Hollow stabilizer and method of manufacturing the same

a manufacturing method and stabilizer technology, applied in the direction of interconnection systems, metal-working apparatuses, vehicle components, etc., can solve the problems of high manufacturing cost, frequent starting point of fatigue failure, and high manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

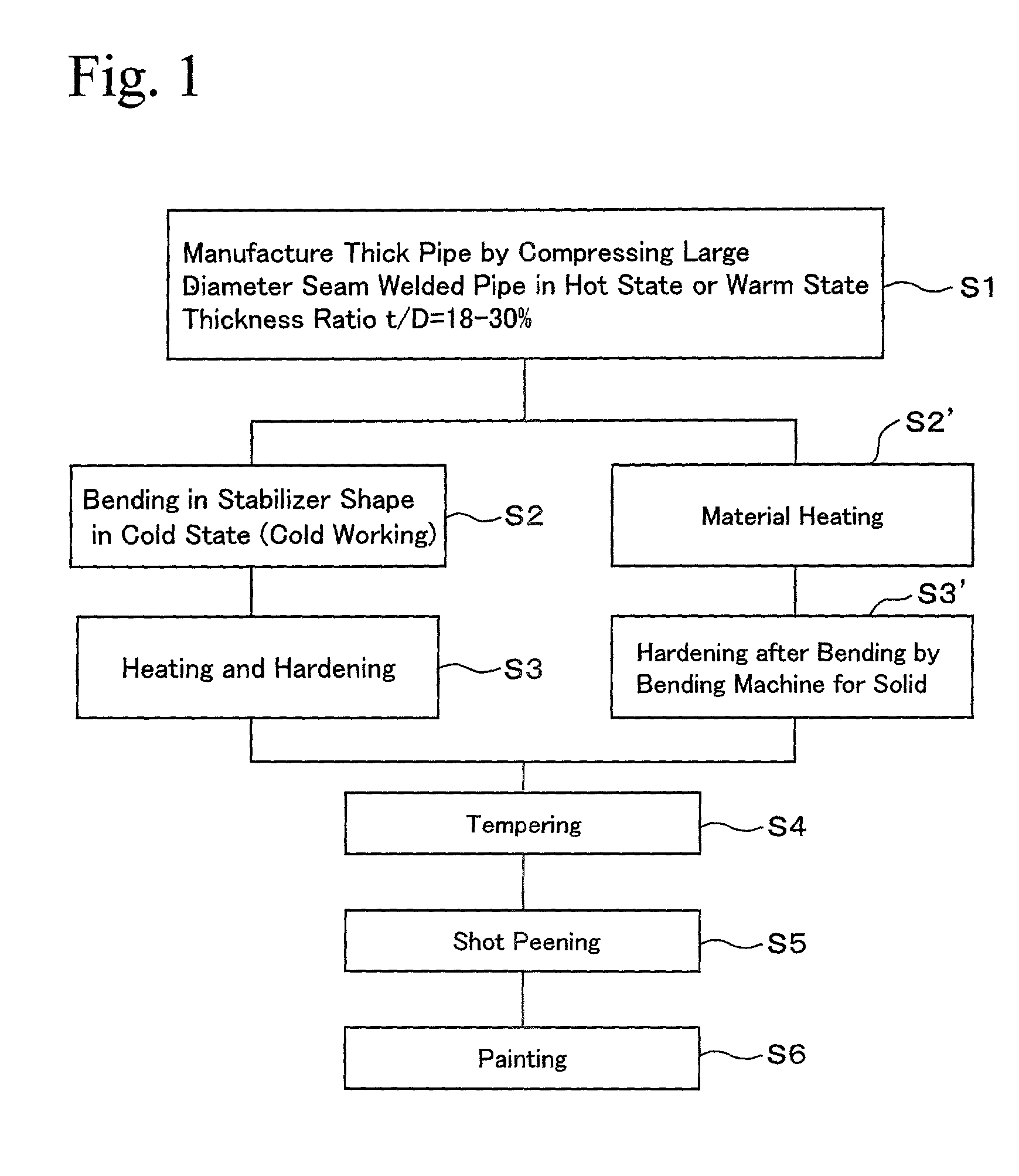

Method used

Image

Examples

embodiment 1

[0037] Embodiment 1

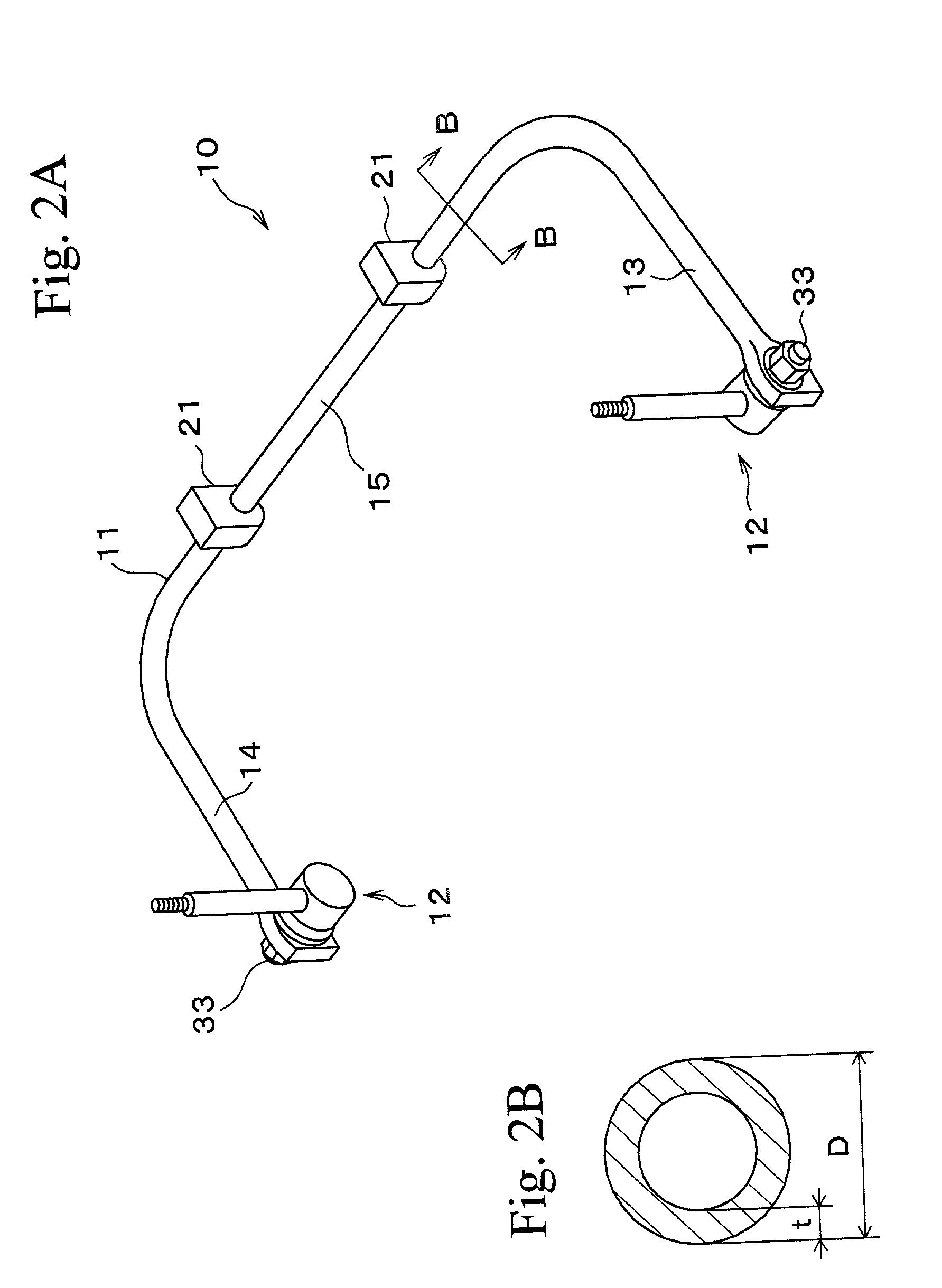

[0038] Next, particular manufactured embodiments are described and further details of the present invention will be given. Table 1 shows respective specifications of a solid stabilizer having a wire diameter of 27 mm, and a hollow stabilizer having substantially the same spring constant as that of the solid stabilizer. In this case, the respective stabilizers are structured such that the heat treatment, the shot peening, and the coating are applied. Further more, main stresses at the time of imparting a deformation of the same stroke to the respective stabilizers are also described in Table 1, and the values are shown in FIG. 3.

1TABLE 1 Thickness Spring Main Stress at Main Stress at Ratio Constant Outer Surface Inner Surface No Material Size (t / D) (N / mm) Portion (MPa) Portion (MPa) 1 Solid, Diameter 27 -- 25.1 365 --2 Diameter 30.0 .times. t3.5 11.7% 24.9 591 458 3 Diameter 28.6 .times. t4.7 16.4% 24.8 499 339 4 Diameter 28.0 .times. t5.5 19.6% 25.2 475 304 5 Diam...

embodiment 2

[0041] Embodiment 2

[0042] A durability test was performed by employing nine hollow stabilizers having outer diameters and thicknesses as shown in Table 2 and solid stabilizers having a diameter of 25 mm. Further more, it was investigated at which of the inner or outer surface portions of the hollow stabilizer the starting point of breakage was generated, a ratio of maximum stresses generated on the inner and outer surfaces (inner surface stress / outer surface stress) is investigated, and the results thereof are also described in Table 2. Further more, a ratio of fatigue life of the hollow stabilizer with respect to a fatigue life of the solid stabilizer and a ratio of mass are calculated, and the results thereof are also described in Table 2. An S-N graph of the hollow stabilizer is shown in FIG. 5.

[0043] As shown in Table 2 and FIG. 5, in the hollow stabilizer in which the thickness ratio is equal to or greater than 20%, all of the starting points of breakage exist in the outer surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com