Patents

Literature

241results about How to "Low energy efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

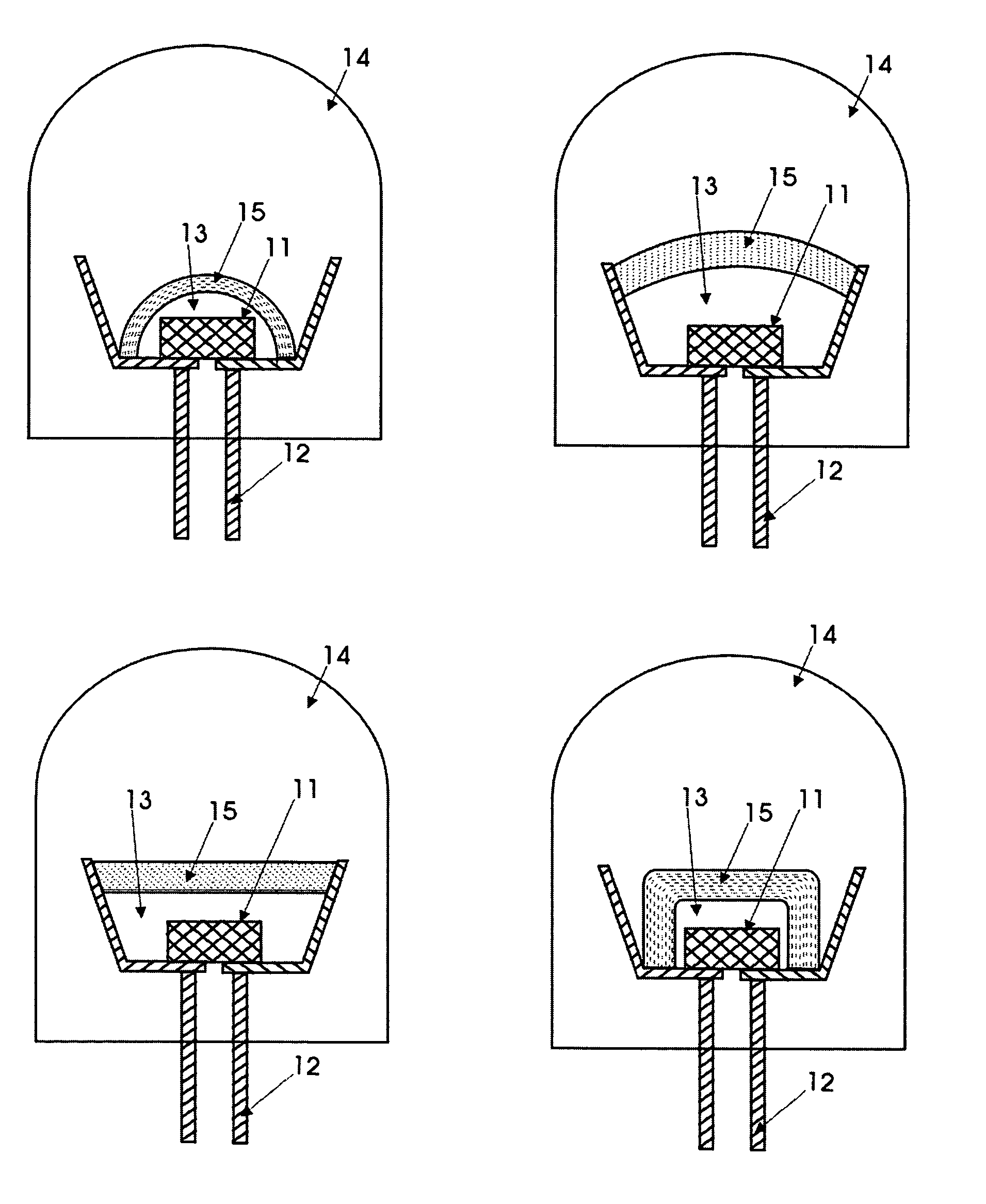

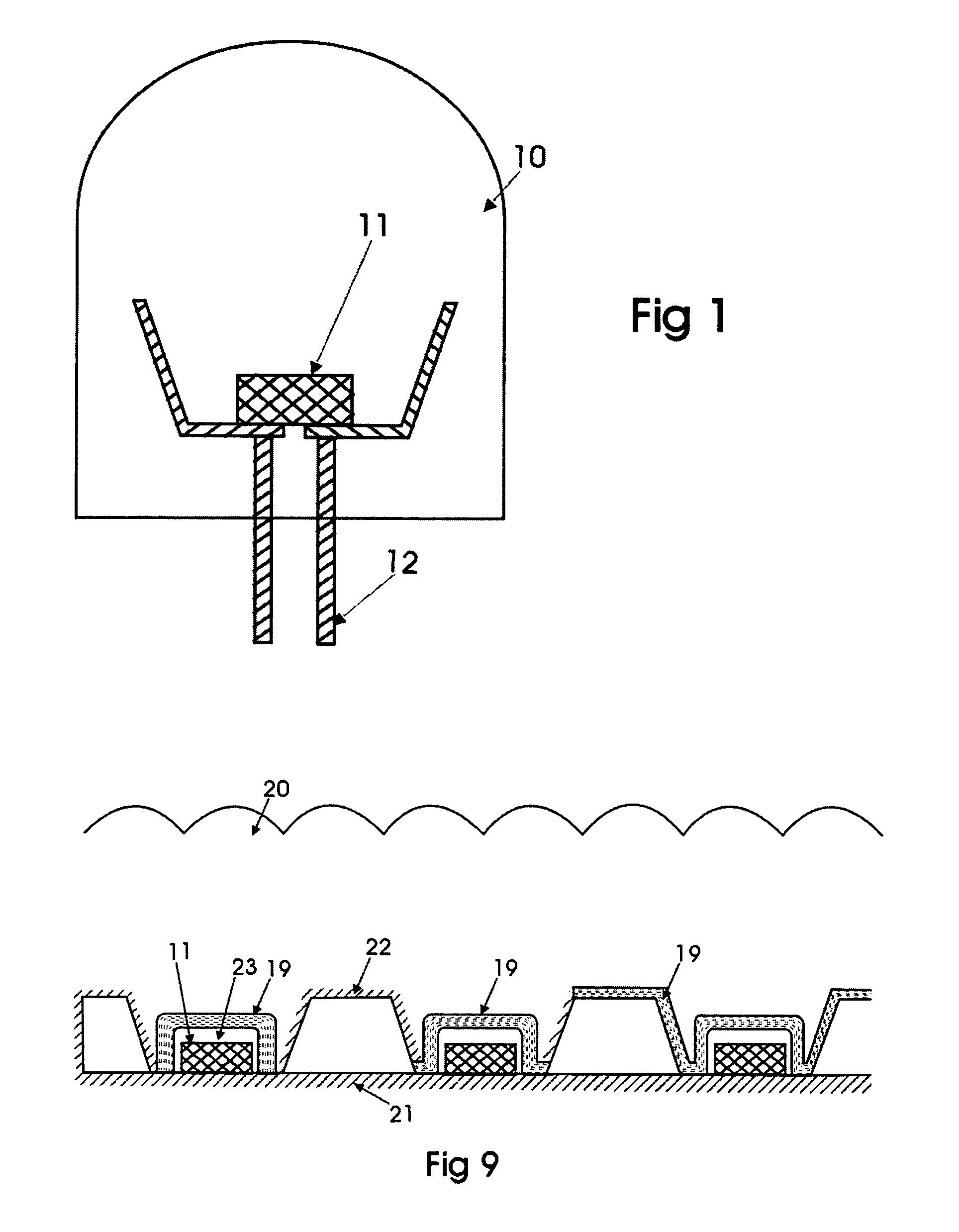

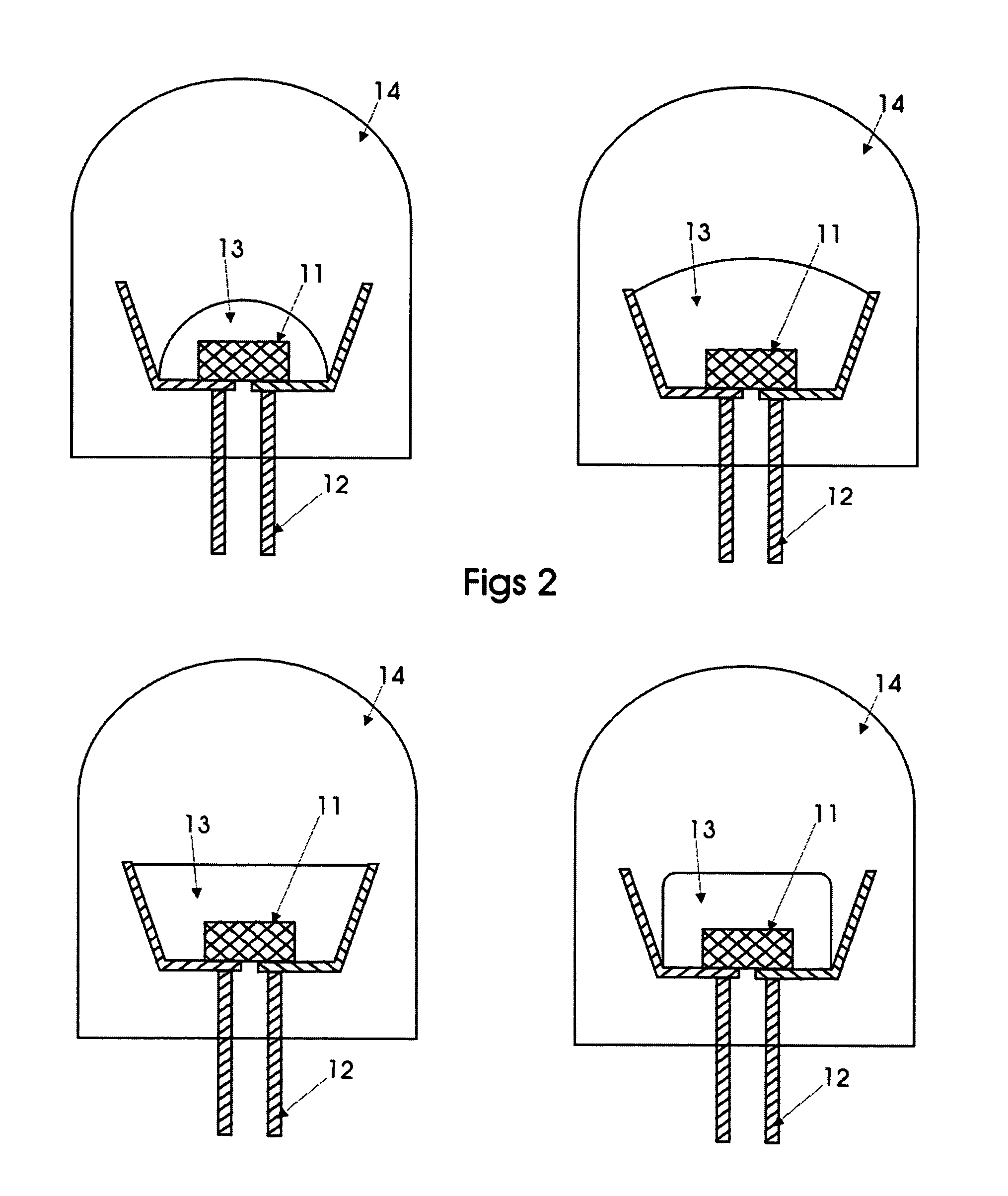

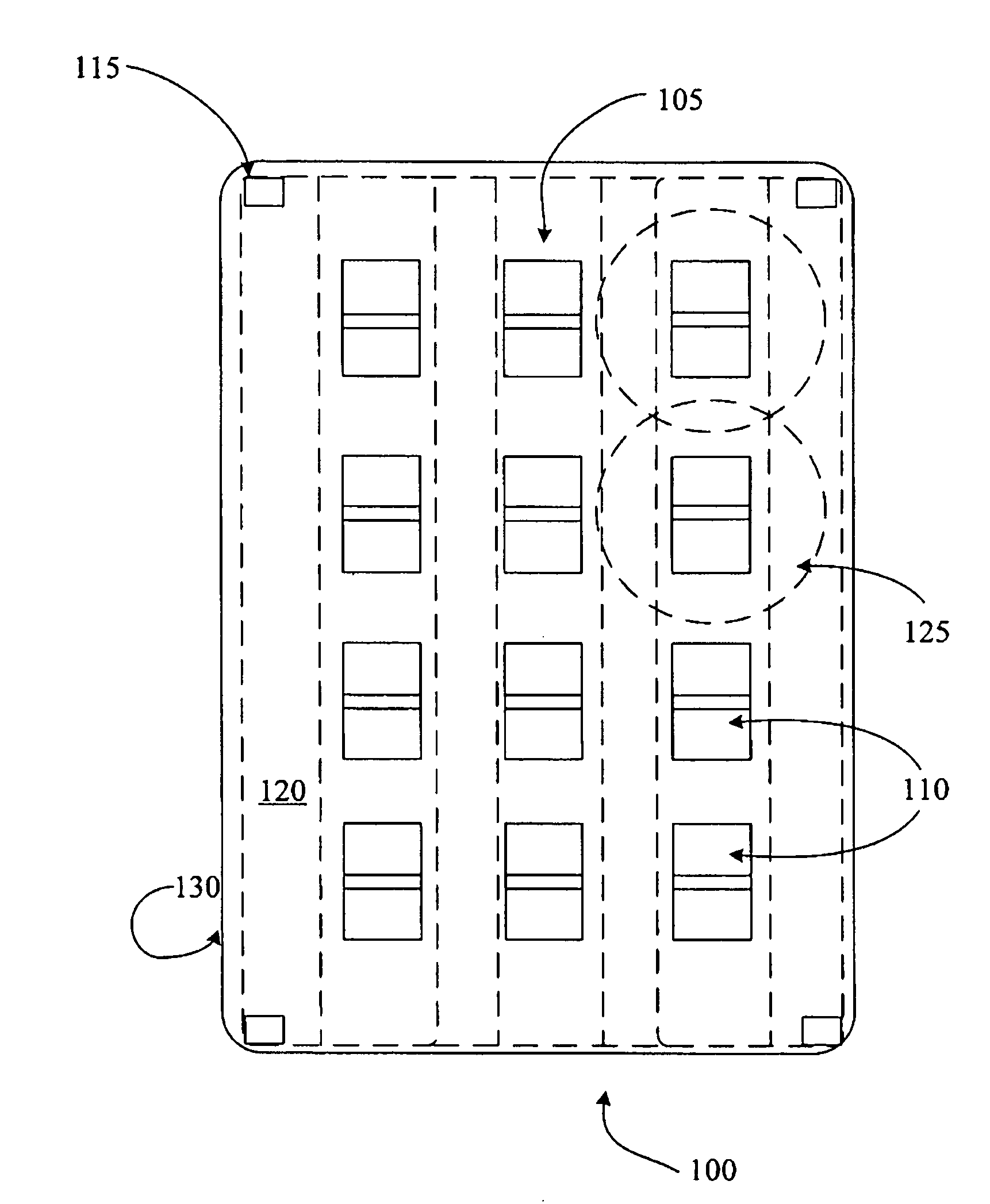

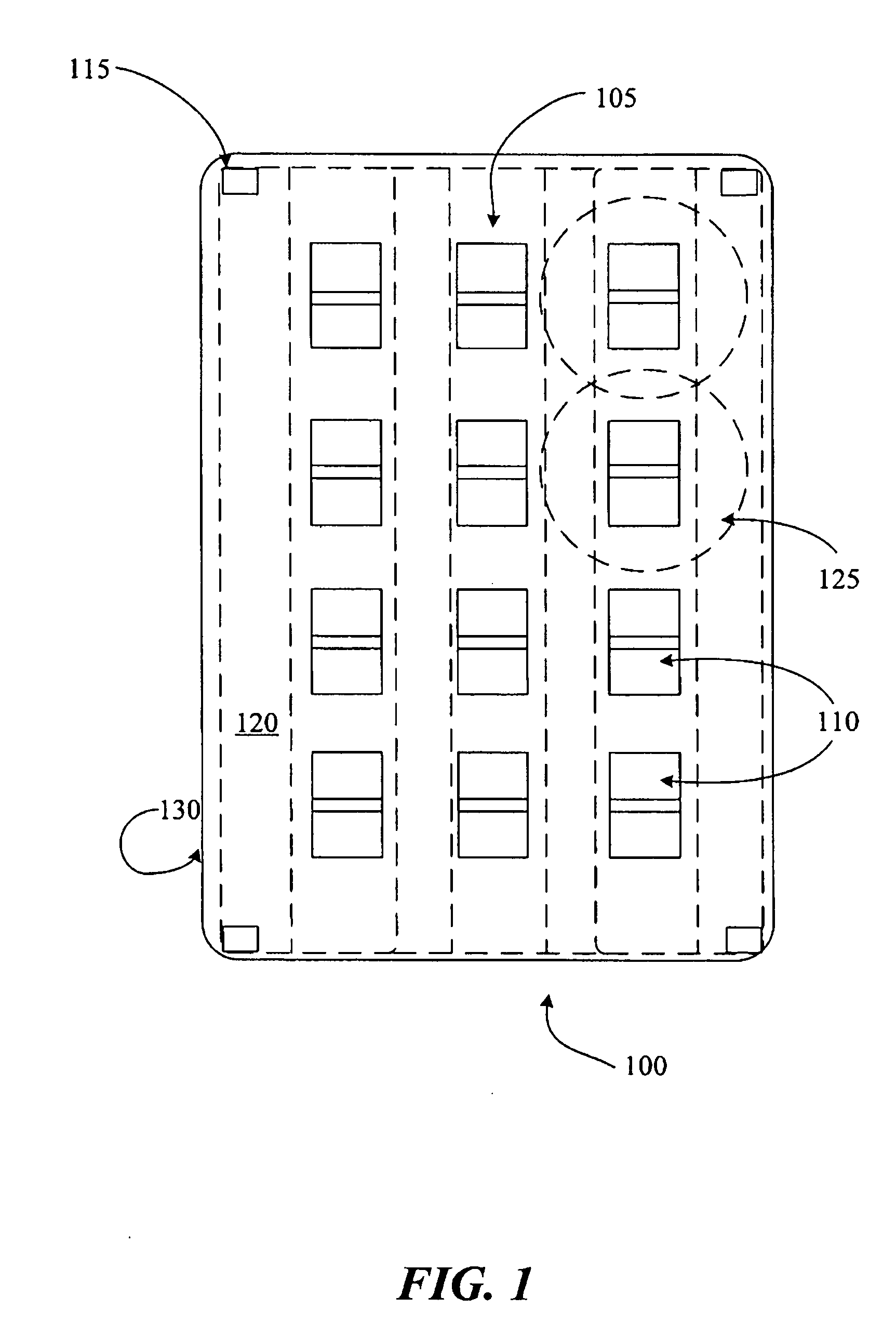

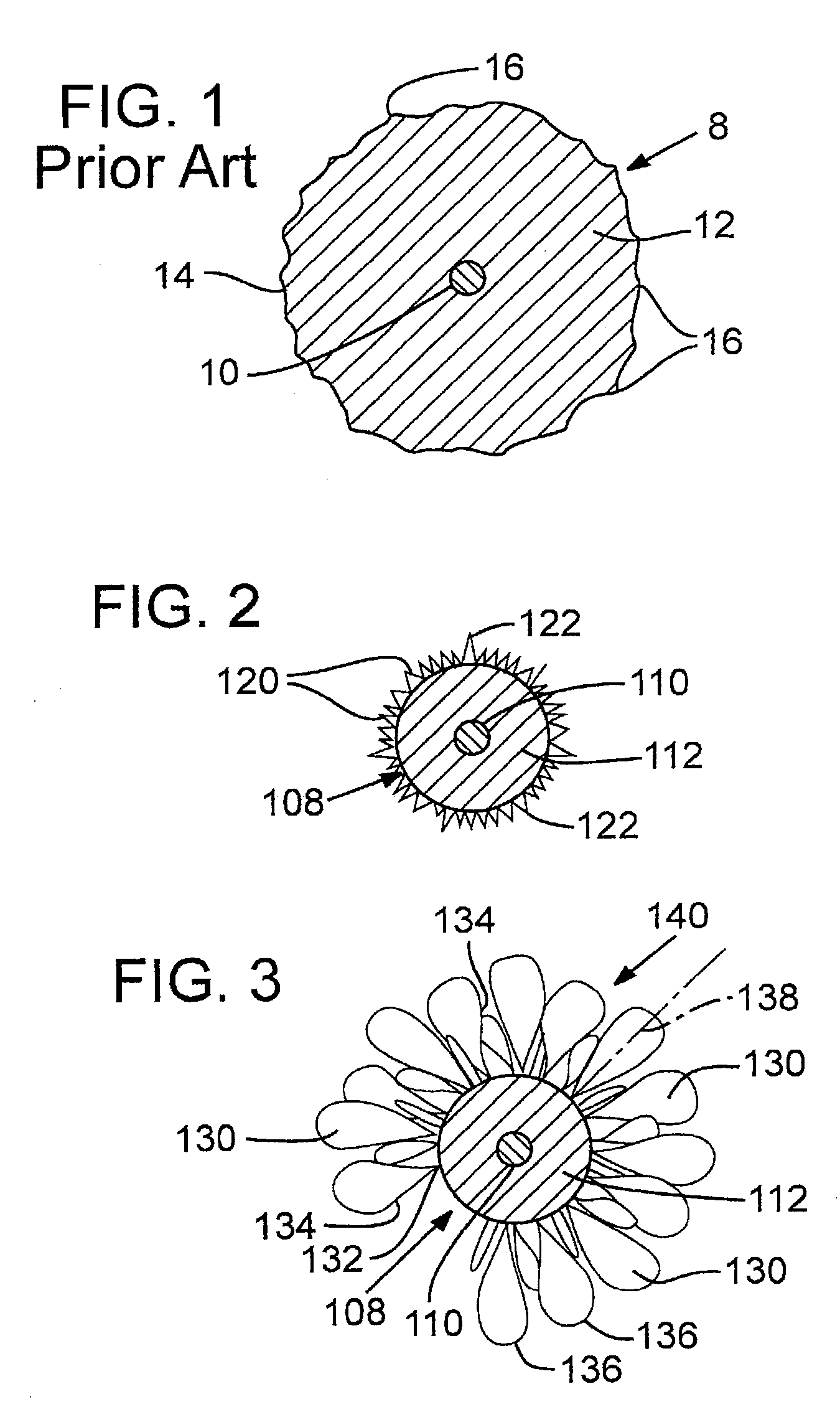

Nanocomposite photonic structures for solid state lighting

InactiveUS7259400B1Quality improvementHigh color rendering indexDischarge tube luminescnet screensCathode ray tubes/electron beam tubesPhosphorNanoparticle

A photonic structure for “white” light generation by phosphors under the excitation of a LED. The photonic structure mounts the LED and an optically transparent nanocomposite matrix having dispersed therein phosphors which will emit light under the excitation of the radiation of the LED. The phosphors dispersed in the matrix may be nanocrystalline, or larger sized with the addition of non light emitting, non light scattering nanoparticles dispersed within the matrix material so as to match the index of refraction of the matrix material to that of the phosphors. The nanocomposite matrix material may be readily formed by molding and formed into a variety of shapes including lenses for focusing the emitted light. A large number of the photonic structures may be arranged on a substrate to provide even illumination or other purposes.

Owner:NANOCRYSTAL LIGHTING

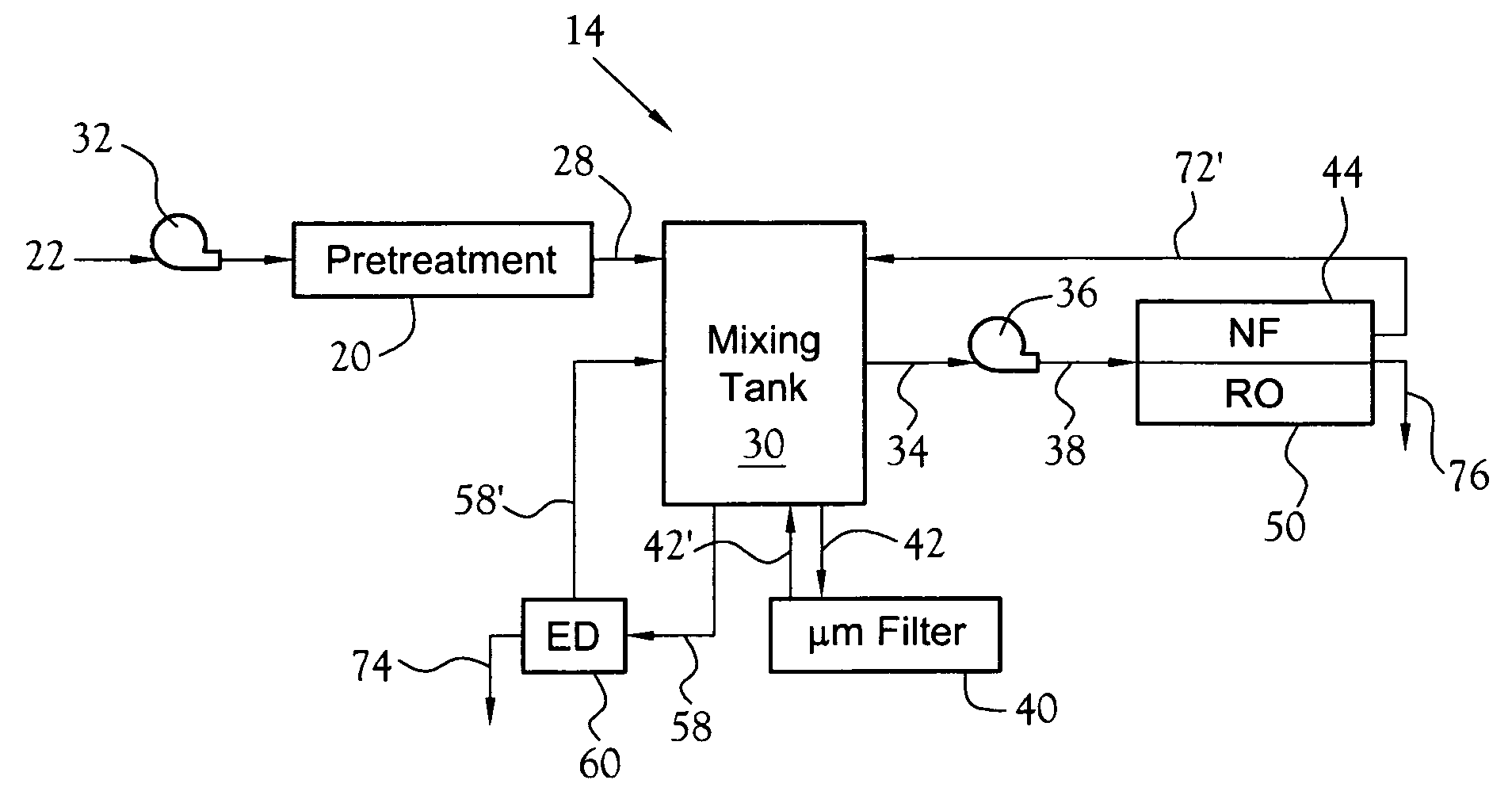

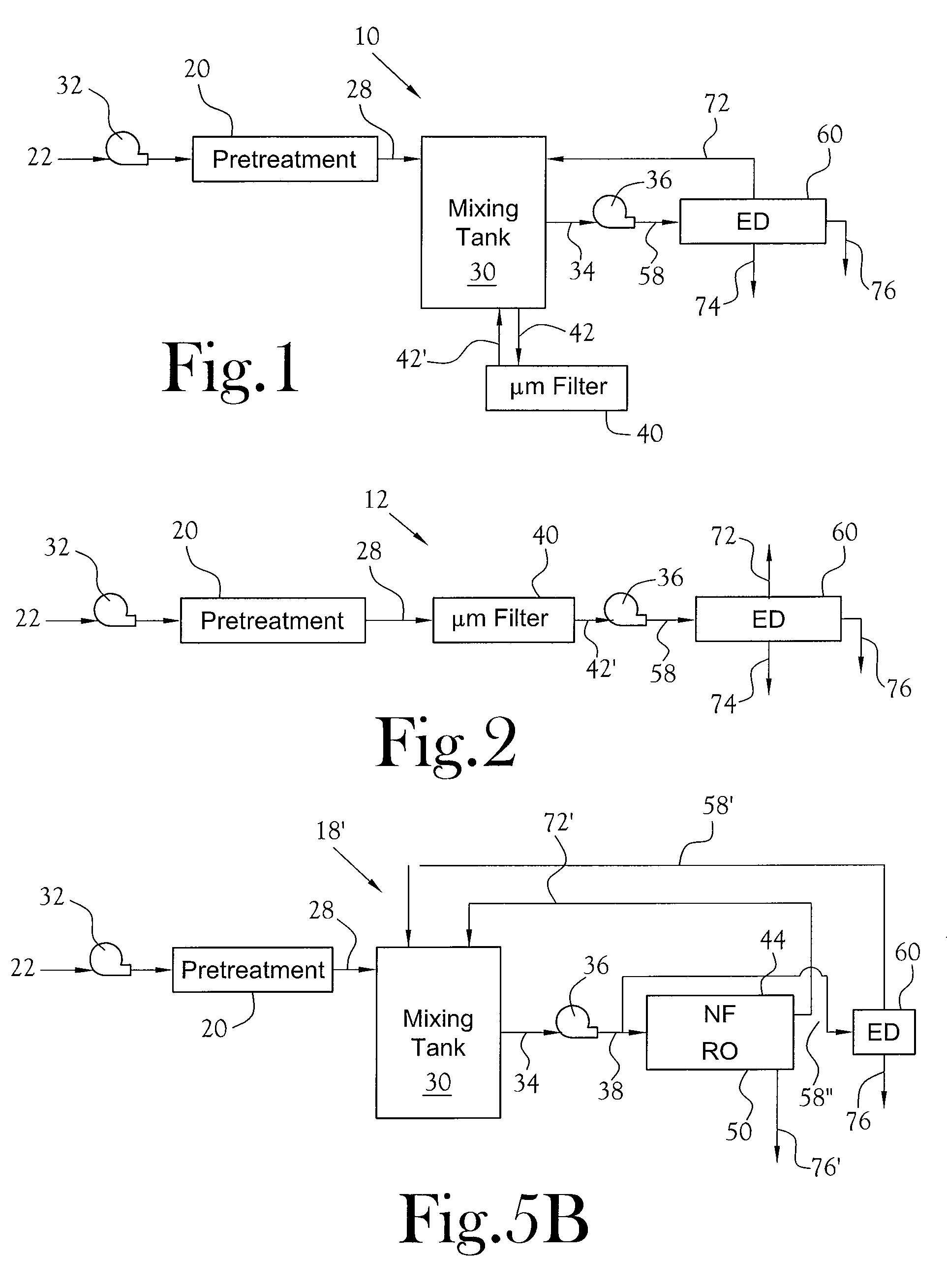

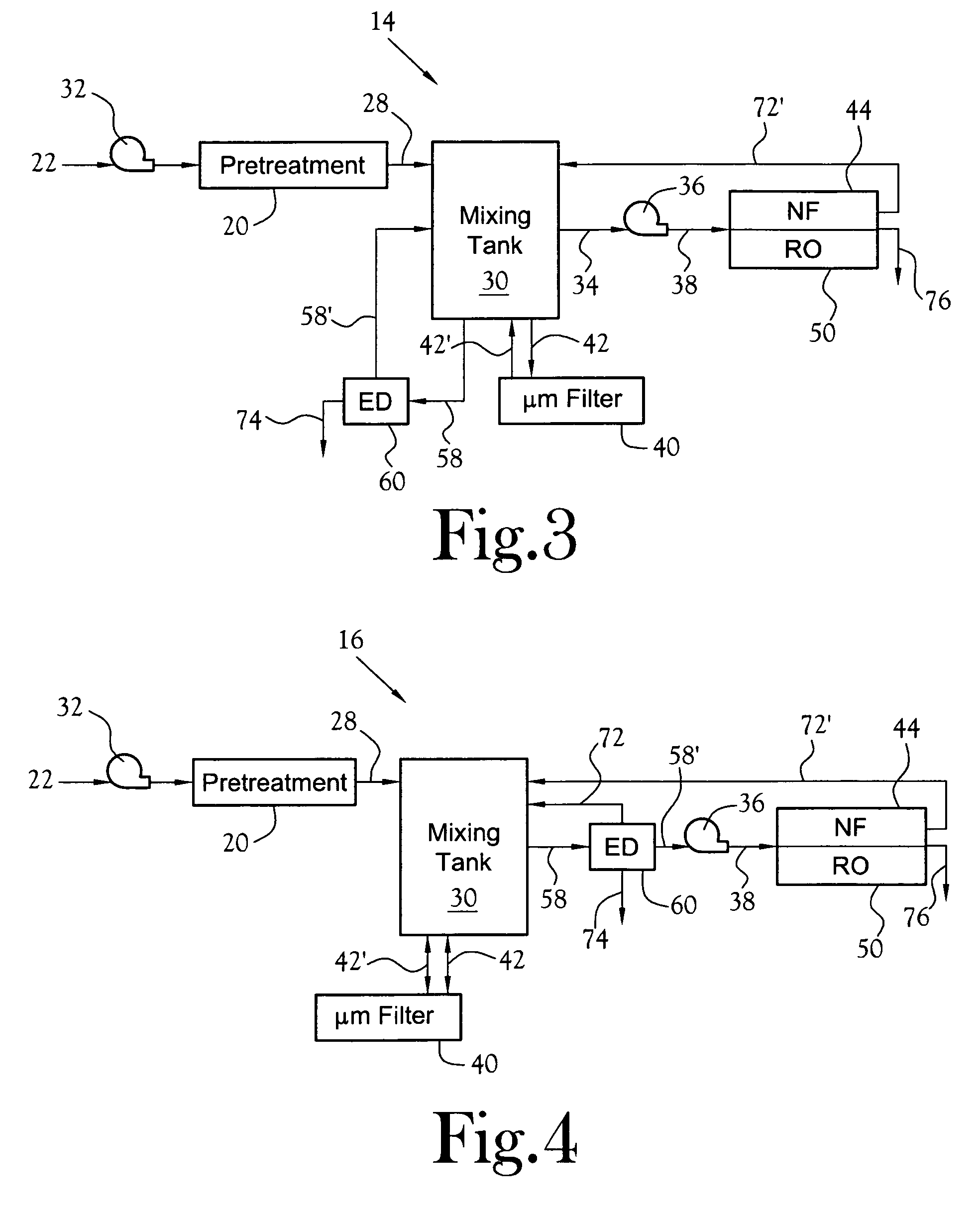

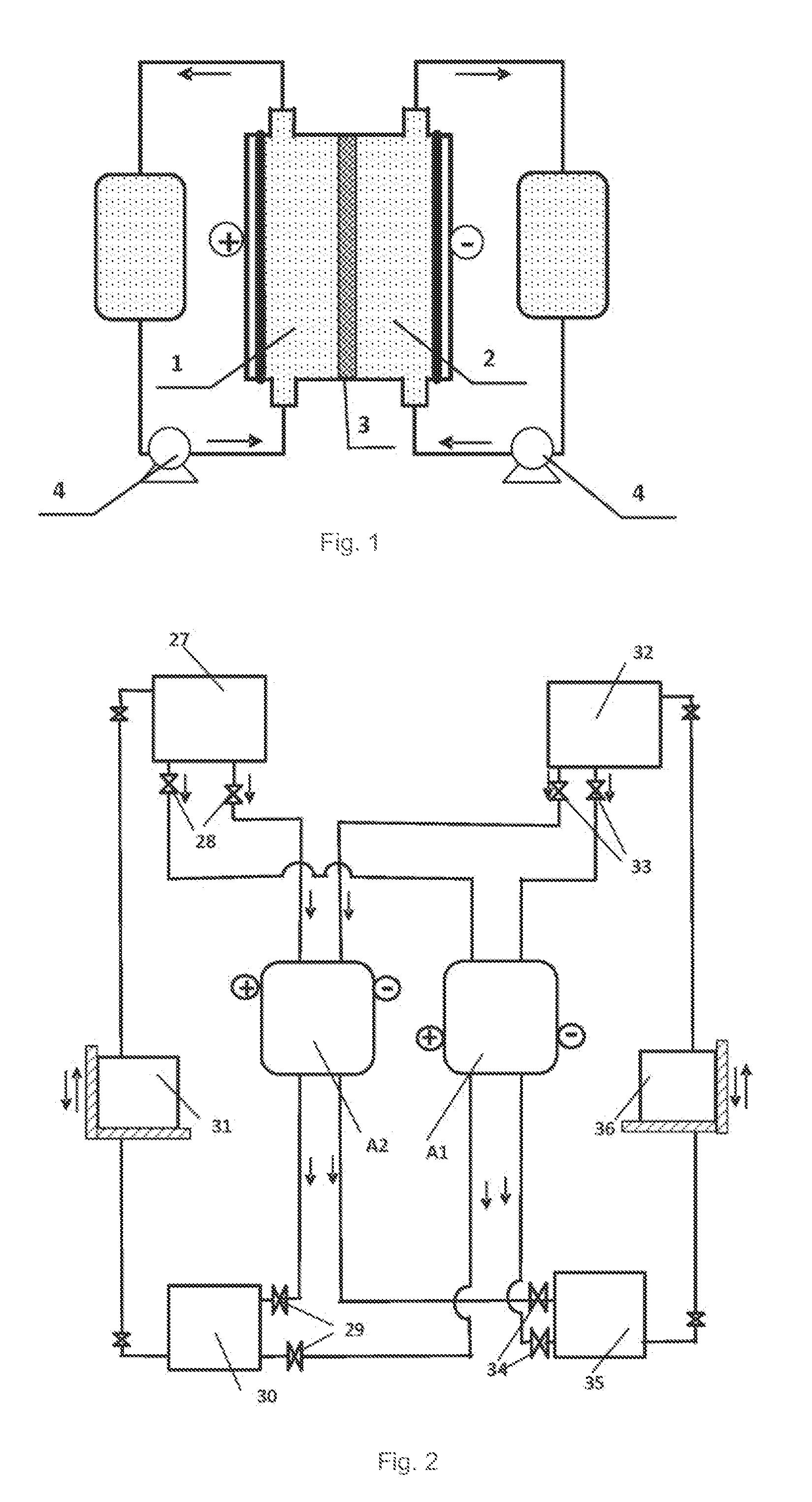

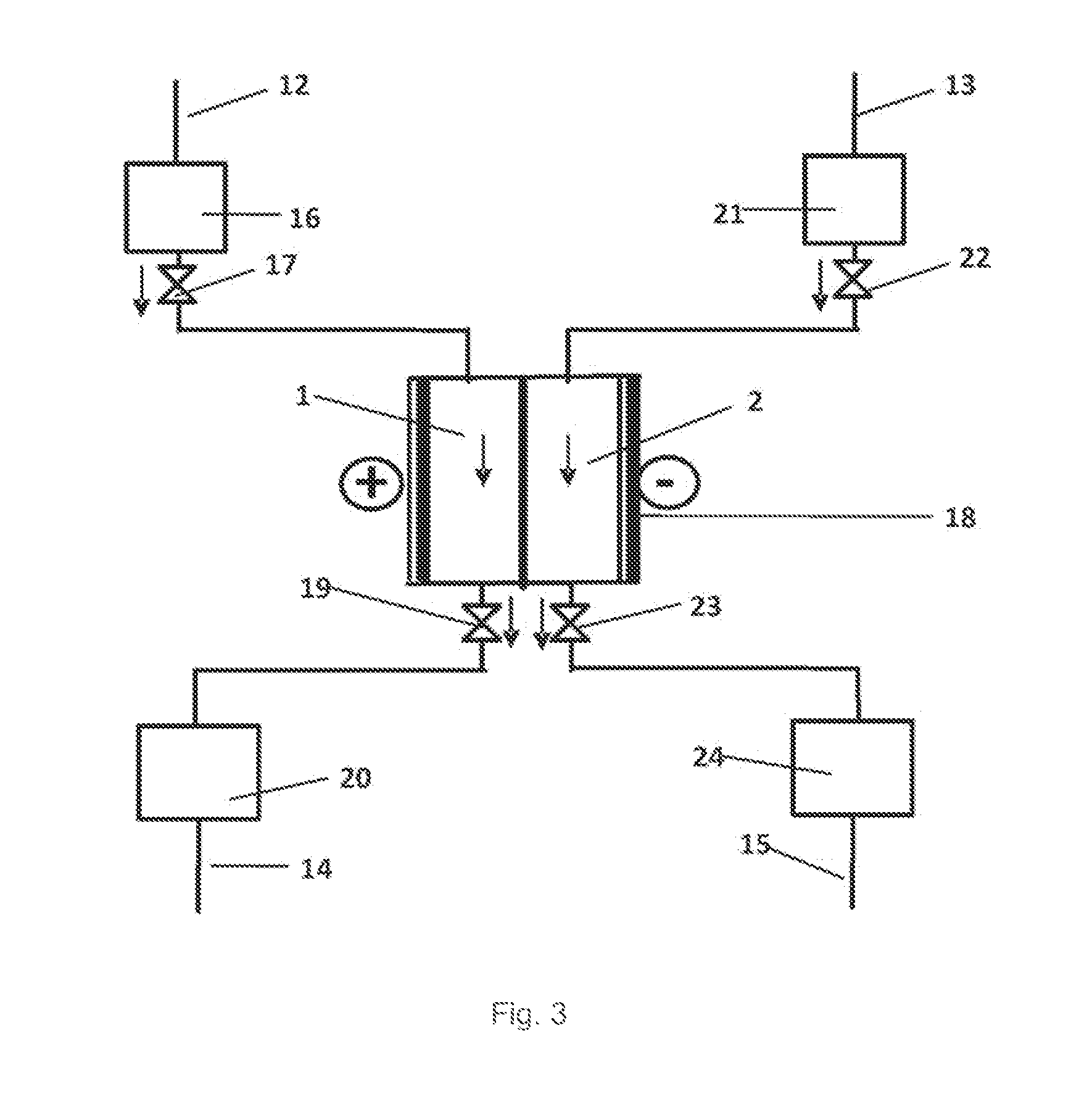

Integrated electro-pressure membrane deionization system

InactiveUS7501064B2Improve performanceLower energy requirementsElectrolysis componentsVolume/mass flow measurementReverse osmosisCapital cost

Owner:EET TN

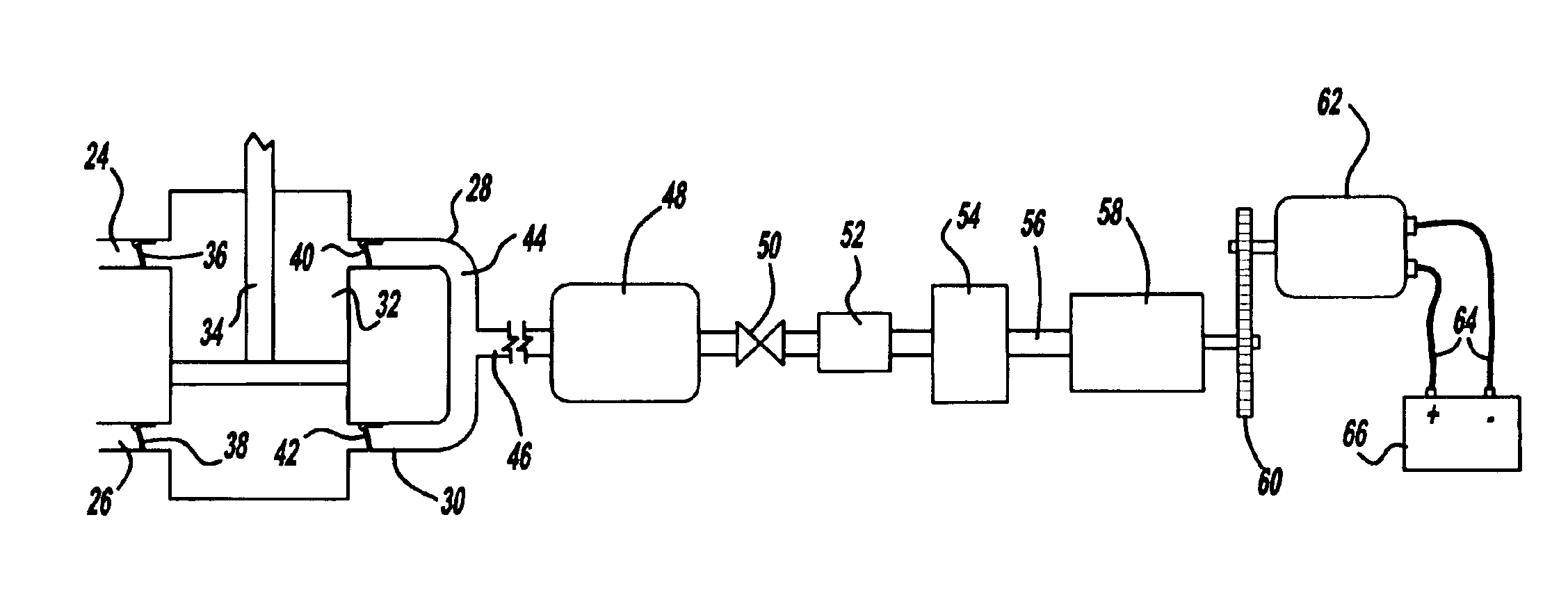

Pneumatic human power conversion system based on children's play

InactiveUS7005757B2Low efficiencyLow-cost of operationFrom muscle energyAmusementsStored energyElectricity

When large numbers of children play in a playground, part of the power of their play could be usefully harnessed resulting in large energy storage. This stored energy can then be converted for basic, low-power, applications in the school such as lighting, communication, or operating fans. Energy can be produced through the use of pneumatic (i.e., compressed air) systems such as cylinders, motors, valves, and regulators for the conversion of human power of children's play in school playgrounds and other public places. The energy of the compressed air can then be converted to electricity for purposes such as lighting and communication. This provides a low-cost, low-resource means of generation of electricity, especially for use in developing countries.

Owner:PANDIAN SHUNMUGHAM RAJASEKARA

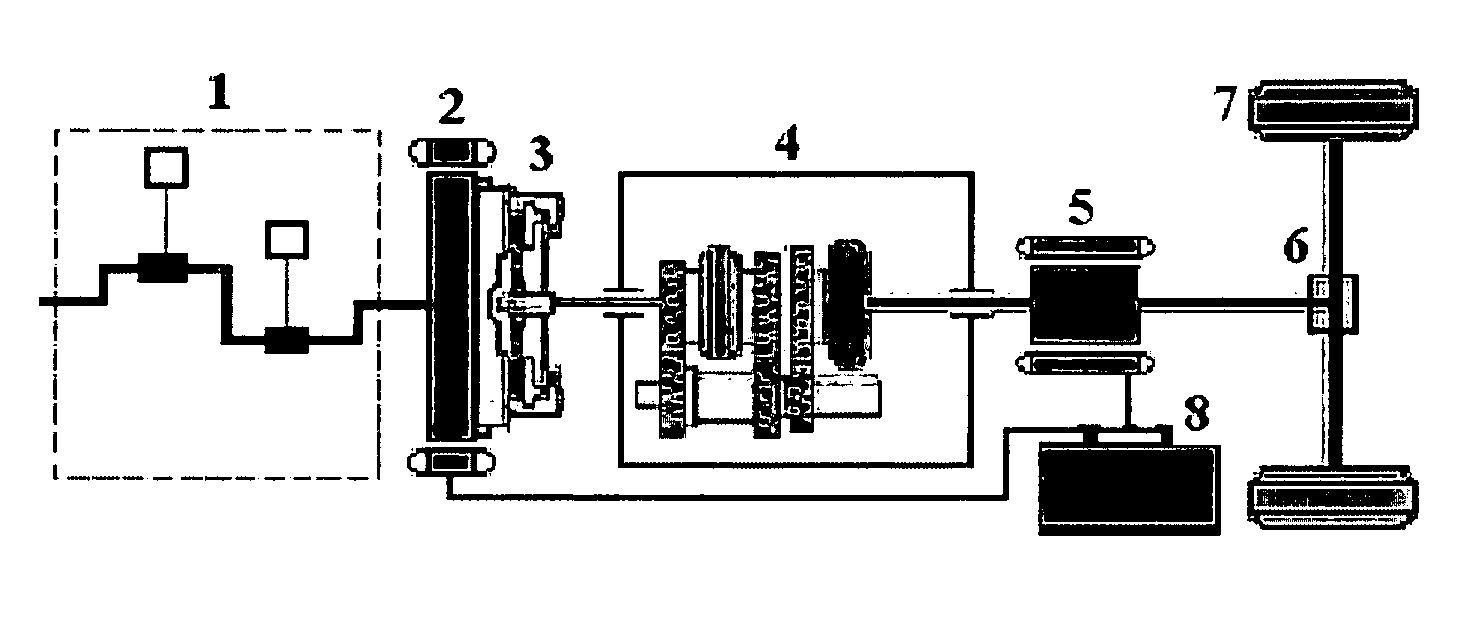

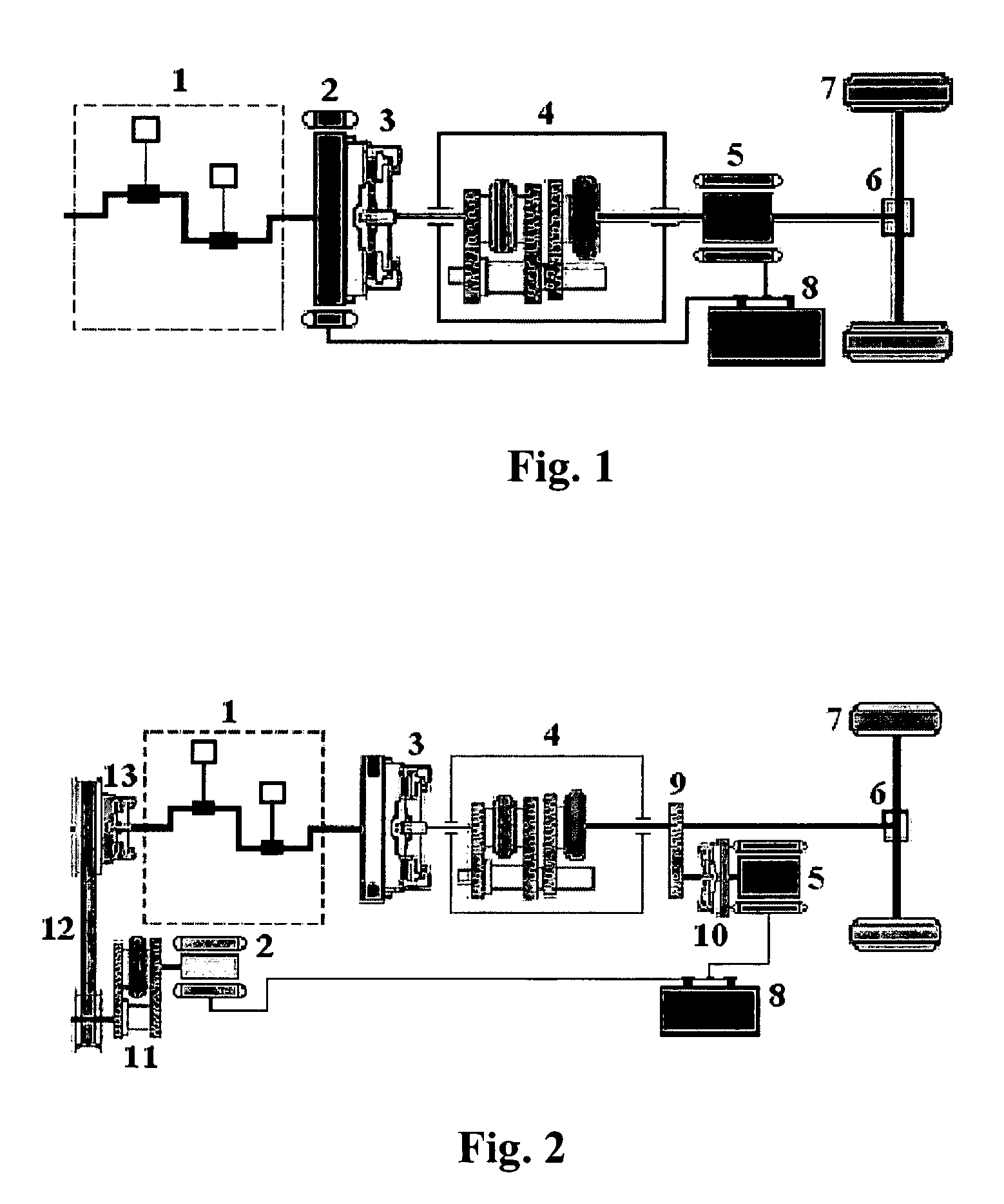

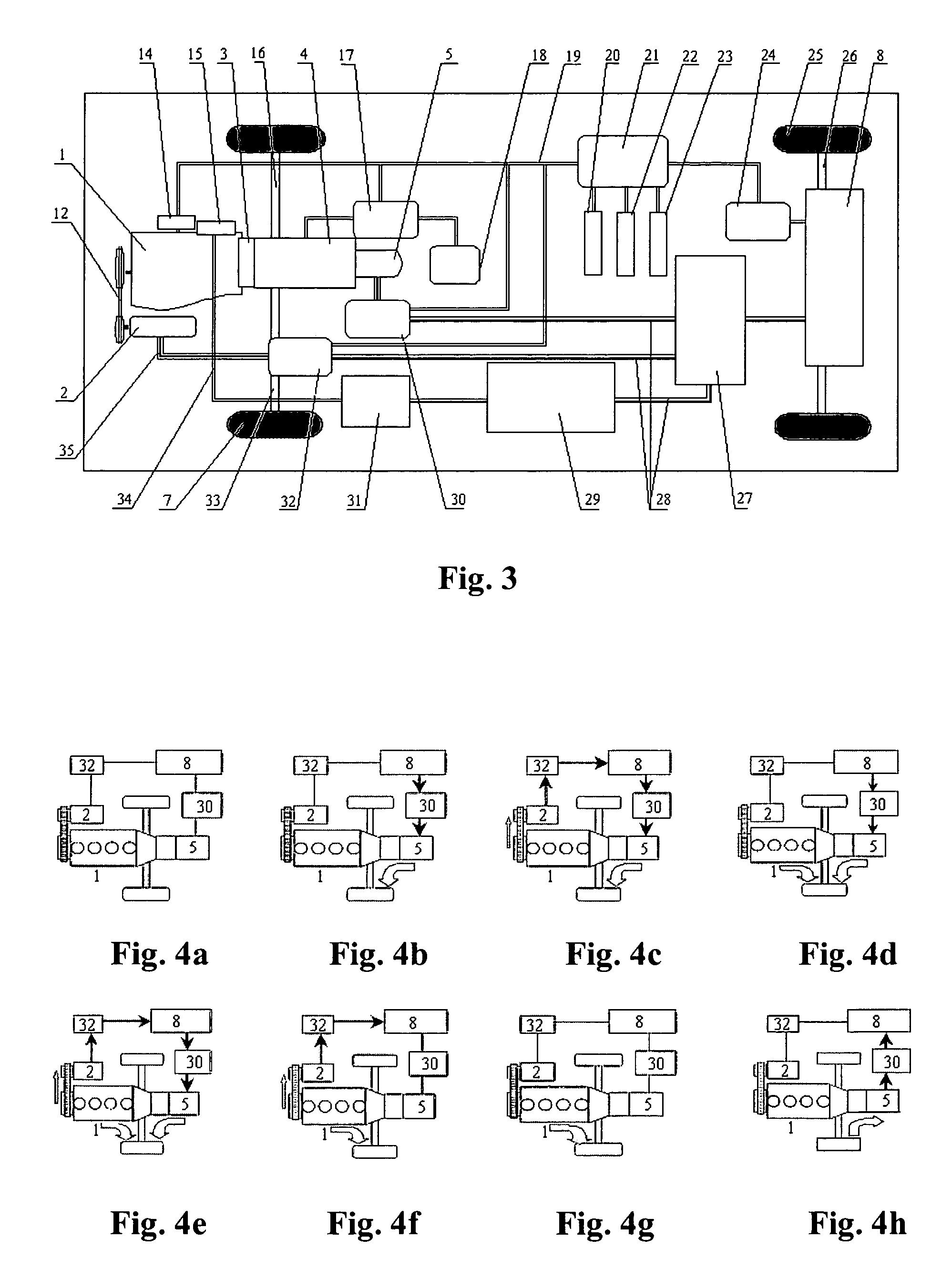

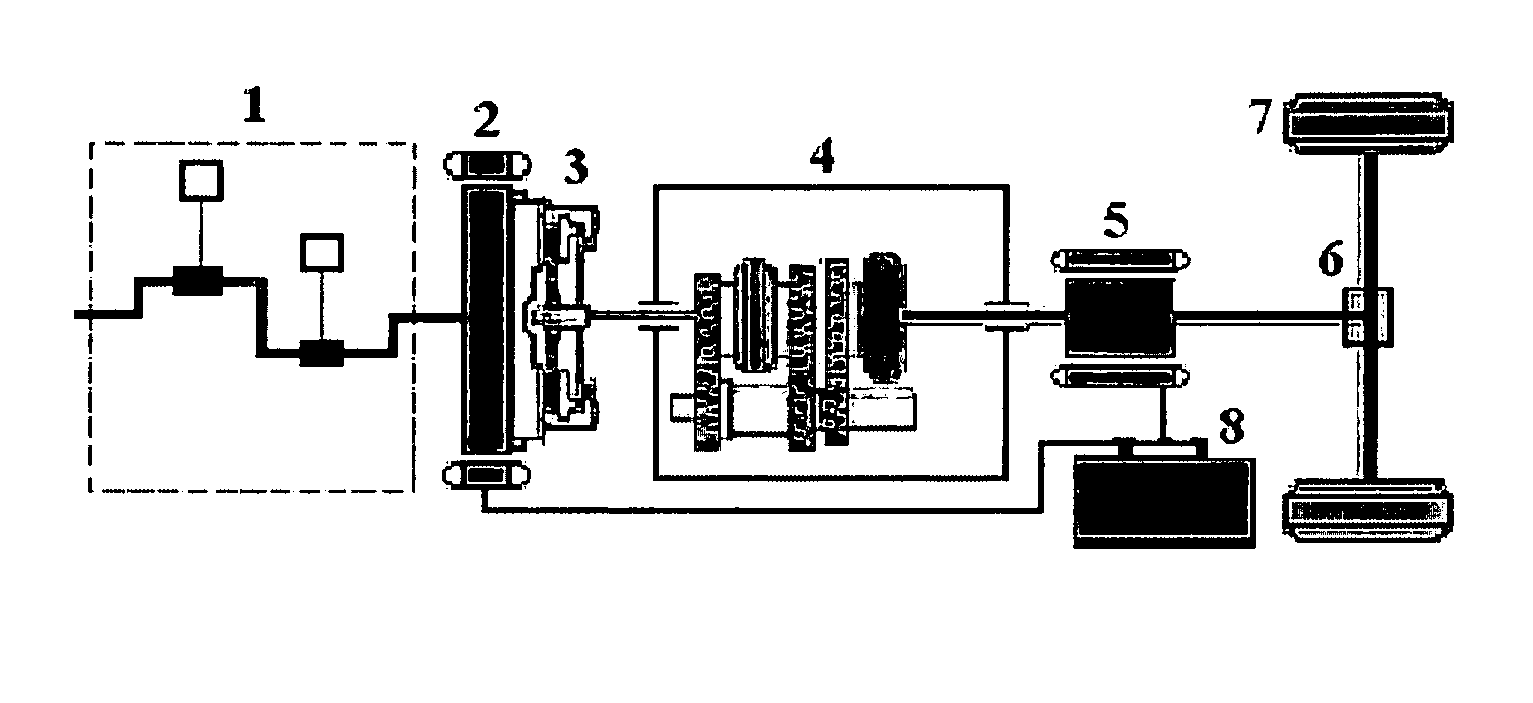

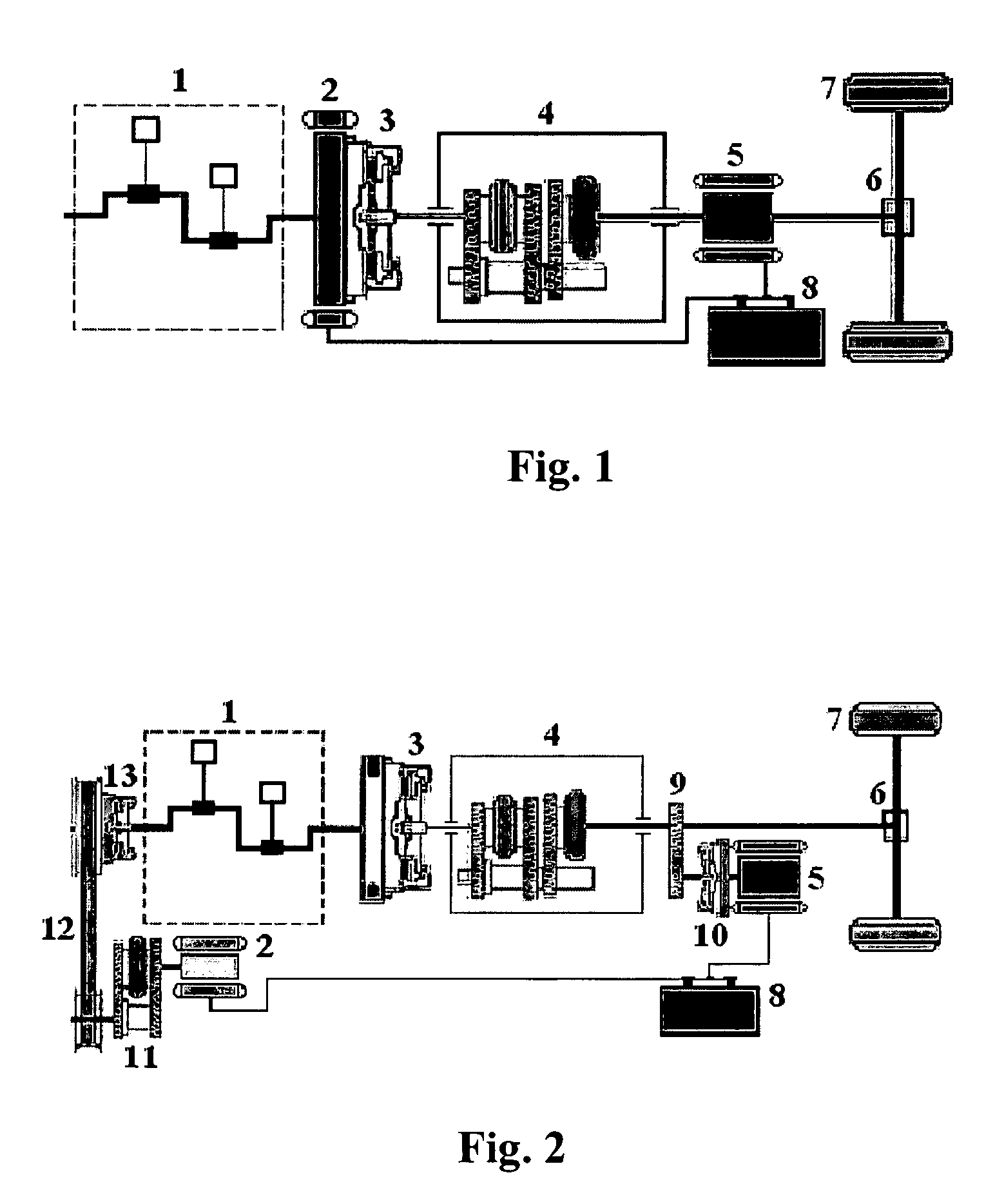

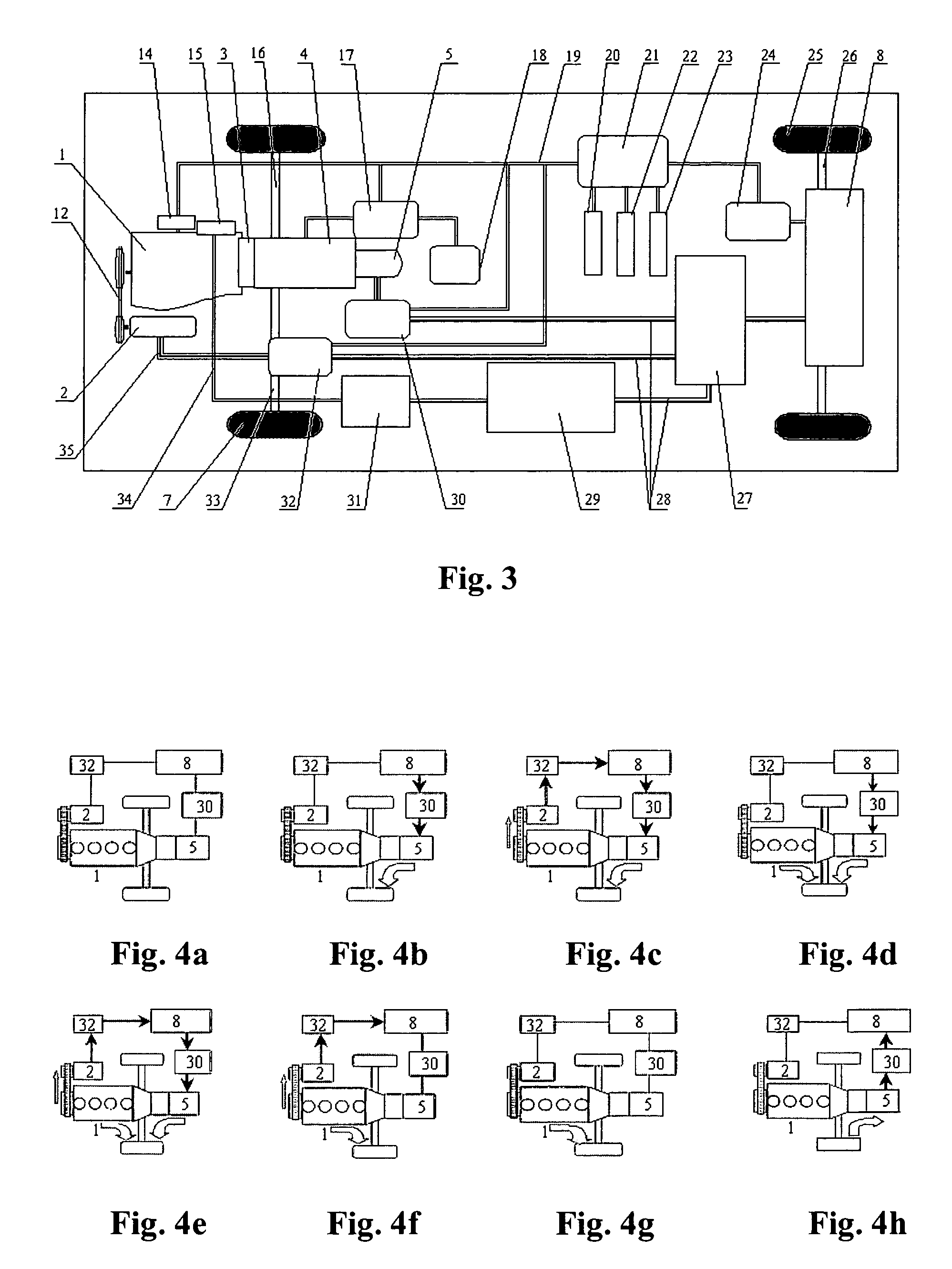

Power system for dual-motor hybrid vehicle

InactiveUS20060113127A1Simple and compact structureLight weightDigital data processing detailsElectric propulsion mountingExhaust gas emissionsEnergy recovery

A power system for dual-motor hybrid vehicle is a combined driving unit fed with fuel and electric power, comprising: an internal combustion engine, a motor, a clutch, a transmission, a power battery, a braking system and an entire vehicle controller, wherein the system further comprises: a main motor, an auxiliary motor, and a mechanical stepped transmission, a rotor shaft of the main motor being connected with the output shaft of the transmission, a rotor shaft of the auxiliary motor being connected with the crankshaft of the internal combustion engine; the main motor and the auxiliary motor being electrically connected with the power battery. With the control of the entire vehicle controller, the vehicle can be driven automatically by the hybrid power system in the follow modes: pure motor driving mode, series driving mode, parallel driving mode, hybrid driving mode, idling stop mode of the internal combustion engine, braking energy recovery mode, independently driving mode of the internal combustion engine, and motor auxiliarily driving mode during shifting. The present invention provides a new power system for hybrid vehicle, with simple structure, lower cost, less energy consumption and less exhaust gas emissions.

Owner:CHINA FIRST AUTOMOBILE GRP

Vanadium redox battery electrolyte

InactiveUS20040241552A1Loss in Coulombic efficiencyEvolution of hydrogen is thereby avoidedTantalum compoundsRegenerative fuel cellsVanadium redox batterySlurry

The present invention relates generally to the production of a vanadium electrolyte, including a mixture of trivalent and tetravalent vanadium ions in a sulphuric acid solution, by the reactive dissolution of vanadium trioxide and vanadium pentoxide powders, the surface area and particle size characteristics being controlled for complete reaction to produce the desired ratio of V(III) to V(IV) ions in the solution. The solution may be suitable for direct use in the vanadium redox battery, or the solution can provide an electrolyte concentrate or slurry which can be reconstituted by the addition of water or sulphuric acid prior to use in the vanadium redox battery.

Owner:UNISEARCH LTD

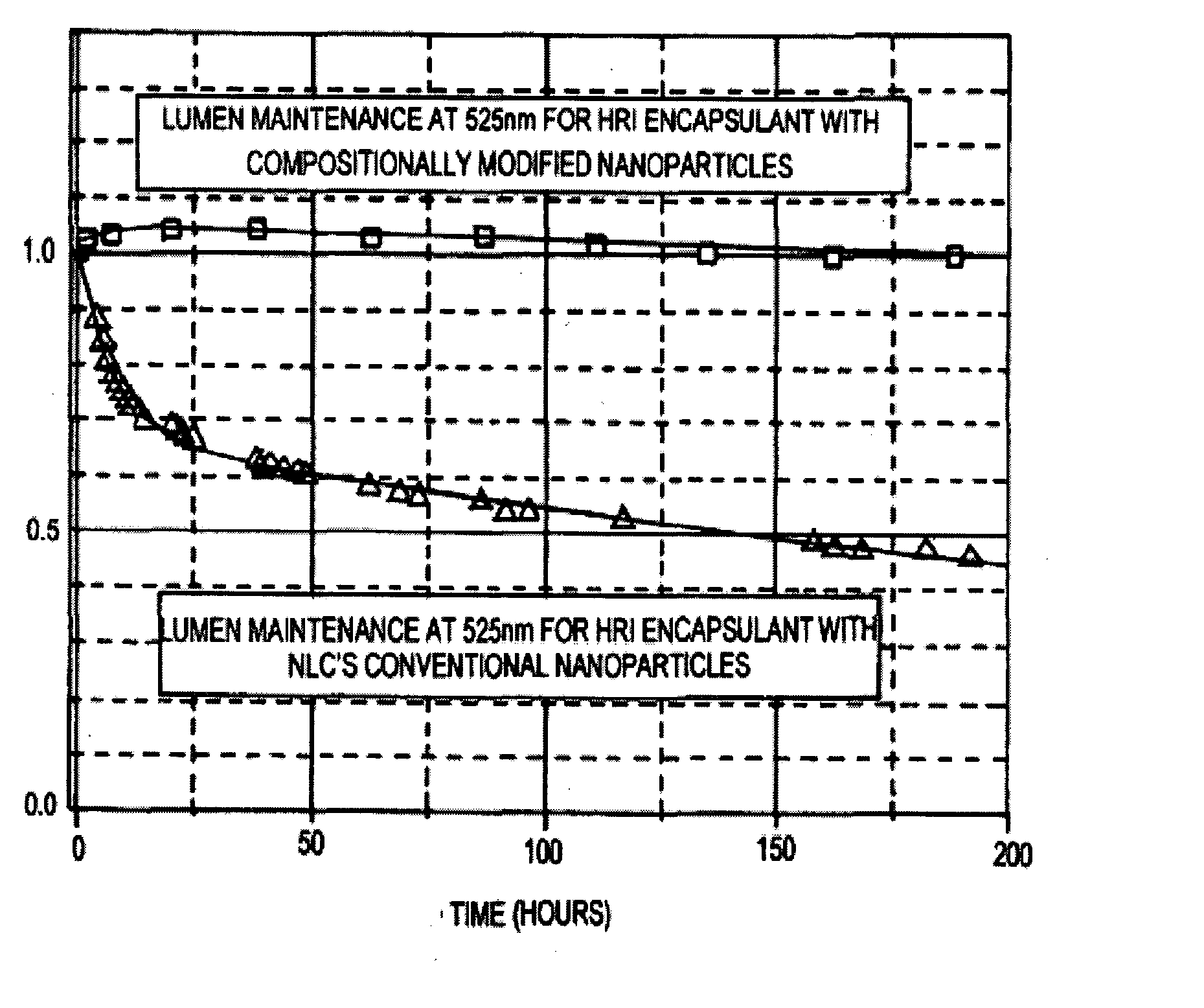

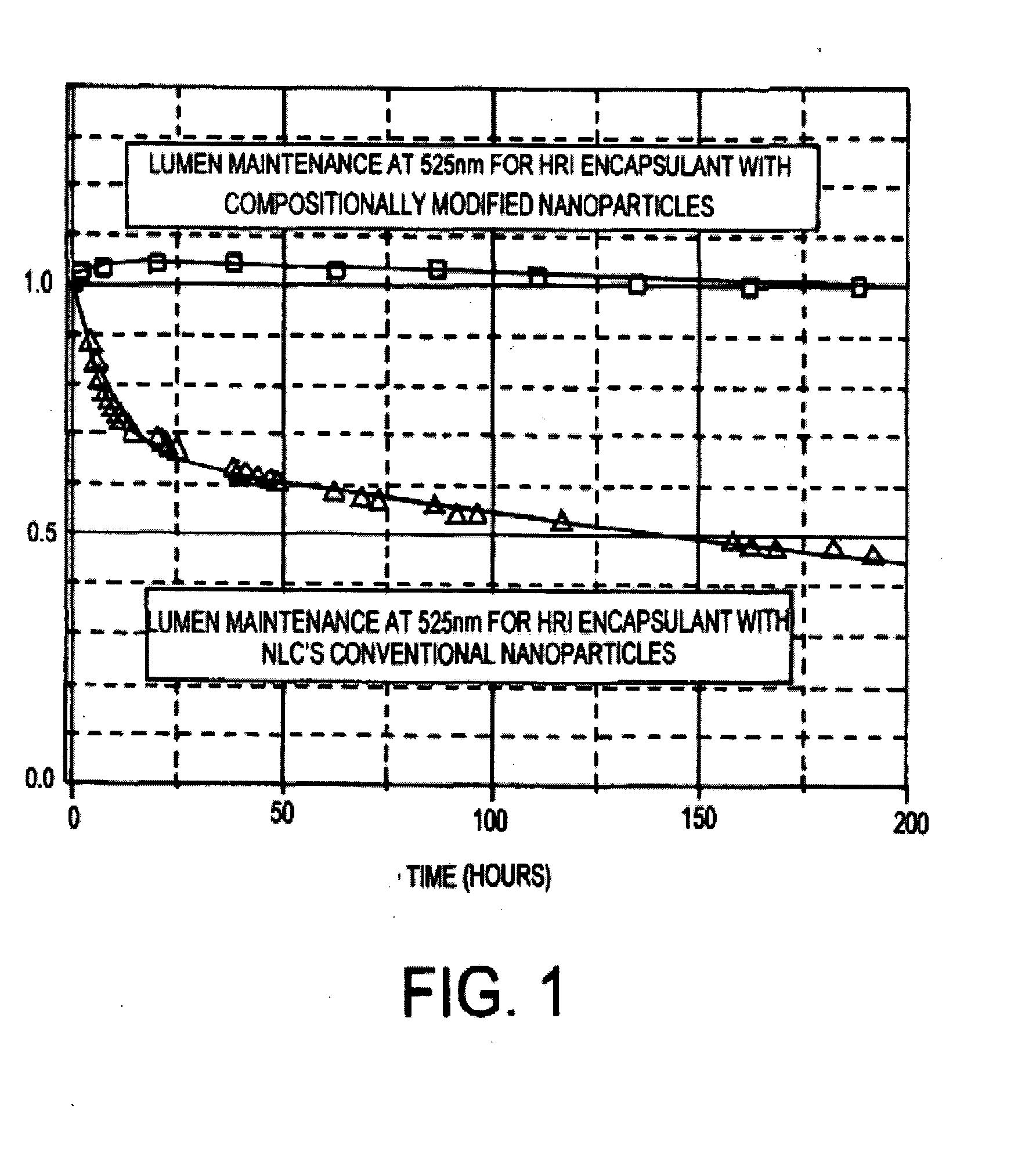

Optically reliable nanoparticle based nanocomposite HRI encapsulant, photonic waveguiding material and high electric breakdown field strength insulator/encapsulant

InactiveUS20070221939A1Good physical propertiesImprove photodegradation resistanceMaterial nanotechnologySemiconductor devicesEpoxyLight equipment

An optically reliable high refractive index (HRI) encapsulant for use with Light Emitting Diodes (LED's) and lighting devices based thereon. This material may be used for optically reliable HRI lightguiding core material for polymer-based photonic waveguides for use in photonic-communication and optical-interconnect applications. The encapsulant includes treated nanoparticles coated with an organic functional group that are dispersed in an Epoxy resin or Silicone polymer, exhibiting RI˜1.7 or greater with a low value of optical absorption coefficient α<0.5 cm−1 at 525 nm. The encapsulant makes use of compositionally modified TiO2 nanoparticles which impart a greater photodegradation resistance to the HRI encapsulant.

Owner:NANOCRYSTALS TECH

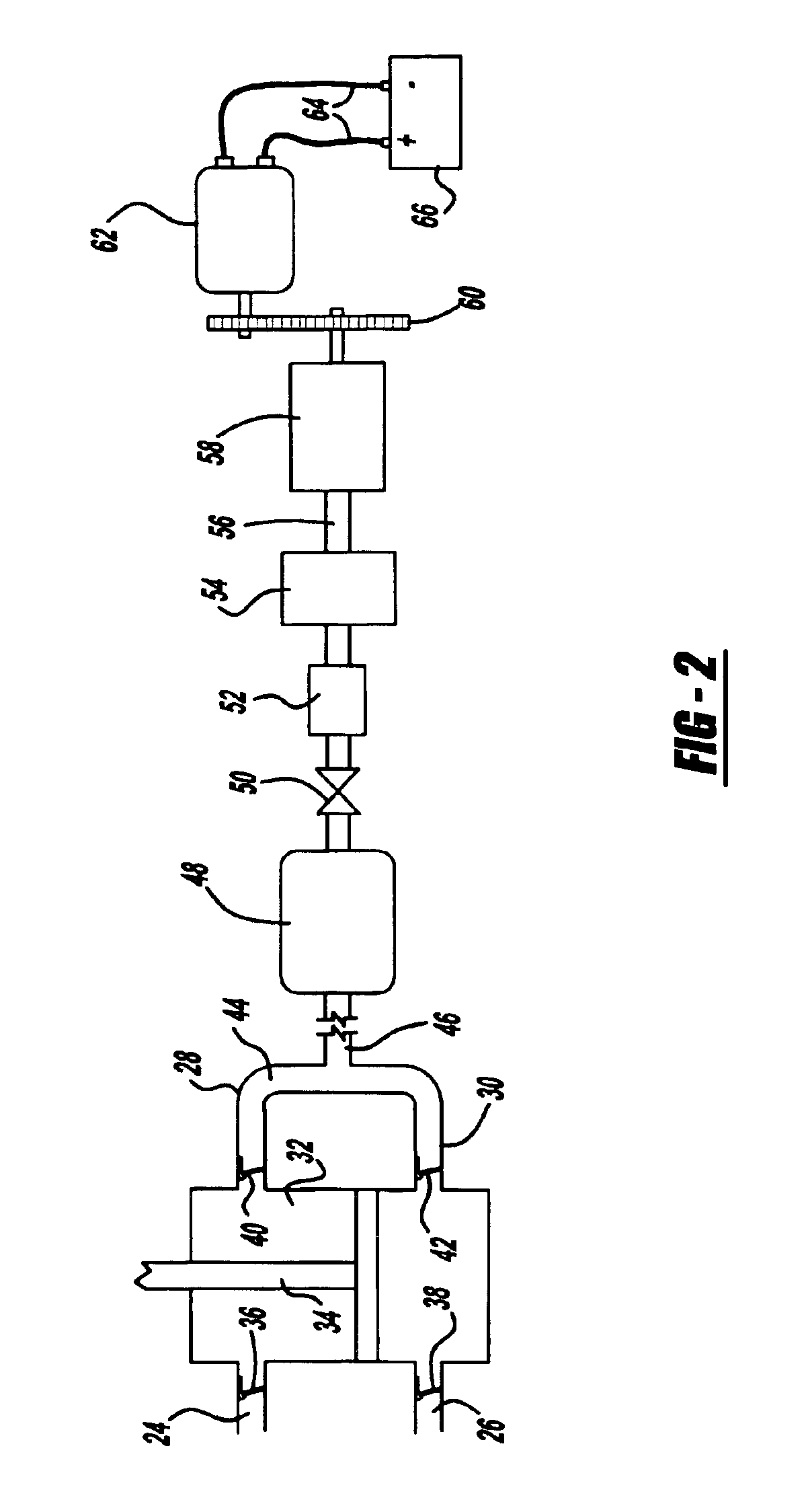

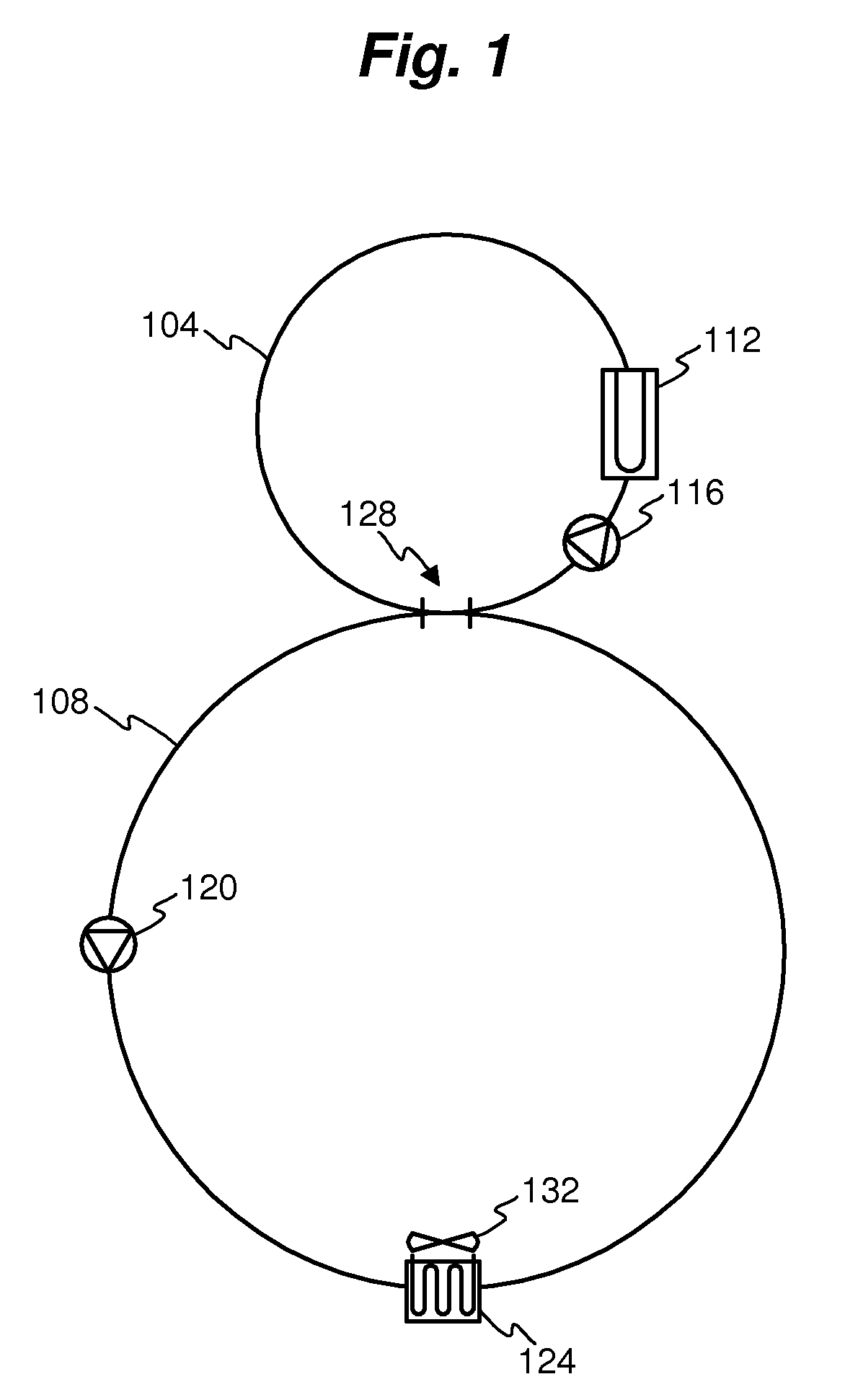

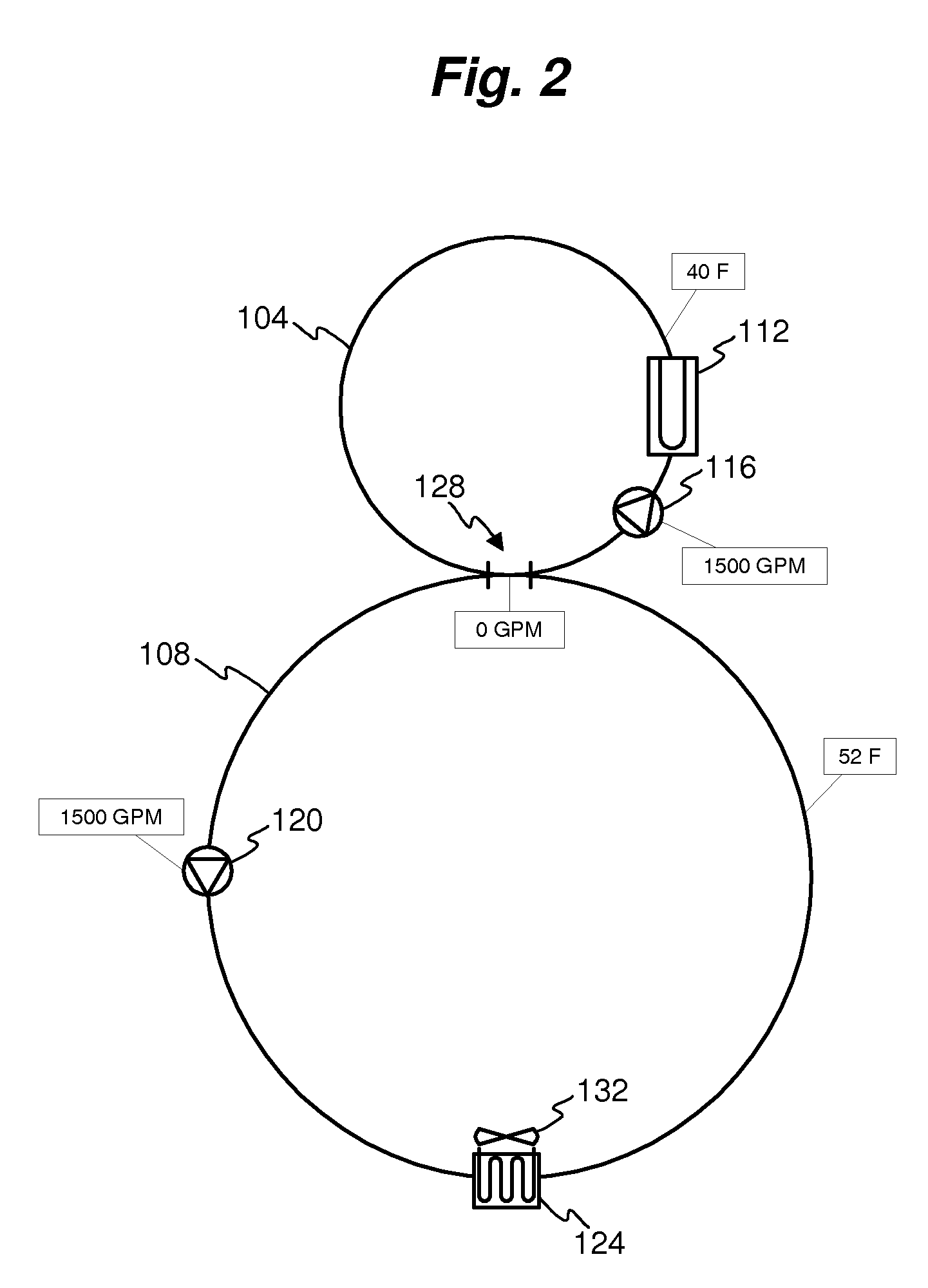

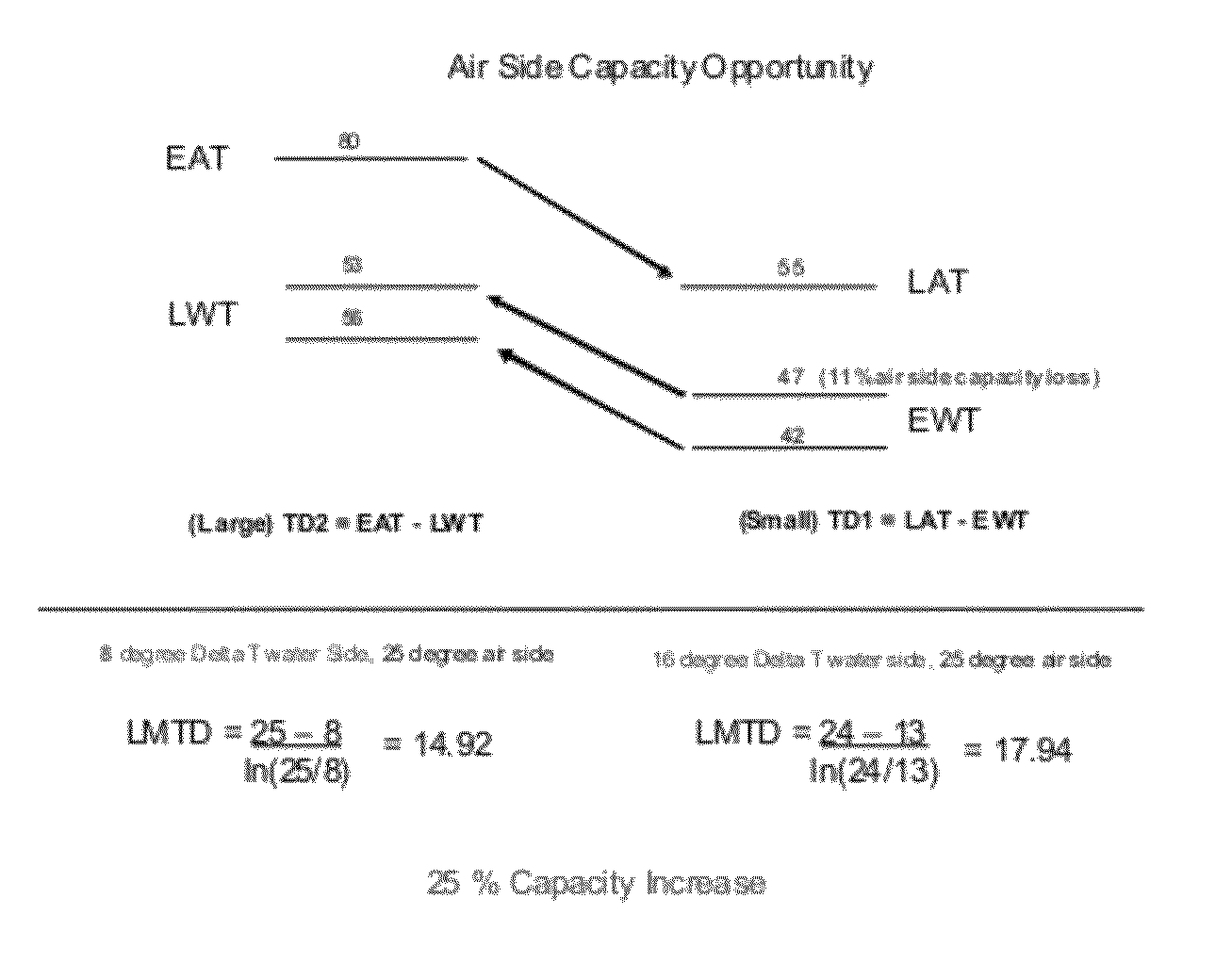

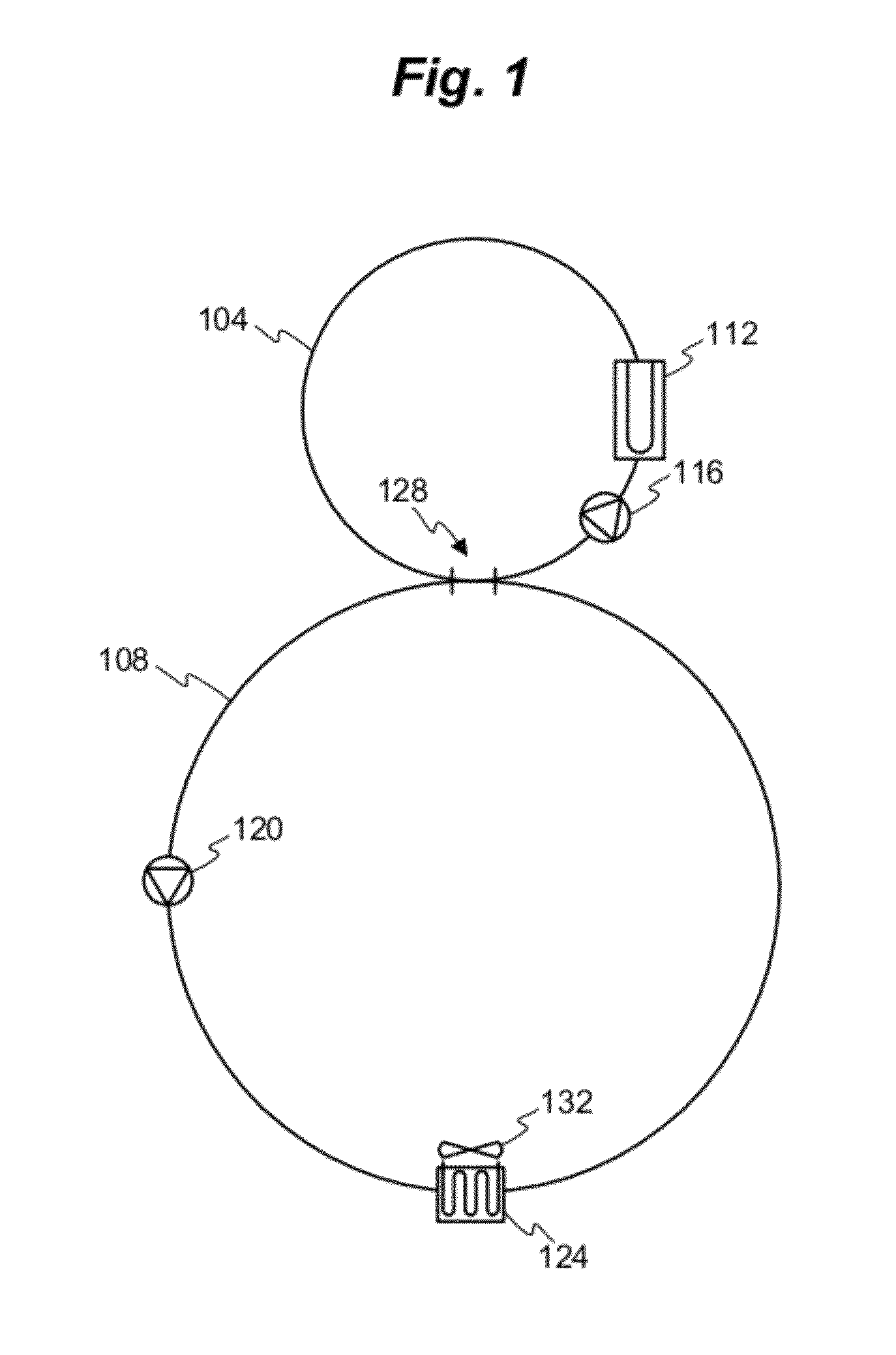

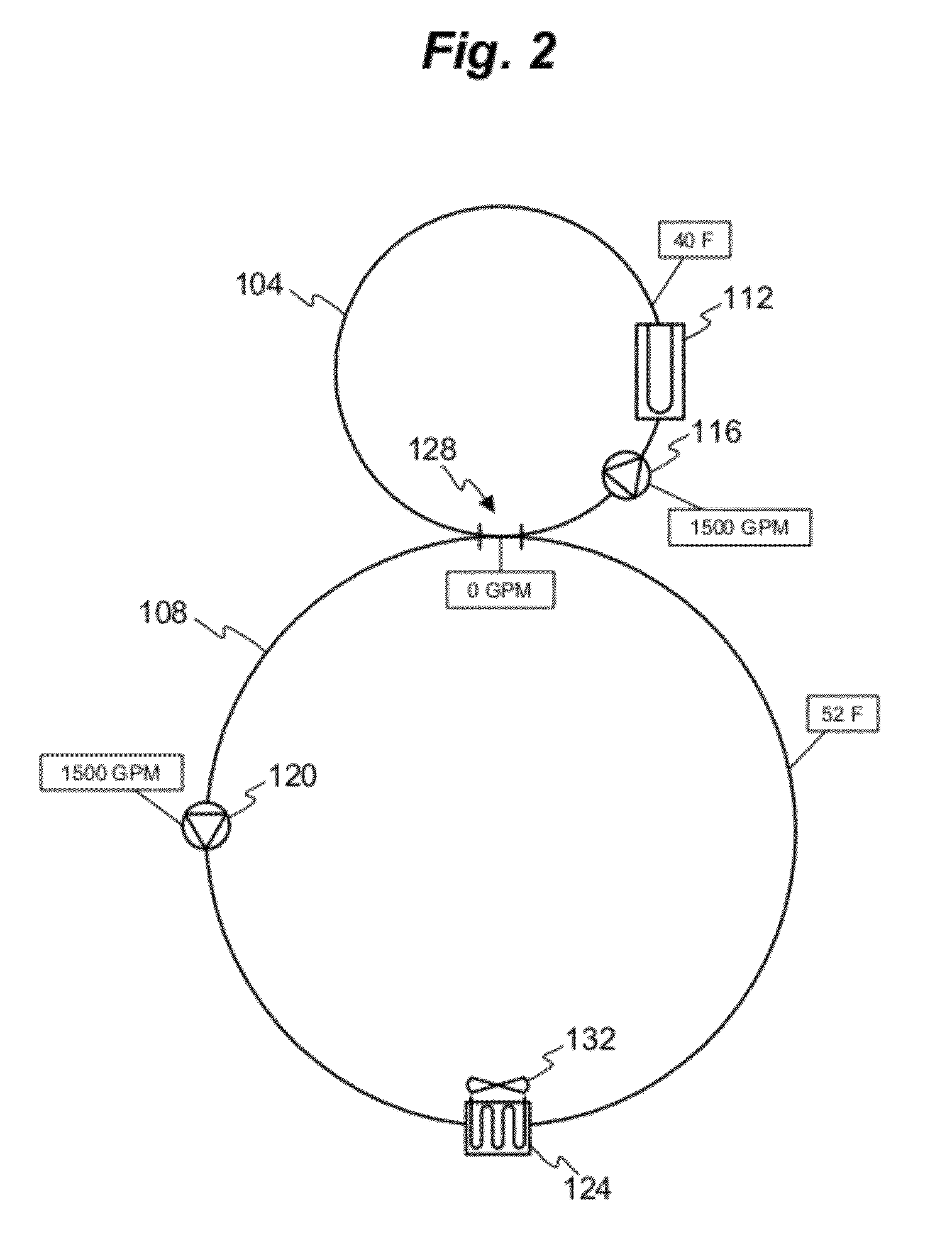

Demand flow pumping

ActiveUS20110022236A1Easy to operateSignificant energy savingMechanical apparatusTemperatue controlAir handlerEngineering

Demand Flow operates chilled water plants at substantially improved efficiency, regardless of plant load conditions. In general, Demand Flow utilizes an operating strategy which controls chilled and condenser water pumping according to a constant Delta T line, which is typically near or at design Delta T. This reduces or eliminates Low Delta T Syndrome and reduces energy usage by chilled and condenser water pumps for given load conditions. Operation of chilled water pumps in this manner creates a synergy which generally balances flow rates throughout the plant, reducing undesirable bypass mixing and energy usage at air handler fans and other components of the chilled water plant. At plant chillers, application of Demand Flow increases the refrigeration effect through refrigerant sub-cooling and superheating, while preventing stacking. Demand Flow includes a critical zone reset feature which allows the constant Delta T line to be reset to adjust to changing load conditions.

Owner:SIEMENS IND INC

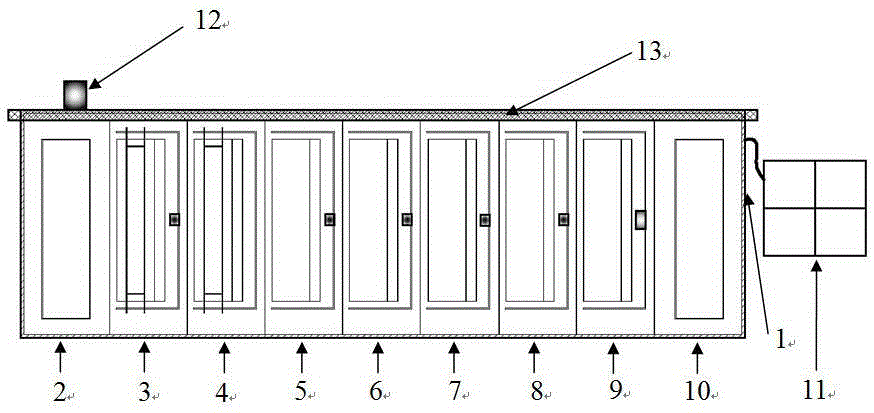

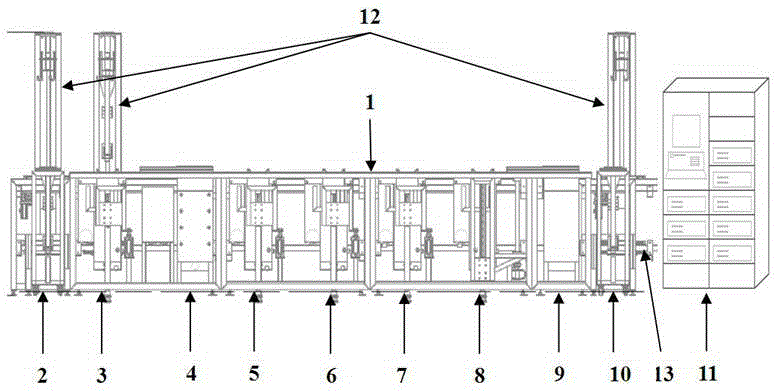

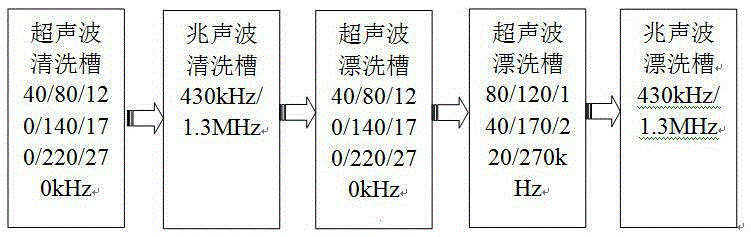

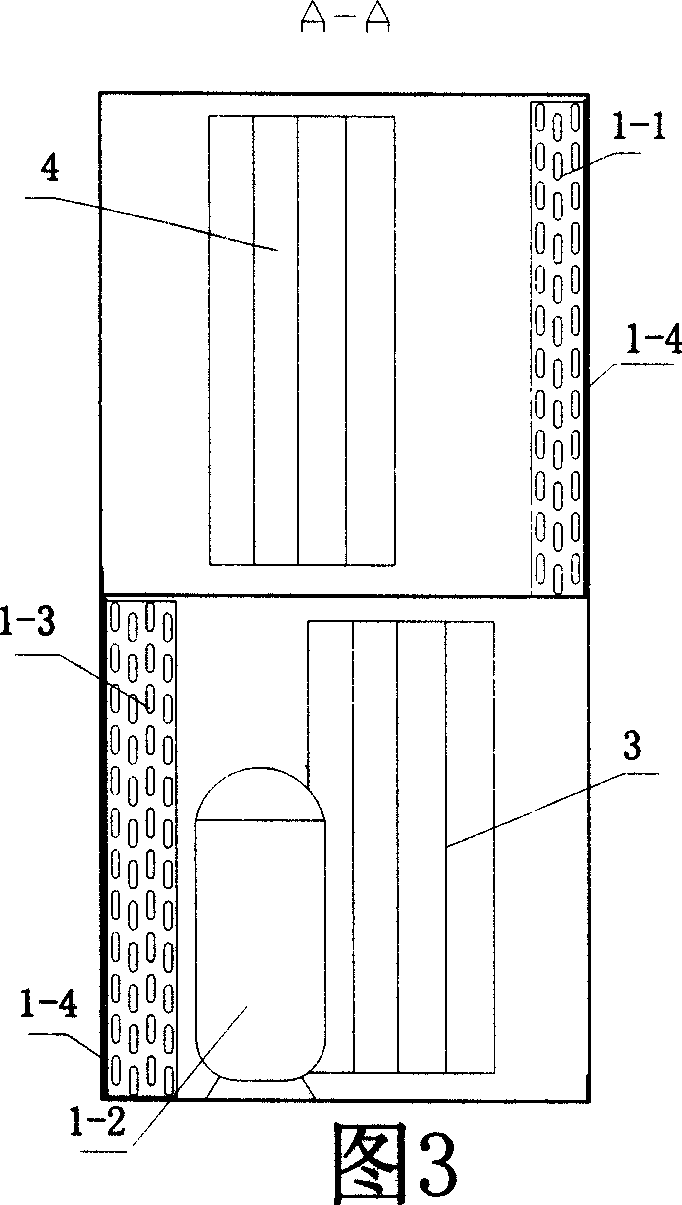

Fully-automatic optical element cleaning device with ultrasonic-megasonic composite frequency

InactiveCN105195465AInhibition retentionMeet cleaning and removal needsFlexible article cleaningCleaning using liquidsMicron scaleFiltration

The invention discloses a fully-automatic optical element cleaning device with an ultrasonic-megasonic composite frequency. The ultrasonic-megasonic composite frequency covers low / intermediate / high ultrasonic frequencies and low / intermediate / high megasonic frequencies. Particularly, an appropriate program and process parameters are selected to aim at super-clean washing requirements for an optical element, and pollutants from a micron scale to a nanometer scale on the surface of the optical element can be effectively removed. The fully-automatic optical element cleaning device with the ultrasonic-megasonic composite frequency has the main characteristics that an ultrasonic solution soaking cleaning tank, a megasonic cleaning tank and a spraying tank are designed; different frequency ultrasonic and megasonic waves are adopted, and cleaning requirements from a micron size to a nanometer size are covered; a workpiece is driven by a cylinder to reciprocate up and down in a tank body, a wave node of a standing wave field is prevented from being generated in a fixed area of the surface of the workpiece by virtue of a frequency sweeping function of an ultrasonic-megasonic generator, and the surface damage is avoided; the tank body adopts overflow cycle heating filtration; the total length of an overflow front edge is increased by using a trapezoidal saw-tooth type overflow edge design to obtain uniform and stable overflow; an inclined workpiece clamping device cooperates with an air knife and a slow lifting mechanism to dry the workpiece.

Owner:TONGJI UNIV +1

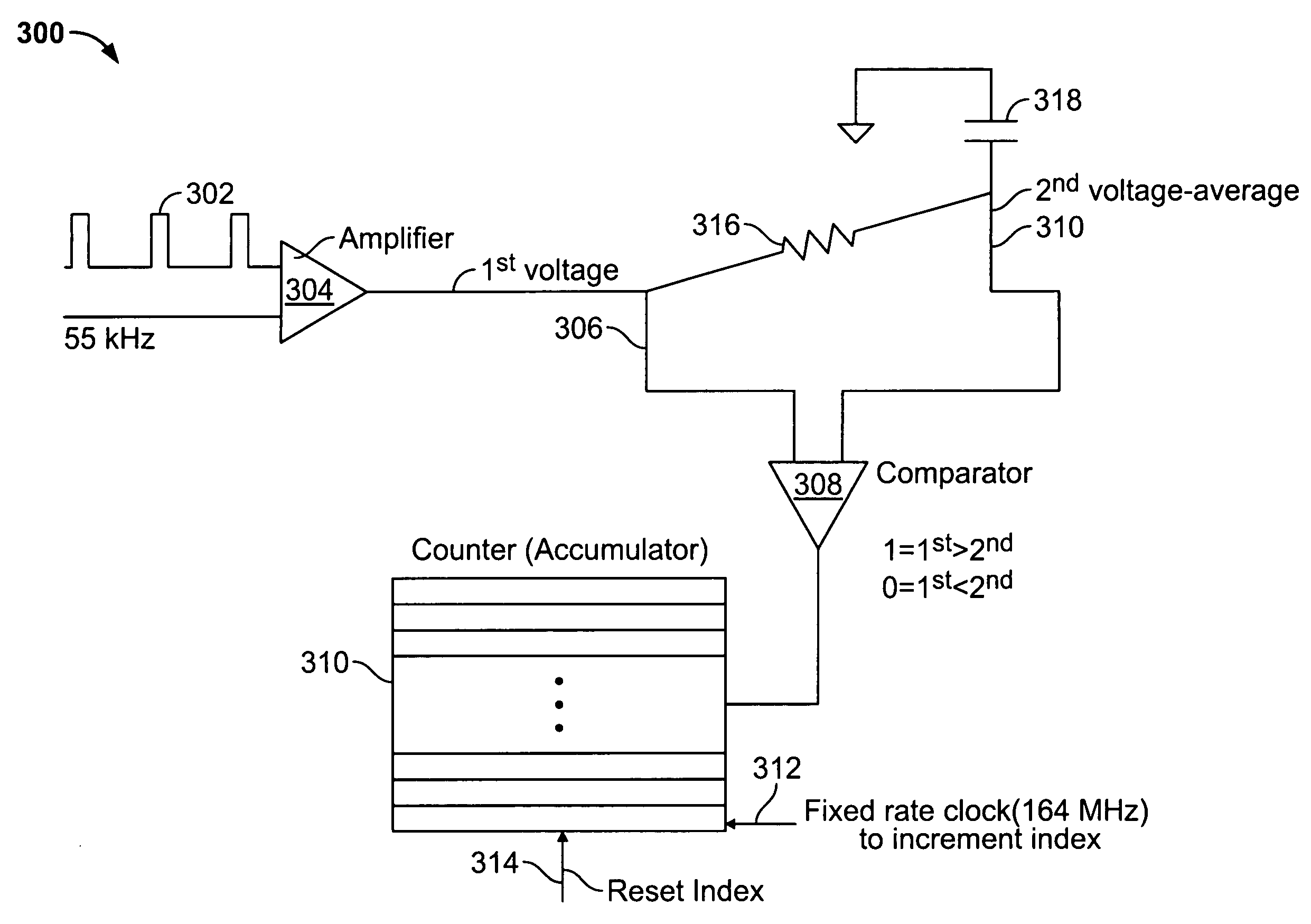

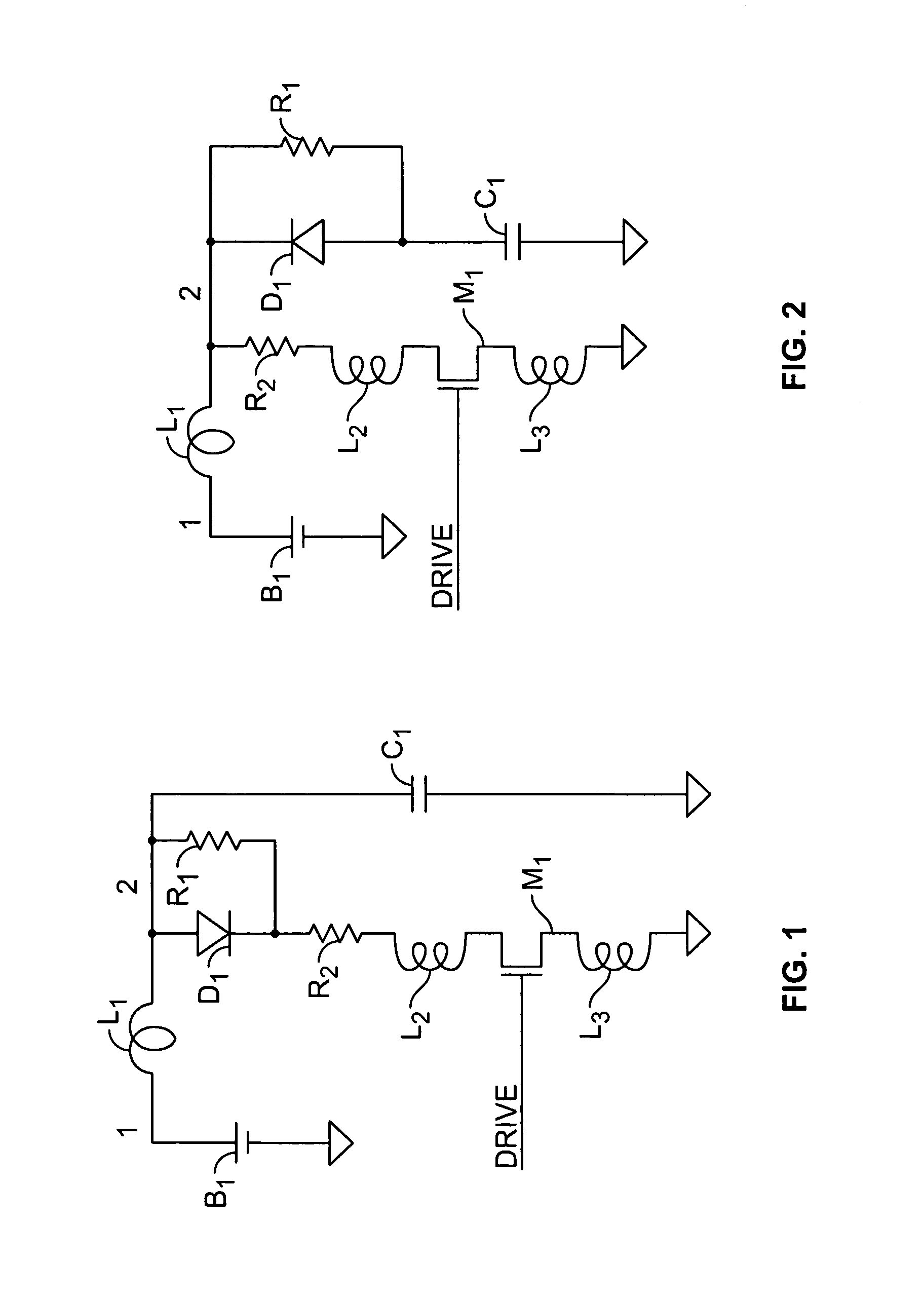

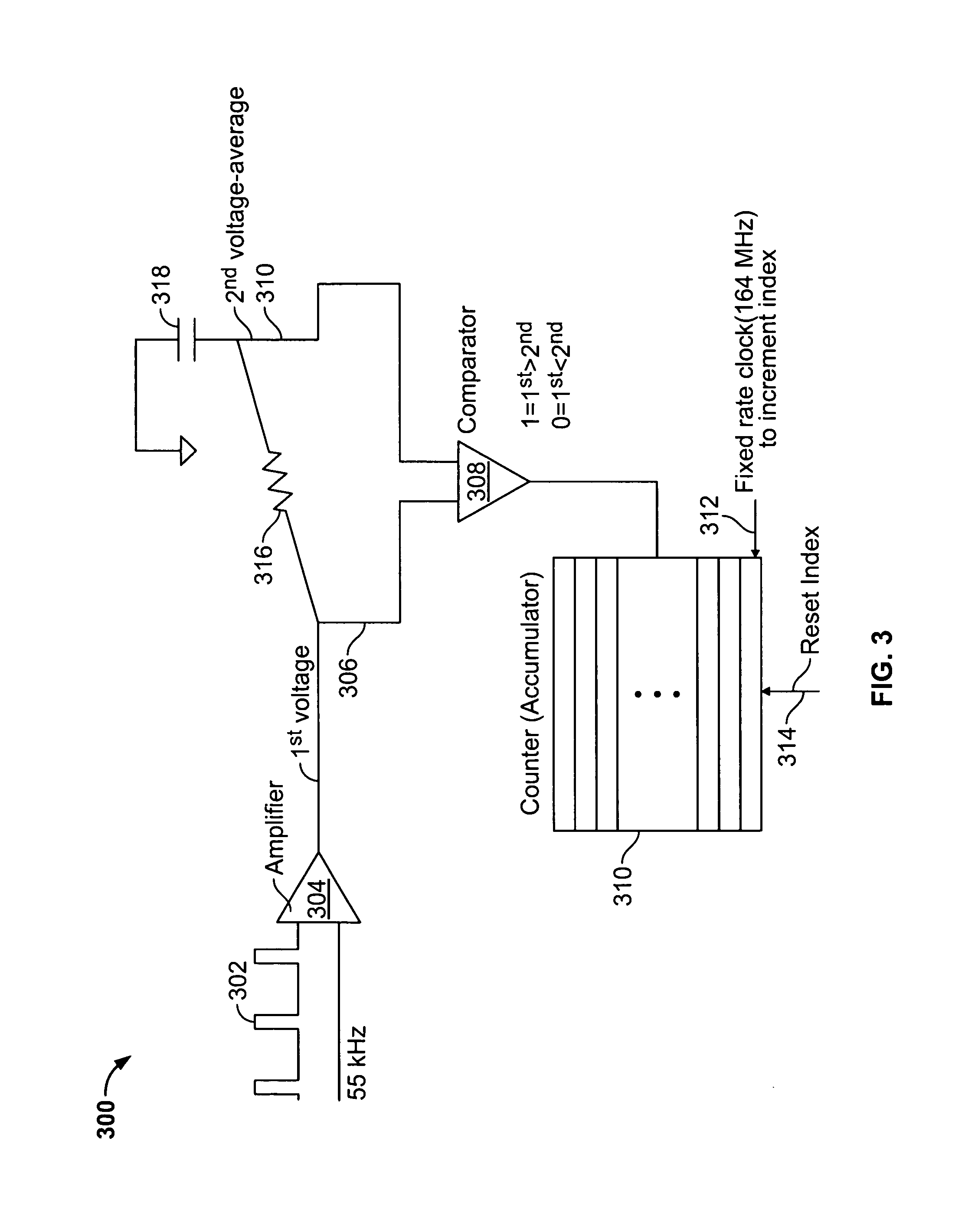

Method for improving the received signal to noise ratio of a laser rangefinder

InactiveUS7184130B1Reduce the impactReduce the impact of noiseOptical rangefindersElectromagnetic wave reradiationSignal-to-noise ratio (imaging)Laser light

An improved technique for a laser rangefinder includes a pulsed laser sending out a repetition of light pulses and the received signal (light pulse and noise components combined) being analyzed by continuous averaging of successive received signal discrete time sequences, each sequence beginning with the onset of transmitted laser light. Also, a circuit generates high potentials for the laser diode driving circuitry that simultaneously drives the laser diode, having at least one of several beneficial characteristics: It is conveniently synchronous with the light pulse send / receive process to reduce the effects of noise on the receive section. It is energy efficient in converting low battery potentials to higher voltages. Finally, it utilizes a minimized number of components, leading to high product economy.

Owner:EXELYS

Warming Blankets, Covers, and Apparatus, and Methods of Fabricating and Using the Same

InactiveUS20090299442A1Comfortable and goodReduce chanceBlanketTherapeutic coolingEngineeringWarming blanket

Embodiments of the invention can provide warming blankets, covers, and apparatus, and methods of fabricating and using the same. In at least one embodiment, a warming blanket can be provided. The warming blanket can include a body; and one or more pockets mounted to the body, wherein each of the one or more pockets is adapted to hold a respective removable warming element. Associated methods of fabrication and use are also described.

Owner:VERGONA JOSEPH BLASE +1

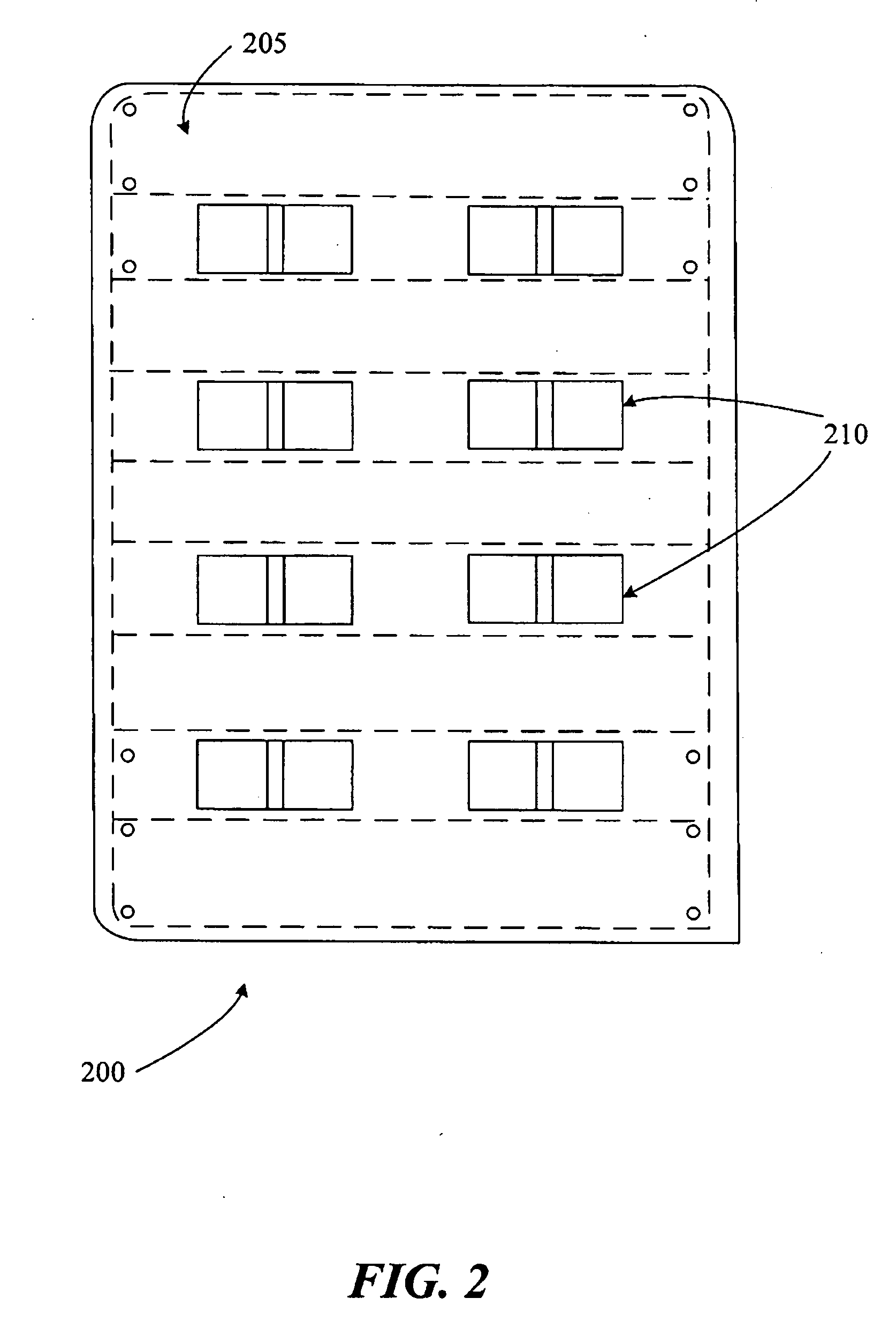

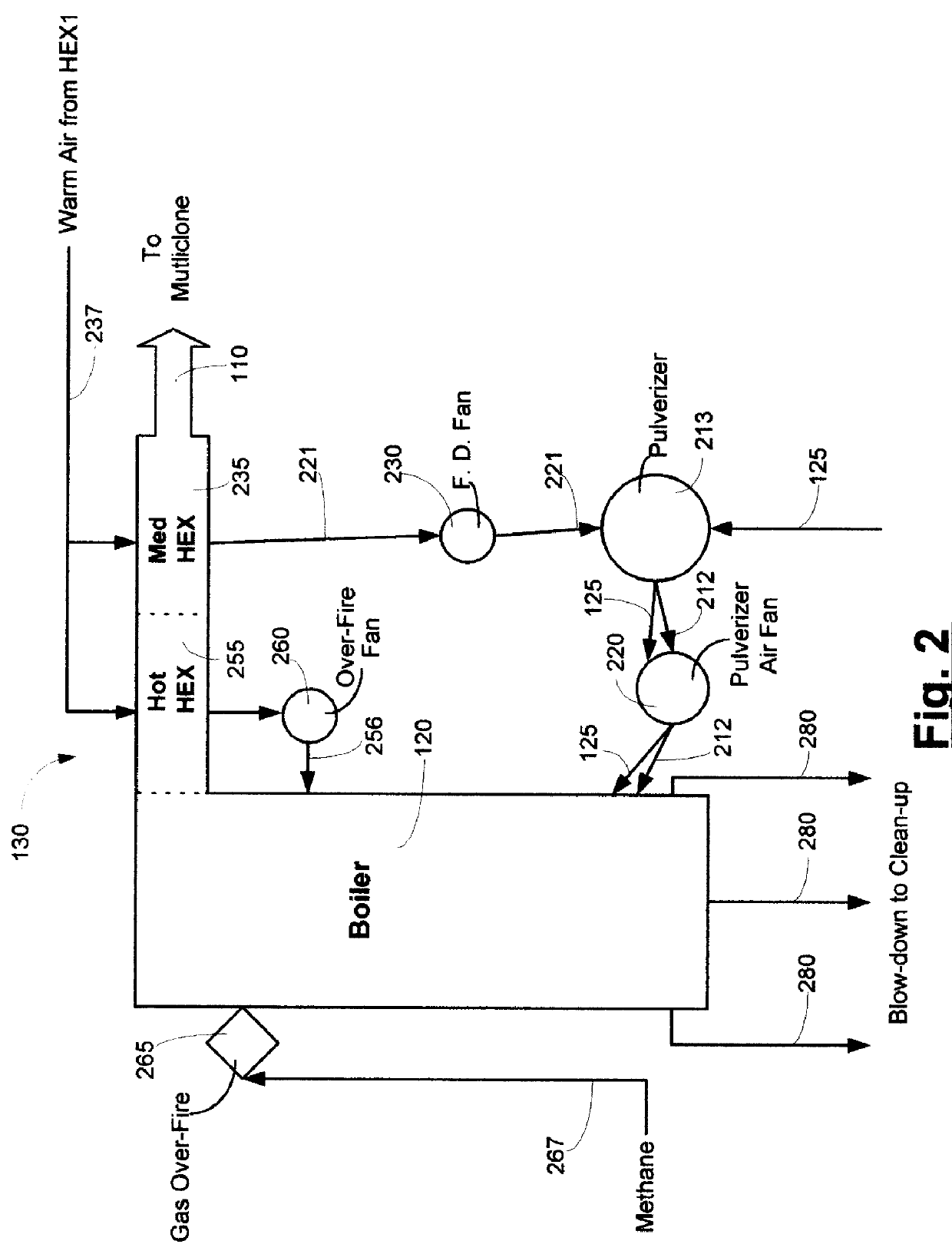

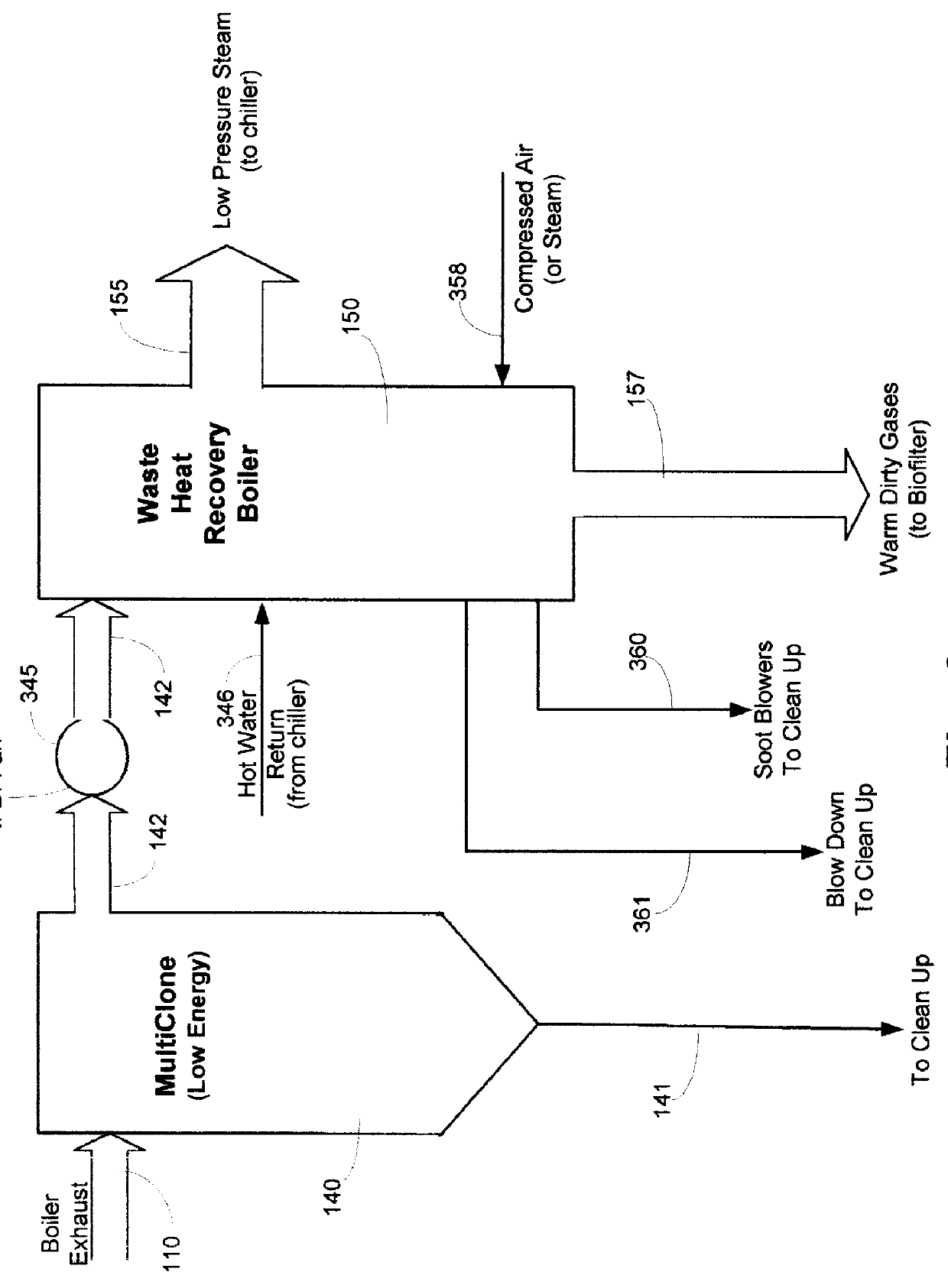

Moving bed biofilter and condenser for flue gas pollutant removal and collection

InactiveUS6117672ALow costReduce water consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid wasteCombustion chamber

A system for removing particulate, sulfur dioxide, nitrogenous oxides and other condensables from the flue gas of a coal, lignite, or other solid fuel combustor. The system can combine biomass filtration, anaerobic digestion, steam absorption refrigeration, and heat exchangers to minimize parasitic energy consumption, solid and liquid waste disposal and interference with combustion efficiency, while achieving near total reduction of contaminants without regard to sulfur or ash content of fuel. Gases at the exit of a multiclone of a fuel-combustor enter a waste heat boiler, generating low pressure steam that drives a steam absorption chiller. The flue gas which still contains small particulate material pass through a moving belt system conveying a mat of chopped biomass that can be impregnated with bacteria that feed on nitrogenous oxides. The mat is sufficiently thick and moist to entrap the remaining solids and smoke in the exhaust stream. The particulate-free flue gas passes through a staged heat exchanger which can utilize ambient air, pond water, and the refrigerated water from the steam absorption chiller to condense the water vapor in the exhaust stream. Sulfur oxides exits the flue gas stream with the condensed water vapor which can be processed in an anaerobic digester. Methanogenic bacteria within the digester can convert the mat and the acidic condensate into a biogas, a combination of methane and carbon dioxide, and plant growth media.

Owner:TECHN INFORMATION

LED wall pack

InactiveUS20150167936A1Improve cooling effectLow energy efficiencyPlanar light sourcesPoint-like light sourceLED lampHeat spreader

This invention discloses an LED wall pack, which comprises a power supply box; a power supply disposed in the power supply box; a door covered on the power supply box; wherein the LED wall pack also comprises a heat sink, an LED light panel, and a transparent or translucent protective case; in which the LED light panel is connected to the power supply and secured to the front side of the health sink; the protective case is covered on the LED light panel and is secured to the front side of the heat sink; the door is secured on the back side of the heat sink; and the heat sink is connected with the power supply box. The LED wall pack of the invention has good heat dissipation, provides uniform light, enables easy maintenance, and provides long usage life. It can be widely used in the field of lighting.

Owner:SHENZHEN YAORONG TECH

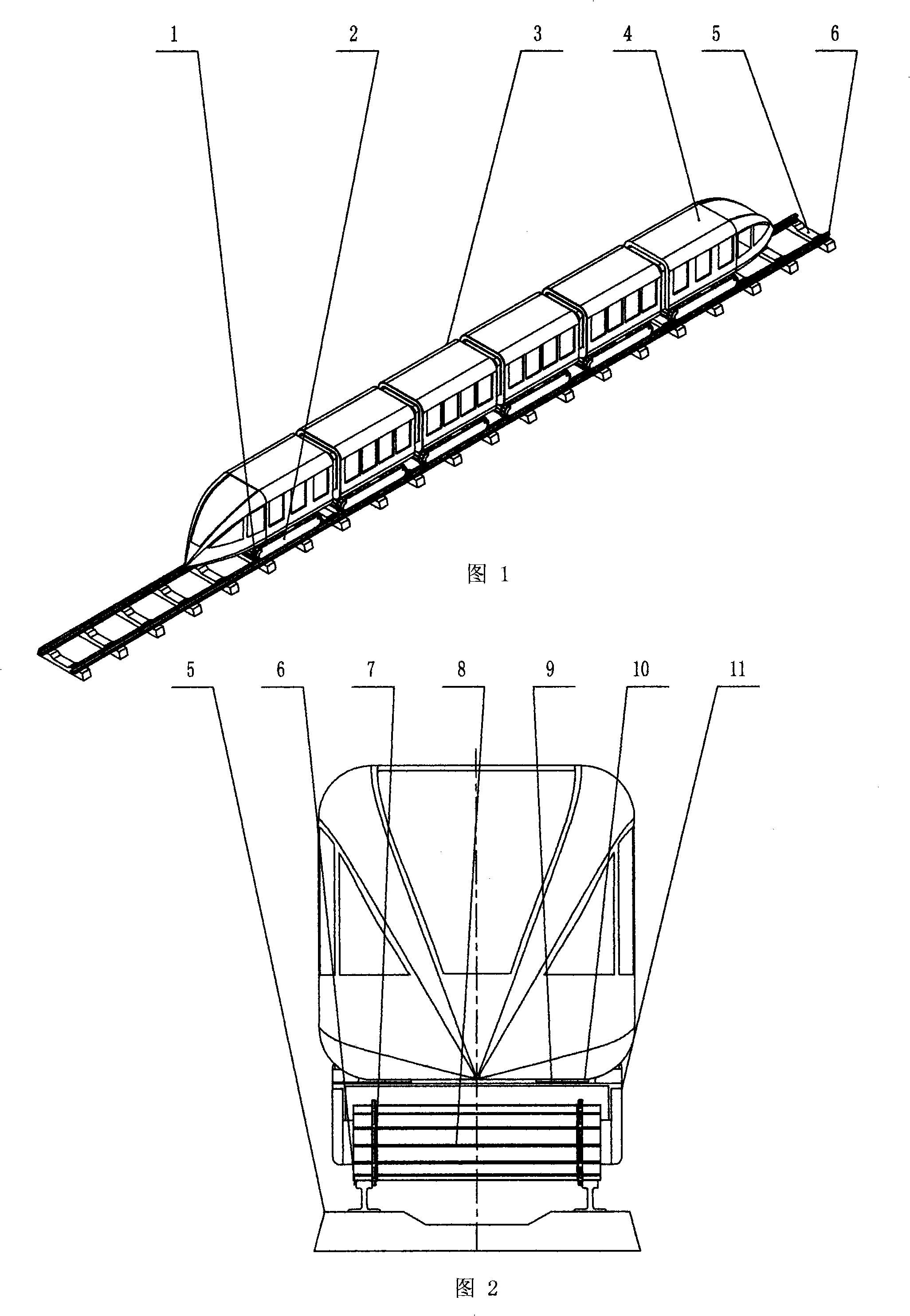

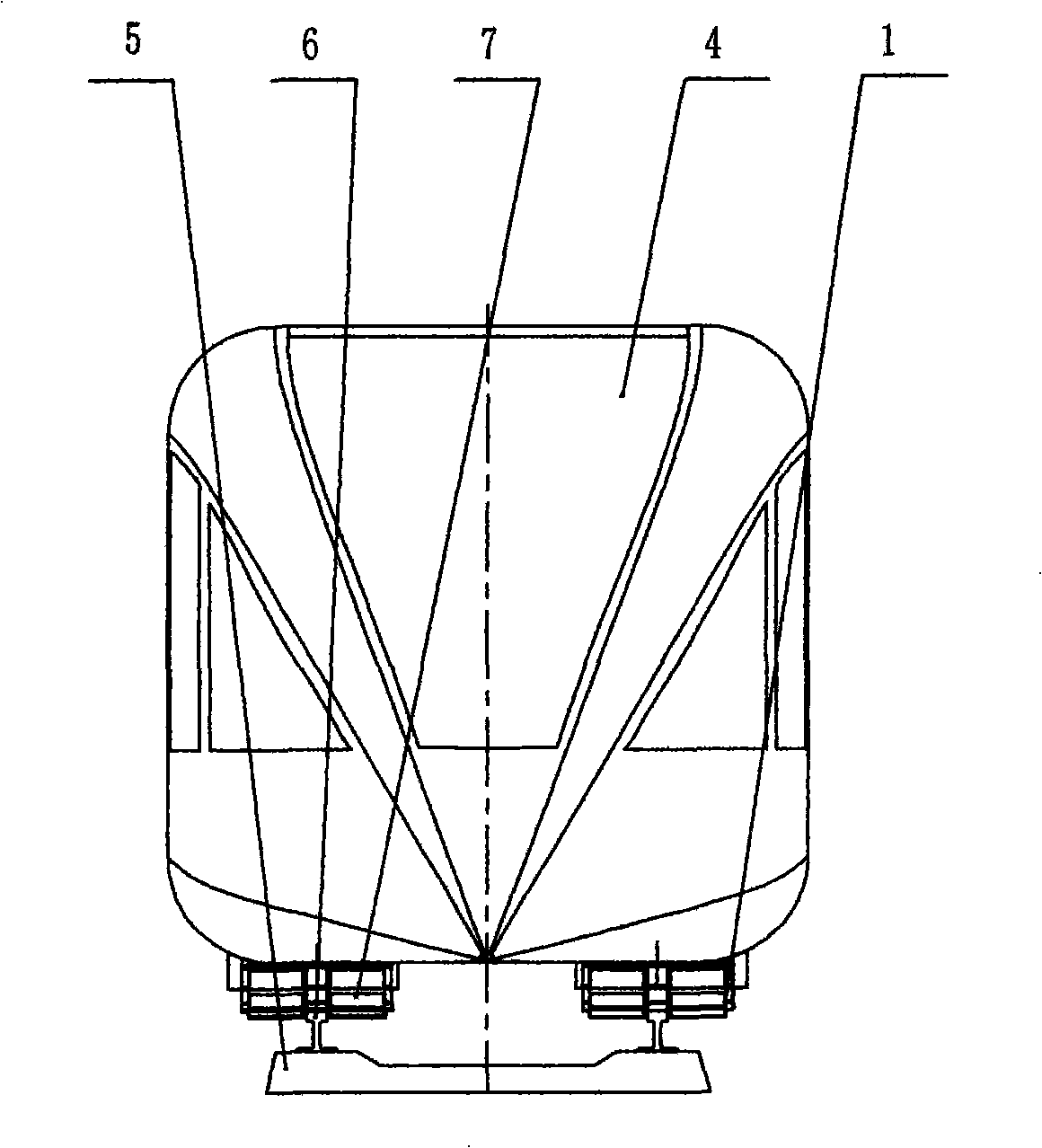

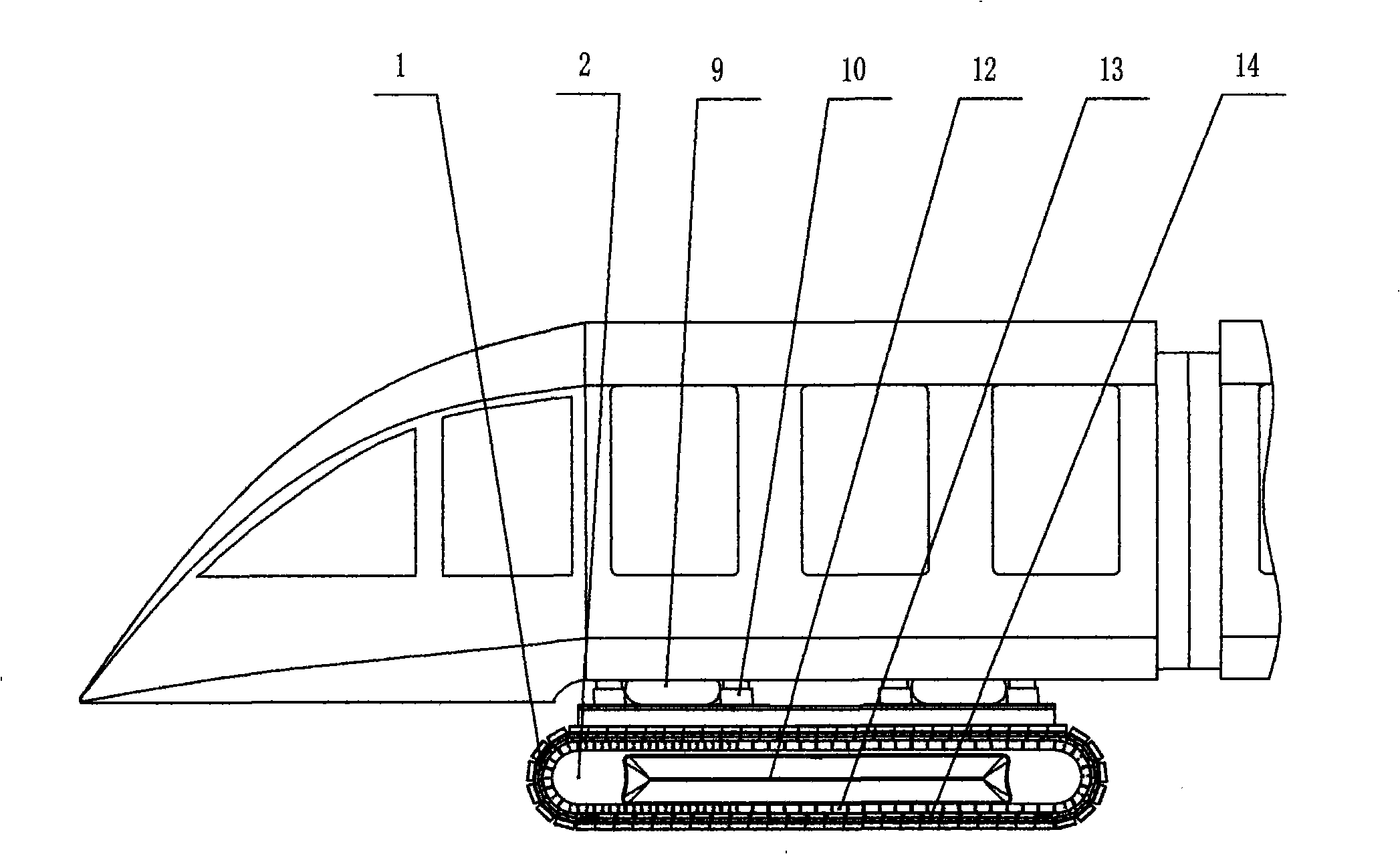

Crawler maglev vehicle and conveyor

InactiveCN101407181ASimple structureLow costEndless track vehiclesElectric propulsionDrive wheelFriction force

The invention provides a tracked magnetic suspension vehicle / a conveyer, which comprise a track, permanent magnets, a suspension seat and a driving wheel. The track is fixedly connected with the permanent magnet or a magnetizer, the suspension seat is fixedly connected with the permanent magnet, and the permanent magnet on the track and the permanent magnet on the suspension seat have homopolarity (or heteropolarity) and are arranged oppositely, generate magnetic suspension repulsive force (or attractive force) opposite to gravitational attraction, reduce or eliminate friction force when a vehicle runs, and reduce energy dissipation. The tracked magnetic suspension vehicle has the advantages of no energy consumption during suspension, low energy consumption during running, and energy saving. The tracked magnetic suspension vehicle achieves trackless magnetic suspension, also can run on a road, and is not limited by railway track any more. The tracked magnetic suspension vehicle also can be used as a magnetic suspension conveyer, and is energy-saving, clean and dustless.

Owner:刘忠臣

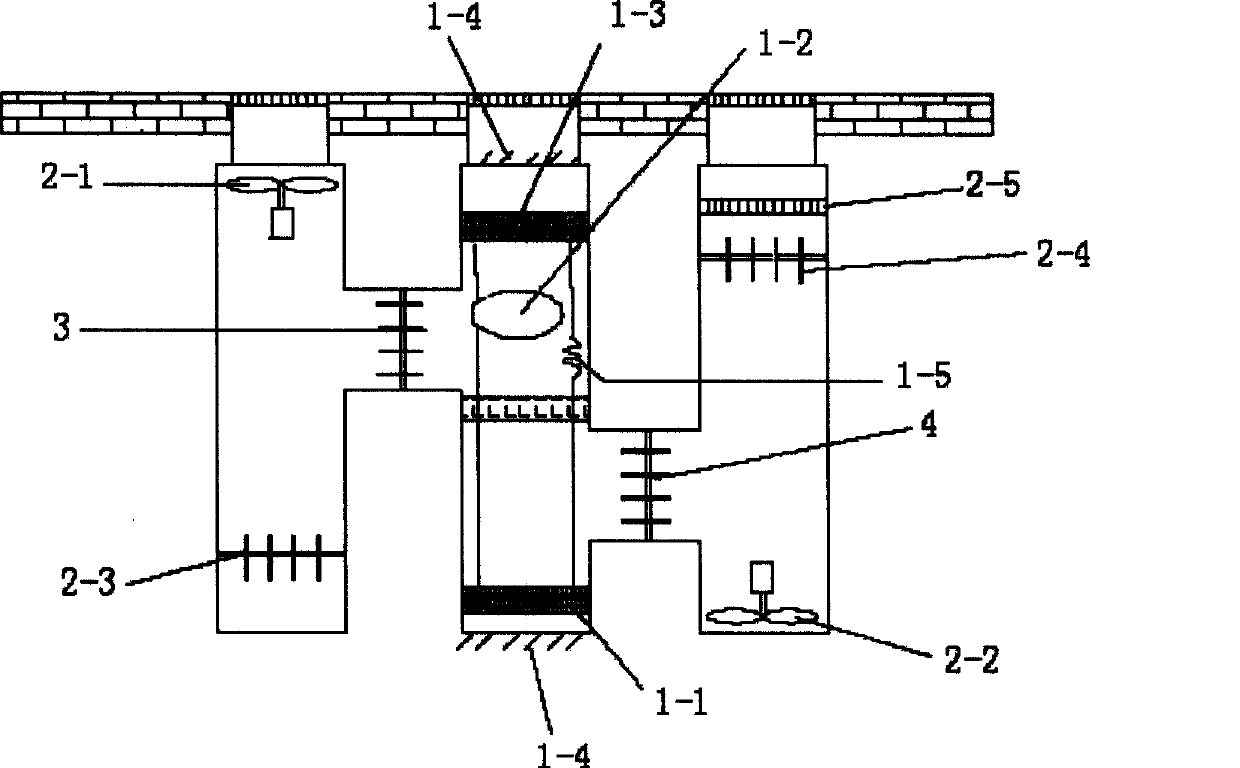

Power system for dual-motor hybrid vehicle

InactiveUS7343993B2Complex structureSimple structureDigital data processing detailsElectric propulsion mountingExhaust gas emissionsEnergy recovery

A power system for dual-motor hybrid vehicle is a combined driving unit fed with fuel and electric power, comprising: an internal combustion engine, a motor, a clutch, a transmission, a power battery, a braking system and an entire vehicle controller, wherein the system further comprises: a main motor, an auxiliary motor, and a mechanical stepped transmission, a rotor shaft of the main motor being connected with the output shaft of the transmission, a rotor shaft of the auxiliary motor being connected with the crankshaft of the internal combustion engine; the main motor and the auxiliary motor being electrically connected with the power battery. With the control of the entire vehicle controller, the vehicle can be driven automatically by the hybrid power system in the follow modes: pure motor driving mode, series driving mode, parallel driving mode, hybrid driving mode, idling stop mode of the internal combustion engine, braking energy recovery mode, independently driving mode of the internal combustion engine, and motor auxiliarily driving mode during shifting. The present invention provides a new power system for hybrid vehicle, with simple structure, lower cost, less energy consumption and less exhaust gas emissions.

Owner:CHINA FIRST AUTOMOBILE GRP

Integral fuel gas buring catalyst and process for preparing the same

InactiveCN1504260AHigh activityImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCatalytic functionHigh activity

The invention discloses an integral style gas, combustion catalyst and method for the making same, wherein the base material of the catalyst is integral ceramic honeycomb body or metallic honeycomb body, the catalyst coating layer coated on the base material surface comprises catalytic functional components and coating layer aiding agents, the catalytic functional components are classified into compound catalytic functional components having at least three different catalytic functions, each of which is prepared through corresponding predecessor physical process. The catalyst by the invention has high activity, high stability, high heat efficiency and low contaminant discharge.

Owner:SICHUAN TIANJIAN CATALYTIC COMBUSTION

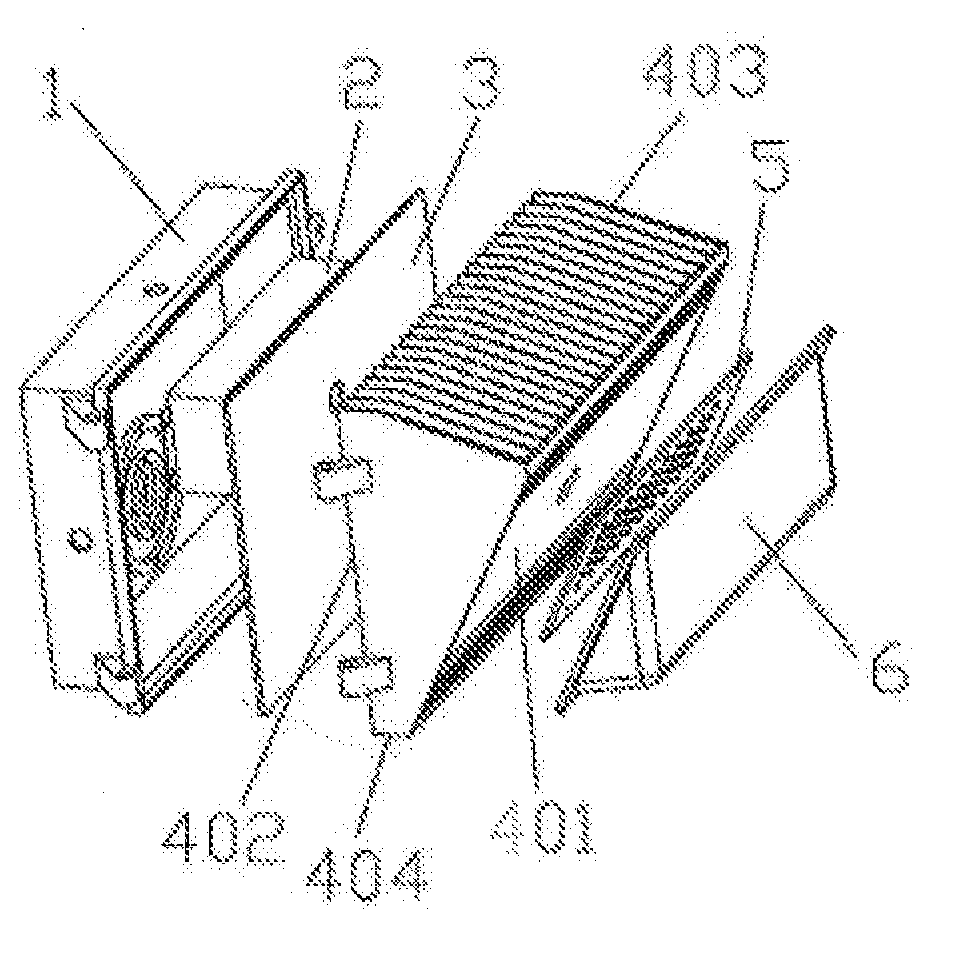

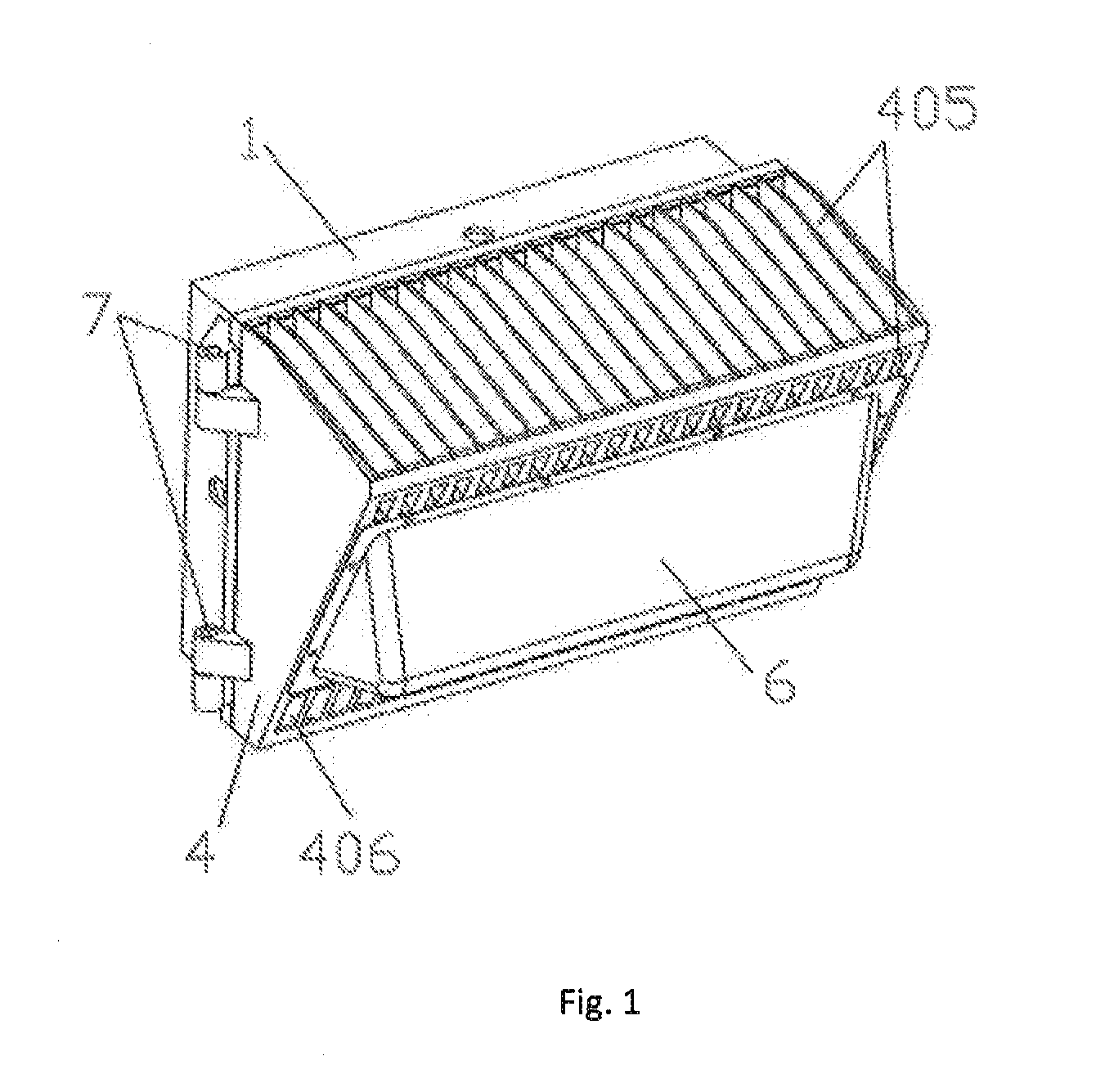

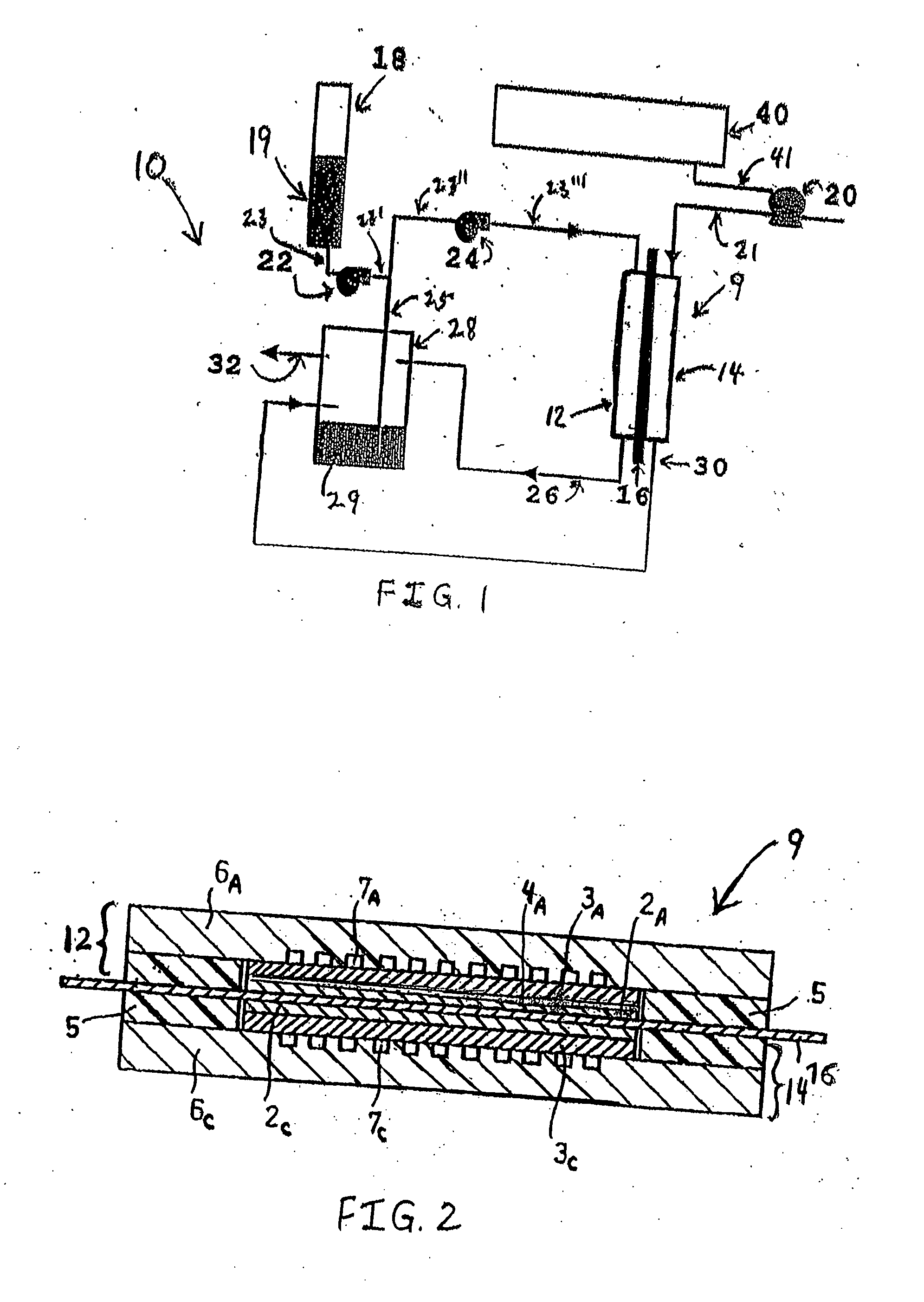

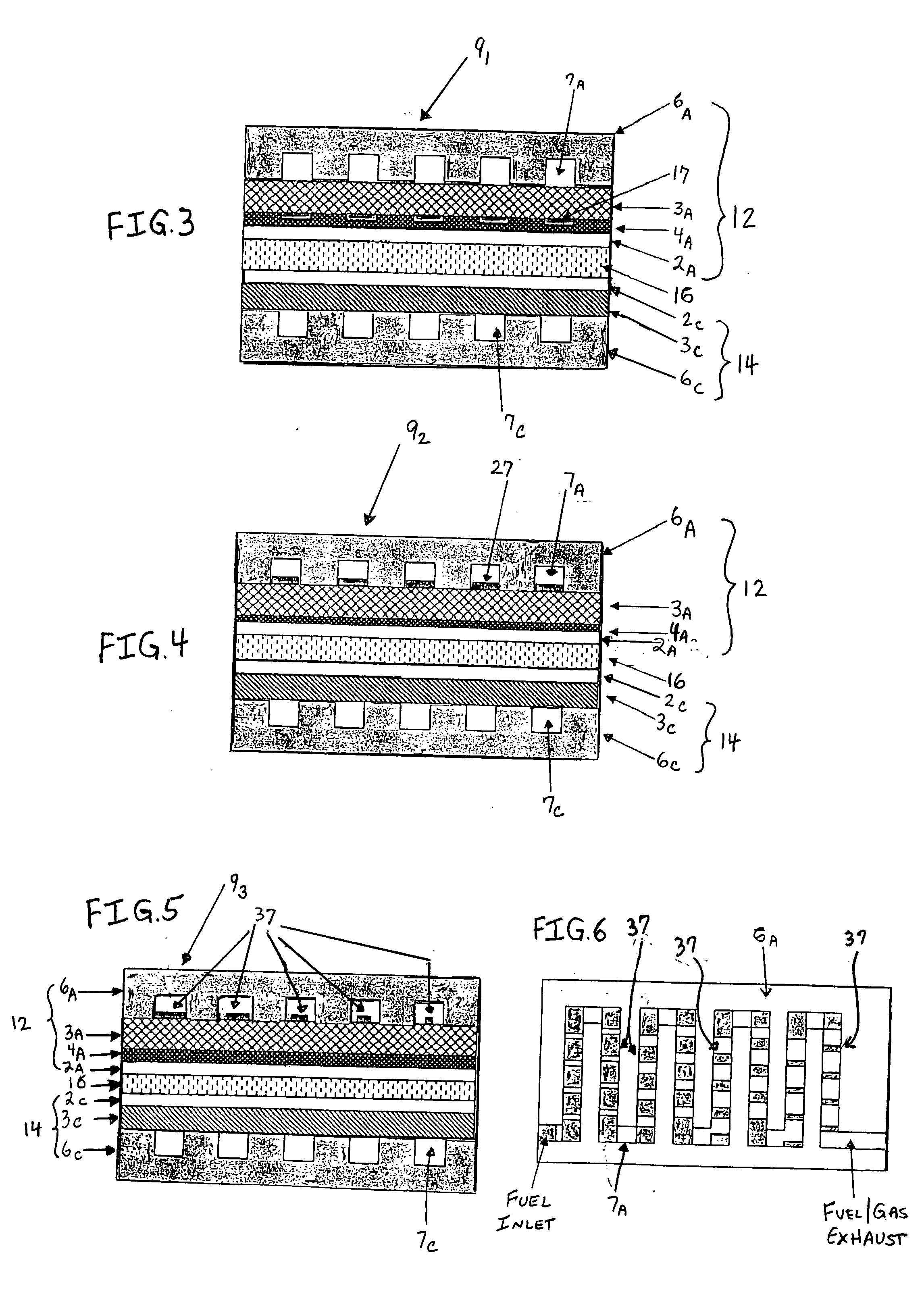

Anode electrodes for direct oxidation fuel cells and systems operating with concentrated liquid fuel

InactiveUS20070190401A1Increase energy densityLow energy efficiencyWater management in fuel cellsActive material electrodesFuel cellsAs Directed

An anode electrode for use in a fuel cell comprises a stacked structure including, in sequence: a catalyst layer, a hydrophobic, microporous layer (“MPL”), a porous gas diffusion layer (“GDL”), and an anode plate with at least one recessed fuel supply-fuel / gas exhaust channel formed in a surface thereof facing the GDL, wherein the stacked structure further comprises at least one hydrophobic region aligned with the at least one recessed channel. The electrode is useful in direct oxidation fuel cells and systems, such as direct methanol fuel cells operating with highly concentrated liquid fuel. An anode electrode for use in a fuel cell comprises a stacked structure including, in sequence: a catalyst layer, a hydrophobic, microporous layer (“MPL”), a porous gas diffusion layer (“GDL”), and an anode plate with at least one recessed fuel supply-fuel / gas exhaust channel formed in a surface thereof facing the GDL, wherein the stacked structure further comprises at least one hydrophobic region aligned with the at least one recessed channel. The electrode is useful in direct oxidation fuel cells and systems, such as direct methanol fuel cells operating with highly concentrated liquid fuel.

Owner:PANASONIC CORP +1

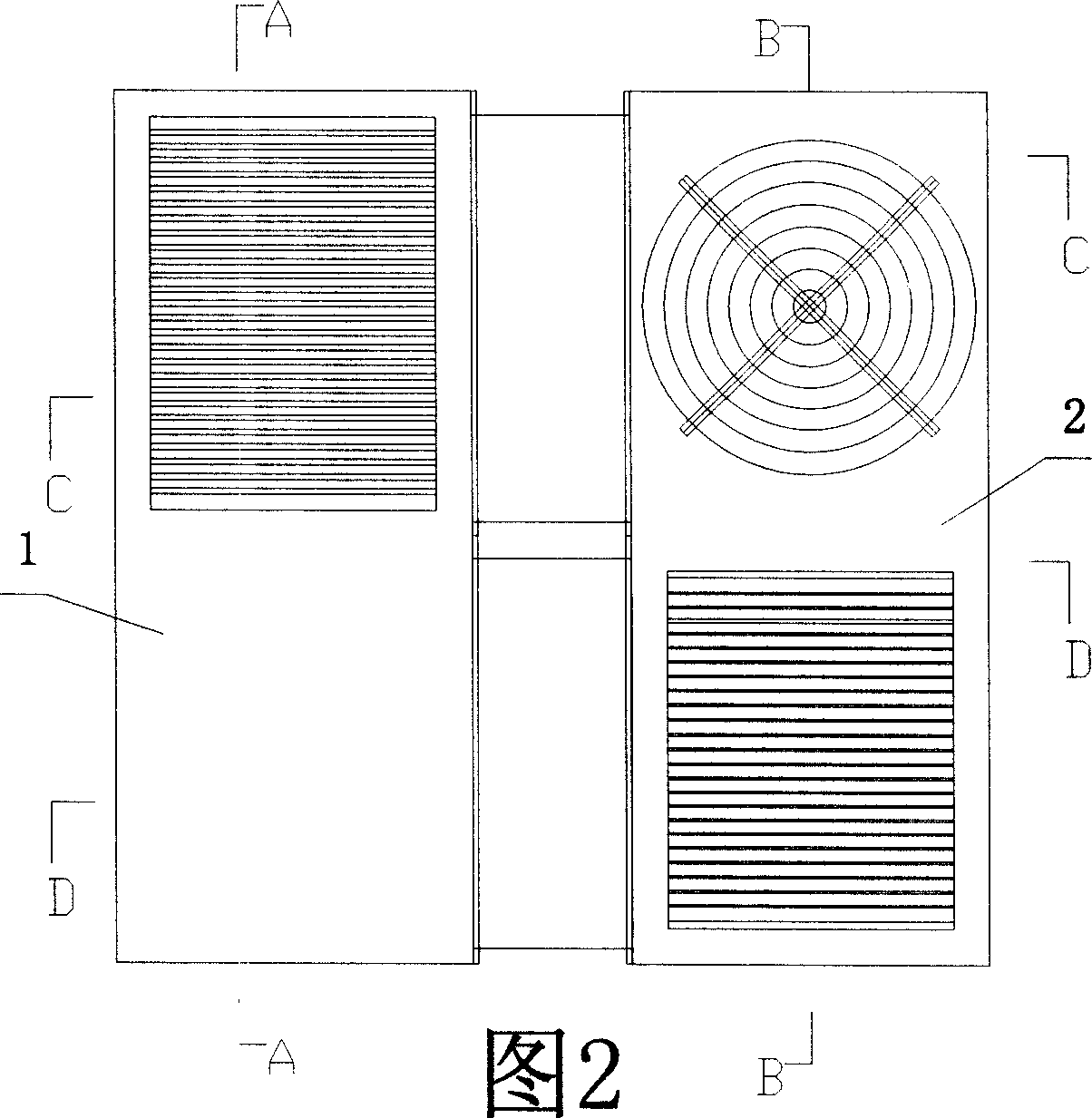

Fresh air integral energy-saving air conditioner unit special for machinery room

InactiveCN101373087AImprove insulation effectIncrease temperatureLighting and heating apparatusAir conditioning systemsBusiness efficiencyFresh air

The invention relates to a fresh air integral-type air conditioning unit used particularly in an energy-saving equipment room. The unit comprises an air conditioner, an automatic air brake, a controller and a fresh air machine, wherein, a compressor, a condenser, an evaporator, a capillary throttle pipe and a connecting pipe are assembled to form an integral air conditioner which is divided into an upper layer and a lower layer by a clapboard; the fresh air machine comprises an automatic air inlet brake, an automatic air exhaust brake, an air inlet fan and an air exhaust fan; the fresh air machine is divided into an upper layer and a lower layer corresponding to the air conditioner; the automatic air inlet brake and the air inlet fan are arranged on the upper layer of the fresh air machine; the automatic air exhaust brake and the air exhaust fan are arranged on the lower layer of the fresh air machine; the fresh air machine is respectively connected through the pipe with the upper and the lower layer of the air conditioner to form a whole; an automatic air brake is respectively arranged at the connecting part between the upper layer of the air conditioner and the fresh air machine and the connecting part between the lower layer of the air conditioner and the fresh air machine; and the controller is respectively connected with the automatic air exhaust brake, the automatic air inlet brake, the air exhaust fan, the air inlet fan, two automatic air brakes, and the air conditioner. The air conditioning unit is characterized in that the energy efficiency ratio between fresh air cooling and fresh air heating is particularly high; furthermore, the air conditioning unit can be integrally installed in the equipment room for security concern, or outside the equipment room for reducing noise and occupied space.

Owner:姚京生

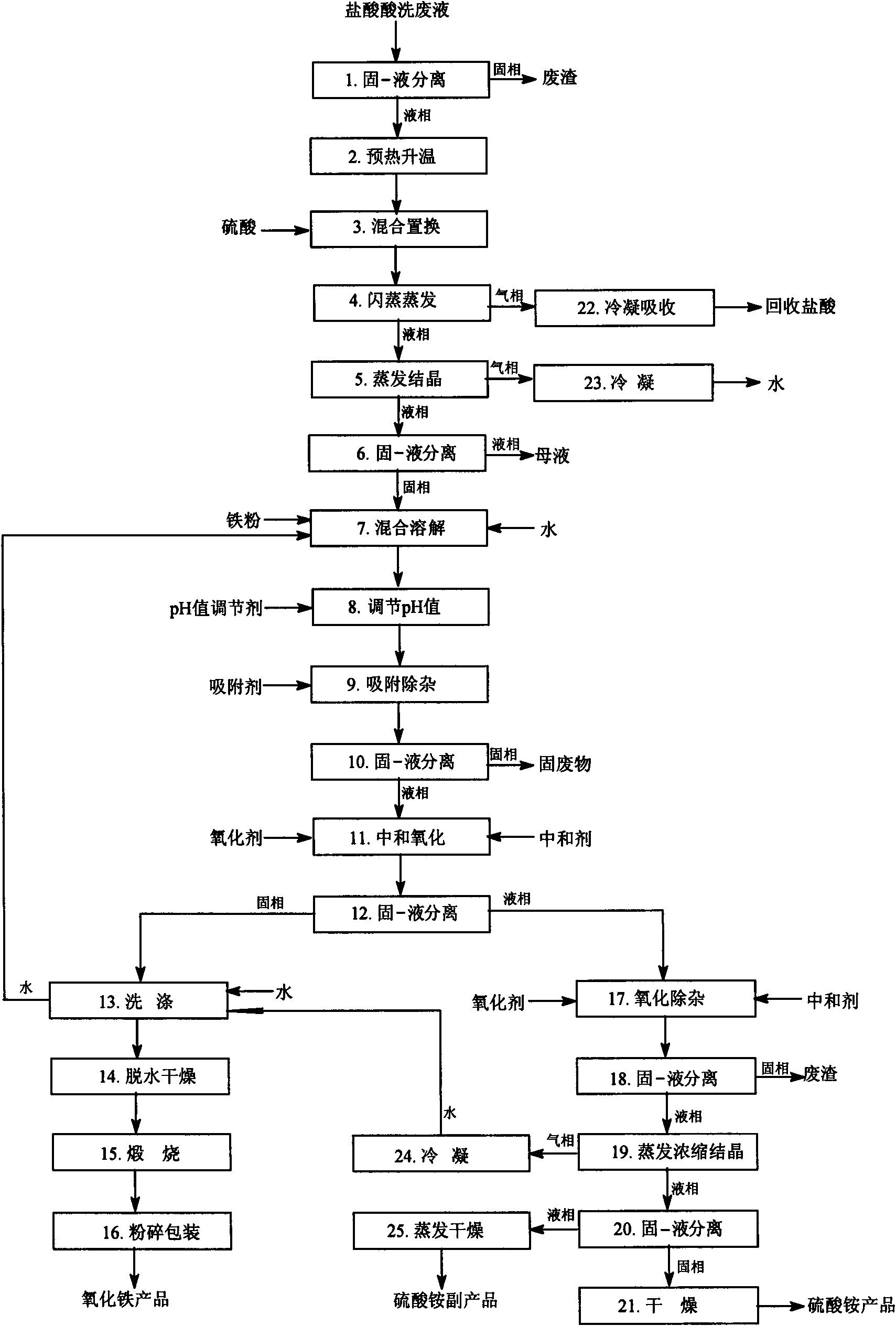

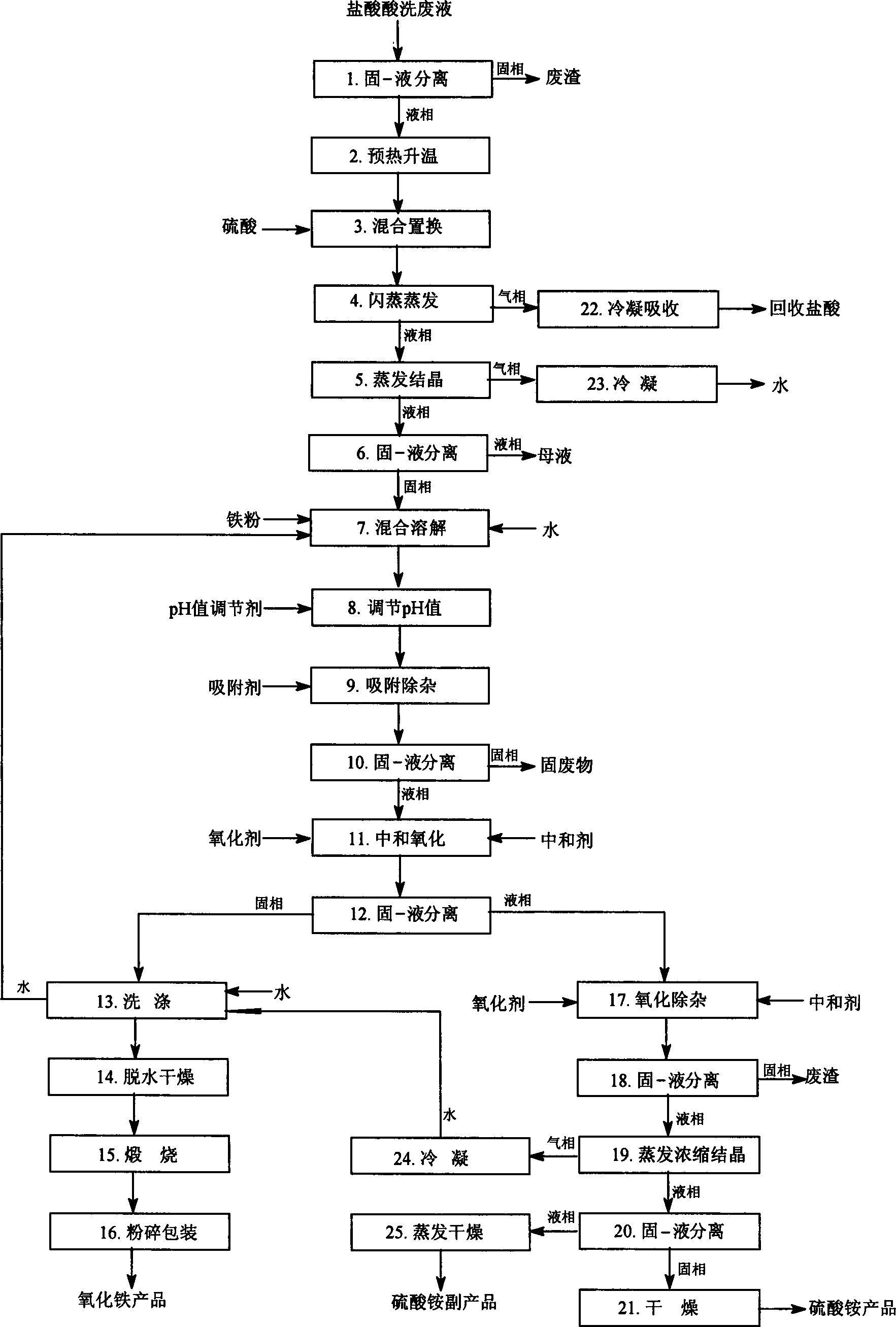

Hydrochloric acid pickling waste liquid resource integrated utilization method for preparing iron oxide and ammonium sulfate

InactiveCN102689930AFull replacementWell mixedChlorine/hydrogen-chlorideEnergy inputEvaporationImpurity

The invention relates to a hydrochloric acid pickling waste liquid resource integrated utilization method for preparing iron oxide and ammonium sulfate. Iron-containing hydrochloric acid pickling waste liquid obtained from a pickling treatment process, which uses hydrochloric acid solution as a pickle to remove surface oxides on a steel element, is used as a raw material. The method comprises the following steps of: (1) solid-liquid separation; (2) preheating and heating; (3) miscible displacement; (4) flash evaporation; (5) evaporation and crystallization; (6) solid-liquid separation; (7) mixing and dissolving; (8) pH adjusting; (9) adsorption for impurity removal; (10) solid-liquid separation; (11) neutralization and oxidation; and (12) solid-liquid separation. A liquid phase material is further used for preparation of an ammonium sulfate product, and a solid phase material is further used for preparation of an iron oxide product; besides, ammonium sulfate by-products can be prepared in further preparation of the ammonium sulfate product. The invention has advantages of reasonable technology, simple method, environment-friendliness, energy saving, low preparation cost, good product quality and high utilization rate of valuable components.

Owner:江苏江盛南节能科技有限公司

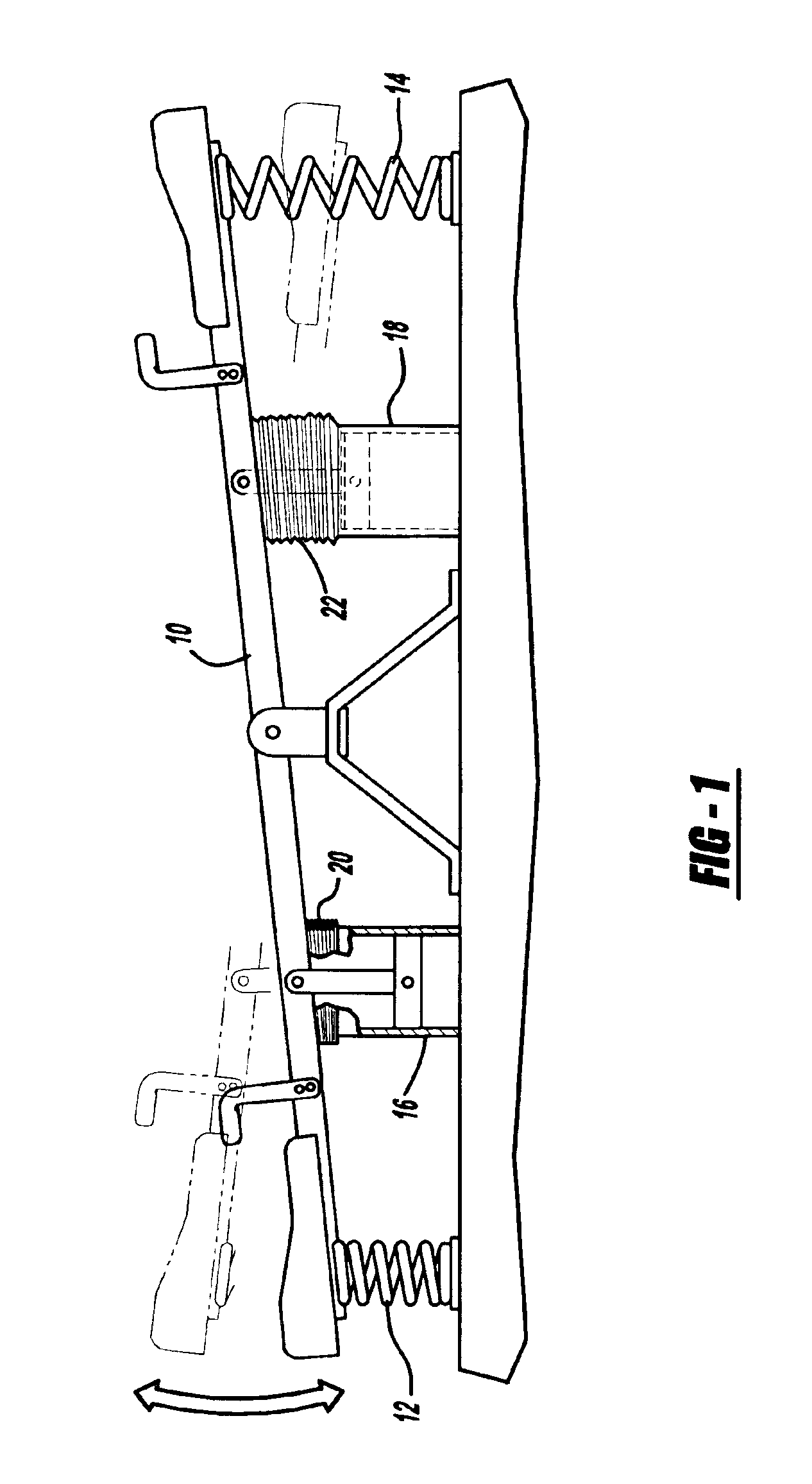

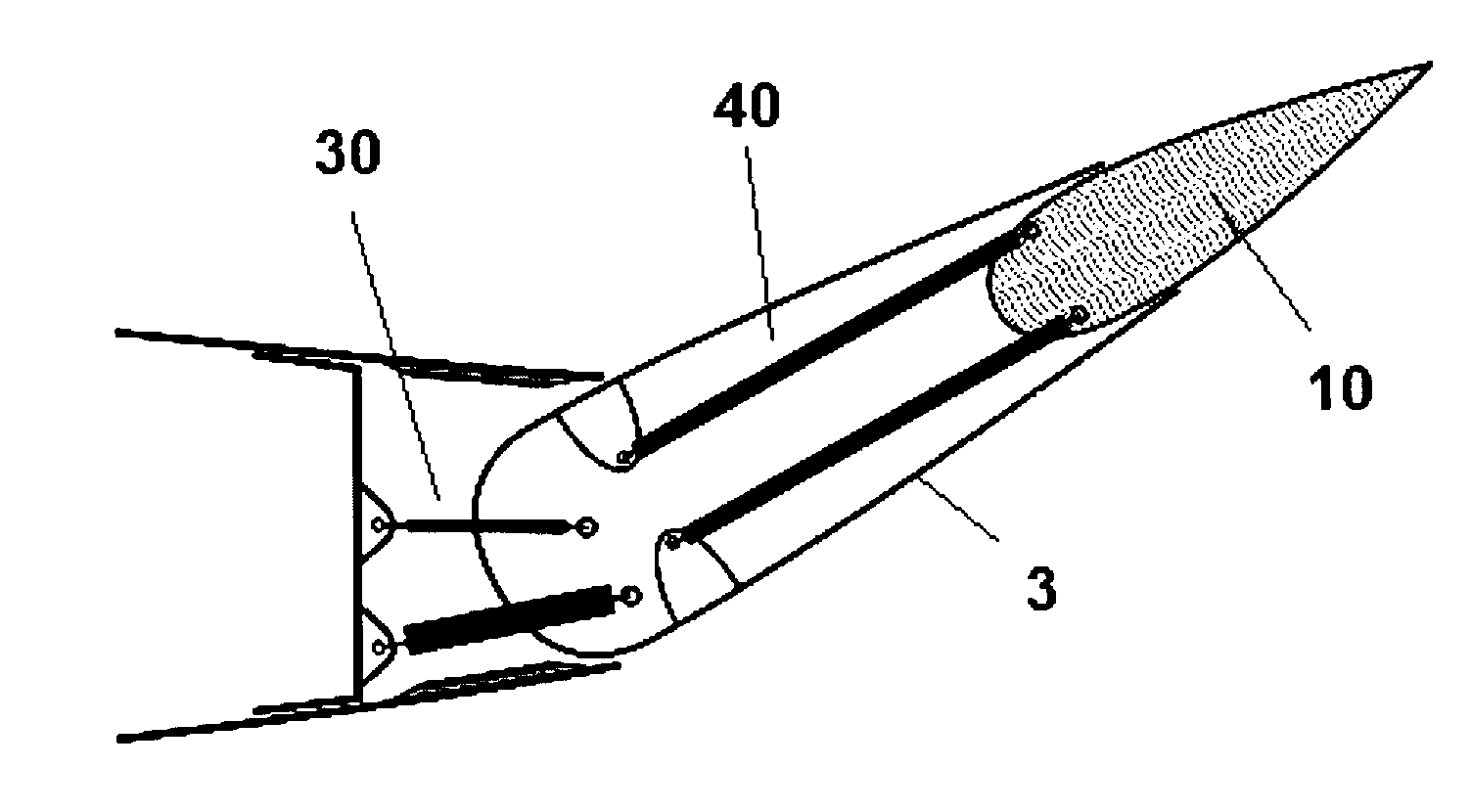

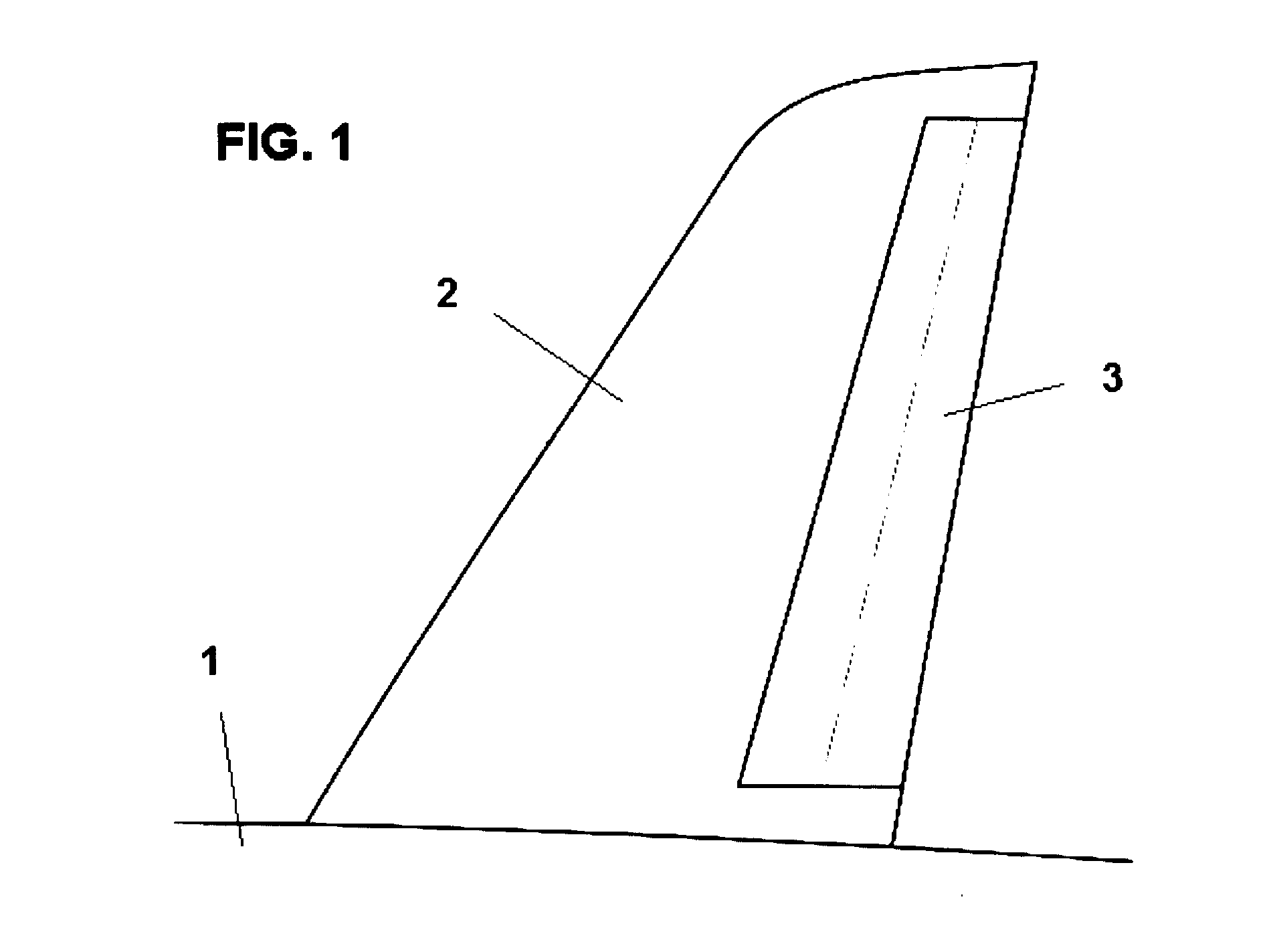

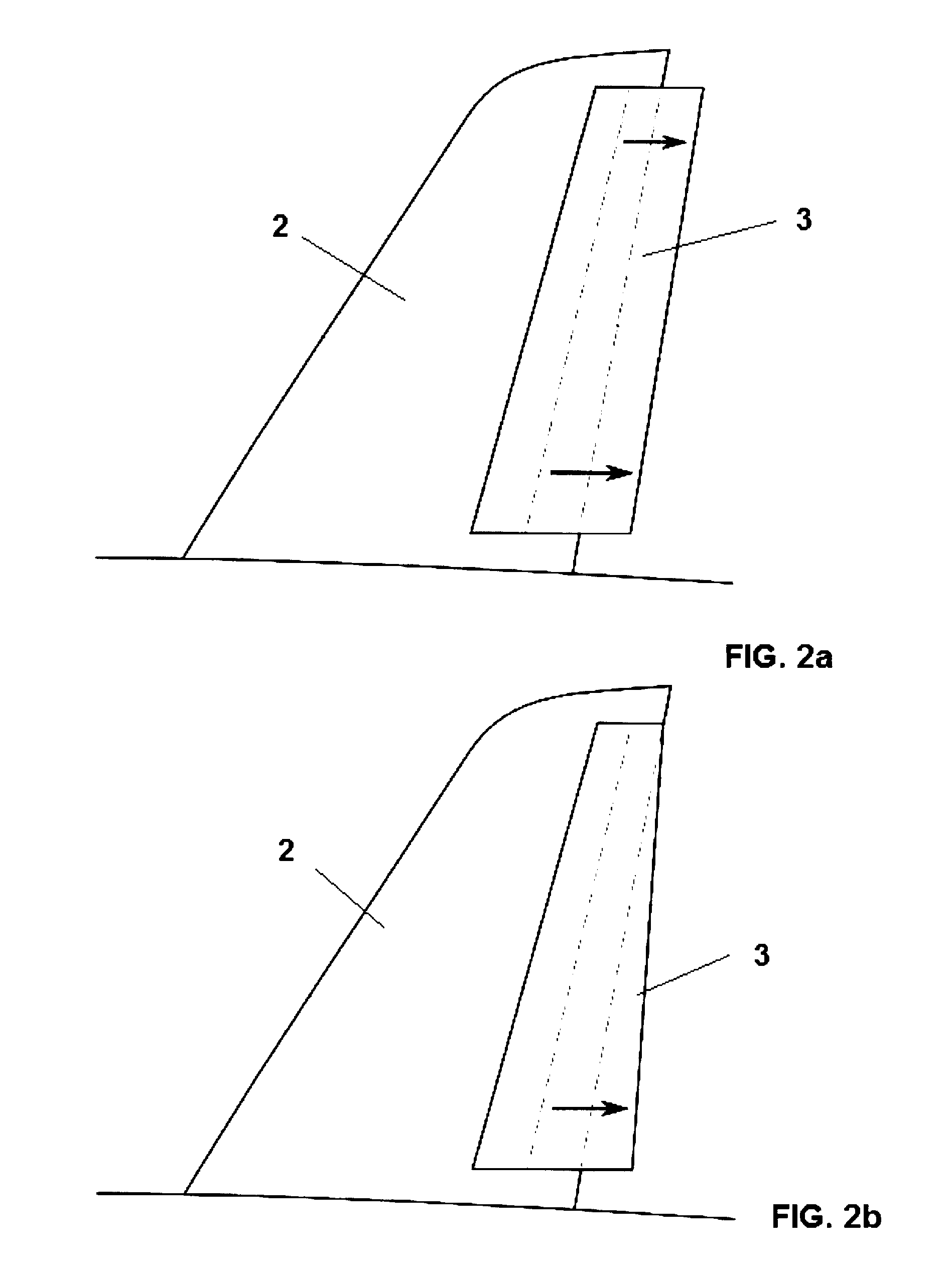

Stabilizing and directional-control surface of aircraft

InactiveUS20090256025A1Increases weight of unitLow energy efficiencyAircraft stabilisationWing lift eficiencyLow speedControllability

Stabilizing and directional-control surface of an aircraft, said surface comprising a vertical stabilizer (2) and a rudder (3), it being possible for said rudder (3) to be deflected relative to the vertical stabilizer (2), and moreover the rudder (3) comprises an internal profile (10) that can be extended and retracted by means of an actuating system (40) relative to the rest of the structure of the rudder (3), so that the stabilizing and control surface, in the retracted position of the internal profile (10) of the rudder (3), is an excellent aerodynamic surface in normal flying conditions, and at the same time increase of the aerodynamic control surface of the vertical stabilizer (2) is achieved for requirements of controllability of the aircraft at low speeds of said aircraft and against strong yawing moments acting thereon, in the position in which the internal profile (10) of the rudder (3) is extended, and moreover the structure of the rudder (3) can be opened, to permit extension of the internal profile (10), and said structure closes once the internal profile (10) is fully extended, so that the rudder (3) forms, with the extended internal profile (10), a structure that preserves its properties of aerodynamic surface and continuity of flow.

Owner:AIRBUS OPERATIONS SL

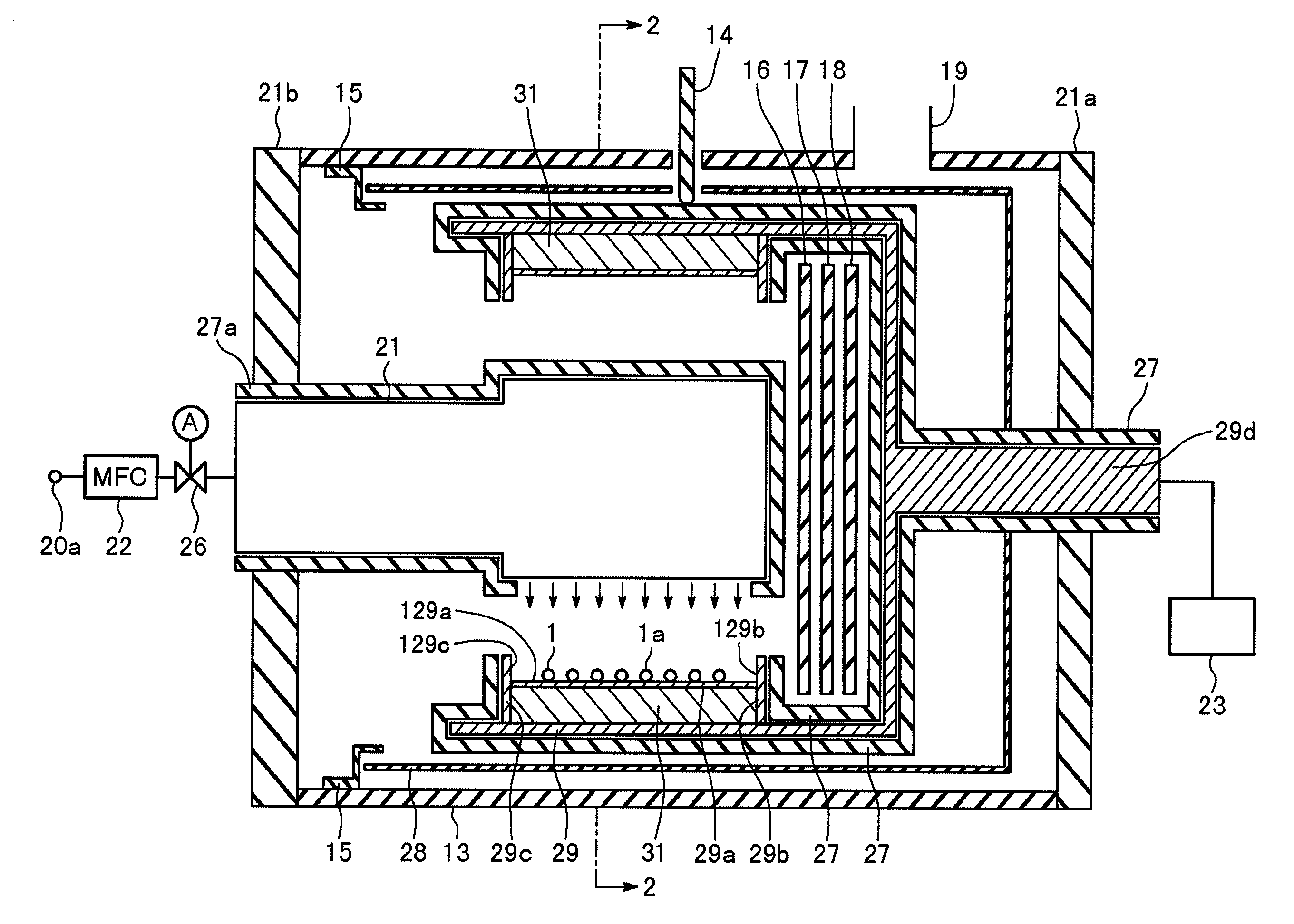

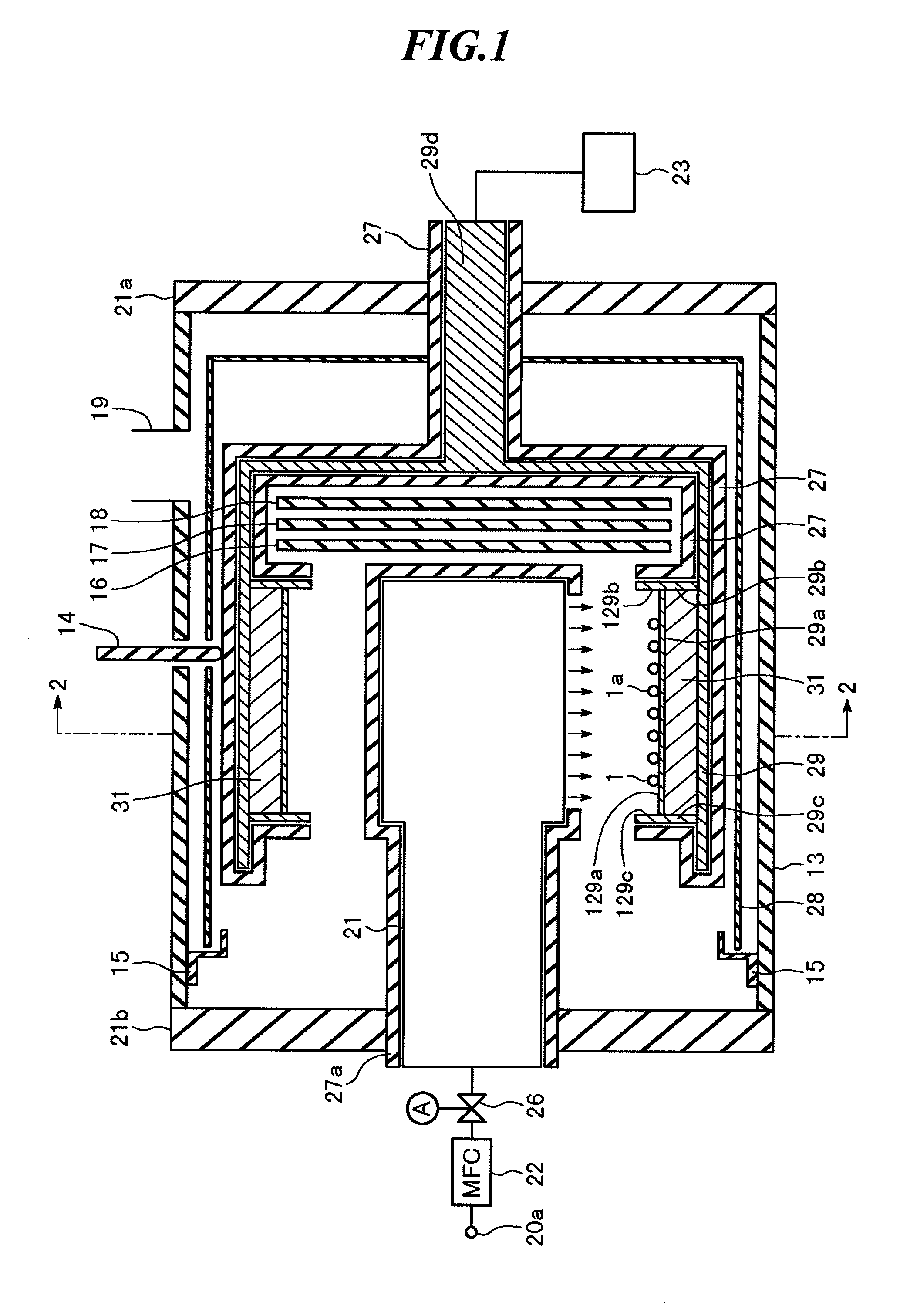

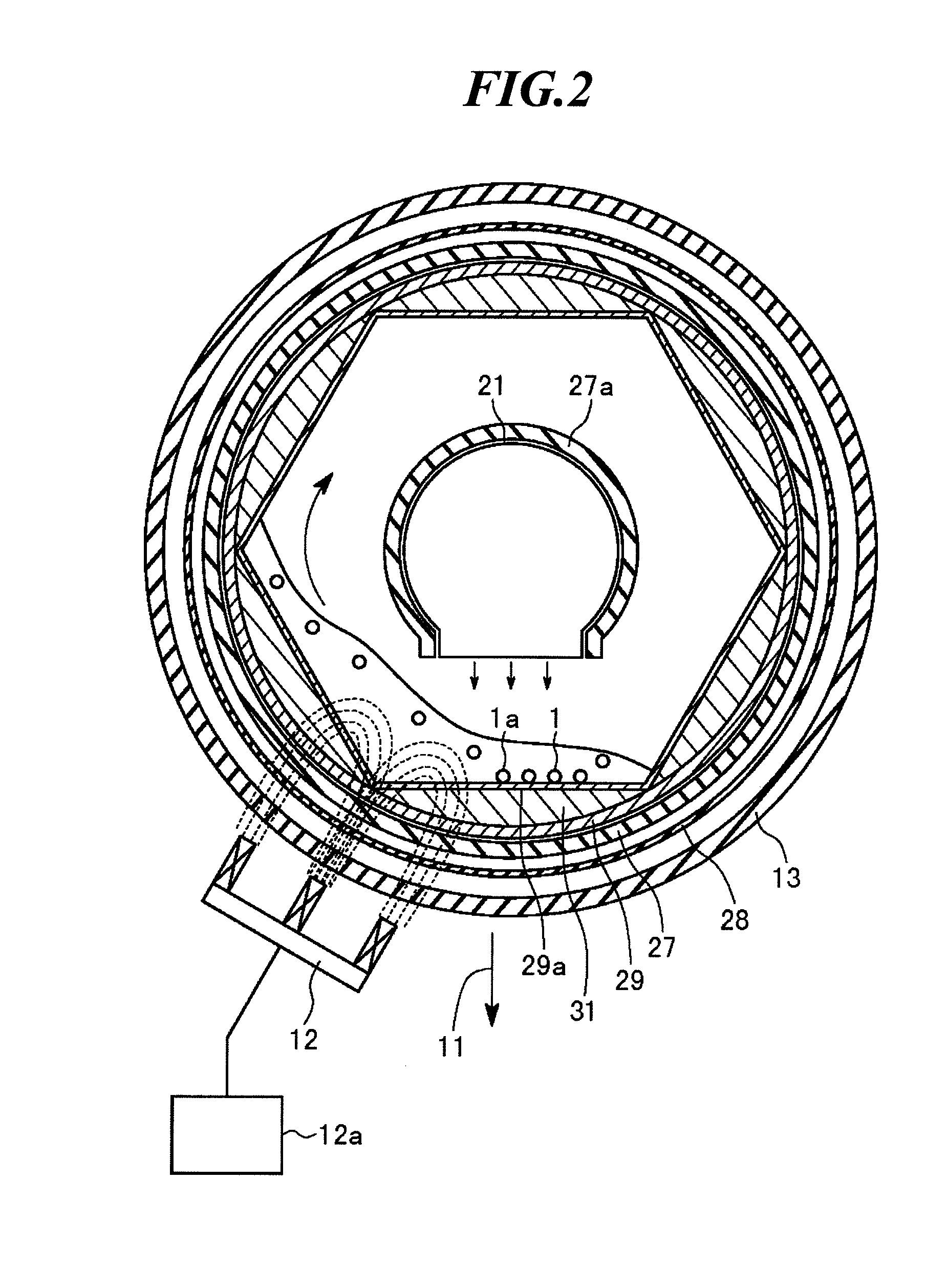

Plasma CVD apparatus, plasma CVD method, and agitating device

InactiveUS20110003088A1Low energy efficiencyA large amountGranule coatingElectric discharge tubesProduct gasEngineering

The present invention provides a plasma CVD apparatus and a plasma CVD method capable of efficiently coating the surfaces of fine particles with a thin film or super-fine particles by concentrating a plasma near the fine particles. The plasma CVD apparatus according to the present invention is characterized by including a chamber 13, a container disposed in the chamber for housing fine particles 1, the container having a polygonal inner shape in a section approximately parallel to the direction of the gravity,a ground shielding member 27 for shielding the surface of the container other than a housing face for housing the fine particles 1, a rotation mechanism for causing the container to rotate or act as a pendulum on the axis of rotation approximately perpendicular to the section,an opposed electrode 21 disposed in the container so as to face the housing face,a plasma power source 23 electrically connected to the container,a gas introducing mechanism for introducing a raw gas into the container, andan evacuation mechanism for evacuating the inside of the chamber.

Owner:ADVANCED MATERIAL TECH INC

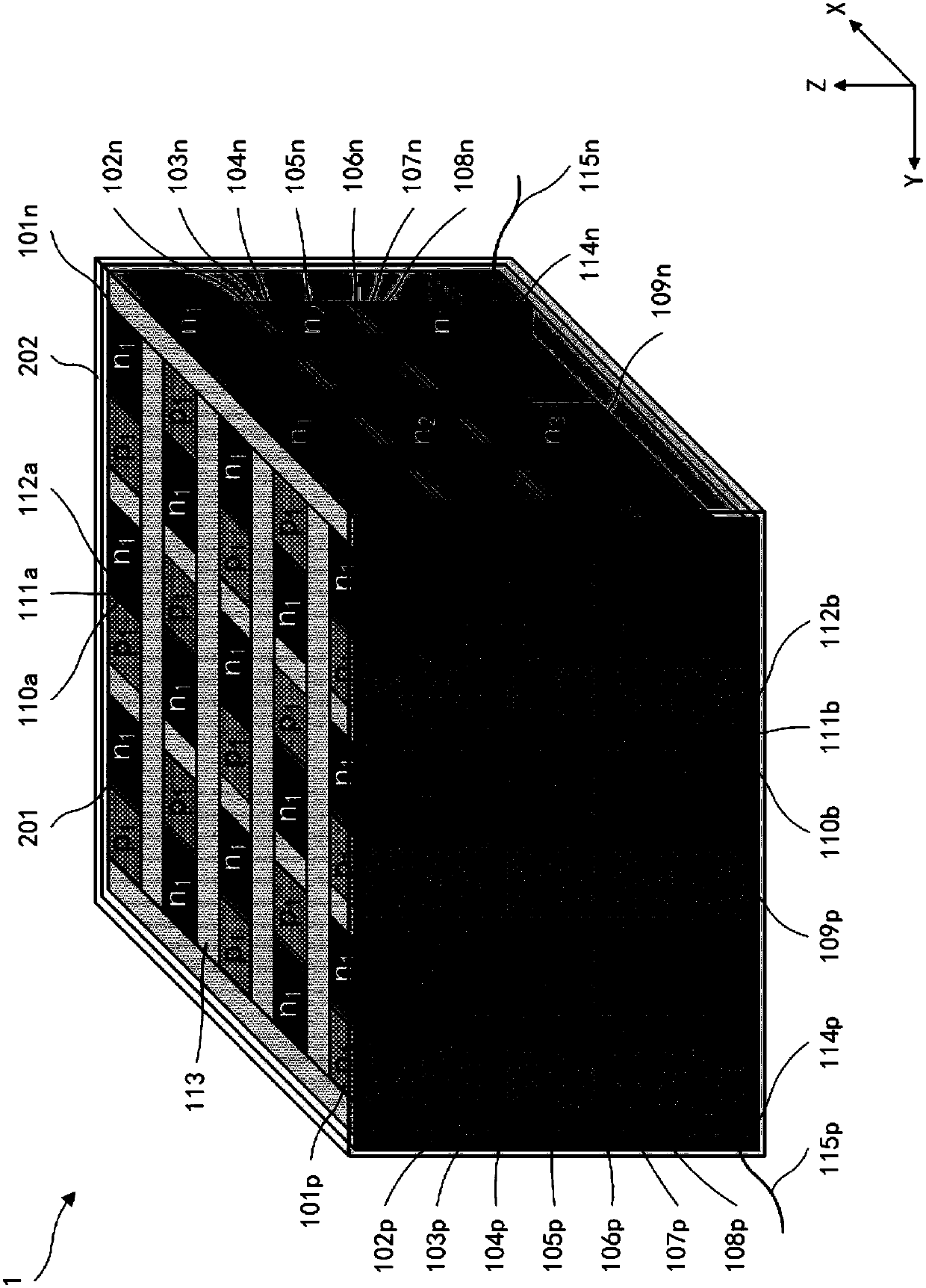

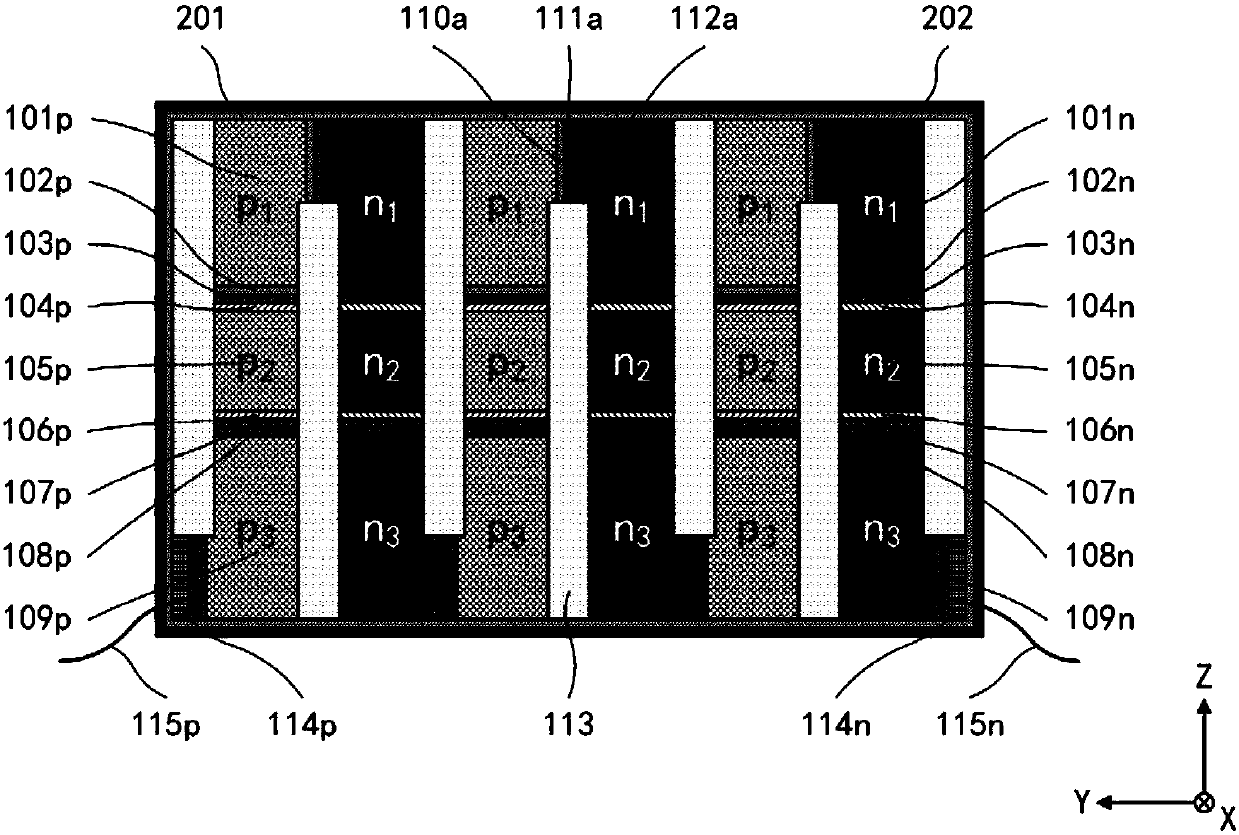

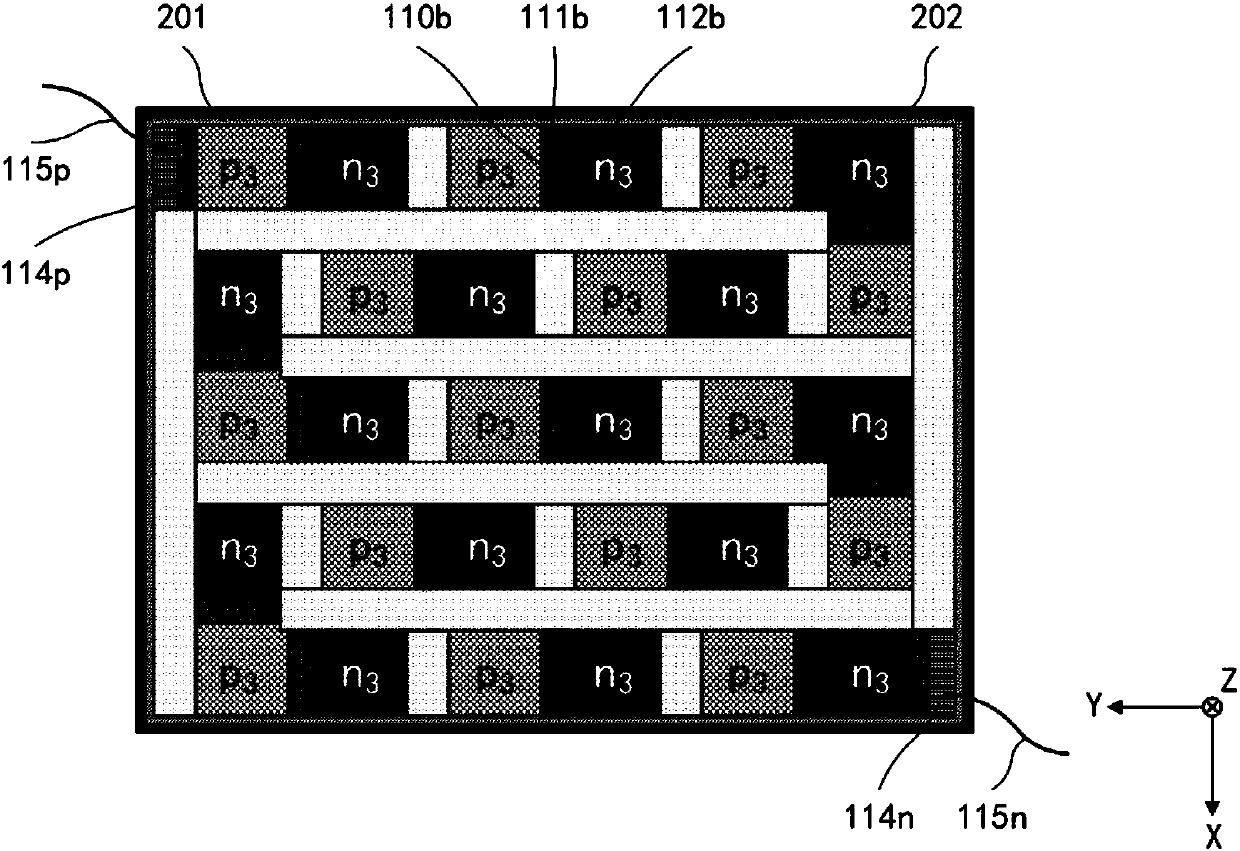

High-performance thermoelectric device and ultrafast fabrication method thereof

ActiveCN107946452AImprove electrical output performanceImprove job stabilityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsEnergy conversion efficiency

The invention discloses a high-performance thermoelectric device and an ultrafast fabrication method thereof. In the high-performance thermoelectric device, a segmented structure is employed to perform optimal matching of a thermoelectric material and a temperature difference environment, a blocking layer and a buffer stress layer are employed to reduce interface element migration and longitudinalcontact thermal expansion stress and improve bonding strength, a phonon scattering layer and a negative thermal expansion buffer layer are embedded to fix a thermoelectric leg so as to improve internal thermal resistance and horizontal thermal matching performance of the high-performance thermoelectric device, internal package and external package are employed to prevent the thermoelectric material from being oxidized and sublimed and improve external collision-resistant capability, the technical bottlenecks of low energy conversion efficiency, small specific power, poor thermal stability, poor collision performance, complicated fabrication process and the like of a traditional thermoelectric device are effectively broken through, meanwhile, the thermal stability and the mechanical structural performance of the high-performance thermoelectric device are improved to a great extent, long-term and excellent electrical output performance is guaranteed, and the working environment is expanded.

Owner:深圳热电新能源科技有限公司

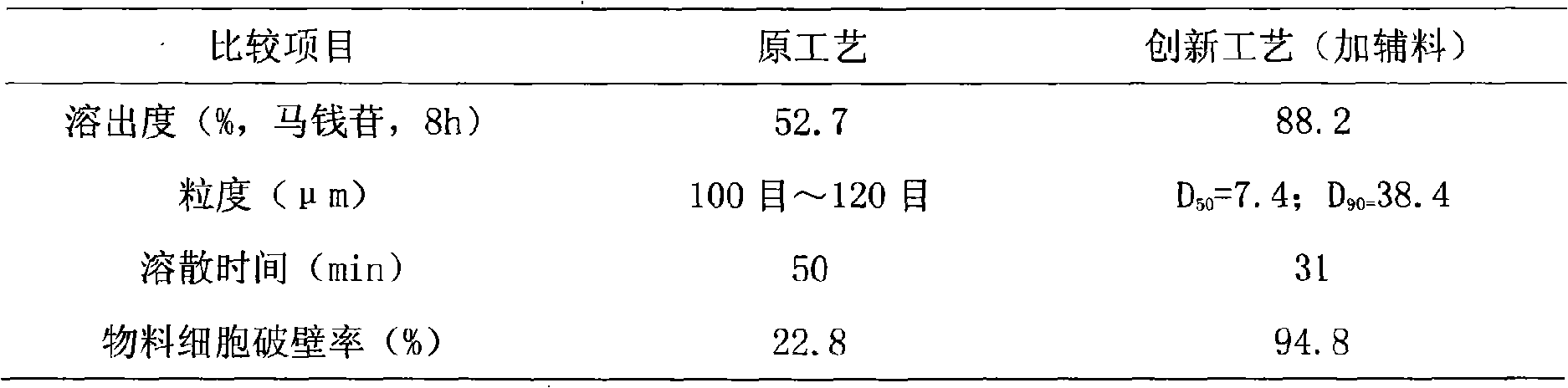

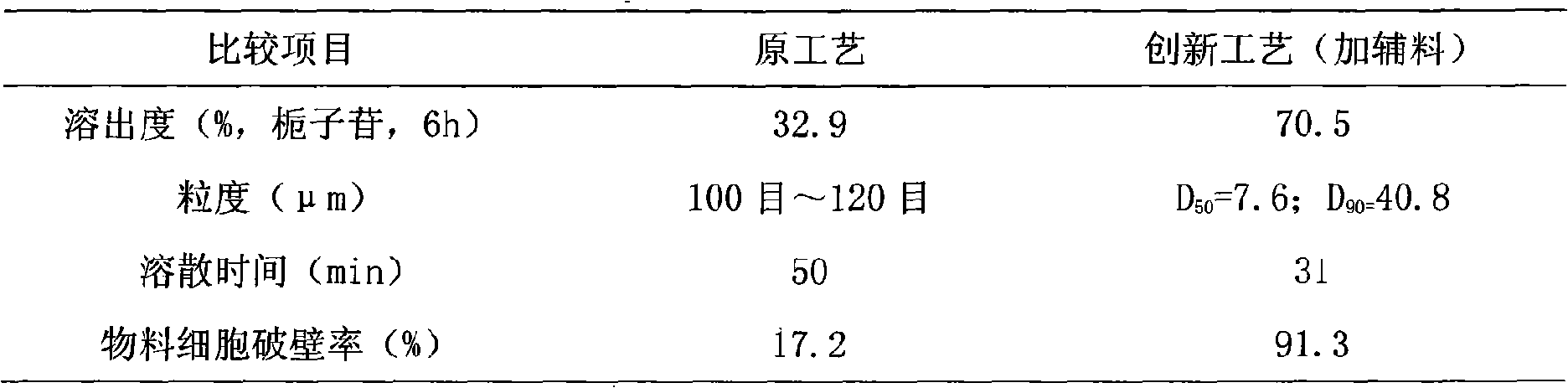

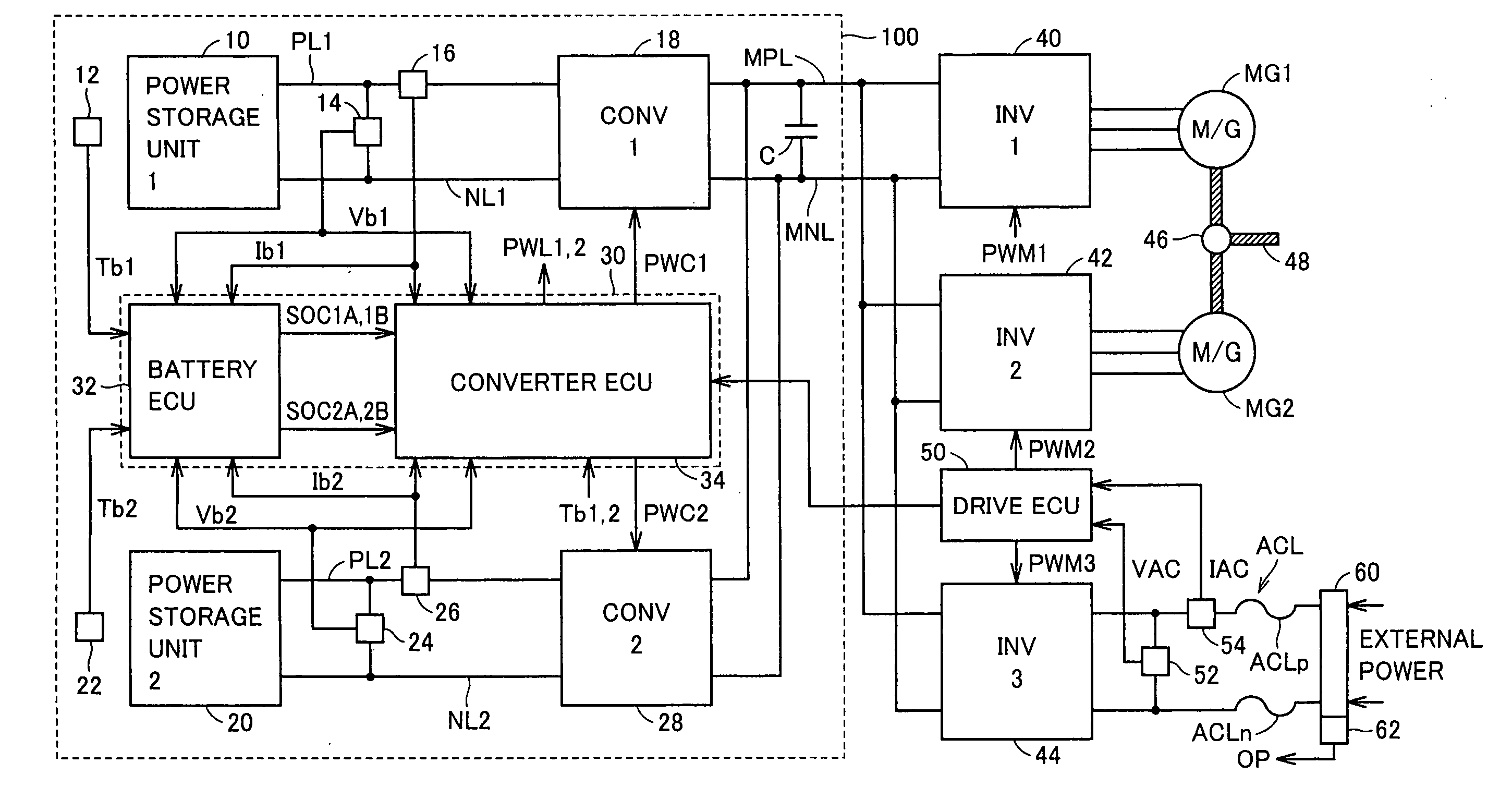

Pharmaceutical composition and preparation method thereof

InactiveCN101579364ASmall surface areaNo more clumpingPill deliveryCapsule deliveryHas active ingredientGranularity

The invention discloses a pharmaceutical composition, in particular a pharmaceutical composition prepared by adopting a prescription medicine originated from a traditional Chinese medicine pill and an ultrafine grinding technology, and a preparation method thereof. The preparation method induces an auxiliary material ultrafine grinding technology, thereby enabling mineral medicines to have smaller granularity and greatly increased specific areas, ensuring that medicinal materials from animals and plants have over 90 percent of cell shell-broken rate after being ground in an ultrafine way, active ingredients in the cells can be better exposed to be in a release condition, and the dissolution rate and the bioavailability of the active ingredients are greatly enhanced, maintaining the compound grinding homogenization and fully embodying the traditional Chinese medicine features. The preparation has the advantages that the dissolution rate of the active ingredients is high, the dissolution time is short, the absorption and the utilization are full, the curative effect is good, the production cycle is short, the production cost is low, and the like, thereby having wide market prospect and further satisfying and guaranteeing the requirements of people on medicines.

Owner:BEIJING HERUN INNOVATION PHARMA TECH DEV

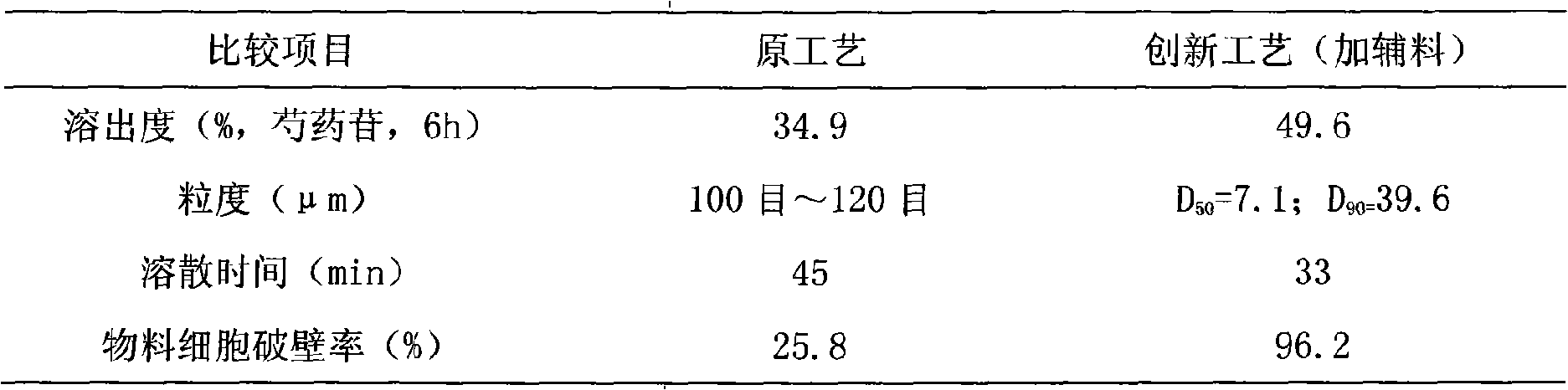

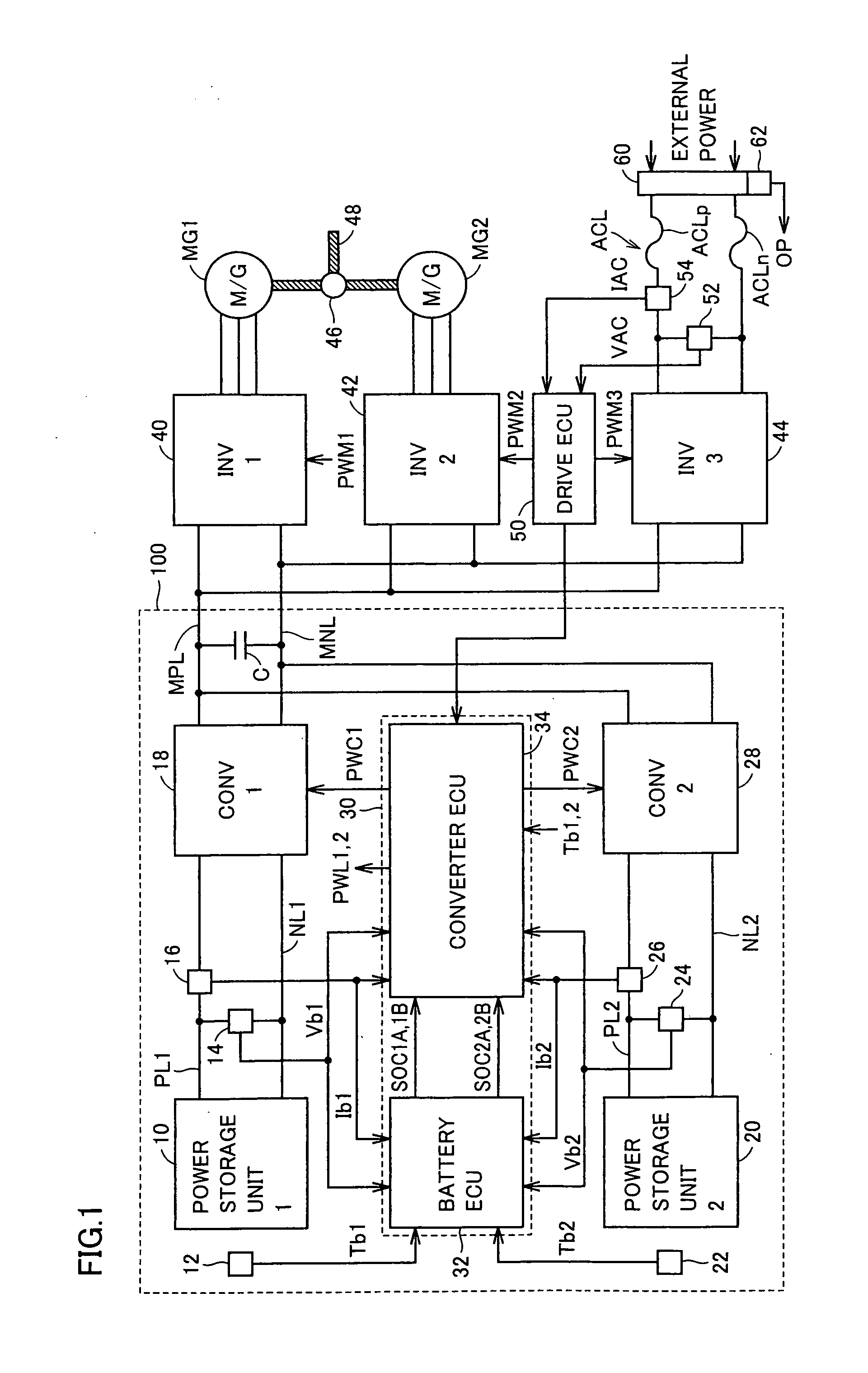

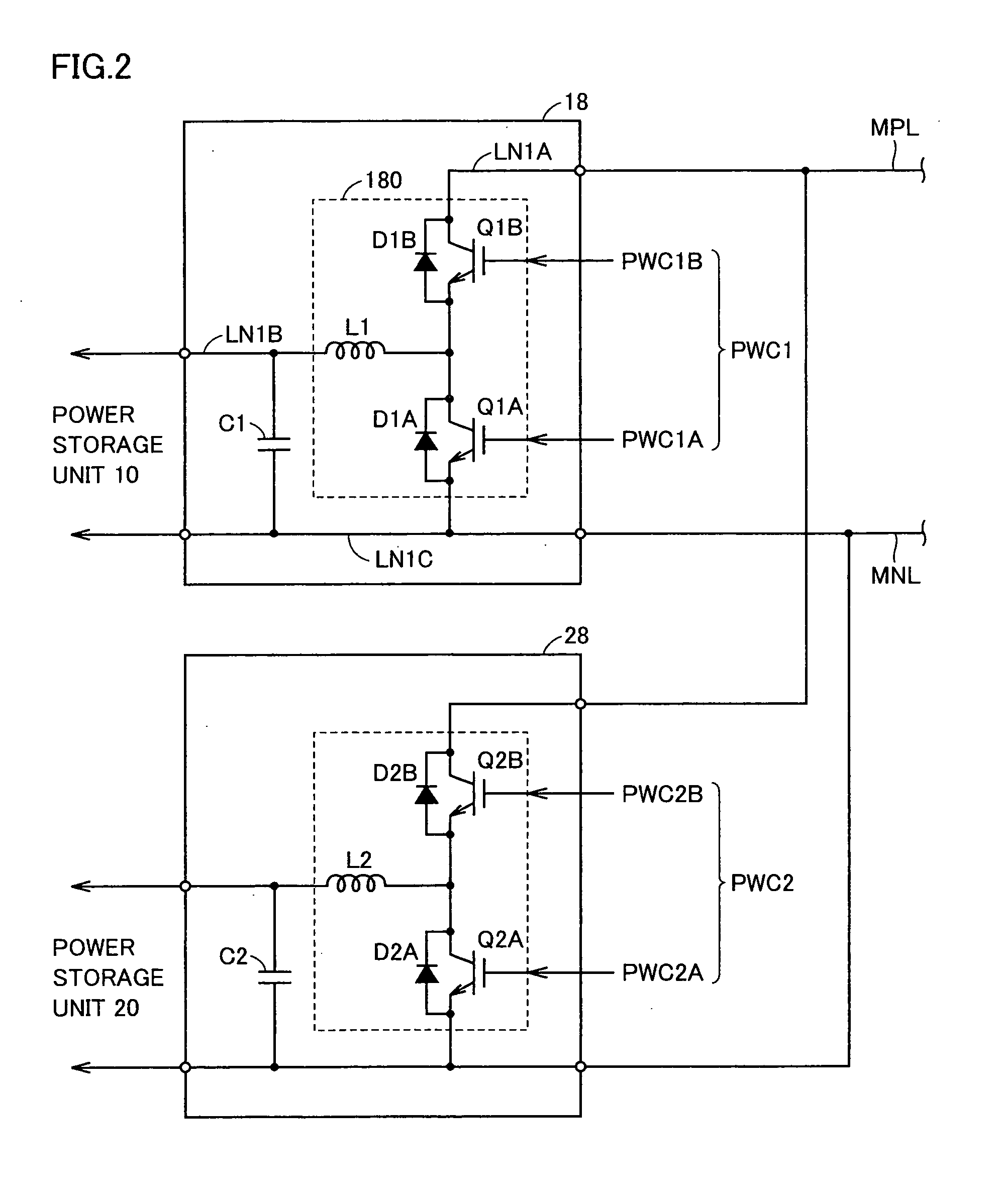

Power supply device and vehicle including the same

ActiveUS20100001866A1Increase temperatureLow energy efficiencyHybrid vehiclesBatteries circuit arrangementsElectrical batteryState of charge

A power supply device includes a power storage unit capable of being charged and a control unit controlling charging of the power storage unit. Control unit includes a battery ECU for setting, at the start of charging of the power storage unit, a target value of state of charge of the power storage unit to a first value based on the condition of power storage unit and setting, when a temperature increase instruction (change instruction) is received after the start of charging, the target value to a predetermined second value higher than the first value, and a converter ECU for executing the charging process so that the state of charge of the power storage unit attains to the target value.

Owner:TOYOTA JIDOSHA KK

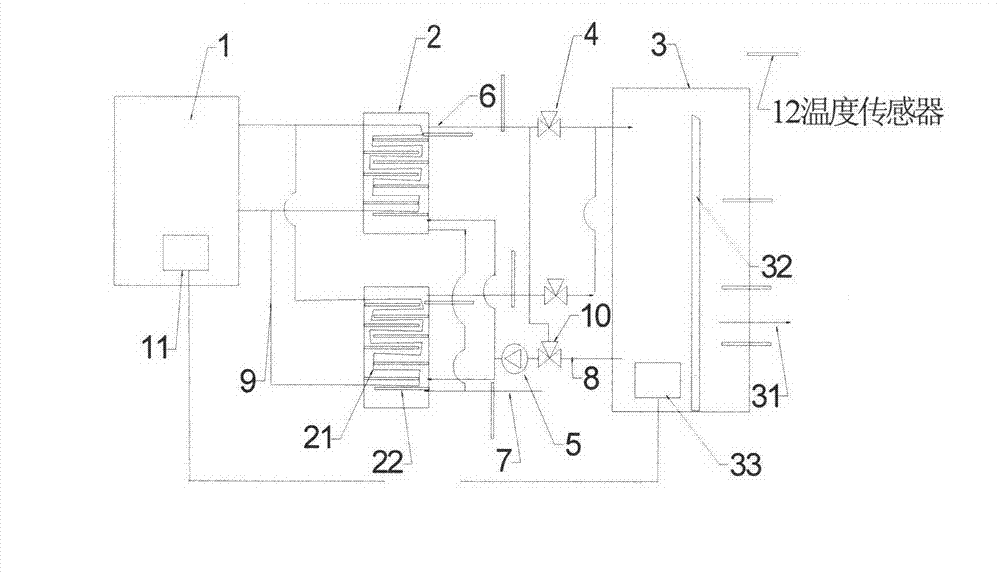

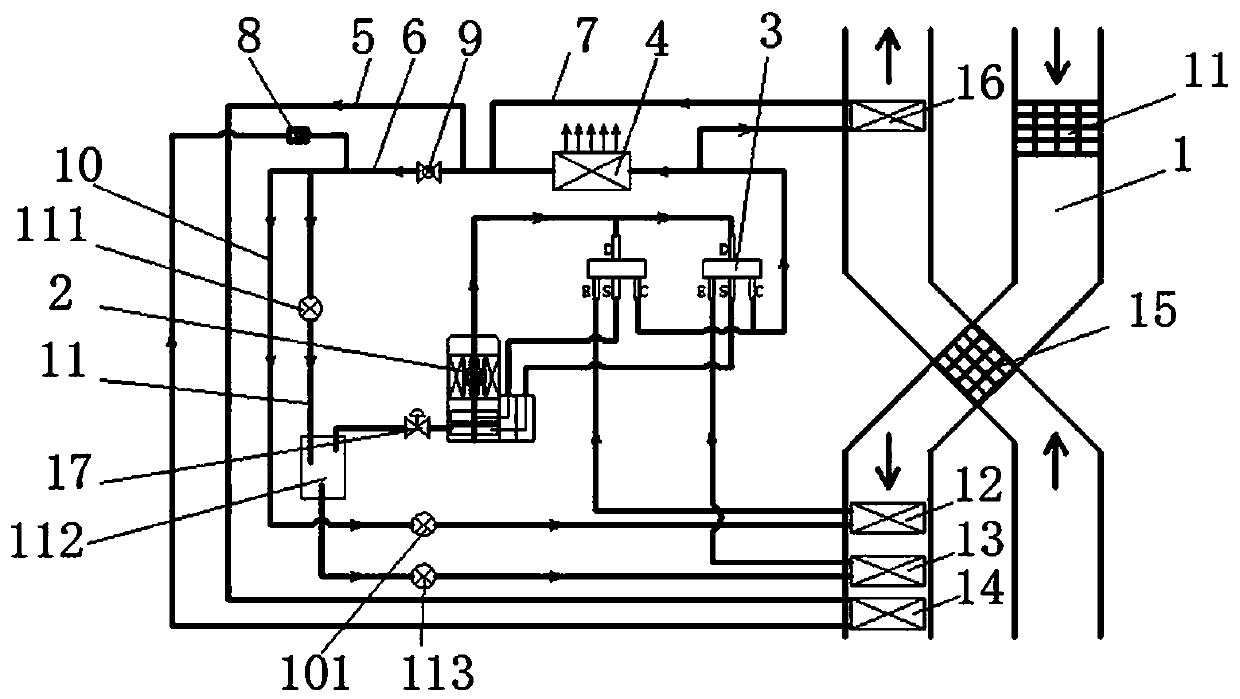

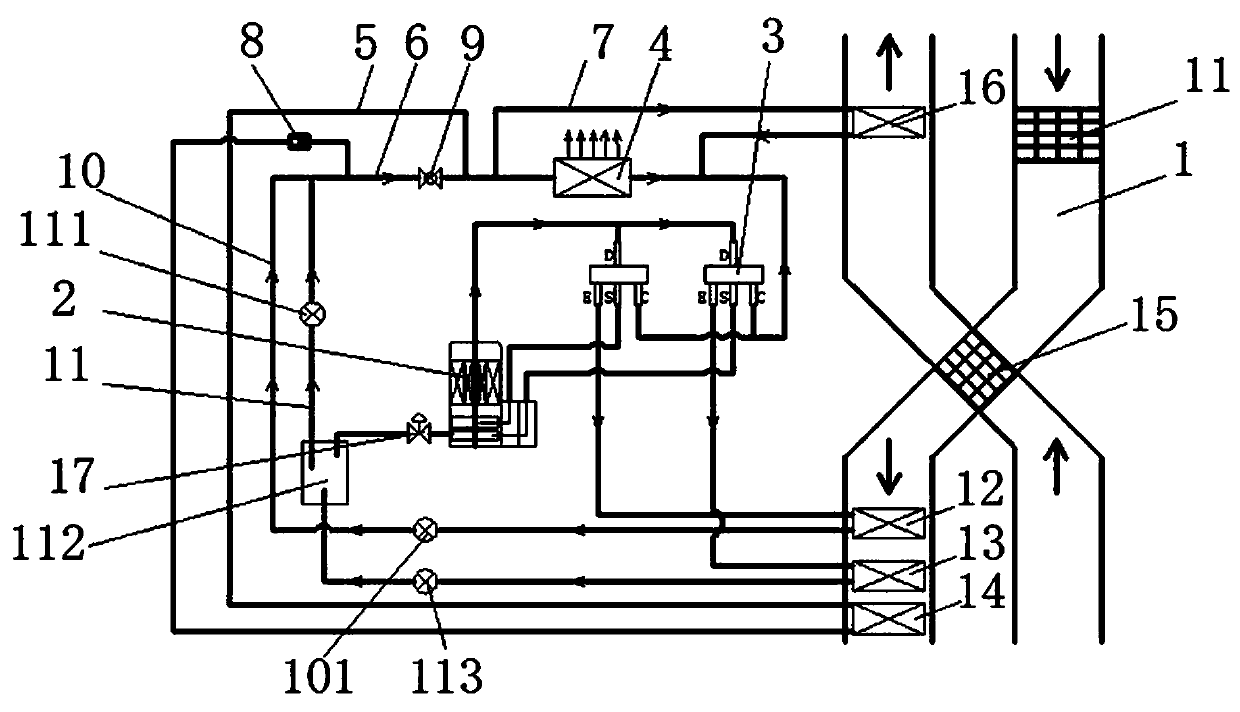

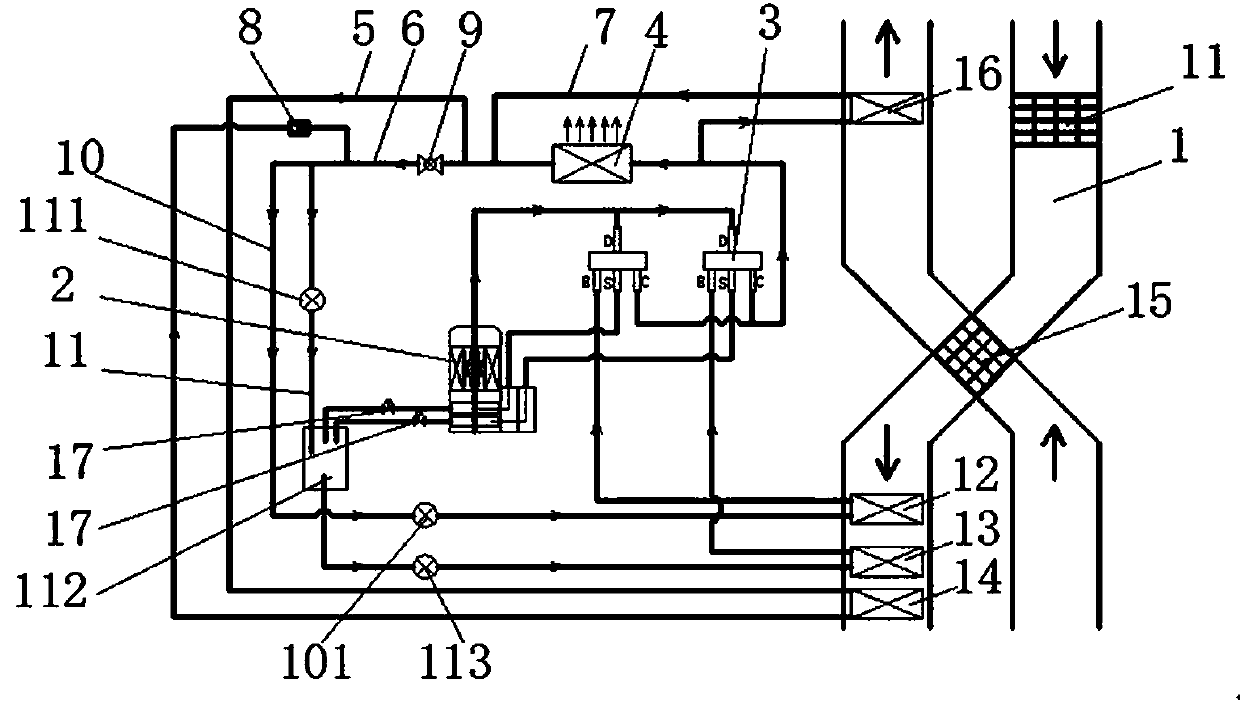

Directly-heated type and circular type integrated heat-pump water heater system

InactiveCN103245055AAddress unmanageable shortcomingsImprove energy efficiencyFluid heatersWater storage tankEngineering

The invention provides a directly-heated type and circular type integrated heat-pump water heater system. According to the system, a directly-heated type hot water supply mode and a circular type hot water supply mode are provided simultaneously. The system is composed of a host machine, a heat transfer water tank, a water storage tank and corresponding control parts. By means of the system, defects of low energy efficiency and reliability caused by the high return water temperature and difficult control of a directly-heated type heat-pump water heater are overcome, and the system can operate in an efficient and high-reliable mode.

Owner:王静宇

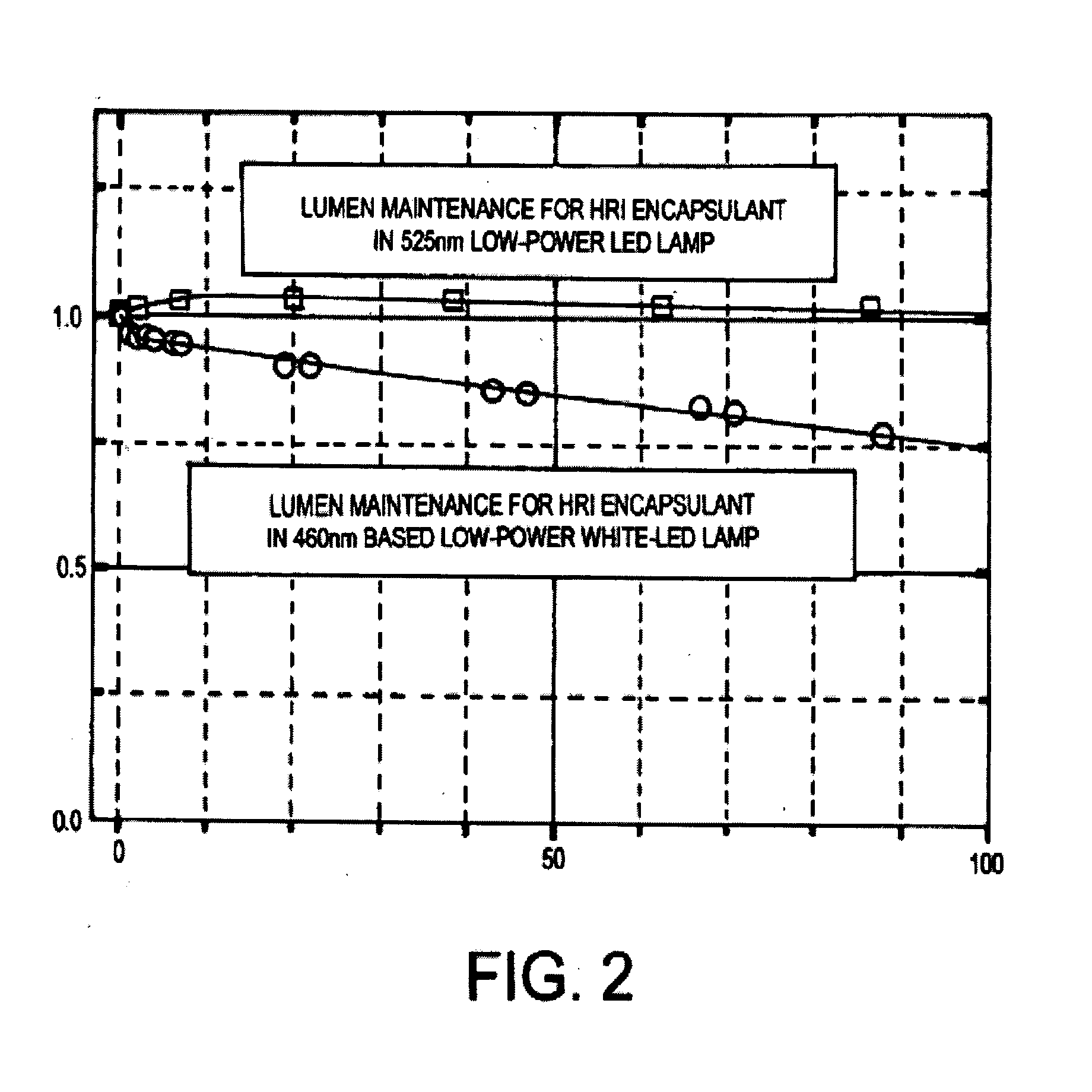

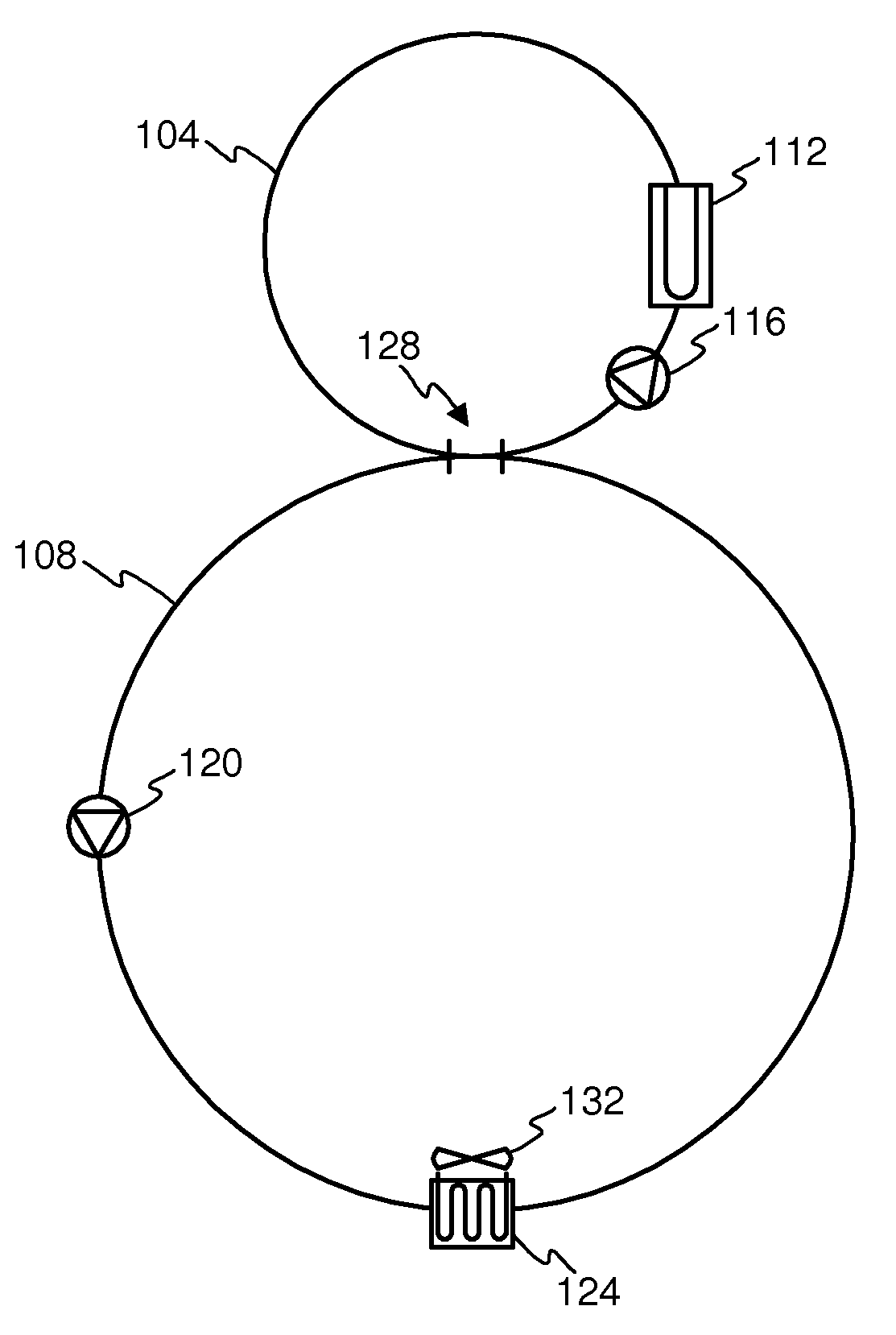

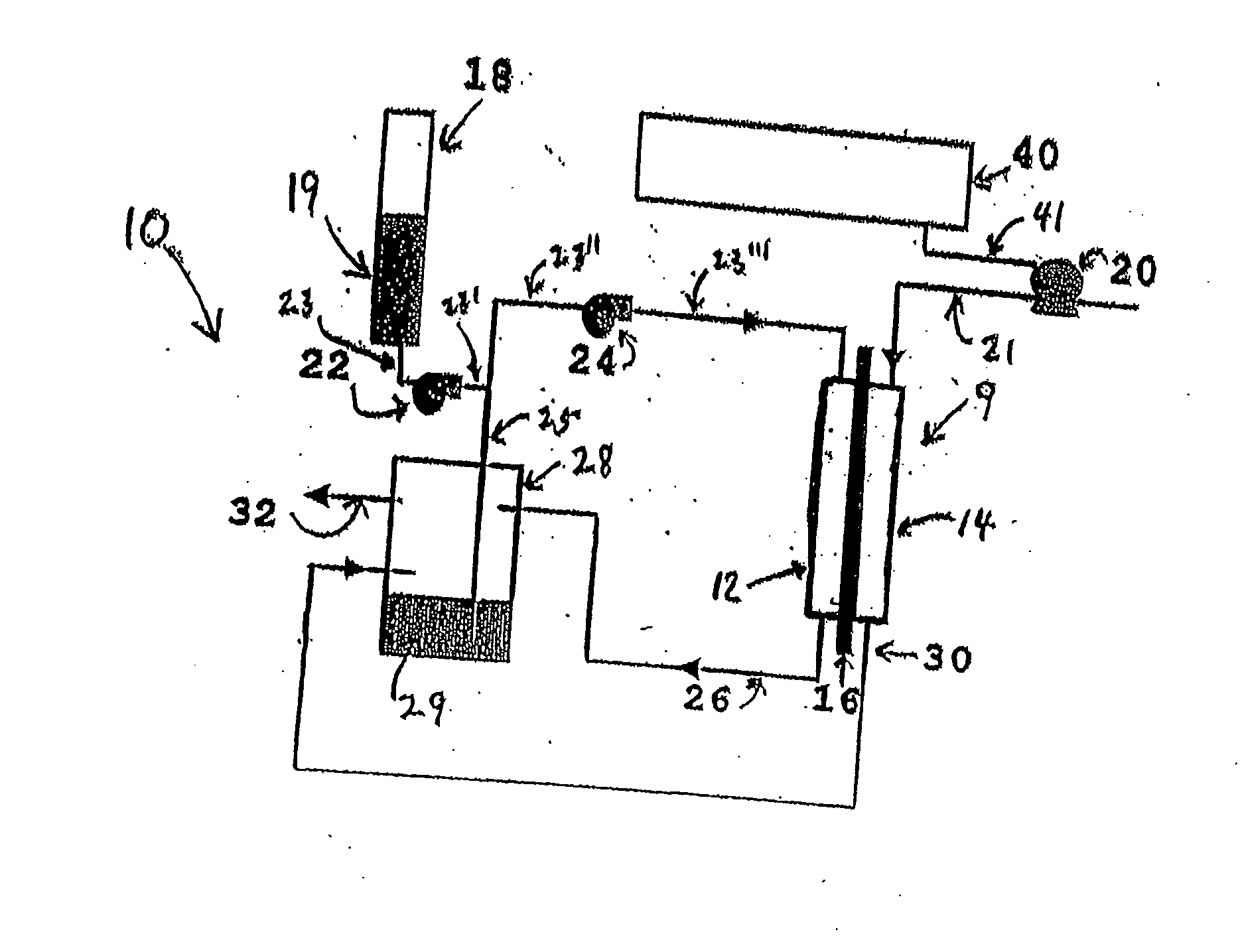

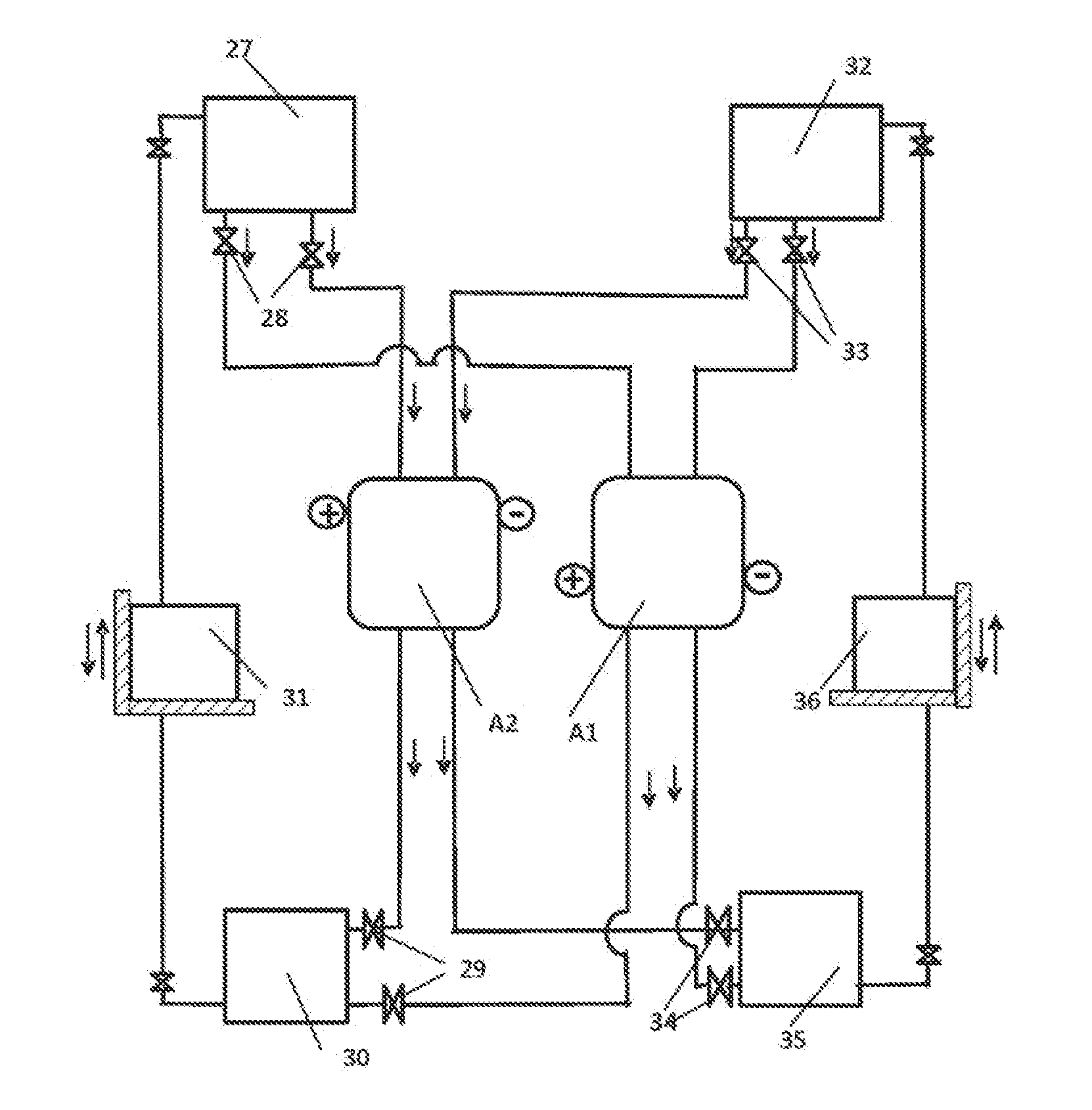

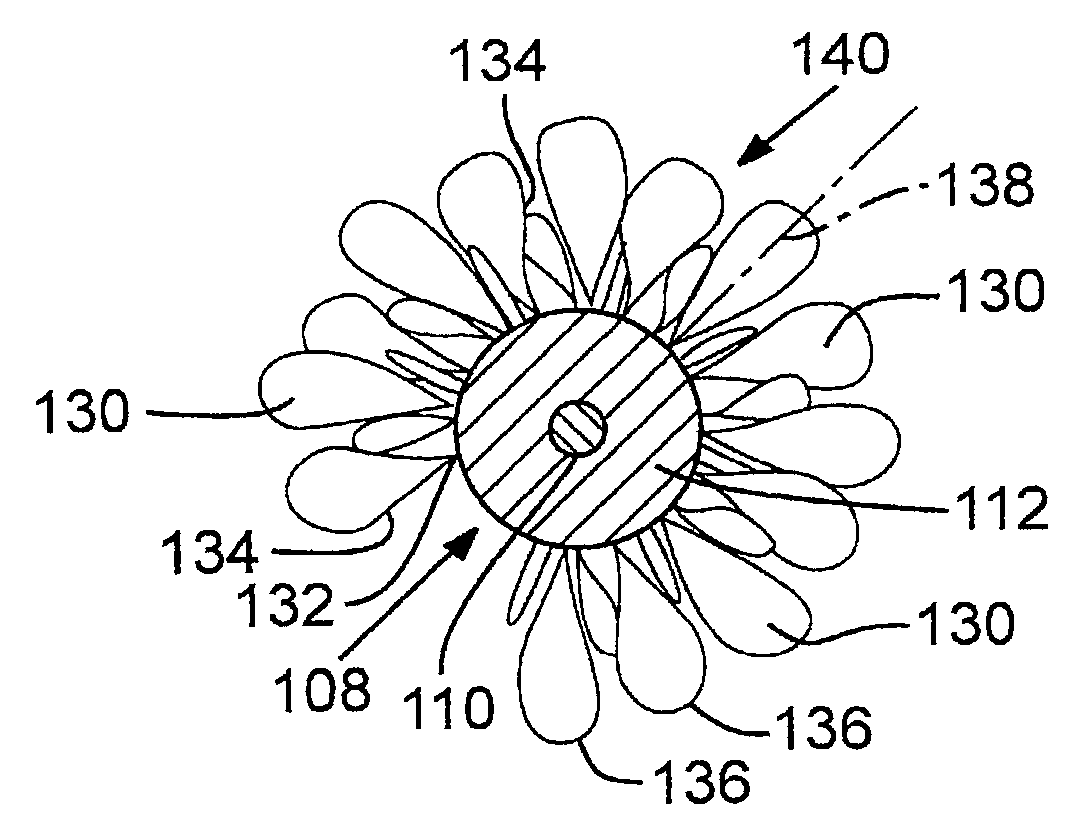

Pump-free lithium ion liquid flow battery, battery reactor and preparation method of electrode suspension solution

InactiveUS20150093606A1Easy to controlEasy to operateCell electrodesRegenerative fuel cellsLithiumEngineering

A Pump-free lithium ion liquid flow battery, battery reactor and preparation method of electrode suspension solution. The Pump-free lithium ion liquid flow battery includes a positive electrode liquid preparation tank (27), a negative electrode liquid preparation tank (32), a positive electrode liquid collection tank (30), a negative electrode liquid collection tank (35), a positive electrode conveying tank (31), a negative electrode conveying tank (36) and several battery sub-systems. The positive electrode conveying tank (31) intermittently moves vertically to and fro for the transportation of positive electrode suspension solution between the positive electrode liquid collection tank (30) and the positive electrode liquid preparation tank (27). The negative electrode conveying tank (36) intermittently moves vertically to and fro for the transportation of negative electrode suspension solution between the negative electrode liquid collection tank (35) and the negative electrode liquid preparation tank (32). The circuit combination of several battery sub-systems is in series connection. The Pump-free lithium ion liquid flow battery provided in the present invention can reduce mechanical losses and security risks, improve battery working efficiency and ensure better safety performance.

Owner:BEIJING HAWAGA POWER STORAGE TECH

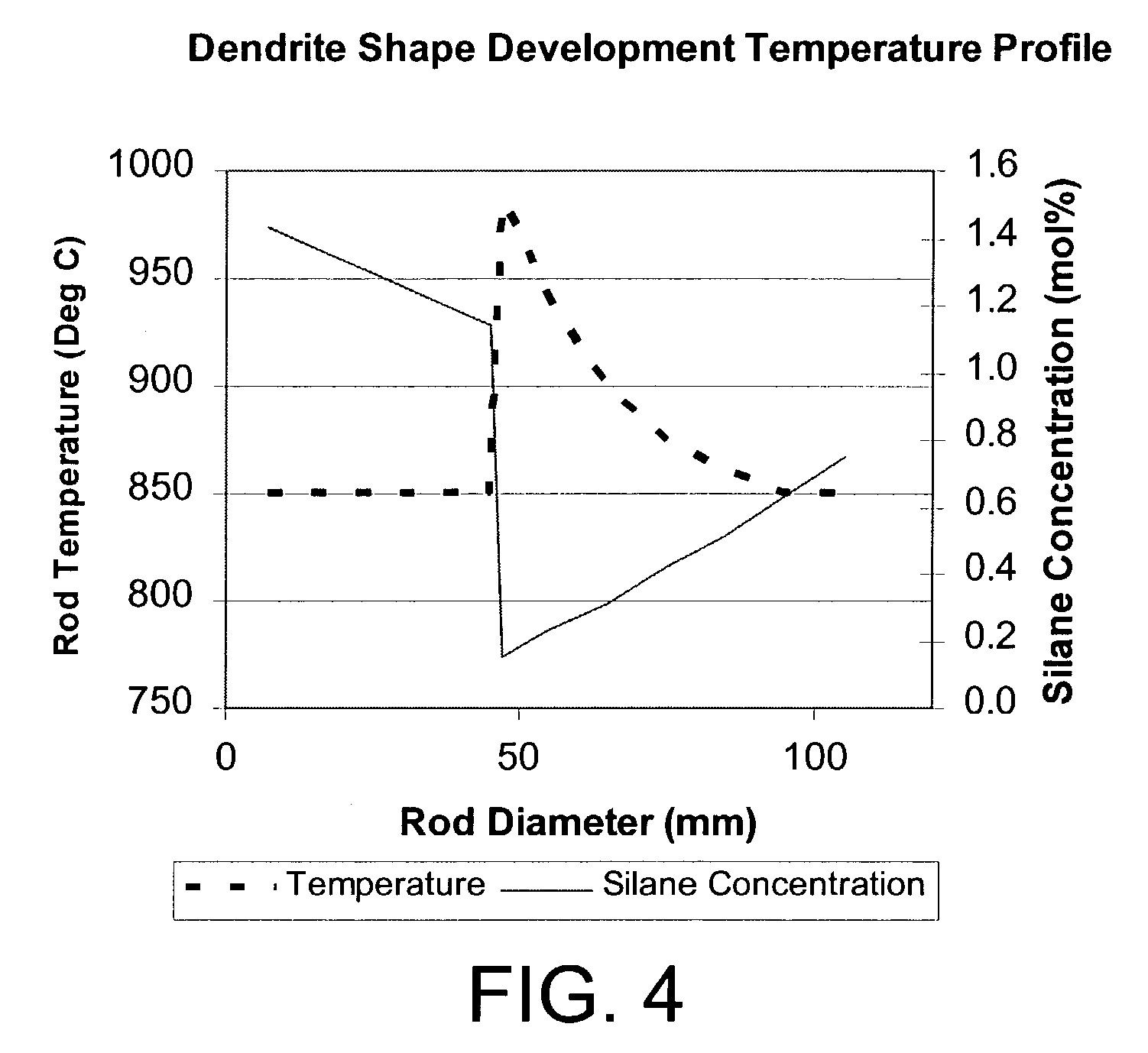

Energy efficient method for growing polycrystalline silicon

ActiveUS7105053B2Low energy efficiencyEasily broken awayPolycrystalline material growthSiliconDendriteAtmosphere

Polysilicon dendrites are grown by depositing silicon on a polysilicon rod or other substrate. Surface temperature is increased to a temperature at which needle-like dendrites develop due to the deposition of silicon from silicon-containing molecules in the surrounding reactor atmosphere. Thereafter, the surface temperature is gradually reduced so that silicon that deposits on the needle-like dendrites causes the dendrites to grow and assume a generally flared shape.

Owner:REC SILICON

Demand flow pumping

ActiveUS8275483B2Easy to operateSignificant energy savingMechanical apparatusTemperatue controlAir handlerChilled water

Demand Flow operates chilled water plants at substantially improved efficiency, regardless of plant load conditions. In general, Demand Flow utilizes an operating strategy which controls chilled and condenser water pumping according to a constant Delta T line, which is typically near or at design Delta T. This reduces or eliminates Low Delta T Syndrome and reduces energy usage by chilled and condenser water pumps for given load conditions. Operation of chilled water pumps in this manner creates a synergy which generally balances flow rates throughout the plant, reducing undesirable bypass mixing and energy usage at air handler fans and other components of the chilled water plant. At plant chillers, application of Demand Flow increases the refrigeration effect through refrigerant sub-cooling and superheating, while preventing stacking. Demand Flow includes a critical zone reset feature which allows the constant Delta T line to be reset to adjust to changing load conditions.

Owner:SIEMENS IND INC

Fresh air dehumidification air conditioner system

PendingCN108679747AReduce heat lossLow energy efficiencyMechanical apparatusFluid circulation arrangementFresh airEngineering

The invention discloses a fresh air dehumidification air conditioner system. The fresh air dehumidification air conditioner system comprises an air conditioner device and a fresh air device. Multipleheat exchangers are sequentially arranged in a pipeline of the fresh air device, the air conditioner device adopts a double-temperature enthalpy-increasing compressor and a step cooling technology tosolve the problems that the evaporation temperature is too low due to the large difference of the inlet air temperature and the outlet air temperature of an evaporator and the system energy efficiencyis low. By the adoption of the fresh air dehumidification air conditioner system, the high-efficiency operation of the fresh air dehumidification air conditioner is realized, it is ensured that the air outlet temperature and the moisture content satisfy the requirements, and meanwhile the condensation problem, caused by the excessively low temperature of an air-drying ball, of the air outlet is avoided.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

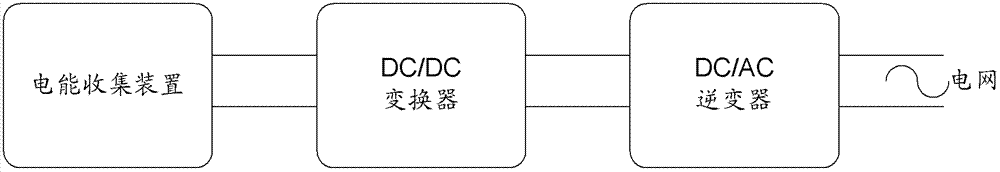

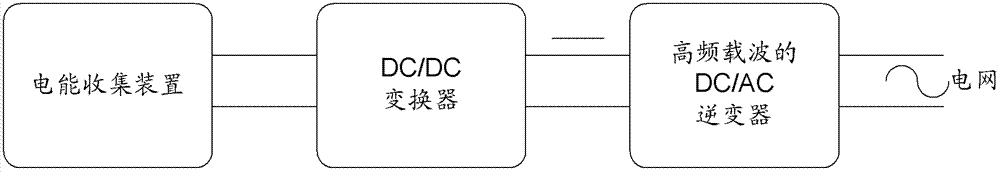

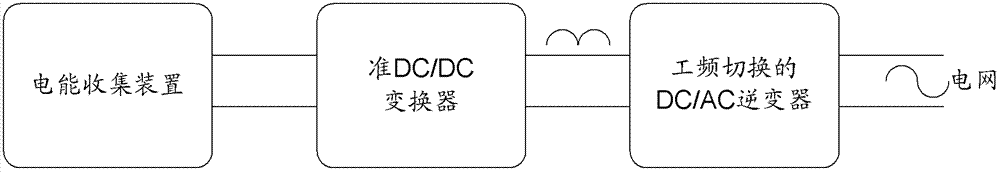

Bridgeless inverter circuit and solar bridgeless inverter

InactiveCN103023362AImprove efficiencyReduce in quantityEfficient power electronics conversionDc-dc conversionTime-sharingPower grid

The invention discloses a bridgeless inverter circuit and a solar bridgeless inverter, wherein the bridgeless inverter circuit comprises an electric energy collection device, a power grid, a DSP (Digital Signal Processor), and a plurality of quasi-resonant DC / DC (Direct Current) converters which are in multiphase parallel connection or multiphase interleaving parallel connection; the input ends of the converters are respectively connected to the output end of the electric energy collection device, the control ends of the converters are respectively connected to the DSP, and the output ends of the converters are respectively connected to the output end of the power grid; and, under the control of the DSP, the plurality of quasi-resonant DC / DC converters work in a preset power frequency period in a time-sharing manner and splice the obtained positive half quasi-sine-wave voltage and the obtained negative half quasi-sine-wave voltage to obtain standard sine-wave voltage. The bridgeless inverter circuit and the solar bridgeless inverter provided by the invention can overcome the defects of the prior art of high loss, low energy utilization rate, high heat treatment components number, large equipment weight, high transportation cost and the like so as to realize the advantages of low loss, high energy utilization rate, low heat treatment components number, small equipment weight, low transportation cost and the like.

Owner:LEADSOLAR ENERGY

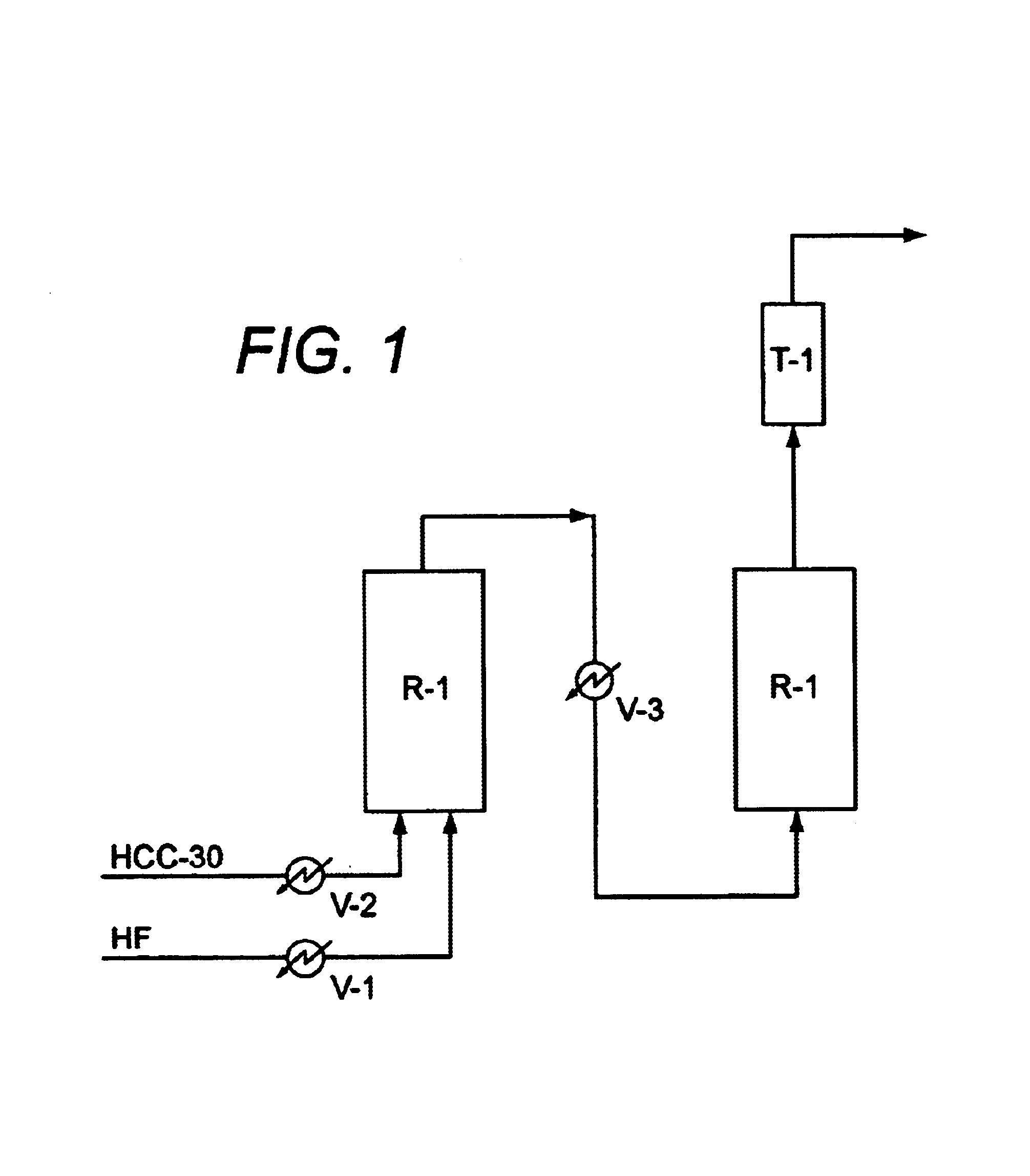

Method of producing difluoromethane

InactiveUS6841705B2High yieldSignificant disadvantagePreparation by halogen halide additionPreparation by halogen replacementHydrogen fluorideGas phase

A method of producing difluoromethane (HFC-32), which includes firstly reacting methylene chloride with hydrogen fluoride in gas phase at 280 to 340° C. in the presence of a fluorination catalyst to produce chlorofluoro methane, and secondly reacting the chlorofluoro methane with hydrogen fluoride in liquid phase at 60 to 80° C. in the presence of an antimony chloride catalyst. The method is advantageous in that HFC-32 is produced in high yield under mild reaction conditions using a relatively small amount of energy.

Owner:FOOSUNG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com