Laser-rotating arc hybrid welding system and its hybrid welding method

A rotary arc welding and rotary arc technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of small assembly gap, hidden quality problems, unfused sidewalls, etc., to reduce assembly requirements and enhance absorption. , seam tracking easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

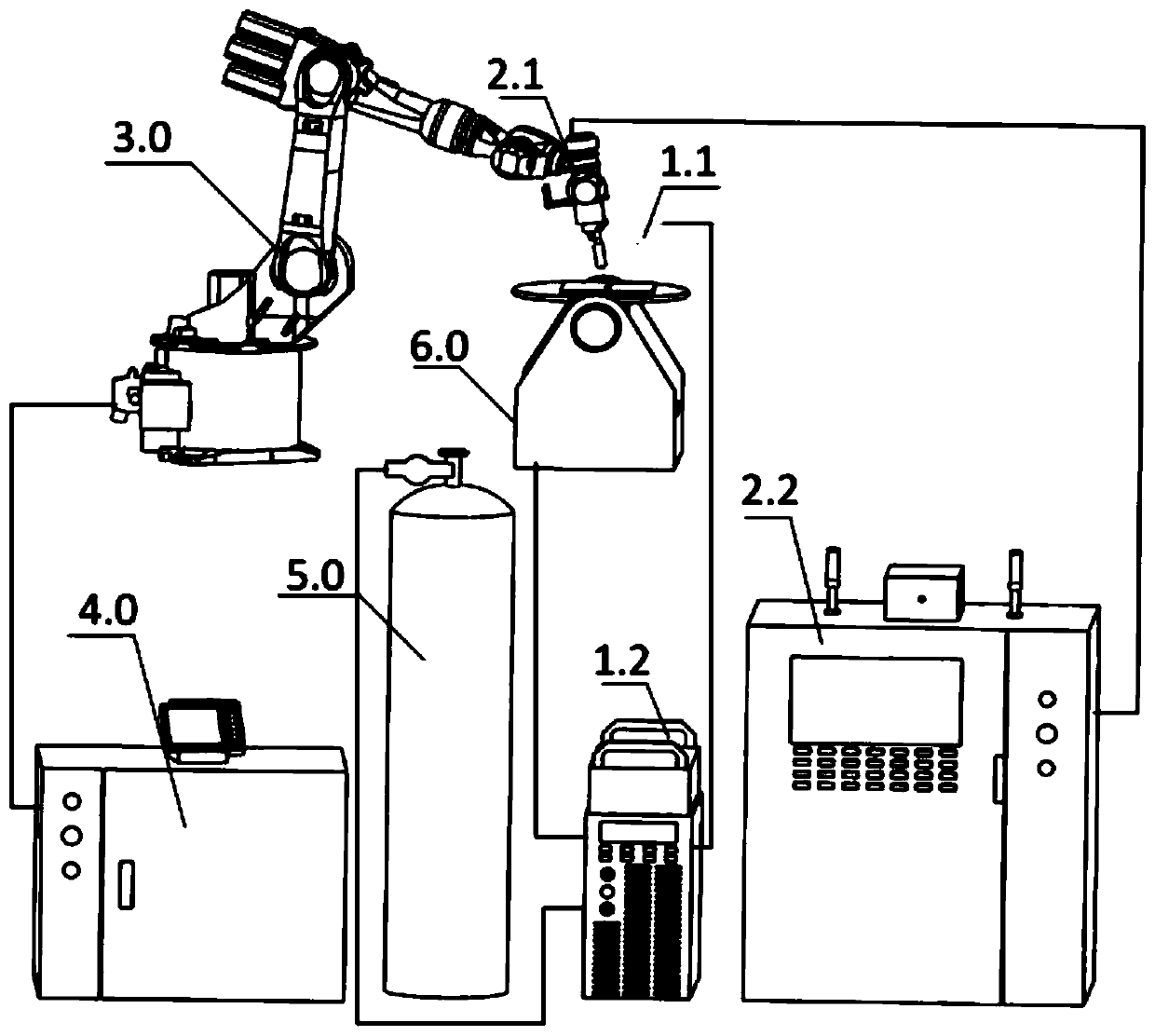

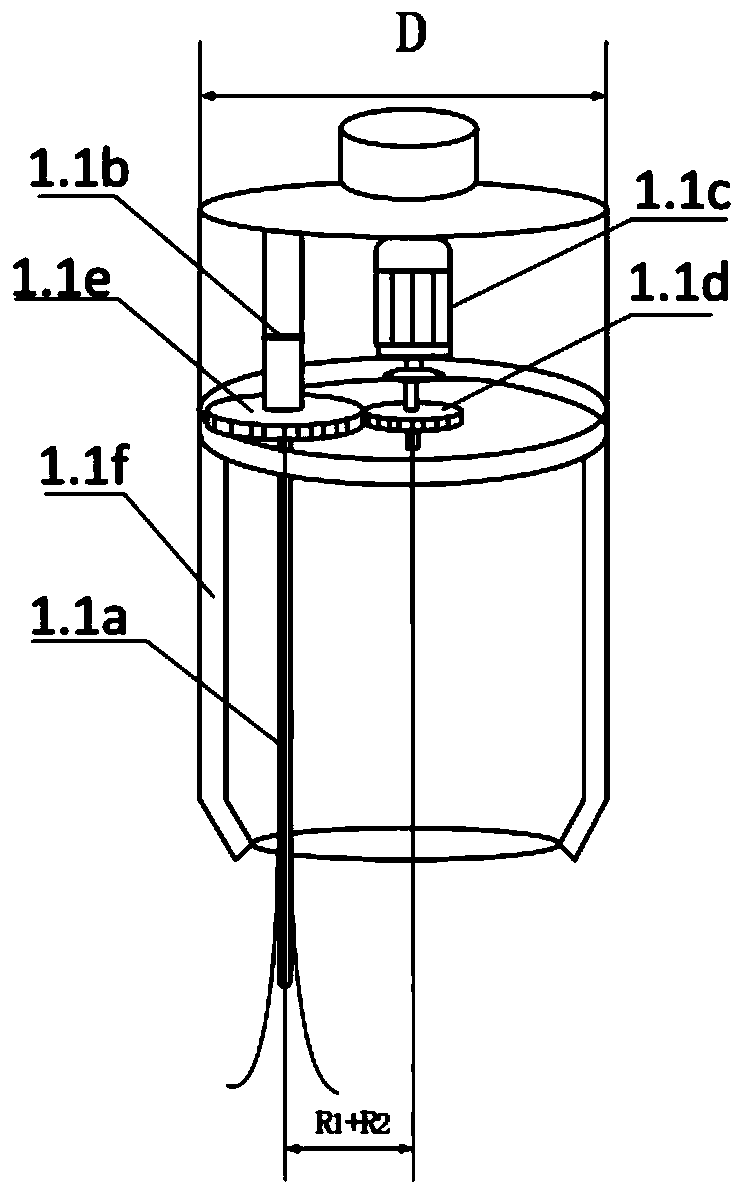

[0028] figure 1 It shows that a laser-rotating arc hybrid welding system includes a laser welding part for generating laser beams and an arc welding part for generating arcs, and its structural feature is that the arc welding part includes a TIG that can realize arc rotation Rotary arc welding torches; e.g. figure 2 As shown, the TIG rotary arc welding torch includes a cylindrical shell, a ring gear located on the inner wall of the cylindrical shell, a driving gear driven by a motor inside the cylindrical shell, and a driven gear that cooperates with the driving gear and the ring gear; The tungsten pole of the TIG rotary arc welding torch is connected to the center of the driven gear. When the motor drives the driving gear to rotate, the rotation of the driven gear around the driving gear drives the tungsten pole of the TIG rotary arc welding torch to rotate around the driving gear, thereby forming a rotating arc. The control terminals of the laser welding part, the arc weld...

Embodiment 2

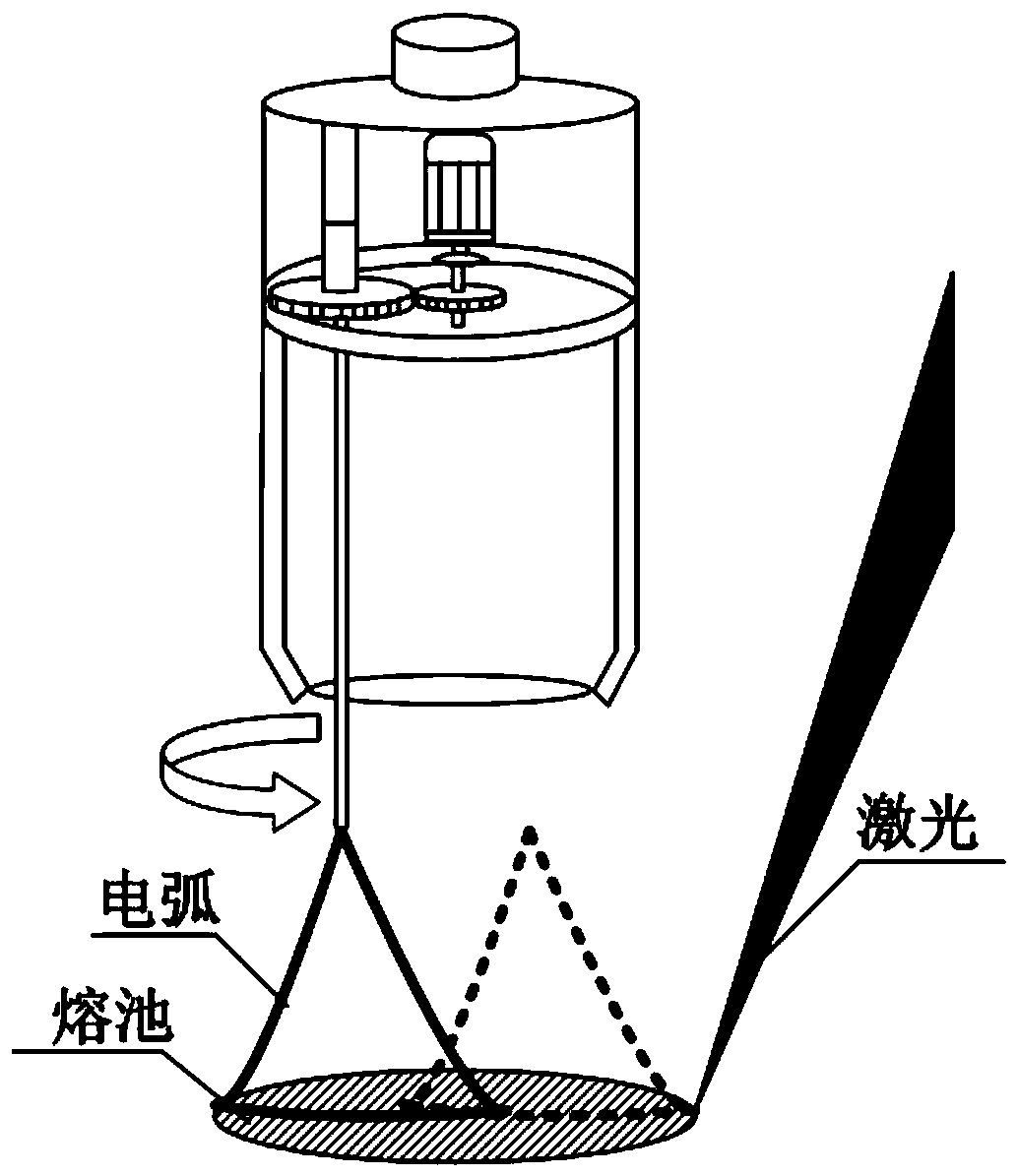

[0037] Figure 4 It shows that a hybrid welding method of the laser-rotary arc hybrid welding system in Embodiment 1 includes that when the welding system is started, the laser welding part generates a laser beam, and the arc welding part generates an arc, which is characterized in that: when the welding system works At the same time, the integrated control center controls the motor to drive the driving gear to rotate at the set rotation frequency, and drives the driven gear to rotate around the driving gear, thereby driving the tungsten pole of the TIG rotary arc welding torch to rotate around the driving gear, forming a rotating arc that acts on the surface of the weldment , forming a rotating arc pool on the surface of the weldment; the integrated control system controls the laser beam to always align with the center of the rotating arc pool during the welding process.

[0038] In this example, the integrated control center controls the motor to drive the driving gear to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com