Drilling speed increasing device with composite drill bit

A composite drill bit and drilling technology, which is applied to the driving device, drill bit, drilling equipment, etc. for drilling in the wellbore, can solve the problems of low rotation speed of the pilot bit and insignificant drilling speed increase, and achieves the advantages of fast drilling, convenient and accurate drilling. The effect of directional drilling and reducing the difficulty of rock breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

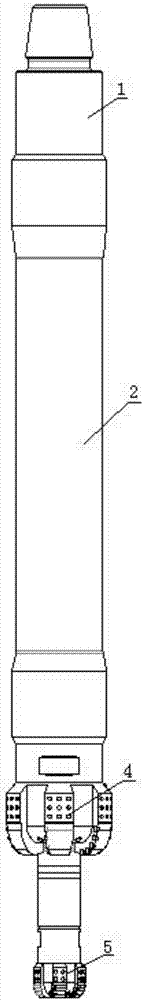

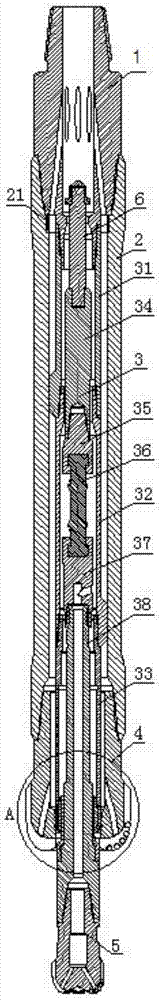

[0043] Such as figure 1 and figure 2 As shown, the present invention includes a multi-kinetic joint 1. The multi-functional joint 1 is respectively connected with an outer shell 2 and a screw drive assembly 3. The screw drive assembly 3 is sleeved in the outer shell 2, and the outer shell 2 is far away from the multi-functional joint 1. One end of the screw drive assembly 3 is connected with a reaming drill bit 4, and the end of the screw drive assembly 3 away from the multifunctional joint 1 is connected with a pilot drill bit 5, and both the reaming drill bit 4 and the pilot drill bit 5 are provided with water holes; the reaming drill bit 4 is a diamond It is a kind of drill bit and roller cone bit, and the pilot bit 5 is a kind of diamond drill bit and roller cone bit.

[0044] Driven by the external driving device, the present invention has a certain rotational speed, so that the multifunctional joint 1 drives the outer casing 2 and the screw drive assembly 3 to rotate t...

Embodiment 2

[0049] On the basis of the first embodiment, the multifunctional joint 1 is provided with several oblique holes 11 , and the cavity between the outer casing 2 and the screw drive assembly 3 communicates with the oblique holes 11 . The cavity between the outer shell 2 and the screw drive assembly 3 communicates with the inclined hole 11, so the drilling fluid flowing through the multifunctional joint 1 can enter the space between the outer shell 2 and the screw drive assembly 3 through the inclined hole 11 cavity. Drilling fluid will not directly wash the bearing between the outer casing 2 and the screw drive assembly 3, which avoids the leakage of drilling fluid from the bearing or the failure of the bearing.

Embodiment 3

[0051] Such as Figure 4 As shown, on the basis of Embodiment 1 or Embodiment 2, the screw drive assembly 3 includes a screw housing assembly and a drive assembly, and the drive assembly is sleeved in the screw housing assembly; the screw housing assembly includes a stator housing 31. One end of the stator housing 31 is connected to the multifunctional joint 1, and the other end of the stator housing 31 is sequentially connected to a cardan shaft housing 32 and a bearing housing 33, and the bearing housing 33 is sleeved in the reaming drill bit 4.

[0052] The drilling fluid passing through the pilot bit 5 and the reaming bit 4 is isolated by the screw housing assembly to ensure that the drilling fluid without pressure drop directly enters the screw drive assembly 3 to drive the pilot bit 5 to rotate, improving the drilling fluid driving screw drive assembly 3 stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com