Mold for hot bending and forming trough type solar concentrating collector parabolic mirrors and manufacturing method thereof

A trough solar energy and molding die technology, applied in solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of high cost, high quality and high energy consumption, achieve easy processing, improve cost performance, and reduce overall quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

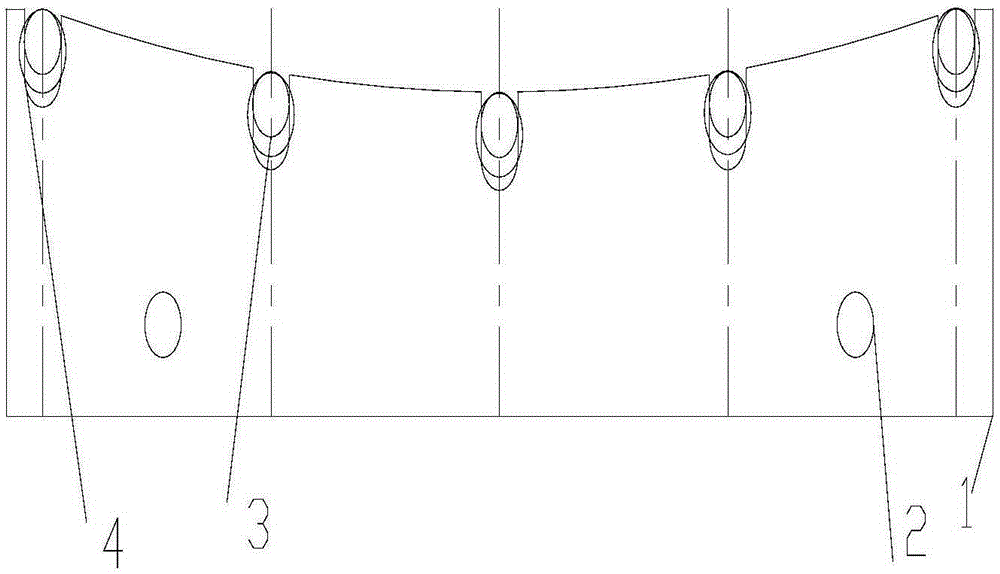

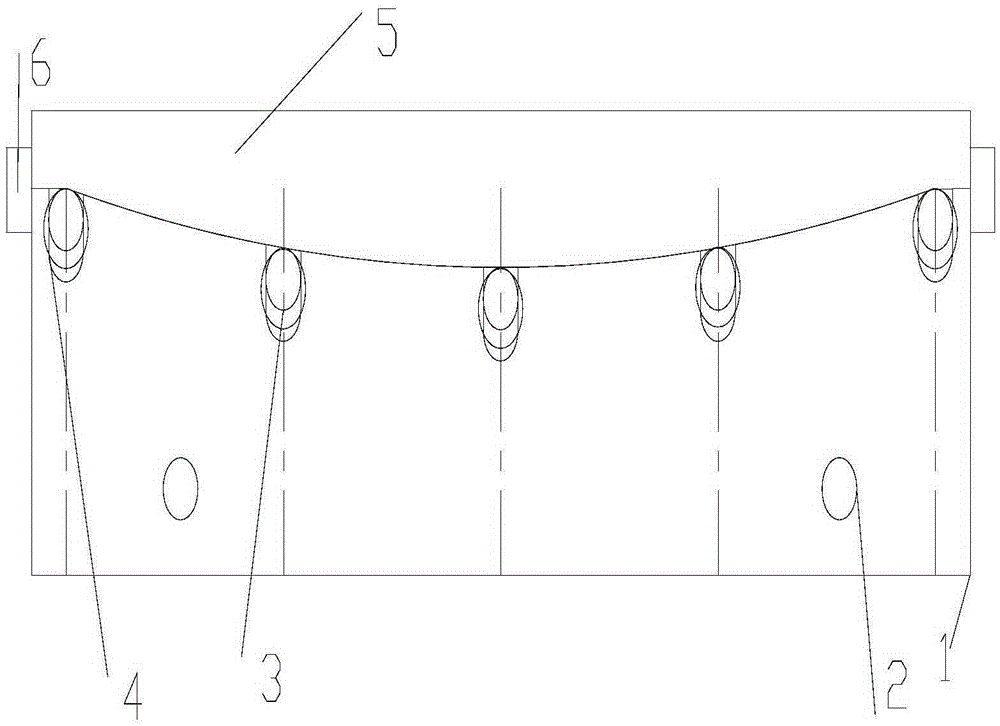

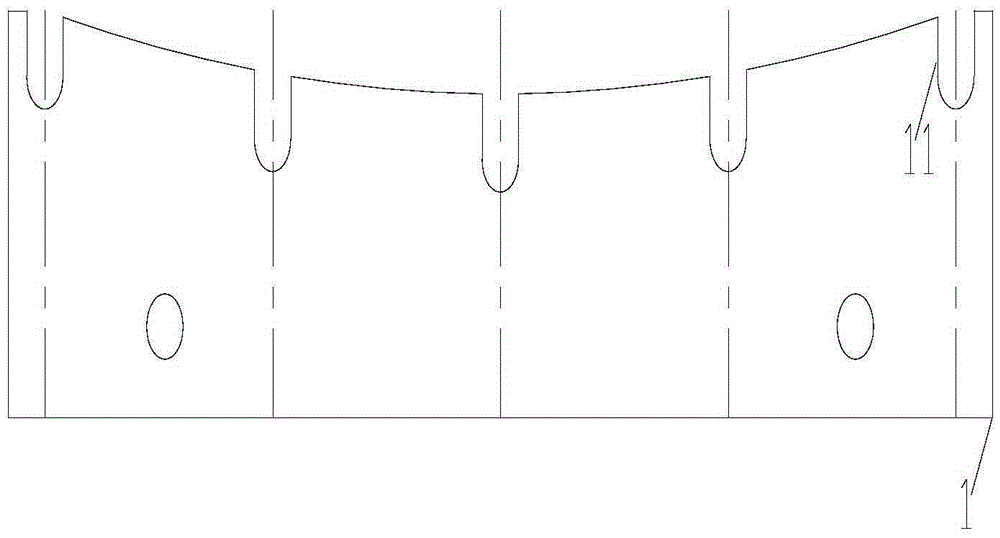

[0024] like figure 1 , 3 Shown in and 4 are a kind of parabolic mirror hot-bending forming mold of a trough solar concentrating collector, including a plurality of support plates 1 and a support plate fixing device 2, and a plurality of support plates 1 are formed by the support plate fixing device 2 Groove-shaped space fixed structure; the support plate 1 is a recessed part structure obtained by cutting the entire steel plate according to the parabolic mirror profile line, and the cutting end surface of the profile line side of the support plate 1 is provided with a plurality of open grooves 11, adjacent to support The corresponding formed steel pipe 3 is arranged in the corresponding opening groove 11 of the plate 1, and any two formed steel pipes 3 are parallel to each other.

[0025] The cross-section of the formed steel pipe 3 is circular; the glass between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com