Patents

Literature

54 results about "Intact tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

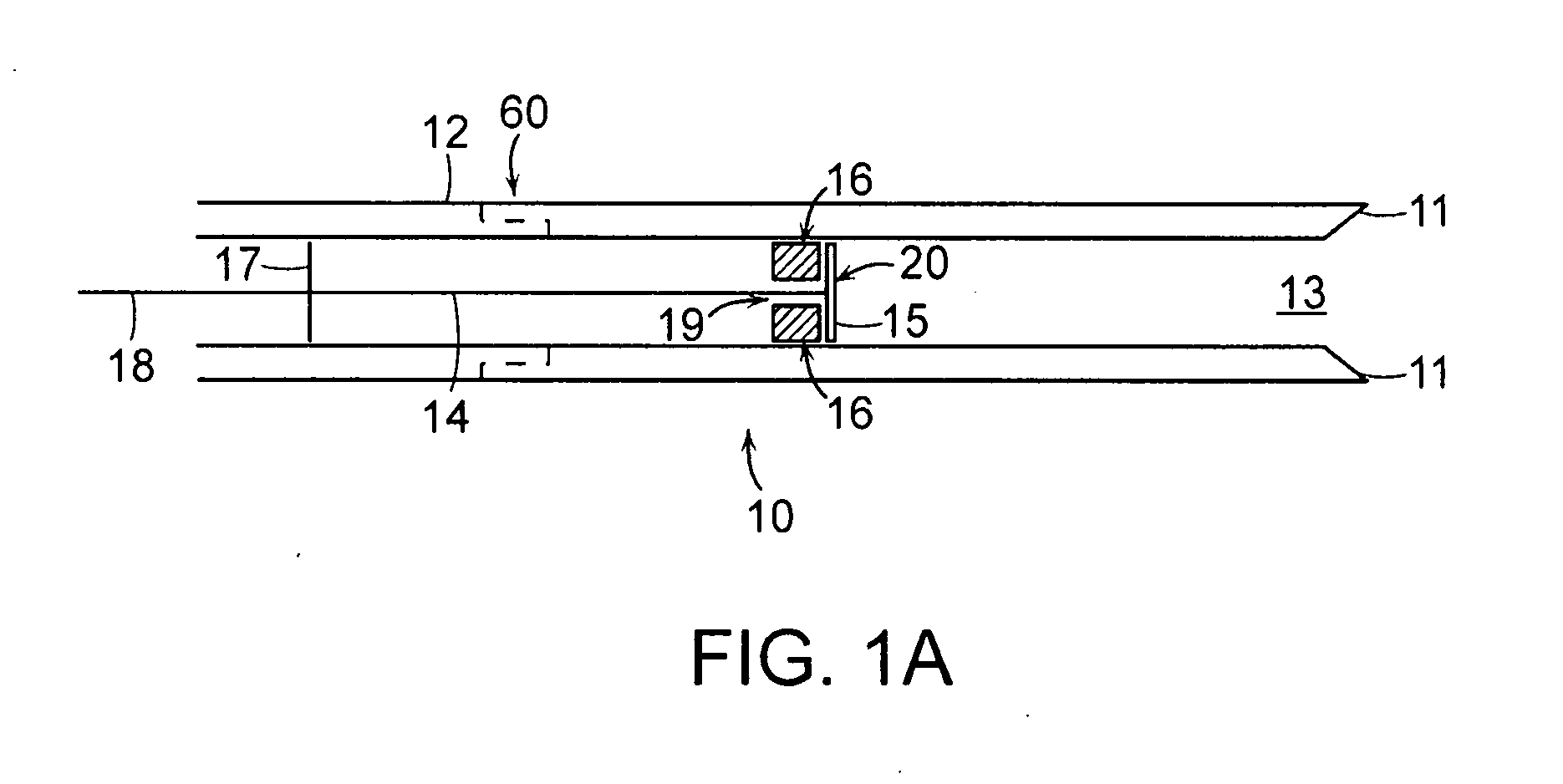

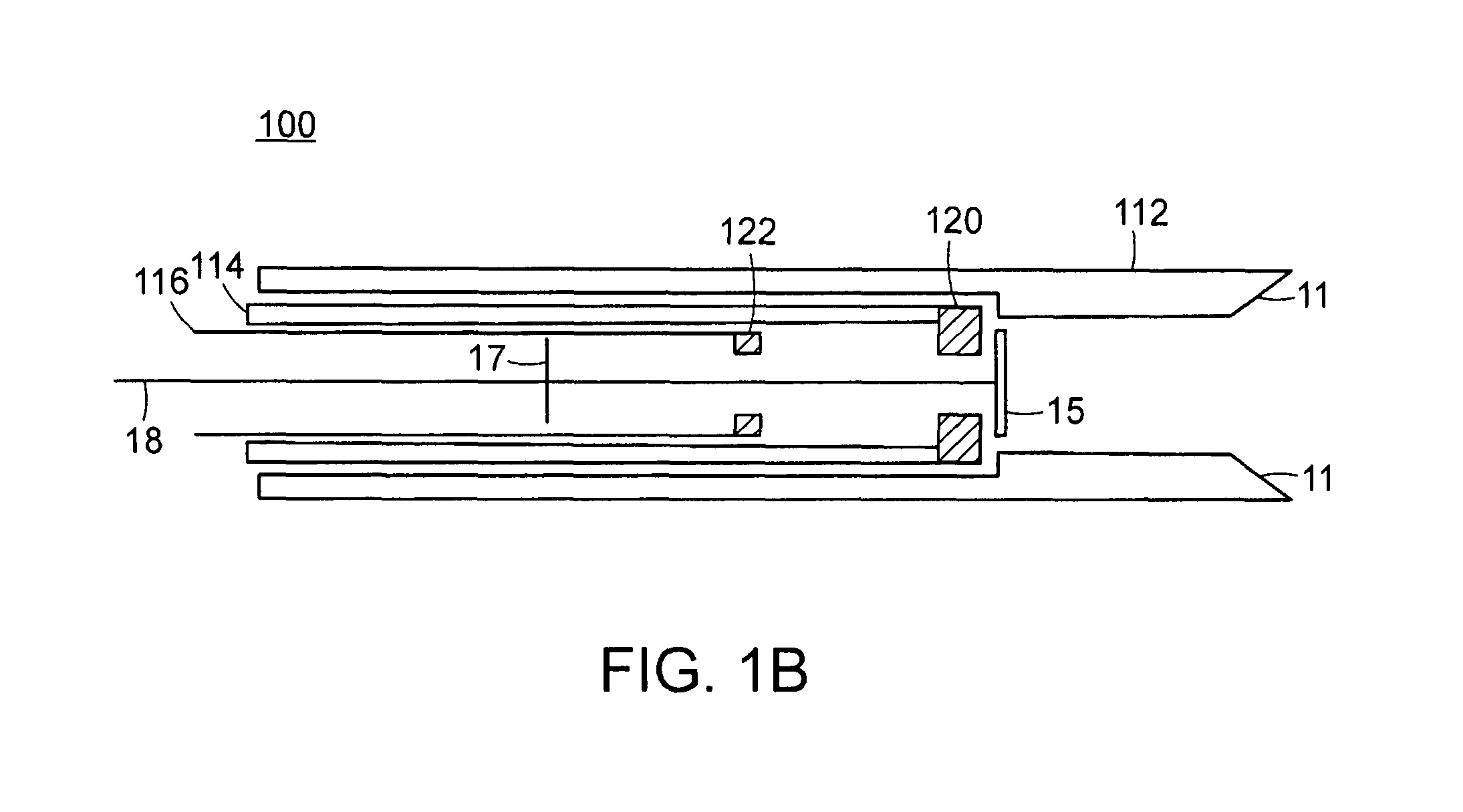

Method and device to obtain percutaneous tissue samples

InactiveUS20060122535A1Surgical needlesVaccination/ovulation diagnosticsDiagnostic Radiology ModalityResonance

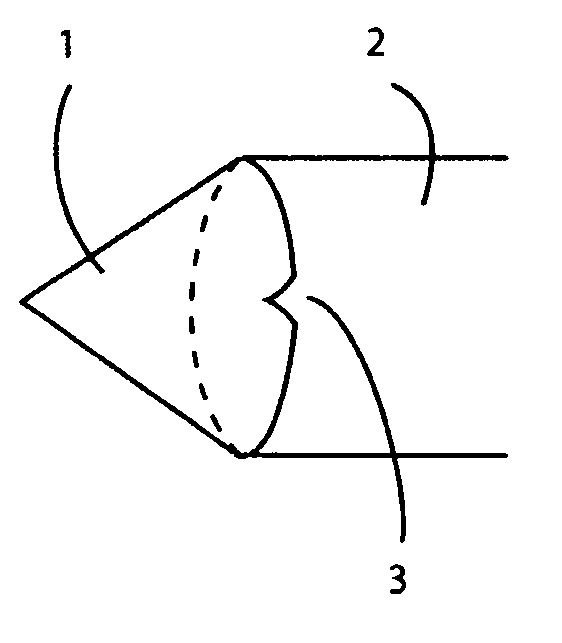

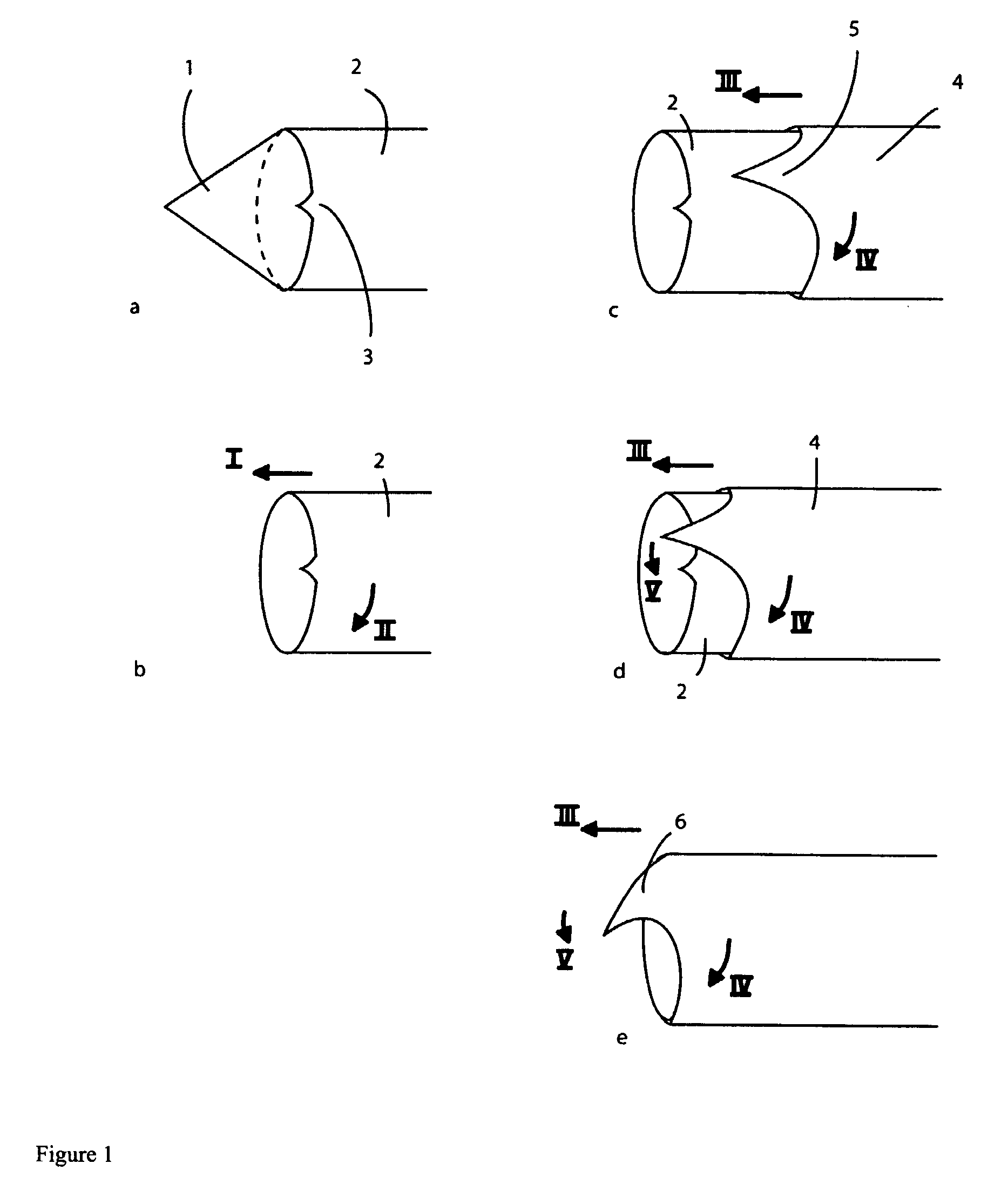

A new method and design for a percutaneous biopsy system that cuts only the tissue lesion specimen and that does not penetrate through or beyond the targeted tissue into intact tissue. The proposed mechanism operates only in the targeted lesion space and leaves healthy or unsuspicious tissue intact. The proposed biopsy mechanism will cut the specimen in front of the tip of the guiding needle. The device may be image guided by ultrasound, any x-ray based modality or magnetic resonance (MRI).

Owner:DAUM WOLFGANG

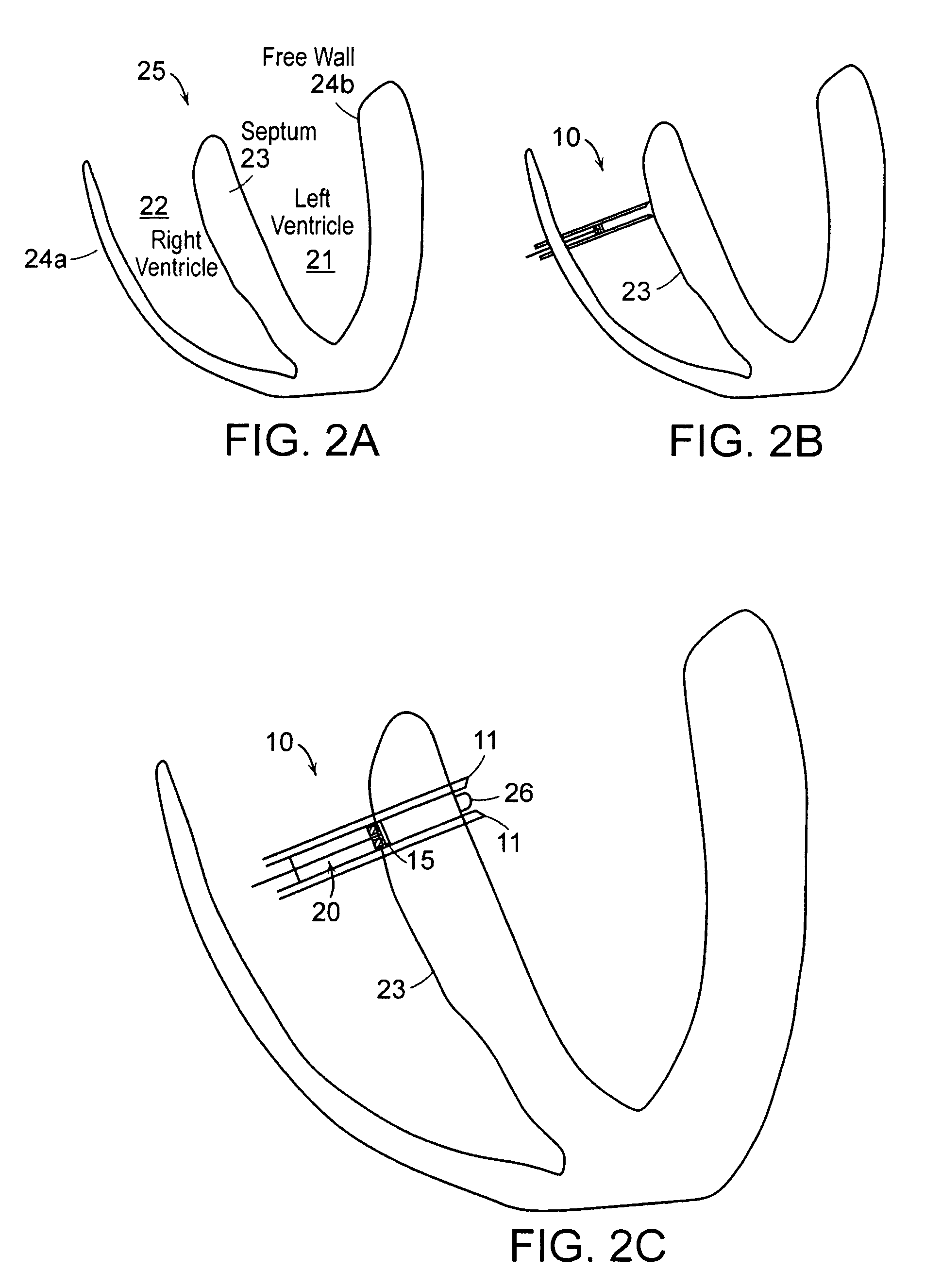

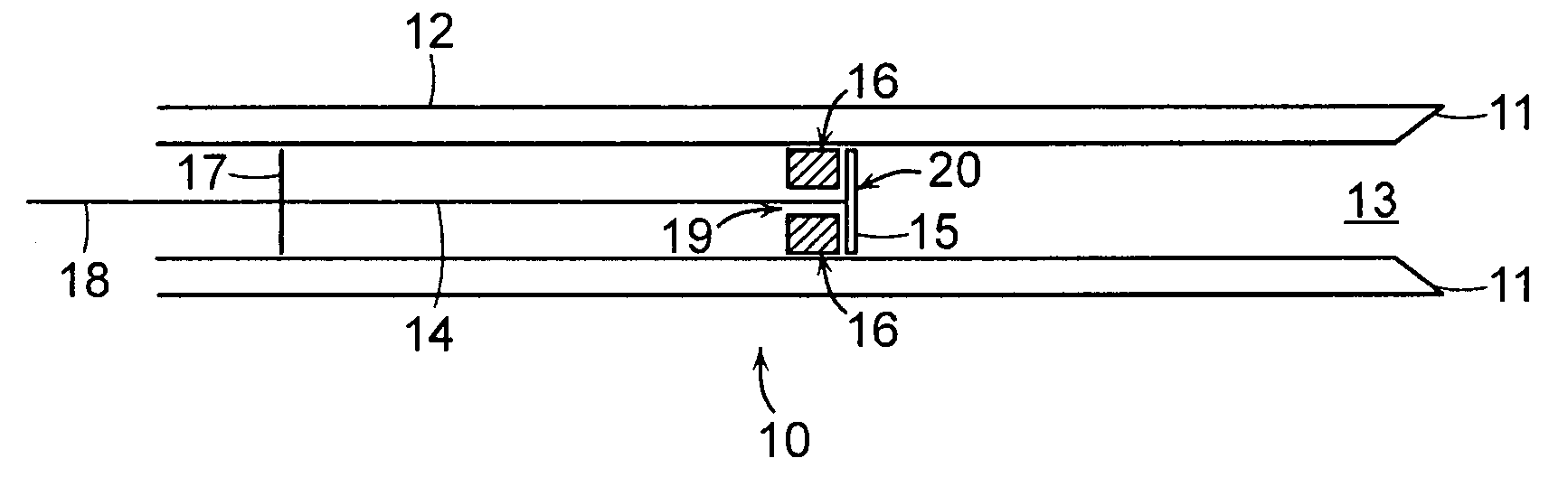

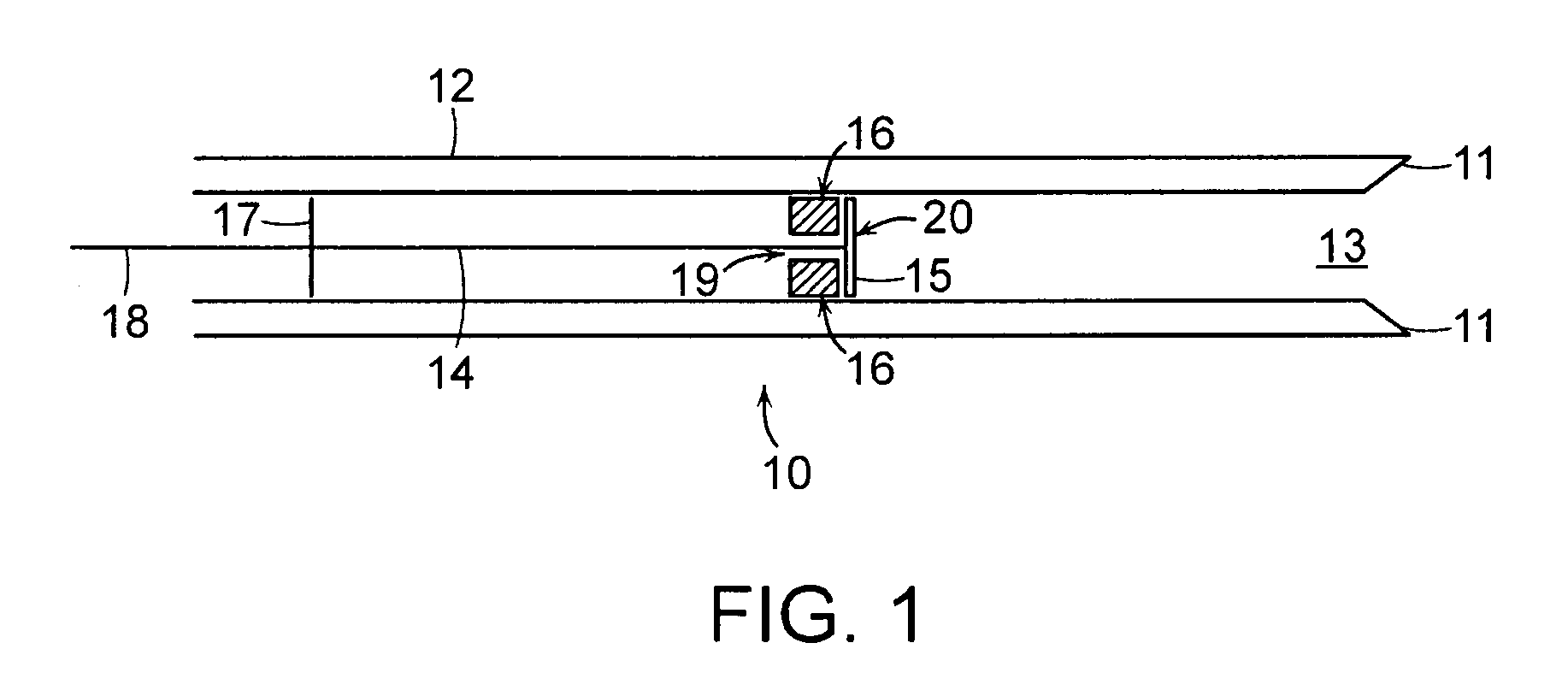

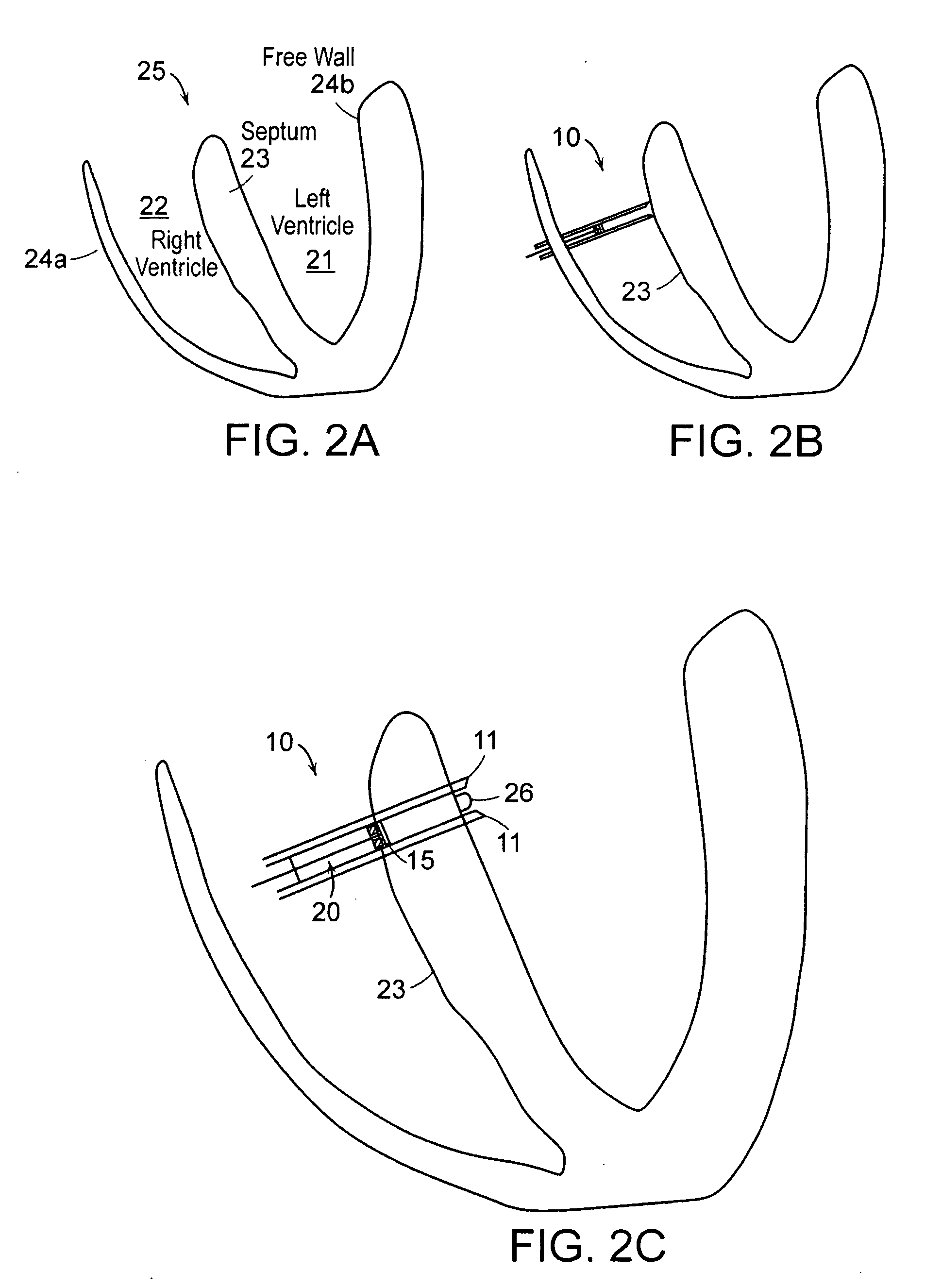

Devices and methods for tissue transplant and regeneration

InactiveUS20070239066A1Promote cell growthIncrease the number ofSurgical needlesVaccination/ovulation diagnosticsIntact tissueMedicine

Devices and methods for transplanting tissue for the purpose of regeneration, for treating a patient having injured myocardial tissue, and / or for improving cardiac function through cell regrowth. More specifically, the devices and methods obviate the need for cellular alteration. The devices comprise a hollow tube with a sharp distal end, a stylet that is disposed and movable within the hollow tube, and a stopping device that constrains movement of the stylet. The methods comprise removing intact tissue from a first region of a mammalian organ and implanting the tissue in a second region of the same organ.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

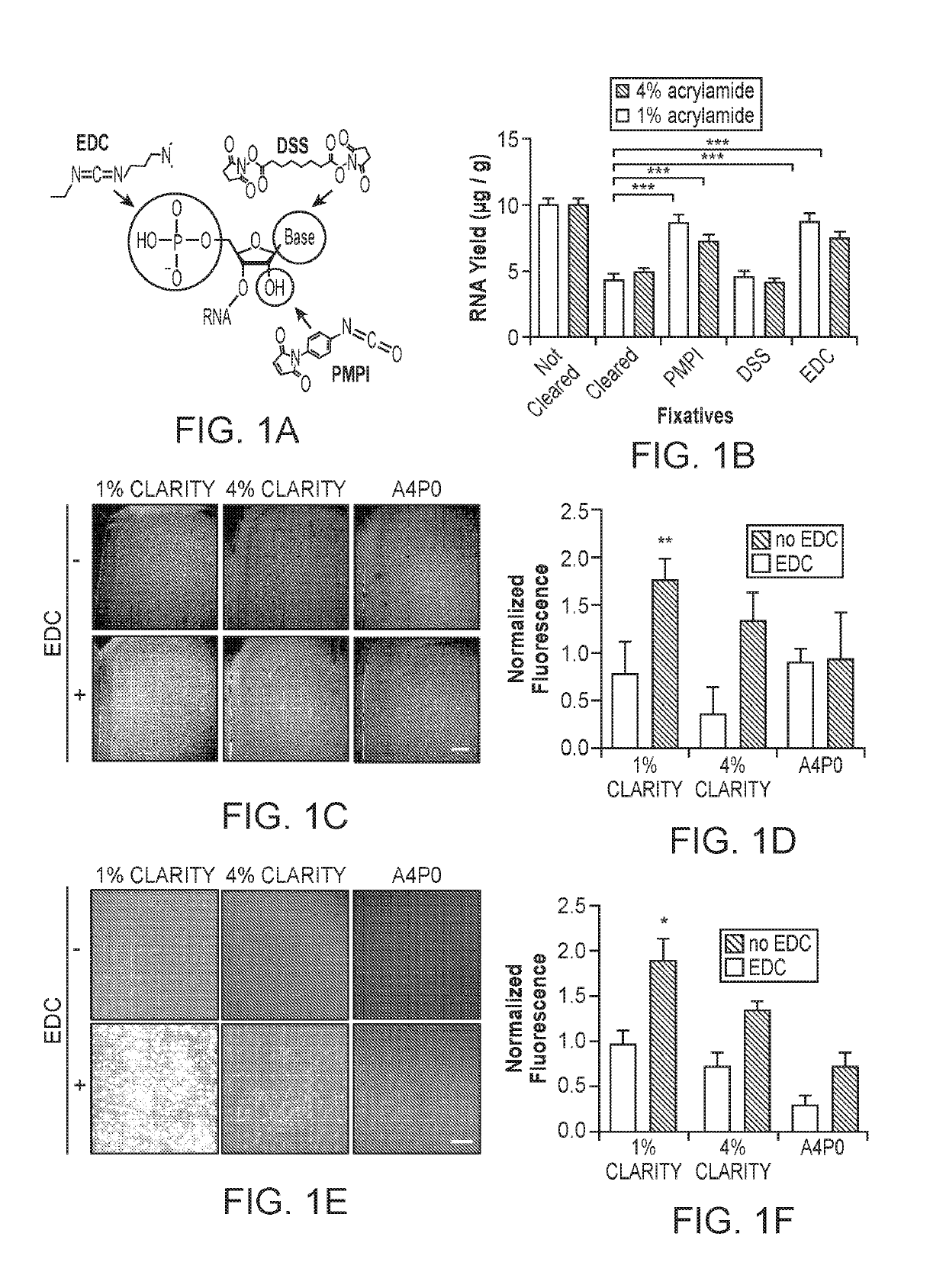

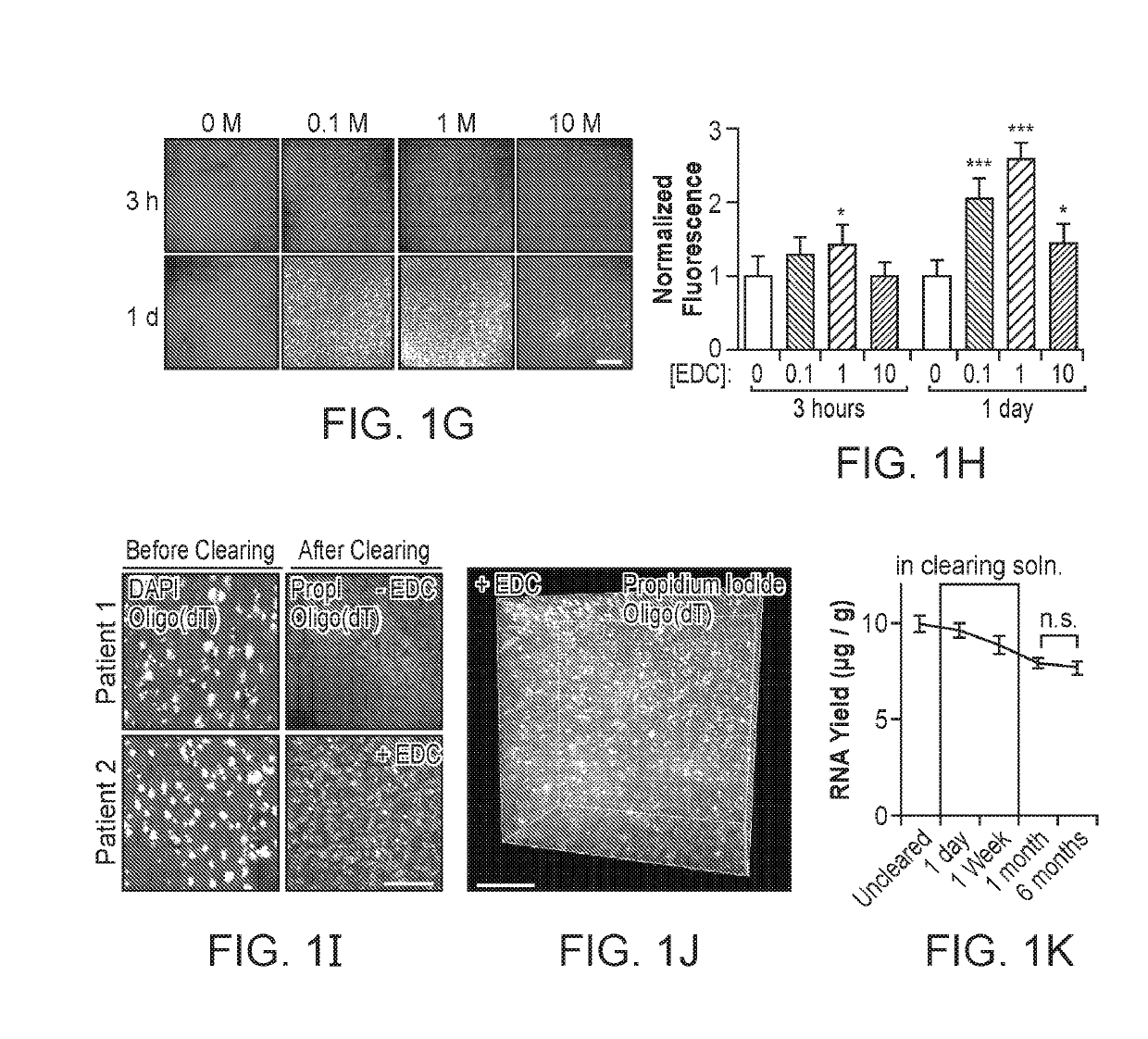

RNA Fixation and Detection in CLARITY-based Hydrogel Tissue

ActiveUS20190119735A1Microbiological testing/measurementPreparing sample for investigationCLARITYIntact tissue

Methods, kits, and systems for fixation of RNA permitting its detection in intact tissue, such as, large volume of mammalian tissue are disclosed. The methods, kits, and systems utilize carbodiimide-based chemistry to stably retain RNAs in tissue clarified using CLARITY. Also provided herein are methods, kits, and systems for detection of RNAs in clarified tissue.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

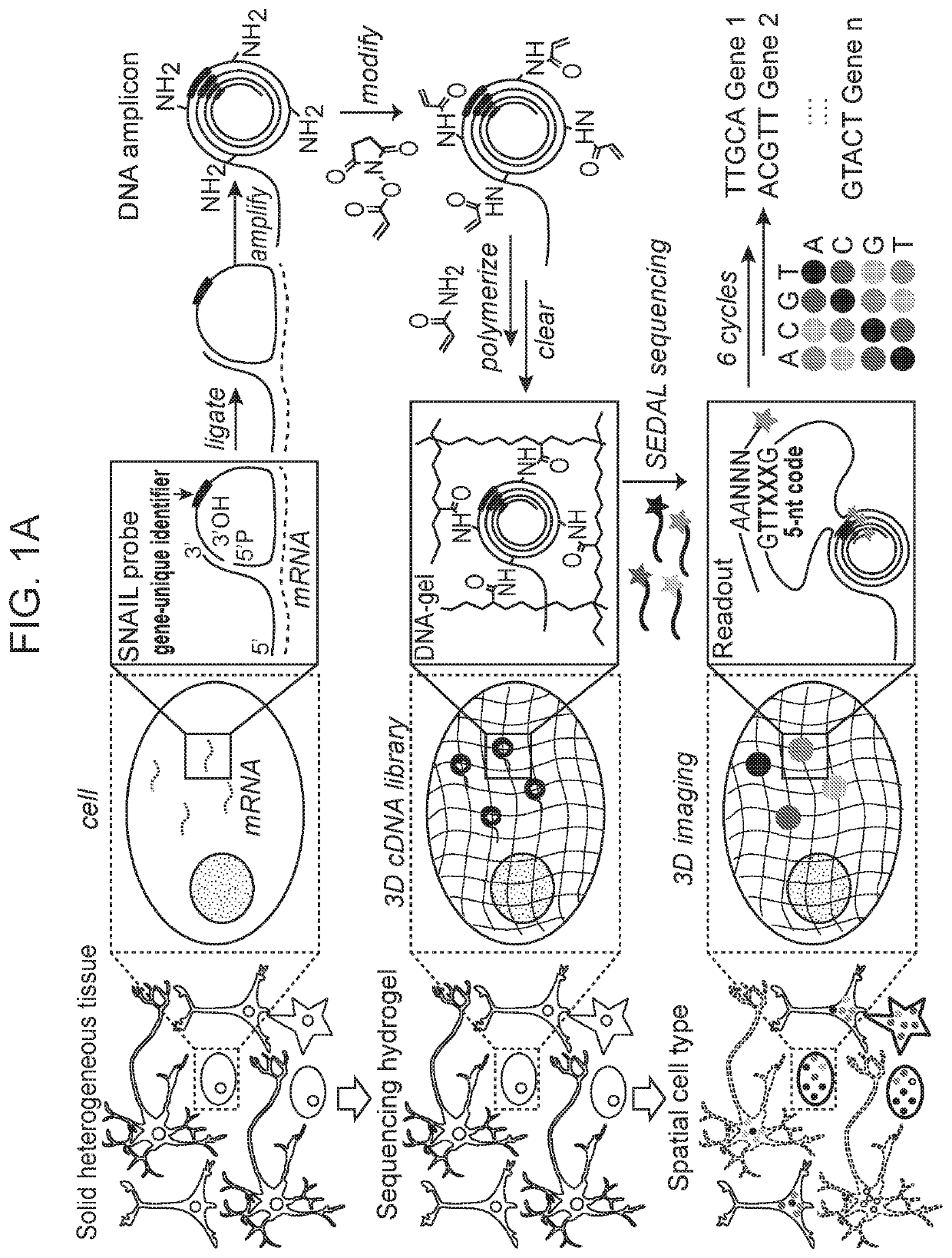

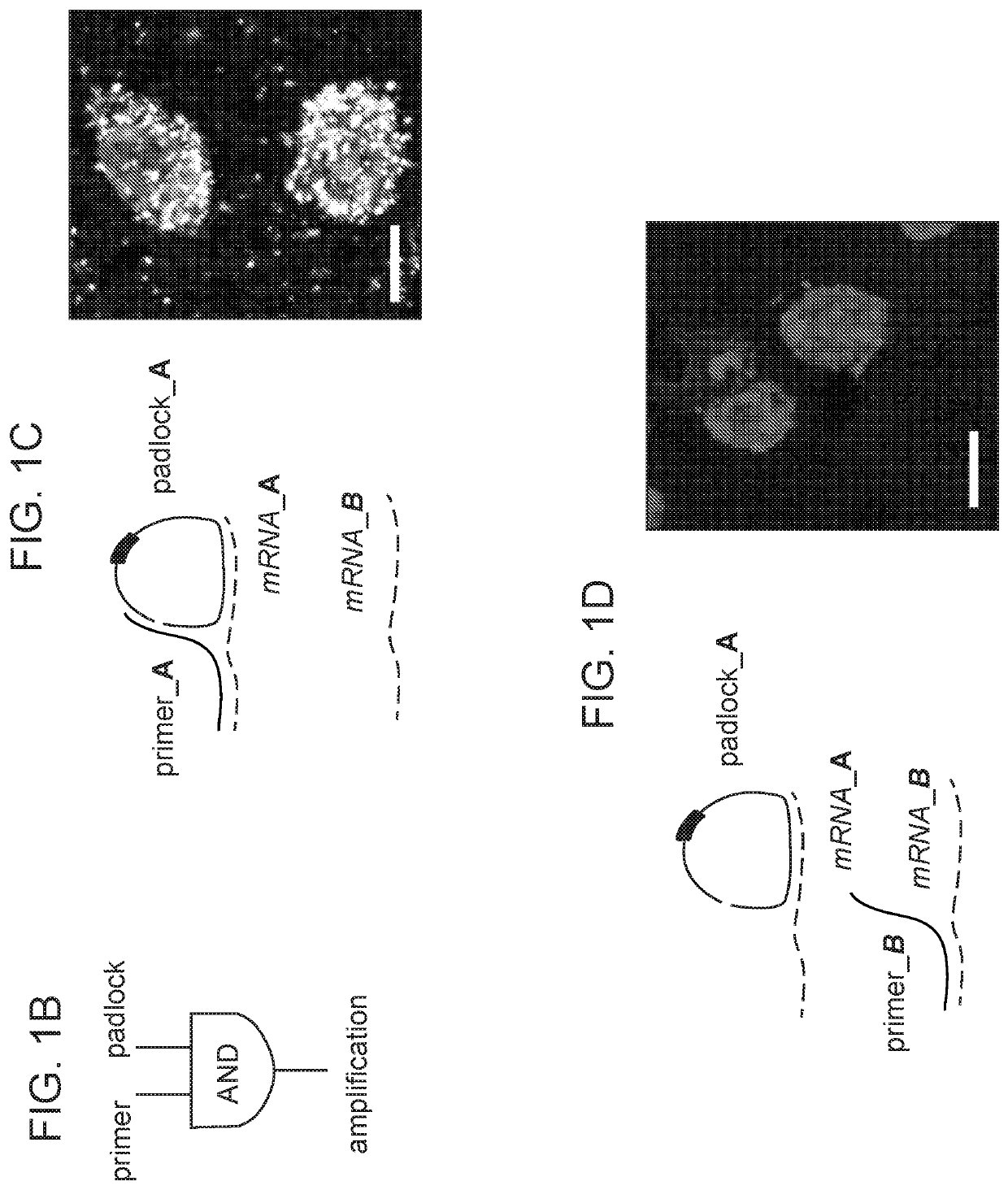

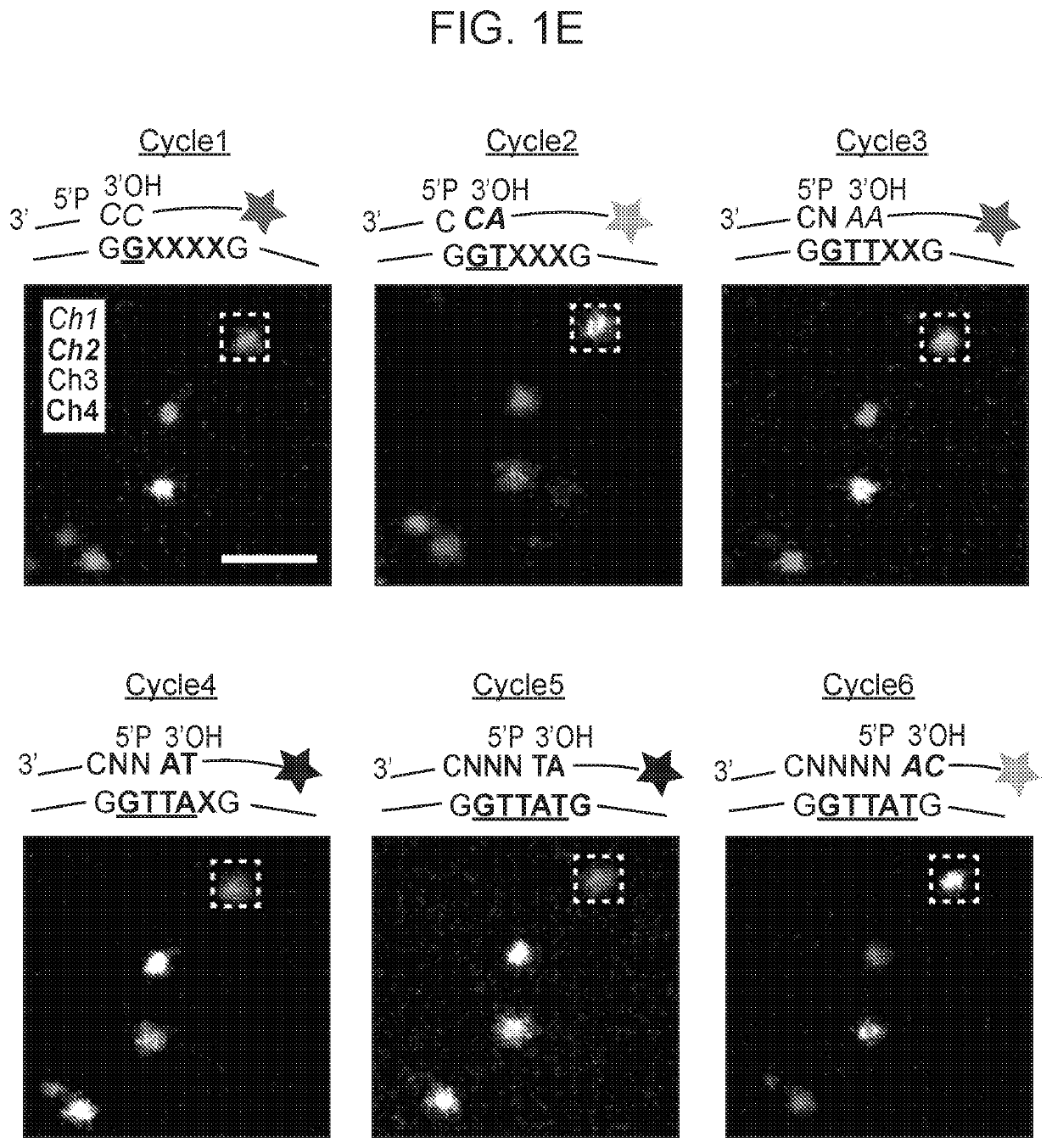

Method of in situ gene sequencing

Provided herein are devices, methods, and systems for in situ gene sequencing of a target nucleic acid in a cell in an intact tissue. Methods of screening a candidate agent to determine whether the candidate agent modulates gene expression of a nucleic acid in a cell in an intact tissue are also provided herein.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

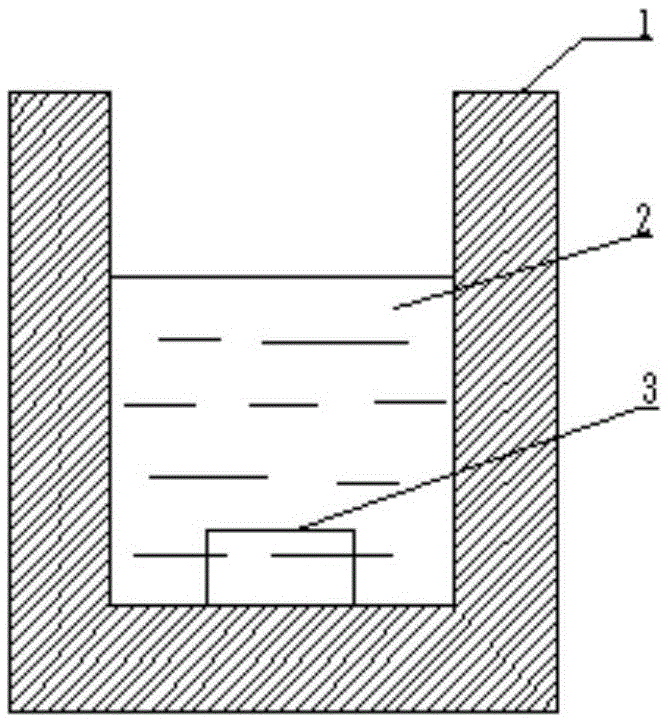

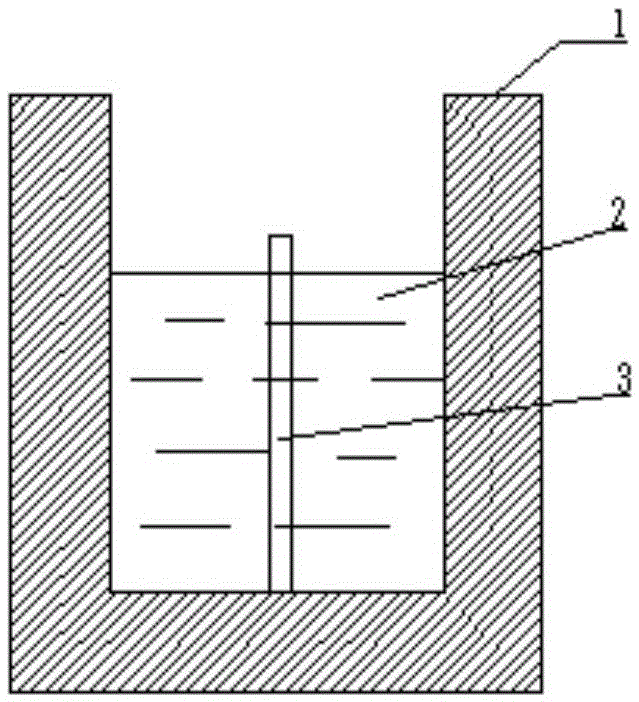

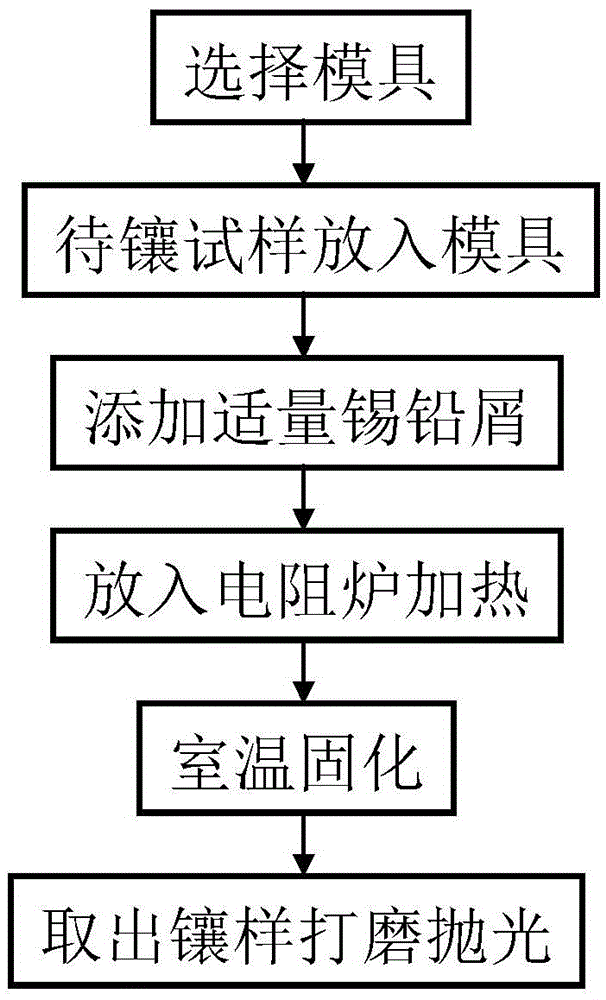

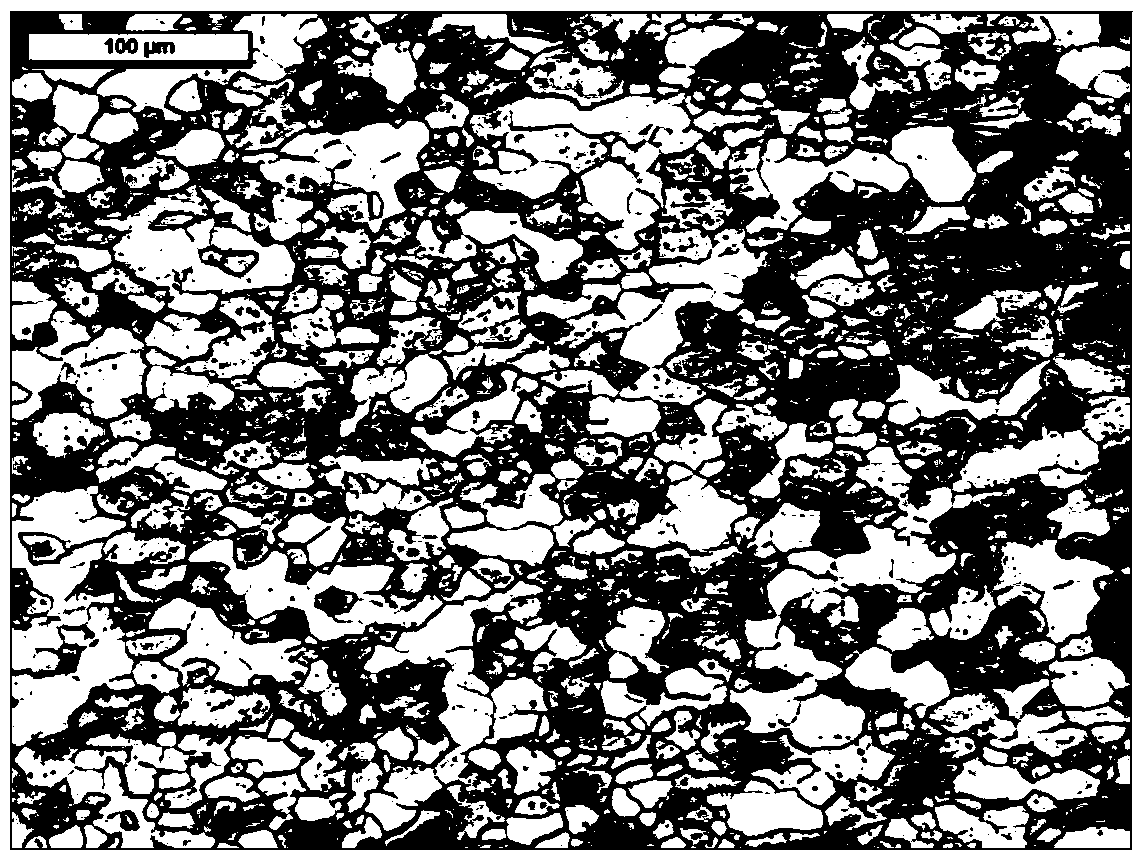

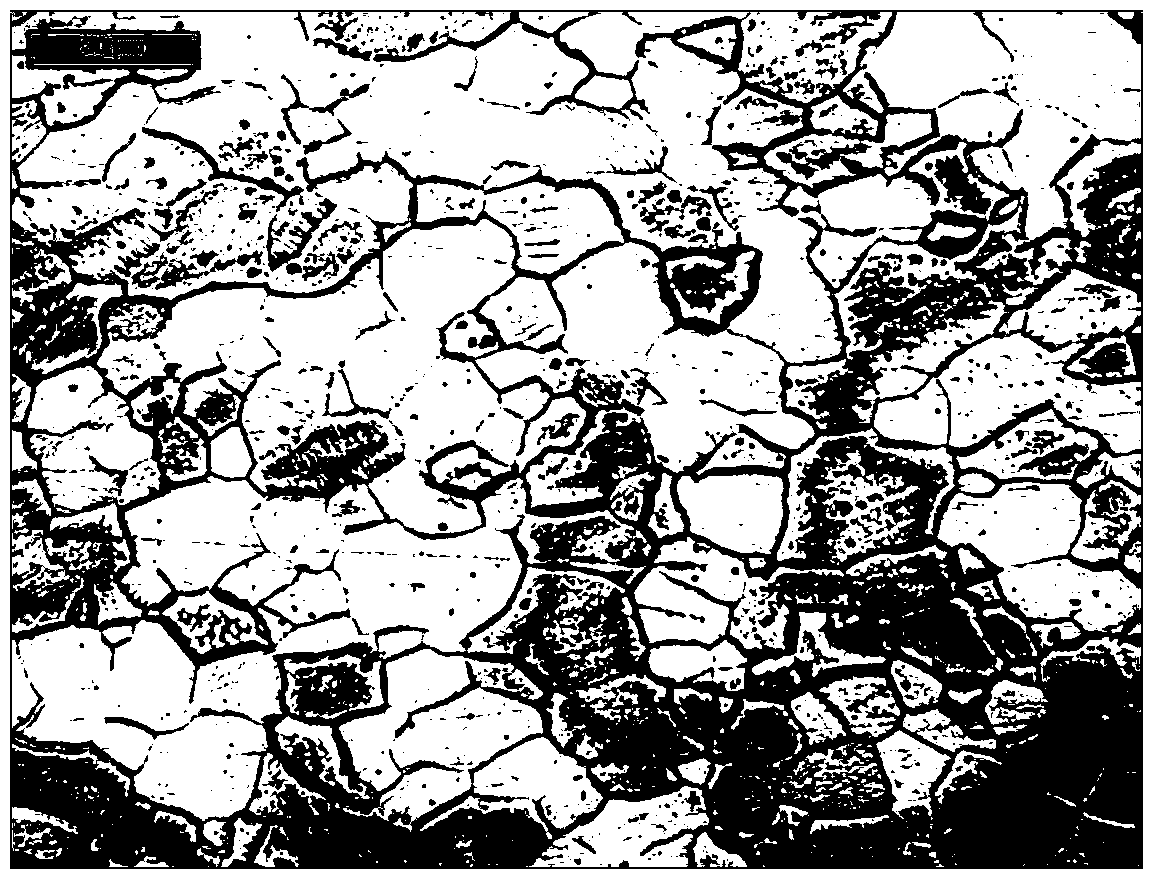

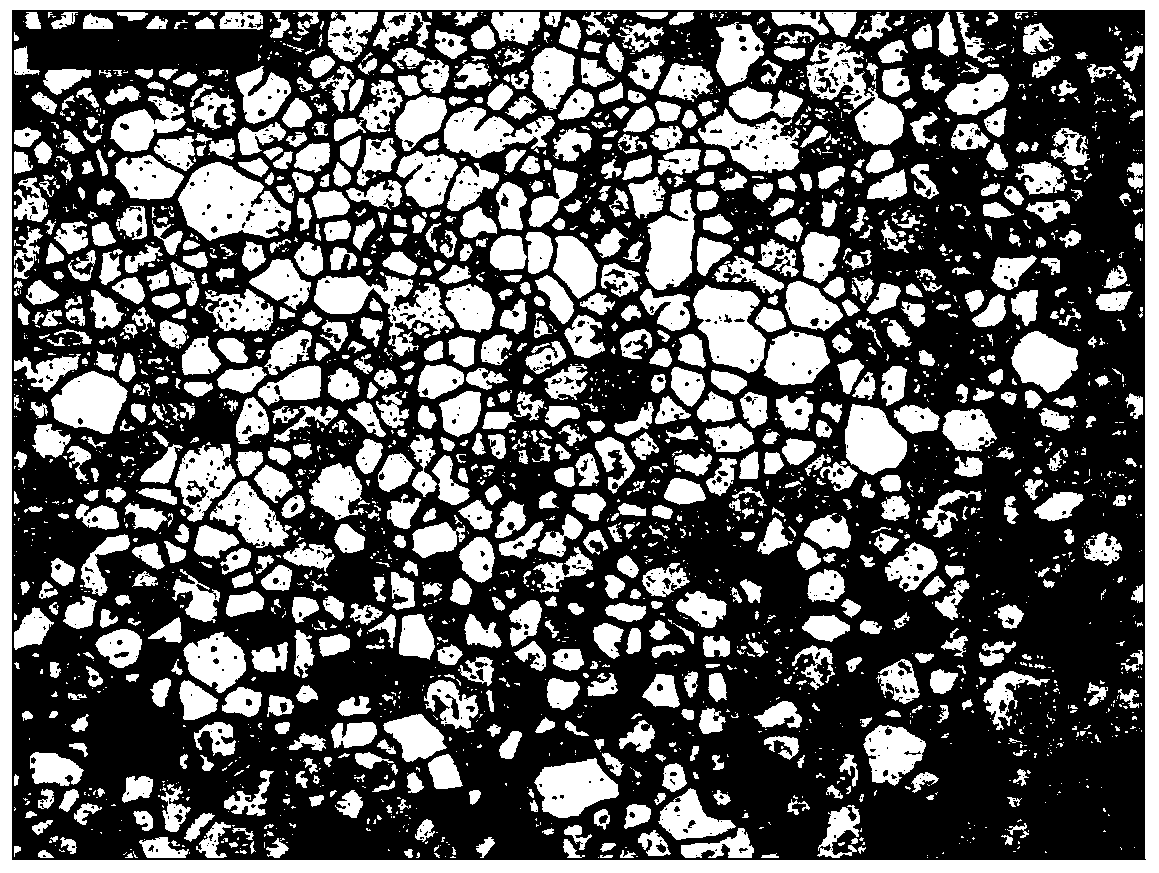

Embedding method for metallographic specimen

ActiveCN105547783AEasy to prepareImprove conductivityPreparing sample for investigationIntact tissueElectronic differential

The invention relates to an embedding method for a metallographic specimen. The required device comprises a low-temperature chamber electric furnace and a mould; a mould crucible is prepared by taking the following components by weight percent: more than or equal to 99% of Al2O3, less than or equal to 0.2% of SiO2, less than or equal to 0.1% of Fe2O3 and the balance of alkali; the mould can be in various specifications, such as 15mm*15mm*20mm and phi 15mm*20mm; and tin and lead scraps containing 60-80wt% of tin are taken as embedding materials. The method comprises the following steps: putting a to-be-embedded specimen into the mould; adding a right amount of the tin and lead scraps according to the size of the mould; putting into an electric furnace at a preset temperature and then heating for 0.5-5h; taking out and solidifying for 0.5-2h at room temperature, thereby being capable of taking out the specimen; polishing the specimen step by step by using 120#, 320#, 800#, 1000# and 1500# abrasive paper, and then observing by the polished etched specimen. The specimen prepared according to the method provided by the invention can be applied to the observation for a metallographic microscope or a scanning electron microscope and EBSD (Electron Back-Scattered Diffraction) and EDS (Electronic Differential System) detection, and the data, such as a true and complete organization structure of the specimen, can be acquired.

Owner:BEIJING CISRI GAONA TECH +1

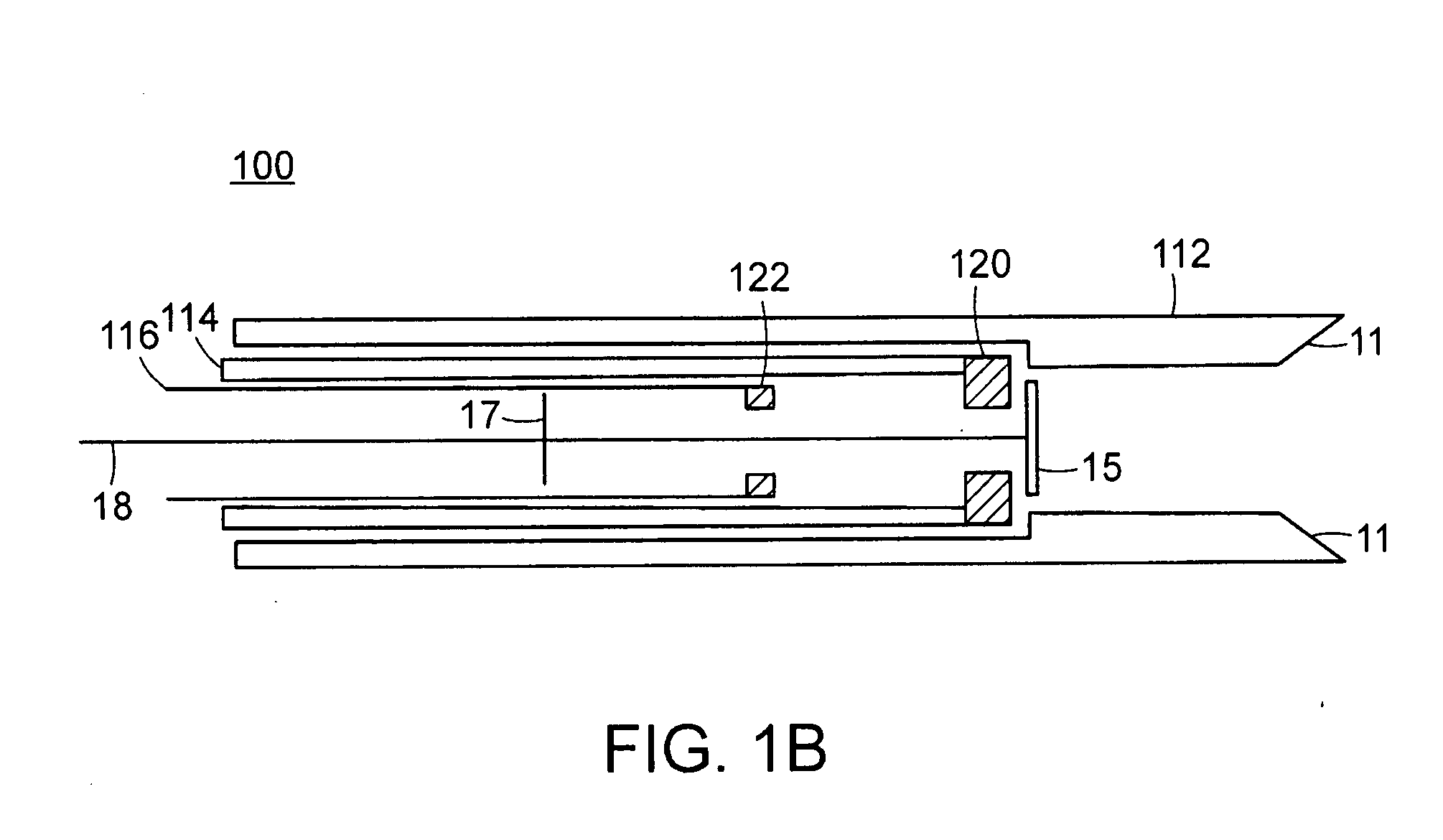

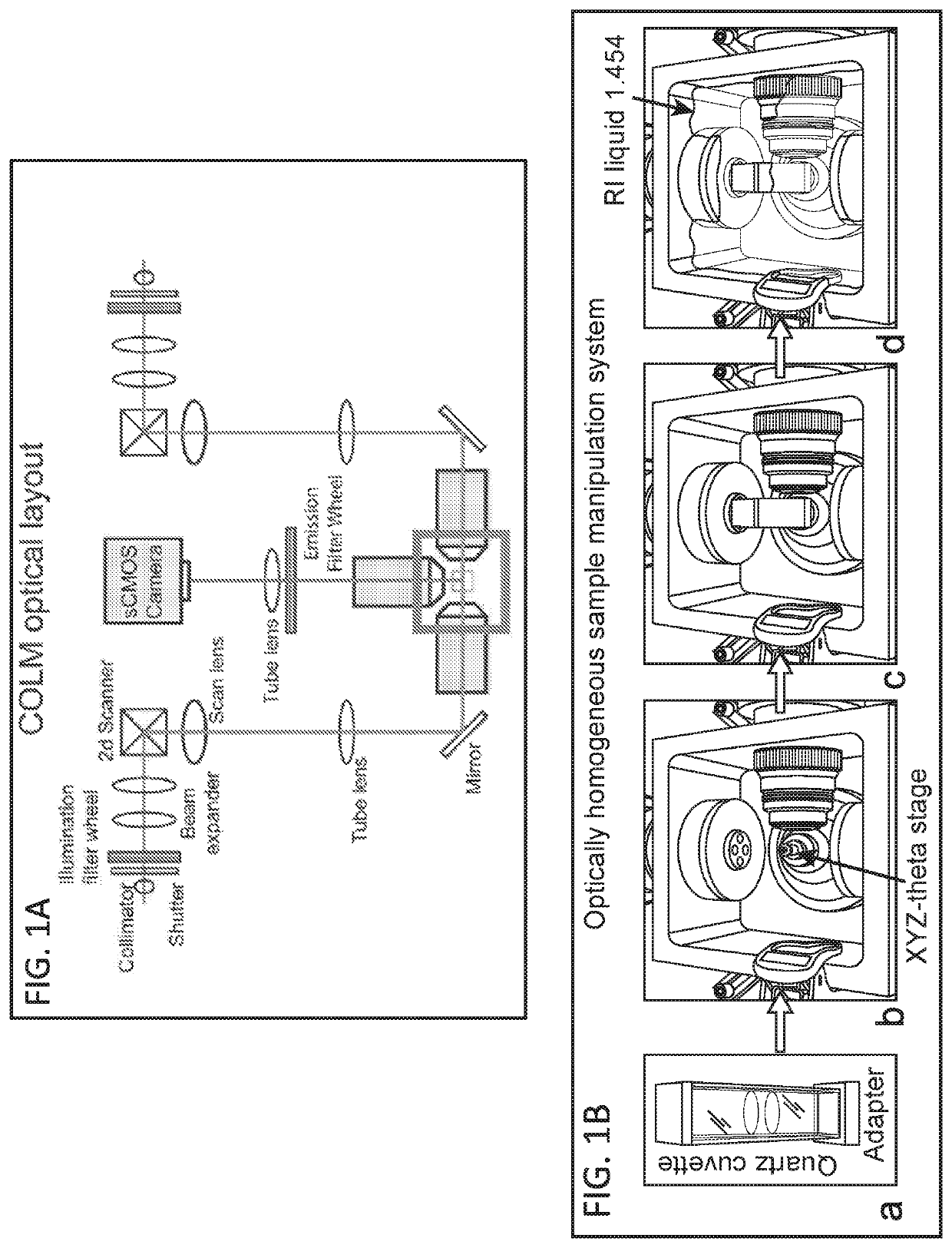

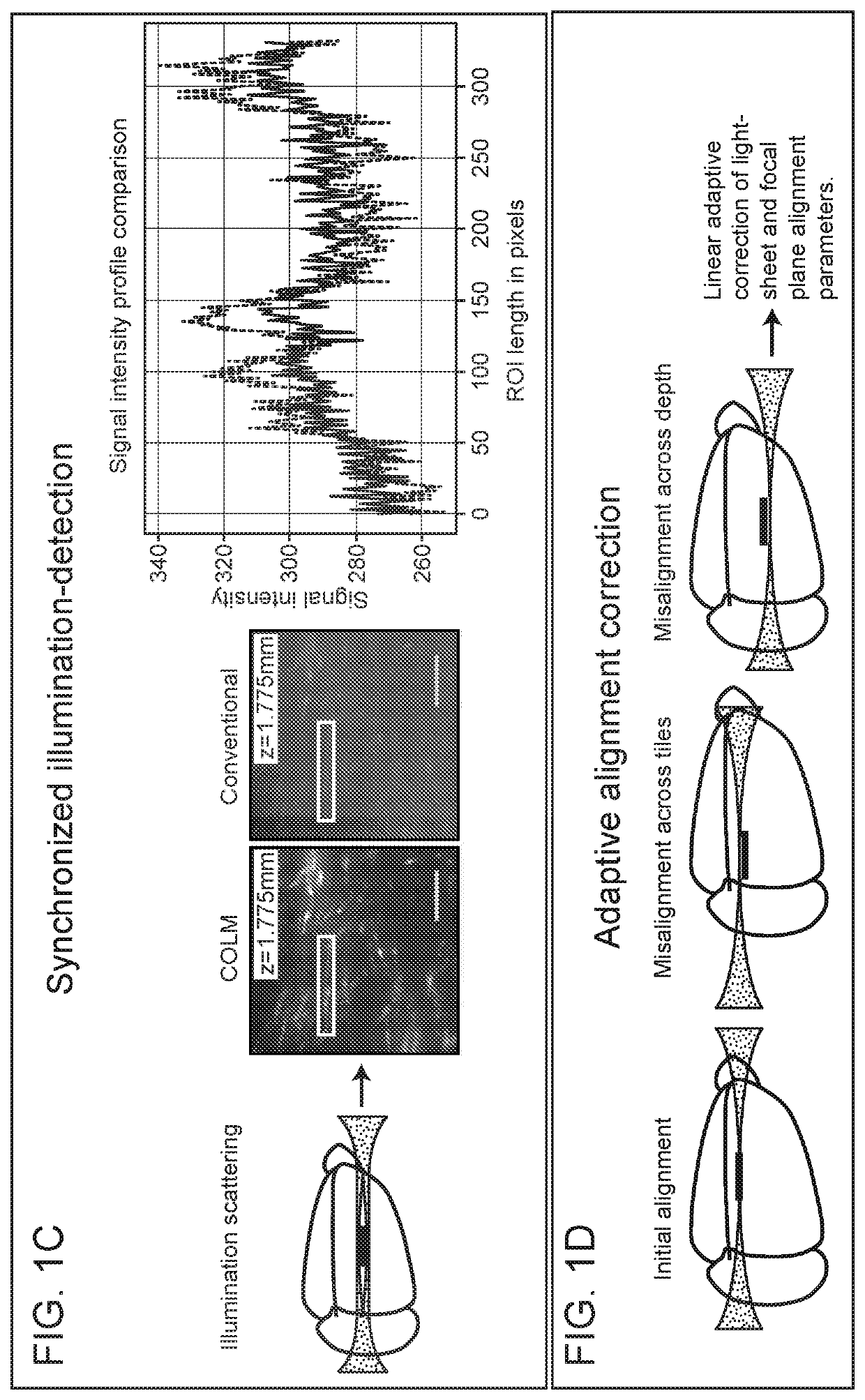

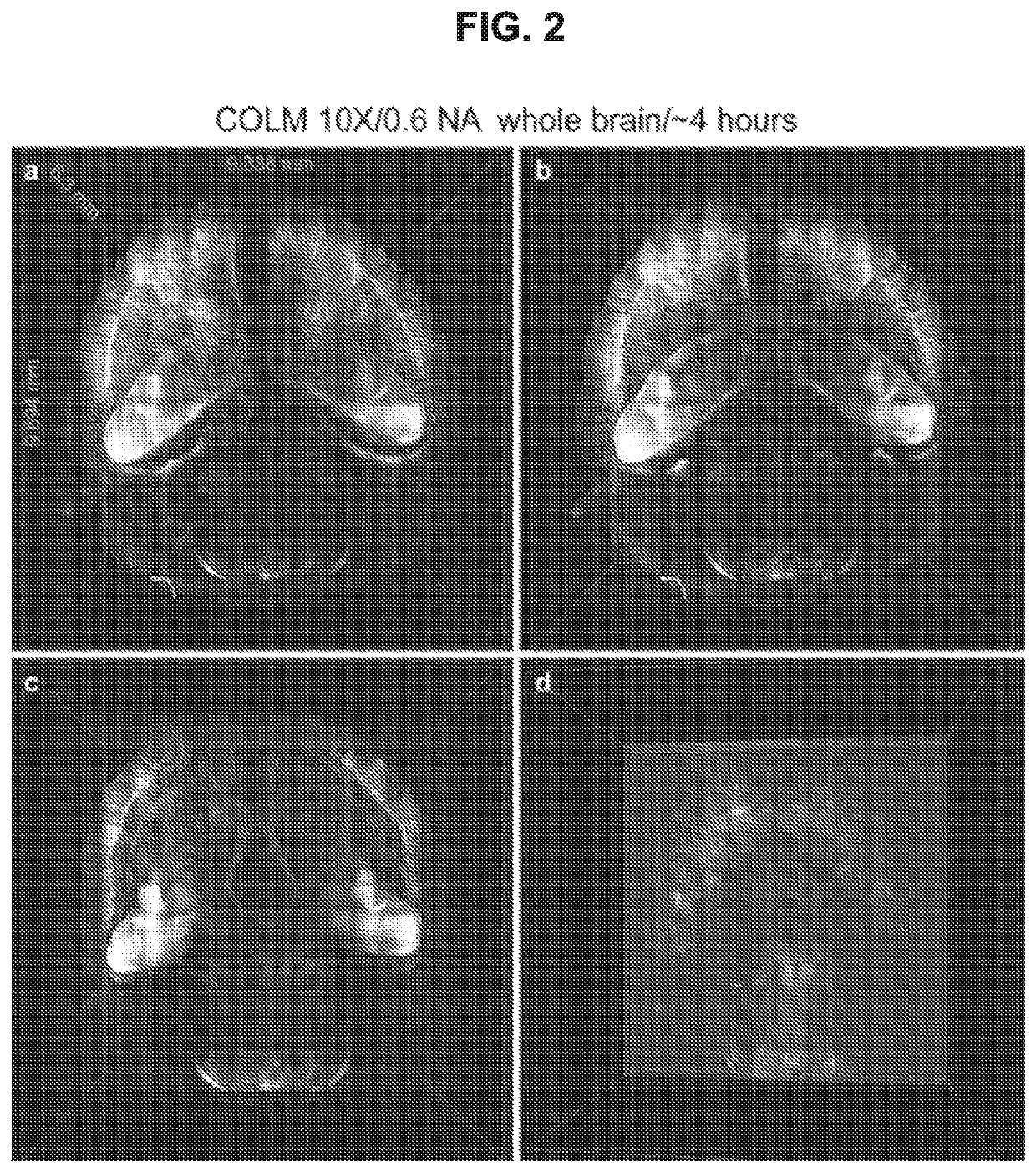

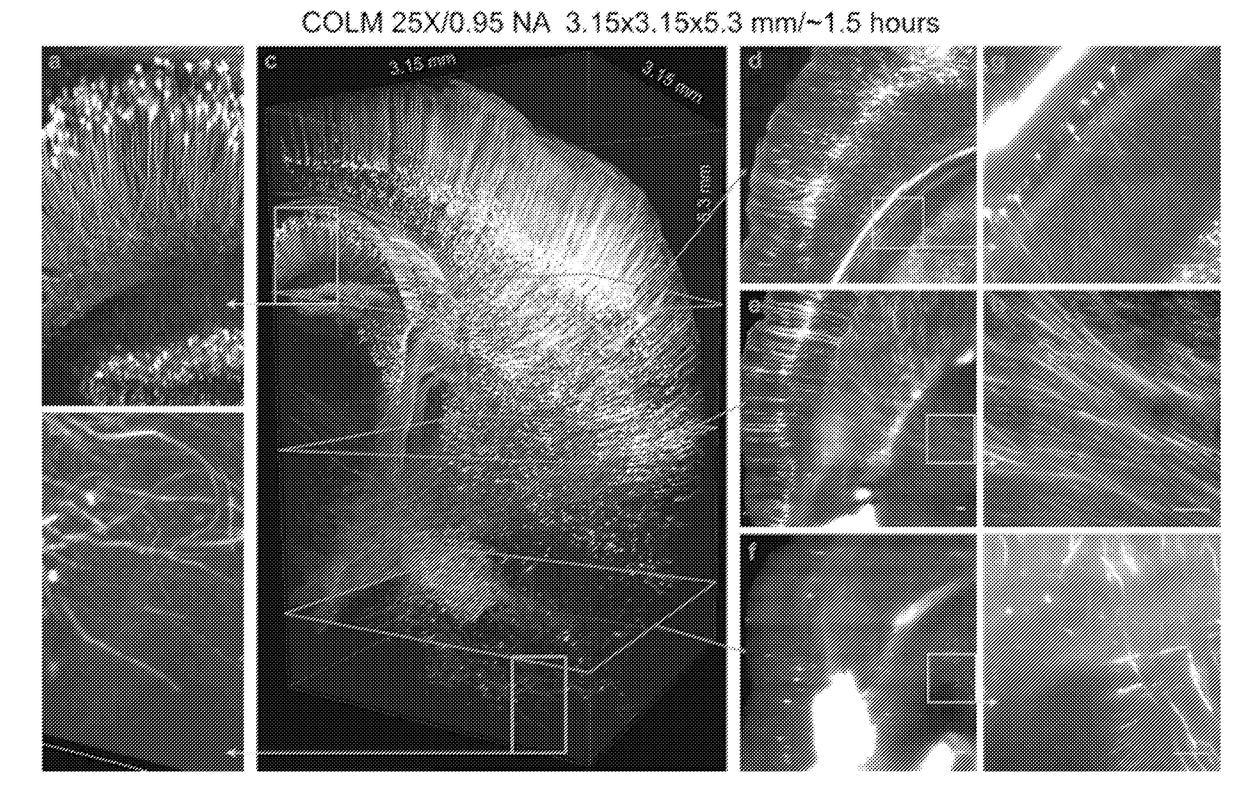

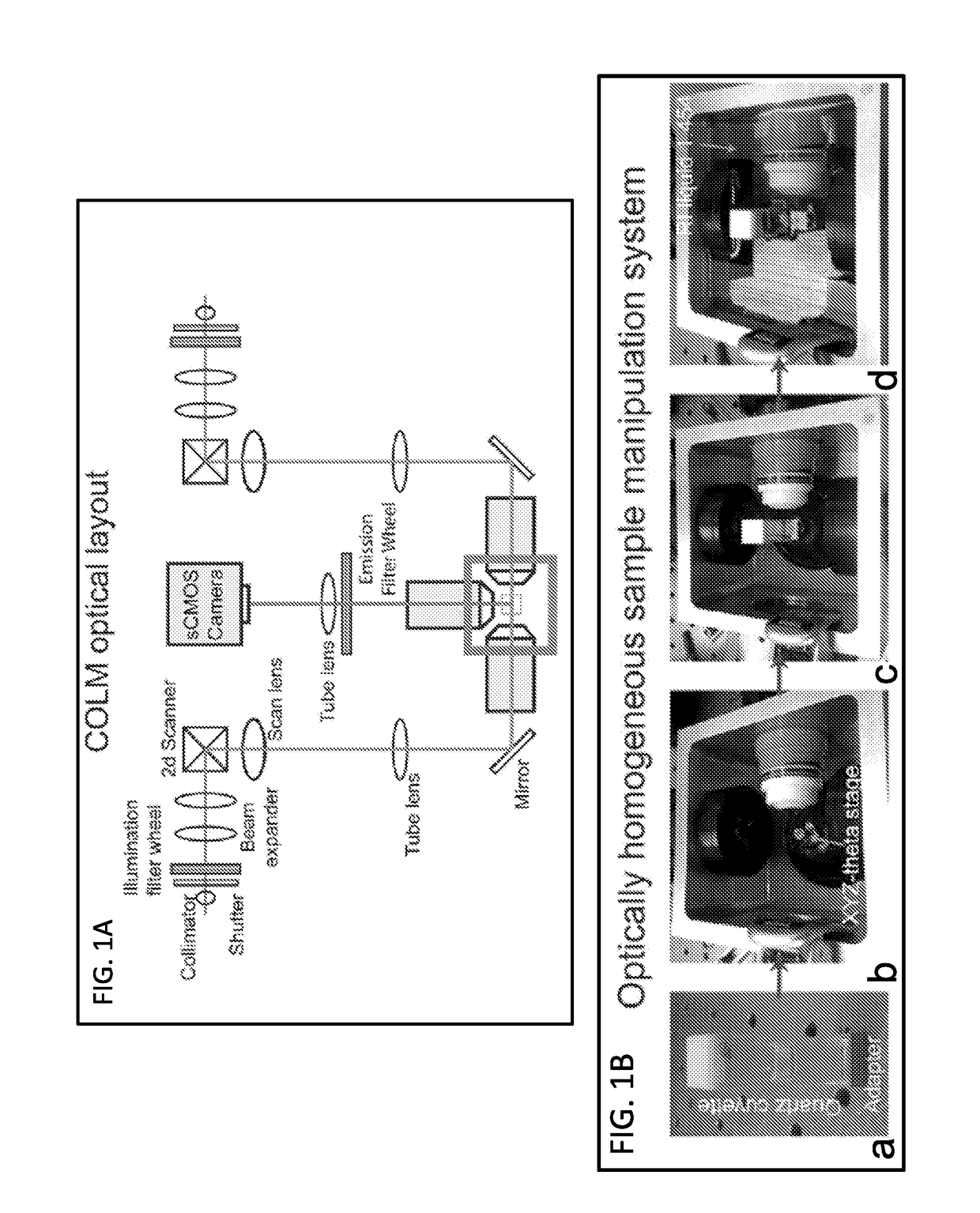

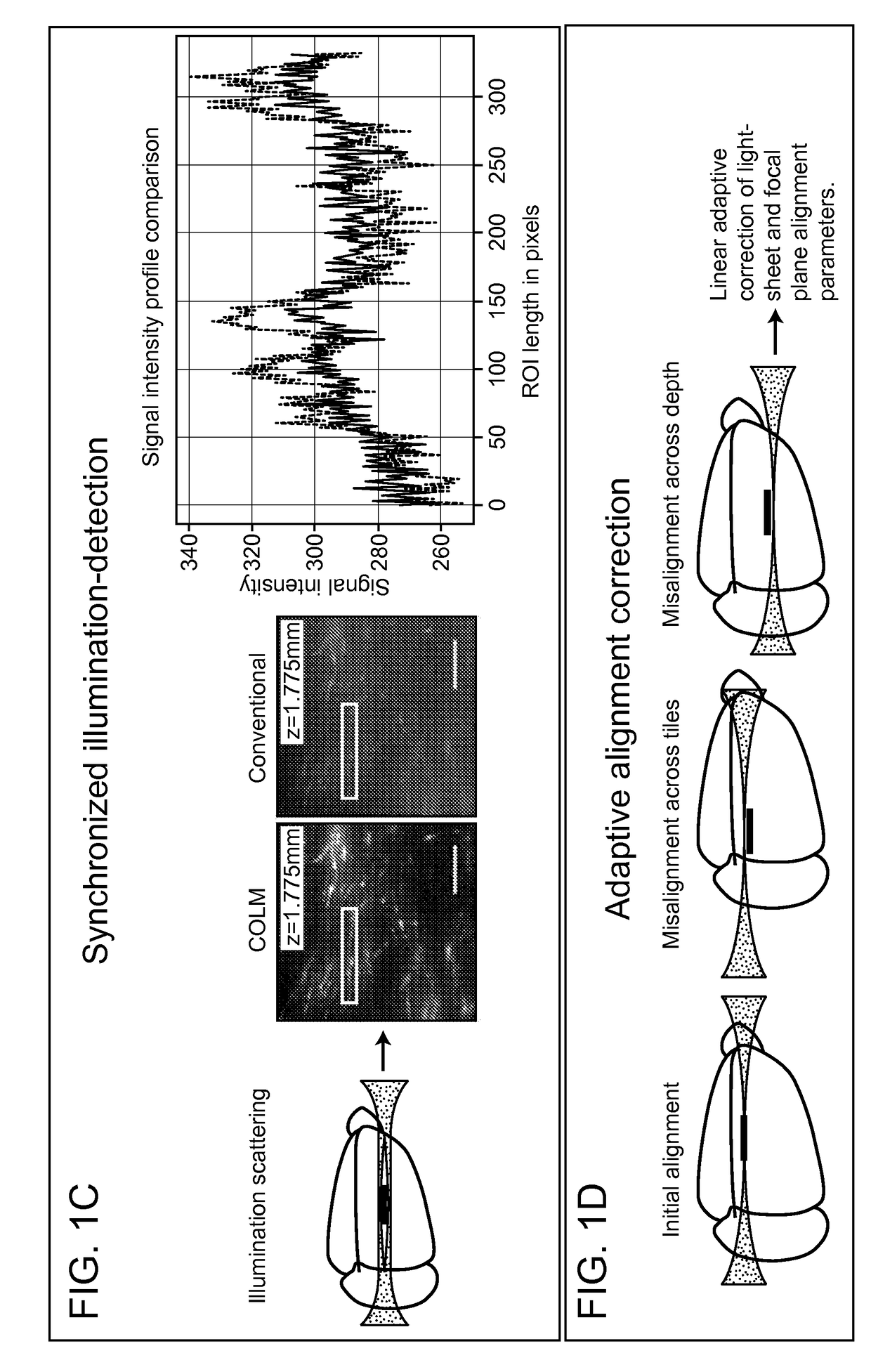

Methods and devices for imaging large intact tissue samples

Methods and devices for conducting high-speed, high-resolution imaging of large intact tissue samples are provided. Aspects of the methods include placing a sample in an optically homogenous sample manipulation component, performing a calibration procedure to align a light sheet and a detection focal plane at a plurality of locations within the sample, and performing an imaging procedure on the sample to collect an image from each location. The collected images are reconstructed to form a three-dimensional image of the sample. Devices for carrying out the steps of the methods are also provided.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

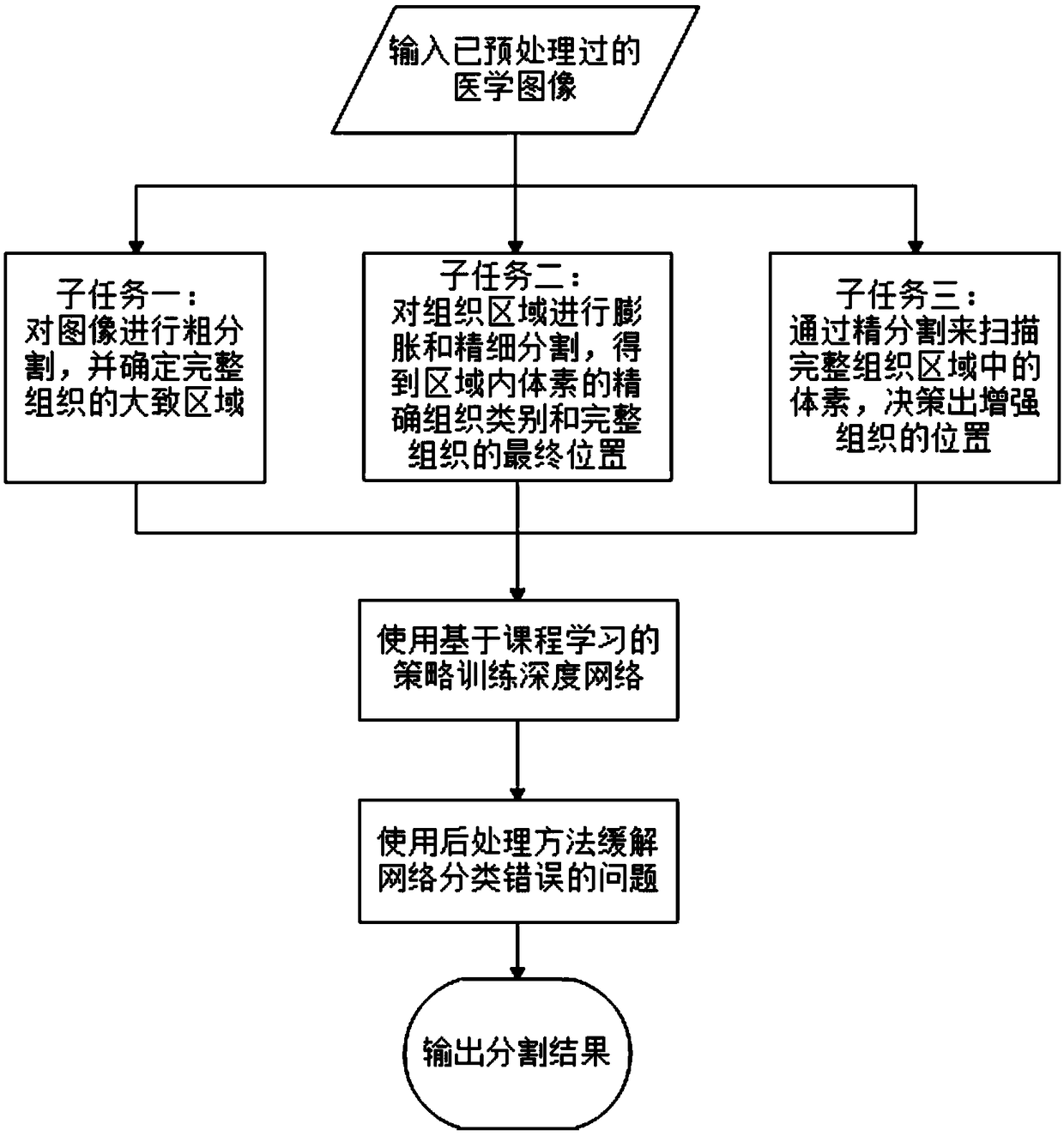

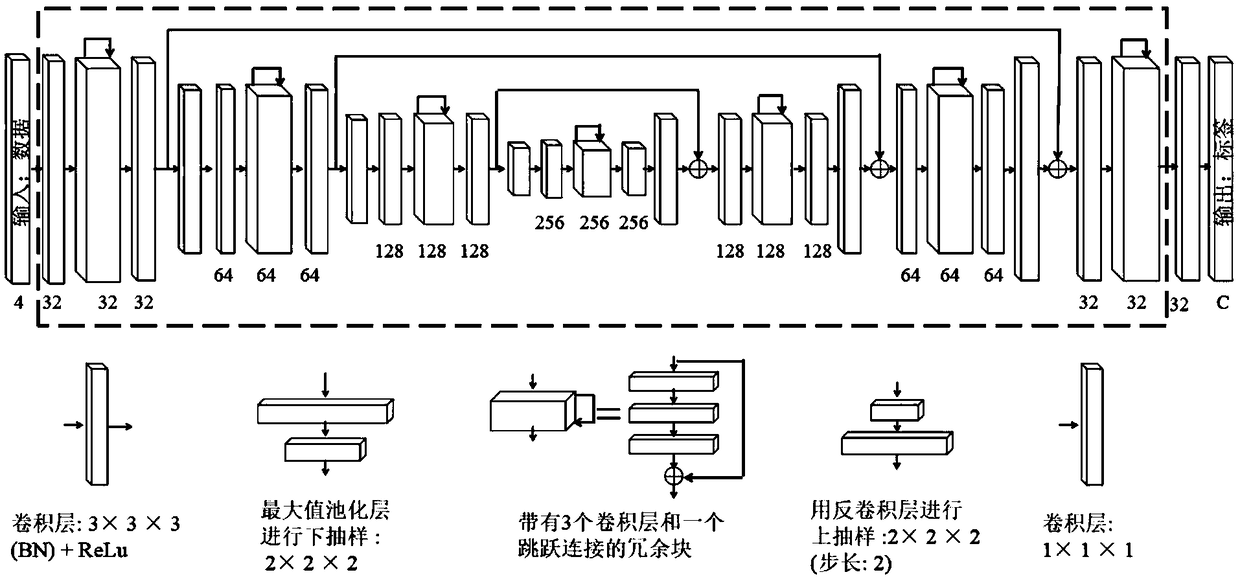

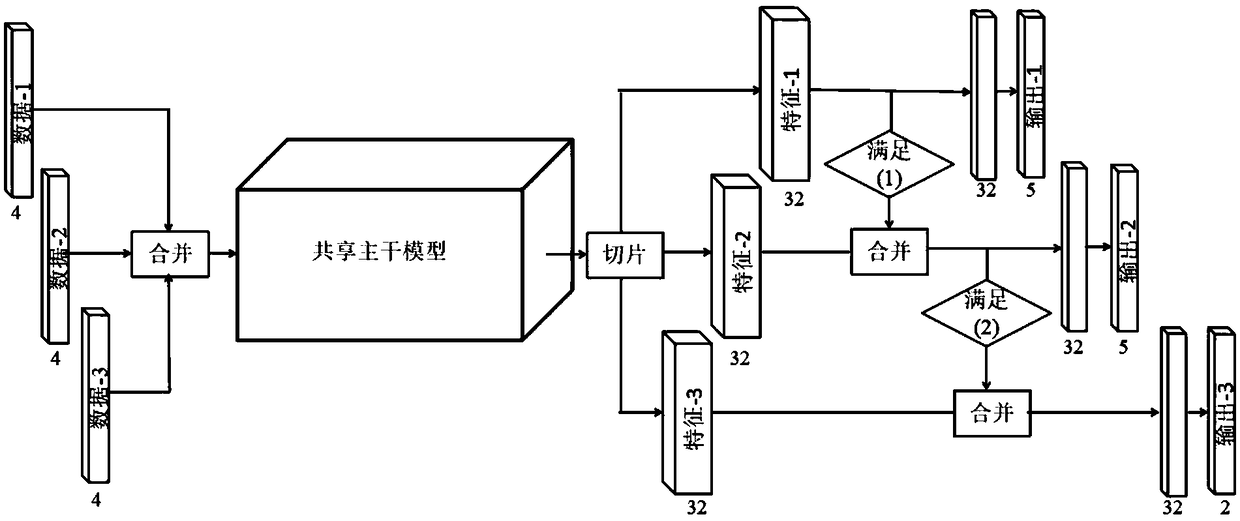

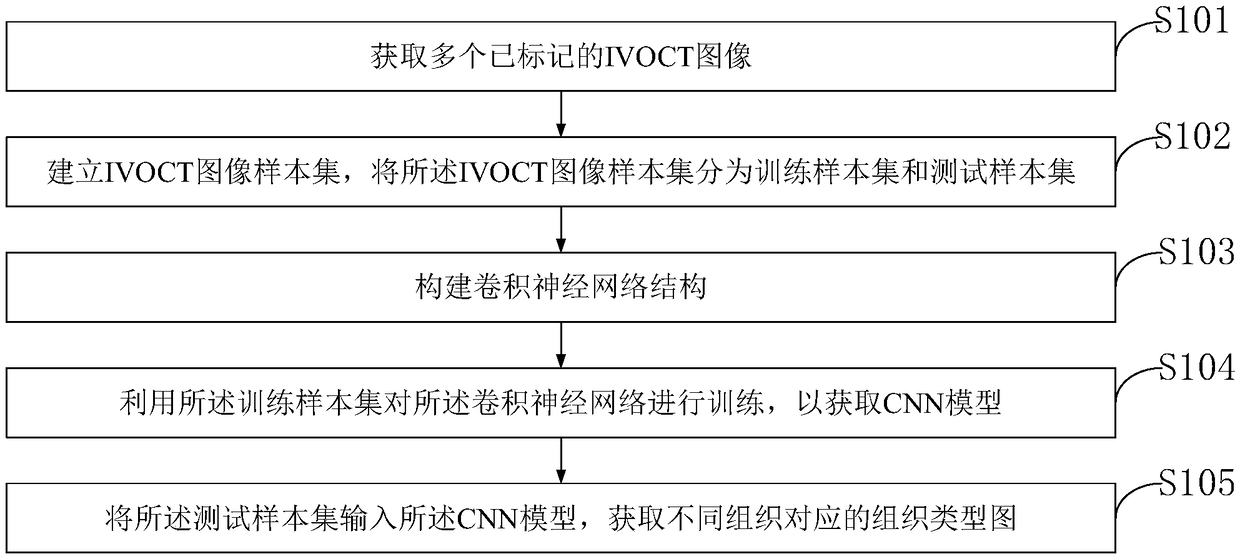

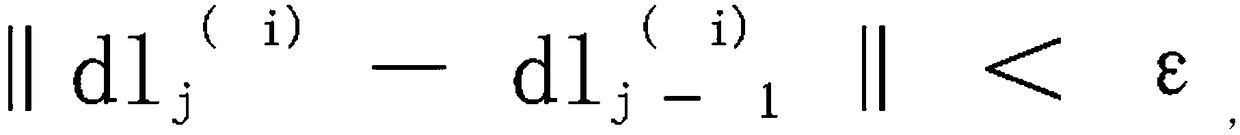

A medical image segmentation method based on a one-way multi-task convolution neural network

InactiveCN109360208AFast convergenceIgnore associativityImage enhancementImage analysisVoxelIntact tissue

The invention discloses a medical image segmentation method based on a one-way multi-task convolution neural network. Firstly, the segmentation task is divided into three different but related sub-tasks by using the network. A first sub-task carries out rough segmentation on that image to determine a rough area of the whole organization; a second subtask dilates and fine-segments the area to getthe exact tissue type and exact position of the whole tissue. Subtask 3 uses refined segmentation to scan voxels in the intact tissue and determine the location of the enhanced tissue. Then the threesub-tasks are trained in stages with course learning strategy from easy to difficult to realize data and parameter sharing among sub-tasks. Finally, the post-processing method is used to improve the classification error problem and output the final segmentation results. The invention synthesizes the associated sub-tasks into a single network for simultaneous training, improves the shortcomings ofcascade model training sub-tasks one by one and better solves the category imbalance problem, realizes the segmentation of the image from coarse to fine by one-way operation, and improves the segmentation effect while reducing the complexity of the system.

Owner:SOUTH CHINA UNIV OF TECH

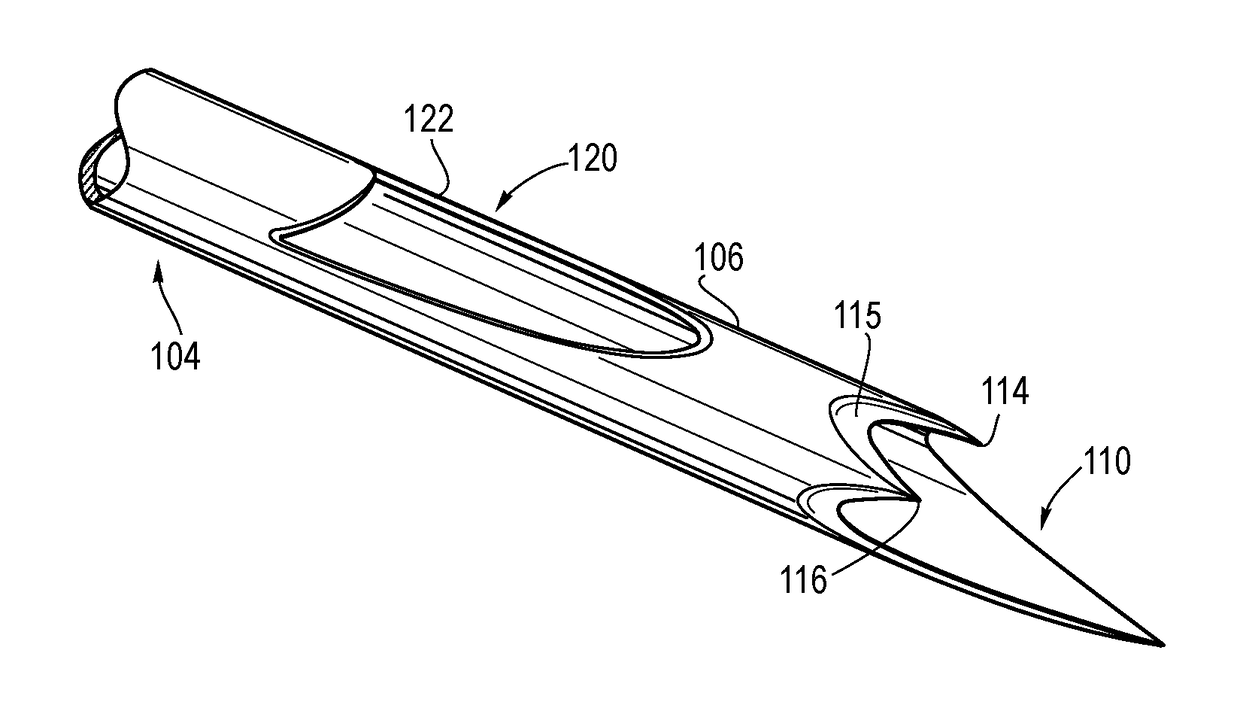

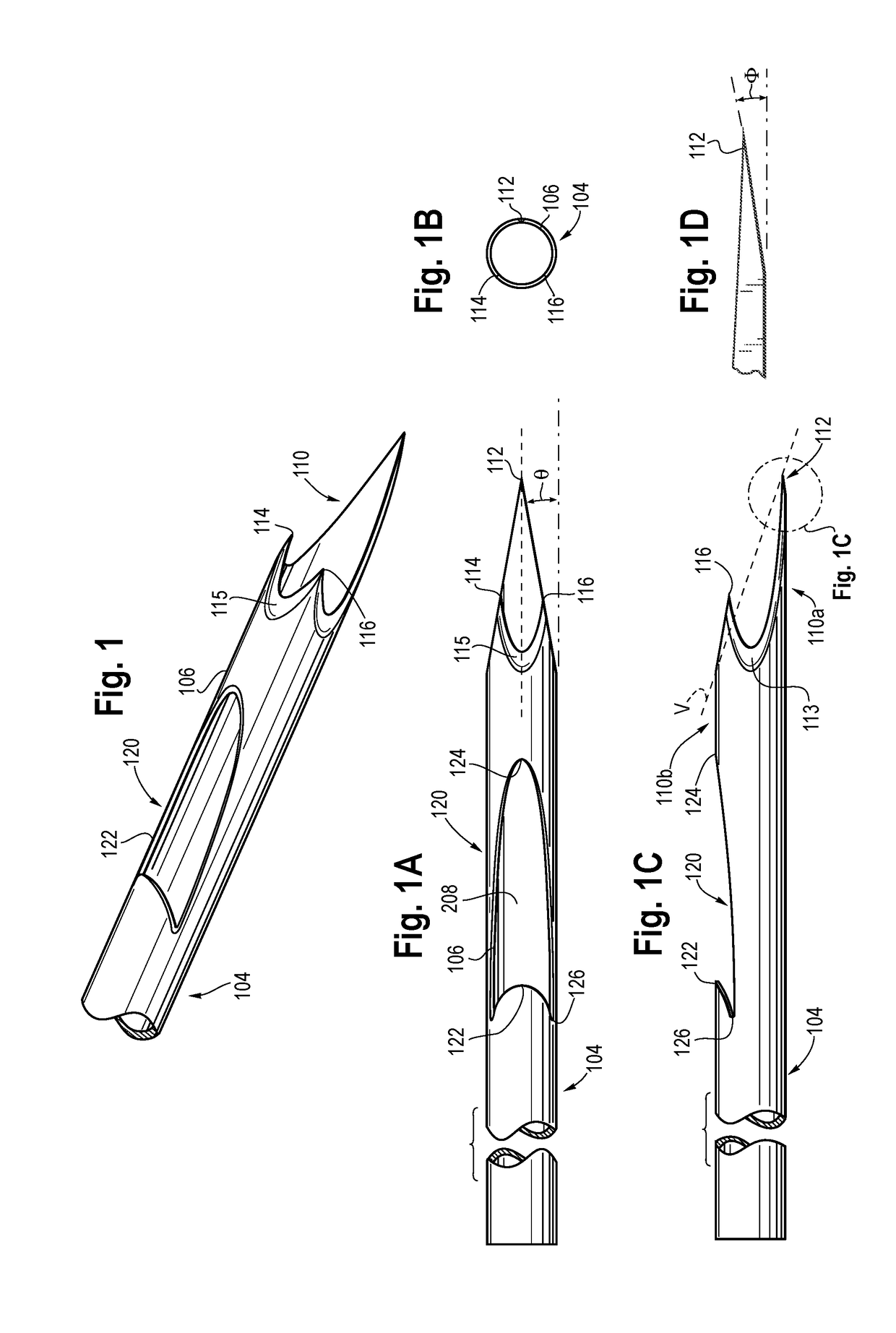

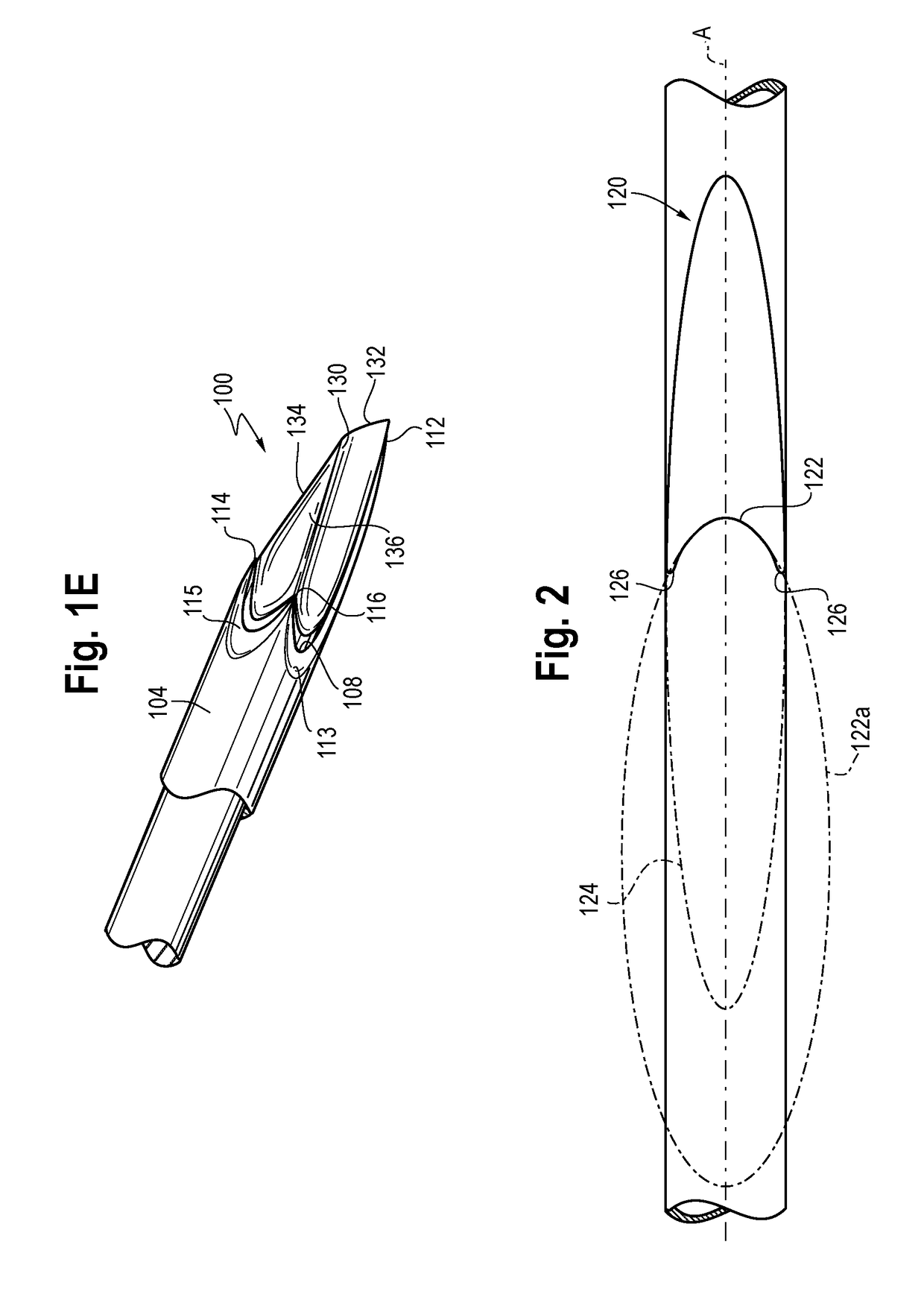

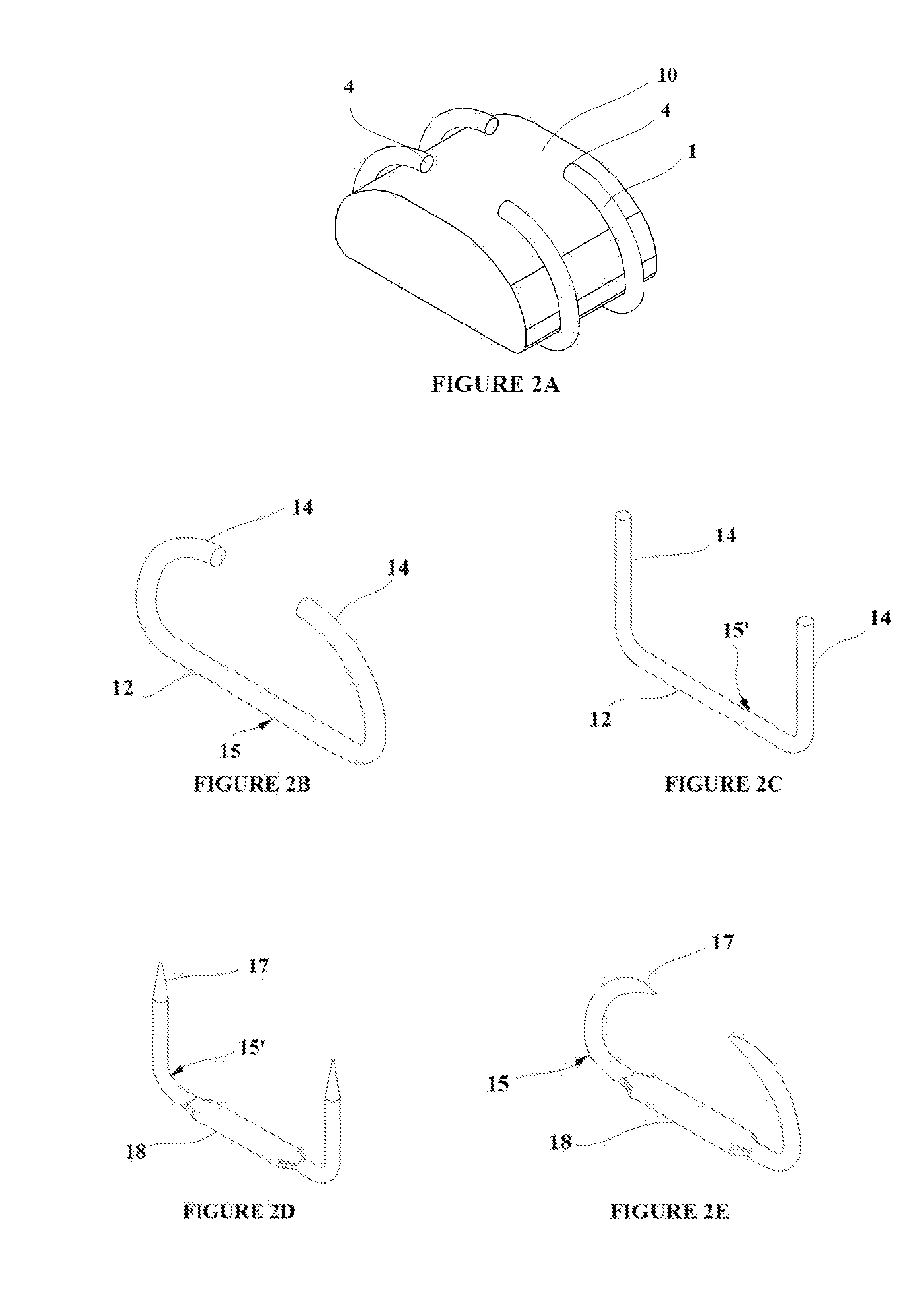

Endoscopic tri-point biopsy needle

ActiveUS20180228476A1Surgical needlesVaccination/ovulation diagnosticsIntact tissueTissue Collection

A tri-point tissue-collection needle configured similarly to a fine-needle-aspiration needle is configured to excise intact tissue cores for collection. The distal tip is configured with three beveled points separated by cutting edges, where a single longer / more distal point is trailed by and circumferentially separated from a symmetrical pair of points, providing a bilaterally symmetrical needle cannula distal end. A stylet may be provided through a lumen of the needle during introduction into a patient body, where the distal end surface of the stylet may be configured to complement the tri-point needle end configuration.

Owner:COOK MEDICAL TECH LLC

Methods and Devices for Imaging Large Intact Tissue Samples

ActiveUS20170068086A1Television system detailsColor television detailsHigh resolution imagingImage resolution

Methods and devices for conducting high-speed, high-resolution imaging of large intact tissue samples are provided. Aspects of the methods include placing a sample in an optically homogenous sample manipulation component, performing a calibration procedure to align a light sheet and a detection focal plane at a plurality of locations within the sample, and performing an imaging procedure on the sample to collect an image from each location. The collected images are reconstructed to form a three-dimensional image of the sample. Devices for carrying out the steps of the methods are also provided.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Method for displaying ultralow carbon IF (Interstitial-Free) sheet metallographic structure

The invention provides a method for displaying an ultralow carbon IF (Interstitial-Free) sheet metallographic structure, belonging to the technical field of metallographic examination. The method comprises the testing steps of inserting a test sample, roughly grinding, elaborately polishing and etching, and collecting pictures. The method has the advantages that clear and complete structure pictures of ferrite crystal grains can be obtained through the technology, the operation is simple, the problems that ultralow carbon sheet ferrite crystal grains are incompletely displayed and grain boundaries are embossed seriously can be solved, and the method is especially applicable to structure display of ultralow carbon IF sheet steel with the carbon content of 0.002% below.

Owner:SHOUGANG CORPORATION

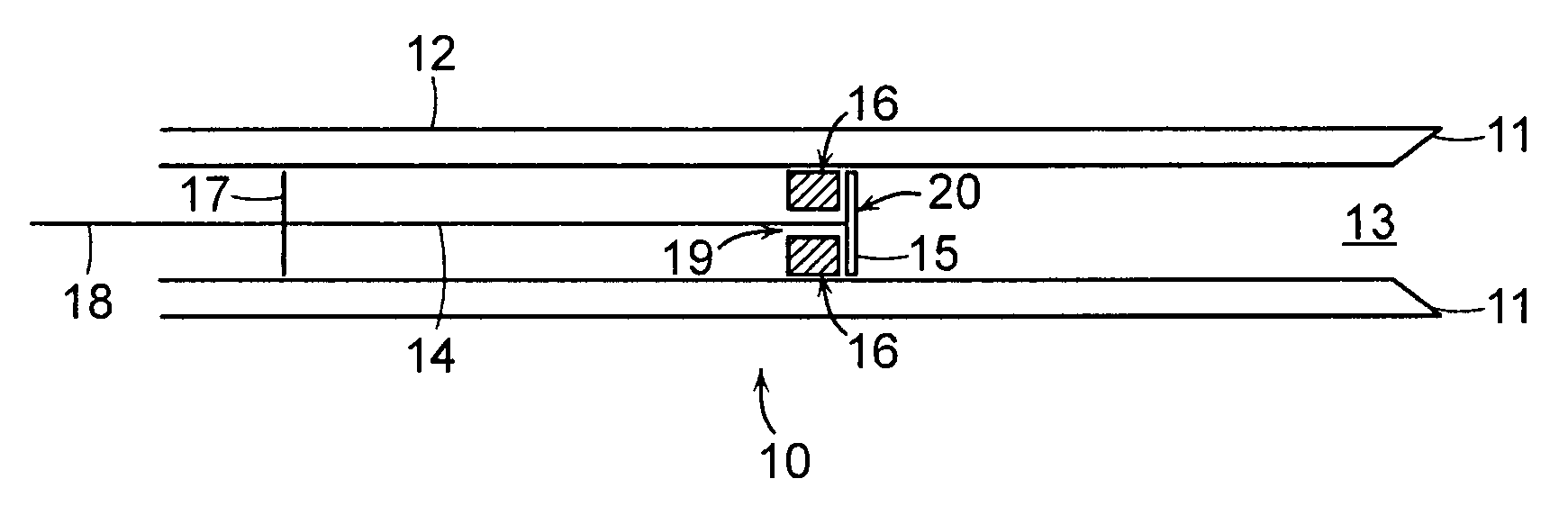

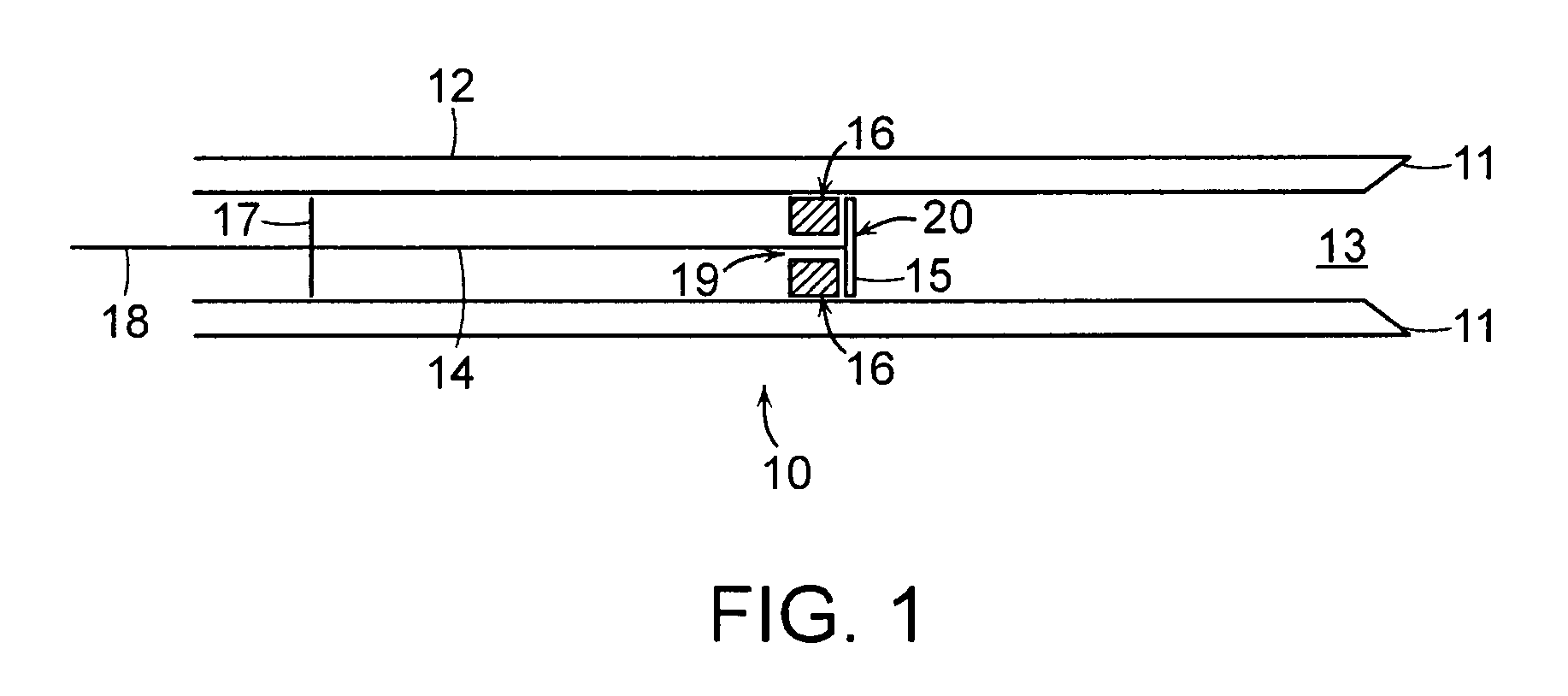

Apparatus and method for tissue adhesion

ActiveUS20120324975A1Metal-working feeding devicesPharmaceutical delivery mechanismIntact tissueShape-memory alloy

Shape memory tissue engagement elements (15) are created using shape memory alloys or shape memory (SM) composite sheets (33, 36) with one or more SM material sheets (20, 32). Arrays of the tissue engagement elements may then be inserted or molded into flexible base materials forming pads for tissue engagement. In certain embodiments, the composite sheets incorporate two SM material layers (20, 32) having differing transition temperatures to allow activation of one layer for tissue engagement and activation of the second layer for tissue release. In exemplary embodiments, insertion of interconnected tissue engagement elements (46) into a base layer (19) with slots (48) provides a completed pad array. In alternative exemplary embodiments, vacuum forming of composite sheets (51) with cutting of corrugated sides (53) to form tissue engagement elements allow production of complete arrays of tissue engagement elements. Overmolding the arrays with a flexible base material (19) provides a completed pad.

Owner:MICROKOLL

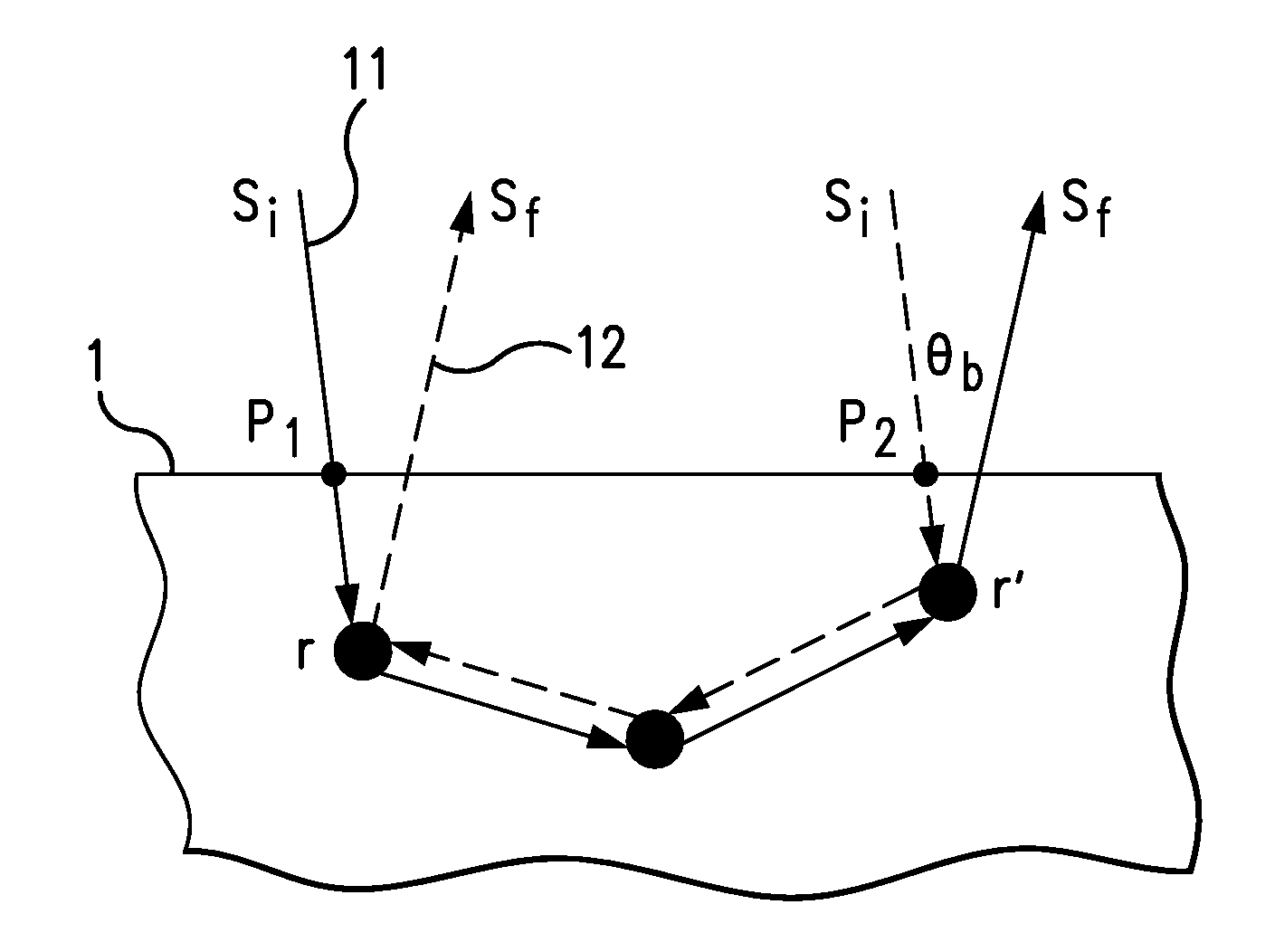

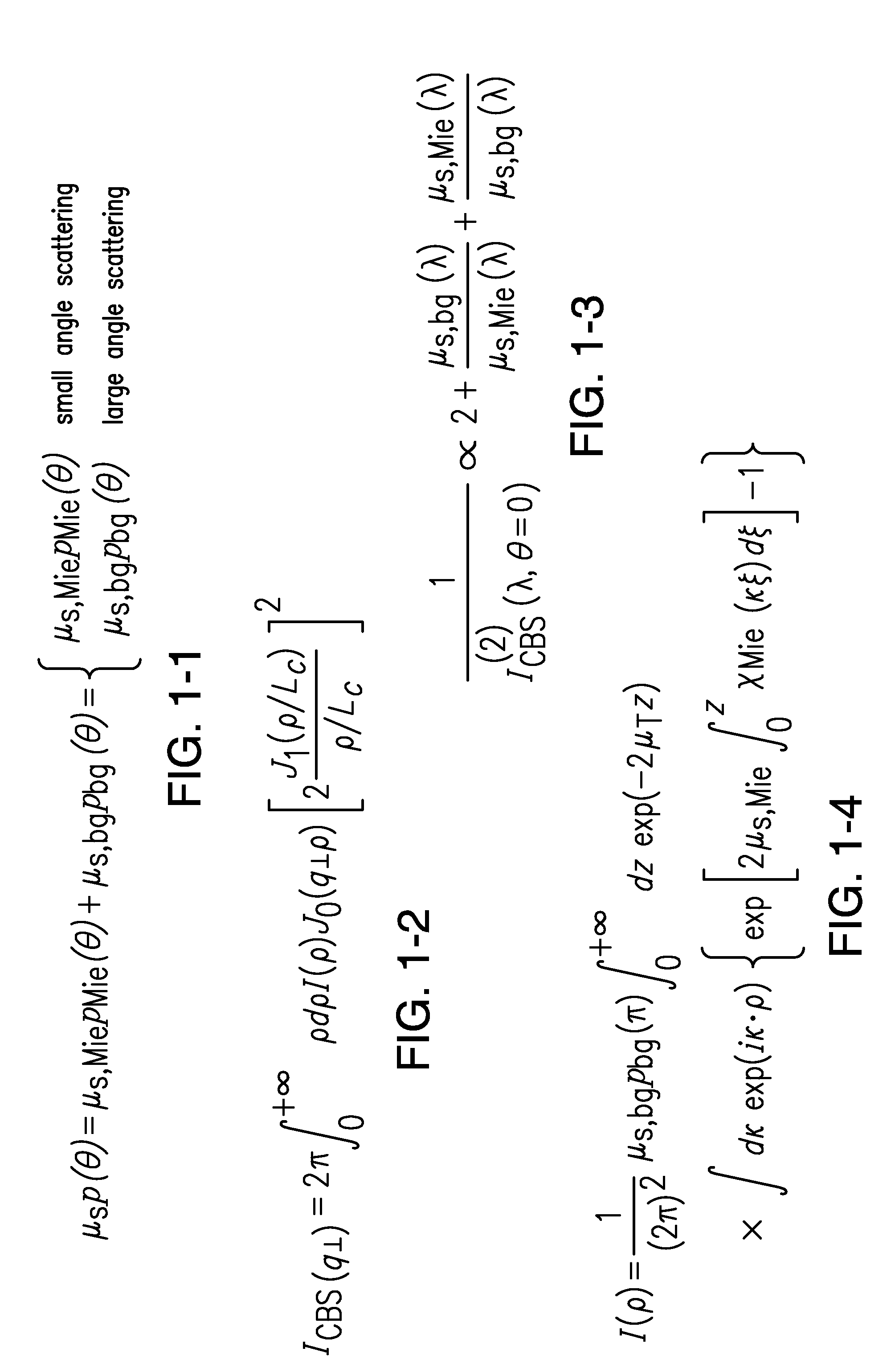

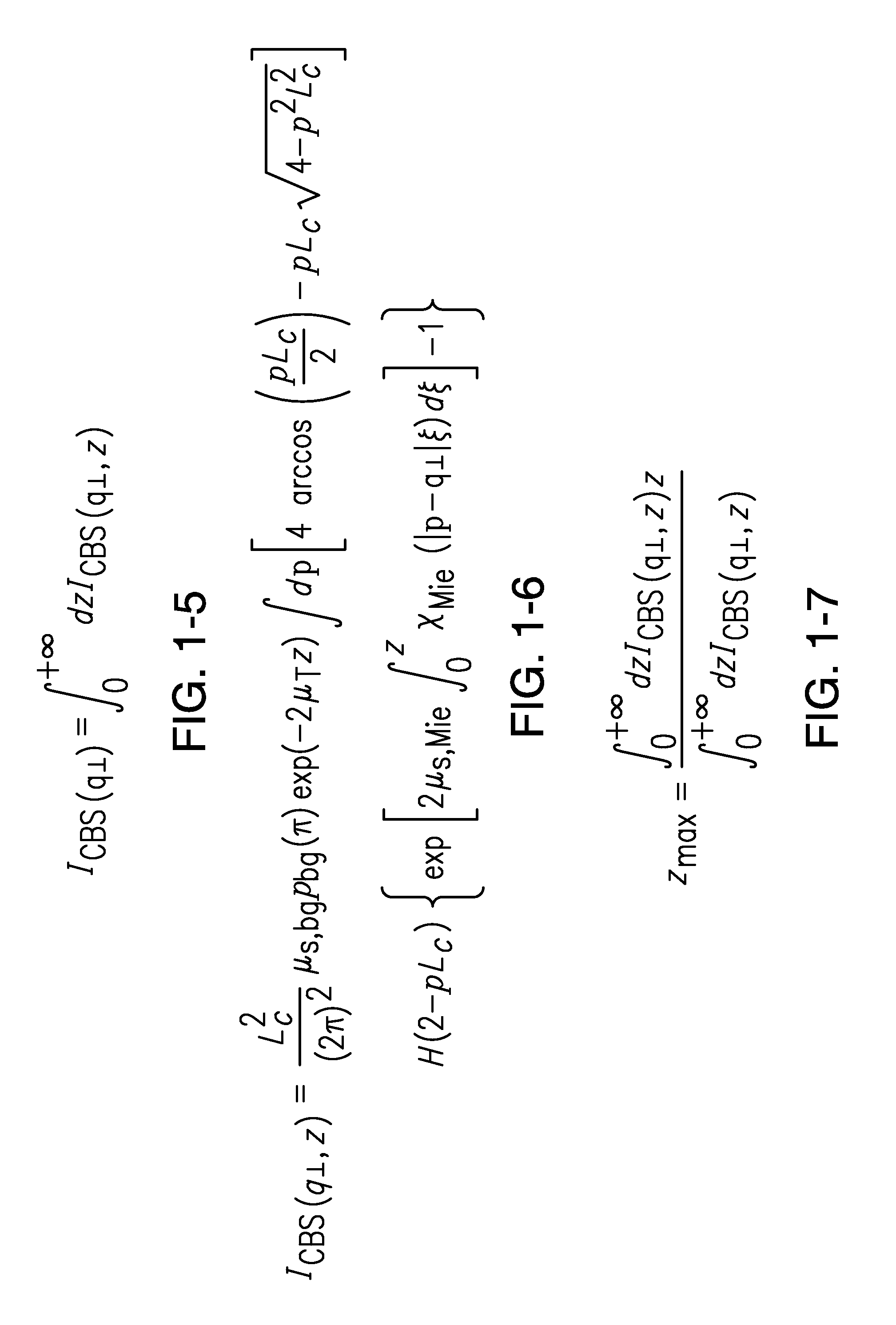

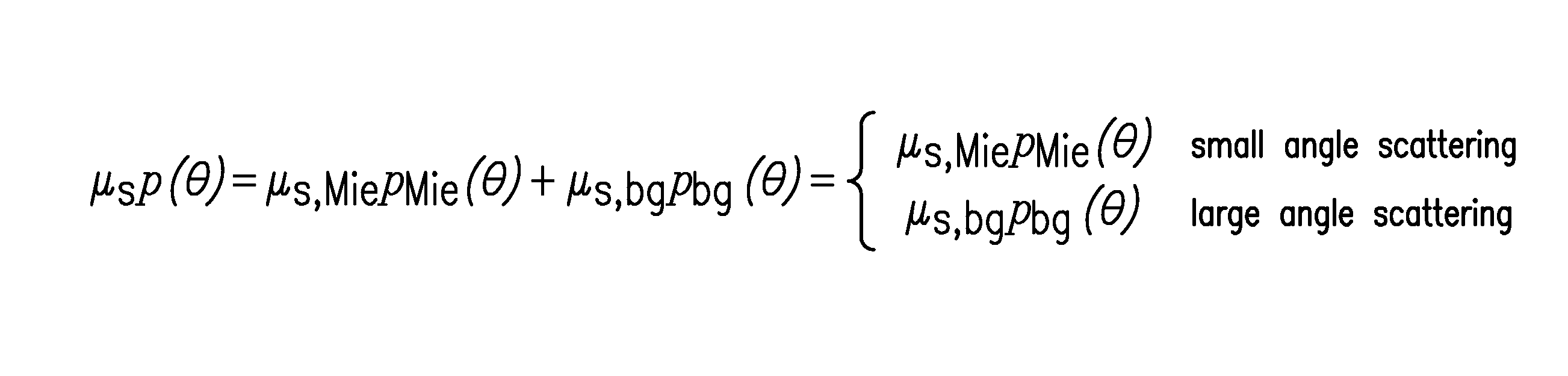

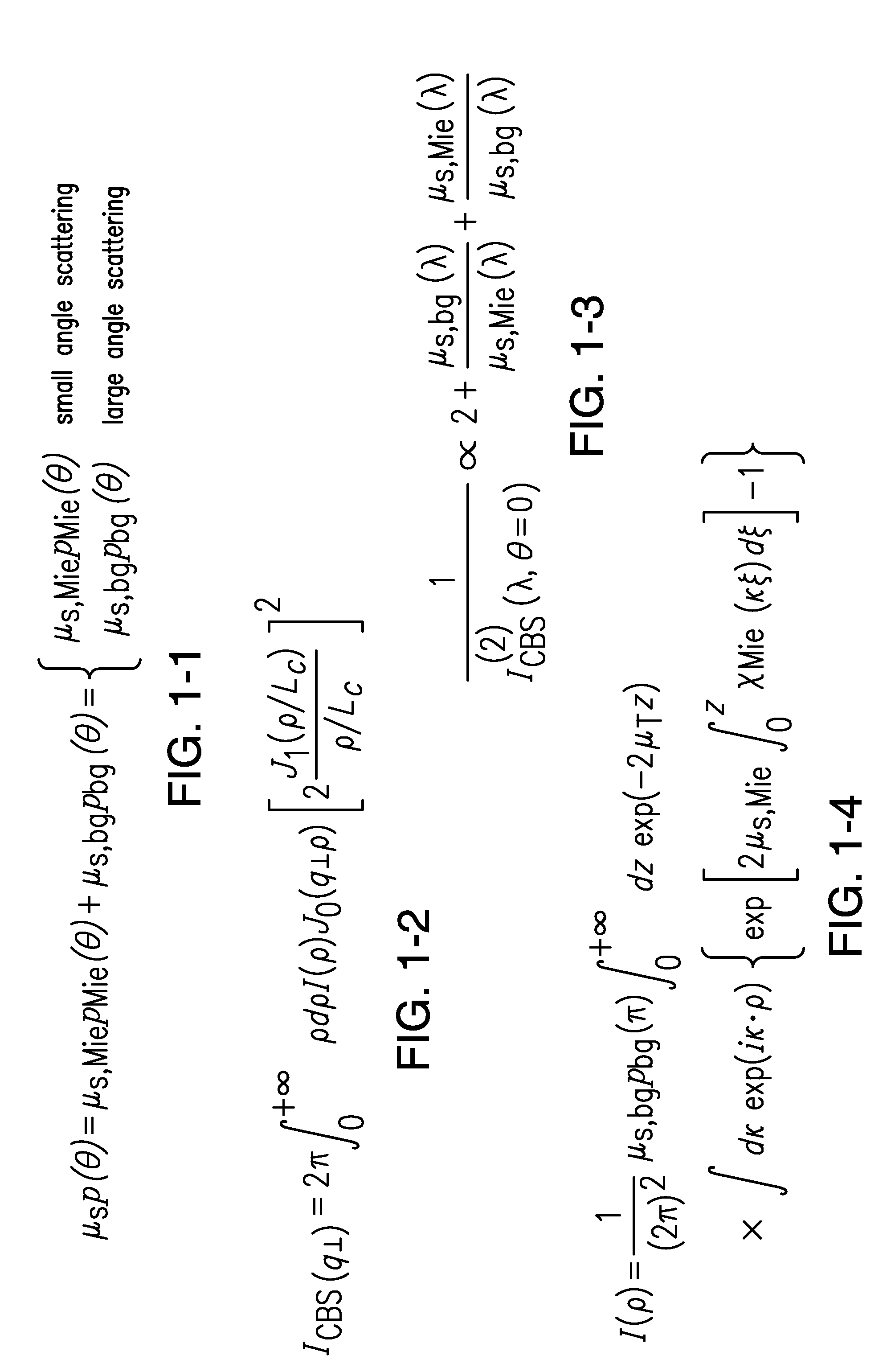

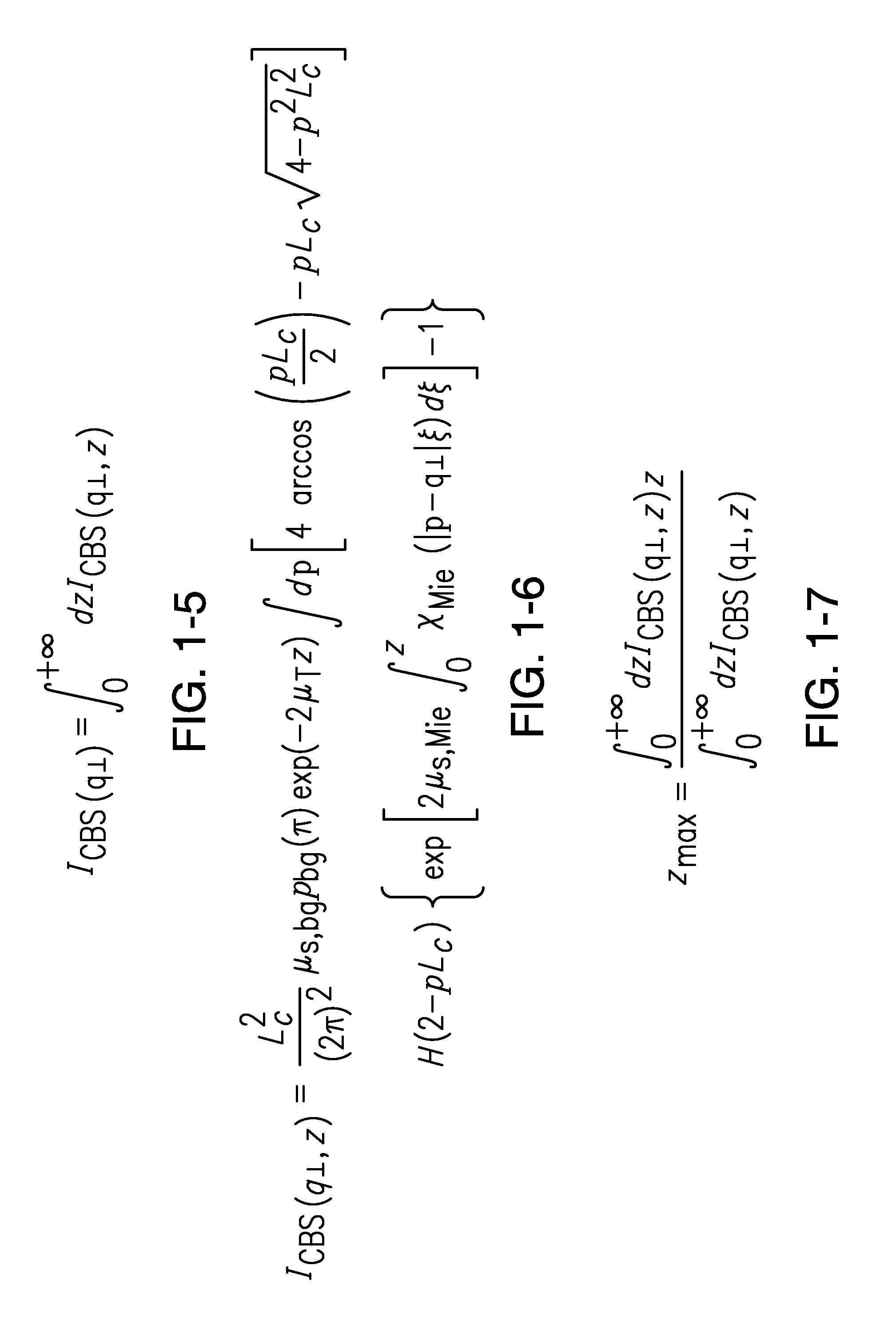

Low coherence enhanced backscattering tomography and techniques

ActiveUS20130063727A1Reduce coherenceEnhanced advantageMaterial analysis by optical meansDiagnostic recording/measuring3d imageNuclear morphology

A low coherence enhanced backscattering tomography (LEBT) method is disclosed for depth-selective sensing of the superficial layer of tissue. 3D images of the microarchitecture and molecular conformation of the superficial layer of tissue are obtained. The method combines the high resolution advantage of low coherence light and the high sensitivity advantage of light scattering to tissue structure and composition. Intact tissue can be examined without the need of excision or processing. The method can be applied in in situ measurements. According to the method, 3D images of the nuclear morphology and cellular structure for the superficial layer of the tissue are generated; this is particularly useful in detecting cancer and precancer at the earliest stage of carcinogenesis.

Owner:FAIRFIELD UNIVERSITY

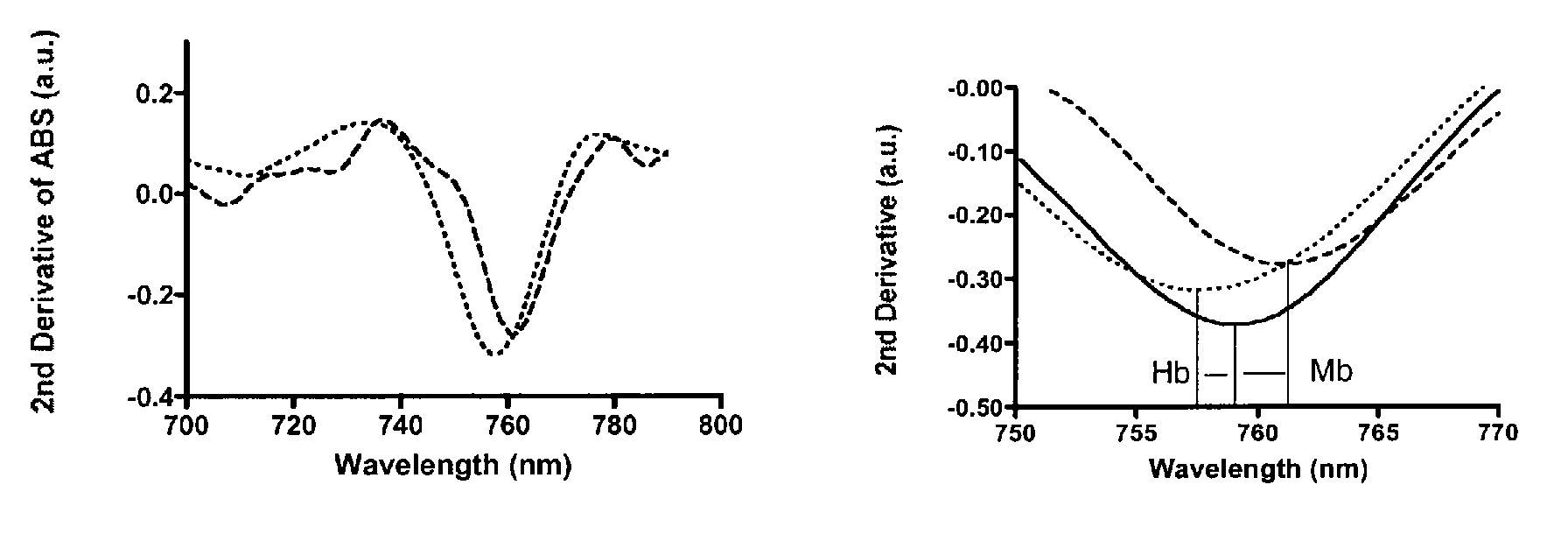

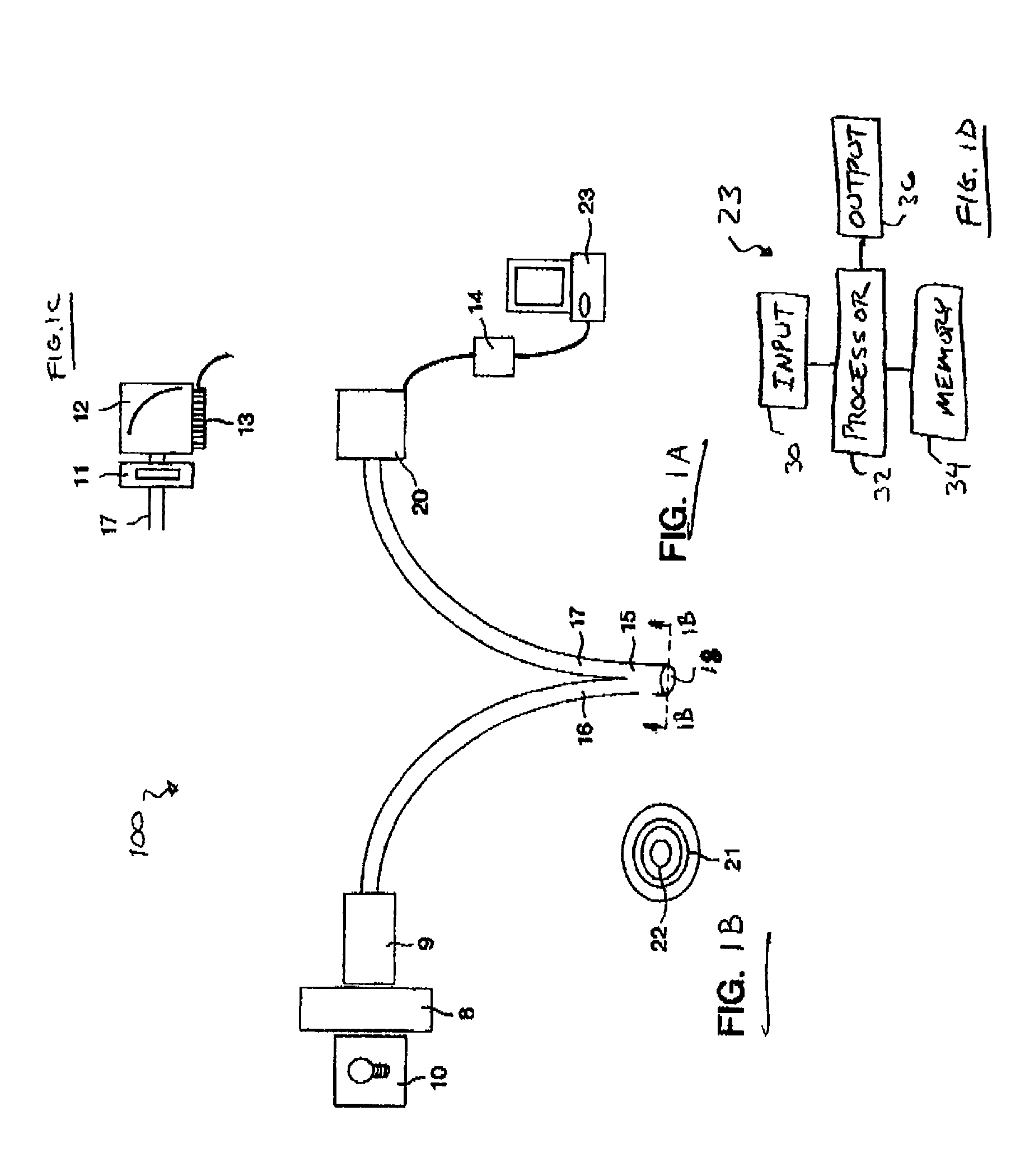

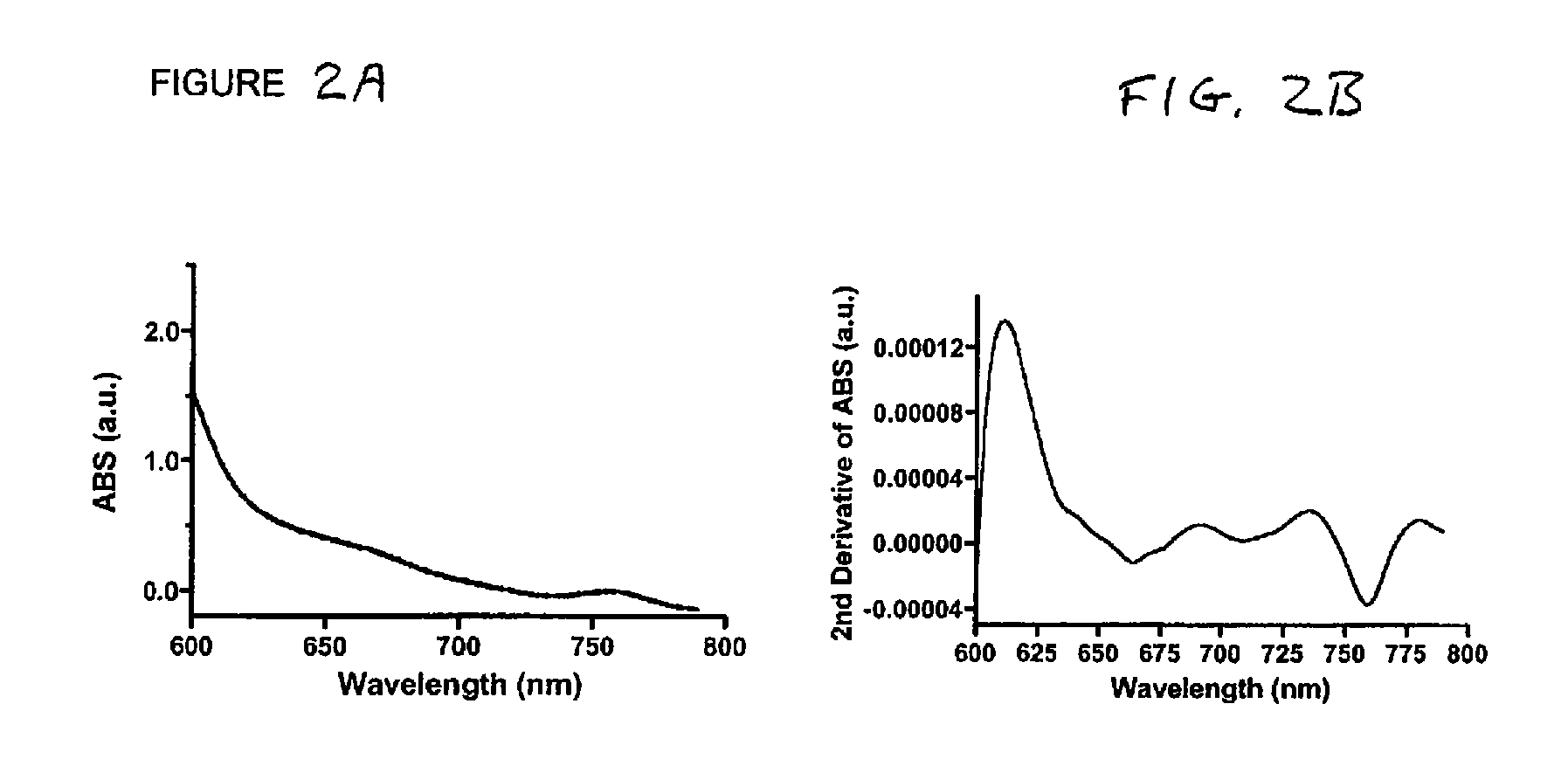

Method and system for determining the contribution of hemoglobin and myoglobin to in vivo optical spectra

InactiveUS8126527B2Diagnostics using lightColor/spectral properties measurementsIntact tissueNon invasive

This document discusses, among other things, quantification of hemoglobin content, and therefore blood volume, of muscle. An analysis of the optical spectra can determine the ratio of hemoglobin (Hb) to myoglobin (Mb) content in intact muscle. The peak position of the in vivo optical spectra from intact tissue is used to determine the ratio of Hb to Mb contributing to the optical signal. The wavelength of the peak is a linear function of the percent contribution of Hb to the optical spectra. Such analysis in combination with known Mb concentrations yields a non-invasive measure of the Hb content for in vivo muscle.

Owner:UNIV OF WASHINGTON

Tissue culture method of rhizoma atractylodis

InactiveCN106359088AHigh induction rateIncrease the succession coefficientHorticulture methodsPlant tissue cultureShootIntact tissue

The invention discloses a tissue culture method of rhizoma atractylodis. The tissue culture method is characterized by being a method for rapidly obtaining a large number of tube seedlings of a good rhizoma atractylodis variety within a short time by a plant tissue culture technology. By the tissue culture method, with shoot tips of the rhizoma atractylodis as explants, through processes of sterilizing the explants, performing start culture, performing proliferation culture, performing seedling strengthening culture, performing rooting culture, hardening seedlings, transplanting and the like, the shoot inducing rate, the subculture coefficient and the rooting rate are effectively improved, and thus an intact tissue culture system for rhizoma atractylodis is established.

Owner:李志勇

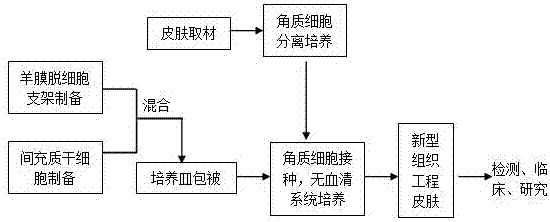

Preparation method of novel tissue engineering skin

InactiveCN107254431ANo adverse effects on growthGrowth impactEpidermal cells/skin cellsCulture processDiseaseSKIN SCARRING

The invention discloses a preparation method of novel tissue engineering skin. The method includes steps of jointly culturing an amniotic membrane decellularized scaffold and a mesenchymal stem cell to be a carrier, inoculating horn cell; culturing by a serum-free culturing system, and acquiring a complete tissue engineering skin membrane. Through the method, the method can culture a complete skin membrane and the skin membrane can be applied to the skin scar repair and leucoderma treatment. The horn cell is originated from body skin or prepuce of the newborn. The carrier is low in immunogenicity while also has biological activity; the serum-free culturing system can realize the in-vitro serum-free cultivation and amplification of the horn cell, and improve cell growth, multiplication, cell form, activity and function instead of bad influence; the skin membrane cultivated by the method is approached to natural skin; after the skin-grafting culturing, it can be applied to the scar repair of scaled and other injured skins as well as treatment of skin disease such as leucoderma.

Owner:林翠霞

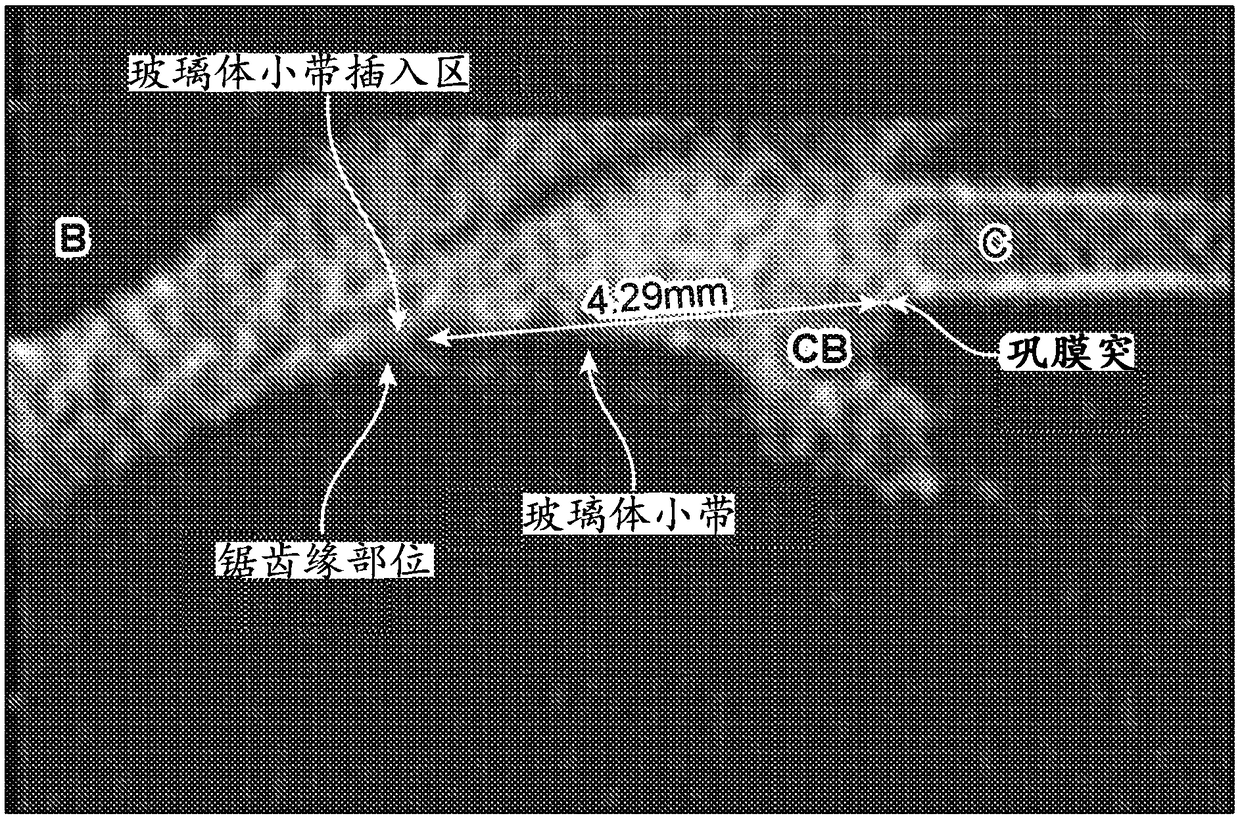

Ultrasound directed cavitational methods and system for ocular treatments

Owner:ALEYEGN TECH LLC

Dehydration method

InactiveCN101001533AEfficient extractionEfficient removalMeat/fish preservationFood preparationIntact tissueSorbent

The present invention relates to a method of dehydrating pieces of intact plant or animal tissue, said pieces containing at least 30 wt. % of water, the method comprising (i) contacting the pieces of intact tissue with a pressurised gas to reduce the water contenit of the pieces by at least 50 %, said pressurised gas having a pressure of at least 0.5xPc and a temperature of at least Tc-60 DEG C, Pc representing the critical pressure of the gas and Tc representing the critical temperature of the gas, and (ii) separating the pressurised gas from the dehydrated pieces, wherein at least 80 wt. %, preferably at least 90 wt. % of the matter removed by the gas from the pieces of intact plant or animal tissue is water. The invention also provides a method of dehydrating a material containing at least 30 wt. % of water, using a method as described before, followed by drying the separated pressurised gas by contacting said pressurised gas with a water absorbent water adsorbent; and recirculating the dried pressurised gas to the partially dehydrated material.

Owner:FEYECON DEV & IMPLEMENTATION

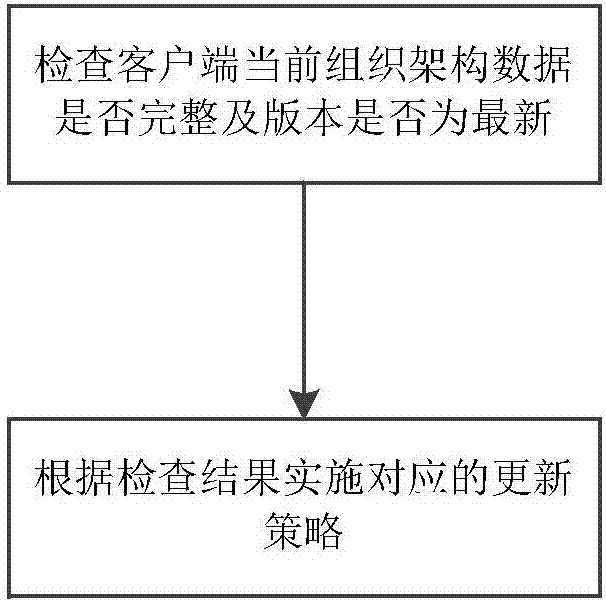

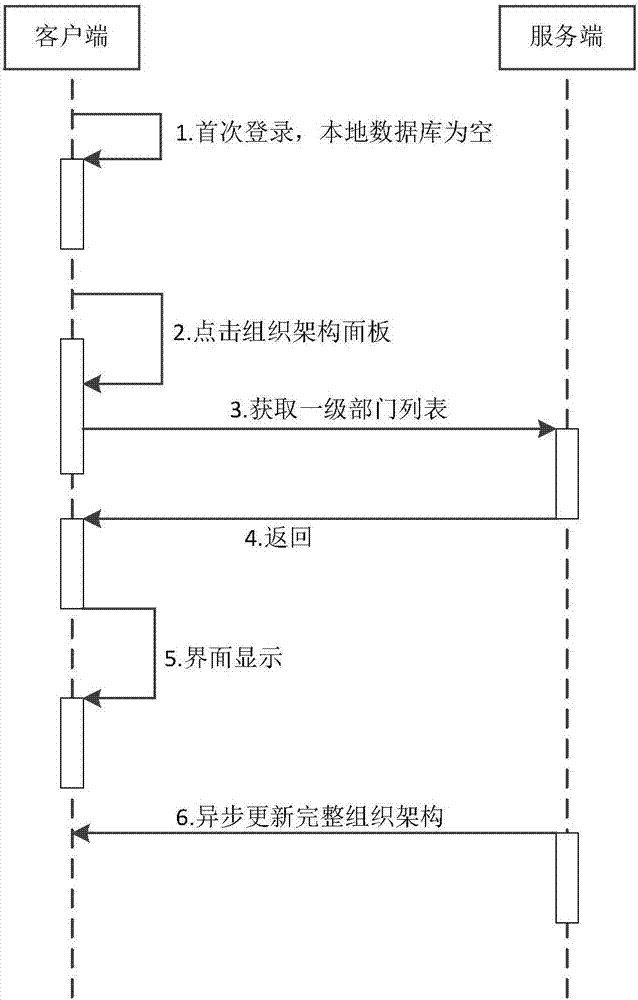

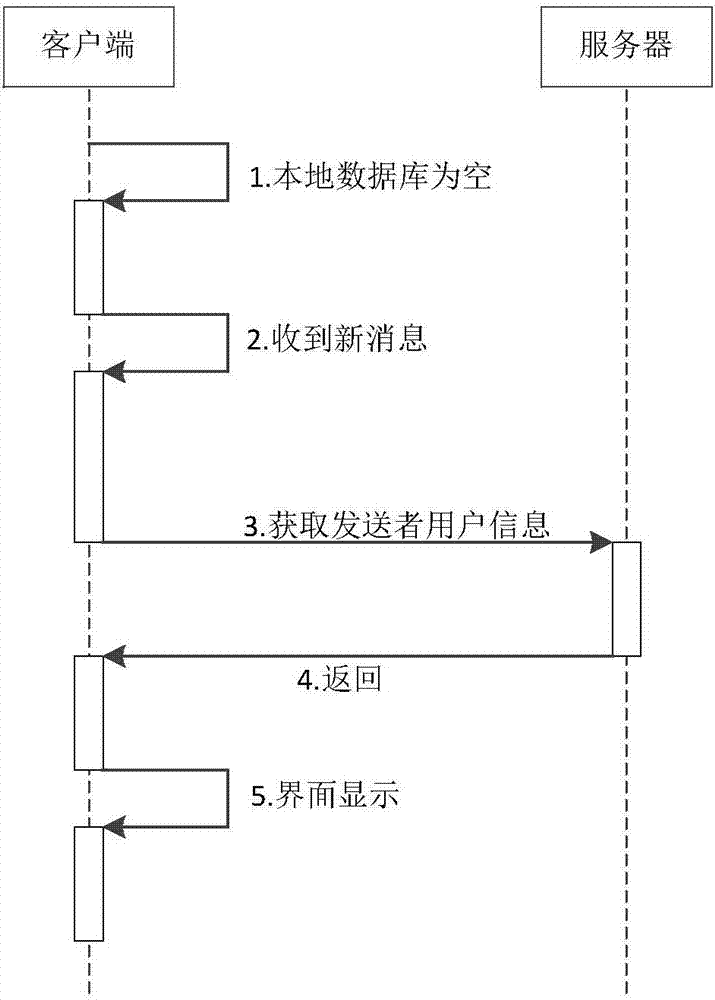

Fast update method for framework of instant messaging system

InactiveCN107171856AReduce waiting time for organizational structure displayDoes not affect browsingData switching networksIntact tissueUnique identifier

The invention comprises a fast update method for the framework of an instant messaging system. The method comprises the steps of acquiring a corresponding primary department list from a server according to an interface framework panel clicked by a user, and loading and displaying the list in a user interface; acquiring user interaction information and thus acquiring a unique identifier of the user, downloading a complete framework according to the user identifier, and loading and displaying the complete framework in the user interface; when local data of the user has complete framework data, loading the local framework data and asynchronously updating node data under the framework; downloading update data from the server at regular intervals, using an independent thread to update the framework, and suspending the other threads of a client when in updating. The method provided by the invention has the beneficial effects that user time for waiting for displaying of the framework is effectively reduced, meanwhile browsing of the framework is not influenced due to occasional network interruption, and the client can update the framework once the server updates the framework.

Owner:珠海信达九州科技有限公司

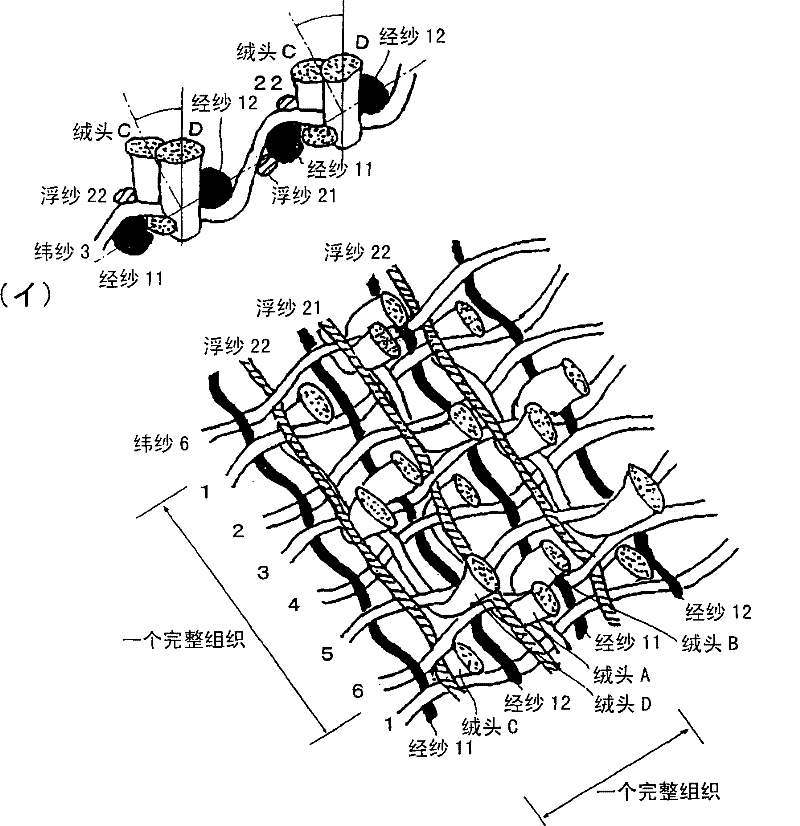

Processing method of low-carbon ultra-cool yarn-dyed fabric

InactiveCN105274703AImprove performanceImprove antibacterialWoven fabricsProtective garmentIntact tissueCombing

The invention discloses a processing method of low-carbon ultra-cool yarn-dyed fabric. According to the processing method, levell fiber yarns adopted as warp yarns, and high-moisture absorbency and sweat-release nylon fibers adopted as weft yarns, are interwoven so as to form the low-carbon ultra-cool yarn-dyed fabric; the fabric is of a plain weave structure of which each thread is vertically and alternately staggered; two warp yarns and two weft yarns are adopted form one complete organizational structure in a completely repeated mode; the warp yarns comprise the first warp yarns and the second warp yarns; the weft yarns comprise the first weft yarns and the second weft yarns; 30-count single yarn, 40-count single yarn, 70-count double-strand and 90-count double-strand long stapled cotton combed tightly spined while yarns and dyed yarns are adopted as the first warp yarns and the second warp yarns; high-moisture absorbency and sweat-release cool nylon fiber 70 D and 90 D semi-dulling FDY white filaments are adopted as the first weft yarns and the second weft yarns; the while yarns and dyed yarns of the warp yarns which are arranged according to the requirements of pongee dobby and bar type patterns are interwoven with the high-moisture absorbency and sweat-release nylon white filaments of the weft yarns.

Owner:陆飞飞

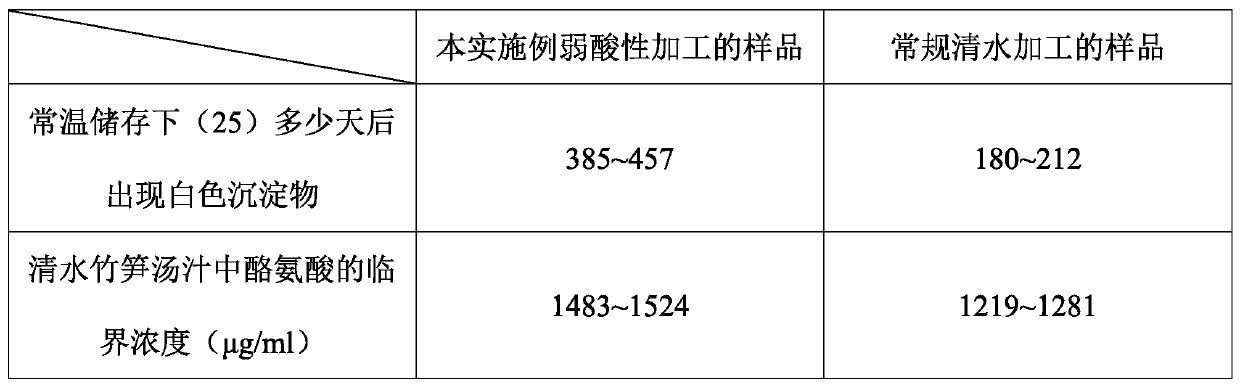

Processing method of primary taste clean water bamboo shoots

InactiveCN109846005ACrisp and tenderComplete organizational formFood scienceIntact tissueWater rinsing

The invention discloses a processing method of primary taste clean water bamboo shoots. The processing method comprises the steps of (1) performing pretreatment; (2) performing vacuum low-temperatureprecooking in a citric acid aqueous solution for 1-2h; (3) performing low-temperature water rinsing; (4) performing vacuum low-temperature recooking in a mixed solution of salt and Baijiu for 10-30min; (5) performing low-temperature cooling with running water; (6) adding a fresh keeping agent and bacteriostat, regulating the pH with citric acid, and performing packing; and (7) performing sterilization and performing cooling. According to the processing method, the working procedure of cooking twice under the vacuum low-temperature condition at the weak acid environment is adopted, so that mostof nutrient value can be reserved, the running off of beneficial components can be avoided to the greater extent, besides, the complete tissue shape can be maintained, the precooking and the recooking time can also be prolonged, white precipitate can be reduced greatly, and the bitterness of bamboo shoots can be efficiently removed. The processing method also comprises the working procedures of low-temperature cooling and rinsing, so that the clean water bamboo shoots can be clear and melodious in mouth feel, and is free from bitterness, and bright in color.

Owner:江西广雅食品有限公司

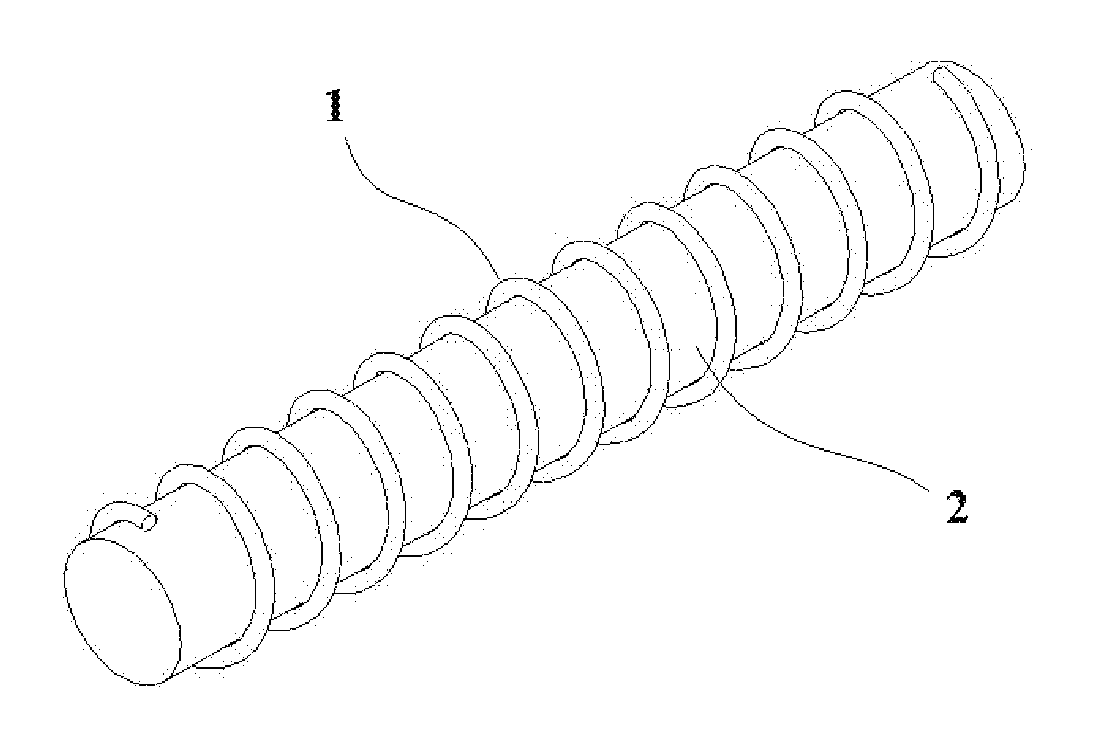

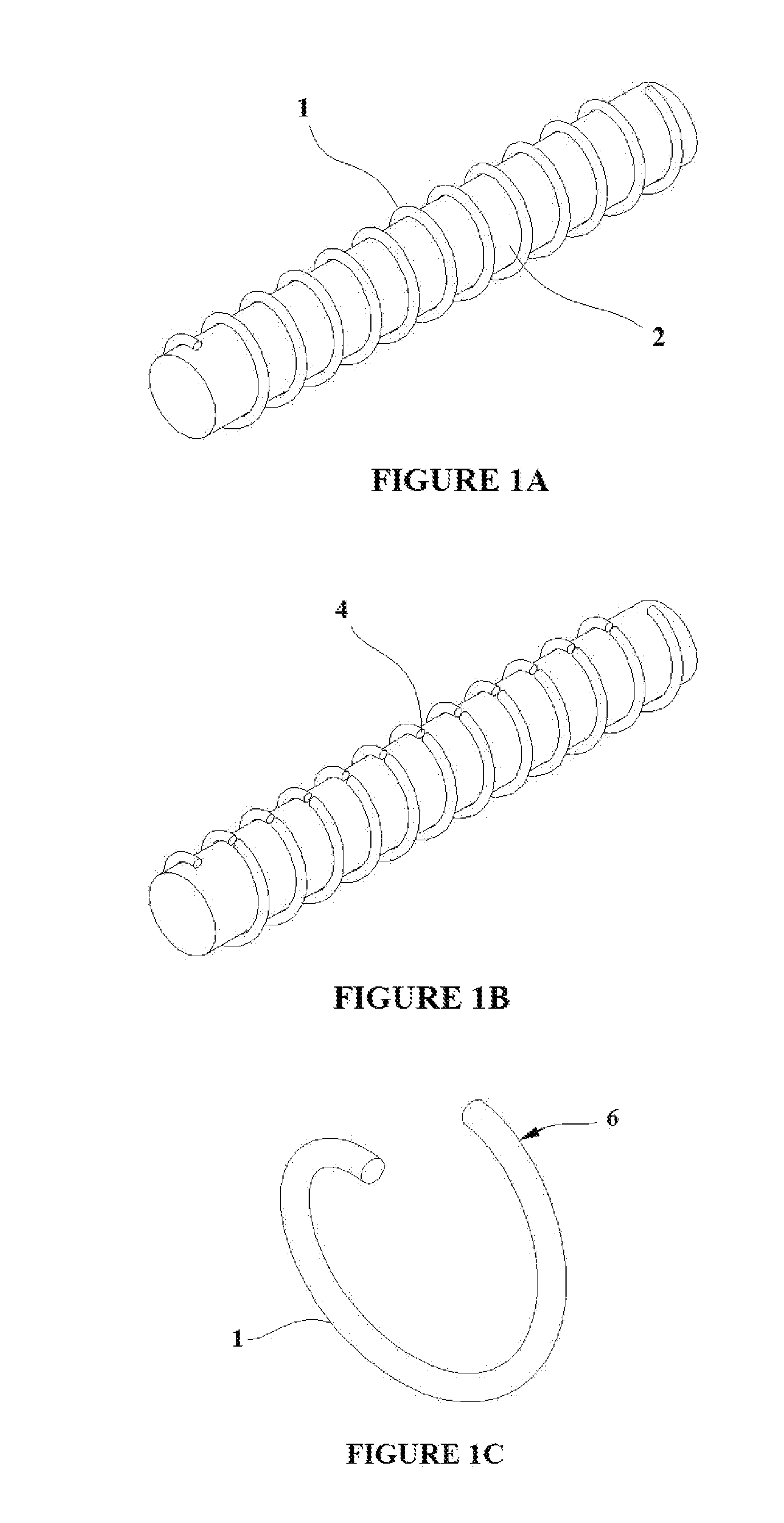

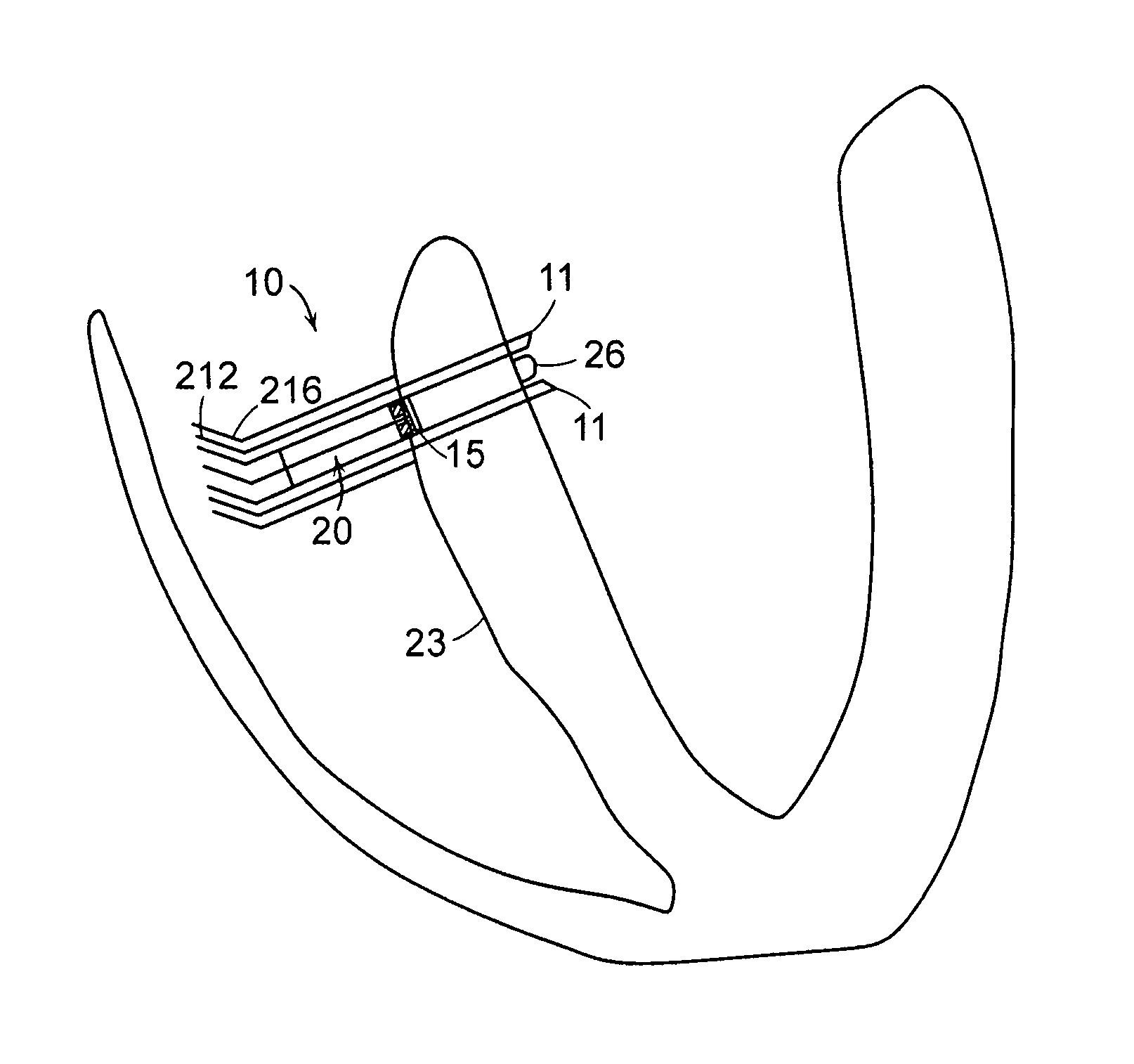

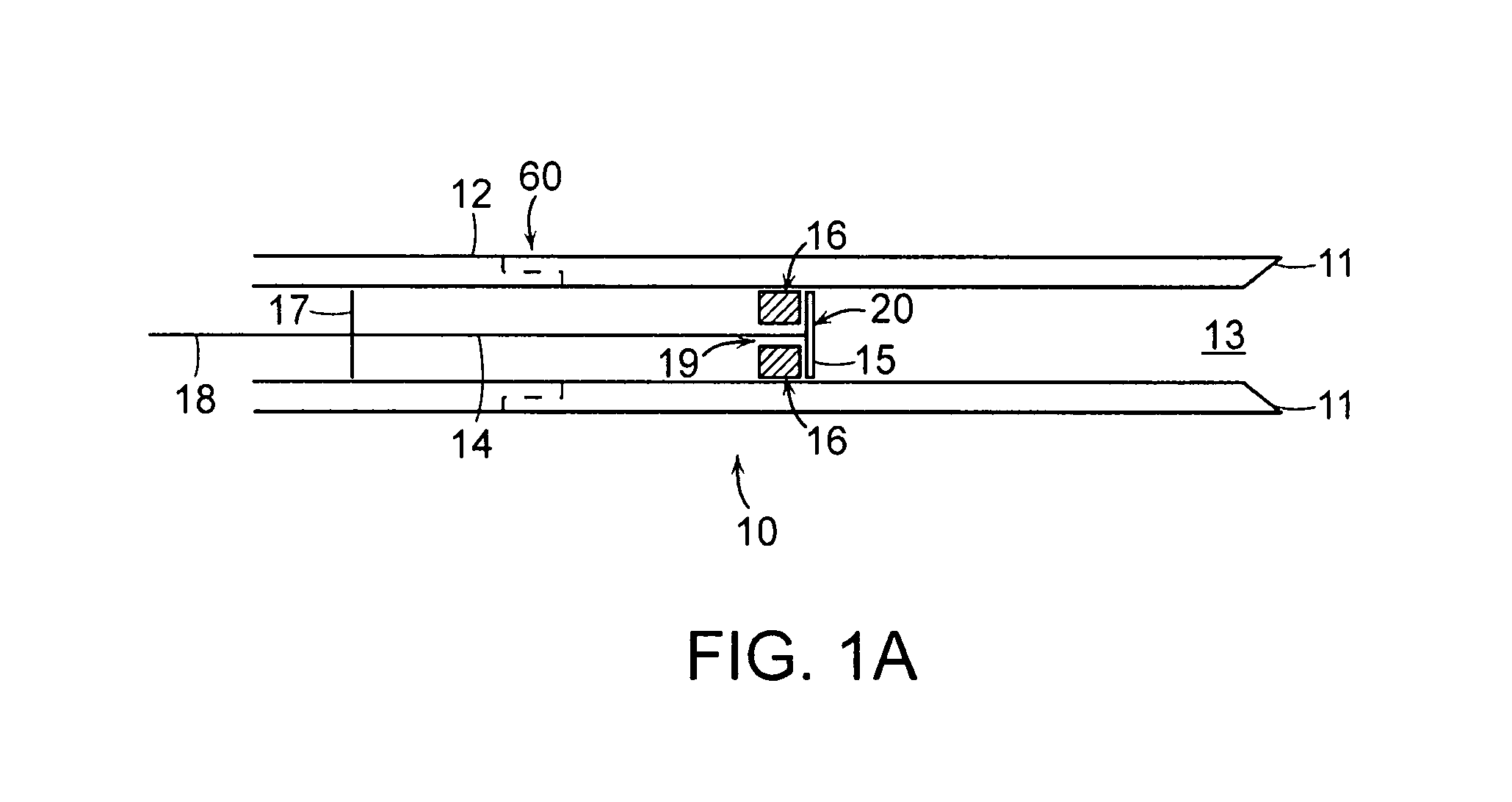

Devices and methods for tissue transplant and regeneration

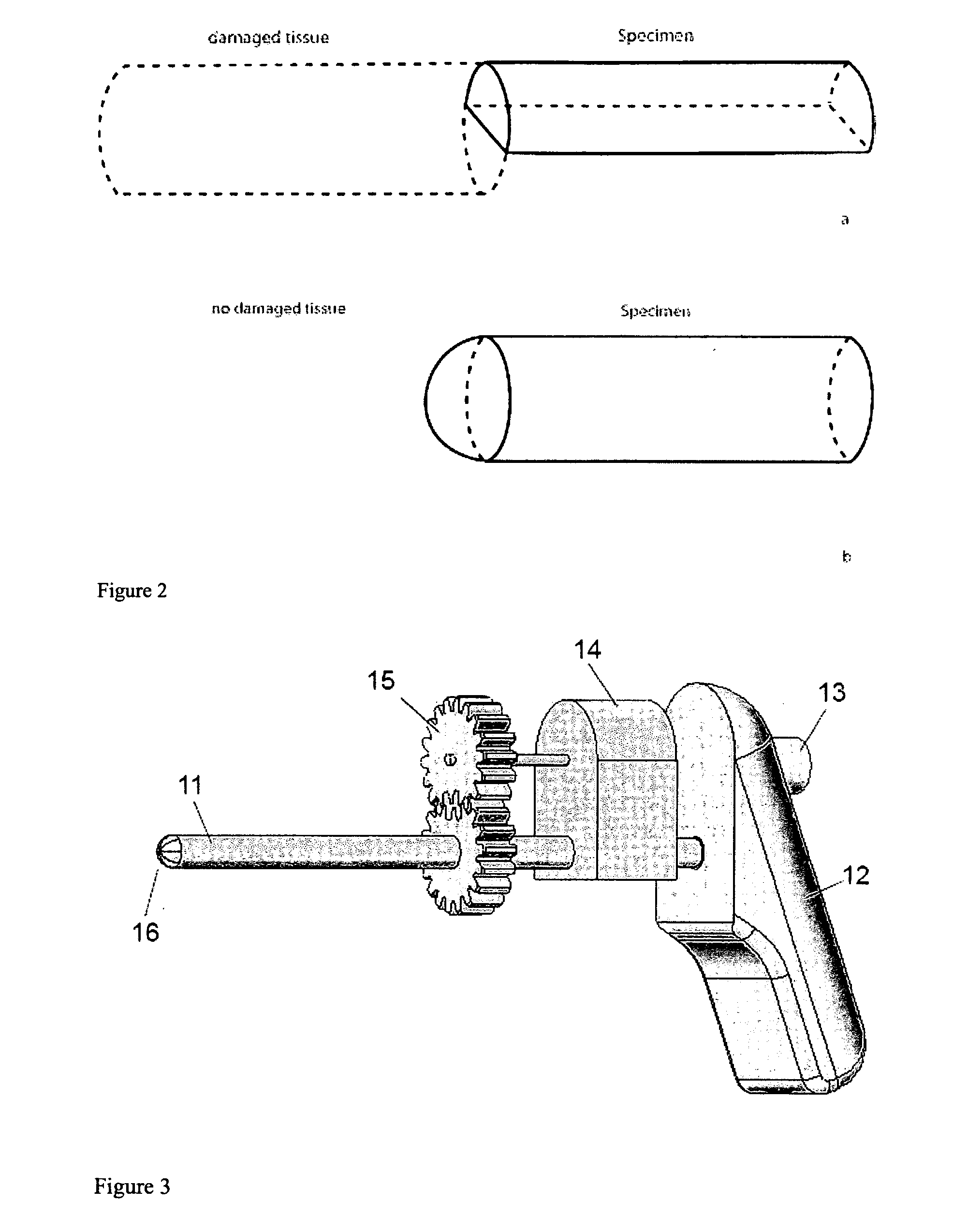

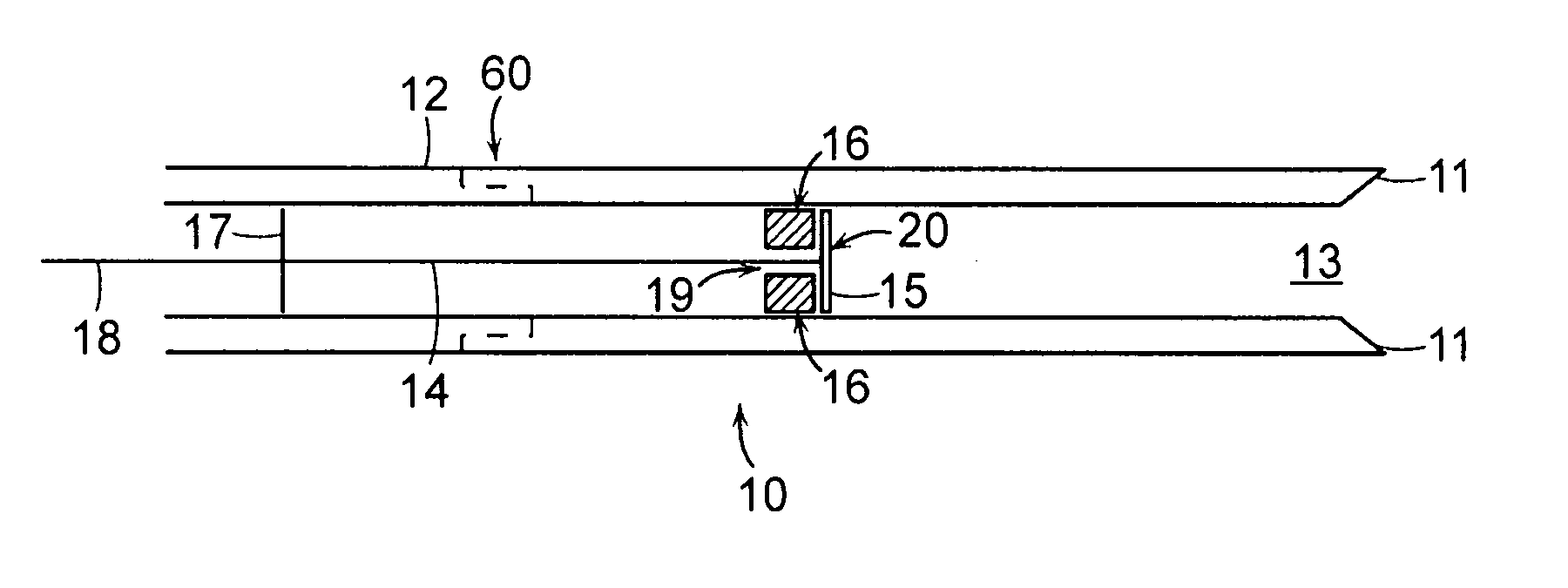

InactiveUS8038595B2Promote cell growthIncrease the number ofSurgical needlesVaccination/ovulation diagnosticsIntact tissueCardiac muscle

Devices and methods for transplanting tissue for the purpose of regeneration, for treating a patient having injured myocardial tissue, and / or for improving cardiac function through cell regrowth. More specifically, the devices and methods obviate the need for cellular alteration. The devices comprise a hollow tube with a sharp distal end, a stylet that is disposed and movable within the hollow tube, and a stopping device that constrains movement of the stylet. The methods comprise removing intact tissue from a first region of a mammalian organ and implanting the tissue in a second region of the same organ.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

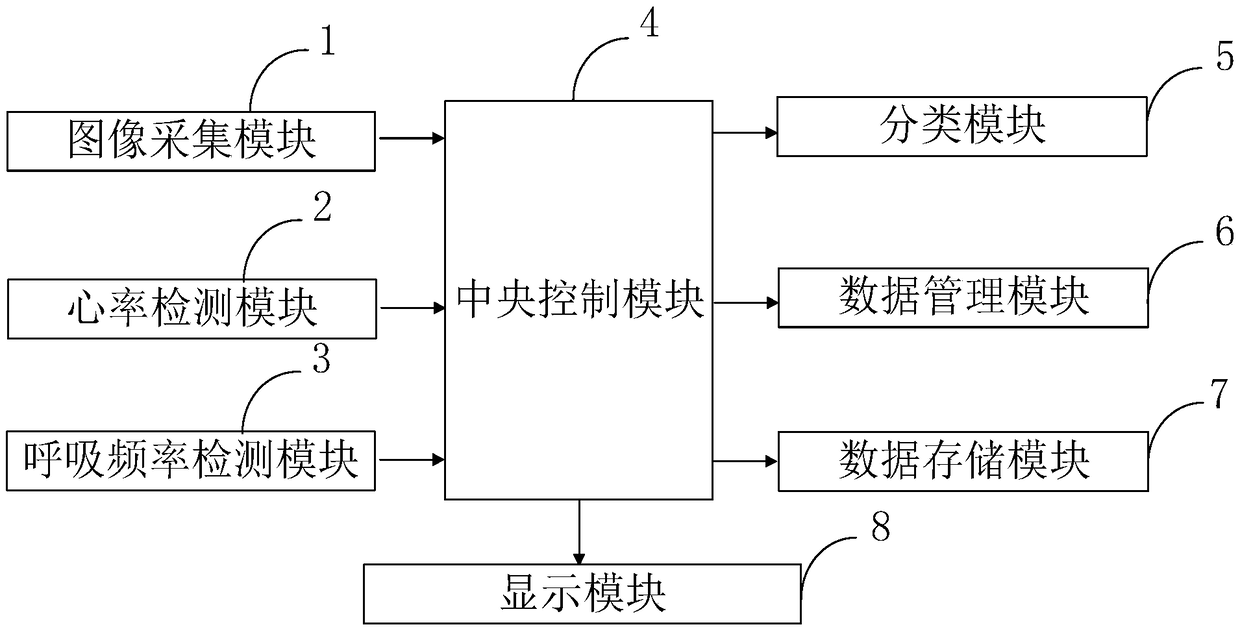

A cardiovascular intubation image auxiliary detection device and detection method

InactiveCN109087284AHigh degree of structural restorationMake up for the lossImage enhancementImage analysisPattern recognitionCardiovascular cannula

The invention belongs to the technical field of medical instruments, and discloses a cardiovascular intubation image auxiliary detection device and a detection method. The cardiovascular intubation image auxiliary detection device comprises an image acquisition module, a heart rate detection module, a respiratory frequency detection module, a central control module, a classification module, a datamanagement module, a data storage module and a display module. The invention establishes a new optimized CNN model through a classification module, and then superimposes the boundary map and the segmentation map to form a complete organization structure map, which makes up for the loss of image information caused by the reduction of the output image resolution, has high restoration degree of theorganization structure and better image display effect. At the same time, the data management module establishes different data quality evaluation models according to the data characteristics and datause purposes of different stages, so as to ensure the accurate and effective evaluation of the data quality, and overcome the shortcomings of lacking effective data quality evaluation models in the prior art.

Owner:重庆康华众联心血管病医院有限公司

Low coherence enhanced backscattering tomography and techniques

ActiveUS8823954B2Reduce coherenceEnhanced advantageBioreactor/fermenter combinationsBiological substance pretreatmentsIntact tissue3d image

A low coherence enhanced backscattering tomography (LEBT) method is disclosed for depth-selective sensing of the superficial layer of tissue. 3D images of the microarchitecture and molecular conformation of the superficial layer of tissue are obtained. The method combines the high resolution advantage of low coherence light and the high sensitivity advantage of light scattering to tissue structure and composition. Intact tissue can be examined without the need of excision or processing. The method can be applied in in situ measurements. According to the method, 3D images of the nuclear morphology and cellular structure for the superficial layer of the tissue are generated; this is particularly useful in detecting cancer and precancer at the earliest stage of carcinogenesis.

Owner:FAIRFIELD UNIVERSITY

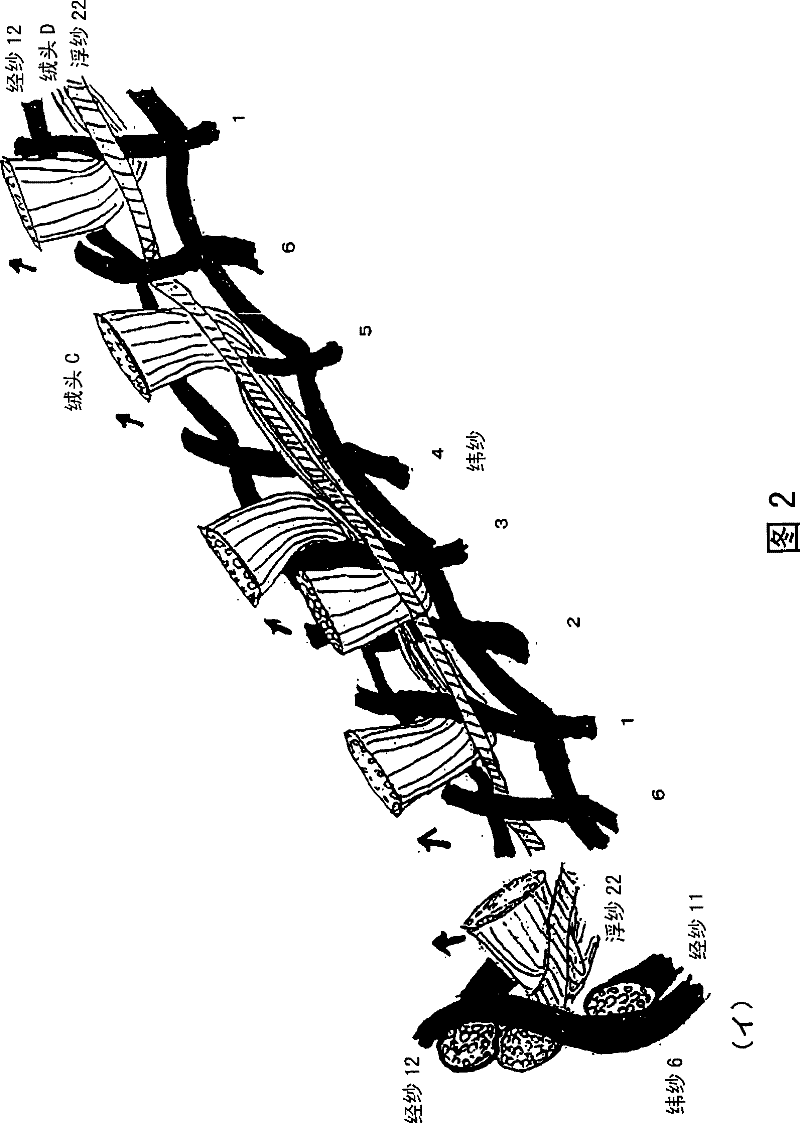

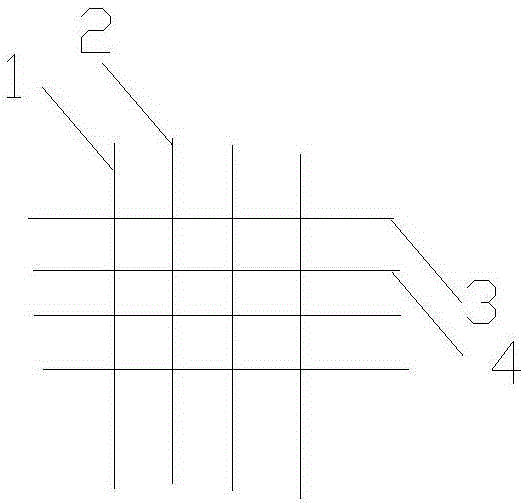

Friction cloth for liquid crystal panel manufacturing

InactiveCN101443496BUniform and stable tiltEasy to fixWoven fabricsNon-linear opticsIntact tissueEngineering

The invention provides a friction cloth for manufacturing liquid crystal panels of velvet fabric, the velvet fabric has: a base fabric structure formed by warp yarns (11)-(22) and weft yarns (1)-(6) and warp yarns along the base fabric structure Pile yarns (A) to (D) woven in the direction, the friction cloth for liquid crystal panel manufacturing is characterized in that: in a complete weave of the velvet fabric, the warp yarn has: a part (11) forming a plain weave and (12) and floating yarns (21) and (22) which are woven in a state of floating on the upper side of the weft yarn at the surface on the side where the end of the pile yarn protrudes enter.

Owner:SOMACHO

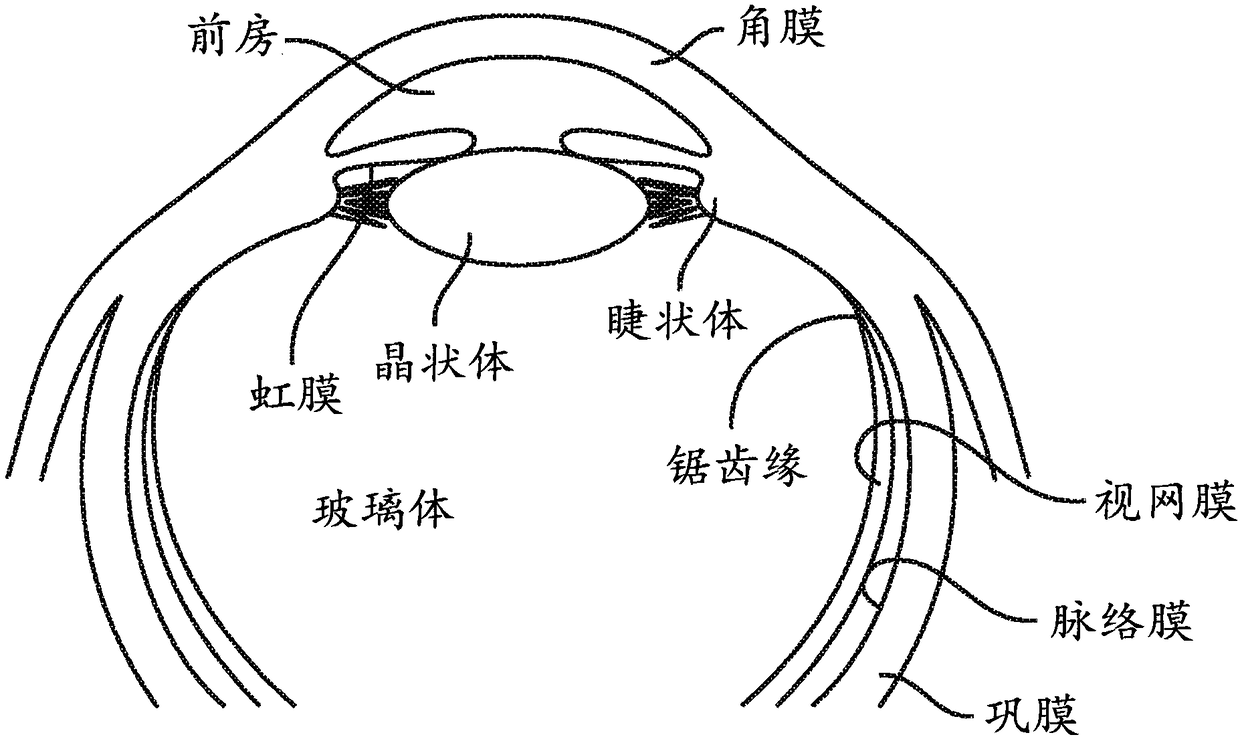

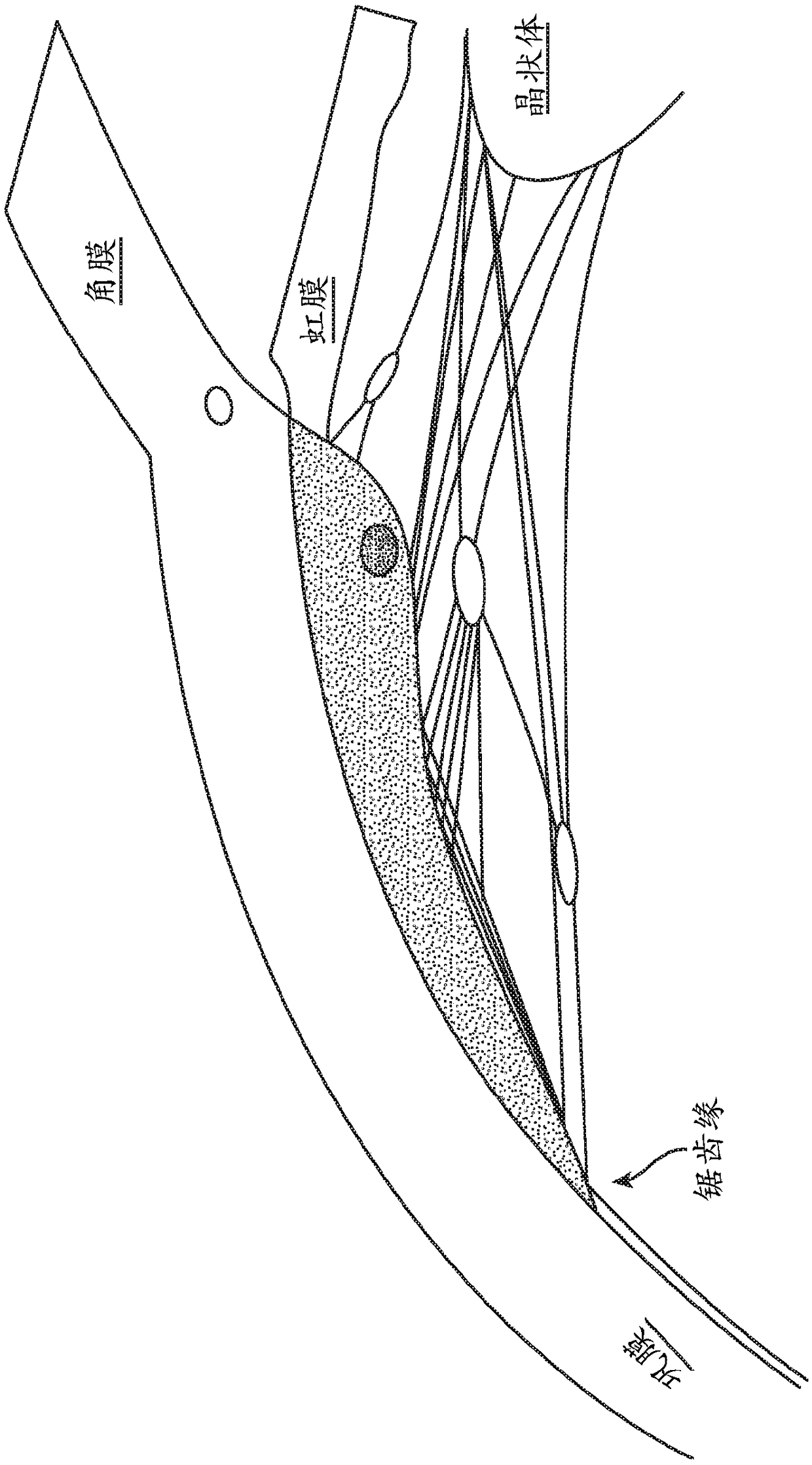

Preparation method of PLGA fibrous coat used for corneal tissue transplant

The invention relates to a synthetic-biodegradable PLGA fibrous coat which is prepared in an electrostatic spinning method and used for corneal tissue transplant, and in particular to a fibrous coat which is synthetic and germfree and capable of being rapidly degraded. The fibrous coat is supportive of rapid growth of separated corneal epithelial cells and has the capability that intact tissue transplant is directly placed on the coat and the corneal epithelial cells can grow outwards, and the separated cells or the cells growing outwards from the corneal transplant have good transmission performance on the coat. The fibrous coat prepared by the method can be directly used for substitute things of human amniotic membrane and has wide application prospect in the field of clinical corneal regeneration.

Owner:WUXI ZHONGKE GUANGYUAN BIOMATERIALS

Devices and methods for tissue transplant and regeneration

InactiveUS8852120B2Promote cell growthIncrease the number ofInfusion syringesSurgical needlesIntact tissueCardiac muscle

Devices and methods for transplanting tissue for the purpose of regeneration, for treating a patient having injured myocardial tissue, and / or for improving cardiac function through cell regrowth. More specifically, the devices and methods obviate the need for cellular alteration. The devices comprise a hollow tube with a sharp distal end, a stylet that is disposed and movable within the hollow tube, and a stopping device that constrains movement of the stylet. The methods comprise removing intact tissue from a first region of a mammalian organ and implanting the tissue in a second region of the same organ.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

Tissue culture and rapid propagation method of seed germination way of semiliquidambar cathayensis

InactiveCN106171986AIncrease vitalityShorten the time to adapt to the external environmentPlant tissue cultureHorticulture methodsShootIntact tissue

The invention discloses a tissue culture and rapid propagation method of a seed germination way of semiliquidambar cathayensis. The tissue culture and rapid propagation method comprises the following steps of step 1, making sterile materials; step 2, performing seed germination culture; step 3, inducing callus tissue; step 4, performing callus tissue proliferation; step 5, performing callus tissue differentiation; step 6, inducing multiple shoots; step 7, cutting off base parts of the differentiated multiple shoots obtained in the step 6, and inoculating the differentiated multiple shoots without the base parts into culture mediums so as to obtain sound seedlings; and step 8, cutting off base parts of the sound seedlings obtained in the step 7, inoculating the sound seedlings without the base parts into the culture mediums, and performing rooting culture. The invention aims to provide a complete tissue culture method for the semiliquidambar cathayensis, which is rapid, high in proliferation rate and high in survival rate.

Owner:YULIN NORMAL UNIVERSITY

Devices and methods for tissue transplant and regeneration

InactiveUS20070238177A1Promote cell growthIncrease the number ofSurgical needlesVaccination/ovulation diagnosticsIntact tissueCardiac muscle

Devices and methods for transplanting tissue for the purpose of regeneration, for treating a patient having injured myocardial tissue, and / or for improving cardiac function through cell regrowth. More specifically, the devices and methods obviate the need for cellular alteration. The devices comprise a hollow tube with a sharp distal end, a stylet that is disposed and movable within the hollow tube, and a stopping device that constrains movement of the stylet. The methods comprise removing intact tissue from a first region of a mammalian organ and implanting the tissue in a second region of the same organ.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

Processing method for environmentally-friendly multifunctional leisure dyed fabric

The invention discloses a processing method for an environmentally-friendly multifunctional leisure dyed fabric. The fabric is formed by interweaving level fibers which are used as warps and polyacrylonitrile fibers which are used as wefts. The fabric is in a one-up-one-down plain weave structure. A complete weave structure is a complete circulation of two warps and two wefts, totally four warps and wefts. The warps comprise a first warp and a second warp. The wefts comprise a first weft and a second weft. The warps use white yarns and dyed yarns which are formed by 30 single yarns, 40 single yarns, 70 double-strand, and 90 double-strand long stapled cotton by combing compact spinning, and the white yarns and dyed yarns are used as the first warp and the second warp. The first weft and the second weft use Dashuang fiber cool nylon fibers, 70D and 90D fine denier semi-dull FDY white filament yarns. The arrangement of the white yarns and dyed yarns of the warps conforms to requirements of Mitong or Chaoyang strips of yarn-dyed fabric, and the white yarns and dyed yarns are interwoven with the Dashuang fiber cool nylon fibers of the wefts.

Owner:陆飞飞

Dehydration method

ActiveUS8187655B2Shelf-life of the dehydrated product is appreciably extendedRehydrate quickly and easilyDrying solid materials with heatDrying solid materials without heatIntact tissueProduct gas

The present invention relates to a method of dehydrating pieces of intact plant or animal tissue, said pieces containing at least 30 wt. % of water, the method comprising (i) contacting the pieces of intact tissue with a pressurized gas to reduce the water content of the pieces by at least 50%, said pressurized gas having a pressure of at least 0.5×Pc and a temperature of at least Tc−60° C., Pc representing the critical pressure of the gas and Tc representing the critical temperature of the gas, and (ii) separating the pressurized gas from the dehydrated pieces, wherein at least 80 wt. %, preferably at least 90 wt. % of the matter removed by the gas from the pieces of intact plant or animal tissue is water. The invention also provides a method of dehydrating a material containing at least 30 wt. % of water, using a method as described before, followed by drying the separated pressurized gas by contacting said pressurized gas with a water absorbent water adsorbent; and recirculating the dried pressurized gas to the partially dehydrated material.

Owner:FEYECON DEV & IMPLEMENTATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com