Processing method of primary taste clean water bamboo shoots

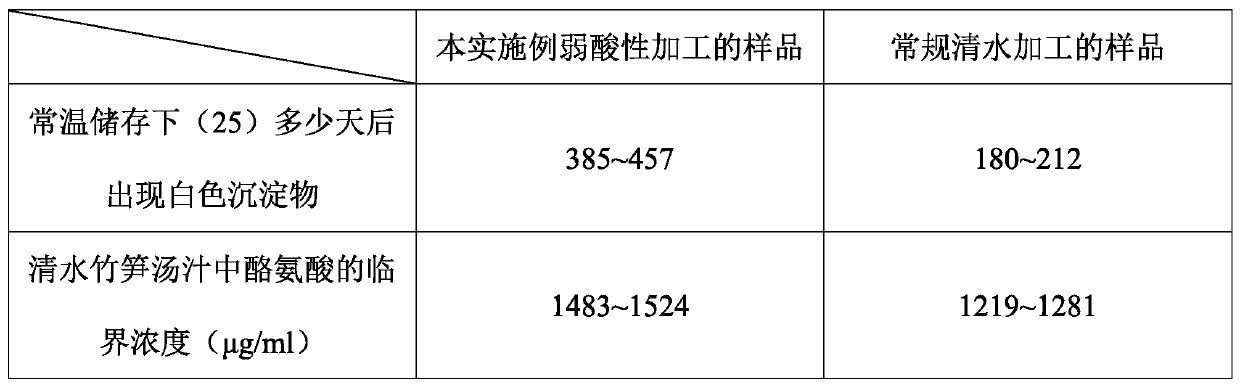

A technology of clear water bamboo shoots and processing methods, which is applied in the food field, can solve the problems of broken bamboo shoot cells, soft taste of bamboo shoots, and damaged tissue shape, so as to extend the time of precooking and recooking, crisp and tender taste, and maintain tissue shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of processing technology flow of winter bamboo shoots packed in plain clear water slices

[0030] Include the following steps in order:

[0031] (1) Pretreatment, peel off the shells of fresh winter bamboo shoots that have been collected for no more than 24 hours, then cut off the hardened and fibrous parts of the base, and flick off the bamboo shoots on the surface of the winter bamboo shoots, and then cut them into thicknesses of about 2mm to 3mm. Bamboo shoots with a length of about 45mm to 75mm and a width of about 10mm to 15mm, and then cleaned.

[0032] (2) precooking, put the winter bamboo shoots pretreated in step (1) into 0.08% (mass percentage) citric acid aqueous solution and carry out vacuum low-temperature slow cooking for 120min, wherein the vacuum degree is about 0.04~0.06MPa, and the temperature is maintained at 53 ℃~55℃, the solid-liquid ratio of winter bamboo shoots and citric acid aqueous solution is 1g: 3mL.

[0033] (3) rinsing...

Embodiment 2

[0038] Embodiment 2 A kind of processing technology flow of original taste clear water packaged bamboo shoots

[0039] Include the following steps:

[0040] (1) Pretreatment: peel off the shells of fresh bamboo shoots that have been collected for no more than 16 hours, then cut off the hardened and fibrous parts at the base, and flick the bamboo shoots on the surface of the bamboo shoots, and then wash them.

[0041] (2) precooking, putting the whip bamboo shoots pretreated in step (1) into 0.2% (mass percentage) citric acid aqueous solution and carrying out vacuum low-temperature slow cooking for 70min, wherein the vacuum degree is 0.04~0.06MPa, and the temperature is maintained at 50 °C to 55 °C, preferably 53 °C, the solid-to-liquid ratio of bamboo shoots and citric acid aqueous solution is 1 g: 6 mL.

[0042] (3) Rinsing: Soak the bamboo shoots precooked in step (2) or quickly rinse them in low-temperature flowing water, so that the temperature of the bamboo shoots can qu...

Embodiment 3

[0047] Embodiment 3 A kind of processing step of original taste clear water split bamboo shoots

[0048] Include the following steps:

[0049] (1) Pretreatment: peel off the shells of fresh bamboo shoots that have been collected for no more than 16 hours, then cut off the hardened and fibrous parts of the base, and remove the bamboo shoots on the surface of the bamboo shoots, and then clean them.

[0050] (2) precooking, put the bamboo shoots pretreated in step (1) into 0.15% (mass percentage) aqueous citric acid solution and carry out vacuum low-temperature slow cooking for 90min, wherein the vacuum degree is 0.04~0.06MPa, and the temperature is maintained at 55°C ~60°C, the solid-to-liquid ratio of bamboo shoots to citric acid aqueous solution is 1g: 10mL.

[0051] (3) Rinse, soak the precooked bamboo shoots in step (2) or quickly rinse them with running water, so that the temperature of the bamboo shoots returns to normal temperature 20-30°C, and the water temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com