Flue gas waste heat recovery system of large flue of sintering machine

A flue gas waste heat recovery system technology, applied in waste heat treatment, climate sustainability, lighting and heating equipment, etc., can solve problems such as large changes in working conditions, flue gas condensation, complex equipment systems, etc., to achieve convenient operation control , The effect of low operating cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

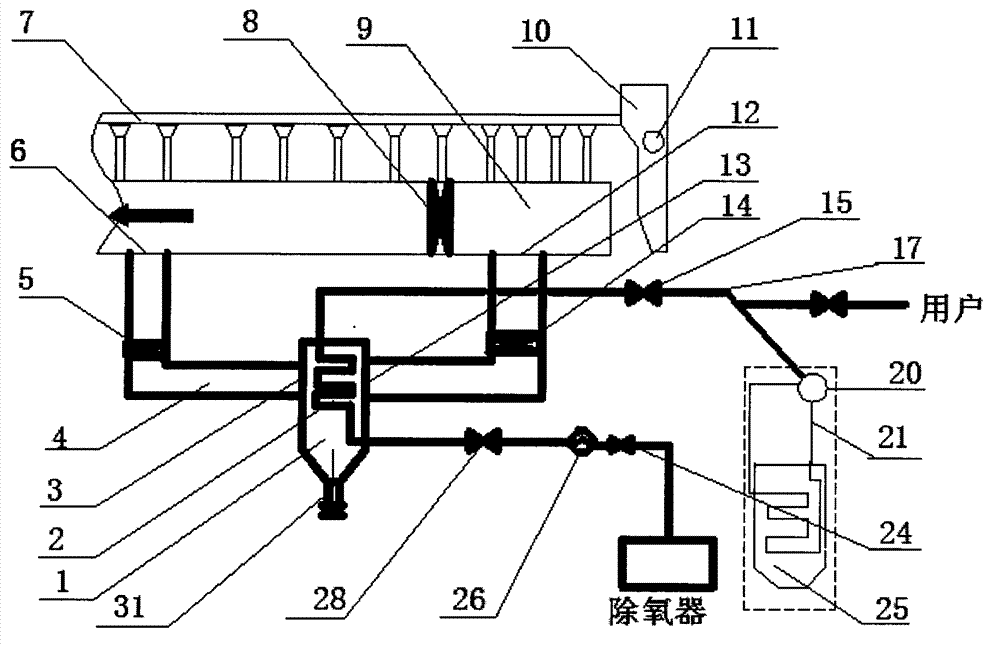

[0021] Such as figure 1 As shown, the sintering machine large flue flue gas waste heat recovery system of the present invention mainly includes a waste heat boiler (25), a heat exchanger (1), a sintering machine large flue (9), a sintering machine large flue control valve ( 8), the bypass flue (4) and deaerator of the large flue of the sintering machine; install the bypass flue (4) on the side of the large flue of the sintering machine (9), and install the bypass flue (4) on the side of the large flue of the sintering machine (9). ) is installed in the middle of the heat exchanger (1); the large flue control valve (8) is installed on the large flue (9) between the penultimate to the sixth air boxes at the tail of the sintering machine; the large flue control valve (8) is installed on the large flue control Between the valve (8) and the tail of the large flue (in the direction of the tail of the sintering machine), it connects the large flue (9) of the sintering machine with th...

Embodiment 2

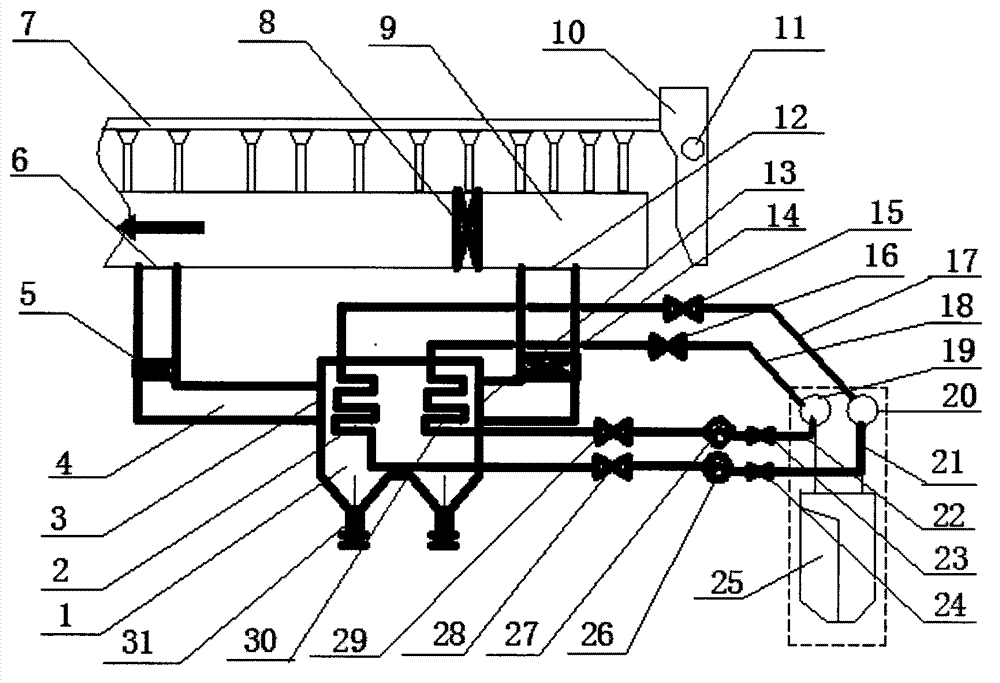

[0023] Such as figure 2As shown, the sintering machine large flue flue gas waste heat recovery system of the present invention mainly includes a waste heat boiler (25), a heat exchanger (1), a sintering machine large flue (9), and a sintering machine large flue control valve ( 8), the bypass flue (4) of the large flue of the sintering machine; press the bypass flue (4) on the side of the large flue (9) of the sintering machine, press the middle part of the bypass flue (4) Install a heat exchanger (1); install a large flue control valve (8) on the large flue (9) between the penultimate to the sixth wind boxes at the tail of the sintering machine; install a large flue control valve (8) on the large flue control valve (8) In the middle of the tail of the large flue (in the direction of the tail of the sintering machine), the large flue (9) of the sintering machine is connected with the bypass flue (4). At the flue (9), connect the large flue (9) with the bypass flue (4); betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com