Method for controlling operation of complex pipeline based on deep learning

A technology of deep learning and operation control, applied in adaptive control, general control system, control/regulation system, etc., can solve problems such as high energy consumption, short reliable running time, frequent safety problems, etc., and achieve long reliable running time , reduced energy consumption, and fewer safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

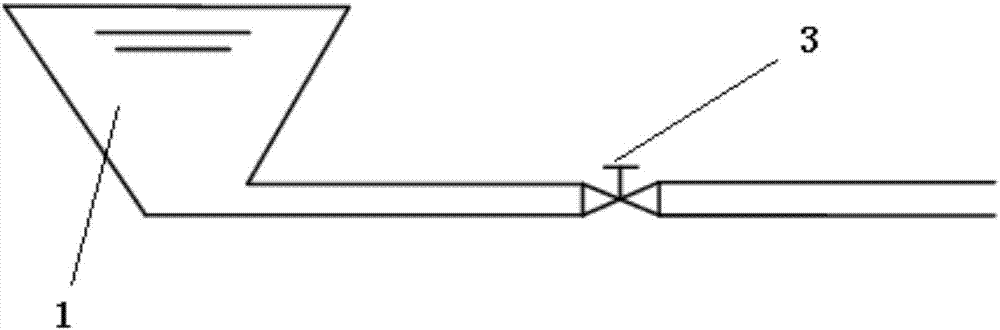

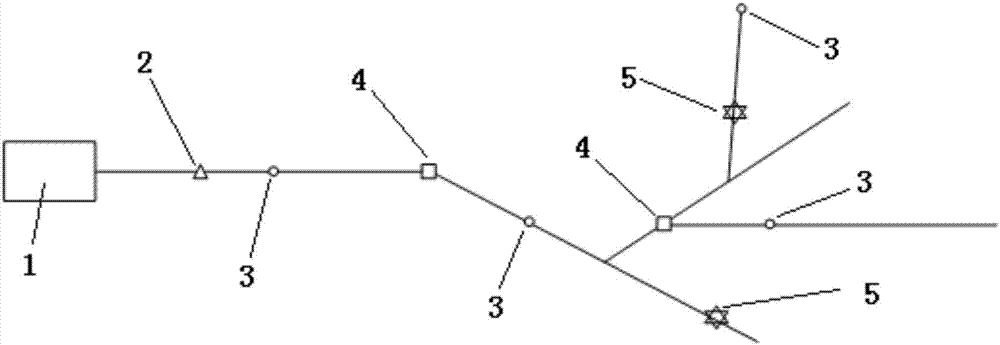

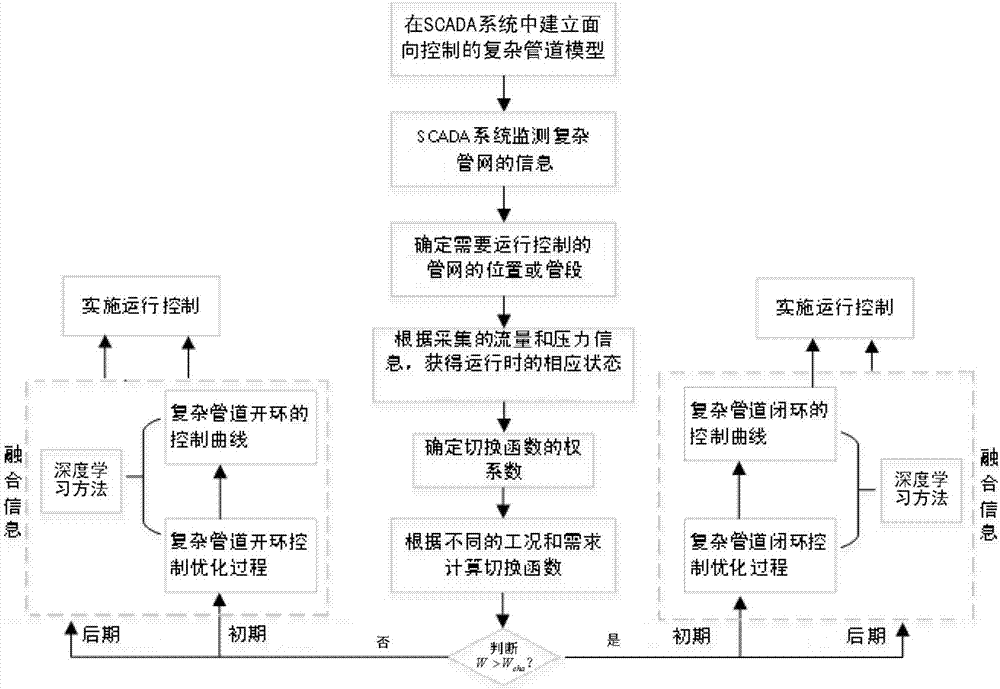

[0029] Specific implementation mode one: combine figure 1 , figure 2 , image 3 This embodiment is described. The complex pipeline operation control method based on deep learning given in this embodiment is as follows: image 3 As shown, the specific steps are as follows:

[0030] Step 1. For each section of the pipeline in the pipeline network, a control-oriented complex pipeline model is established in the SCADA system. A complex pipeline network usually consists of water source 1 (reservoir), flow meter 2, pressure gauge 5, pump 4 (pumping station), valve 3 and so on. Flow meter 2, pressure gauge 5, pump 4 (pump station), valve 3 are connected to the central control room through wired or wireless; the central control room dispatches and monitors the entire pipeline network in real time through SCADA system and powerful numerical calculation, information fusion, etc. information (a schematic diagram of a complex pipeline network such as figure 1 , figure 2 shown);

...

specific Embodiment approach 2

[0046] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 3, the specific steps for determining whether to adopt the complex pipeline open-loop control strategy based on the deep learning method or to adopt the complex pipeline closed-loop control strategy based on the deep learning method include: :

[0047] Define the following toggle function:

[0048]

[0049] Among them, P e1 , P e2 is the switching function weight, is the flow value at the preset pipeline position or the flow value in the pipeline section, is the pressure value at the preset pipeline position or the pressure value in the pipeline section, q i Indicates the flow value measured by the i-th flowmeter in the pipe network, i∈[1,M], p j Indicates the pressure value measured by the jth pressure gauge in the pipe network, j∈[1,N], M is the number of flowmeters in the pipe network, and N is the number of pressure gauges in the pipe network;

[0050] Generally speaking...

specific Embodiment approach 3

[0052] Specific implementation mode three: as Figure 4 As shown, the difference between this embodiment and the specific embodiment 1 is that in step 41, the specific steps of the complex pipeline open-loop control strategy include:

[0053] A1. Starting from the mechanism model of complex pipelines, establish a control-oriented space-time evolution model, give boundary valves, and write them into the pipeline space-time evolution module;

[0054] A2. Set the performance index of complex pipeline open-loop control and write it into the performance index module of open-loop control;

[0055] A3. Introduce Lagrangian functions λ(l, t), μ(l, t) into the co-state module of open-loop control to obtain the performance index of extended open-loop control and obtain the performance of open-loop control by variational method Co-state model, write the co-state model of open-loop control into the co-state module of open-loop control, and write the obtained gradient form into the gradie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com