Hybrid drill bit

A technology of mixing drill bits and drill bit bodies, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of easy impact damage of cutting elements, slow ROP of diamond bits, and slow ROP of roller cone bits, etc. Eliminate stick-slip phenomenon, improve cutting efficiency and ROP, and smooth pre-crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further illustrate the embodiment of the patent of the present invention below in conjunction with accompanying drawing.

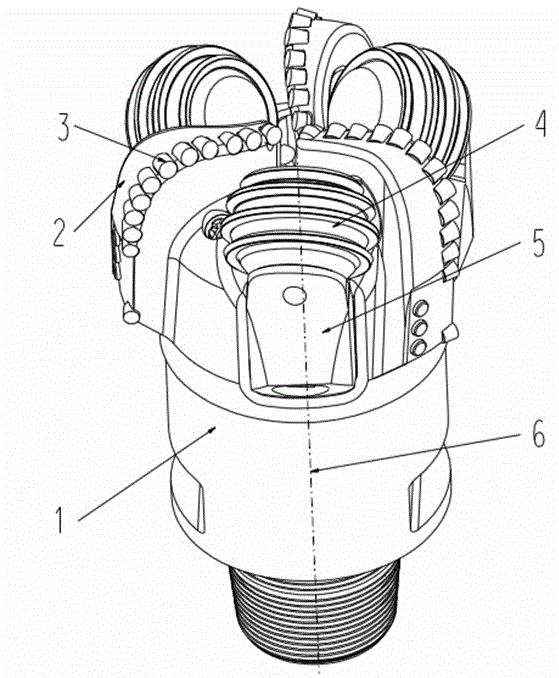

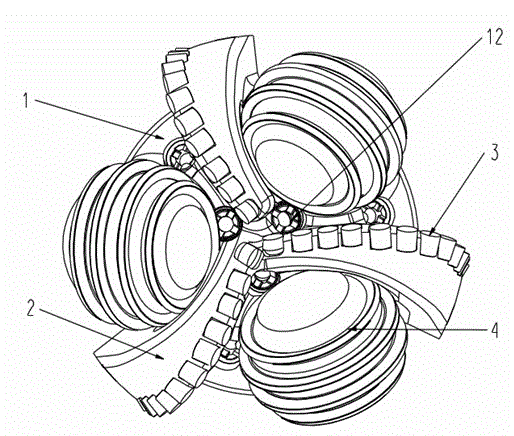

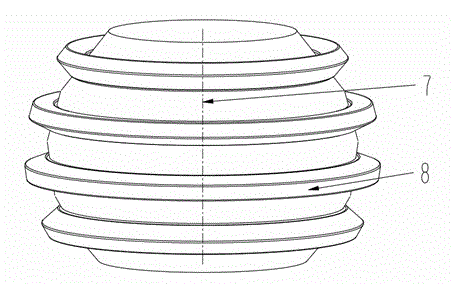

[0022] Including a bit body 1, three blades 2 are arranged on the bit body, cutting teeth are arranged on the inner cone, nose and shoulder of the blades 2, the cutting teeth are diamond composite sheets 3, and the bit body 1 is provided with cutting teeth. There are hydraulic injection holes, and nozzles 12 are fixed on each injection hole. Disc cones 4 are installed between the blades 2, and three blades are equipped with three disc cones 4, which are interlaced with each other; the disc cones are connected to the bit body through the palm 5, and the The upper end of the tooth palm 5 is welded into one body with the bit body 1, and the lower end of the tooth palm 5 is provided with a journal, on which the disc cone 4 is set and axially locked by steel balls. The surface of the disc cone is a spherical surface, the angle a between the rotation axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com