Patents

Literature

47 results about "Drill bit shank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

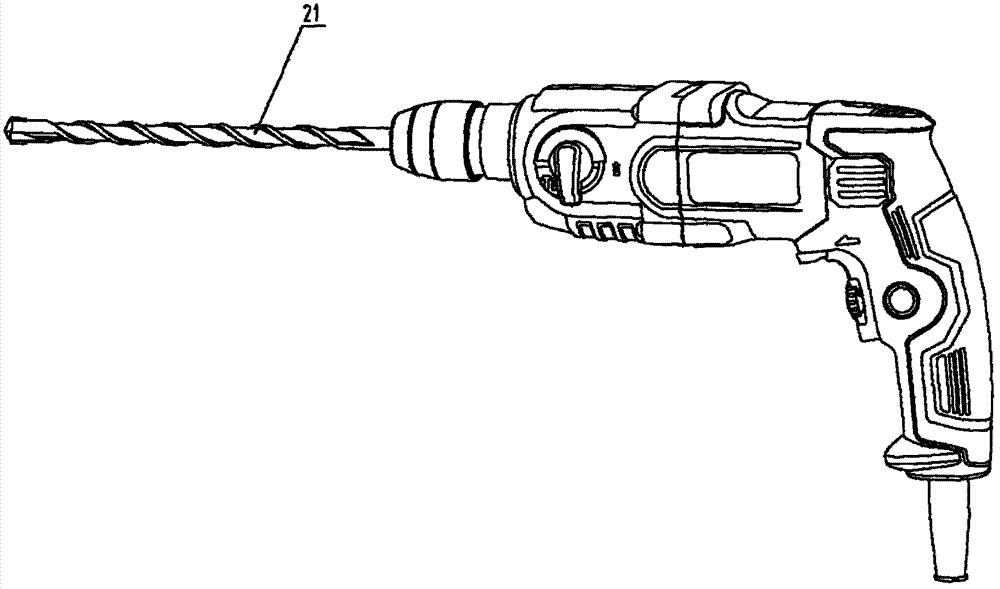

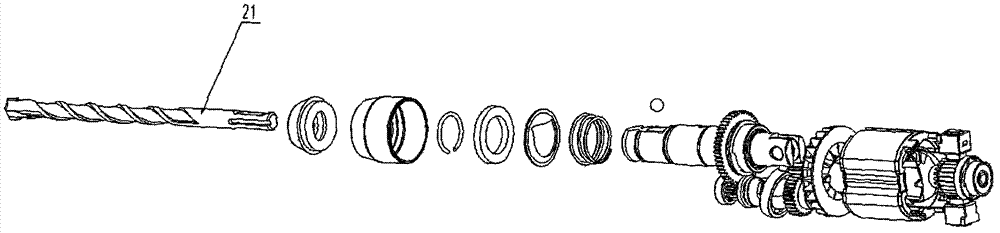

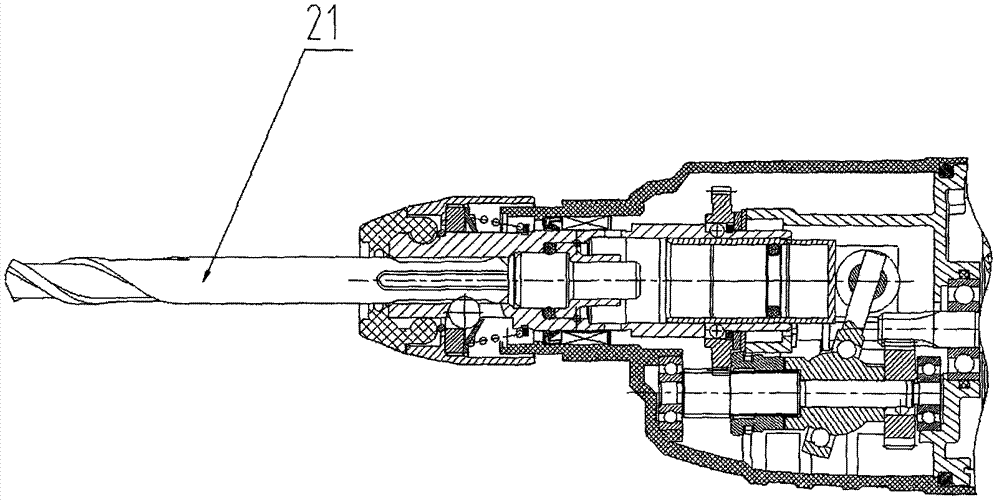

The shank is the end of a drill bit grasped by the chuck of a drill. The cutting edges of the drill bit contact the workpiece, and are connected via the shaft with the shank, which fits into the chuck. In many cases a general-purpose arrangement is used, such as a bit with cylindrical shaft and shank in a three-jaw chuck which grips a cylindrical shank tightly. Different shank and chuck combination can deliver improved performance, such as allowing higher torque, greater centering accuracy, or moving the bit, but not the chuck, with a hammer action.

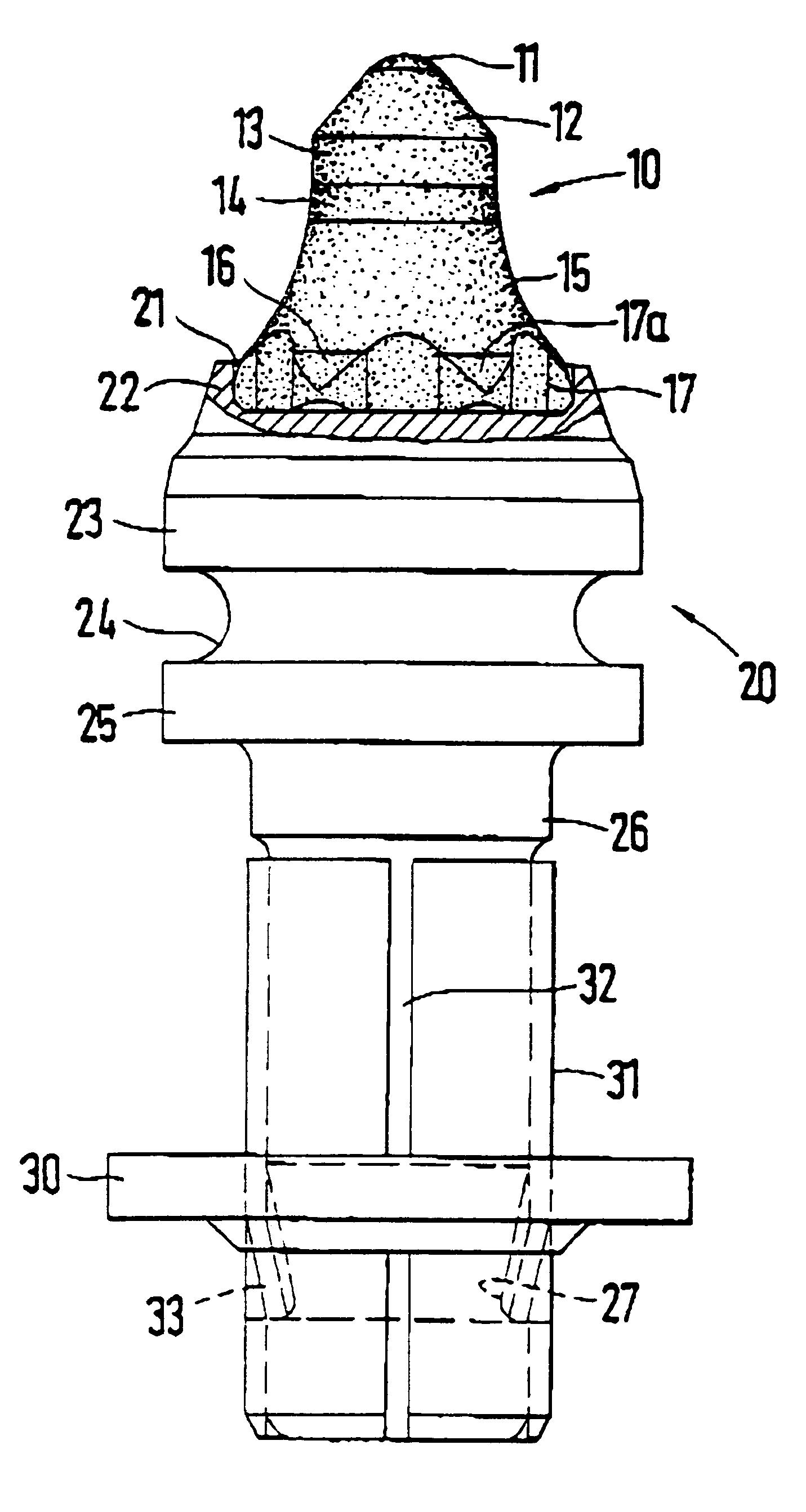

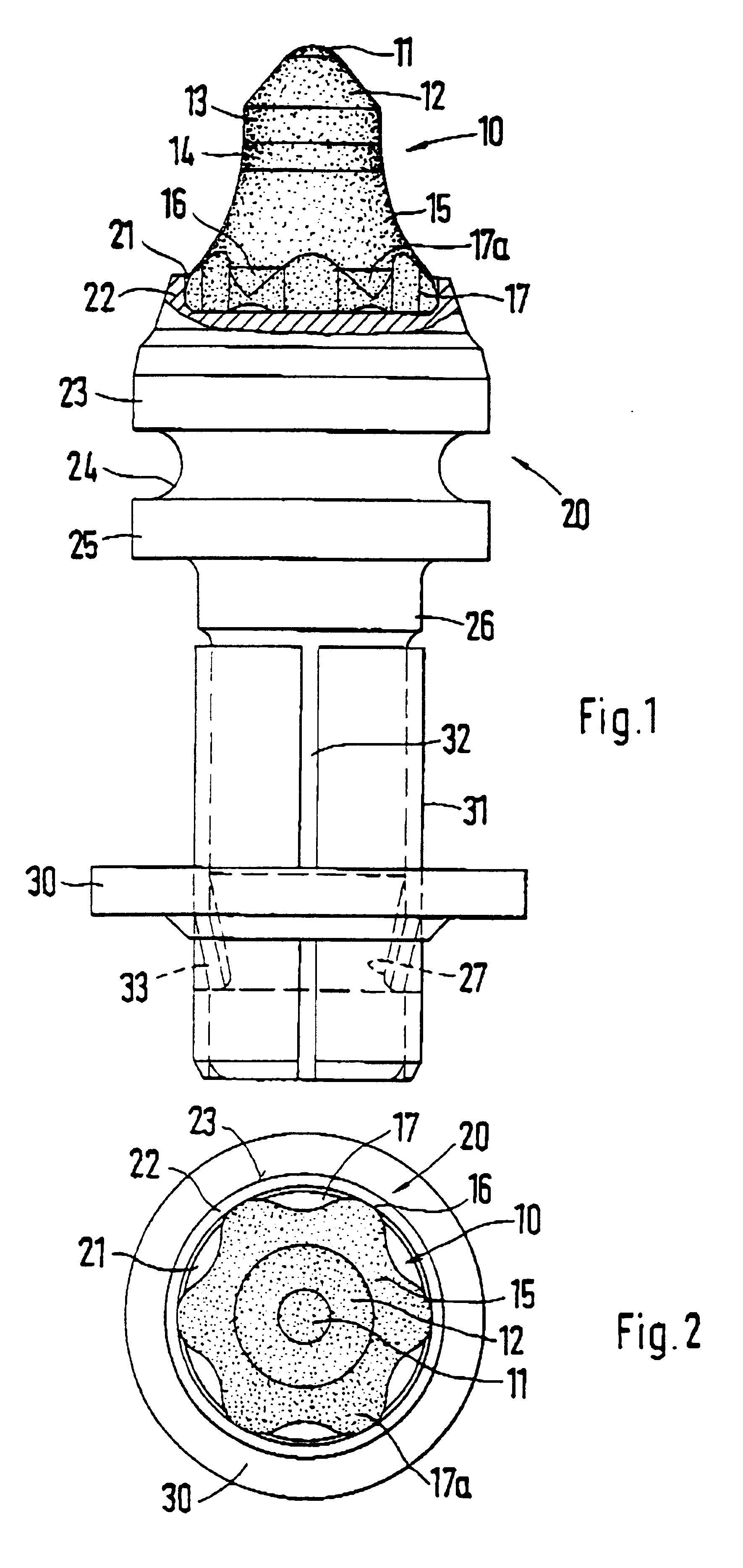

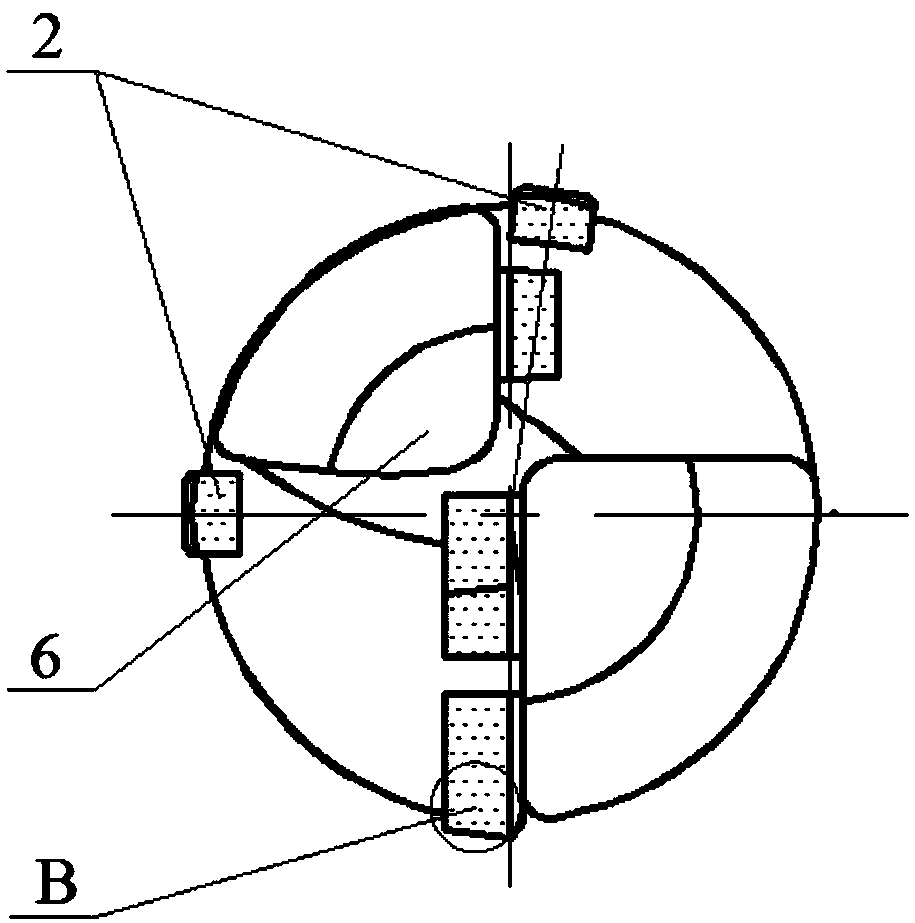

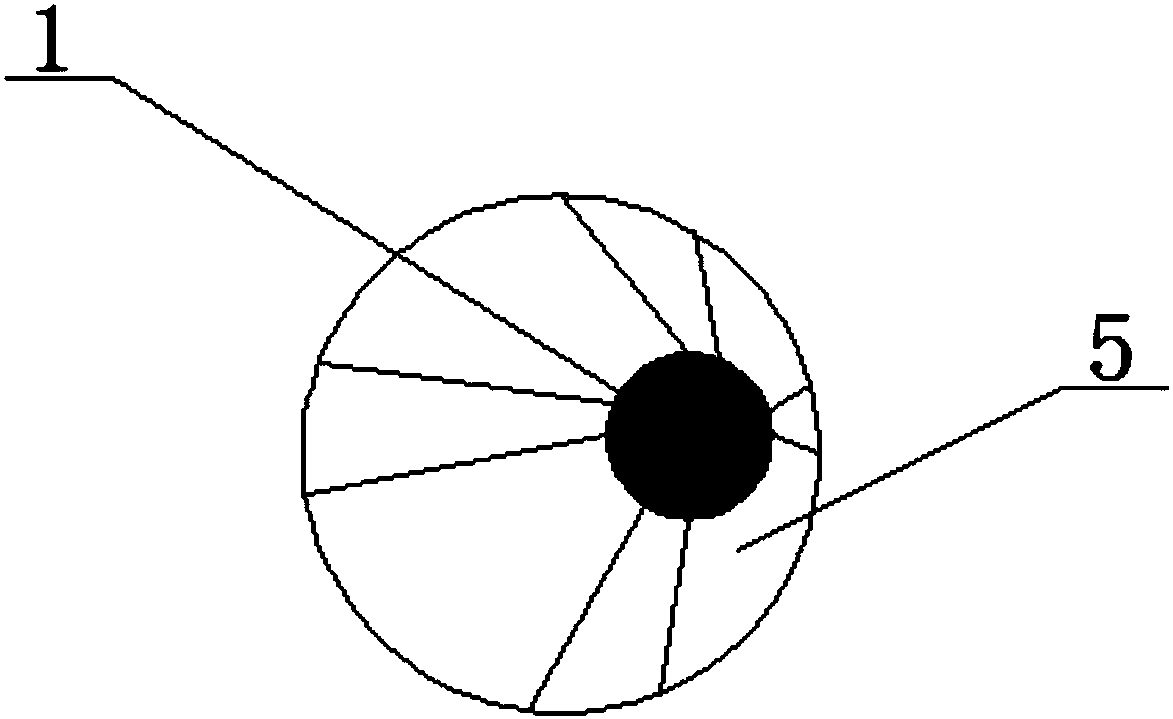

Round-shank bit for a coal cutting machine

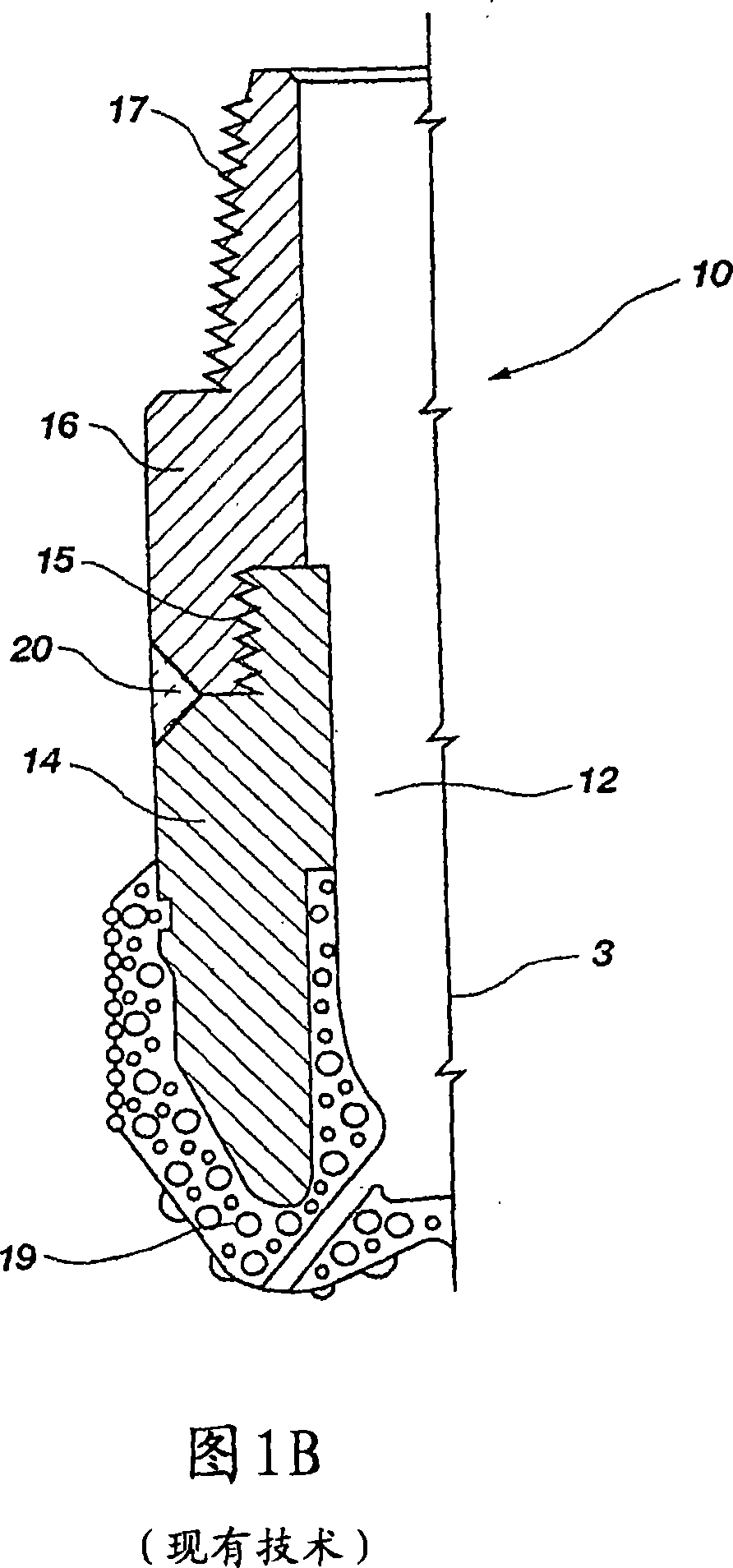

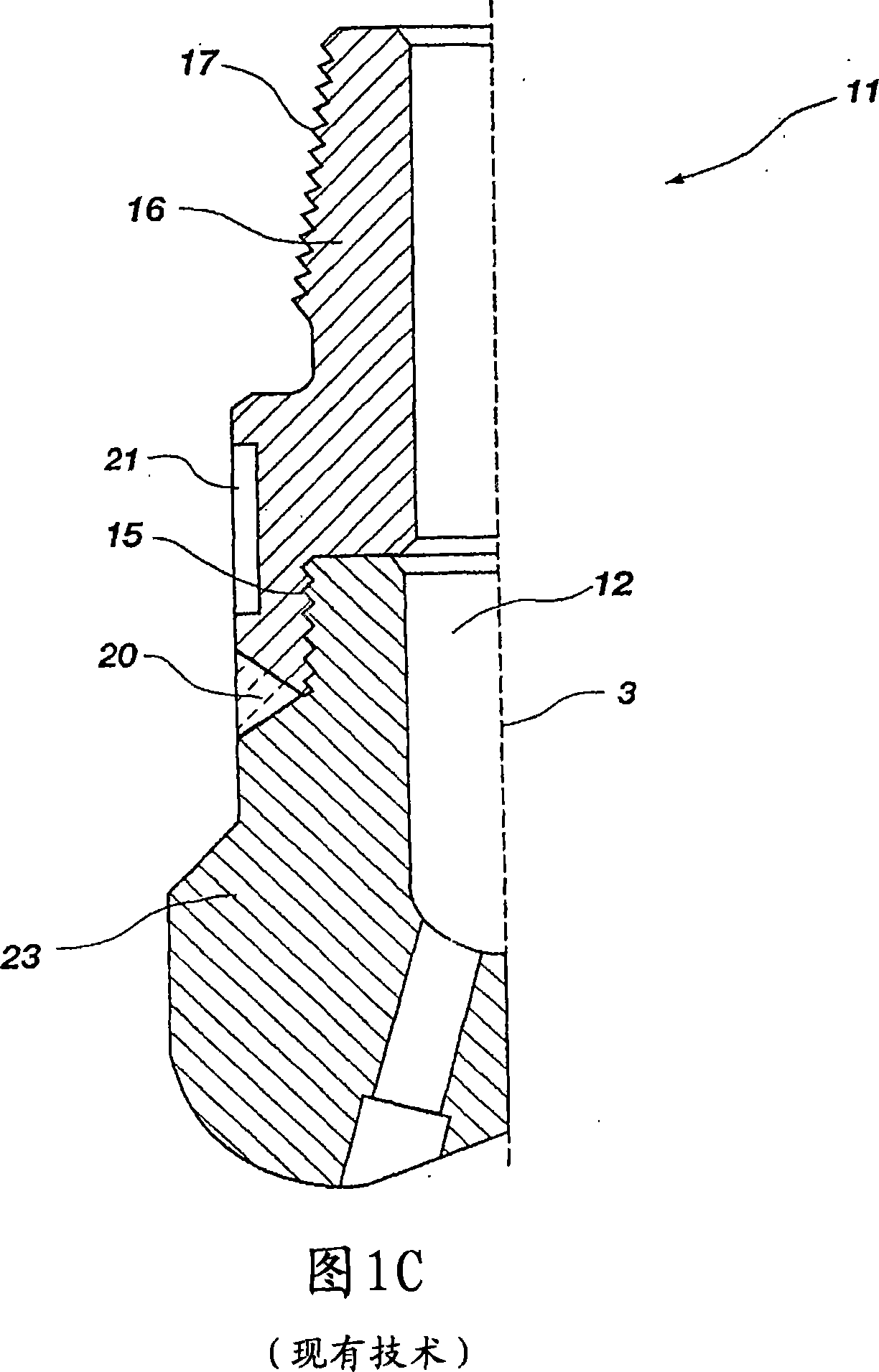

InactiveUS6199956B1Sufficient supportLess stressPolishing machinesRevolution surface grinding machinesMaximum diameterEngineering

A round-shank bit for a coal cutting machine or the like, having a bit head and a bit shank, wherein the bit head has a bit tip, maintained by a base element in a receptacle of the bit head. Starting at the base element, the bit tip tapers in a direction toward the free end of the bit tip, wherein the base element forms a maximum diameter of the bit tip, and wherein the bit tip has recesses on its outer contour. In order to assure good rotational behavior over the entire length of the operating time, the base element has the recesses on an outer circumference forming the maximum diameter.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

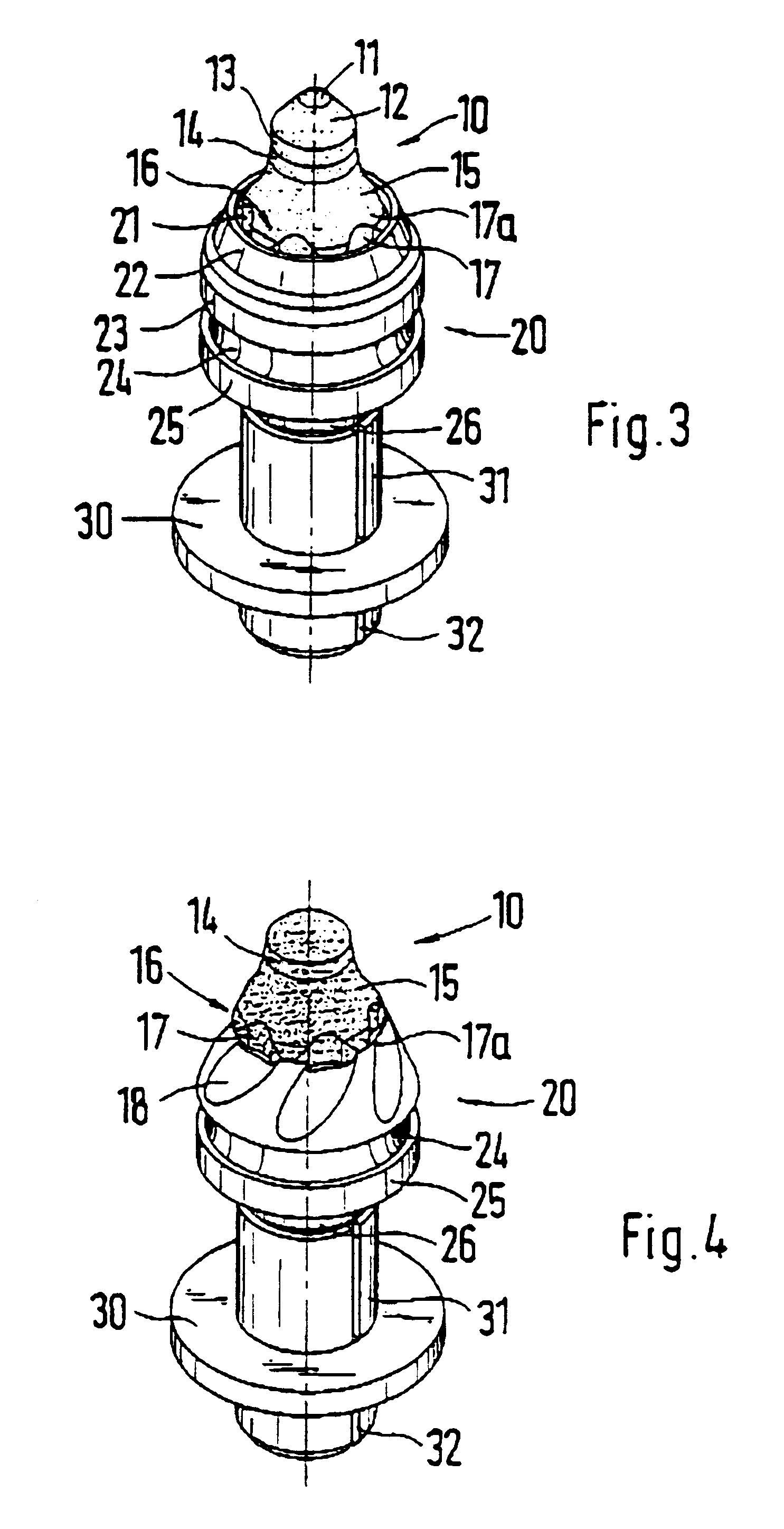

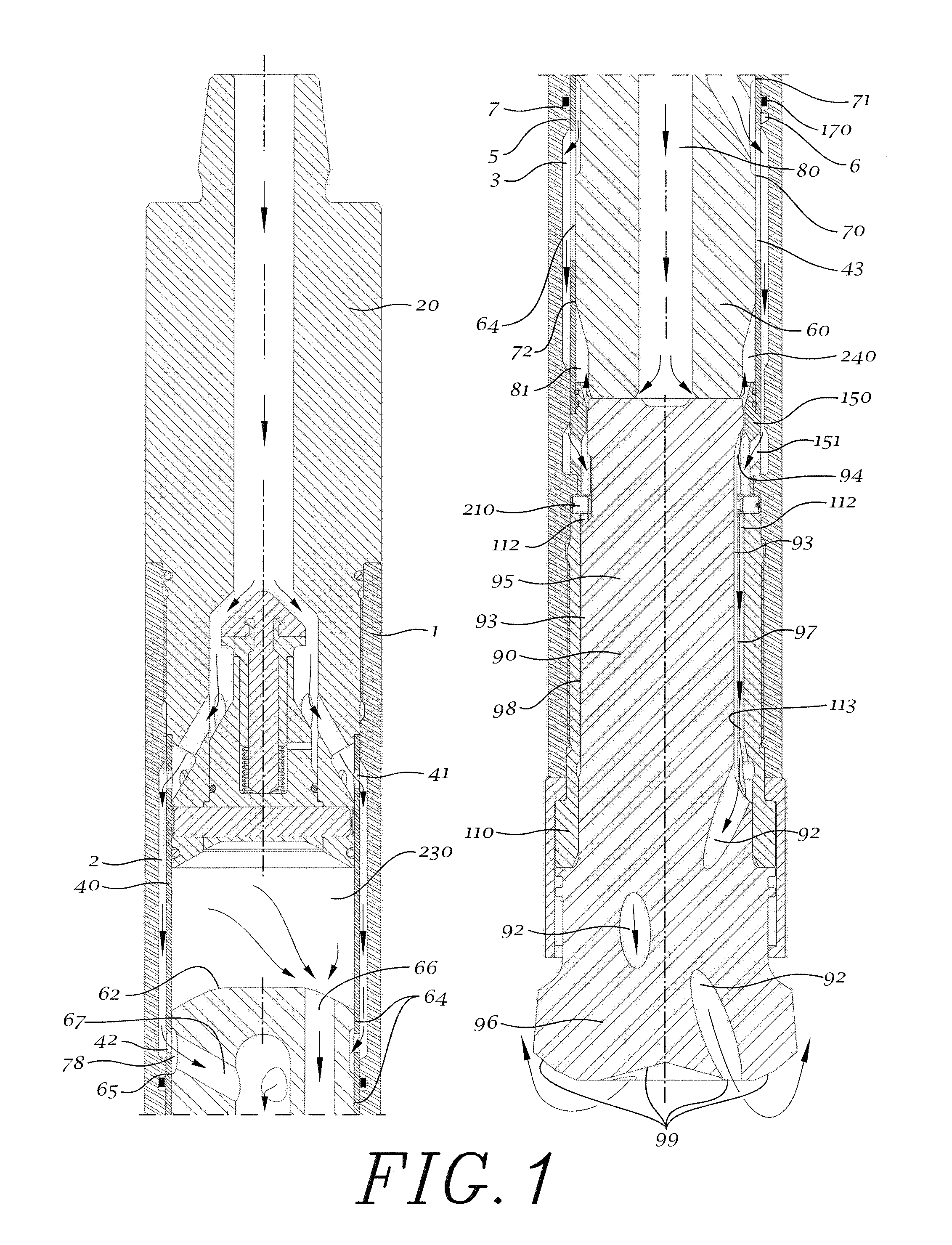

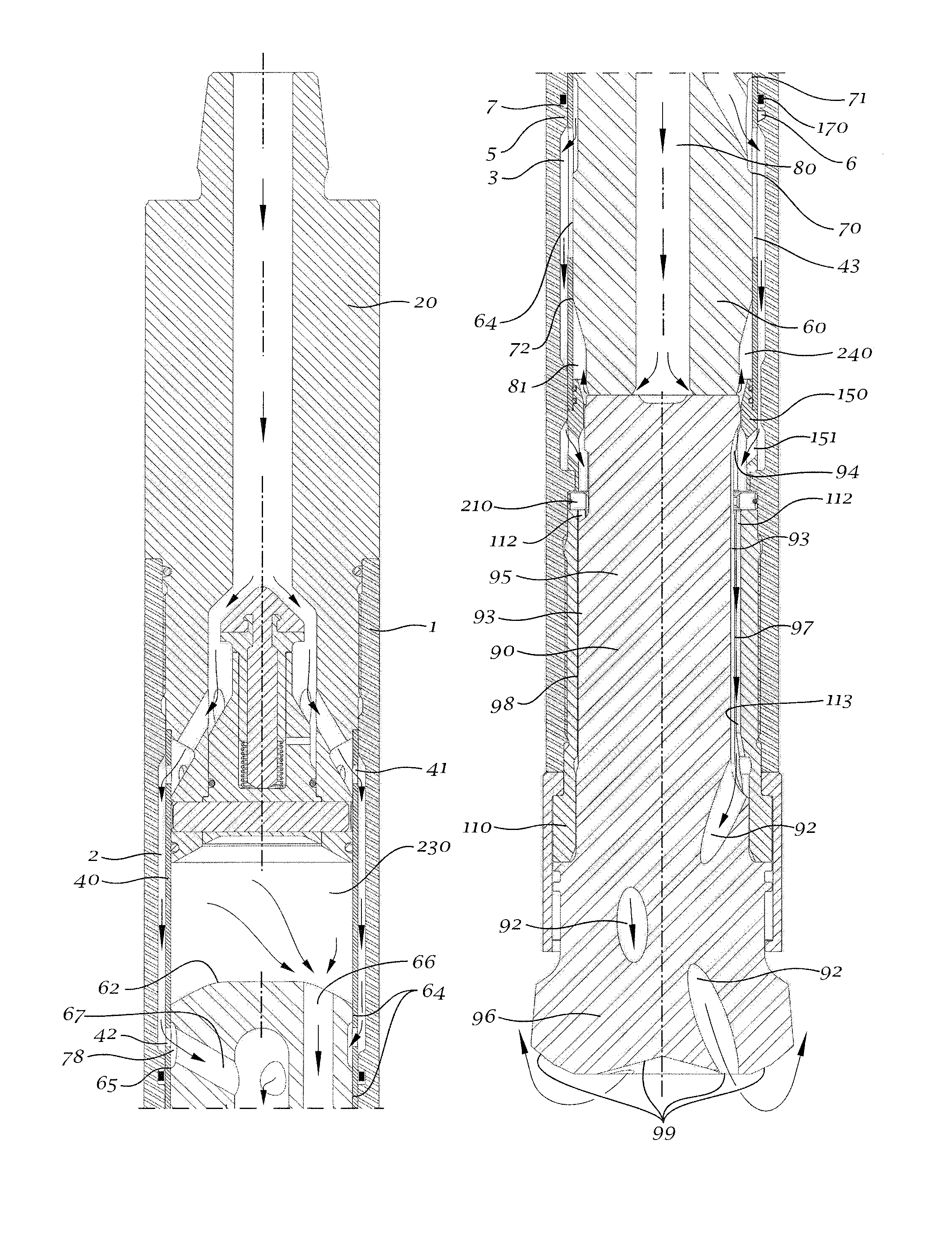

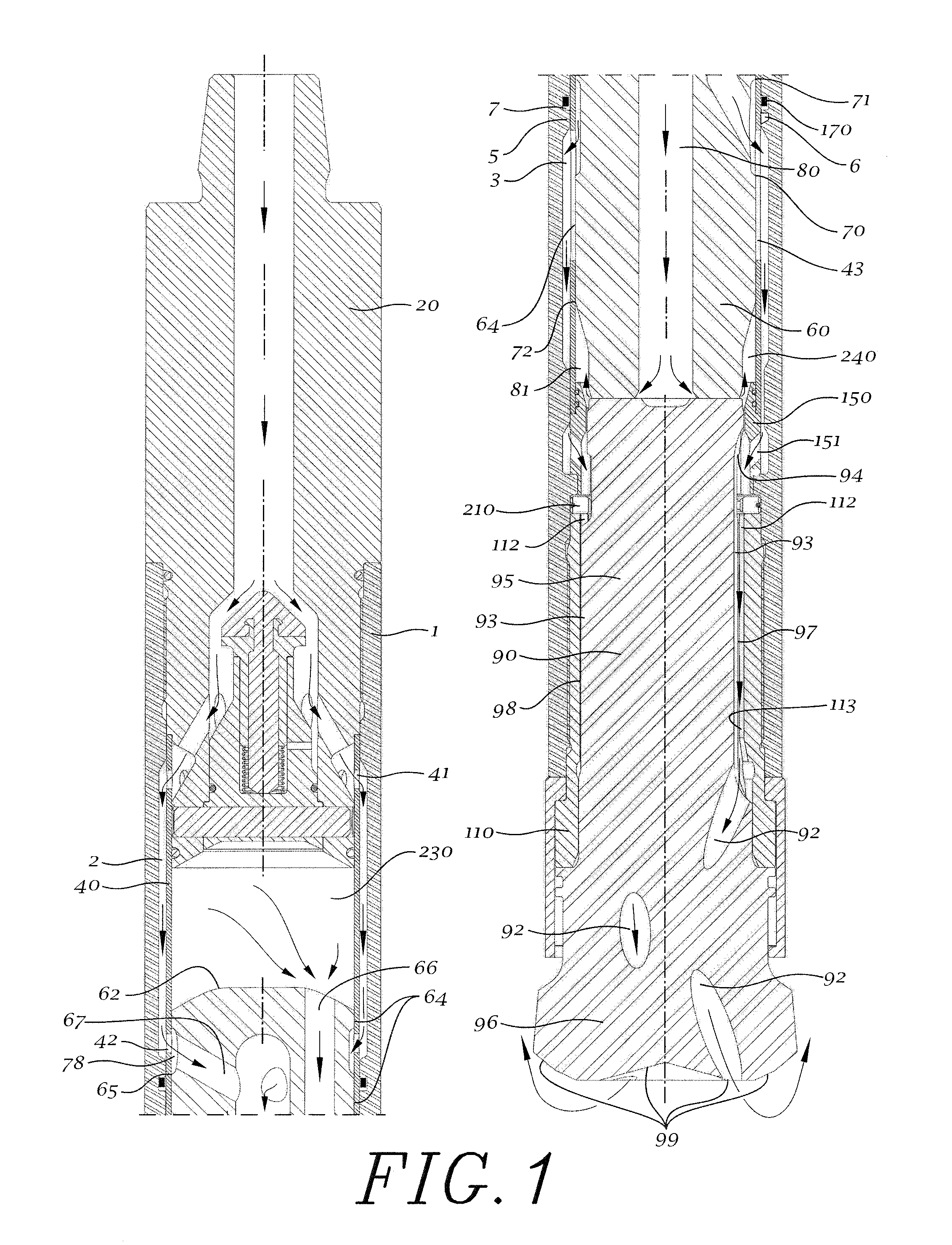

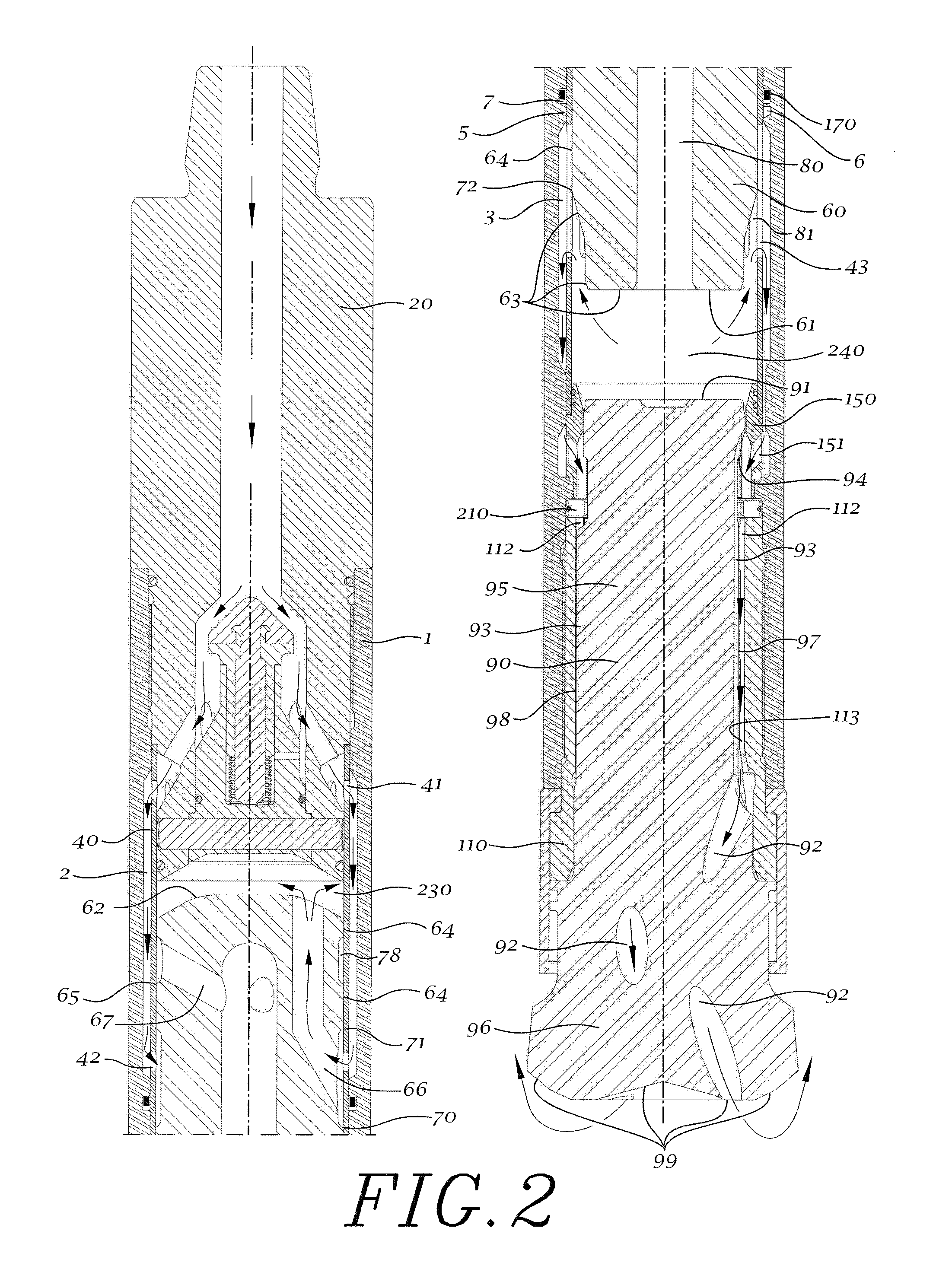

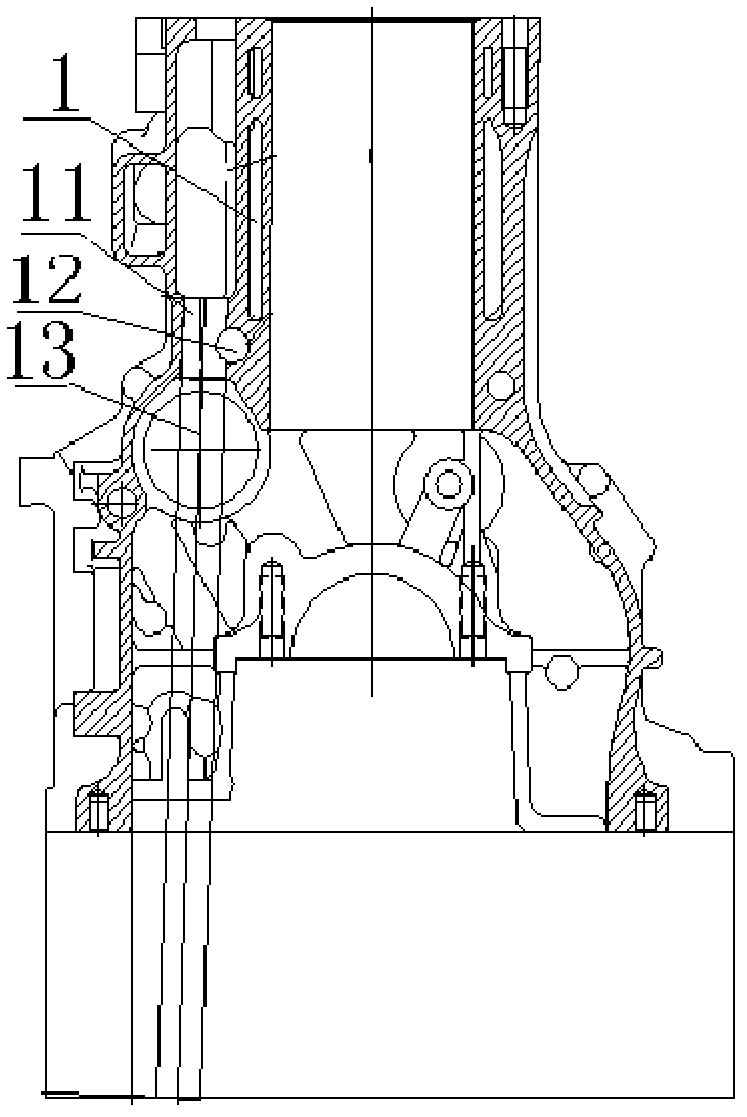

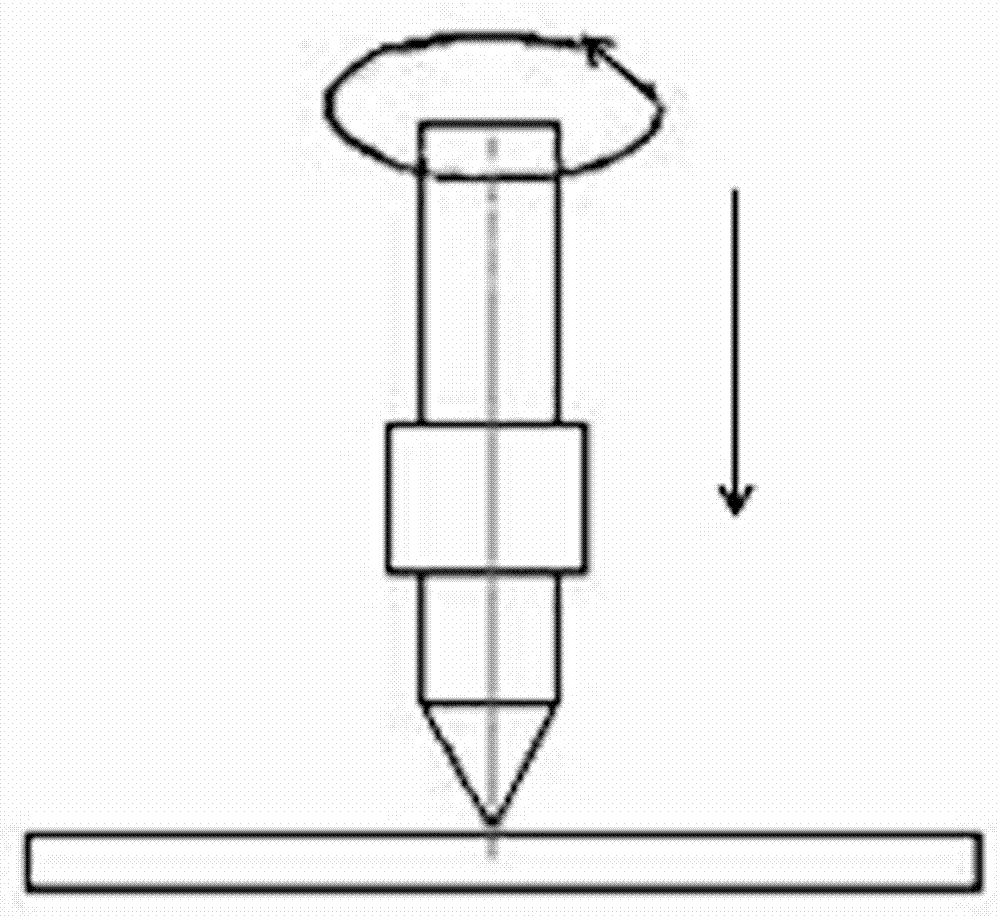

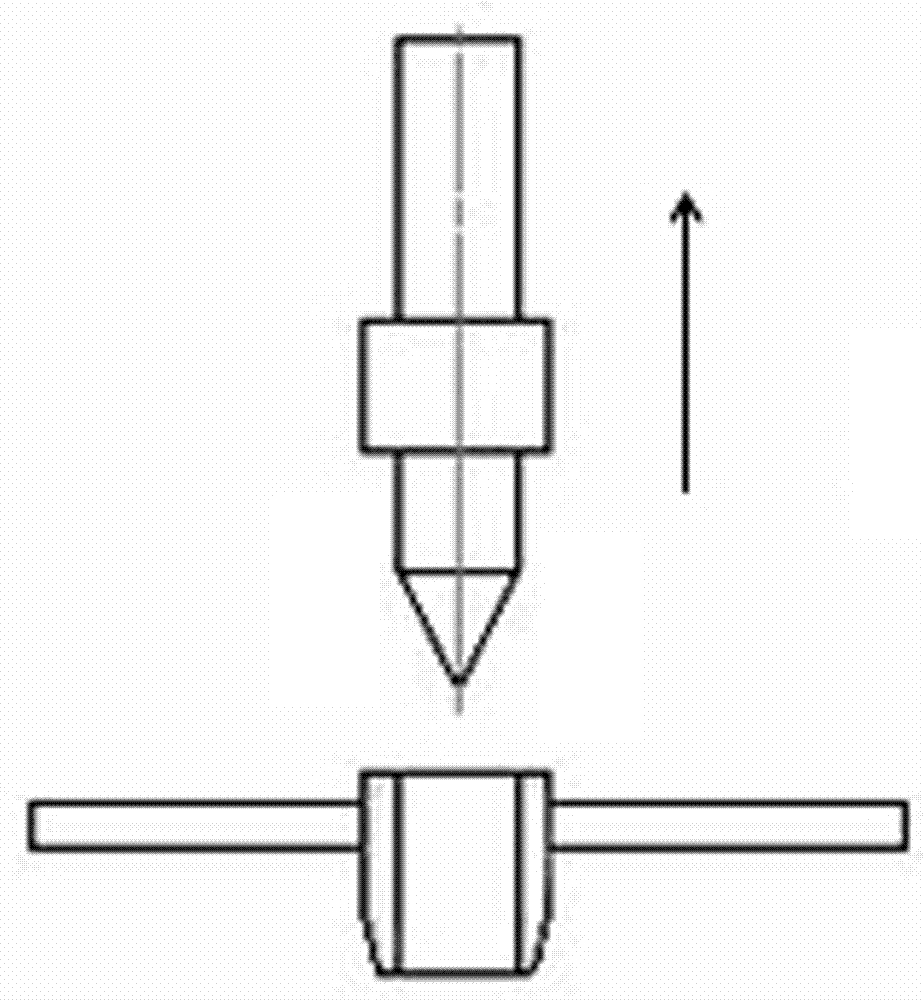

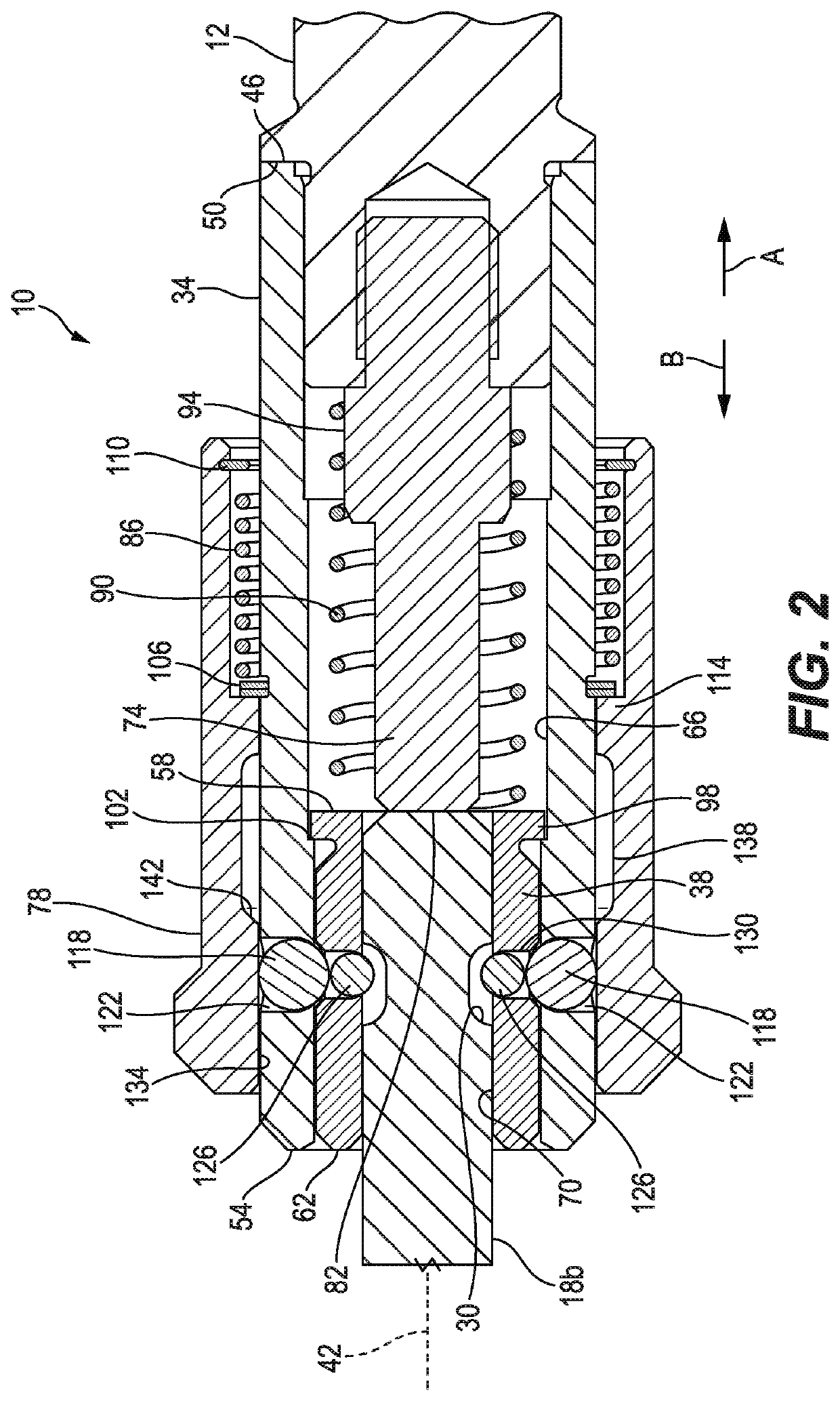

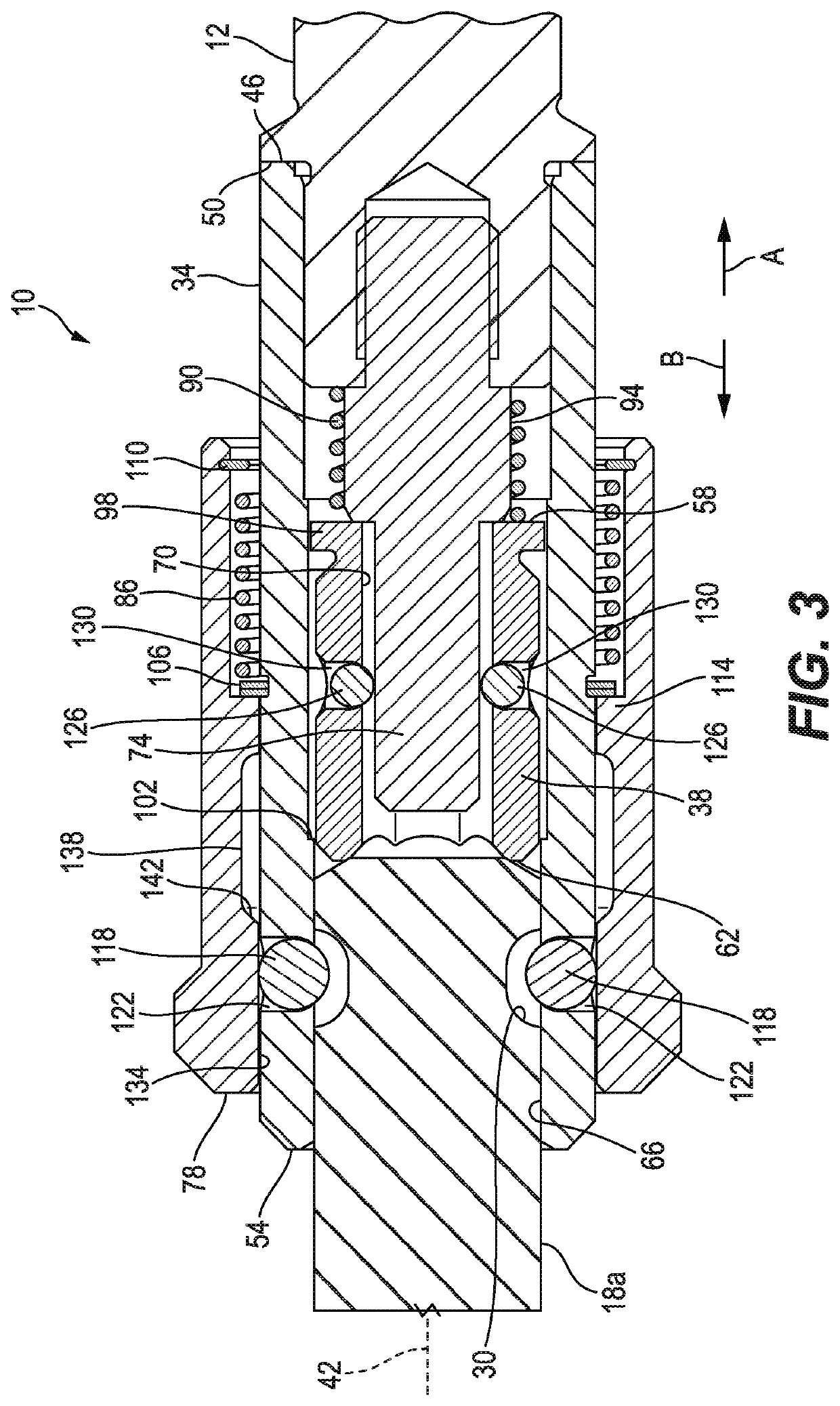

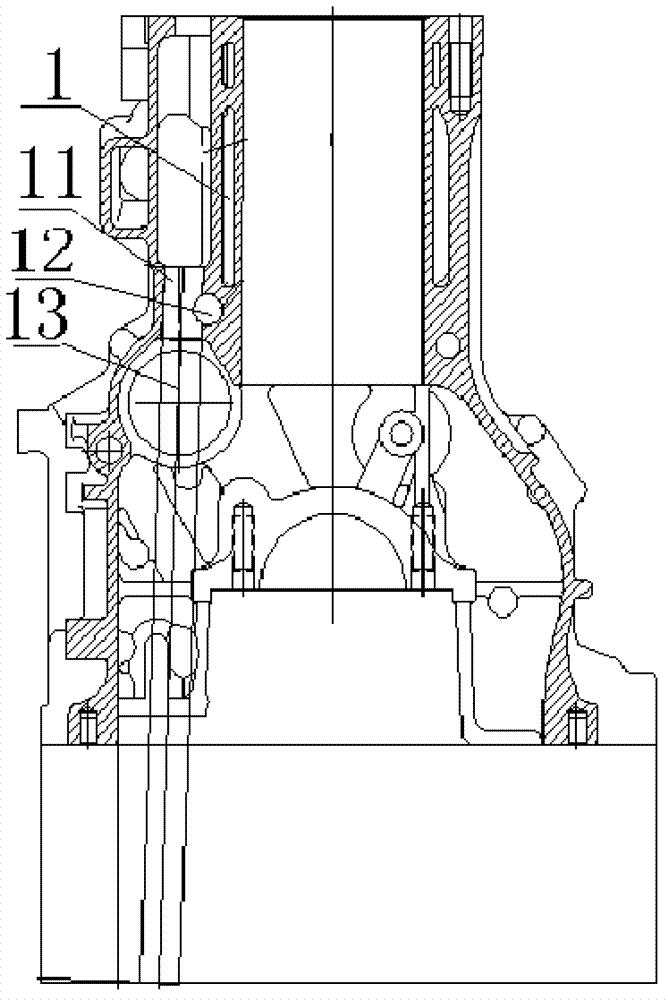

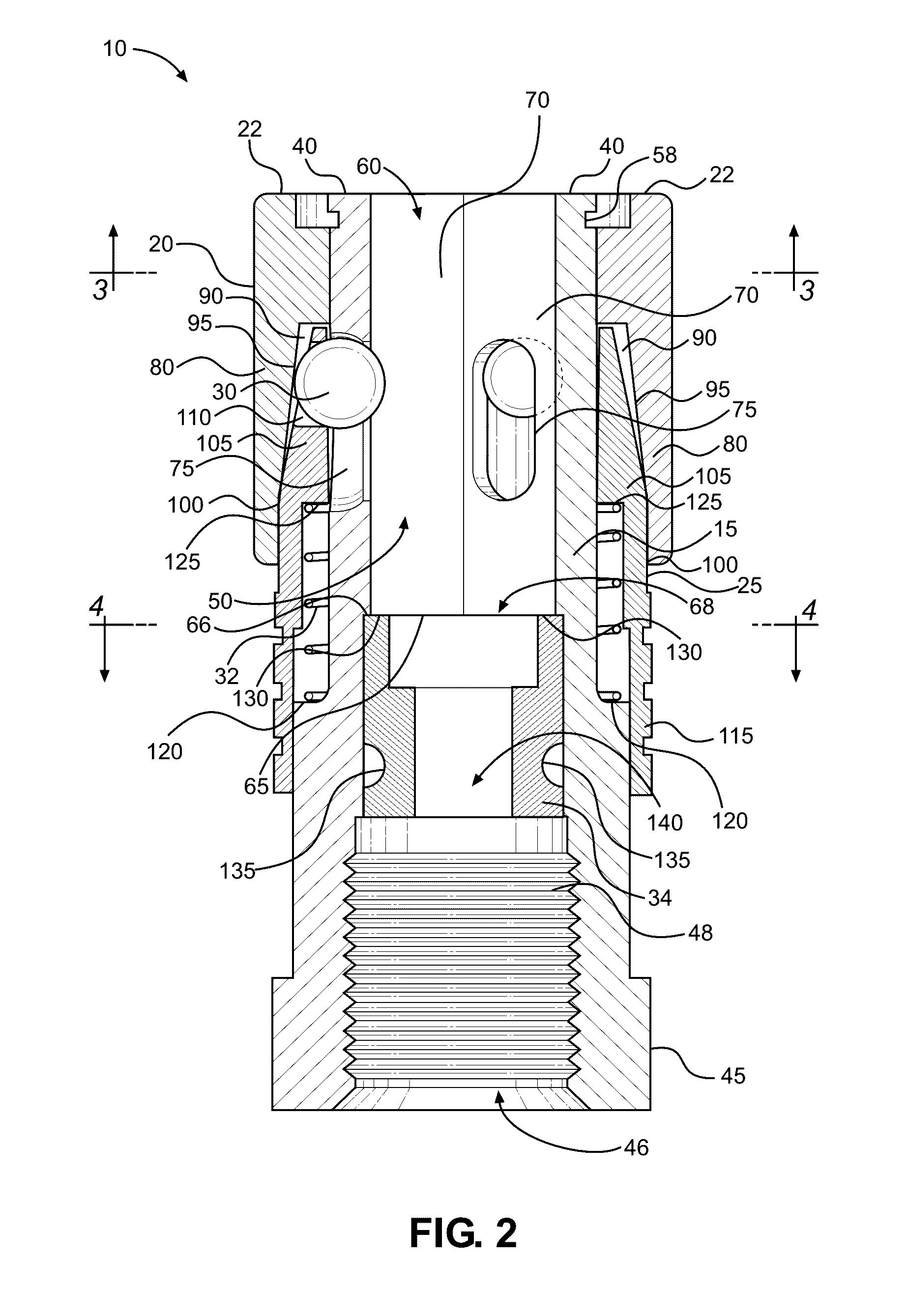

Pressurized fluid flow system for a normal circulation hammer and hammer thereof

ActiveUS20110209919A1Improve reliabilityHigh sturdinessDrill bitsBorehole drivesDrill bit shankReciprocating motion

A pressurized fluid flow system for a normal circulation down-the-hole hammer comprises a cylinder coaxially disposed in between an outer casing and a piston that reciprocates due to changes in pressure of the pressurized fluid contained inside of a front chamber and a rear chamber located at opposites sides of the piston, wherein the flow into and out of these chambers is controlled solely by the overlap or relative position of the piston and the cylinder as a supply chamber and a discharge chamber defined by recesses on the inner surface of the outer casing and separated by a dividing wall control the flow of pressurized fluid in and out of the front and rear chambers the. A down-the-hole normal circulation hammer with this system comprises a drill bit with one or more flushing passages that extend from channels cooperatively formed between splines on the inner surface of the driver sub and splines on the outer surface of the drill bit shank, to the front face of the drill bit for discharging the pressurized fluid out of the hammer.

Owner:DRILLCO TOOLS

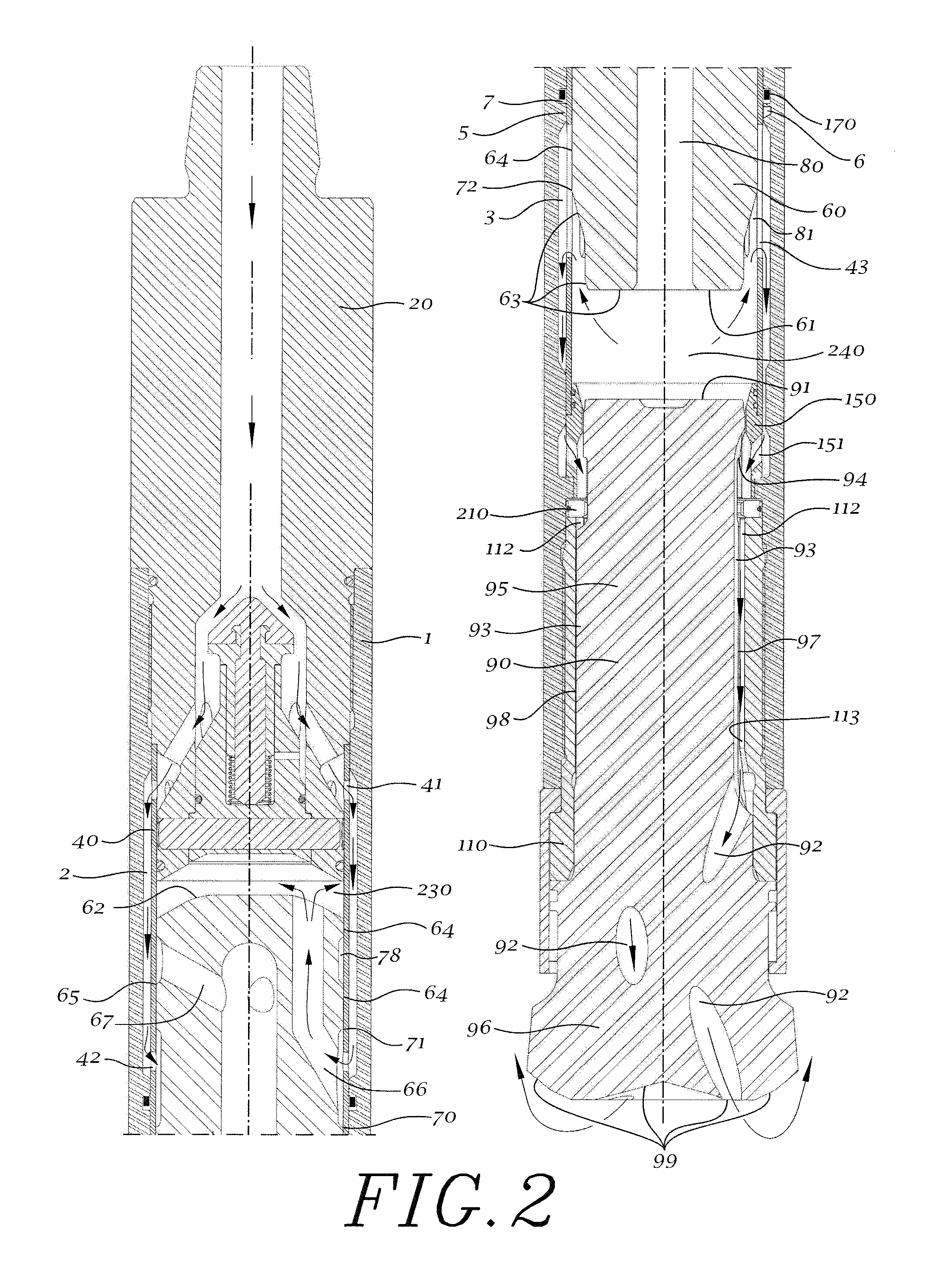

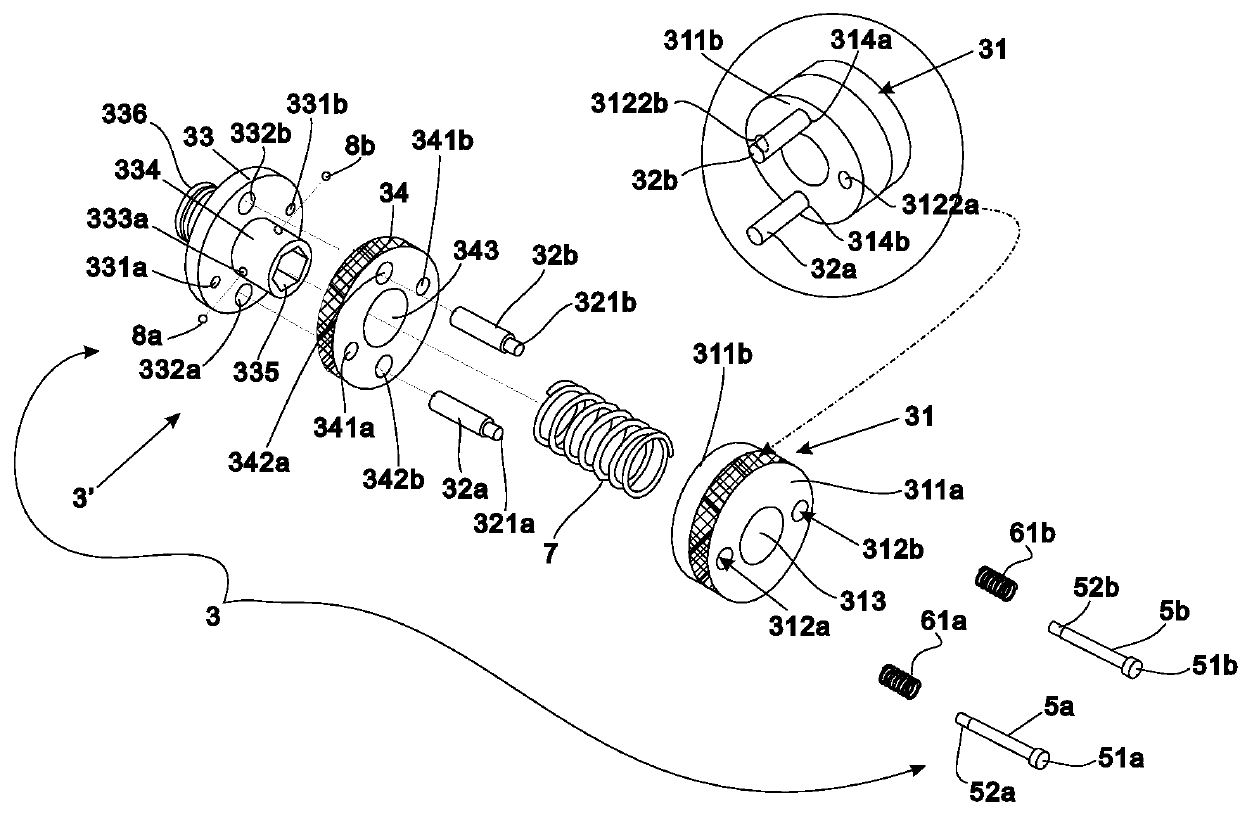

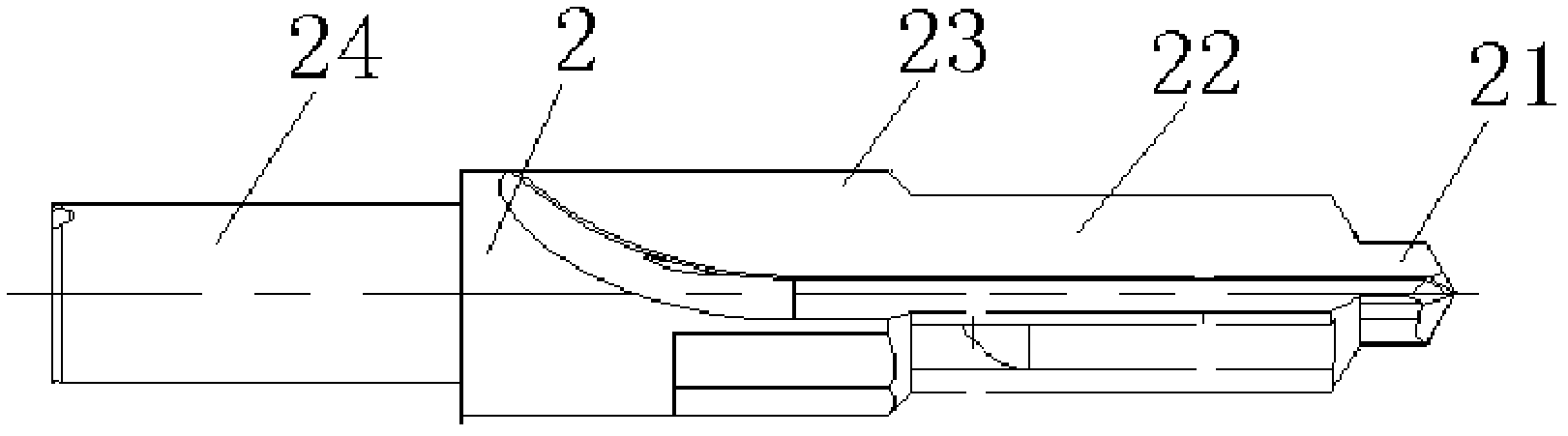

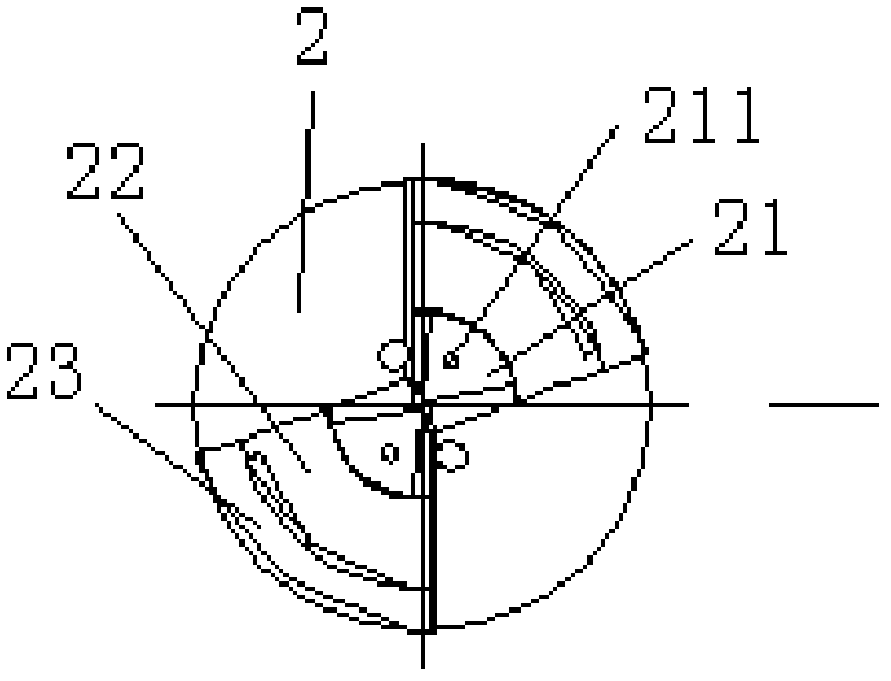

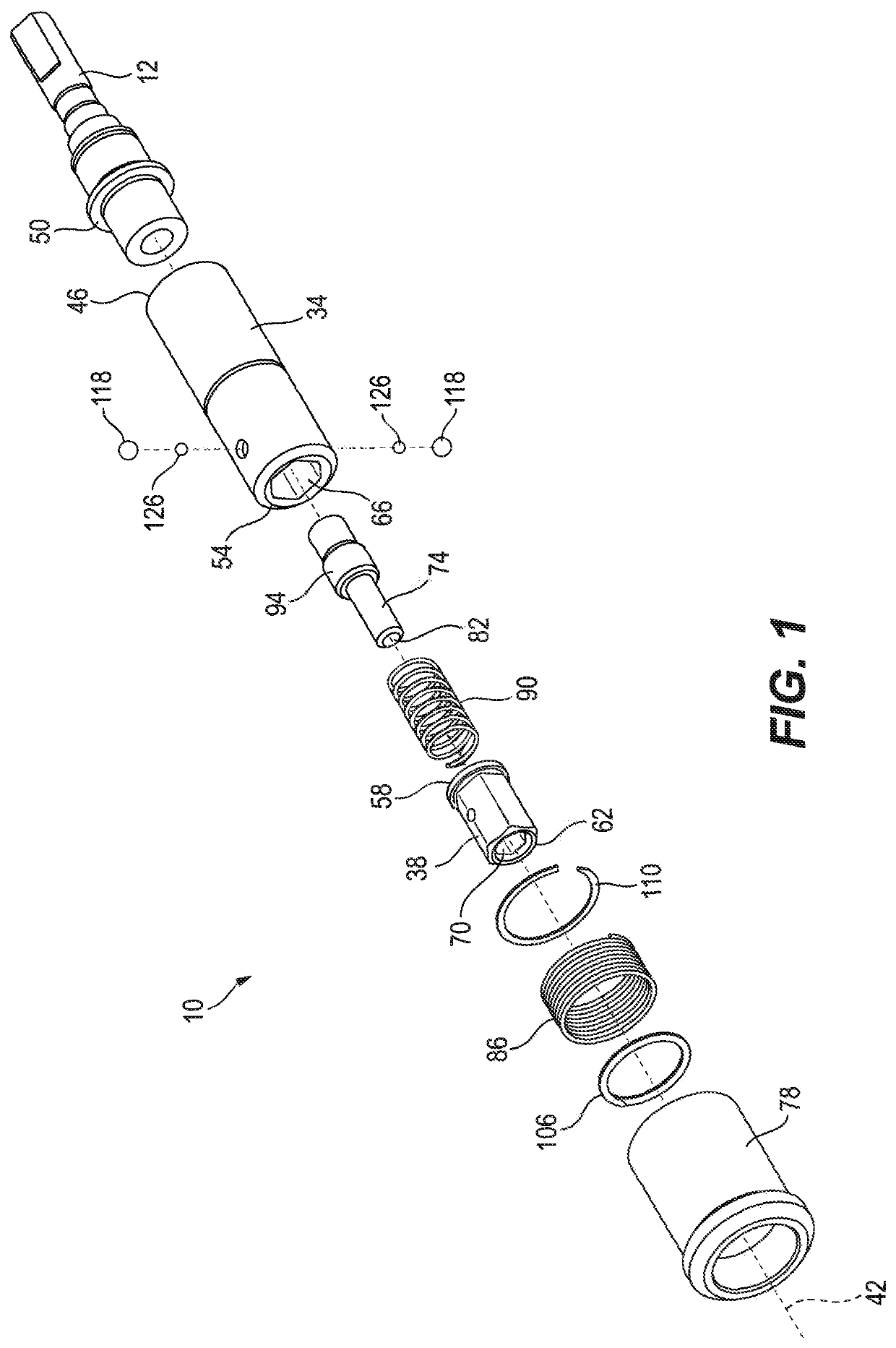

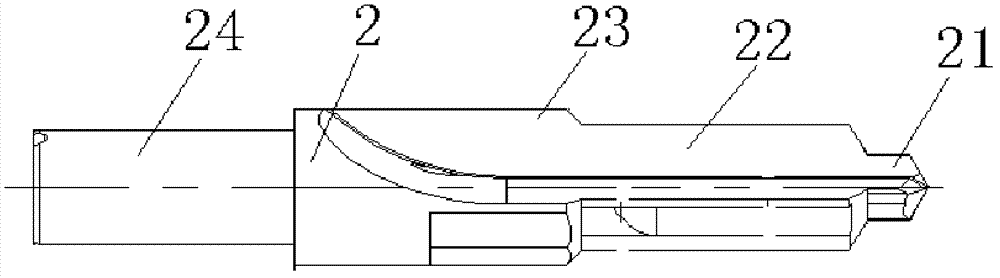

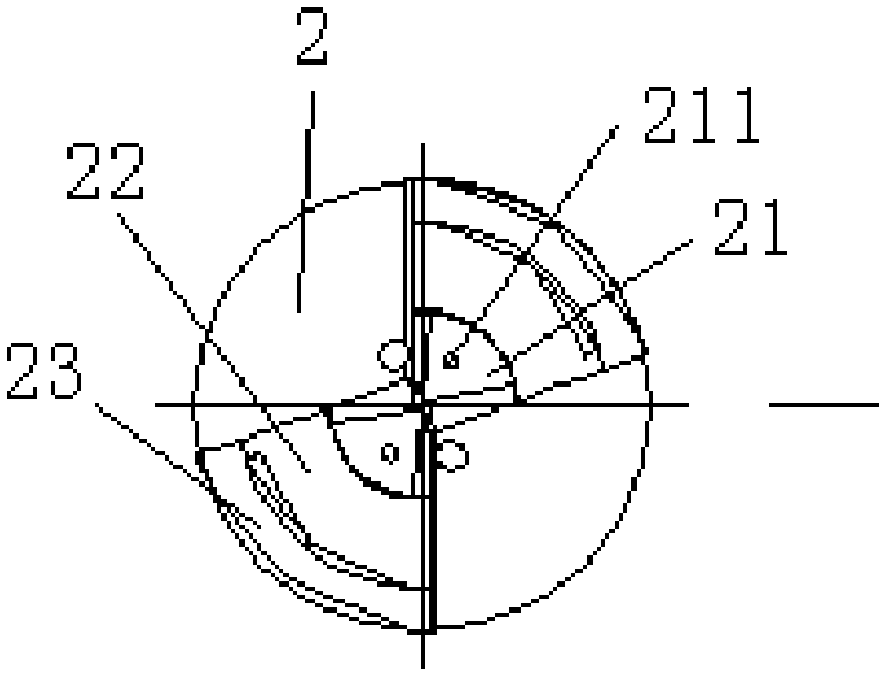

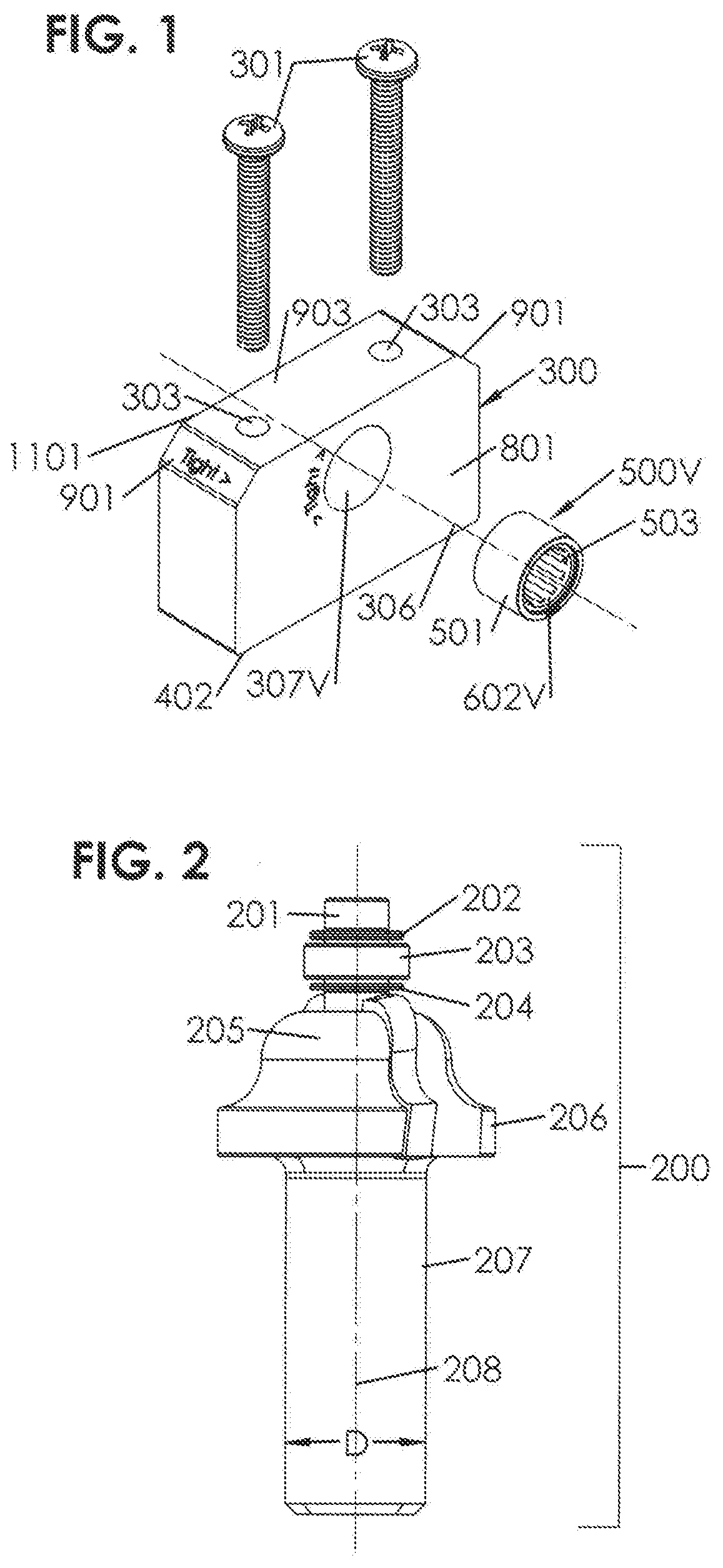

Quick-change attachment configuration for a hole saw

ActiveUS9248513B2Reduce forceReduce construction difficultyTransportation and packagingChucksDrill bit shankHole saw

A quick-change attachment configuration is directed to a tool for use with a hole saw for boring holes on a wooden plank, particularly the quick-change attachment configuration is arranged for quickly replacing a longitudinal body, which is a drill bit shank having a driving end, a tool end, and a limiting portion. The configuration includes a quick-change attachment for assembling a longitudinal body and a hole saw which has an axial hole for allowing a longitudinal body to move on the quick-change attachment, and a locking component for locking and releasing the longitudinal body on and from the quick-change attachment. The locking component has a first component and a second component, which when used, the longitudinal body is easily moved slidably and locked so the shreddings emerging from the hole saw are cleaned.

Owner:ROTE MATE IND

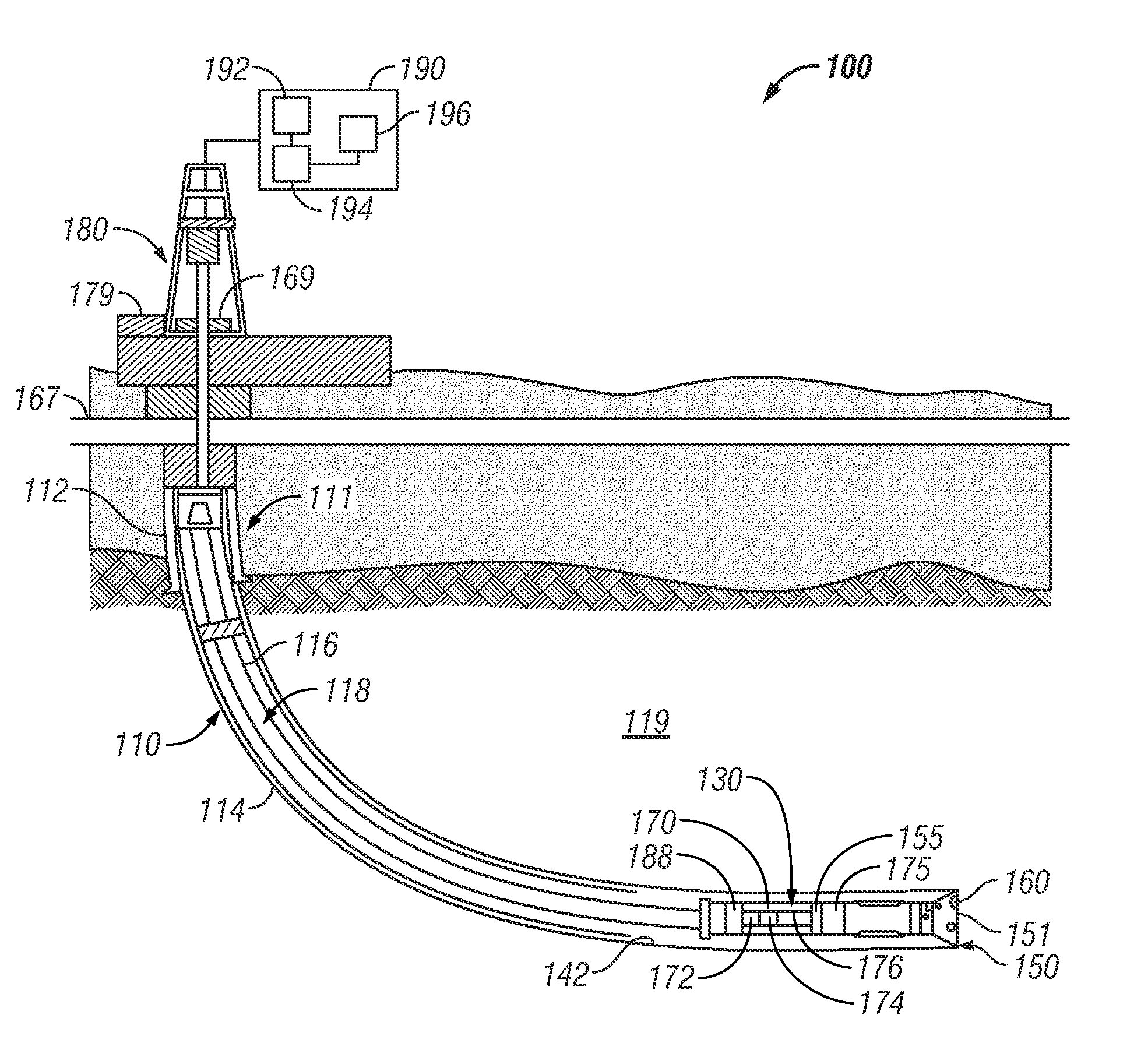

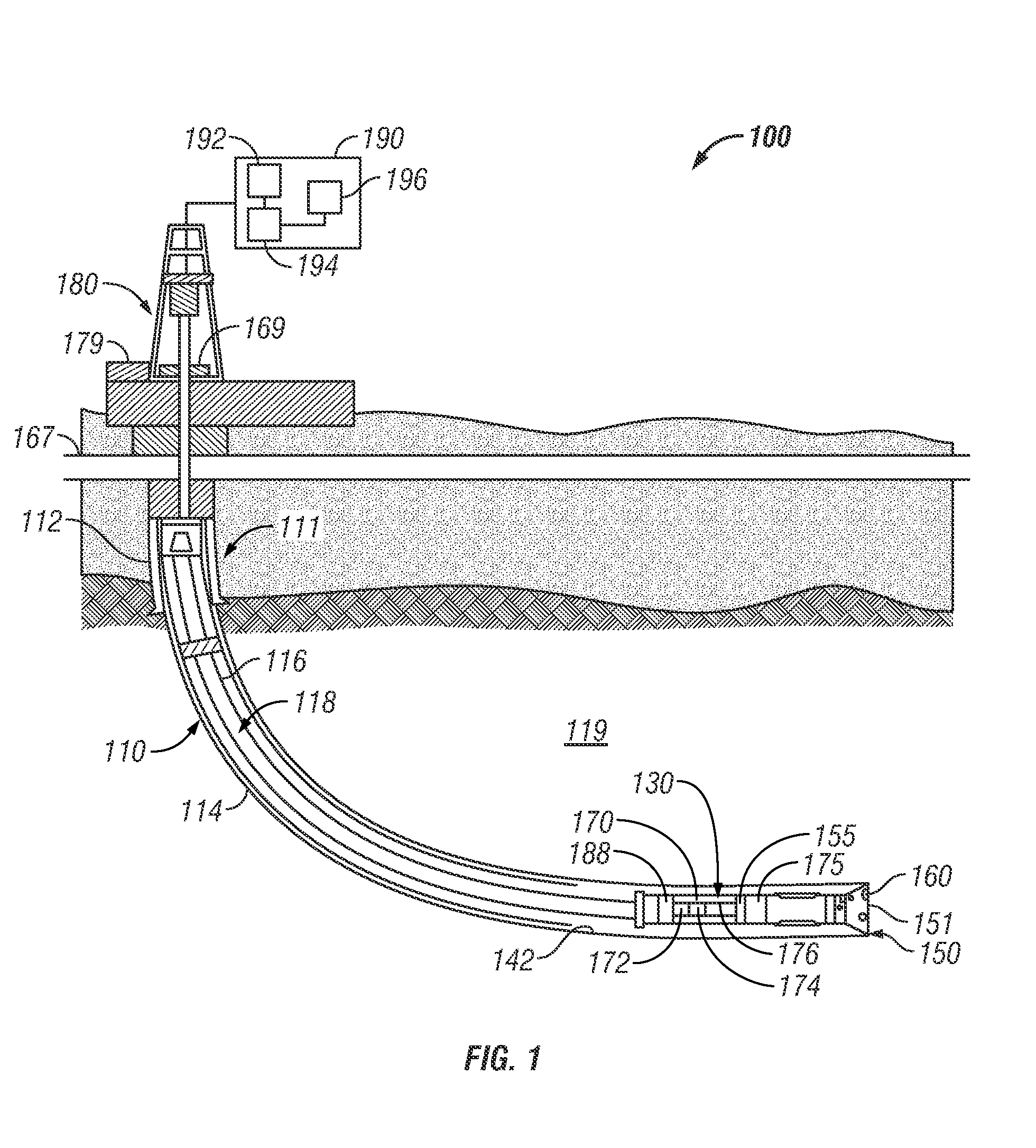

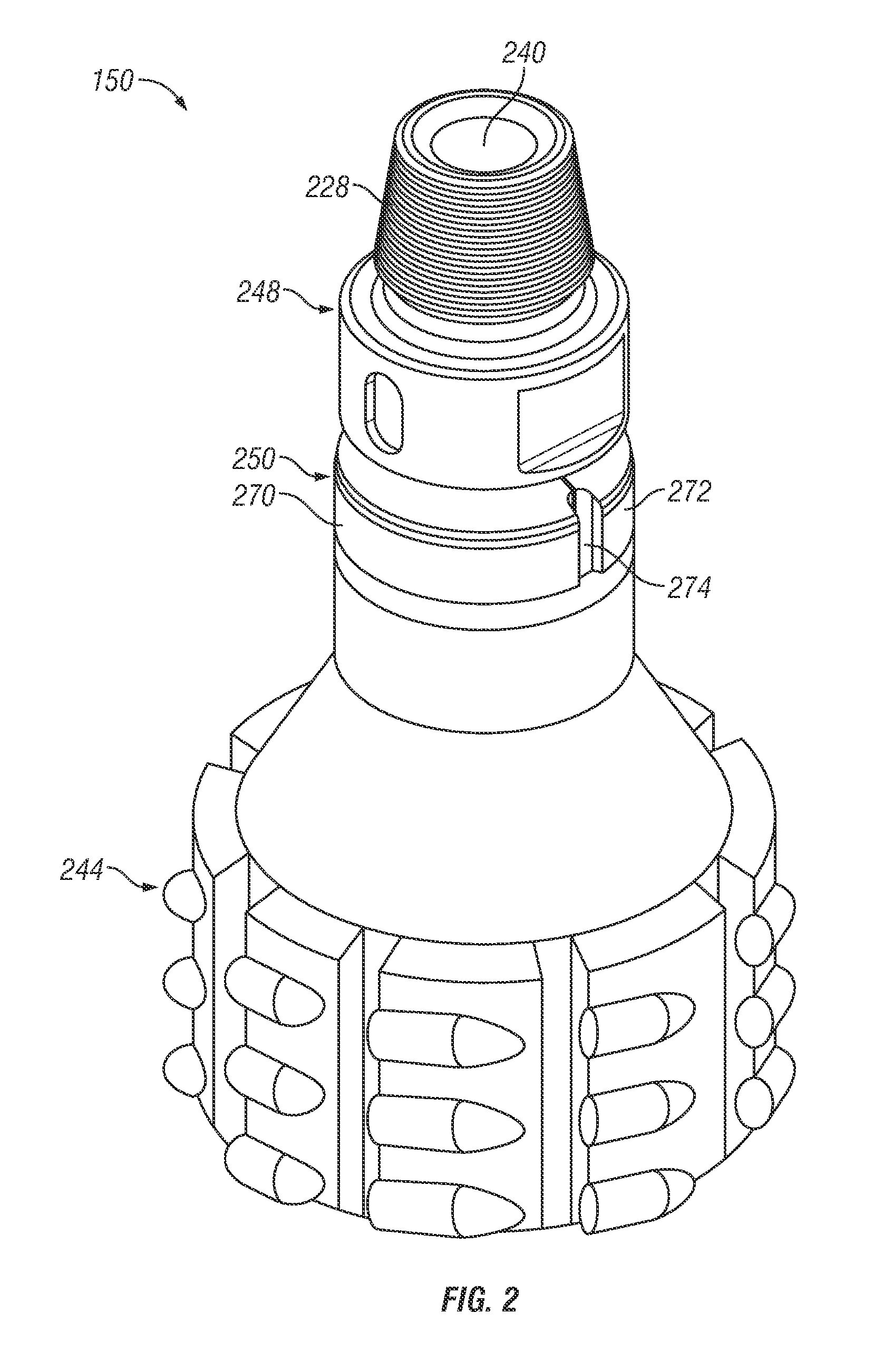

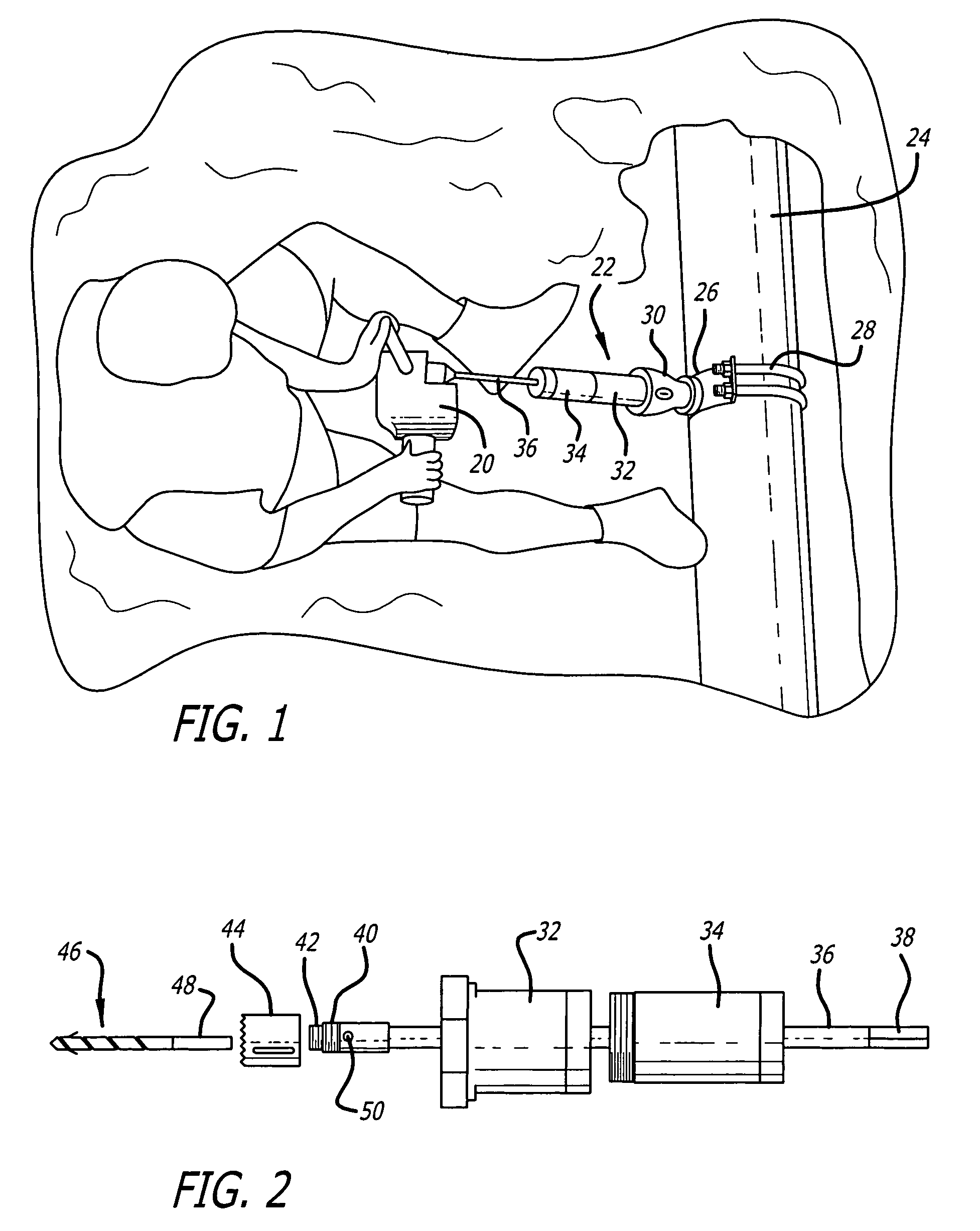

Method and Apparatus to Adjust Weight-On-Bit/Torque-On-Bit Sensor Bias

Apparatuses and methods for adjusting weight-on-bit / torque-on-bit sensor bias in a drill bit. The apparatus may include a bit adjustment device disposed at least partially in a cavity in a bit shank. The bit adjustment device includes electronics and sensors for estimating a weight-on-bit / torque-on-bit bias. The method includes adjusting the weight-on-bit / torque-on-bit sensor bias of a drill bit. The method may include adjusting force on a bit adjustment device to adjust weight-on-bit / torque-on-bit sensor bias. The method may also include securing the bit adjustment device within the cavity of the bit shank after the desired weight-on-bit / torque-on-bit sensor bias has been achieved.

Owner:BAKER HUGHES INC

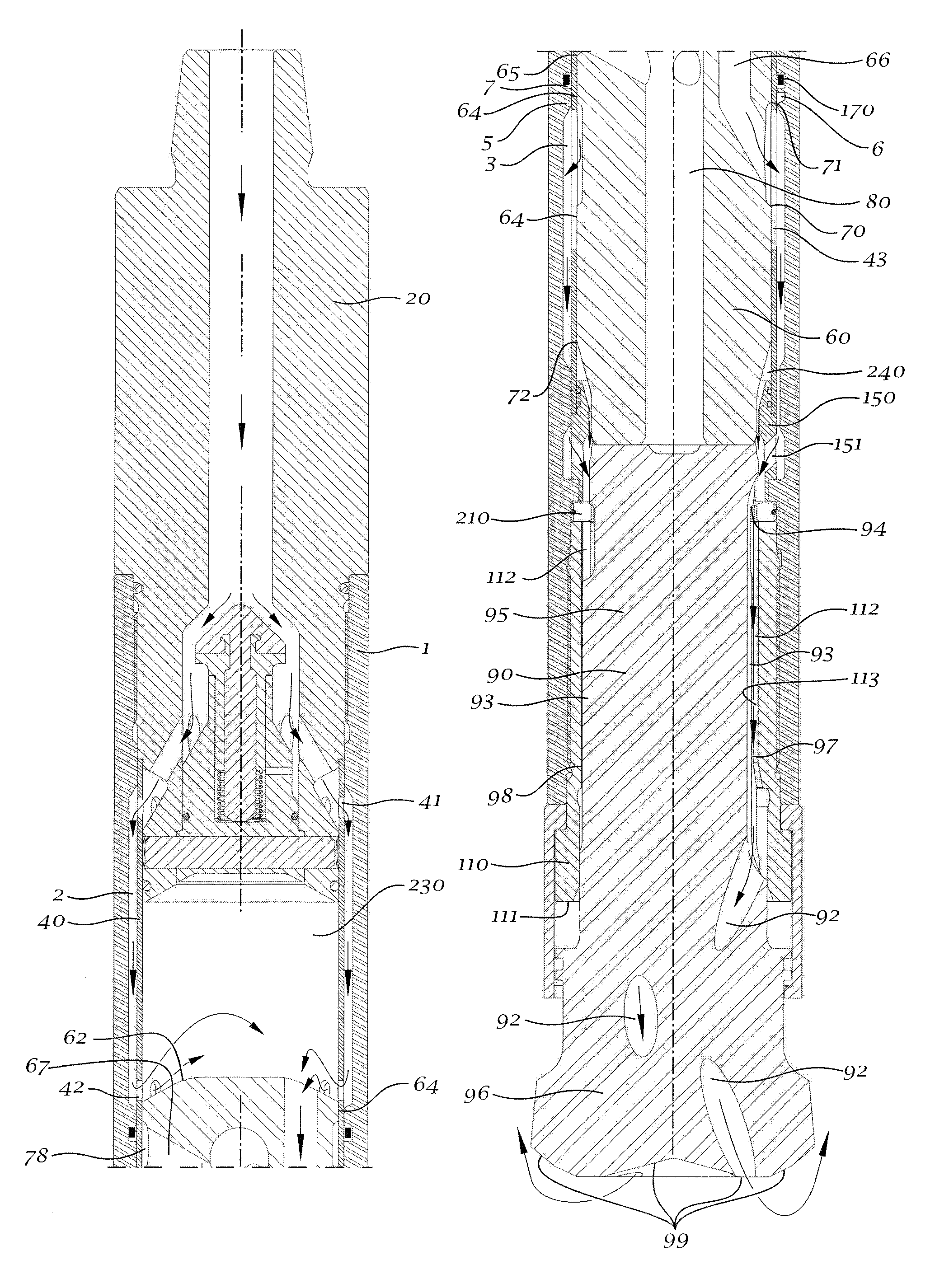

Pressurized fluid flow system for a normal circulation hammer and hammer thereof

ActiveUS8640794B2Increase powerImprove efficiencyDrill bitsBorehole drivesDrill bit shankReciprocating motion

A pressurized fluid flow system for a normal circulation down-the-hole hammer comprises a cylinder coaxially disposed in between an outer casing and a piston which reciprocates due to changes in pressure of pressurized fluid contained inside a front chamber and rear chamber located at opposites sides of the piston, supply / discharge of fluid to / from these chambers being conducted through a supply chamber and a discharge chamber defined by recesses on the inner surface of the casing and separated by a dividing wall, the front / rear chambers' in / out fluid flow being controlled solely by the overlap of the piston and the cylinder. A hammer having this system comprises a drill bit with one or more flushing passages which extend from channels cooperatively formed between splines on the inner surface of the driver sub and on the outer surface of the drill bit shank up to the front face of the drill bit.

Owner:DRILLCO TOOLS

Rotary drill bit shank, rotary drill bits so equipped, and methods of manufacture

A shank configuration for rotary drill bits is disclosed for positioning of the shank in relation to the bit body. A tapered surface or feature of the shank may be configured and sized to matingly engage a complementarily shaped surface or feature of the drill bit body and thereby become centered or positioned in relation thereto. A deformable element may be disposed between the shank and bit body. Also, the shank may comprise a material having a carbon equivalent of less than about 0.35%. A multi-pass weld procedure may be employed to affix the shank and bit body to one another wherein welds may be formed so that one weld originates at a circumferential position that differs from the origination circumferential position of its immediately preceding weld by at least about 90°. Further, a stress state may be developed within the multi-pass weld. A method of manufacture is also disclosed.

Owner:BAKER HUGHES INC

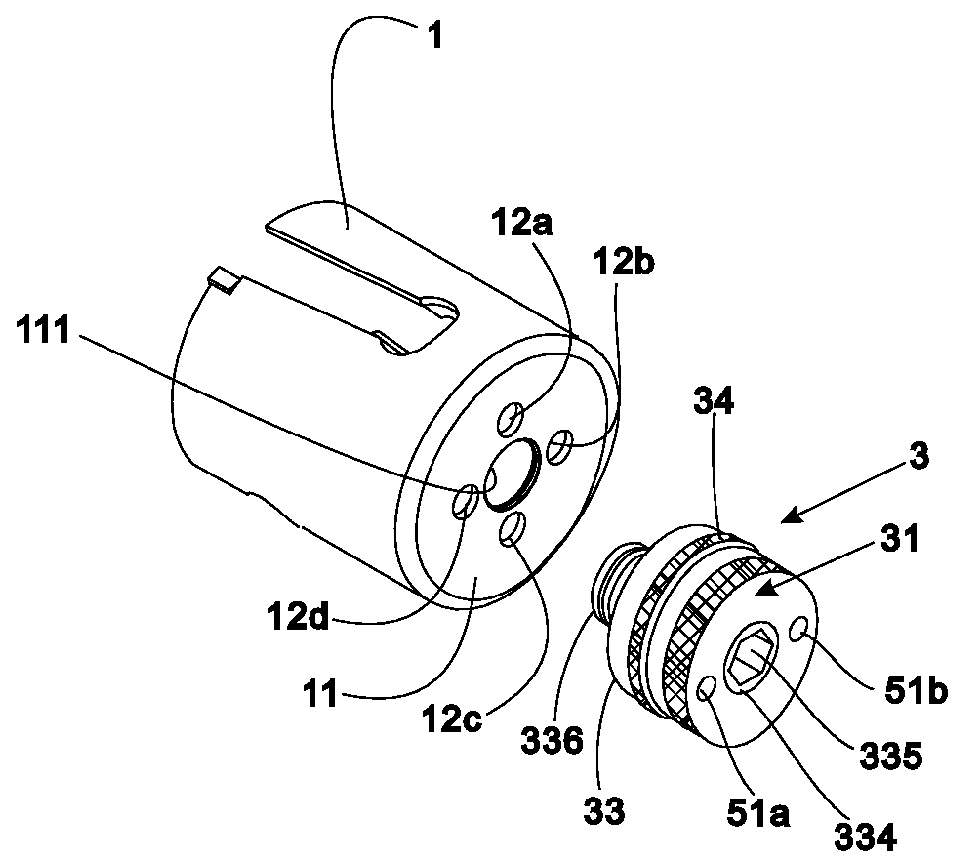

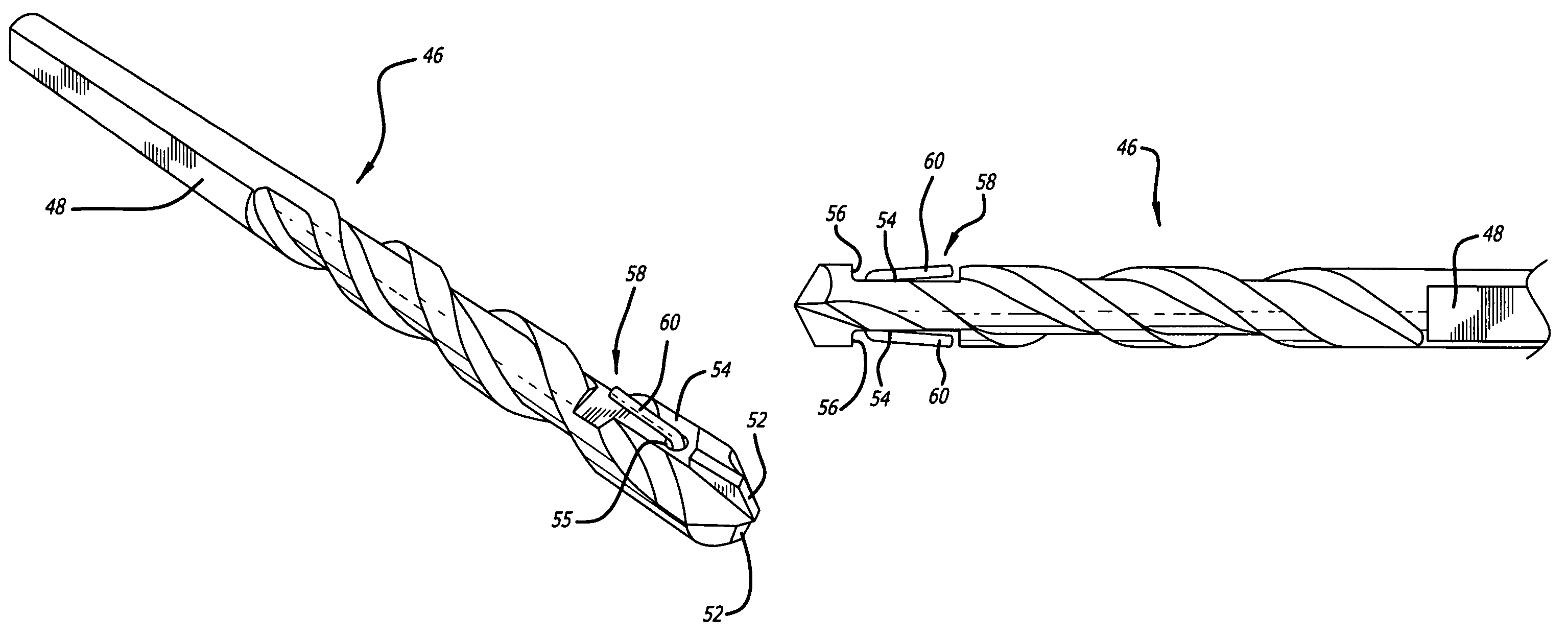

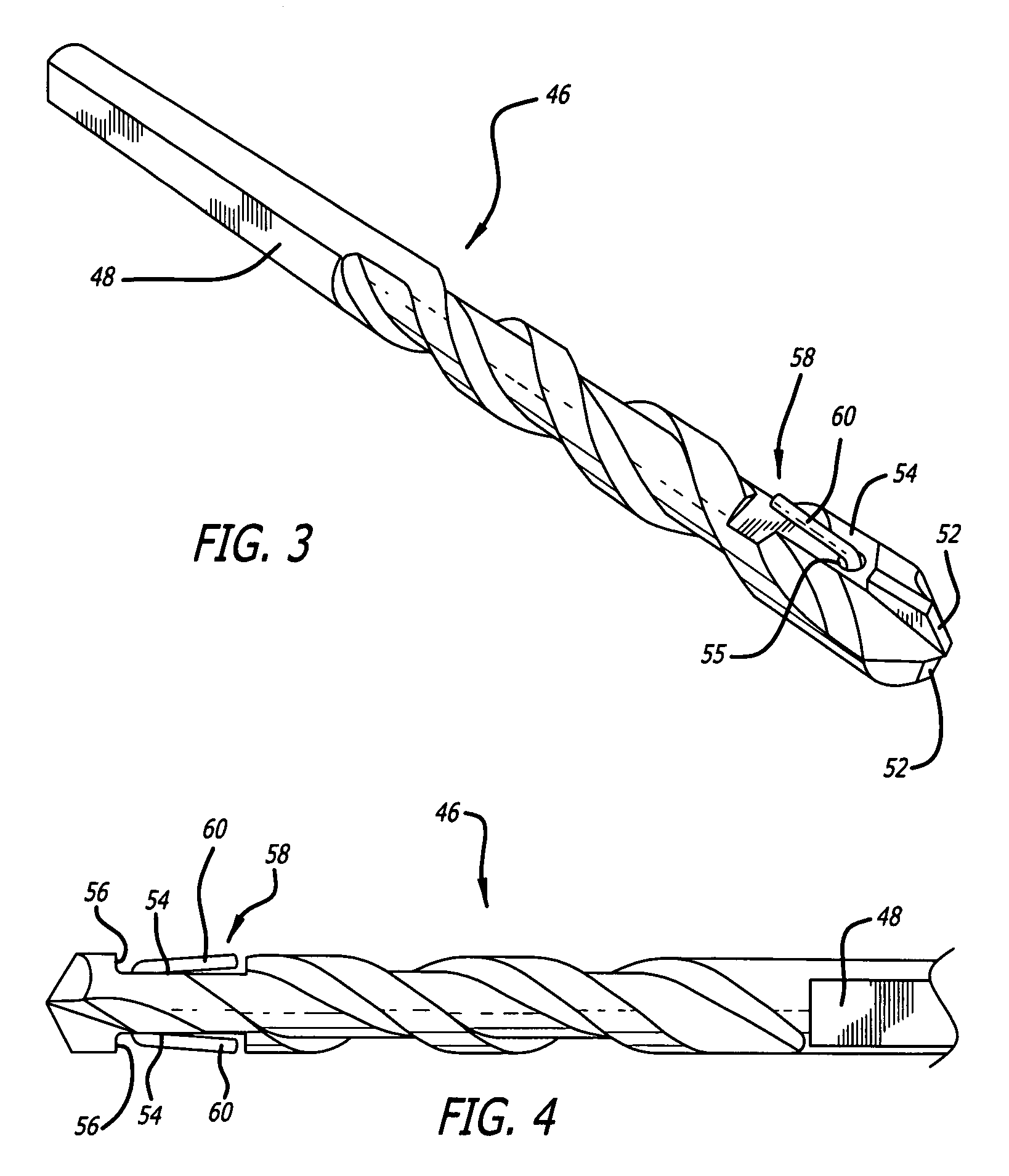

Pilot drill with coupon retainer and hot tapping machine using the same

Pilot drill with coupon retainer and hot tapping machine using the same that positively retains a coupon cut out by a hole saw. The pilot drill bit has a shank having a driving end for attachment to a drill driver and a cutting end having a cutting edge thereon, the cutting edge being sized to drill a hole of selected diameter through a workpiece, and a movable retaining finger mounted on the shank adjacent the cutting edge, the movable retaining finger having a first position fitting within the cutting diameter of the cutting edge and a second, extended position where a portion thereof lies outside the cutting diameter to retain on the drill shank a workpiece through which the drill bit may have drilled.

Owner:YAMSMOS & COMPANY

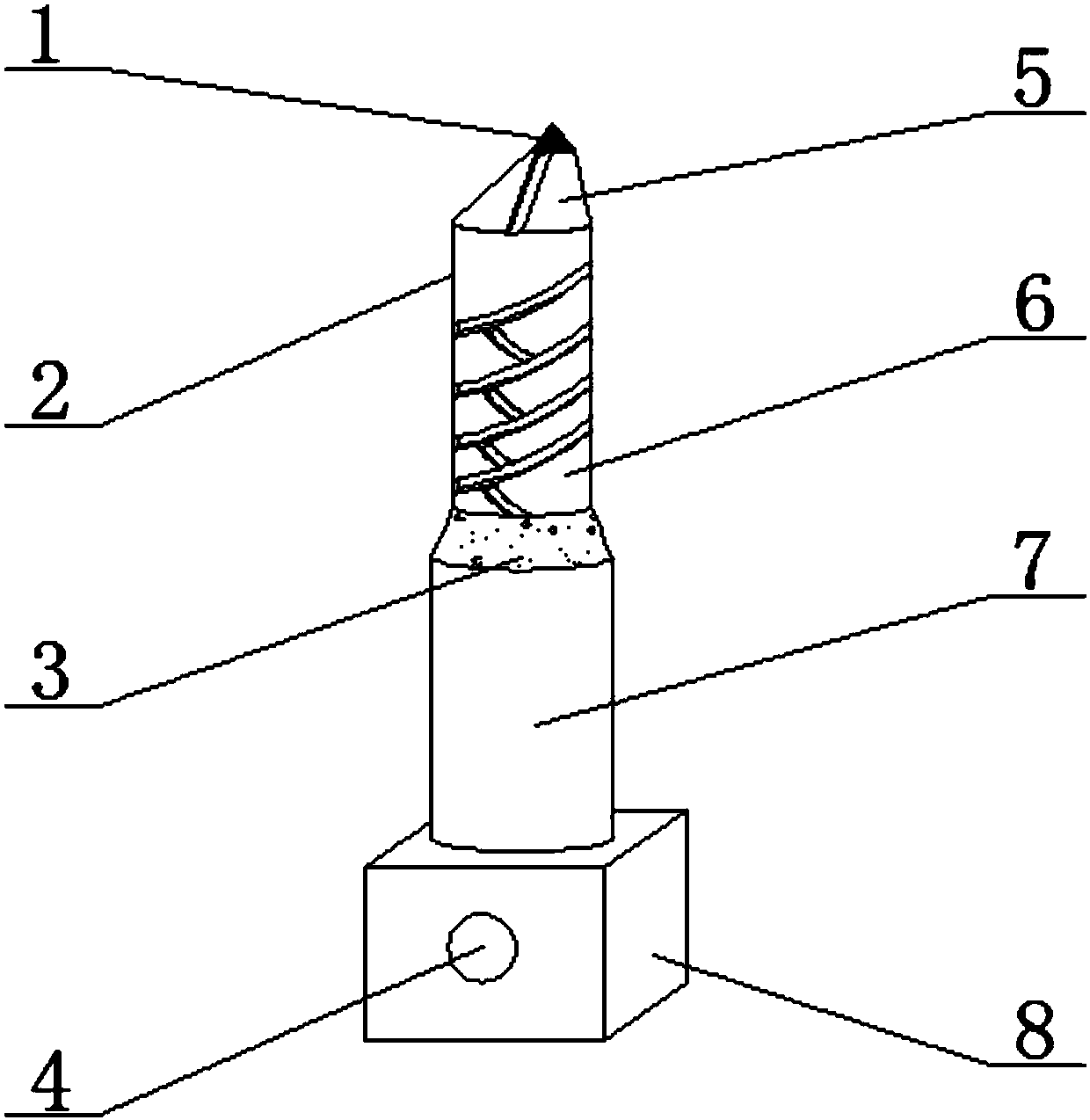

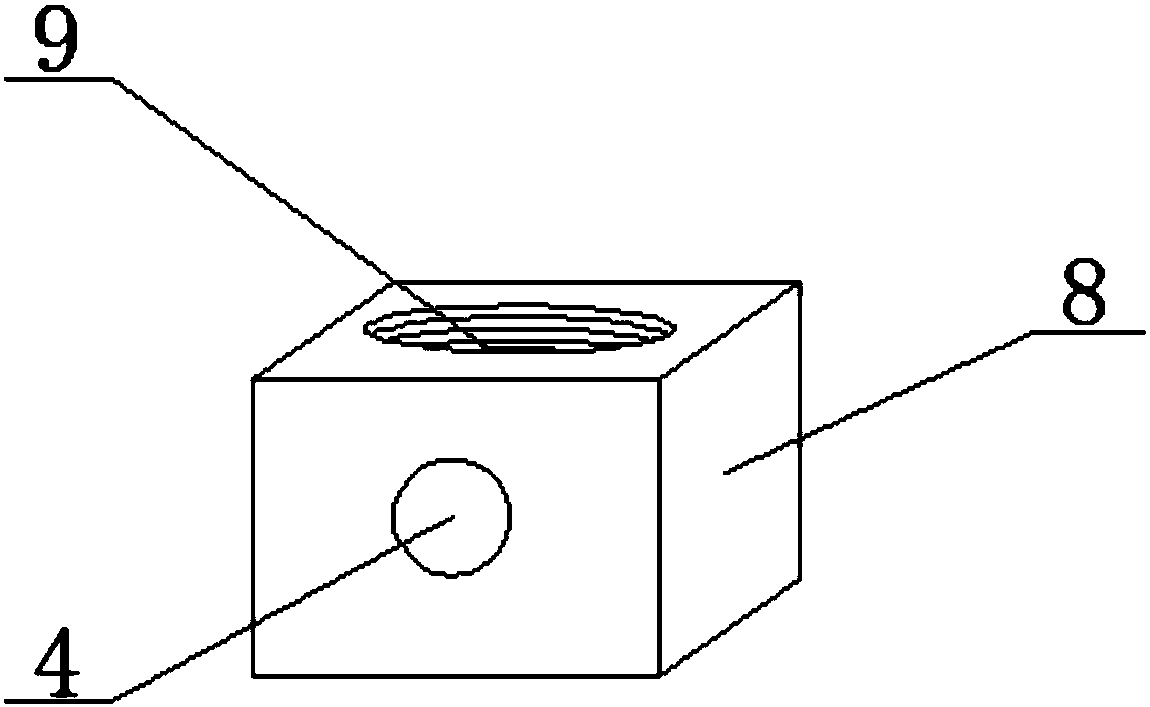

Method of V-shaped welding of solid carbide drill and solid carbide drill thereof

ActiveCN102814532AReduce material costsLow priceTransportation and packagingWorkpiece edge portionsDrill bit shankSocial benefits

Owner:江苏信达克工具技术有限公司

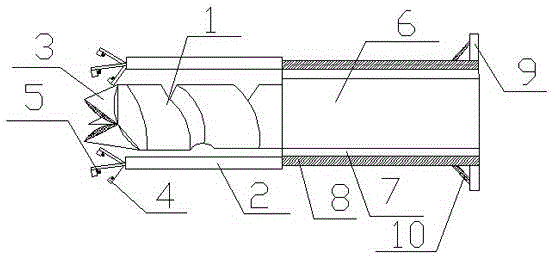

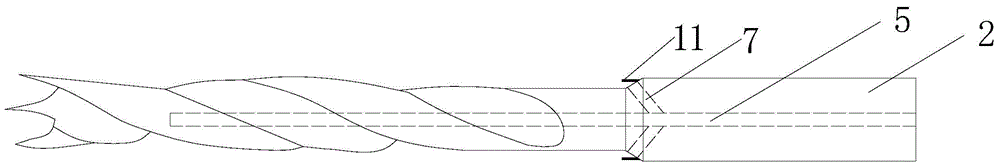

Micro-textured BTA deep-hole drill bit and preparation process thereof

PendingCN109482930AExtended service lifeReduce contact areaTransportation and packagingBoring/drilling machinesDrill bit shankMicro texture

The invention relates to a micro-textured BTA deep-hole drill bit and a preparation process thereof. A cutter body is included, the surface of the cutter body is provided with a guide block, the fracture surface of the cutter body is provided with cutter teeth, the cutter teeth include internal teeth, center teeth and external teeth from top to bottom, all cutter teeth are staggered, and a certainoverlap amount is reserved; and a chip removal hole is formed in the middle of the cutter body, the other end of the cutter body comprises a drill bit shank, the outer portion of the drill bit shankis provided with threads, and a micro-texture is arranged on the front cutter surface of the cutter teeth. By means of the micro-textured BTA deep-hole drill bit and the preparation process, through the surface topography innovation of the micro-texture, the new micro-texture deep-hole drill bit with high durability is designed, and the purpose of reducing cutting heat is achieved by reducing friction and reducing cutter abrasion.

Owner:XI'AN PETROLEUM UNIVERSITY

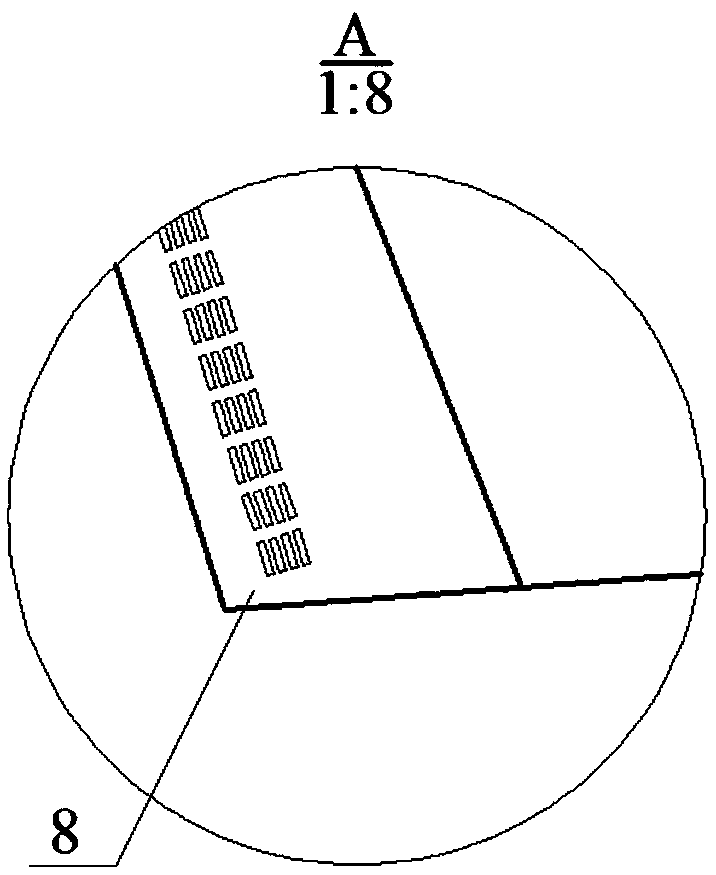

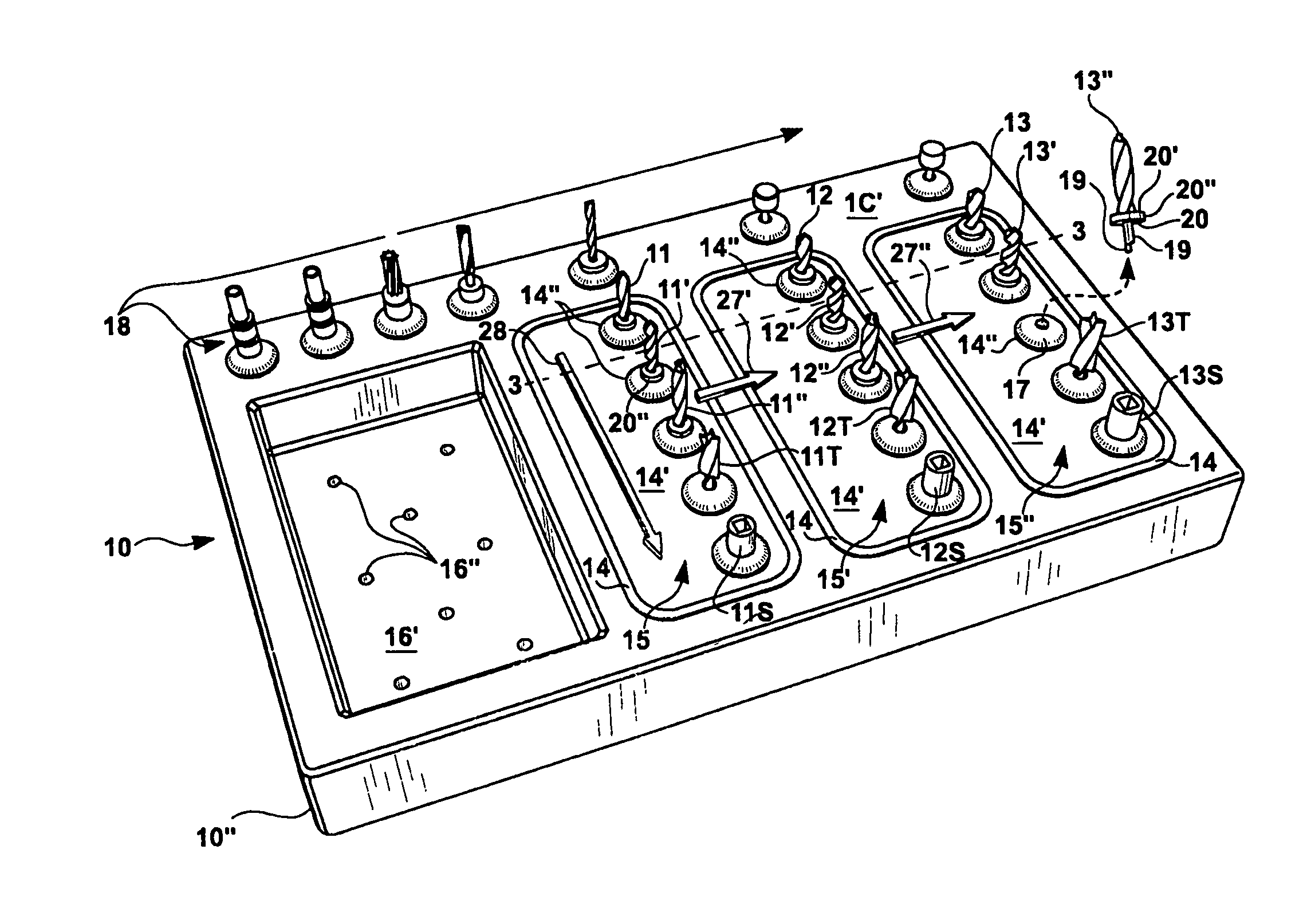

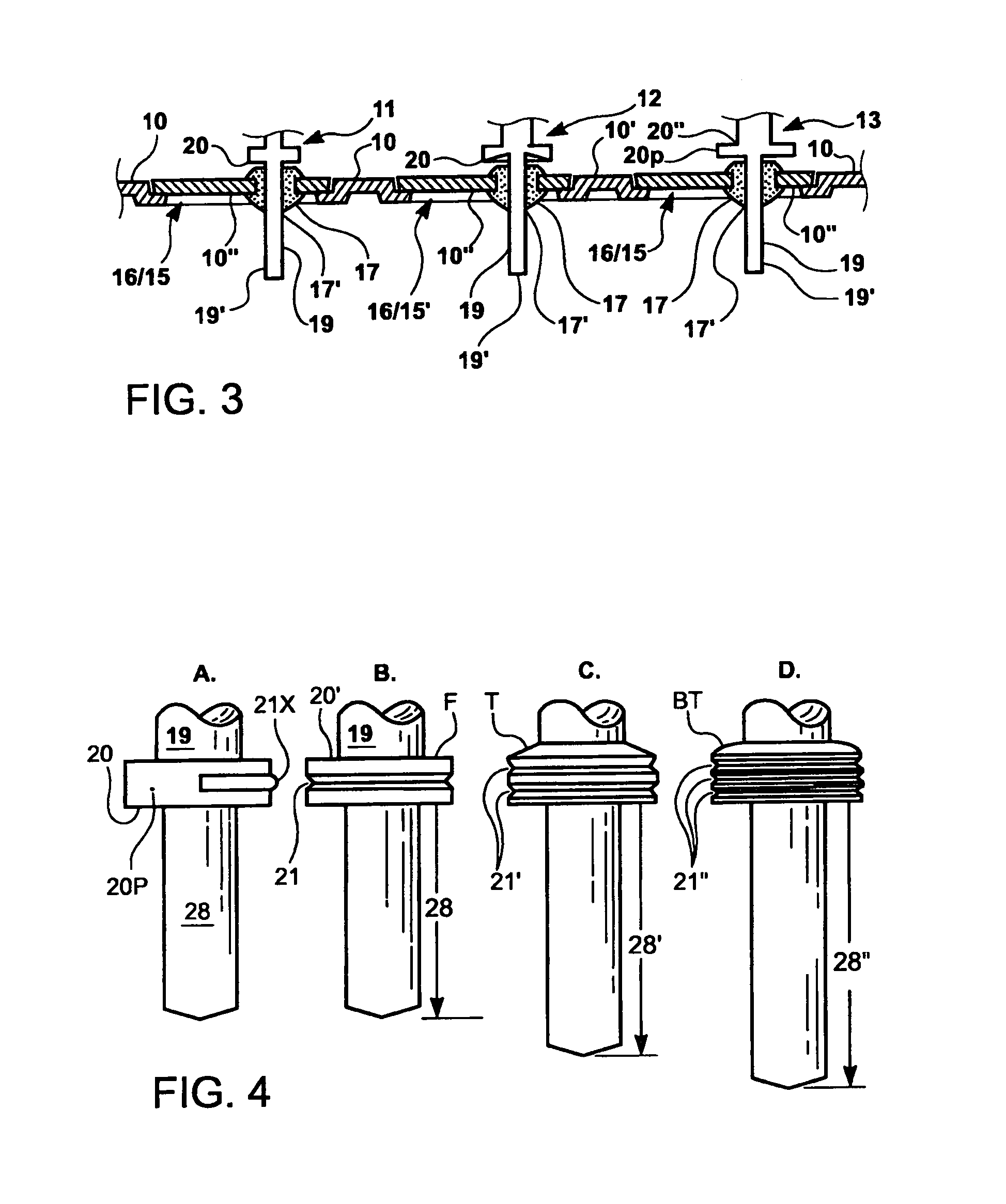

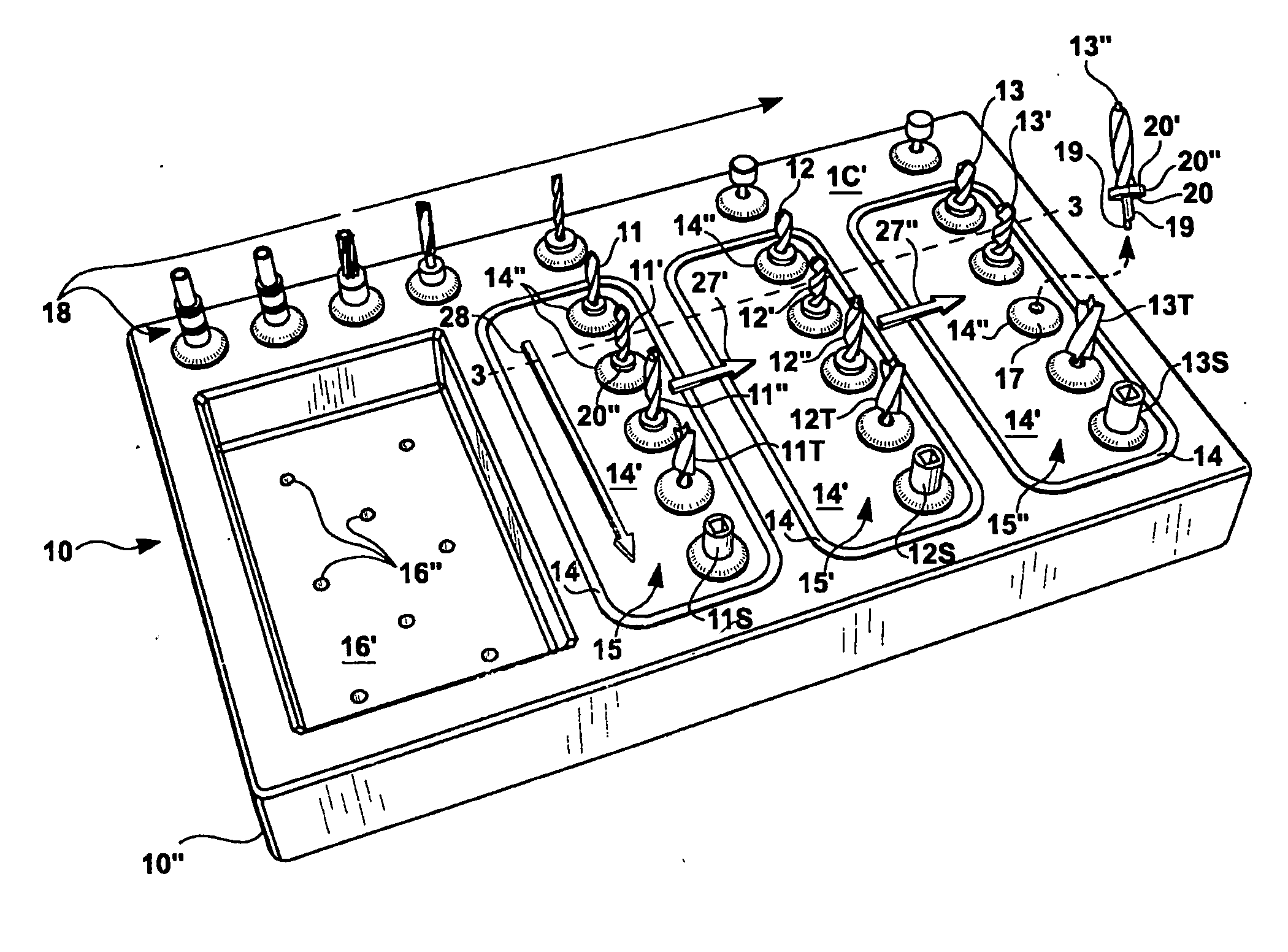

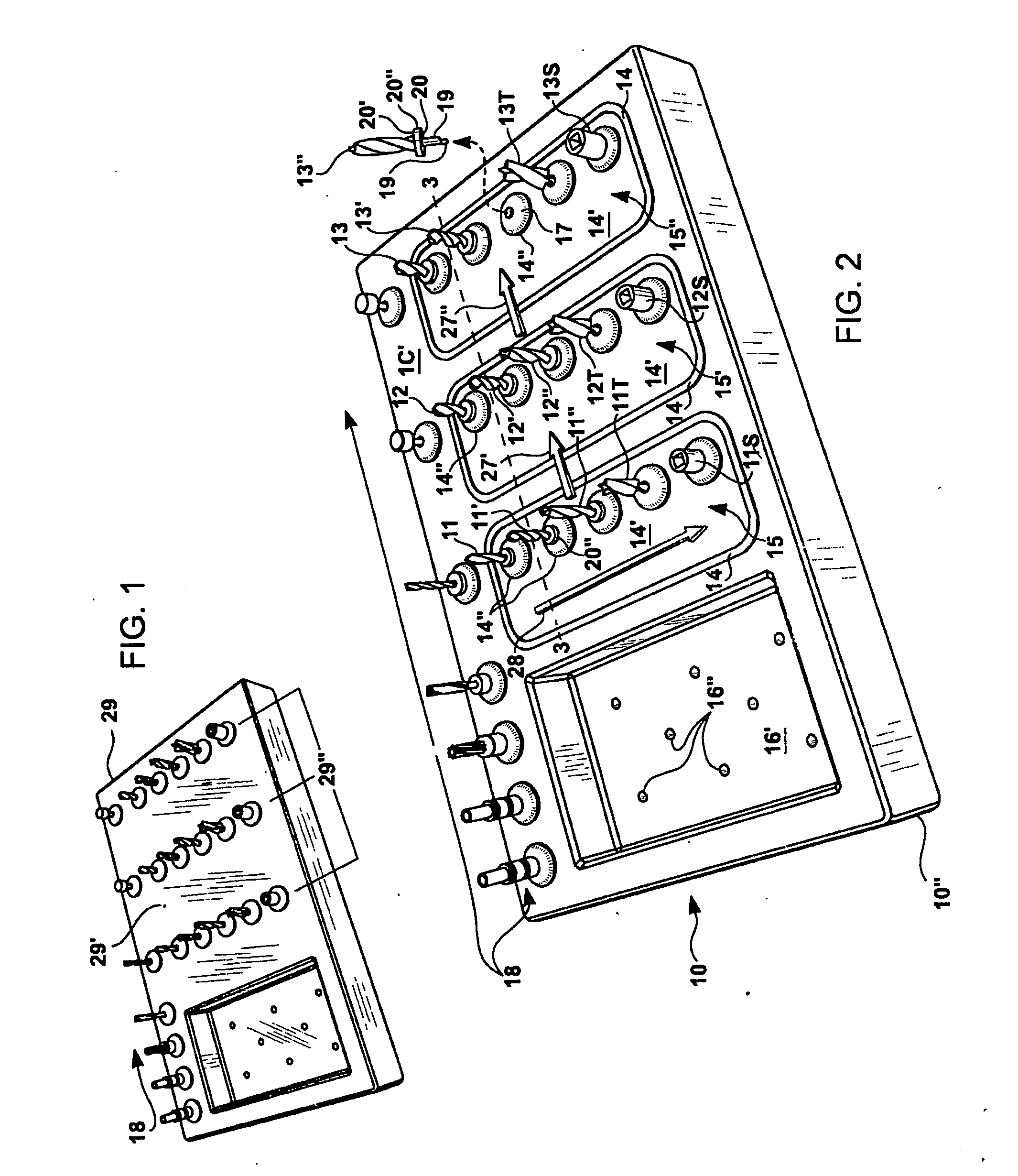

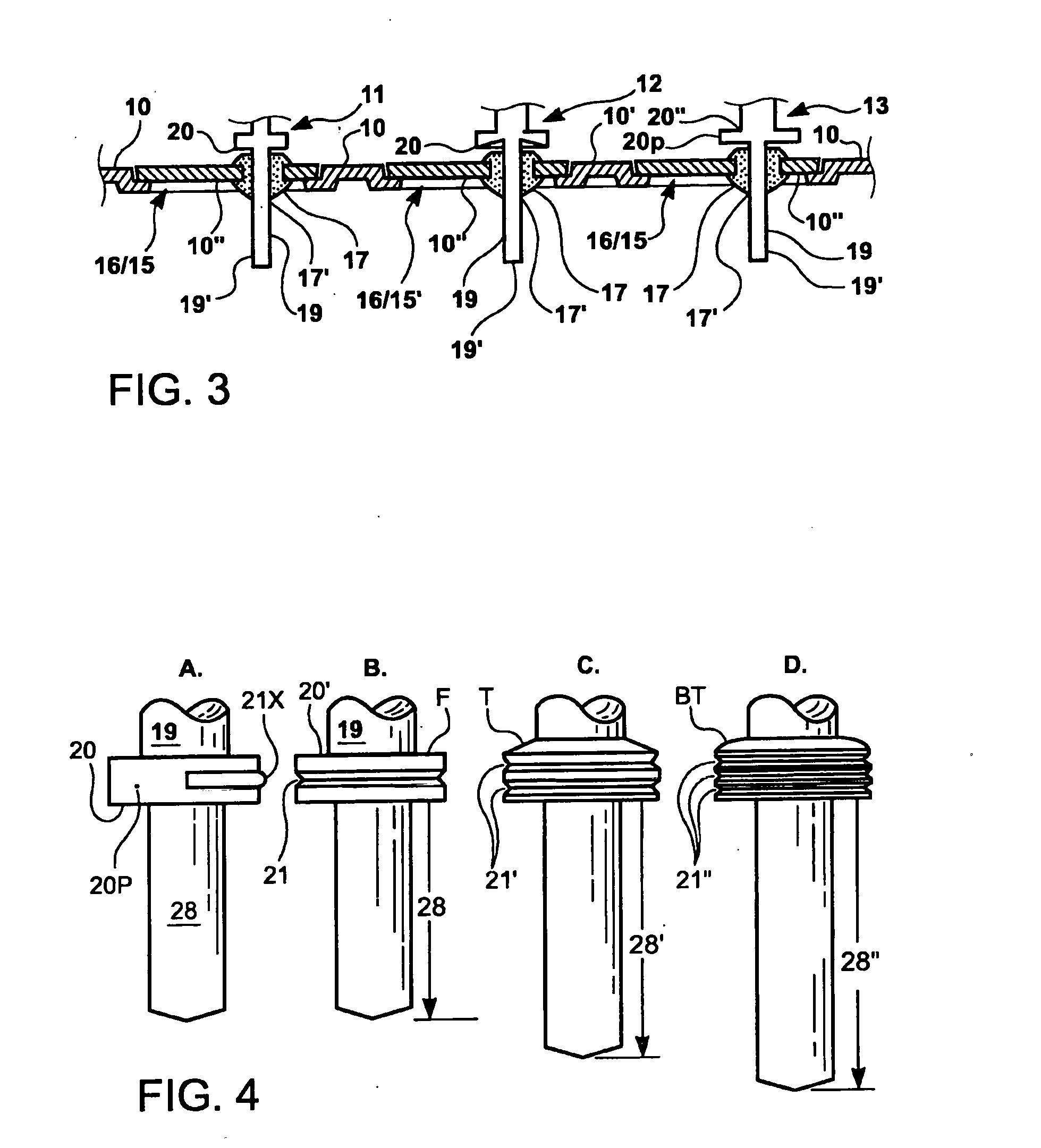

Color safeguarded dental-implant surgical-kit with drilling depth limiter

InactiveUS9414894B1Improves vital time- & -motion procedureAccelerated programDental implantsDiagnosticsDrill bit shankHand held

An apparatus is an implant-dentist more readily identifiable visual segregation amongst their oral-surgery arbor-tools used conjunction with a conventional hand-held power / rotary-tool. The arbor-tools generally has at least a tri-echeloned set, wherein are included progressions of drill-bit lengths and companion thread-taps appearing in three different diameters. Additionally, the drill-bit shanks are optionally provided with a radial-flange serving as an automatic depth-stop device and these radial-flanges may include a distinctive annular-marker device serving to readily indicate the length of the selected drill-bit, thereby obviating usual procedure of stopping to confirm via the obscure conventional alpha-numeric indicia.

Owner:MANSUETO ROBERT F

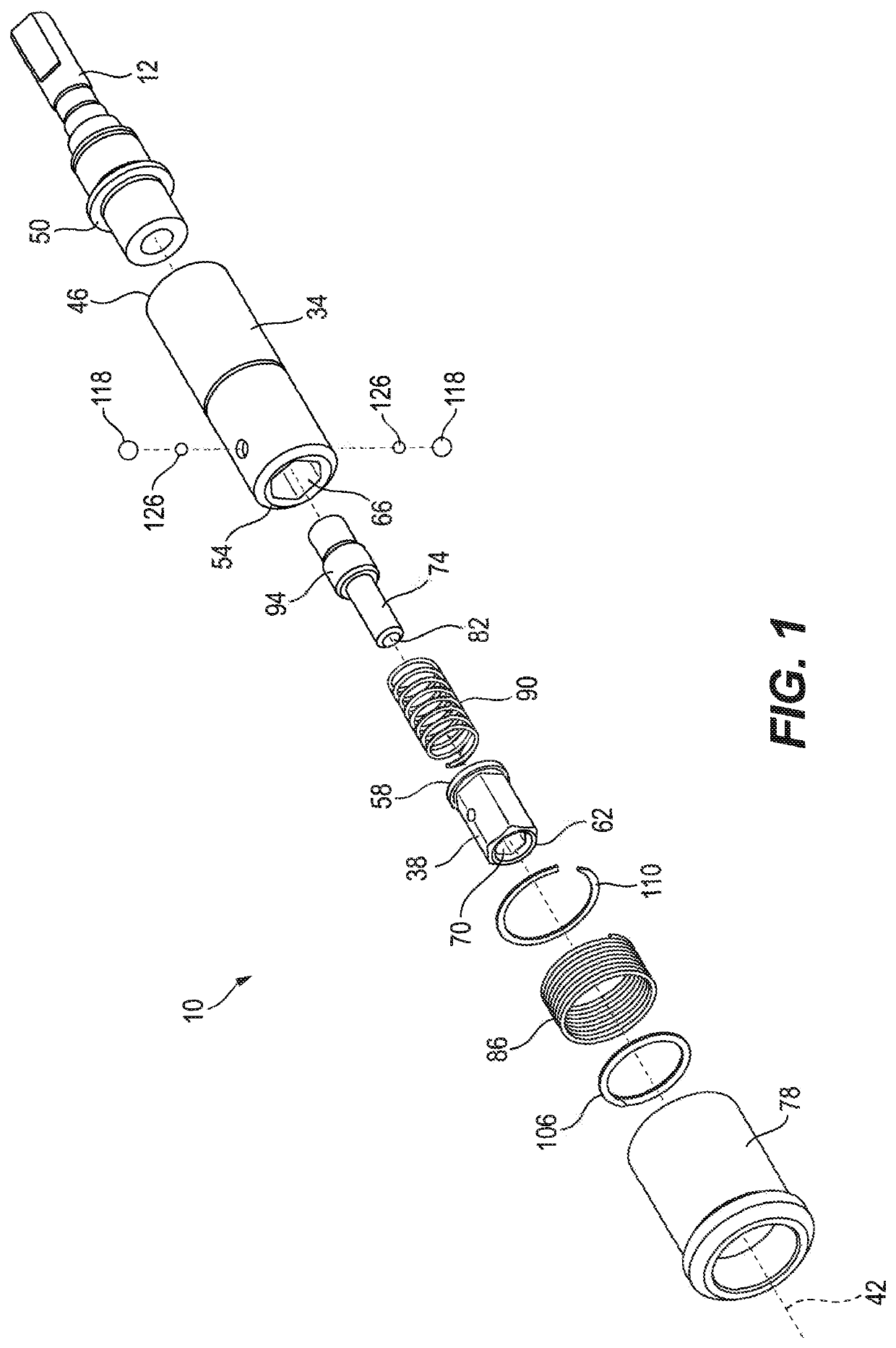

Enhanced drill bit lubrication apparatus and method

Owner:TIGER 19 PARTNERS

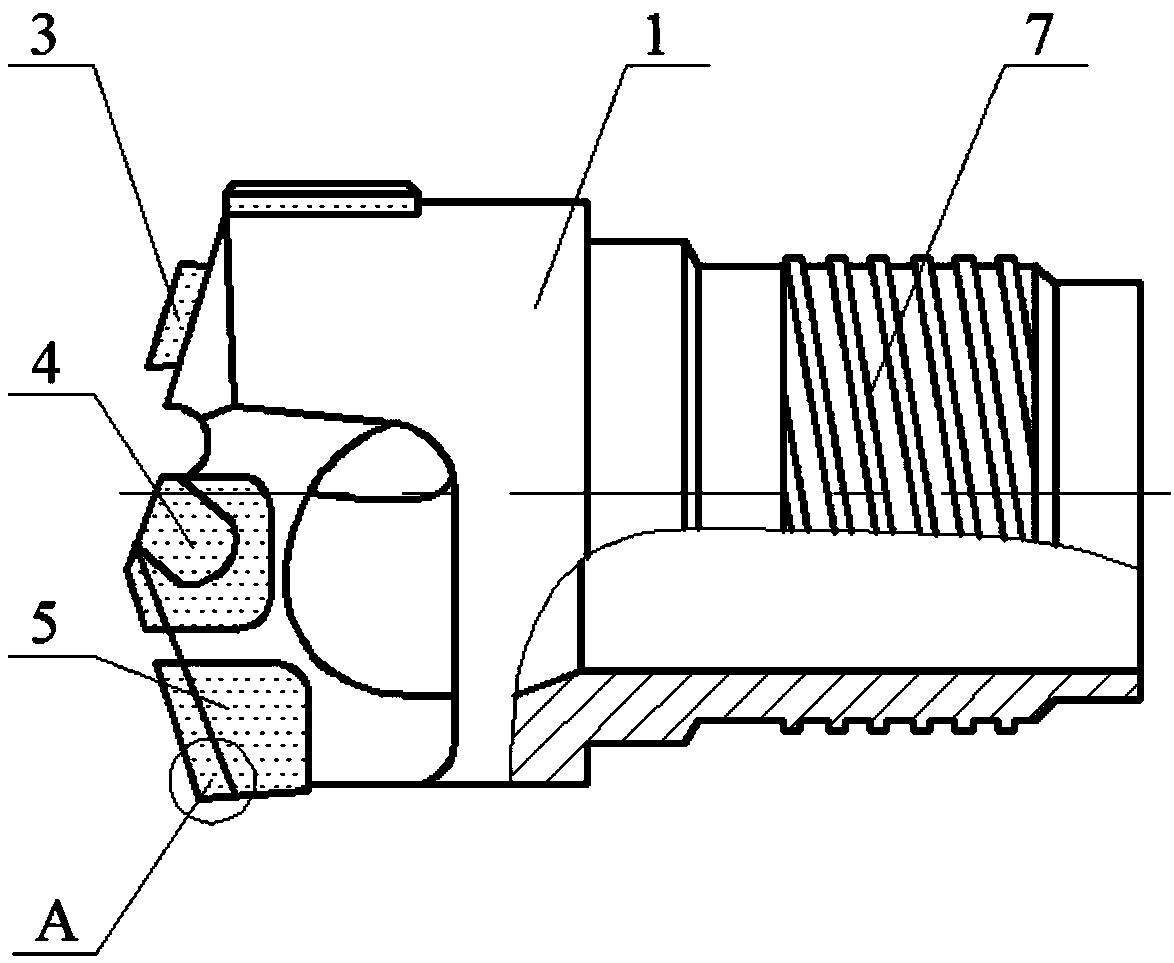

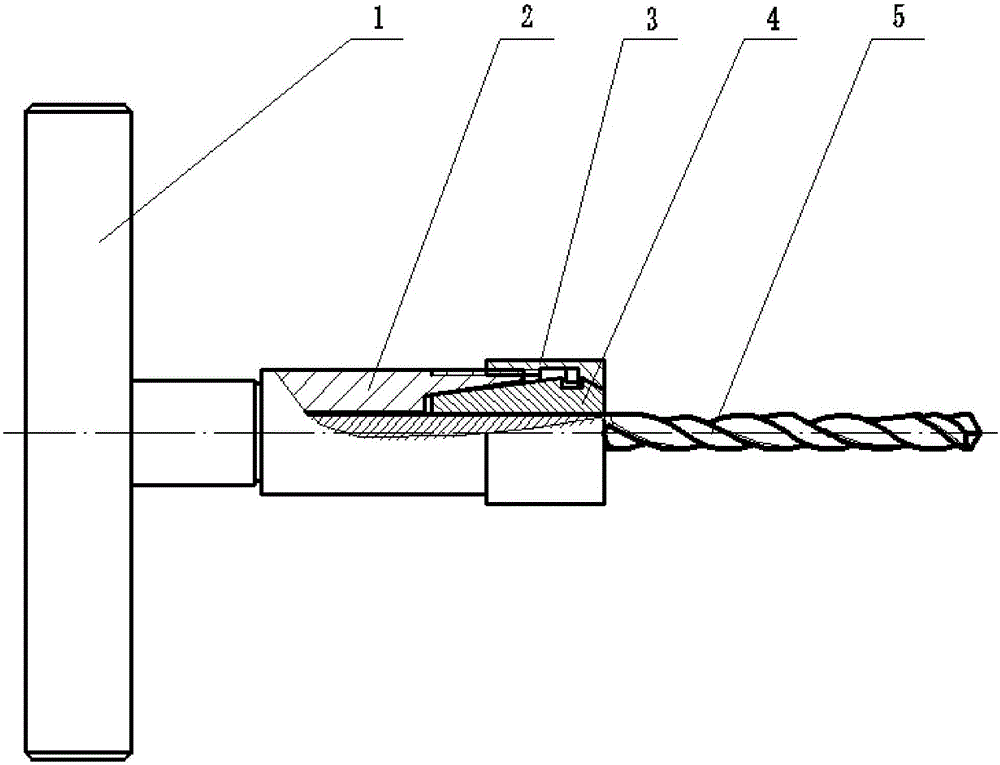

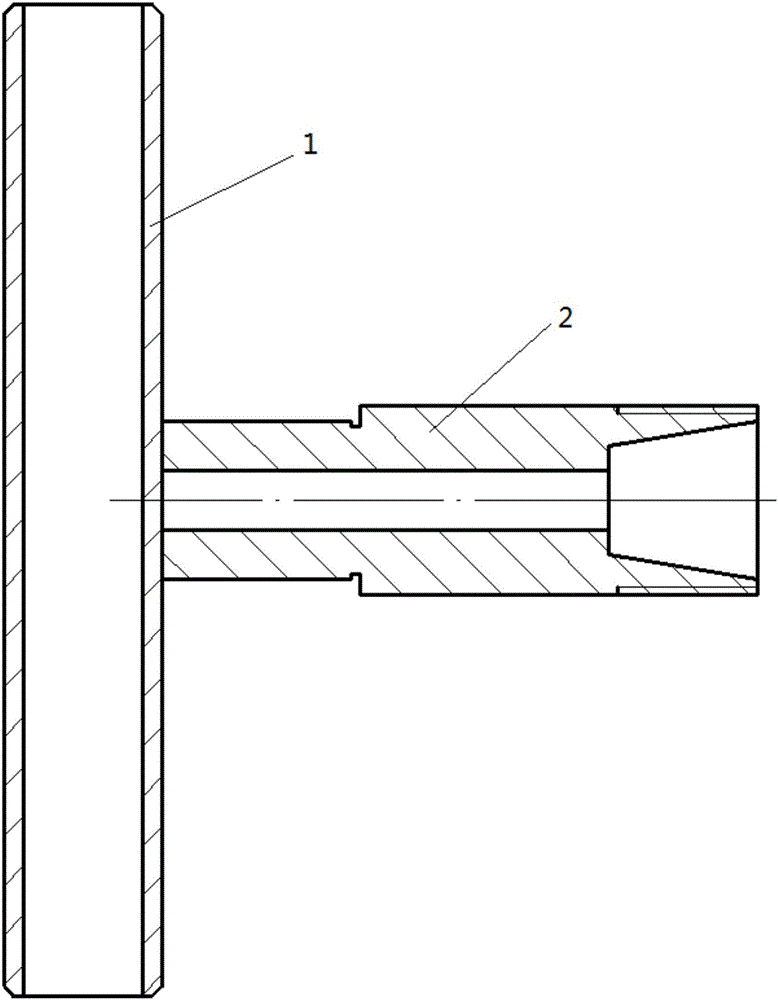

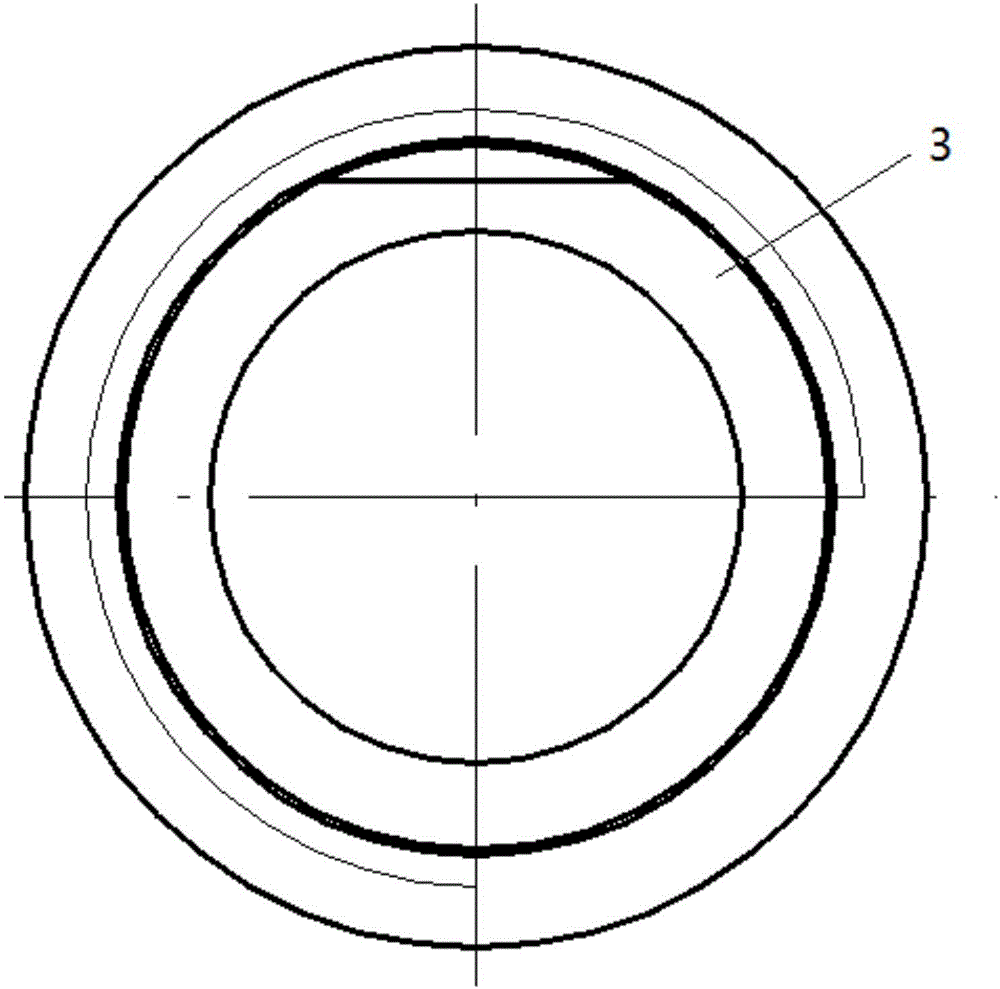

Lifter bore drilling cutter assembly and lifter bore machining method

ActiveCN103182553ASolve the problem of uneven force and easy aperture ellipseGuaranteed roughness requirementsTransportation and packagingTrepanning drillsDrill bit shankReamer

The invention discloses a lifter bore drilling cutter assembly and a lifter bore machining method. The cutter assembly comprises an internal-cooled pilot step drill bit and a heavy-metal hot shrink-fit shank. The internal-cooled pilot step drill bit is of a step structure with internal cooling holes and specifically comprises a core bit, an expanding section, a chamfering section and a drill bit shank, wherein the diameter of the core bit is the smallest to enable the core bit to avoid cross main oil passage holes when the core bit drills the bottom hole of the lifter bore; the internal cooling holes are formed in the end part of the core bit; the expanding section is close to the core bit; the chamfering section is connected with the expanding section; and the internal-cooled pilot step drill bit is installed on the heavy-metal hot shrink-fit shank through the drill bit shank. By machining the bottom hole of the lifter bore through the heavy-metal hot shrink-fit shank in cooperation with internal-cooled pilot step drill bit, the problems that the cutter is unevenly stressed and the elliptical aperture is apt to occur during the machining of offset cross lifter bores are well solved. In addition, by using a diamond honing reamer to hone and ream the lifter hole, the requirement on the roughness of the lifter hole is satisfied and the durability of the cutter is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

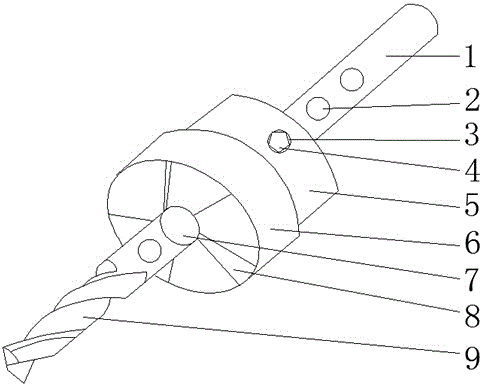

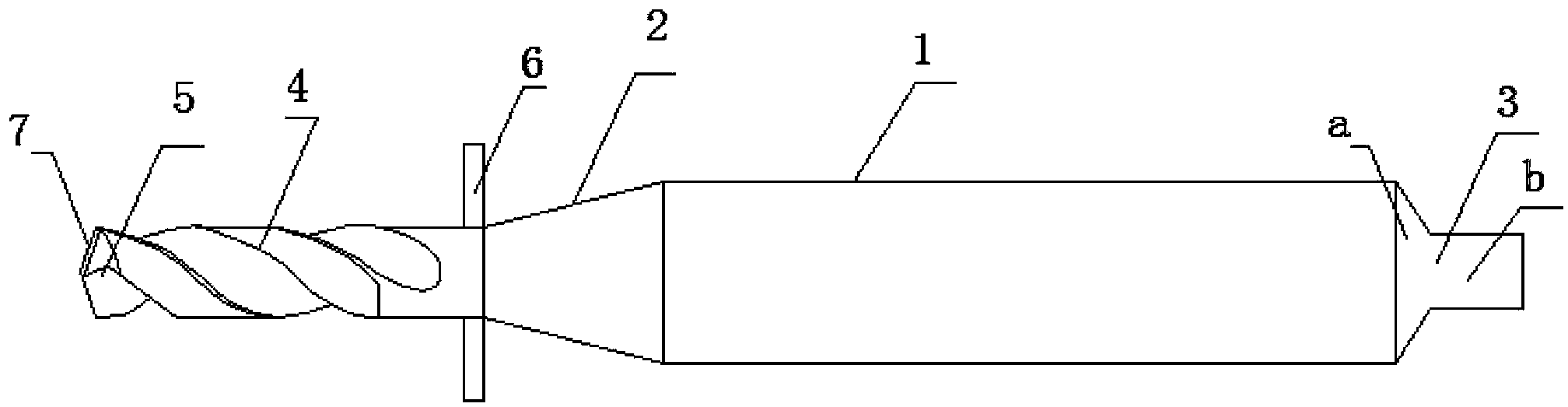

Multifunctional vertical milling cutter

InactiveCN104785834APowerfulSimple structureTransportation and packagingMilling cuttersDrill bit shankMilling cutter

The invention discloses a multifunctional vertical milling cutter which comprises a drill shank, positioning holes, a fixing hole, a fixing bolt, a cutter handle, a cutter head, a round hole, cutting edges and a drill bit, wherein the bottom of the drill shank is fixedly connected with the drill bit; the positioning holes are formed in the drill shank, the cutter handle is fixedly connected with the cutter head, the fixing hole is formed in the cutter handle, the cutting edges are arranged on the cutter head, the drill shank transversely penetrates through centers of the cutter handle and the cutter head through the round hole, and the cutter handle and the drill shank are fixedly connected through the fixing bolt. The multifunctional vertical milling cutter is simple in structure, low in cost and powerful in function; through matching use of the cutter head and the drill bit, the milling cutter replacement time is greatly shortened, all that is required is to adjust the position of the fixing hole in the cutter handle in the positioning holes in the drill shank, and the milling cutter and the drill bit can be rapidly switched.

Owner:南京益精机械刀具制造有限公司

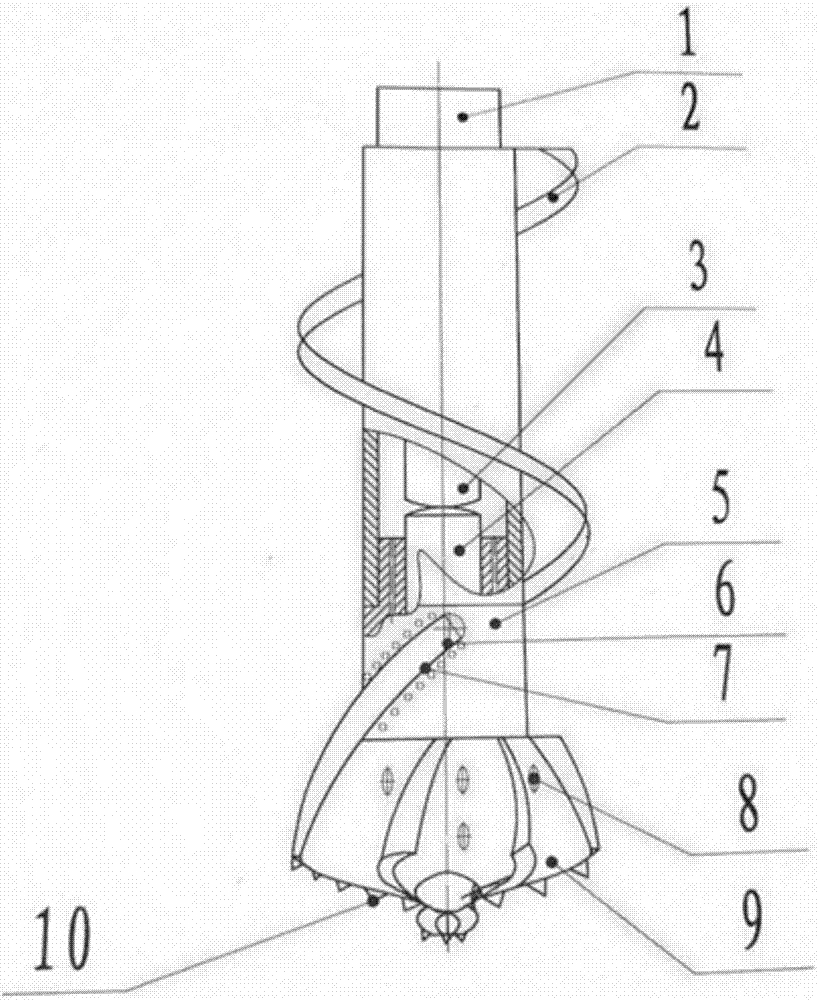

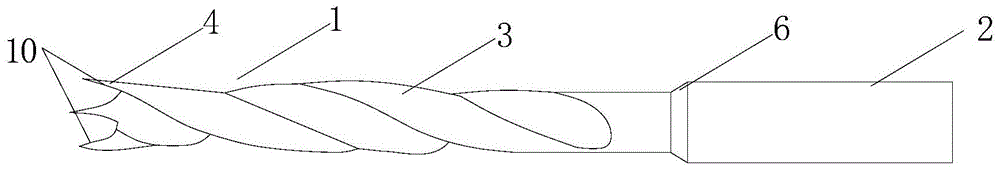

Combined multifunctional rock and soil spiral drill tool

PendingCN107420047AAvoid disturbanceGuaranteed bearing capacityDrill bitsDrill bit shankSpiral blade

The invention discloses a combined multifunctional rock and soil spiral drill tool which comprises a spiral blade, an impact hammer, a sleeve and a drill bit. A connector is connected with the upper end of the sleeve and is connected with a drill rod, and the spiral blade is welded on the outer wall of the sleeve; the impact hammer is arranged inside the sleeve, and an impact drill bit is connected with the bottom of the sleeve; a drill bit shank is mounted in the sleeve and is positioned at the bottom of the impact hammer, and a plurality of air holes are formed in the side walls of the drill bit. The combined multifunctional rock and soil spiral drill tool has the advantages that the construction cost can be reduced to a great extent and only accounts for 1 / 5 of the original construction cost; disturbance of impact force on base rock can be effectively prevented by micro-impact technologies, the bearing capacity of pile foundations can be guaranteed, and air pollution due to silt can be prevented; the combined multifunctional rock and soil spiral drill tool which is a novel product is safe, and loss of drill machines and equipment can be minimized; guide functions are designed for the bottom of the drill bit, accordingly, work applying directions can be changed, and accordingly rotary striking can be carried out; destruction of the base rock due to the impact force can be reduced to a great extent owing to micro-impact and little-impact technologies, and the quality of drilled holes can be improved.

Owner:李大勇

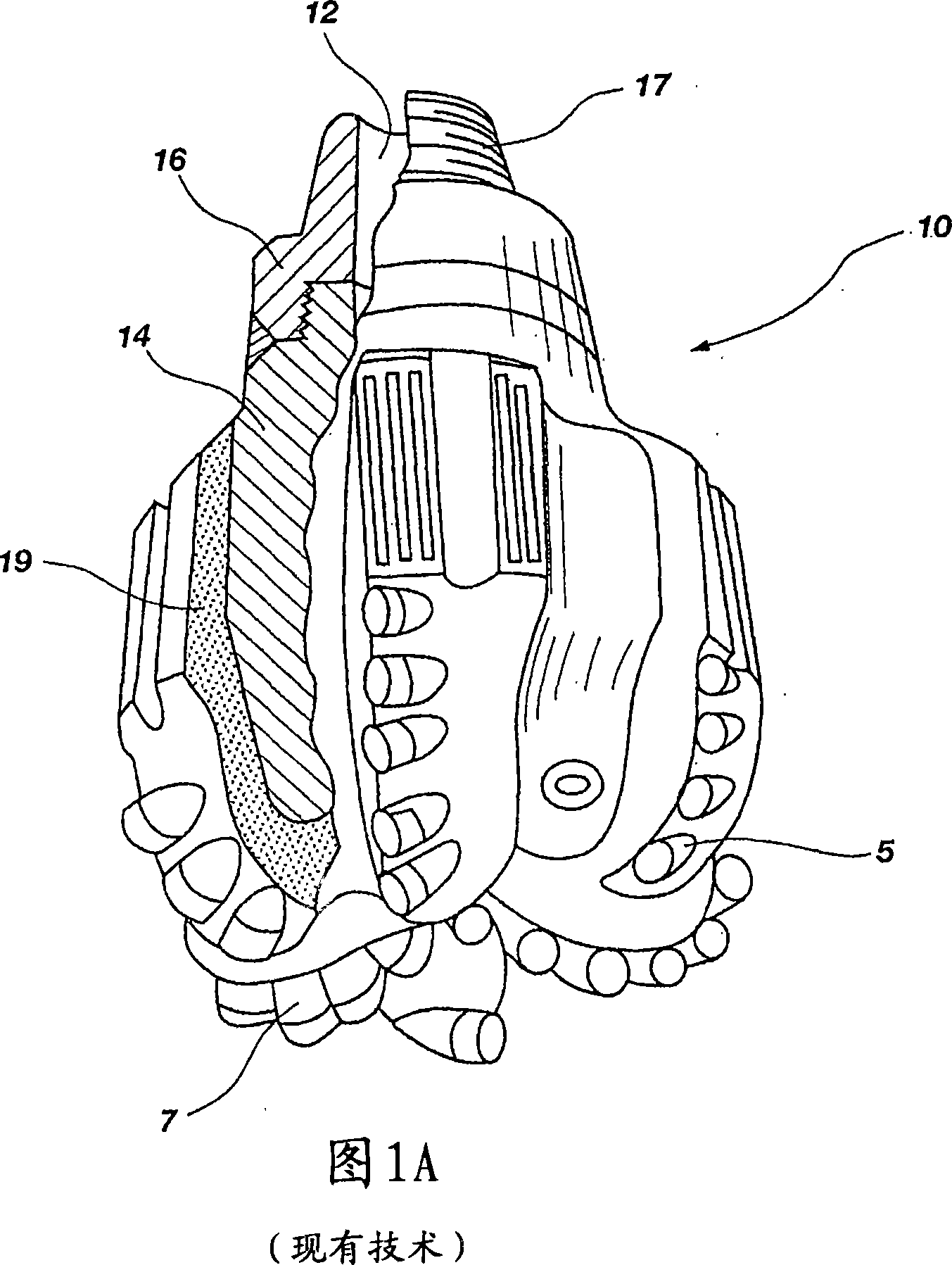

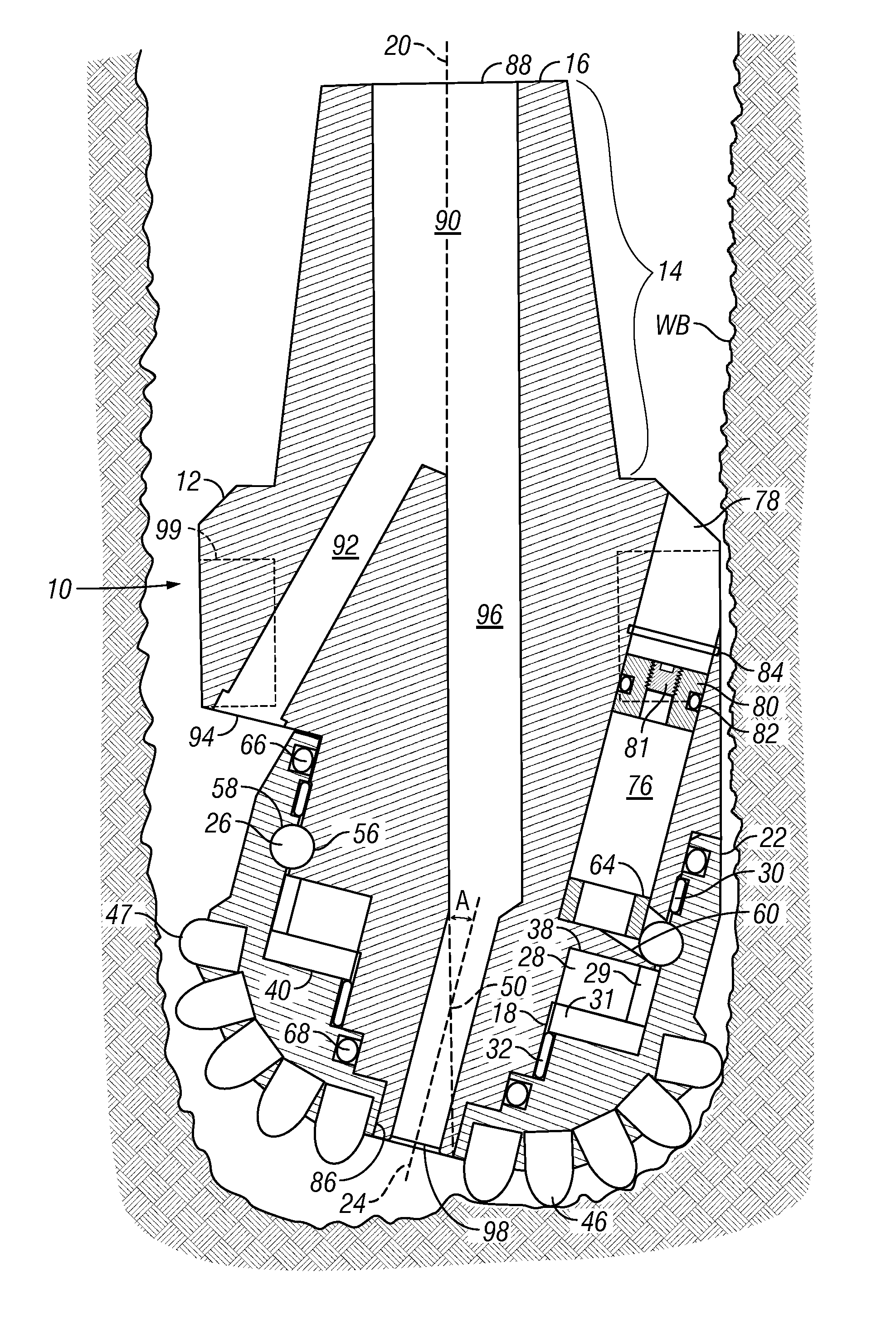

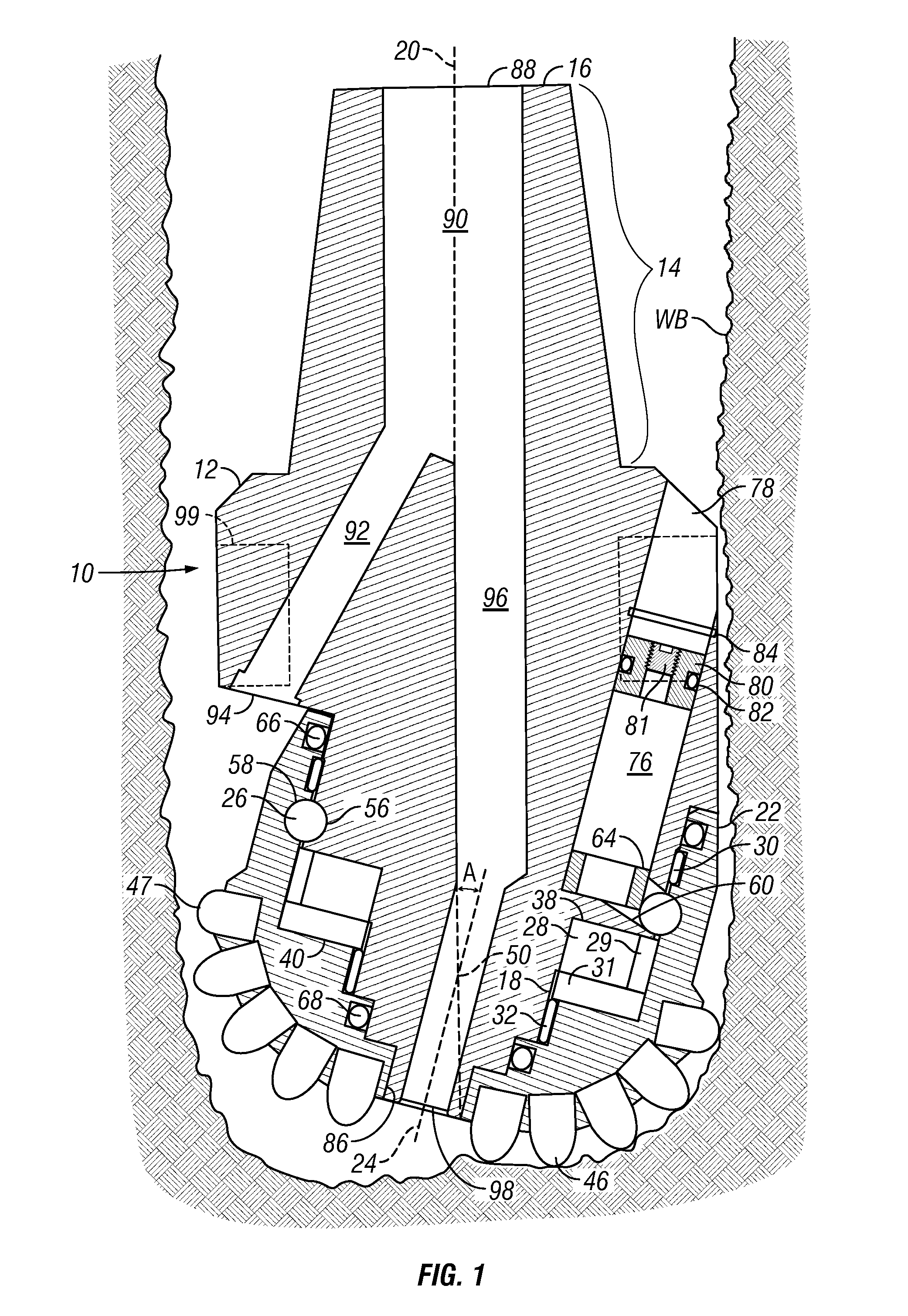

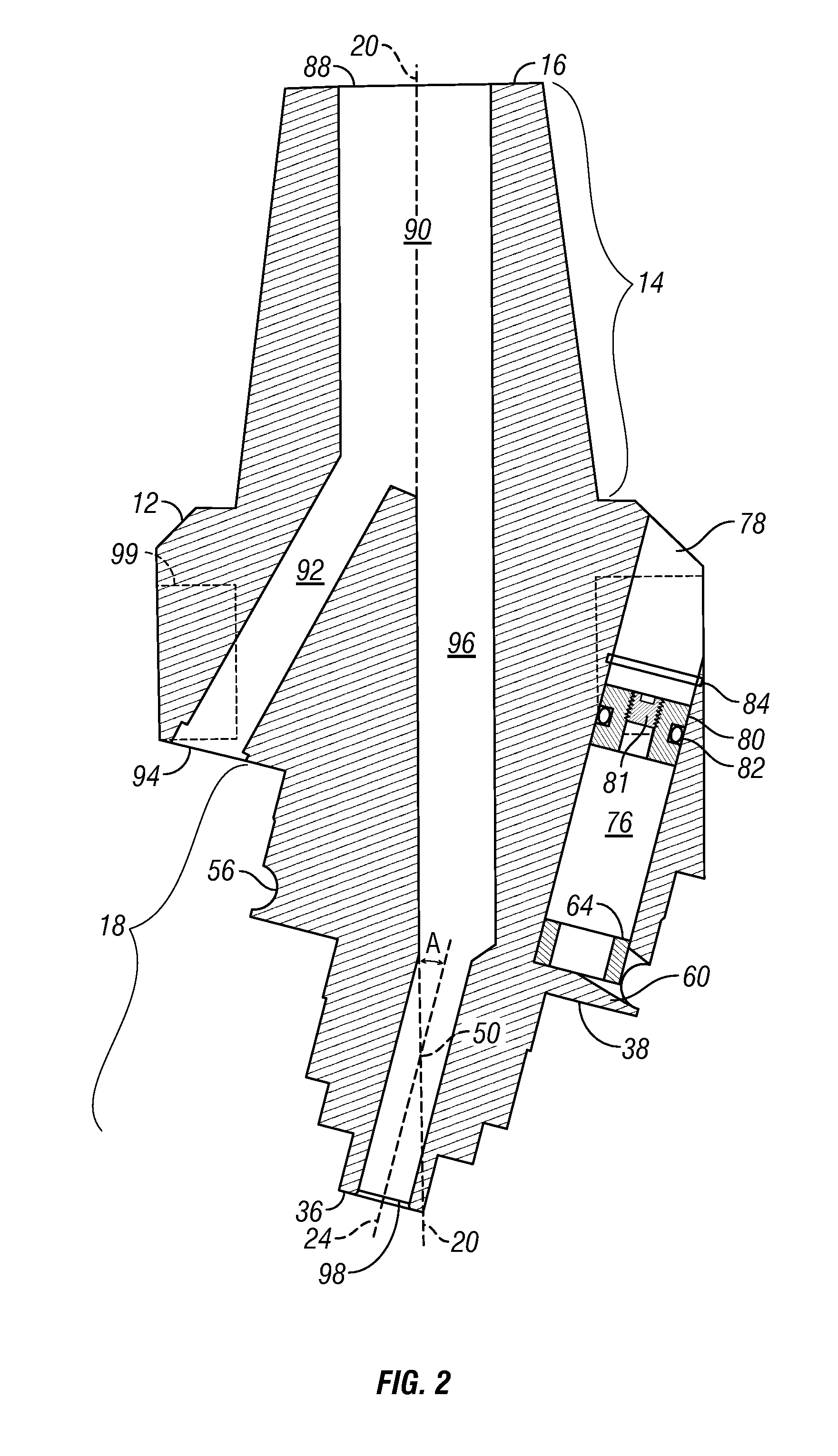

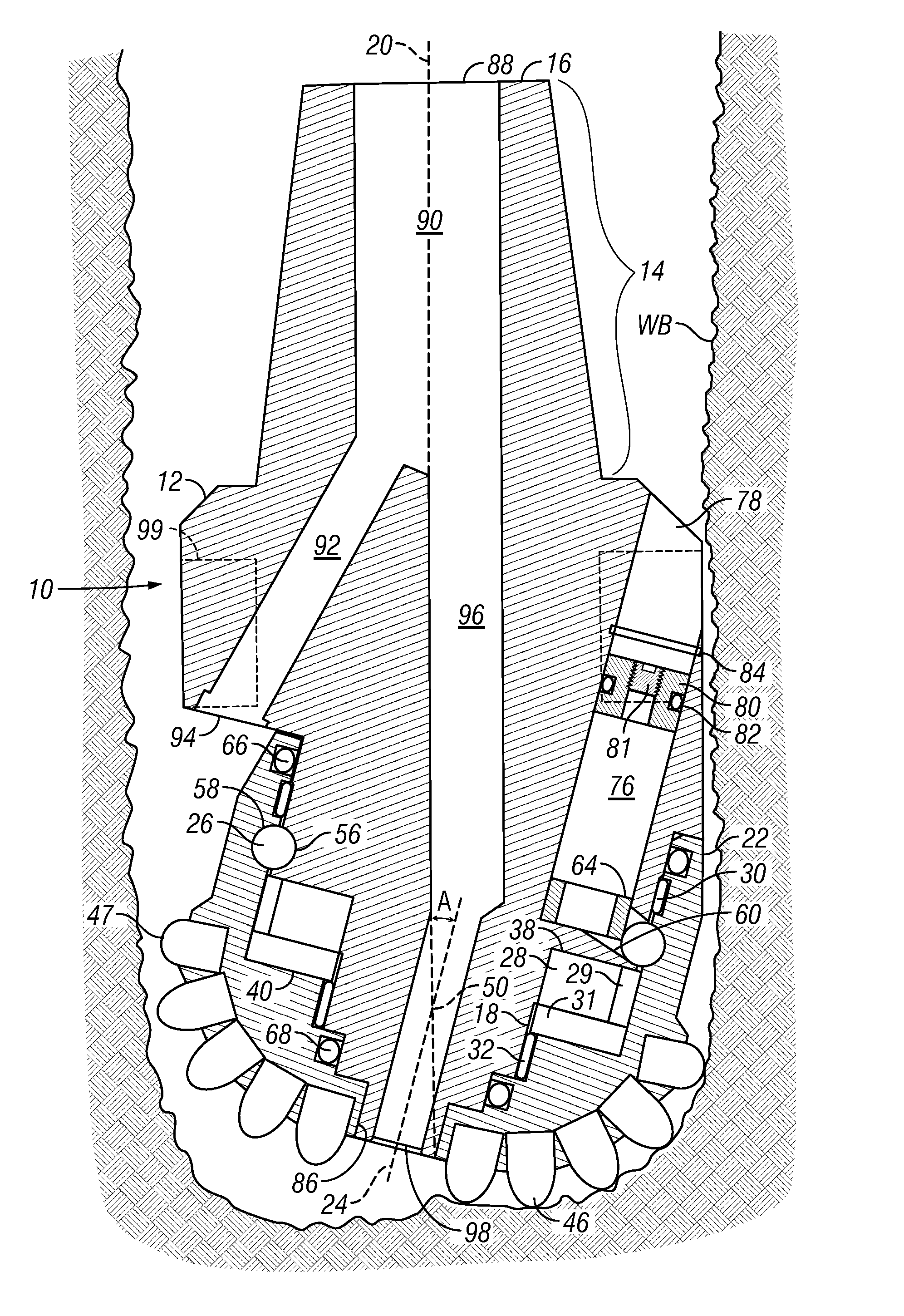

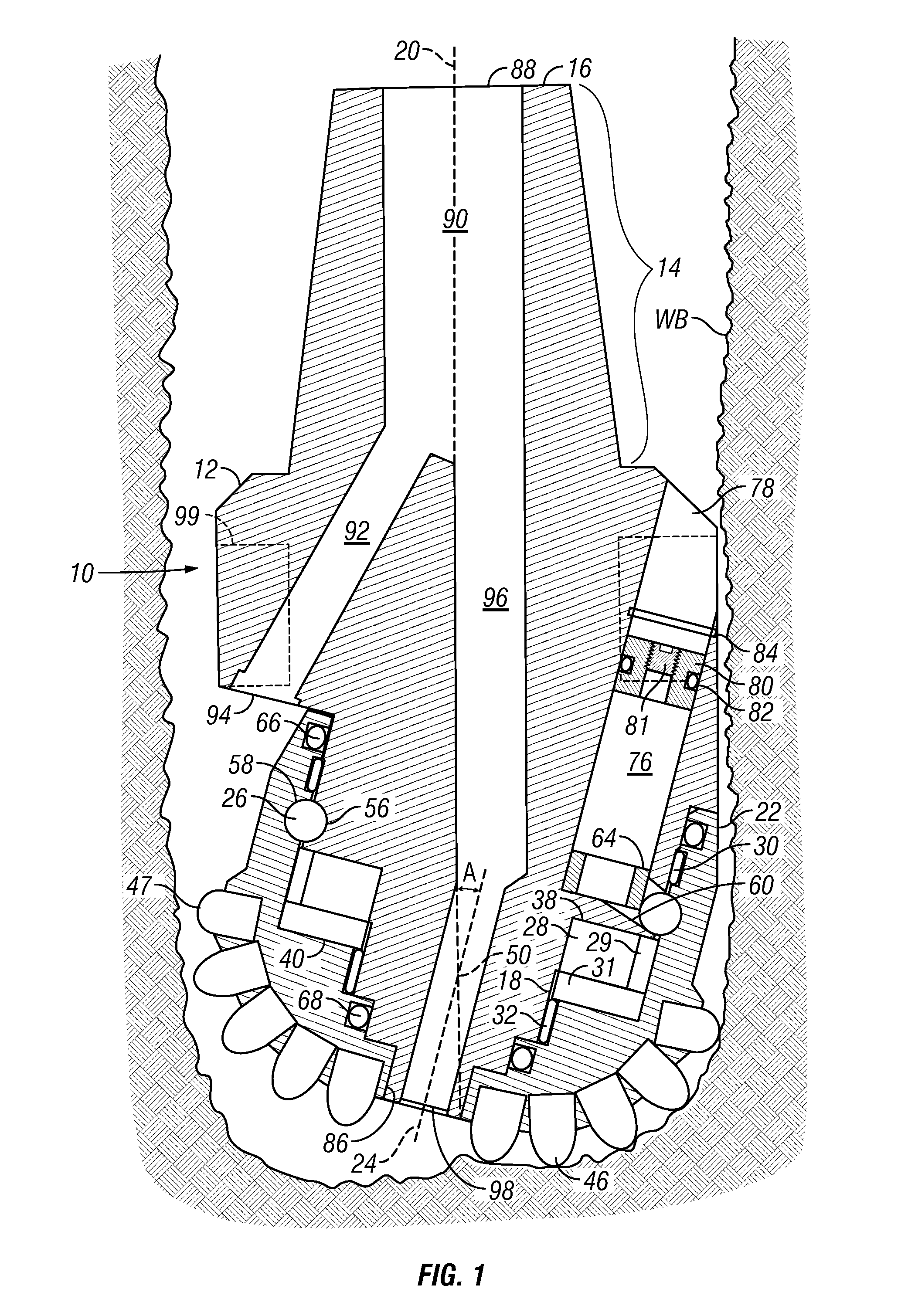

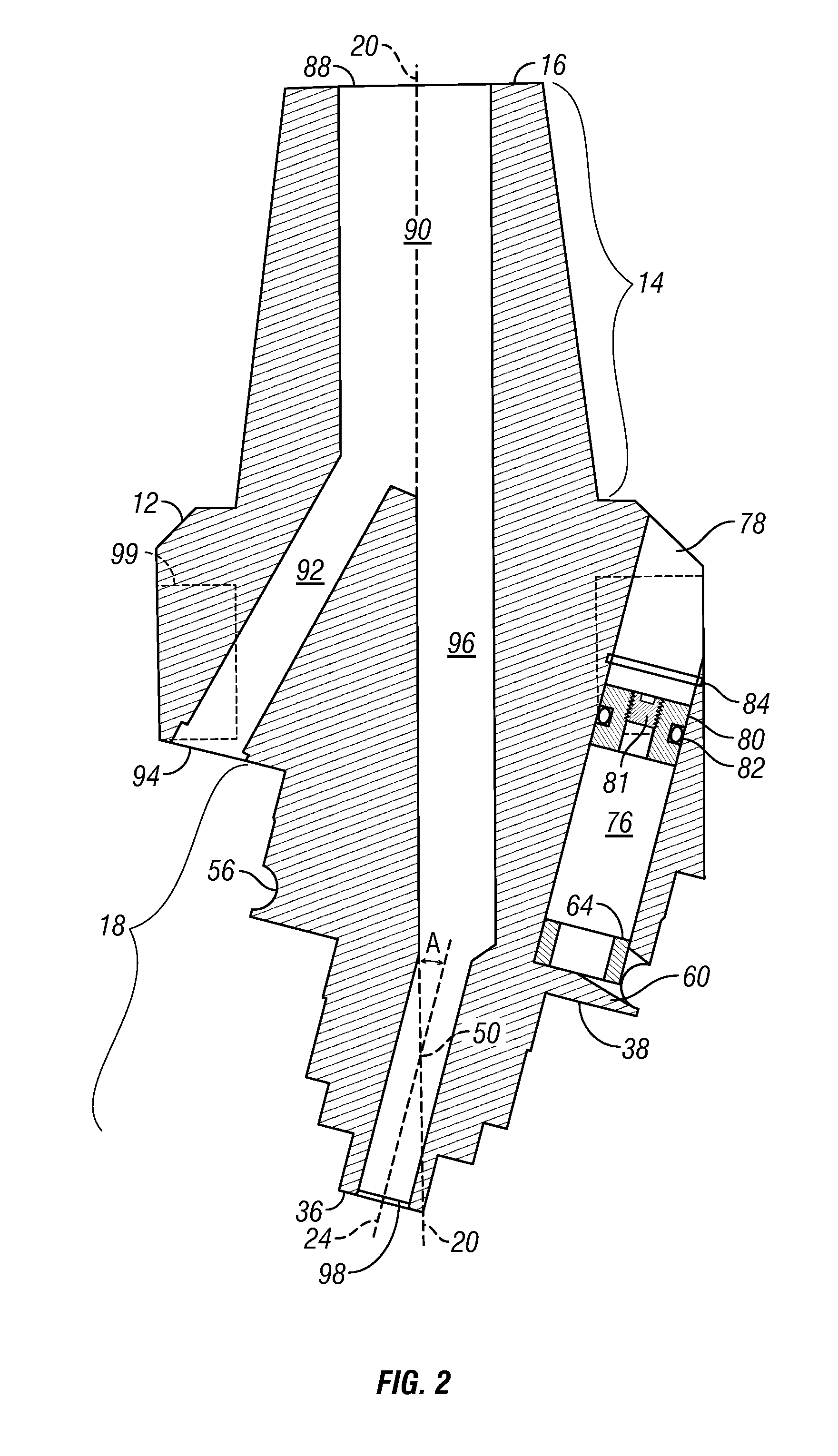

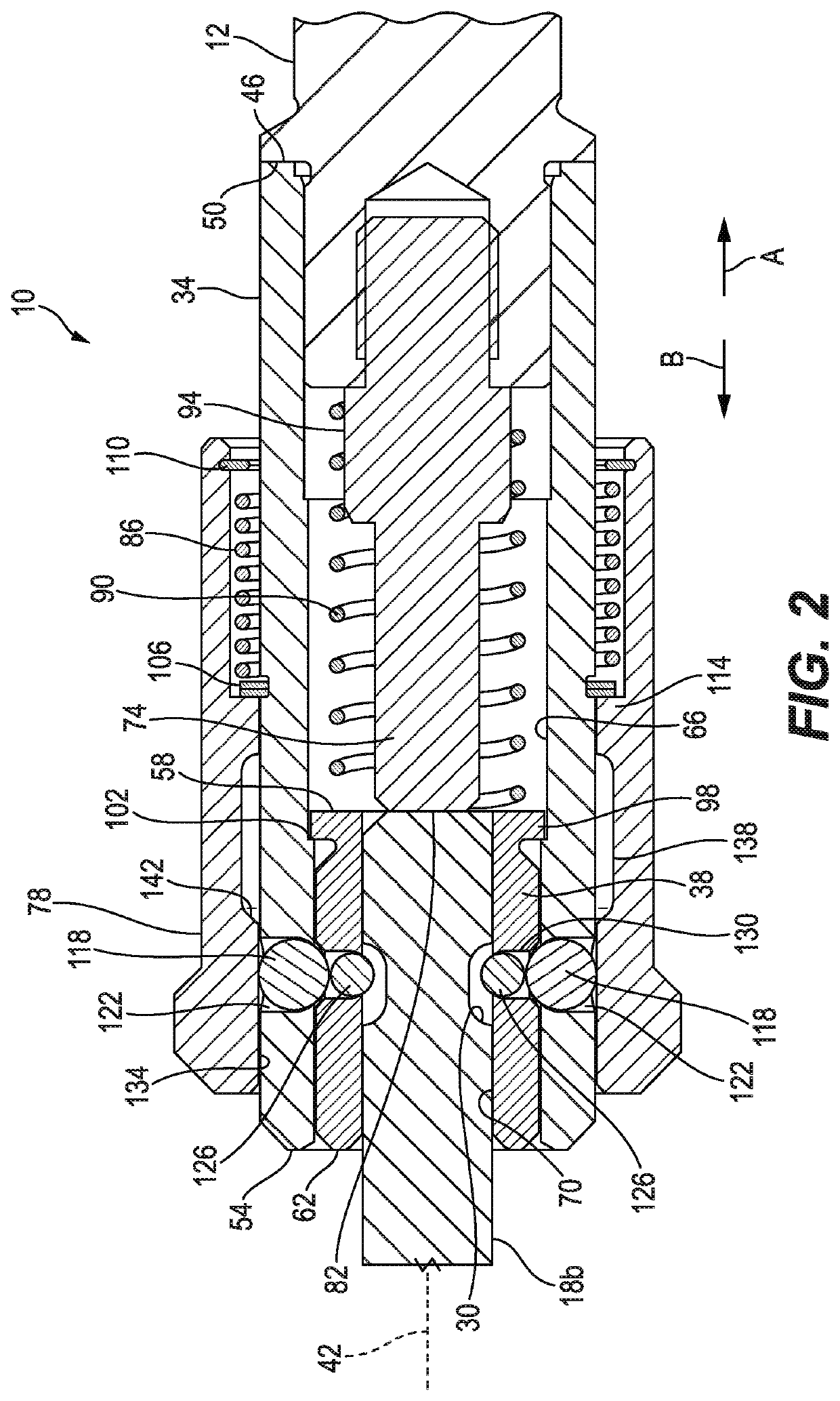

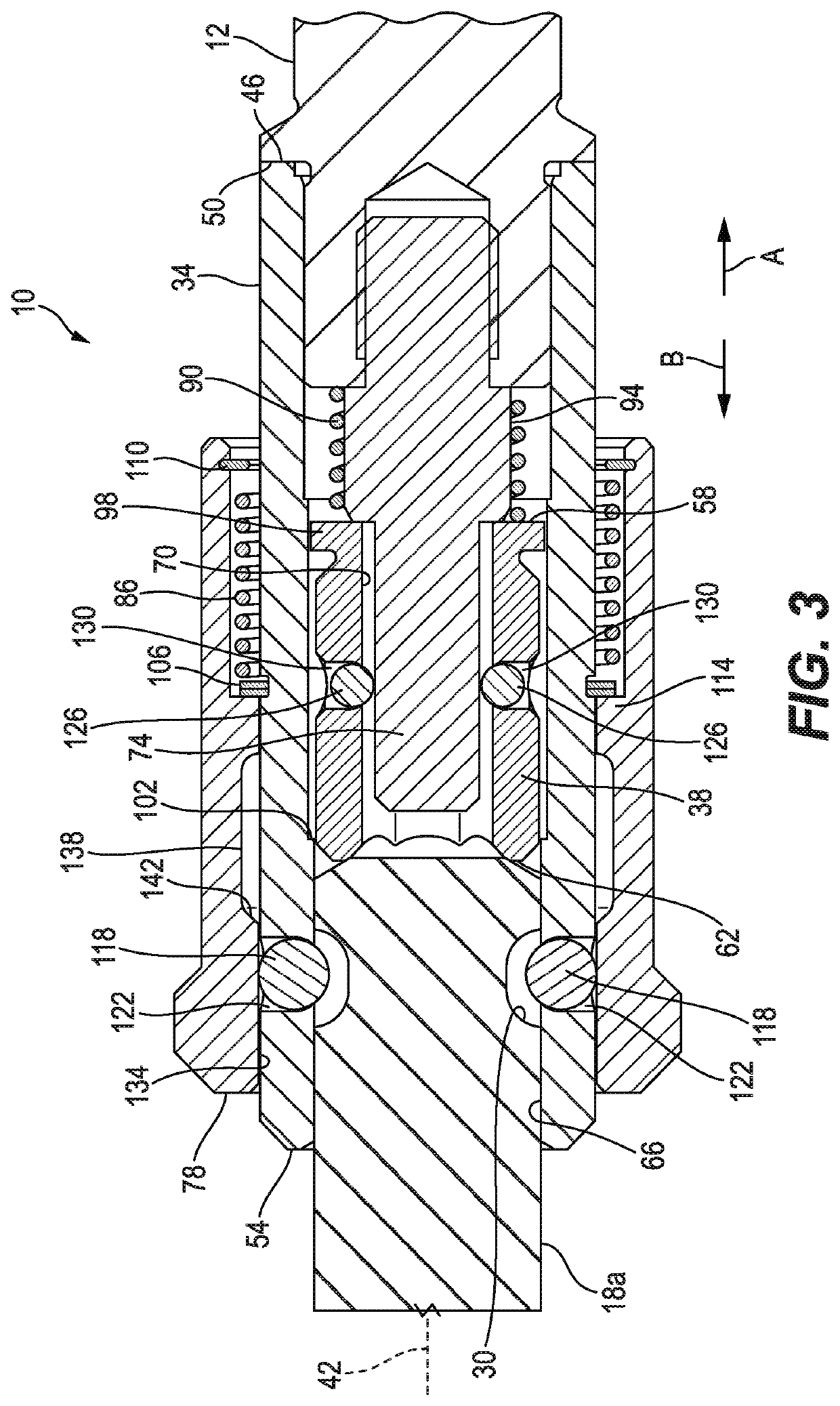

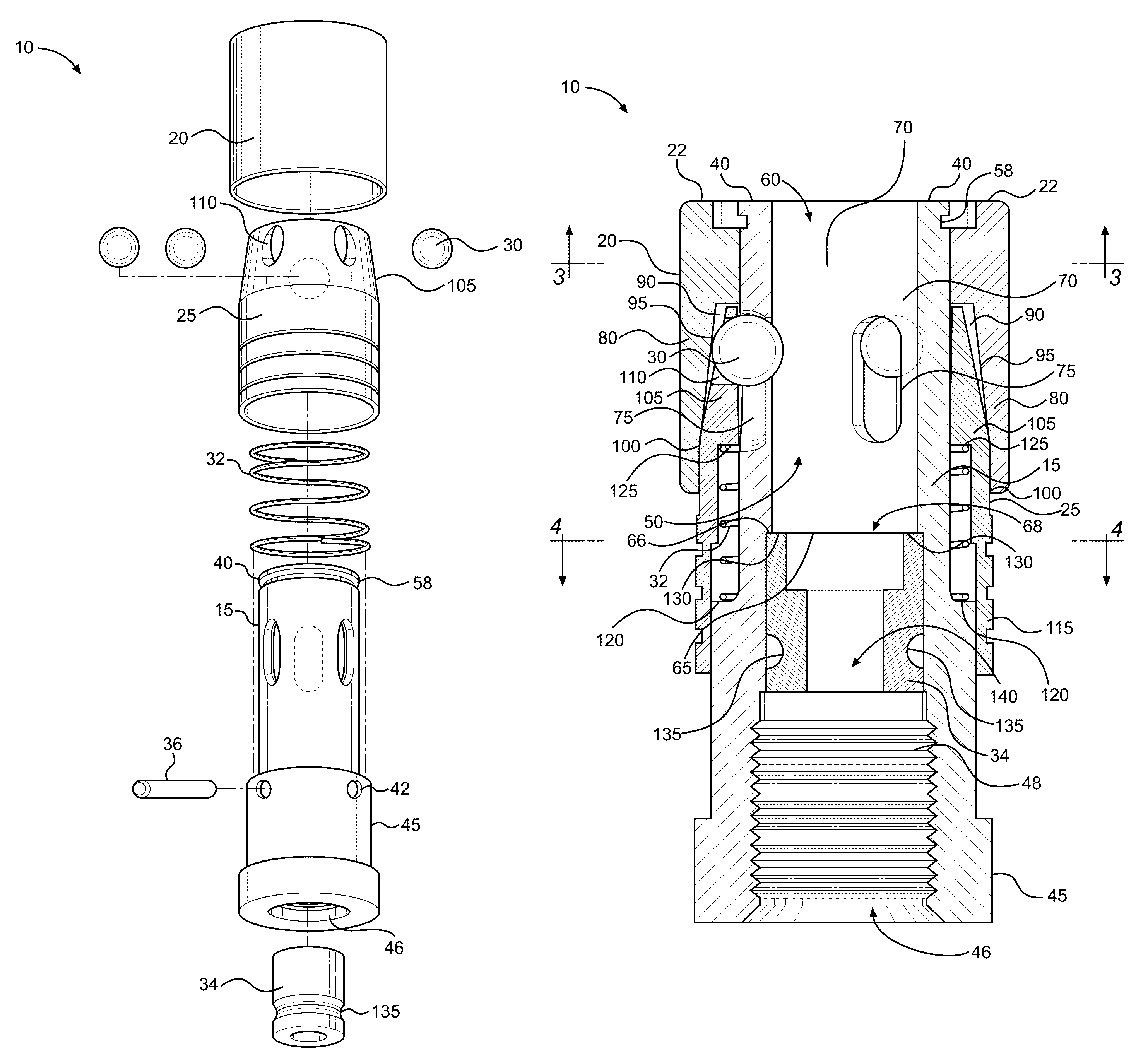

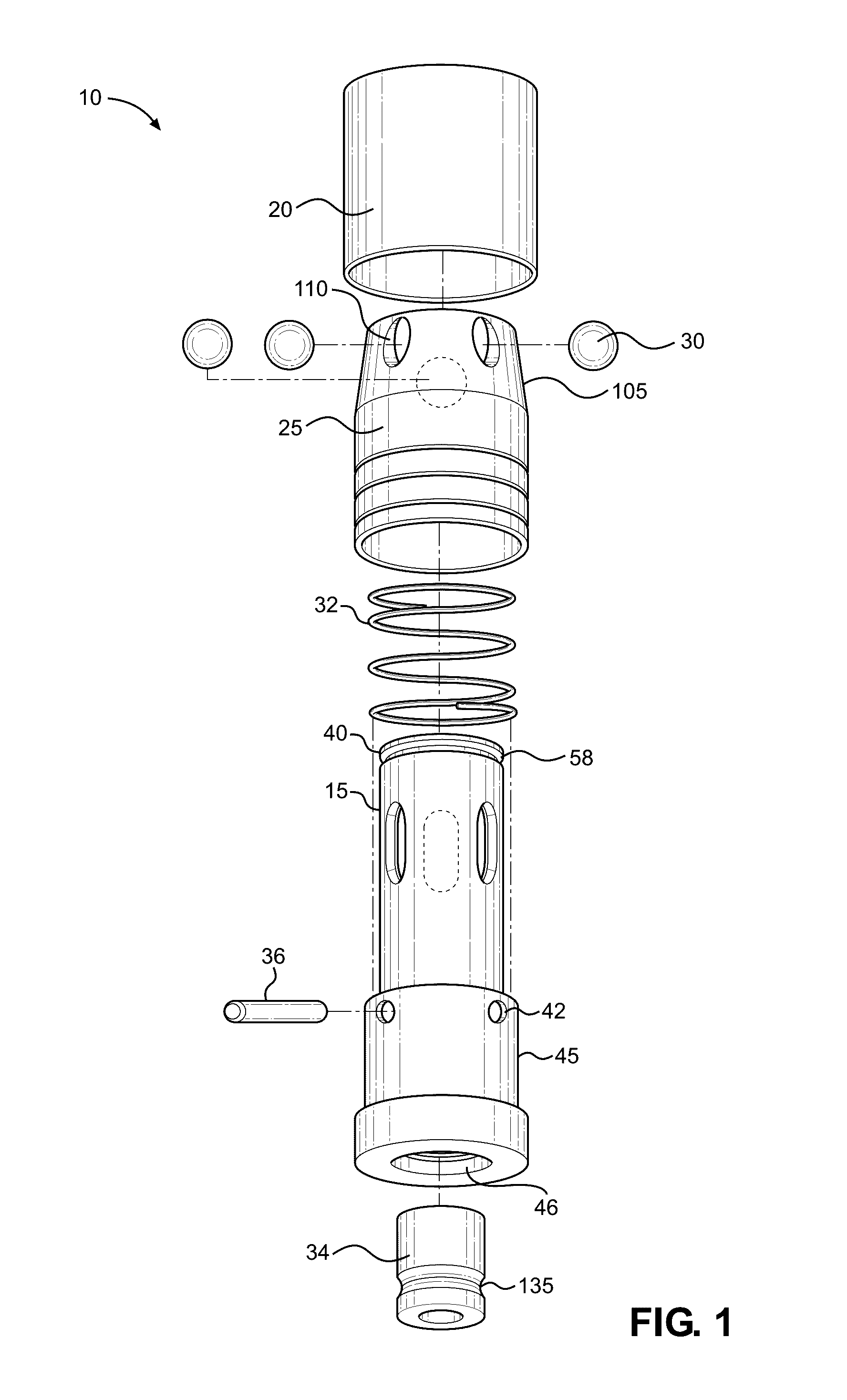

Enhanced Drill Bit Lubrication Apparatus and Method

ActiveUS20080041627A1Prevent egressImprove bearing lifeDrill bitsCutting machinesLubricationBiomedical engineering

A lubricating nutating single cone drill bit 10 is disclosed. Bit 10 includes bit shank 12 with an axially skewed journal 18 rotatably retaining cutter body 22. Bearings (26, 28, 30, 32) can enable rotation of the cutter body 22. Lubricant is dispensed to a gap between the axially skewed journal 18 and cutter body 22 from lubricant chamber 76 having plunger 80 acted on by an annulus fluid, the gap bounded by first 66 and second 68 radial dynamic seals. A fluid passage 90 extending through the bit 10 is in communication with fluid inlet port 88 on the proximal end 16 of the bit shank 12. Fluid passage 90 is in further communication with a first fluid outlet port 98 on the distal end 36 of the axially skewed journal 18 and with a second fluid outlet port 94 formed on a lateral portion of bit shank 12.

Owner:TIGER 19 PARTNERS

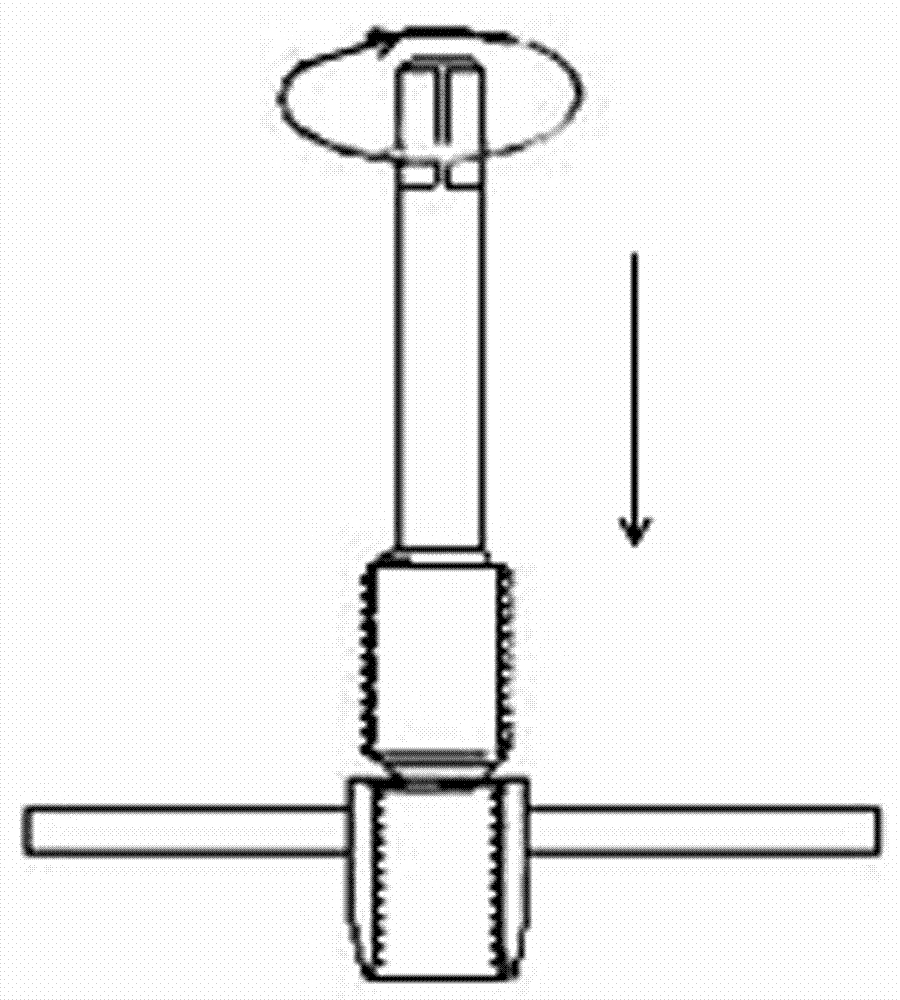

Hot melting drilling tapping thread forming tap

InactiveCN104842025AImprove qualityImprove connection strengthThread cutting toolsTransportation and packagingDrill bit shankNonferrous metal

The invention discloses a screw tap, in particular a hot melting drilling tapping thread forming tap. The hot melting drilling tapping thread forming tap comprises a handle part, a tapping drill bit and a hot melting drill bit, wherein the handle part, the tapping drill bit and the hot melting drill bit are integrally molded; the hot melting drill bit is positioned at the front end; the tapping drill bit is positioned in the middle; the handle part is positioned at the tail end; the diameter of the tapping drill bit is larger than the diameter of the hot melting drill bit; the diameter of the handle part is smaller than the diameter of the hot melting drill bit; and the tapping drill bit is a thread forming tap. The hot melting drilling tapping thread forming tap combines two procedures of hot melting drilling and internal thread processing as a whole, and has the advantages of simplicity, convenience, high positioning precision, good thread quality and high working efficiency compared with traditional processing by two tools (the hot melting drill bit and the thread forming tap); as the thread forming tap is used for chipless processing, molded surfaces of threads are full, and the thread connecting strength is improved; the hot melting drilling tapping thread forming tap is an internal thread processing tool with excellent performance, and in particular, is suitable for drilling and tapping various black metals, stainless steels and such nonferrous metals as copper and aluminum alloys.

Owner:圆兴(厦门)精密工具有限公司

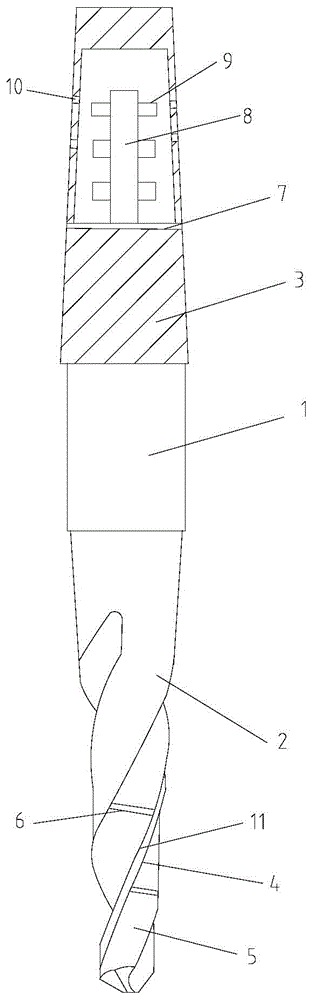

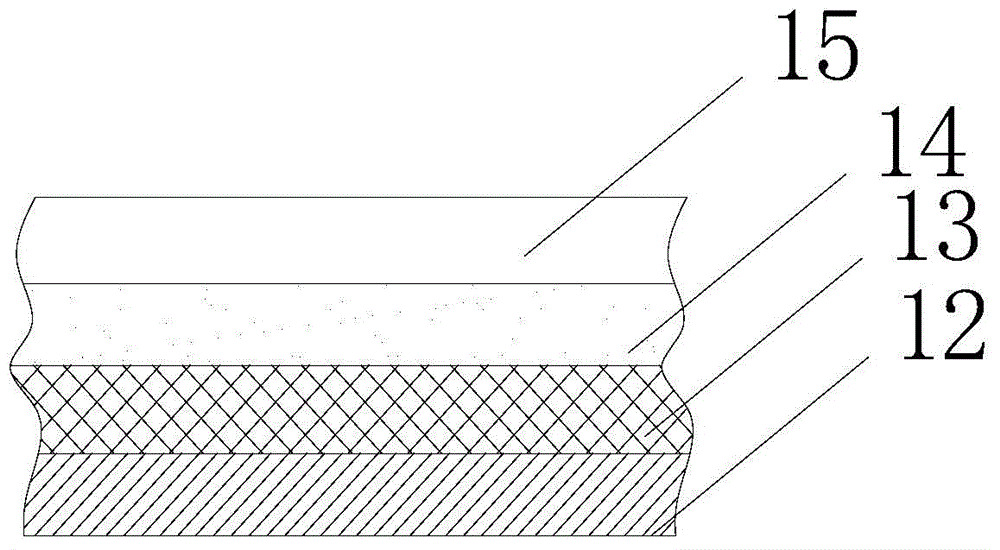

Welded alloy drill

The invention belongs to the field of drill bits and particularly relates to a welded alloy drill comprising a drill bit shank. A drill bit connecting portion is arranged at one end of the drill bit shank, a drill bit positioning portion is arranged at the other end of the drill bit shank, an alloy drill body is welded to the drill bit connecting portion, a drill point is arranged at the end of the alloy drill body, and drilling retaining plates are arranged on the peripheral surface of the joint of the alloy drill body and the drill bit connecting portion. The welded alloy drill has the advantages that drillings can be retained through the drillings retaining plates, and cost can be saved as the drill bit is welded.

Owner:常州耐尔特精密工具有限公司

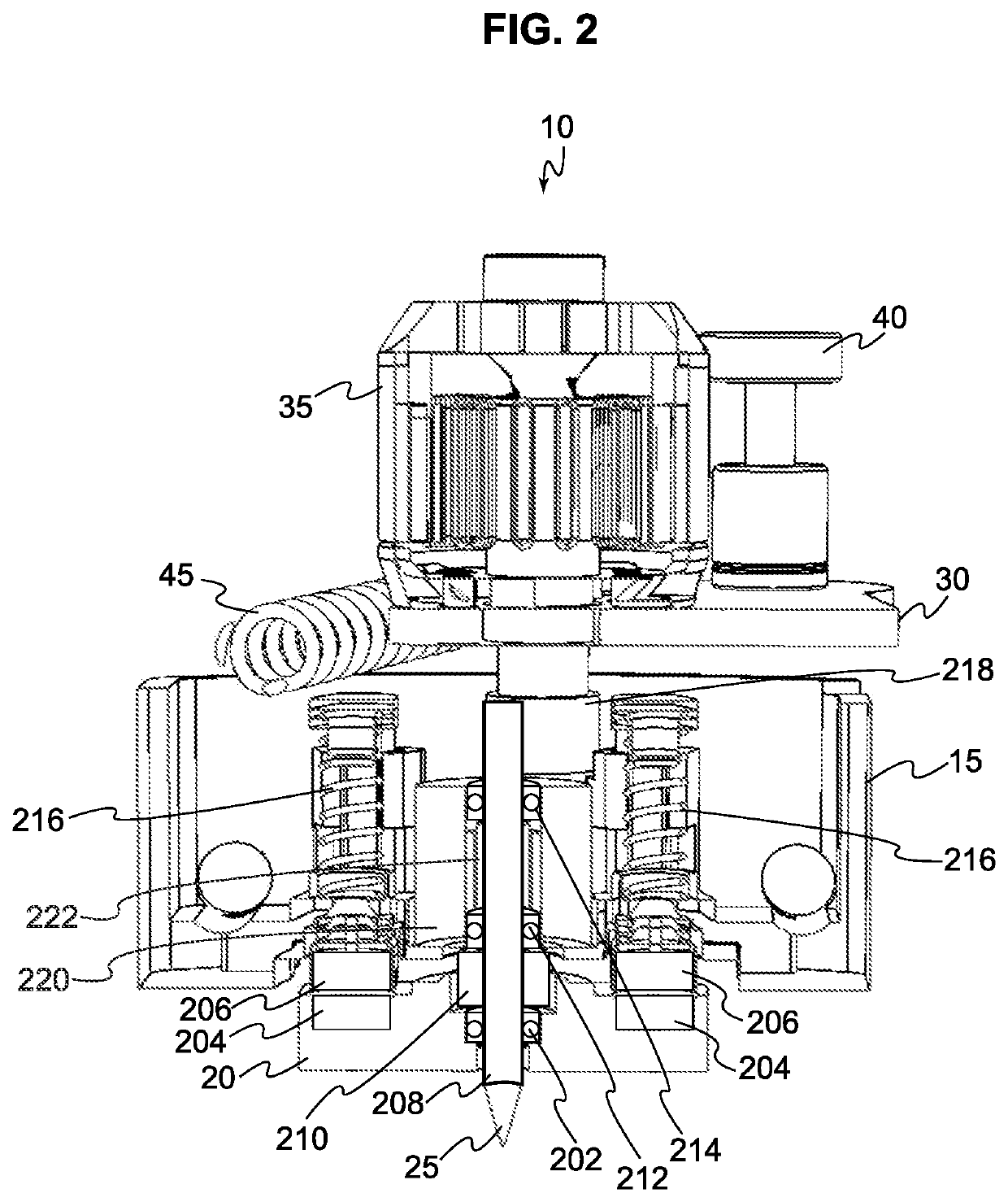

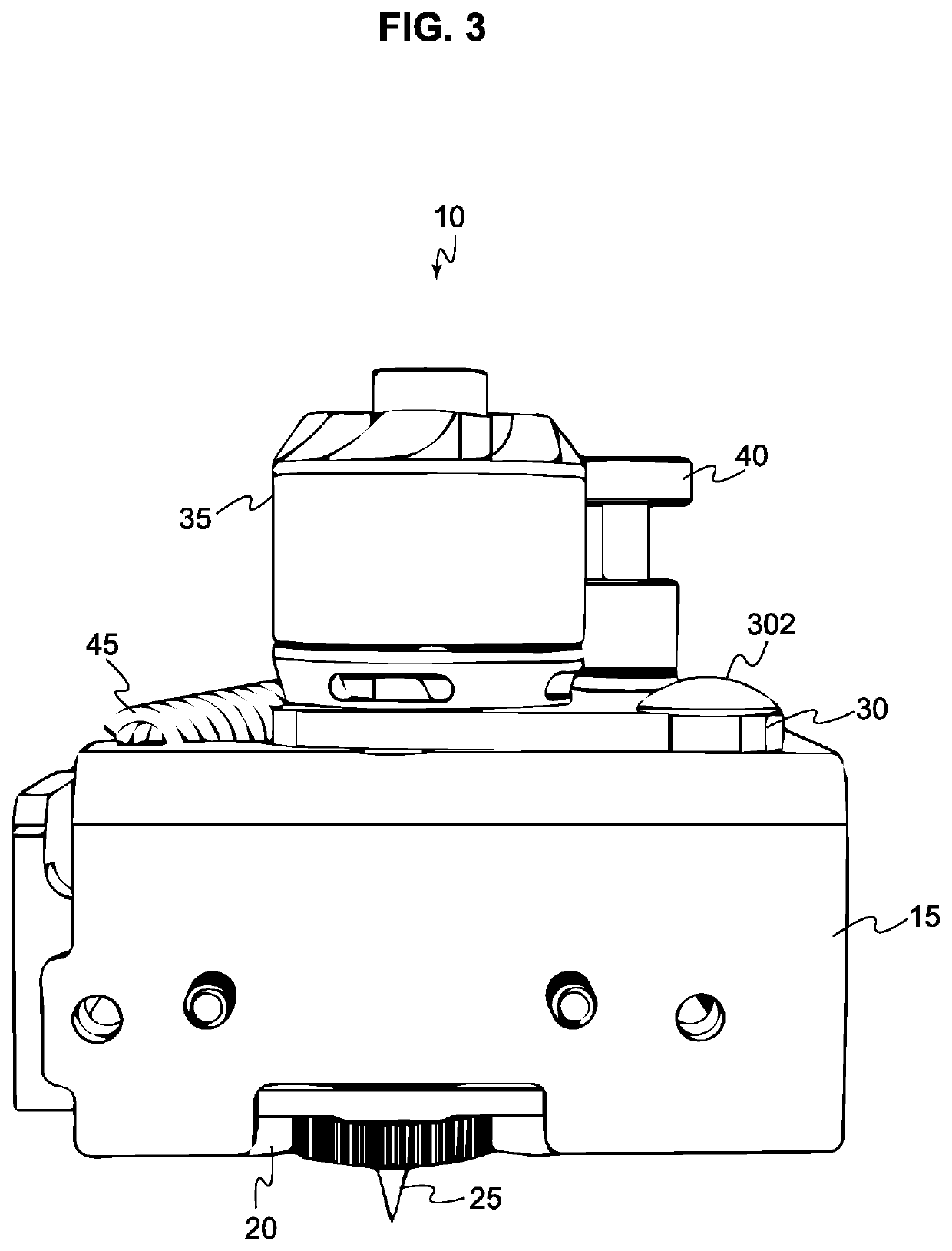

Multi-size tool bit holder for a rotary power tool

A multi-size tool bit holder includes a first sleeve having a first bit holding bore extending along an axis, and a second sleeve coupled for co-rotation with the first sleeve and movable relative to the first sleeve between a first position and a second position. The second sleeve includes a second bit holding bore. A first bit shank of a first nominal size is insertable into the first bit holding bore when the second sleeve is in the second position to secure the first bit shank within the first sleeve. A second bit shank of a second nominal size different than the first nominal size is insertable into the second bit holding bore when the second sleeve is in the first position to secure the second bit shank within the second sleeve.

Owner:MILWAUKEE ELECTRIC TOOL CORP

High-performance antiskid shank shrinkage drill bit

InactiveCN105583443AEasy to processPrevent slippingTwist drillsTool adaptersDrill bit shankPetroleum engineering

A high-performance antiskid shank shrinkage drill bit comprises a drill bit body and a clamping device. The drill bit body is a twist bit. Cutting edges are arranged on the drill bit body and intersect with one another. The clamping device is arranged around the drill bit body and is a jaw, and the jaw is a four-foot jaw and is provided with fixed pieces. The fixed pieces are rectangular fixed blocks. Absorption pieces are arranged on the rectangular fixed blocks and distributed on the jaw. The clamping device is arranged on the drill bit, and therefore machining of the drill bit can be facilitated, and the situation that the drill bit skids on a workpiece, and consequently the quality of the outer surface of the workpiece is influenced can be avoided; meanwhile, the locating effect of the drill bit can be improved, the drill bit can be located conveniently by itself, and the work efficiency of the drill bit is improved; and a sheath is arranged on a connecting shank and can protect the connecting shank, and the connecting shank is prevented from being rusted.

Owner:江苏万金工具有限公司

Tool for removing orifice burrs

The invention discloses a tool for removing orifice burrs. The tool comprises a handle, a connecting rod, a drill bit, a collet chuck and a tightening cover. One end of the connecting rod is vertically fixed to the middle of the side face of the handle. The connecting rod is provided with an axial drill bit shank insertion hole, and a conical hole is formed in the outer end of the drill bit shank insertion hole. A drill bit insertion hole is formed in the axial direction of the collet chuck. The collet chuck has elasticity and can achieve shrinkage distortion so that the drill bit can be clamped. One end of the periphery of the collet chuck is provided with an insertion outer conical surface matched with the conical hole of the connecting rod. A clamping groove is formed in the upper middle portion of the periphery of the collet chuck. A locking outer conical surface is arranged at the other end of the periphery of the collet chuck. One end of the inner circumference of the tightening cover is fixedly connected with the other end of the connecting rod. The upper middle portion of the inner circumference of the tightening cover is provided with a clamping boss matched with the clamping groove of the collet chuck, and the other end of the inner circumference of the tightening cover is provided with a pressing conical surface matched with the locking outer conical surface of the clamping collet chuck. By means of the tool for removing the orifice burrs, the orifice burrs can be removed thoroughly; and moreover, the orifice wall cannot be scratched, consumed time is short, and burr removing efficiency is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

Multi-size tool bit holder for a rotary power tool

A multi-size tool bit holder includes a first sleeve having a first bit holding bore extending along an axis, and a second sleeve coupled for co-rotation with the first sleeve and movable relative to the first sleeve between a first position and a second position. The second sleeve includes a second bit holding bore. A first bit shank of a first nominal size is insertable into the first bit holding bore when the second sleeve is in the second position to secure the first bit shank within the first sleeve. A second bit shank of a second nominal size different than the first nominal size is insertable into the second bit holding bore when the second sleeve is in the first position to secure the second bit shank within the second sleeve.

Owner:MILWAUKEE ELECTRIC TOOL CORP

Four-blade drill bit for forming elliptical hole

InactiveCN107717018ACompact connectionClosely connectedTransportation and packagingTool adaptersDrill bit shankEllipse

The invention discloses a four-edged drill for making elliptical holes, which comprises a tip, a drill body, a casing, a pin opening, a cutting device, drill teeth, a drill handle, a connecting device and a fixing hole. The beneficial effects of the present invention are: the drill has a compact structure and is easy to use. The drill body is a four-edged drill, and blades are arranged in an array outside the cutting device, which can improve chip breaking effect. The tip is a cone structure, and the cutting device is an eccentric structure. It is used to make elliptical holes, and the drill teeth are equipped with chip grooves. When the drill bit is advanced, it prevents debris from clogging and makes the advancement more difficult. The surface of the drill body is coated with a metal layer, which has high smoothness and drilling accuracy. The connecting device There is a pin opening on one side, which can be fixed by pins. The inner side of the fixing hole is provided with threads, which can firmly install the drill bit on the drilling machine to prevent the drill bit from moving. There is a buckle inside the casing, and the drill teeth are installed on the drill handle. Inside the top, the drill teeth can rotate flexibly and have strong stability during work.

Owner:常州山迪智能科技有限公司

Tappet hole drilling tool assembly and method for processing the tappet hole

ActiveCN103182553BGuaranteed roughness requirementsIncreased durabilityTransportation and packagingTrepanning drillsDrill bit shankReamer

The invention discloses a lifter bore drilling cutter assembly and a lifter bore machining method. The cutter assembly comprises an internal-cooled pilot step drill bit and a heavy-metal hot shrink-fit shank. The internal-cooled pilot step drill bit is of a step structure with internal cooling holes and specifically comprises a core bit, an expanding section, a chamfering section and a drill bit shank, wherein the diameter of the core bit is the smallest to enable the core bit to avoid cross main oil passage holes when the core bit drills the bottom hole of the lifter bore; the internal cooling holes are formed in the end part of the core bit; the expanding section is close to the core bit; the chamfering section is connected with the expanding section; and the internal-cooled pilot step drill bit is installed on the heavy-metal hot shrink-fit shank through the drill bit shank. By machining the bottom hole of the lifter bore through the heavy-metal hot shrink-fit shank in cooperation with internal-cooled pilot step drill bit, the problems that the cutter is unevenly stressed and the elliptical aperture is apt to occur during the machining of offset cross lifter bores are well solved. In addition, by using a diamond honing reamer to hone and ream the lifter hole, the requirement on the roughness of the lifter hole is satisfied and the durability of the cutter is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

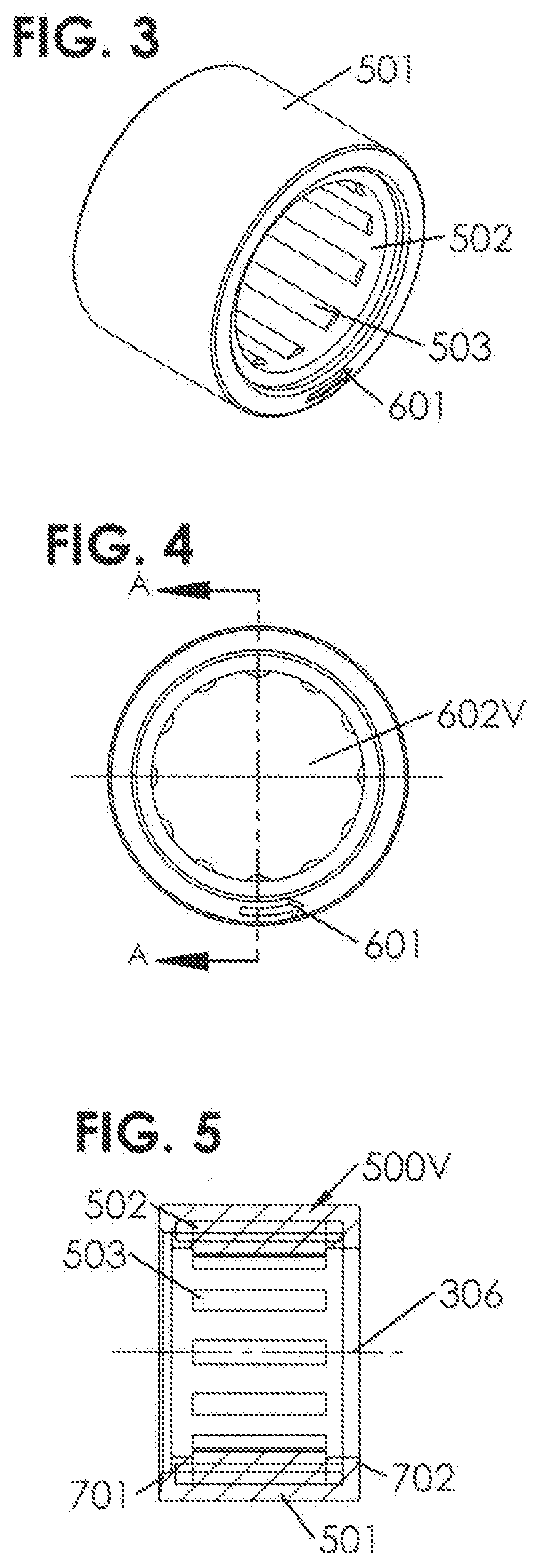

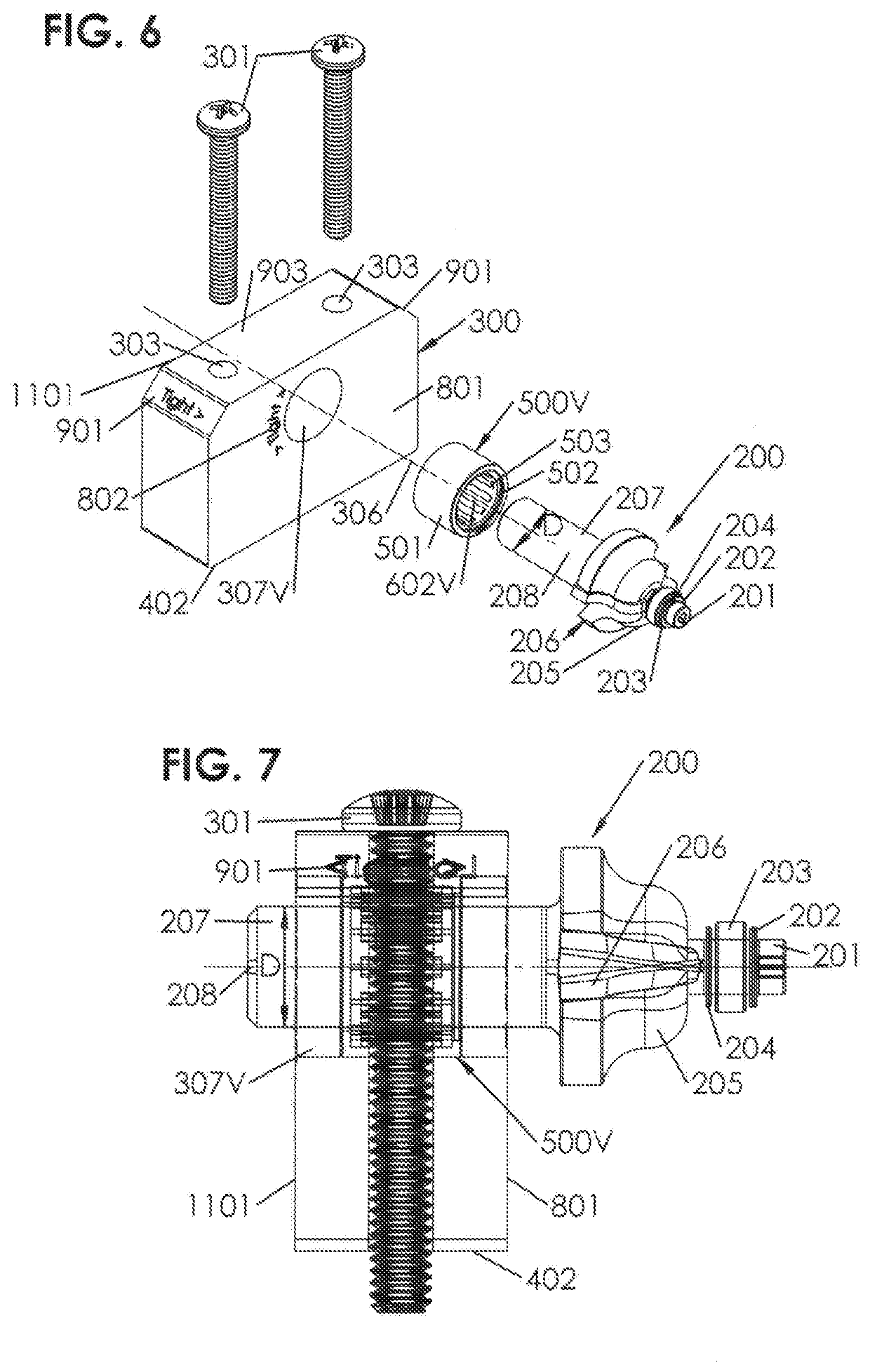

Router Bit Holding Vise

InactiveUS20210107072A1Prevent rotationTorque appliedMilling cuttersProfiling/shaping machinesDrill bit shankEngineering

A router bit vise that holds and prevents the rotation of a router bit in a selected direction. It includes a tool housing and a cylindrical throughbore. Located in the throughbore is a one-way clutch assembly sized to accept a router bit shank. When inserted into the one-way clutch passageway, the router bit shank is engaged by the one-way clutch mechanism preventing movement in one rotational sense and allowing freewheeling movement in the opposite sense. No externally applied clamping force is required. With the router bit shank engaged with the one-way clutch circumferential rotation of the router bit is controlled allowing for bit maintenance, including cleaning, sharpening and most importantly enabling the application of the torque necessary to tighten or loosen a router bit fastener with no potential for shank slipping or damage.

Owner:MILLER JAMES ROBERT

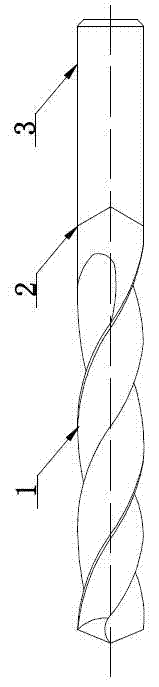

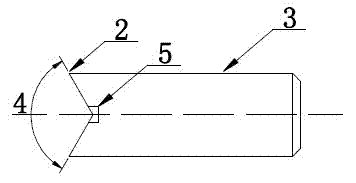

Taper shank twist drill

InactiveCN104353873AIncrease practical rangeReduce wearTransportation and packagingTwist drillsDrill bit shankEngineering

The invention relates to the technical field of tools, in particular to a taper shank twist drill. The taper shank twist drill comprises a drill bit body and a taper shank, wherein the drill bit body comprises a drill bit working part and a drill bit shank part; the taper shank is arranged on the drill bit shank part in a sleeving manner; the taper shank twist drill is characterized in that the drill bit working part is provided with three spiral cutting edges, wherein a chip discharge groove is formed between every two spiral cutting edges; a transverse chip cutting edge is arranged in each chip discharge groove; the drill bit working part is taper; the drill bit shank part is connected with the taper shank through threads; a radiating component is arranged in the upper part of the taper shank; the taper shank below the radiating component is provided with a clamping groove; a supporting plate is clamped on the clamping groove; a communicating through hole is formed between the supporting plate and the bottom of the drill bit working part; the radiating component is fixedly arranged on the supporting plate and comprises an aluminum radiating cylinder; the radiating cylinder is uniformly provided with radiating fins; the taper shank on the outer side of the radiating cylinder is provided with a plurality of ventilation holes. The twist drill has the advantages of good machining efficiency, good chip discharge effect, contribution to clamping and low cost.

Owner:常州华尔澜工具有限公司

Three-sharp wood drill

InactiveCN104354197AHigh strengthExtended service lifeWood turning toolsWood boring toolsDrill bit shankEngineering

The invention relates to the technical field of cutting tools, in particular to a three-sharp wood drill. The three-sharp wood drill comprises a drill shank, a drill bit, and a drill neck for connecting the drill shank with the drill bit, wherein the drill neck is cone-shaped, and the drill neck and the drill shank are integrally formed; two spiral cutting edges are arranged on the circumference surface of the drill shank, and edge points are respectively arranged at the edges and the bottoms of the cutting edges; outwards projecting tool noses are respectively arranged at the joints of the edge points at the edges and the bottoms of the cutting edges, and the inner tool faces of the two tool noses respectively extend towards two opposite directions. The three-sharp wood drill is stable in centering, a tool and a handle are hardly broken, and the production cost is low.

Owner:常州华尔澜工具有限公司

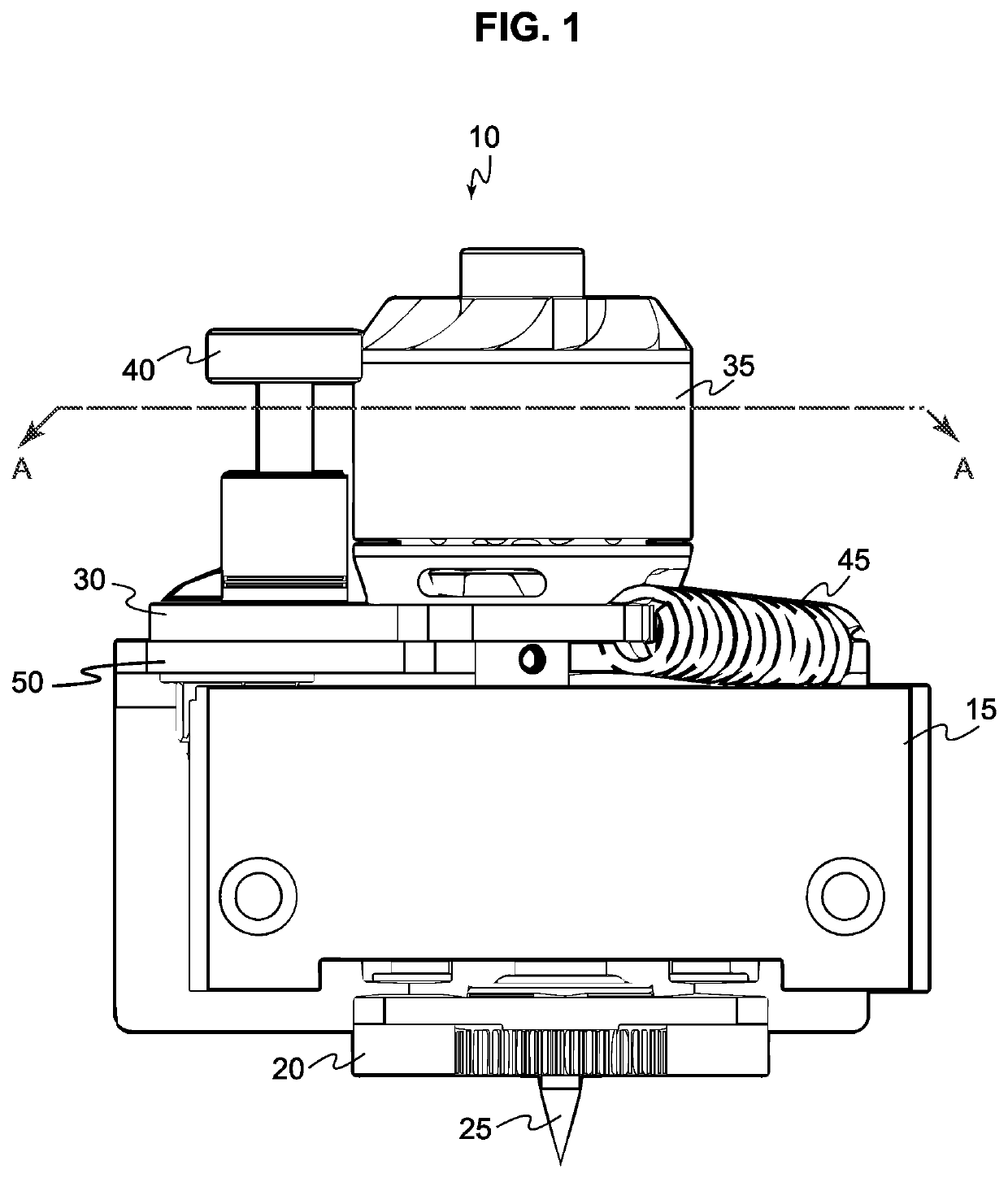

High-speed, low runout spindle assembly

PendingUS20220056951A1Low runout spindleSecurely holdRolling contact bearingsShaftsDrill bit shankDrive wheel

A high-speed low runout spindle assembly is provided. The spindle assembly includes a friction drive wheel configured to be coupled to an output shaft of a motor. The friction drive wheel is configured and disposed to directly contact a shank of a bit. A set of bearings is configured to contact the shank of the bit. A bit clamp assembly includes a clamp bearing having a central through-hole dimensioned to accept a lower portion of the shank of the bit. The bit clamp assembly is configured to hold the bit in contact with the set of bearings.

Owner:ZIPPY ROBOTICS INC

Drill chuck assembly

A drill chuck assembly. The drill chuck assembly includes a rapid change mechanism configured to retain a drill bit shank inserted therein. The drill chuck assembly includes a body having a bore with a trilobe cross-section that is configured to receive a triangular and hexagonally shaped drill bit shank, interchangeably. The bore includes a slot positioned in each lobe that slidably contains a detent ball therein. A collar is affixed annularly around the body and defines a channel extending around the body. A sleeve is slidably mounted around the body. The sleeve includes a tapered end that is slidably disposed within the channel and has circular apertures that are in communication with the slots of the bore for reception of the detent balls. The sleeve is spring biased towards the collar, which forces the detent balls against an angular wall within the channel. The angular wall in turn forces the detent balls laterally towards a center of the bore, thereby exerting a force on a drill bit shank inserted into the bore and preventing the withdrawal of the shank from the bore. When the bias force of the sleeve is counteracted by sliding the sleeve about its longitudinal axis, the detent balls move outwardly along the angular wall, thereby relieving the force exerted onto the shank by the wall and allowing the shank to be withdrawn.

Owner:HOMOLA KAARLE

Color safeguarded dental-implant surgical kit with drilling-depth limiter

InactiveUS20170049531A1Accelerated programQuick selectionDental implantsDiagnosticsDrill bit shankHand held

An apparatus is an implant-dentist more readily identifiable visual segregation amongst their oral-surgery arbor-tools used conjunction with a conventional hand-held power / rotary-tool. The arbor-tools generally has at least a tri-echeloned set, wherein are included progressions of drill-bit lengths and companion thread-taps appearing in three different diameters. Additionally, the drill-bit shanks are optionally provided with a radial-flange serving as an automatic depth-stop device and these radial-flanges may include a distinctive annular-marker device serving to readily indicate the length of the selected drill-bit, thereby obviating usual procedure of stopping to confirm via the obscure conventional alpha-numeric indicia.

Owner:MANSUETO ROBERT F

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com