Drawing and hydraulic integrated forming method

A composite forming and pre-stretching technology, which is applied in the field of metal pressure processing, can solve problems such as springback, achieve uniform wall thickness distribution, solve springback problems, and achieve high material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

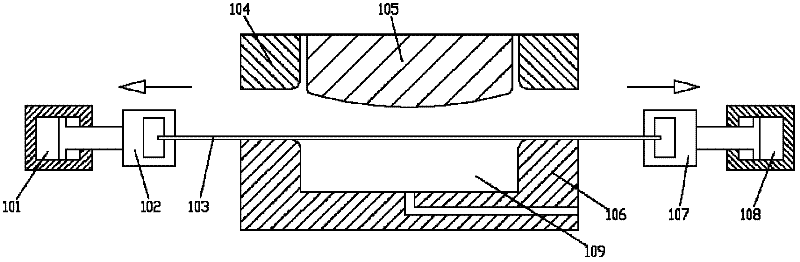

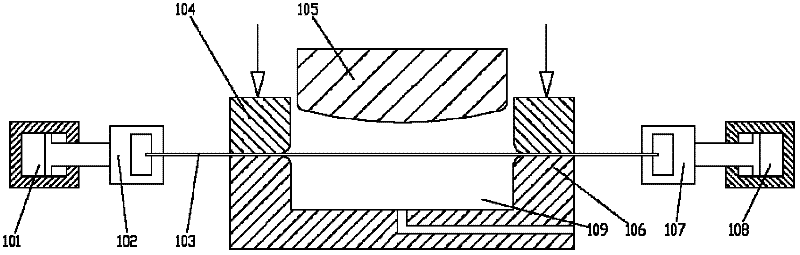

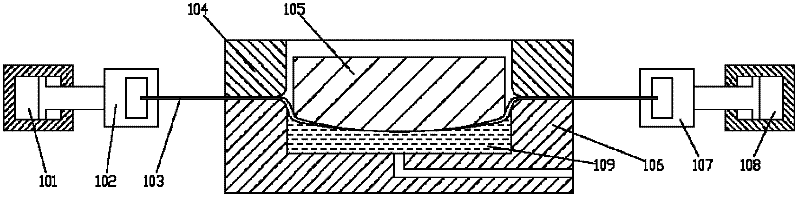

[0039] In the drawing liquid-filled composite forming method provided in this embodiment, when the upper die 105 is a convex die, such as Figure 1 ~ Figure 3 shown, including the following steps:

[0040] Step 1: pre-stretching the board 103 .

[0041] Using the plate 103 as a blank, place the plate 103 on the workbench 106 of the plate hydroforming machine, use the left clamp 102 and the right clamp 107 to clamp the two ends of the plate 103, and control the left stretching hydraulic cylinder 101 and The stretching hydraulic cylinder 108 on the right side performs pre-stretching, and the clamps on both sides move in the direction of increasing relative distance. According to the properties of the sheet material, the pulling force F is controlled between 0<F≤100000N. By stretching, Make the plate 103 enter the plastic deformation stage;

[0042] Step 2: Clamp the mold.

[0043] Press the plate 103 by the blank holder 104 to complete the mold clamping process;

[0044] Ste...

Embodiment 2

[0048] The stretching fluid-filled composite forming method provided in this embodiment, such as Figure 4-Figure 6 shown, including the following steps:

[0049] Step 1: pre-stretching the board 103 .

[0050]Using the plate 103 as a blank, place the plate 103 on the workbench 106 of the plate hydroforming machine, use the left clamp 102 and the right clamp 107 to clamp the two ends of the plate 103, and control the left stretching hydraulic cylinder 101 and The stretching hydraulic cylinder 108 on the right side performs pre-stretching, and the clamps on both sides move in the direction of increasing relative distance. According to the properties of the sheet material, the pulling force F is controlled between 0<F≤100000N. By stretching, Make the plate 103 enter the plastic deformation stage;

[0051] Step 2: Clamp the mold.

[0052] Press the plate 103 by the upper mold 105 to complete the mold clamping process;

[0053] Step 3: Perform liquid filling and bulging.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com