Drive control system of double motors of rear axle of electric automobile

A dual-motor drive and control system technology, applied in the direction of multiple motor speed adjustment, control of multiple DC motors, etc., can solve the problems of high cost, low efficiency, heavy weight, etc., to achieve control of wheel transition slip, reduce costs, The effect of reducing energy loss

Inactive Publication Date: 2010-08-25

SHANDONG DEYANG ELECTRONICS TECH CO LTD

View PDF5 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Most of the current electric vehicles use a dedicated permanent magnet brushless DC bridge motor. This integral bridge structure connects two independent permanent magnet brushless DC motors into one body. The problem of gear box deceleration and gear differential speed also overcomes the shortcomings of electric vehicle drive system, such as large volume, low efficiency, heavy weight and high cost, and has the advantages of small size, light weight, low cost and high efficiency. It is a modern electric vehicle preferred

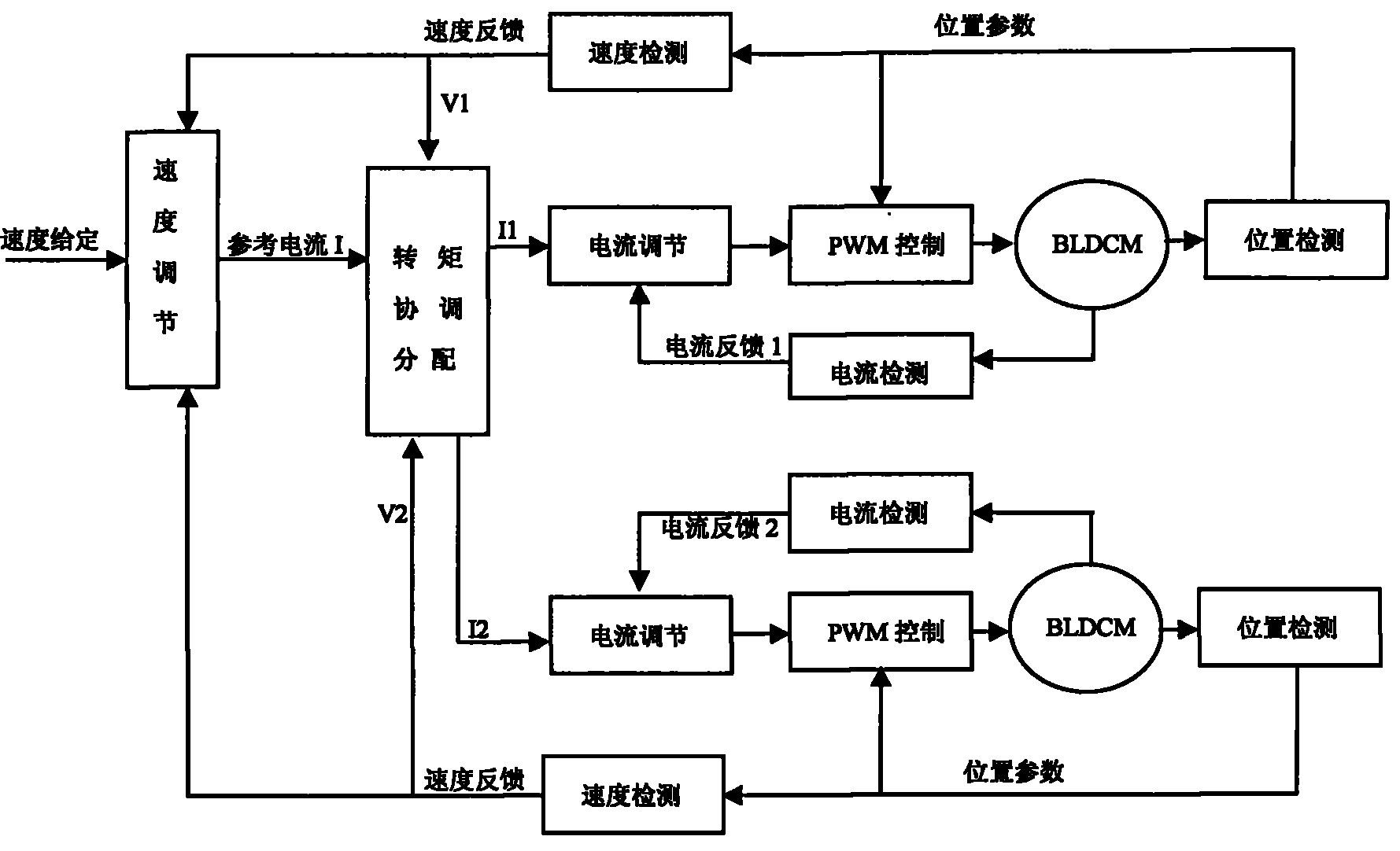

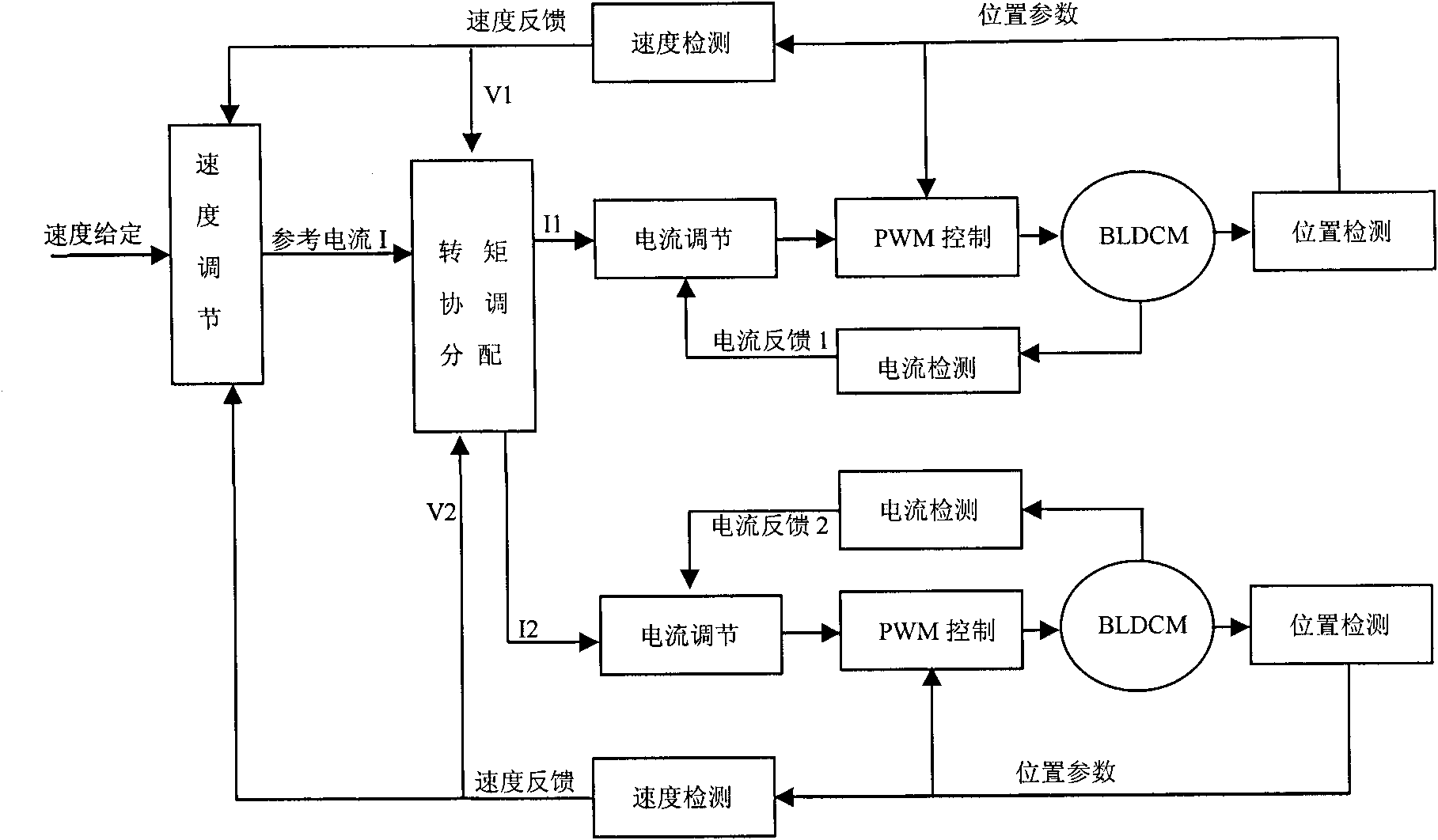

For the dual motors of this structure, the commonly used control method is to use the independent direct drive mode of the dual motors. The drive motors are respectively controlled by two controllers of the same specification. The accelerator pedal signal is distributed to the left and right motors through the electronic differential to realize Electronic differential function, and such a control structure is relatively complicated, and the control algorithm of the electronic differential is complicated, the cost is high, and the superior performance of the dual-motor coordinated work cannot be fully utilized

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

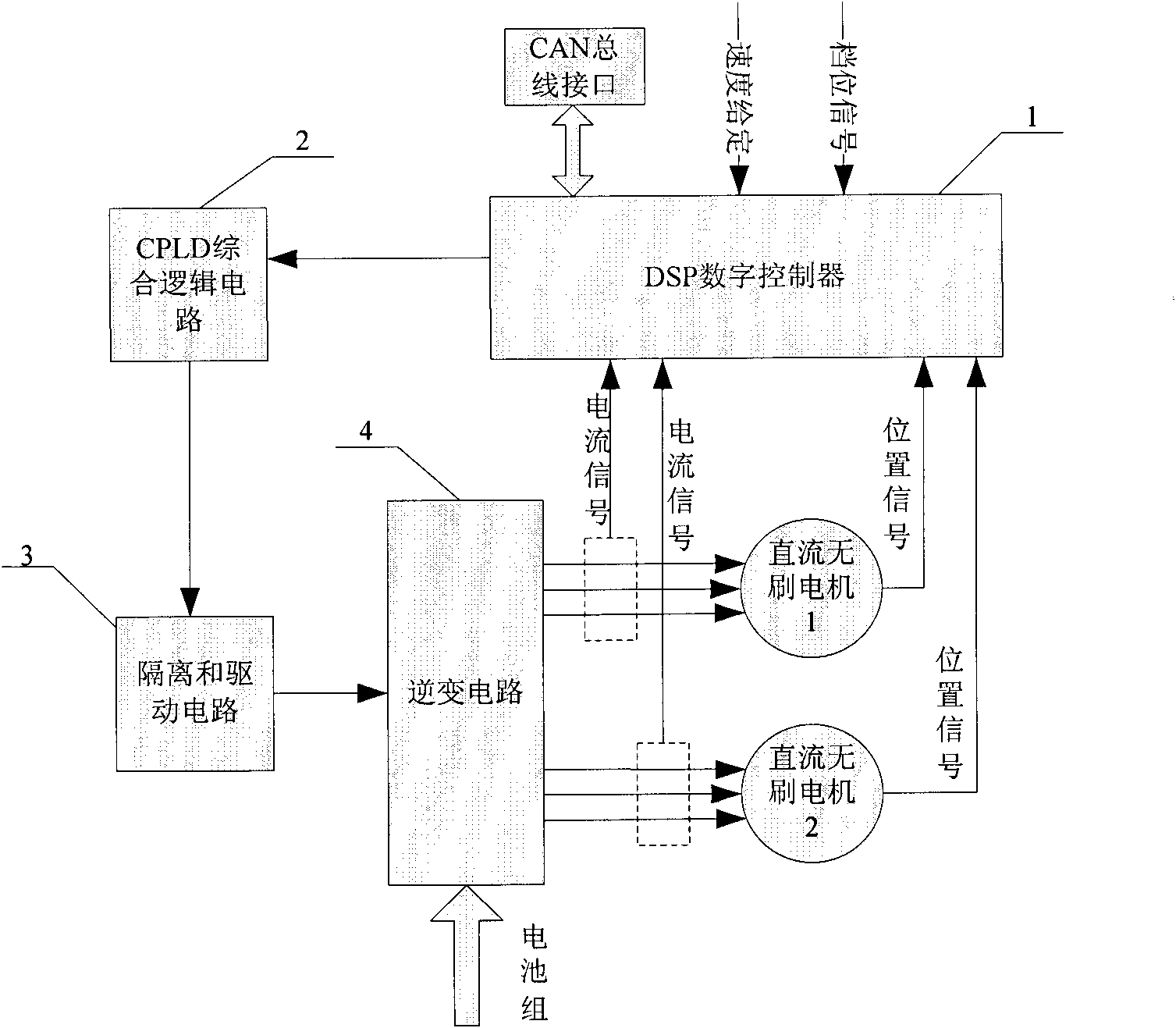

The invention relates to a drive control system of double motors of a rear axle of an electric automobile. To the closed-loop control of the average speed of double motors in the control system, a single driving wheel adopts a method of given torque control and speed follow-up to carry out the closed-loop control of the average speed of double motors, so that the automobile can run according to the target automobile speed of a driver, the rotational speeds of double motors are also permitted to be inconsistent under the condition of different loads, and the self-adapting differential performance of the turning of the low-speed running of the electric automobile is realized. By designing in this way, the differential control requirement of the curve running of a low-speed electric automobile is met, the use of a complicated electronic differential algorithm is avoided, and the cost of the system is lowered. By utilizing the self-adapting differential performance during turning, the torque distribution of double motors is further regulated according to the difference of the rotational speeds of double motors, the power-assisted steering of the curve running of the automobile is realized, the energy loss is decreased, and the effect of energy saving is achieved.

Description

A dual-motor drive control system for the rear axle of an electric vehicle technical field The invention relates to a dual-motor drive control system for the rear axle of an electric vehicle. Background technique Most of the current electric vehicles use a dedicated permanent magnet brushless DC bridge motor. This integral bridge structure connects two independent permanent magnet brushless DC motors into one body. The problem of gearbox deceleration and gear differential speed also overcomes the shortcomings of electric vehicle drive system, such as large volume, low efficiency, heavy weight, and high cost. It has the advantages of small size, light weight, low cost, and high efficiency. It is a modern electric vehicle first choice. For the dual motors of this structure, the commonly used control method is to use the independent direct drive mode of the dual motors. The drive motors are respectively controlled by two controllers of the same specification. The accelerator...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02P5/46H02P5/68

Inventor 鲍文光盛占石齐伟华周小福陈方立陈训张东花费德成徐兴何志刚全力江浩斌陈龙周孔亢

Owner SHANDONG DEYANG ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com