Double-motor controller with electronic differential function

An electronic differential, drive motor control technology, applied in multiple motor speed/torque control, motor, control drive and other directions, can solve the problems of low drive system efficiency, inability to actively differential, inconvenient layout, etc., to achieve flexible mechanical The effect of driving characteristics, reduction of wiring links, and ease of arrangement and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

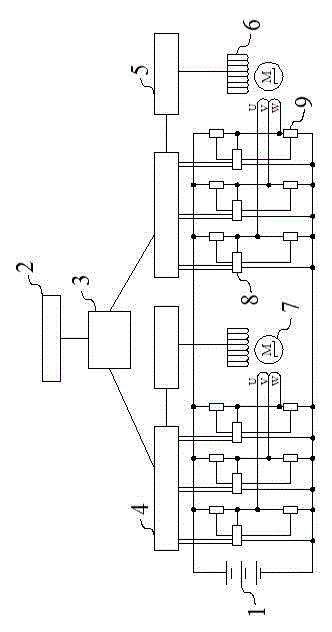

[0020] Such as figure 1 As shown, a dual-motor controller with electronic differential function, which includes a main control chip 1 integrating an electronic differential module, two sets of drive motor control chips 2, two sets of resolver 9 decoding chips 3, two sets of control motors Running power drive module, capacitor group 4, angle decoding and conditioning circuit 5, two permanent magnet motors 8 with built-in resolver 9 and main power battery pack 10, each set of power drive modules includes power device group 6 and drive circuit board 7 , the resolver 9 in the permanent magnet motor is connected to the resolver 9 decoder chip 3 through a signal line, the resolver 9 decoder chip 3 is connected to the drive motor control chip 2 through a communication line, and the drive motor control chip 2 is connected to the main control chip through a communication line 1 connection, the angle decoding and conditioning circuit 5 is connected to the main control chip 1 through a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com