Full-scale marine propulsion shafting vibration transmission characteristic testing device

A technology of vibration transmission and characteristic testing, which is applied in the direction of measuring devices, machine gear/transmission mechanism testing, mechanical component testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

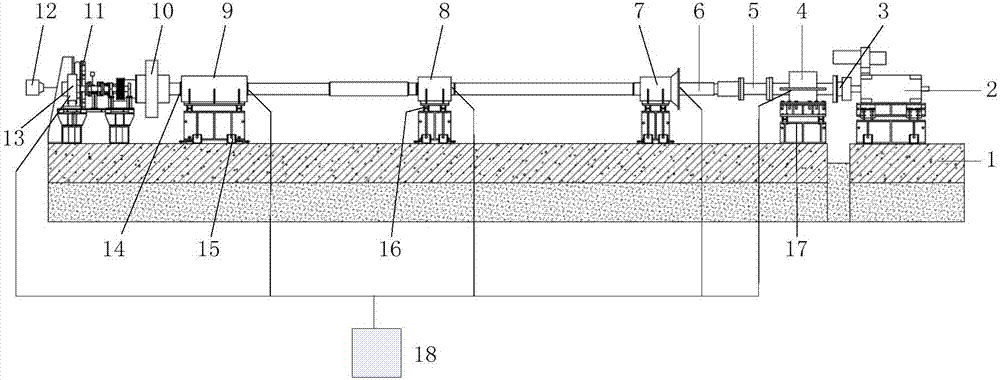

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

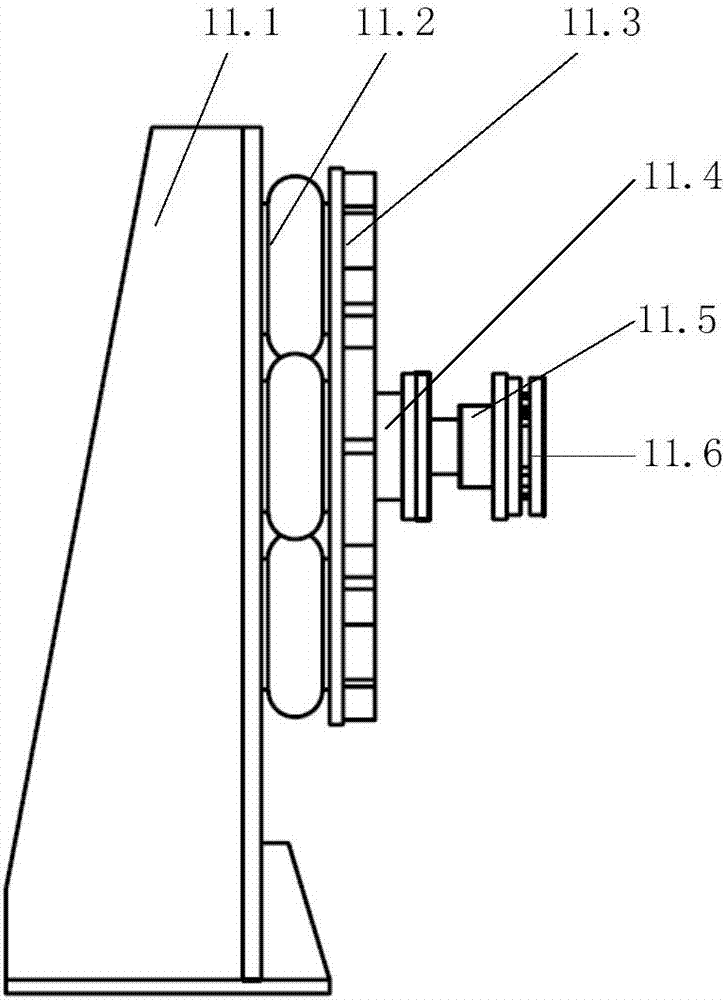

[0031] Such as figure 1 As shown, a test device for vibration transmission characteristics of a land-based full-scale ship propulsion shafting system of the present invention mainly consists of a base platform 1, a DC motor 2, a highly elastic coupling 3, a thrust bearing assembly 4, an intermediate shaft 5, and a propulsion shaft 6 , bow bearing 7, midship bearing 8, stern bearing 9, propeller simulation block 10, axial static thrust loading device 11, dynamic force loading device 12, torque loading device 13, sealing device 14, shaft alignment adjustment device 15, bearing The base dynamic force test element 16, the supporting base 17 of each part and the lubrication and cooling device 18 are composed.

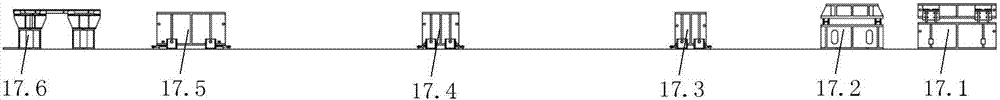

[0032] Such as figure 2 As shown, the supporting base 17 of each part is installed on the foundation platform 1, and the main componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com