Patents

Literature

223results about How to "Fast drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

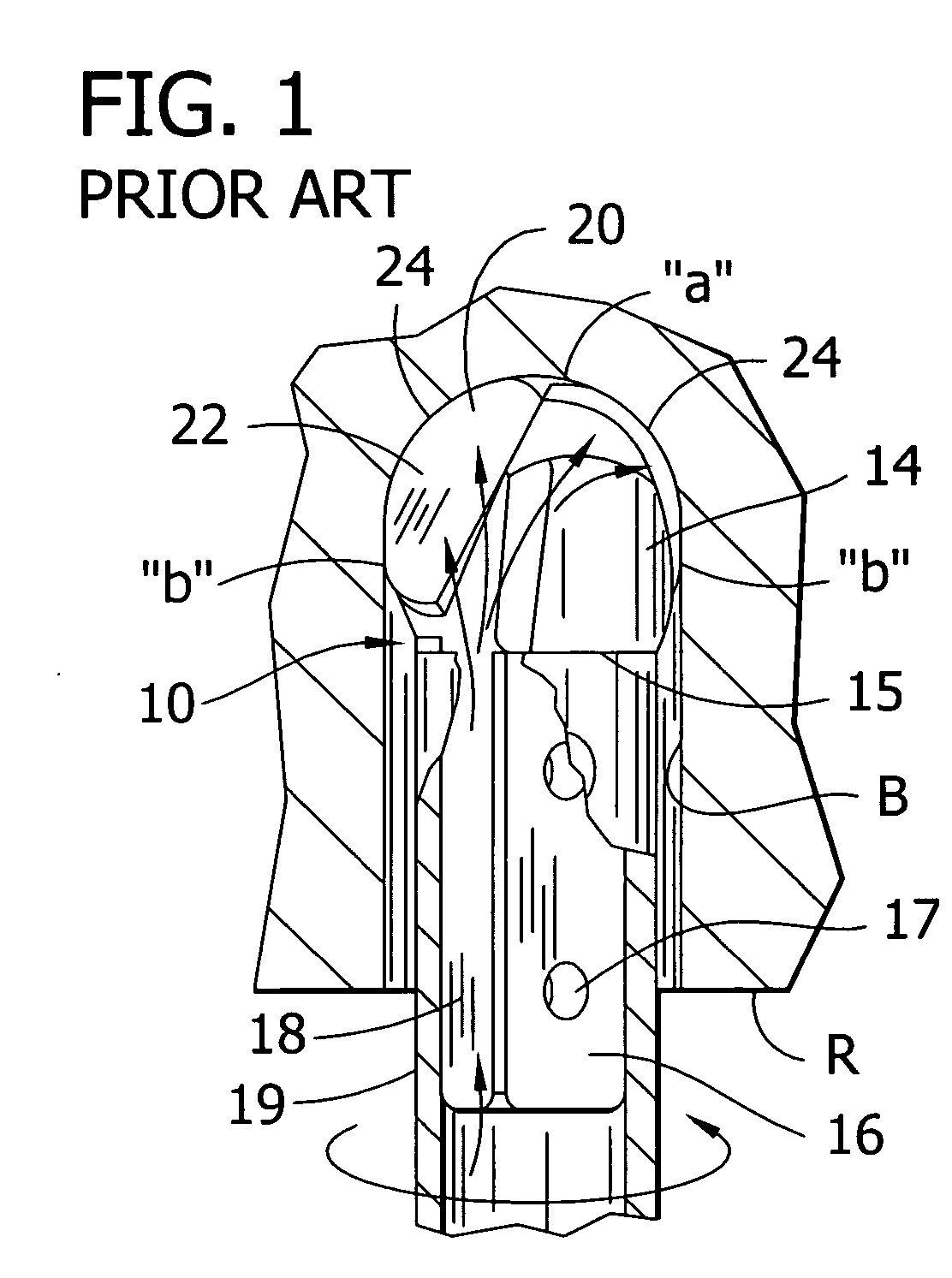

Modular kerfing drill bit

InactiveUS20060196699A1Component part be reduceQuickly assembleDrill bitsCutting machinesEngineeringDrill bit

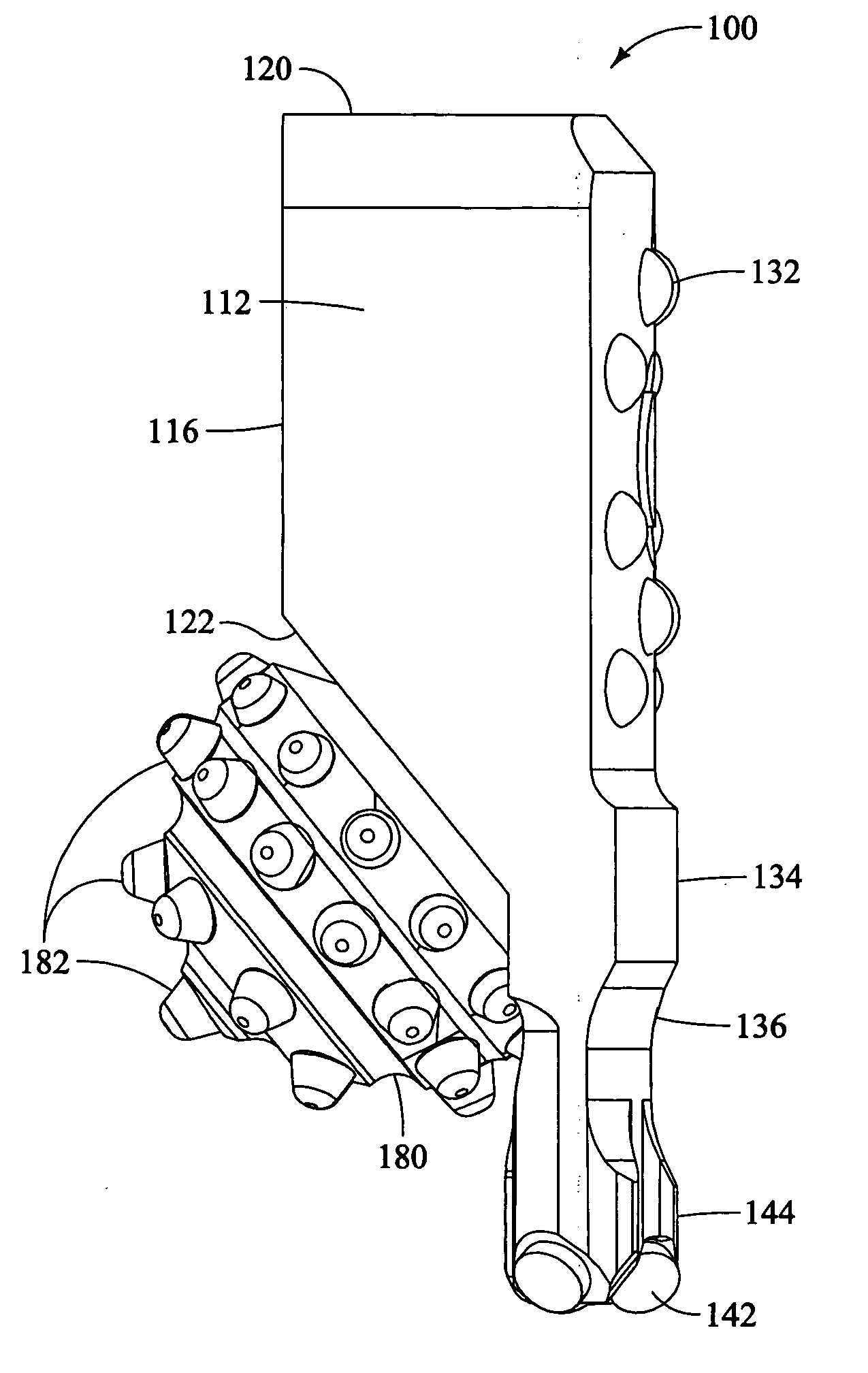

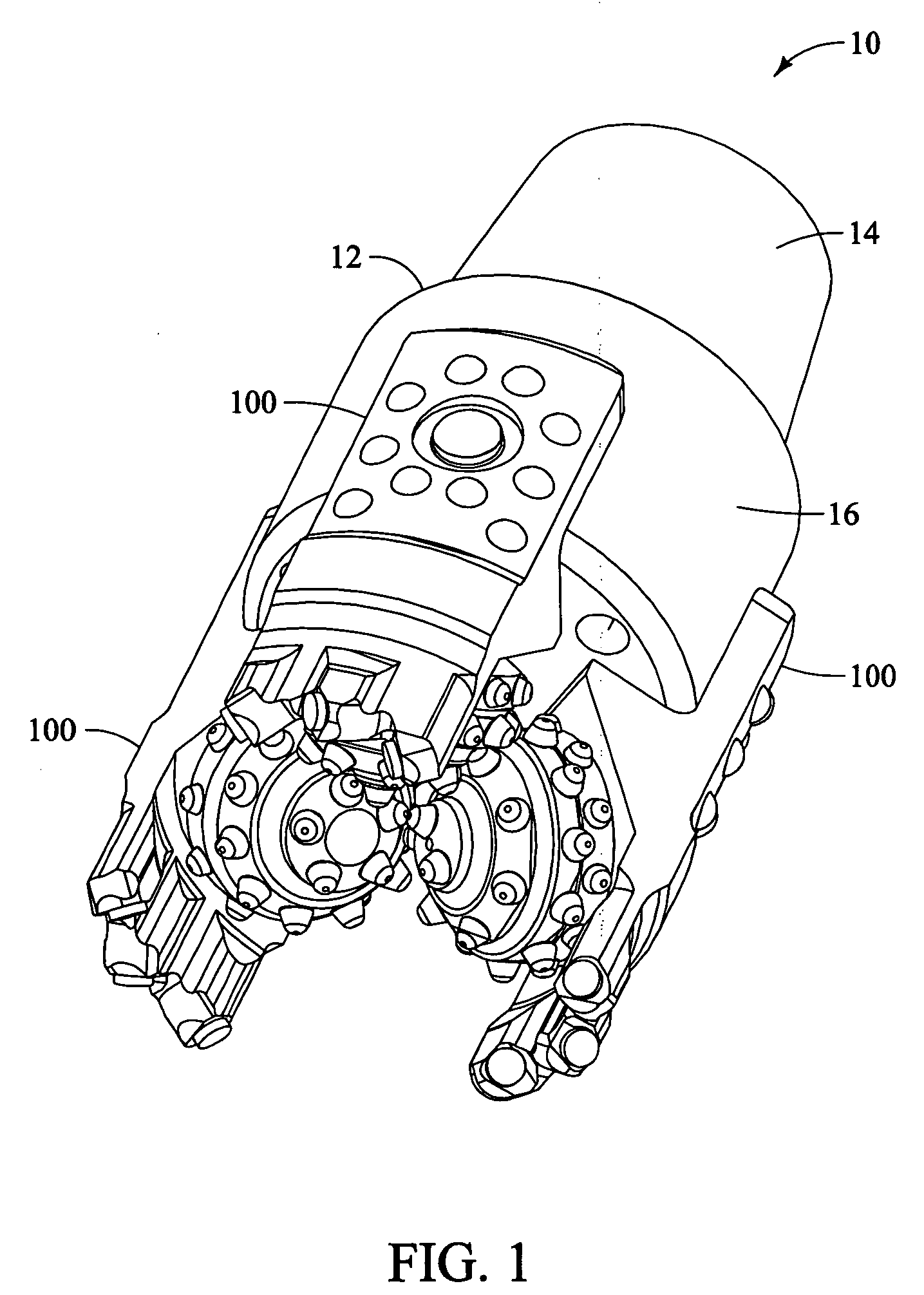

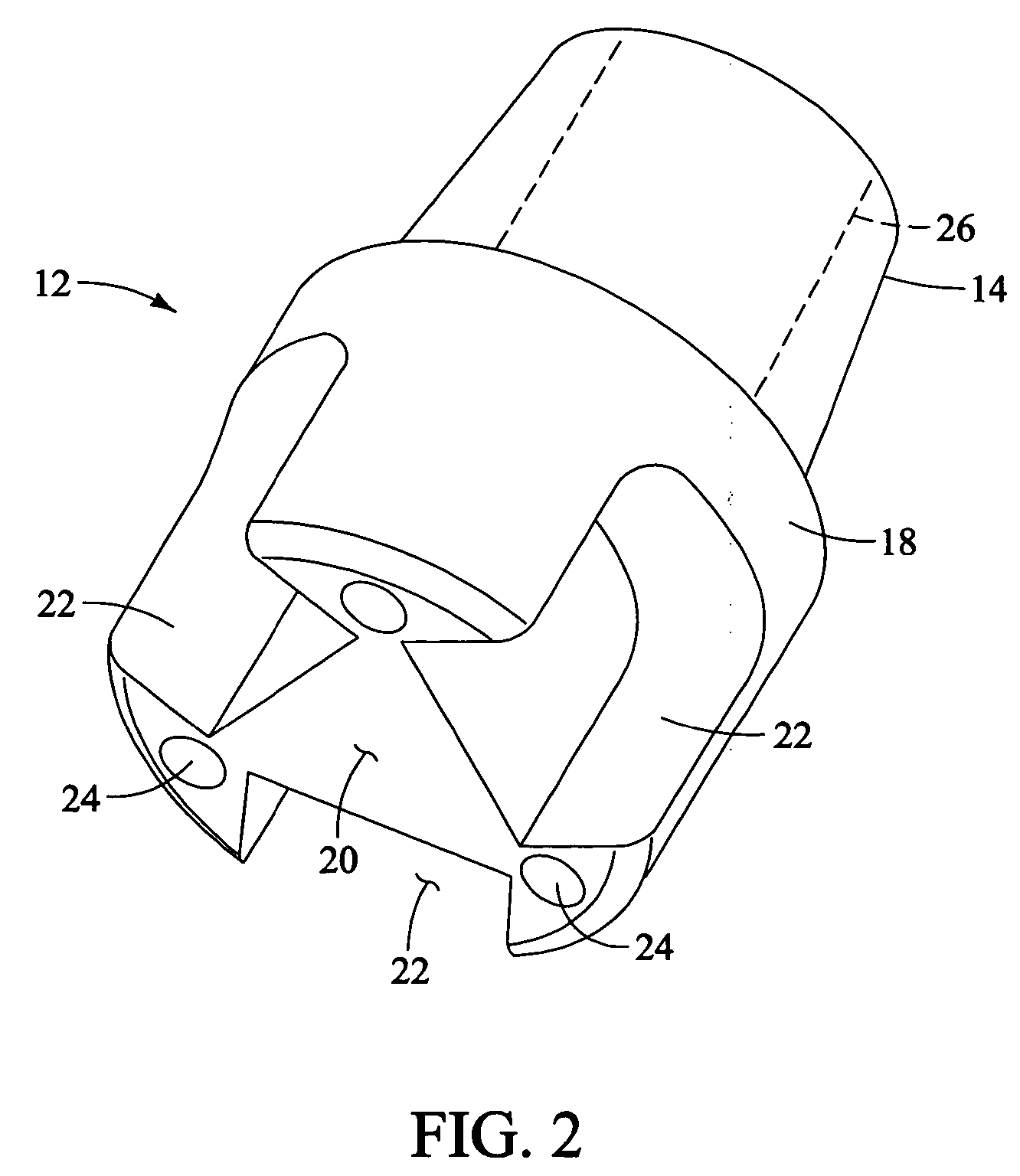

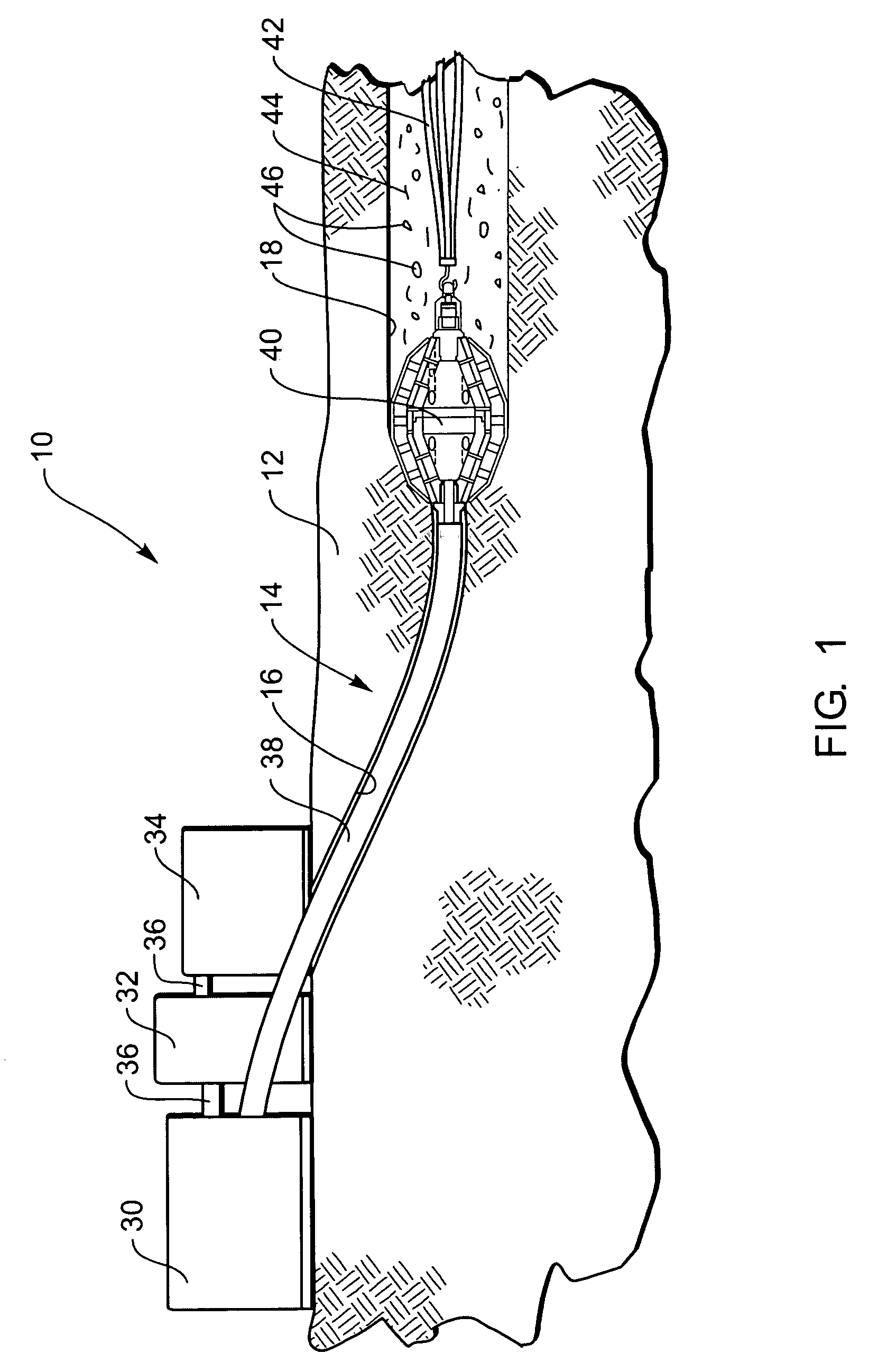

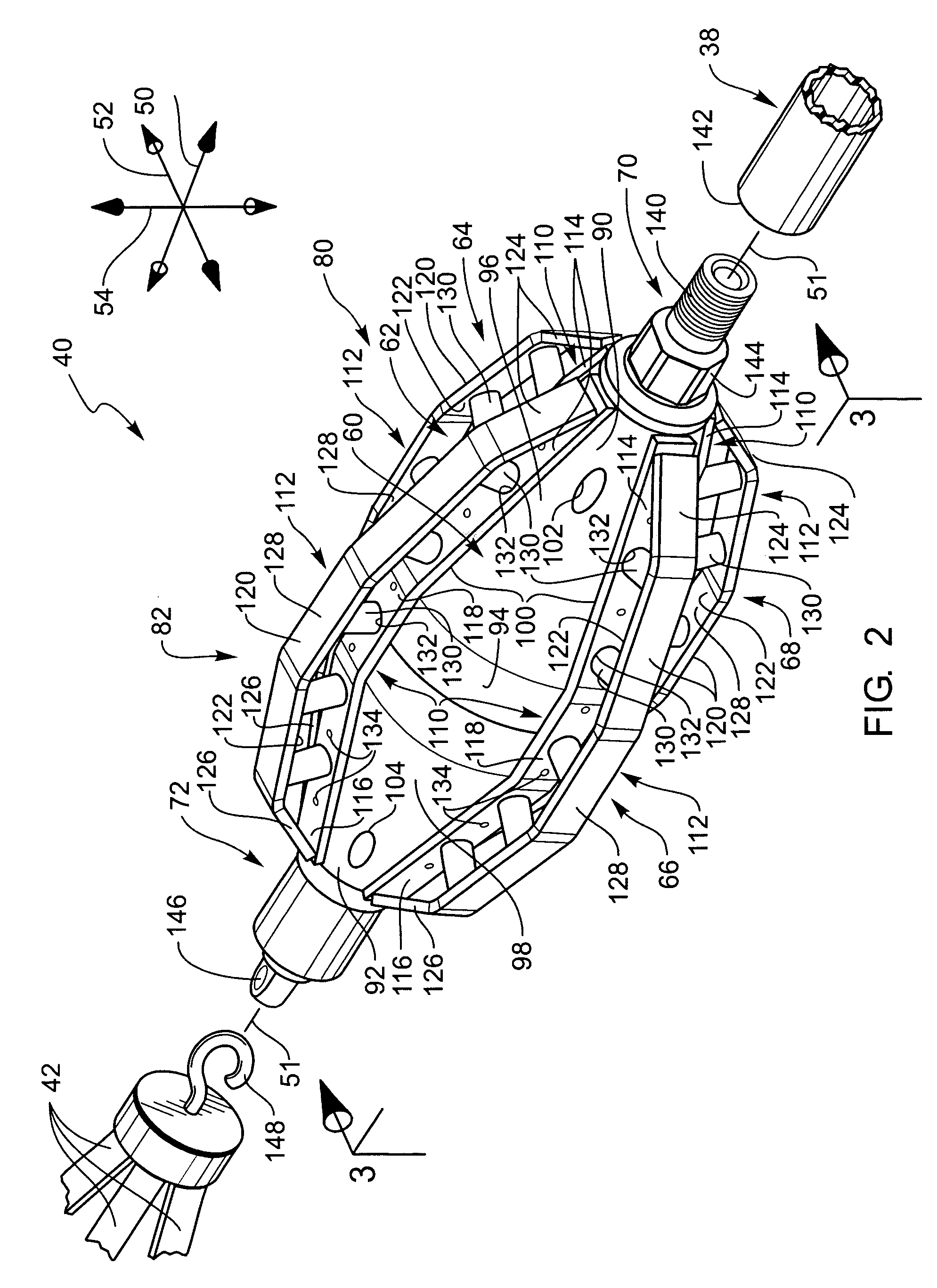

A modular kerfing rock drilling bit (10) is presented. Drill bit (10) comprises a bit body (12) having a connection (14) for attachment to a drill string member. A base portion (16) below the connection (14) has an outer portion (18) and a bottom (20). Slots (22) are formed in the base portion (16). A cutter assembly (100) comprises a leg (110) insertable into the slot (22) of the bit body (16). A journal (126) extends angularly downward and inward from the leg (110) for bearing support of a cone (180) rotatably mounted on the journal (126). A plurality of cutters (182) extend outward from the surface of the cone (180). A kerfing segment (140) extends downward from the leg (110) beyond the cone (180). A plurality of kerf cutters (142) are attached to the bottom of the kerfing segment (140).

Owner:GEN ELECTRIC CAPITAL +2

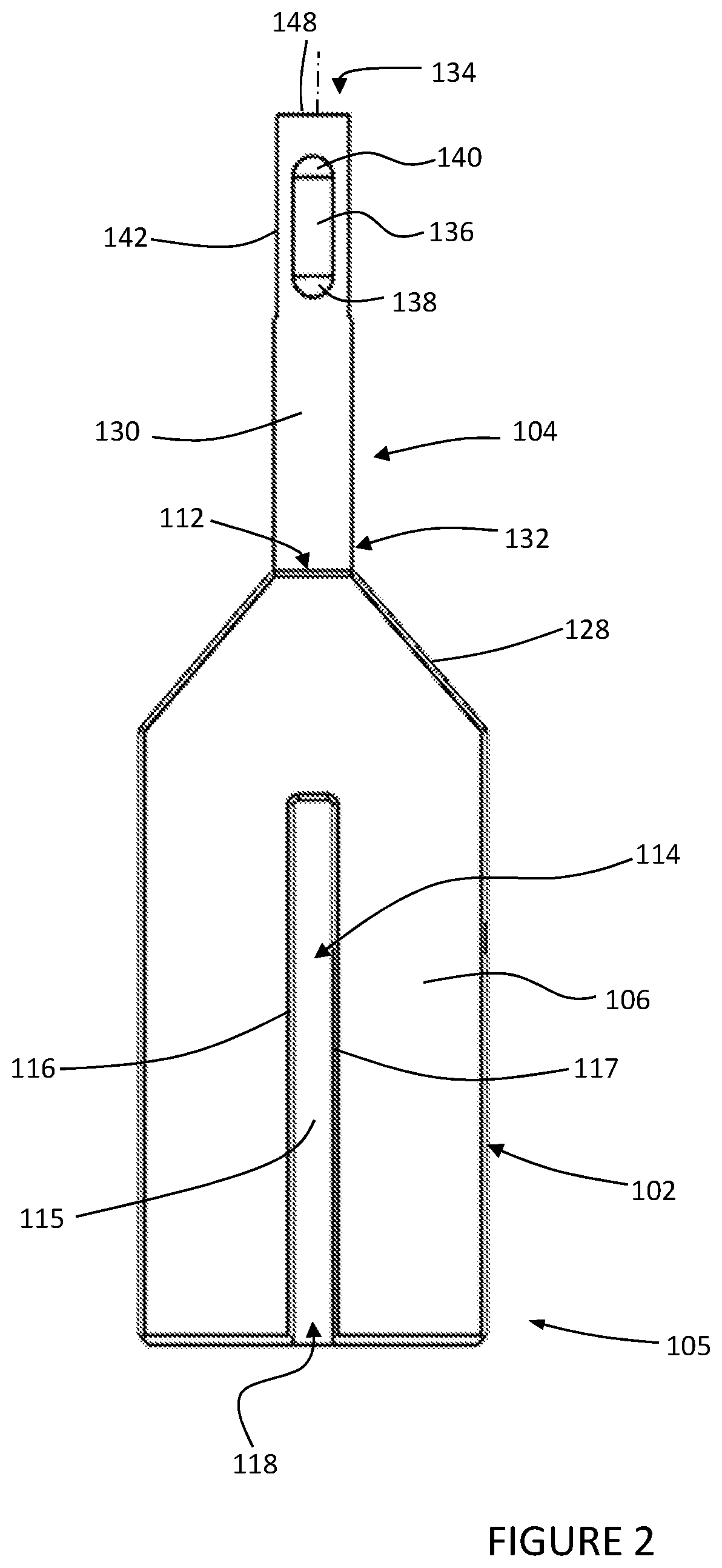

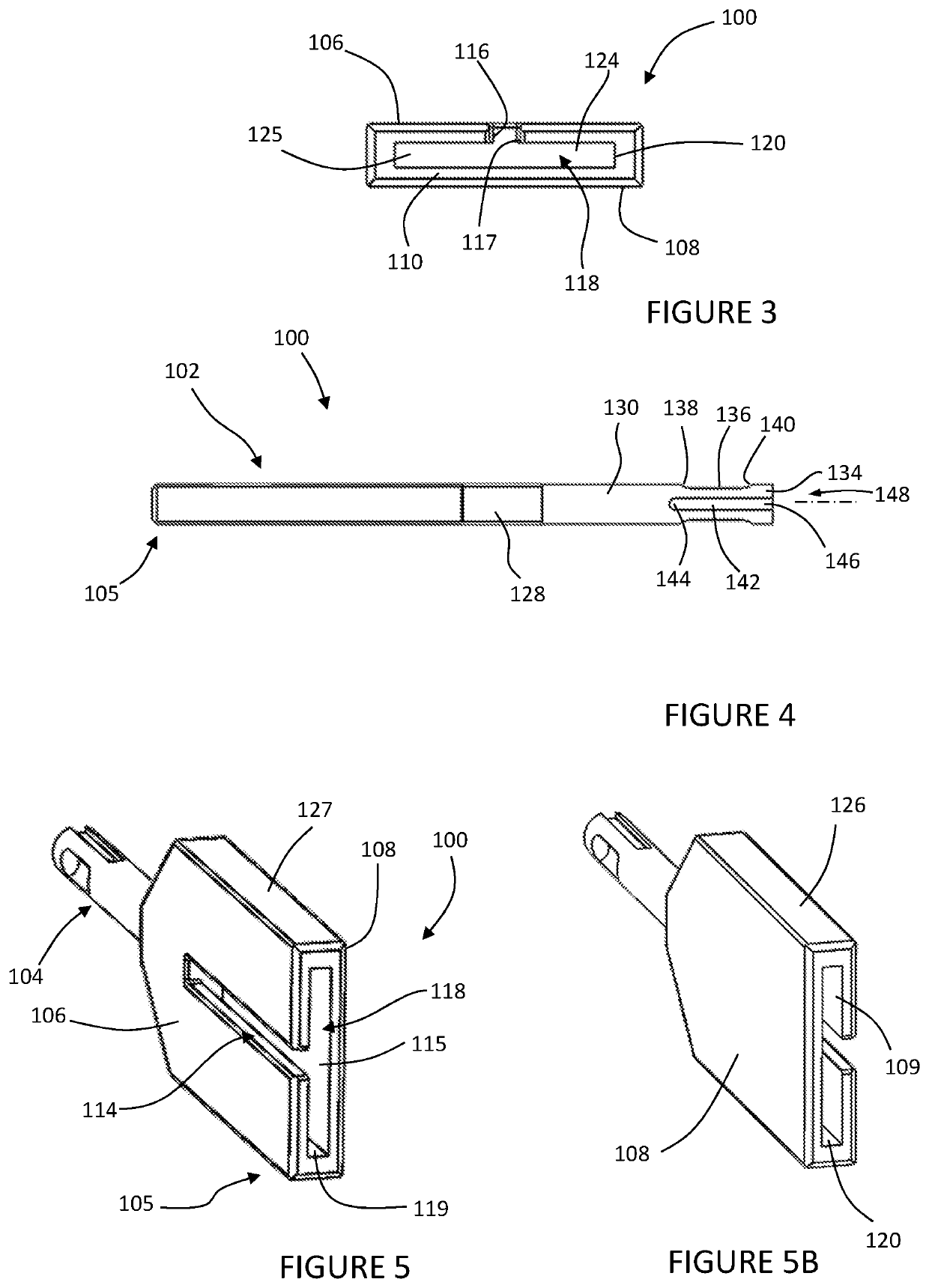

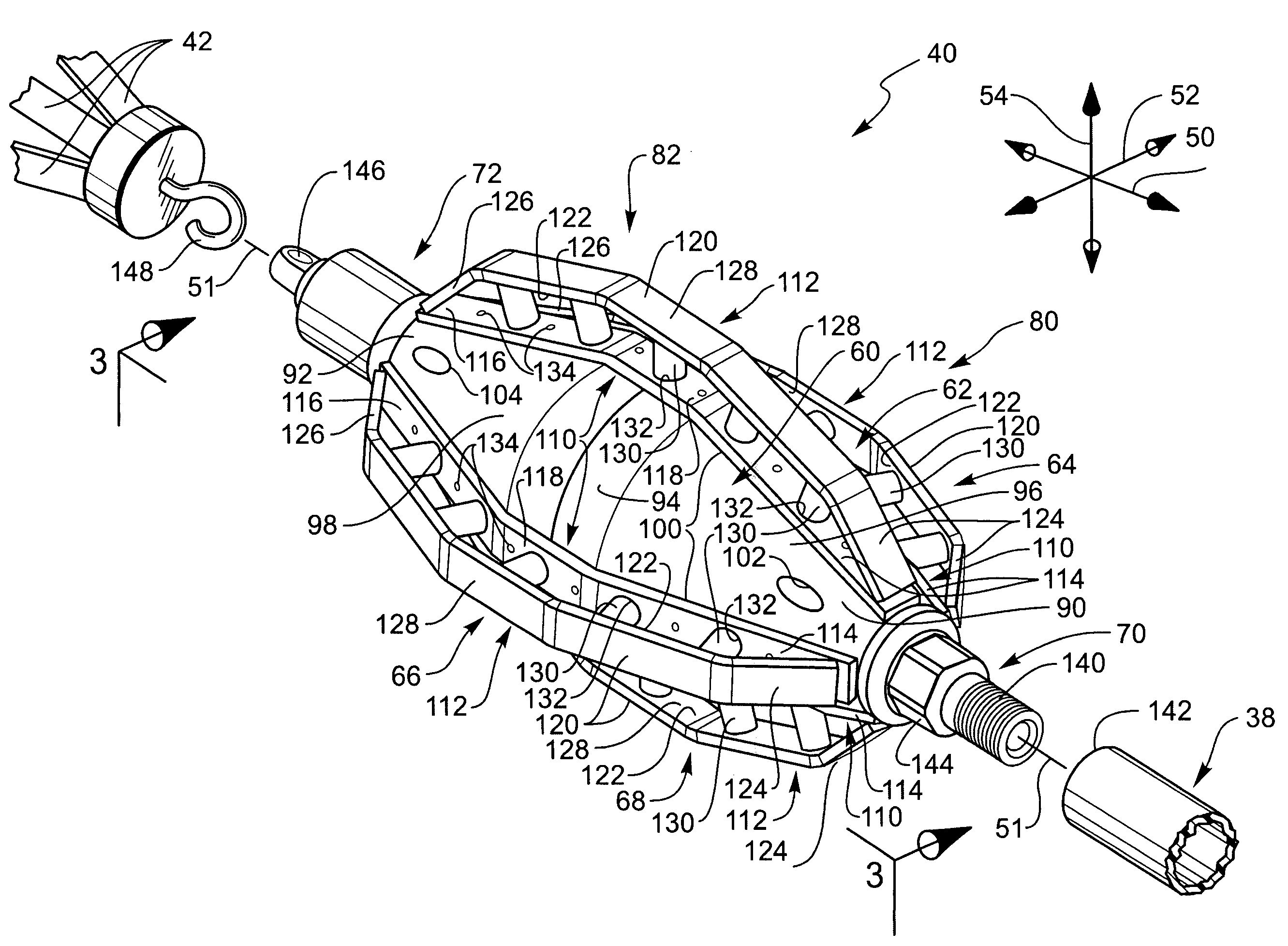

Hammer drill adaptors and methods of use

ActiveUS10589410B2Short, rapid hammer thrustBrittle materialPortable percussive toolsStructural engineeringMechanical engineering

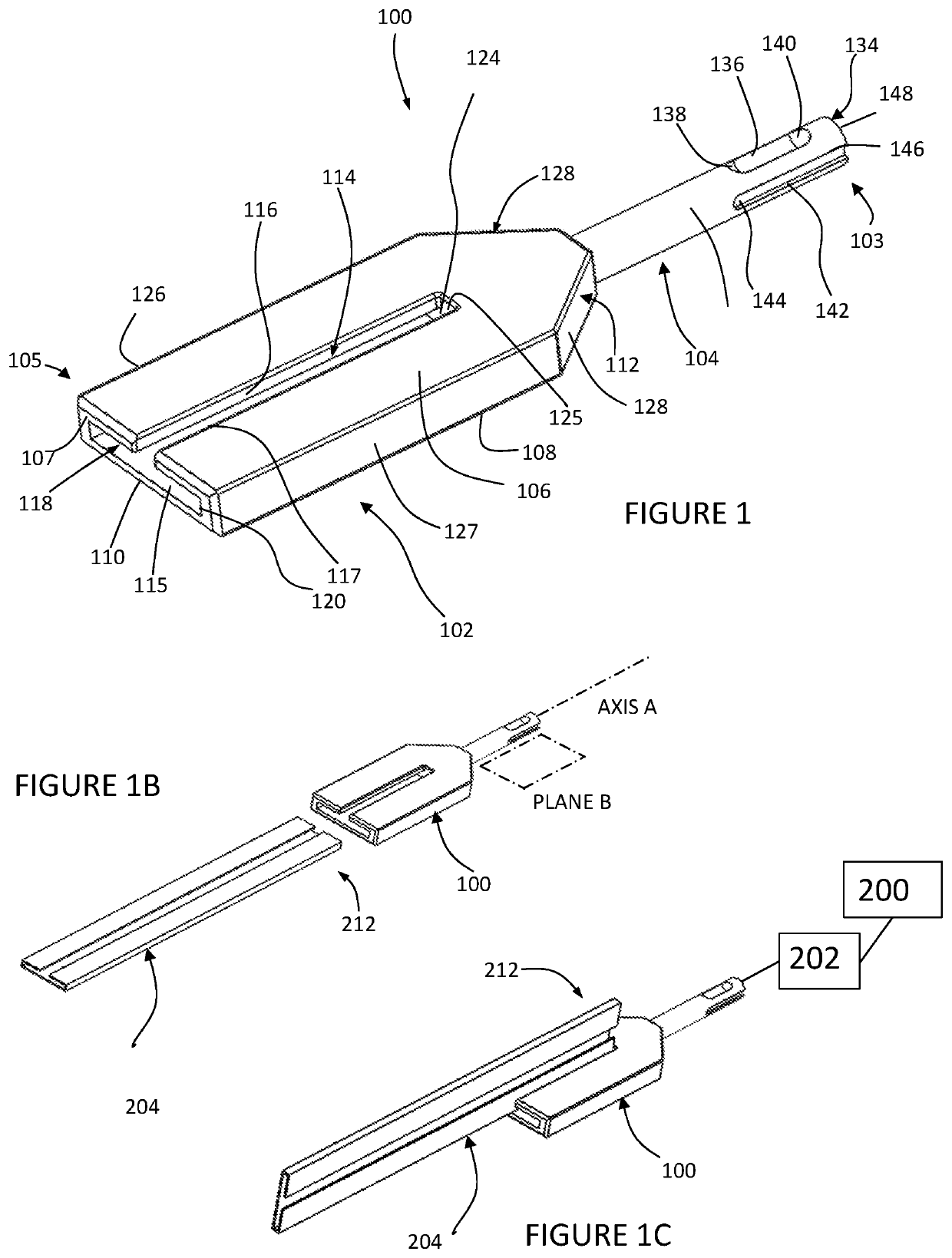

A hammer drill adapter for driving a drive cleat to join opposed ends of a duct comprising: a first portion generally aligned in a plane; a shaft portion having an elongate axis generally parallel to said plane; the first portion fixed to the shaft portion; an entry surface at a distal end of the first portion; a capture cavity extending through the entry surface; the capture cavity defined proximally by a rear surface and by an opposed lower and upper capture surfaces; the capture cavity also laterally defined by an opposed first capture surface and a second capture surface; the capture cavity sized to house a trailing end portion of a drive cleat; and wherein the shaft portion comprises a connection portion at a proximal end of said shaft portion for fixation within a hammer drill chuck. Also disclosed are methods for use to advance a drive cleat.

Owner:AHO RONALD

Precision drill bit

InactiveUS6126367AReduce frictionExtended bit lifeWood turning toolsTransportation and packagingHand heldDrill bit

Owner:LOCK N STITCH INC

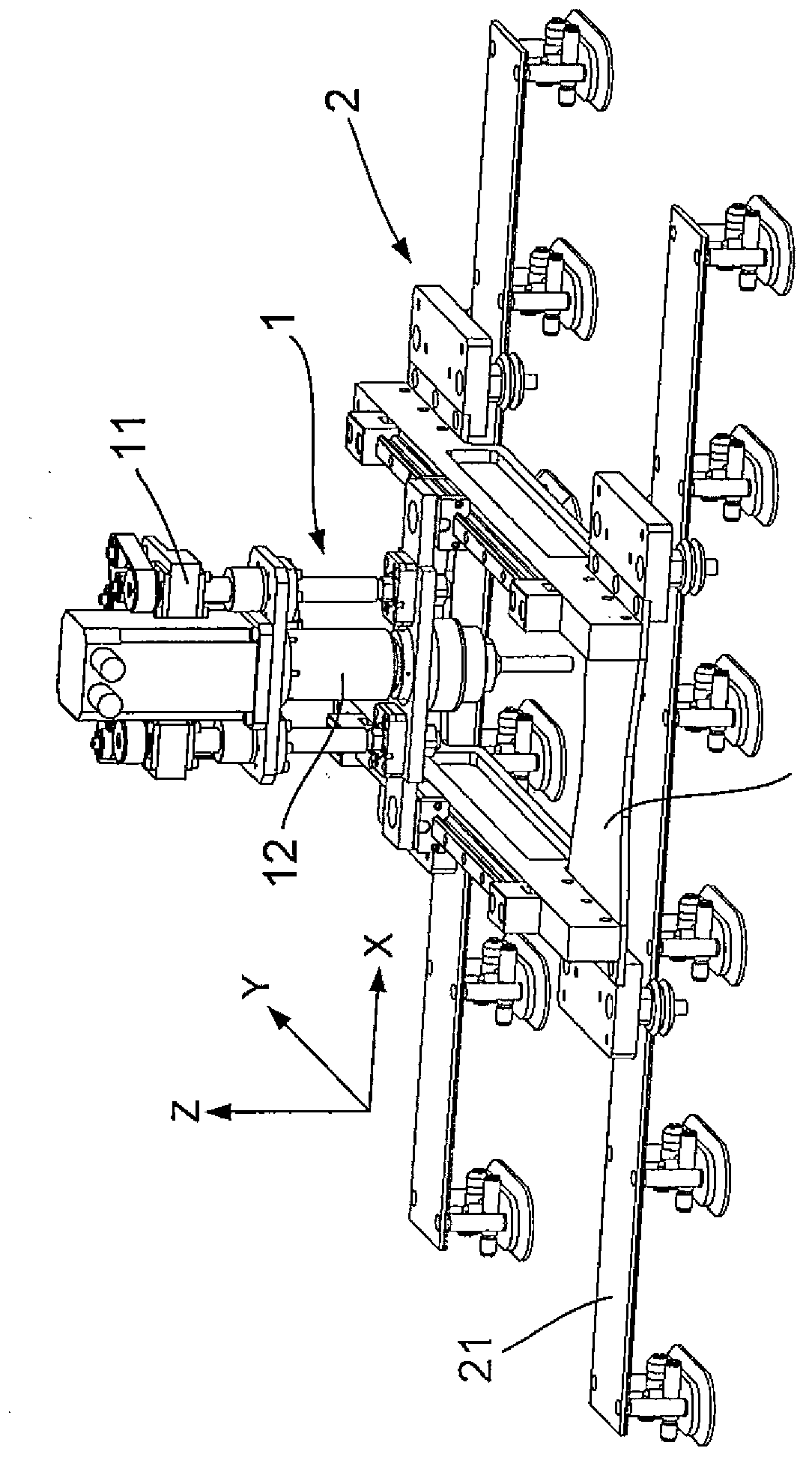

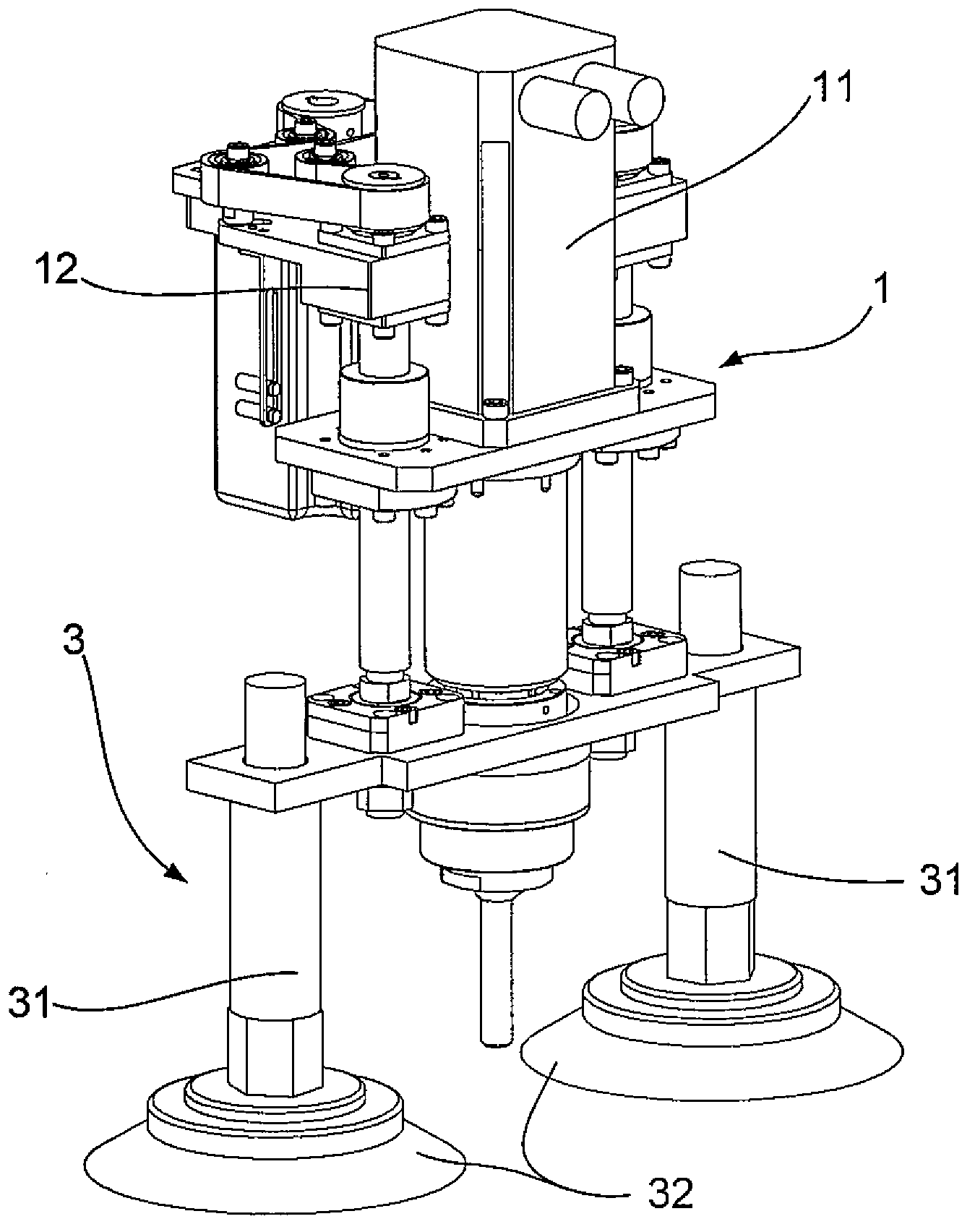

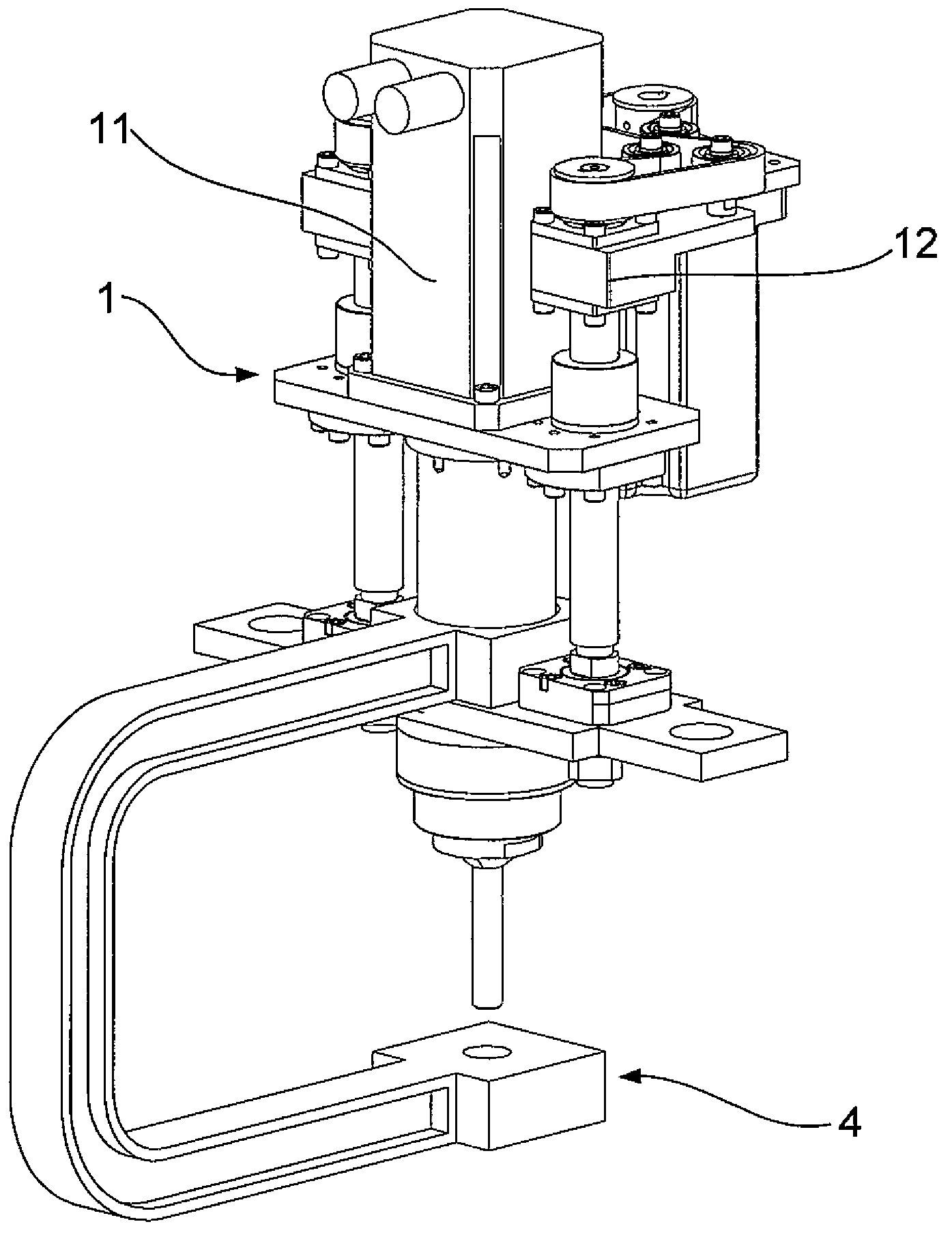

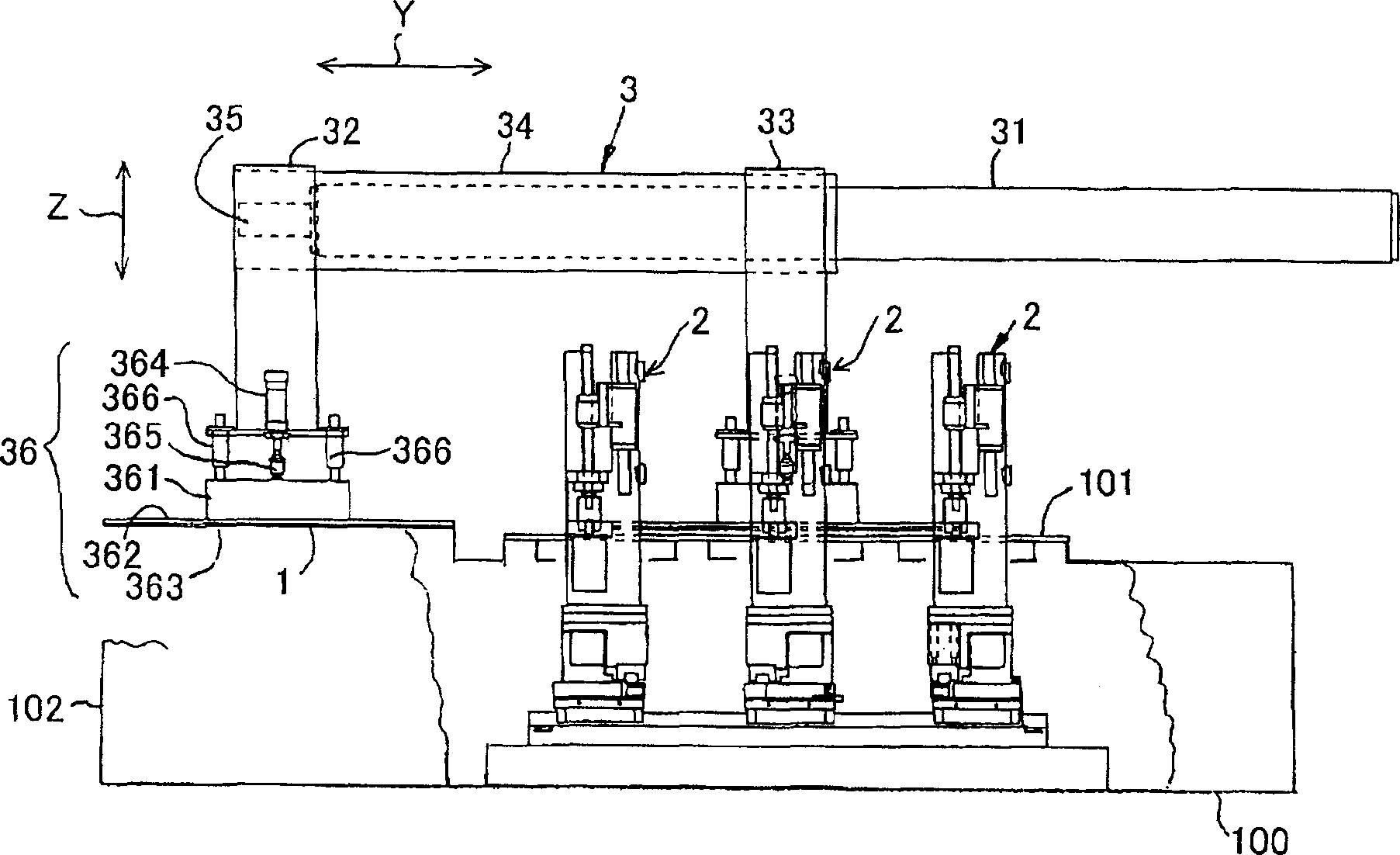

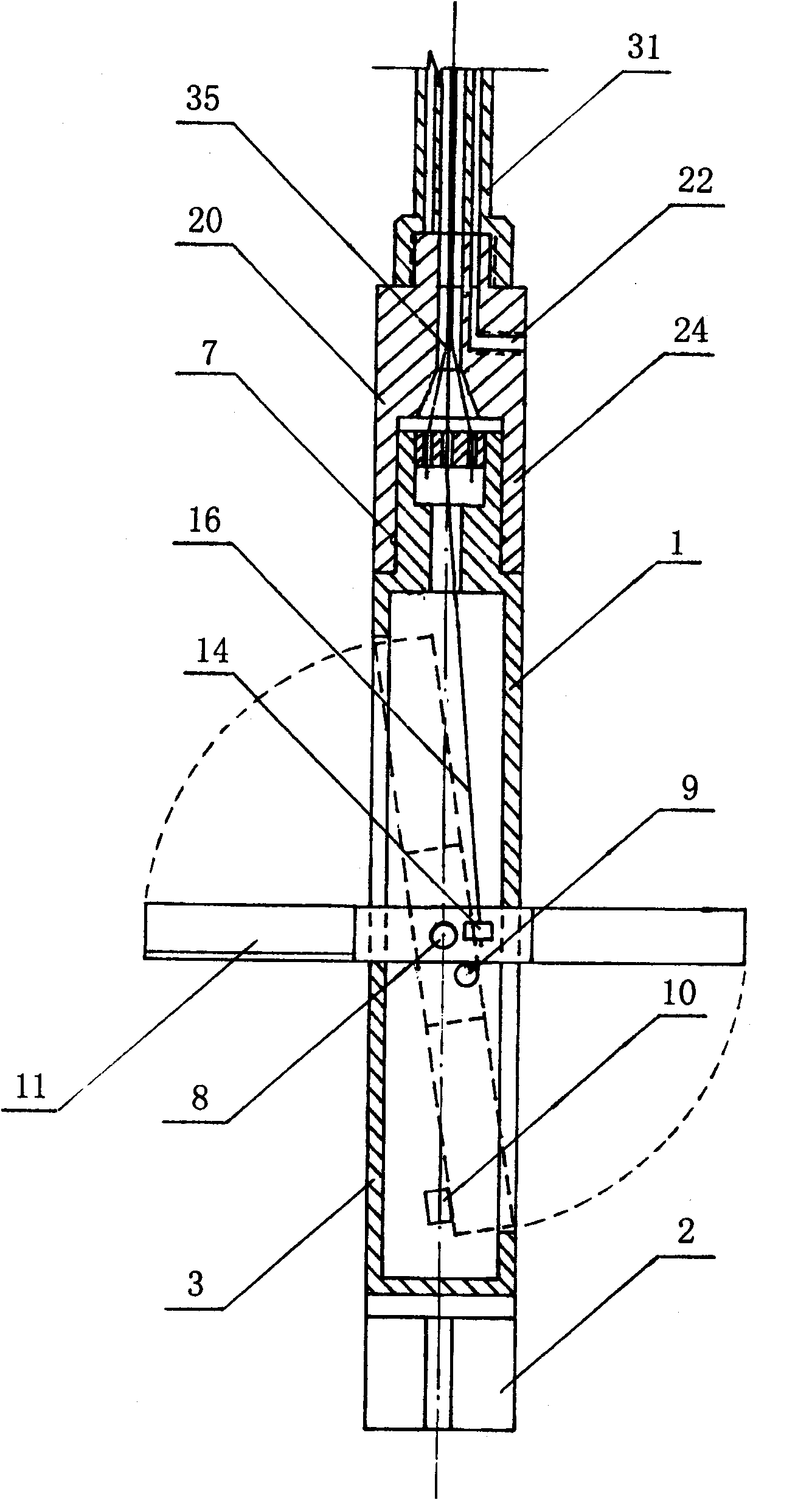

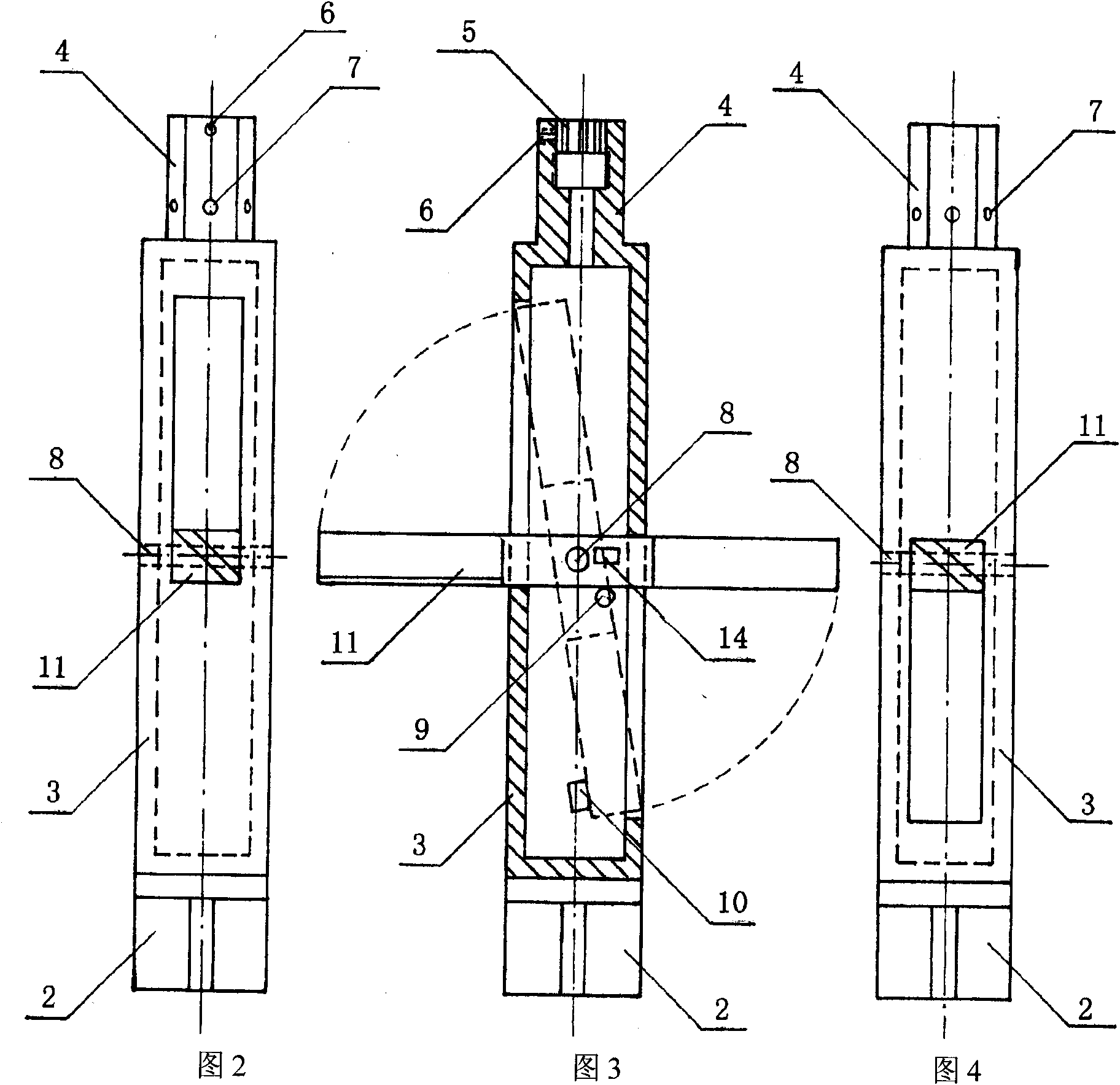

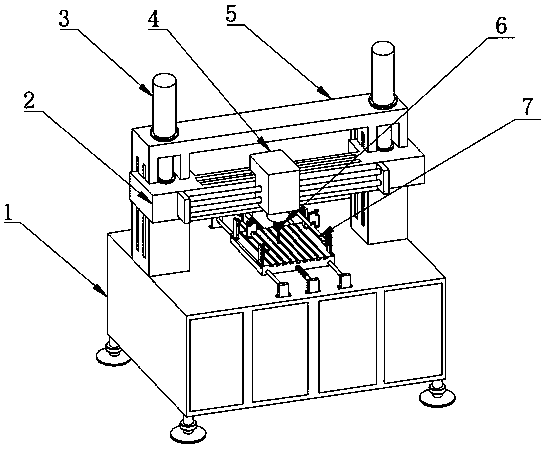

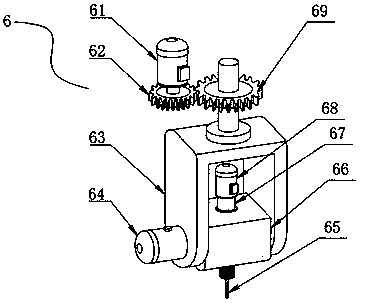

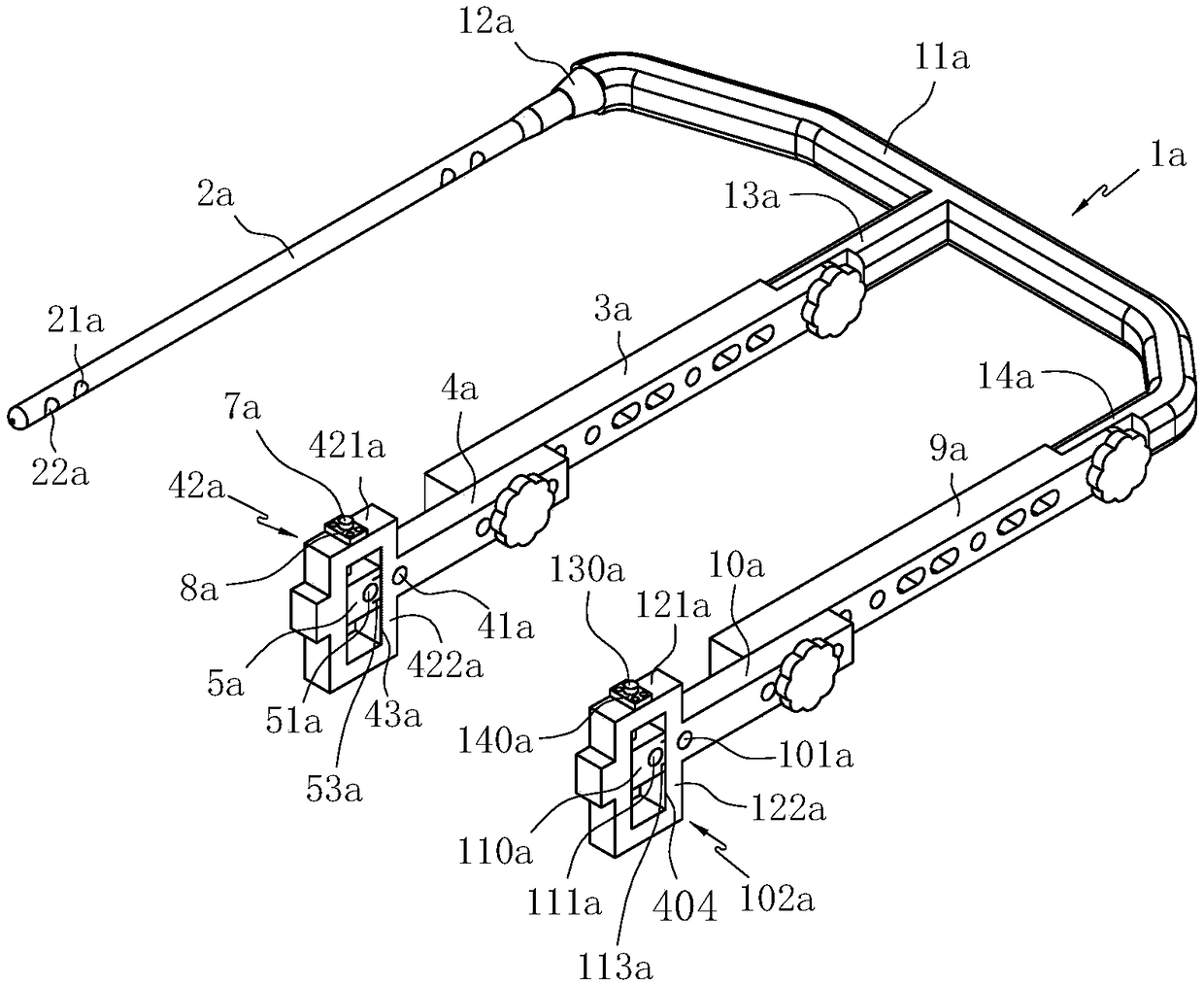

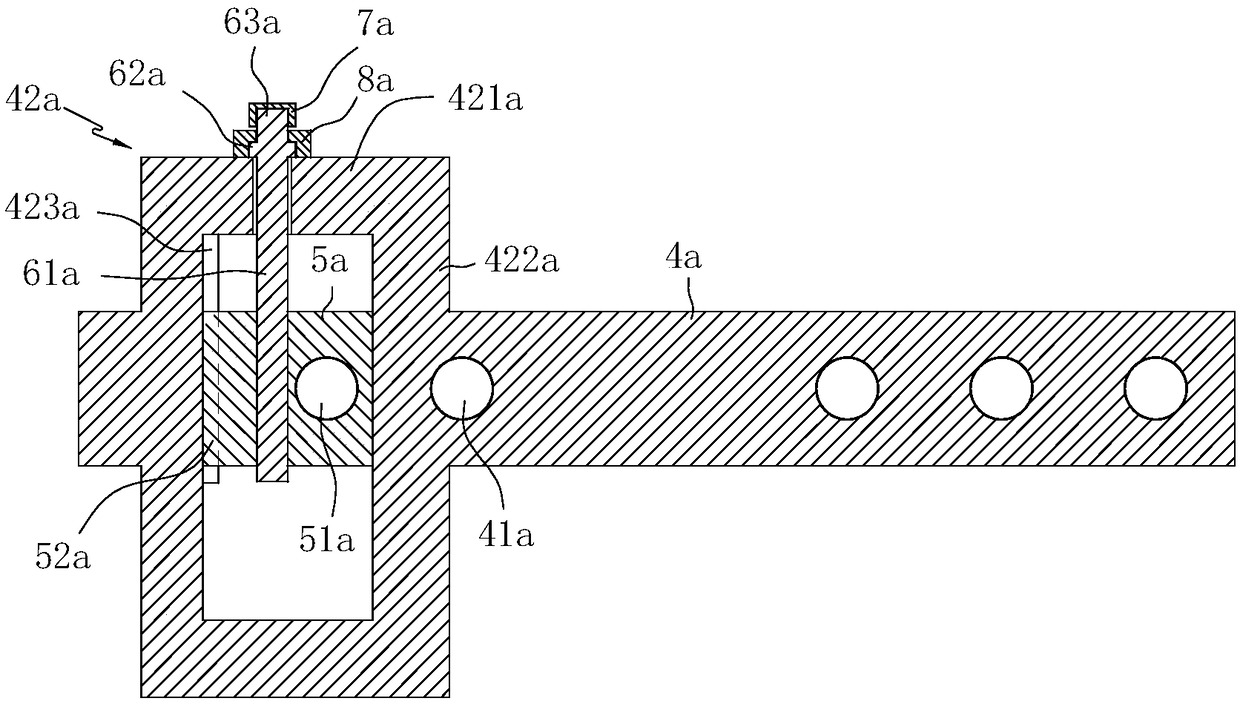

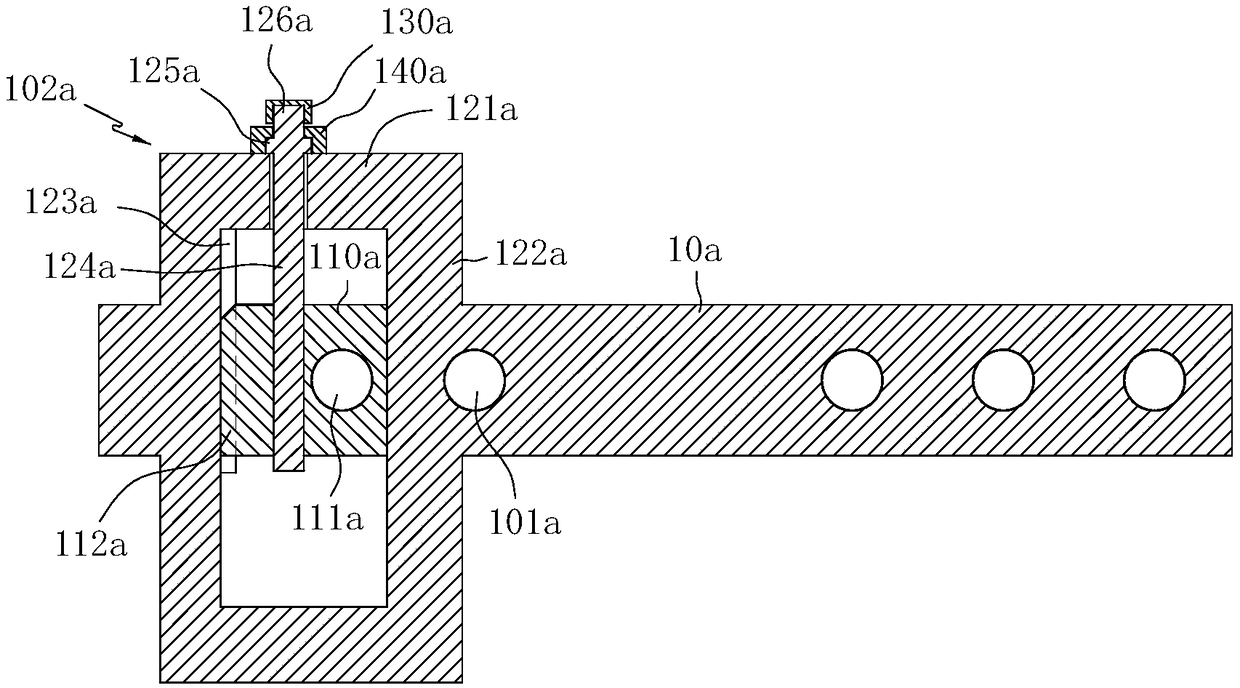

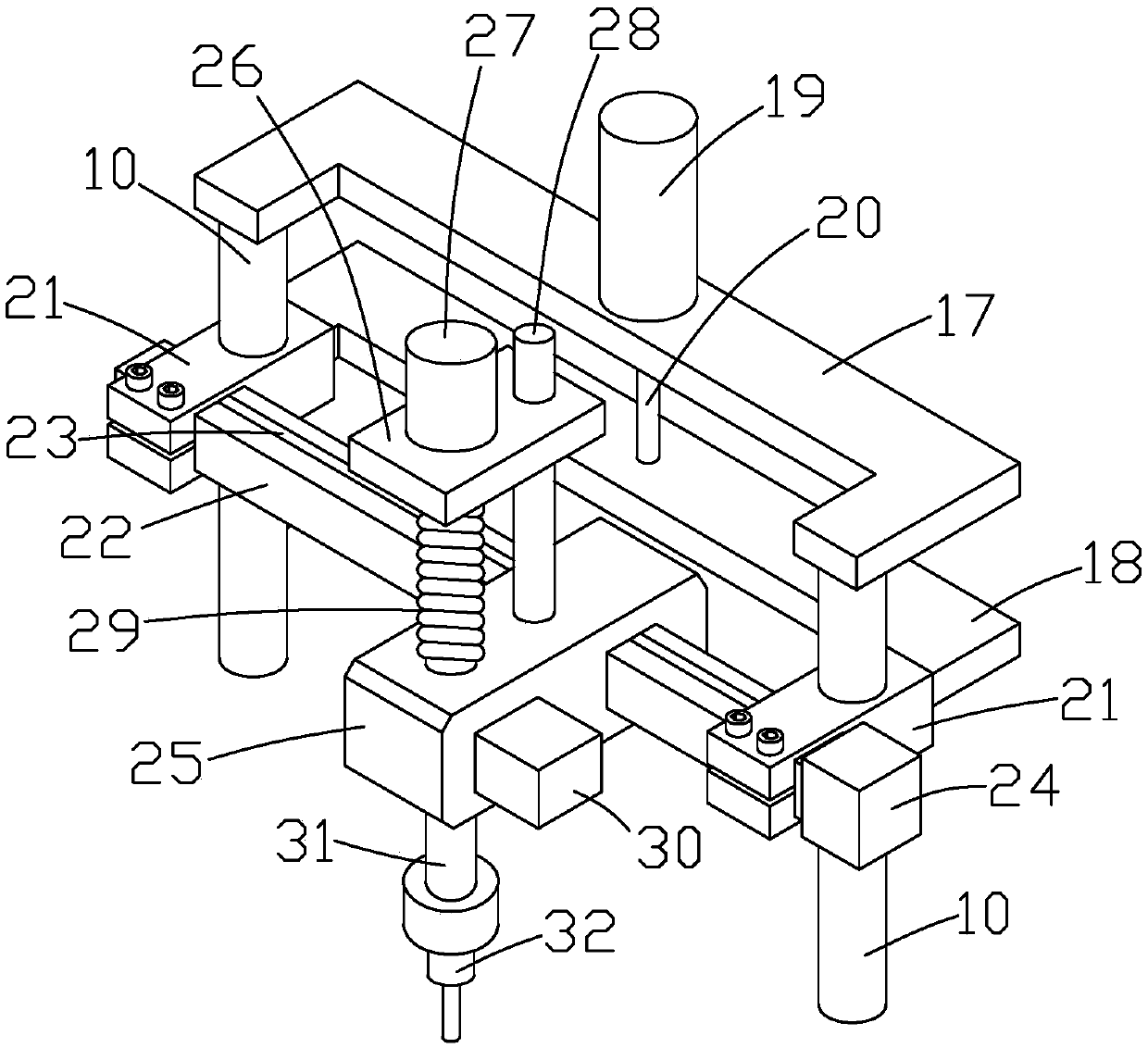

Replaceable precise automatic feeding drill

The invention discloses a replaceable precise automatic feeding drill, which consists of an automatic feeding drill main body and working platforms. Different working platforms can be selected according to different using environments or conditions, and operation of drilling, reaming, counter sinking and the like of machined workpieces are implemented. The working platforms comprise an X-Y flexible track platform (1), a bilateral sucking disc platform (2) and a C-shaped jaw platform (3), wherein the X-Y flexible track platform (1) can adapt to and attract surfaces with different curvatures; the bilateral sucking disc platform (2) can attract the fixed workpieces in a narrow space; and the C-shaped jaw platform (3) can be used for conventional drilling as a bench drill. The invention has the advantages that the automatic feeding drill is precise and portable, can be quickly replaced and can be used for accurately and quickly drilling various different workpieces.

Owner:SHANGHAI AIRCRAFT MFG +1

Rotary drag bit and methods therefor

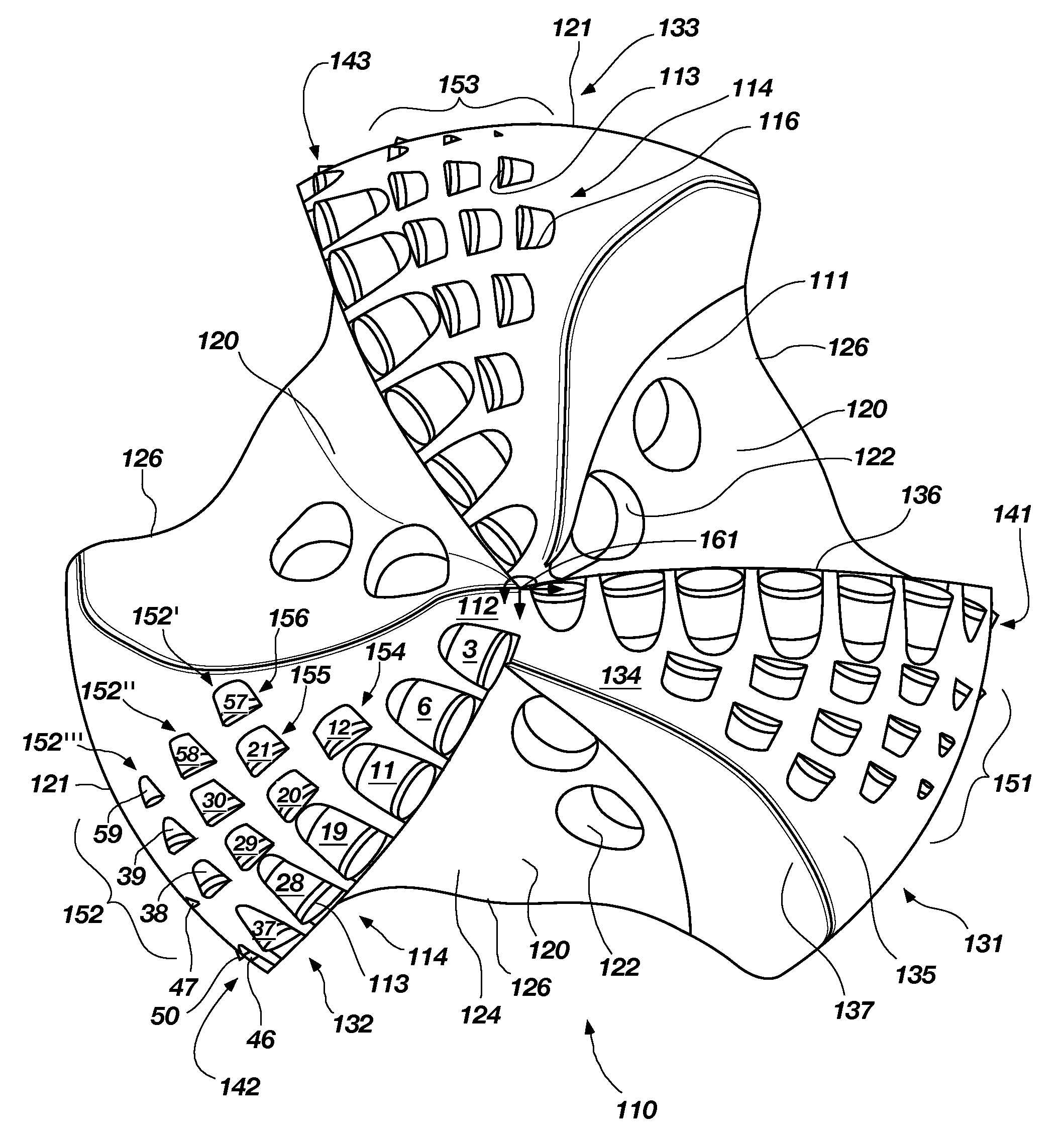

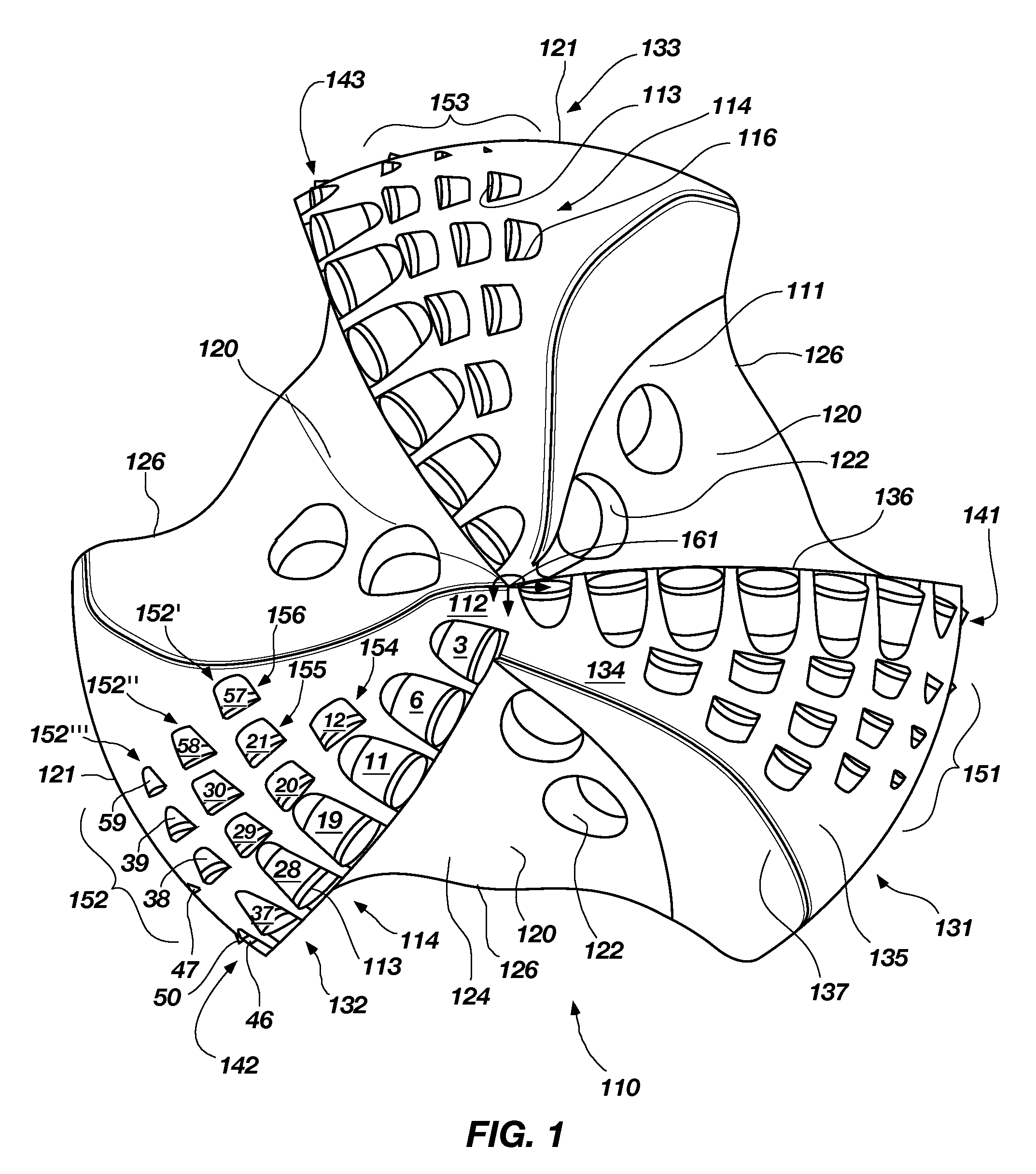

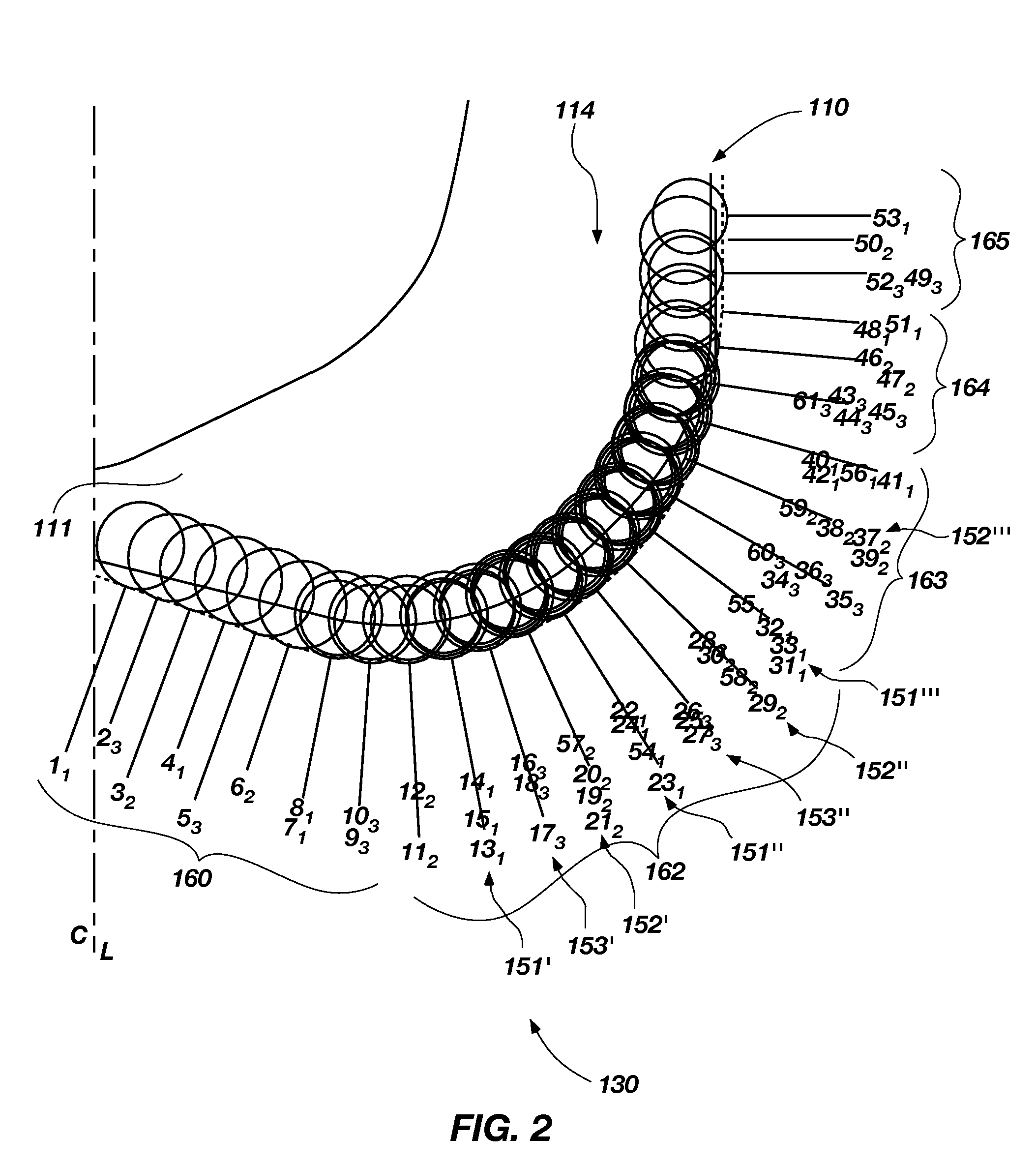

A rotary drag bit includes a bit body having a face and an axis, a plurality of blades extending radially and longitudinally outward from the face, and at least one split cutter set. The split cutter set includes a plurality of cutters, where at least two of the cutters are primary and / or kerfing cutters located on different blades of the plurality of blades. The pair of primary and / or kerfing cutters of the split cutter set may be located substantially the same radial distance from a center line, or axis of rotation, of the bit and located at substantially the same longitude, or elevation, on the bit as one another, or follow substantially the same rotational or helical cutting path as each other. In addition, at least one backup cutter may be located substantially the same radial distance from a center line, or axis of rotation, of the bit and located at substantially the same longitude, or elevation, on the bit as one or both primary and / or kerfing cutters, or follow substantially the same rotational or helical path as one or both of the primary and / or kerfing cutters. The cutters of a split cutter set may be configured and oriented to provide improved bit life and reduced stress on the cutters. Other embodiments of rotary drag bits are also provided, including methods therefor.

Owner:BAKER HUGHES INC

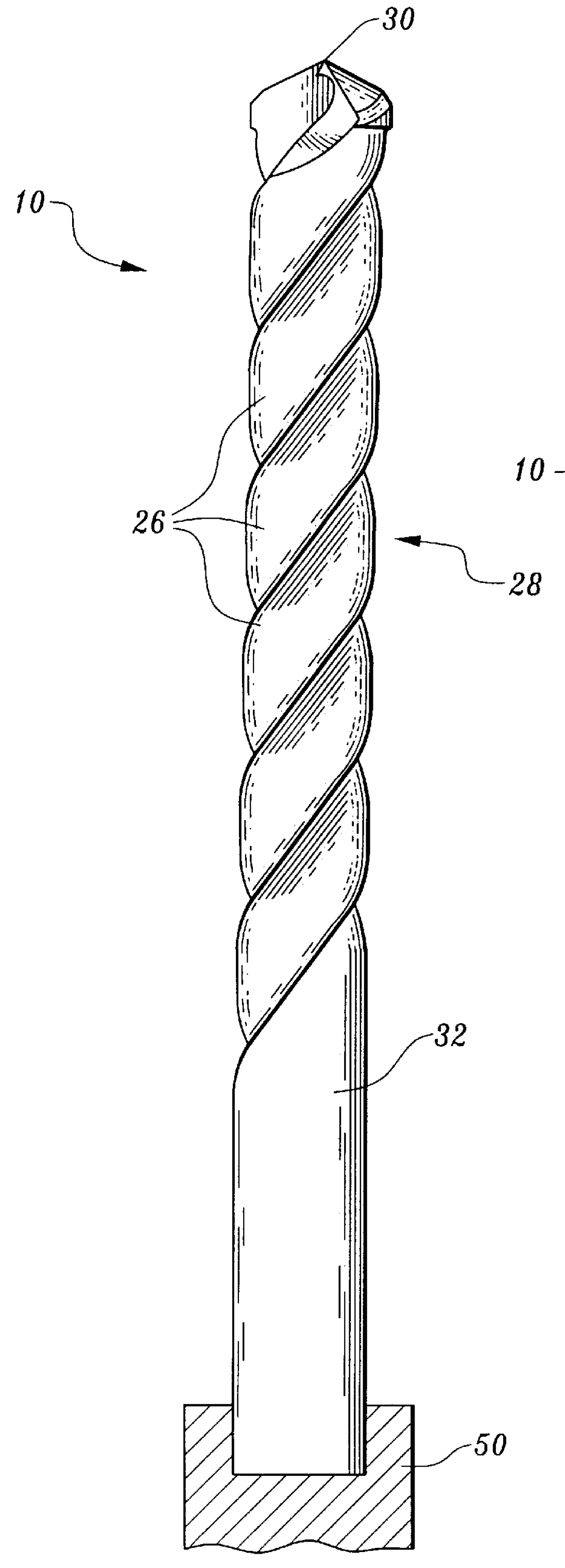

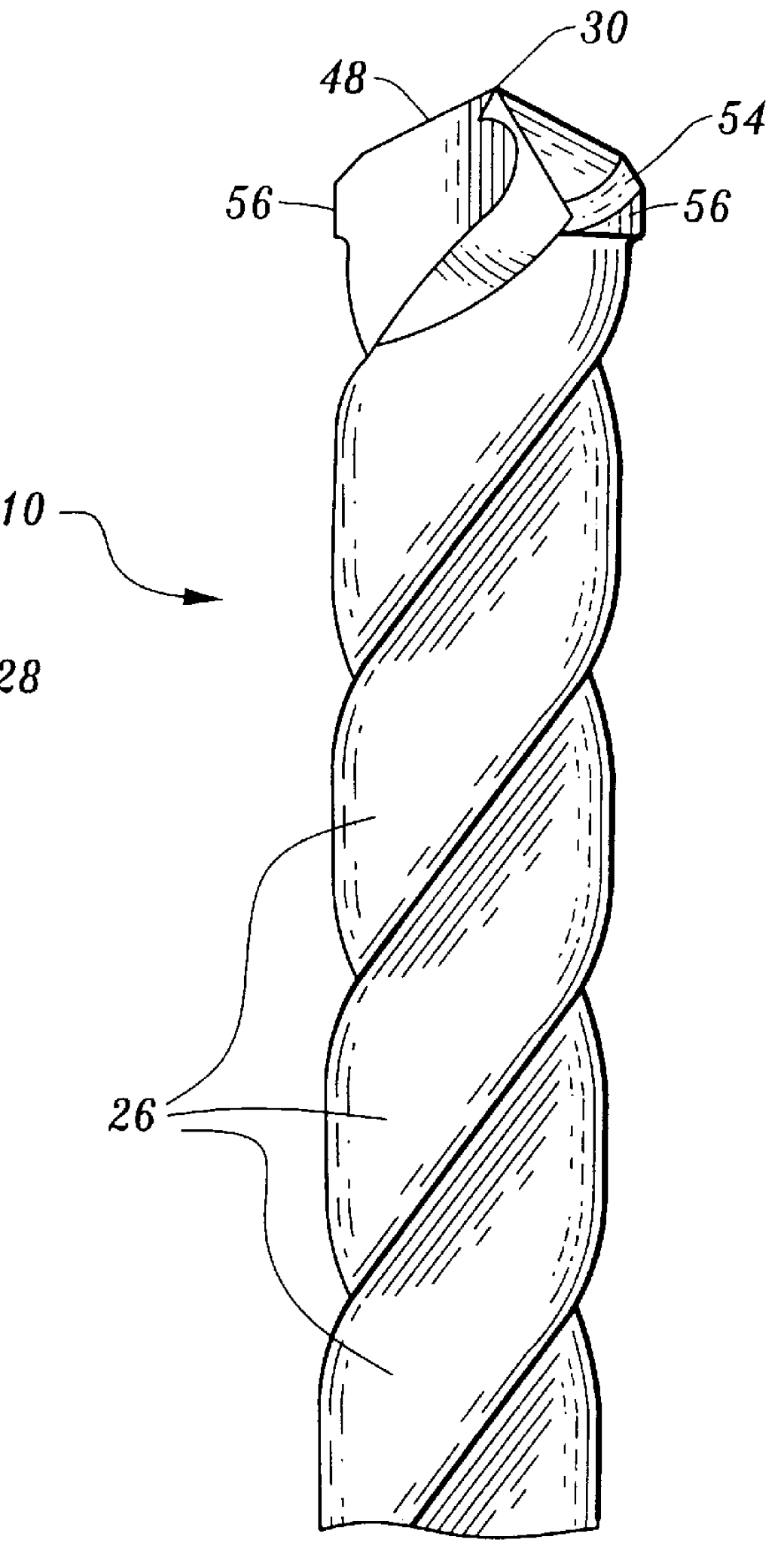

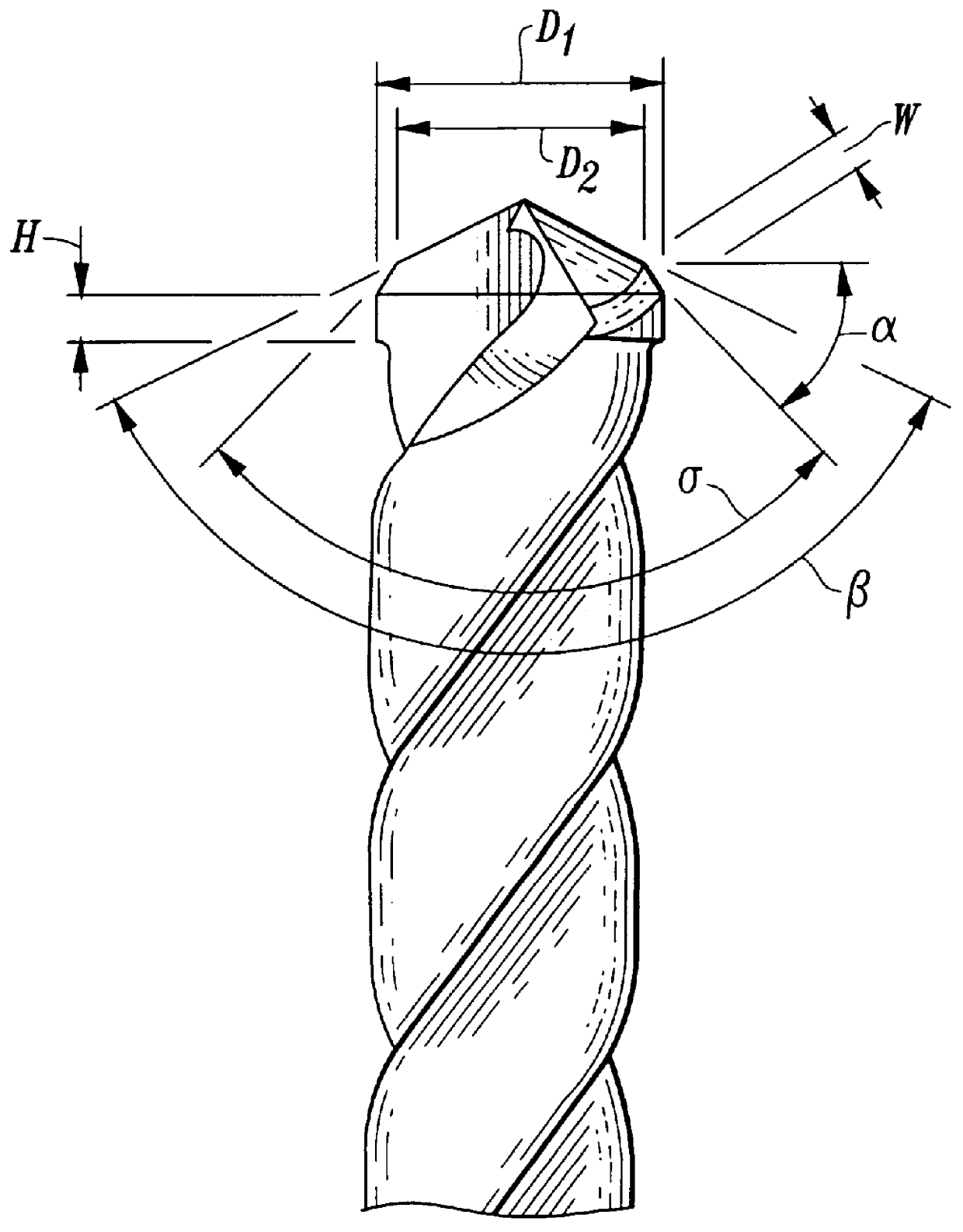

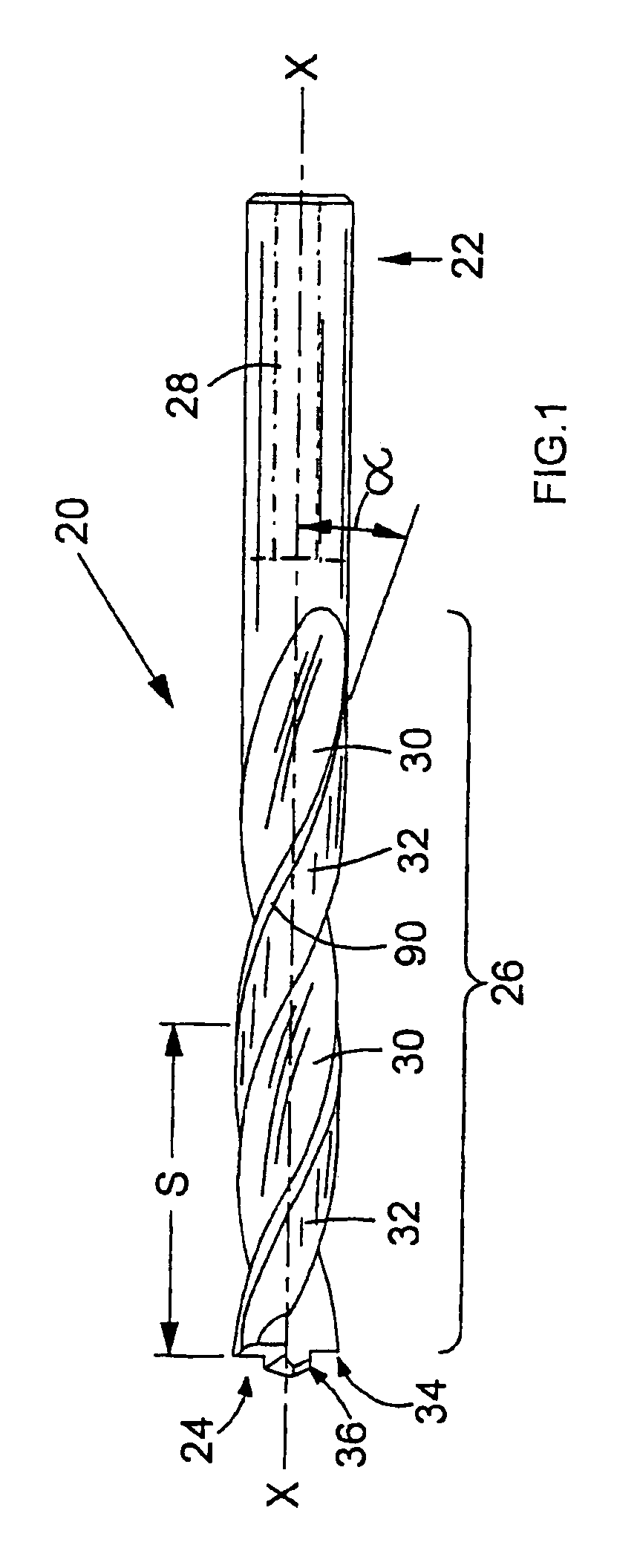

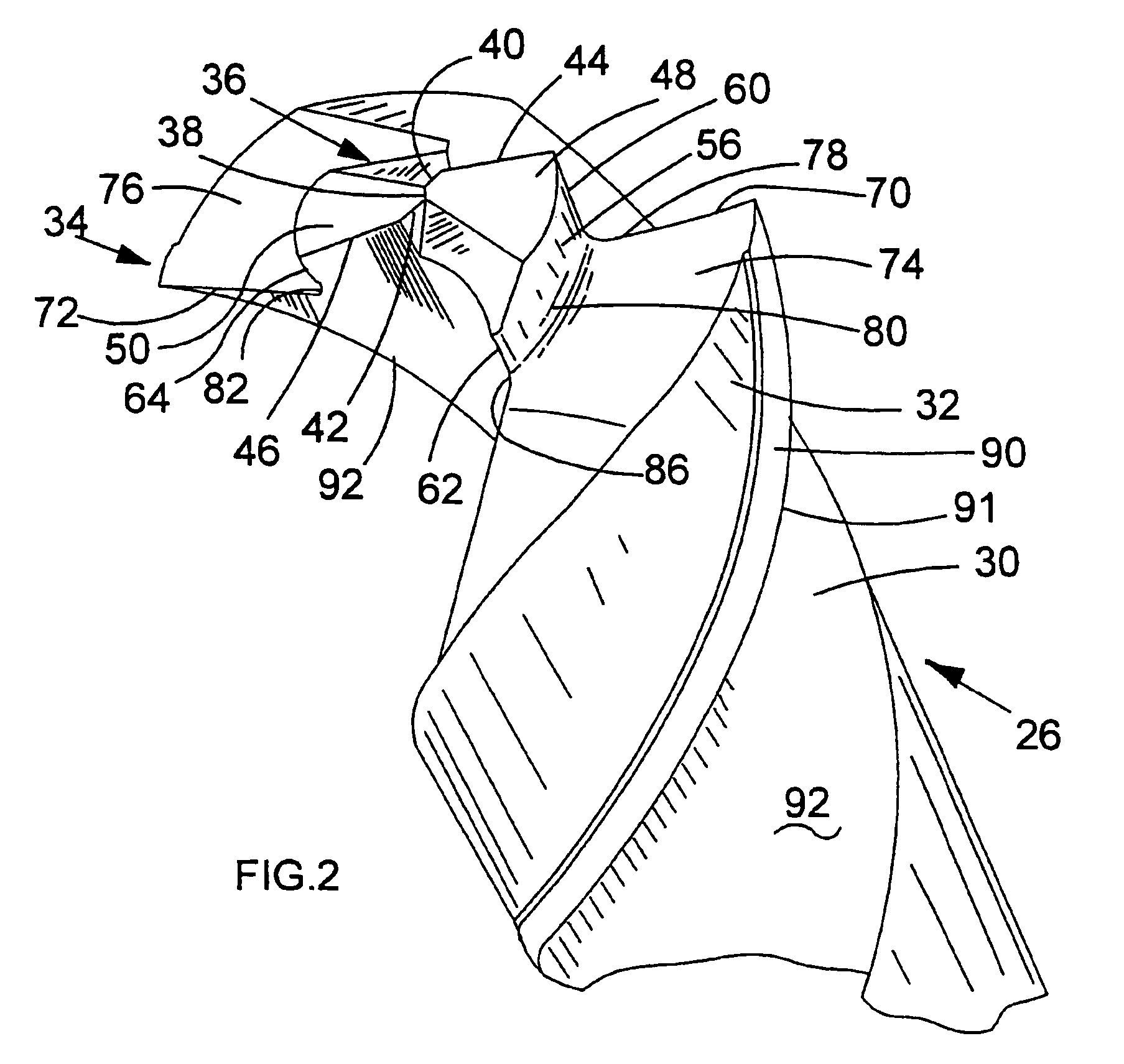

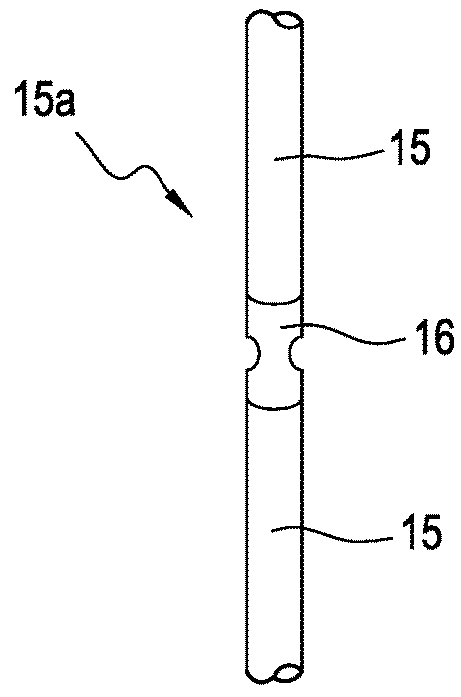

Self-centering drill bit with pilot tip

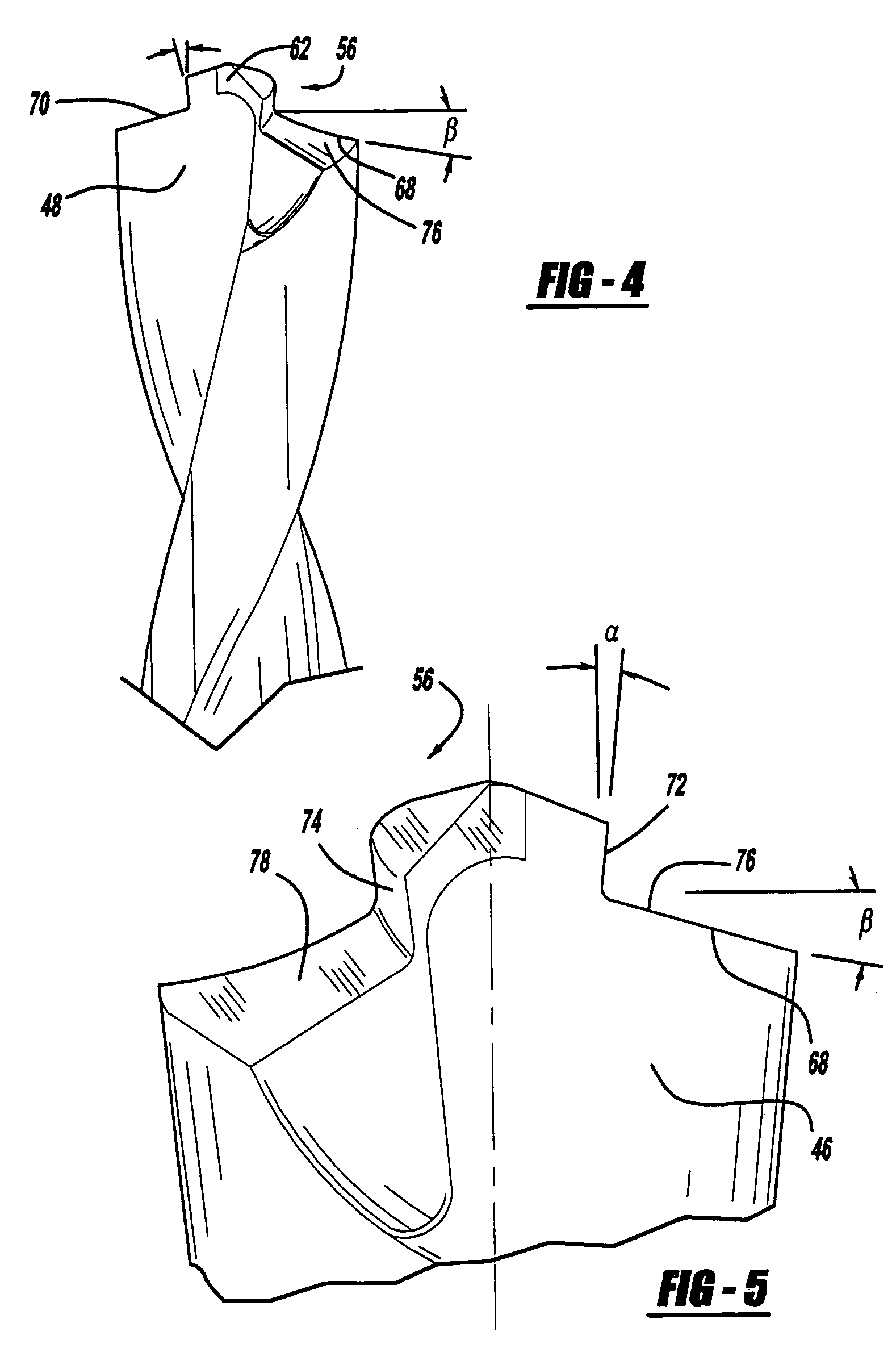

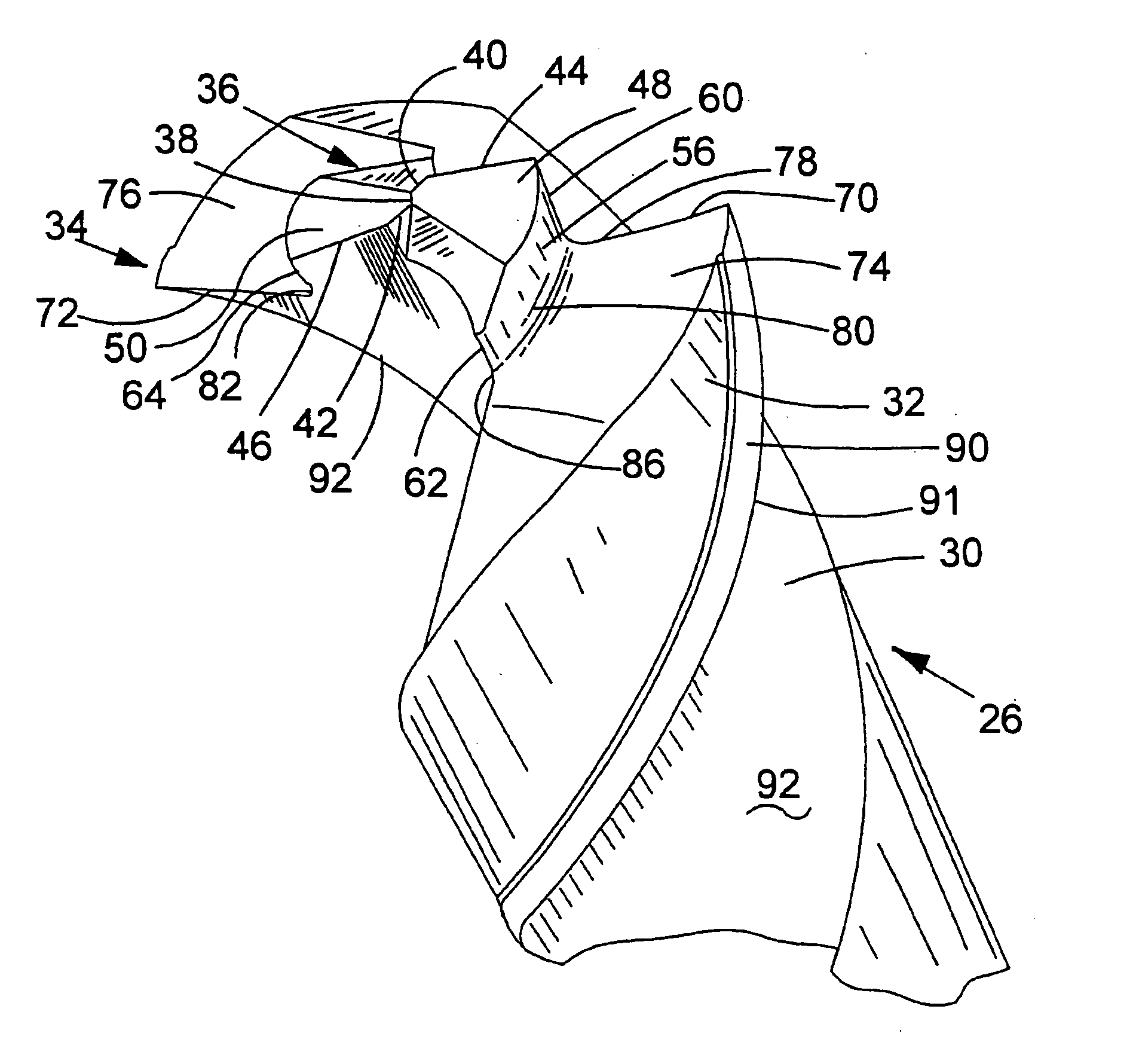

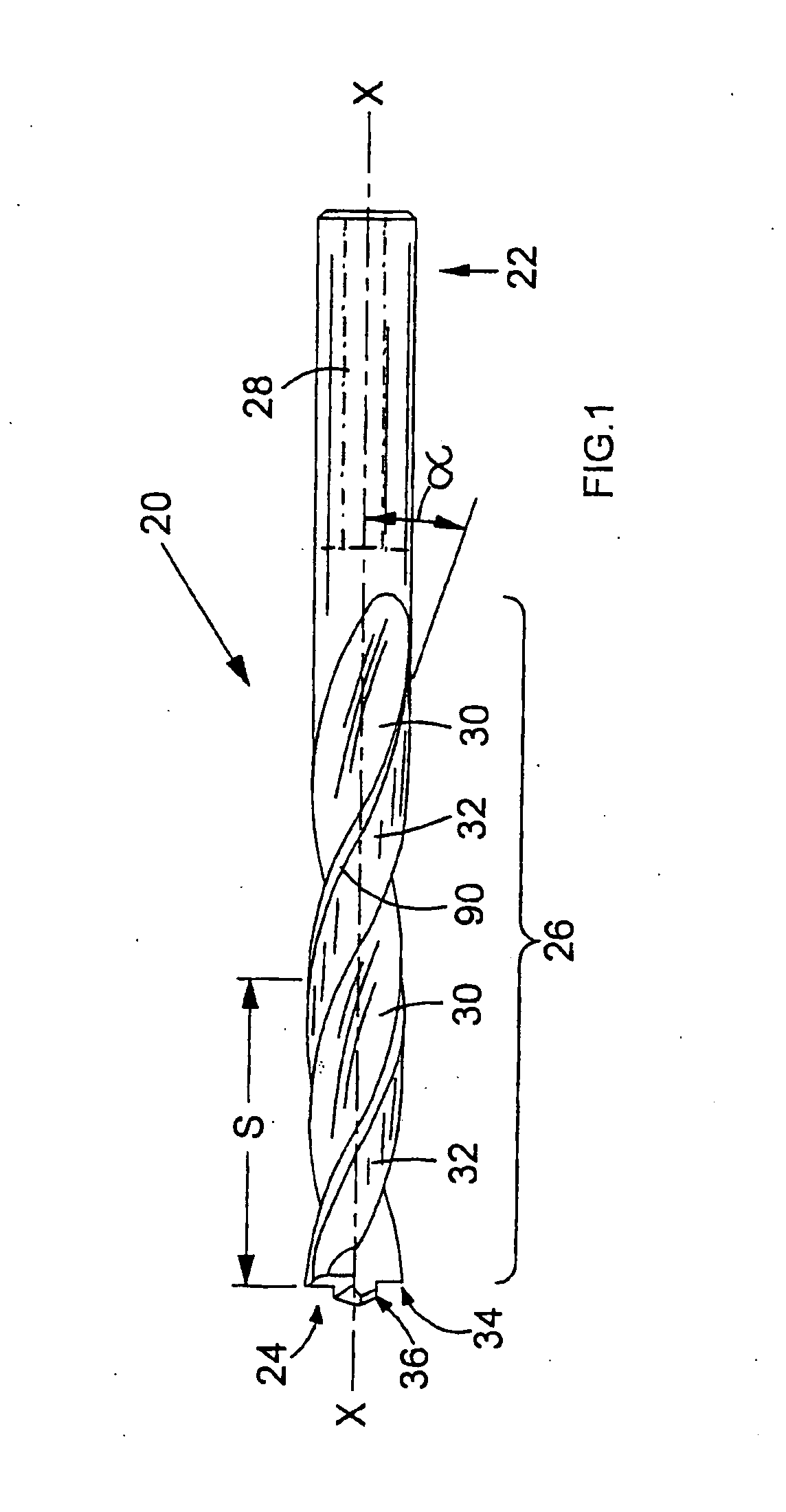

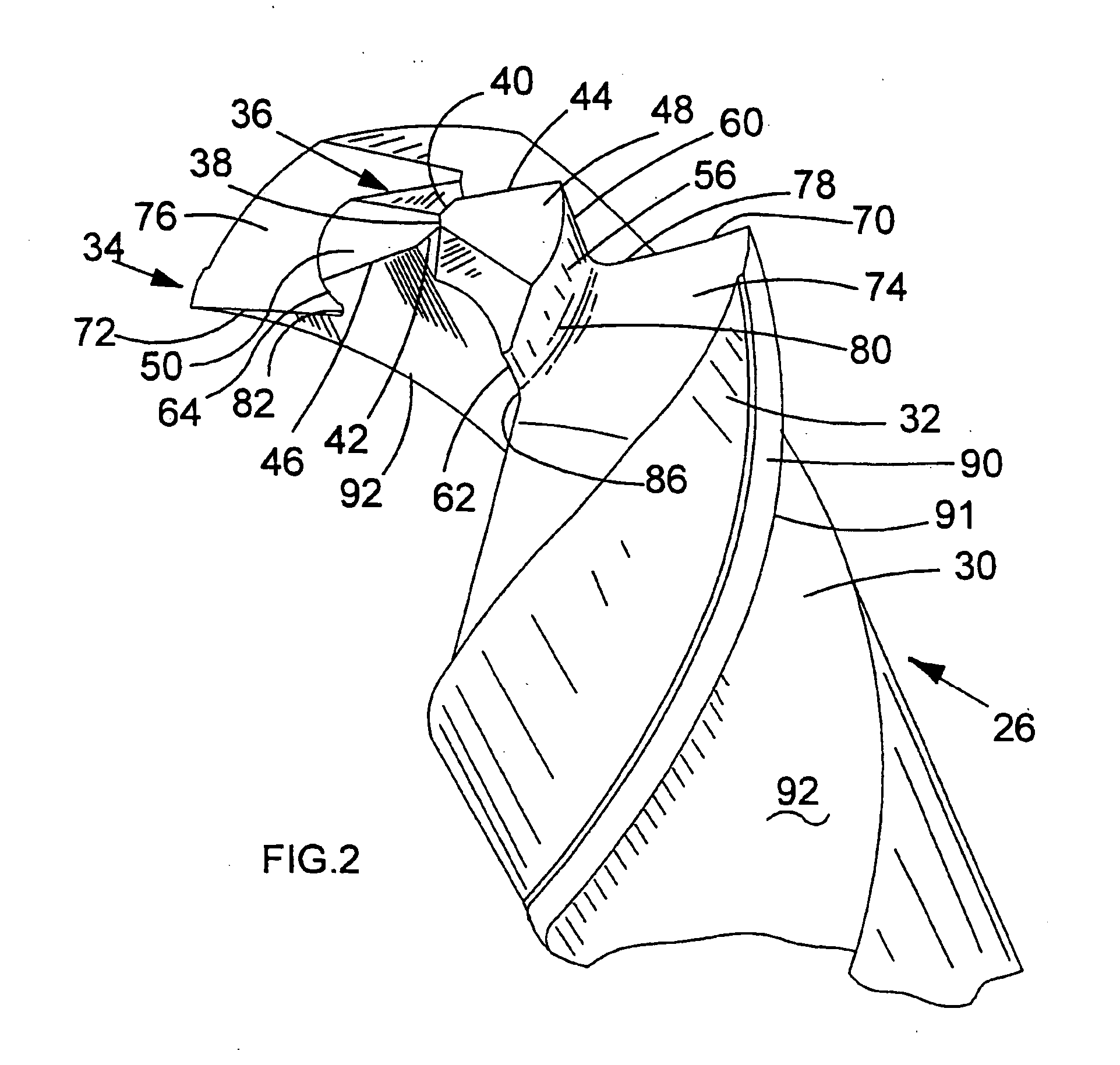

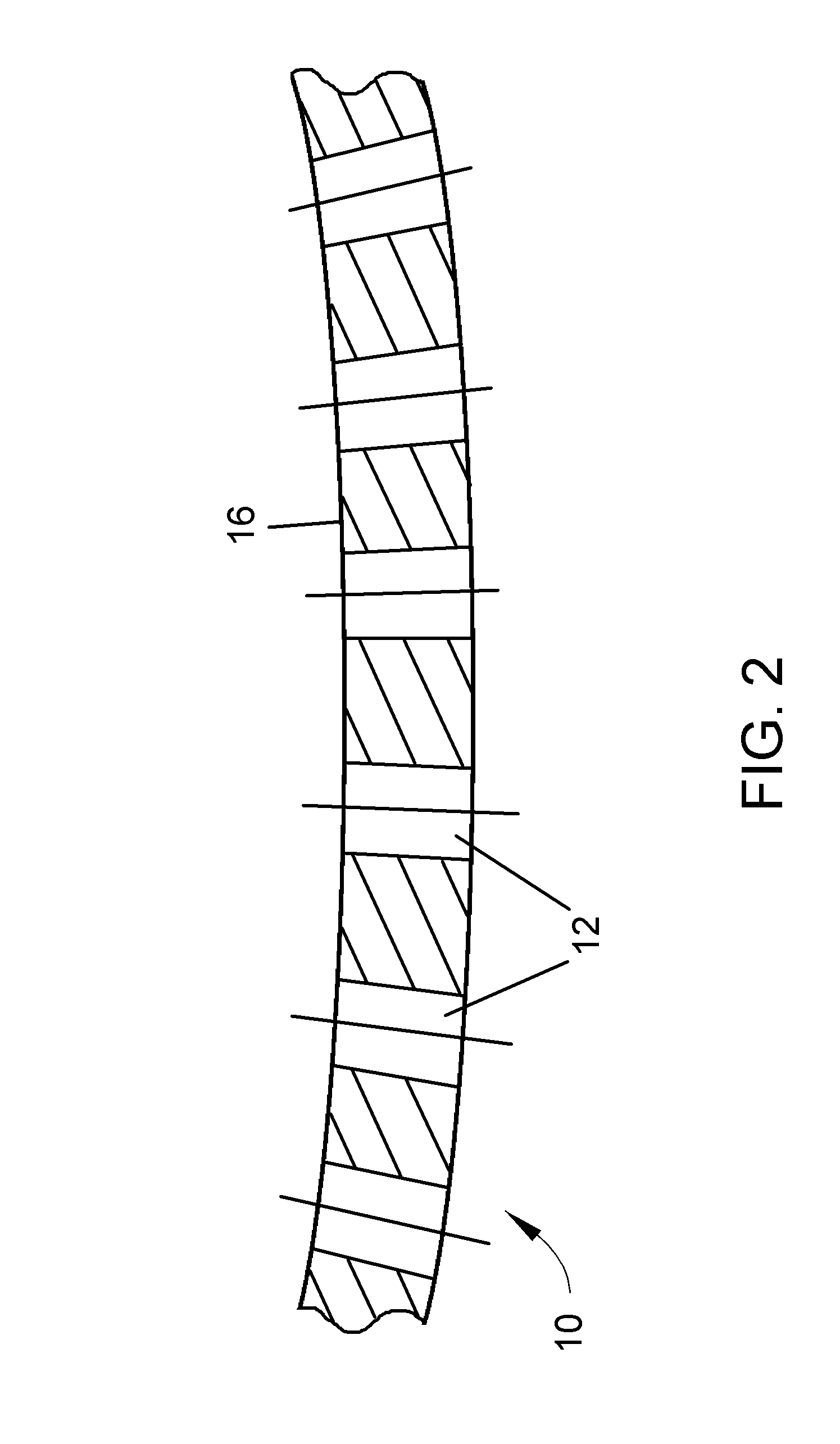

ActiveUS7267514B2Maintain strengthIncrease drilling speedWood turning toolsTransportation and packagingFluteMechanical engineering

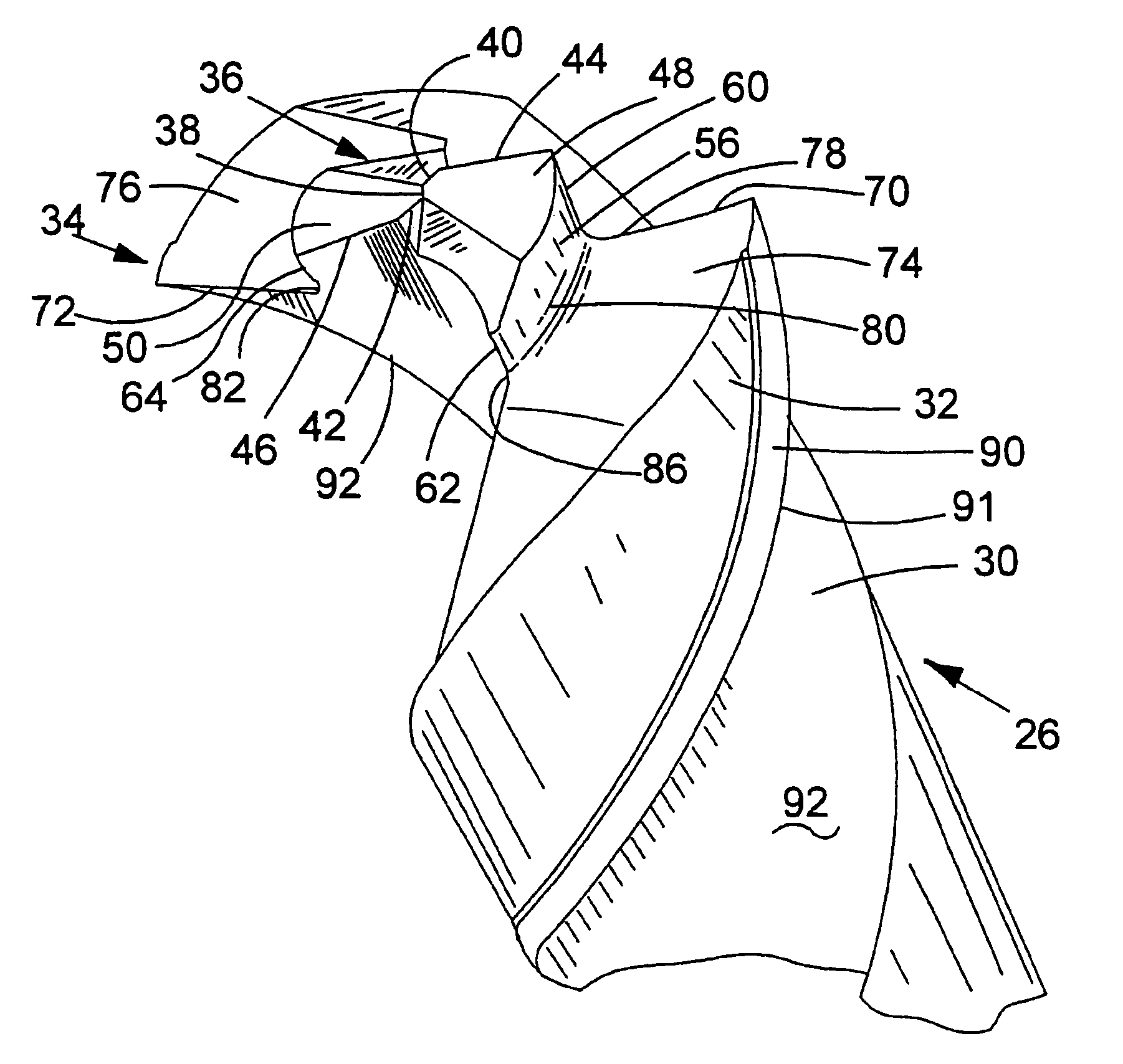

An elongate drill bit (20) with a longitudinal axis (X-X) has a shank (28), a working end (24), and a fluted section (26) between the shank and the working end. The shank, the working end and the fluted section are all formed integrally in the drill bit. The working end has an outer cutting portion (34) and a central pilot tip (36) which extends axially ahead of the outer cutting portion. The pilot tip is formed with at least one pair of minor cutting edges (40, 42; 44, 46) arranged on opposite sides of the axis. The outer cutting portion is formed with a pair of major cutting edges (70, 72) arranged on opposite sides of the axis. The outer cutting portion has a major diameter (D) defined by the pair of major cutting edges. The pilot tip has a minor diameter (d) defined by the at least one pair of minor cutting edges. The fluted section has a pair of helical lands (32) each with a respective inner surface (92) extending axially rearward from one of the major cutting edges and from one of the minor cutting edges. The helical lands define a web (94). Each helical land defines a respective helical flute (30). The helical lands have a pitch (S) and the web has a web thickness (K) at the pilot tip such that the ratio of the pitch to the major diameter (S:D) falls within a range of about 380% to about 410%. Also, the ratio of the minor diameter to the web thickness at the pilot tip (d:K) falls within a range of about 220% to about 380%.

Owner:BLACK & DECKER INC

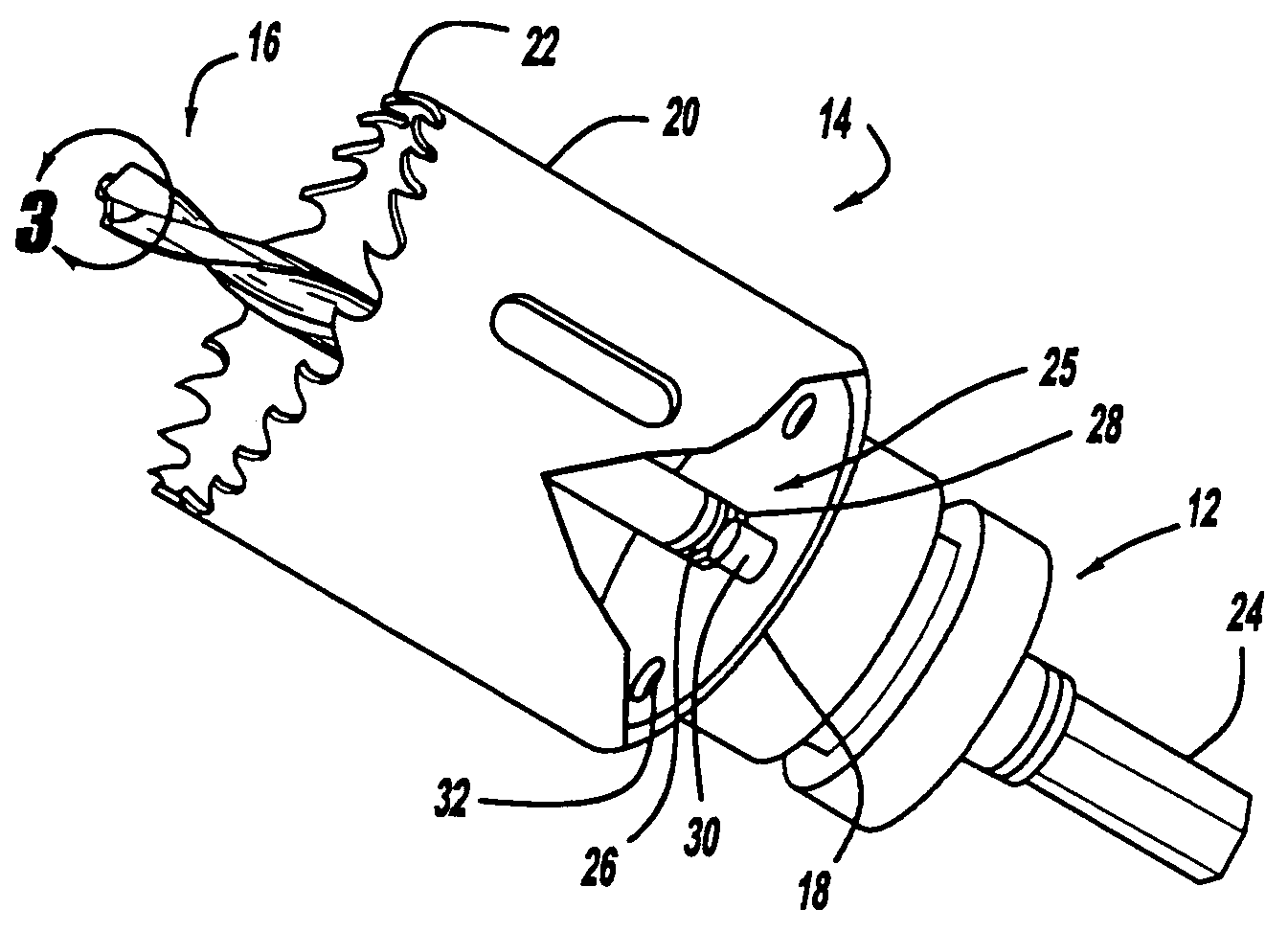

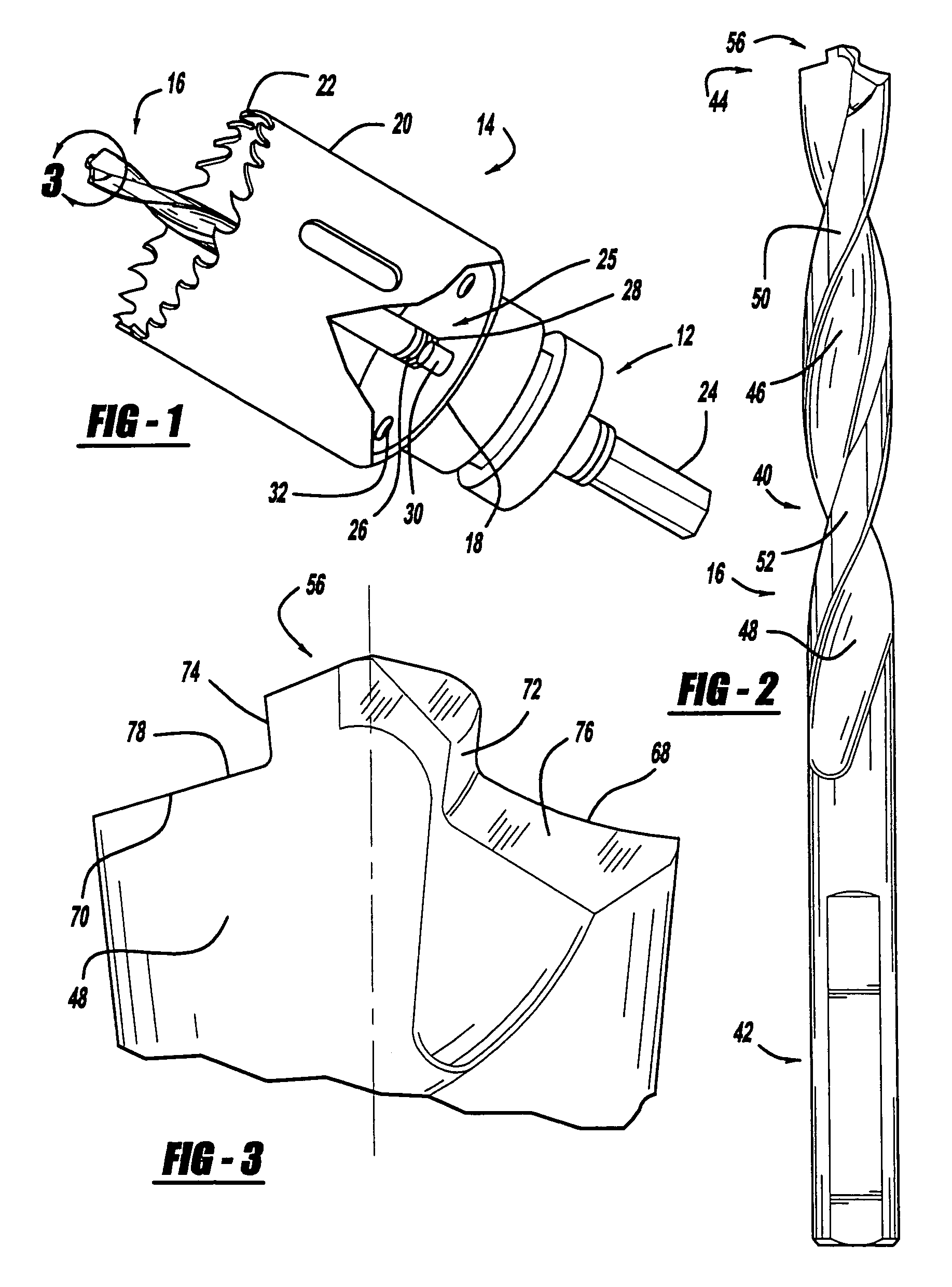

Hole saw having a drill bit with a pilot tip

ActiveUS7556459B2Shorten the timeReduces walking and skipping phenomenonWood turning toolsTransportation and packagingHole sawEngineering

A hole saw has an arbor and a cup shaped cutting member. The cup shaped cutting member has an annular skirt with a plurality of teeth at its free end. A drill bit is secured on the arbor. The drill bit includes a pilot point with a first cutting edge. A second edge is formed on the body portion of the drill bit to form a constant diameter hole in the workpiece.

Owner:BLACK & DECKER INC

Self-centering drill bit with pilot tip

ActiveUS20050053438A1Increase drilling speedMaintain strengthWood turning toolsTransportation and packagingFluteMechanical engineering

An elongate drill bit (20) with a longitudinal axis (X-X) has a shank (28), a working end (24), and a fluted section (26) between the shank and the working end. The shank, the working end and the fluted section are all formed integrally in the drill bit. The working end has an outer cutting portion (34) and a central pilot tip (36) which extends axially ahead of the outer cutting portion. The pilot tip is formed with at least one pair of minor cutting edges (40, 42; 44, 46) arranged on opposite sides of the axis. The outer cutting portion is formed with a pair of major cutting edges (70, 72) arranged on opposite sides of the axis. The outer cutting portion has a major diameter (D) defined by the pair of major cutting edges. The pilot tip has a minor diameter (d) defined by the at least one pair of minor cutting edges. The fluted section has a pair of helical lands (32) each with a respective inner surface (92) extending axially rearward from one of the major cutting edges and from one of the minor cutting edges. The helical lands define a web (94). Each helical land defines a respective helical flute (30). The helical lands have a pitch (S) and the web has a web thickness (K) at the pilot tip such that the ratio of the pitch to the major diameter (S:D) falls within a range of about 380% to about 410%. Also, the ratio of the minor diameter to the web thickness at the pilot tip (d:K) falls within a range of about 220% to about 380%.

Owner:BLACK & DECKER INC

Screw with protruding sheets on head portion

A screw with protruding sheets on a head portion comprises a thread portion; a screw tail at one end of the thread portion, a slot formed on the screw tail; a plurality of screwing sheets formed at another end of the thread portion; a plurality of recesses formed between the plurality of screwing sheets for removing undesired pieces; a drilling head being formed at front ends of the screwing sheets; the drilling head formed with a plurality of protruding sheets made of soft metal. By screwing the screw by rotating from the slot, the screw will rotate so as to drill a hole and enter into a wood plate. Then the protruding sheets enlarge the hole. The undesired wood pieces are removed from the recesses. When the screw further drills into a metal plate, the protruding sheet will be worn out because the protruding sheet is made of soft metal.

Owner:TOP GREEN CORP

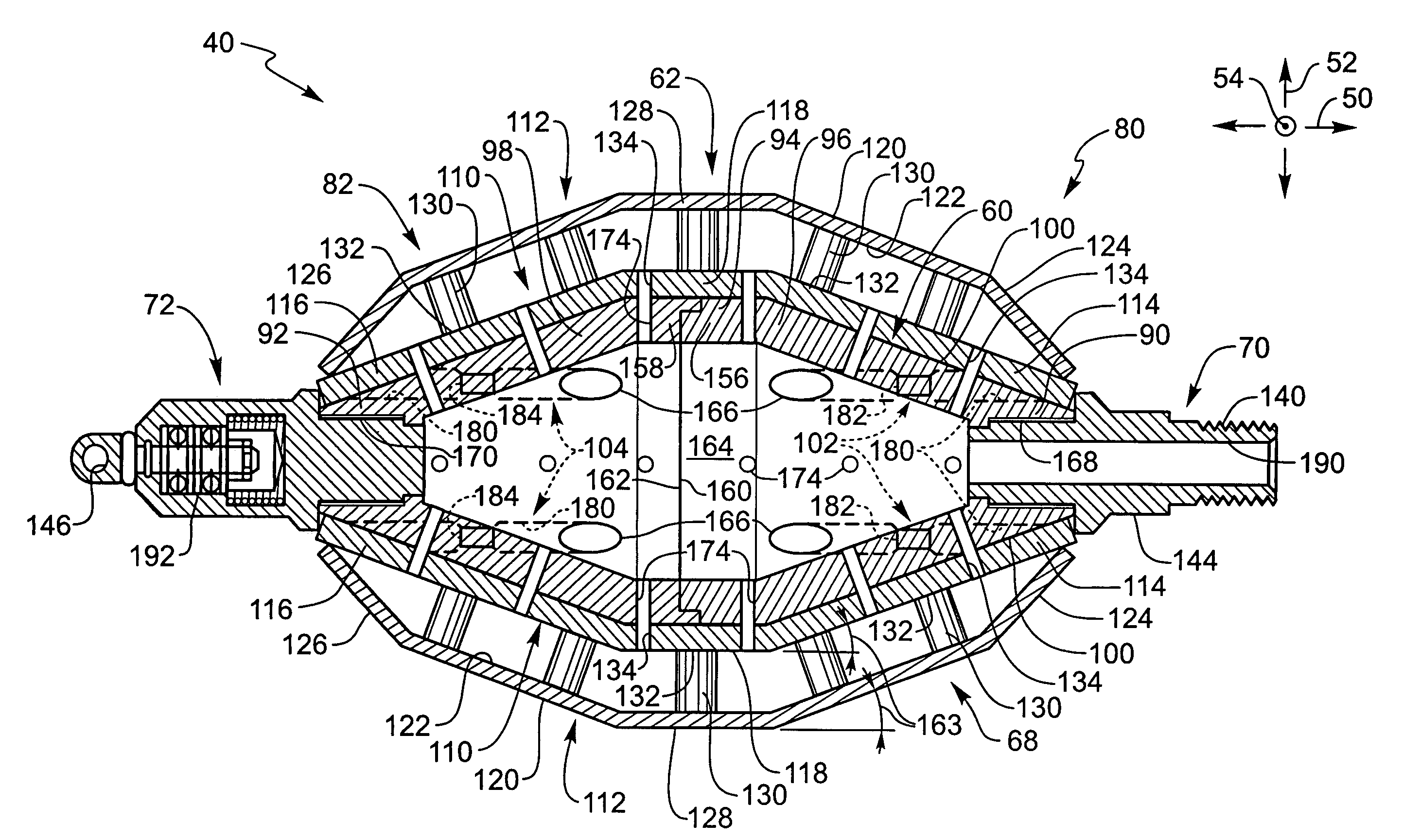

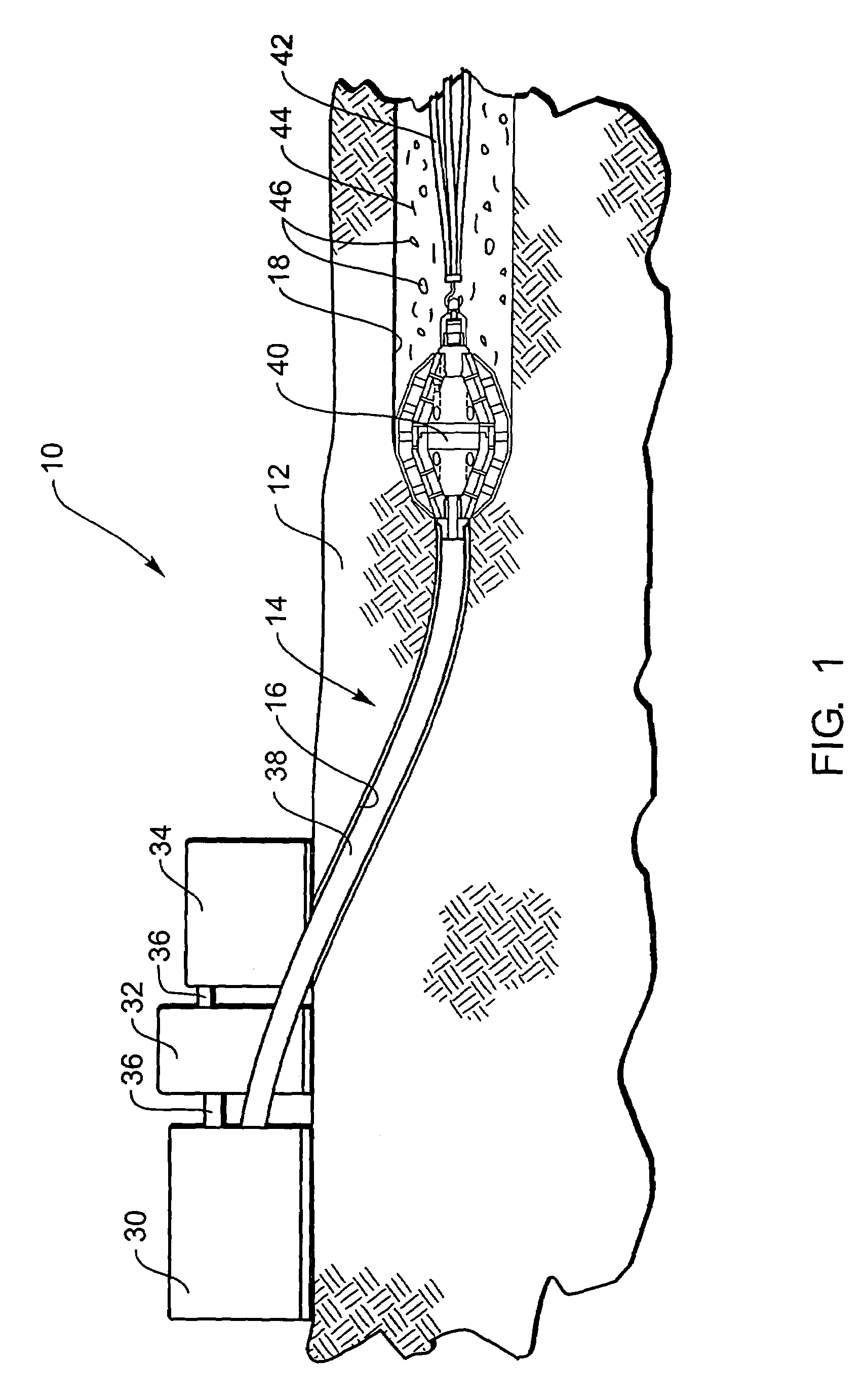

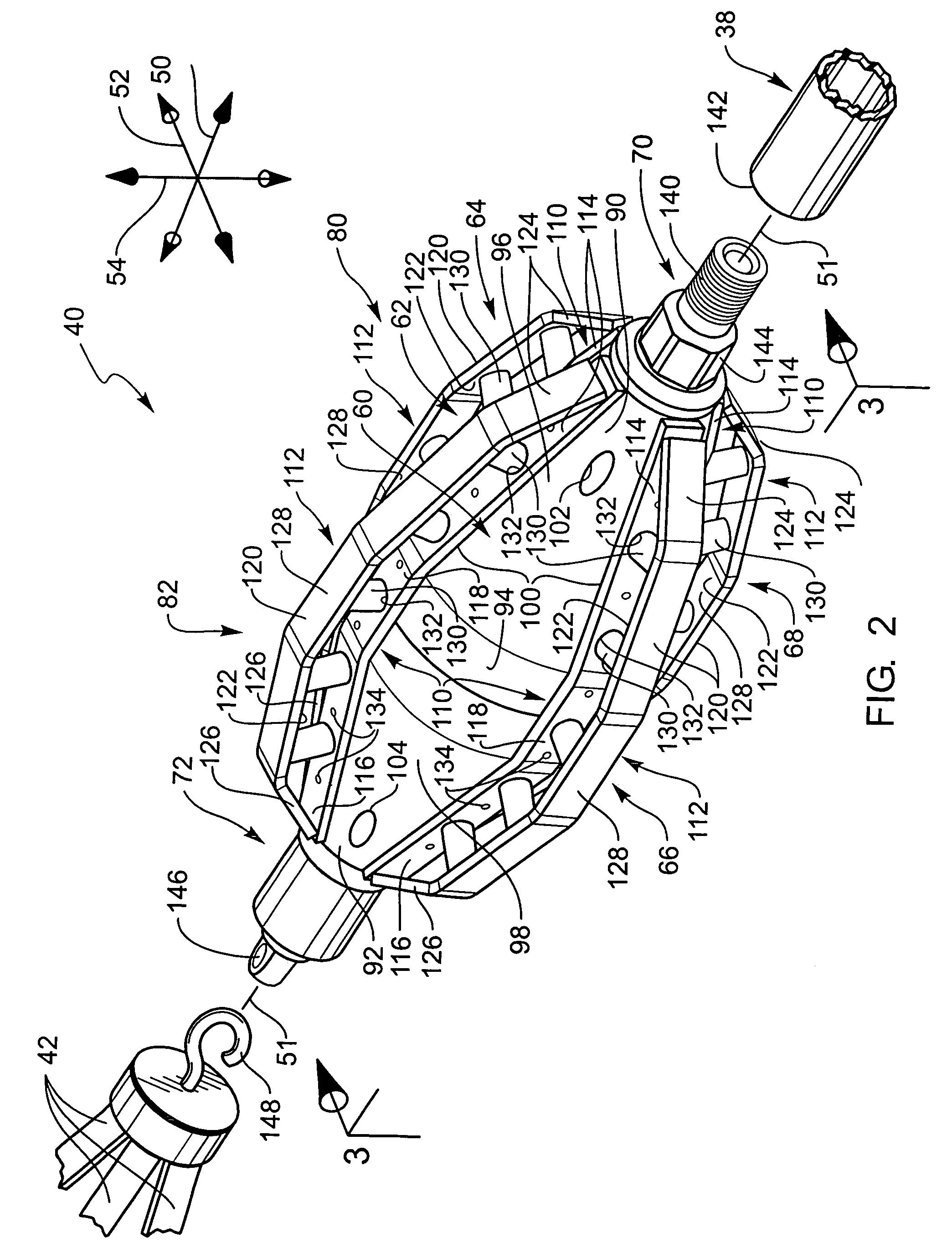

Hole reaming apparatus and method

An enhanced reaming apparatus and method are disclosed. A reaming assembly may have a motor and a pump that provide linear force, torsional force, and pressurized drilling fluid to a reamer to cause the reamer to enlarge the bore of a pilot hole. The reamer may have a body and a plurality of blade assemblies that cooperate to define two substantially symmetrical, oppositely oriented reaming sections. Each blade assembly may have an inner blade attached to the body and an outer blade extending outward from the body. Hard cutting elements may be used in place of the outer blade. The blade assemblies may be field-replaced, or the orientation of the reamer may be reversed to enhance the life of the reamer. The reamer has jets and circulation openings that release the drilling fluid into the bore to facilitate penetration and remove cuttings.

Owner:XTECH INDS INT

Hybrid drill bit

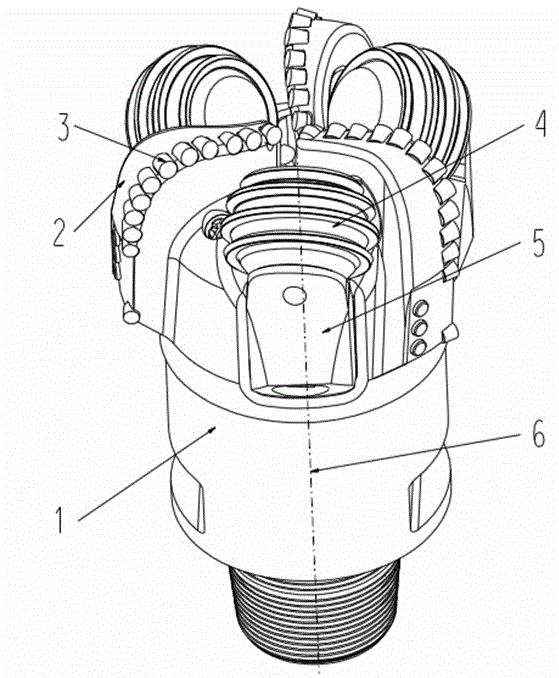

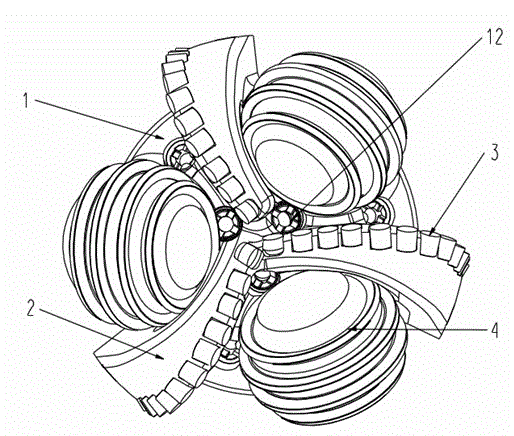

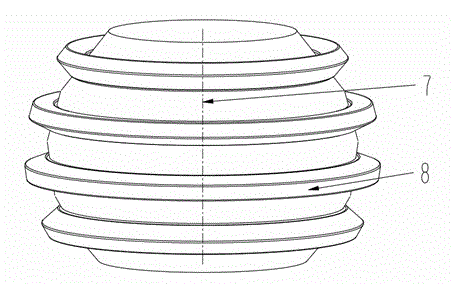

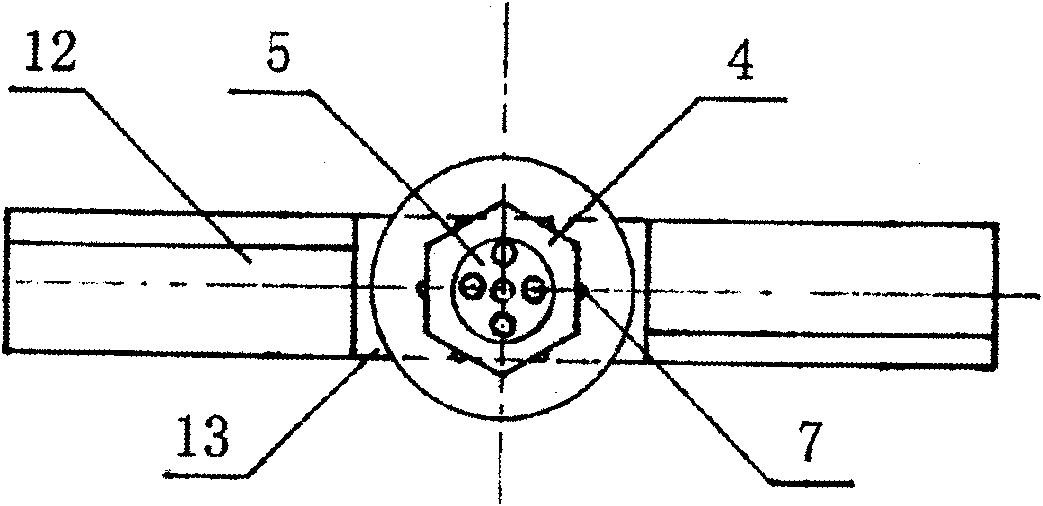

InactiveCN102747960AEliminate stick-slipImprove cutting efficiencyDrill bitsDiamond cuttingWell drilling

The invention relates to a hybrid drill bit for petroleum, natural gas and geological drilling. The hybrid drill bit comprises a drill bit body, wherein a cutter wing and a roller cone are arranged on the drill bit body, cutting teeth are arranged on the cutter wing, the roller cone is connected with the drill bit body through a cone leg, and the hybrid drill bit is characterized in that the roller cone is a disk type roller cone. A cutting element on the disk type roller cone is shaped like a disk cutter or an intermittent disk cutter. The patent disclosed by the invention has the beneficial effects that, 1) the scraping motion of a diamond drill bit and the rolling motion of a disk type roller cone drill bit are combined for realizing precrushing at the bottom of a well, thereby ensuring that the diamond cutting teeth can effectively bite rock, eliminating the stick-slip phenomenon of the drill bit in some special formations and the probability of impact disrepair of a polycrystalline diamond compact (PDC) and improving the cutting efficiency and the mechanical drilling speed of the drill bit; and 2) the disk type roller cone can realize the precrushing of a rock layer at the bottom of the well more steadily, reduce the impact on the PDC, enhance the stability in drilling of the drill bit and enable the drill bit to realize faster and more stable drilling.

Owner:SINOPEC OILFIELD EQUIP CORP

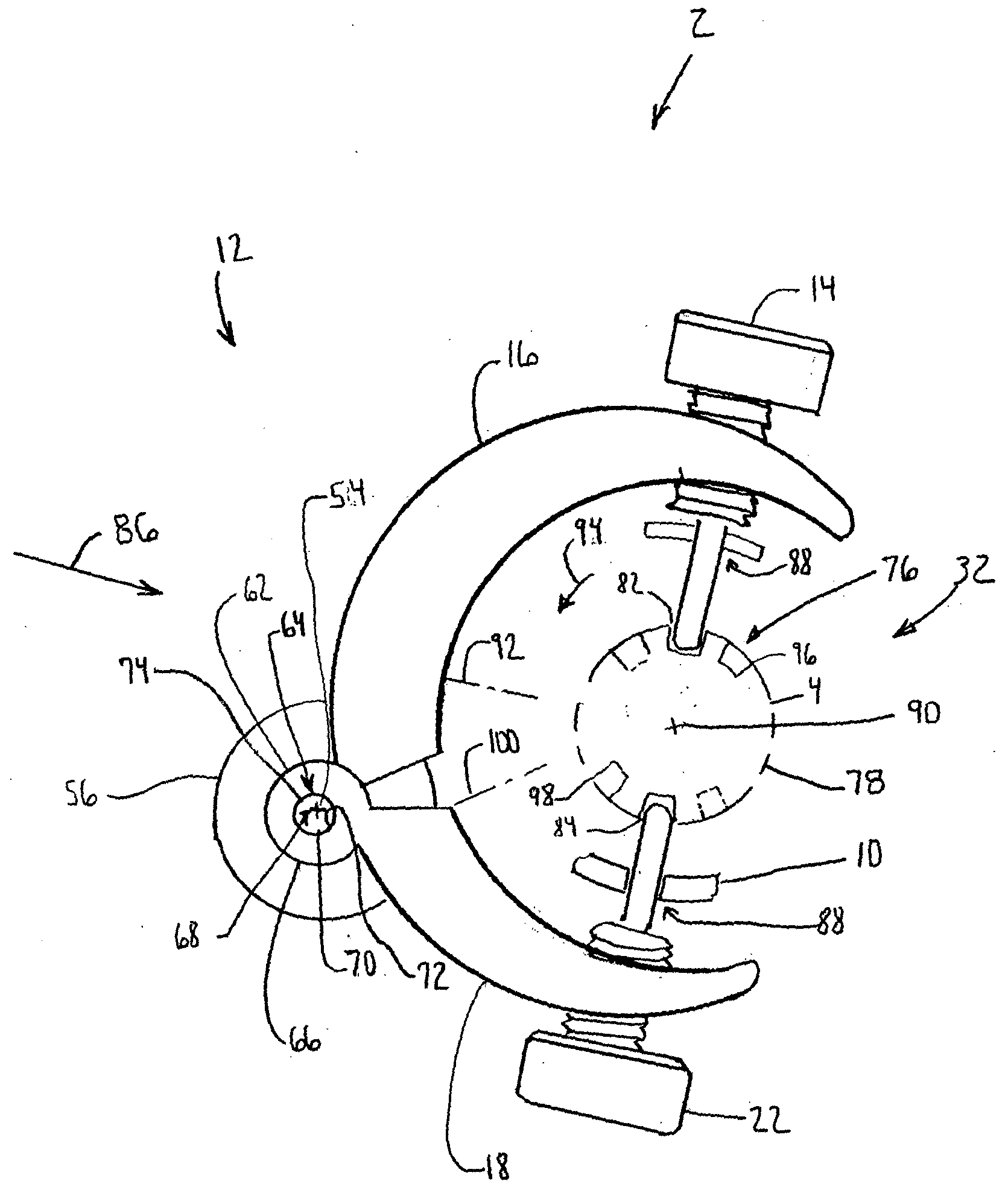

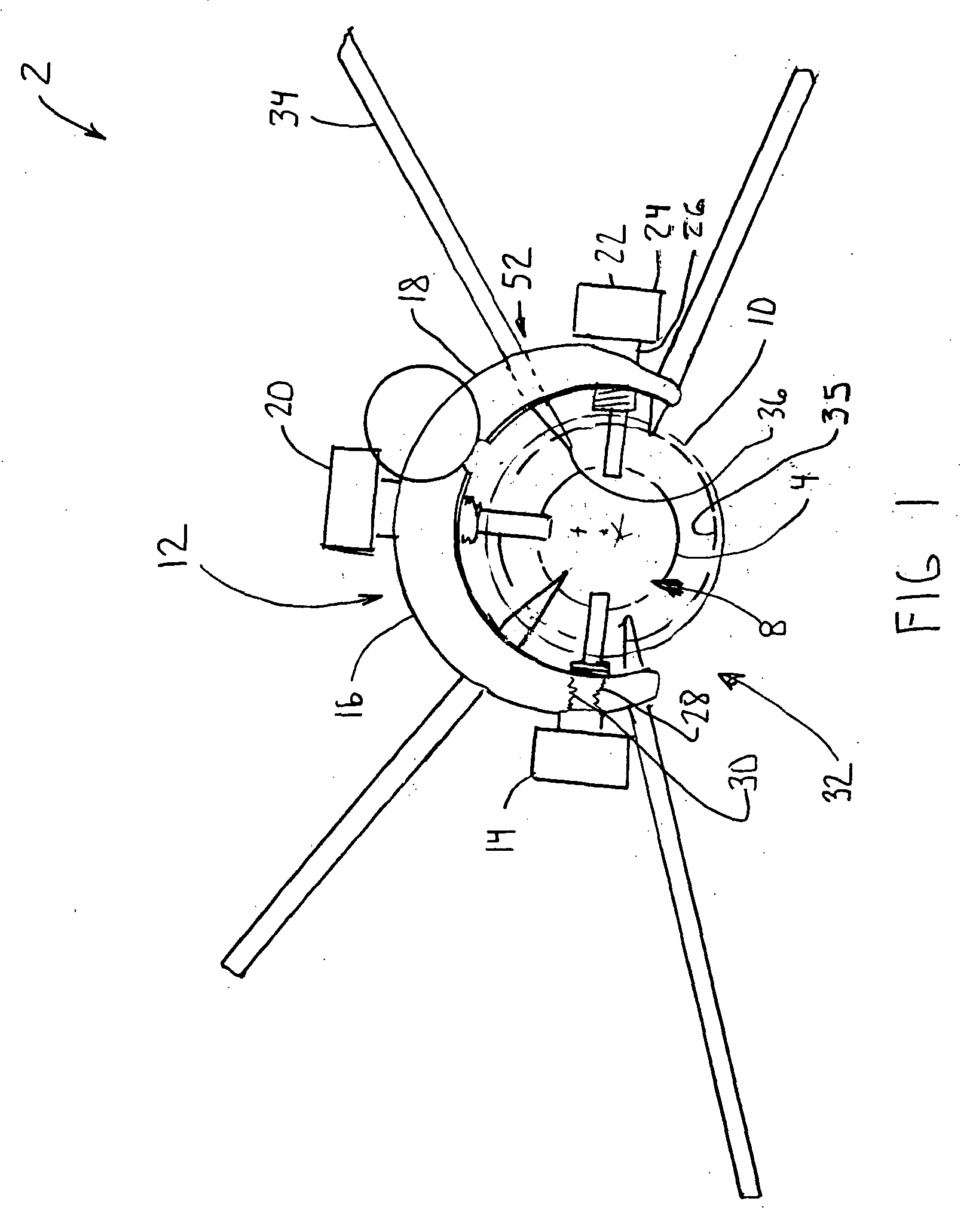

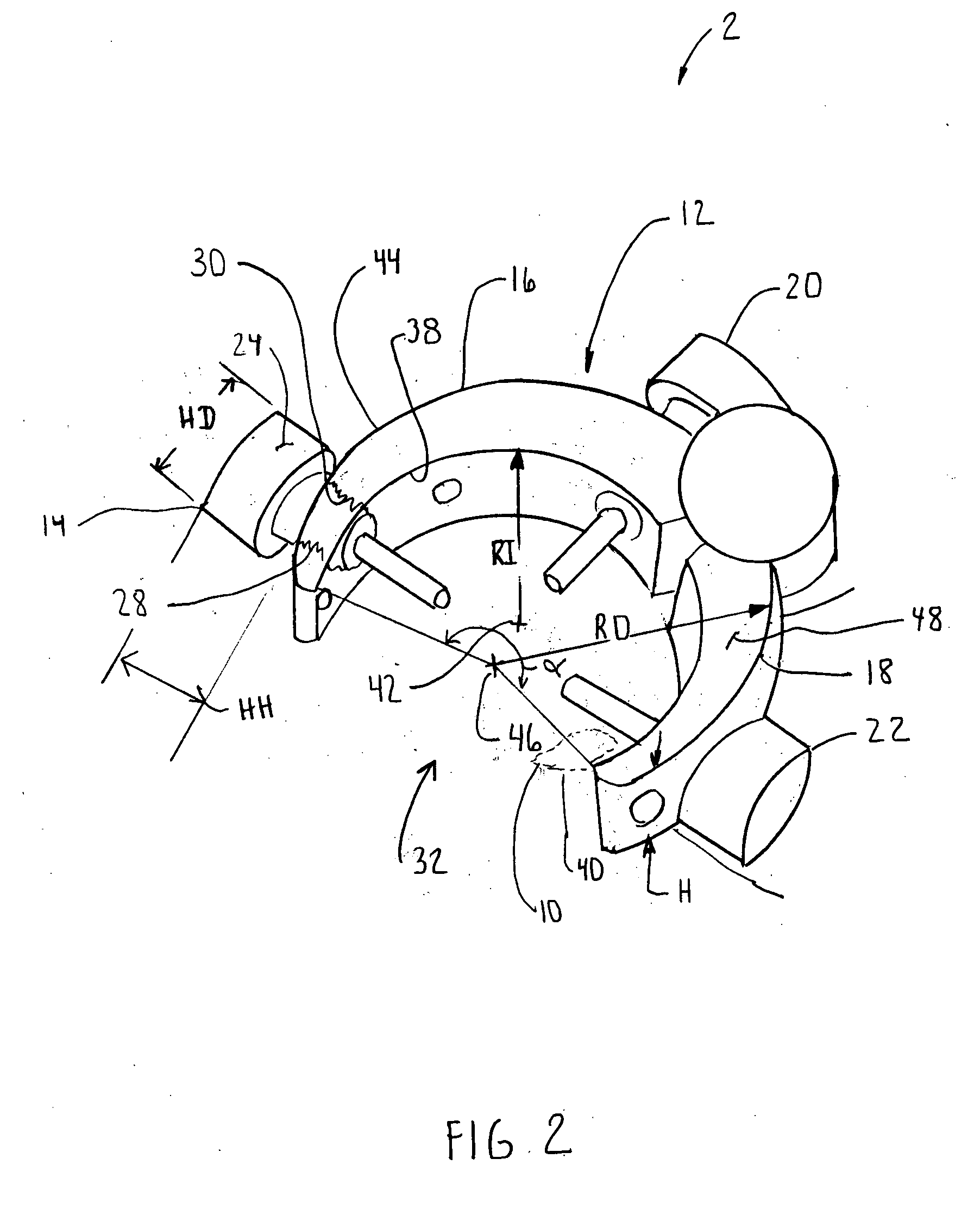

Shoulder Positioning fixture, trials and associated method

InactiveUS20050049712A1Easy to fixExtended range of motionJoint implantsFemoral headsProsthesisBiomedical engineering

A positioning fixture for positioning at least one of a trial and a prosthesis in the medullary canal of a long bone is provided. The fixture includes a body and a member for cooperation with the body. The member extends from the body through at least a portion of the long bone and into the medullary canal. The member is adapted to support at least one of the trial and the prosthesis as the one of the trial and the prosthesis is positioned with respect to the long bone.

Owner:DEPUY PROD INC

Borehole wall stabilization method applicable to underbalanced drilling and experimental device

InactiveCN104563927APrevent intrusionImprove stabilitySemi-permeable membranesFlushingWell drillingWater activity

The invention relates to a borehole wall stabilization method applicable to underbalanced drilling and an experimental device. The method comprises the following steps: (1) determining stratum water activity of mud shale; (2) determining the pore pressure of a stratum to be drilled; (3) calculating the temperature of the stratum; (4) measuring the membrane efficiency of the stratum by using a membrane efficiency test experiment device; (5) determining the density of drilling fluid according to the liquid column pressure of the drilling fluid and borehole depth; (6) determining a difference value as an underbalanced value between the liquid column pressure of the drilling fluid and the pressure of the stratum if the density of the drilling fluid is determined, obtaining chemical potential difference by using the underbalanced value according to the principle that the total potential energy is balanced, and determining the activity of the drilling fluid according to the chemical potential difference and the stratum water activity; (7) adjusting the density or activity of the drilling fluid according to determined results so as to keep a borehole wall stable. The method has the beneficial effects that the action of chemical potential is taken into full consideration, the density of the drilling fluid at the time when the total potential energy of the stratum is kept balanced is given accurately, a drilling fluid filtrate is effectively prevented from invading the stratum, the stability of the borehole wall is improved, and the application and popularization of an underbalanced drilling technology are enhanced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

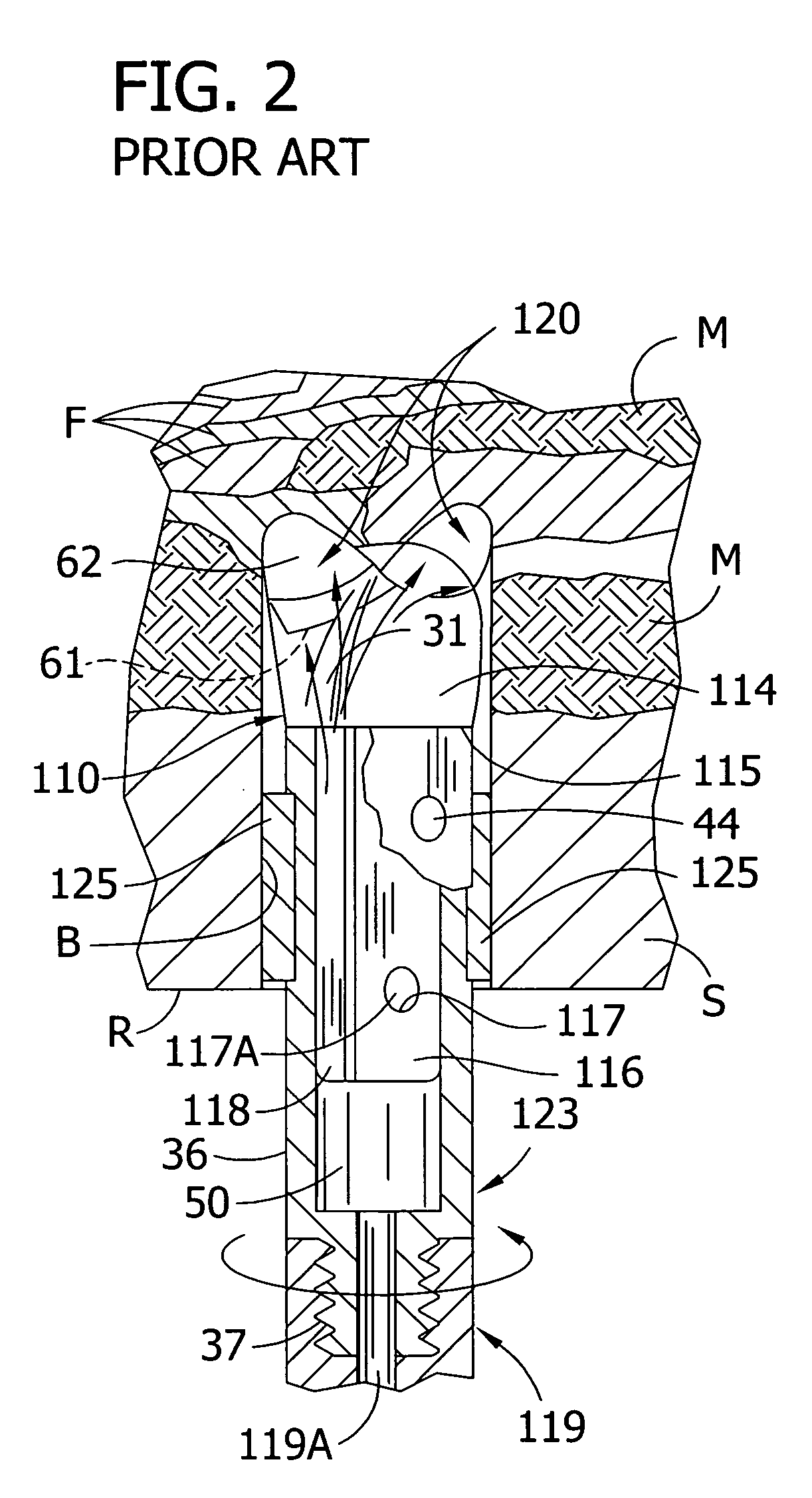

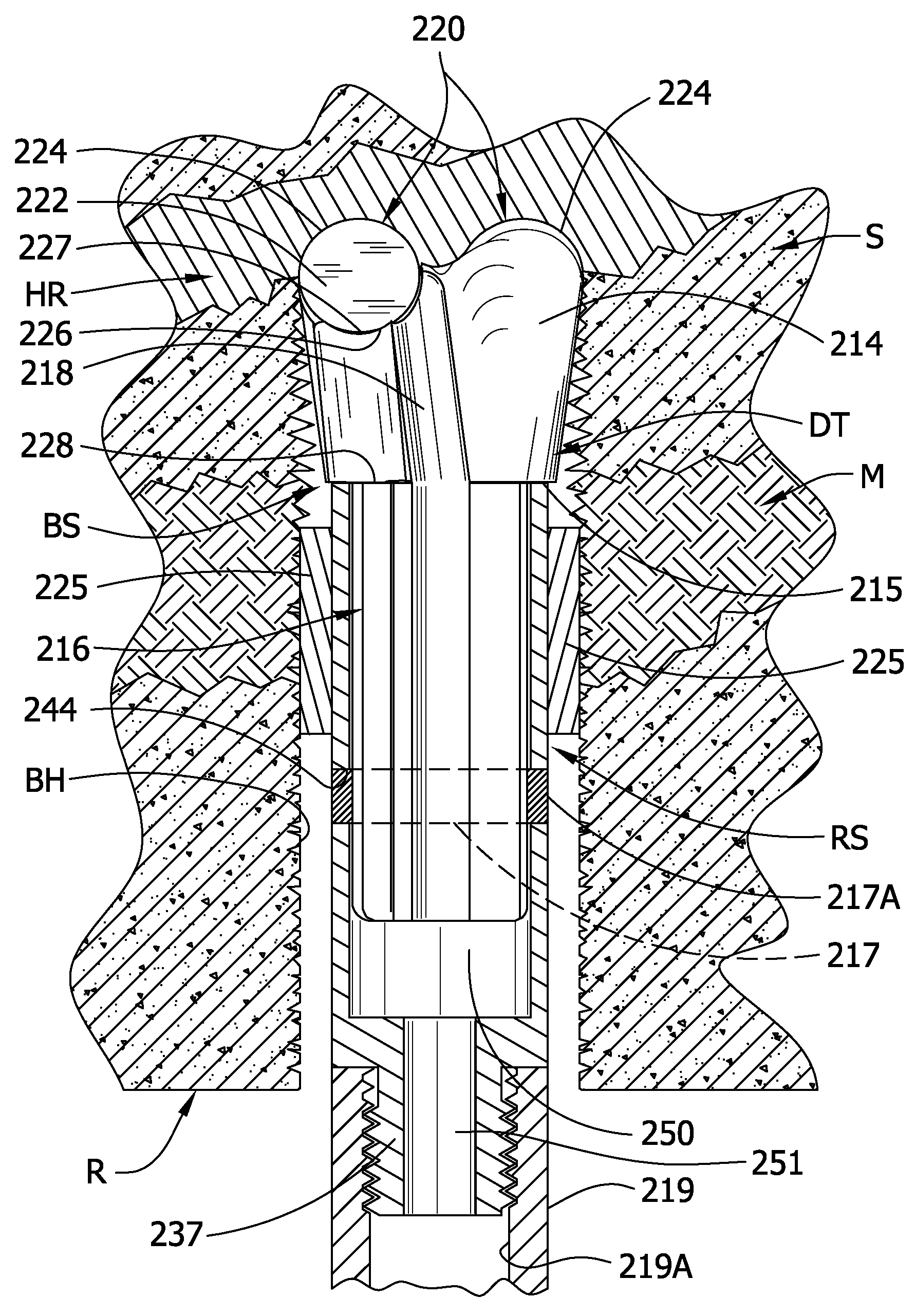

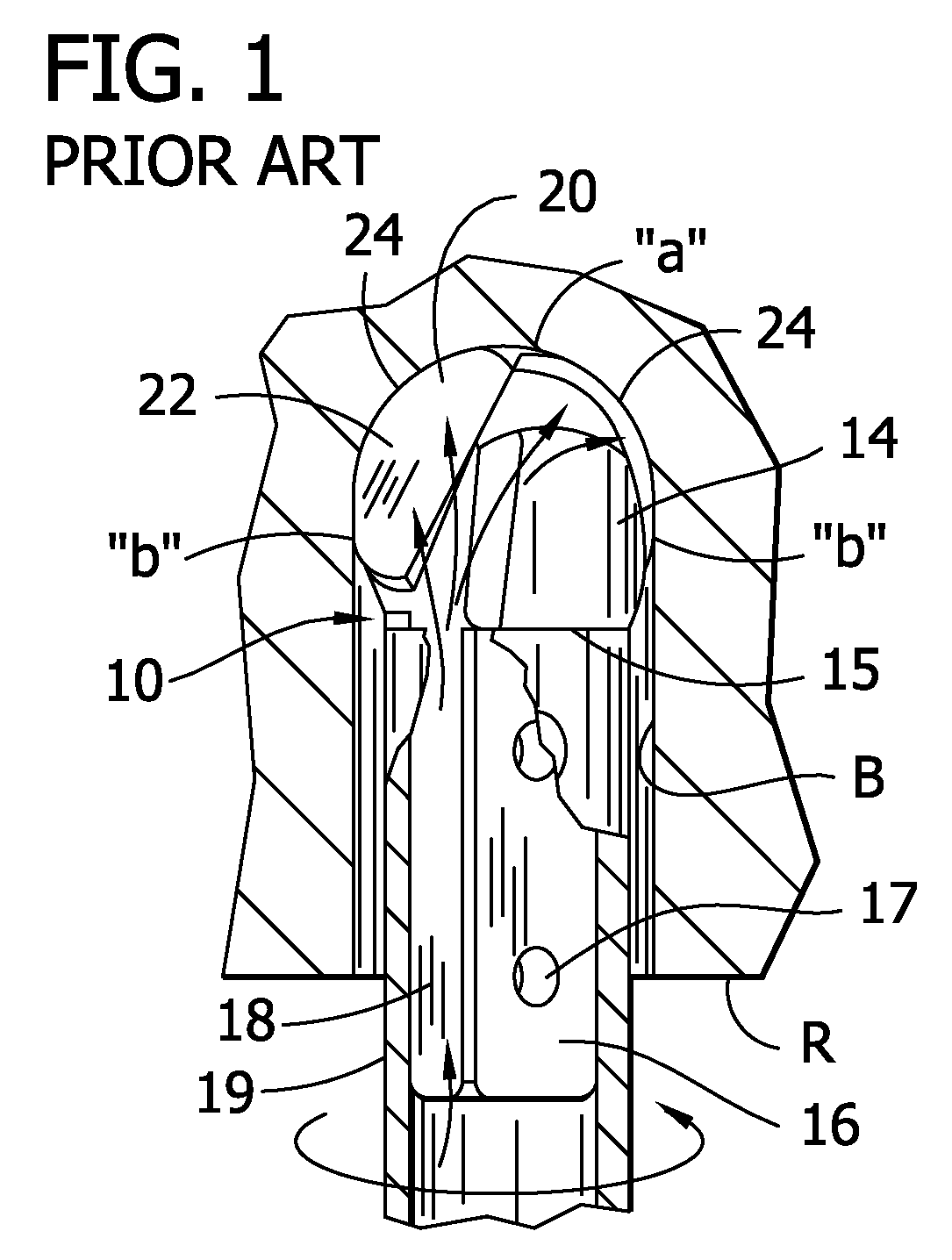

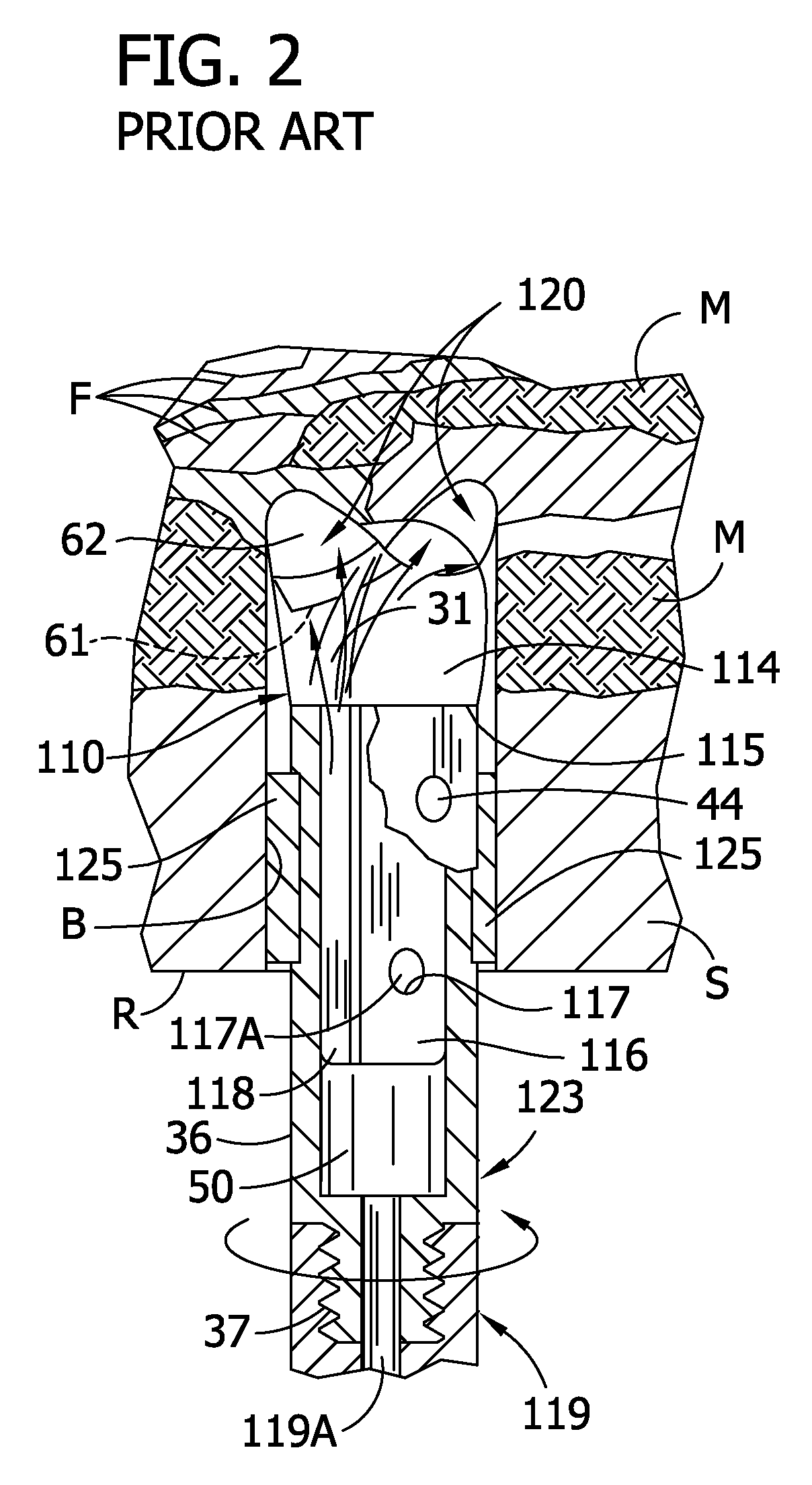

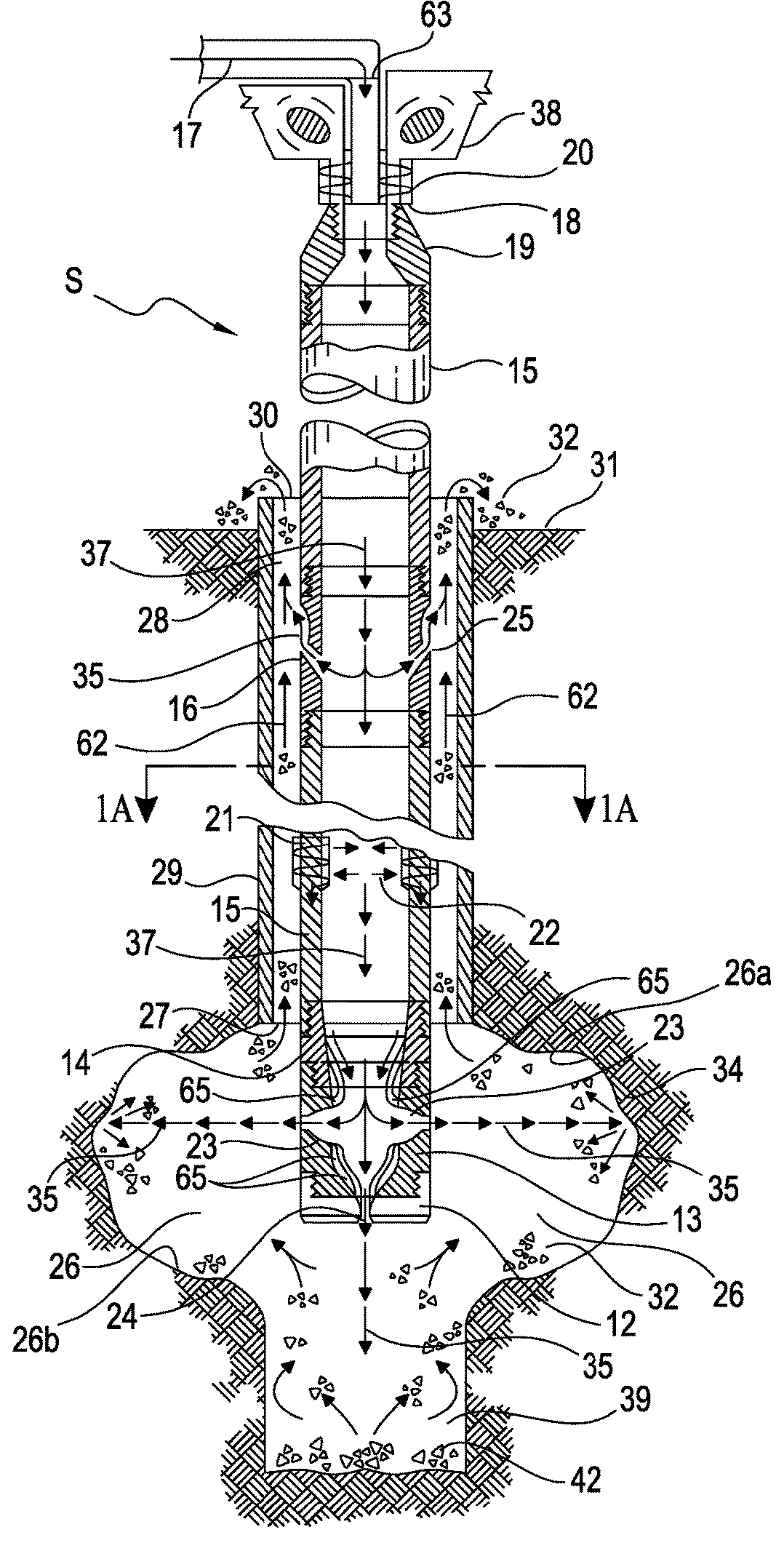

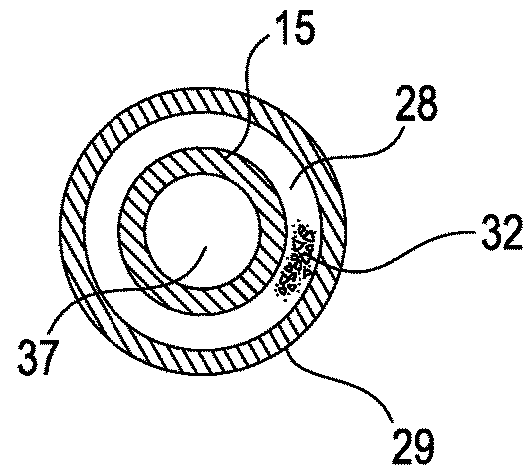

Roof drilling improvements

InactiveUS20070119624A1Extended service lifeFast drillingDrill bitsAnchoring boltsSuperhard materialHardness

The invention is embodied in a heavy duty drill bit for hard / soft rock drilling comprising a high fatigue resistant, high alloy steel bit body having a PCD cutter element of super hard material and an enlarged shank portion constructed to accommodate torsional forces at high thrust pressures, and reamer means for compensating the effect of bore hole rifling. The invention further involves the method of forming a roof bolting matrix in extremely hard rock formations having a compression strength up to about 50,000 psi using PCD wafers on a high tensile strength steel body coupled by a heavy duty shank through high fatigue resistant reamer means to a high strength drive steel member.

Owner:WILLIAM J BRADY LOVING TRUST THE

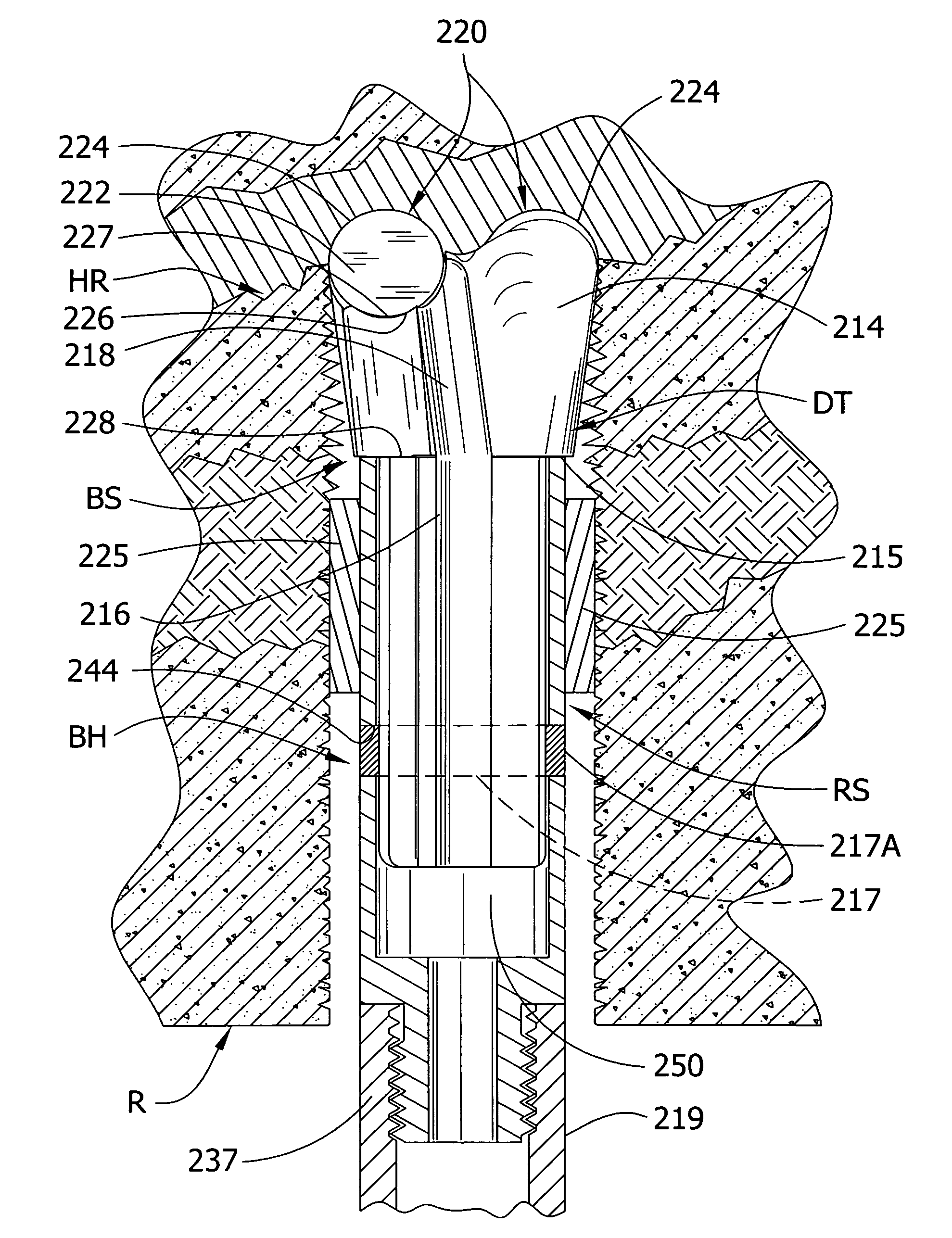

Roof drilling system improvements

ActiveUS20070119625A1Fast drillingExtended service lifeDrill bitsAnchoring boltsWell drillingHardness

The invention is embodied in a heavy duty drill bit for hard / soft rock drilling comprising a high fatigue-resistant, high alloy steel bit body having a PCD cutter member and an enlarged shank portion constructed to accommodate torsional forces at high thrust pressures, and reamer means for compensating the effect of bore hole rifling. The invention further involves the method of forming a roof bolting matrix in extremely hard rock formations having a compression strength up to about 50,000 psi using PCD wafers on a high tensile strength steel body coupled by a heavy duty shank through high fatigue-resistant reamer means to a high strength drive steel member.

Owner:WILLIAM J BRADY LOVING TRUST THE +1

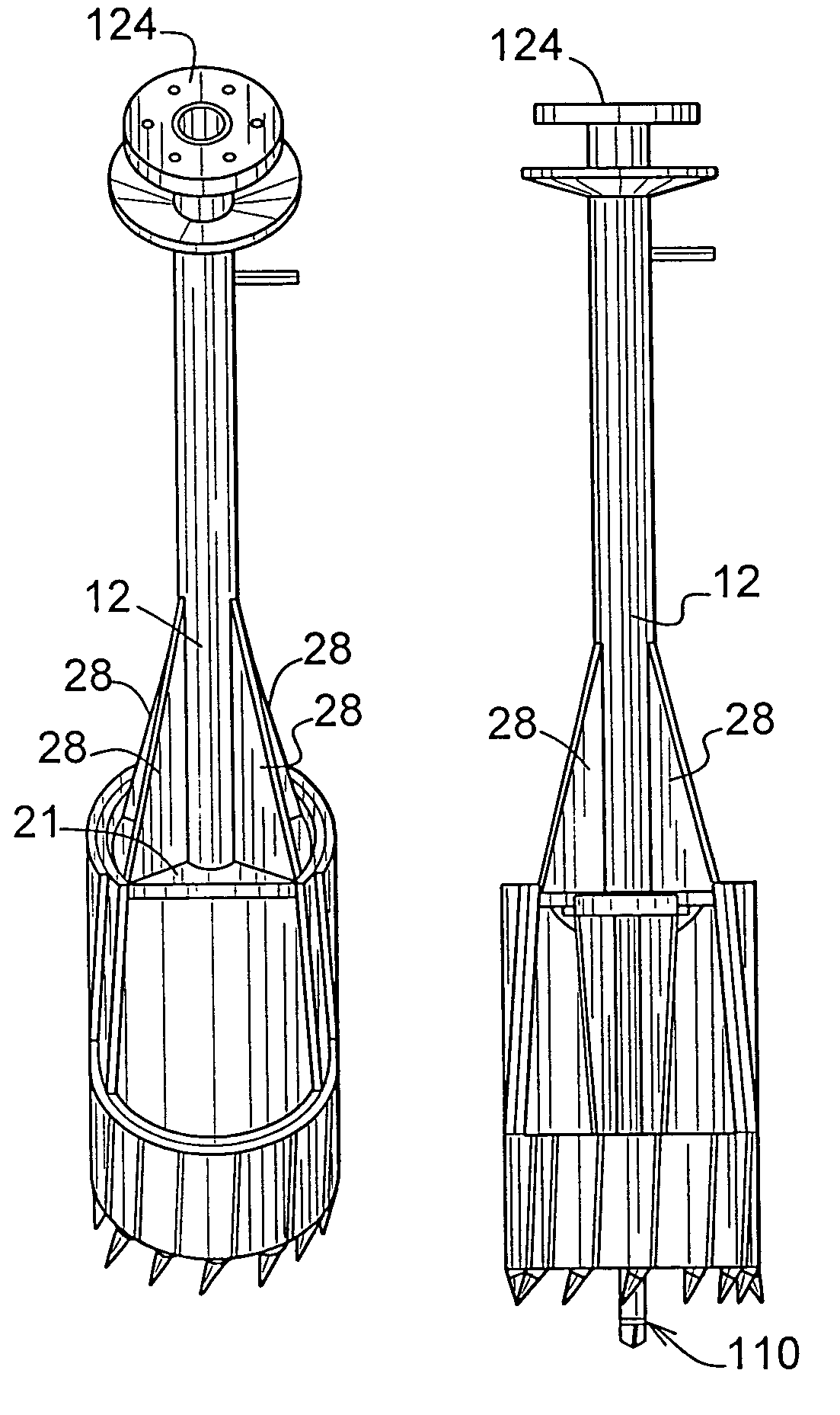

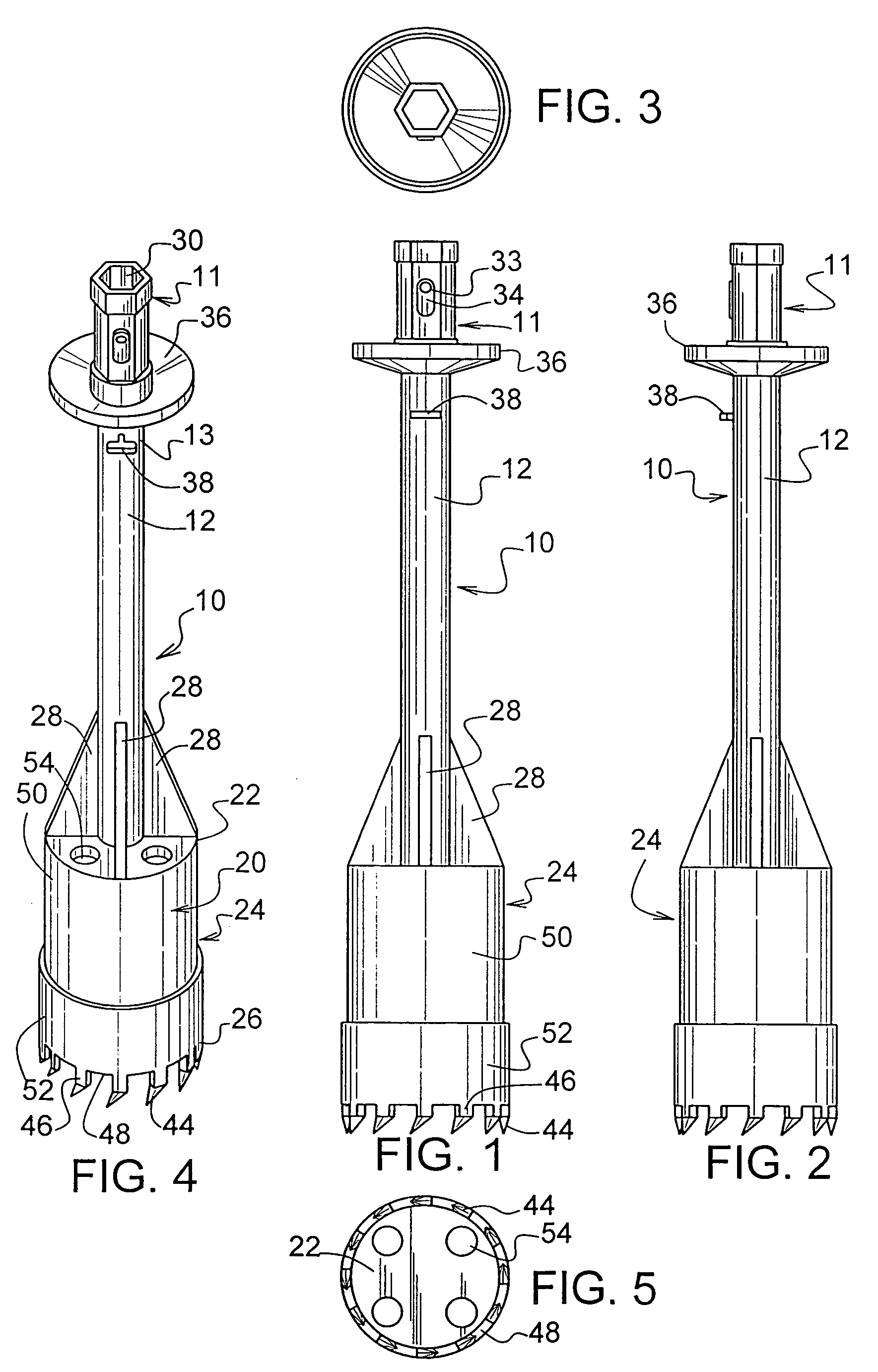

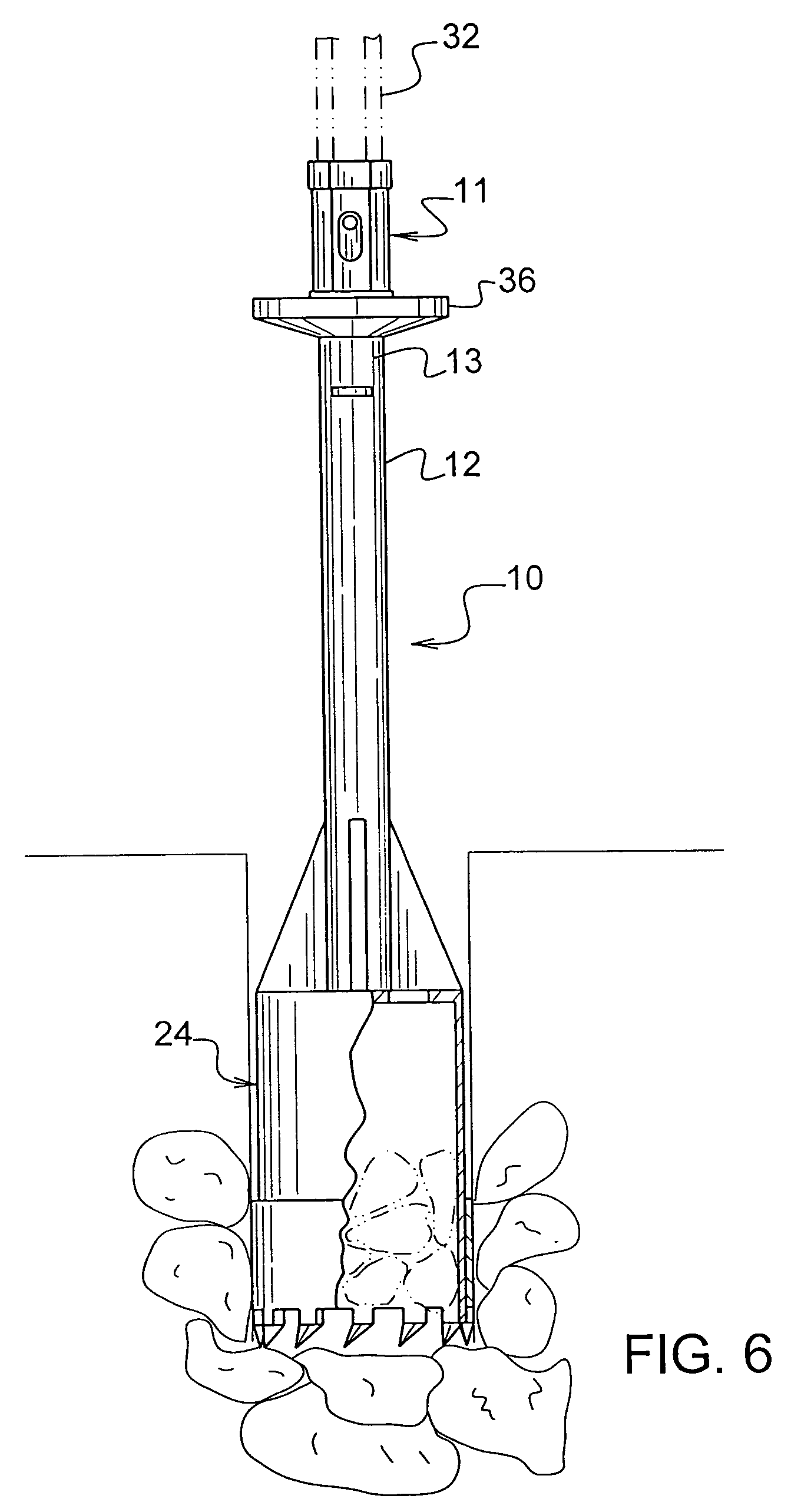

Flightless rock auger for use with pressure drills with quick attachment and method of use

A flightless rock auger is used for drilling postholes through rock with the use of hydraulic pressure and at slow revolution per minute. The rock auger is used in combination with a conventional flighted auger used for drilling postholes in dirt and clay. During a posthole drilling operation, the rock auger is substituted for a conventional flighted auger as needed for drilling through and removing rock or other hard material such as concrete from the posthole. The rock auger is designed for use at very low revolutions per minute and can function utilizing only the weight of the auger; however, the rock auger is designed for use with pressure drilling units as well for cutting a circular hole through the rock and forming a plug which is to be lodged in the cavity of the rock auger cylinder to be removed from the posthole. The quick connection enables the shaft of a pressure drill unit to engage the flightless auger to be quickly substituted for the rock auger to facilitate fast removal of soft dirt from the posthole. A pilot drill bit can be disposed within the cutting head for extending outwardly pass the cutting edge thereof for starting the hole, breaking up rock, and holding the auger in position during the drilling operation. A portion of the cylindrical body can be removed to allow quick clearance of the plug.

Owner:GATOR ROCK BITS

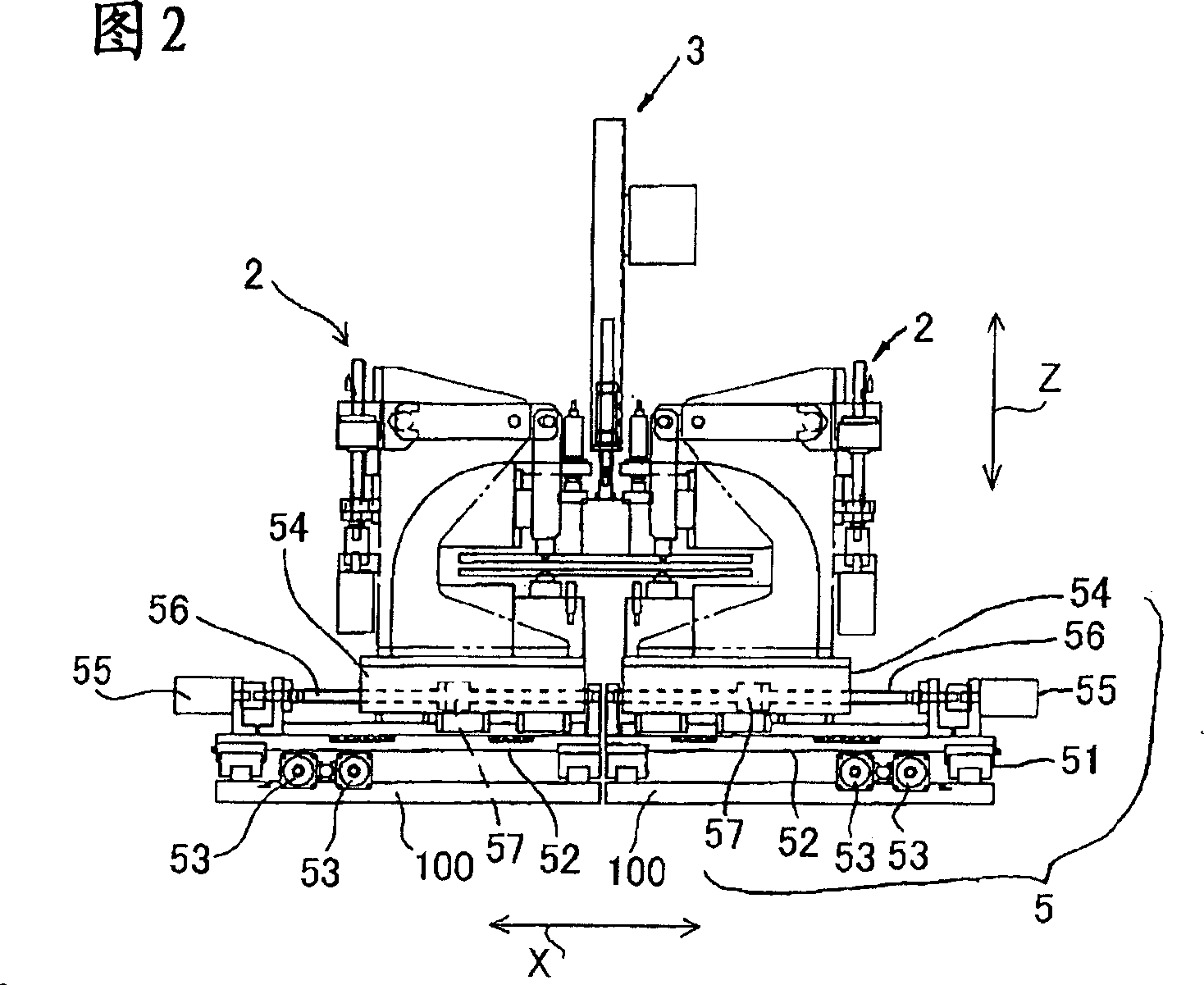

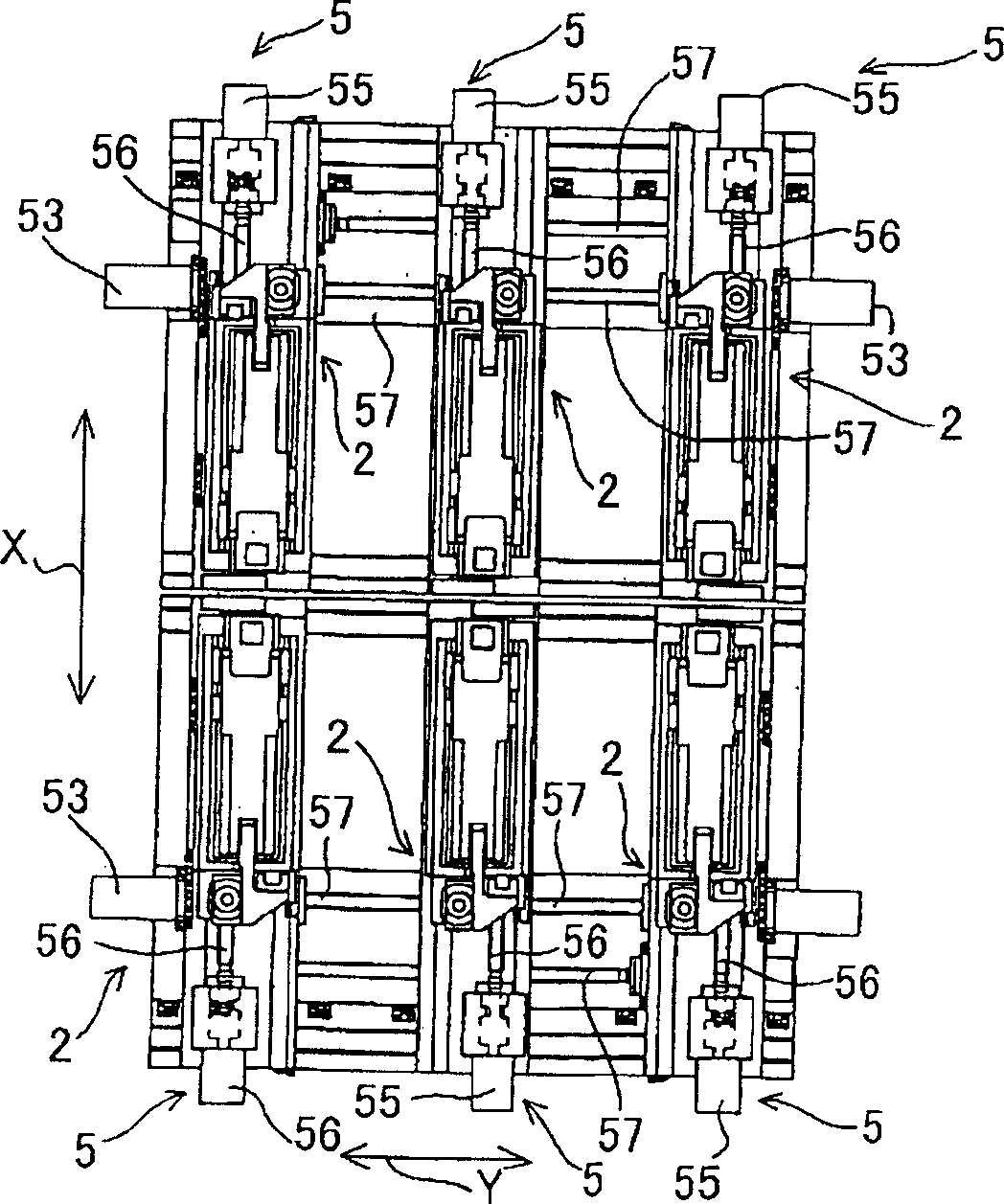

Perforating apparatus and method for slab workpiece

InactiveCN1526524ADoes not affect replacement operationsEasy and fast replacement workAutomatic control devicesMeasurement/indication equipmentsIndustrial engineering

Owner:SEIKO PRECISION CO LTD

Anchorage unit and construction method using same to ream ground anchor

InactiveCN101806061AGive full play to the characteristicsReasonable structural designBulkheads/pilesSingle useCement slurry

Owner:HEFEI UNIV OF TECH

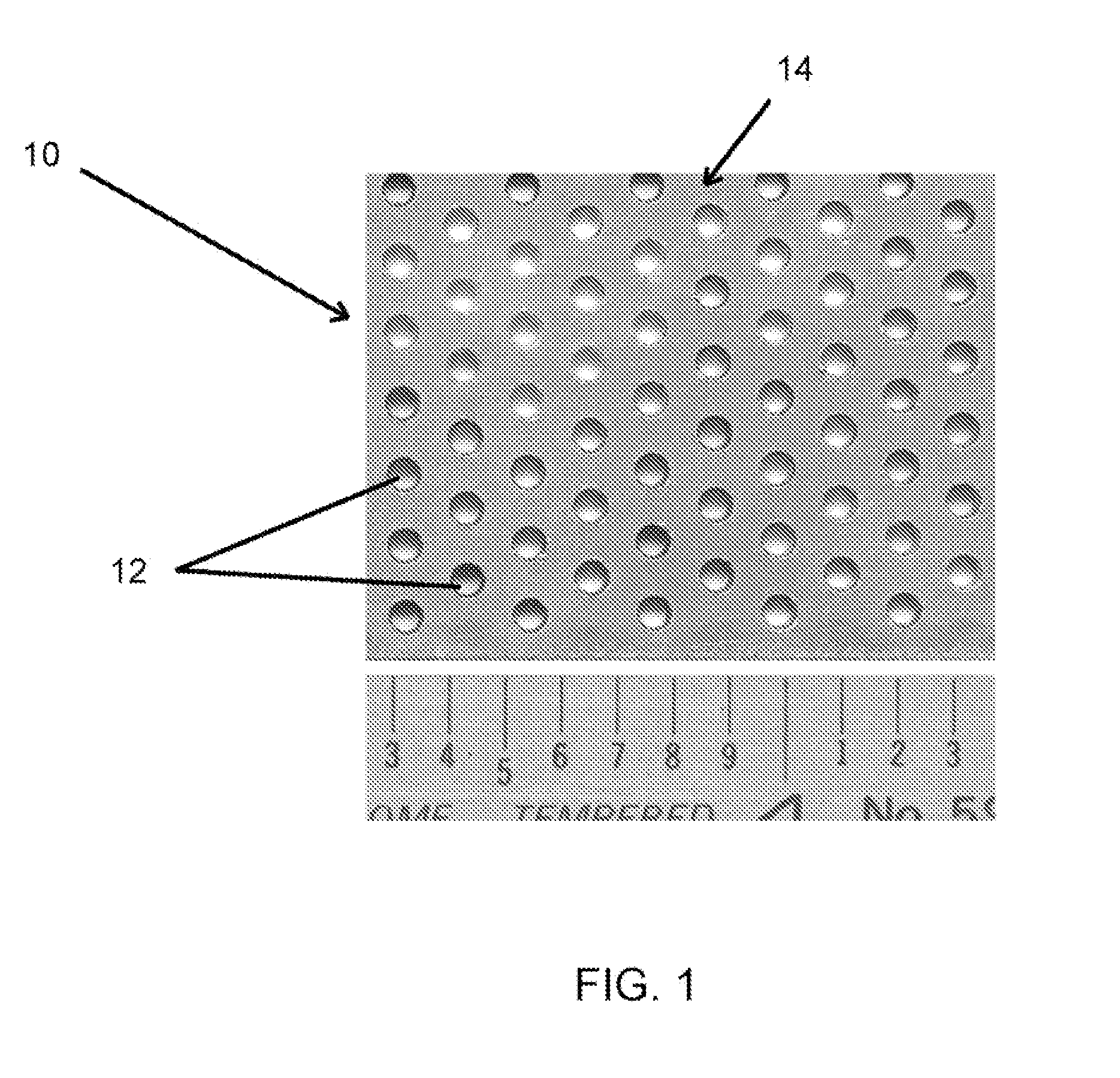

Process for producing through-holes in sheet members

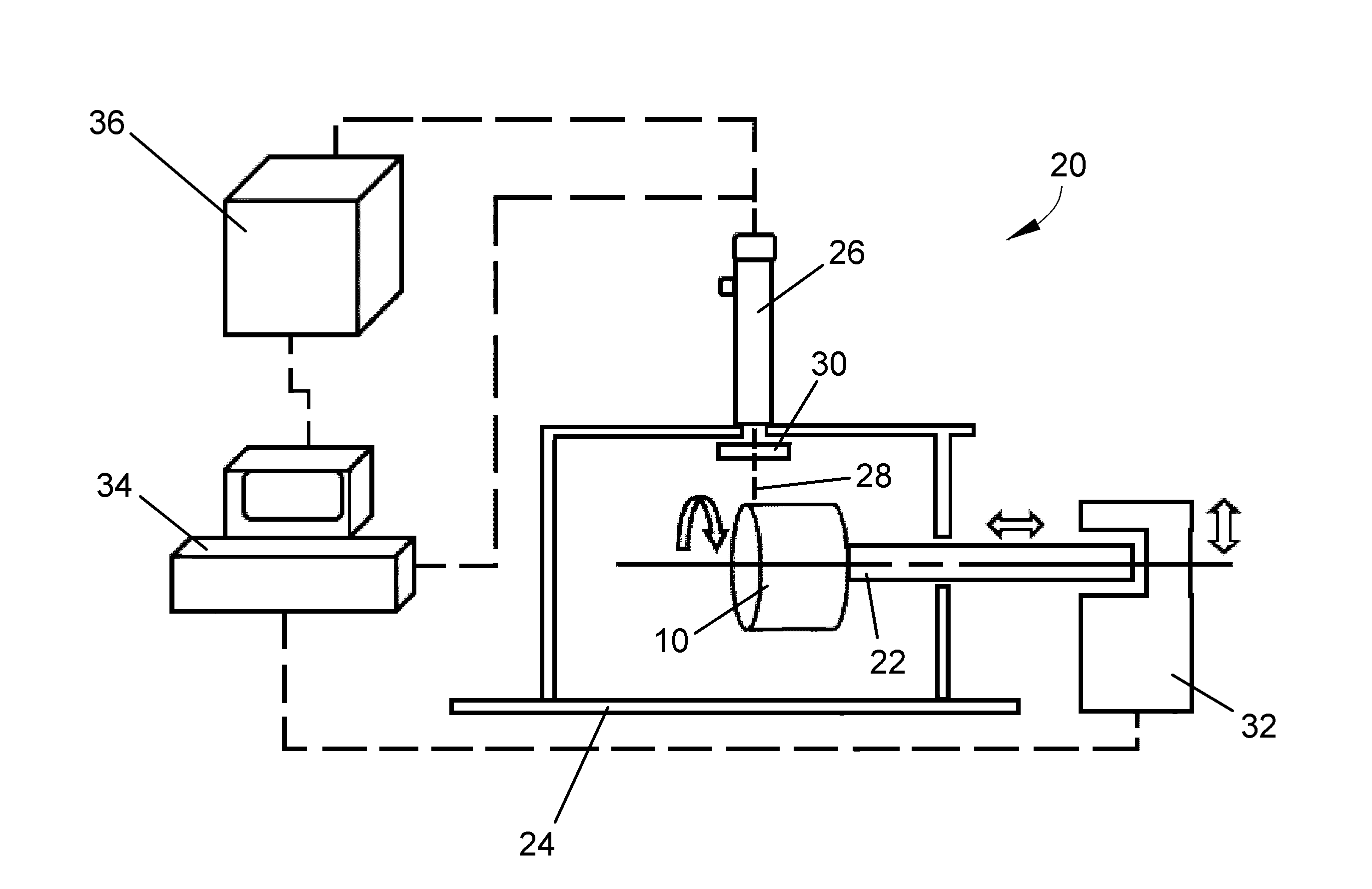

ActiveUS20100126971A1Consistently produceFast drillingElectron beam welding apparatusSound proofingNacelleEngineering

Owner:MRA SYST LLC

Hole reaming apparatus and method

An enhanced reaming apparatus and method are disclosed. A reaming assembly may have a motor and a pump that provide linear force, torsional force, and pressurized drilling fluid to a reamer to cause the reamer to enlarge the bore of a pilot hole. The reamer may have a body and a plurality of blade assemblies that cooperate to define two substantially symmetrical, oppositely oriented reaming sections. Each blade assembly may have an inner blade attached to the body and an outer blade extending outward from the body. Hard cutting elements may be used in place of the outer blade. The blade assemblies may be field-replaced, or the orientation of the reamer may be reversed to enhance the life of the reamer. The reamer has jets and circulation openings that release the drilling fluid into the bore to facilitate penetration and remove cuttings.

Owner:XTECH INDS INT

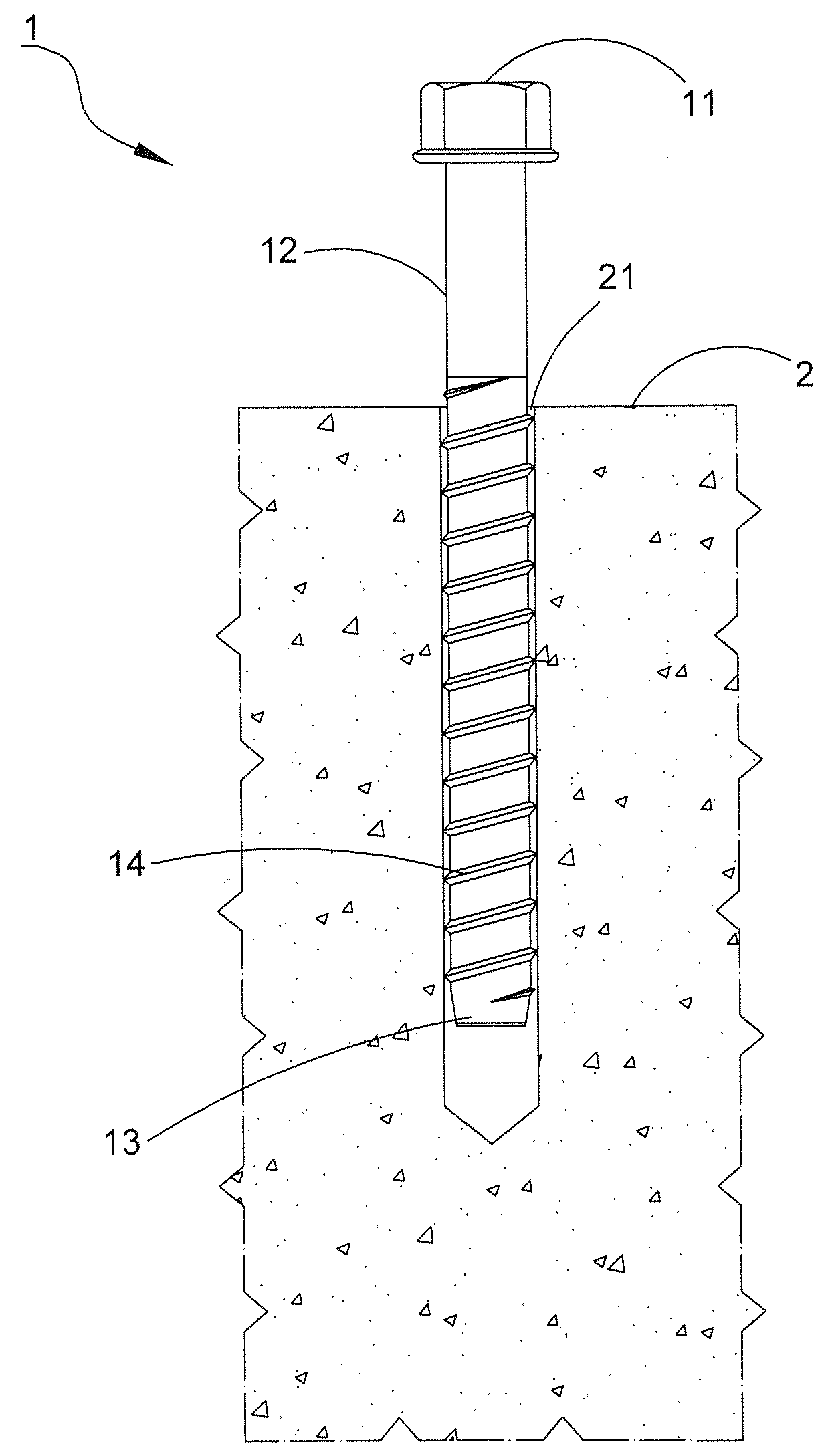

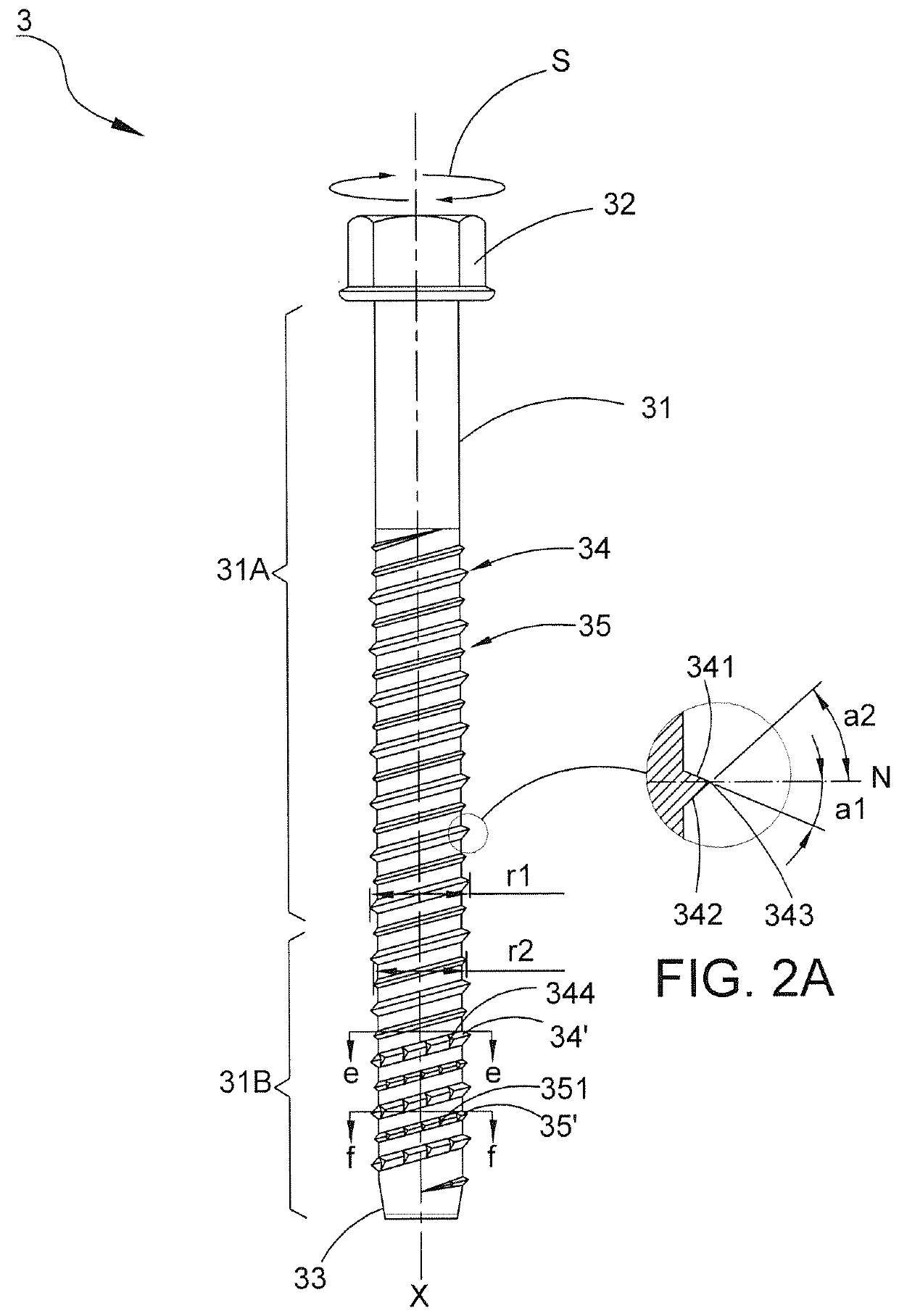

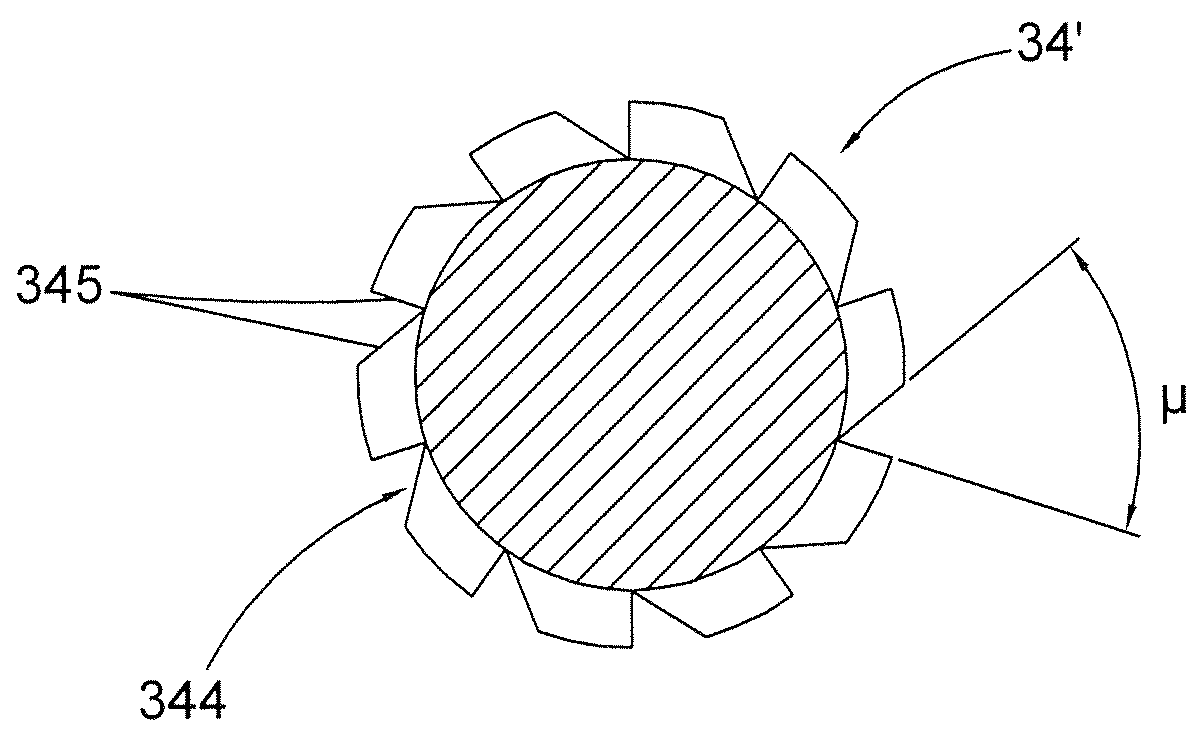

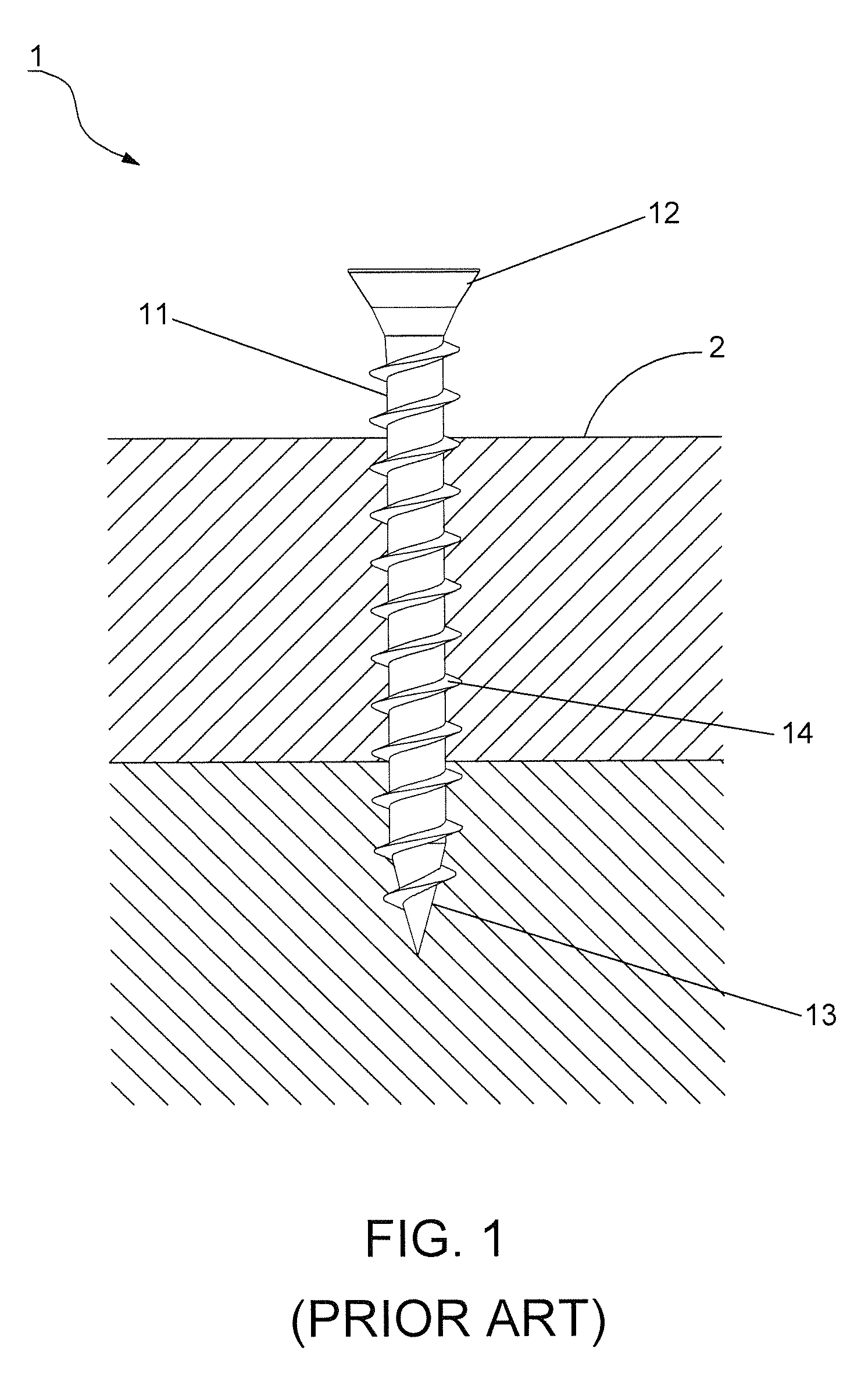

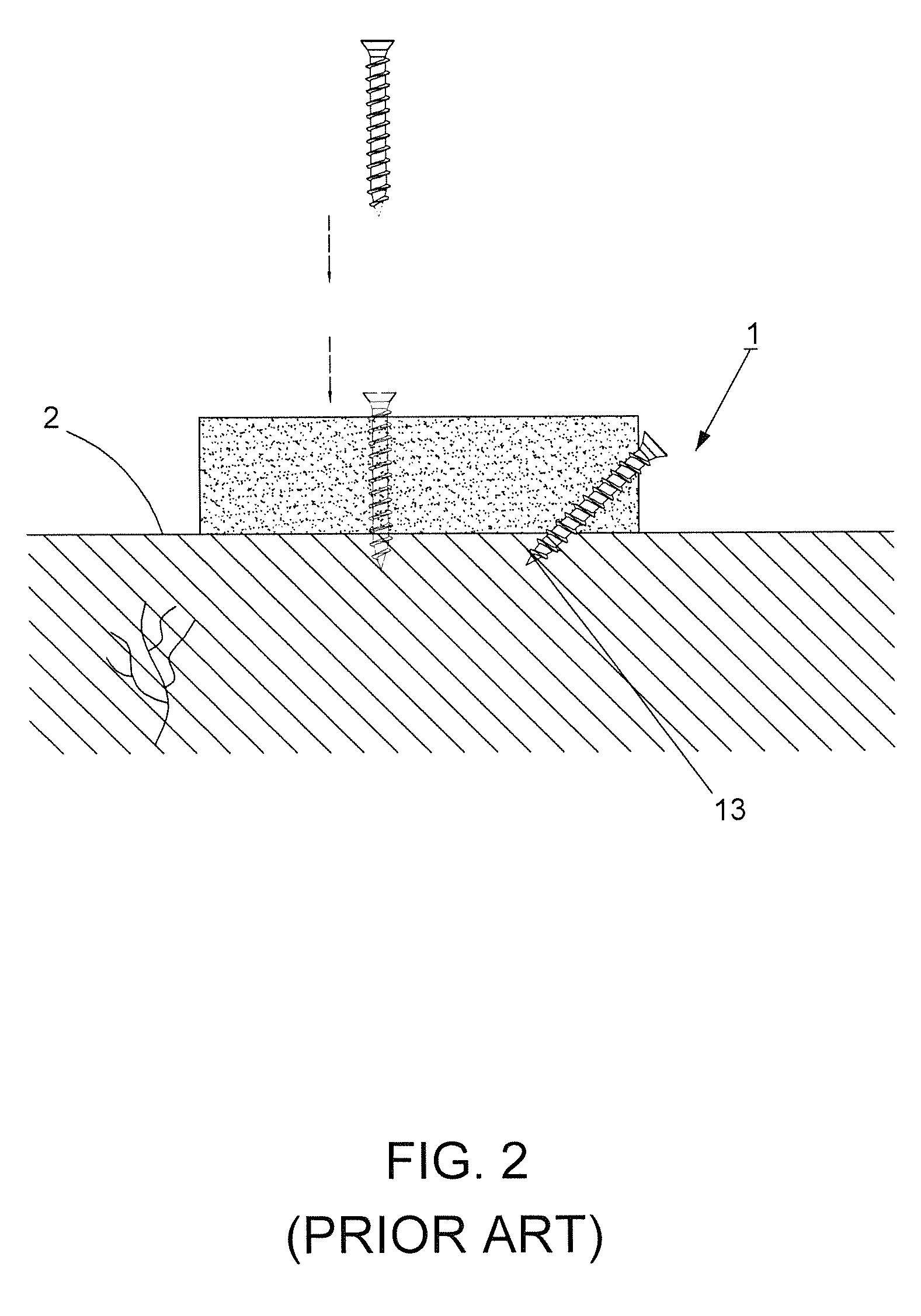

Fastening bolt for use in concrete

ActiveUS20160032956A1Quick drilling operationPreferable mechanical propertyScrewsEngineeringScrew thread

A fastening bolt includes a shaft defining a central axis, a head, a drilling portion, and first threads alternating with second threads. The first threads and the second threads have different outer diameters. Each first thread has a trailing surface facing the head and inclined to a line perpendicular to the central axis by a trailing angle and a leading surface facing the drilling portion and inclined to the line by a leading angle. The trailing angle is smaller than the leading angle to build an asymmetrical form. Some threads near the drilling portion form respective cutting grooves and recesses thereon. Each cutting groove is formed by walls with different lengths and opened at an angle which does not exceed 90 degrees. The bolt breaks the workpiece quickly by the cutting grooves and recesses. The asymmetrical first threads help enter the workpiece quickly and attain a firm engagement therewith.

Owner:HOME SEN

Clamping-type drilling device used for machining communication equipment

ActiveCN109648117AImprove practicalityQuick clampingFeeding apparatusPositioning apparatusHydraulic cylinderMotor drive

The invention discloses a clamping-type drilling device used for machining communication equipment, and relates to the technical field of communication equipment machining. The clamping-type drillingdevice comprises a device body. A machining platform is mounted at the top end of the device body and is close to the inner side of a portal frame. Hydraulic cylinders are arranged on the two sides ofthe top end of the portal frame in a penetrating mode. A drilling mechanism is arranged at the bottom end of a movable box in an embedded mode. According to the clamping-type drilling device, a firstmotor drives a rotary frame to rotate in an X-axis plane and a Y-axis plane of the three-dimensional space, a second motor drives a spindle box to rotate in the Y-axis plane and the Z-axis plane of the three-dimensional space, and a third motor drives a drill bit to rotate so that holes at any inclination angles can be drilled in the surface of the communication equipment; the to-be-machined communication equipment can be rapidly and firmly clamped through the clamping mechanism so that holes can be rapidly and efficiently drilled in the surface of the communication equipment; and a sliding mechanism drives a supporting mechanism to slide to fine adjust the vertical height of the machining platform relative to the drilling mechanism so that communication equipment with different sizes canbe machined.

Owner:安徽轩纬科技有限公司

Low-frequency pulsing sonic and hydraulic mining system

ActiveUS9995126B1Improve economyHigh slurry recovery rateDisloding machinesLiquid/gas jet drillingSlurryEngineering

An improvement to a sonic drilling system comprising a high-pressure, high-volume water pump connected to a fluid supply and a length of casing in a borehole; an elastic sonic rod string; an eductor coupling having an upwardly directed convergent nozzle; a transition rod; a sub-coupling having a laterally directed convergent nozzle; and a shoe rock bit having a downwardly directed convergent nozzle. The water pump provides fluid down the bore of the sonic rod string, the eductor, the transition rod, the sub-coupling and the rock bit whereby adjustable high-pressure, high-volume fluid is forced through the sonic rod string, the eductor, the transition rod, the sub-coupling and the rock bit to fracture, cut and agitate targeted mineral into slurry and whereby the light slurry is directed effectively upwardly through the annulus to the surface for extraction and heavy slurry gravitates into a sump trap and is recovered with a core barrel.

Owner:GEODRILLING TECH INC

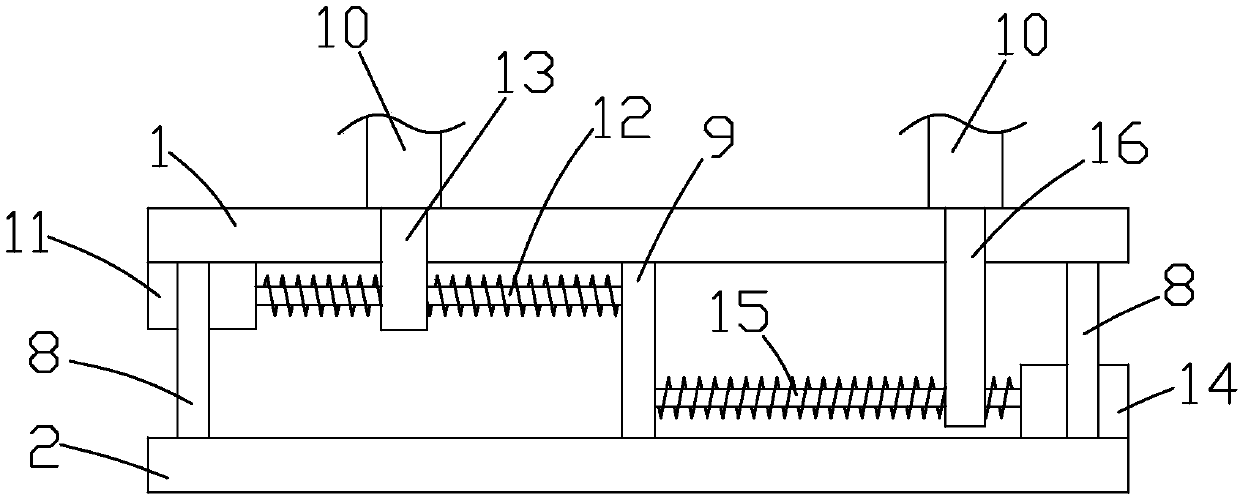

Distal locking nail sighting device for interlocking intramedullary nail

InactiveCN109223150AWill not affect the operationSolve problemsInternal osteosythesisIntramedullary rodEngineering

The invention discloses a distal locking nail sighting device for an interlocking intramedullary nail, and relates to the technical field of orthopaedic trauma medical instruments. A guide slider is slidably arranged in the guide slider mounting frame of the distal guide rod, Between that mount frame of the guide slider and the guide slider, a first slide movement adjusting mechanism is arranged,a distal guide rod is provided with a first guide hole, the guide slider is provided with a second guide hole, the upper and lower sides of the second guide hole are respectively provided with a firstmetal indicating line, and the side frame of the guide slider mounting frame is provided with a metal graduation line. The calibration slider mounting frame of the calibration lever is slidably provided with a calibration slider, a second slider movement adjusting mechanism is arranged between the calibration slider mounting frame and the calibrated slider, the calibration lever is provided witha first calibration hole, the calibration slider is provided with a second calibration hole, and the upper and lower sides of the second calibration hole are respectively provided with a second metalindicating line. The distal locking nail sighting device solves the problem that the distal end of the intramedullary nail is difficult to lock, shortens the operation time and improves the operationefficiency.

Owner:熊海阔 +1

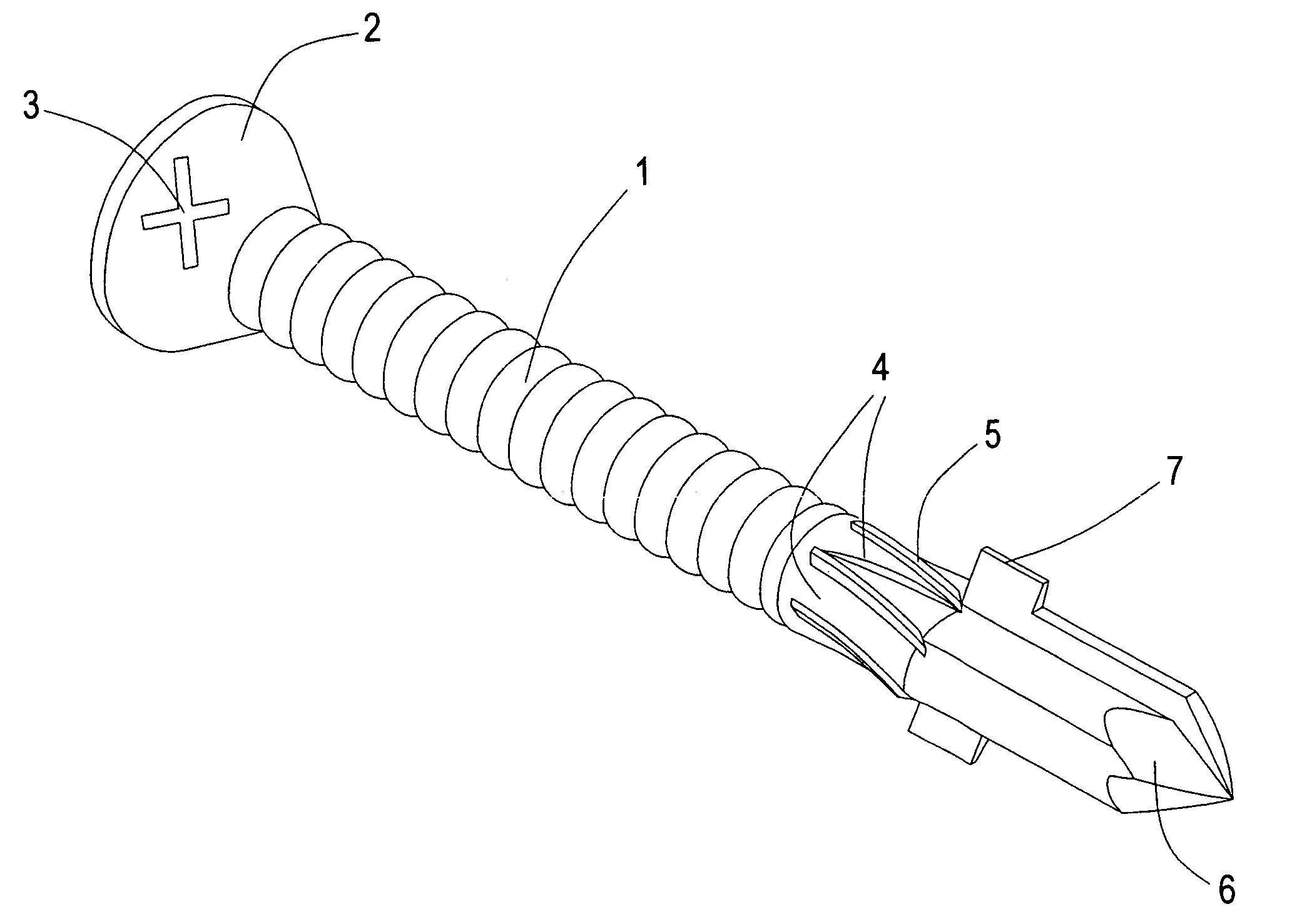

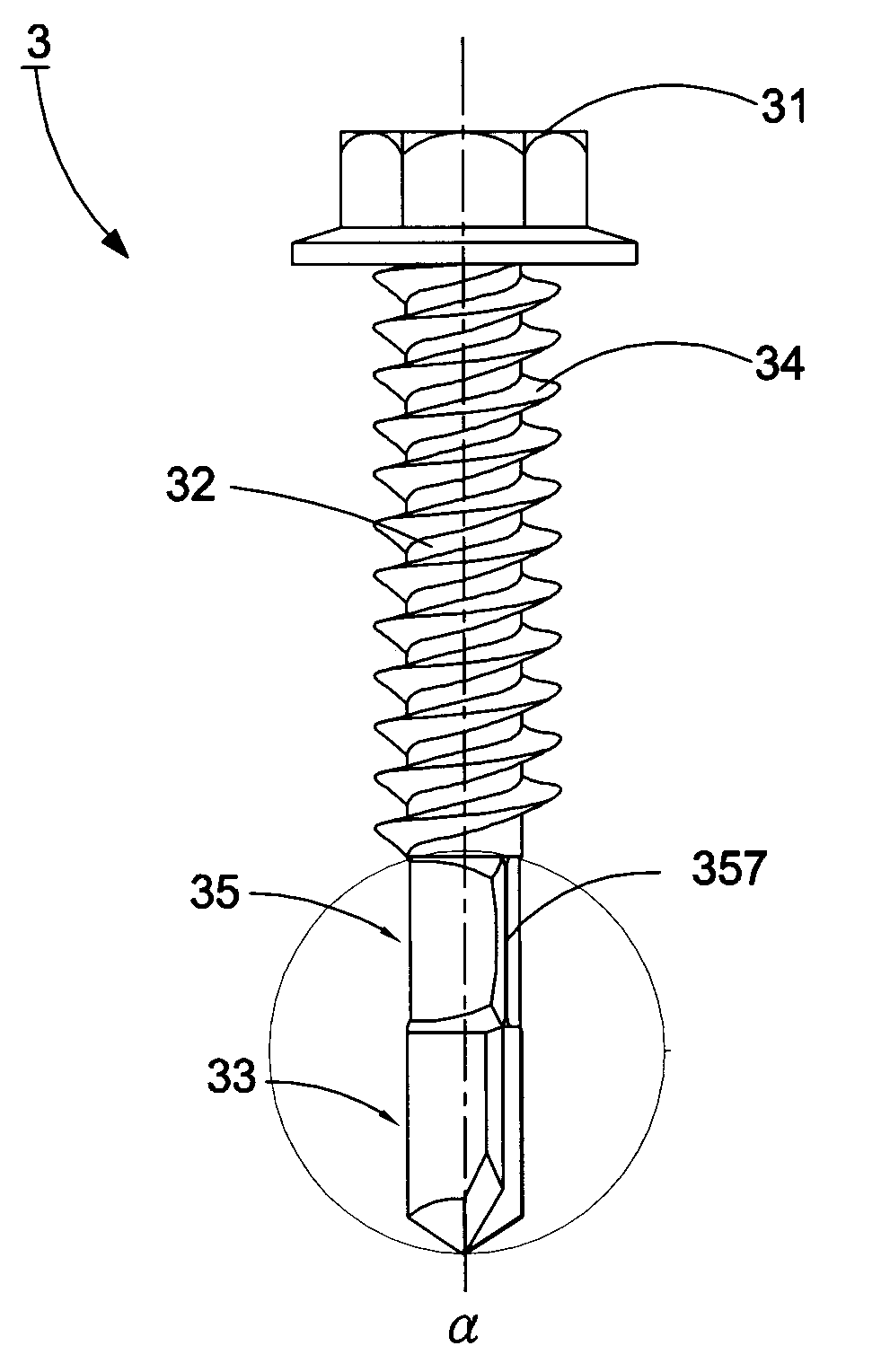

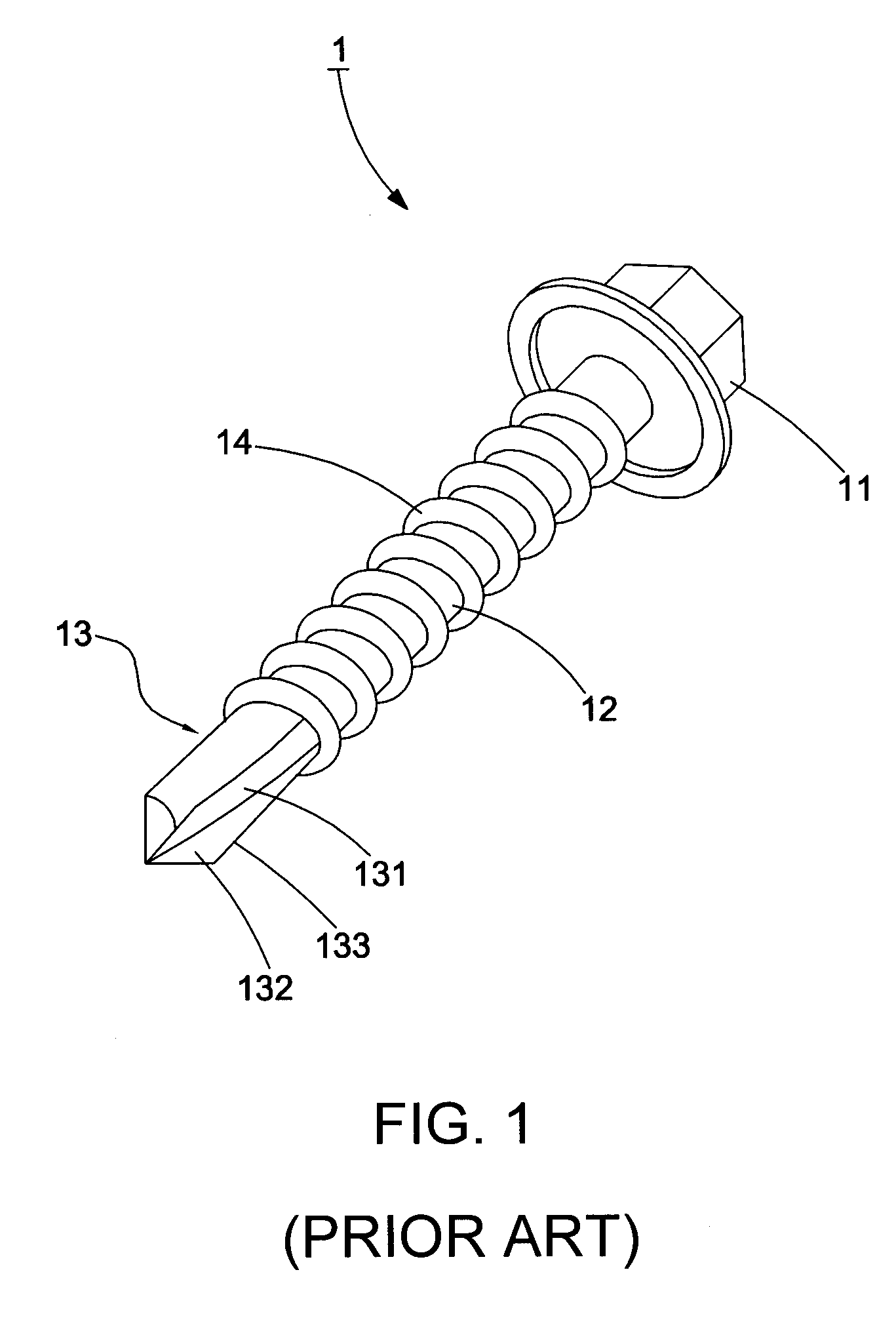

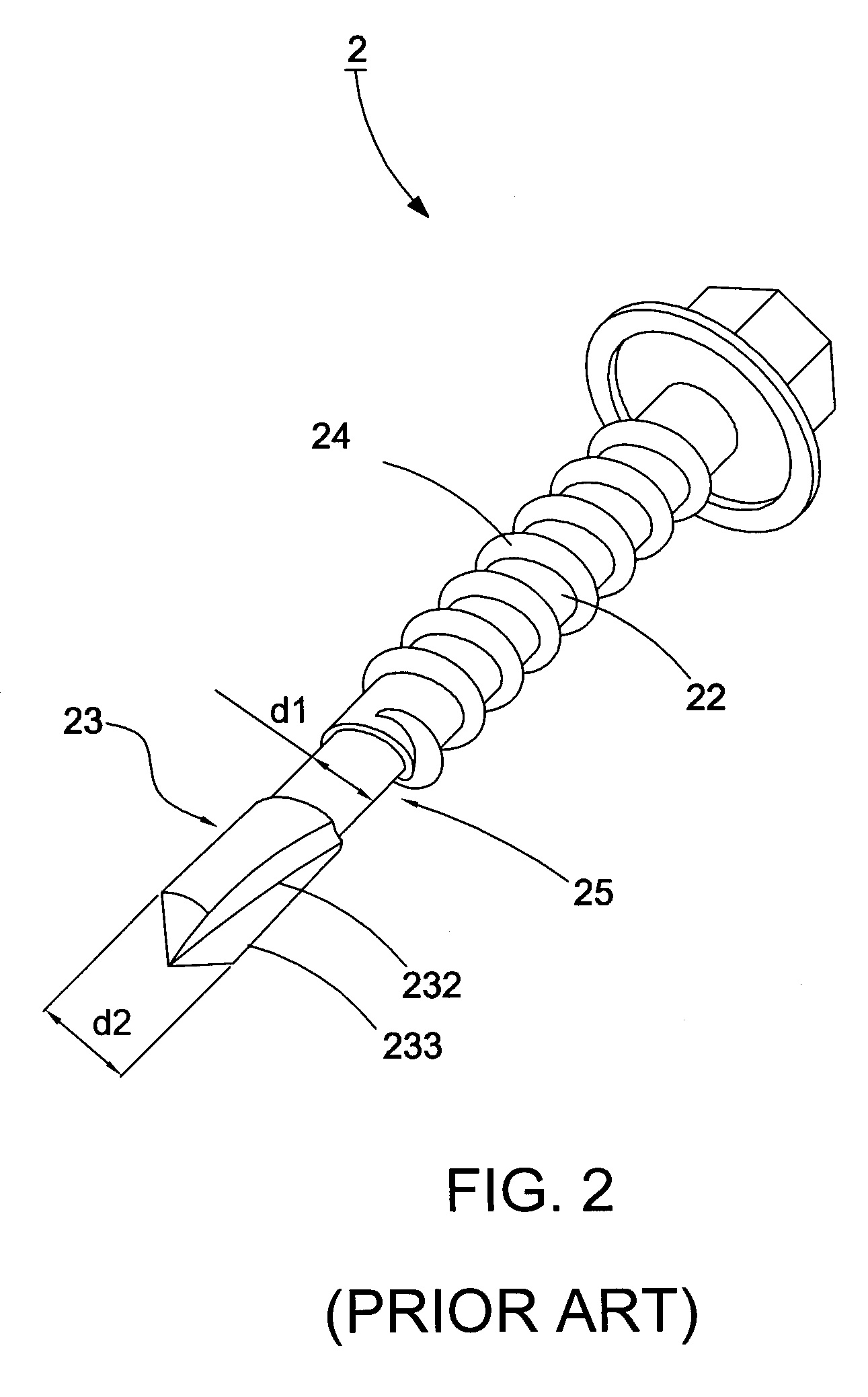

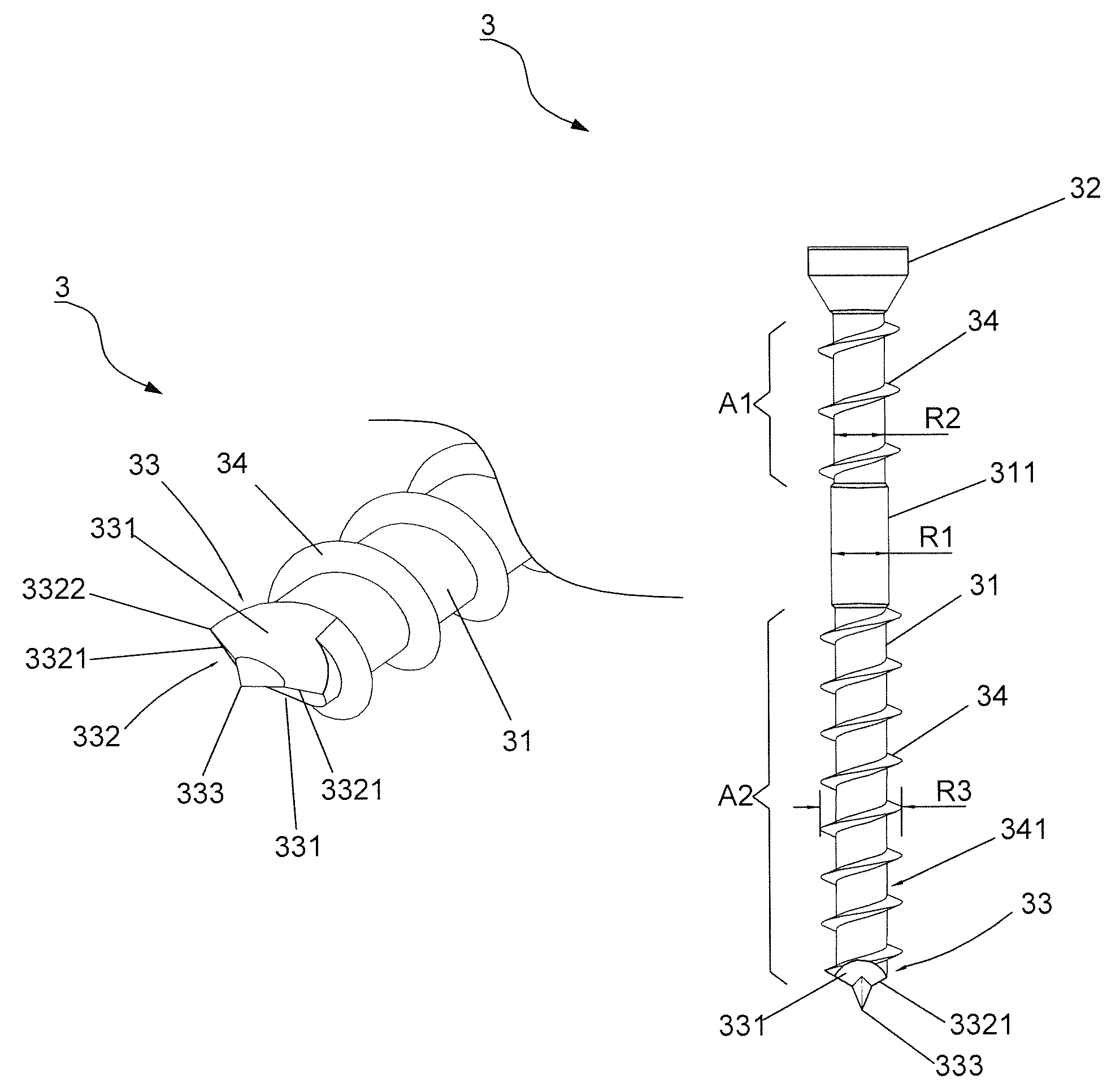

Self-drilling screw with multi-drilling portions

A self-drilling screw with multi-drilling portions mainly comprises a shank, a head and a drilling portion separately disposed on both ends of the shank, and a thread section spiraled on the shank. Wherein, at least one sub-drilling portion formed amid the drilling portion and the thread section further defines a sequence of indentations and prominent areas, and each indentation generates a cutting surface outwardly extended from one side thereof so as to converge the cutting surface with the adjacent prominent area at a cutting ridge. Accordingly, the application of the cutting ridges and the indentations facilitates the drilling portion with the chipping capability and renders an appropriate guidance to redundant debris, thereby efficiently achieving a swift screwing and the lowered screwing resistance to promote the screwing efficiency.

Owner:CHAN LIANG ENTERPRISE

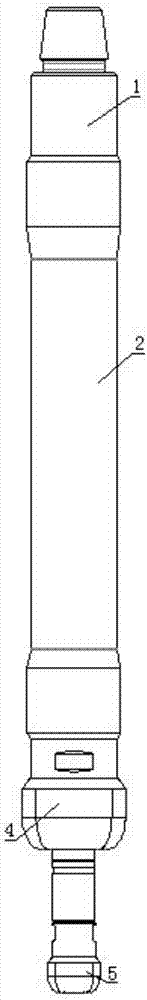

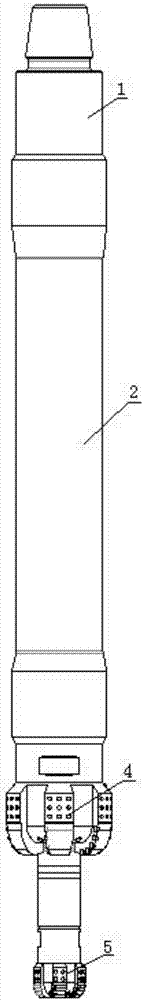

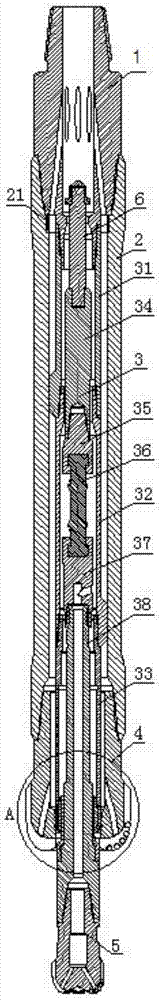

Drilling speed increasing device with composite drill bit

The invention relates to the field of petroleum and natural gas drilling equipment, in particular to a drilling speed increasing device with a composite drill bit. According to the technical scheme, the drilling speed increasing device with the composite drill bit comprises a multifunctional connector, the multifunctional connector is connected with a shell and a screw driving assembly, and the screw driving assembly is sleeved with the shell; the end, away from the multifunctional connector, of the shell is connected with a reaming drill bit body, and the end, away from the multifunctional connector, of the screw driving assembly is connected with a pilot drill bit body; water holes are formed in the reaming drill bit body and the pilot bit body; and the reaming drill bit body is a diamond drill bit or a roller bit, and the pilot bit body is a diamond drill bit or a roller bit. According to the drilling speed increasing device, the pilot bit body can achieve two-stage speed increasing, accordingly the overall drilling speed is increased, and the problems that a pilot bit of an existing two-stage drilling device is low in rotation speed and not obvious in drilling speed increasing are solved.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

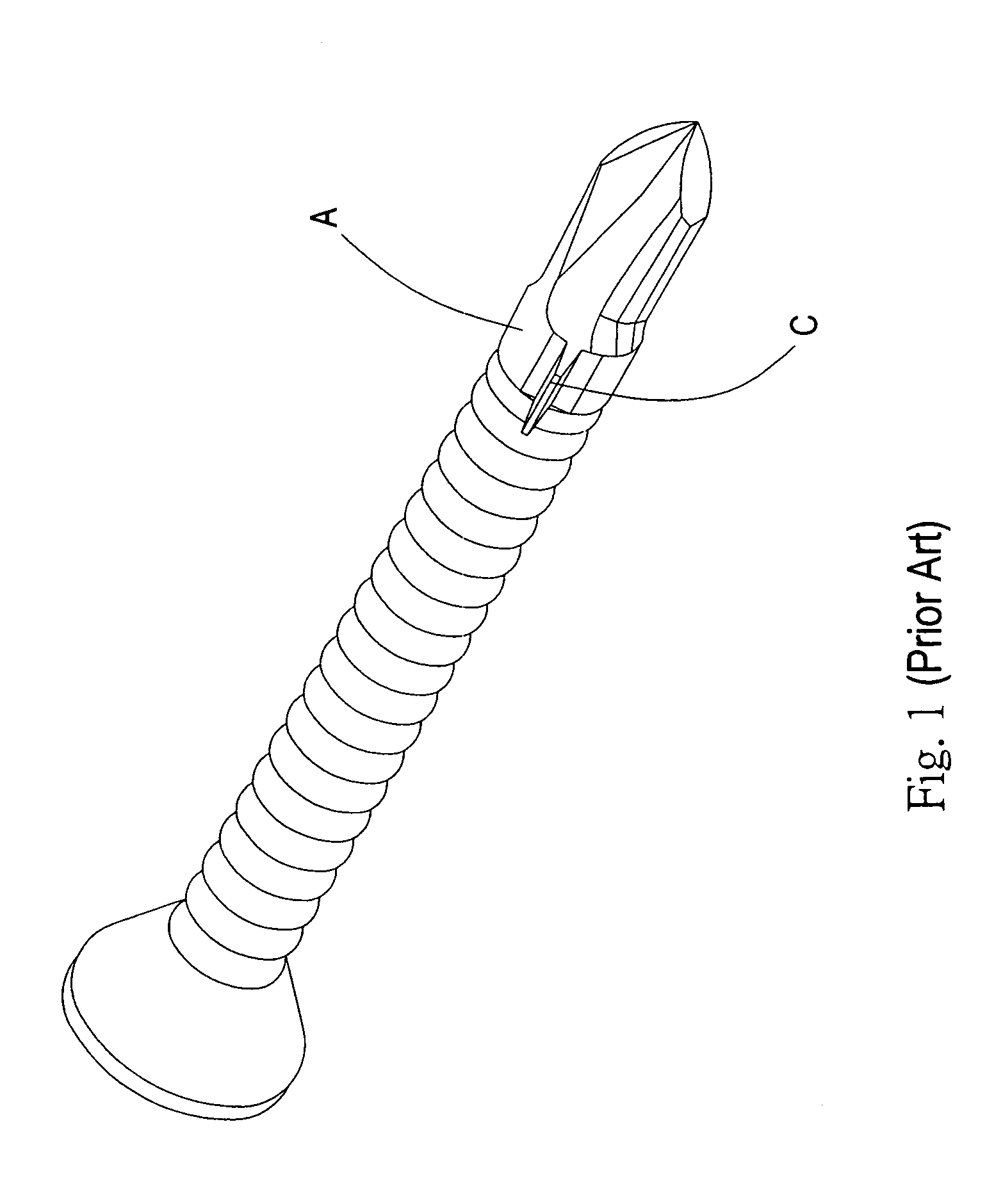

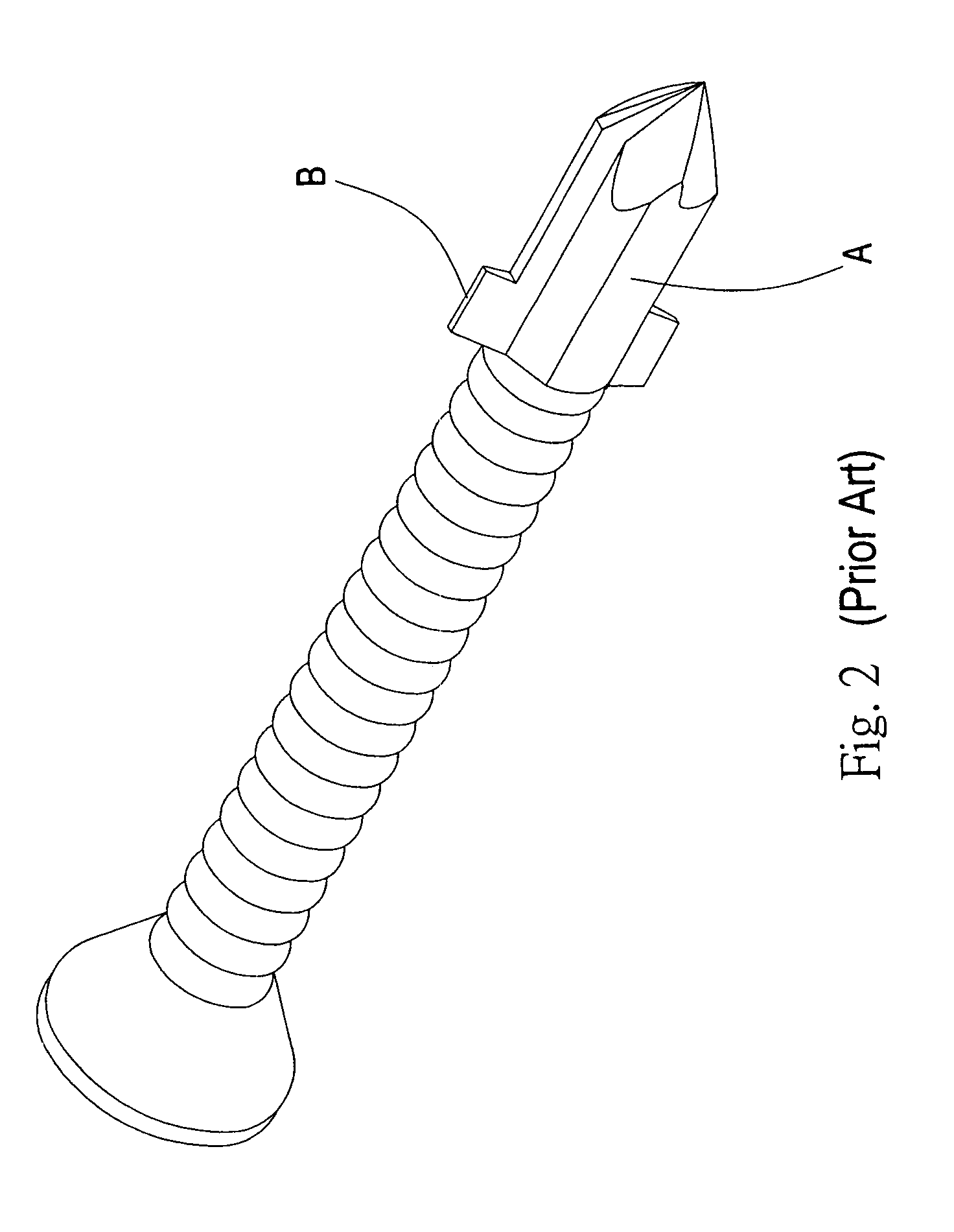

Screw capable of rapidly drilling and cutting

A screw capable of drilling and cutting includes two inclined cutting planes with a cutting edge formed on a convergence of the cutting planes. A tapered positioning member extends from the convergence of the cutting planes, where the cutting edge is divided into dual sub cutting edges by means of the positioning member. Each sub cutting edge has an inclined angle. An included angle included by the sub cutting edges is smaller than 180 degrees. Threads spiral on a shank and extend to the sub cutting edges. Setting the positioning member against on an object permits a steady performance during the first stage of screwing. Subsequently, the sub cutting edges provides a scraping effect on the object during drilling. Torque is reduced and drilling speed is promoted.

Owner:TAIWAN SHAN YIN INT CO LTD

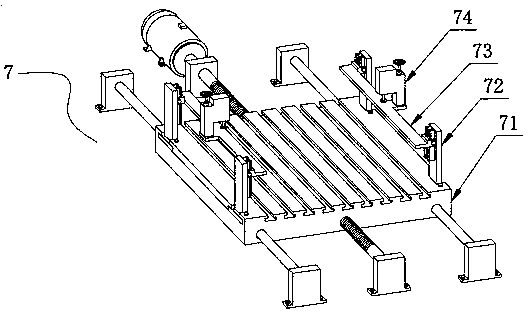

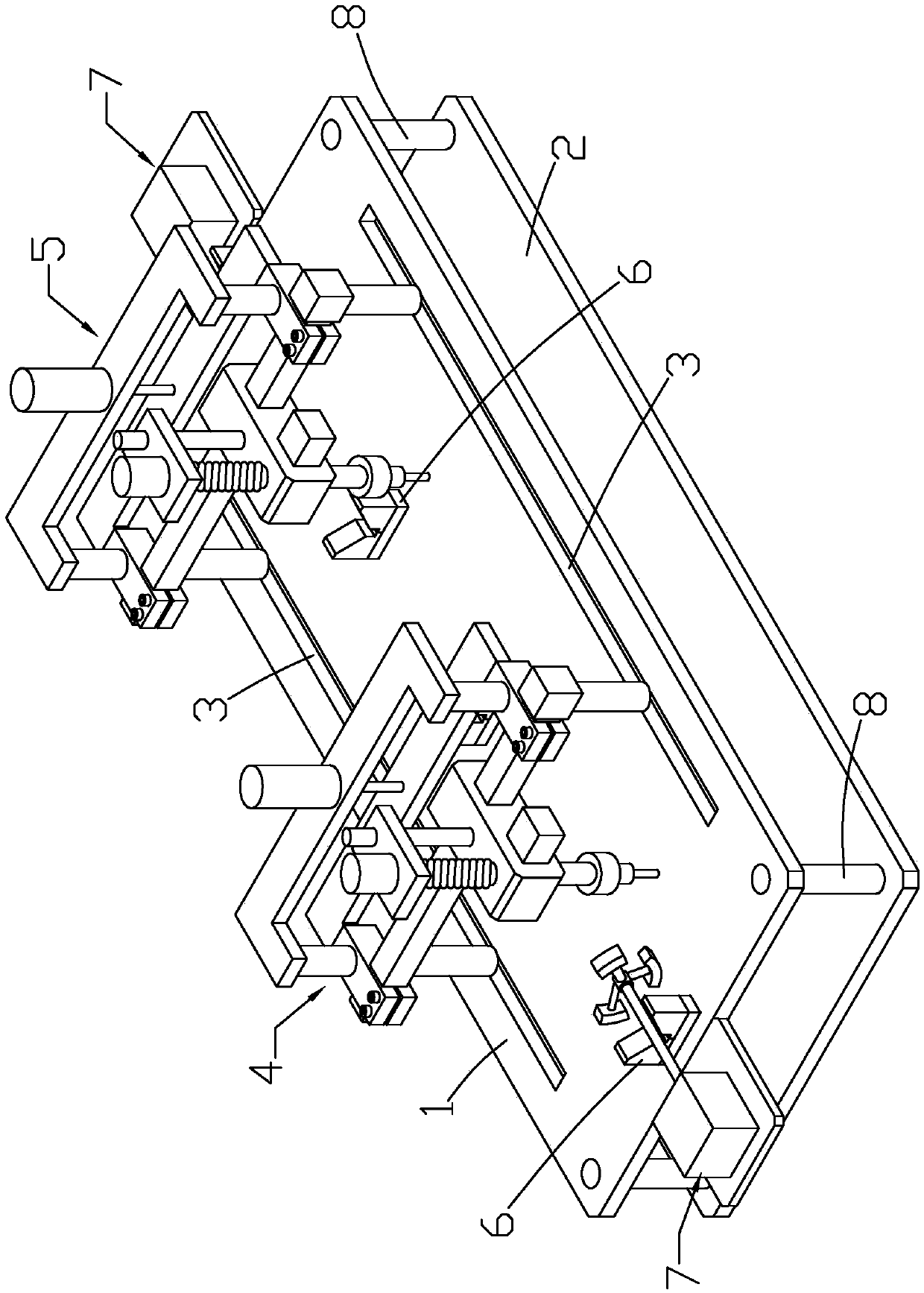

M-type drilling tool for pipes with multiple rows of holes

InactiveCN106112594AReduce scribing processGuarantee the quality of drilling processPositioning apparatusMetal-working holdersRadial positionEngineering

The invention discloses an M-type drilling tooling for multi-row hole pipe fittings. The workpiece radial positioning device is fixedly installed on the base, and includes a workpiece support surface and a workpiece pressing mechanism. The workpiece support surface has an M-shaped structure in section; the workpiece shaft The orientation positioning device includes an end face positioning mechanism and a center angle positioning mechanism; the end face positioning mechanism is set at one end of the workpiece supporting surface; the circle center angle positioning mechanism is set at the other end of the workpiece supporting surface, including indexing plates, front and rear telescopic parts and positioning locking parts The front and rear telescopic parts are set in the cavity formed between the M-shaped structure of the workpiece support surface and the base, and the front and rear telescopic parts are slidingly connected with the workpiece support surface; the indexing plate is fixedly installed at one end of the front and rear telescopic parts; the positioning locking mechanism corresponds to The front and rear telescopic parts are arranged on the base or the workpiece radial positioning device. The M-type drilling processing tool for the multi-row hole pipe fitting can realize rapid positioning drilling processing and improve drilling work efficiency under the premise of ensuring the drilling processing quality.

Owner:徐州恒佳机械科技有限公司

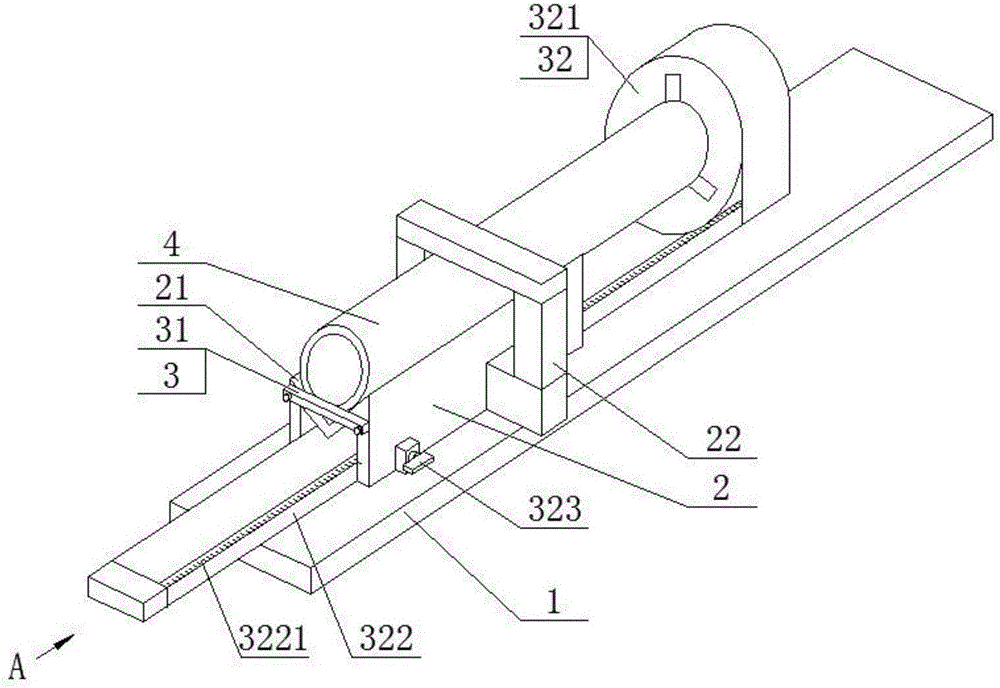

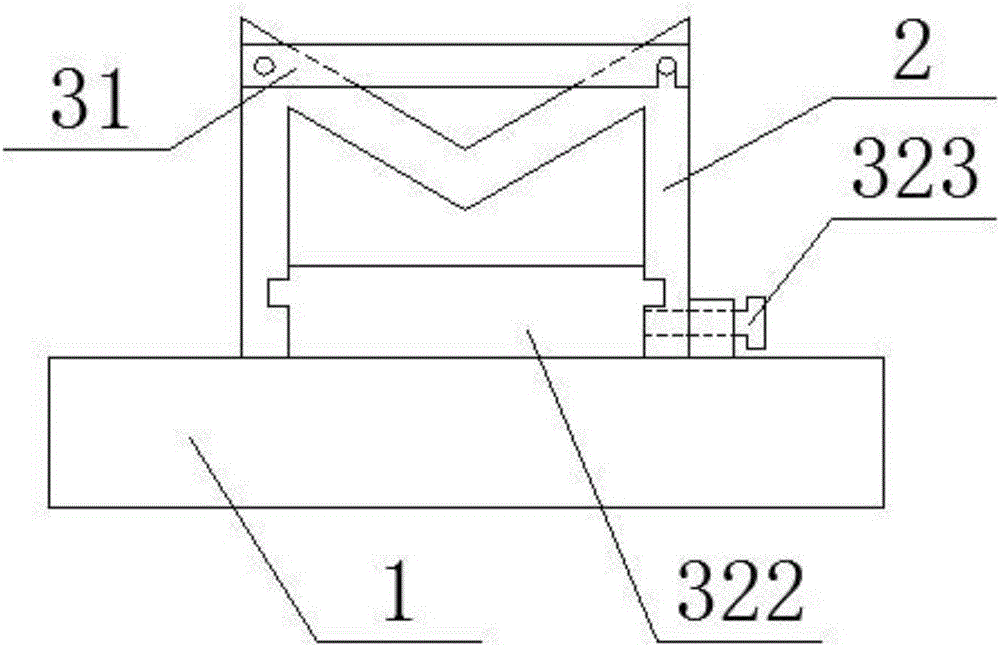

Surface hole drilling device for non-excavation construction pipelines

ActiveCN109570557AImprove drilling efficiencyIncrease flexibilityLarge fixed membersPositioning apparatusArchitectural engineeringPipe support

The invention discloses a surface hole drilling device for non-excavation construction pipelines. The device comprises a base board, a bottom board, a first hole drilling machine, a second hole drilling machine and pipeline rotary mechanisms; the bottom board is located below the base board; the base board is fixedly connected with the bottom board through a supporting rod; two guide grooves are formed in the top face of the base board in parallel; the first hole drilling mechanism and the second hole drilling mechanism are movably connected to the guide groove; a drive mechanism is arranged between the base board and the bottom board and is connected with the first hole drilling mechanism and the second hole drilling mechanism; pipeline supporting mechanisms are arranged on the center straight line of the top face of the base board at equal intervals; and the two pipeline rotary mechanisms are symmetrically arranged on two sides of the base board. The surface hole drilling device fornon-excavation construction pipelines is simple in structure and high in practicability, not only can achieve single-hole or dual-hole machining for construction pipelines and improve the hole drilling efficiency, but also can clamp and position construction pipelines, rotates construction pipelines at the constant speed according to hole drilling needs at the same time, and greatly improves the hole drilling precision and quality.

Owner:嵊州市越通非开挖建设有限公司

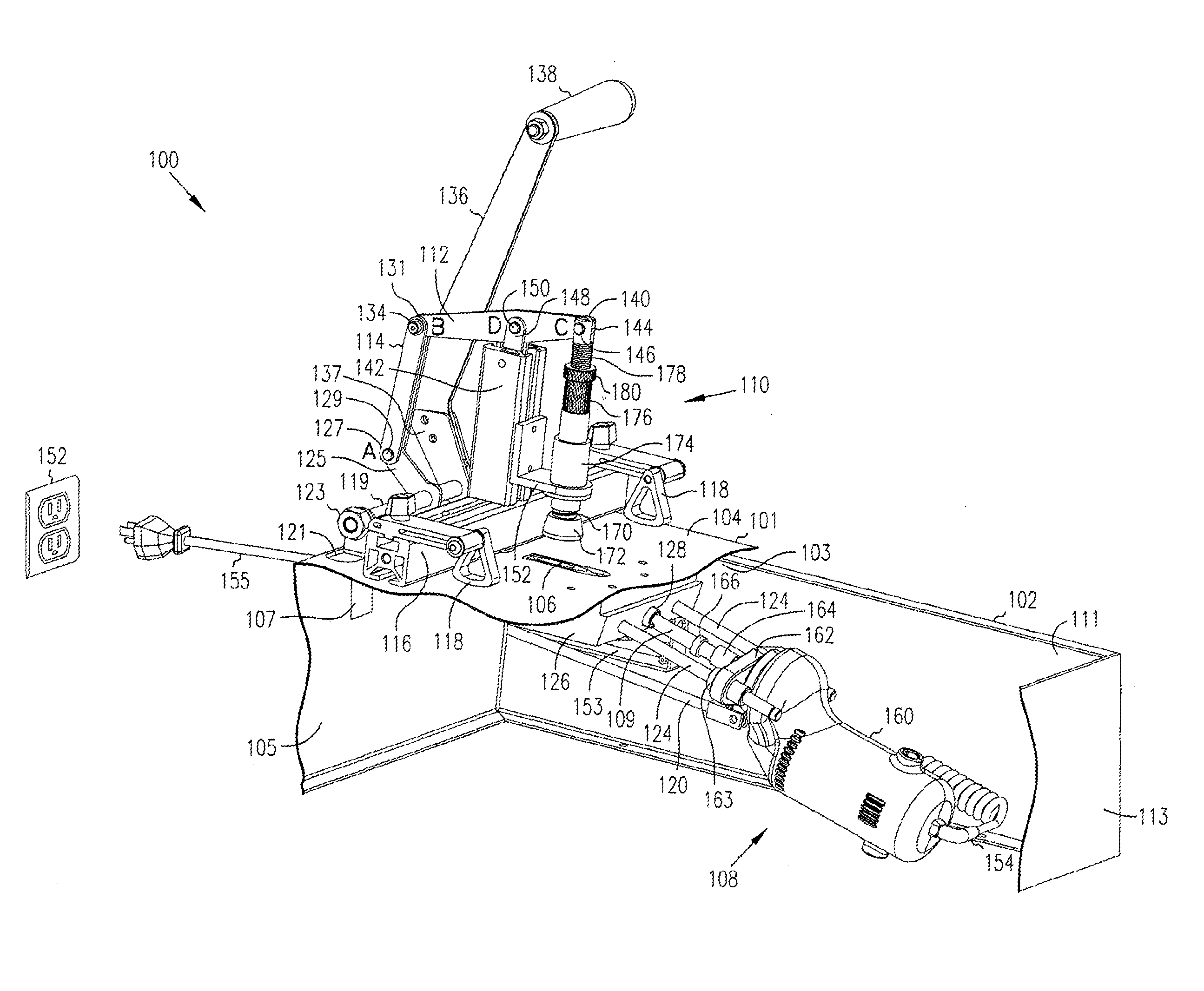

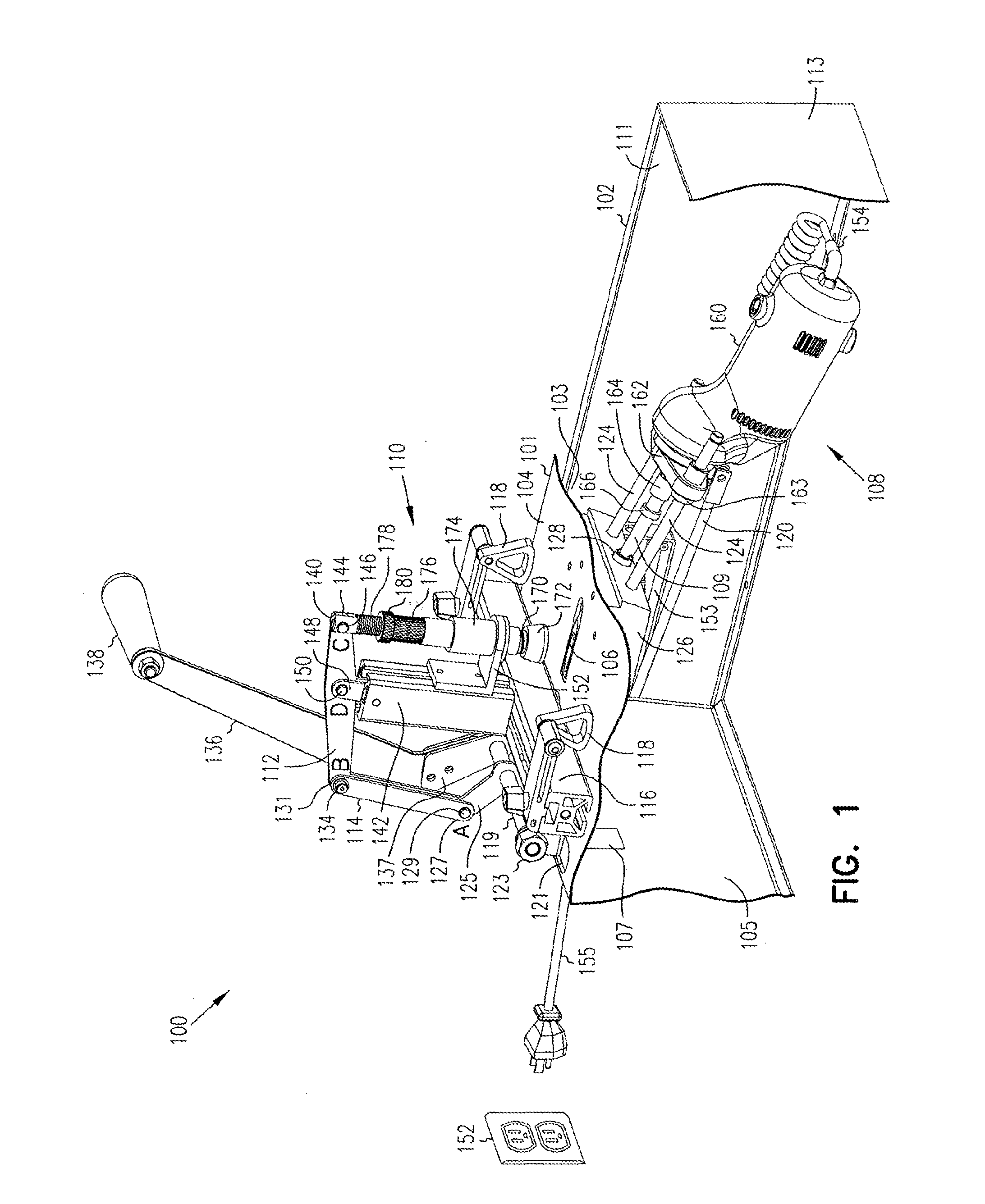

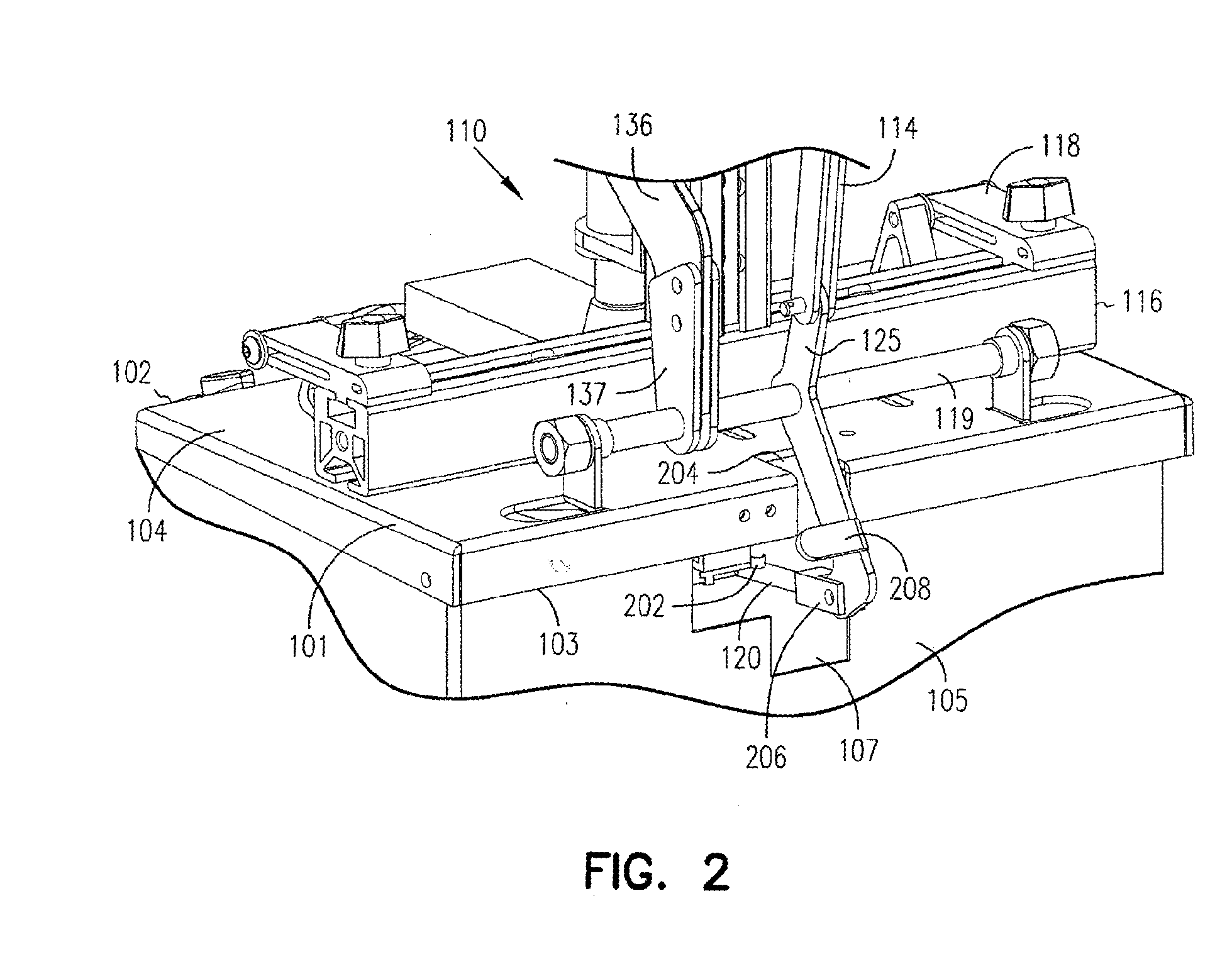

Tool with Remote Switch

InactiveUS20080219788A1Quickly drillFast drillingThread cutting toolsDrilling/boring measurement devicesPower toolEngineering

A non-pneumatic system for use with a workpiece is described. A clamp assembly having a clamp pad is secured to the cabinet. An electrically operated tool is movably secured to the cabinet. The tool has a remote switch which when activated in turn activates the tool. A lever (e.g., a handle) is operatively coupled to the clamp assembly and the tool. When the lever is manually moved, the remote switch is activated and the clamp pad moves towards the work surface. Preferably, the tool also moves towards the work surface opening by manually moving the lever. For example, the tool utilized in this non-pneumatic system may be a drill or saw.

Owner:KREG ENTERPRISES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com