Patents

Literature

409 results about "Pre tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre tensioning : In this method the concrete is prestressed with tendons before it is placing in position. This method is developed due to bonding between the concrete and steel tendons . Pre tensioning is preferred when the structural element is small and easy to transported. In this method similar prestressed members are prepared .

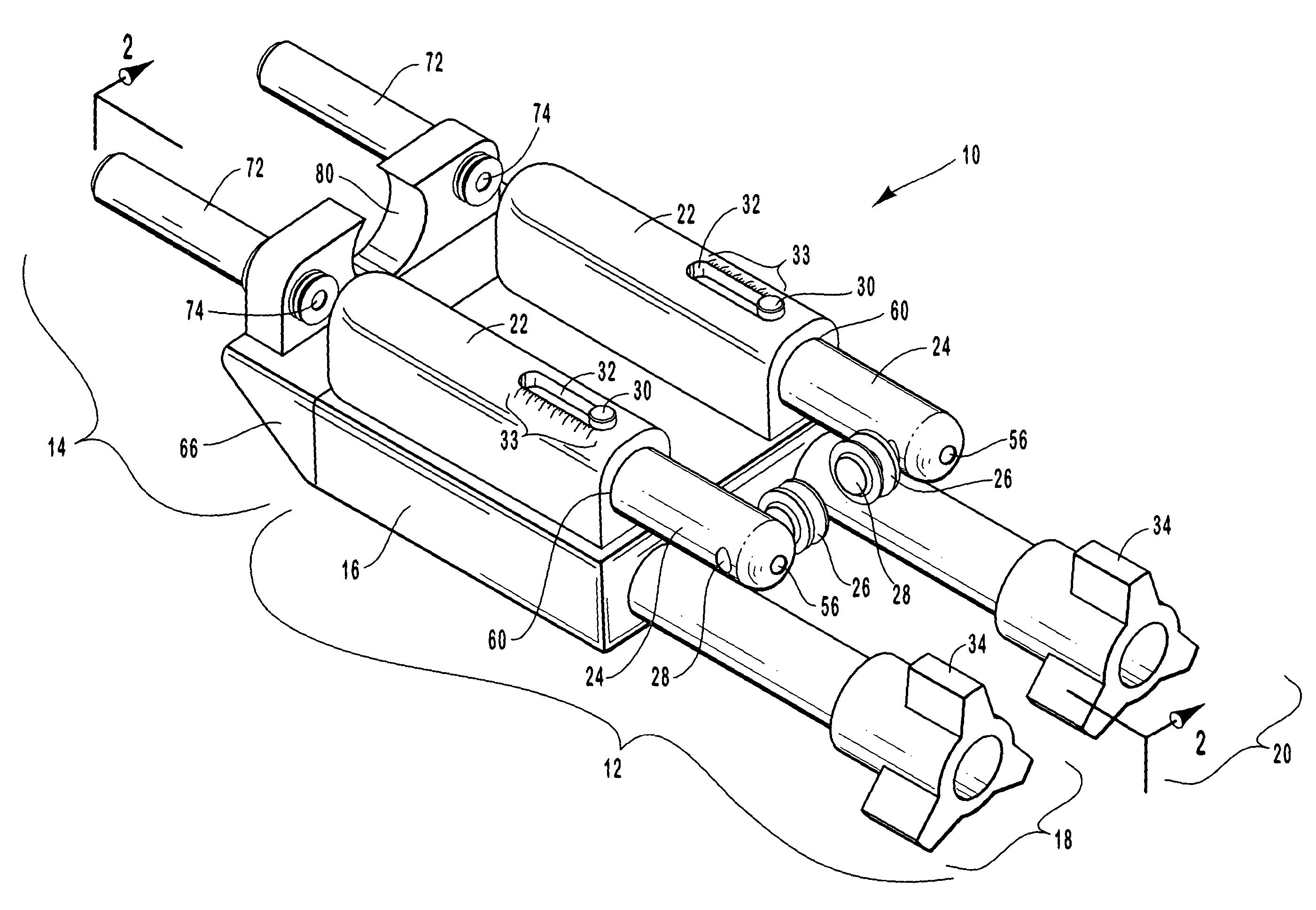

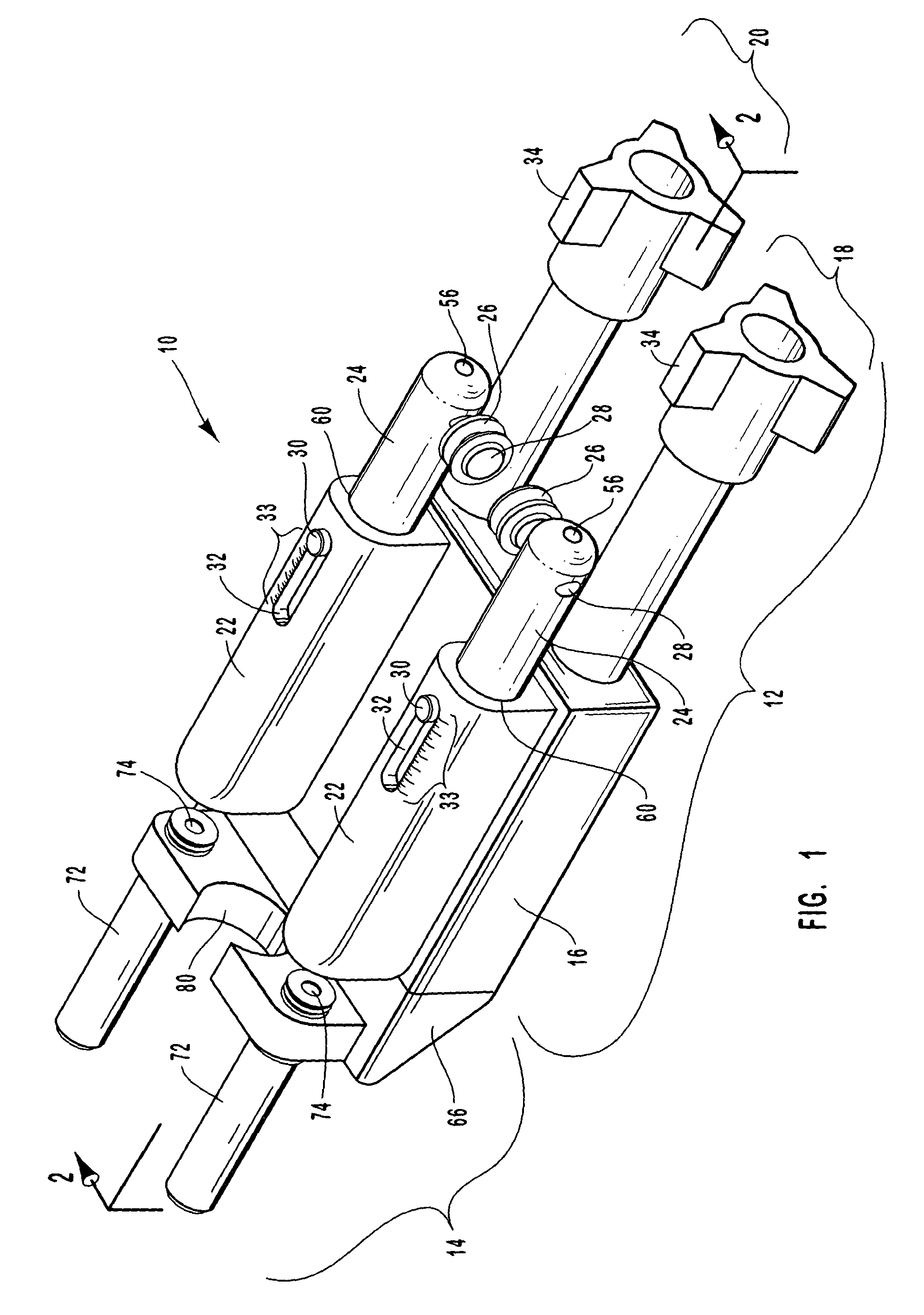

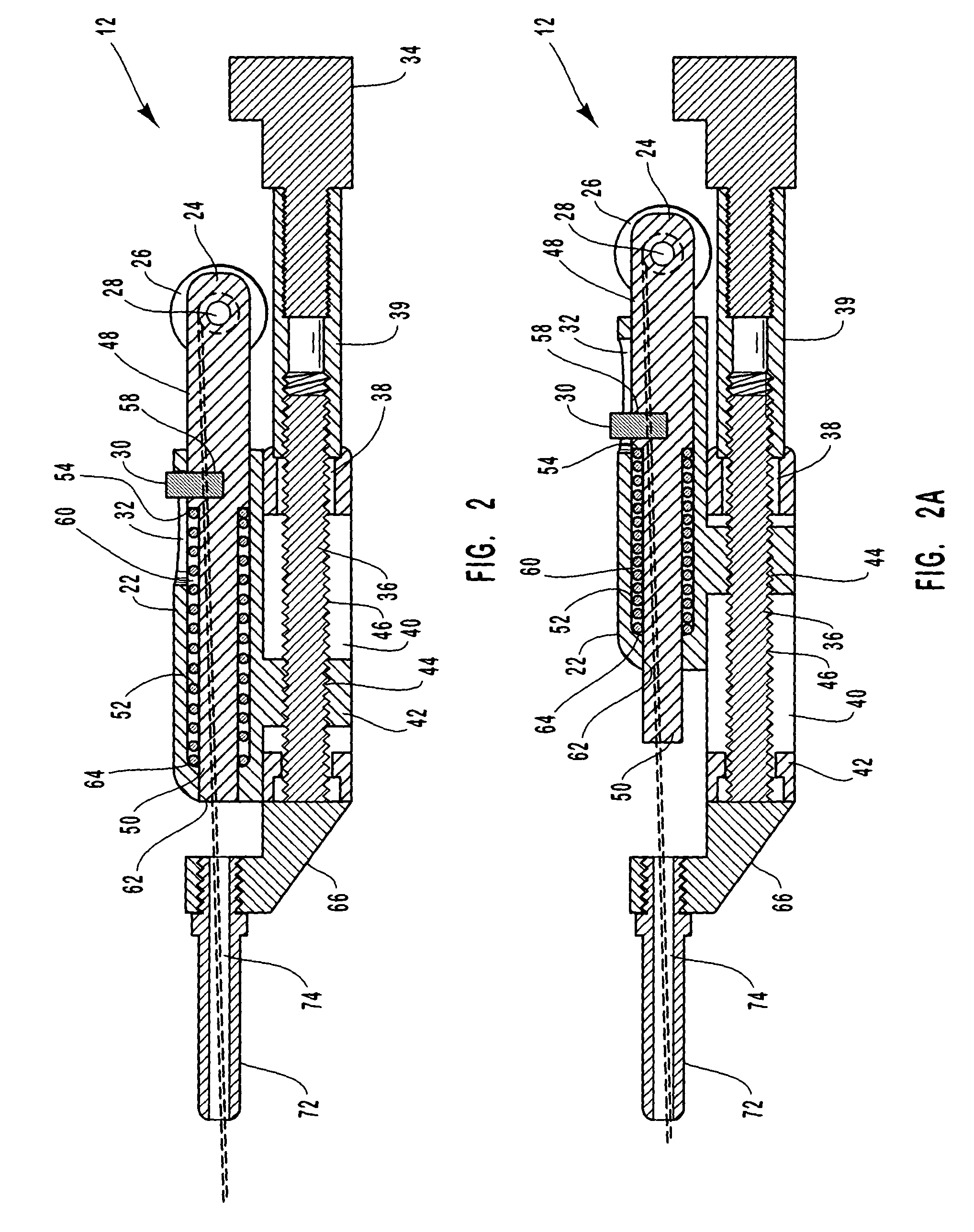

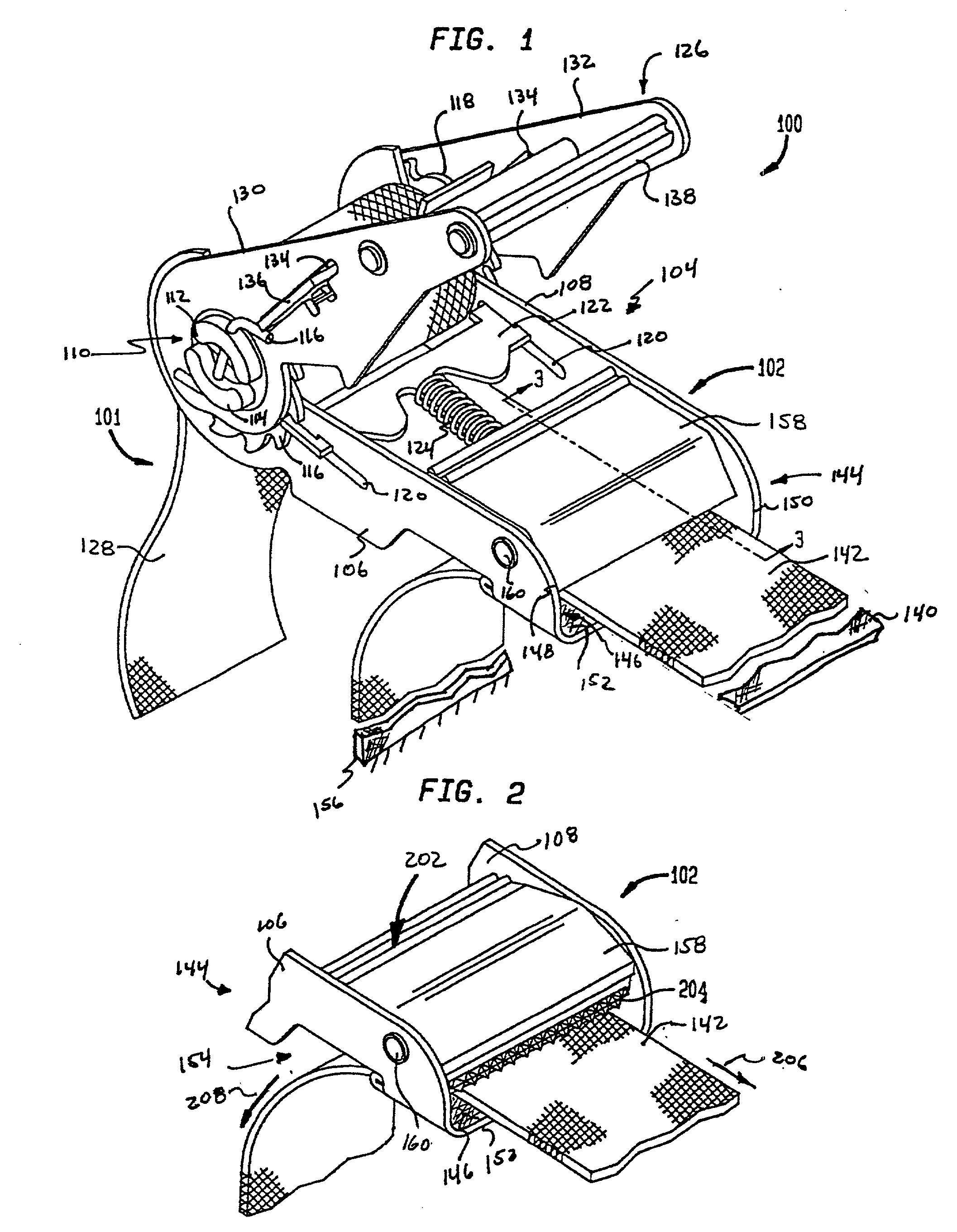

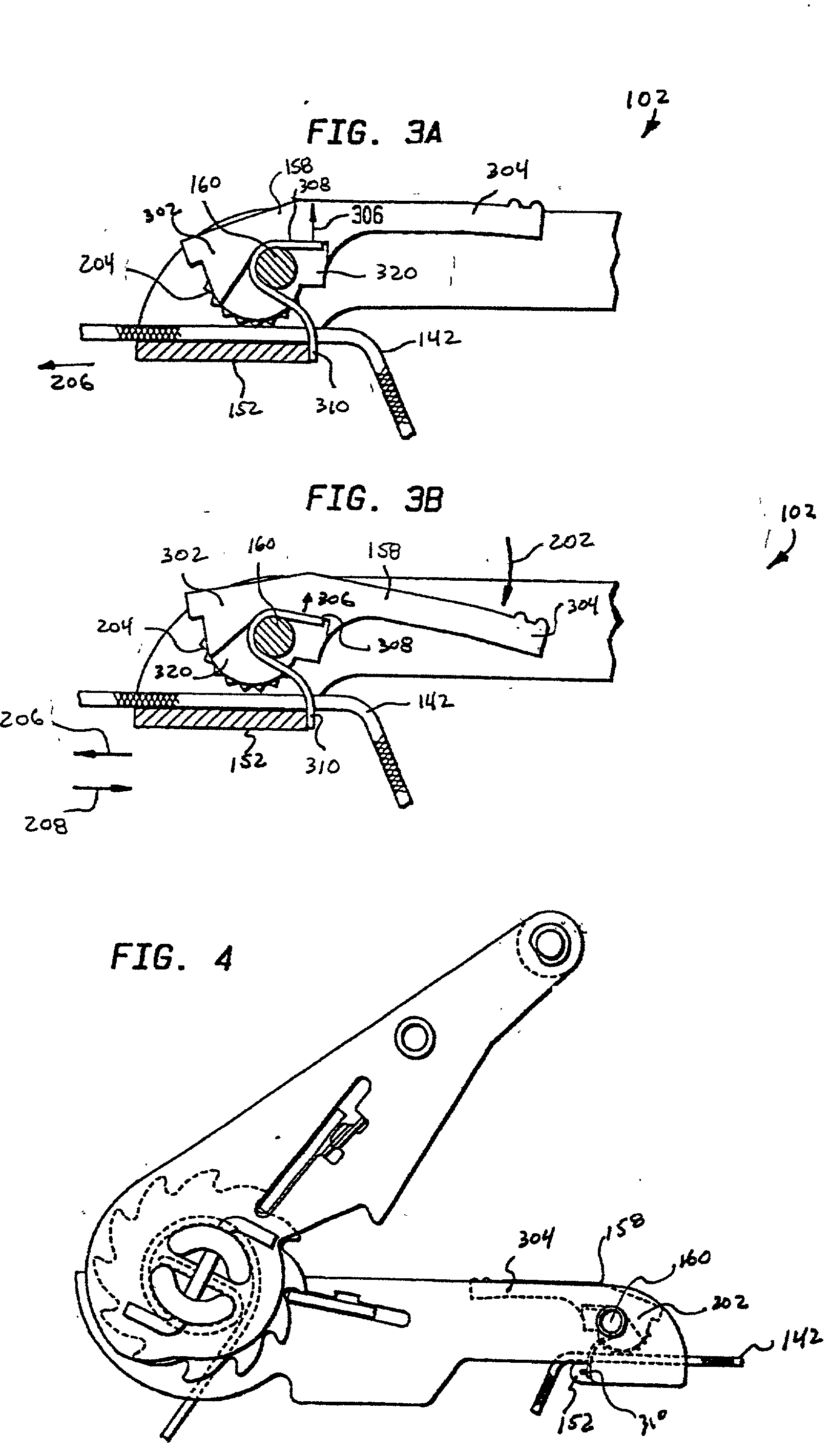

Apparatus and methods for independently conditioning and pre-tensioning a plurality of ligament grafts during joint repair surgery

InactiveUS7118578B2Promote faster adhesionFixationJoint implantsLigamentsTissue GraftSurgical department

Apparatus and methods for conditioning and pre-tensioning soft tissue grafts during joint repair surgery, such as during repair of the anterior cruciate ligament (ACL). The inventive apparatus is advantageously adapted and configured so as to enable a surgeon to independently apply a desired tensile load to individual graft strands or graft bundles of a multi-strand tissue graft. The inventive methods enable each graft strand or bundle to be properly tensioned so as to both “condition” the graft to prevent subsequent stretching, relaxation or elongation following surgery, which can destabilize the joint, and to pre-tension each graft strand or bundle to a predetermined amount so that each contributes to the strength and stability of the joint, thus resulting in a stronger and more durable joint. The tensioning device is advantageously equipped with structure for attachment to a patient's limb during the conditioning and pre-tensioning procedure. It has multiple adjustable tension applicators that can be independently manipulated so as to apply a separate tensile load to one or more ends of a tissue graft strand attached to each adjustable tension applicator.

Owner:HS WEST INVESTMENTS LLC

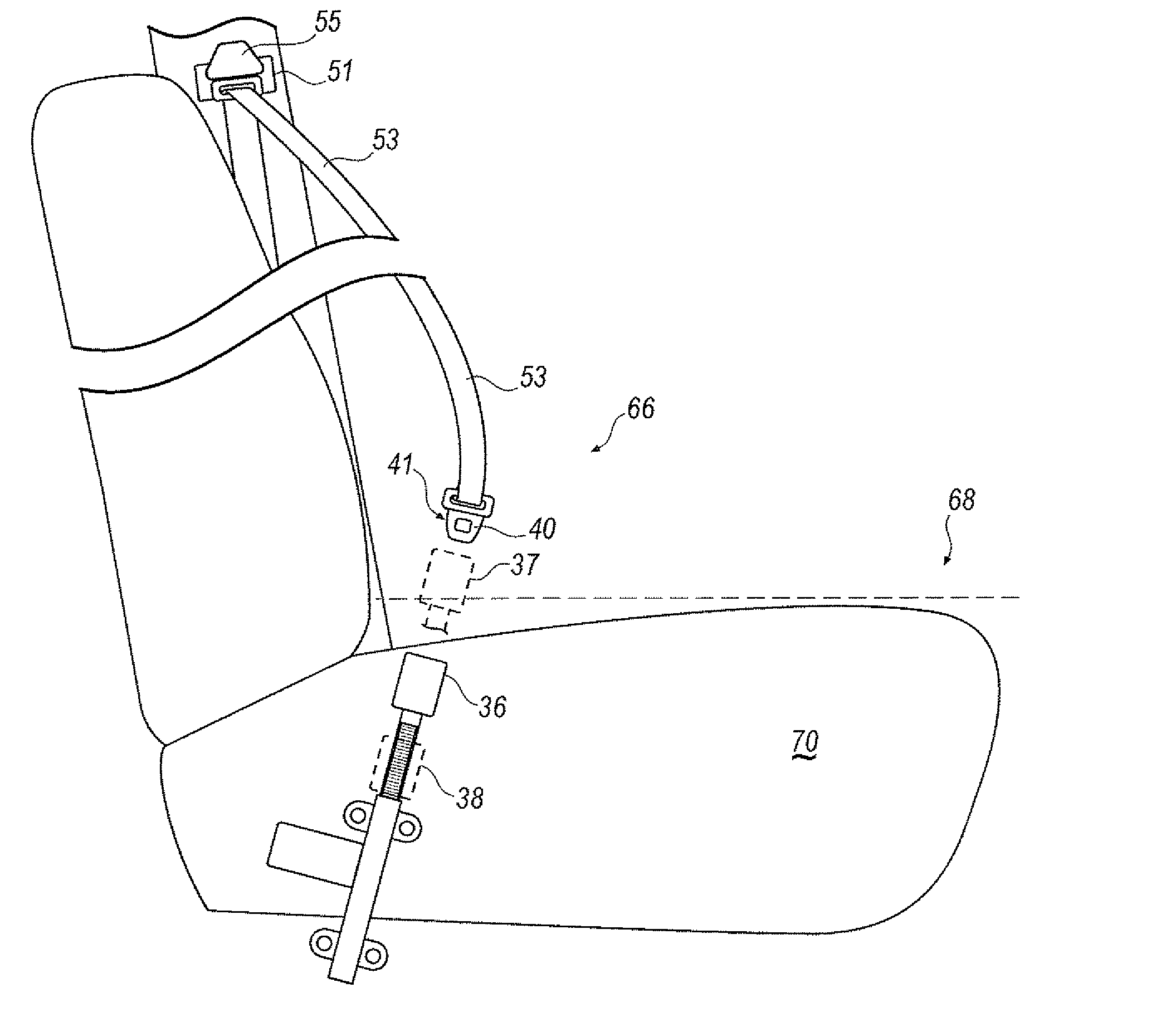

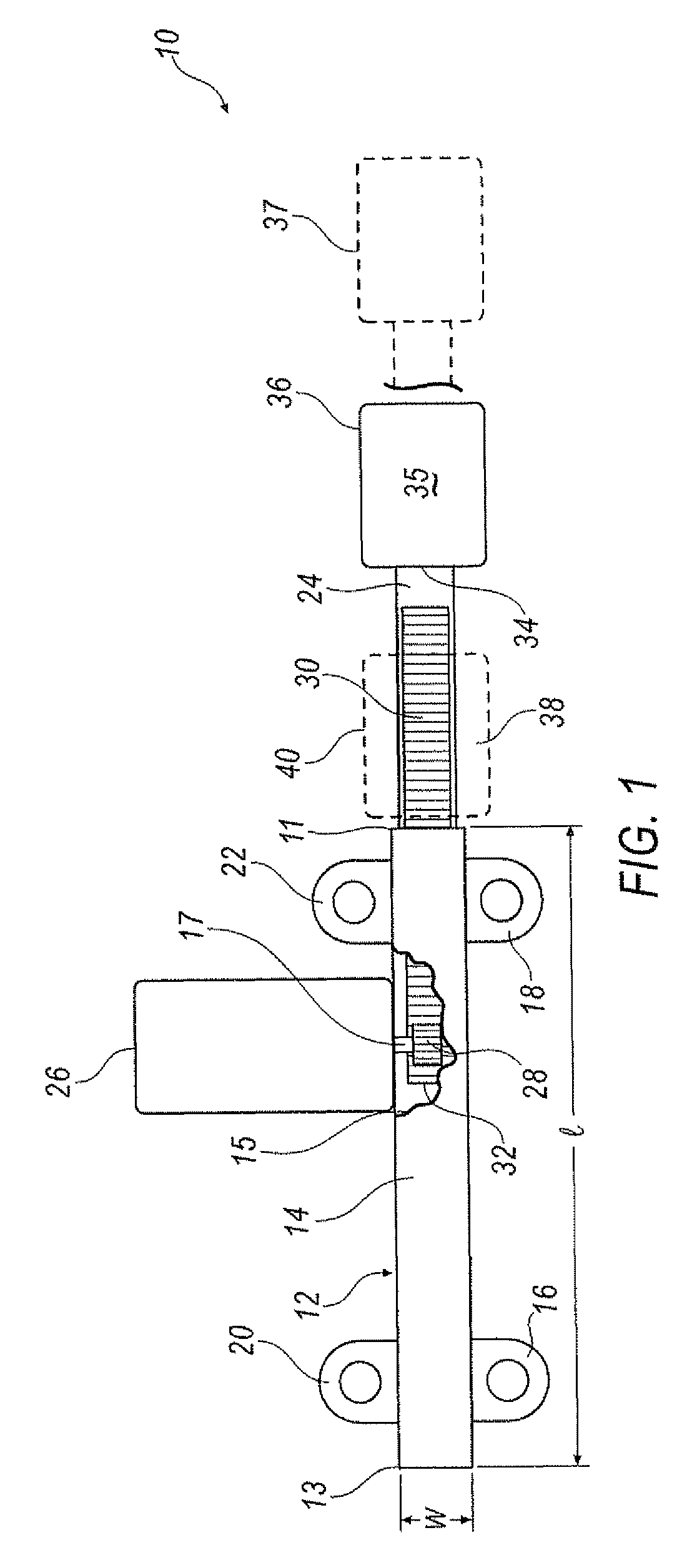

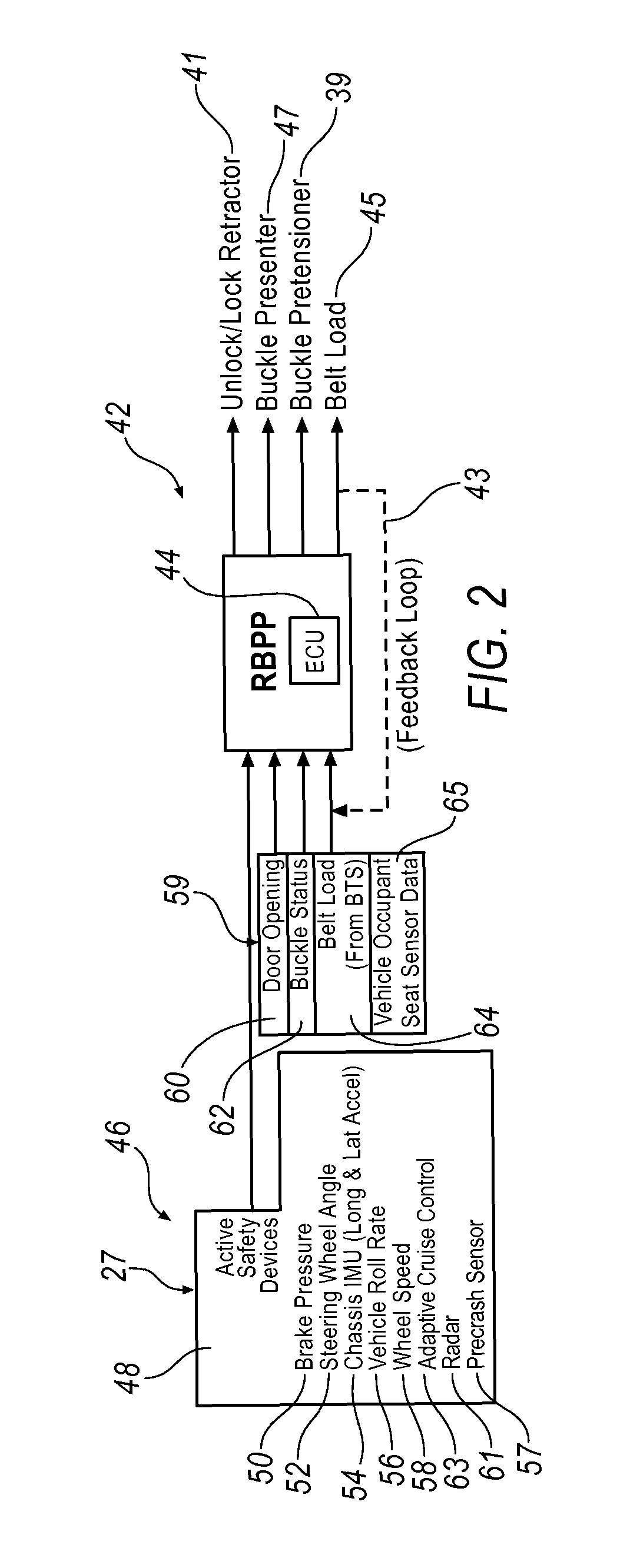

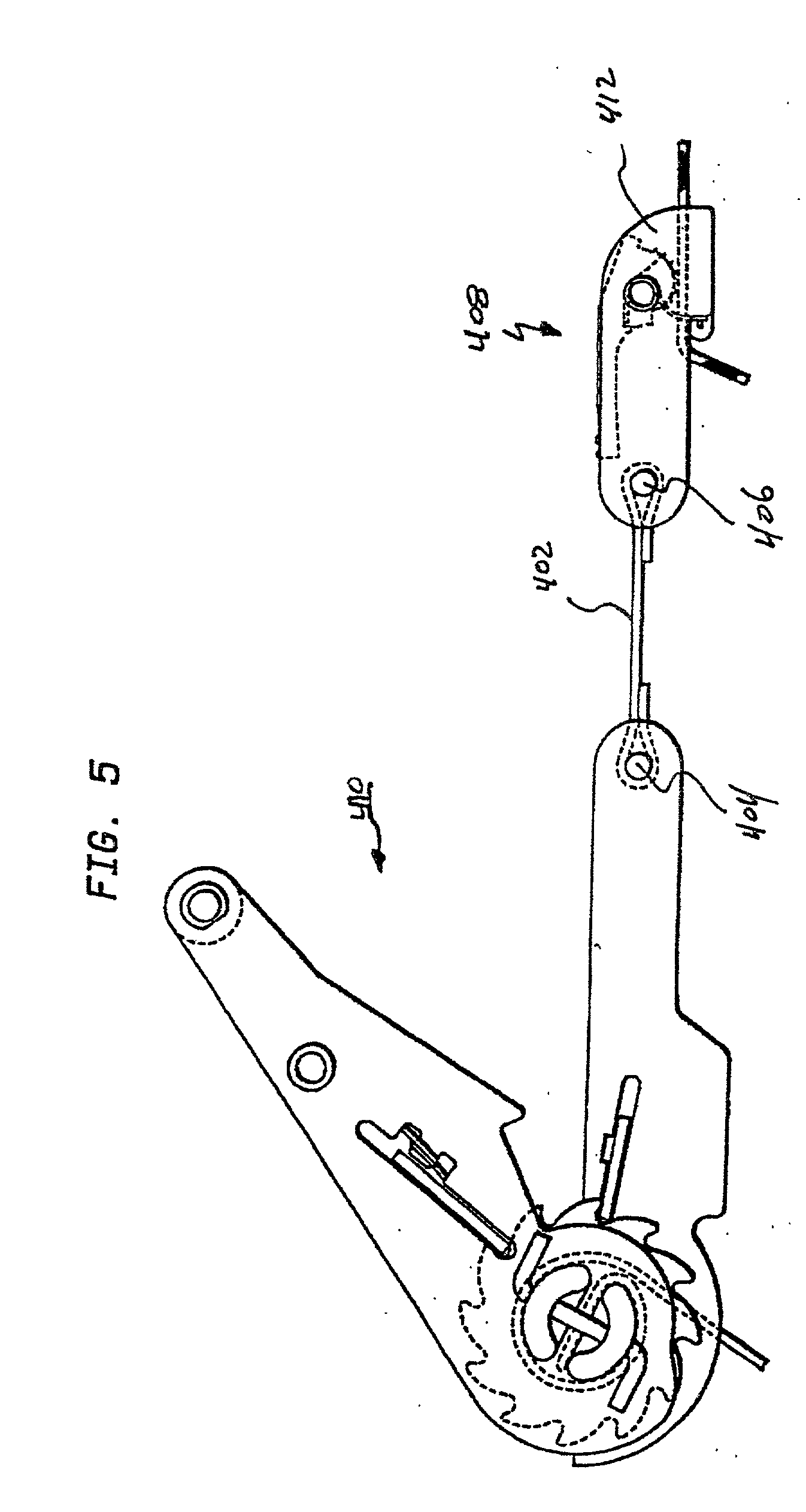

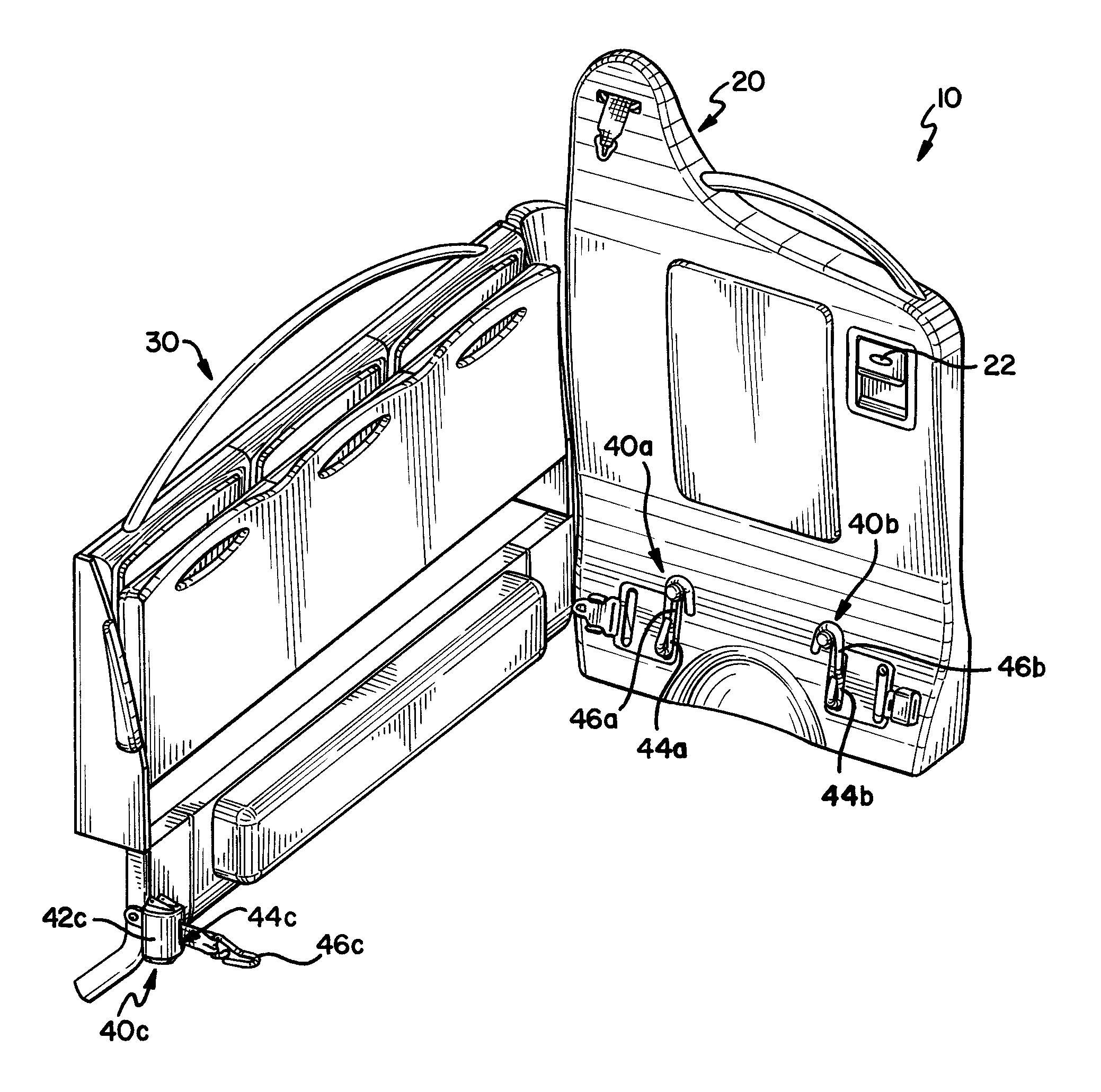

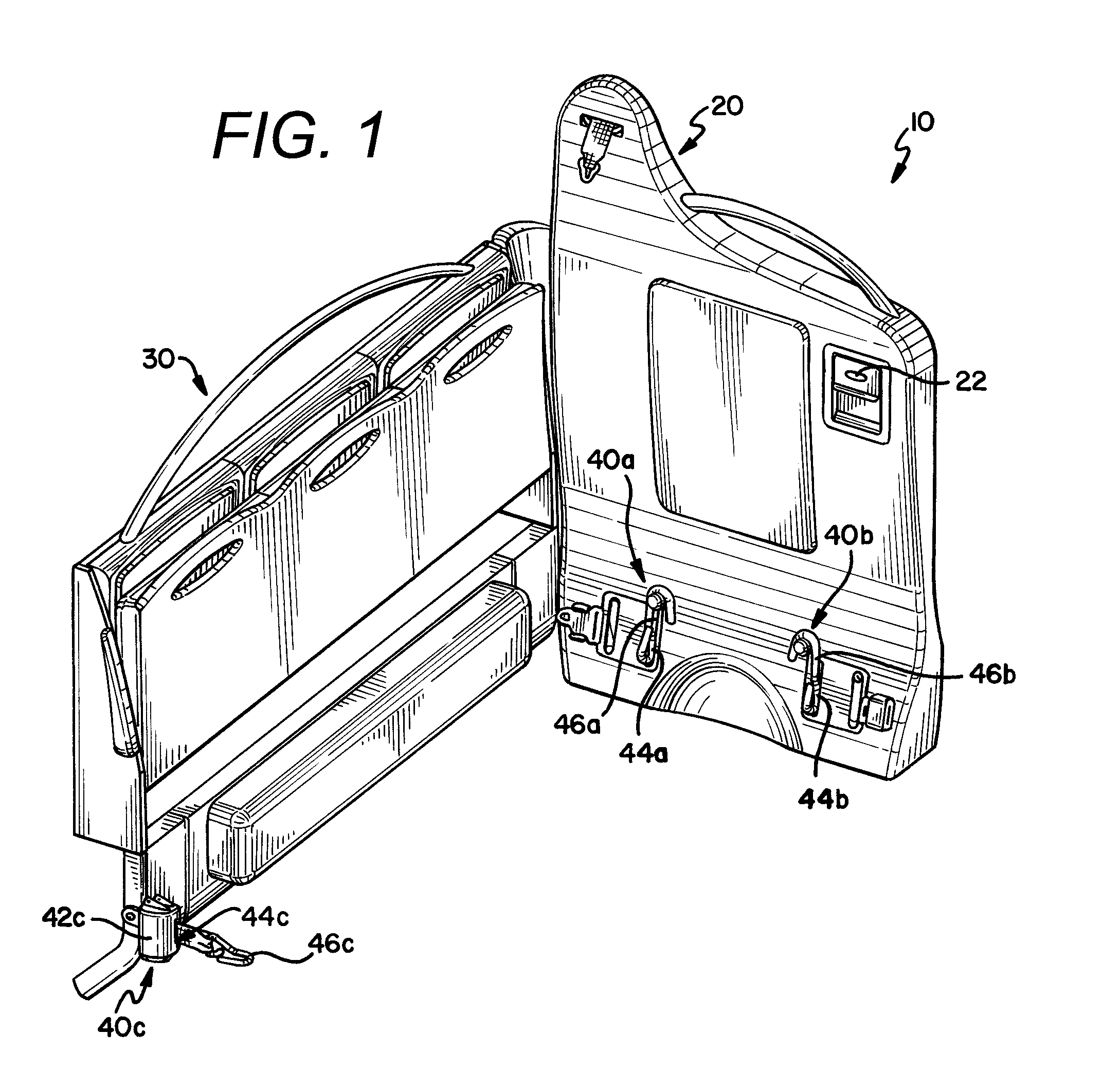

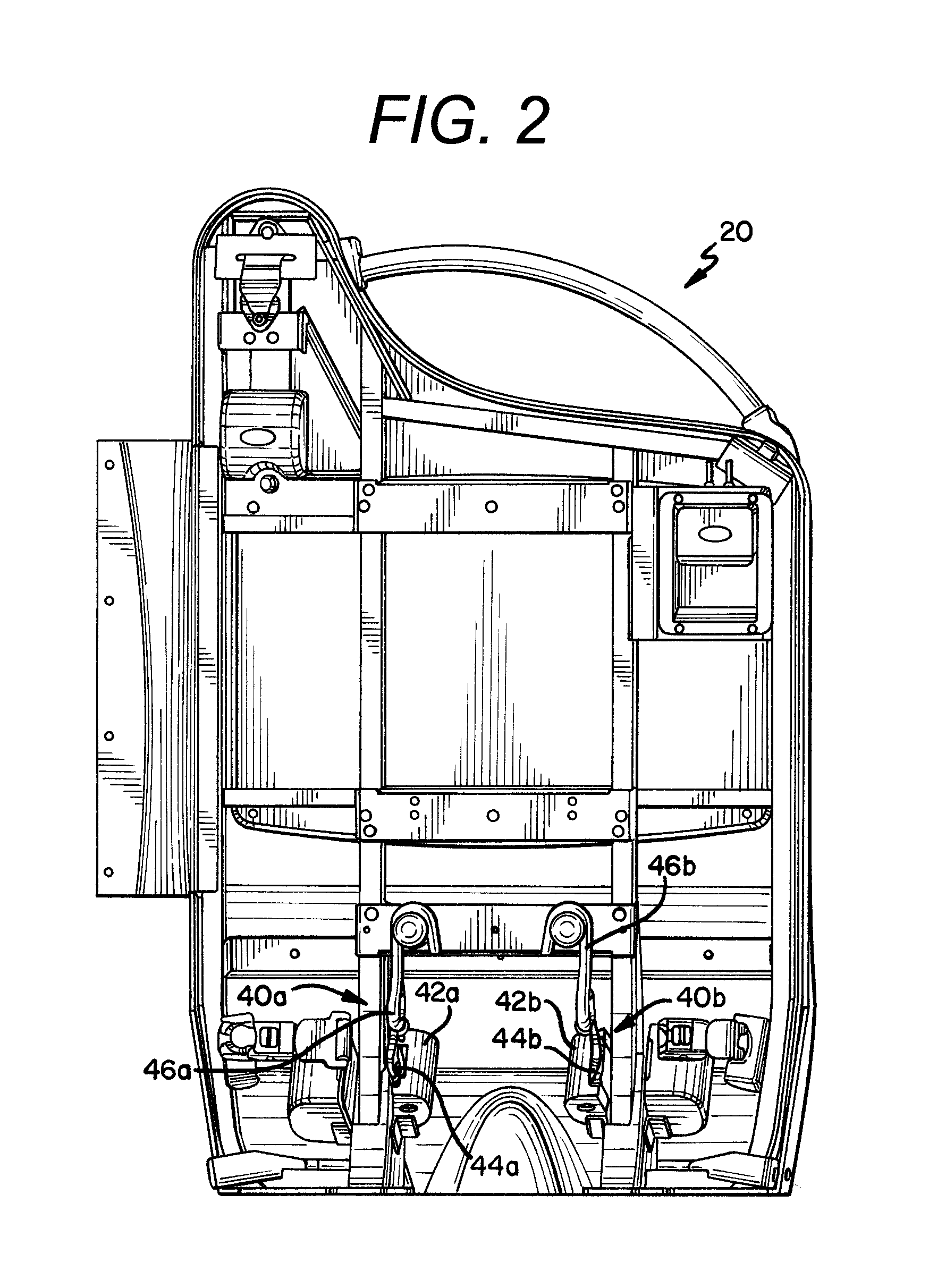

Re-settable vehicle seat belt buckle pre-tensioner presenter system and method of operation

InactiveUS7866703B2Easy accessEasy to fixBelt retractorsSemi-passive restraint systemsSeat beltEngineering

A re-settable vehicle seat belt pre-tensioner apparatus is disclosed having a first member engagable with a second member that is moveable relative to the first member, and re-settable in response to various sensed driving conditions to pretension the seat belt around the operator and return to a non pre-tensioned status when the driving conditions have passed. The apparatus may be operated by positioning the belt for use; determining whether the seat belt buckle is in use; locking the pre-tensioner and lowering the seat belt buckle below the seat occupation plane; determining whether a threshold vehicle seat belt pre-tension load has been met; raising the belt buckle to a design position, unlocking the retractor; determining whether a threat event is imminent and locking the retractor; lowering the vehicle seat buckle relative to the plane of occupation, determining whether a crash event is occurring, and if yes, deploying a pyrotechnic deployment to secure the occupant in the seat.

Owner:FORD GLOBAL TECH LLC

Ratchet and cam buckle tensioning assembly and method for using same

InactiveUS20010045548A1Quickly and conveniently pre-tensionEasy to useLifting devicesLoad securingEngineeringMechanical engineering

A ratchet and cam buckle tensioning assembly or strap tensioner, interposed between a lashing strap tensioned by the ratchet buckle and a lead strap tensioned by the cam buckle. The invention enables an operator to quickly and conveniently pre-tension the lashing and lead straps by removing an un-tensioned length of the lead strap without having to operate the ratchet buckle. The tensioning assembly includes a ratchet buckle for tensioning the lashing strap in stepped increments and a cam buckle for slidingly adjusting the lead strap. The cam buckle housing and the ratchet buckle frame member are a unitary member, forming an single, integrated tensioning assembly. Alternately, the cam buckle is permanently attached adjacent to the ratchet buckle. The cam buckle includes a housing adapted to slidably receive the lead strap. The housing has a pressure plate with a first restraining surface, such as a friction surface, over which the lead strap slides. A pawl is movably mounted, such as by pivoting, to the housing. The pawl has a second restraining surface and is biased in an engaged position to restrain the lead strap between the first and second restraining surfaces so as to prevent movement of the lead strap in one or both directions. The pawl also may assume a disengaged position wherein the lead strap can move freely between the first and second restraining surfaces.

Owner:WRIGHT JEFFREY DAVID MR

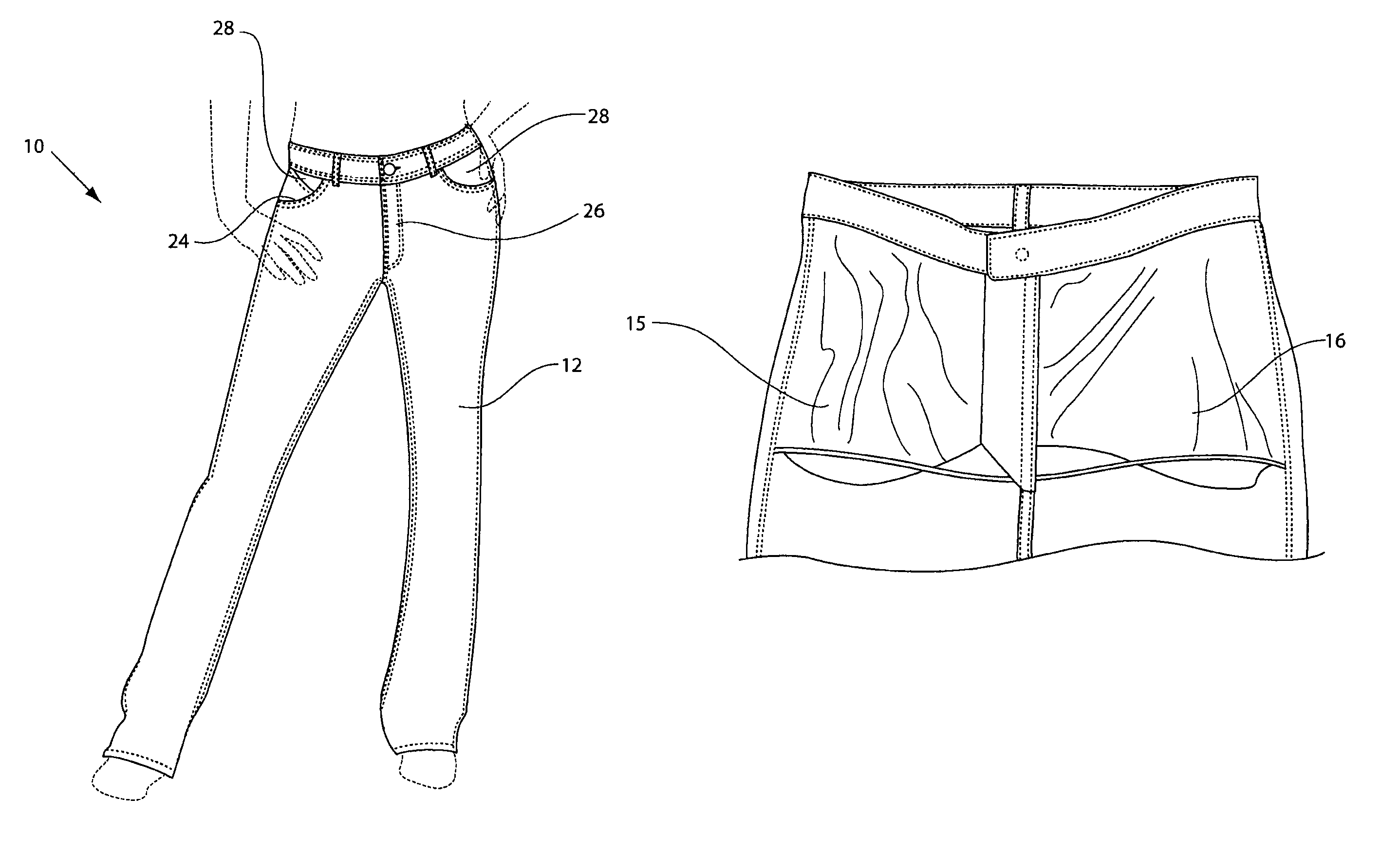

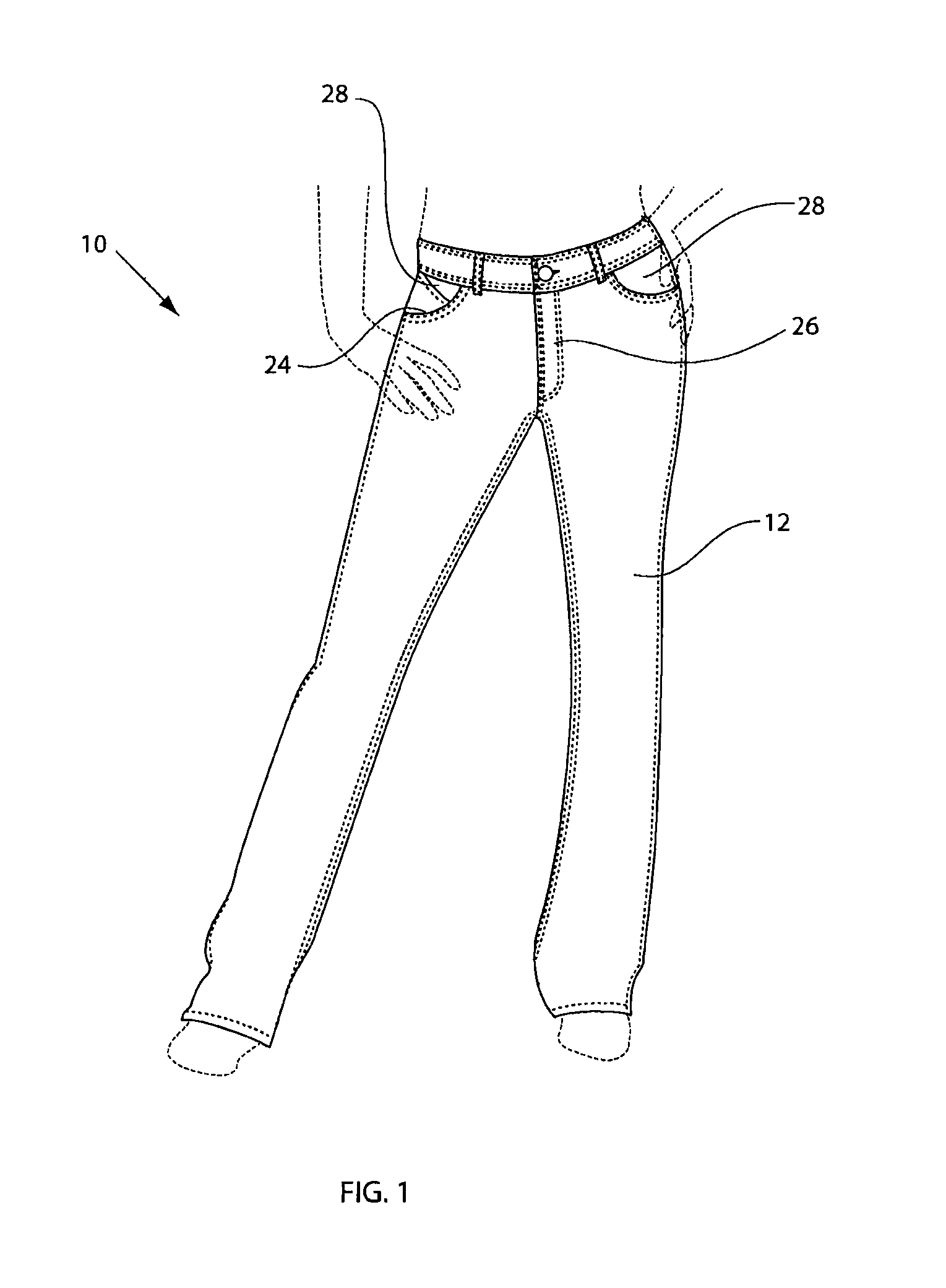

Bottom garment having improved tummy control

A bottom garment for providing improved appearance to the wearer. The garment includes a front panel; a back panel; and at least one tummy control panel formed of a low-stretch, high pre-tensioned fabric attached to the inside of the front panel beneath the waistband of the front panel. In one embodiment, the low-stretch, high pre-tension fabric is formed of a mesh construction. The front panel may further include at least one pocket assembly.

Owner:WRANGLER APPAREL CORP

Fastener tightening analysis

InactiveUS7499845B1Design optimisation/simulationSpecial data processing applicationsComputer Aided DesignBiomedical engineering

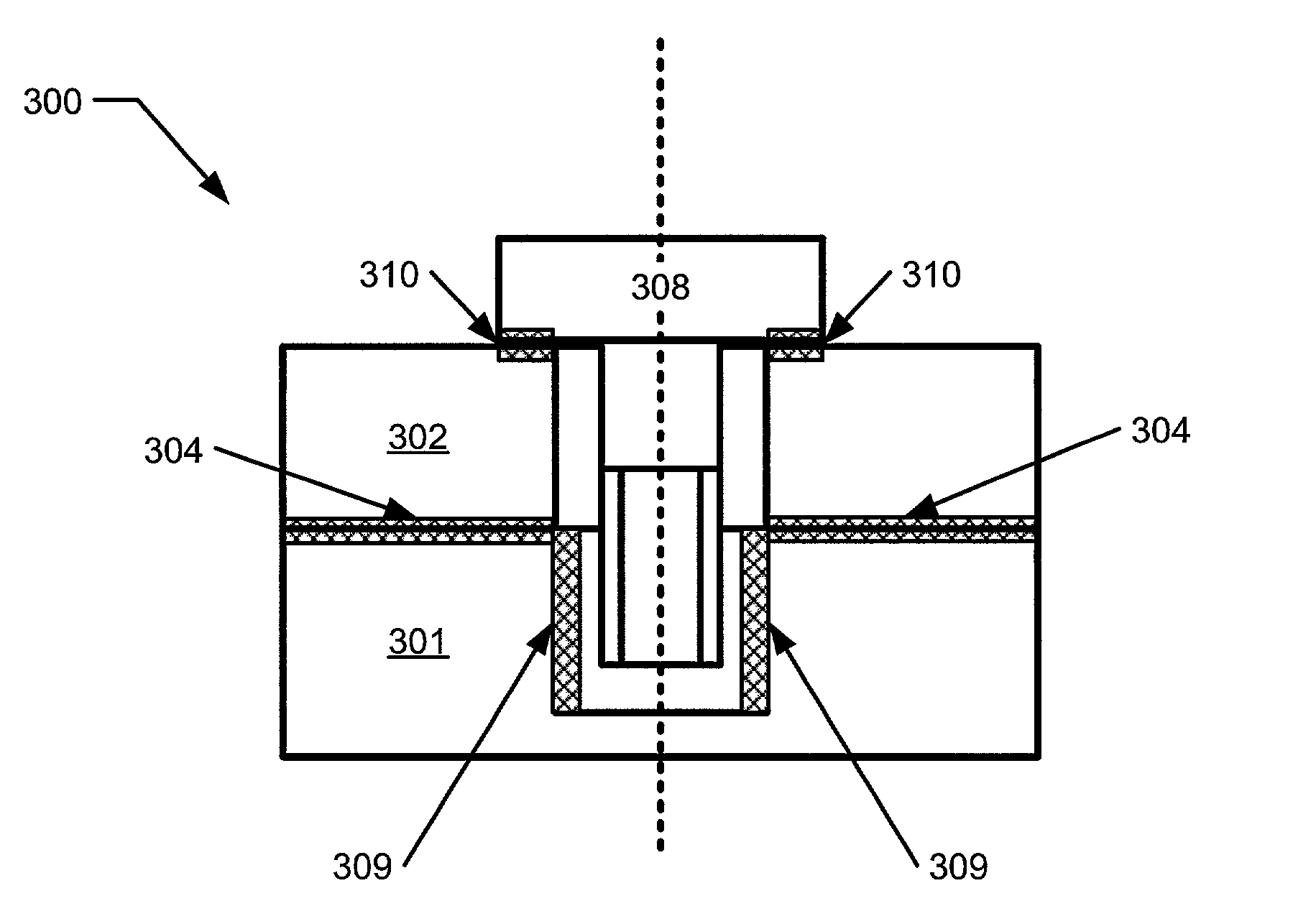

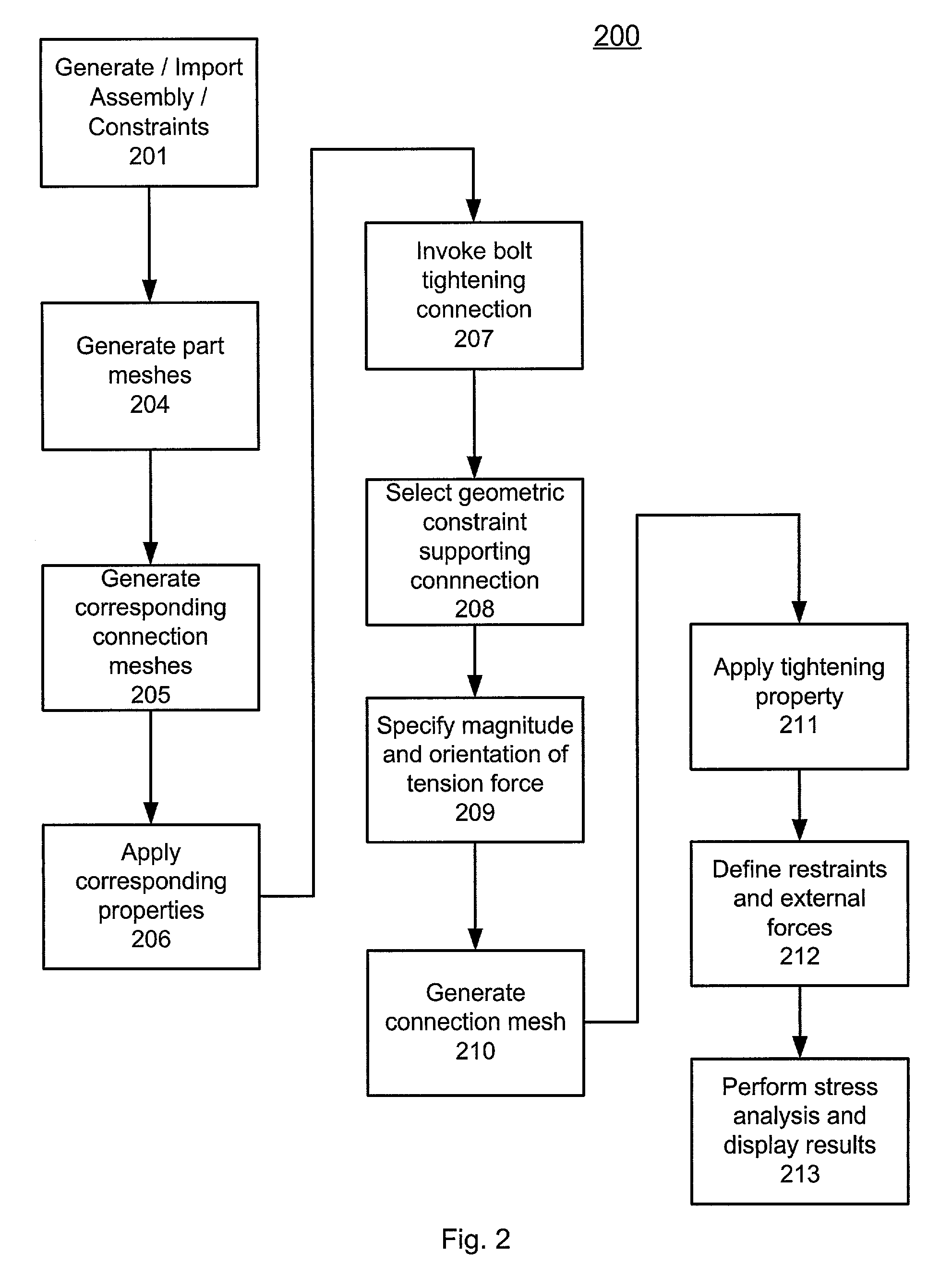

Analyzing the mechanical state of an assembly modeled by a computer aided design system includes generating a model of a fastener and a part of the assembly. The fastener model includes an engaging region and the part model includes a receiving region to fastenably receive the engaging region. The fastener and the part are each represented by finite element representations that include elastically interconnected nodes. A tightening mesh interconnecting nodes of the engaging region and nodes of the receiving region is generated and a force applied between the nodes of the engaging and receiving region is determined based on a pre-tension force occurring upon engaging the engaging region with the receiving region.

Owner:DASSAULT SYSTEMES

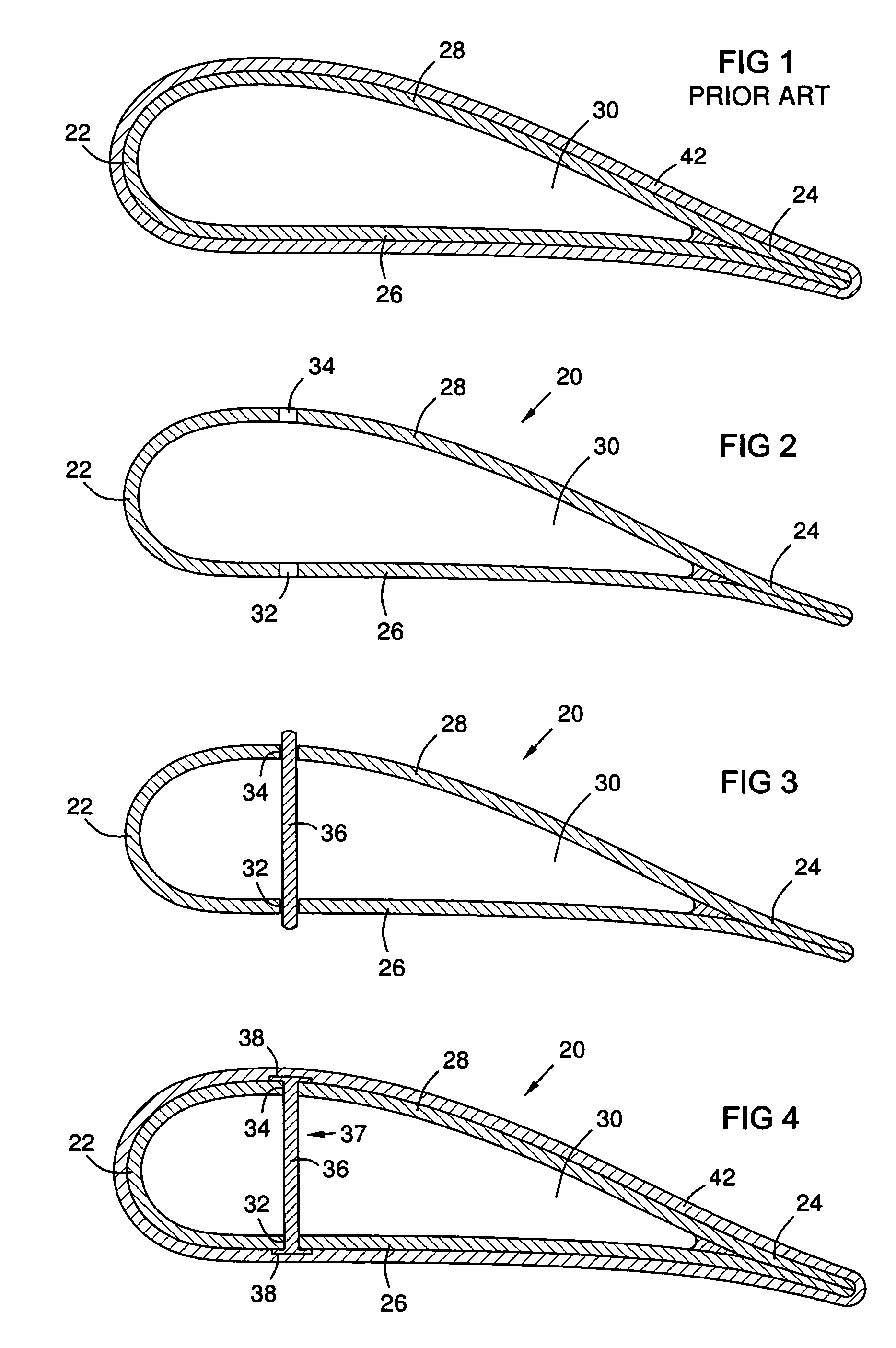

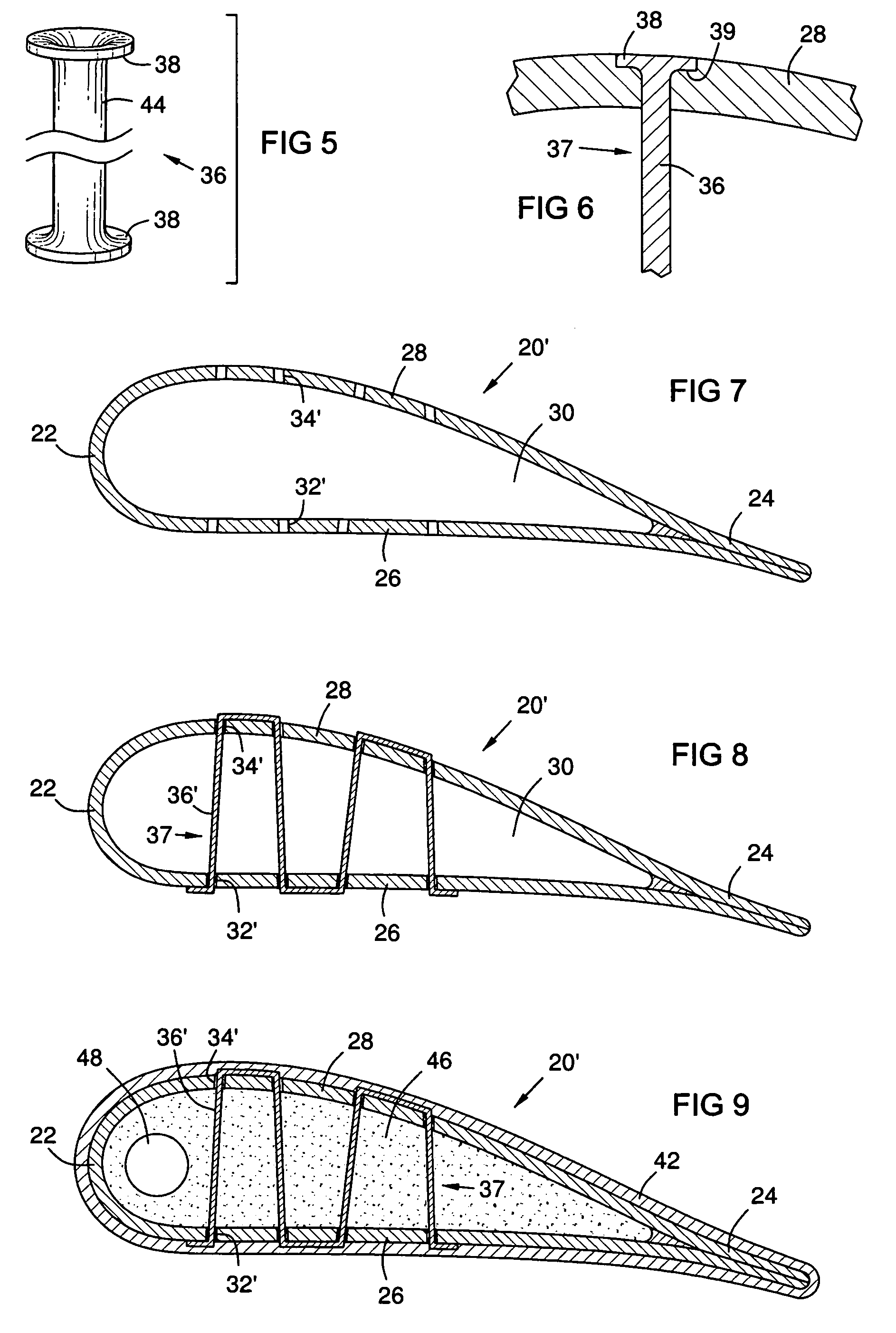

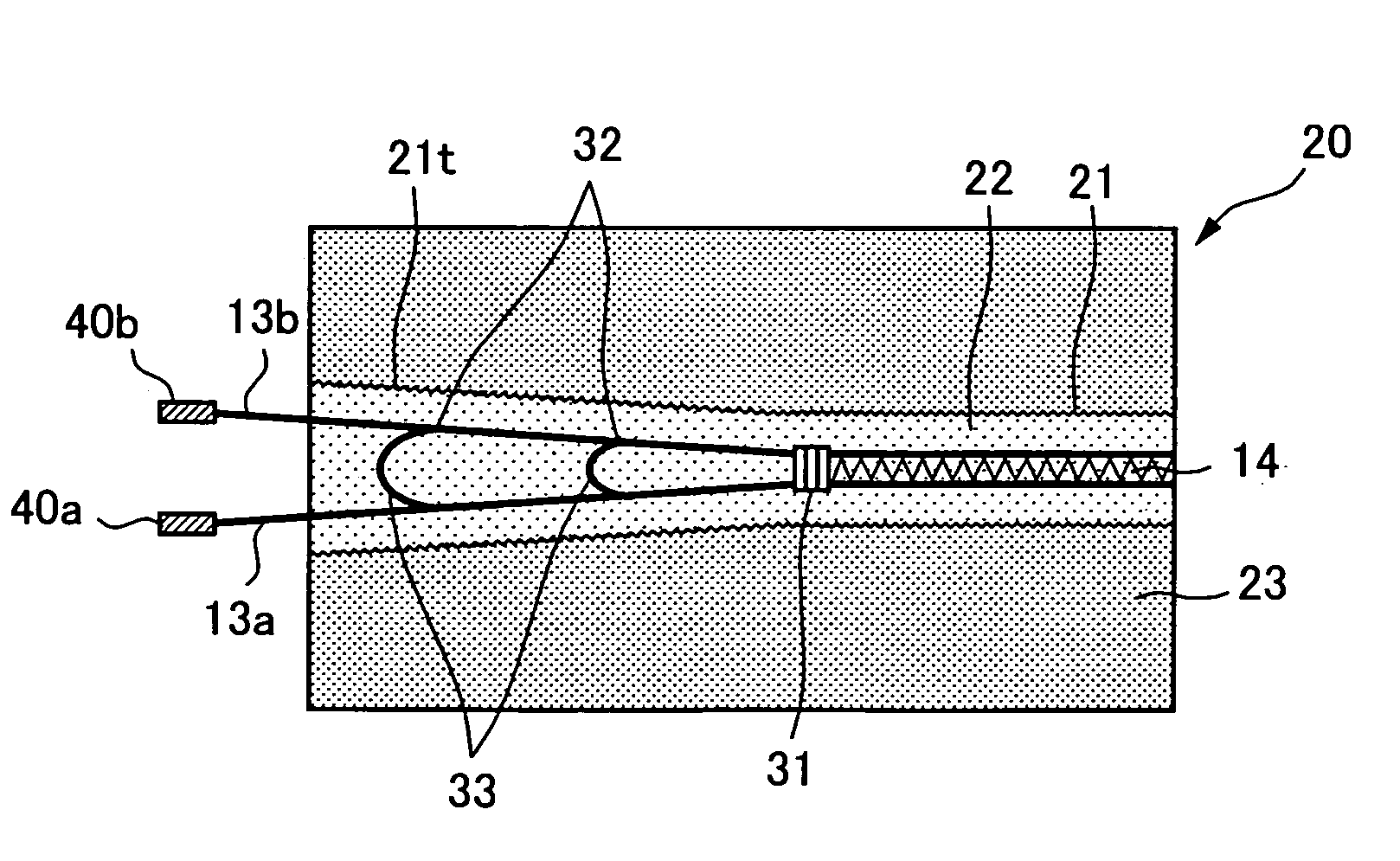

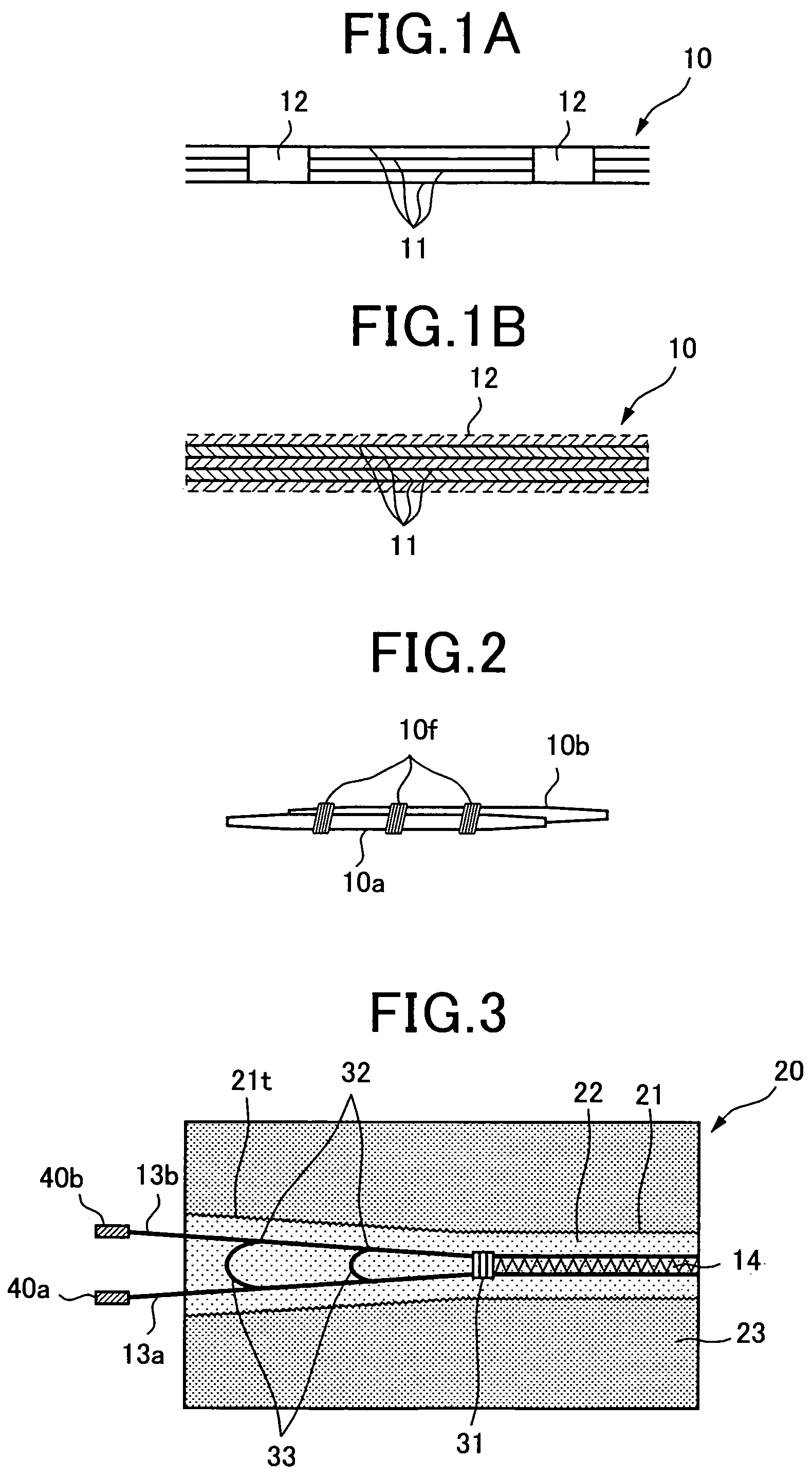

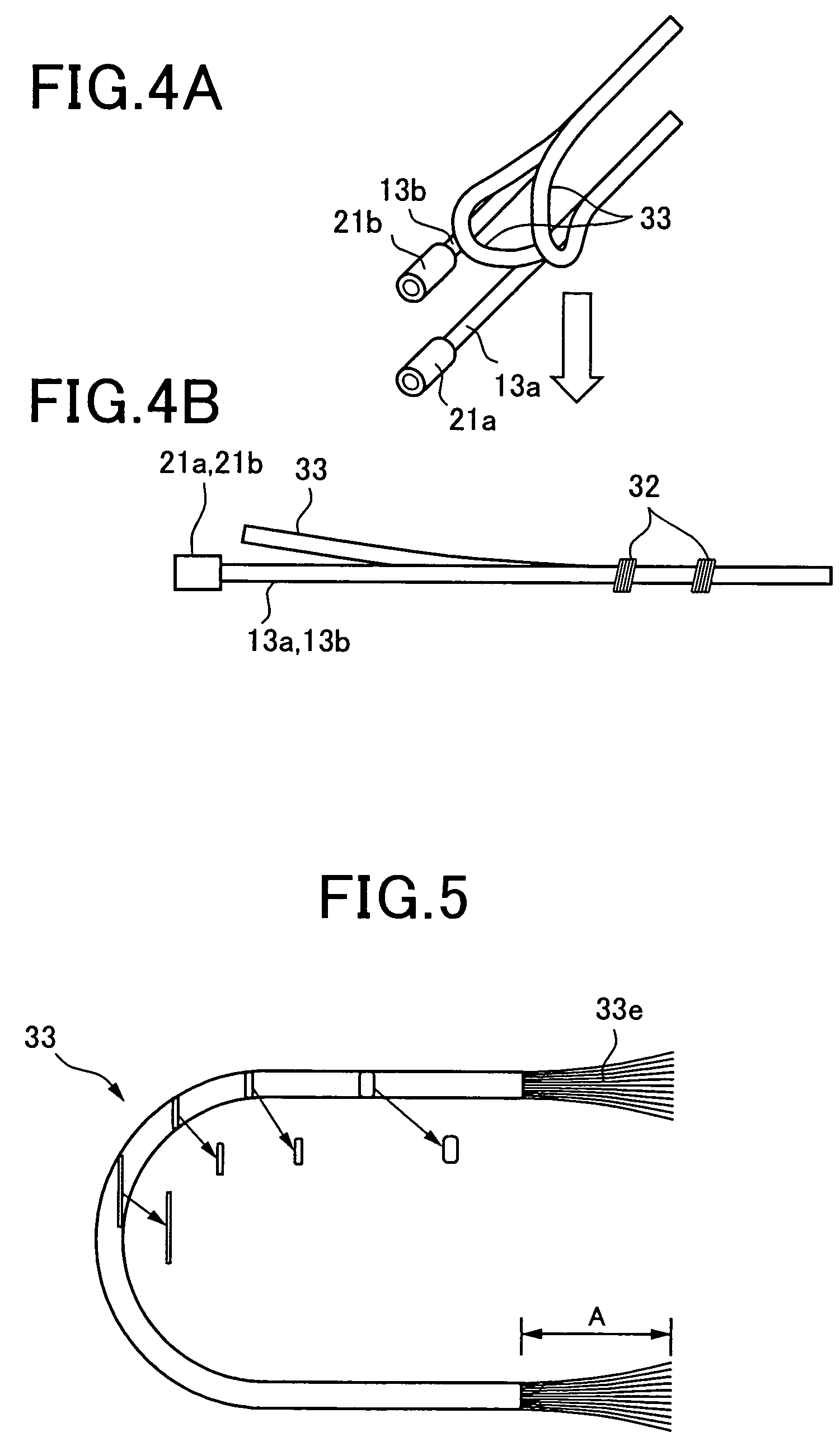

Hollow CMC airfoil with internal stitch

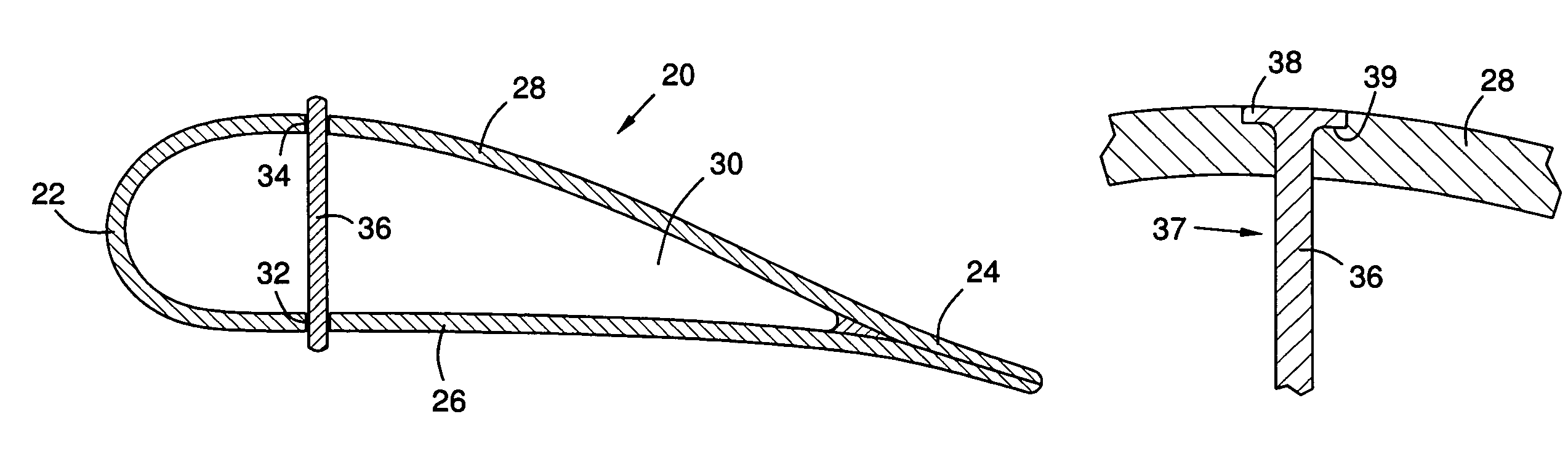

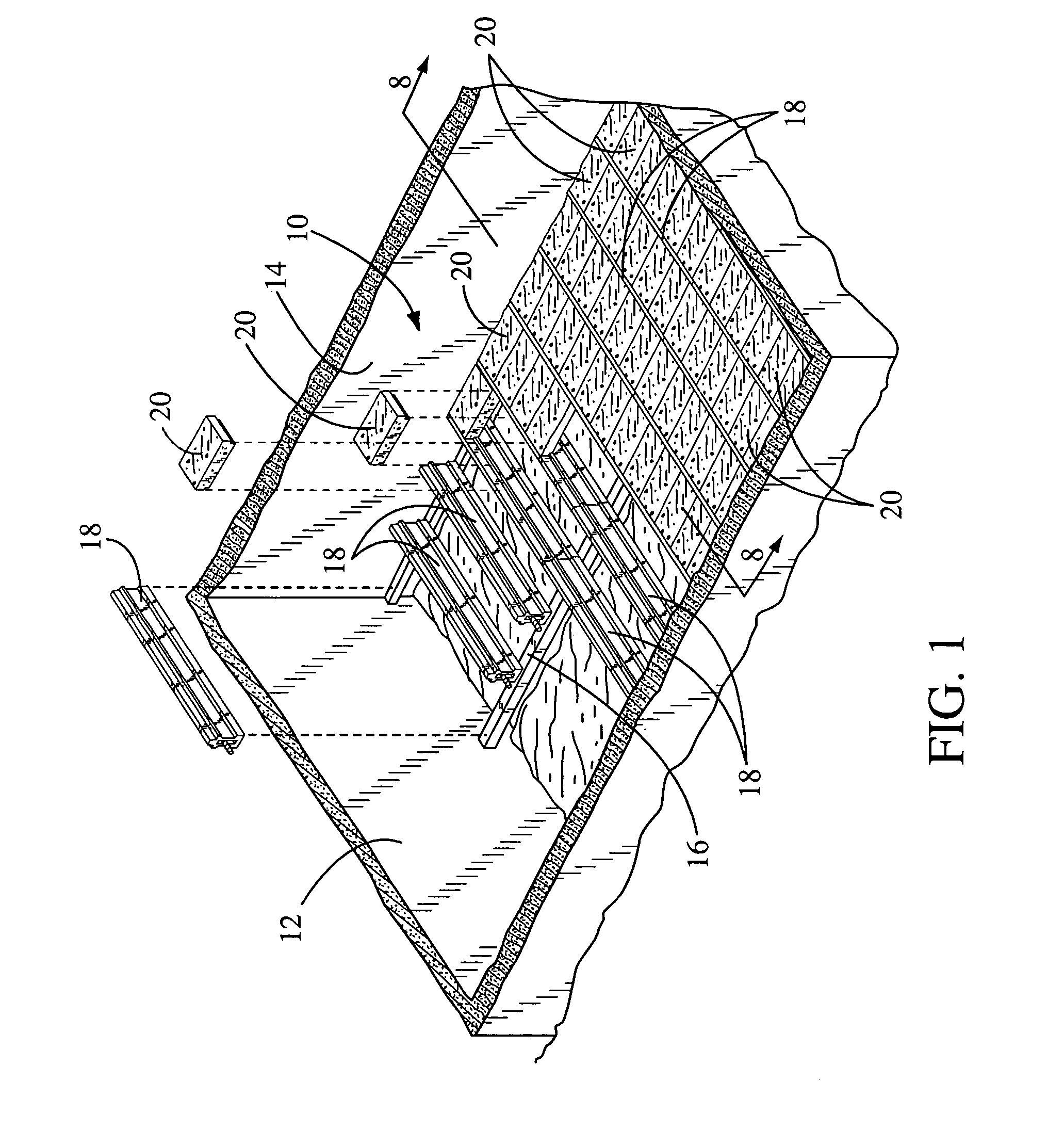

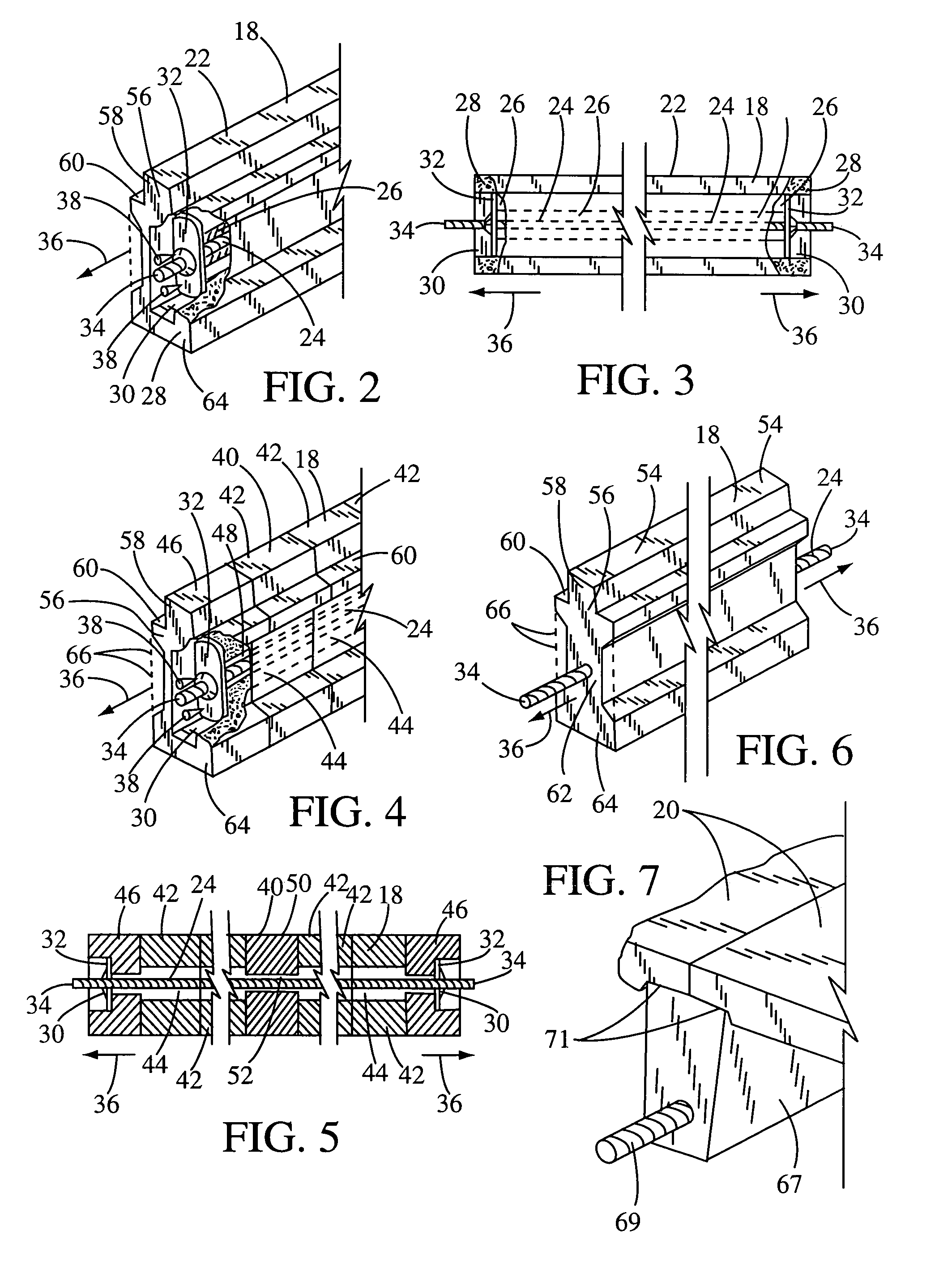

A CMC airfoil (20) formed with CMC stitches (37) interconnected between opposed walls (26, 28) of the airfoil to restrain outward flexing of the walls resulting from pressurized cooling air within the airfoil. The airfoil may be formed of a ceramic fabric infused with a ceramic matrix and dried, and may be partially to fully cured. Then holes (32, 34) are formed in the opposed walls of the airfoil, and a ceramic stitching element such as ceramic fibers (36) or a ceramic tube (44) is threaded through the holes. The stitching element is infused with a wet ceramic matrix before or after threading, and is flared (38) or otherwise anchored to the walls (26, 28) to form a stitch (37) there between. The airfoil and stitch are then cured. If the airfoil is cured before stitching, a pre-tension is formed in the stitch due to relative curing shrinkage.

Owner:SIEMENS ENERGY INC

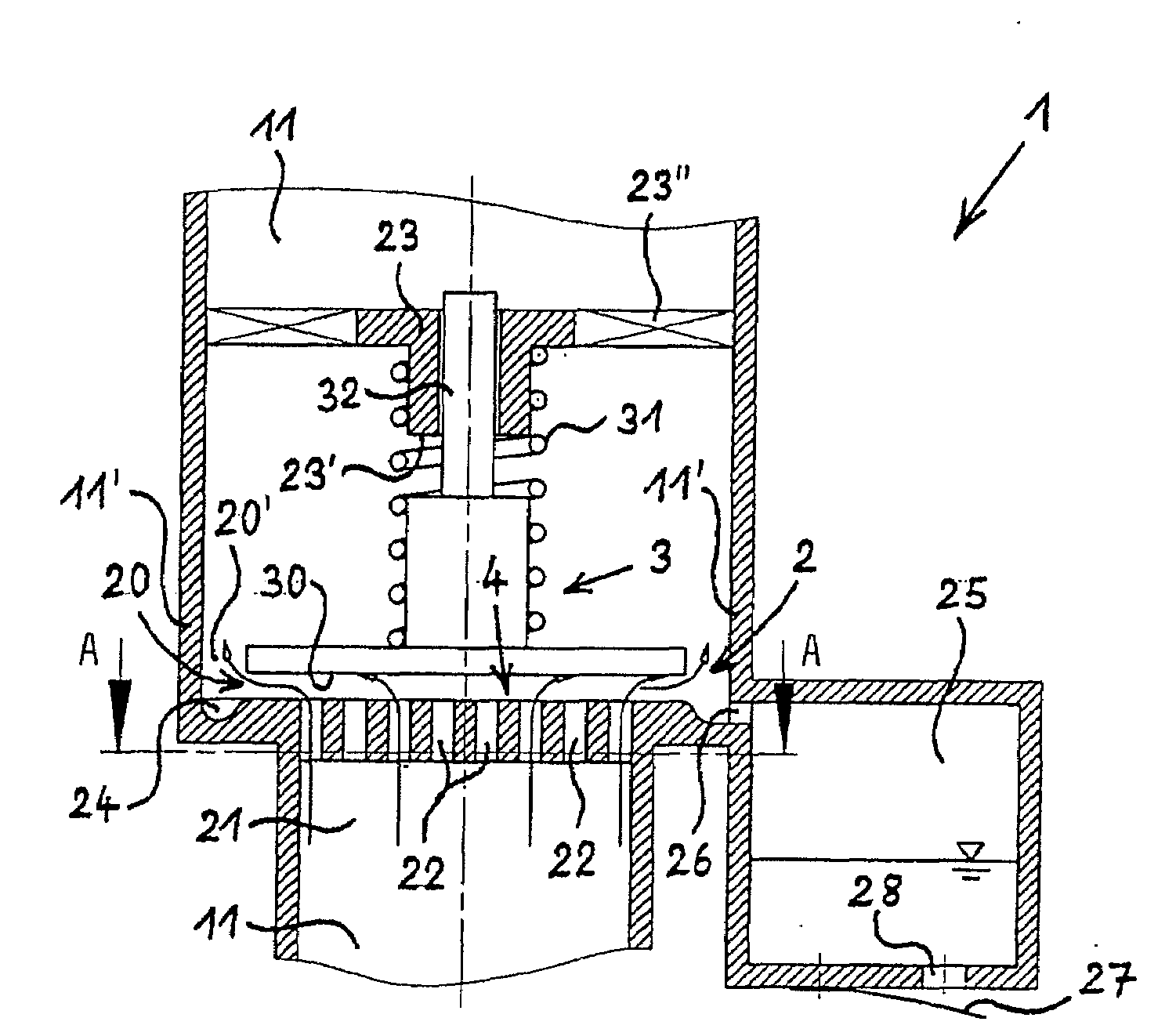

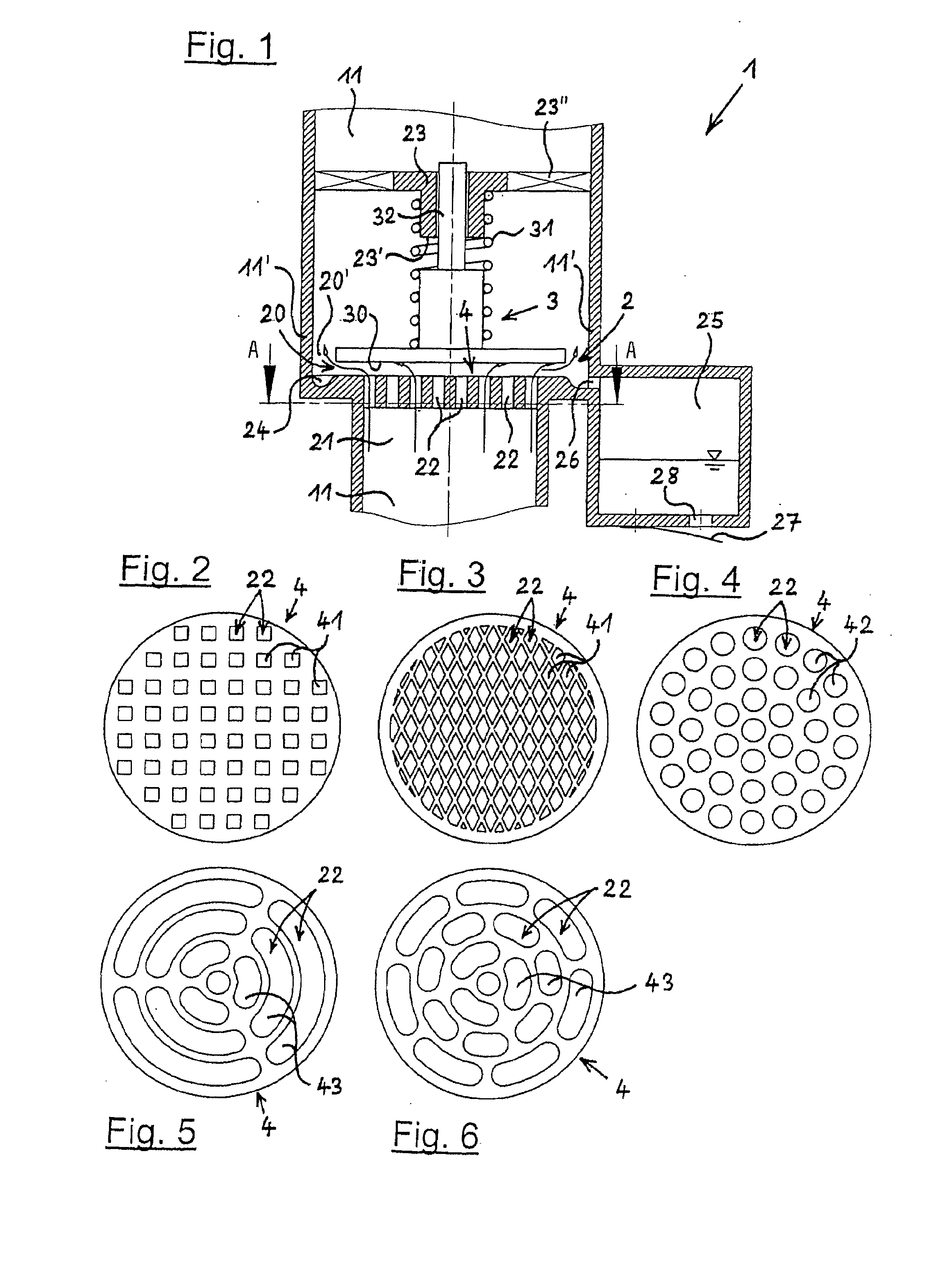

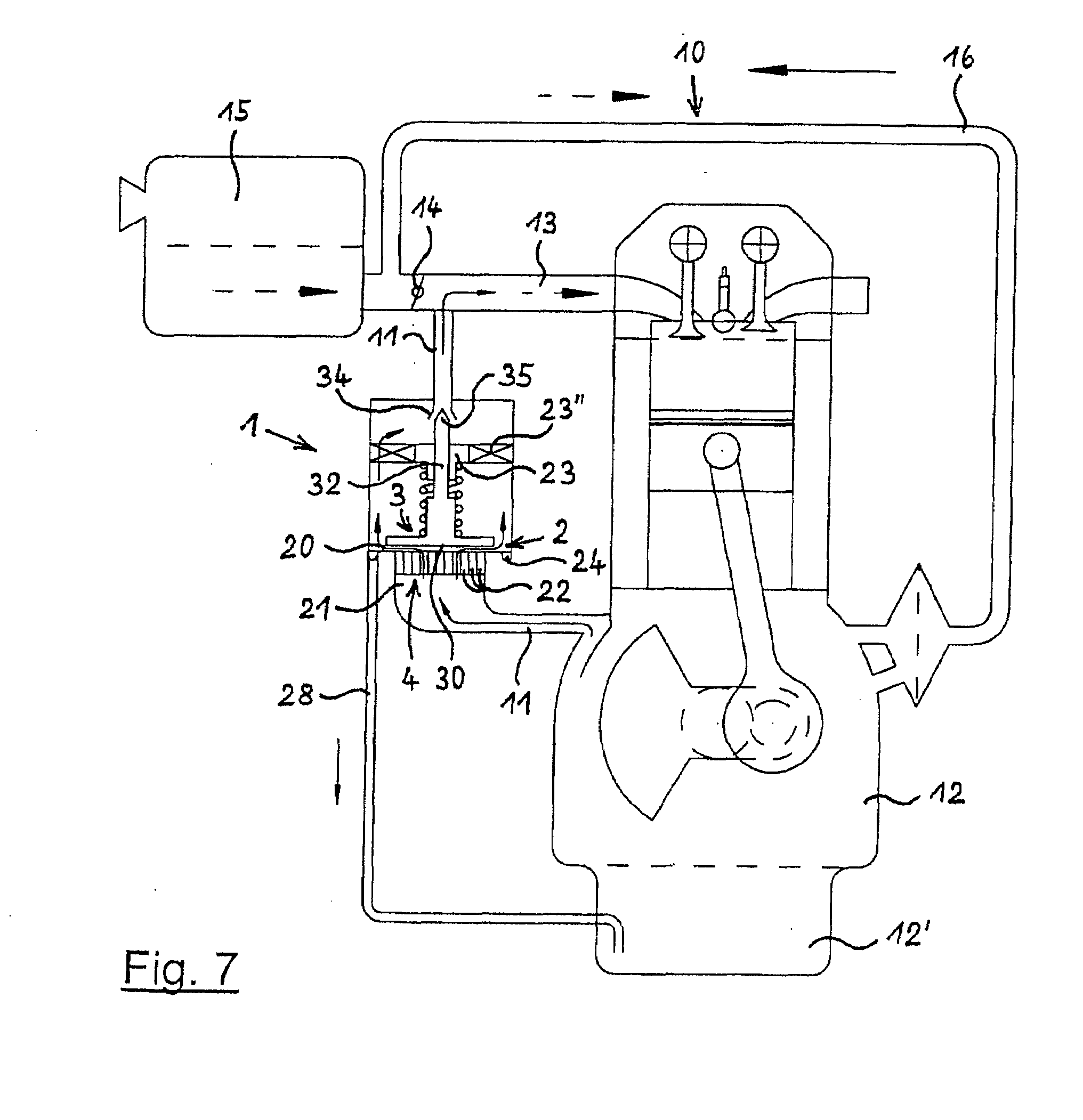

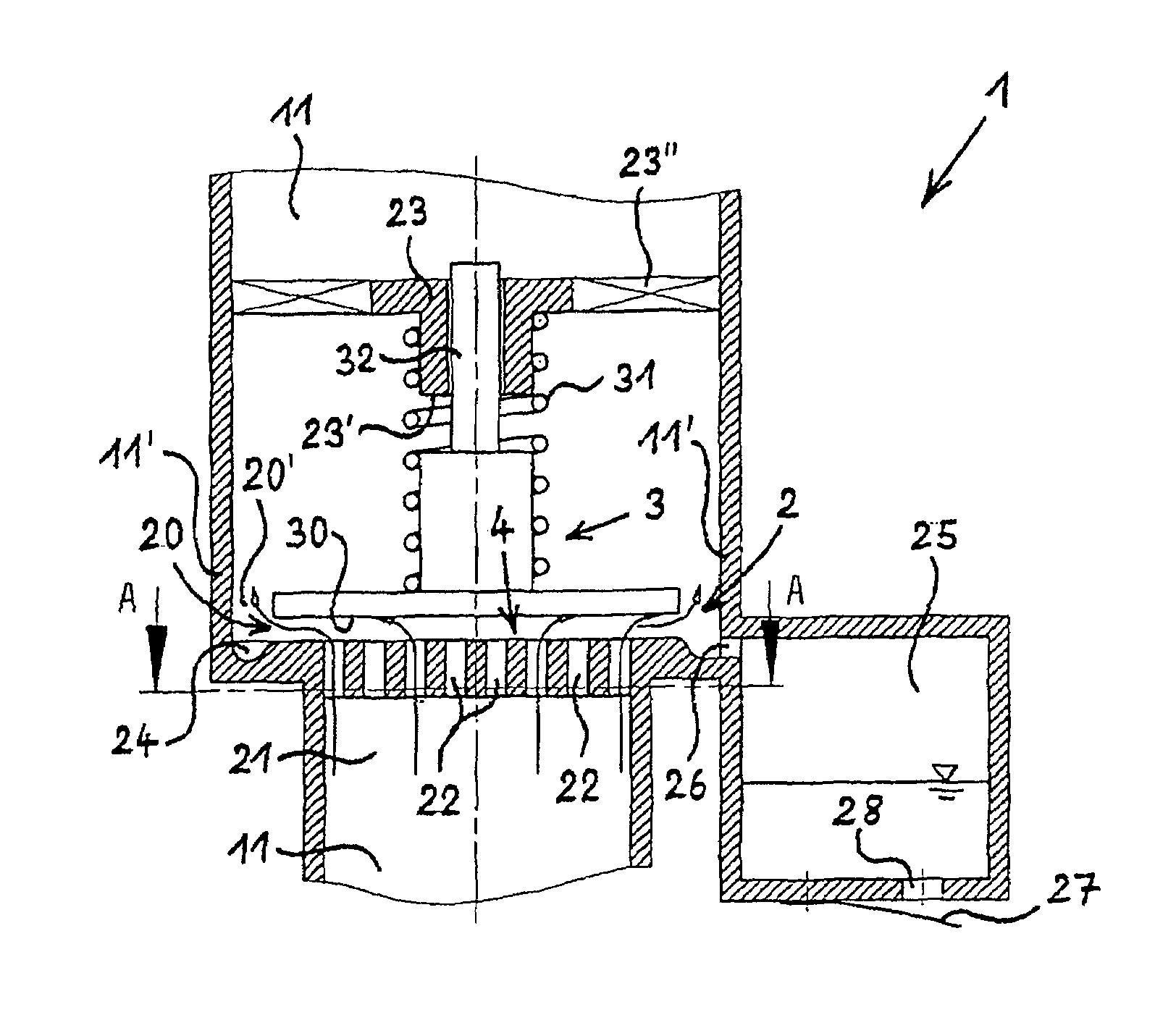

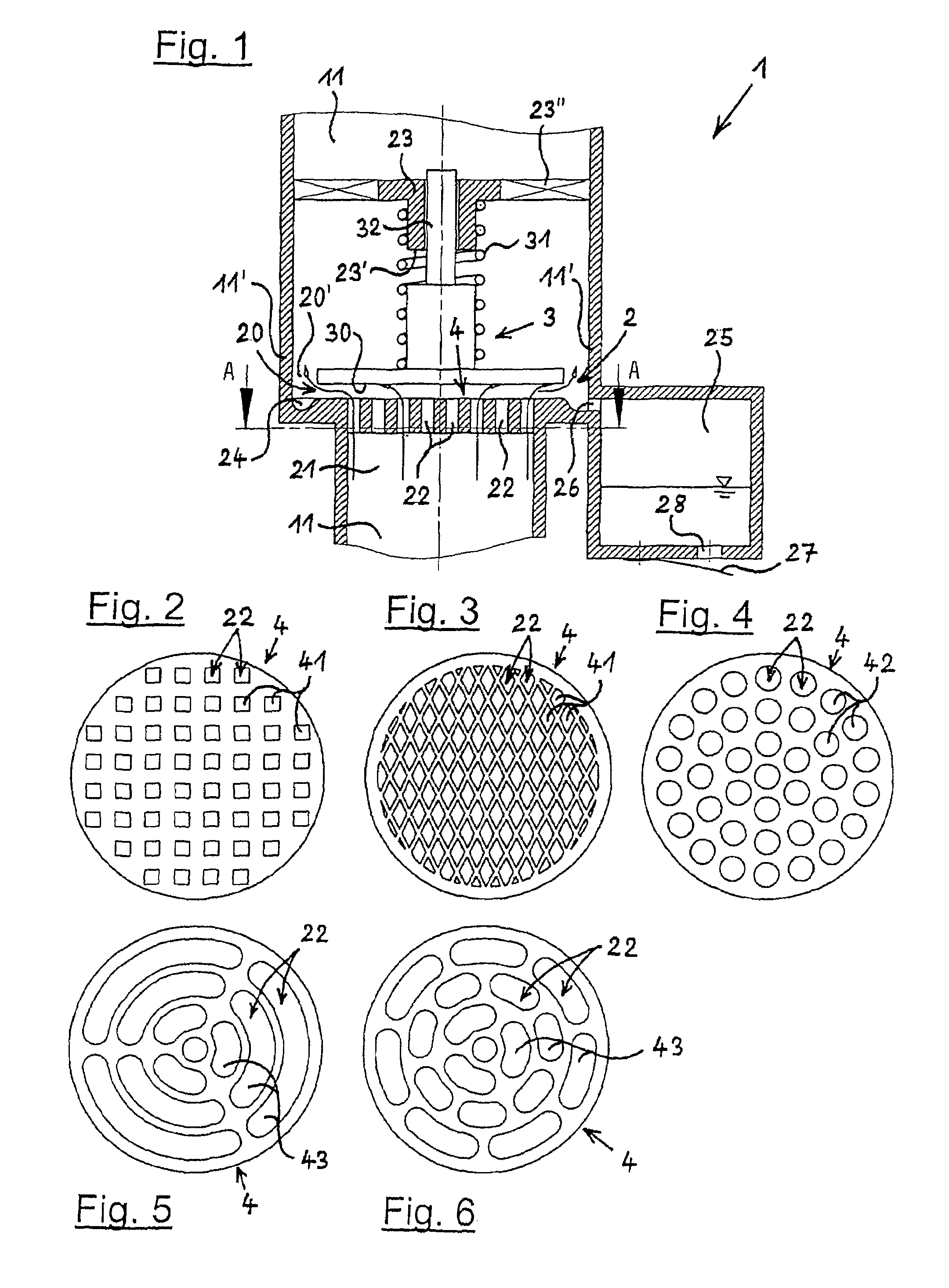

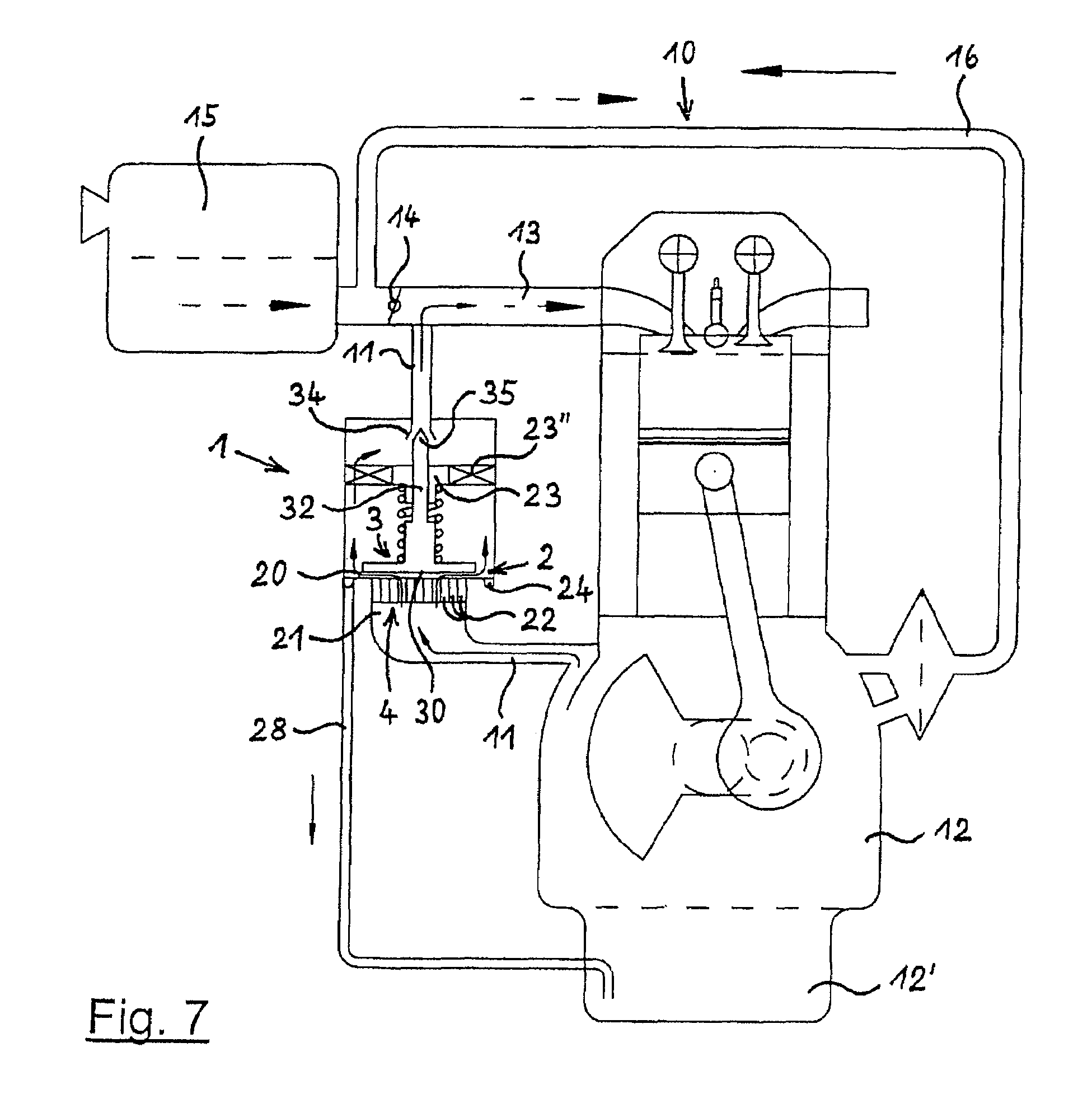

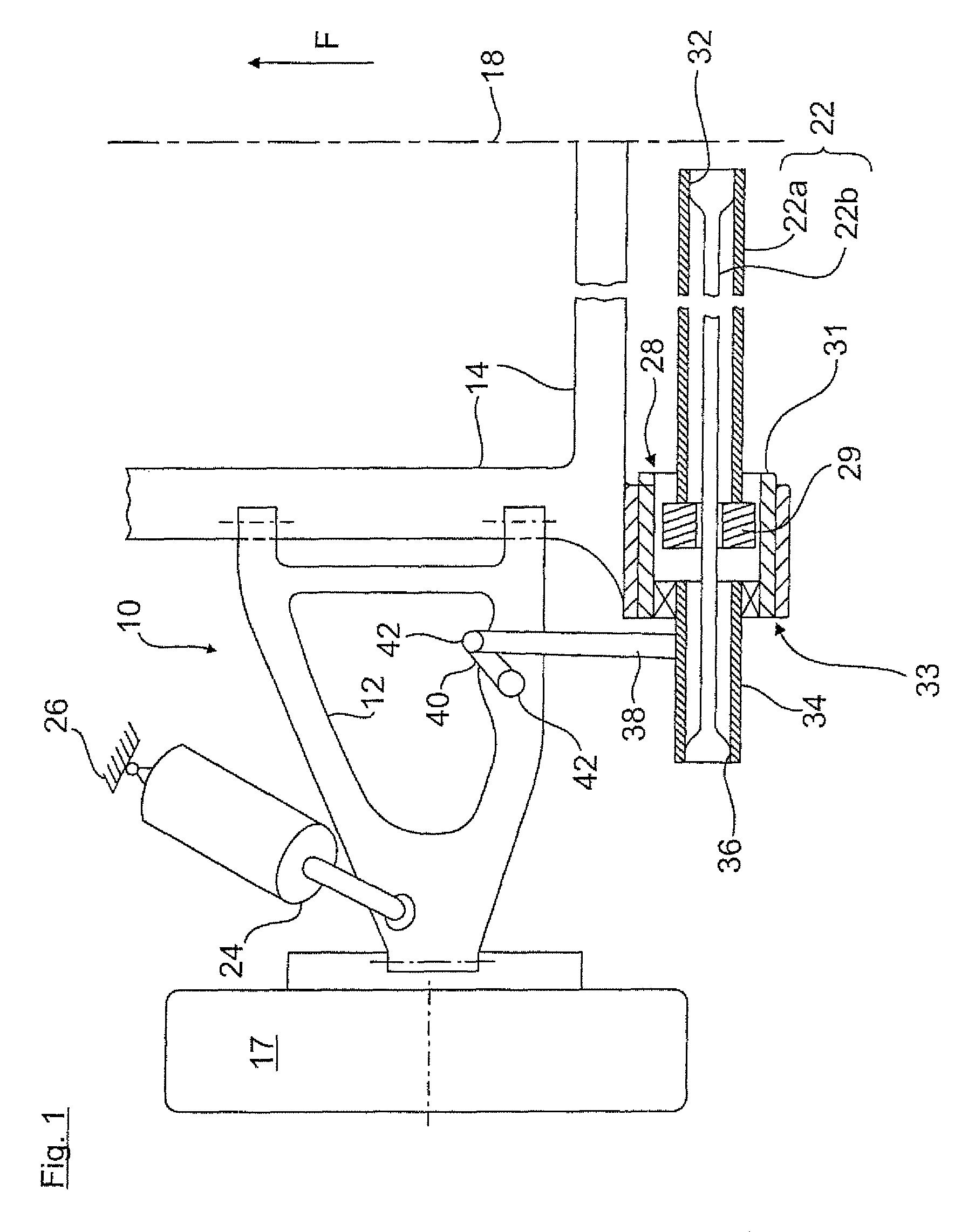

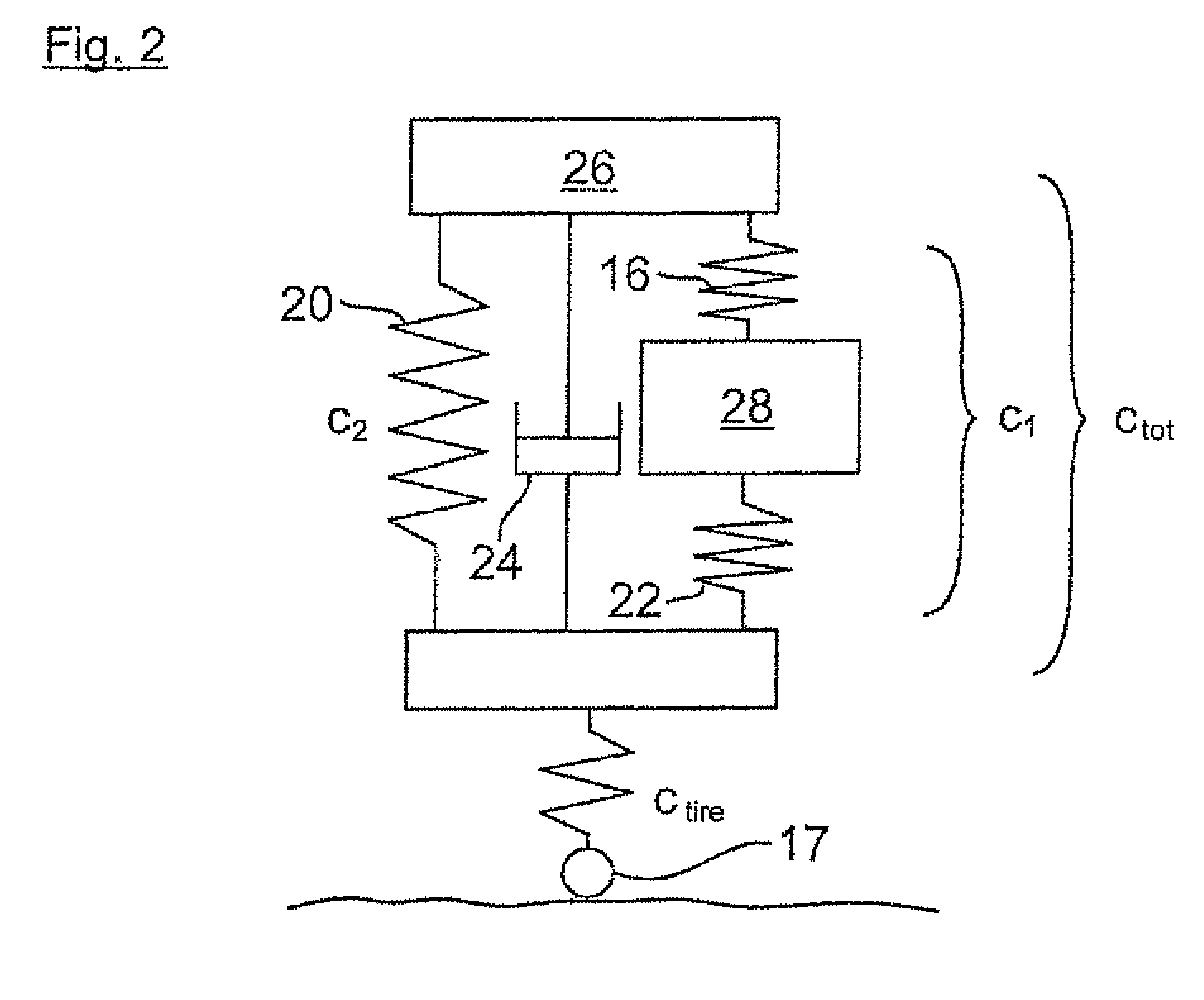

Device for eliminating oil particles from the crankcase ventilation gas in an internal combustion engine

ActiveUS20090199826A1Exhibit optimumPrevents degree of separationCombination devicesAuxillary pretreatmentDifferential pressureExternal combustion engine

A device for eliminating oil particles from the crankcase ventilation gas of an internal combustion engine. The device is located in the flow duct of the gas that runs from the crankcase to an induction tract of the engine. The device includes an oil separator in the form of an outlet for the gas with a deflection of the flow, causing the oil particles to be deposited on a baffle surface and thus to be eliminated from the crankcase ventilation gas flow. The device has an infeed cross-section, which lies upstream of the baffle surface when viewed from the flow direction of the crankcase ventilation gas, and which is sub-divided into several infeed sub-sections. The baffle surface is a solid surface that is devoid of perforations. The baffle surface is configured on a valve body, which lies downstream of the infeed sub-sections when viewed in the flow direction of the gas, and which is pre-tensioned by a force. The valve body can be displaced in the opening direction in opposition to the pre-tension, as a result of the differential pressure in the gas between the crankcase and the induction tract.

Owner:HENGST WALTER

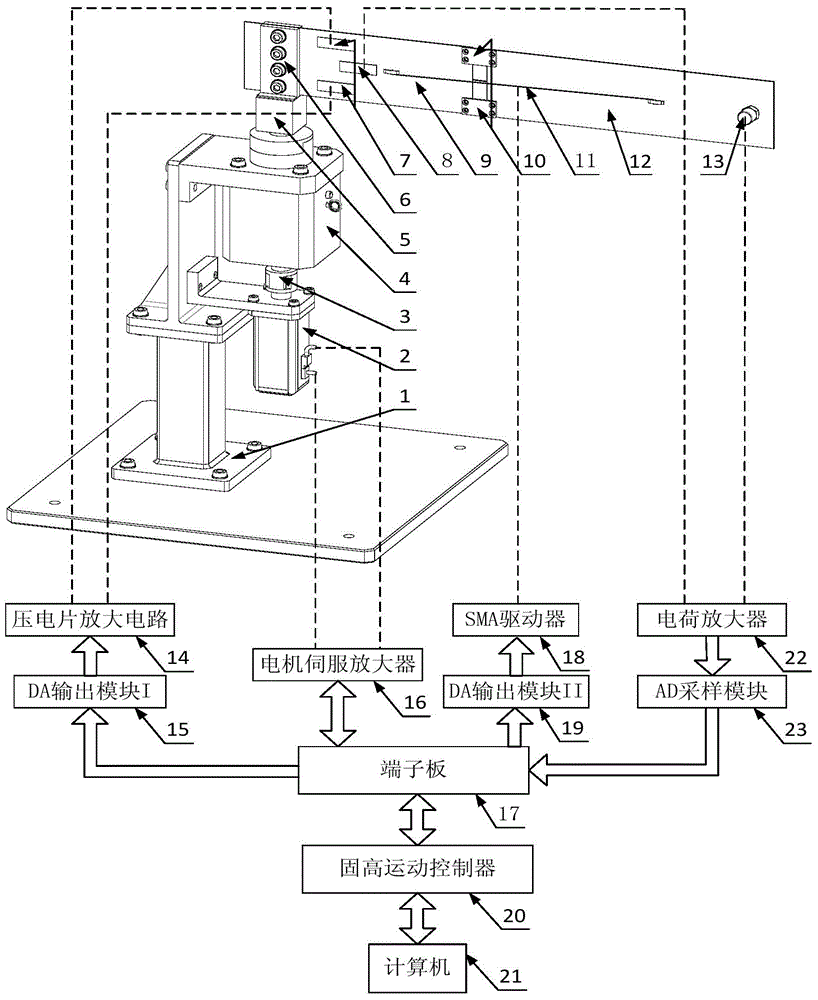

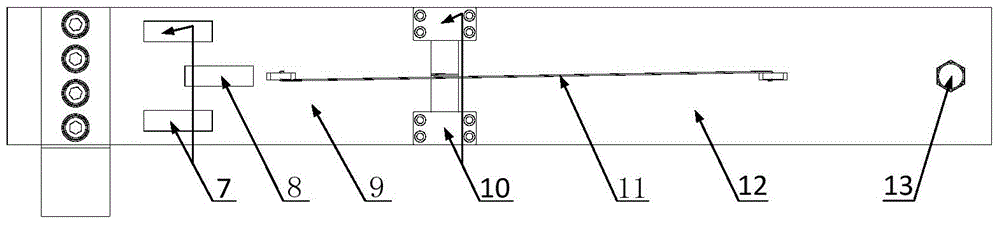

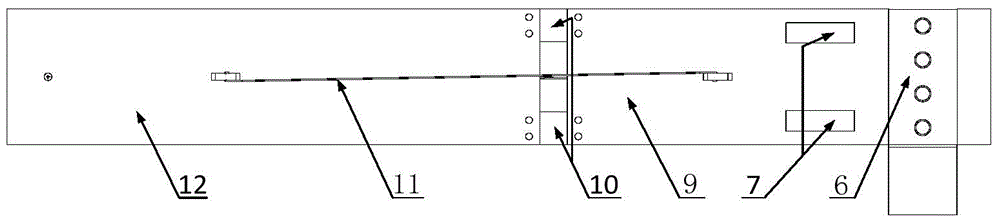

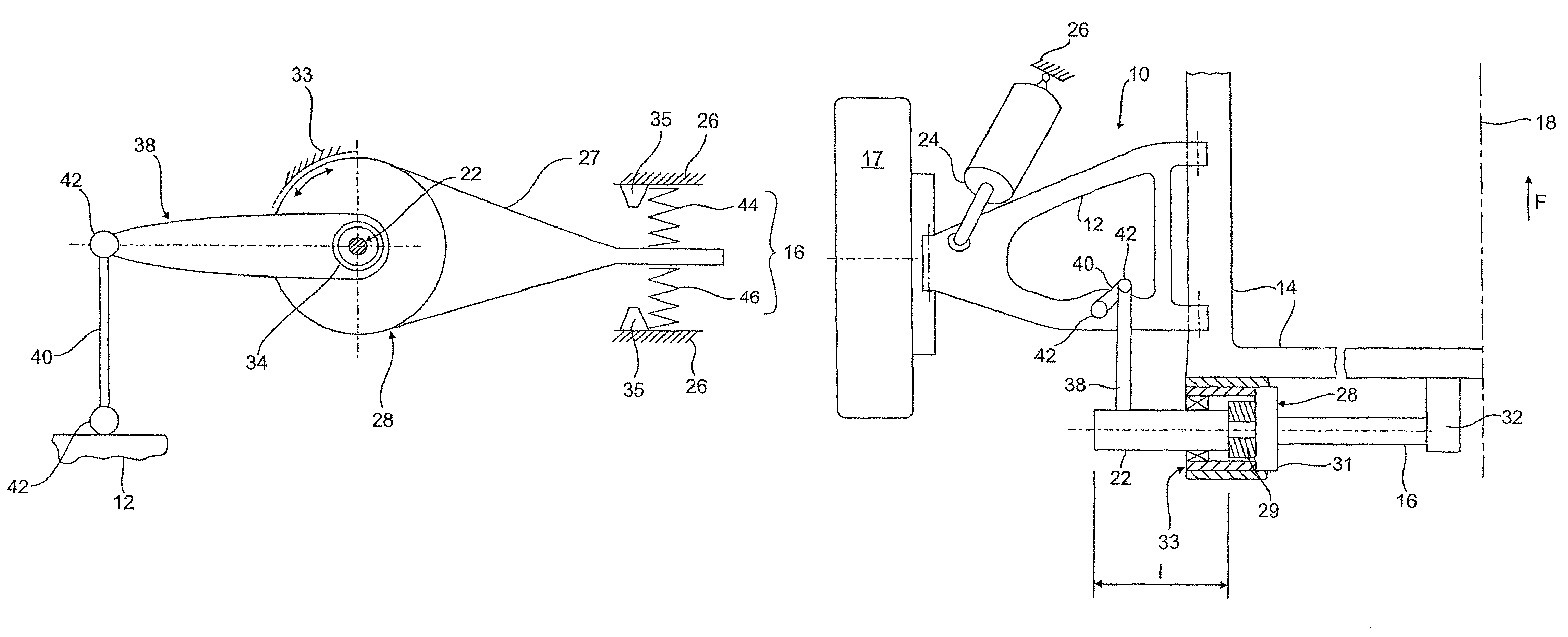

Vibration measurement and control device and method of rotary flexible hinge beam

InactiveCN104006110AGood for studying vibrationsAccurate Experimental PlatformNon-rotating vibration suppressionElectricityVibration measurement

The invention discloses a vibration measurement and control device and method of a rotary flexible hinge beam. The vibration measurement and control device comprises a flexible hinge beam body portion, a vibration signal detecting portion and a driving control portion. The flexible hinge beam is formed by connecting two beams through a hinge, and a prestretching shape memory alloy wire is arranged between the two beams, and is used for restraining low-frequency large-amplitude bending vibration of the connecting position. A piezoelectric ceramic piece sensor and a piezoelectric ceramic piece driver are pasted on to the front face and the rear face, close to a mechanical tightening device, of the flexible hinge beam respectively, and are used for detecting and restraining the bending vibration of the hinge beam. An acceleration sensor used for detecting vibration is arranged at the tail end of the hinge beam. The device is used for simulating vibration measurement and control over a space flexible joint and a flexible mechanical arm, the sensors and the composite control drivers are adopted, the corresponding control algorithm is operated, and active control over the bending vibration of the rotary hinge flexile beam is achieved.

Owner:SOUTH CHINA UNIV OF TECH

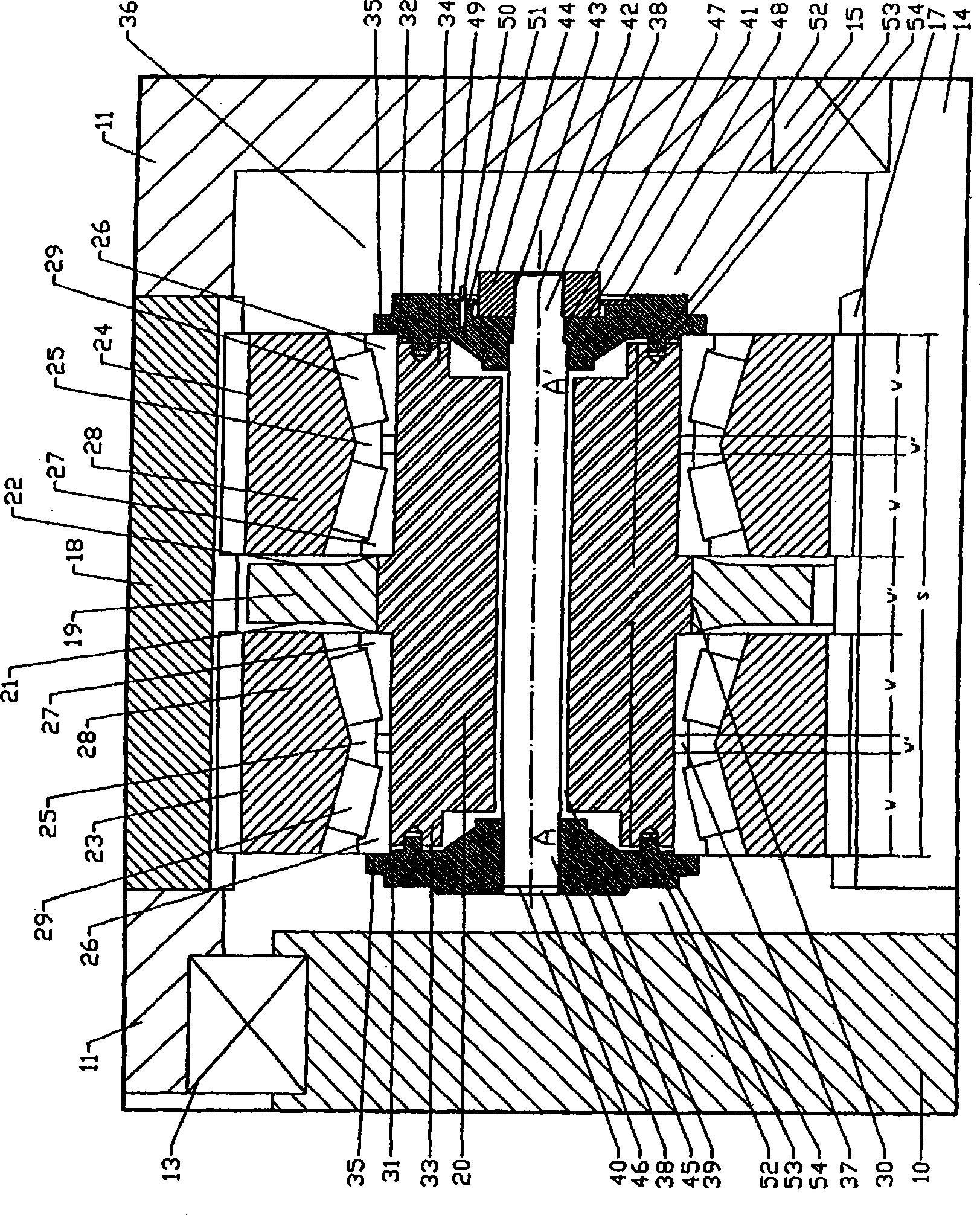

Method for manufacturing a permanent-magnet excited rotor for a high speed electric motor

InactiveUS7228615B2Quick and easy to manufactureImprove featuresMagnetic circuit rotating partsManufacturing stator/rotor bodiesWorking temperatureEngineering

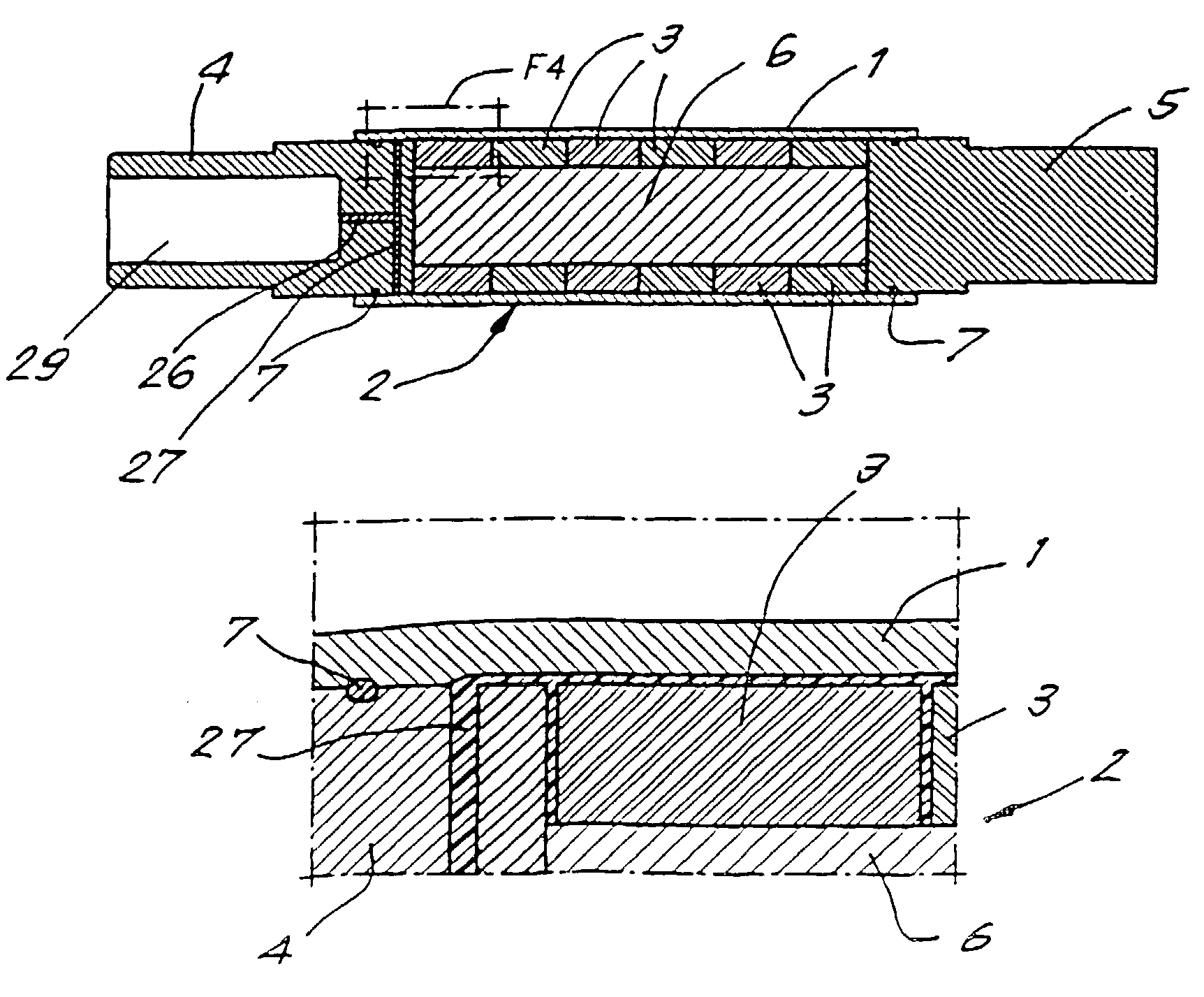

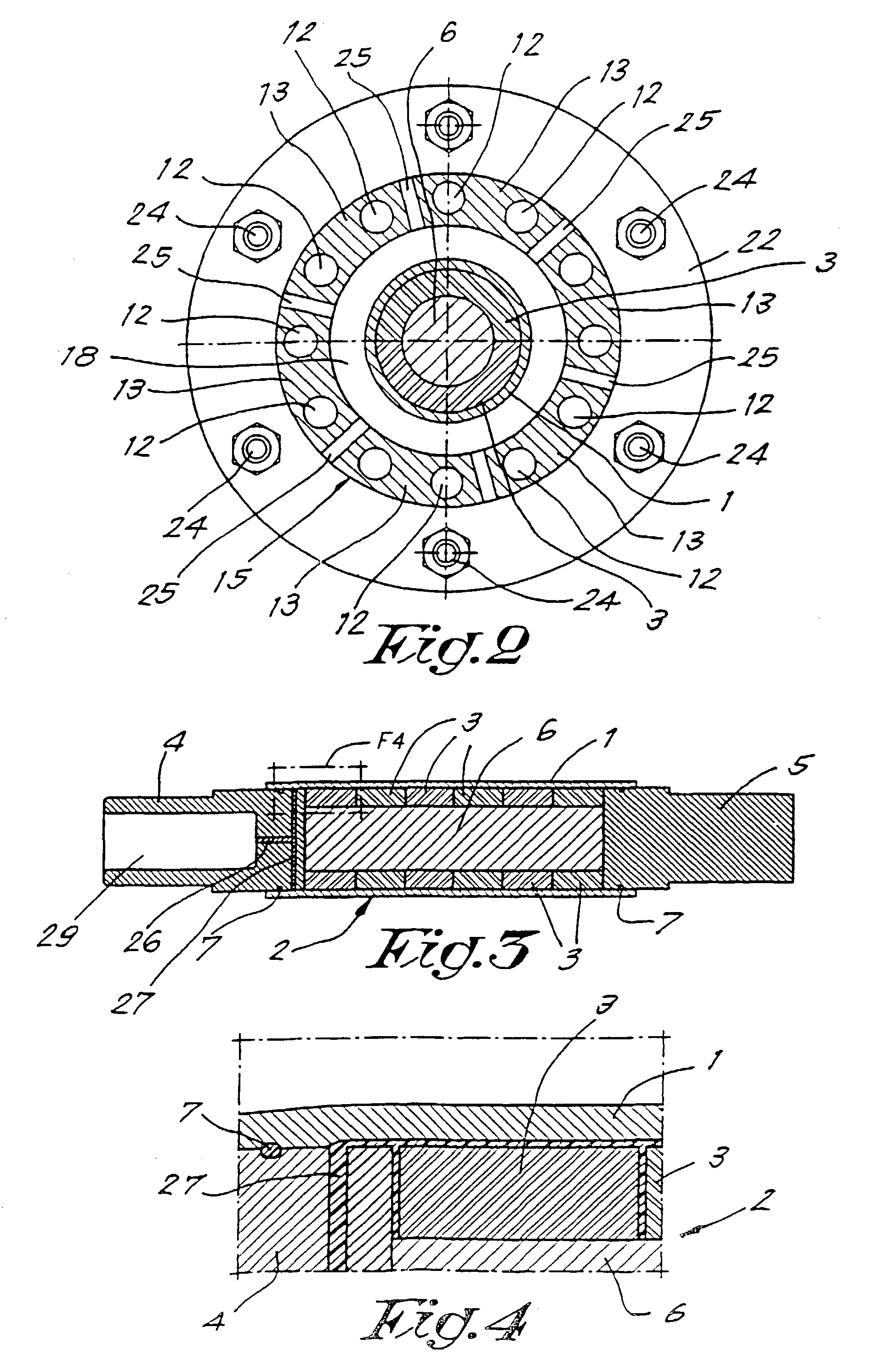

The invention relates to a method for manufacturing a permanent-magnet excited rotor for a high speed electric motor, according to which method a support sleeve (1) is mounted with a pre-tension around the rotor body (2), characterised in that the sleeve is expanded by a liquid that solidifies and is solid at the working temperatures of the rotor, said liquid is injected under pressure between the sleeve and the rotor body and held under pressure during solidification.

Owner:ATLAS COPCO AIRPOWER NV

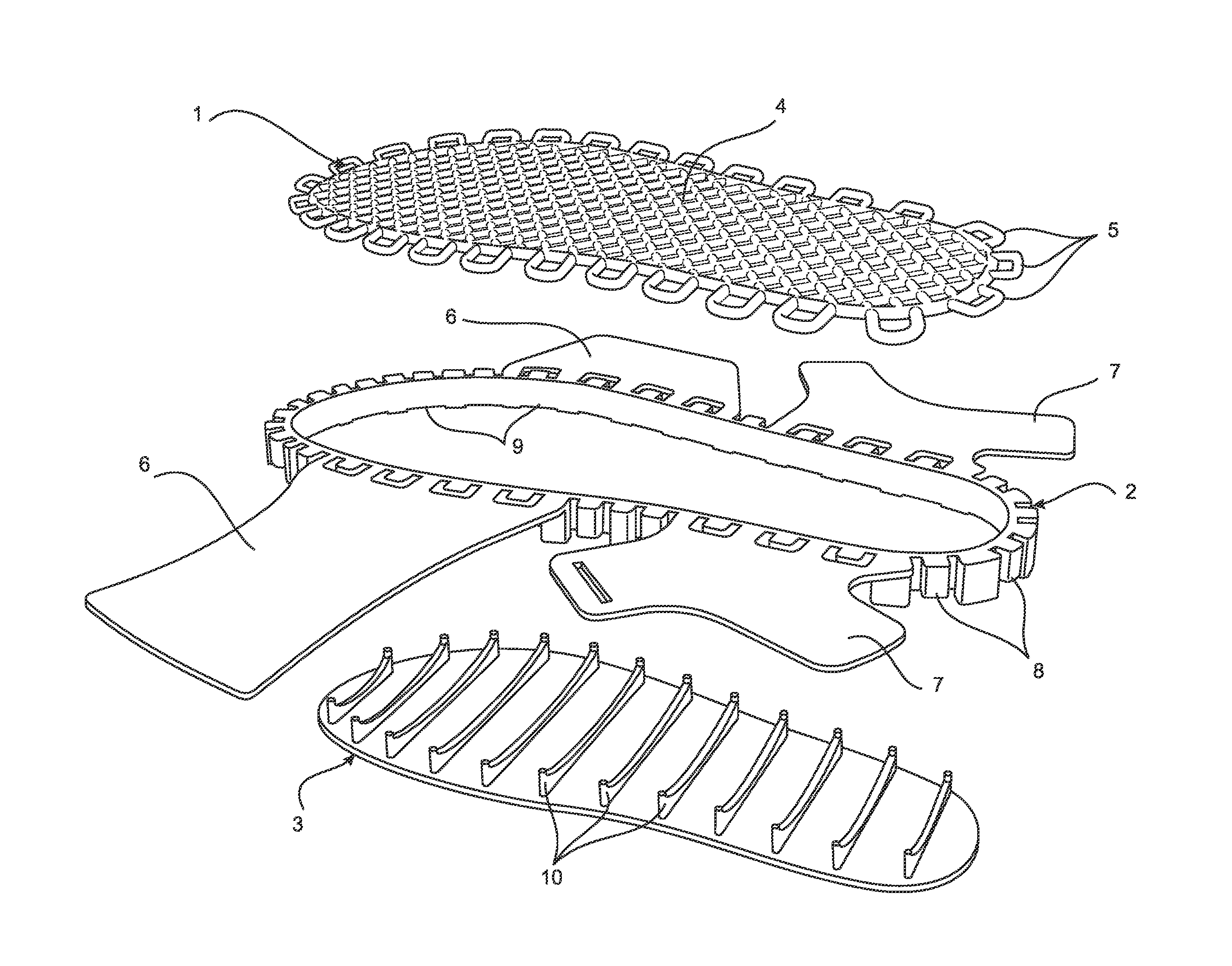

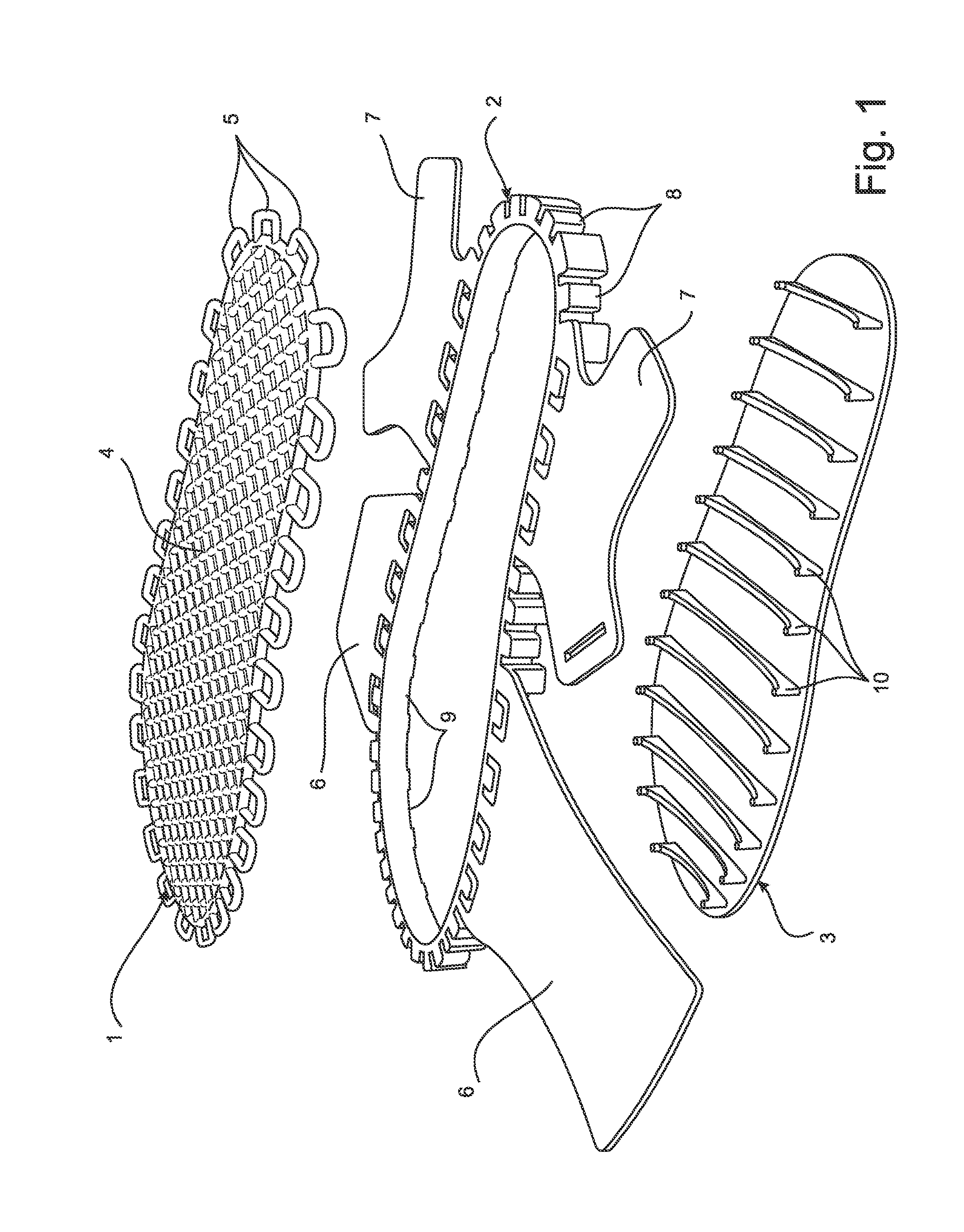

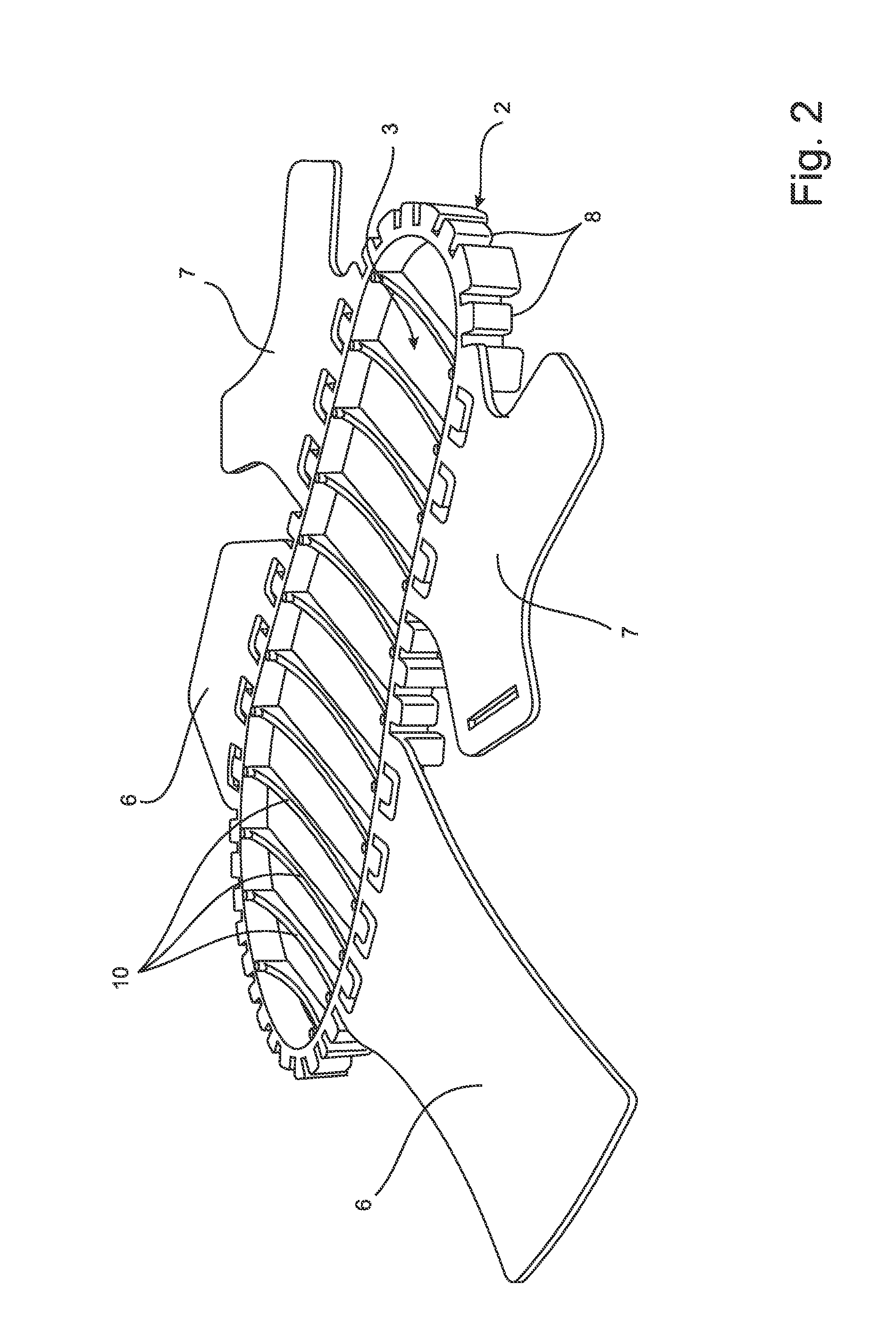

Footwear Sole Structure with Suspended Elastomeric Web or Mesh Support

A footwear sole structure has a suspended elastomer web or mesh (1) support for a foot of a wearer of the footwear. A gap or space under the web / mesh allows it to flex down e.g. towards the outsole (3) or the ground. The web or mesh can be secured to a peripheral portion of the sole base by projections or loops (5) on the web or mesh. The web or mesh can be a one piece or multi part moulded component. The web or mesh can provide a peripheral zone around a central zone. The central body (2) can be a moulding incorporating a front strap pair (6) and rear strap pair (7) folded up into a wearing position and lugs (8), and have a higher density elastomer sole that fits up and is bonded into a matching lip in the base of the central body (2) and the elastomer web or mesh (1) fits down over the central body (2) such that the loops (5) stretch around corresponding lugs (8) on the central body (2) and the web or mesh (1) is largely held in pre-tension via the strength of the sole supports and there is still space between the web or mesh 1 and the sole for the web / mesh (1) to flex down into via weight of foot.

Owner:ATTEY GRAEME SCOTT +1

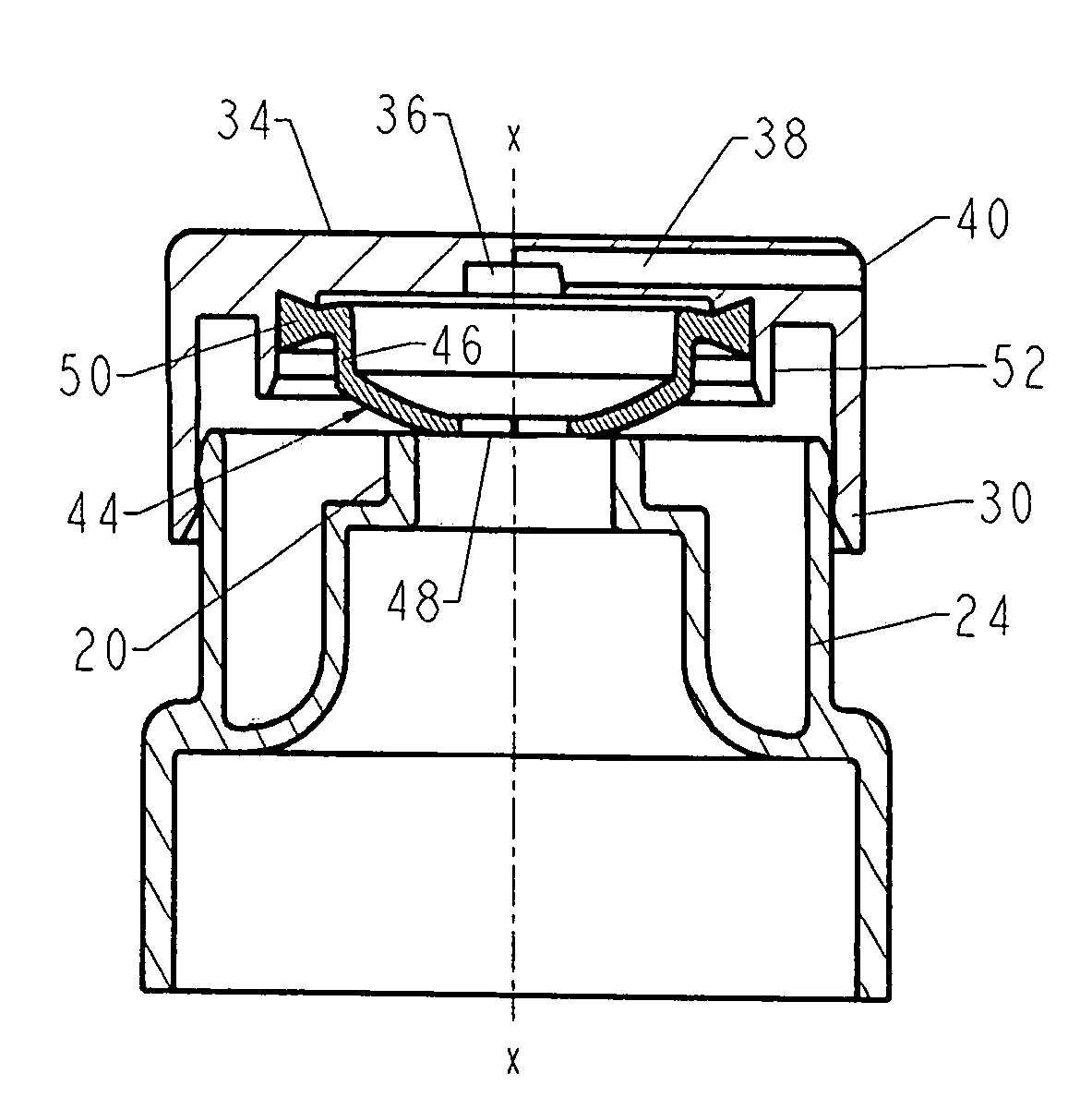

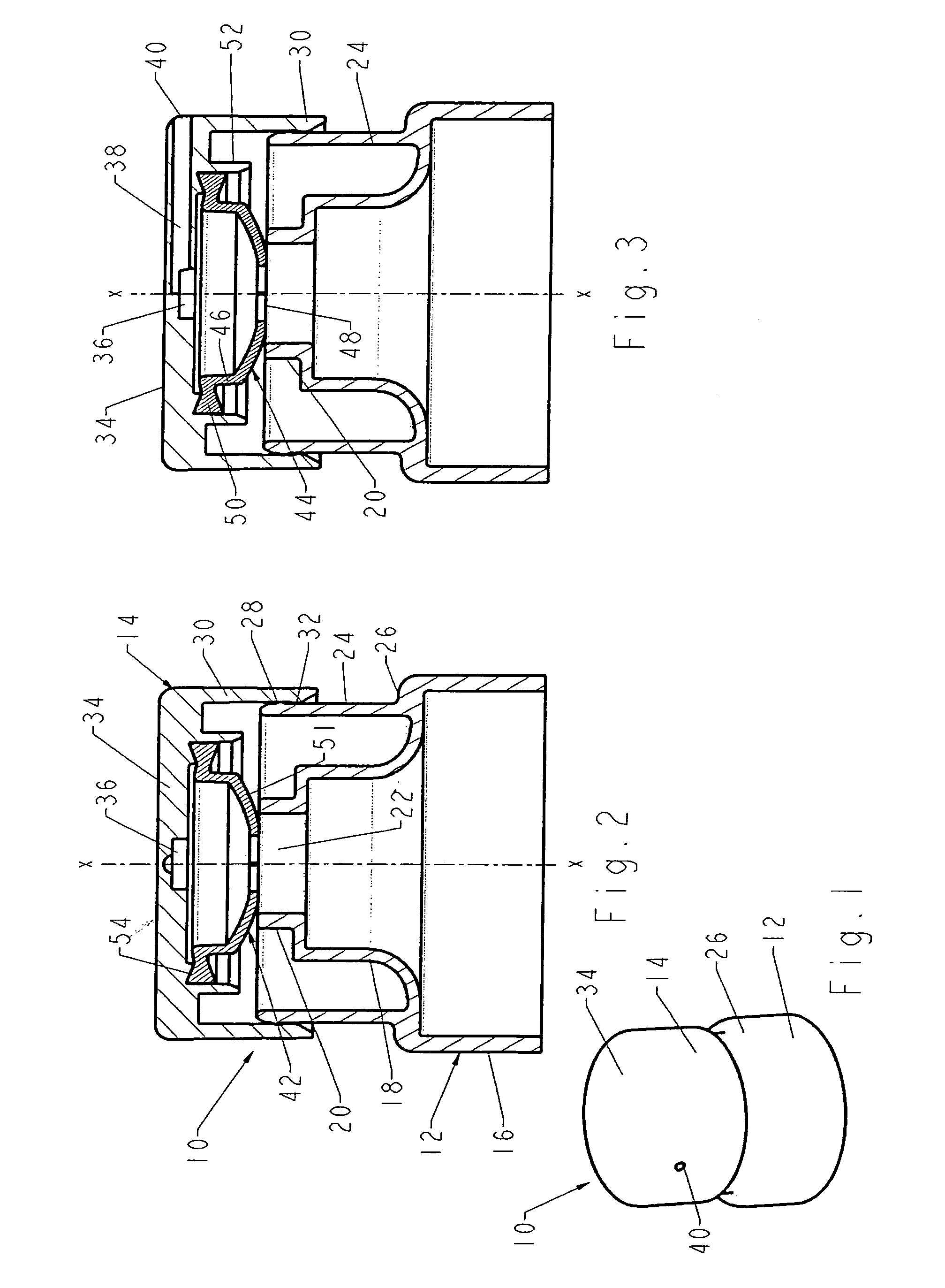

Closure for a container that holds a free-flowing product

The invention relates to a closure for a container that holds a free-flowing product. The container is characterized by the following: a fixed lower part which can be fastened to a container neck that surrounds a container opening in order to seal said neck; a cover comprising a protruding connecting piece that forms a passage for the free-flowing product; a displaceable upper part which can be coaxially displaced on the lower part in and against the direction of the container between an outer resting position and an inner actuating position; a breaker or dish-shaped diaphragm valve which has a base consisting at least of a flexible elastic material and whose upper edge seals the underside of the upper part; perforations in the base of the diaphragm valve which are closed in the testing position of the upper part; and a diameter of the base that is greater than the inner cross section of the connecting piece. The outer end of the connecting piece continuously supports the base of the diaphragm valve, and the latter continuously pre-tensions the upper part in the direction of its resting position in such a way that, when axial pressure is exerted on the upper part in the direction of the container, the diaphragm valve is bent outwards, thus opening the perforations in the base.

Owner:SEAQUIST LOEFFLER KUNSTWERK

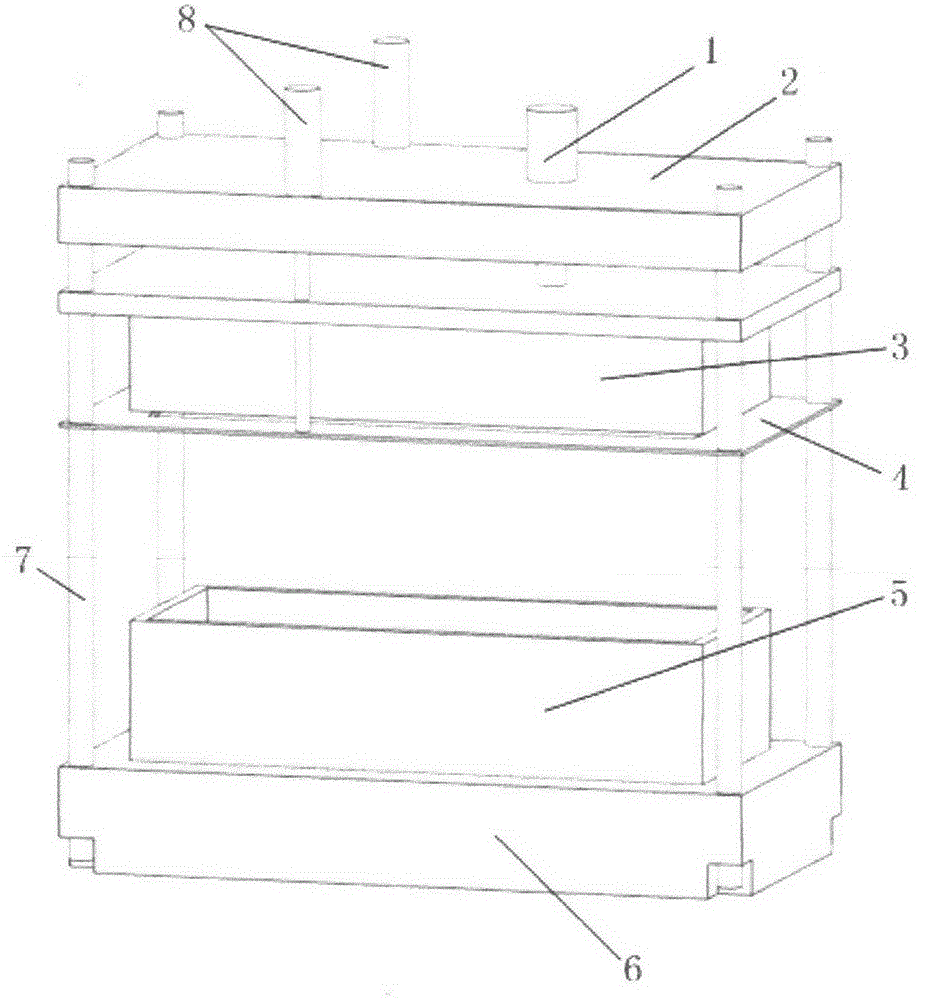

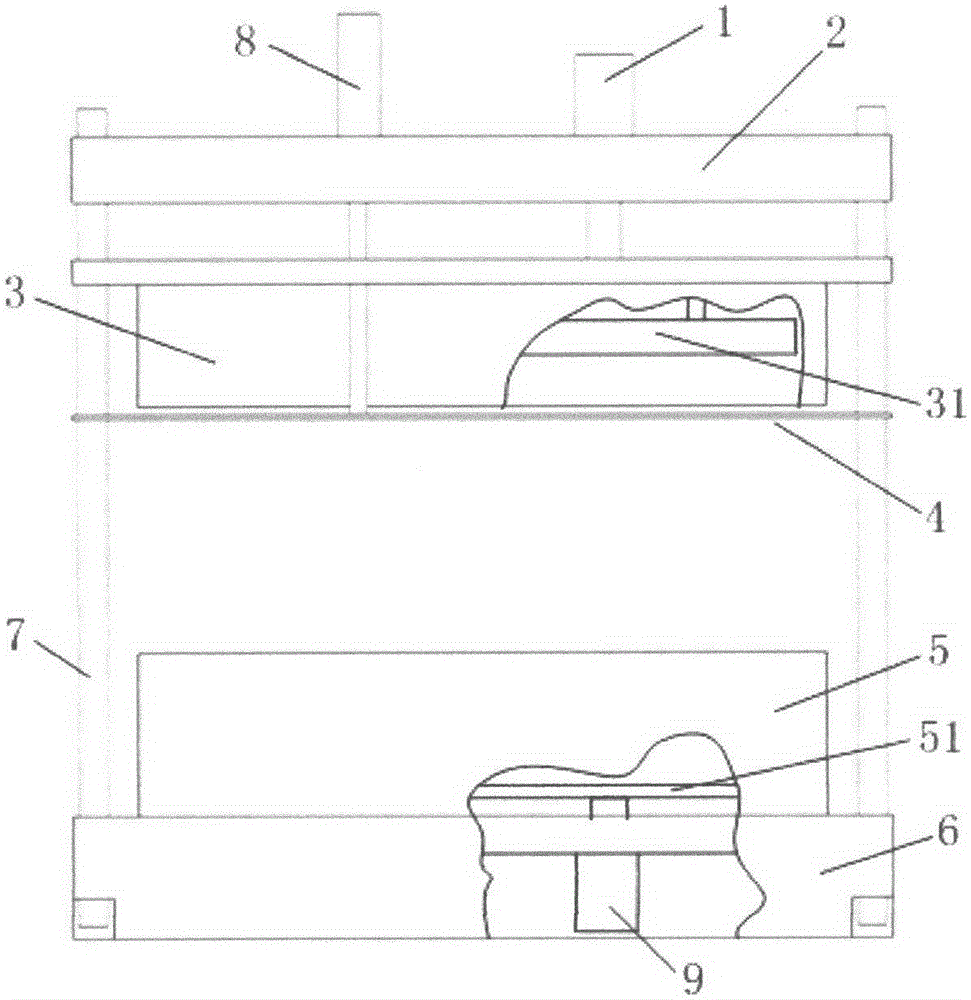

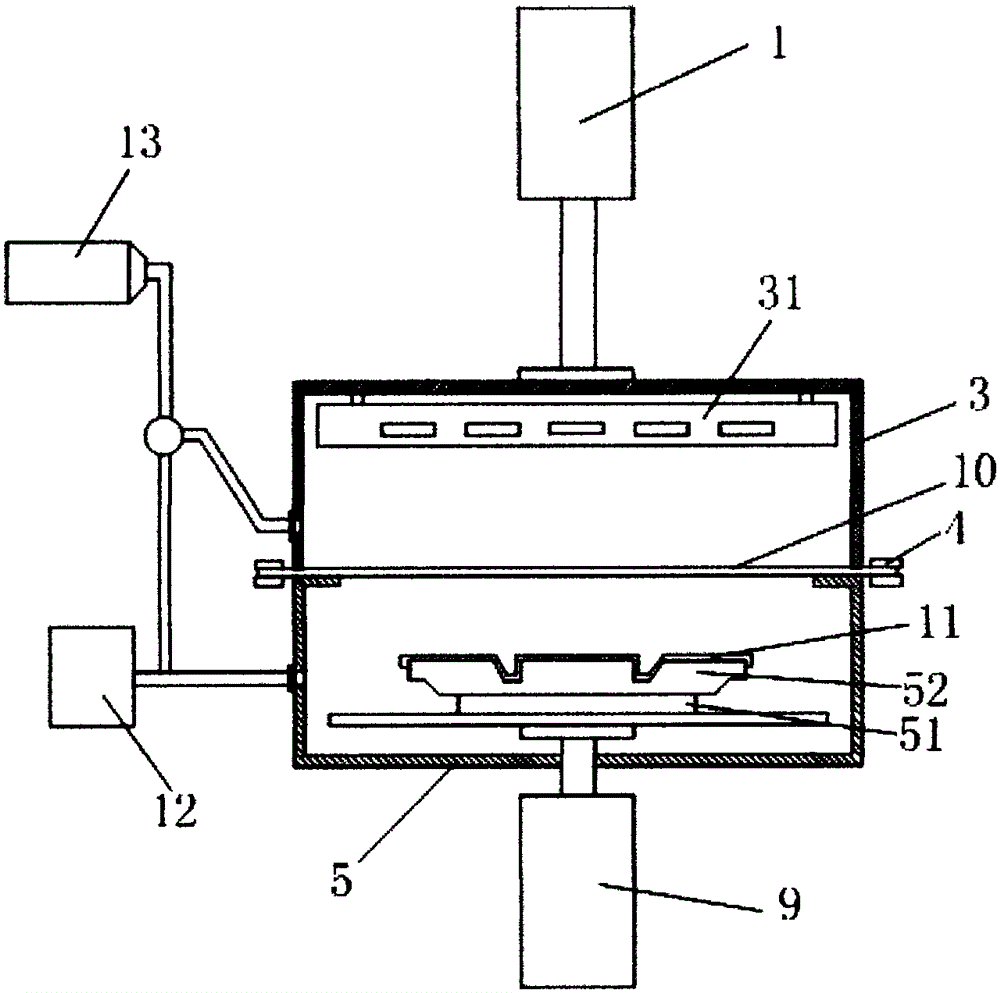

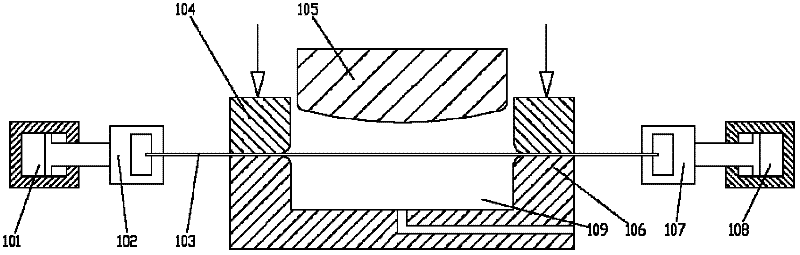

Positive/negative pressure vacuum film covering machine

ActiveCN105015130AMeet the long-term cycle workFor accidental down-down protectionLaminationLamination apparatusEnvironment effectPressure system

The invention discloses a positive / negative pressure vacuum film covering machine, and belongs to the technical field of mechanical devices. The positive / negative pressure vacuum film covering machine is composed of a main machine, a hydraulic system, a heating system, an electric system and a positive and negative system. The main machine comprises an upper cylinder, an upper beam, an upper vacuum chamber, a film pressing plate, a lower vacuum chamber, a lower beam, stand columns, a film pressing cylinder and a lower cylinder. The hydraulic system is located on the rear side of the main machine. The heating system is arranged at the top end in the upper vacuum chamber. The electric system is located on the right side of the main machine. The positive / negative pressure system is located on the left side of a machine body. A main body is a closed cavity, the closed cavity is partitioned into two independent air chambers through a decorative film, the forming process is conducted in the same closed space and not likely to be affected by the external environment, and the stability of processing can be improved so as to achieve the purpose of improving positioning accuracy; the elongation of the film can be improved by the adoption of prestretching, the interior of a plastic part can be wrapped by the film smoothly, and the high-quality film-decorative plastic part is obtained.

Owner:SICHUAN JIEBANG SCI & TECH CO LTD

Process for cutting silicon wafer by using steel wire with diameter of 0.1mm

InactiveCN102059749AReduce thicknessSignificant comprehensive benefitsFine working devicesSingle crystalRisk stroke

The invention discloses a process for cutting a silicon wafer by using a steel wire with the diameter of 0.1mm. In the process, silicon carbide (SiC) and a cutting fluid are proportioned according to the mass ratio of 1:1 to 1:1.2; in a glue curing process, single crystals are pressurized for 0.5 to 3h by a 5 to 10kg heavy pressurizing punch to remove redundant glue; and the cutting is performed by using the steel wire with the diameter of 0.10mm under the pre-tension of 15 to 23N, a wire speed is 400 to 1,000m / min, the descending speed of a workbench is 0.3 to 1mm / min, and a cutting stroke is set according to the actual diameter of the single crystal. The process for cutting the silicon wafer by using the steel wire with the diameter of 0.1mm can effectively reduce cutting loss and improve the quality of a cut surface, achieves more remarkable benefits if the silicon wafer is thinner, and compared with the processes in which the steel wires with the diameters of 0.14mm and 0.12mm are adopted generally, saves raw materials by 6.45 percent and 2.15 percent respectively.

Owner:TIANJIN HUANOU SEMICON MATERIAL TECH CO LTD

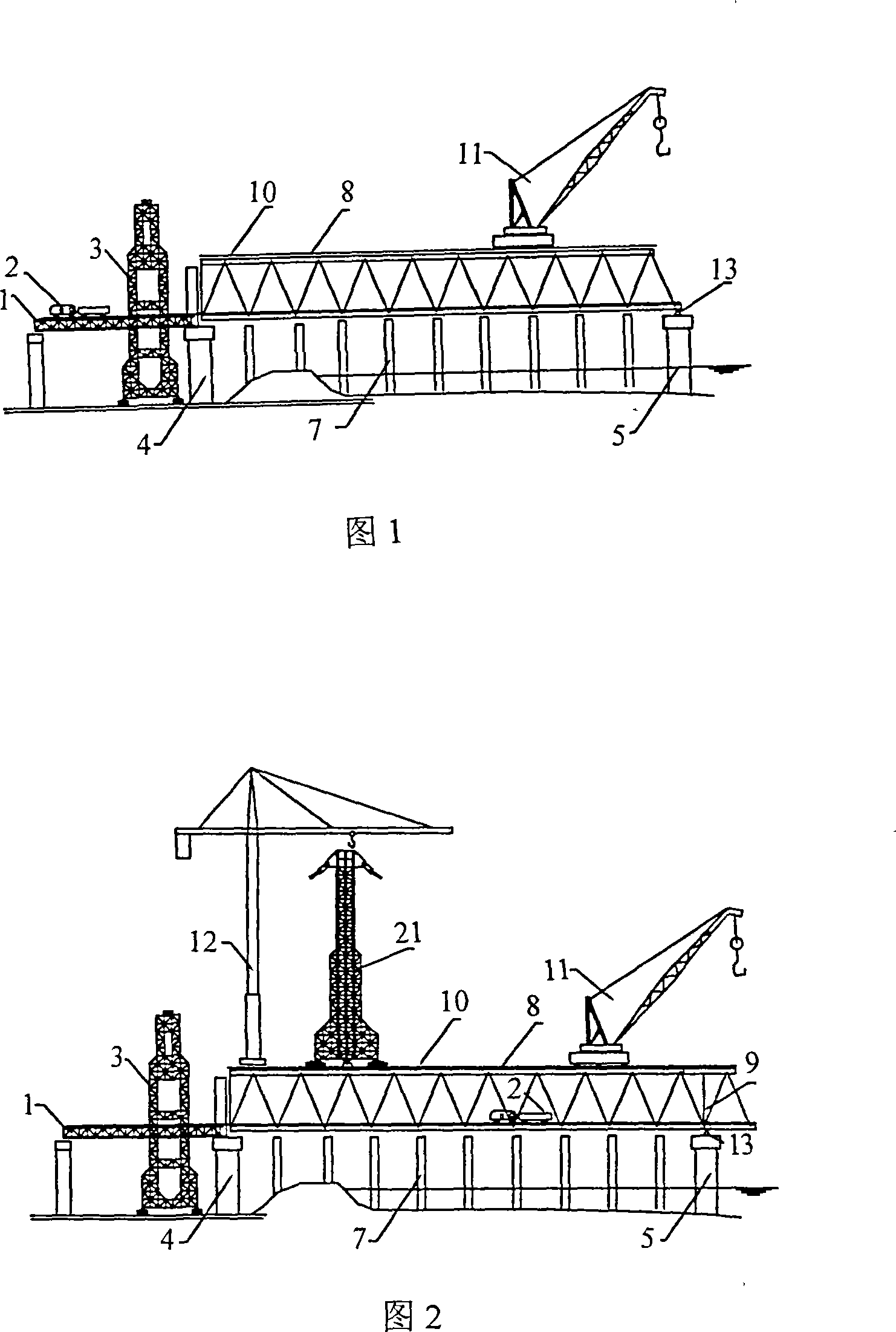

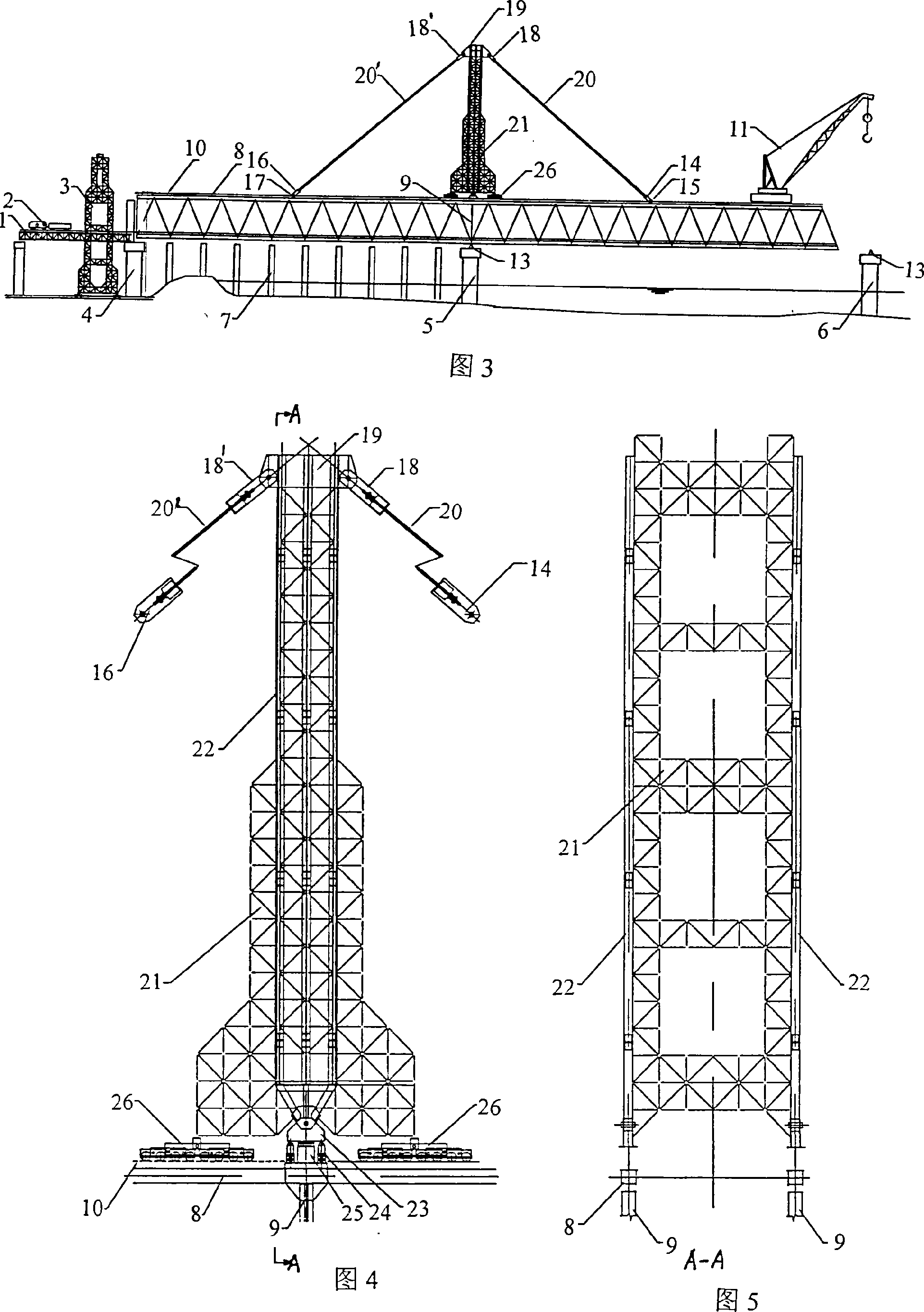

Method and system for erecting steel trusses by stay cable auxiliary complete cantilever

ActiveCN101139821AShort construction period for temporary structuresLess investmentTruss-type bridgeBridge erection/assemblyEngineeringPush ups

The invention is a method of erecting all-cantilever erected steel truss beams assisted by diagonal ropes, as well as a relevant system. The method utilizes a bearer cable tower combined with a steel structure center tower column with diagonal ropes; install a tower-type crane on the top face of the steel truss beam end at the first hole with an overhead bridge crane in a ground craning station; anchor cases below the front and rear diagonal ropes are connected with side plates at steel beam nodes, and after that, directly lift the tower to apply pre-tension on the diagonal ropes; perform all-cantilever erection for the front steel truss beam. After finishing erection of the orifice steel beam, complet load removal from the diagonal ropes with a method of pushing up the temporary seat for the front pier and lowering back a pushing and craning device between upper and lower seats of the bearer cable tower. The system comprises an auxiliary tower truss, a tower center vertical column, the upper and lower support seats, the front and rear diagonal ropes, the upper and lower anchor cases for diagonal ropes, a tower top anchor beam and a walking mechanism. The invention has the following advantages: For large-span continuous steel truss beams, utilize a special device additionally to erect multi-span steel truss beams, so as to reduce internal stress in installation of steel truss beam members, lower end deflection of the front extension arm, and increase the inclination stability of a steel truss beam on the extension arm. Meanwhile, the invention can low investment and short construction period and provide very convenient operation.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

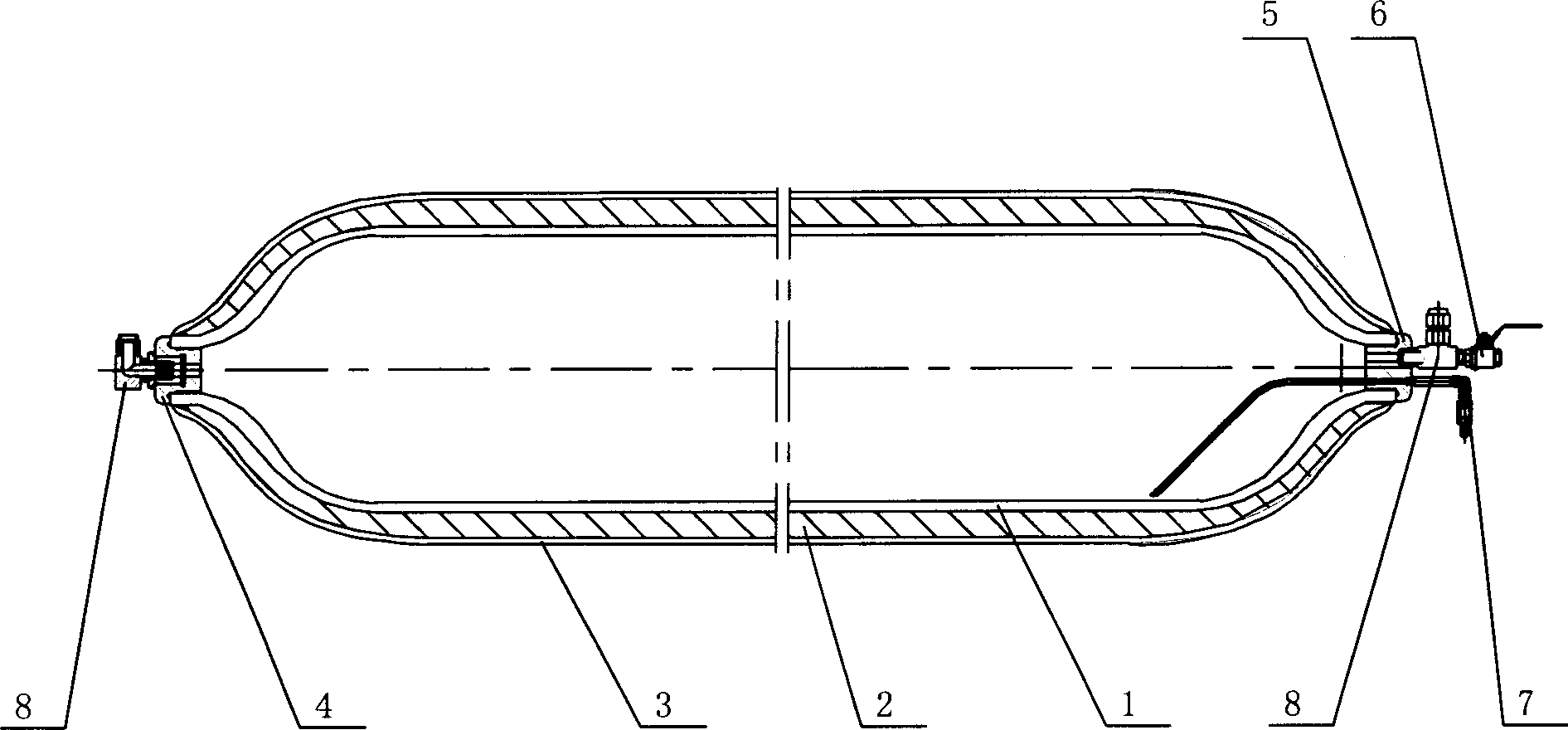

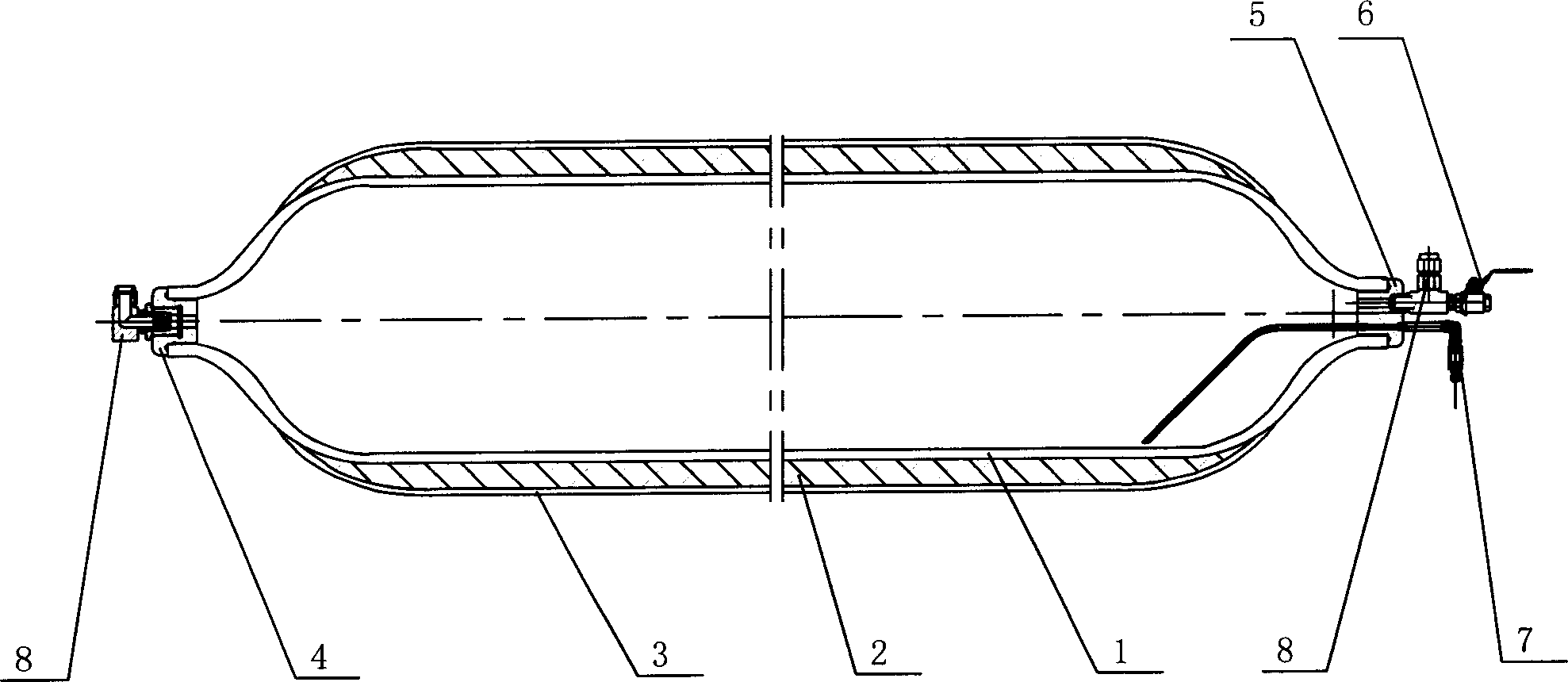

Steel inner container big capacity high pressure tank and its preparation

ActiveCN1908501AImprove pressure bearing capacityLarge water volumePressure vesselsFiber bundleMetallurgy

The present invention relates to a steel inner container big capacity high pressure tank and its preparation, which includes an inner bag made of steel high pressure seamless pipe, an intensive compound shell with the outwall wrap solidified and a protection course. The structure adopts the following steps to process: 1. selecting matching steel high pressure seamless pipe and adopting the spinning beading, heat treatment modulator, trueing machine processing to make the inner bag; 2. rotating the bracket to position the inner bag; 3. setting the high tensile fiber glue roller guide on the inner bag; 4. setting the initial wrap helix angle smaller than 40 degree and the pre-tension 5-15% of the fiber bundle tensile strength; 5. gapless thickly wrapping between the two beadings of the inner bag alternate in the clockwise and counter-clockwise; 6. adding the wrapping angle 0.5-1.5 degree completing the alternation every time; 7.maintaining the design thickness of the intensive compound layer when the wrapping angle increases to the 75-85 degree; 8. being posted into the curing oven for drying, curing, shaping process.

Owner:SHIJIAZHUANG ENRIC GAS EQUIP

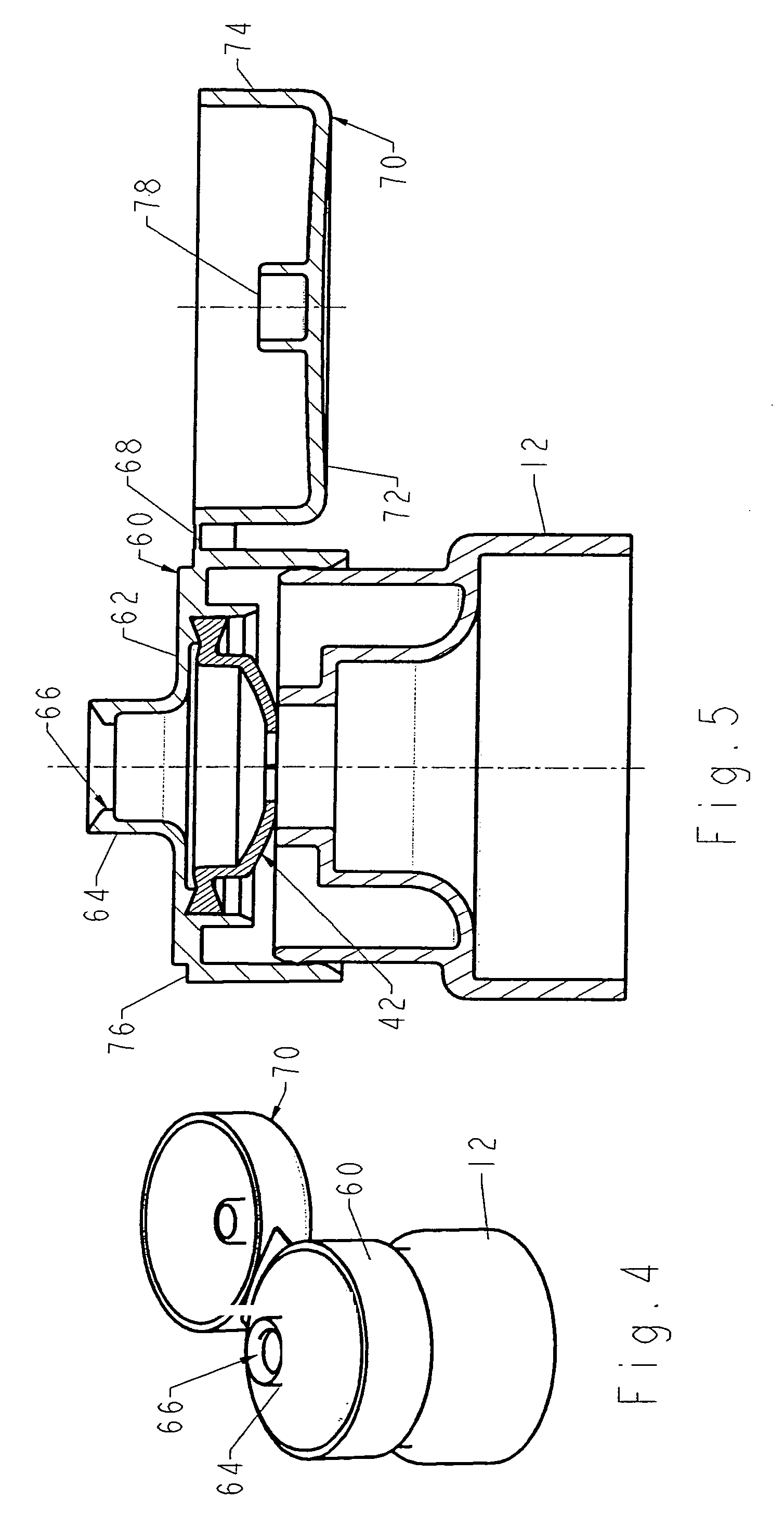

Seat belt pretensioner

A pretensioning apparatus for seat belt webbing is located in the vicinity of a belt anchor end of a three-point vehicle safety restraint seat belt. The pretensioning apparatus has a fixed member in the form of a tubular member that may be anchored to a vehicle seat at the belt anchor side of the vehicle. A movable member in the form of a piston is connected to the webbing in the region of the belt anchor end. A means is provided for moving the movable member relative to the fixed member in a generally horizontal direction, to move the seat belt webbing in a pretensioning direction in response to a signal from a crash sensor. A webbing guide is fixed to the seat to provide an effective anchorage point spaced from the belt anchor end of the webbing under pretensioning conditions.

Owner:KEY SAFETY SYST

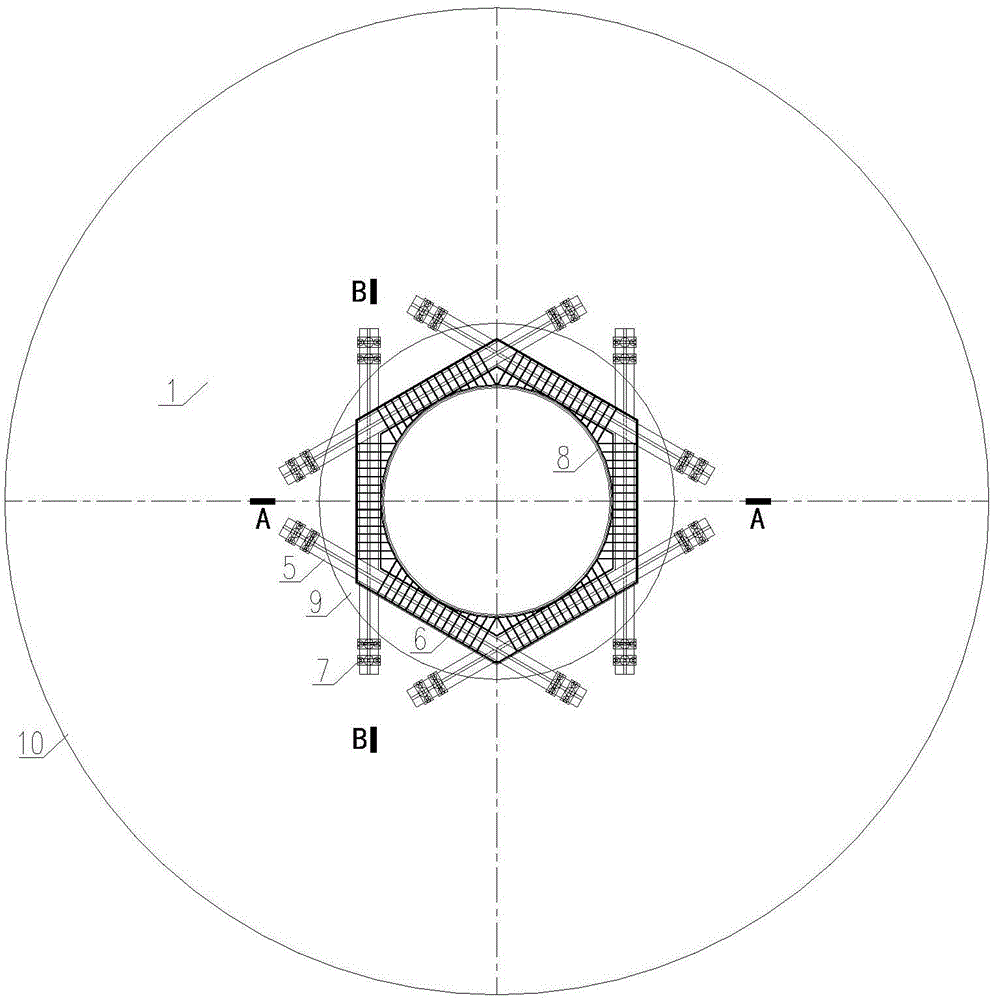

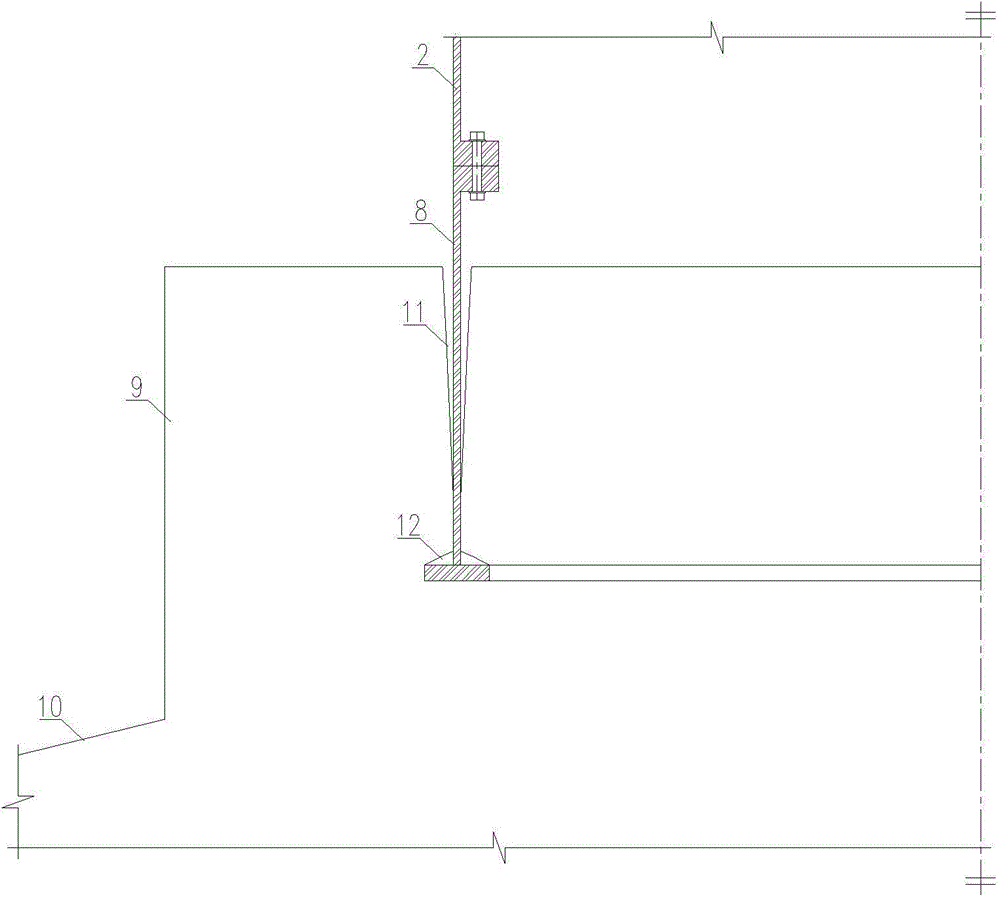

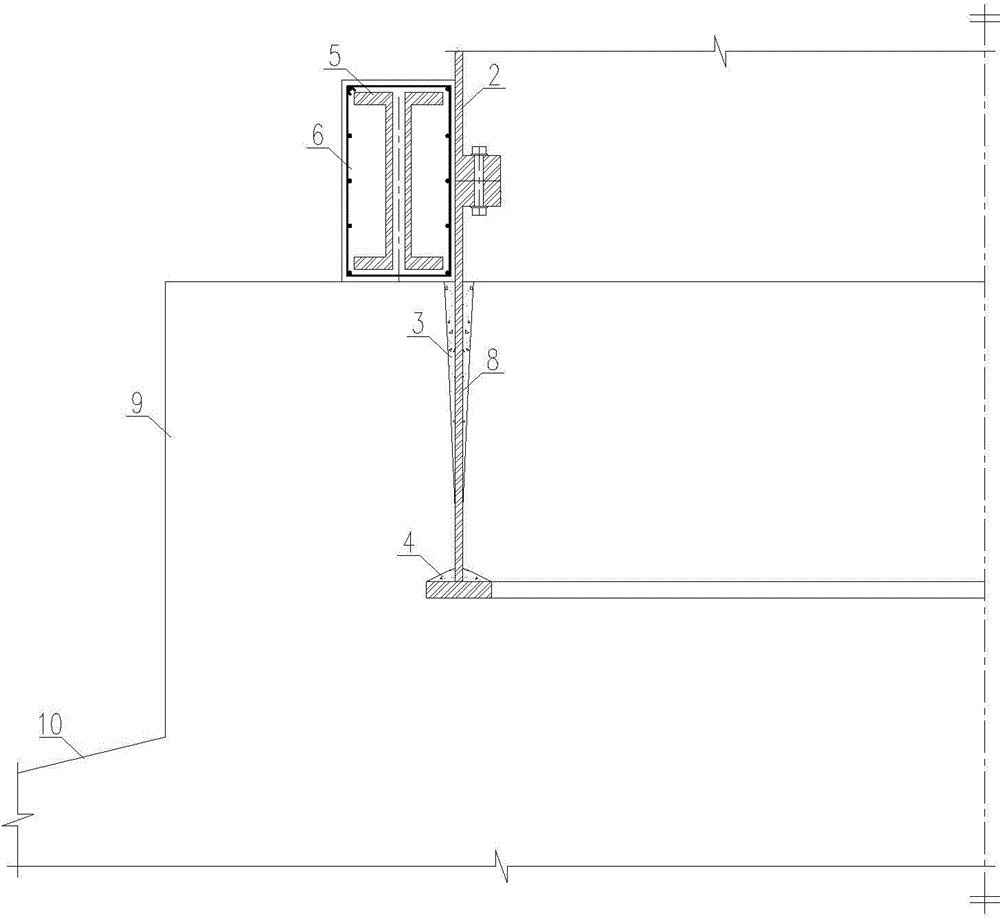

Reinforcing system and reinforcing method of wind power generation tower foundation ring foundation

ActiveCN104790424AAvoid fatigue damageReasonable structural designFoundation repairReinforced concretePre stress

The invention relates to a reinforcing system and reinforcing method of a wind power generation tower foundation ring foundation. The system comprises the foundation ring foundation (1) and a draught fan tower drum (2). The foundation ring foundation (1) comprises a foundation bottom plate (10), a concrete column pier (9) and a foundation ring (8), and the foundation ring (8) is connected with the draught fan tower drum (2). Steel beams (5) are symmetrically arranged on the outer side of the foundation ring (8) and on the top of the concrete column pier (9), the steel beams (5) surround the foundation ring (8) to form a regular-hexagon-shaped area, and steel-reinforced concrete beams (6) are poured around the regular-hexagon-shaped steel beams (5) and on the outer side of the foundation ring (8). The two ends of the steel beams (5) are connected with prestress anchor rod assemblies (7), and the lower ends of the stress anchor rod assemblies (7) are anchored in the foundation bottom plate (10). Pre-tension force is applied to a prestress anchor rod, so that pre-compressive stress is generated on concrete around the foundation ring, and accordingly the crack problem of the foundation ring foundation caused by fatigue can be fundamentally solved.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD +2

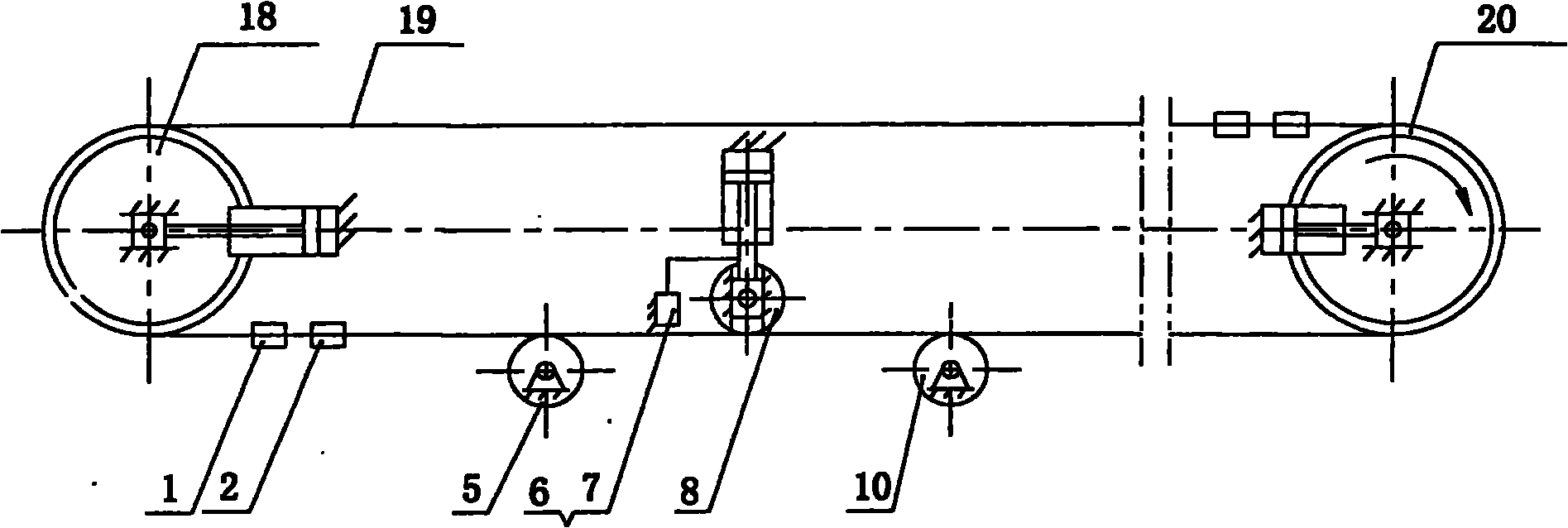

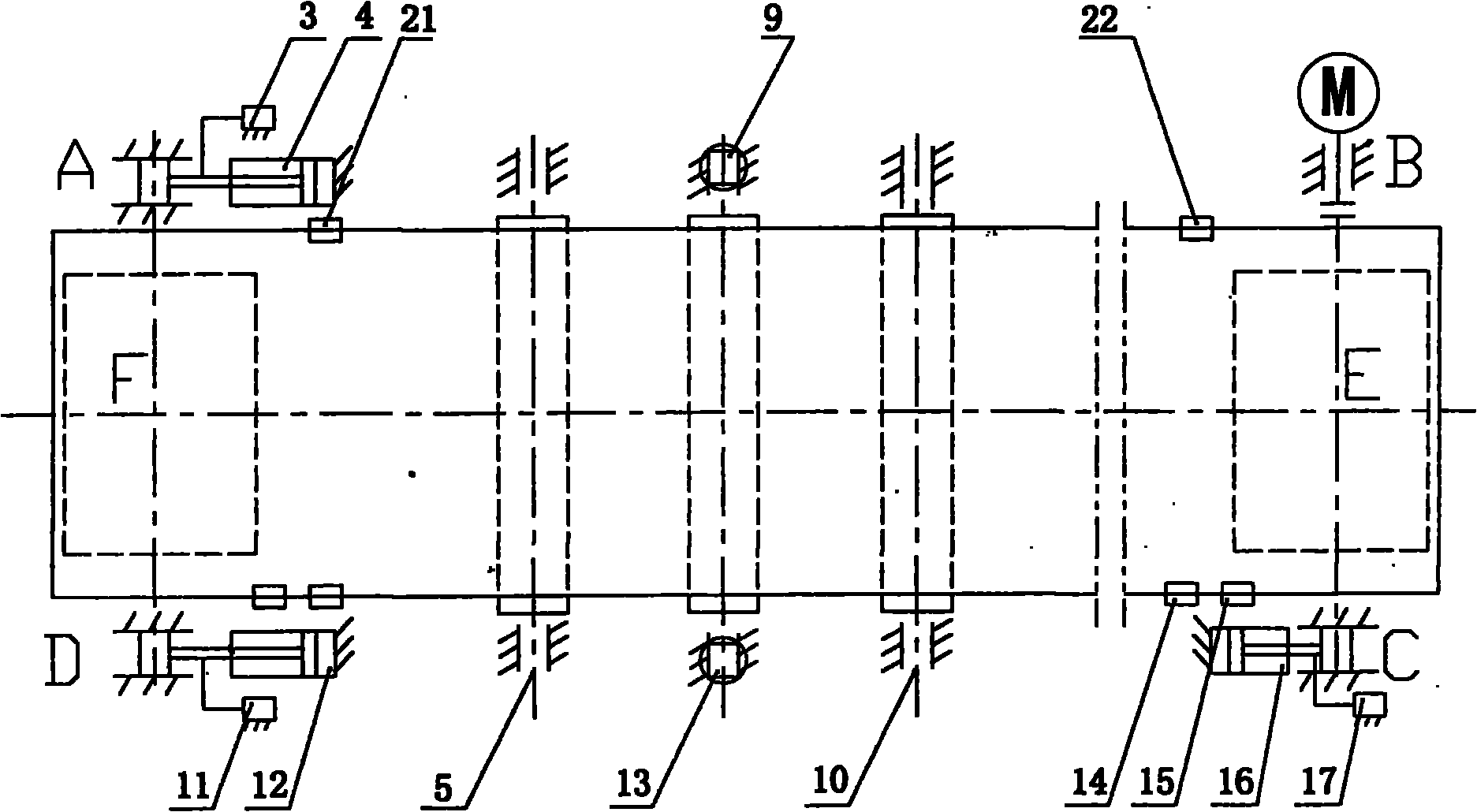

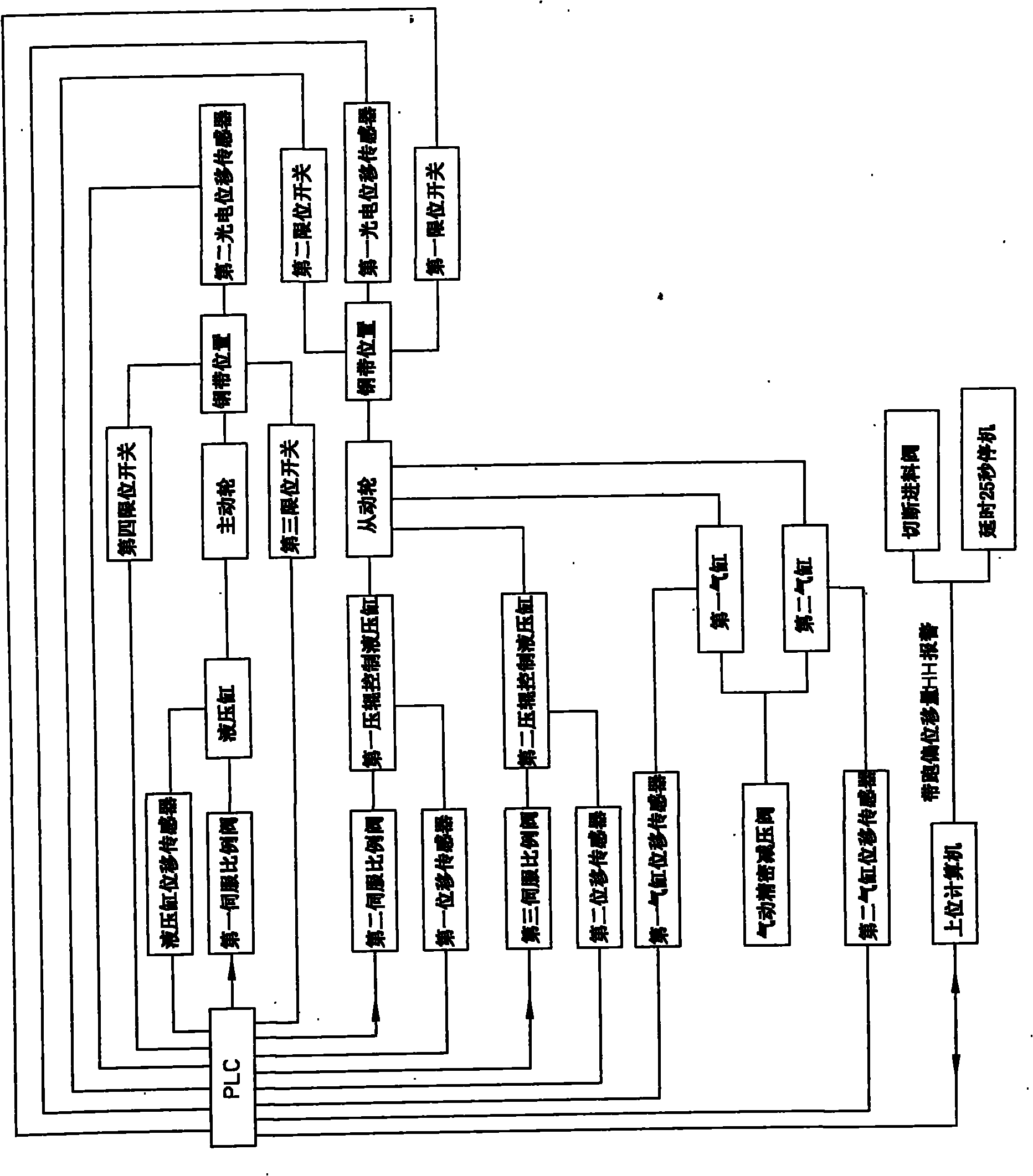

Steel belt deviation correction system of cooling forming machine for remote transportation of high-temperature material

InactiveCN102060174AQuick correctionSimple structureConveyorsRollersTime deviationHydraulic cylinder

The invention discloses a steel belt deviation correction system of a cooling forming machine for remote transportation of a high-temperature material. A driving wheel and a driven wheel are connected through a steel belt, wherein one end of the driving wheel is fixed, and the other end of the driving wheel is fixed through a hydraulic cylinder; the two ends of the driven wheel are fixed respectively through a cylinder; the pre-tension of the steel belt between the driving and driven wheels is adjusted by two cylinders; the bottom of the steel belt is provided with a driving wheel carrier roller and a driven wheel carrier roller to support the bottom of the steel belt respectively; a compression roller is arranged at the upper side of the bottom of the steel belt between the driving wheel carrier roller and the driven wheel carrier roller; limit switches are arranged close to the bottoms at the two sides of the driven wheel steel belt respectively, limit switches are arranged close to the tops at the two sides of the driving wheel respectively, and each limit switch is connected with an alarm; the driven wheel is provided with a photoelectric sensor close to the bottom of each cylinder, a photoelectric sensor is arranged at a position, which is close to the top of the hydraulic cylinder, on the driving wheel, and the photoelectric sensors detect the deviation quantity of the steel belt respectively; and all the sensors and limit switch alarms are connected with an upper computer through a PLC (programmable logic controller). According to the invention, double-closed-loop control on the position of the steel belt at the driving wheel end and driven wheel end is realized, and real-time deviation correction of the steel belt transmission system is finished.

Owner:HANGZHOU FURUDE TECH

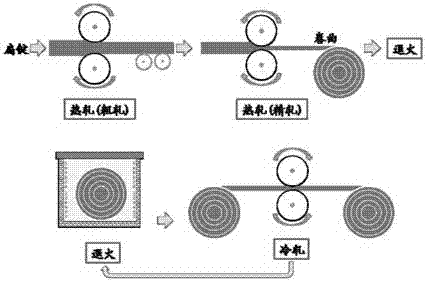

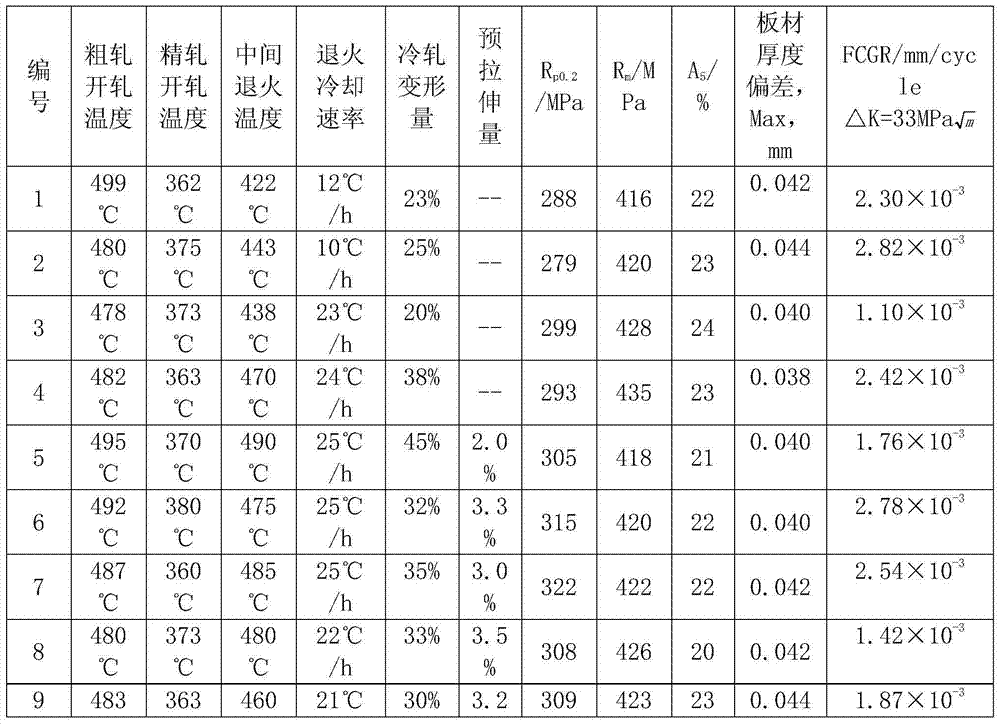

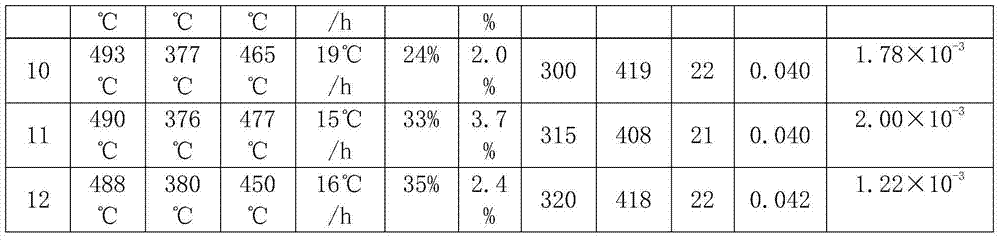

Preparation method of Al-Cu-Li-X series aluminum lithium alloy sheet

The invention discloses a preparation method of an Al-Cu-Li-X series aluminum lithium alloy sheet. The sheet prepared by the method is 0.8mm-8.0mm in thickness. The method comprises the following steps: cogging and hot-rolling homogenized slab ingots to a specified thickness and coiling; carrying out annealing treatment, uncoiling and carrying out band-type cold-rolling; carrying out intermediate annealing according to deformation during cold-rolling, thus obtaining the sheets with uniform thicknesses. The sheets can be in different states after being subjected to solution treatment, prestretching and aging treatment, so as to meet different usage requirements. Compared with the prior art, the aluminum lithium alloy sheet with high surface quality, uniform sheet size and smooth sheet shape is prepared by the method through band-type cold-rolling. The sheets can be in different states by different heat-treating processes, so as to meet usage requirements under different application conditions.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

3-point wheelchair passenger securement system

ActiveUS8414234B2Simpler to useReduce the amount requiredItem transportation vehiclesWagons/vansWheelchairRight triangle

The embodiments described and claimed herein are improved wheelchair passenger securement systems and stations. In particular, one embodiment described and claimed herein is a drop-in system comprising a barrier module and a wall-side module, which incorporate three separate restraint devices which are configured to secure a wheelchair at three separate attachment points. The system can optionally include a moveable excursion barrier or a pull-mechanism to pre-tension at least one of the restraint devices the wheelchair securements. In a simpler embodiment, three restraint devices, such as retractors, are provided for attachment to the vehicle surfaces or structures in, for example, a generally right-triangular configuration.

Owner:VALEDA

Bimetallic compound Cu/Ag plate making process

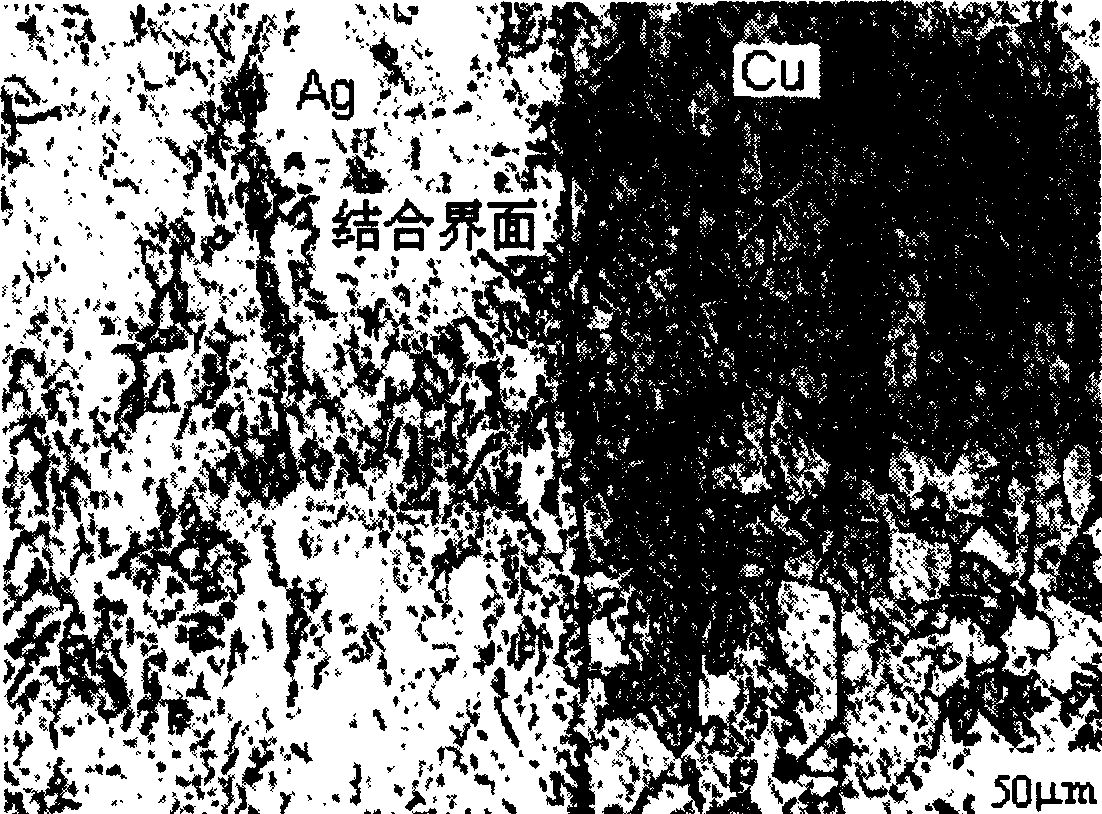

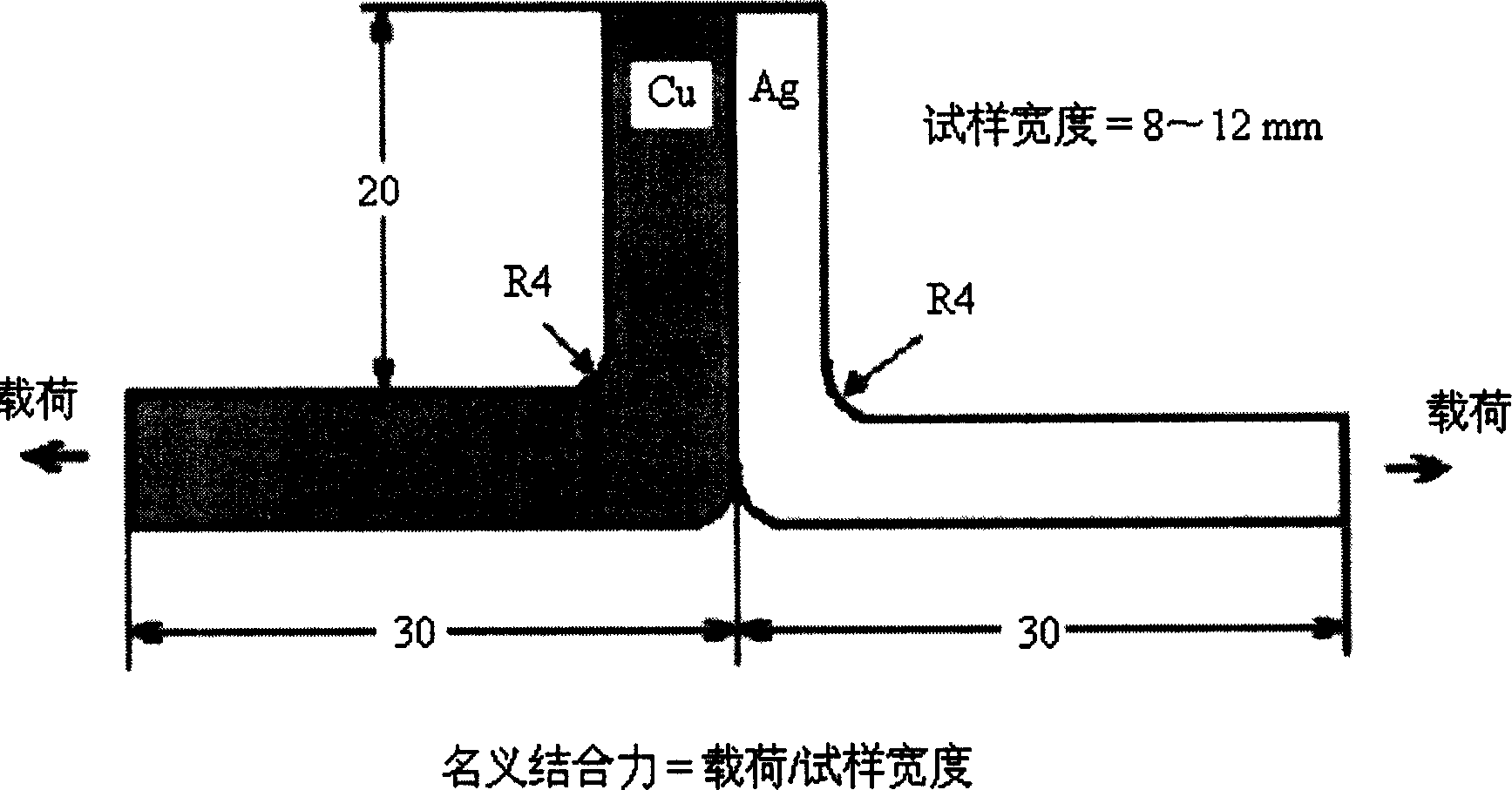

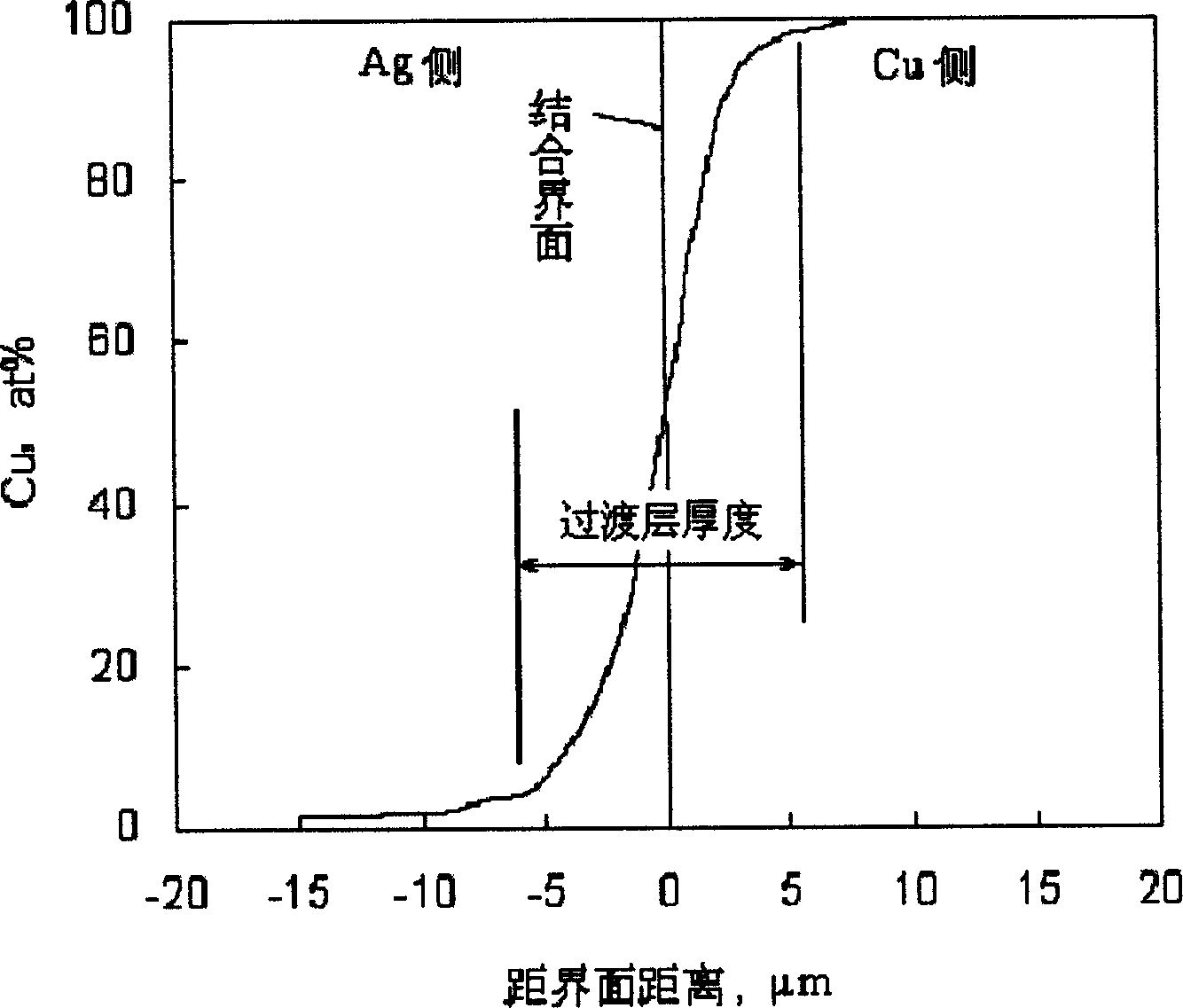

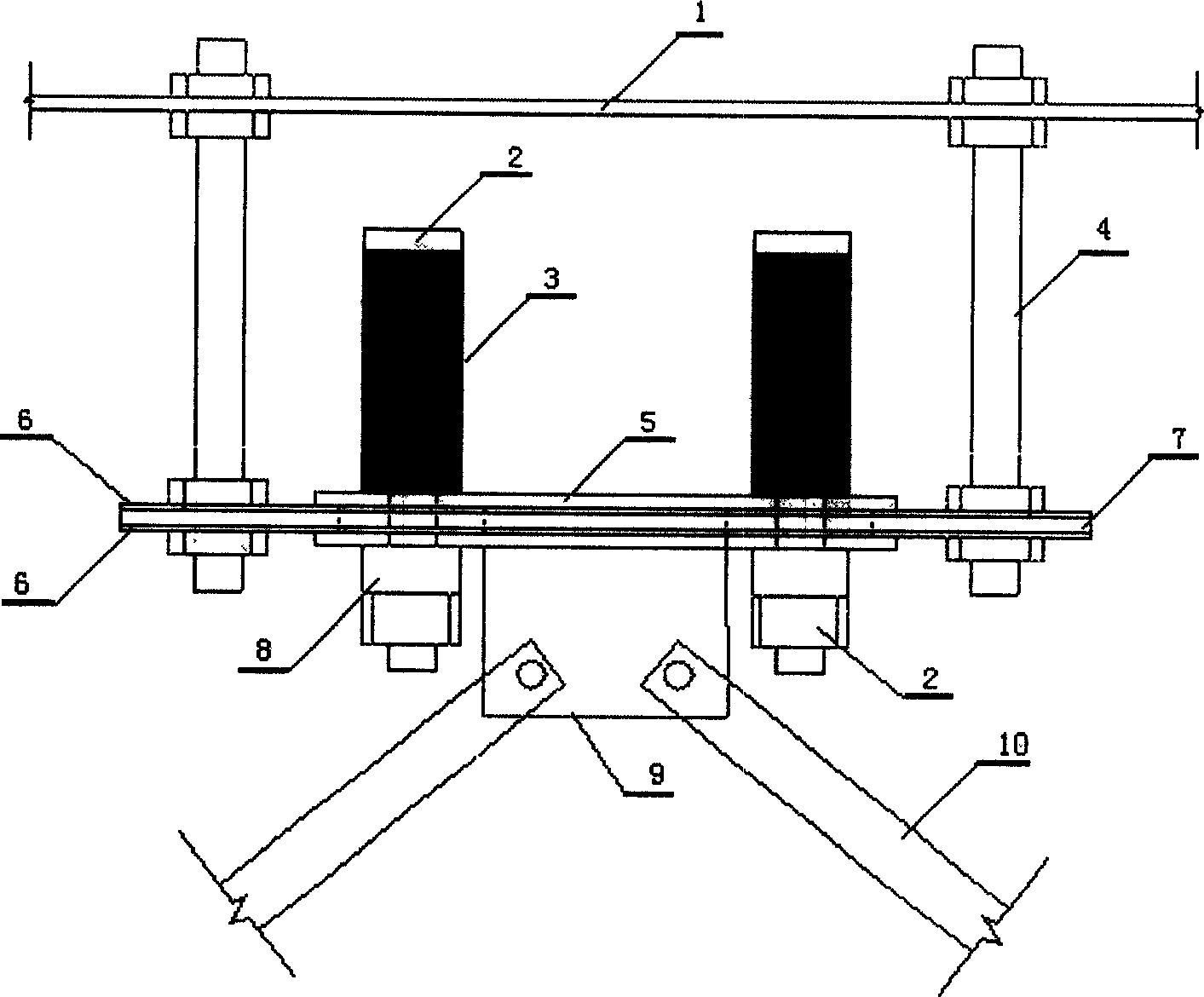

InactiveCN1739913AGood for mechanical engagementGood initial composite stateOther manufacturing equipments/toolsBinding forceTransition layer

The bimetallic compound Cu / Ag plate making process includes the following steps: annealing hard industrial pure Cu and Ag base material at 250-300 deg.c, pre-tension straining, mechanically grinding to form composite surface of roughness Ra 12.5-50 micron, cold rolling for deformation of 5 % and pre-compounding, rolling at normal temperature or 200 deg.c for deformation of 70-80 % and physical compounding, and annealing and diffusion compounding at 400-450 deg.c for 2-4 hr. The prepared compound plate has nominal interface binding force of 40-45 N / mm, diffusion transition layer in the thickness of 10-14 micron, homogeneous structure and close interface binding. In addition, the present invention has also the effects of obvious technological stages, convenient parameter control, etc.

Owner:ZHEJIANG UNIV

Semiactive piezoelectric friction damper

InactiveCN1594775AImprove securityEnsure stabilityVibration suppression adjustmentsShock proofingMetallurgyProject structure

The invention relates to a semiactive piezoelectric friction damper comprising tube type piezoelectric ceramic driver, tube force sensor, upper steel plate, a lower steel plate, a sliding steel plate, a fiction piece (brass or brake pad). The character is that bolt hole is opened on the upper steel palate and lower steel plate, also screw and sliding groove are opened on the fiction piece and the sliding steel plate. A pre-tension bolt connects the upper steel plate, a lower steel plate, a sliding steel plate to the fiction piece with inner hole of the piezoelectric ceramic driver and inner hole of the force sensor. The semiactive piezoelectric friction damper has convenient process, stable capacity, low energy consumption, also can change force of sliding friction by adjusting the voltage applied on the piezoelectric ceramic driver according to the signal of quake of ground and respond to the project structure. The invention can connect to multi-layer building via V type support or slant support, which has certain economic and using value, also can be widely used to dissipation of energy and shock absorption field of civil engineering structure.

Owner:DALIAN UNIV OF TECH

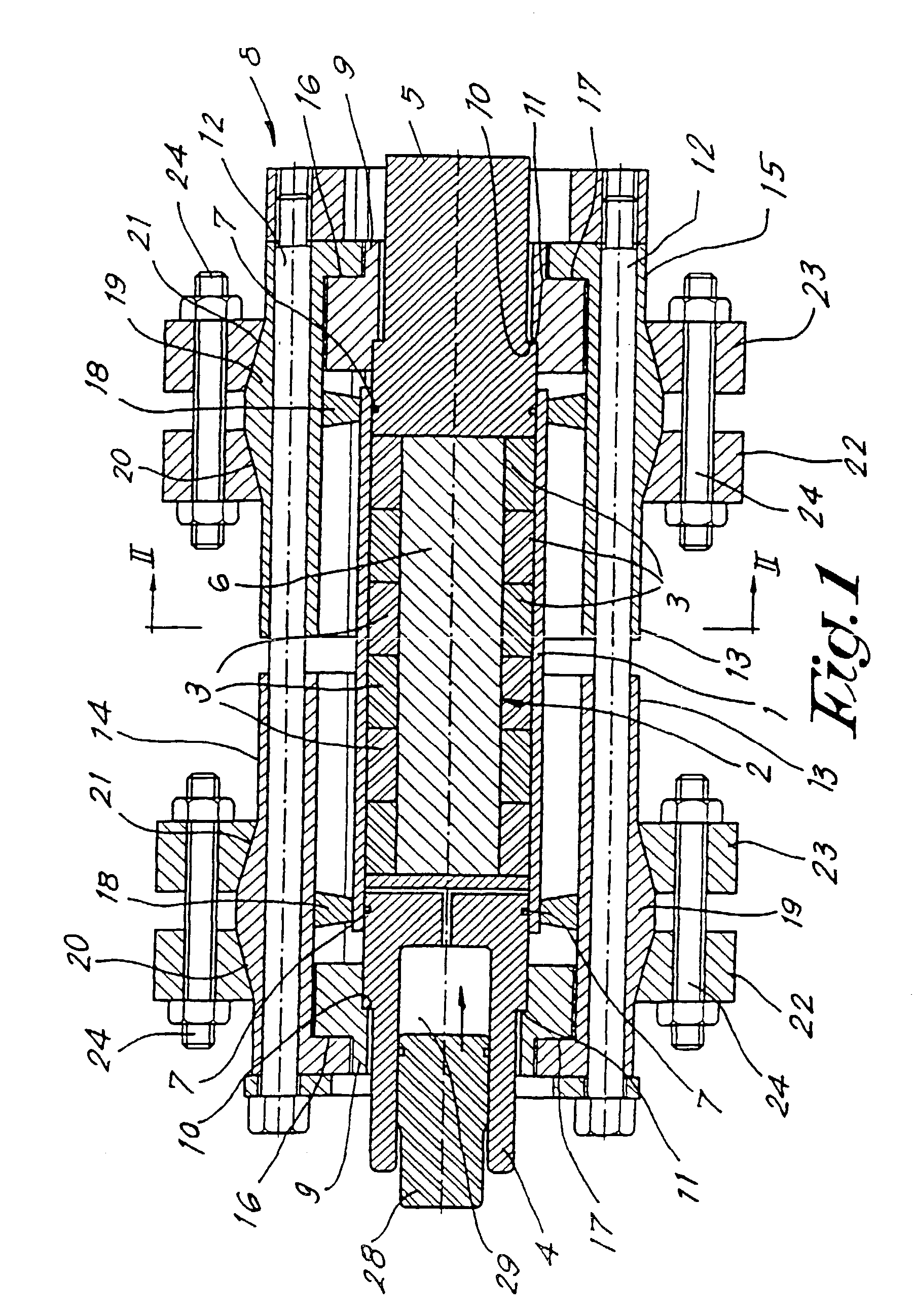

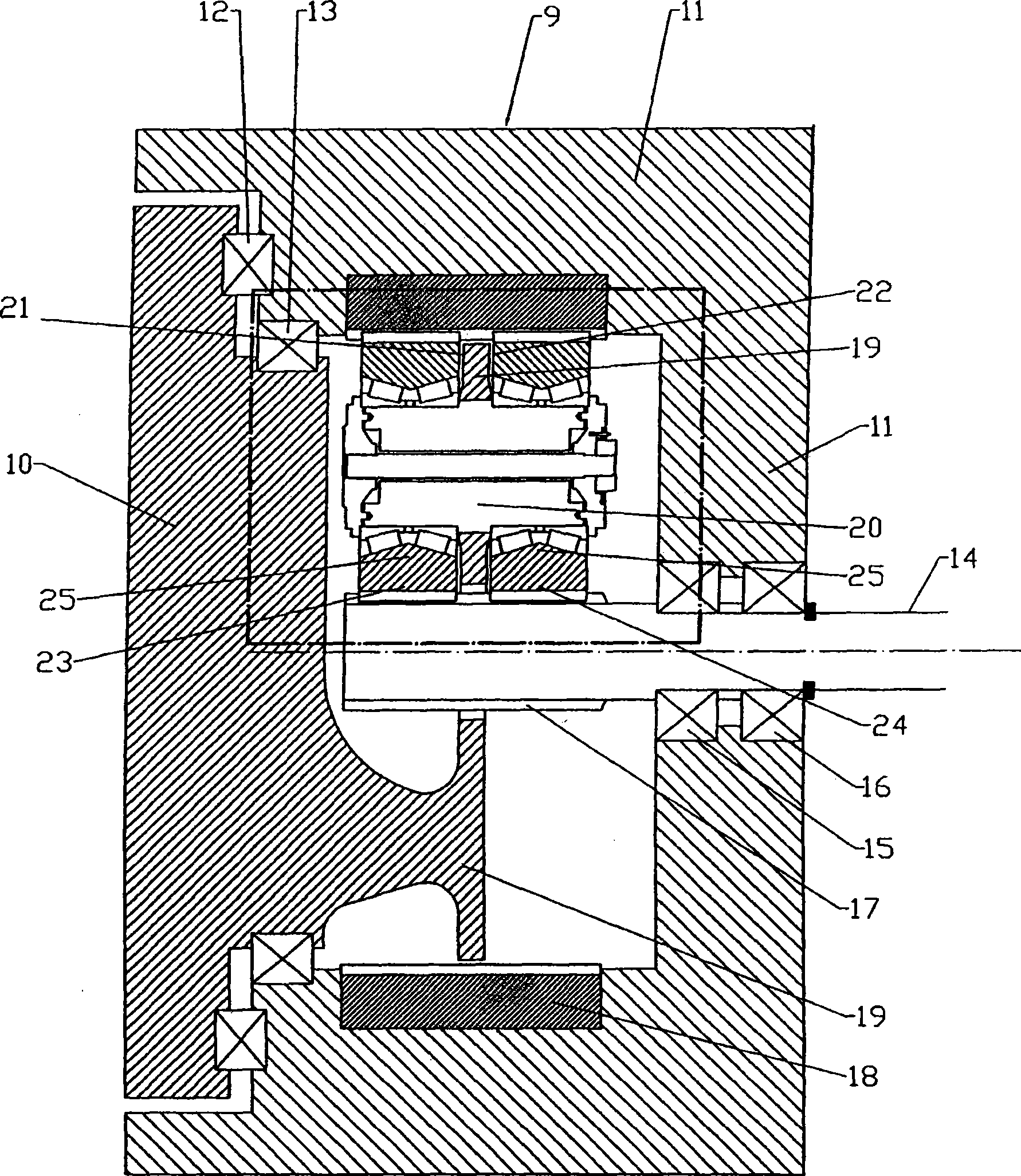

A planetary type gear unit comprising a planet carrier with a planet bogie plate

ActiveCN101469760AControl pretensionReduce misalignmentRolling contact bearingsEngine fuctionsBogieGear wheel

The invention provides a planet gear unit for a planet carrier with a planet load plate. The planet carrier is provided with at least a planet shaft; therefore, on the both sides of the load plate, the planet wheel is arranged on the planet shaft through a taper roller bearing, and the extremities of the planet shaft are provided with axial shifting parts to forms a support; the support provides axial support for an internal bearing ring of the taper roller bearing; a tension device is arranged on the planet shaft, which enables the axial shifting part to mutually shift and is used for controlling the pre-tension of the taper roller bearing. By shifting the axial shifting part through the tension device, the pre-tension on the taper roller planet bearing can be controlled, so as to avoid or at least limit the gap in the bearing, thereby reducing the failure of the planet bearing caused by misplacement and dynamic effect.

Owner:HANSEN TRANSMISSIONS +1

Device for eliminating oil particles from the crankcase ventilation gas in an internal combustion engine

ActiveUS8042529B2Simple designSimple and cost-effective productionDispersed particle separationCombustion enginesThumb oppositionExternal combustion engine

A device for eliminating oil particles from the crankcase ventilation gas of an internal combustion engine. The device is located in the flow duct of the gas that runs from the crankcase to an induction tract of the engine. The device includes an oil separator in the form of an outlet for the gas with a deflection of the flow, causing the oil particles to be deposited on a baffle surface and thus to be eliminated from the crankcase ventilation gas flow. The device has an infeed cross-section, which lies upstream of the baffle surface when viewed from the flow direction of the crankcase ventilation gas, and which is sub-divided into several infeed sub-sections. The baffle surface is a solid surface that is devoid of perforations. The baffle surface is configured on a valve body, which lies downstream of the infeed sub-sections when viewed in the flow direction of the gas, and which is pre-tensioned by a force. The valve body can be displaced in the opening direction in opposition to the pre-tension, as a result of the differential pressure in the gas between the crankcase and the induction tract.

Owner:HENGST WALTER

Method of manufacturing prestressed concrete

InactiveUS7056463B2Improve fatigue strengthExcellent in corrosion-resistanceCeramic shaping apparatusBuilding reinforcementsFiberCarbon fibers

Pre-tension and post-tension processes for the manufacture of pre-stressed structures in which bonded carbon fiber cables are provided with burial anchors and temporary anchors outward of the burial anchors. The burial anchors are embedded in the structure. The temporary anchors enable stressing of the carbon fiber cables.

Owner:JAPAN SCI & TECH CORP

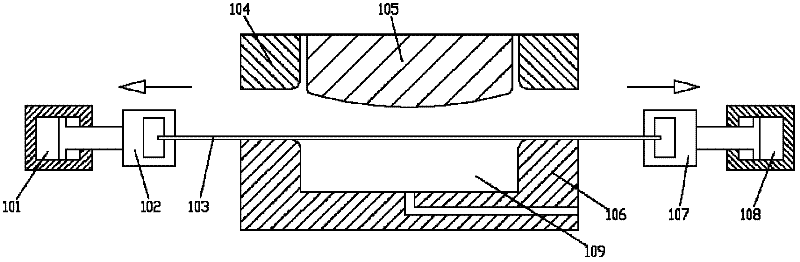

Drawing and hydraulic integrated forming method

The invention provides a drawing and hydraulic integrated forming method. The method comprises the following steps of: step 1: pre-drawing a sheet material, step 2: closing a die; step 3: expanding by introducing a liquid, step 4: releasing the pressure of a liquid chamber, opening the die and taking out the molded part. The drawing and hydraulic integrated forming method provided by the invention can solve the rebound problem of the molded part while well ensuring surface quality and wall thickness distribution of the part. Besides, the formed part has a high surface quality and a uniform distribution of wall thickness.

Owner:BEIHANG UNIV

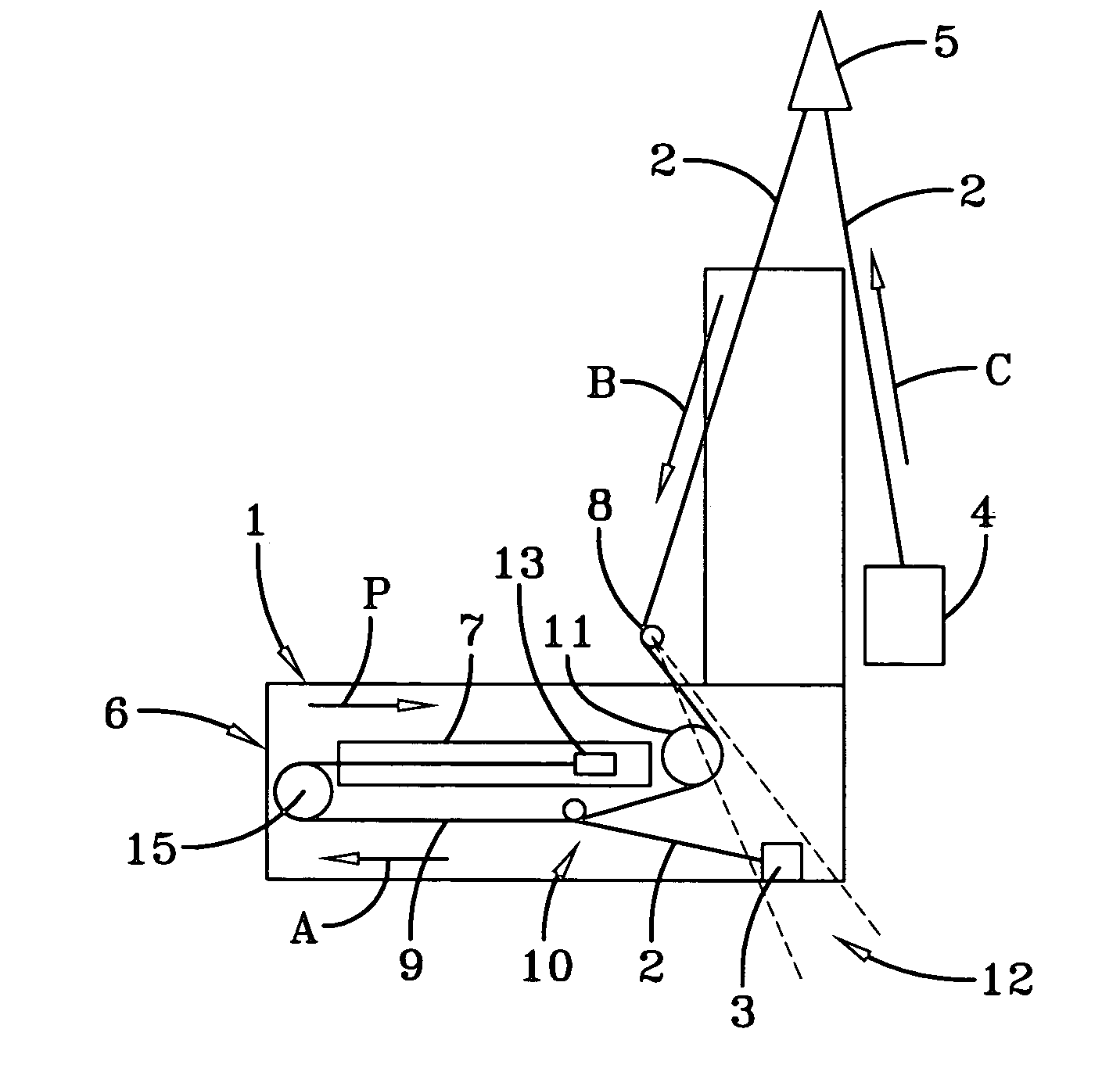

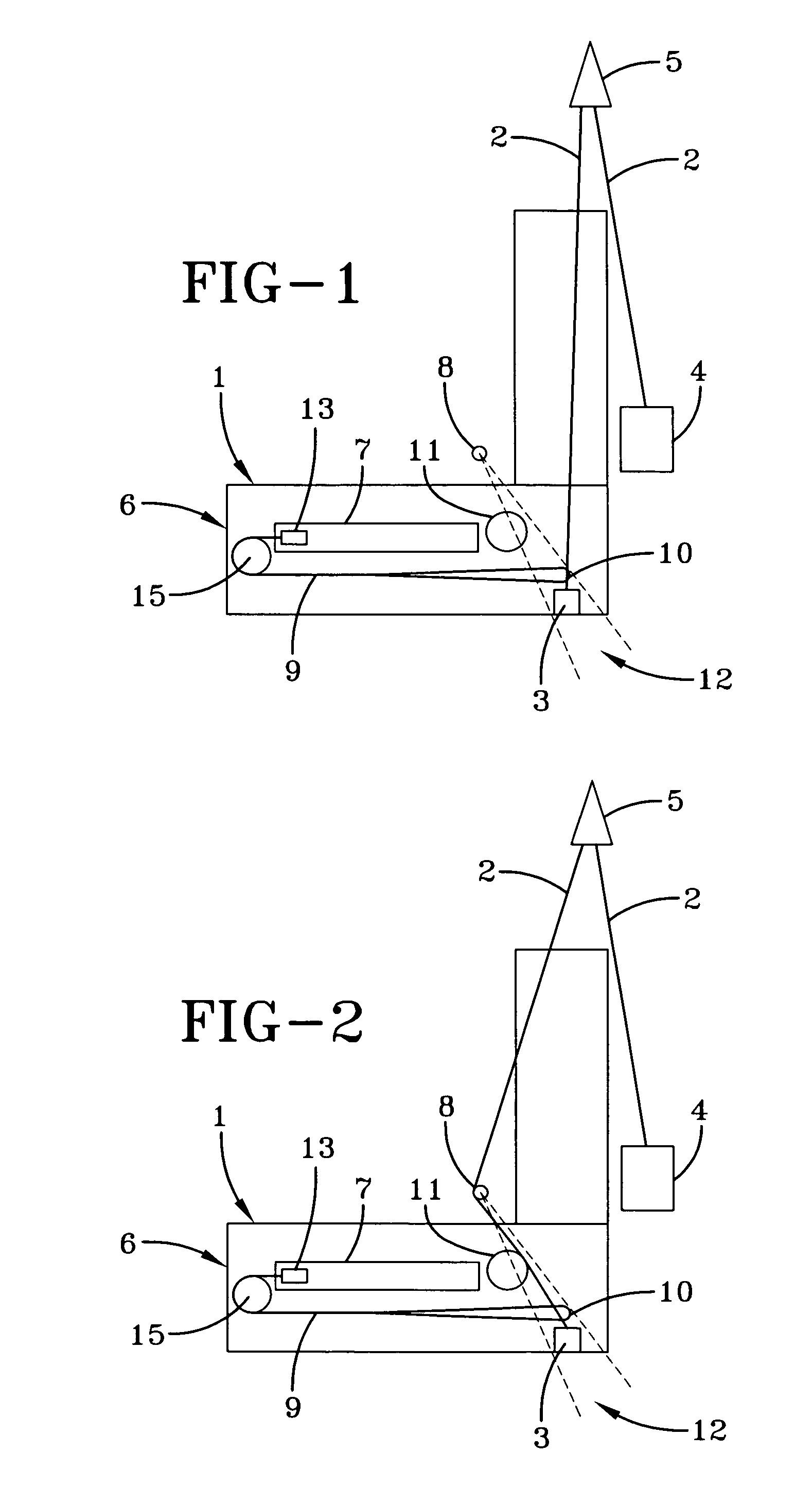

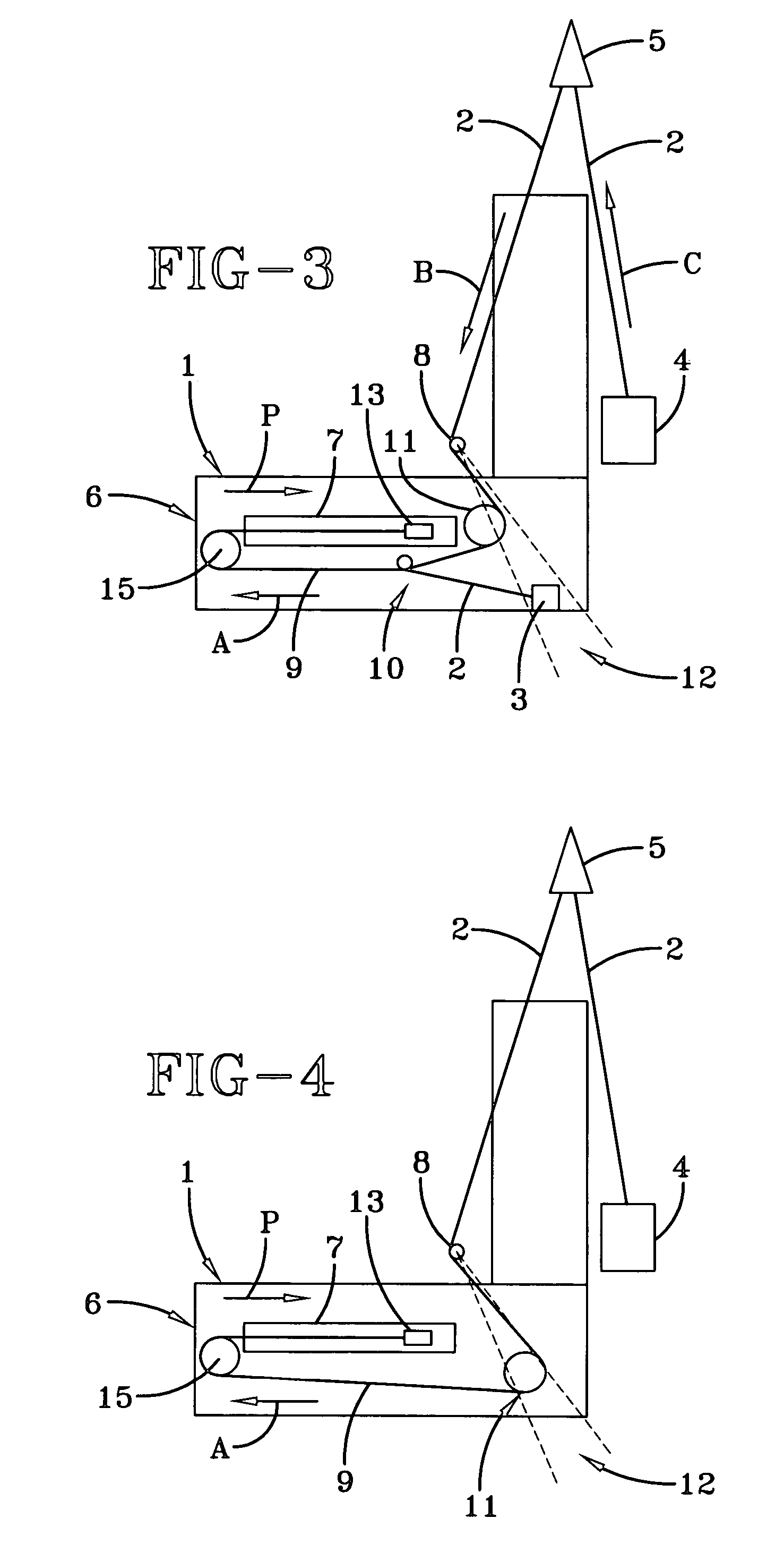

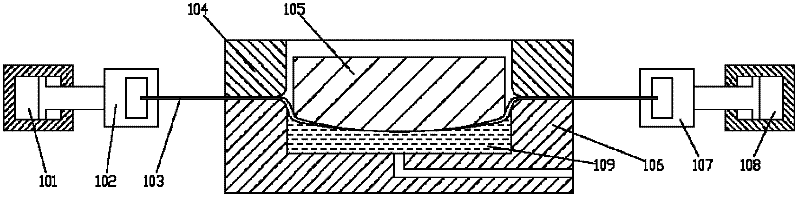

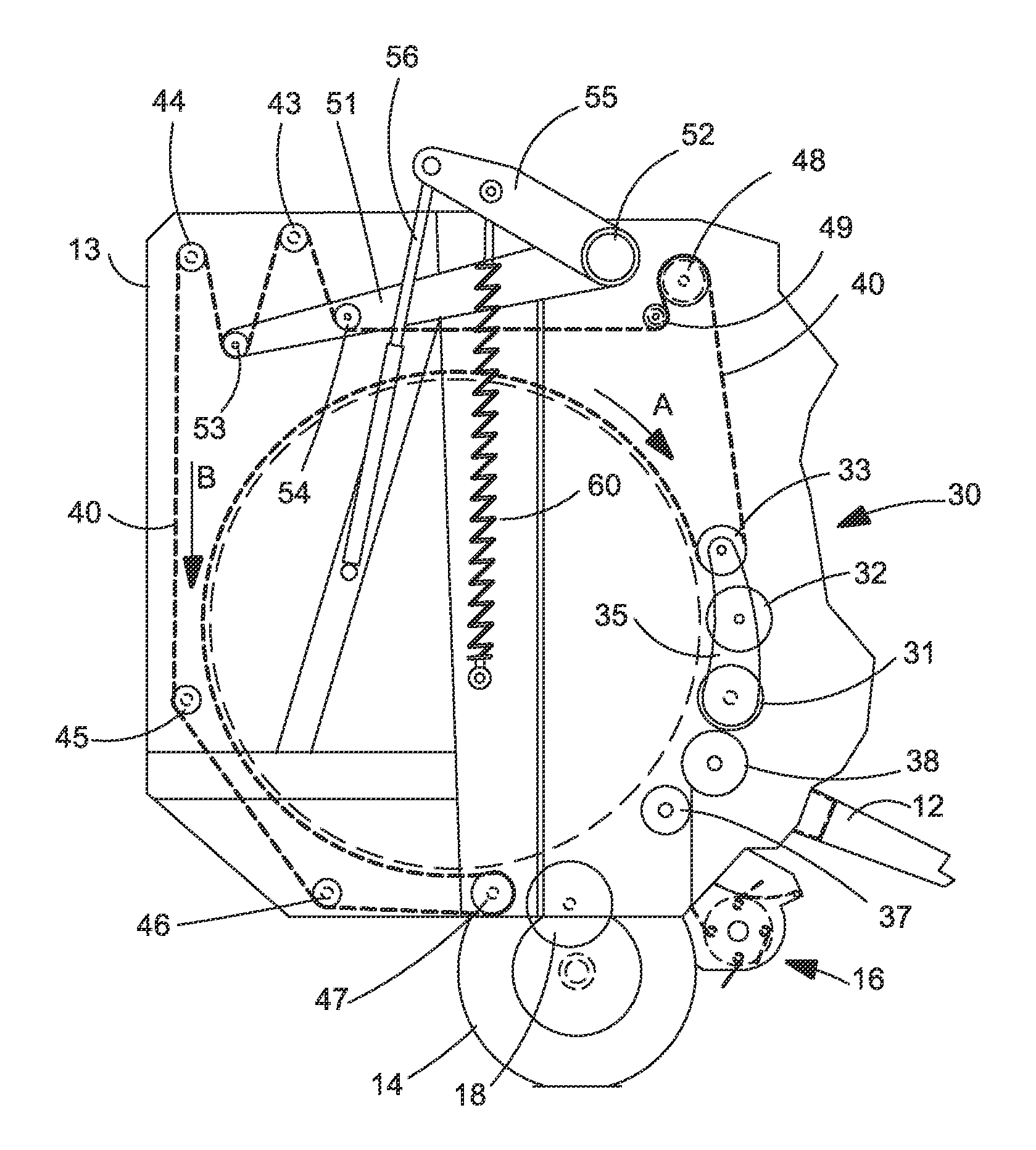

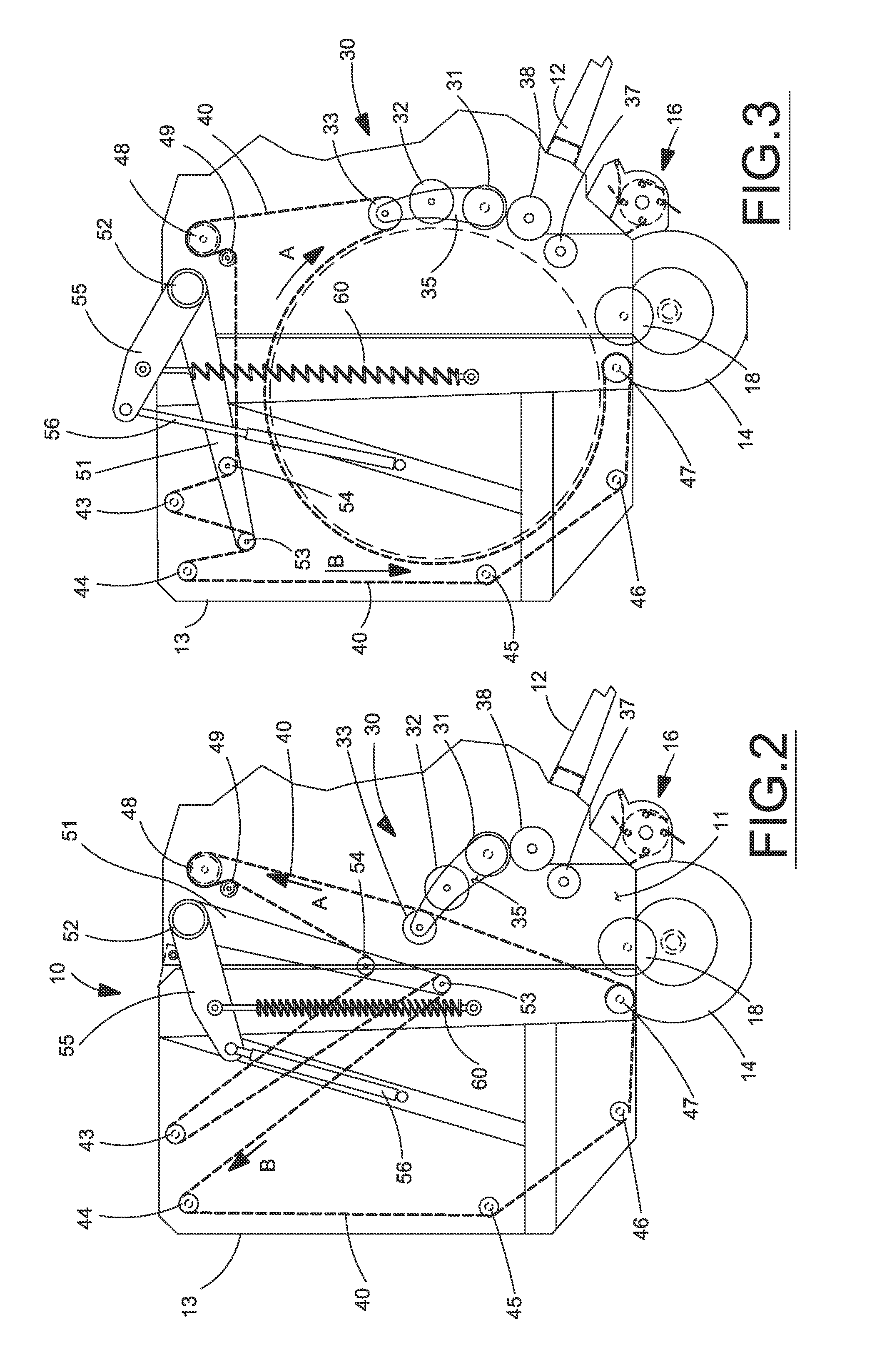

Density system bypass for a round baler

ActiveUS20130298787A1Easy to operateIncrease pressurePaper/cardboard articlesBalingEngineeringBiological activation

An improved belt tensioning system for an agricultural round baler that allows temporarily bypasses a bale density, belt tension increasing system while the baler tailgate is moved out of a closed position thereby allowing the tailgate to be opened without encountering resistance from the belts and the belt tensioning system. Bypass operation is coordinated with the tailgate position so that the bypass is not activated when such activation would frustrate operation of the belt tensioning system. In balers equipped with a belt tensioning pre-tensioning system, the bypass operation is further coordinated with the pre-tensioning system to maintain proper pre-tension function.

Owner:BLUE LEAF I P INC

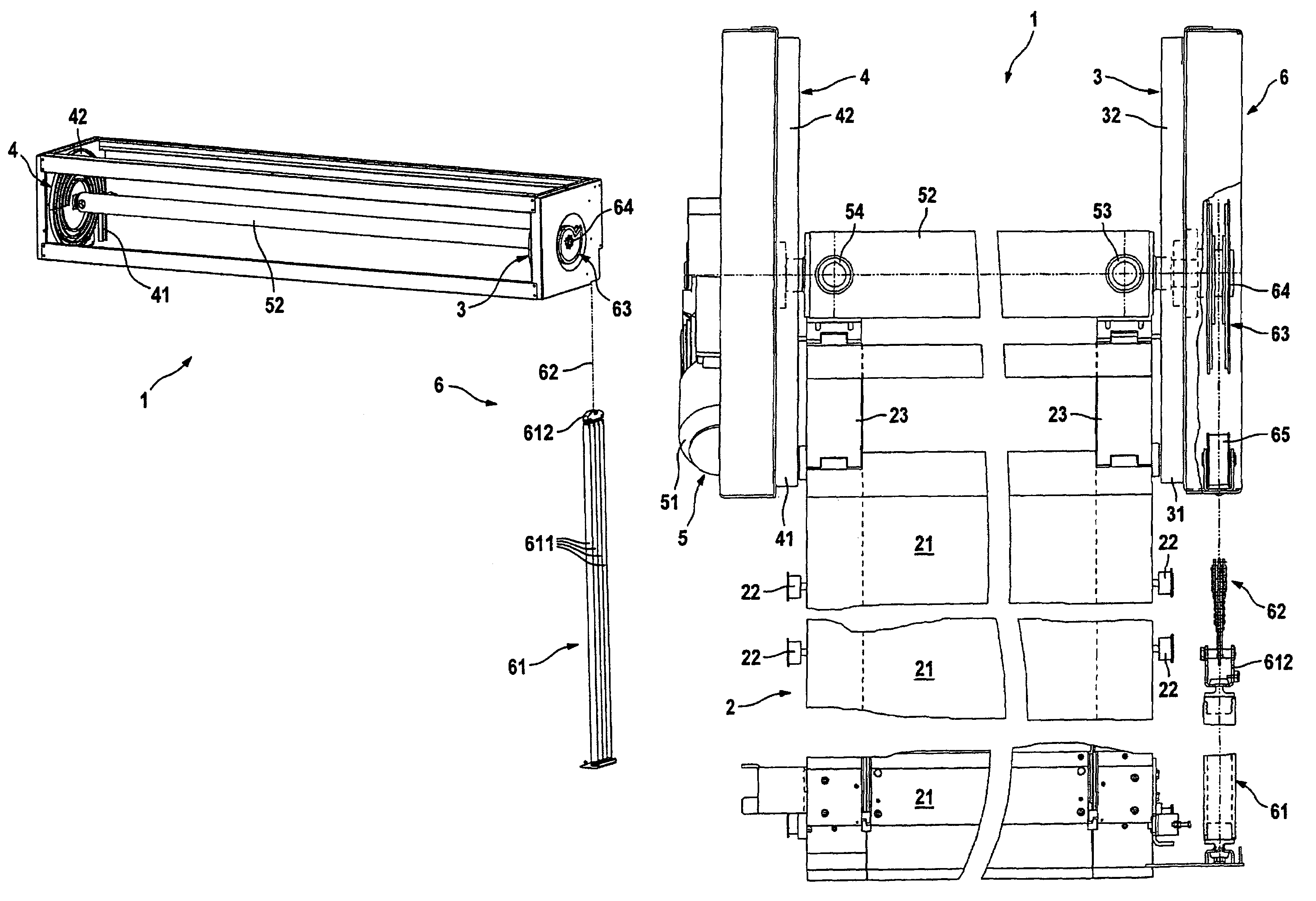

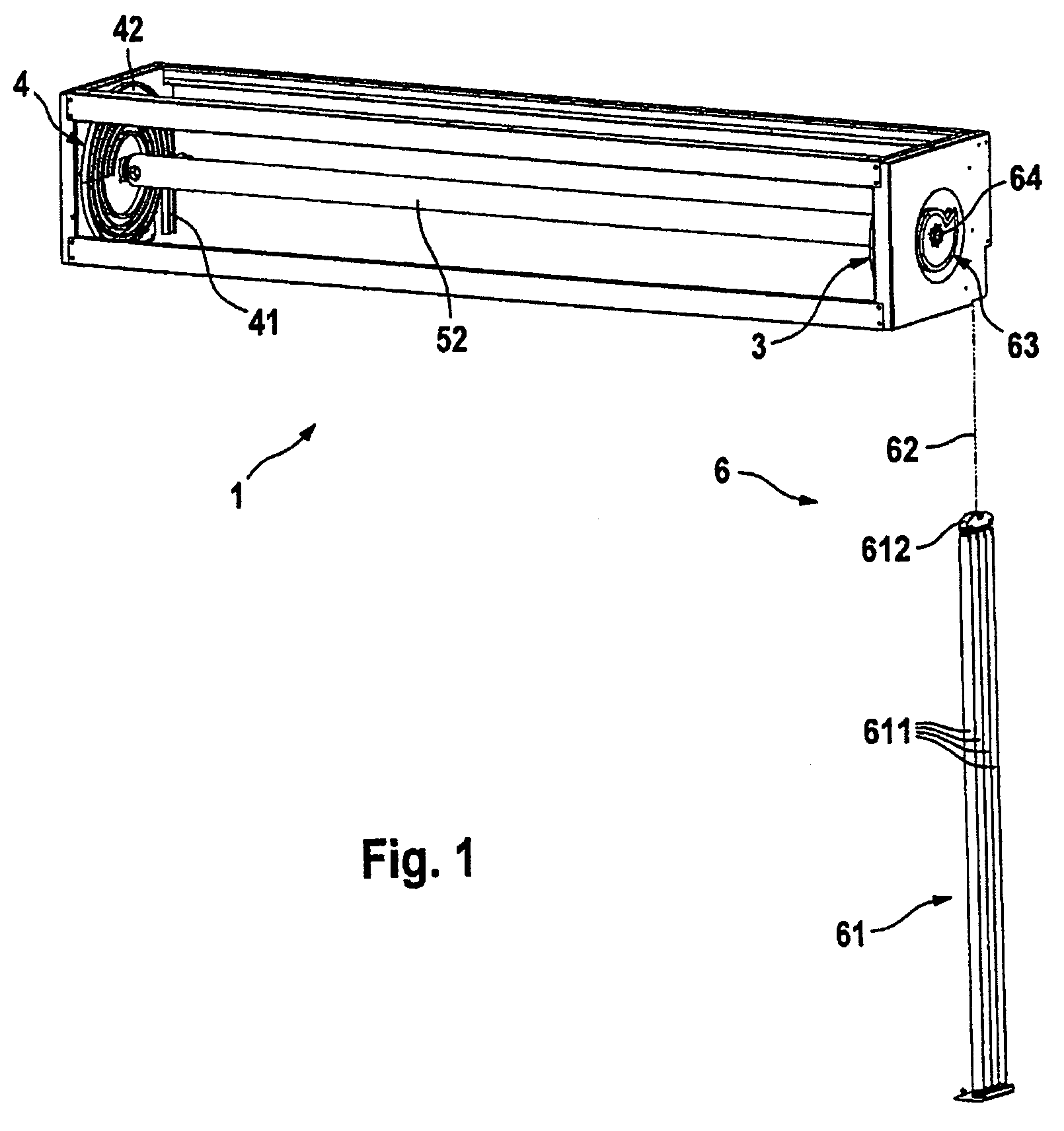

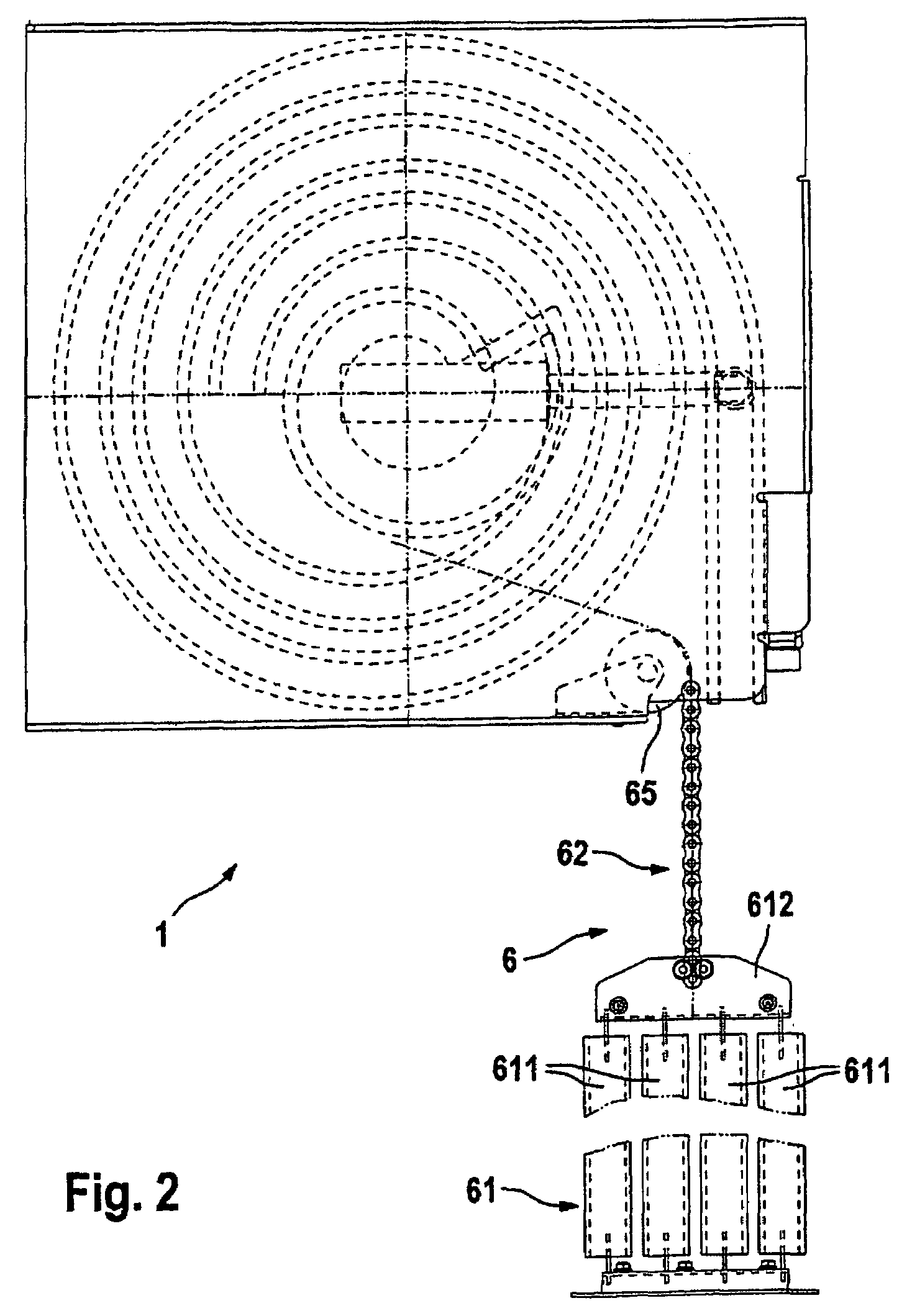

Weight compensation device for a lifting door

ActiveUS7798198B2Reduce the numberNot easy to wearShutters/ movable grillesBuilding braking devicesEngineeringMechanical engineering

A weight compensation device for a lifting door, includes a spring element and a tensile element, which can be wound onto or unwound from a winding device in such a way that the spring element achieves its greatest pre-tension when the door leaf is in the closed position and is essentially tension-free when the door leaf is in the open position. The tensile element is narrower at the end facing the winding device than at the end facing the spring element and the winding device includes a guide device, which is used to wind the tensile element in such a way that the wound layers lie adjacent to one another without making contact. To achieve this, the guide faces around the perimeter of the guide device have a continuously increasing radius in the winding direction. This enables the provision of a weight compensation device that achieves the torques required for effective weight compensation by means of a simple construction. This also relates to a lifting door that is equipped with a weight compensation device of this type.

Owner:EFAFLEX INZENIRING D O O LJUBLJANA

Torsion bar spring arrangement for a wheel suspension of a motor vehicle

InactiveUS9108482B2Reduce the spring rateReduce torsional loadInterconnection systemsResilient suspensionsVehicle frameEngineering

Owner:AUDI AG

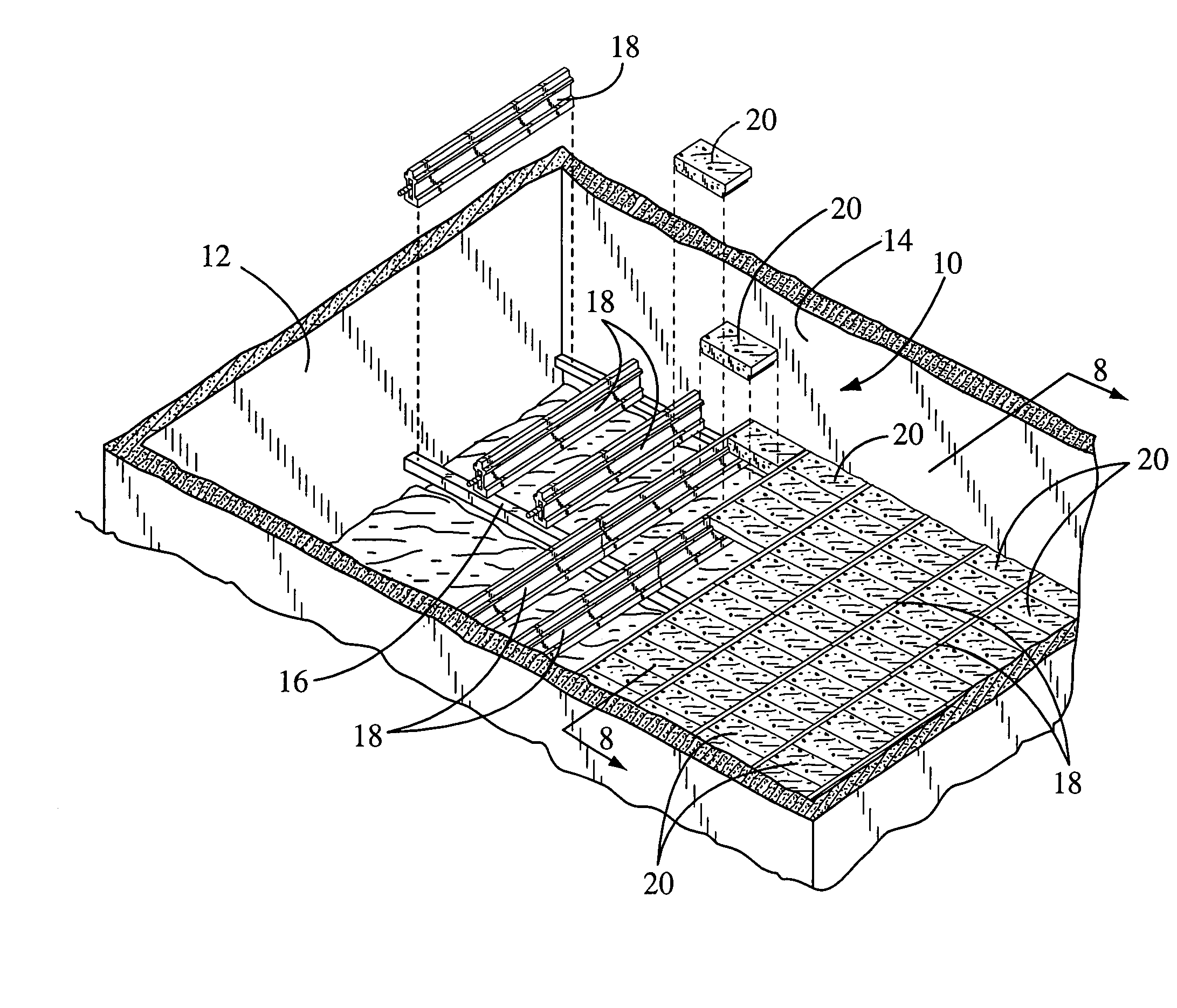

Concrete floor system and method of making floor components

A concrete floor system used in a building structure and a method of making floor components used with the floor system. The concrete floor system, if installed on grade, provides for expansion and contraction due to expansive soils and eliminates cracks, which heretofore occurred in poured concrete slab floors. The concrete floor system includes a plurality of parallel concrete beams. The beams can be made up of hollow concrete blocks for reduced weight and receiving a tension cable therethrough. Also, the beams can be either solid pre-cast beams, solid pre-cast, pre-tension beams or solid pre-cast, post-tension beams. Opposite ends of the cable are held on end plates inside recessed ends of each hollow beam. The ends of the beams are adapted for mounting next to the inside of the sides of a building foundation wall. The beams can be in a range of 5 to 20 feet and greater in length depending on the dimensions of the concrete floor. A top portion of the each parallel beam is adapted for receiving a plurality of angular shaped floor panels. The floor panels interlock next to the top portion of the beam. The floor panels and concrete blocks, used in making up one of the embodiments of the concrete tension beams, are readily adapted for making in a standard high production concrete block machine.

Owner:CLARK RYAN +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com