Patents

Literature

205 results about "Electronic differential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

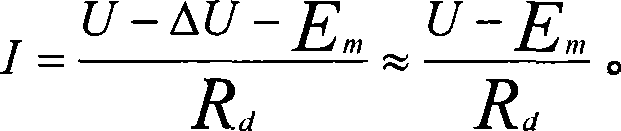

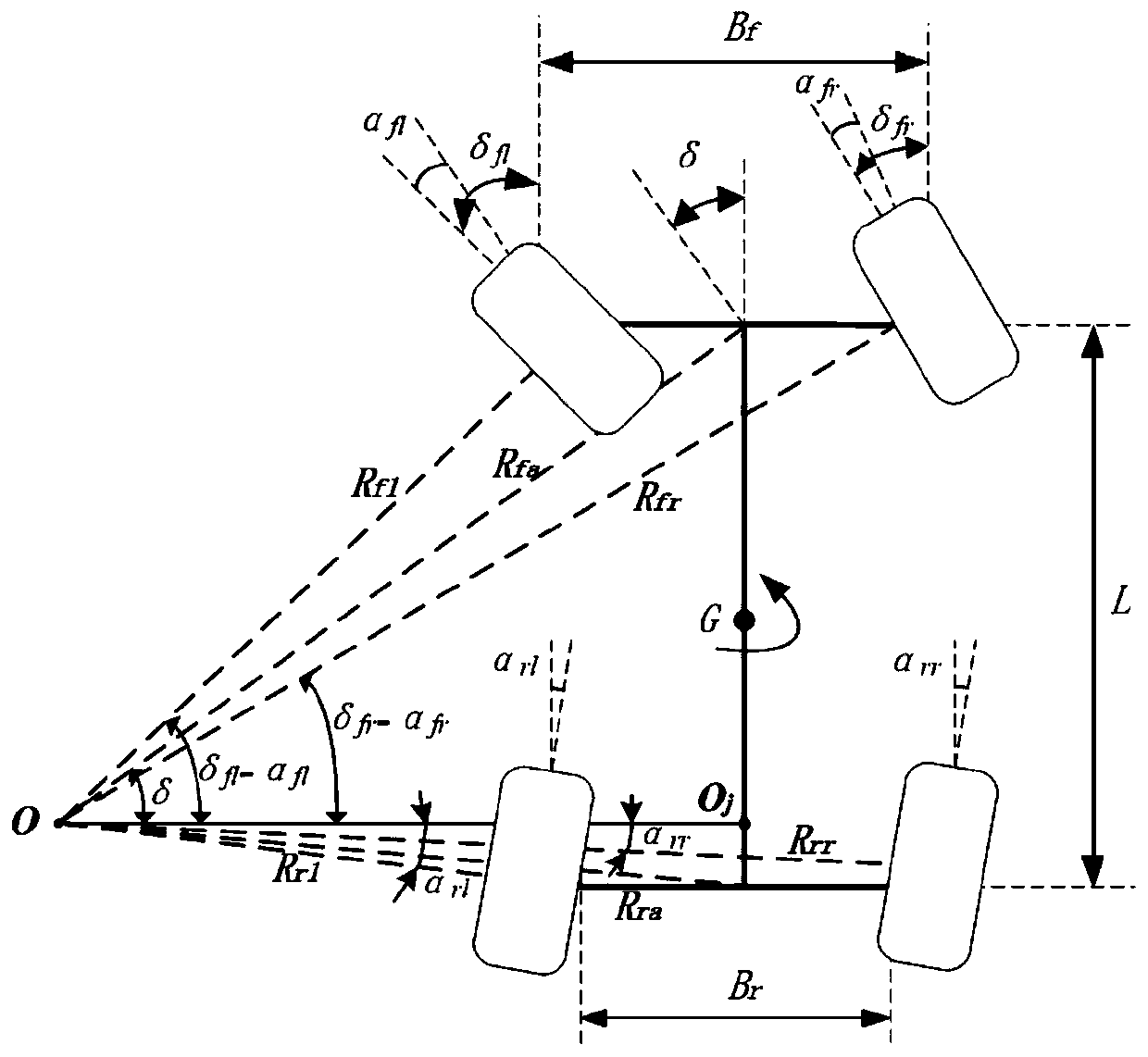

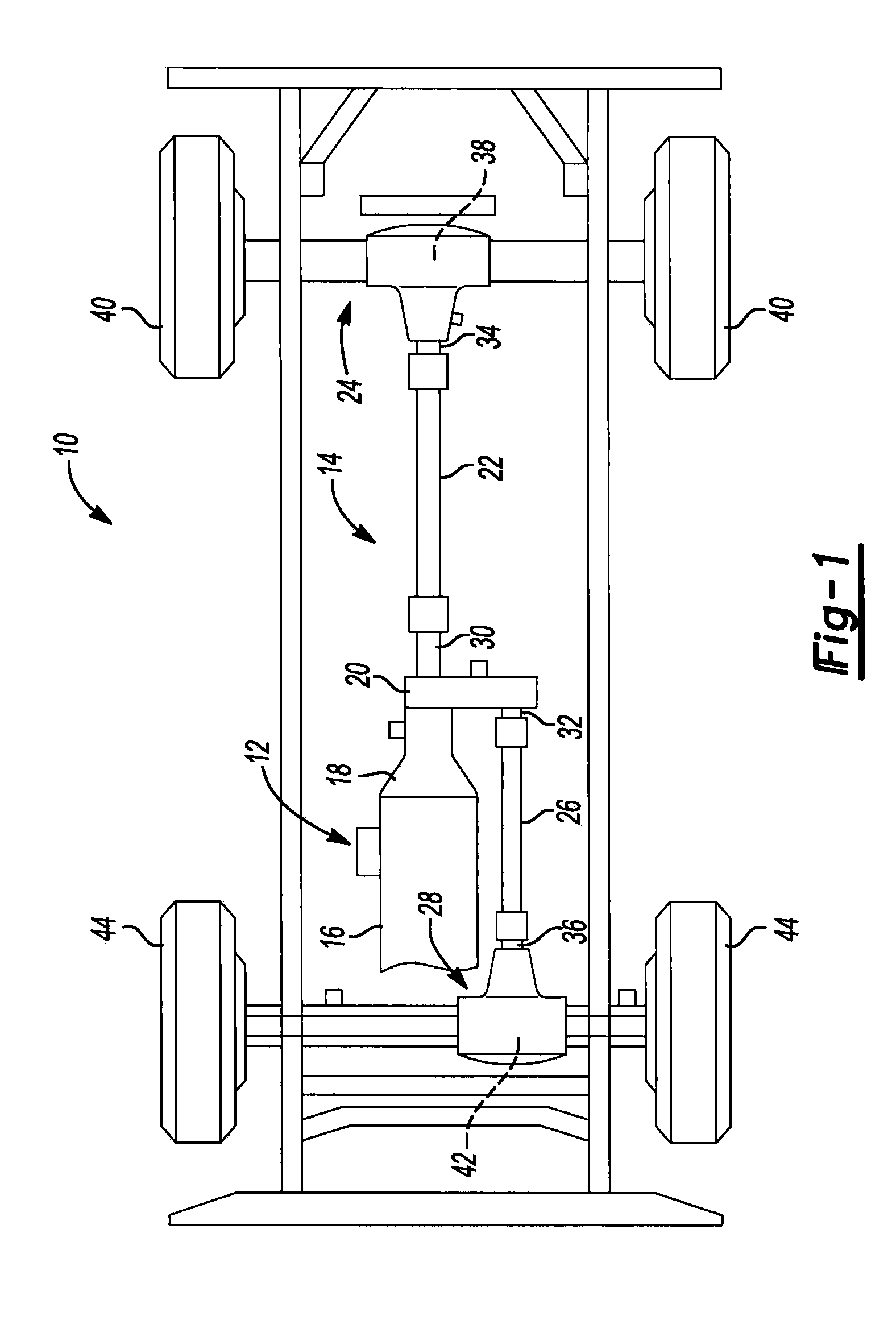

In automotive engineering the electronic differential is a form of differential, which provides the required torque for each driving wheel and allows different wheel speeds. It is used in place of the mechanical differential in multi-drive systems. When cornering, the inner and outer wheels rotate at different speeds, because the inner wheels describe a smaller turning radius. The electronic differential uses the steering wheel command signal and the motor speed signals to control the power to each wheel so that all wheels are supplied with the torque they need.

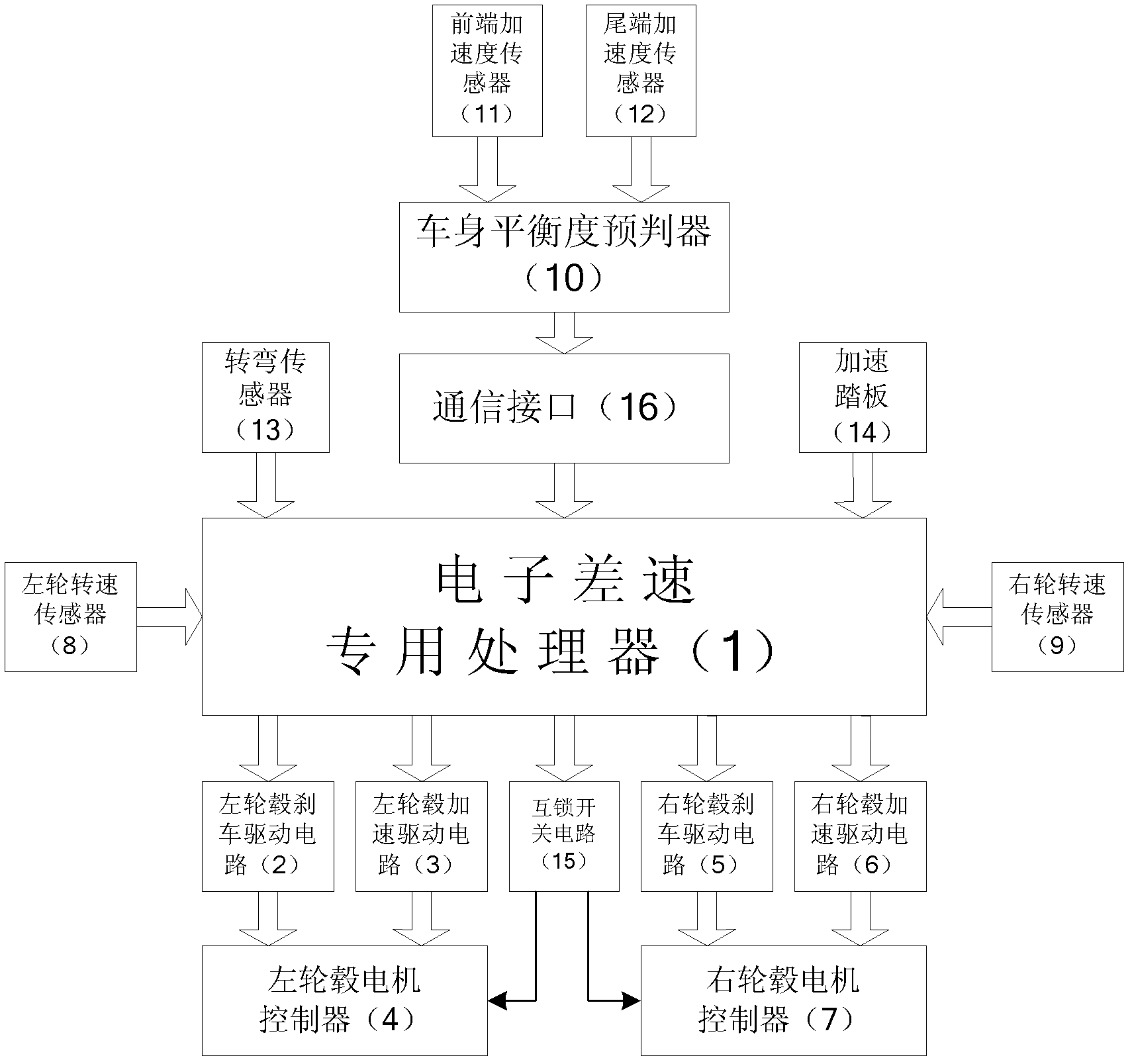

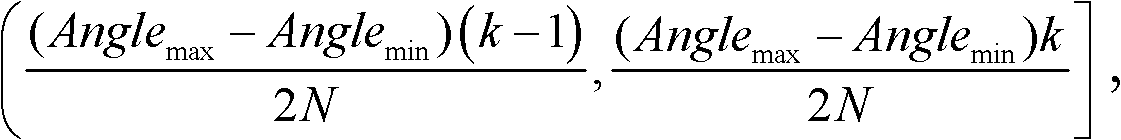

Self-adaptive balance steering control method of double-hub motor driving system

ActiveCN103204180APrecise and effective differential speed controlHazard containmentSpeed controllerElectric devicesCommunication interfaceBody balance

The invention provides a self-adaptive balance steering control method of a double-hub motor driving system. A basic control system comprises an electronic differential speed special processor, a left hub brake driving circuit, a left hub acceleration driving circuit, a left hub motor controller, a right hub brake driving circuit, a right hub acceleration driving circuit, a right hub motor controller, a left wheel rotation speed sensor, a right wheel rotation speed sensor, an inter-locking switch circuit, a vehicle body balance degree prejudging device, a front acceleration sensor, a tail acceleration sensor, a steering sensor, an acceleration pedal and a communication interface. The method has the advantage that a method for evaluating a vehicle steering safety degree is established by utilizing steering sensing information, vehicle body tilting degree information, vehicle speed and vehicle speed deviation rate, an electronic brake processing method is adopted in the field of steering control, and then the steering balance of the double-hub motor driving system can be controlled more efficiently and accurately, so the stability of the vehicle in the running process is improved.

Owner:SNTO TECH GRP

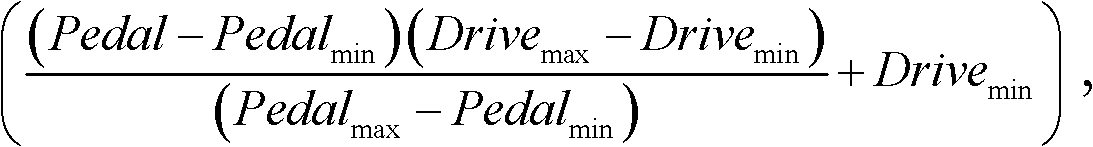

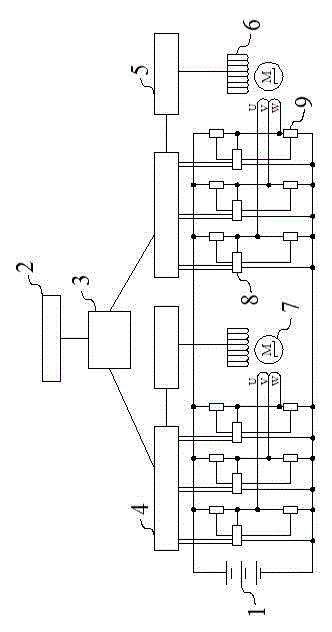

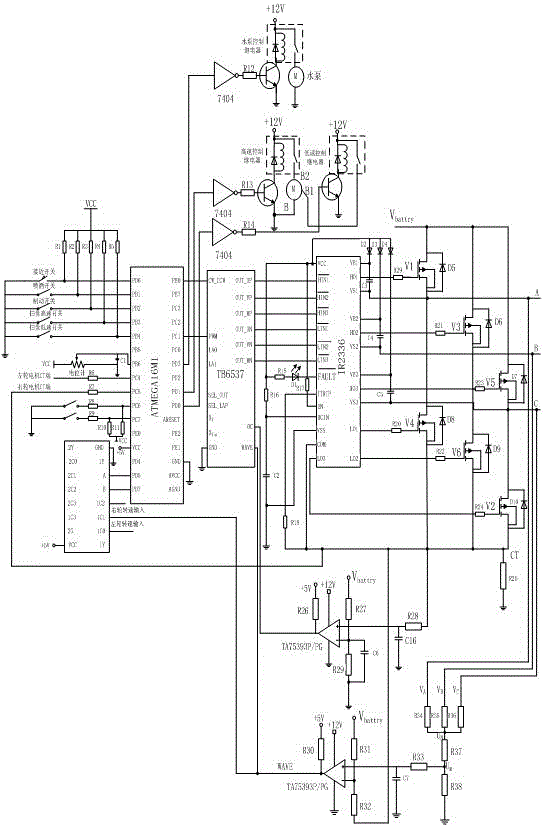

Double-hub electrical motor electronic differential and speed regulation integrated controller

ActiveCN103101451ARealize the advantages of electronic controlEasy wiringSpeed controllerControl devicesControl signalElectric vehicle

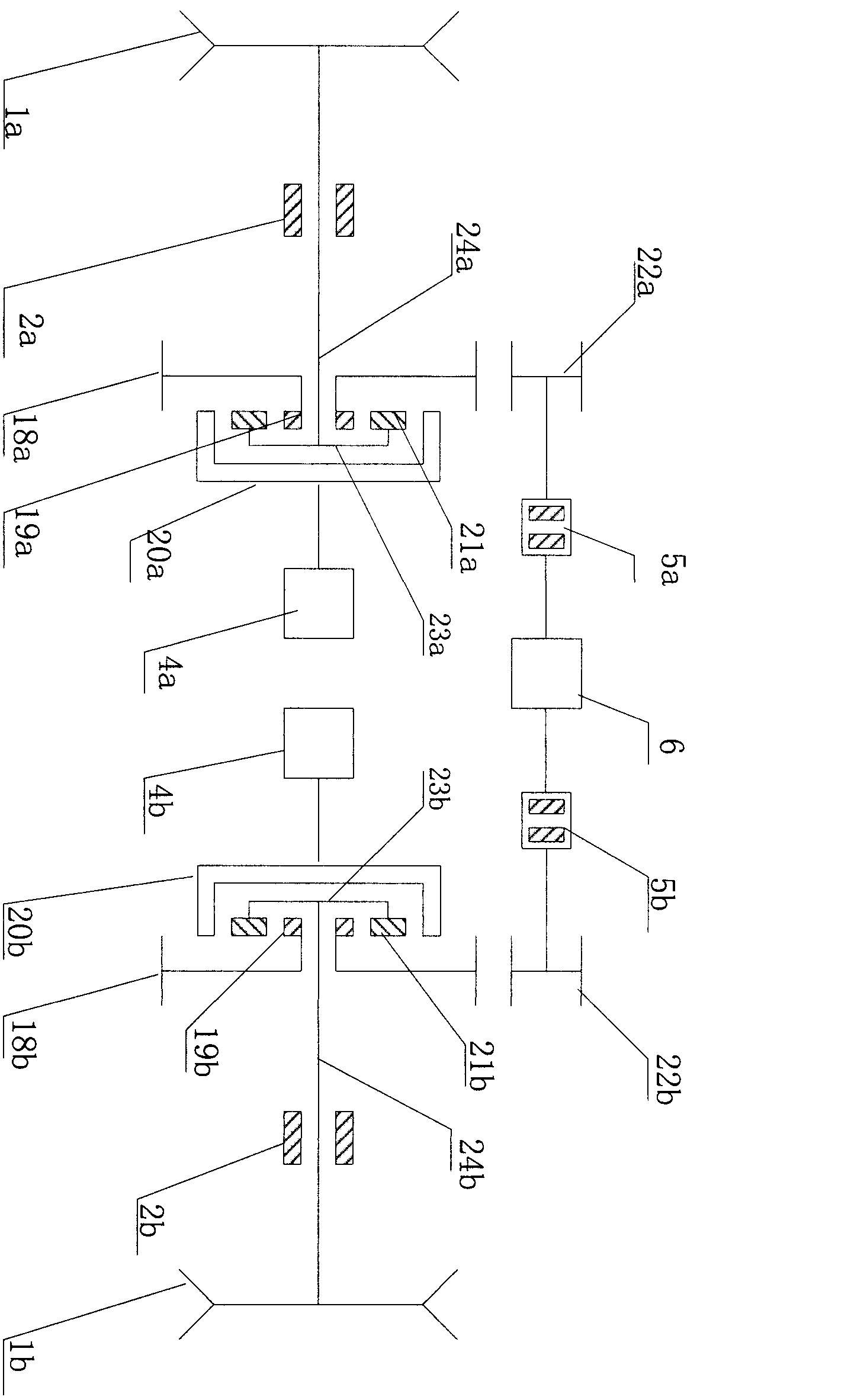

The invention provides a double-hub electronic motor electrical differential and speed regulation integrated controller. A control signal integrated adjusting unit module, a right wheel speed signal preprocessing module, a right wheel pre-driving unit module, a left wheel pre-driving unit module, a left wheel speed signal preprocessing module, a left hub electrical motor controller, a right hub electrical motor controller, a driving module unit and a monolithic computer are arranged inside the double-hub electrical motor electronic differential and speed regulation integrated controller. The double-hub electrical motor electronic differential and speed regulation integrated controller is characterized in that an electronic differential mechanism, the left hub electrical motor controller and the right hub electrical motor controller are combined into a whole inside the double-hub electrical motor electronic differential and speed regulation integrated controller simultaneously, and all components inside the double-hub electrical motor electronic differential and speed regulation integrated controller are of module structures. Meanwhile, a control signal and speed feedback signal processing module needed by an electric vehicle is arranged inside the controller, pre-control circuits and terminal driving circuits of a left electrical motor and a right electrical motor are inserted in the controller, and thus the fact that a control assembly of the electric motor driven by a double-hub electrical motor has differential control in turning, speed control in driving, stop control in temporary stop and anti-theft control in parking is guaranteed.

Owner:徐州科悦电子科技有限公司

Double-motor controller with electronic differential function

InactiveCN102874129AReduce volumeOptimize layoutSpeed controllerMultiple motor speed/torque controlCapacitanceDrive wheel

The invention discloses a double-motor controller with an electronic differential function. The double-motor controller comprises a main control chip integrated with an electronic differential module, two groups of drive motor control chips, two groups of rotary transformer decoding chips, two groups of power drive modules for controlling a motor to operate, a capacitor bank, an angle decoding and conditioning circuit, two permanent magnet motors with built-in rotary transformers, and an active force battery pack, wherein the main control chip is used for processing a received signal; and a left drive wheel control signal and a right drive wheel control signal are transmitted into the drive motor control chips corresponding to wheels respectively through the operation of an electronic differential operation module. The drive motor control chips receive information of position values, speed values and the like of the drive motor returned by corresponding rotary transformer decoding chips; information provided by the main control chip is combined so as to be processed comprehensively; and a waveform is output to a corresponding power drive module so as to operate the wheels through the drive motor. The double-motor controller with the electronic differential function has the advantages of high drive efficiency, small volume, convenience in arrangement and installation, and capability of active differential.

Owner:CHENGDU LAINTEM MOTORS CONTROL TECH

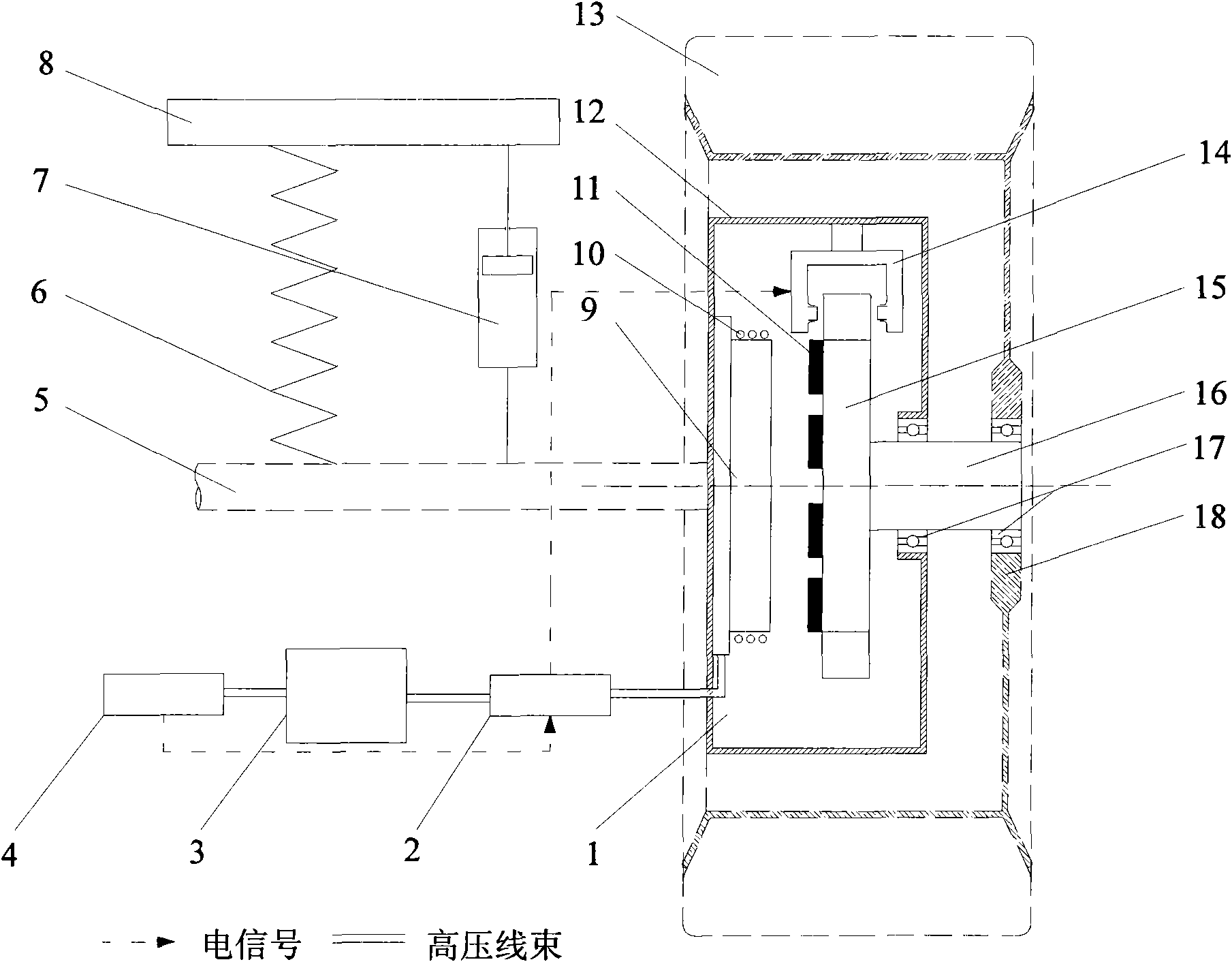

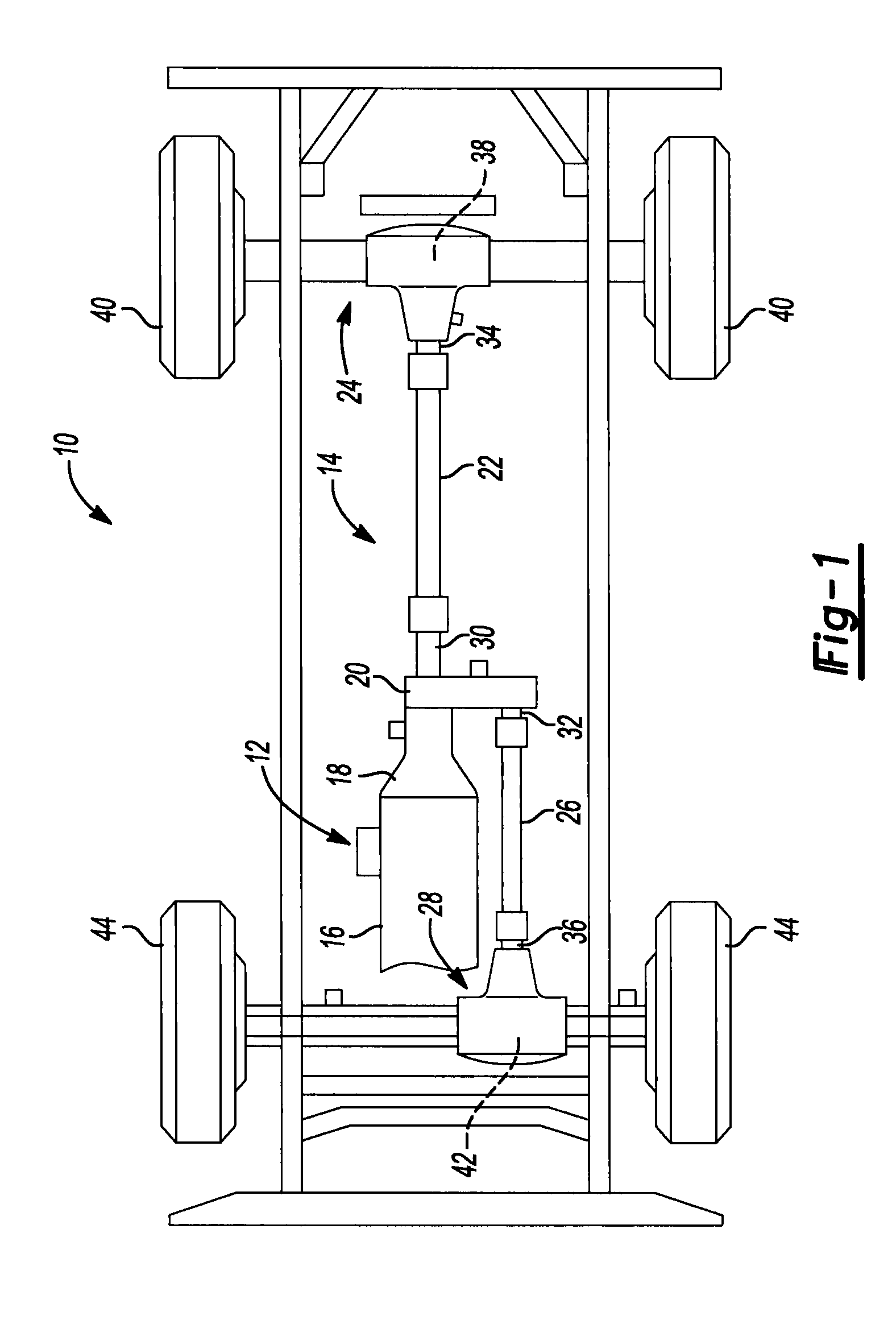

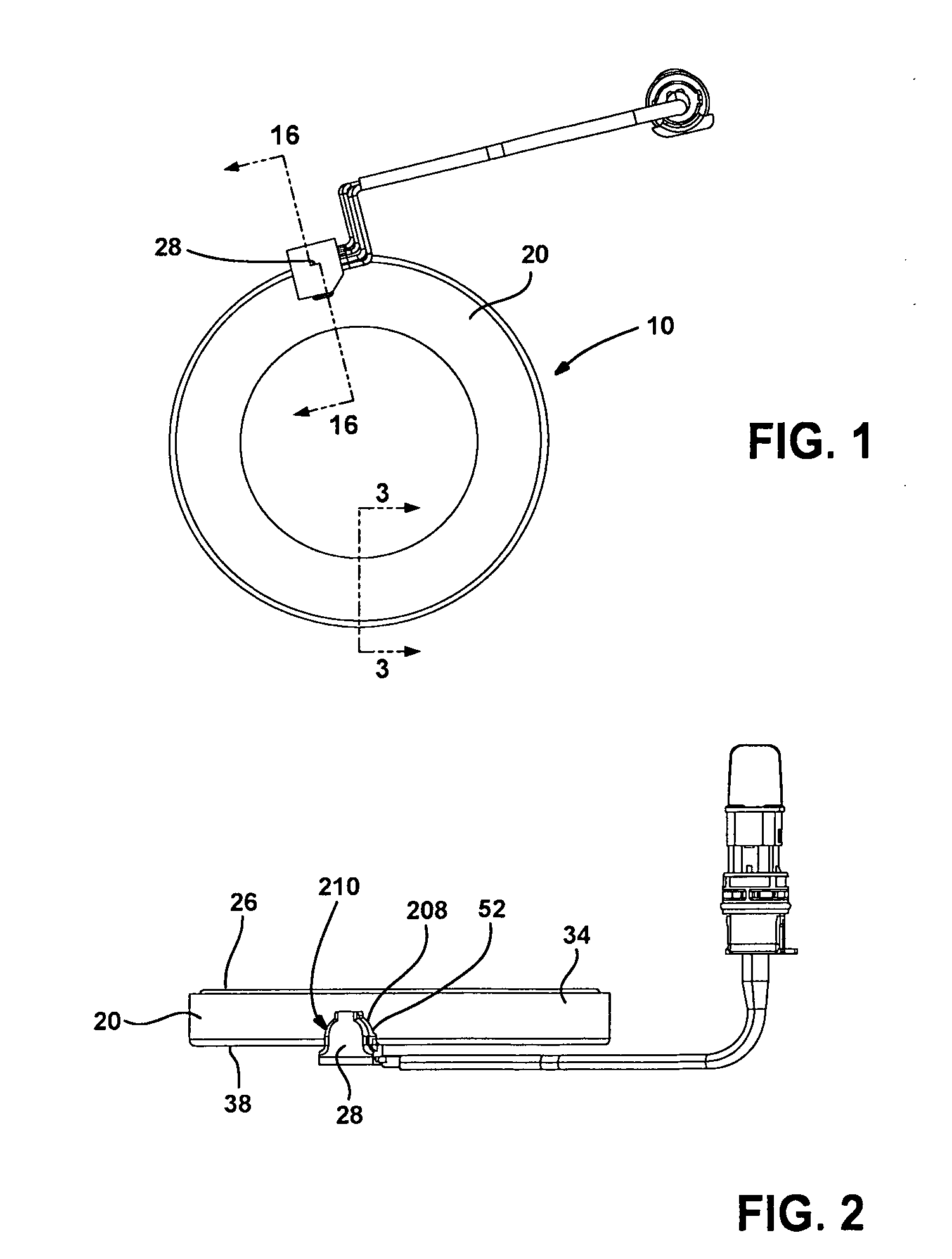

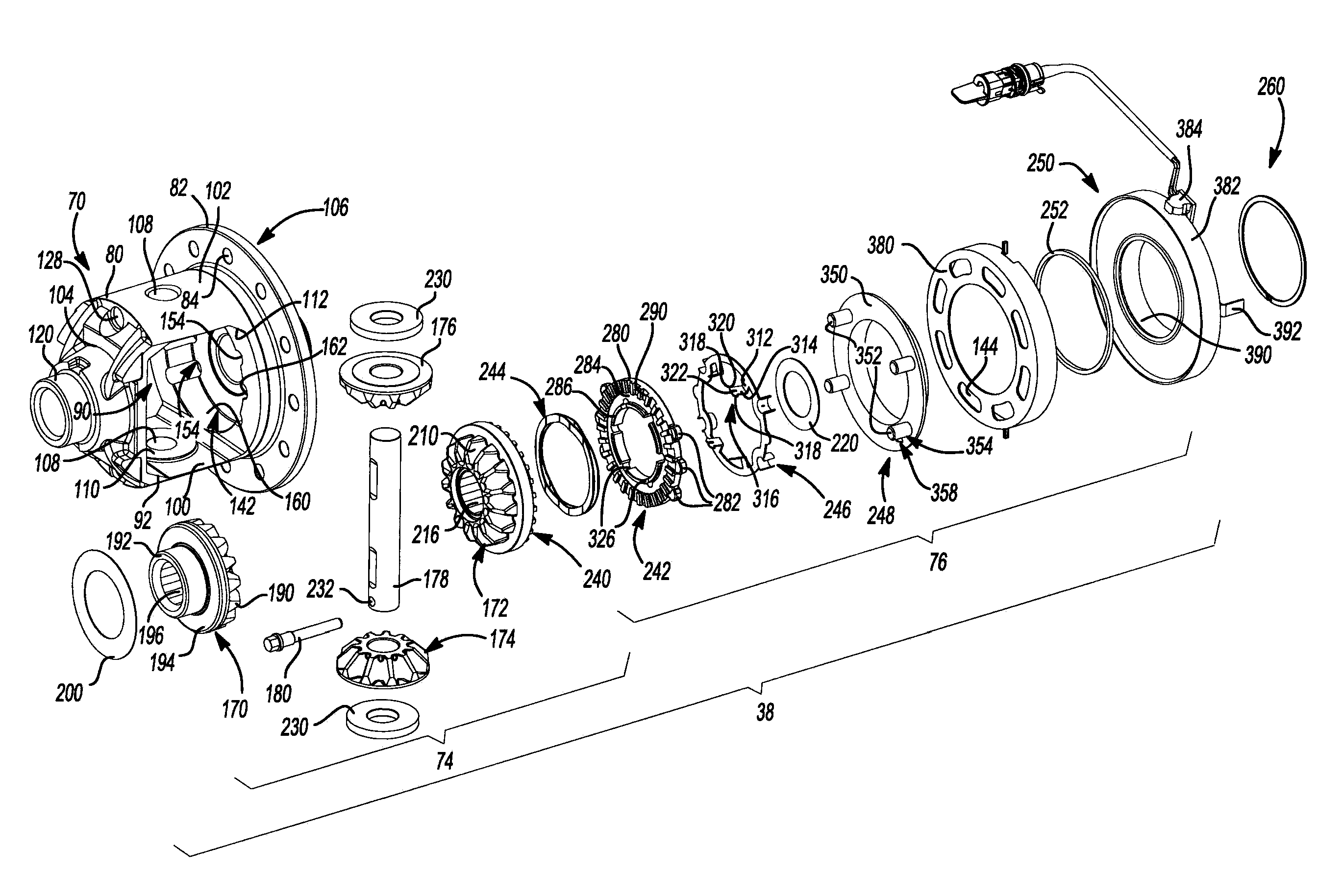

Integrated electric wheel drive unit for electric automobile

InactiveCN101564986ASimple structureRealize differential speed controlElectrodynamic brake systemsElectric machinesReduction driveElectronic differential

The invention discloses an integrated electric wheel drive unit for an electric automobile, which comprises a disc motor, a motor controller, a battery unit, a whole vehicle electronic control unit ECU, a vehicle bridge and a brake caliper, wherein the brake caliper is fixed on a motor shell and matched with a rotor and brakes the rotor to rotate; the rotor is fixed at one end of a motor rotor shaft, while the other end is fixed on a vehicle wheel hub of a tire through a bearing; a stator is fixed on the motor shell which is fixed with the vehicle bridge; the whole vehicle electronic control unit ECU, the battery unit, the motor controller and the stator are connected with each other in turn through a high voltage wire bale; and the whole vehicle electronic control unit ECU is also in signal connection with the motor controller which is in signal connection with the brake caliper. The invention saves the conventional clutch, the conventional gear box, the conventional main speed reducer, the conventional differential mechanism and other components, simplifies the structure of the whole vehicle, improves the transmission efficiency, and can realize the electronic differential speed control of an electric wheel by control technology.

Owner:SOUTH CHINA UNIV OF TECH

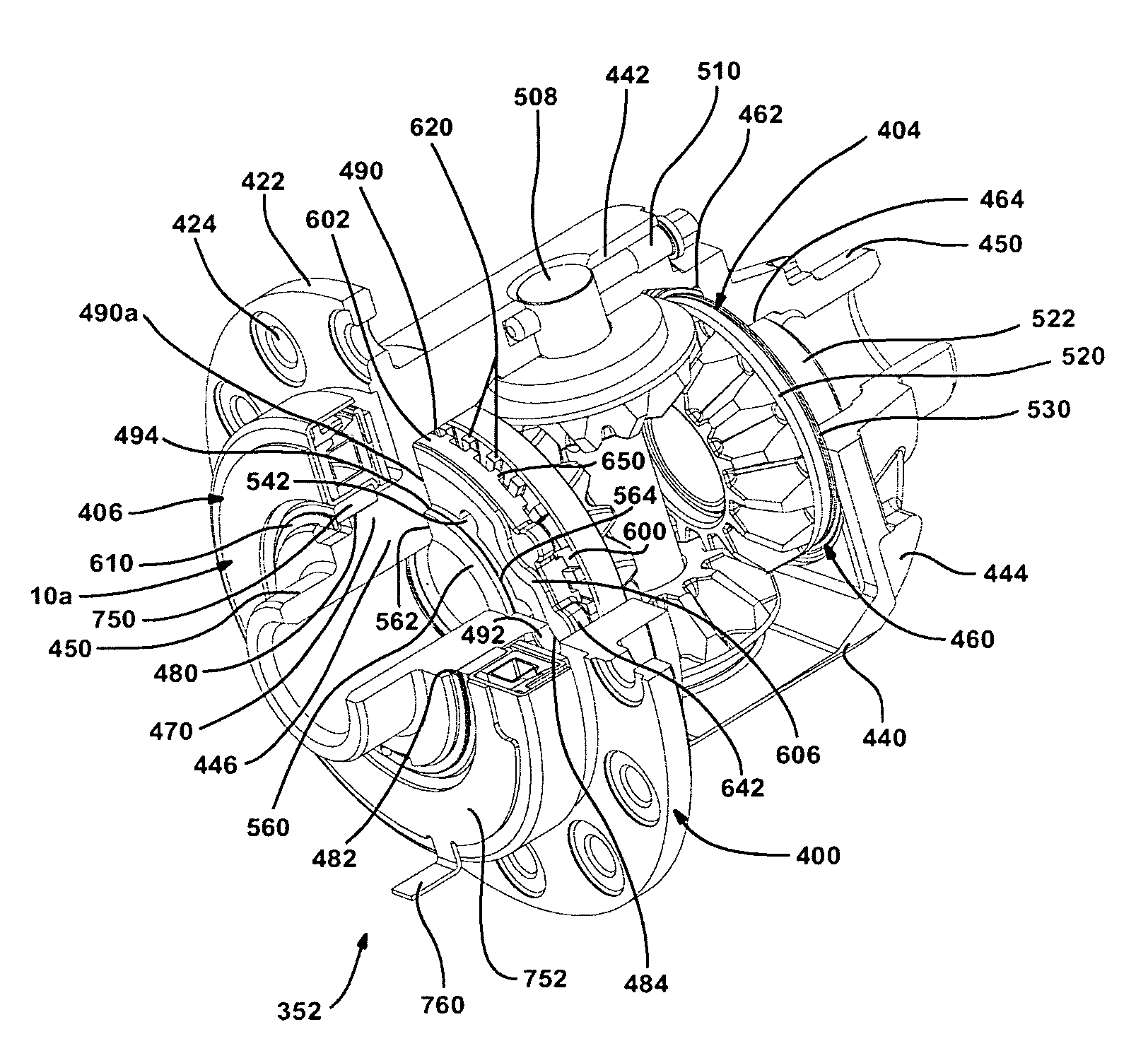

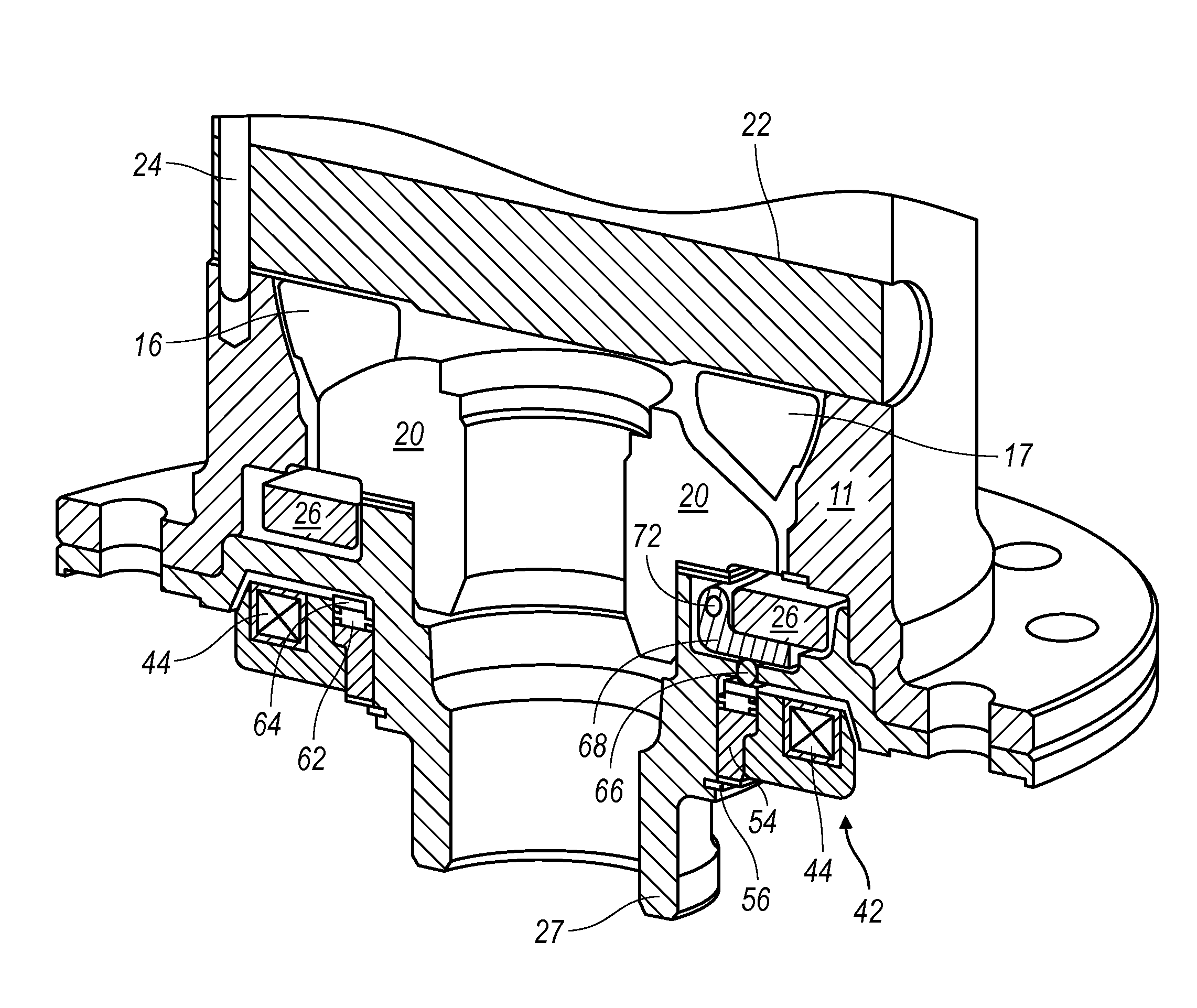

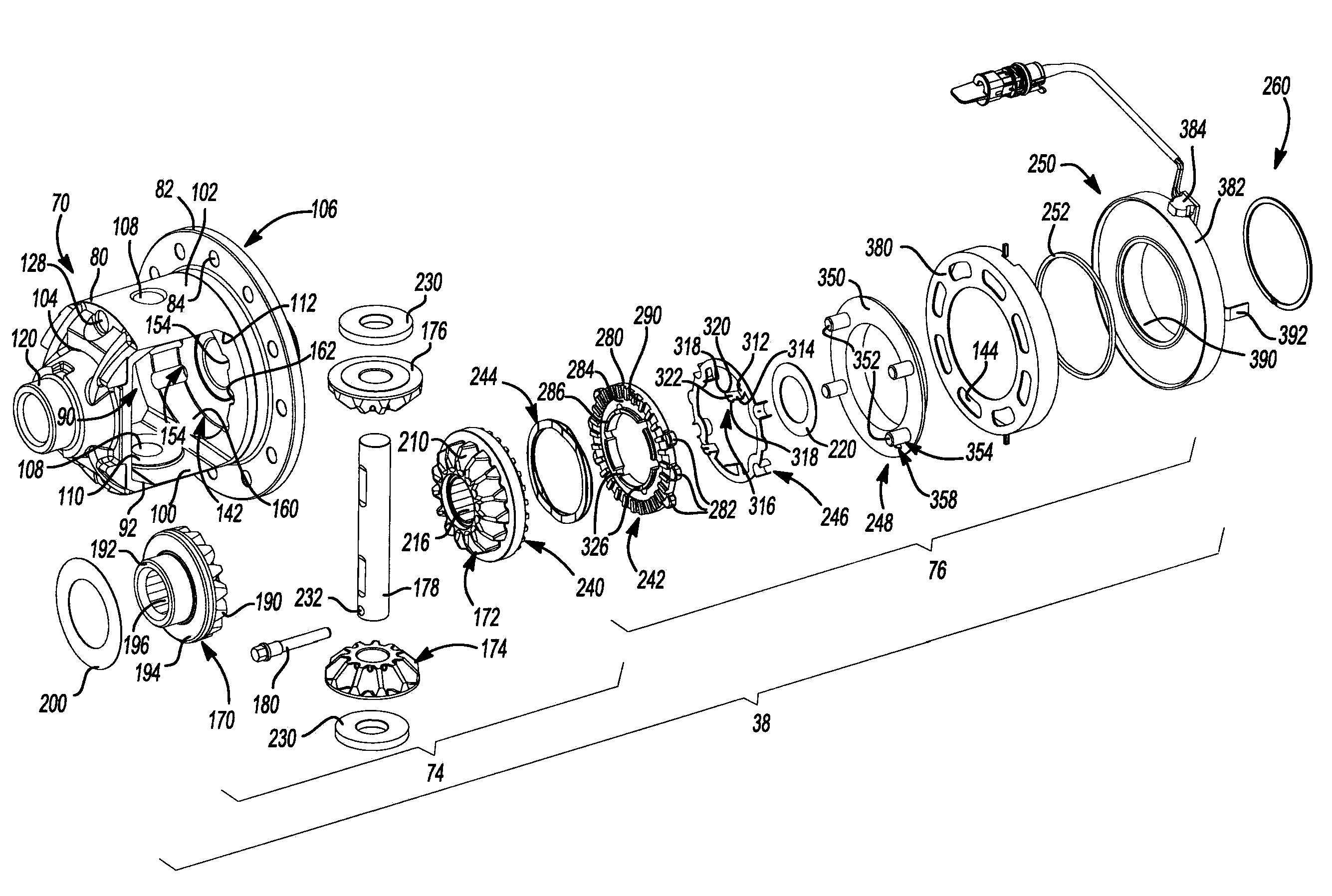

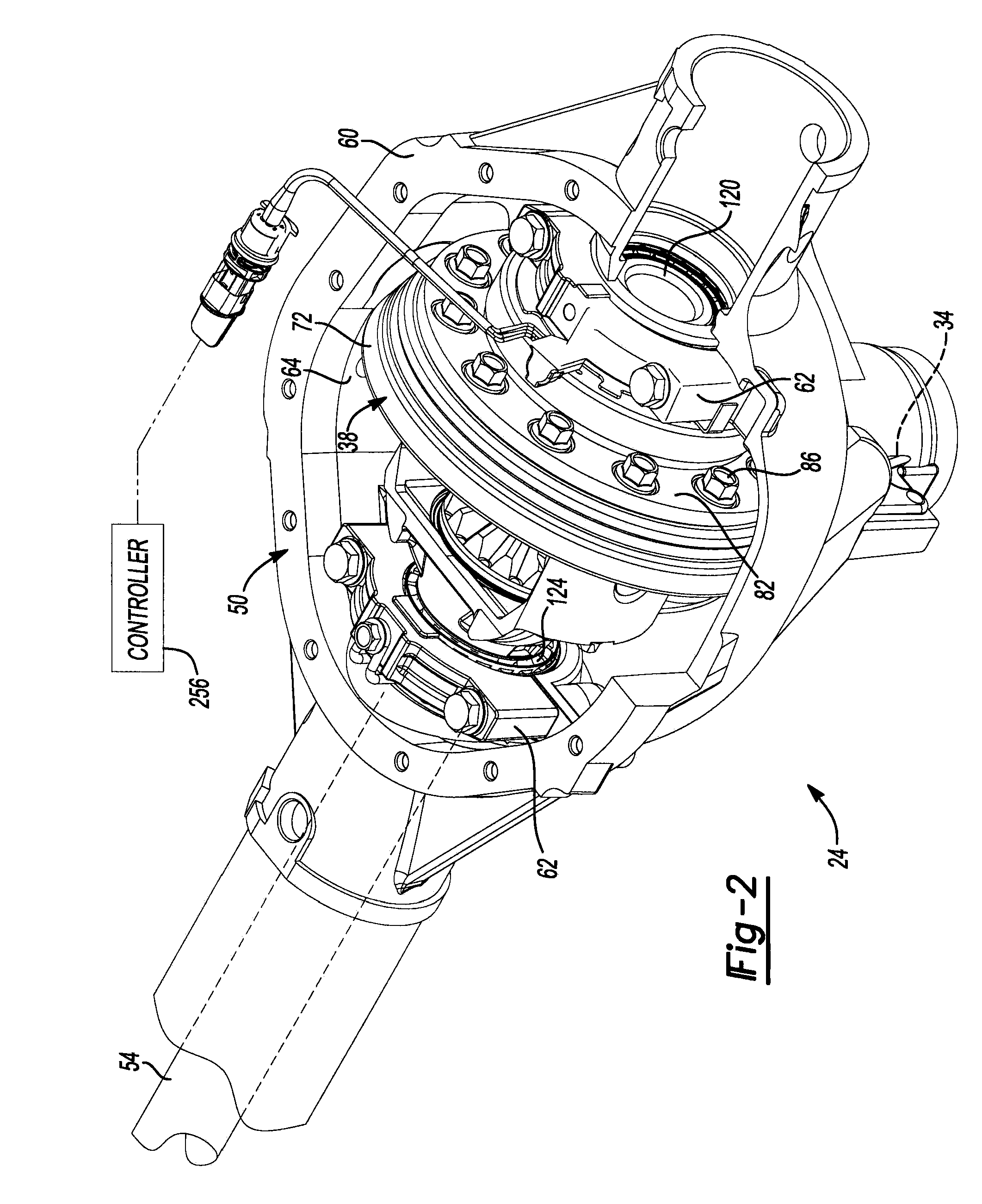

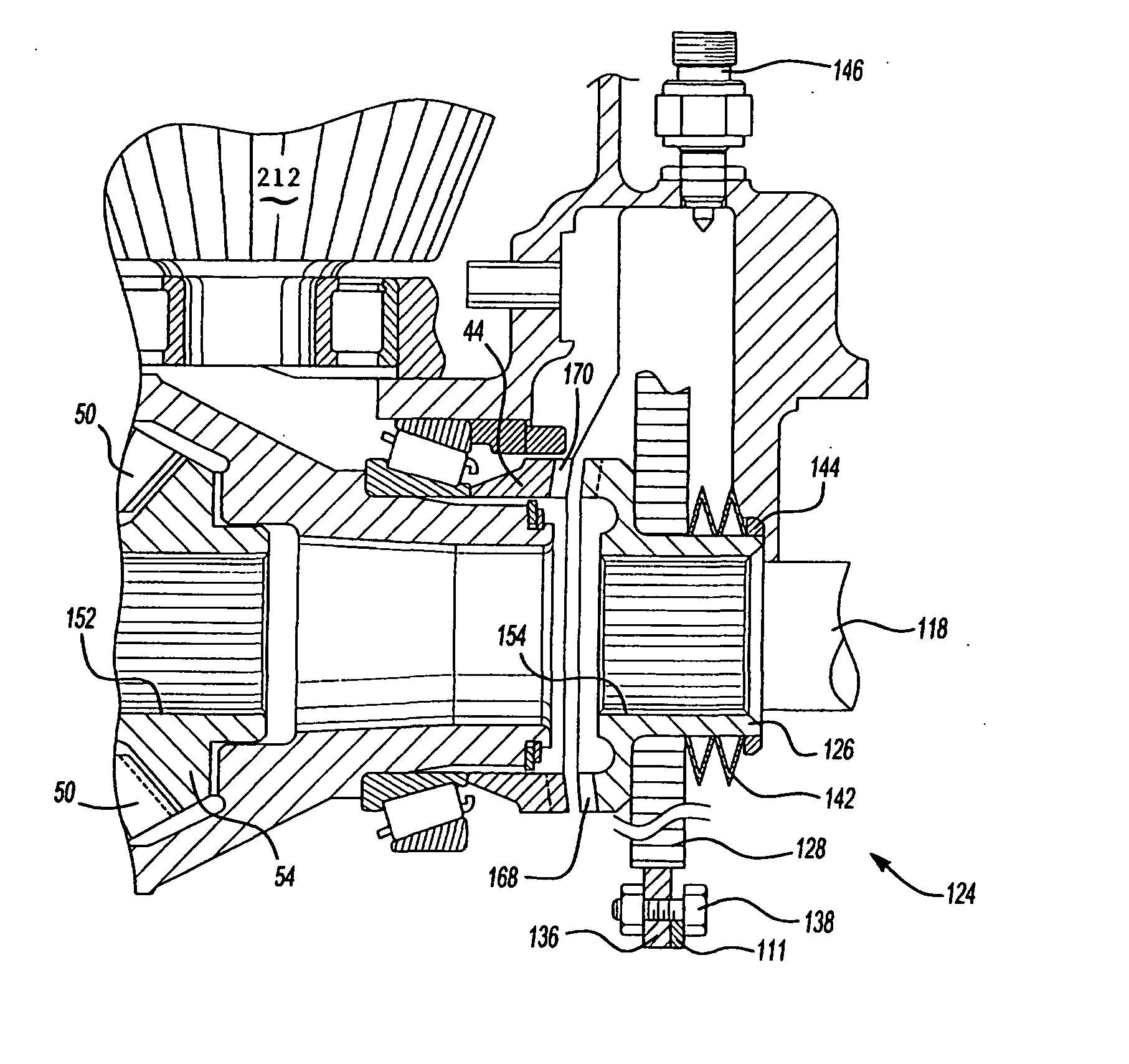

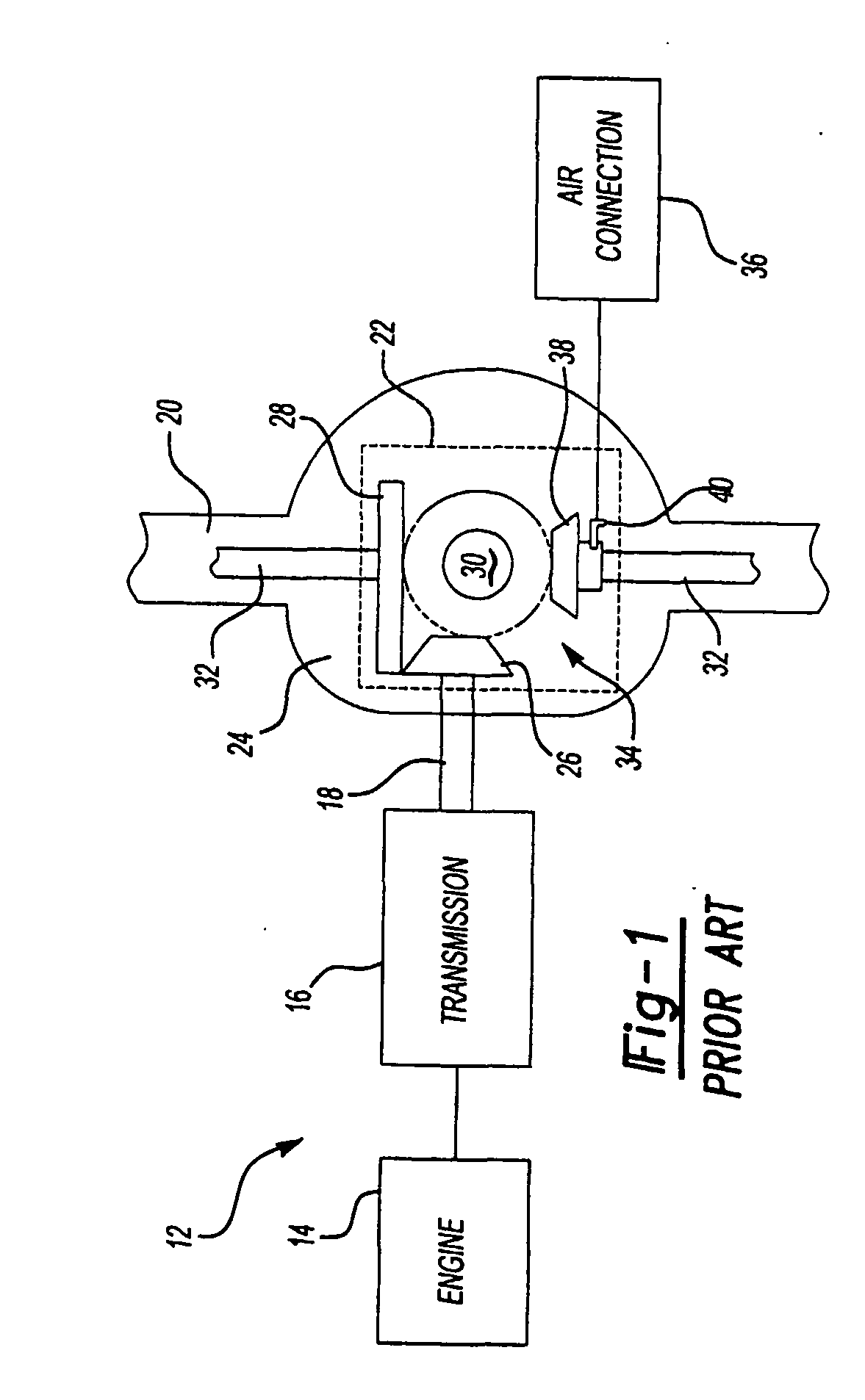

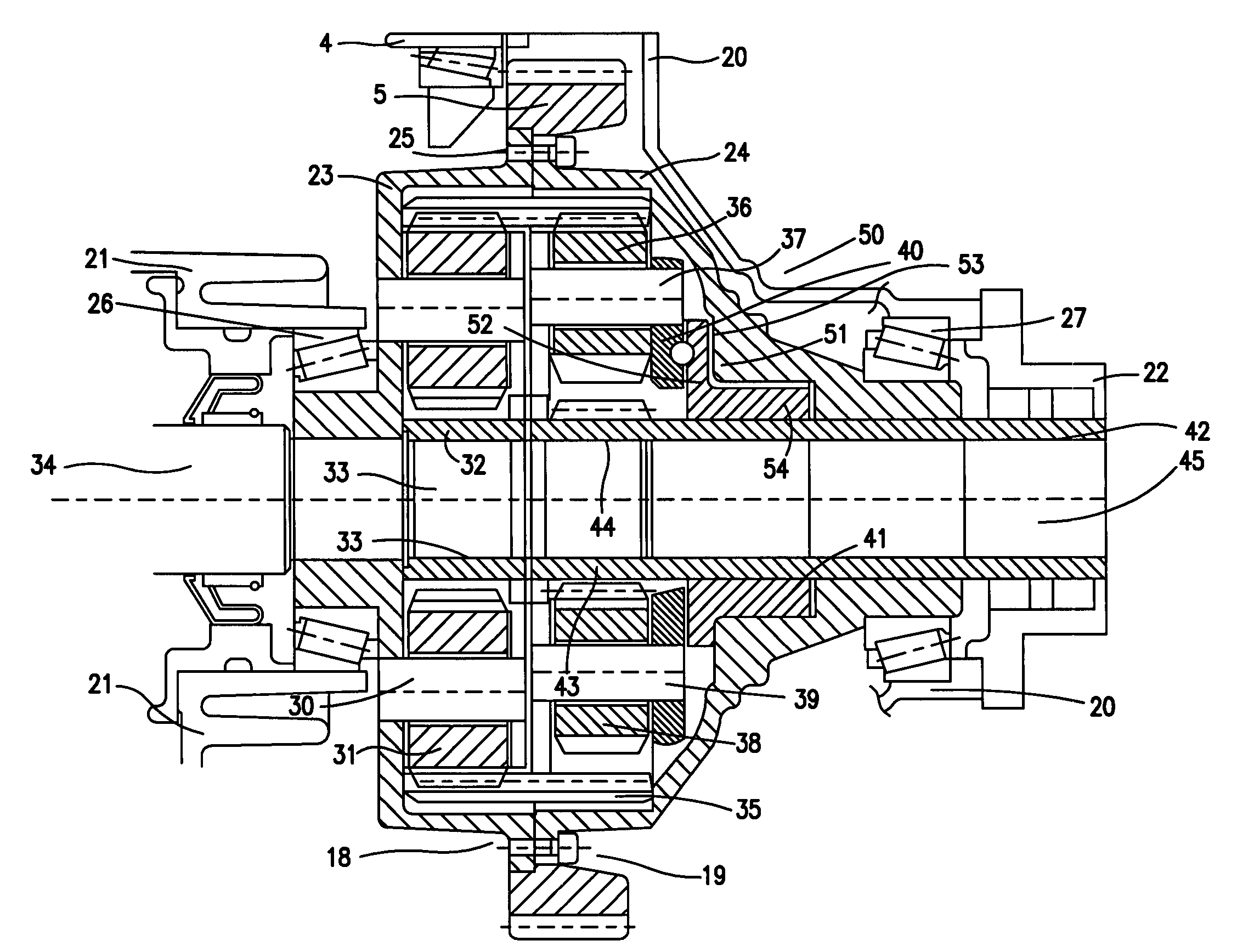

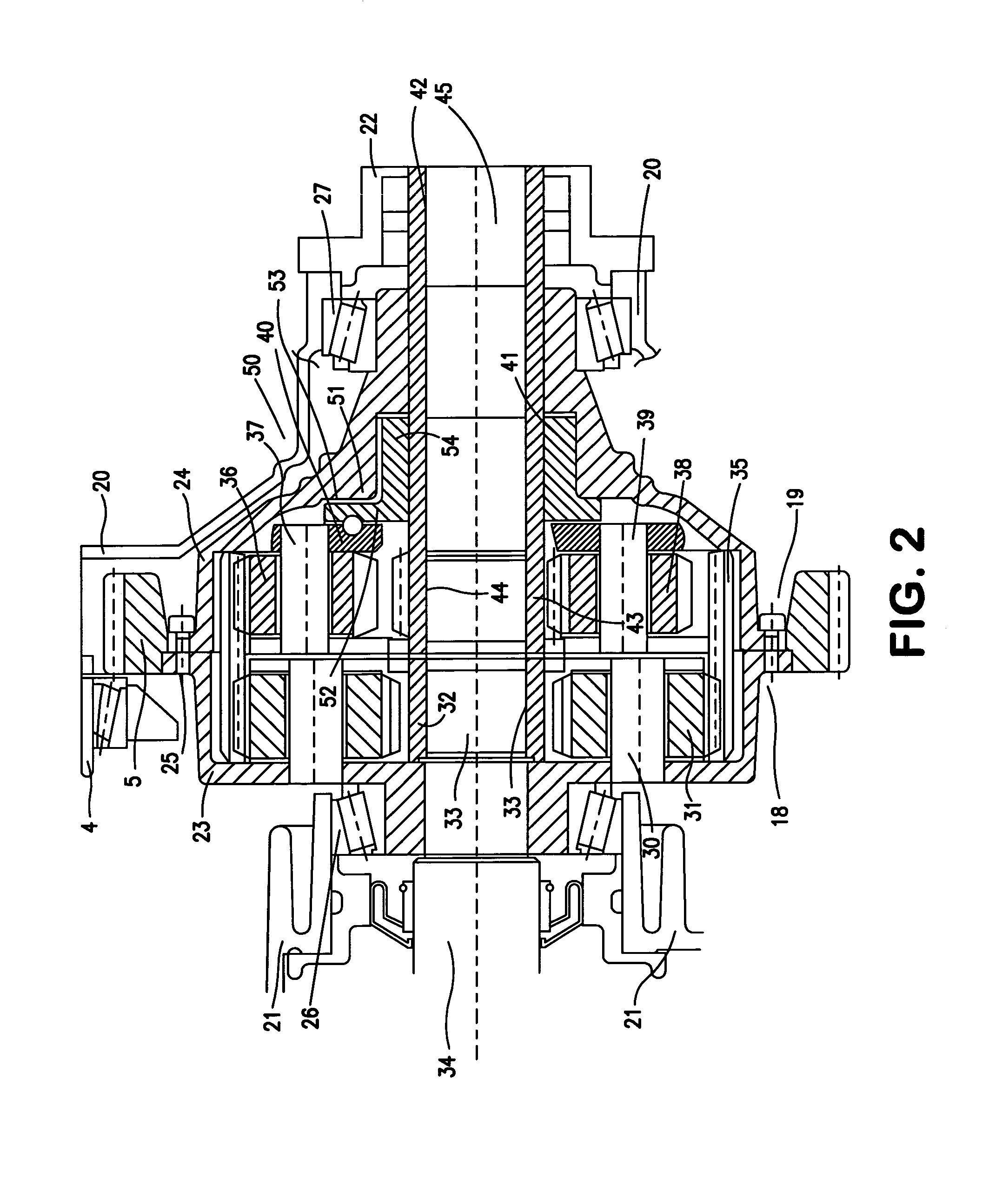

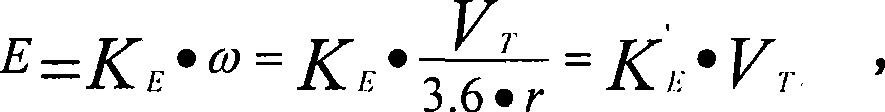

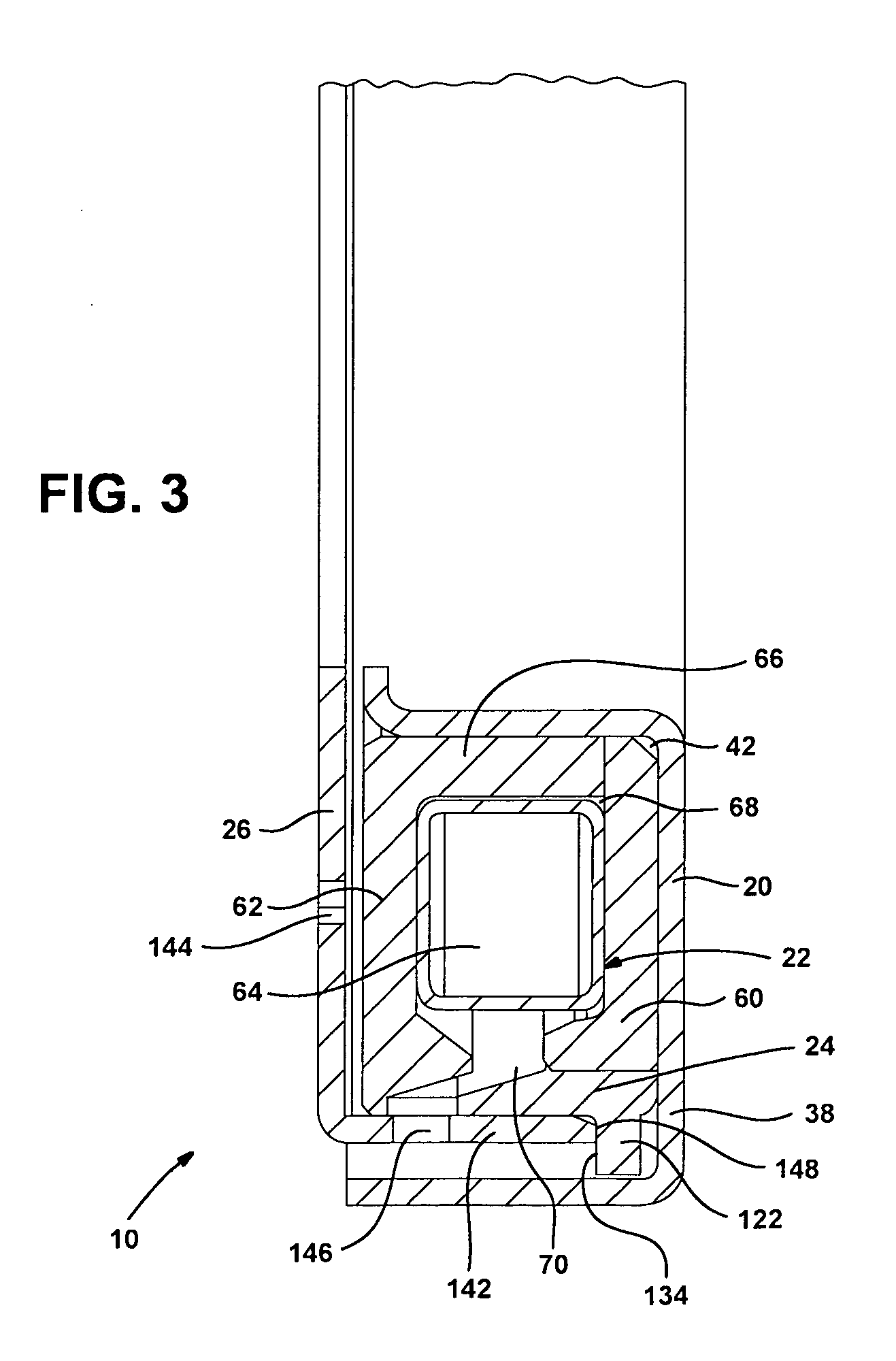

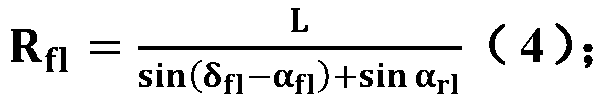

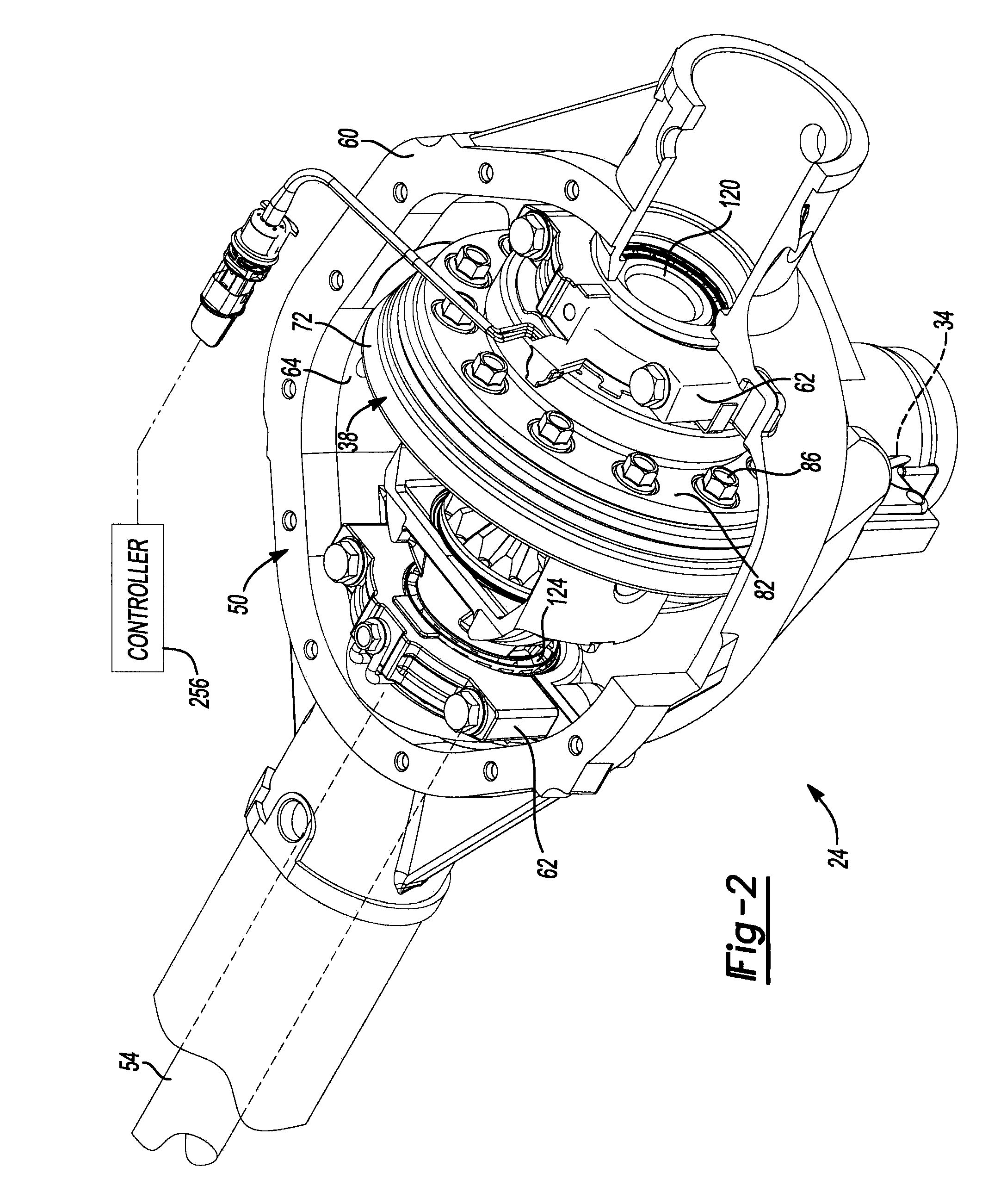

Axle assembly with electronic locking differential

An axle assembly with an electric locking differential that can include a one-piece differential case and a locking device. The locking device includes a dog that is nonrotatably but axially slidably received into a pocket that is formed in an end of the differential case. An actuator is mounted on the differential case. Actuation of the actuator moves the dog into engagement with a second dog that is coupled to a side gear of the differential to thereby lock the side gear to the differential case.

Owner:AMERICAN AXLE & MFG

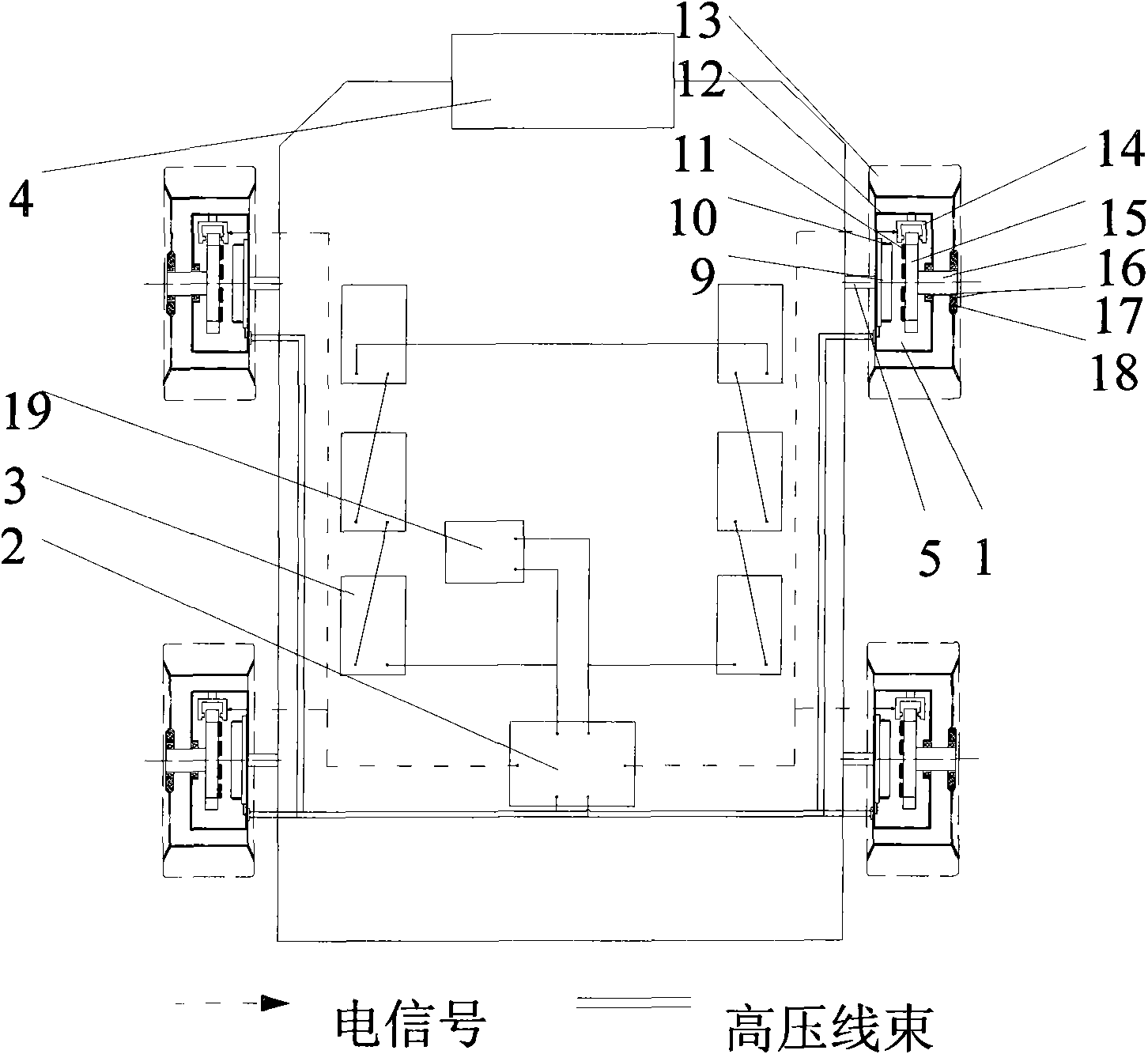

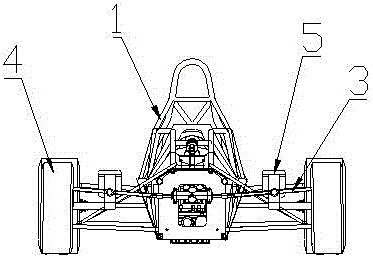

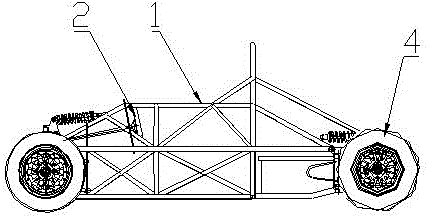

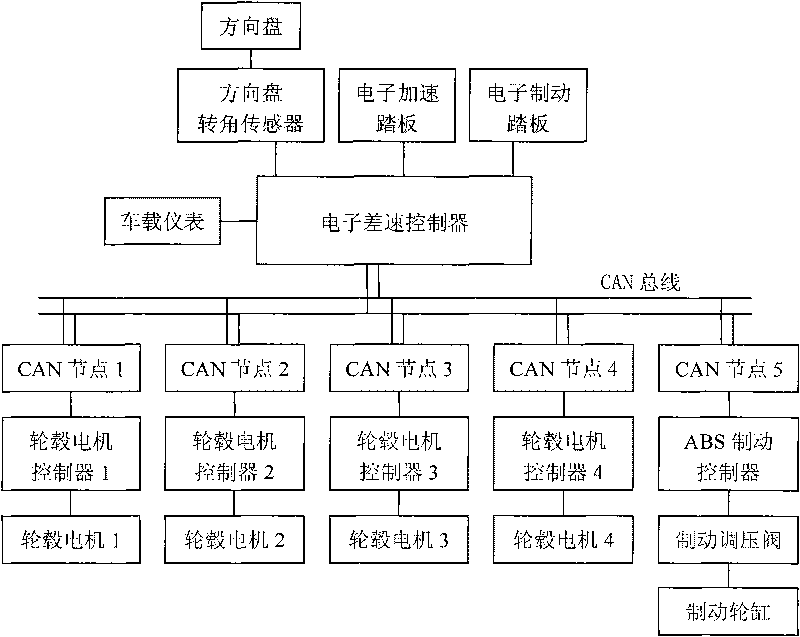

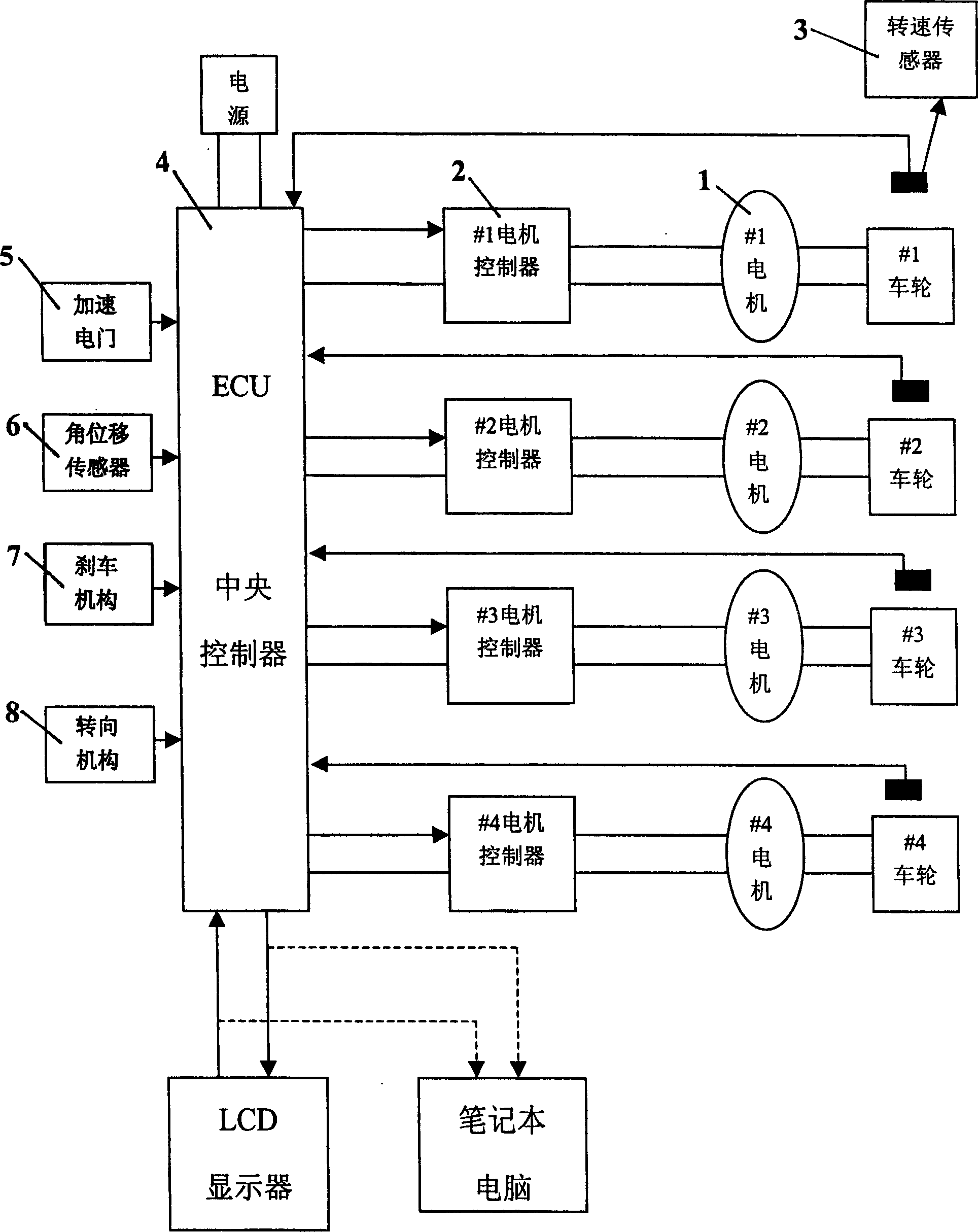

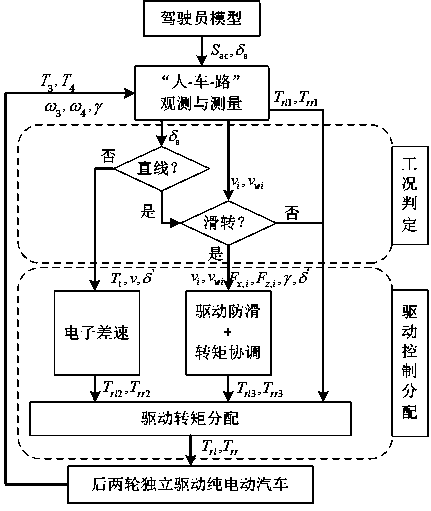

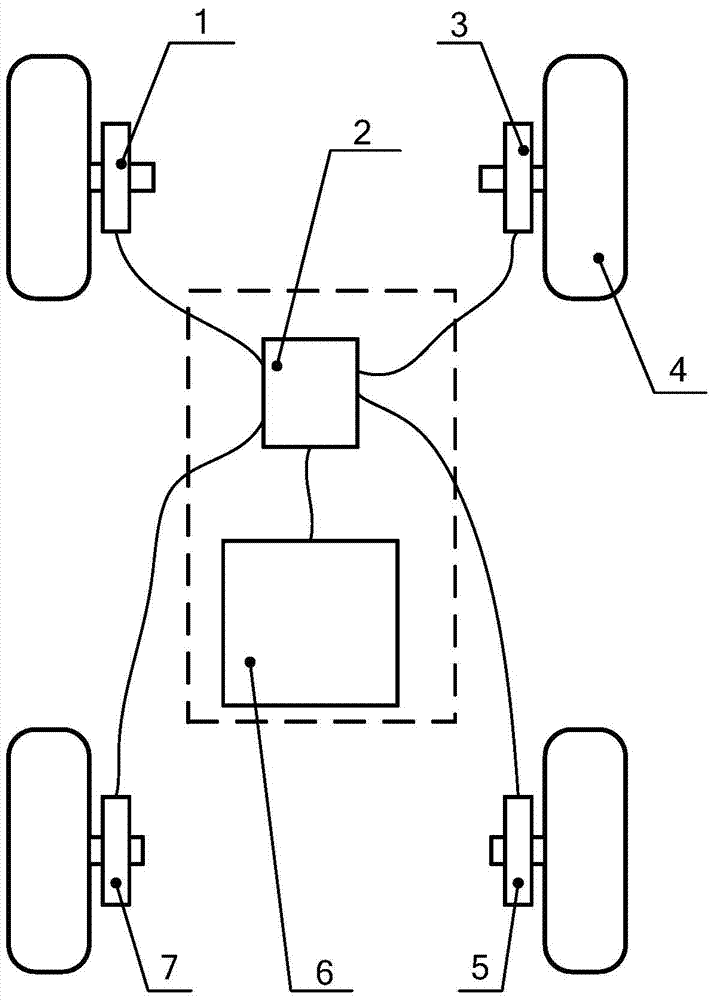

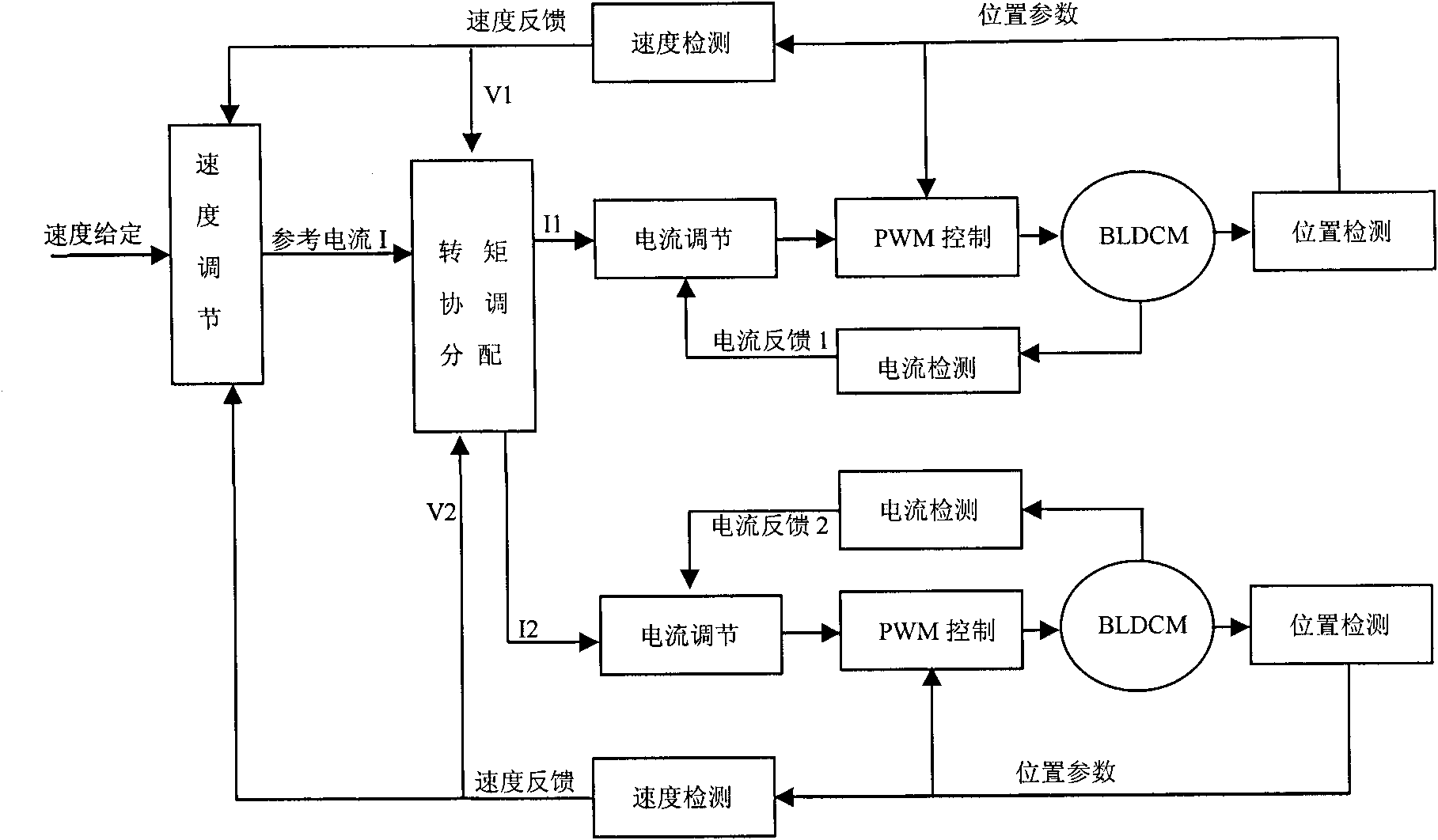

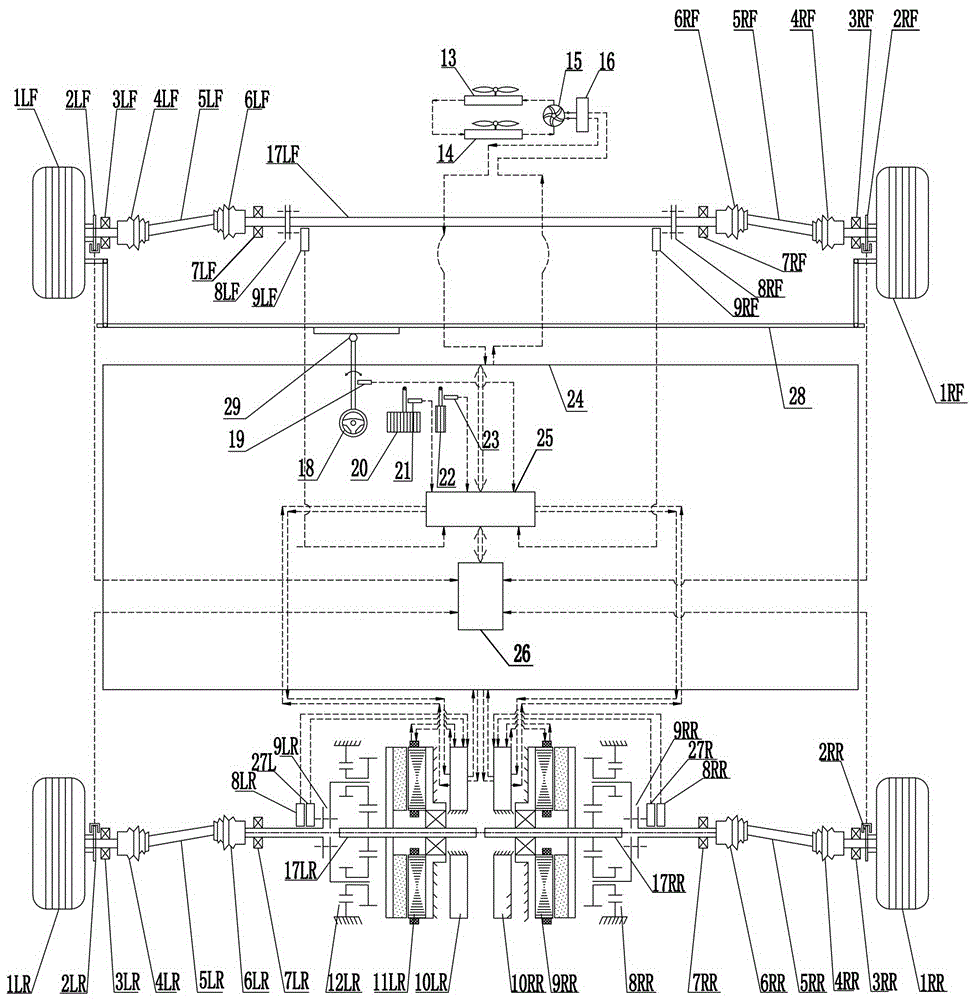

Test prototype automobile of electric wheel driving automobile and driving stability control method

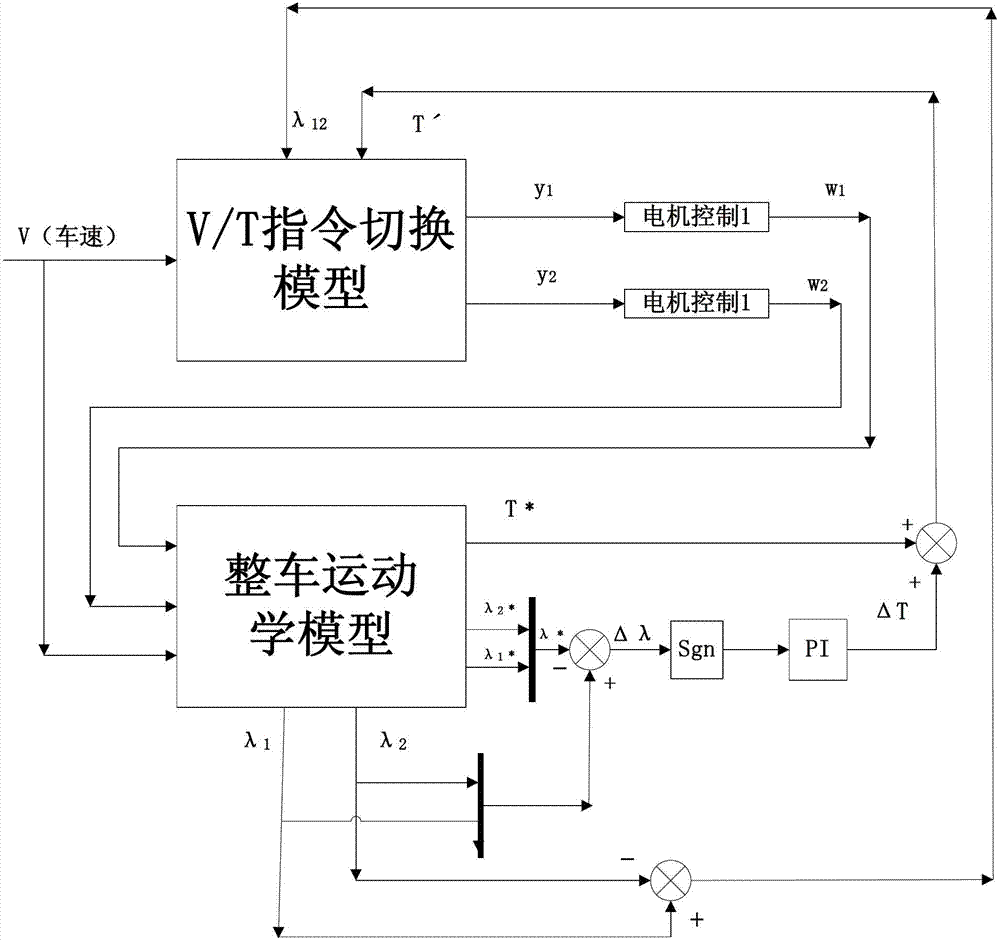

InactiveCN106183892ASimple structureImprove scalabilitySpeed controllerDriver input parametersGyroscopeCar driving

The invention discloses a test prototype automobile of an electric wheel driving automobile and a driving stability control method. The test prototype automobile of the electric wheel driving automobile comprises an automobile body, a steering wheel, an independent suspension and an electric wheel assembly. A wheel speed sensor, a steering wheel rotation angle sensor, a gyroscope and a control system are arranged on the automobile body. The control system comprises a sensor signal processor, a road surface state evaluator, a CAN bus, an electronic differential controller, a yawing moment controller, a driving skid-resistance controller, a torque coordinating distributor and an automobile driving state evaluation system. The driving stability control method comprises the following steps that (A) the automobile driving state is calculated and judged; (B) driving skid-resistance control is conducted; (C) electronic differential control is conducted; and (D) yawing moment control is conducted. By the adoption of the test prototype automobile of the electric wheel driving automobile and the driving stability control method, four-wheel independent driving and independent steering can be achieved, and various control methods of the electric wheel driving automobile can be verified through the test prototype automobile.

Owner:CHONGQING UNIV OF TECH

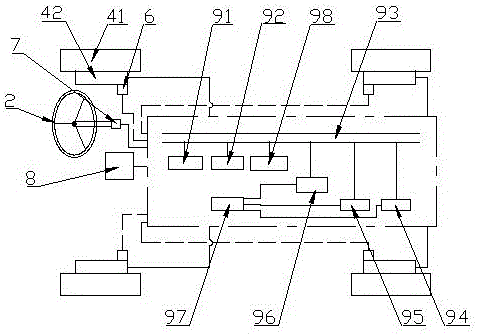

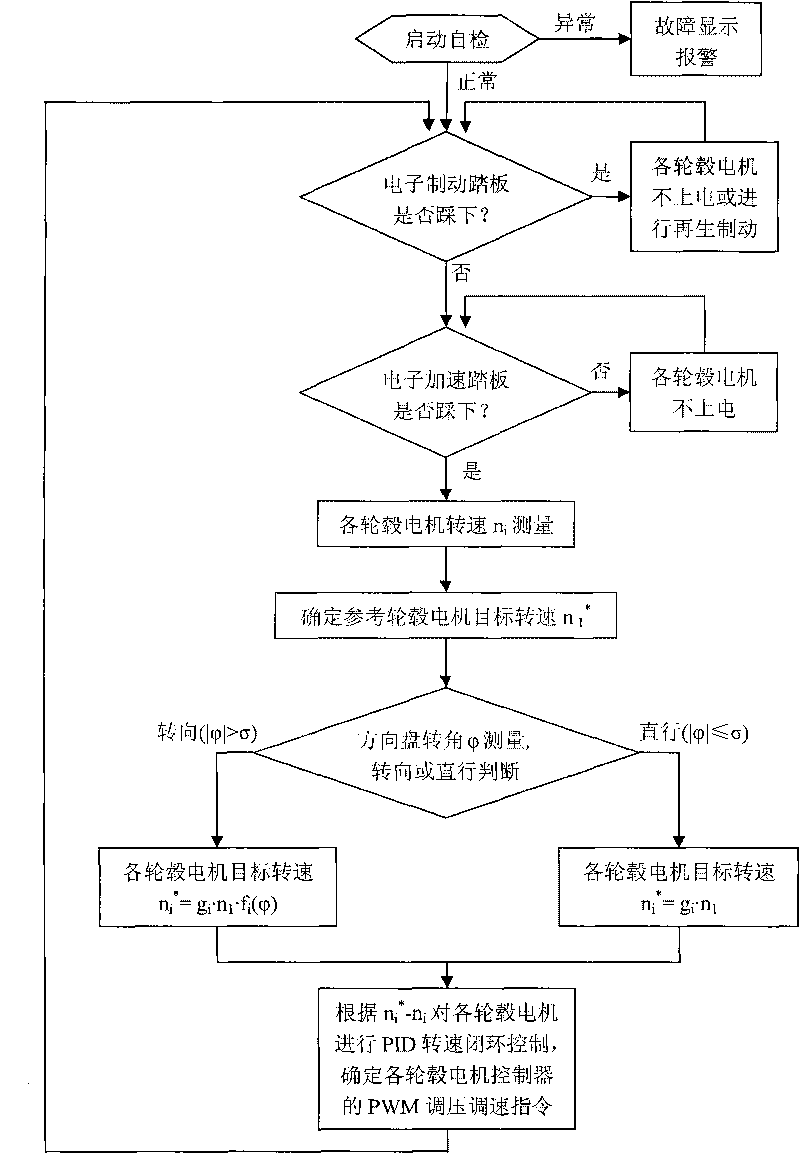

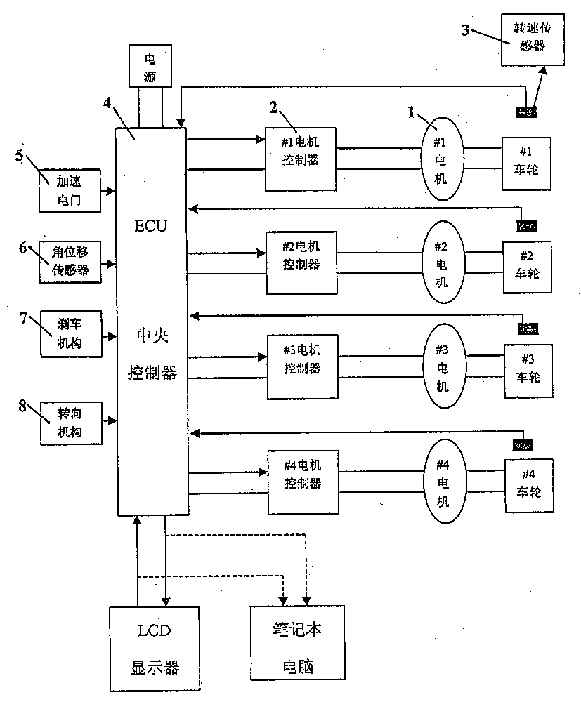

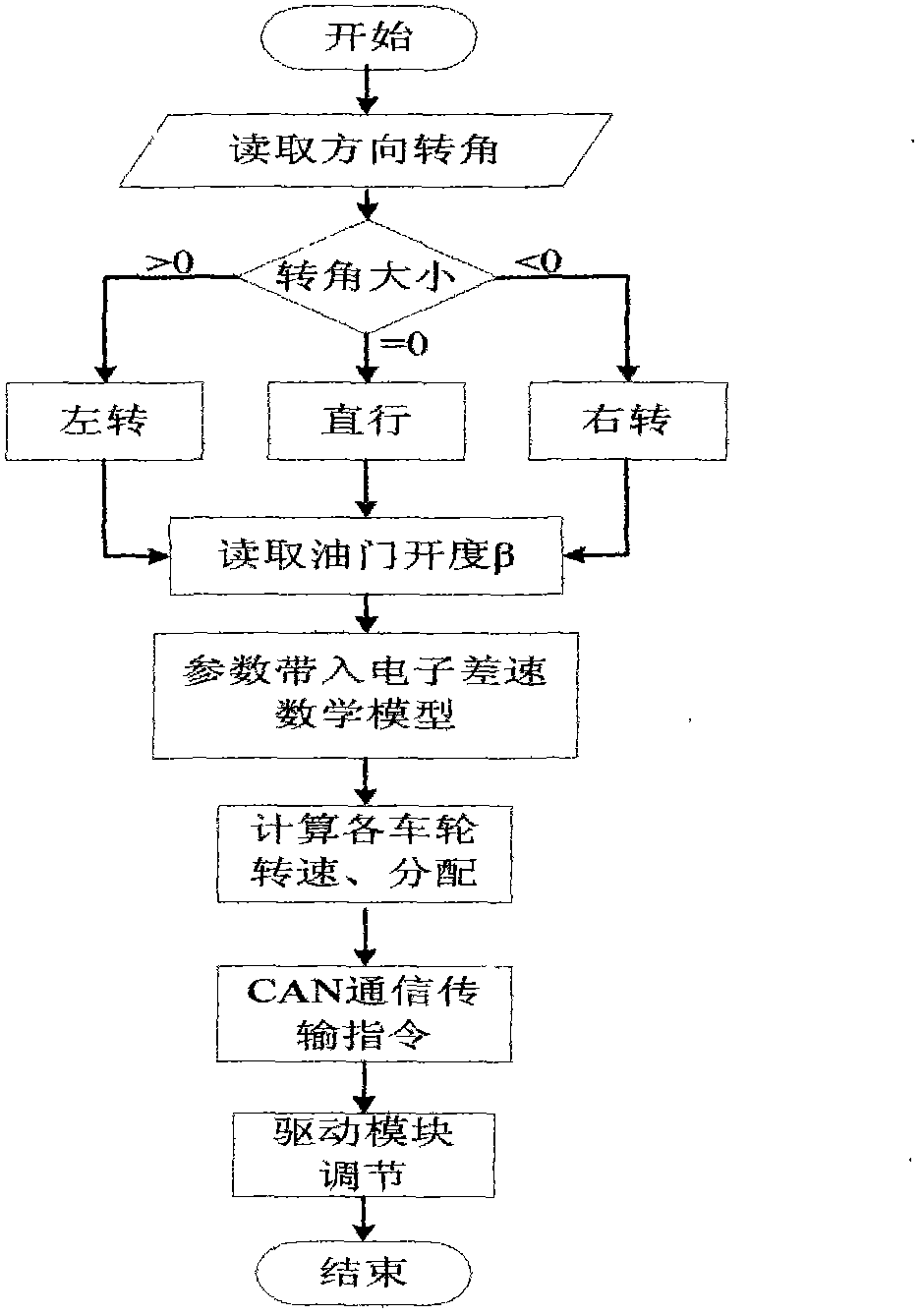

Electronic speed differential control system of an electric wheel drive vehicle

ActiveCN101758854AReasonable differential controlMeet differential requirementsSpeed controllerSteering linkagesElectronic differentialControl system

The invention relates to an electronic speed differential control system of an electric wheel drive vehicle, which comprises a controller, a motor controller of each hub motor, a rotation angle sensor, an electronic accelerating pedal and a rotation speed sensor, wherein the rotation angle sensor is used for measuring the rotation angles of a steering wheel; the electronic accelerating pedal can output opening values; and the rotation speed sensor is used for measuring the actual rotation speed of the hub motor. The signal output ends of the electronic accelerating pedal, the rotation speed sensor and the rotation angle sensor are respectively connected with the signal input ends of the controllers. The controller is communicated and connected with the controller of each hub motor. Each controller comprises a first-stage following control module and a second-stage following control module. The invention can be used for reasonably controlling the electronic differential speed of each driving motor.

Owner:武汉经开科创运营有限公司

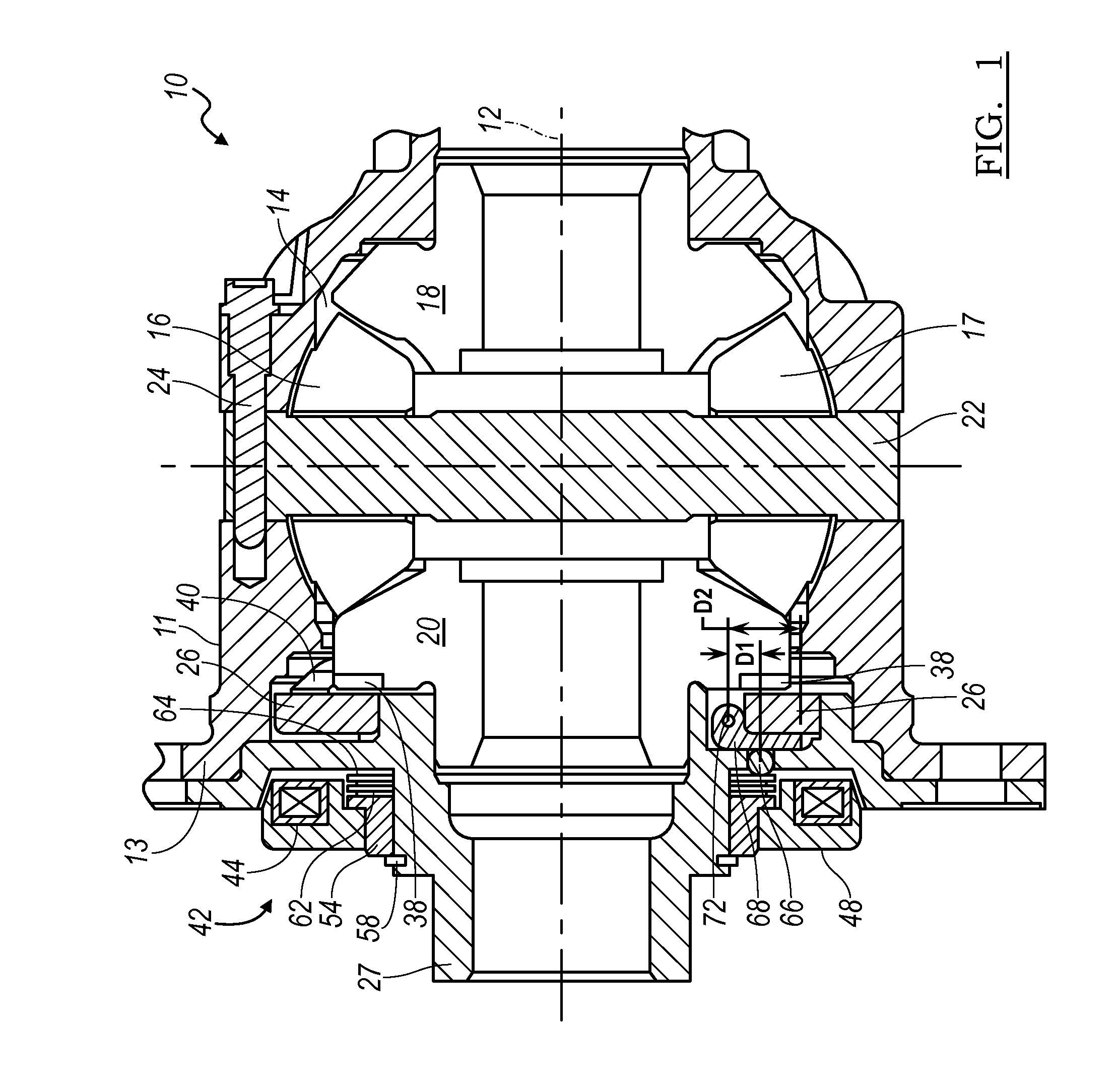

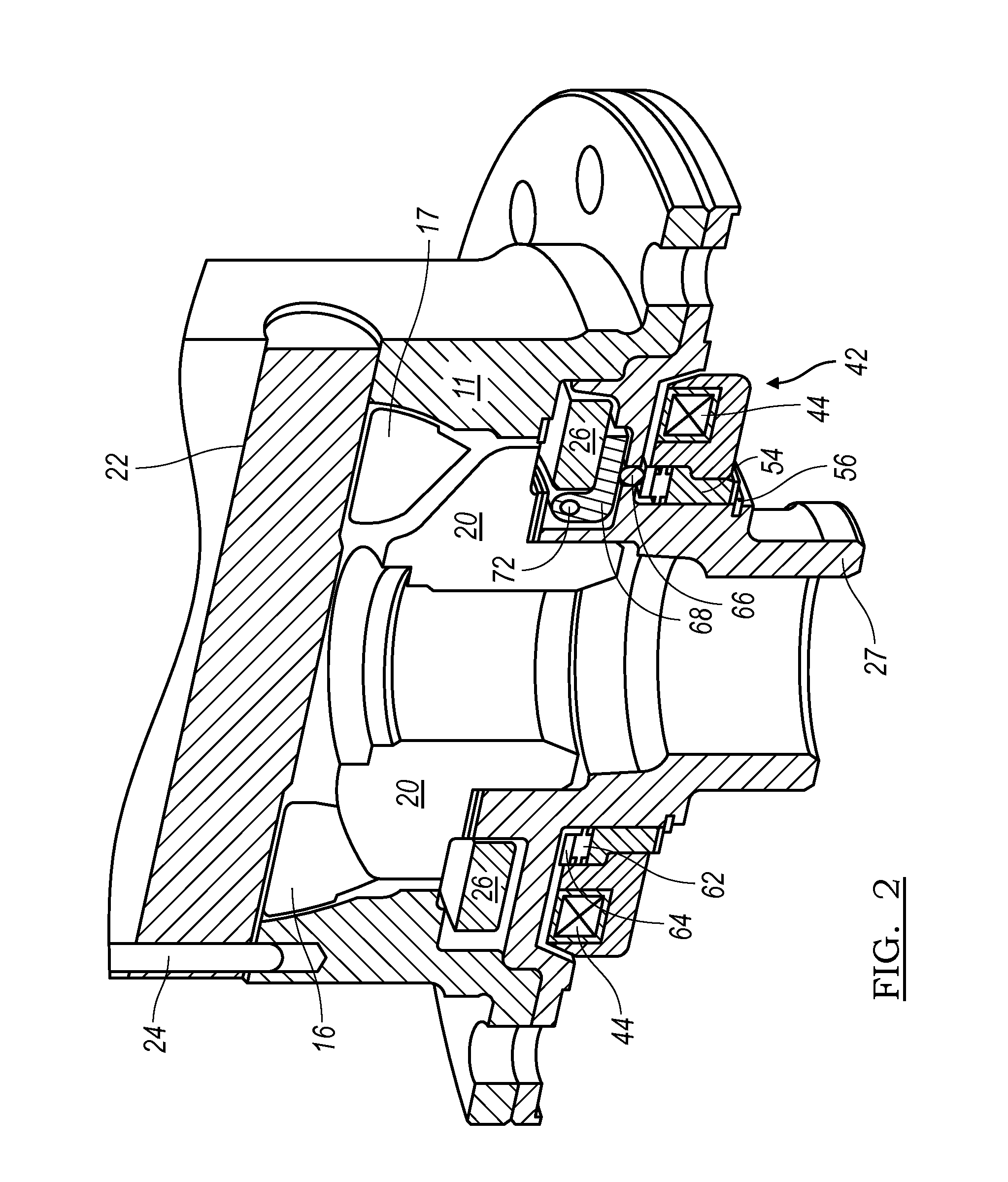

Electronic Locking Differential

InactiveUS20120021862A1Low costReduce weightMechanical actuated clutchesMagnetically actuated clutchesElectronic differentialMechanical engineering

A differential mechanism includes a case, a gear rotatable about an axis, a lock ring held against rotation relative to the case, a lever contacting the lock ring, and an electromagnetic coil that is displaced axially when energized, pivoting the lever, engaging the lock ring with the side gear, and preventing the gear from rotating relative to the case.

Owner:FORD GLOBAL TECH LLC

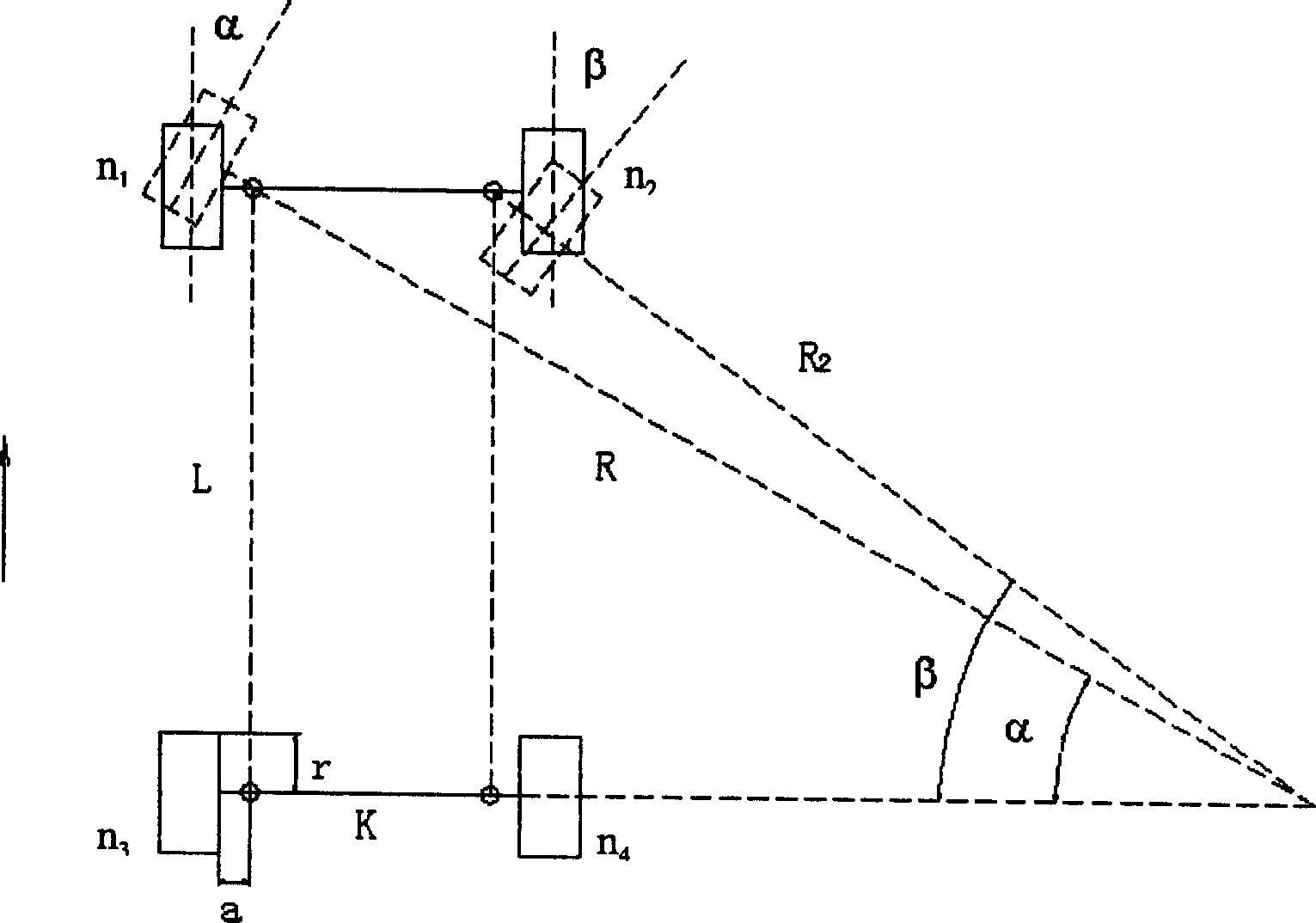

Four wheel electronic differential speed steering control system

InactiveCN1475390AExtended service lifeReduce frictionSteering linkagesAutomatic steering controlElectronic differentialControl system

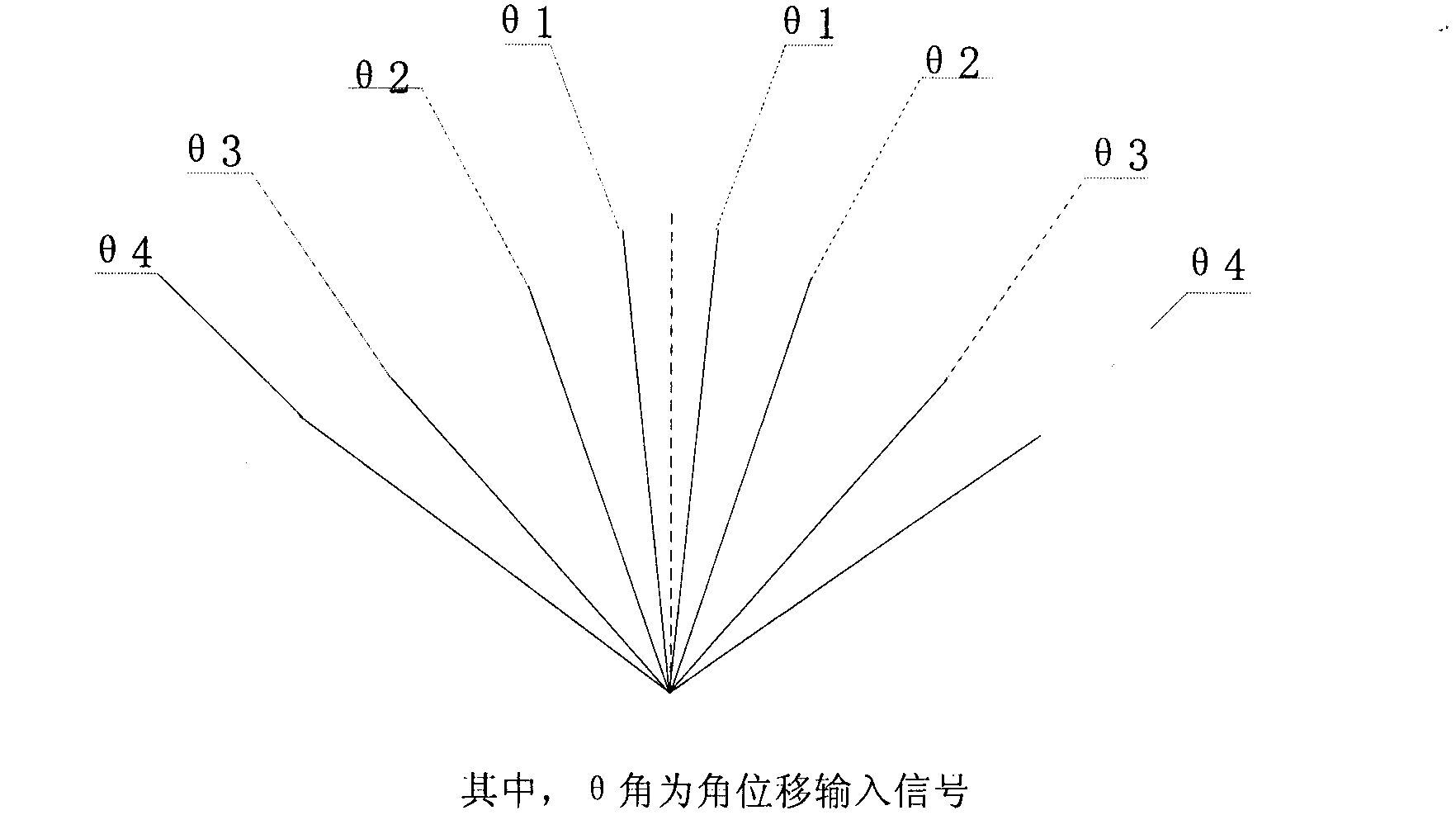

An electronic differential steering control system for 4 wheels is composed of motors, steering mechanism, braking unit, accelerating switch, motor conrollers, angle displacement sensors, rotation speed sensors, and CPU which can acquire all signals, calculating the target rotation speed of each wheel, and issuring relative instruction to regulate the rotation speed of each wheel. It can ensure the pure rolling between wheel and ground to decrease friction and elongate service life of each part.

Owner:同济大学新能源汽车工程中心 +1

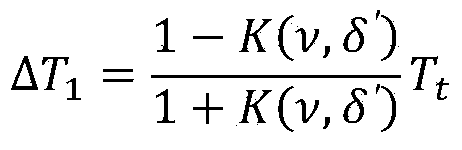

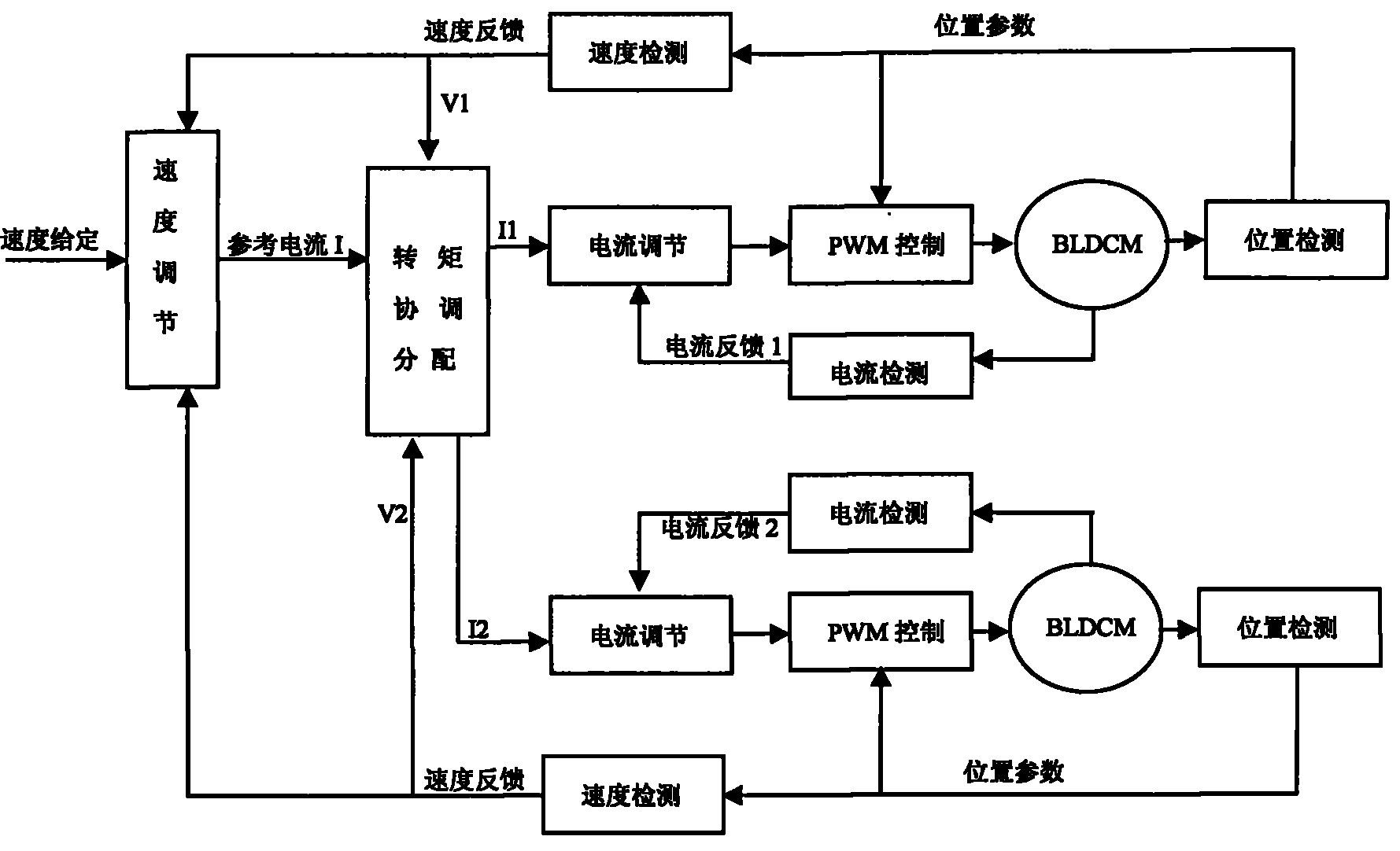

Rear wheel independent drive control system and method for electric automobile

ActiveCN103879307AImprove handling stabilityGood driving economySpeed controllerElectric vehicle charging technologyControl systemElectronic differential

The invention discloses a rear wheel independent drive control system and method for an electric automobile. The system comprises a steering wheel rotation angle sensor, a yaw velocity sensor, an electronic accelerator pedal, a whole automobile drive controller, a CAN communication network, a rear right hub motor, a rear right hub motor controller, a rear left hub motor controller and a rear left hub motor. The whole automobile drive controller is connected with the steering wheel rotation angle sensor, the yaw velocity sensor, the electronic accelerator pedal, the rear right hub motor controller and the rear left hub motor controller through the CAN communication network. The rear right hub motor controller is connected with the rear right hub motor. The rear left hub motor controller is connected with the rear left hub motor. Electronic differential and drive skid prevention are combined to conduct comprehensive control, the novel integrated drive control method which integrates electronic differential, drive skid prevention and torque coordination control is put forward, operation stability and driving safety are improved when the electric automobile driven by rear wheels independently is under various actual complex working conditions.

Owner:天津天海轮毂电机科技有限公司

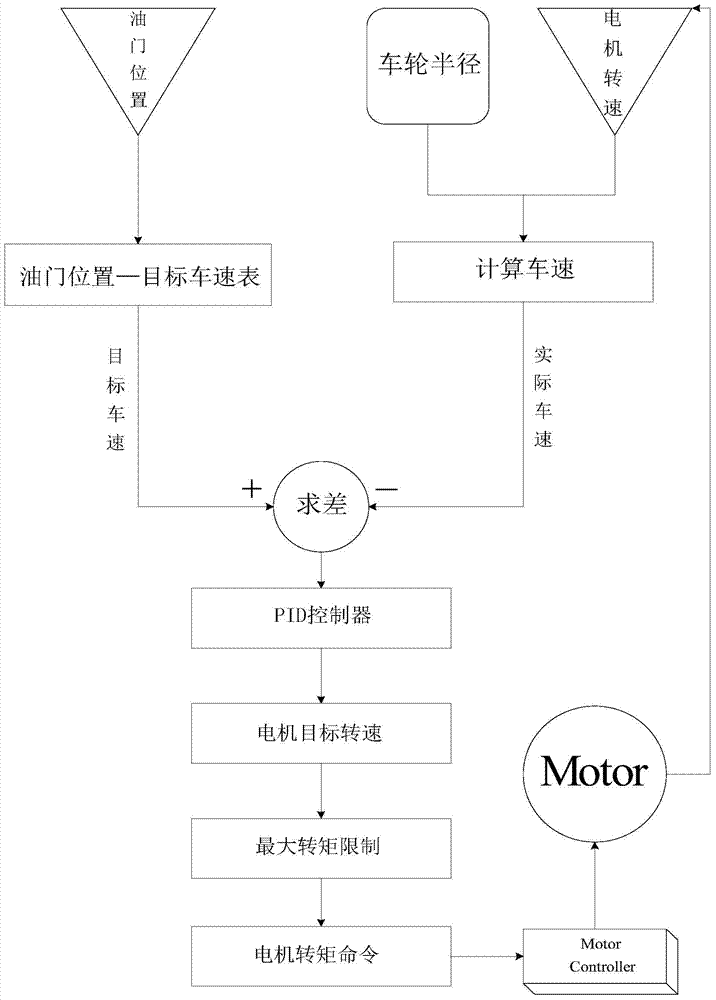

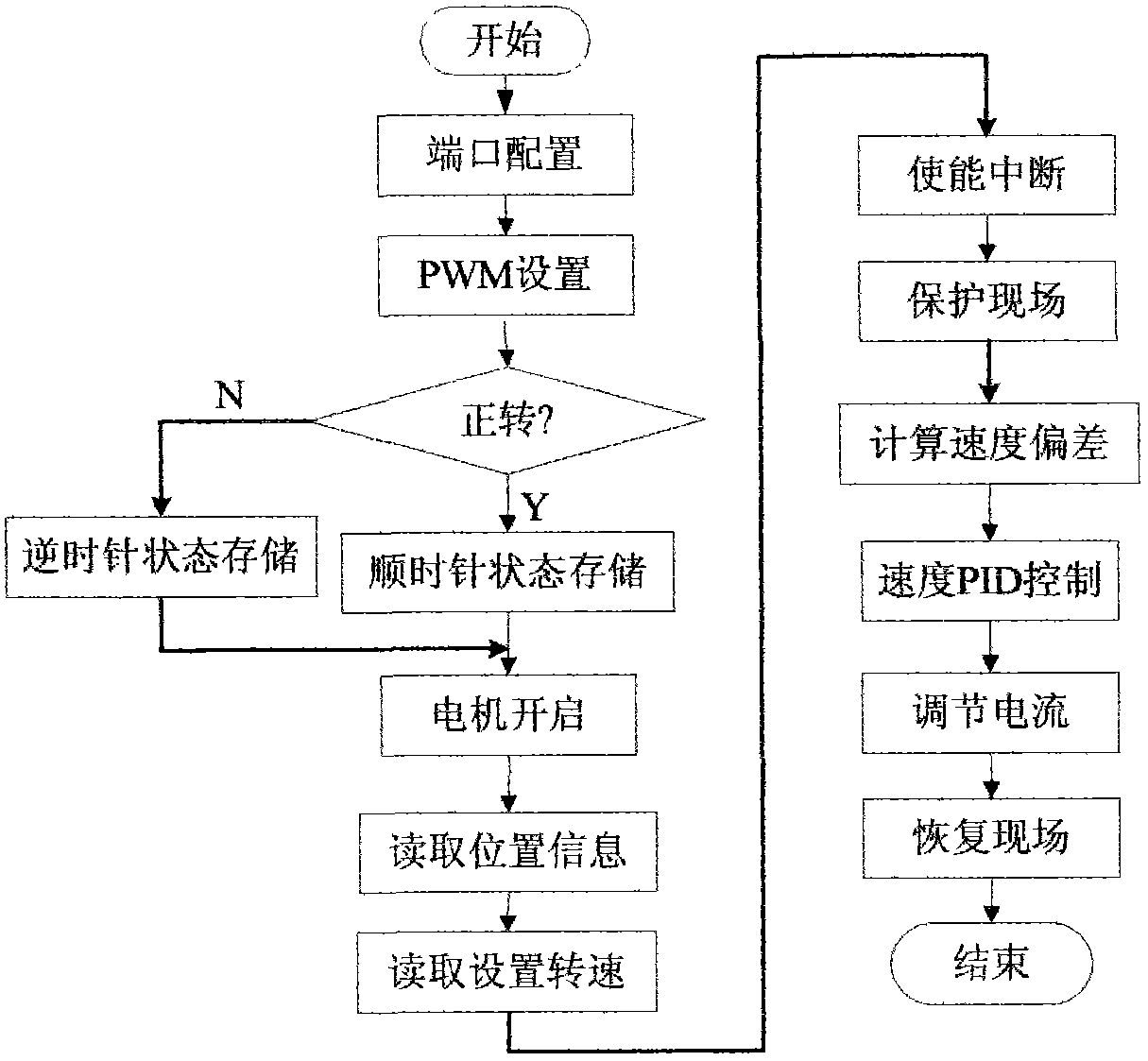

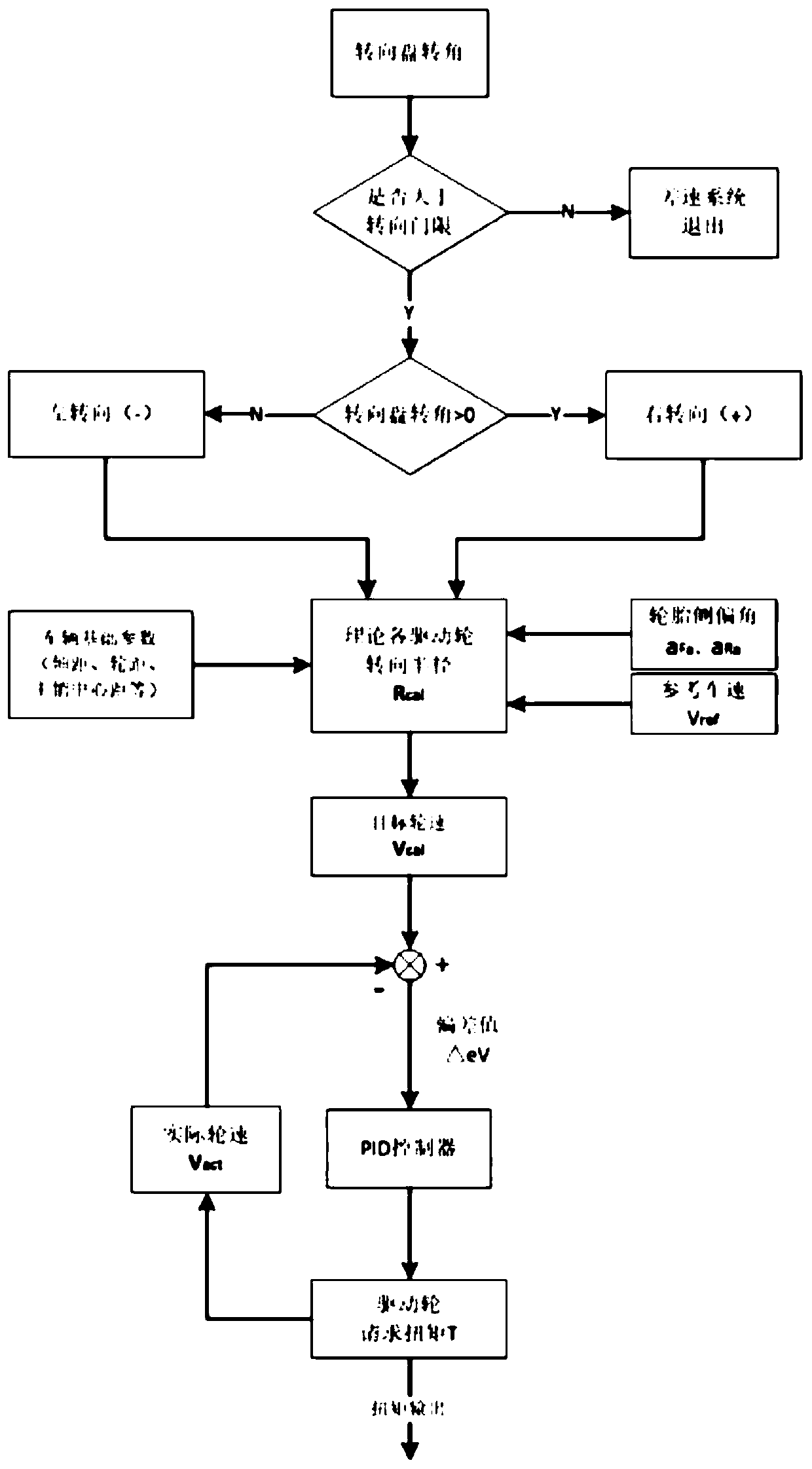

Vehicle speed control method for wheel hub motor-driven vehicle

ActiveCN104228609ARealize adaptive differential functionPowerfulSpeed controllerVehicle fittingsMotor driveWheel speed sensor

The invention relates to a vehicle speed control method for a wheel hub motor-driven vehicle, and belongs to the technical field of automobiles. An input end is arranged in a finished automobile controller and is connected with a position sensor of a vehicle accelerator pedal via signals, is connected with a wheel speed sensor via signals, or is replaced with a motor rotating speed signal which is fed back by a motor controller; and a vehicle speed control module is arranged inside the finished automobile controller. The module calculates an actual vehicle speed by using the speed of four wheels, then calculates the difference value between the actual vehicle speed and the target vehicle speed, and inputs the difference value into a PID controller; the PID controller outputs target torque of a drive motor, thus, the output torque and the rotating speed of the motor are controlled by the accelerator pedal, and the drive motor is controlled in a power control manner. The finished automobile controller also estimates the road resistance when the vehicle moves at a constant speed according to the finished automobile parameter, so as to ensure that the vehicle runs at the constant speed when reaching the target vehicle speed. According to the method, the electronic differential function of the wheel hub motor-driven vehicle is achieved in a relatively simple manner.

Owner:JILIN UNIV

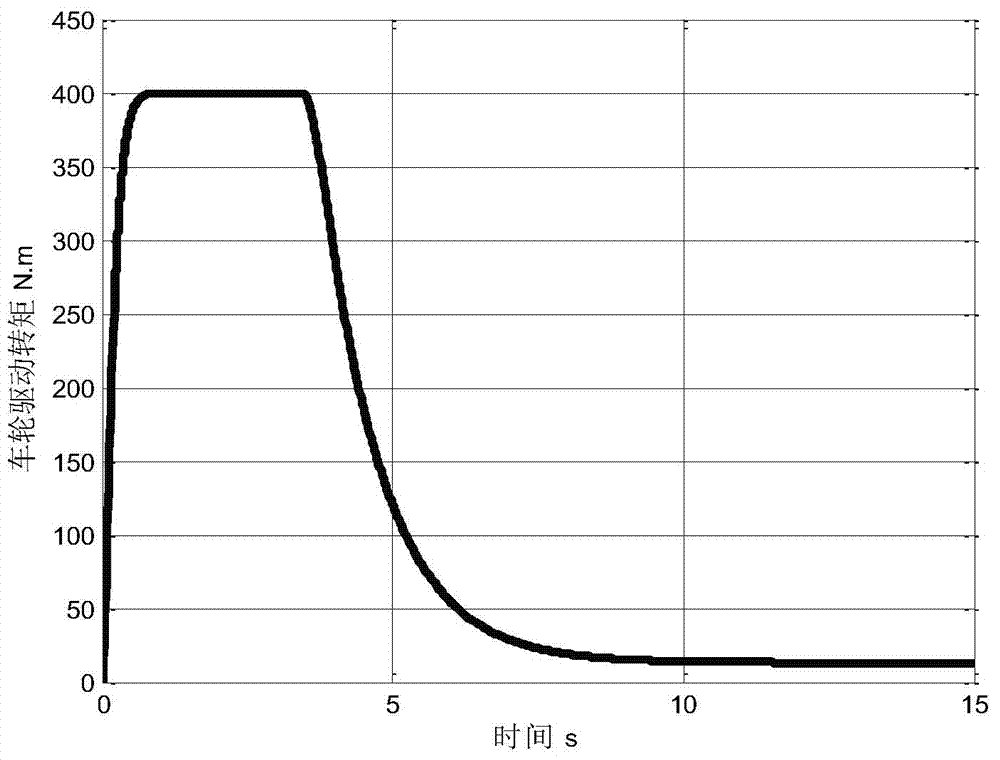

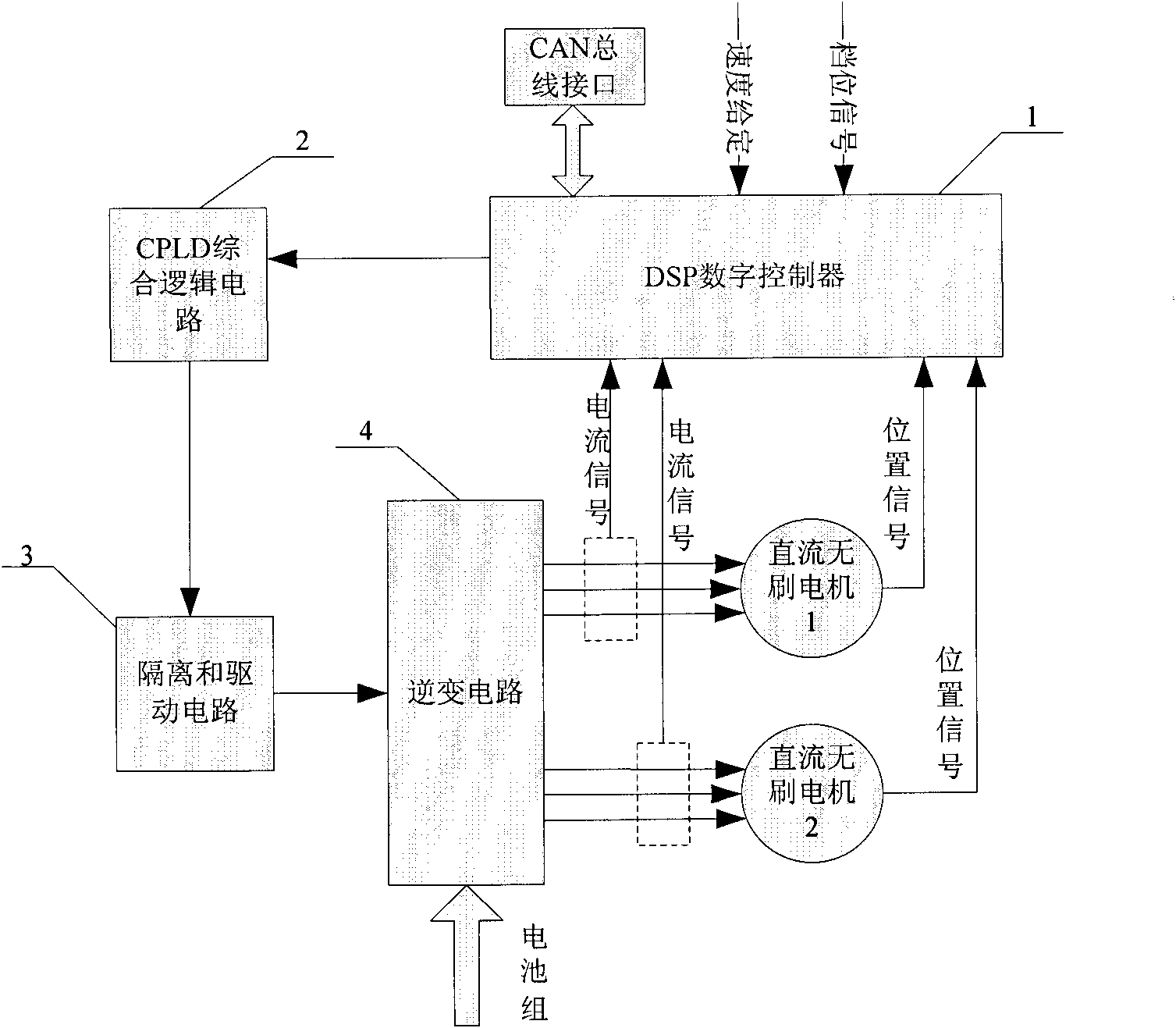

Drive control system of double motors of rear axle of electric automobile

InactiveCN101814876AThe role of control transition slipReduce lossMultiple dc dynamo-electric motors controlMultiple dynamo-electric motors speed regulationDrive wheelDriver/operator

The invention relates to a drive control system of double motors of a rear axle of an electric automobile. To the closed-loop control of the average speed of double motors in the control system, a single driving wheel adopts a method of given torque control and speed follow-up to carry out the closed-loop control of the average speed of double motors, so that the automobile can run according to the target automobile speed of a driver, the rotational speeds of double motors are also permitted to be inconsistent under the condition of different loads, and the self-adapting differential performance of the turning of the low-speed running of the electric automobile is realized. By designing in this way, the differential control requirement of the curve running of a low-speed electric automobile is met, the use of a complicated electronic differential algorithm is avoided, and the cost of the system is lowered. By utilizing the self-adapting differential performance during turning, the torque distribution of double motors is further regulated according to the difference of the rotational speeds of double motors, the power-assisted steering of the curve running of the automobile is realized, the energy loss is decreased, and the effect of energy saving is achieved.

Owner:SHANDONG DEYANG ELECTRONICS TECH CO LTD

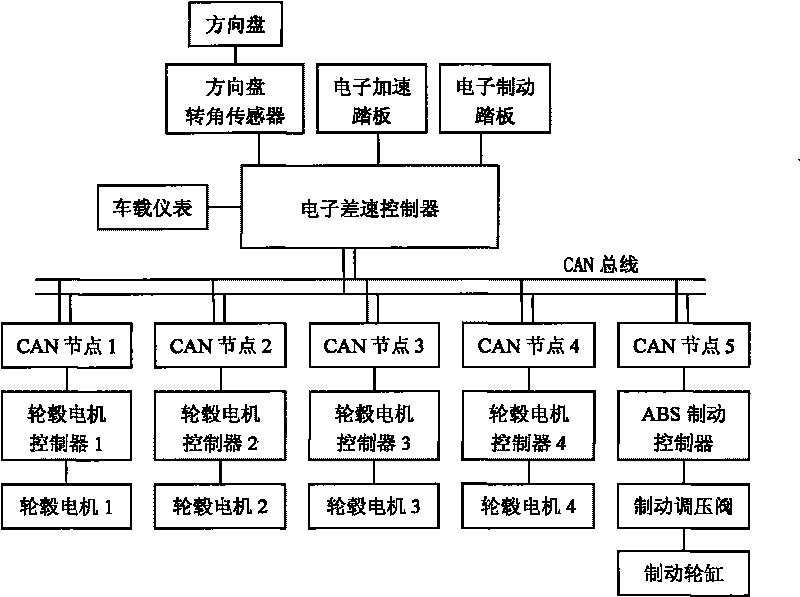

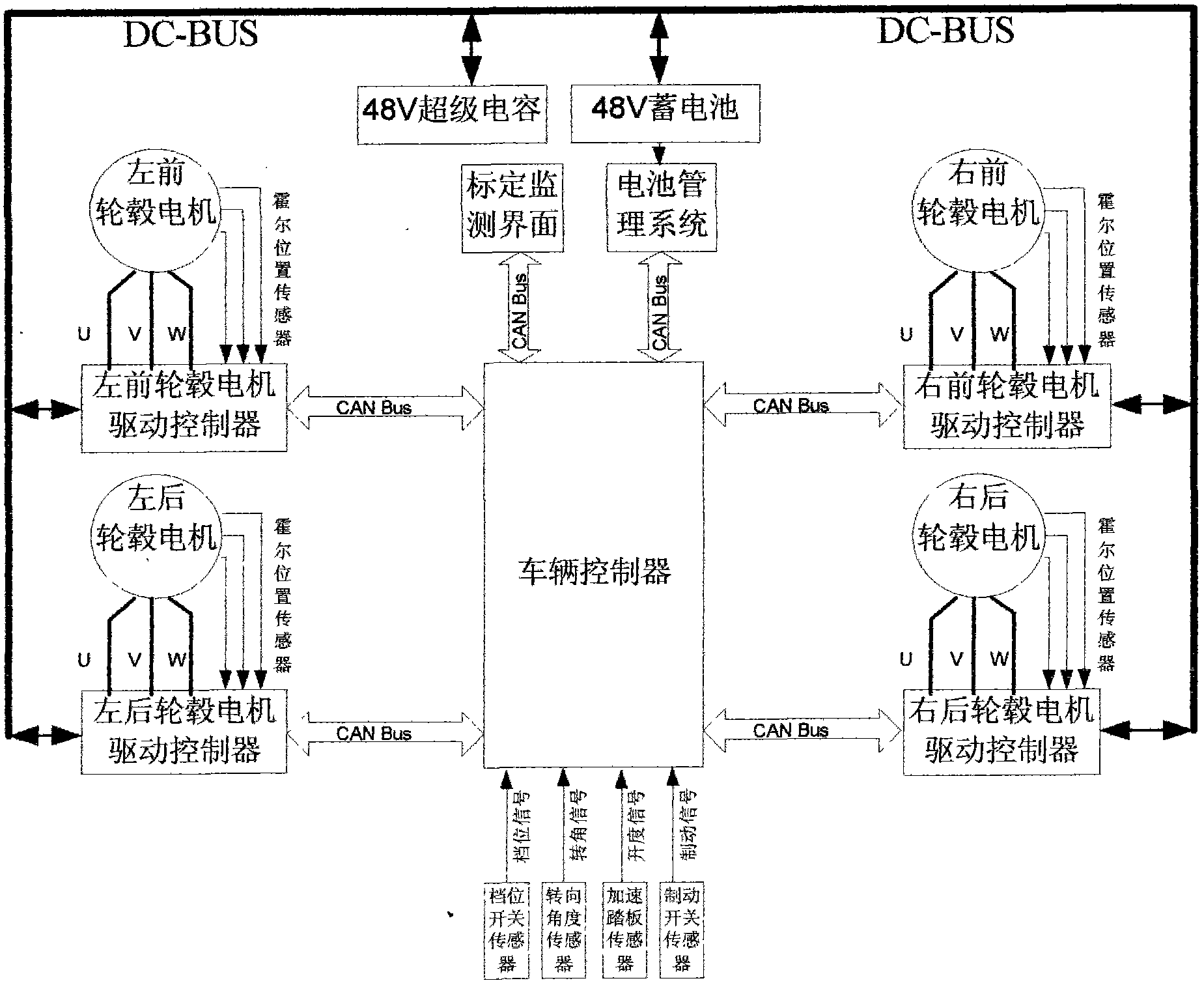

CAN (controller area network) bus-based driving-driven distribution type control system of electric vehicle driven by hub motors

InactiveCN103481798AEffective controlSpeed controllerElectric vehicle charging technologyArea networkSteering angle

The invention relates to a CAN (controller area network) bus-based driving-driven distribution type controlled four-wheel-drive electric vehicle control system. A vehicle controller and four hub motor drive controllers form a driving-driven distribution type control system, the vehicle controller receives a control command of a driver to carry out differential computation of operation of the vehicle and sends the rotation speed, obtained through the computation, of each wheel to the hub motor drive controllers, and the hub motor drive controllers control motors to rotate, so that the running or braking energy recovery of the whole vehicle is realized; when the vehicle carries out a steering operation, the vehicle controller utilizes electronic differential control to replace a mechanical differential device of the traditional vehicle according to signals of a steering angle sensor to carry out the regulation on the running speed of each hub motor, so that an expected running state is realized; the CAN bus-based driving-driven distribution type controlled four-wheel-drive electric vehicle control system simplifies the driving structure of the traditional vehicle, has the advantages of light weight of the whole vehicle, flexibility in control, safety, energy-saving and environment friendliness, and is suitable for the control of electric vehicles.

Owner:镇江恒驰科技有限公司

Steering system with coupling of electric drive tracked vehicle steering motor and unilateral drive motor

The invention relates to a steering system with coupling of an electric drive tracked vehicle steering motor and a unilateral drive motor, which is employed to the steering running of bilateral motor drive tracked vehicles. The steering system comprises a mechanical system and an electrical system, wherein the electrical system comprises a power system and a control system. The electronic differential steering mode is used when the power needed by steering is less than the maximum power of the unilateral motor; and the steering is realized by mechanical coupling when the power needed by steering is greater than the maximum power of the unilateral motor. A composite electronic controller controls the separation of the inside electromagnetic clutch and the combination of an outside electromagnetic clutch by a CAN (controller area network) bus, so that the steering motor runs through the outside electromagnetic clutch and an outside planetary coupler orderly, and then is coupled with the power of an outside drive motor by the outside planetary coupler so as to drive the outside driver wheel, so that the power requirement of the steering motor is satisfied.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

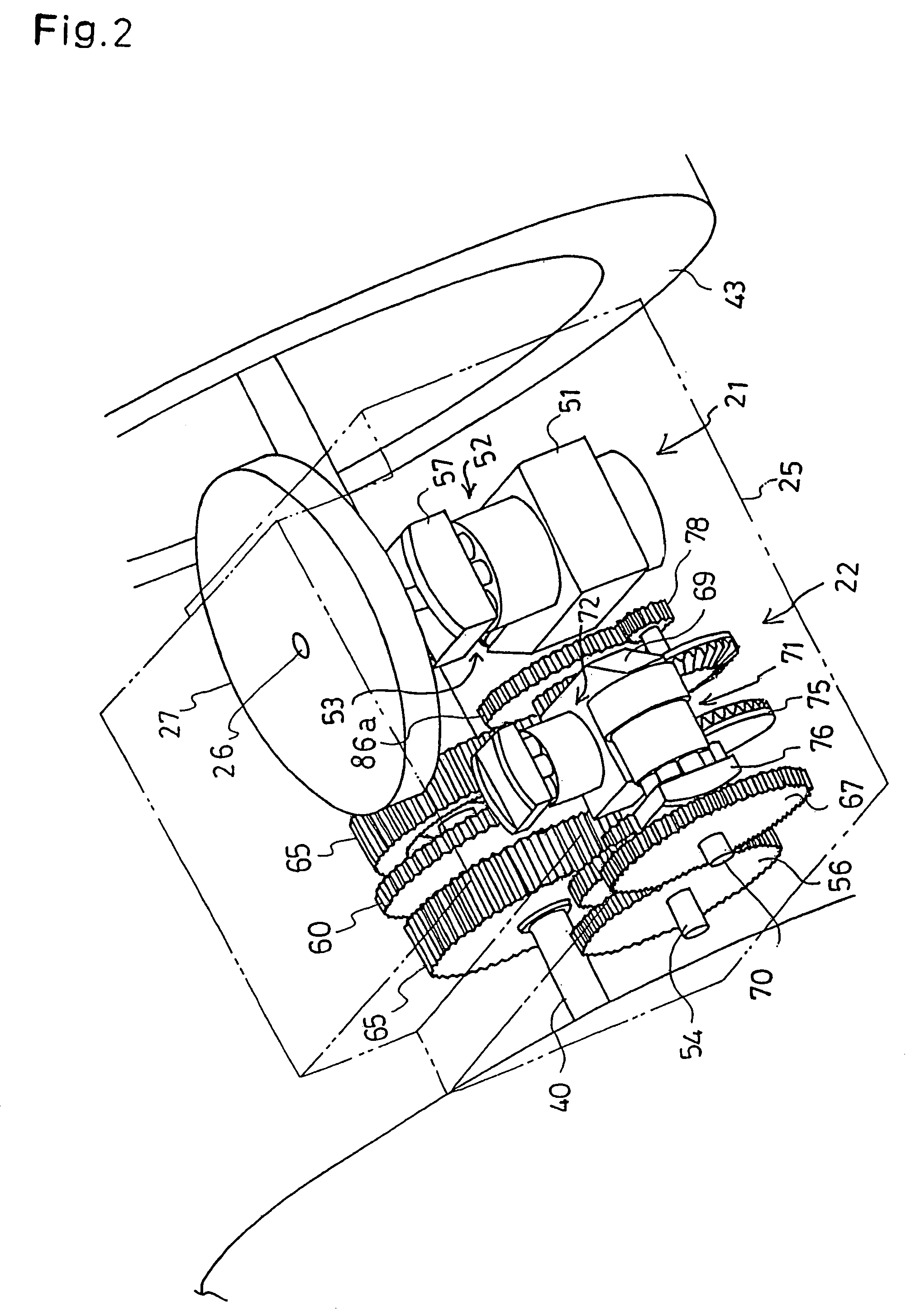

Riding lawn mower

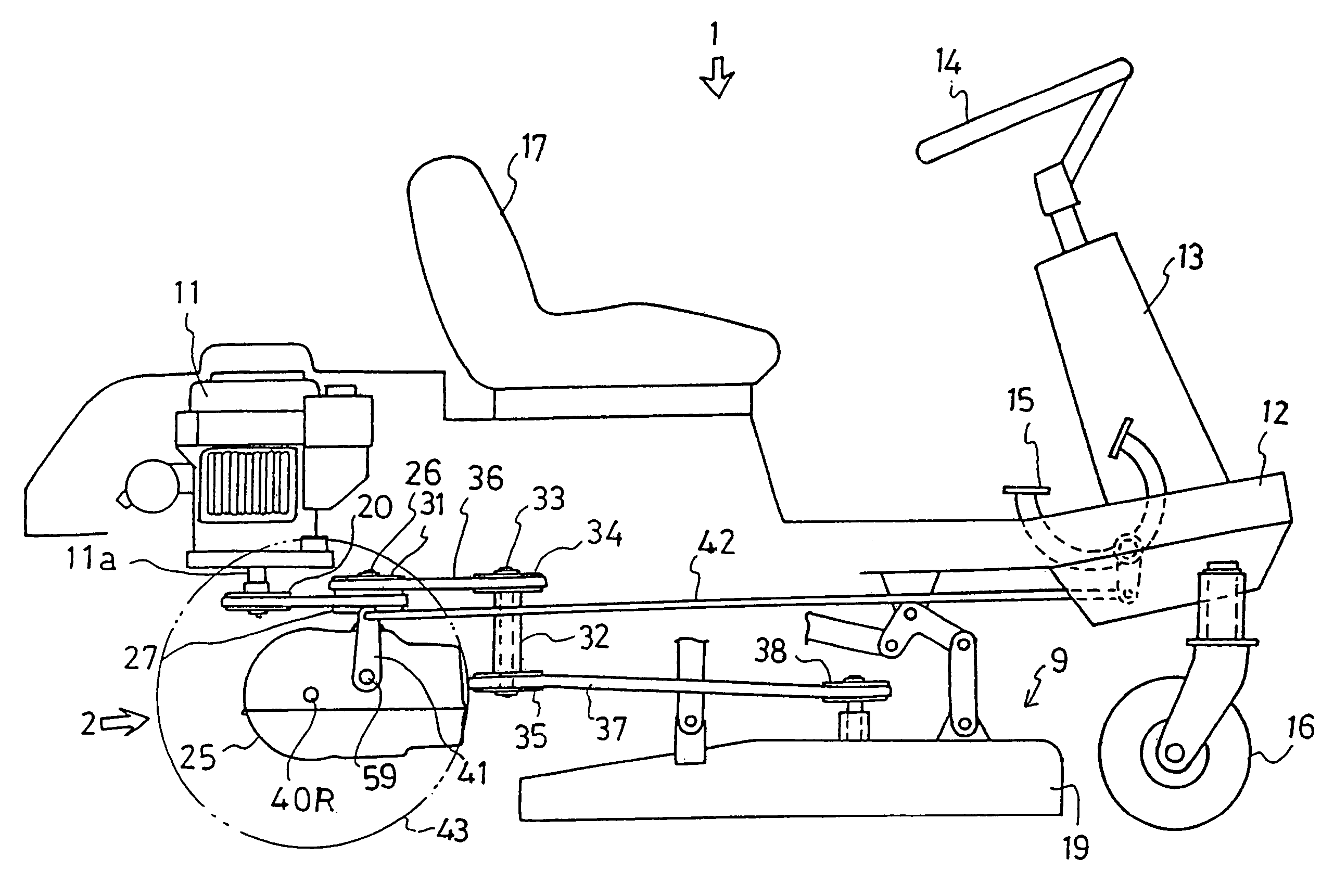

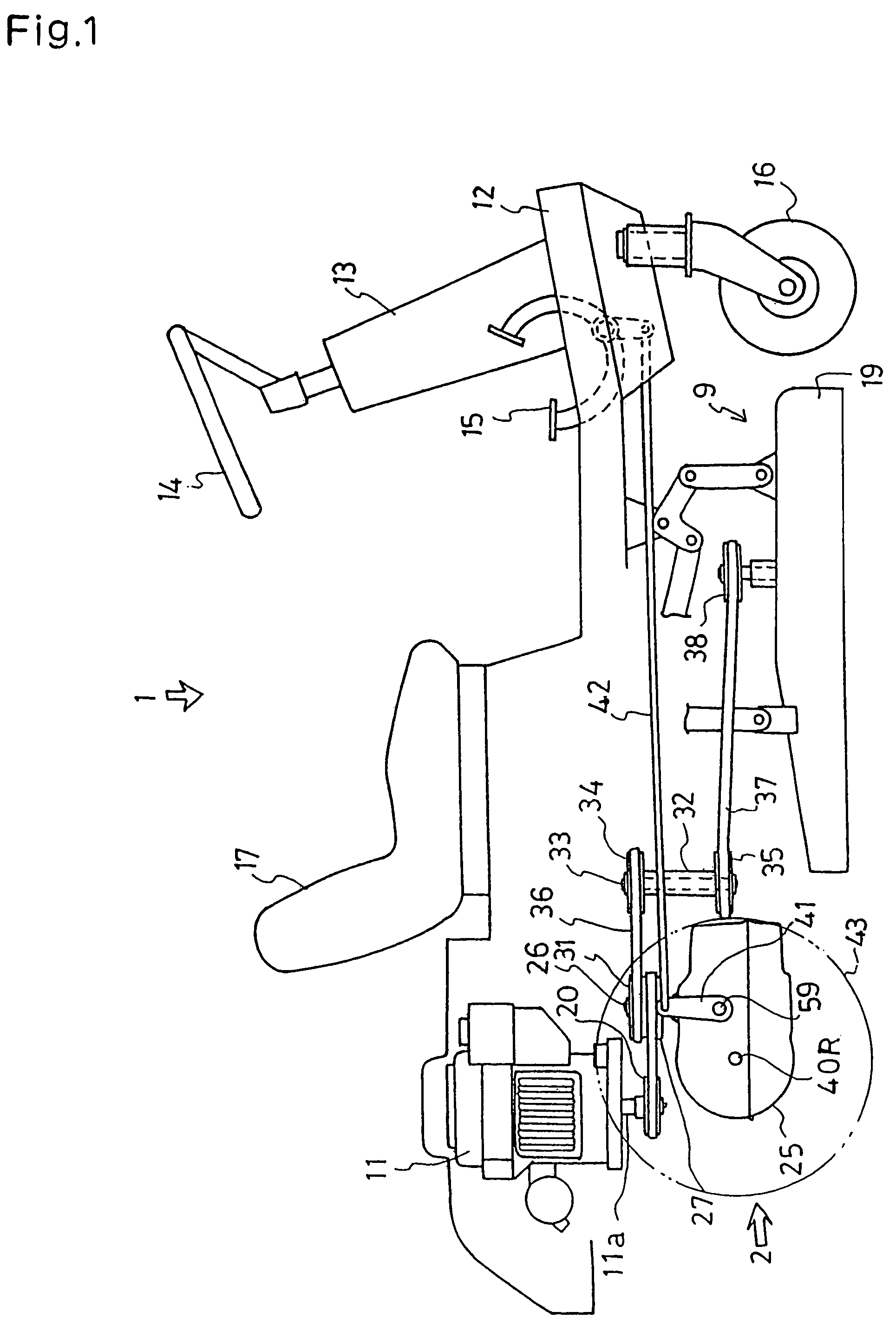

InactiveUS7059433B2Oil circuits thereof can be simplifiedReduce manufacturing costSteering linkagesAutomatic steering controlElectronic differentialHydraulic pump

Owner:HASEGAWA TOSHIYUKI +3

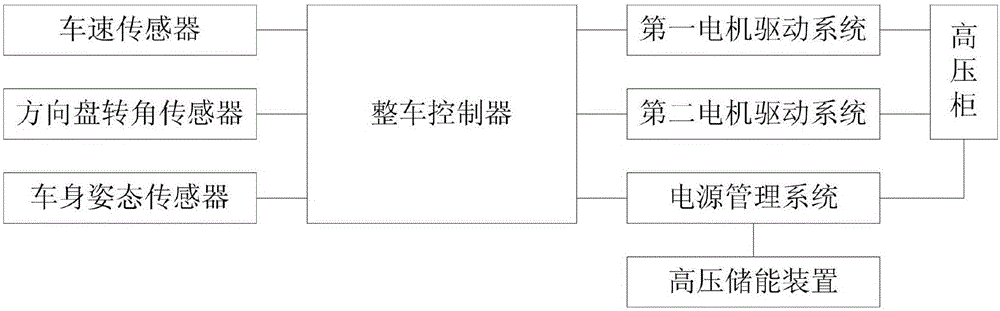

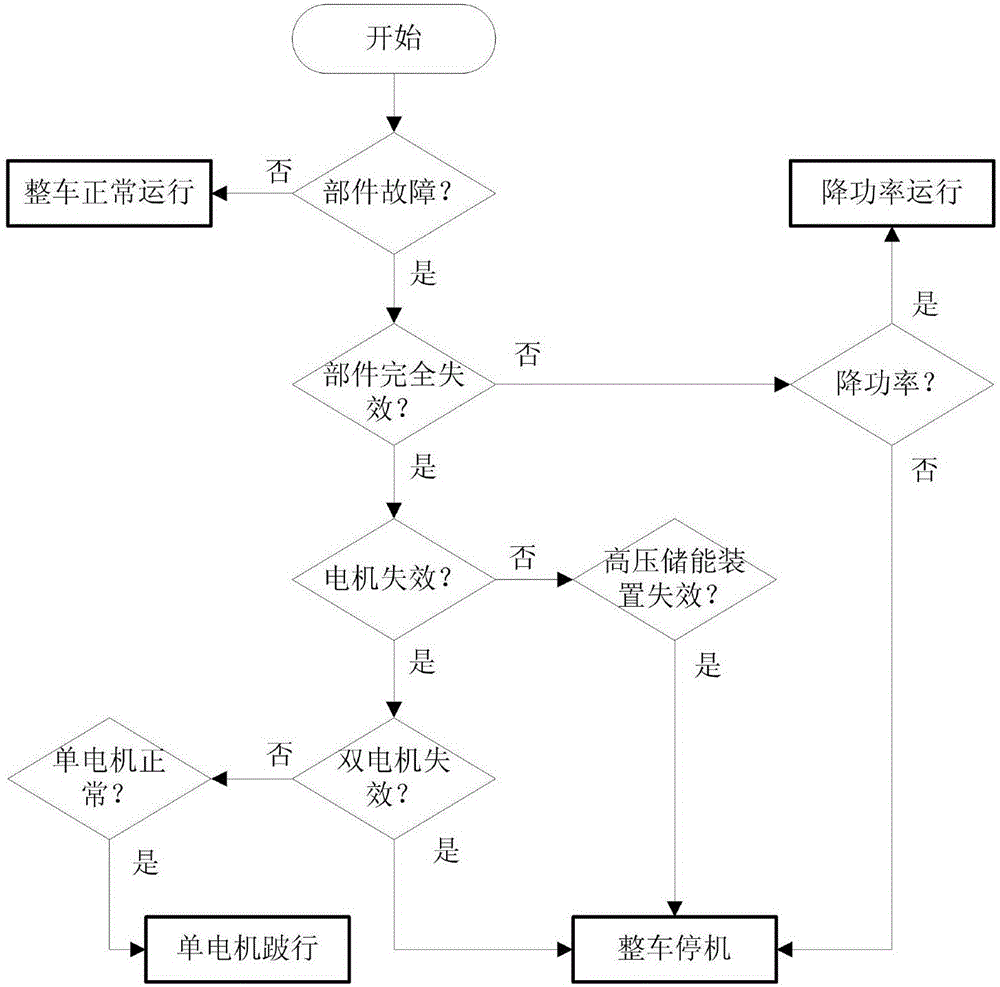

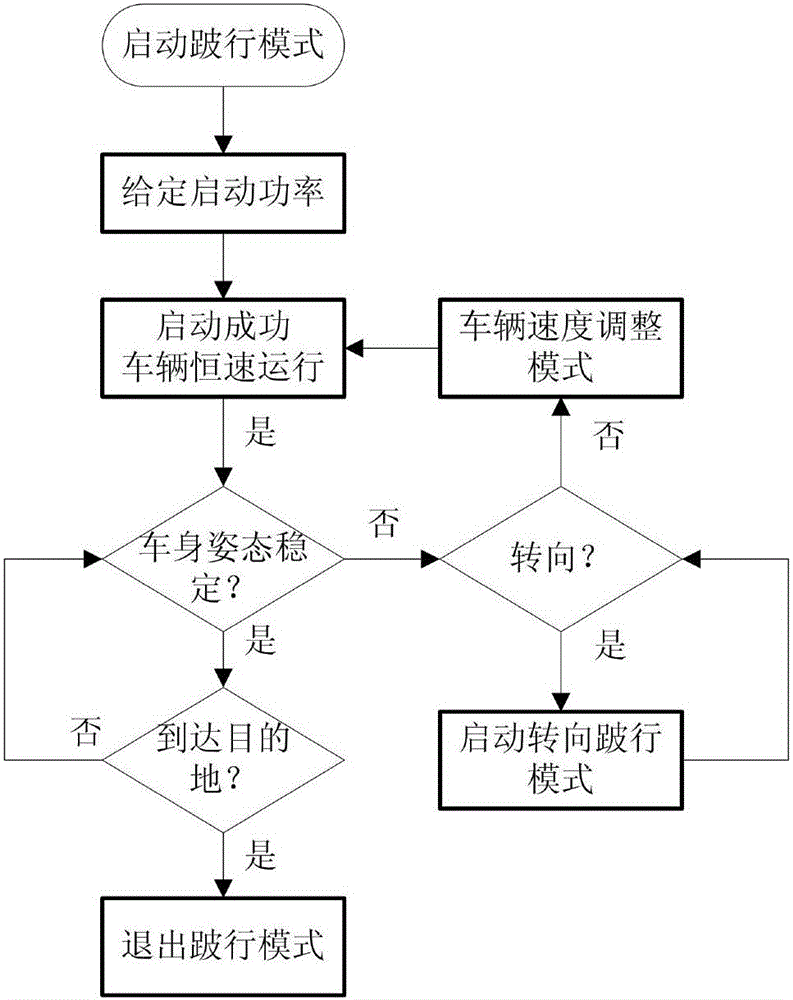

Limp control method and system based on electric car distributed drive system

ActiveCN106740264AGuaranteed running stabilityEnsure safetySpeed controllerElectric energy managementElectric machineElectronic differential

The invention discloses a limp control method and system based on an electric car distributed drive system. The limp control method and system has the advantages that when a single drive motor fails, the output power of the drive motor is controlled on the basis of an electronic differential system necessary to hub (wheel rim) drive operation and a sensor to guarantee the operation stability of a car and achieve a limp function, the car can be timely driven to the nearest maintenance station, road occupation and roadside assistance and trailer costs during the failure are lowered, and car safety is guaranteed while unnecessary troubles are reduced.

Owner:HIGER

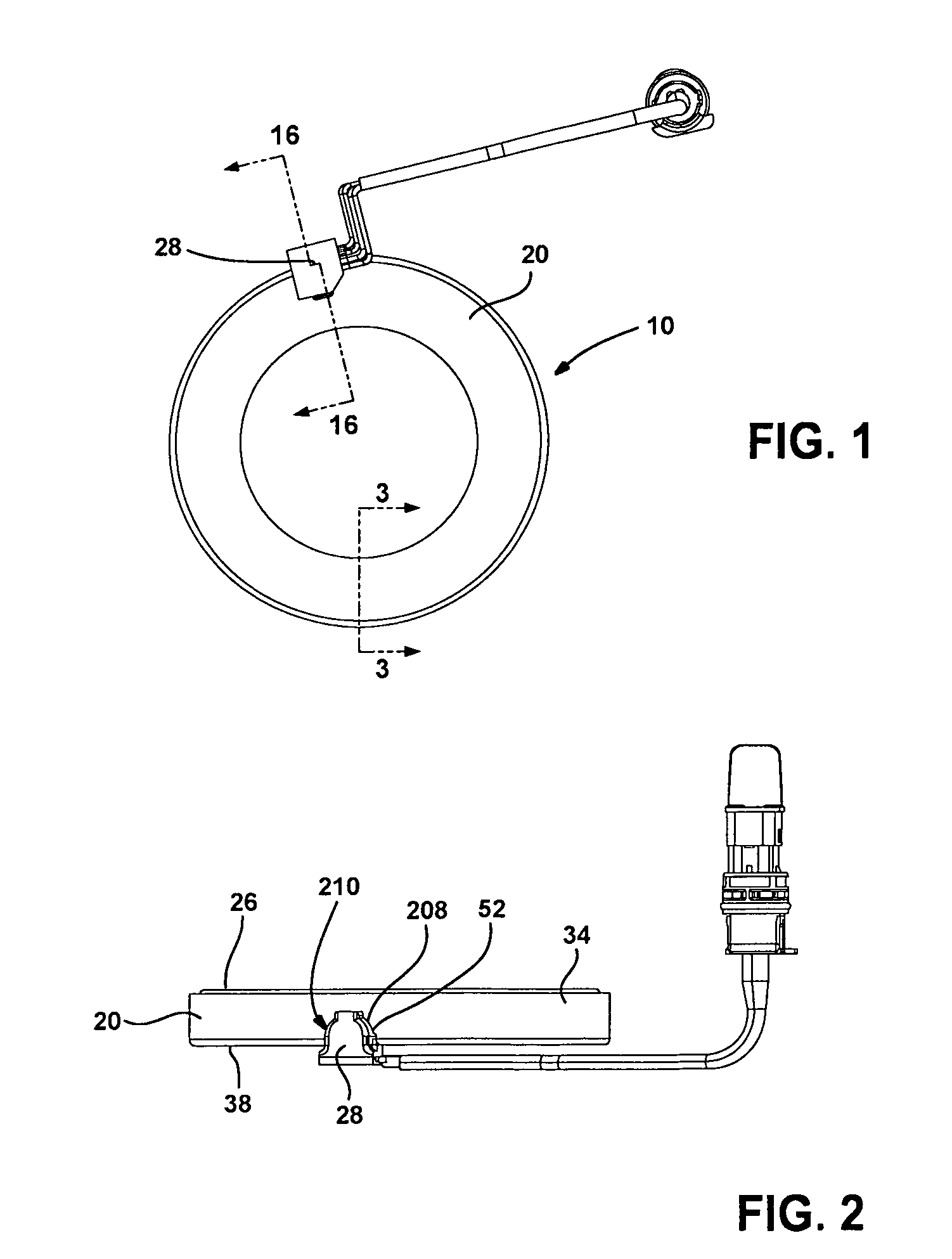

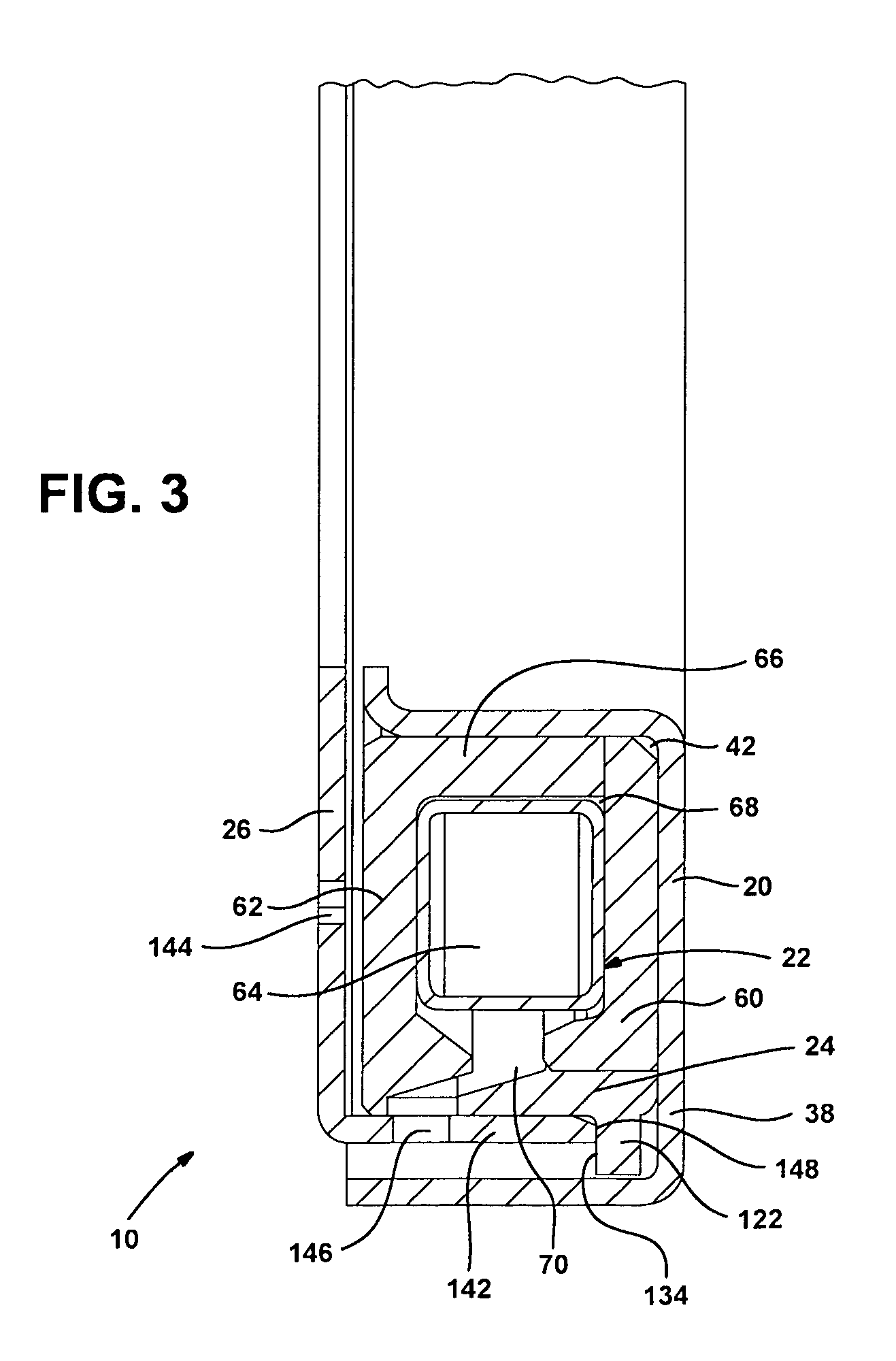

Electronic locking differential with direct locking state detection system

ActiveUS7744500B2Mechanical actuated clutchesMagnetically actuated clutchesLocking mechanismElectronic differential

An axle assembly with an electronic locking differential that employs a locking mechanism having components that are fixed to one another along an axis such that they co-translate with one another when the actuator that effects the locking and unlocking of the differential is operated.

Owner:AMERICAN AXLE & MFG

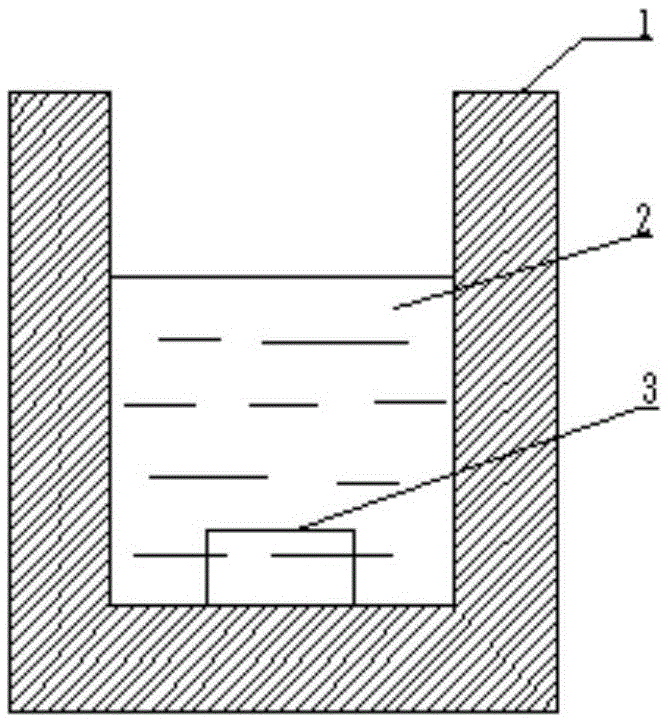

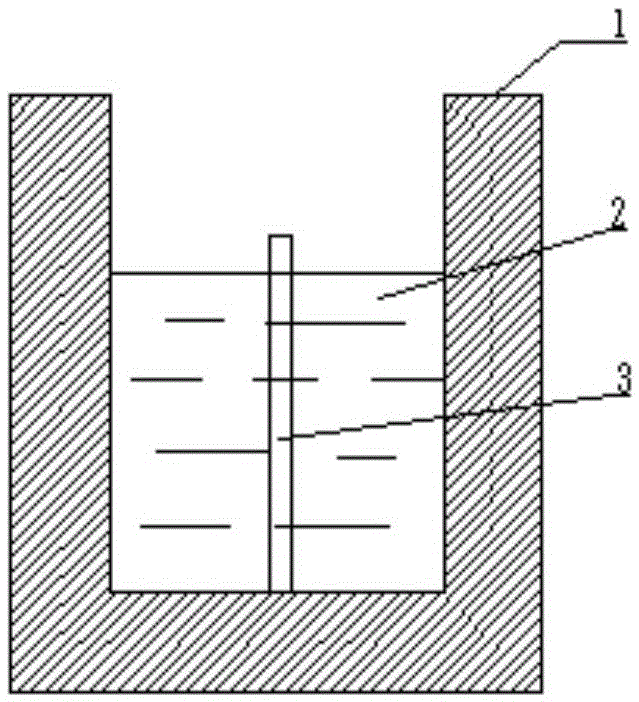

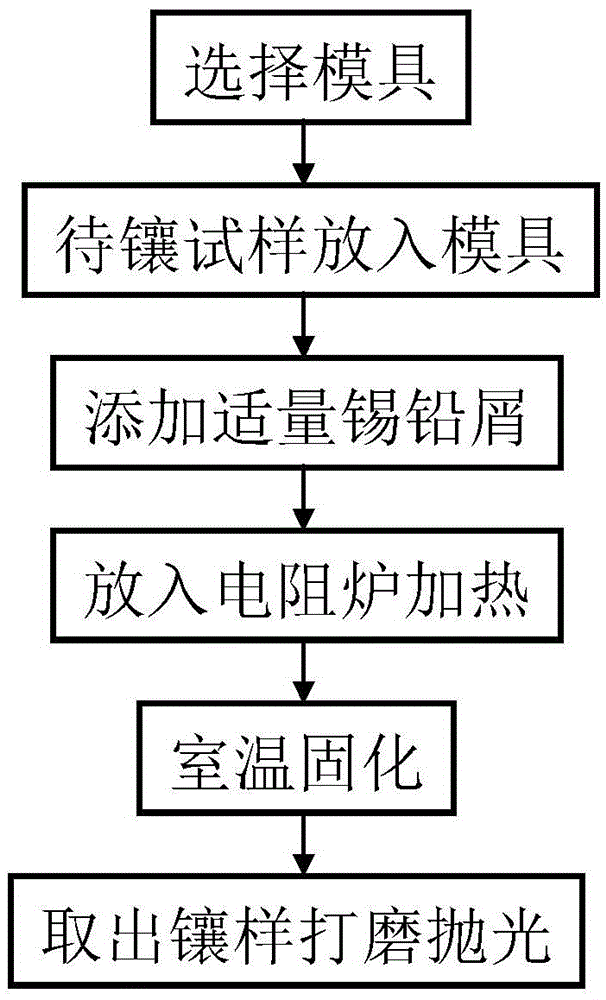

Embedding method for metallographic specimen

ActiveCN105547783AEasy to prepareImprove conductivityPreparing sample for investigationIntact tissueElectronic differential

The invention relates to an embedding method for a metallographic specimen. The required device comprises a low-temperature chamber electric furnace and a mould; a mould crucible is prepared by taking the following components by weight percent: more than or equal to 99% of Al2O3, less than or equal to 0.2% of SiO2, less than or equal to 0.1% of Fe2O3 and the balance of alkali; the mould can be in various specifications, such as 15mm*15mm*20mm and phi 15mm*20mm; and tin and lead scraps containing 60-80wt% of tin are taken as embedding materials. The method comprises the following steps: putting a to-be-embedded specimen into the mould; adding a right amount of the tin and lead scraps according to the size of the mould; putting into an electric furnace at a preset temperature and then heating for 0.5-5h; taking out and solidifying for 0.5-2h at room temperature, thereby being capable of taking out the specimen; polishing the specimen step by step by using 120#, 320#, 800#, 1000# and 1500# abrasive paper, and then observing by the polished etched specimen. The specimen prepared according to the method provided by the invention can be applied to the observation for a metallographic microscope or a scanning electron microscope and EBSD (Electron Back-Scattered Diffraction) and EDS (Electronic Differential System) detection, and the data, such as a true and complete organization structure of the specimen, can be acquired.

Owner:BEIJING CISRI GAONA TECH +1

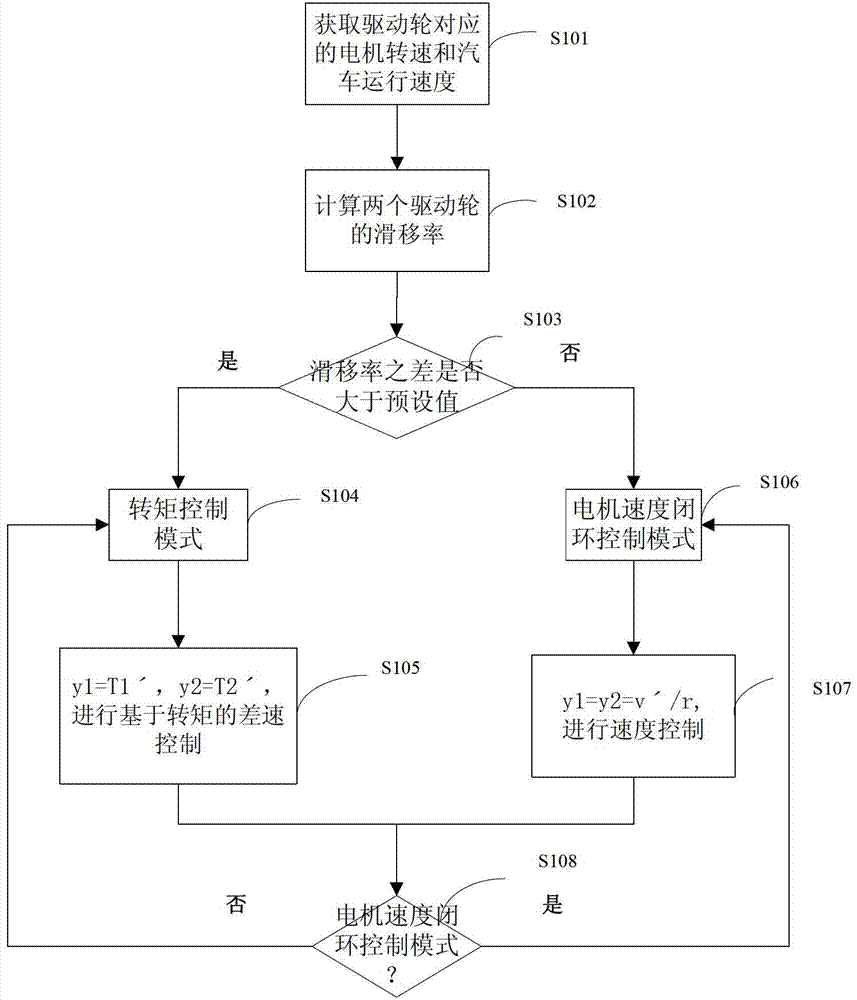

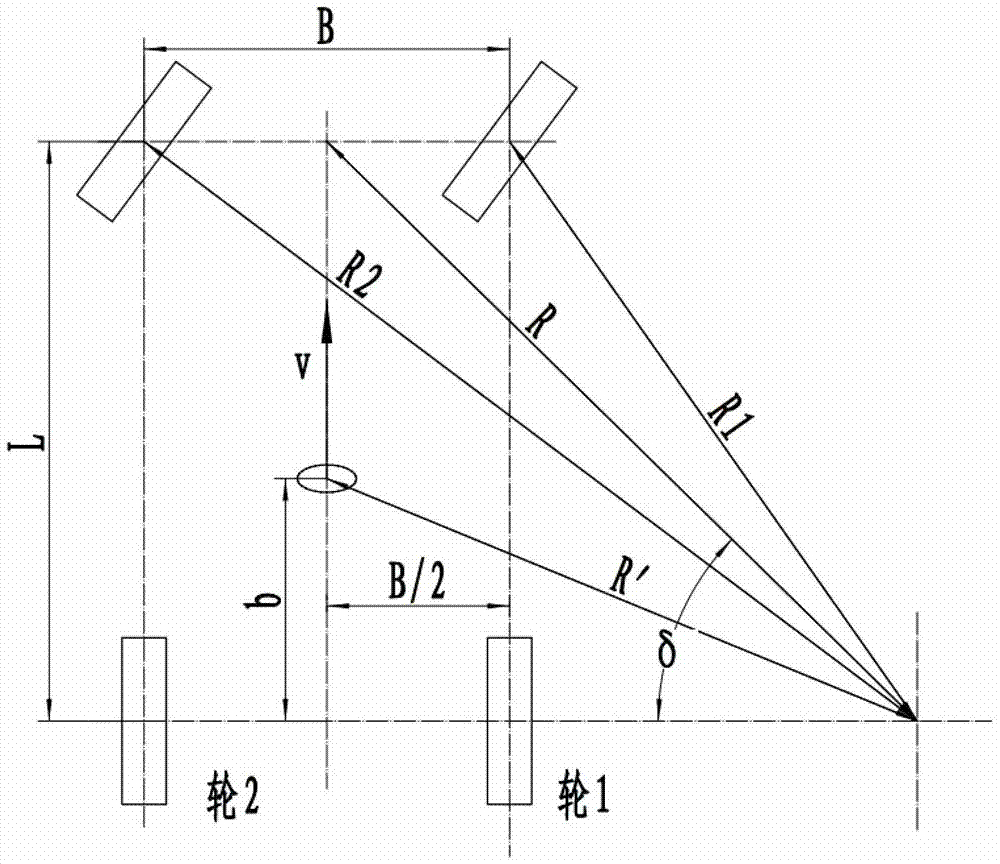

Self-adaption electronic differential control system

ActiveCN103112365AAdaptive Electronic Differential Control RealizationGuaranteed synchronizationSpeed controllerElectric energy managementArea networkDrive wheel

The invention discloses a self-adaption electronic differential control system which comprises a vehicle controller, an upper computer, two inverters and two driving motors which correspond to two driving wheels. The upper computer is connected with the vehicle control system, the upper machine is connected with two inverters through a controller area network (CAN) bus, and the driving motors are controlled to rotate by the inverters. Difference between slip rate of two driving pulleys is taken as a steering signal of an automobile so as to achieve self-adaption steering and switching. In the process of direct movement, the control system can guarantee that wheel speed is synchronous to vehicle speed, and simultaneously, motor power is changed in a real-time mode along with resisting moment of motion so as to achieve stable motion. In the process of bending movement, a torque control model based on best slip rate is used for revising a torque command in a real-time mode so as to control the slip rate to achieve the best place and stable steering. In addition, the self-adaption steering control based on the slip rate does not need a steering sensor and can save cost.

Owner:HUBEI AXLE

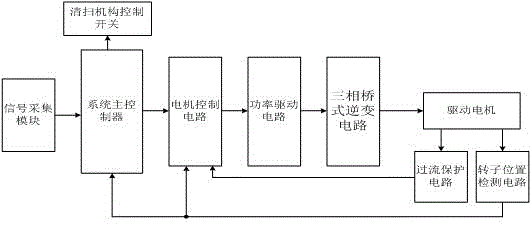

Vehicle control circuit of micro hub-style electric sweeper

The invention discloses a vehicle control circuit of a micro hub-style electric sweeper. The vehicle control circuit of the micro hub-style electric sweeper manly comprises two parts: a vehicle control unit and a motor control unit. The vehicle control unit comprises a system main controller, a signal acquisition module and a sweep mechanism control switch; the motor control unit mainly comprises a motor control circuit, a power driving circuit, a three-phase bridge-type inverter circuit, a driving motor, an overcurrent protection circuit and a rotor position detecting circuit. The vehicle control circuit of the micro hub-style electric sweeper utilizes the electronic differential technology to realize steering control over the vehicle, the system main controller calculates the controlled variable of each hub motor according to the differential control algorithm through collecting relative parameters of the vehicle in running, and the rotatory speed which controls the left hub motor and the right hub motor is directly outputted, to realize stable operation and differential steering of the vehicle. The hub-style brushless direct current motor is adopted to serve as the driving motor, so that the vehicle control circuit of the micro hub-style electric sweeper is in low noise during operation and suitable for working at public places. The vehicle control circuit of the micro hub-style electric sweeper is efficient and practical, convenient to control, energy-saving and environment-friendly and has high anti-interference capacity.

Owner:DALIAN JIAOTONG UNIVERSITY

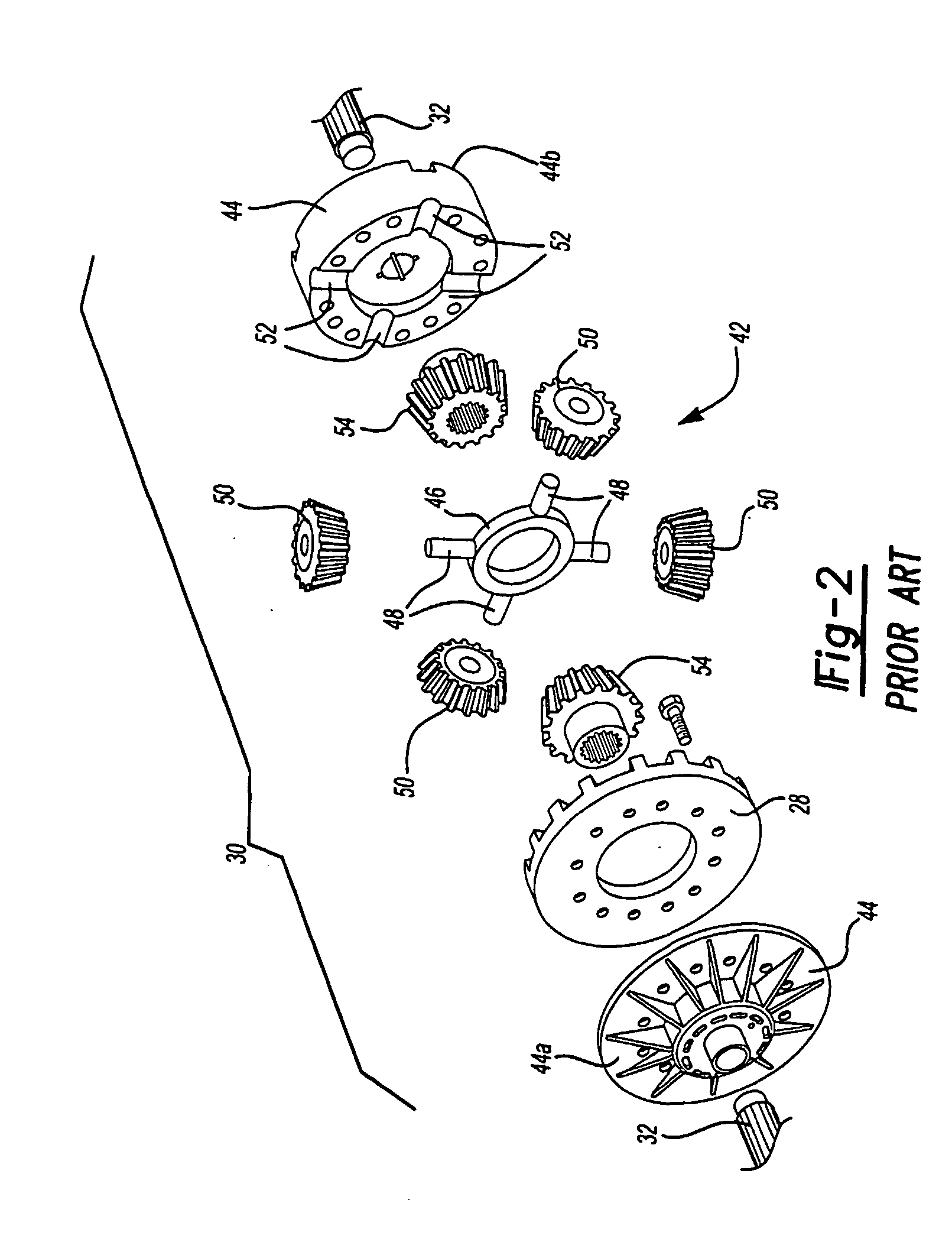

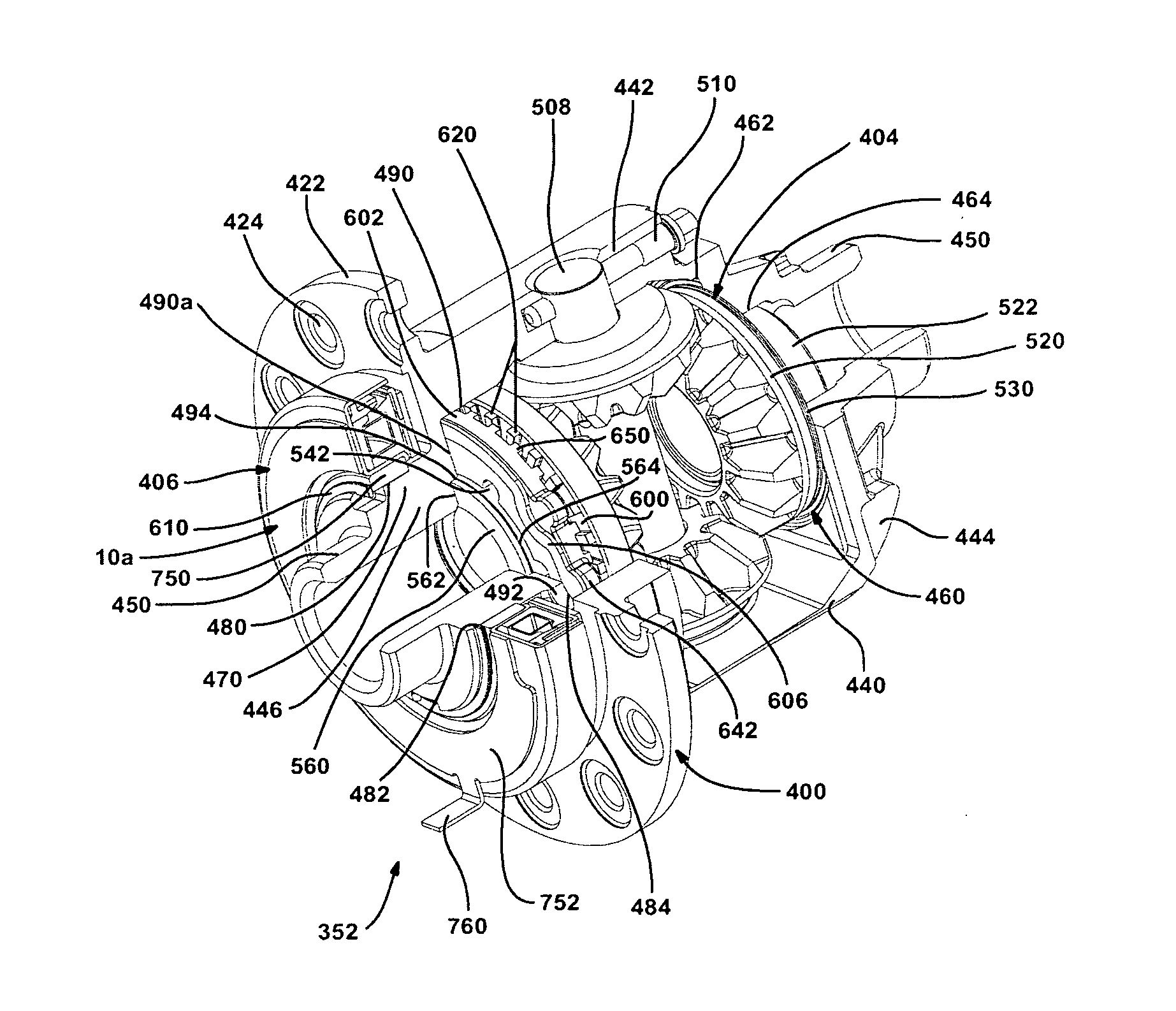

Electronic differential lock assembly

ActiveUS20060247087A1Simplified and effective differential lockReduce component countDifferential gearingsControl devicesElectronic differentialGear wheel

An electronic differential lock assembly includes a shift collar that is movable in response to an electronic signal from an unlocked position where axle shaft speed differentiation under predetermined conditions is permitted to a locked position where a pair of axle shafts are fixed for rotation together. Speed differentiation is provided by a differential that includes a differential gear assembly supported within a differential case. A coil surrounds the shift collar and is selectively energized to move the shift collar from the unlocked position to the locked position. The shift collar is splined to one of the axle shafts and is selectively splined to the differential case to lock the axle shafts together. The electronic differential lock assembly includes a return spring that automatically disengages the shift collar from the differential case once the coil is no longer energized.

Owner:MERITOR HEAVY VEHICLE SYST CAMERI

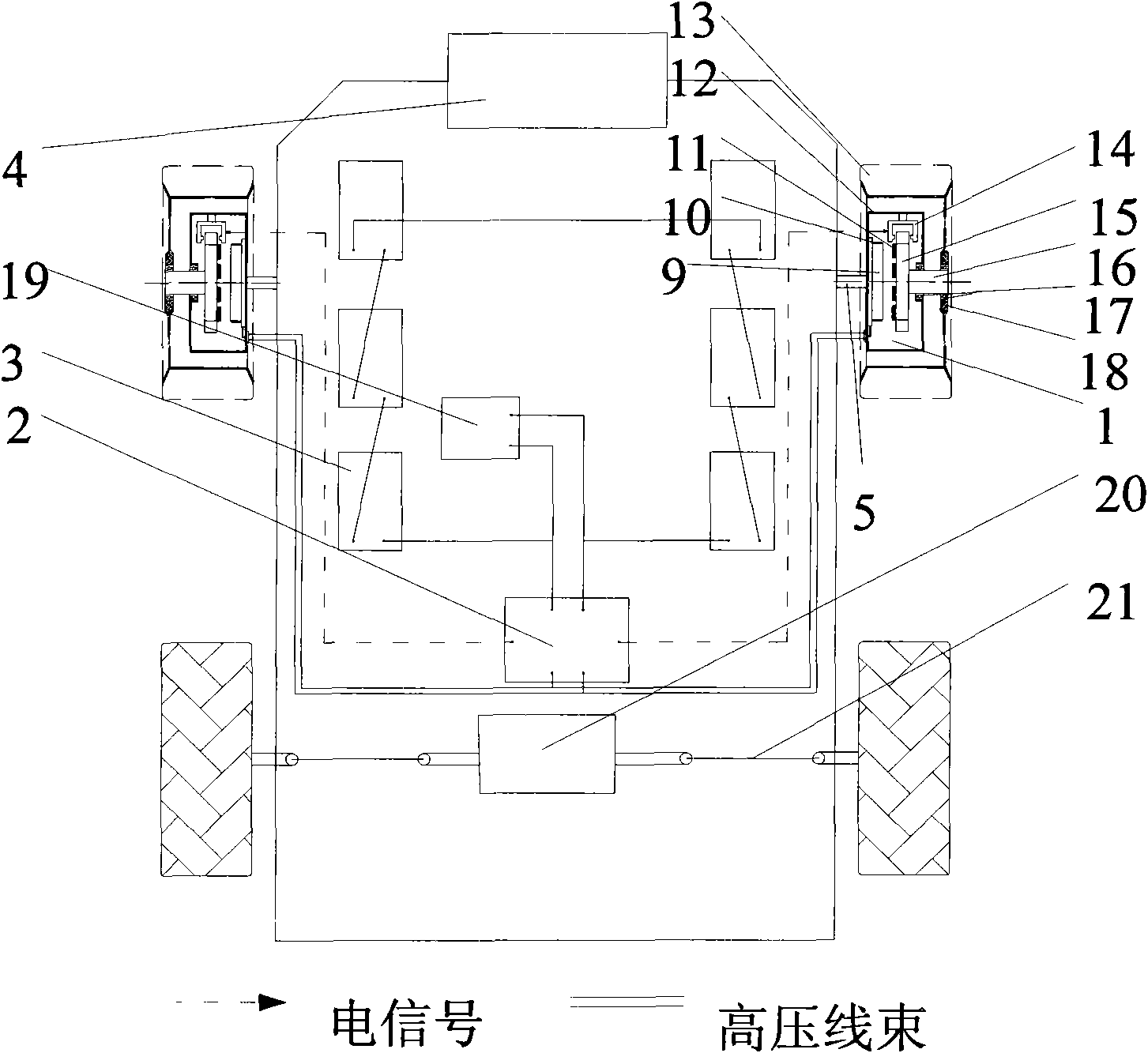

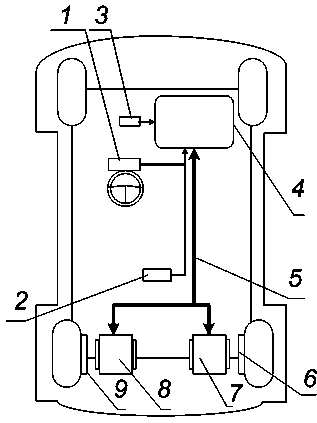

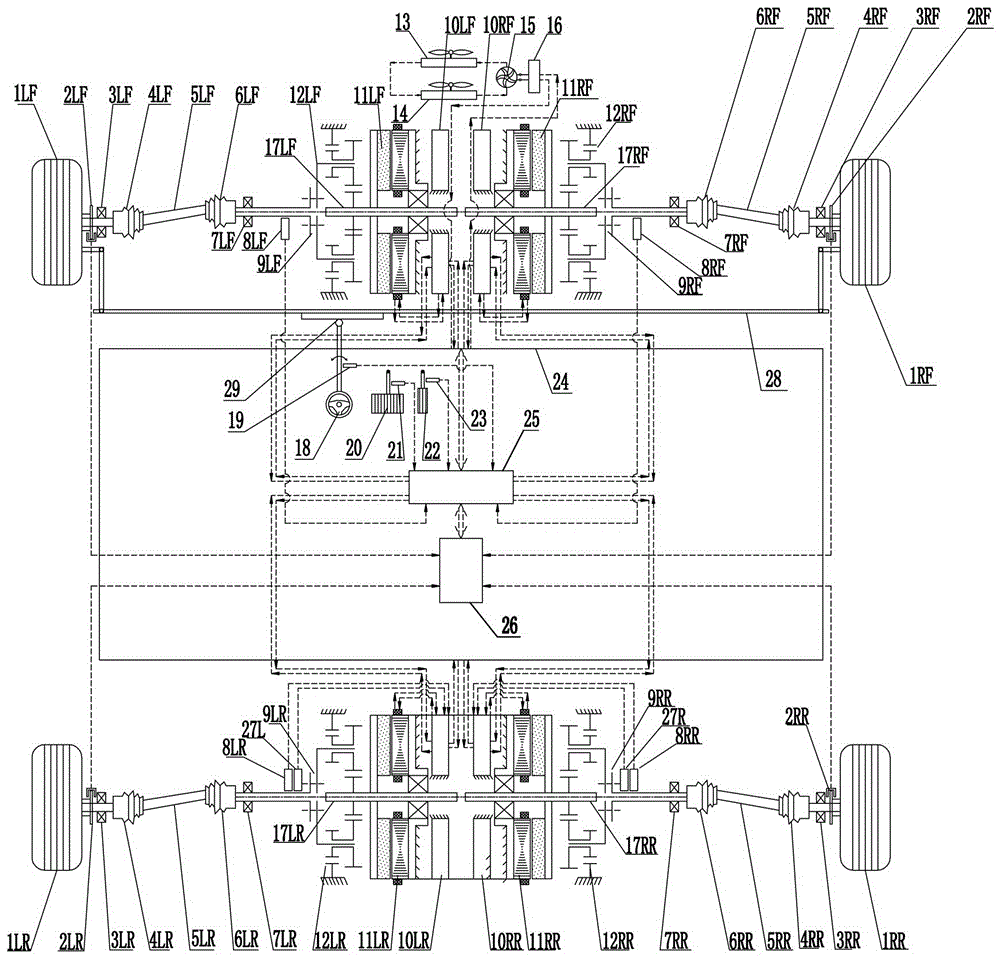

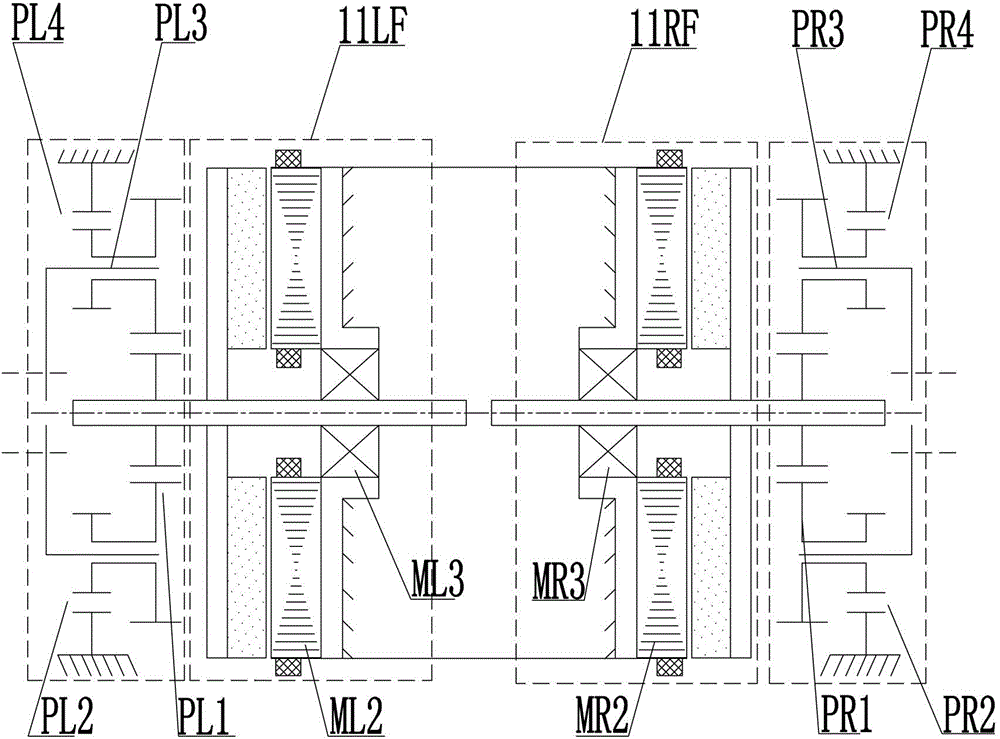

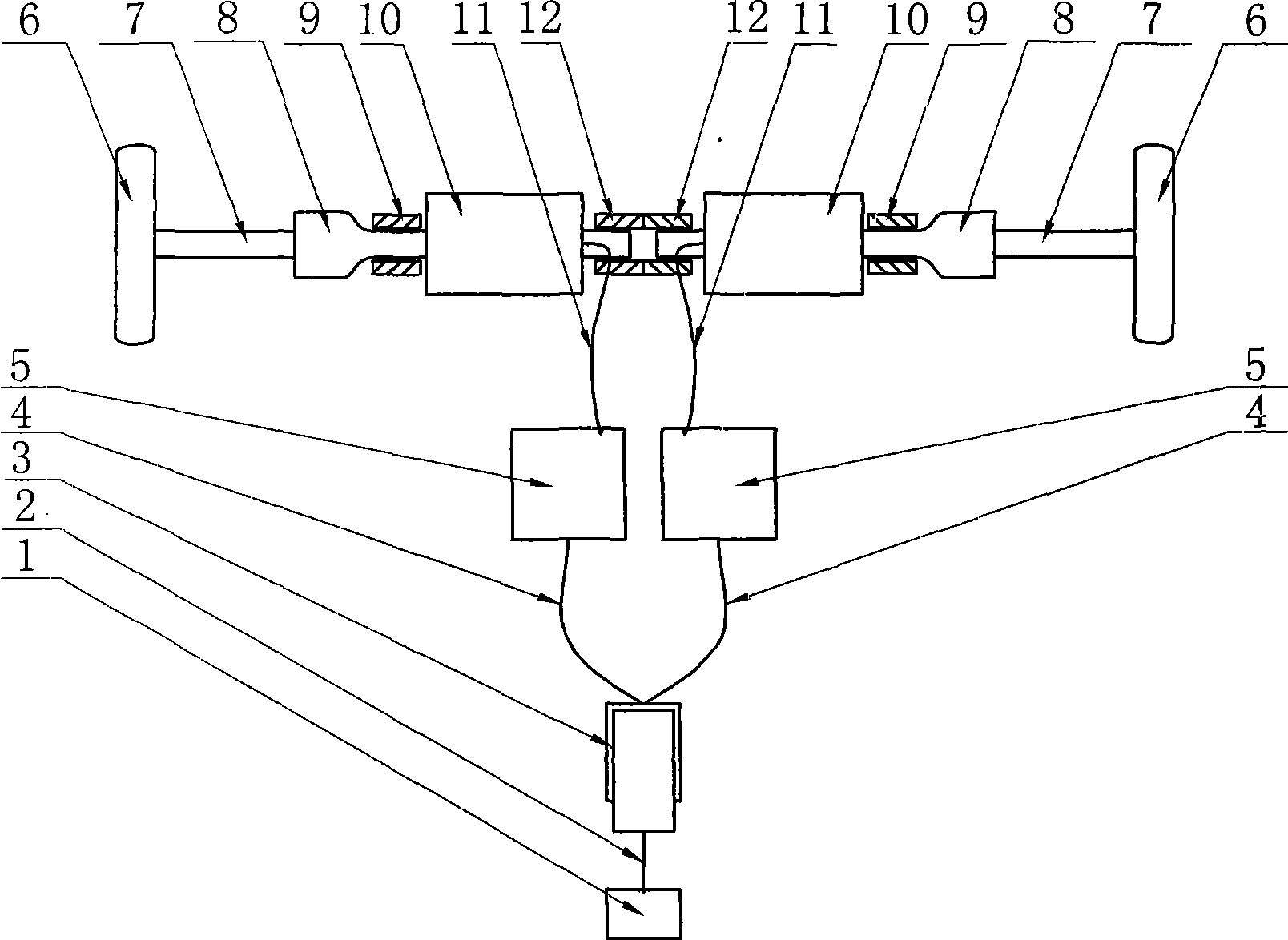

Electronic differential coupling four-wheel pure electrically-driven electric car

InactiveCN105966229ALarge capacitySave spaceSpeed controllerElectric devicesElectrical batteryElectric cars

The invention discloses an electronic differential coupling four-wheel pure electrically-driven electric car. The independent suspension design is adopted by a front axle and a rear axle, and the front axle and the rear axle are divided into two half drive axles correspondingly. Each half axle adopts an independent disc type motor and a planetary reducer for driving car wheels to rotate. A complete car ECU coordinates actions of disc type motor controllers by receiving information collected by sensors on the car, and the corresponding disc type motors are controlled through the four disc type motor controllers correspondingly. The advantages that the disc type motors and the planetary reducers are small in axial size and large in output torque are fully used, and the disc type motors and the planetary reducers are arranged on the left half drive axles and the right half drive axles, so that the mass of parts under suspension springs is better lowered, especially the mass of tyre parts is lowered. Compared with the combination mode of a tradition motor and a conventional step parallel shaft reducer, the chassis space can be effectively saved, and a battery pack with the larger capacity can be arranged conveniently.

Owner:SANMENXIA SUDA TRANSPORTATION ENERGY SAVING TECH

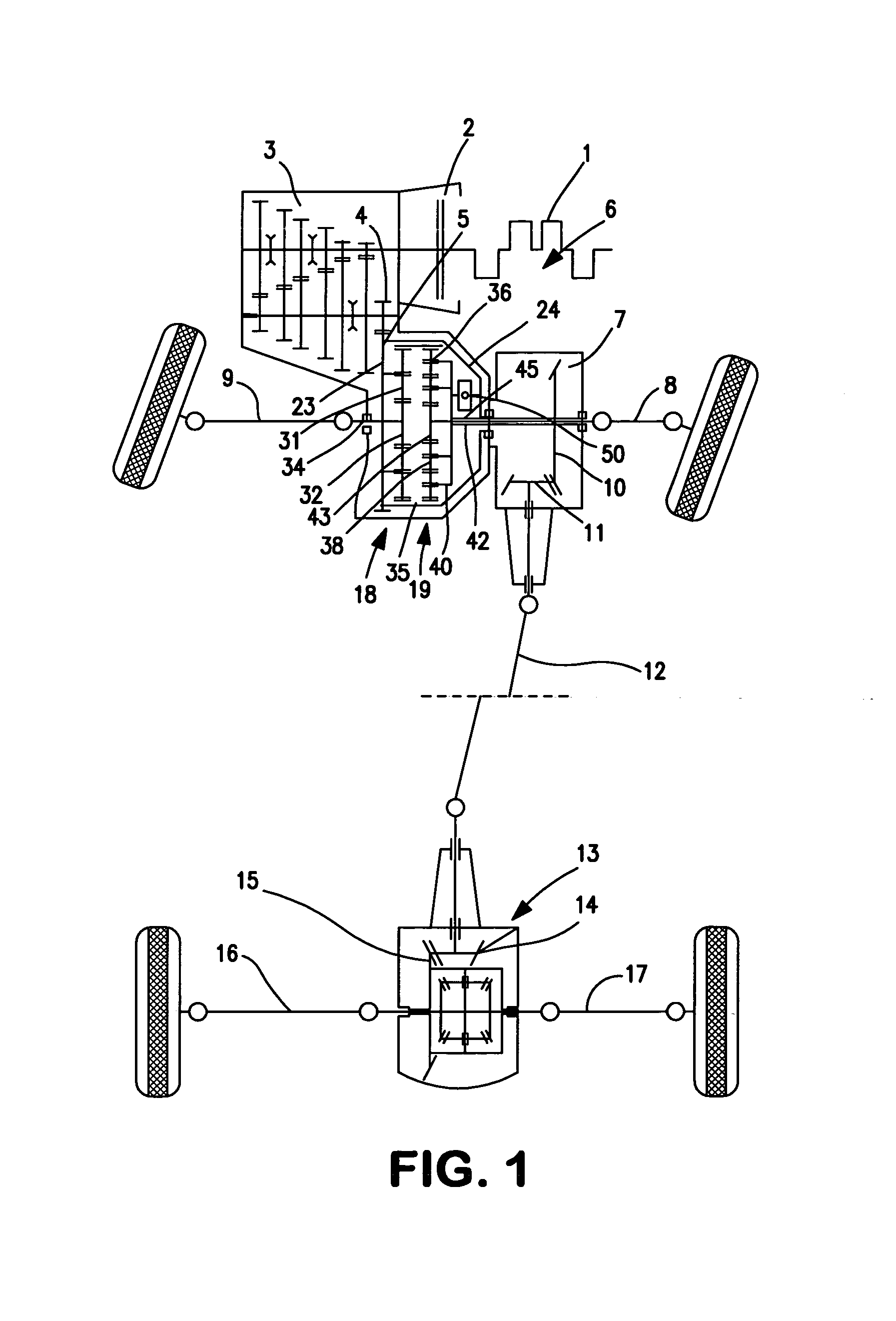

Axle drive block with a differential lock

An axle drive block for a motor vehicle, comprising a first and a second differential in a driven housing. Both of the differentials are coaxially aligned planetary spur gears, the sun wheels of which are drivably connected to the semiaxes of the first driven axle. The planet wheels of both differentials mesh the joint ring gear of the sun wheels. In order to lock the interaxle differential, the housing is provided with a first striking surface interacting with a second striking surface which is pressed thereto by ball ramps.

Owner:MAGNA STEYR FAHRZEUGTECHN

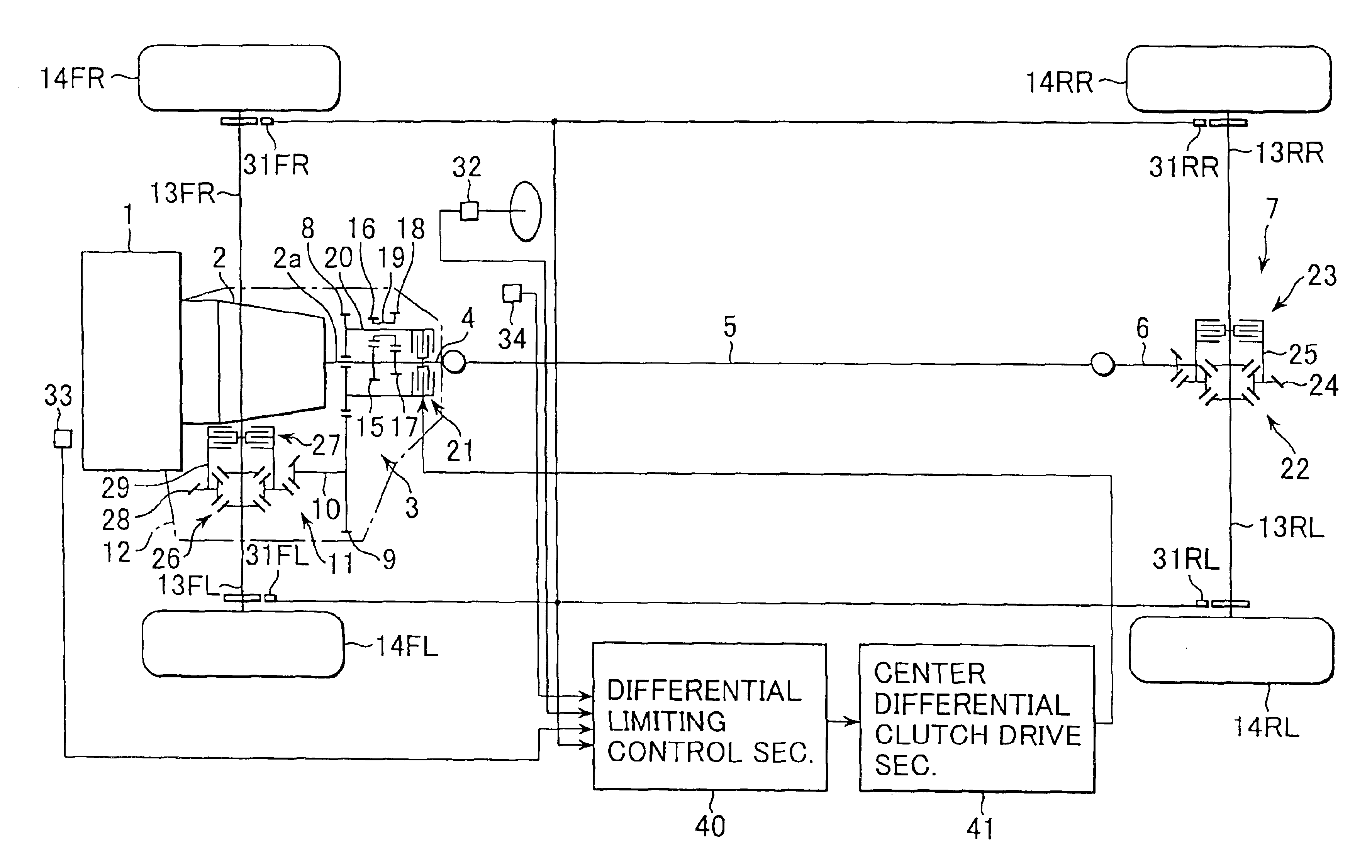

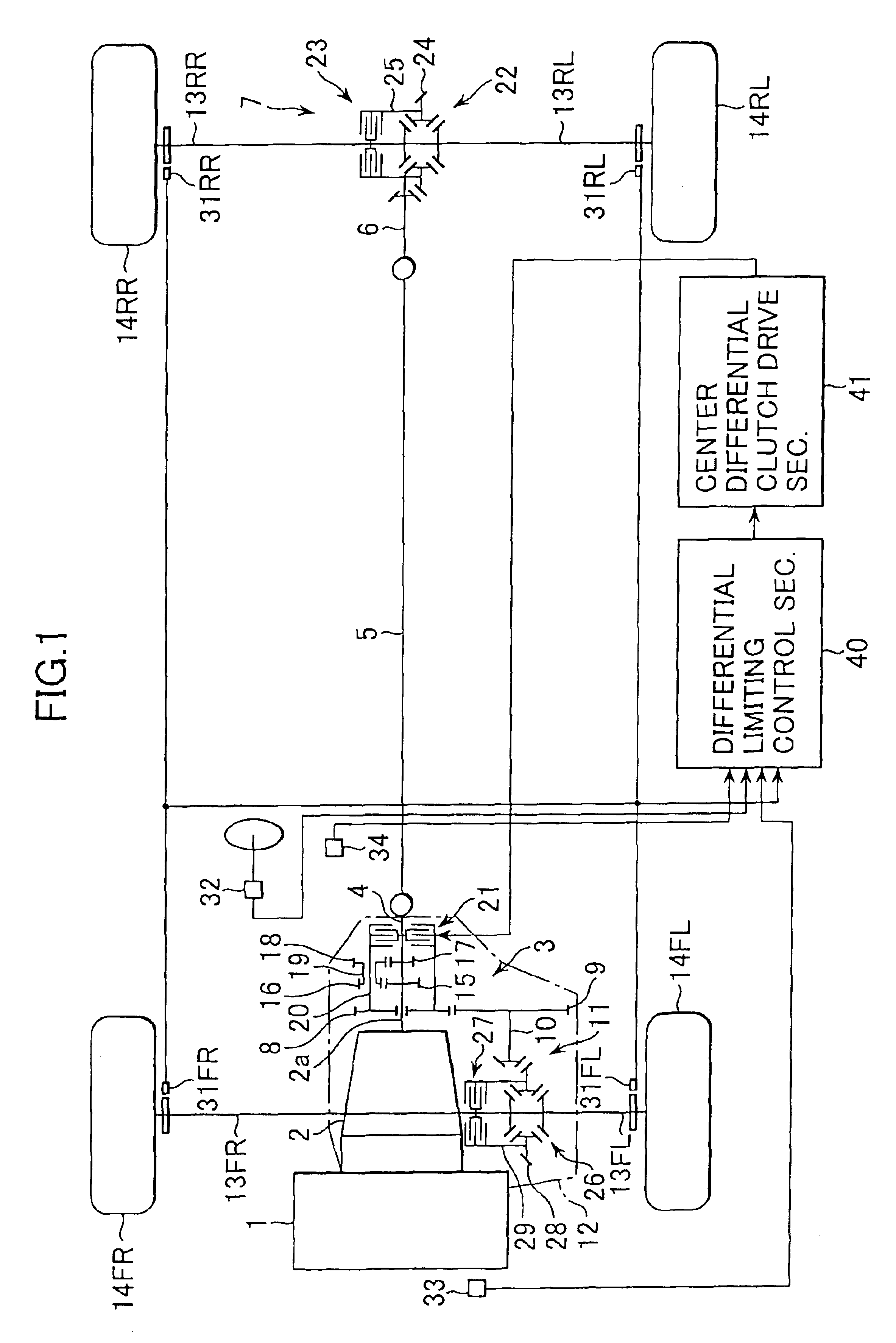

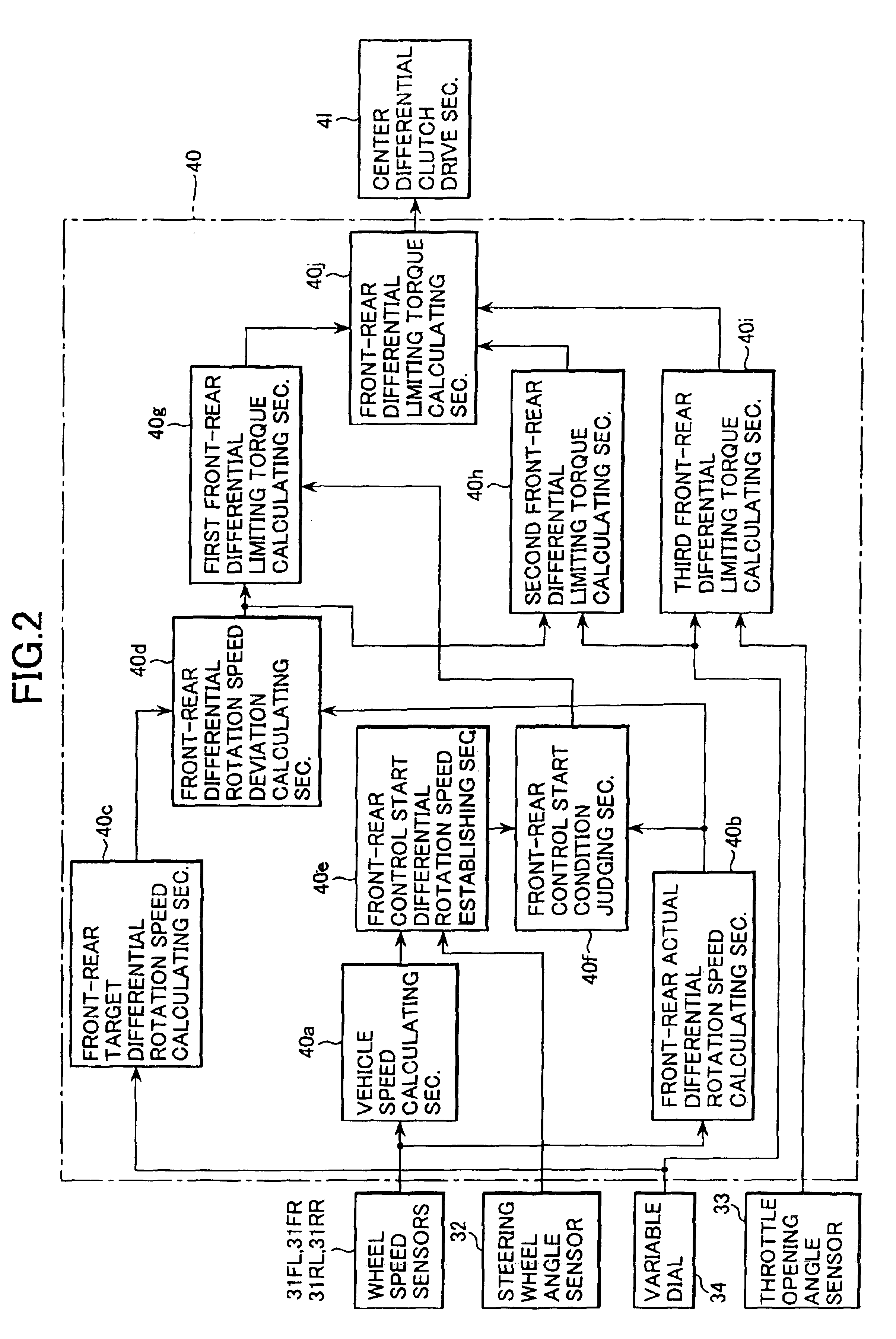

Power distribution control apparatus and control method

InactiveUS6878085B2Improve mobilityDigital data processing detailsToothed gearingsDistribution controlDrive shaft

In a differential limiting torque control section, a target differential rotation speed between front and rear drive shafts is established according to a dial position inputted by a driver of a variable dial. Further, an actual differential rotation speed between front and rear drive shafts is calculated and a deviation between the target differential rotation speed and the actual differential rotation speed is calculated. Based on the deviation, a first differential limiting torque and based on a dial position of a variable dial a second differential limiting torque are calculated. Further, a third differential limiting torque is calculated based on the dial position and a throttle opening angle. A final differential limiting torque between front and rear drive shafts is obtained by summing up these first, second and third differential limiting torques.

Owner:SUBARU CORP

Self-adjusting electric speed differential

InactiveCN101380908ASpeed controllerElectric propulsion mountingDrive wheelElectronic control system

The invention relates to a self-regulating electronic differential mechanism which is an electronic control system of an electric car and is mainly applied to a dual-motor independent driving mode electric car. Two driving wheels are respectively driven by two motors directly. The driving motors are respectively controlled by two controllers with the same specification. The dual-motor independent and direct driving mode is realized and the self-regulating function of the electric differential is realized. The two controllers are controlled by an accelerator so that the two motors work under the same power and voltage. Due to the characteristics of the motors, the electric differential self-regulating function is realized through the regulation of different slipping rates and the flow limiting function of the controllers. As the driving torque of an internal driving wheel is larger than the external driving torque, therefore, different slipping rates appear and understeer is represented.

Owner:ZAOZHUANG UNIV

Axle assembly with electronic locking differential

An axle assembly with an electric locking differential that can include a one-piece differential case and a locking device. The locking device includes a dog that is nonrotatably but axially slidably received into a pocket that is formed in an end of the differential case. An actuator is mounted on the differential case. Actuation of the actuator moves the dog into engagement with a second dog that is coupled to a side gear of the differential to thereby lock the side gear to the differential case.

Owner:AMERICAN AXLE & MFG

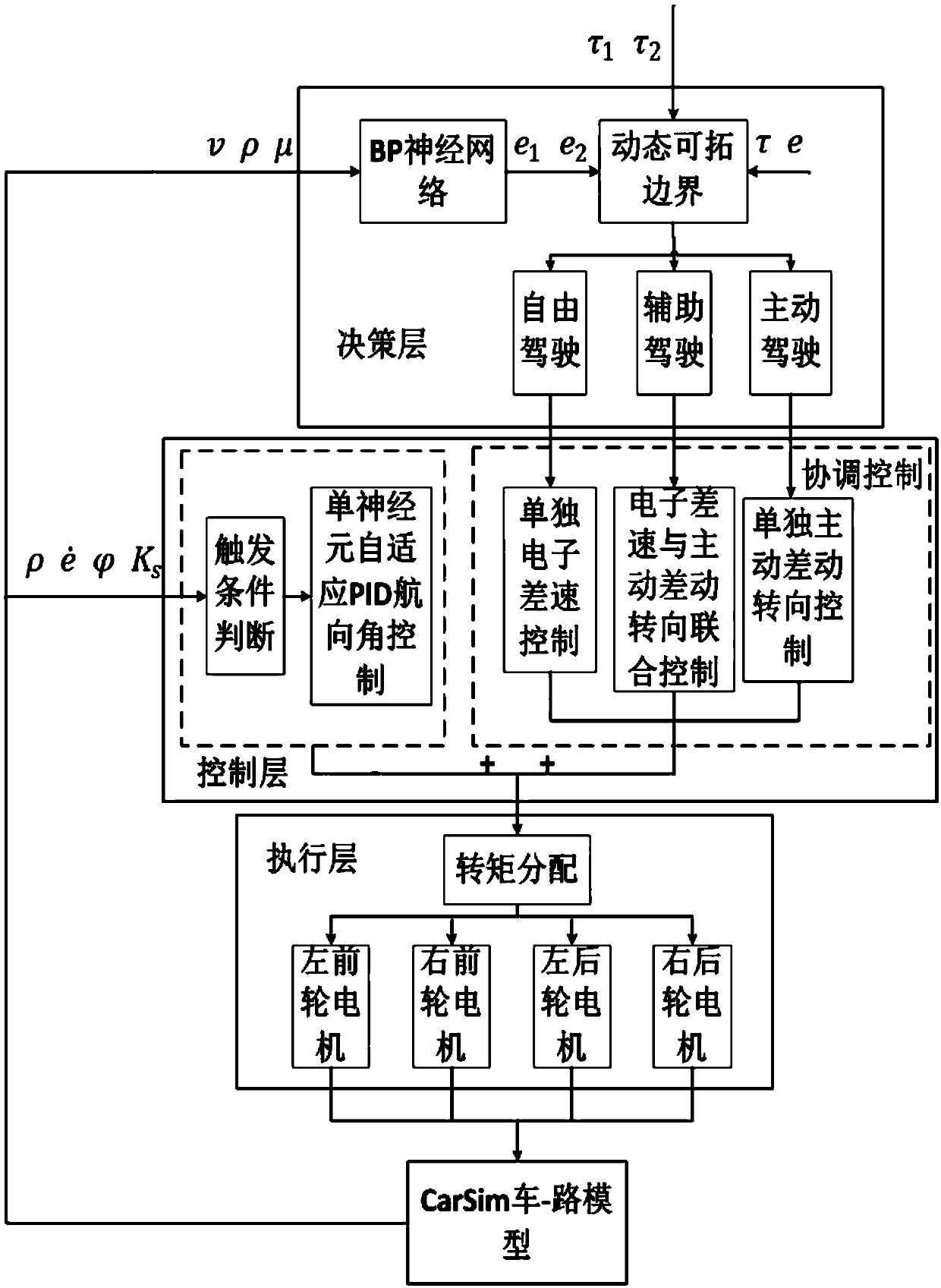

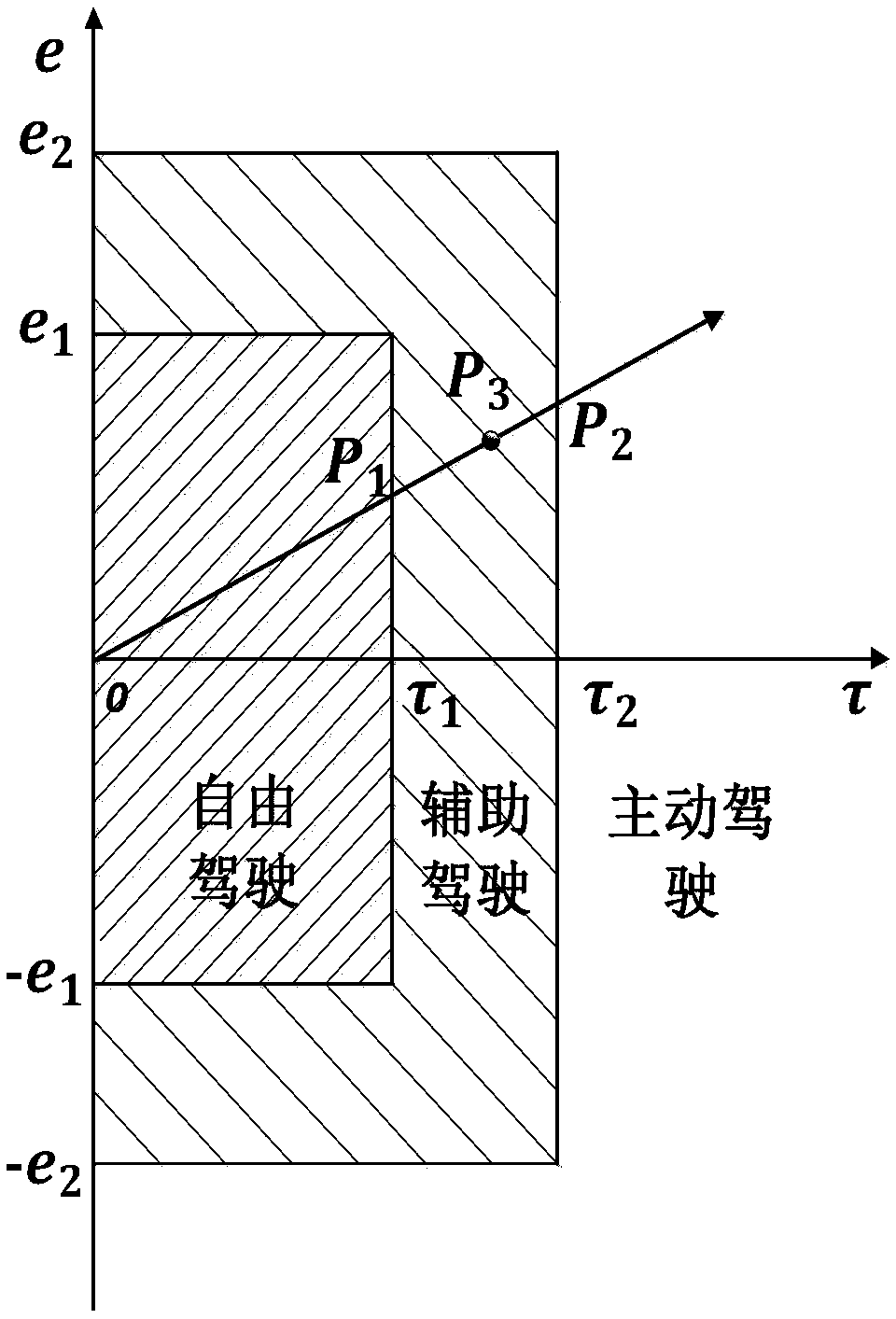

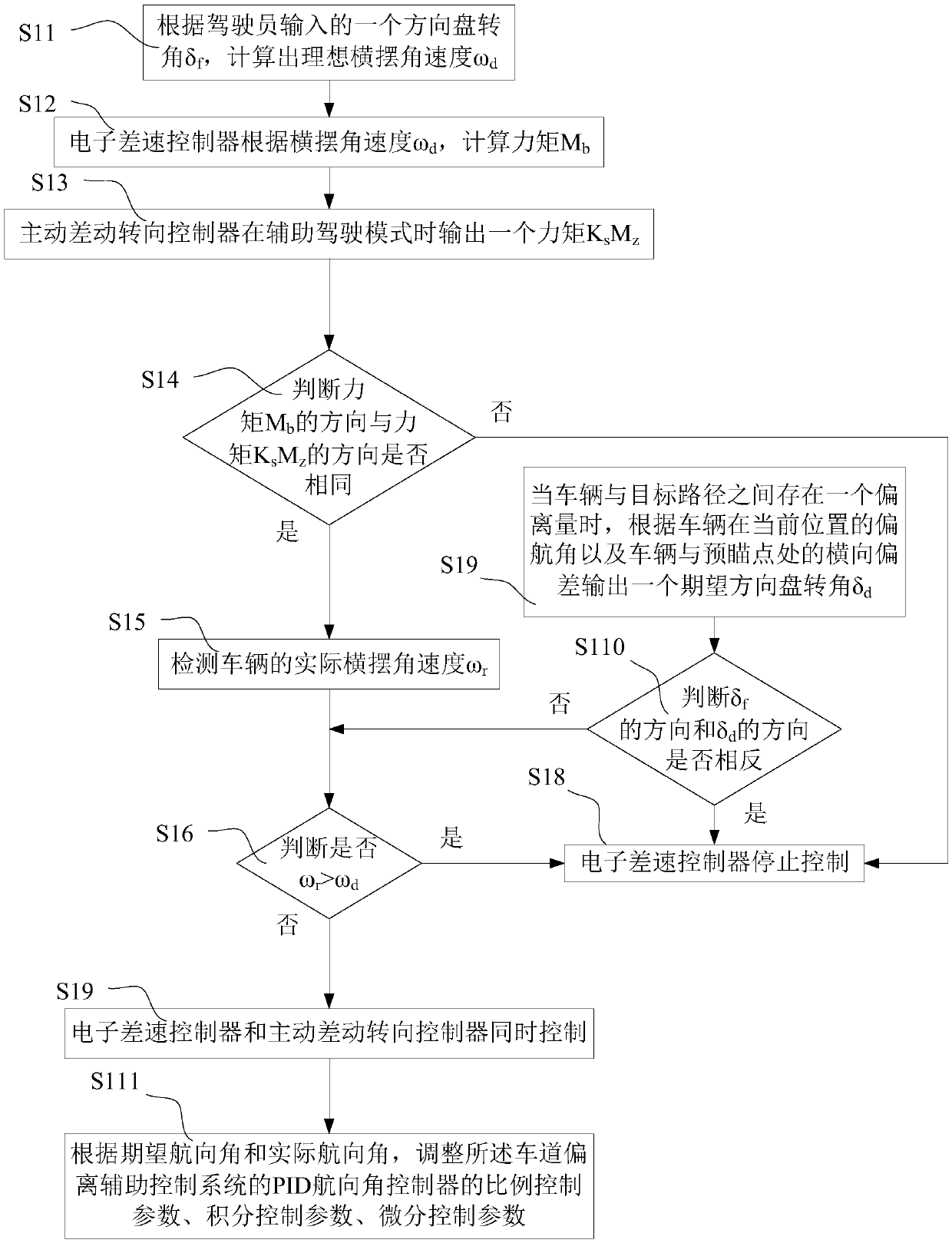

Coordinated control method and coordinated control device for electronic differential and active differential steering

ActiveCN109050661ACoordinating working relationshipResolve mutual interferenceNon-deflectable wheel steeringElectronic differentialControl system

The invention discloses a coordinated control method and a coordinated control device for electronic differential speed and active differential steering. The coordinated control method comprises the following steps of: calculating an ideal yaw angular velocity omega d according to a steering wheel rotation angle delta f input by a driver; Calculating a moment Mb according to the yaw angular velocity omega d; Judging whether the direction of the output rated torque KsMz of the active differential steering controller is the same as the direction of the torque Mb when the active differential steering controller is in the auxiliary driving mode, and detecting the actual yaw angular speed omega r of the vehicle if the direction of the output rated torque KsMz is the same as the direction of thetorque Mb; Otherwise, it is judged whether[Omega] r ( [Omega] D); If yes, the electronic differential controller and the active differential steering controller control simultaneously, otherwise, theelectronic differential controller stops the control. The invention can reasonably and effectively coordinate the working relationship between the two controllers, and solves the problem that the driver and the control system interfere with each other when the lane departure auxiliary control system of the traditional automobile is designed based on the steering.

Owner:HEFEI UNIV OF TECH

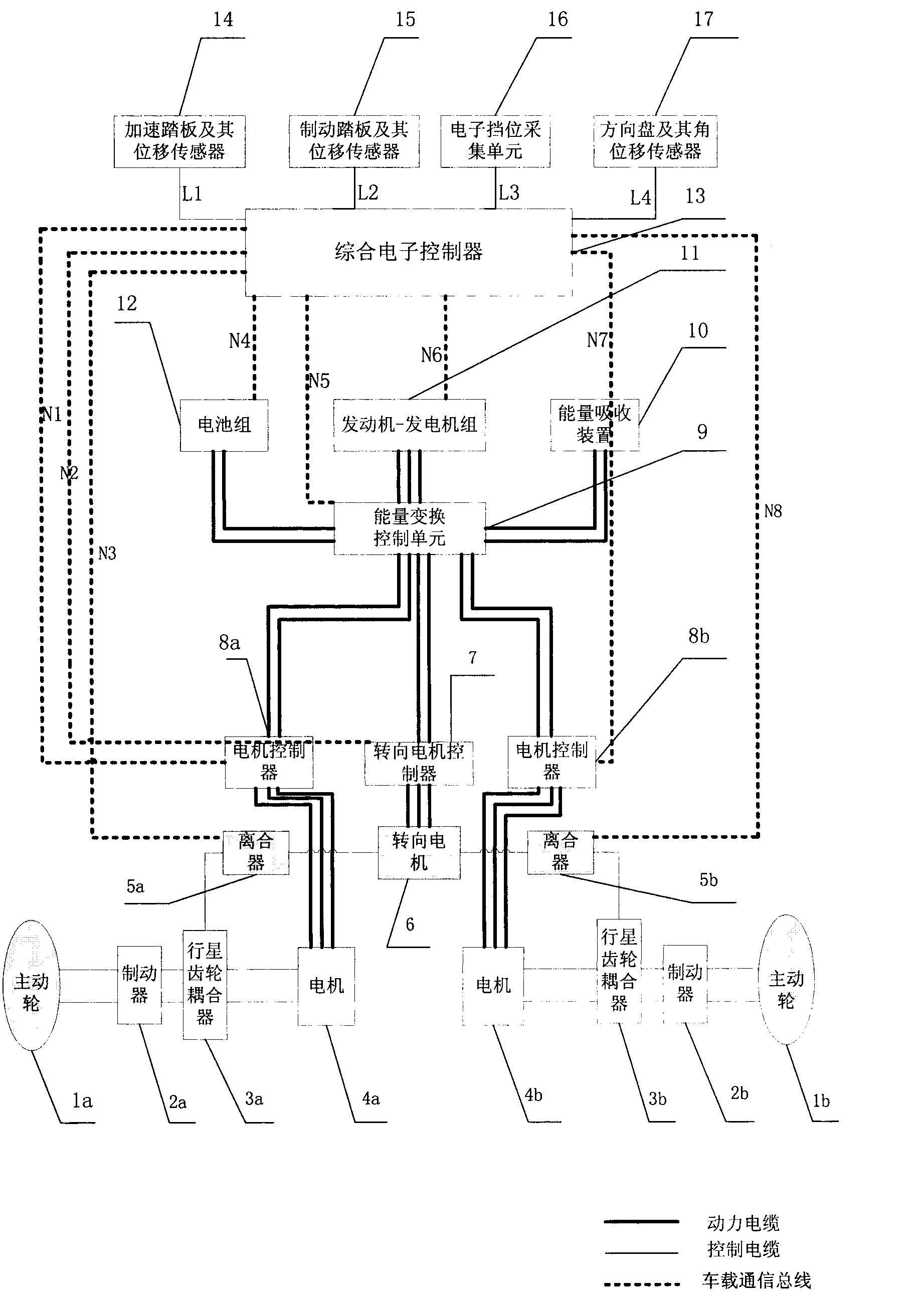

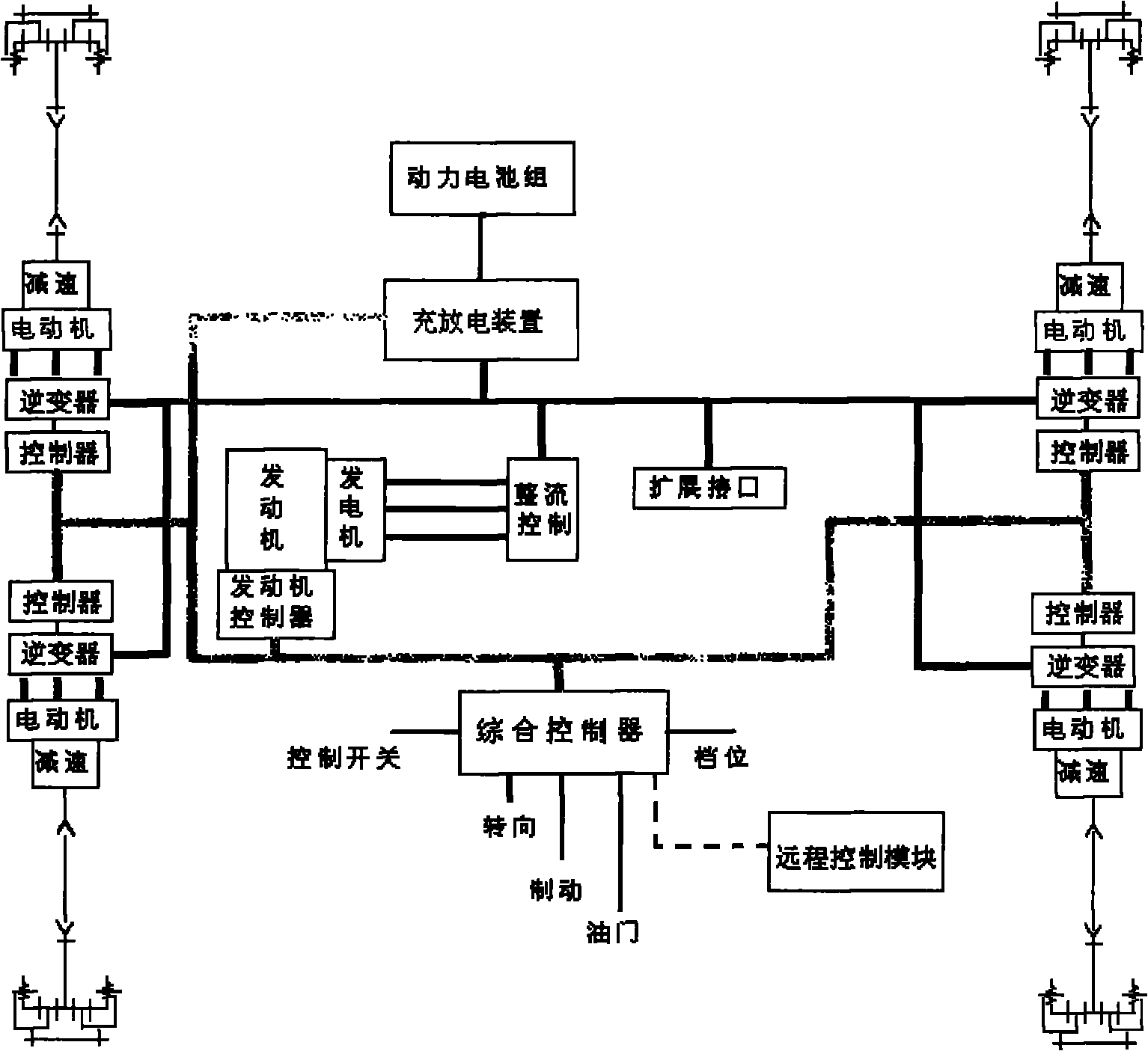

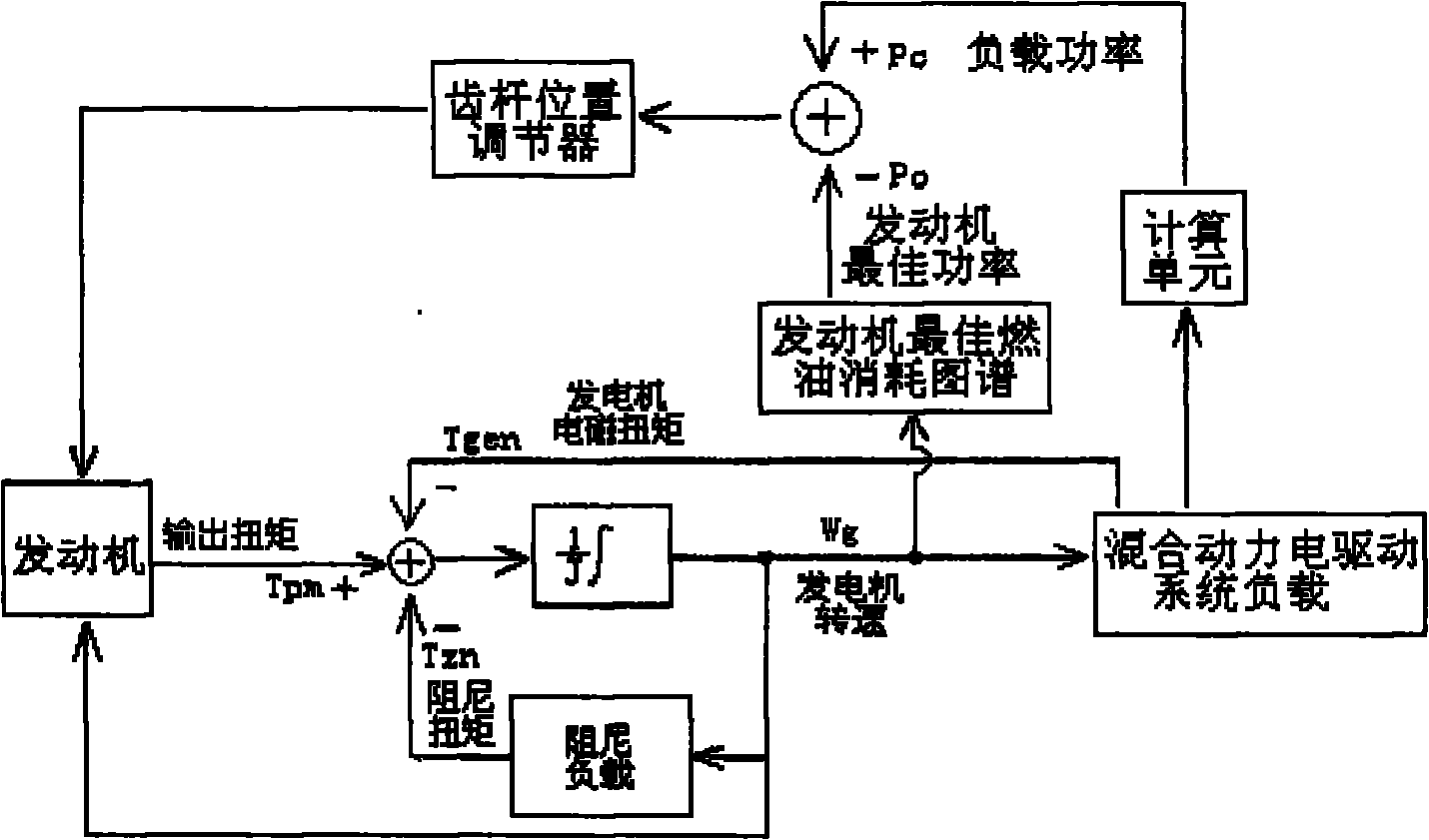

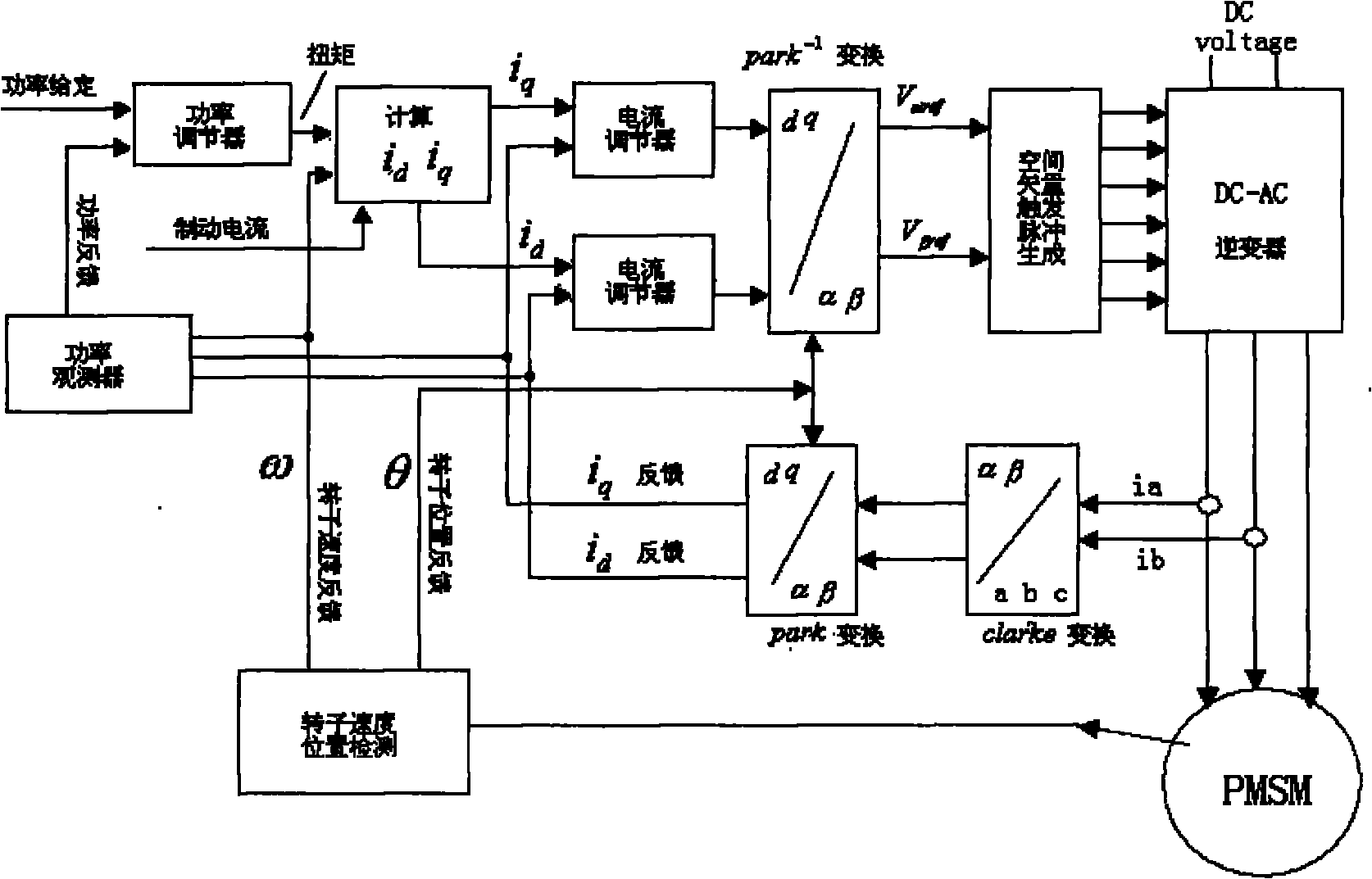

Vehicle hybrid four-wheel electric drive system

ActiveCN101774379ASolve the problem of insufficient driving mileageRealize any radius turningHybrid vehiclesElectric vehicle charging technologyClosed loopFuel oil

The invention provides a vehicle hybrid four-wheel electronic drive system, which comprises an integrated controller respectively connected with a motor controller, a charge-discharge device and all the controllers of traction electric machines through a CAN bus and controls in-time energy supply and demand, and power distribution of the whole electric drive system. The invention has the advantages of both a four-wheel drive and the eclectic drive system, thereby solving the problem of insufficient driving range. The integrated controller saves the traditional machinery differential mechanismthrough an electronic differential control algorithm, can realize vehicle steering with optional radiuses without the function of a machinery transfer device, enables the vehicle to move freely through remote control under the condition of driving without a driver, widens the application range of the vehicle, can reach the best dynamic property by adopting the best fuel oil consumption control method, and introduces a power ring besides the double closed loop control structure of velocity and current, so as to ensure that the whole system is stable during working and has ideal pulling figure.

Owner:WUXI NEW GREAT POWER ELECTRICAL MACHINE

Electronic differential control method and system of four-wheel drive electric vehicle

ActiveCN110667402AImprove tracking performanceReduce wearSpeed controllerElectric devicesDrive wheelElectronic differential

The invention discloses an electronic differential control method of a four-wheel drive electric vehicle. The electronic differential control method includes the steps of calculating the turning radiuses of two front wheels and the turning radiuses of two rear wheels according to the turning angles of wheels and the slip angles of tires correspondingly, calculating target wheel speeds of the fourwheels according to the reference vehicle speed and the obtained turning radiuses of the two front wheels and the two rear wheels correspondingly, monitoring the difference between the actual wheel speeds of the four wheels and the target wheel speed in real time, determining the output modification feedback torque of each wheel by multiplying the difference by a preset torque modification proportionality coefficient, modifying the output torque, and obtaining the actual torque of the driving wheels inside and outside a front axle and a rear axle by subtracting the torque difference from the driving wheels inside, adding the torque difference to the driving wheels outside and meanwhile adding the feedback torque based on target wheel speed modification correspondingly. The electronic differential control method is suitable for the four-wheel independent drive electric vehicle, the turning radius and target torque of each driving wheel are calculated independently, the torque can be rapidly and precisely controlled, the slip angles of the tires are introduced to participate in calculation, and precision is improved.

Owner:清华大学苏州汽车研究院(吴江)

Electronic locking differential with direct locking state detection system

ActiveUS20090247350A1Mechanical actuated clutchesMagnetically actuated clutchesLocking mechanismElectronic differential

An axle assembly with an electronic locking differential that employs a locking mechanism having components that are fixed to one another along an axis such that they co-translate with one another when the actuator that effects the locking and unlocking of the differential is operated.

Owner:AMERICAN AXLE & MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com