Tritiated water recycling device and achieving method thereof

A recovery device and technology of tritiated water, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of low reliability, high construction and operating costs of tritiated water recovery systems, and complex operation control, etc. problems, to achieve the effect of low price, simple structure, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

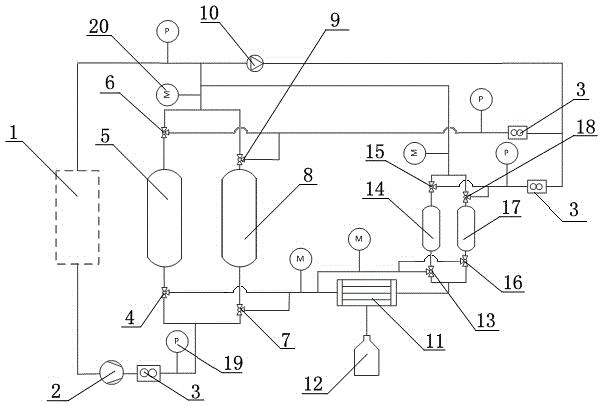

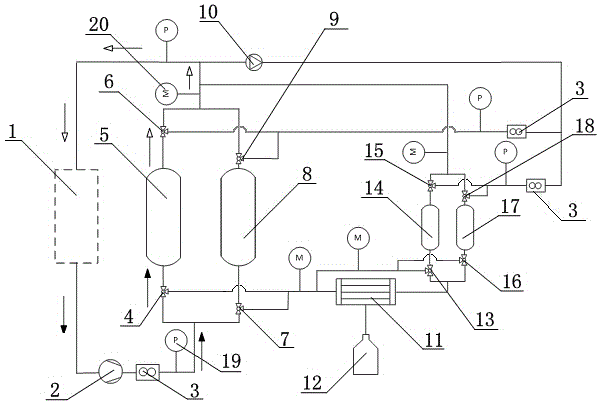

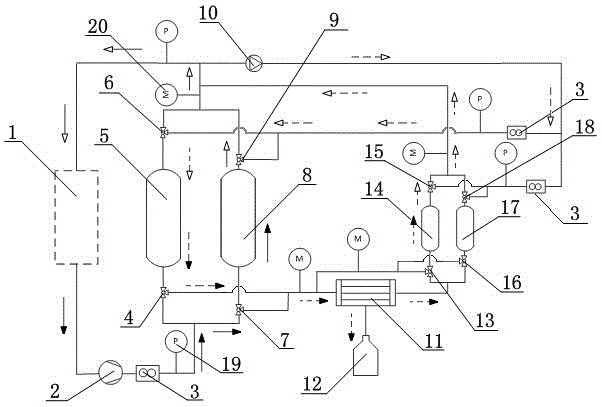

[0061] Such as figure 1 As shown, the present invention provides a device capable of recovering tritiated water from gas, which is mainly used in tritiated water treatment in nuclear facility tritium chemistry and tritium process. The present invention includes a tritiated water supply device, a first adsorption bed 5 , a second gas circulation pump 10 , a condenser 11 , a tritiated water storage tank 12 and a third adsorption bed 14 . Both the first adsorption bed 5 and the third adsorption bed 14 are filled with 5A molecular sieves, and the tritiated water supply device is used to provide gas containing tritiated water to the first adsorption bed 5, so that the first The adsorption bed 5 removes the tritiated water in the gas. The tritiated water supply device comprises process equipment 1 containing tritiated water gas, and the first gas circulation pump 2 connected with the process equipment 1 and the first adsorption bed 5 at the same time; the first adsorption bed 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com