Patents

Literature

179results about How to "Reduce time and cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

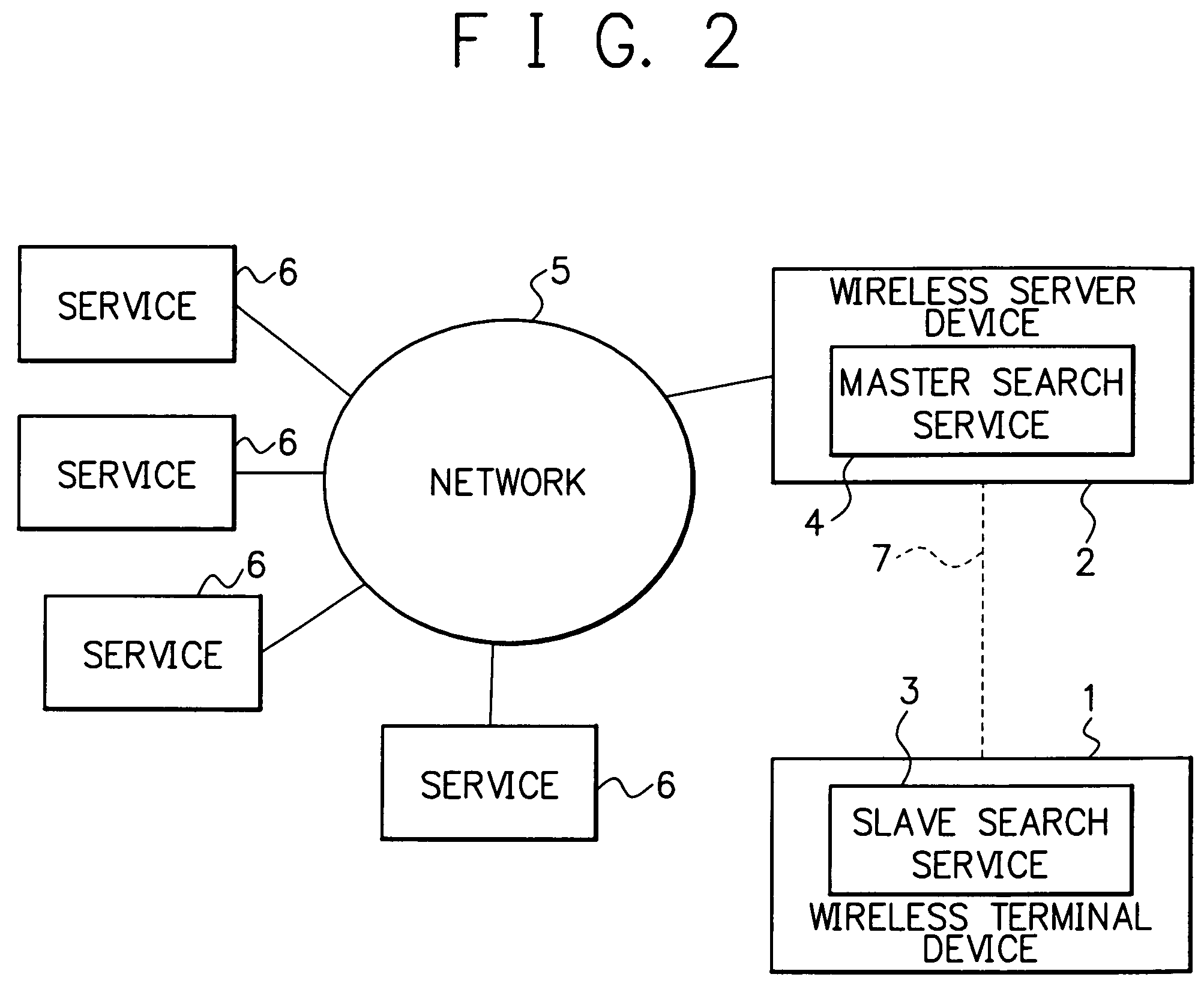

Service searching system

InactiveUS7139569B2Improve service rateReduce communication data volumeSpecial service for subscribersDigital computer detailsTerminal equipmentServer appliance

A service searching system for searching a service in a distributed system comprises a wireless server device and a wireless terminal device. The wireless server device is connected to a network and implements a master search service. On the other hand, the wireless terminal device implements a slave search service, and is capable of communicating with the server by wireless and utilizing the master search service. Besides, the wireless terminal device comprises a storage means that caches service objects obtained through the master search service. In addition, in searching the slave search service for a service, the wireless terminal device begins by searching the service objects cached in the storage means. In the case where the service is not detected, the wireless terminal device searches the master search service. The service objects are cached by being related to priority data. Thereby, there is provided a service searching system comprising a wireless terminal device, which is intended to search for a service in a distributed system in which a range of services are distributed in a network, wherein it is possible to cut down a service-searching time and costs, and further, it is possible to cut down communication interruptions by noise etc. in the wireless communication section compared to the conventional one.

Owner:NEC CORP

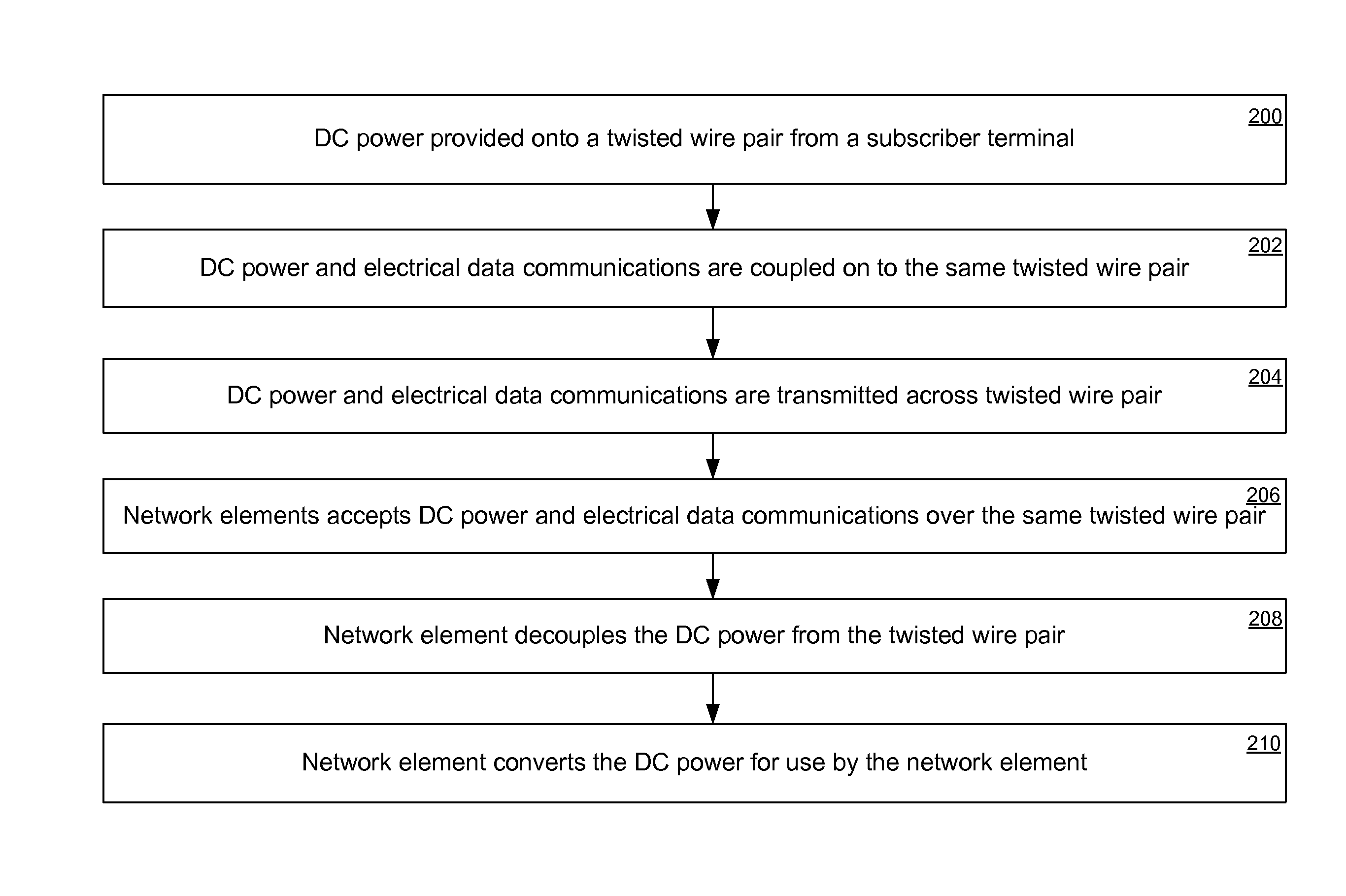

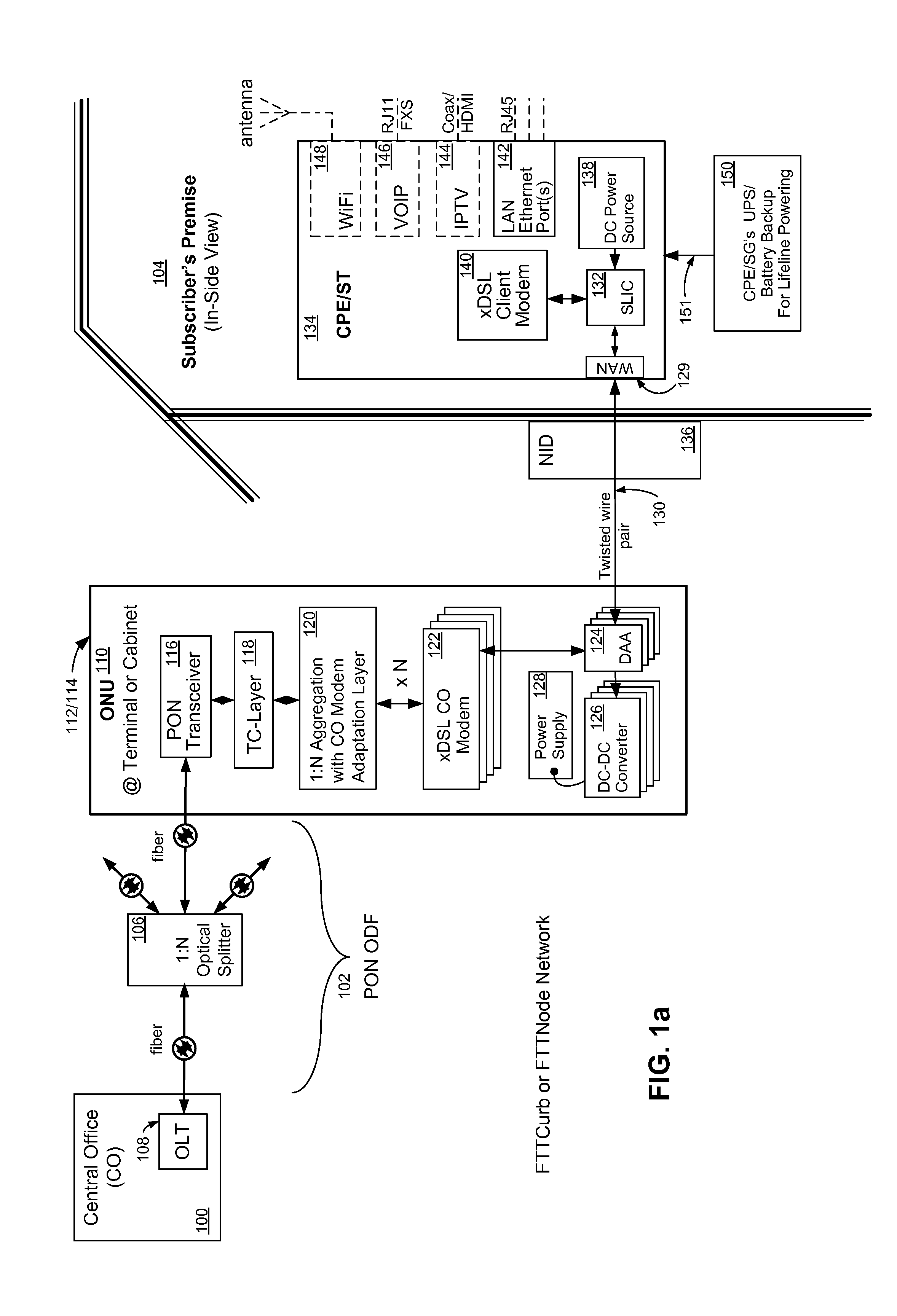

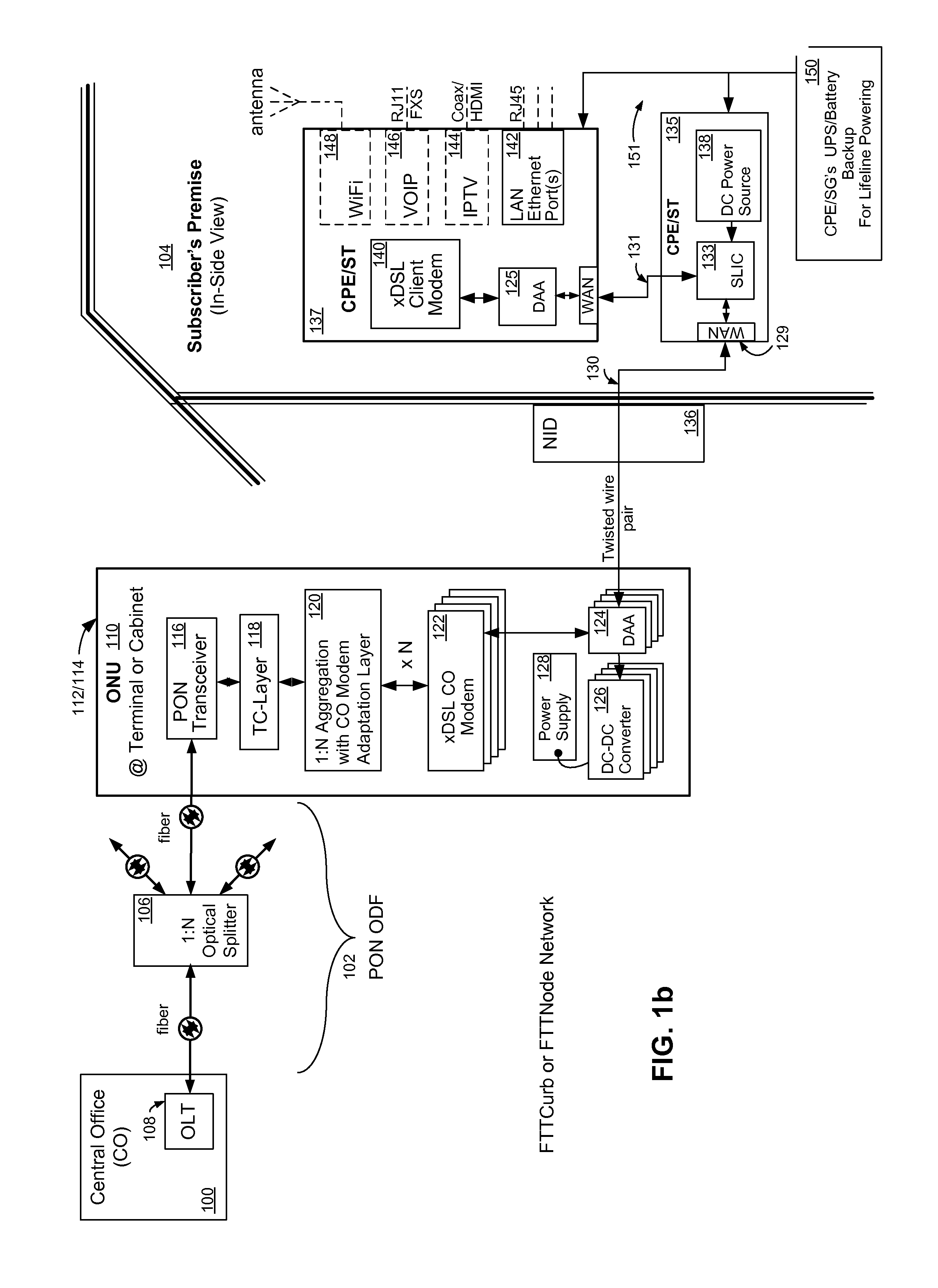

System and method for a subscriber-powered network element

ActiveUS20150078756A1Reduce time and costCost-effectiveCurrent supply arrangementsClose-range type systemsCable transmissionNetwork element

A system for powering a network element of a fiber optic wide area network is disclosed. When communication data is transferred between a central office (CO) and a subscriber terminal using a network element to convert optical to electrical (O-E) and electrical to optical (E-O) signals between a fiber from the central office and twisted wire pair, coaxial cable or Ethernet cable transmission lines from the subscriber terminal, techniques related to local powering of a network element or drop site by the subscriber terminal or subscriber premise remote powering device are provided. Certain advantages and / or benefits are achieved using the present invention, such as freedom from any requirement for additional meter installations or meter connection charges and does not require a separate power network.

Owner:SOTO ALEXANDER IVAN +1

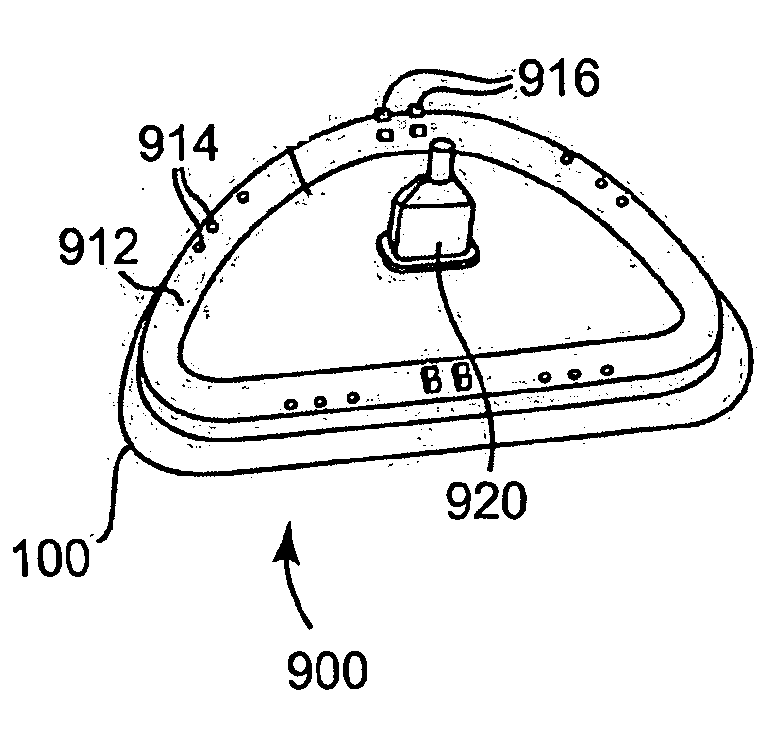

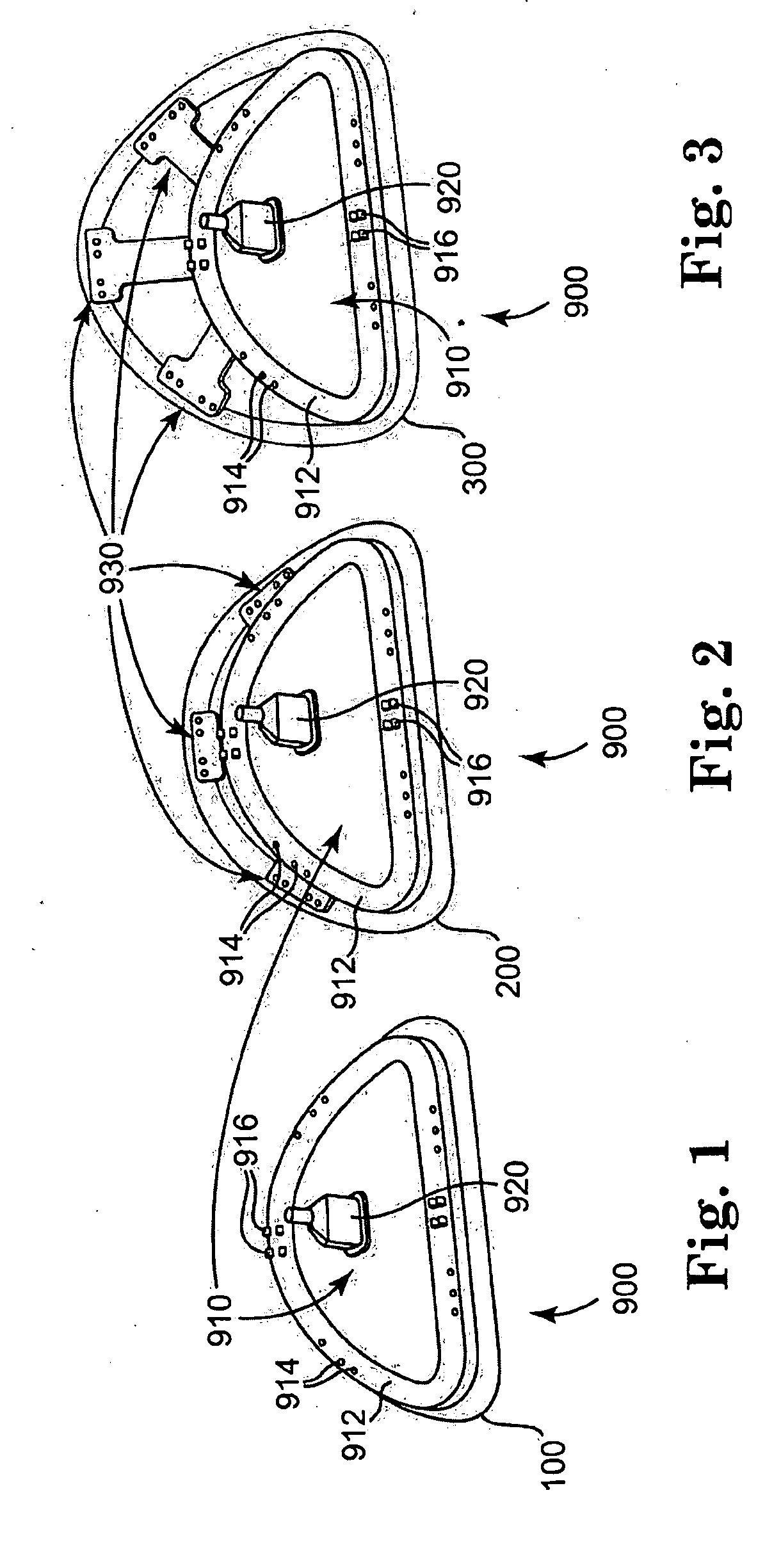

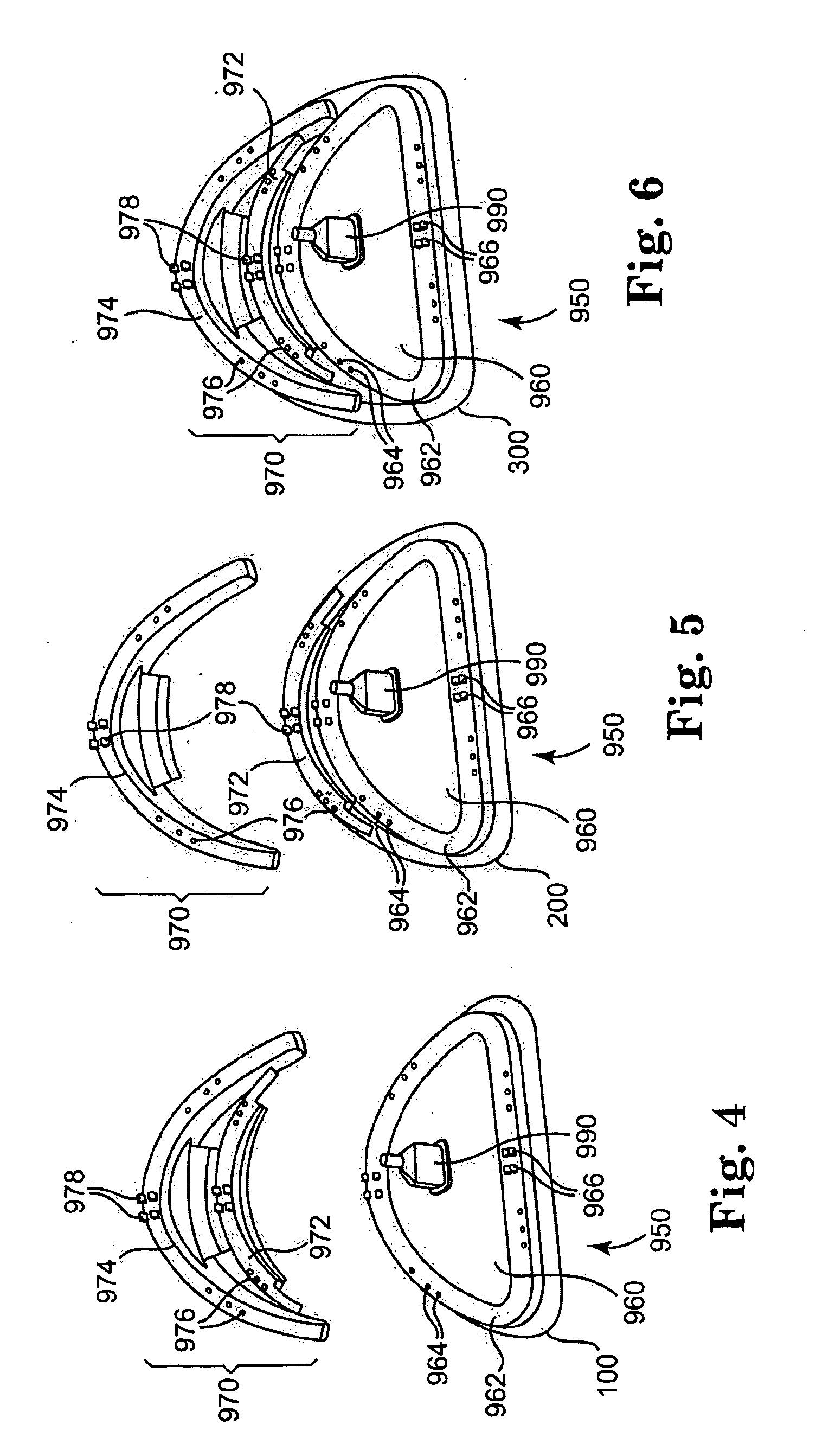

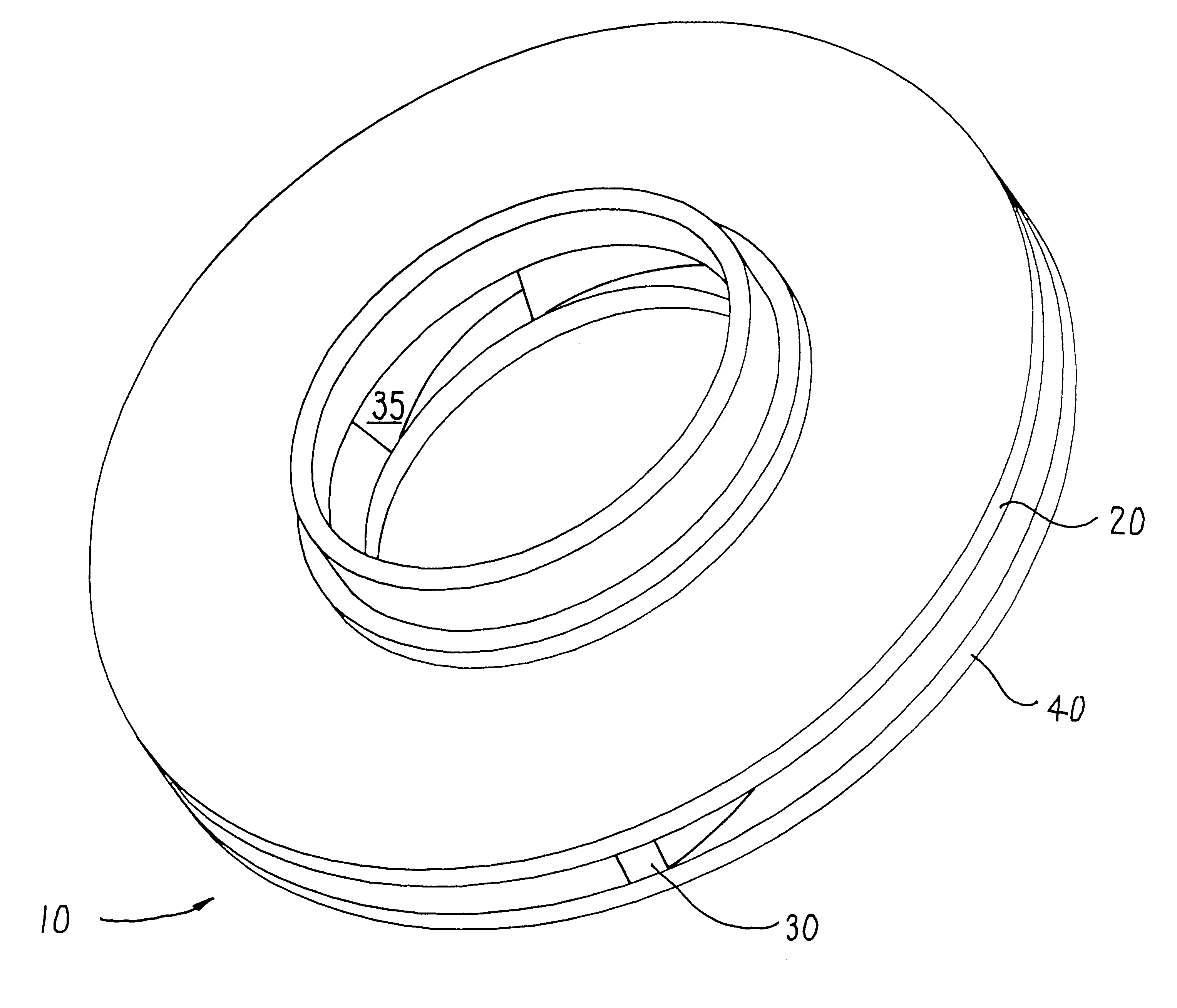

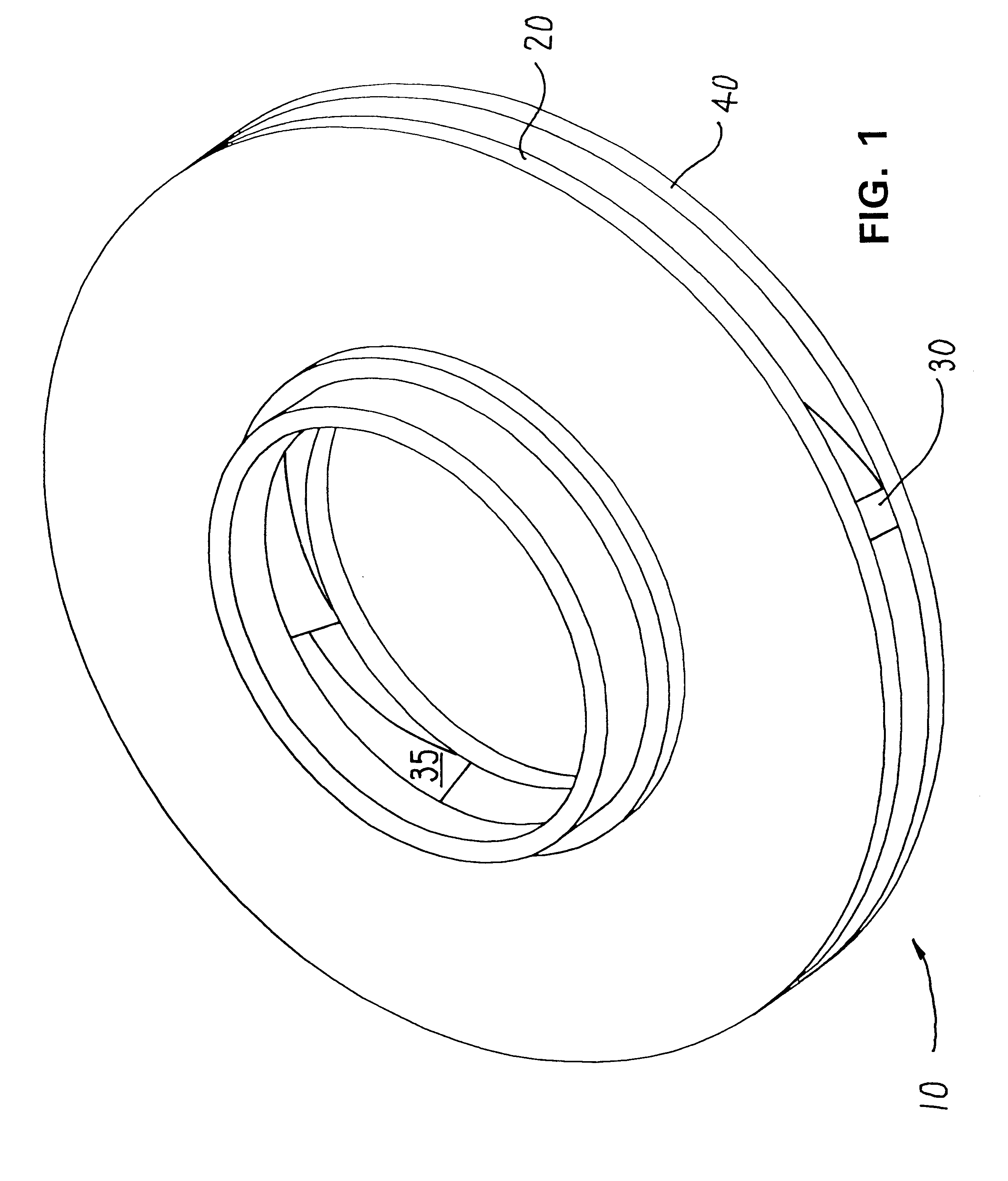

Holder Devices for Annuloplasty Devices Having a Plurality of Anterior-Posterior Ratios

ActiveUS20090192606A1Change ratioReduce time and costBone implantAnnuloplasty ringsBiomedical engineeringAnterior posterior

Owner:MEDTRONIC INC

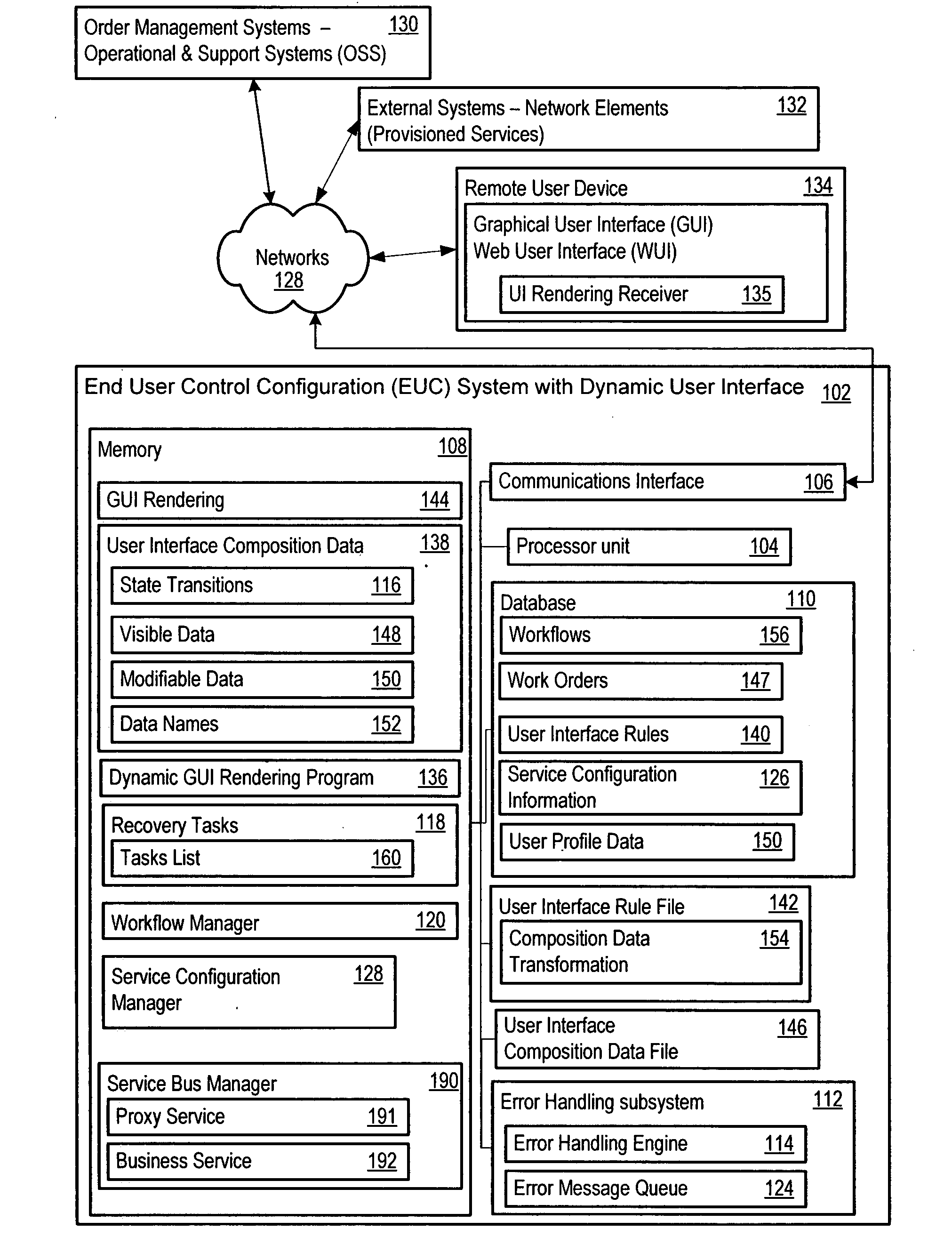

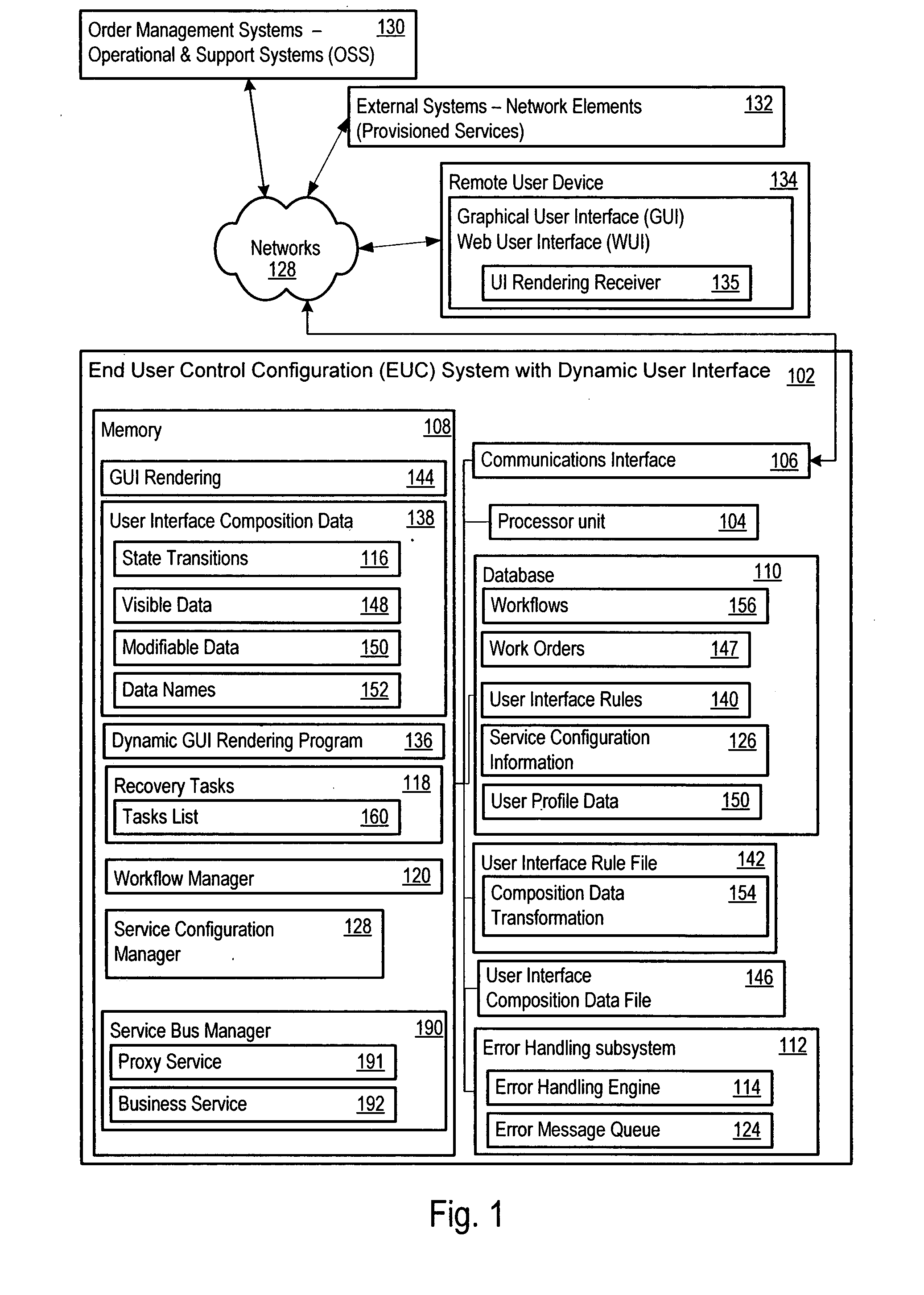

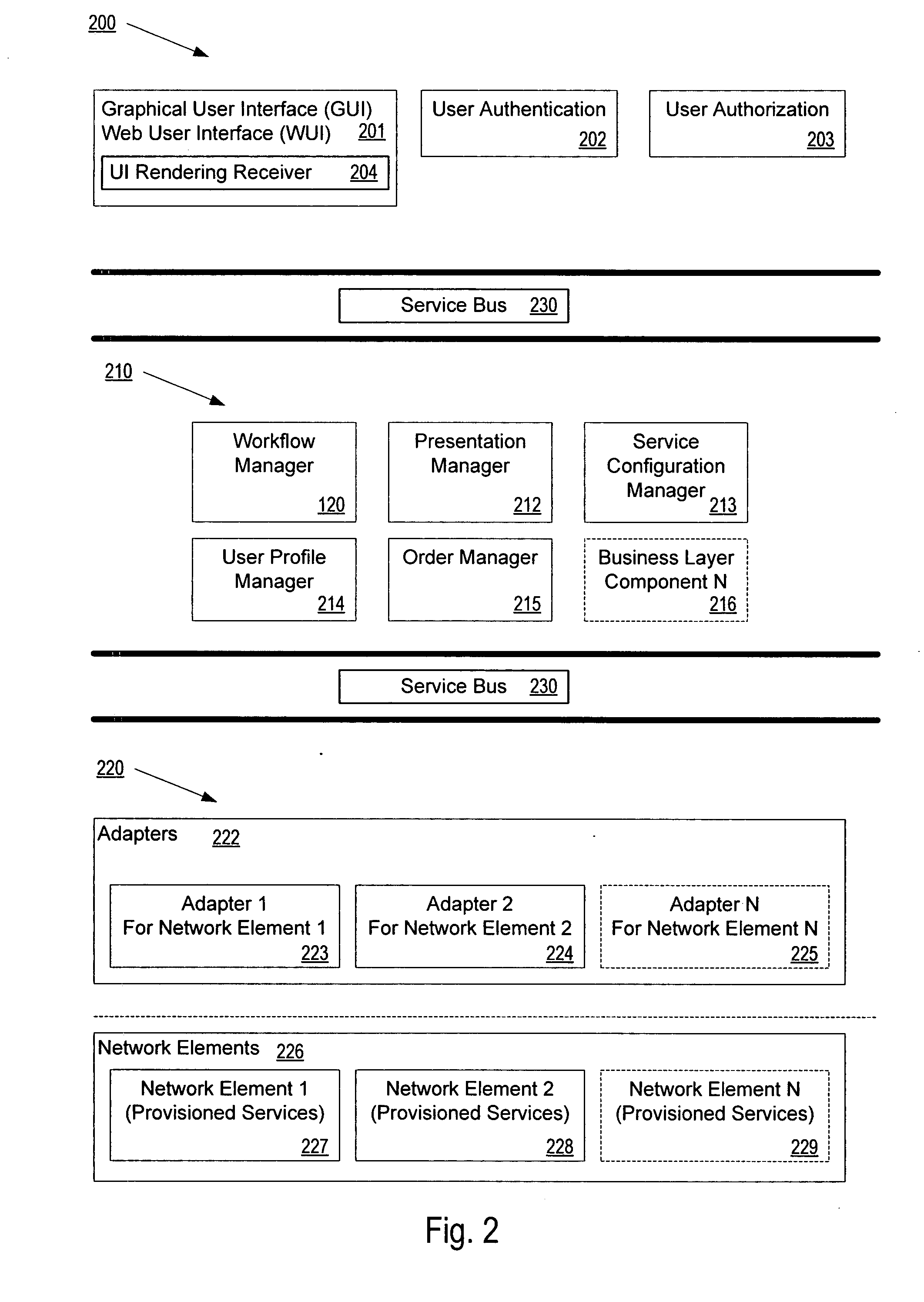

End user control configuration system with dynamic user interface

ActiveUS20080270597A1Low costShorten the timeDigital computer detailsAutomatic exchangesNetwork serviceGraphical user interface testing

An end user control configuration (EUC) system with dynamic user interface provides a user friendly tool for consumers to self-provision and manage network services such as Voice over Internet Protocol (VoIP) services. The EUC system dynamically generates graphical user interface (GUI) renderings that assist users in the completion of tasks related to provisioning, and managing network services. The EUC system allows telecommunication service providers to effectively hide the complexity of operational support systems (OSS) and the network elements that deliver the network services. The EUC system solves the technical problems of reducing the cycle-time to self-provision network services, assisting users to complete the tasks required to activate, and manage network services, and actually activating and managing the network services.

Owner:ACCENTURE GLOBAL SERVICES LTD

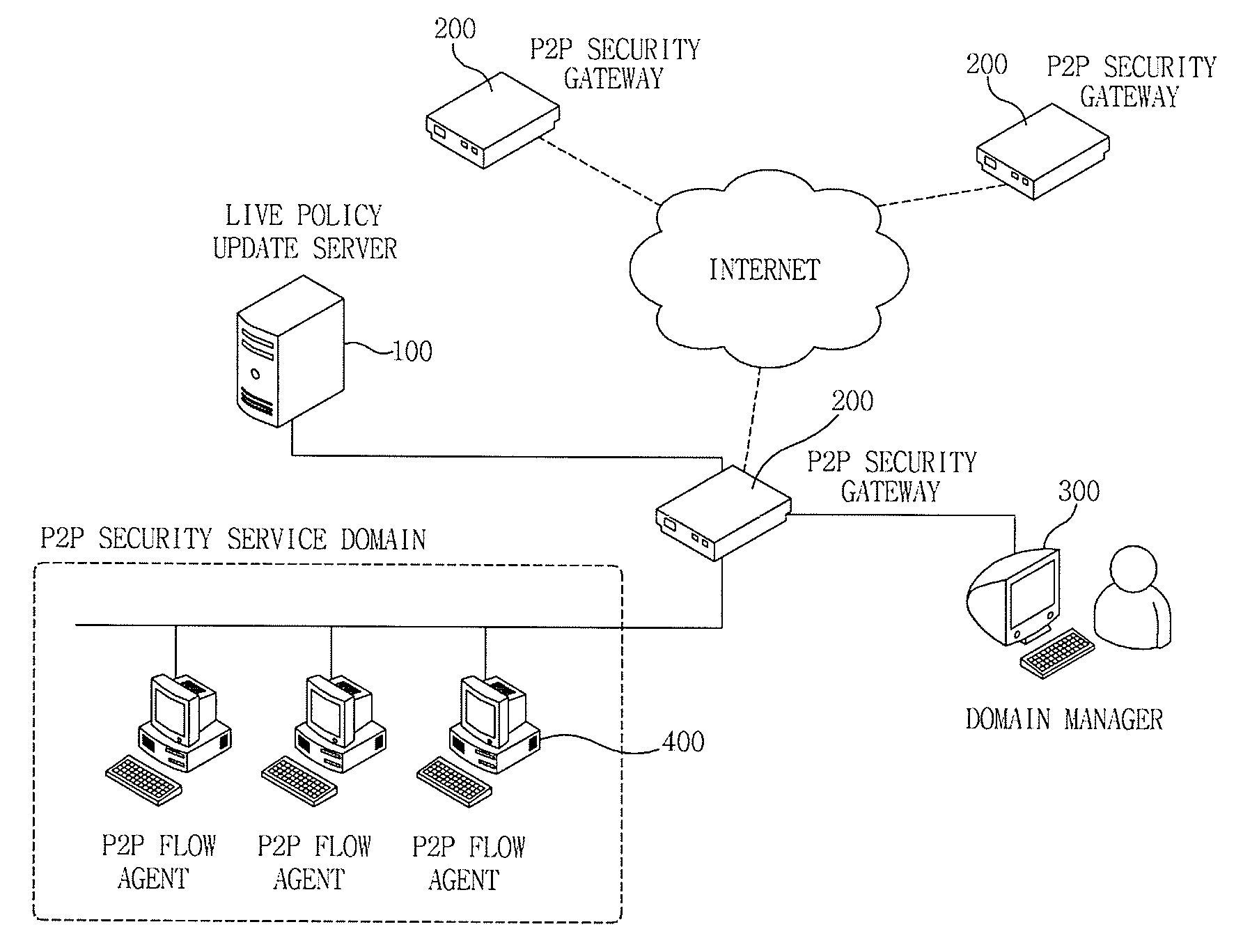

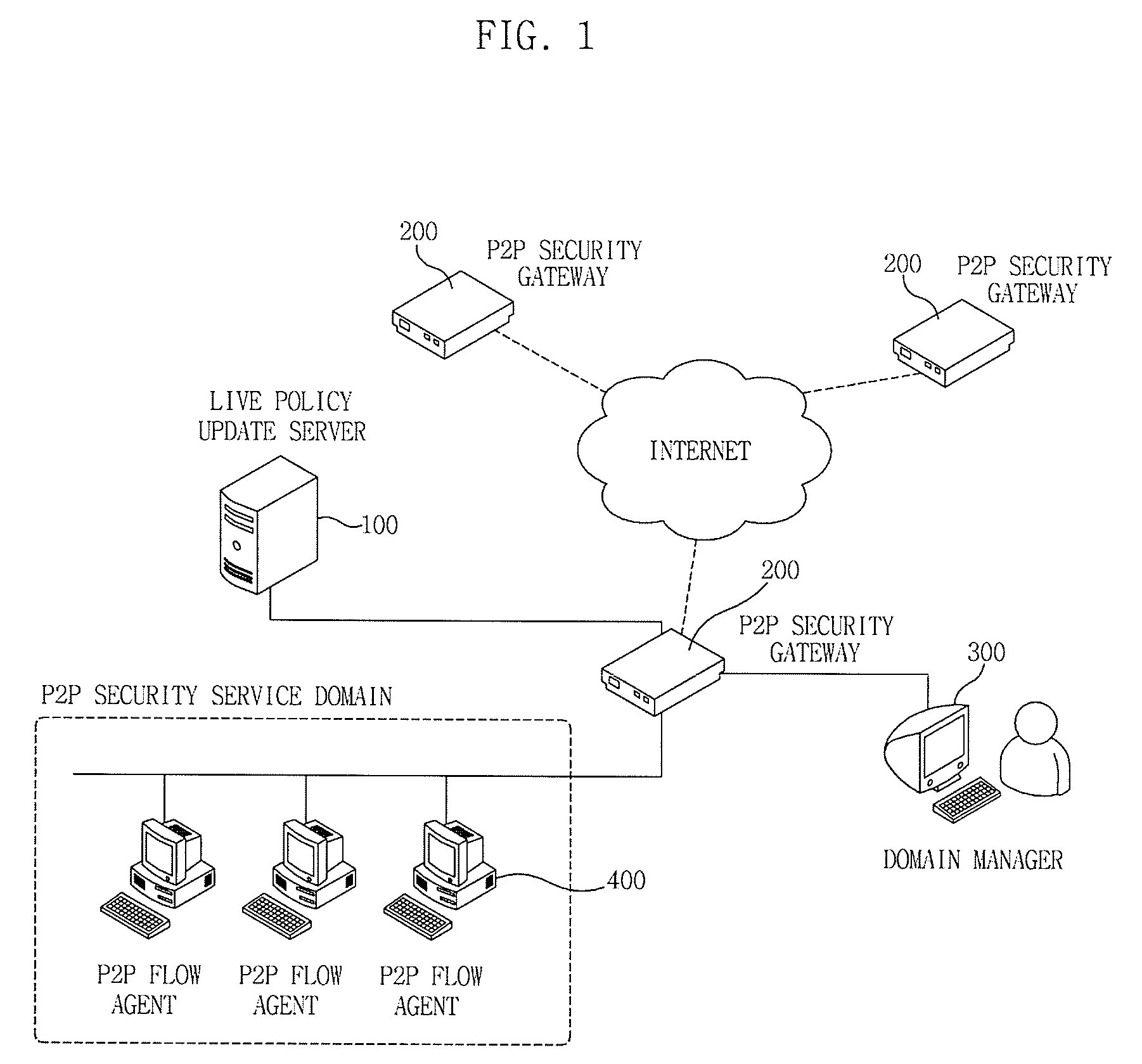

Apparatus and method for managing p2p traffic

ActiveUS20090150972A1Reduce overheadReduce time and costDigital data processing detailsUnauthorized memory use protectionTraffic volumeTraffic capacity

The invention relates to a P2P traffic management apparatus and method. A P2P flow agent monitors an executed application program to extract a P2P application program, adds application identifiers to packets generated by the application program according to a set policy, and transmits the packets. In this case, a P2P security gateway monitors the inflowing packets from the P2P flow agent to extract packets having the application identifiers, uses the extracted application identifiers to inquire and acquire a related policy, and controls the packets according to the acquired policy.

Owner:ELECTRONICS & TELECOMM RES INST

Impeller manufacturing process

InactiveUS6276899B1Strengthen subsequent connectionReduce time and costPropellersRotary propellersImpellerEngineering

A method of manufacturing an impeller, comprising machining hub, shroud and core portions, such that contacting surfaces between the hub and core, and shroud and core form mating surfaces, for mating and alignment with each other. Material is removed from the core without disturbing the contour of its surfaces, resulting in one or more vanes which mate with the respective hub and shroud portions. The mating portions are then coupled together.

Owner:FLOWSERVE MANAGEMENT CO

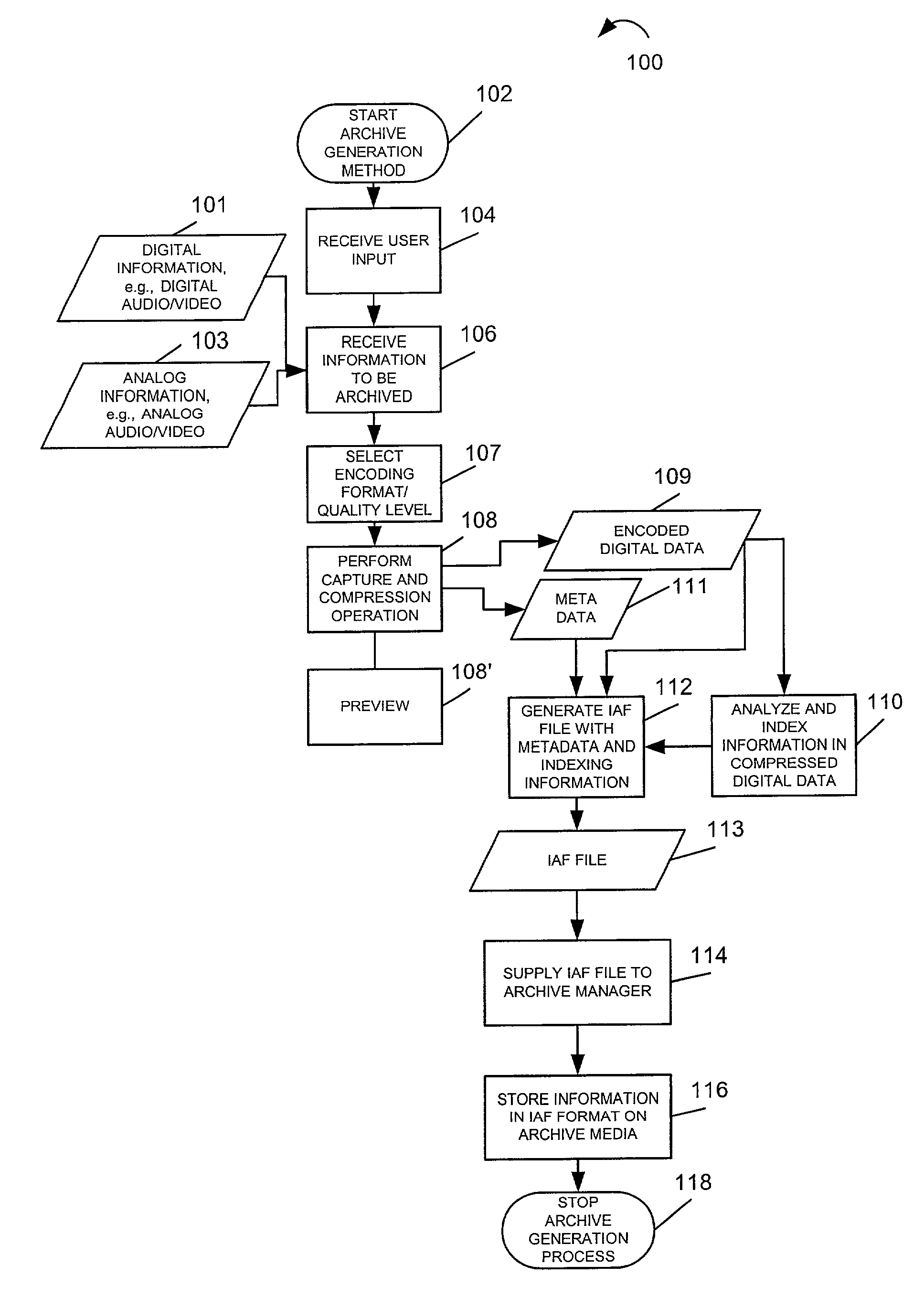

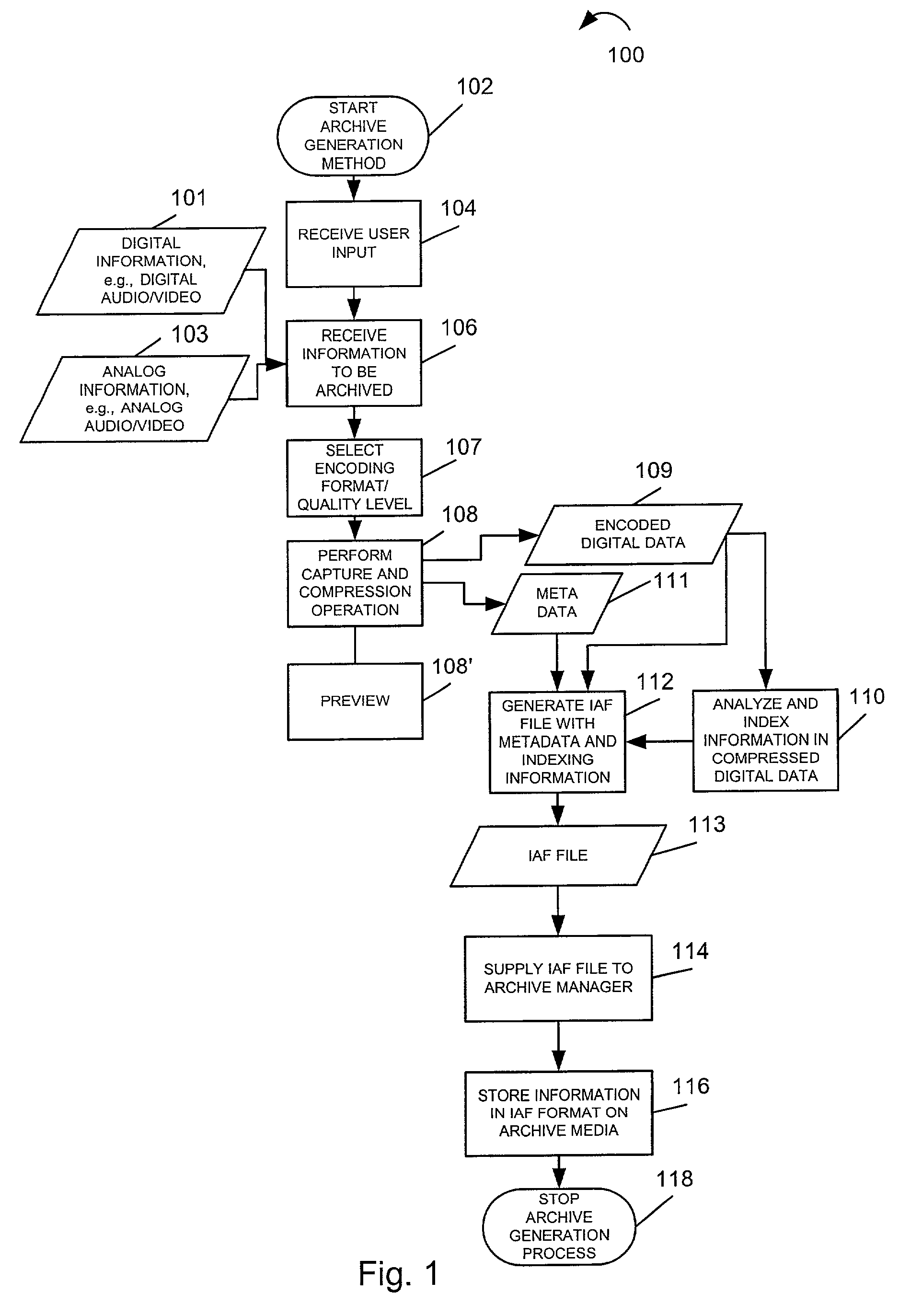

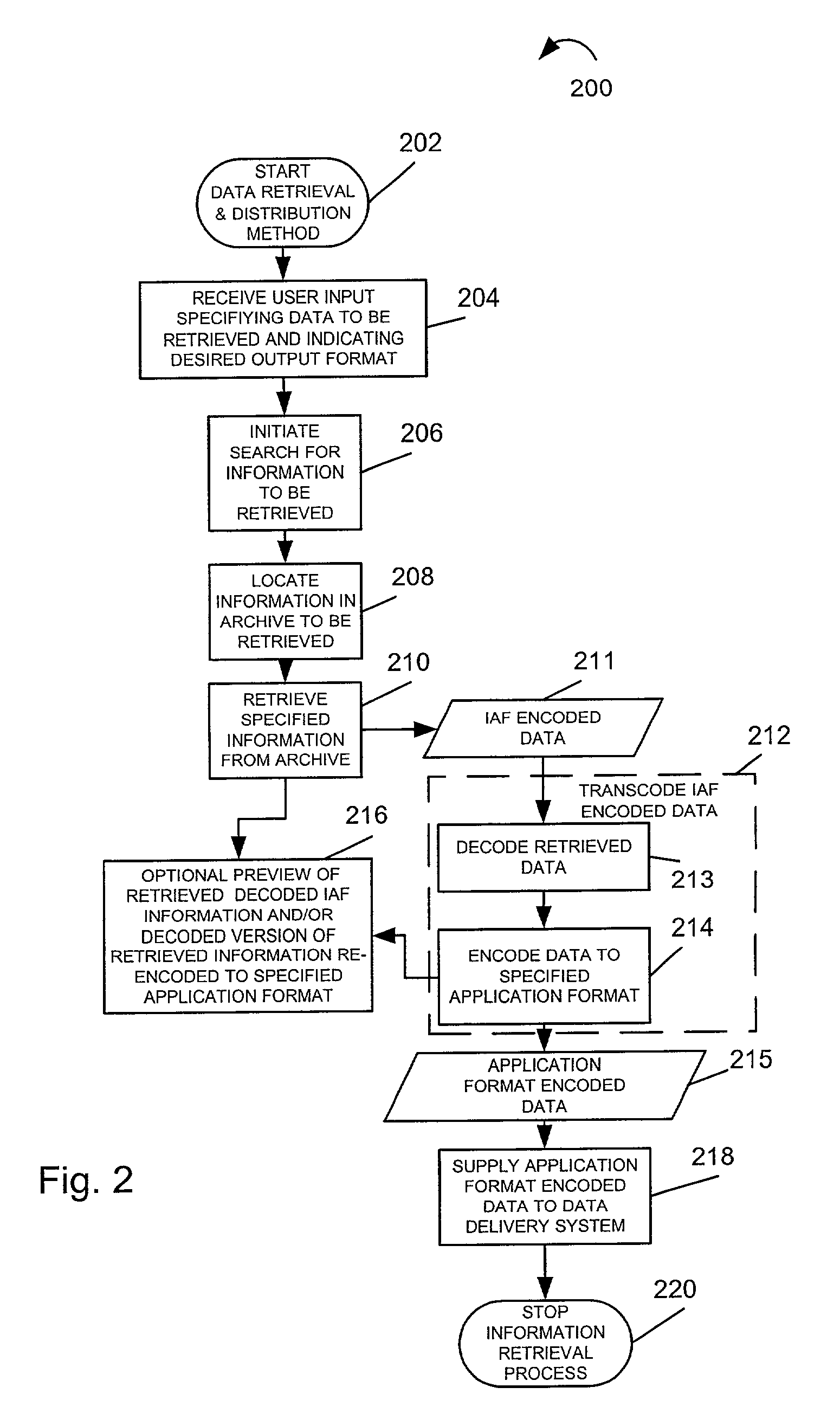

Methods and apparatus for archiving, indexing and accessing audio and video data

InactiveUS7035468B2Reduce time and costEliminate needMetadata audio data retrievalVideo data indexingInformation retrievalData content

Archival storage and retrieval of audio / video information is described. Audio and / or video information is digitized, compressed and stored in an intermediate archive format (IAF), which preserves the content at a high-enough quality for subsequent retrieval and conversion into various formats required at the time of use or distribution. A single capture operation is performed with ancillary metadata being added to facilitate subsequent searching, indexing and format conversion. Captured data content is catalogued and indexed at or subsequent to the creation of an IAF file that includes the archived information. The IAF includes a family of audio-video digital encoding formats based on public standards. The encoding format used in any particular application is determined at encoding time from information provided by the archive system user. At encoding, the particular encoding scheme is selected to optimize a tradeoff between storage constraints and end use quality requirements.

Owner:DISTRIBUTED MEDIA SOLUTIONS LLC

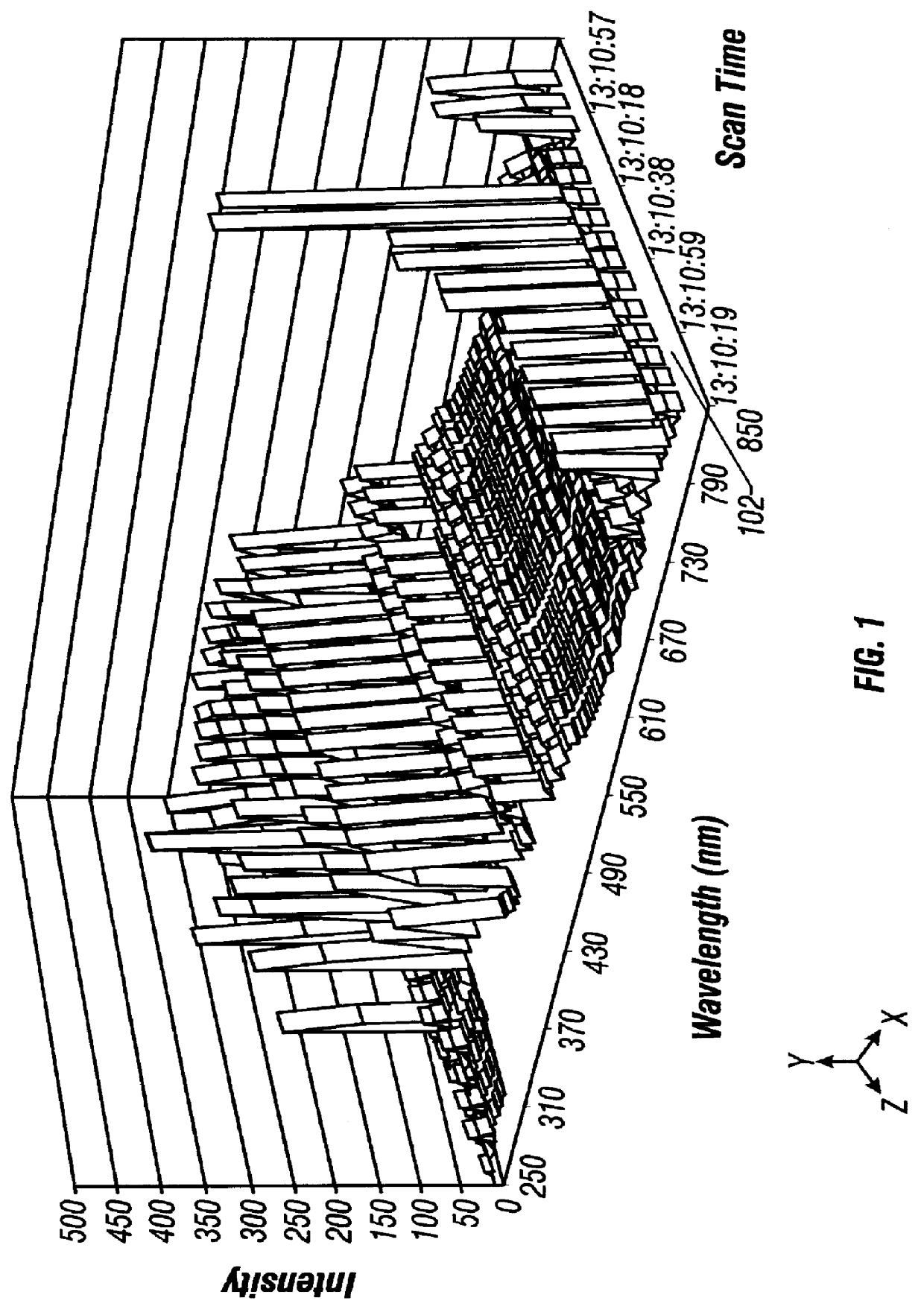

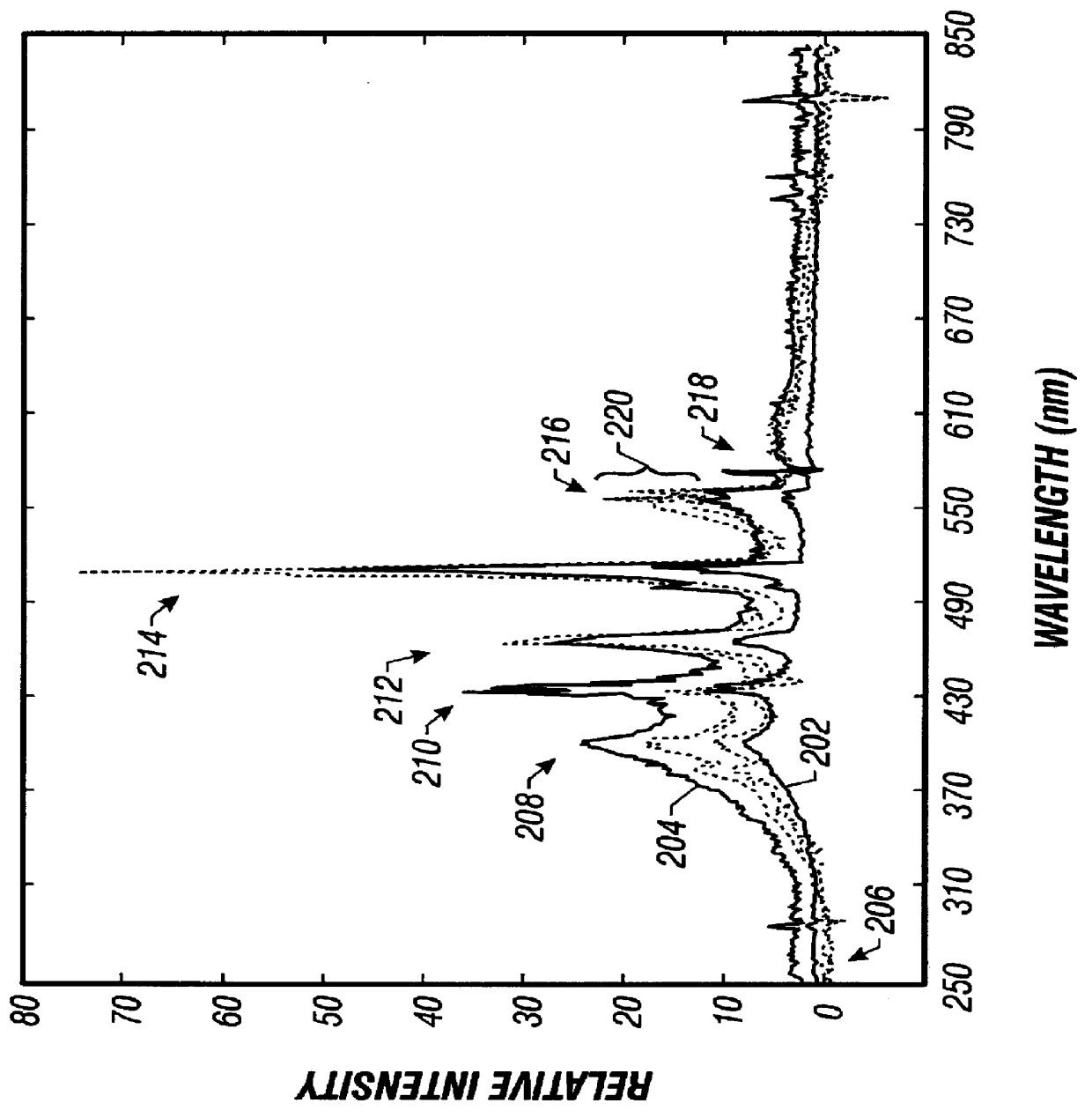

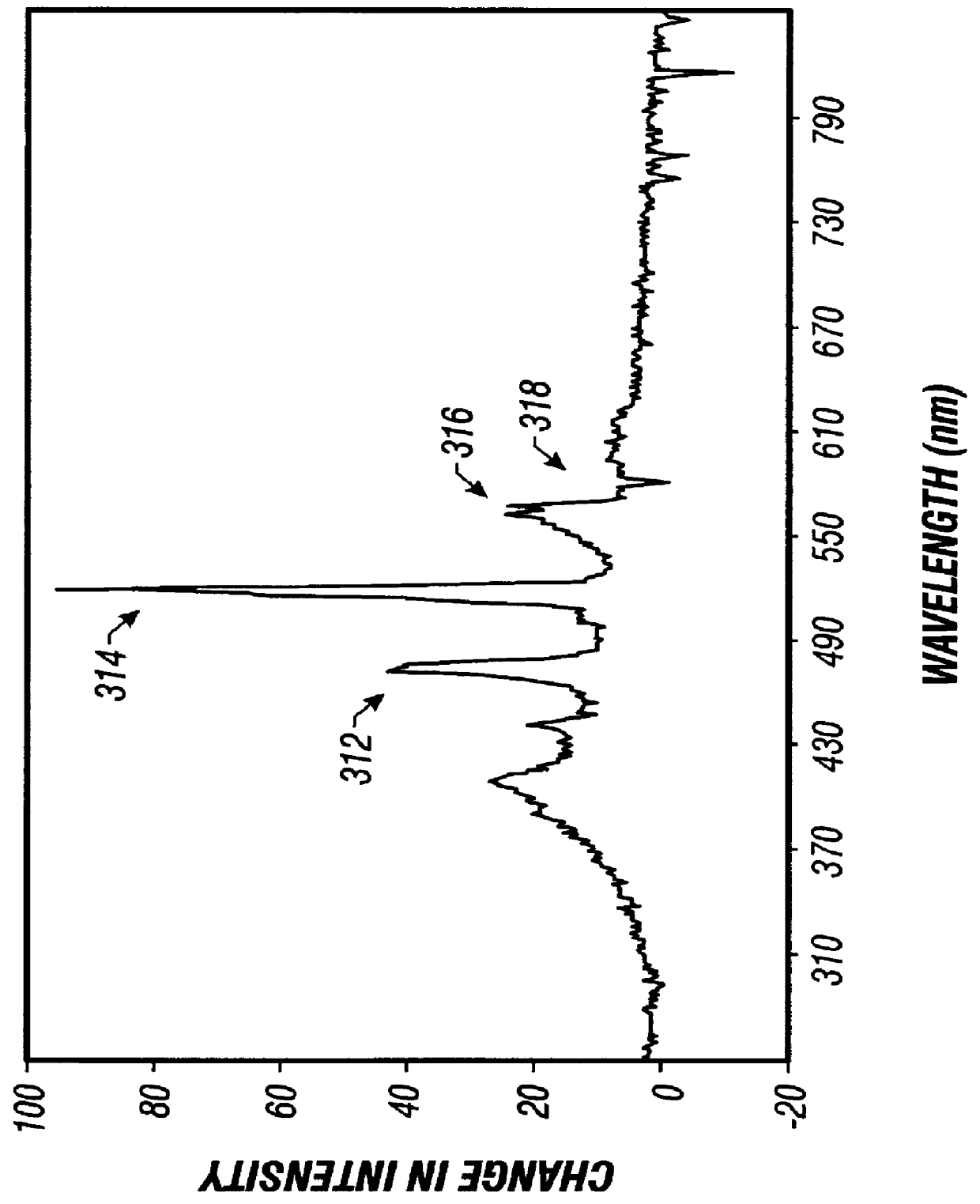

Methodology for improved semiconductor process monitoring using optical emission spectroscopy

InactiveUS6046796AReduce consumable costsReduce time and costEmission spectroscopyRadiation pyrometryNumeric ValueEtching rate

In a semiconductor process which utilizes a plasma within a process tool chamber, a method of using optical emission spectroscopy (OES) to monitor a particular parameter of the process is disclosed. A first wavelength present in the plasma is determined which varies highly in intensity depending on the particular parameter by observing a statistically significant sample representing variations of the particular parameter. A second wavelength of chemical significance to the process is also determined which is relatively stable in intensity over time irrespective of variations of the particular parameter, also by observing a statistically significant sample representing variations of the particular parameter. These two wavelengths may be determined from test wafers and off-line physical measurements. Then, the intensity of the first and second wavelengths present in the plasma is measured on-line during normal processing within the process tool chamber, and the ratio between the first and second wavelength's respective intensities generates a numeric value which is correlated to the particular parameter. As an example, such a method may be used to generate a reliable alarm signal indicating the presence of etch stop conditions within a plasma oxide etcher, as well as to indicate the oxide etch rate.

Owner:ADVANCED MICRO DEVICES INC

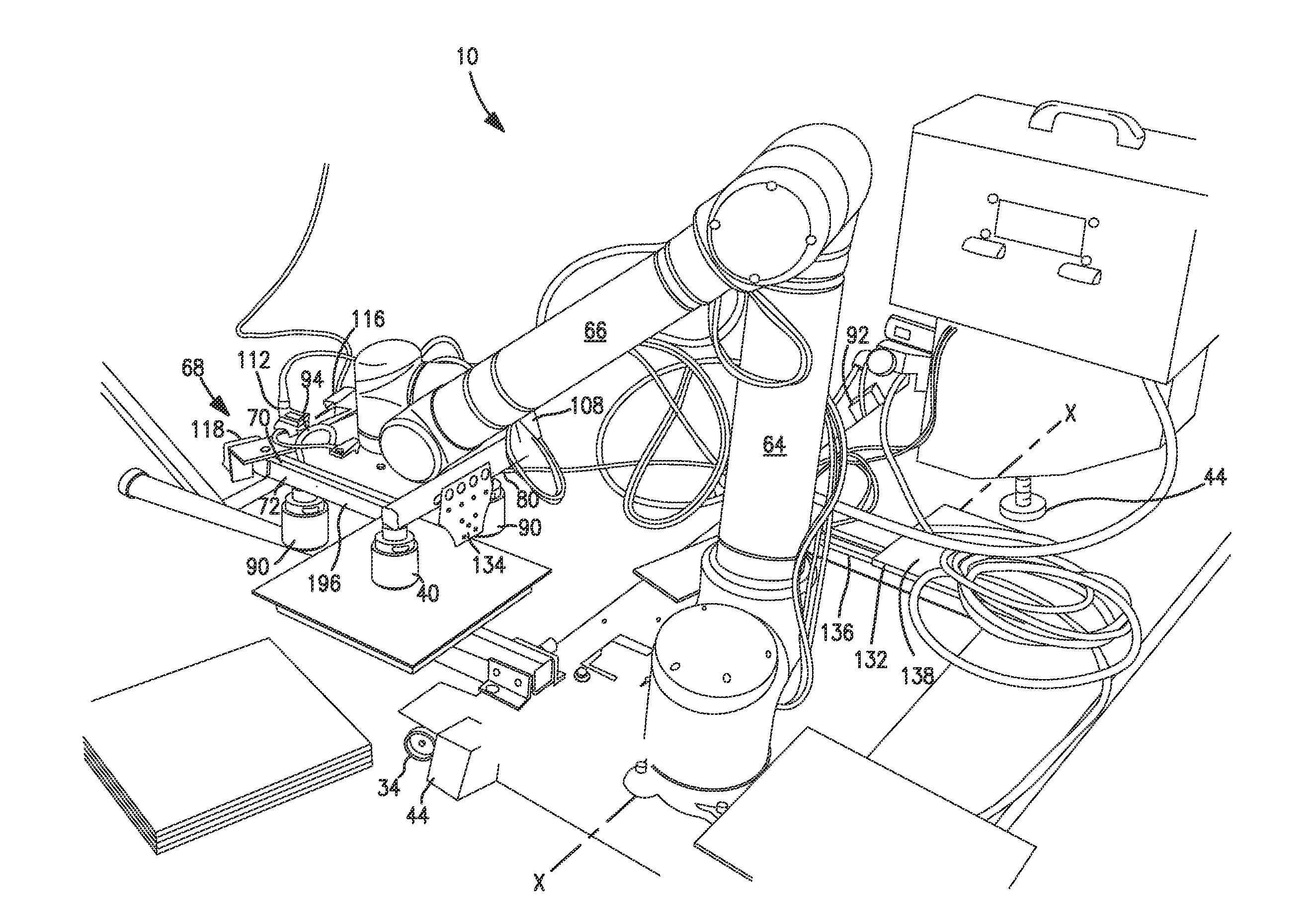

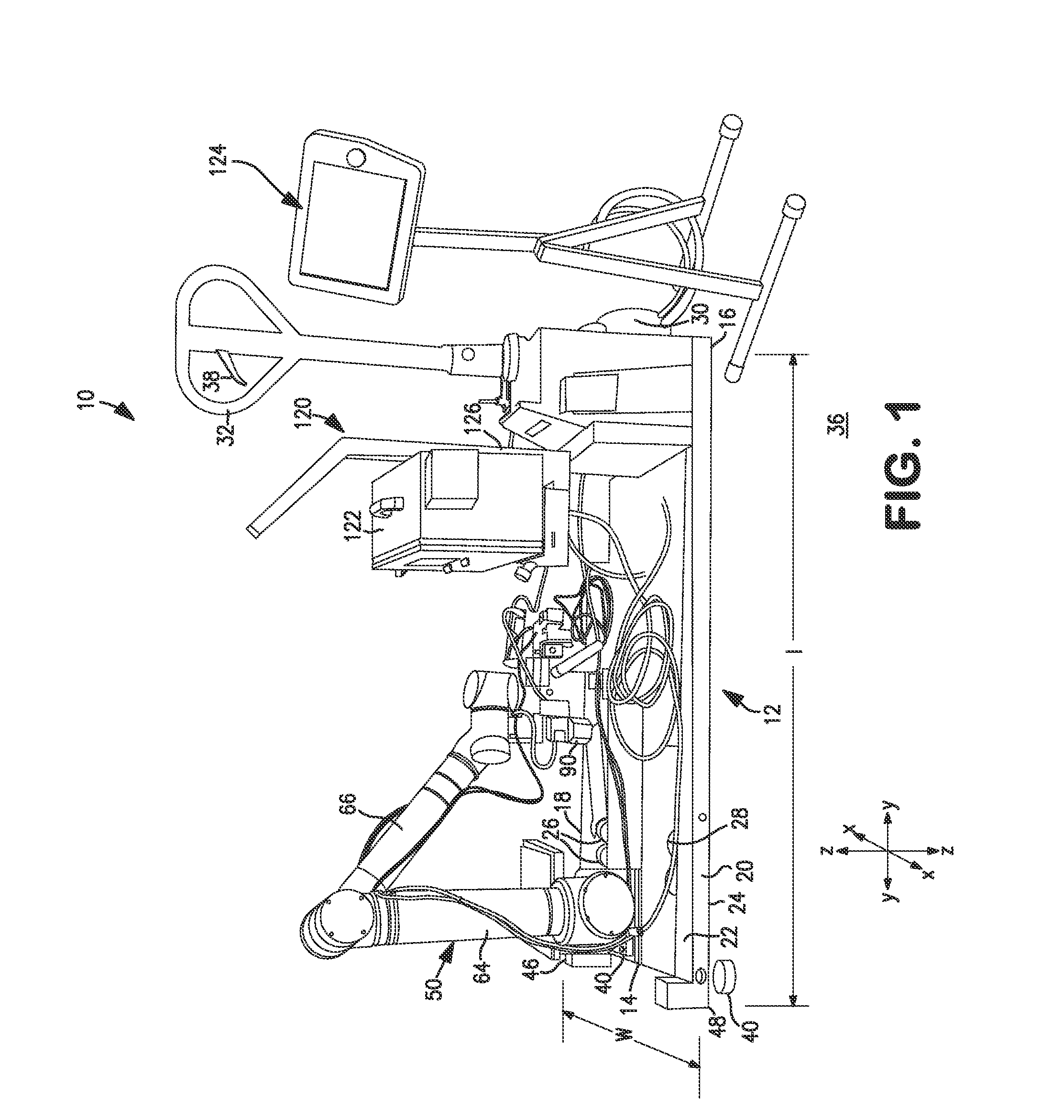

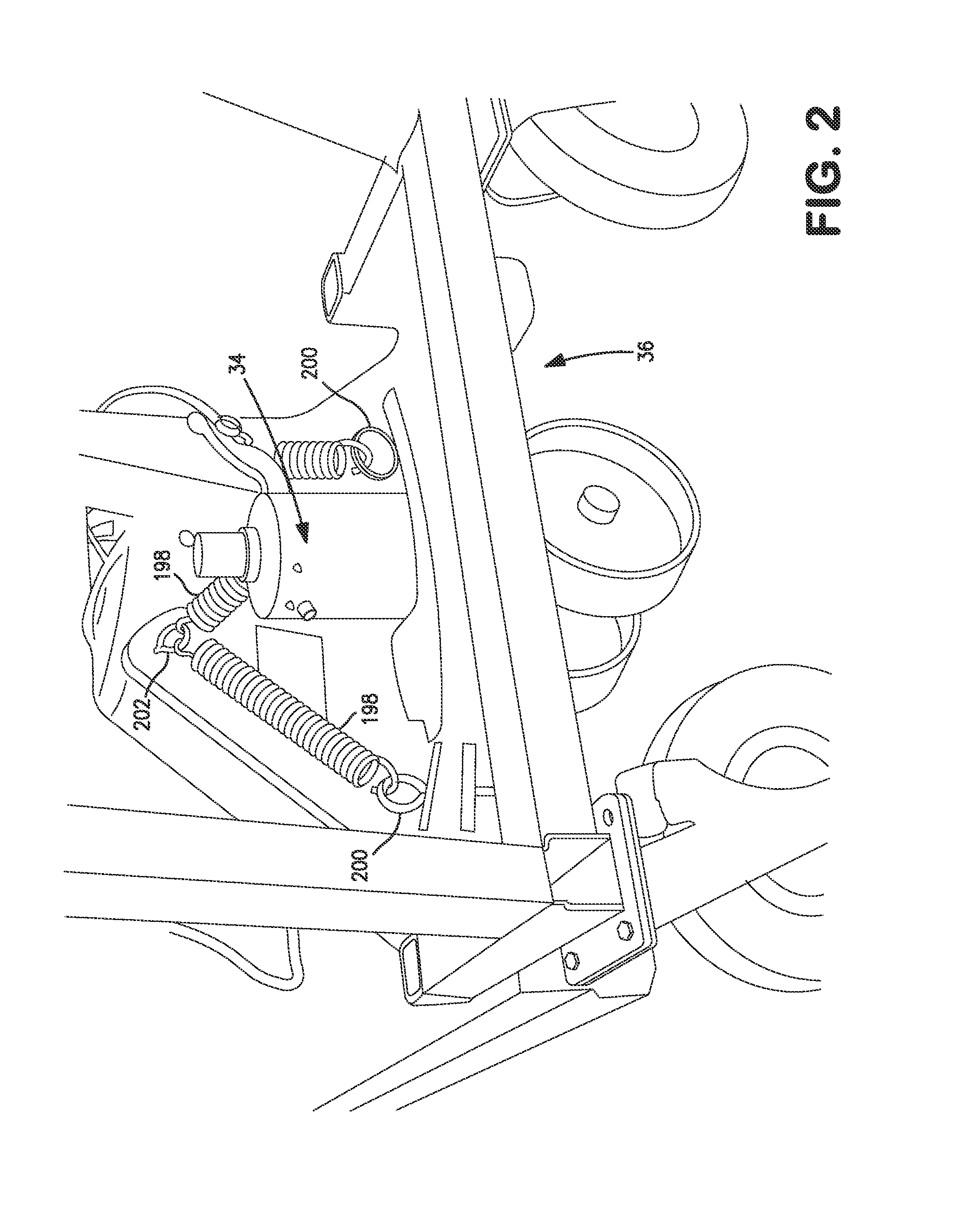

Machine for aligning items in a pattern and a method of use

ActiveUS20150336272A1Reduce time and costAlign and in faster and moreProgramme-controlled manipulatorLamination ancillary operationsWrist jointsMechanical engineering

A machine for aligning items in a pattern and a method of using the machine. The machine includes a robotic assembly having four spaced apart joints. The joints including a base joint which is mounted to a stationary surface and a wrist joint onto which an effector is secured. A suction cup is mounted on the effector and is connected to a vacuum source. The suction cup is capable to picking up, positioning and releasing a new item relative to a first laid item and a second laid item. The first and second laid items each have an upper surface and each is aligned perpendicular to one another. The machine further includes three edge sensors and three height sensor. At least one of the edge and height sensors are secured to a first side of the effector and is capable of detecting an edge aligned along an X-X axis of the first laid item and the height of the upper surface of the first laid item, and at least one of the edge and height sensors are secured to a second side of the effector and is capable of detecting an edge aligned along a Y-Y axis of the second laid item and the height of the upper surface of the second laid item. The machine further includes a control mechanism for operating the robotic assembly, the vacuum source and the edge and height sensors. Lastly, the machine includes a power source for supplying power to the control mechanism.

Owner:DREW GARY LEE

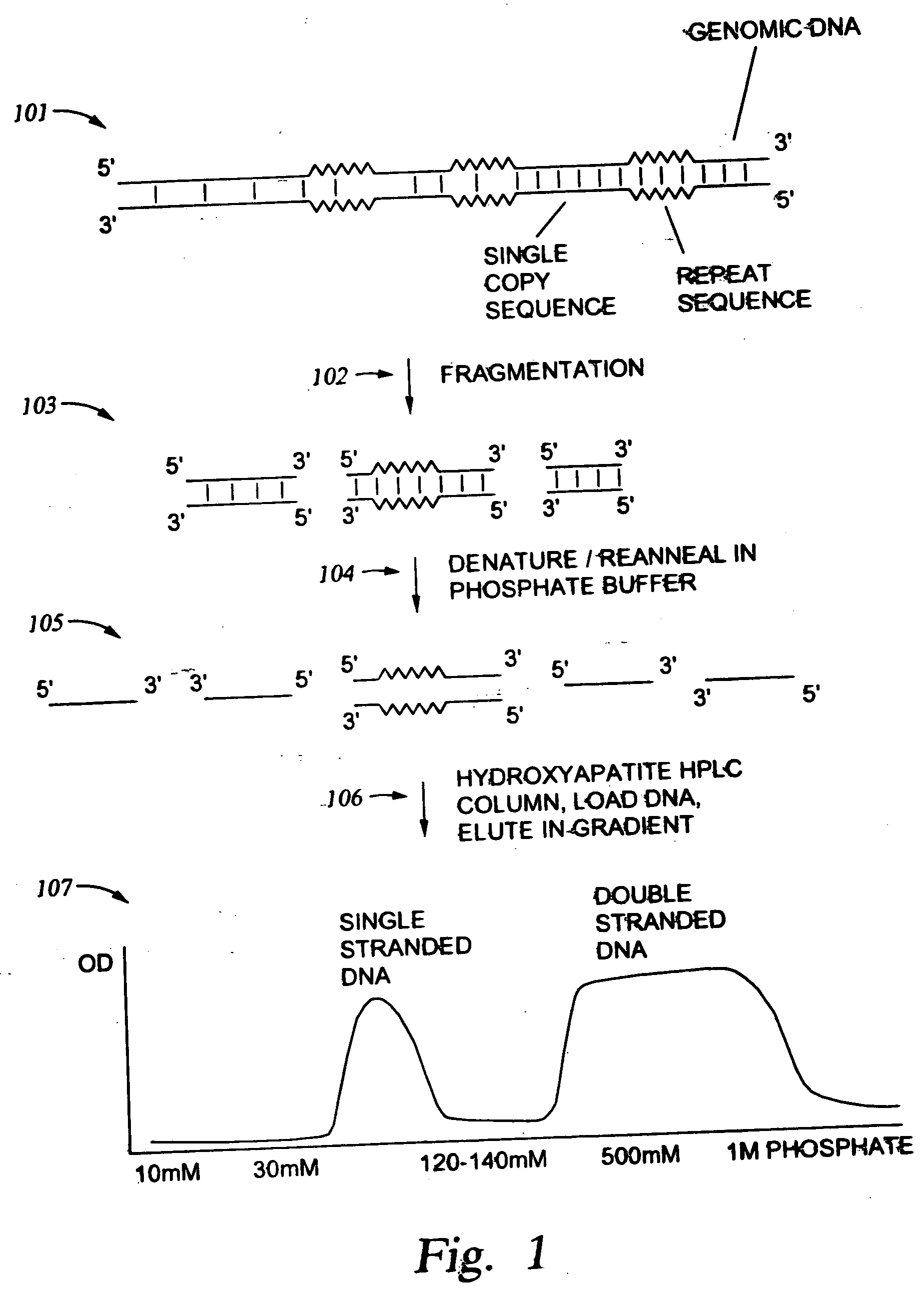

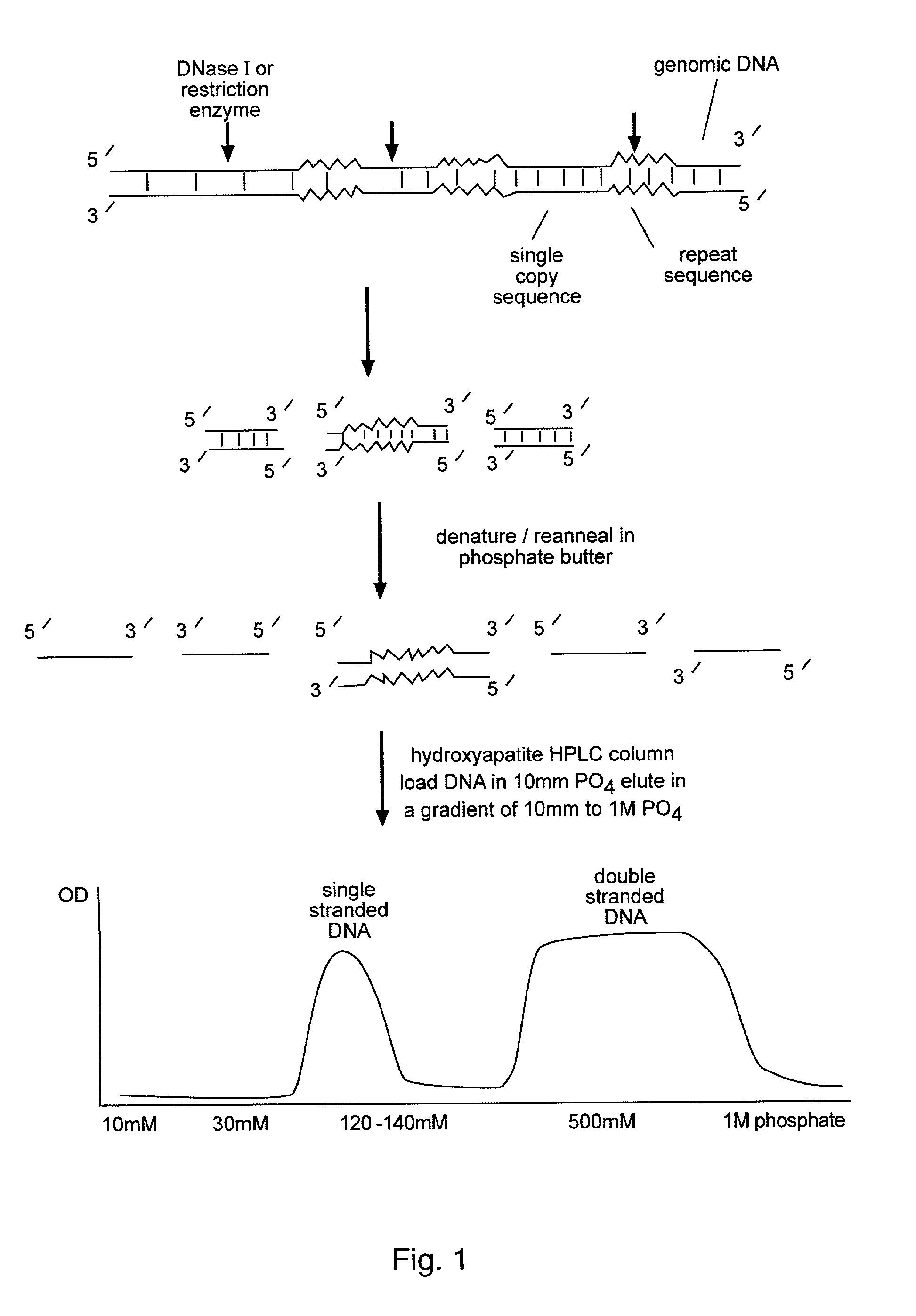

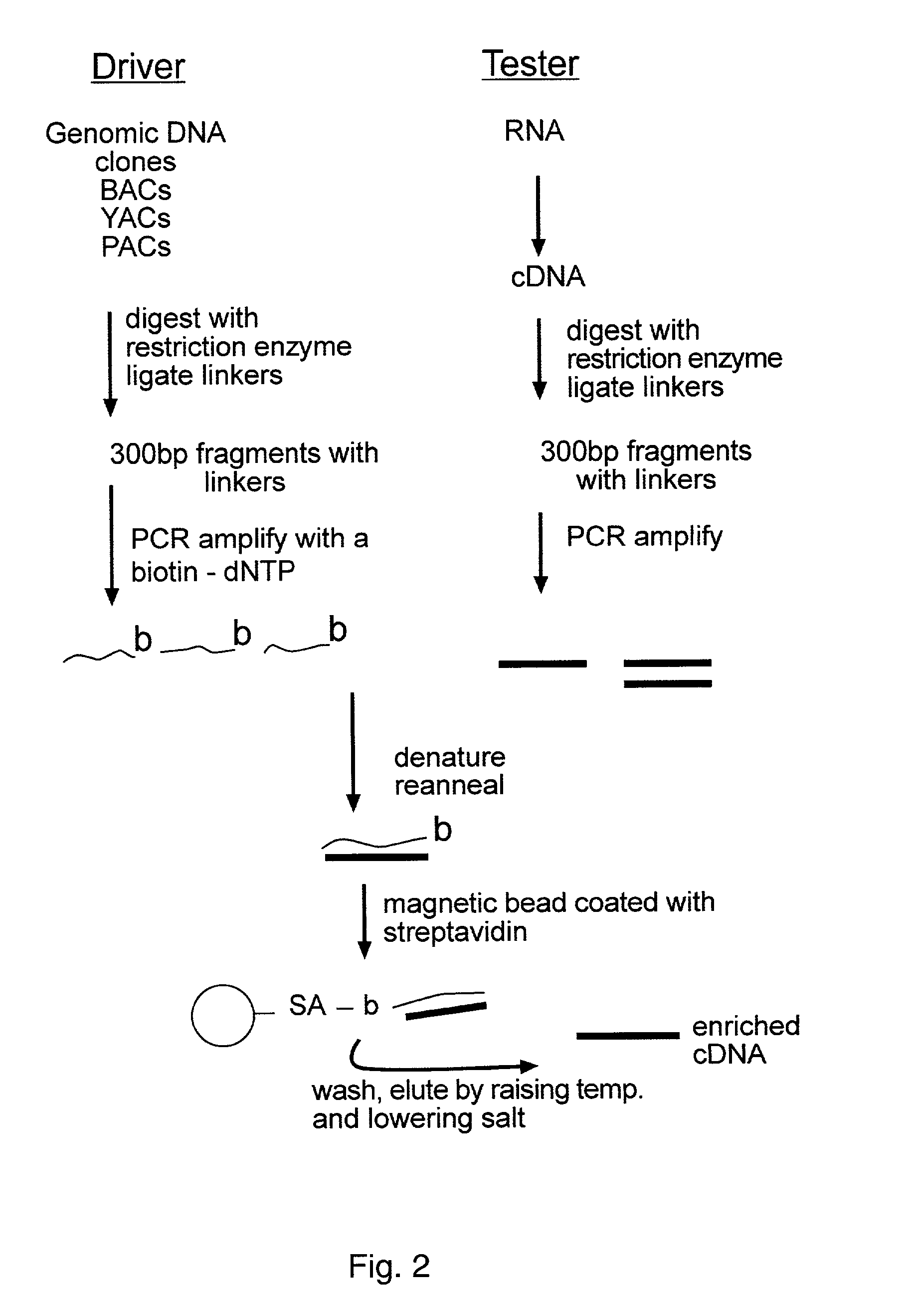

Methods for enriching populations of nucleic acid samples

InactiveUS20050100911A1Reduce complexityIncreased complexityMicrobiological testing/measurementFermentationNucleic Acid ProbesGenomic DNA

The invention provides several methods for reducing the complexity of a population of nucleic acids prior to performing an analysis of the nucleic acids on a nucleic acid probe array. The methods result in a subset of the initial population enriched for a desired property, or lacking nucleic acids having an undesired properly. The resulting nucleic acids in the subset are then applied to the array for various types of analysis. The methods are particularly useful for analyzing populations having a high decree of complexity, for example, chromosomal-derived DNA, or whole genomic DNA, or mRNA population. In addition, such methods allow for analysis of pooled samples.

Owner:PERLEGEN SCIENCES INC

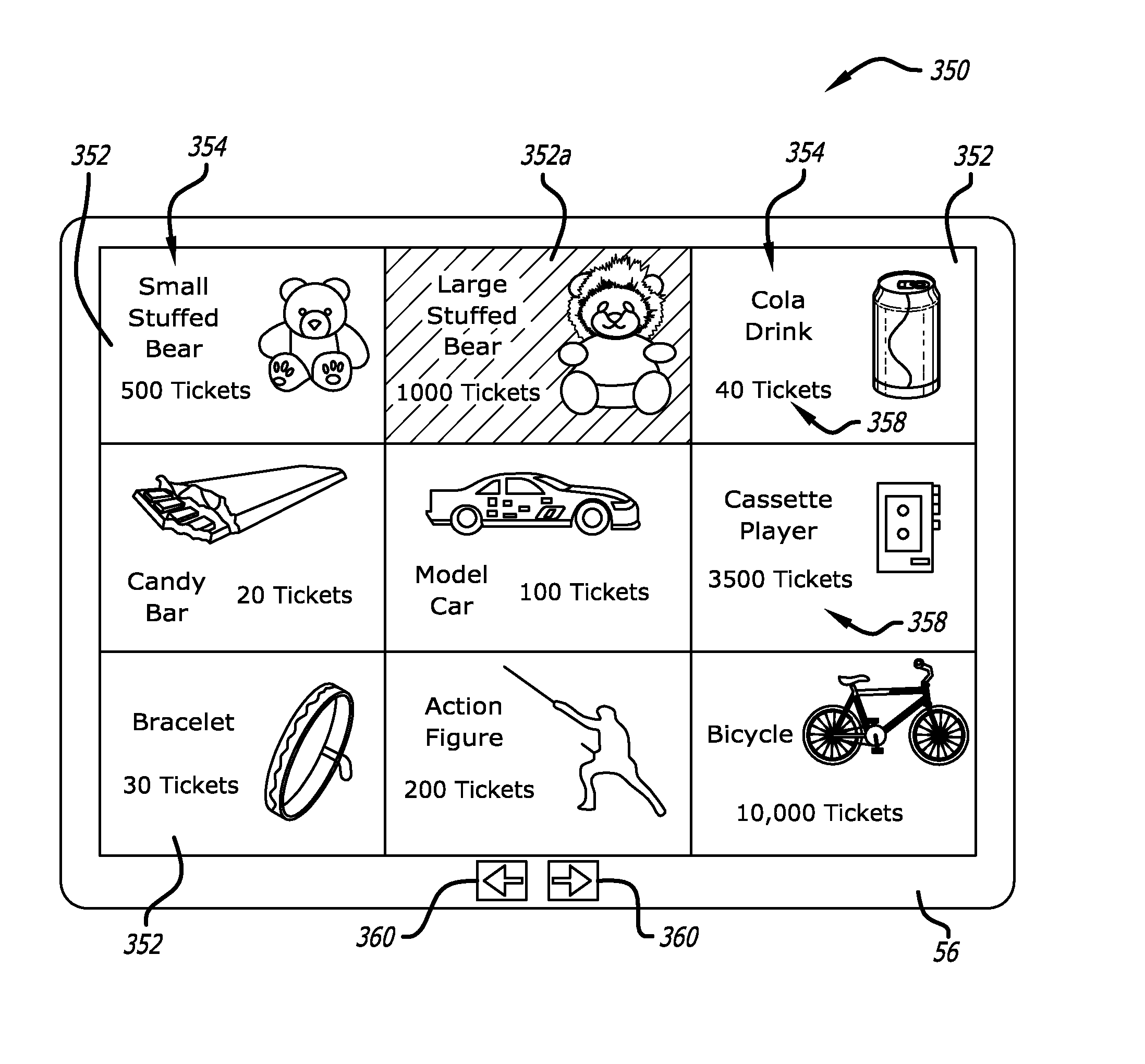

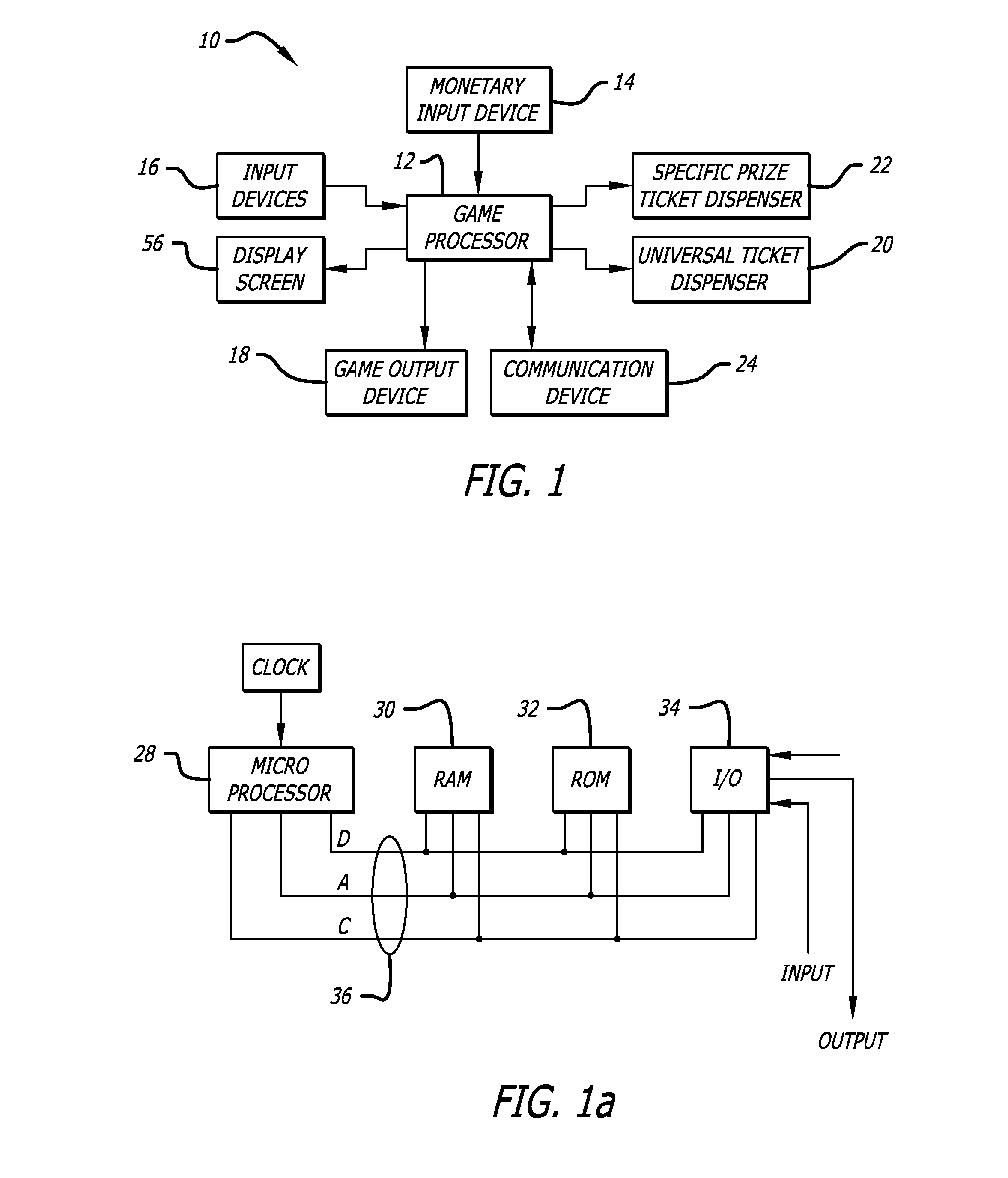

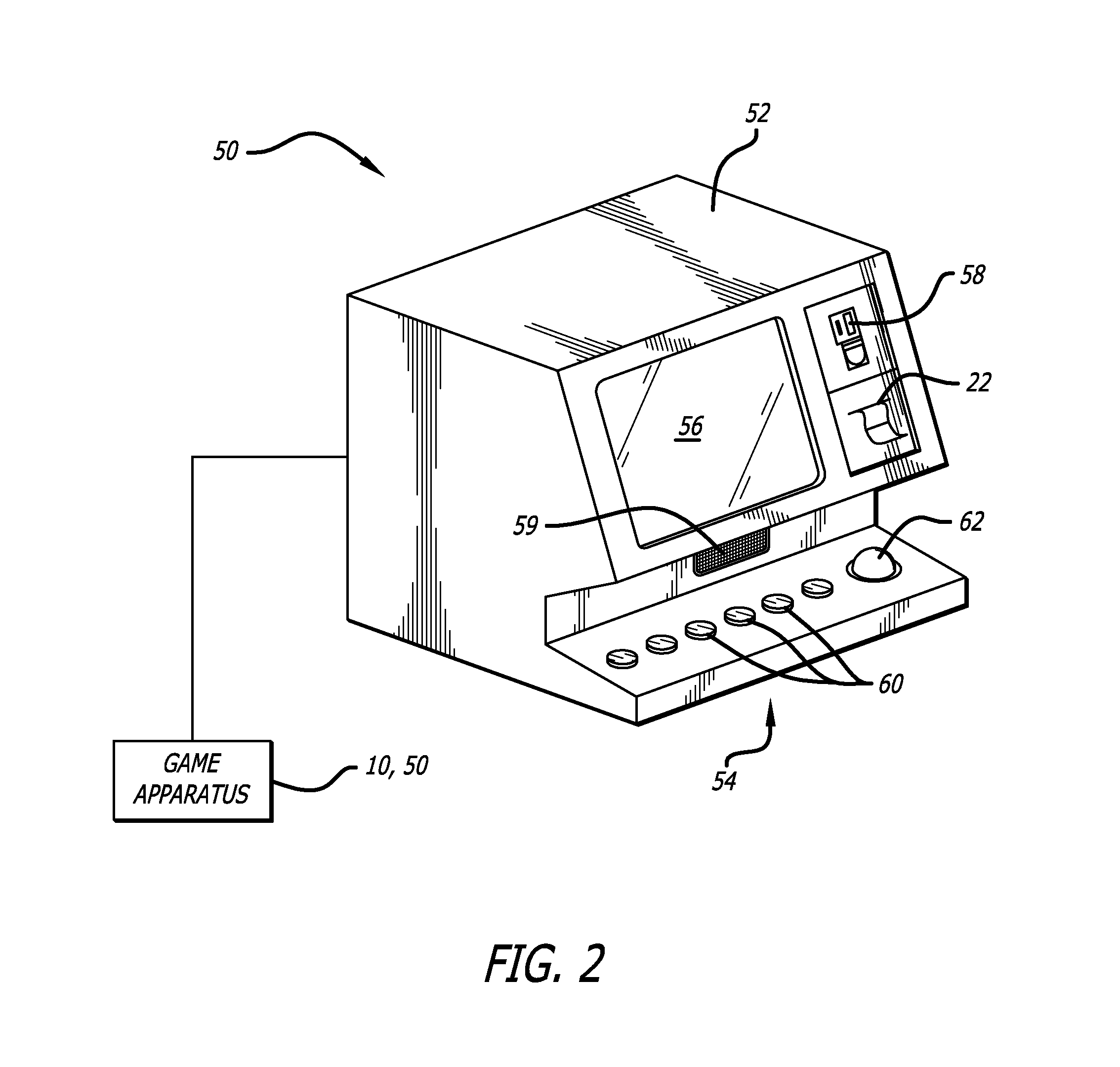

Networked gaming system

InactiveUS8052518B1Shorten the timeLow costBoard gamesApparatus for meter-controlled dispensingWeb siteUser identifier

The invention provides method and article of manufacture for implementing a user profile-driven gaming and prize redeeming system. The user profile-driven gaming and prize redemption system allows for the tailoring of a user's experience of playing a computer implemented game on a network gaming system by first receiving an identifier selected from a group of identifiers including a user identifier relating to the user (i.e., player) of the network gaming system, a game identifier relating to a particular game played by the User of the network gaming system, and a site identifier relating to the location (i.e. web site) from which the game is being played. The network gaming system then alters the computer-implemented game played by the user in a manner based upon the selected identifier. The foregoing technique may also be applied to a prize redemption system.

Owner:BALLY GAMING INC

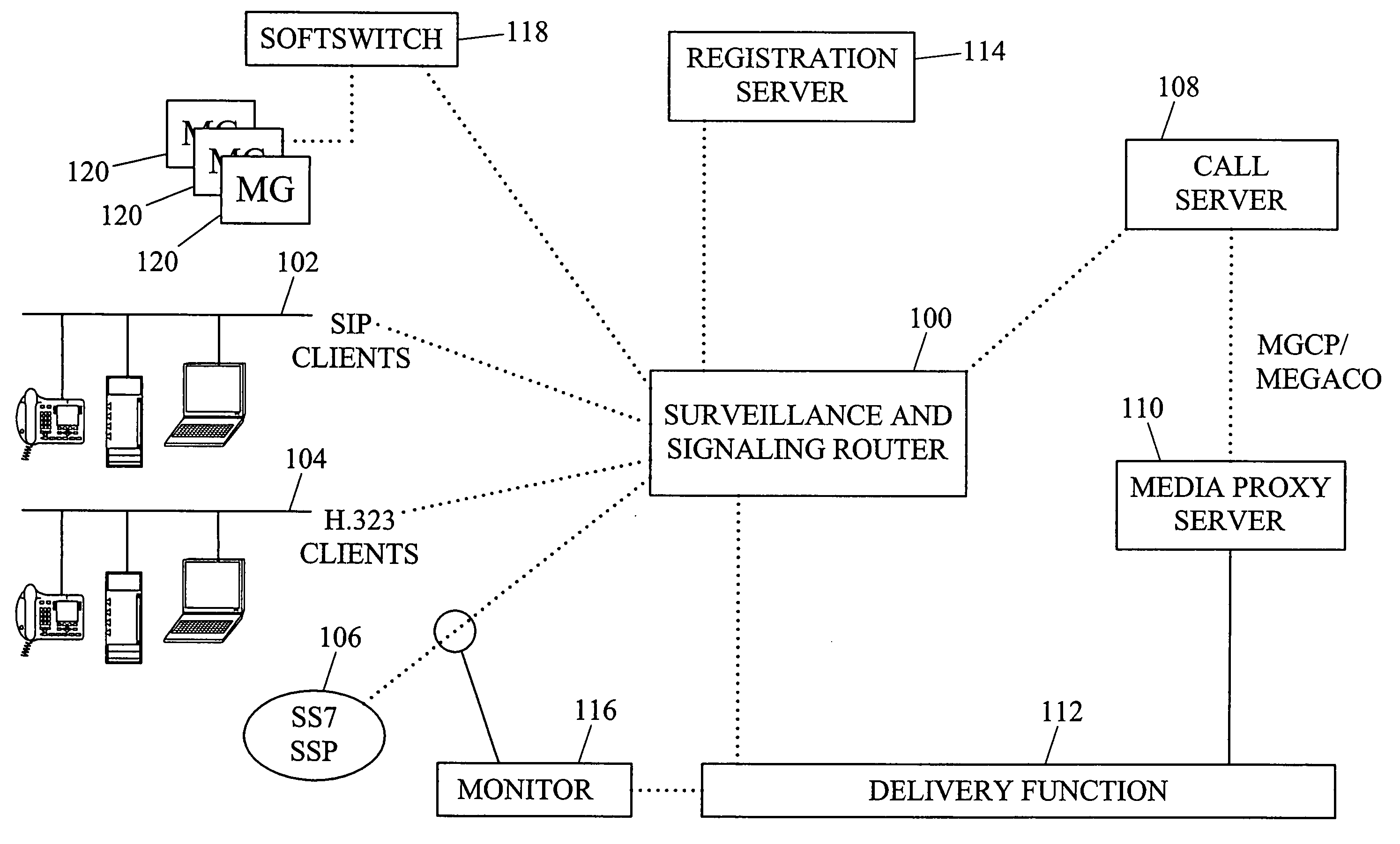

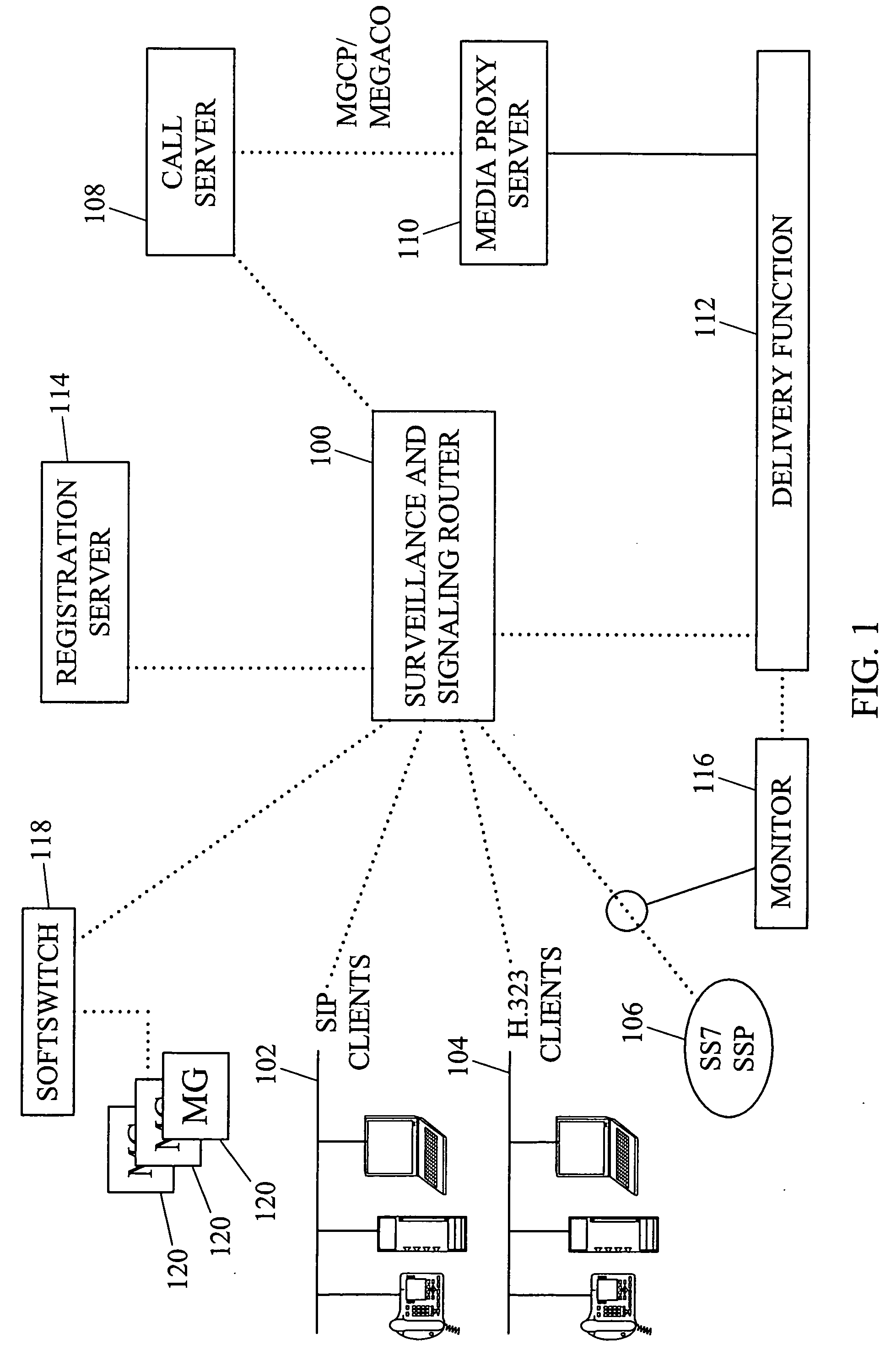

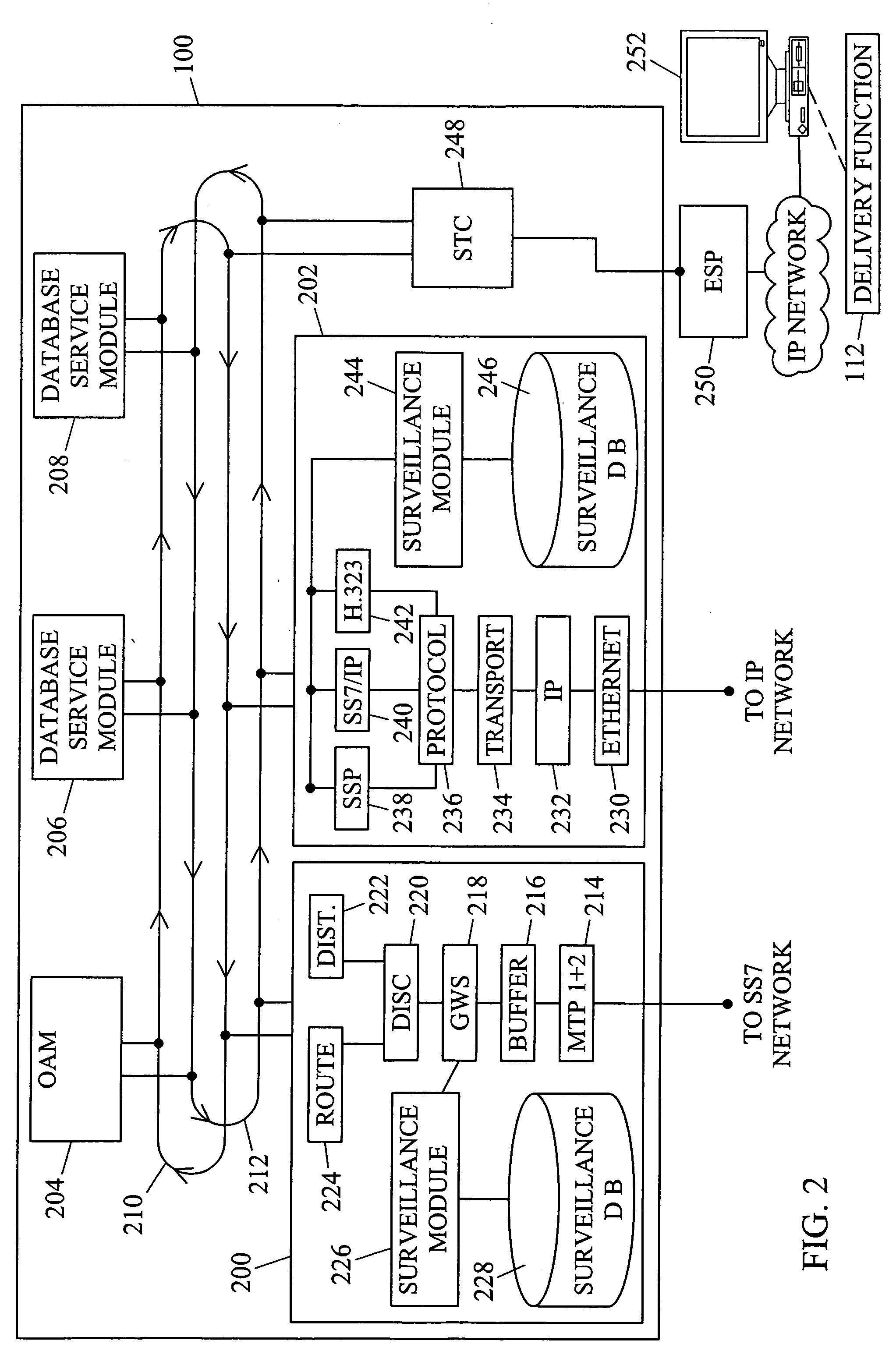

Method and systems for intelligent signaling router-based surveillance

InactiveUS20060133595A1Reduce time and costEfficient executionSupervisory/monitoring/testing arrangementsSubstation equipmentProxy serverSurveillance Methods

Methods and systems for intelligent signaling-router-based surveillance are disclosed. A surveillance and signaling router receives call signaling messages, identifies call signaling messages associated with users under surveillance and determines a surveillance type for the call signaling messages. If the surveillance type is content-related, the surveillance and signaling router forwards the message to a call server. The call server replaces parameters in the message and in subsequent messages so that the call is transparently set up through a media proxy server. The media proxy server copies the media stream to a delivery function. If the surveillance type is non-content-related, the surveillance and signaling router sends a copy of the message or information extracted from the message to an external device.

Owner:TEKELEC GLOBAL INC

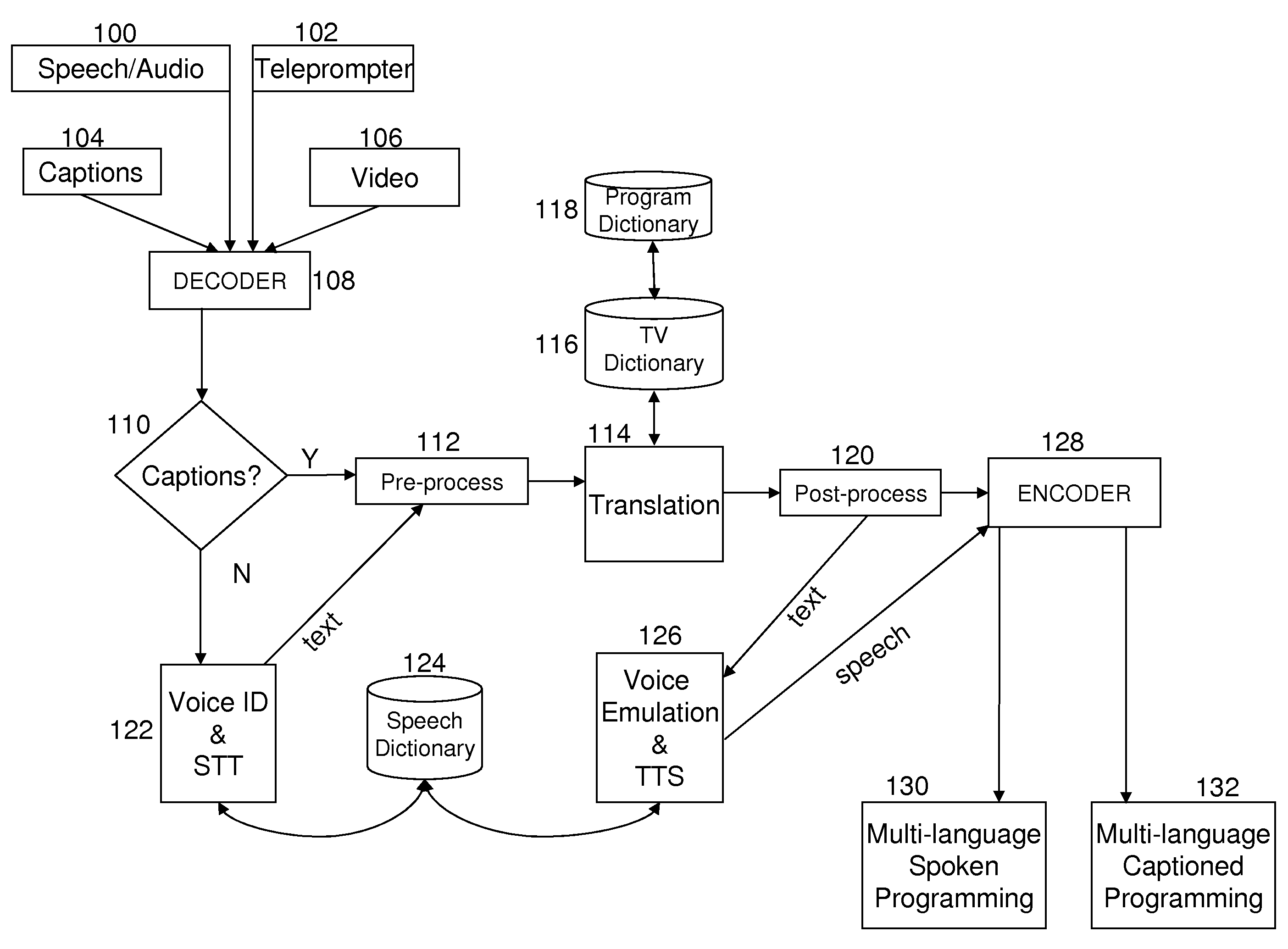

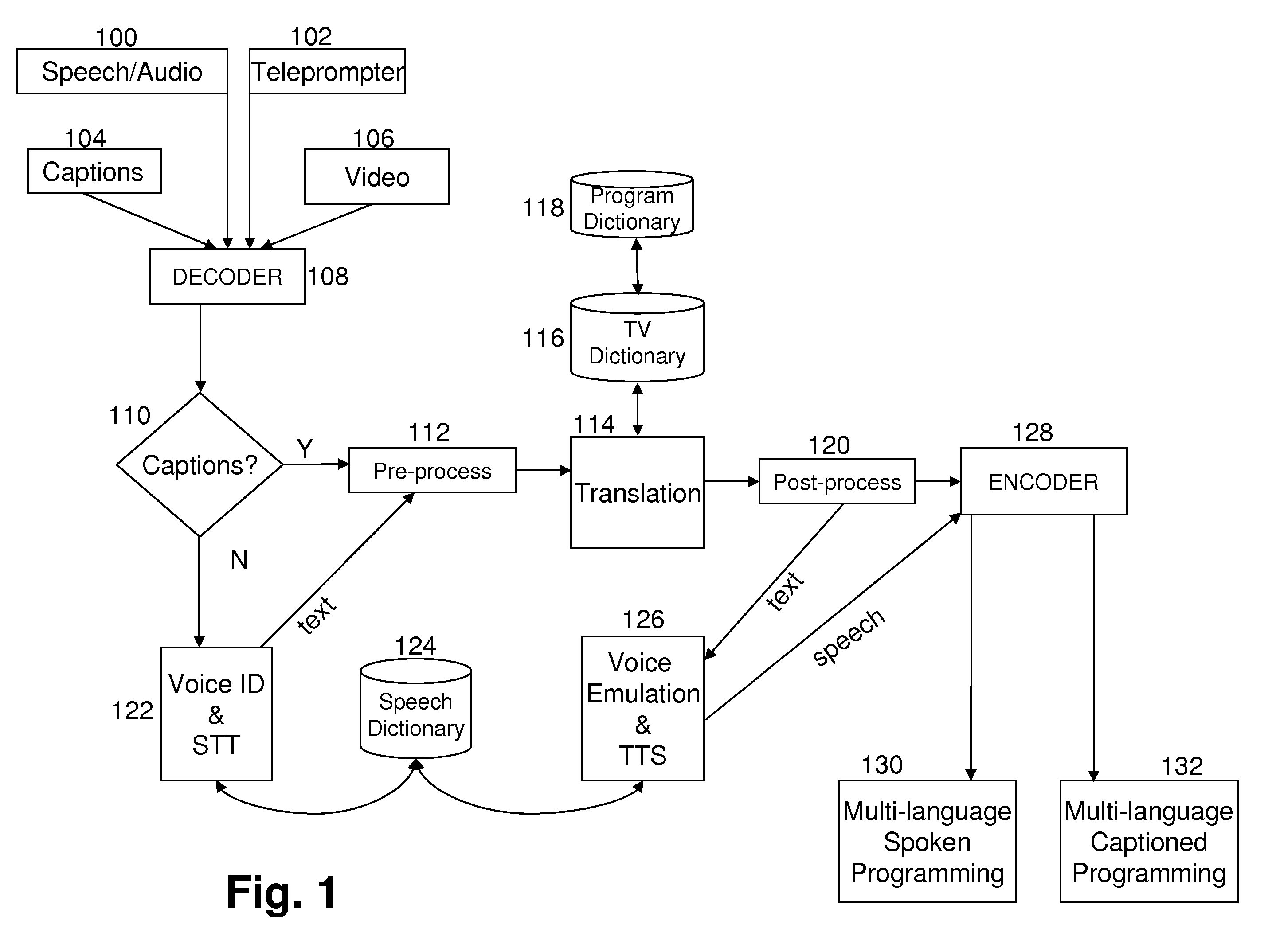

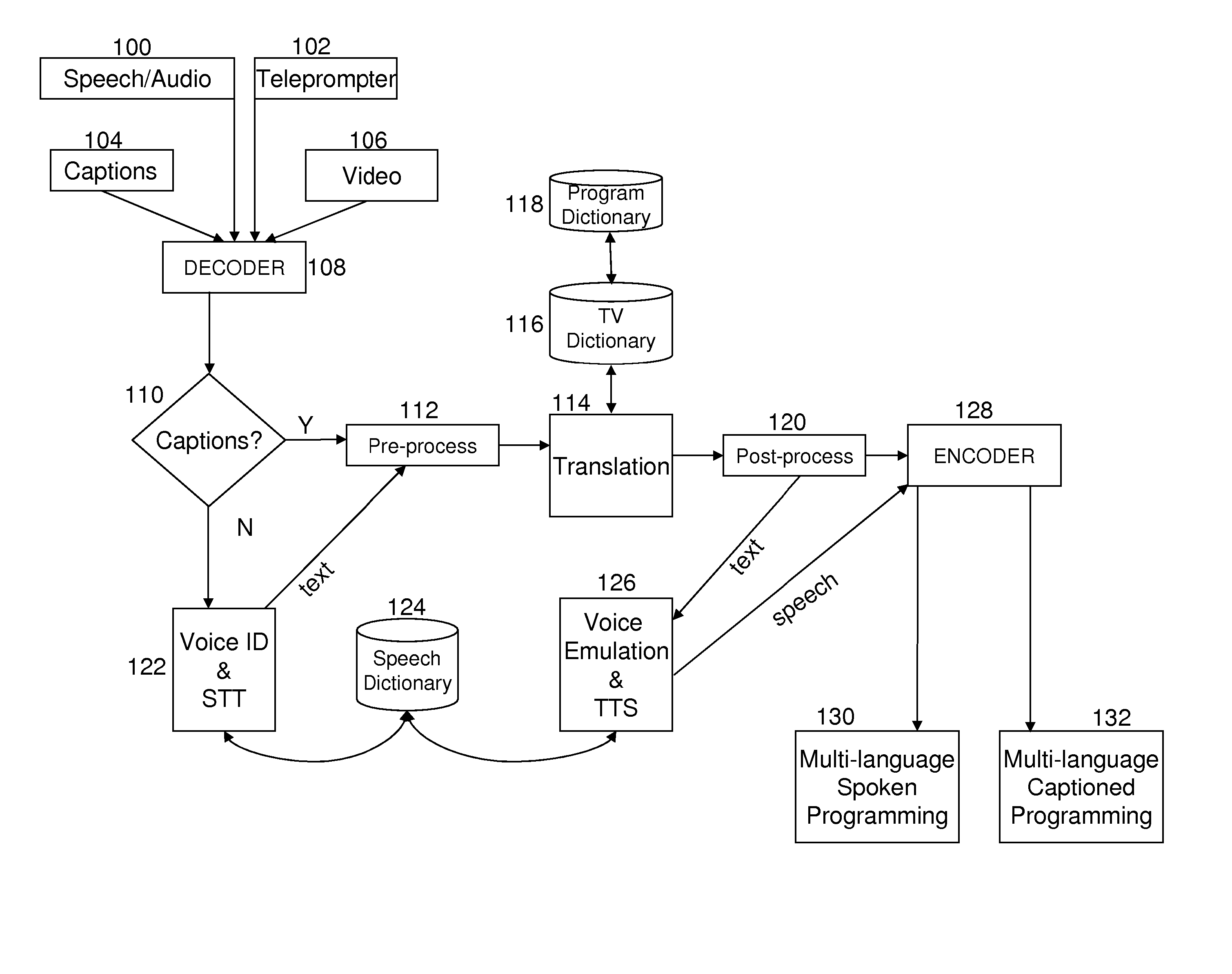

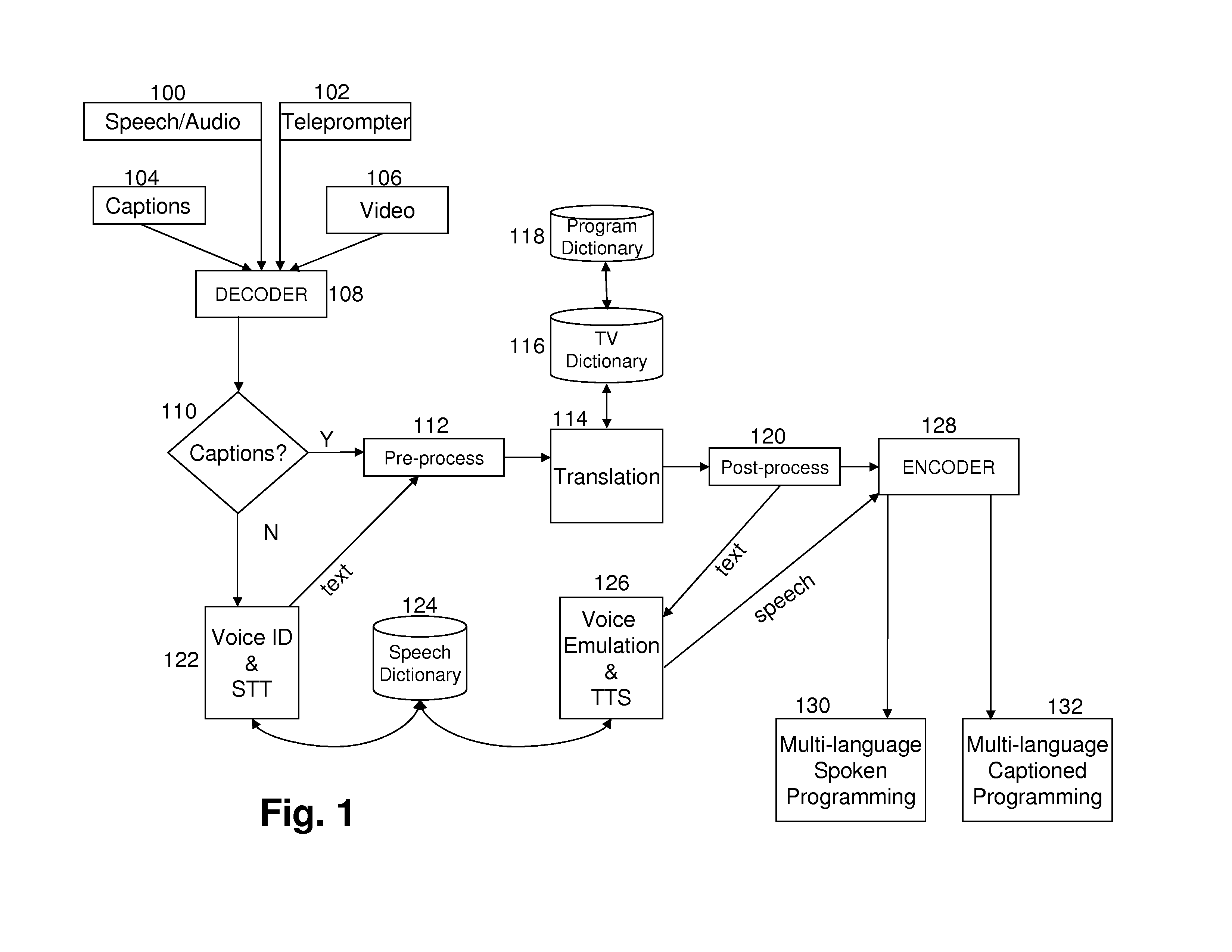

Integrated speech recognition, closed captioning, and translation system and method

InactiveUS7747434B2Cost effectiveLow costNatural language translationTelevision system detailsClosed captioningMulti language

A system and method that integrates automated voice recognition technology and speech-to-text technology with automated translation and closed captioning technology to provide translations of “live” or “real-time” television content is disclosed. It converts speech to text, translates the converted text to other languages, and provides captions through a single device that may be installed at the broadcast facility. The device accepts broadcast quality audio, recognizes the speaker's voice, converts the audio to text, translates the text, processes the text for multiple caption outputs, and then sends multiple text streams out to caption encoders and / or other devices in the proper format. Because it automates the process, it dramatically reduces the cost and time traditionally required to package television programs for broadcast into foreign or multi-language U.S. markets.

Owner:GLOBAL TRANSLATION

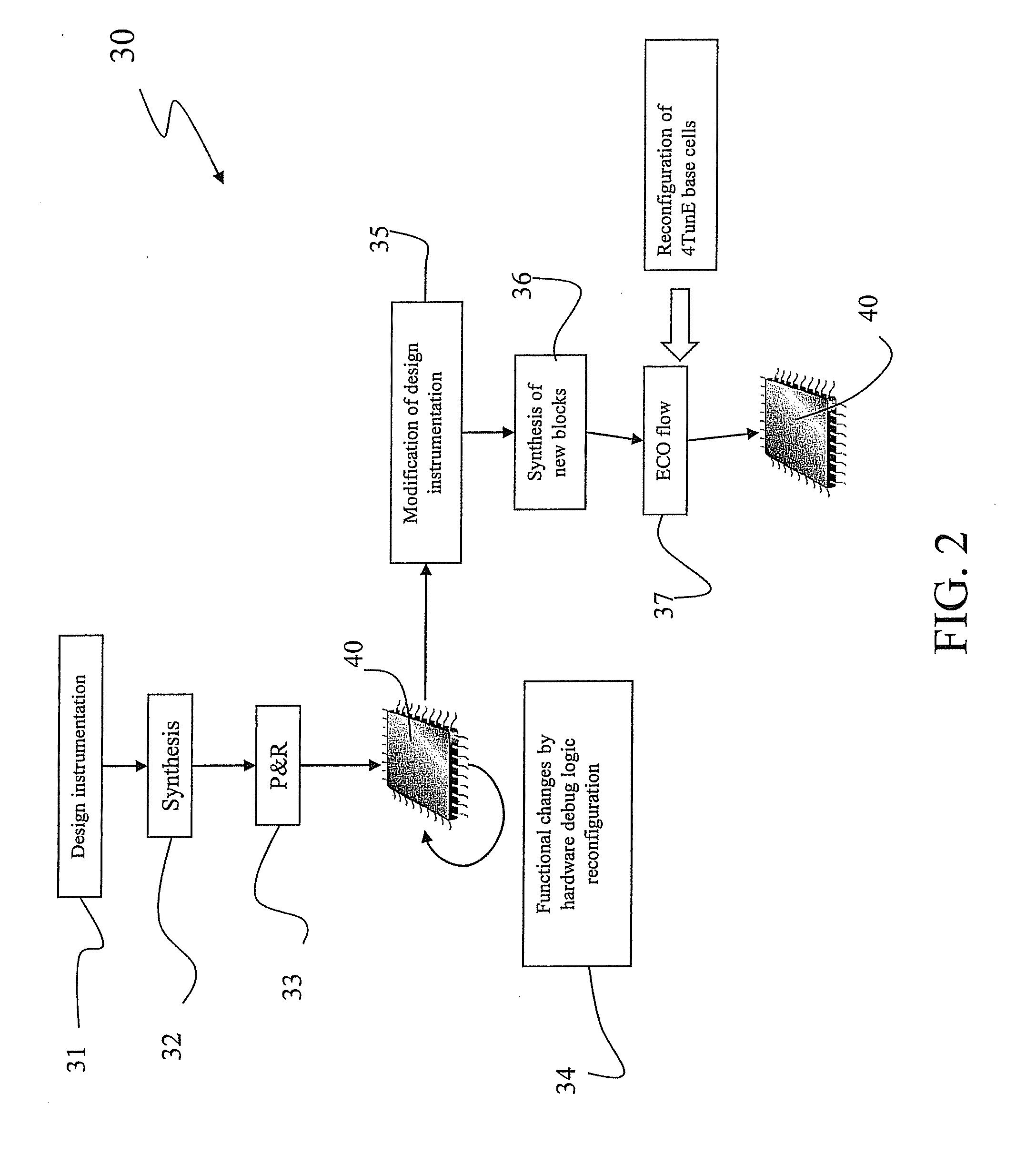

Method for implementing functional changes into a design layout of an integrated device, in particular a system-on-chip, by means of mask programmable filling cells

ActiveUS20100201400A1Reduce time and costLow costElectronic circuit testingSolid-state devicesExternal connectionIntegrated devices

A System-on-Chip (SoC) may include logic blocks connected to each other and to external connections, and a hardware debug infrastructure logic connected to the logic blocks and for performing functional changes to a design layout of the SoC. The hardware debug infrastructure logic may include software re-configurable modules based upon the logic blocks obtained from substituting a mask programmable ECO base cell configured as a functional logic cell for a logic cell in the design layout.

Owner:STMICROELECTRONICS SRL

Integrated speech recognition, closed captioning, and translation system and method

InactiveUS20080052069A1Low costCost effectiveNatural language translationTelevision system detailsClosed captioningMulti language

A system and method that integrates automated voice recognition technology and speech-to-text technology with automated translation and closed captioning technology to provide translations of “live” or “real-time” television content is disclosed. It converts speech to text, translates the converted text to other languages, and provides captions through a single device that may be installed at the broadcast facility. The device accepts broadcast quality audio, recognizes the speaker's voice, converts the audio to text, translates the text, processes the text for multiple caption outputs, and then sends multiple text streams out to caption encoders and / or other devices in the proper format. Because it automates the process, it dramatically reduces the cost and time traditionally required to package television programs for broadcast into foreign or multi-language U.S. markets.

Owner:GLOBAL TRANSLATION

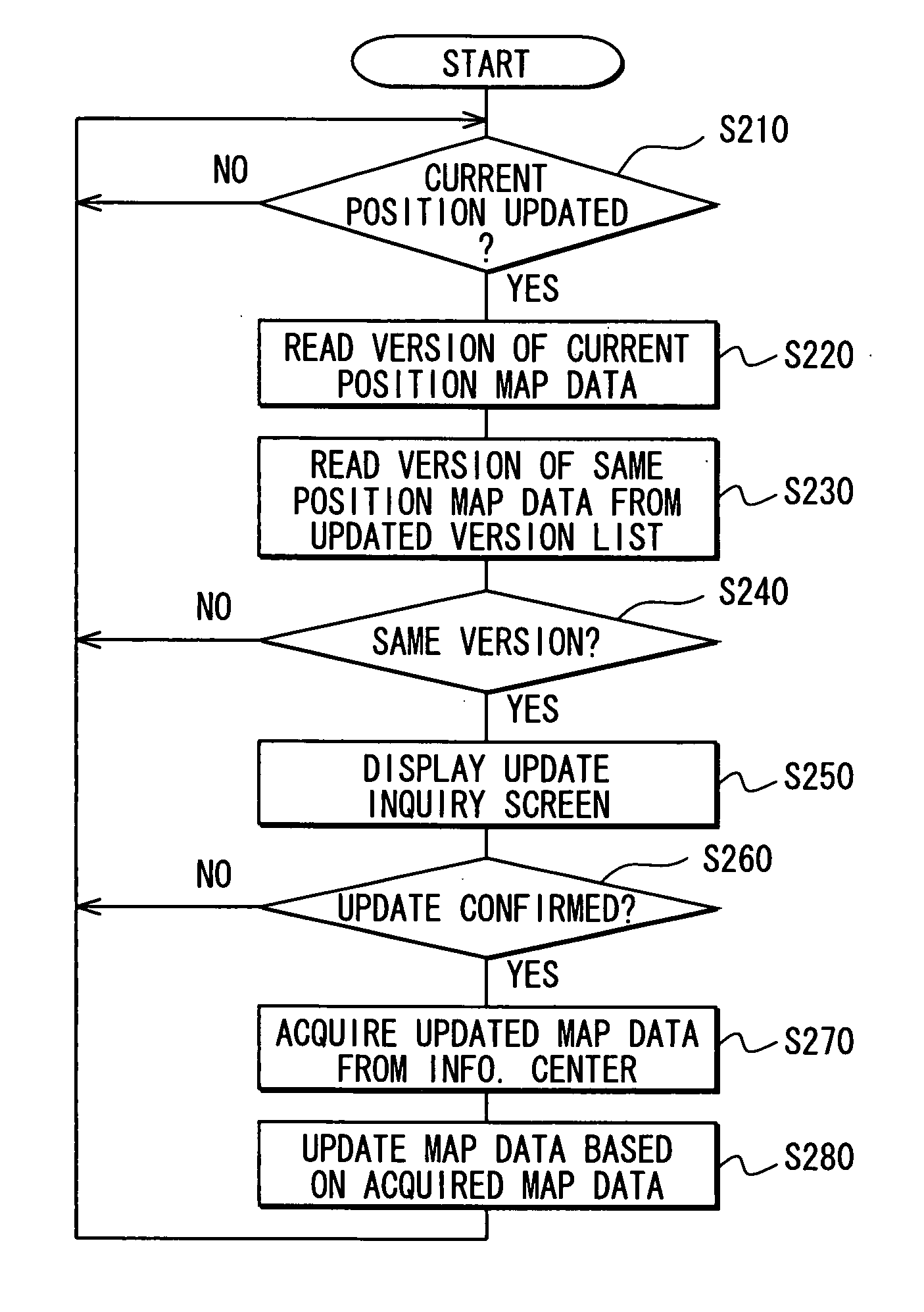

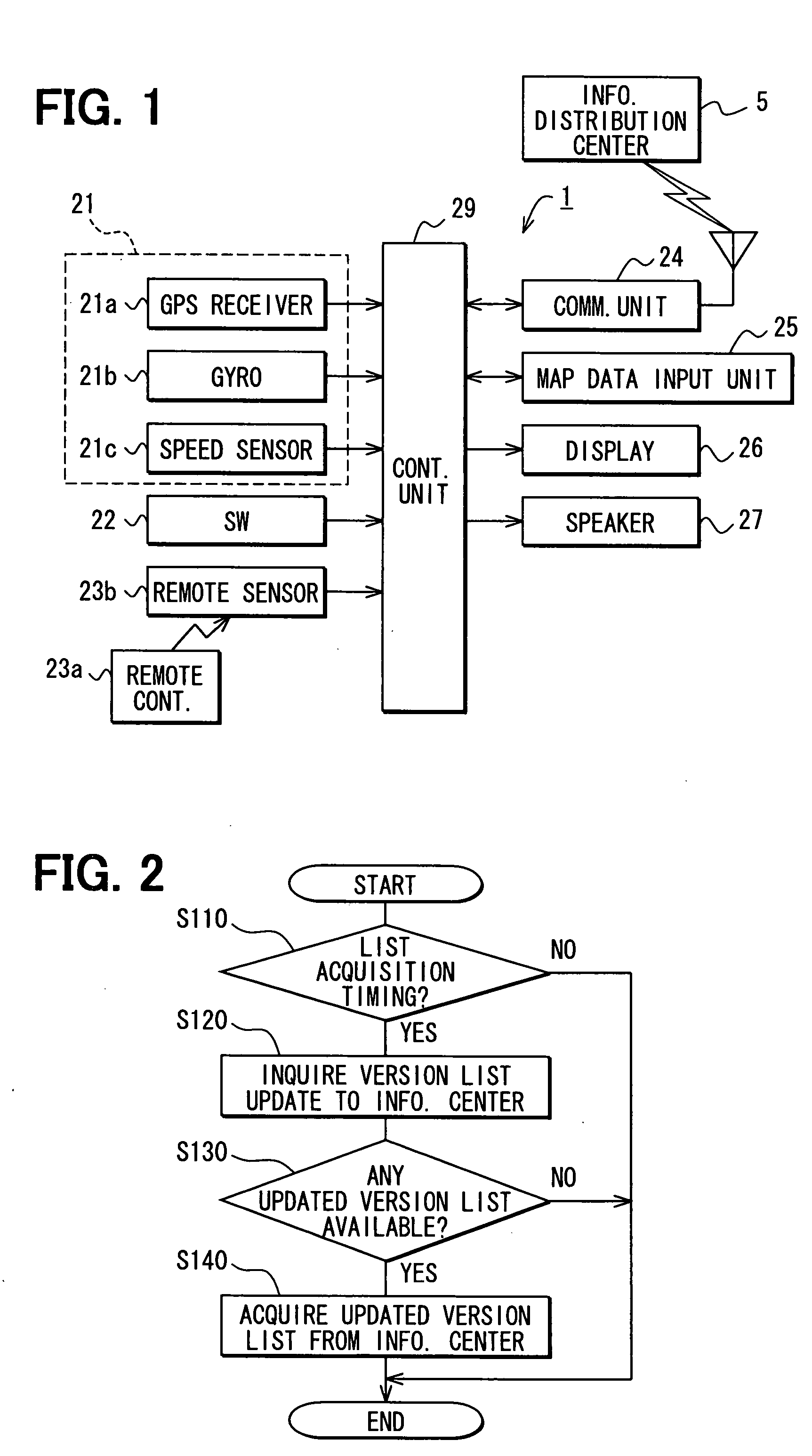

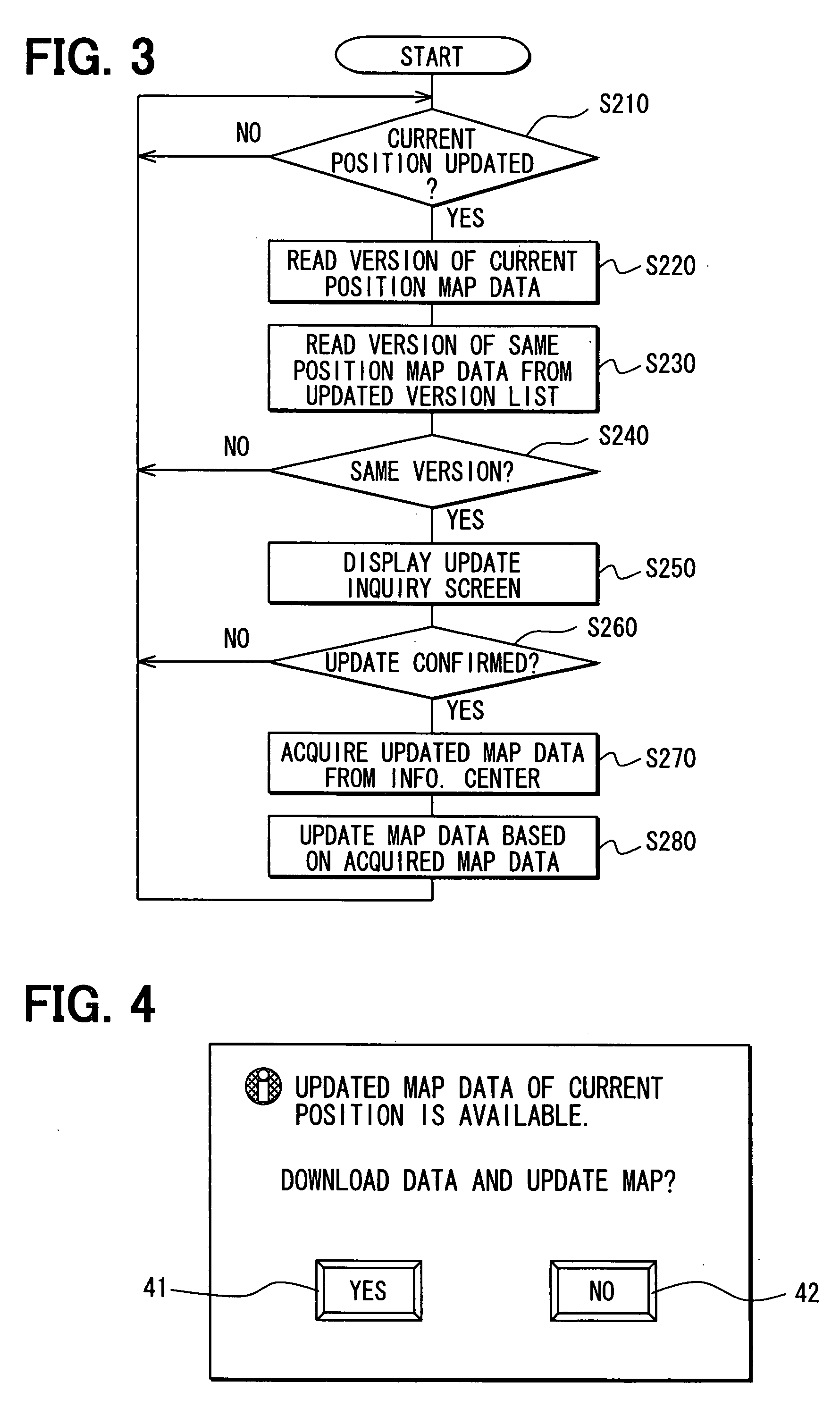

Map data utilization apparatus

InactiveUS20080082260A1Reduce time and costHigh demandInstruments for road network navigationRoad vehicles traffic controlInformation centerComputer science

Owner:DENSO CORP

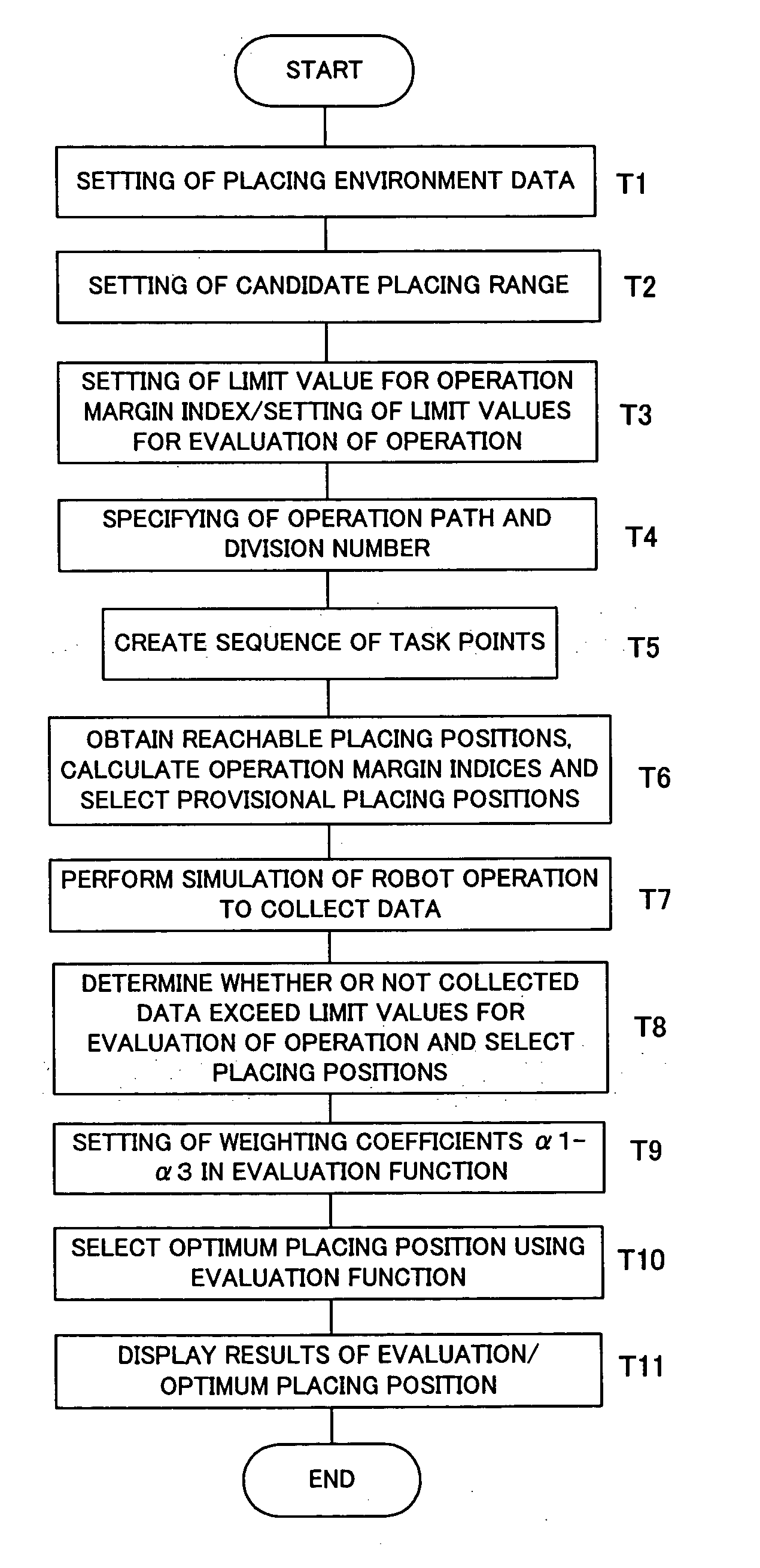

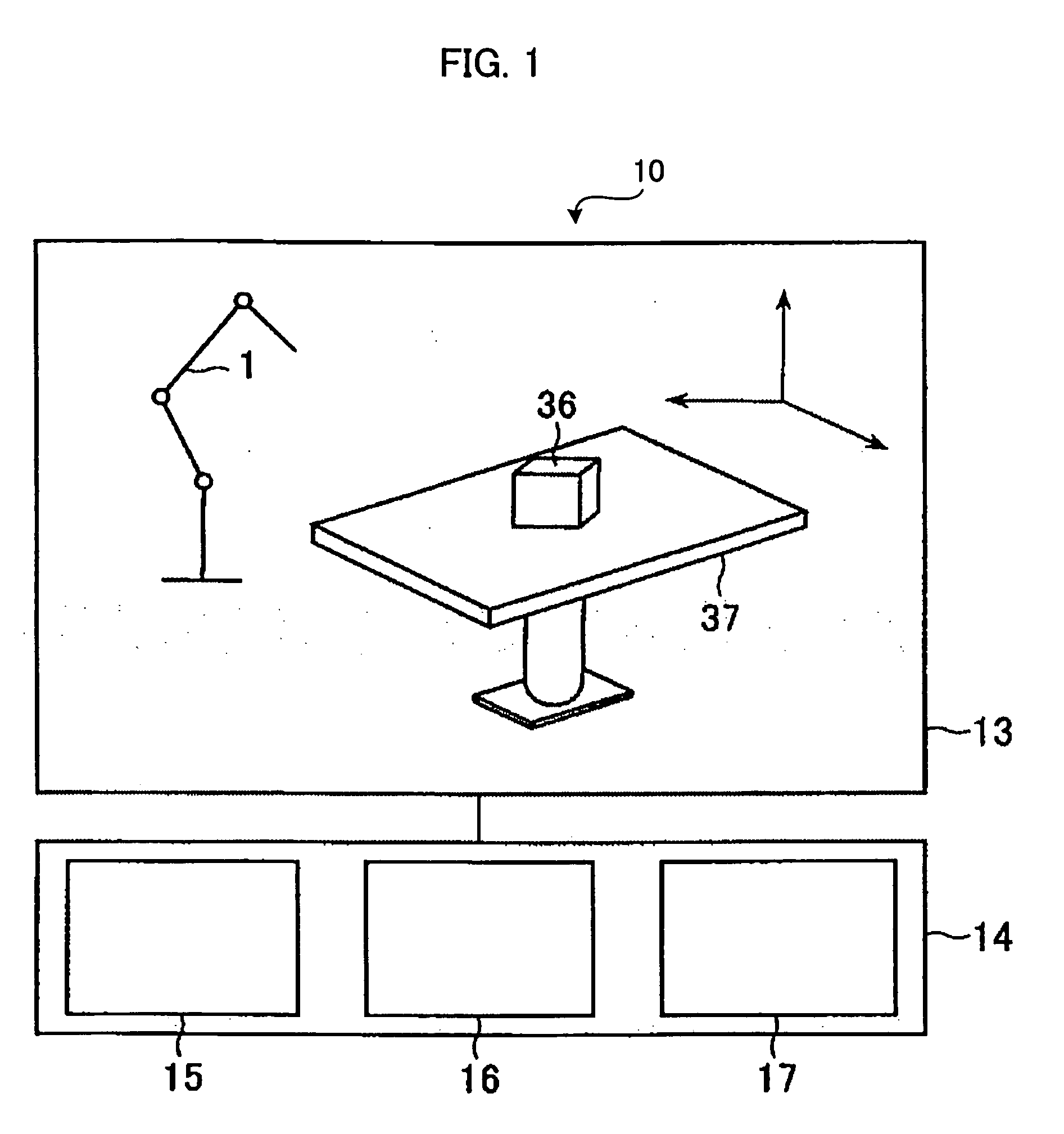

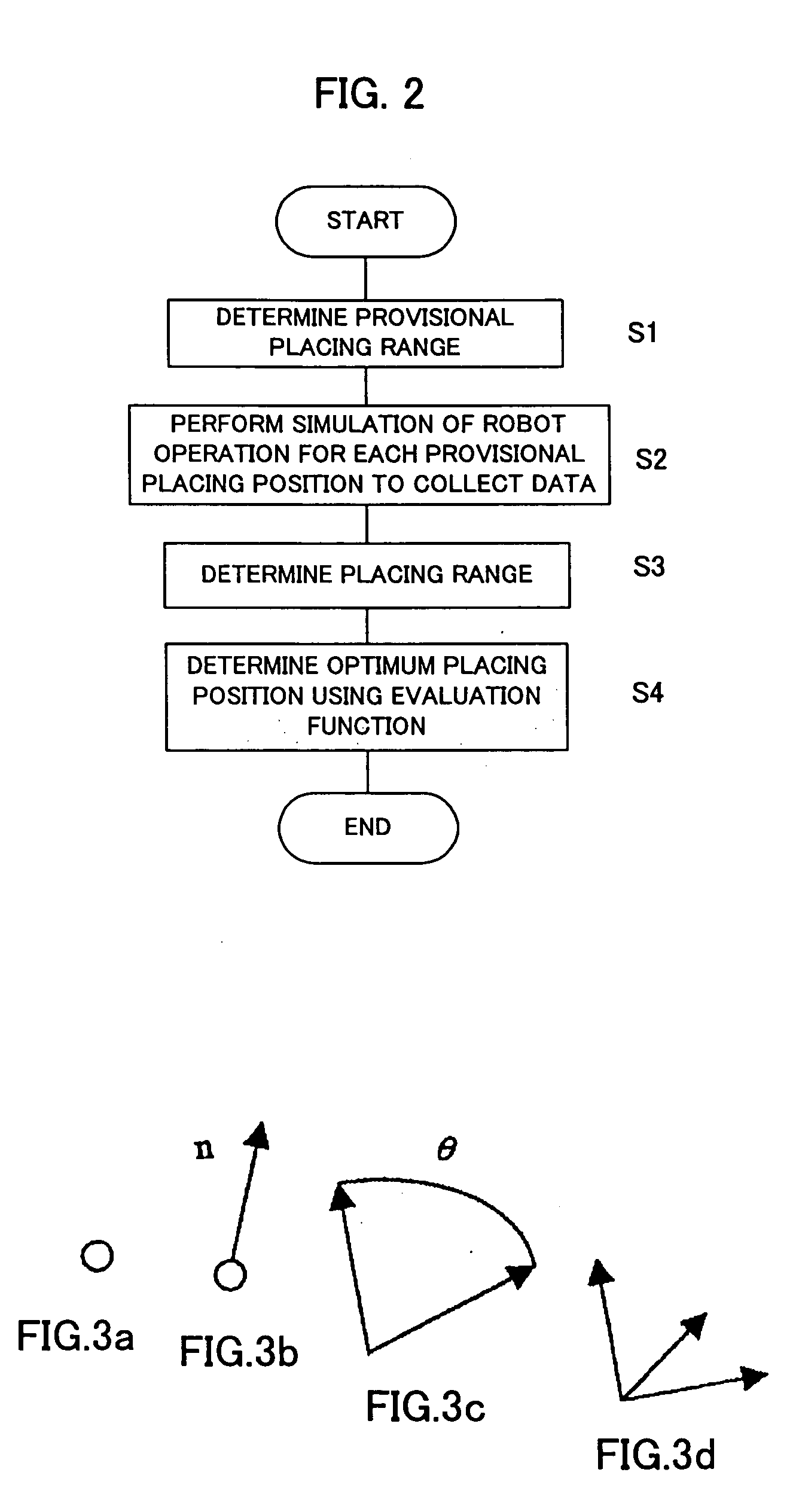

Robot off-line simulation apparatus

ActiveUS20050004709A1Easy to placeLow costProgramme controlProgramme-controlled manipulatorData selectionSimulation

A robot off-line simulation apparatus that allows a person to know an optimum placement for a robot, an operation margin index, etc. before going to an actual working site. Provisional robot placing positions are selected using data about a given sequence of task points (operation path), etc. The conditions for selection are (i) that solution to the inverse kinematics should be found regarding the entire sequence of task points, (ii) that the robot should not interfere with a peripheral device, and (iii) that regarding all the axes of the robot, the operation margin index should satisfy a criterion value. Simulation is performed according to operation programs under the condition that the robot is placed at each of the provisional placing positions, where data about cycle time, duty, energy value, change in acceleration / speed, etc. is collected. Using the collected data, evaluation of operation is performed regarding each of the provisional placing positions, and those provisional placing positions which allow good operation are identified as placing positions ensuring the robot operation. Further, using an evaluation function in which each aspect is given a weighting, the placing positions ensuring the robot operation are reduced to optimum placing positions ensuring the robot operation.

Owner:FANUC LTD

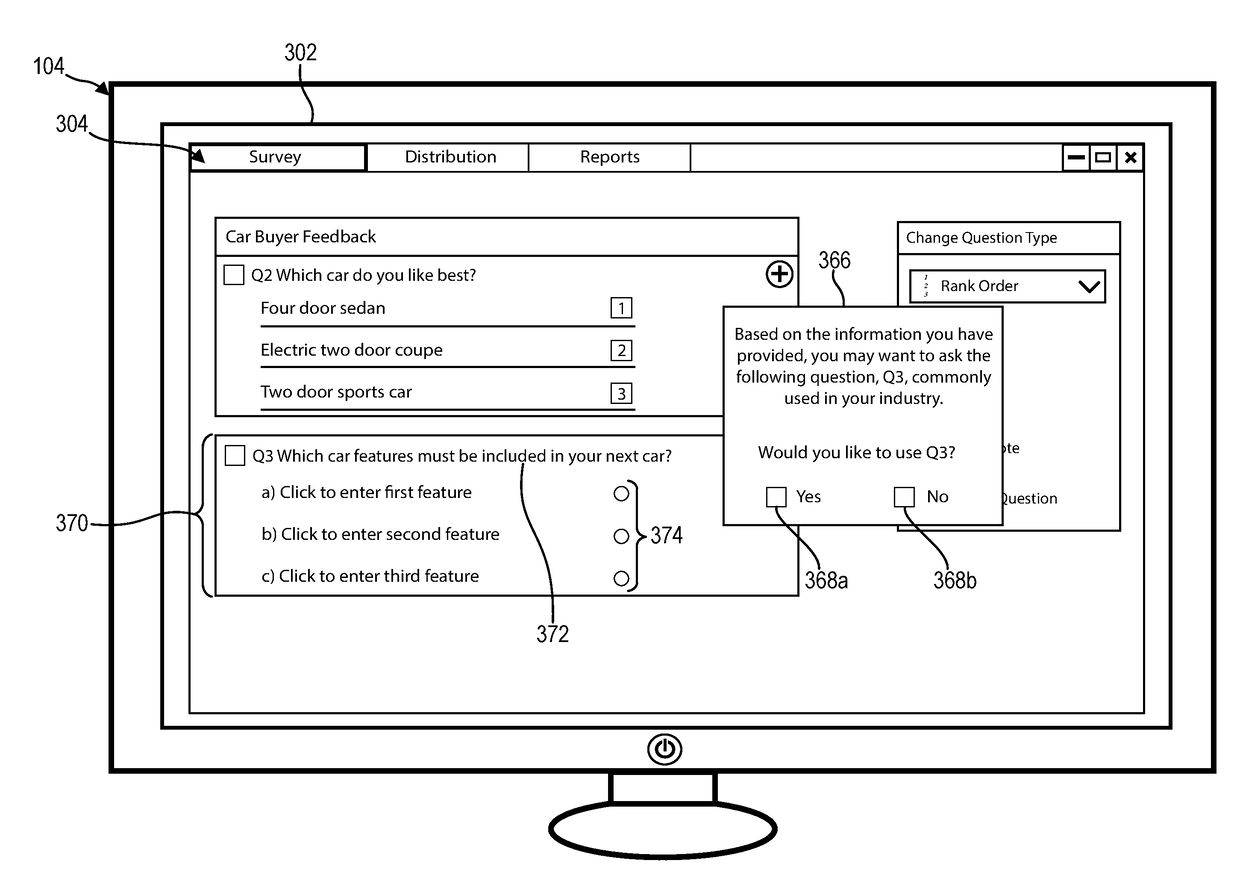

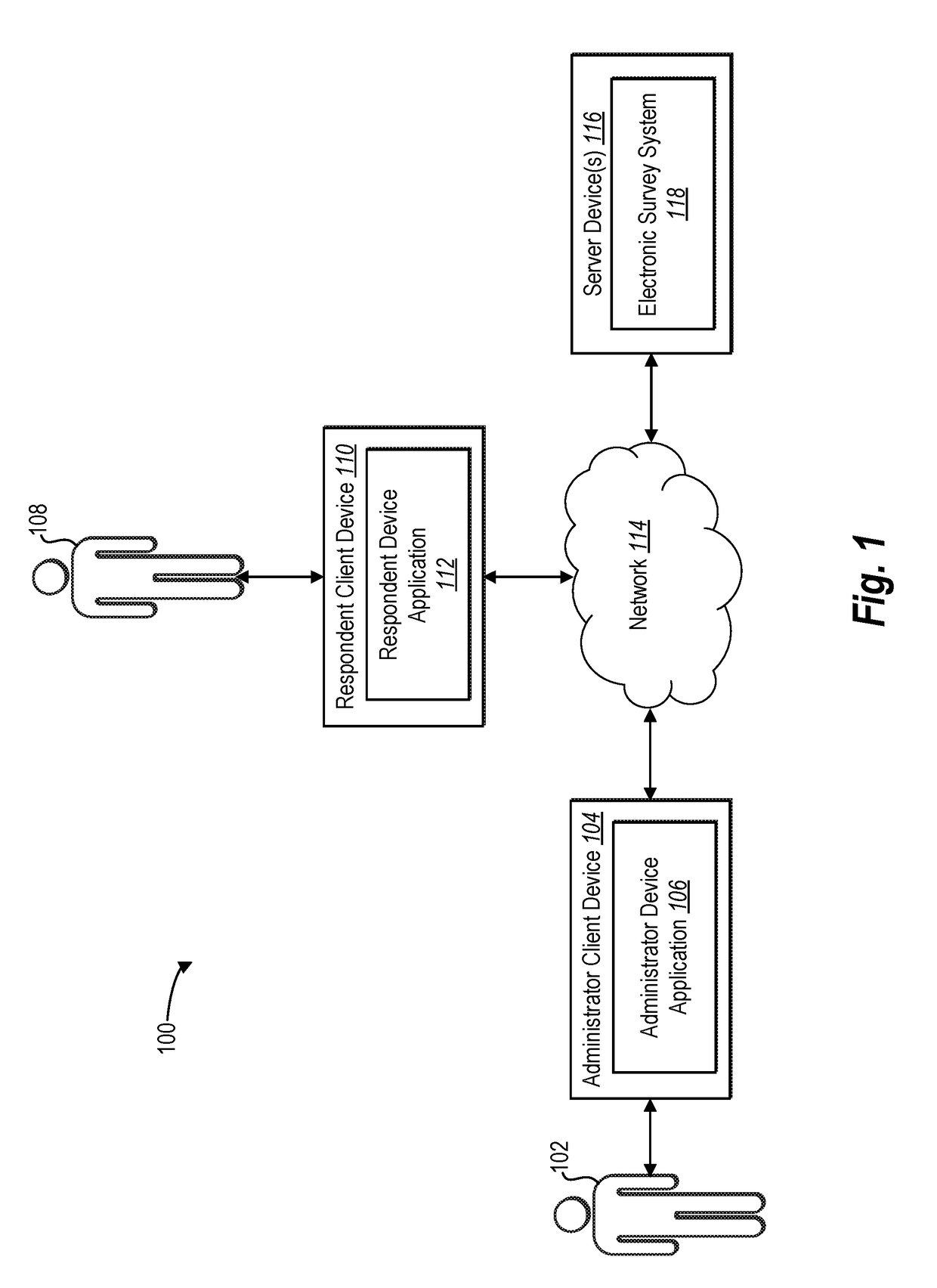

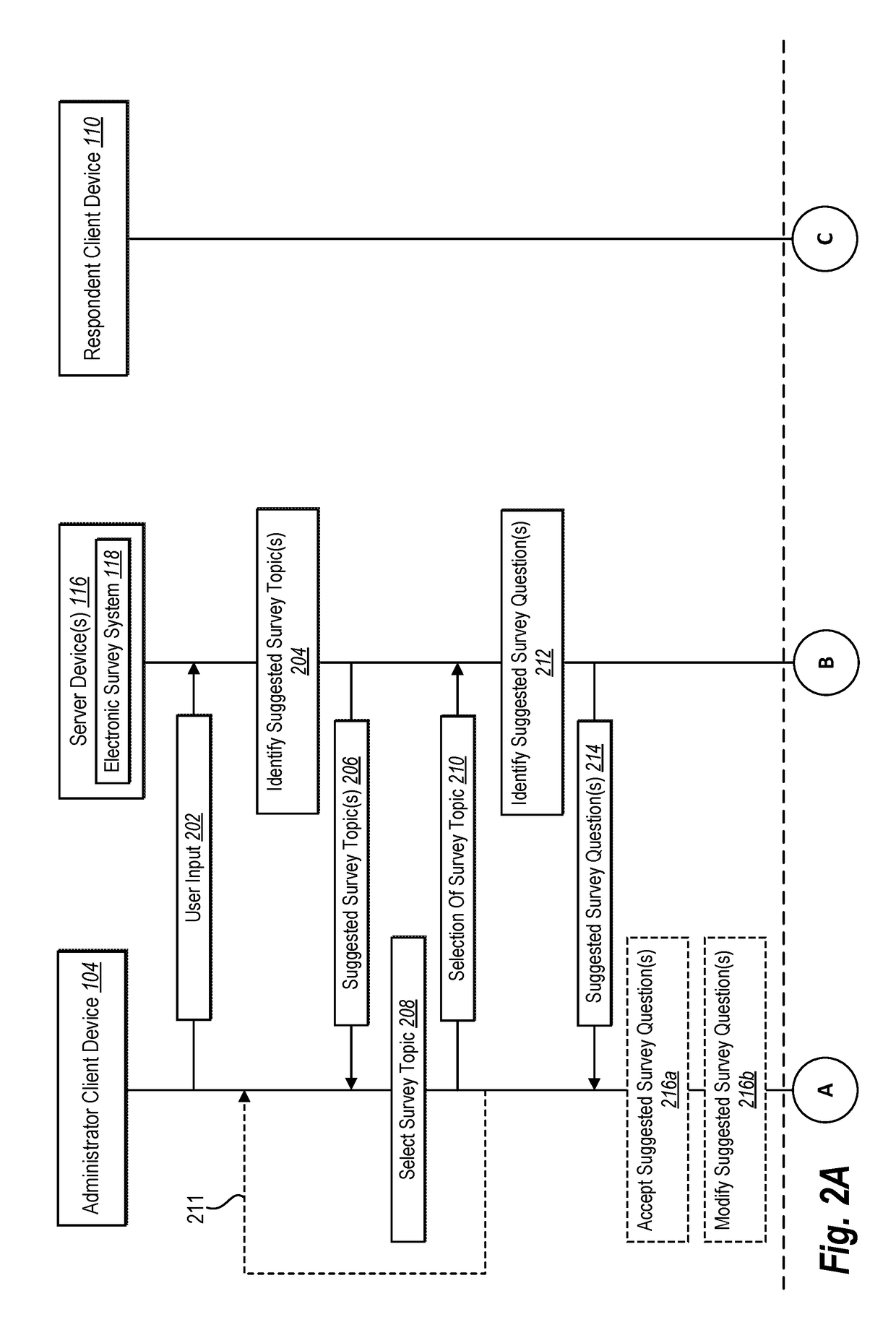

Guiding creation of an electronic survey

ActiveUS20180122256A1Easy and efficient creationReliable dataNatural language data processingElectrical appliancesUser inputCovering system

This disclosure generally covers systems and methods that provide guidance to create an electronic survey. In some embodiments, the systems and methods identify and provide a suggested survey topic—with a corresponding option to create an electronic survey—based on user input. In some embodiments, the systems and methods identify and provide one or more suggested electronic survey questions based on user input. In such embodiments, the systems and methods provide, for example, components of suggested electronic survey questions, previously composed and benchmarking electronic survey questions, or suggested revisions to electronic survey questions. In addition, the systems and methods can provide entire premade electronic surveys based on receiving user input from a survey administrator.

Owner:QUALTRICS

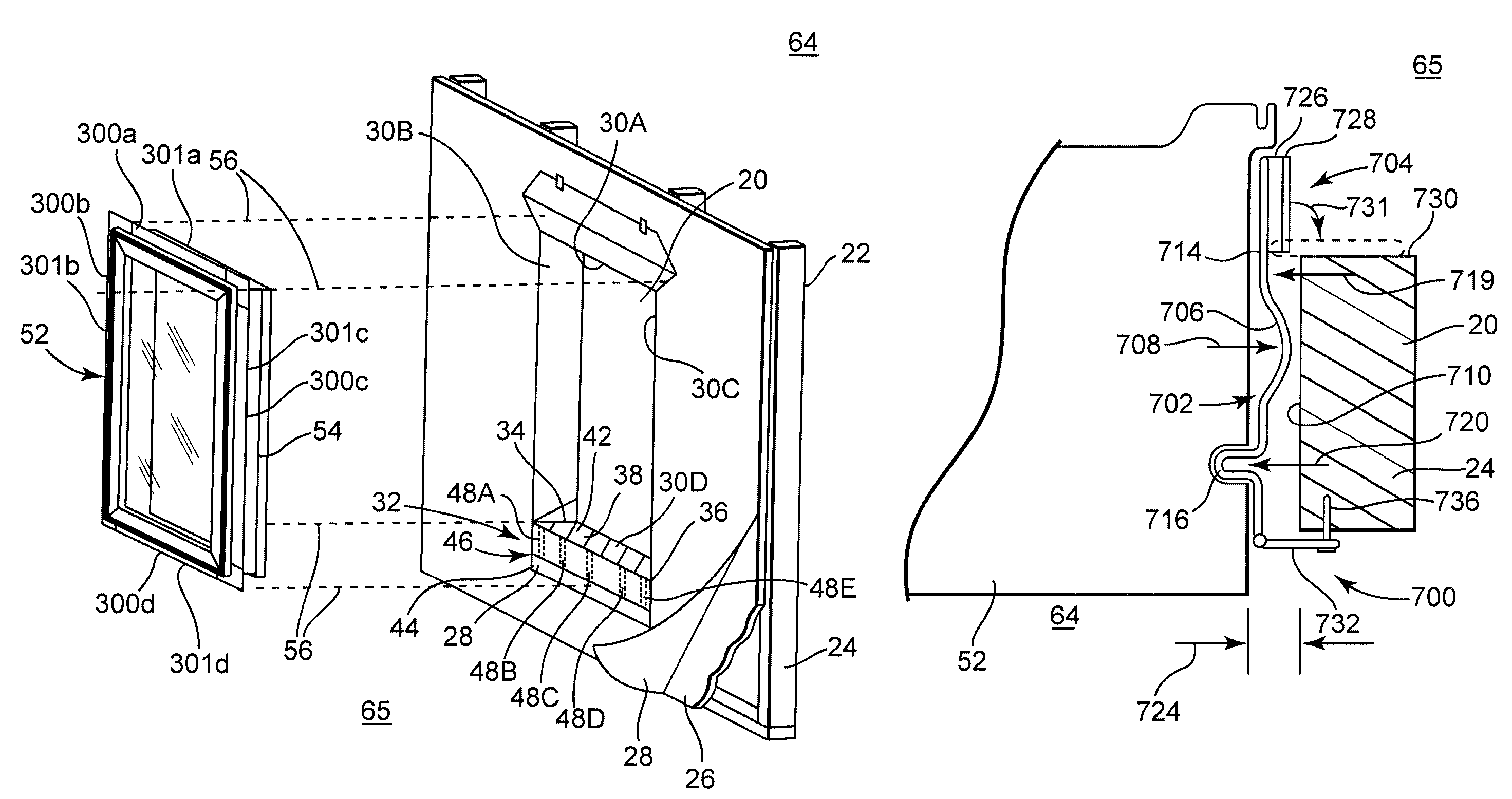

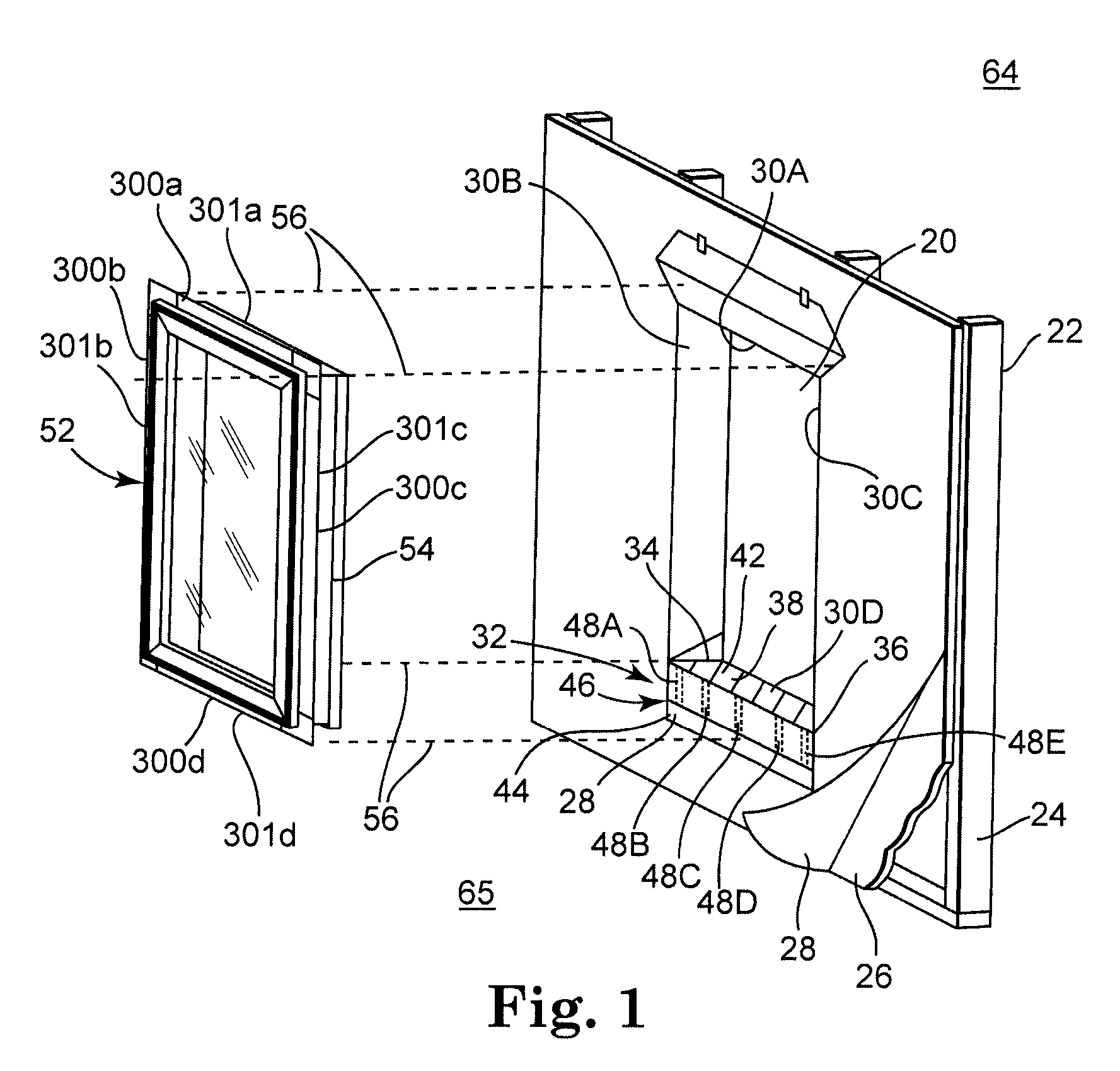

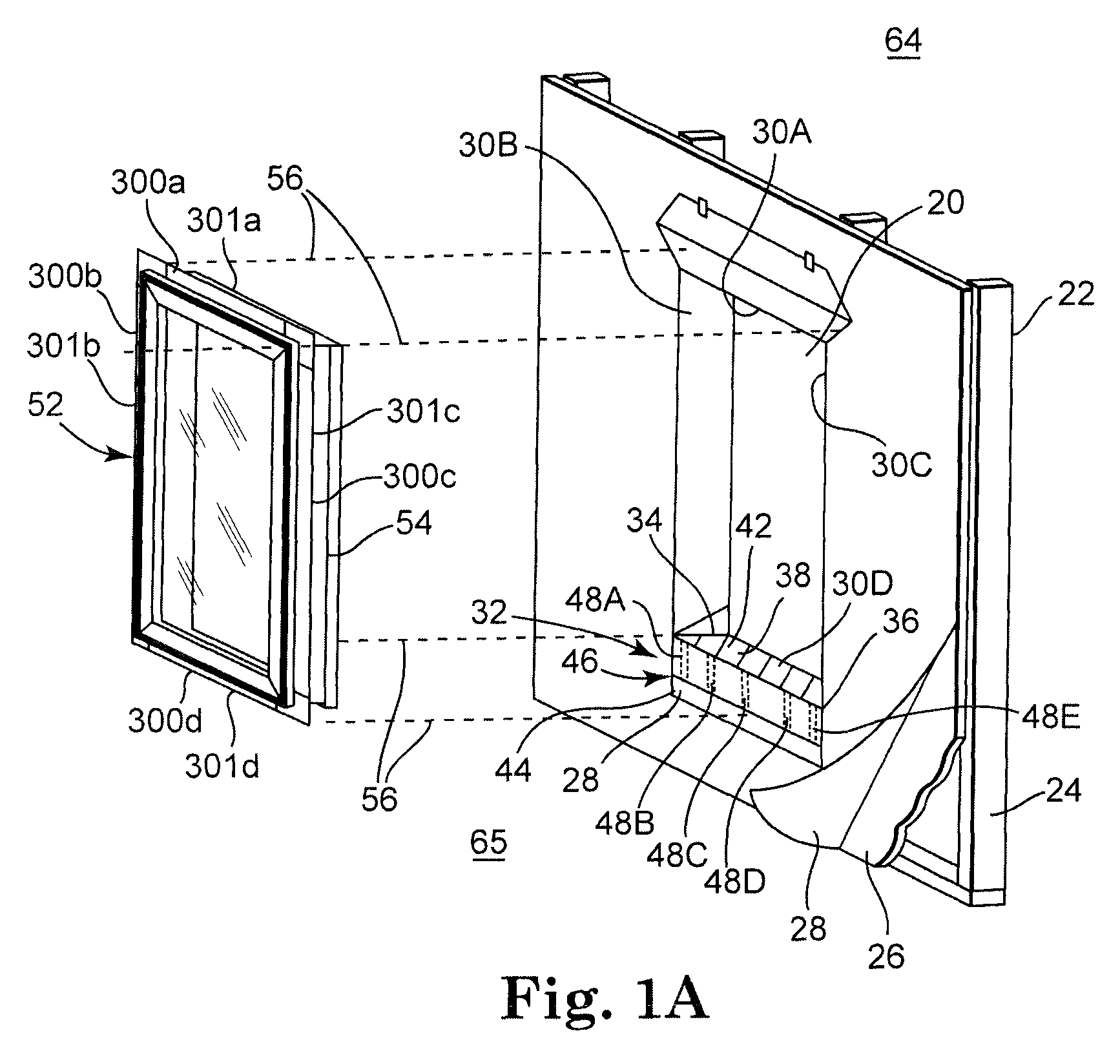

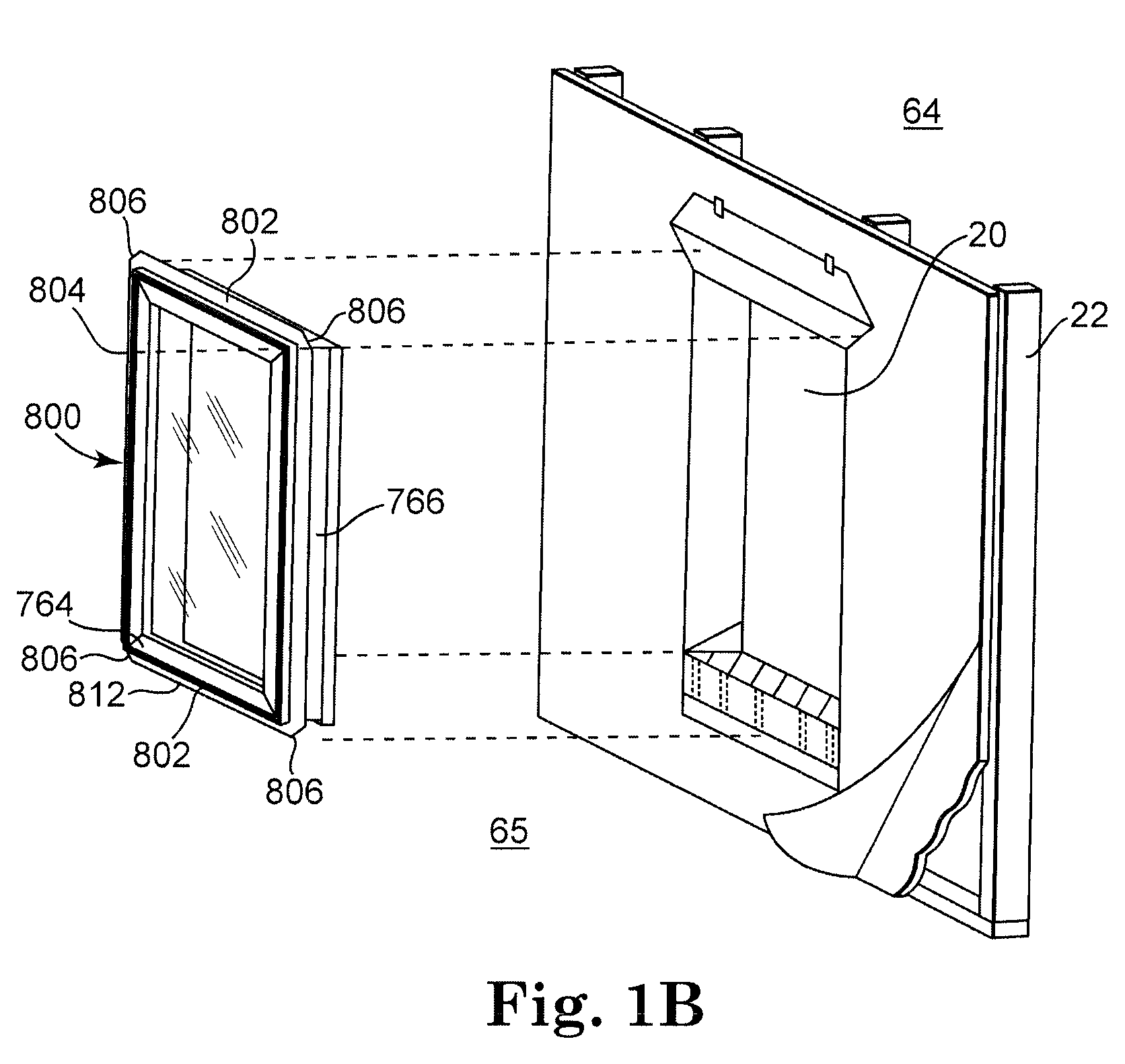

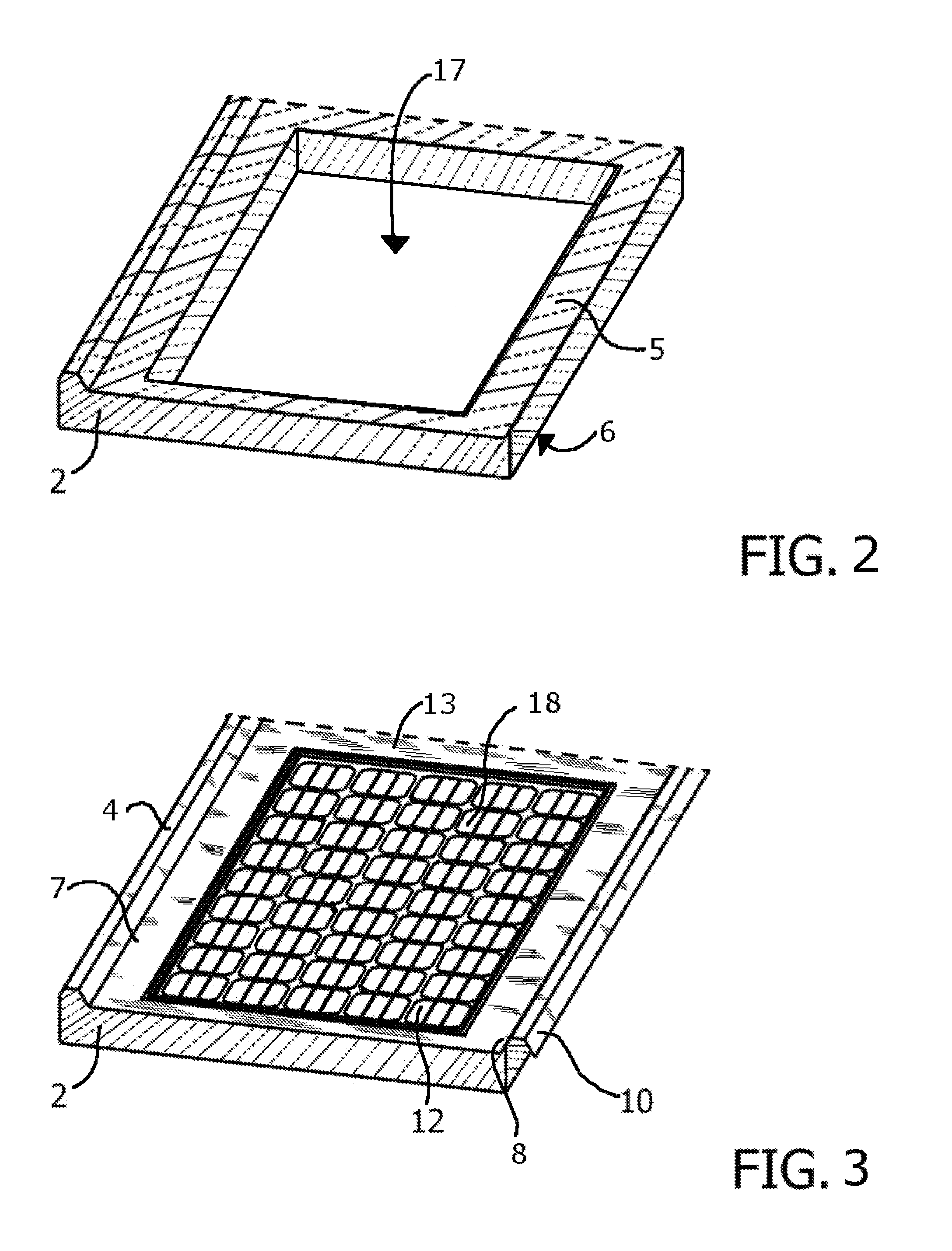

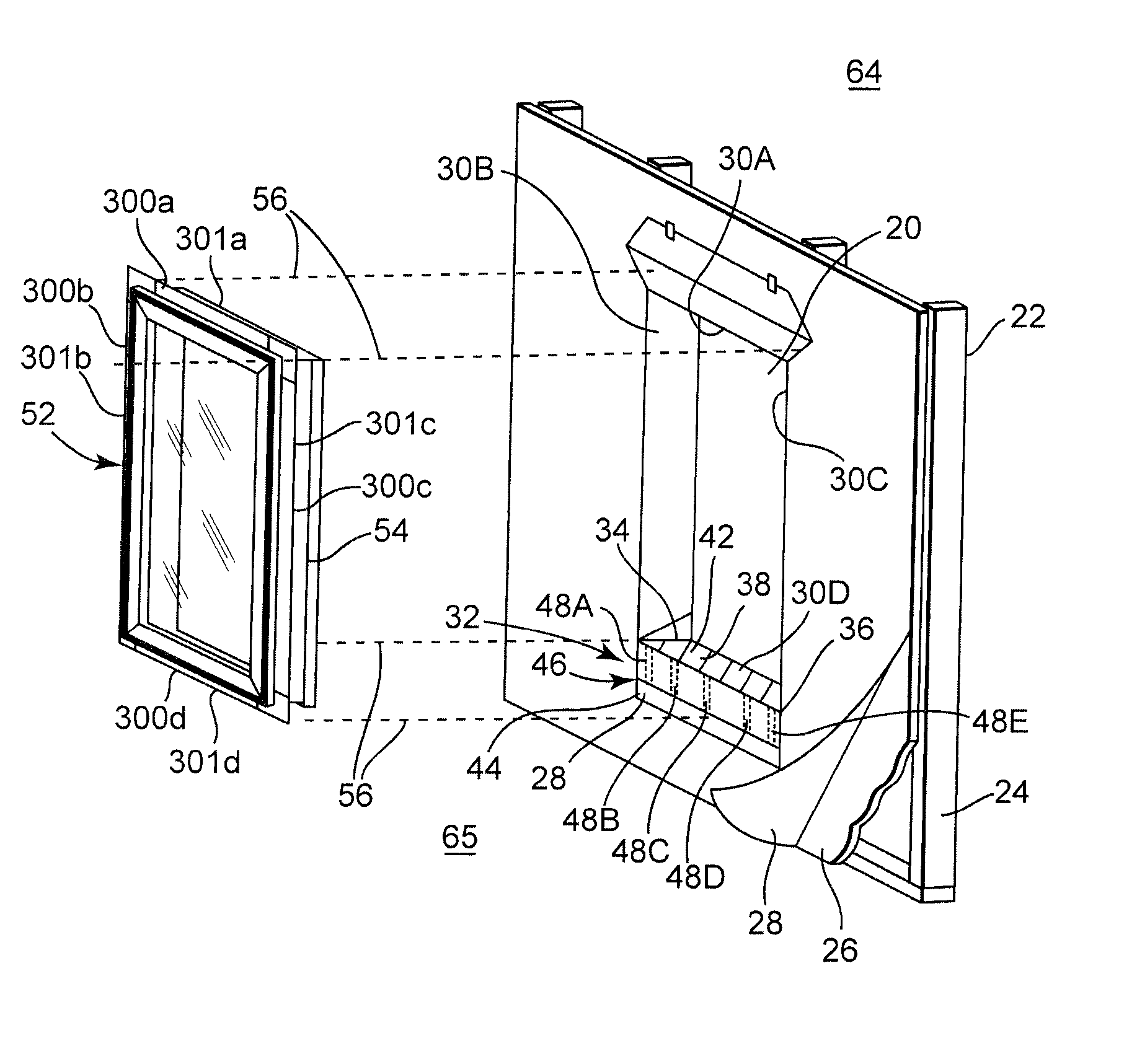

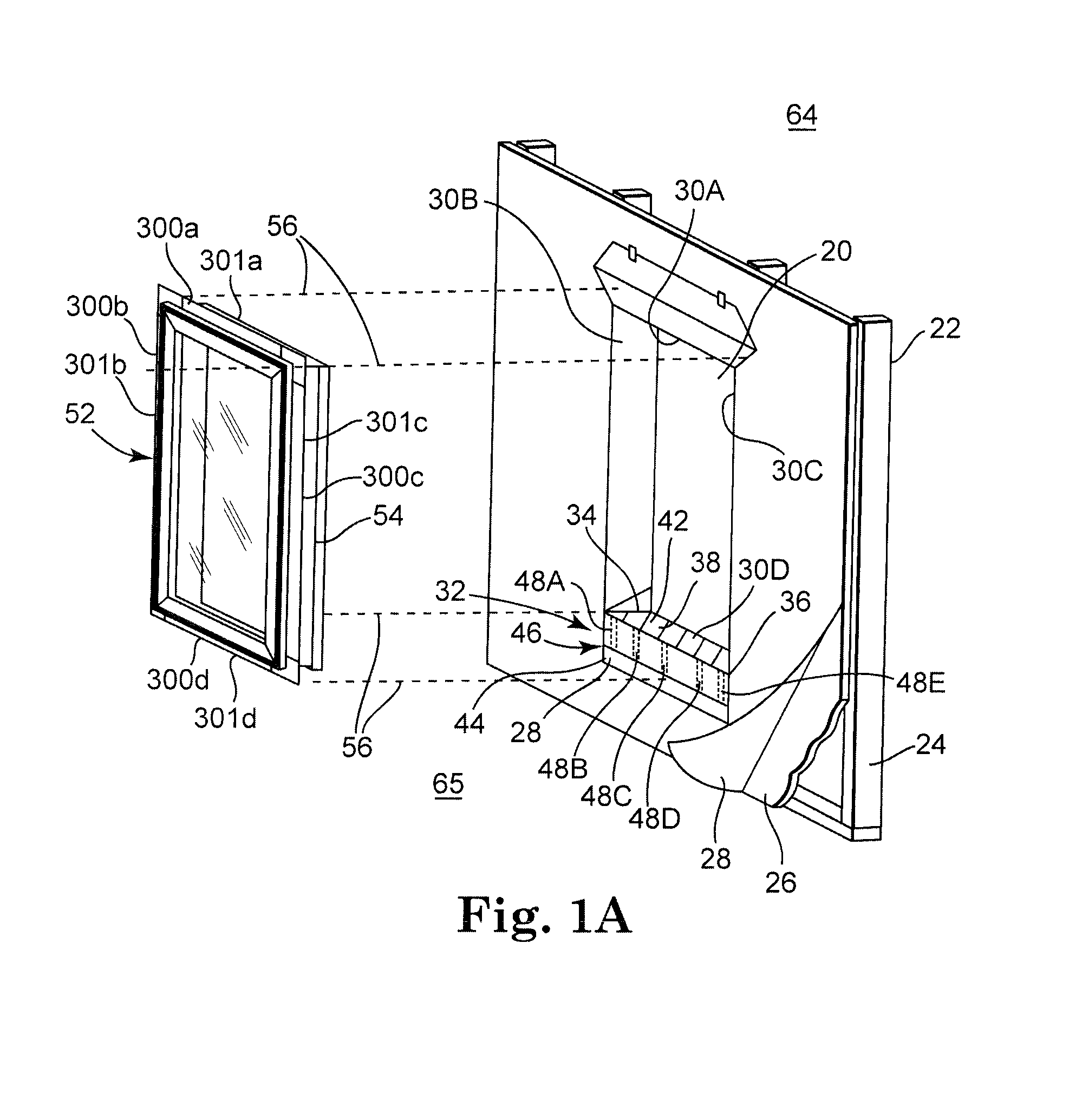

Window installation method

ActiveUS7669382B2Reduce time and costImprove performanceRoof covering using slabs/sheetsRoof covering using tiles/slatesEdge surfaceEngineering

A closure assembly and a method of installing the closure assembly are provided. A insertion opening is formed in water resistant barrier covering a rough opening that generally corresponds to a perimeter of the rough opening. A drainage system including a channel assembly is installed on a sill surface of the rough opening. The closure assembly is inserted into the rough opening and temporarily secured to the structure. At least one shim carried on the closure assembly is adjusted to level the closure assembly in the rough opening. A sealing member attached to the closure assembly is engaged with the water resistant barrier. A foam material is delivered into at least a portion of a space between perimeter edge surfaces of the closure assembly and inner surfaces of the rough opening to permanently secure the closure assembly within the rough opening.

Owner:PELLA

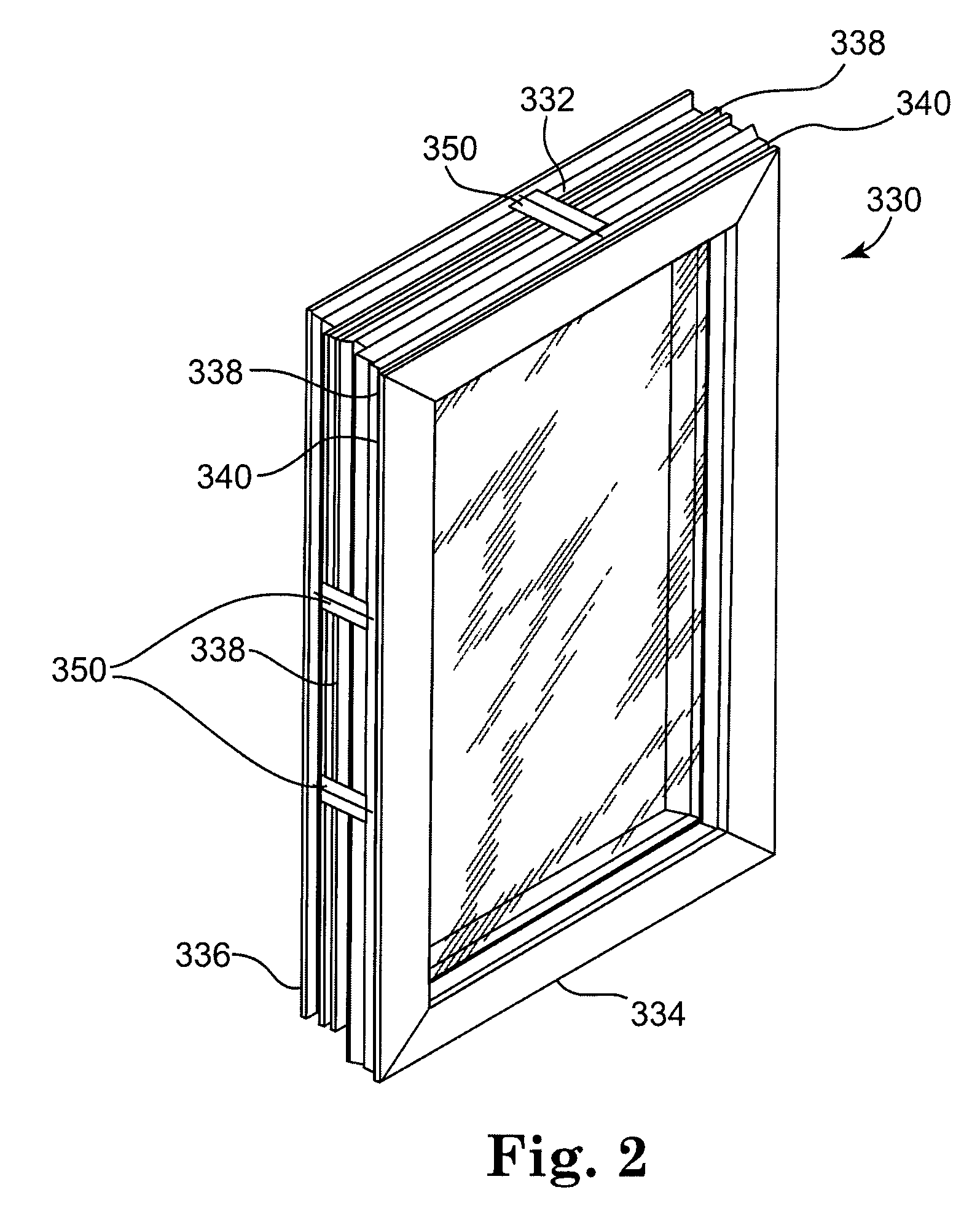

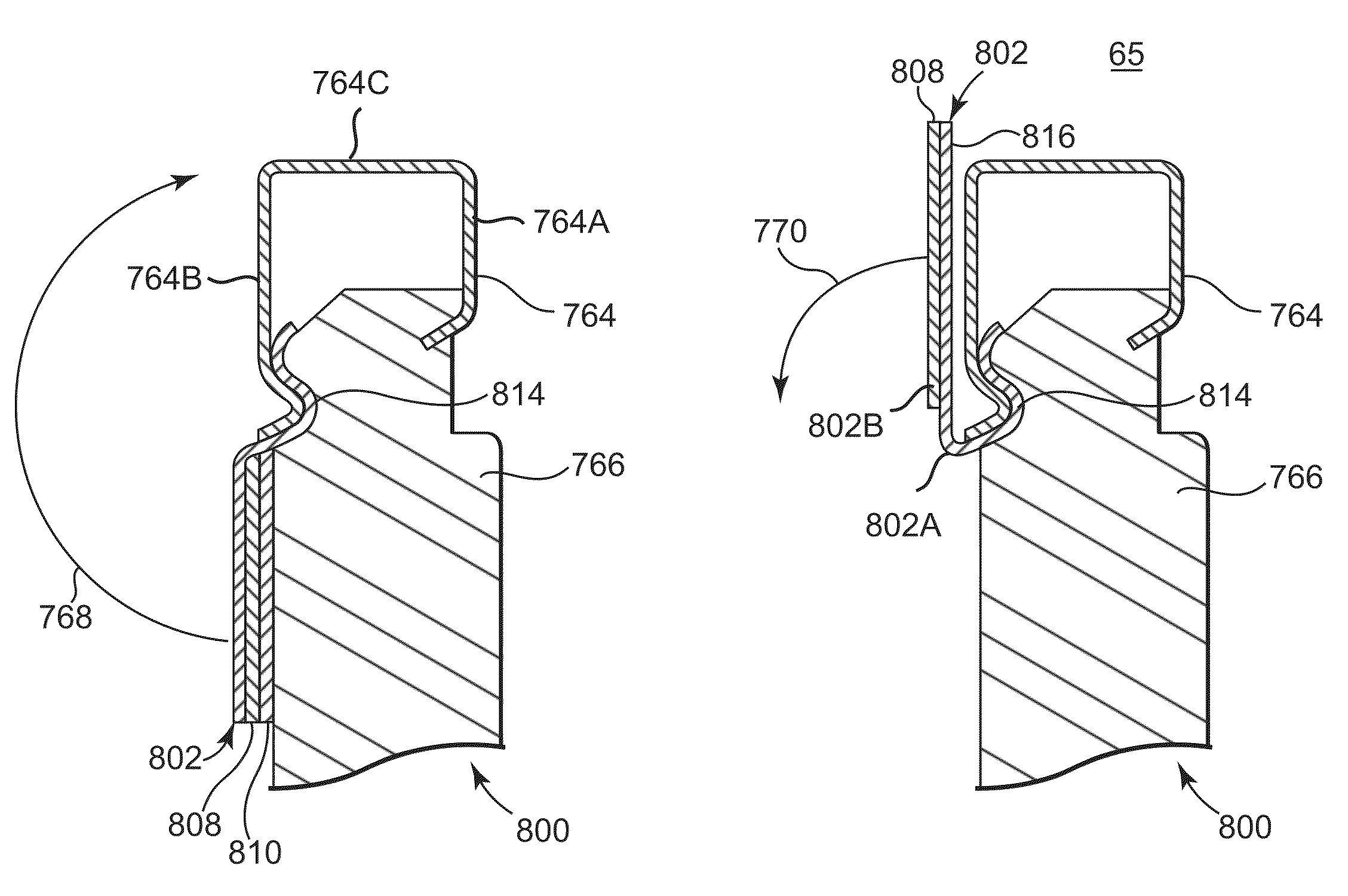

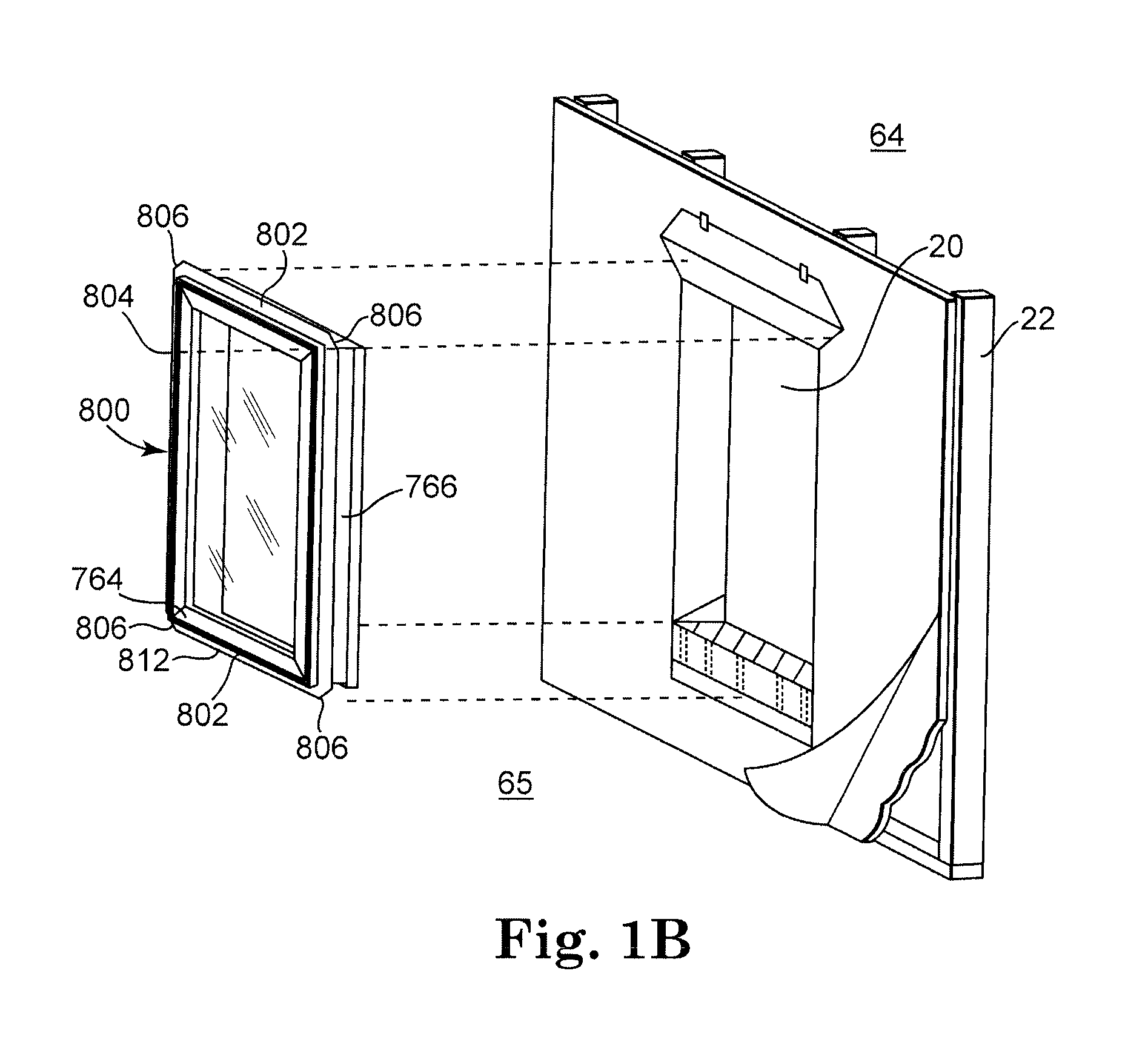

Self-sealing window installation and method

ActiveUS8006445B2Reduce time and costImprove performanceFrame fasteningWindow/door framesEdge surfaceEngineering

A self-sealing window with a flexible gasket that extends around the entire perimeter of closure assemblies and a method of installing such closure assemblies in a rough opening. A sealing member is attached continuously around an entire perimeter of the closure assembly to form a water impermeable seal between the sealing member and the closure assembly. The closure assembly is inserted into the rough opening. Accurate positioning of the closure assembly in the rough opening is verified. The closure assembly is secured in the rough opening. The sealing member is engaged with an exterior surface of the structure proximate the rough opening. A foam material is delivered into at least a portion of a space between perimeter edge surfaces of the closure assembly and inner surfaces of the rough opening.

Owner:PELLA

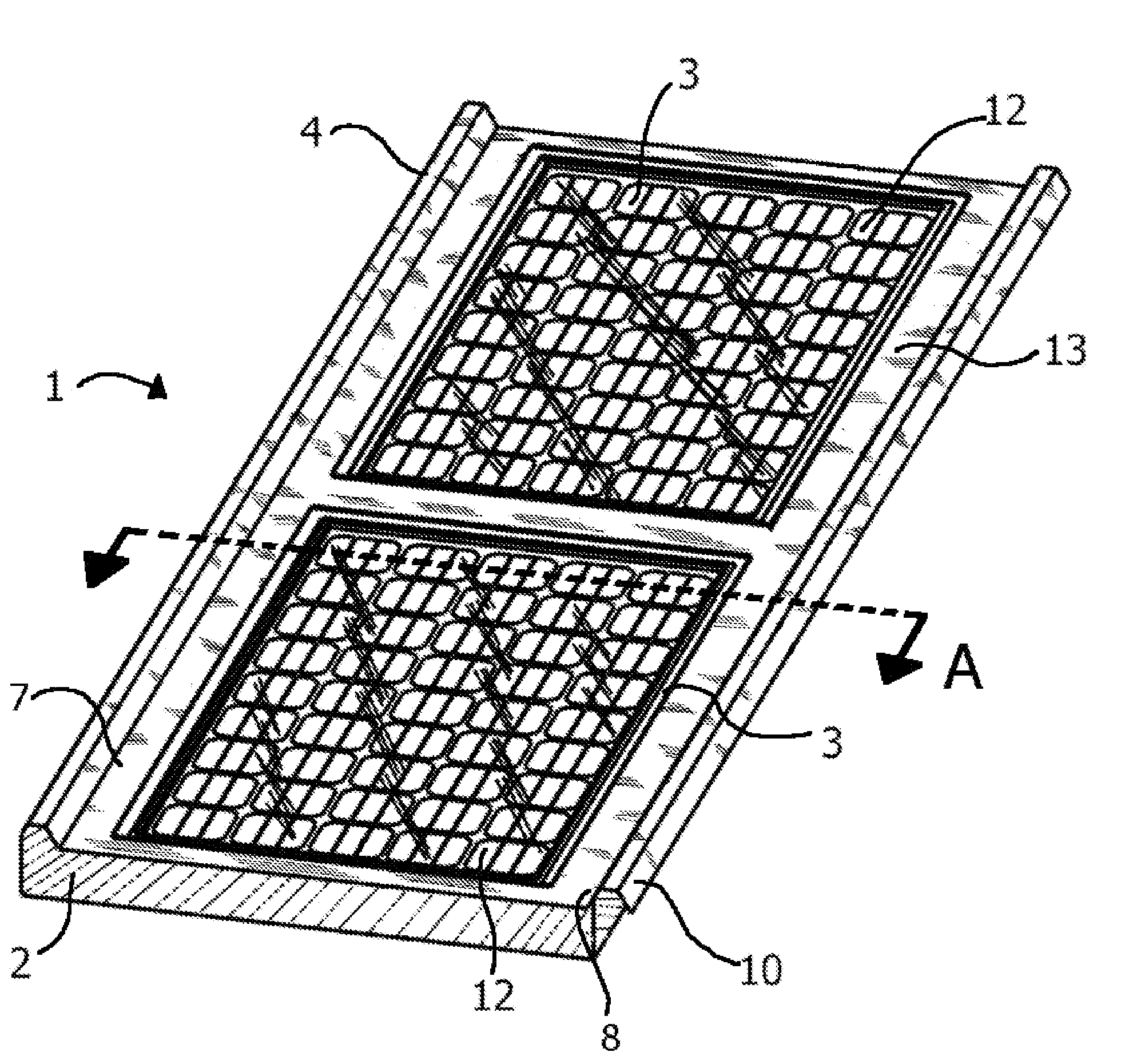

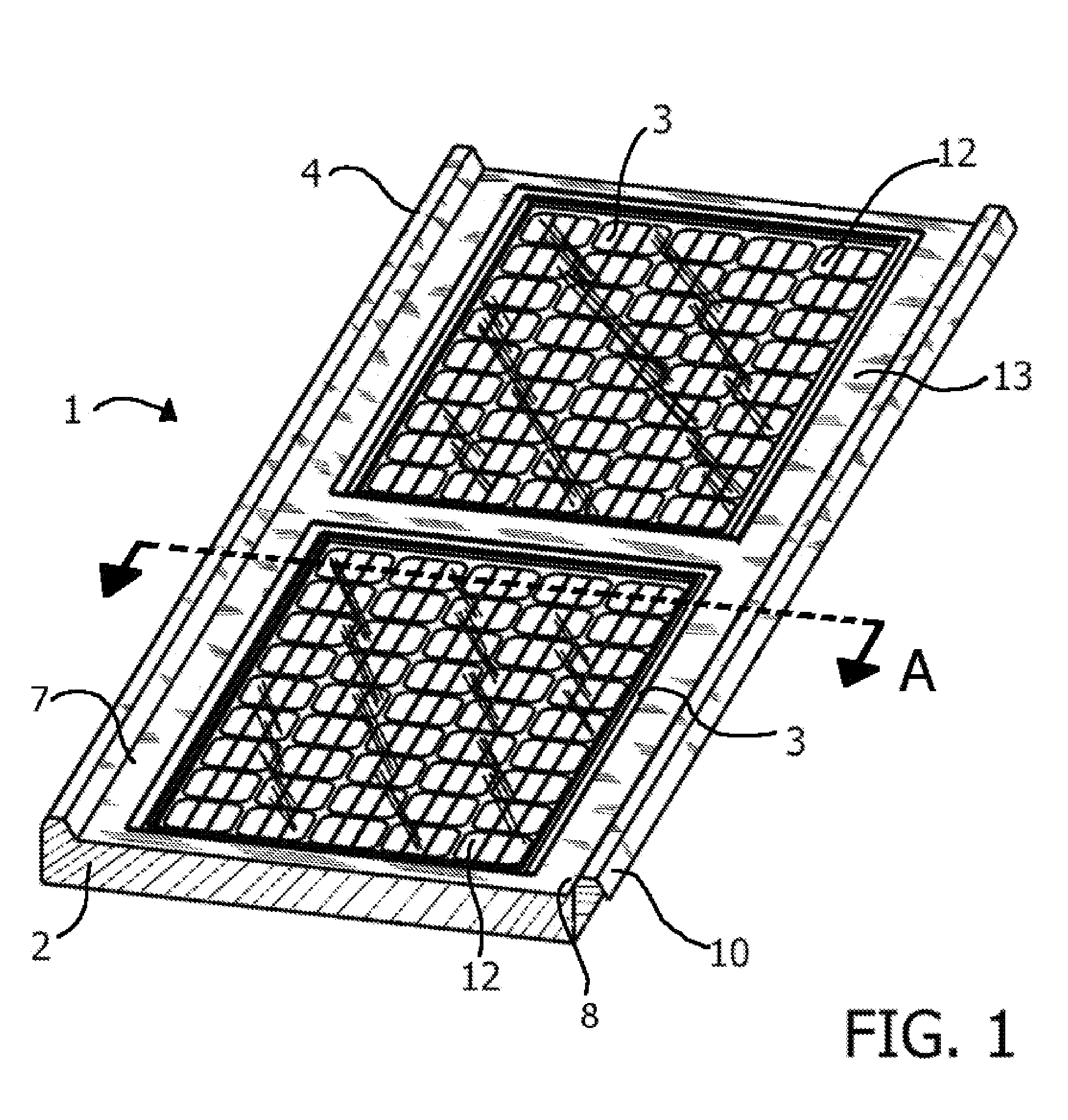

Insulating construction panel with photovoltaic module

InactiveUS20110041888A1Low costShorten the timePhotovoltaic supportsRoof covering using slabs/sheetsElectrical and Electronics engineeringPhotovoltaics

Disclosed is an insulating construction and solar panel comprising an insulating core that defines at least one opening. A rigid skin covers the insulating core and defines a ridge extending along a first edge and a channel extending along a second edge. A crystalline photovoltaic module is fitted within the opening, and a translucent pane covers the outer surface of the crystalline photovoltaic module. The insulating construction and solar panel is configured to connect to a second and third insulating construction and solar panel by interconnecting the corresponding ridges and channels.

Owner:POWER NANOTECH

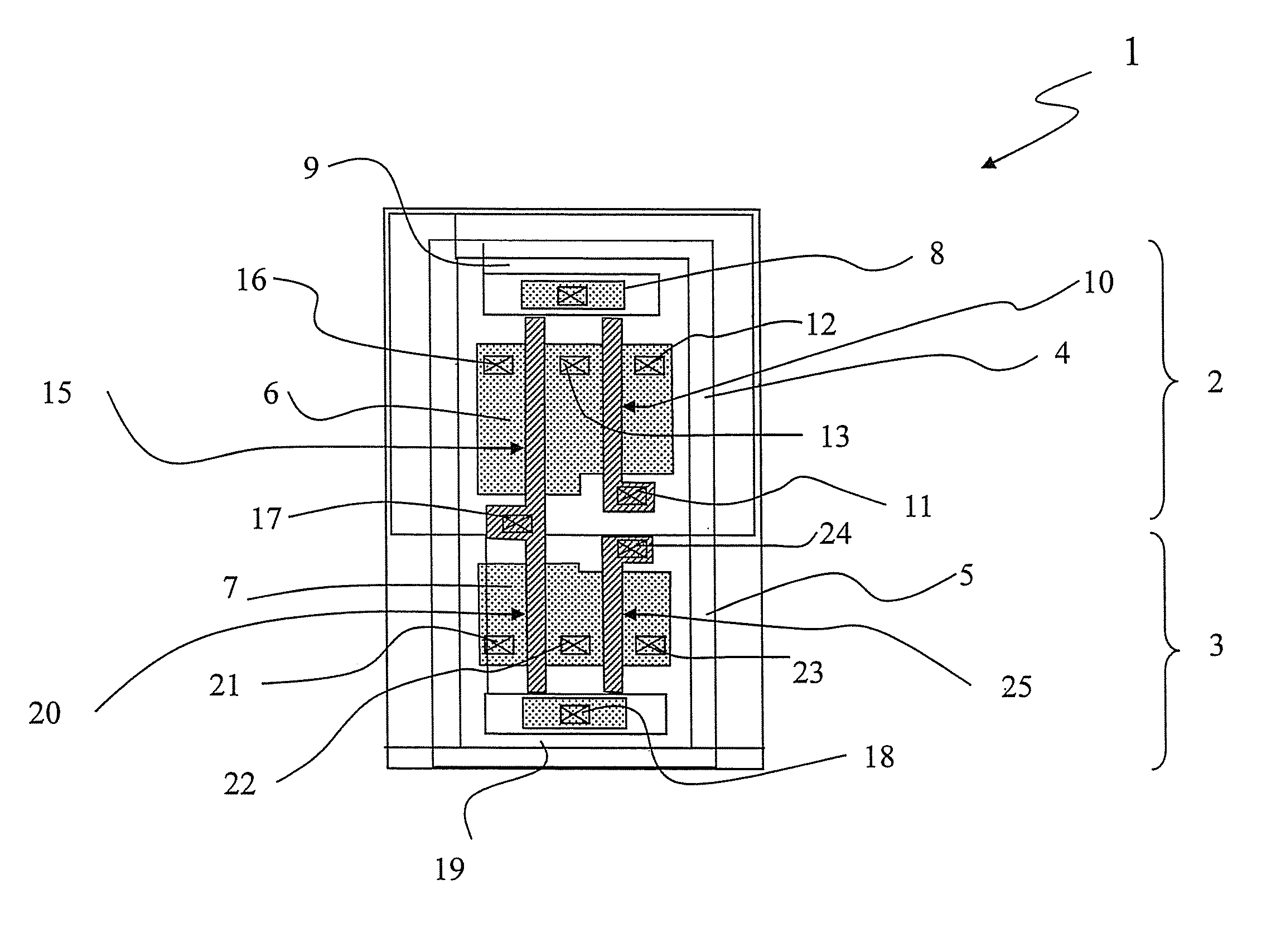

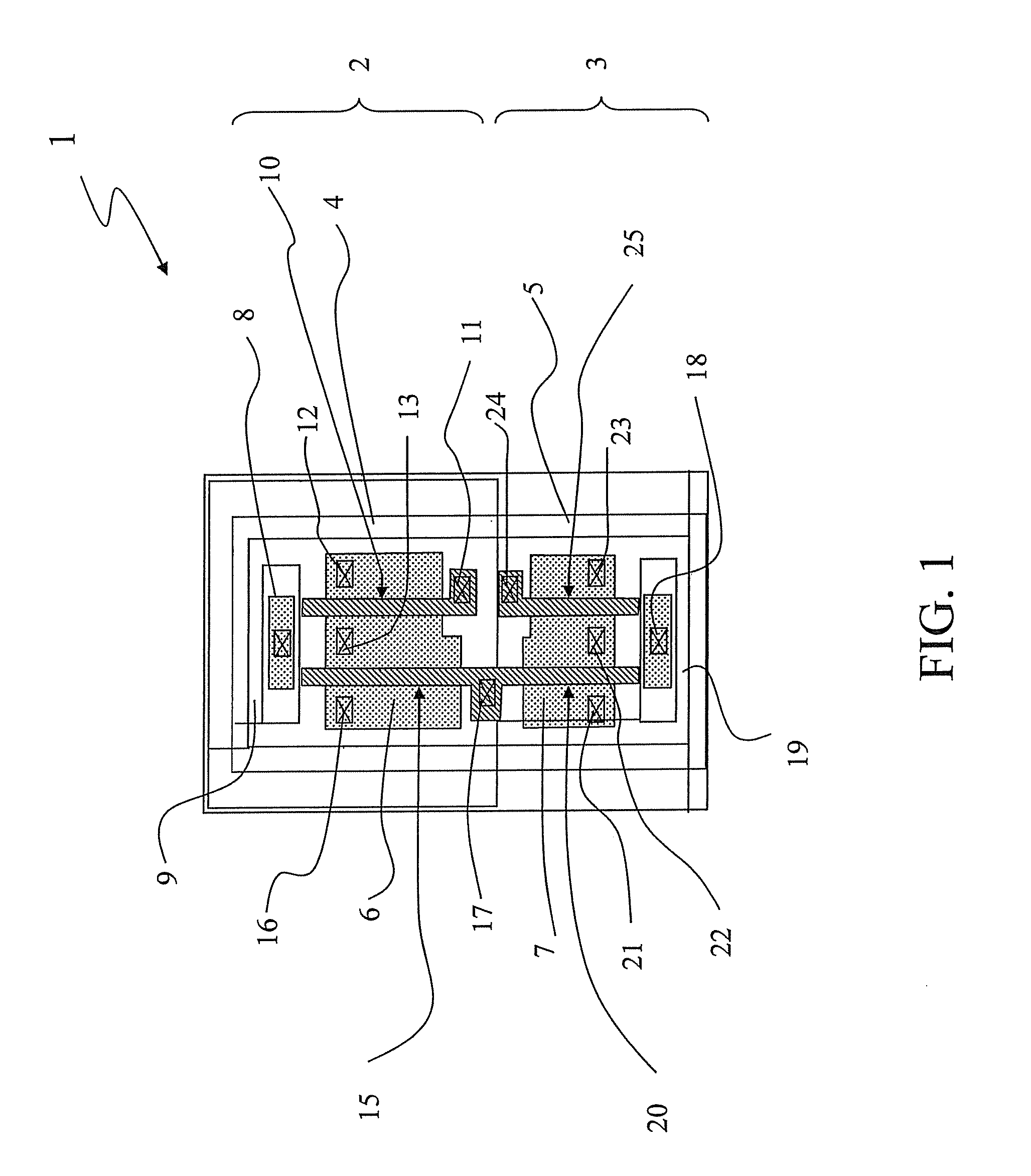

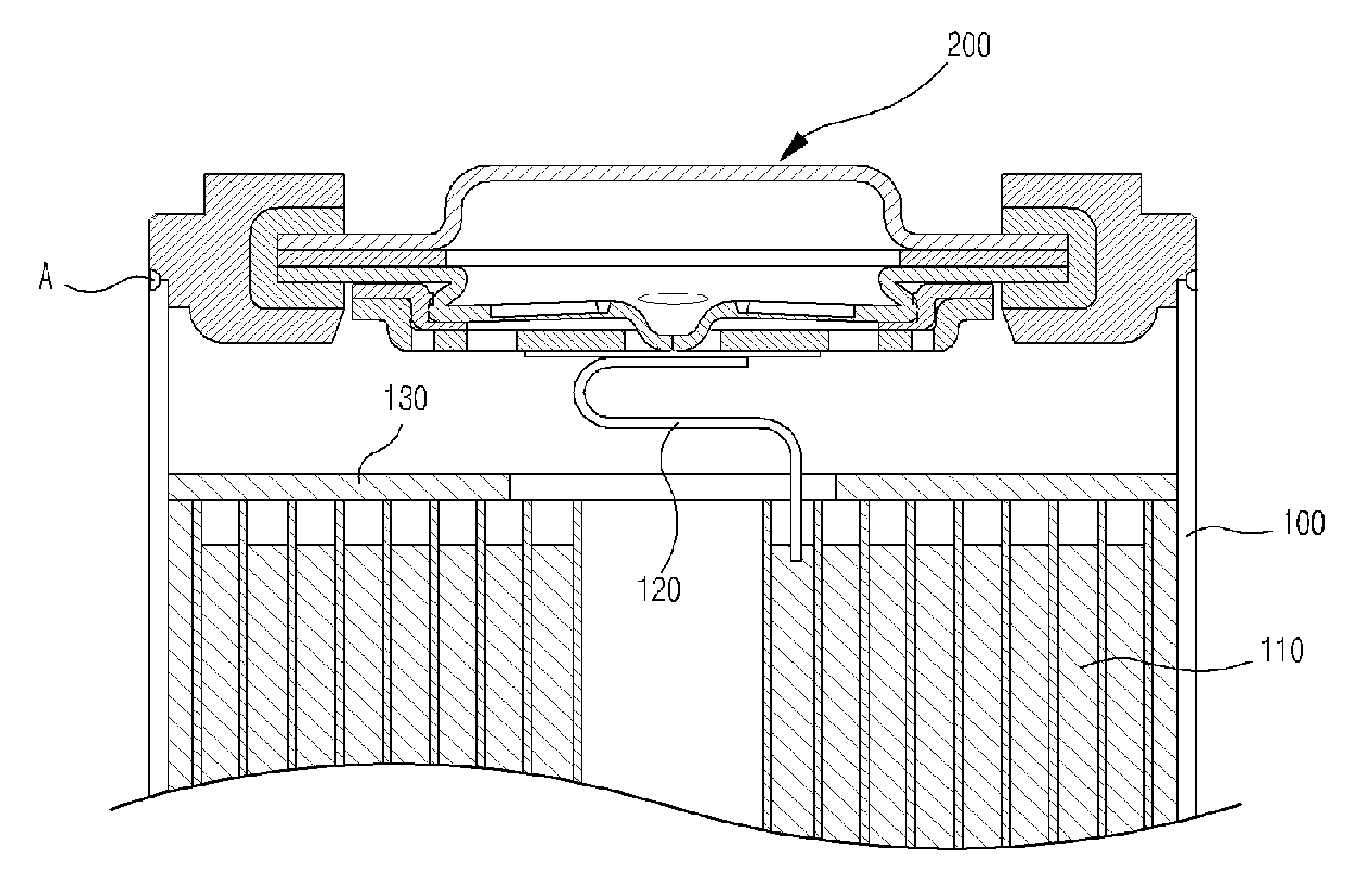

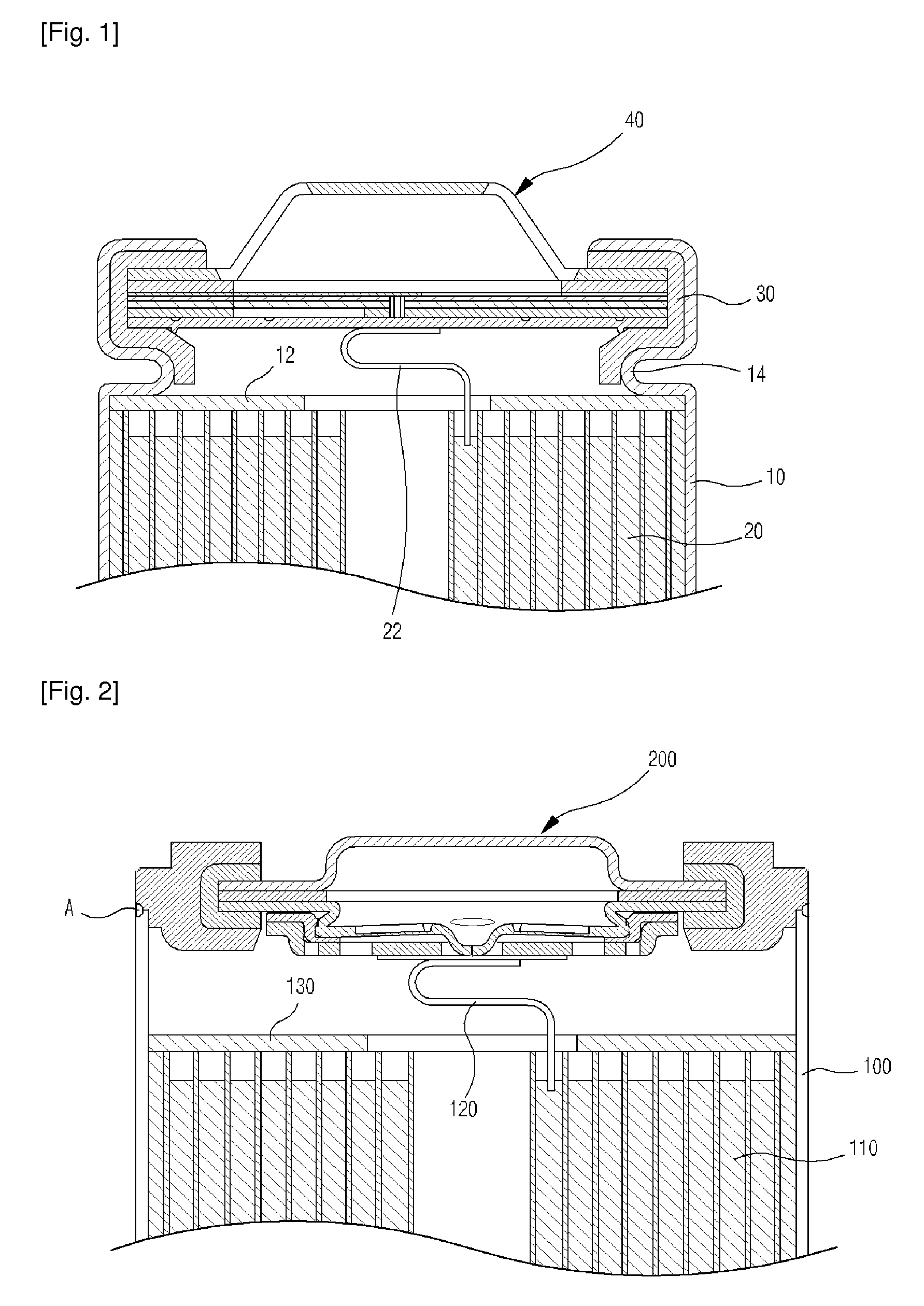

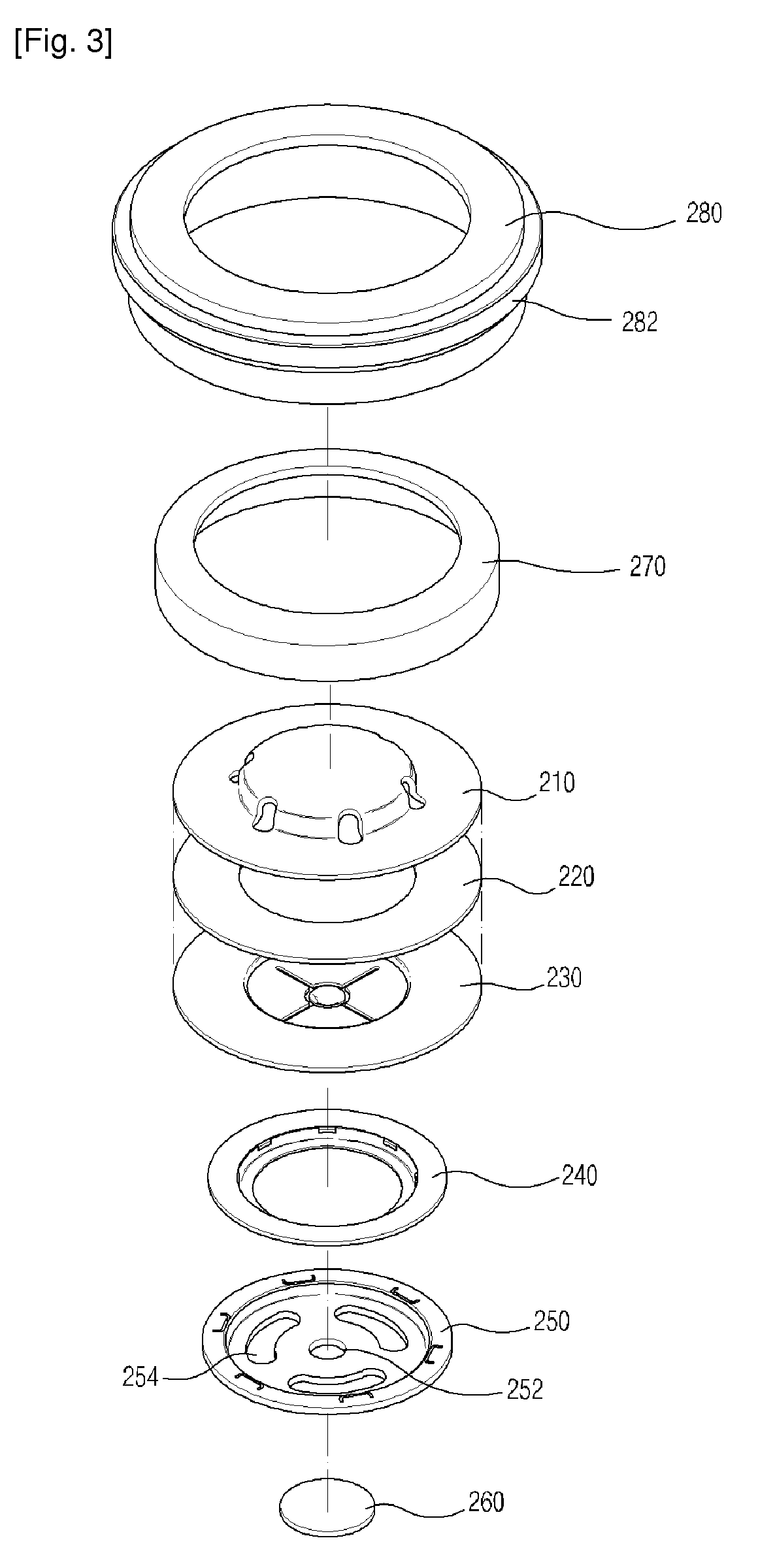

Cylindrical secondary battery and method of manufacturing the same

InactiveUS20100015508A1Simplify assembly processReduce time and costFinal product manufactureElectrode carriers/collectorsBiomedical engineeringElectrolyte

Provided is a cylindrical secondary battery including a cylindrical exterior can having an open top portion into which an electrode assembly and electrolyte can be inserted and having an electrode tap which is drawn from the electrode assembly and extends upward; and a cap assembly assembled as an integrated structure, having an outer side surface welded and fixed to an inner side surface of an upper portion of the exterior can, and having a bottom surface joined and electrically connected to the electrode tap to transmit electric current generated by the electrode assembly to the outside. In addition, provided is a method of manufacturing a cylindrical secondary battery. The method includes assembling a cap assembly as an integrated structure; inserting an electrode assembly and electrolyte into a cylindrical exterior can having an open top portion; joining and electrically connecting an electrode tap, which is drawn from the electrode assembly, to a bottom surface of the cap assembly; inserting the cap assembly into the open top portion of the exterior can and thus bending the electrode tap; and welding an outer side surface of the cap assembly to an inner side surface Of an upper portion of the exterior can.

Owner:HWANG IN YOUNG

Self-sealing window installation and method

A self-sealing window with a flexible gasket that extends around the entire perimeter of closure assemblies and a method of installing such closure assemblies in a rough opening. A sealing member is attached continuously around an entire perimeter of the closure assembly to form a water impermeable seal between the sealing member and the closure assembly. The closure assembly is inserted into the rough opening. Accurate positioning of the closure assembly in the rough opening is verified. The closure assembly is secured in the rough opening. The sealing member is engaged with an exterior surface of the structure proximate the rough opening. A foam material is delivered into at least a portion of a space between perimeter edge surfaces of the closure assembly and inner surfaces of the rough opening.

Owner:PELLA

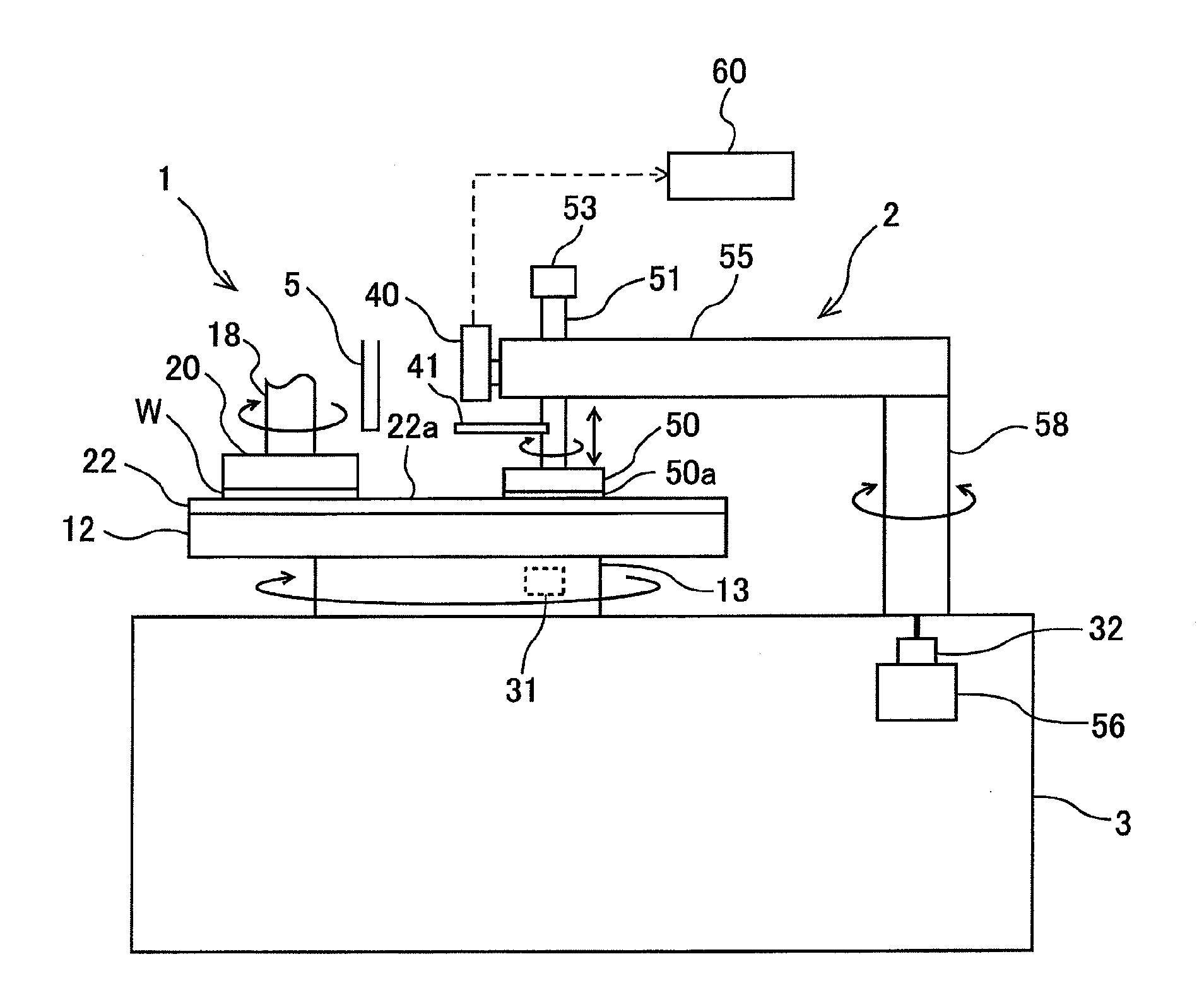

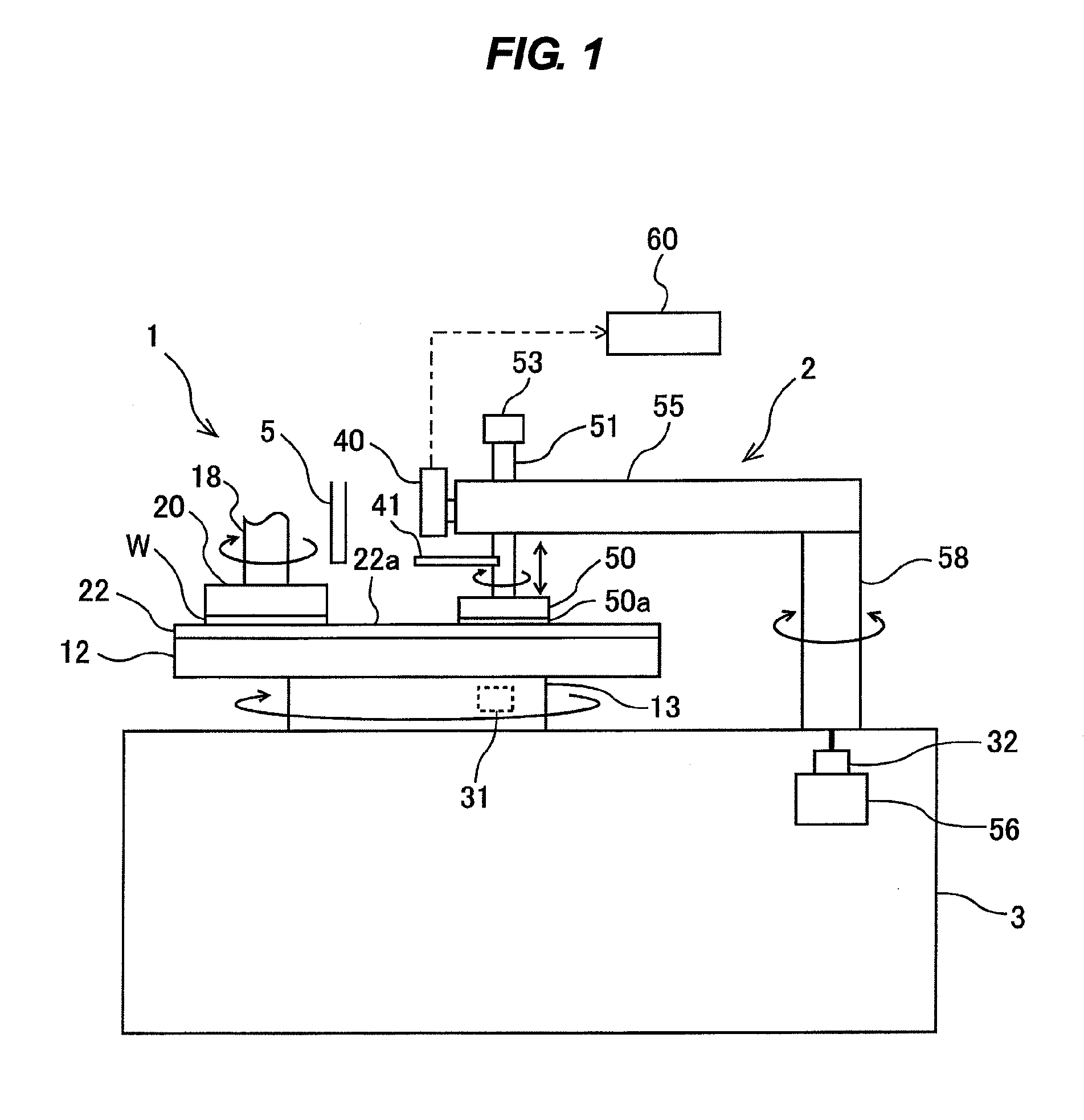

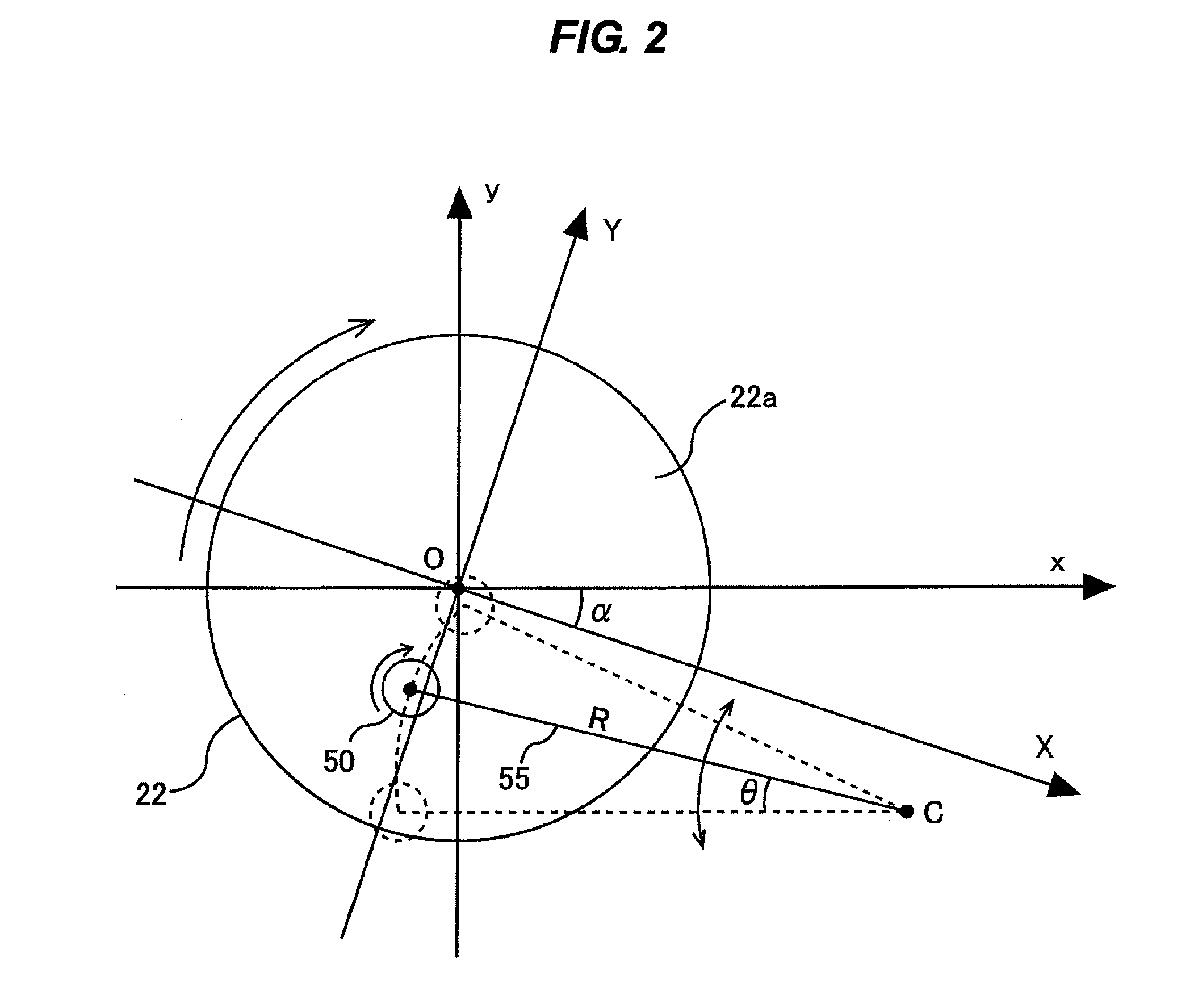

Method and apparatus for monitoring a polishing surface of a polishing pad used in polishing apparatus

ActiveUS20120309267A1Reduce time and costMeasure can be takenSemiconductor/solid-state device manufacturingLapping machinesMeasurement pointEngineering

The present invention provides a method capable of monitoring the polishing surface of the polishing pad without removing the polishing pad from the polishing table. The method includes: conditioning the polishing surface of the polishing pad by causing a rotating dresser to oscillate on the polishing surface; measuring a height of the polishing surface when the conditioning of the polishing surface is performed; calculating a position of a measuring point of the height on a two-dimensional surface defined on the polishing surface; and repeating the measuring of the height of the polishing surface and the calculating of the position of the measuring point to create height distribution in the polishing surface.

Owner:EBARA CORP

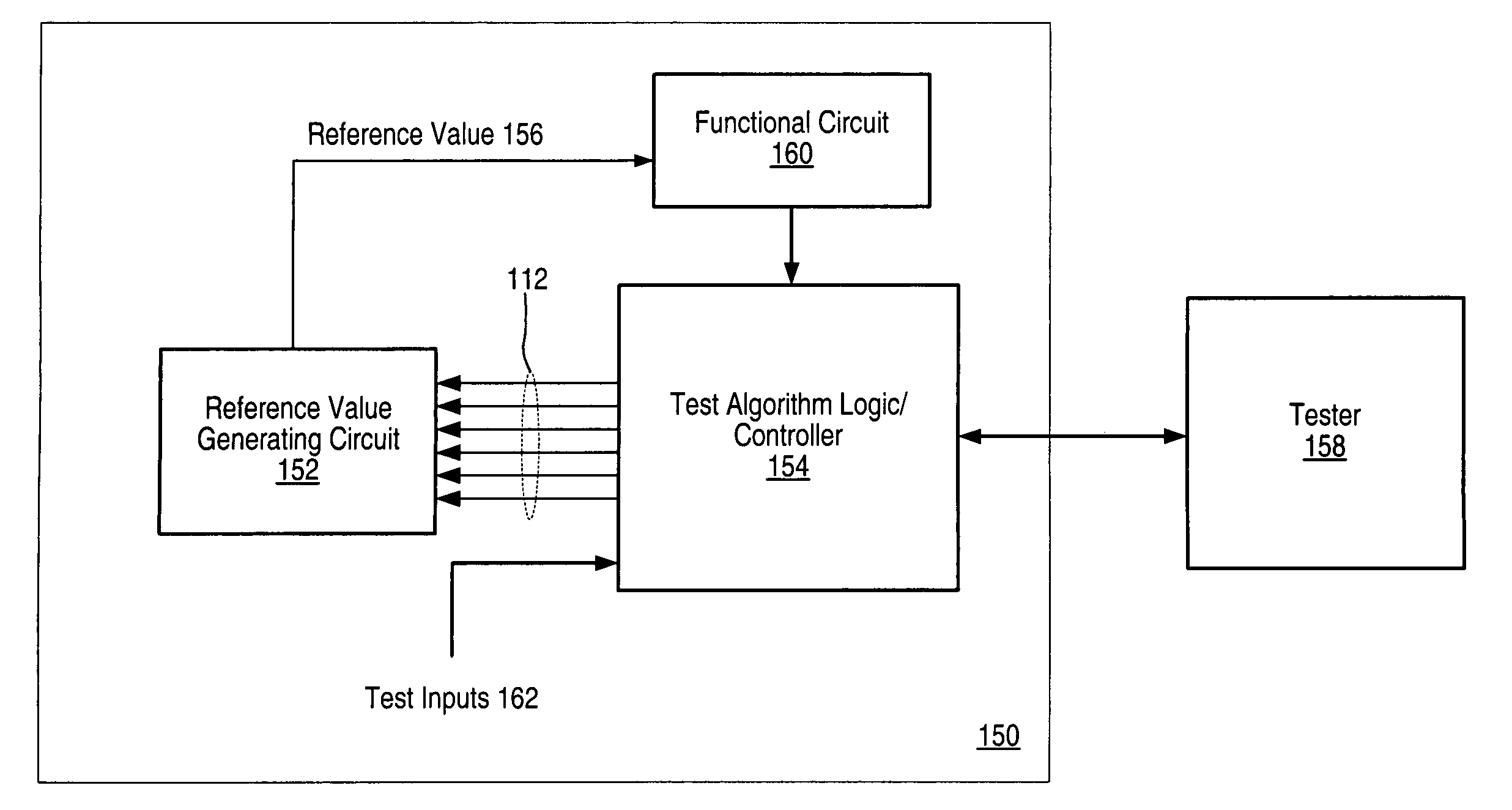

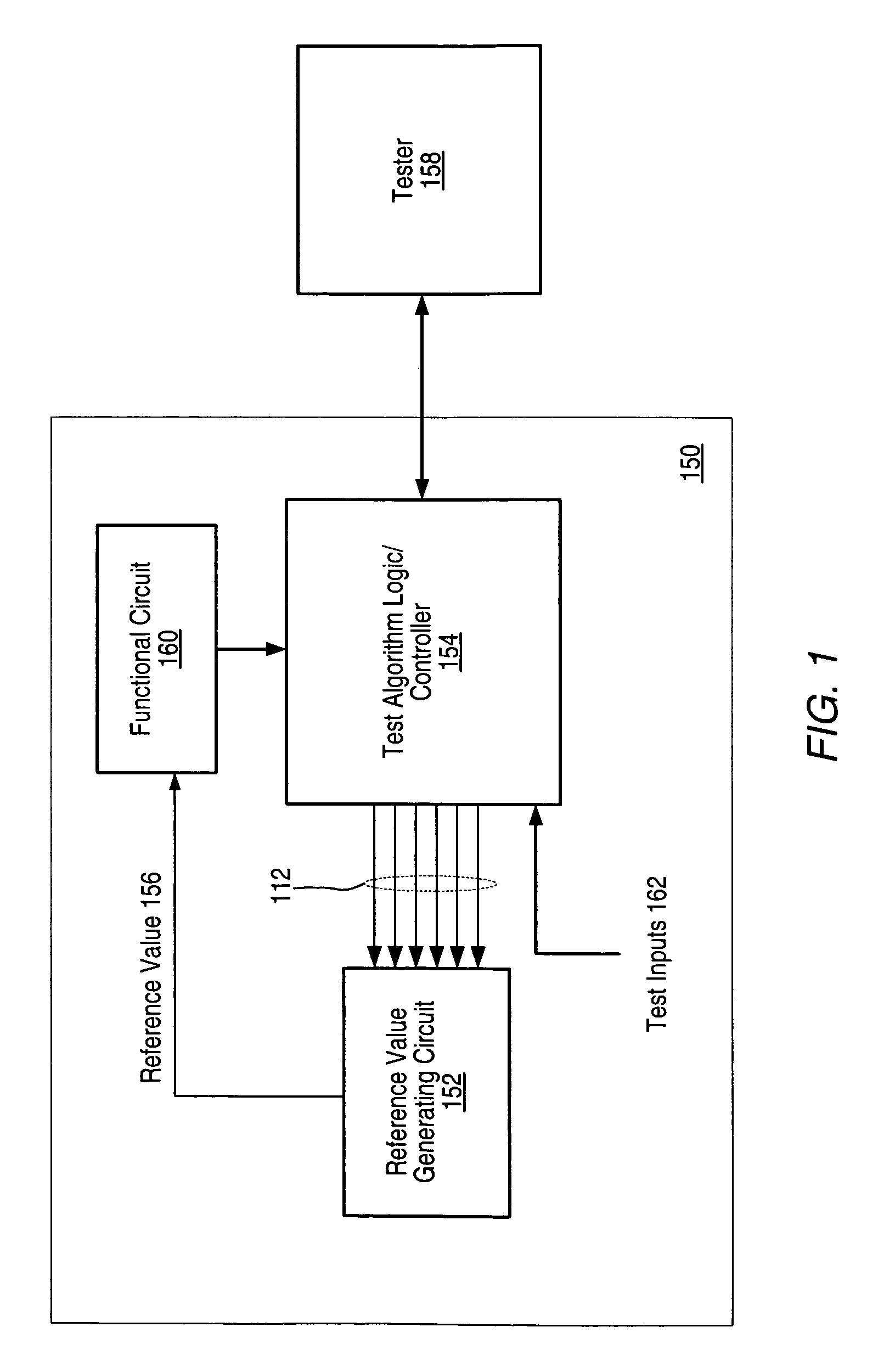

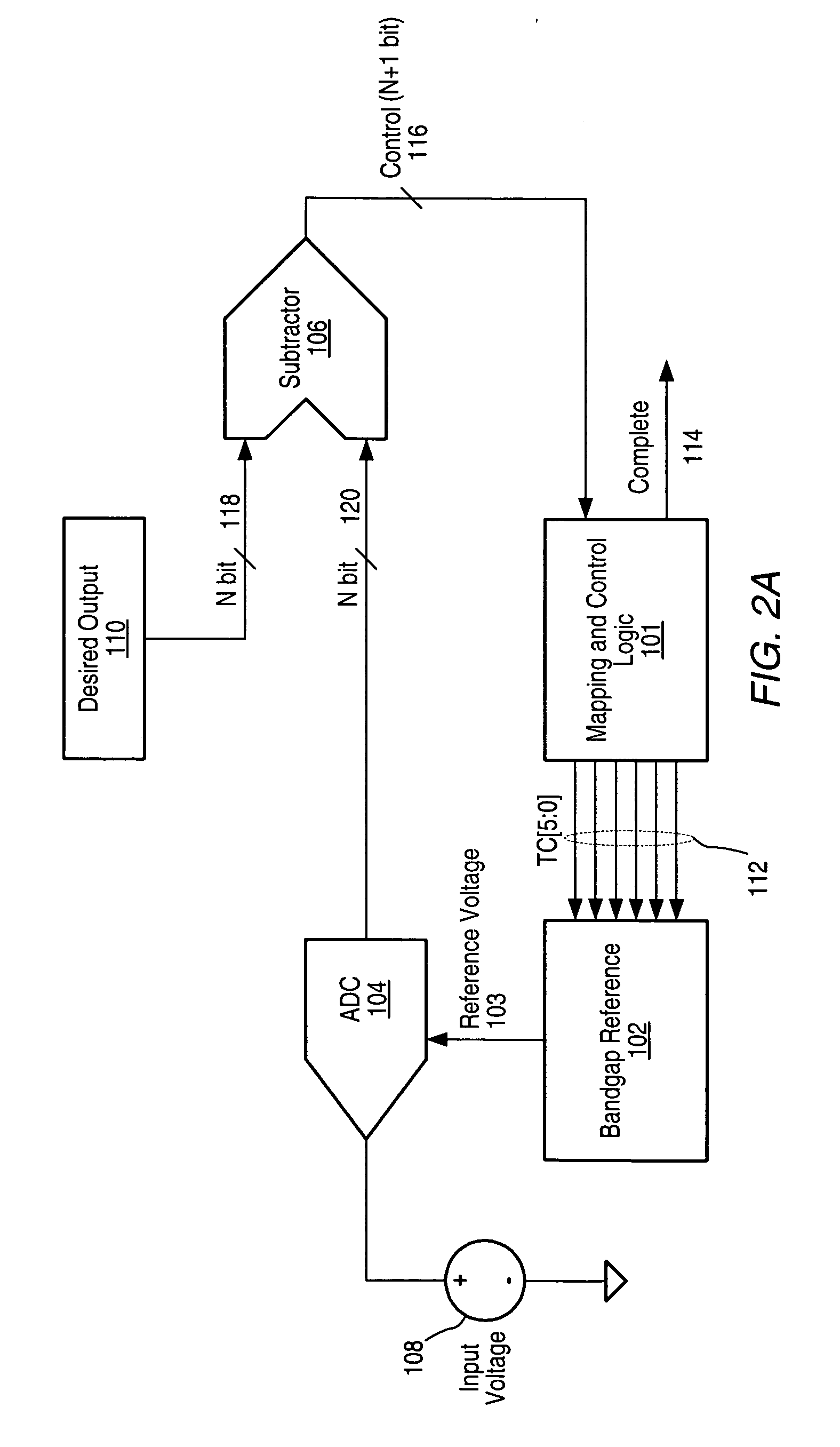

Automatic reference voltage trimming technique

ActiveUS20060276986A1Reduce time and costFree controlThermometers using electric/magnetic elementsElectrical testingA d converterIntegrated circuit

In one set of embodiments, trimming of a reference, which may be a bandgap reference and which is configured on an integrated circuit, may be controlled by an algorithm executed by logic circuitry also configured on the integrated circuit. The bandgap reference may be configured to generate a reference voltage provided to an analog to digital converter (ADC) comprised in a temperature sensor that may also be configured on the integrated circuit. The logic circuitry may be configured to execute one or more of a variety of test algorithms, for example a Successive Approximation Method or remainder processing, that are operable to adjust values of reference trim bits used in trimming the bandgap reference. A tester system configured to perform testing of the integrated circuit may initiate execution of the test algorithm, thereby initiating the trimming process, and may wait for the test algorithm to complete within a previously defined amount of time, or may poll the logic circuitry to determine when the trimming process is complete.

Owner:MICROCHIP TECH INC

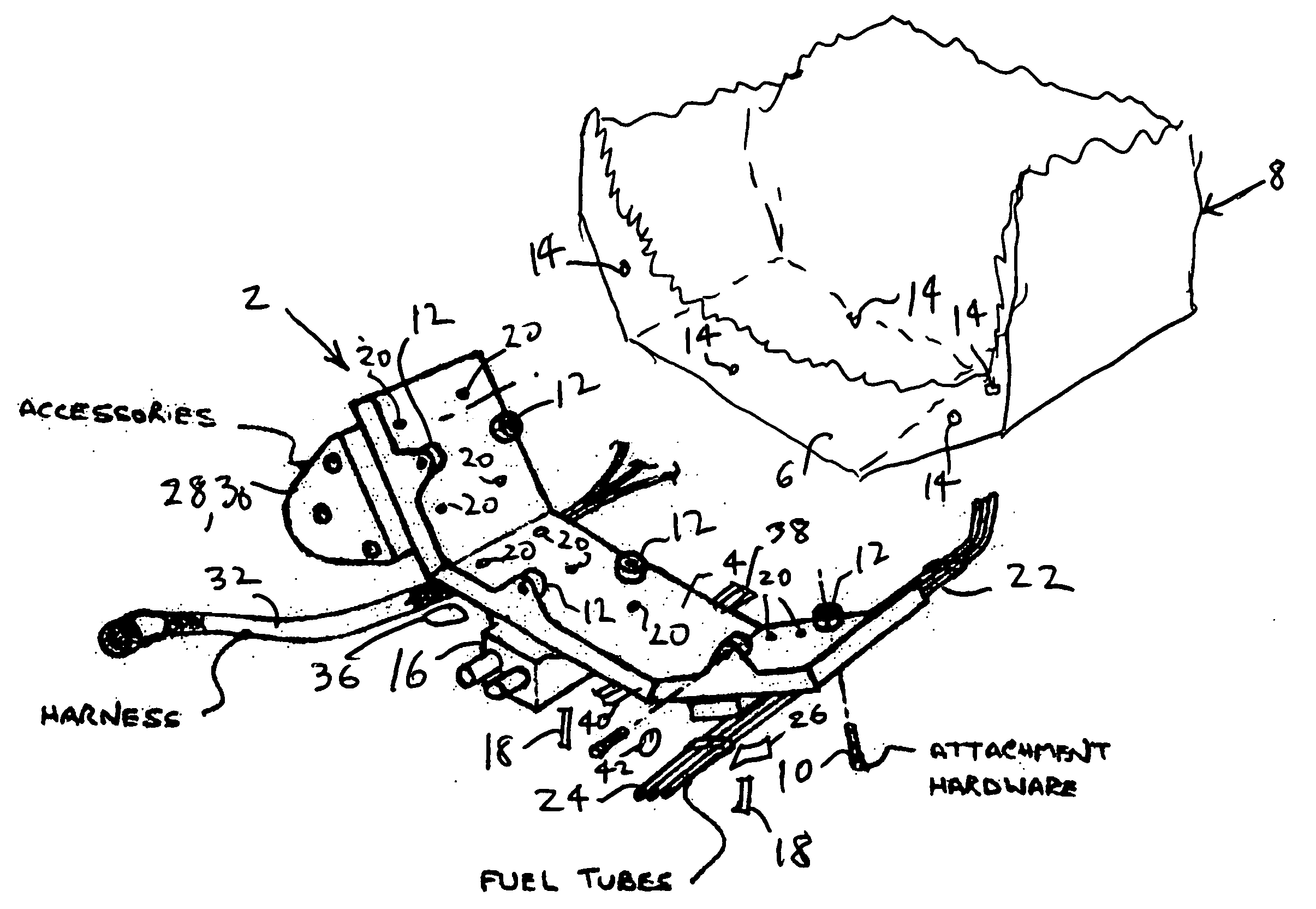

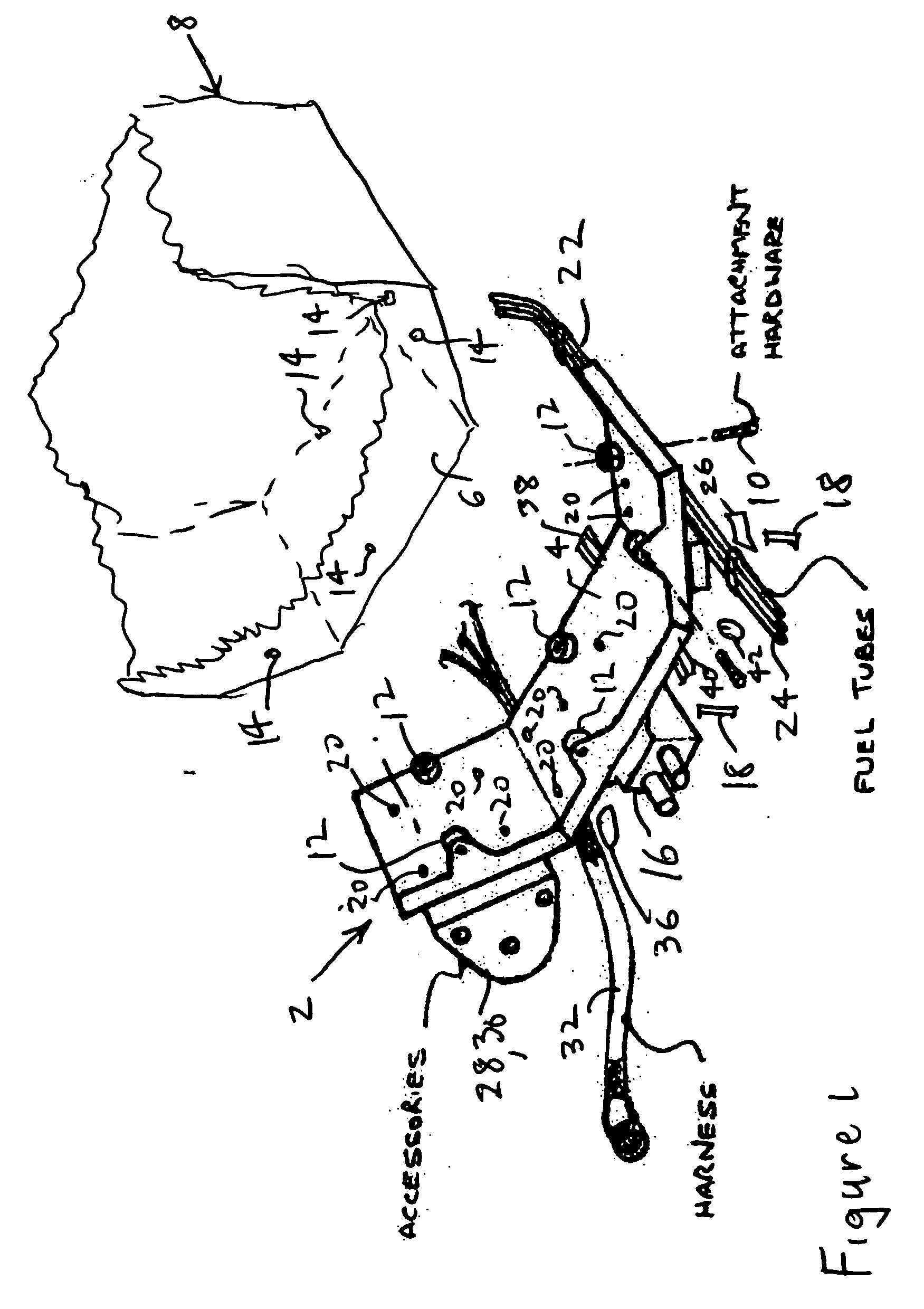

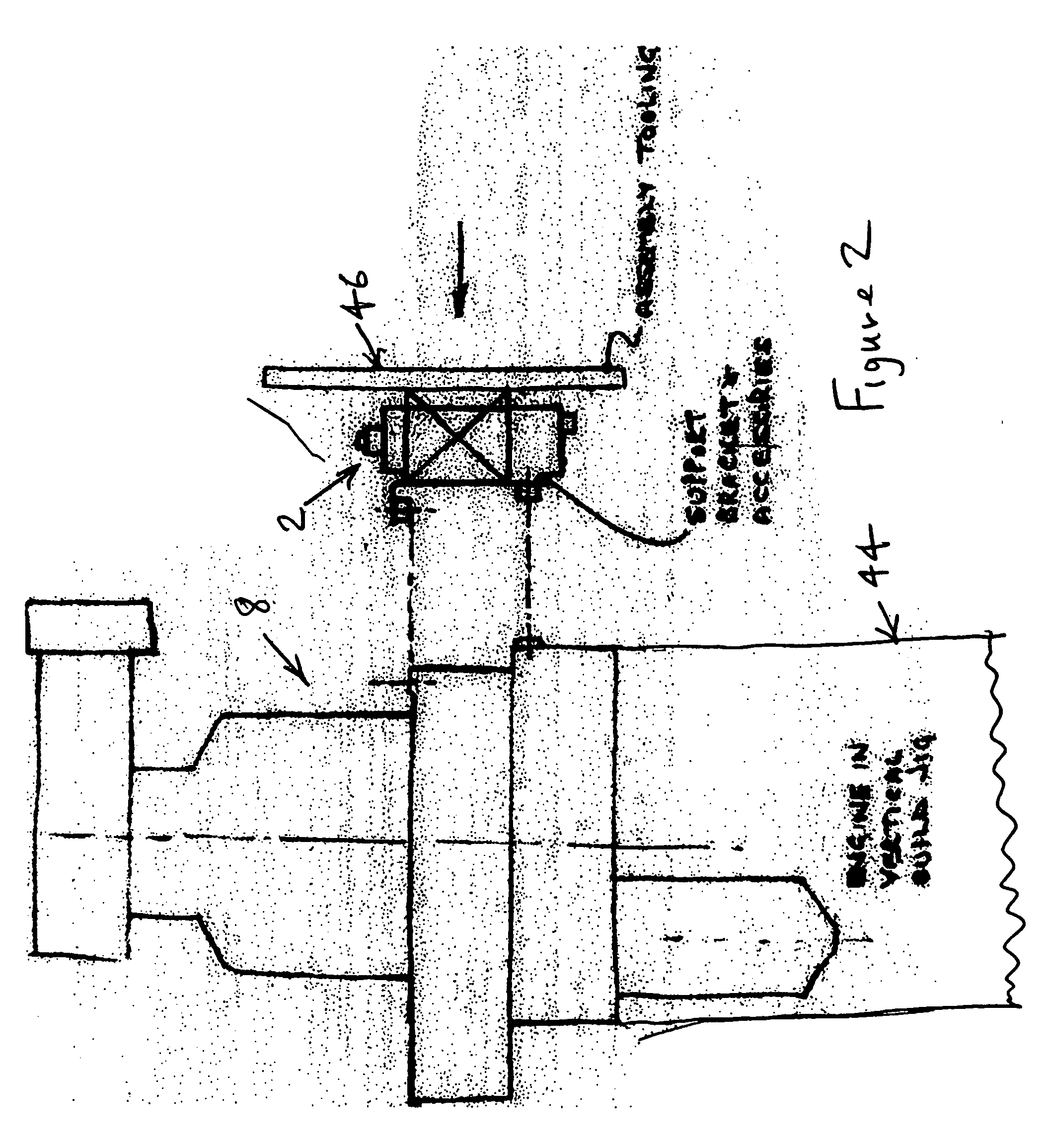

Modular LRU accessory mounting substrate for auxiliary power unit

InactiveUS20070029454A1Reduce inventory and costReduce time and costPortable framesCandle holdersModularityEngineering

A multiple accessory support bracket that mounts a plurality of external accessories for an auxiliary power unit (APU) so that all the external accessories may be mounted to the APU in a single operation.

Owner:HAMILTON SUNDSTRAND CORP

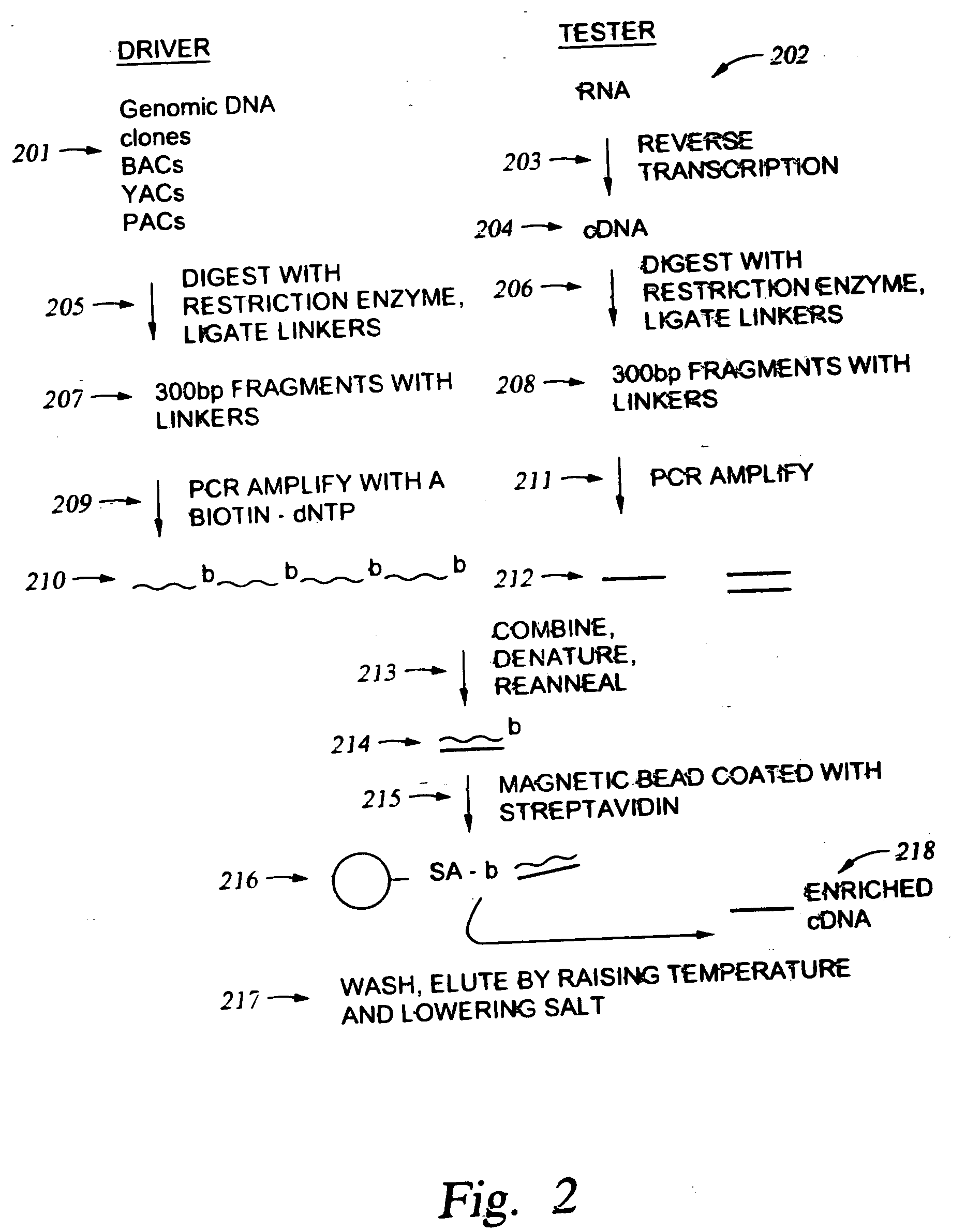

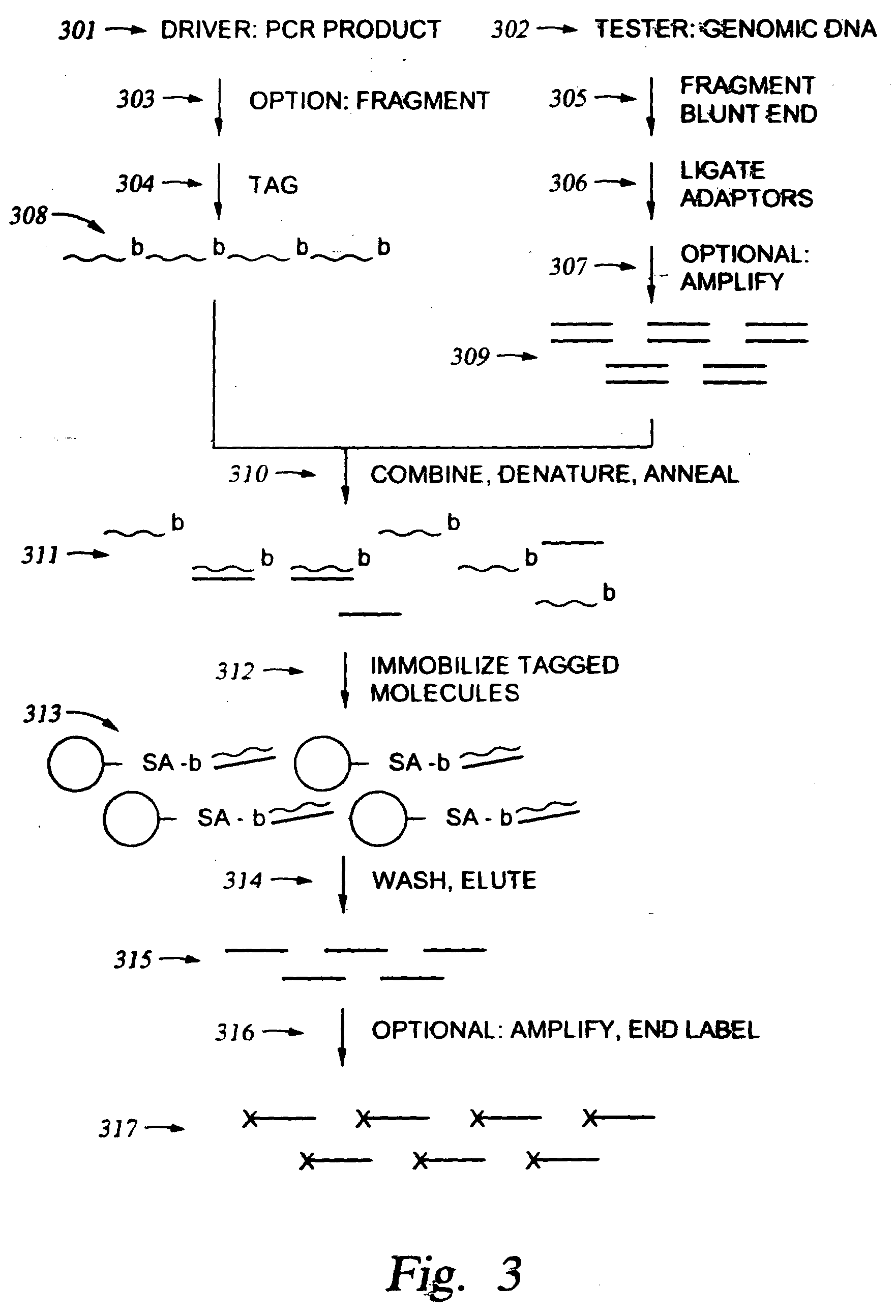

Methods for reducing complexity of nucleic acid samples

InactiveUS20020055112A1Reduce complexityReduce time and costMicrobiological testing/measurementFermentationNucleic Acid ProbesGenomic DNA

The invention provides several methods for reducing the complexity of a population of nucleic acids prior to performing an analysis of the nucleic acids on a nucleic acid probe array. The methods result in a subset of the initial population enriched for a desired property, or lacking nucleic acids having an undesired property. The resulting nucleic acids in the subset are then applied to the array for various types of analysis. The methods are particularly useful for analyzing populations having a high degree of complexity, for example, chromosomal-derived DNA, or whole genomic DNA, or mRNA population. In addition, such methods allow for analysis of pooled samples.

Owner:PERLEGEN SCIENCES INC

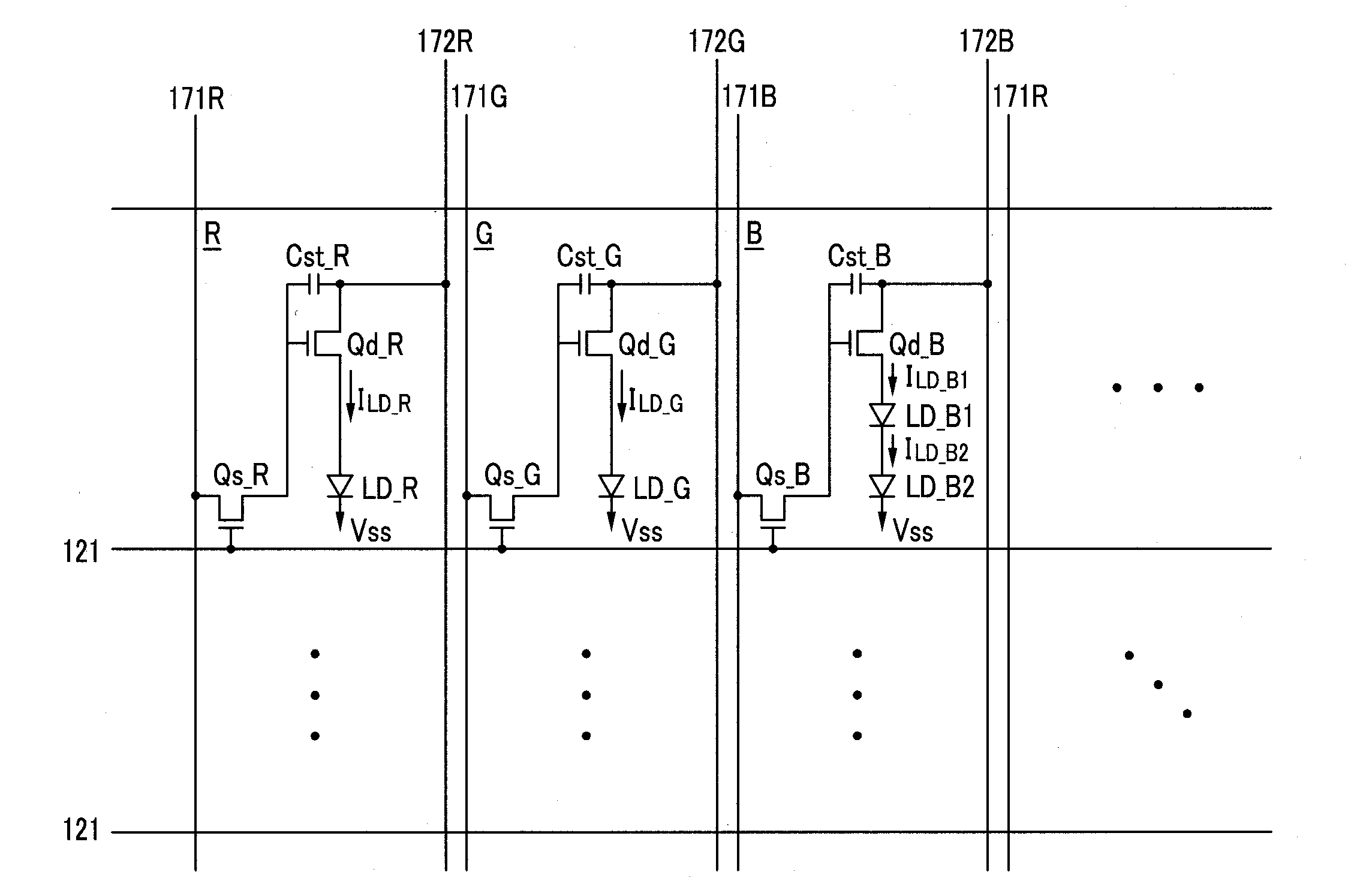

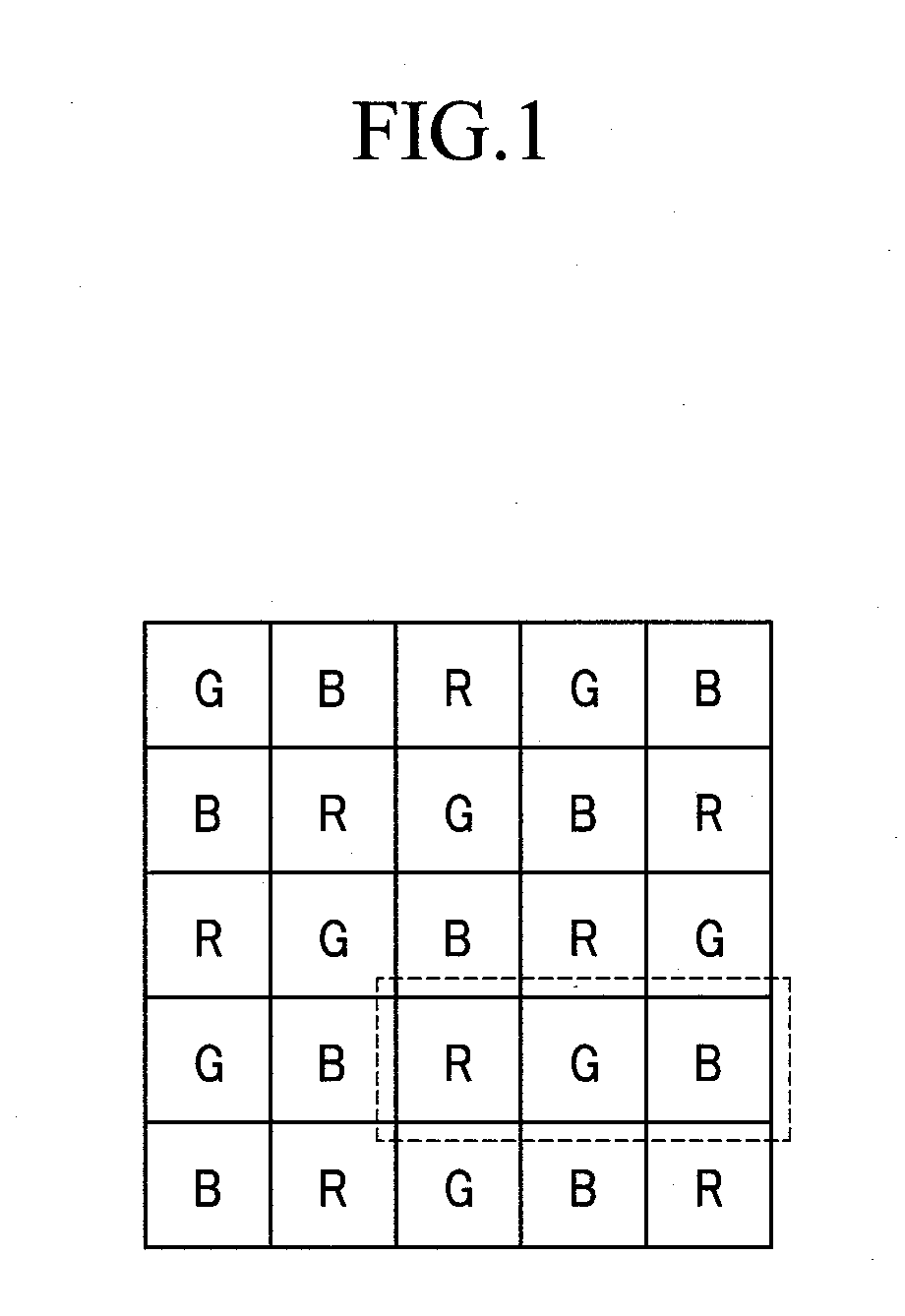

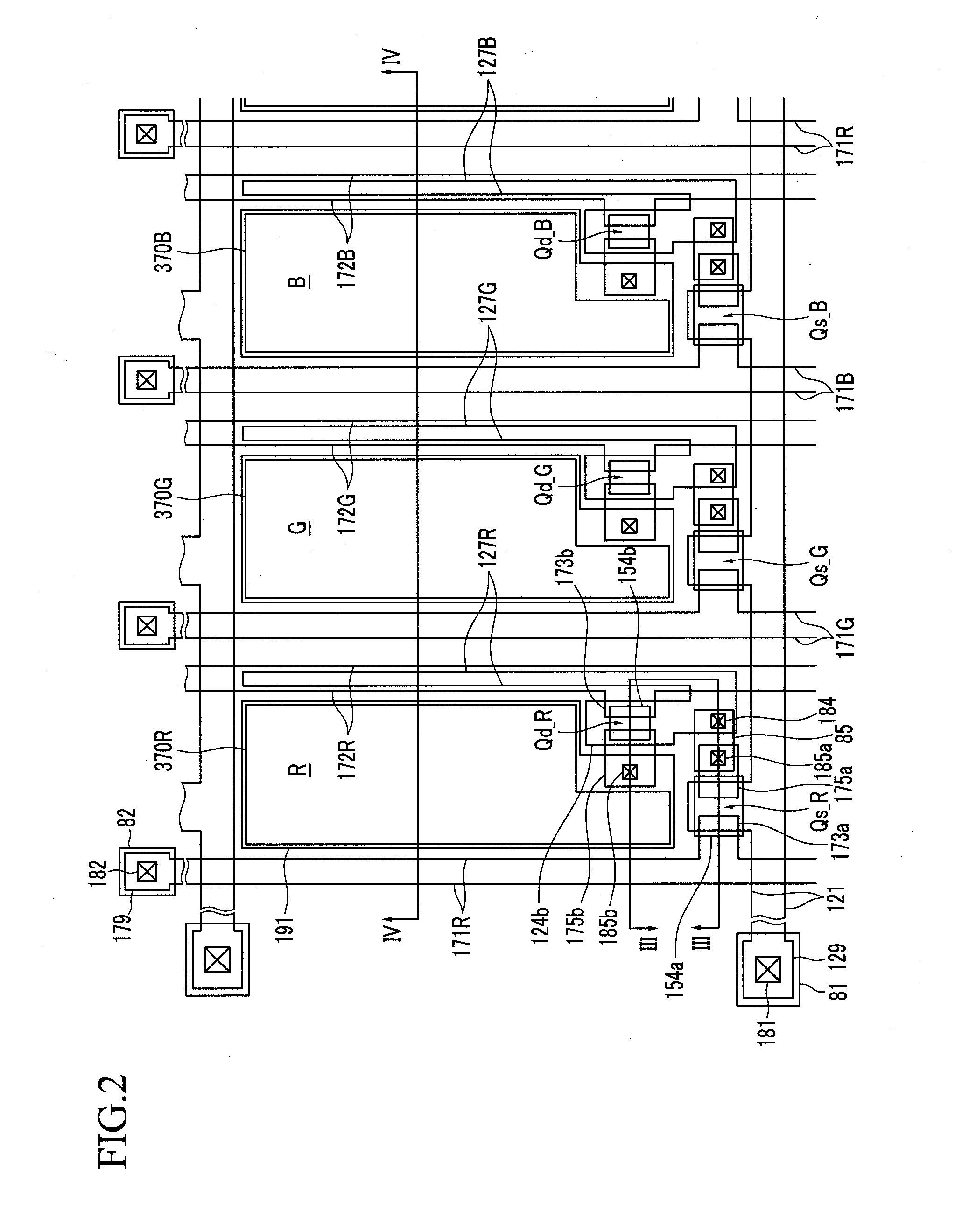

Organic light emitting diode display

InactiveUS20090146929A1Increase life timeReduce time and costDischarge tube luminescnet screensStatic indicating devicesDisplay deviceOLED

In an organic light emitting diode display comprising a first pixel and a second pixel that are associated with respective different colors, each of the first and second pixels being for displaying its associated color, each of the first and second pixels comprises: a first electrode; a second electrode facing the first electrode; and a light emitting member formed between the first electrode and the second electrode; wherein the light emitting member of the first pixel comprises: at least two light-emitting elements for emitting light of the color associated with the first pixel; and a charge generation layer between the at least two light-emitting elements; and wherein the second pixel has fewer light-emitting elements than the first pixel.

Owner:SAMSUNG DISPLAY CO LTD

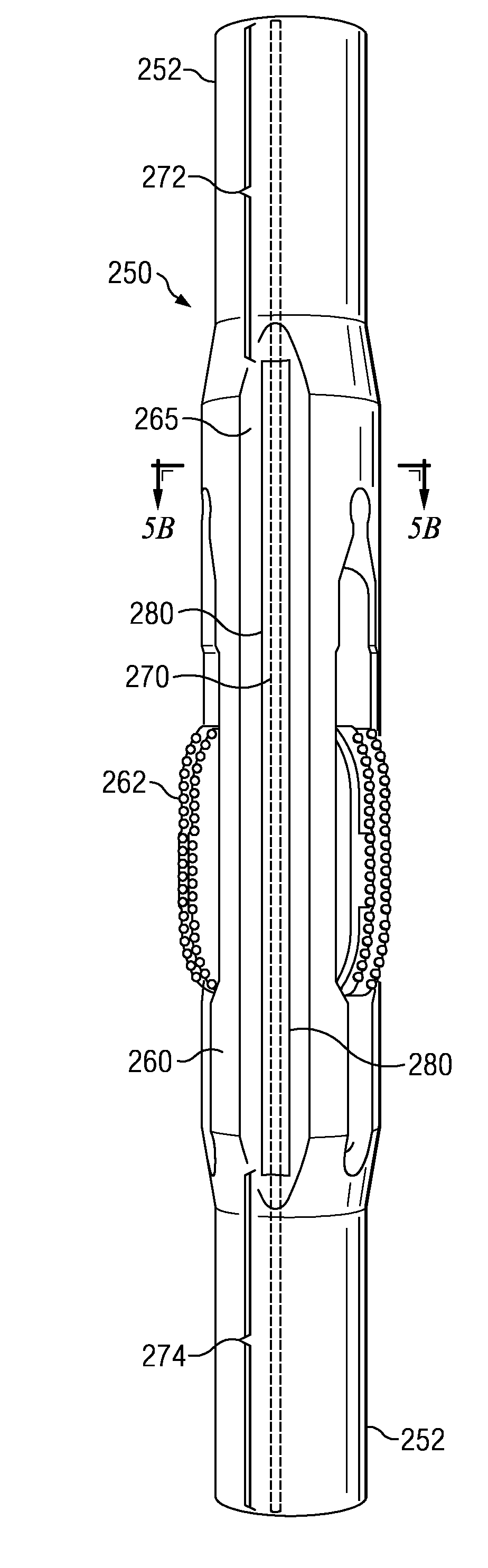

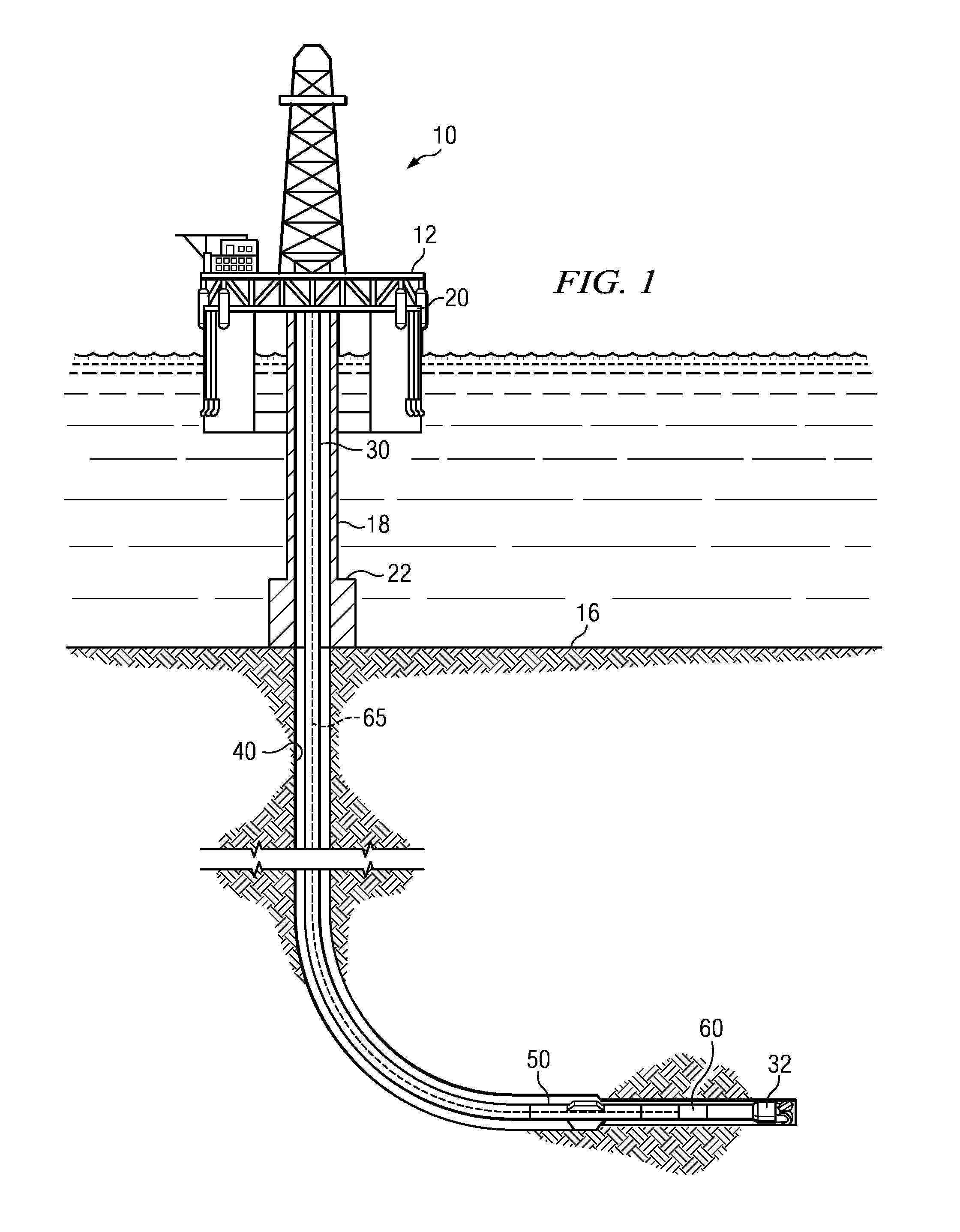

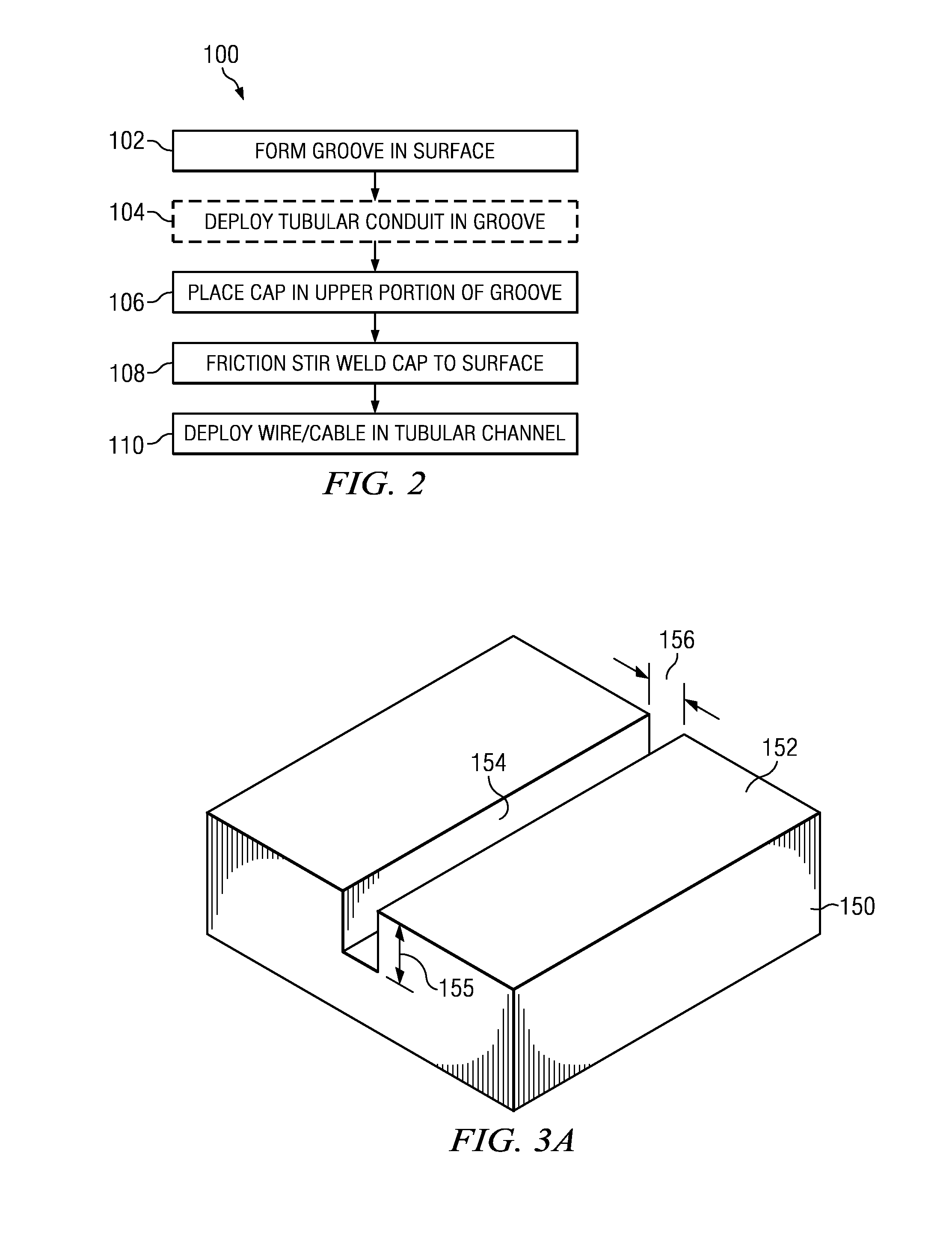

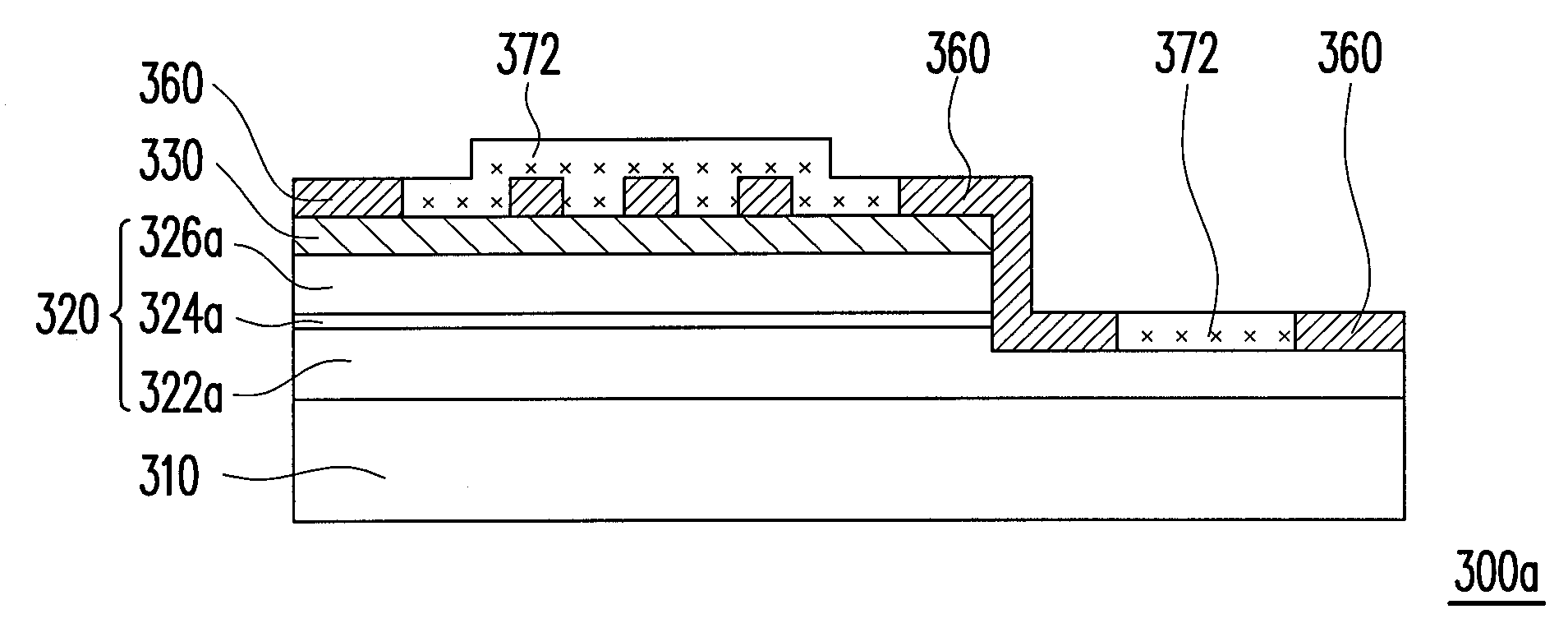

Article of manufacture having a sub-surface friction stir welded channel

InactiveUS20110240372A1Low costShorten the timeDrill bitsDrilling rodsElectrical conductorWear resistant

A method for routing an electrical conductor through a sub-surface channel in substantially any suitable metallic article of manufacture includes friction stir welding a cap in a groove formed in a surface of the article so as to form the sub-surface channel. An electrical conductor is then routed through the channel. The channel may further include a substantially tubular conduit formed therein with the electrical conductor being routed through the conduit. The friction stir weld zone formed during friction stir welding is generally harder and more wear resistant that the article body.

Owner:SMITH INT INC

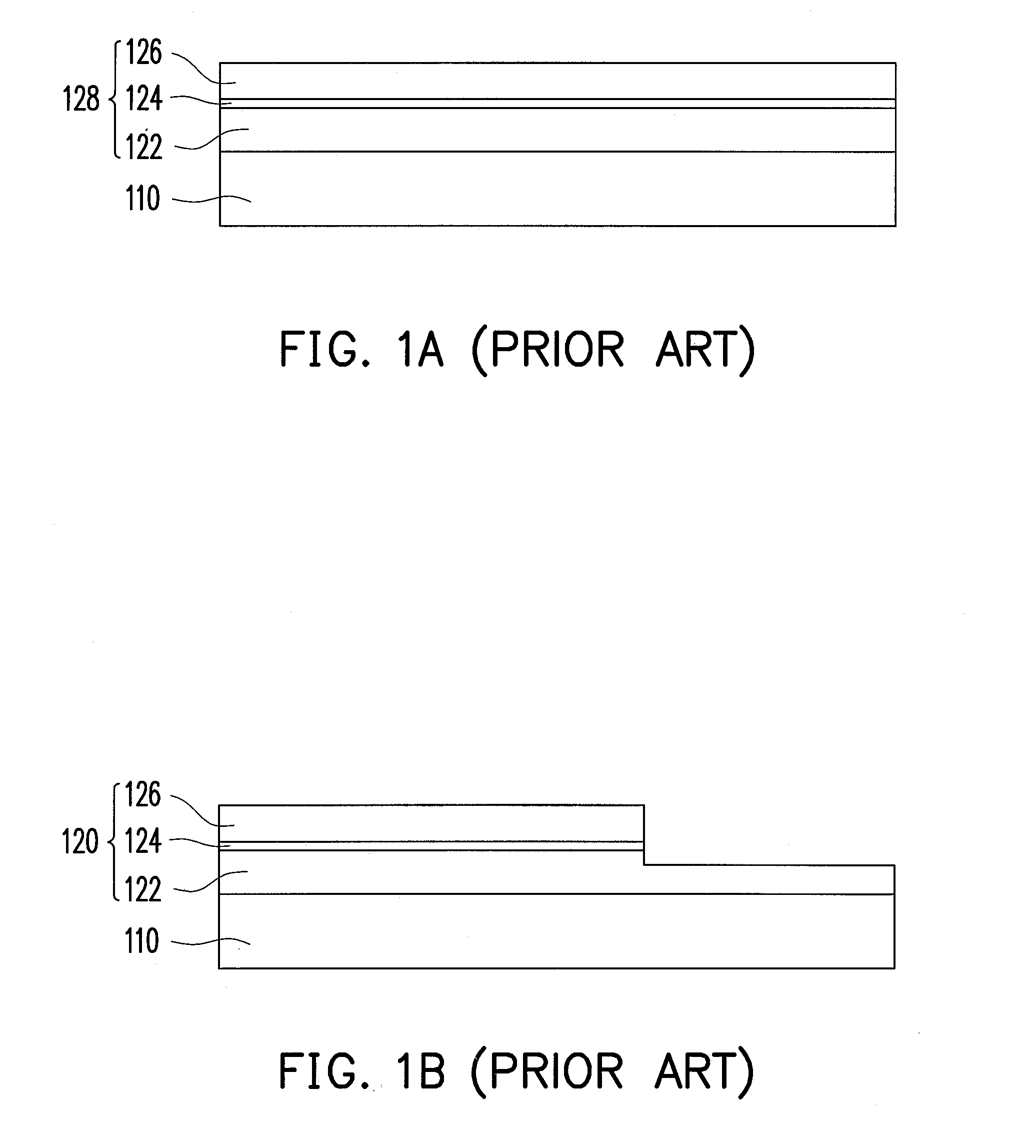

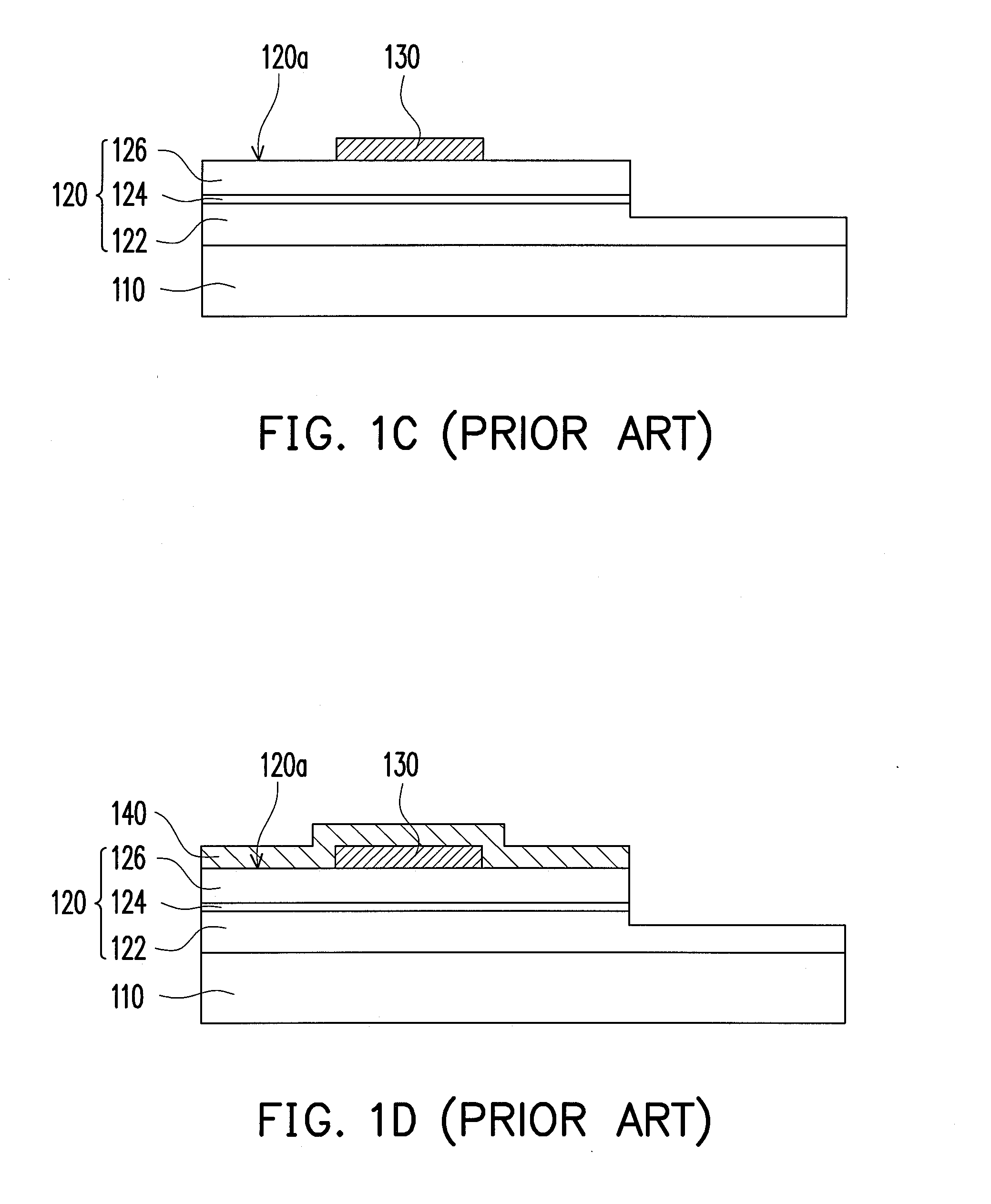

Method for fabricating light emitting diode chip

ActiveUS20100015742A1Reduce time and costReduce processing stepsSolid-state devicesSemiconductor/solid-state device manufacturingColor toneDiode

A method for fabricating a light emitting diode chip is provided. In the method, a half-tone mask process, a gray-tone mask process or a multi-tone mask process is applied and combined with a lift-off process to further reduce process steps of the light emitting diode chip. In the present invention, some components may also be simultaneously formed by an identical process to reduce the process steps of the light emitting diode chip. Consequently, the fabricating method of the light emitting diode provided in the present invention reduces the cost and time for the fabrication of the light emitting diode.

Owner:LEXTAR ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com