Forming method of flat pipe fitting

A forming method and technology of flat tubes, which are applied in the field of pipe fittings forming, can solve the problems of excessive grinding amount, reduced grinding amount, and low part qualification rate, etc., and achieve reduced grinding amount, reduced workload, and good forming effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Pipe processing method of the present invention, its steps are as follows:

[0035] Step A:

[0036] Picking: pick up 1Cr18Ni9Ti plate or other plates;

[0037] Inspection 1: Check whether there are scratches and other defects on the surface of the material that are half of the negative difference of the thickness of the plate, check whether the batch number of the material is consistent and record it, the material standard is in accordance with GJB2505-95, the plate specification and grade and the plate thickness are 2±0.15mm;

[0038] Cutting: brush the surface of the sheet before cutting to protect it from splashing;

[0039] Inspection 2: Appearance inspection, there are no scratches, crushes, pits and other defects on the surface of the wool that exceed half of the negative difference of the board;

[0040] Fitter 1: Before bending the plate, first remove the splash and edge ablation layer on the surface of the plate, polish the surface defects of the wool, polis...

Embodiment 2

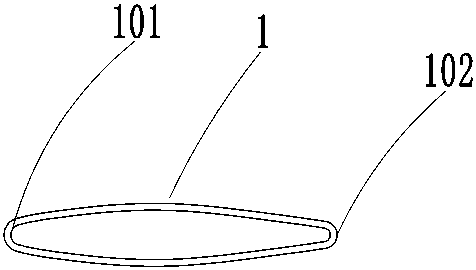

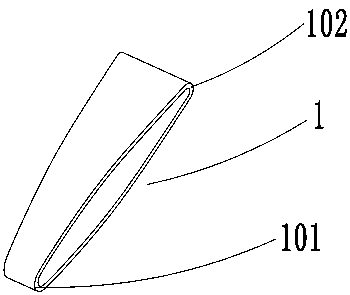

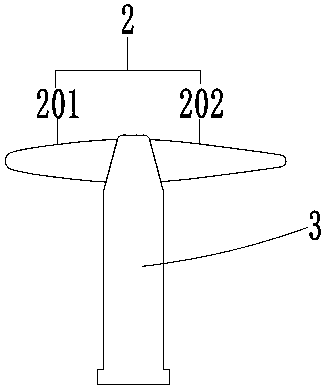

[0057] In this embodiment, the difference from Embodiment 1 is that the mold core in the step B adopts a left and right two-lobed structure, including a left mold core 201 and a right mold core 202, and the left mold core 201 and the right mold core 202 A supporting device 3 is arranged between them, and the supporting device 3 satisfies: it can apply force to the left mold core 201 and the right mold core 202 at the same time, so that the left mold core 201 fits the left inflection point 101 position of the inner wall of the pipe fitting, and the right mold core 202 Fit the right inflection point 202 position of the inner wall of the pipe fitting.

[0058] In this solution, during the radial forming process of the flat pipe fitting 1, the mold core 2 of the two-sided structure is used and the supporting device 3 is provided, so that the mold core 2 at the left inflection point 101 and the right inflection point 102 in the forming process fits more closely with the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com