Handmade argon arc welding process capable of eliminating defects of incomplete fusion of weld joints of hastelloy

A technology of manual argon arc welding and non-fusion defects, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve problems such as inter-pass, inter-layer and side wall non-fusion, so as to improve quality, improve welding efficiency, reduce The effect of a small amount of sanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6

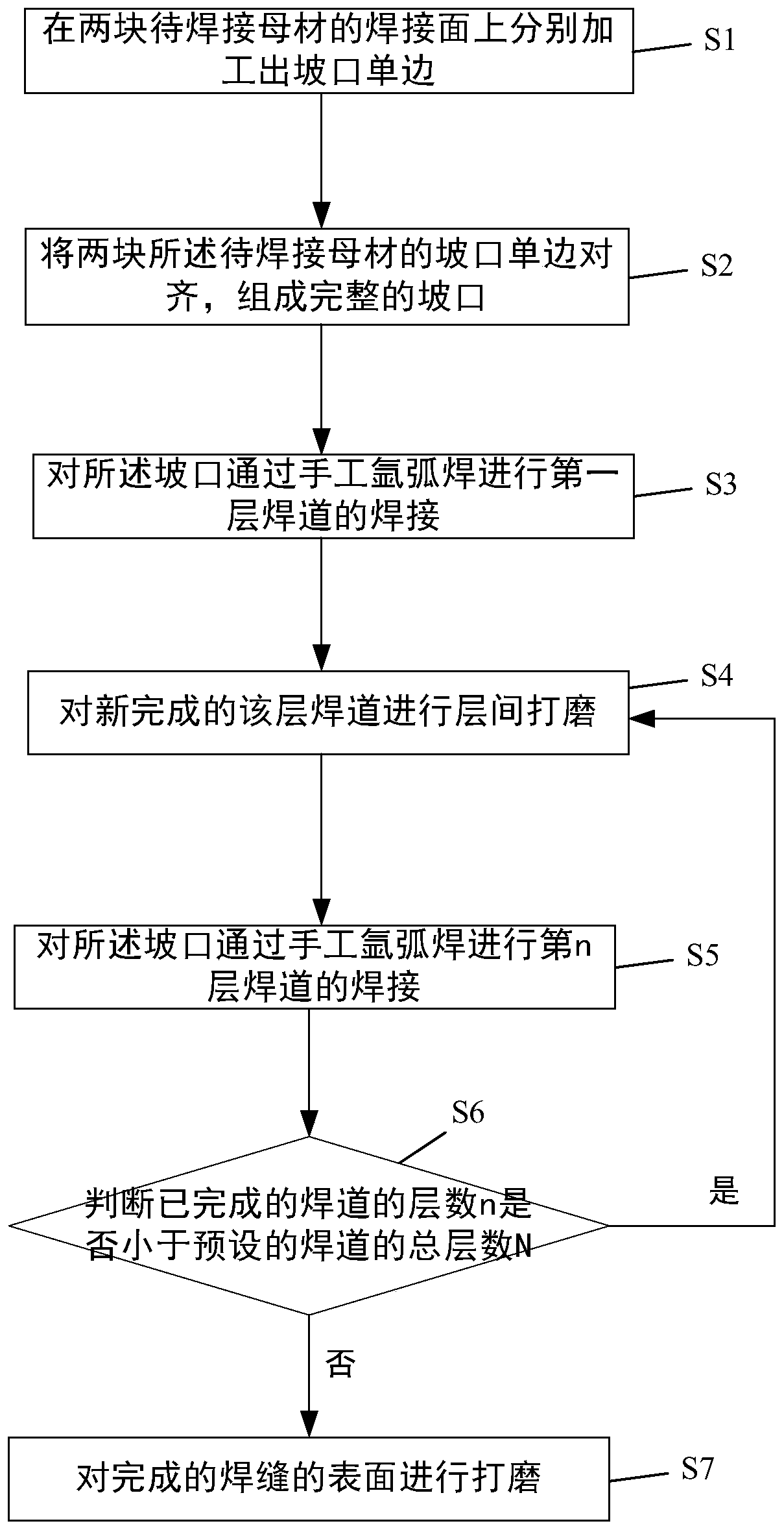

[0035] Such as figure 2 As shown, the present invention eliminates the manual argon arc welding process of the non-fusion defect of the Hastelloy weld seam, comprising the following steps:

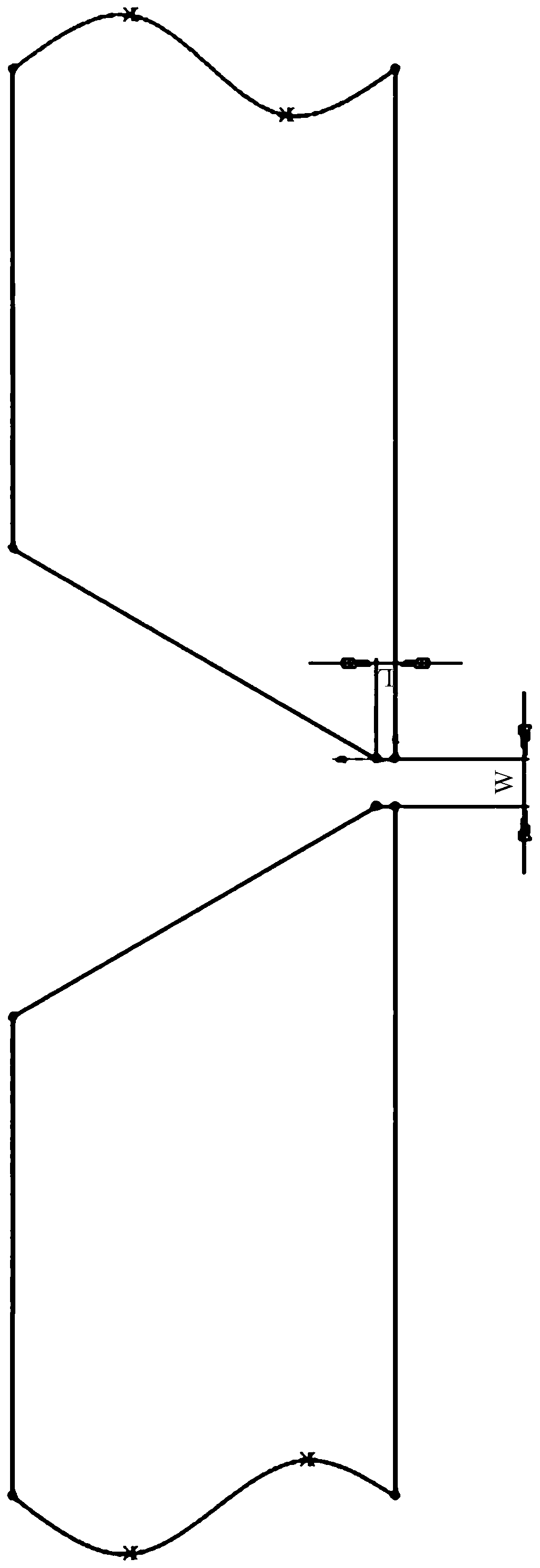

[0036] S1. Process one side of the groove on the welding surfaces of the two base metals to be welded, and the base metal is Hastelloy;

[0037] S2. Aligning the grooves of the two base metals to be welded on one side to form a complete groove;

[0038] S3. Carry out the welding of the first layer of weld bead by manual argon arc welding to the groove, the welding current used is direct current, the welding material is nickel-based alloy welding wire, and the welding process parameters of backing welding are as shown in table 1;

[0039] S4. Perform interlayer grinding on the newly completed weld bead, and the flatness of the weld bead is ≤3mm;

[0040] S5. Carry out the welding of the nth layer of weld bead by manual argon arc welding to the groove, the welding current used is direct c...

Embodiment 7 to 9

[0051] The process steps of the manual argon arc welding process for eliminating the non-fusion defect of the Hastelloy weld seam in embodiments 7 to 9 are the same as in embodiment 1. Wherein, the protective gas in step S3 and step S5 is a helium-argon mixed gas, and the volume percentage of helium in the helium-argon mixed gas is shown in Table 2.

[0052]The volume percent of helium in the helium-argon mixed gas of table 2 embodiment 7 to 9

[0053] Example 7 Example 8 Example 9 The volume percentage of helium in the mixed gas of helium and argon 20% 25% 30%

[0054] The welding process parameters of Examples 7 to 9 are shown in Table 3.

[0055] The welding process parameter of table 3 embodiment 7 to 9

[0056]

[0057] In Embodiments 1 to 6, the shielding gas may also be a mixed gas of helium and argon, and the volume percentage of helium in the mixed gas of helium and argon is 20% to 30%.

[0058] By adding a certain volume percentage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| weld impact energy | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com