Processing method of low-carbon ultra-cool yarn-dyed fabric

A processing method and fabric technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of poor heat dissipation and moisture absorption, poor cool feeling, etc., and achieve the effect of easy care, excellent antibacterial and antibacterial, comfortable and soft to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

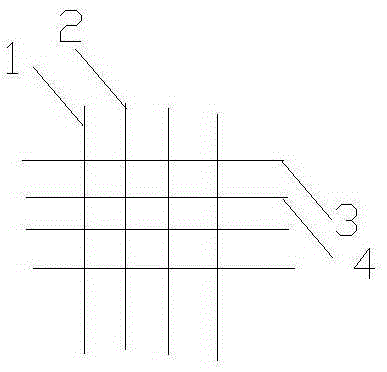

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] As shown in the figure, the fabric is interwoven with Lyville fiber yarn as the warp yarn and Dashuang fiber as the weft yarn. The fabric adopts a plain weave structure with one up and one down. A total of four warp and weft threads is a complete cycle, the warp yarns include the first warp yarn 1 and the second warp yarn 2 , and the weft yarns include the first weft yarn 3 and the second weft yarn 4 .

[0014] In the present embodiment, described warp yarn adopts the white yarn and the color yarn that are combed and compactly spun by 40 single yarns, 50 single yarns, 80 double strands, and 100 double strands of long-staple cotton, as the first Warp yarn 1 and the second warp yarn 2; The first weft yarn 3 and the second weft yarn 4 all adopt Dashuanglun cool nylon 6 fiber, 75D, 100D fine denier semi-dull FDY white filament; the white yarn of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com