Vibration measurement and control device and method of rotary flexible hinge beam

A flexible hinge and vibration measurement technology, applied in the direction of non-rotational vibration suppression, can solve the problems of inability to carry out large-scale, harmonic gear reducer lag, mechanical arm impact breakage, etc., to achieve suppression of low-frequency large-value vibration and optimal control effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

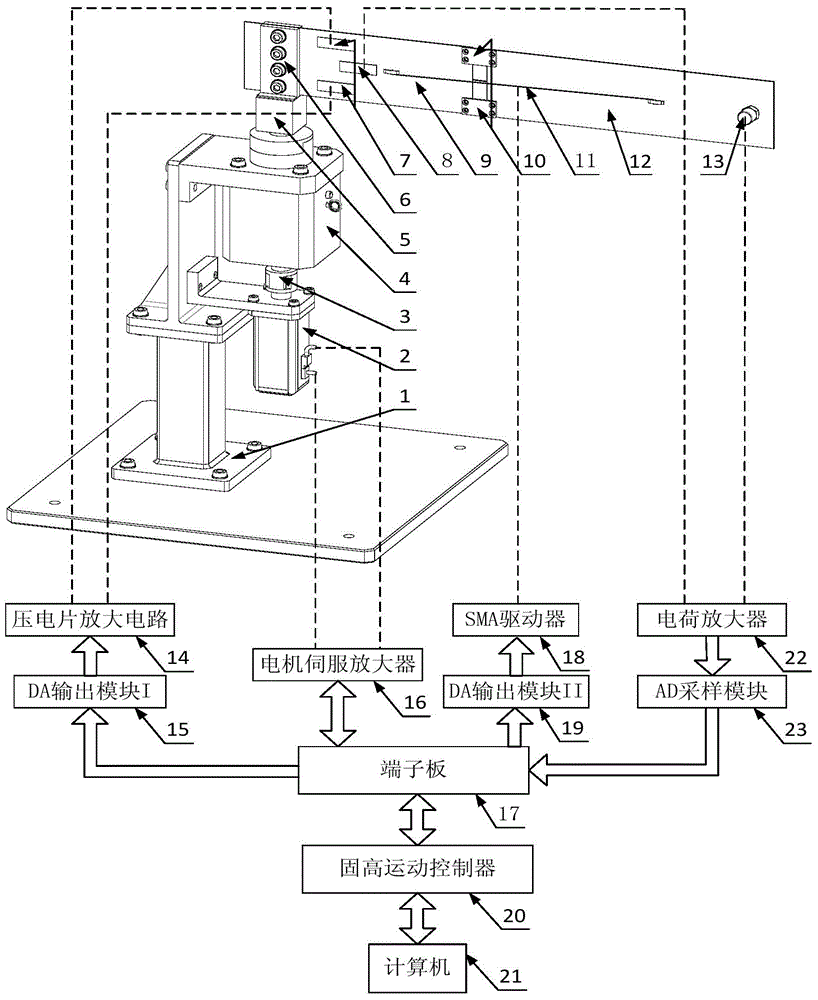

[0038] like figure 1 As shown, a vibration measurement and control device for rotating a flexible hinged beam includes a flexible hinged beam body part, a vibration signal detection part and a drive control part;

[0039] —Flexible hinged beam body part

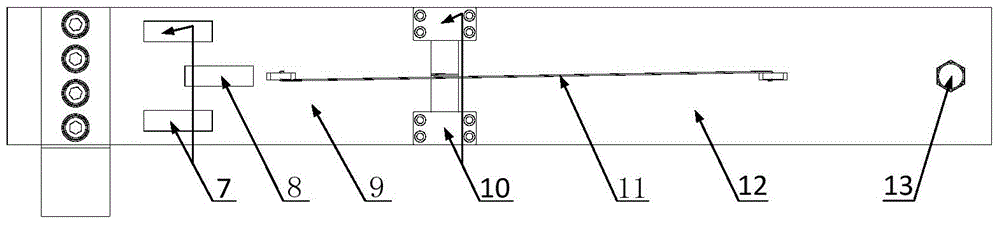

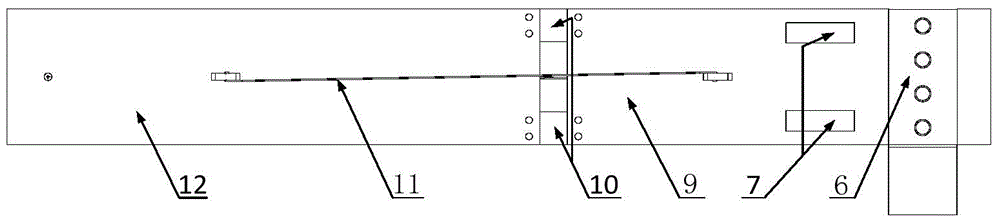

[0040] The flexible hinged beam is formed by hinged flexible beam I9 and flexible beam II12 through the hinge 10, one end of the flexible hinged beam is free, the other end is fixed, the fixed end is clamped by the mechanical clamping device 6, and then connected with the harmonic gear reducer 4 Output shaft hub 5 is connected;

[0041] — Vibration signal detection part:

[0042] like figure 2 , image 3 As shown, comprise piezoelectric ceramic sheet sensor 8 and acceleration sensor 13, described piezoelectric ceramic sheet sensor 8 is installed on the centerline of flexible beam 19, the position apart from fixed end 60mm, is positioned between two piezoelectric actuators; The sensor 13 is installed on the center line o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com