Head-changeable hard alloy twist drill

A cemented carbide and twist drill technology, applied in the direction of twist drills, etc., can solve the problems of weakened clamping force of the replaceable head, difficulty in coaxiality positioning, complex structure of the replaceable head, etc., to ensure coaxiality and avoid Fatigue failure, effect of improving stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

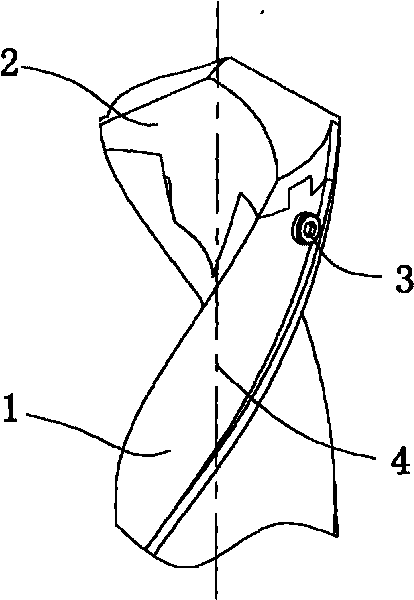

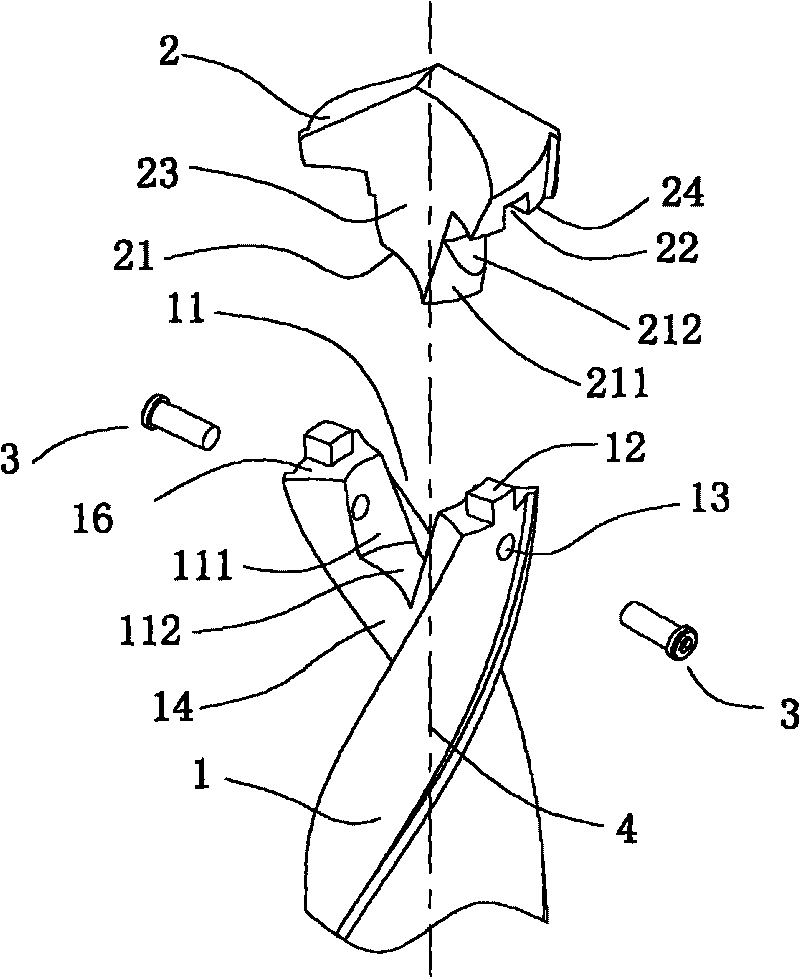

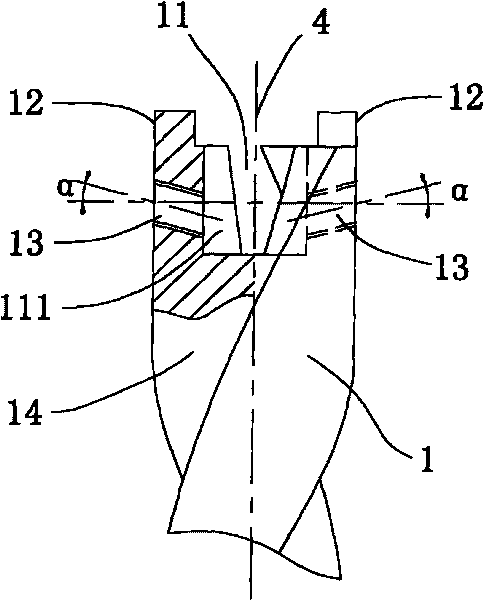

[0031] Such as Figure 1 to Figure 6 As shown, the replaceable head hard alloy twist drill of the present invention comprises a drill rod 1, a drill tip 2 and a set screw 3, the bottom end surface of the drill tip 2 is provided with a radial positioning block 21 in the middle, and a radial positioning block 21 is provided on both sides. Circumferential positioning grooves 22, the top end surface of the drill pipe 1 is provided with a radial positioning groove 11 in the middle, and both sides are provided with circumferential positioning blocks 12. Threaded hole 13. The radial positioning block 21 is placed in the radial positioning groove 11, and the drill rod 1 and the drill tip 2 are radially positioned by using the cooperation of the two; the circumferential positioning block 12 is placed in the circumferential positioning groove 22, and the two are used The drill pipe 1 and the drill tip 2 are coordinated to be circumferentially positioned and play the role of torque tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com