Embedding method for metallographic specimen

A metallographic sample and mounting technology, which is applied in the field of metallographic detection, can solve the problems of poor electrical conductivity, low mounting strength, and voids, etc., and achieves the effects of good production effect, high sample preparation efficiency, and reduced damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

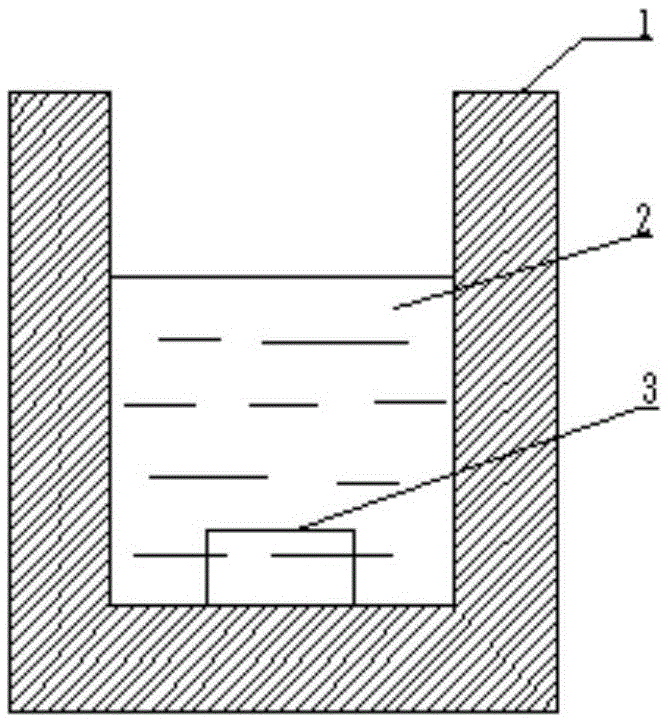

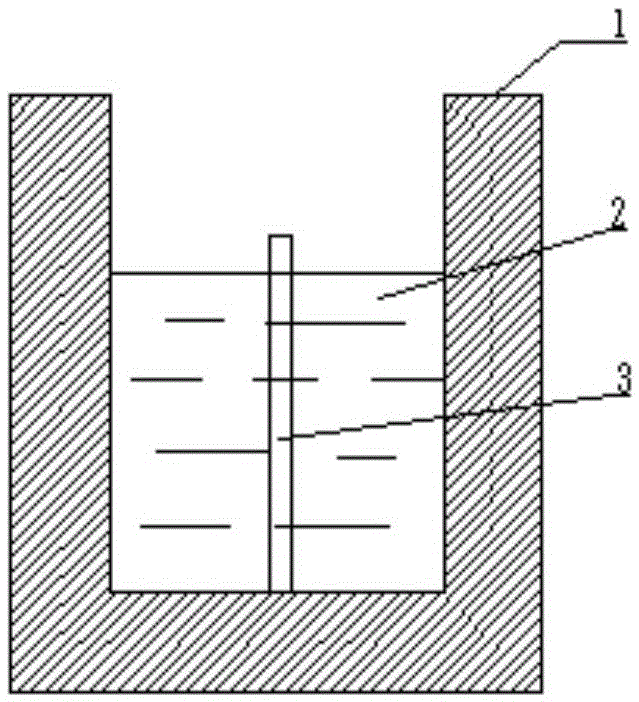

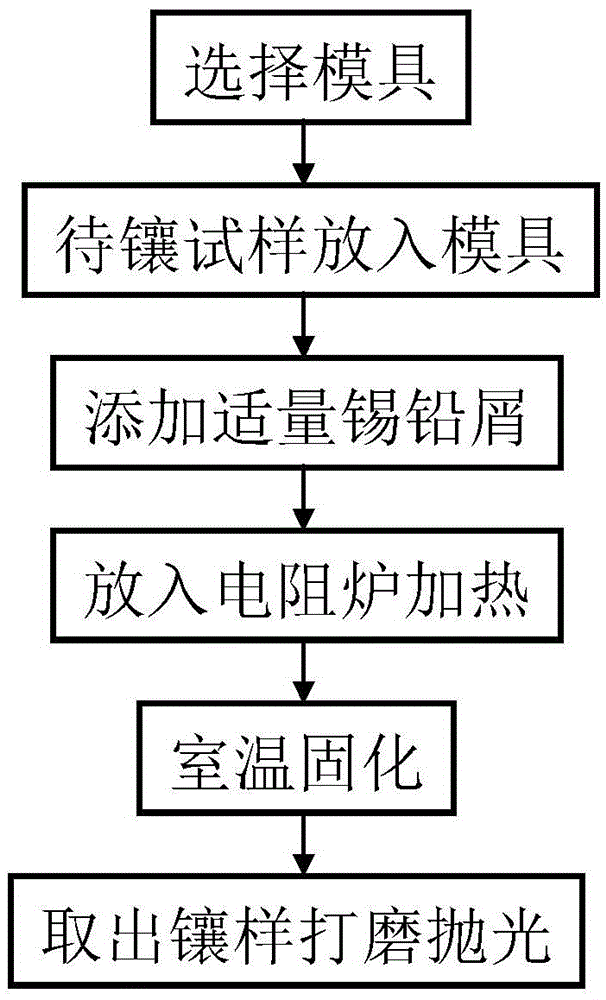

[0026] The technological process of the sample mounting method of the metallographic sample of the present invention is as follows:

[0027] Mold preparation: Al in mass percent 2 o 3 ≥99%, SiO 2 ≤0.2%, Fe 2 o 3 ≤0.1%, and the balance is caustic soda to prepare a mold crucible, and the mold size is 15mm×15mm×20mm.

[0028] Mounting the sample into the mold: place the sample to be mounted in the appropriate position of the mold.

[0029] Add appropriate amount of tin-lead scraps: Add appropriate amount of tin-lead scraps according to the size of the mold, and the mosaic material is tin-lead scraps with a tin content of 60-80wt%.

[0030] Heating: heat in a box-type resistance furnace for 0.5h, and the temperature in the resistance furnace is controlled at 300°C.

[0031] Curing at room temperature: take it out and cure it at room temperature for 0.5h, then the mount can be taken out.

[0032] Grinding and polishing: Use 120#, 320#, 800#, 1000#, 1500# sandpaper to grind t...

Embodiment 2

[0034] The technological process of the sample mounting method of the metallographic sample of the present invention is as follows:

[0035] Mold preparation: Al in mass percent 2 o 3 ≥99%, SiO 2 ≤0.2%, Fe 2 o 3 ≤0.1%, and the balance is caustic soda to prepare a mold crucible, and the mold size is Φ15mm×20mm.

[0036] Mounting the sample into the mold: place the sample to be mounted in the appropriate position of the mold.

[0037] Add appropriate amount of tin-lead scraps: Add appropriate amount of tin-lead scraps according to the size of the mold, and the mosaic material is tin-lead scraps with a tin content of 60-80wt%.

[0038] Heating: Put it into a box-type resistance furnace for heating for 5 hours, and the temperature in the resistance furnace is controlled at 500°C.

[0039] Curing at room temperature: take it out and cure it at room temperature for 2 hours, then you can take out the mount.

[0040] Grinding and polishing: Use 120#, 320#, 800#, 1000#, 1500# sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com