Directly-heated type and circular type integrated heat-pump water heater system

A heat pump water heater, circulating technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of low energy efficiency, limited volume of pressurized water tanks, waste, etc.

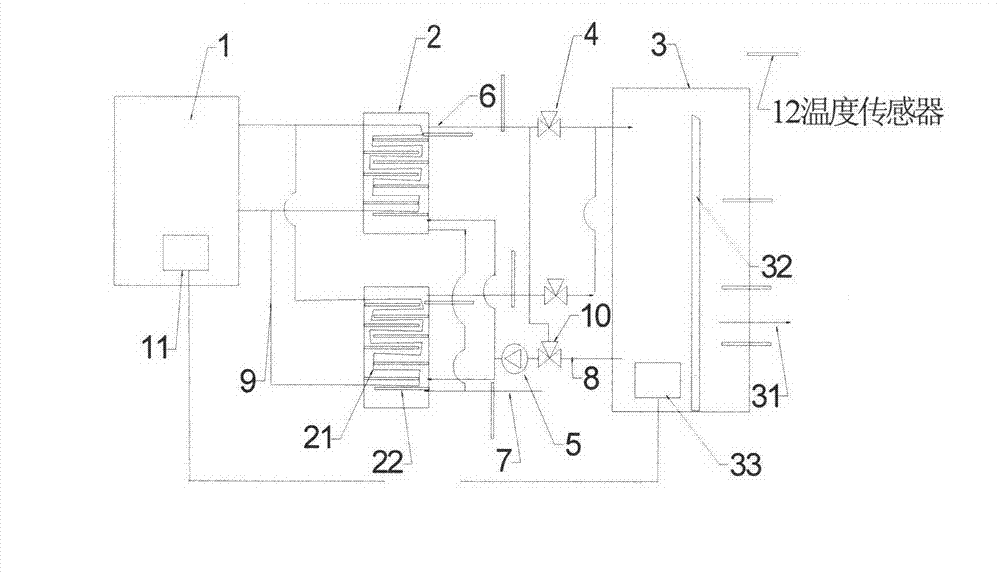

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] There are three situations:

[0015] 1) It includes a preheating mode (forced convection), that is, to heat the water inside the heat exchange tank according to the needs of the user and the temperature of the water outlet from the heat exchange tank does not meet the set value. At this time, the main engine and the circulating water pump are turned on, and the electric control valve (4) close, and the backwater three-way valve (10) opening direction is from the direct hot water pipe to the heat exchange tank direction, and the outlet water temperature in the heat exchange tank is heated to a set value.

[0016] 2) It includes direct heating mode (weak forced convection). After the water in the exchange water tank is preheated, if the water level of the heat storage tank does not meet the requirements (the water level switch (32) sends an open circuit signal or the water level sensor (32) does not reach the set value) value, the main engine is turned on, the outlet wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com