Processing method for harsh-taste-free taro leaf stalk pickle

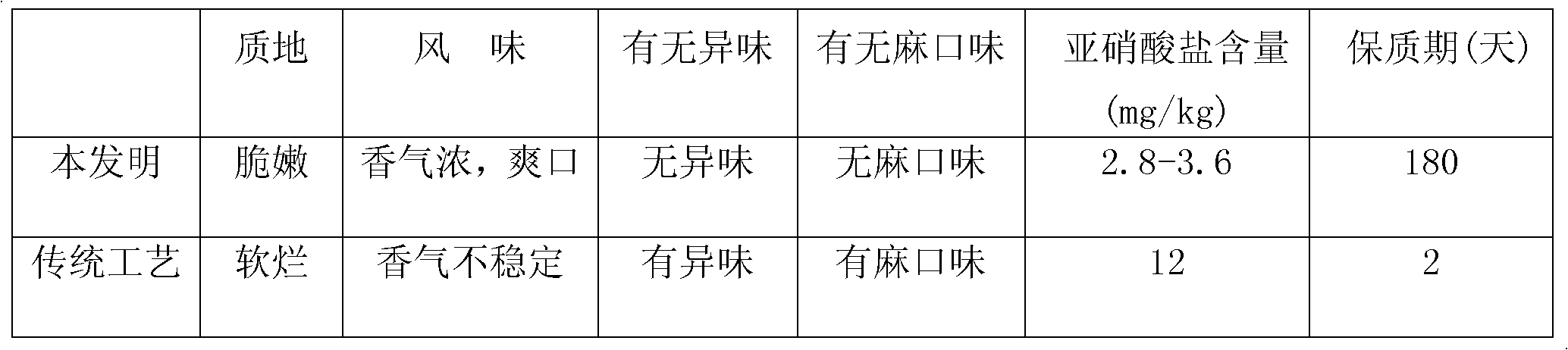

A processing method and petiole technology, which is applied in the processing field of taro petiole kimchi, can solve the problems of taro petiole kimchi that is rough, cannot be produced on a large scale, and cannot be stored for a long time, and achieves the effect of strong flavor, easy long-term storage, and crisp and tender texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take the fresh taro petiole with a growth time of 10 days, wash it with drinking water, cut off the discolored petiole, and cut the taro petiole into short and uniform segments; take 3kg of lactic acid bacteria starter and 7kg of salt dissolved in 60kg of 25℃ Stir evenly in drinking water; then take 30kg of fresh taro petiole segments and immerse them in the solution. The taro petiole segments should be pressed into the water to prevent them from being exposed. At room temperature, seal and ferment for 4 days until the hemp taste disappears and the taste is palatable. The texture is suitable and there is no soft and rotten phenomenon; take out the fermented taro petiole, put it into a polyethylene cooking bag, squeeze it manually to drive out the air in the bag, and then use a plastic heat sealing machine to heat seal the bag mouth. Sterilize the sealed bagged product at 70°C for 5 minutes, and immediately cool to normal temperature with cooling water after sterilization...

Embodiment 2

[0025] Take the fresh taro petiole with a growth time of 15 days, wash it with drinking water, cut off the discolored petiole, and cut the taro petiole into short and uniform segments; dissolve 10kg of table salt in 52kg of drinking water at 35°C, and stir well Then take 38kg of fresh taro petioles and immerse them in the solution. The taro petioles should be pressed into water to prevent them from being exposed. At room temperature, seal and ferment them for 8 days until the hemp taste disappears. Phenomenon: Take out the small section of fermented taro petiole, put it into a polyethylene cooking bag, squeeze it manually to remove the air in the bag, and then use a plastic heat sealing machine to heat seal the bag mouth. Sterilize the sealed bagged product at 90°C for 3 minutes, and immediately cool to normal temperature with cooling water after sterilization.

Embodiment 3

[0027] Take the fresh taro petiole with a growth time of 20 days, wash it with drinking water, cut off the discolored petiole, and cut the taro petiole into short and uniform segments; take 2kg of lactic acid bacteria starter and 3kg of salt dissolved in 45kg of 10°C Stir evenly in drinking water; then take 50kg of fresh taro petioles and immerse them in the solution. The taro petioles should be pressed into the water to prevent them from being exposed. At normal temperature, seal and ferment for 7 days until the hemp taste disappears and the taste is palatable. The texture is suitable and there is no soft rotten phenomenon; take out the fermented taro petioles, put them into glass bottles, press them tightly, and leave a head gap of 5 to 8 mm, and seal them with a vacuum sealing machine. Sterilize the sealed bottled product at 60°C for 8 minutes, and immediately cool to normal temperature with cooling water after sterilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com