Integrated electric wheel drive unit for electric automobile

An integrated electric wheel and electric vehicle technology, applied in the direction of electric vehicles, electromechanical devices, power devices, etc., can solve the problems of reducing the axial space of the wheel and increasing the axial size of the hub motor, and achieves compact structure, easy installation, and improved The effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

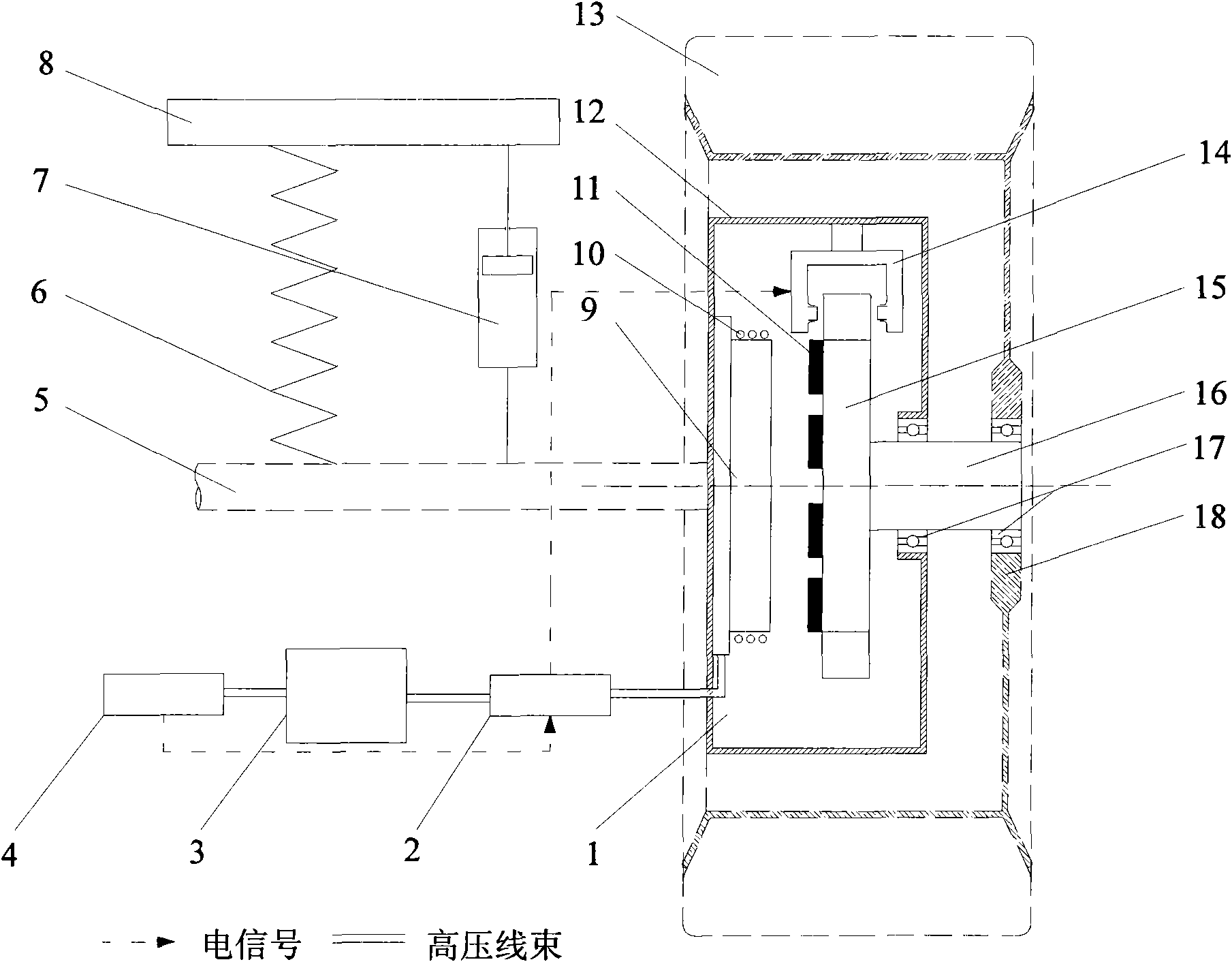

[0029] Such as figure 1 As shown, the integrated electric wheel drive device for electric vehicles of the present invention includes a disc motor 1 , a motor controller 2 , a battery pack 3 , a vehicle control unit ECU4 and an axle 5 . The disc motor 1 is installed in the tire 13 through the axle 5; the disc motor 1 includes a stator 9, a rotor 15, a brake caliper 14, a permanent magnet 11, a stator winding 10, a motor rotor shaft 16 and a motor housing 12; the stator winding 10 Wound on the stator 9, the permanent magnet 11 is attached to the rotor 15, which is located on the opposite side of the stator 9; the brake caliper 14 is fixed on the motor casing 12, and cooperates with the rotor 15 to brake the rotation of the rotor; the rotor 15 is fixed on the rotor shaft of the motor One end of 16, the other end of motor rotor shaft 16 is fixed on the wheel hub 18 of tire 13 through bearing 17; 6 and shock absorber 7 are connected with frame 8. The vehicle control unit ECU4, th...

Embodiment 2

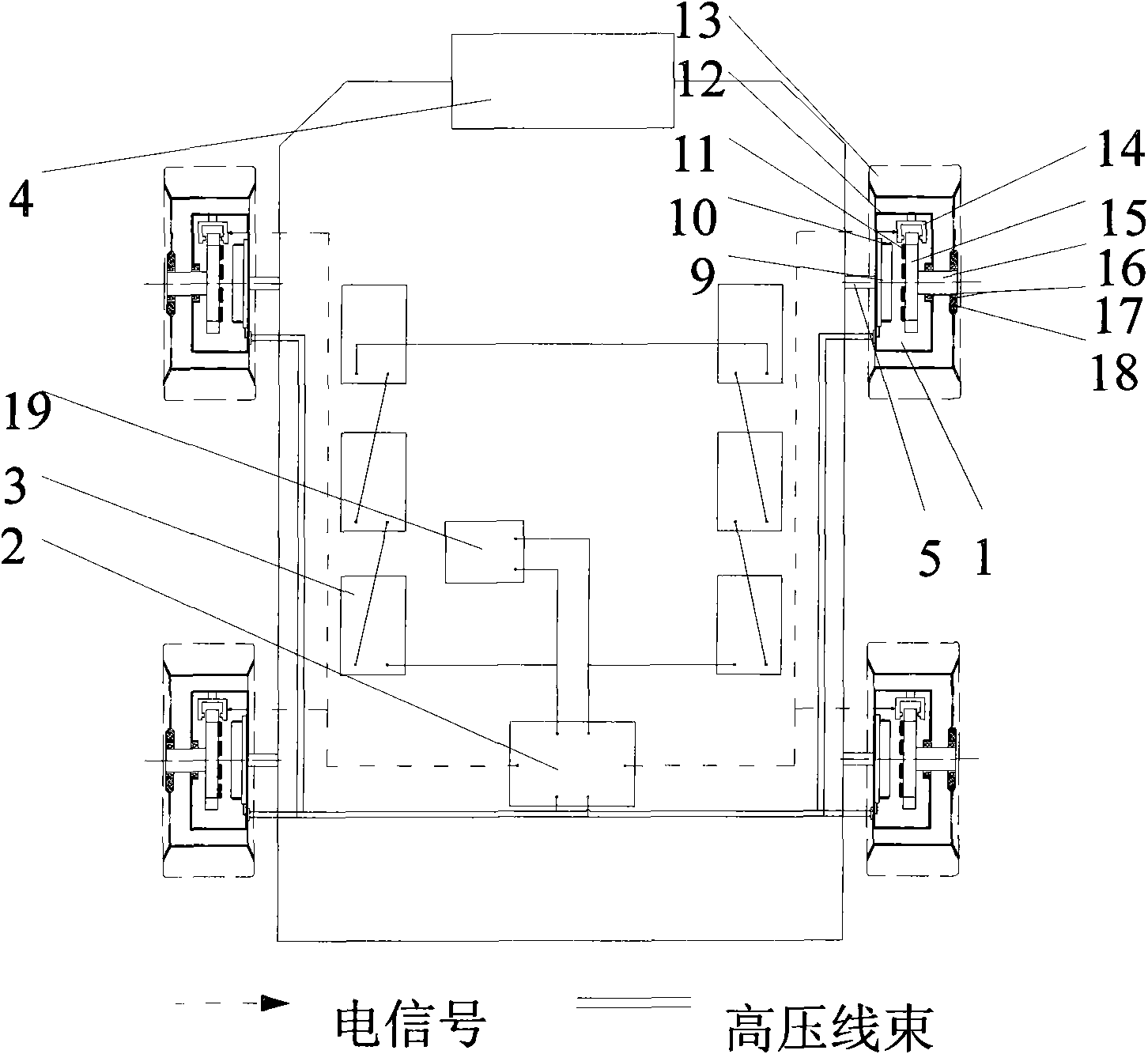

[0033] figure 2 It is a schematic diagram of the driving device used to realize the four-wheel drive pure electric vehicle. The four-wheel drive electric vehicle does not need to use a traditional engine, so the emission is zero, and it is a new type of pollution-free vehicle. Such as figure 2 Shown: each wheel has a figure 1In the electric drive device shown, the motor controller 2 controls each wheel electric drive device individually. The battery pack 3 is a storage battery, and the vehicle-mounted DC / DC 19 is a power electronic device, which is connected with the motor controller 2 at a high voltage, and is used to control the voltage of the disc motor. The vehicle control unit ECU4 is connected to the battery pack 3, the motor controller 2 and the stator 9 sequentially through a high-voltage wire harness, and the vehicle control unit ECU4 is also connected to the motor controller 2 for signals, and the motor controller 2 is respectively connected to the four wheel ele...

Embodiment 3

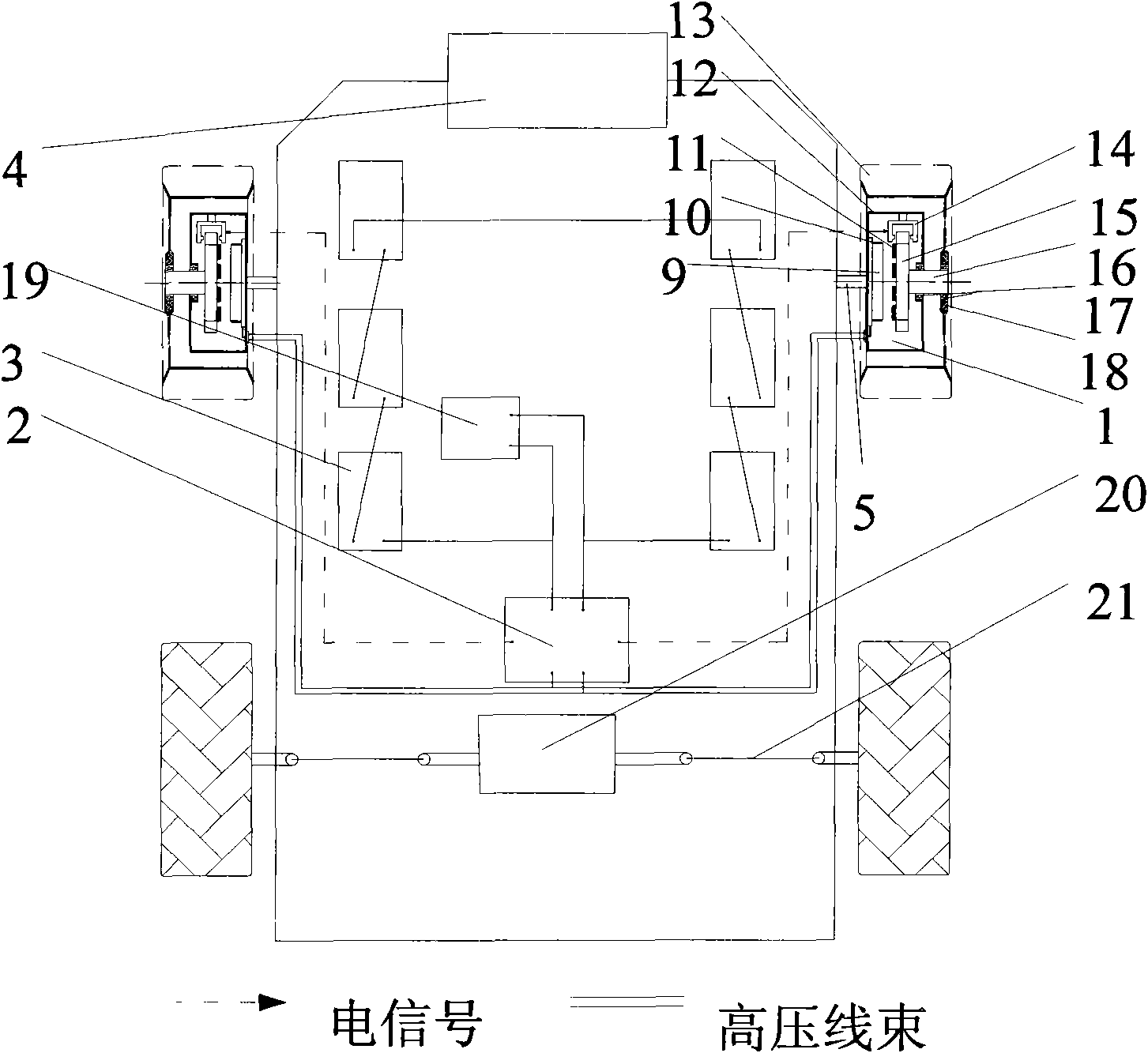

[0039] image 3 It is a schematic diagram of the principle used to realize the driving device of the front-drive pure electric vehicle. Like Embodiment 1, it does not need to use a traditional engine, and the emission is zero. It is a new type of non-polluting vehicle. Such as image 3 As shown, each wheel of the front axle is equipped with figure 1 In the electric drive device shown, the motor controller 2 controls the two wheel electric drive devices separately. The rear axle is a non-drive axle, using a differential 20 and a transmission shaft 21 to connect the two wheels to realize the differential function of the axle. Other structural forms and control functions are similar to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com