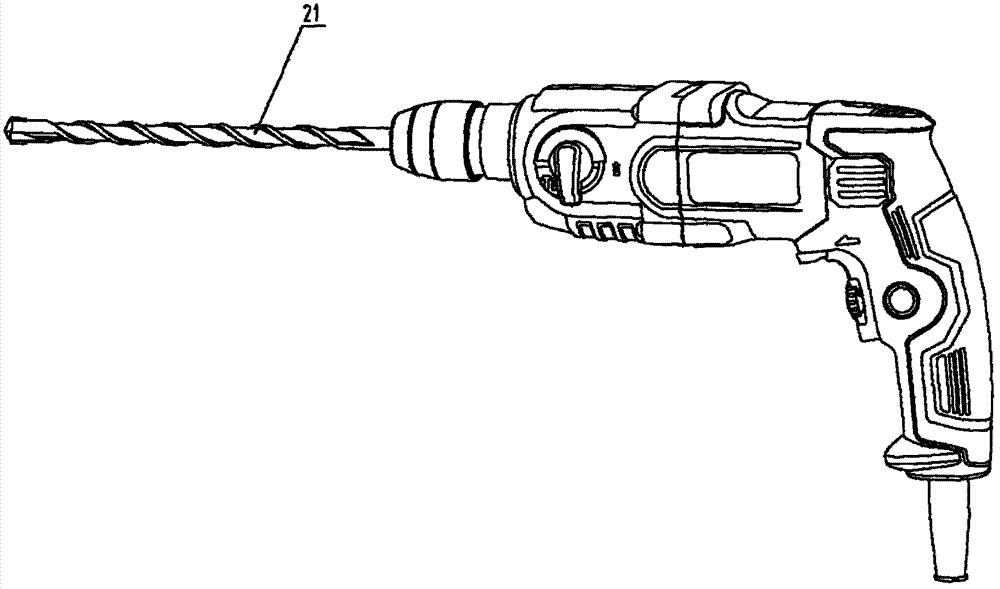

Dual-purpose drill clamp and electric hammer drill using drill clamp

A drill fixture and dual-purpose technology, applied in the direction of drilling/drilling equipment, manufacturing tools, striking tools, etc., can solve the problems of inconvenient operation, low drilling precision, and low processing efficiency, and achieve convenient operation and compact structure , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

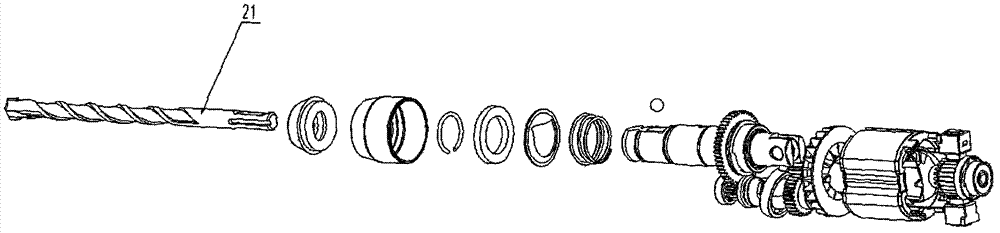

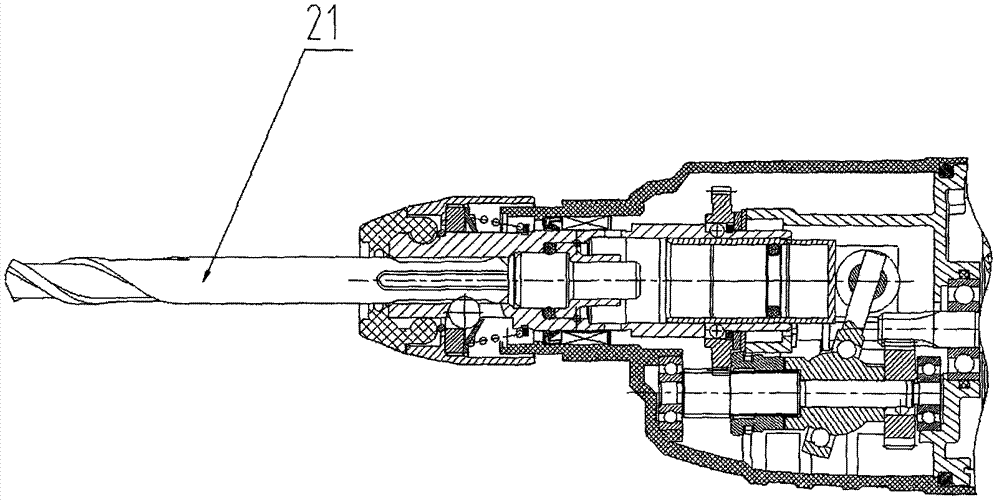

[0045] refer to Figure 3 ~ Figure 12A , a dual-purpose electric hammer drill fixture and an electric hammer drill 20 using the same. The dual-purpose electric hammer drill fixture includes a rotating sleeve 39, a drill chuck 22 that is socketed with the rotating sleeve 39 and connected through a fixed connection device; The through hole, the electric hammer drill 21 can pass through the through hole and be installed in the rotating sleeve 39, the socket of the rotating sleeve 39 and the drill chuck 21 is axially corresponding to the shank of the electric hammer drill 21, and the outer wall of the drill chuck is provided with a clamping Holder for electric drill bits. Other electric drill bits such as twist drills can be assembled on the clamping piece. The fixed sleeve 36 is located at the rear of the drill chuck 22 and is set on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com