Patents

Literature

552results about "Free piston engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

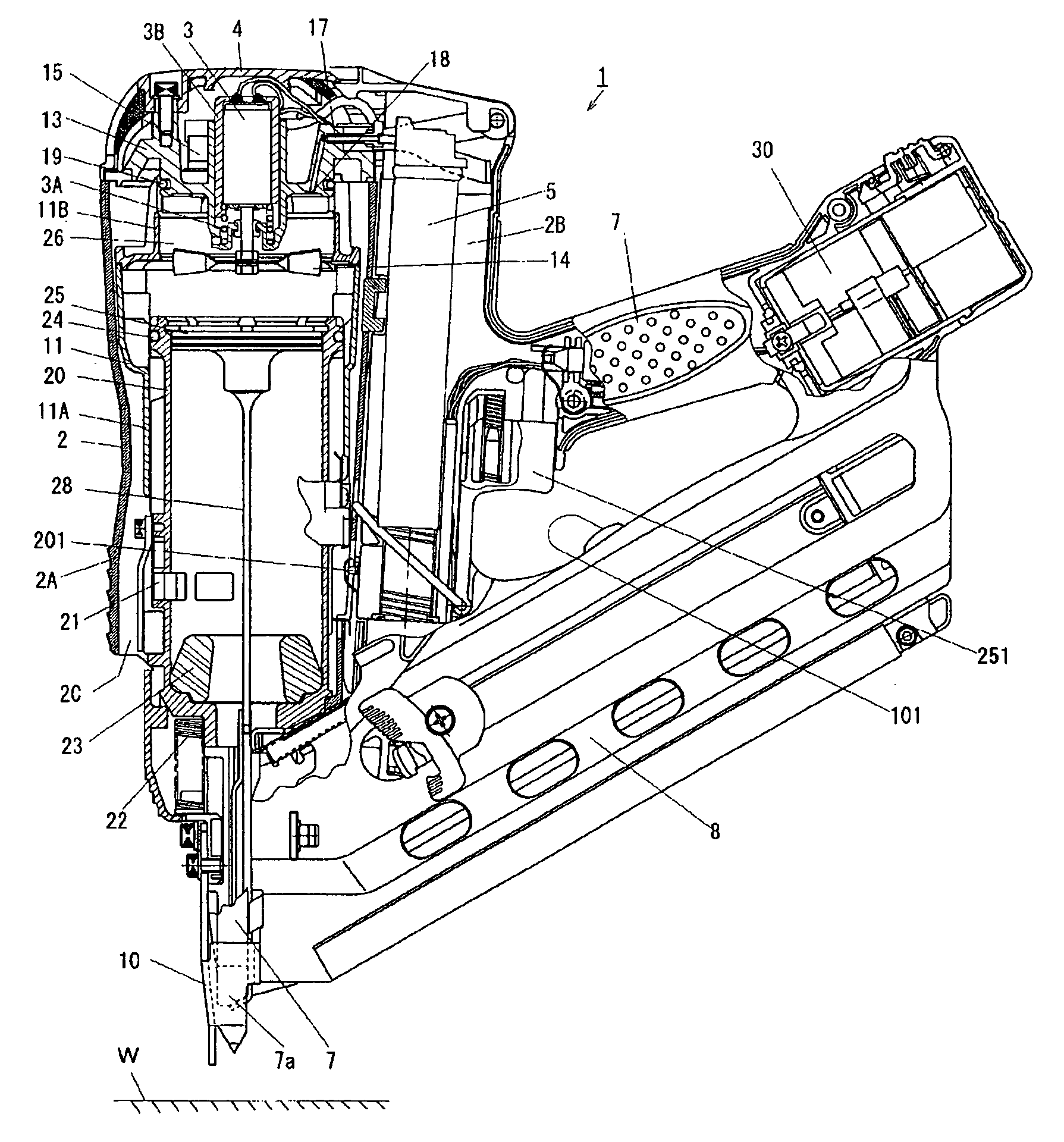

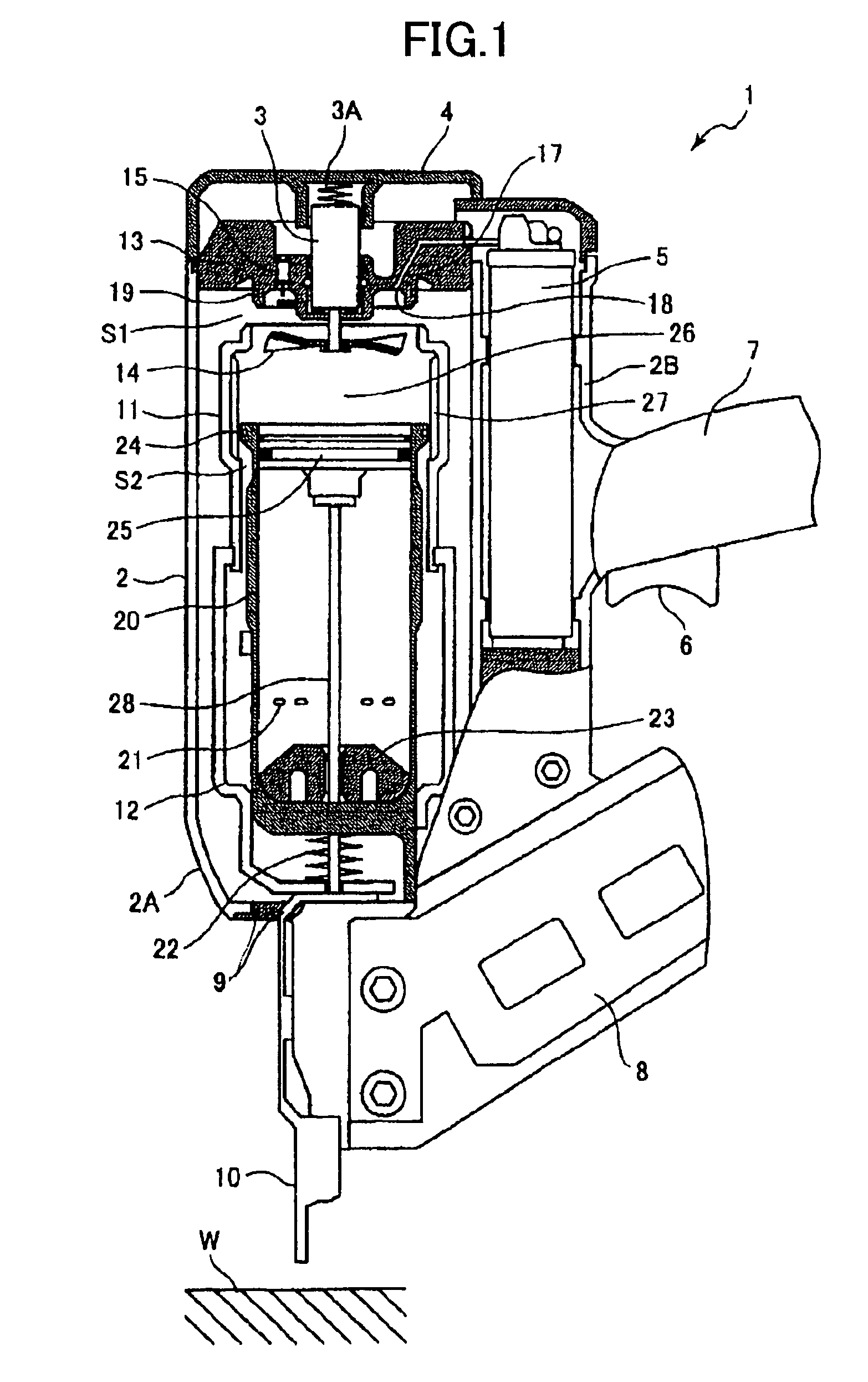

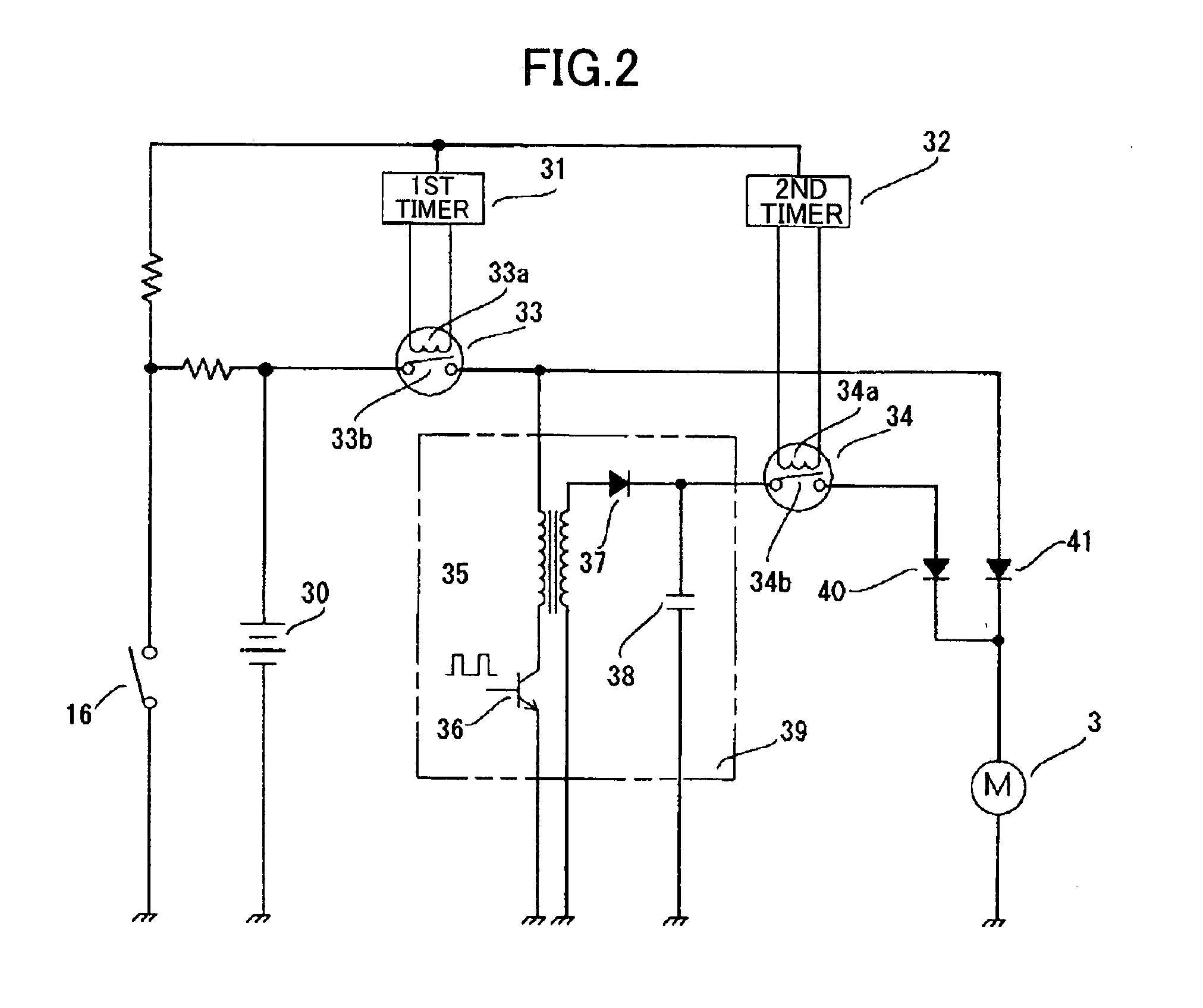

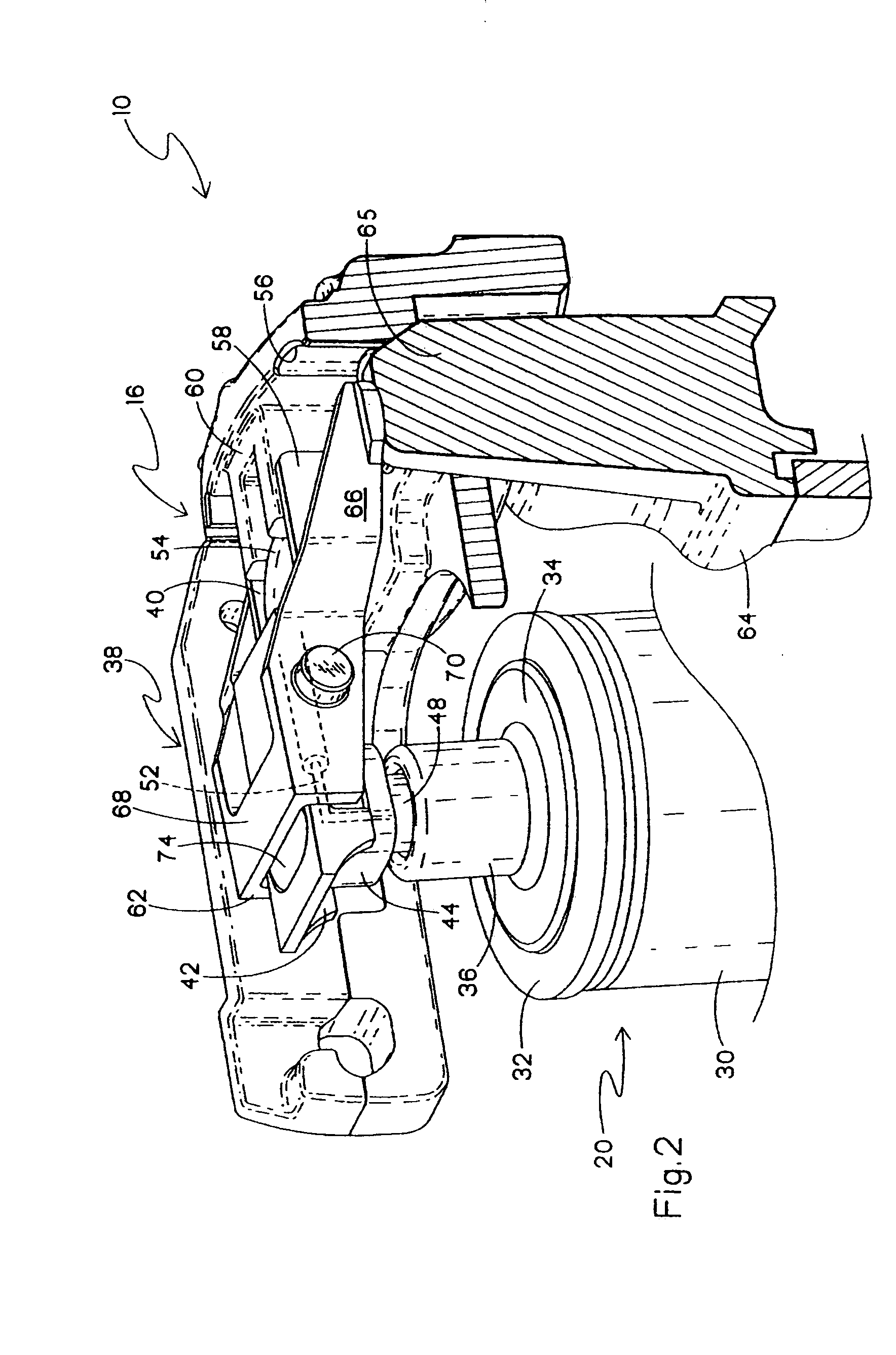

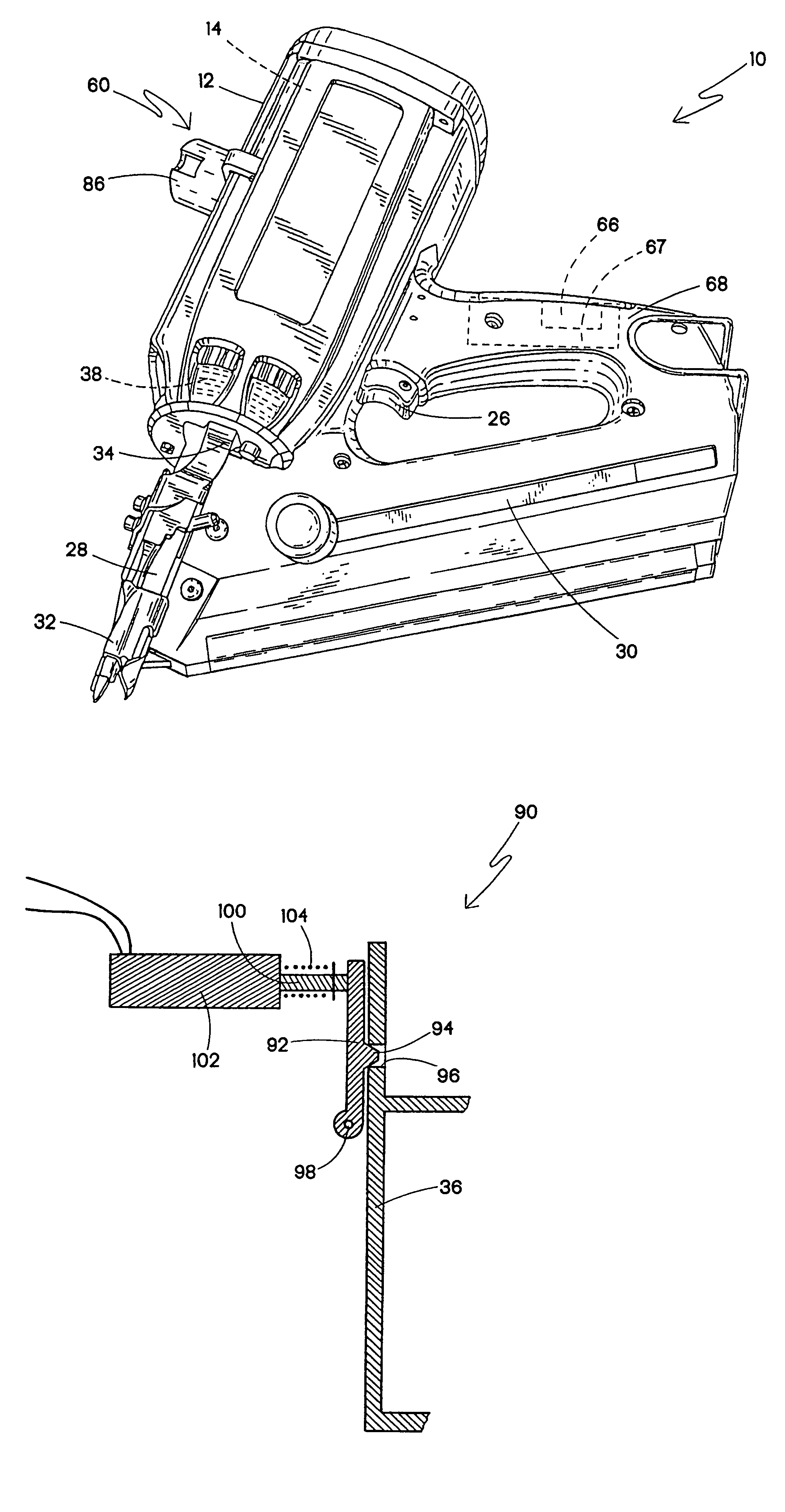

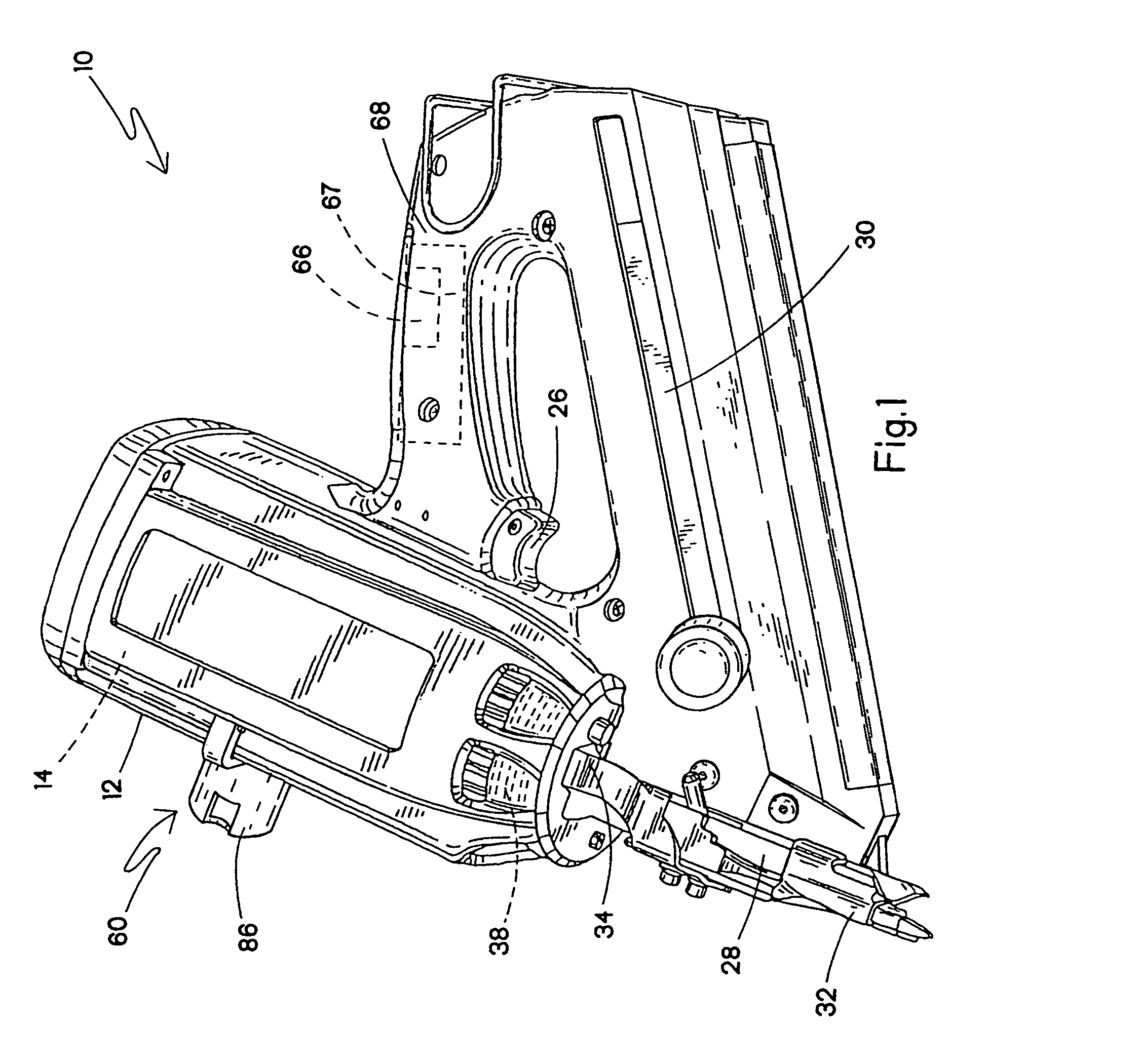

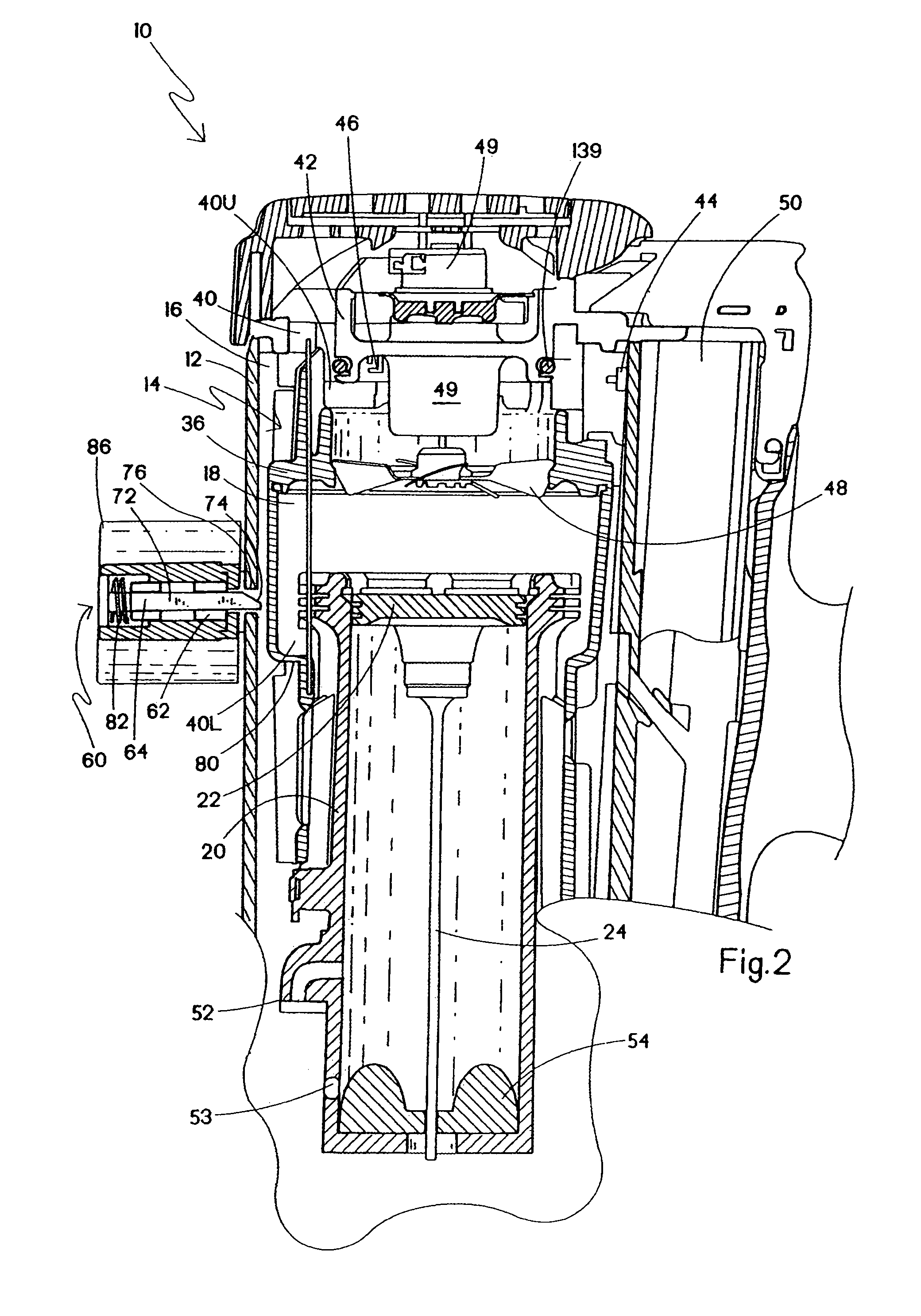

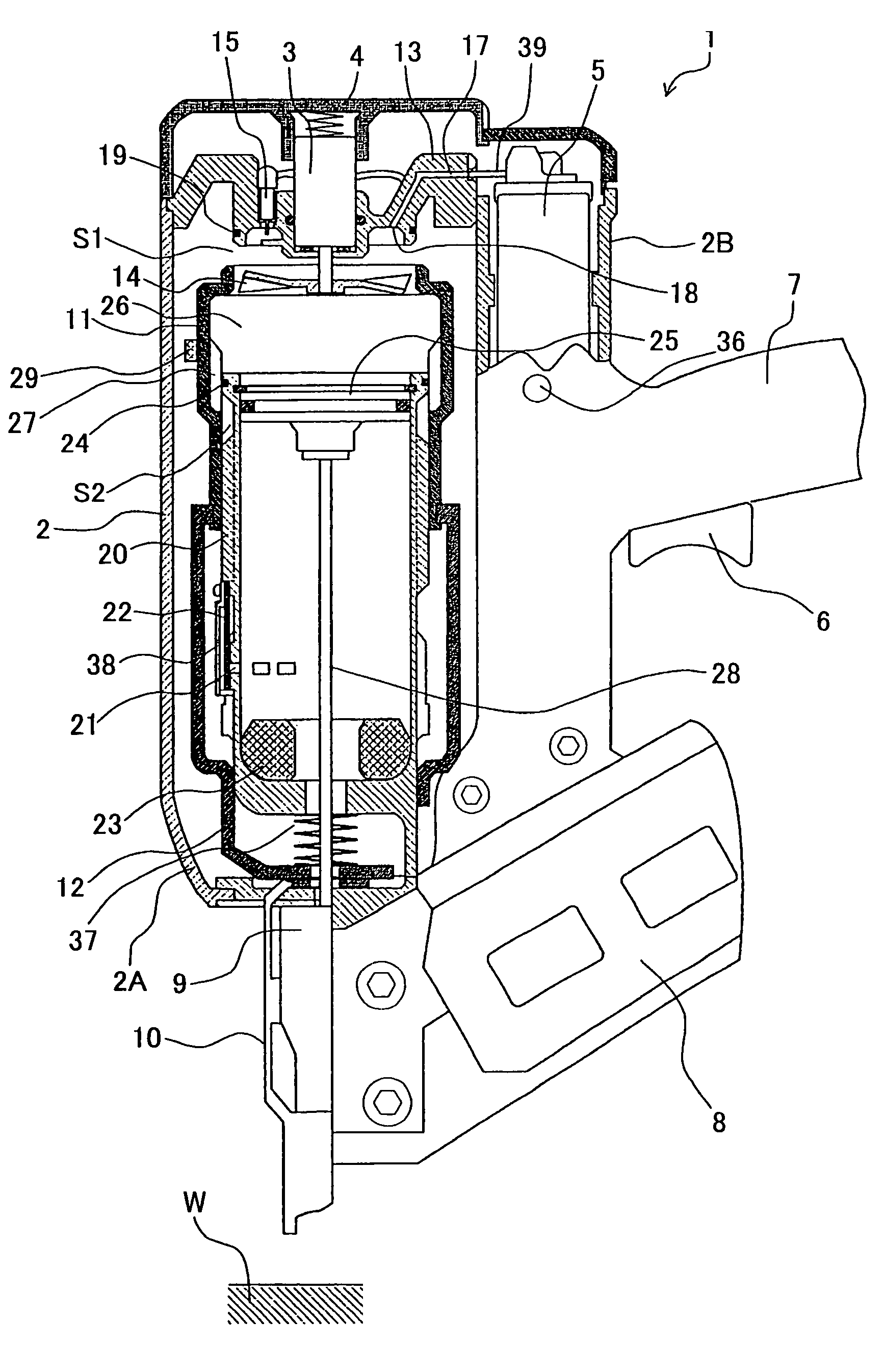

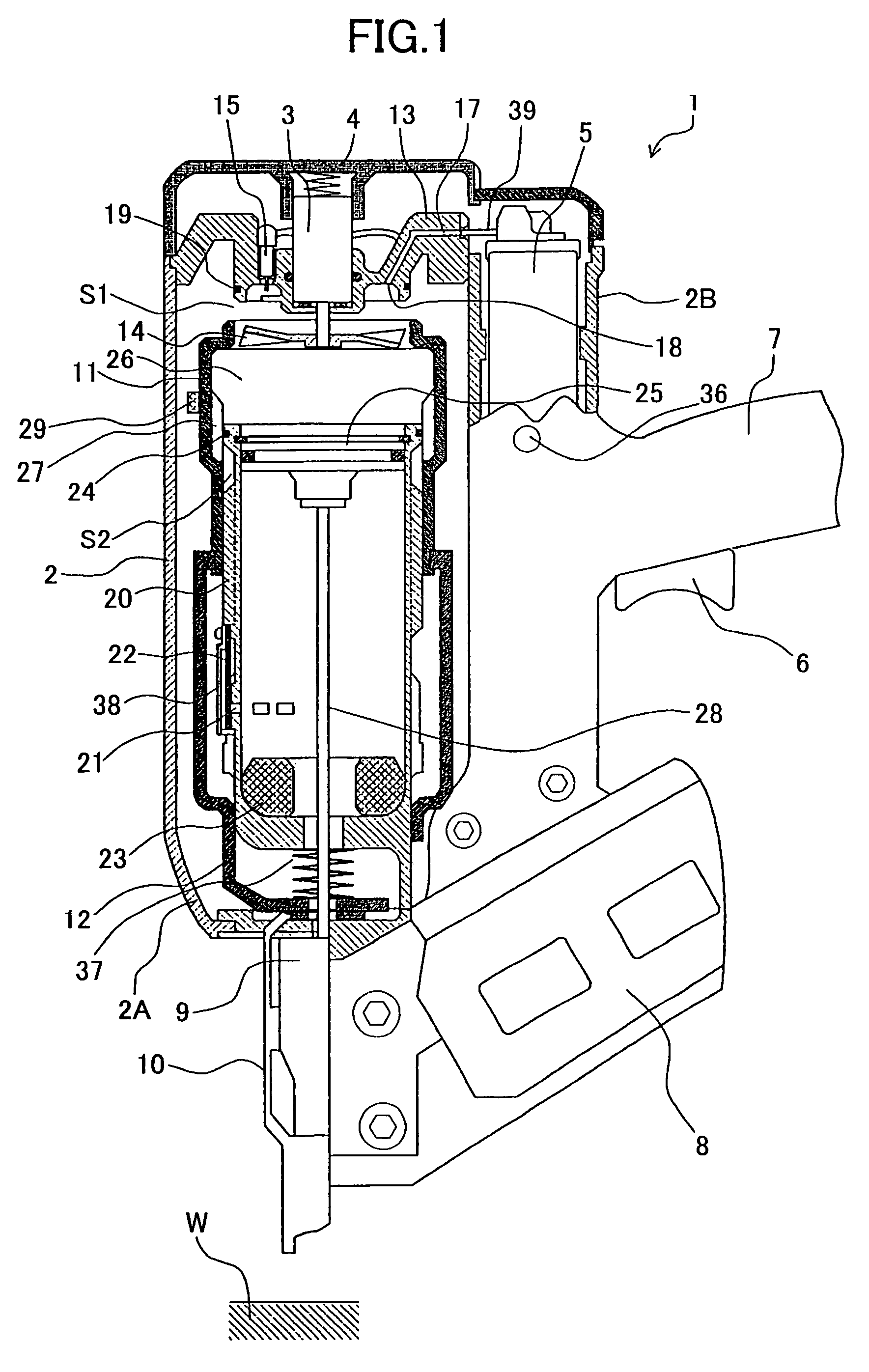

Combustion-powered driving tool

InactiveUS6886730B2Efficient and cheapLong-term useStapling toolsFree piston enginesCombustionUser friendliness

A combustion-powered driving tool for driving nails or other fasteners in which the starting characteristics of a motor in the tool are improved by varying the amount of voltage applied to the motor when starting the motor and during normal operations so that the motor is driven to reach the rotational speed required in normal operations quickly. Therefore, the combustion-powered driving tool does not require the use of an expensive low-inertia motor, but can use a relatively inexpensive core-type motor or the like with inferior starting characteristics, while improving the work efficiency and user-friendliness of the combustion-powered driving tool.

Owner:KOKI HLDG CO LTD

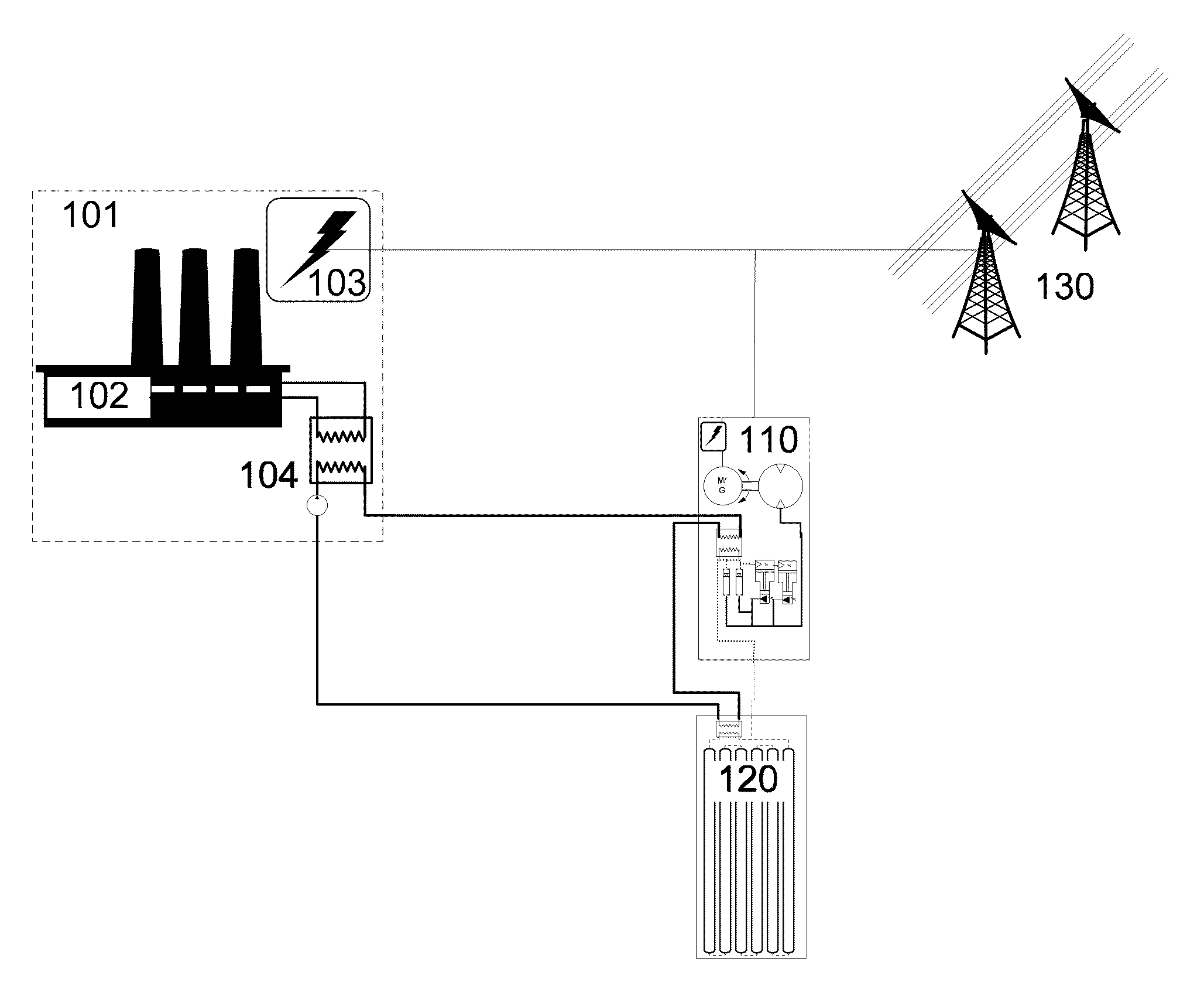

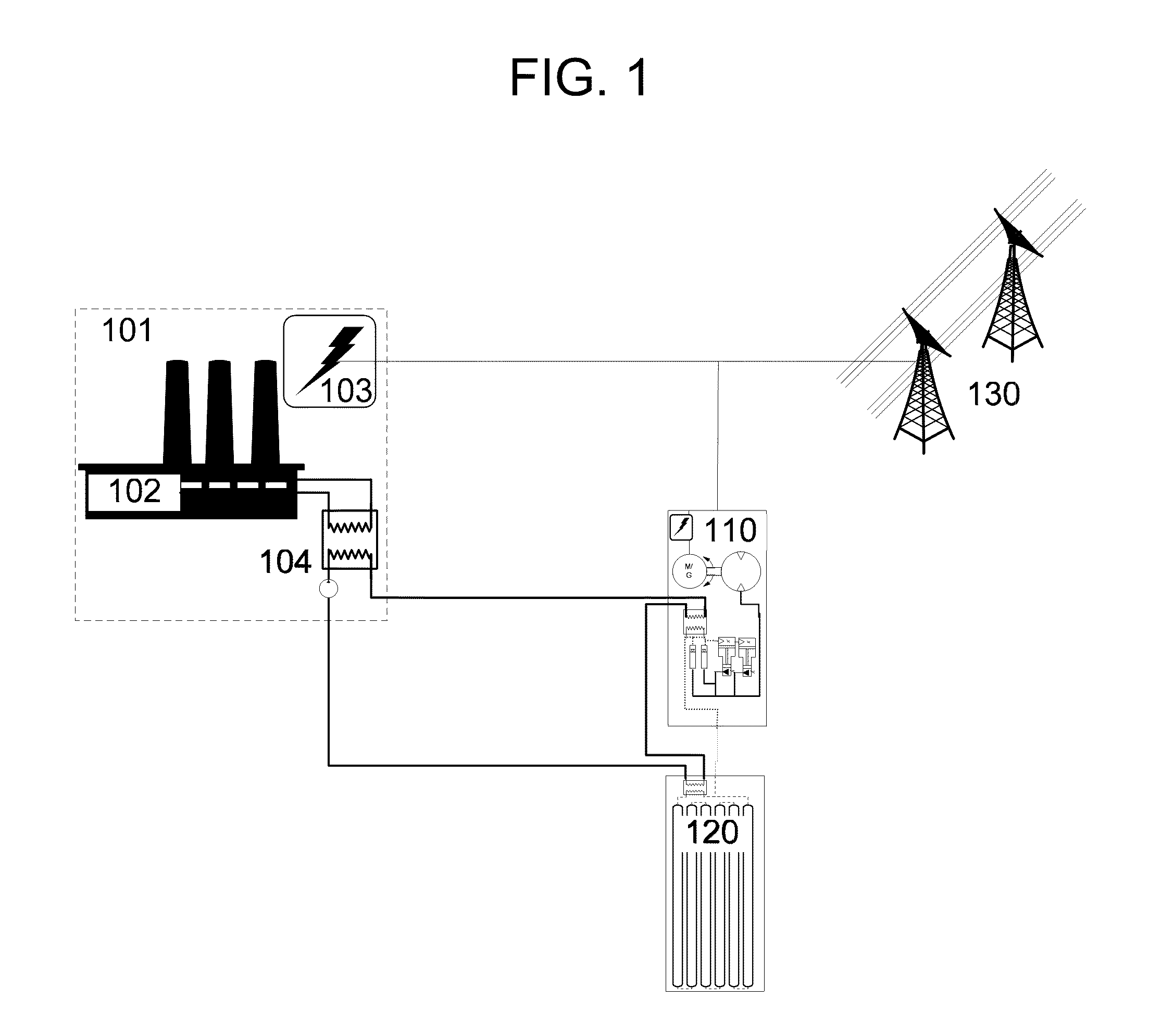

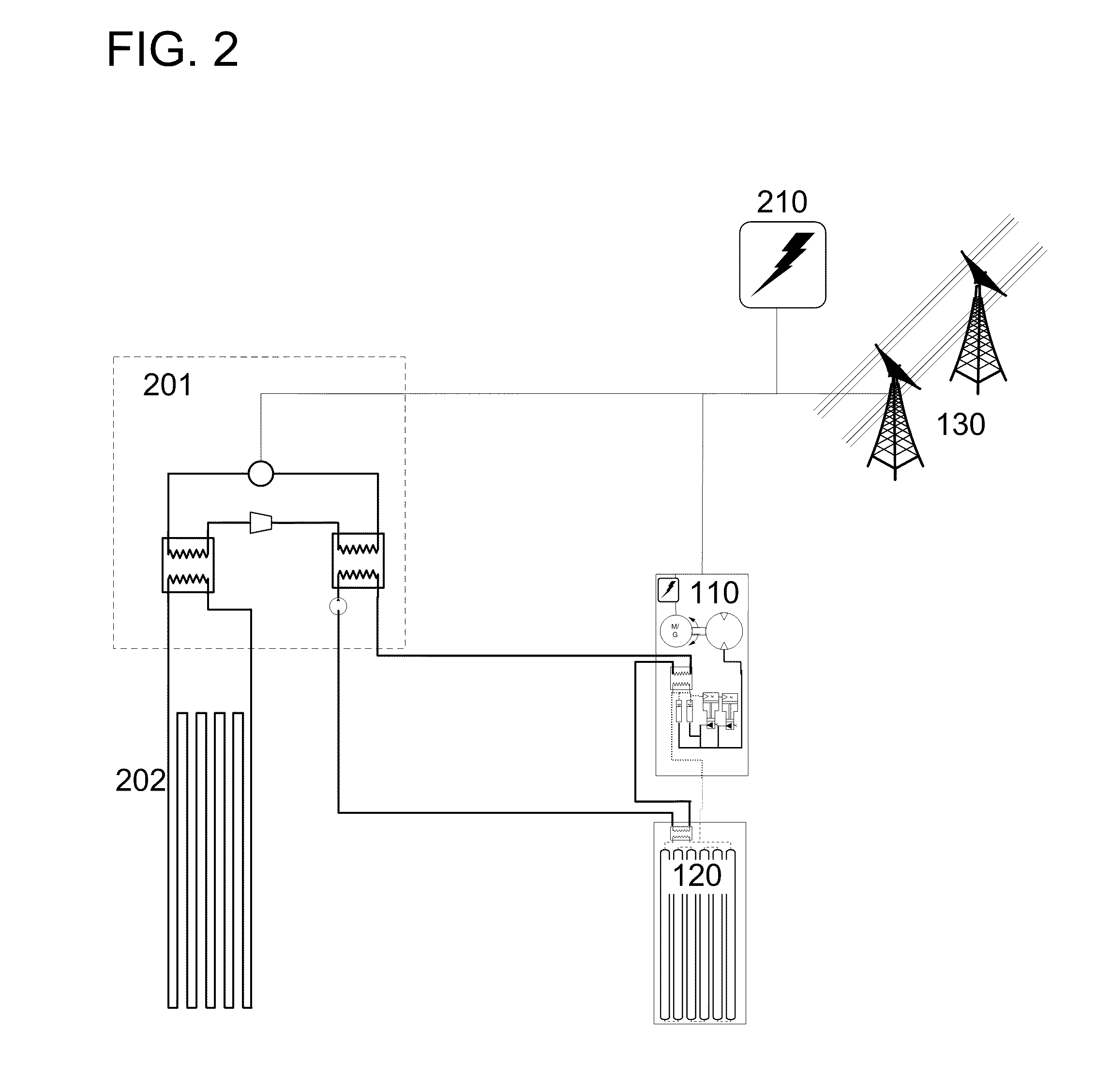

Systems and Methods for Combined Thermal and Compressed Gas Energy Conversion Systems

InactiveUS20100205960A1Cost-effective and efficient energy storageImprove efficiencyAuxillary drivesFrom solar energyThermal energyEngineering

The invention relates to systems and methods including an energy conversion system for storage and recovery of energy using compressed gas, a source of recovered thermal energy, and a heat-exchange subsystem in fluid communication with the energy conversion system and the source of recovered thermal energy.

Owner:SUSTAINX +1

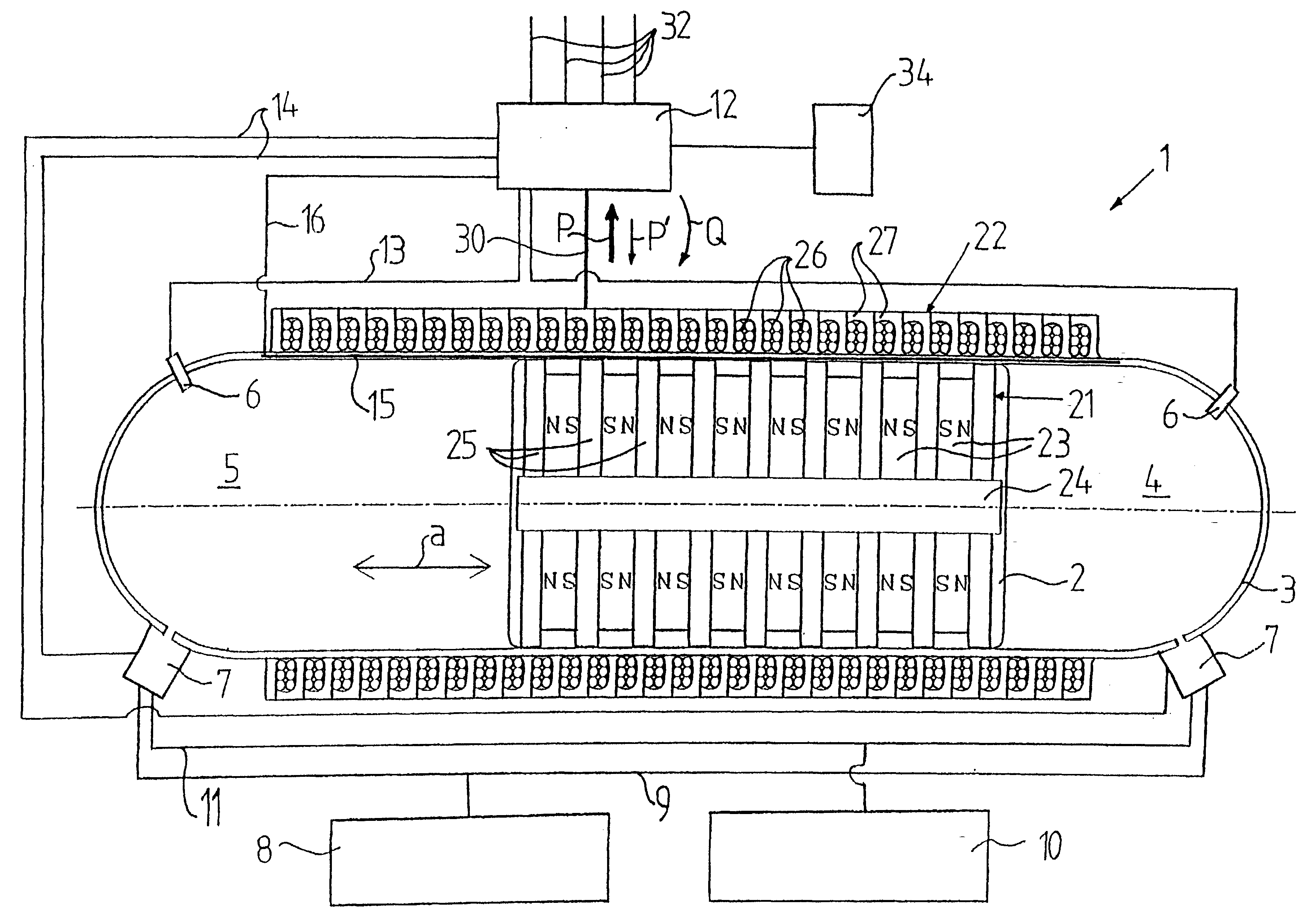

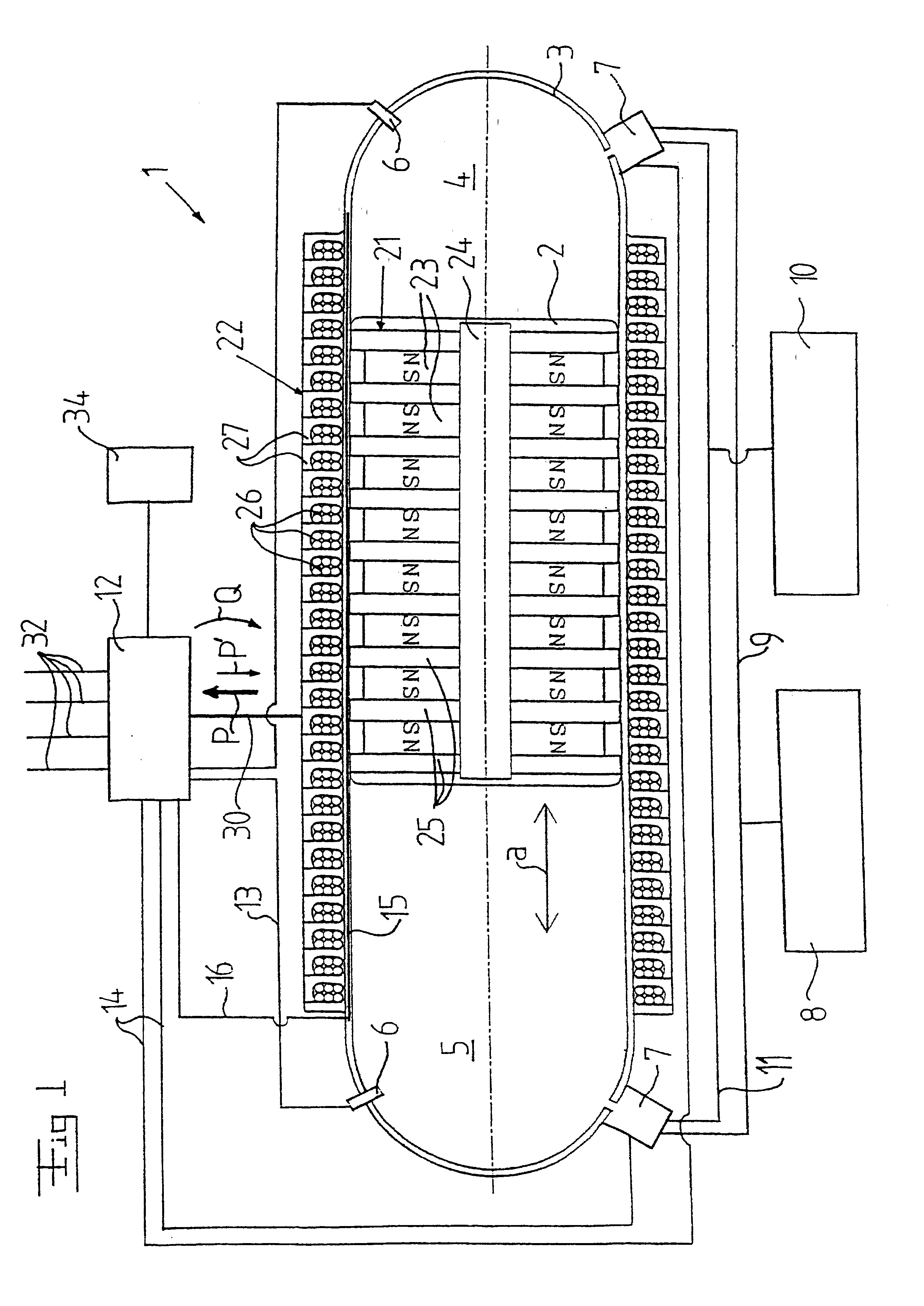

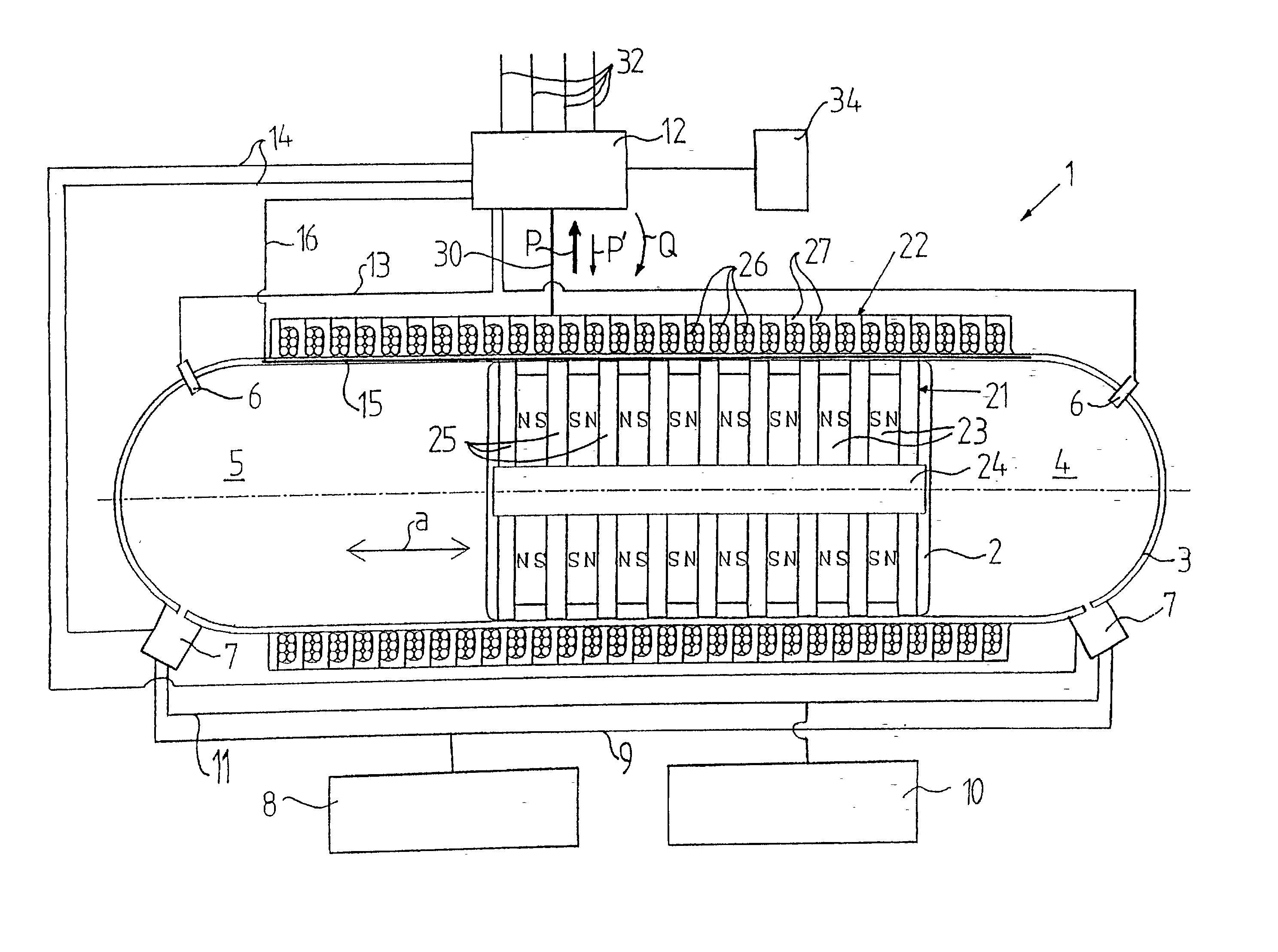

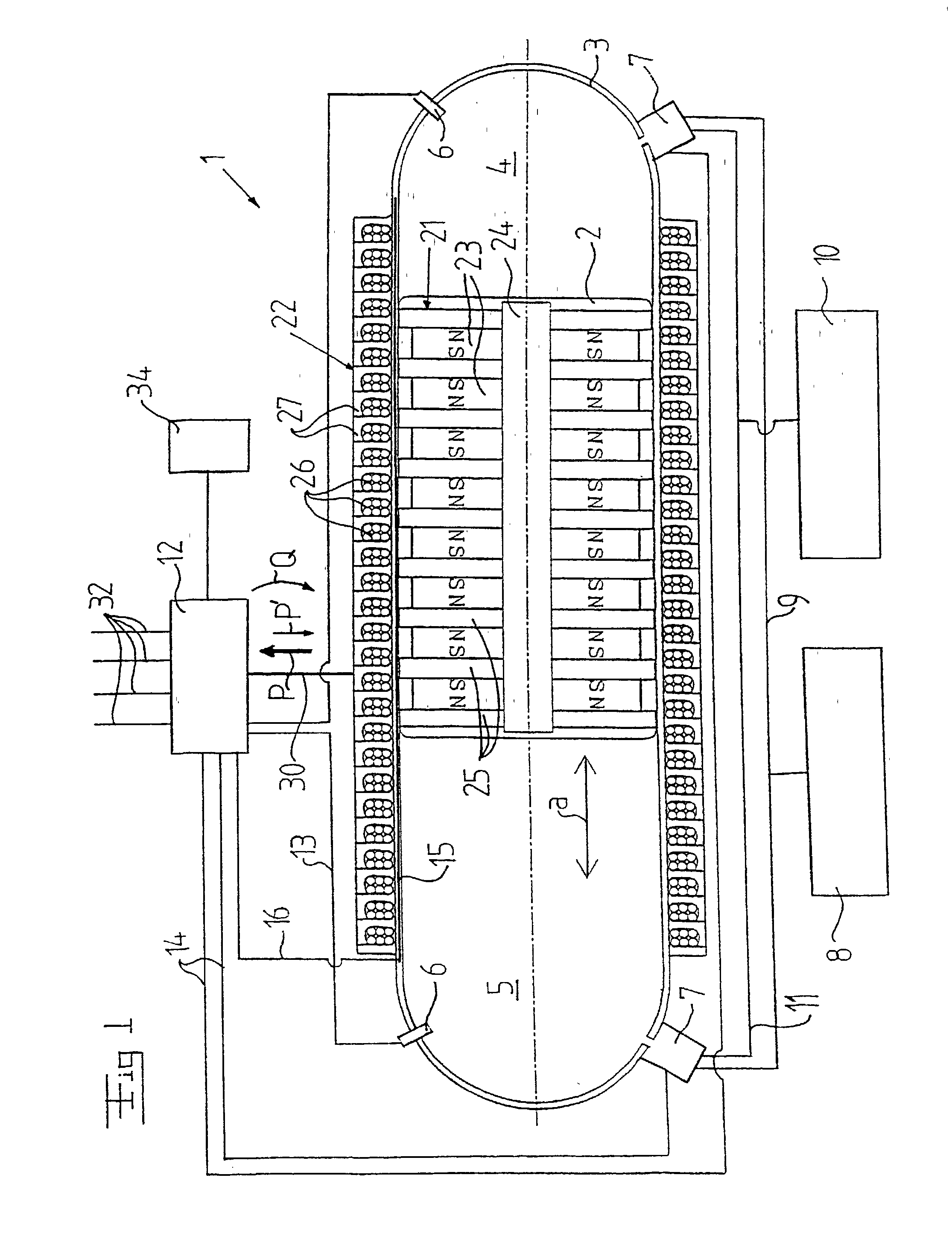

Device including a combustion engine, a use of the device, and a vehicle

InactiveUS6748907B2Improve efficiencyImproved combustion controlElectrical controlCombustion enginesCombustionTransducer

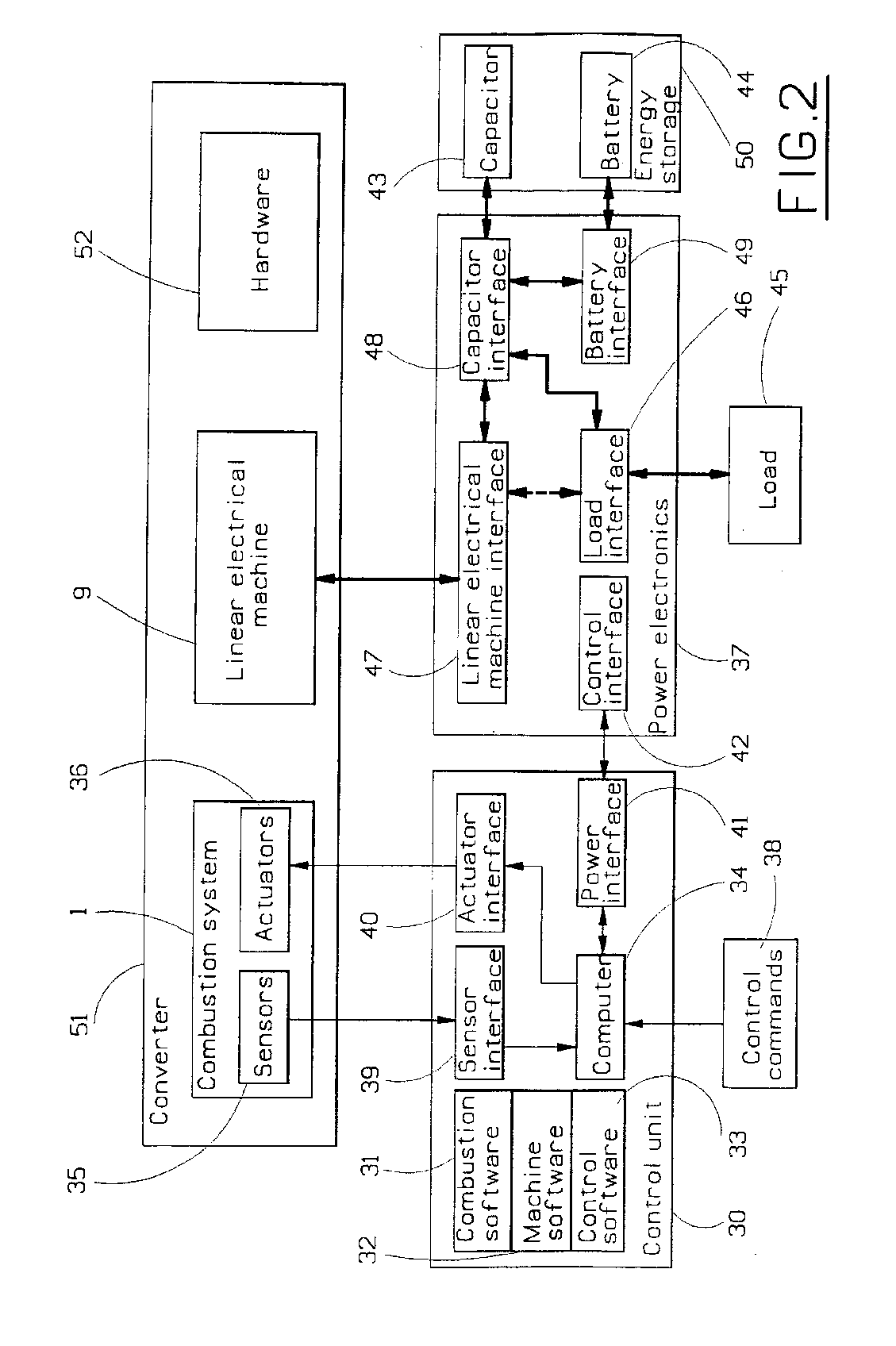

A device that includes a combustion engine with a piston that is mechanically freely movable in a housing. The device permits combustion of a fuel mixture to produce a pushing force to the piston. The device includes an electromagnetic energy transducer and an external current circuit, which is connected to the energy transducer for exchange of effect in a direction to or from the energy transducer. A control unit controls the direction of the effect, which is exchanged between the energy transducer and the external current circuit, during operation of the device. Such a device can be used to generate electrical energy, and can be employed in a vehicle.

Owner:VOLVO TECH

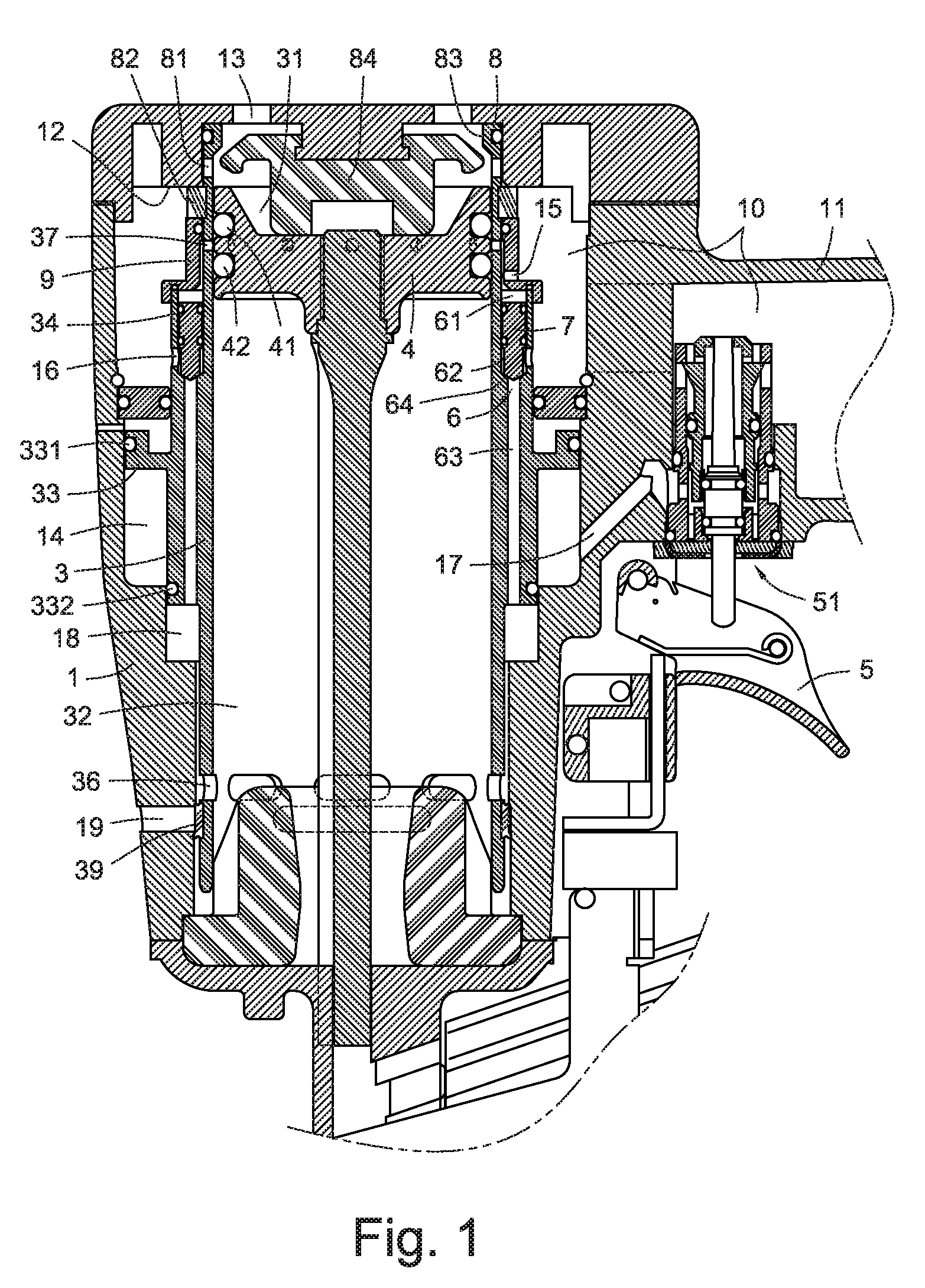

Energy converter

InactiveUS20080036312A1Low costReduce weightCoolant flow controlInternal combustion piston enginesCombustion chamberElectric machine

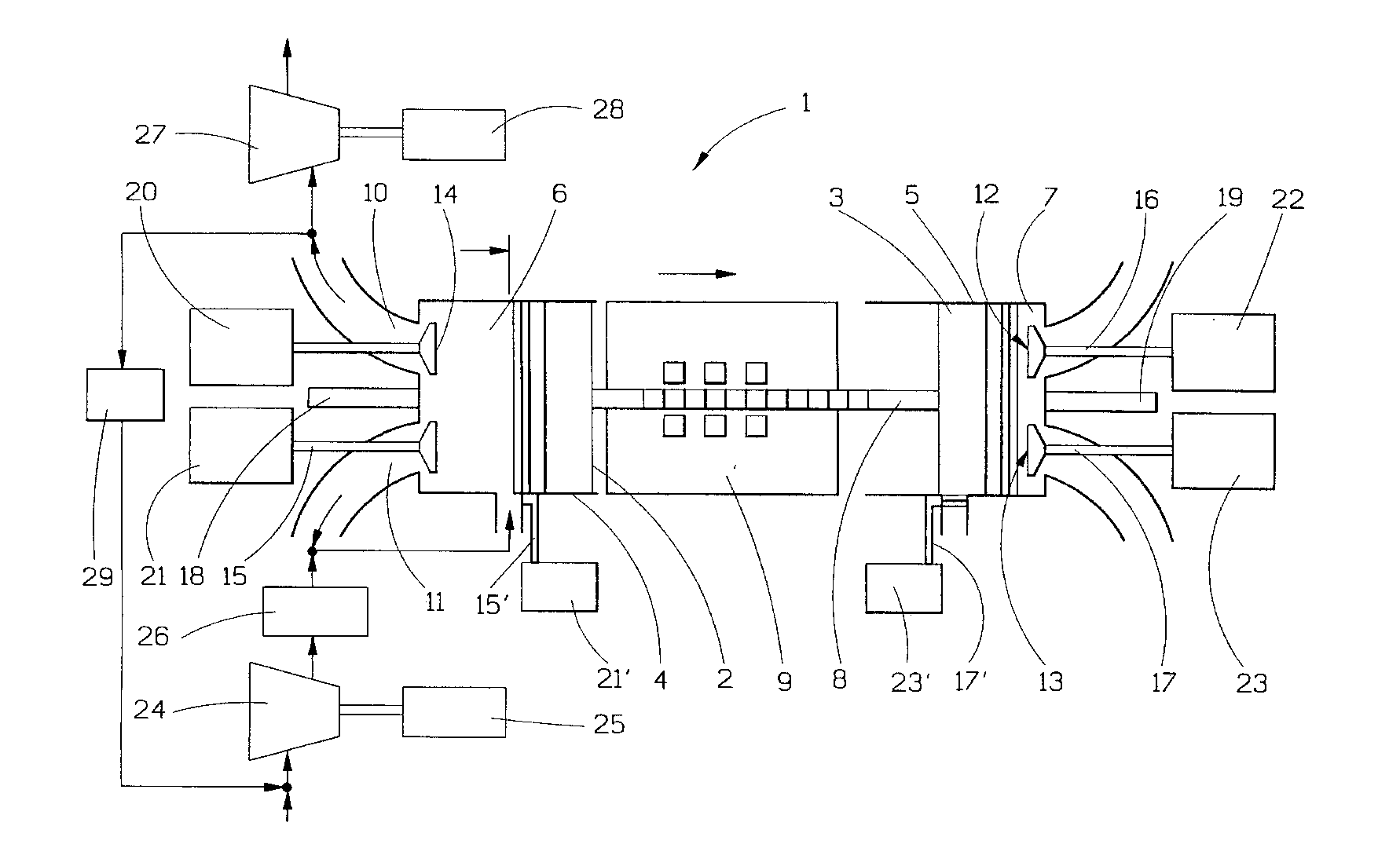

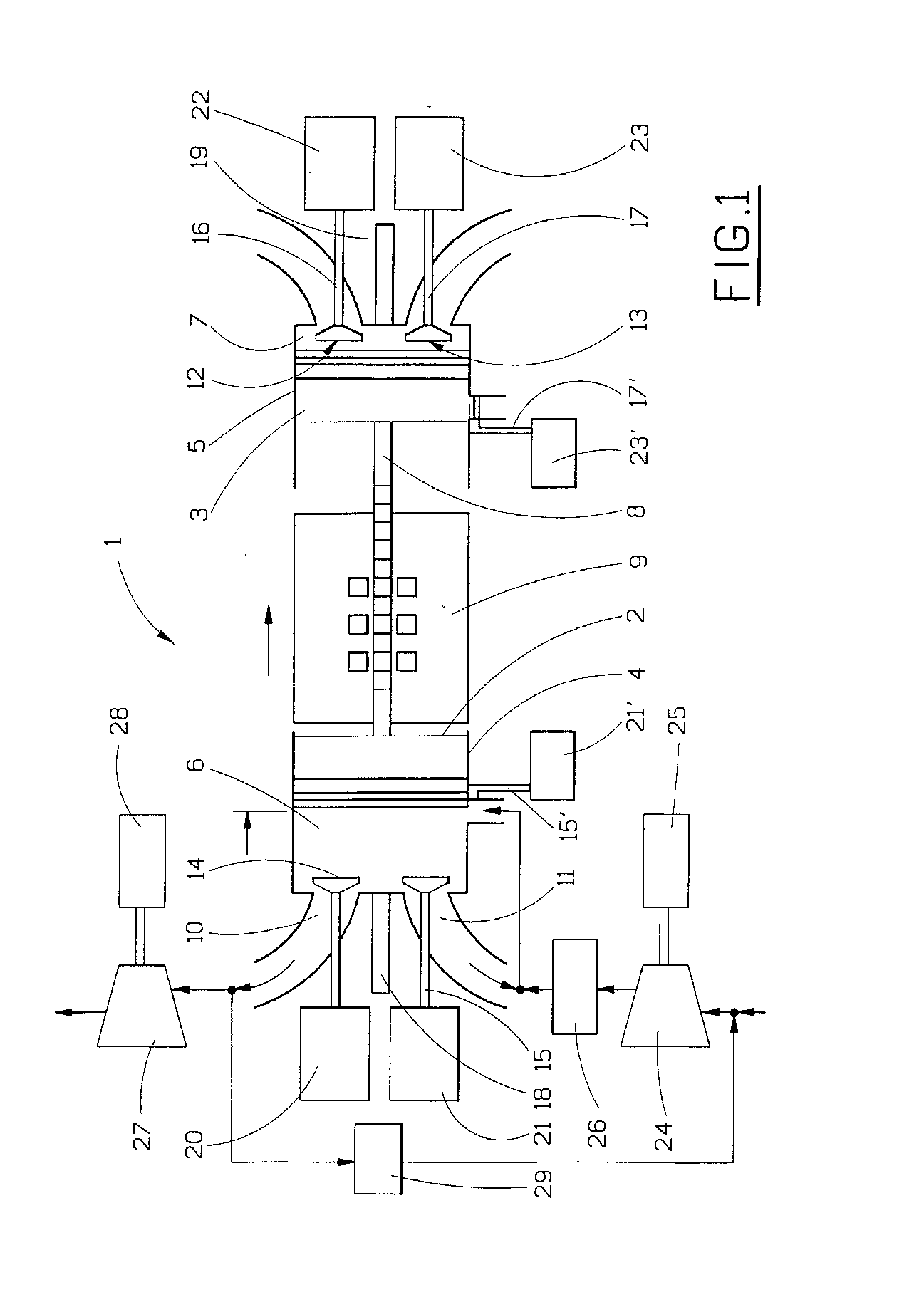

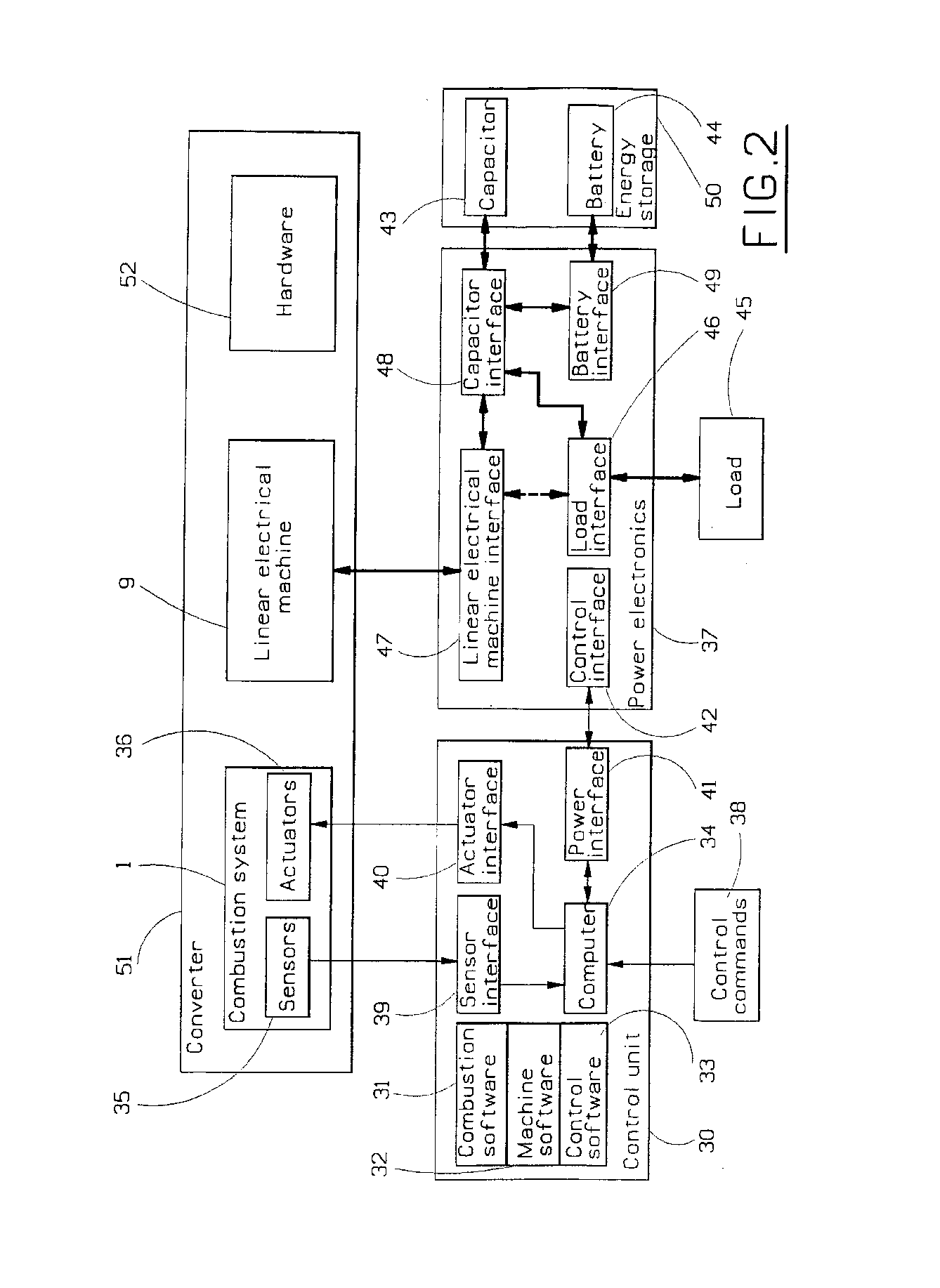

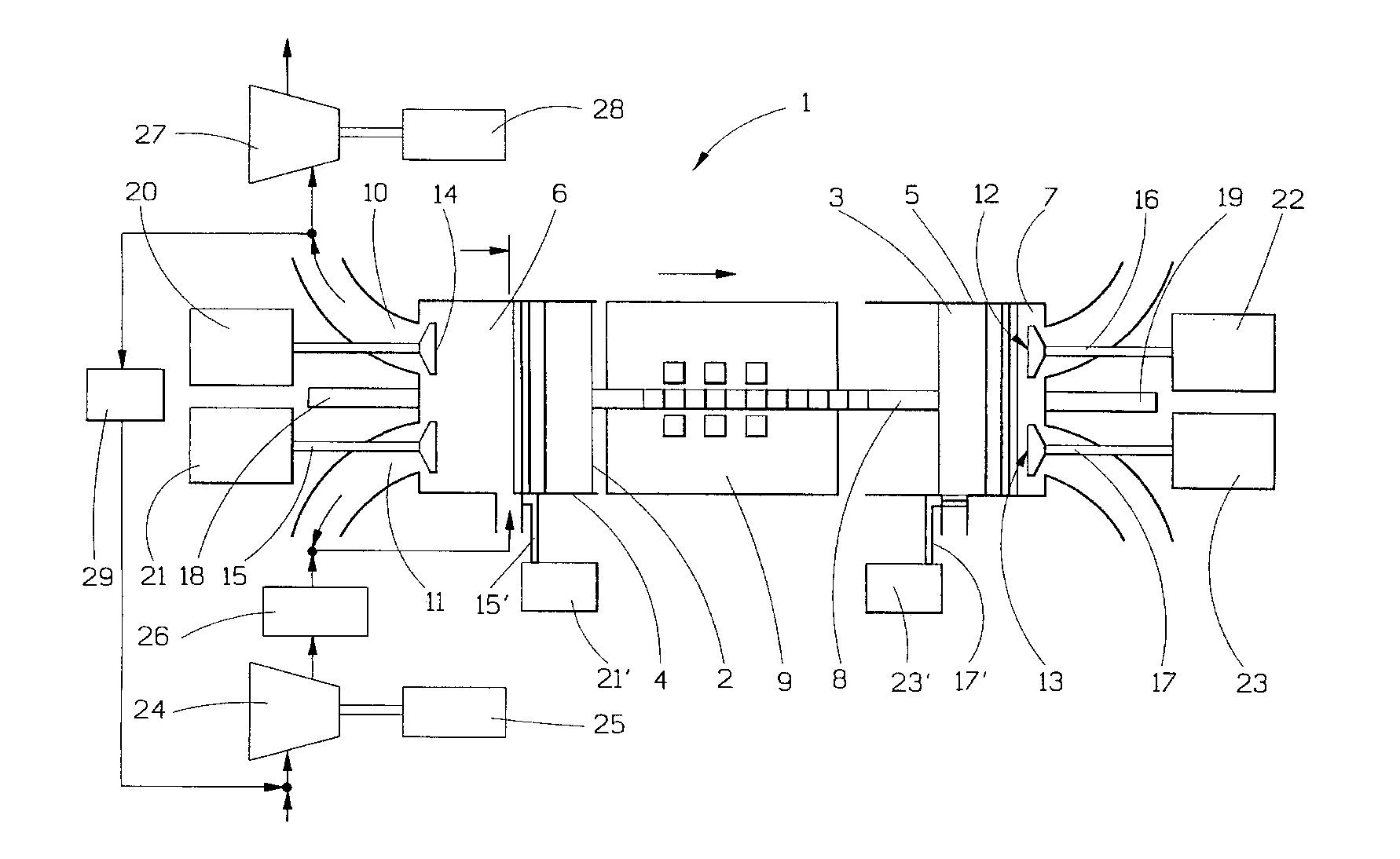

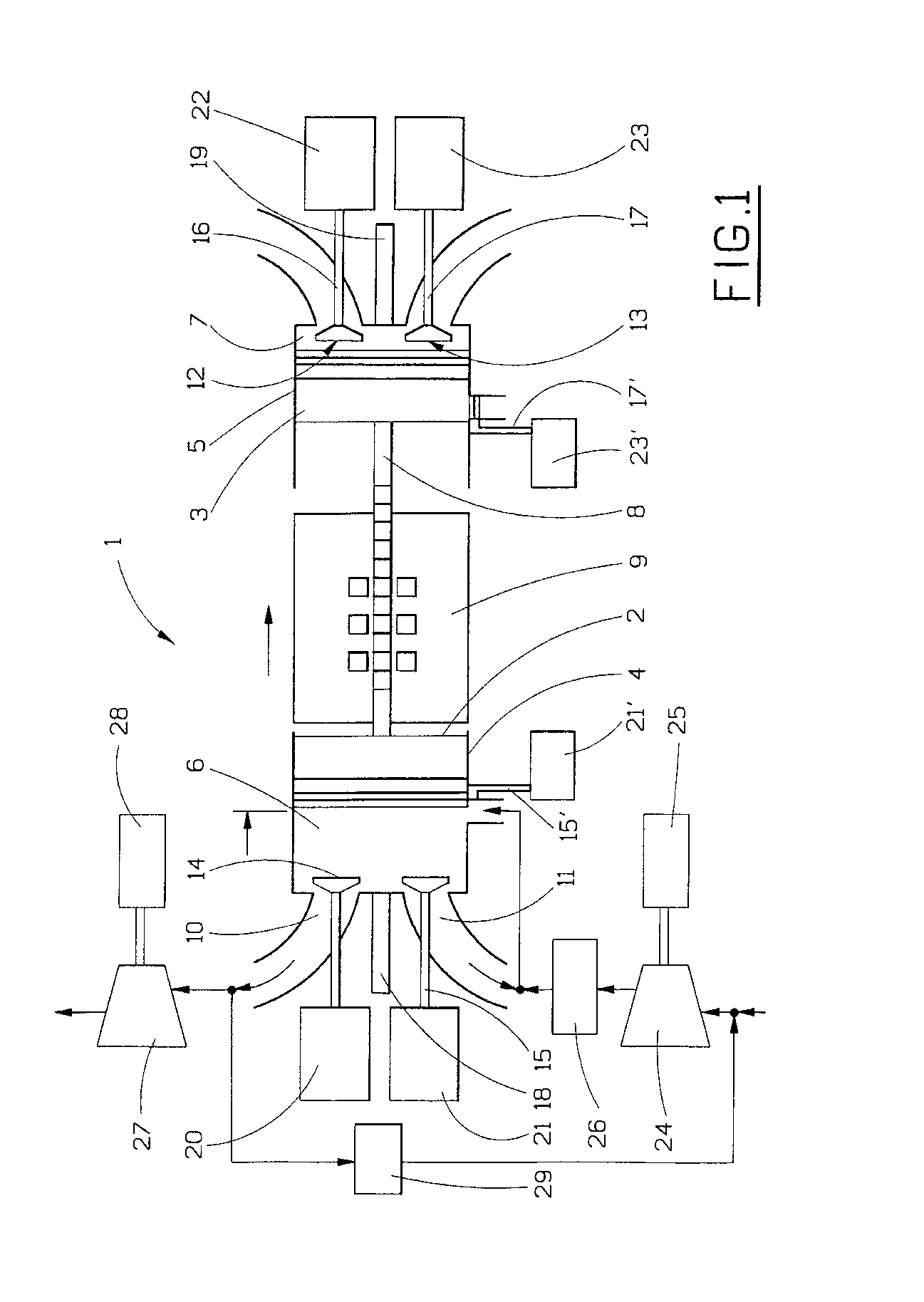

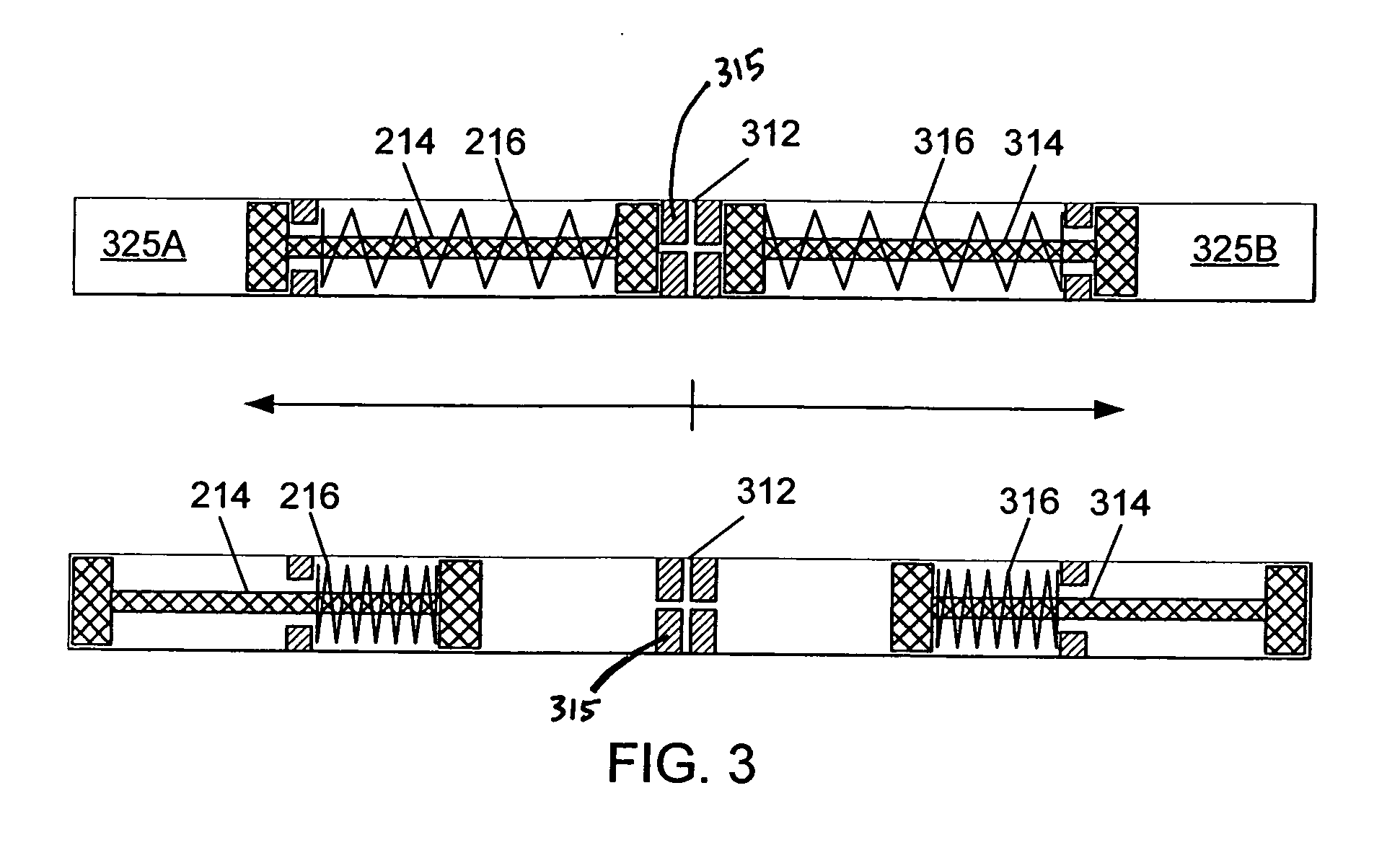

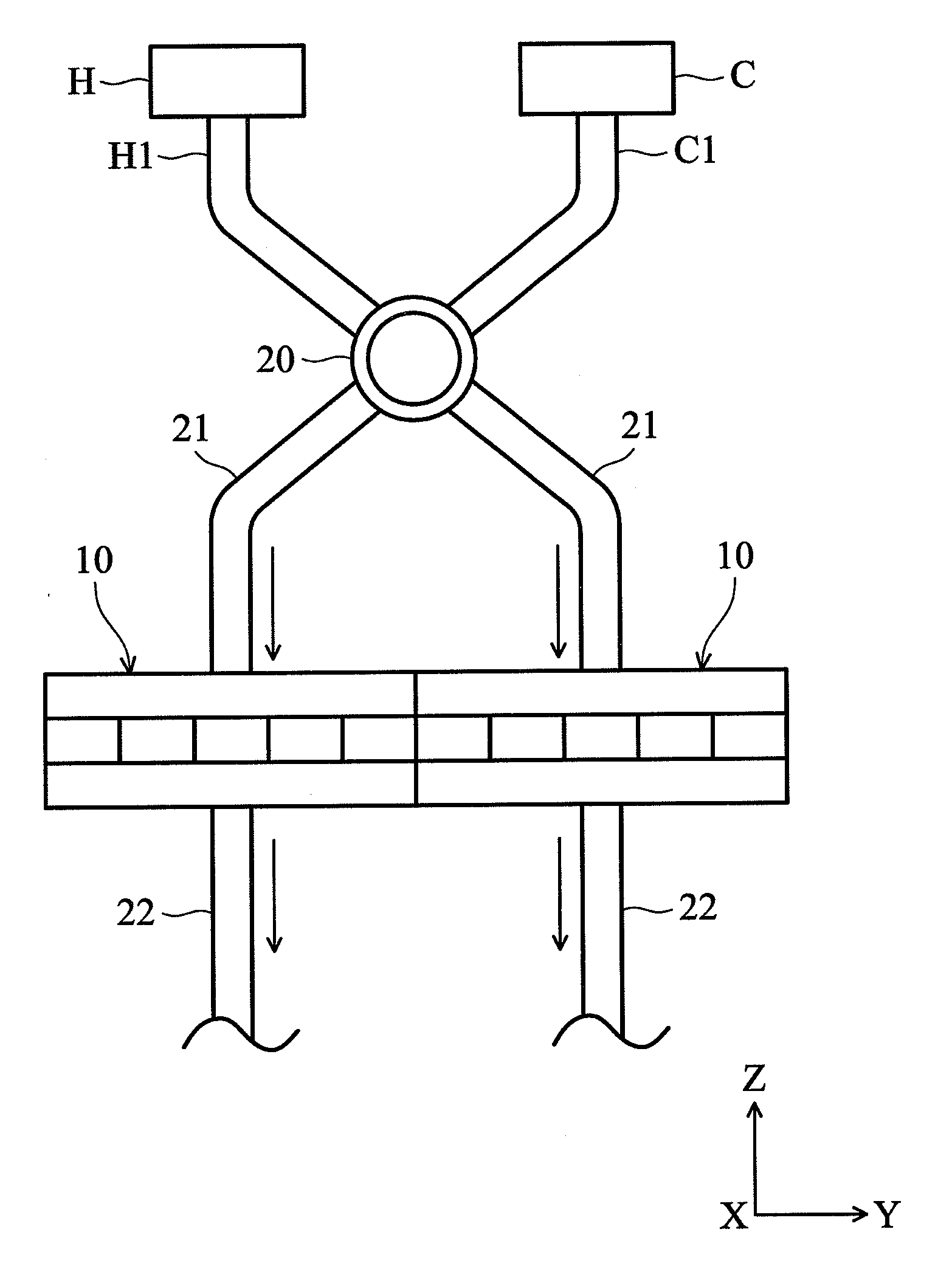

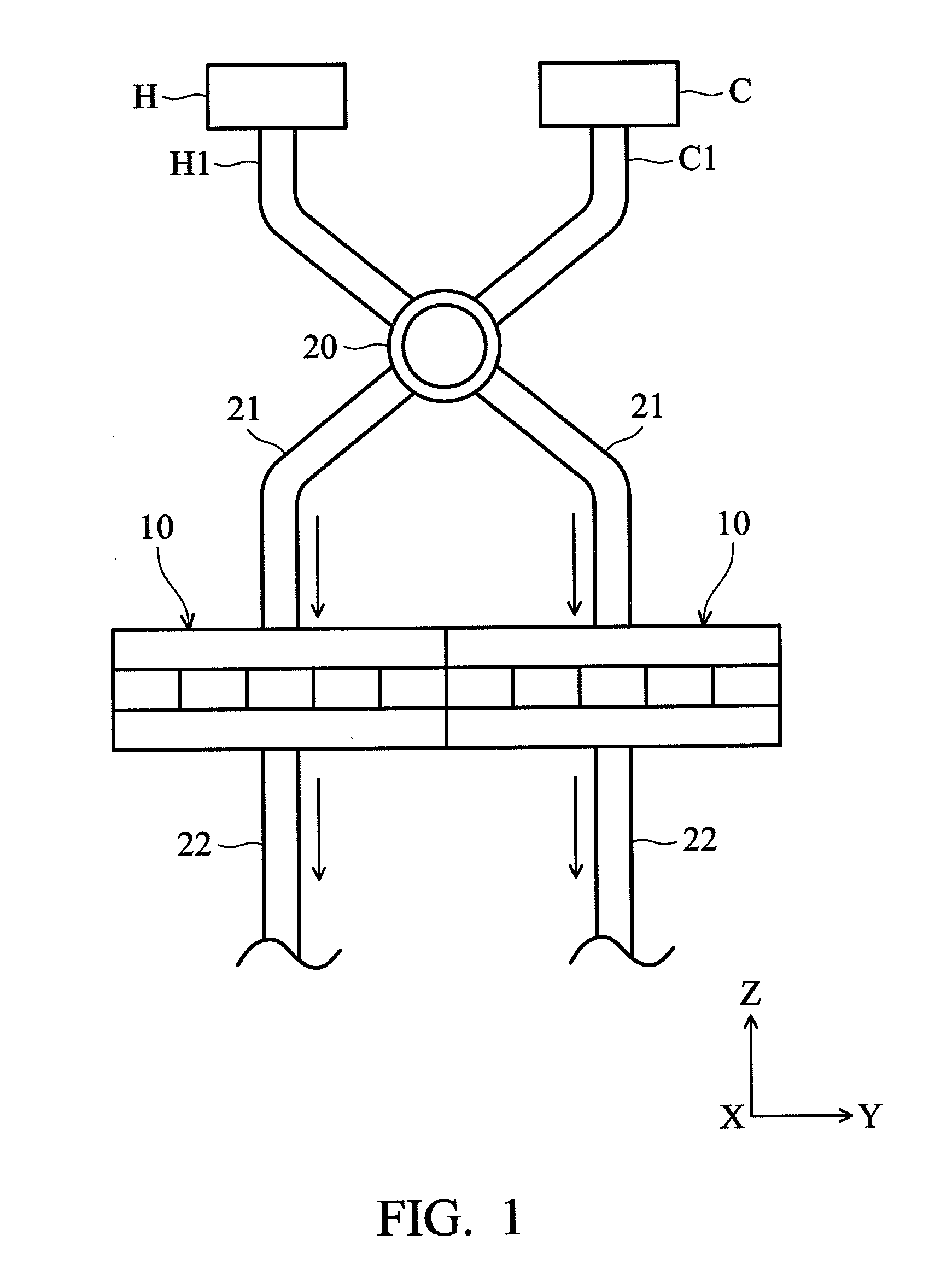

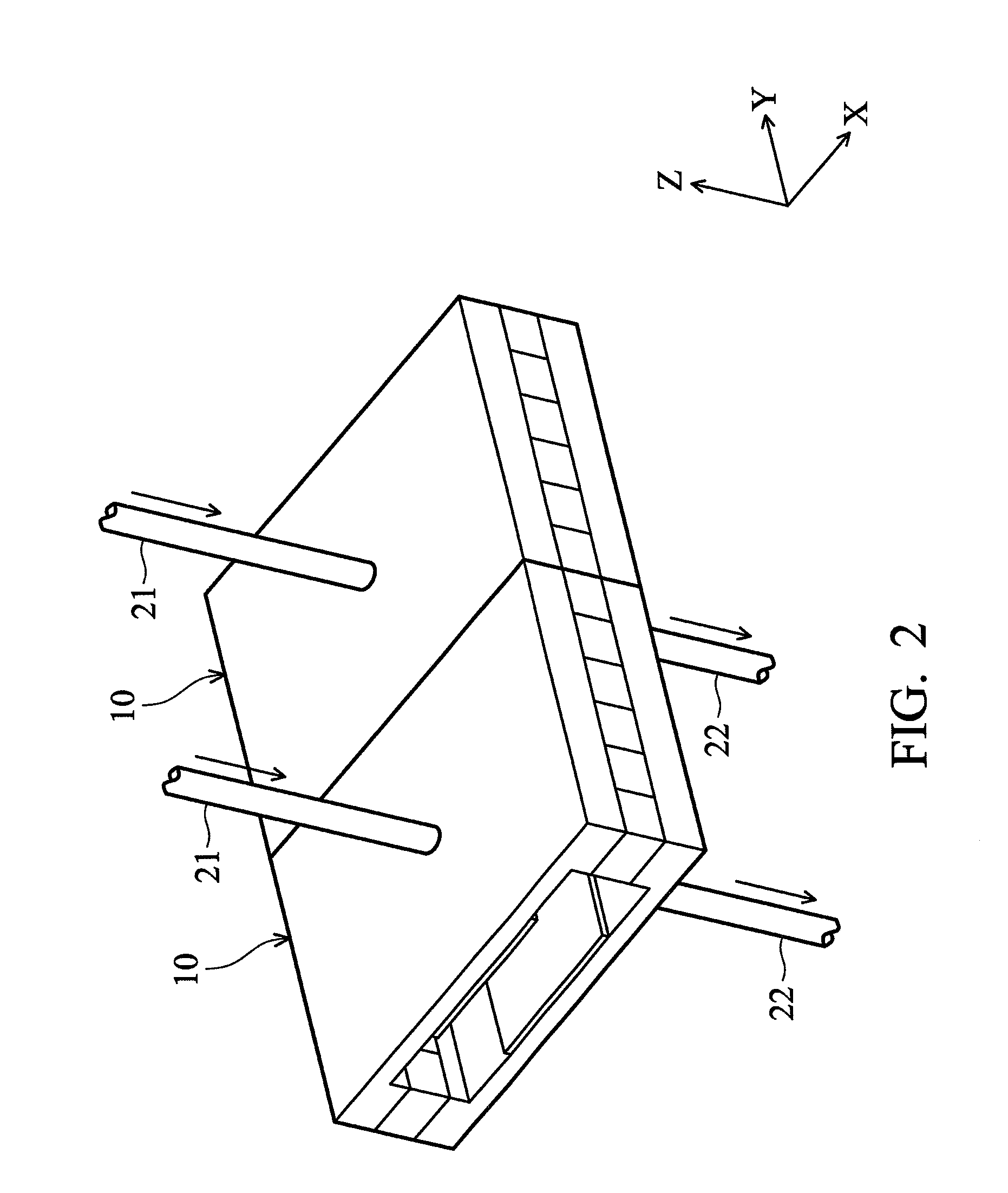

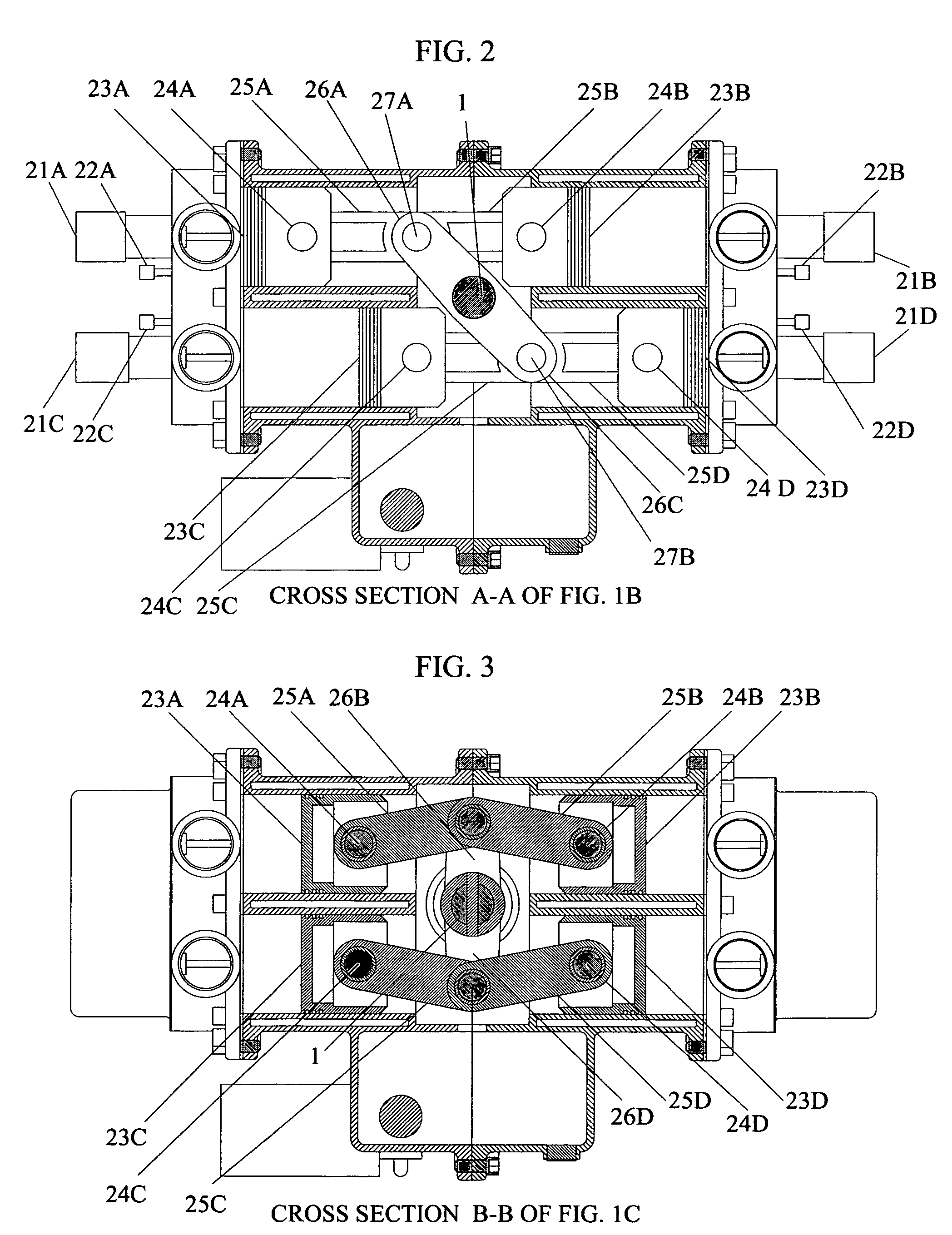

Method and arrangement for providing an energy converter that includes a combustion system ( 1 ) including at least one piston ( 2, 3 ), at least one combustion chamber ( 6, 7 ) having at least one inlet ( 11, 13 ) and at least one outlet ( 10, 12 ) with inlet and outlet valves ( 14, 15, 16, 17 ). At least one controllable inlet valve and at least one outlet valve is also provided. A fuel supply is provided ( 18, 19 ) for supplying fuel and a medium containing oxygen is provided for induction into the combustion chamber ( 6, 7 ). An electric machine ( 9 ) is arranged to interact directly or indirectly with the piston ( 2, 3 ) in an electromagnetic manner such that it produces electrical energy from the piston movements, as well as uses electrical energy to affect the piston movement. A control unit ( 30 ) controls the combustion system ( 1 ) and the electric machine ( 9 ). The energy converter is arranged to adapt its power output depending on the required load of the energy converter. The invention also relates to a method for for starting an energy converter.

Owner:VOLVO CAR CORP +1

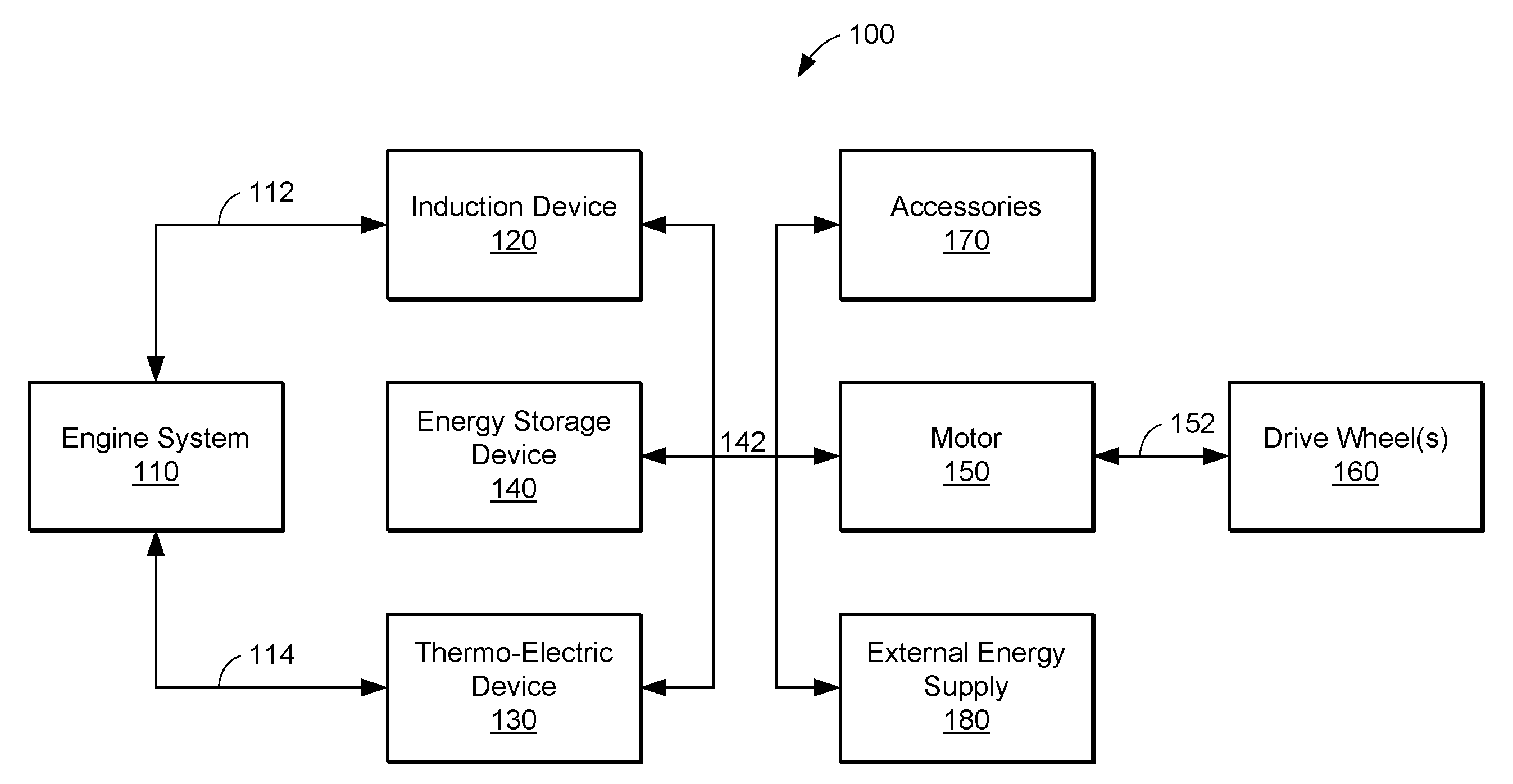

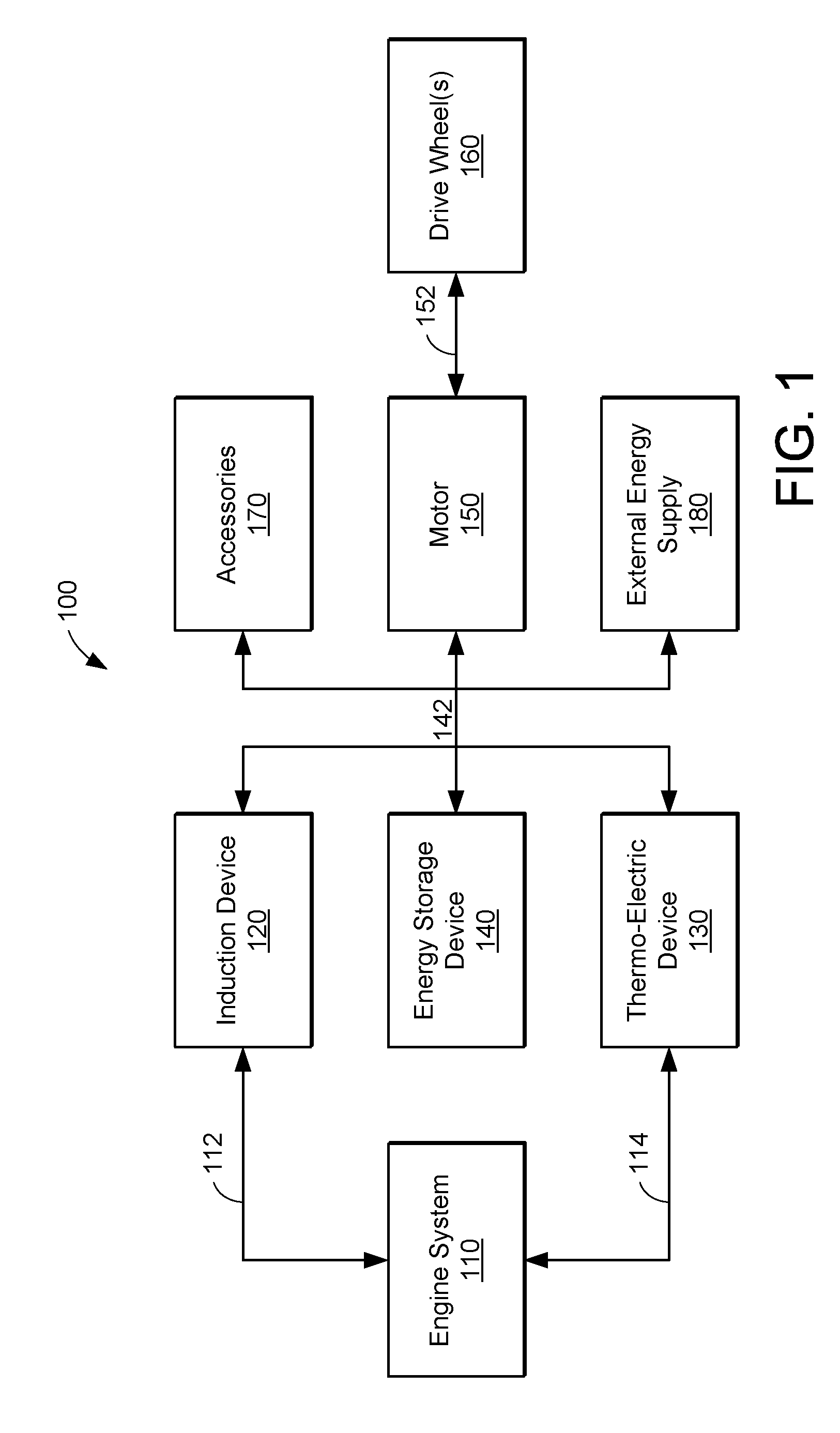

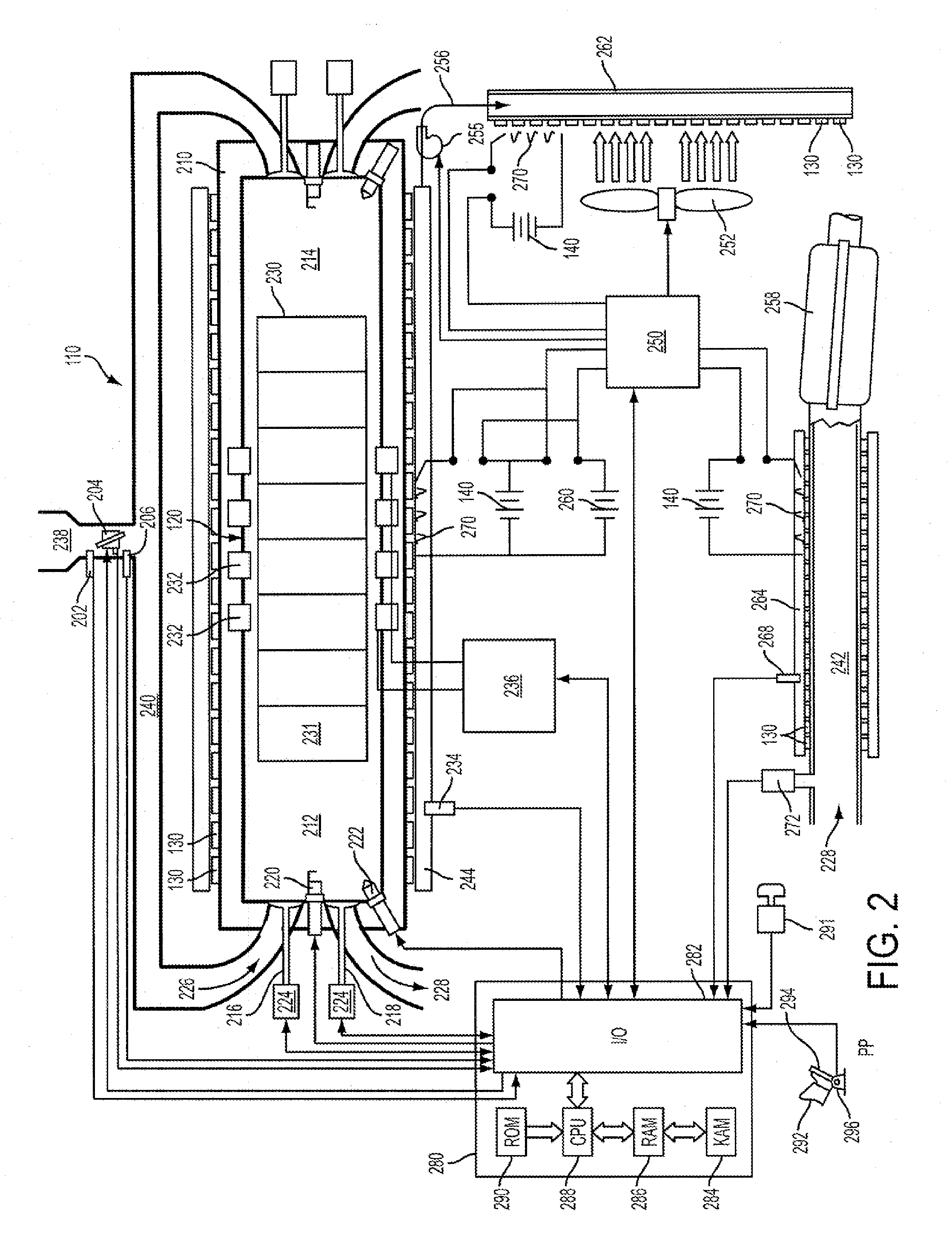

Engine System Having Improved Efficiency

InactiveUS20080098972A1Efficient temperature rangeReducing high-temperature conditionHybrid vehiclesElectrical controlExternal combustion engineControl system

A propulsion system for a vehicle, comprising of an internal combustion engine, a thermoelectric device in thermal communication with the engine, and a control system for controlling the engine and the thermoelectric device during a first mode, supply electrical energy to the thermoelectric device to cause the thermoelectric device to produce at least some heat, and during a second mode, operate the engine to produce at least some heat, where the thermoelectric device is operated to convert a temperature gradient at the thermoelectric device to electrical energy.

Owner:FORD GLOBAL TECH LLC

Internal combustion engine driven turbo-generator for hybrid vehicles and power generation

InactiveUS20090179424A1Increased electrical system efficiencyLow costCombustion enginesVehicle sub-unit featuresExternal combustion engineEngineering

A piston compression system converts energy from a conventional combustion cycle engine driving a piston to displace a working gas for flow through a turbine for output power. The working gas is derived by diverting a portion of the charge during combustion at near peak combustion pressure (PCP) into a closed working volume. The working gas is maintained at high pressure within the working volume. The working volume has a first displacement compartment and a second displacement compartment, a supply manifold connected for receiving pressurized working gas alternately from the first and second compartments and connected to an inlet of the turbine, and a return manifold connected to an outlet of the turbine and alternately returning working gas to the second and first compartments. The engine is configured with first and second pistons housed in first and second combustion cylinders respectively powering a first displacing surface for displacement of working gas in the first compartment and a second displacing surface for displacement of working gas in the second compartment.

Owner:INTERNAL COMBUSTION TURBINES

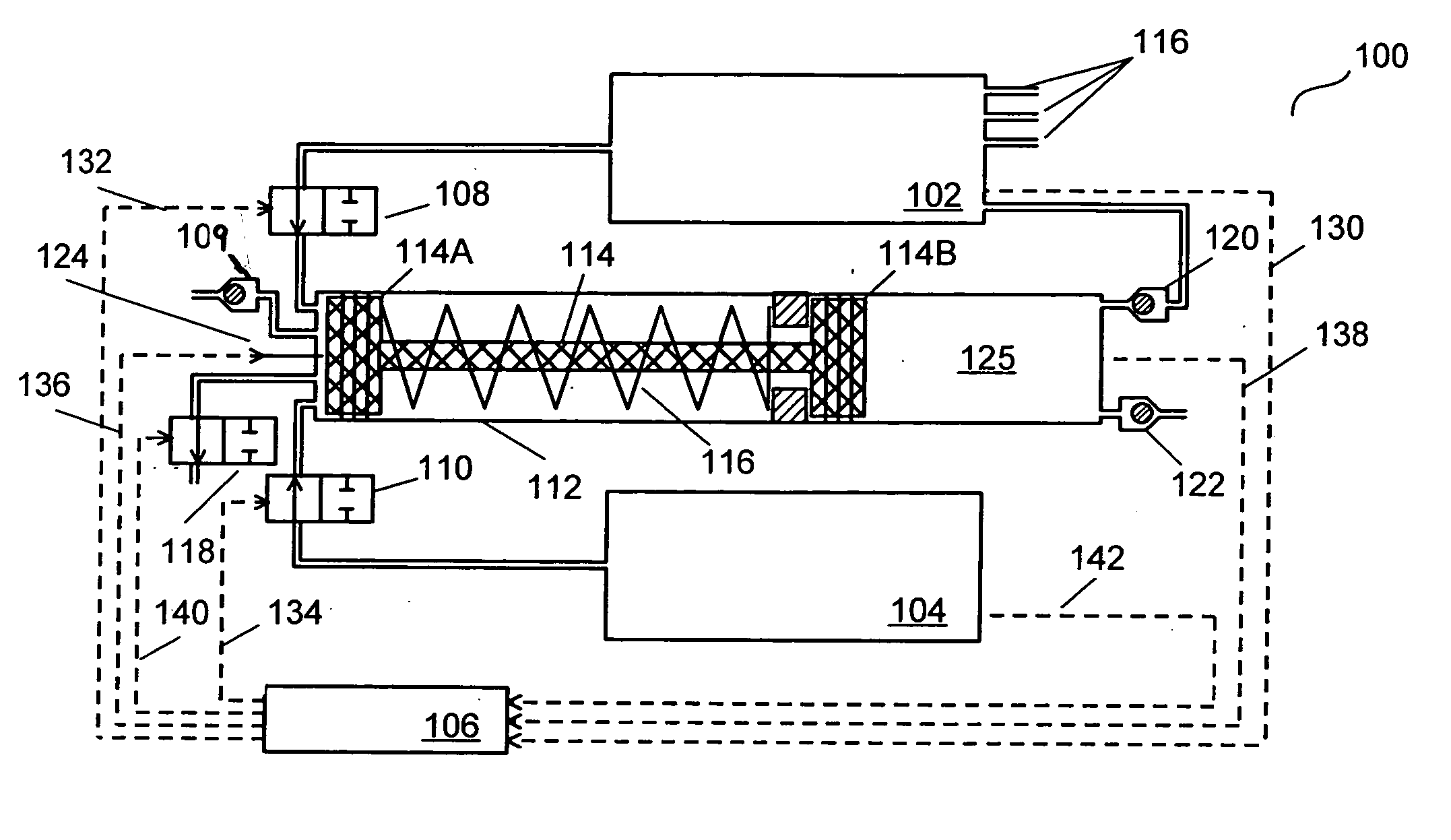

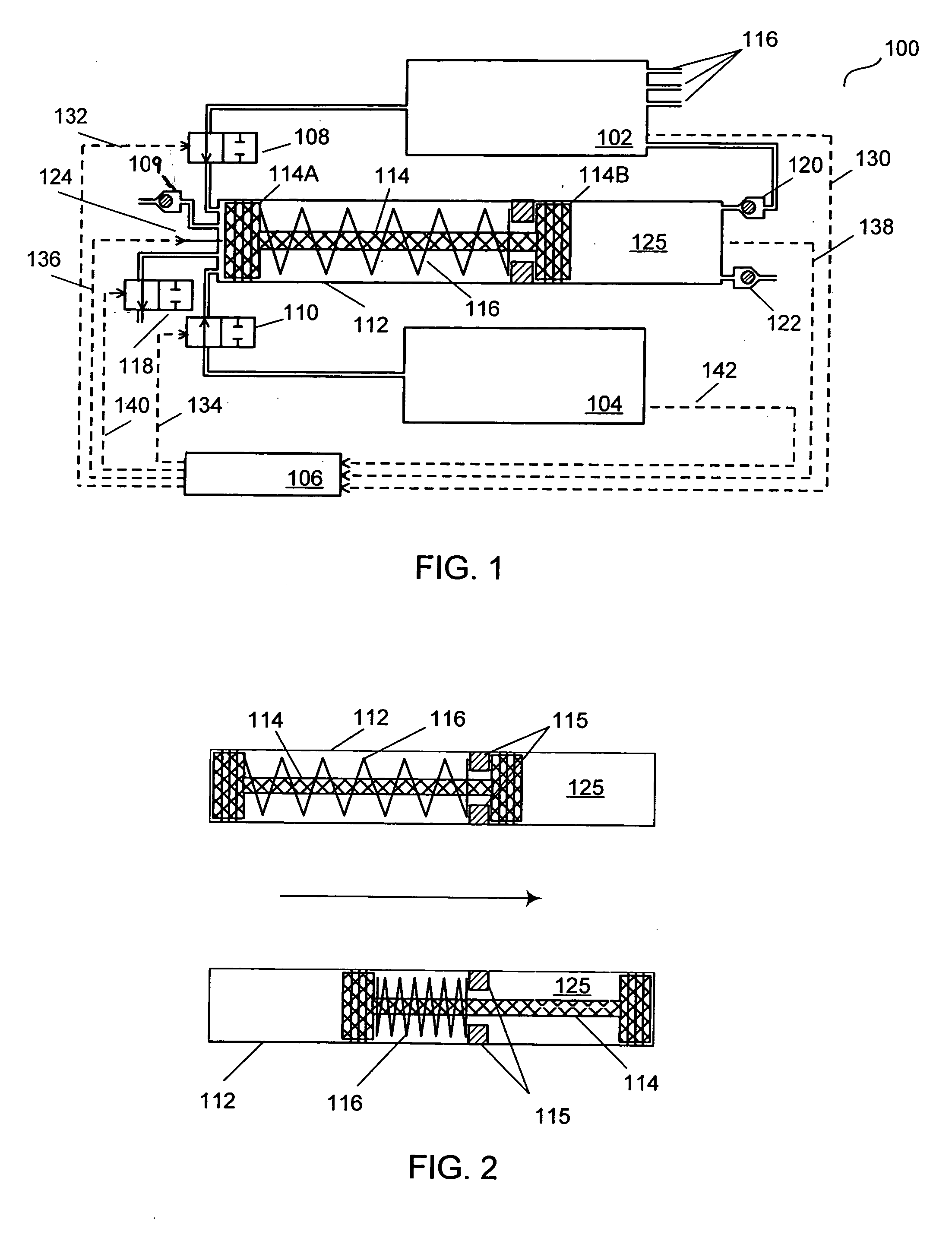

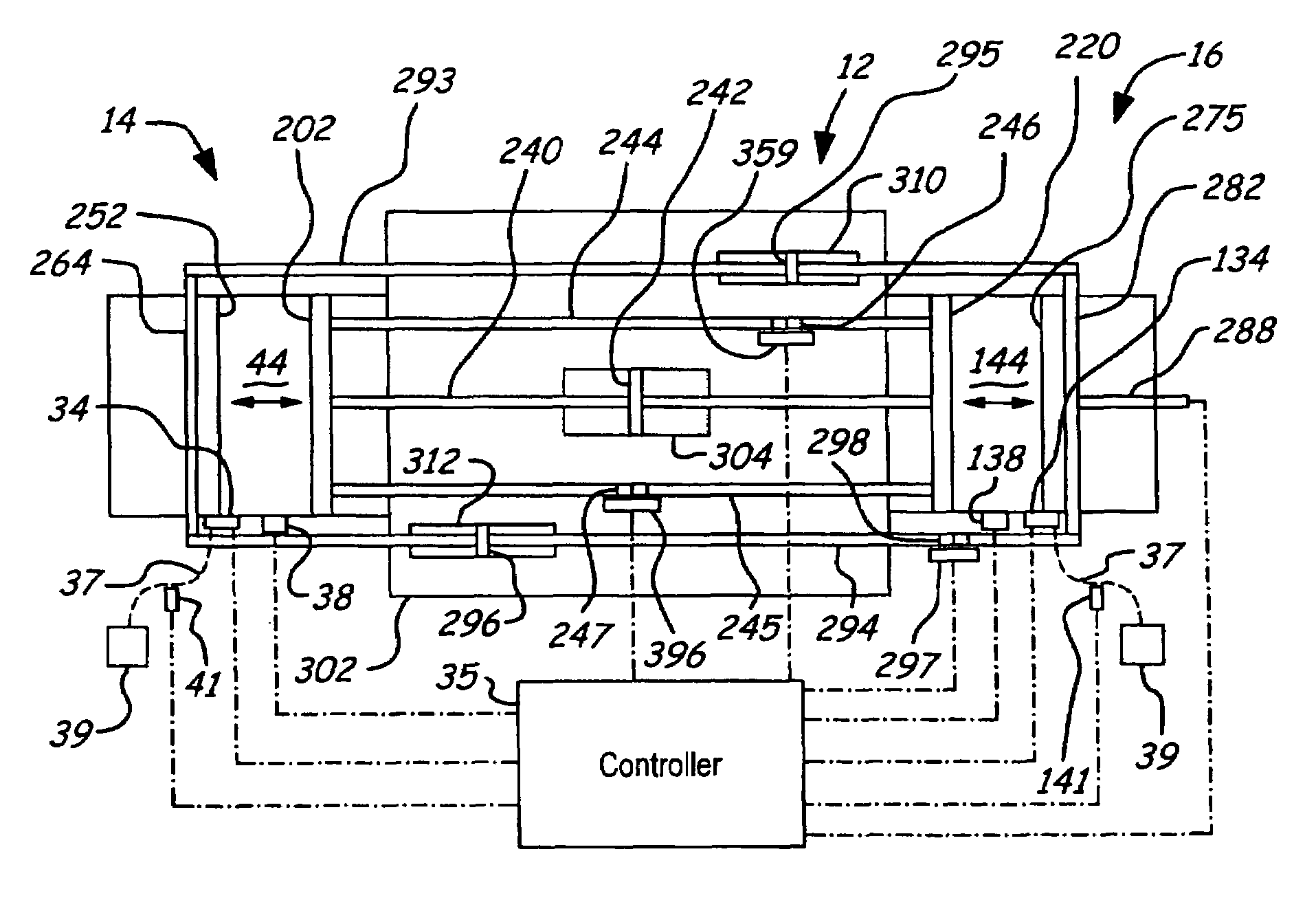

Power generating system

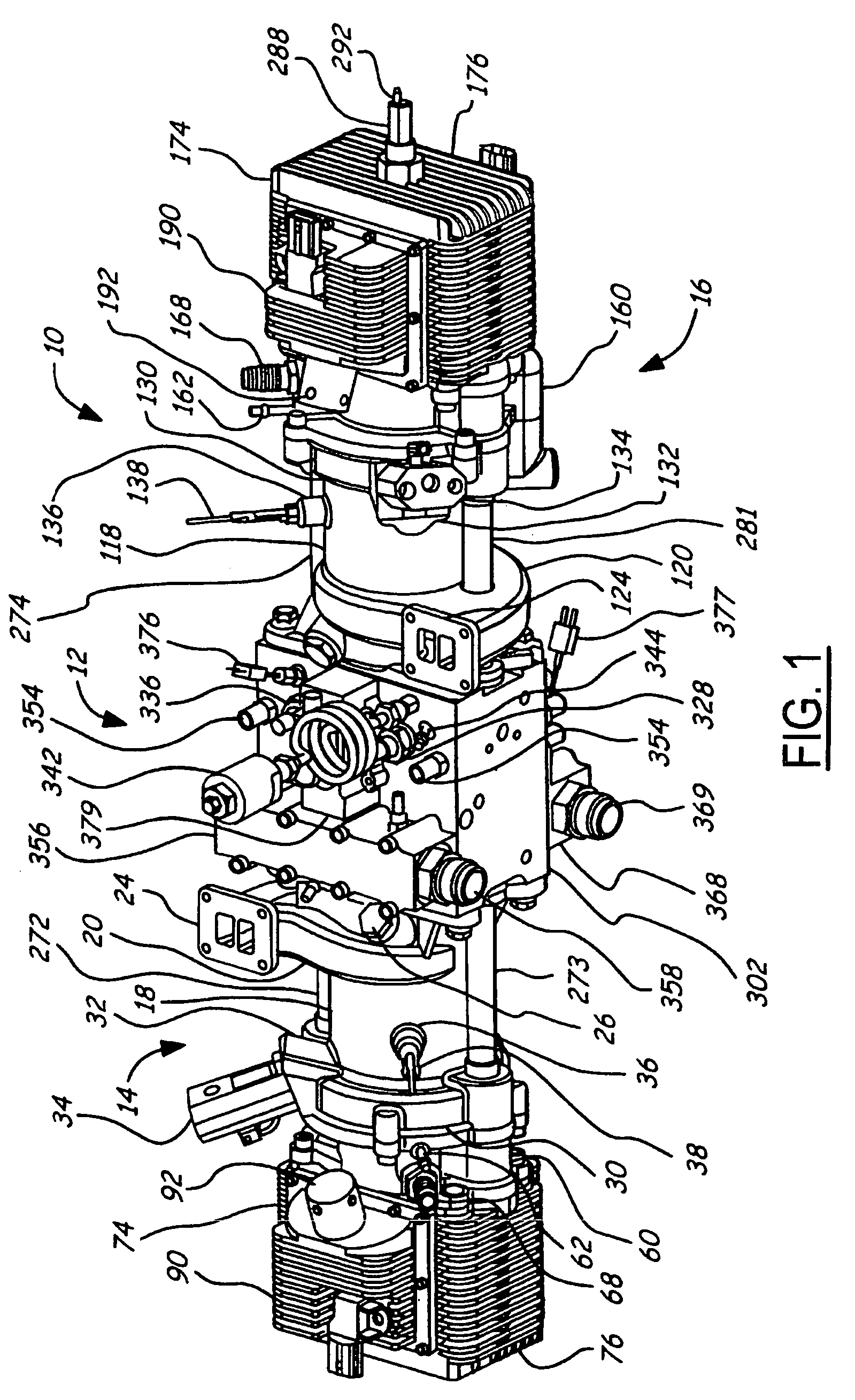

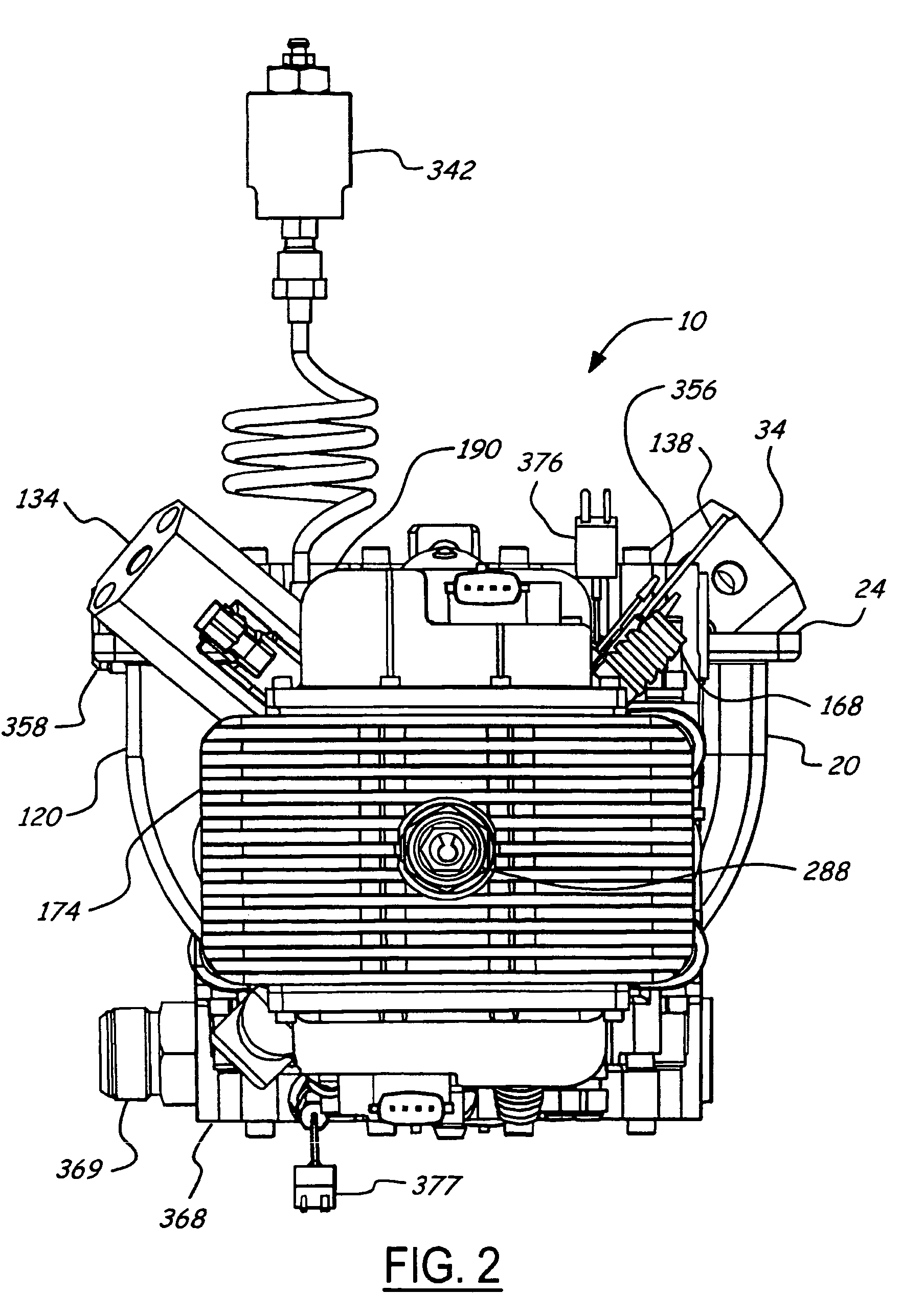

ActiveUS20070158946A1Reduce lateral movementControl moreCombustion enginesGaseous engine fuelsCircular discEngineering

This invention overcomes the disadvantages of the prior art by providing a power generating system particularly suitable for field use in remote locations, which is fuel-efficient, relatively quiet, tolerant of dust, capable of operating on low grade logistics and diesel-like fuels and capable of generating between 500 W and 2 KW of continuous electrical power. This generator employs a miniature internal combustion engine / generator (MICE) having a piston moving within a cylinder arranged for two-cycle operation, and an interconnected, axially arranged piston shaft that oscillates an alternator coil within a magnetic core. The piston shaft is opposed by a strong, multiple-helix spring. The cylinder head, in which the piston operates, is cooled by moving (electrically pumped) fluid in a cooling head, or by another heat-transfer mechanism. The MICE generator's intake arrangement includes a preheater heated by a heated fluid flow thereon. The MICE generator is vibration-isolated using a base that supports the MICE on a plurality of soft coil springs. The MICE generator is encased in an acoustic enclosure having a shell composed of sheet metal or another stiff material extending from the base plate and being covered by a top side. Holes in the enclosure top are covered by porous discs that allow exhaust gasses from the internal muffler to pass therethrough. The acoustic enclosure resides in a large, typically portable, external package enclosure.

Owner:AERODYNE RES

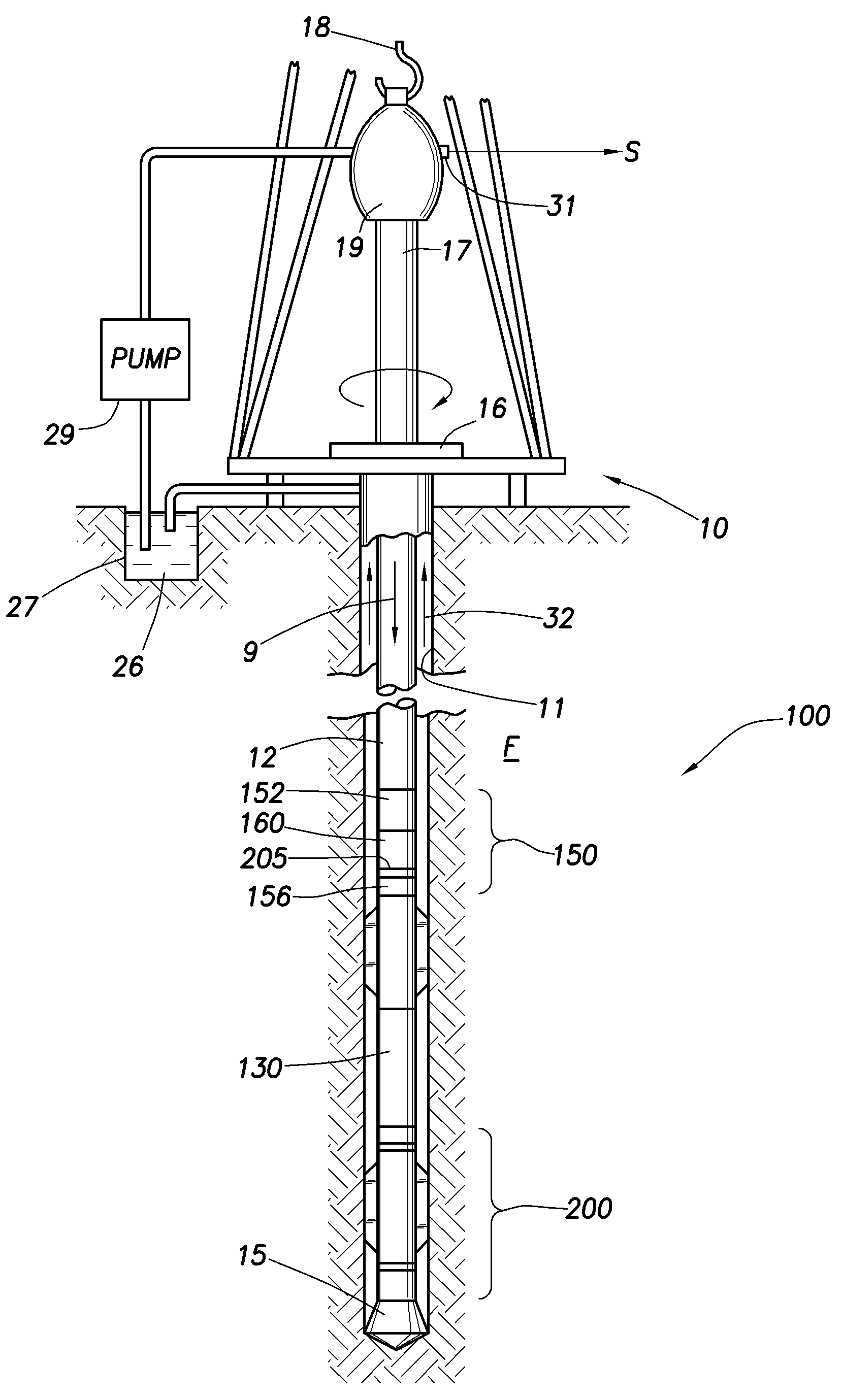

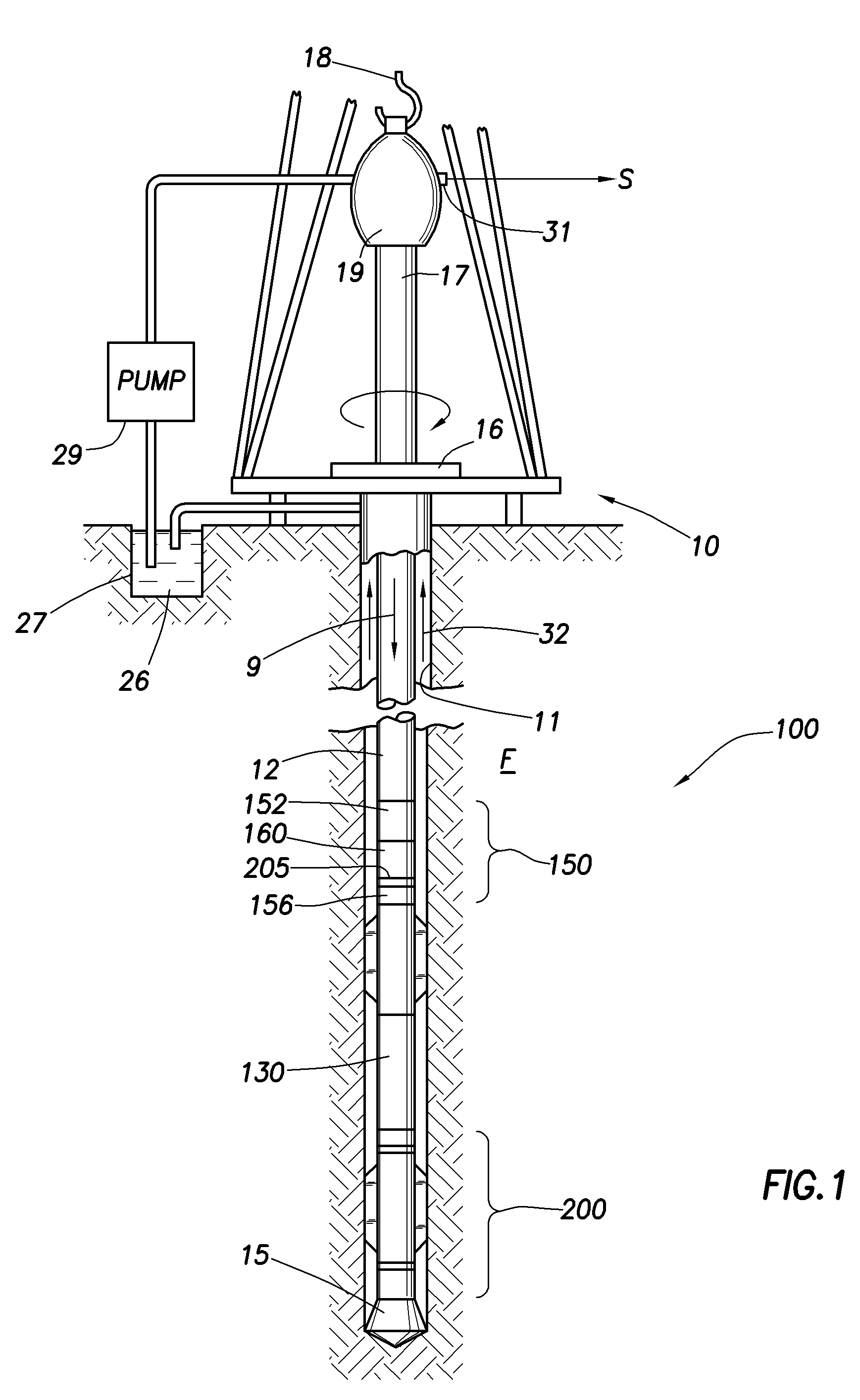

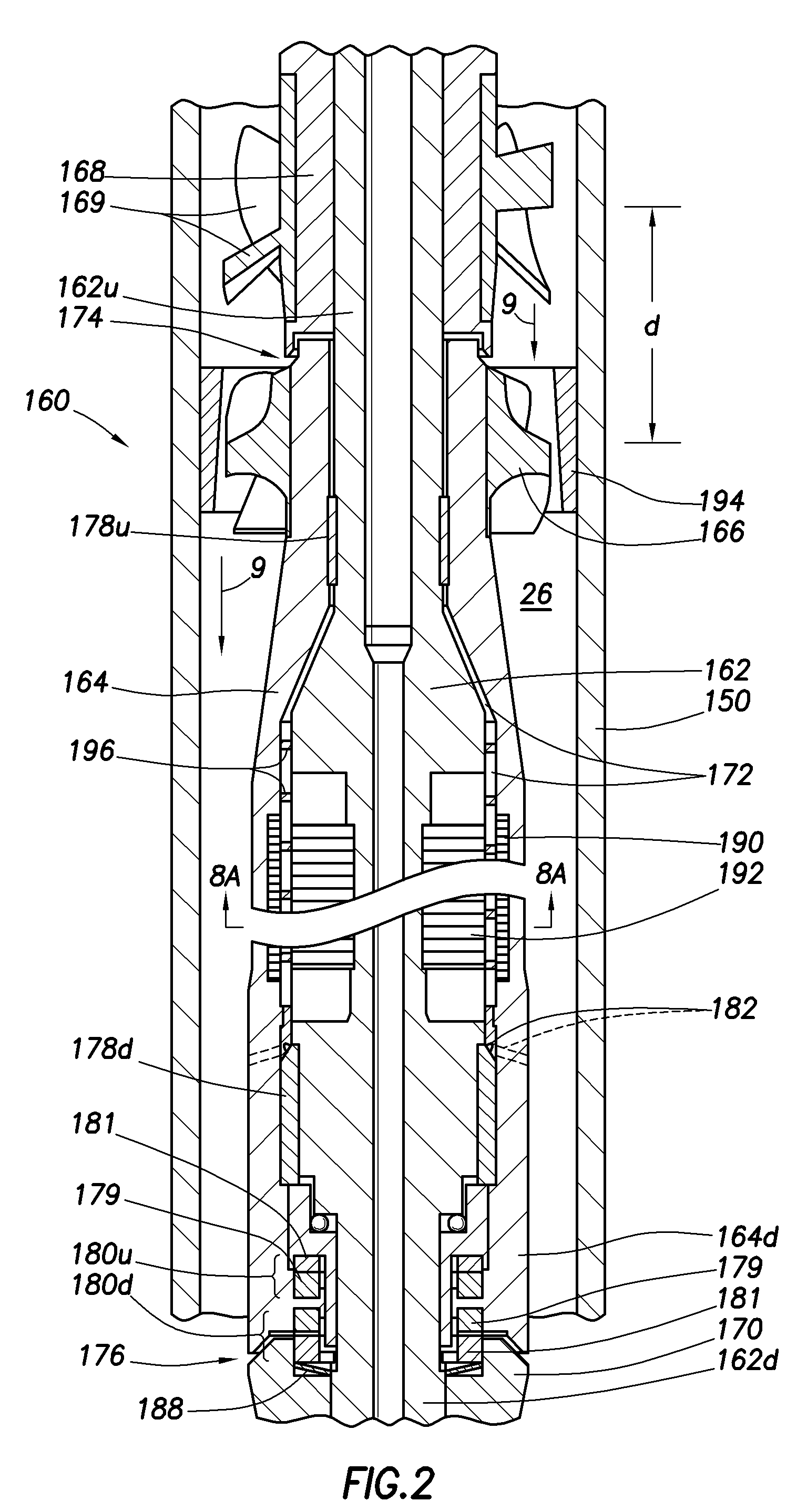

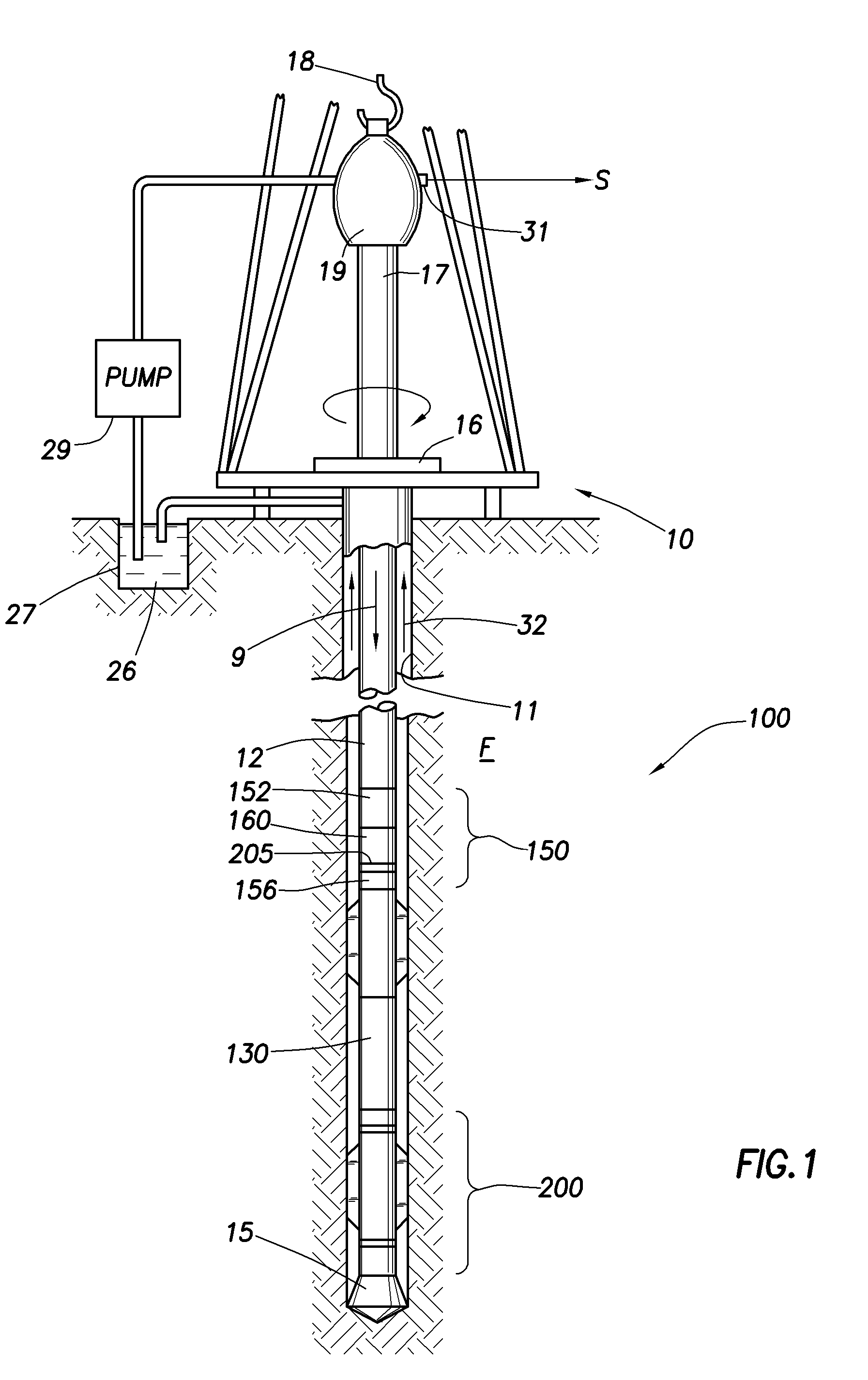

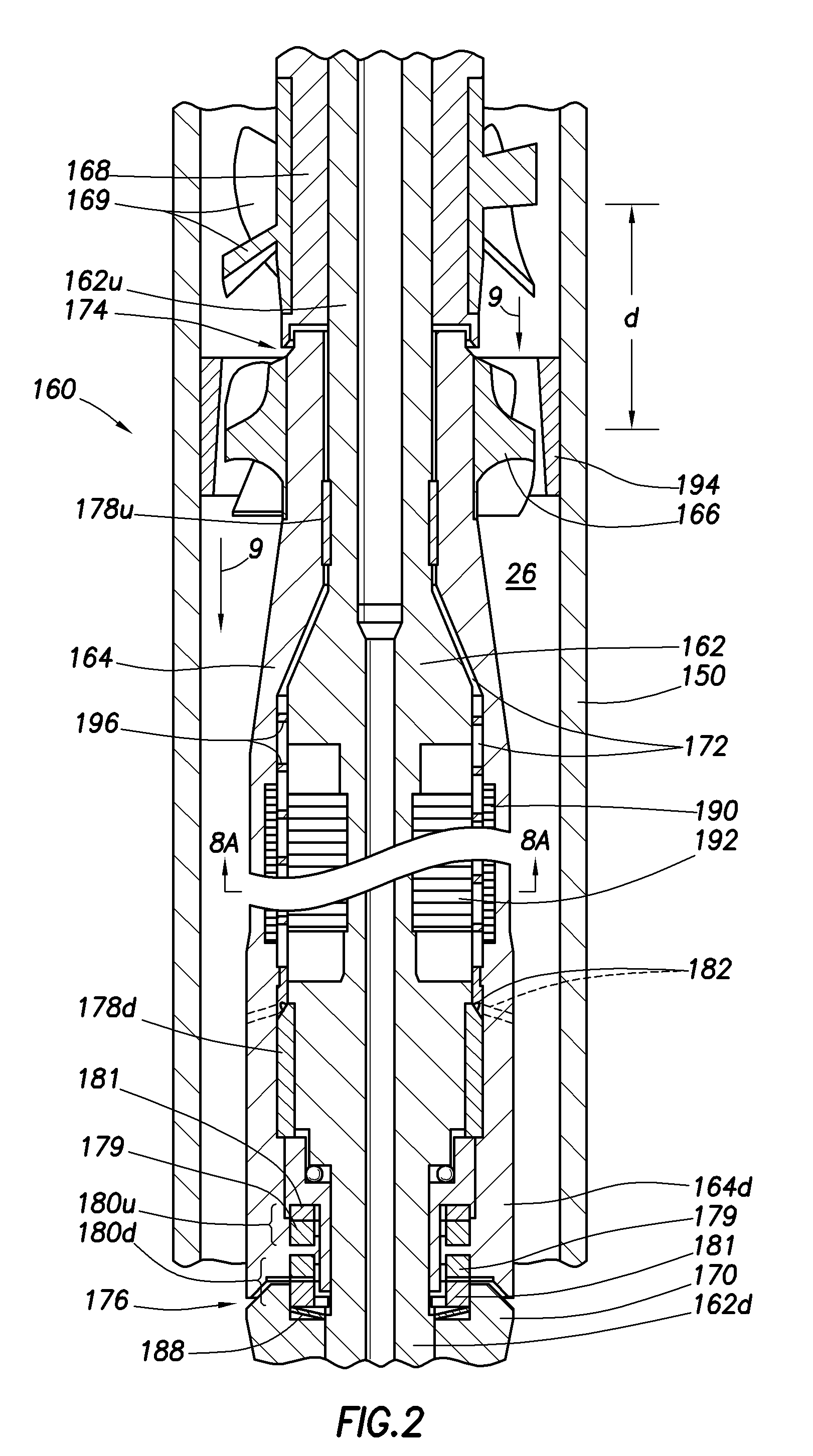

Apparatus and method for generating electrical power in a borehole

ActiveUS7133325B2Reduce the possibilityRemove heatElectric/magnetic detection for well-loggingConstructionsImpellerAlternator

An apparatus and related method generate electrical power in a tubular housing, such as a drill collar, disposed in a borehole when drilling fluid flows through the tubular housing. The apparatus includes a stator adapted for being secured within the tubular housing against rotation relative to the tubular housing, a tubular rotor rotatably carried about the stator, and an impeller peripherally affixed to the rotor. The stator has an array of conductive windings therein, and is preferably an alternator stator. The rotor has an array of magnets therein, and is preferably an alternator rotor. Accordingly, drilling fluid flowing through the tubular housing when the apparatus is disposed therein engages the impeller and induces rotation of the rotor about the stator to generate electrical power.

Owner:SCHLUMBERGER TECH CORP

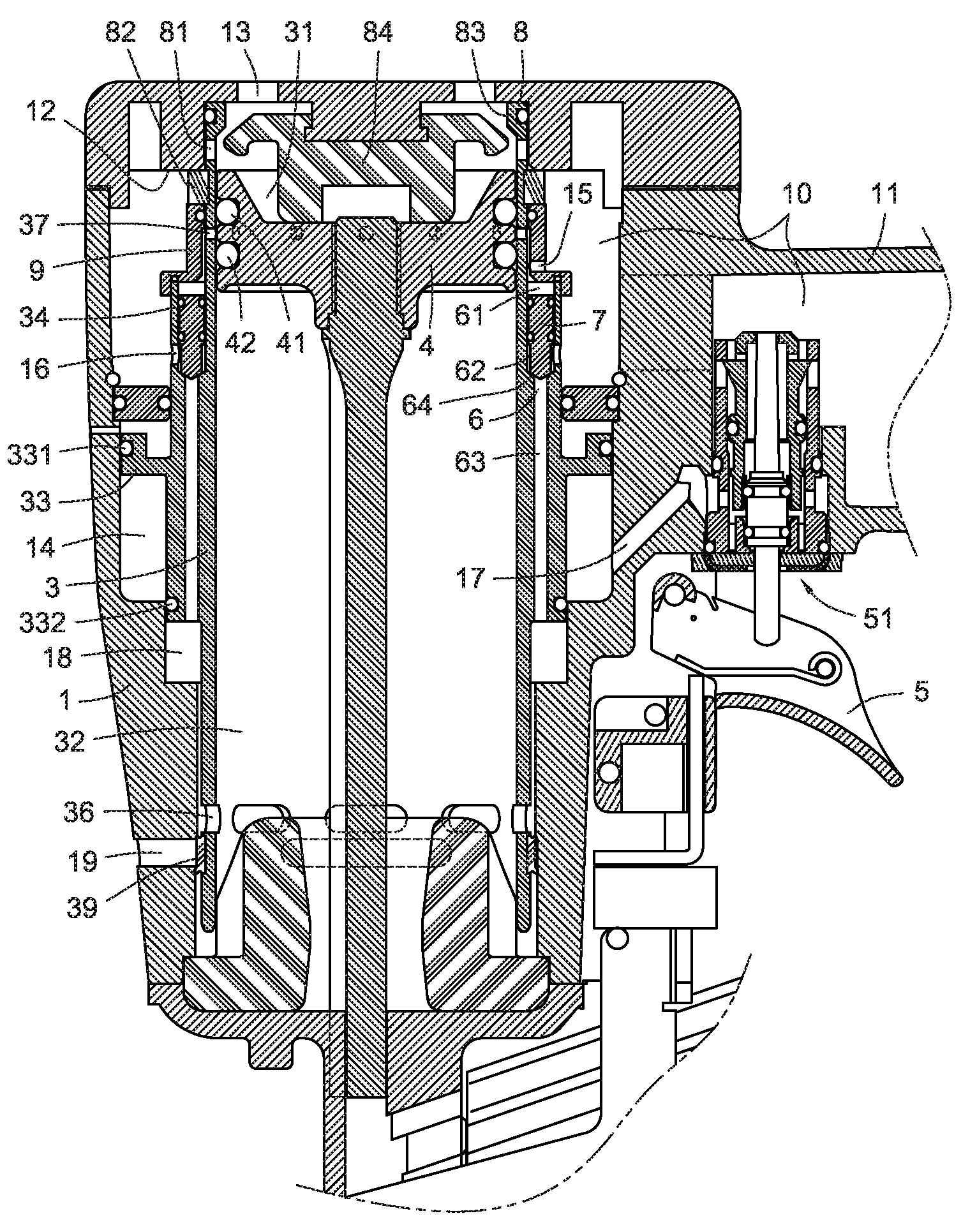

Energy converter

InactiveUS7845317B2Low costReduce weightCoolant flow controlNon-fuel substance addition to fuelCombustion chamberElectric machine

Method and arrangement for providing an energy converter that includes a combustion system (1) including at least one piston (2, 3), at least one combustion chamber (6, 7) having at least one inlet (11, 13) and at least one outlet (10, 12) with inlet and outlet valves (14, 15, 16, 17). At least one controllable inlet valve and at least one outlet valve is also provided. A fuel supply is provided (18, 19) for supplying fuel and a medium containing oxygen is provided for induction into the combustion chamber (6, 7). An electric machine (9) is arranged to interact directly or indirectly with the piston (2, 3) in an electromagnetic manner such that it produces electrical energy from the piston movements, as well as uses electrical energy to affect the piston movement. A control unit (30) controls the combustion system (1) and the electric machine (9).The energy converter is arranged to adapt its power output depending on the required load of the energy converter. The invention also relates to a method for starting an energy converter.

Owner:VOLVO CAR CORP +1

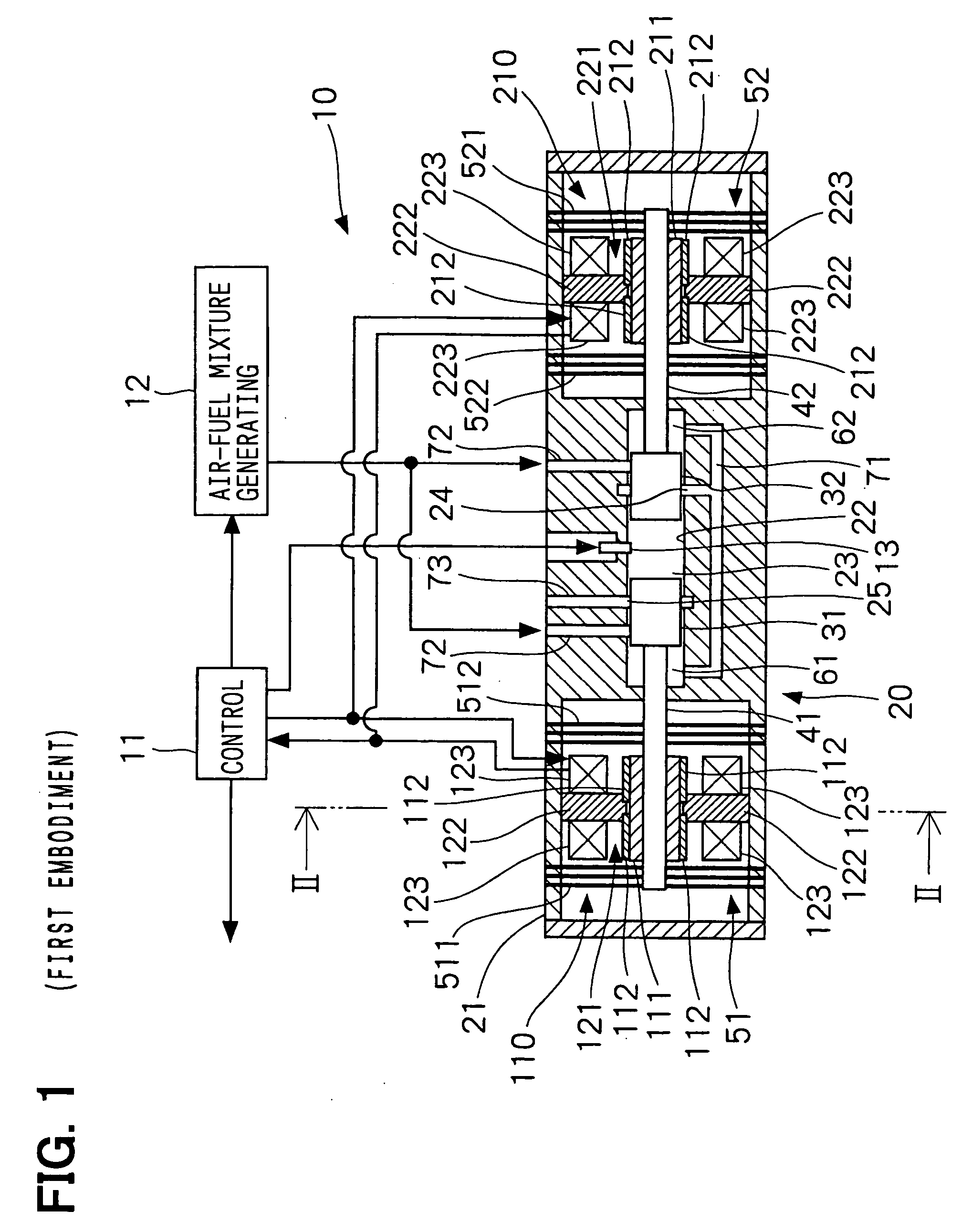

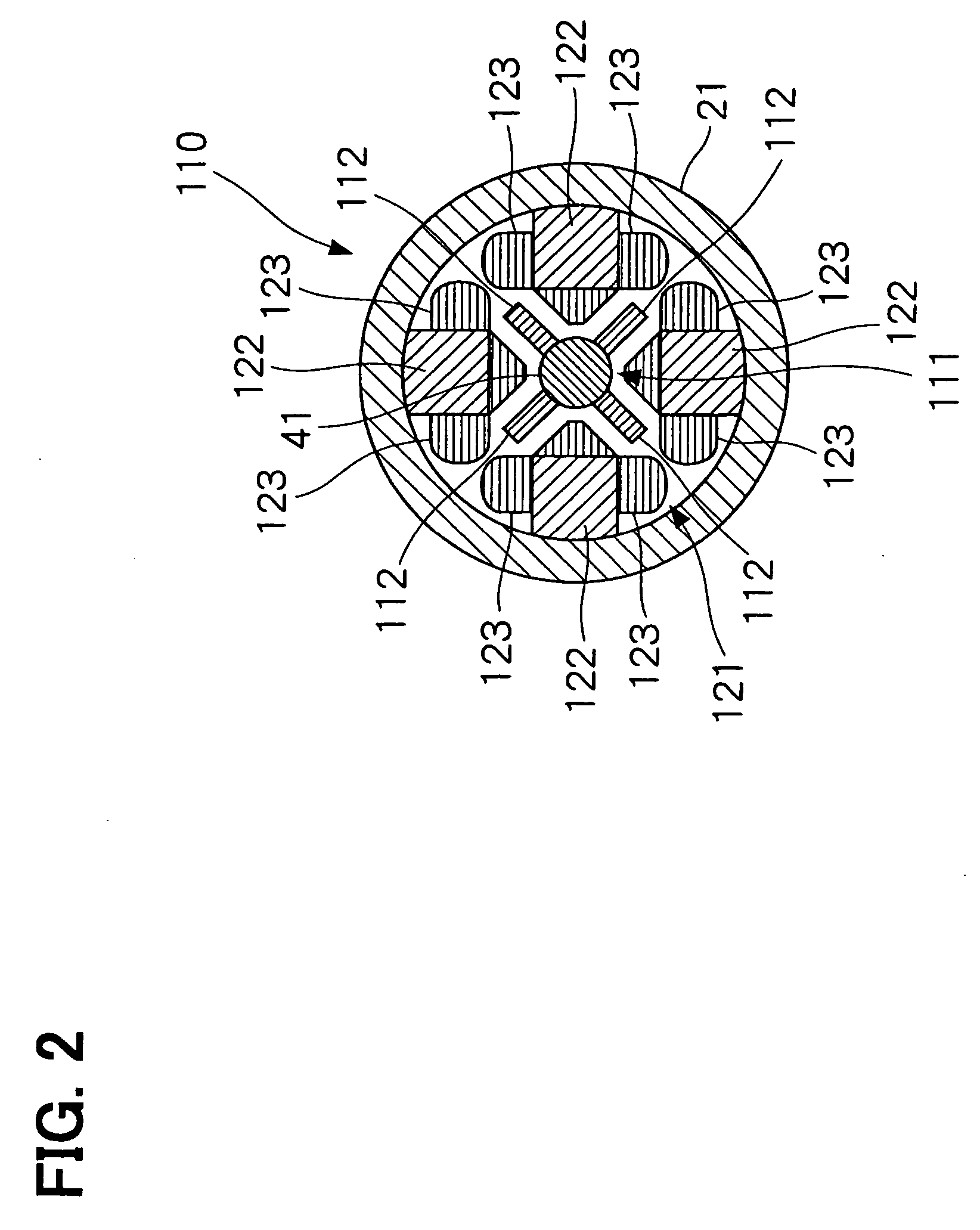

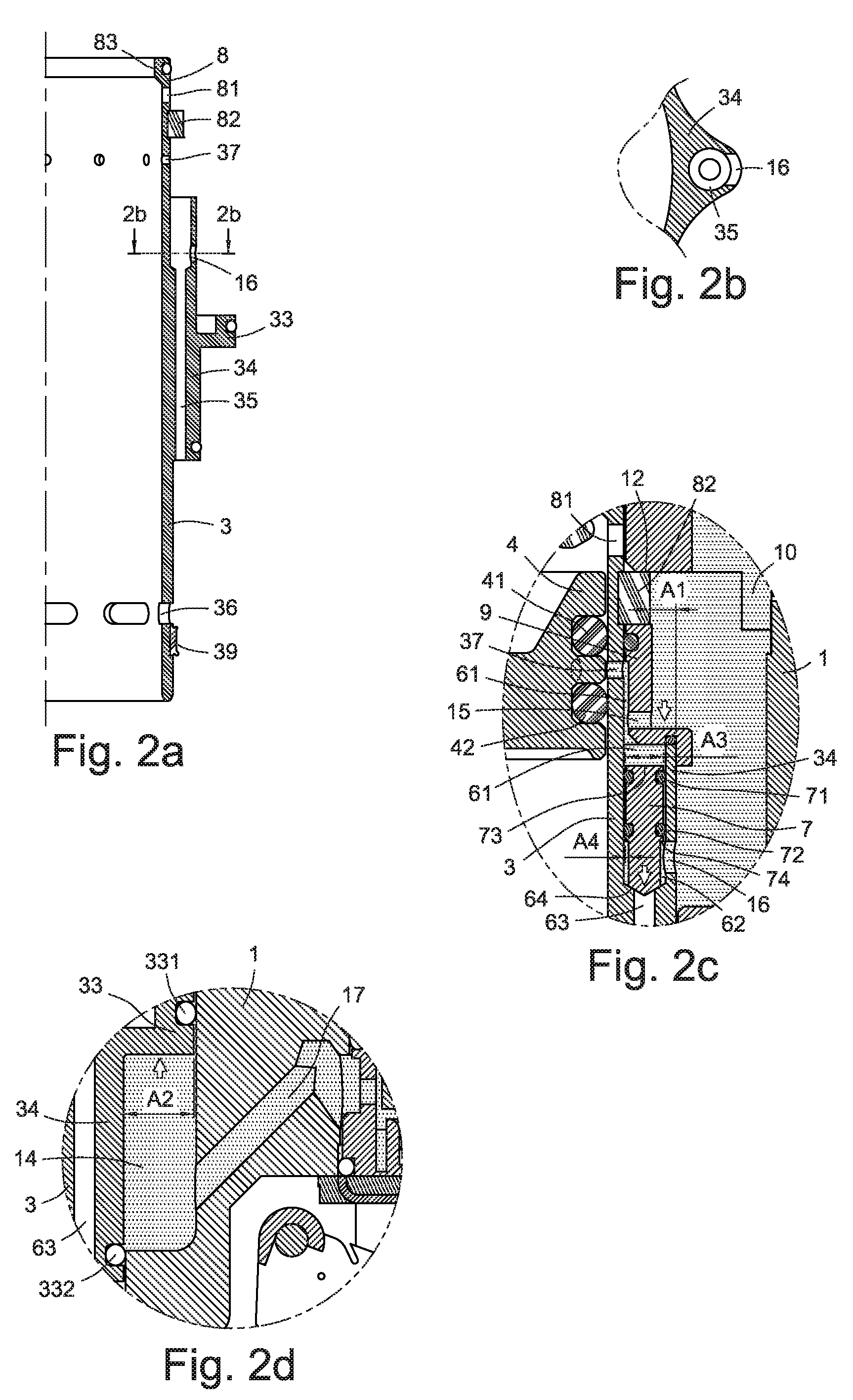

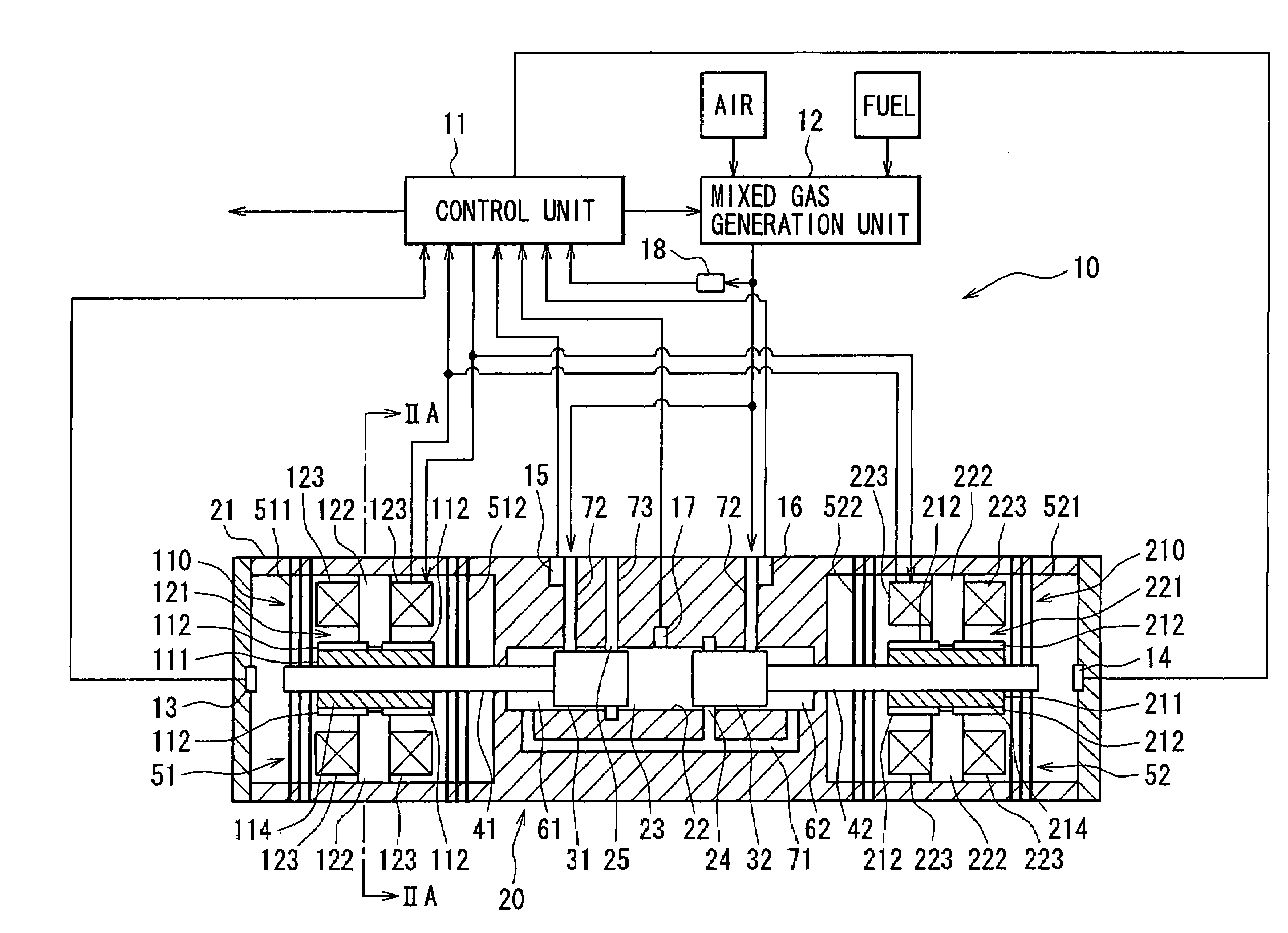

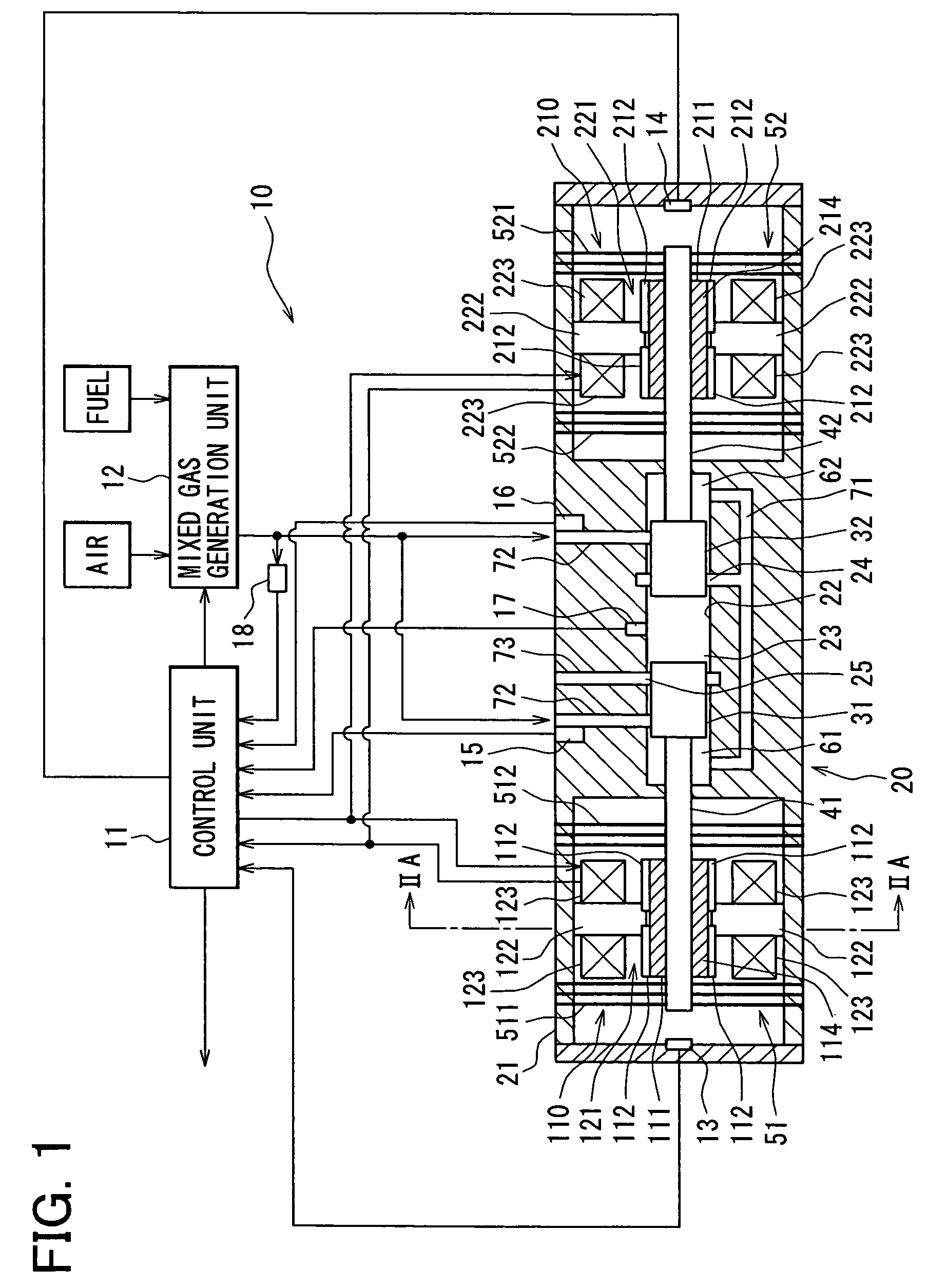

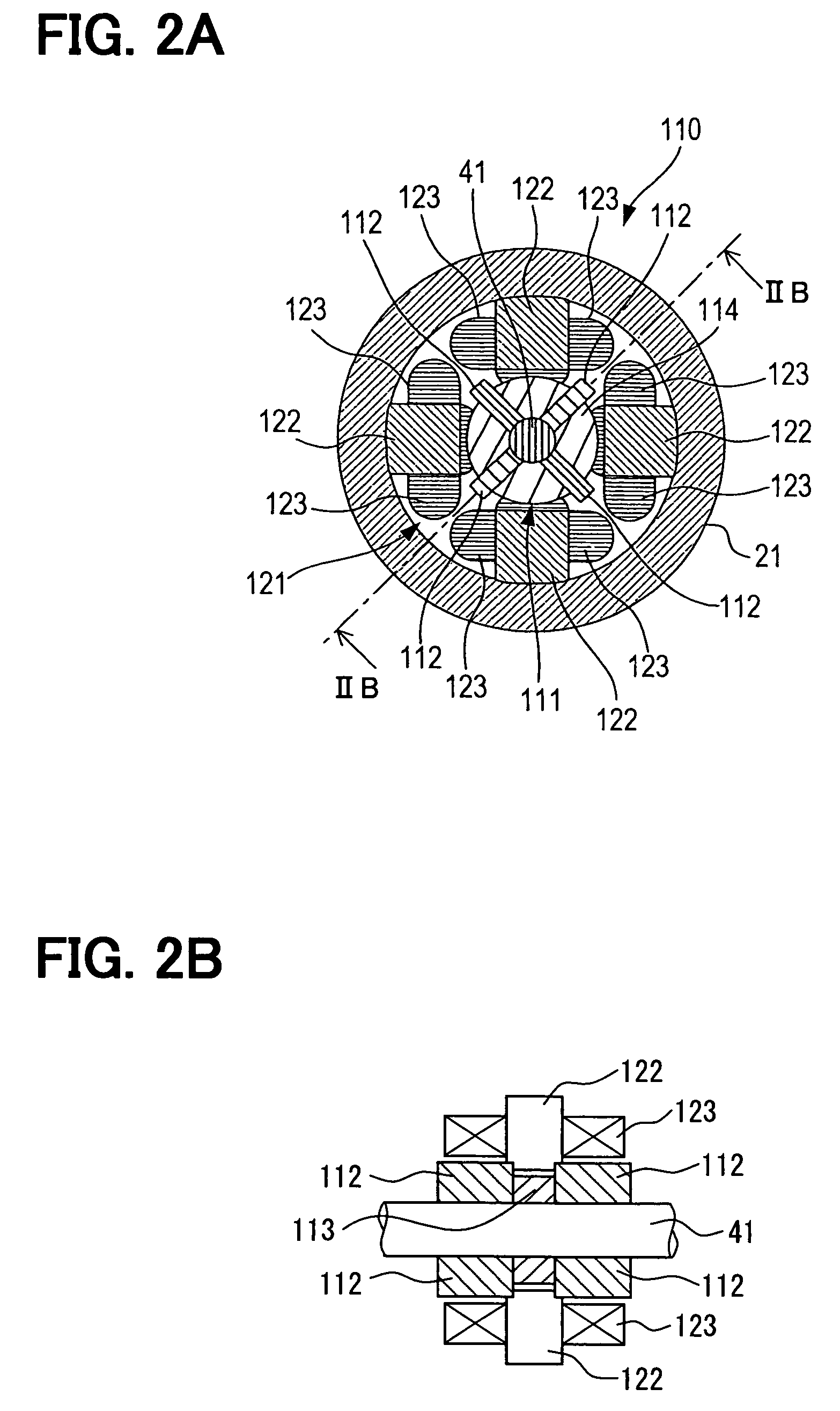

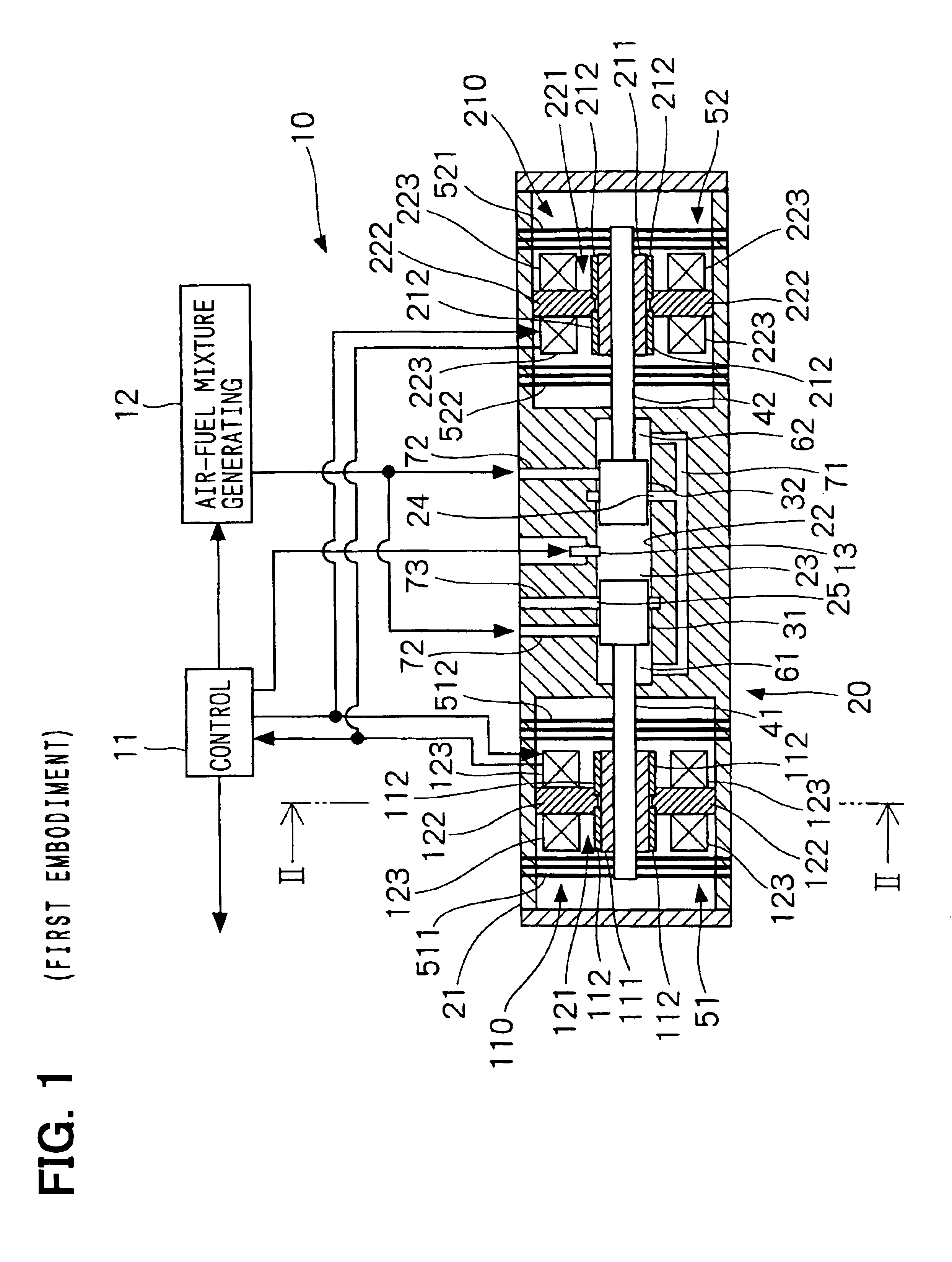

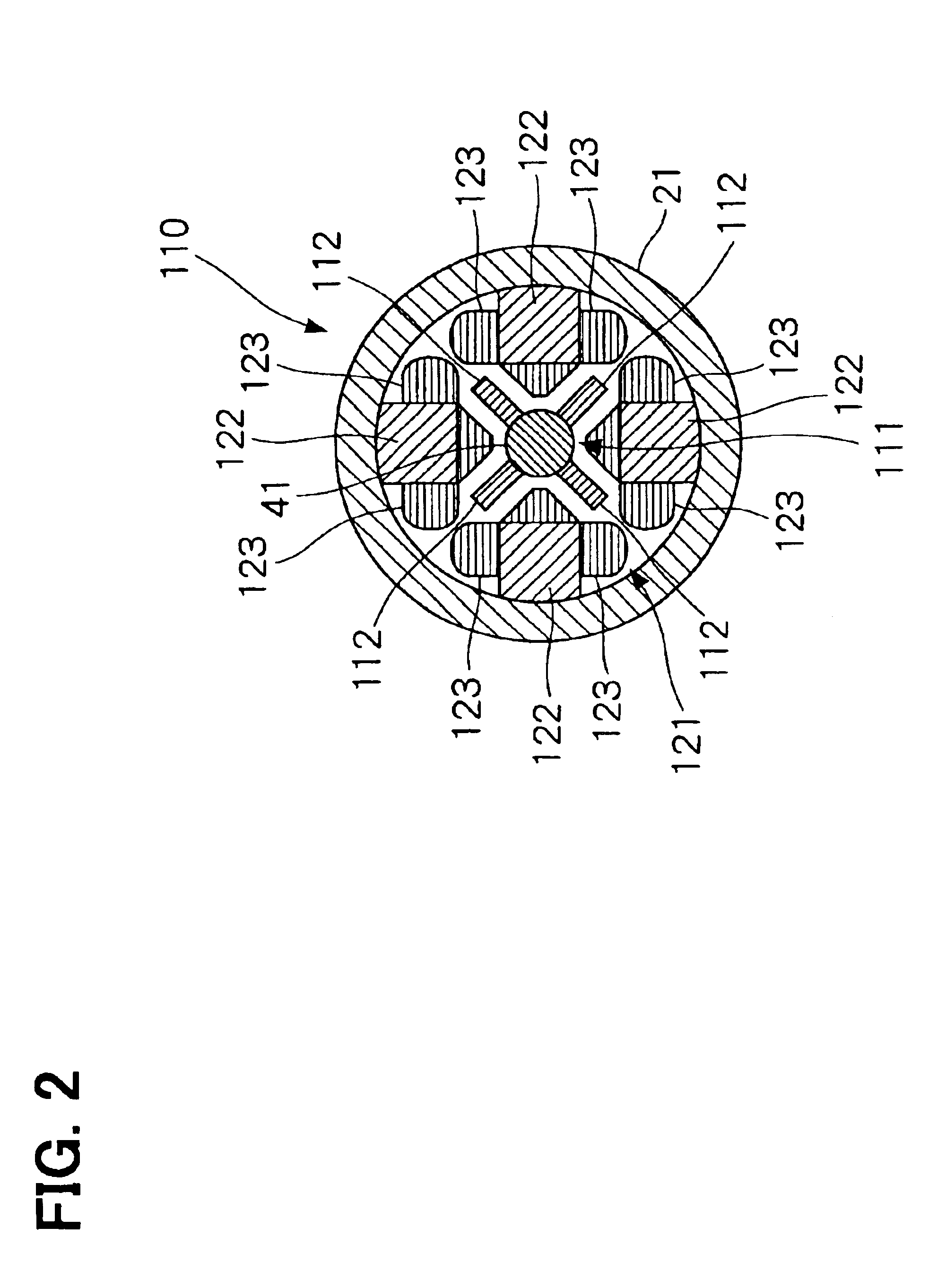

Free piston engine and power generation system therewith

InactiveUS20050109295A1Improve efficiencyReduce vibrationMechanical energy handlingFree piston enginesFree-piston engineEngineering

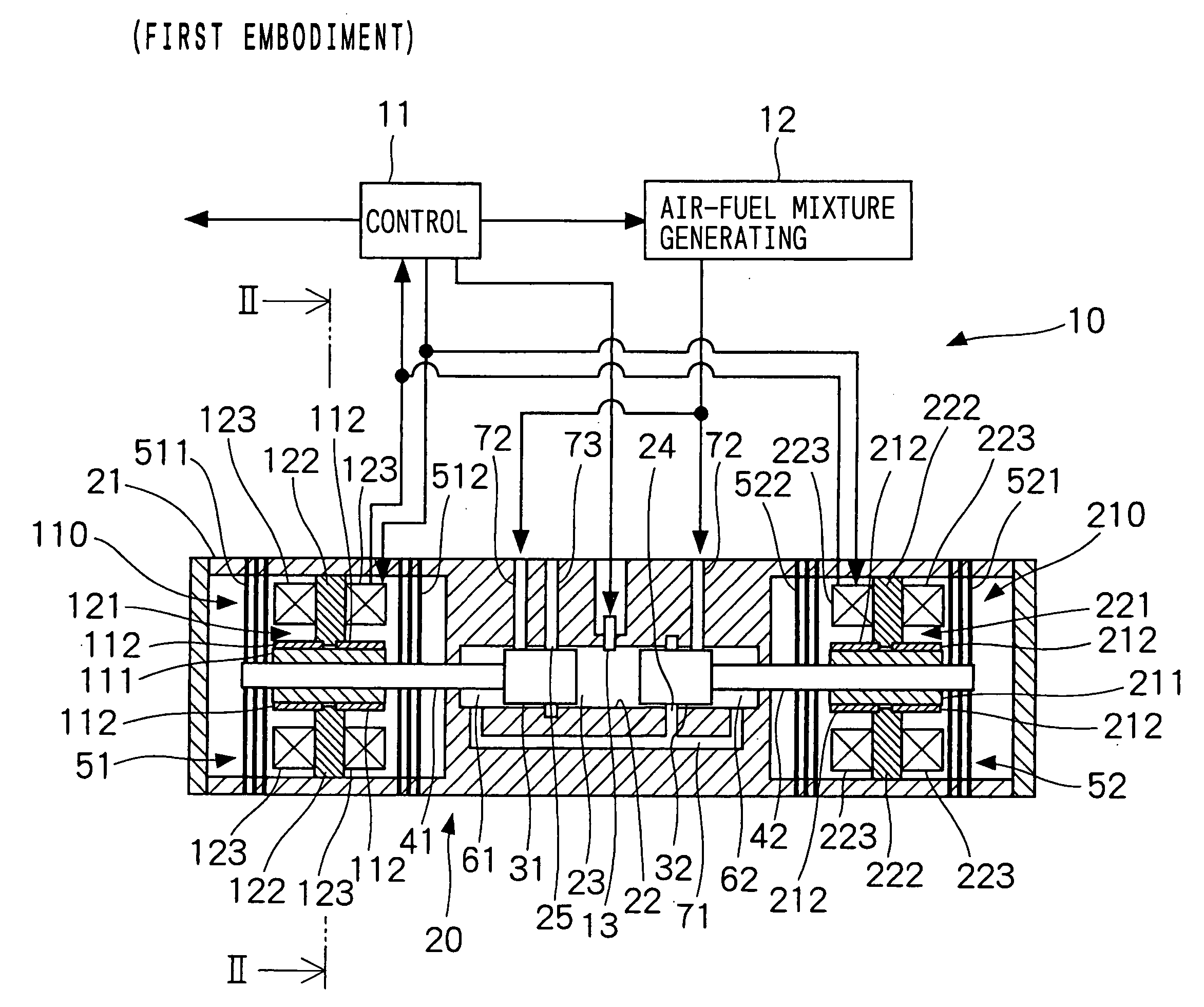

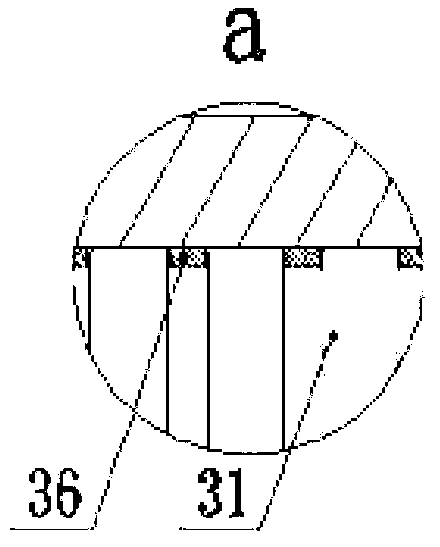

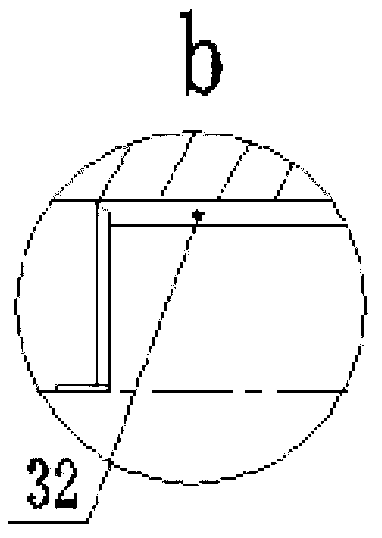

A first piston connected to a first shaft and a second piston connected to a second shaft are supported within a housing by using a first leaf-spring unit and a second leaf-spring unit, respectively. Therefore, axial movement of the first shaft or the second shaft can be allowed, while circumferential rotational movement and radial movement can be restricted. The first leaf-spring unit includes two leaf-spring groups that are disposed in a row around the first shaft in the direction of the axis of the first shaft; similarly, the second leaf-spring unit includes two leaf-spring groups that are disposed in a row around the second shaft in the direction of the axis of the second shaft. Therefore, inclinations of the first shaft and the second shaft can be decreased. This results in reduction in contact between the first and second shafts and a cylinder within the housing and friction due to the contact.

Owner:DENSO CORP

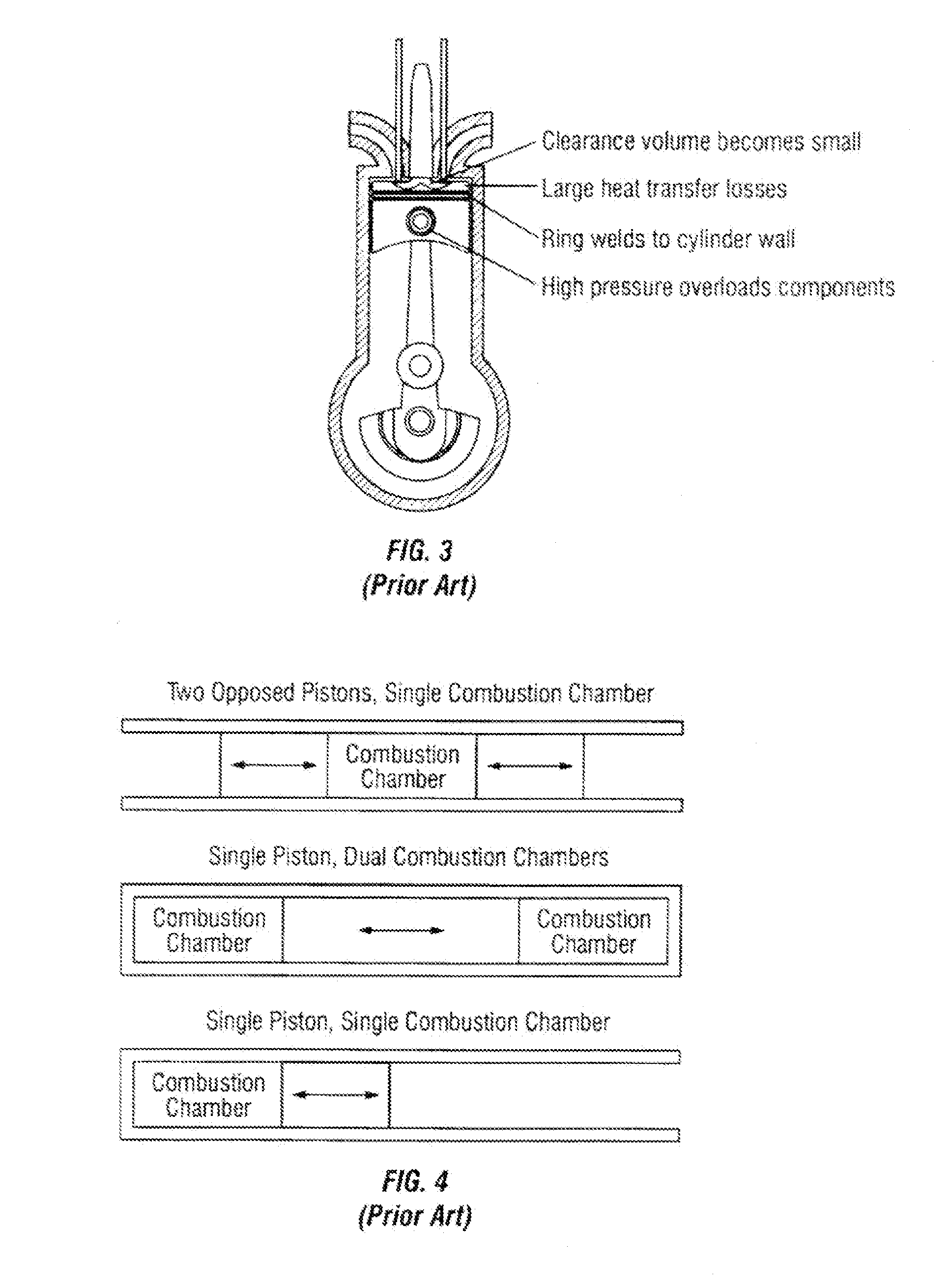

Four-Stroke Free Piston Engine

InactiveUS20080271711A1Expand accessIncrease loadInternal combustion piston enginesFree piston enginesFree-piston engineCombustion chamber

A free piston engine utilizes a shuttle frame external to combustion chambers to rigidly link shuttle parts reciprocating along a centerline. If the shuttle parts are spaced apart along the centerline, the shuttle frame may be struts extending from the shuttle parts and linked by rods. Alternatively the shuttle parts are within a tubular shuttle frame that forms part of the combustion chamber boundary. If one shuttle part is arranged around the other with both centered about the centerline, the shuttle frame may include an annular plate between a cylindrical inner shuttle part and an annular outer shuttle part. Alternatively the shuttle frame may include an inner tube with a cylindrical inner shuttle part within the inner tube, and an outer tube with an annular outer shuttle part arranged between the inner and the outer tubes so that the shuttle frame forms part of the combustion chamber boundary.

Owner:CHEESEMAN PETER CHARLES

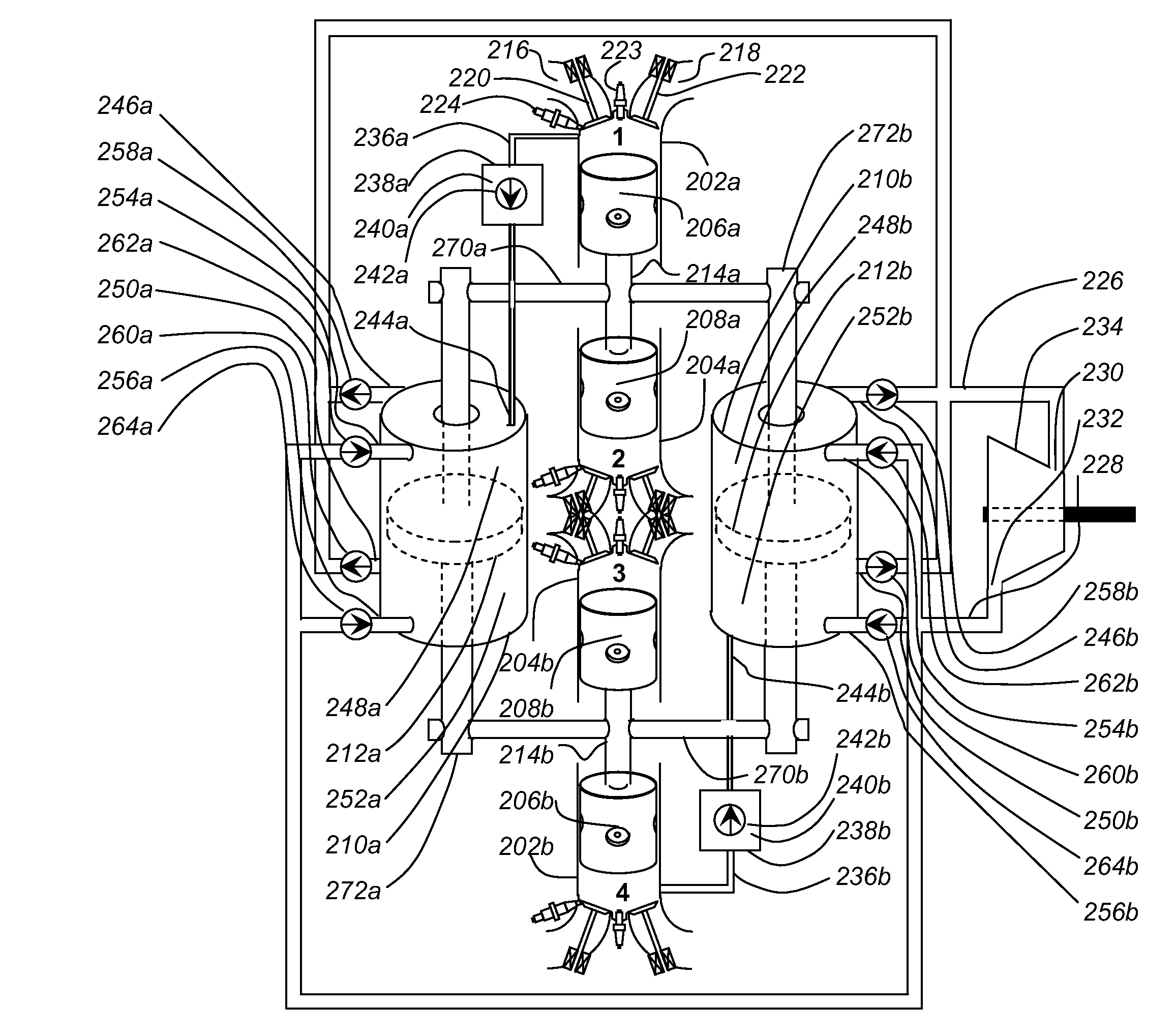

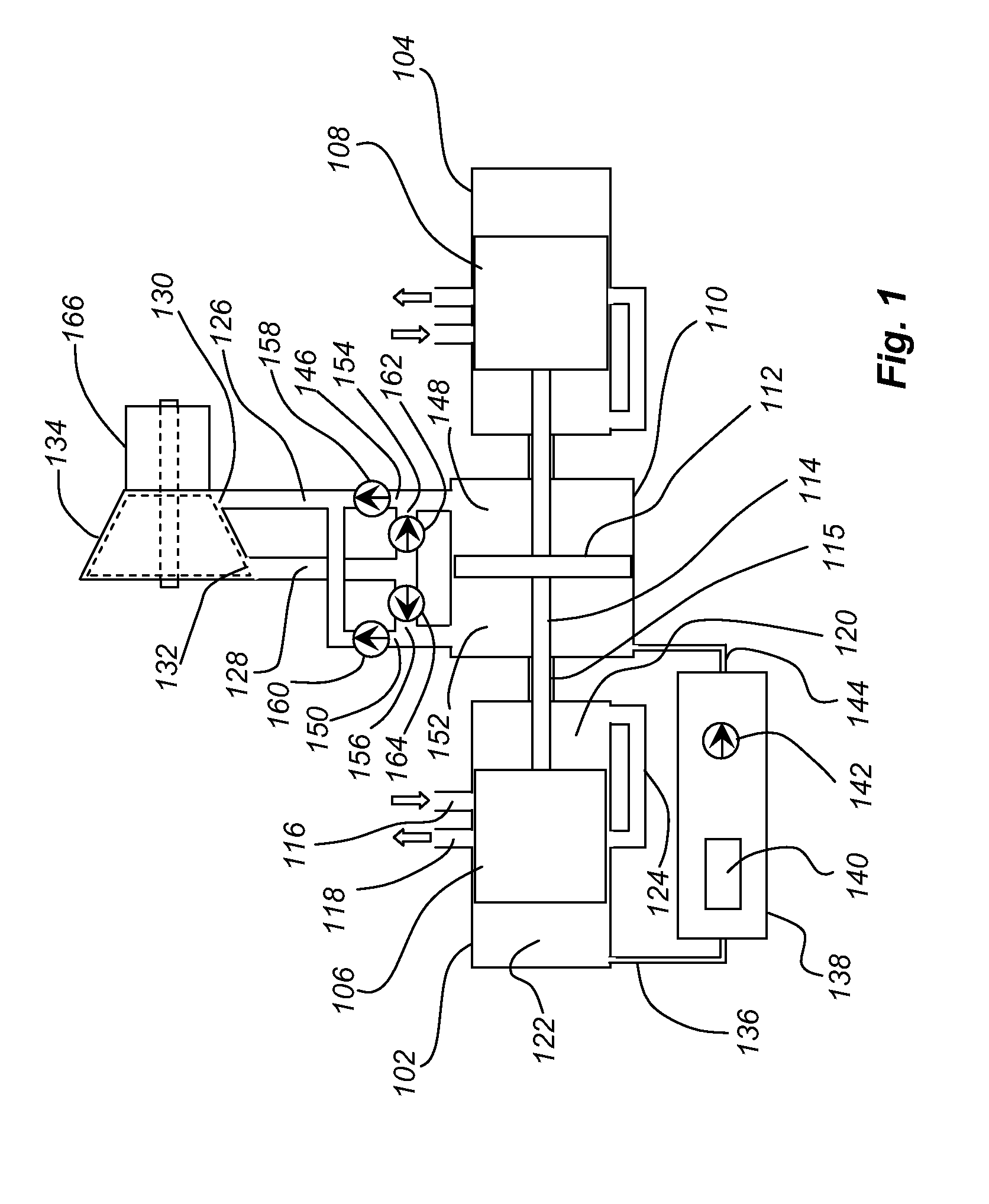

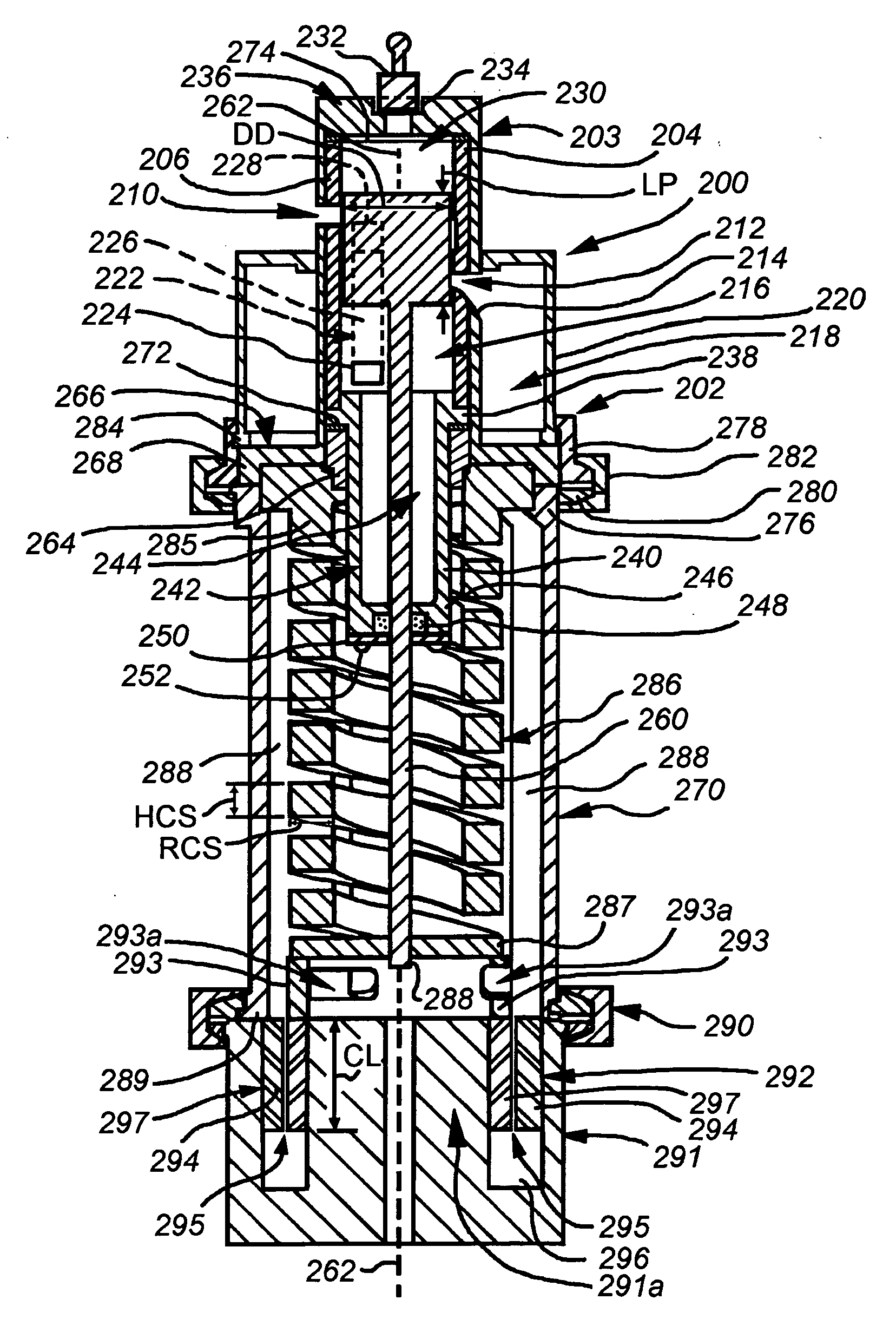

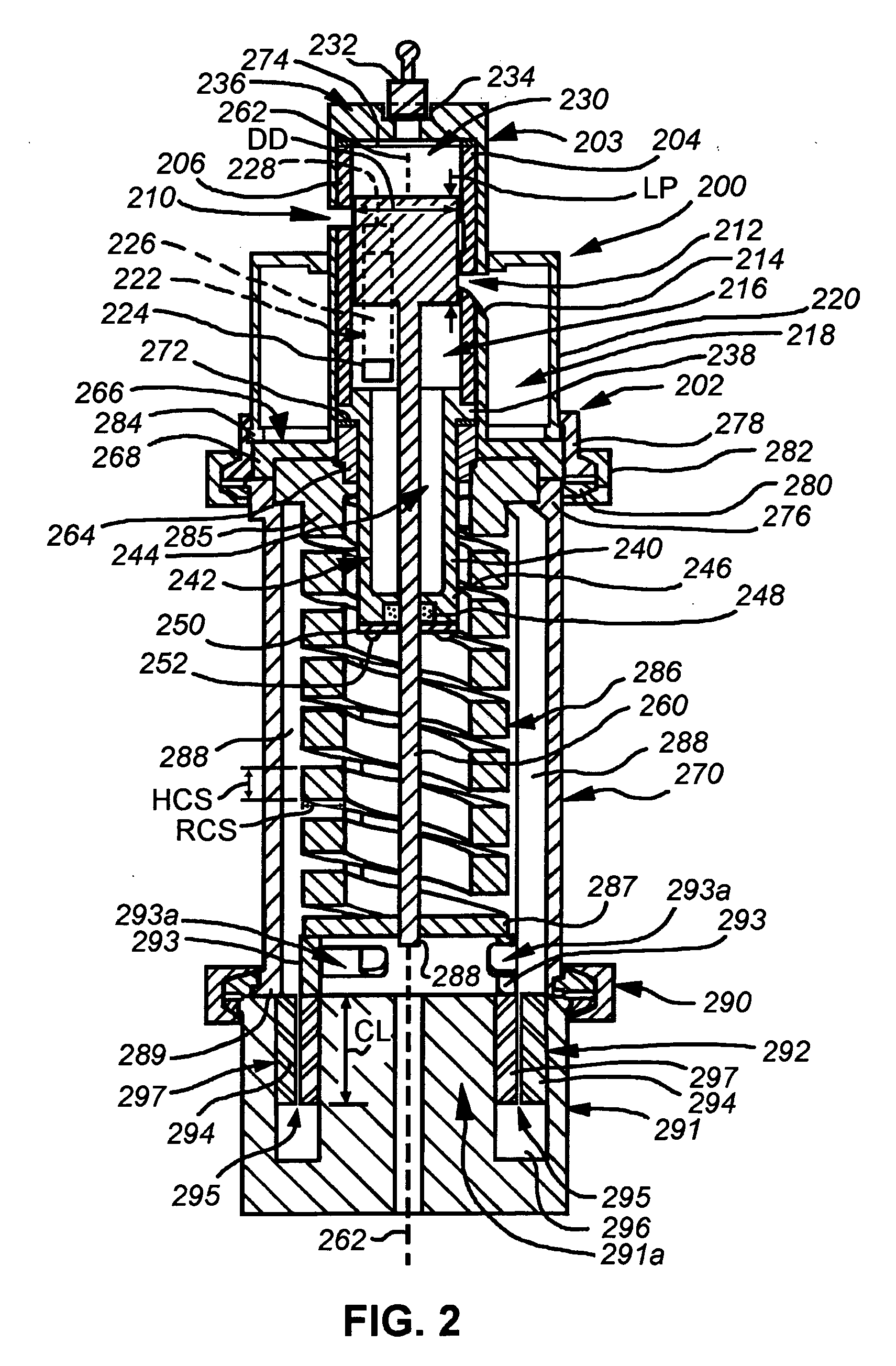

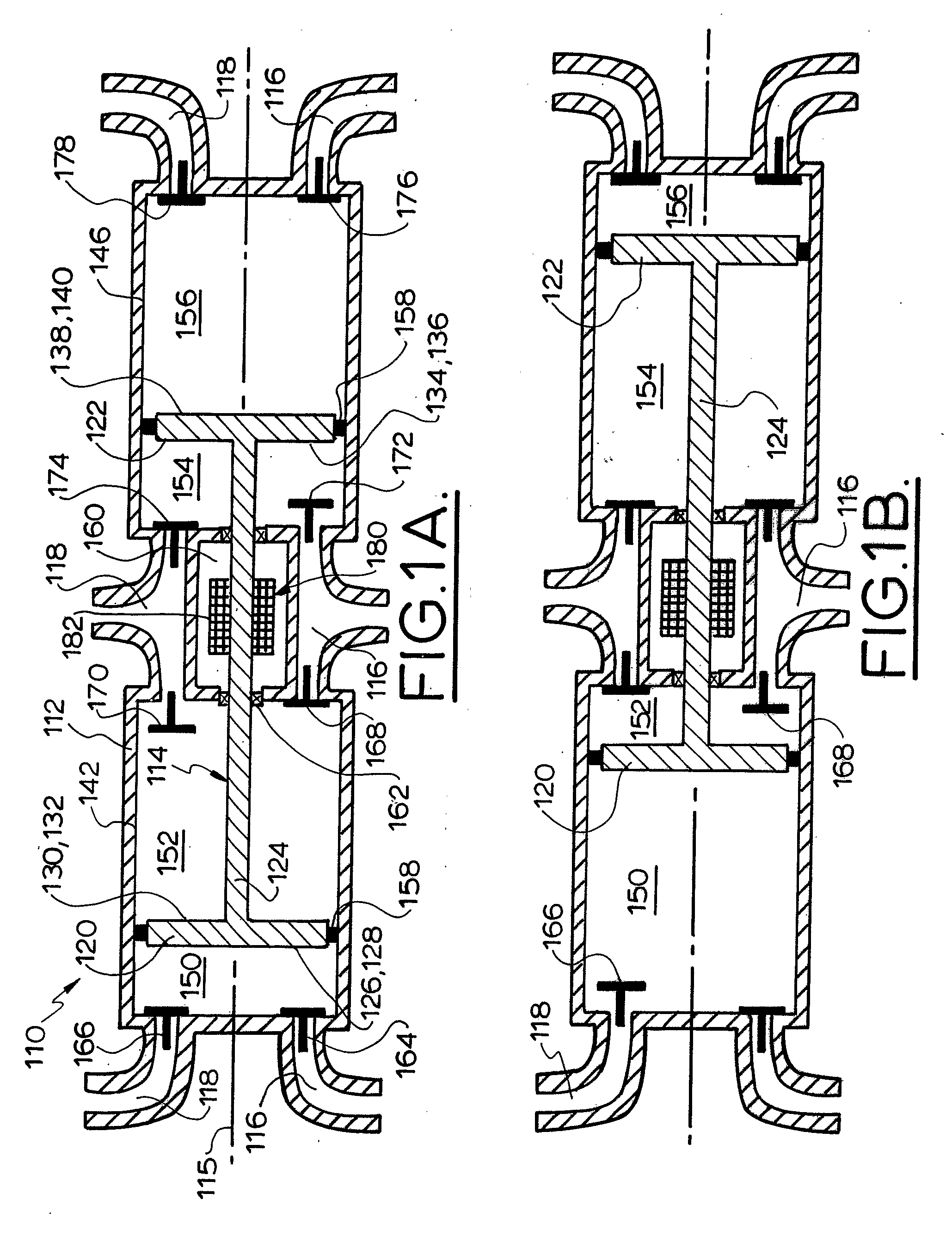

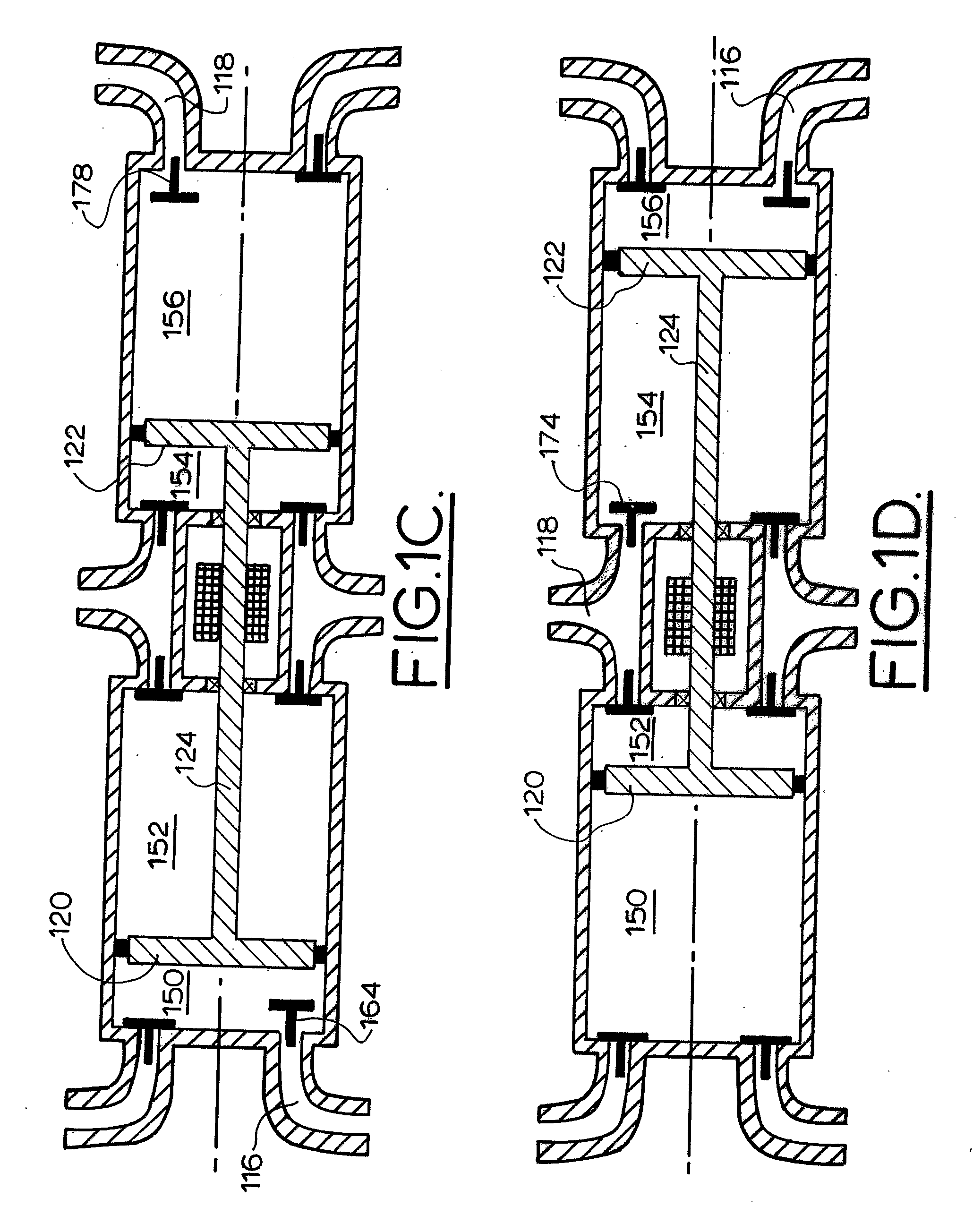

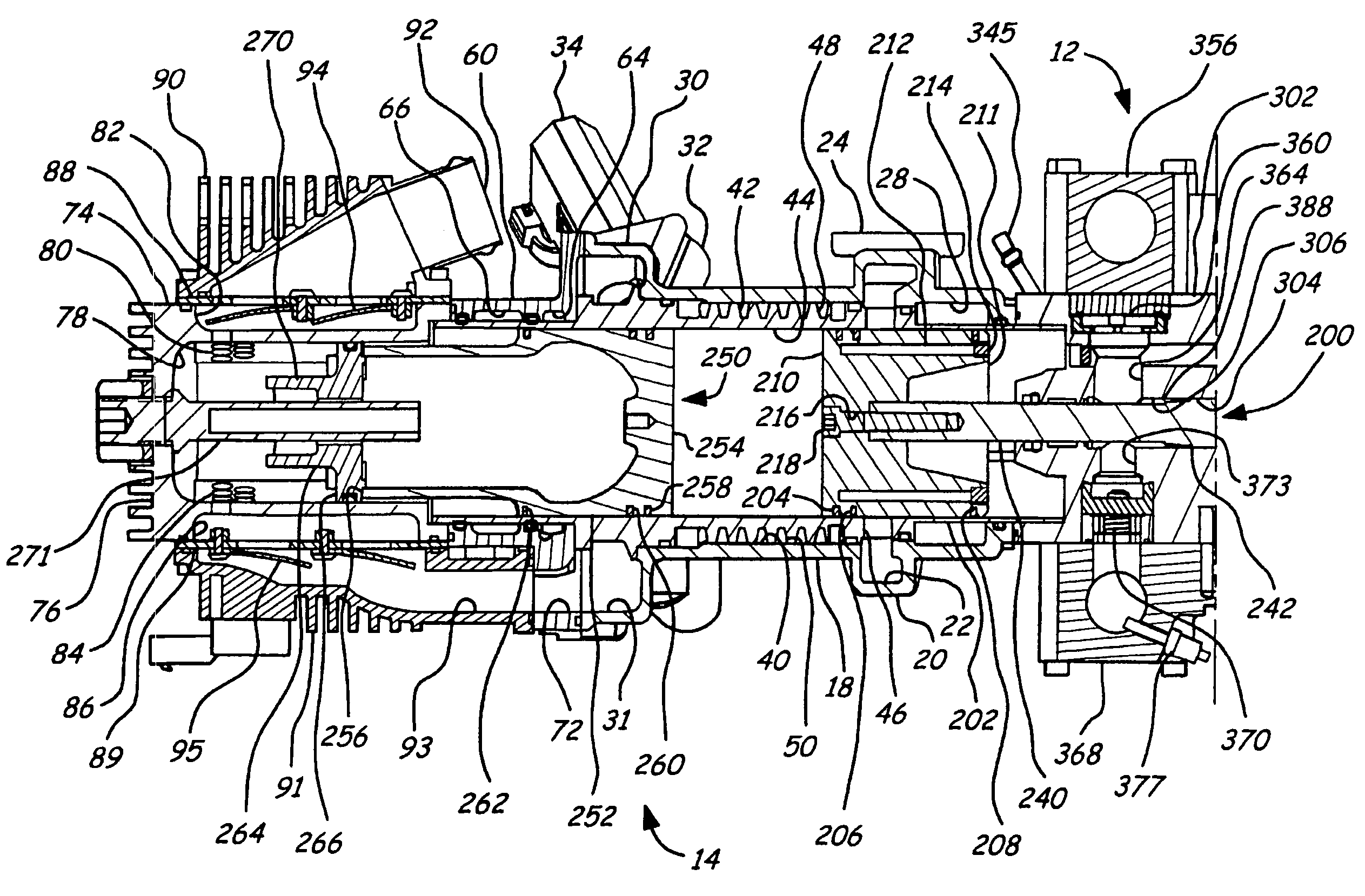

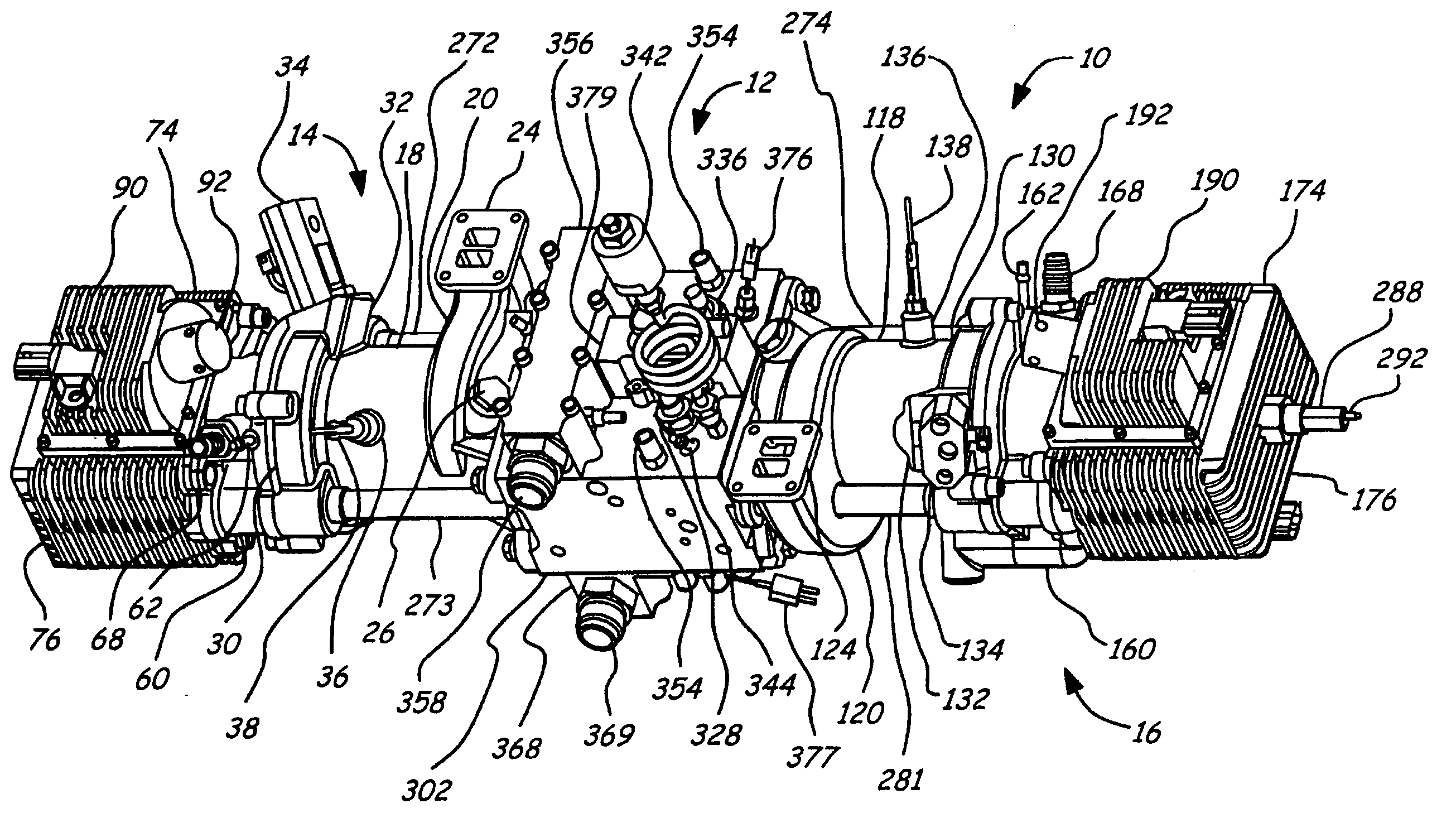

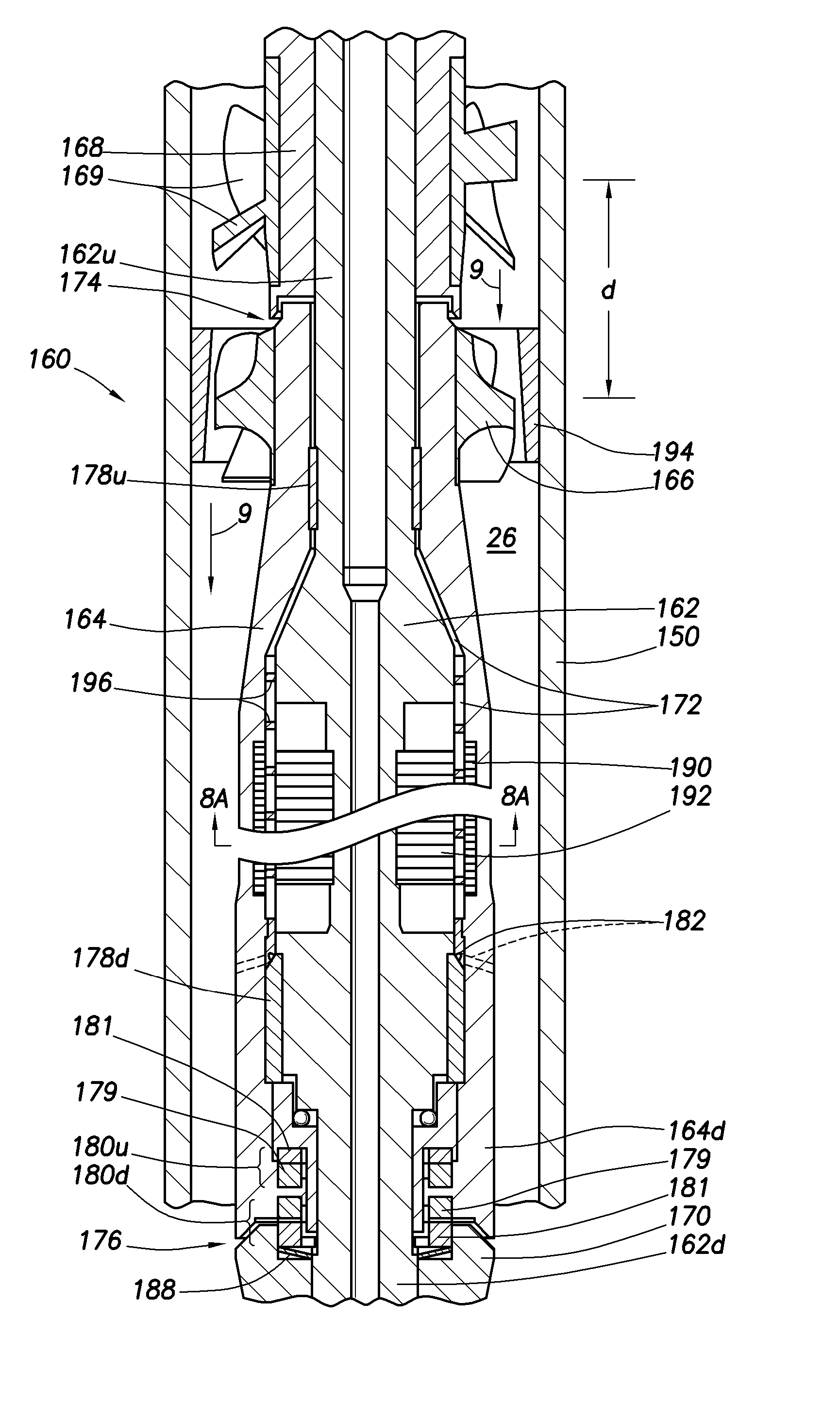

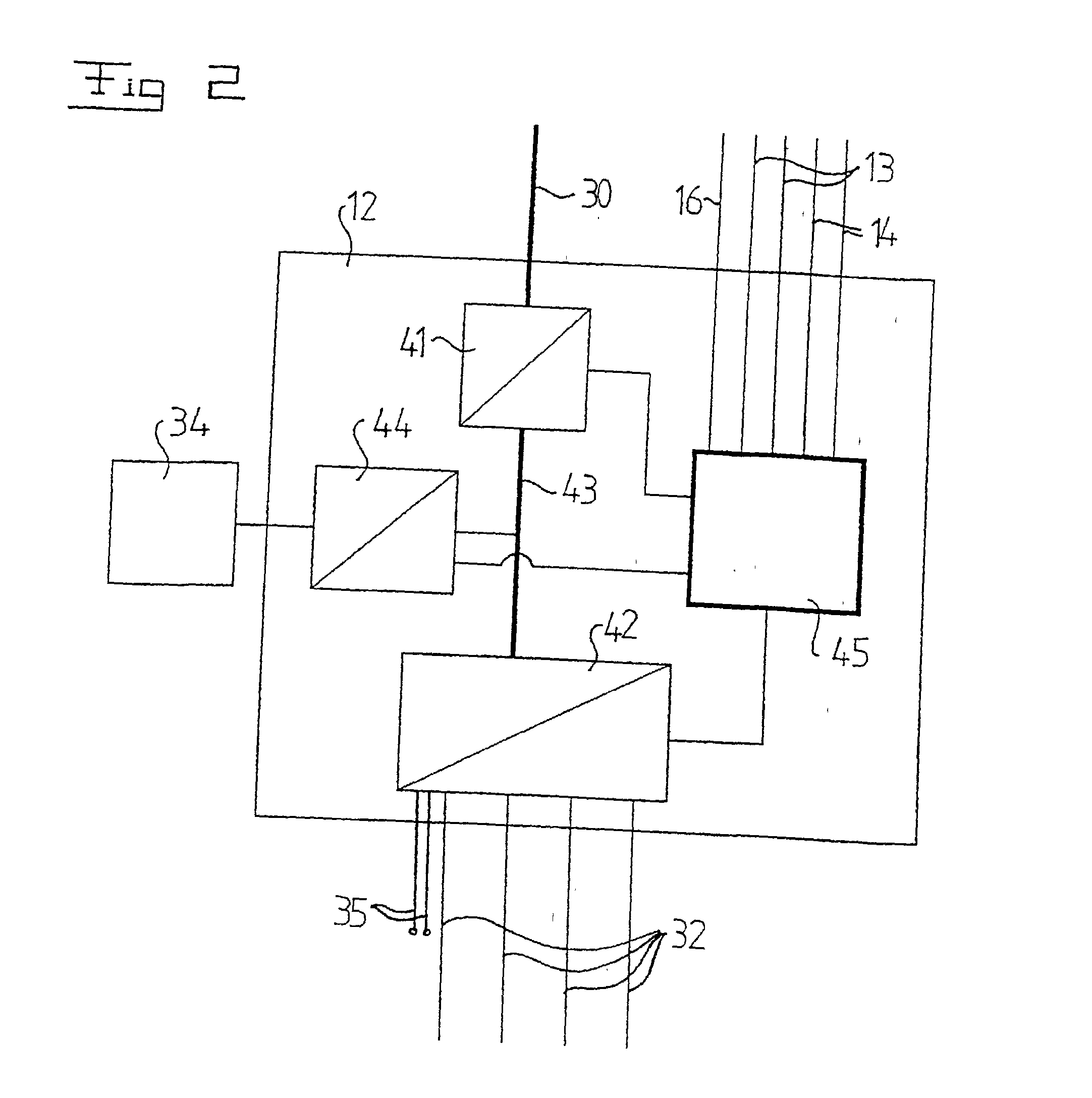

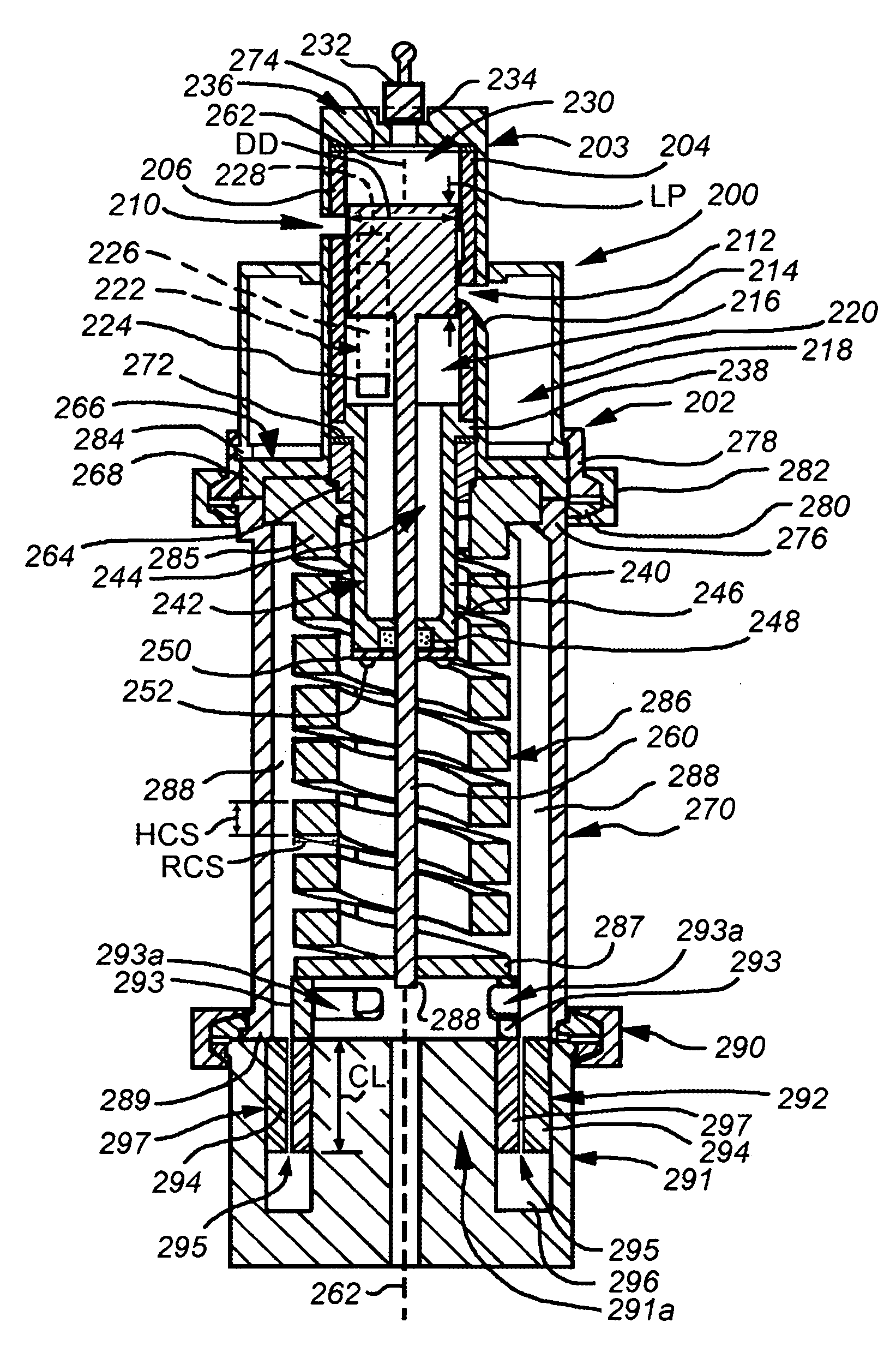

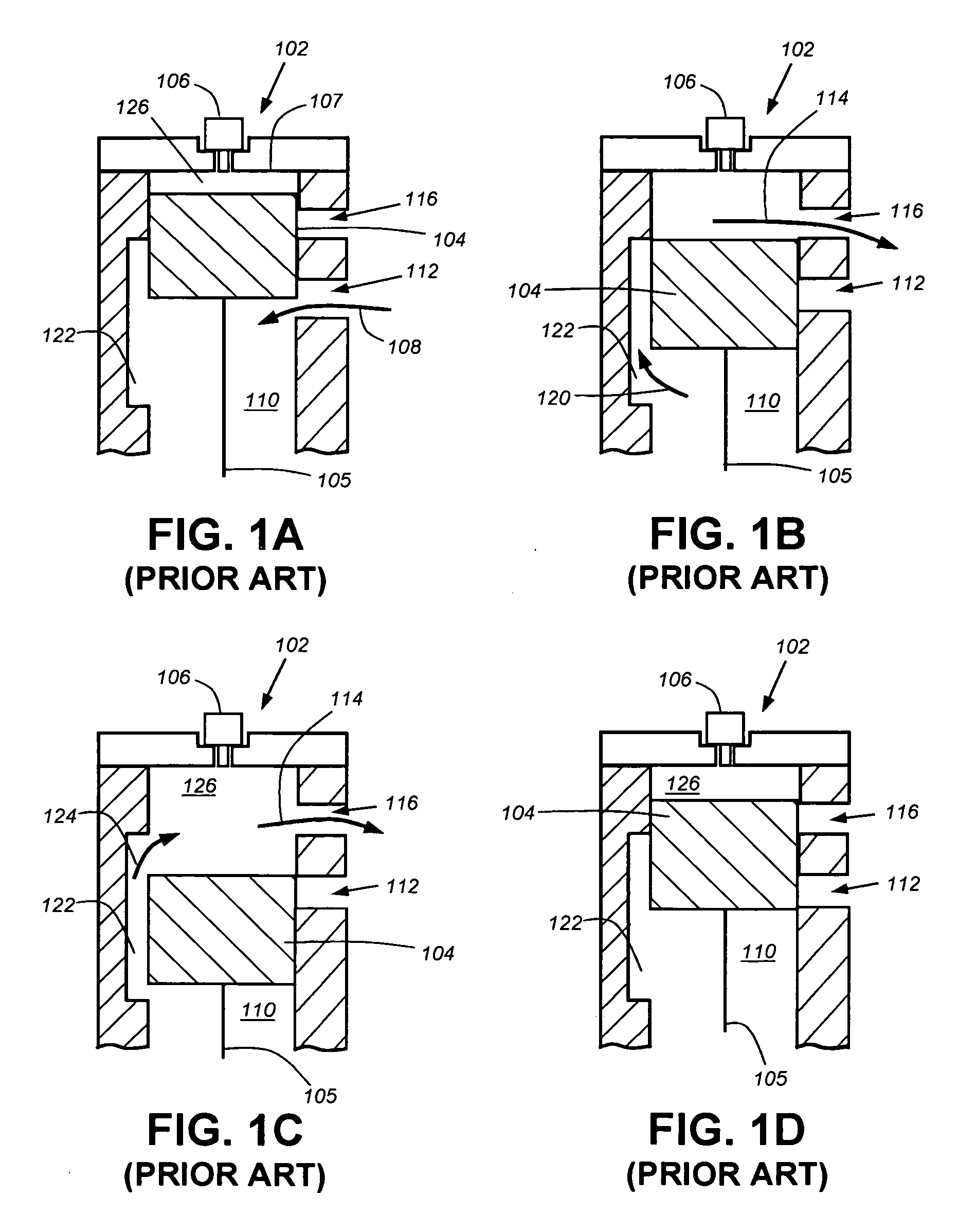

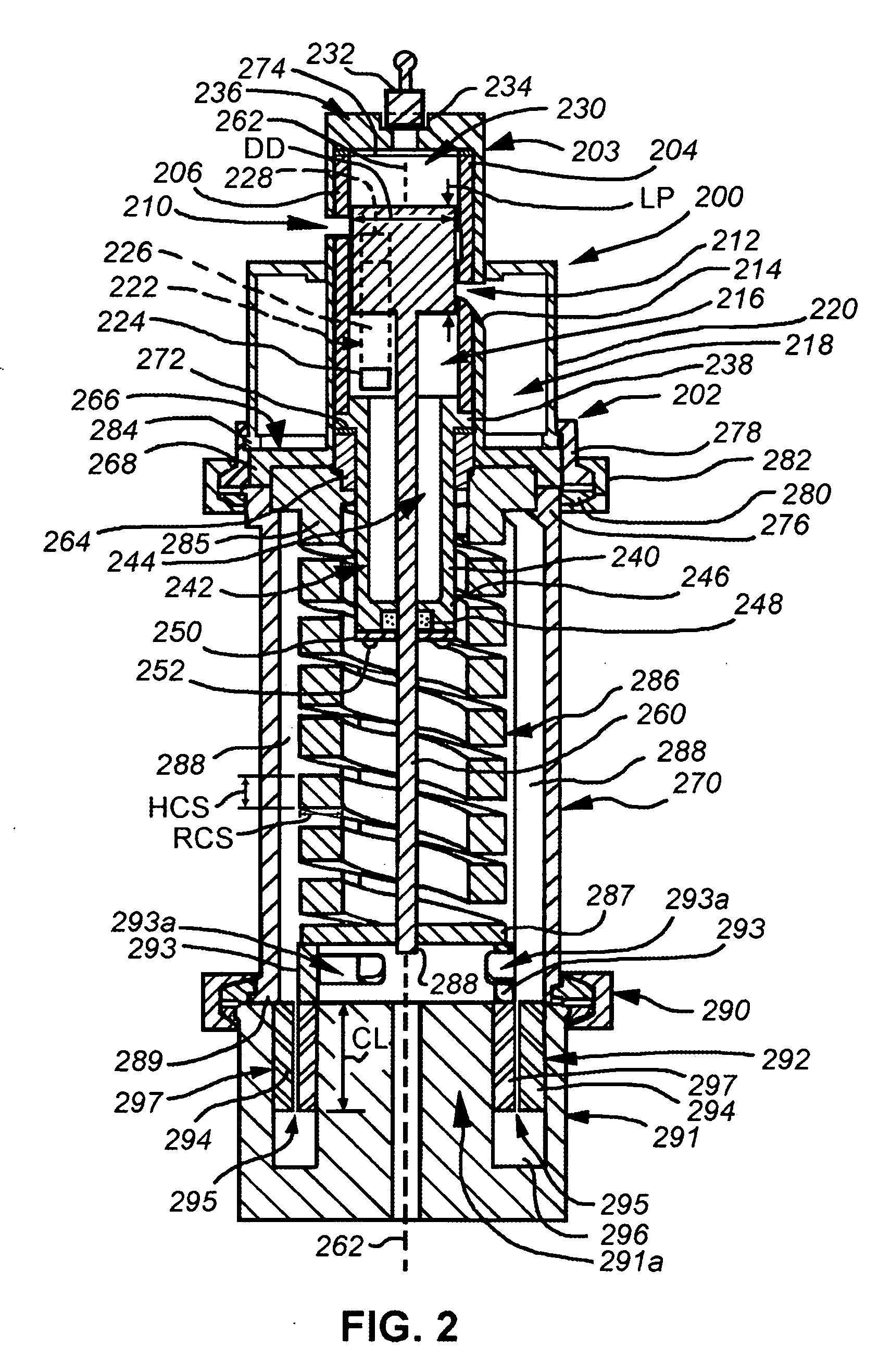

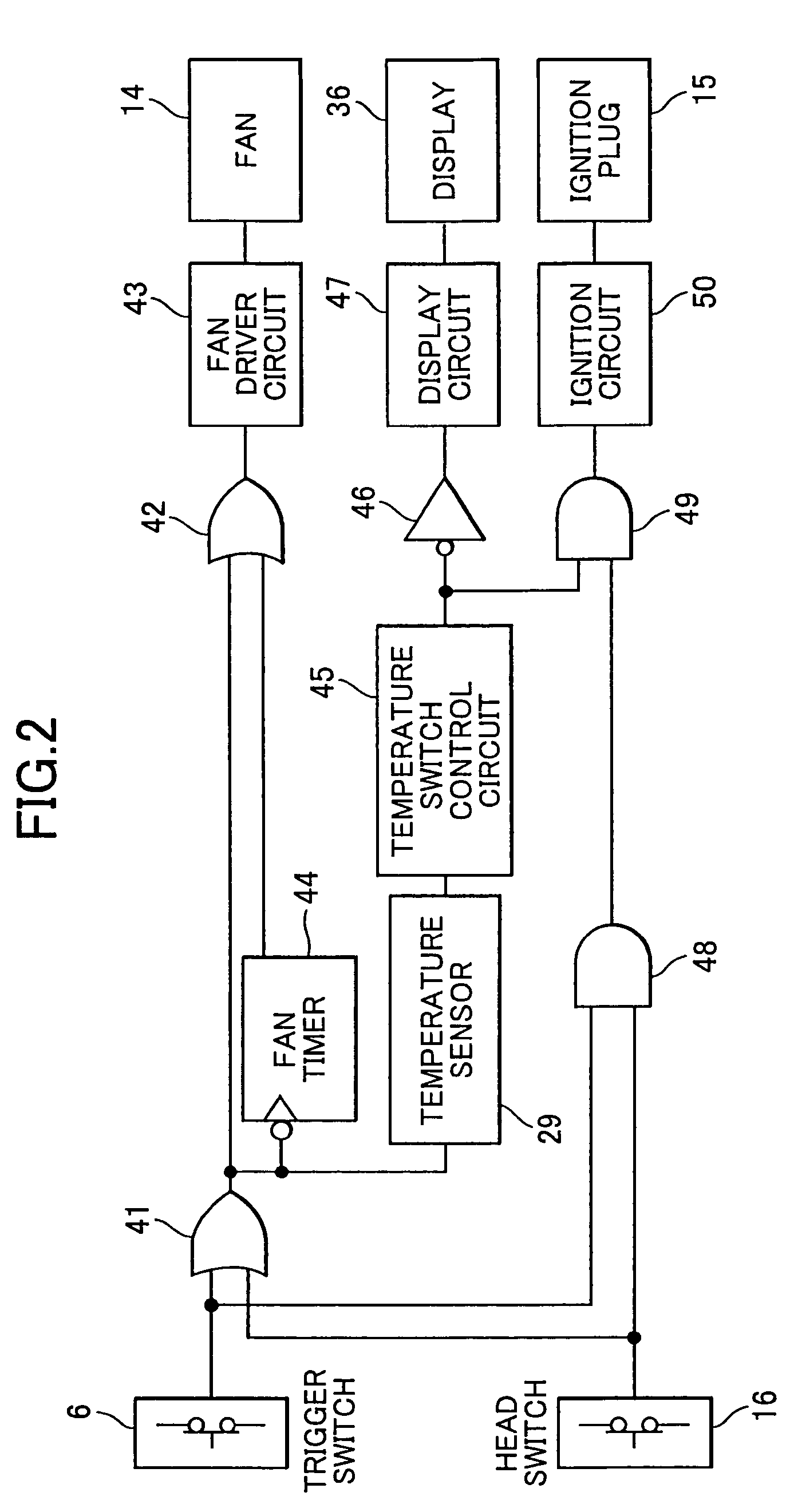

Air charging system for an opposed piston opposed cylinder free piston engine

InactiveUS6957632B1Avoid less frictionEfficient chargingElectrical controlInternal combustion piston enginesFree-piston enginePump chamber

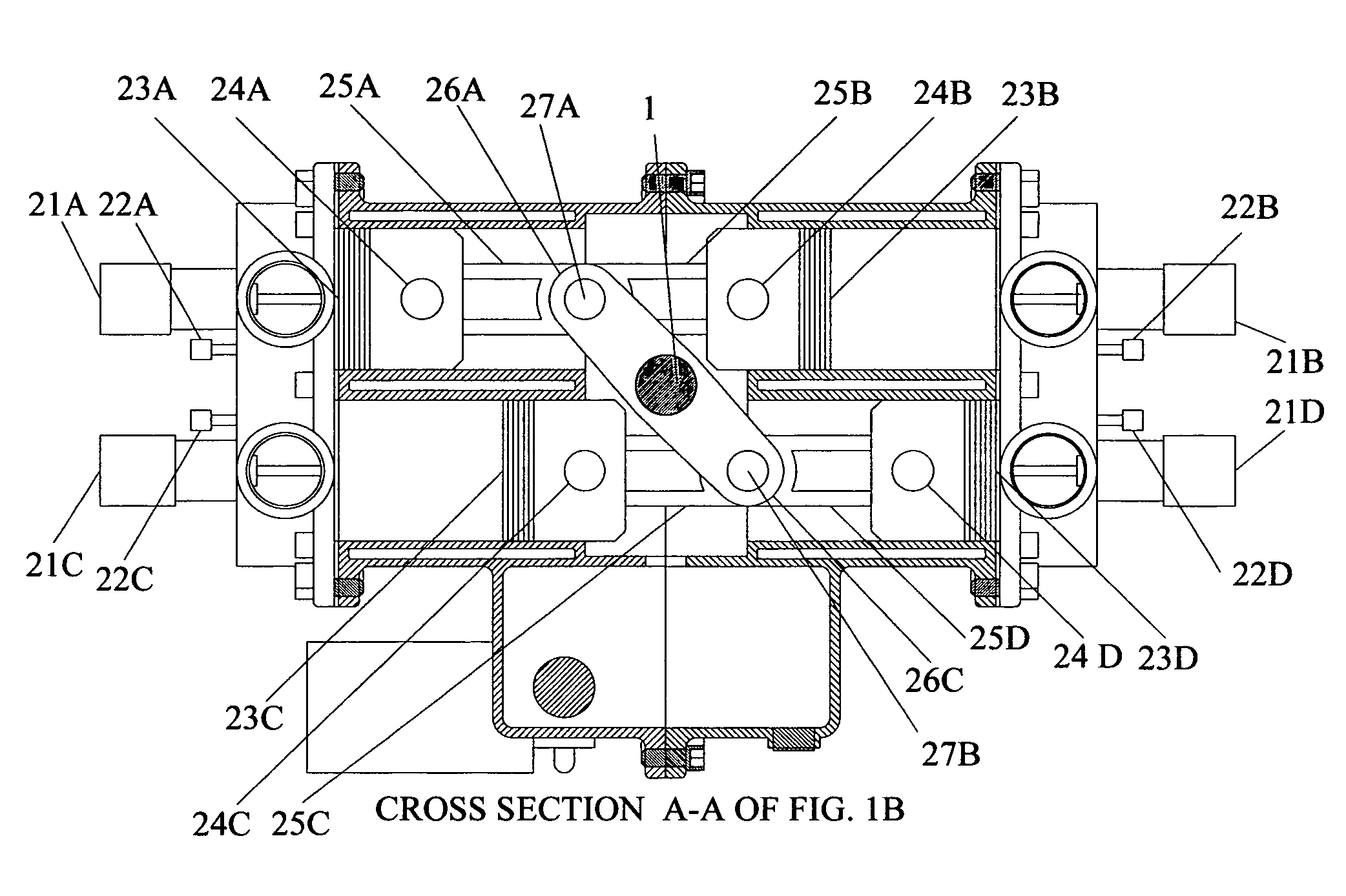

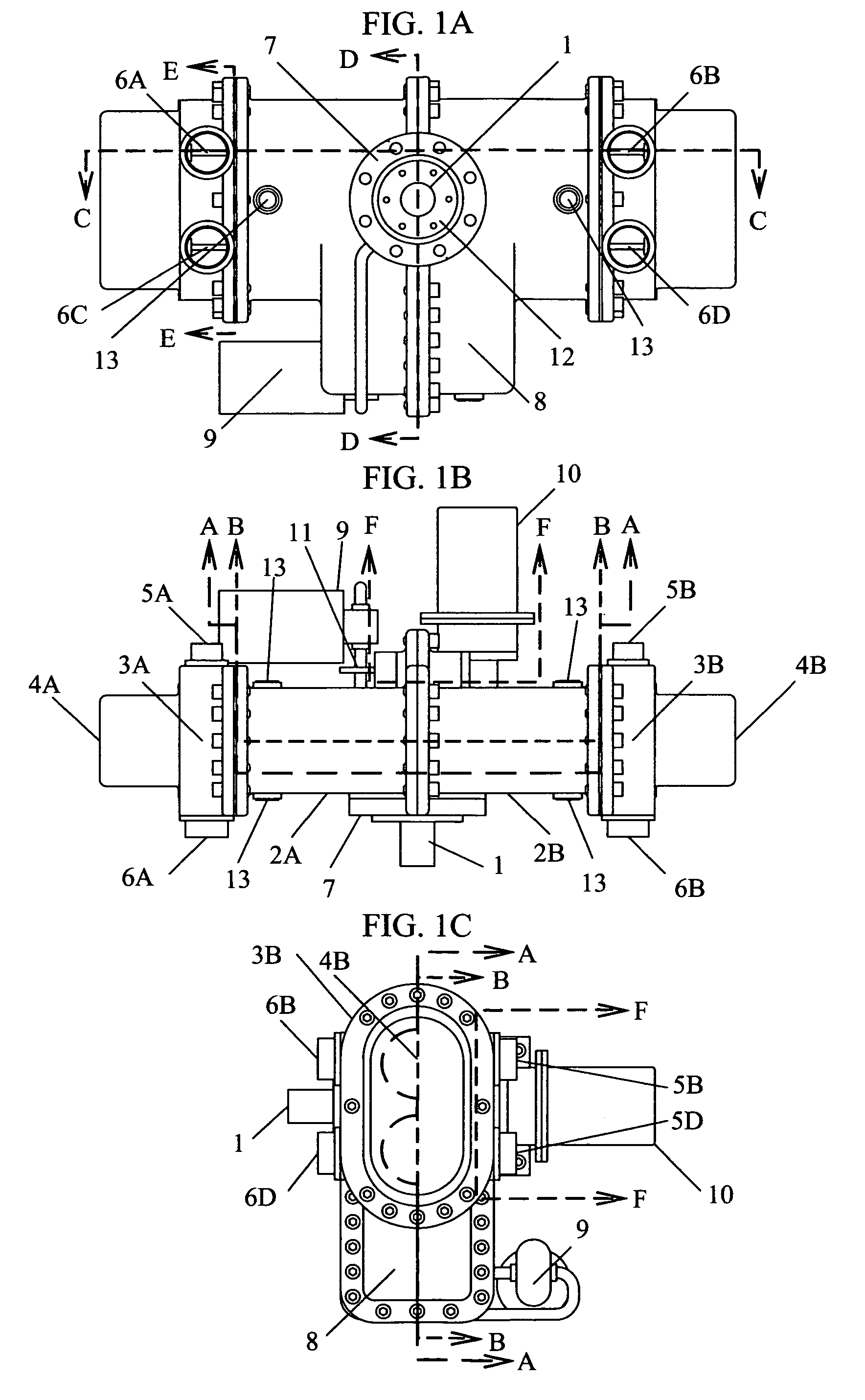

A free piston engine is configured with a pair of opposed engine cylinders located on opposite sides of a fluid pumping assembly. An inner piston assembly includes a pair of inner pistons, one each operatively located in a respective one of the engine cylinders, with a push rod connected between the inner pistons. The push rod extends through an inner pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. An outer piston assembly includes a pair of pistons, one each operatively located in a respective one of the engine cylinders, with at least one pull rod connected between the outer pistons. The pull rod extends through an outer pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. Each outer piston cooperates with an integrated scavenge pump in order to compress the charge air, thus significantly increasing the air charge density into the engine cylinders for each stroke of the engine.

Owner:FORD GLOBAL TECH LLC

Thermomagnetic generator

InactiveUS8729718B2Thermoelectric deivce with magnetic permeability thermal changeVolume compression/expansion having semiconductor devicesEngineeringMagneto

Owner:DELTA ELECTRONICS INC

Exhaust gas recirculation for a free piston engine

InactiveUS6925971B1Easy to changeConducive effective homogeneous chargeNon-fuel substance addition to fuelExhaust gas recirculationFree-piston engineExhaust valve

A free piston engine is configured with a pair of opposed engine cylinders located on opposite sides of a fluid pumping assembly. An inner piston assembly includes a pair of inner pistons, one each operatively located in a respective one of the engine cylinders, with a push rod connected between the inner pistons. The push rod extends through an inner pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. An outer piston assembly includes a pair of outer pistons, one each operatively located in a respective one of the engine cylinders, with at least one pull rod connected between the outer pistons. The pull rod extends through an outer pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. The movement of the inner and outer piston assemblies during engine operation will cause the fluid plungers to pump fluid from a low pressure container into a high pressure chamber as a means of storing the energy output from the engine. Alternatively, the piston assemblies may drive a linear alternator. The exhaust ports for each engine cylinder are sized and located to retain the desired amount of internal EGR in each cylinder without the need for exhaust valves. As an alternative, an external EGR system may supplement the internal EGR in order to obtain the desired EGR at the desired temperature.

Owner:FORD GLOBAL TECH LLC

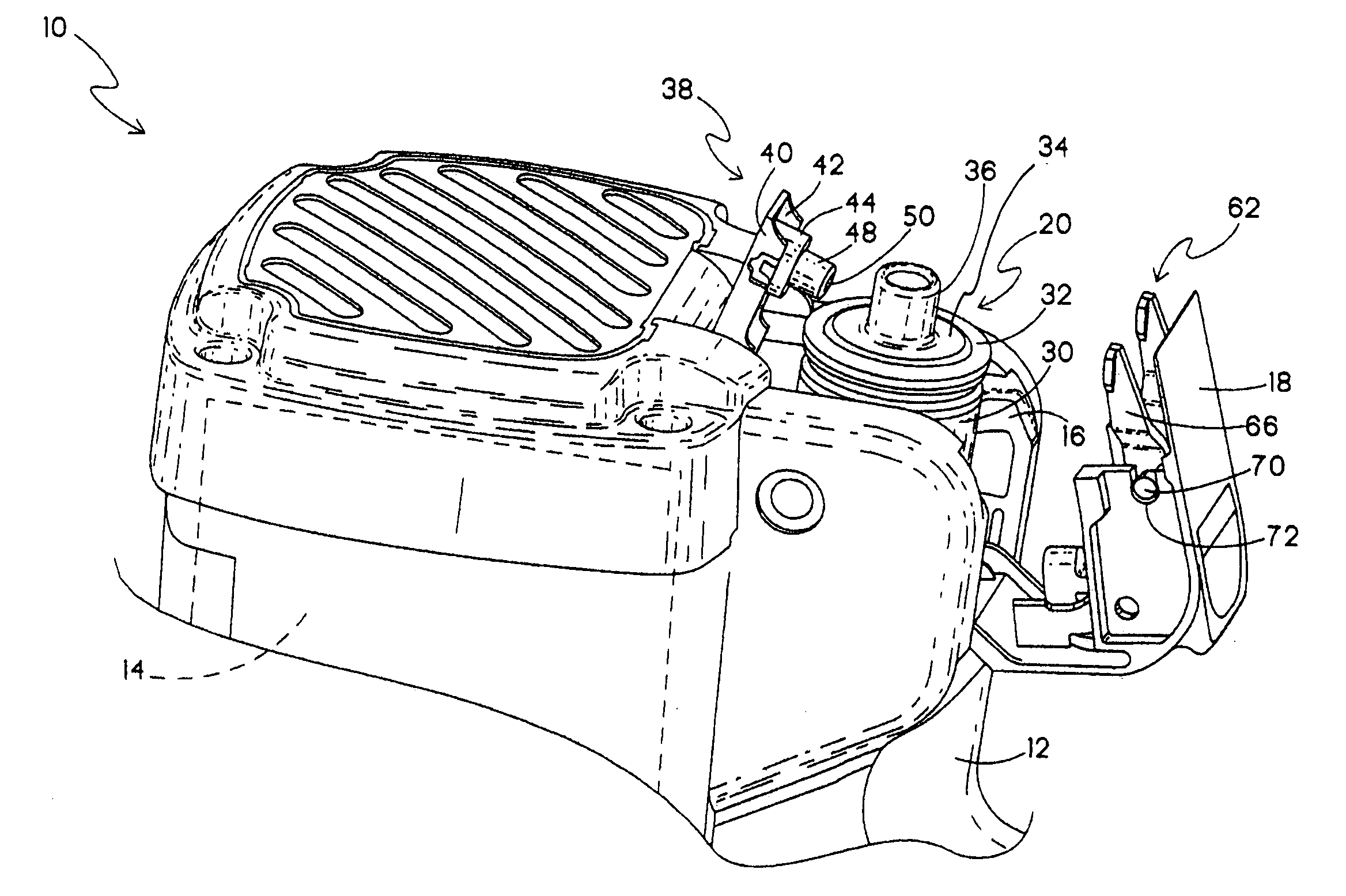

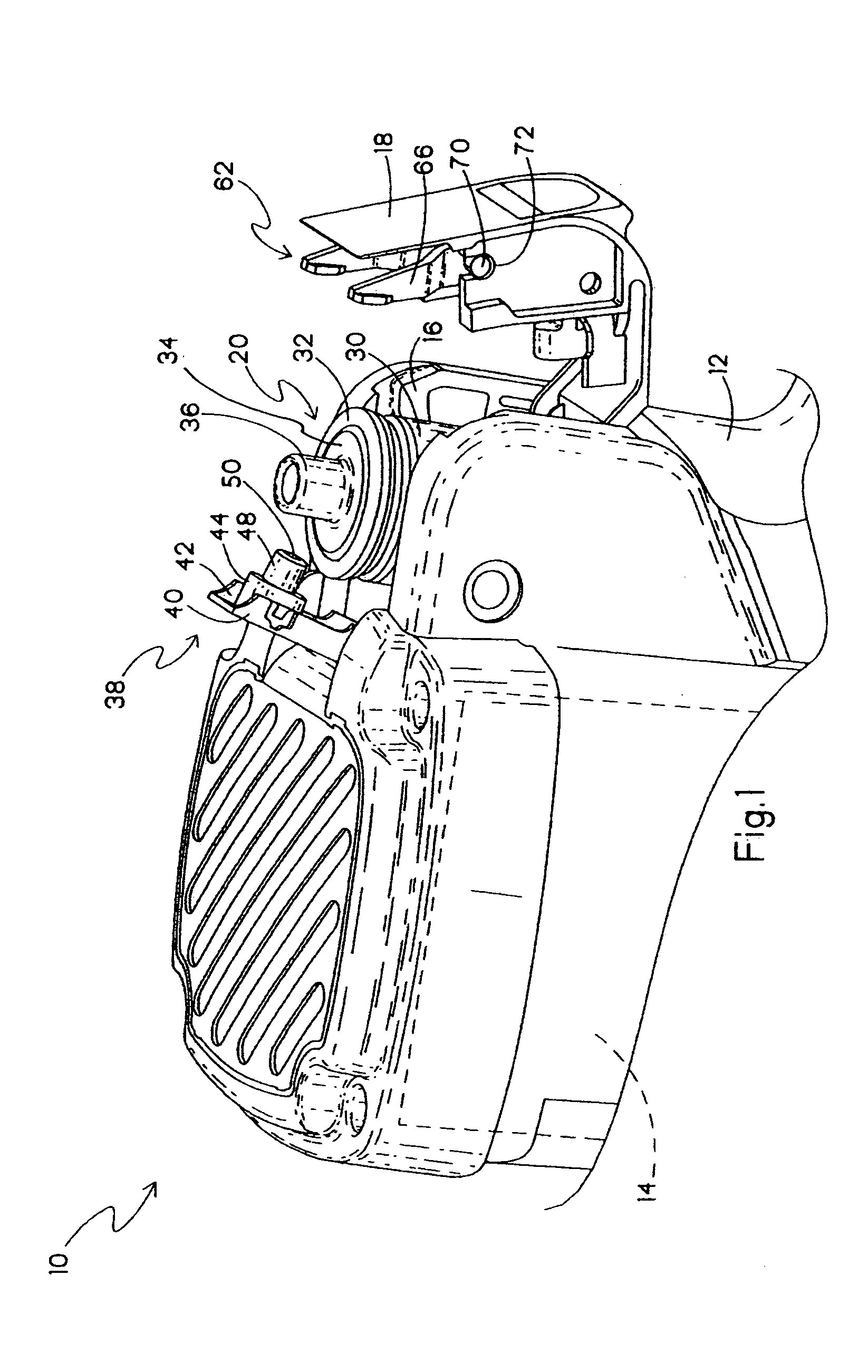

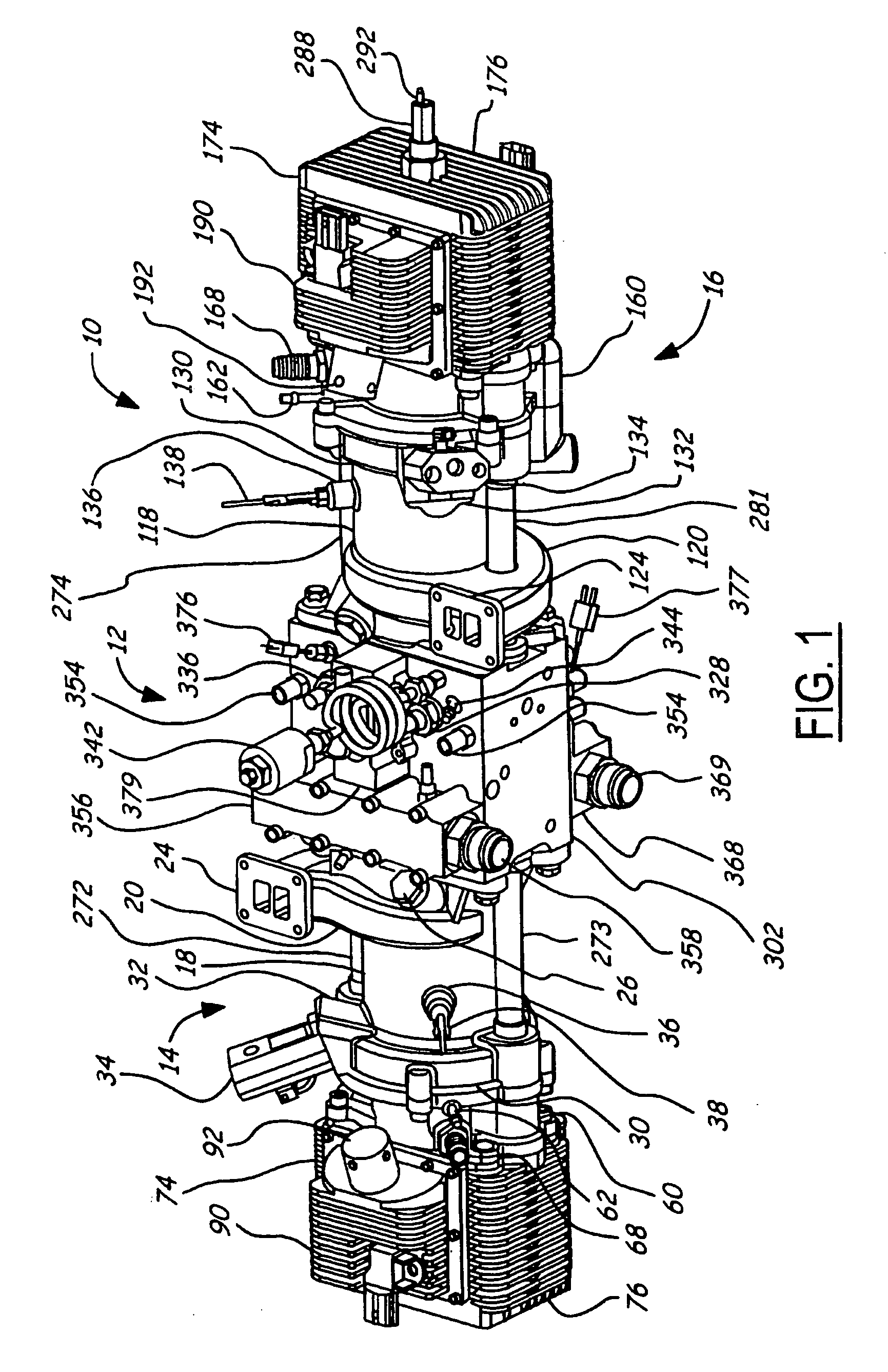

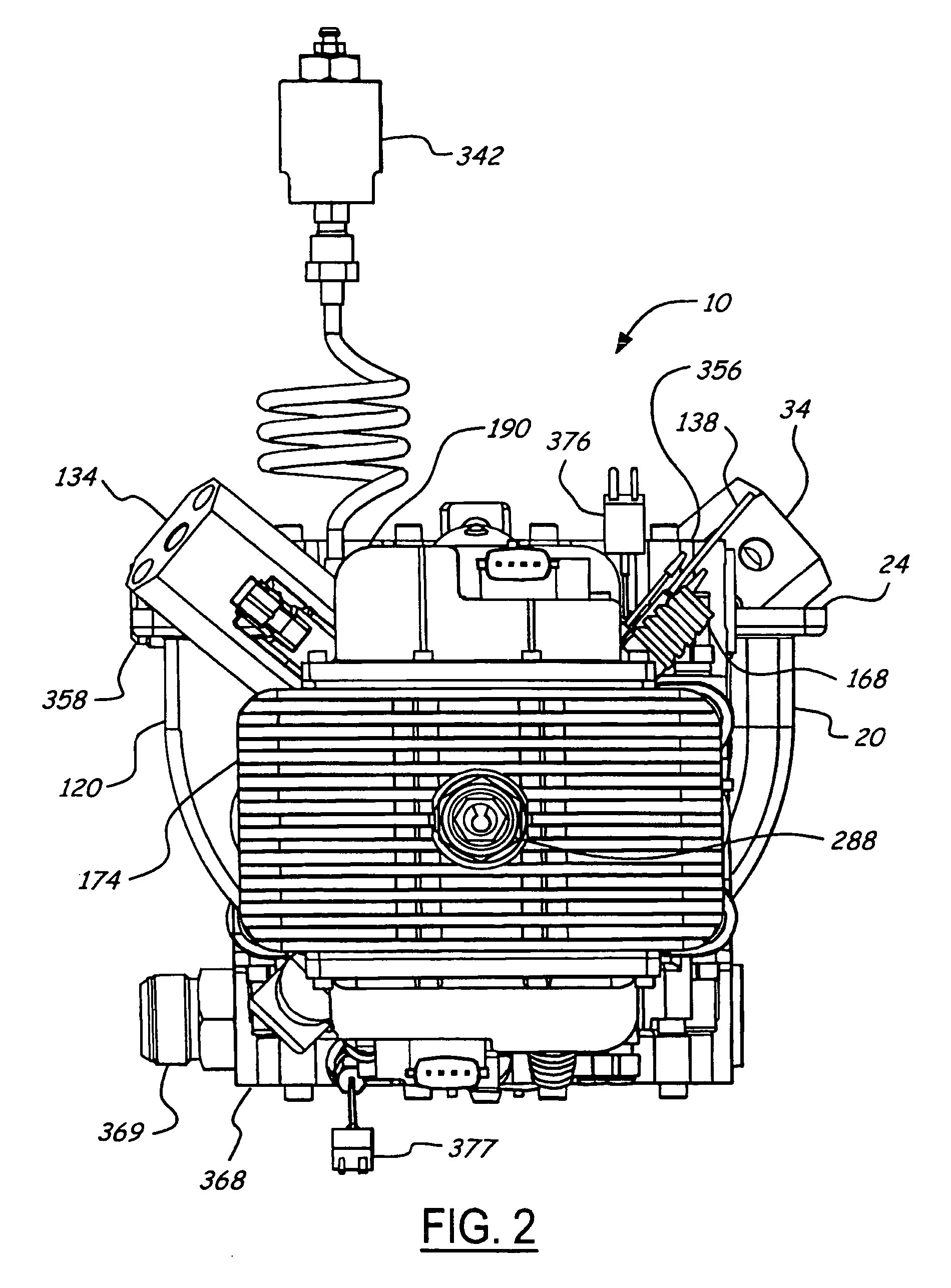

Enhanced fuel passageway and adapter for combustion tool fuel cell

A combustion nailer is configured for use with a fuel cell having an internal metering valve and a reciprocating, biased main stem. The nailer includes a tool housing defining a fuel cell chamber constructed and arranged for receiving the fuel cell, a fuel cell actuator assembly configured for actuating the fuel cell in the chamber to emit a measured dose of fuel during tool operation, and a fuel delivery apparatus associated with the actuator assembly for receiving the emitted dose of fuel and providing it to a combustion chamber. The fuel delivery apparatus is configured for preventing actuation of the main stem by the actuator assembly upon the fuel cell being adapter-free.

Owner:ILLINOIS TOOL WORKS INC

Pneumatic nail gun

InactiveUS7293684B1Increase airflowSimplifies valve controlling mechanismStapling toolsFree piston enginesEngineeringHigh pressure

A pneumatic nail gun includes a gun body with a trigger, collecting a compressed high pressure air with a constant pressure, a movable cylinder installed in the gun body, a hitting piston disposed in the cylinder, a valve ring formed outside the cylinder, a head valve disposed on the top of the cylinder, at least one return passage formed outside the cylinder, and a valve bolt disposed in the return passage. Before the trigger is pressed, the high pressure air drives the valve ring to keep the cylinder at the upper position to close the head valve. When the trigger is pressed, the high pressure air drives the cylinder move downwardly to open the head valve for guiding the high pressure air to drive the piston downwardly move to hit nails. When the trigger is released, the high pressure air drives the valve bolt open for guiding the high pressure air via the return passage to drive the piston rapidly move upwardly to reposit.

Owner:DE POAN PNEUMATIC

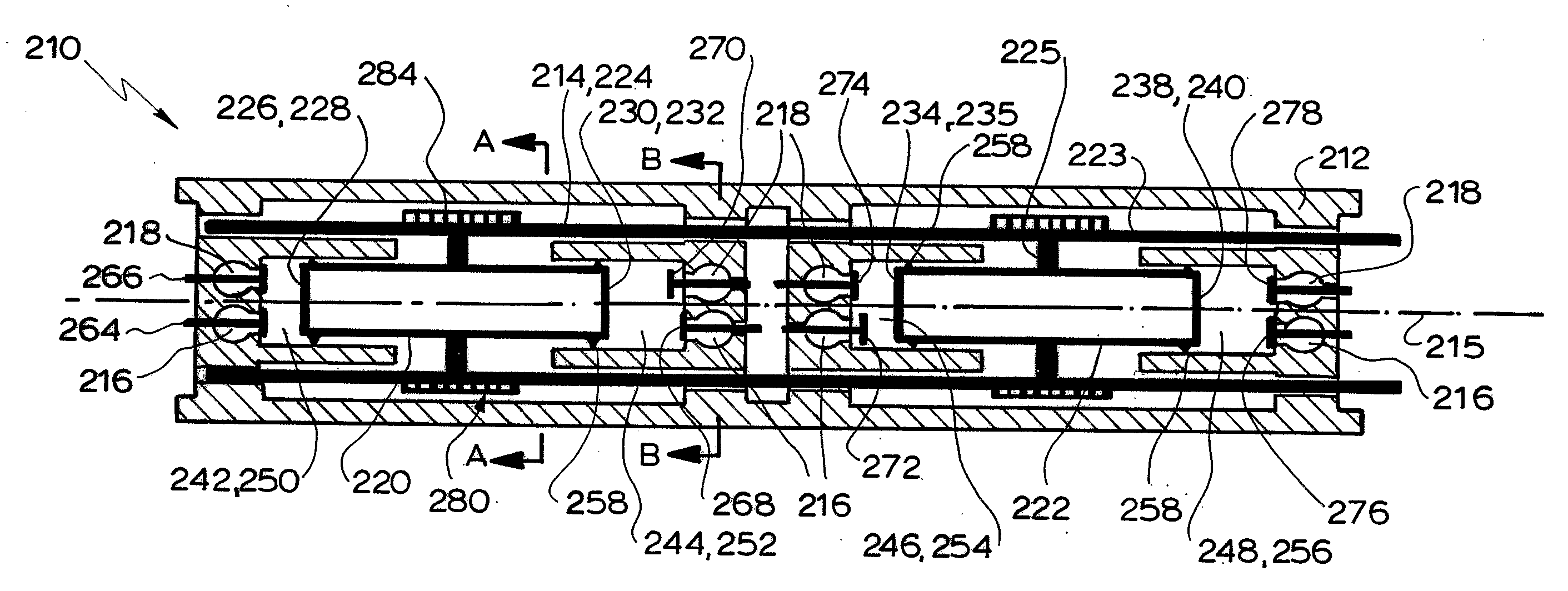

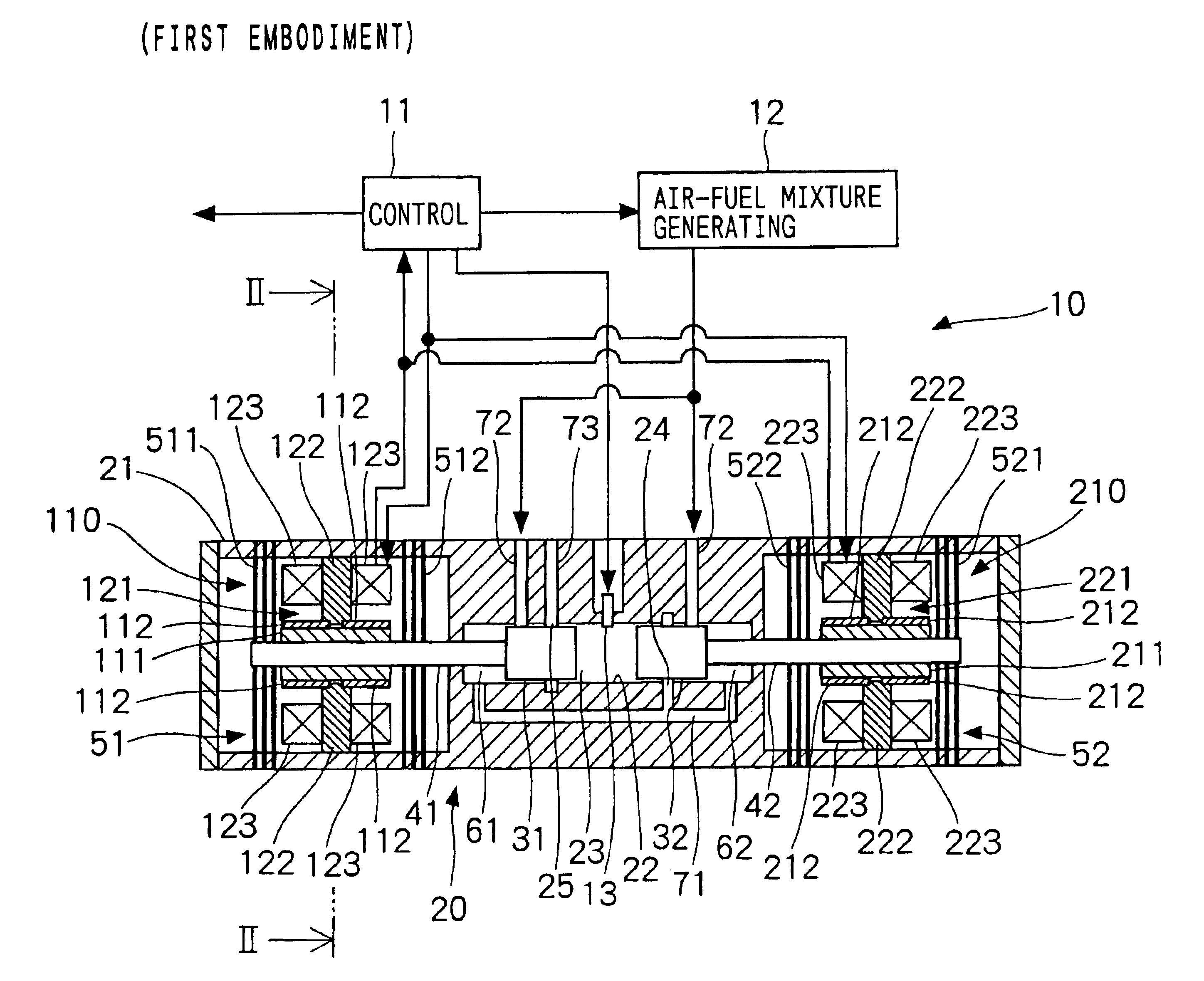

Control device for free piston engine and method for the same

InactiveUS7258085B2Easy to operateEnergy efficiencyFree piston enginesFree-piston engineCombustion chamber

A free piston engine has a pair of pistons opposing to each other and movable in a cylinder, to form a combustion chamber between the pistons. A mixed gas of air and fuel is supplied into the combustion chamber and the mixed gas is auto-ignited when it is compressed by the pistons. A temperature and / or an air-fuel ratio of the mixed gas, and / or a pressure in the combustion chamber is detected to control displacements of the pistons, so that the mixed gas is auto-ignited at an optimum timing to efficiently operate the free piston engine.

Owner:DENSO CORP

Free piston engine and power generation system therewith

InactiveUS6945202B2Reduce outputIncreased durabilityMechanical energy handlingFree piston enginesFree-piston engineLeaf spring

Owner:DENSO CORP

Free piston compressor

InactiveUS20050284427A1Increase energy densityImprove efficiencyPistonsFree piston enginesEngineeringHigh pressure

Methods and systems associated with free piston compressors. Fuel is ignited within a combustion chamber to increase pressure. A free piston is displaced within the combustion chamber. The free piston acts as an inertial load to high-pressure gas generated by combustion of the fuel. High pressure gas is pumped from the combustion chamber into a reservoir using the free piston. A spring, magnet, or other mechanism engaging the free piston may be used to assist the process. In the case of a spring, the spring assists returning the free piston to its approximate initial position as the spring expands. In the case of a magnet, the magnet may engage opposite ends of the free piston during the process. Two or more free pistons may be used. The system may be used as a power source for equipment such as a robot.

Owner:VANDERBILT UNIV

Thermomagnetic generator

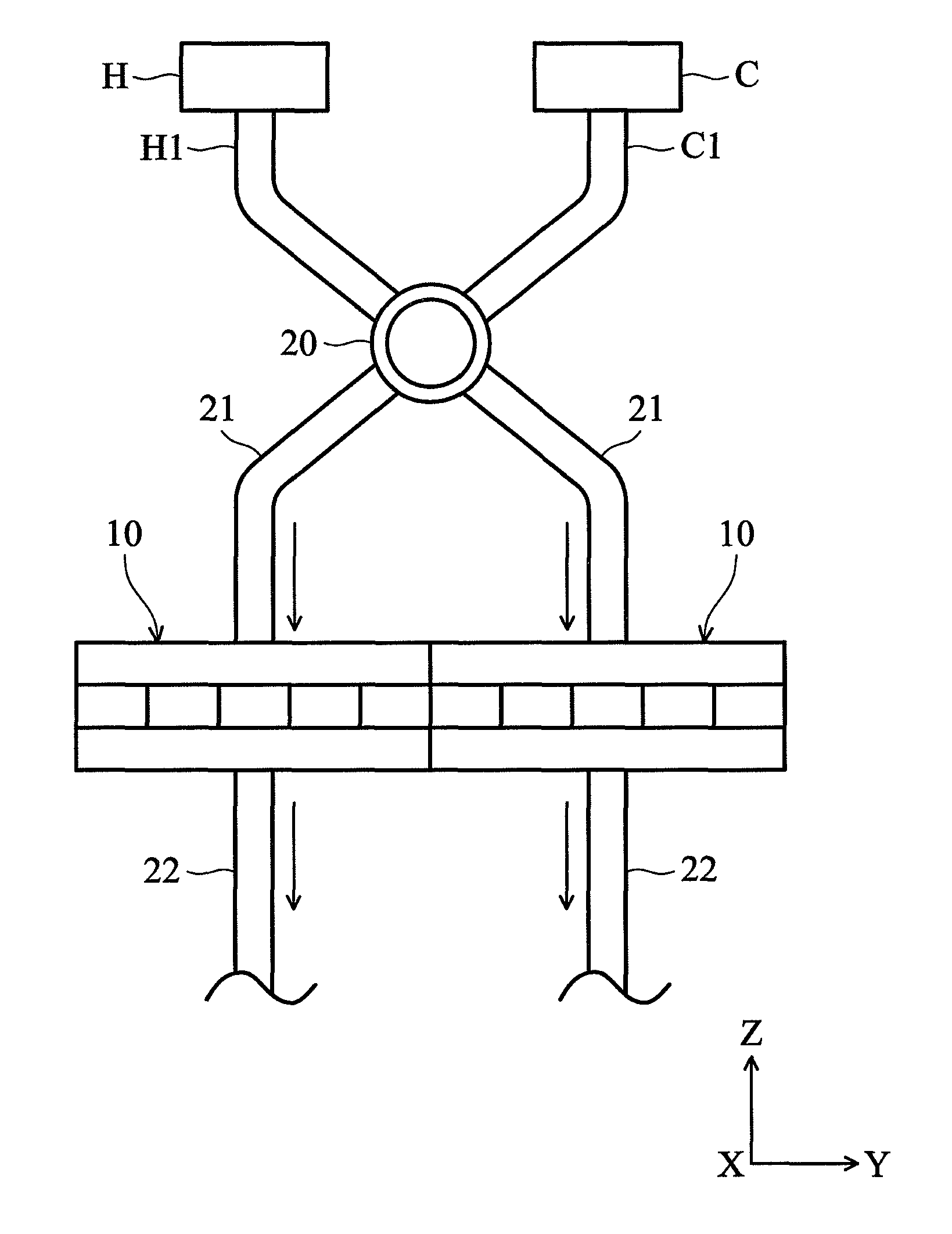

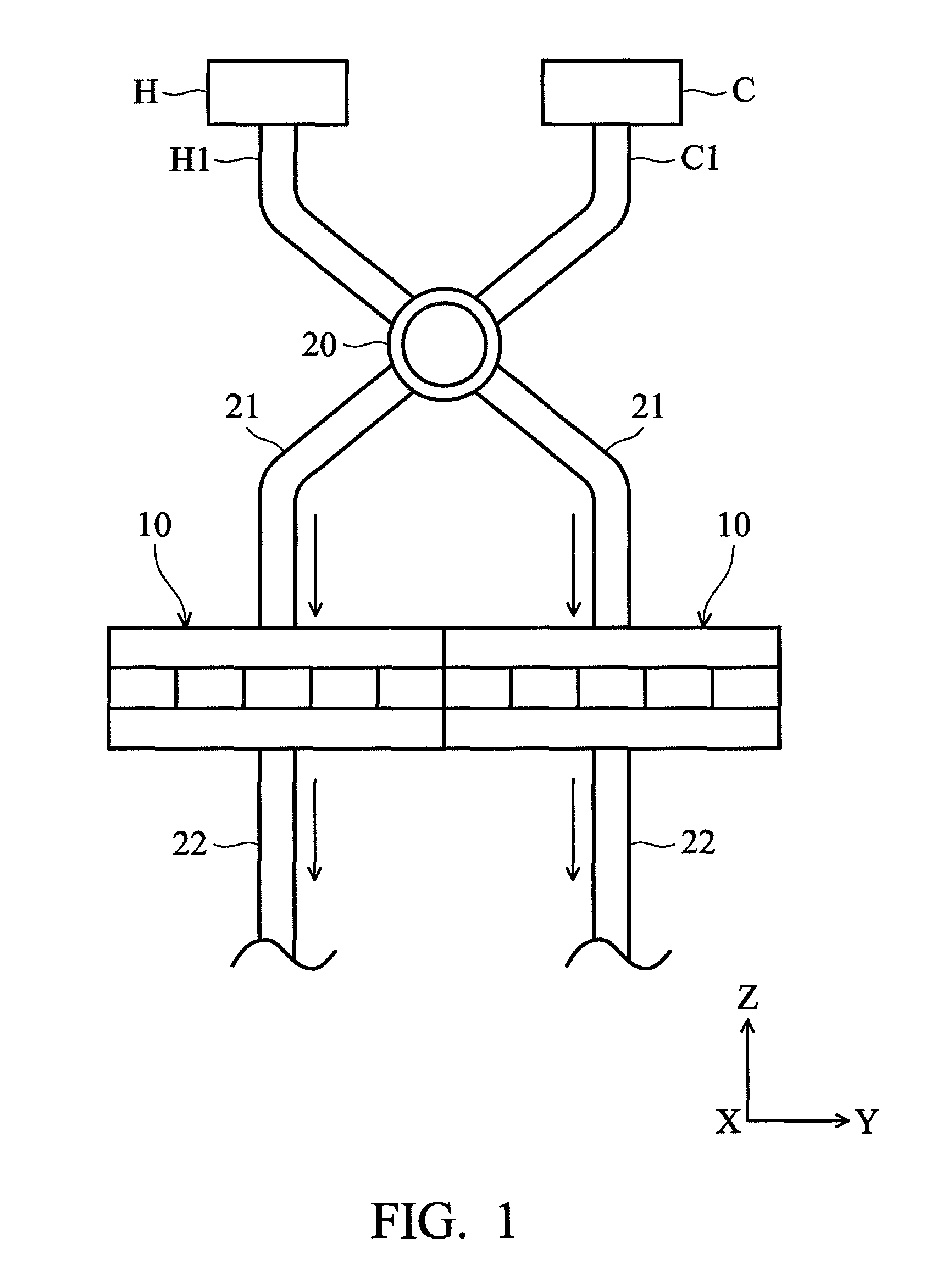

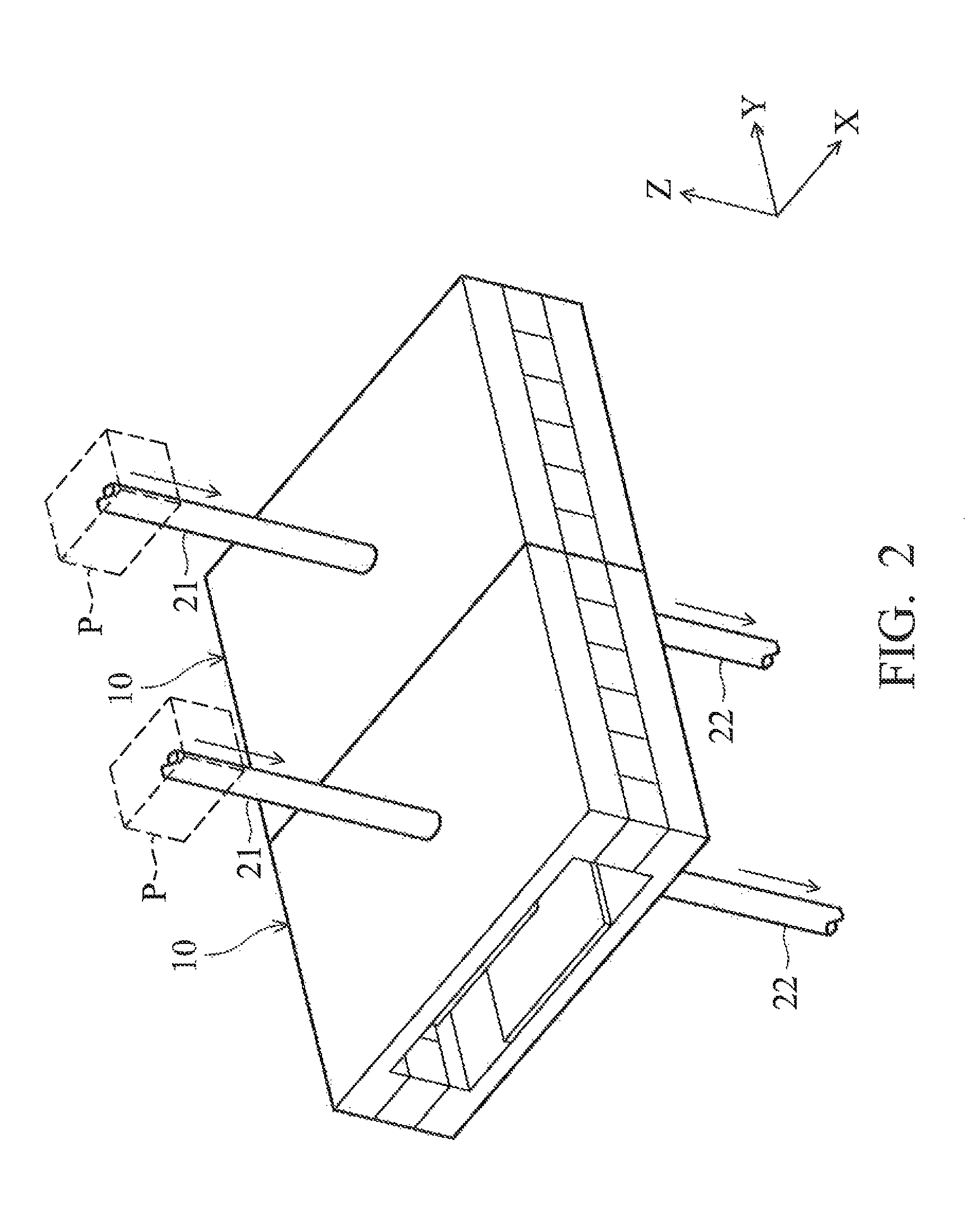

InactiveUS20130106116A1Thermoelectric deivce with magnetic permeability thermal changeVolume compression/expansion having semiconductor devicesEngineeringMagneto

A thermomagnetic generator is provided, including a switch valve, a plurality of magnetic circuit units, a coil, and a plurality of inlet pipes connecting the magnetic circuit units to the switch valve. Each of the magnetic circuit units includes a magneto-caloric member. The switch valve repeatedly and alternatively switches at a predetermined frequency to guide hot and cold fluids to the magnetic circuit units, such that the magneto-caloric members are magnetized and demagnetized, respectively, by the cold and hot fluids. The coil is coupled to at least one of the magnetic circuit units for obtaining an induced voltage.

Owner:DELTA ELECTRONICS INC

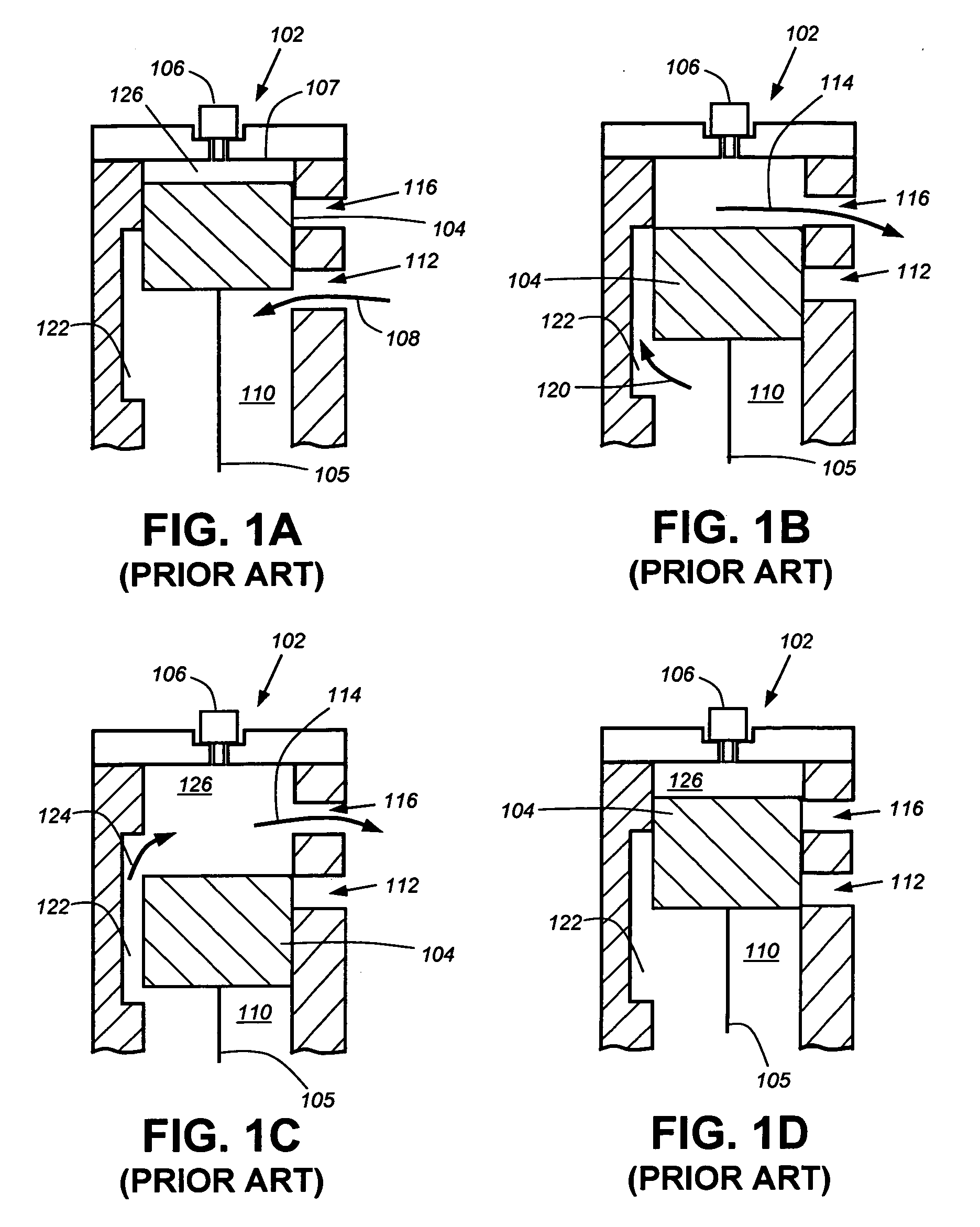

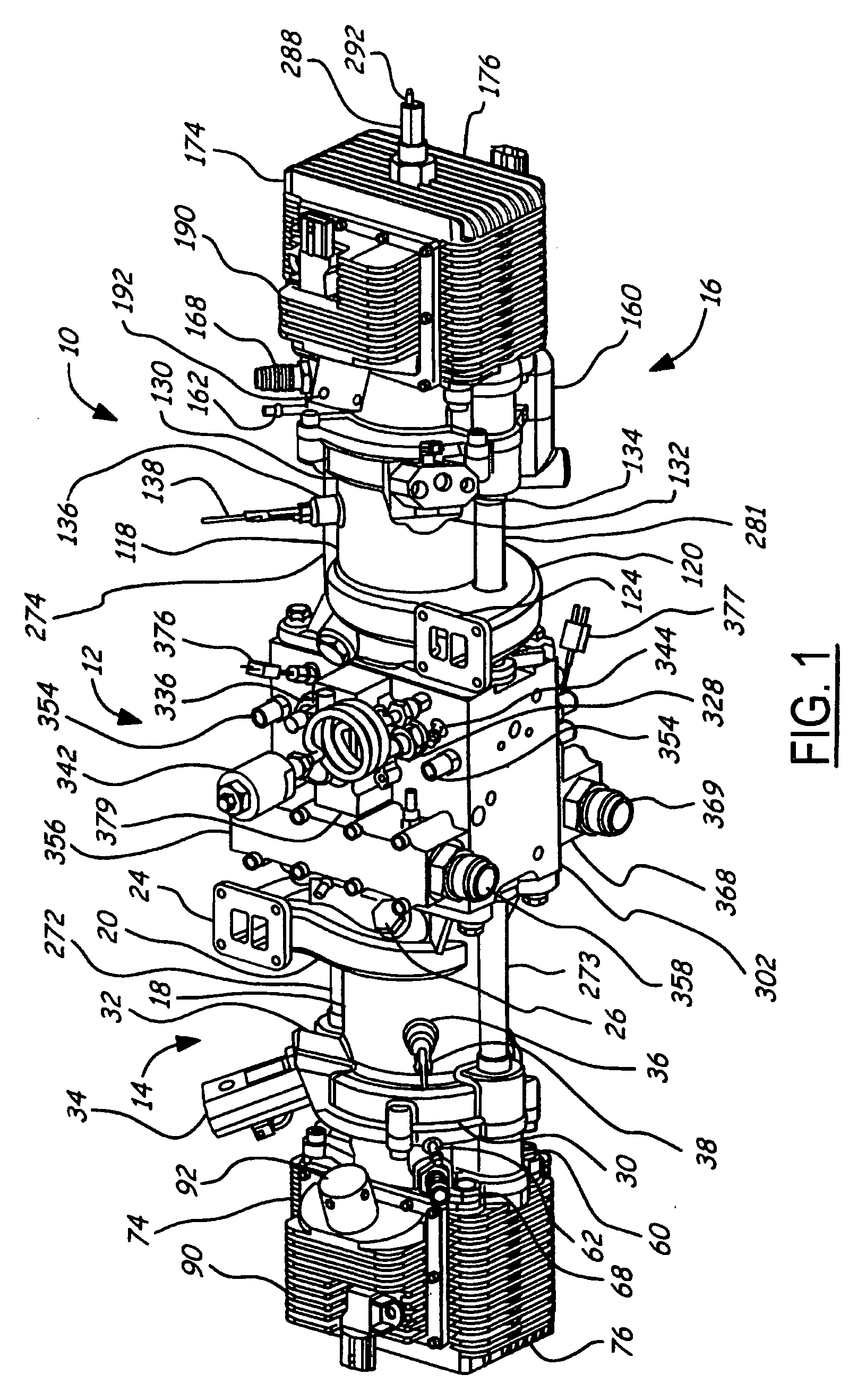

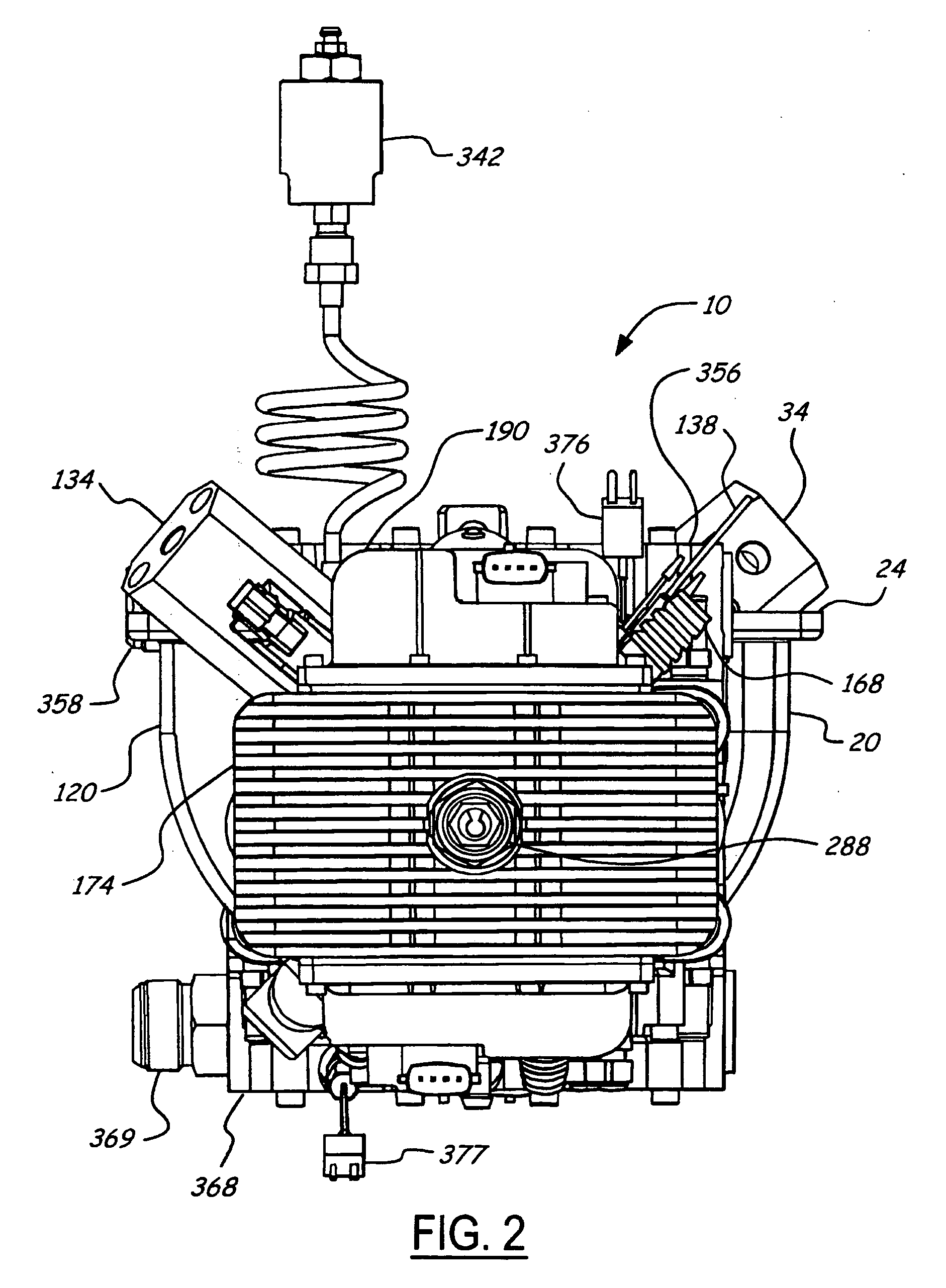

Combustion chamber control for combustion-powered fastener-driving tool

ActiveUS7383974B2Overcome limitationsStapling toolsFree piston enginesRest positionCombustion chamber

A combustion-powered fastener-driving tool includes a combustion-powered power source, a valve sleeve reciprocable relative to the power source between a rest position and a firing position, and a lockout device in operational proximity to the valve sleeve and configured for automatically preventing the reciprocation of the valve sleeve from the firing position until a piston in the power source returns to a pre-firing position.

Owner:ILLINOIS TOOL WORKS INC

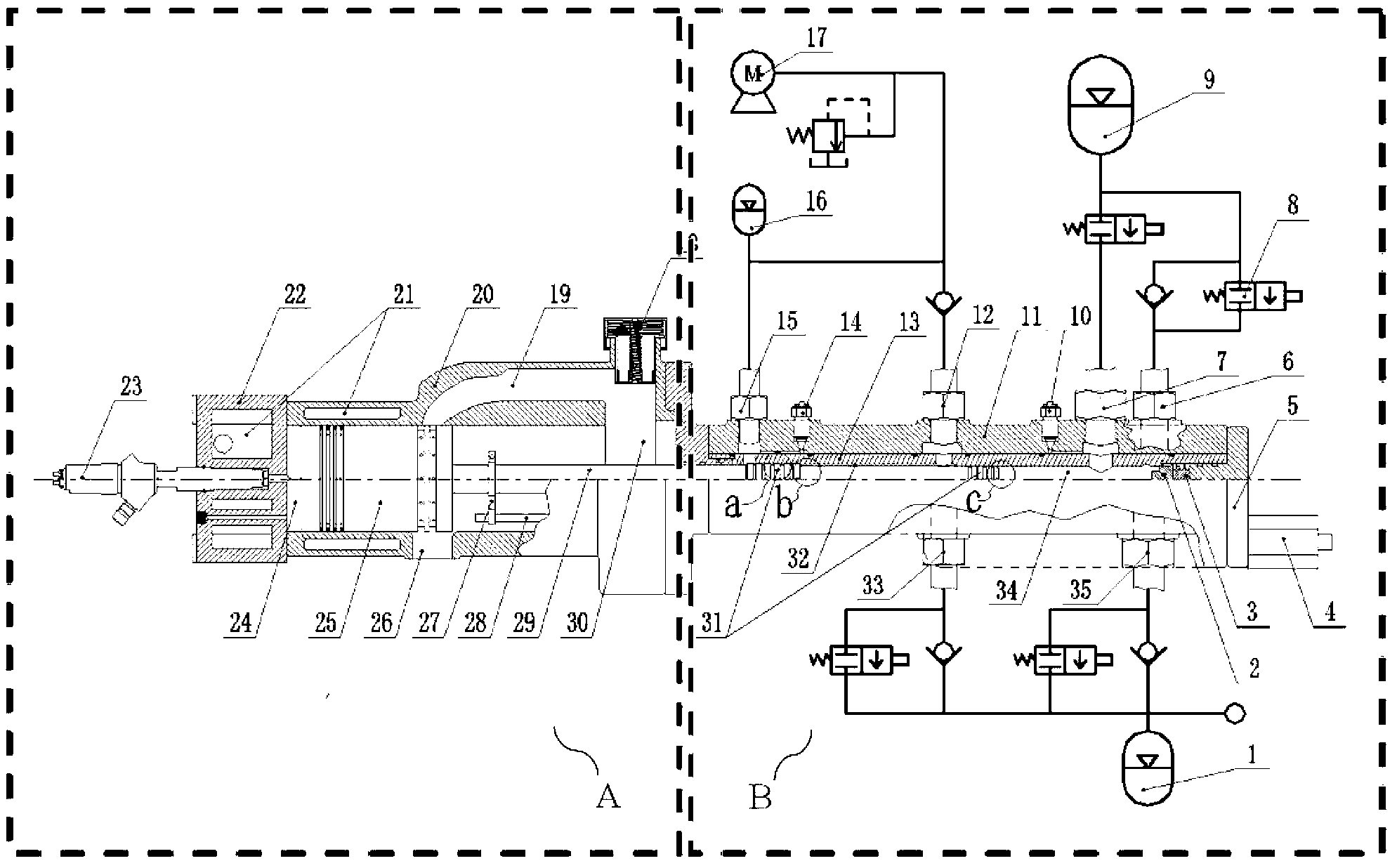

Return flow scavenging type hydraulic free piston diesel engine

InactiveCN102705076AOmit the crankshaftReduce intermediate conversion linksInternal combustion piston enginesFree piston enginesHydraulic motorHydraulic pump

The invention discloses a return flow scavenging type hydraulic free piston diesel engine, which comprises a single-cylinder two-stroke diesel engine without a crankshaft connecting rod and a valve distribution mechanism, and a hydraulic system provided with a linear hydraulic pump and a hydraulic motor, wherein a piston in the single-cylinder two-stroke diesel engine is connected with a plunger in the hydraulic system, and a space in the linear hydraulic pump in the hydraulic system is divided into a high-pressure cavity and a low-pressure cavity; the piston in the single-cylinder two-stroke diesel engine can drive the linear hydraulic pump to output high-pressure oil in an expansion travel, and the high-pressure oil is output to the hydraulic motor from a pipe joint C; the piston is pushed back to an upper dead center from a lower dead center by the low-pressure oil end, so that a compression travel of the piston is completed. According to the invention, a crankshaft in the conventional internal combustion engine is omitted, and a middle conversion step of power output is reduced, so that the heat efficiency is about 5% higher than that of the conventional internal combustion engine, the diesel engine can be operated at a variable compression ratio, the best heat efficiency of a full operation work condition is ensured, and the fuel economy is improved.

Owner:JILIN UNIV

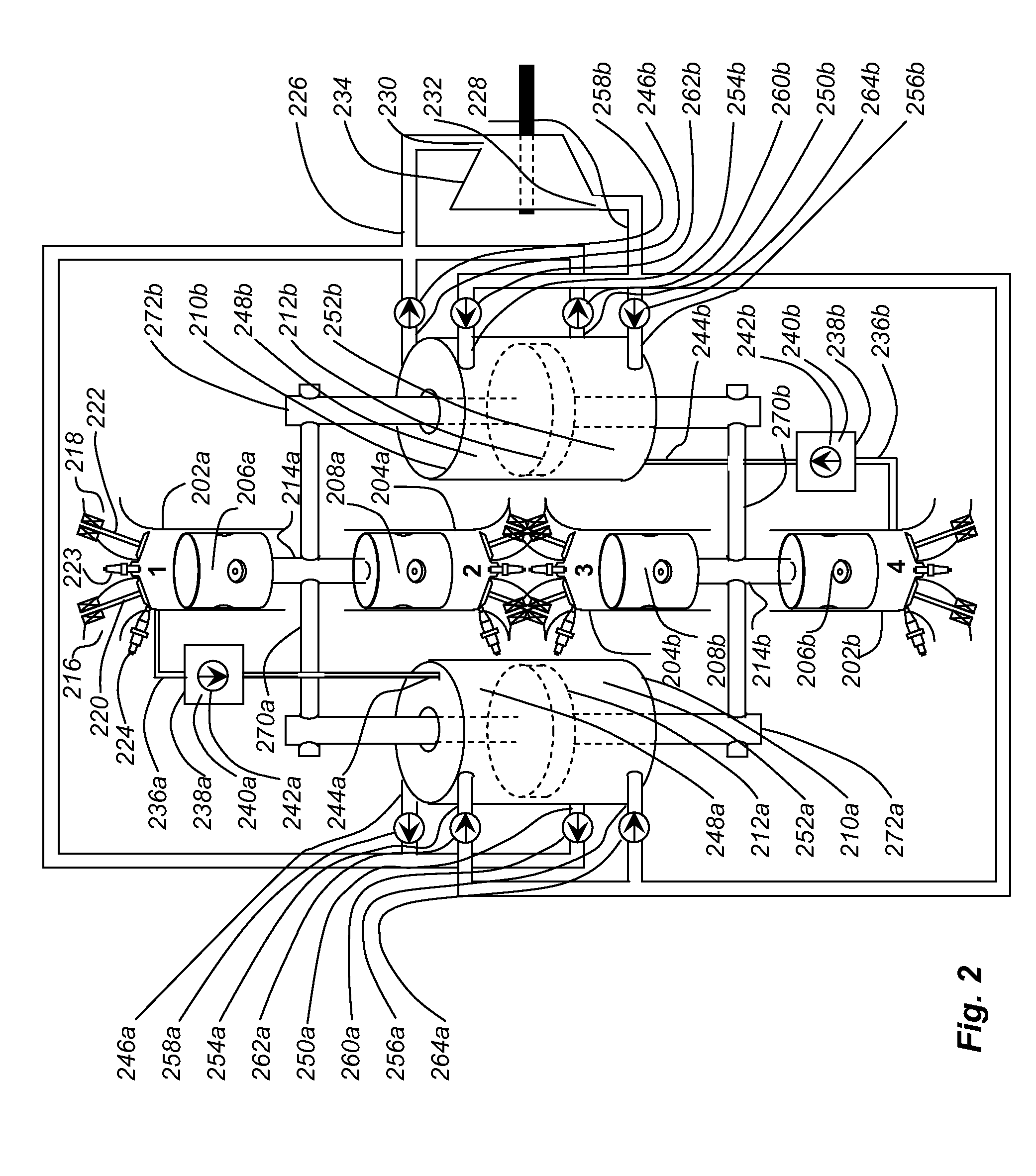

Four-cylinder, four-cycle, free piston, premixed charge compression ignition, internal combustion reciprocating piston engine with a variable piston stroke

ActiveUS7258086B2Increase the compression ratioImprove engine efficiencyElectrical controlInternal combustion piston enginesFree-piston engineHomogeneous charge compression ignition

A four-cycle, four-cylinder, premixed charge compression ignition internal combustion reciprocating free piston engine with a variable piston stroke and a compression ratio that varies as needed to provide charge ignition, to offer the potential of higher efficiency, lower emissions, and multi-fuel operation. The engine does not have a crankshaft, and therefore does not provide direct rotary output. Instead its free pistons oscillate, in a manner similar to a two cycle free piston engine. For many applications, such as piston pumps and compressors, the engine provides an output directly driven by the oscillating pistons. In other applications, such as but not limited to use as a gas generator for a power turbine, the engine provides an indirect means of producing rotary power. When the engine is used with high-speed power turbines, the power turbine may be directly coupled to a high-speed alternator for electrical power output.

Owner:SUSTAINABLE ENERGY TECH DEV TRUST

Apparatus and method for generating electrical power in a borehole

ActiveUS20050200210A1Narrowing range of outputEasily damagedElectric/magnetic detection for well-loggingConstructionsImpellerAlternator

An apparatus and related method generate electrical power in a tubular housing, such as a drill collar, disposed in a borehole when drilling fluid flows through the tubular housing. The apparatus includes a stator adapted for being secured within the tubular housing against rotation relative to the tubular housing, a tubular rotor rotatably carried about the stator, and an impeller peripherally affixed to the rotor. The stator has an array of conductive windings therein, and is preferably an alternator stator. The rotor has an array of magnets therein, and is preferably an alternator rotor. Accordingly, drilling fluid flowing through the tubular housing when the apparatus is disposed therein engages the impeller and induces rotation of the rotor about the stator to generate electrical power.

Owner:SCHLUMBERGER TECH CORP

Device including a combustion engine, a use of the device, and a vehicle

InactiveUS20030024492A1Raise the possibilityElectrical controlCombustion enginesControl cellInternal combustion engine

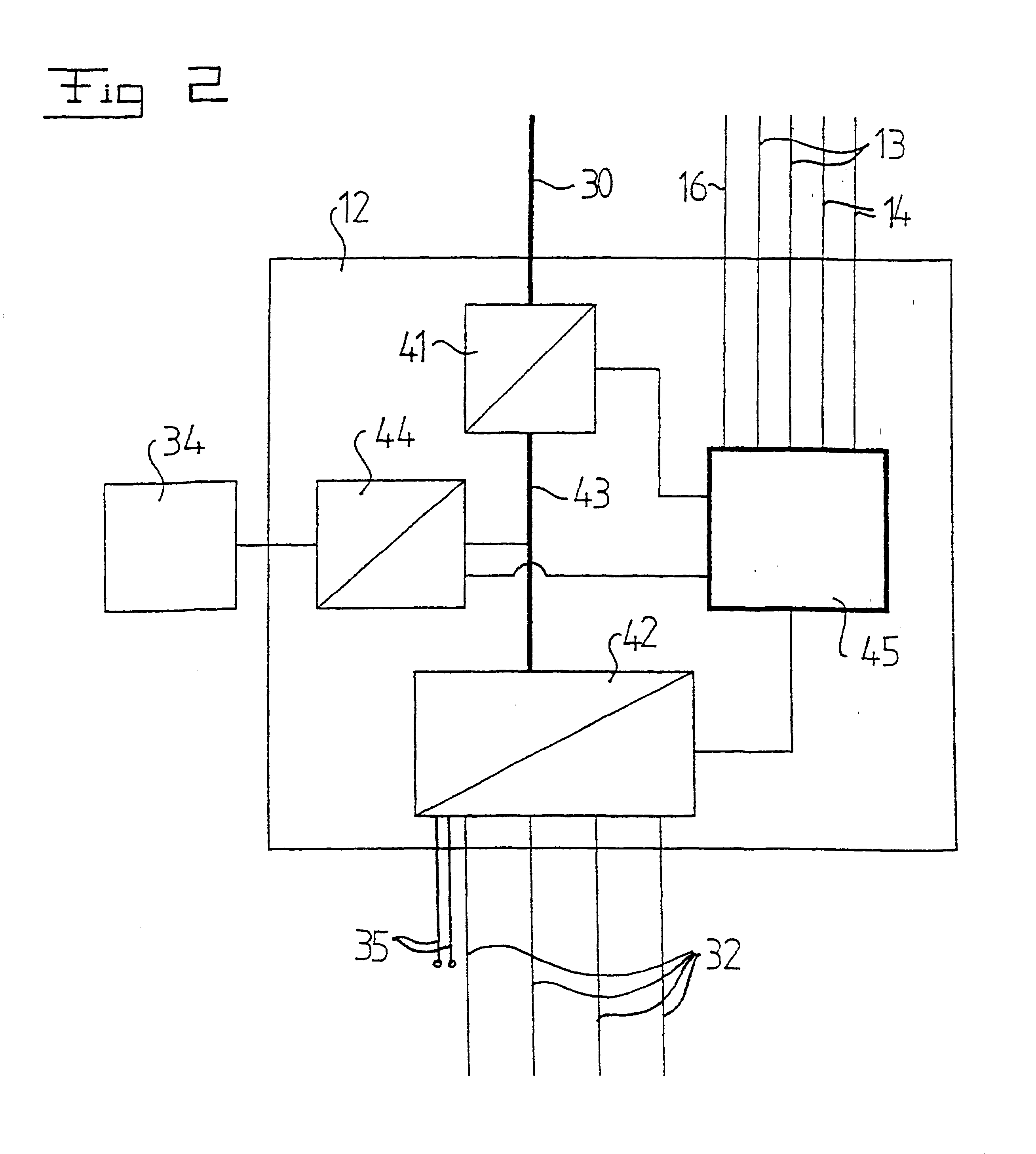

The invention refers to a device, which includes a combustion engine (1) with a piston (2), which is mechanically freely movable in a housing (3). The device is arranged to permit combustion of a fuel mixture in order to produce a pushing force to the piston (2). The device includes an electromagnetic energy transducer (21, 22) and an external current circuit (34, 41), which is connected to the energy transducer for exchange of effect in a direction to or from the energy transducer. A control unit (12) is arranged to control the direction of the effect, which is exchanged between the energy transducer (21, 22) and the external current circuit, during operation of the device. The invention also refers to a use of such a device for generating electric energy, and a vehicle with such a device.

Owner:VOLVO TECH

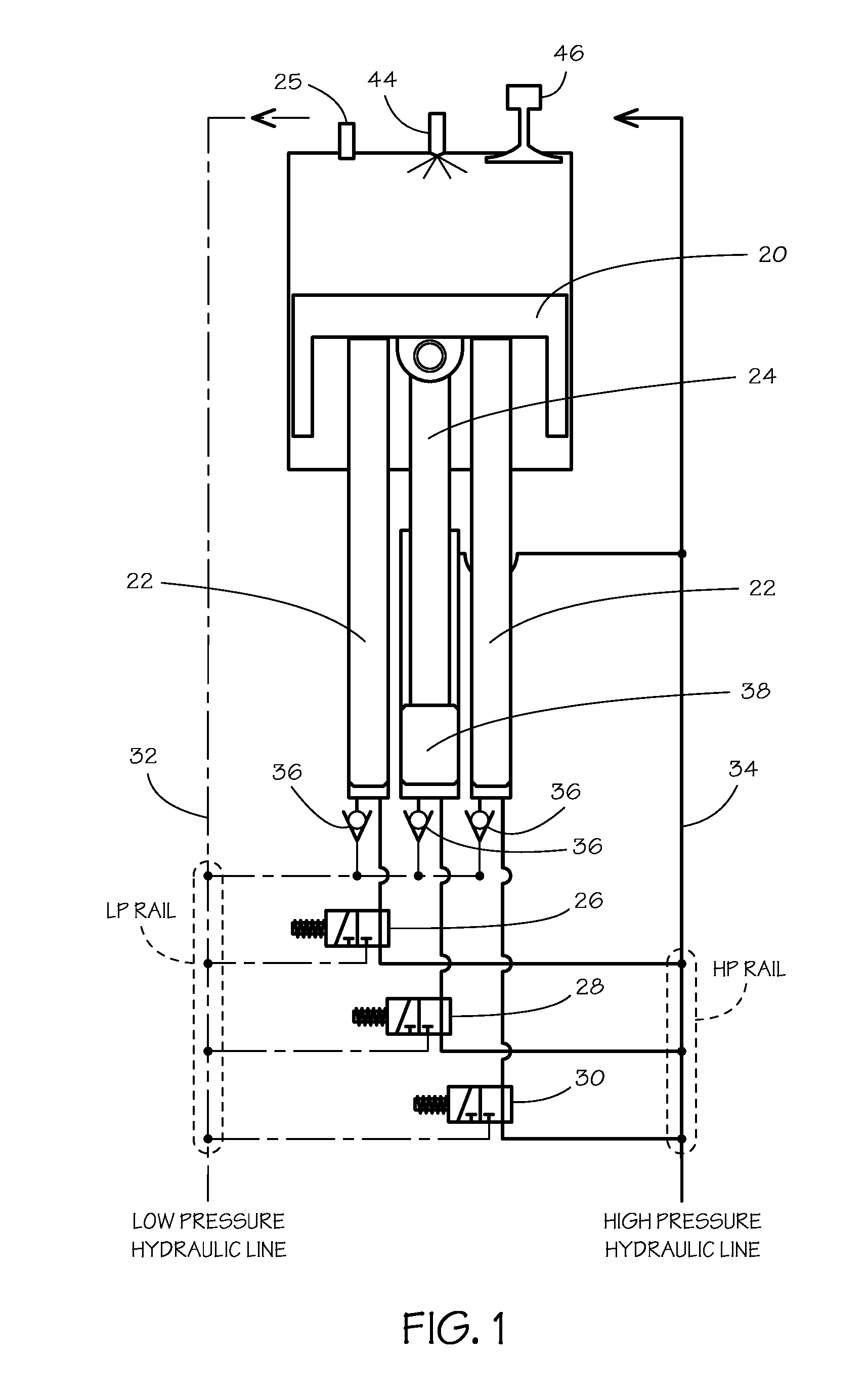

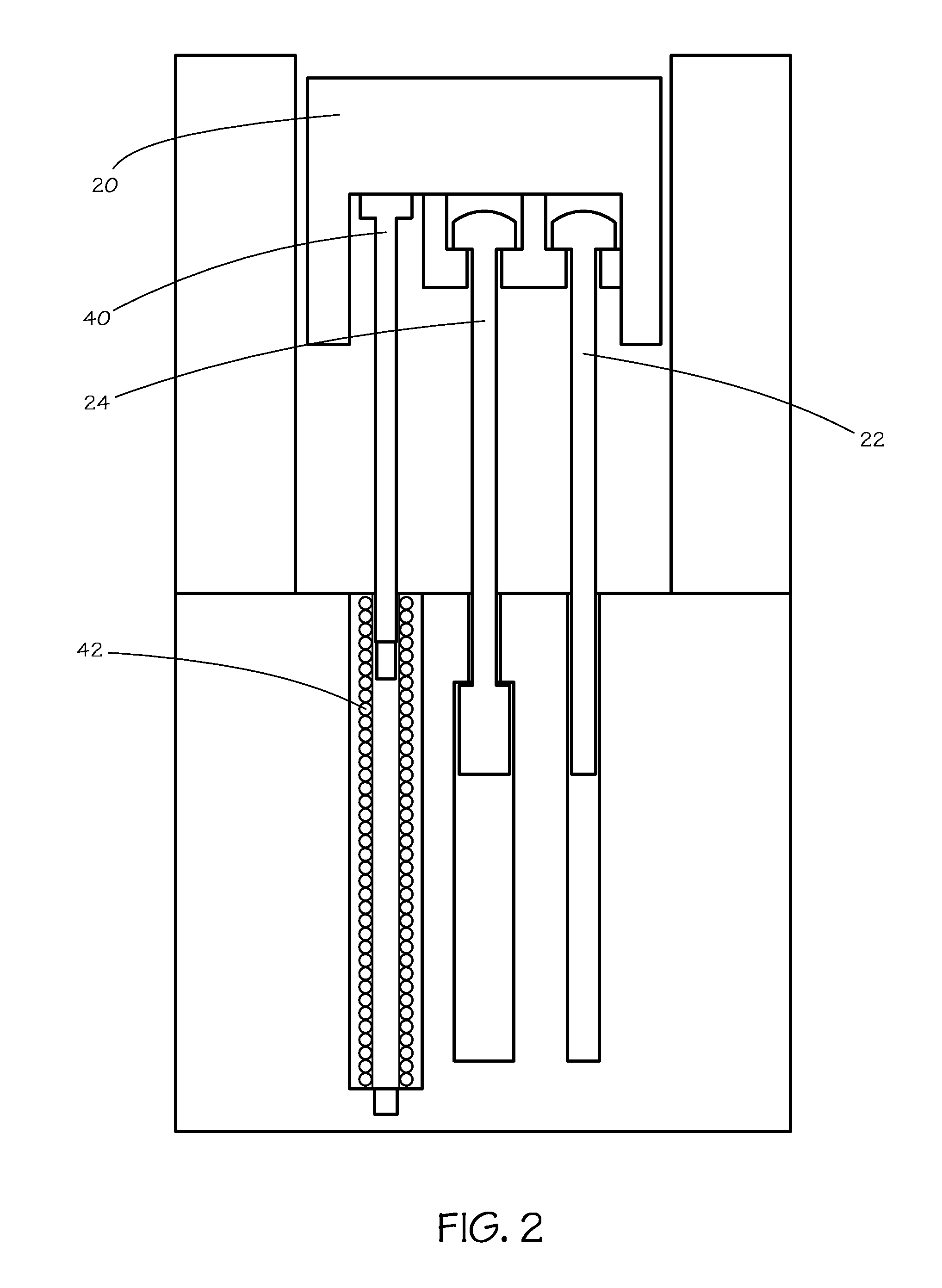

Hydraulic Internal Combustion Engines

ActiveUS20110083643A1Free piston enginesEngines without rotary main shaftHydraulic equipmentHydraulic fluid

Hydraulic internal combustion engines having at least one combustion piston not mechanically connected to a crankshaft or any other combustion piston, but instead acting on hydraulic plungers through valving that is electronically controlled to control the piston position and velocity, typically through an intake stroke, a compression stroke, a combustion or power stroke and an exhaust stroke. Electronically controlled fuel injection and electronically controlled engine valves provided great flexibility in the operating cycles that may be used, with the engine pumping hydraulic fluid to a high pressure accumulator for use in hydraulic motors or other hydraulic equipment. Embodiments using high pressure air injection to sustain combustion are also disclosed.

Owner:STURMAN DIGITAL SYST

System and method for controlling a power generating system

InactiveUS20070158947A1Fuel efficiencyLimit power outputMechanical energy handlingFree piston enginesControl theoryElectric power

This invention overcomes the disadvantages of the prior art by providing a power generating system particularly suitable for field use in remote locations, which is fuel-efficient, relatively quiet, tolerant of dust, capable of operating on low grade logistics and diesel-like fuels and capable of generating between 500 W and 2 KW of continuous electrical power. This generating system employs a two-cycle MICE generator having a piston that operates within a cylinder, and an interconnected, axially moving piston shaft that oscillates an alternator coil within a magnetic core. The piston shaft is attached to, and resisted by, the free end of a strong spring with a second, opposing end fixed to the MICE casing. To control operation of the MICE generator a dual clipper circuit is operatively connected with the alternator coil. The clipper circuit senses the current and at least two voltage levels and applies at least two respective loads in response to the sensed voltage levels and current so as to (a) prevent overstroke of the piston and (b) control power output of the alternator coil. The MICE generator also includes a fuel intake preheater that selectively heats fuel / air mixture entering the casing and a controller that senses load on the alternator coil varies a level of preheating to thereby control a level of power output.

Owner:AERODYNE RES

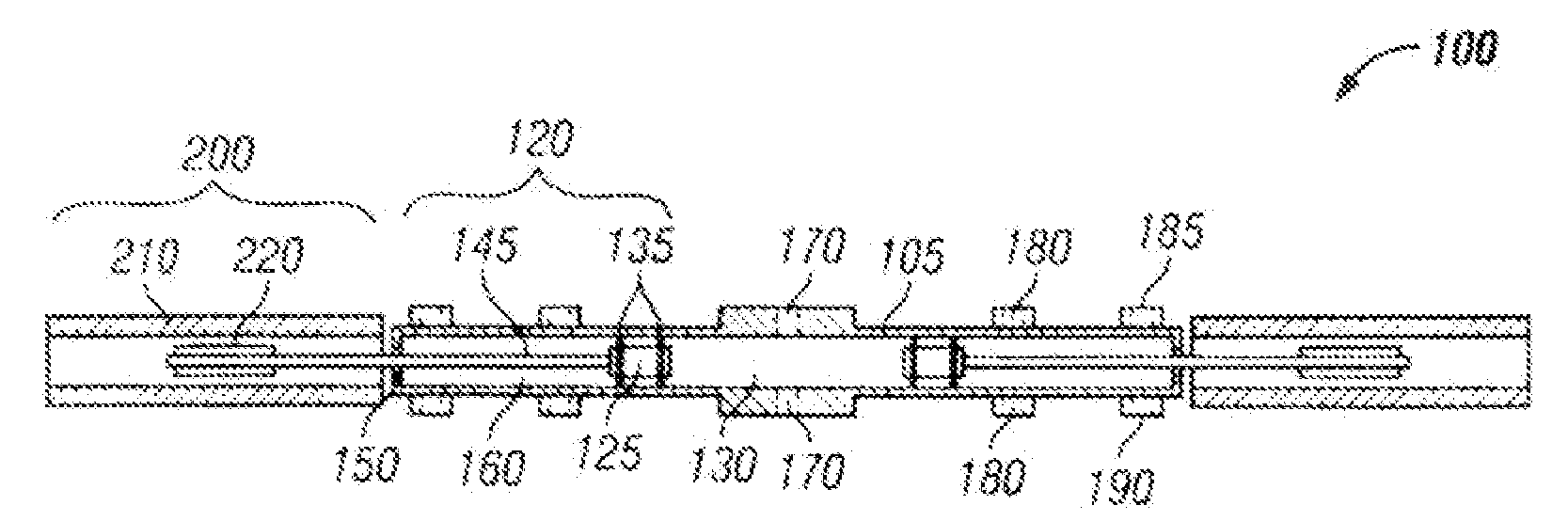

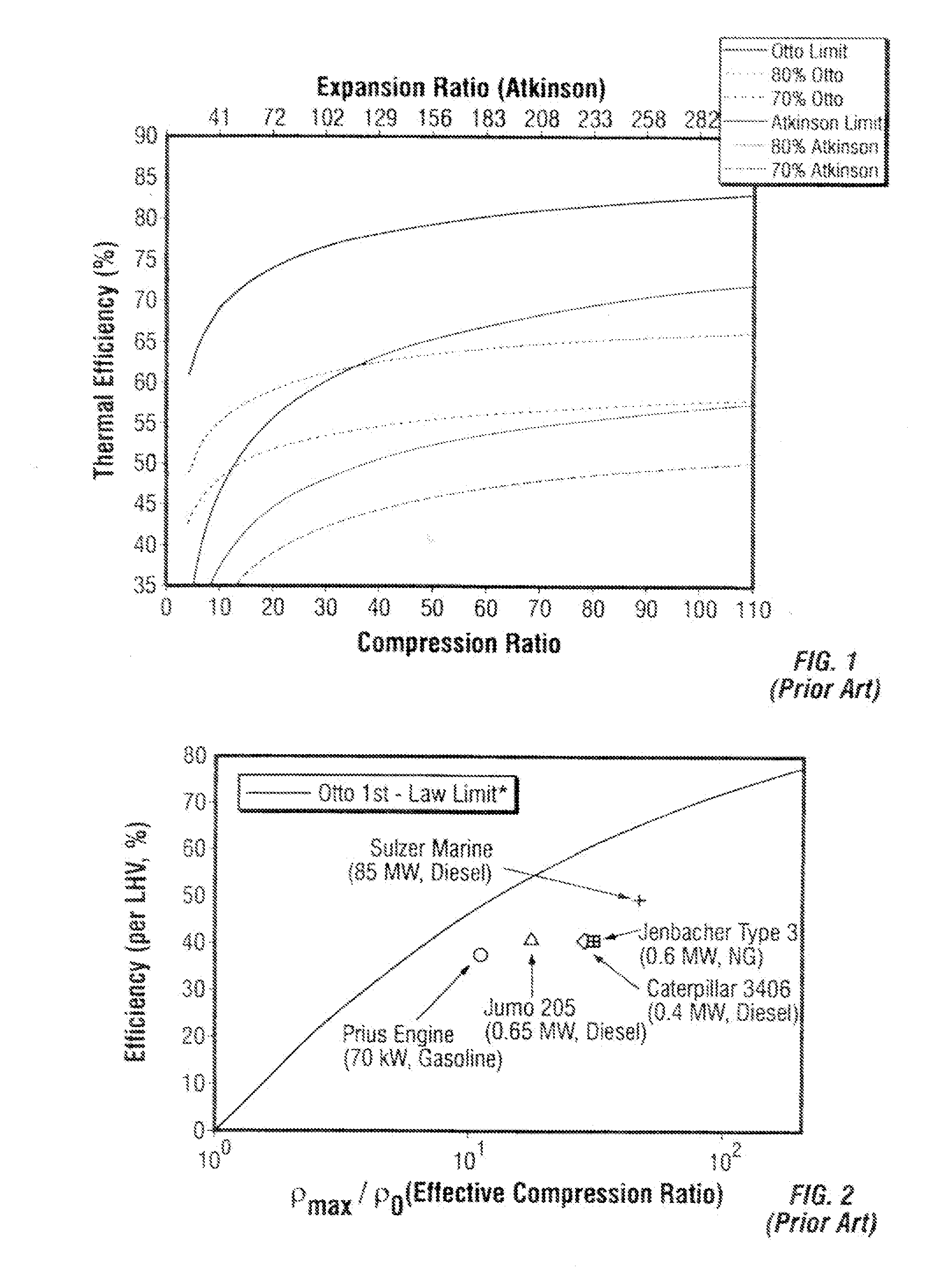

High-efficiency linear combustion engne

ActiveUS20120125288A1Improve thermal efficiencyRaise the ratioCombustion enginesEngine controllersCombustionGas spring

Various embodiments of the present invention are directed toward a linear combustion engine, comprising: a cylinder having a cylinder wall and a pair of ends, the cylinder including a combustion section disposed in a center portion of the cylinder; a pair of opposed piston assemblies adapted to move linearly within the cylinder, each piston assembly disposed on one side of the combustion section opposite the other piston assembly, each piston assembly including a spring rod and a piston comprising a solid front section adjacent the combustion section and a hollow back section comprising a gas spring that directly provides at least some compression work during a compression stroke of the engine; and a pair of linear electromagnetic machines adapted to directly convert kinetic energy of the piston assembly into electrical energy, and adapted to directly convert electrical energy into kinetic energy of the piston assembly for providing compression work during the compression stroke; wherein the engine includes a variable expansion ratio greater than 50:1.

Owner:MAINSPRING ENERGY INC

Combustion type power tool having avoiding unit for avoiding overheating to mechanical components in the tool

InactiveUS7021251B2Work lessEliminate thermal deformationFree piston enginesNailing toolsMechanical componentsCombustion chamber

A combustion type power tool capable of avoiding damage to seal members and a housing to prolong a service life, and capable of enhancing operability and workability. Temperature elevation of a combustion chamber frame due to combustion of a mixture of combustible gas and air is detected by a temperature sensor disposed in a housing. If the detected temperature exceeds a preset temperature, ignition of an ignition plug is prohibited by a prohibiting unit in spite of ON operation of a trigger switch. In this state, alarming is performed by a display to notify the user of the inoperable state of the tool. Similar control can be made when the temperature sensor is disposed at a cylinder, an exhaust cover and the housing.

Owner:HITACHI KOKI CO LTD

Position sensing for a free piston engine

A free piston engine is configured with a pair of opposed engine cylinders located on opposite sides of a fluid pumping assembly. An inner piston assembly includes a pair of inner pistons, one each operatively located in a respective one of the engine cylinders, with a push rod connected between the inner pistons. The push rod extends through an inner pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. Also connected between the pistons are a position sensor and a calibration position sensor that are employed to determine the position and velocity of the inner piston assembly. An outer piston assembly includes a pair of outer pistons, one each operatively located in a respective one of the engine cylinders, with at least one pull rod connected between the outer pistons. The pull rod extends through an outer pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. Also engaging the outer piston assembly are a position sensor and a calibration position sensor that are employed to determine the position and velocity of the outer piston assembly. The movement of the inner and outer piston assemblies during engine operation will cause the fluid plungers to pump fluid from a low pressure container into a high pressure chamber as a means of storing the energy output from the engine.

Owner:FORD MOTOR CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com