Patents

Literature

127results about How to "Avoid fatigue failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

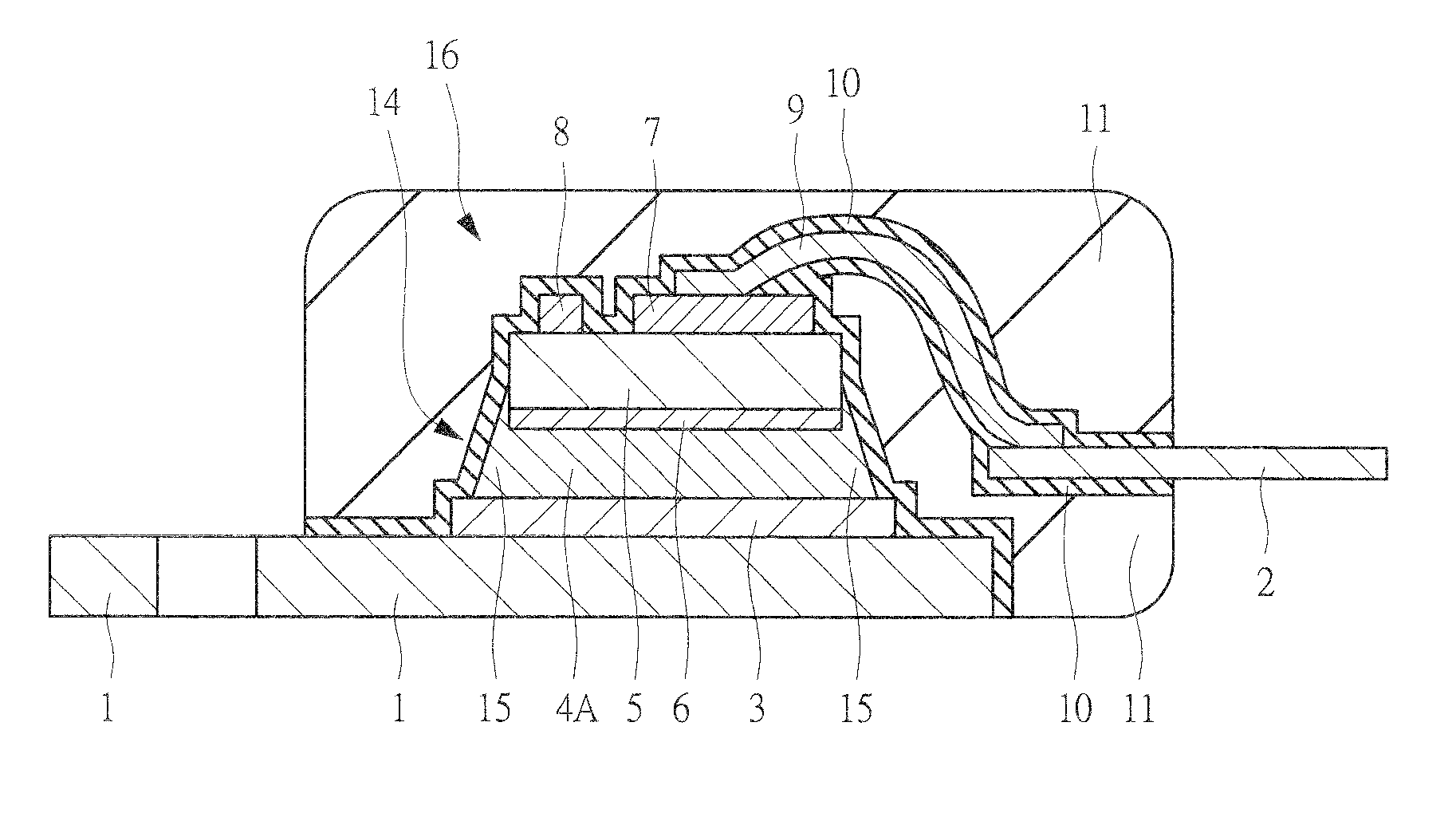

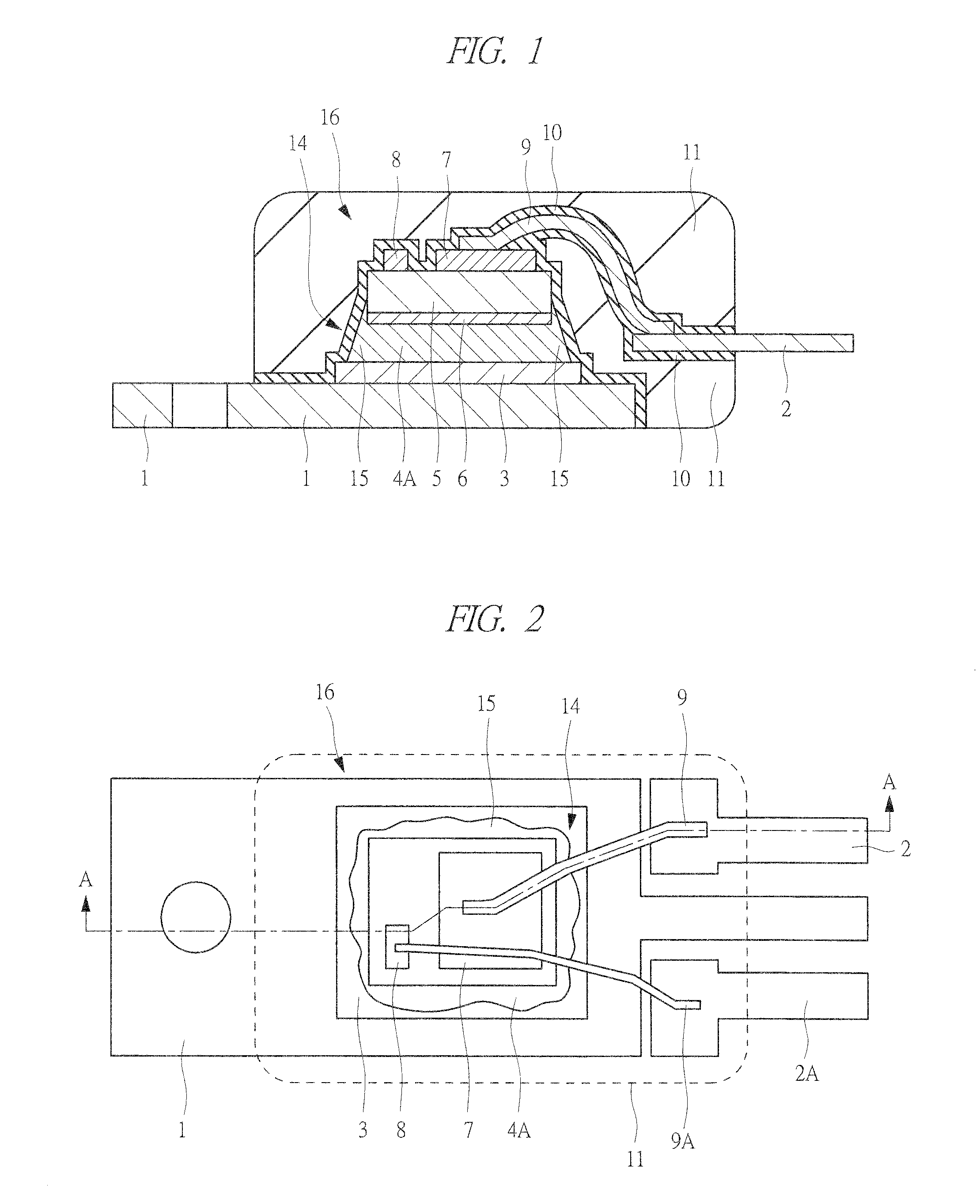

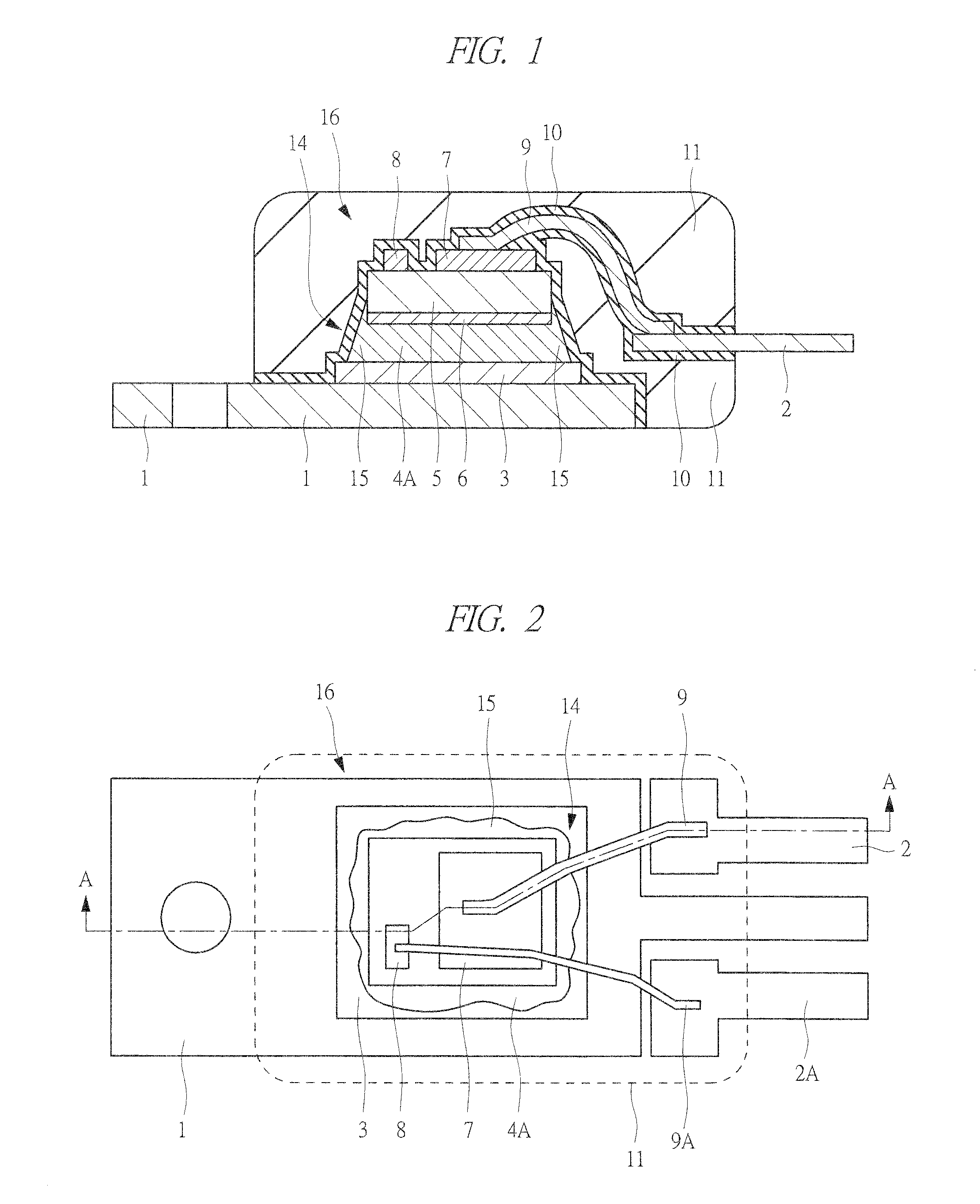

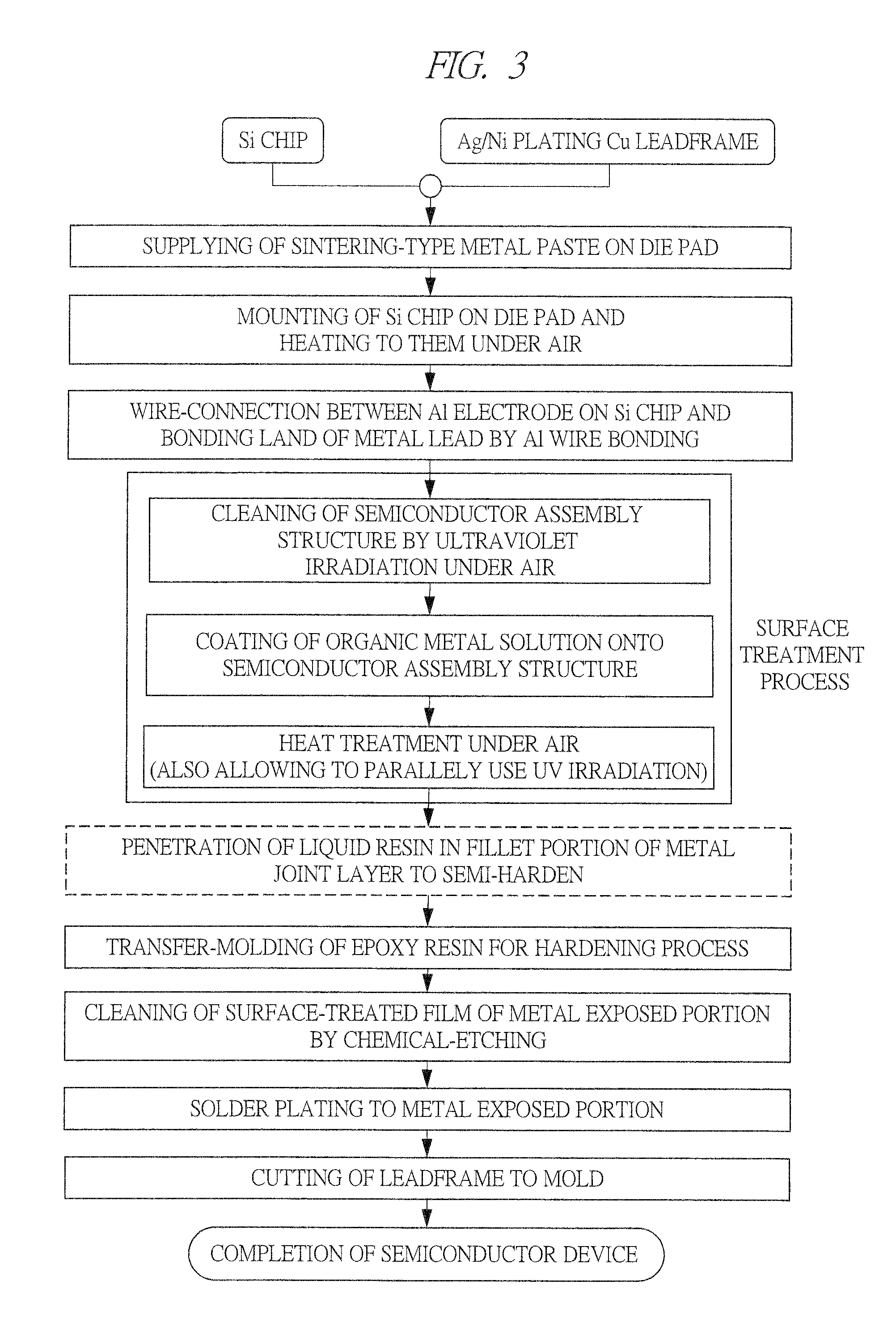

Semiconductor device and method of manufacturing the same

ActiveUS20100187678A1Avoid fatigue failureImprove bendabilitySemiconductor/solid-state device detailsSolid-state devicesPolymer resinNetwork structure

In a structure of a semiconductor device, a Si chip and a metal leadframe are jointed by metallic bond via a porous joint layer made of high conductive metal, having a three-dimensional network structure and using Ag as a bonding material, and a film containing Zn oxide or Al oxide is formed on a surface of a semiconductor assembly contacting to a polymer resin. In this manner, by the joint with the joint layer having the porous structure mainly made of Ag, thermal stress load of the Si chip can be reduced, and fatigue life of the joint layer itself can be improved. Besides, since adhesion of the polymer resin to the film can be enhanced by the anchor effect, occurrence of cracks in a bonding portion can be prevented, so that a highly-reliable Pb-free semiconductor device can be provided.

Owner:RENESAS ELECTRONICS CORP

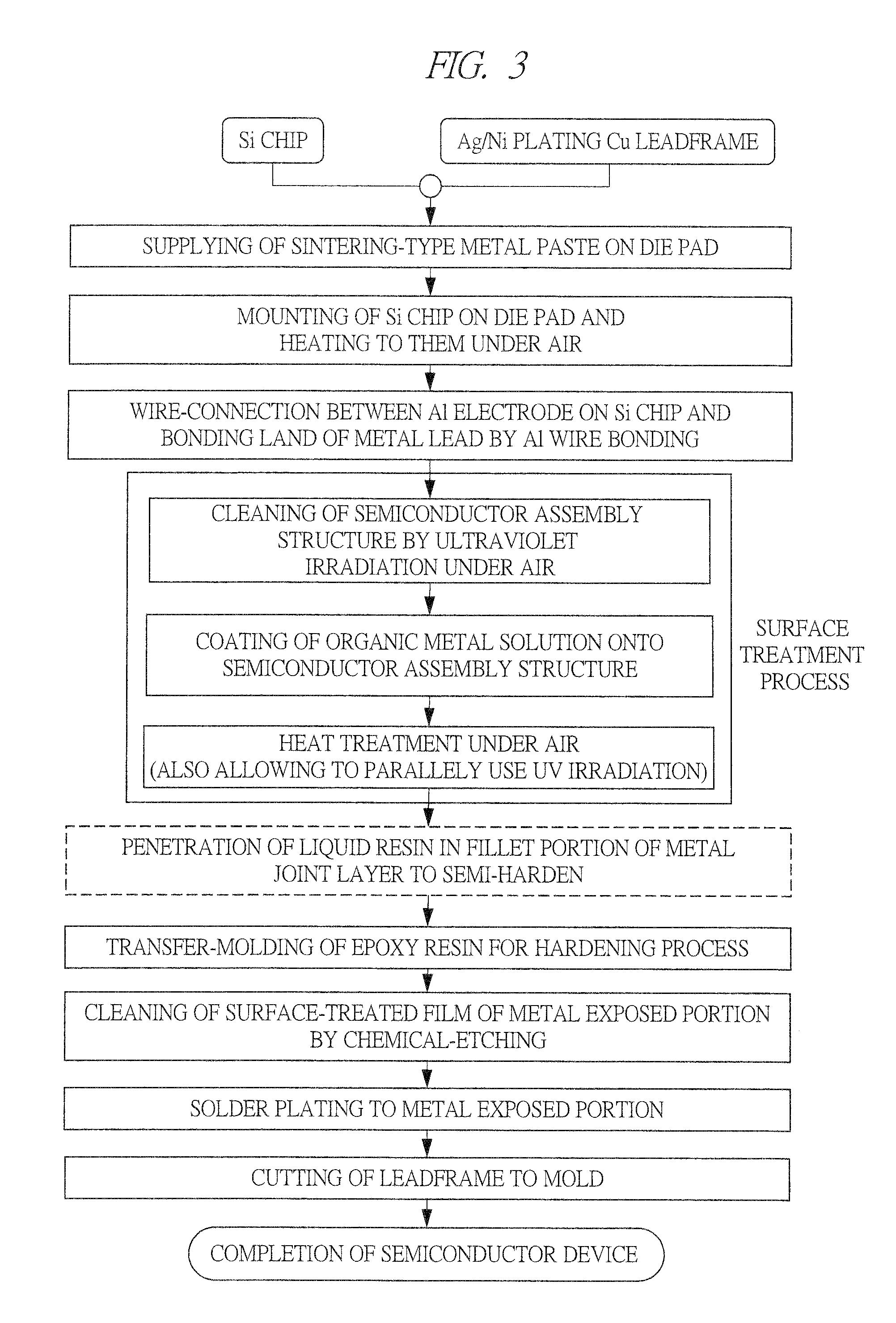

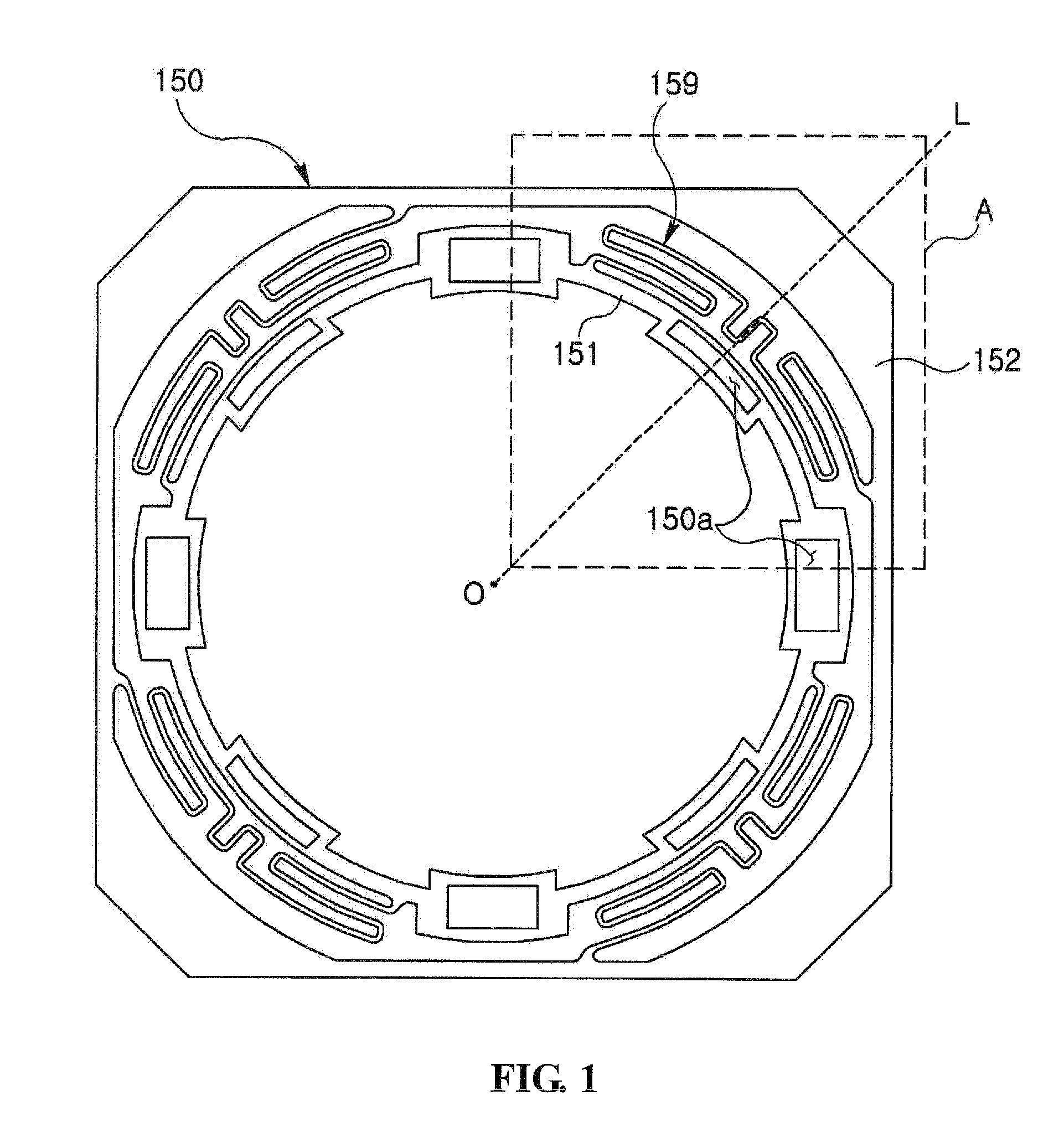

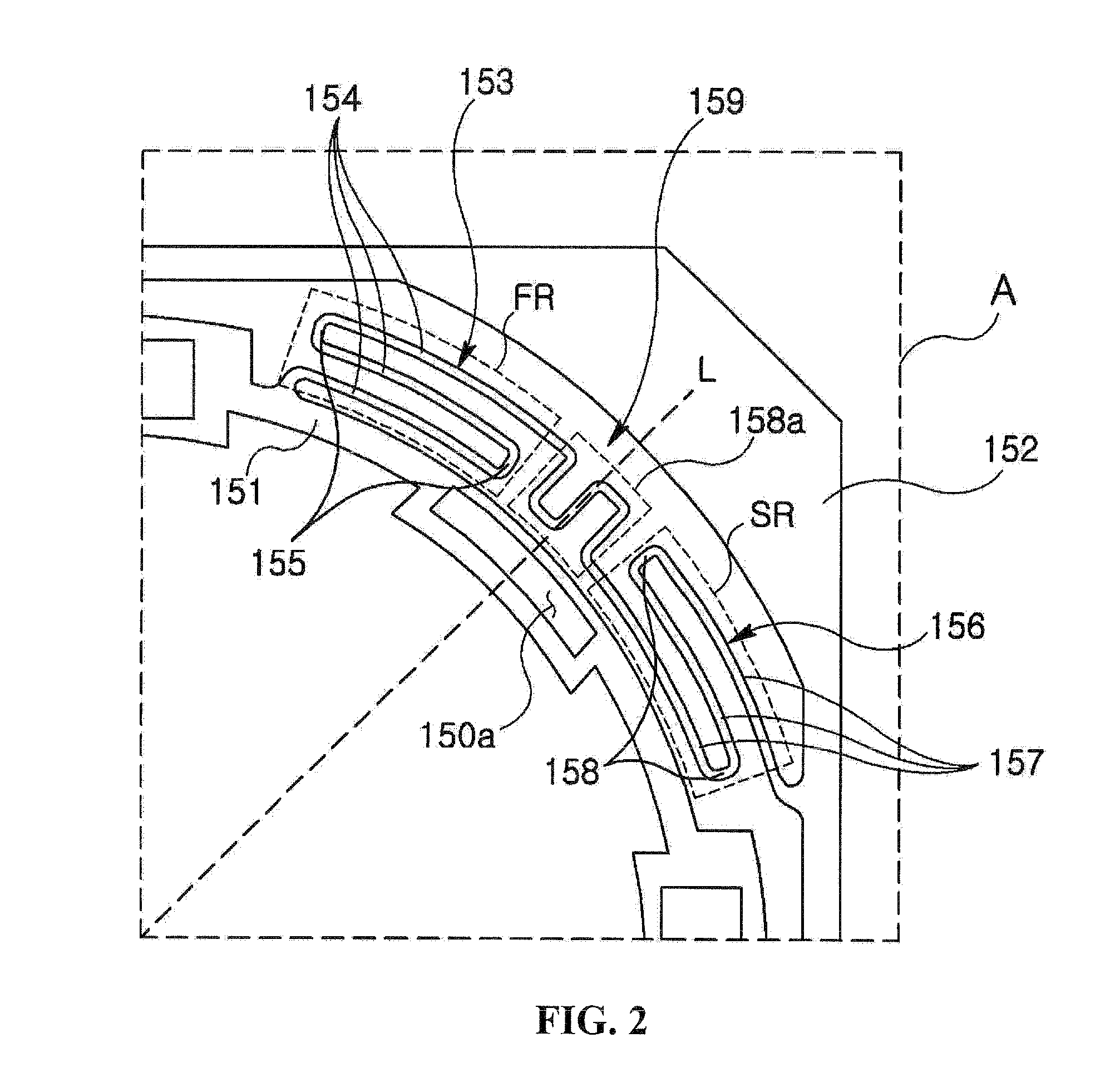

Flat spring and voice coil motor using the same

ActiveUS20110169348A1Avoid fatigue failureProjector focusing arrangementLeaf springsEngineeringVoice coil

A flat spring for a voice coil motor includes an curved internal flat spring, an outer flat spring placed outward the internal flat spring, a first connection body folded at least twice and interposed between the internal flat spring and the outer flat spring, a second connection body placed between the internal flat spring and the outer flat spring in parallel with the first connection body and having an identical shape with the first connection body, and a connection flat spring including a connecting part connecting adjacent ends of the first and the second connection body, where an end of the first connection body which has no connection with the connecting part is connected to the internal flat spring, and an end of the second connection body which has no connection with the connecting part is connected to the outer flat spring.

Owner:LG INNOTEK CO LTD

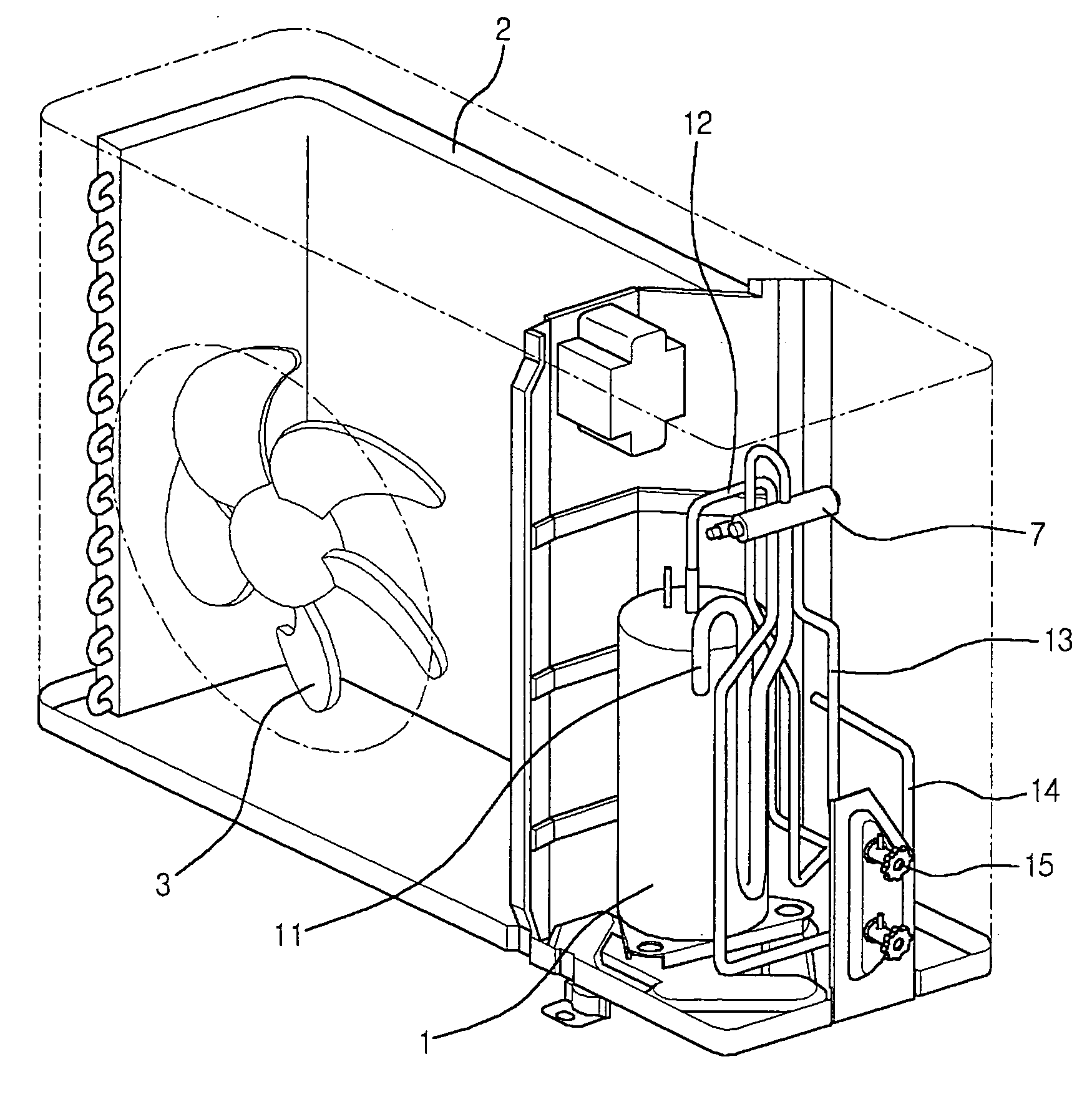

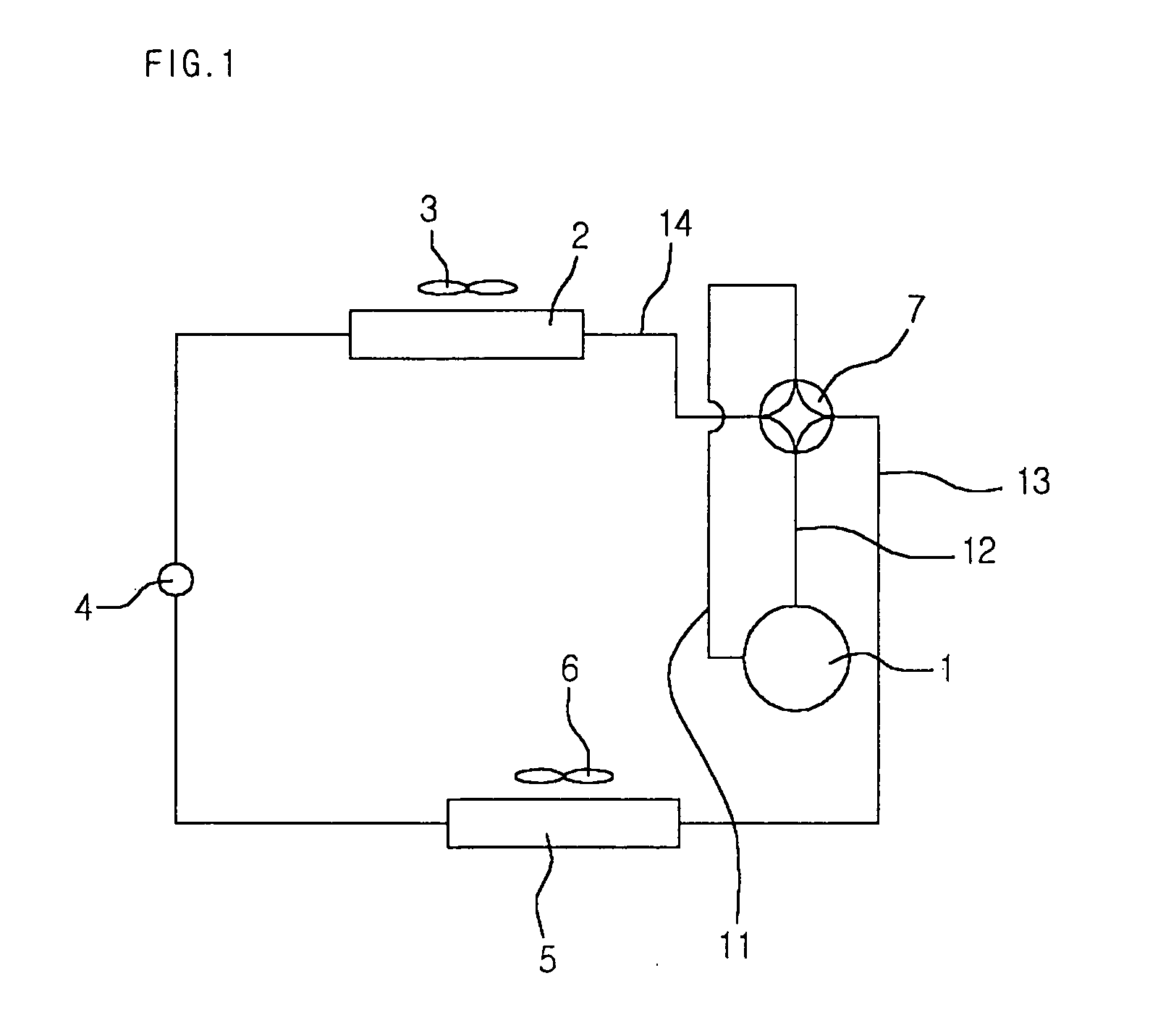

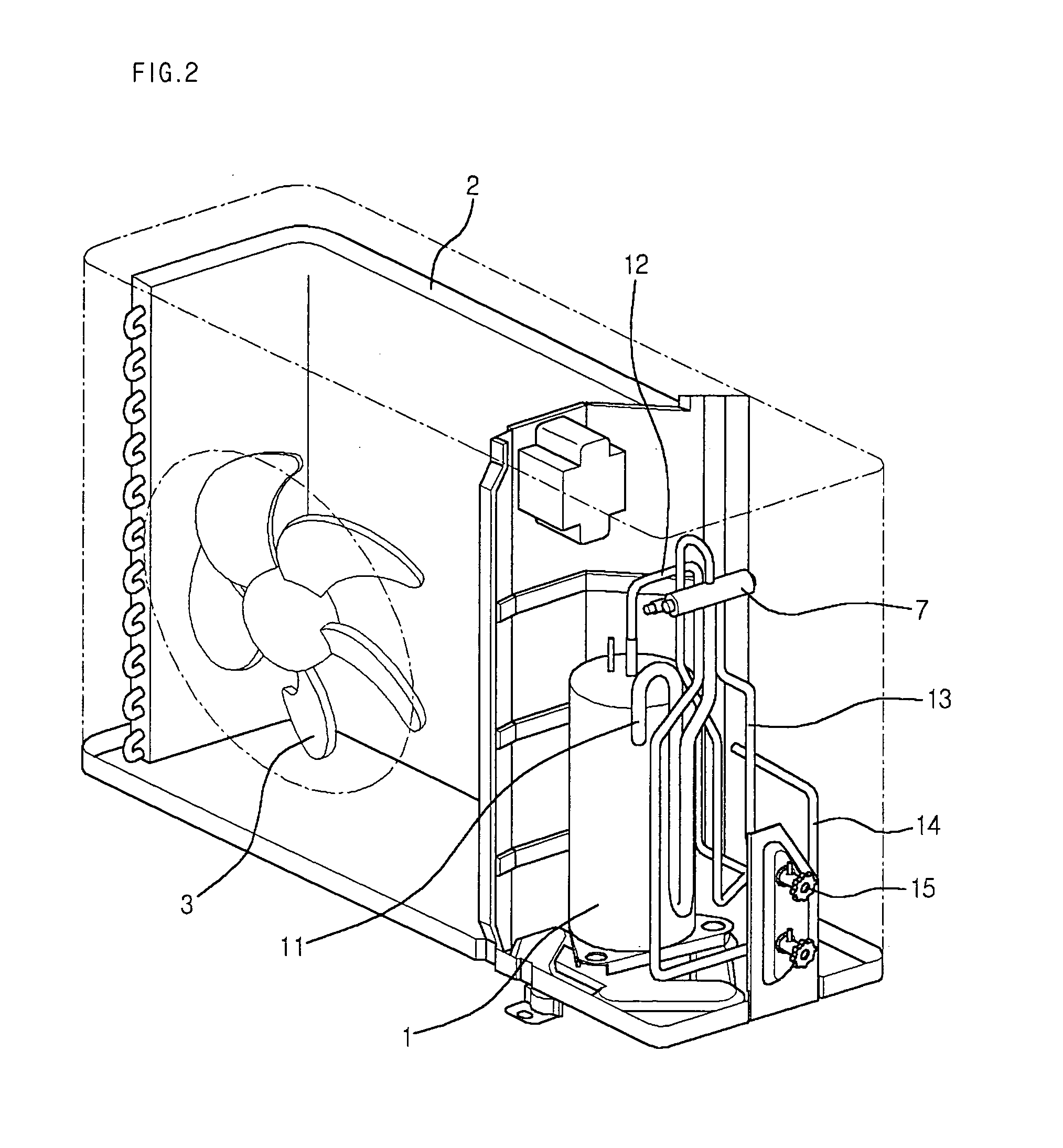

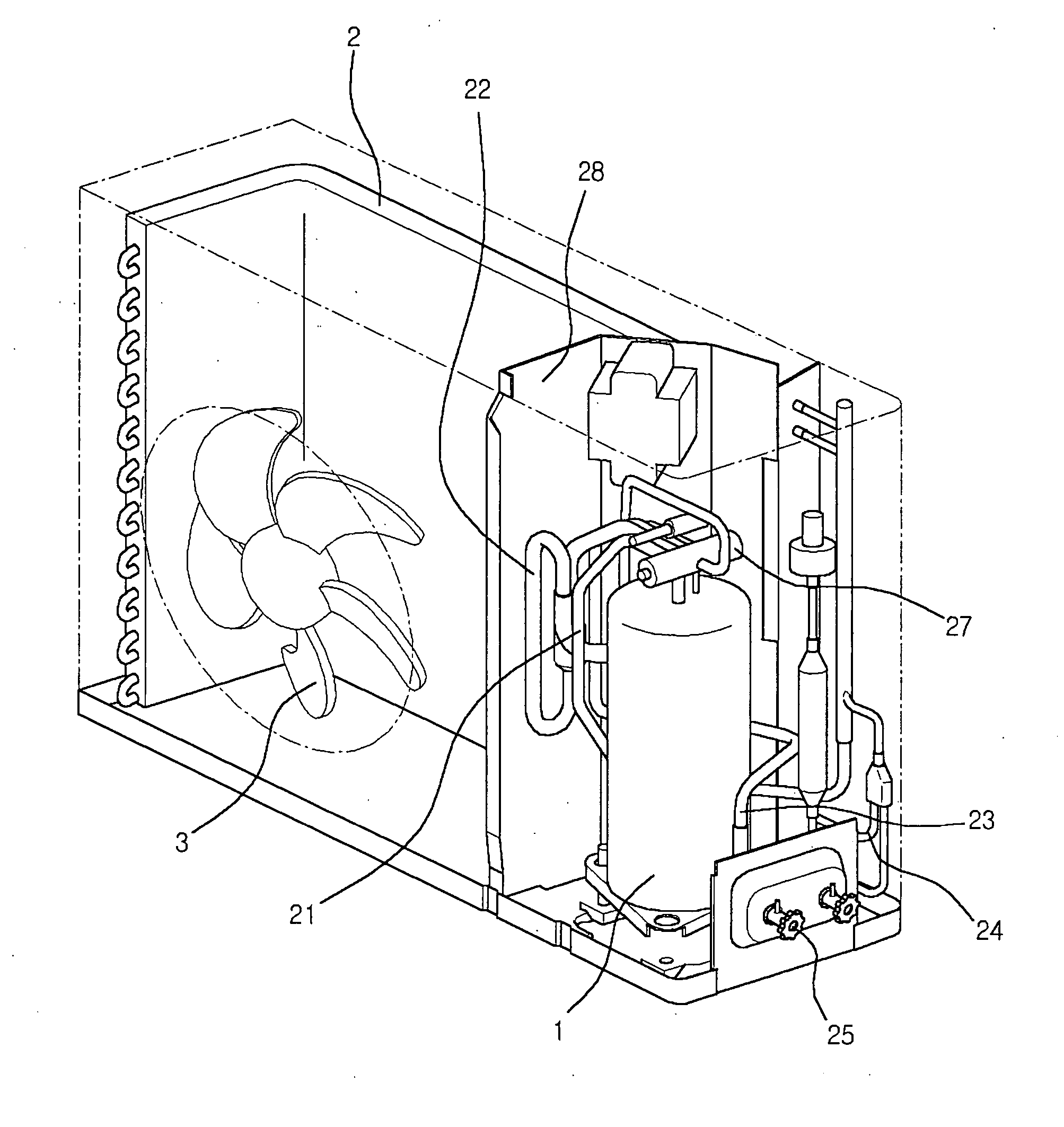

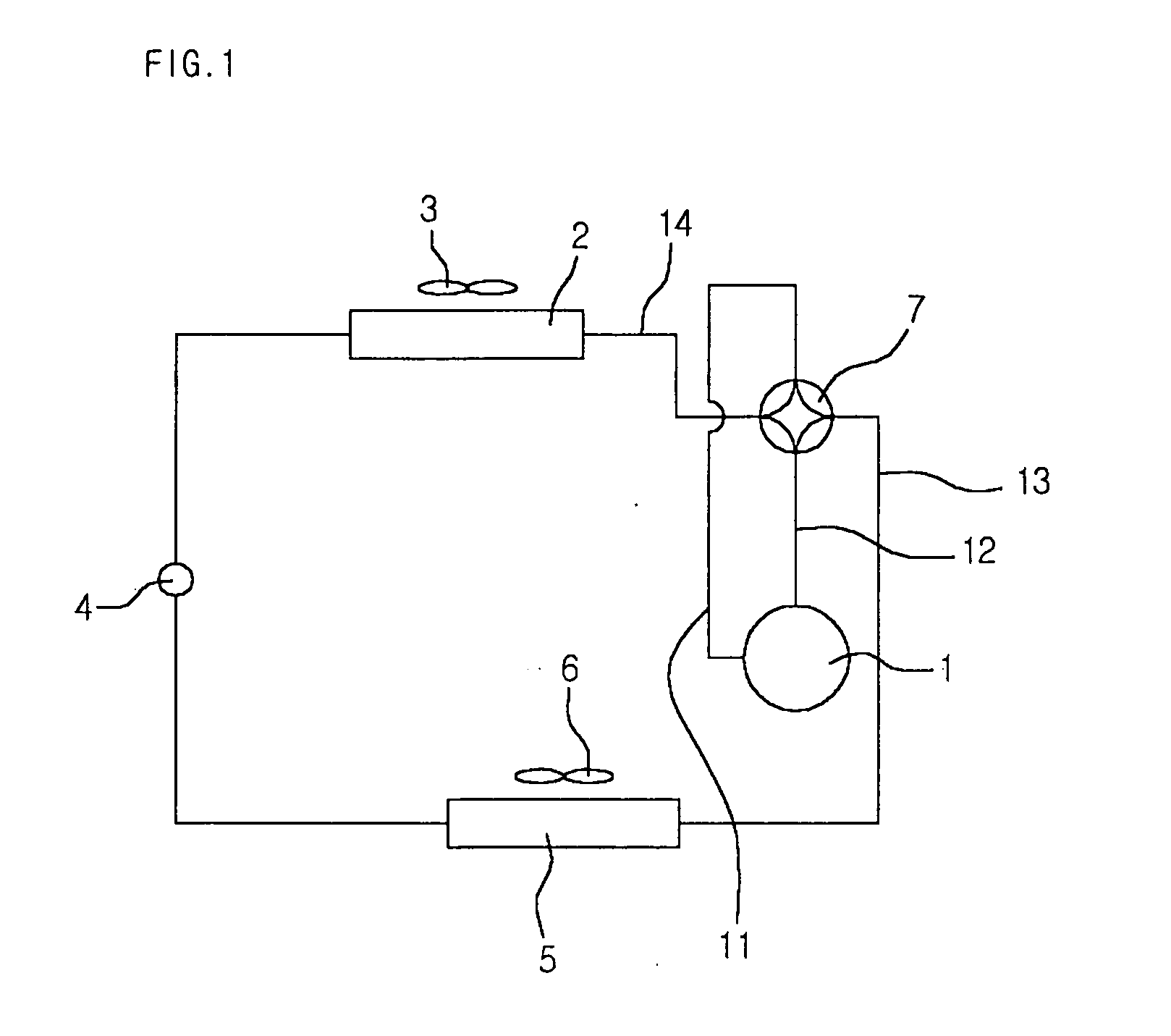

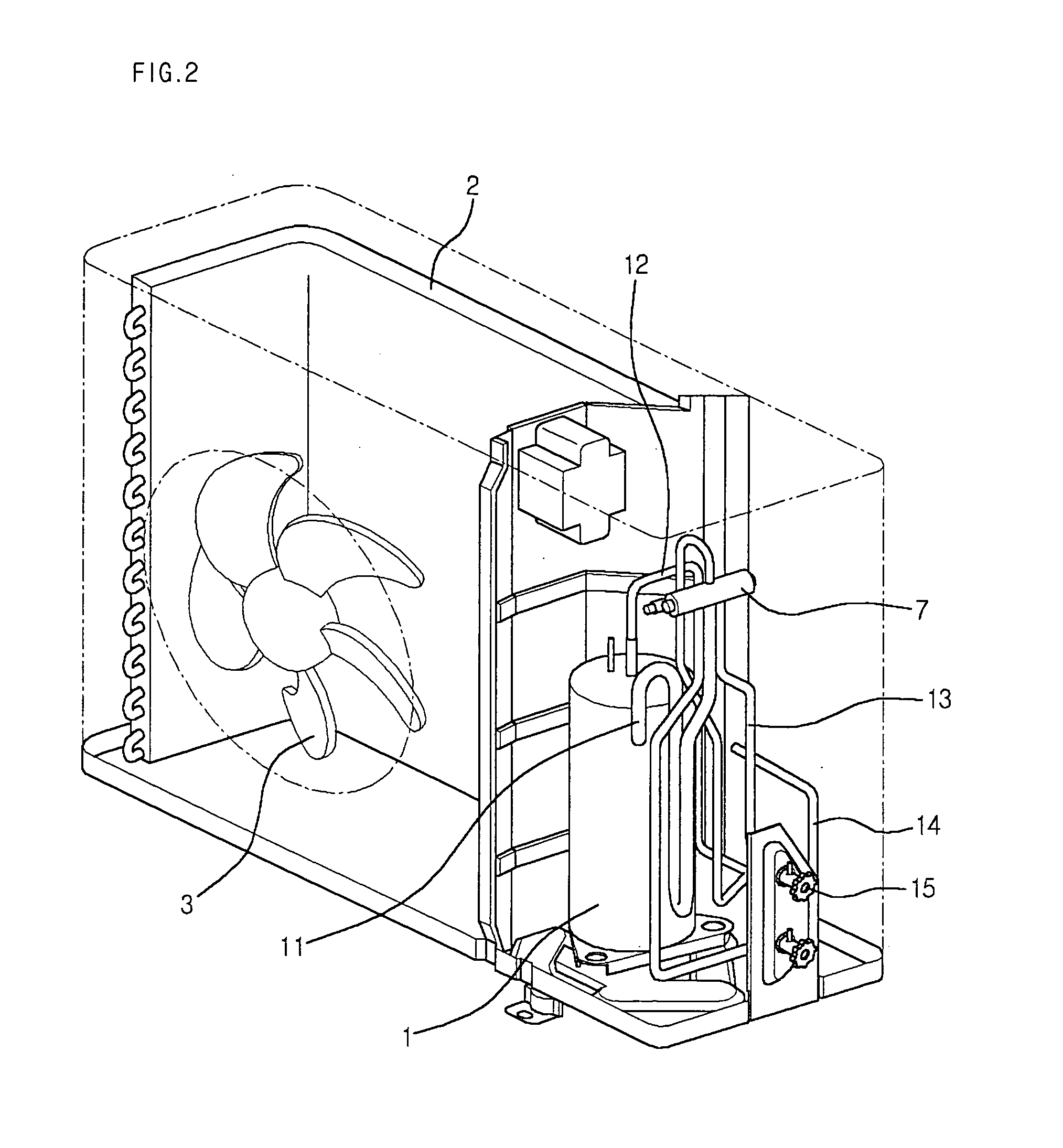

Pipe structure for outdoor unit of air conditioner

InactiveUS7121106B2Reduce noiseAvoid fatigue failureMechanical apparatusFluid circulation arrangementElectrical and Electronics engineeringEngineering

Owner:LG ELECTRONICS INC

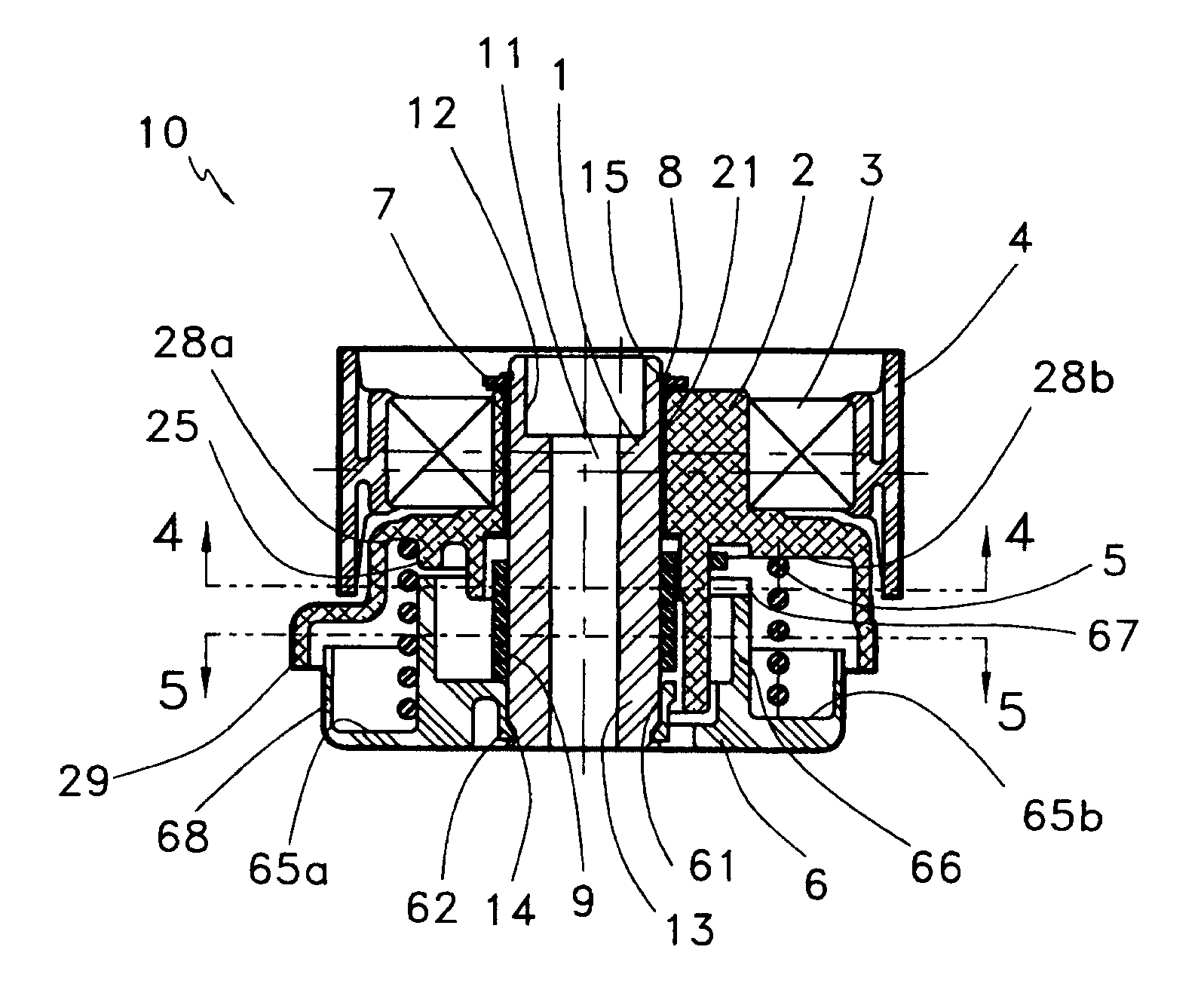

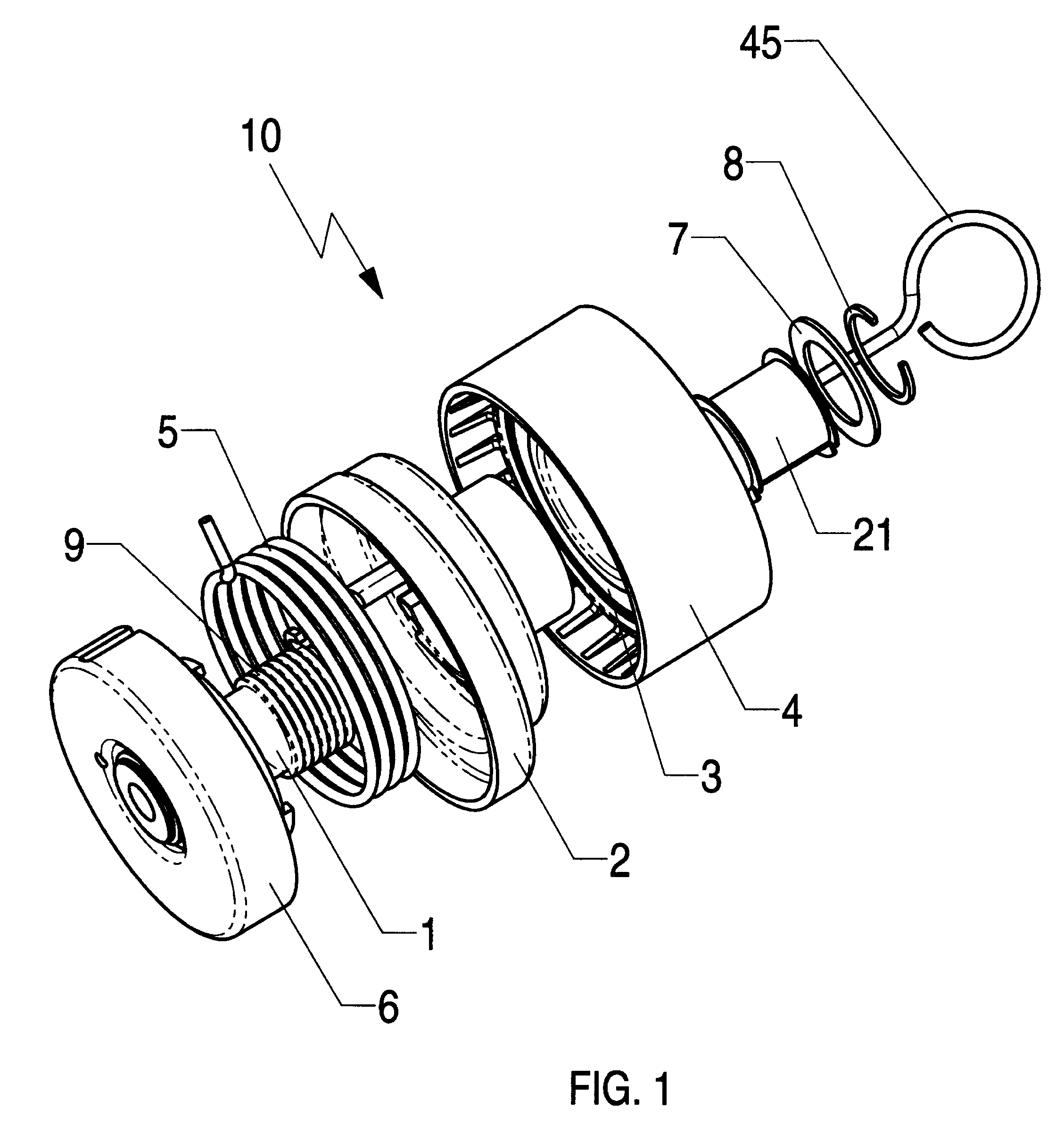

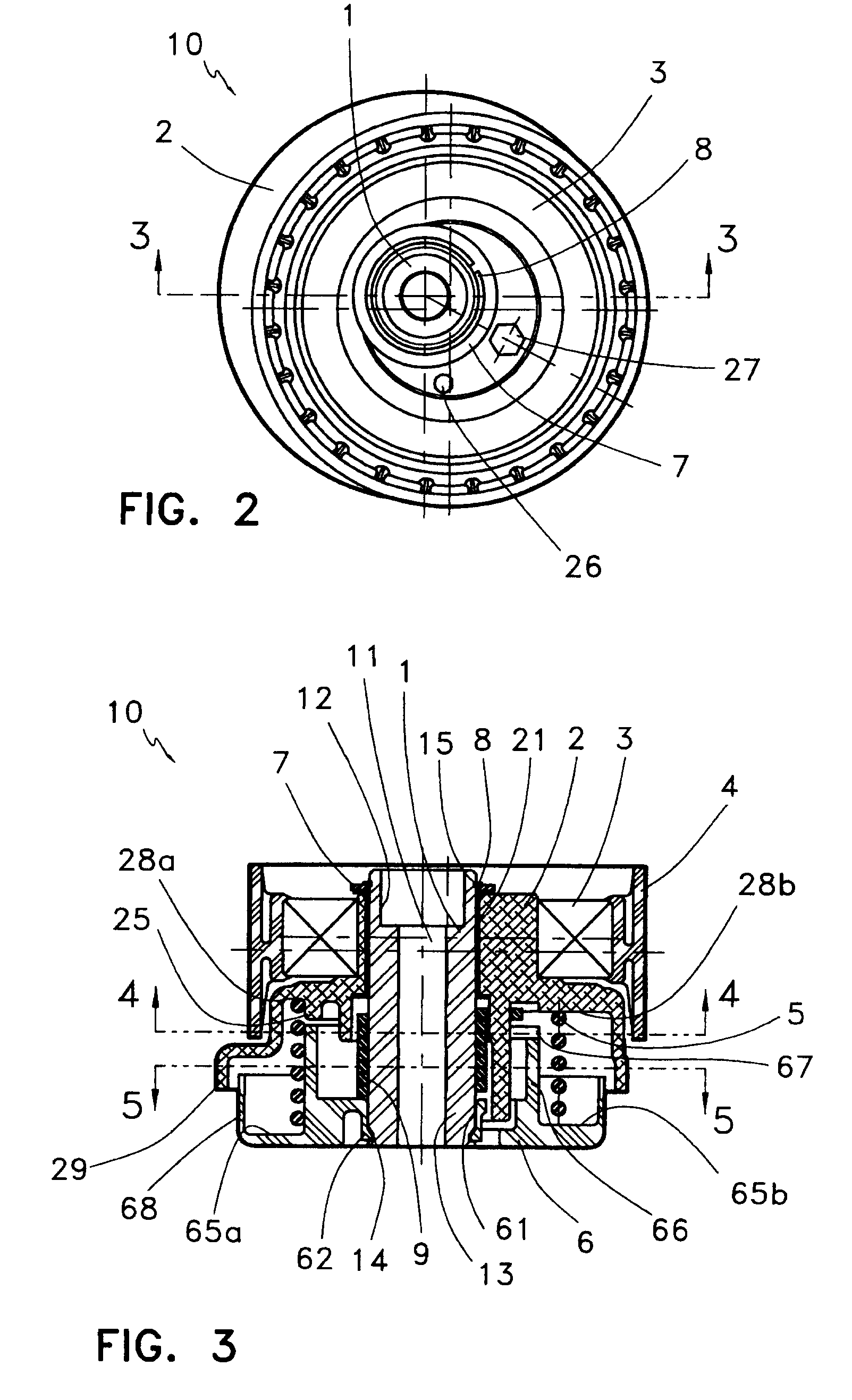

Tensioner with reinstallation feature

ActiveUS7874950B2Easy and reliable reinstallationAvoid excessive bending and yieldingGearingEngineeringField service

Owner:LITENS AUTOMOTIVE INC

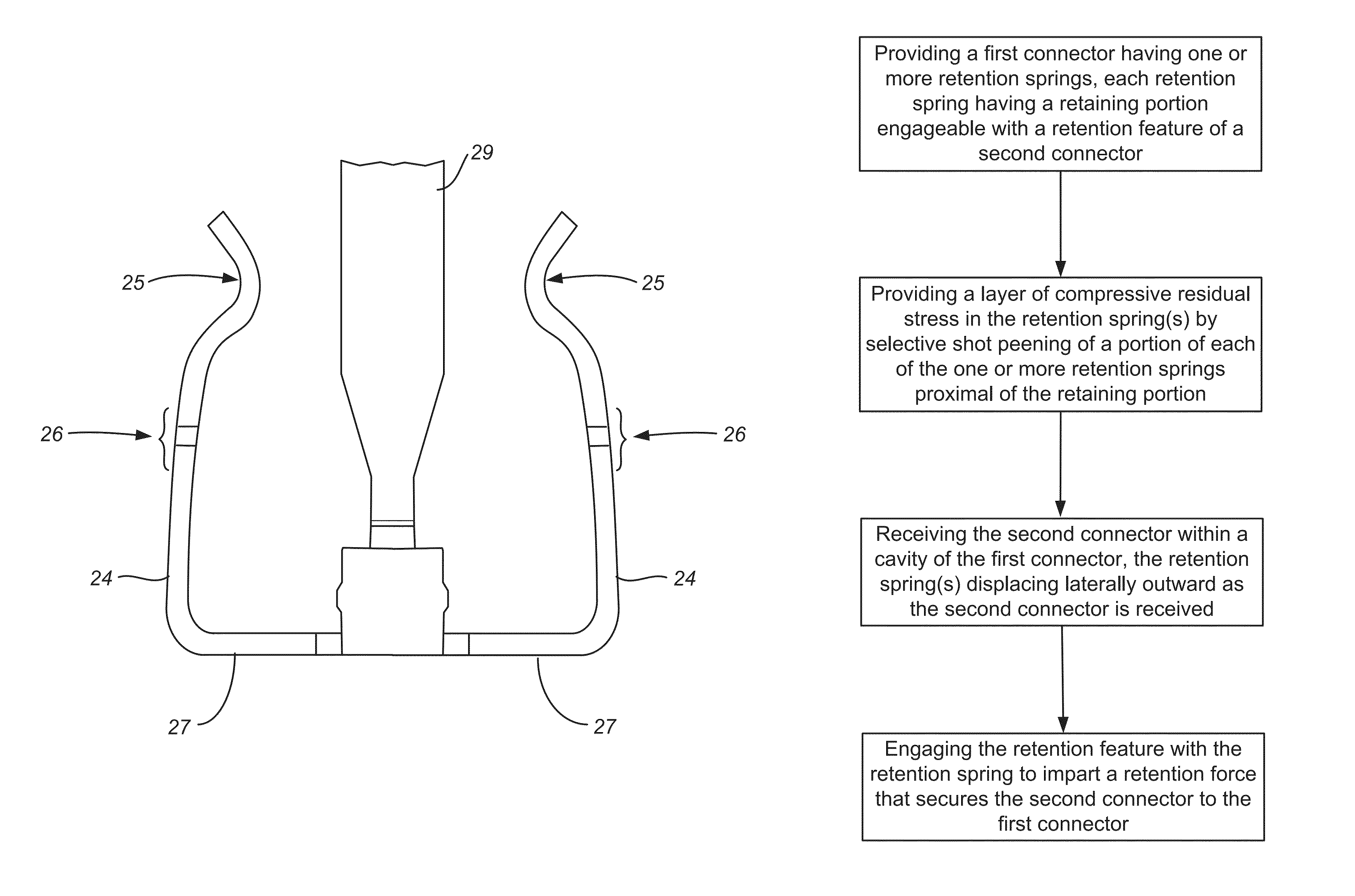

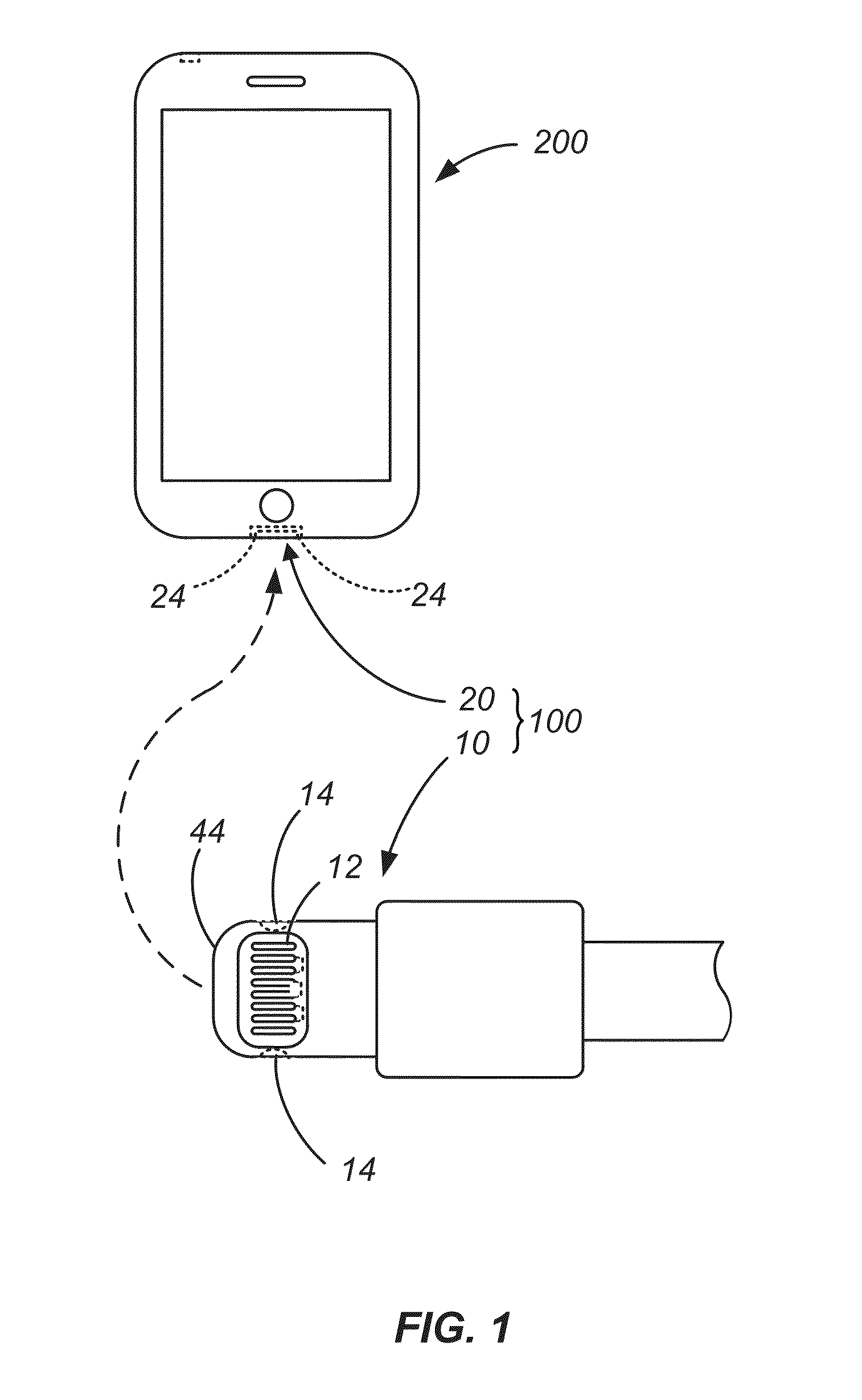

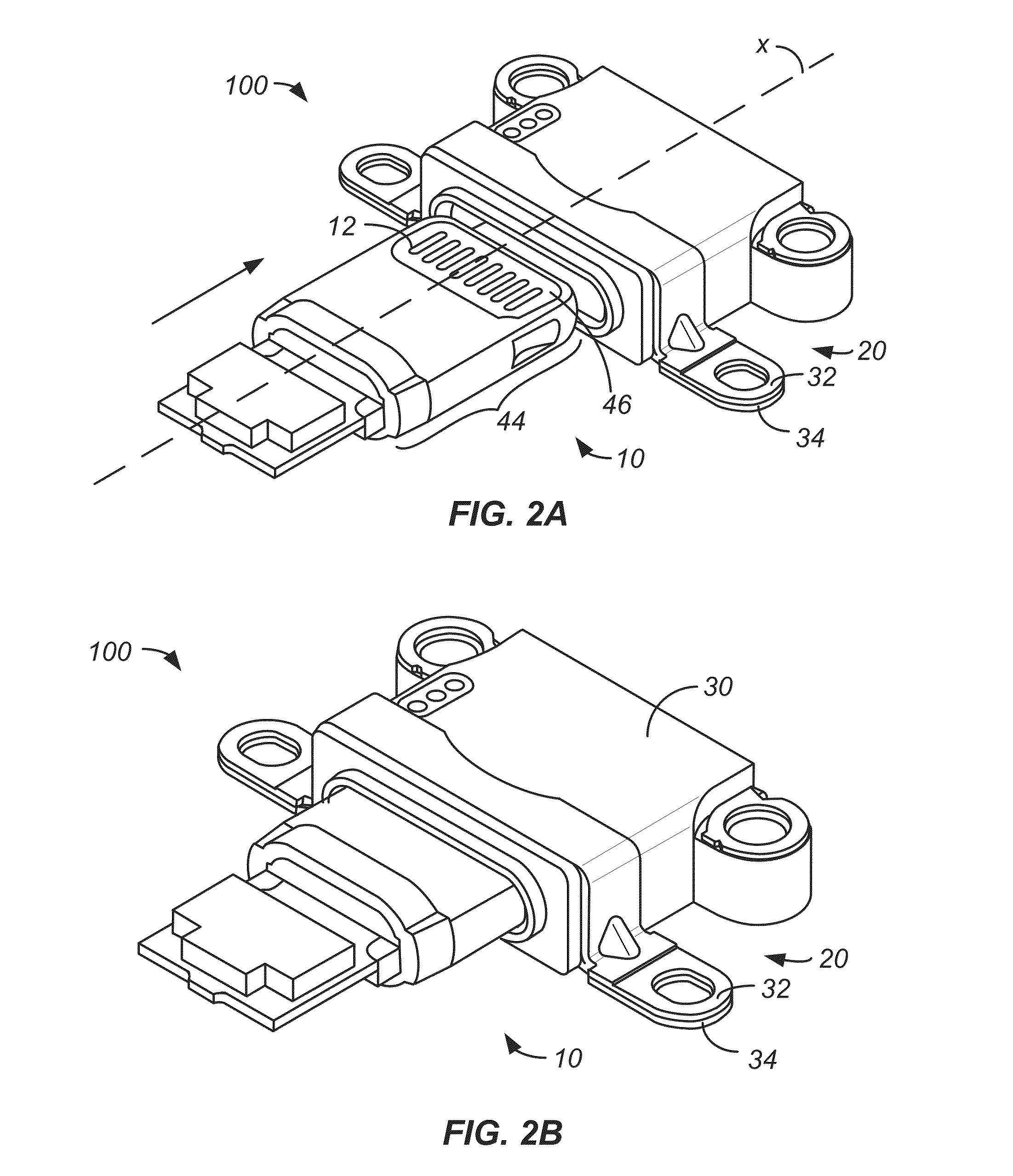

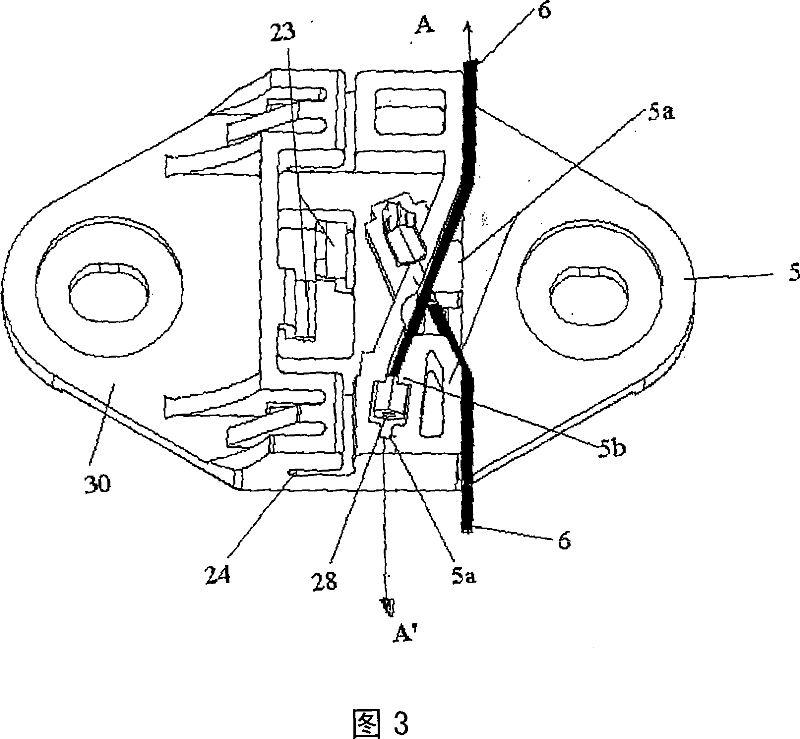

Latch assembly having spring arms each with a retaining portion and a reinforced portion

InactiveUS8882529B2Increased normal forceAvoid fatigue failureContact member cases/bases manufactureCoupling device engaging/disengagingMechanical engineeringResidual compressive stress

A retention latch mechanism having a retention spring of a first connector engageable with a retention feature of a second connector. The retention spring may include a spring arm having a distal, curved retaining portion that is resiliently received within the retention feature and a reinforced portion that is proximal of the distal retaining portion. The reinforced portion includes a layer having residual compressive stress to inhibit fatigue failure during repeated cycling of the latch mechanism. The reinforced portion may be formed by a cold working method, such as shot peening a select region of the spring arm. The reinforced portion is formed to inhibit fatigue failure during repeated cycling of the latch mechanism. Methods of forming a retention mechanism having a retention spring with a reinforced portion are provided herein.

Owner:APPLE INC

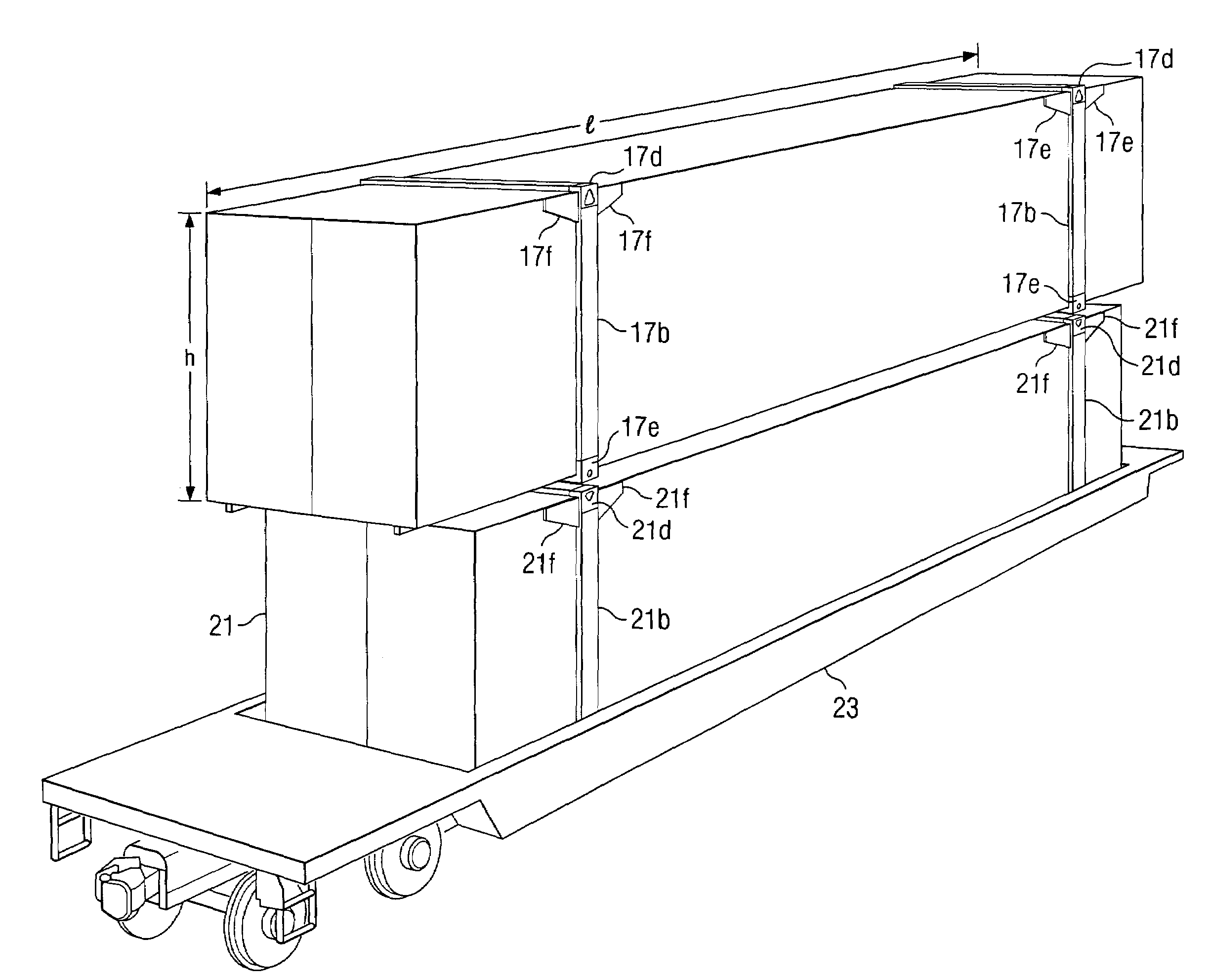

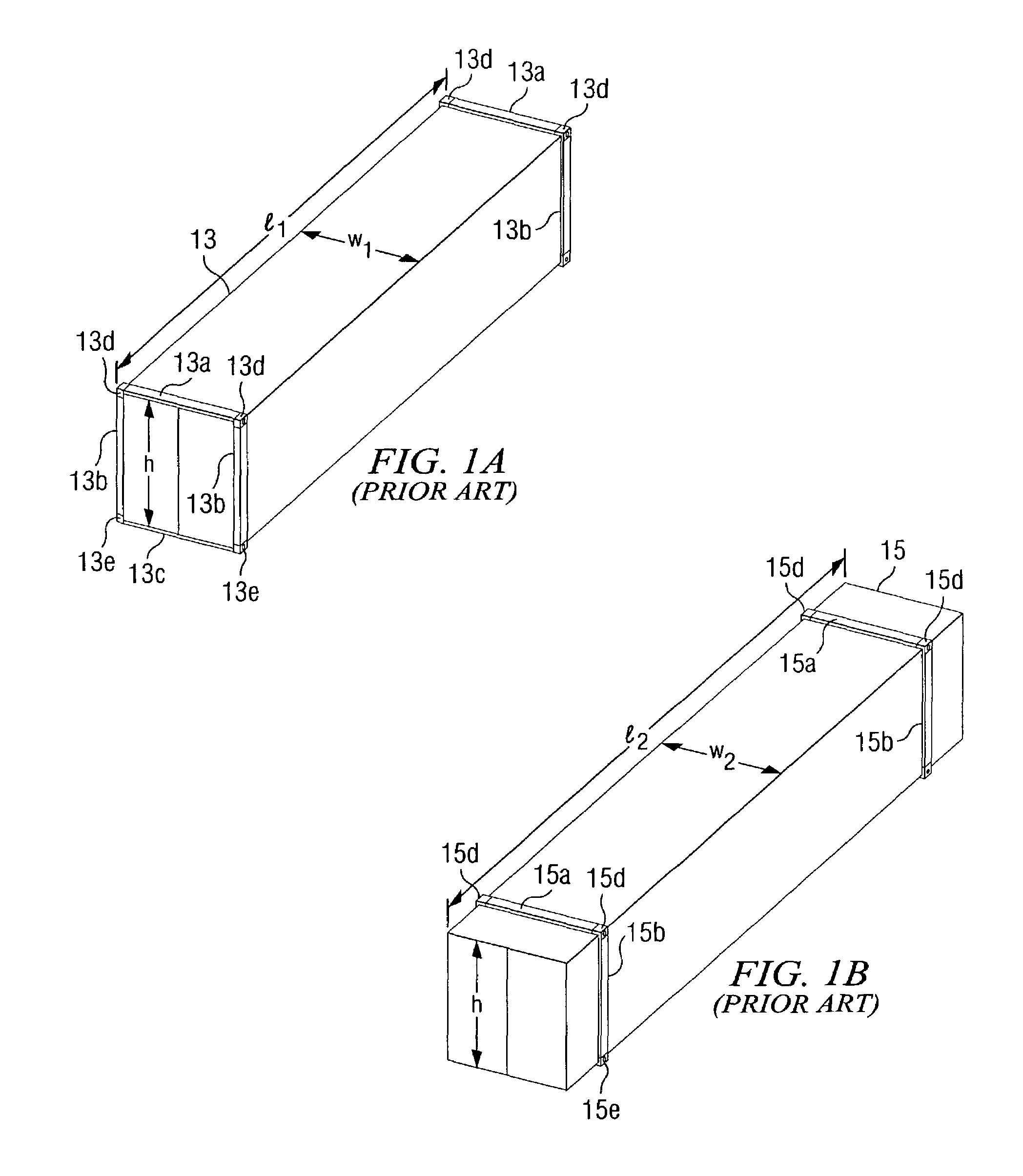

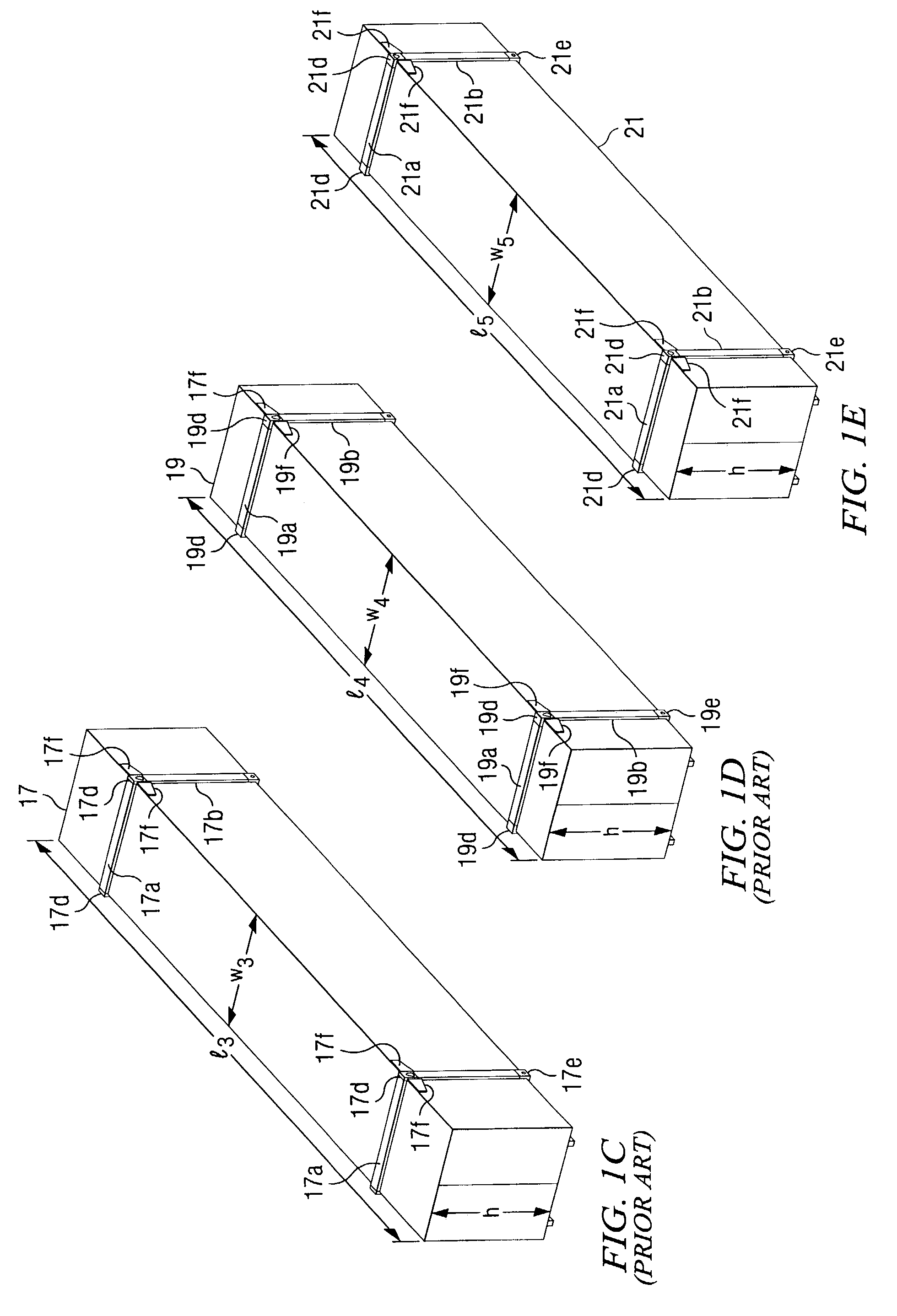

Freight container and lift casting therefore and method for lifting and transporting same

InactiveUS7056081B2Reduce intrusionShort heightClosuresElectric locomotivesMechanical engineeringCasting

An improved freight container for use in intermodal freight transportation systems that includes lift castings having a top lift aperture located on the lift casting at an outboard position, such that when other containers are stacked on top of the improved container, loads are properly distributed through reinforcement beams of the improved container, thereby substantially reducing bending stresses in the improved container, substantially reducing the possibility fatigue failure of the improved container, and reducing the costs of maintenance and inspection of the improved container.

Owner:BNSF RAILWAY

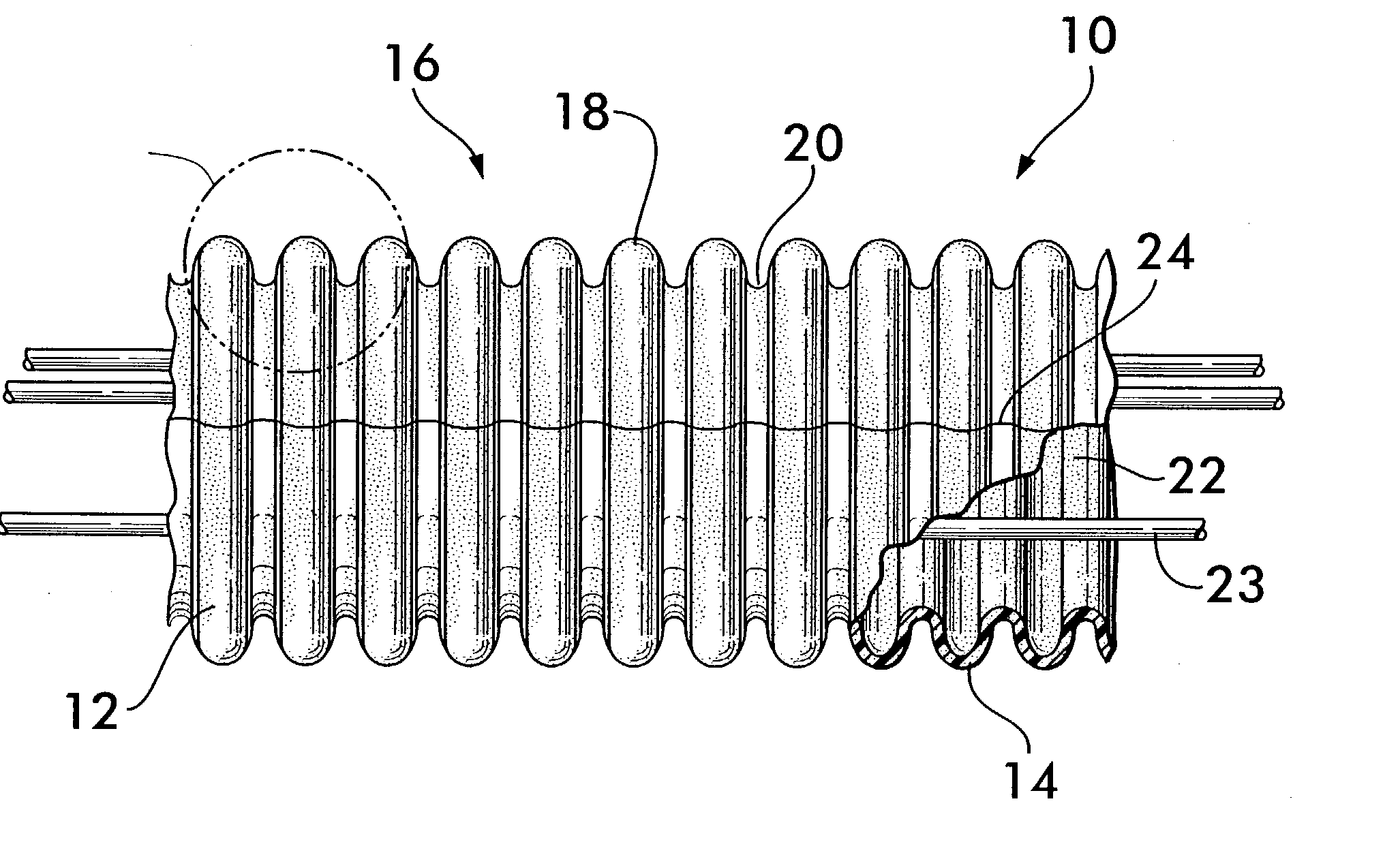

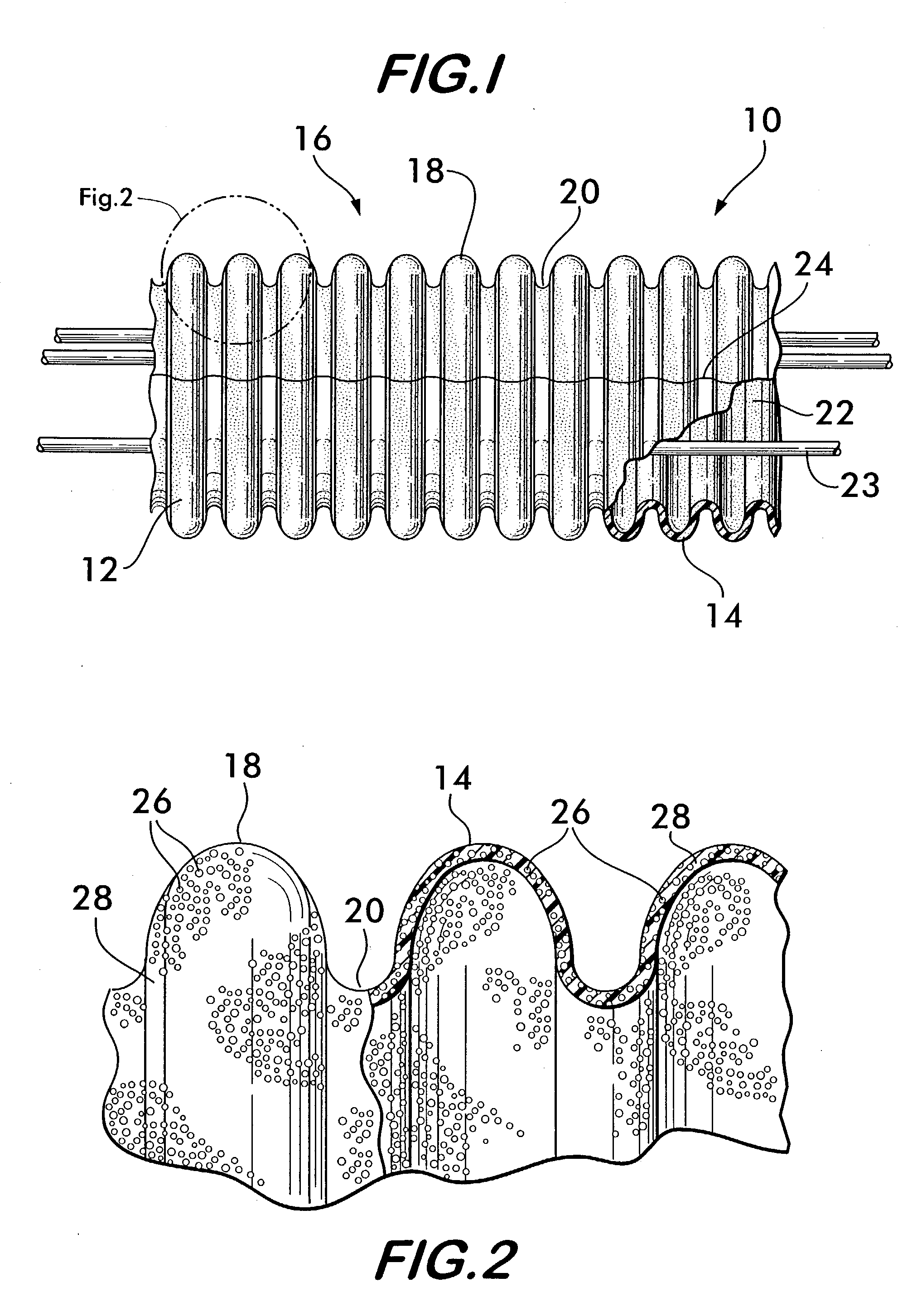

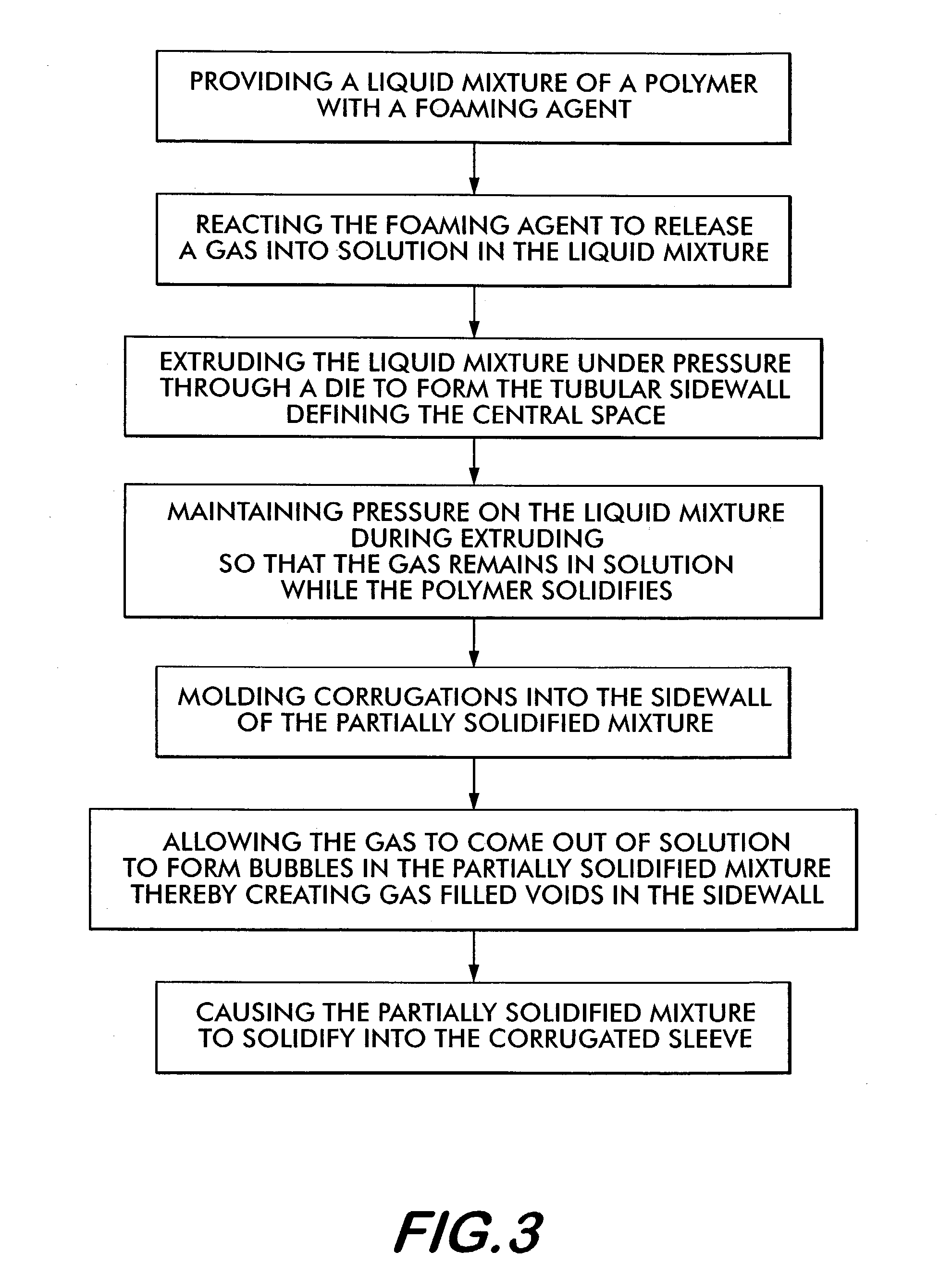

Monolayer foamed corrugated sleeve

InactiveUS20040060609A1Prevent crashConvenient thermal protectionLaminationLamination apparatusThermoplasticFoaming agent

A monolayer foamed corrugated sleeve for protecting elongate substrates is disclosed. The sleeve is extruded from a polymer and a foaming agent. The polymer may be a non-elastomeric thermoplastic, a thermoplastic elastomer or a combination of the two. The sleeve is extruded from a nozzle having a cross sectional area which decreases along its length to maintain pressure on the extrudate and prevent premature foaming. The extrudate is released from the nozzle into moving mold blocks. A blow rod within the mold blocks provides gas pressure to force the extrudate against the blocks. An obturation device is mounted on the blow rod to control the gas pressure.

Owner:FEDERAL MOGUL WORLD WIDE

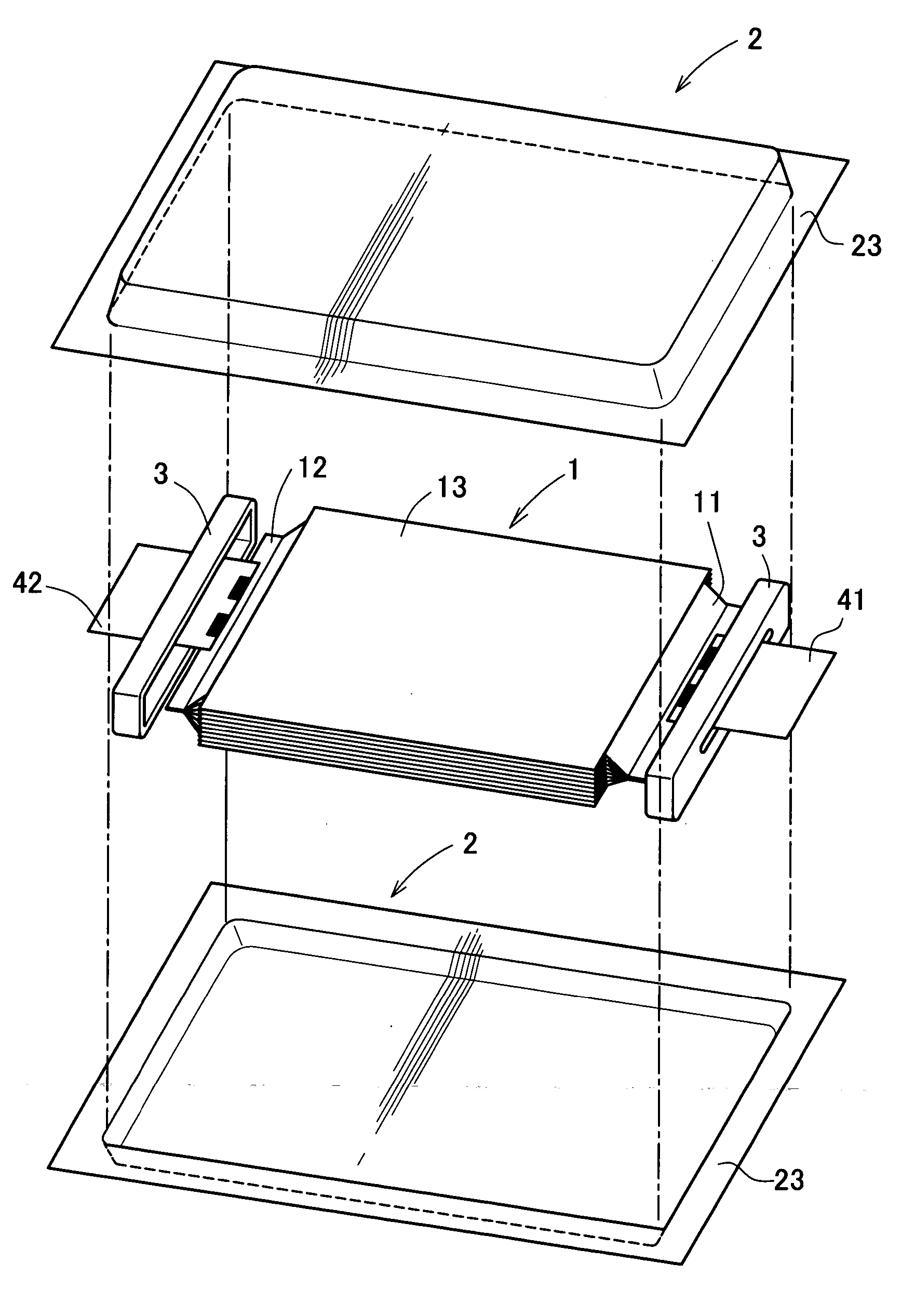

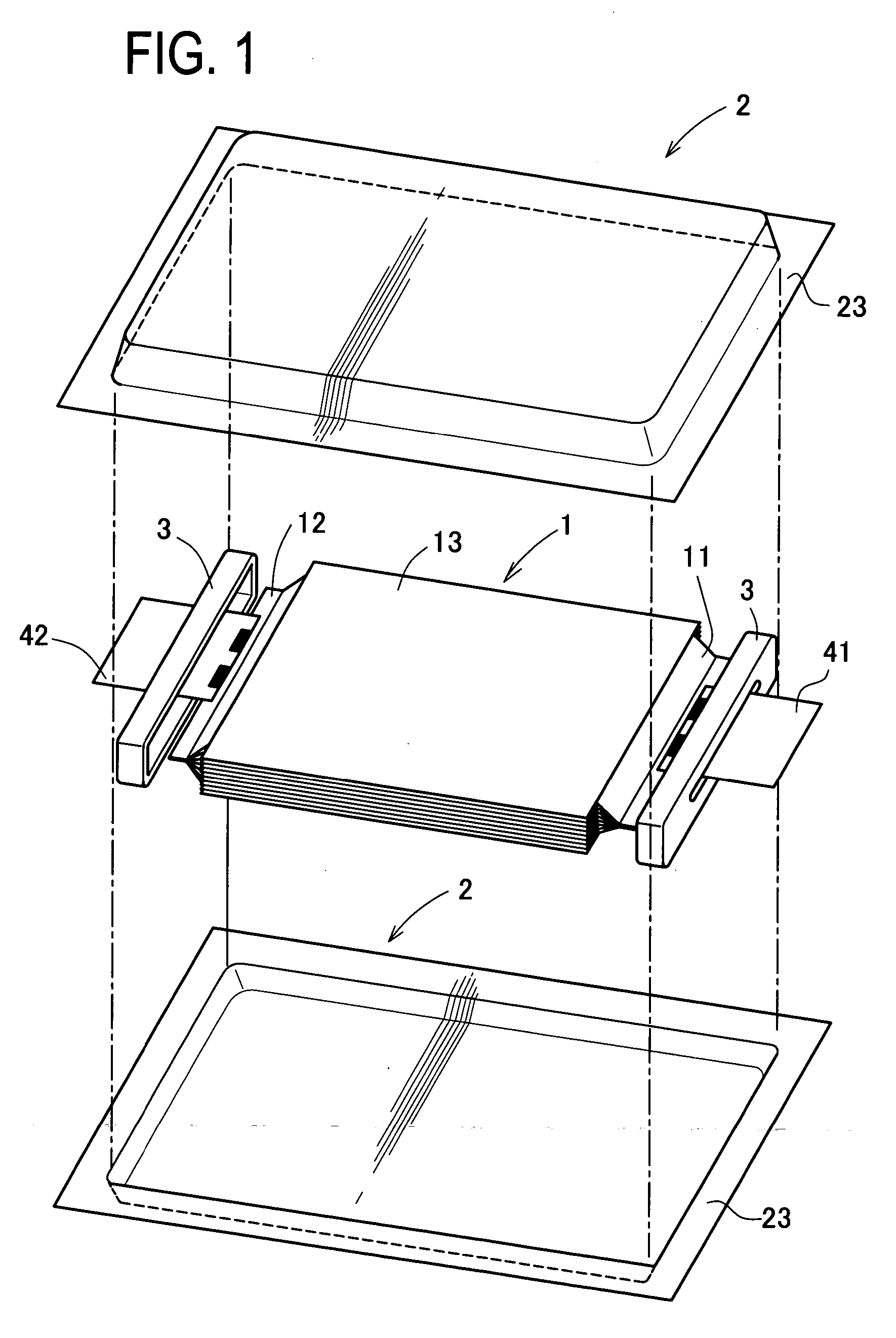

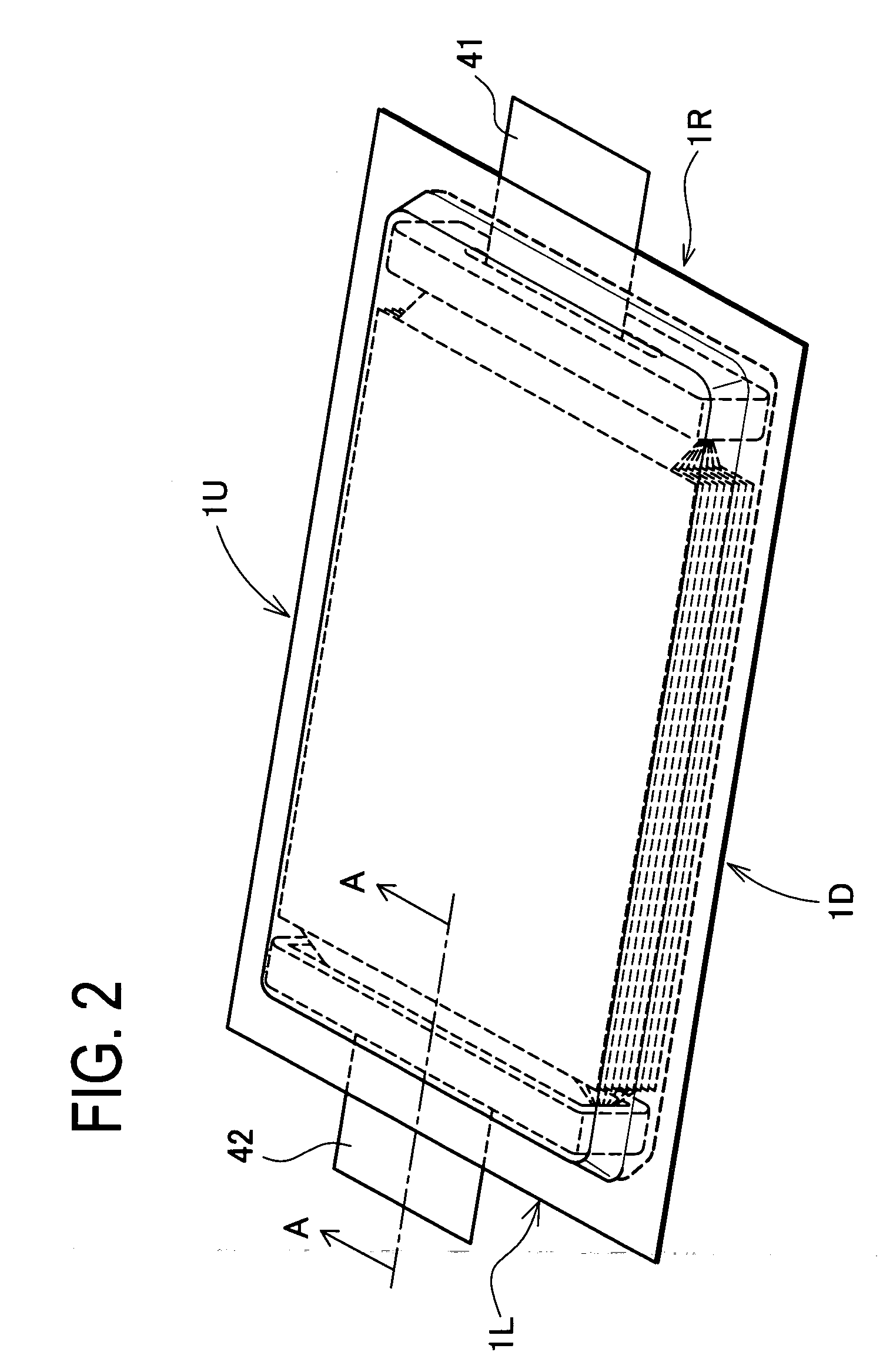

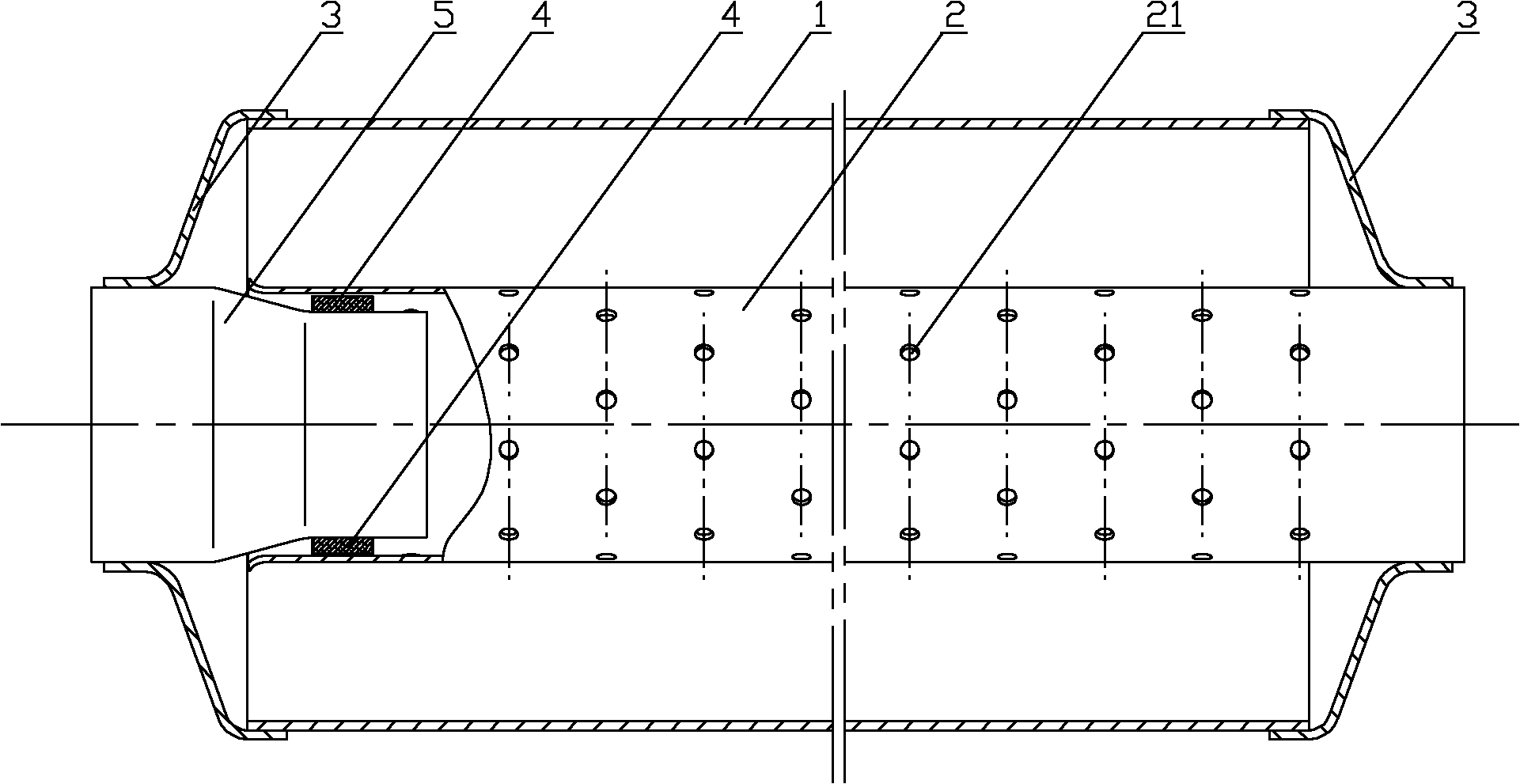

Laminate Type Secondary Battery and Battery Pack Thereof

InactiveUS20070231685A1Avoid fatigue failureAvoid it happening againFinal product manufactureSmall-sized flat cells/batteriesInternal pressureBattery pack

An electrode terminal 42 is connected to a current collector part 12 of electrodes through a deformation restricting member 3. Between laminate seals 2 and 2, a space 15 is formed above and below the current collector part 12. The deformation restricting member 3 is placed close to the inner wall peripheral portion of an outer package including sealing parts 23, thereby forming a deformation-restricting part 22 to restrict the inward deformation of the laminated films 2. In a section extending from the inside end of the deformation restricting member 3 to a battery element 1, the laminated films 2 face the space 15 to allow the deformation of the laminated films 2 in response to the change of internal pressure. At the decrease of internal pressure, the contraction of the laminated films 2 can be localized in the deformation-allowing part 21, thereby reducing the bending stress on an end portion of the sealing parts 23. Thus, the laminate type secondary battery and the battery pack thereof can be provided with the effect that the concentration of stress on the bonded part of the laminated films can be suppressed even when the expansion and contraction of the laminated films are repeated in response to the change of internal pressure of the laminated films bonded to hermetically accommodate the battery element.

Owner:TOYOTA JIDOSHA KK

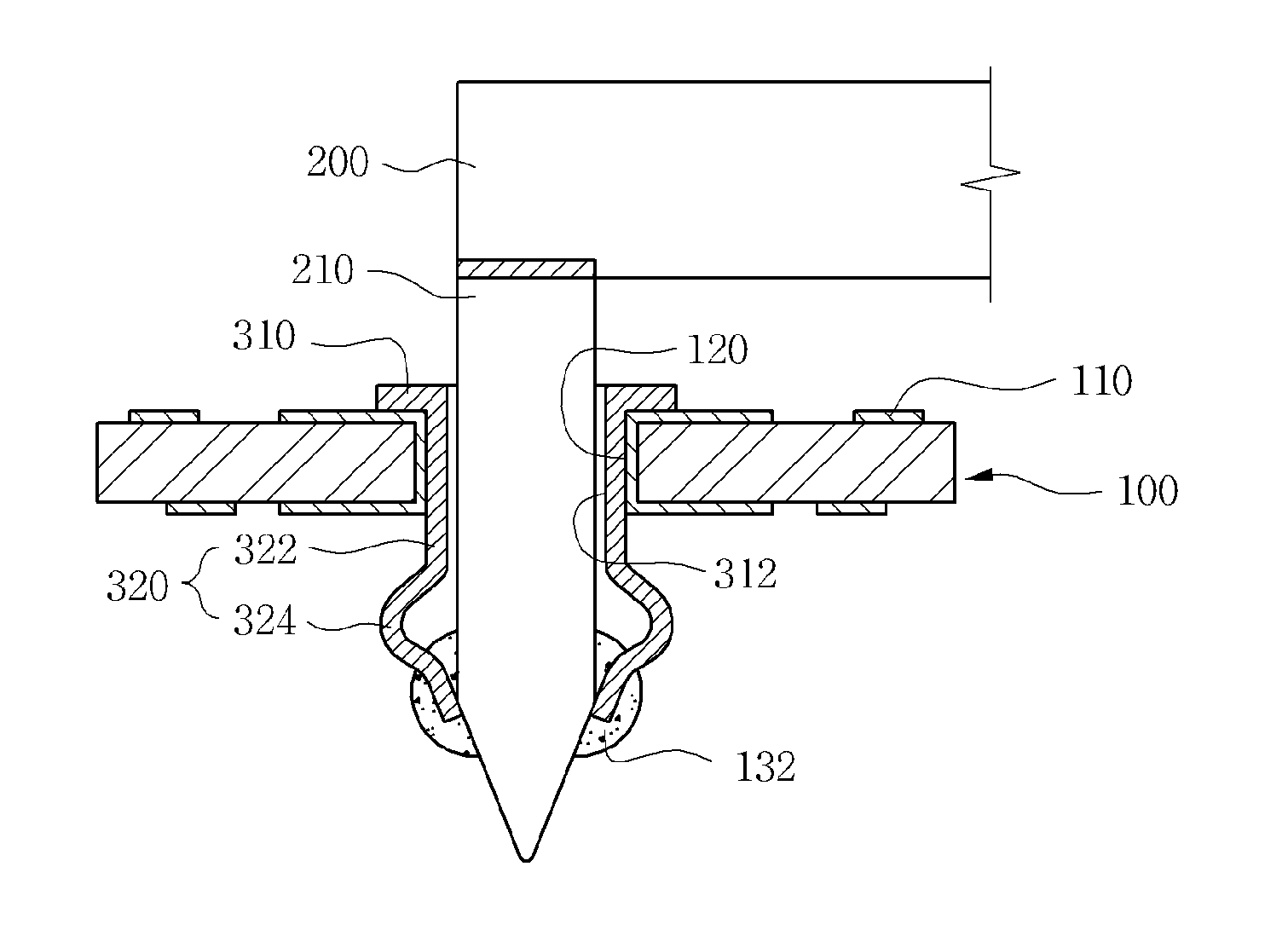

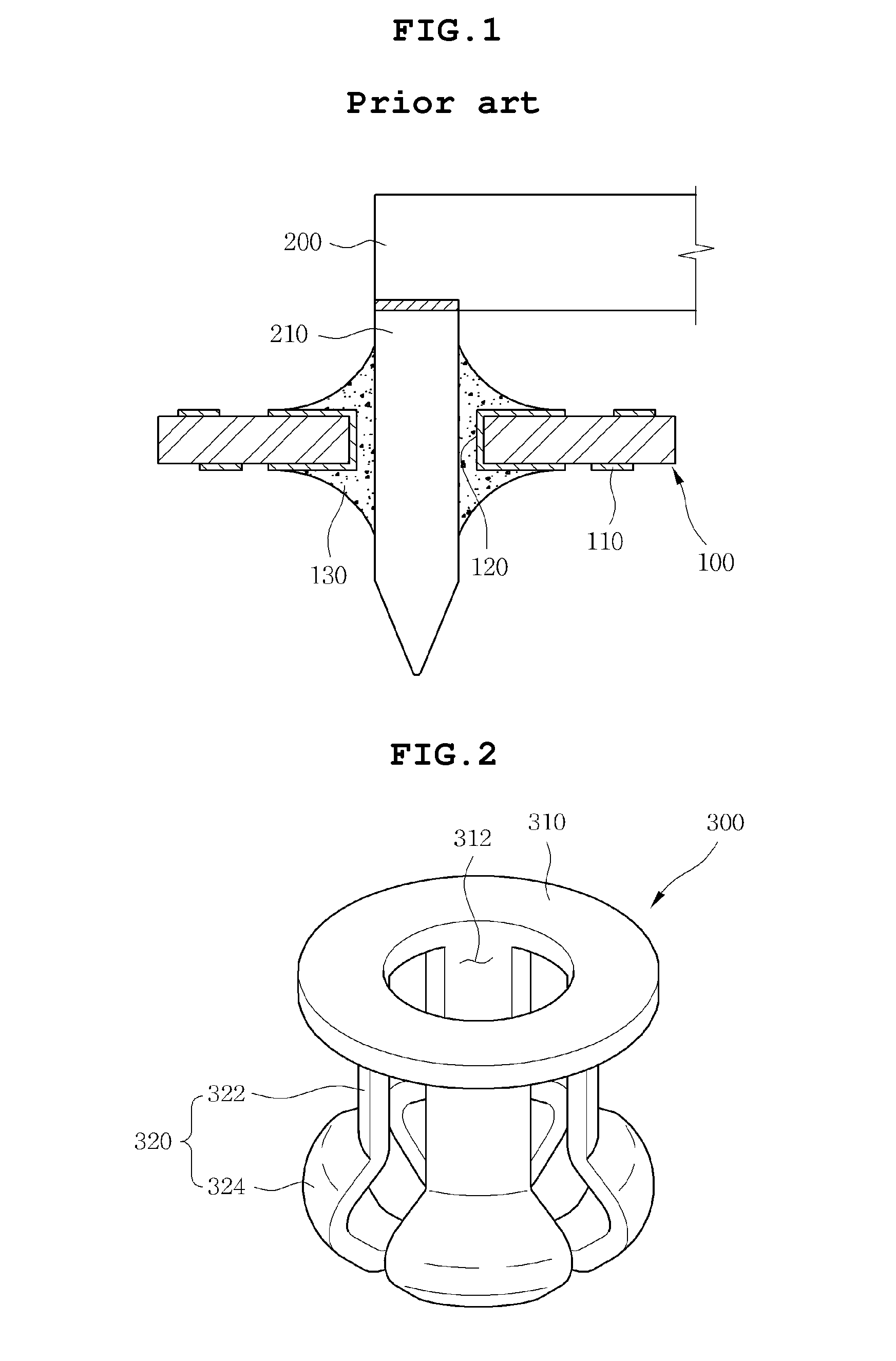

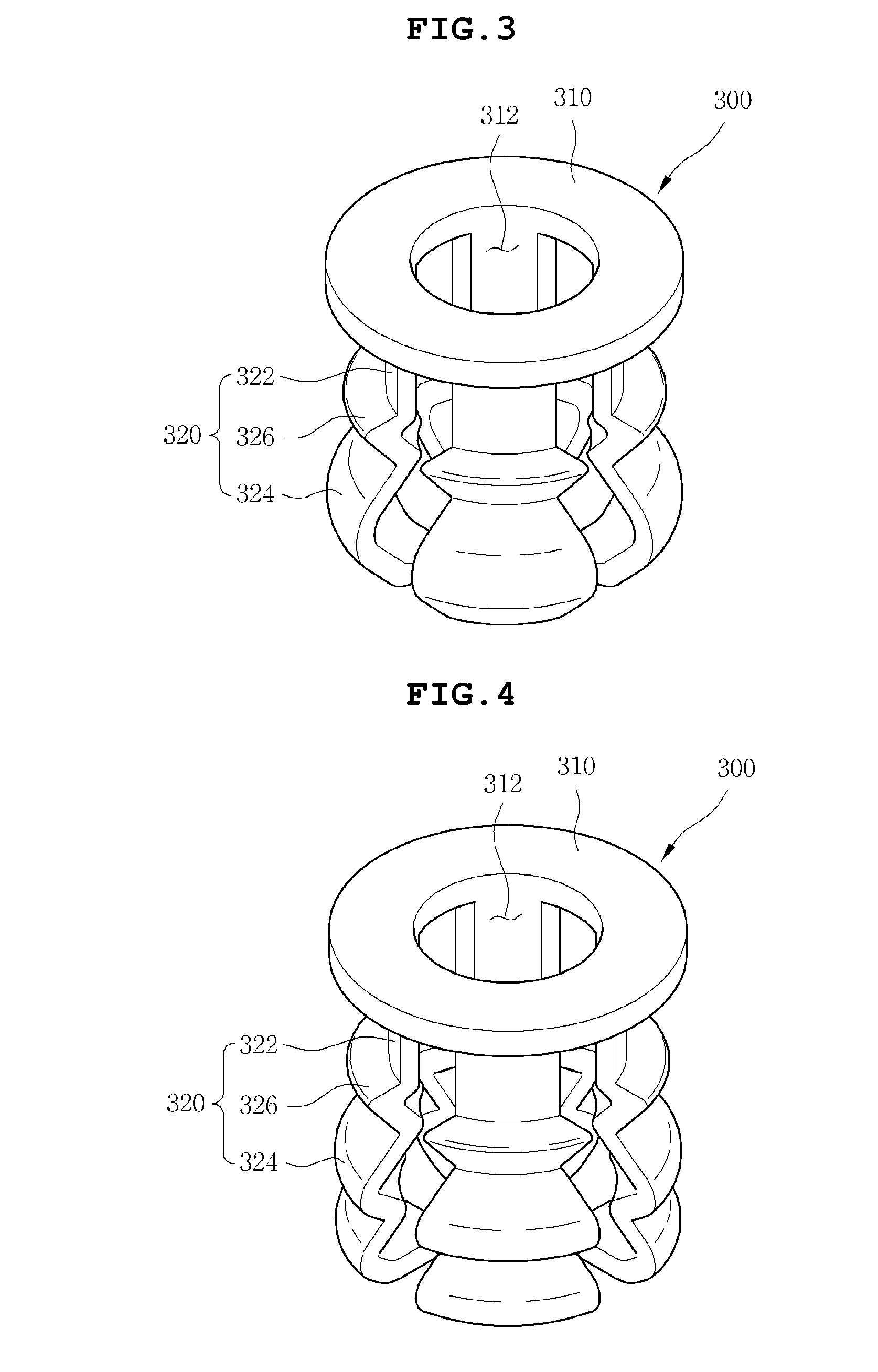

Soldering connecting pin, semiconductor package substrate and method of mounting semiconductor chip using the same

InactiveUS20120127681A1Reduce thermal stressAvoid fatigue failureNon-insulated conductorsElectrically conductive connectionsSemiconductor chipSemiconductor package

Disclosed herein are a soldering connecting pin, a semiconductor package substrate and a method of mounting a semiconductor chip using the same. A semiconductor chip is mounted on the printed circuit board using the soldering connecting pin inserted into a through-hole of the printed circuit board, thereby preventing deformation of the semiconductor package substrate and fatigue failure due to external shocks.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

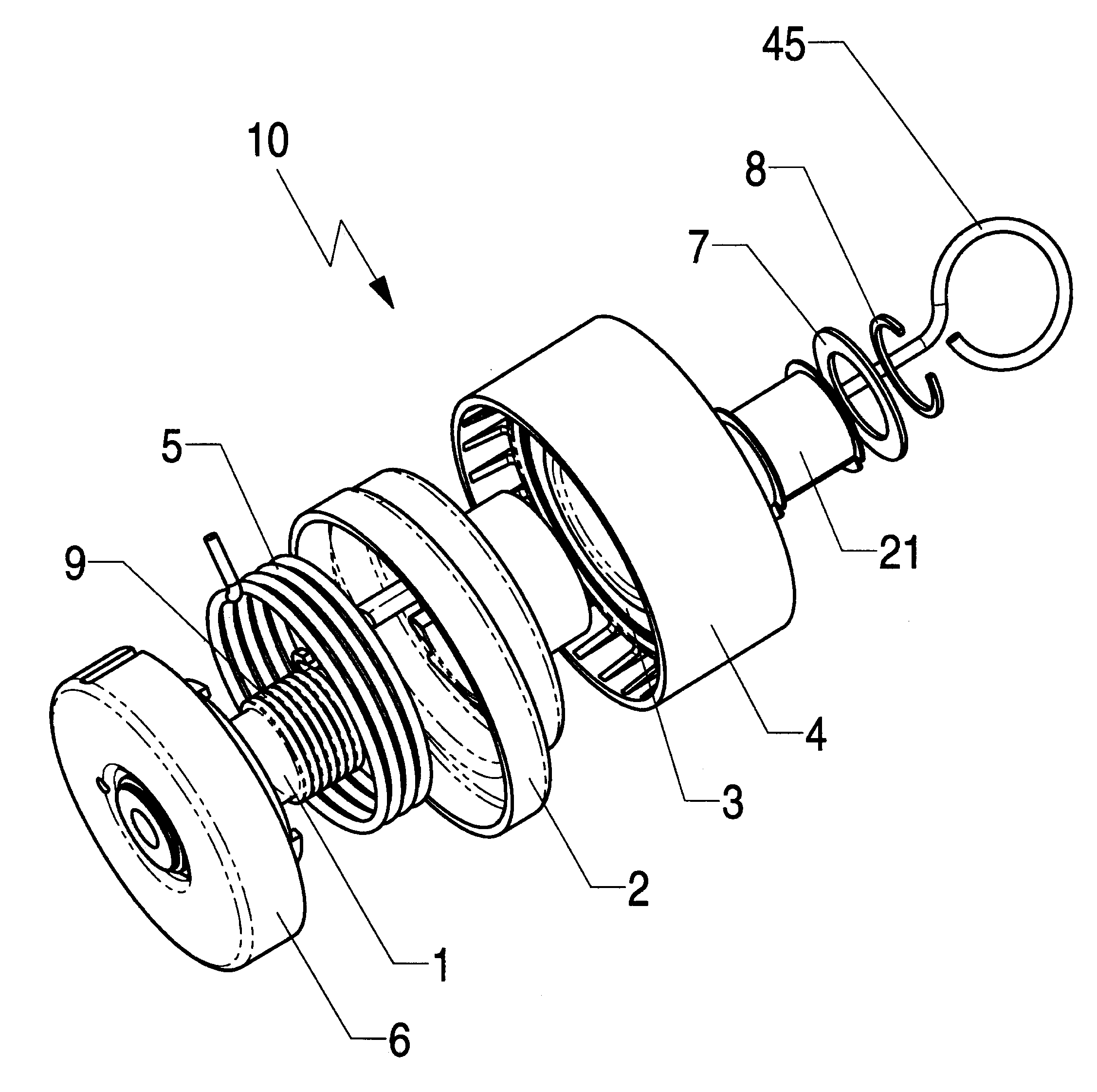

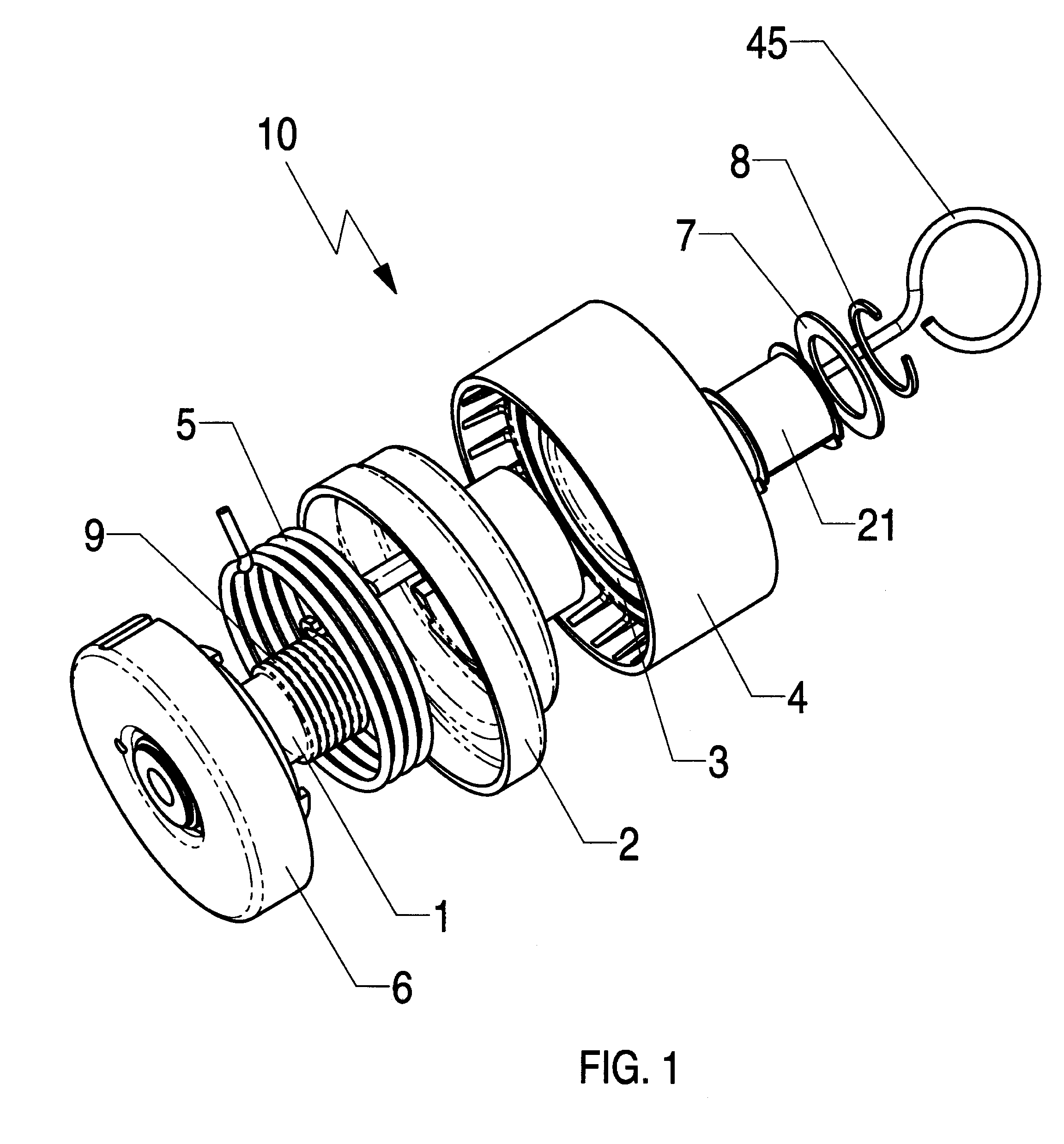

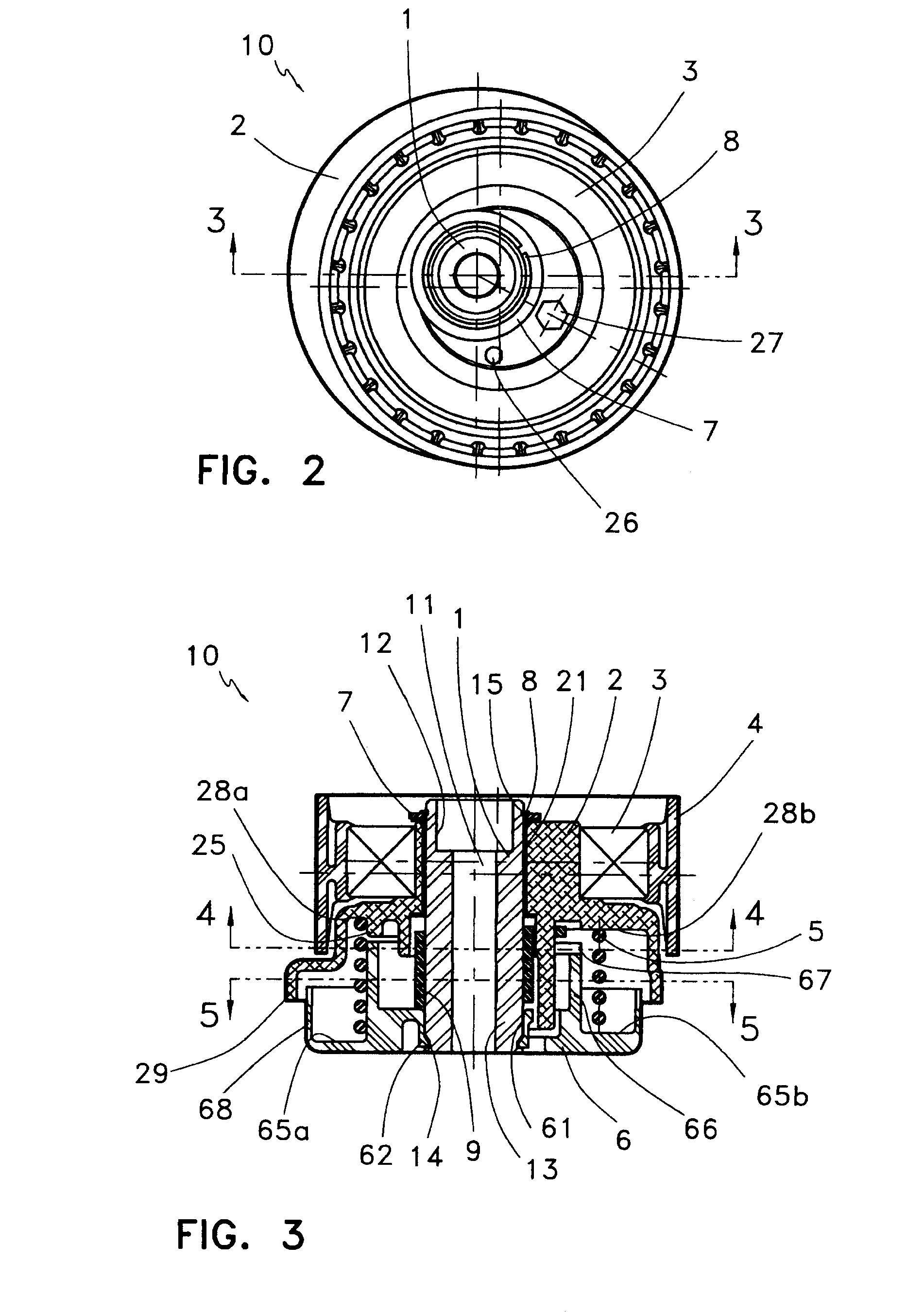

Tensioner with Reinstallation Feature

A tensioner enables easy and reliable reinstallation of the tensioner and belt in the field service while simultaneously making it possible to utilize a one-way clutch device to ensure continuous belt tension control without cumbersome manual alignment and / or realignment procedures. The tensioner has a pivot shaft configured for mounting on an engine surface. A tensioner arm is mounted on the pivot shaft for pivotal movement between a free arm stop position and premount stop position. A belt-engaging pulley is mounted for rotation on the tensioner arm. A base cup is rotatably mounted around an end of the pivot shaft. The base cup has an arcuate slot having a free arm stop end and a premount stop end. The tensioner arm cooperates with the arcuate slot limiting the pivotal movement of the tensioner arm. A spring is coupled between the tensioner arm and the base cup biasing the tensioner arm in a belt-tensioning direction. An anti-kickback stop mechanism engages the pivot shaft and has a lost motion connection with the tensioner arm wherein the tensioner arm moves through a free range without engaging the anti-kickback mechanism. The tensioner arm 1) rotates the anti-kickback mechanism as the tensioner arm moves beyond the free range towards the premount stop position and 2) enables the anti-kickback mechanism as the tensioner arm moves beyond the free range towards the free arm stop position, limiting travel of the tensioner arm therebeyond. The spring is fixable relative to the pivot shaft upon the tensioner being mounted on the engine surface.

Owner:LITENS AUTOMOTIVE INC

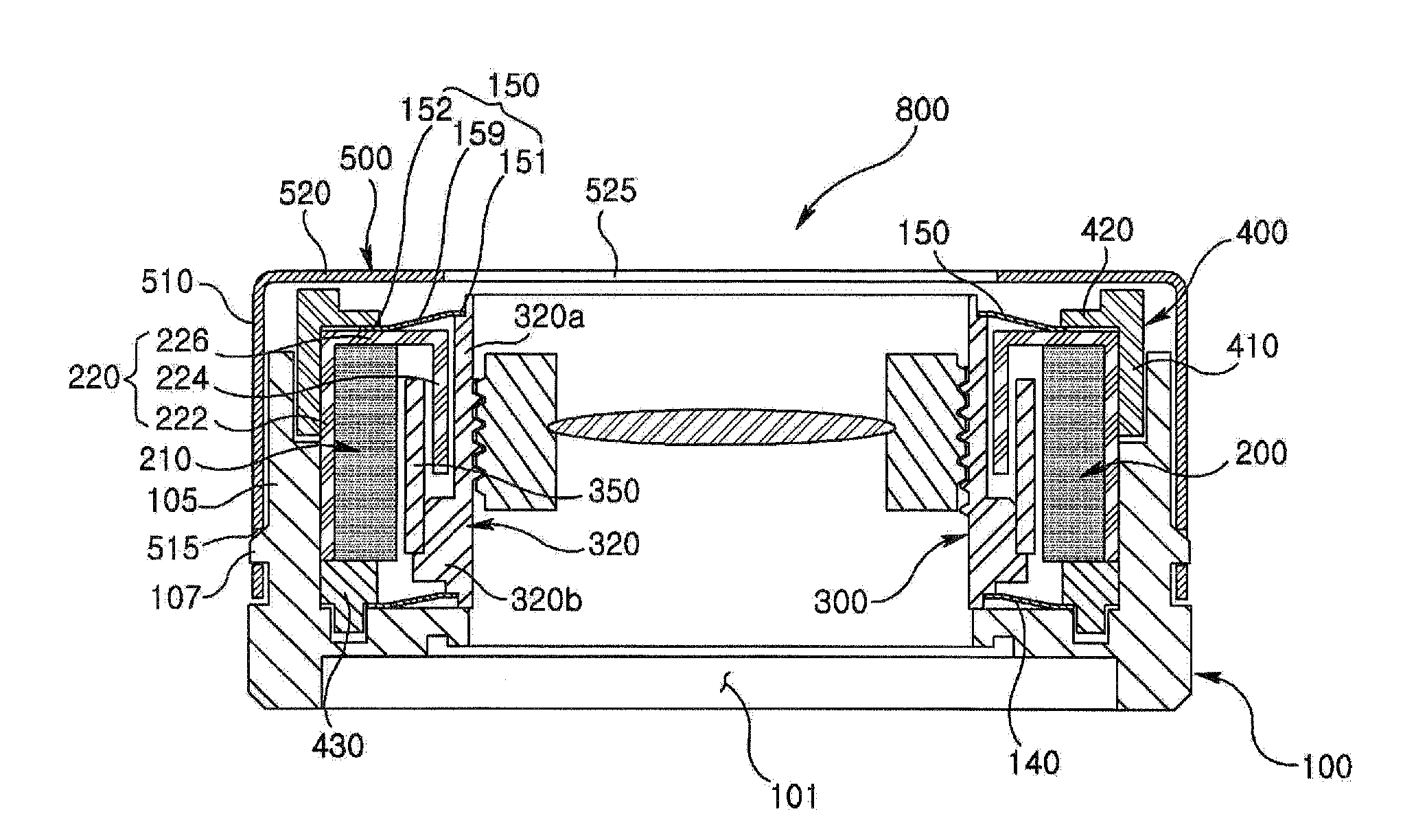

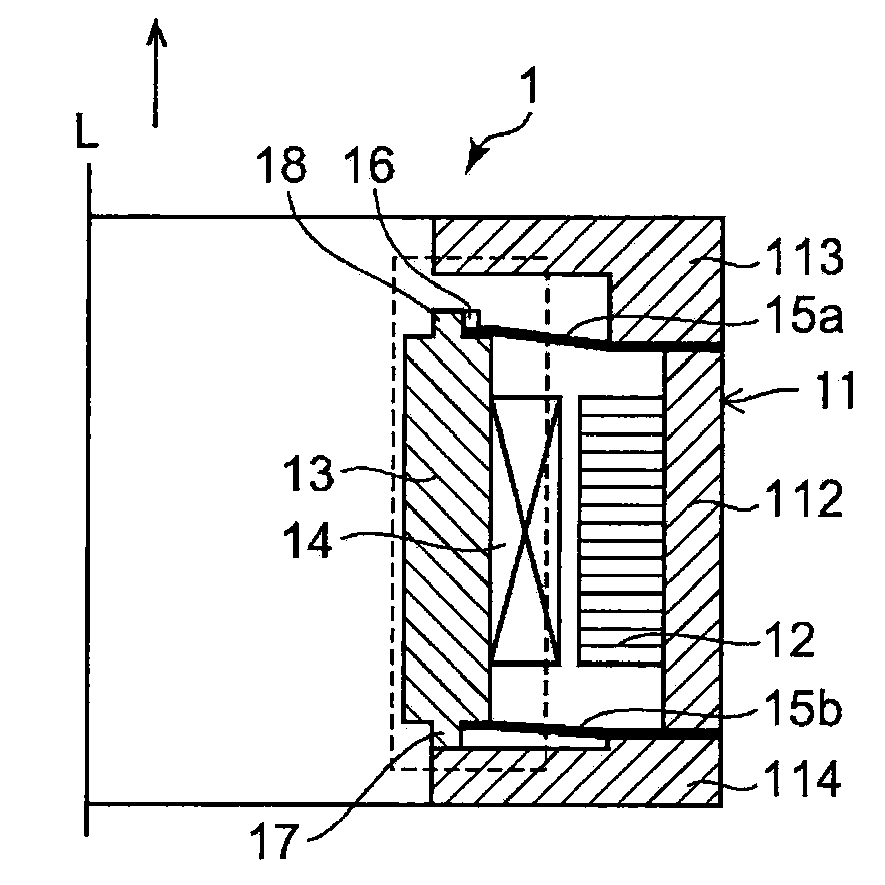

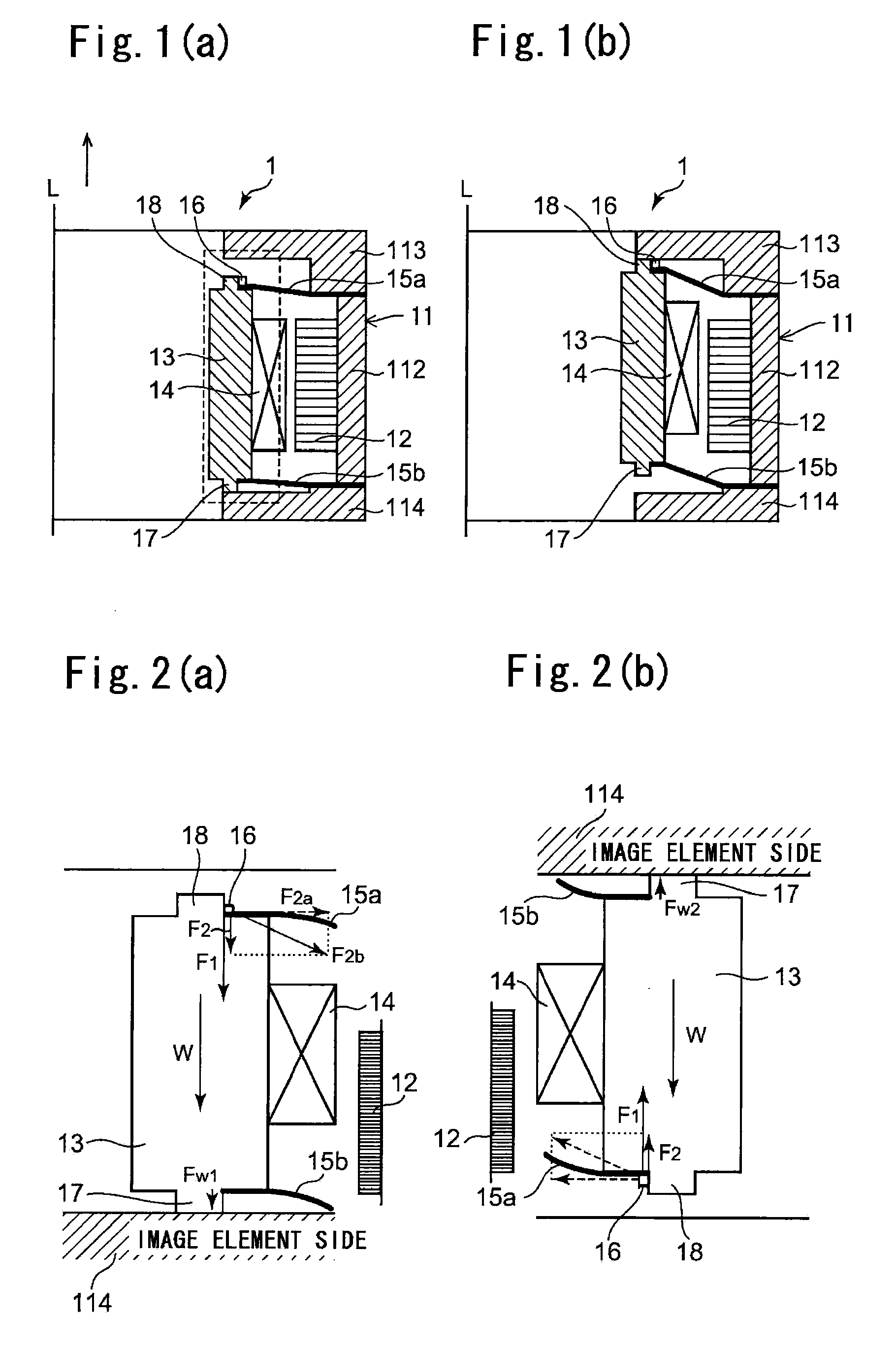

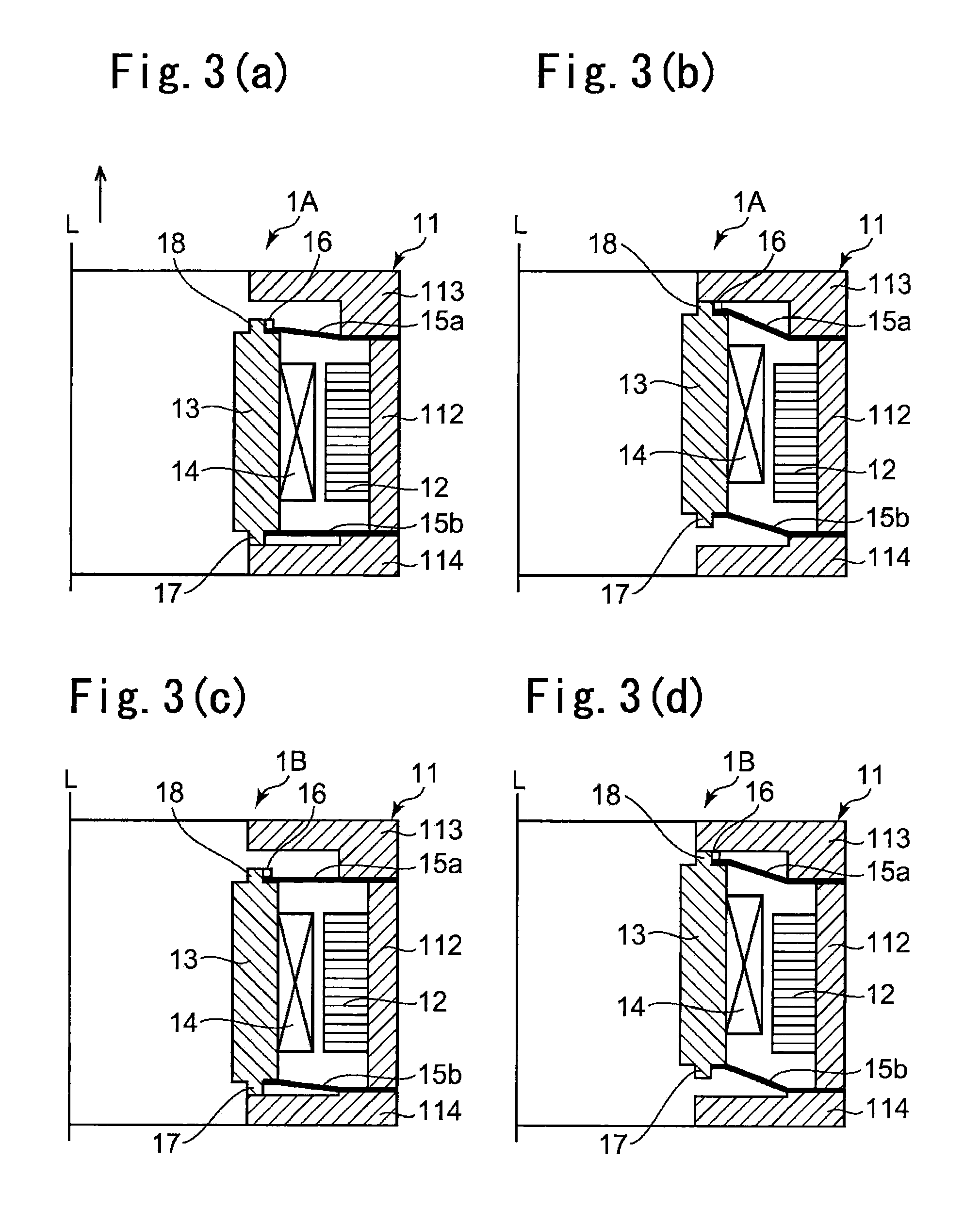

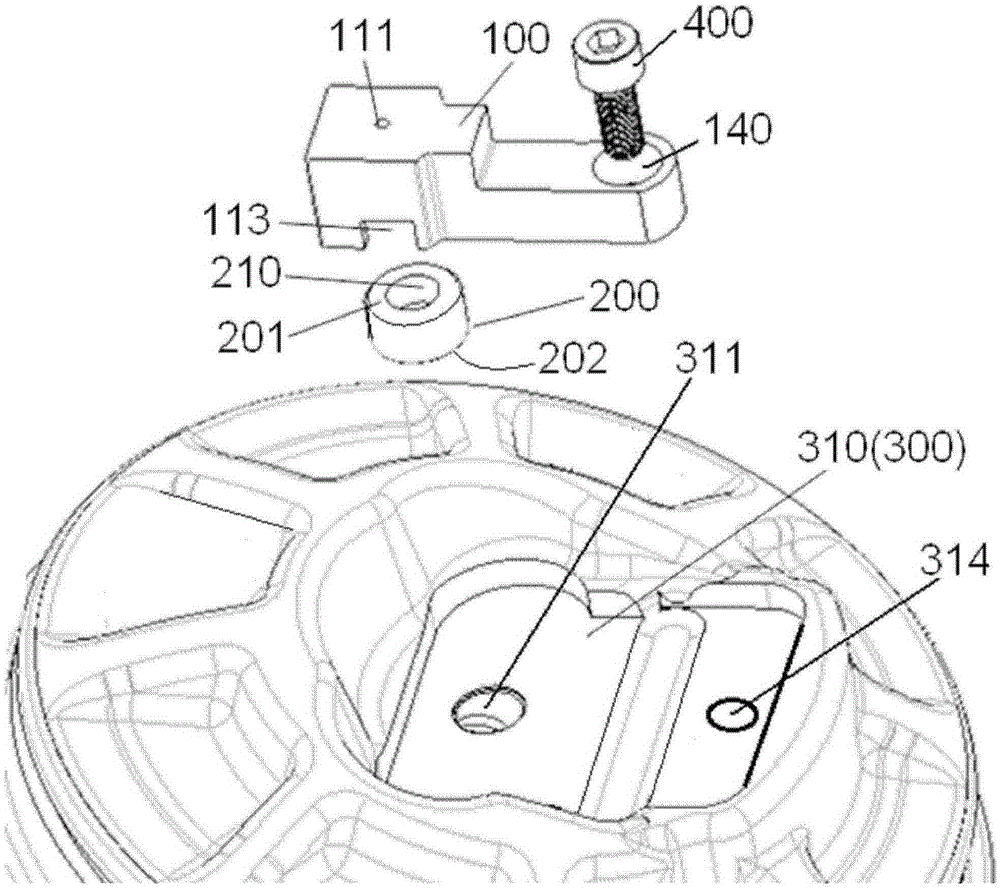

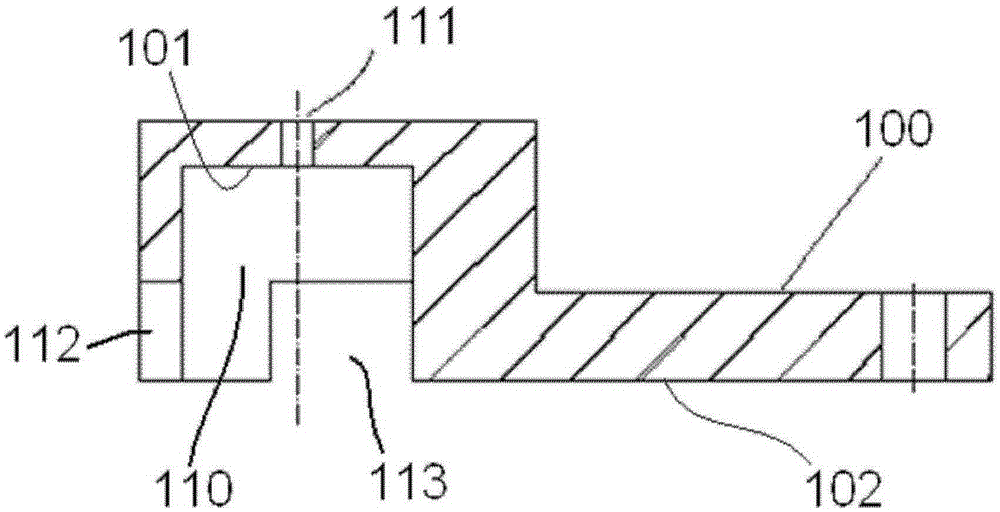

Lens drive device

A lens drive device may include a movable body having a lens and a coil, a support body movably supporting the movable body, a magnetic drive mechanism having a magnet for driving the movable body together with the coil, a restricting member for restricting movement of the movable body due to an electromagnetic force generated when an electric current is supplied to the coil, a magnetic member disposed in the movable body to be magnetically attracted by the magnet. In a non-energized state where the coil is not energized, following relationships are satisfied:W>F1, W>F2, and W<F1+F2. wherein a force with which the restricting member urges the movable body toward a non-energized position is “F1”; a force in the optical axis direction with which the magnetic member is attracted by the magnet is “F2”; and a weight of the entire movable body is “W”.

Owner:SANKYO SEIKI MFG CO LTD

Pipe structure for outdoor unit of air conditioner

InactiveUS20050172656A1Reduce noiseAvoid fatigue failureMechanical apparatusFluid circulation arrangementEngineeringElectrical and Electronics engineering

Owner:LG ELECTRONICS INC

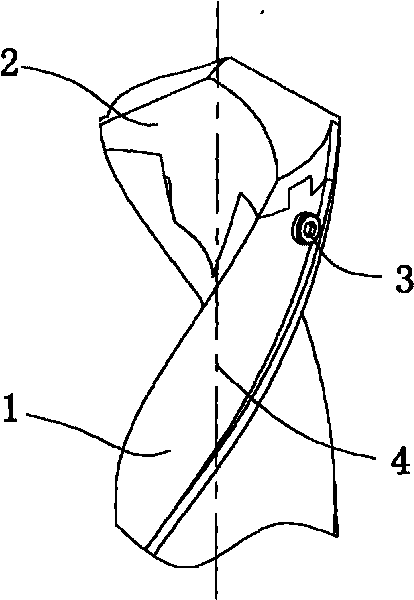

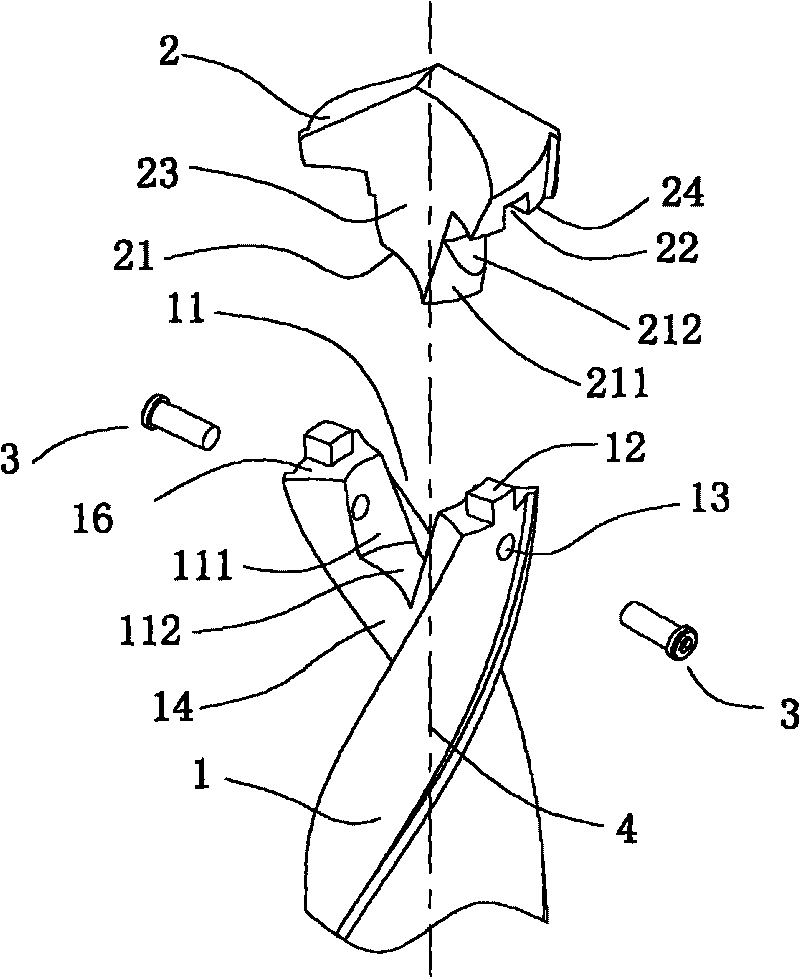

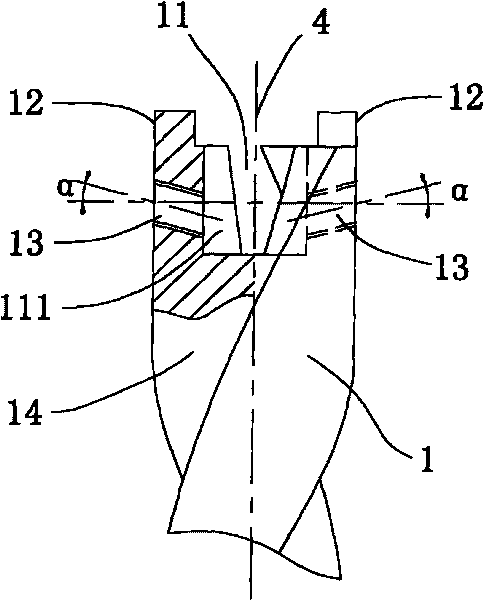

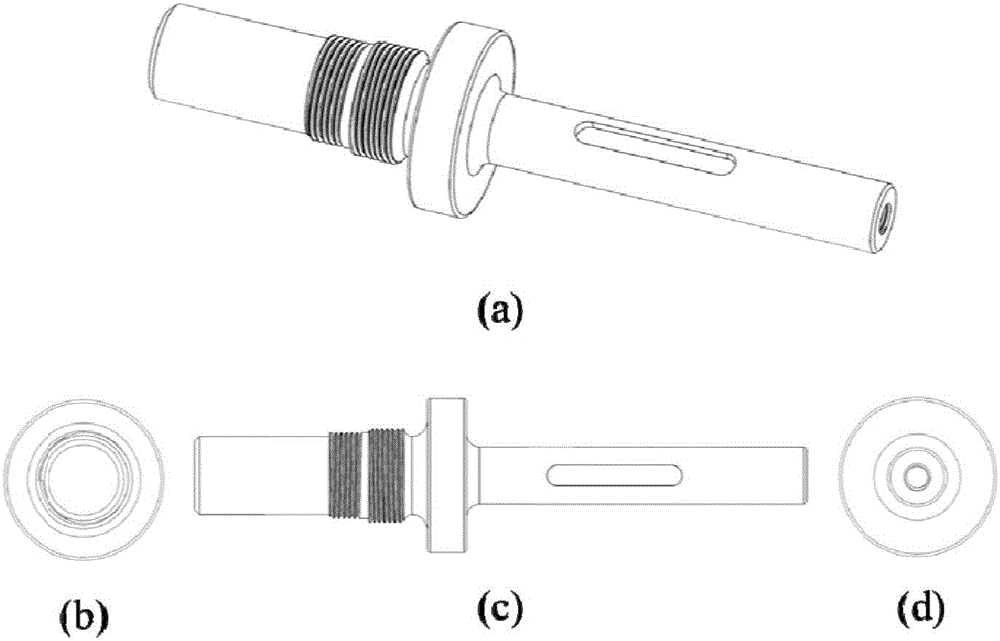

Head-changeable hard alloy twist drill

The invention discloses a head-changeable hard alloy twist drill which comprises a drill stem, a drill tip and a stopper screws, wherein the middle of the end face at the bottom of the drill tip is provided with a radial positioning block and two sides of the drill tip are provided with peripheral positioning grooves, the middle of the end face at the top of the drill stem is provided with a radial positioning groove and two sides of the drill stem are provided with peripheral positioning blocks, the drill stem is also provided with a threaded hole penetrating through the side wall of the radial positioning groove, the radial positioning block is arranged in the radial positioning groove, the peripheral positioning blocks are arranged in the peripheral positioning grooves, and the stopper screw is accommodated in the threaded hole and is in contact with the radial positioning block. The head-changeable hard alloy twist drill has the advantages of simple structure, convenient processing, accurate positioning, stability and reliability.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD +1

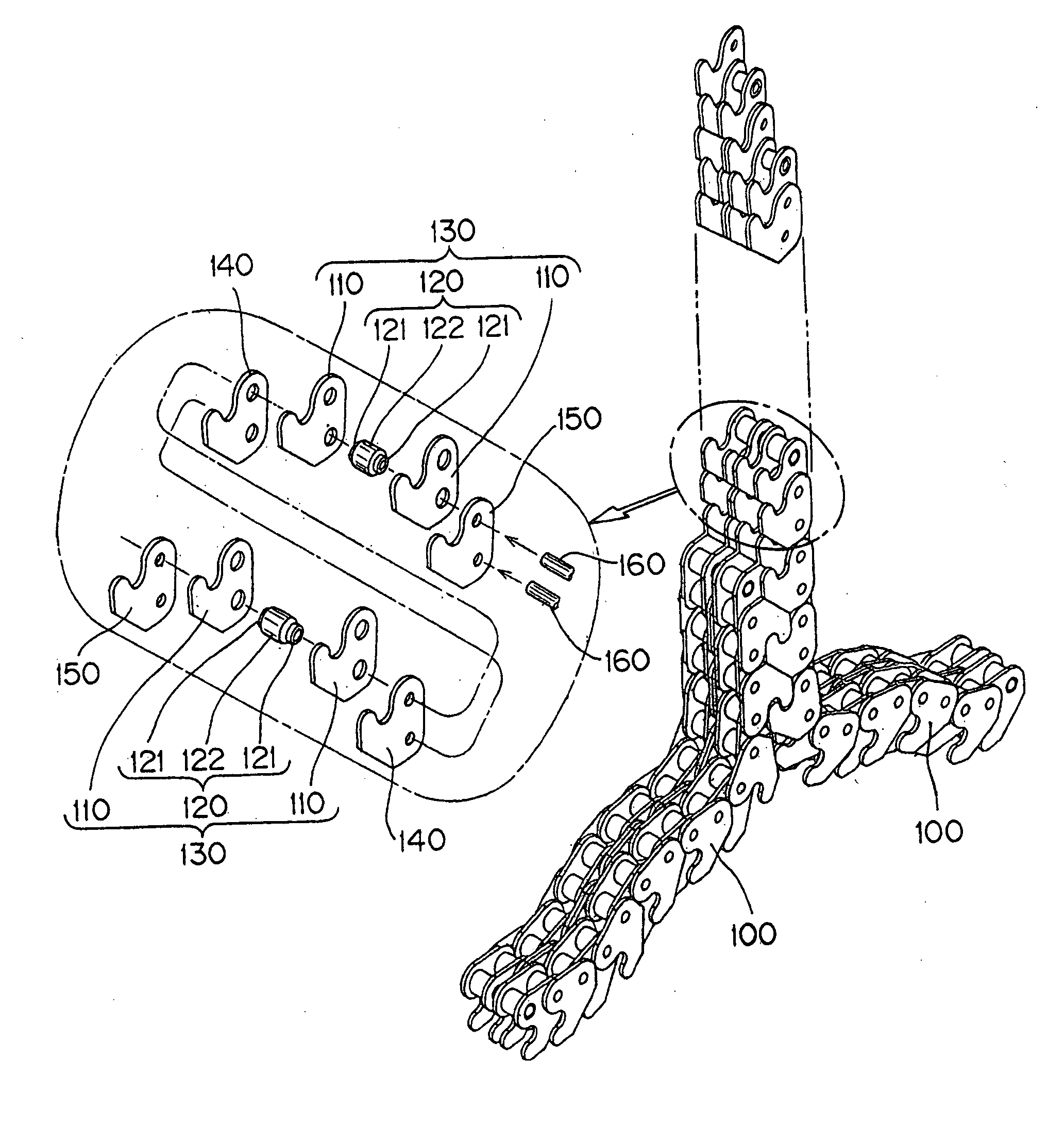

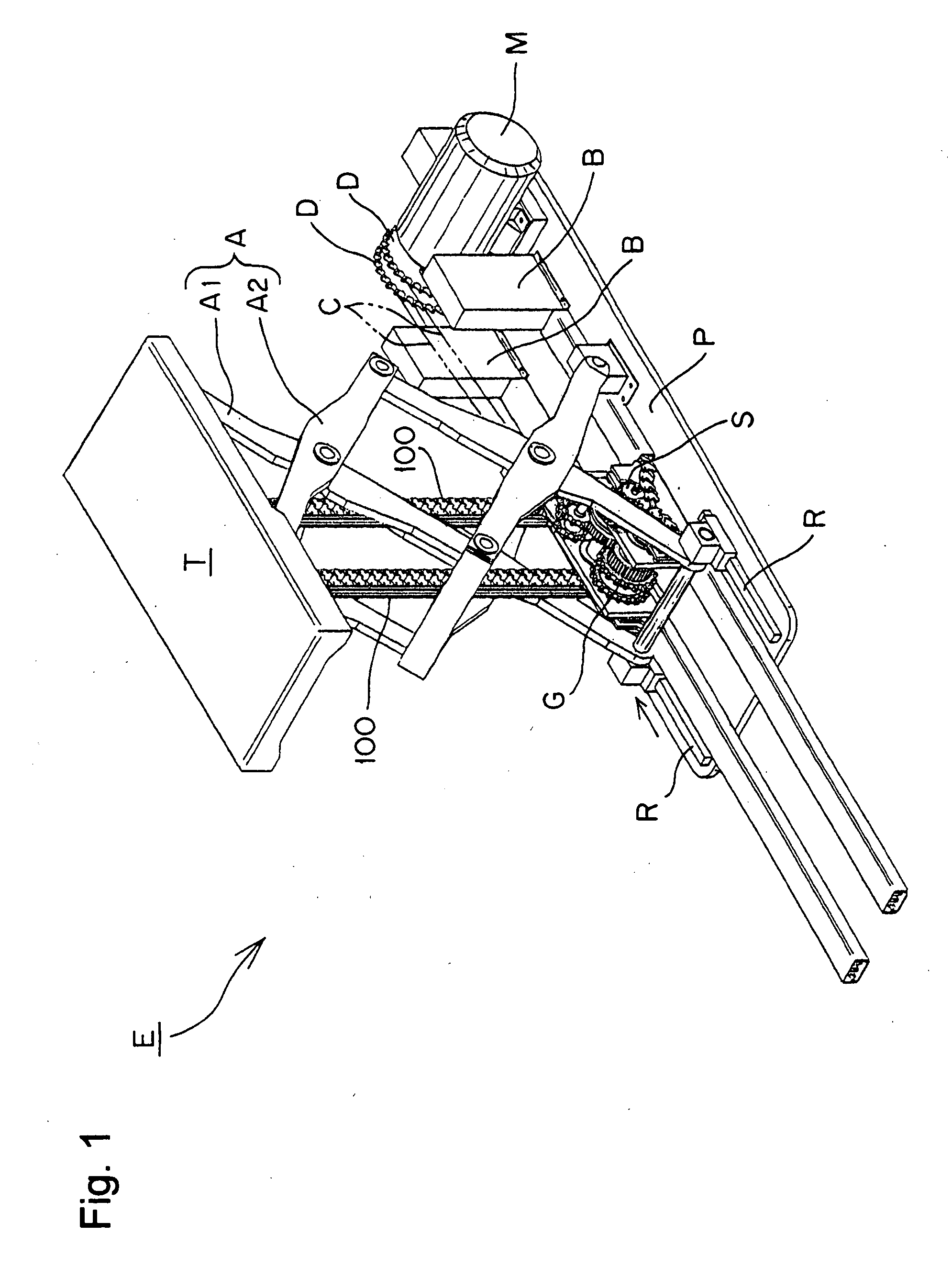

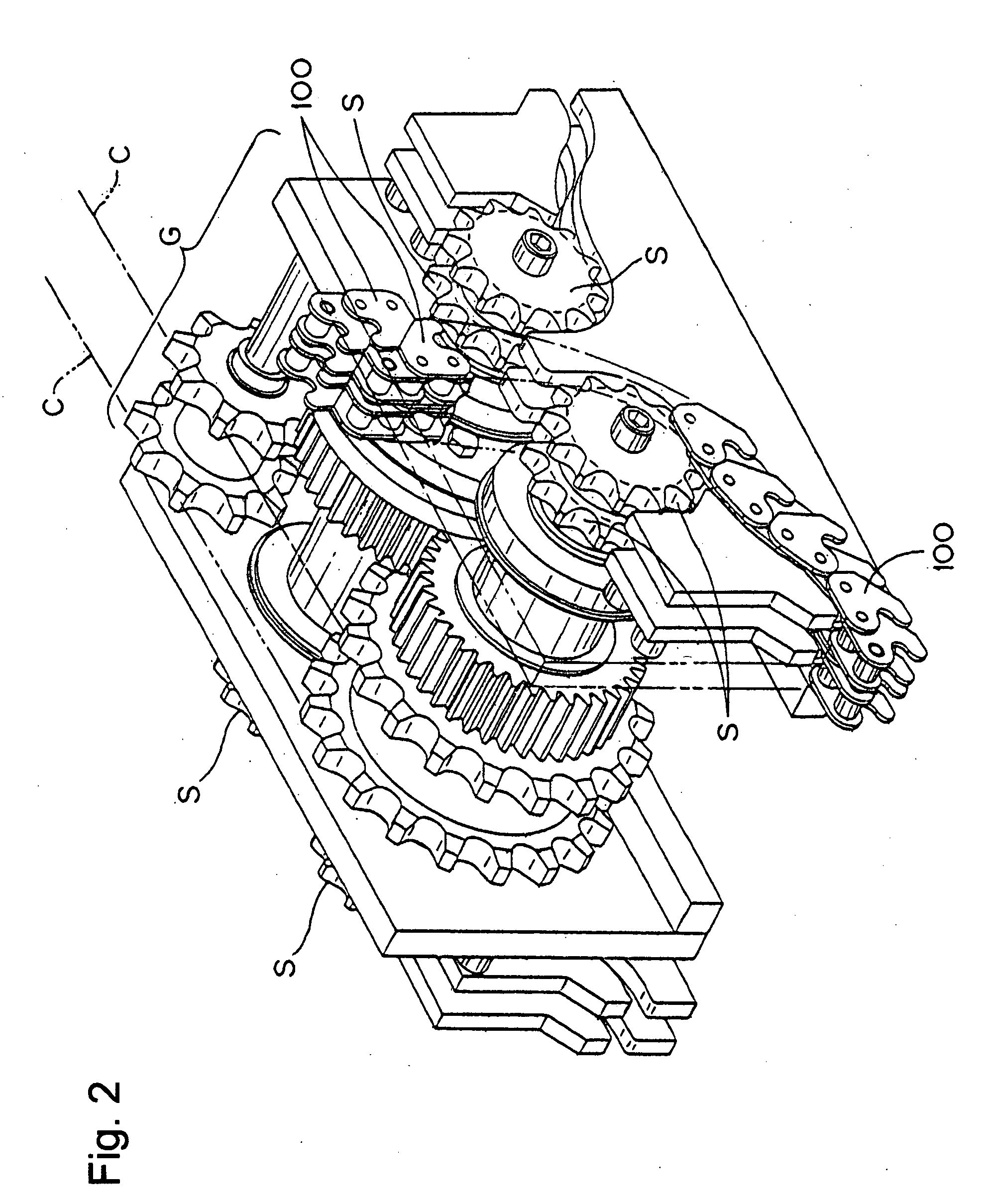

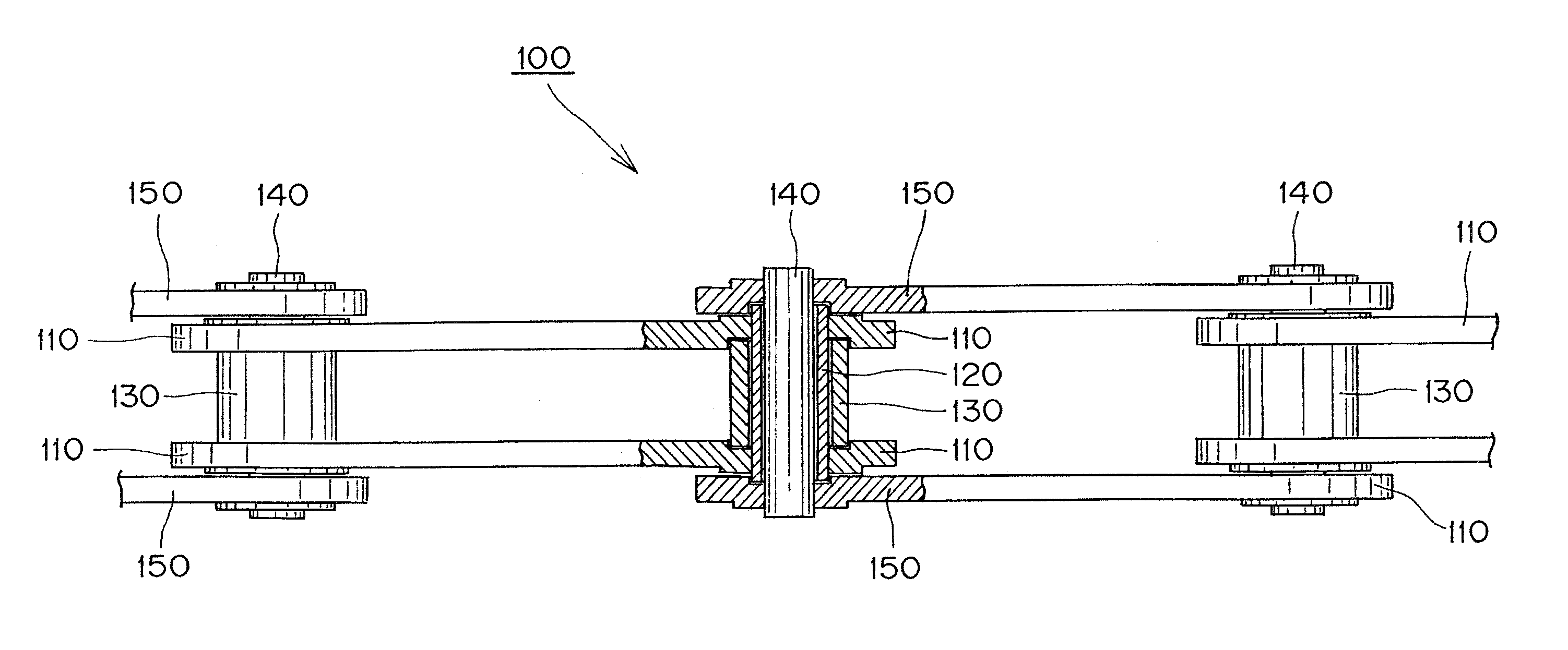

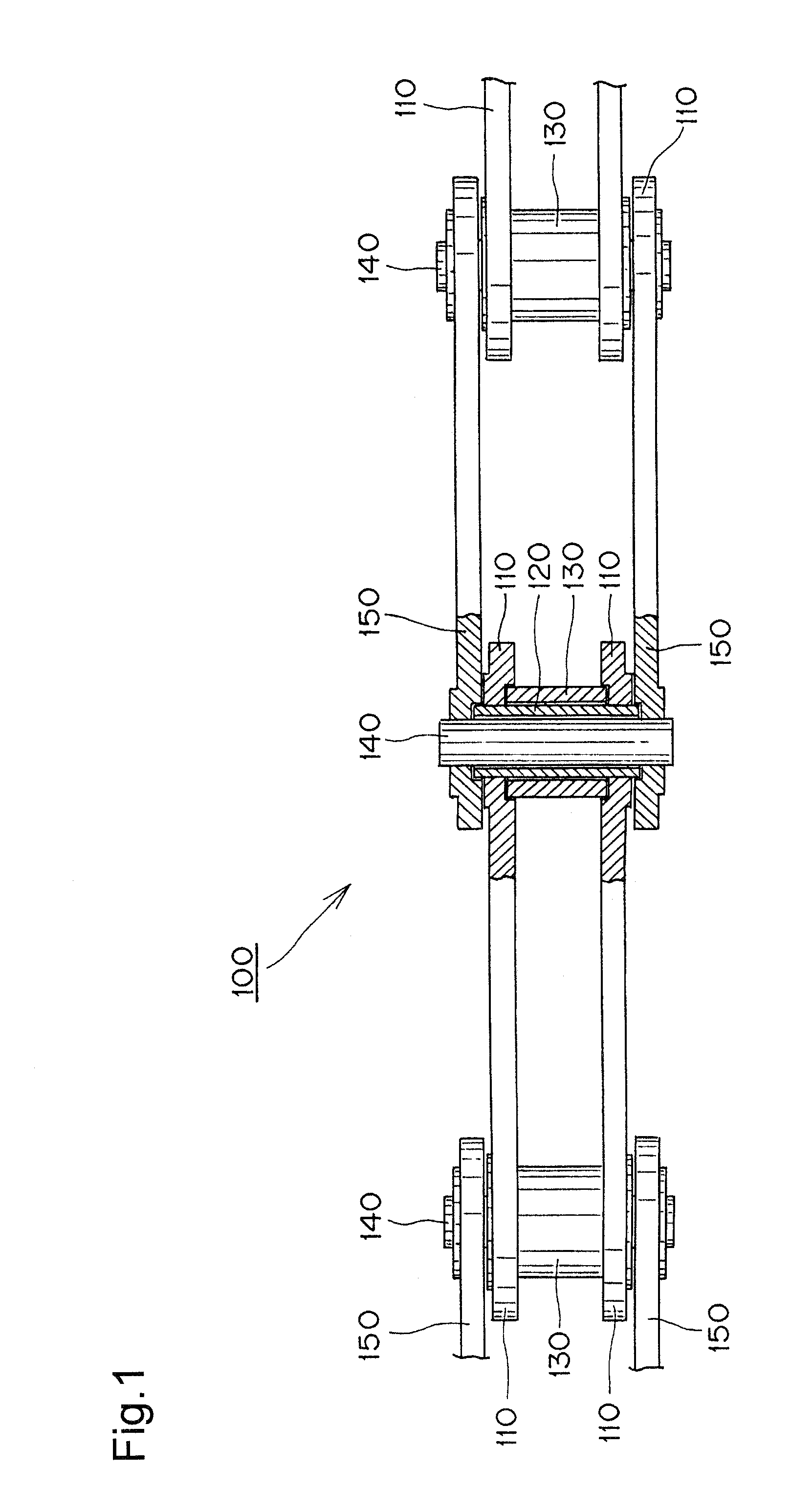

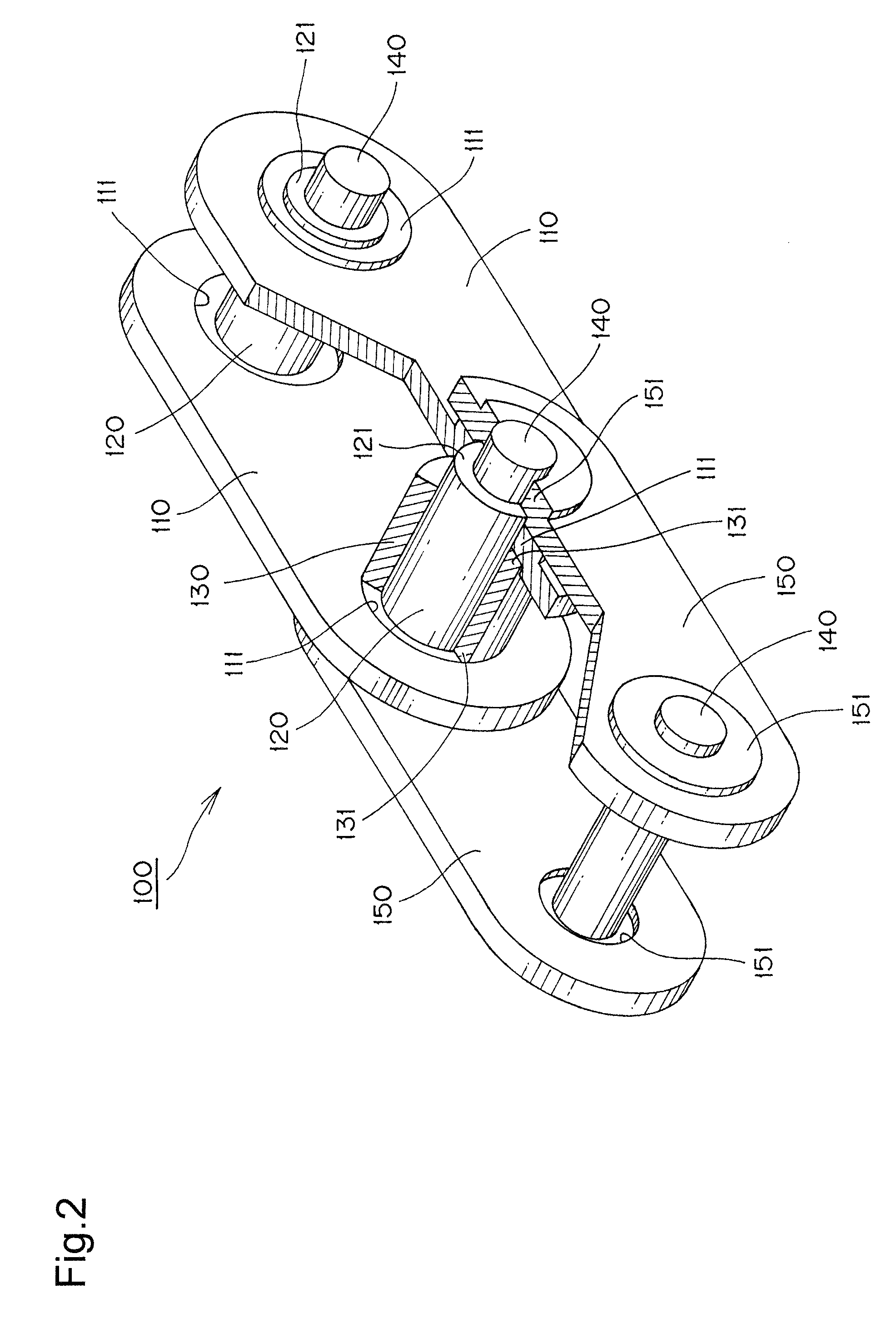

Hoisting and lowering driving engagement multi-row chain

ActiveUS20090118048A1Reduce the balanceIncrease widthLifting framesDriving chainsEngineeringSprocket

A hoisting and lowering driving engagement multi-row chain is disclosed, in which bending of the connecting pins in the chain is suppressed to avoid fatigue failure. Additionally, the load carrying balance in the chain width direction is improved, and contact vibrations and contact noises generated between the chain and the hoisting and lowering sprockets are suppressed. Endurance of the bush in the chain is thereby improved. Bending of connecting pins is avoided by press-fitting bushes, through which connecting pins pass, into intermediate tooth plates. This also improves load carrying balance widthwise. Contact noises and vibrations between the bushes and sprockets are suppressed by providing bushes with a separate sprocket engagement portion having a larger diameter than the press-fitting portion of the bushes.

Owner:TSUBAKIMOTO CHAIN CO

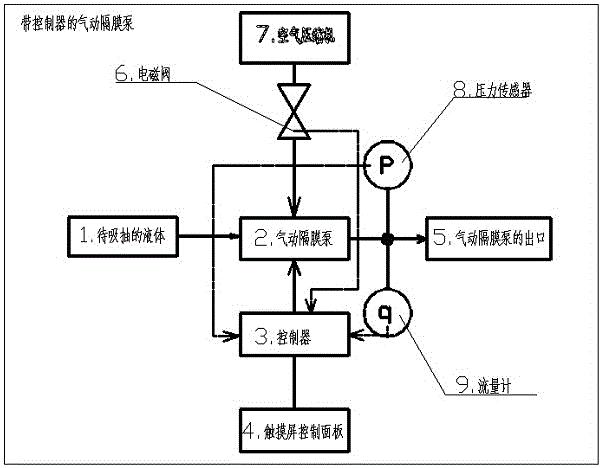

Pneumatic diaphragm pump with controller

InactiveCN105756907AAvoid cloggingAvoid accidentsExternal parameterFluid parameterDiaphragm pumpSolenoid valve

The invention relates to a pneumatic diaphragm pump with a controller. The pneumatic diaphragm pump with the controller comprises the pneumatic diaphragm pump, the controller, a touch screen control panel, a solenoid valve, an air compressor, a pressure sensor and a flow meter, wherein the controller is connected with the pneumatic diaphragm pump, the touch screen control panel, the solenoid valve, the pressure sensor and the flow meter through signal wires; the air compressor is connected with the pneumatic diaphragm pump through the solenoid valve; the pressure sensor is mounted at an outlet of the pneumatic diaphragm pump and is used for detecting the outlet pressure of the pneumatic diaphragm pump and sending a detected result to the controller; the flow meter is mounted at the outlet of the pneumatic diaphragm pump and is used for detecting the liquid flow at the outlet of the pneumatic diaphragm pump and sending the detected result to the controller; the touch screen control panel is used for displaying the pressure and flow and setting a pressure threshold value and a flow value. The pneumatic diaphragm pump with the controller provided by the invention can be used for effectively preventing the accidents caused by pipeline blockage.

Owner:SHANGHAI UNIV

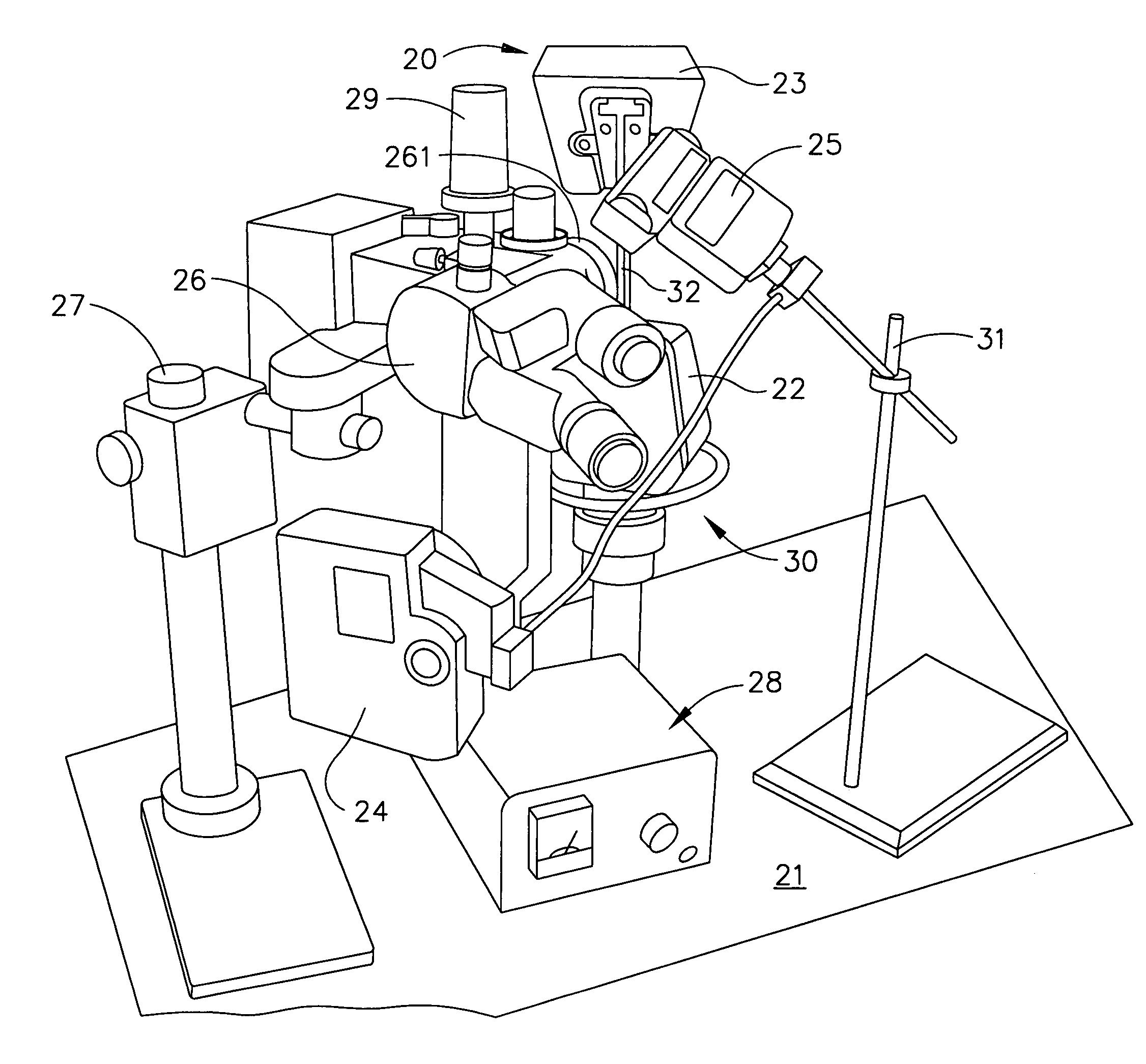

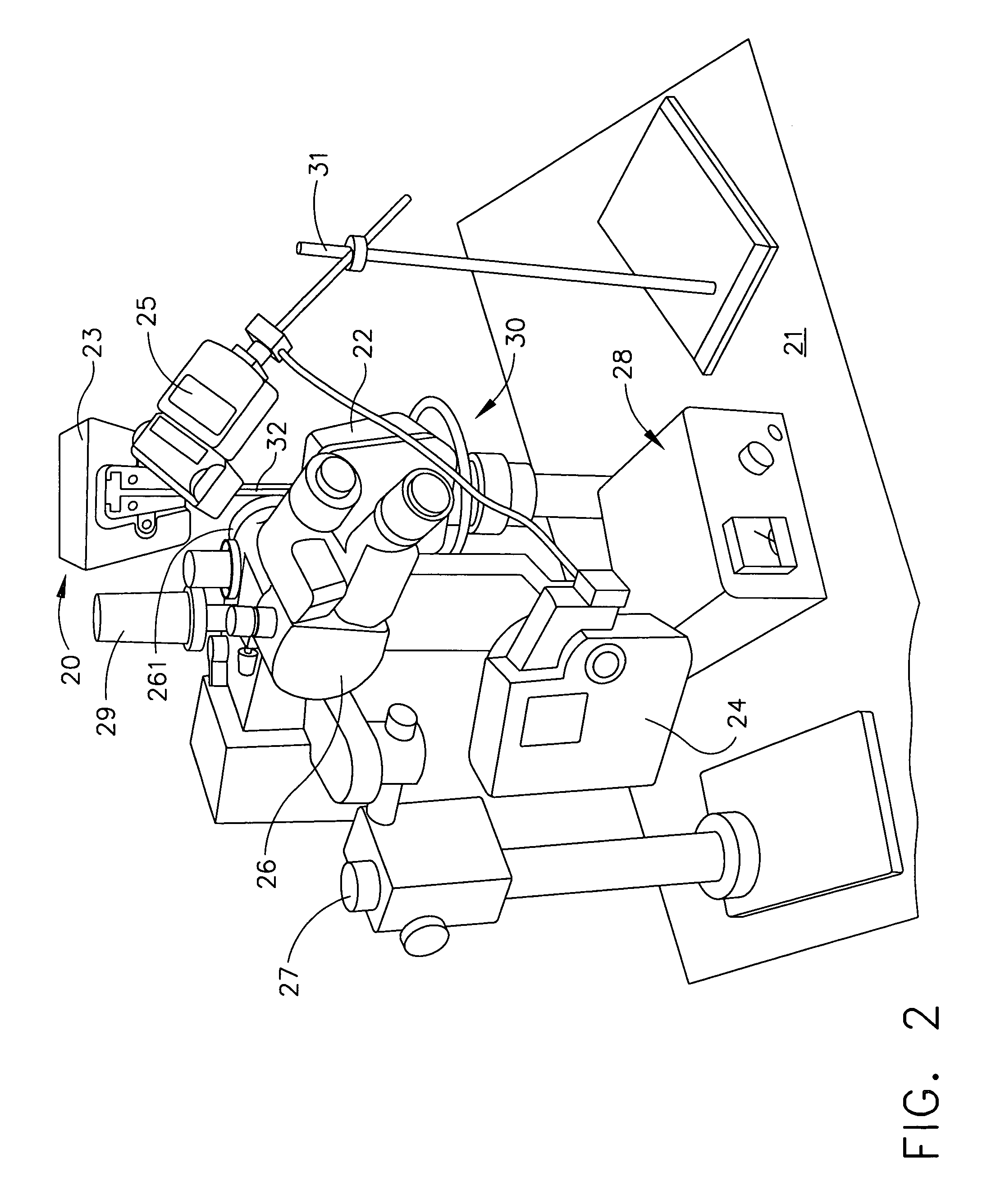

Visual documentation of micro-cracks during tensile coupon testing

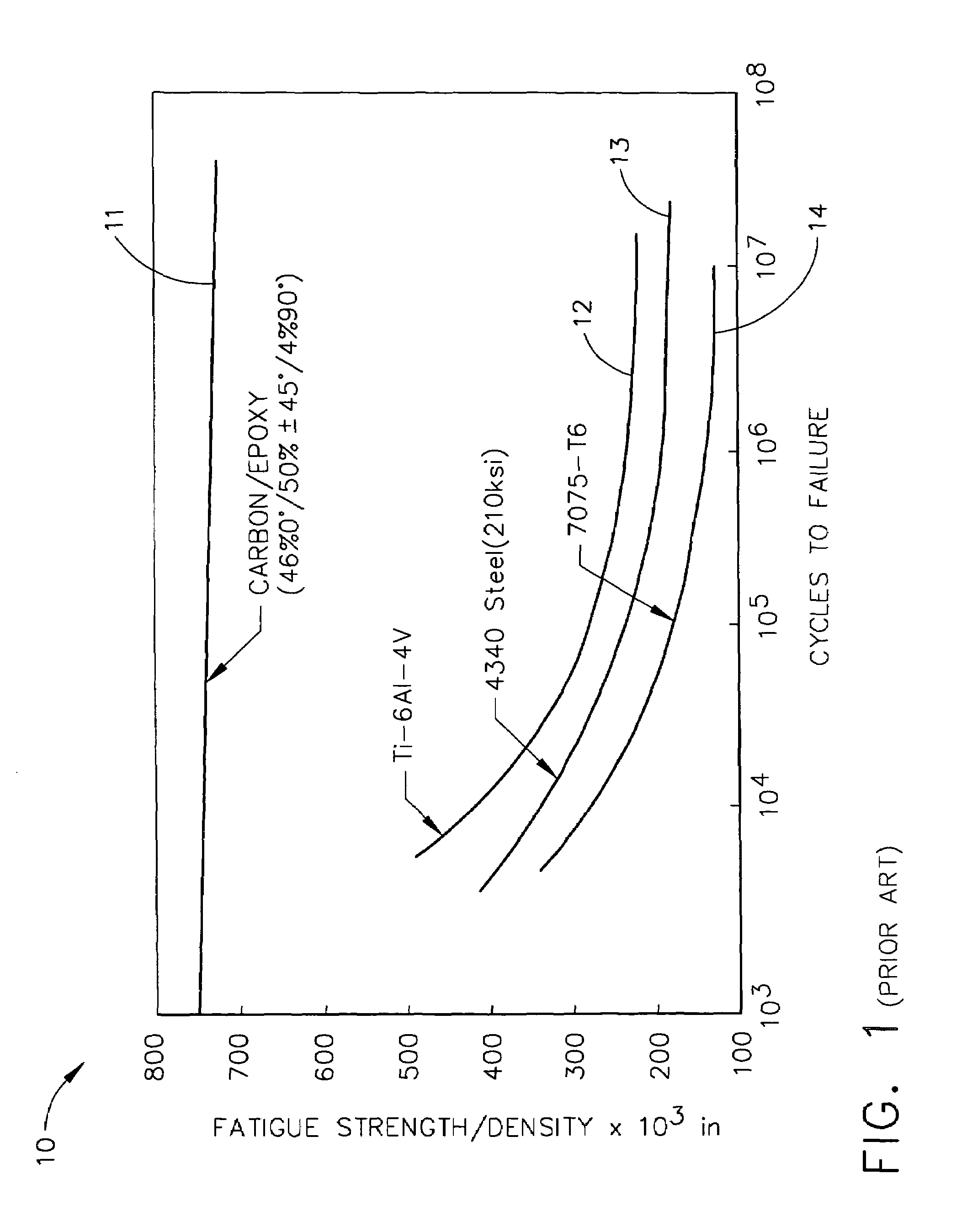

ActiveUS7080561B2Avoid fatigue failureForce measurement by measuring optical property variationMaterial analysis by optical meansAviationCrazing

A test method for visual documentation of micro-cracks during tensile coupon testing includes the steps of: assembling a test unit; inserting a carbon-reinforced composite specimen having a prepared edge into the tensile coupon testing machine; illuminating the prepared edge of the specimen with a camera strobe light and a microscope light; applying a tensile load to the specimen; and capturing images (at 10% increments of the expected failing stress) of the prepared edge of the specimen with a digital camera that is attached to a stereomicroscope. Using the test method of the present invention photographic documentation of the formation and growth of micro-cracks in carbon-reinforced composite materials under tensile load is possible. The obtained data may be used to avoid or limit fatigue failure of carbon-reinforced structures used, for example, in the aerospace industry, for example, in spacecrafts and advanced military aircraft.

Owner:THE BOEING CO

Gas discharge valve and compressor with same

ActiveCN106609758ASmooth exhaustAvoid fatigue failureRotary/oscillating piston pump componentsLiquid fuel engine componentsProduct gasEngineering

The invention discloses a gas discharge valve. The gas discharge valve comprises a valve seat, a valve body and a valve deck. A containing cavity is formed in the valve deck. A gas channel communicating with the containing cavity is formed in the circumferential wall of the containing cavity. A gas outlet hole communicating with the containing cavity is formed in the top wall of the containing cavity. A blind hole is formed in the valve body. The valve body is contained in the containing cavity of the valve deck. When compressed gas having a preset pressure is discharged out from a gas discharging hole, the valve body contained in the containing cavity of the valve deck is ejected by the discharged gas and is sucked to the inner side of the top wall of the containing cavity, and the compressed gas discharged from the gas discharging hole flows out from the gas channel of the valve deck. According to the gas discharge valve, when the gas is discharged, the valve body can be reliably sucked to the inner side of the top wall of the containing cavity of the valve deck; and in this way, the gas discharge valve can be reliably kept at the opened state when the gas is discharged, gas discharging is guaranteed to be smooth, and the situation that the gas discharge valve is frequently switched and fatigued and is ineffective because of gas pressure fluctuation can be avoided.

Owner:DANFOSS (TIANJIN) CO LTD

Clamp device for telescopic poles

InactiveUS20110138584A1Precise tensionAvoid fatigue failureSnap fastenersRod connectionsBiomedical engineering

Owner:UNION METAL CORP

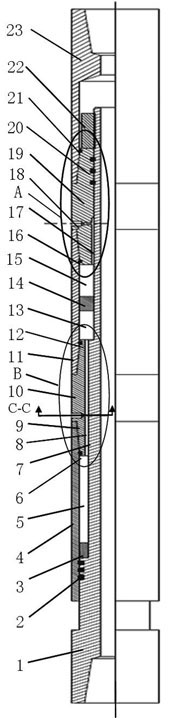

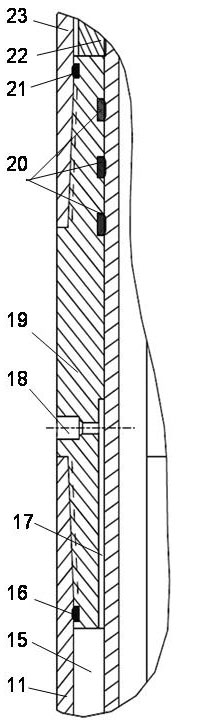

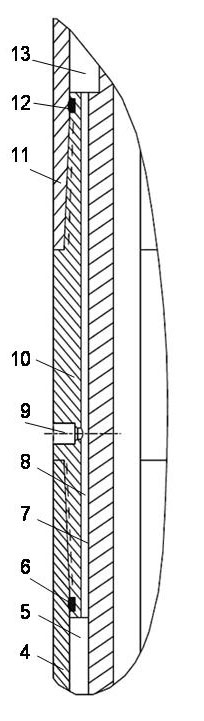

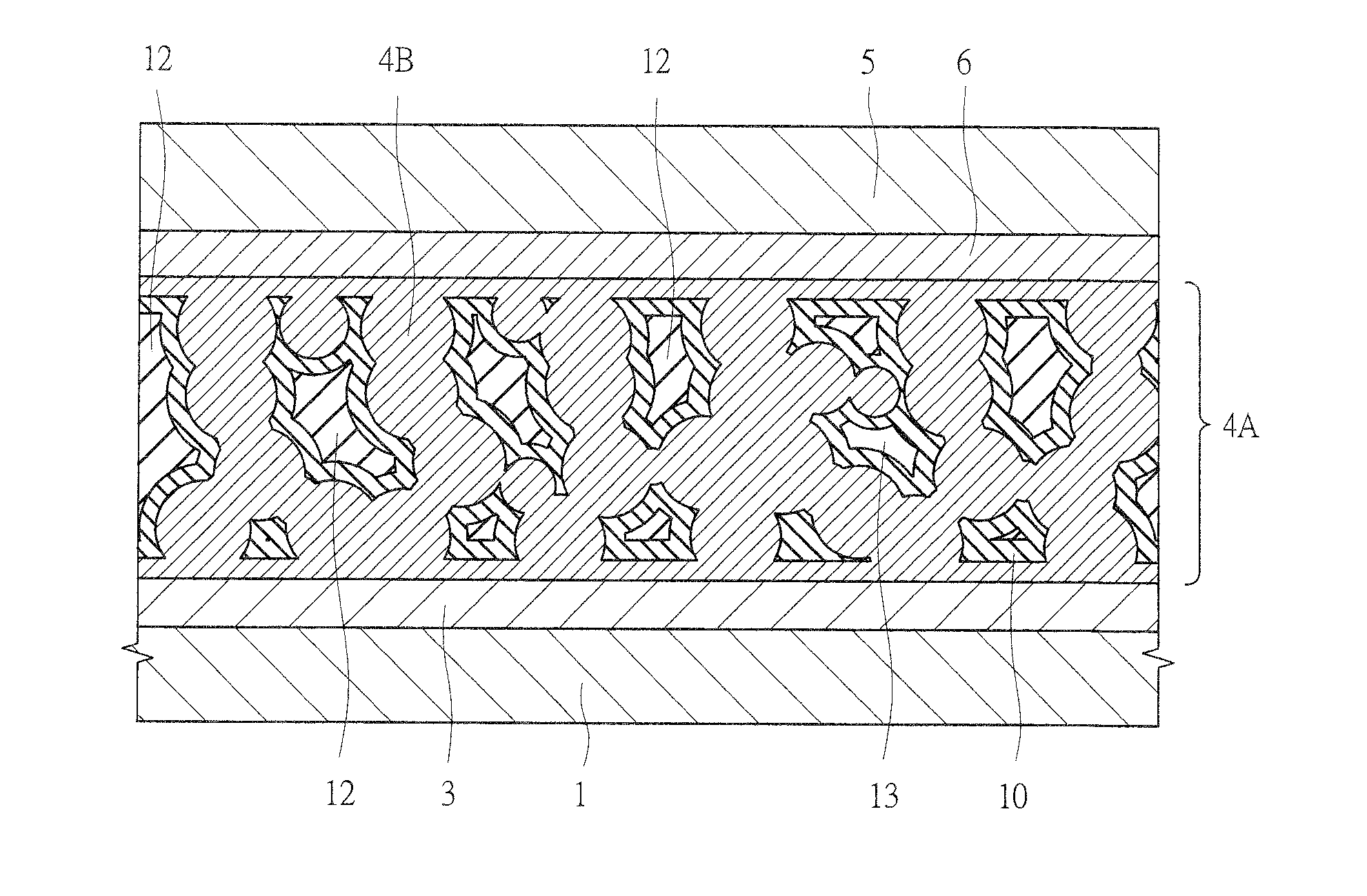

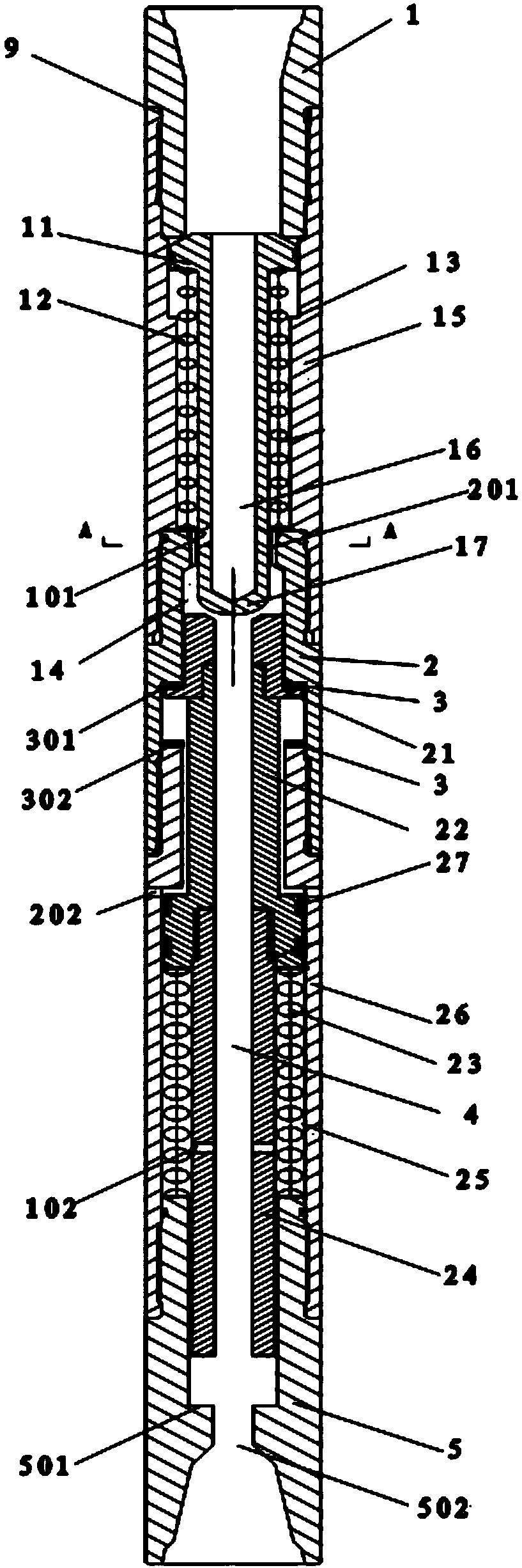

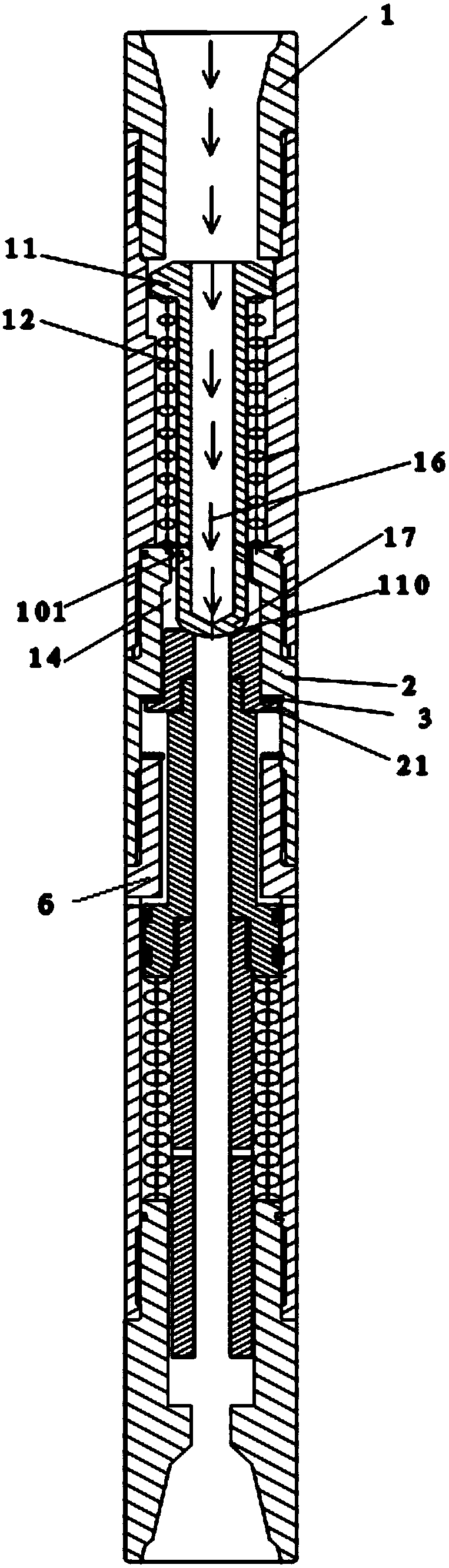

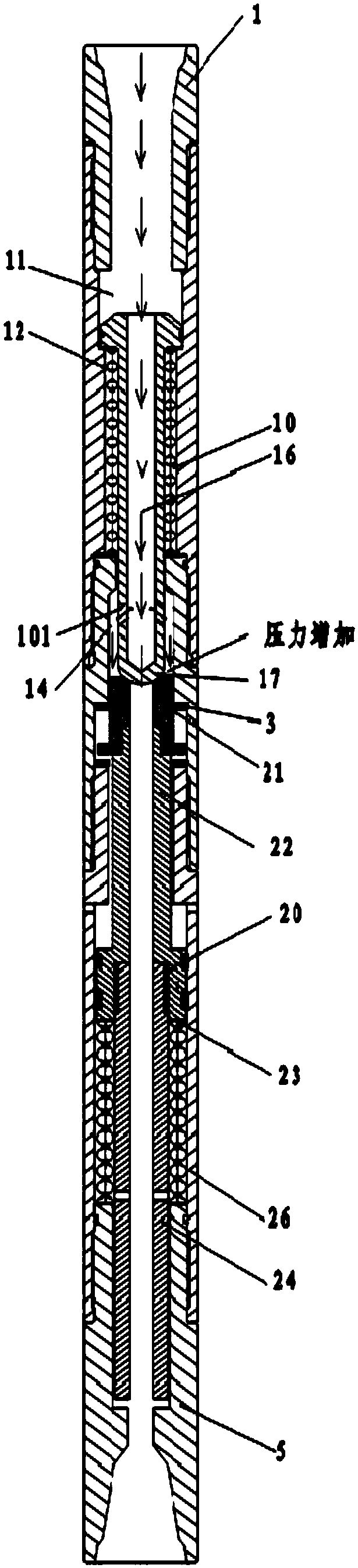

Shock absorber for drilling tool in oil-gas drilling

ActiveCN102031938AAvoid fatigue failureGreat vibration reductionDrilling rodsDrilling casingsUpper jointWell drilling

The invention discloses a shock absorber for a drilling tool in oil-gas drilling. The shock absorber comprises a mandrel, wherein a spline and a fixed piston are arranged on the mandrel; a spline outer cylinder is arranged on the spline, and the spline outer cylinder and the spline form an axial sliding pair; a plurality of damping channels are axially formed between the spline and the spline outer cylinder; the lower end of the spline outer cylinder is connected with a lower outer cylinder, and the upper end of the spline outer cylinder is sequentially connected with an upper outer cylinder,an upper seal joint and an upper joint; the spline outer cylinder and the upper outer cylinder, the upper seal joint and the lower outer cylinder, the fixed piston respectively form an upper annular cavity and a lower annular cavity at the periphery of the mandrel, and the two cavities are communicated through the damping channels; an oil injection nozzle and a gas injection nozzle are respectively formed on the spline outer cylinder and the upper seal joint in the radial direction; the oil injection nozzle is communicated with the damping channels; the gas injection nozzle is communicated with the upper annular cavity through a gas injection annular channel; and a movable piston is arranged in the upper annular cavity. The shock absorber for the drilling tool in the oil-gas drilling integrates liquid, damping and gas shock absorption so as to avoid the fatigue failure of the drilling tool, and has the characteristics of high shock absorption performance, long service life, low manufacturing cost, simple structure, a few quick-wear parts, convenience of maintenance and the like.

Owner:CHINA PETROLEUM & CHEM CORP

Semiconductor device and method of manufacturing the same

ActiveUS8314484B2Improve reliabilityAvoid fatigue failureSemiconductor/solid-state device detailsSolid-state devicesPolymer resinNetwork structure

In a structure of a semiconductor device, a Si chip and a metal leadframe are jointed by metallic bond via a porous joint layer made of high conductive metal, having a three-dimensional network structure and using Ag as a bonding material, and a film containing Zn oxide or Al oxide is formed on a surface of a semiconductor assembly contacting to a polymer resin. In this manner, by the joint with the joint layer having the porous structure mainly made of Ag, thermal stress load of the Si chip can be reduced, and fatigue life of the joint layer itself can be improved. Besides, since adhesion of the polymer resin to the film can be enhanced by the anchor effect, occurrence of cracks in a bonding portion can be prevented, so that a highly-reliable Pb-free semiconductor device can be provided.

Owner:RENESAS ELECTRONICS CORP

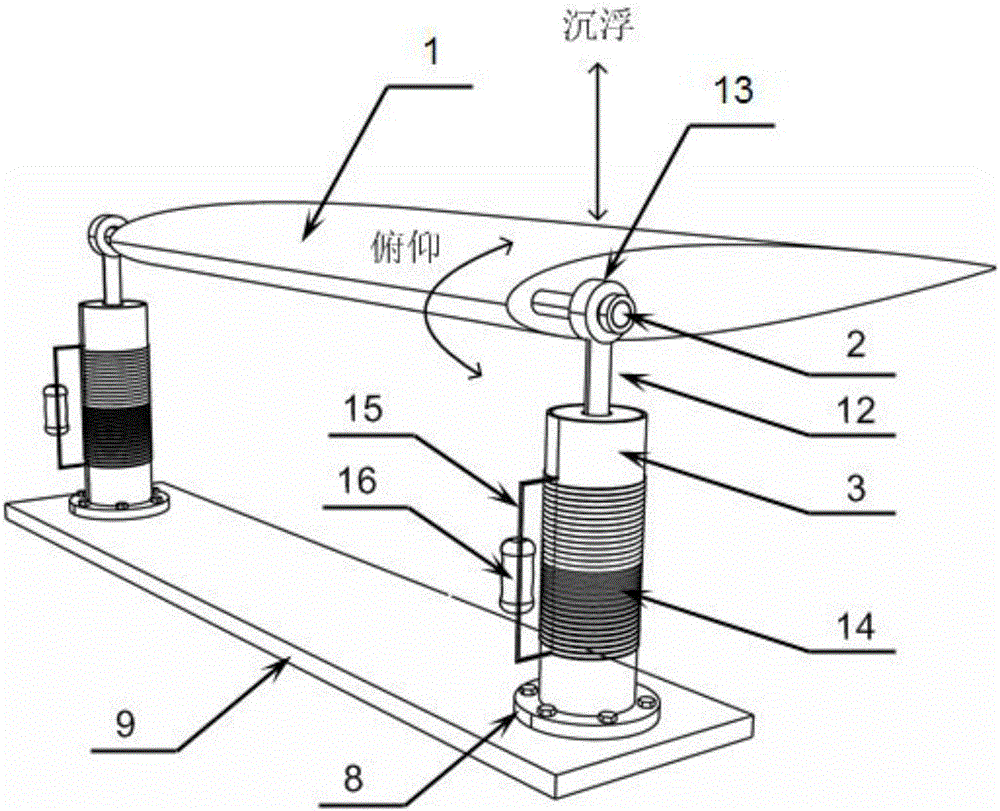

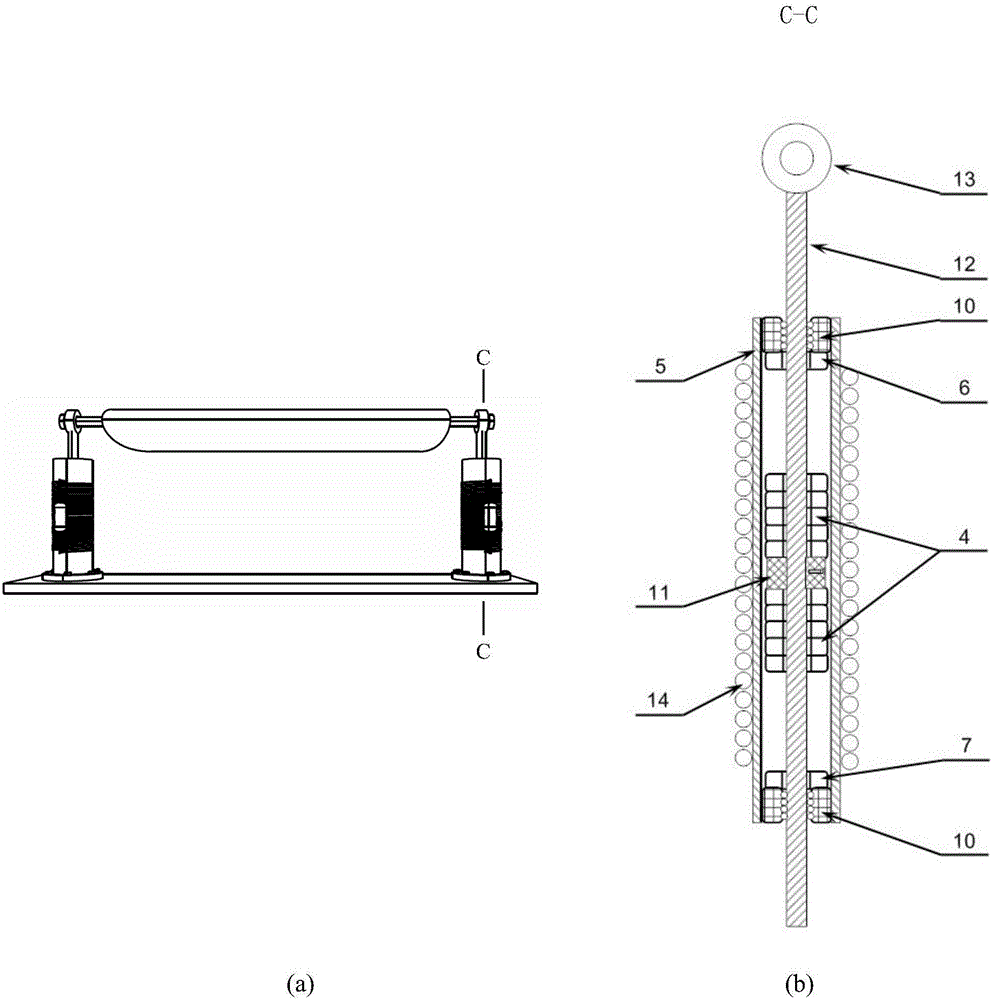

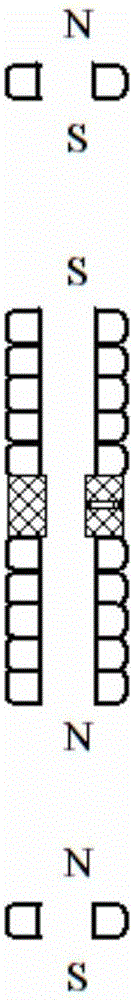

Permanent magnet suspension wing panel aeroelastic vibration generating set

InactiveCN105846644AAvoid fatigue failureReduce frictionMachines/enginesWind energy generationSingle supportNonlinear stiffness

The invention provides a permanent magnet suspension wing panel aeroelastic vibration generating set. The permanent magnet suspension wing panel aeroelastic vibration generating set comprises two support forms, namely, a double-side double support form and a middle single support form, a wing panel is supported by permanent magnet suspension; and an electromagnetic induction energy transformation type is adopted. Power is generated by means of aeroelastic vibration of a permanent magnet suspension support wing panel, and a mechanical elastic support element in a conventional wing panel aeroelastic vibration generating set design is removed, so that the problem of fatigue of a wing panel support element is solved fundamentally. A linear bearing is taken as a guide device for a support rod to perform ups and downs in conjunction with the wing panel, and a suspension annular permanent magnet is fixedly connected to the support rod, so that surface contact between the suspension annular permanent magnet and a cylindrical sleeve is avoided, and friction force of permanent magnet suspension support is lowered. The permanent magnet suspension support has a nonlinear rigidity feature, and the non-linear rigidity feature of the suspension annular permanent magnet can be changed by adjusting a distance between fixed annular permanent magnets at two ends of the cylindrical sleeve, so that the wing panel can perform chattering motion at a relatively low wind speed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Continuous jar

ActiveCN108868680AAvoid fatigue failureOvercome structural constraintsBorehole/well accessoriesMechanical engineeringEngineering

The embodiment of the invention discloses a continuous jar. The continuous jar comprises a shell, a jarring block, a hydraulic driving assembly and an elastic driving assembly, wherein an upper jarring table shoulder and a lower jarring table shoulder which are oppositely arranged are arranged in the shell; the jarring block is arranged in the shell and located between the upper jarring table shoulder and the lower jarring table shoulder, a first axial through hole is formed in the jarring block, and the jarring block can axially move along the shell; the hydraulic driving assembly is locatedat the upper portion of the jarring block, can move opposite to the shell, can plug the first axial through hole, and therefore drives the jarring block to move downwards in the axial direction of theshell; the elastic driving assembly is located at the lower portion of the jarring block, and can drive the jarring block to move upwards in the axial direction of the shell when the hydraulic driving assembly is separated from the jarring block. By means of the continuous jar in the embodiment, it can be avoided that as a conventional jar is repeatedly pulled and pressed, a pipe column is fatigue and ineffective.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Oil-free chain

In an oil-free roller chain, the inner faces of the outer link plates have recesses that receive the ends of bushings, and the inner faces of the inner link plates have recesses that receive the ends of rollers surrounding the bushings. Each such recess is formed by punching, so that the outer surface of each plate has a bulged portion opposite each recess. The diameters of the bulged portions are greater than the diameters of the corresponding recesses. The bushing can have an oil passage located midway between its ends and serving as an oil reservoir supplying oil to the gap between the bushing and the roller and between the bushing and a connecting pin.

Owner:TSUBAKIMOTO CHAIN CO

Car silencer and barrel thereof

ActiveCN102011628AExtended service lifeAvoid fatigue failureExhaust apparatusSilencing apparatusEngineeringVibration isolation

The invention discloses a barrel for a car silencer, comprising a shell (1) and a vibration isolation element (4), wherein the inner part of the shell (1) is provided with an inner tube (2), and the two ends of the shell (1) are respectively provided with an end cover (3) which is provided with an opening; at least one end of the inner tube (2) is installed on the corresponding opening of the end cover (3) through the vibration isolation element (4), and the relative position between the part of connecting the vibration isolation element (4) and the inner tube (2) and the end cover (3) is variable along the axial direction of the inner tube (2). Through the automatic adjustment of the inner tube length in the axial direction of the inner tube, thermal stress is released, and thermal stress action does not exist between the inner tube and the end cover, thereby avoiding fatigue failure of the inner tube and the end cover under the action of the thermal stress so that the barrel has long service life so as to prolong the service life of the car silencer. The invention also provides the car silencer comprising the barrel.

Owner:LIUZHOU WULING MOTORS +1

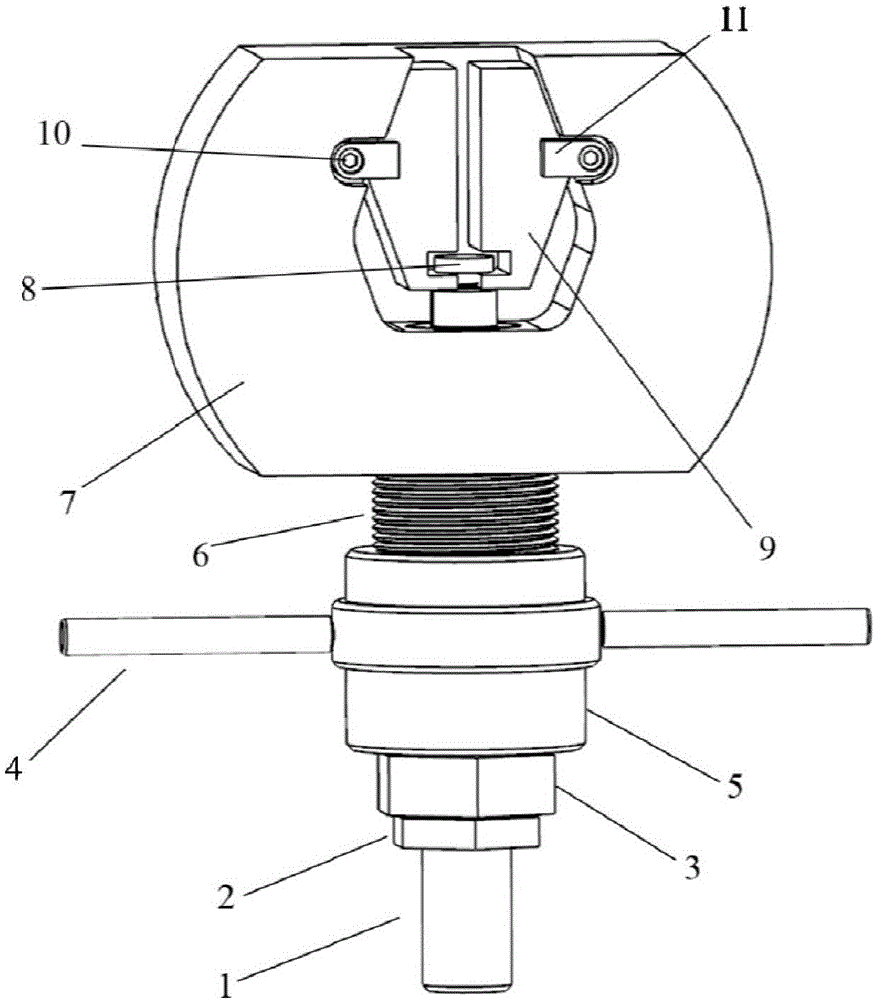

High temperature tensile fatigue test fixture for panel test piece and method

ActiveCN106840867AStable clampingAchieving Stretch FatigueMaterial strength using tensile/compressive forcesTensile fatigueTest fixture

The invention discloses a high temperature tensile fatigue test fixture for a panel test piece and a method. The clamping for the panel test piece in a high temperature test is realized, so that the tensile fatigue test for the panel test piece can be performed under a high temperature condition. A hydraulic chuck of a fatigue machine is used for clamping an optical rod end of a central shaft and is connected with a connecting rod through a sleeve; a fixing nut is arranged on the central shaft; the fixing nut is used for limiting the downward movement of the sleeve; the connecting rod is fixed with the sleeve through a screw; the connecting rod is in threaded connection with a wedge-shaped chuck body; the central shaft passes through a through hole in the middle of the connecting rod; a shaft end is connected with a guiding platform; the guiding platform is located in a groove between two wedge-shaped clamp blocks and is used for guiding the wedge-shaped clamp blocks to move up and down; the test piece is clamped by the wedge-shaped clamp blocks in the wedge-shaped chuck body; the bottoms of the wedge-shaped clamp blocks are propped by the top end of the guiding platform; the two sides are in contact with the wedge-shaped plane in the wedge-shaped chuck body; the upwards movement of the wedge-shaped clamp blocks is limited. The high temperature tensile fatigue test fixture can meet the requirement for stably clamping the panel test pieces in various sizes and can realize the single-shaft tensile fatigue under the high temperature condition.

Owner:BEIHANG UNIV

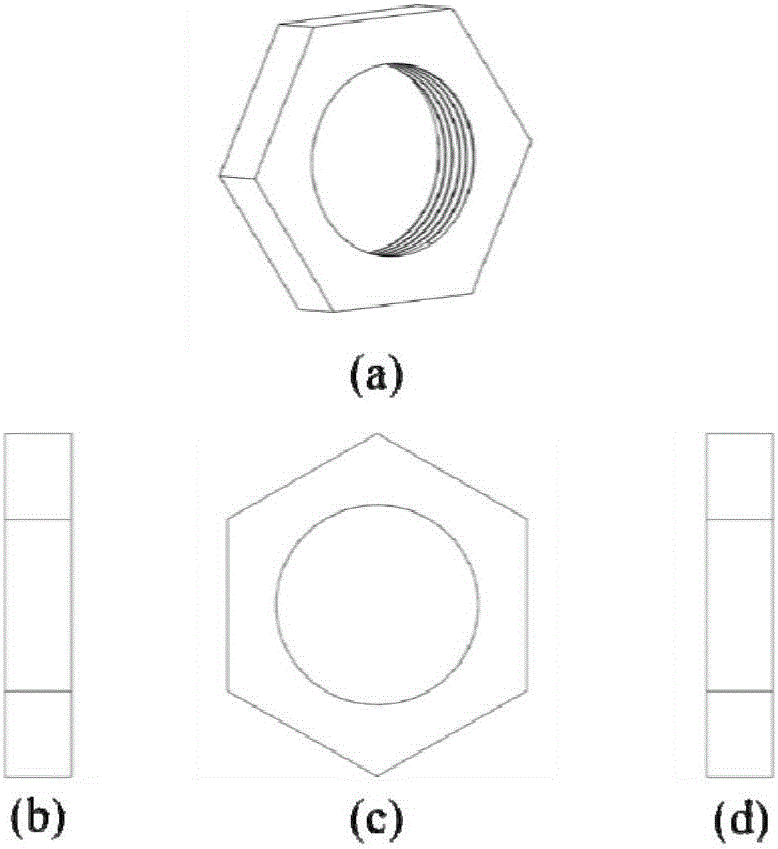

Waveform movable pressing pretightening butterfly spring

The invention relates to a waveform movable pressing pretightening butterfly spring, which is arranged statically on a joint of a bolt and a fastened piece and is static relative to a contact component. The waveform movable pressing pretightening butterfly spring is characterized in that: the waveform movable pressing pretightening butterfly spring is a butterfly gasket; an inner hole and an excircle of the waveform movable pressing pretightening butterfly spring which has uniform thickness have a shape of cone; upper and lower reverse surfaces are both waveform surfaces; each surface is at least provided with more than one complete waveform; each waveform has resilience capacity; the waveforms of the upper and lower reverse surfaces are staggered sequentially to be arrayed uniformly from the inner hole to the periphery or from the outer diameter to the inner hole; and a plurality of waveform movable pressing pretightening butterfly springs can be combined in a folding or overlapping mode.

Owner:超化公司

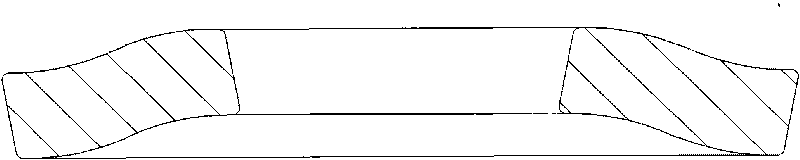

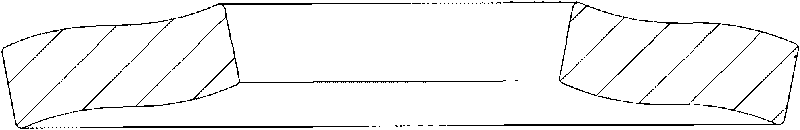

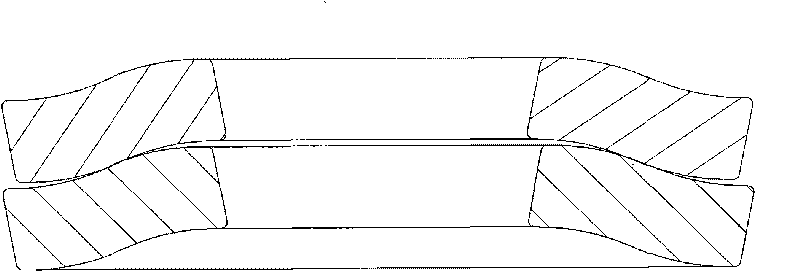

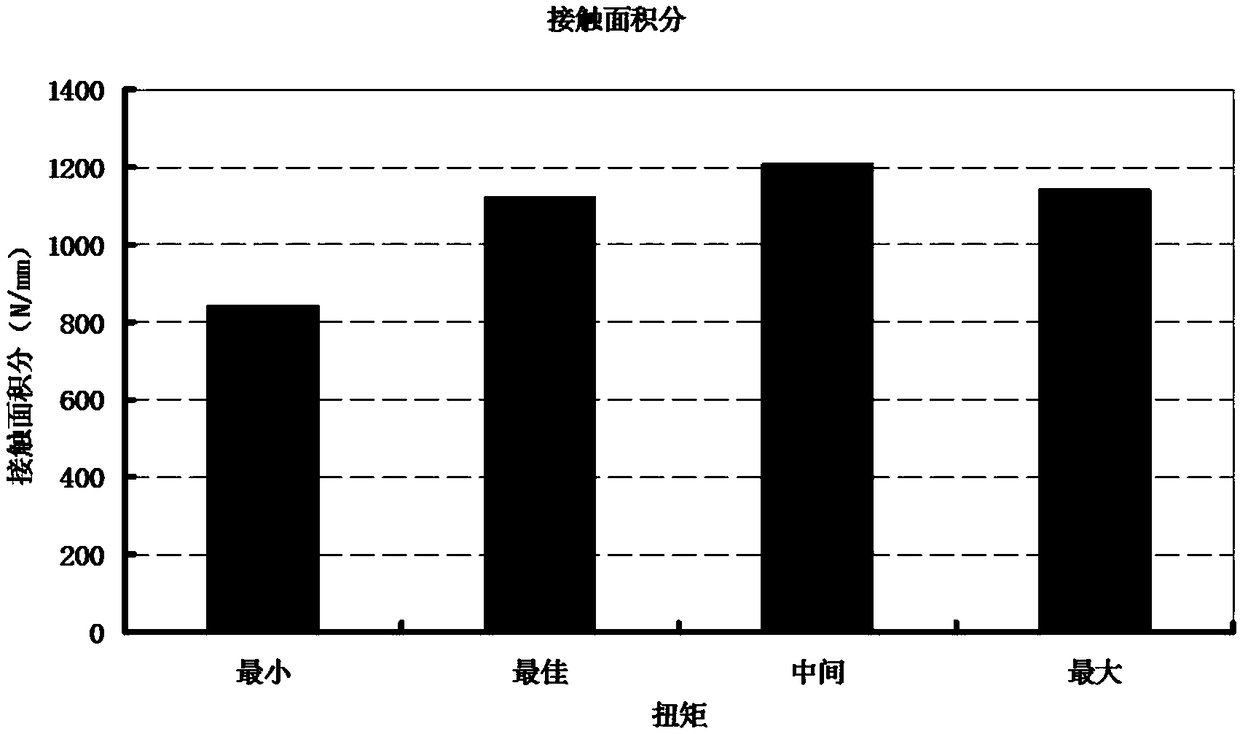

Analysis and evaluation method for hermetic seal thread of tubing of high-temperature high-pressure gas well

ActiveCN108982076AAvoid failureApplicable and optionalMachine part testingVibration testingHermetic sealEngineering

The invention discloses an analysis and evaluation method for hermetic seal thread of a tubing of a high-temperature high-pressure gas well. The hermetic seal applicability of a limit tolerance samplein the condition load and stress correction environment under different make-up torques is tested and evaluated by analyzing the make-up torque of the hermetic seal thread according to down-hole workenvironment characteristics of the high-temperature high-pressure gas well and structural characteristics of the thread; according to analysis on the make-up torque of the hermetic seal thread, the limit tolerance and torque are selected to analyze hermetic seal finite elements under the condition load spectrum, and the down-hole condition load spectrum sealing after make-up of the hermetic sealthread is analyzed; and thread dynamic-load anti-fatigue analysis in the gas production process of a down-hole tubing string is analyzed, an applicability test and evaluation process is determined according to links likely to fail in analysis, and the applicable reliability of the thread is evaluated and analyzed comprehensively. The method can be widely applied to high-temperature high-pressure gas wells as well as unconventional multi-segment high cracking gas wells, especially to evaluate selection and applicability of threads of well-completion tubing strings of deep and ultradeep wells inTarim and southwest oil and gas fields.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

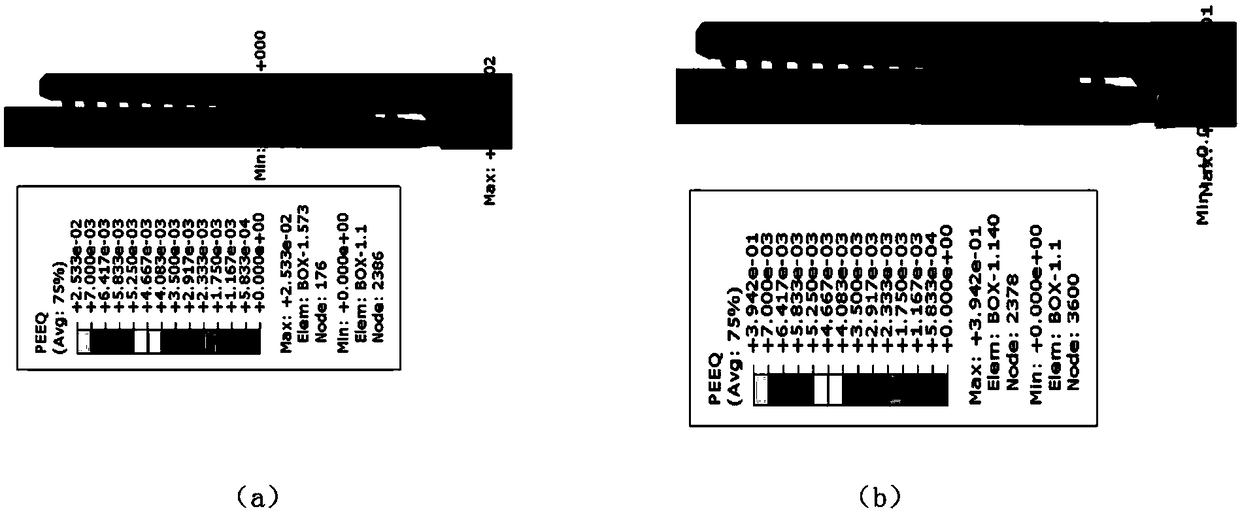

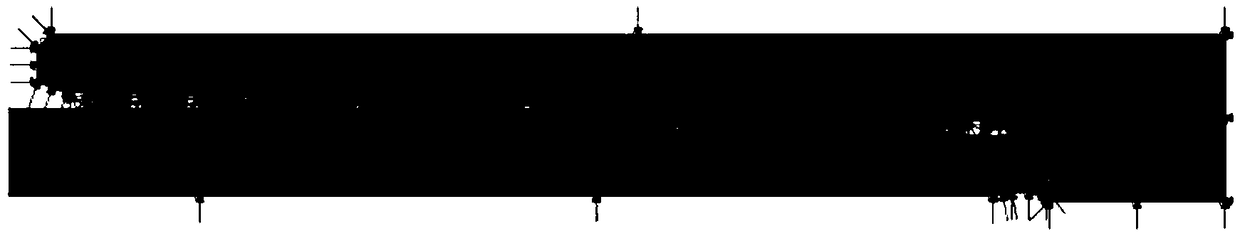

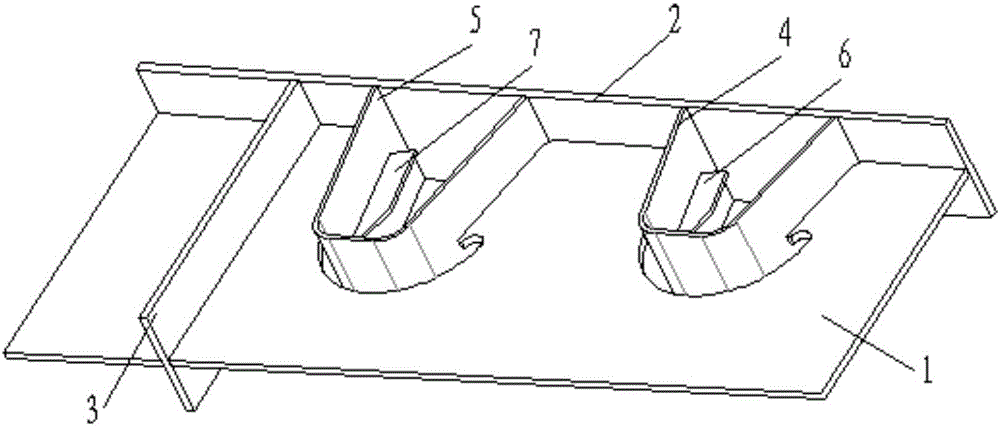

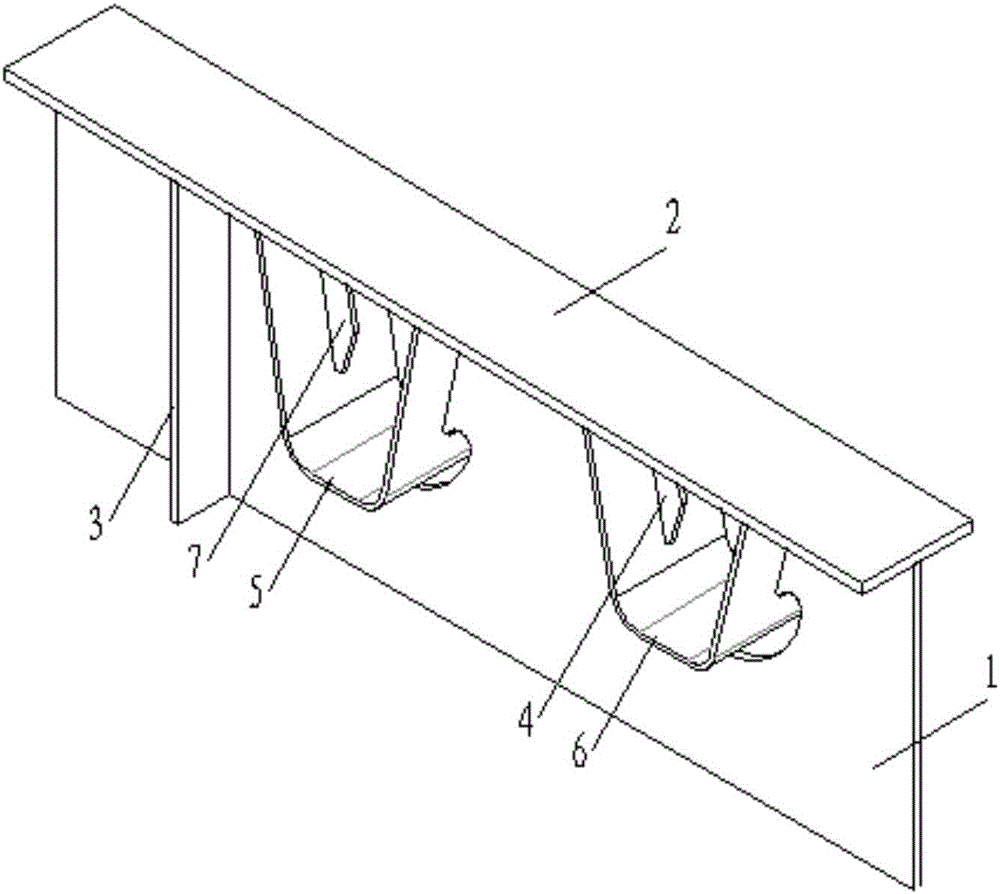

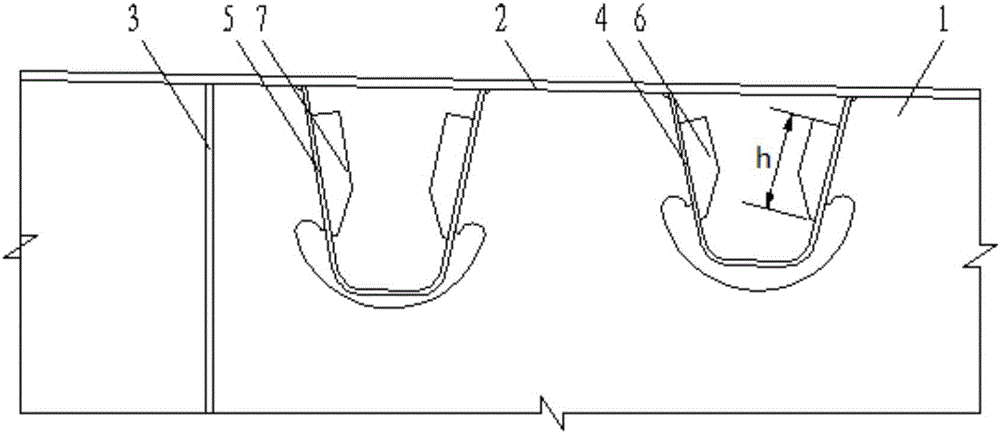

Orthotropic steel bridge deck closed stiffening rib structure with built-in rib strips

InactiveCN106522093AImprove deformationIncrease stressBridge structural detailsBridge materialsBridge engineeringBridge deck

The invention relates to the technical field of bridge engineering, in particular to an orthotropic steel bridge deck closed stiffening rib structure with built-in rib strips. The orthotropic steel bridge deck closed stiffening rib structure with the built-in rib strips comprises a bridge deck slab, a diaphragm plate fixed to the bottom of the bridge deck slab, a middle web and a plurality of closed stiffening ribs. The diaphragm plate is perpendicular to the middle web. The multiple closed stiffening ribs are evenly arranged on the diaphragm plate and located on two sides of the middle web. The two side walls of each closed stiffening rib are both fixedly connected with the diaphragm plate. The rib strips are arranged in the positions, corresponding to the connecting portions of the diaphragm plate, of the two inner sides of each closed stiffening rib. The plate surfaces of the rib strips and the diaphragm plate are arranged in a coplanar mode. By arranging the small rib strips in closed stiffening rib inner cavities, corresponding to the connecting portions of the diaphragm plate, of the closed stiffening ribs, the diaphragm plate provides effective elastic supporting for the closed stiffening ribs, and thus deformation and stress of force bearing sensitive areas of the closed stiffening ribs and the connecting portions of the diaphragm plate are improved, the problem of fatigue cracks in the intersecting positions of the closed stiffening ribs and the diaphragm plate of an orthotropic steel bridge deck is solved, and the fatigue performance of the orthotropic steel bridge deck is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

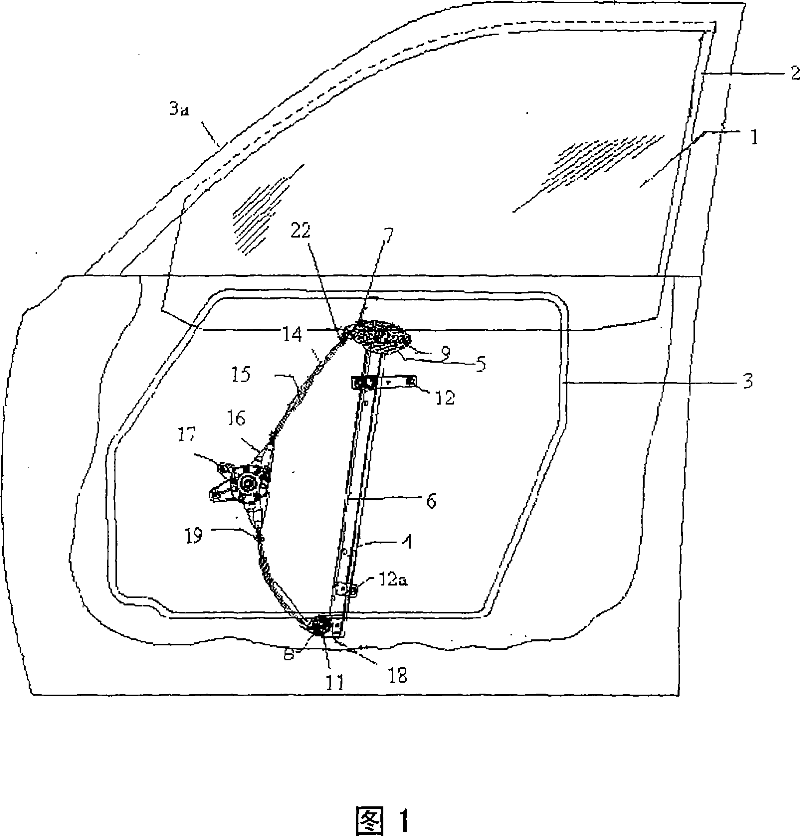

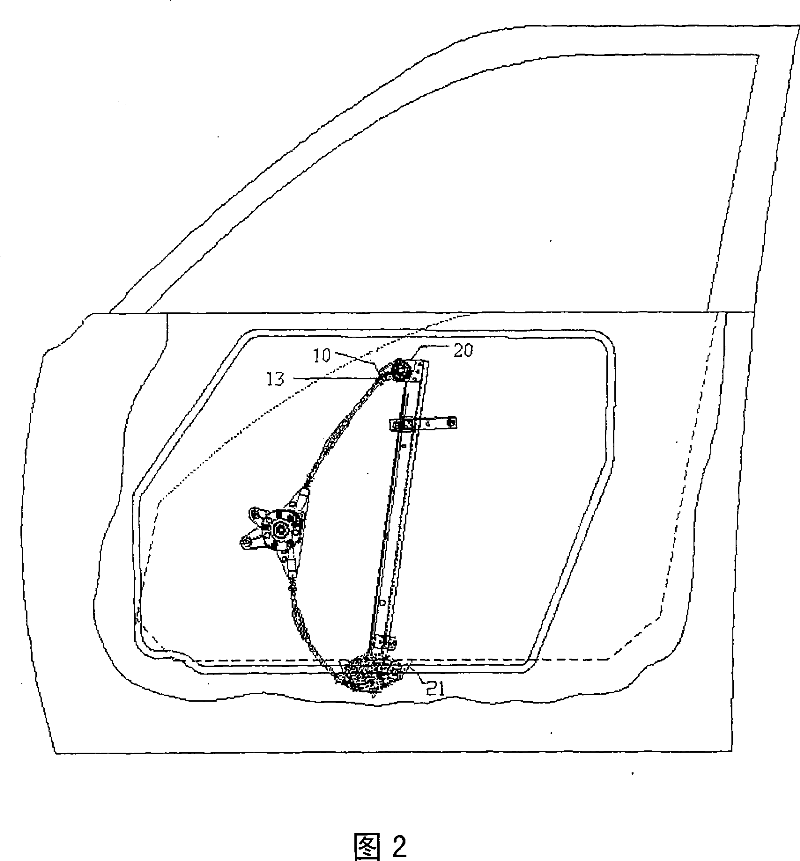

Window regulator actuating device for automobile

The present invention particularly provides a lifting plate of a window regulator with retainers that are operably interconnected by means of a motion-transmitting element for a tilt-free operation of a window screen. The window regulator comprising a slidable lifting plate mounted on a vertical guide rail, a pair of flanges disposed on the rear side of lifting plate to mate with said guide rail and to provide a tilt-free sliding support to the lifting plate. A pair of retainers with locking means is operably connected by means of a motion-transmitting element. The motion transmitting element is disposed to form a contact-free crossover of said motion-transmitting element on the rear side of the lifting plate.

Owner:IFB AUTOMOTIVE PTE LTD

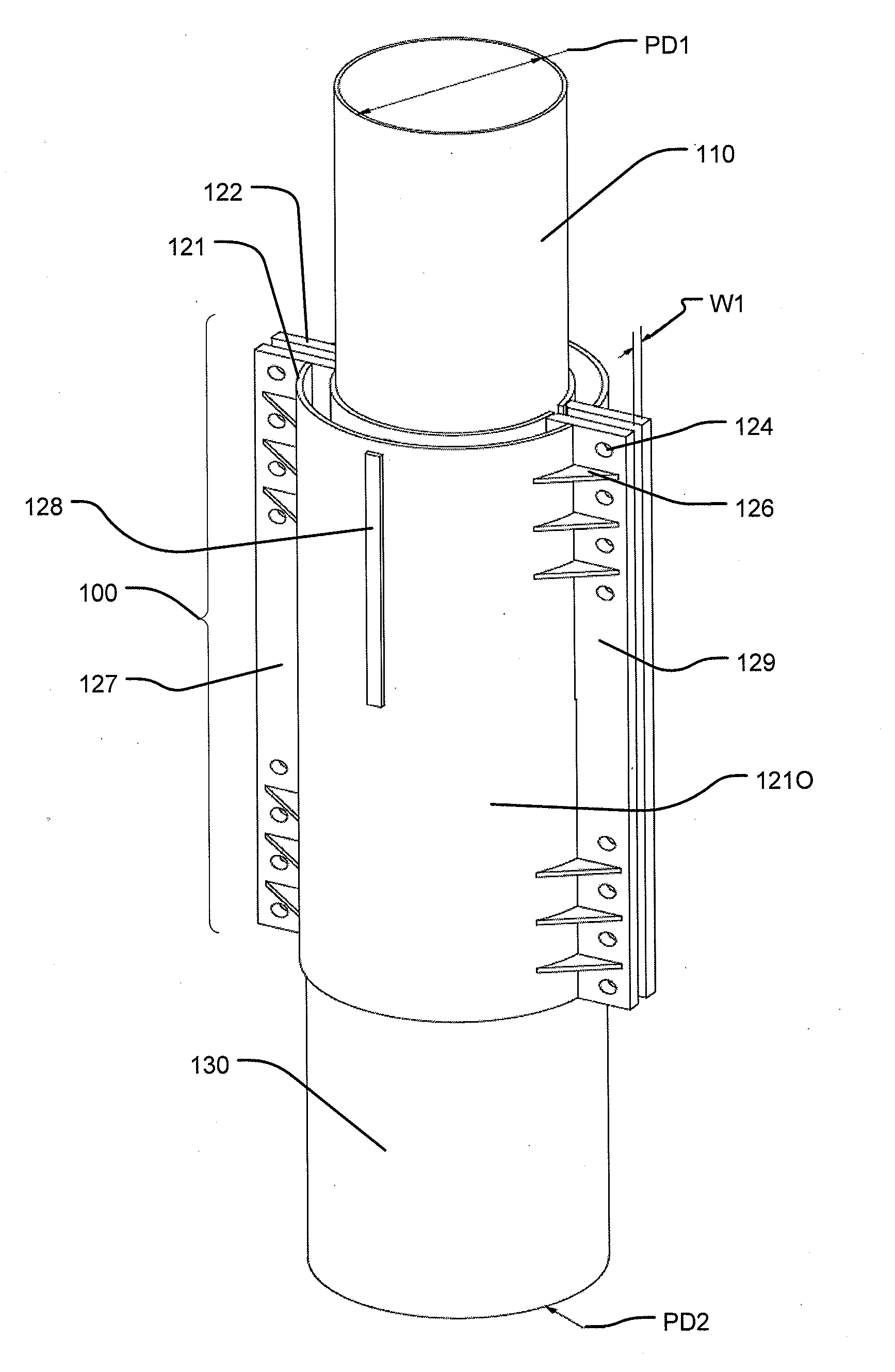

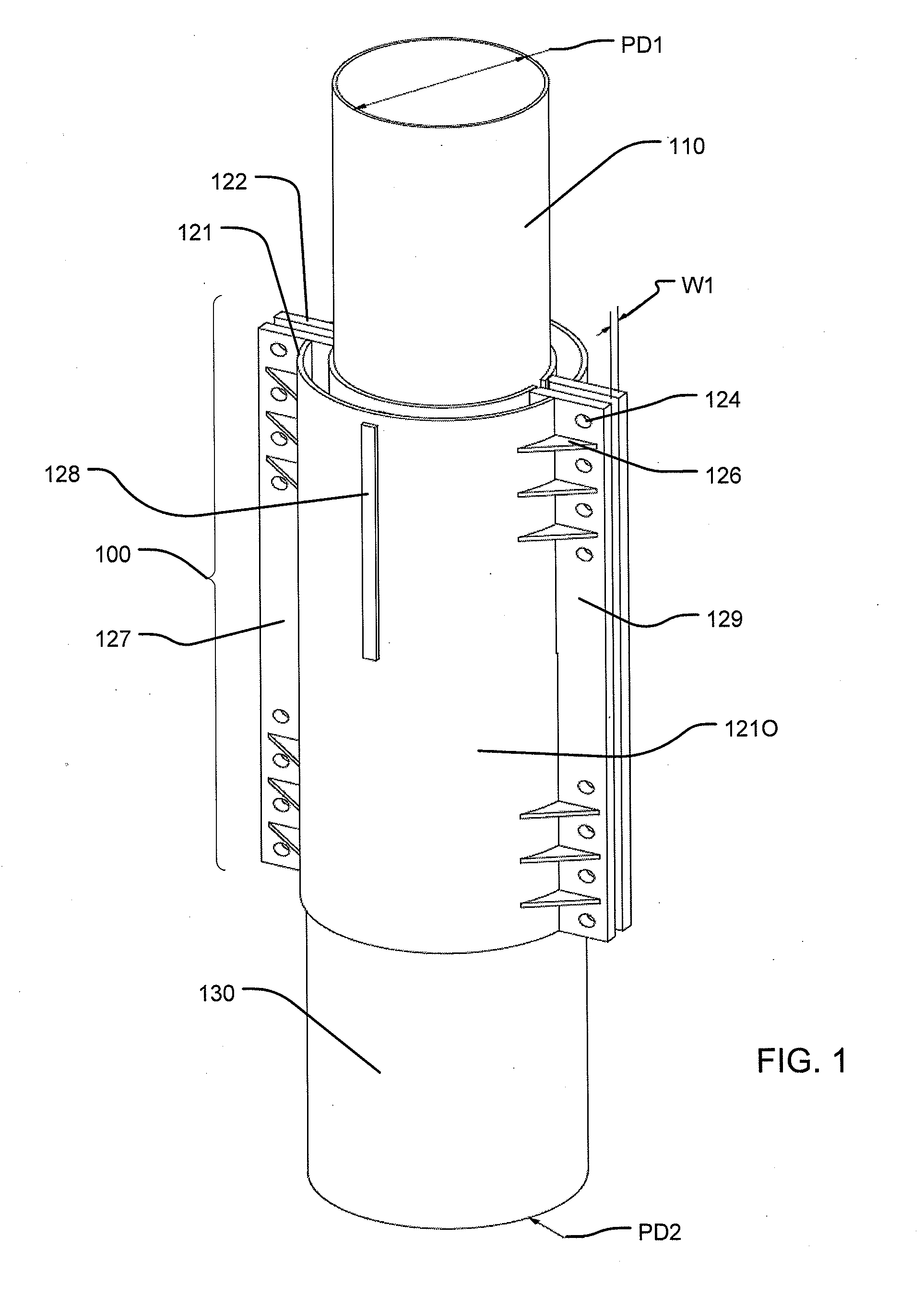

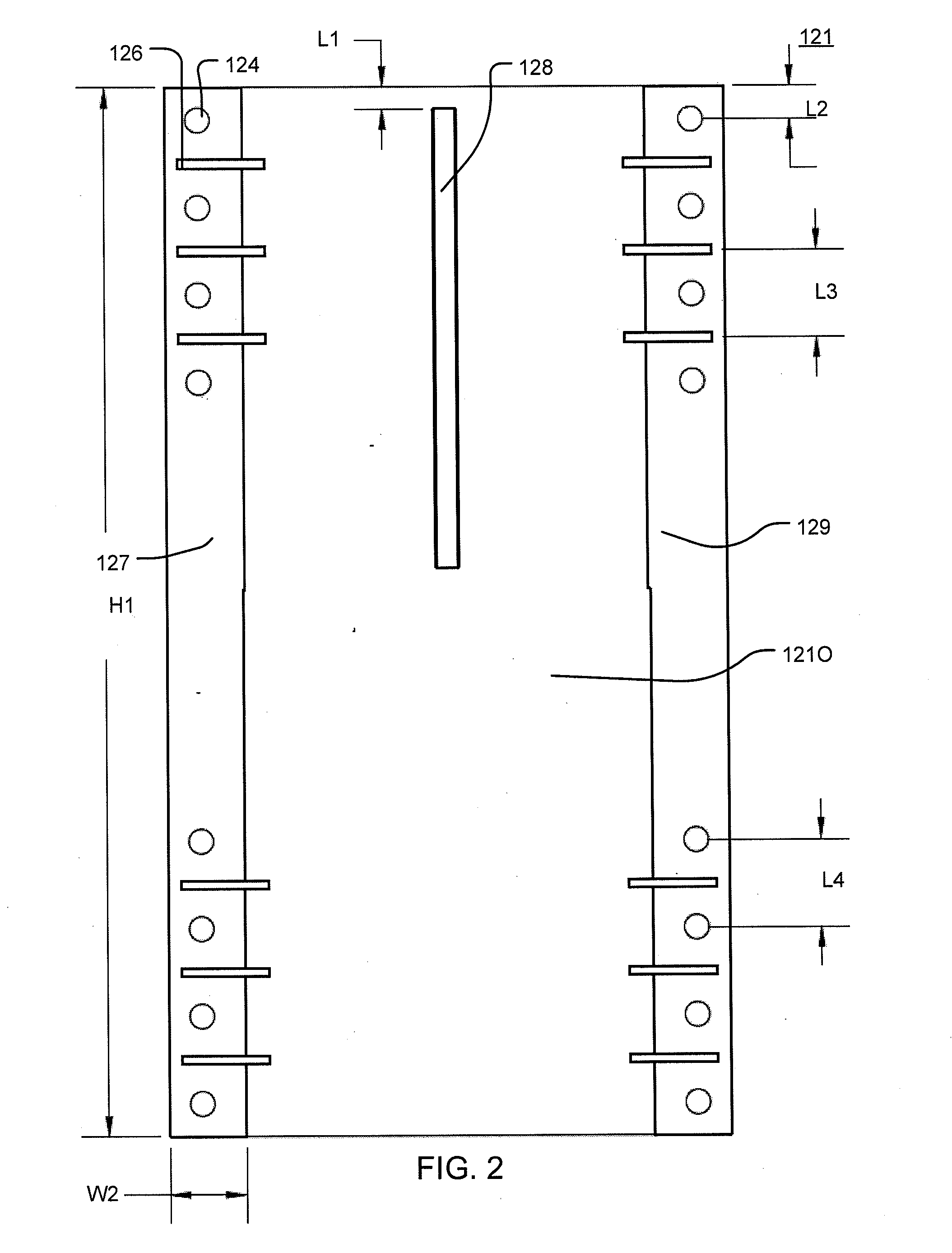

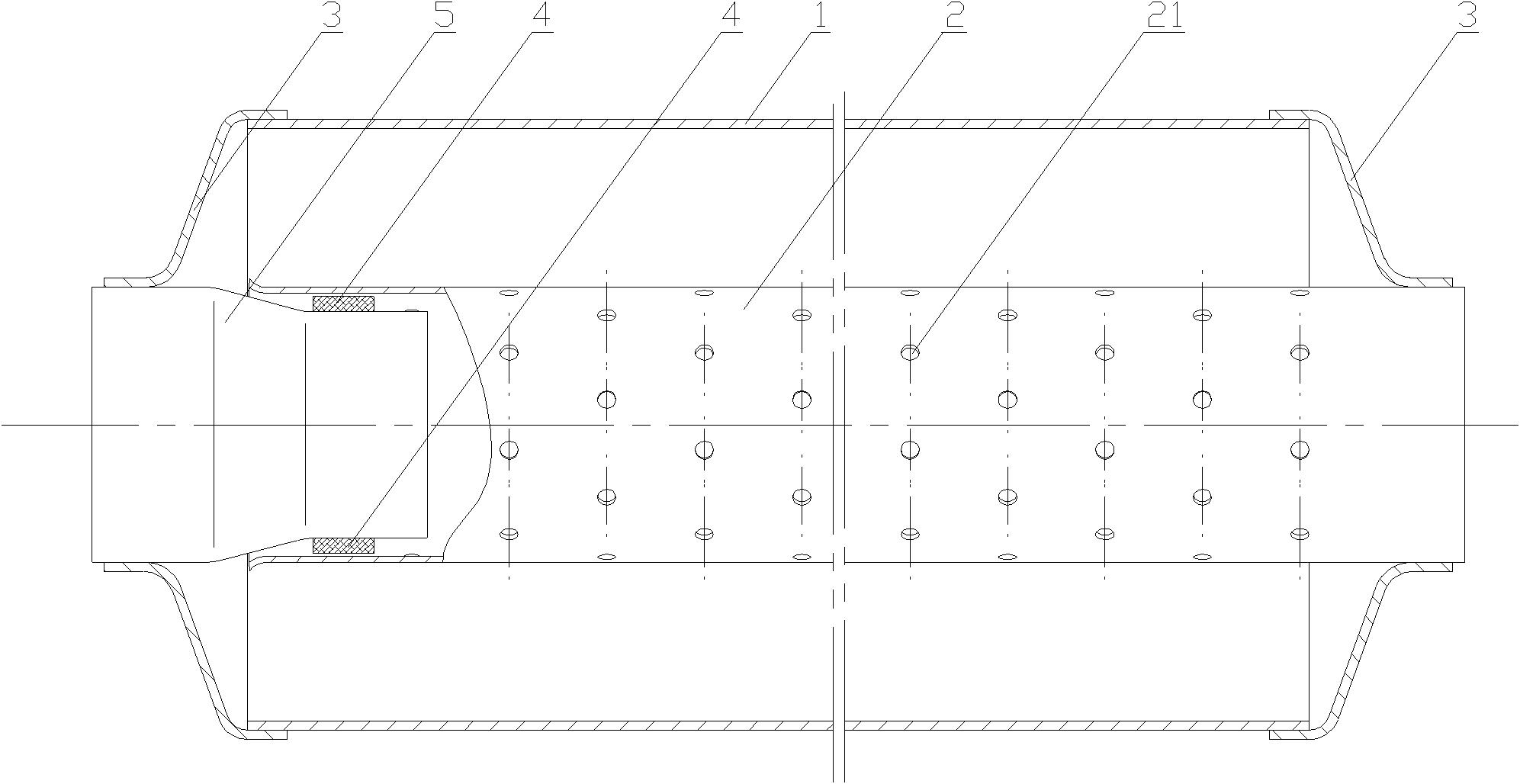

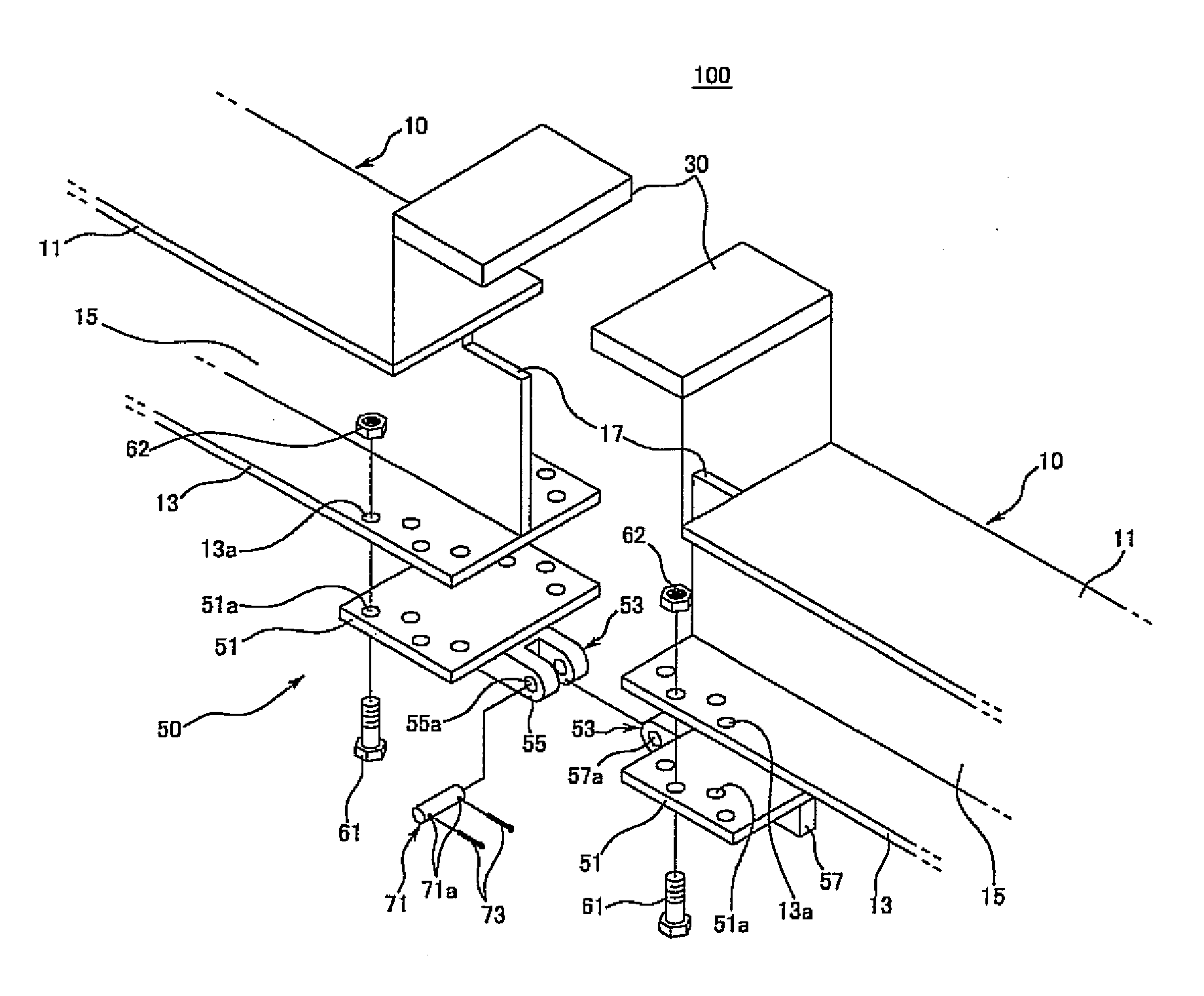

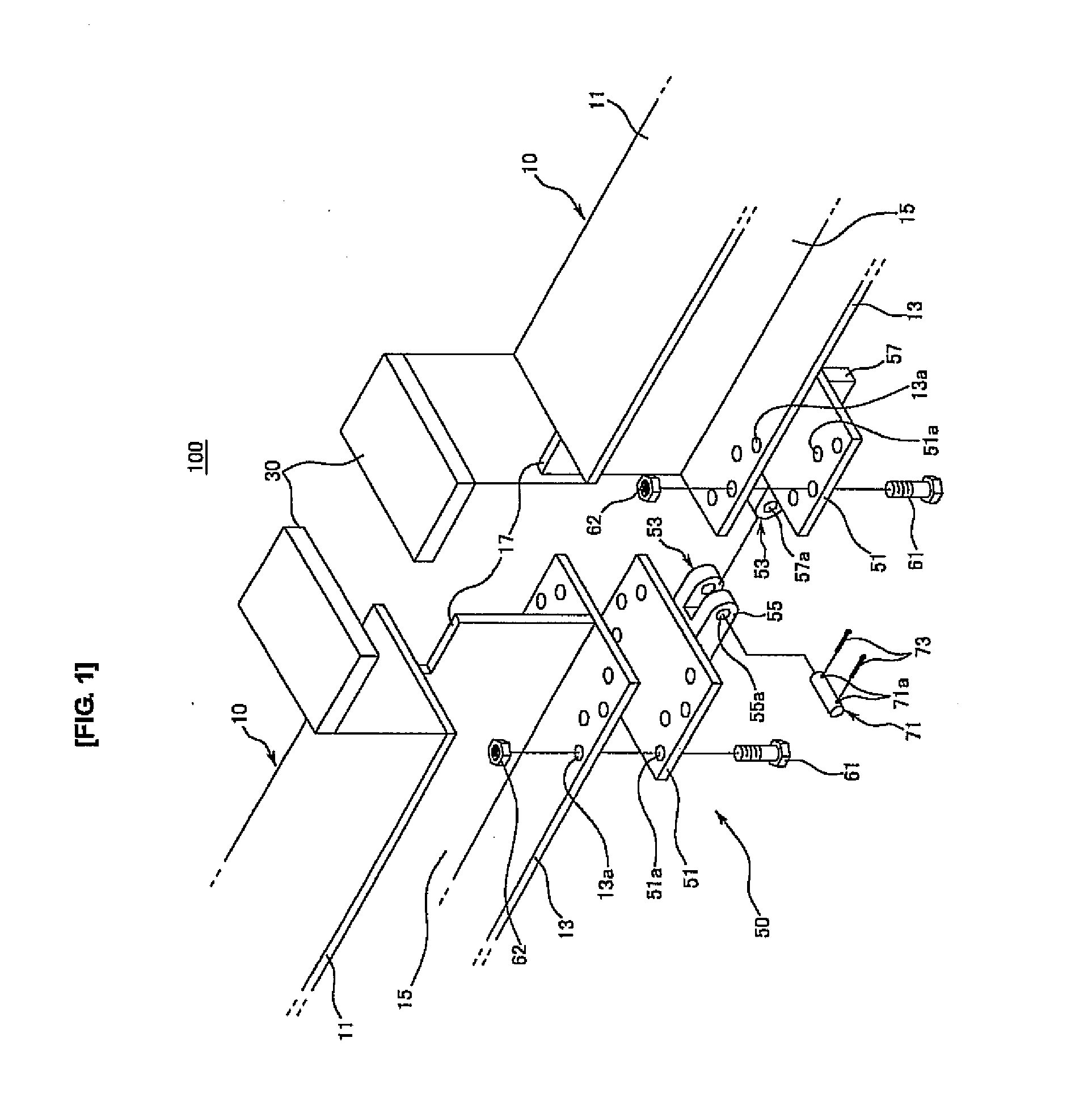

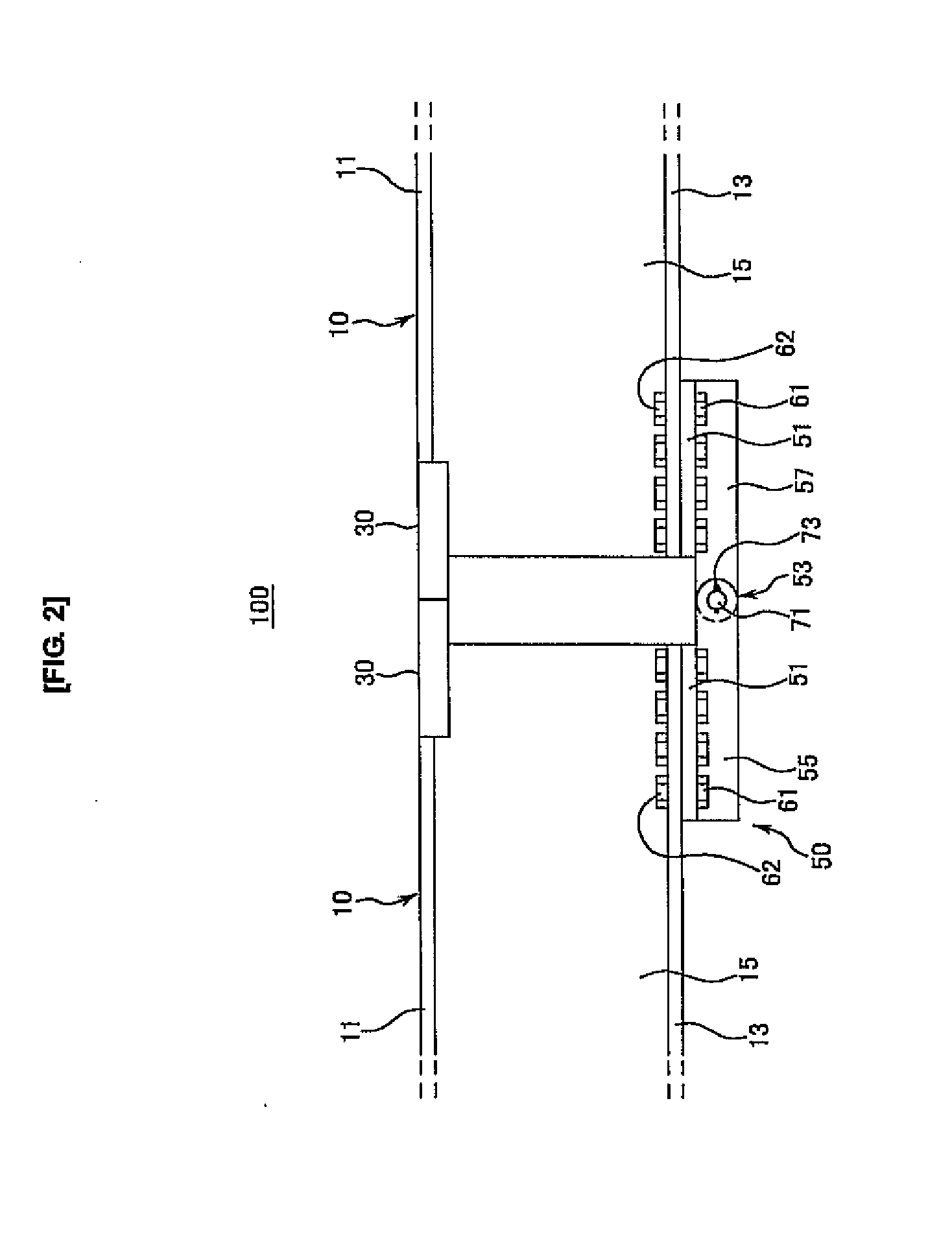

Modular steel bridge

InactiveUS20100192313A1Easy partial repairAvoid fatigue failureBridge structural detailsBridge materialsEngineeringFlange

A modular steel bridge is configured by combining at least two steel girder segments, and it includes a bearing block installed to be connected to an upper flange of a connection end of each steel girder segment and a web, and a hinge assembly installed to be attachable to the lower flange of each connection end and hinge-connecting the connection ends.

Owner:RES INST OF IND SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com