Friction cloth for liquid crystal panel manufacturing

A technology for liquid crystal panels and fabrics, used in textiles and papermaking, instruments, optics, etc., can solve the problems of unstable brushing, no fixed tilting method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

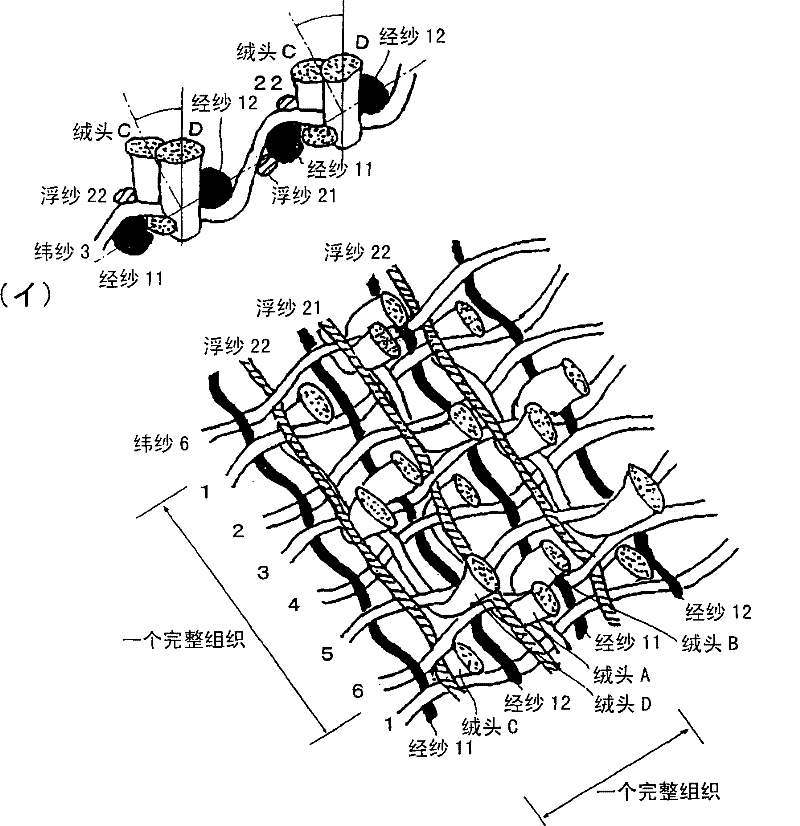

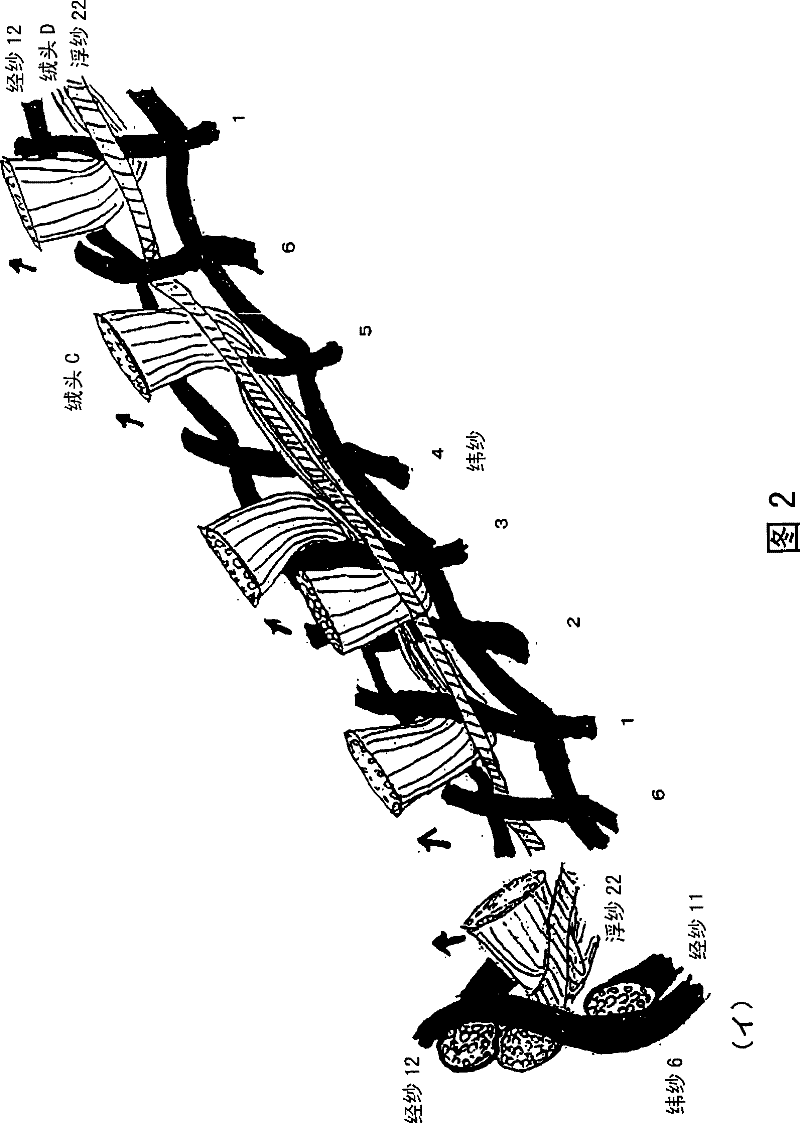

Embodiment 1

[0054] use figure 1 Trial-manufacture friction cloth with fabric structure. The results are collated in Table 1. Use cotton yarn No. 60 double-ply yarn as the ground warp yarn, use polyester 56 dtex double-ply yarn as the 5 / 1 floating yarn and the ground warp yarn of the plain weave, and the pile yarn is woven into a pile yarn with 30.6 pieces per centimeter Linear density. Four kinds of 165 decitex, 110 decitex, 84 decitex, and 33 decitex double-ply yarns were used for the weft yarn, and were woven under the conditions listed in the table. The angle of inclination is changed by friction during the back coating (バツクコ—ト), so the uncoated fabric (raw cloth) is fixed with a wooden frame. ), a solution of polyvinyl acetate resin dissolved in acetone and ethanol was applied from the back and dried to fix the pile, and the inclination angle in the weft direction was measured. tilt angle as Figure 15 As shown, it is defined as the angle θ with respect to the friction cloth 1...

Embodiment 2

[0056] use Figure 8 The fabric structure of is woven using the same pile yarn and ground warp yarn as in Example 1. The weft yarn is 33 decitex double-ply and has a total fiber count of 74600 per square centimeter. The weaving shrinkage of floating yarn was 2.2%. The pile of the gray cloth was fixed in the same manner as in Example 1, and the angle of inclination was measured. The inclination angle of the weft direction in the above case is 74 degrees. Heat and dry the remaining gray cloth of the above-mentioned cloth at 150°C and make it shrink. After cutting, washing, and drying, use a brush to make the pile yarns tilt laterally, and coat the back of the cloth with about 50g / m 2 acrylic resin, dry and then bake. The width of the cloth after processing was 112 cm in the portion where the pile was present.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com