Flue gas waste heat recovery system of sintering machine tail

A flue gas waste heat recovery system technology, applied in waste heat treatment, climate sustainability, lighting and heating equipment, etc. To achieve the effect of convenient operation control, low operation cost and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

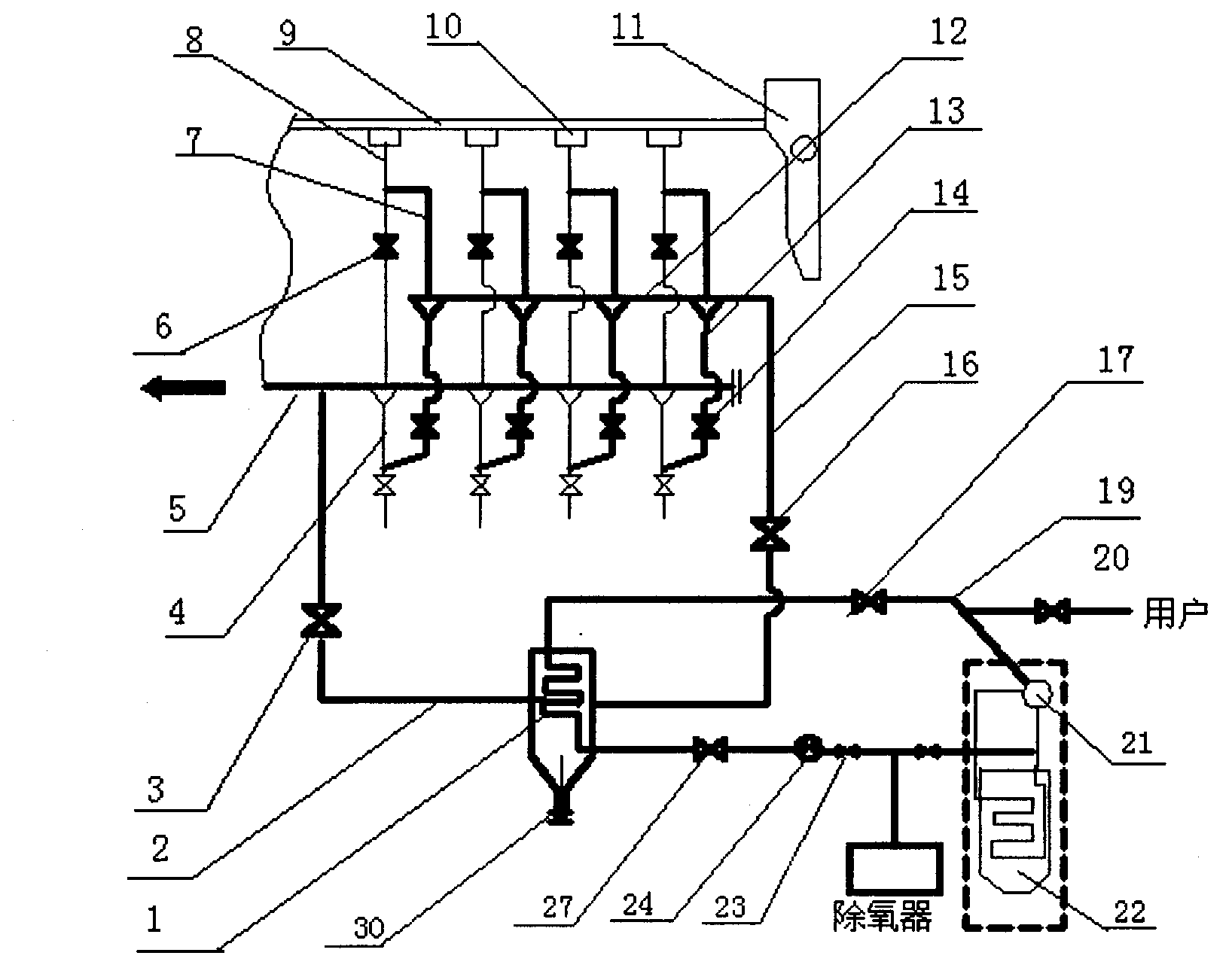

[0021] Such as figure 1 As shown, the sintering machine tail flue gas waste heat recovery system of the present invention mainly includes a heat exchanger (1), a sintering machine (9), a tail wind box (10) of a sintering machine, and a smoke exhaust of the tail wind box (10) of the sintering machine. Branch pipe (8), bypass smoke exhaust branch pipe (7) of machine tail wind box (10), bypass smoke exhaust main pipe (12), smoke exhaust branch pipe control valve (6) of machine tail wind box (10), large sintering machine Flue (5), large flue ash discharge device (4); the selected heat exchanger (1) is a shell-and-tube heat exchanger. For flue gas, the steel pipe of the heat exchanger (1) is equipped with a water inlet port and a water outlet port, and the box body of the heat exchanger (1) is equipped with an air inlet port and an air outlet port; On the four smoke exhaust branch pipes (8) between the four machine tail bellows (10) and the large flue (5), press four smoke exhaust...

Embodiment 2

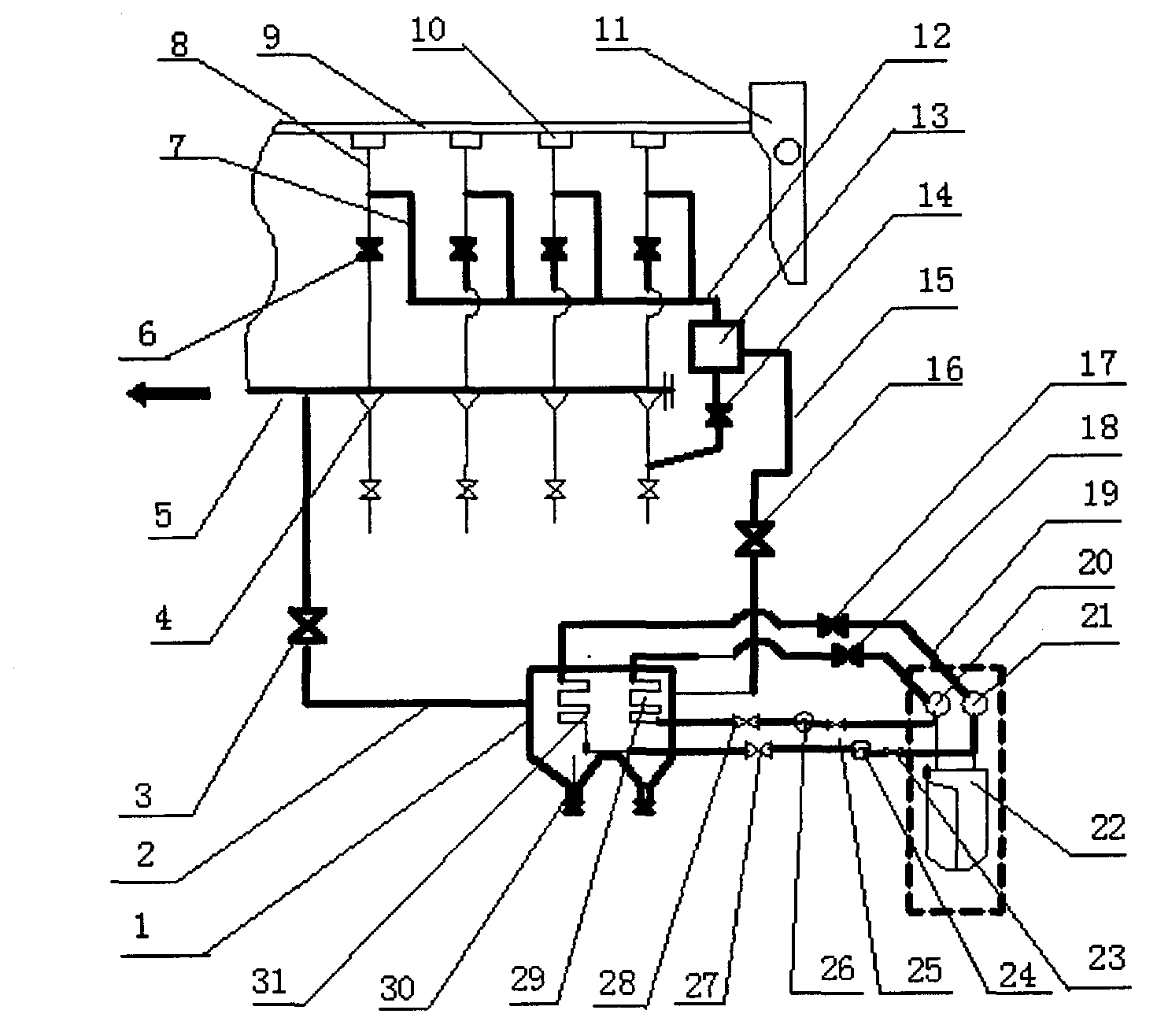

[0024] Such as figure 2As shown, the sintering machine tail flue gas waste heat recovery system of the present invention mainly includes a heat exchanger (1), a sintering machine (9), a tail wind box (10) of a sintering machine, and a smoke exhaust of the tail wind box (10) of the sintering machine. Branch pipe (8), bypass smoke exhaust branch pipe (7) of machine tail wind box (10), bypass smoke exhaust main pipe (12), smoke exhaust branch pipe control valve (6) of machine tail wind box (10), large sintering machine The flue (5), the large flue ash discharge device (4); the selected heat exchanger (1) is a double-temperature shell-and-tube heat exchanger, and the heat exchanger (1) is equipped with a high-temperature heat exchange device (29 ), the dual-temperature heat exchanger of the low-temperature heat exchange device (31), water flows inside the steel pipe in the heat exchanger (1) box, and flue gas flows outside the steel pipe, and the low-temperature heat exchange dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com