Patents

Literature

69results about How to "Optimal Operational Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

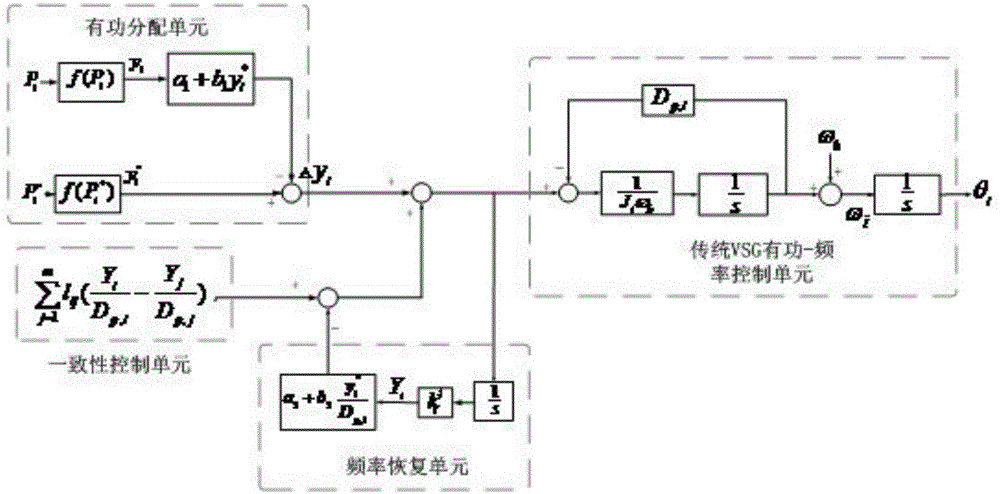

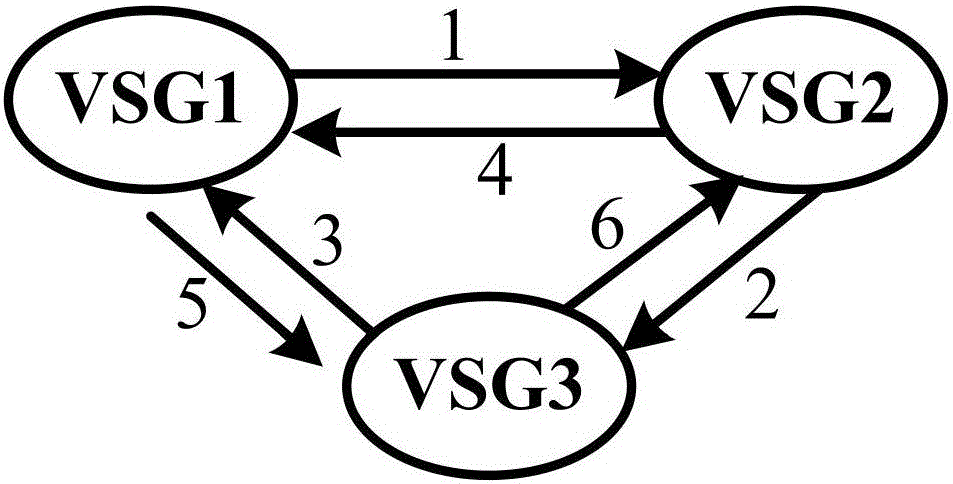

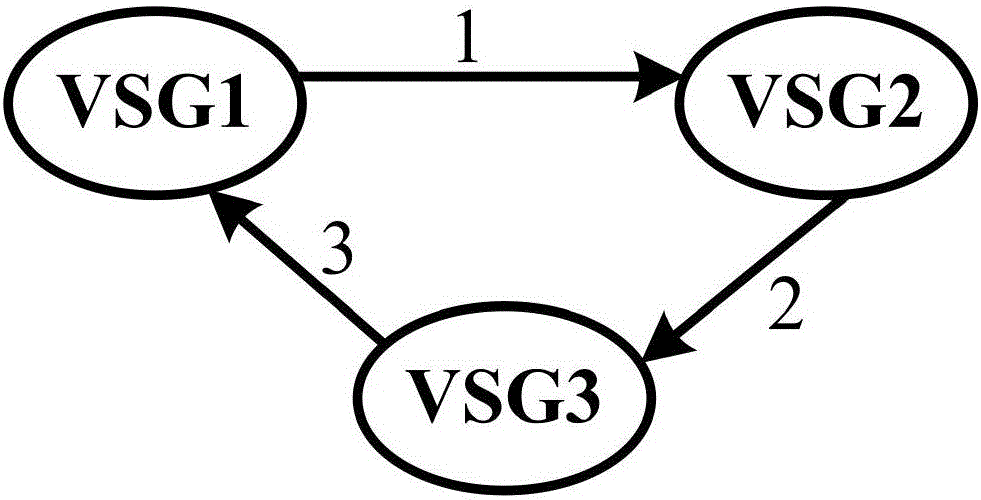

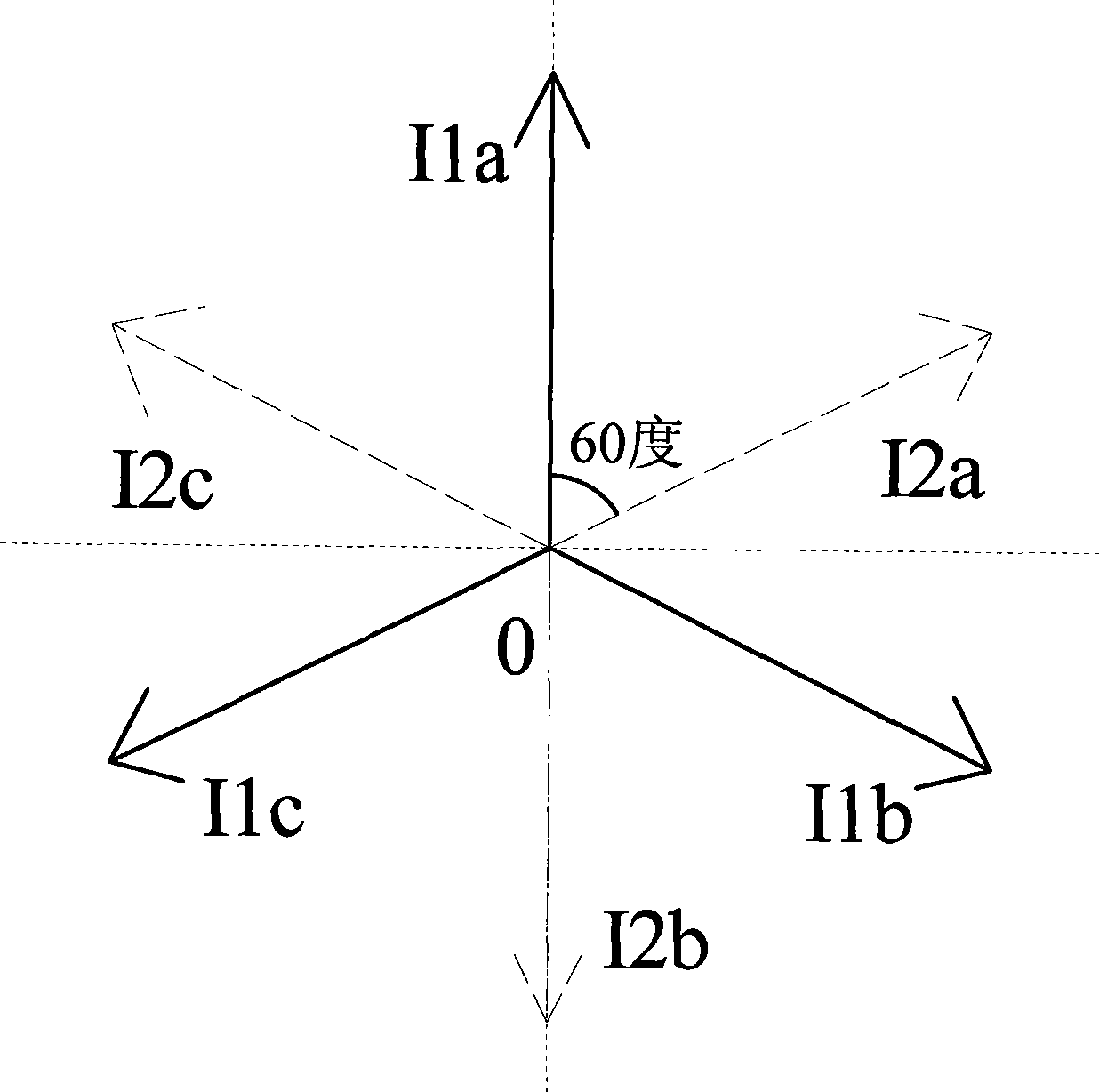

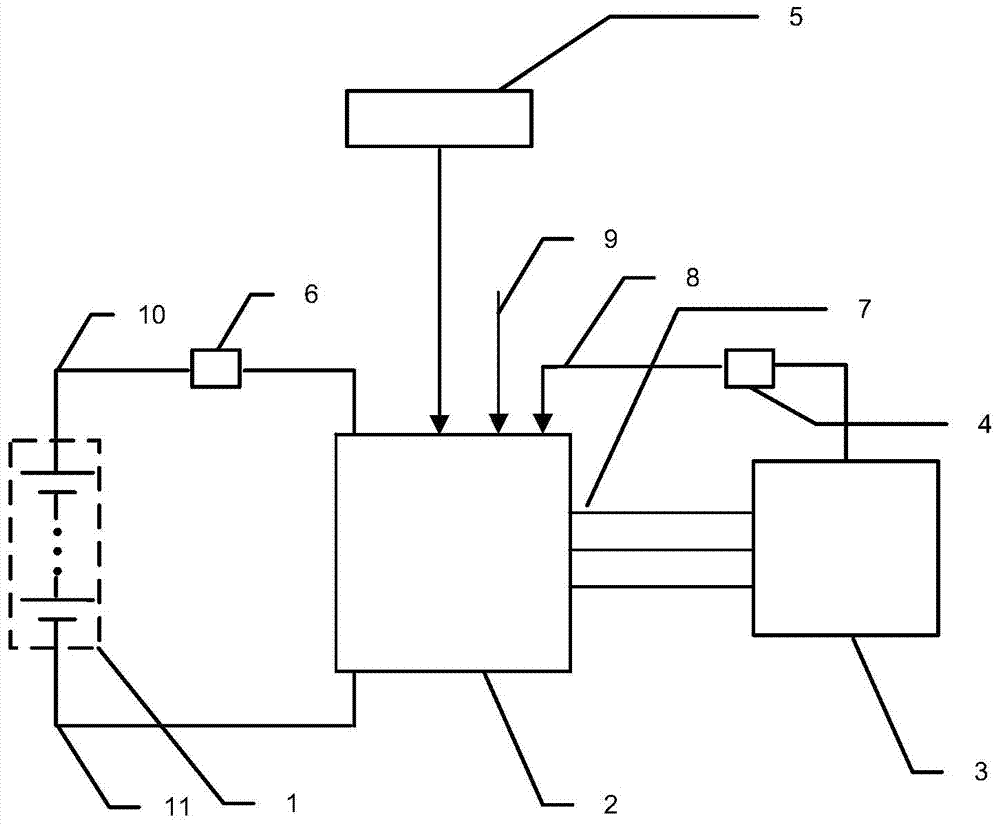

Parallel virtual synchronous generator distributed coordinated operation control method and system

ActiveCN105762841AOptimal Operational ControlLess run controlSingle network parallel feeding arrangementsVirtual synchronous generatorConsistency control

The invention discloses a parallel virtual synchronous generator (VSG) distributed coordinated operation control method and system. The system comprises a sagging control unit, a frequency recovery unit, an active distribution unit and a consistency control unit. VSGs employ distributed communication. The method and system can realize system power distribution, frequency recovery and stable and reliable operation only through a small amount of information interaction between adjacent VSGs, meanwhile reduce communication base construction and cost, and overcome the deficiencies of distributed and centralized models, and are of great importance in operation controlling of parallel VSGs.

Owner:TSINGHUA UNIV

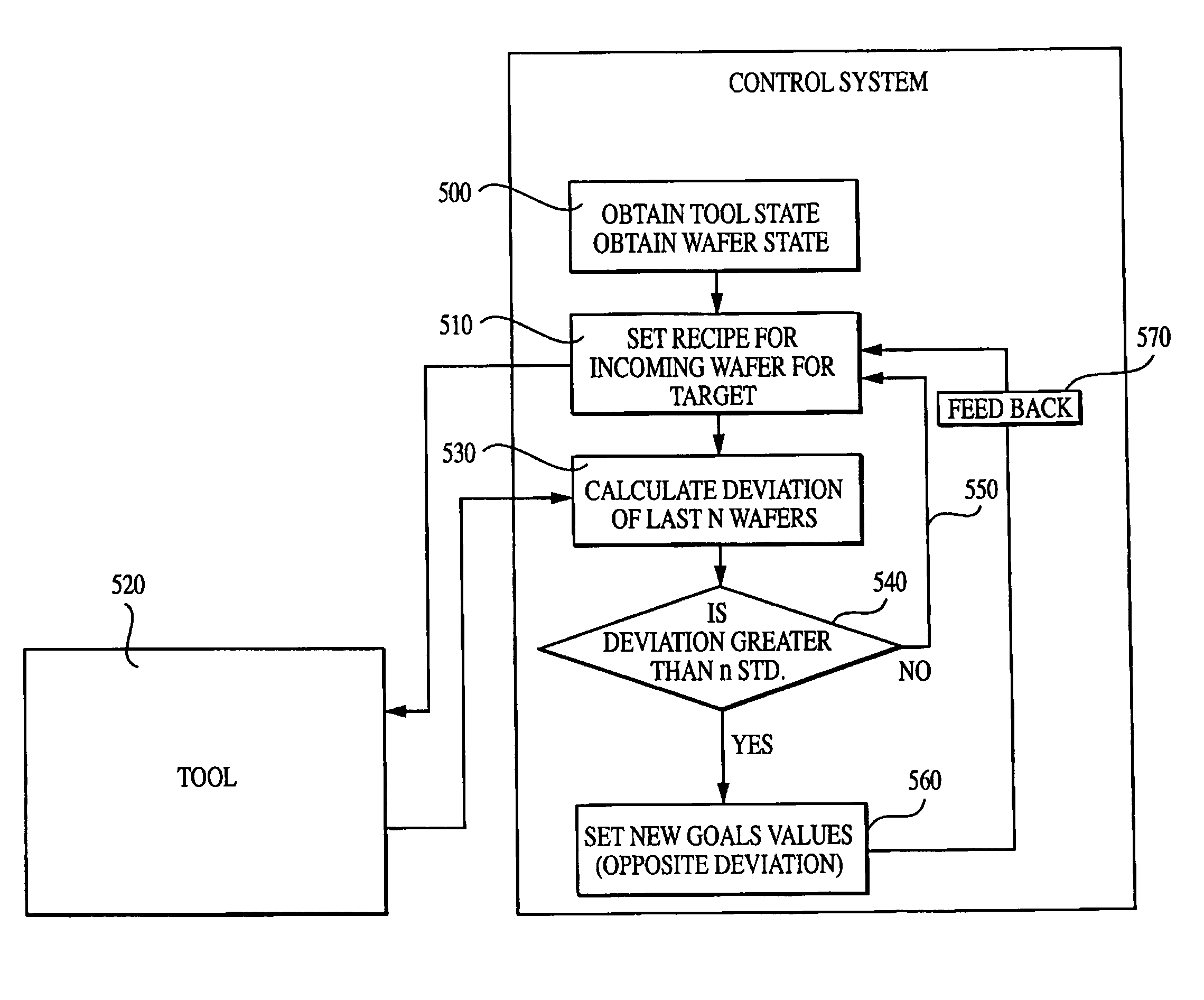

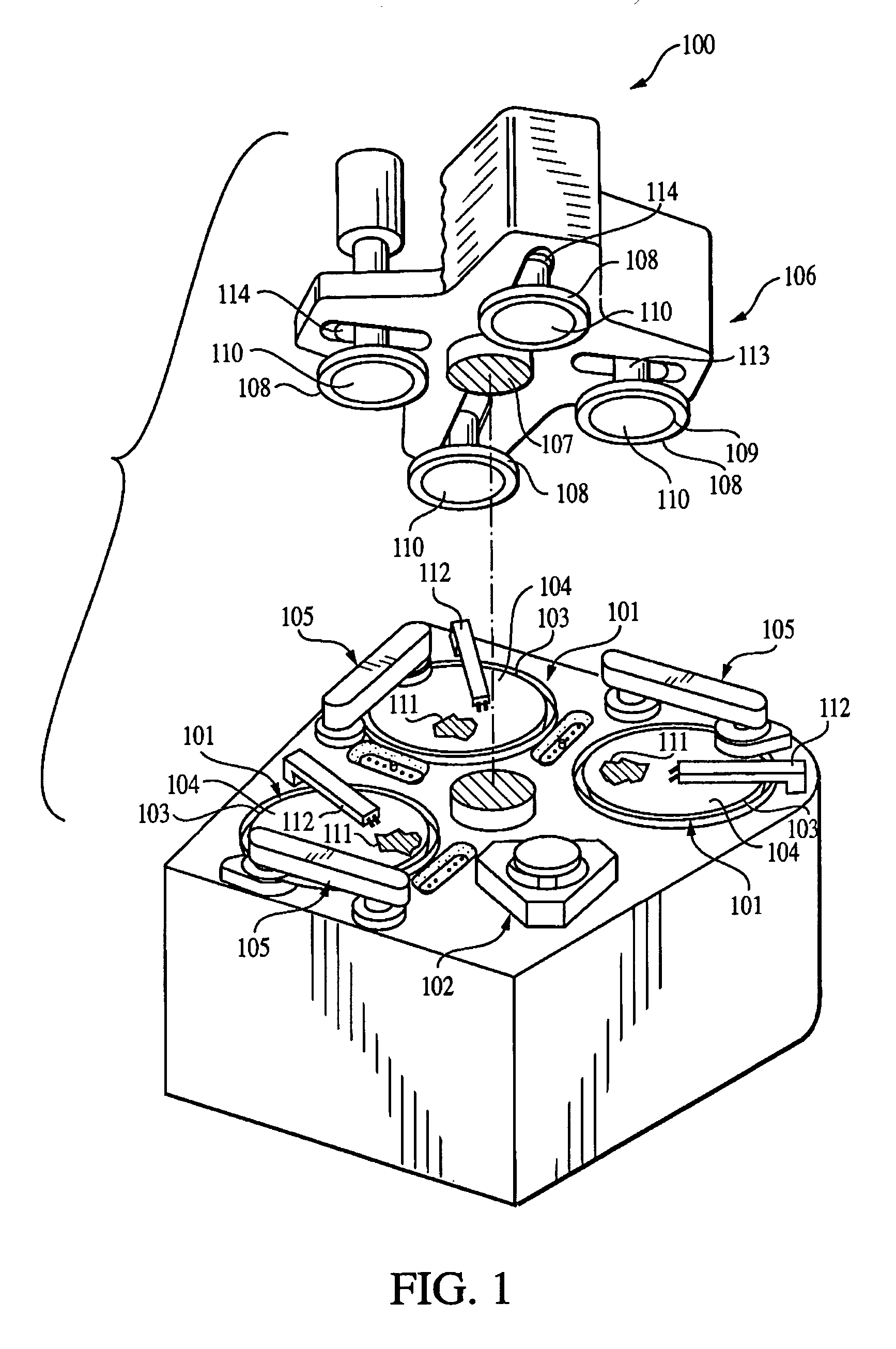

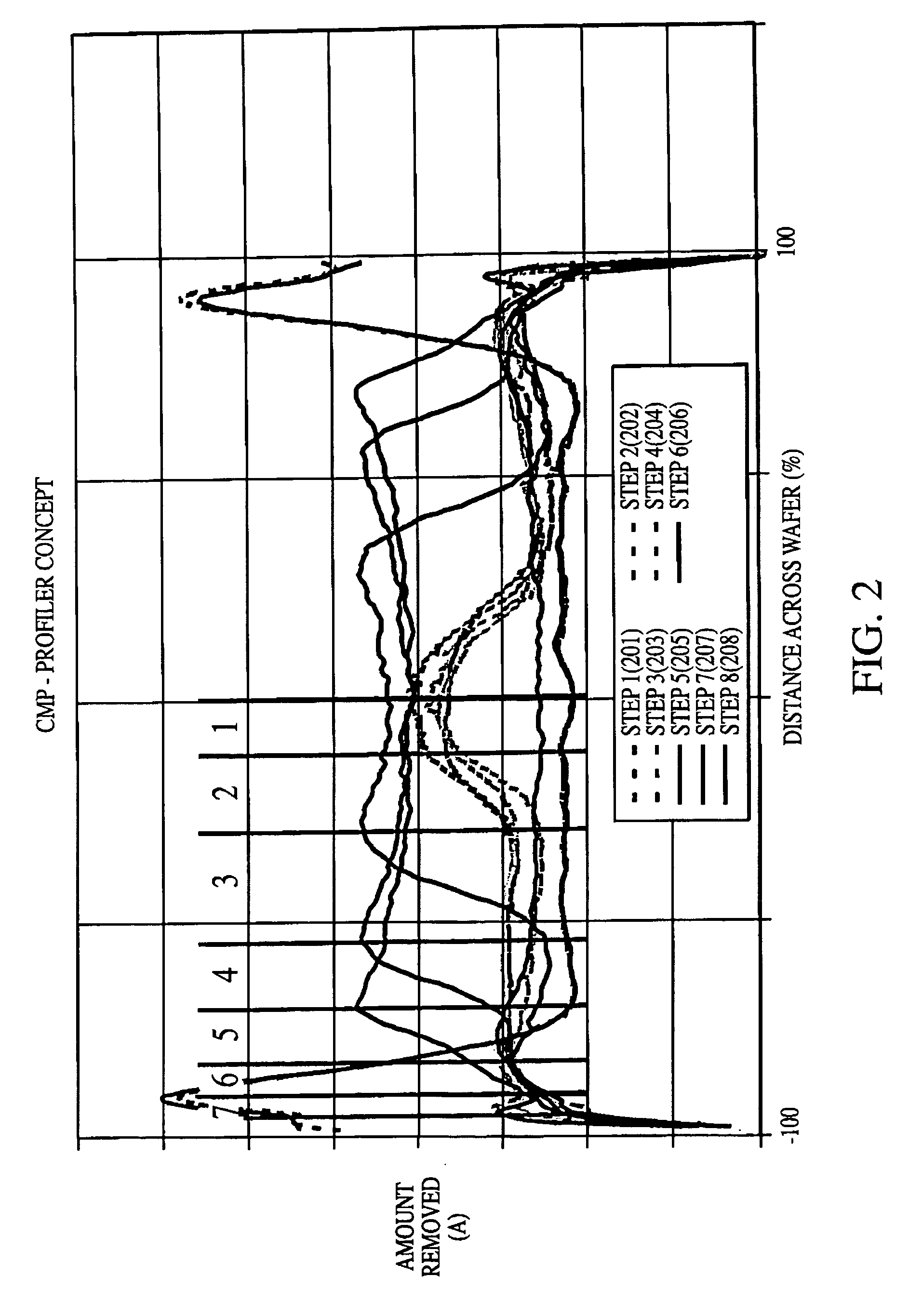

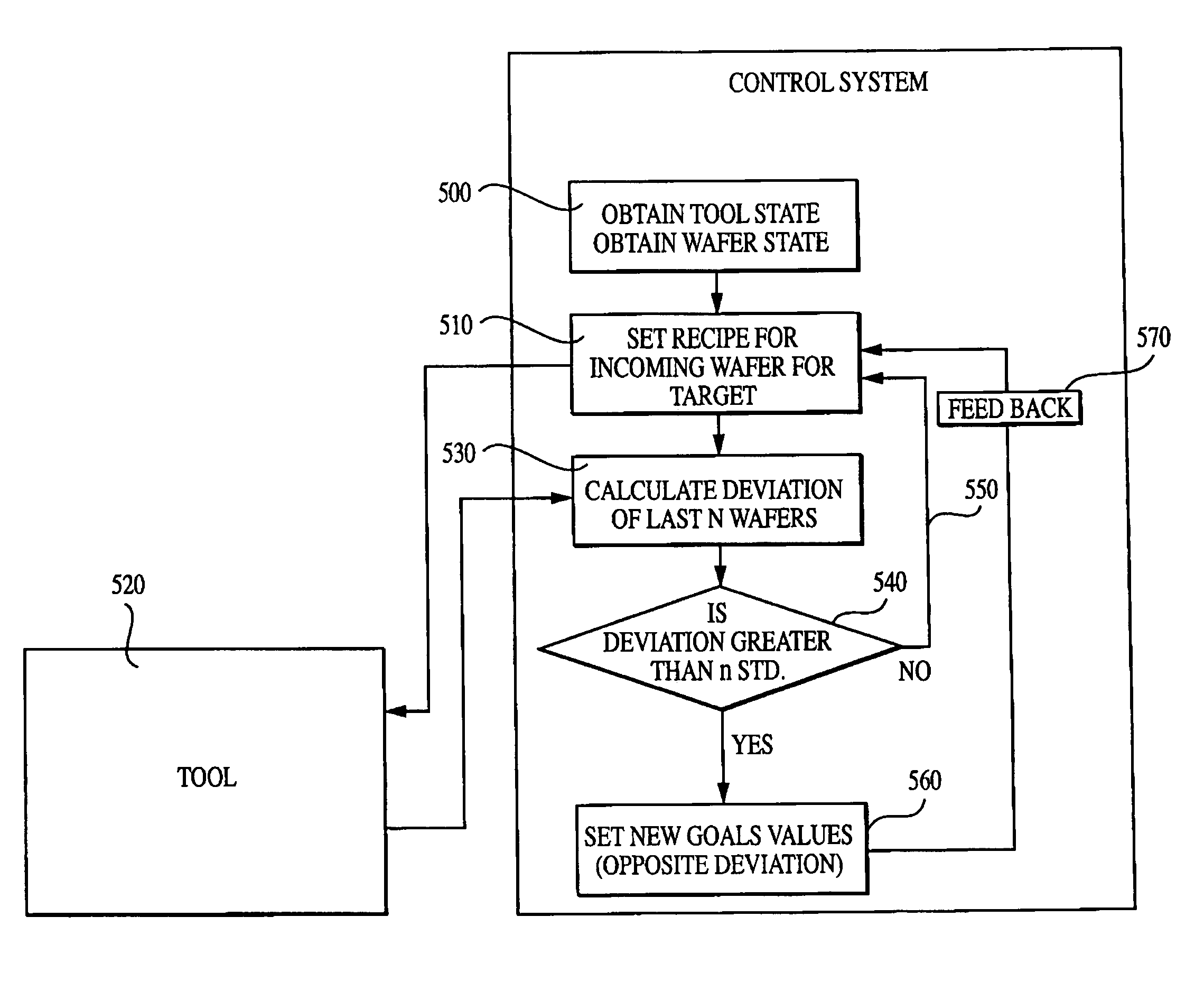

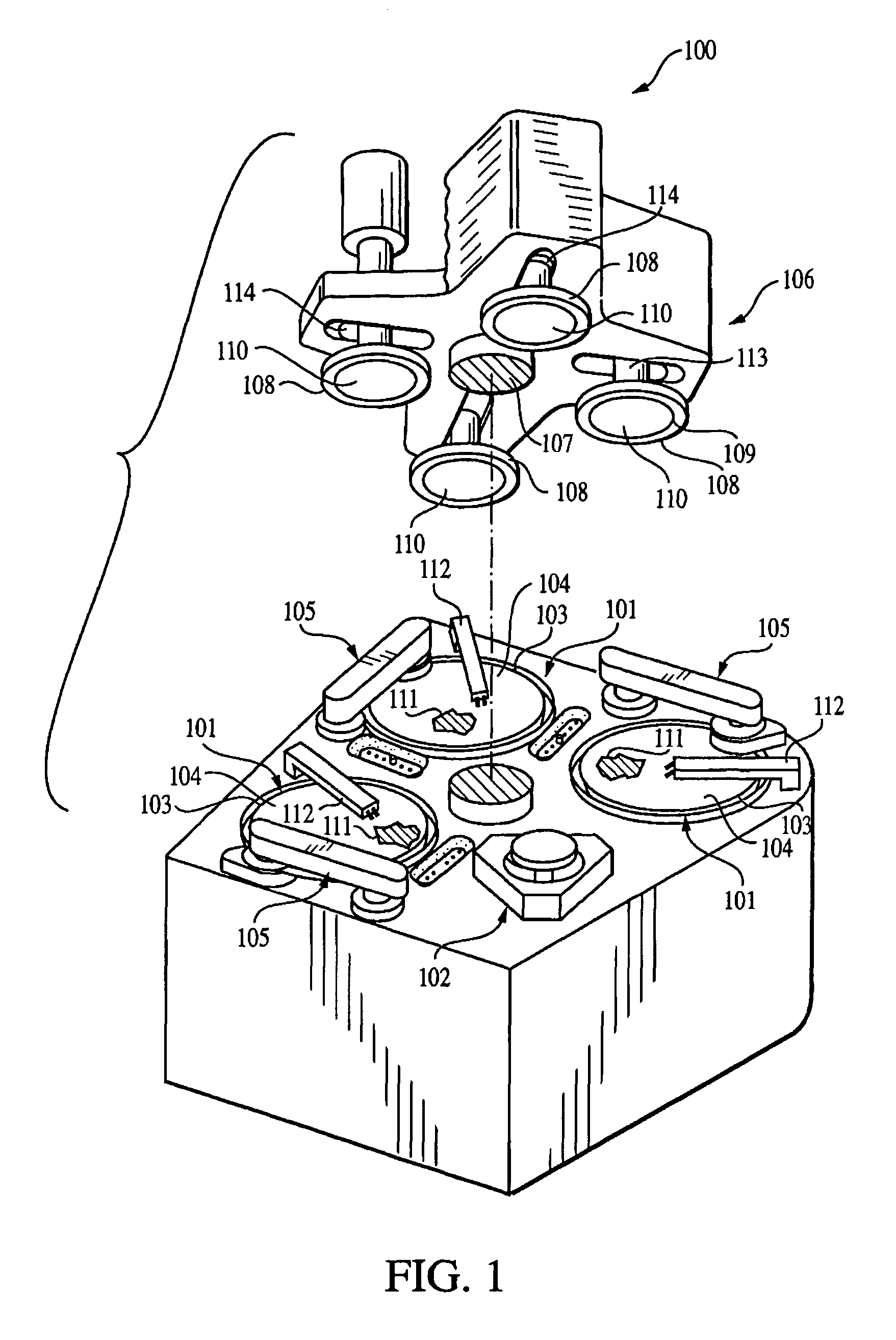

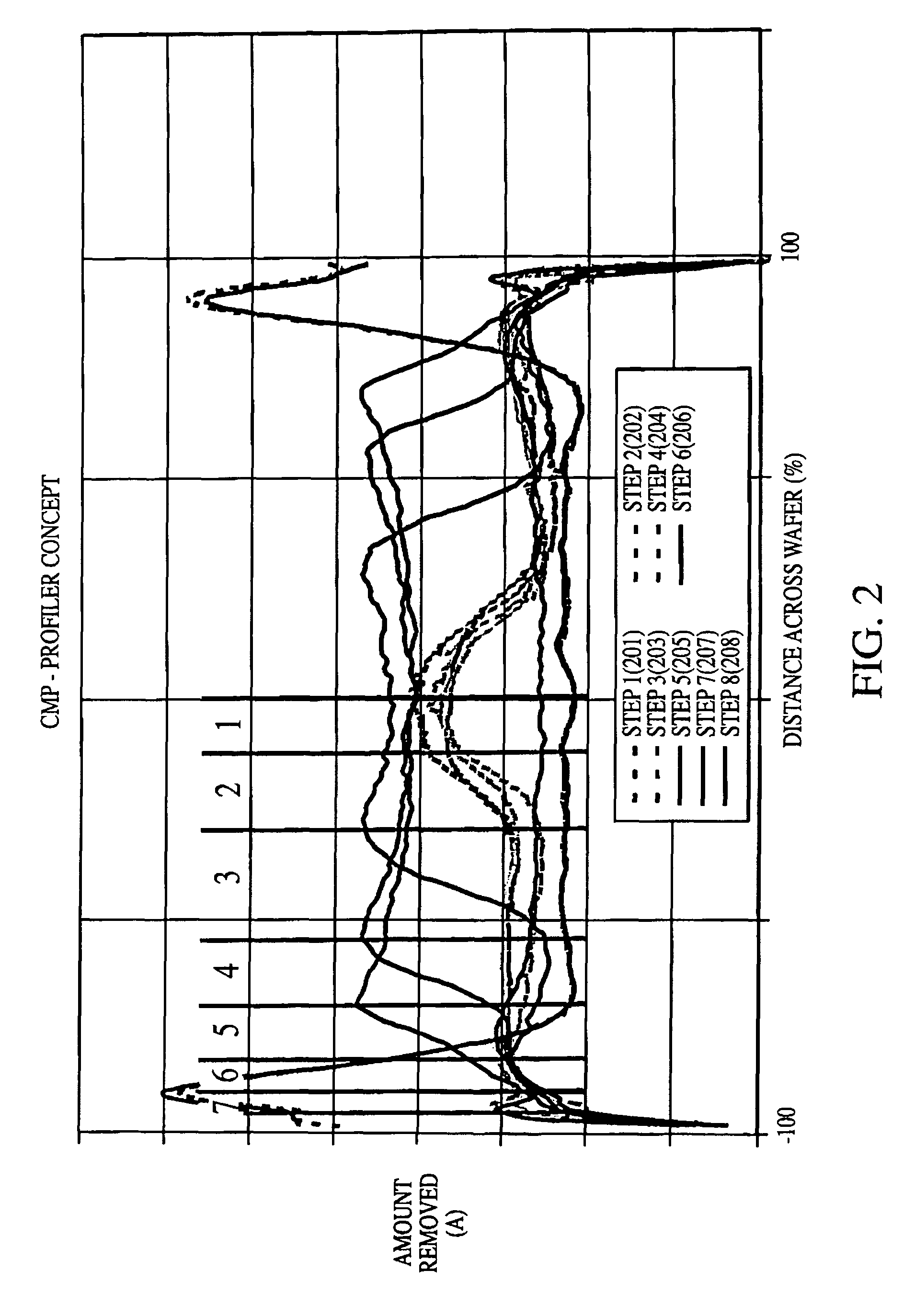

Feedback control of chemical mechanical polishing device providing manipulation of removal rate profiles

InactiveUS20070102116A1Optimal Operational ControlImprove thickness uniformitySemiconductor/solid-state device testing/measurementComputer controlMaterial removalModel quality

A method of controlling surface non-uniformity of a wafer in a polishing operation includes (a) providing a model for a wafer polishing that defines a plurality of regions on a wafer and identifies a wafer material removal rate in a polishing step of a polishing process for each of the regions, wherein the polishing process comprises a plurality of polishing steps, (b) polishing a wafer using a first polishing recipe based upon an incoming wafer thickness profile, (c) determining a wafer thickness profile for the post-polished wafer of step (b), and (d) calculating an updated polishing recipe based upon the wafer thickness profile of step (c) and the model of step (a) to maintain a target wafer thickness profile. The model can information about the tool state to improve the model quality. The method can be used to provide feedback to a plurality of platen stations.

Owner:APPLIED MATERIALS INC

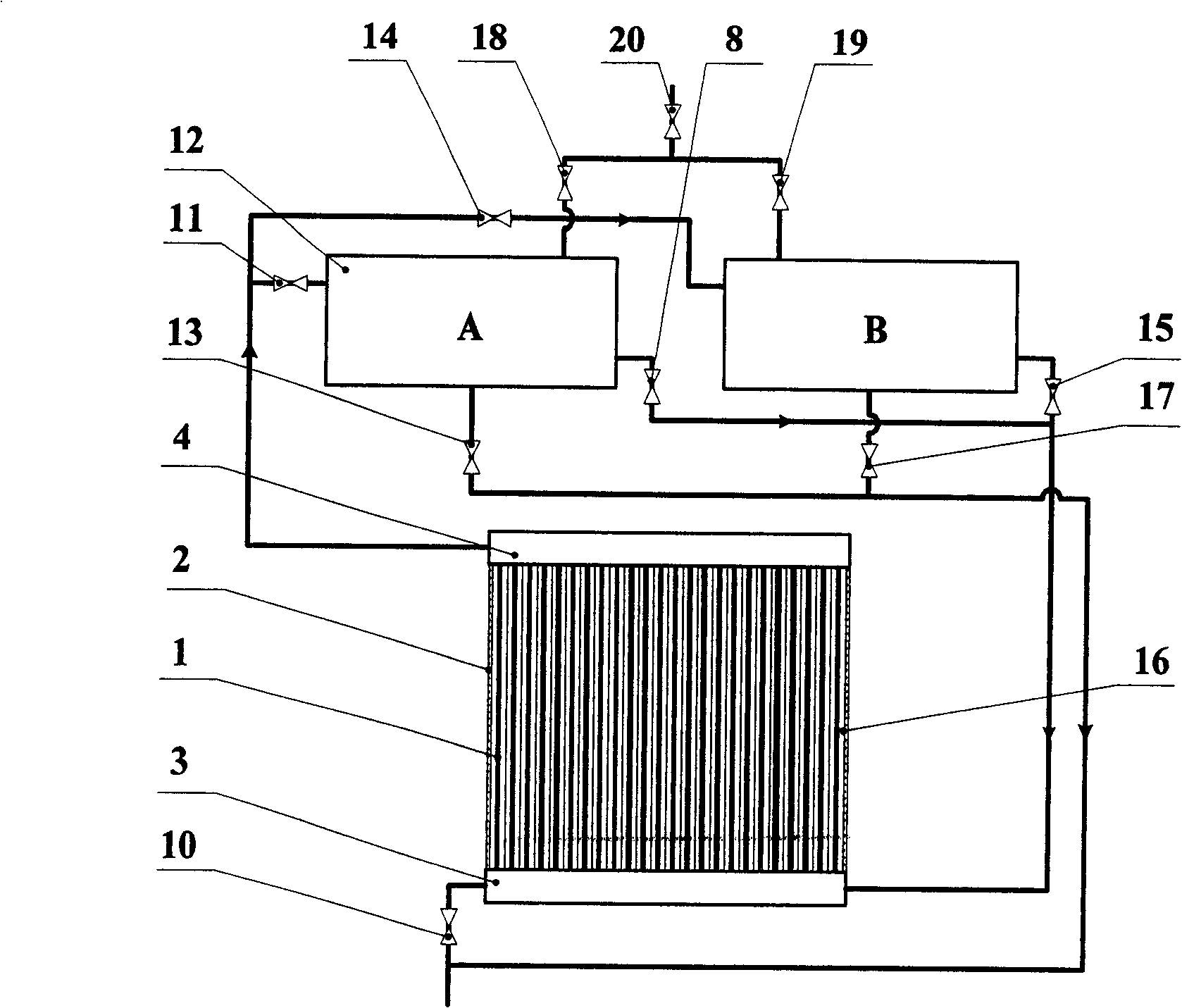

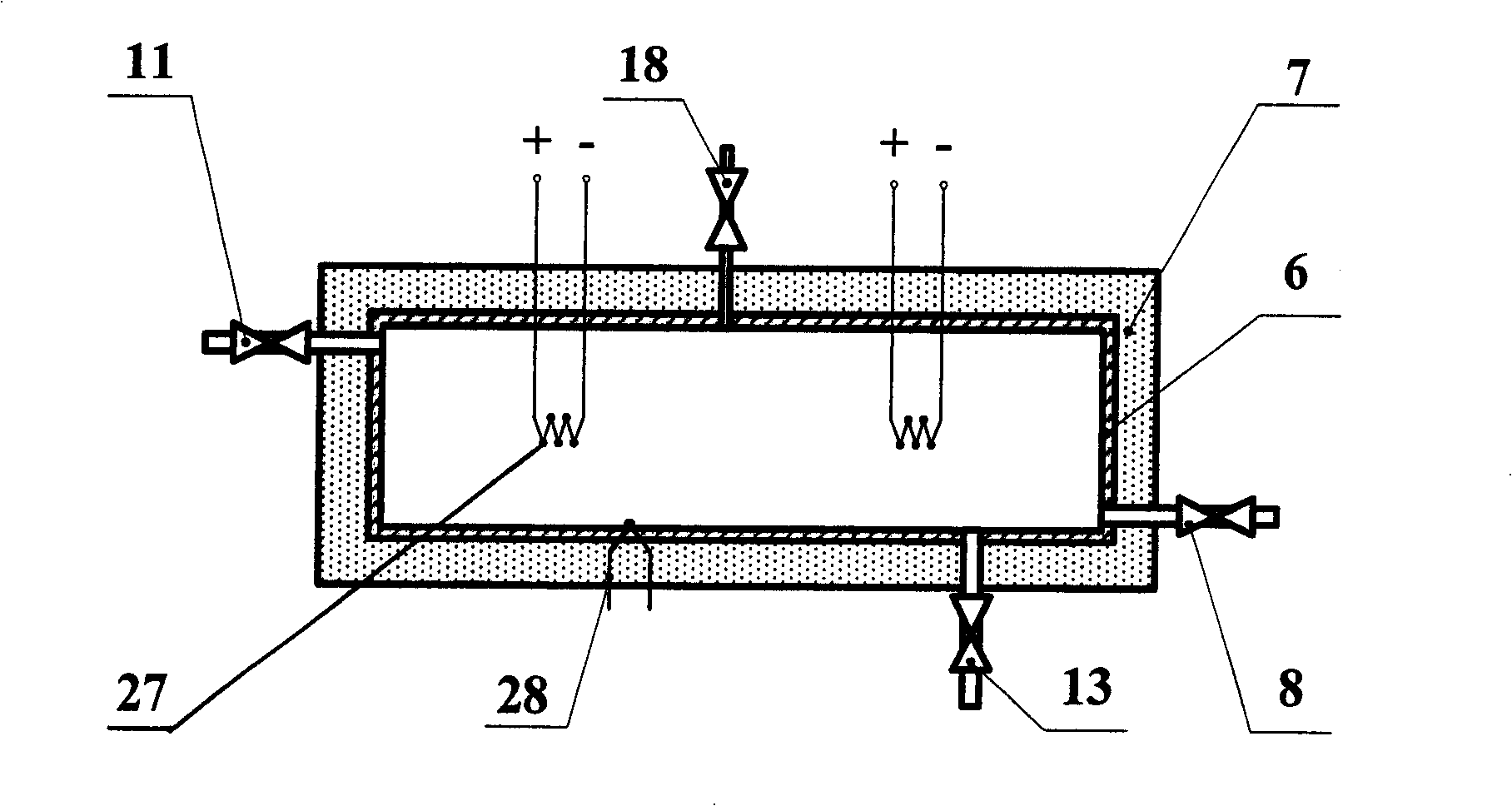

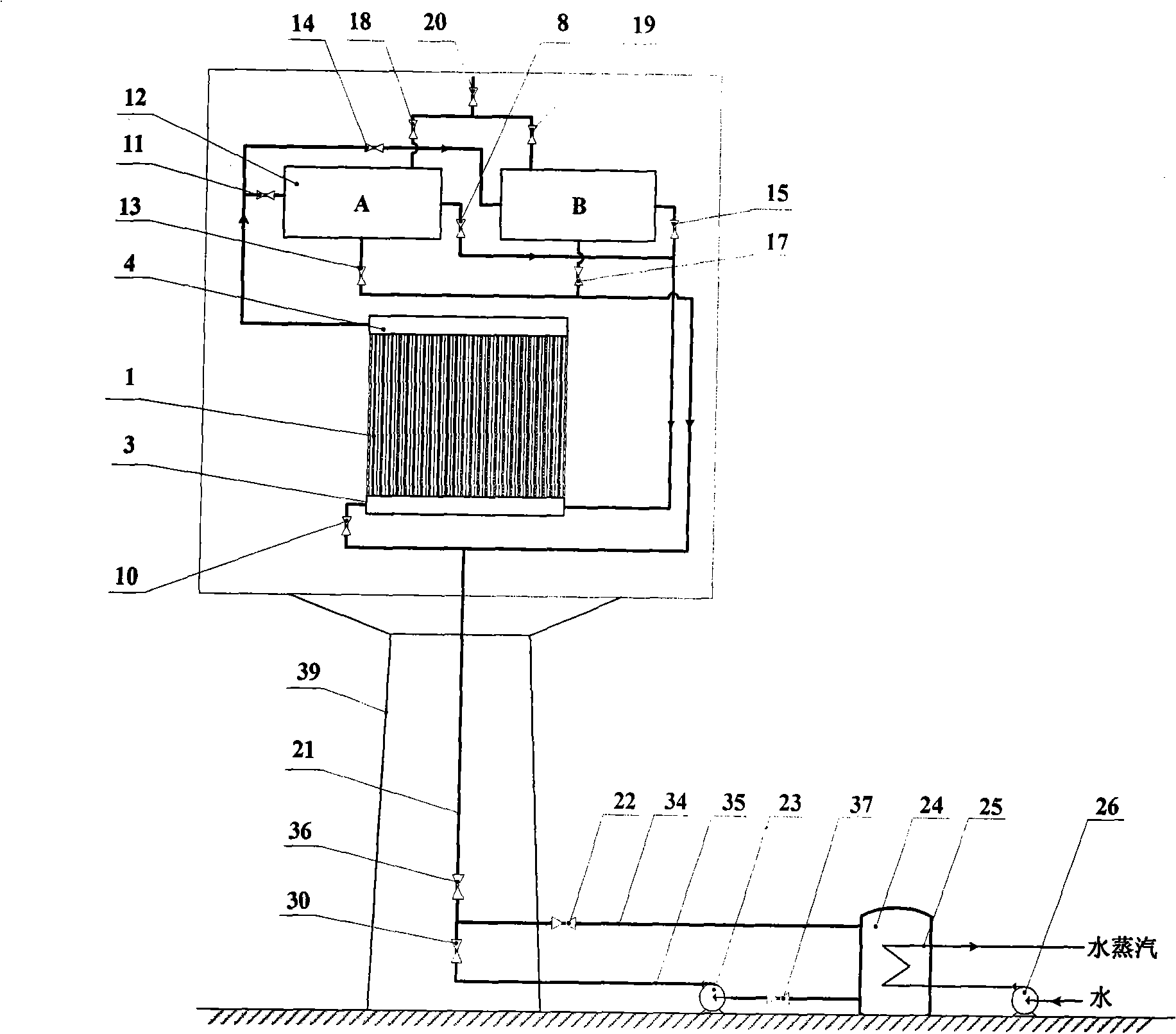

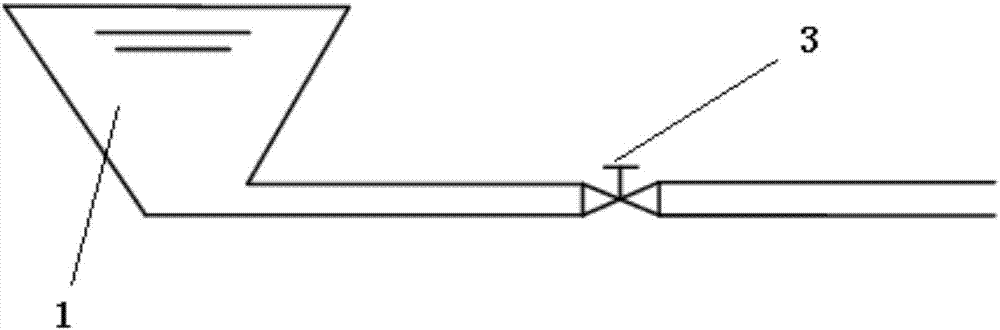

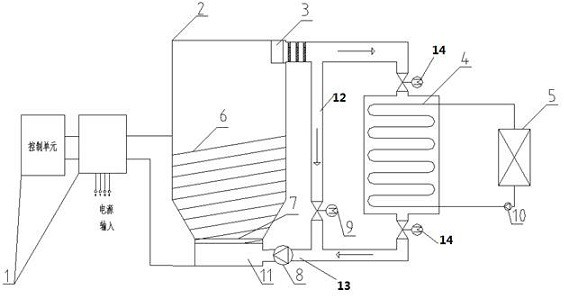

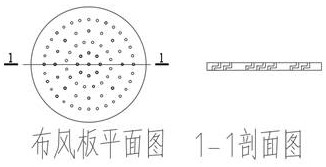

Passive molten salt thermal absorber

InactiveCN101298944AEnsure safetyOptimal Operational ControlSolar heating energySolar heat devicesMelting tankMolten salt

A passive fused salt heat absorber includes an endothermic pipe 1, a heat-resistant warming plate 2, a fused salt insulating layer 7, a lower collecting pipe 3, an upper collecting pipe 4; a fused salt tank 6 is arranged above the endothermic surface composed of a plurality of endothermic pipes 1. The endothermic surface faces to the heliostat field, the back of which is arranged with the heat-resistant warming plate 2. The outside of the fused salt tank 6 enwaraps the heat-resistant insulating layer 7, and the fused salt tank 6 and the heat-resistant insulating layer 7 enwrapped on the outside constitute a high temperature melt tank 12. The upper collecting pipe 4 is connected with the fused salt tank 6 through a rising pipe 5; the lower collecting pipe 3 is arranged at the lower part of the endothermic pipe 1, and the lower collecting pipe 3 is connected with fused salt tank 6 through a return pipe 9 to form a fused salt natural circulation loop. A endothermic surface can be used to match with a plurality of high temperature fused salt tanks 12, which forms the process of continuous heat absorption and heat charge and discharge.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

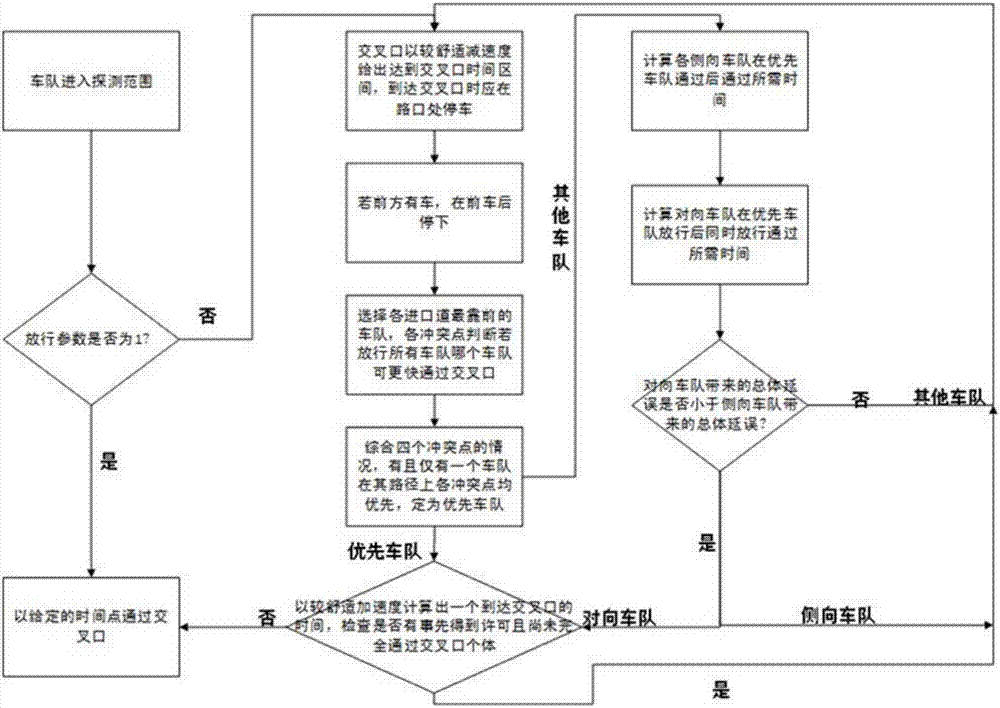

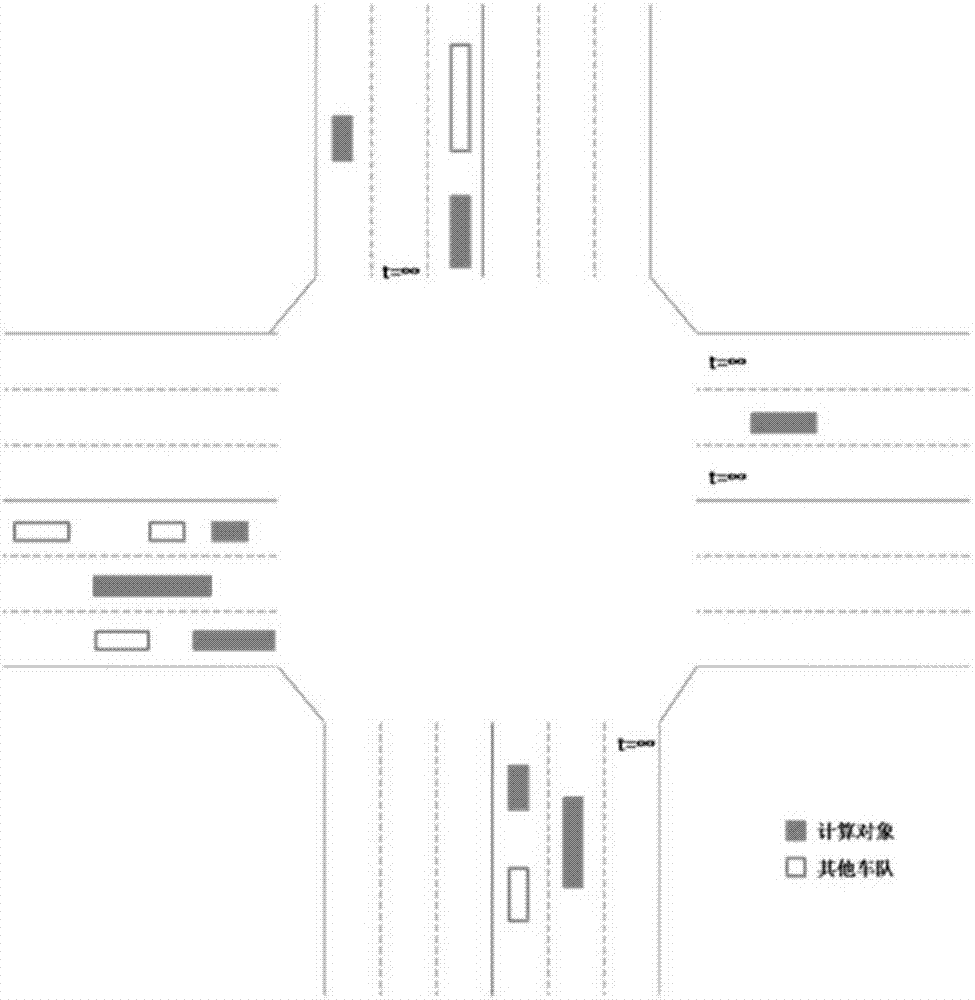

Intersection self-organizing control method for networking automatic driving vehicle

ActiveCN106875710AHelp develop applicationsImprove driving autonomyRoad vehicles traffic controlAdaptive controlOrganizational controlVehicle driving

The invention relates to an intersection self-organizing control method for a networking automatic driving vehicle. The method comprises: according to flow directions of all entrance lanes of an intersection, grouping of all vehicles is carried out, wherein vehicles without any flow direction conflict are classified into one group; vehicles at all entrance lanes form one fleet by using a control unit as a center; first control units of all entrance lanes carry out communication to send respective states as application information to an intersection control center; the intersection control center determines a fleet passing by the intersection firstly and sends passing time to the corresponding control unit, and the intersection control center sends the passing time to the control unit which is capable of completing passing within the passing time and belongs to the same group as the fleet passing by the intersection firstly; and the control unit obtaining the passing time generates a driving track based on the passing time. Compared with the prior art, the method has the following beneficial effects: the vehicle driving autonomy can be improved; and the potential safety hazard, caused by the communication delay, of networking vehicle driving at an intersection can be eliminated.

Owner:同济创新创业控股有限公司

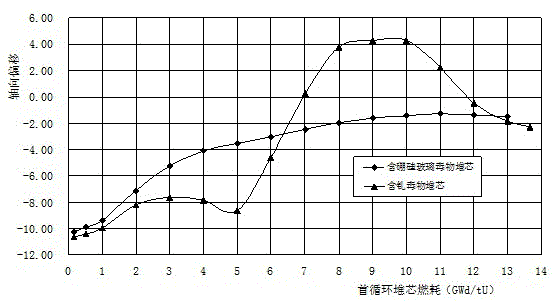

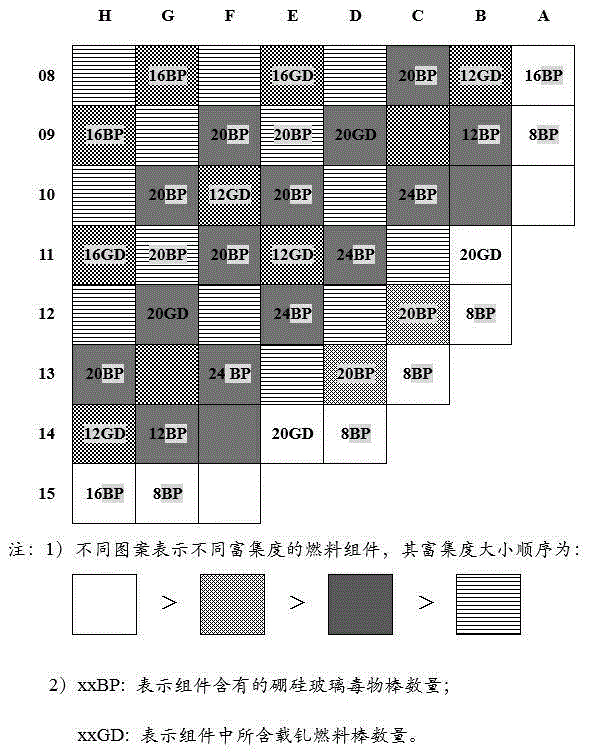

Core loading method of pressurized water reactor nuclear power plant first cycle

InactiveCN105139899AExtended loop lengthAvoiding Contradictions Occupying Control Rod Guide TubesNuclear energy generationShieldingDistribution controlPressurized water reactor

The invention discloses a core loading method of pressurized water reactor nuclear power plant first cycle. A first cycle core adopts a fuel assembly with 4-6 different enrichment degrees, a high leakage loading mode is adopted, and core reactivity inhibition and power distribution control are carried out by simultaneously adopting borosilicate glass solid inflammable poison rods and integrated gadolinium-supported fuel rods. The method greatly prolongs the cycle length of the first cycle core, adopts two solid inflammable poisons to avoid the contradiction of occupation of control rod guiding tubes due to use of too much borosilicate glass and avoid negative influences of unfavorable axial power distribution caused by use of too many integrated gadolinium solid inflammable poisons on running control, makes the core design be flexible, makes the power distribution flattening of the core be easy, has good engineering practicality and design flexibility, and can well realize the economy and safety of the power plant.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

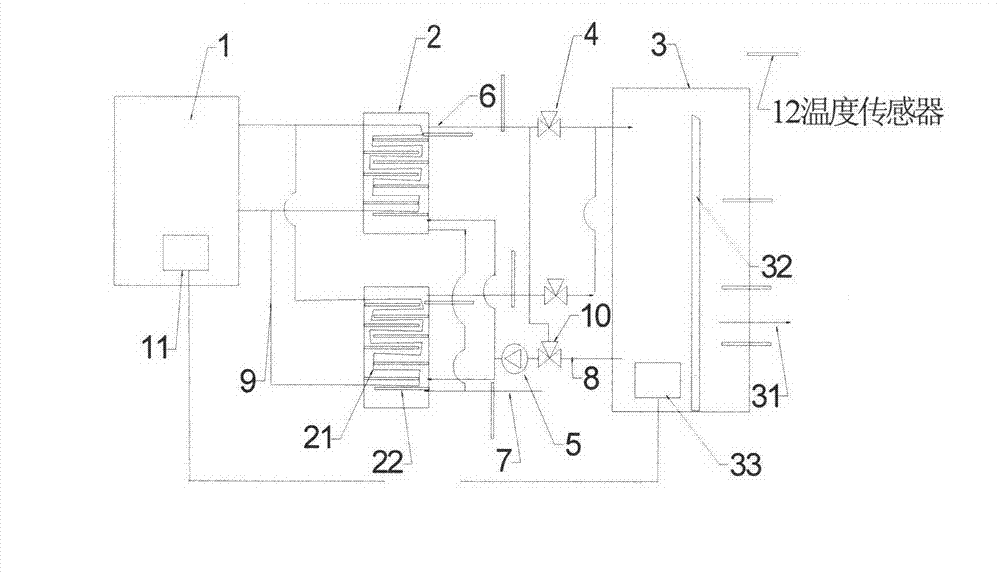

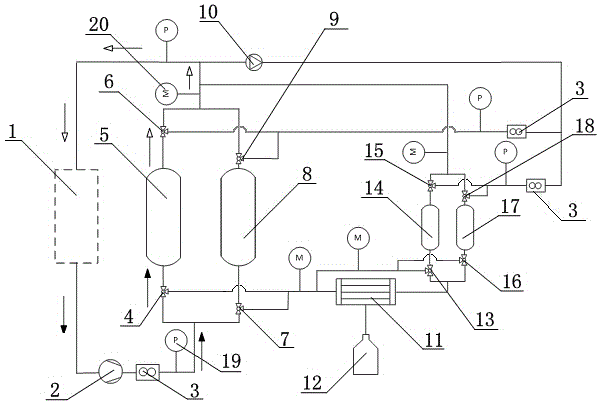

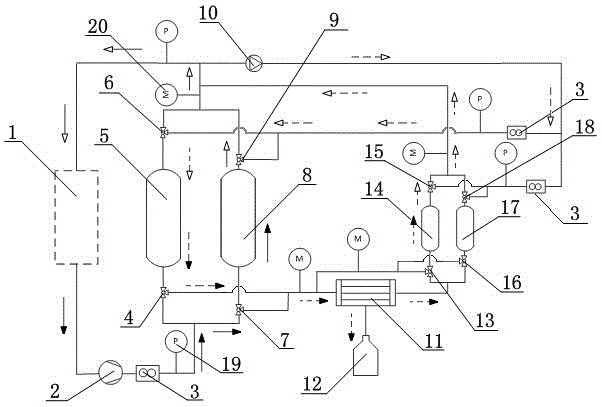

Directly-heated type and circular type integrated heat-pump water heater system

InactiveCN103245055AAddress unmanageable shortcomingsImprove energy efficiencyFluid heatersWater storage tankEngineering

The invention provides a directly-heated type and circular type integrated heat-pump water heater system. According to the system, a directly-heated type hot water supply mode and a circular type hot water supply mode are provided simultaneously. The system is composed of a host machine, a heat transfer water tank, a water storage tank and corresponding control parts. By means of the system, defects of low energy efficiency and reliability caused by the high return water temperature and difficult control of a directly-heated type heat-pump water heater are overcome, and the system can operate in an efficient and high-reliable mode.

Owner:王静宇

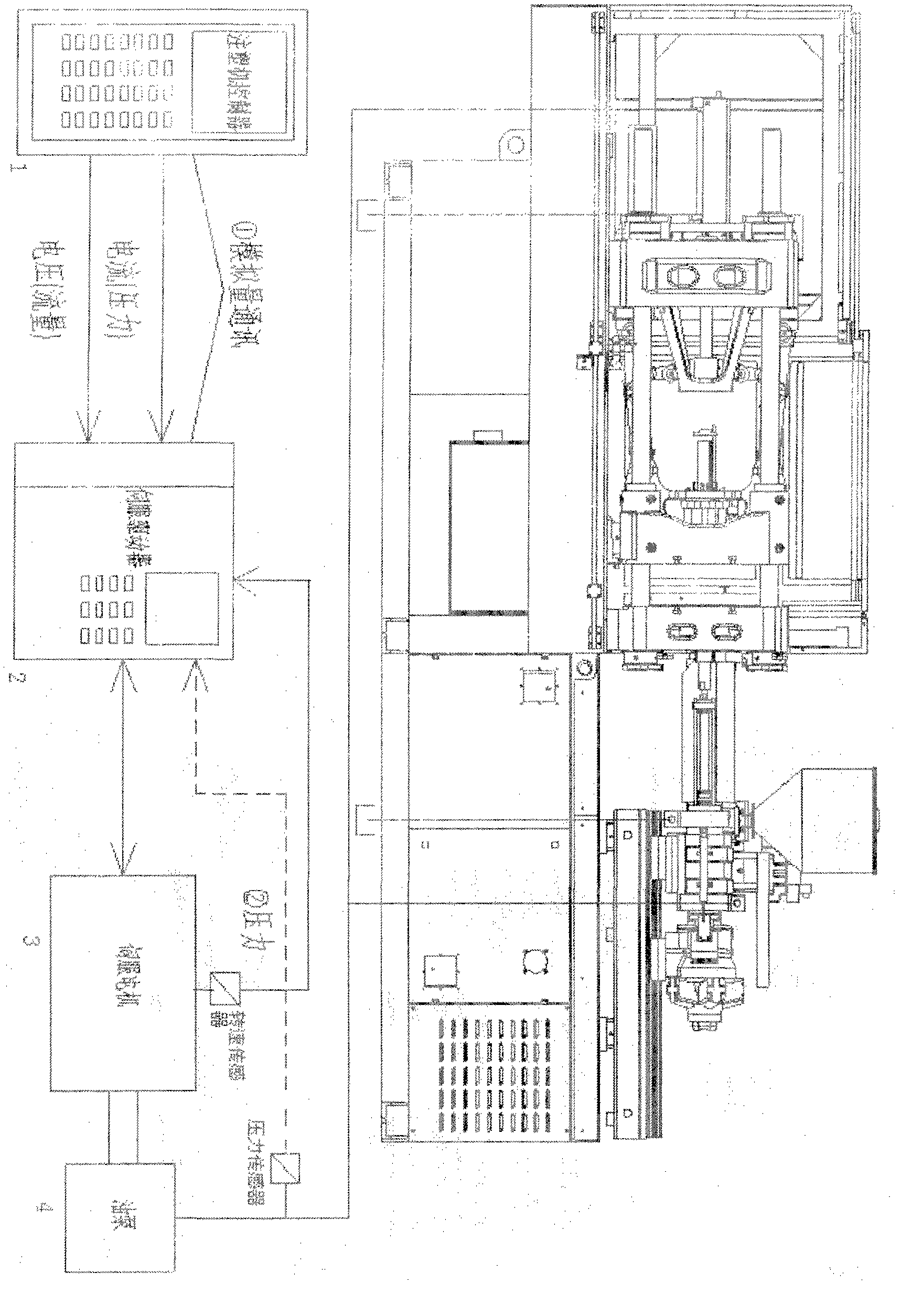

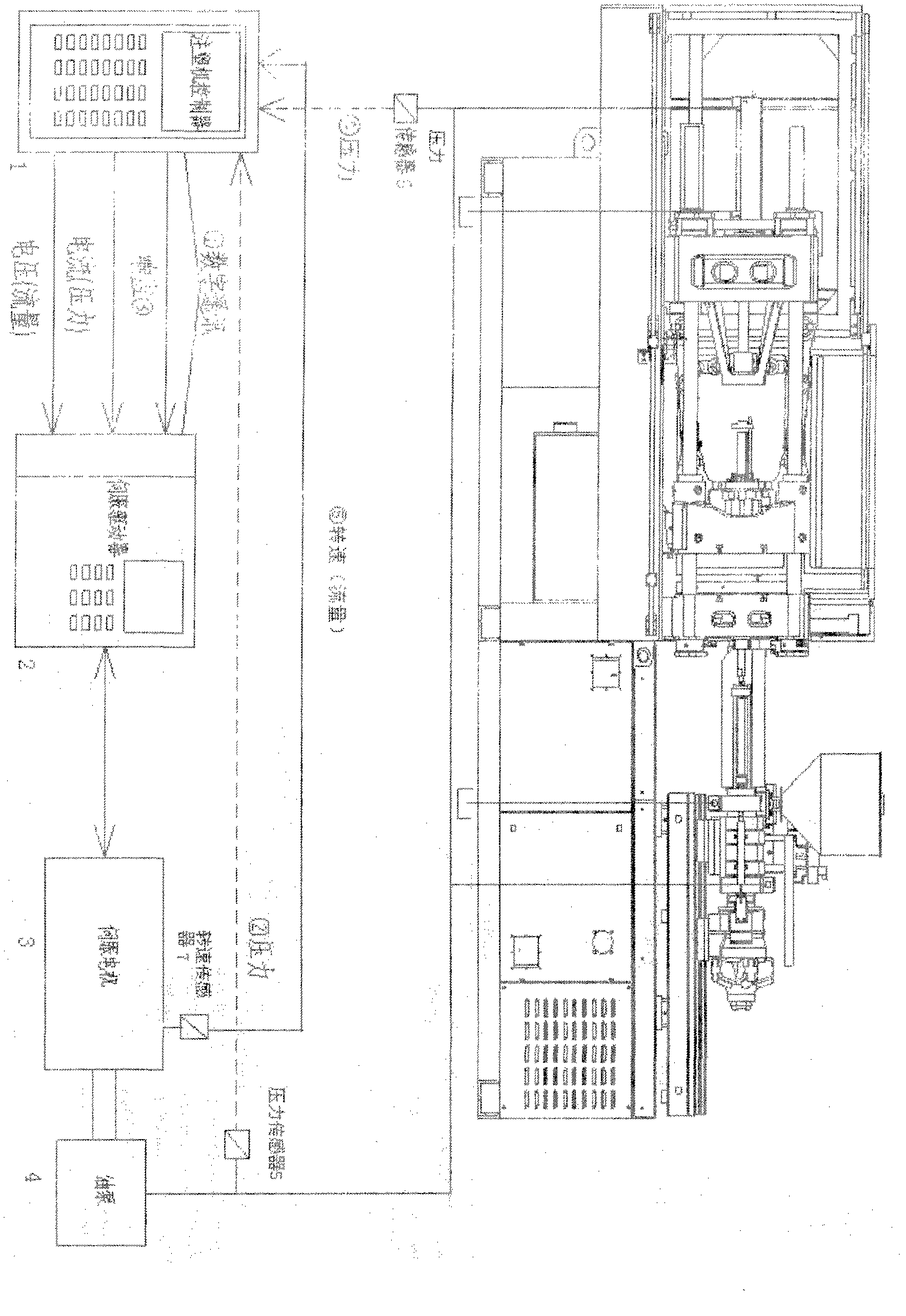

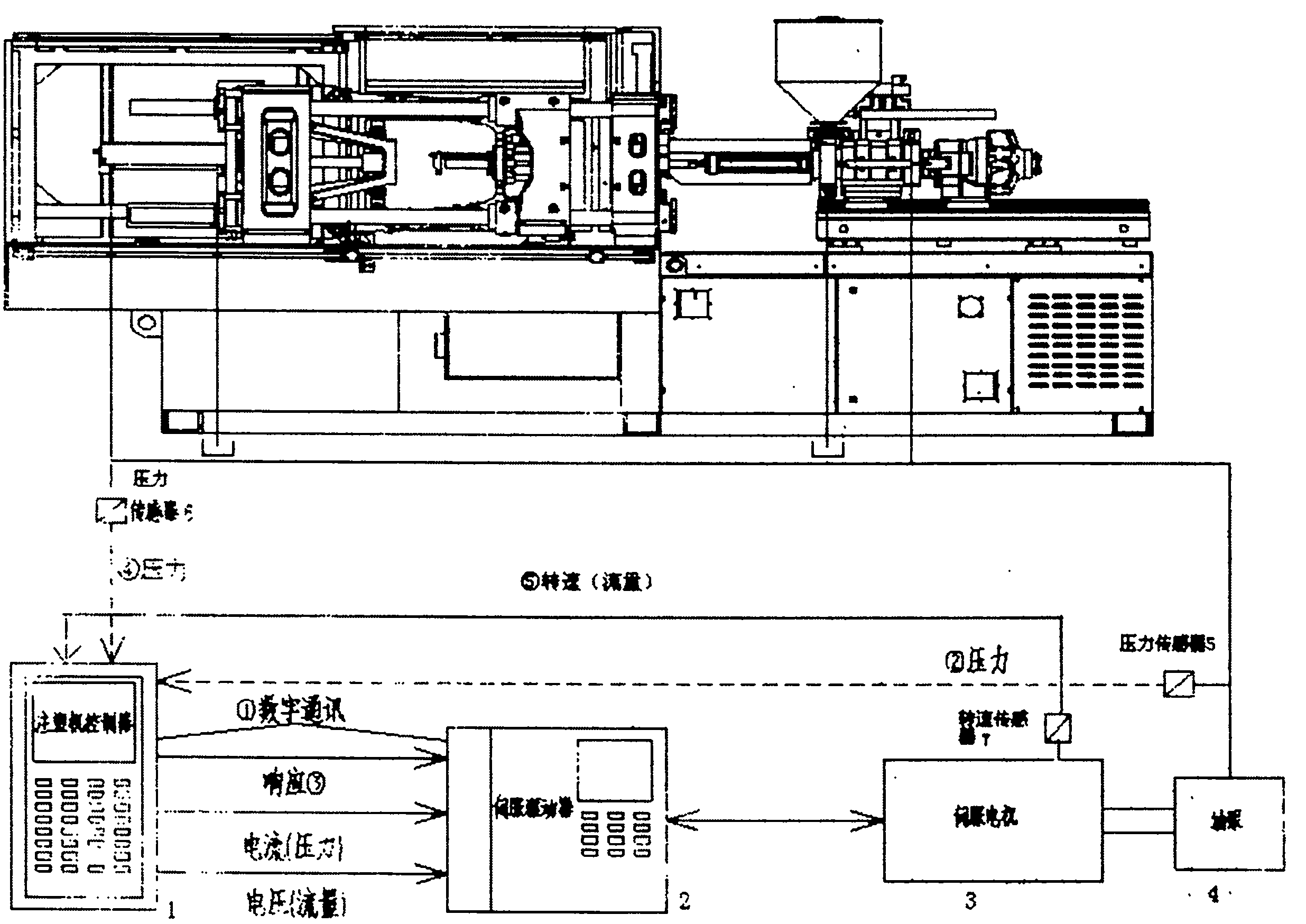

Control system of injection molding machine

InactiveCN102626979ARealize closed-loop controlOptimal Operational ControlControl signalControl system

Provided are a control system of an injection molding machine and a control method thereof. The control system of the injection molding machine is characterized in that (1) a digital communication protocol is built between an injection molding machine controller and a servo driver, and action command is sent to the servo driver in a digital communicating method; (2) information which the injection molding machine controller sends to the servo driver comprises pressure control signals, flow control signals and servo driver response speed control signals; (3) a plurality of pressure sensors are arranged, one end of each pressure sensor is connected with a required detection point, the other end of each pressure sensor is directly connected with the injection molding machine controller so that a plurality of pressure sensor signal feedback systems are formed; and (4) the pressure sensors and a rotating speed sensor are directly connected with the injection molding machine controller so that automatic closed-loop regulation of pressure and flow is achieved.

Owner:宁波恩瑞德机电科技有限公司

Feedback control of chemical mechanical polishing device providing manipulation of removal rate profiles

InactiveUS8070909B2Optimal Operational ControlImprove thickness uniformitySemiconductor/solid-state device testing/measurementComputer controlMaterial removalModel quality

A method of controlling surface non-uniformity of a wafer in a polishing operation includes (a) providing a model for a wafer polishing that defines a plurality of regions on a wafer and identifies a wafer material removal rate in a polishing step of a polishing process for each of the regions, wherein the polishing process comprises a plurality of polishing steps, (b) polishing a wafer using a first polishing recipe based upon an incoming wafer thickness profile, (c) determining a wafer thickness profile for the post-polished wafer of step (b), and (d) calculating an updated polishing recipe based upon the wafer thickness profile of step (c) and the model of step (a) to maintain a target wafer thickness profile. The model can information about the tool state to improve the model quality. The method can be used to provide feedback to a plurality of platen stations.

Owner:APPLIED MATERIALS INC

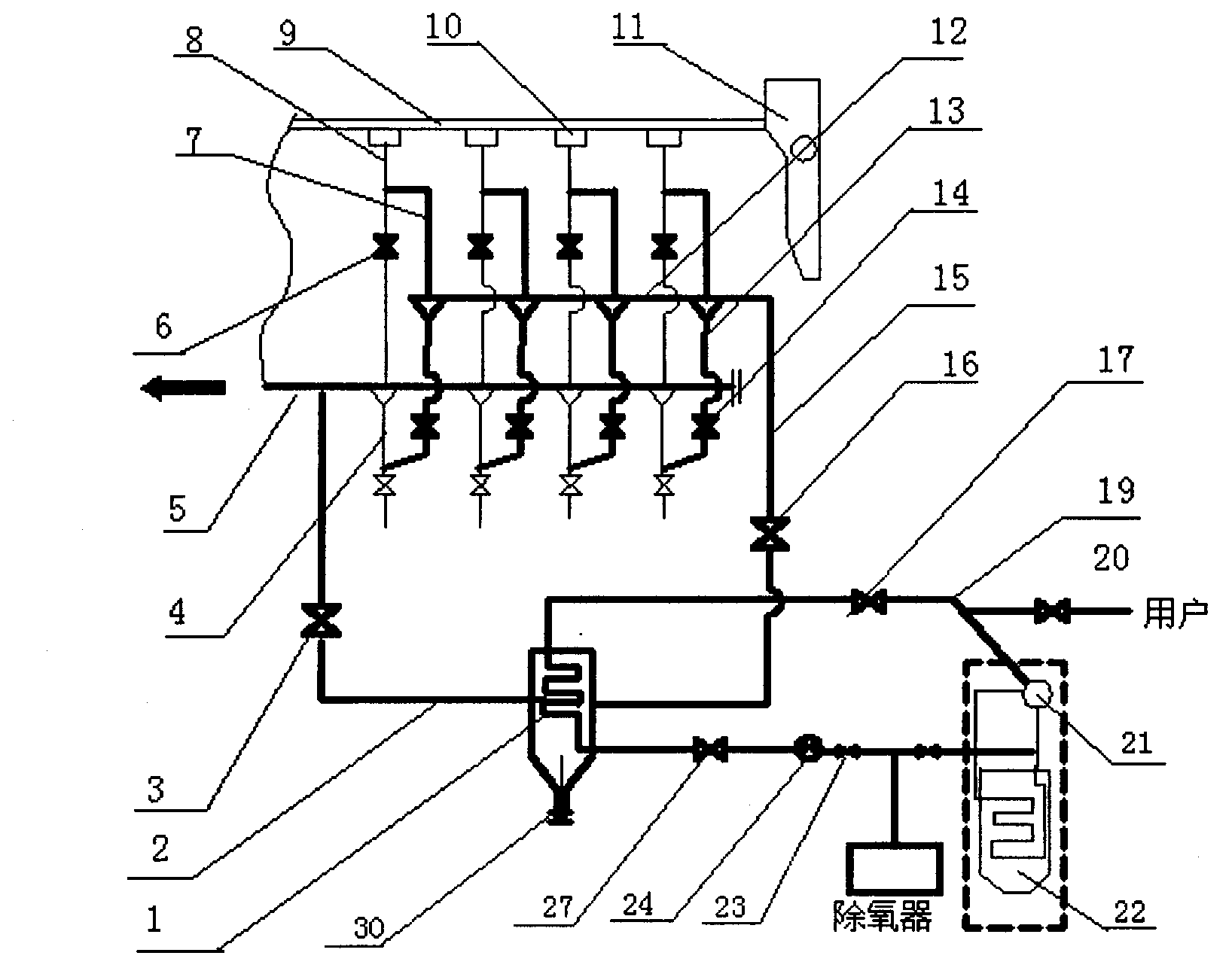

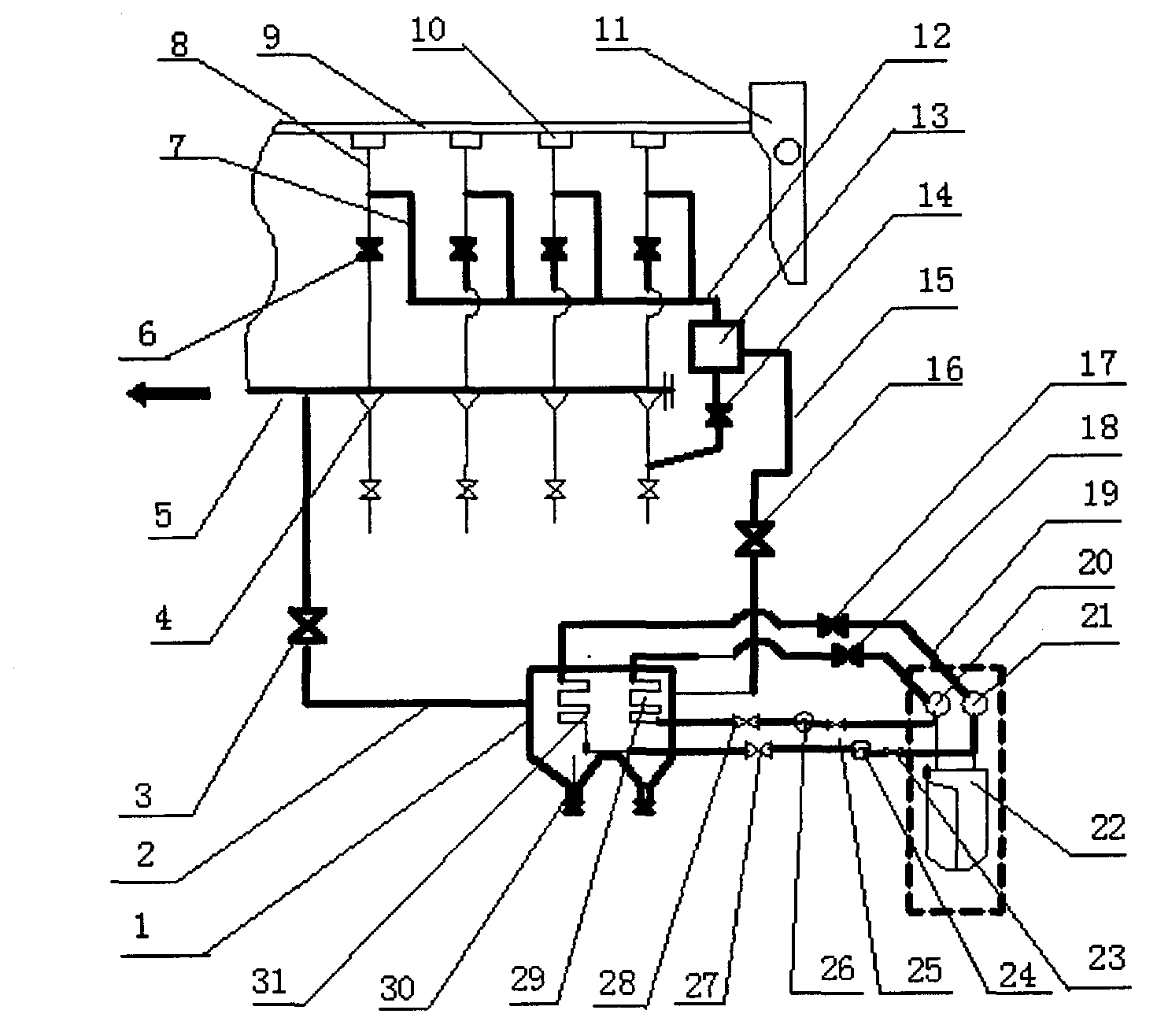

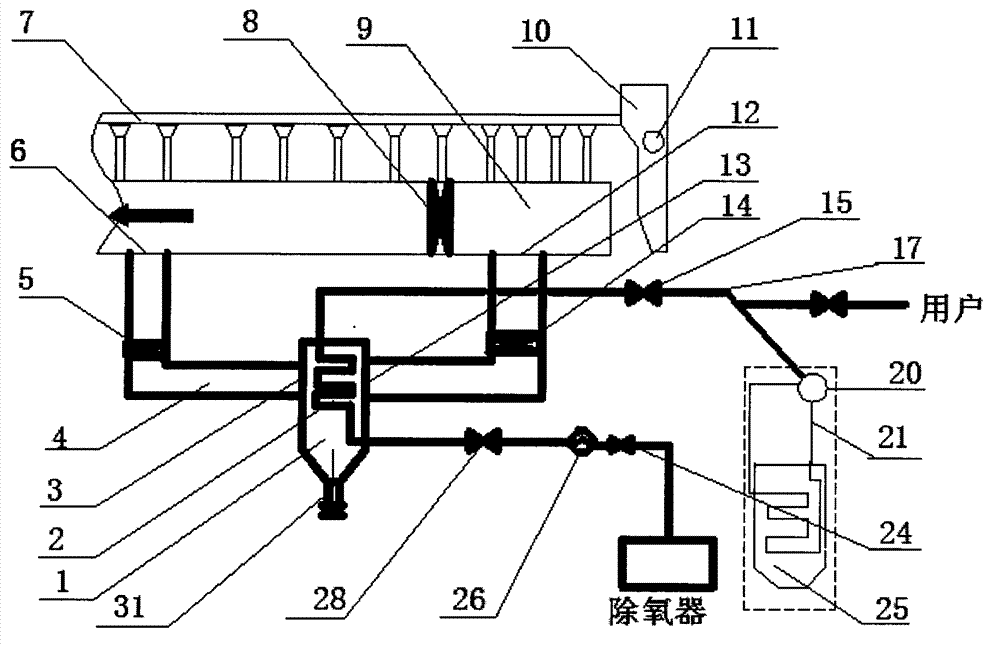

Flue gas waste heat recovery system of sintering machine tail

InactiveCN103292605AReduce the temperatureReduce power consumptionEnergy industryIncreasing energy efficiencyWaste heat recovery unitFlue gas

The invention discloses a flue gas waste heat recovery system of a sintering machine tail, which is characterized in that control valves and bypass smoke exhausting branch pipes are mounted on smoke exhausting branch pipes between bellows of the sintering machine tail and a main flue; a bypass smoke exhausting header pipe is mounted on the main flue side of the sintering machine tail, and connected with the smoke exhausting branch pipes; a heat exchanger is mounted between the bypass smoke exhausting header pipe and the main flue; a water inlet pipe and a steam outlet pipe are mounted on the heat exchanger, and connected with a waste heat boiler; and flue gas heat of the sintering machine tail is recovered by the heat exchanger. According to the flue gas waste heat recovery system, since the flue gas amount from the bellows of the sintering machine tail to the heat exchanger is controlled, the flue gas heat of the sintering machine tail can be recovered sufficiently, the minimum temperature of the flue gas of the main flue is ensured, and the dewing of the flue gas is avoided. The waste heat recovery system is simple in structure and to control, and low in investment and operating cost, and is applicable to the existing sintering system and a new system.

Owner:孙慕文

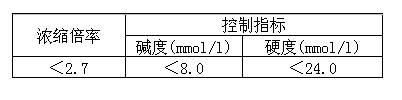

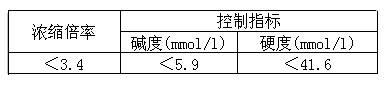

Circulating water system control method

ActiveCN102681452APrevent scalingAvoid corrosionWater/sewage treatment by neutralisationTreatment using complexing/solubilising chemicalsAlkalinitySoil science

The invention relates to a circulating water system control method, which comprises the steps of (1) acquiring a limit concentration ratio in circulating water through a scale inhibition test; (2) determining a limit value of chloride ion concentration ratio, a hardness limit value and an alkalinity limit value of the circulating water at the limit concentration ratio; (3) creating a safe chloride ion concentration ratio for the running control of the circulating water, and determining a control index of the alkalinity and the hardness; (4) detecting the alkalinity and the hardness of the circulating water; (5) observing whether the detection value of the alkalinity and the detection value of the hardness of the circulating water meet the control indexes, and processing the circulating water and re-detecting the circulating water after being adjusted if one or two items of the detection value of the alkalinity or the detection value of the hardness cannot meet the control index; and (6) ending the detection if both the detection value of the alkalinity and the detection value of the hardness meet the control index. The method for detecting and controlling the alkalinity and hardness in the circulating water is used for substituting the method for controlling the concentration ratio so as to prevent the scaling and corrosion problems of the circulating water, so that not only is the running of the circulating water convenient to control, but also the water resource is maximally utilized.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

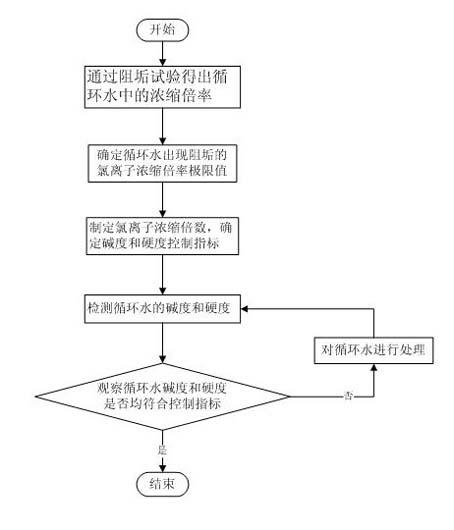

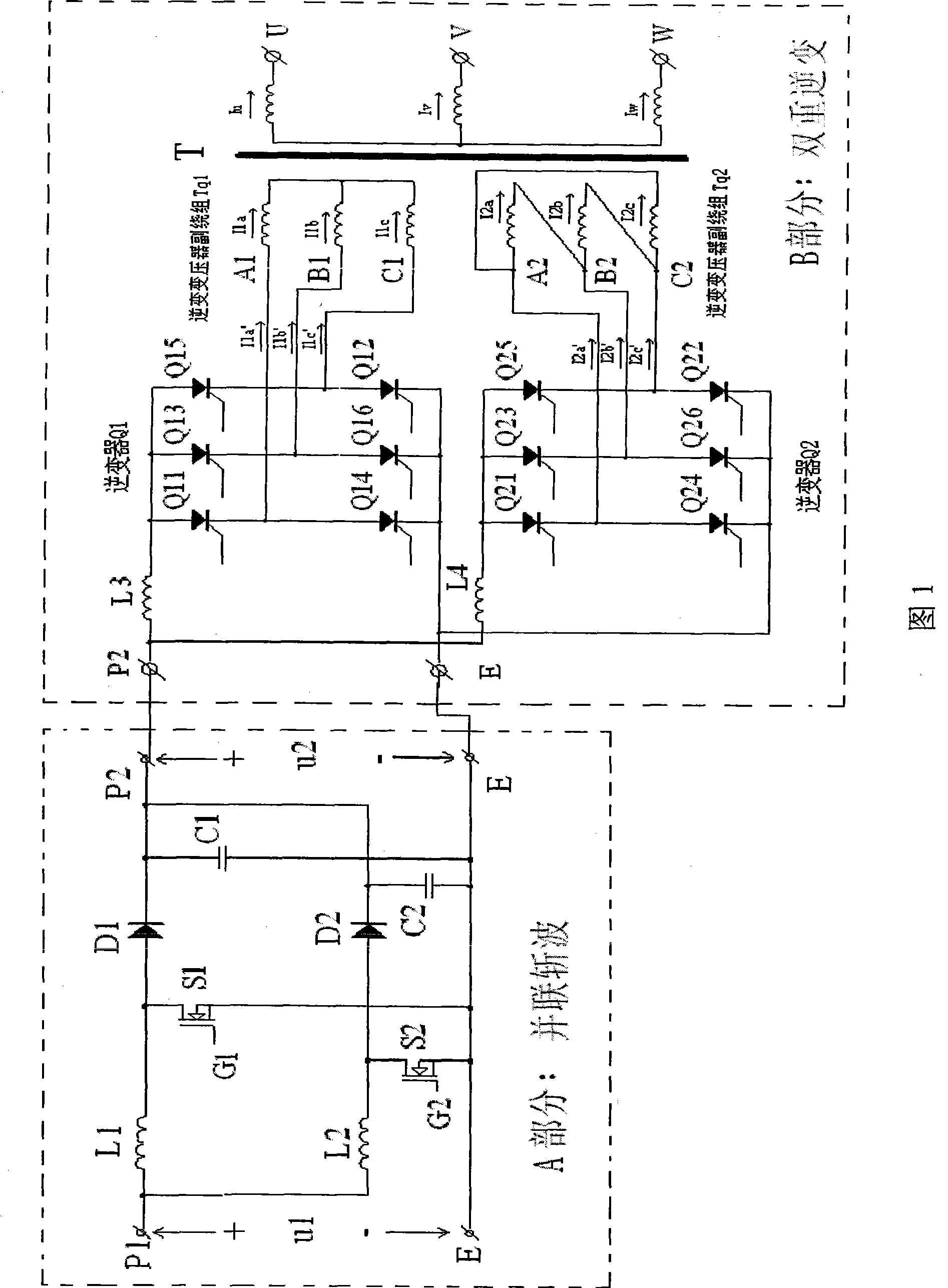

High-voltage motor parallel connection chopping and double-inversion speed-governing energy-saving controller

ActiveCN101378244ASolve the problem of current sharingSame sizeAC motor controlAc-dc conversionLow voltageHigh pressure

The invention discloses a high voltage motor parallel wave chopping and double inversion speed regulation energy-saving controller, which is applied to the stepless speed regulation of a wound rotor type motor loaded on blowers and pumps, and the like in the industries of electric power, cement and metallurgy, and the like. The controller comprises a parallel wave chopper and a double inverter, wherein, the parallel wave chopper comprises flat wave reactors L1 and L2, isolated gate bipolar transistors S1 and S2, fast recovery diodes D1 and D2, and capacitors C1 and C2; the double inverter comprises two independent inverters Q1 and Q2 and a double inversion three winding transformer T, the inverter Q1 comprises six thyristors Q11 to Q16 and a reactor L3, the inverter Q2 comprises six thyristors Q21 to Q26 and a reactor L4, the double inversion three winding transformer T is provided with three sets of windings, wherein, one set of the winding is arranged at the high voltage side and connected into Y-shape by three phases, two sets of the windings are arranged at the low voltage side, wherein, one set of the winding Tq1 is connected into the Y-shape by three phases, and the other set of the winding Tq2 is connected into triangular shape by three phases. The controller can guarantee that the current of the isolated gate bipolar transistors of the parallel loop of each path are basically consistent.

Owner:JIANGSU FANGCHENG ELECTRIC SCI & TECHCO

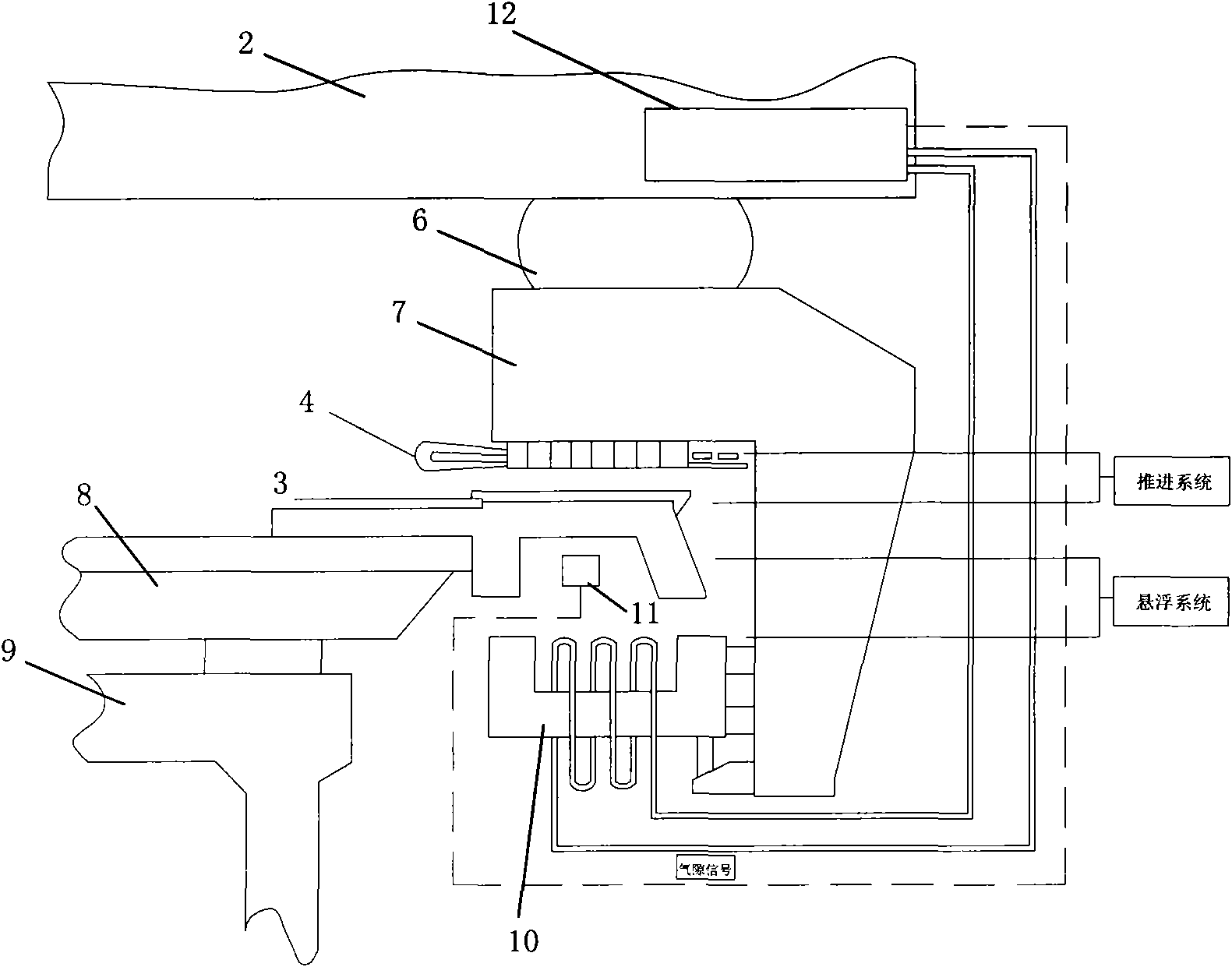

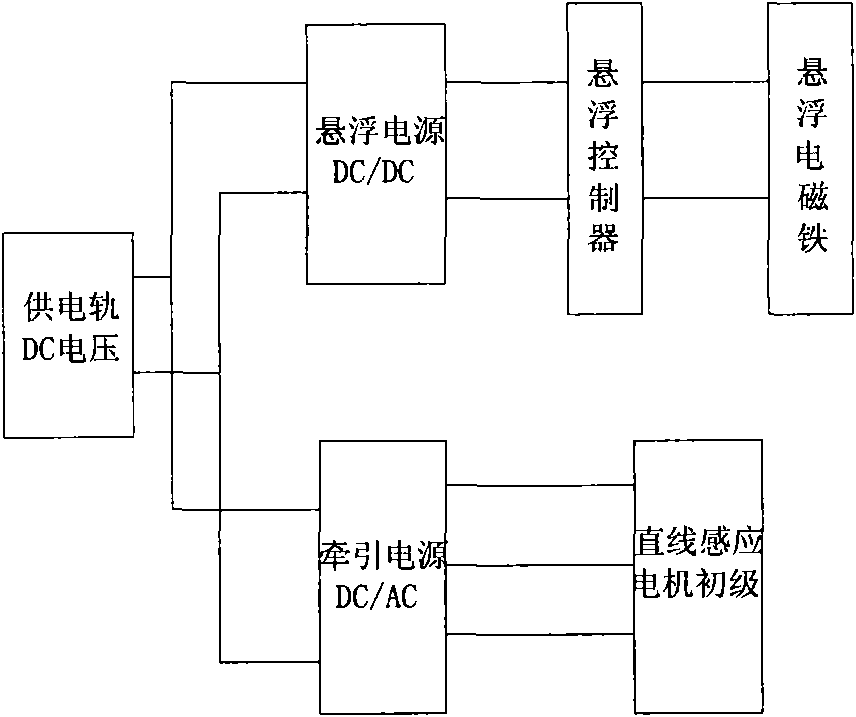

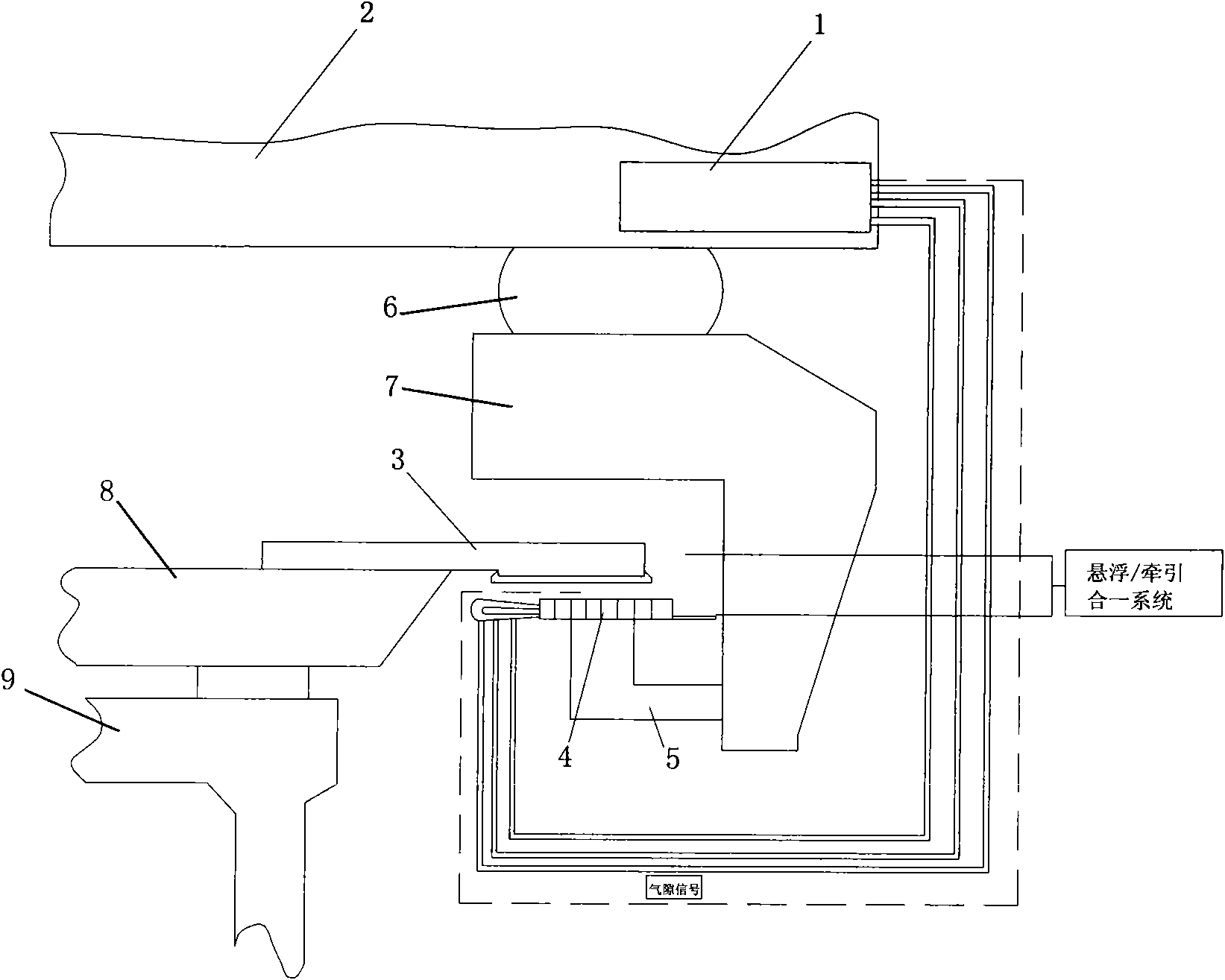

Levitation traction integrated system for high-efficiency magnetic-levitation train

InactiveCN101549653AReduce suspension power consumptionReduced working air gapElectric propulsionLevitationControl theory

The invention discloses a levitation traction integrated system for high-efficiency magnetic-levitation train. The levitation traction integrated system comprises a levitation traction controller, a linear induction machine, a linear induction machine supporting beam and a power supply source. The linear induction machine comprises a secondary linear induction machine and a primary linear induction machine. The levitation traction controller, the primary linear induction machine and the power supply source are fixed to a vehicle body. The primary linear induction machine is below a rail. The secondary linear induction machine is flatly paved along the rail. The invention is the levitation traction integrated system for high-efficiency magnetic-levitation train that has a simple and compact structure, low cost, a simple operating principle and good energy saving effect and is conveniently controlled.

Owner:NAT UNIV OF DEFENSE TECH

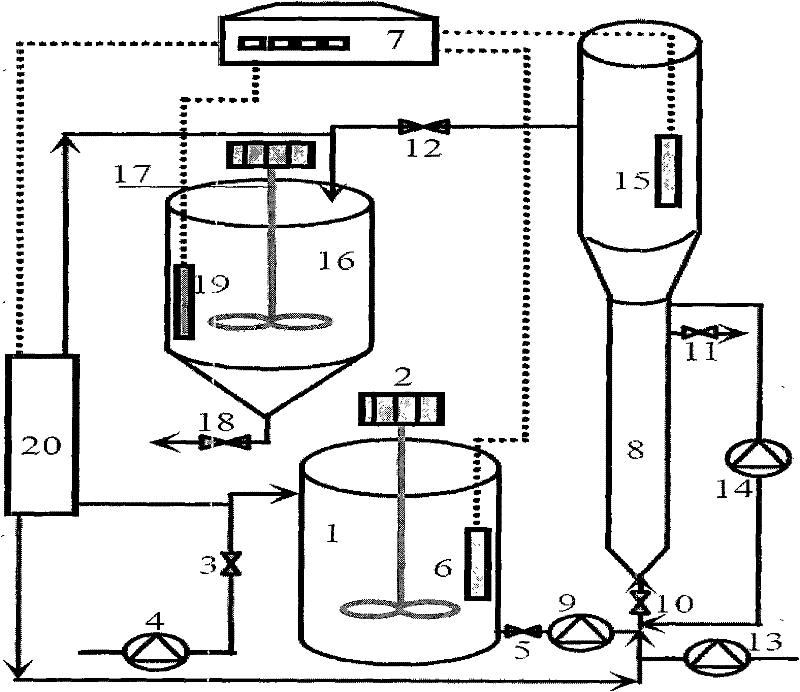

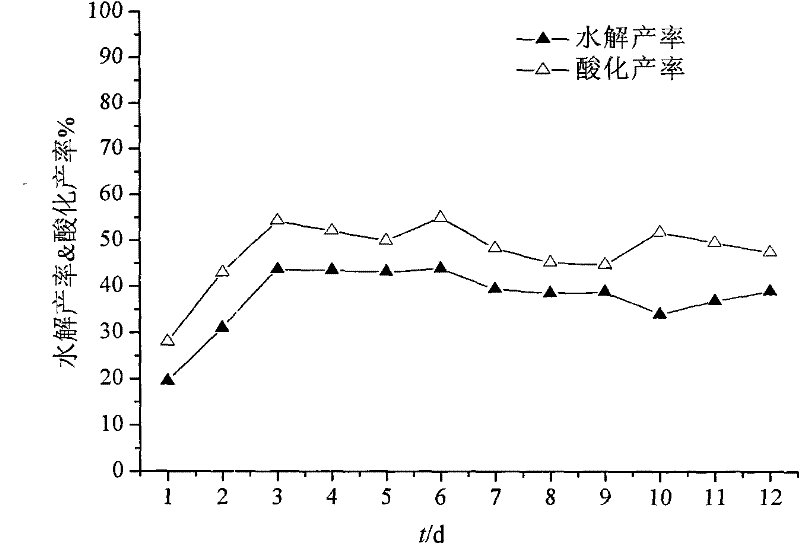

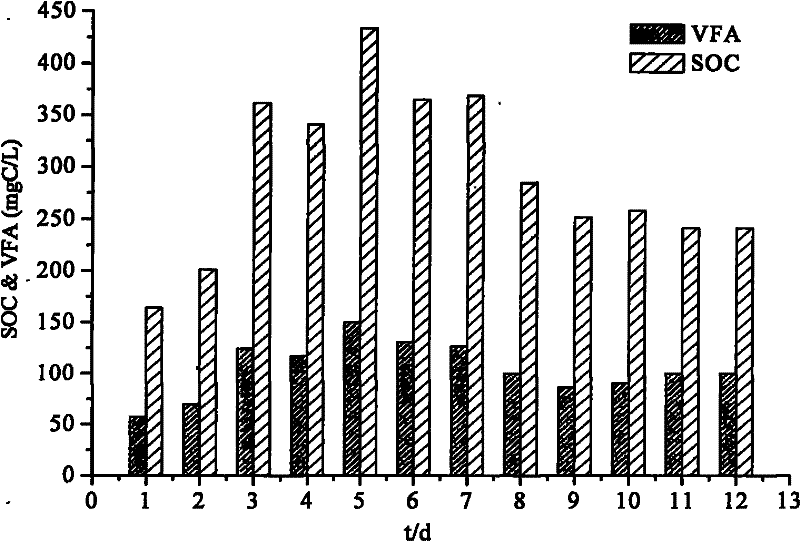

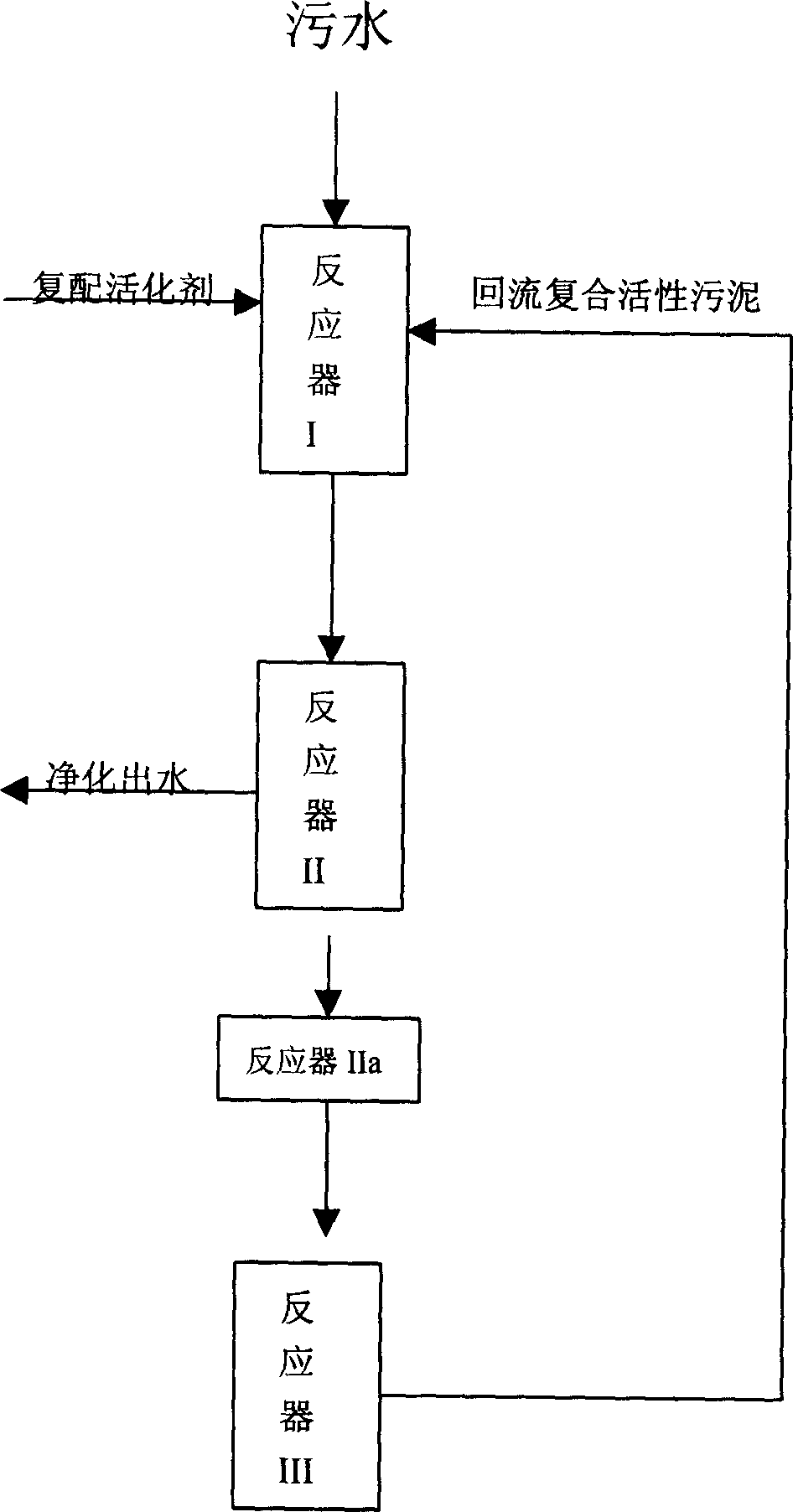

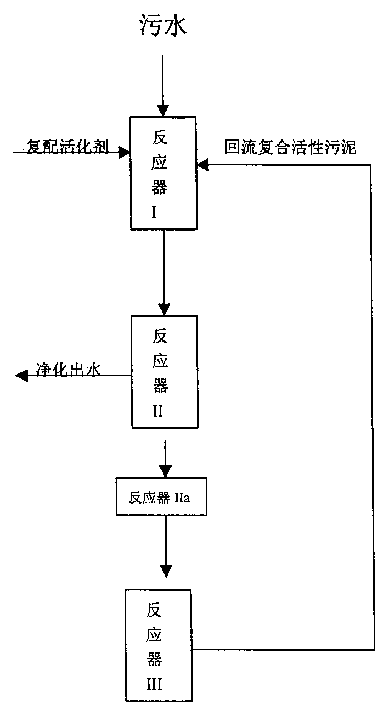

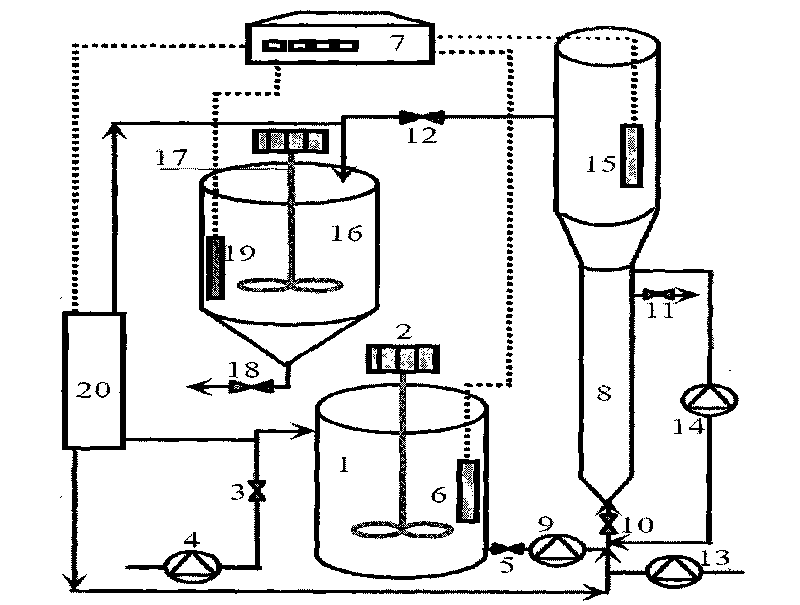

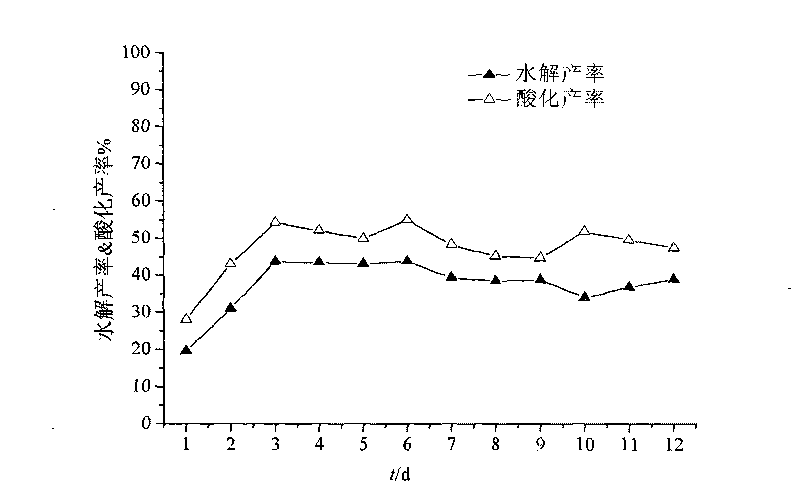

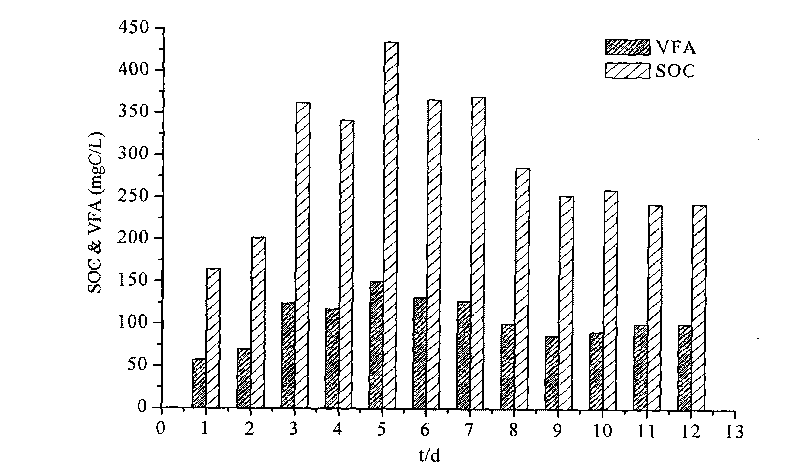

Sludge carbon source two-stage alkaline hydrolysis acidizing recovery method

InactiveCN101708932BImplement reduction processingHigh reduction rateTreatment with anaerobic digestion processesMultistage water/sewage treatmentActivated sludgeRecovery method

The invention relates to a sludge carbon source two-stage alkaline hydrolysis acidizing recovery method, aiming at the problems that the carbon source in a sewage treatment plant is deficient and the sludge treatment is difficult and belonging the field of sludge and sewage treatment technology; the method adopts a strong-alkaline pretreatment method to lead the sludge treatment to be controlled in a hydrolysis acidification stage effectively, SOC and VFAs productivity are improved remarkably and the hydrolysis acidification time can be shortened to be 8.5 days. The method can adopt domestic sewage to elutriate SCOD generated in the sludge hydrolysis acidification, and the flexible selection whether the magnesium ammonium phosphate chemical precipitation method is carried out to sludge hydrolysis acidification liquid to remove nitrogen and phosphorus is carried out. The reduction rate of the remained activated sludge is more than 30 percent after the two-stage alkaline hydrolysis acidification is carried out, and recycling utilization of organic carbon source in the remained activated sludge is realized.

Owner:CHONGQING KANGDA ENVIRONMENTAL PROTECTION IND GRP

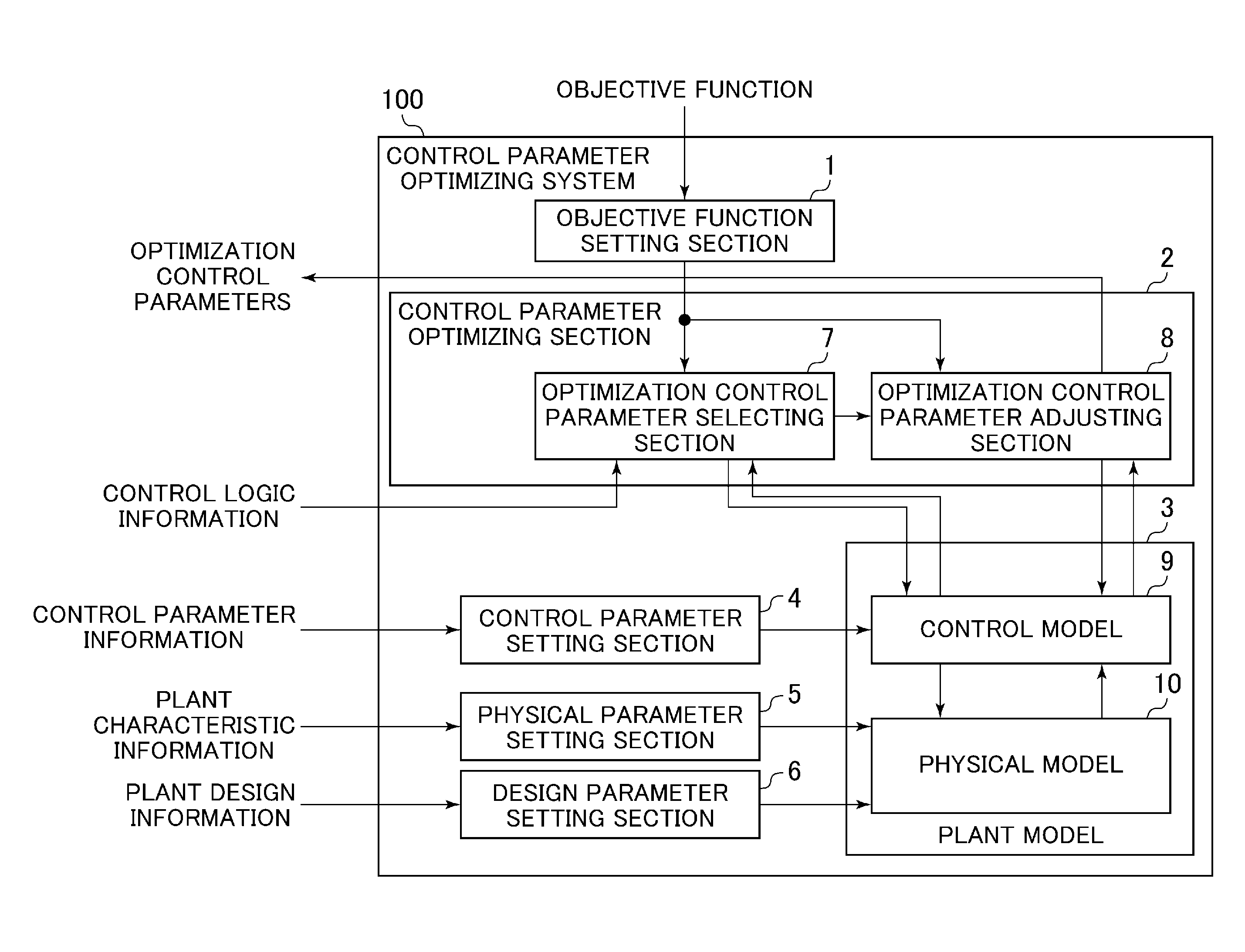

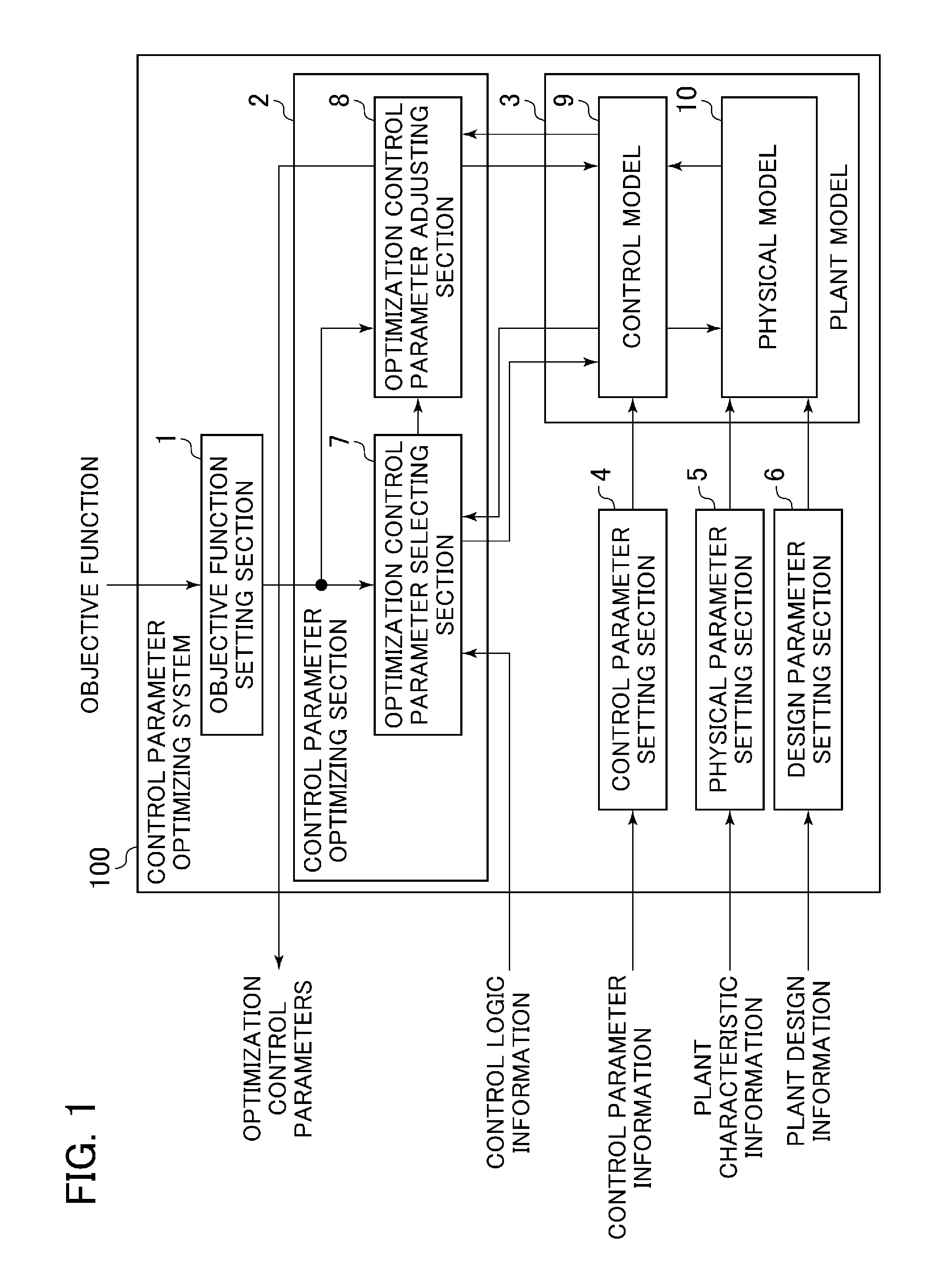

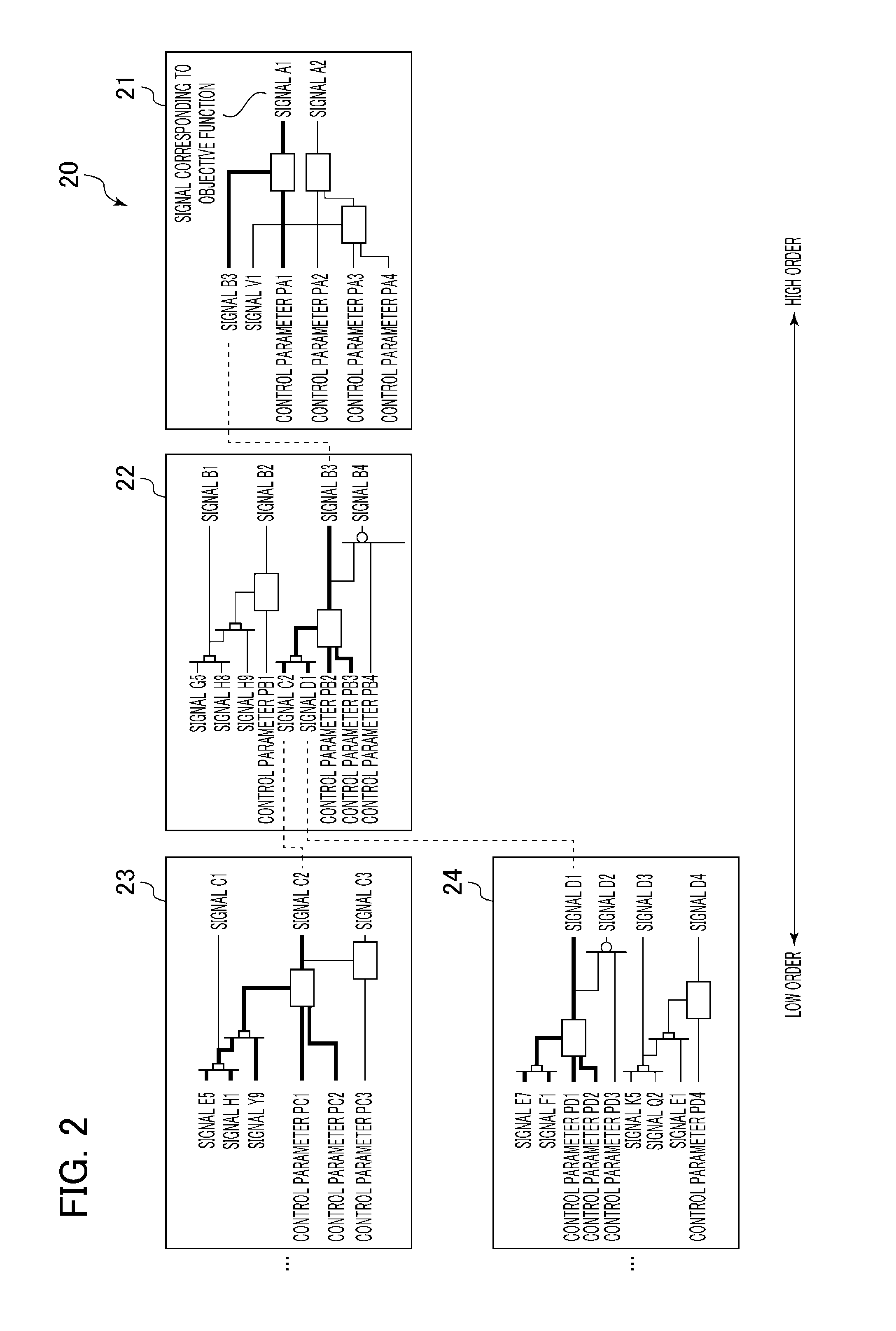

Control Parameter Optimizing System and Operation Control Optimizing Apparatus Equipped Therewith

ActiveUS20170003676A1Optimal Operational ControlComputer controlElectric controllersPower stationProcess engineering

A control parameter optimizing system and an operation optimizing apparatus equipped therewith are provided, the system being applicable to an existing plant without modifying the control panel or equipment of the plant, the system further being capable of optimizing the operation control of the plant in accordance with diverse operational requirements. The system includes an objective function setting section, a plant model, and a control parameter optimizing section. The control parameter optimizing section includes an optimization control parameter selecting section and an optimization control parameter adjusting section. The optimization control parameter selecting section selects as an optimization control parameter the control parameter for optimizing an objective function based on control logic information extracted from a power plant. The optimization control parameter adjusting section adjusts the value of the optimization control parameter using the plant model in such a manner as to optimize the objective function.

Owner:MITSUBISHI POWER LTD

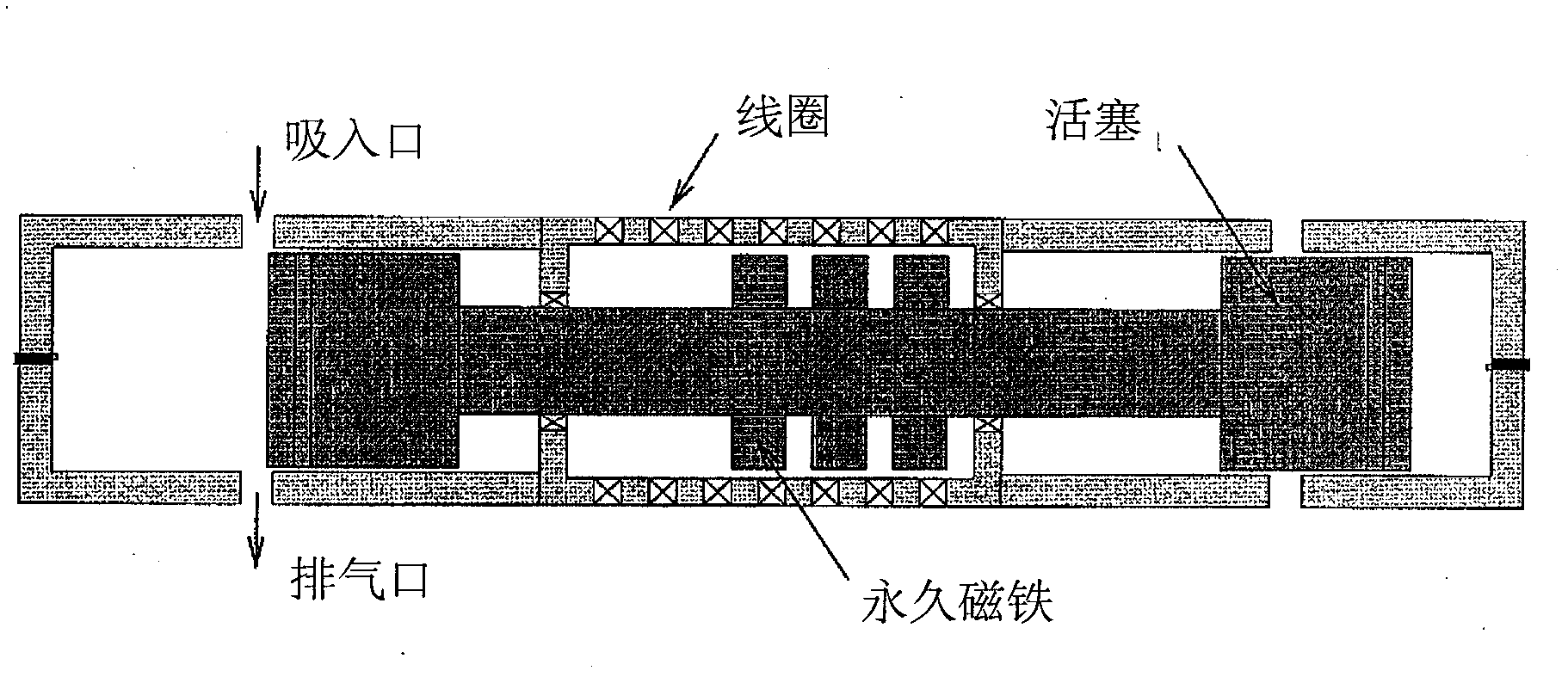

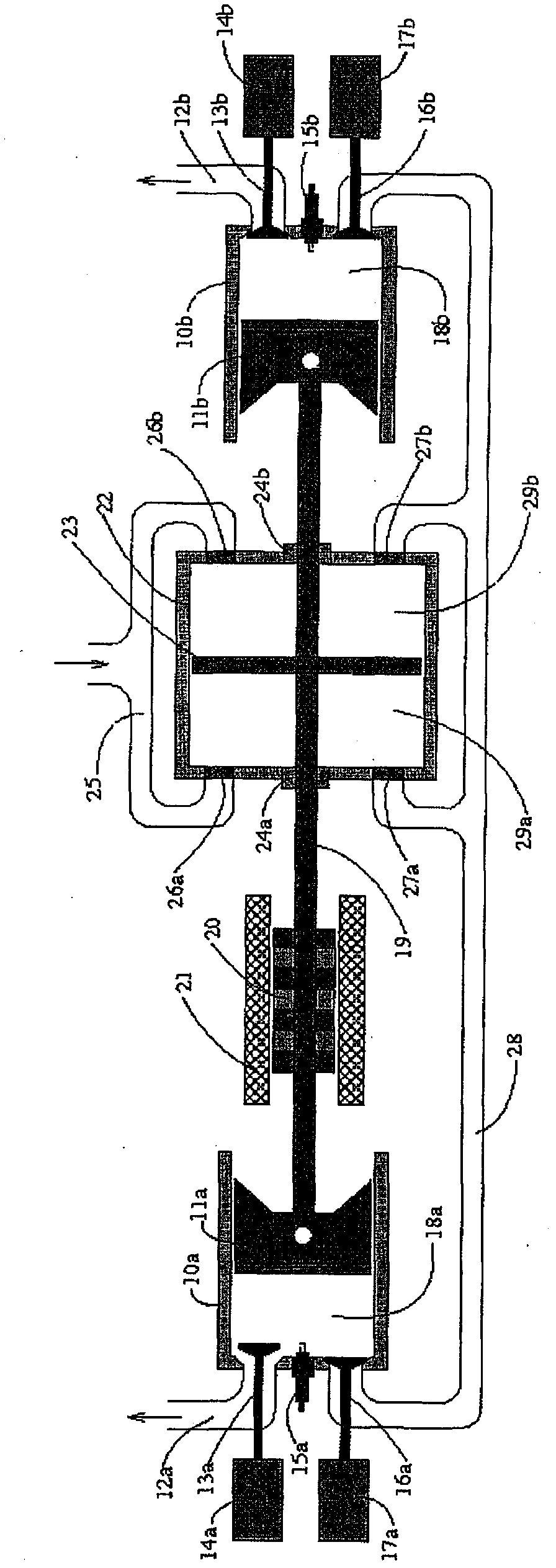

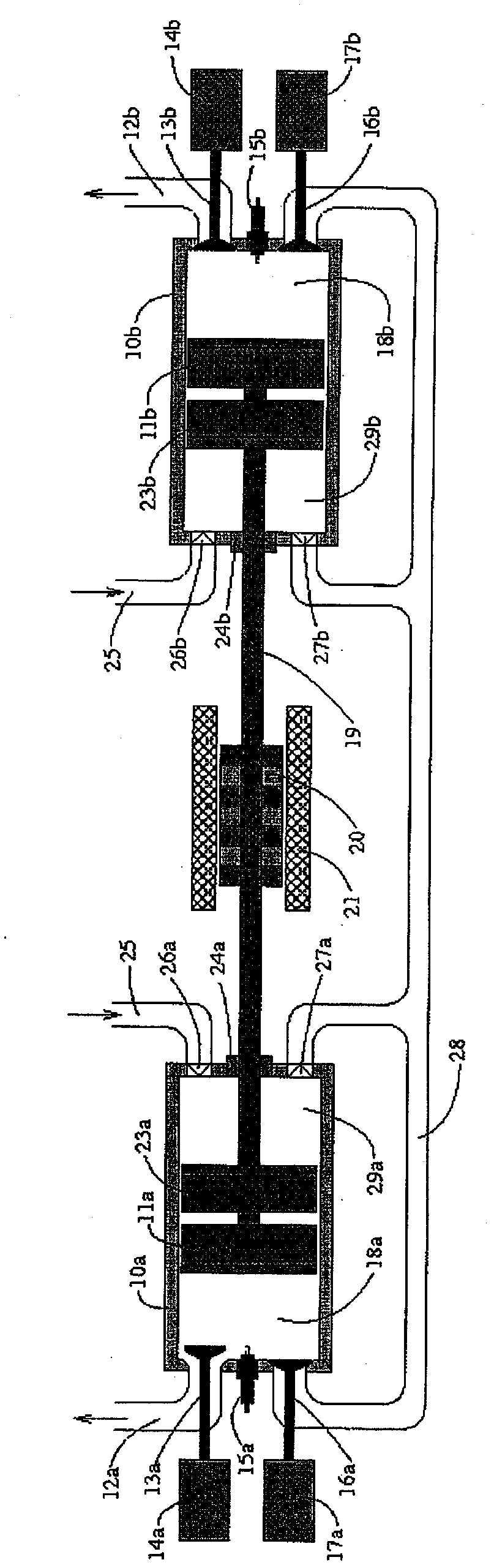

Free-piston internal combustion engine

InactiveCN103038450AEmission reductionImprove fuel efficiencyCombustion enginesFree piston enginesExternal combustion engineFour-stroke engine

A linear-acting, free-piston internal combustion engine suitable for operation on a four-stroke engine cycle comprises a power piston (11a, 11b) reciprocating in a power chamber (18a, 18b) and a compression piston (23, 23a, 23b) reciprocating in a compression chamber (29a, 29b). The power piston (11a, 11b) and the compression piston (23, 23a, 23b) are rigidly connected by means of a rod (19). The compression piston (23, 23a, 23b) performs alternately an intake stroke and a compression stroke and the power piston (11a, 11b) performs alternately a power stroke and an exhaust stroke.

Owner:NEWCASTLE UNIV

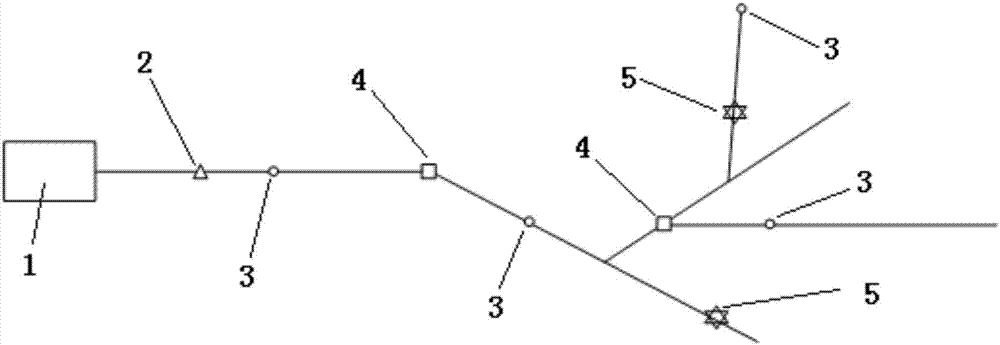

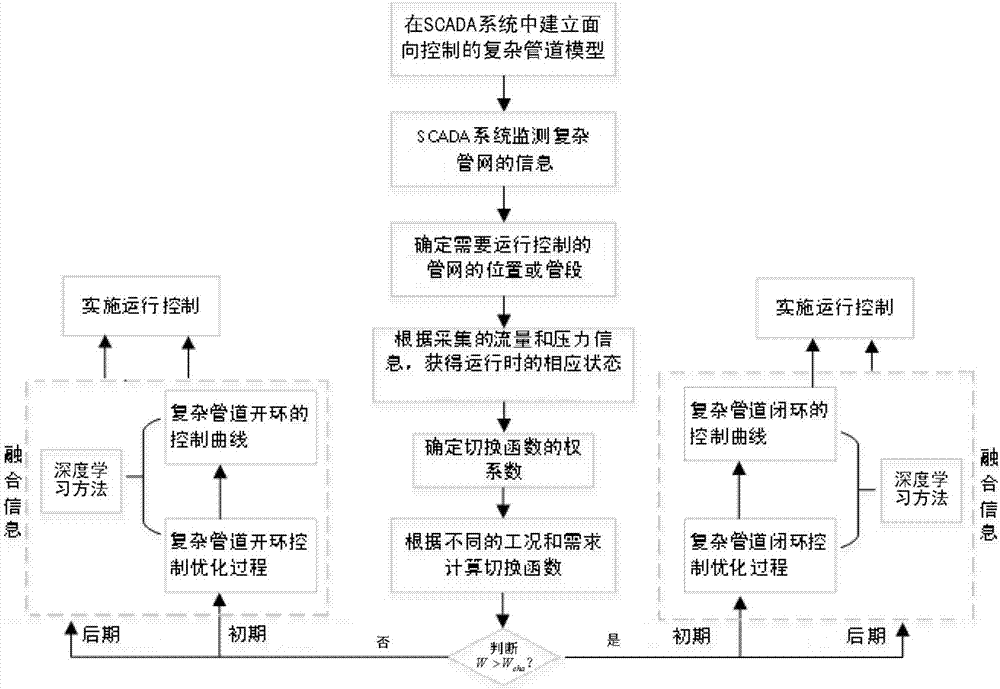

Method for controlling operation of complex pipeline based on deep learning

ActiveCN107885085AReduce energy consumptionReliable long run timeAdaptive controlPipeline transportLoop control

The invention provides a method for controlling the operation of a complex pipeline based on deep learning, belongs to the technical field of pipeline transportation, and especially relates to a method for controlling the operation of a complex pipeline. First, a control-oriented complex pipeline model is built in an SCADA system; the position or section needing operation control is determined according to the pipe network information monitored in real time and the user or industrial demand for the pipeline; then, whether to adopt a complex pipeline open-loop control strategy based on a deep learning method or a complex pipeline closed-loop control strategy based on a deep learning method is decided according to the obtained flow and pressure information of the position or section needingoperation control, and a strategy is performed according to the decision result; and finally, information is fused, and the operation control of the complex pipeline network is completed in a coordinated manner. In the prior art, the operation of a complex pipeline cannot be controlled effectively and reasonably, which leads to frequent occurrence of safety problems, high energy consumption and short reliable running time. The problem is solved by using the method of the invention. The method of the invention can be used in pipeline transportation.

Owner:NINGBO UNIV

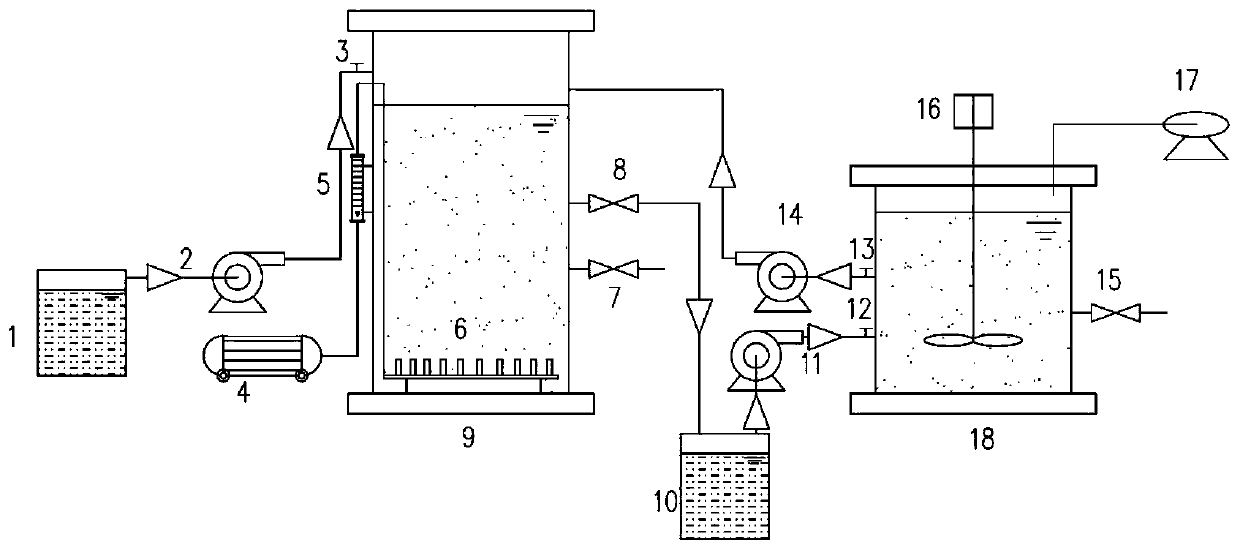

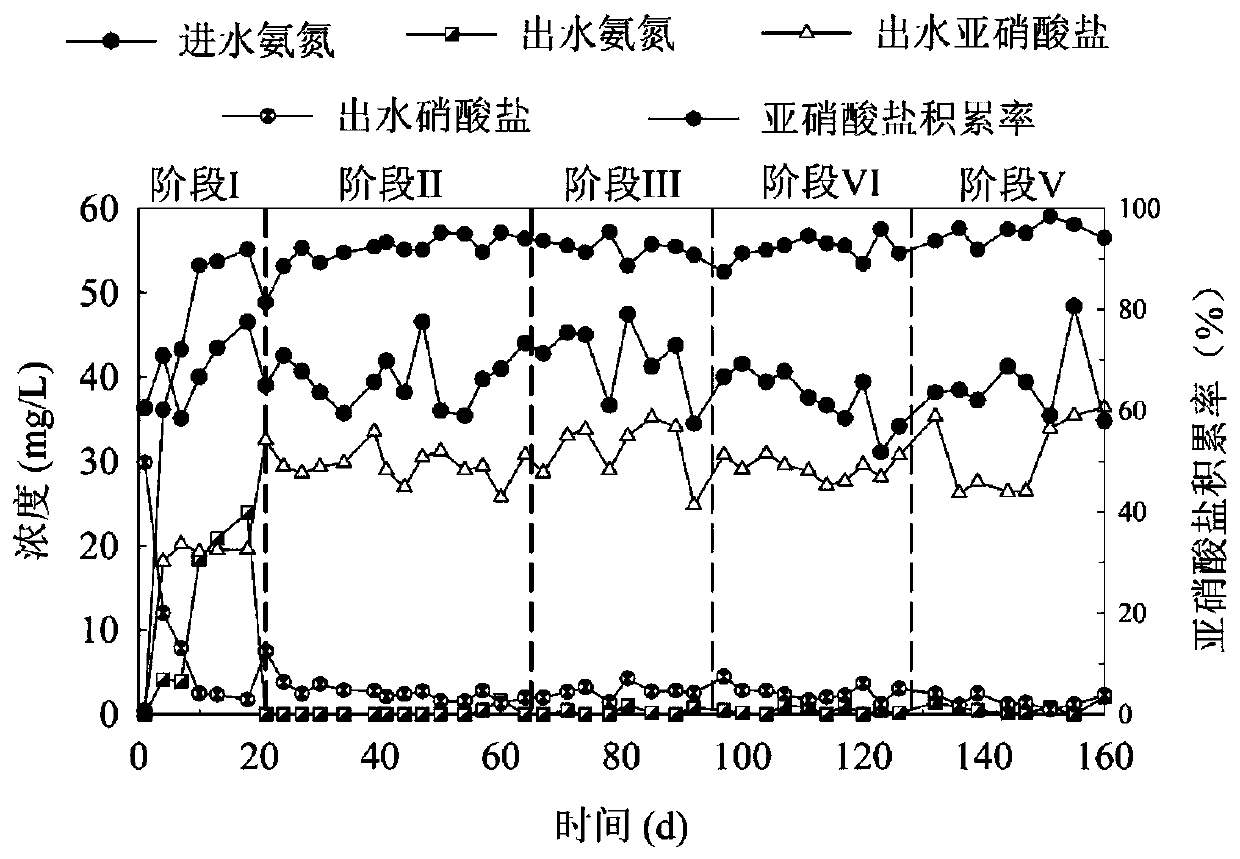

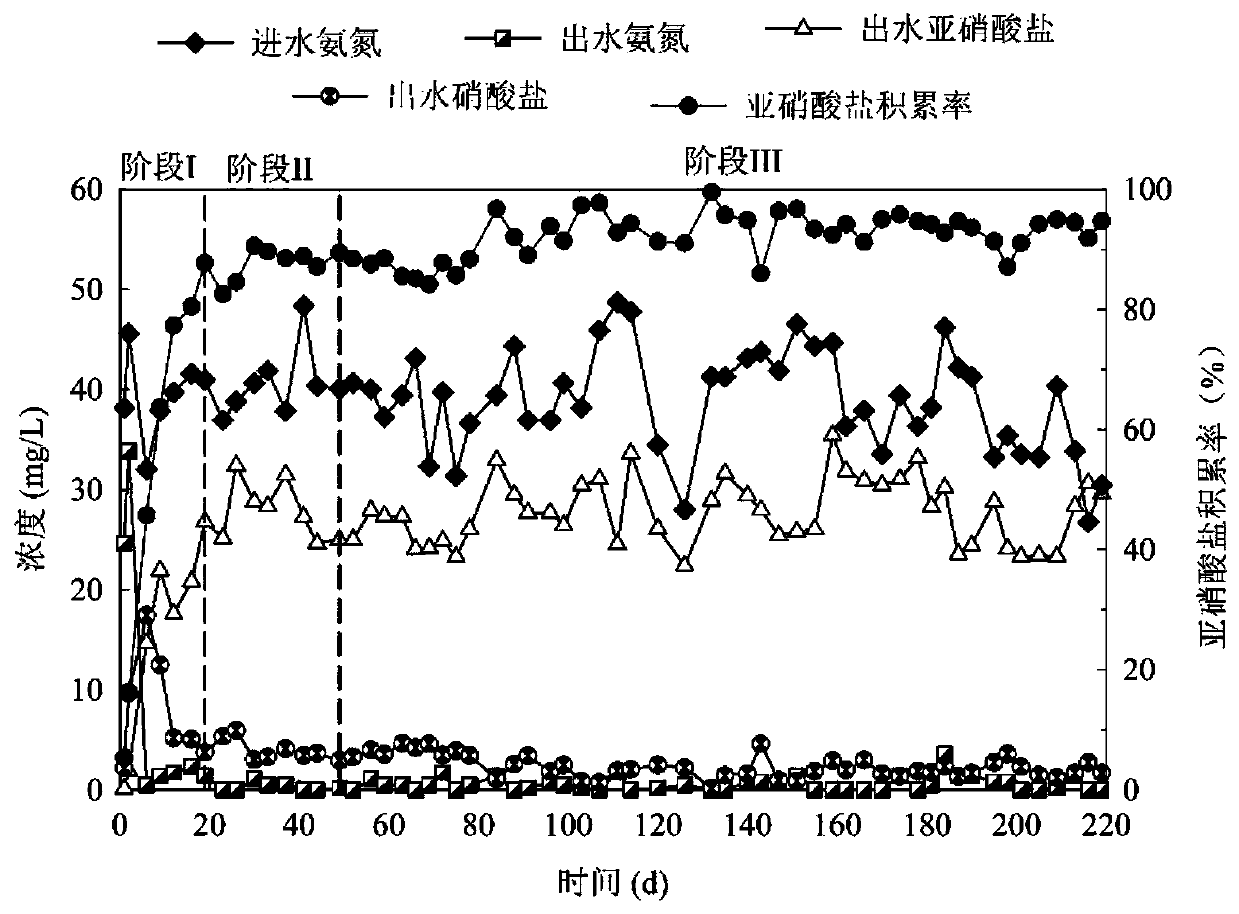

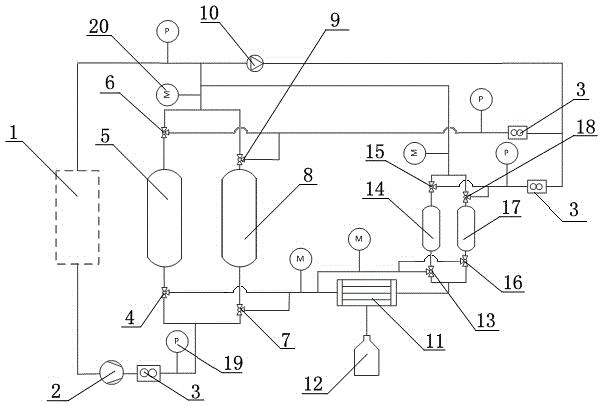

Device and method for quickly starting and maintaining shortcut nitrification of municipal sewage based on p-chloro-m-xylenol

ActiveCN110759467AStabilized source of nitriteOptimal Operational ControlWater treatment parameter controlSpecific water treatment objectivesActivated sludgeNitrate salts

The invention discloses a device and a method for quickly starting and maintaining short-cut nitrification of municipal sewage based on p-chloro-m-xylenol, and belongs to the field of biological sewage treatment. The device mainly comprises a municipal sewage raw water tank, a municipal sewage short-cut nitrification device, a p-chloro-m-xylenol sludge treatment device and a sludge reflux device,the method comprises the following steps: firstly, adding 60mg / L-70mg / L of the p-chloro-m-xylenol into a reactor in a first period; stirring for 15-20 hours to inhibit the activity of nitrifying bacteria, and then laterally treating part of activated sludge instead of adding an inhibitor into the reactor, so that on one hand, the activity of AOB is rapidly recovered, and on the other hand, the activity of NOB is continuously inhibited, and accumulation of nitrite and starting normal-temperature short-cut nitrification of municipal sewage can be realized. According to the method, the activity of the AOB can be recovered at the highest speed, the NOB can be elutriated step by step, and stable short-cut nitrification can be maintained.

Owner:BEIJING UNIV OF TECH

Tritiated water recycling device and achieving method thereof

ActiveCN105032122AExcellent performanceLow priceDispersed particle separationMolecular sieveChemistry

The invention discloses a tritiated water recycling device which comprises a tritiated water supply device, a second gas recycling pump, a condenser, a tritiated water storage tank, a first adsorption bed and a third adsorption bed. The first adsorption bed and the third adsorption bed are each filled with a 5A molecular sieve. The tritiated water supply device and the first adsorption bed are connected to form a tritiated water removal circuit. The second gas circulating pump, the first adsorption bed, the condenser and the third adsorption bed are connected in sequence. The third adsorption bed is connected to the input end of the condenser in a return mode, so that the second gas circulating pump, the first adsorption bed, the condenser and the third adsorption bed form a tritiated water recycling circuit. The tritiated water storage tank is connected with the output end of the condenser. According to the tritiated water recycling device, recycling of tritiated water in gas can be achieved with no extra carrier gas, only liquid tritiated water is output, no other waste tritium-contained water is generated in the running process, and safety and reliability are achieved; meanwhile, the tritiated water recycling device is connected to technological equipment of a tritium technology laboratory, so that continuous recycling of tritiated water in gas of different types is achieved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

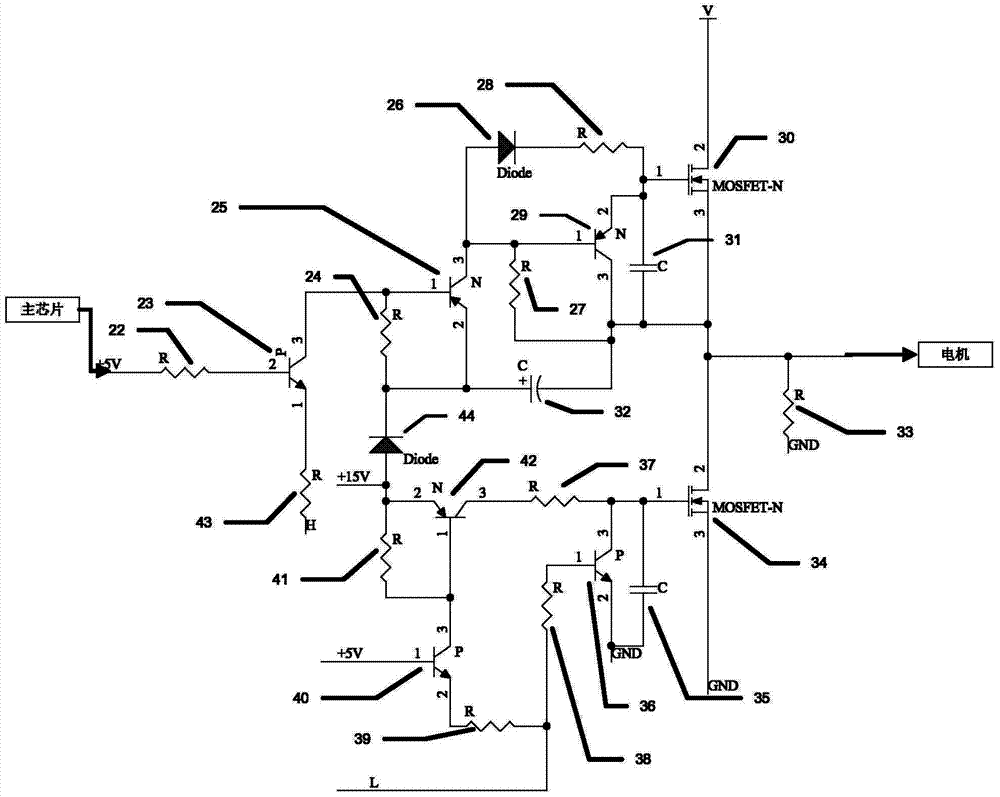

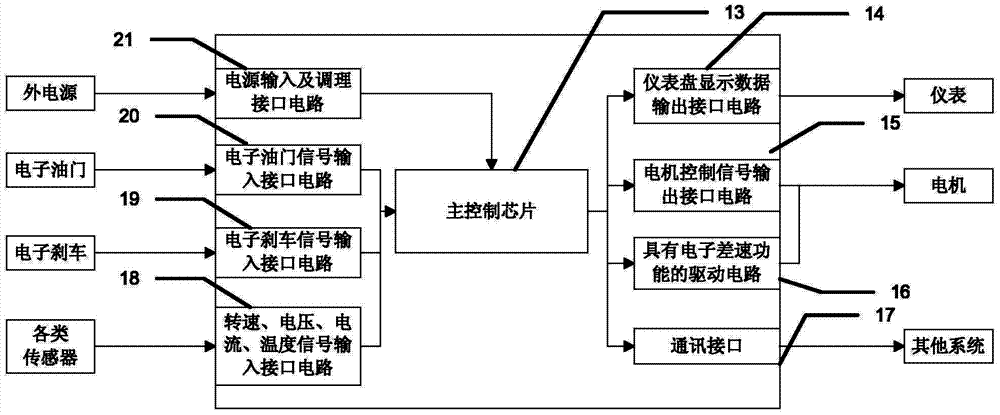

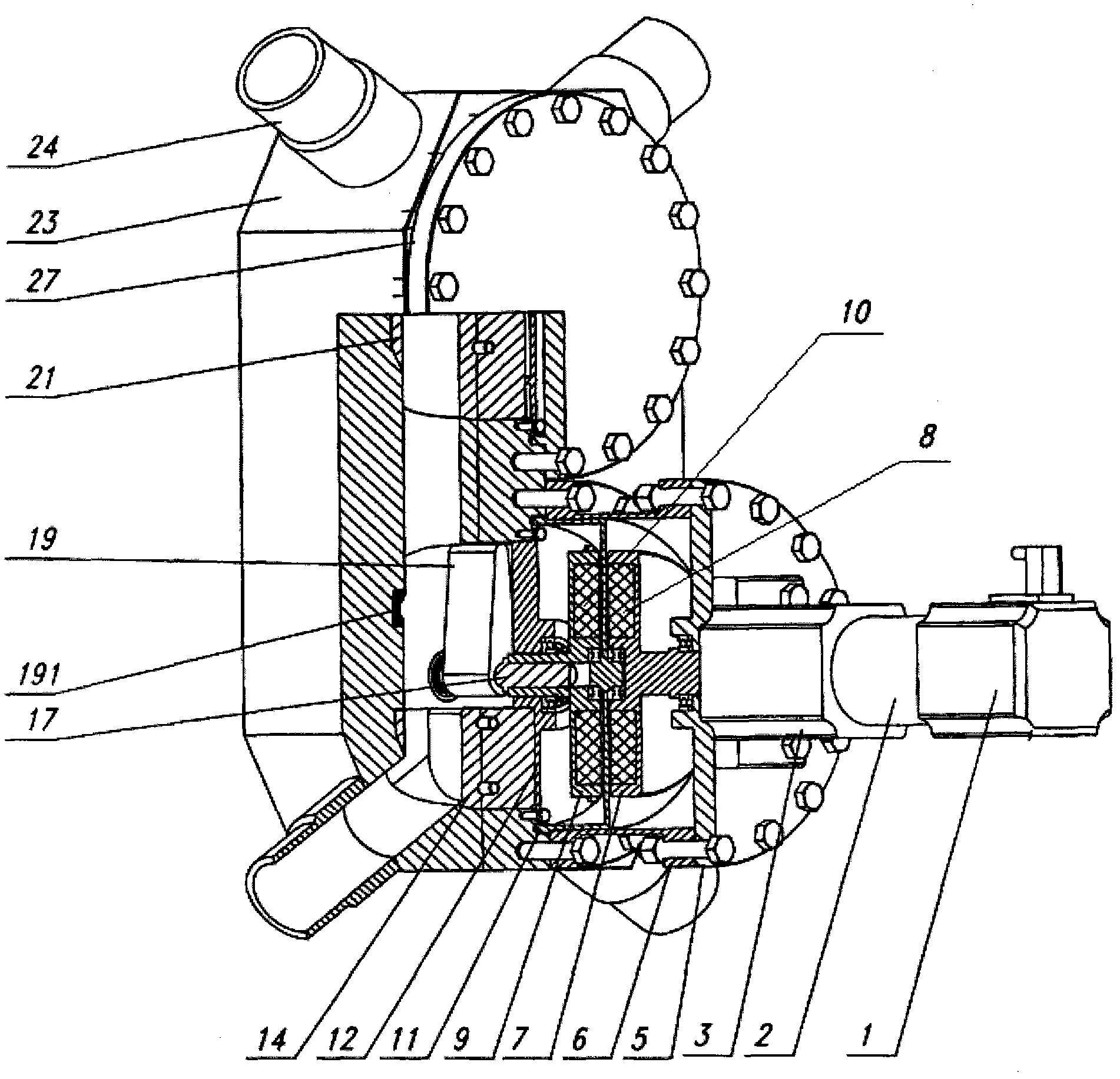

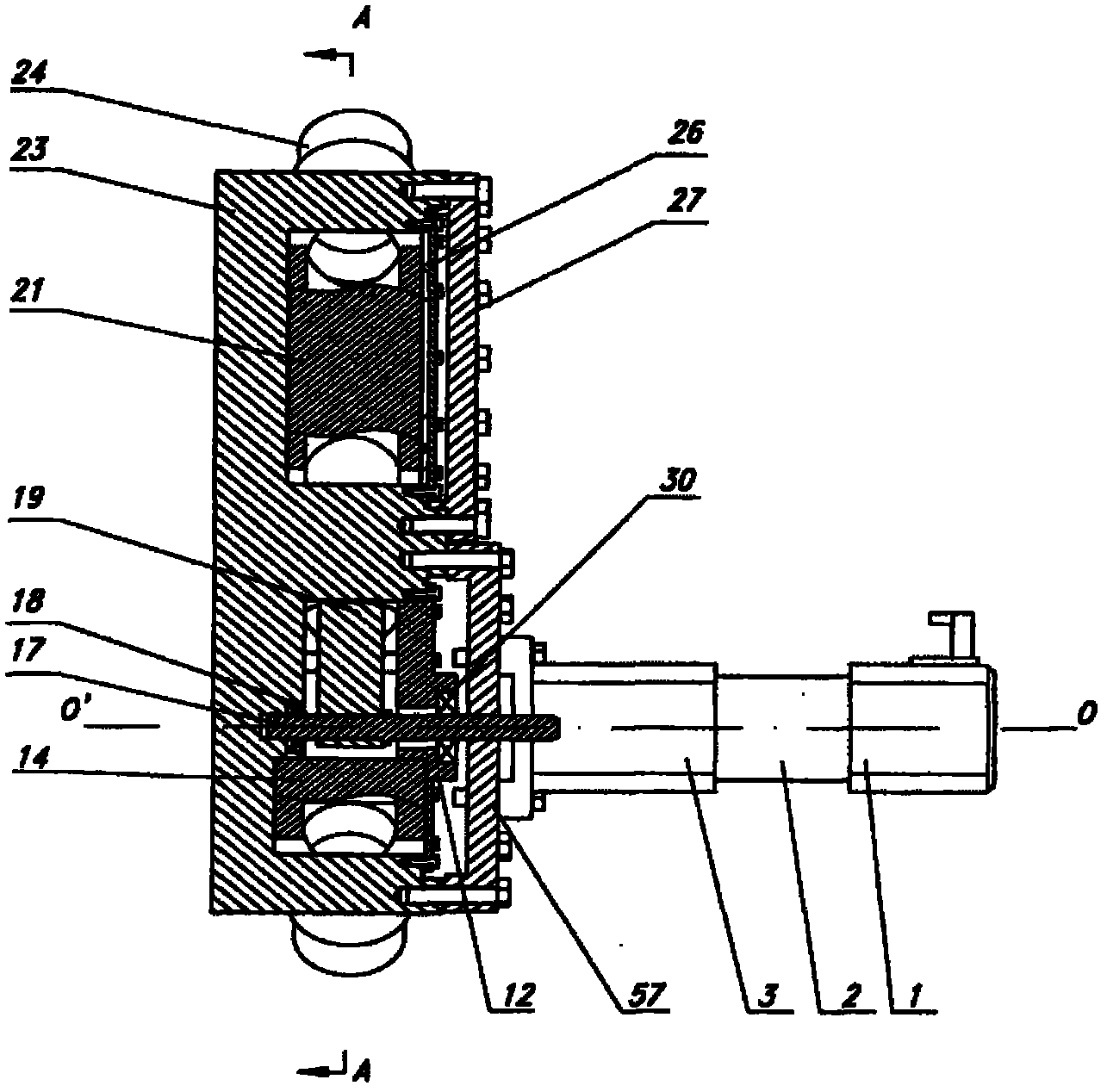

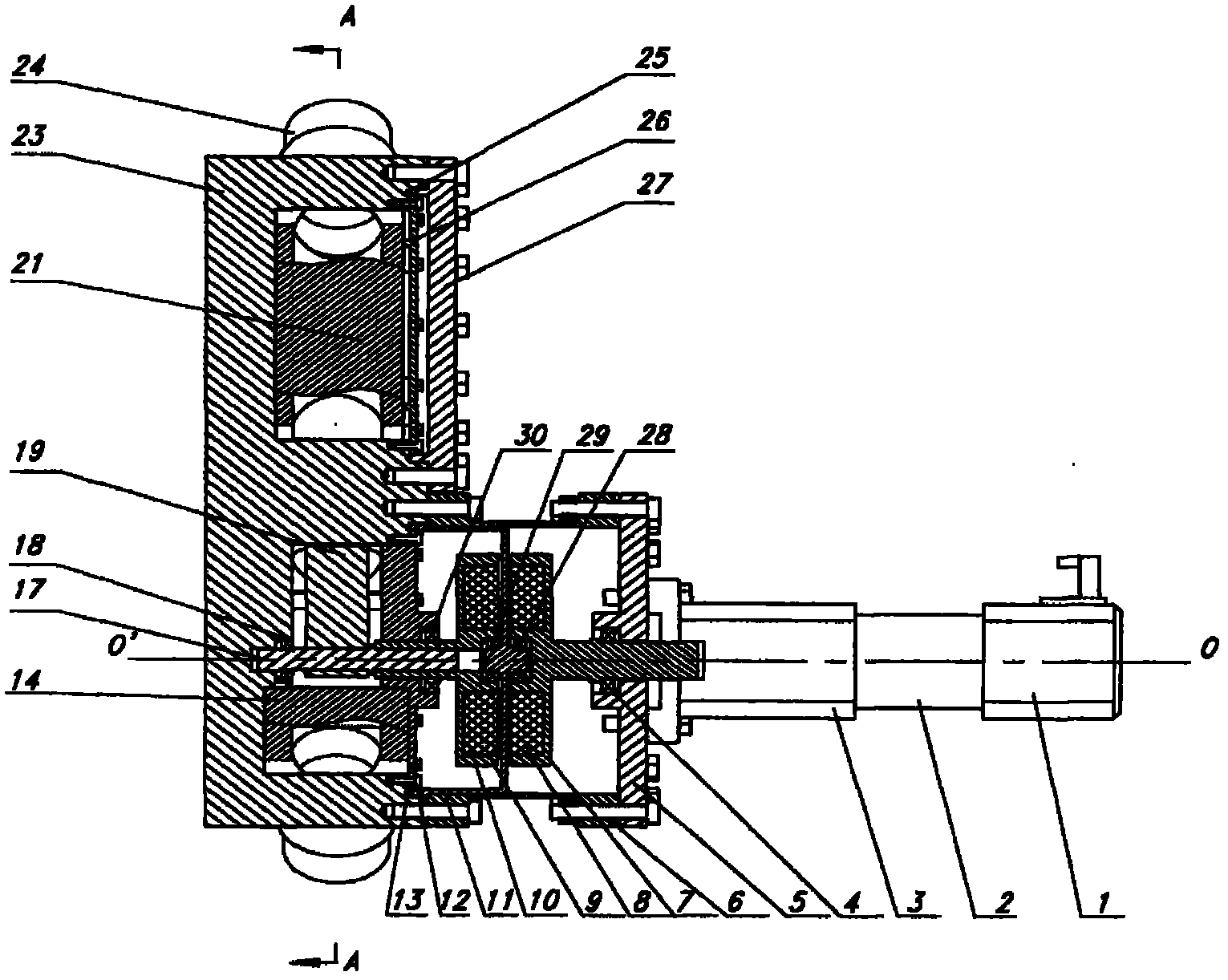

Driving circuit with electronic differential function and application of driving circuit

ActiveCN103921691ADifferential function realizationOptimal Operational ControlSpeed controllerCapacitanceControl signal

The invention discloses a driving circuit with an electronic differential function and application of the driving circuit. The driving circuit comprises an upper-end control bridge circuit and a lower-end control bridge circuit. A base electrode of a first triode of the upper-end control bridge circuit is connected with a master control chip by a first resistor, an emitting electrode of the first triode is connected with an external chip by a tenth resistor, and a collecting electrode of the first triode is connected with a second diode by a second resistor; a base electrode of a second triode is directly connected with the collecting electrode of the first triode, and an emitting electrode of the second triode is respectively directly connected with a second capacitor, a negative electrode of the second diode and the second resistor. The driving circuit with the electronic differential function can be applied to a motor controller, and both the driving circuit with the electronic differential function and a control signal output interface circuit of a motor are connected with the motor. The driving circuit and the application have the advantages that the motor controller has electronic differential and electric quantity evaluating functions, accordingly, the reliability and the efficiency of a system can be improved, and the production cost of equipment can be reduced.

Owner:佛山陀普科技有限公司

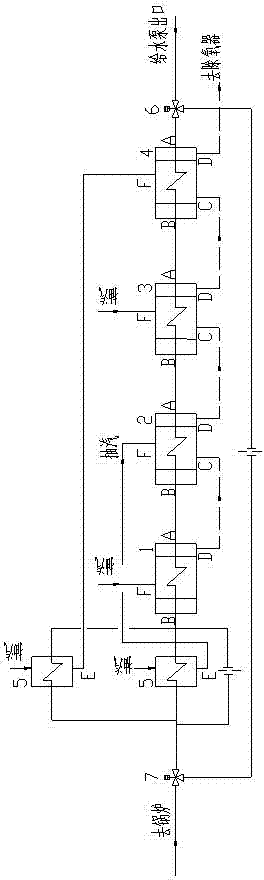

Cyclic bridging device of pebble-bed reactor fuel element pipelines

InactiveCN102148065AImprove operational reliabilitySimple structureNuclear energy generationReactor fuel elementsCushionEngineering

The invention belongs to the technical field of nuclear reactor fuel element conveying, in particular to a cyclic bridging device of pebble-bed reactor fuel element pipelines. The device is successively provided with a bridging mechanism, a magnetic transmission mechanism and a driving mechanism from the back to the front. The box body is provided with a cushion chamber and a guide chamber. A cushion core is arranged in the cushion chamber. A guide core is arranged in the guide chamber. A main transmission shaft of a mounting tongue plate is connected with a rotating shaft of an internal magnetic rotor. A rotating shaft of an external magnetic rotor is connected with an output shaft of the driving mechanism. The tongue plate can rotate to the left limitation position or the right limitation position from the central position under the action of the magnetic transmission between the internal magnetic rotor and the magnetic rotor so as to realize a ball distributing function. The deviceis applied to a pebble-bed reactor fuel element multi-channel cyclic pipeline system, realizes a plurality of cyclic operation modes of fuel elements and improves the reliability of the cyclic system; the sealing structure of magnetic transmission realizes atmosphere isolation; the device is simple in structure, convenient to control, and suitable for the nuclear reactor with the requirement for high-security and high-reliability operation.

Owner:TSINGHUA UNIV

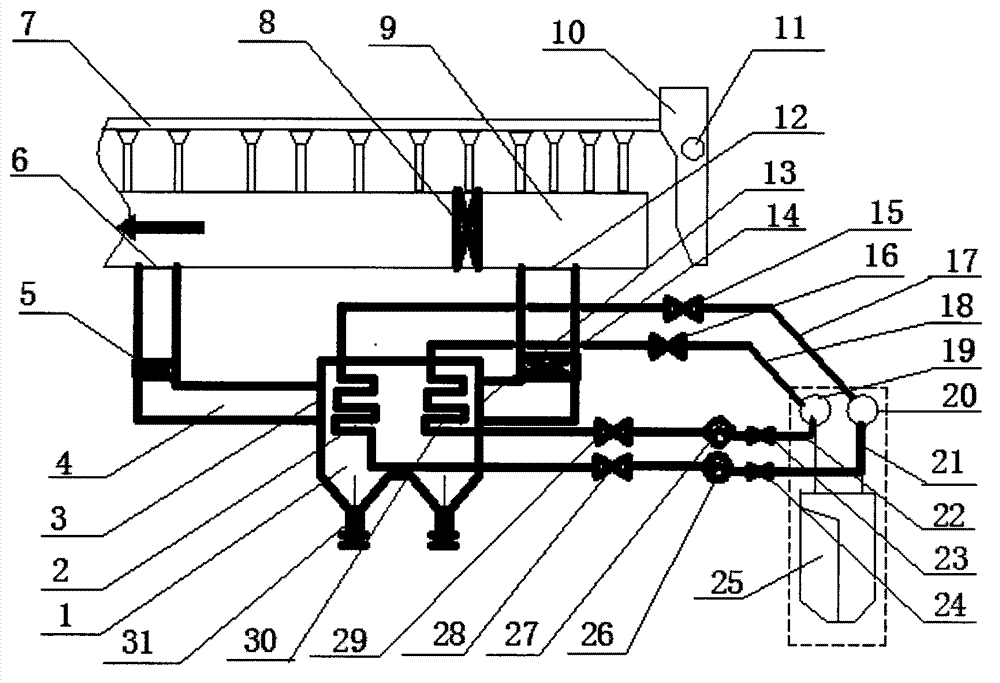

Flue gas waste heat recovery system of large flue of sintering machine

InactiveCN103175412AReduce the temperatureReduce power consumptionEnergy industryIncreasing energy efficiencyFlue gasProcess engineering

The invention discloses a flue gas waste heat recovery system of a large flue of a sintering machine. The waste heat recovery system comprises a large flue near the tail of the sintering machine, wherein the large flue is internally provided with a valve, a bypass flue of the large flue is arranged near the large flue, the bypass flue is internally provided with a heat exchanger, the bypass flue between the heat exchanger and the large flue is provided with control valves, and the heat exchanger is provided with a water inlet pipe and a water outlet steam pipe. According to the invention, by controlling the amount of the flue gas of the large flue and the bypass flue, the flue gas heat amount of the large flue of the sintering machine can be adequately recovered, the lowest temperature of the flue gas of the large flue can be ensured as well, so that dew formation of flue gas can be avoided. The waste heat recovery system disclosed by the invention has the advantages of simple structure and controlling, economical investment, low operating cost, and is applicable to existing sintering systems and newly-built systems.

Owner:孙慕文

New process for treating sewerage

InactiveCN1429780AChange processing pathReduce processing timeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeSewage

A process for treating sewage includes such steps as mixing the sewage with active sludge in a reactor A, cleaning in a reactor B, draining the cleaned sewage, delivering the separated sludge to a reactor C, returning part of it to the reactor A, and discharging the rest. Its advantages are use of small reactors instead of one large aerating pool, and low cost.

Owner:鞠建林 +2

1000MW stage secondary reheating unit single-row high-pressure heater system

InactiveCN104121572ASimple Thermal Measuring PointEasy to controlFeed-water heatersEngineeringHigh pressure

The invention discloses a 1000MW stage secondary reheating unit single-row high-pressure heater system. The system comprises a plurality of high-pressure heaters which are connected in series in sequence through a water supply pipeline, and water evacuating openings of the high-pressure heaters are connected in series in sequence. The water supply pipeline, a steam bleeding pipeline and a heater water evacuating pipeline of the system are respectively in one row; compared with a two-row high pressure heaters, the system is simple, the number of pipelines is reduced, the number of valves in the pipeline system is reduced, thermotechnical measuring points are simple, control is easy to perform, running control is convenient to perform, the steam bleeding pipelines and the water supply pipelines of the high-pressure heaters are short, resistance is small, the 1000MW stage secondary reheating unit single-row high-pressure heater system is also favorable for reducing the heat rate of a steam turbine, single-side operation can not be achieved by the two-row high pressure heaters, and technically, the single-row high-pressure heaters have obvious advantages.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

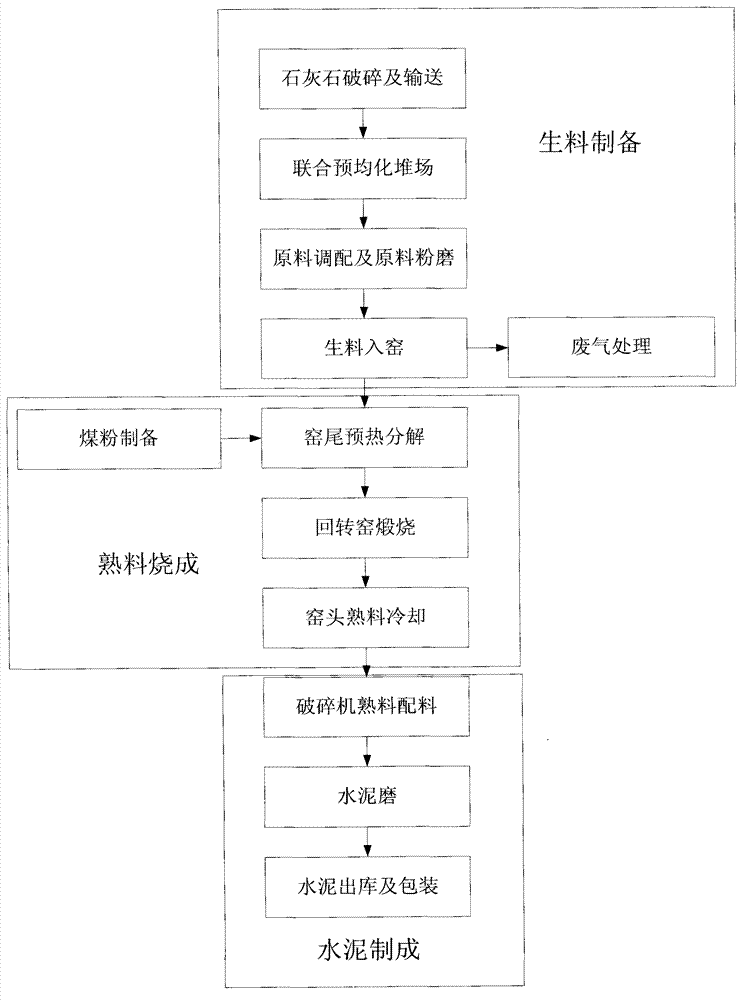

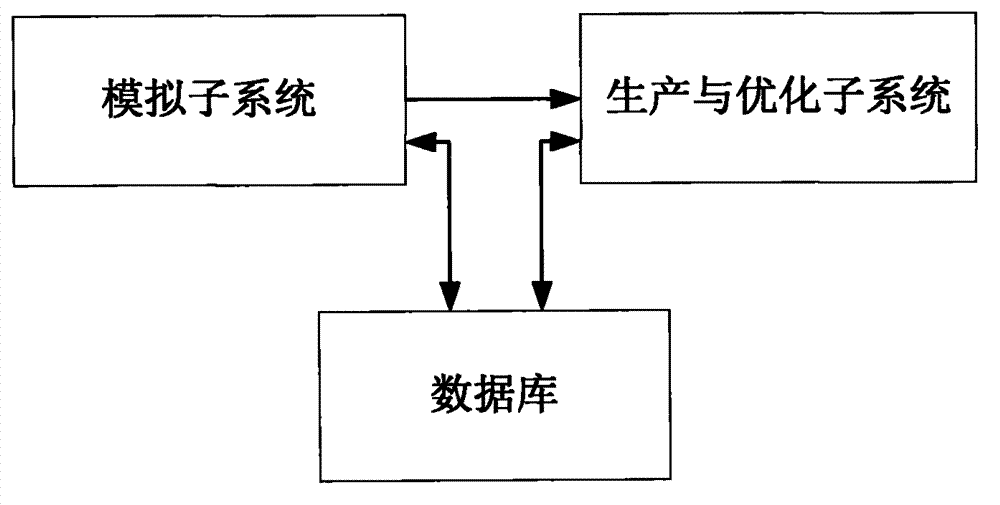

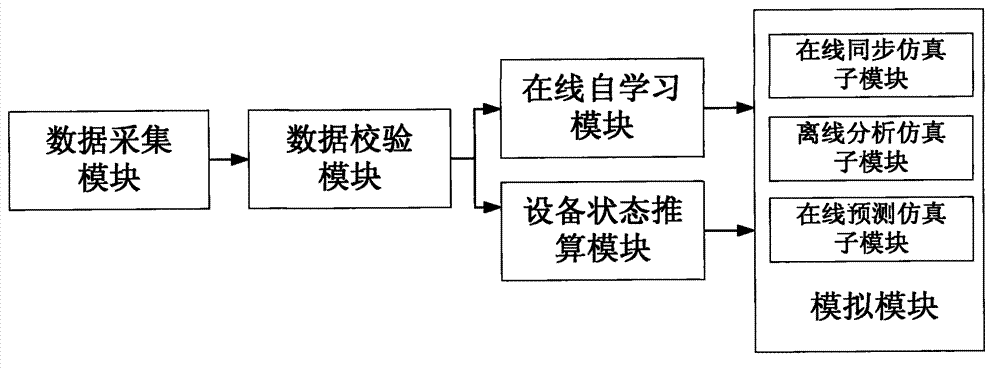

Cement digital management and control system

ActiveCN103092171BTimely decisionAccurate decisionEnergy industryTotal factory controlCement factoryControl system

The invention discloses a cement digital management and control system which comprises a simulate sub system, a production and optimization sub system and a data base. The simulate sub system is connected with the production and optimization sub system. The data base is respectively connected with the simulate sub system and the production and optimization sub system. The simulate sub system is used for performing simulating calculation to cement production. The production and optimization sub system is used for analyzing and judging whether current operating parameters and operation of cement production devices are normal, forecasting whether the operation parameters are normal after current time and controlling the cement production in an optimized mode. The data base is used for storing historic operation parameters and the current operation parameters, the range of the operation parameters and corresponding relationship between the operation parameters and state of the devices. Online simulated analysis technology, historic data analysis technology and an advanced diagnosing and optimizing method are adopted as methods of a digital management and control system so that economical and safe operation of a cement factory is achieved.

Owner:武安市新峰水泥有限责任公司

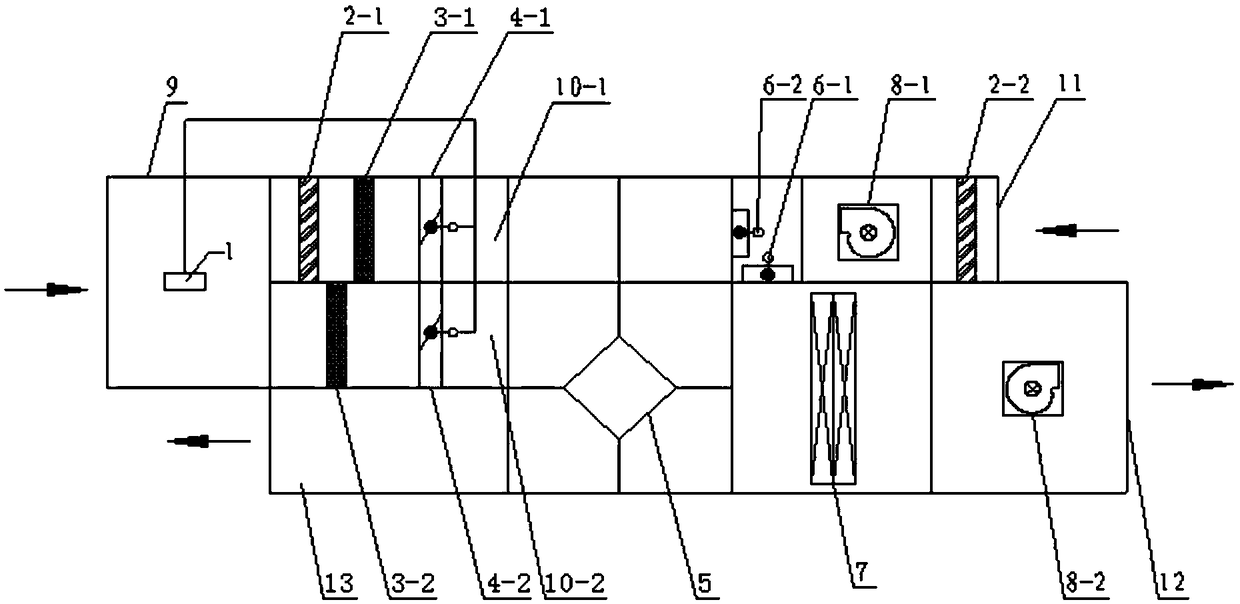

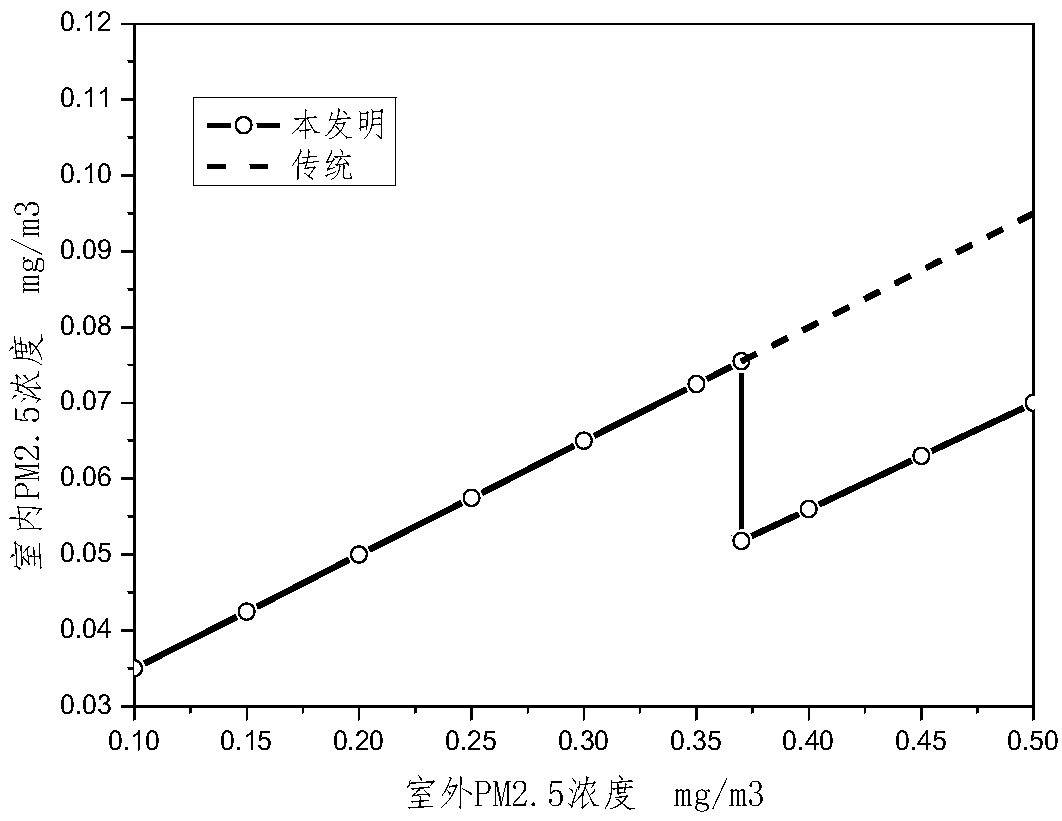

Air conditioner for controlling indoor PM2.5 pollution and control method thereof

InactiveCN108613323AControl concentrationChange speedMechanical apparatusSpace heating and ventilation safety systemsExhaust valveInductor

The invention relates to an air conditioner for controlling indoor PM2.5 pollution. The air conditioner comprises a first fresh air pipe, a second fresh air pipe, a third fresh air pipe, an air returnpipe, an air supply pipe, an exhaust pipe and a heat recycling device. A PM2.5 concentration inductor is arranged in the first fresh air pipe, and a first primary filter, a first medium-effect filterand a first electric air valve are sequentially arranged in the second fresh air pipe. A second medium-effect filter and a second electric air valve are sequentially arranged in the third fresh air pipe, and the PM2.5 concentration inductor, the first electric air valve and the second electric air valve are in interlocking control. A second primary filter, an air return fan, an air return valve and an exhaust valve are sequentially arranged in the air return pipe. A heat exchanger and a double-speed blower are sequentially arranged in the air supply pipe. According to the air conditioner, thesizes of the needed fan and filters and the equipment size can be configured according to different building types, and operation control is convenient.

Owner:CCCC SECOND HARBOR CONSULTANTS CO LTD

Electric heating fluidized bed heat accumulator and heat supply system

ActiveCN112361428AImprove heat transfer effectLarge temperature differenceCentral heating with accumulated heatHeat storage plantsFluidized bedEngineering

The invention provides an electric heating fluidized bed heat accumulator. A winding electromagnetic heating coil is arranged outside the heat accumulator, solid heat accumulation particles are arranged in the heat accumulator, an electromagnetic heating coil (6) is arranged on the outer side of the fluidized bed heat accumulator (2), an air inlet chamber is arranged below the fluidized bed heat accumulator (2), an air outlet pipe is arranged on the upper portion of the fluidized bed heat accumulator (2), and the density of the electromagnetic heating coil is larger and larger from bottom to top in the height direction of the fluidized bed heat accumulator. Due to changes of the distribution density of the designed coil in the height direction, heat exchange in the heat accumulator forms asimilar countercurrent heat exchange process, heat exchange is more effective and sufficient, and the overall heat exchange effect is enhanced.

Owner:河北泽瑞节能新能源有限公司

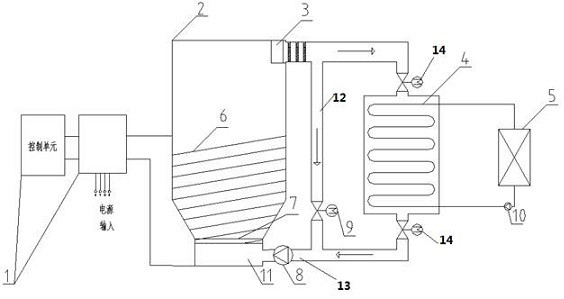

Two grade alkaline hydrolysis and acidification device for processing residual activated sludge

ActiveCN101759336AImplement reduction processingHigh reduction rateBiological sludge treatmentActivated sludgeContinuous stirred-tank reactor

The invention discloses a two grade alkaline hydrolysis and acidification device for processing residual activated sludge, which solves the difficult problems of leakage of carbon source and difficult sludge treatment in wastewater treatment plant, relating to the wastewater sludge processing technology field. The device comprises a strong alkali continuous stirred-tank reactor CSTR, an upflow type strengthened hydrolysis and acidification reactor UHAR, a sludge hydrolysis and acidification fluid chemical denitriding and dephosphorizing reactor CPR, and a master controller; wherein the master controller comprises a time relay, a pH temperature sensor, a pH sensor and a computer, and further comprises a medicine adding device. The device has simple operation and is easy to control. The decrement rate of residual activated sludge after two grade alkaline hydrolysis and acidification is carried out is more than 30%, and the device can achieve recycling use of organic carbon source in the residual activated sludge.

Owner:BEIJING DRAINAGE GRP CO LTD

Electric heating fluidized bed solid heat storage and supply system

ActiveCN112361429ASave electricityImprove heat transfer effectCentral heating with accumulated heatHeat storage plantsFluidized bedEngineering

The invention provides an electric heating fluidized bed solid heat storage and supply system. The system comprises an electromagnetic heating coil, an air inlet chamber, an air distribution plate, afluidized bed heat accumulator, a gas-solid separation device, a heat exchanger, a controller and the like. The system stores heat in a sensible heat form through solid particles; the outer side and the bottom of the fluidized bed heat accumulator are provided with the electromagnetic heating coil, and the air distribution plate is arranged on the lower side; the solid particles such as quartz sand are arranged in the fluidized bed heat accumulator, and an air outlet pipe is also arranged and connected with the heat exchanger; and a grid and an air return pipeline are arranged in the air outlet pipe, the gas-solid separation device is arranged in front of the air outlet pipe, and the heat exchanger is arranged behind the air outlet pipe and connected with the air return pipeline. The system improves the energy utilization in the off-peak electricity period, saves the heat supply operation cost, and overcomes the defects of non-uniform solid heat storage, insufficient heat release and difficult control.

Owner:河北泽瑞节能新能源有限公司

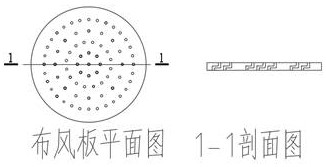

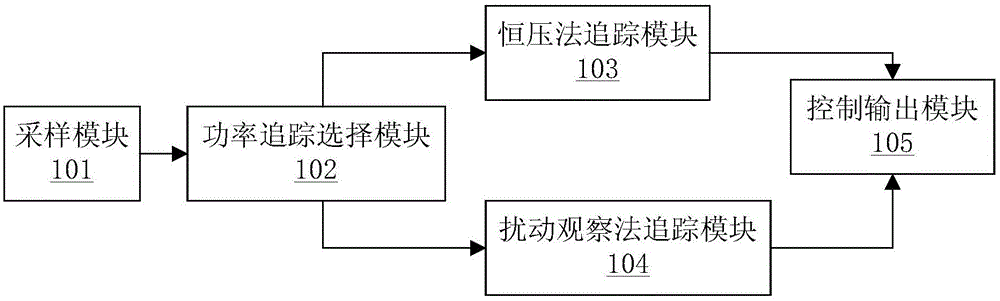

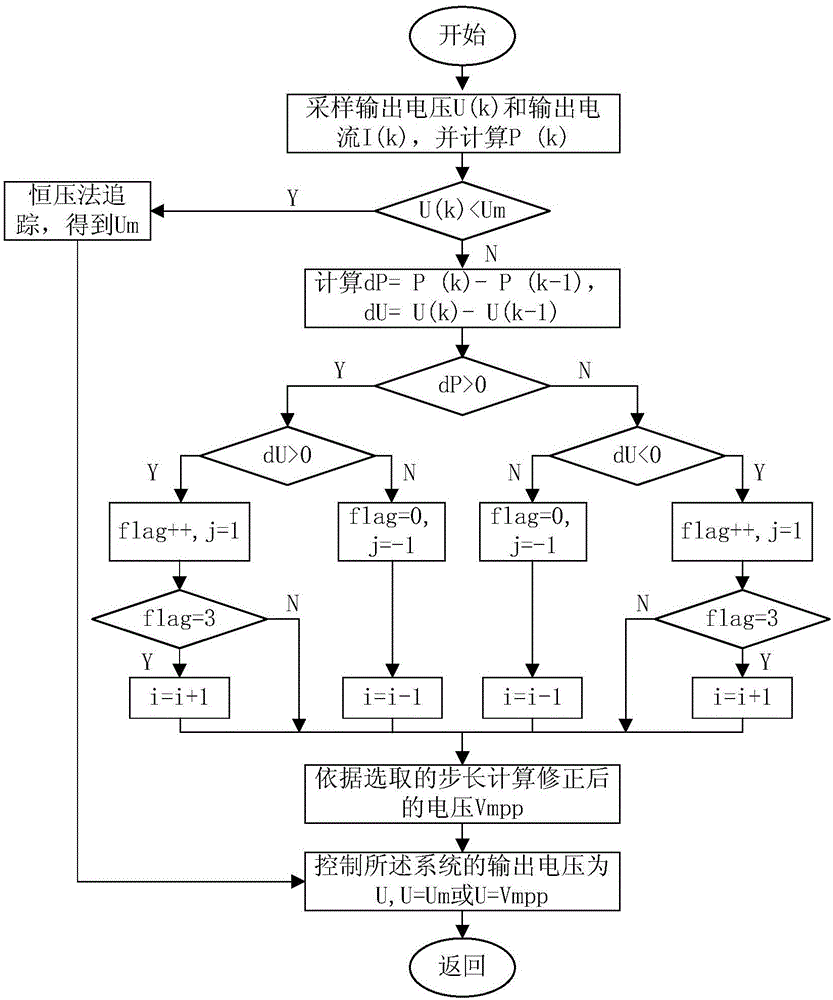

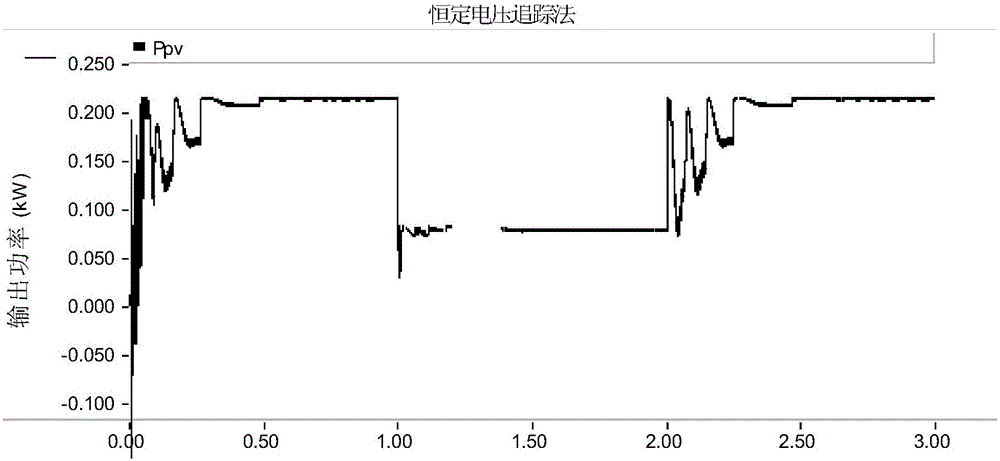

Maximum power point implementation method and device base on three-level step length

ActiveCN105159387AAvoid misjudgmentOptimal Operational ControlPhotovoltaic energy generationElectric variable regulationThree levelPerturbation and observation

The invention provides a maximum power point implementation method based on three-level step length. The method comprises the steps that after the process of tracking a maximum point is started, on the situation of being far away from the maximum power point, priority detection and selection are conducted on whether a constant voltage method is adopted or not to conduct rapid tracking, and the rapid tracking property of a system is improved; on the situation of being close to the maximum power point, a three-level changeable step length perturbation and observation method is adopted, different disturbance steps are selected according to set disturbance direction flag bits, and accurate tracking of maximum power is conducted. The method has the advantages that the method can be suitable for preventing misjudgment on the situation of bad change of the external environment; compared with a conductance increment method, control and operation are easy, and the requirement on hardware is low; by means of the method, rapidity and accuracy of the tracking can be achieved.

Owner:JIANGSU WISCOM TECHNOLOGY CO LTD

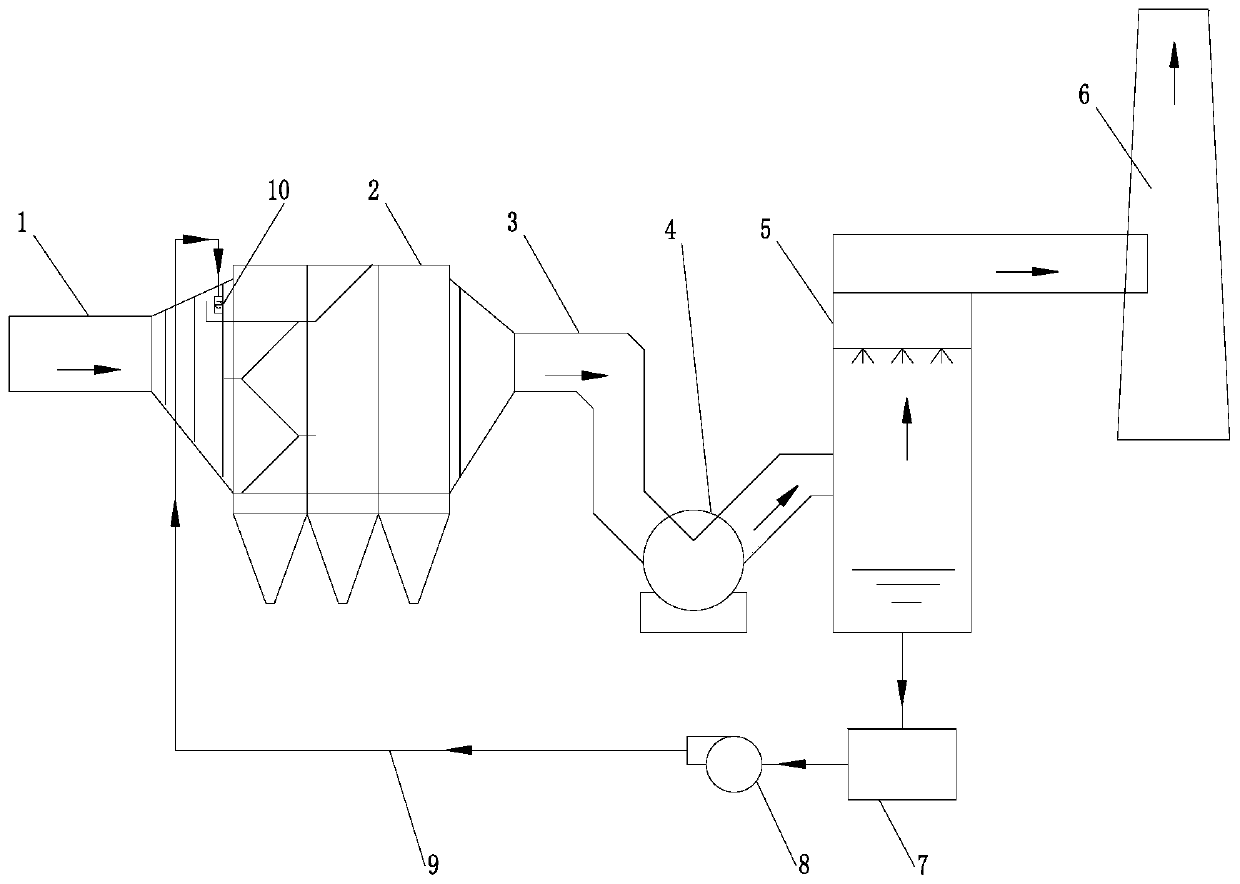

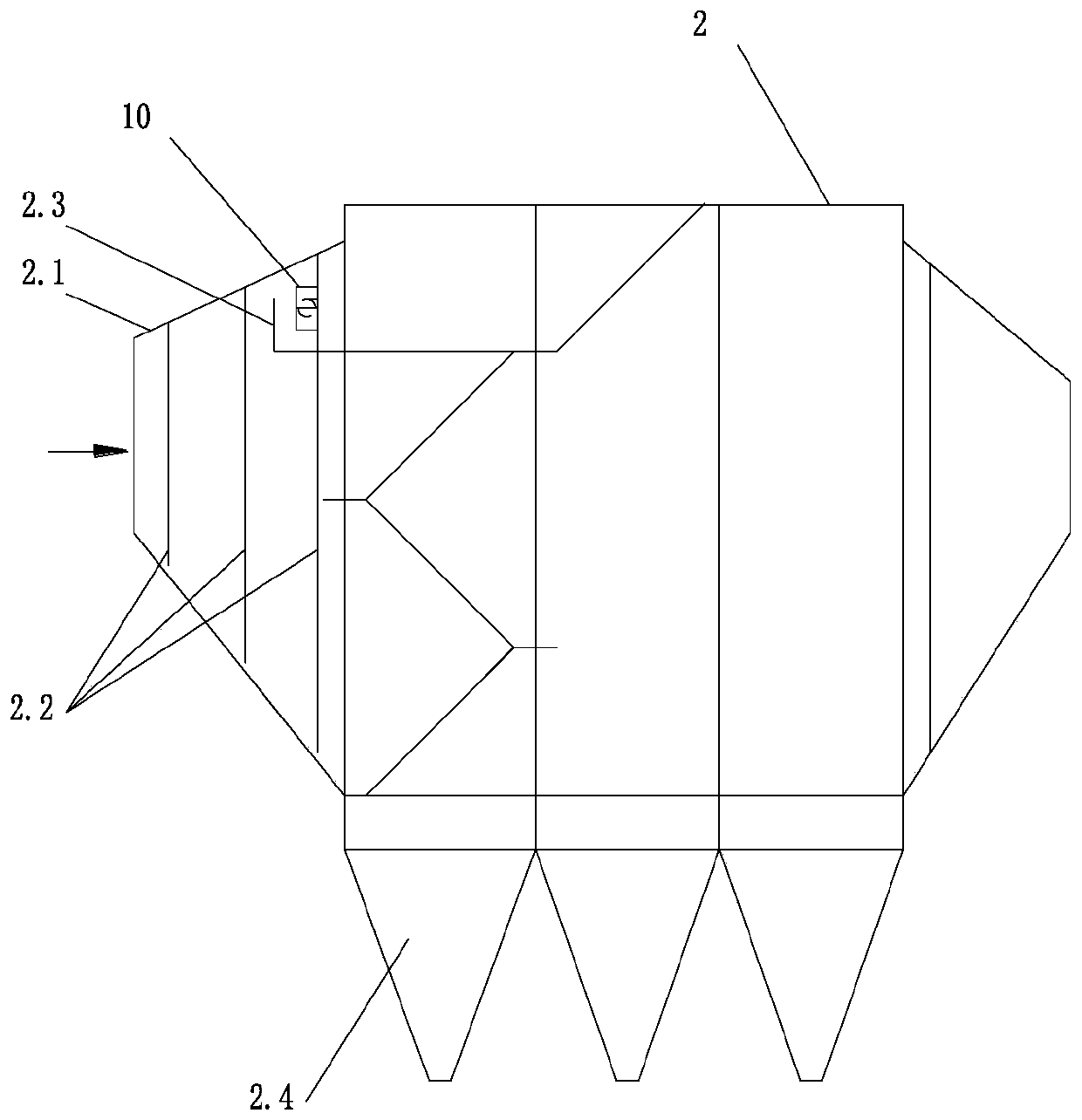

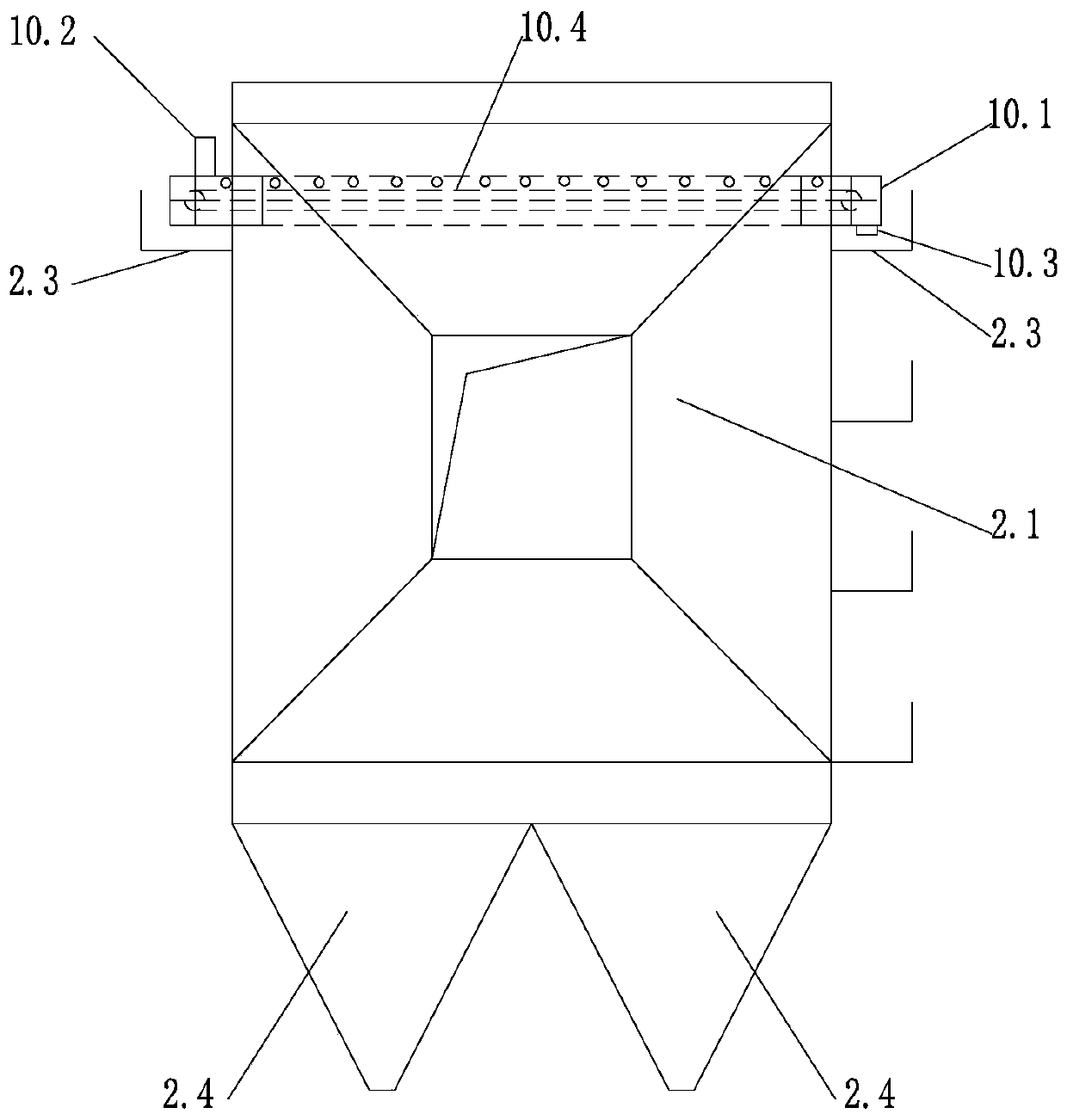

System for treating desulfurization wastewater by evaporation with high-temperature flue gas

ActiveCN109908729AImprove conductivityAchieve zero effluxDispersed particle separationWater/sewage treatmentWater treatment systemFlue gas

The invention discloses a system for treating desulfurization wastewater by evaporation with high-temperature flue gas. The system comprises an original flue, an electrostatic precipitator, an after-dust-removal flue, an induced draft fan, a desulfurization tower and a chimney which are sequentially connected, wherein the bottom of the desulfurization tower is connected with a wastewater tank. Thesystem is characterized in that the electrostatic precipitator comprises an inlet horn, an airflow distribution plate, an outer overhaul platform and an ash hopper, an evaporation device is arrangedin the inlet horn transversely and comprises a casing with a top opening, a feed port and a discharge port are formed in two ends of the casing in the length direction of the casing respectively, a conveying device for conveying desulfurization wastewater is arranged between the feed port and the discharge port, the wastewater tank is connected with the feed port through a wastewater conveying pipeline, and a wastewater pump is arranged on the wastewater conveying pipeline. The system has the characteristics of being low in desulfurization wastewater emission, convenient in operation control,simple in structure and low in energy consumption.

Owner:WUHAN LONGKING ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com