Modular kerfing drill bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

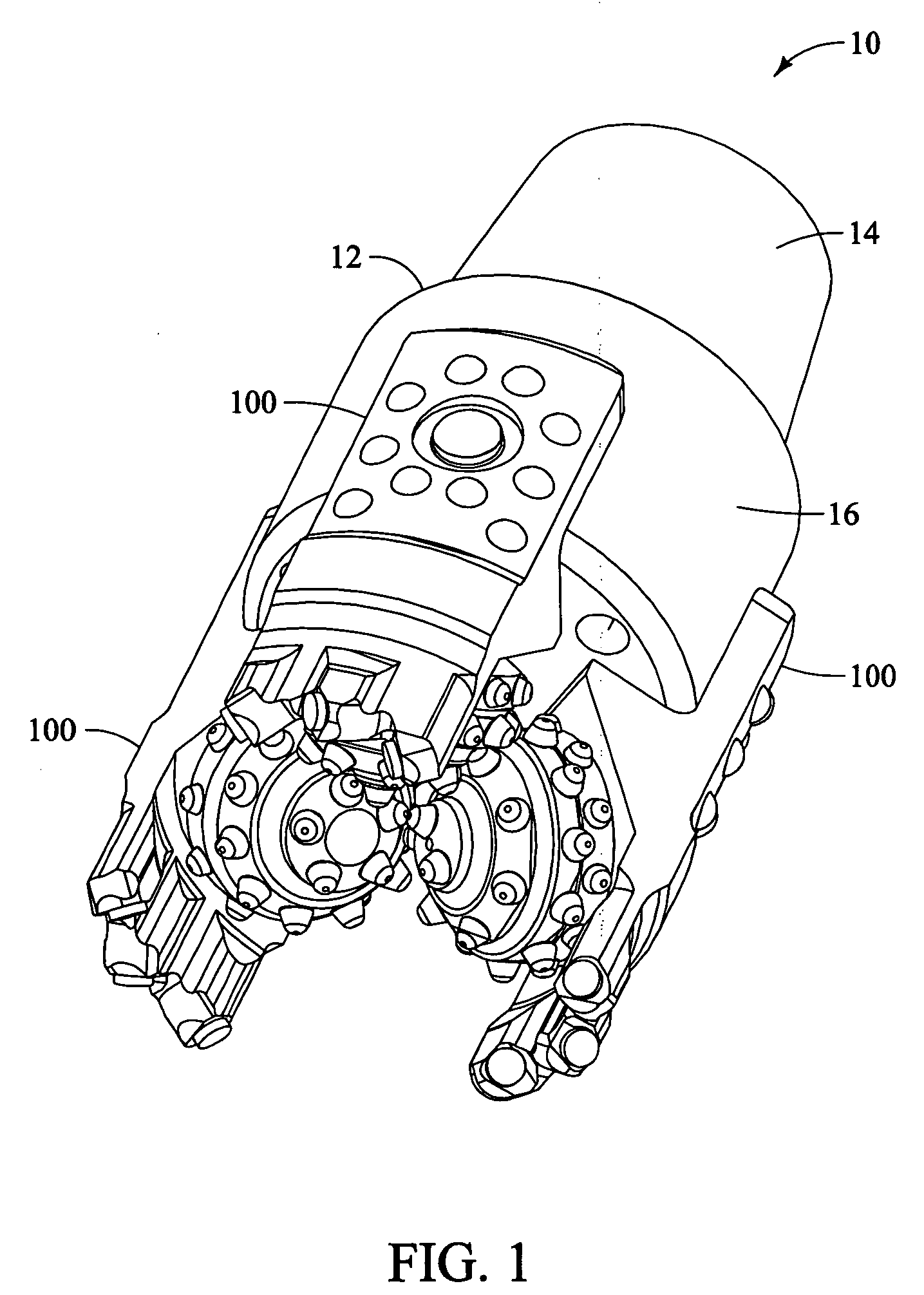

[0035]FIG. 1 is an isometric view of a preferred embodiment of the present invention for a Modular Kerfing Drill Bit 10. In the embodiment shown, drill bit 10 has a body 12. Body 12 has a connection 14 for attachment to a drill string member (not shown). Body 12 has a base 16 below connection 14 and contiguous thereto. Cutter assemblies 100 are shown attached to body 12.

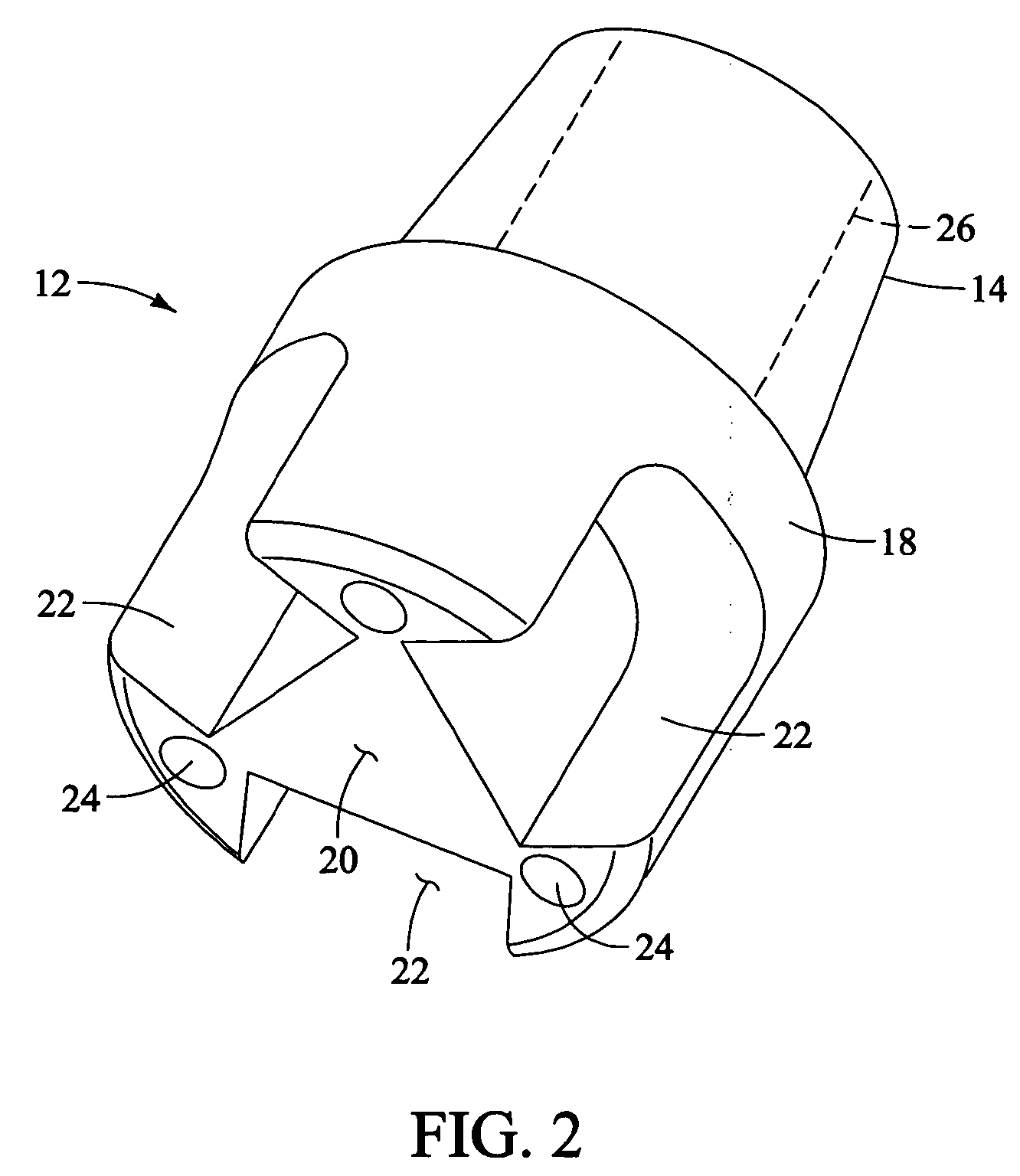

[0036]FIG. 2 is an isometric view of a preferred embodiment of bit body 12 of the present invention, shown with cutter assemblies 100 unattached. In this view, it is seen that base 16 has a generally cylindrical outer portion 18 and a bottom 20. Slots 22 are formed in base 16, and intersect both outer portion 18 and bottom 20. Slots 22 are formed for secure location of cutter assemblies 100. Also in body 12, ports 24 are provided, and interconnect to internal passage 26 (dashed line).

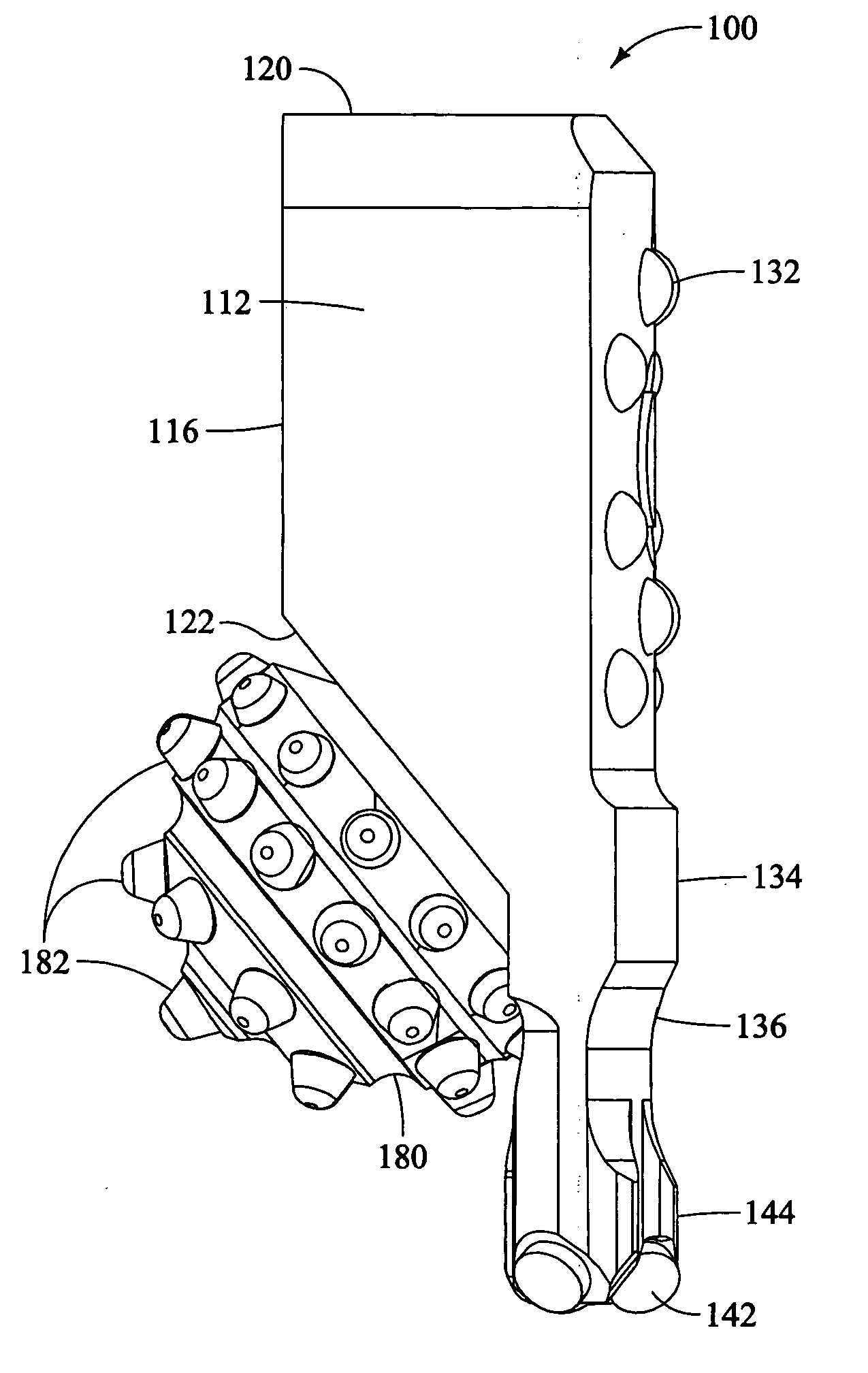

[0037]FIG. 3 is an isometric view of a preferred embodiment of a cutter assembly 100. Cutter assembly 100 has a leg 110. Leg 110 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com