Patents

Literature

1182 results about "Vibration transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shocks Worn shocks can cause your transmission to vibrate. If you find your transmission and car start to vibrate during travel on uneven or bumpy roads, this is because your shocks no longer operate at peak efficiency. Improperly installed or worn-out U-joints can also cause transmission vibration, regardless of speed or road quality.

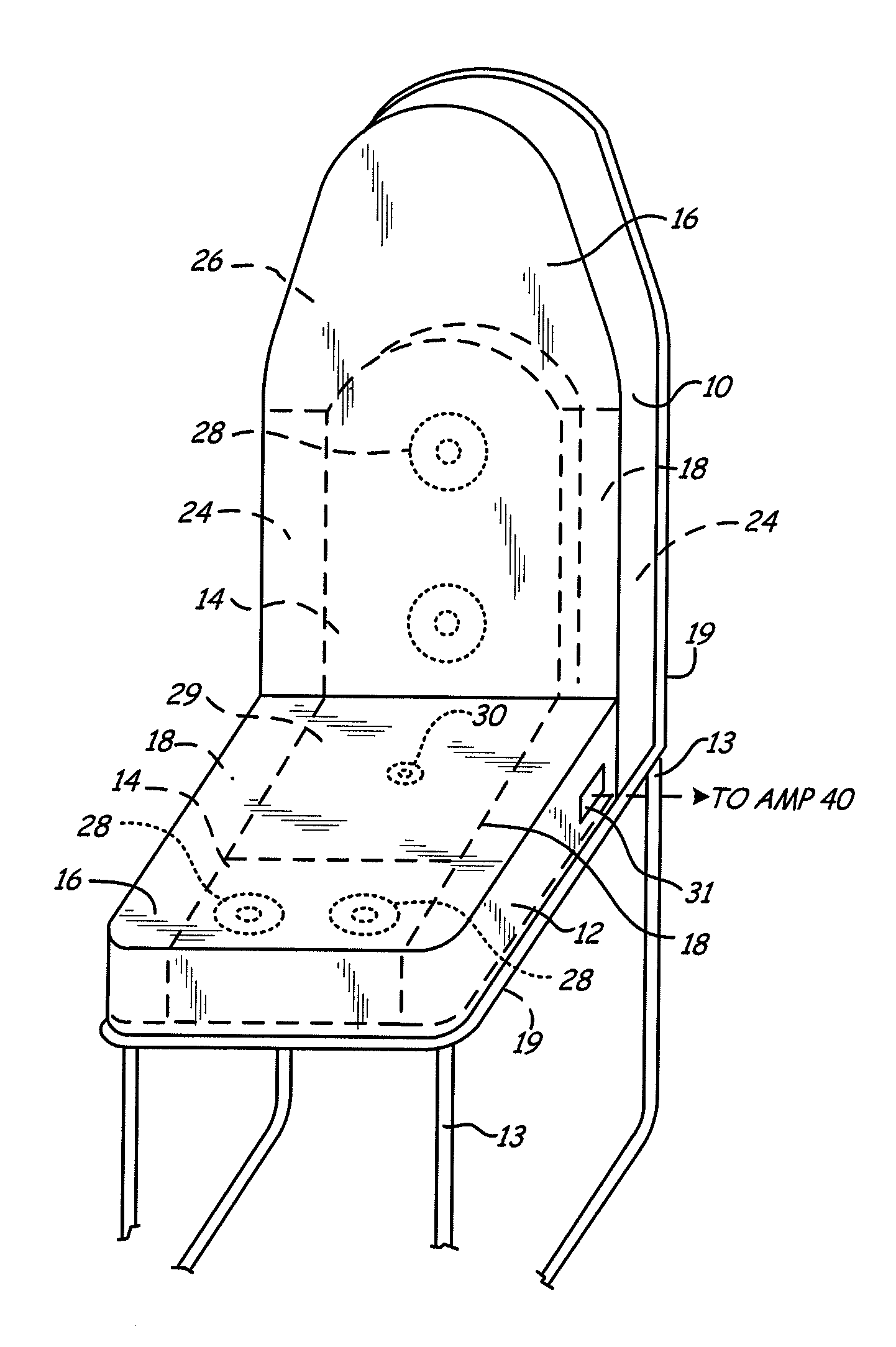

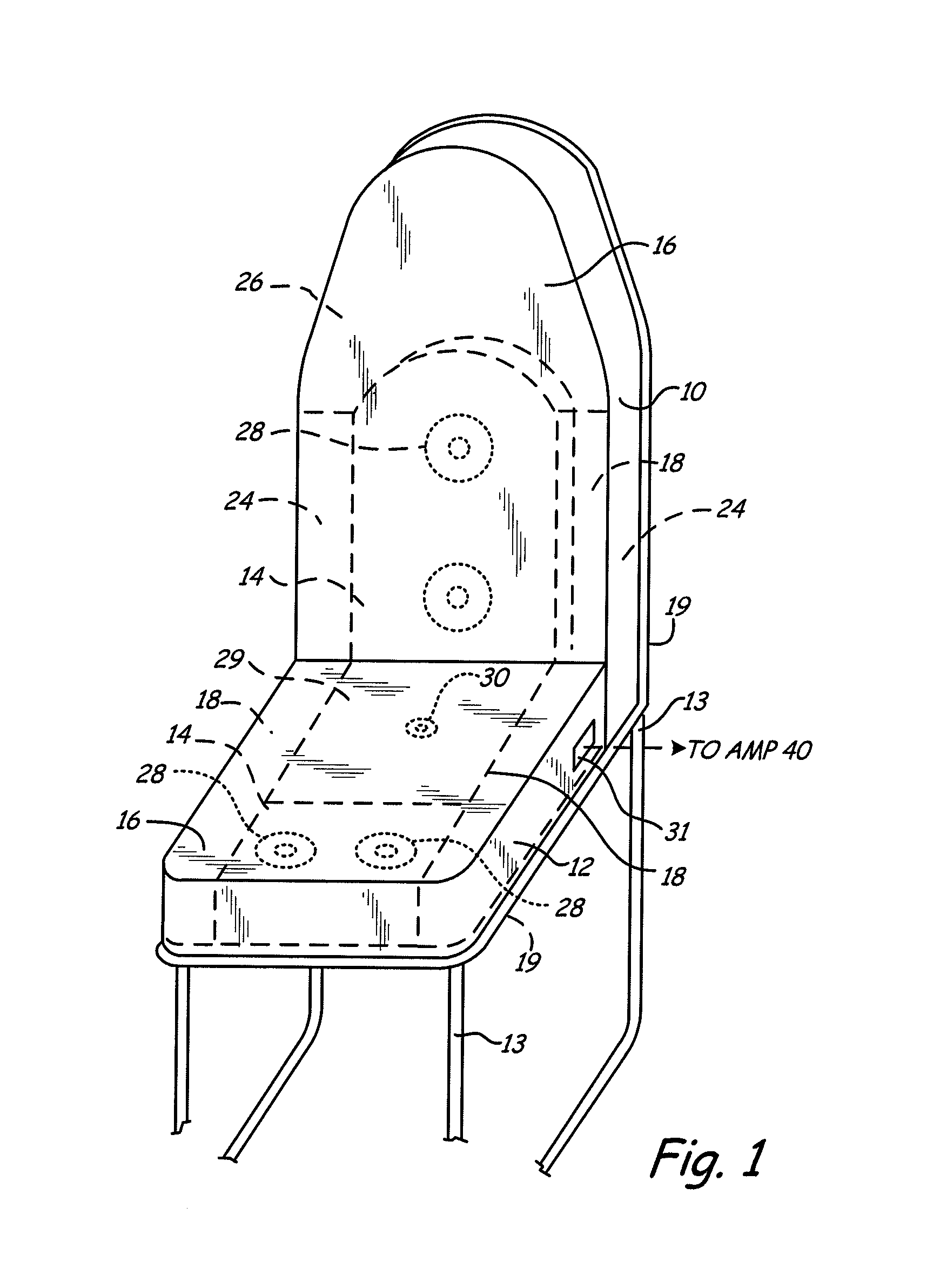

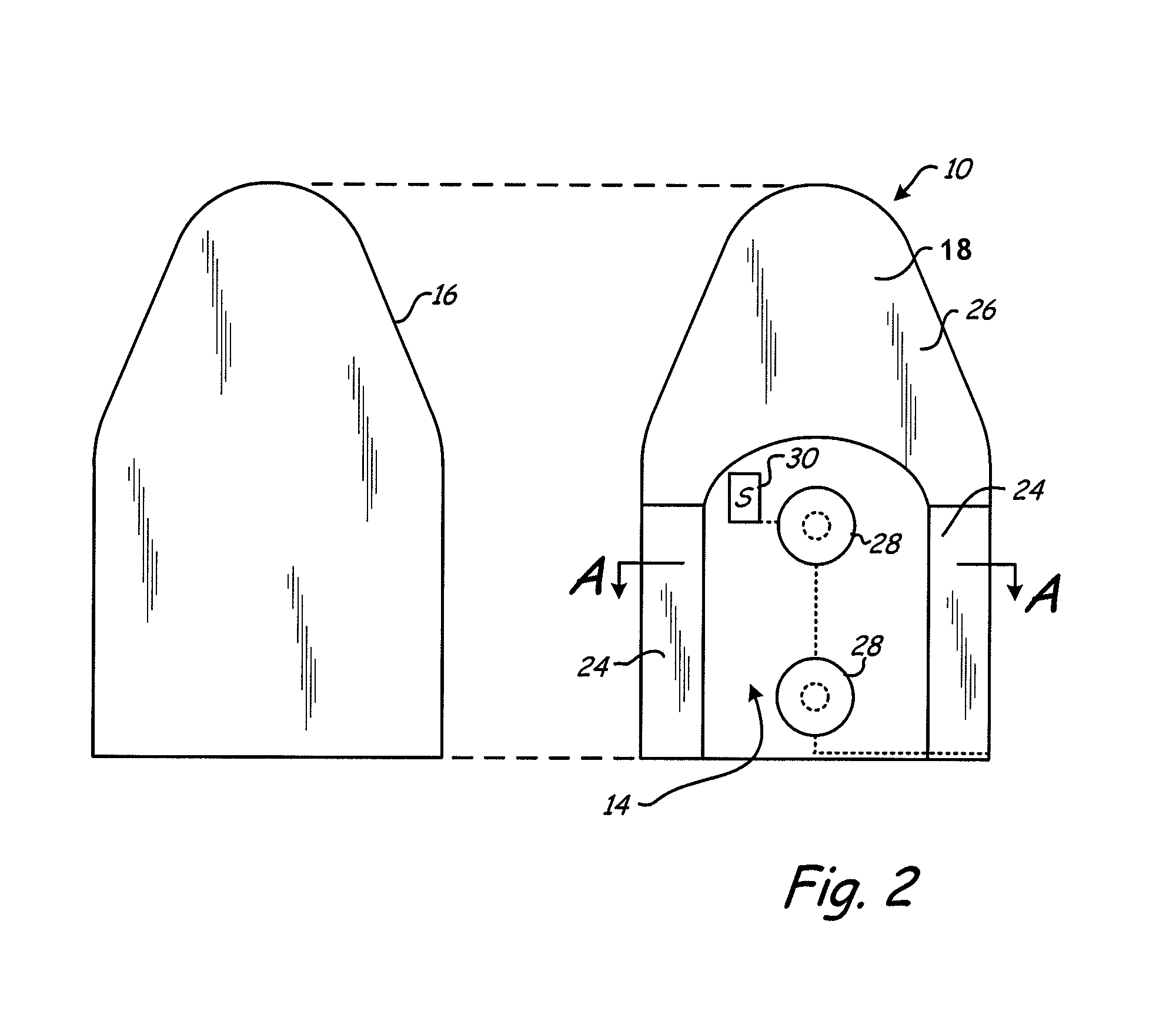

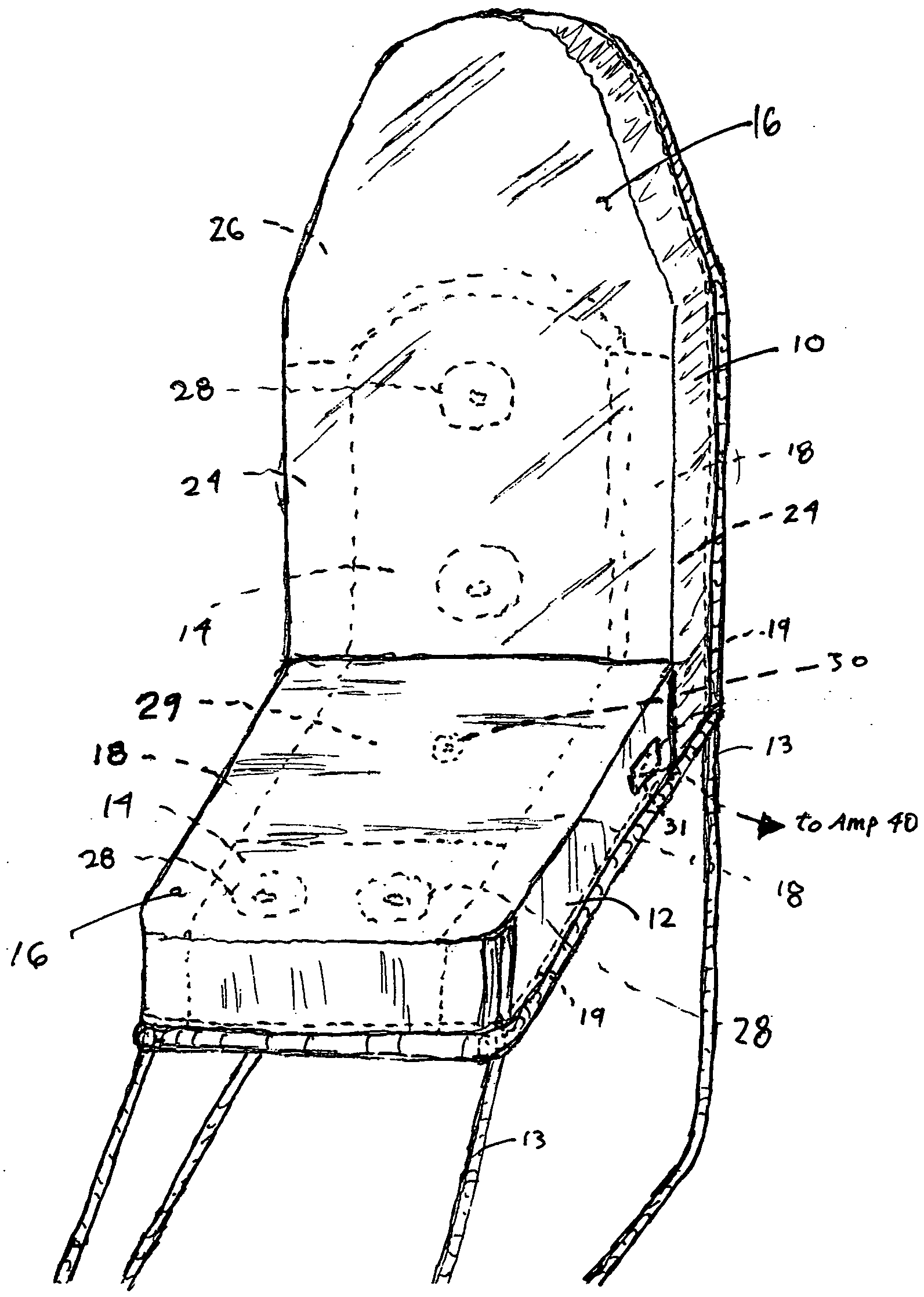

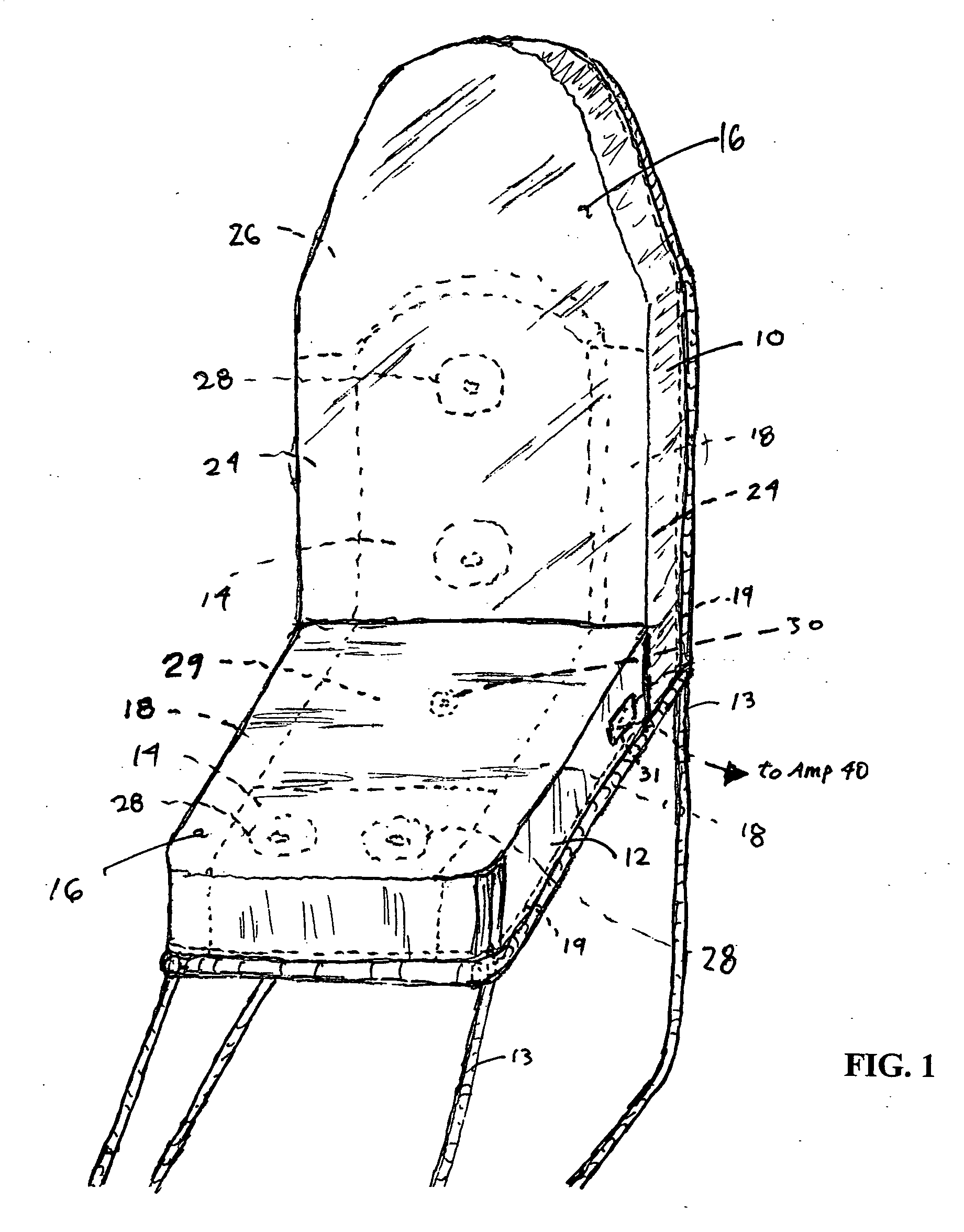

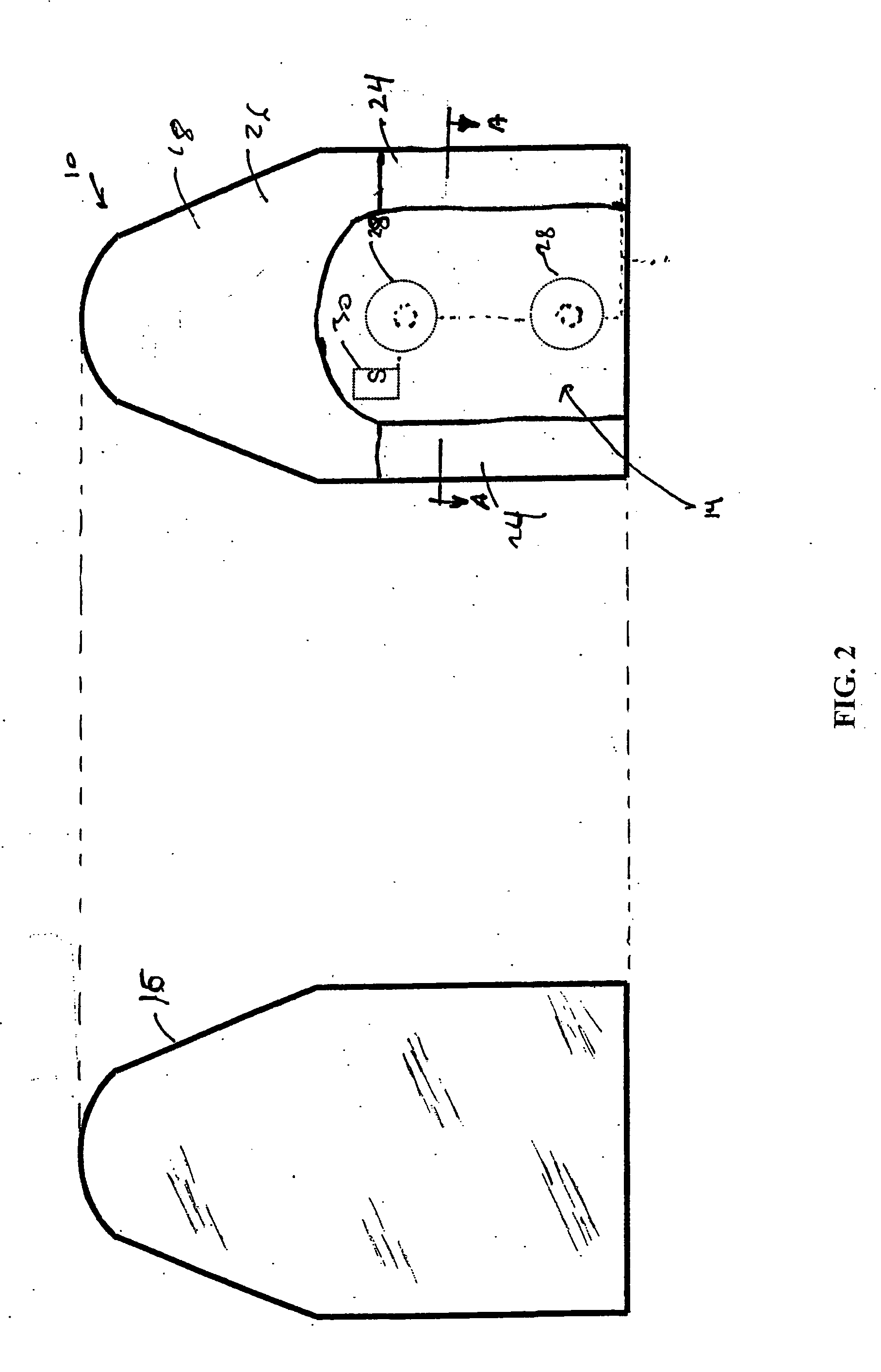

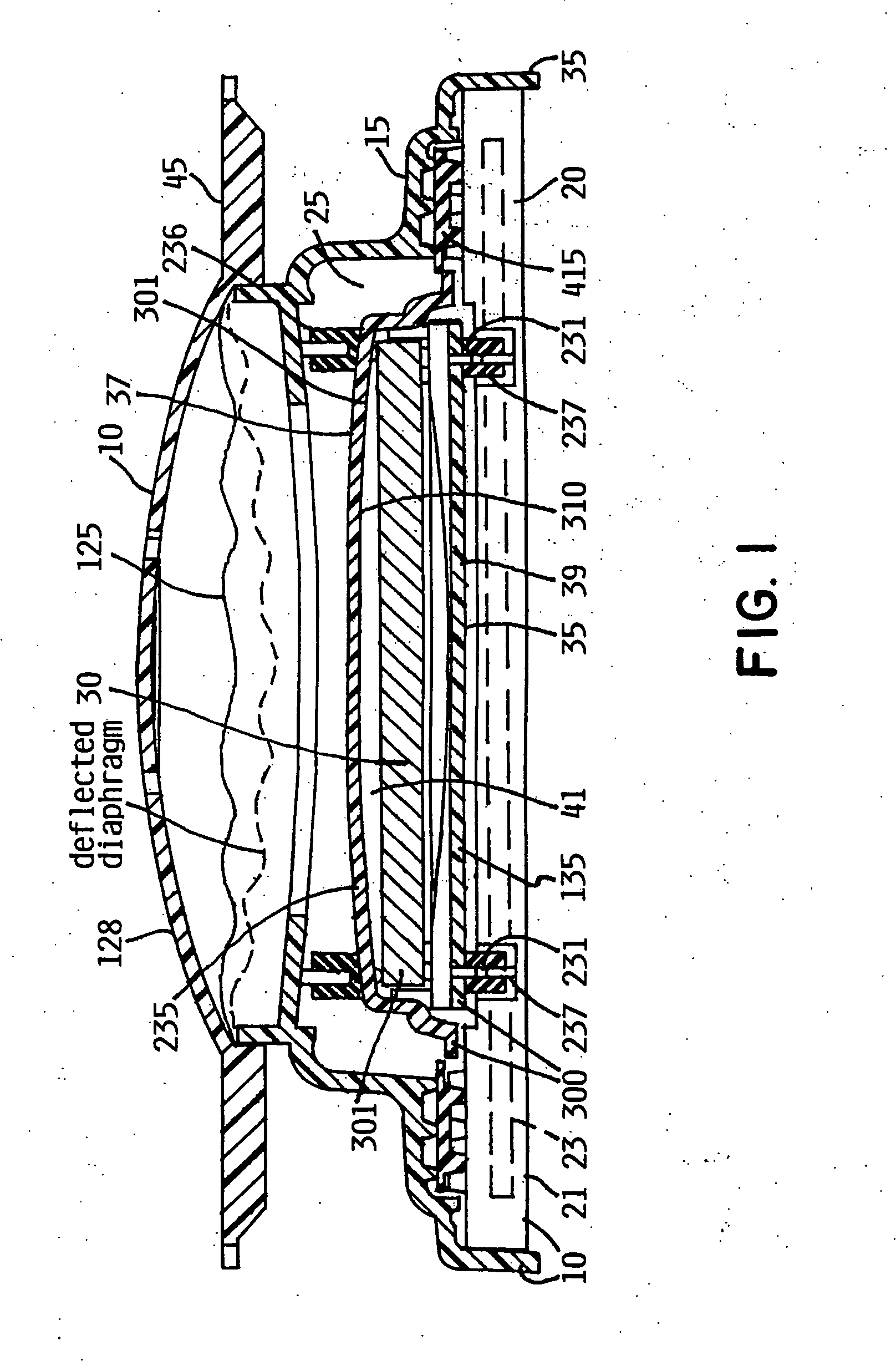

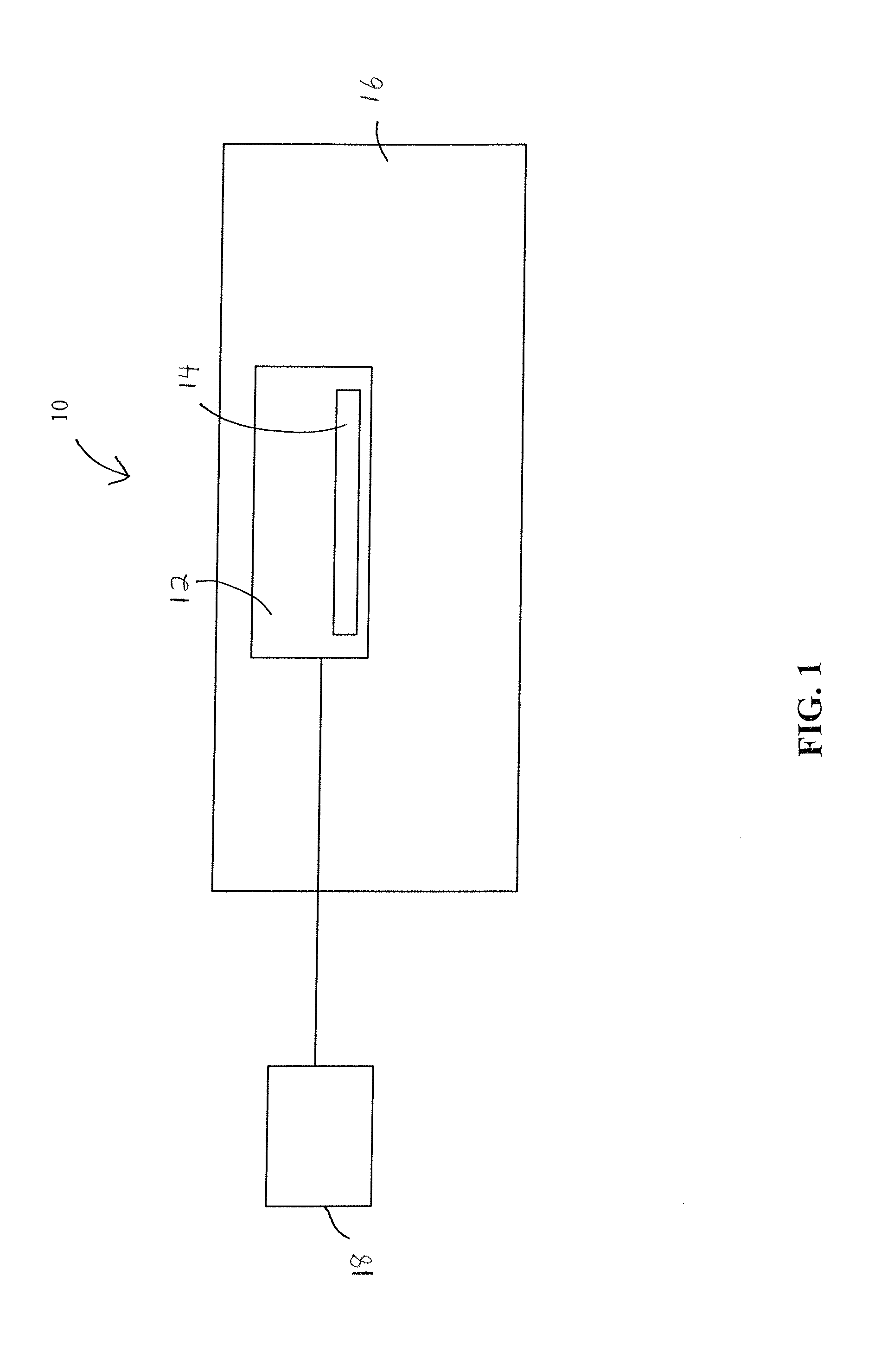

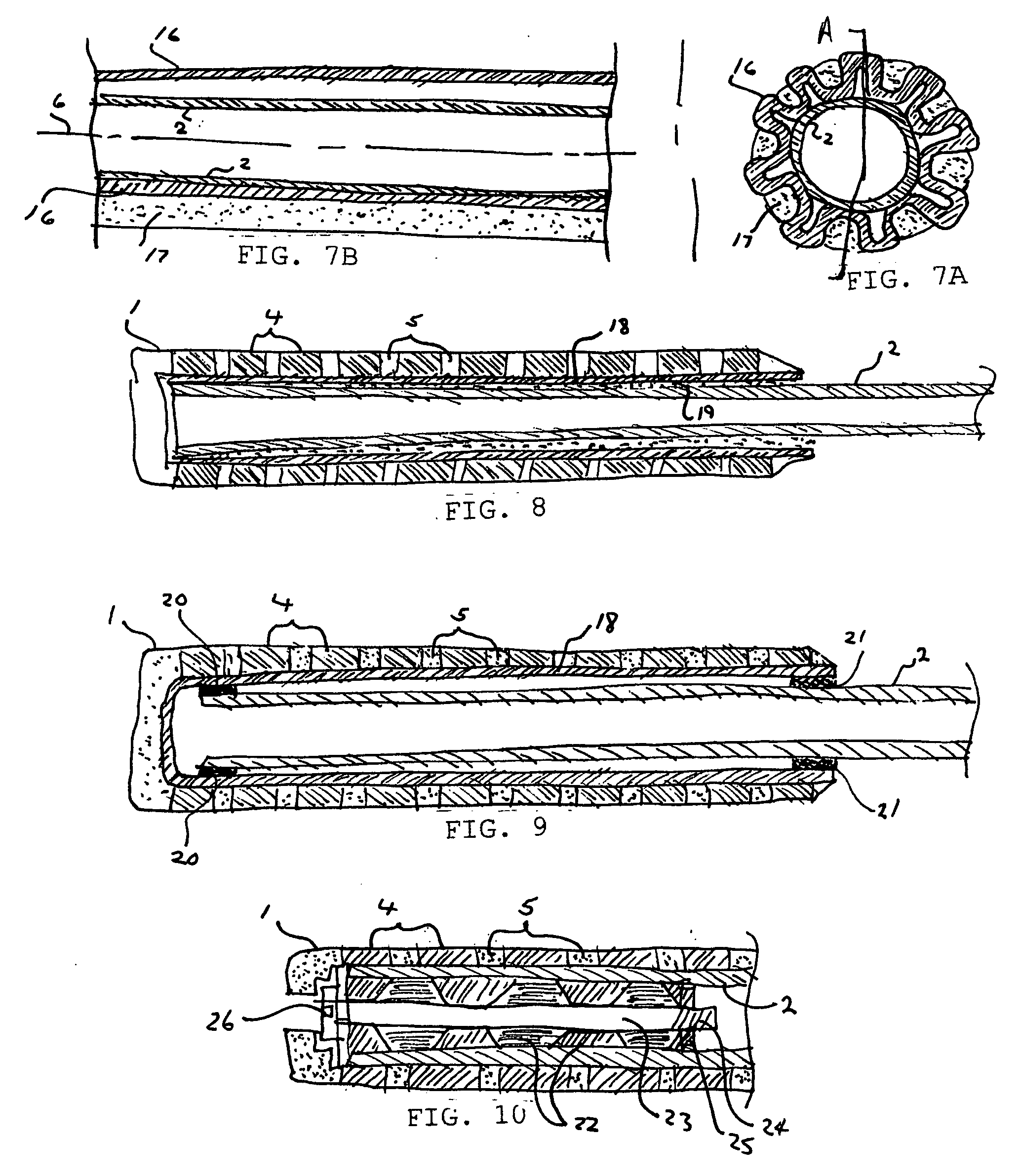

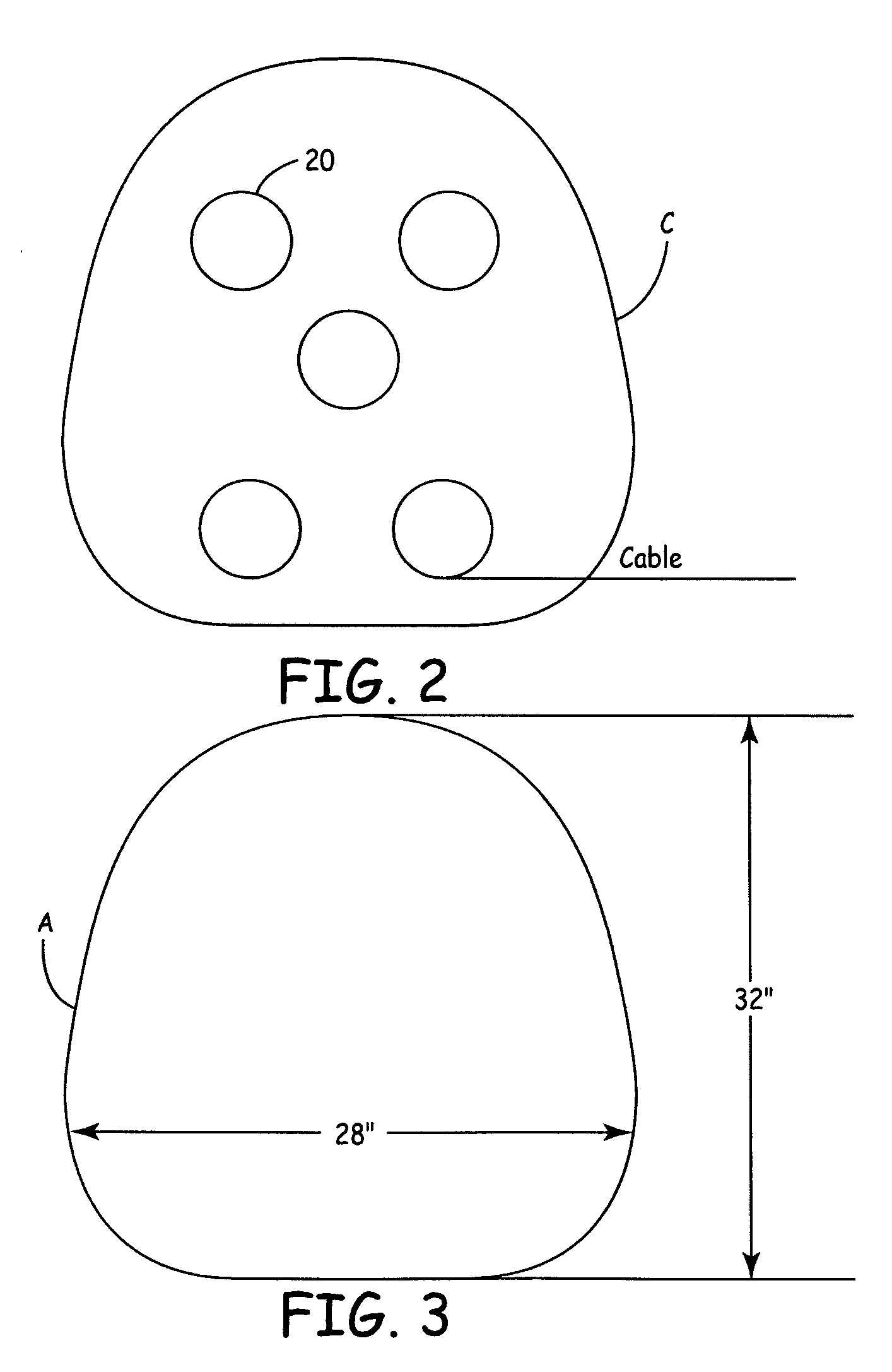

Sound and vibration transmission pad and system

InactiveUS7553288B2Improve the level ofIncrease awarenessStereophonic circuit arrangementsChiropractic devicesComputer moduleHigh intensity

The present invention is directed to a pad and sound transmission system which is adapted to directly transmit audible sound waves into the body at high intensity levels. In one embodiment, the subject invention includes a back pad and a seat pad. Each pad includes a speaker module having an acoustic speaker disposed within the pad and surrounded by a plurality of different layers.

Owner:ROUND RIVER RES CORP

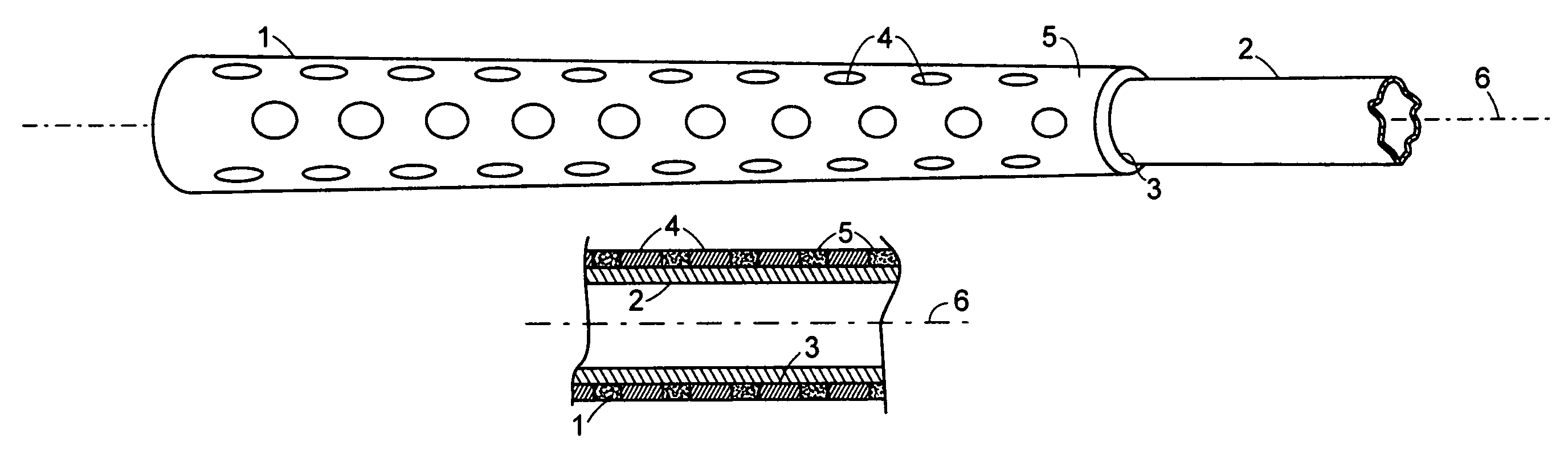

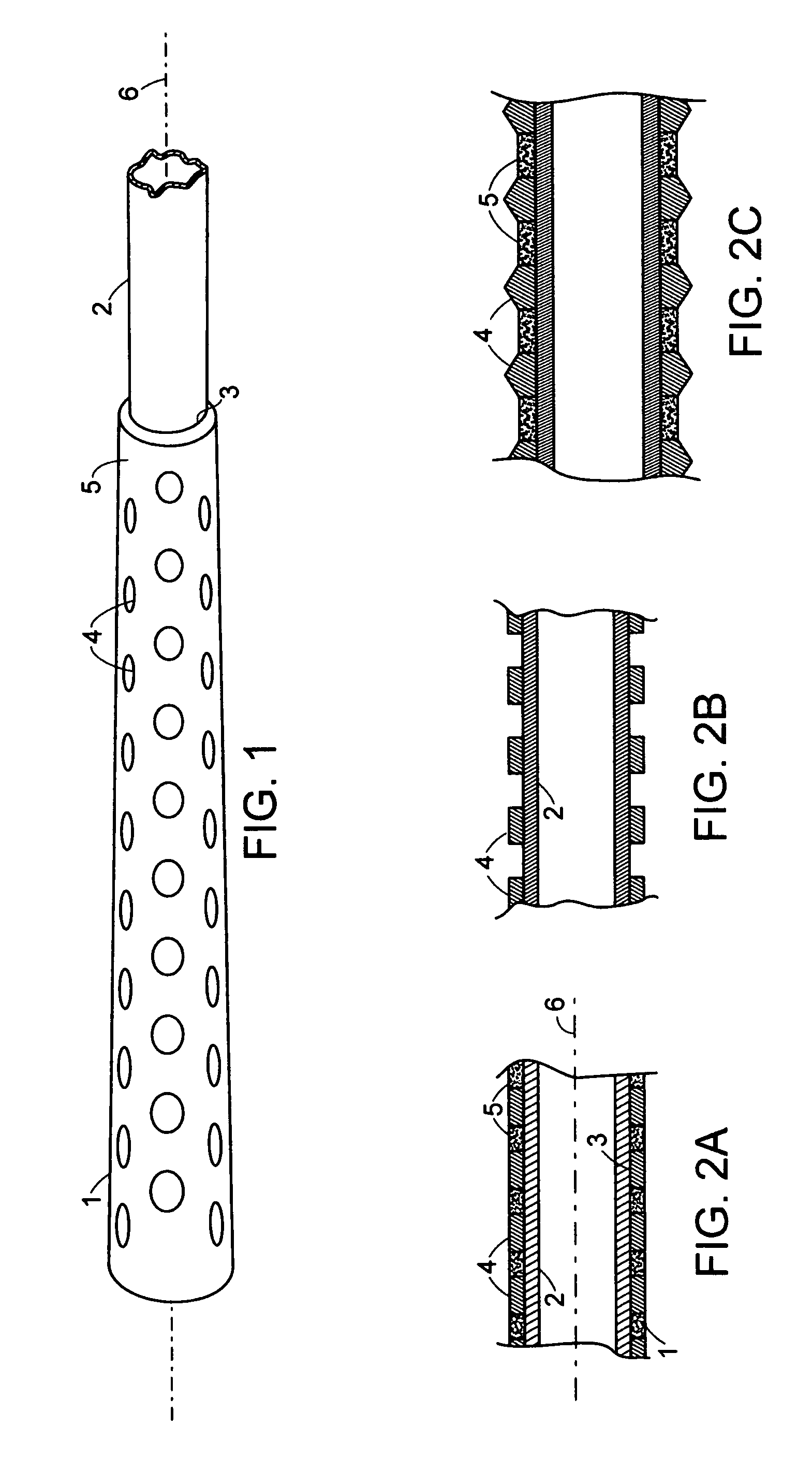

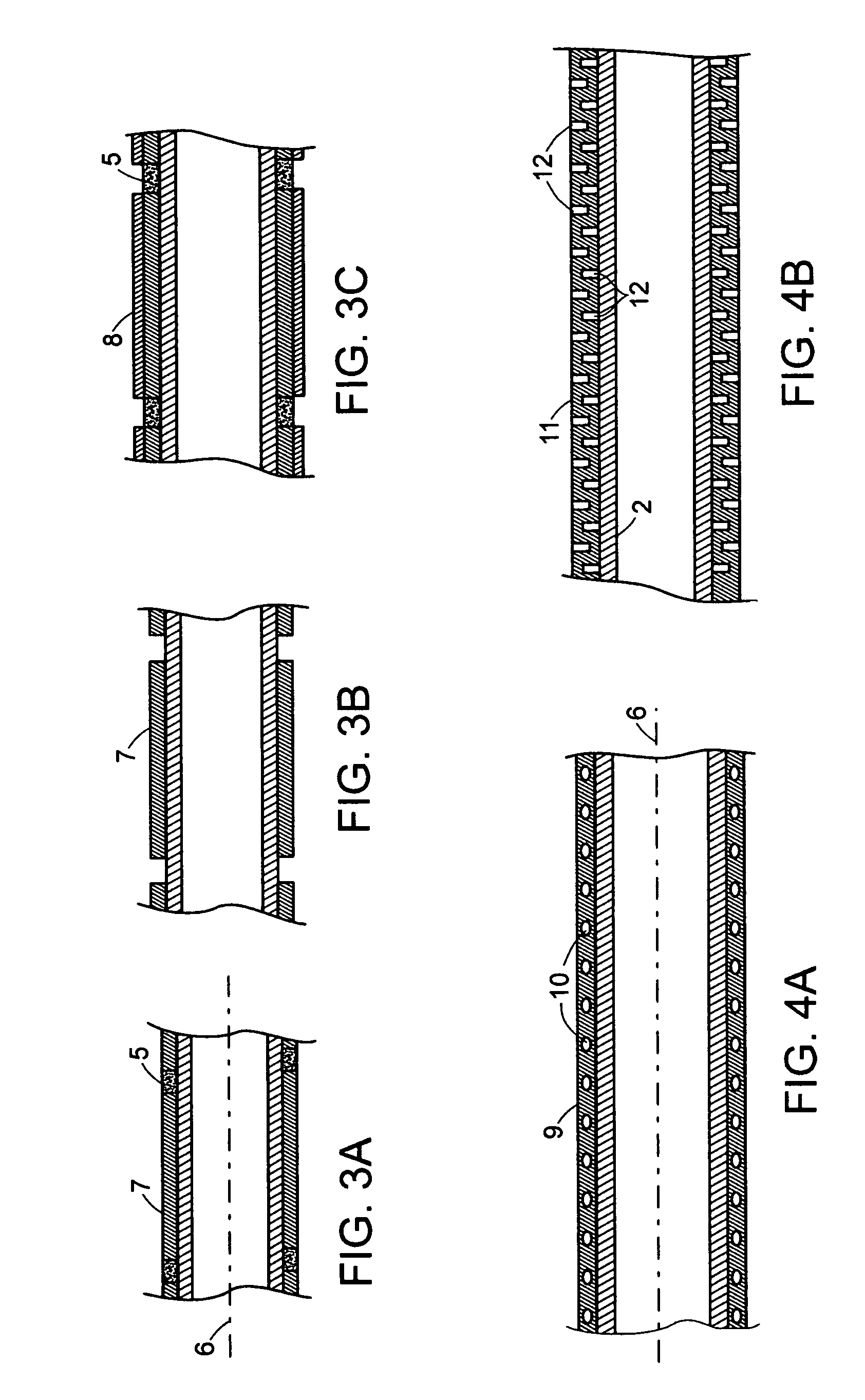

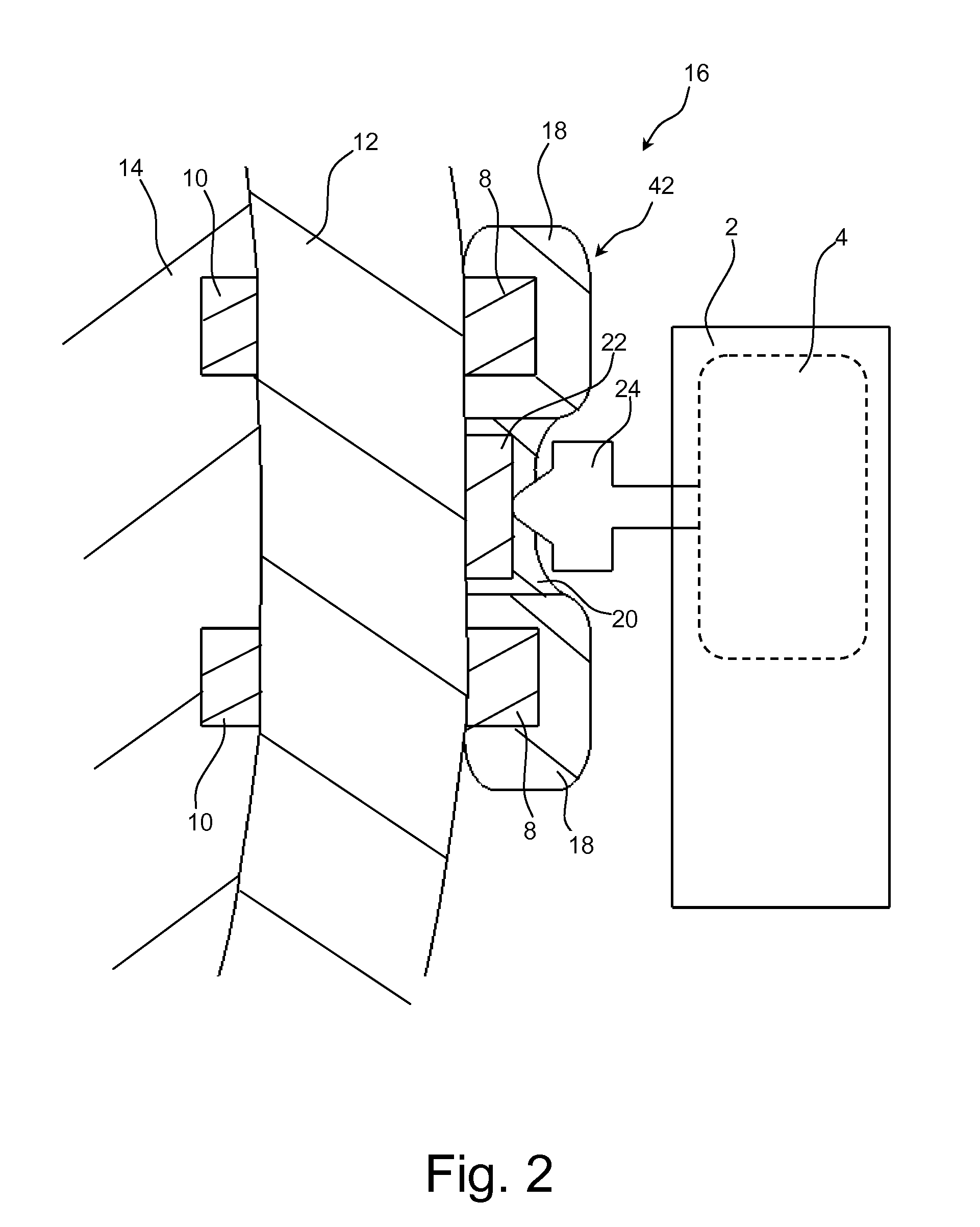

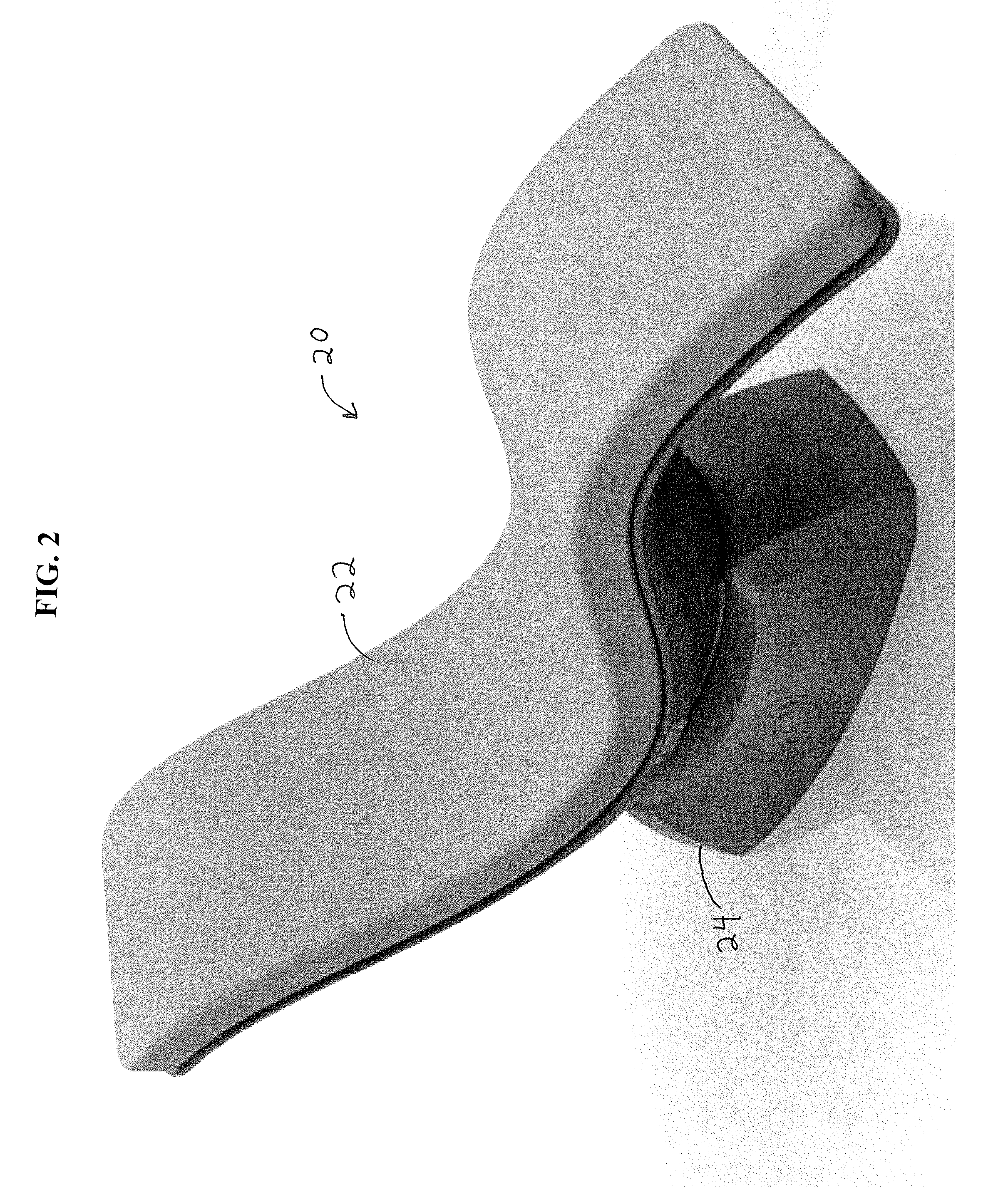

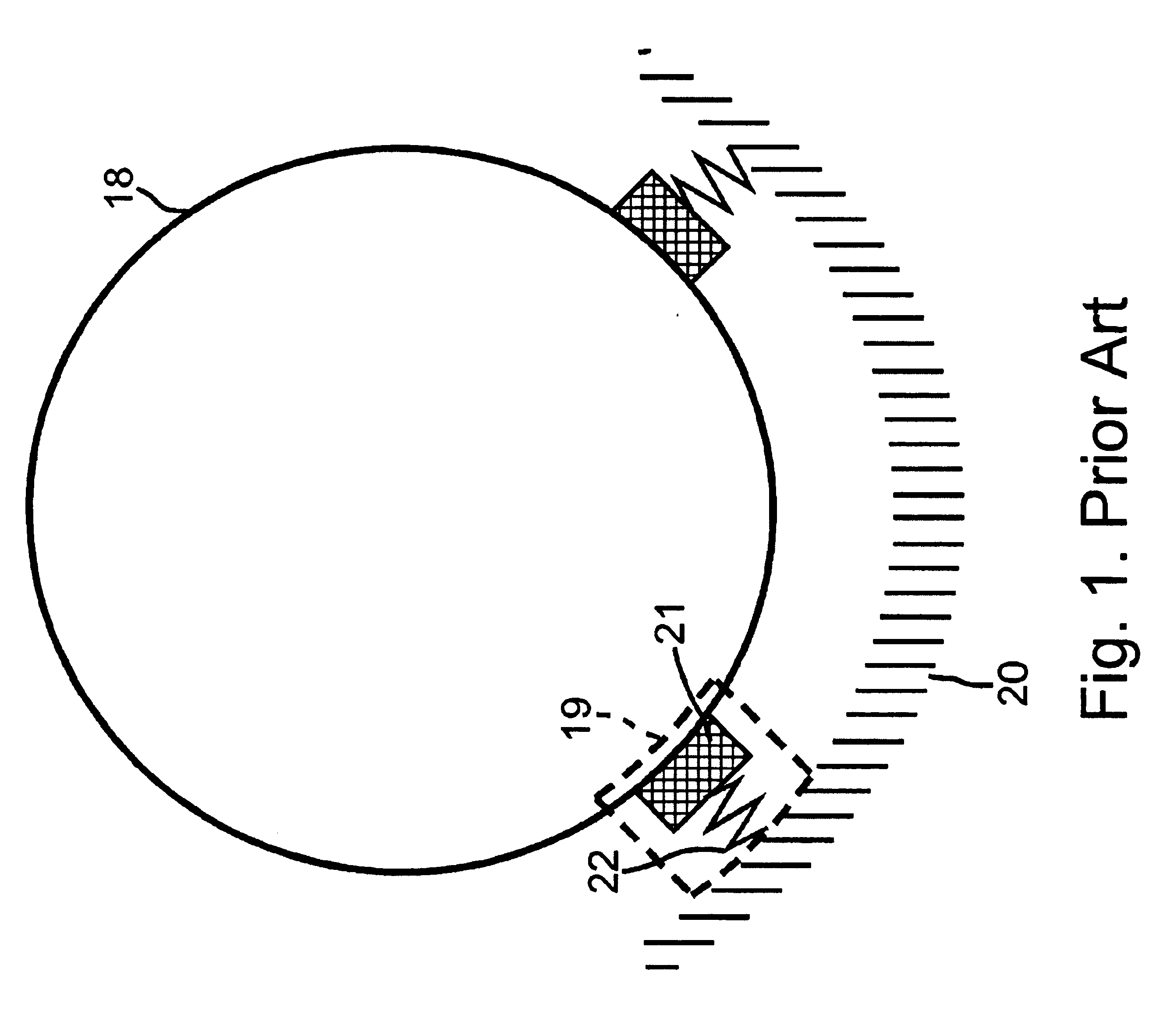

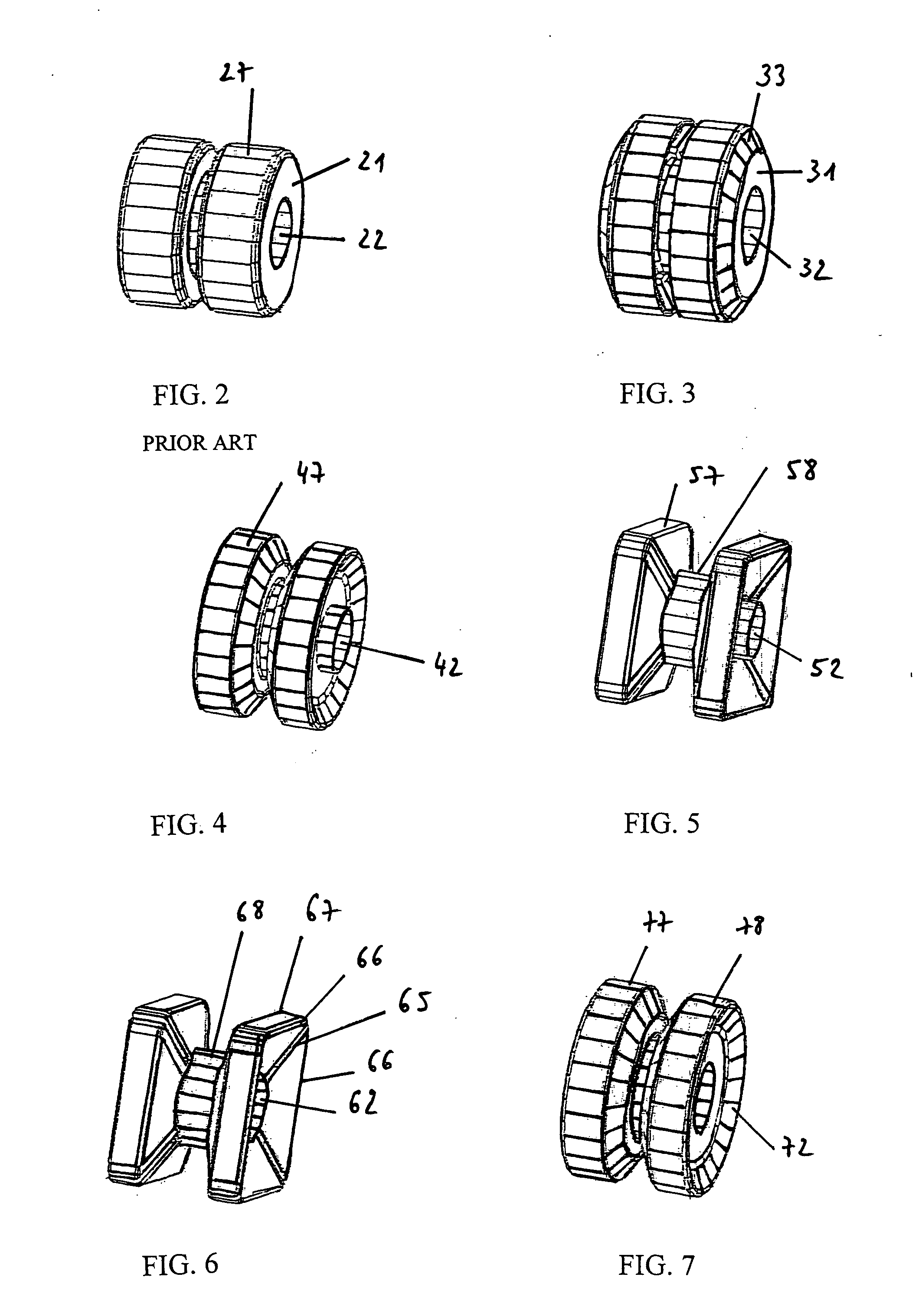

Putter grip with improved vibration transmission to hands

InactiveUS7140973B2Increase impactIncrease vibrationGolf clubsRacket sportsGolf BallVibration transmission

A putter or other golf club grip has rigid vibration transmitting protrusions either attached to the club shaft or in intimate contact with both the shaft and the golfer's hands, areas between said protrusions optionally being filled with conventional grip materials. The grip may be placed over existing club shafts like conventional slip-on or wrap-on grips or become an extension thereof. The grips may be attached and weighted in such a manner to further enhance desirable impact vibrational feedback to a golfer's hands further improving a golfer's distance control while reducing off center hits and the resulting distance and directional loss.

Owner:ROHRER TECH

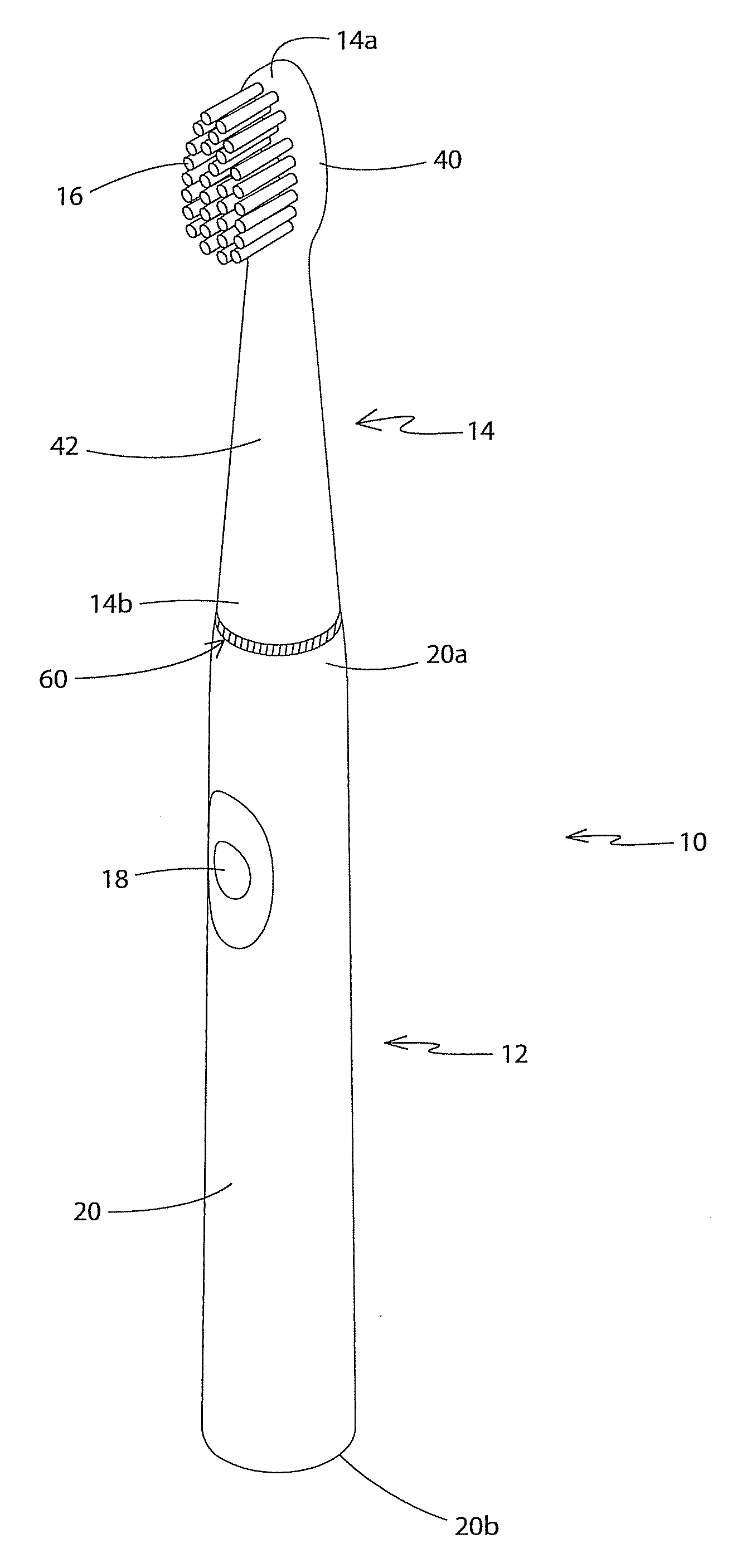

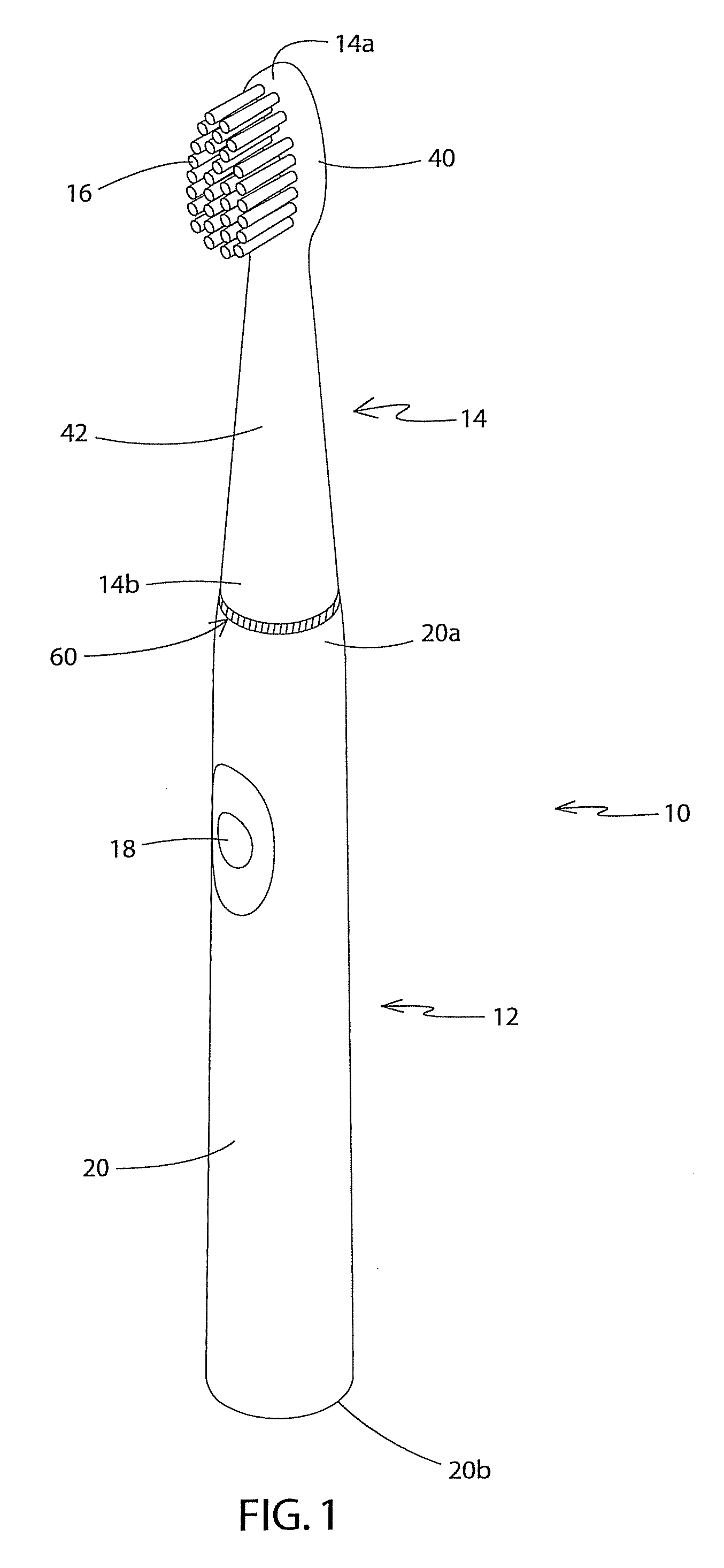

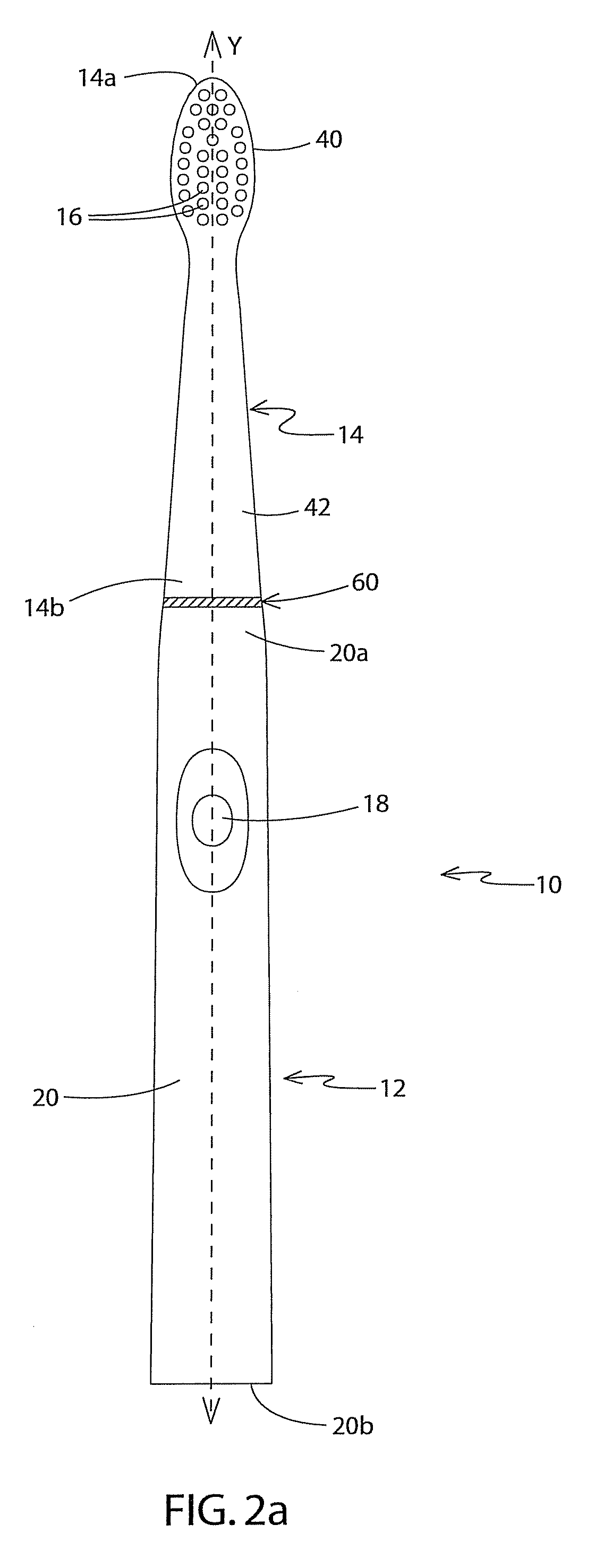

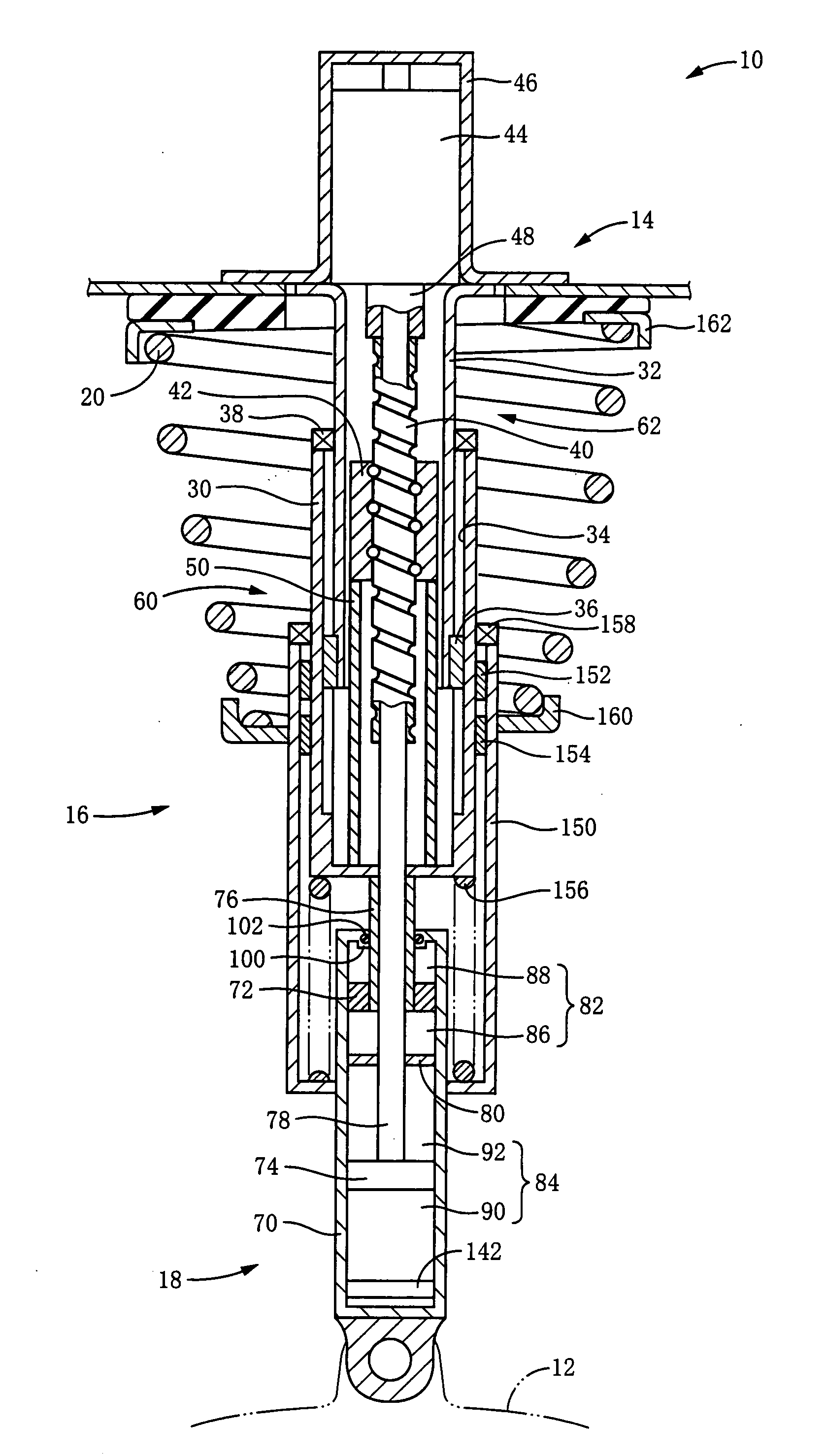

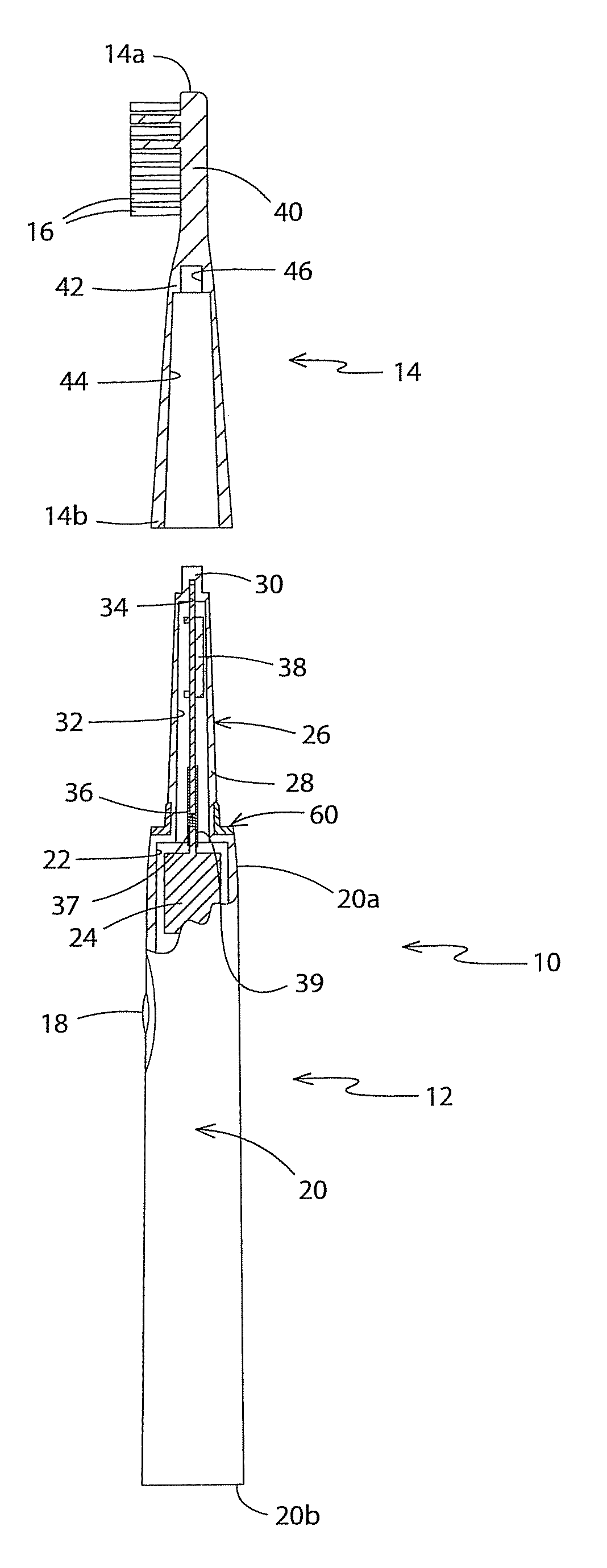

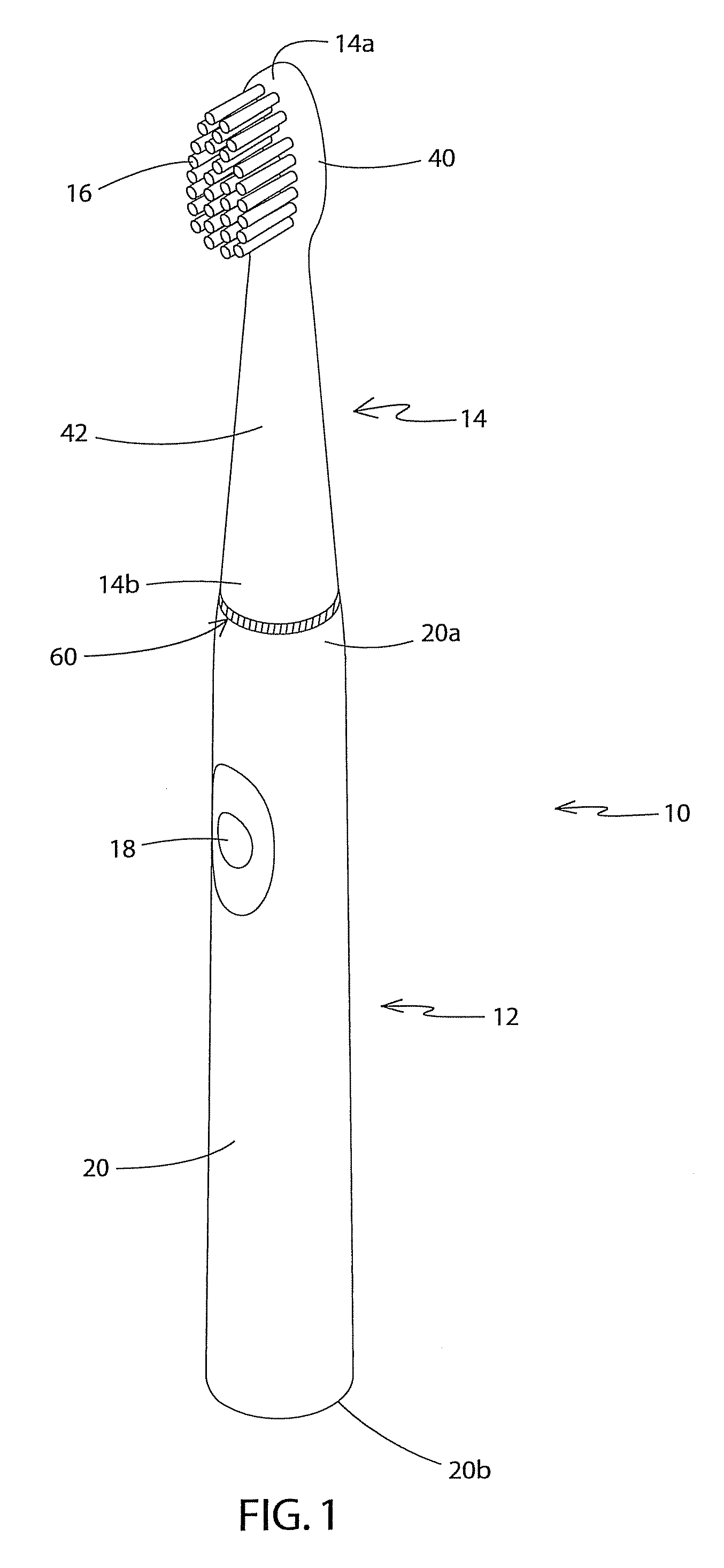

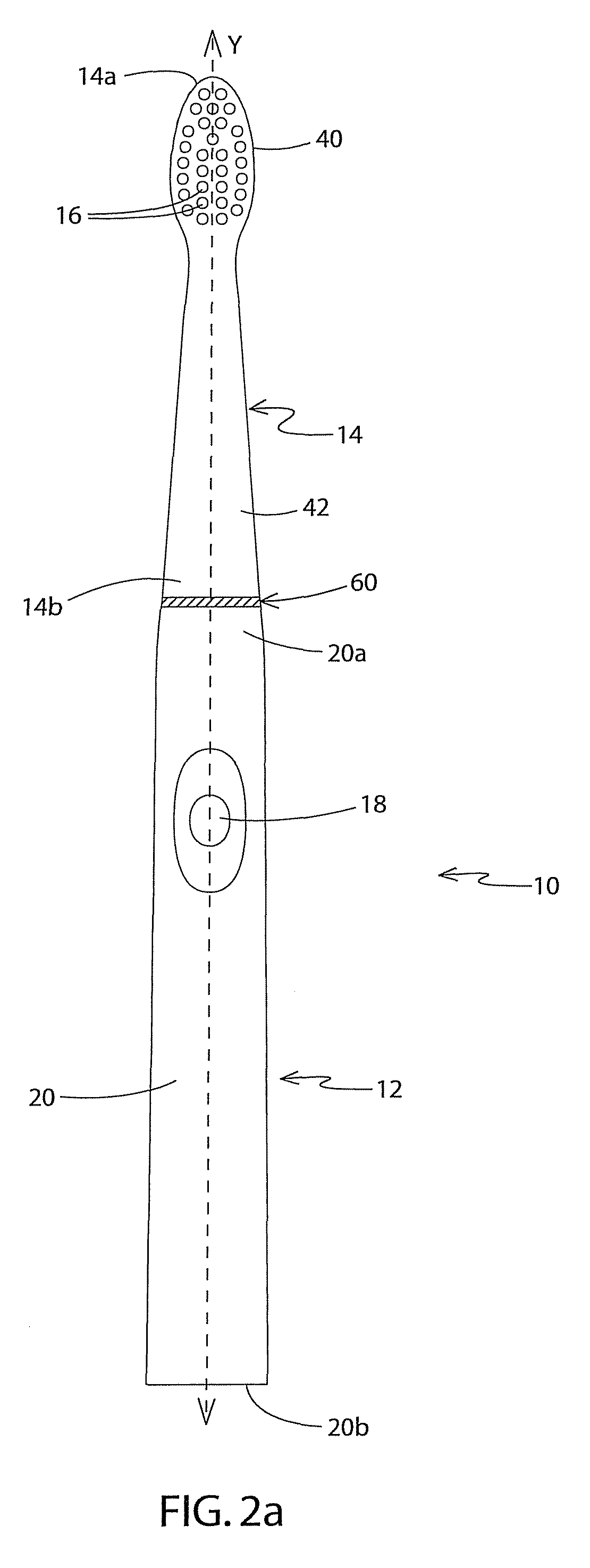

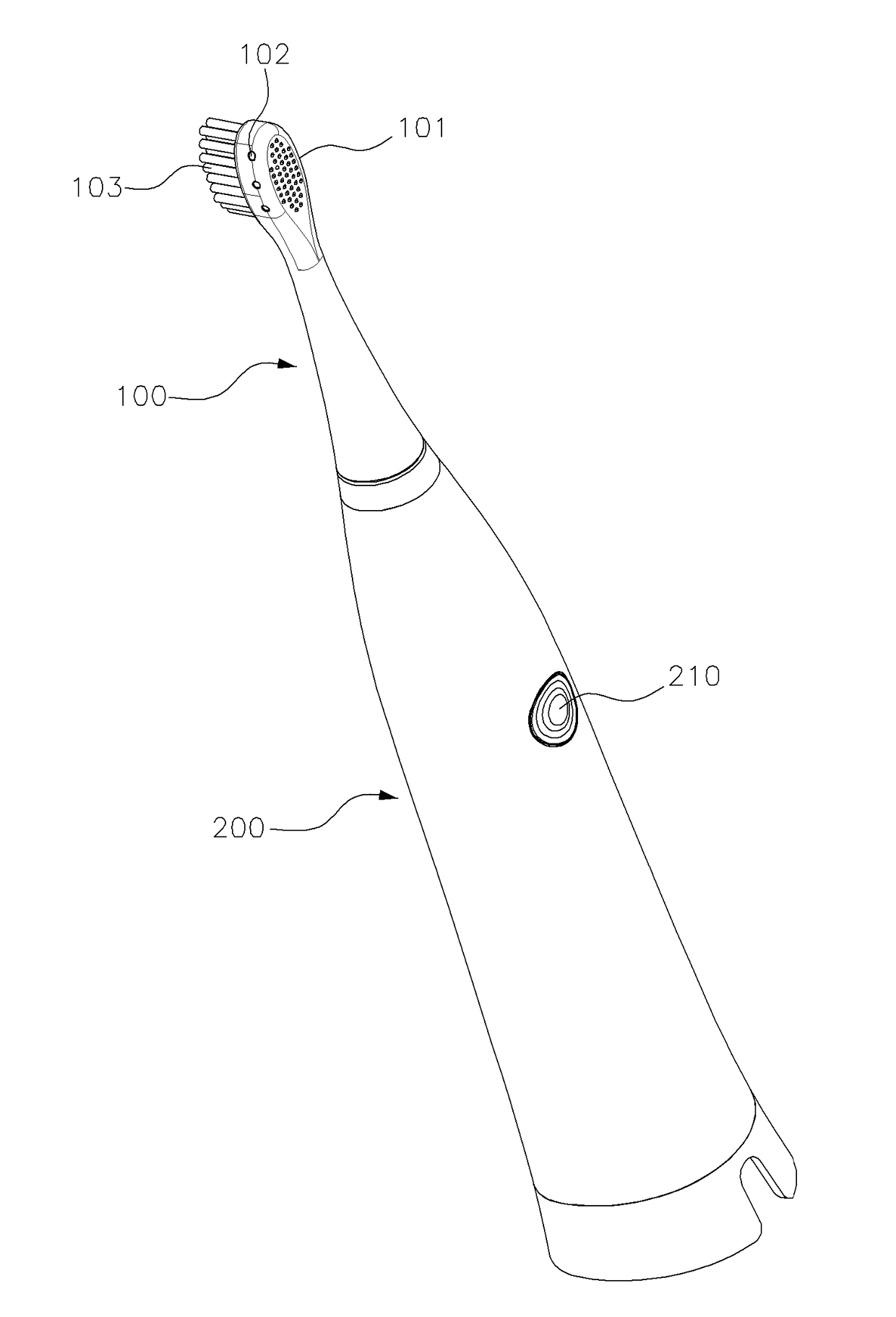

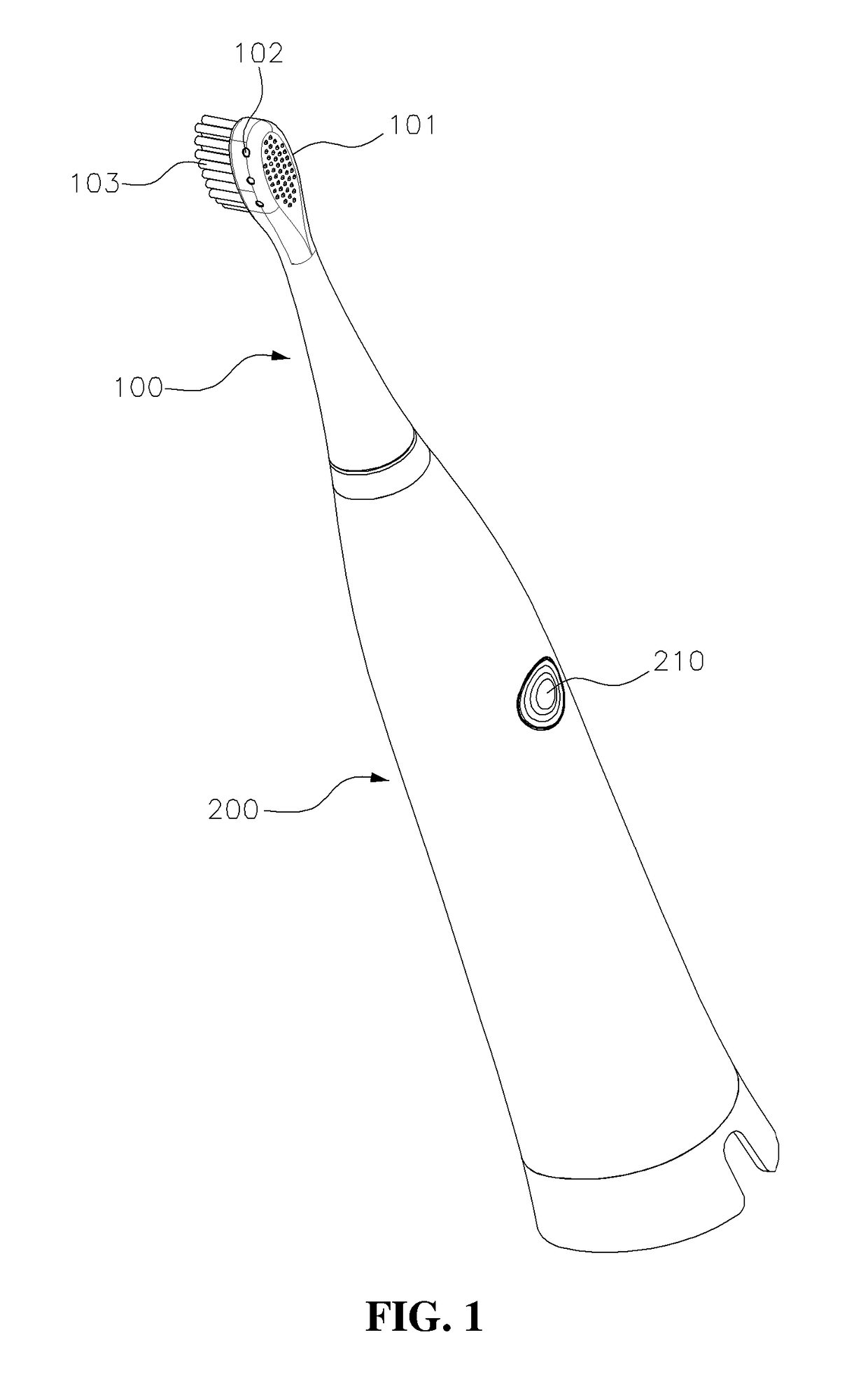

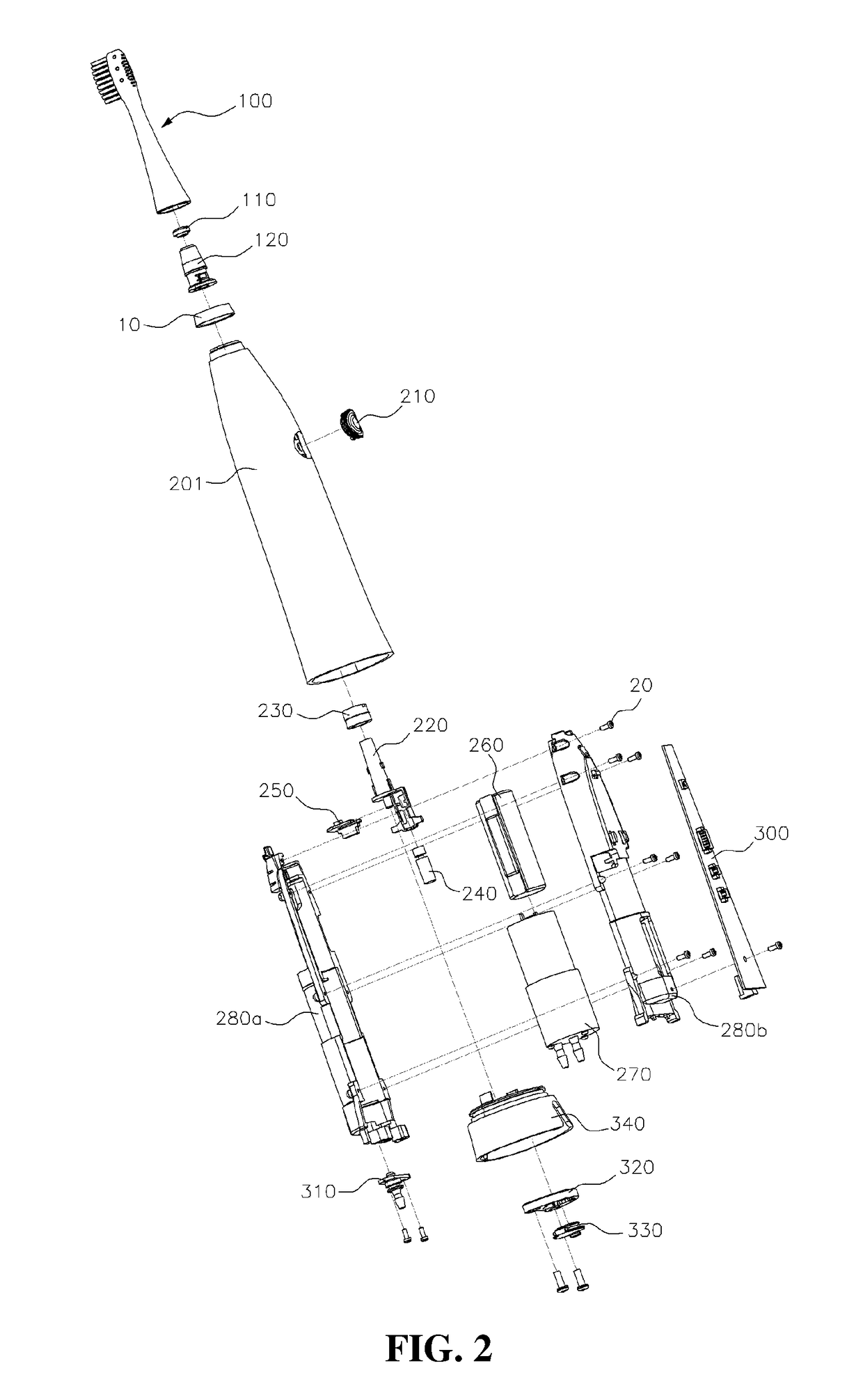

Vibrating toothbrush and a replaceable brush head for use with the same

ActiveUS20110010874A1Reduce vibration transmittedOn the cleaning ability of the toothbrushCarpet cleanersBrush bodiesEngineeringVibration transmission

A vibrating toothbrush comprising a handle including a body with a tubular member extending outwardly from one end. A replaceable sleeve slides over the tubular member and detachably engages the body. One or more of the sleeve, tubular member and body incorporates a vibration damping zone for reducing vibration transmission from the sleeve to the handle. The damping zone is one of a material that differs in damping properties to the material of the rest of the toothbrush; a hole defined in the one of the sleeve, tubular member and body, and a toothbrush where that hole is filled with an elastomeric material.

Owner:RANIR LLC

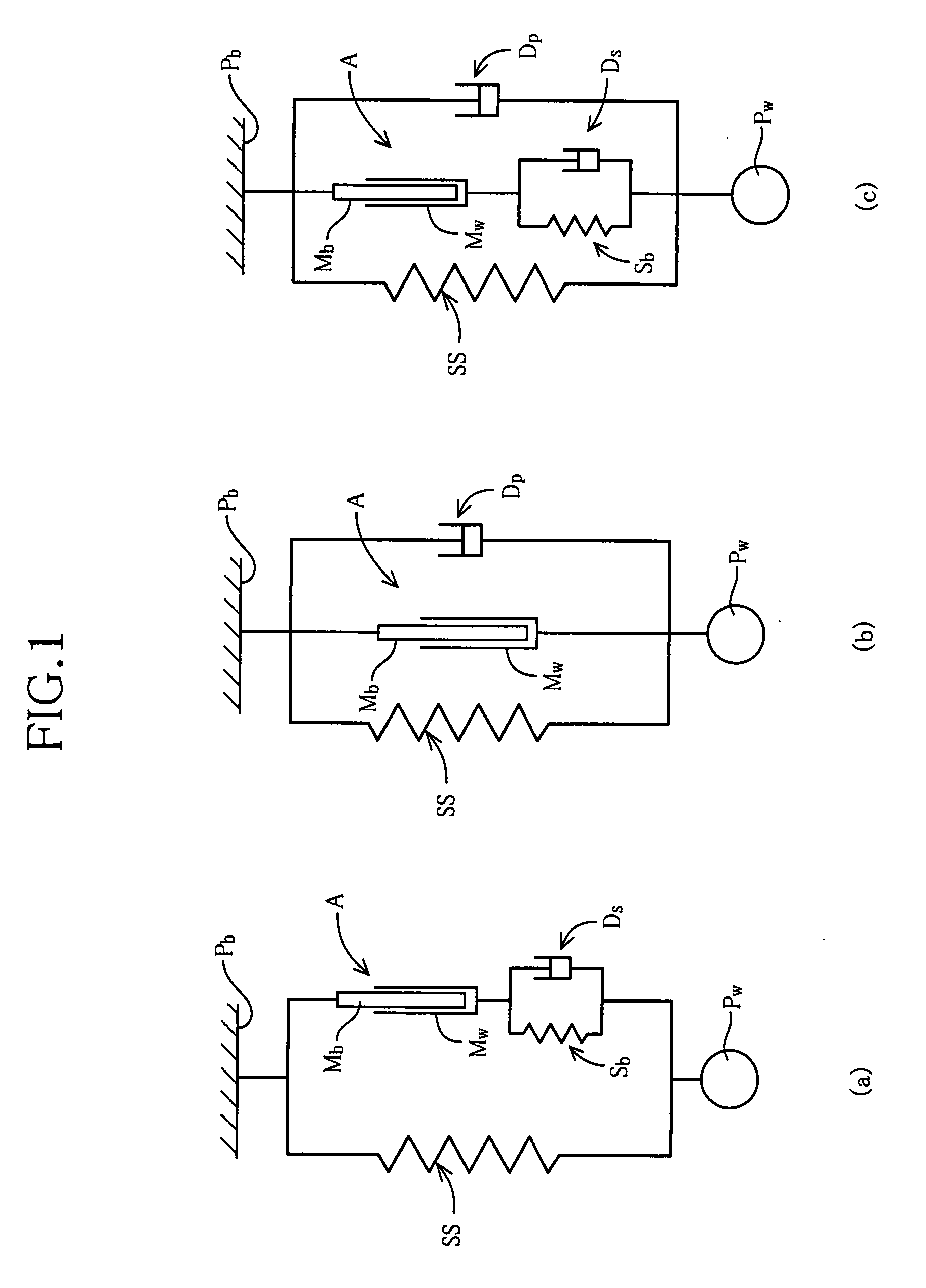

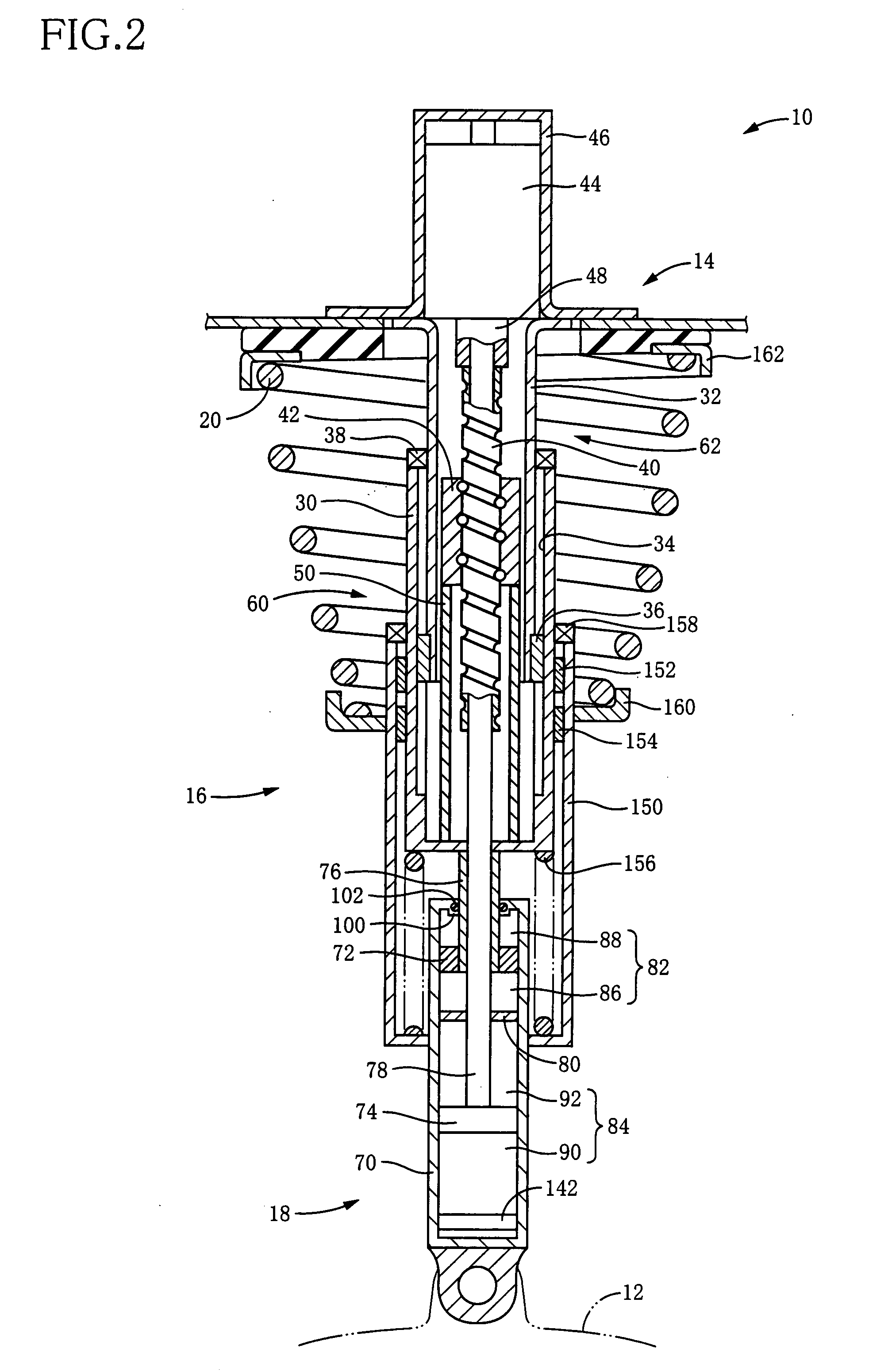

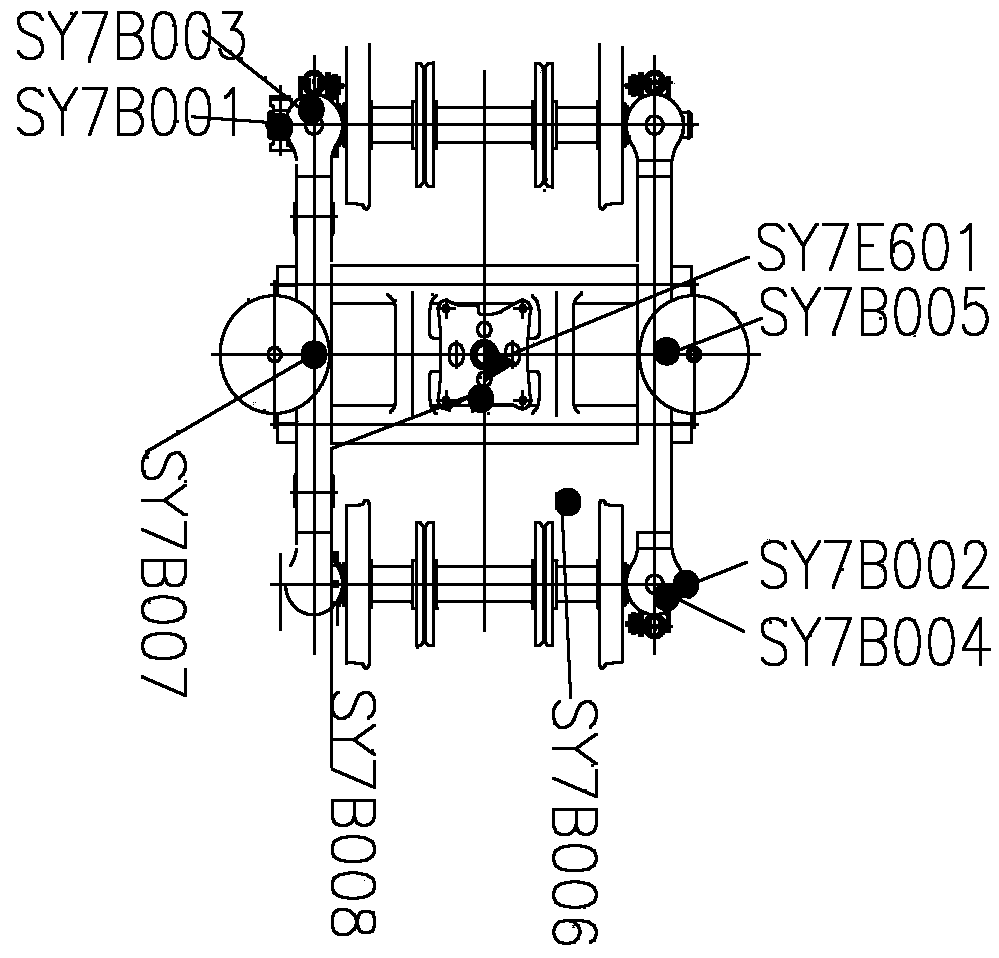

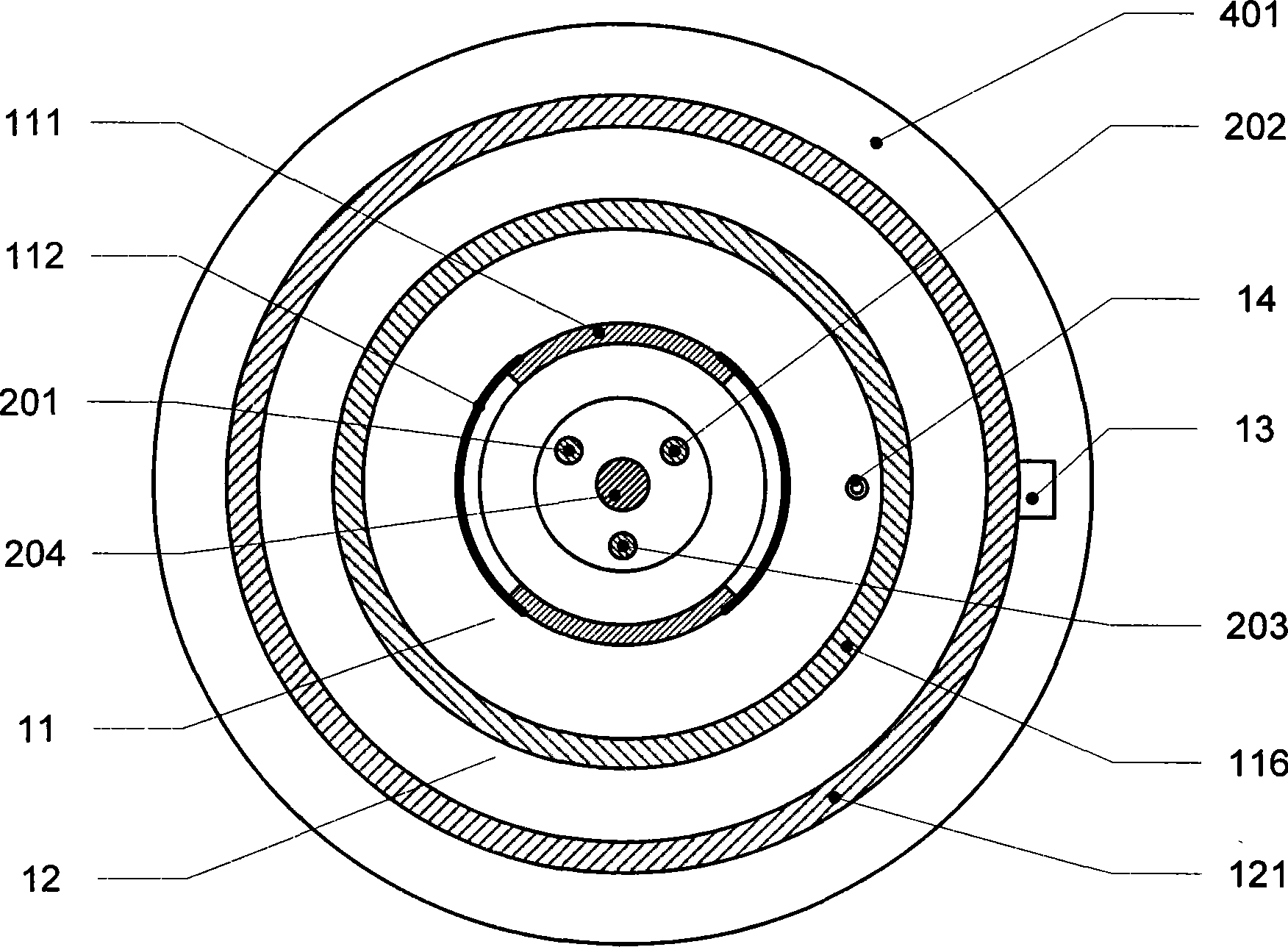

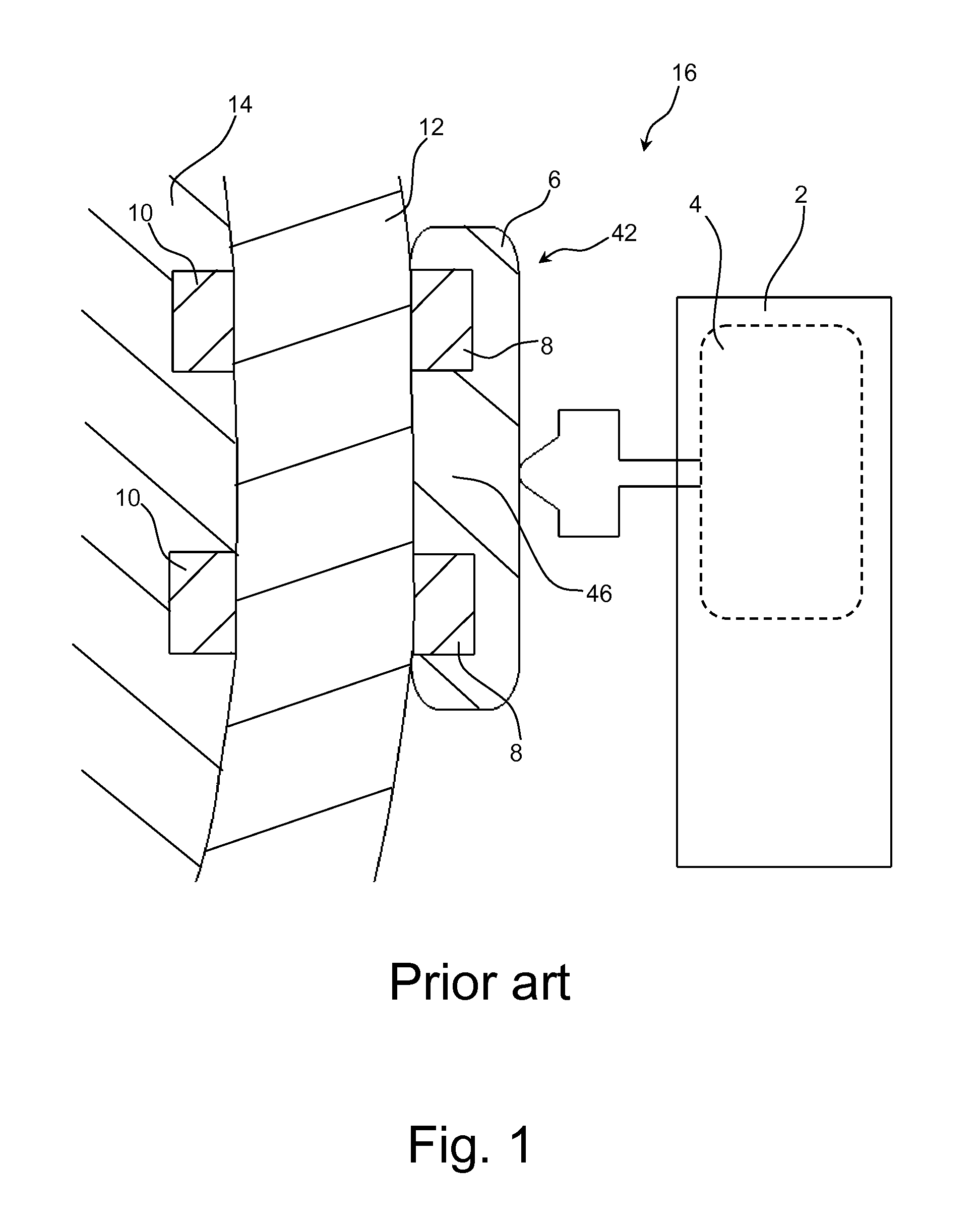

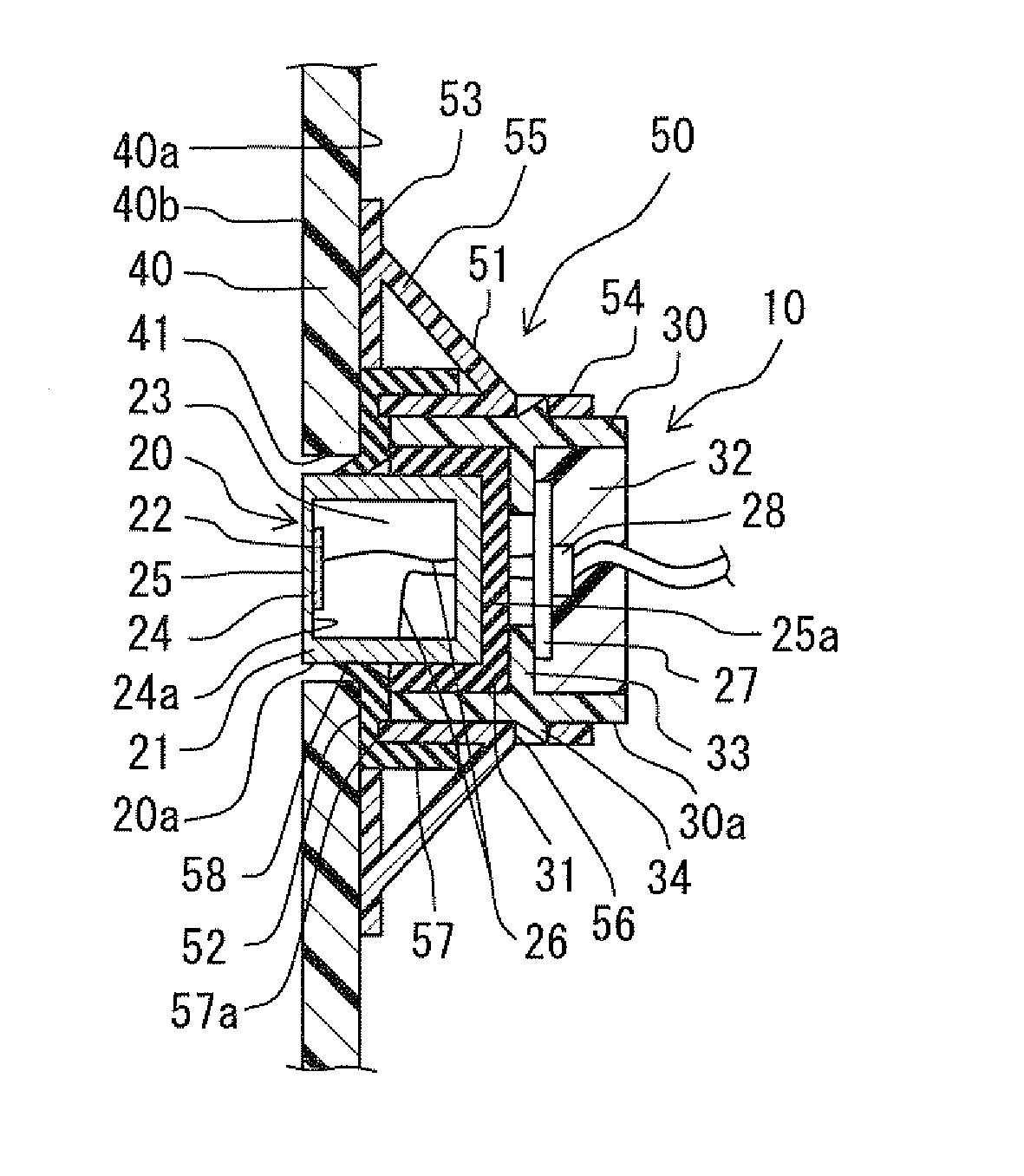

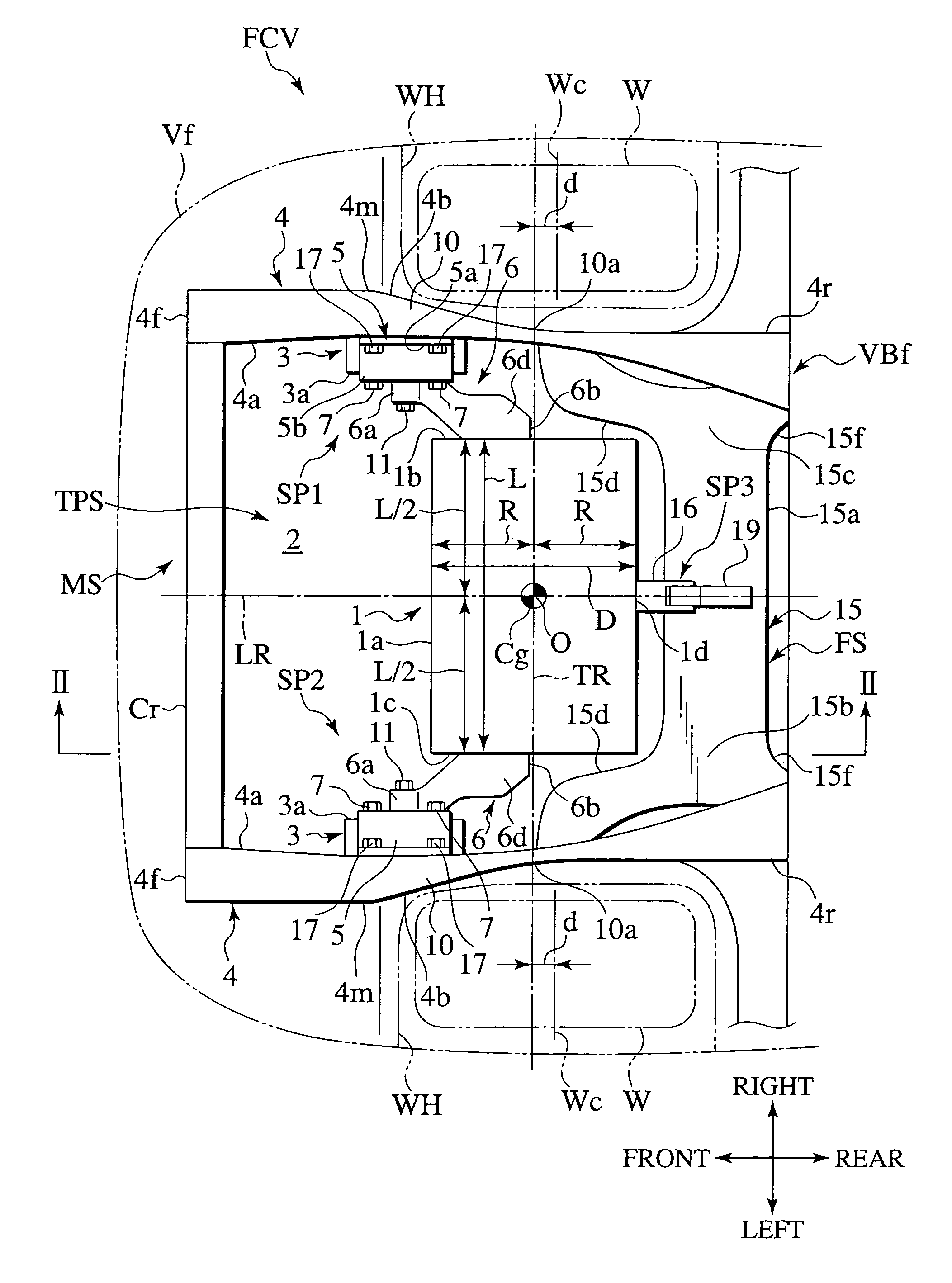

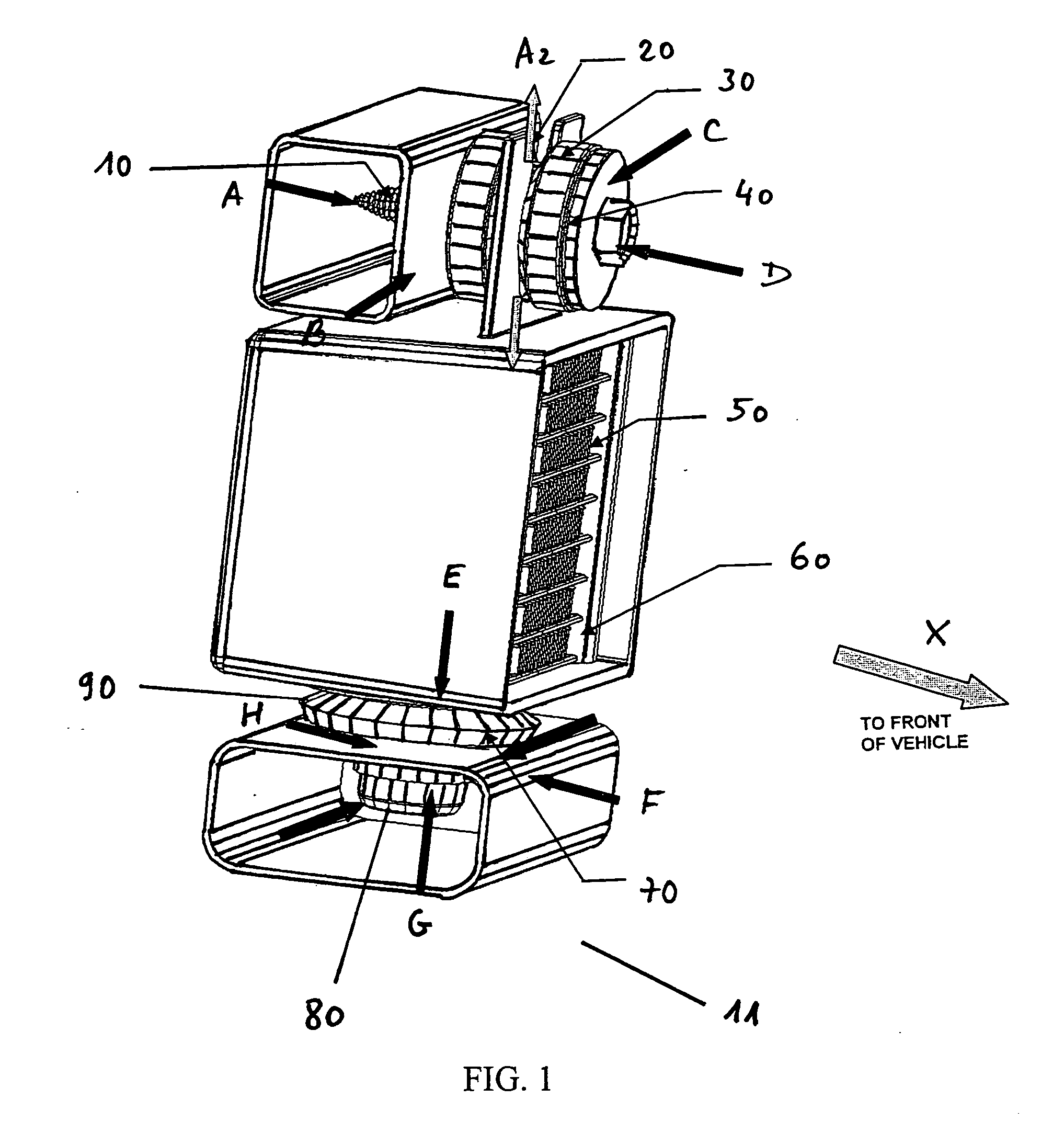

Suspension Apparatus for Vehicle

InactiveUS20080164111A1Simple structureReduce transmissionSpringsNon-rotating vibration suppressionControl theoryPiston rod

It is an object of the invention to improve utility in a suspension apparatus for a vehicle having an electromagnetic actuator and a hydraulic damper. In the suspension apparatus, a hydraulic damper is disposed between an electromagnetic actuator and a wheel-holding portion, and a cover tube is provided for accommodating a seal provided between a piston rod and a housing of the hydraulic damper. In the suspension apparatus according to the present invention wherein the hydraulic damper is disposed between the wheel-holding portion and the electromagnetic actuator, it is possible to effectively mitigate not only transmission of vibrations to the vehicle body from the wheel via the electromagnetic actuator but also transmission of vibrations to the electromagnetic actuator. Further, owing to the presence of the cover tube, entry of dust and the like into the hydraulic damper through the seal can be effectively prevented.

Owner:TOYOTA JIDOSHA KK +1

Vibrating toothbrush and a replaceable brush head for use with the same

ActiveUS8453285B2Reduce vibration transmittedOn the cleaning ability of the toothbrushCarpet cleanersBrush bodiesEngineeringVibration transmission

A vibrating toothbrush comprising a handle including a body with a tubular member extending outwardly from one end. A replaceable sleeve slides over the tubular member and detachably engages the body. One or more of the sleeve, tubular member and body incorporates a vibration damping zone for reducing vibration transmission from the sleeve to the handle. The damping zone is one of a material that differs in damping properties to the material of the rest of the toothbrush; a hole defined in the one of the sleeve, tubular member and body, and a toothbrush where that hole is filled with an elastomeric material.

Owner:RANIR LLC

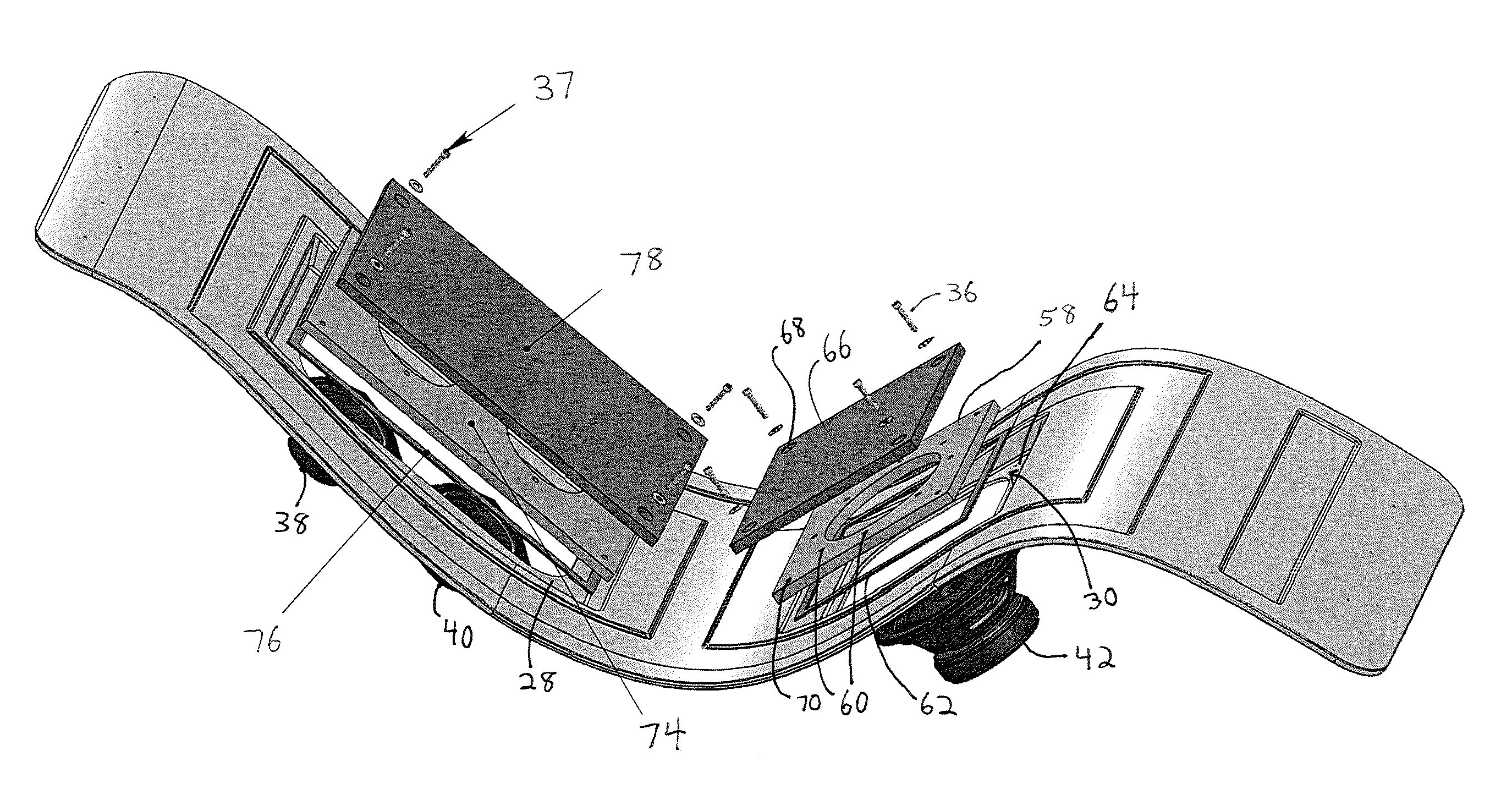

Sound and vibration transmission pad and system

InactiveUS20050053252A1Increase awarenessImprove the level ofStereophonic circuit arrangementsChiropractic devicesAcoustic transmissionEngineering

The present invention is directed to a pad and sound transmission system which is adapted to directly transmit audible sound waves into the body at high intensity levels. In one embodiment, the subject invention includes a back pad and a seat pad. Each pad includes a speaker module having an acoustic speaker disposed within the pad and surrounded by a plurality of different layers.

Owner:ROUND RIVER RES CORP

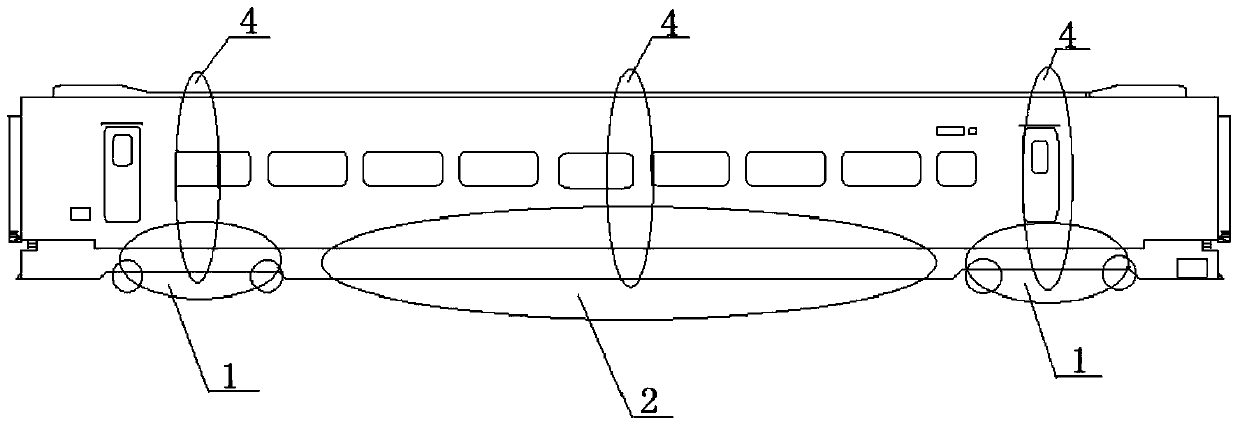

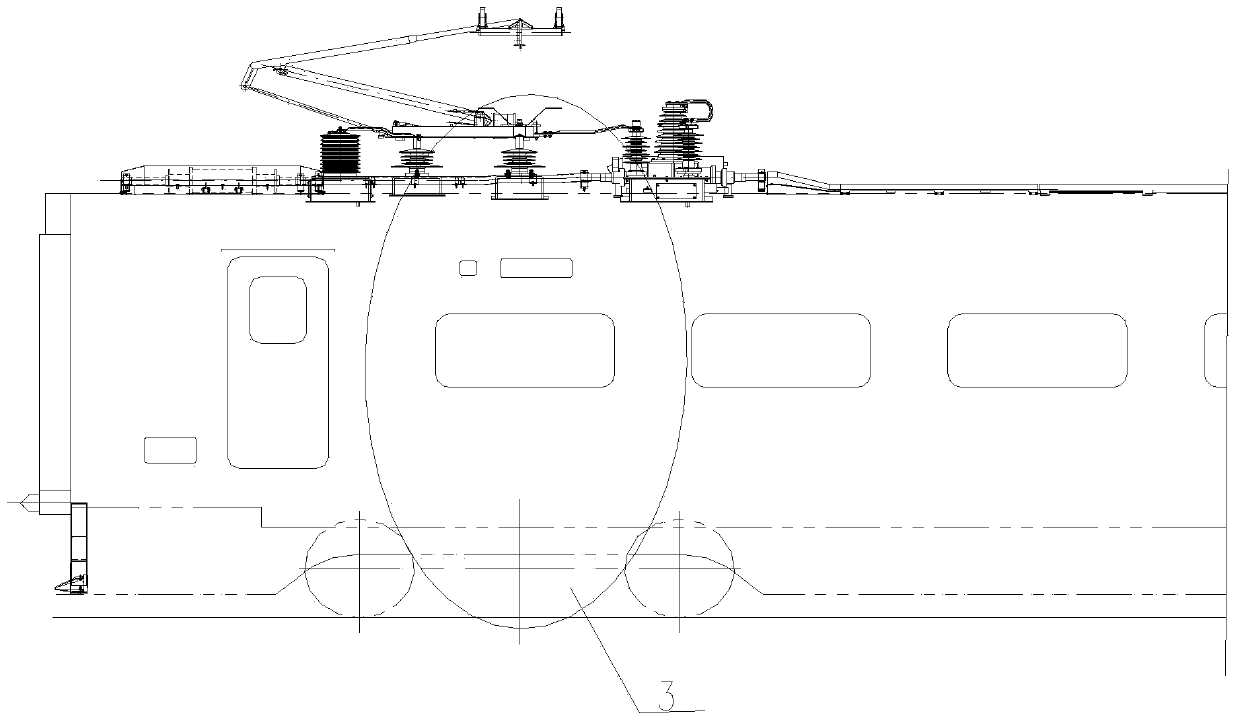

Noise source identifying and testing method for high speed train

ActiveCN103630232ARealize sound source controlImplement path controlSubsonic/sonic/ultrasonic wave measurementBogieSound sources

The invention relates to a noise source identifying and testing method for high speed train. The method comprising the following steps: partitioning noise sources into a steering frame wheel track noise testing area, an equipment noise testing area, a pantograph noise testing area and a pneumatic noise testing area; distributing testing points respectively according to the transmission paths of air sound and structure sound in each area; acquiring testing point data; analyzing through sound and vibration transmission paths; separating the air sound from the structure sound; calculating the contribution of each noise source to interior noise. According to the noise source identifying and testing method, sound sources and vibration sources causing interior noise of the high speed train can be identified, the contribution of each noise source and each vibration source to the interior noise is determined, sound source control and path control of the interior noise are realized fundamentally, and a scientific basis is laid for the vibration and noise reduction structural design of the high speed train.

Owner:CRRC QINGDAO SIFANG CO LTD

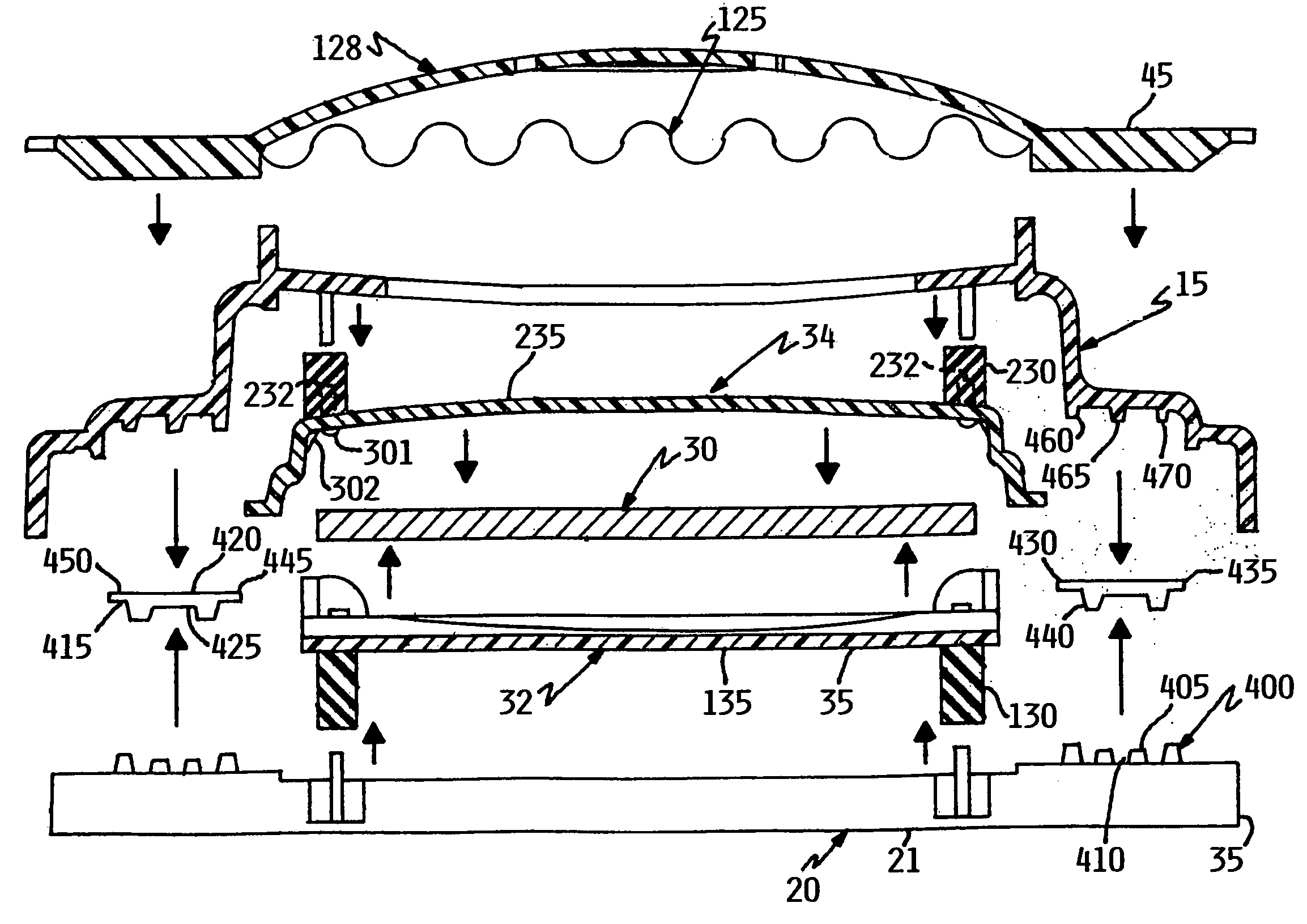

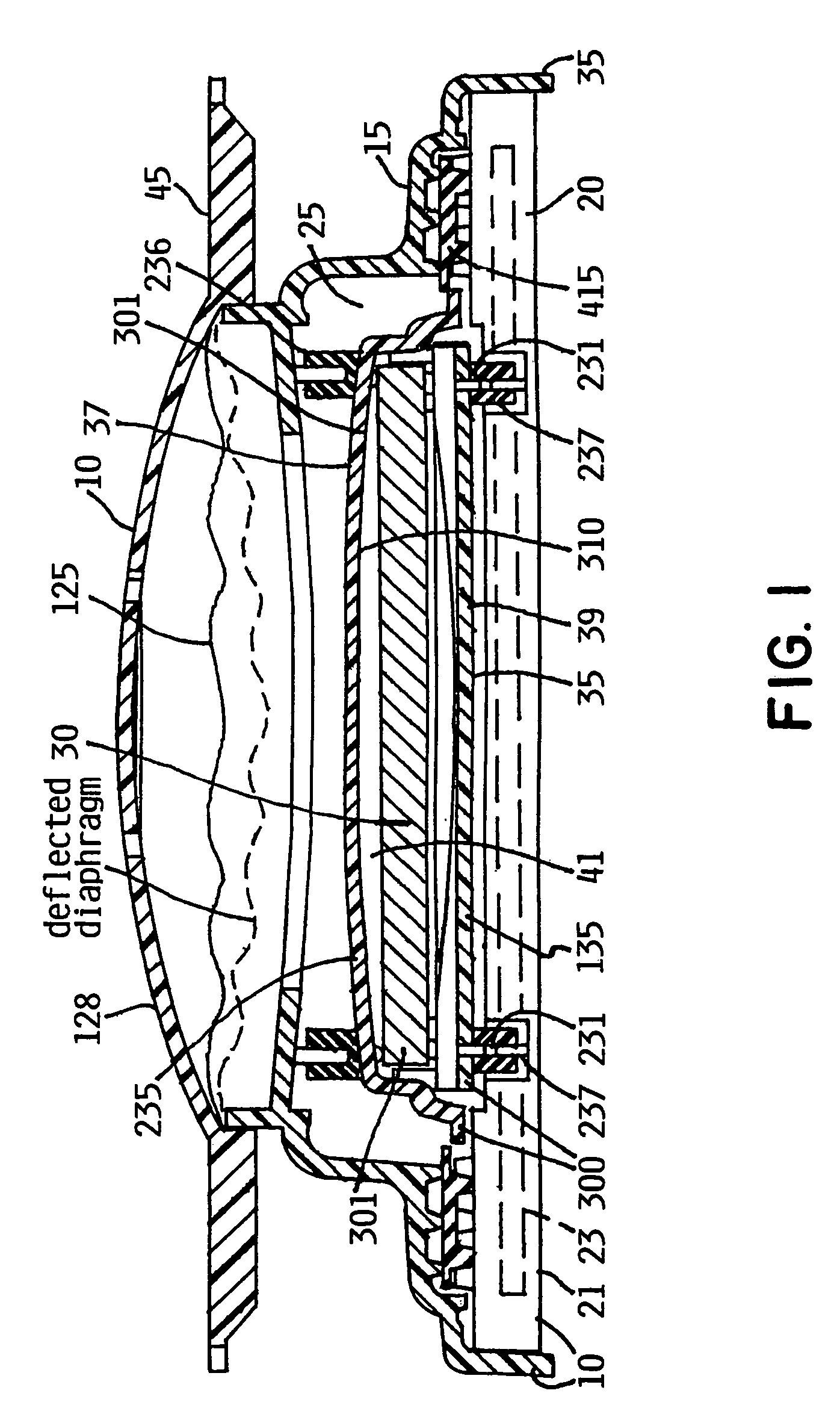

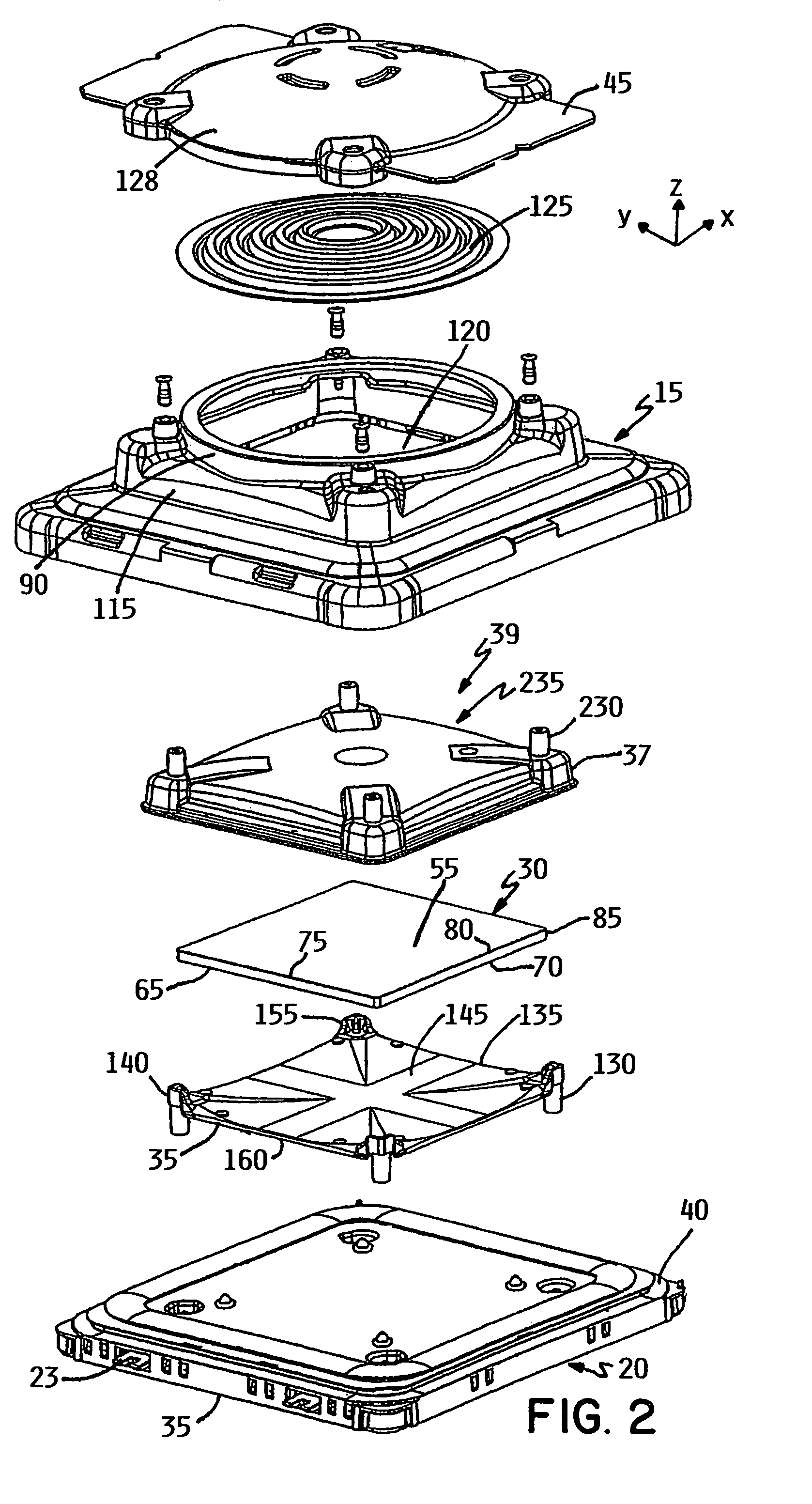

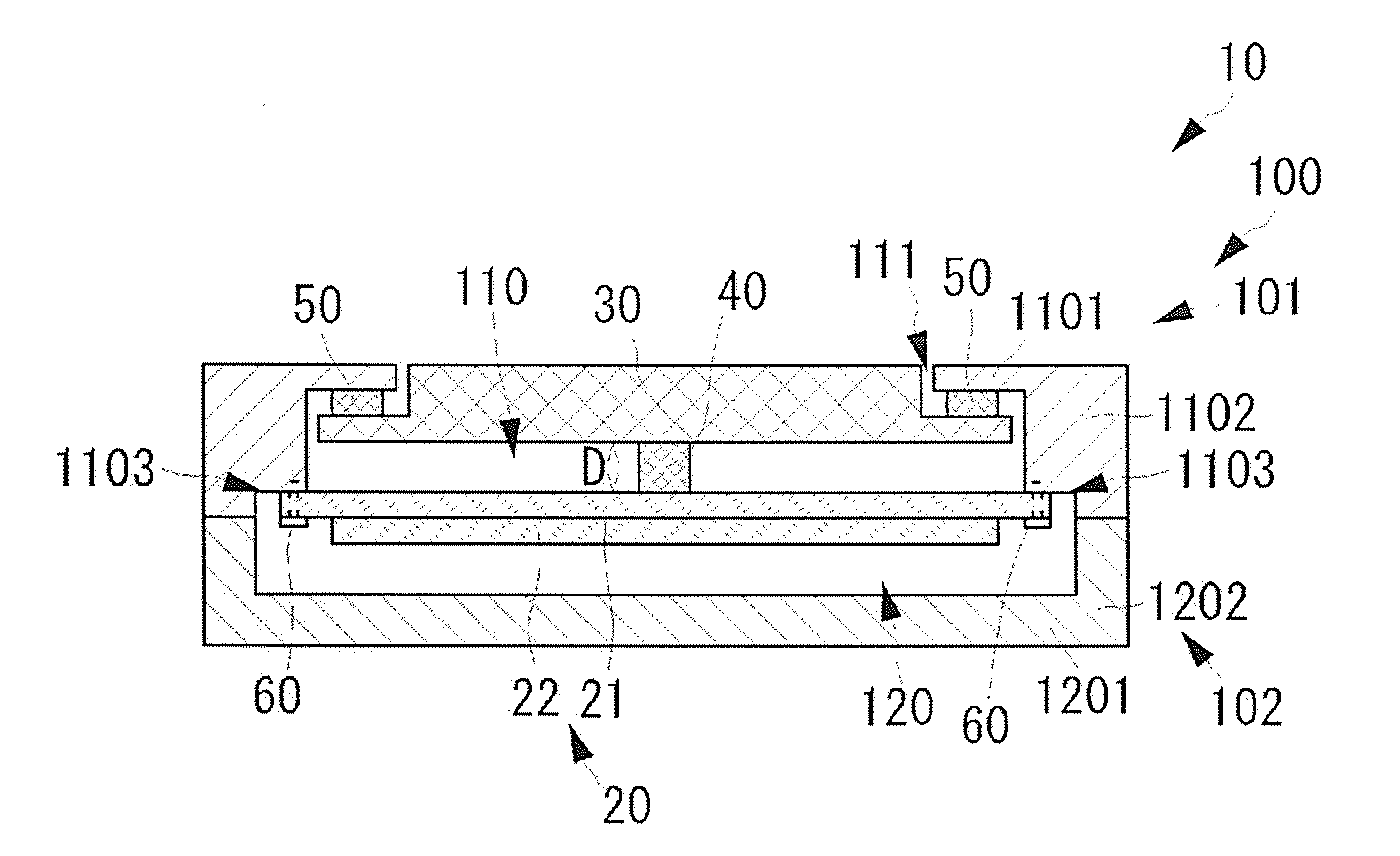

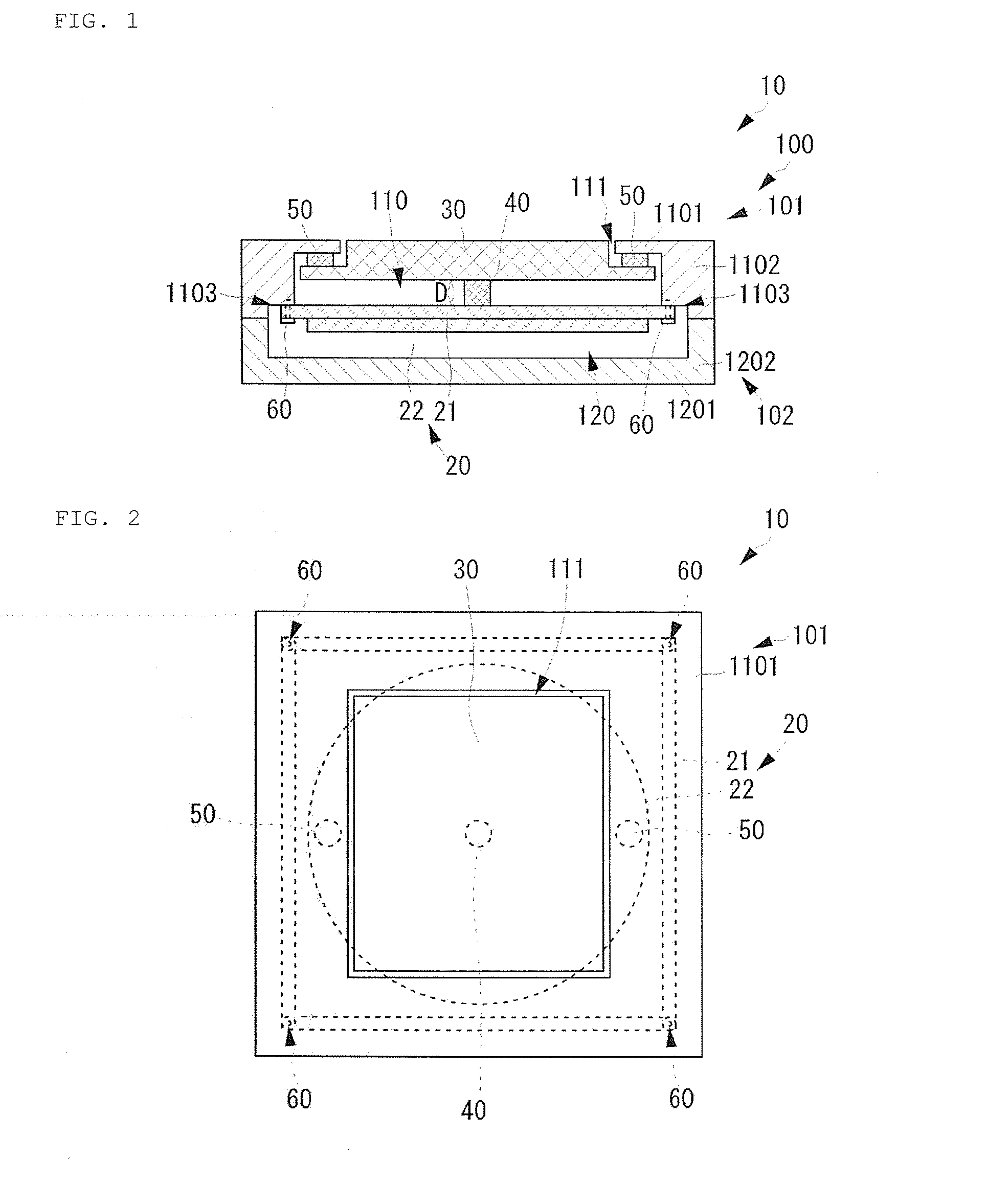

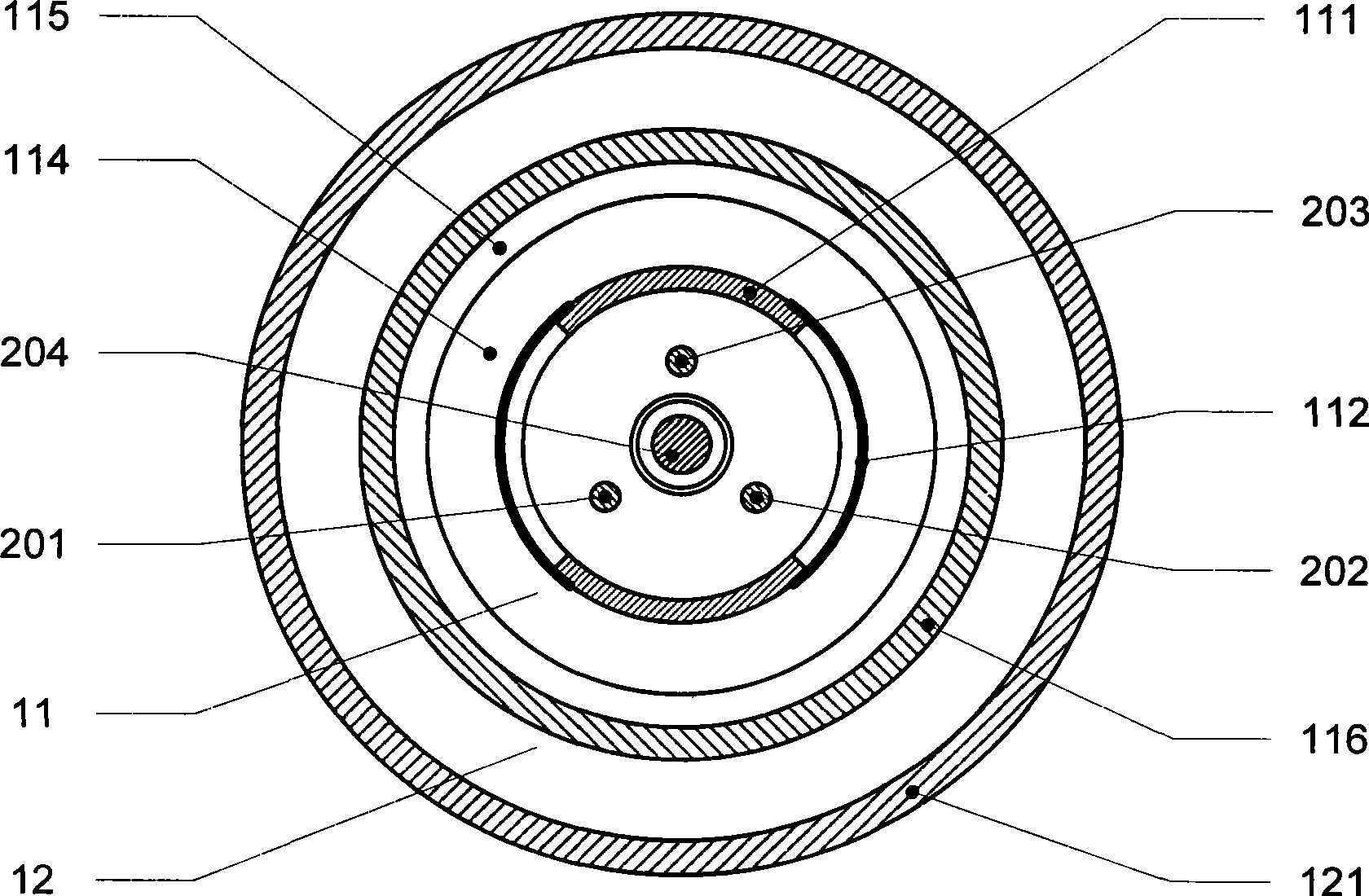

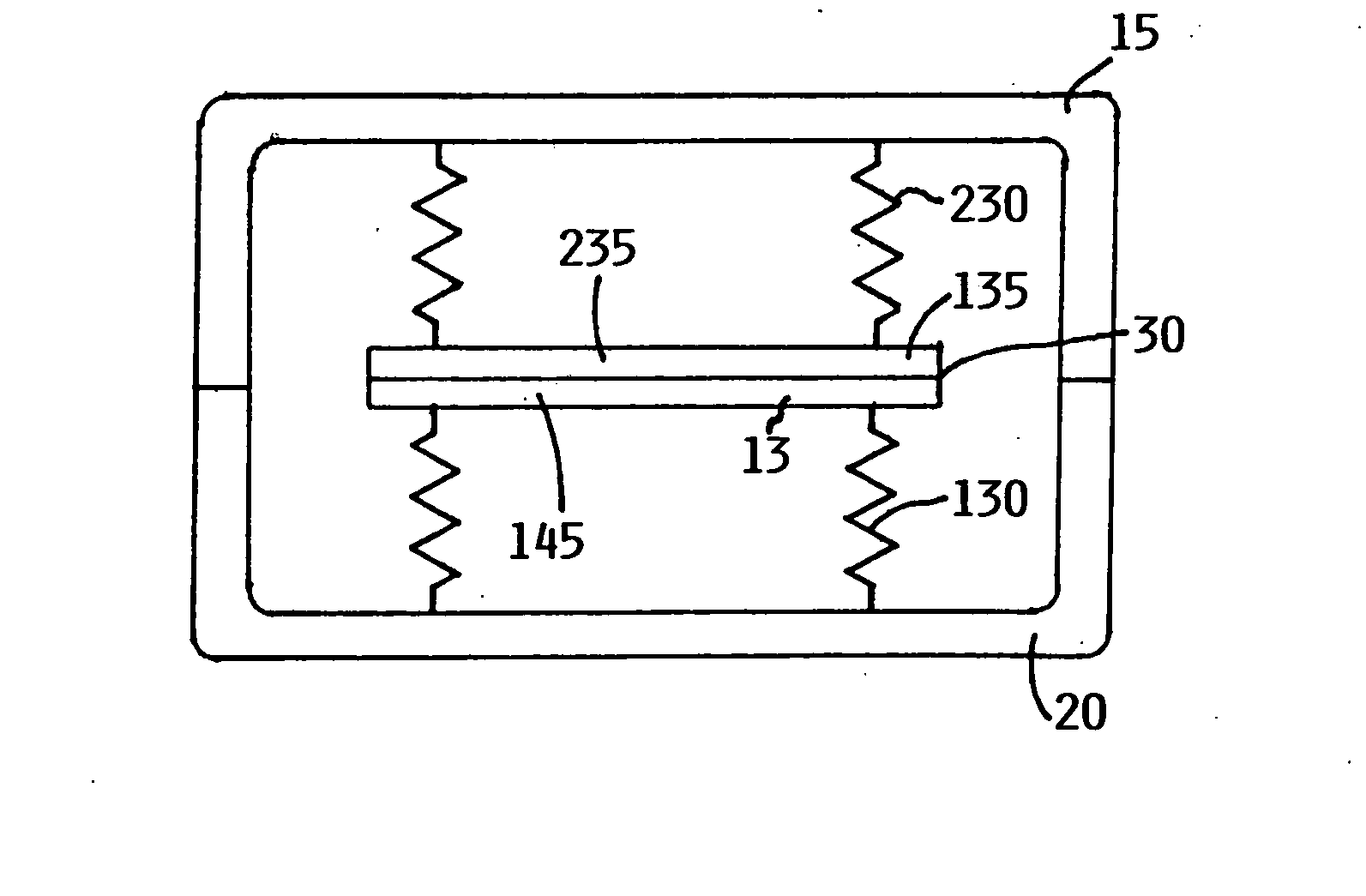

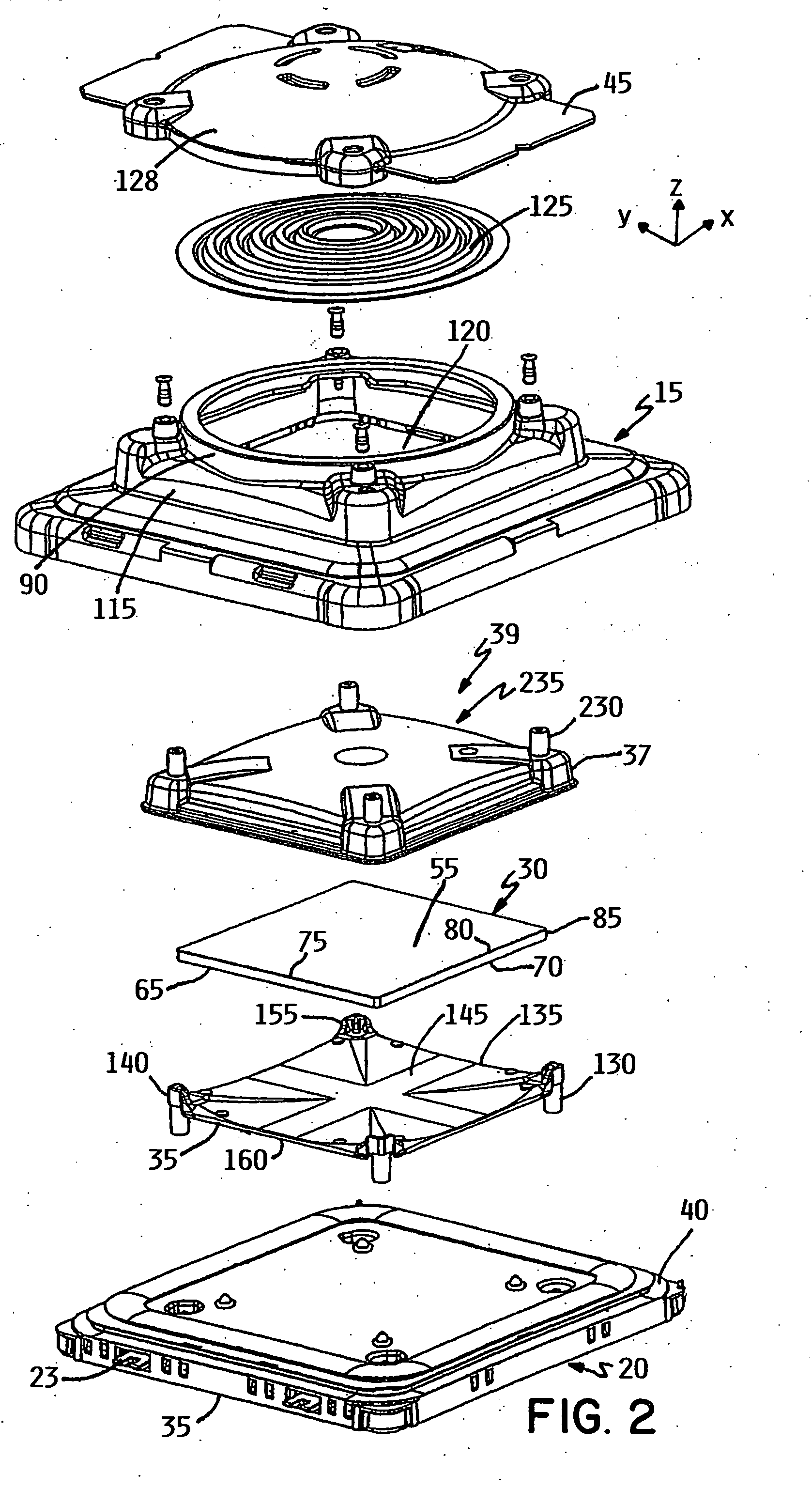

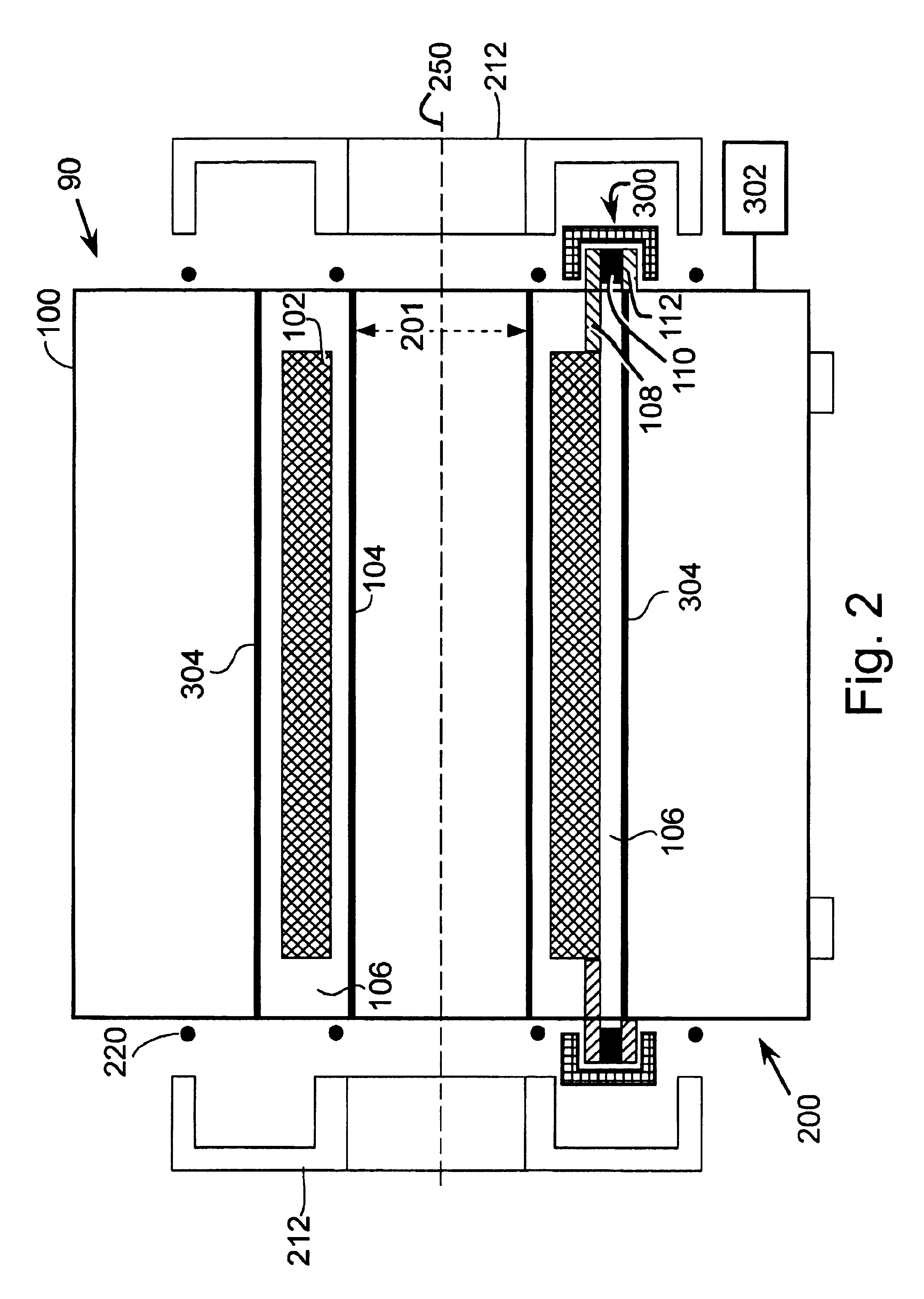

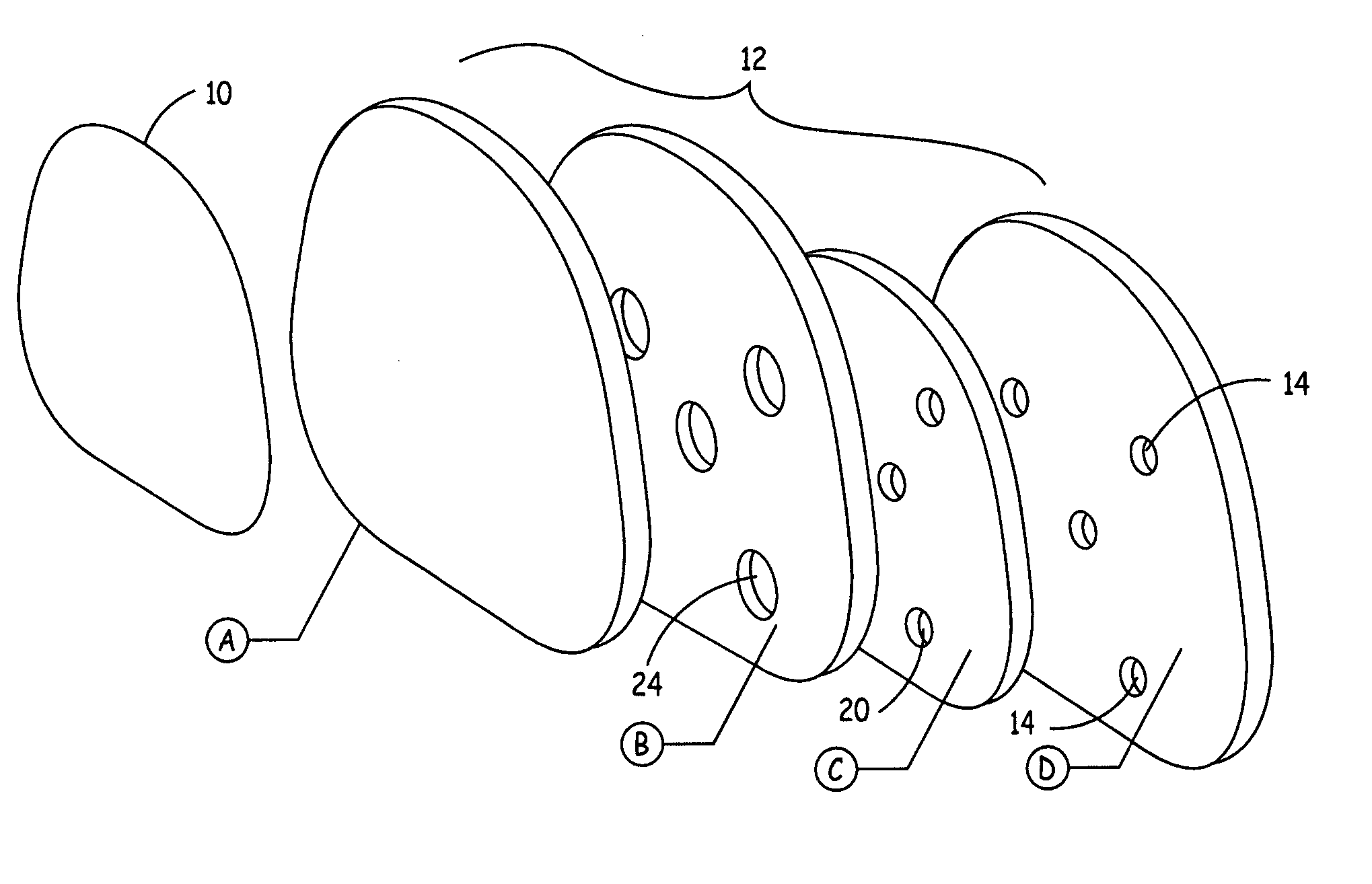

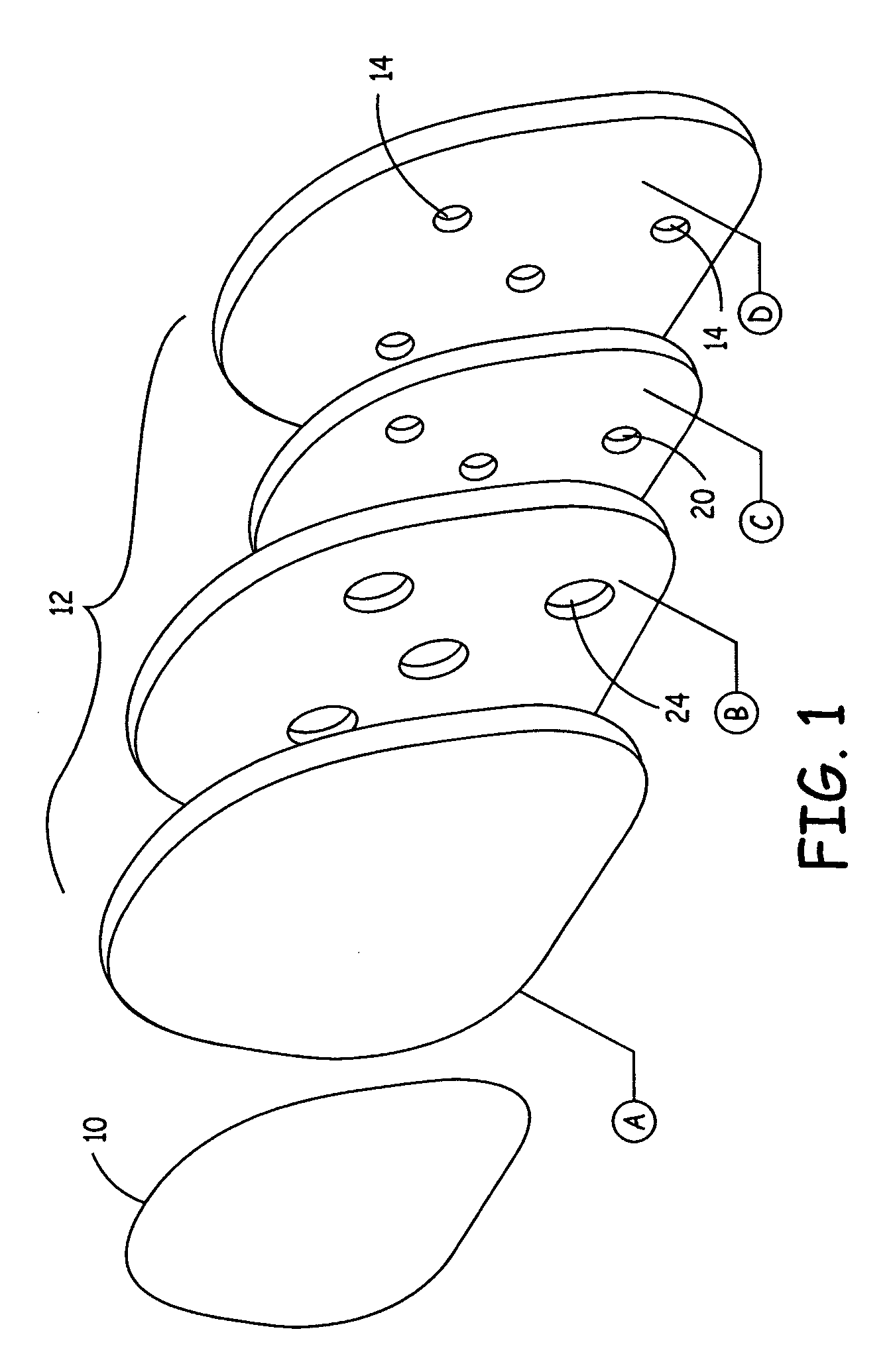

Reticle pod with isolation system

ActiveUS7607543B2Enhanced shock and vibration isolationPromote absorptionPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringVibration transmission

The present invention provides a reticle container that is equipped with a secondary container which houses the reticle and is housed in the primary container. The secondary container is held within the primary container with shock and vibration isolation members so that the secondary container has multiple degrees of freedom of motion within the primary container. The reticle is secured inside the secondary container such that shock and vibration transmission from the reticle container to the reticle is substantially attenuated.

Owner:ENTEGRIS INC

Tactile presentation device

ActiveUS20140306914A1Reduce component countReduce componentsInput/output for user-computer interactionGraph readingTouch panelVibration transmission

A tactile presentation device includes a chassis having a top surface chassis, a bottom surface chassis, and an inner space, a touch panel fixed to the top surface chassis and having an operation surface, an actuator arranged in the inner space, and a vibration transmission member arranged between the actuator and the touch panel. The top surface chassis includes a top surface having a top surface opening exposing the operation surface of the touch panel to outside, and a side surface formed along a peripheral edge of the top surface. The actuator is fixed to the side surface.

Owner:MURATA MFG CO LTD

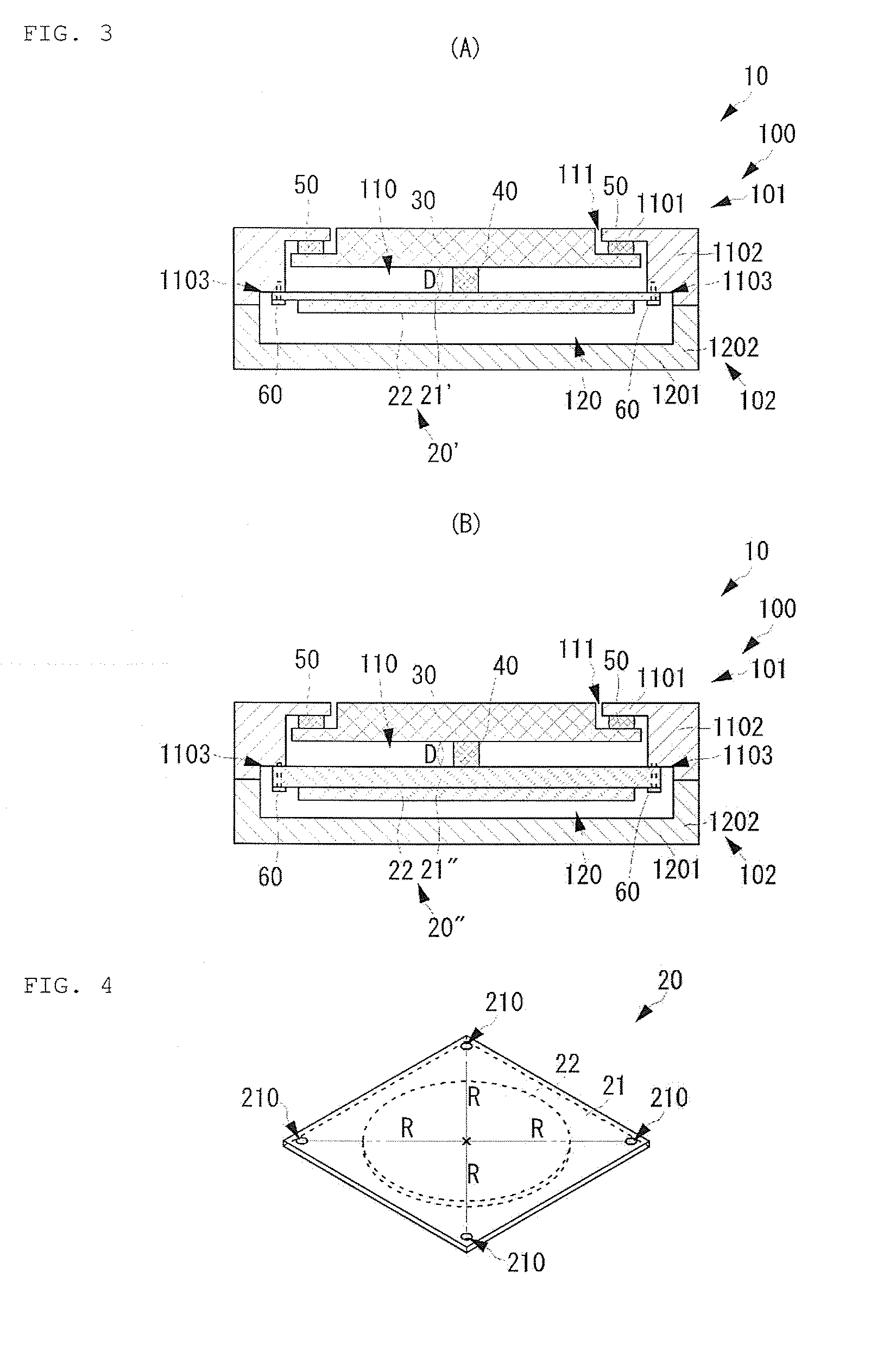

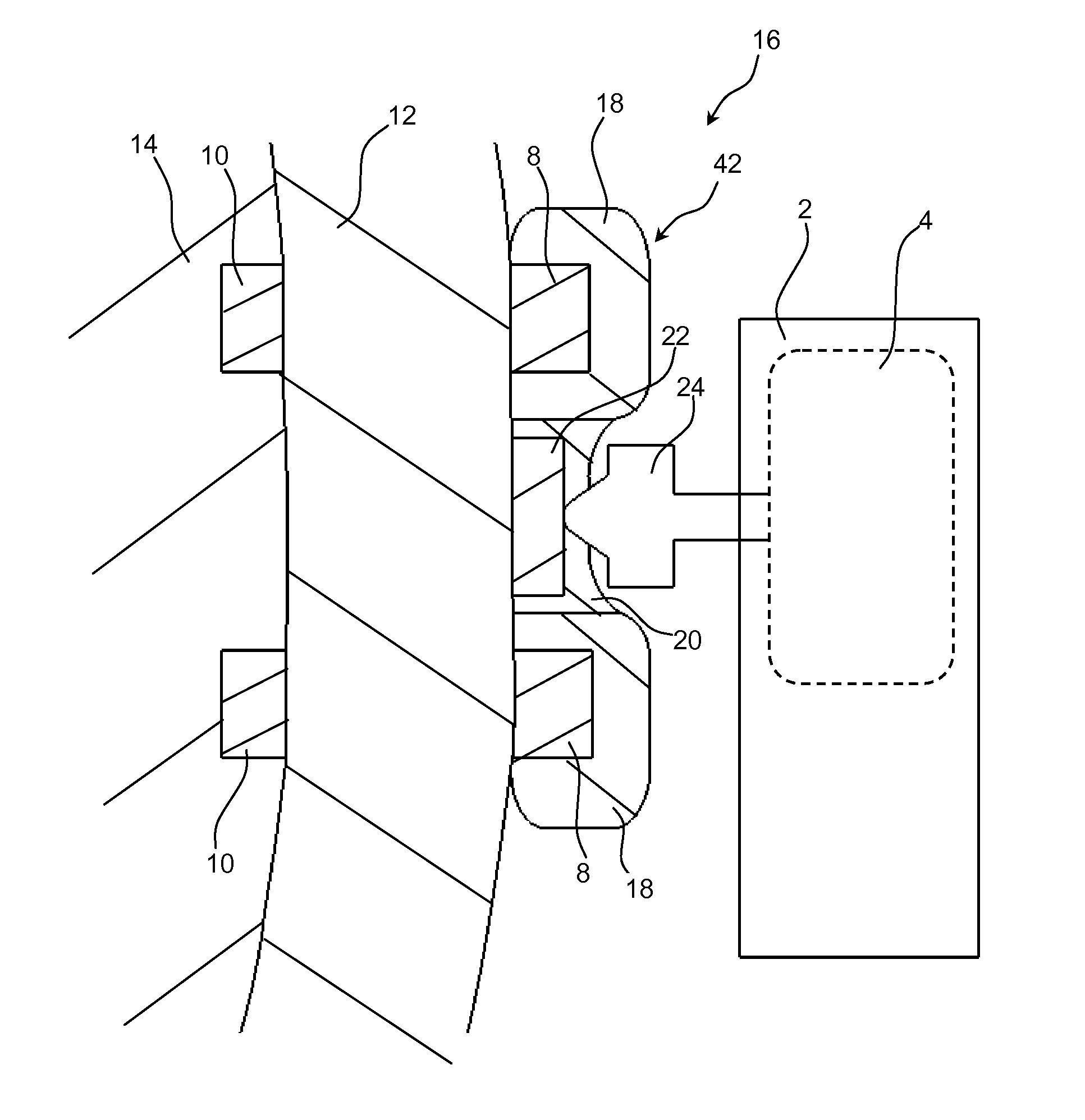

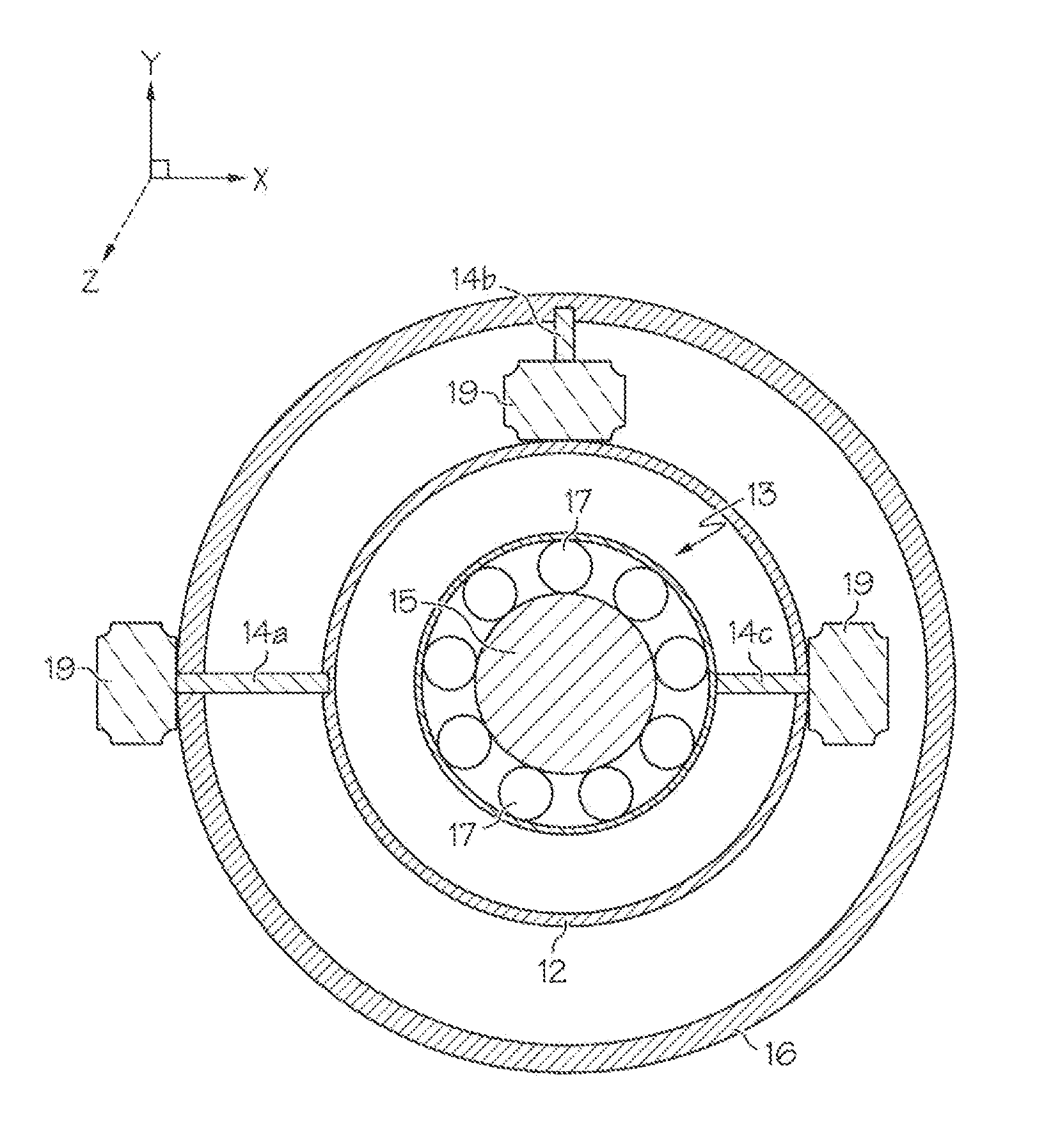

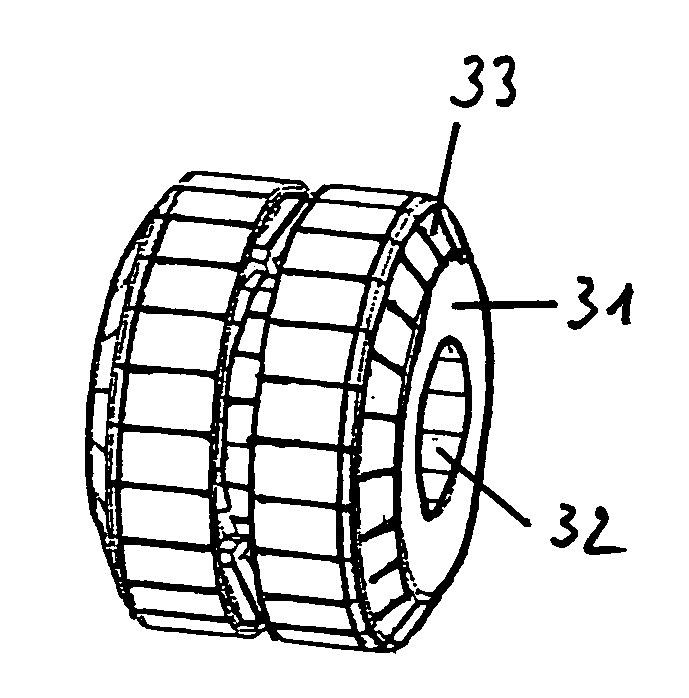

Heavy load precision damper and vibration reduction system formed thereby

InactiveCN101398052AMany degrees of freedomMulti-subwooferGas based dampersVibration suppression adjustmentsEngineeringActuator

The invention pertains to the technical field of precision damping, and is a heavy-load precision damper and a damping system comprising thereof. The damper comprises a low-rigidity air spring with variable damp, an inverted-pendulum structure with low horizontal rigidity and a group of three-degree-of-freedom active damping actuators. The structure of the air spring is external-internal annularity double air chambers communicated with a throttling hole; the inverted-pendulum structure comprises a main supporting rod and at least two flexible swing rods and is located in an annular air chamber; and the active damping actuator comprises three linear motors arranged in an orthogonal manner. The heavy-load precision damper vertically generates large bearing force by the air spring, respectively separates vertical and horizontal vibration transmission by the air spring and the inverted-pendulum structure, and actively controls the damp vibration by acting force of the vertical and horizontal linear motors. The damping system comprises at least three heavy-load precision dampers arranged in the shape of a polygon, and realizes six-degree-of-freedom precision damping of a vibration-isolation device by the mutual action of every heavy-load precision dampers.

Owner:HUAZHONG UNIV OF SCI & TECH

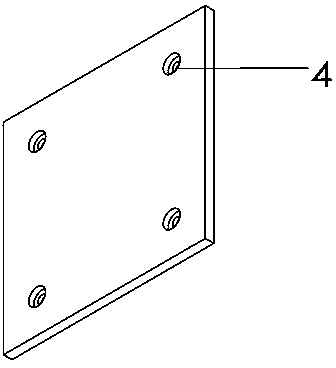

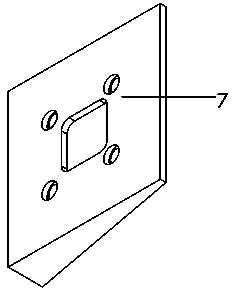

Holding unit for a vibration transmitter and a vibration transmission system using it

ActiveUS20150049889A1Improves feedback marginReduce mechanical resistanceBone conduction transducer hearing devicesImplantable hearing aidsCouplingPersons With Hearing Impairments

A holding unit and a vibration transmission system are disclosed. The holding unit comprising a holding plate is configured to be attached to the skin by means of magnetic attraction between a number of external magnets that are either:a) integrated within the holding plate;b) mechanically attached to the holding plate; orc) constituting the holding plateand a number of internal magnets implanted under the skin of a hearing impaired person. The holding unit comprises a transmission member or plate member configured to transfer mechanical vibrations from a vibrator through the skin to the bone of the person. The transmission member or plate member is interconnected by a mechanical flexible coupling to the magnet(s) of the holding plate.

Owner:OTICON MEDICAL

Reticle pod with isolation system

ActiveUS20060260978A1Improve shockGood vibration isolationPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringVibration transmission

The present invention provides a reticle container that is equipped with a secondary container which houses the reticle and is housed in the primary container. The secondary container is held within the primary container with shock and vibration isolation members so that the secondary container has multiple degrees of freedom of motion within the primary container. The reticle is secured inside the secondary container such that shock and vibration transmission from the reticle container to the reticle is substantially attenuated.

Owner:ENTEGRIS INC

Sound and Vibration Transmission Device

ActiveUS20140010387A1Promote sportsPotent neuro-psychological relaxation responseLoudspeaker transducer fixingStereophonic circuit arrangementsTransducerEngineering

An apparatus capable of transmitting sound and vibrations to a user is described. The apparatus may also generate an electromagnetic field sufficient to stimulate the user's energy system. The apparatus includes a support structure configured to support at least a part of the user's body; a transducer coupled to the frame of the support structure in a manner which allows the transducer to move in relation to the frame; and an audio signal source for transmitting audio signals to the transducer. The transducer is capable of receiving and responding to audio signals having a wide range of audio frequencies when the apparatus is in use.

Owner:ROUND RIVER RES CORP

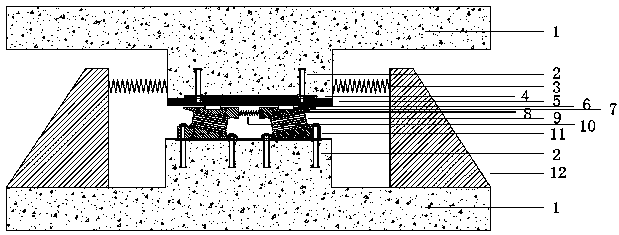

Three-dimensional seism isolation system

InactiveCN103850358AHighlight substantiveSignificant technological progressBridge structural detailsShock proofingVibration controlSlide plate

The invention relates to a three-dimensional seism isolation system, which comprises preburied parts, first horizontal limit springs, a connecting plate, a horizontal slide bearing sliding plate, a horizontal slide bearing slider, upper slope leveling connecting plates, flush bolts, lead rubber bearings, second horizontal limit springs, lower slope leveling connecting plates and retaining blocks. Vertical seism is isolated by the deformation displacement of the inclined lead rubber bearings; horizontal seism is isolated by the sliding of the horizontal slide bearing slider; restoring force is supplied by the springs, and thereby the purpose of three-dimensional seism / vibration absorption is realized. The novel three-dimensional seism isolation system can protect protected objects of an upper building during horizontal and vertical vibration and seism and effectively attenuate the vibration transmission of vibrating equipment. The three-dimensional seism isolation system is applicable to the seism and vibration control and protection of building structures and large equipment.

Owner:SHANGHAI UNIV

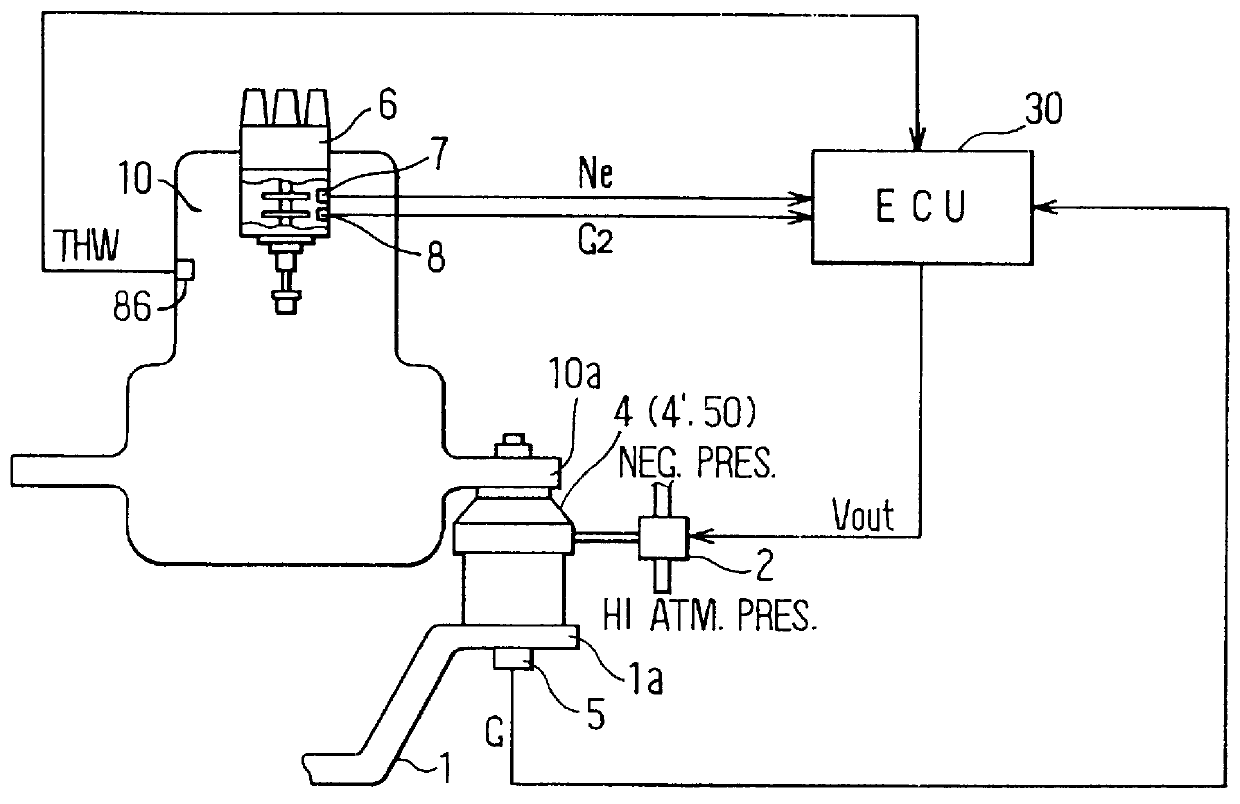

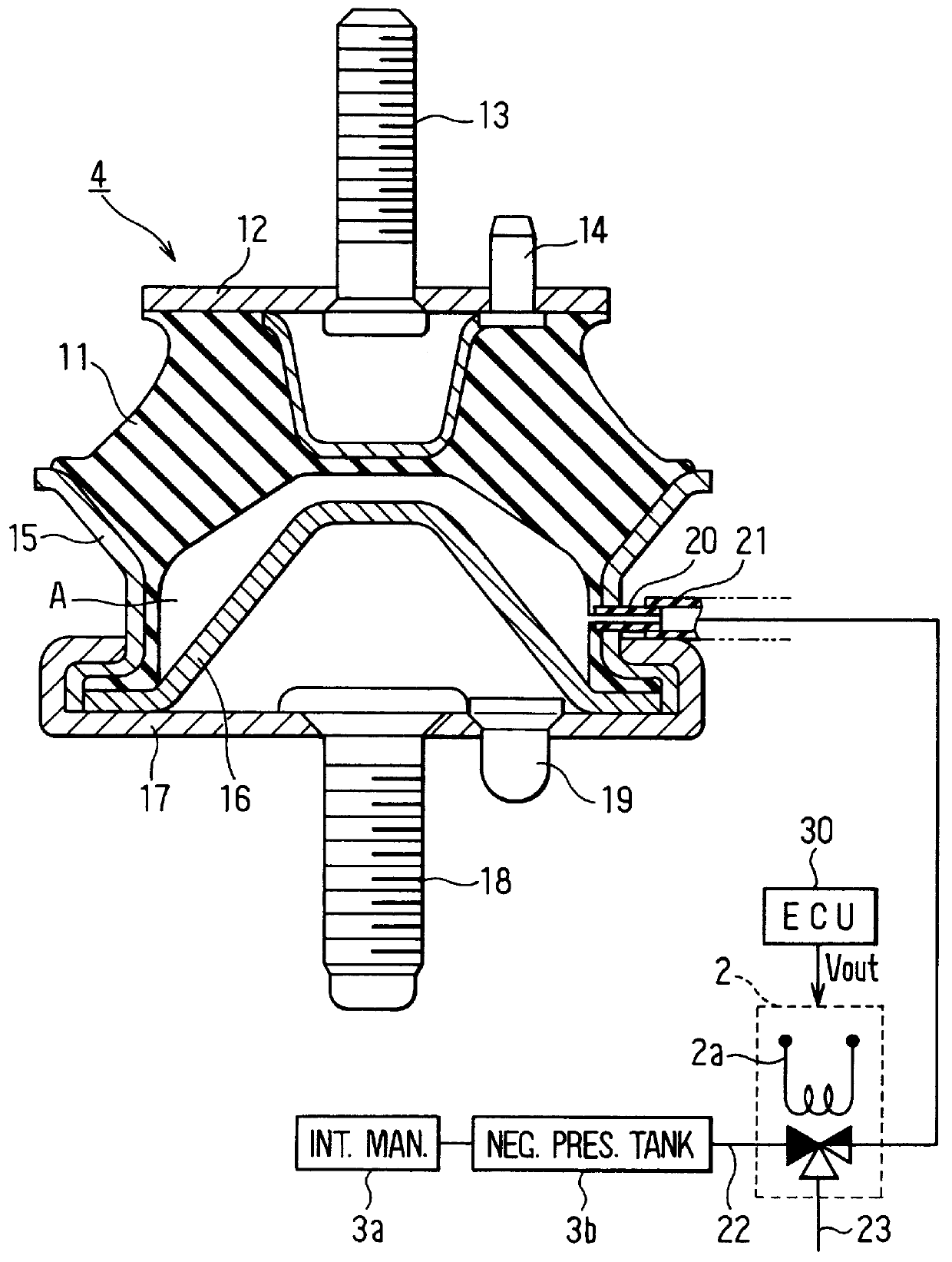

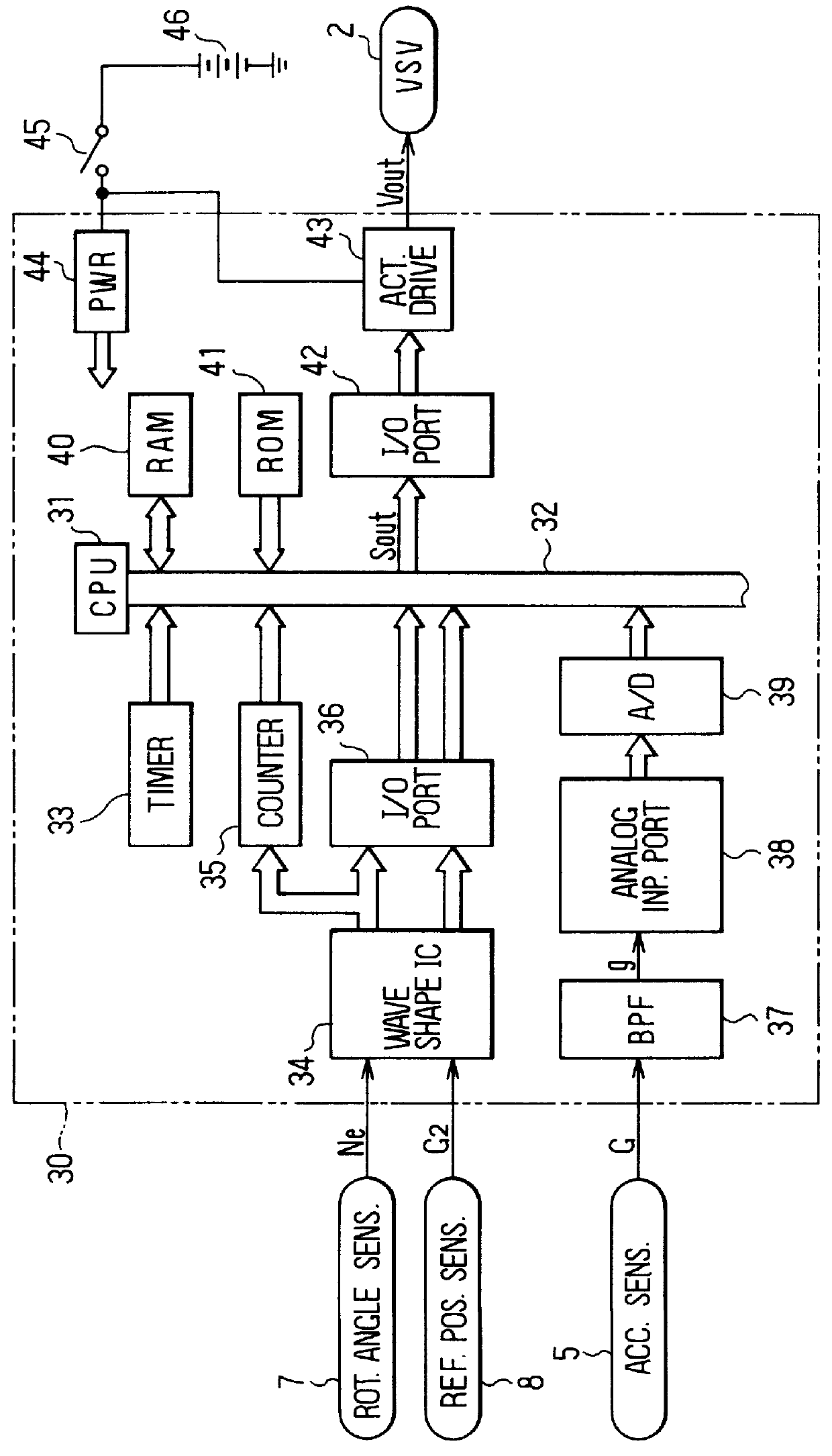

Electronically controlled engine mount

InactiveUS6120012AReduce vibrationSufficient characteristicMachine framesLiquid springsEngineeringVibration transmission

An engine mount which is capable of changing its vibration transmission characteristics with a simple structure using an inexpensive actuator is provided. A partition is inserted to a side member to which a mount rubber (rubber vibration isolator) of the engine mount is spliced to close a space between the mount rubber and to create an air chamber. An air duct pipe which communicates with the air chamber is connected to the side member and is connected to a VSV (vacuum switching valve) via a connection pipe. The VSV is controlled to ON / OFF states based on a driving voltage Vout from an ECU which corresponds to explosive vibrations of the engine to switch pressure within the air chamber to negative pressure of a vacuum tank in which negative pressure of an intake manifold is accumulated or to atmospheric pressure, interlocking with the vibration of the engine. Thereby, the vibration transmission characteristics of the engine mount may be adequately changed and the vehicular vibration may be reduced significantly.

Owner:DENSO CORP

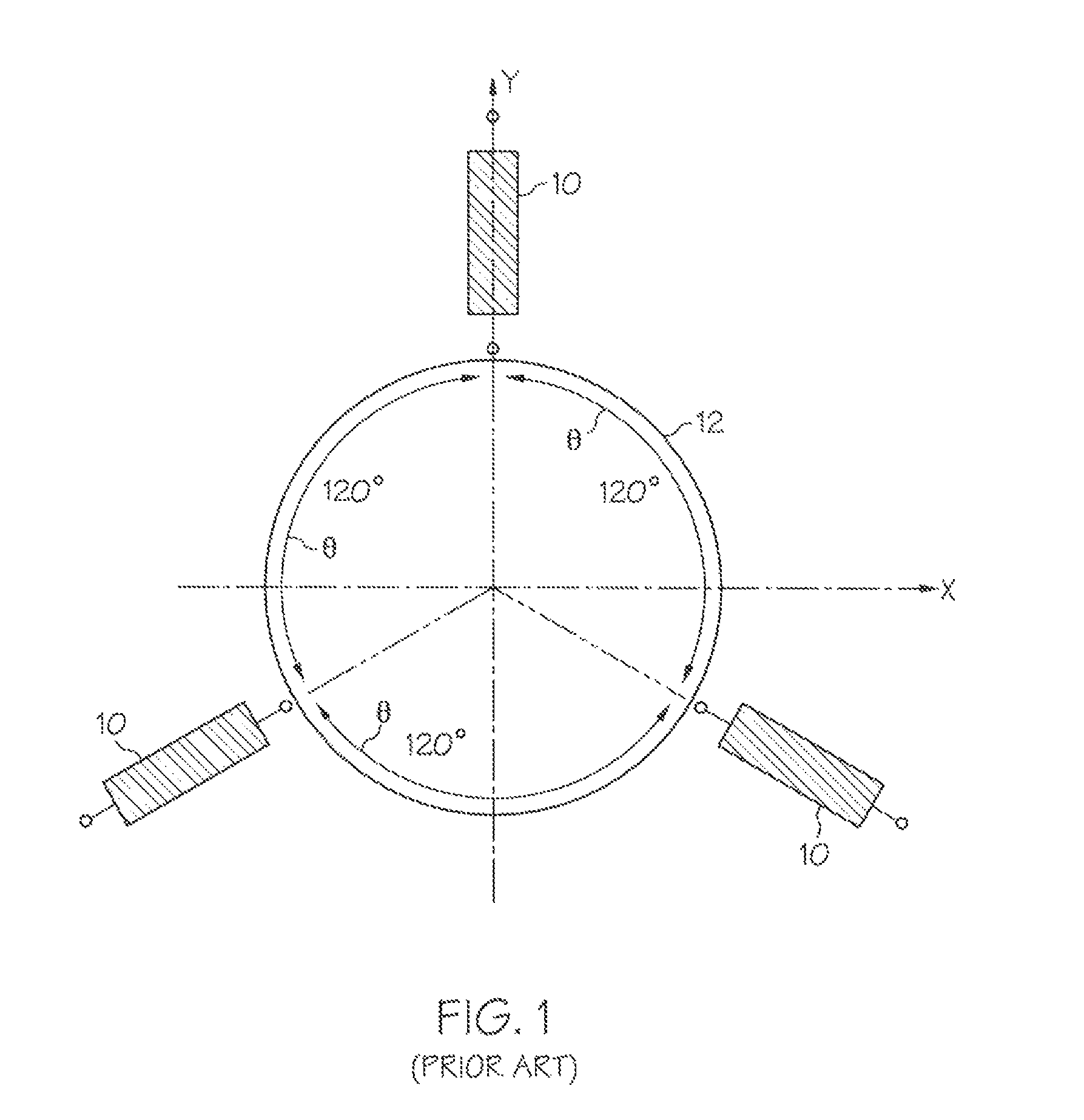

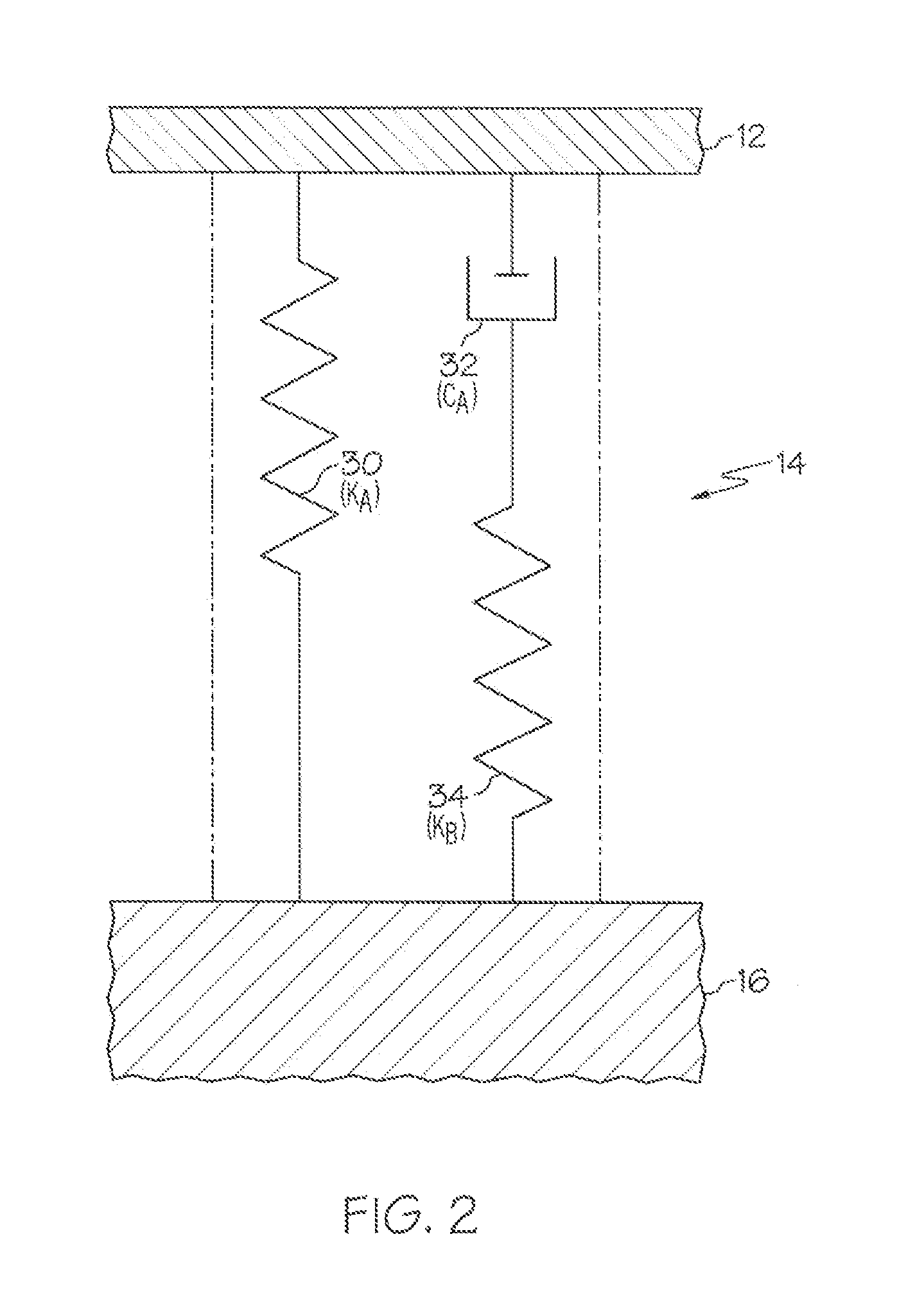

Three parameter damper anisotropic vibration isolation mounting assembly

ActiveUS9297438B2Minimize transmissionPortable framesNon-rotating vibration suppressionEngineeringMachine

An anisotropic vibration isolation mounting assembly includes at least two three-parameter vibration isolators each having a first end configured for attachment to a rotating member assembly or a rotating member assembly housing and each having a second, opposing end configured for attachment to the rotating member assembly housing where the first end is configured for attachment to the rotating member assembly or to a system interface member where the first member is configured for attachment to the rotating member assembly housing. The at least two three-parameter vibration isolators are tuned anisotropically to minimize the transmission of vibrations during operation of the rotating machine.

Owner:HONEYWELL INT INC

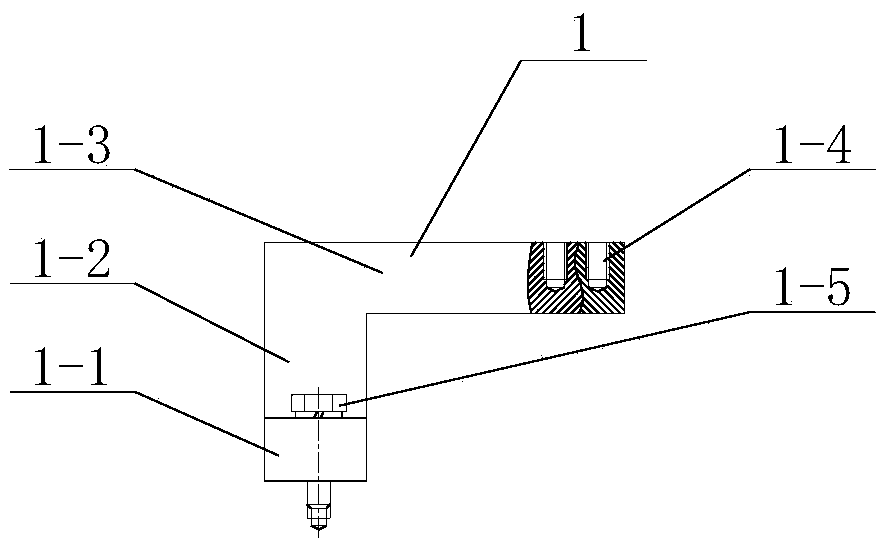

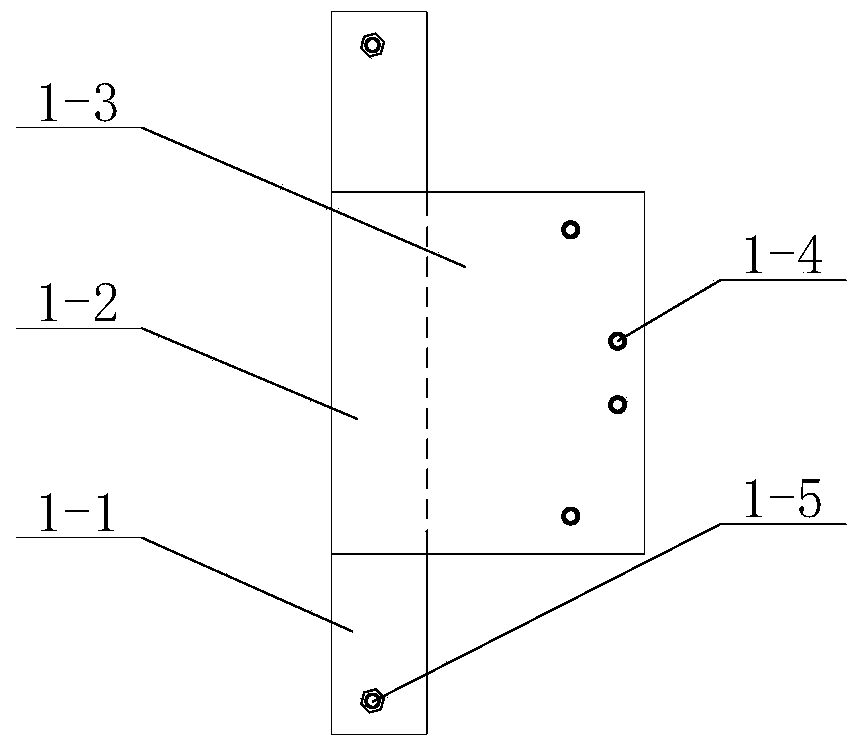

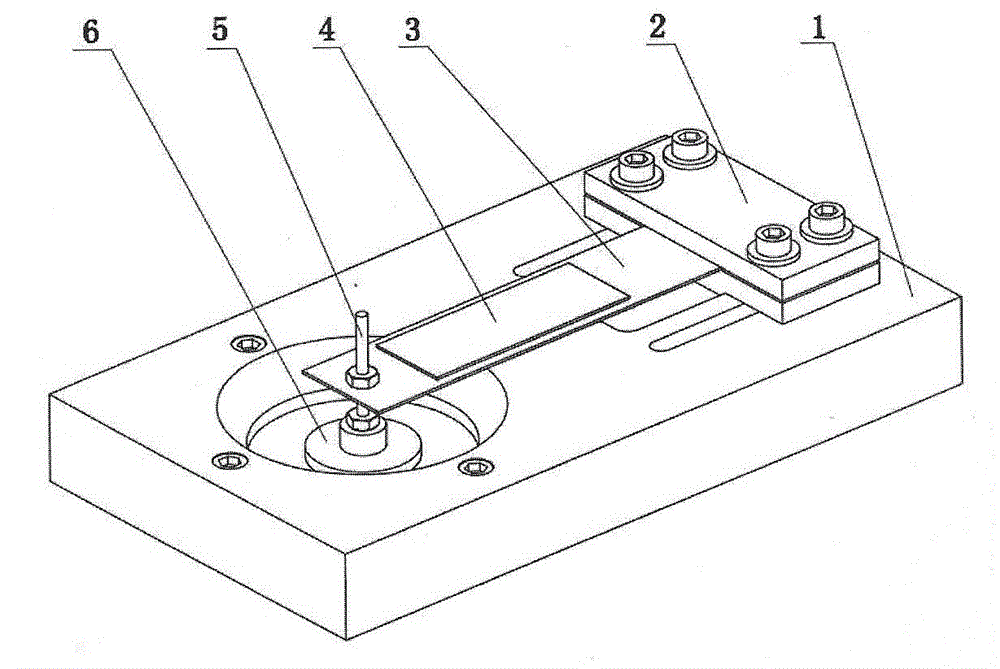

Combinatorial testing accessory of vibration testing platform and static fatigue testing method

ActiveCN104020038AFunction increaseAchieve diversificationMaterial strength using repeated/pulsating forcesVibration testingTest sampleEngineering

The invention relates to a material and structure testing device and method, and in particular relates to a combinatorial testing accessory of a vibration testing platform and a static fatigue testing method. The combinatorial testing accessory consists of support brackets, a test sample clamp, a vibration transmission device and a bridging bracket. When the accessory is combined, the support bracket is mounted on a vibration testing platform rack, the bridging bracket is mounted on the two support brackets in a spanning manner, the test sample clamp is mounted on the support brackets for clamping a test sample, and the vibration transmission device is mounted on the surface of a vibration testing platform. According to the static fatigue testing method, the combinatorial accessory is mounted on the vibration testing platform and is used for performing 7 types of 13 static fatigue tests on the test sample. The testing device and the testing method expand the function of the vibration testing platform, achieve diversification of load modes, including multiple load modes of pulling, compression, bending, twisting and the like and the combination of the load modes, in the fatigue testing, have a large range of testing frequency, are capable of performing fatigue testing on 5-4500 Hz, and are applicable to high cycle and super high cycle static fatigue testing research on materials and structures.

Owner:SHANDONG UNIV

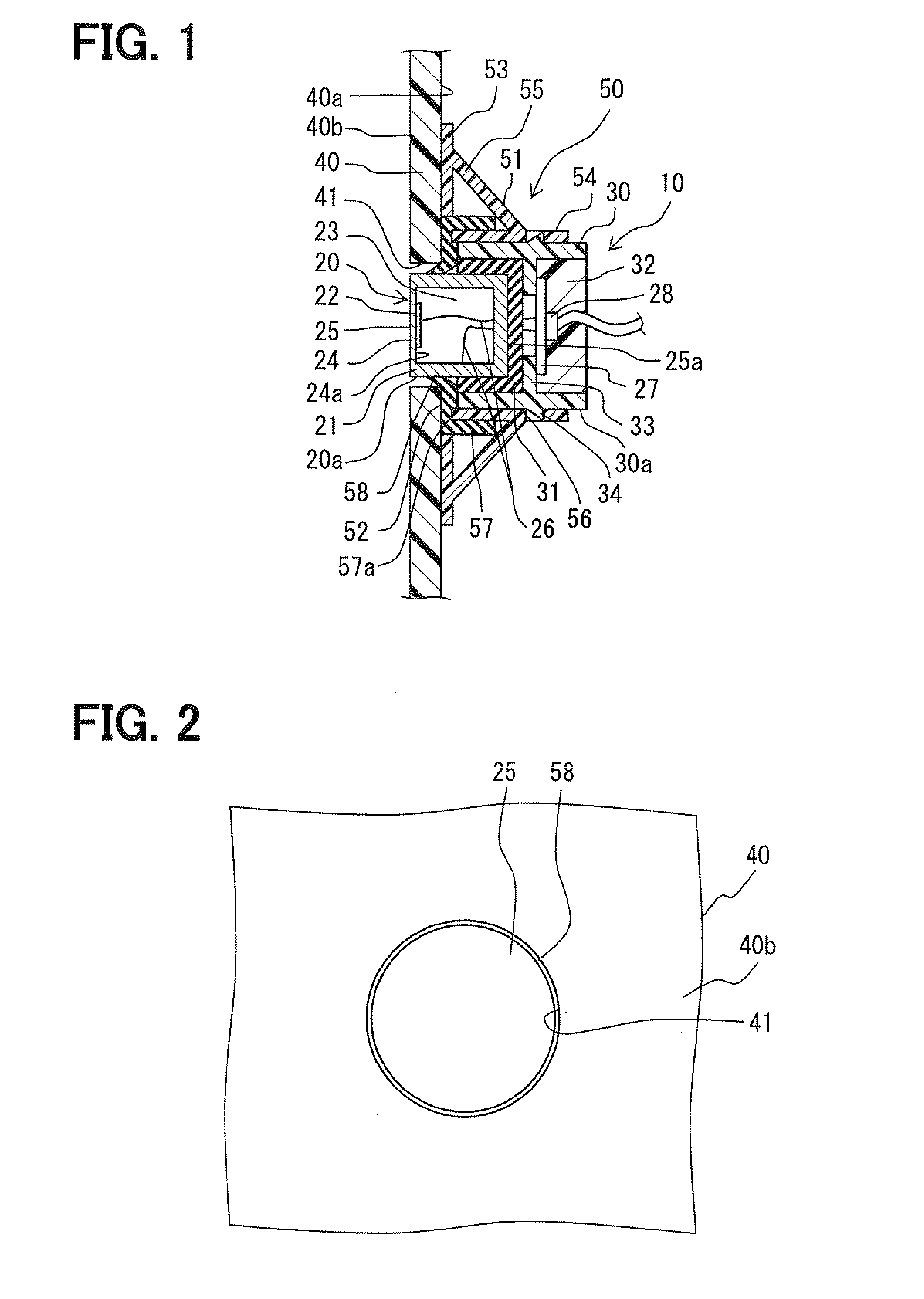

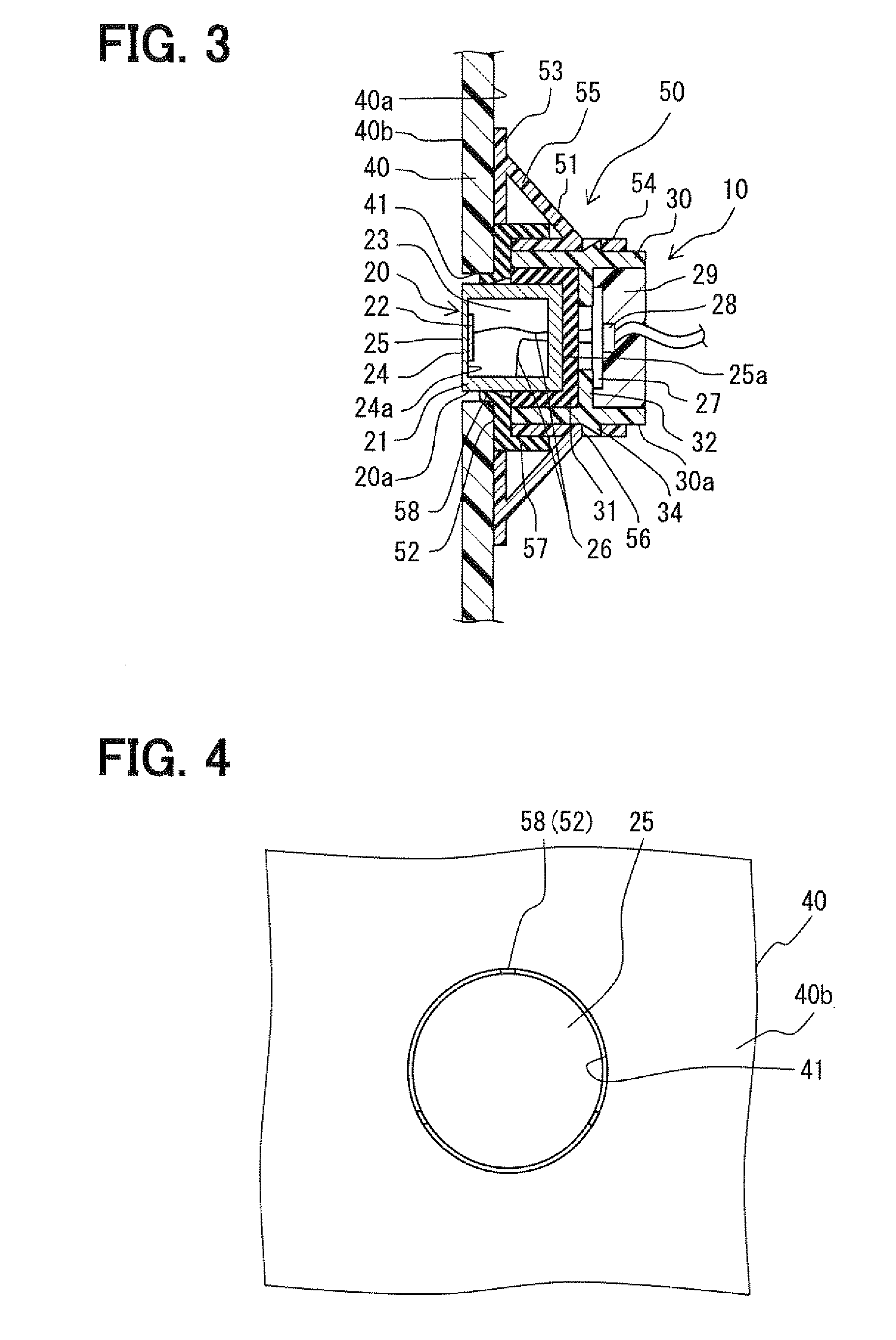

Attachment structure for ultrasonic sensor

InactiveUS20090223296A1Transmission limitCandle holdersMaterial analysis using sonic/ultrasonic/infrasonic wavesUltrasonic sensorVibration transmission

Disclosed is an ultrasonic sensor attachment structure which provides coincidence between a center of the ultrasonic-sensor and that of a through-hole in a simple way, and which restricts unwanted-vibration-transmission between a wall-member of a movable-body and an ultrasonic-transducer without spoiling design. According to the structure, the sensor, which includes the ultrasonic-transducer, a case receiving the ultrasonic-transducer and a vibration-insulation-member for vibration-transmission-suppression, is attached to the wall-member having the through-hole, so that an oscillation-surface is exposed to an outer-surface side through the through-hole. The ultrasonic-sensor is fixed by a fixation-member so that the oscillation-surface and an outer-surface of the wall-member are on a substantially same plane. The fixation-member includes a positioning-member, which provides substantial coincidence between a center of the oscillation-surface of the ultrasonic-sensor and that of the through-hole, and which is made of a material suppressible of vibration-transmission between the ultrasonic-transducer and the wall-member.

Owner:DENSO CORP

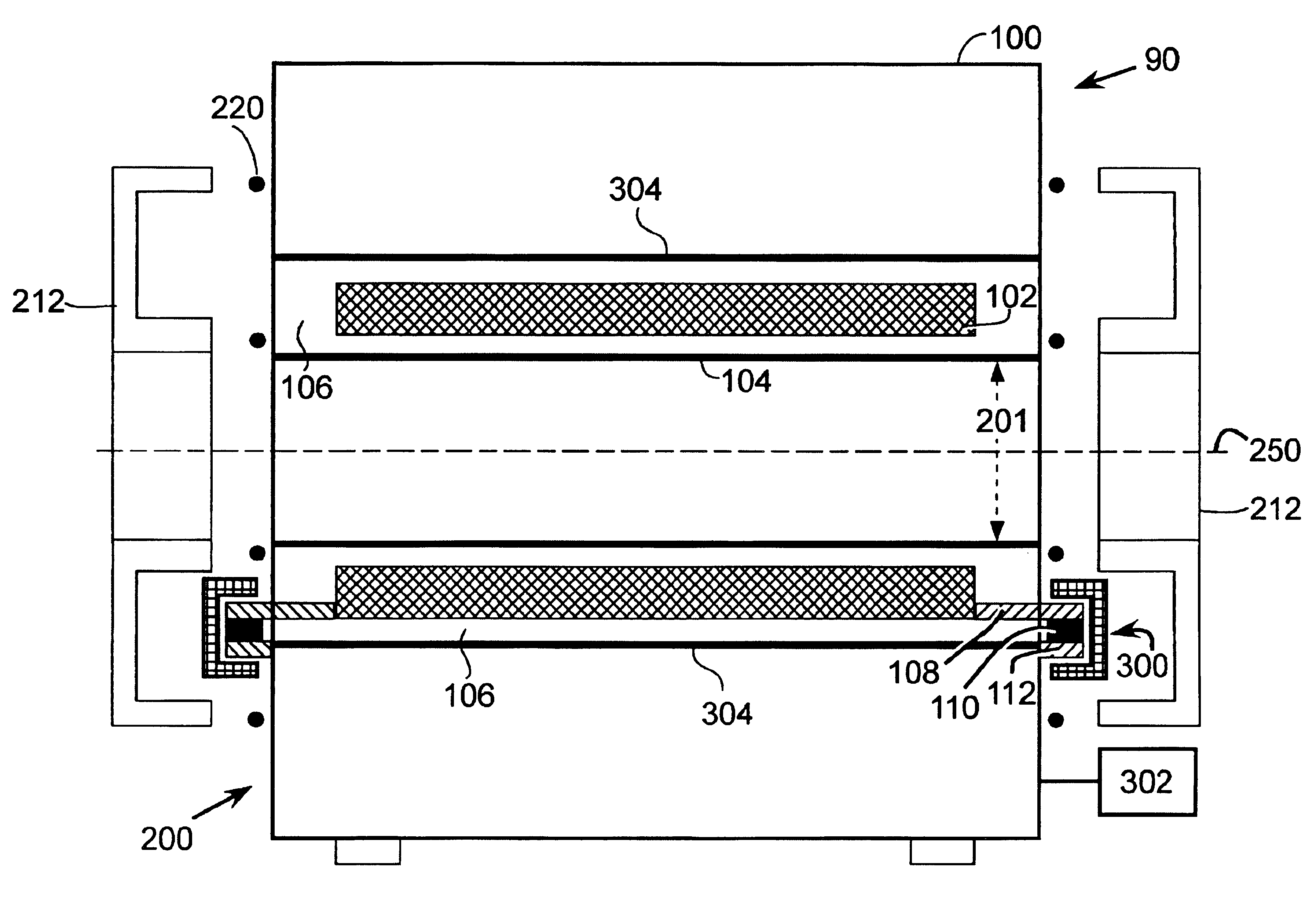

Active vibration compensation for MRI gradient coil support to reduce acoustic noise in MRI scanners

InactiveUS6894498B2Reduce noiseReduce transmissionElectric/magnetic detectionMeasurements using magnetic resonanceEngineeringVibration transmission

The present invention provides an apparatus for reducing acoustic noise in a magnetic resonance imaging device including a suspension element including at least one resilient element and an active drivable element for applying a compensating force to reduce vibration transmission. The active drivable element is positioned so as to not directly support the weight of the gradient coil assembly, which avoids applying strong forces to relatively fragile active drivable elements, such as piezoelectric force transducers. Force signals for the active drivable element are derived in a feed-forward manner from the applied gradient waveform or from motion of the gradient coil assembly bracket. Alternatively, the active drivable element can be driven by signals derived from measured vibration or other motion of parts of the MRI magnet, gradient coils or rf coils.

Owner:SHARKSTONE

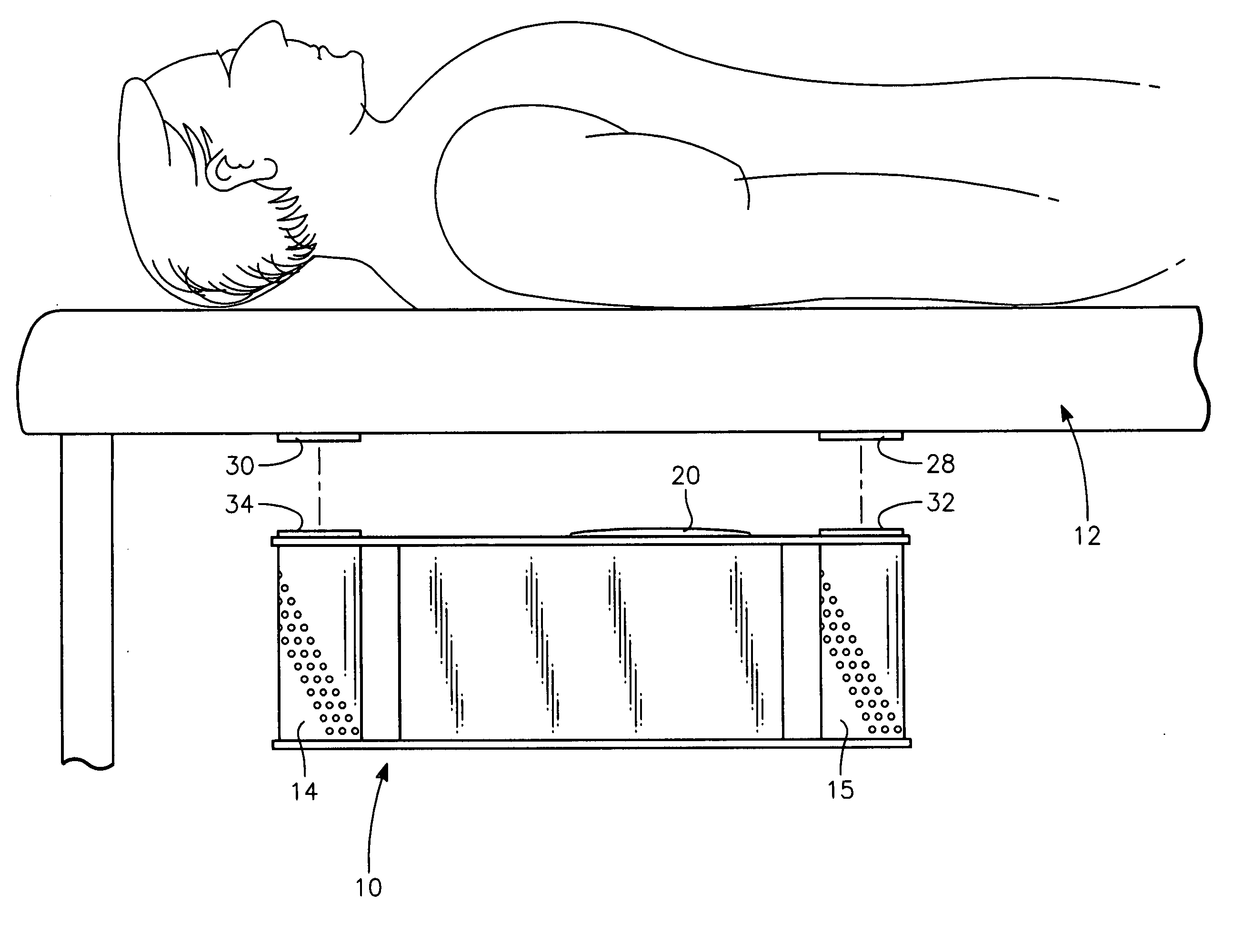

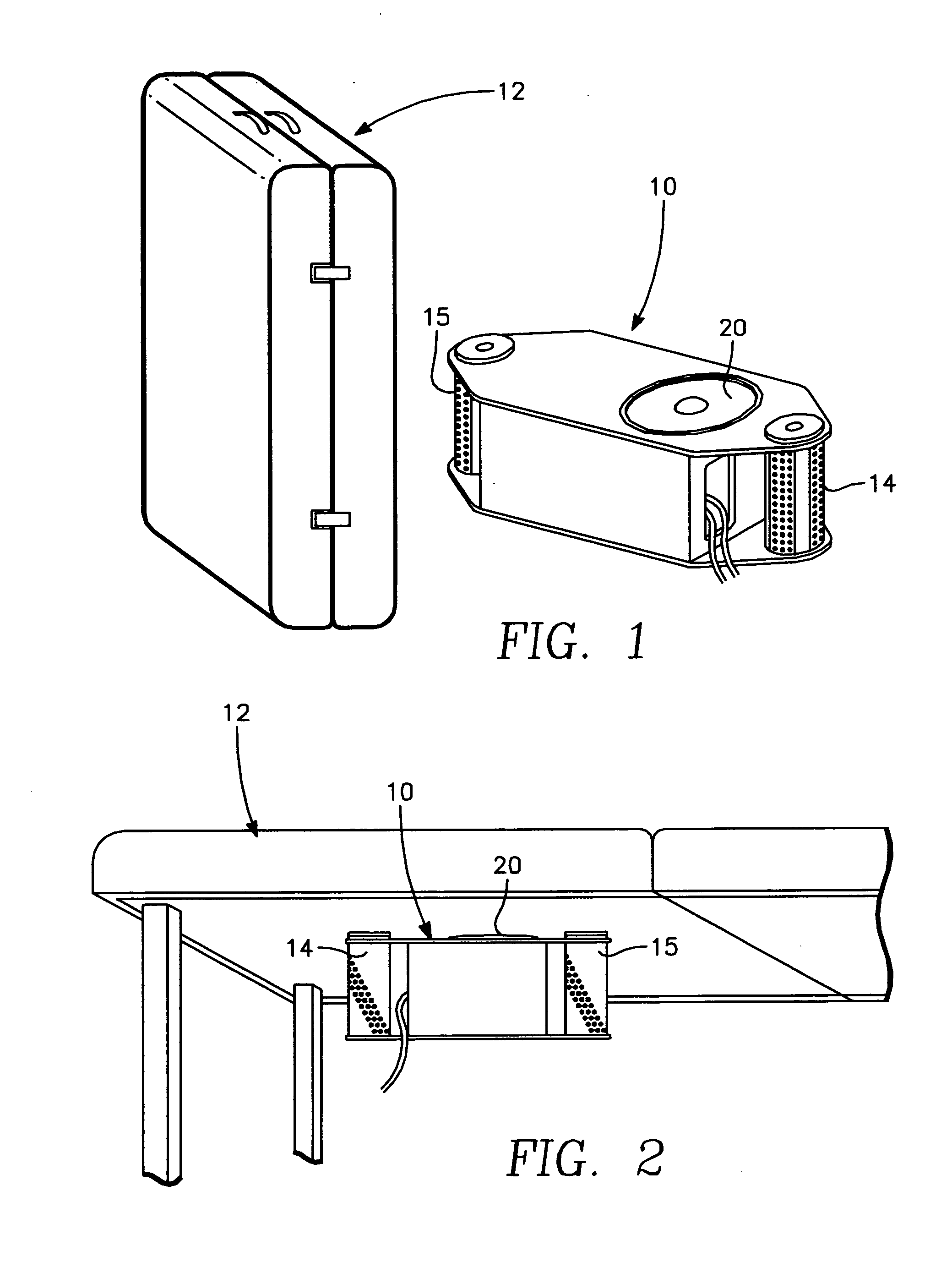

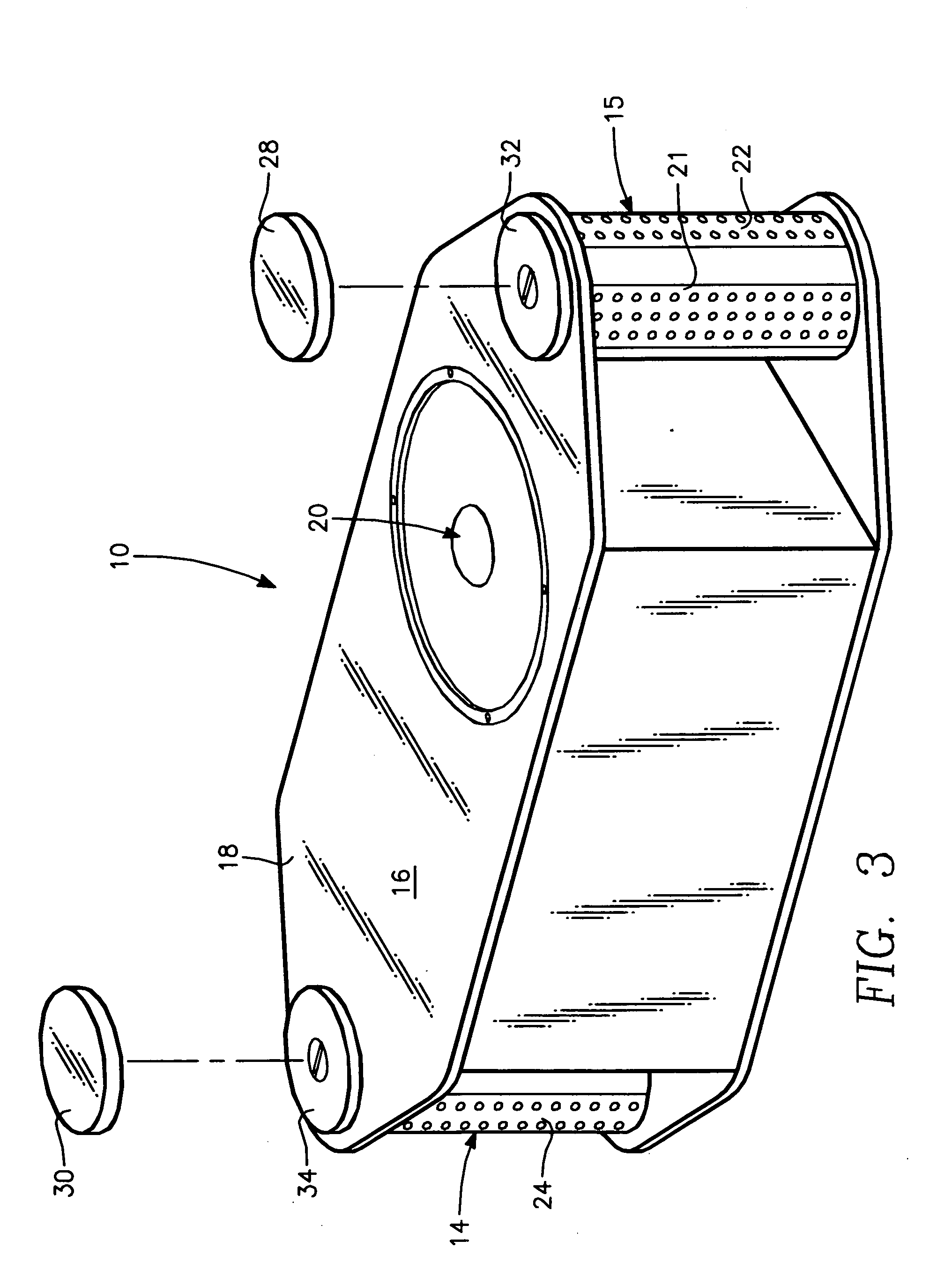

Massage speaker unit

InactiveUS20050226449A1Easy to transportLarge dispersionVibration massageLoudspeaker spatial/constructional arrangementsEngineeringVibration transmission

A portable sound and vibration transmission device, compatible with common audio producing means, designed to enhance the relaxation experienced by a massage therapy client through the use of an upward facing subwoofer and distal cylinders containing speaker drivers positioned to create a surround sound effect.

Owner:YOUNG SCOTT

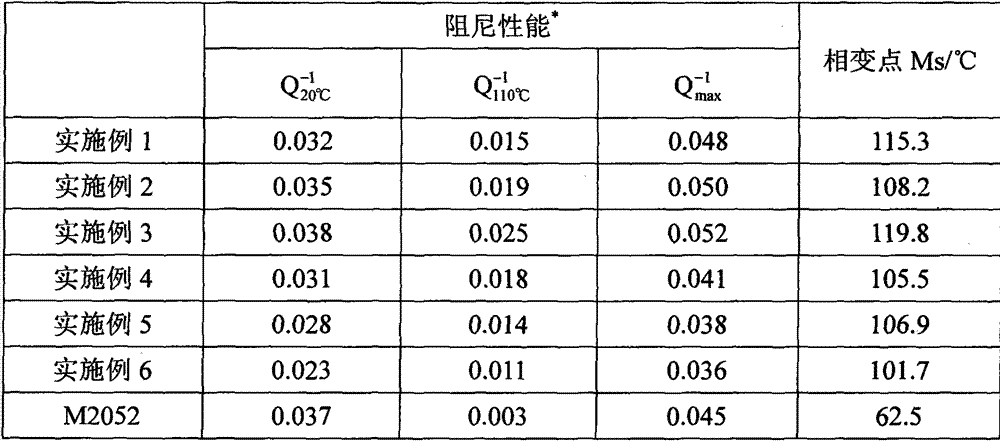

High-damping Mn-Cu damping alloy and manufacturing method thereof

ActiveCN104762540AIncrease temperatureImprove hot and cold working performanceRare earthNoise reduction

The invention provides a high-damping Mn-Cu damping alloy and a manufacturing method thereof. The alloy comprises chemical components of: 60.00-75.00 wt% of 2.00-5.00 wt% of Ni, 0.50-3.00 wt% of Al, 1.50-2.50 wt% of Fe, no more than 0.01 wt% of C, no more than 0.10 wt% of Si, less than 0.020 wt% of P, less than 0.020 wt% of S, no more than 0.050 wt% of N, no more than 0.010 wt% of O, one or more selected from Zr, Ti, La, Ce, Y and mixed rare earth (Mm), and the balance of Cu and inevitable impurities. After heat treatment, the alloy has damping performances as follows: Q<-1><max> of 0.035-0.055, Q<20 DEG C> <-1> of 0.020-0.040, and Q<110 DEG C> <-1> of 0.010-0.030. The alloy has high damping capacity, good temperature stability, wide temperature range, high strength and good processability, can be processed into sectional material and strips, is applicable to the parts requiring vibration and noise reduction in the fields of aviation and space flight, navigation, nuclear industry, automobile manufacturing, electrical equipment and precision instruments and instrumentation, and can play the roles of reducing the vibration transmission, reducing noise and prolonging the service life of structural components.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

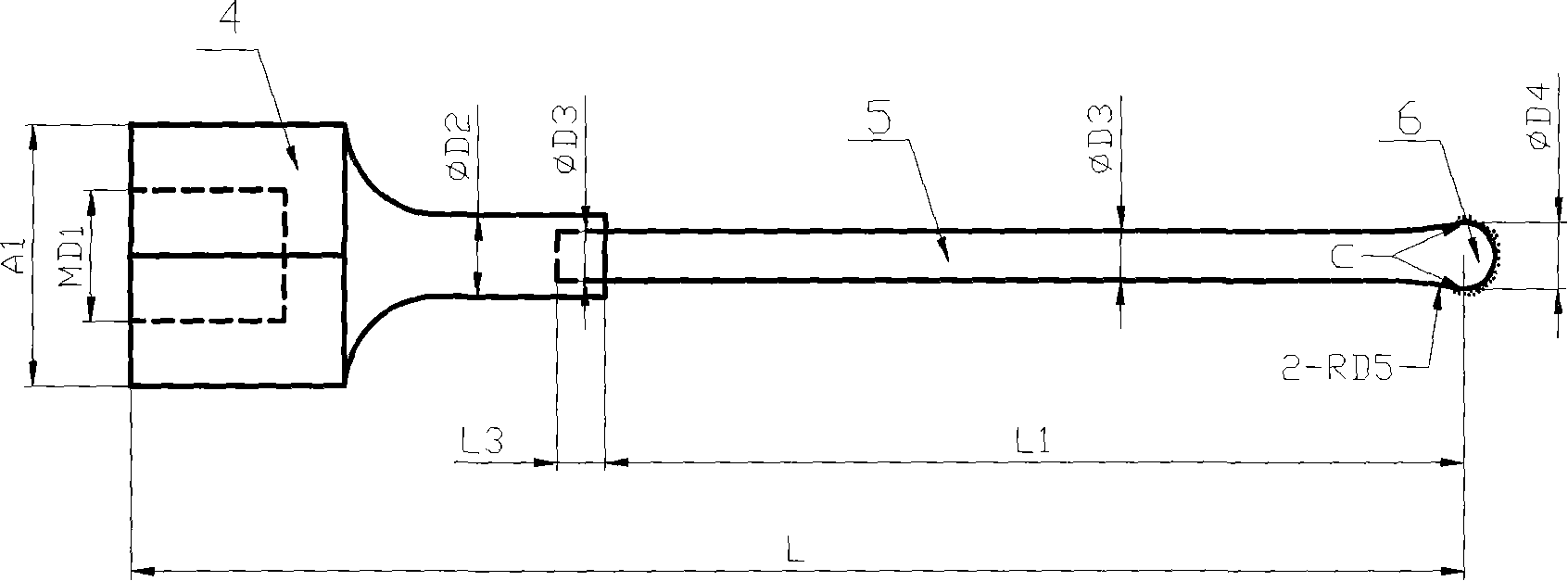

Cantilever-type piezoelectric diaphragm pump

InactiveCN103334907AAdjustable lengthDifferent vibration characteristicsPositive displacement pump componentsFlexible member pumpsDiaphragm pumpEngineering

The invention discloses a cantilever-type piezoelectric diaphragm pump. The cantilever-type piezoelectric diaphragm pump is composed of a vibration excitation unit, a pump cavity body and a flow channel structure. The vibration excitation unit is composed of a pump body, an adjustable pressing mechanism, a piezoelectric vibrator, a vibration transmission piston and a PET diaphragm. The piezoelectric vibrator is composed of a copper substrate and a piezoelectric ceramic piece. Compared with the traditional method of periphery fixing or wave joint supporting of a circular oscillator, the method of cantilever supporting of the rectangular piezoelectric vibrator has the advantages that deflection is large, tail end output amplitude is large, and simple harmonic frequency is low. Meanwhile, the length of a cantilever of the rectangular piezoelectric vibrator is adjustable, and therefore a vibration system has different vibration characteristics so as to meet different requirements for output performance. The adopted PET diaphragm material has the advantages of being good in abrasive resistance, dimensional stability and electrical insulation, nontoxic, impermeable, light in weight and the like, and further has the advantages of being safe and reliable, free of pollution and the like as a pump cavity vibrating diaphragm for conveying chemical and medical liquid. The piezoelectric vibrator is not contacted with the conveyed liquid directly, and therefore the piezoelectric pump can work at high working voltage and is good in output performance.

Owner:JILIN UNIV

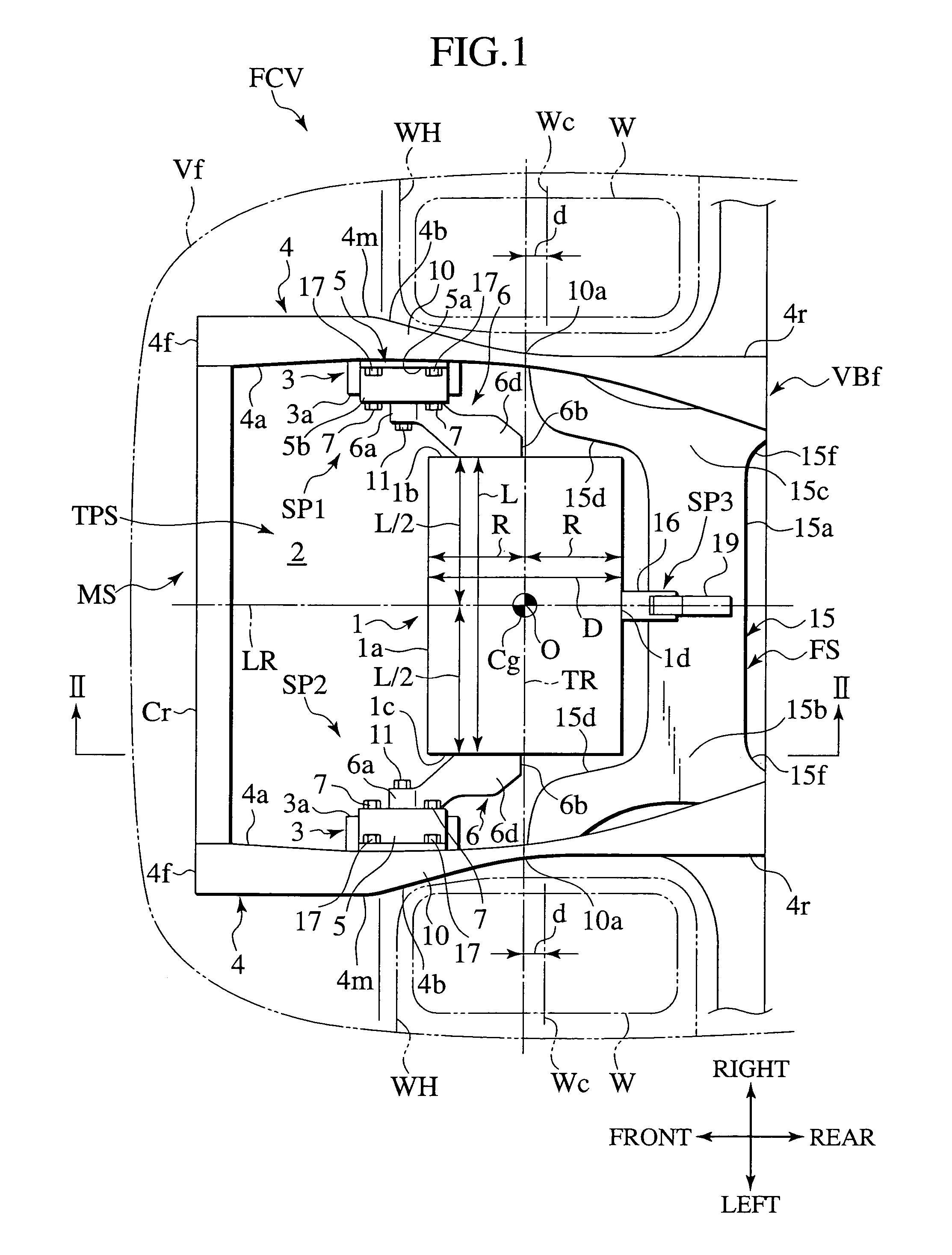

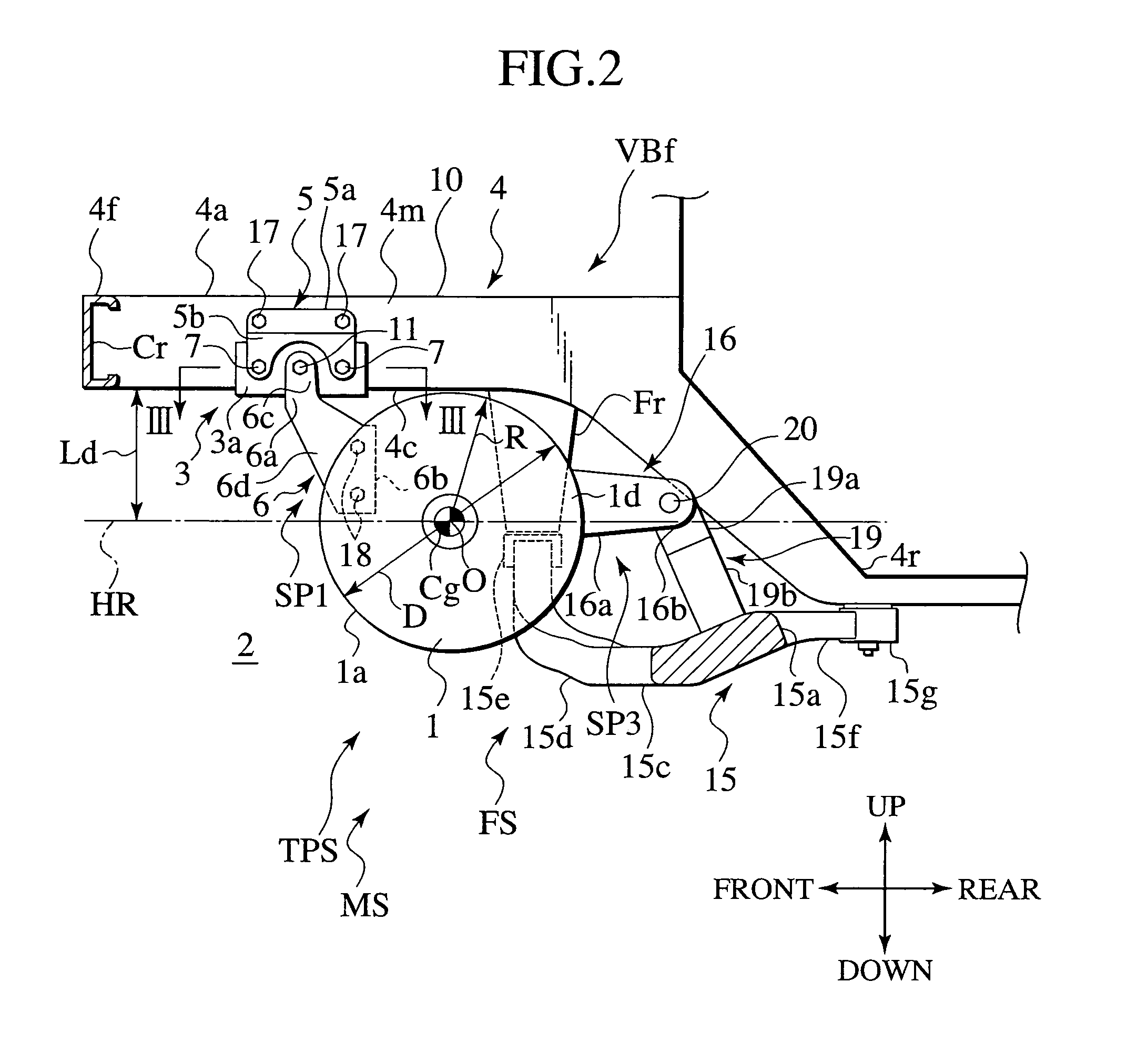

Drive motor mounting structure

ActiveUS7445076B2Large attenuationImprove workabilityElectric propulsion mountingGas pressure propulsion mountingSupporting systemEngineering

For spatial arrangement of a drive motor (1) in a motor room (2), a three-point support system (TPS) includes supports (SP1, SP2) having a vibration suppressing member (3) for suppressing vibrations to be transmitted from the drive motor (1), a first bracket (5) for fixing the vibration suppressing member (3) to a transversely inner lateral side (4a) of a side member (4) of a front part (VBf) of a vehicle body, and a second bracket (6) for fixing the drive motor (1) to the vibration suppressing member (3), while the first bracket (5) is fastened to the inner lateral side (4a) of the side member (4), and the second bracket (6) is fastened at a proximal end (6a) to the vibration suppressing member (3) and at a distal end (6b) to the drive motor (1) to be disposed lower than the side member (4), with a reduced vibration transmission from the drive motor (1) to the vehicle body, allowing a facilitated removal of the drive motor (1).

Owner:NISSAN MOTOR CO LTD

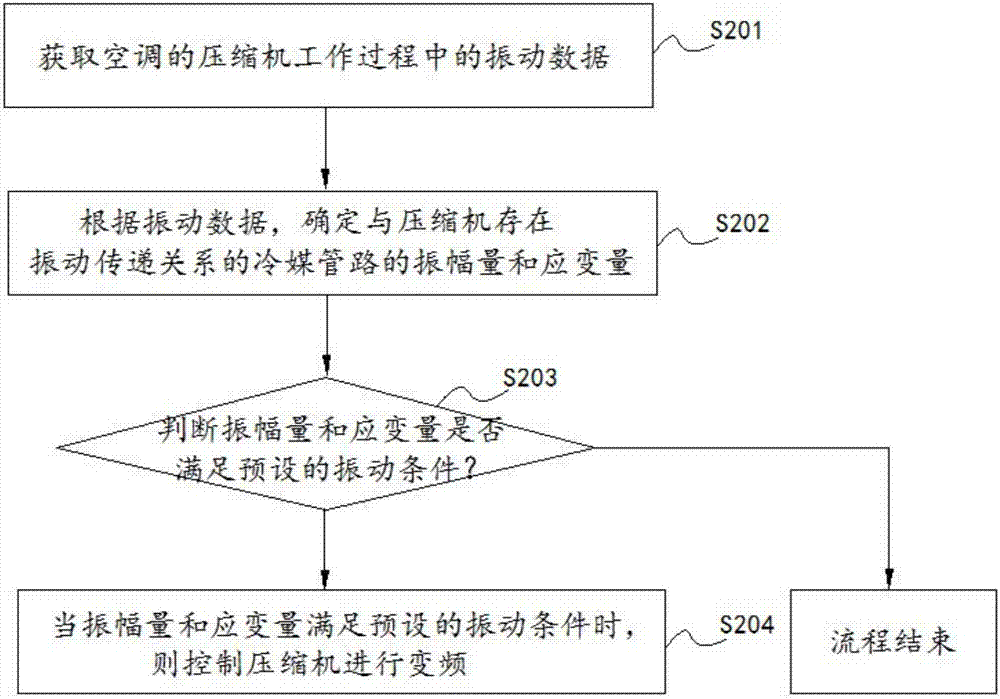

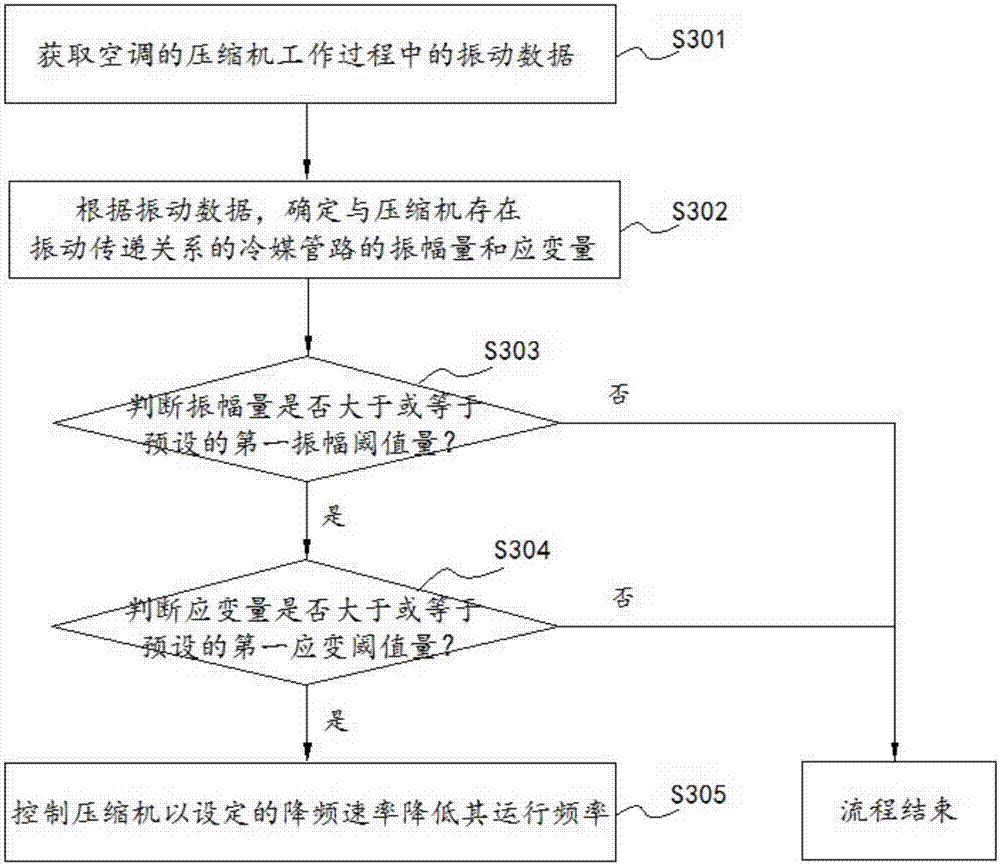

Vibration protection method and device of pipeline of air conditioning compressor

ActiveCN107514839AGuaranteed reliabilityReduce security risksCompressorEfficient regulation technologiesFrequency conversionEngineering

The invention discloses a vibration protection method and a vibration protection device of a pipeline of an air conditioning compressor, which belong to the technical field of air conditioners. The method comprises the steps of obtaining vibration data of the air conditioning compressor during operation; determining the amplitude and strain capacity of a refrigerant pipeline which is in vibration transfer relation with the compressor according to the vibration data; and controlling the compressor to change frequency when the amplitude and strain capacity satisfy preset vibration conditions. According to the vibration protection method of the pipeline of the air conditioning compressor, the vibration data of the compressor during operation are detected, so that whether the amplitude and strain of the related refrigerant pipeline are within a reasonable range can be analyzed and judged, and thus, if the amplitude and strain of the related refrigerant pipeline are not within the reasonable range, resonance points which possibly result in breaking of welding spots of the pipeline can be avoided by performing frequency conversion treatment on the air conditioning compressor, so that the reliability of the air conditioning refrigerant pipeline is guaranteed, and potential safety hazards caused by refrigerant leakage are reduced.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

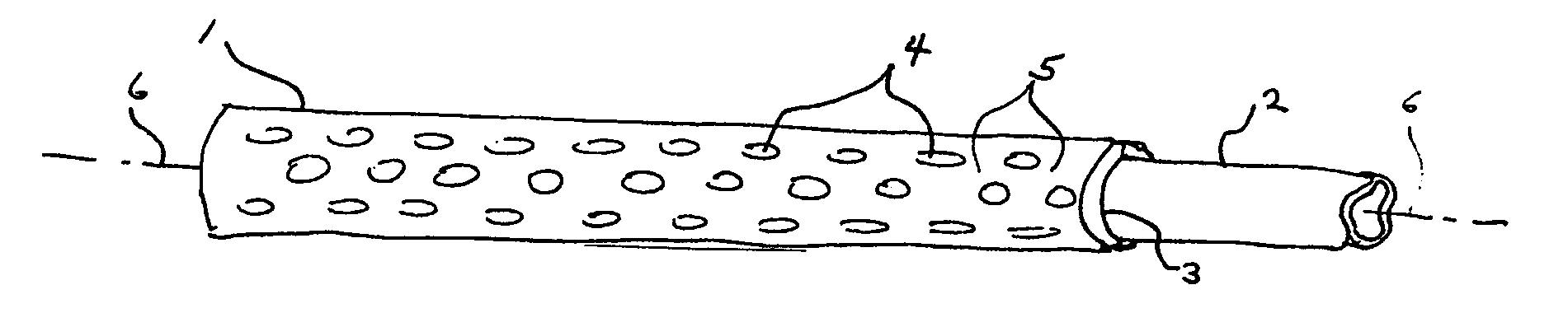

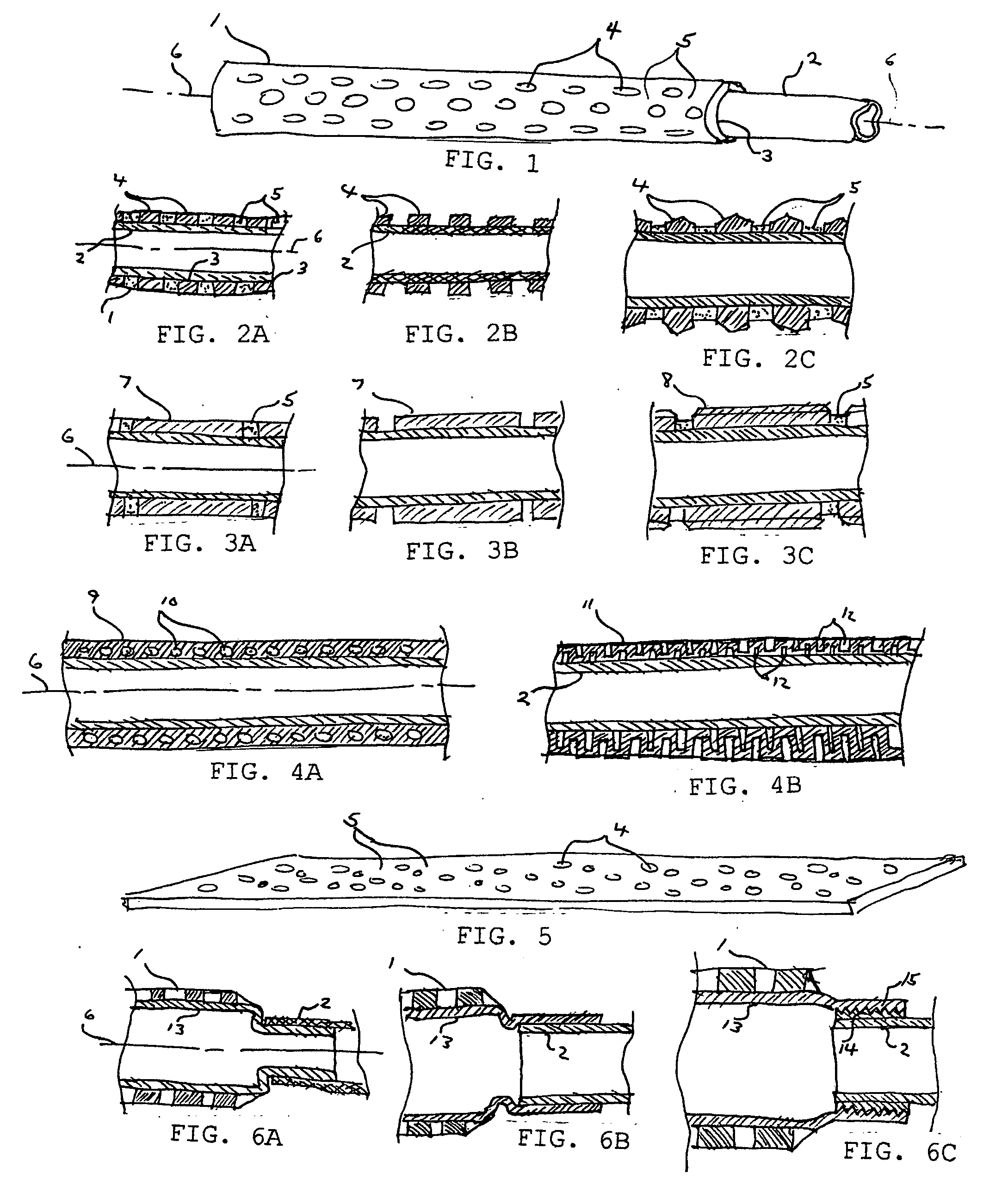

Putter grip with improved vibration transmission to hands

A putter or other golf club grip has rigid vibration transmitting protrusions either attached to the club shaft or in intimate contact with both the shaft and the golfer's hands, areas between said protrusions optionally being filled with conventional grip materials. The grip may be placed over existing club shafts like conventional slip-on or wrap-on grips or become an extension thereof. The grips may be attached and weighted in such a manner to further enhance desirable impact vibrational feedback to a golfer's hands further improving a golfer's distance control while reducing off center hits and the resulting distance and directional loss.

Owner:ROHRER TECH

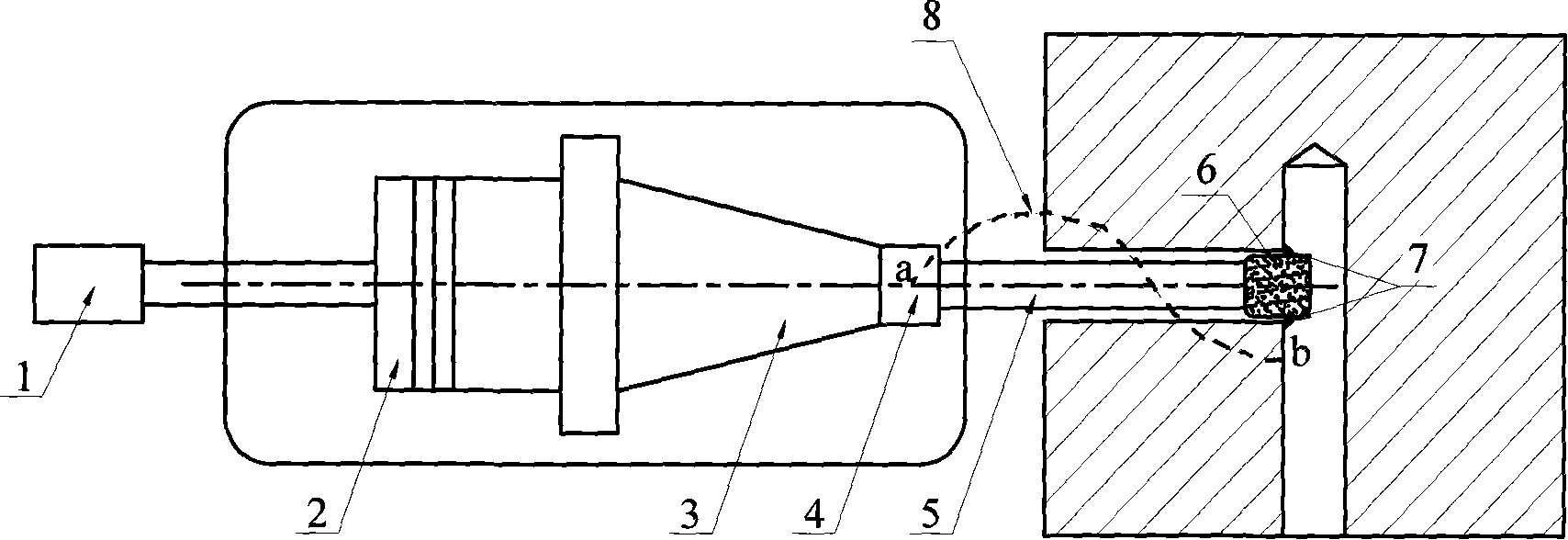

Complex casing deep ascopore ultrasound wave deburring tool and method

InactiveCN101239444AQuick removalUniform removalRevolution surface grinding machinesVibration amplitudeMachined surface

The invention pertains to a mechanically processing tool, relating to an ultrasonic burr removal tool and method for complex casing deep small holes. The invented device and method transform alternating current of 50Hz to supersonic mechanical vibration, the vibration amplitude of mechanical vibration is enlarged by an amplitude transformer bar and is transmitted to a vibration transmission bar to drive the superhard abrasive material thereon to vibrate longitudinally, impact the machined surface with a big velocity and generate maximal compressive force on a unit area to make the material to deform, crack and be peeled off as uncountable microparticles, so that to achieve the burr removal objective. The burr removal ultrasonic can reach position where manual tools are difficult to reach; man-made and environmental affecting factors are small, burrs are removed evenly and thoroughly, the processing accuracy and processing quality are easy to be ensured and controlled, the burrs are removed with identical degrees, and positions where burrs are removed have a same shape; the invented tool and method are suitable for processing holes with middle and small diameters and large length-diameter ratio in complex casing parts, especially holes smaller that phi 3; the processing time is short, and the processing efficiency is enhanced by over 50%.

Owner:中国航空工业第一集团公司北京航空精密机械研究所

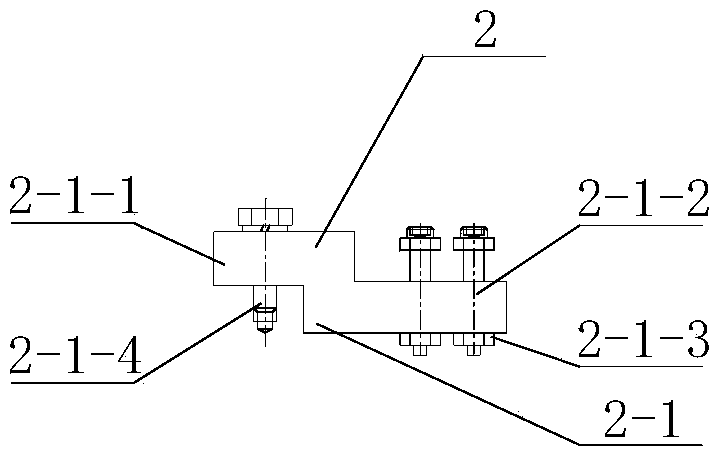

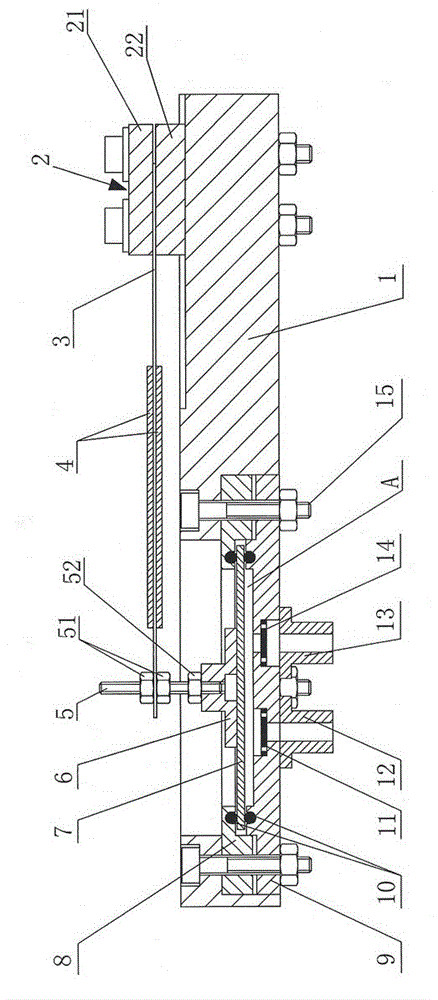

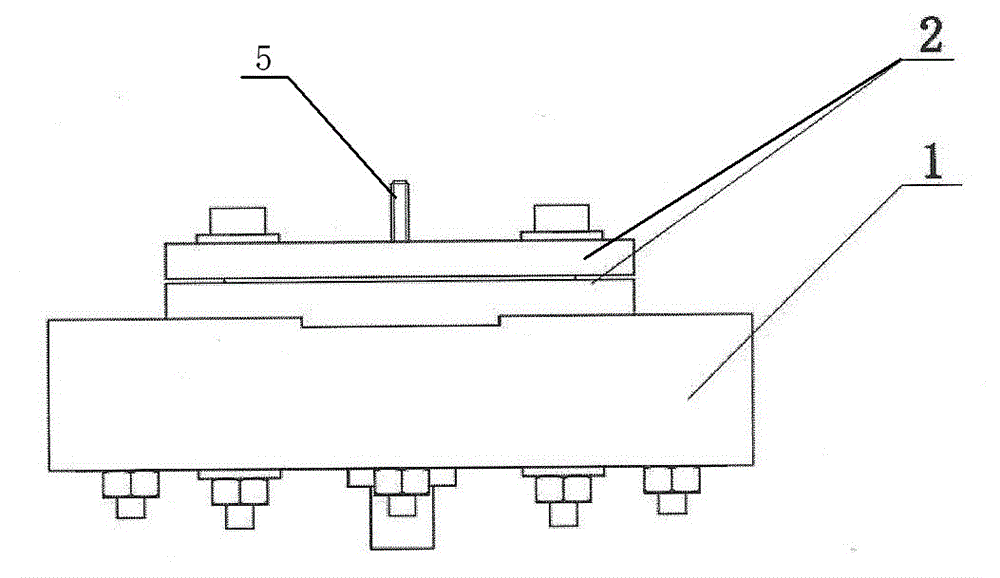

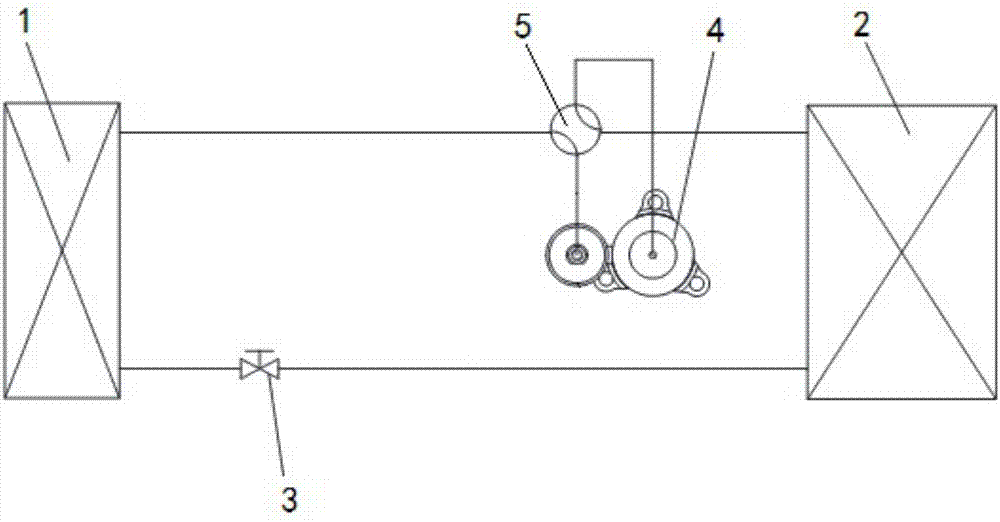

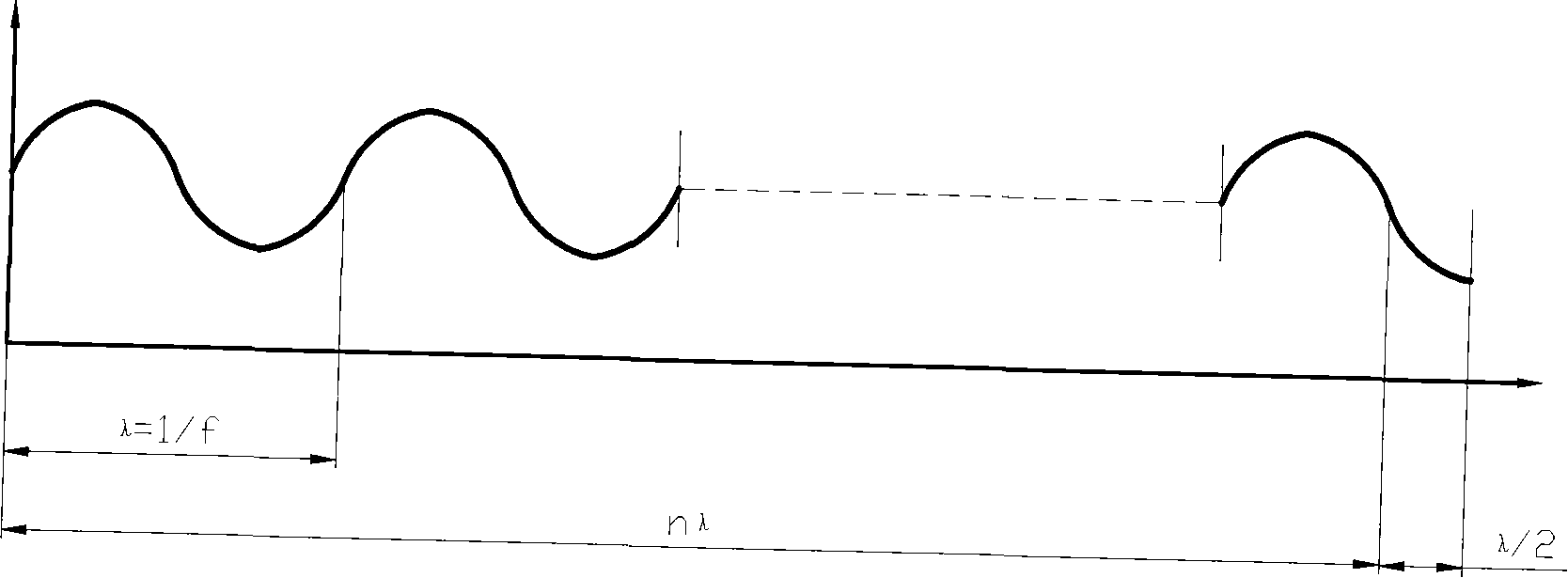

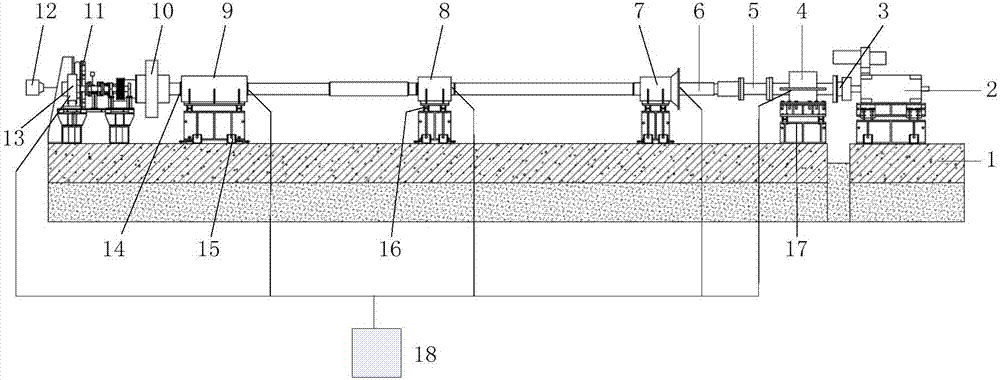

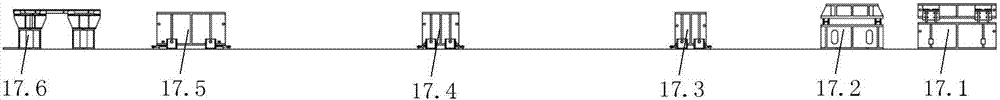

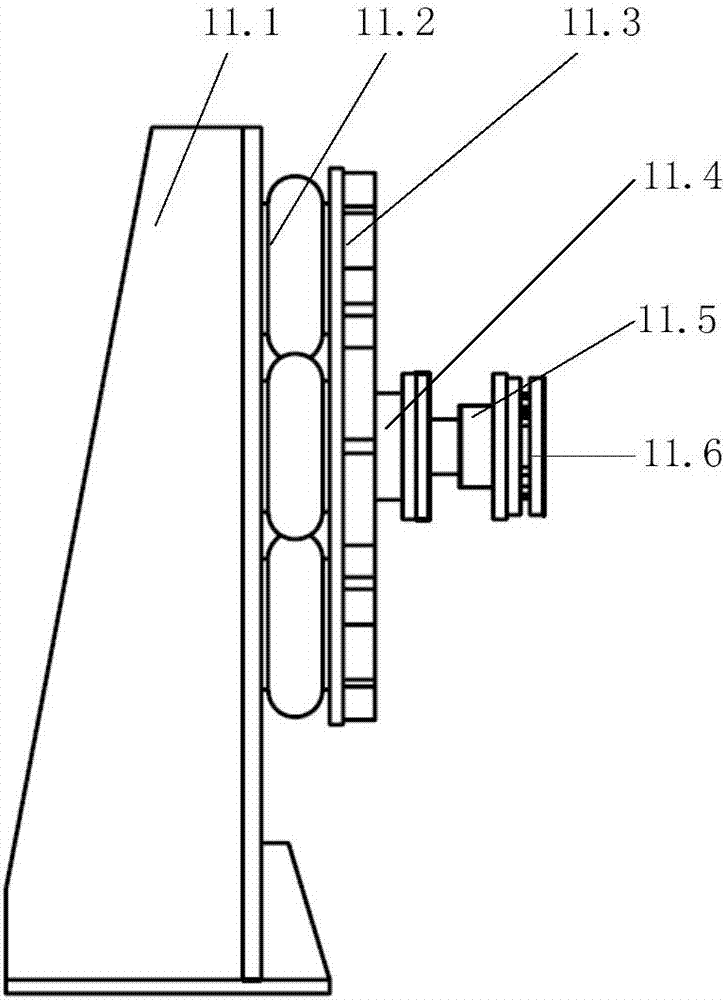

Full-scale marine propulsion shafting vibration transmission characteristic testing device

ActiveCN106996871AOvercome the shortcomings that cannot truly reflect the operation of the real-scale shaft systemMachine gearing/transmission testingVibration measurementCoupling

The invention relates to a land full-scale marine propulsion shafting vibration transmission characteristic testing device. The full-scale marine propulsion shafting vibration transmission characteristic testing device is constituted by a basis platform, a direct current motor, a high elasticity coupling, a thrust bearing unit, a middle shaft, a propulsion shaft, a bow bearing, a midship bearing, a stern bearing, a propeller simulation block, an axial static thrust loading device, a dynamic force loading device, a torsion loading device, a sealing device, a shafting centering adjusting device, a bearing base dynamic force testing element, matched bases of various parts, and a lubricating and cooling device. The matched bases of the various parts are disposed on the basis platform, and the base is provided with the main parts and the matched fittings of the propulsion shafting. The axial static thrust loading, the axial and radial dynamic force loading, and the torsion load are realized during the rotation of the shafting, and at the same time, a shafting centering state adjusting function is provided, and bearing support reaction measurement, base vibration measurement, and shafting vibration and transmission characteristic tests in different centering states are realized.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Multi-storage isolator with conical cross section

InactiveUS20070120301A1Reduce loadEnhances initial flexibilityMultiple spring combinationsHigh internal friction springsVibration transmissionMechanical engineering

Isolator assemblies and isolators between separate parts or components, and, particularly, multi stage isolators, especially, isolators useful in automotive applications are described. The isolators have a conical cross section, made of the same material as the isolator body, which can flex when in a deflection stage, or can compress in a compression stage, thus allowing for reduced vibration transmission and / or wear or longer life for both the isolator and the parts and components separated thereby.

Owner:VALEO INC

Sound and vibration transmission pad and system

InactiveUS20060036201A1Convenient distanceIncrease volumeStereophonic circuit arrangementsChiropractic devicesEngineeringLoudspeaker

The present invention is directed to a pad and sound transmission system which is adapted to directly transmit audible sound waves into the body at high intensity levels. In one embodiment, the pad is comprised of a padding material and speakers disposed within the padding material. The sound transmission system includes an amplifier, an automatic volume control, and a plurality of input parts. The pad includes a padding material comprised of a layer of highly porous material, a layer made of more dense foam and a stiff foam core in which the speakers are connected. The padding material preferably includes a plurality of openings that form resonant chambers that direct sound-generated vibrations to the shoulder blades, the center of the spine, and the hips of the user.

Owner:ROUND RIVER RES CORP

Electric toothbrush

ActiveUS20180008388A1Easy to cleanWeakening rangeBrush bodiesBristle carriersVibration transmissionElectrical and Electronics engineering

The present disclosure relates to an electric toothbrush, and more particularly, to an electric toothbrush including: a main body which includes an outer case; a cleaning body which is coupled to the main body and has a cleaning head formed at one end thereof; a vibration transmission unit which couples the main body and the cleaning body, has a vibration generator mounted thereon to generate vibration, and transmits the vibration to the cleaning body; and a vibration damping unit which is provided between the outer case and the vibration transmission unit, thereby maintaining cleaning performance of the electric toothbrush, reducing magnitude of vibration to be transmitted to a user, and improving convenience for the user.

Owner:BLUEREO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com