impact drill

A technology of impact drill bit and drill bit, which is used in earth-moving drilling, drilling equipment, driving device for drilling in wellbore, etc., can solve the problems of intermittent sticking, stick-slip, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Unless otherwise defined, all technical terms used in the embodiments of the present invention have the same meanings as commonly understood by those skilled in the art.

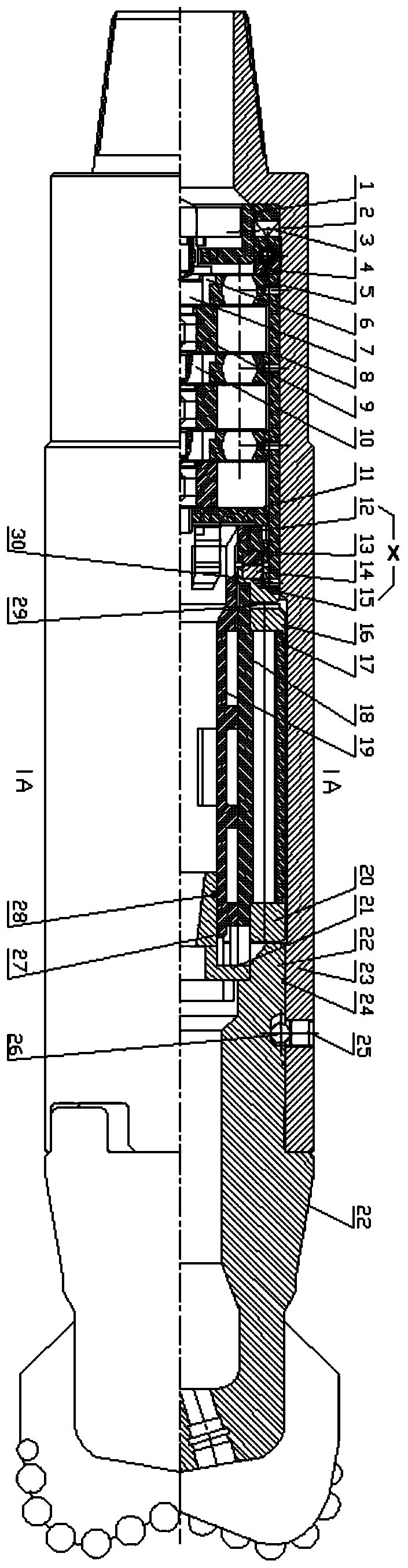

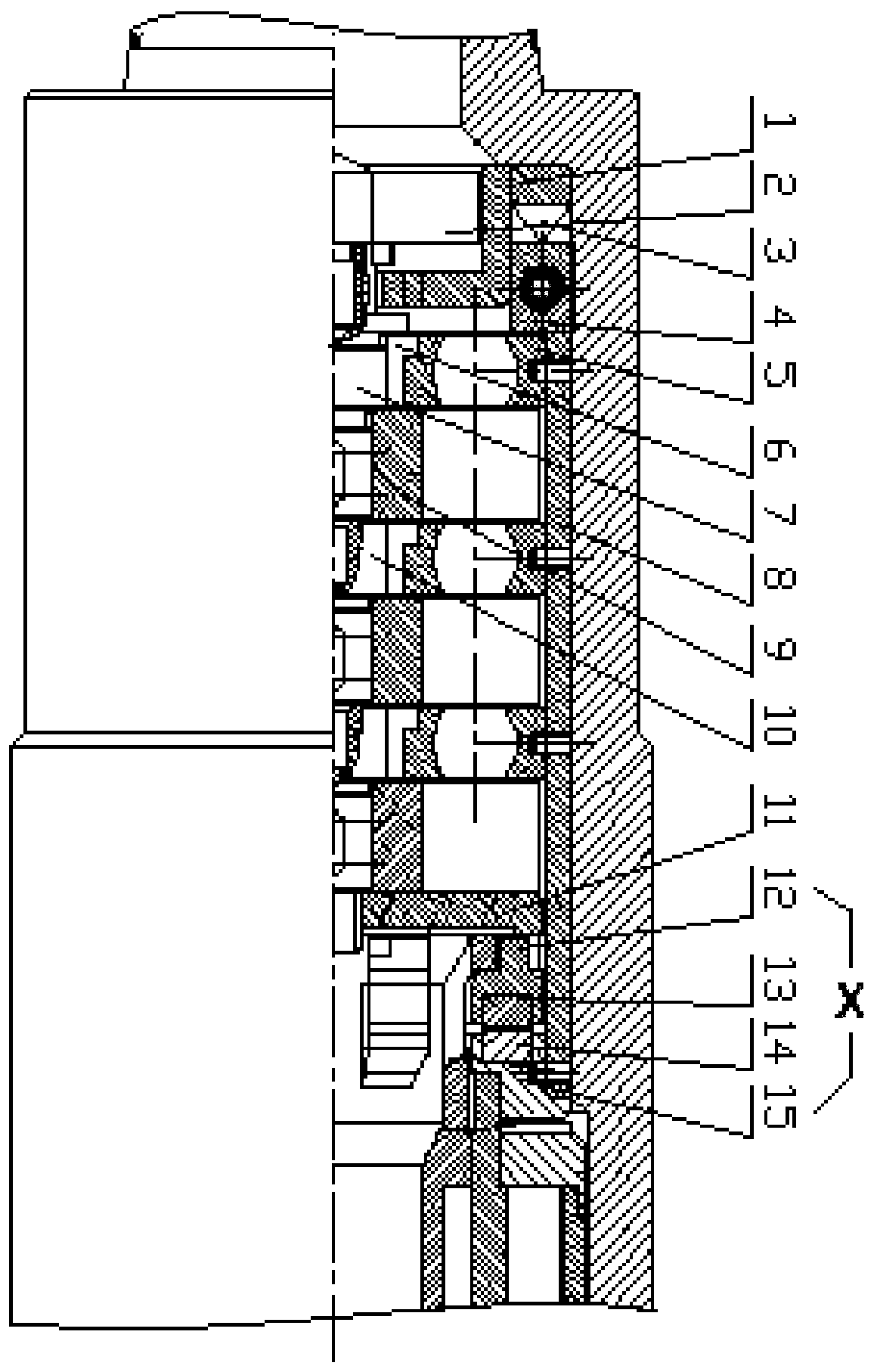

[0047] Embodiments of the present invention provide a percussion drill, see figure 1 and combine image 3 , the impact drill includes:

[0048] The outer cylinder 23 , the drill bit crown 22 fixedly connected to the lower end of the outer cylinder 23 , and the rotating power assembly and the torsional impact assembly arranged inside the outer cylinder 23 in sequence from top to bottom.

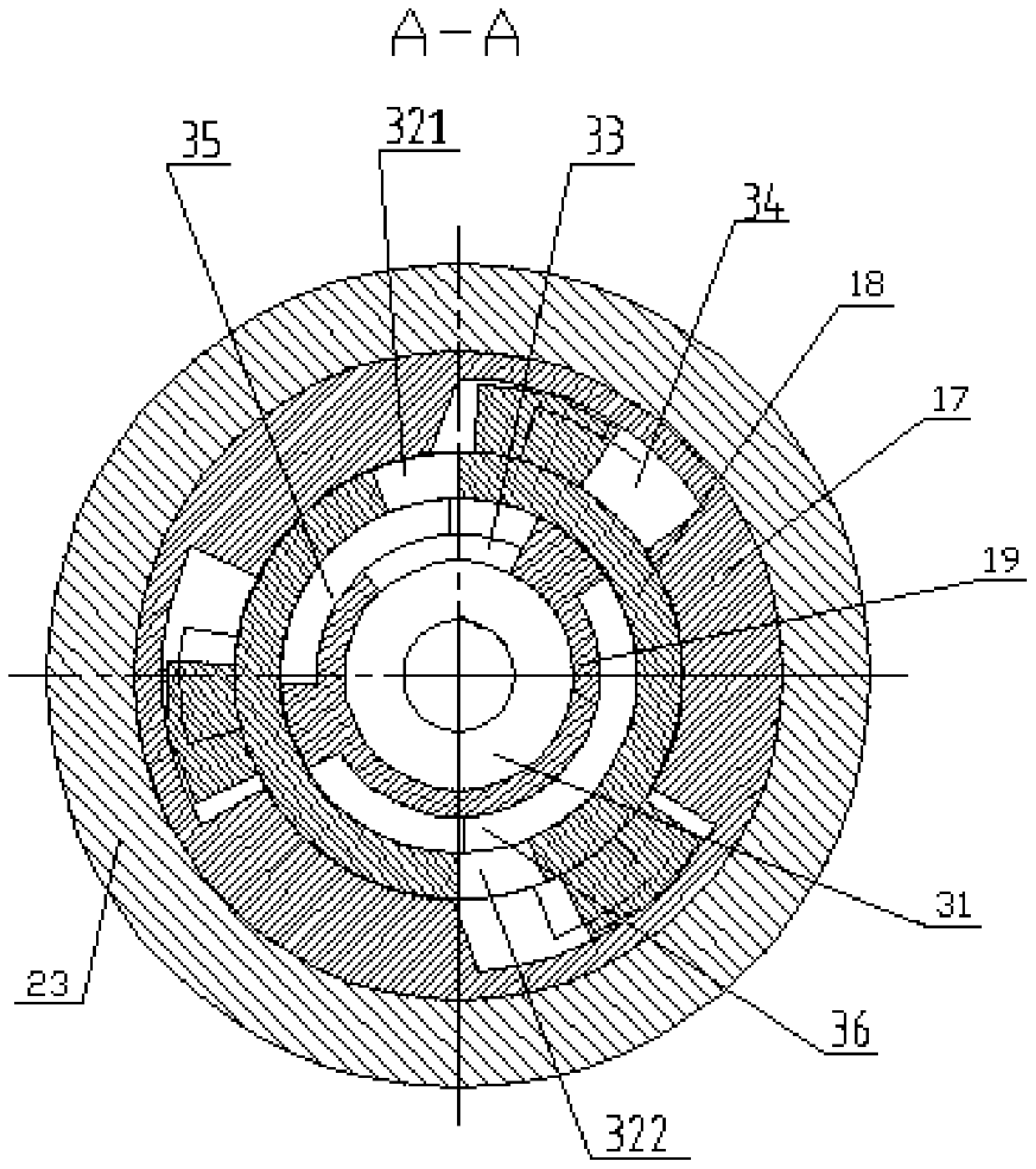

[0049] see figure 1 and combine figure 2 , wherein the torsional impact assembly includes: a hollow cylindrical anvil body 17 coaxial with the outer cylinder 23 , a hollow cylindrical hammer body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com