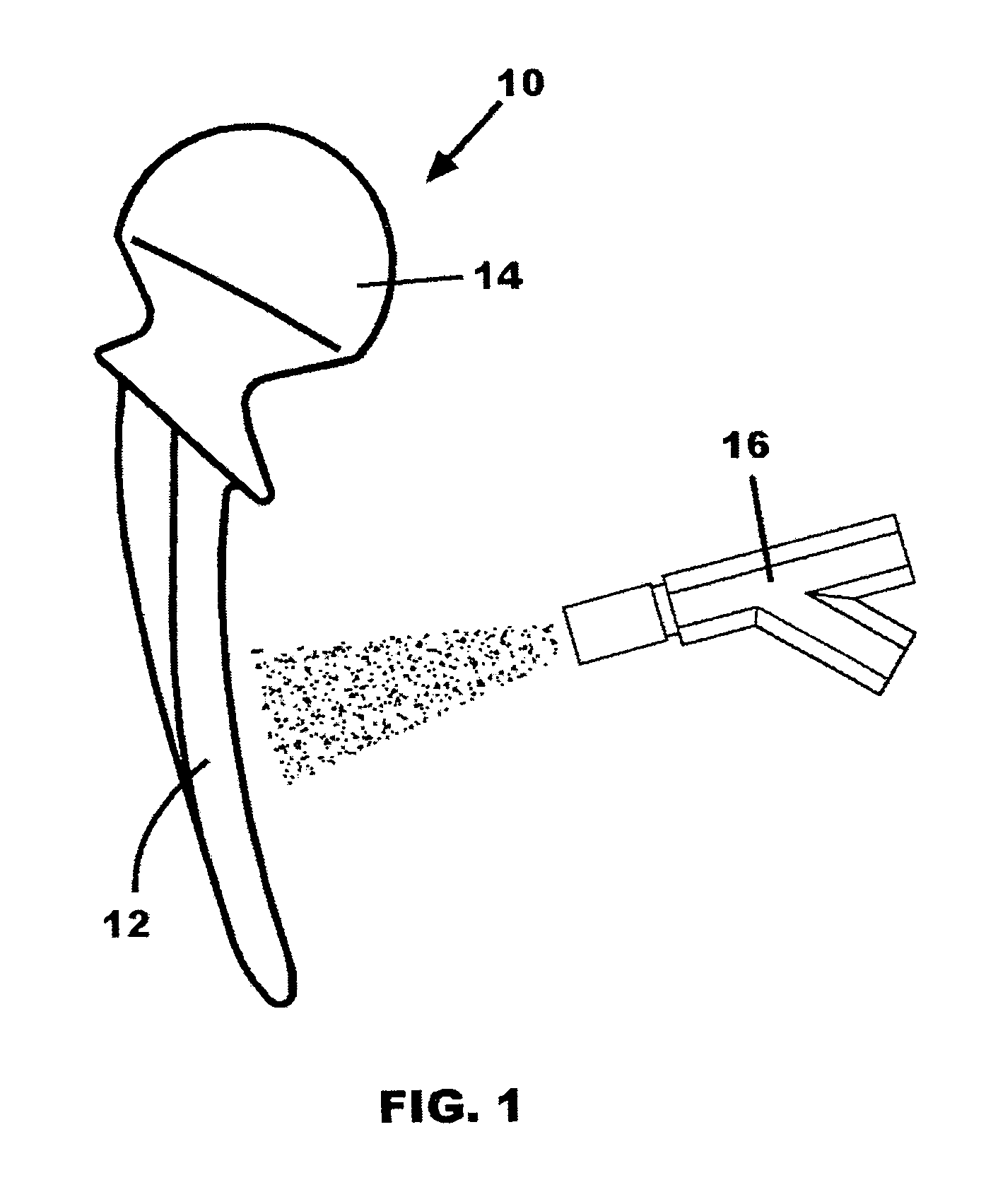

Shot peening of orthopaedic implants for tissue adhesion

ActiveUS7131303B1Simple and inexpensiveEasy to controlAbrasion apparatusBurnishing machinesPlastic surgeryHard tissue

The portion of an orthopaedic implant to which soft tissue adherence is desired is treated by shot peening using microbead having a diameter in the range of about 10 microns–300 microns. This treatment causes indentations on the surface of the implant of about 10 microns to about 50 microns to provide a fine, shallow texturing of the implant that permits the soft tissue to adhere, but is not rough enough that it will interlock with hard tissue.

Owner:ELEKTRONIK

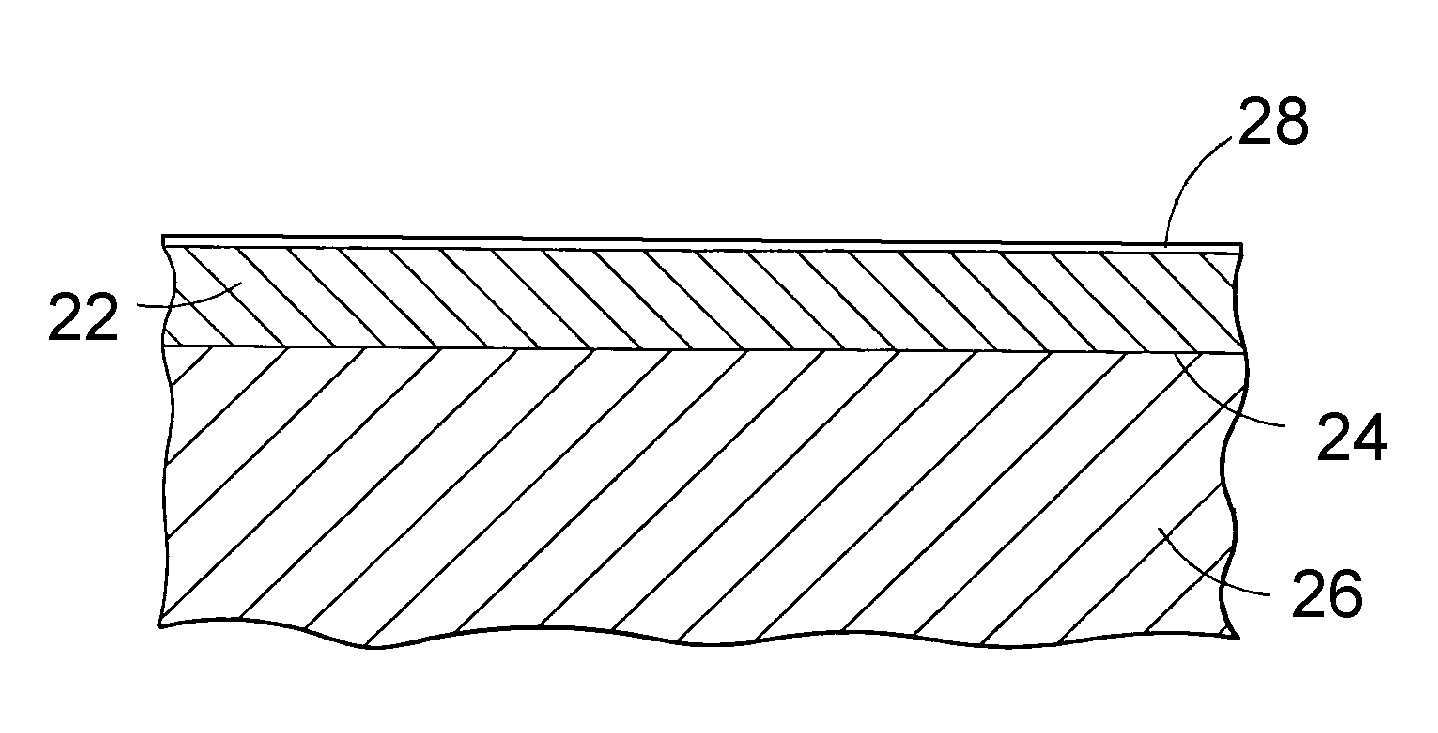

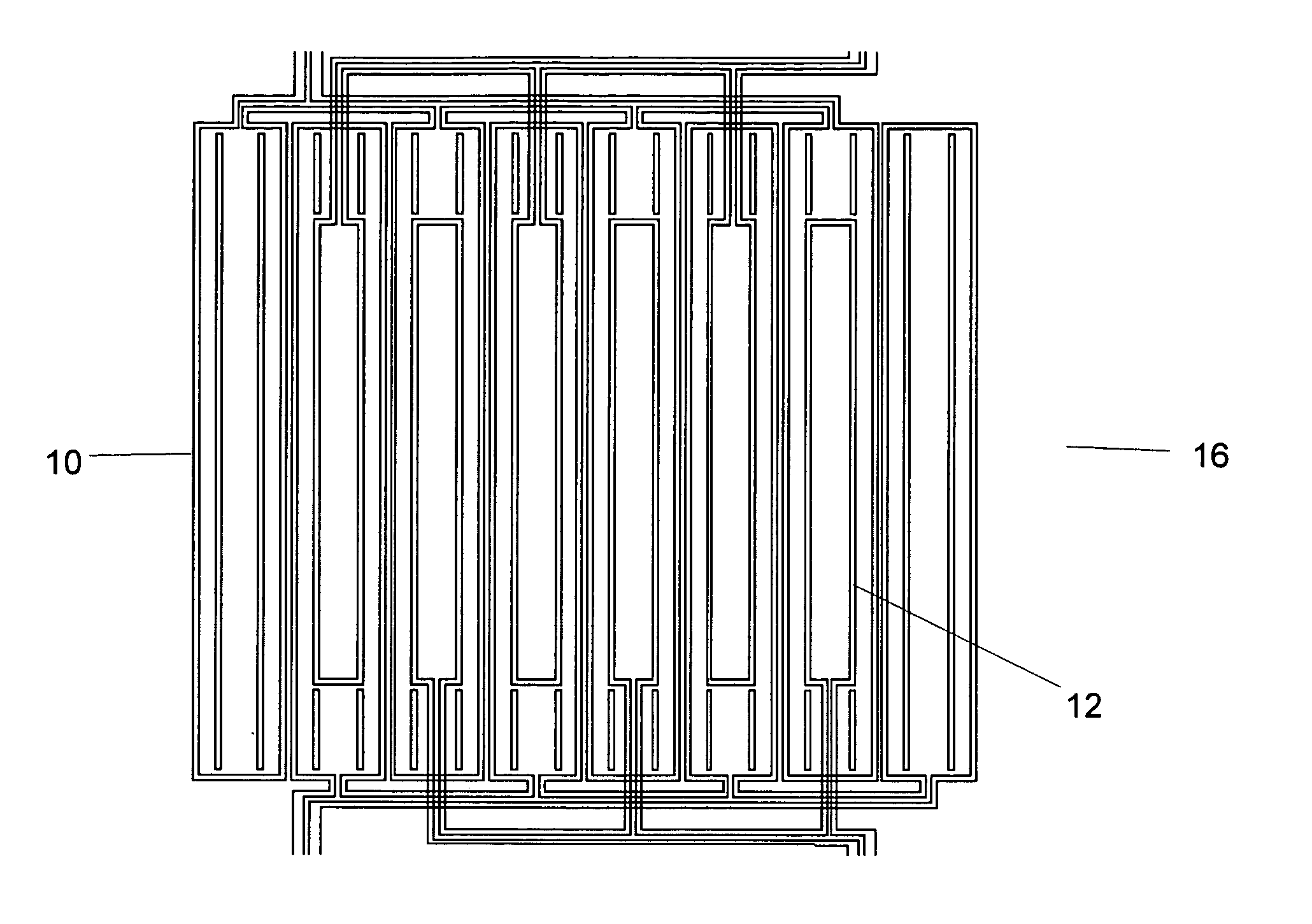

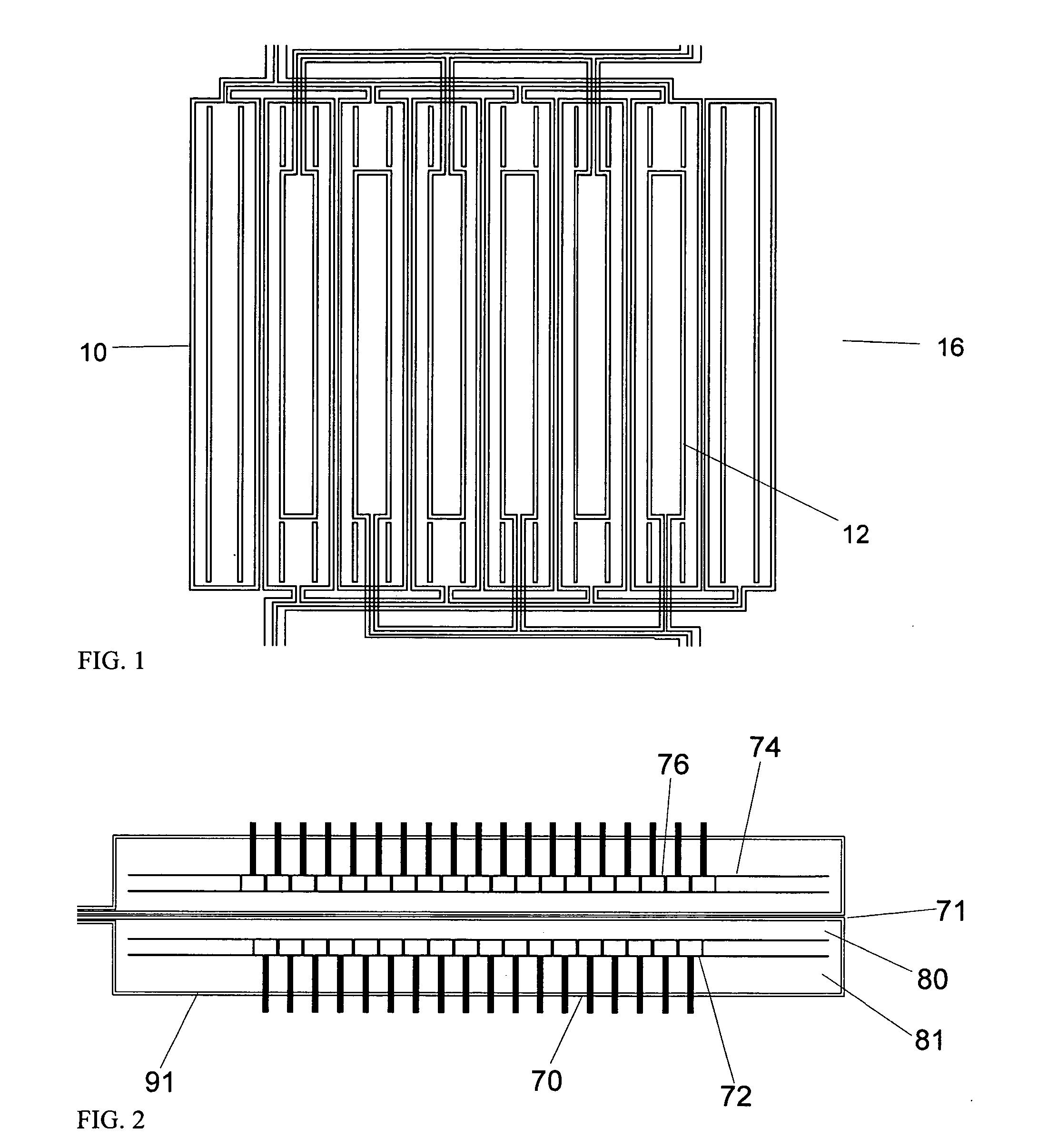

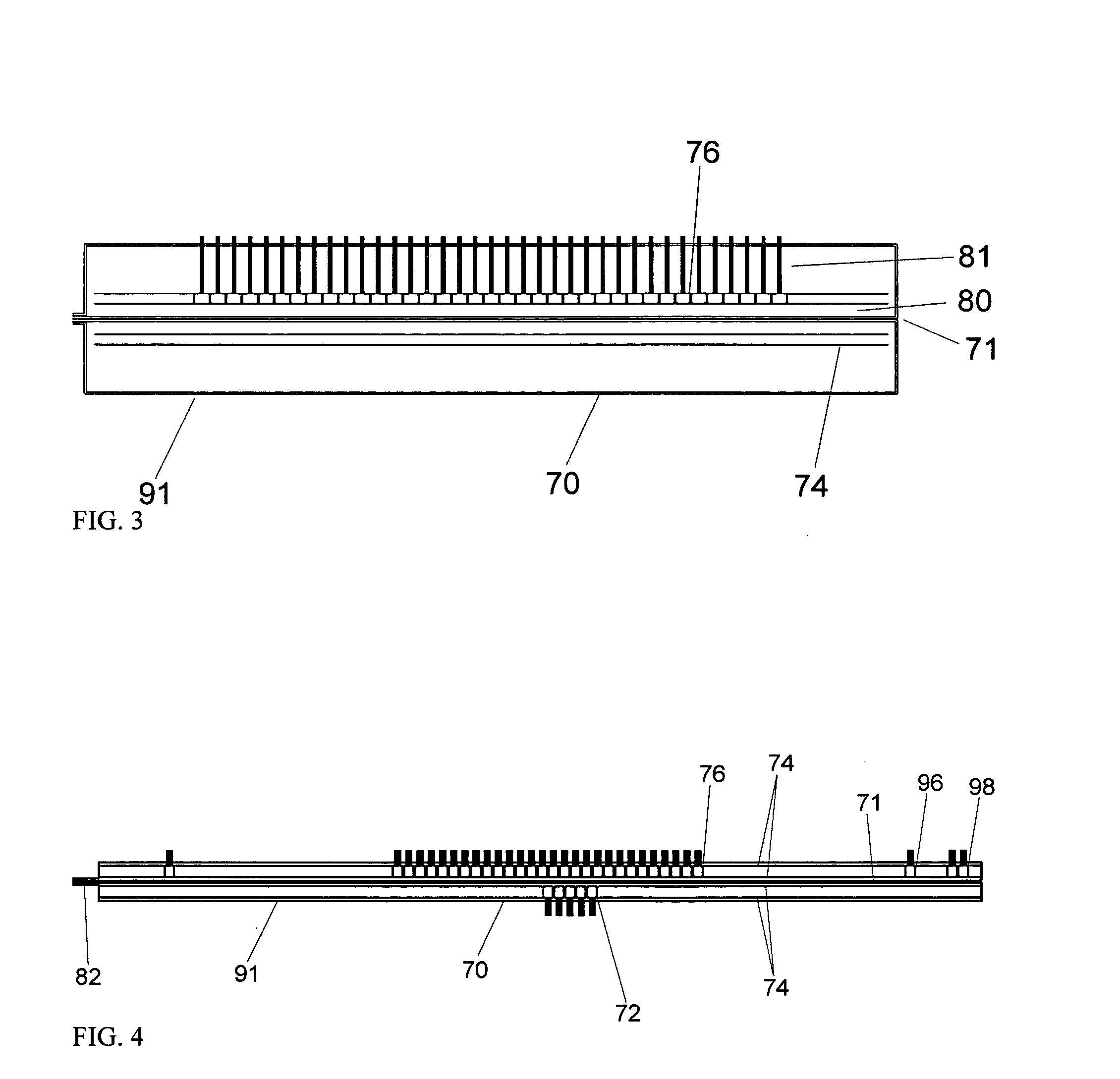

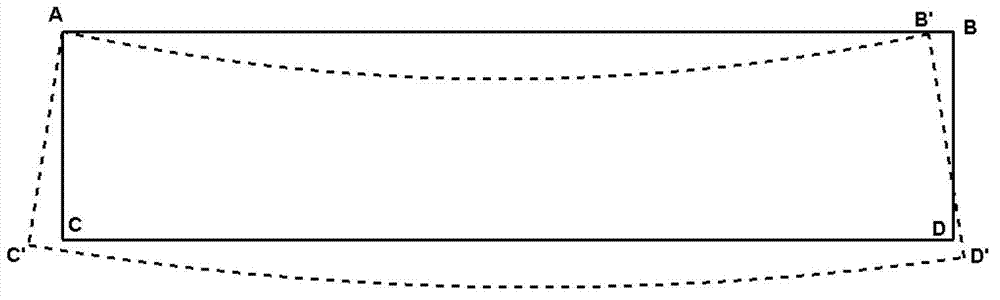

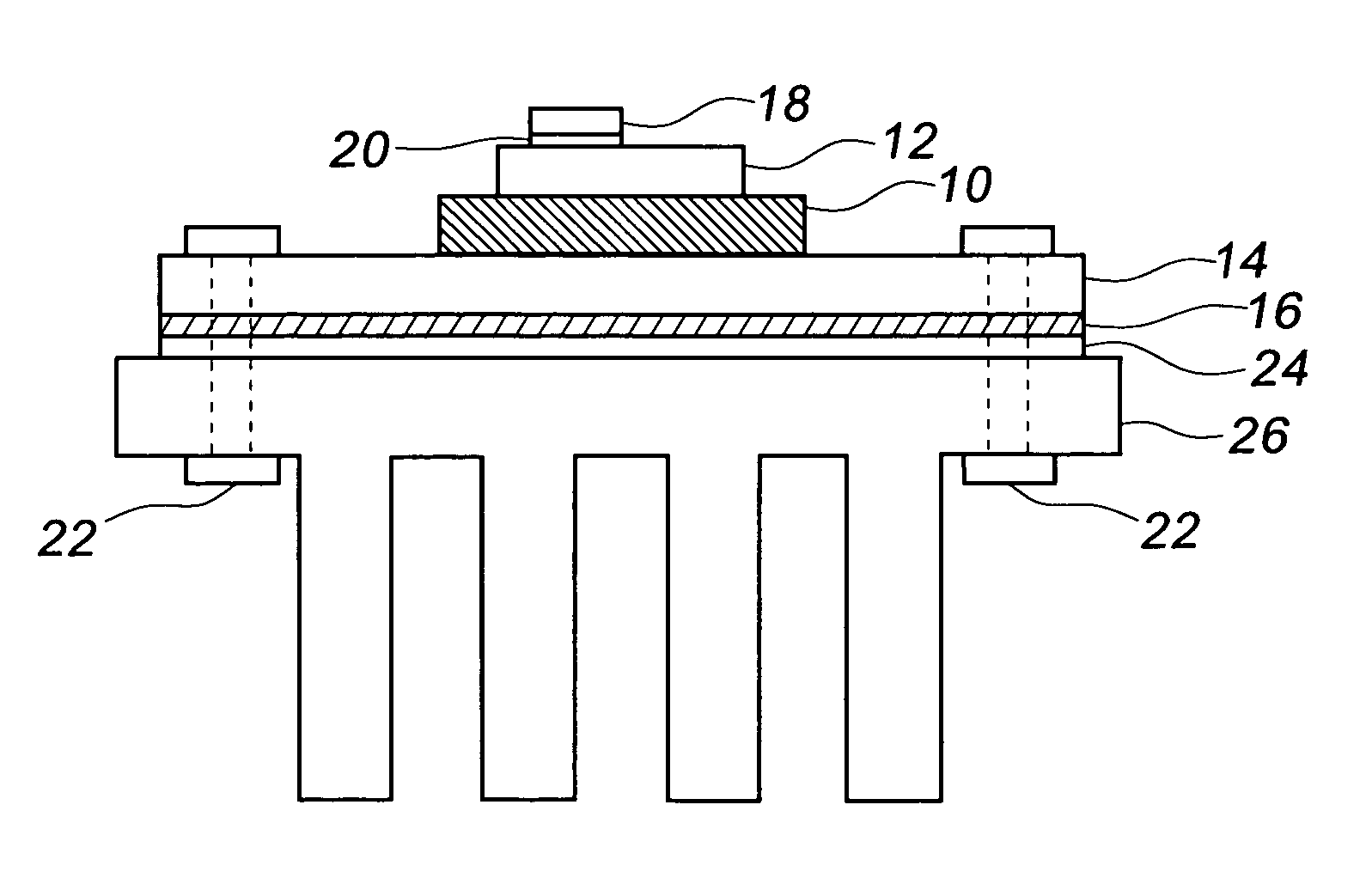

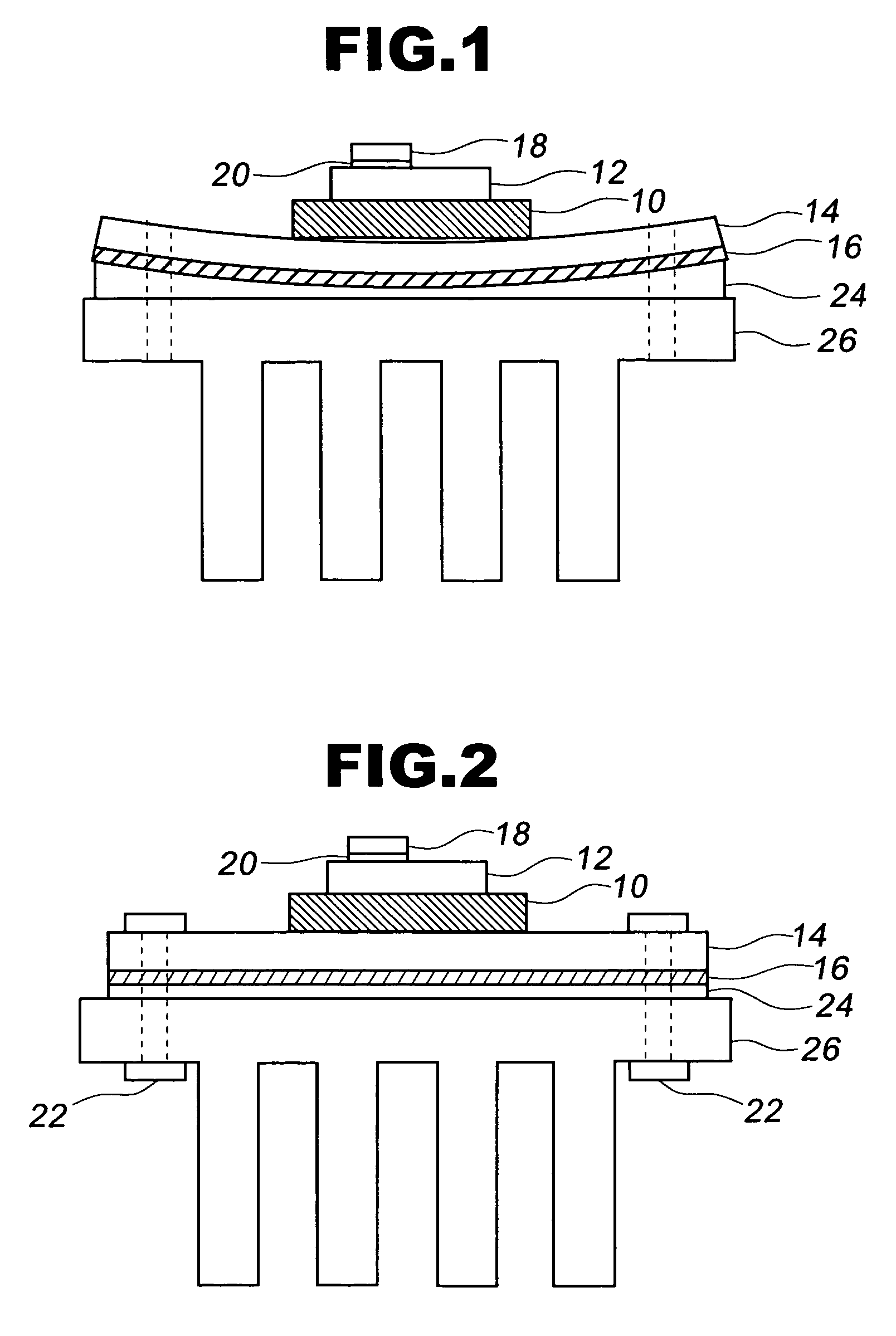

Metal/ceramic bonding substrate and method for producing same

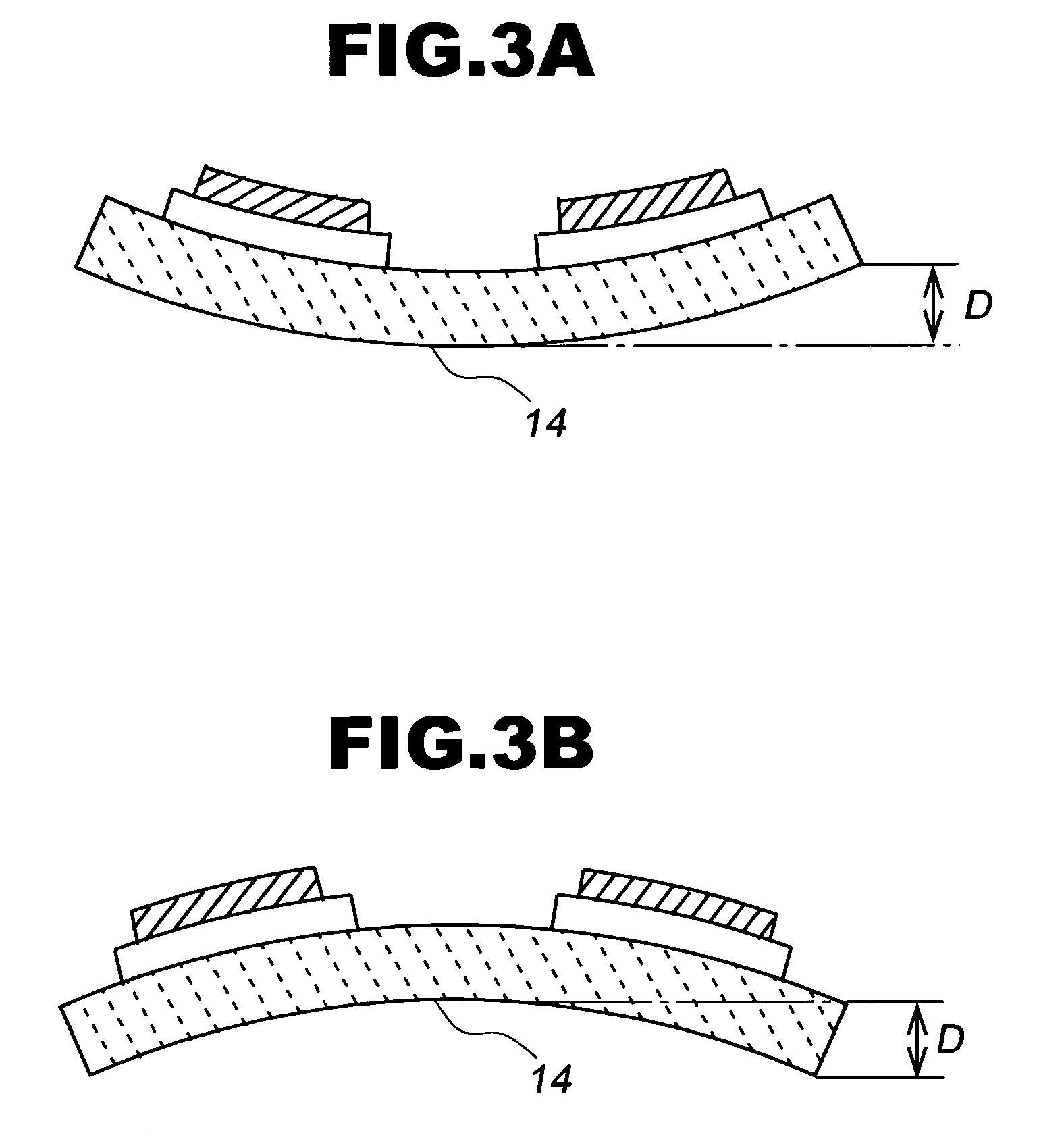

ActiveUS7256353B2Semiconductor/solid-state device detailsLaminating printed circuit boardsSemiconductor chipThermal grease

There is provided a metal / ceramic bonding substrate capable of preventing the reverse thereof from greatly warping so as to be concave even if it is heated for soldering. In the metal / ceramic bonding substrate, a metal circuit plate 12 is bonded to one side of a ceramic substrate 10, and a heat sink plate (metal base plate) 14 is bonded to the other side thereof. On the heat sink plate 14, a work-hardened layer 16 is formed by shot peening. On the metal circuit plate 12 of the metal / ceramic bonding substrate, semiconductor chips (Si chips) 18 are soldered (solder layer 20). Then, a power module is produced by a predetermined process. On the reverse (the side of the work-hardened layer 16) of the power module, a radiating fin 26 is mounted via a thermal grease 24 by means of screws 22 or the like.

Owner:DOWA METALTECH CO LTD

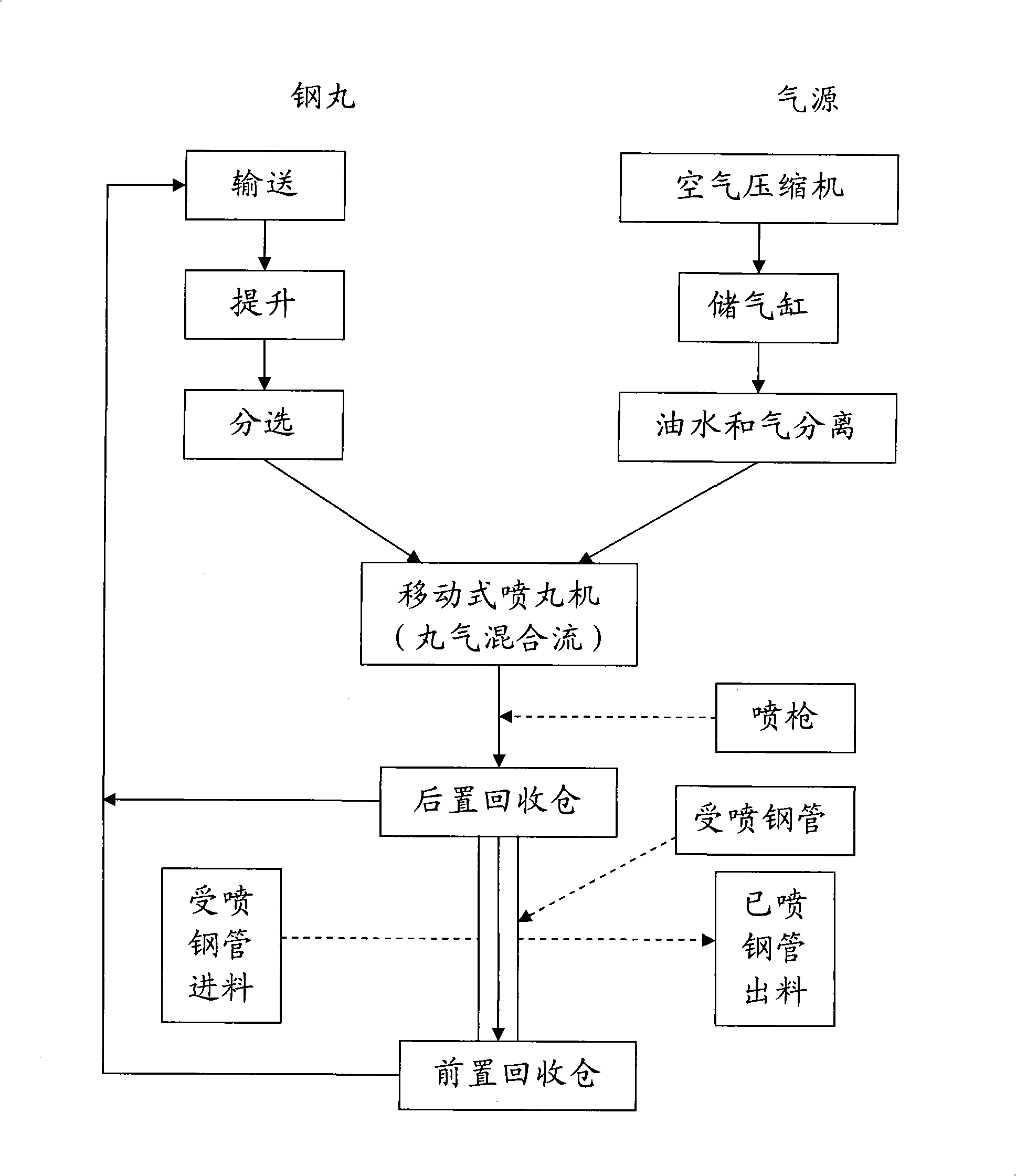

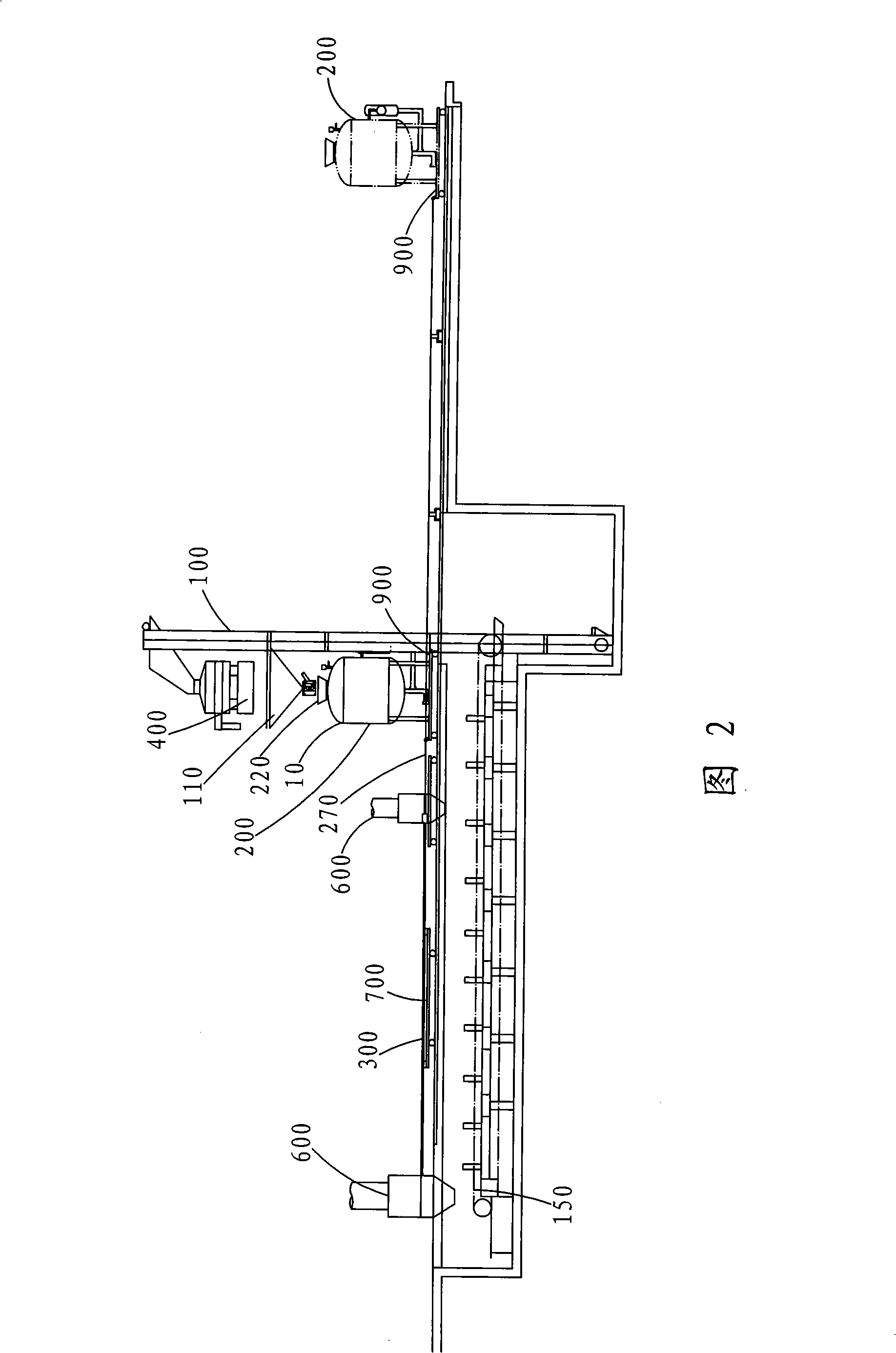

Austenite stainless heat-resisting seamless steel pipe internal wall shot-blasting strengthening technique and device

InactiveCN101265513AAdapt to industrial productionStrengthen the inner wall of the steel pipeHardnessHigh pressure

The invention relates to a shot peening strengthening method for Austenite stainless heat resistant seamless steel pipe inner wall and a device thereof. In the method, the inner wall of a steel shot of hardness more than or equal to 45HRc is shot by a spray gun under pressure more than or equal to 1.0Mpa and with high pressure gas as carrier to form a hardened layer with strengthened structure and stress, and the hardness of the hardened layer with distance 60 mum away from the steel pipe inner wall is more than 280HV or the hardness difference compared with the basal body is more than 100HV, so as to improve the resistance of the steel pipe inner against high temperature, steam, oxidation and corrosion. The device comprises a movable peening machine, a spray gun and two steel shot recovery chambers connected with the peening machine, a conveyer belt arranged below the peening machine, a steel shot elevator connected with the end of the conveyer belt, and a screener connected with the top of the conveyer belt, wherein the chamber openings of the two steel shot recovery chambers are hermitically connected with the external surfaces at the two ends of the steel pipe to form a steel shot recovery sealed chamber doubled with shot-peening function, the peening machine drives the spray gun to move along the direction of the steel pipe, and the recycling of the steel shot is realized via the steel shot recovery chambers at the two ends of the steel pipe and the conveyer belt below the steel pipe.

Owner:SHANGHAI XINYAXIN TECH

Method and apparatus for providing a layer of compressive residual stress in the surface of a part

ActiveUS20050039511A1Reduce processing timeWork lessBurnishing machinesHeat treatment process controlX-rayHigh surface

The shot peening method and apparatus (FIG. 13) of the present invention utilizes control of the shot peening coverage to provide higher surface compression and comparable depth of compression to conventional 100% coverage peening but with reduced cold working providing improved thermal stability and reduction in shot peening time and cost. A preferred embodiment of this invention employs x-ray diffraction (FIG. 13) residual stress and percent cold work determinated by line broadening to establish the optimal degree of coverage for a given material and shot peening intensity.

Owner:SURFACE TECH HLDG

Metal component treated by putting sublayers in compression, and method of obtaining such a component

The invention relates to a metal component comprising at least a first zone treated by putting layers beneath the surface thereof in compression. It is characterized in that it comprises at least a first layer put in compression by shot peening and a deeper subjacent second layer put in compression by laser shock peening.The component may be a turbomachine blade. According to the method, said zone is firstly treated by prestress shot peening followed by compression treatment by laser shock peening.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com