Three-dimensional surface shot peening jet electrodeposition manufacturing method and device

A technology for manufacturing devices and three-dimensional surfaces, which is applied in the field of three-dimensional surface shot peening jet electrodeposition manufacturing methods and devices, can solve the problems of limiting the wide application of electrodeposition technology, affecting the density and uniformity of materials, and deteriorating deposition quality. Realize the effect of rapid manufacturing forming, high work efficiency and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

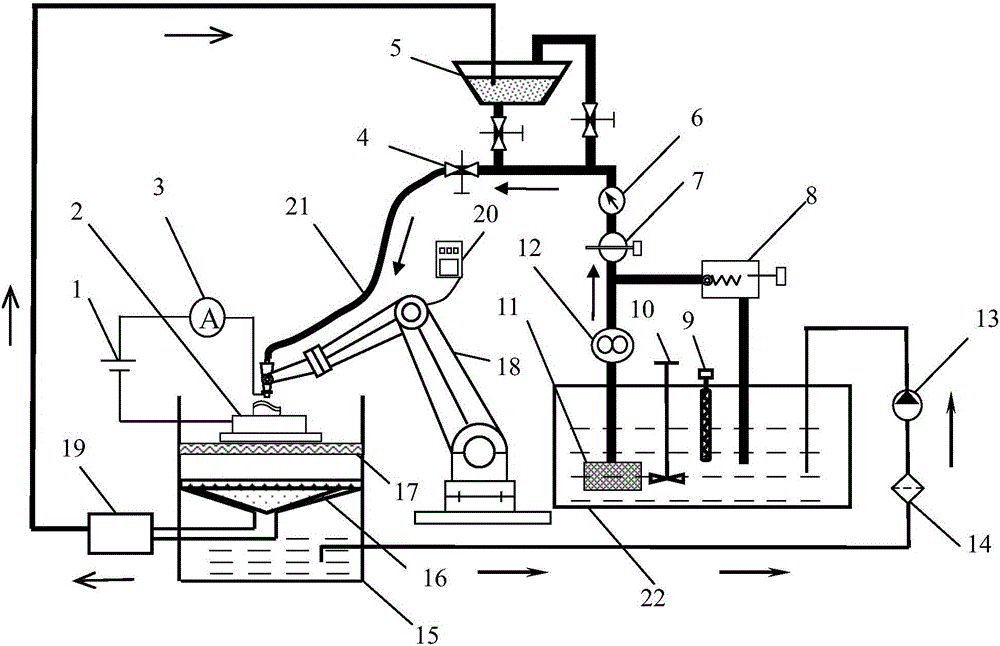

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

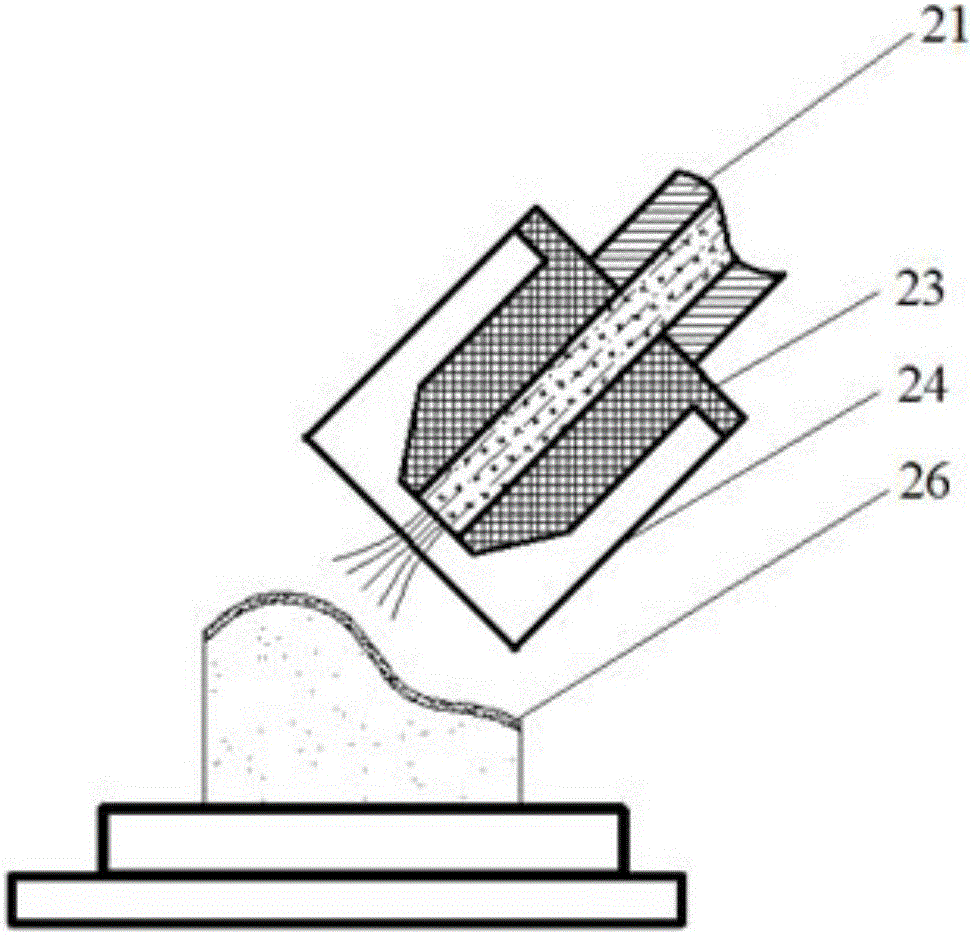

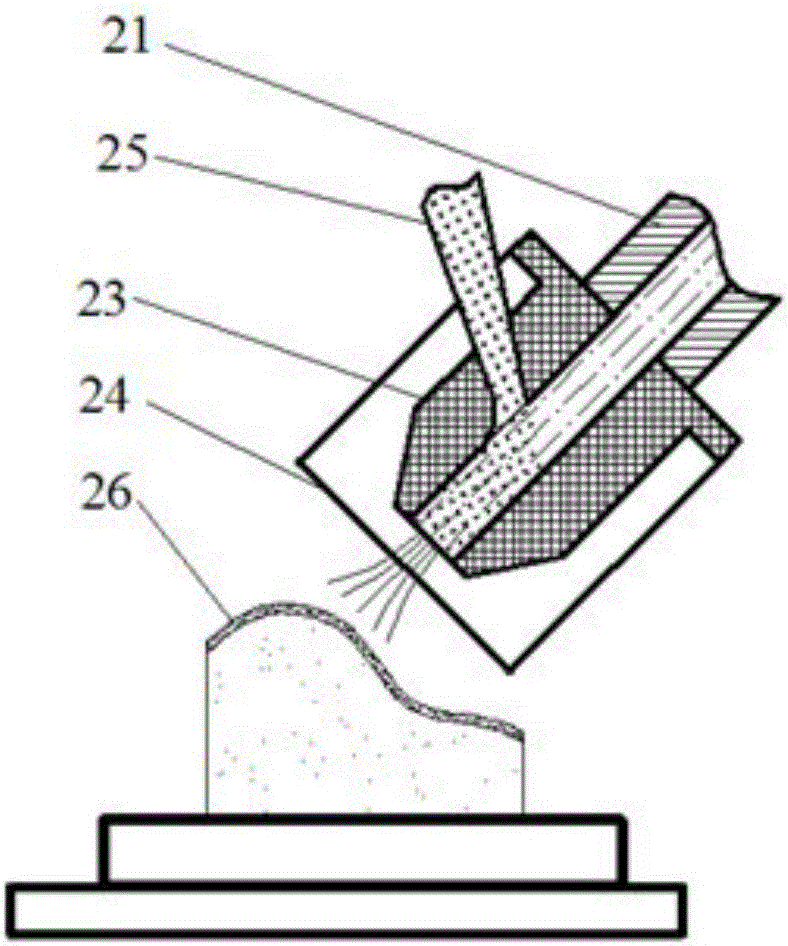

[0037] In the three-dimensional surface shot-peening jet flow electrodeposition manufacturing method described in the present invention, the surface of the cathode conductive substrate is ground, degreased, pickled and washed with water before processing. Fix the cathode conductive substrate, connect the positive and negative electrodes of the power supply to the anode and cathode conductive substrates respectively, turn on the power supply, and the hydraulic pump with adjustable flow can continuously provide liquid flow power for the acid deposition liquid, and the deposition liquid flows in the rubber hose Negative pressure is formed at the interface between the reservoir of the hard particles and the rubber hose, the hard particles are sucked in forcefully, fully mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com