Patents

Literature

44 results about "Linear alternator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A linear alternator is essentially a linear motor used as an electrical generator. An alternator is a type of alternating current (AC) electrical generator. The devices are often physically equivalent. The principal difference is in how they are used and which direction the energy flows. An alternator converts mechanical energy to electrical energy, whereas a motor converts electrical energy to mechanical energy. Like most electric motors and electric generators, the linear alternator works by the principle of electromagnetic induction. However, most alternators work with rotary motion, whereas "linear" alternators work with "linear" motion (i.e. motion in a straight line).

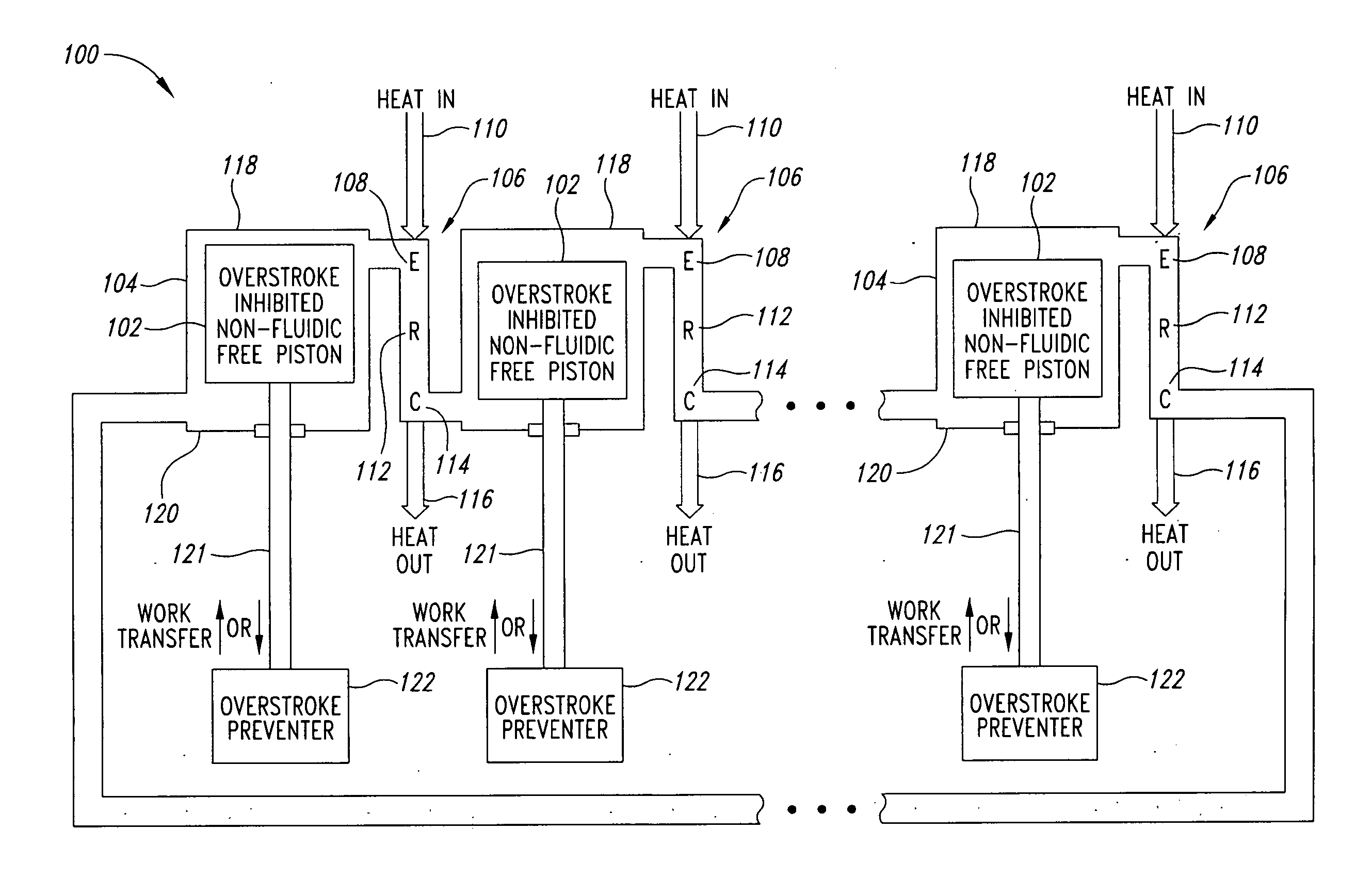

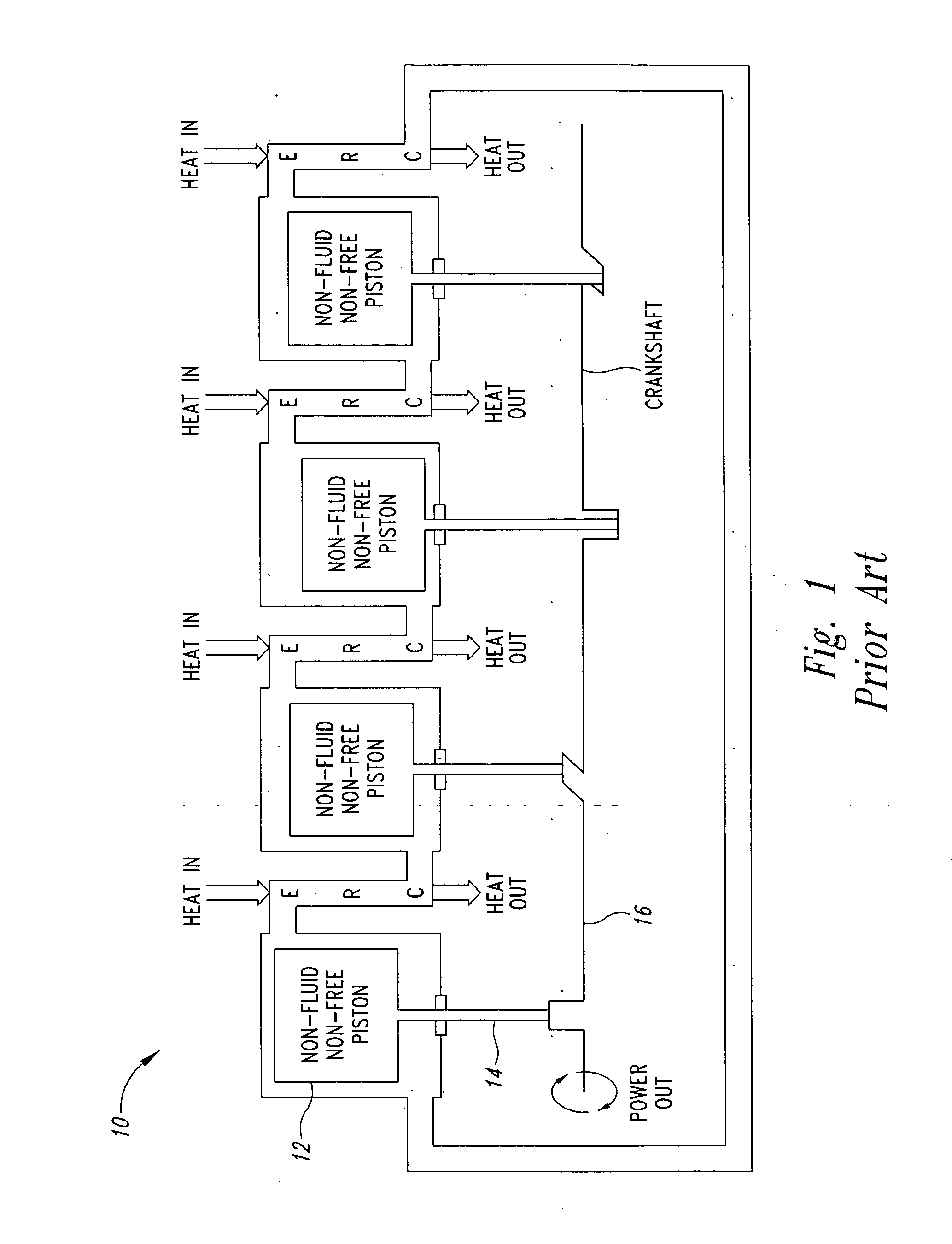

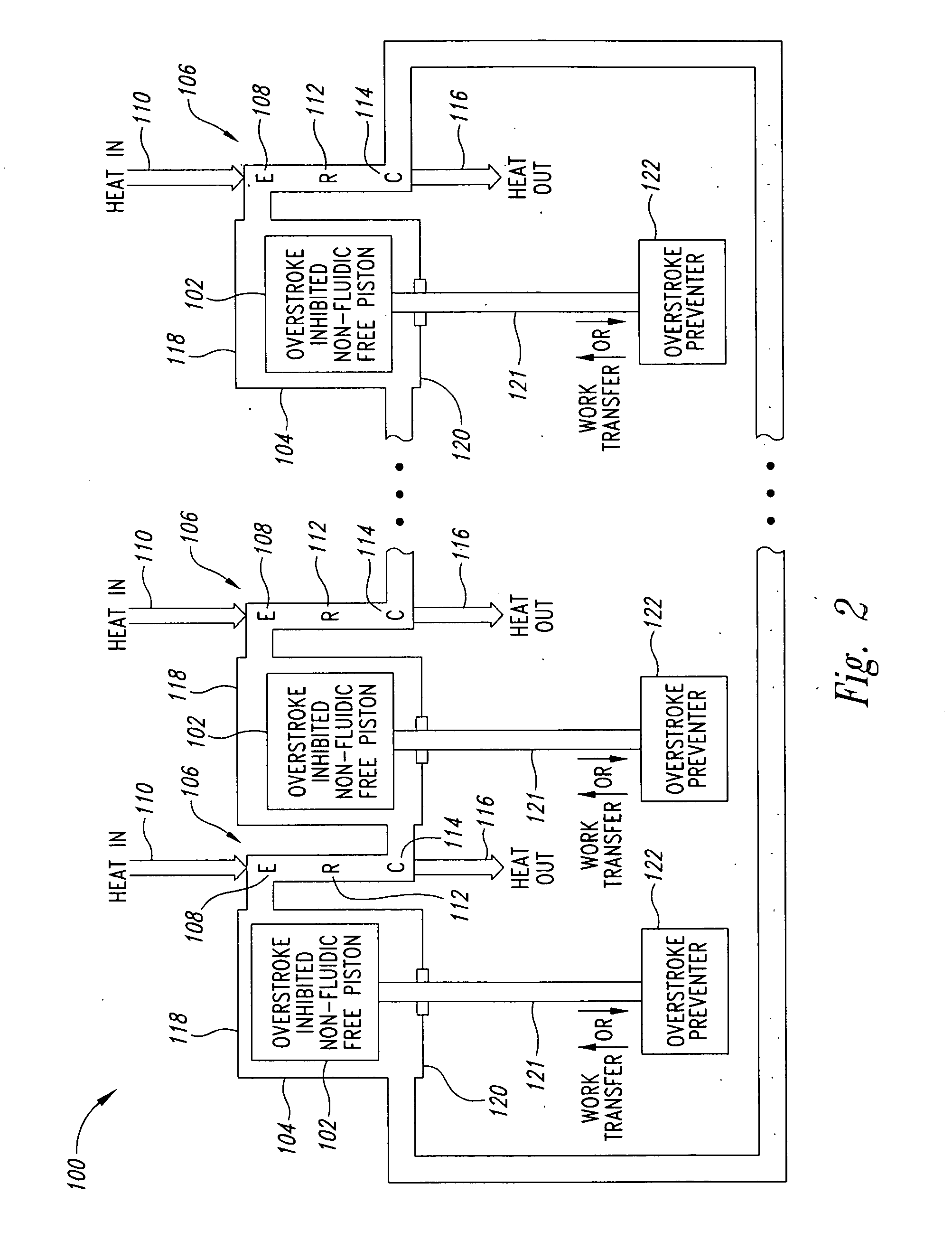

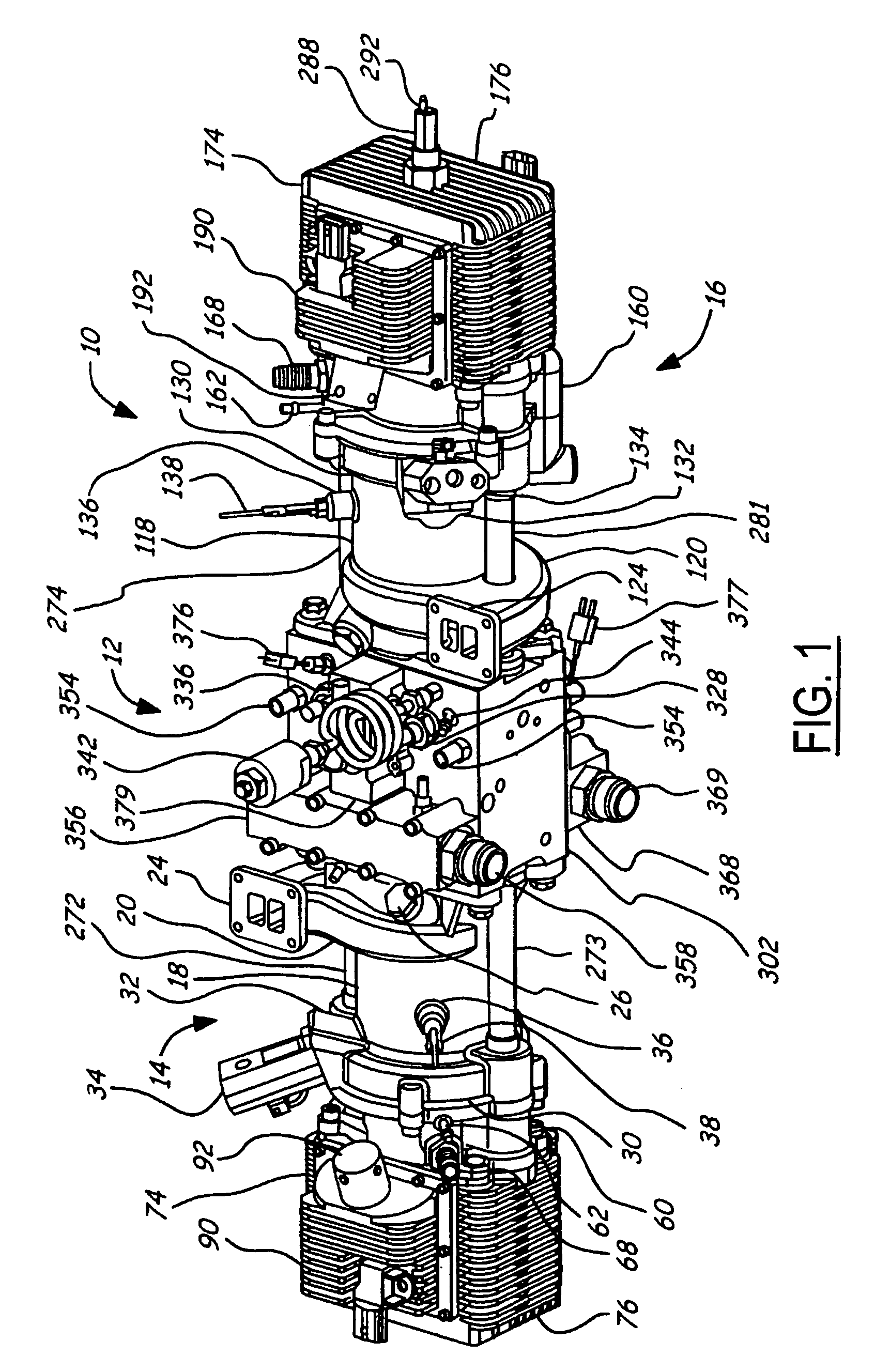

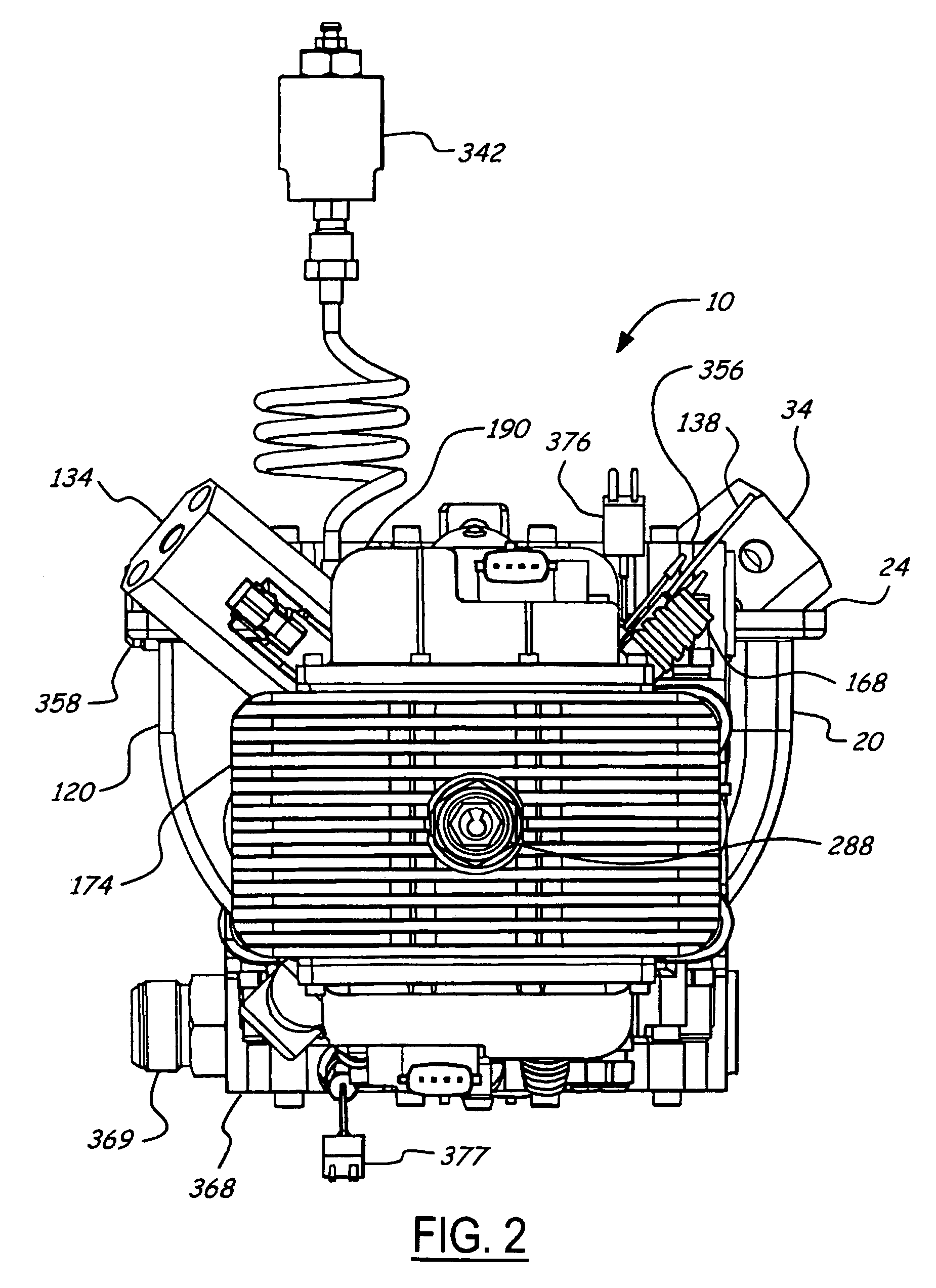

Double acting thermodynamically resonant free-piston multicylinder stirling system and method

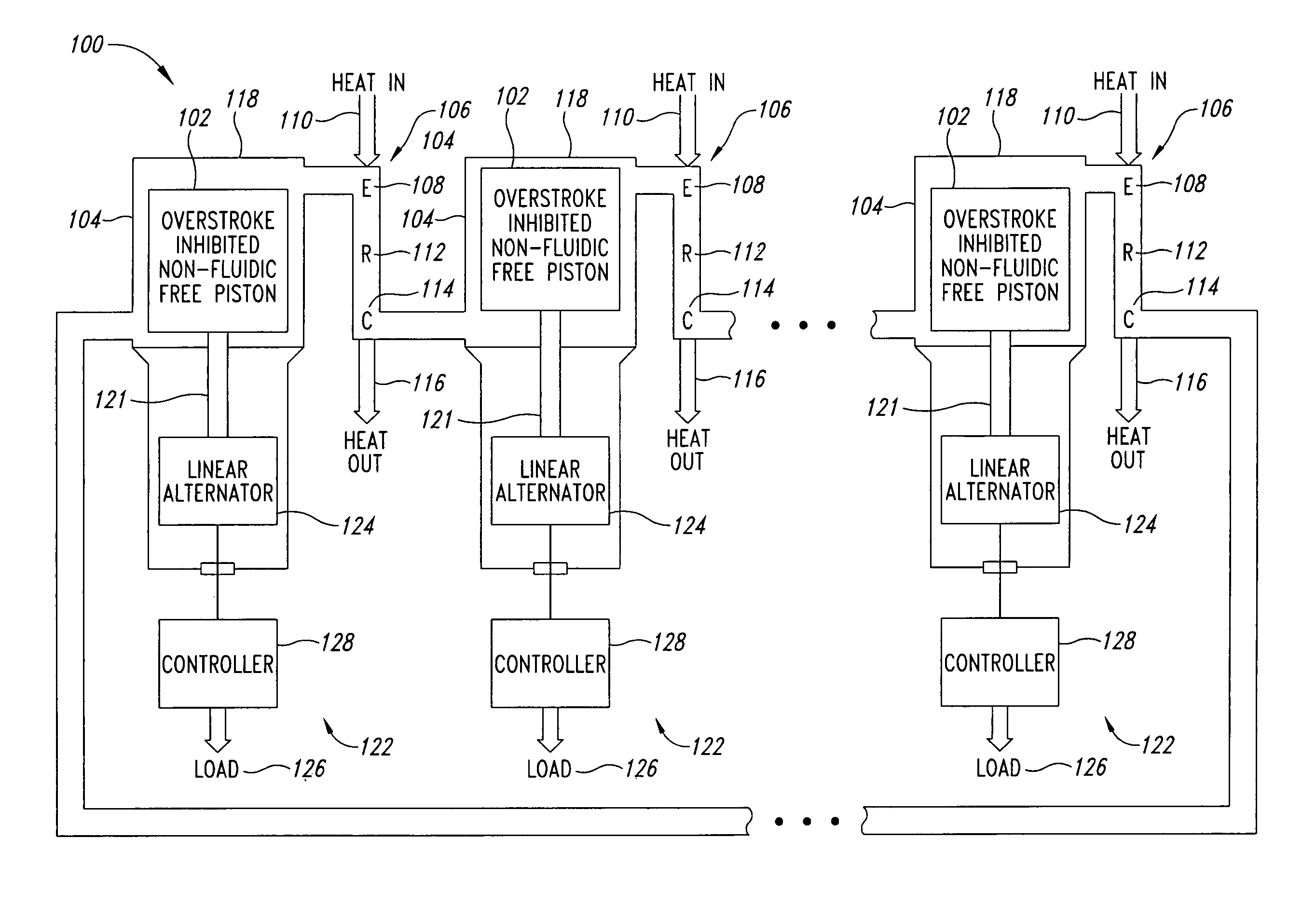

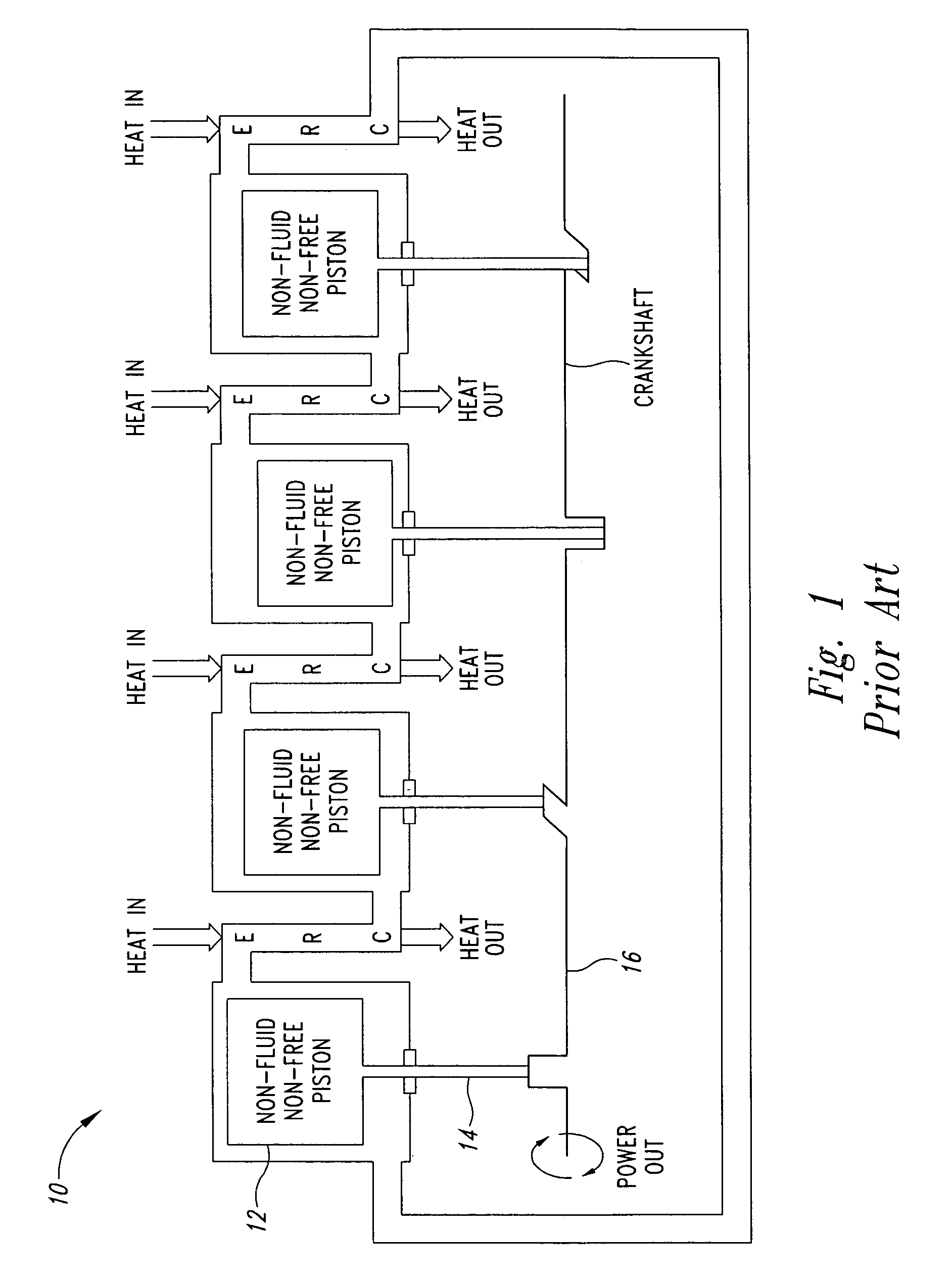

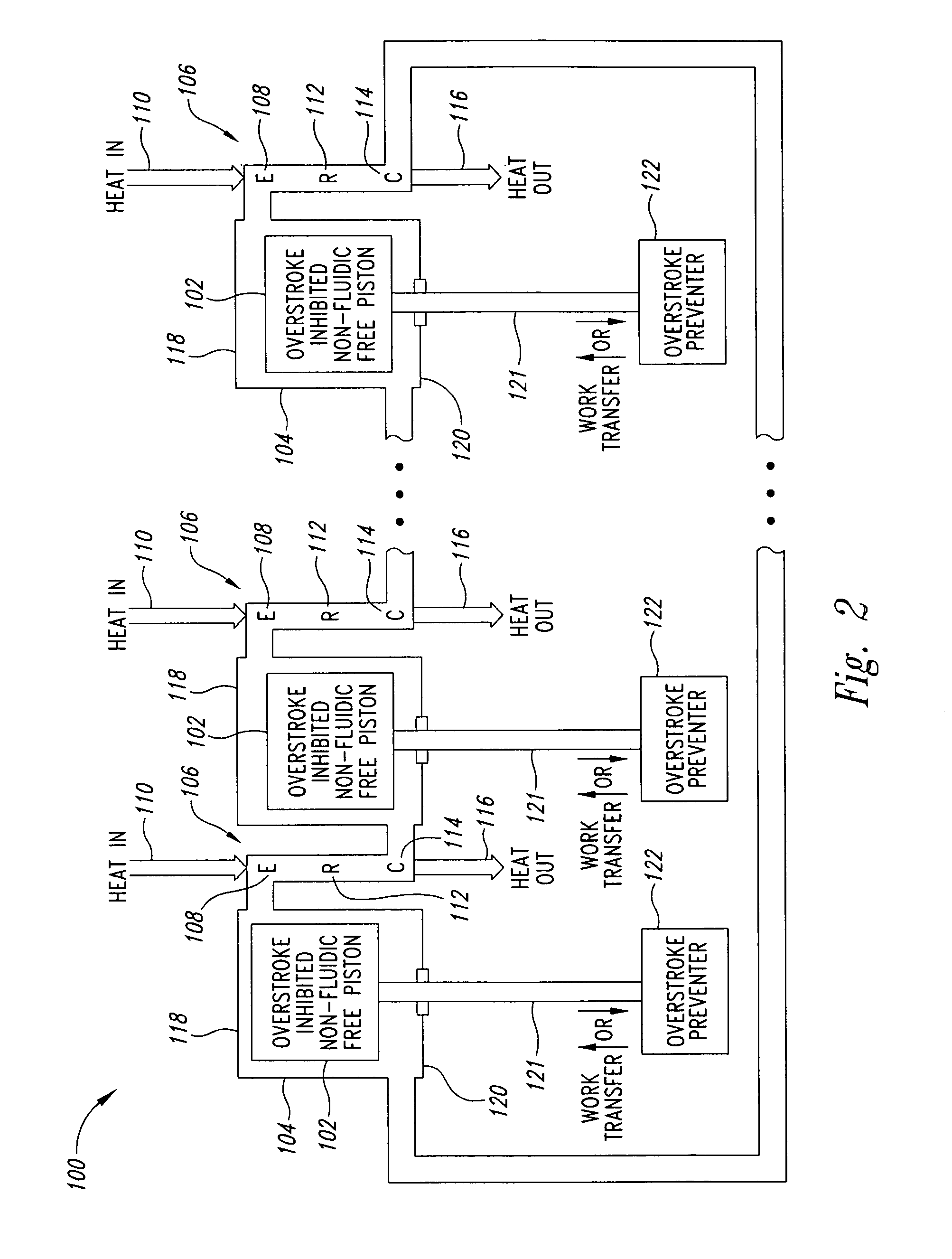

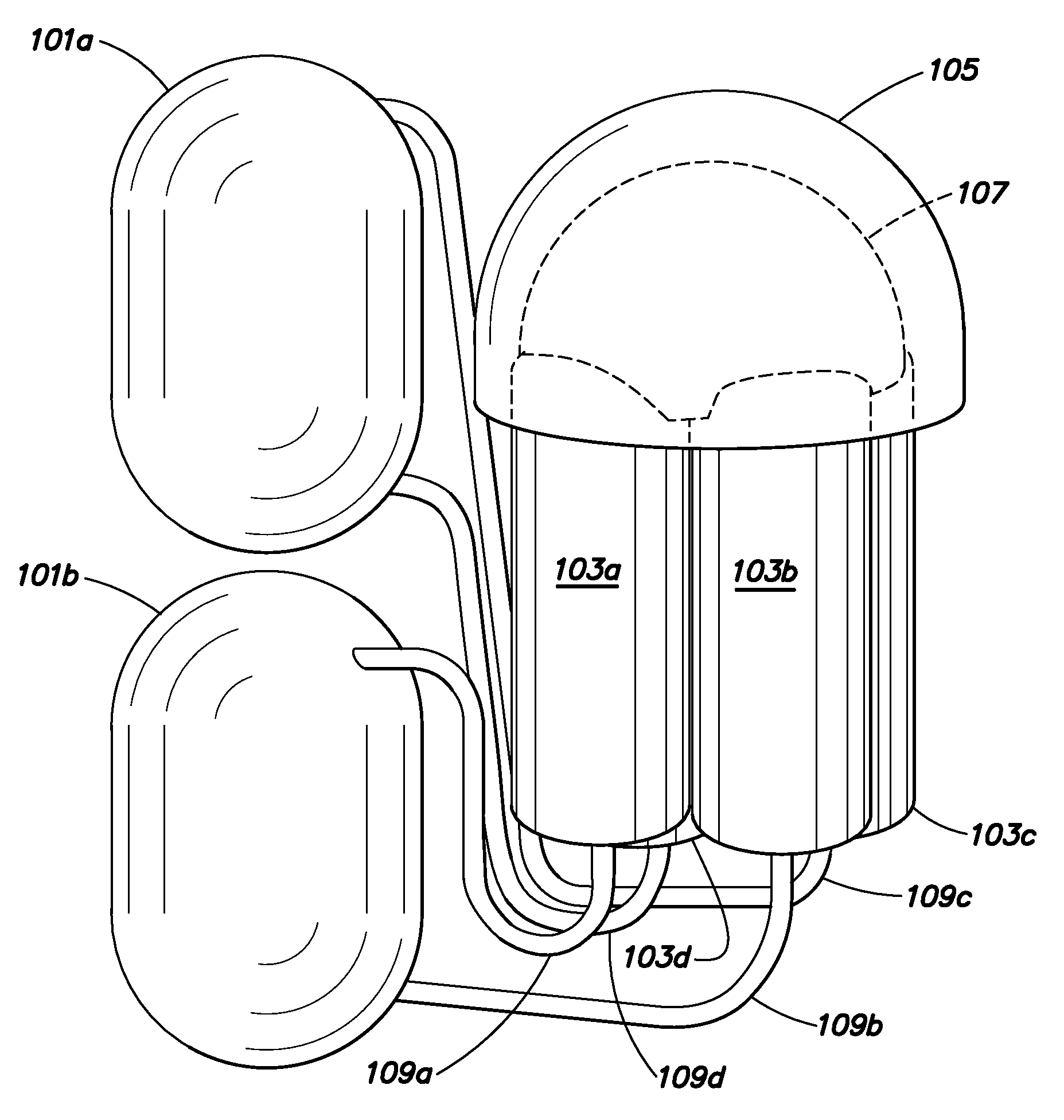

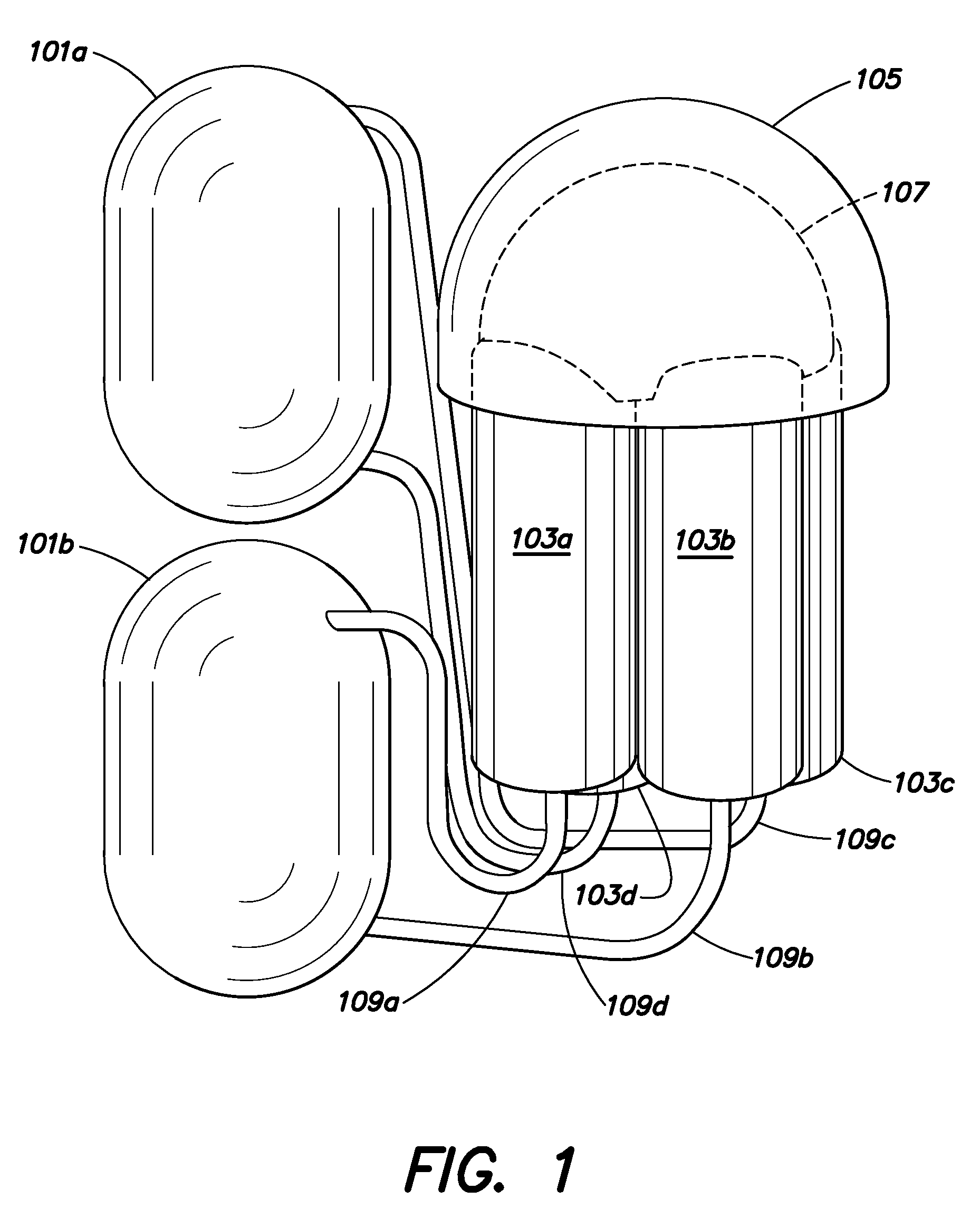

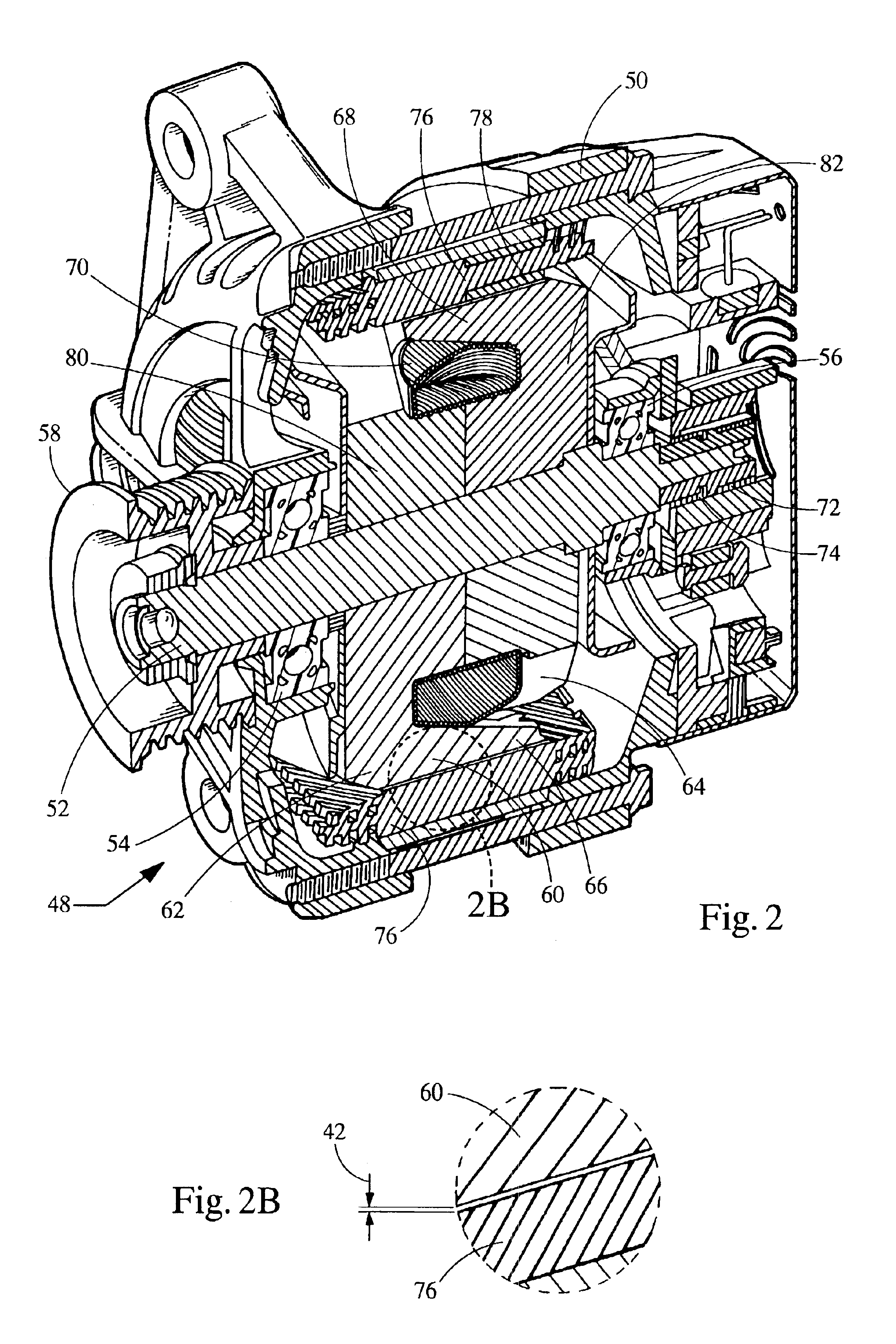

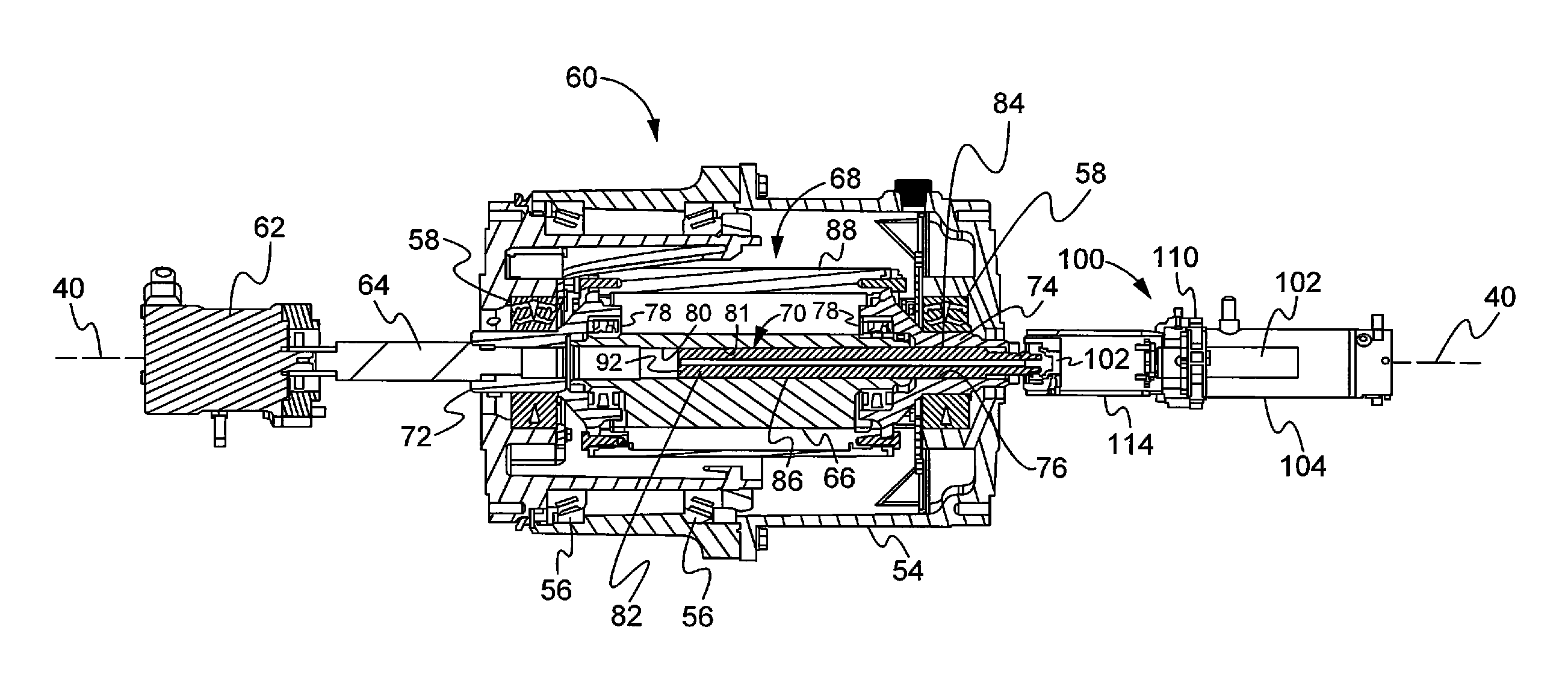

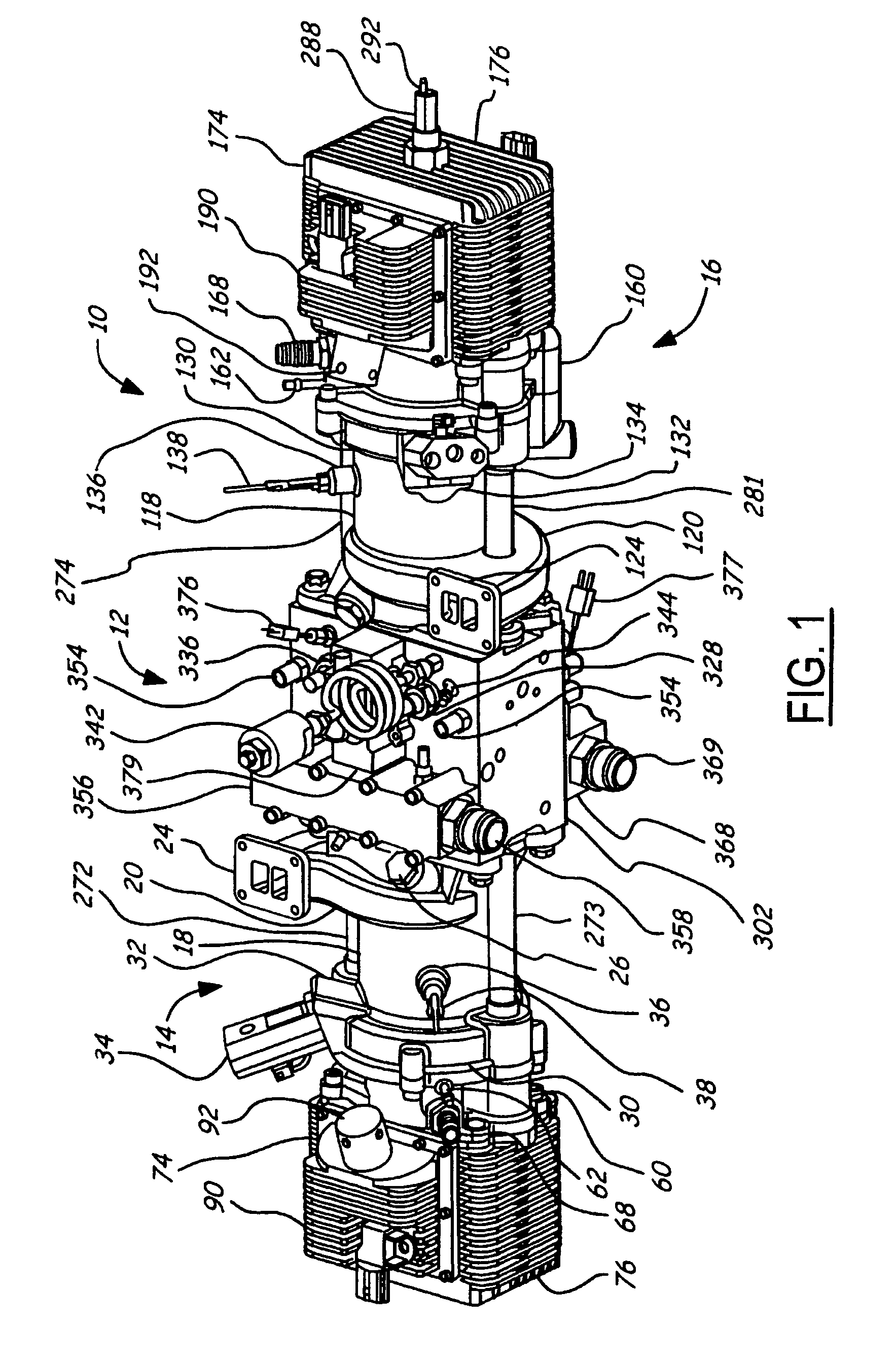

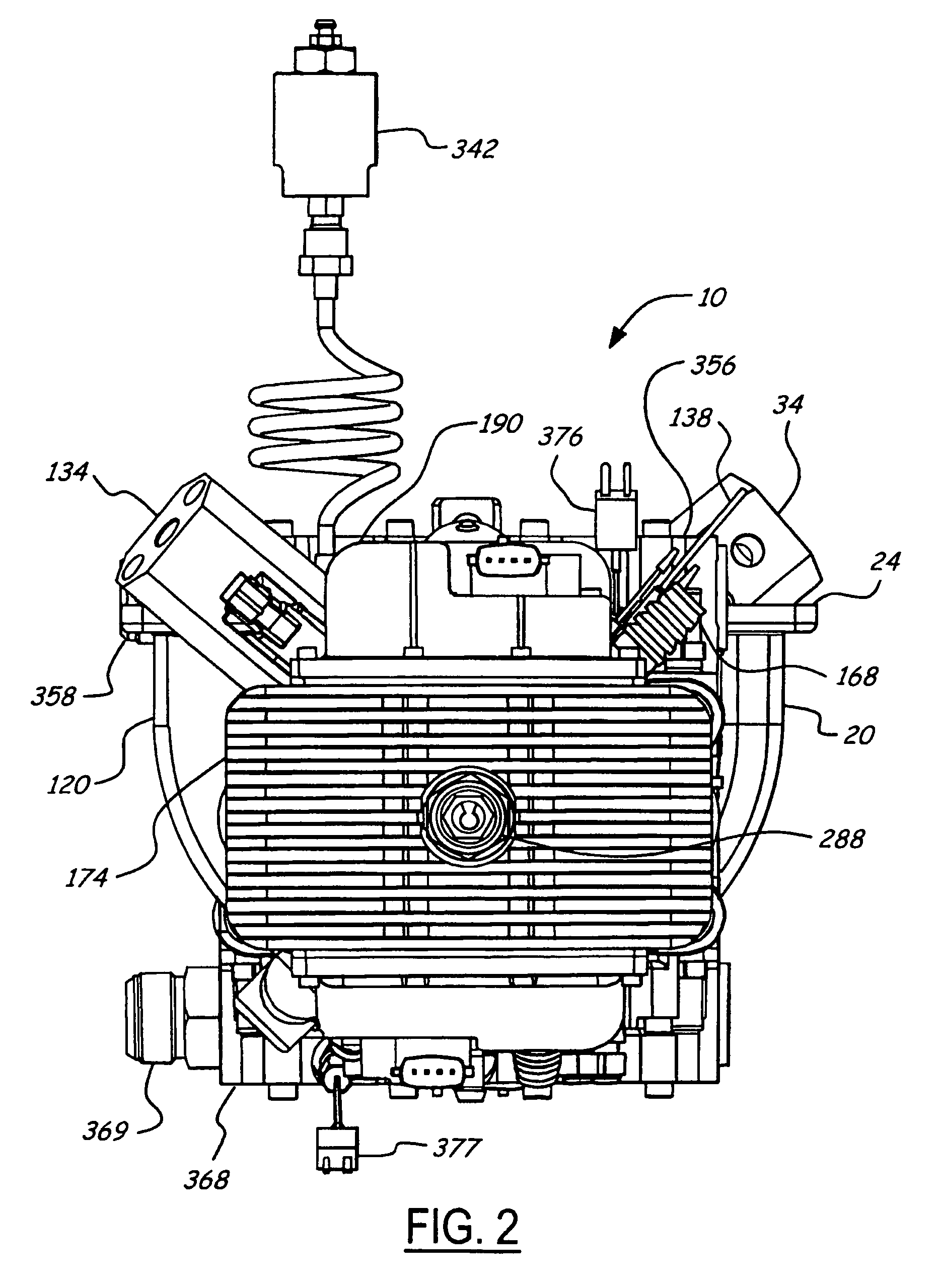

Present implementations provide an approach that allows for a double-acting, multi-cylinder, thermodynamically resonant, alpha configuration free-piston Stirling system. The system includes overstroke preventers that control extent of piston travel to prevent undesirable consequences of piston travel beyond predetermined limits. The overstroke preventers involve controlled work extraction out of the system or controlled work input into the system. Implementations can also include duplex linear alternators, and / or frequency tuning systems, and / or vibration balancing configurations.

Owner:QNERGY

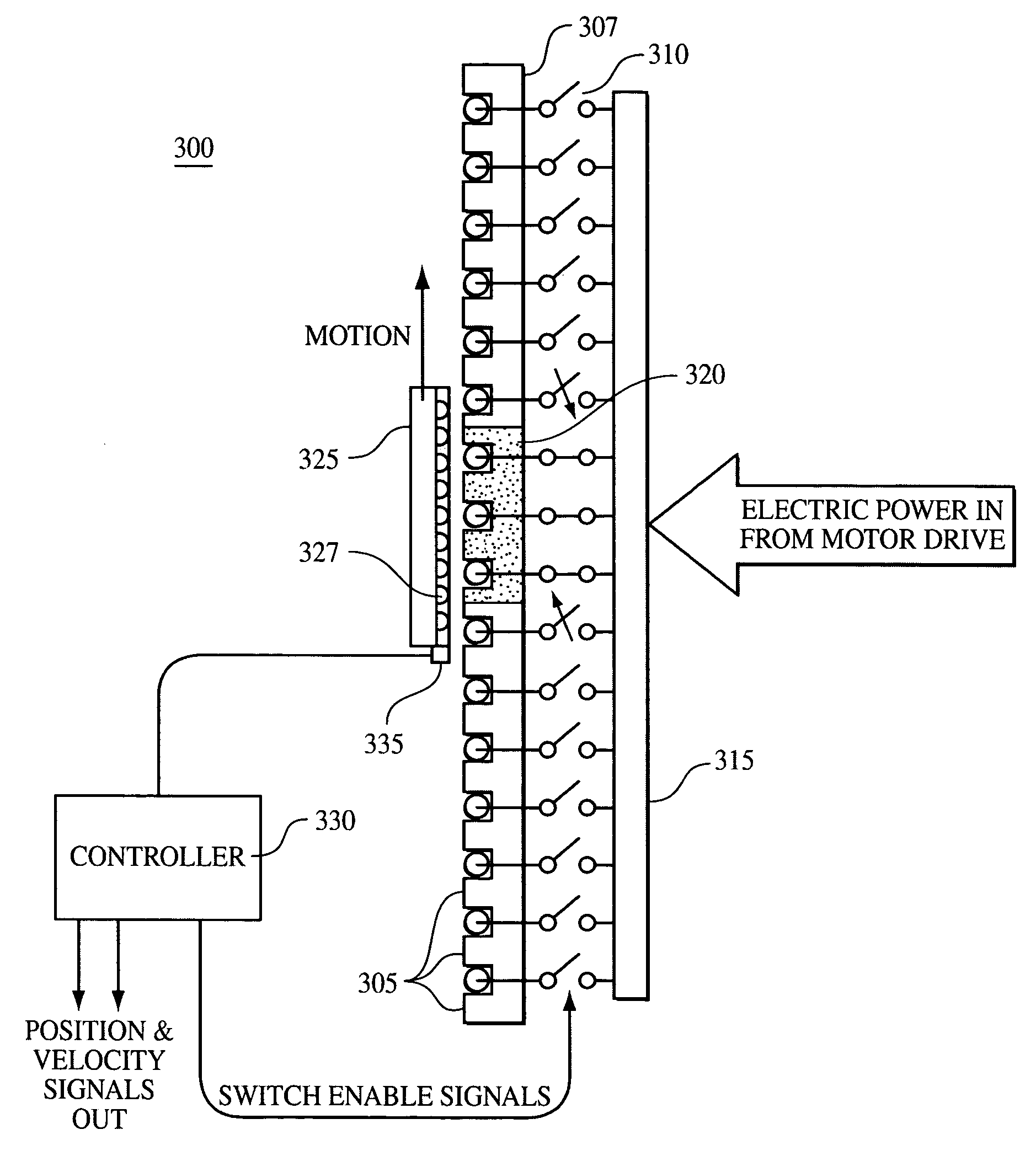

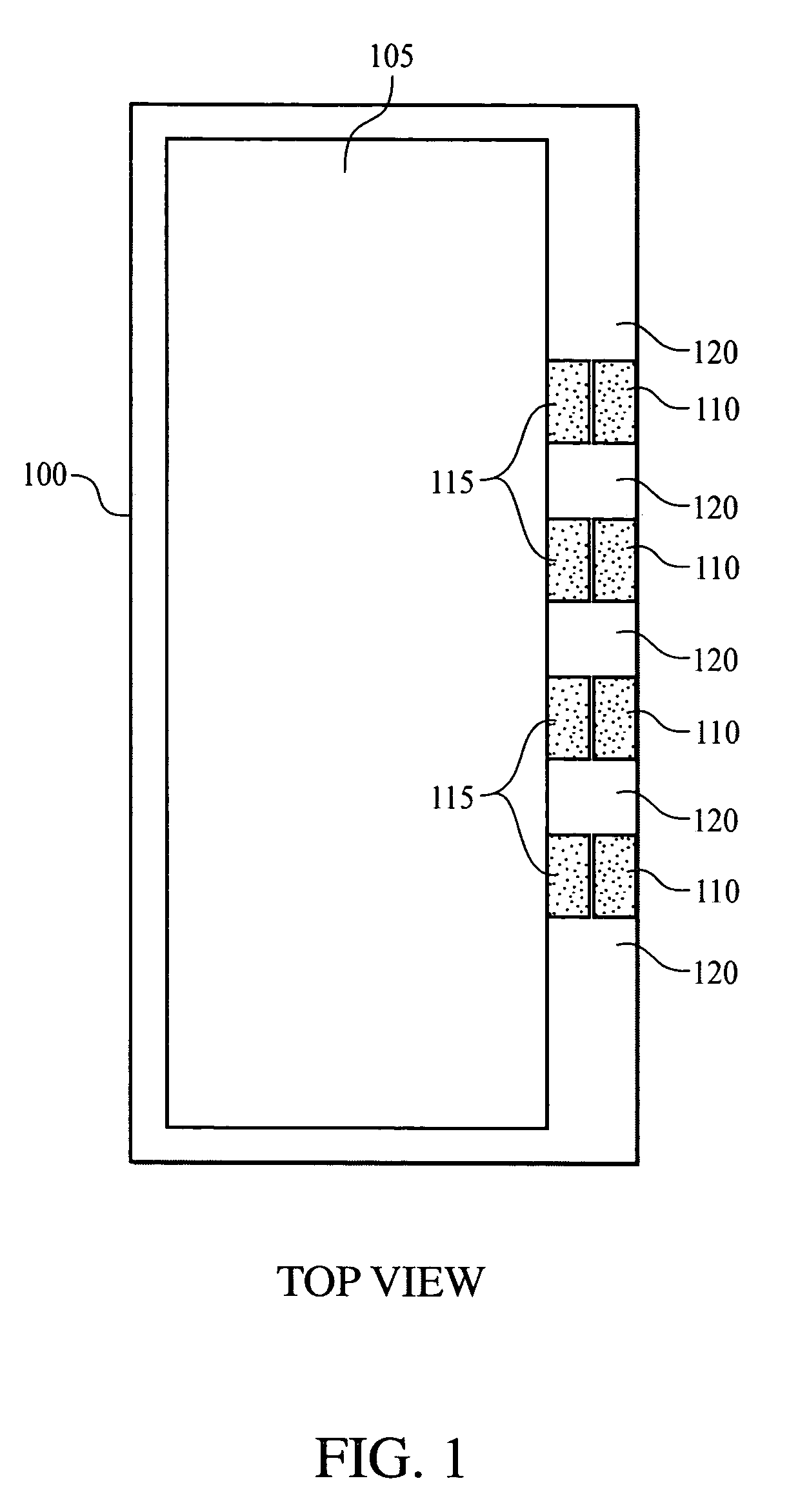

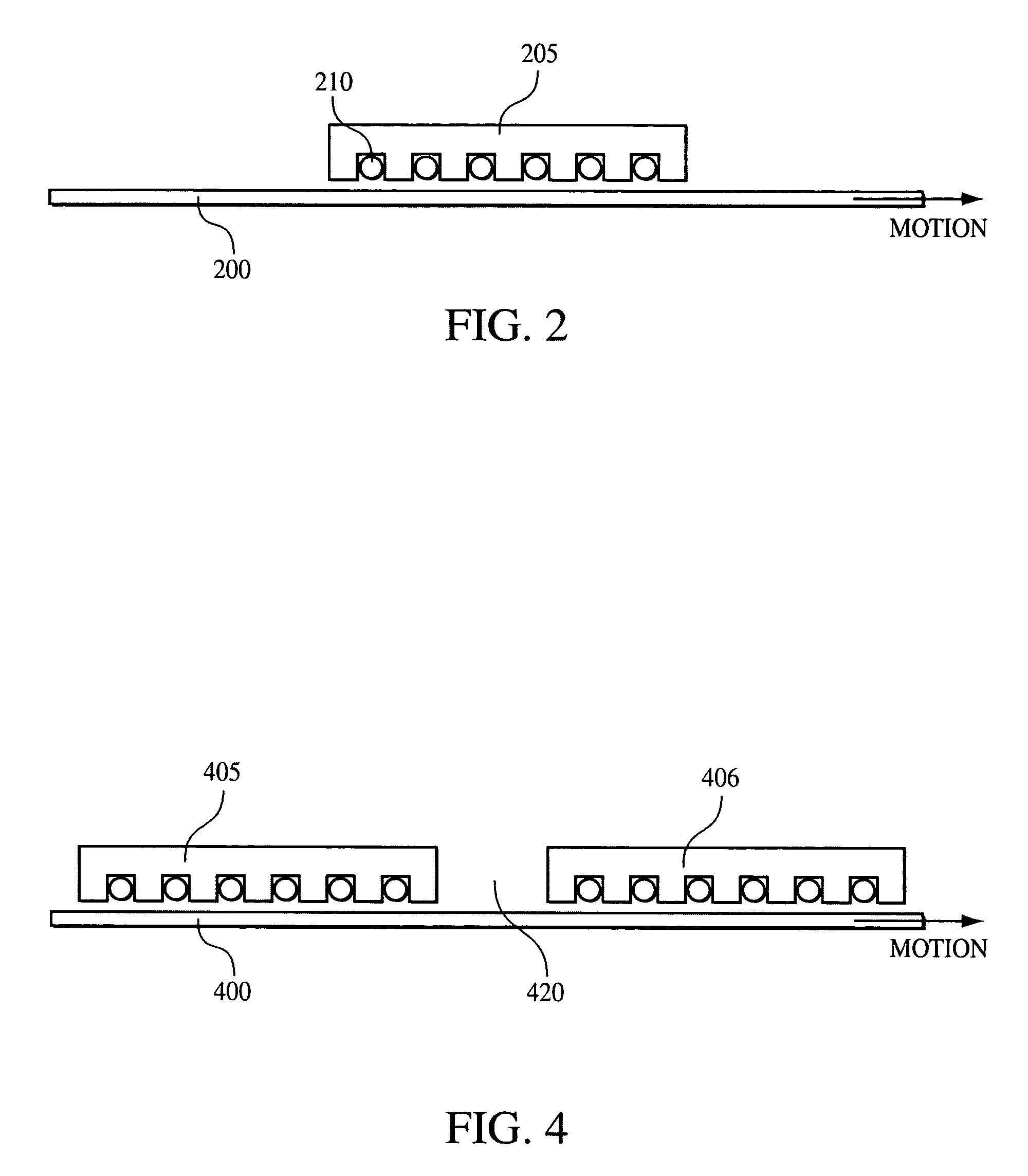

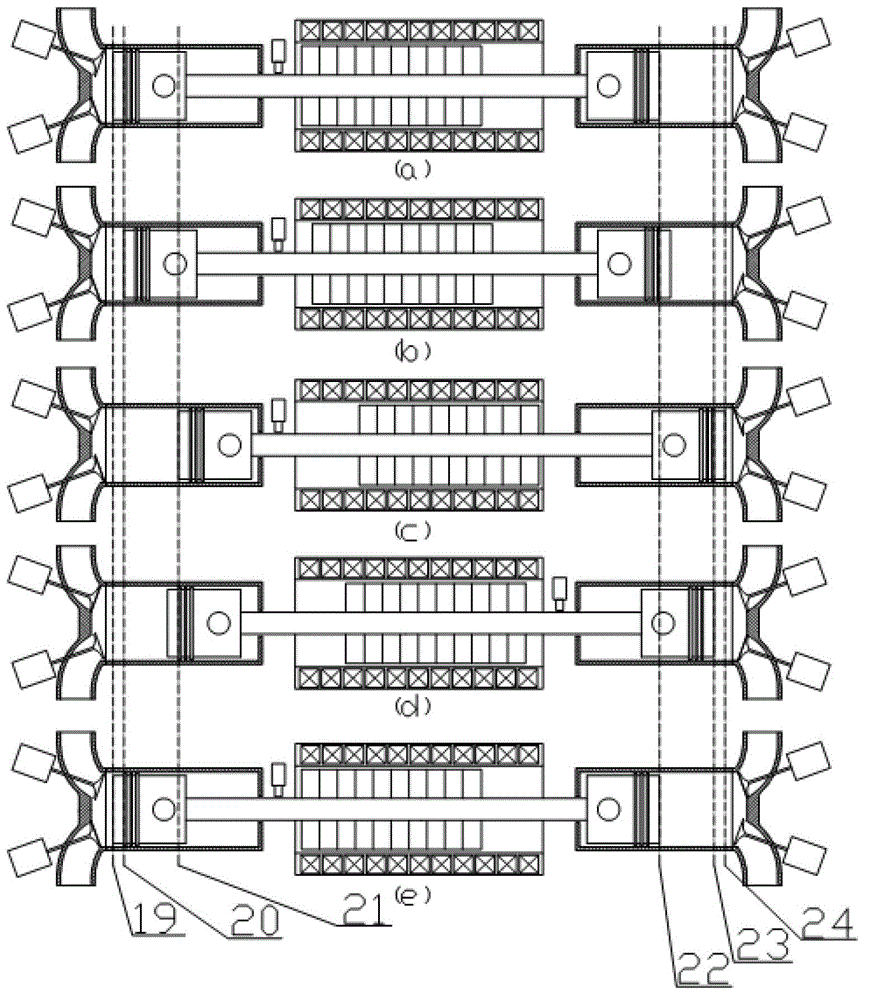

Modular linear electric motor with limited stator excitation zone and stator gap compensation

A linear motor system including compartmentalized stator sections provides an interchangeable and serviceable alternative to other linear motors. The stator sections may be individually-energized so that power is only sent to stator sections adjacent to the thrust plate or rotor of the linear motor. A sufficiently long thrust plate is used to cover any gaps in the linear stator, and additional compensation stator sections are used to provide additional motor force to the thrust plate adjacent to these gap sections. If utilized onboard a ship, additional compensation stator sections may be incorporated into the face of deck hatches. The linear motor system can also be used to counteract gravitational effects in a large hanging door system implementation.

Owner:CURTISS WRIGHT ELECTRO MECHANICAL

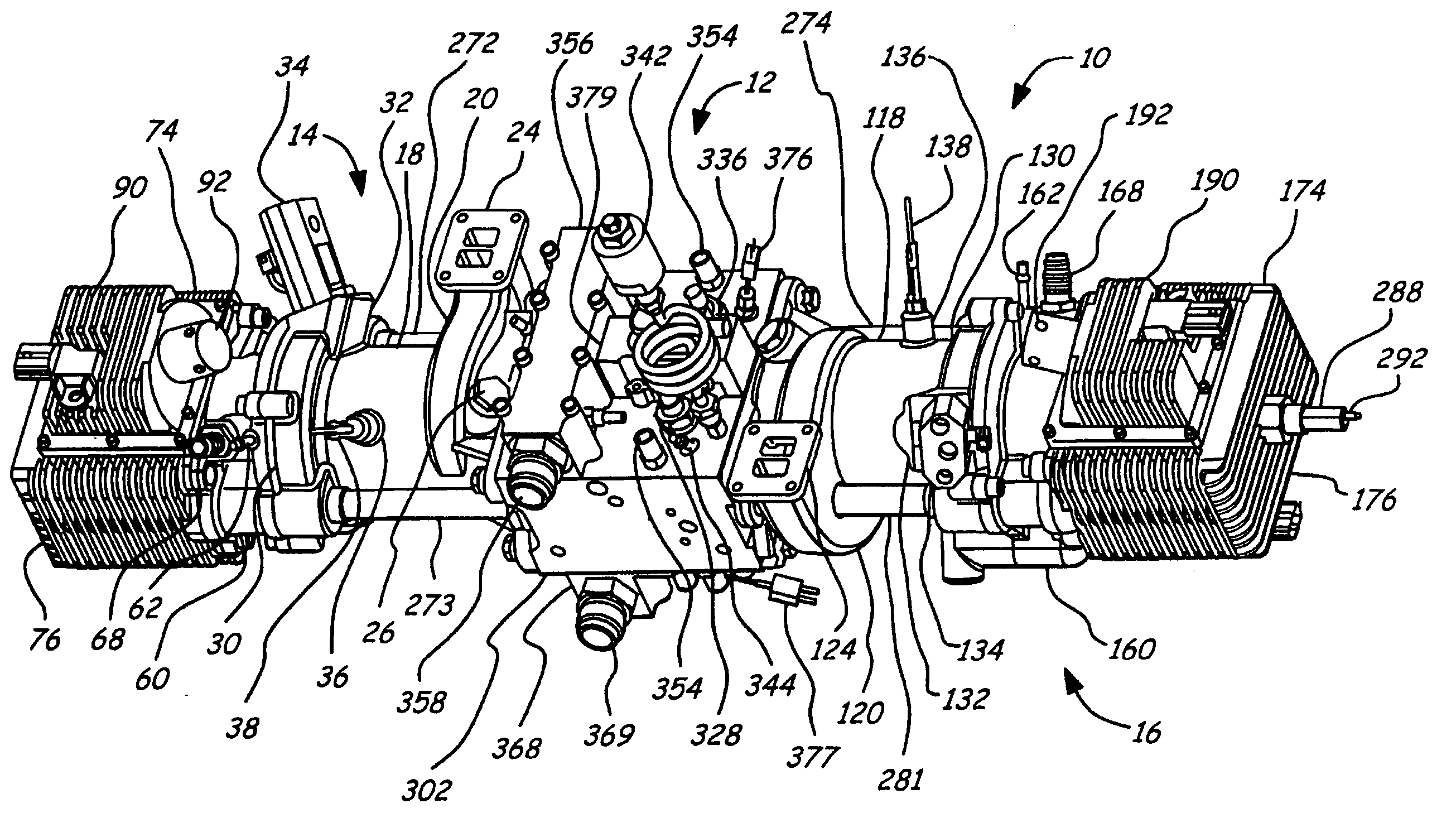

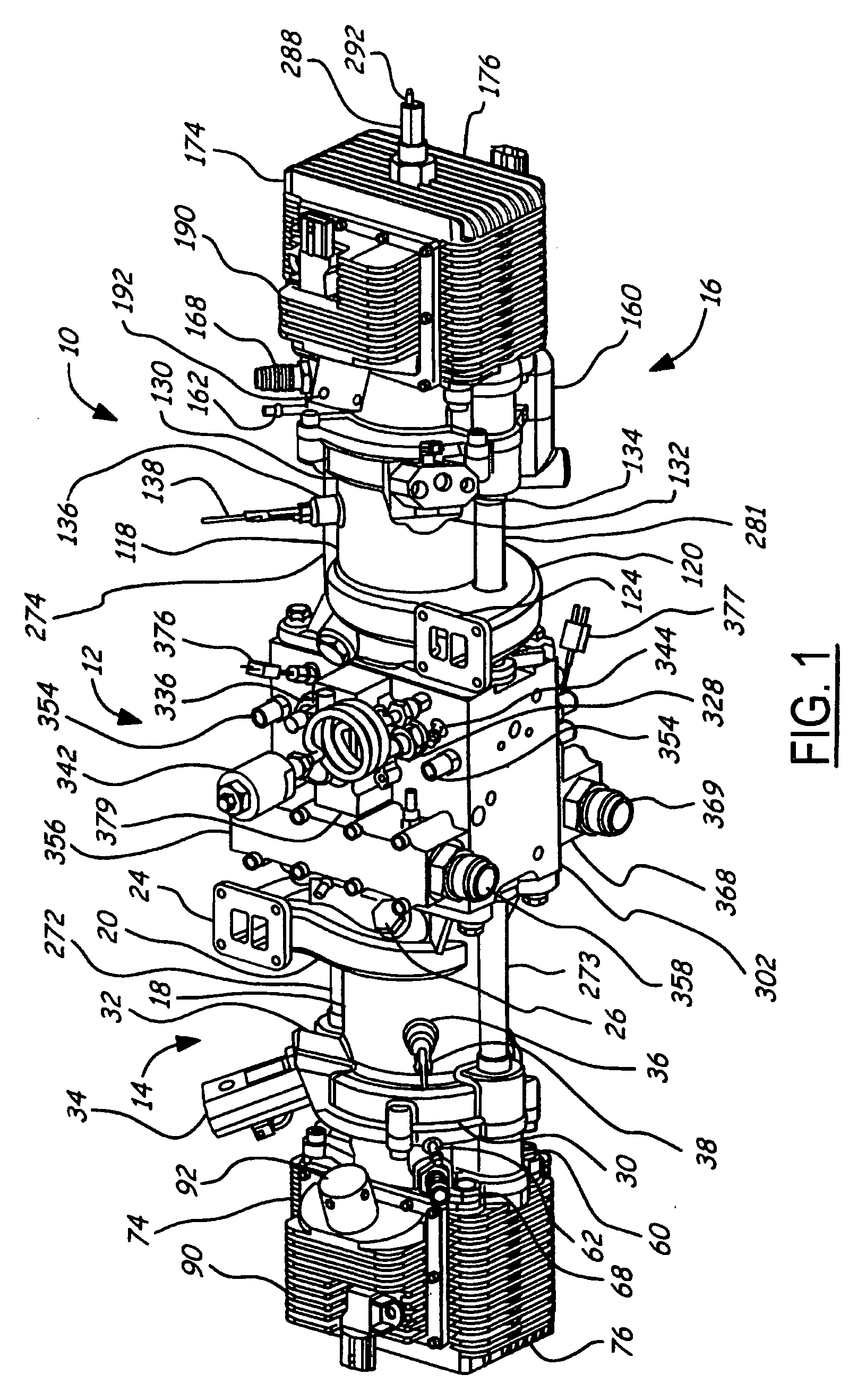

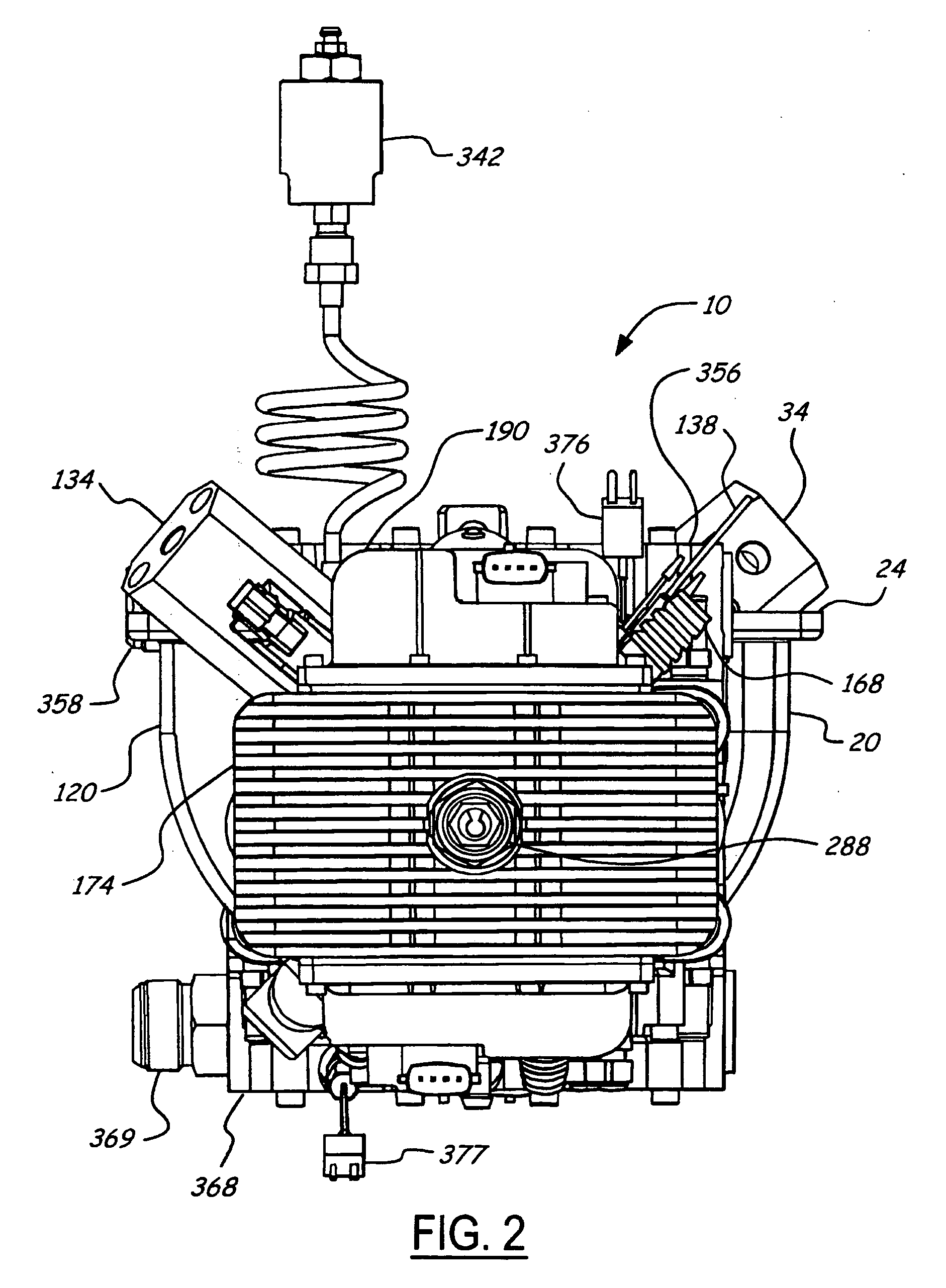

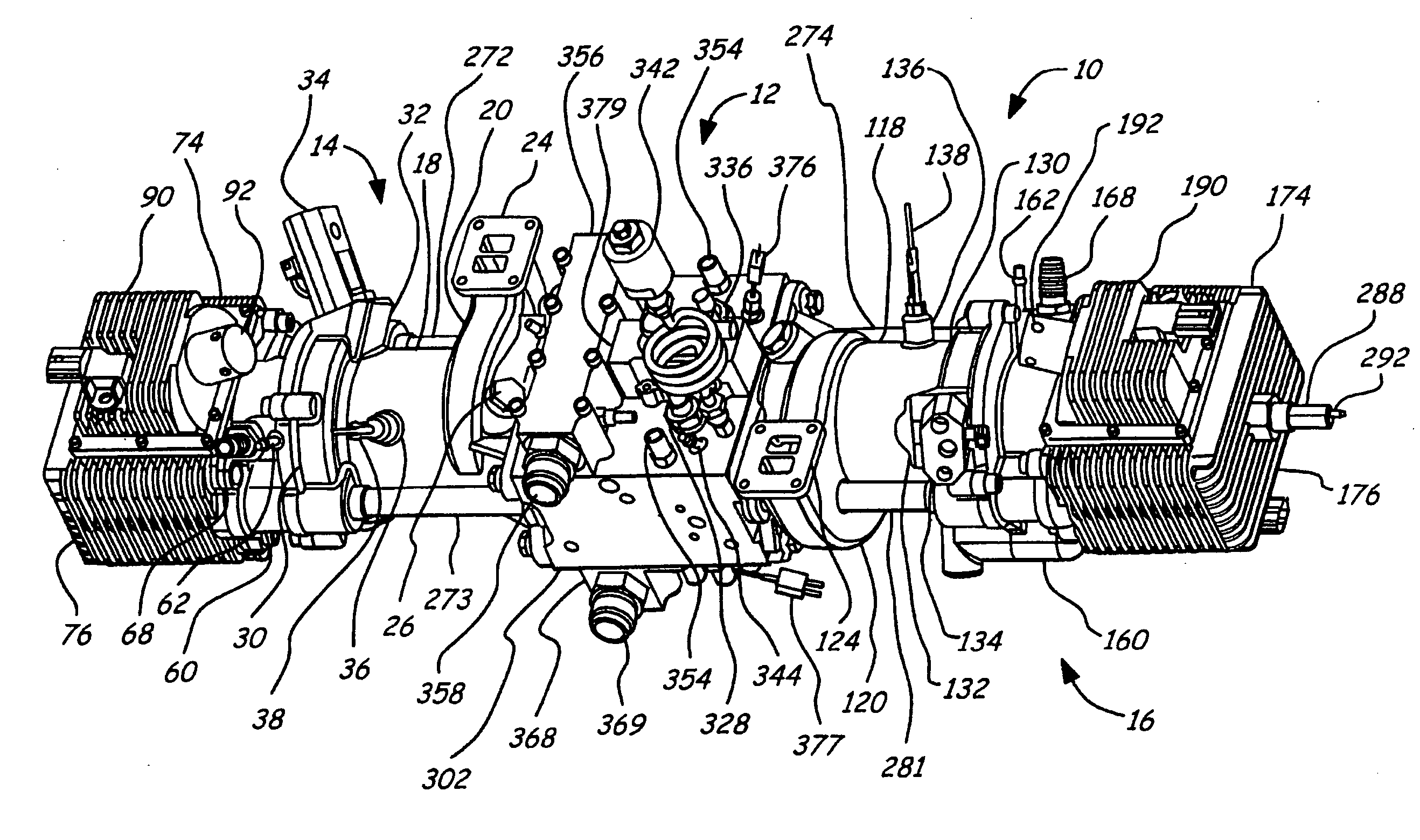

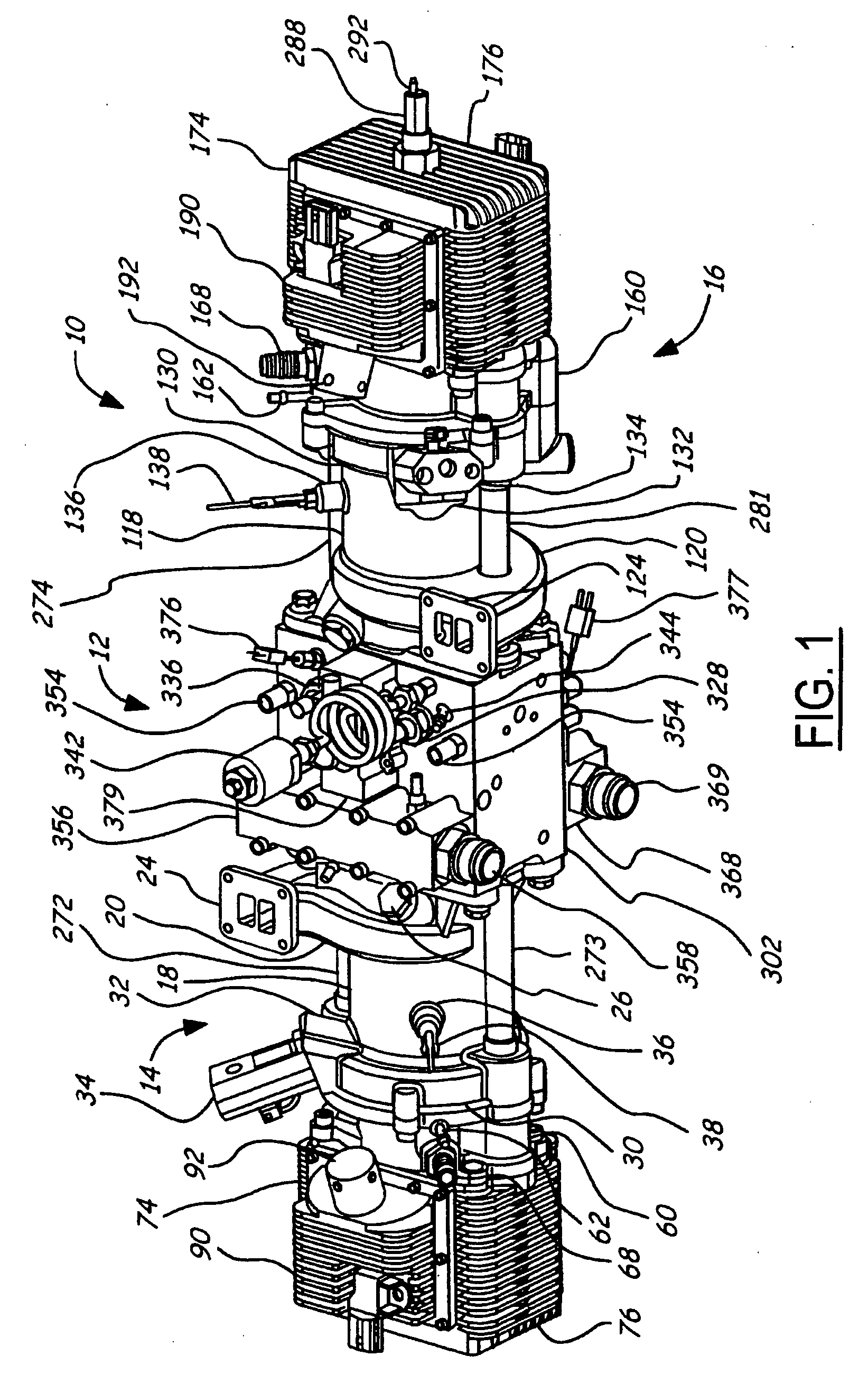

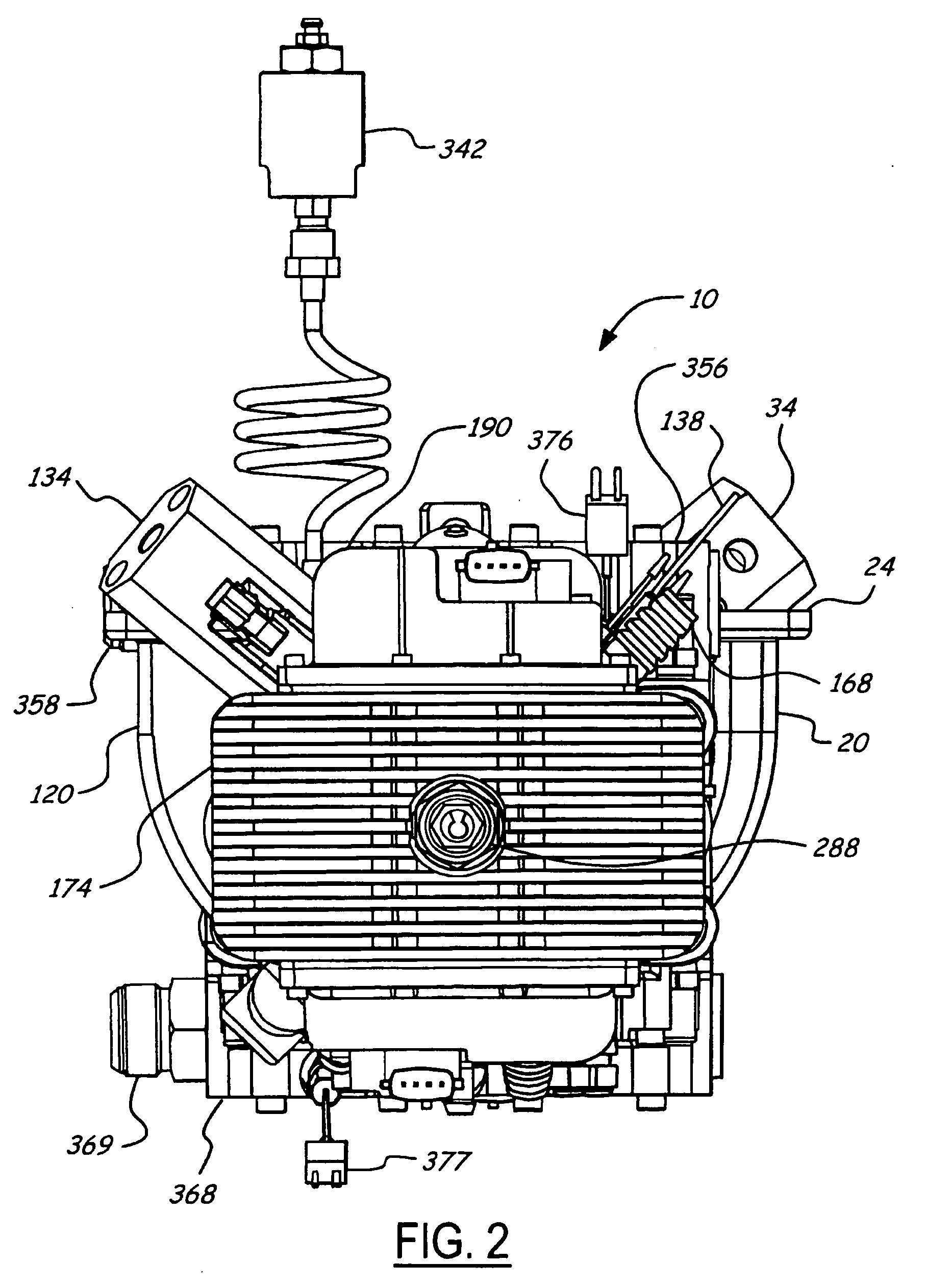

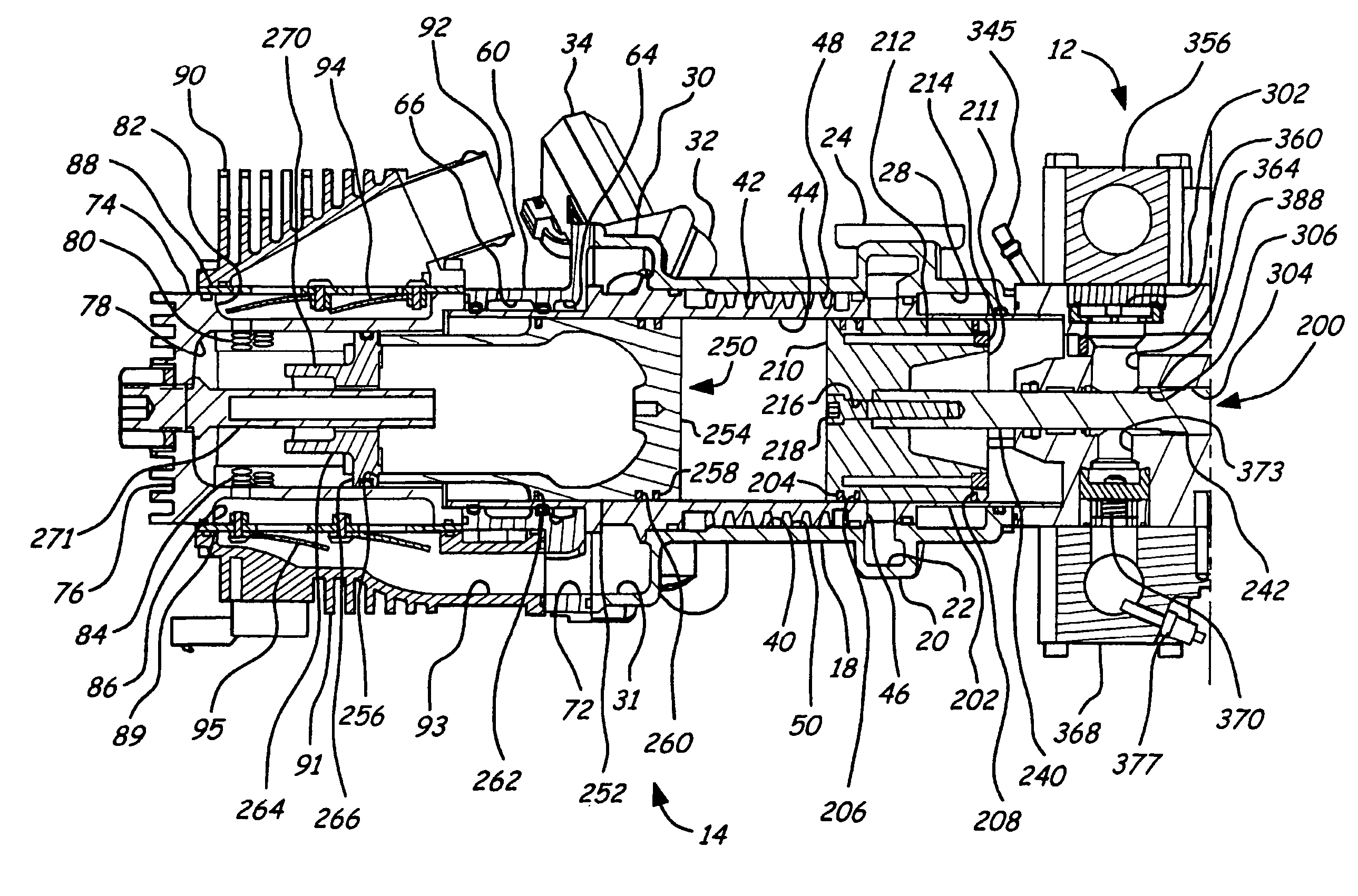

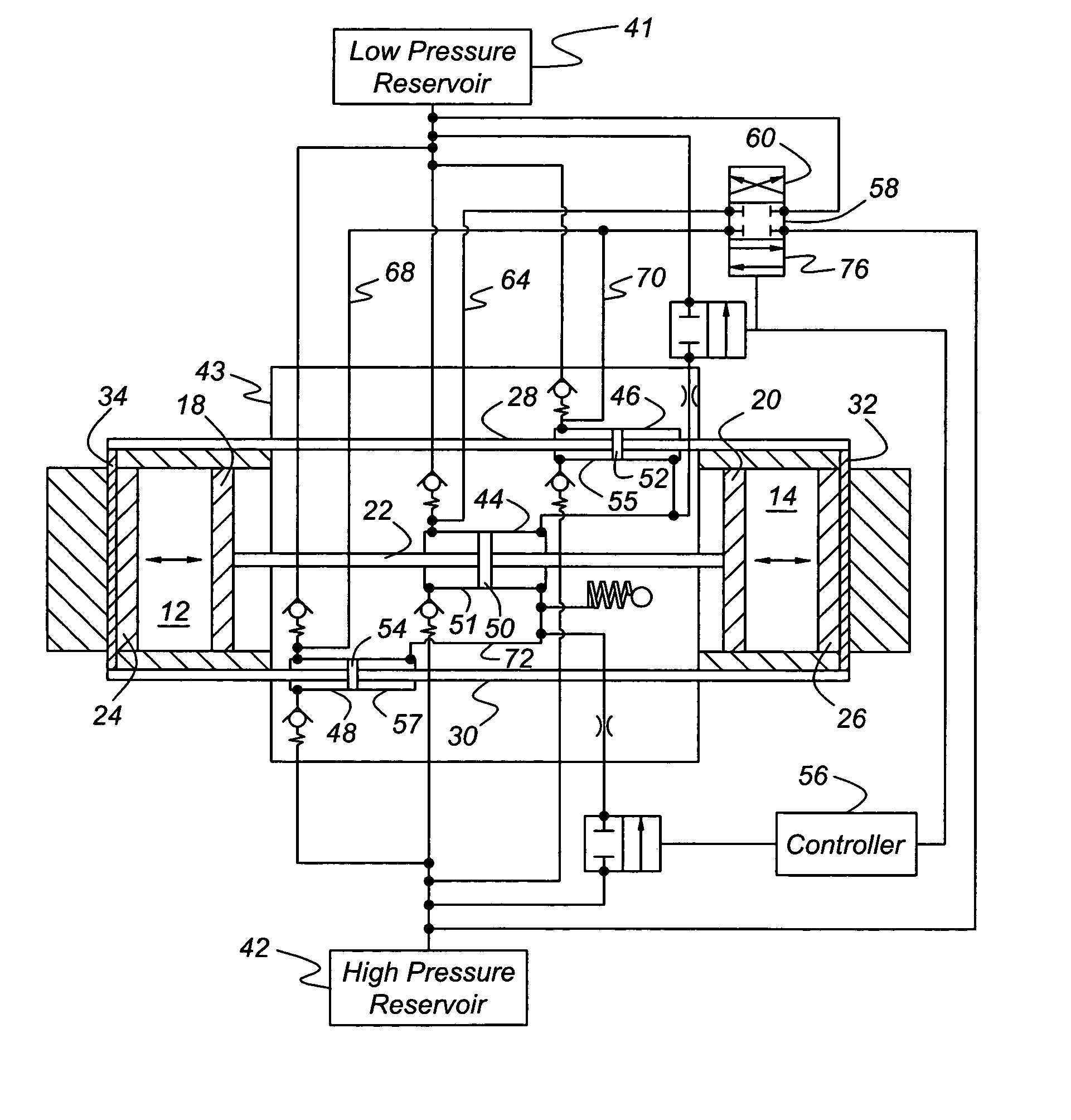

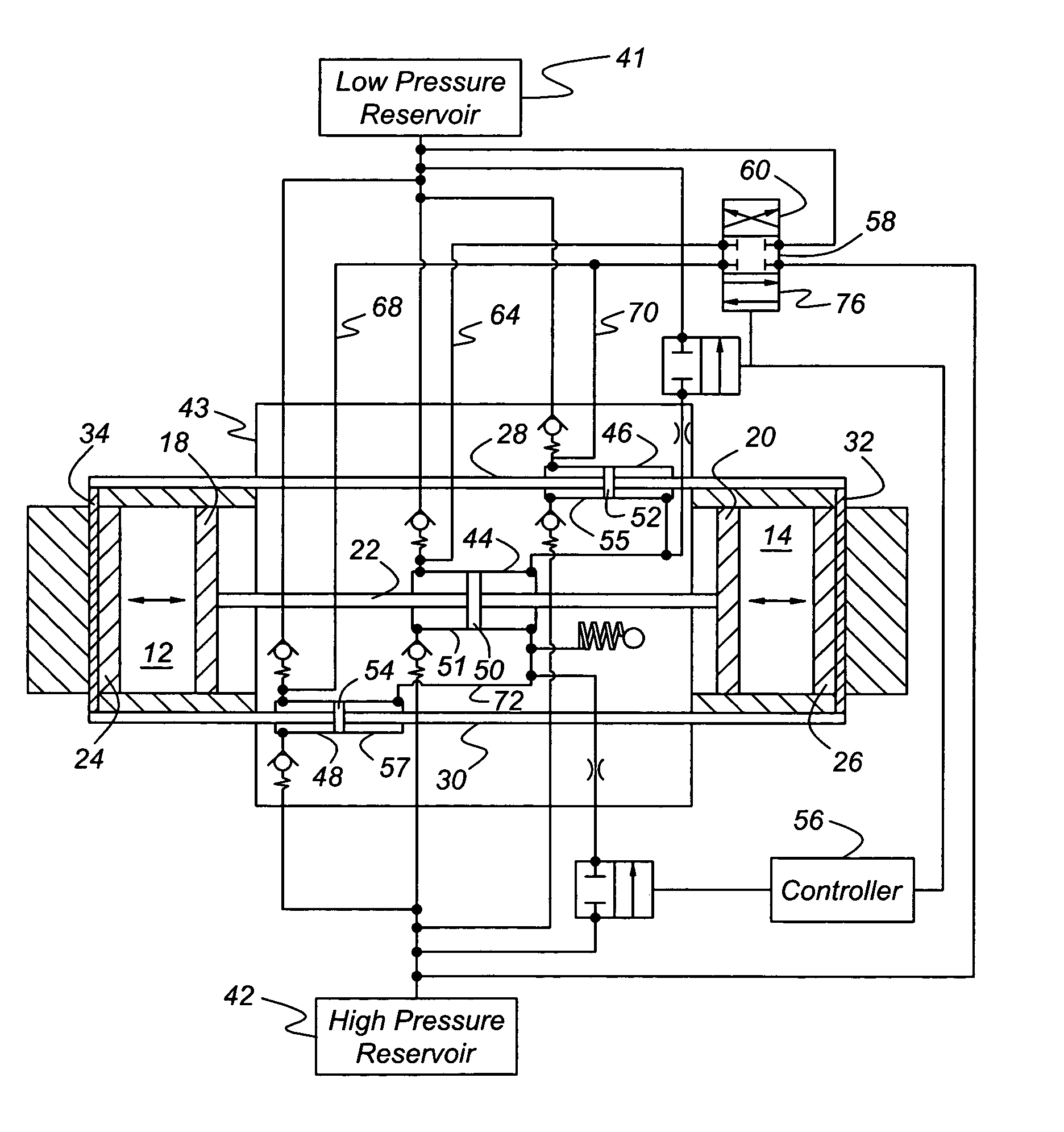

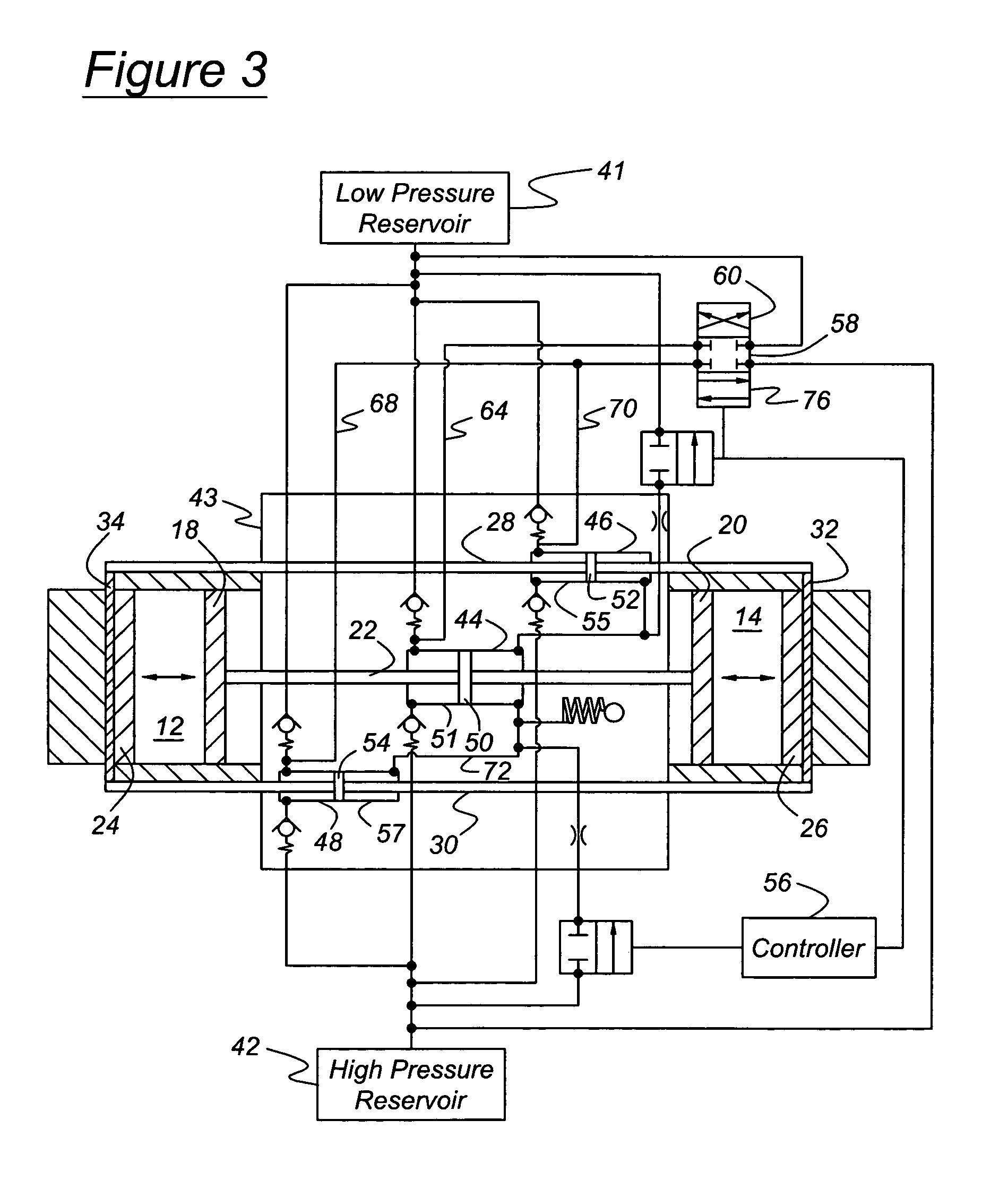

Exhaust gas recirculation for a free piston engine

InactiveUS6925971B1Easy to changeConducive effective homogeneous chargeNon-fuel substance addition to fuelExhaust gas recirculationFree-piston engineExhaust valve

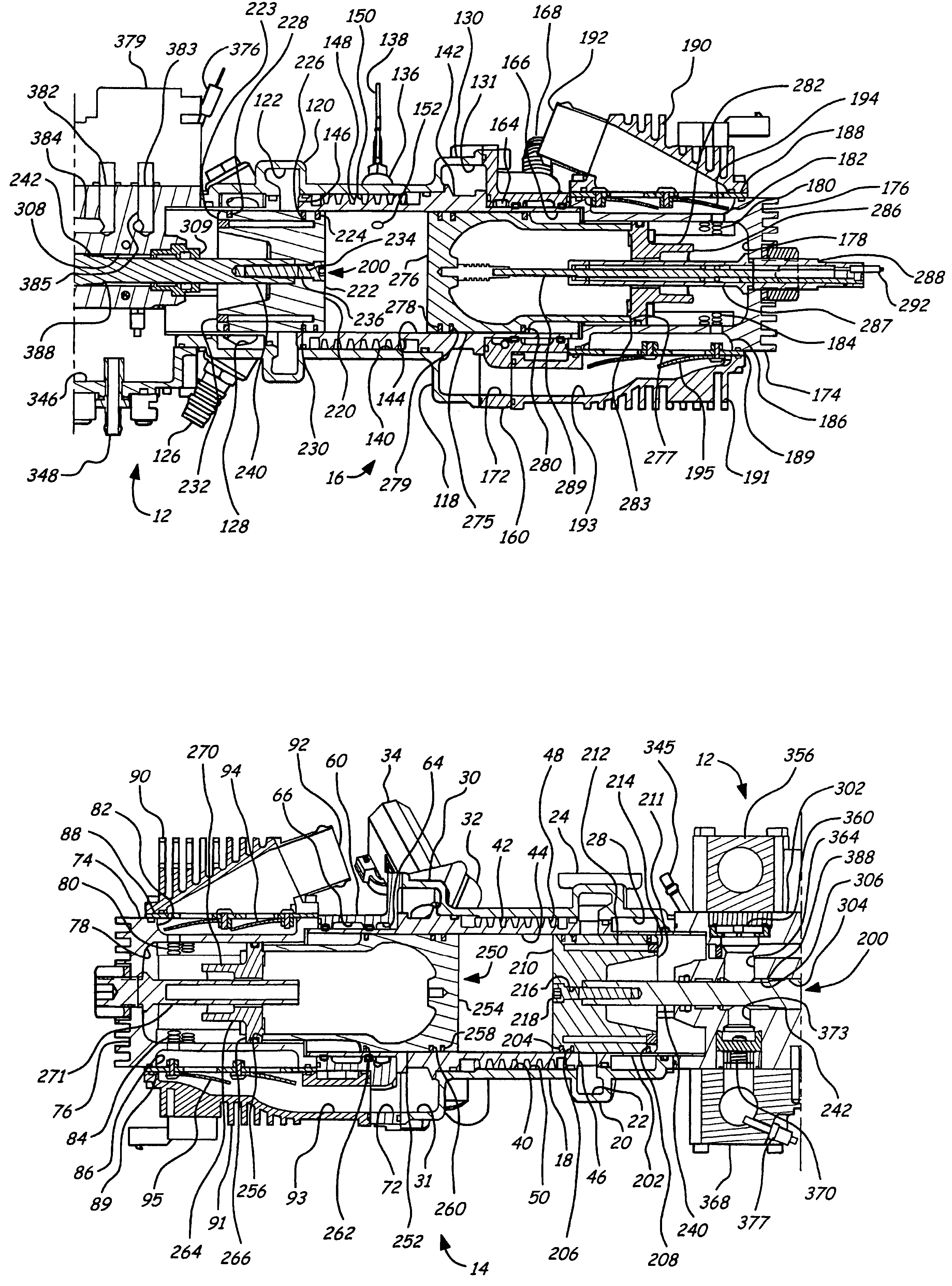

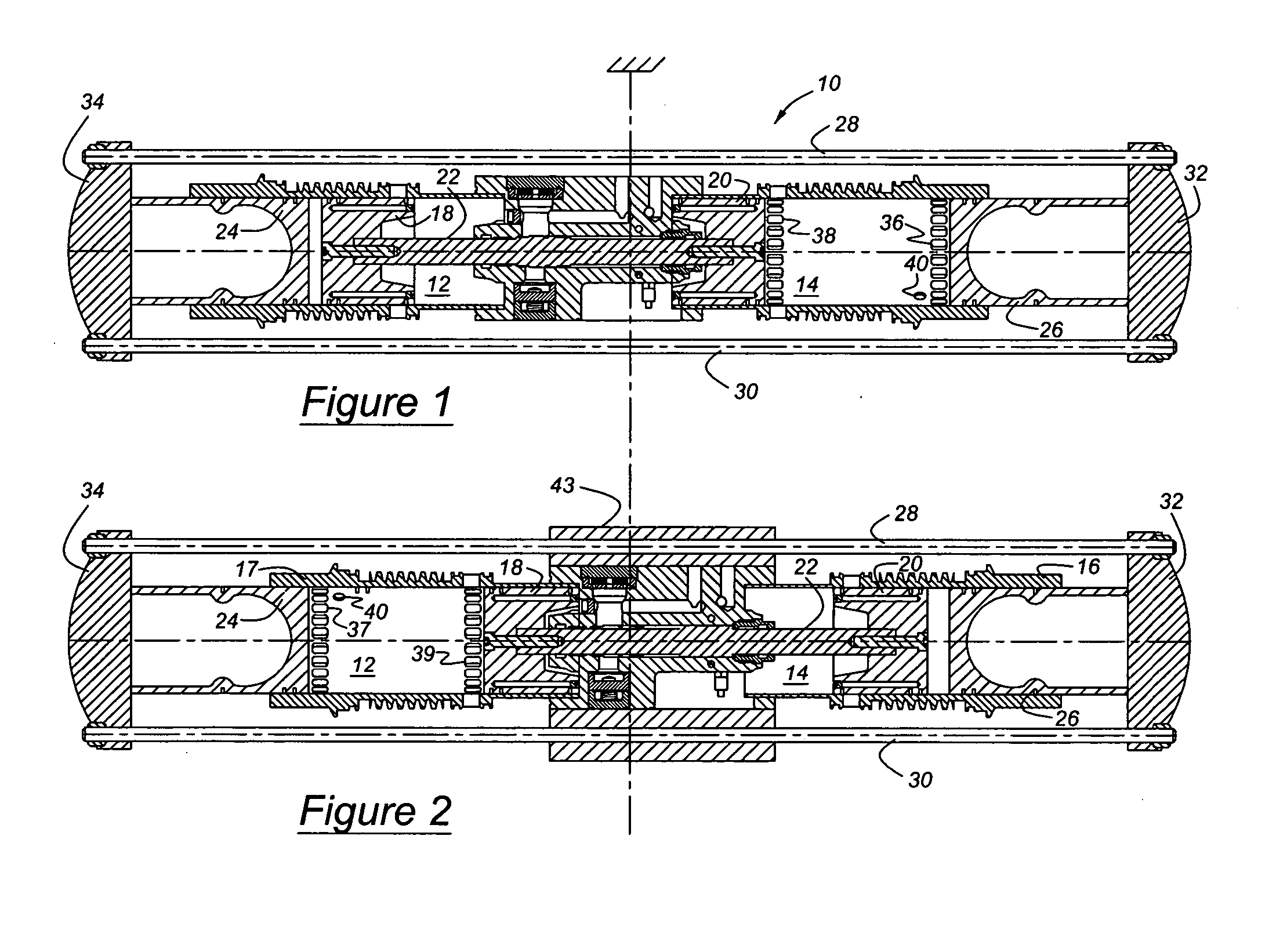

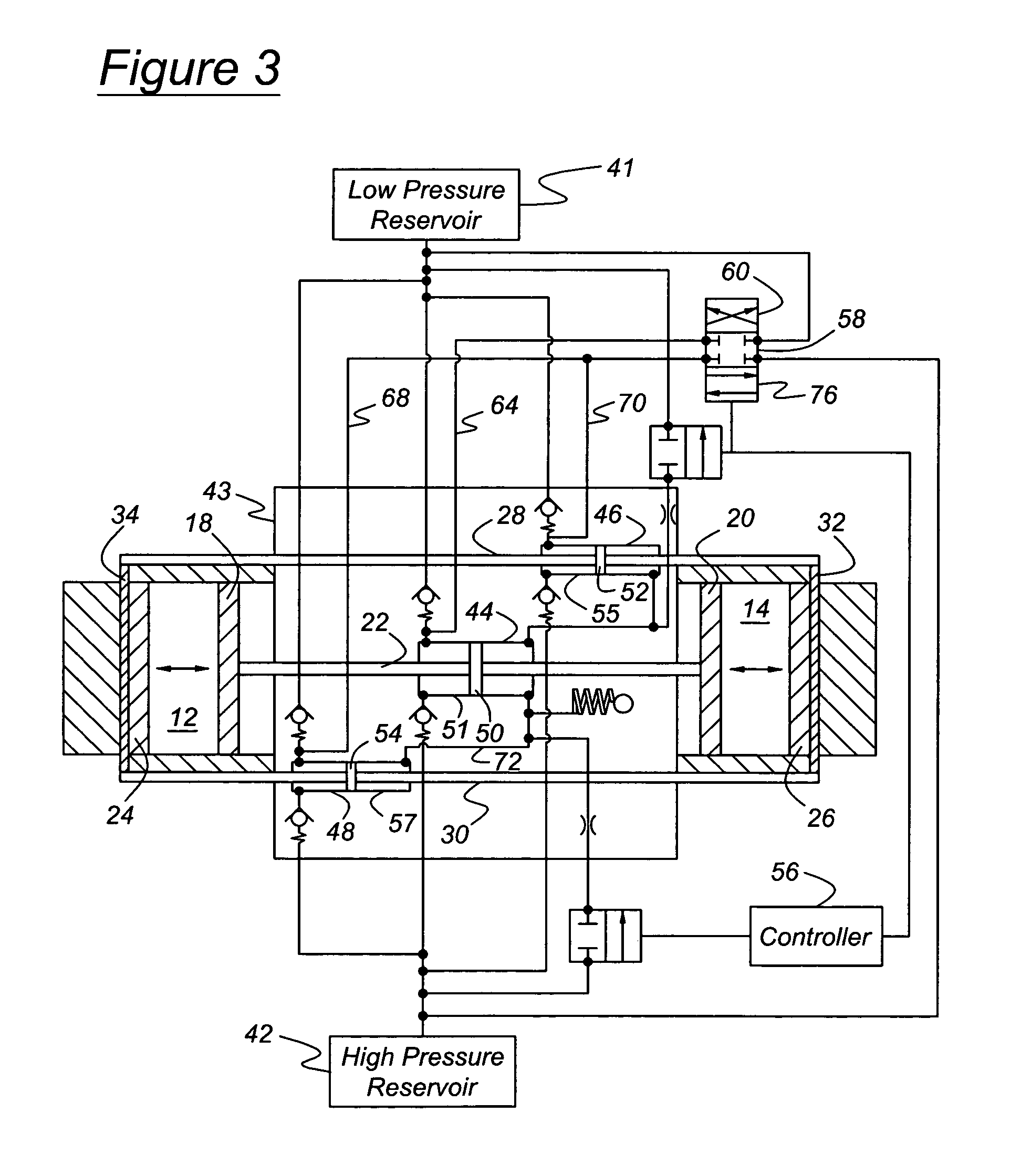

A free piston engine is configured with a pair of opposed engine cylinders located on opposite sides of a fluid pumping assembly. An inner piston assembly includes a pair of inner pistons, one each operatively located in a respective one of the engine cylinders, with a push rod connected between the inner pistons. The push rod extends through an inner pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. An outer piston assembly includes a pair of outer pistons, one each operatively located in a respective one of the engine cylinders, with at least one pull rod connected between the outer pistons. The pull rod extends through an outer pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. The movement of the inner and outer piston assemblies during engine operation will cause the fluid plungers to pump fluid from a low pressure container into a high pressure chamber as a means of storing the energy output from the engine. Alternatively, the piston assemblies may drive a linear alternator. The exhaust ports for each engine cylinder are sized and located to retain the desired amount of internal EGR in each cylinder without the need for exhaust valves. As an alternative, an external EGR system may supplement the internal EGR in order to obtain the desired EGR at the desired temperature.

Owner:FORD GLOBAL TECH LLC

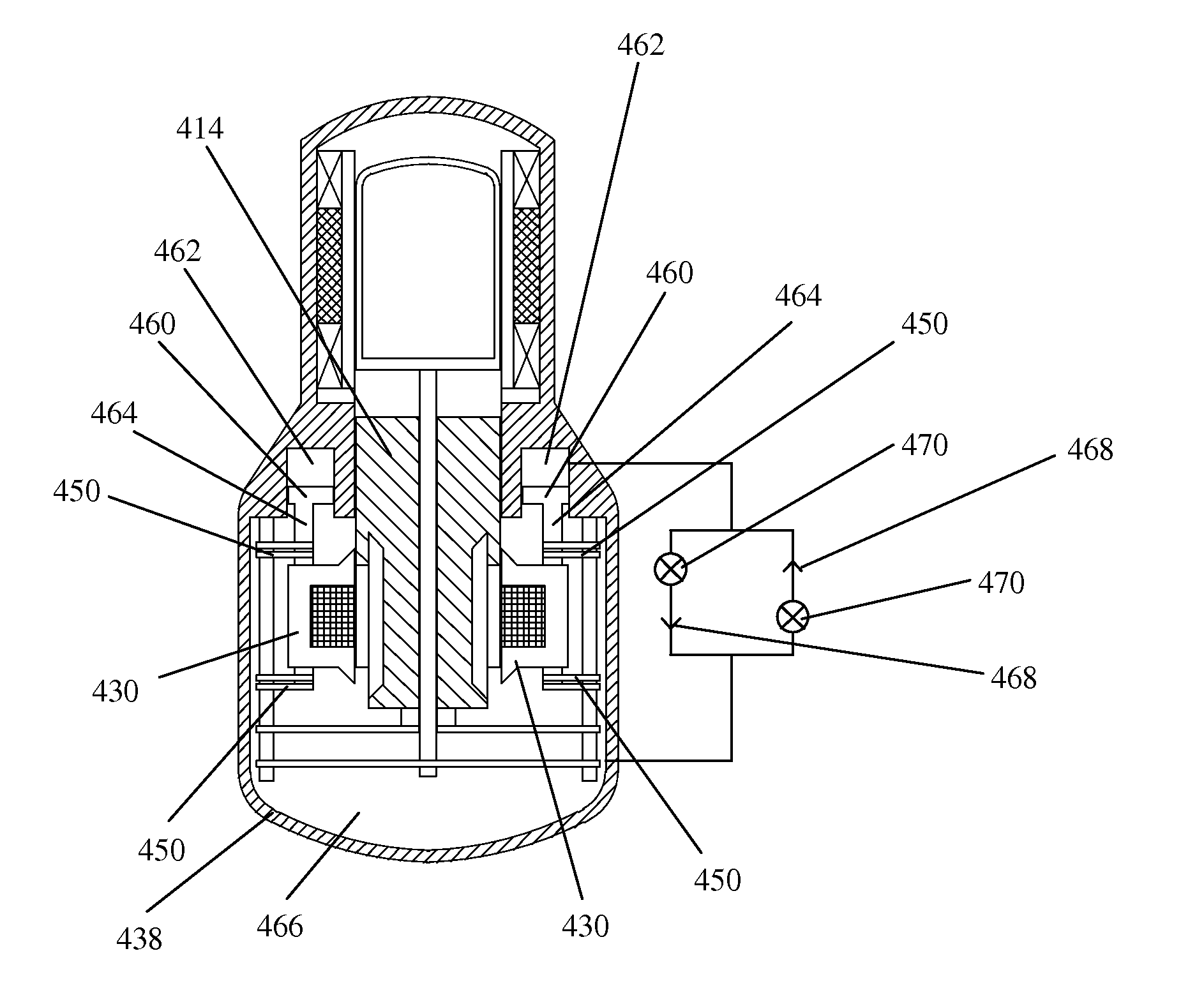

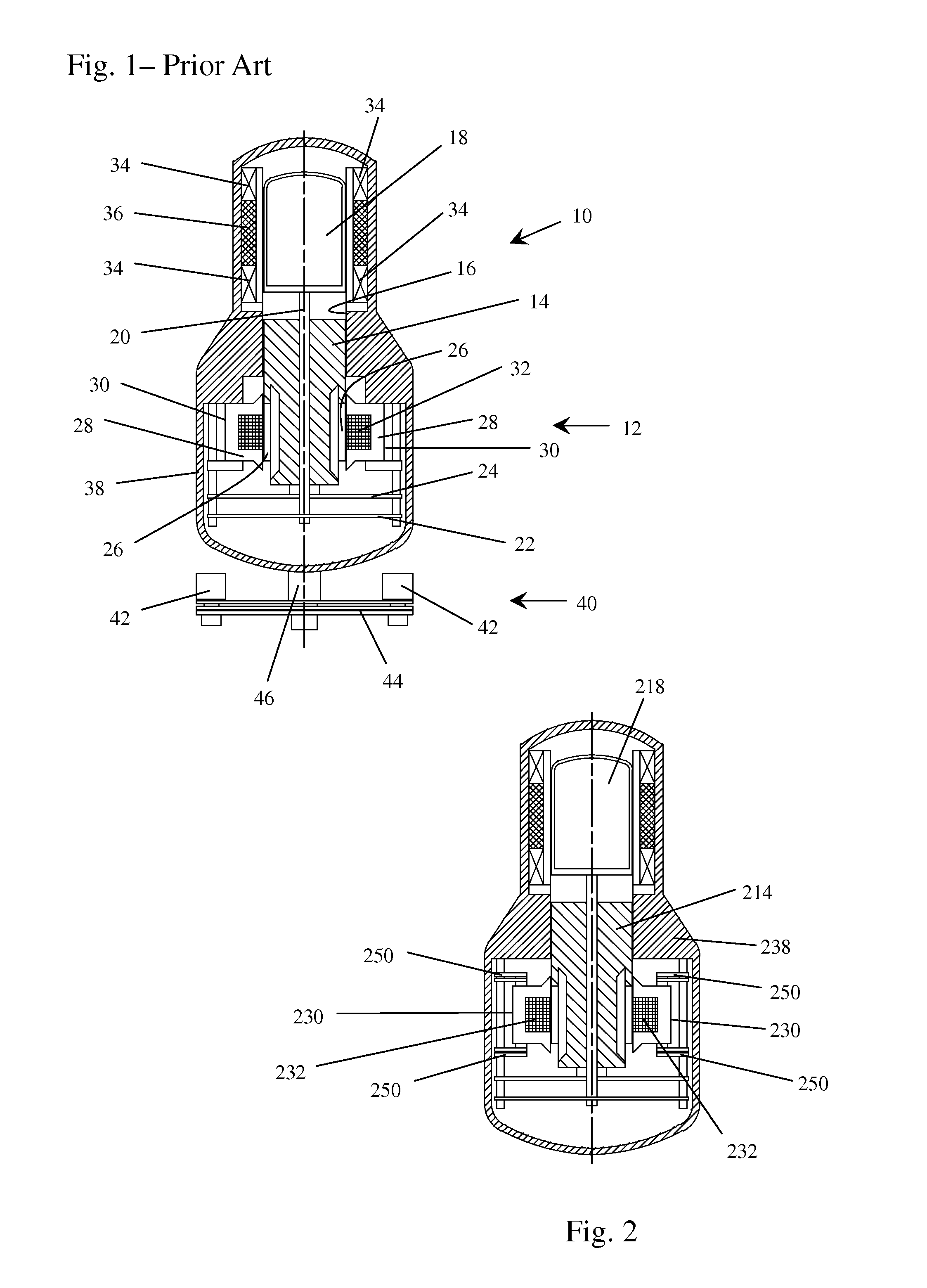

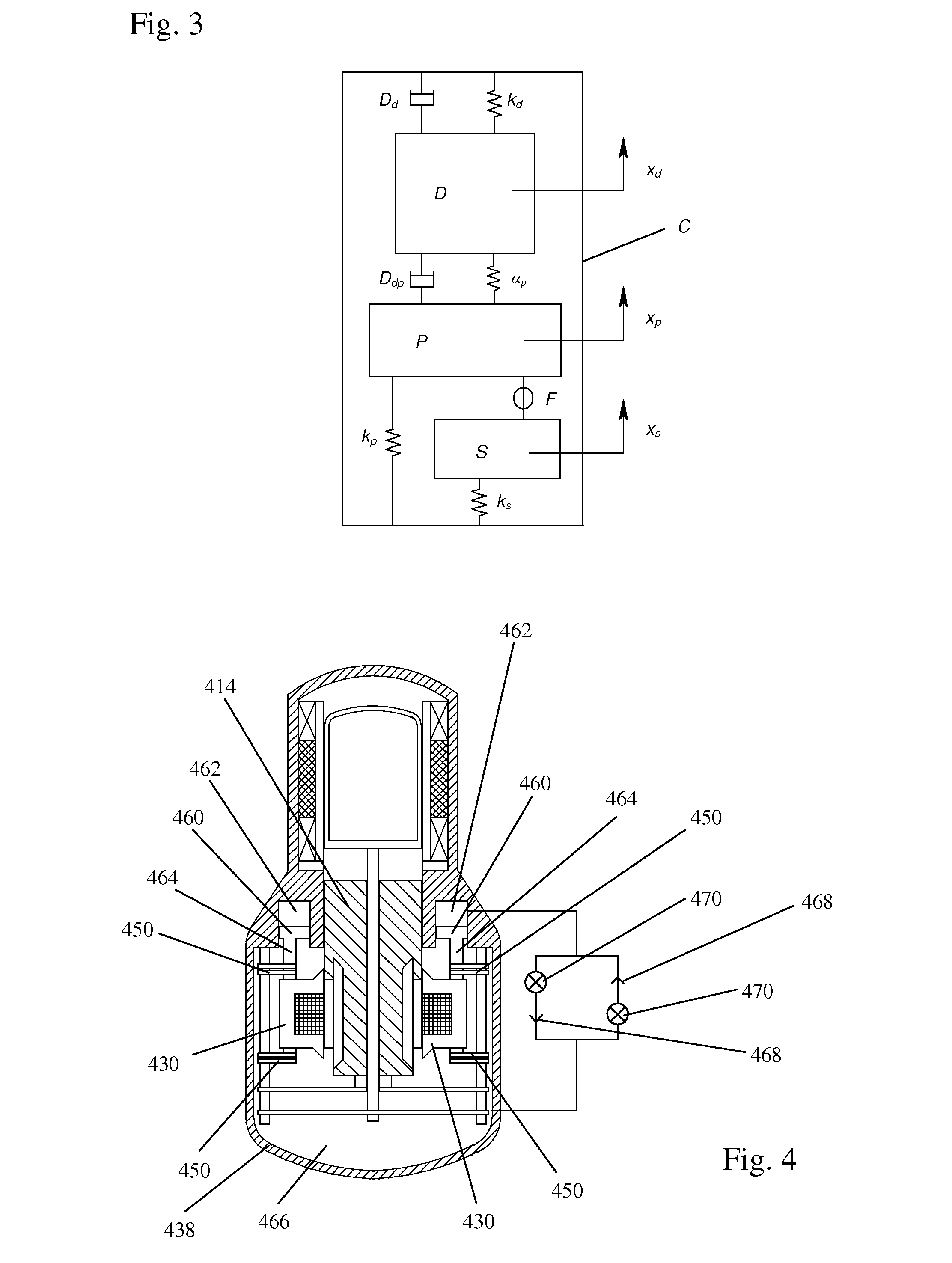

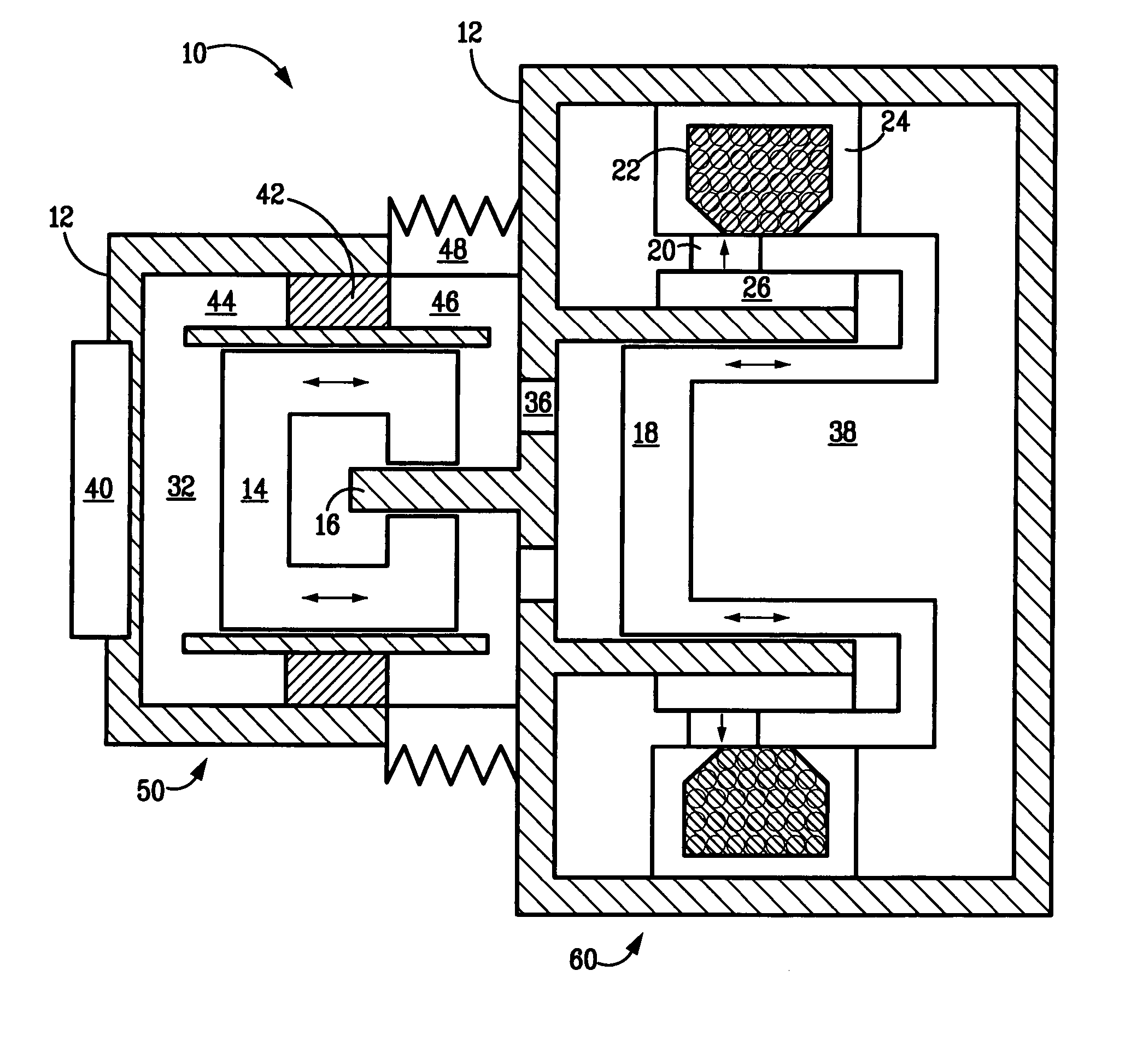

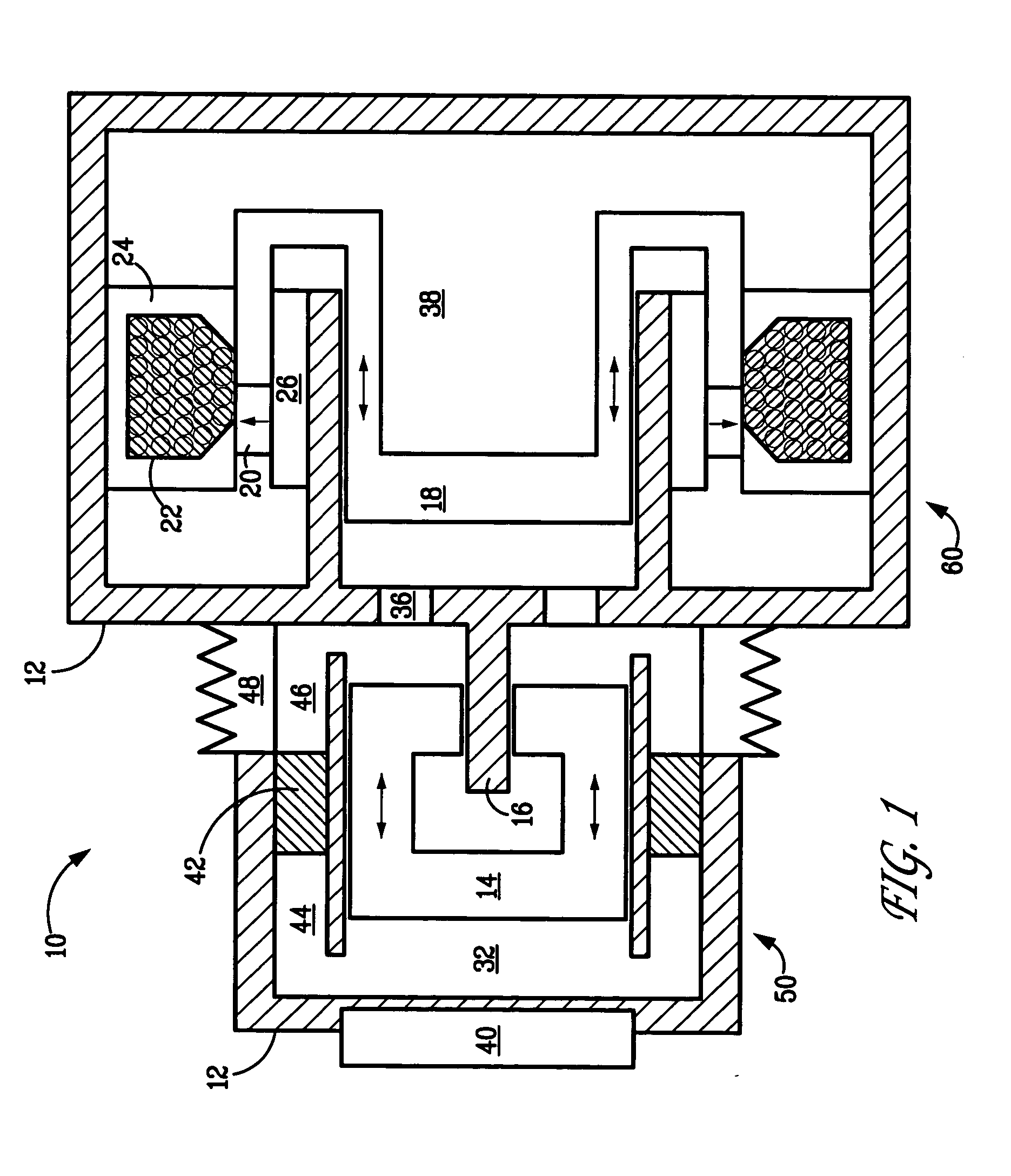

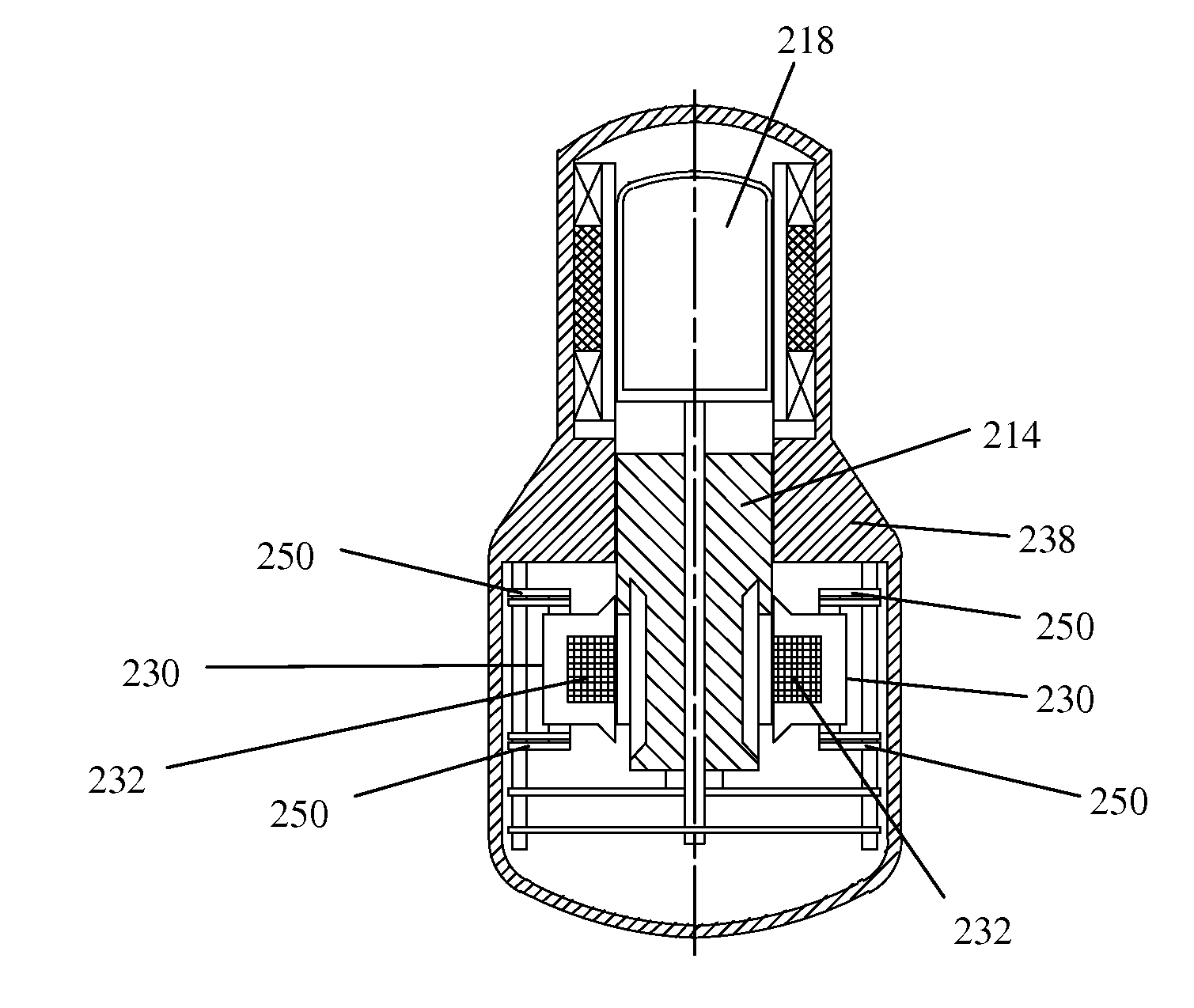

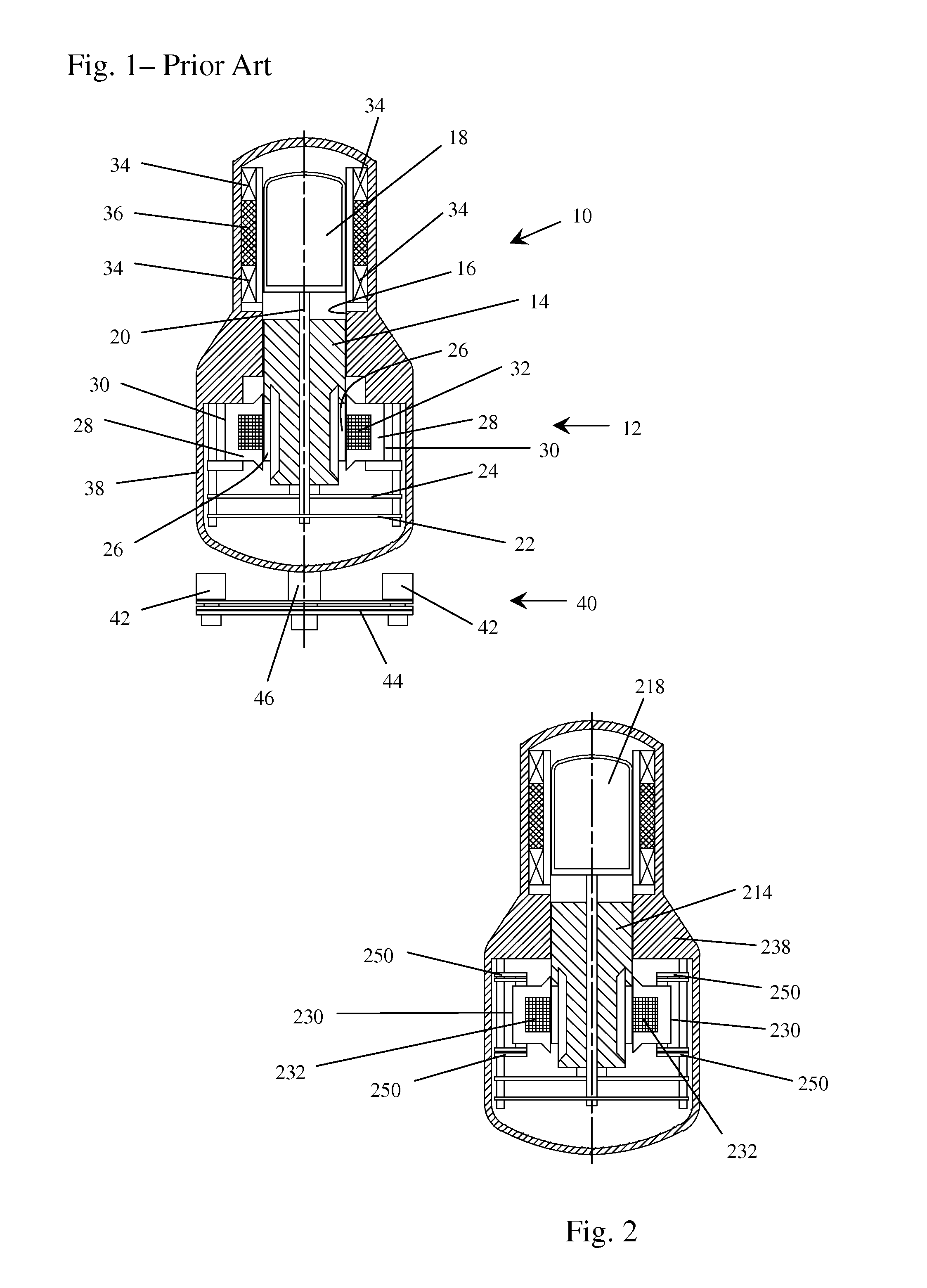

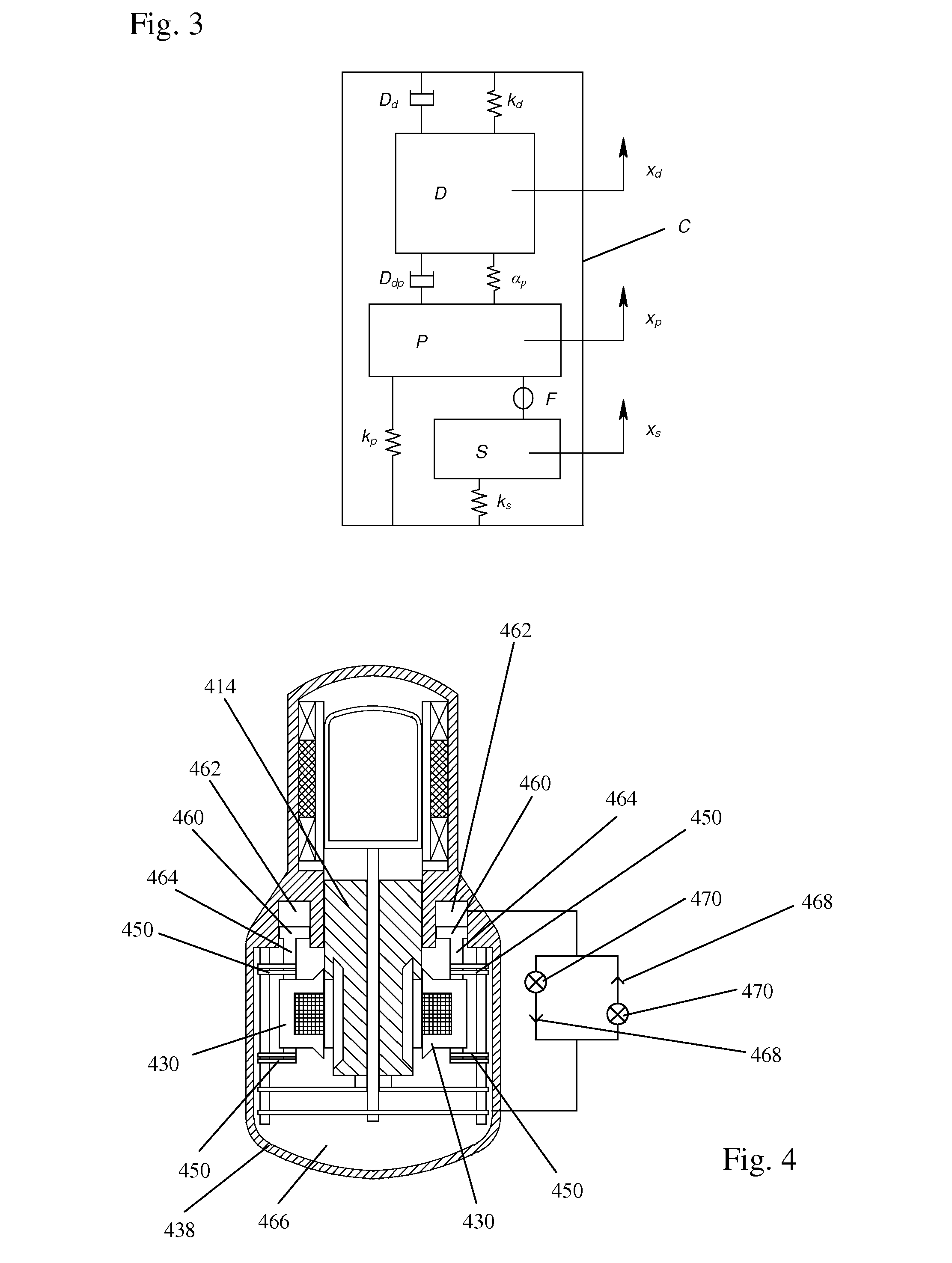

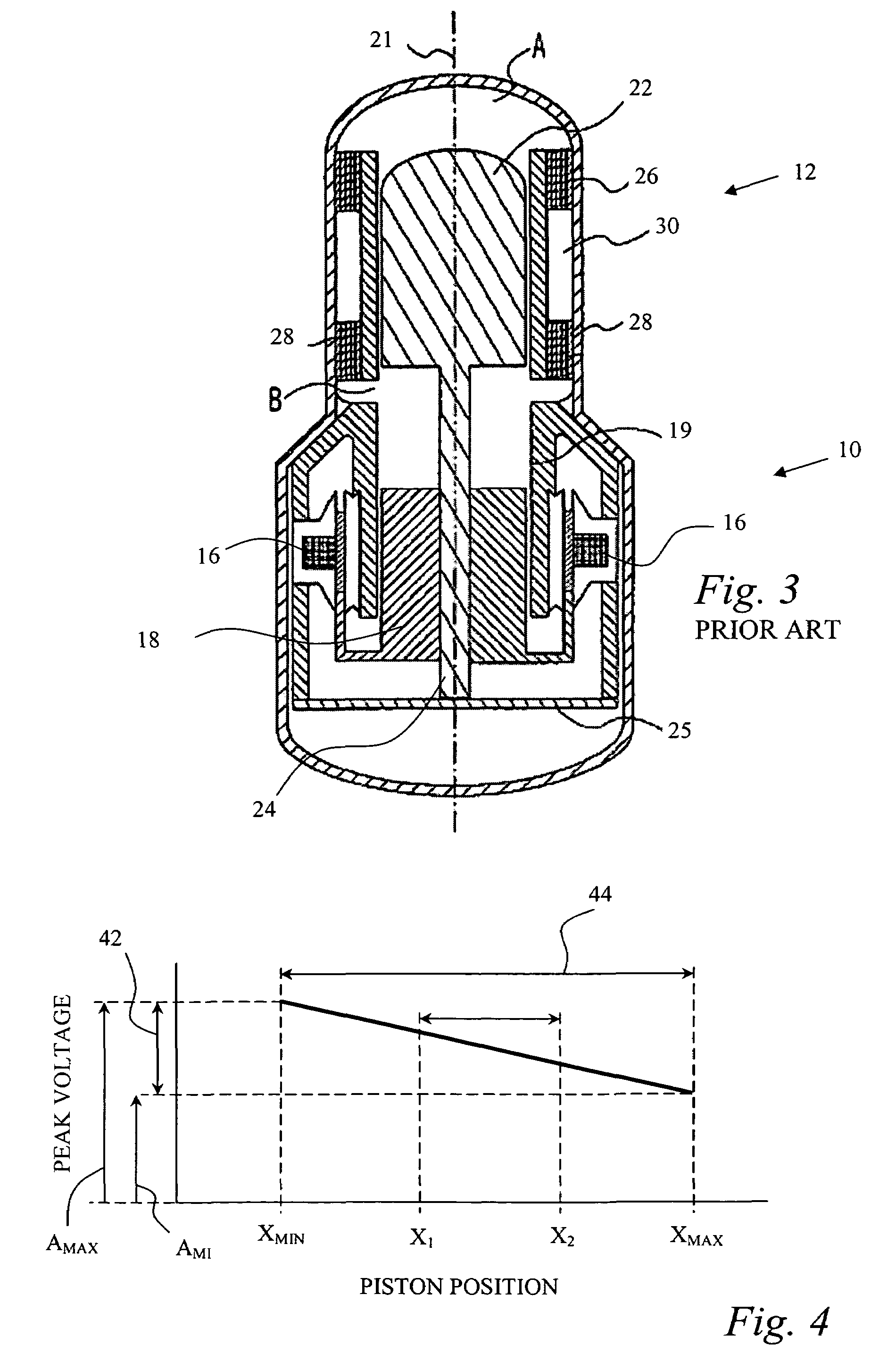

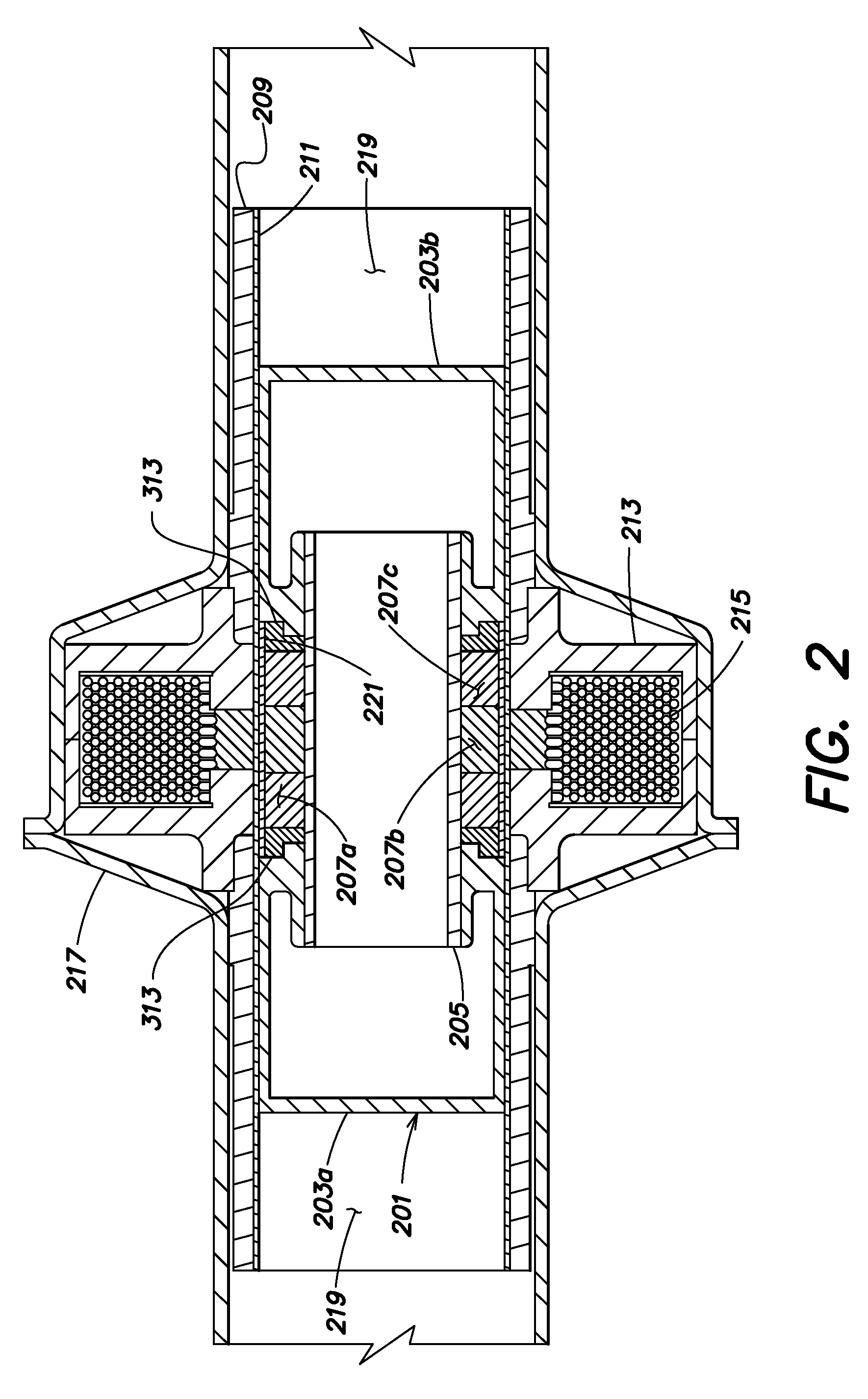

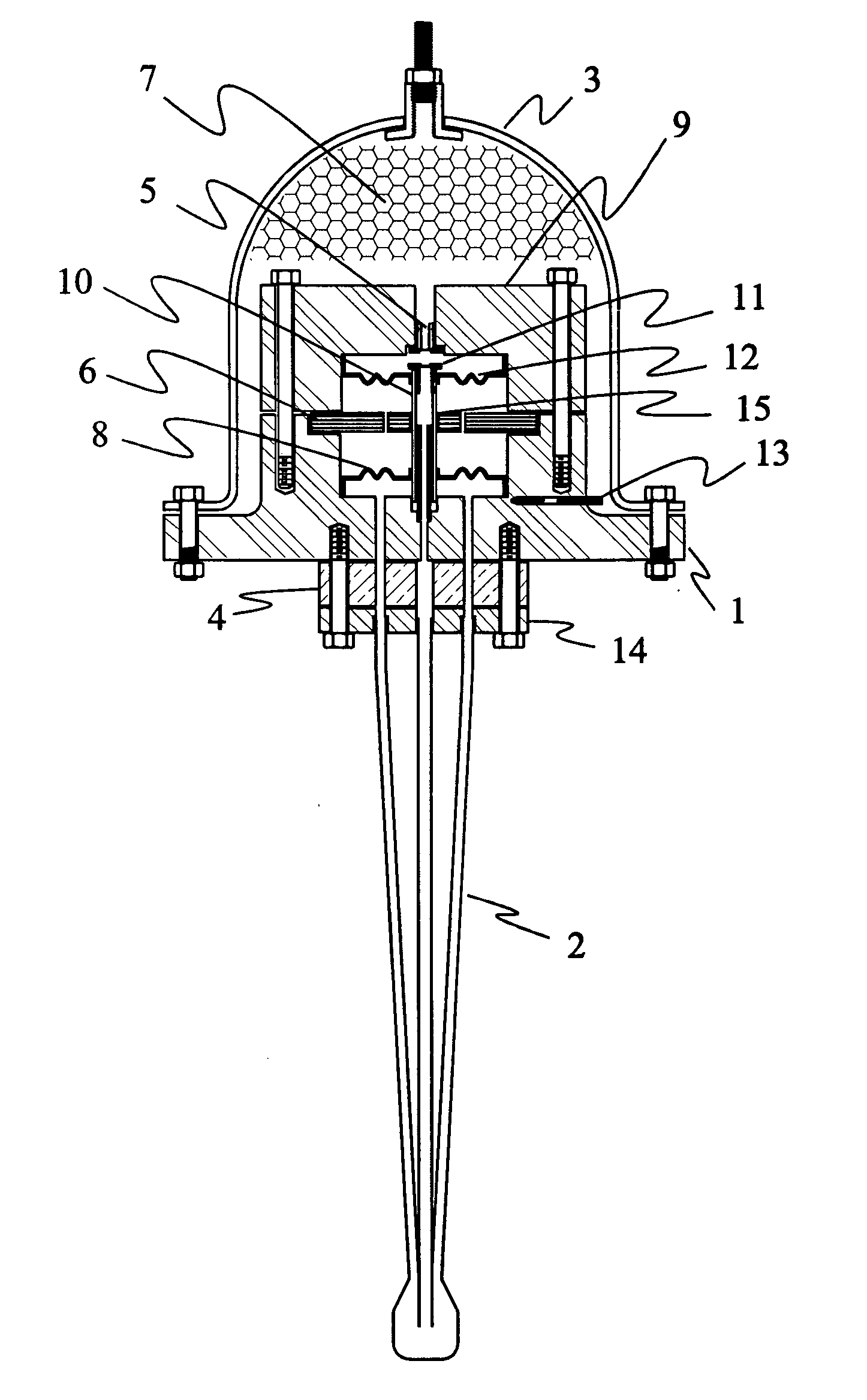

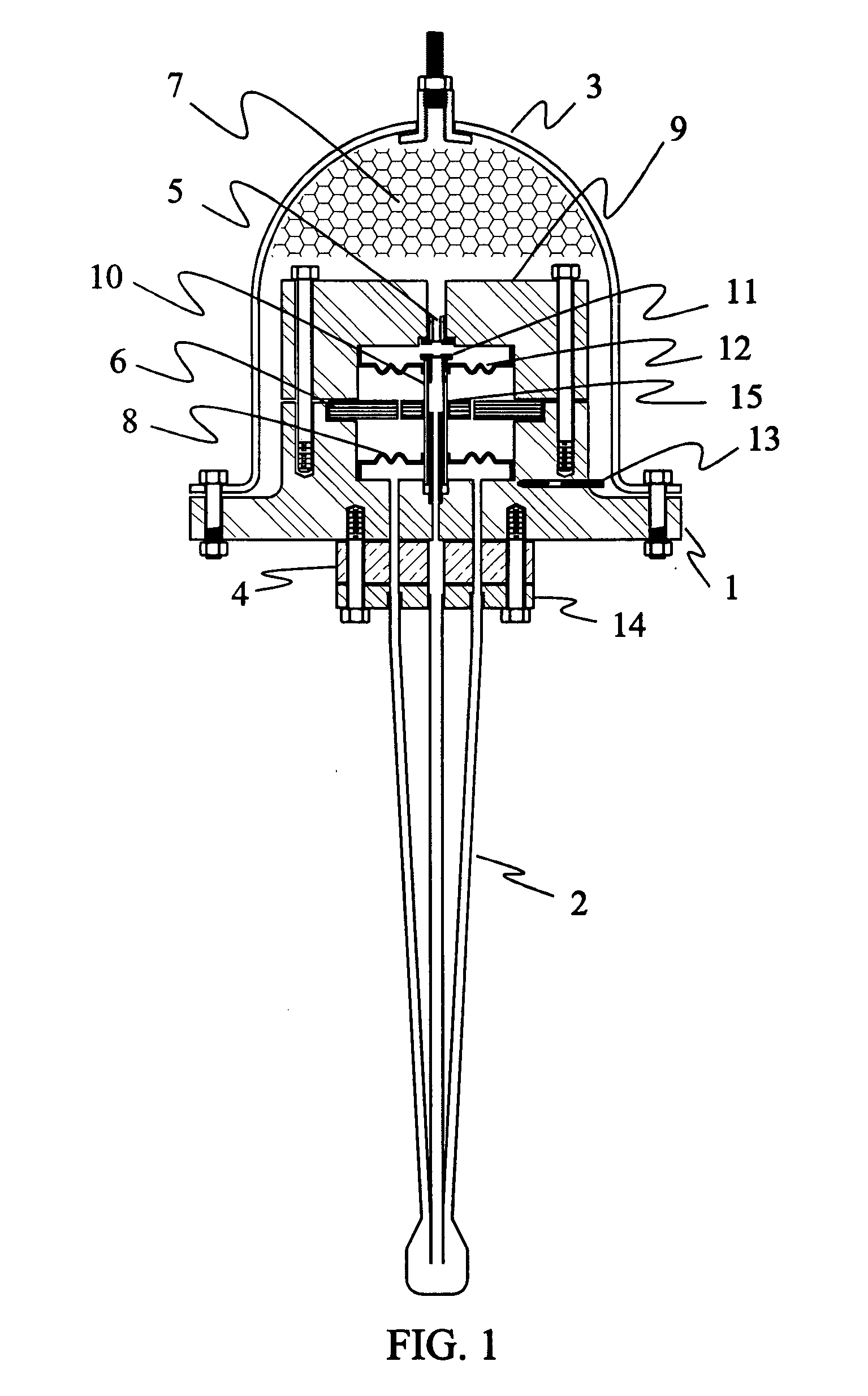

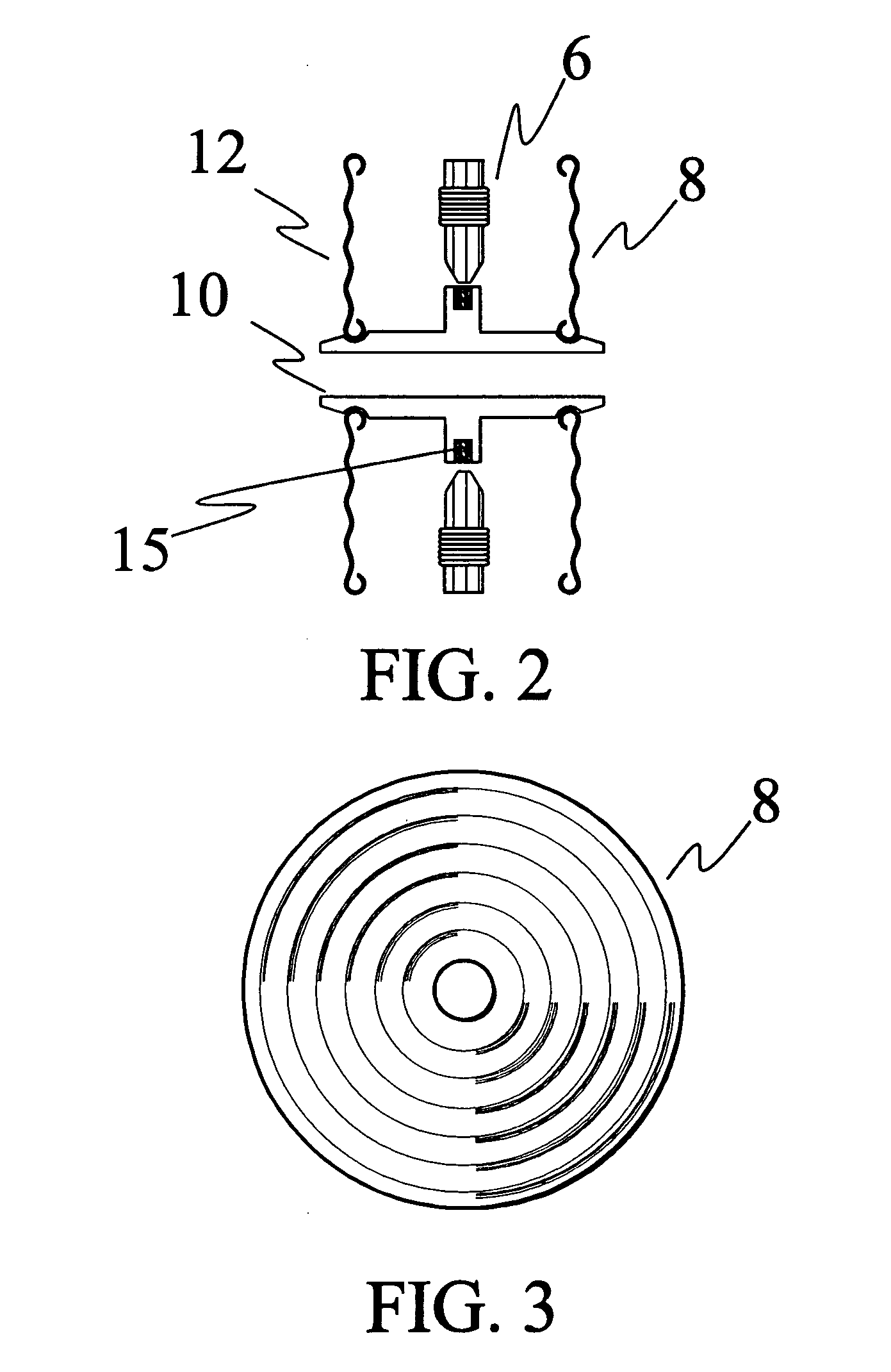

Resonant stator balancing of free piston machine coupled to linear motor or alternator

ActiveUS20090039655A1Vibration is reduced and minimized and eliminatedEliminate needSafety/regulatory devicesMechanical energy handlingEngineeringOperating frequency

A beta-type free-piston Stirling cycle engine or cooler is drivingly coupled to a linear alternator or linear motor and has an improved balancing system to minimize vibration without the need for a separate vibration balancing unit. The stator of the linear motor or alternator is mounted to the interior of the casing through an interposed spring to provide an oscillating system permitting the stator to reciprocate and flex the spring during operation of the Stirling machine and coupled transducer. The natural frequency of oscillation, ωs, of the stator is maintained essentially equal to ωpωp1-αpkpand the natural frequency of oscillation of the piston, ∩p, is maintained essentially equal to the operating frequency, ωo of the coupled Stirling machine and alternator or motor. For applications in which variations of the average temperature and / or the average pressure of the working gas cause more than insubstantial variations of the piston resonant frequency ωp, various alternative means for compensating for those changes in order to maintain vibration balancing are also disclosed.

Owner:GLOBAL COOLING

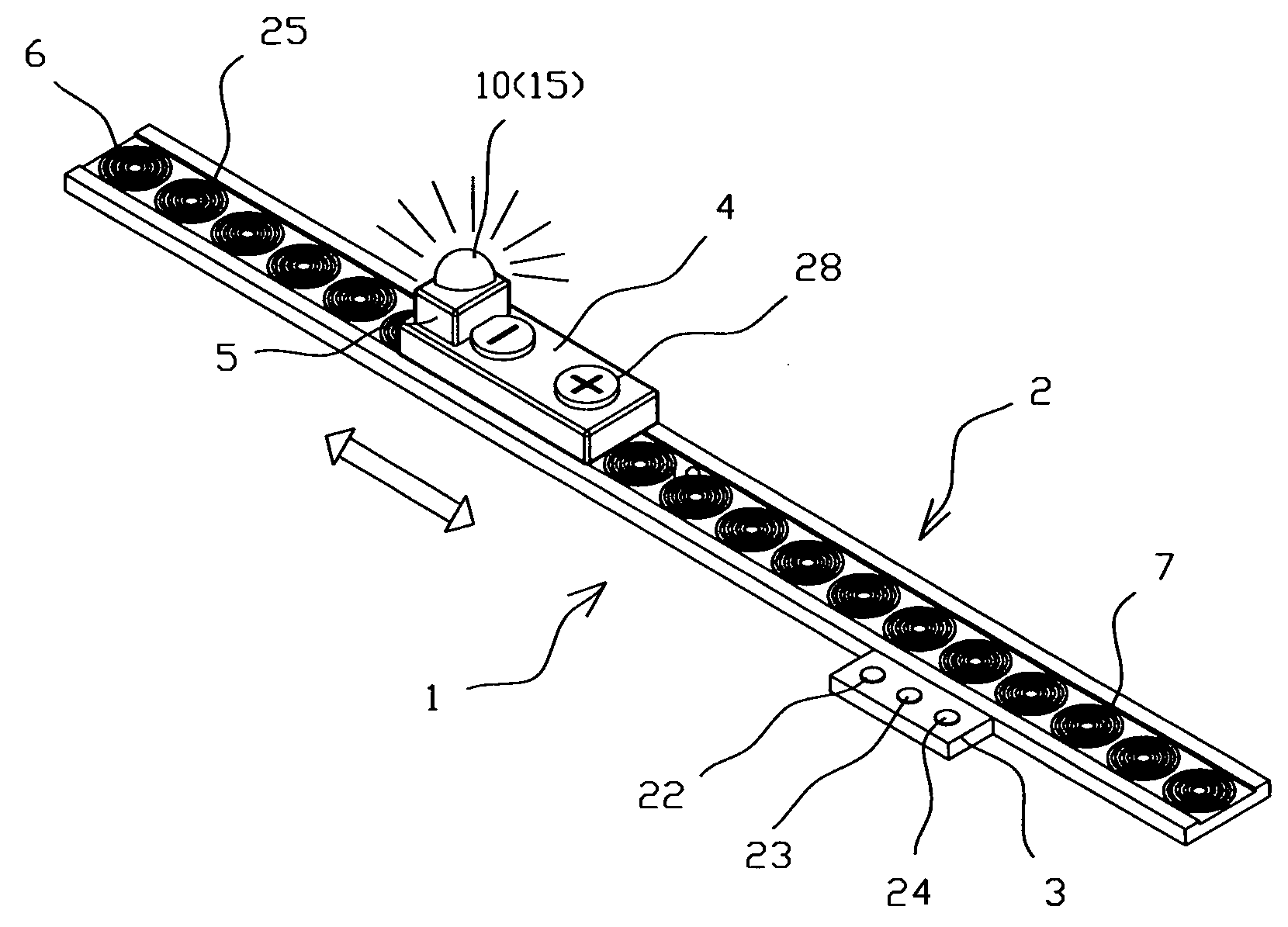

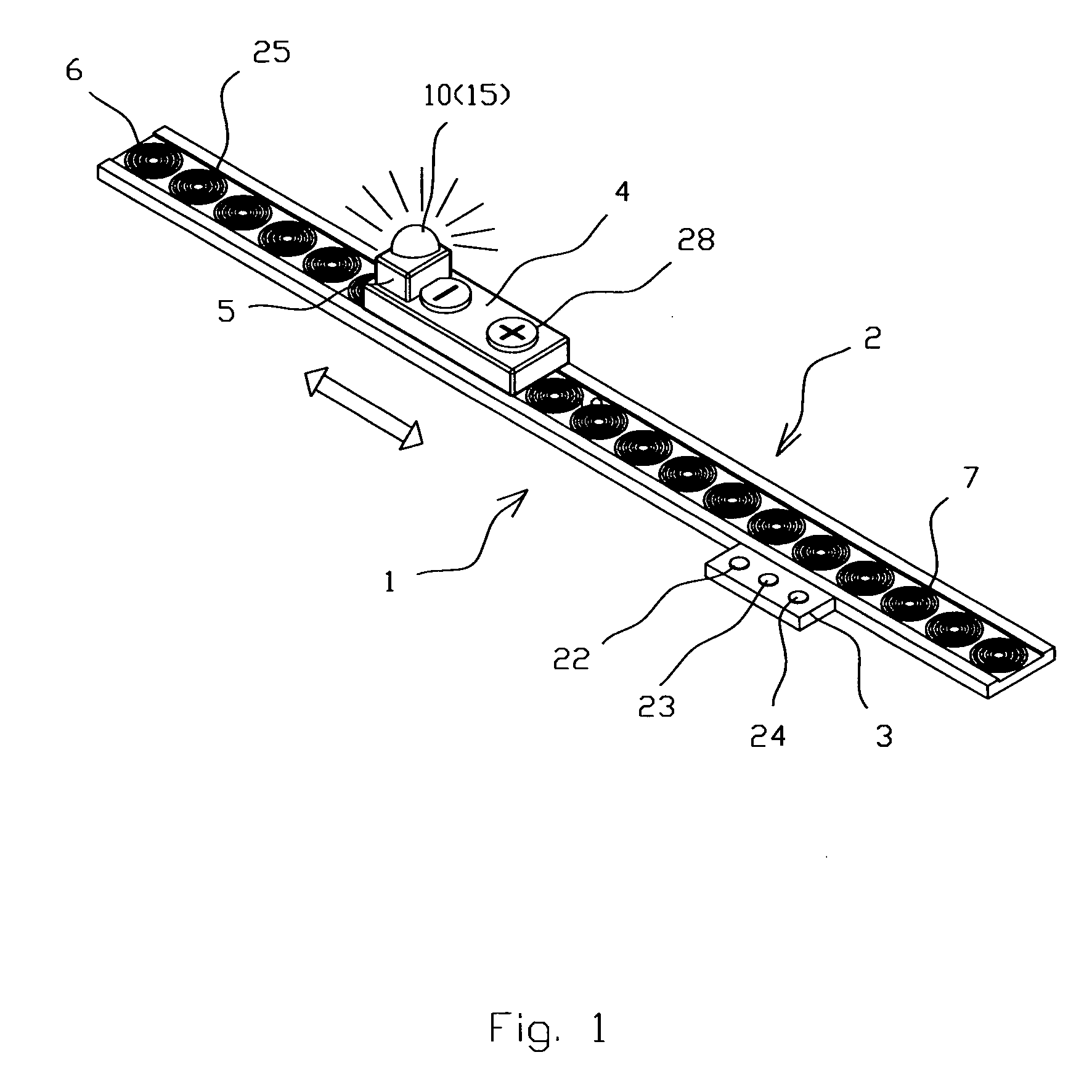

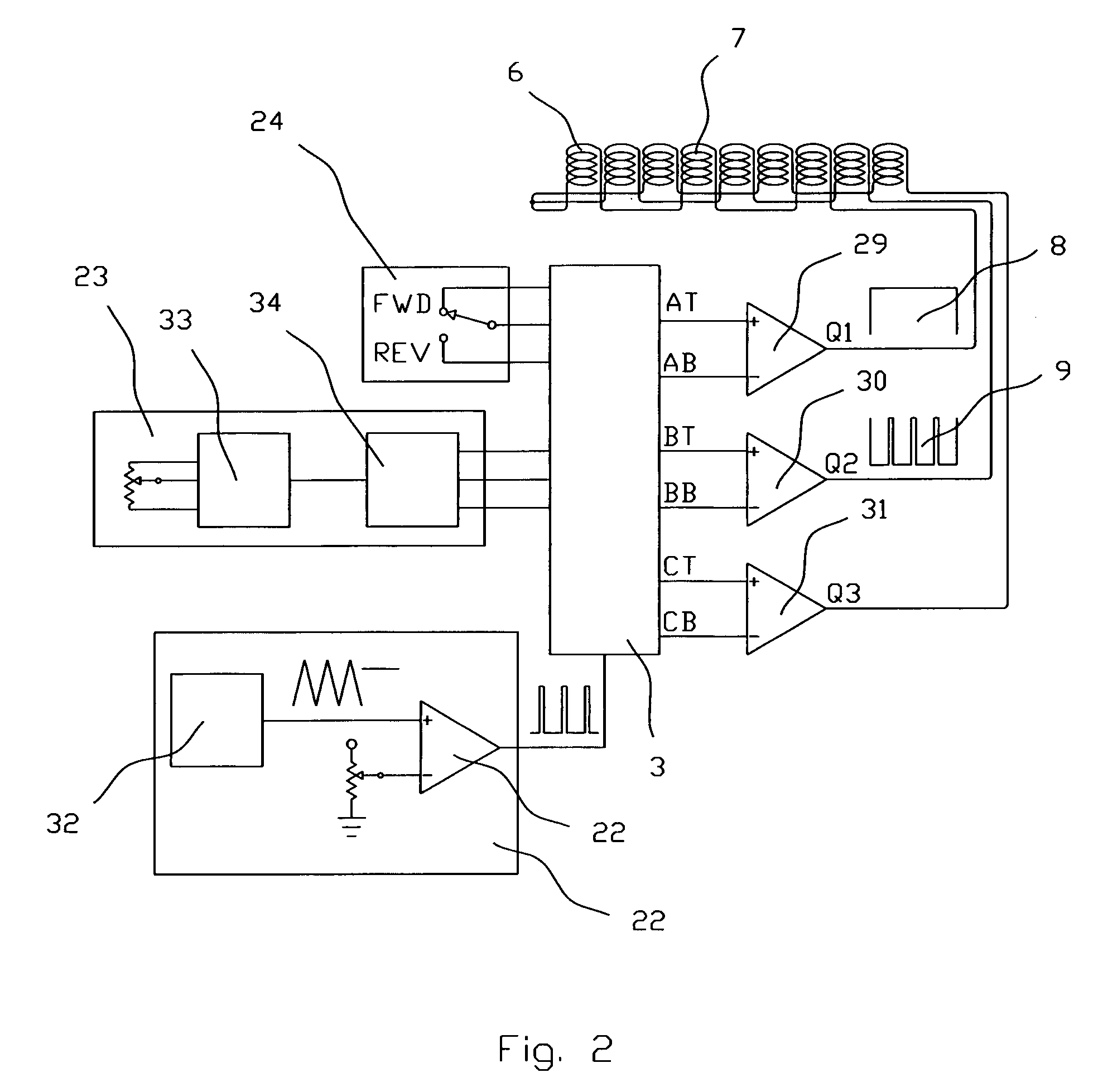

Energy converting system

InactiveUS20070283841A1Improve system efficiencyRailway vehiclesToy trackwaysElectricityLinear alternator

An energy converting system is comprised of a track, a controller, and a magnetized body located on the track and including an energy converting unit. The track comprises electrically connected coil windings spaced apart in a series way along the track to form a 3-phase linear stator. The controller is electrically connected with the linear stator and generates a combination waveform consisting of a multi-phase propulsion signal and a power signal. The propulsion and power signals are at different frequencies. The propulsion signal causes the interaction of the magnetized body with the linear stator, thus propelling the magnetized body along the track. The energy converting unit comprises electrically connected energy consuming means and at least one pick-up coil inductively coupled to the linear stator, thus providing power to the energy consuming means.

Owner:INDAL DESIGN LAB

Thermoacoustic engine-generator

InactiveUS6910332B2Optimized areaLower impedancePiezoelectric/electrostriction/magnetostriction machinesStirling type enginesThermal energyWorking fluid

A thermoacoustic engine-generator that converts waste heat into electrical power. Thermal energy is converted to useful work via temperature-pressure amplification of periodic acoustic traveling waves in a compressible working fluid which cause the armature of a linear alternator to reciprocate and produce alternating current electrical energy. An external oscillator initiates reciprocating motion in the armature of a linear alternator. The armature is a combination fluid pump and fluid motor as well as the induction armature of a linear alternator. The pump end of the armature generates an acoustic traveling wave with each cycle of the armature. The traveling wave enters a waveguide-heat exchanger and is amplified in temperature, pressure and propagation velocity by thermal conduction of energy through the wall of the waveguide. The amplified traveling wave acts upon the opposite end of the armature, causing it to reciprocate within the magnetic field windings of the generator, and generate an electrical current as well as a new acoustic traveling wave. When the operating temperature gradient is attained across the hot and cold heat exchangers, the thermoacoustic engine-generator becomes acoustically resonant and self-regenerative, and will continue to operate as long as the thermal gradient is maintained. The theoretical conversion efficiency is dependent on the thermal gradient, and is 63% of Carnot.

Owner:FELLOWS RES GRP INC

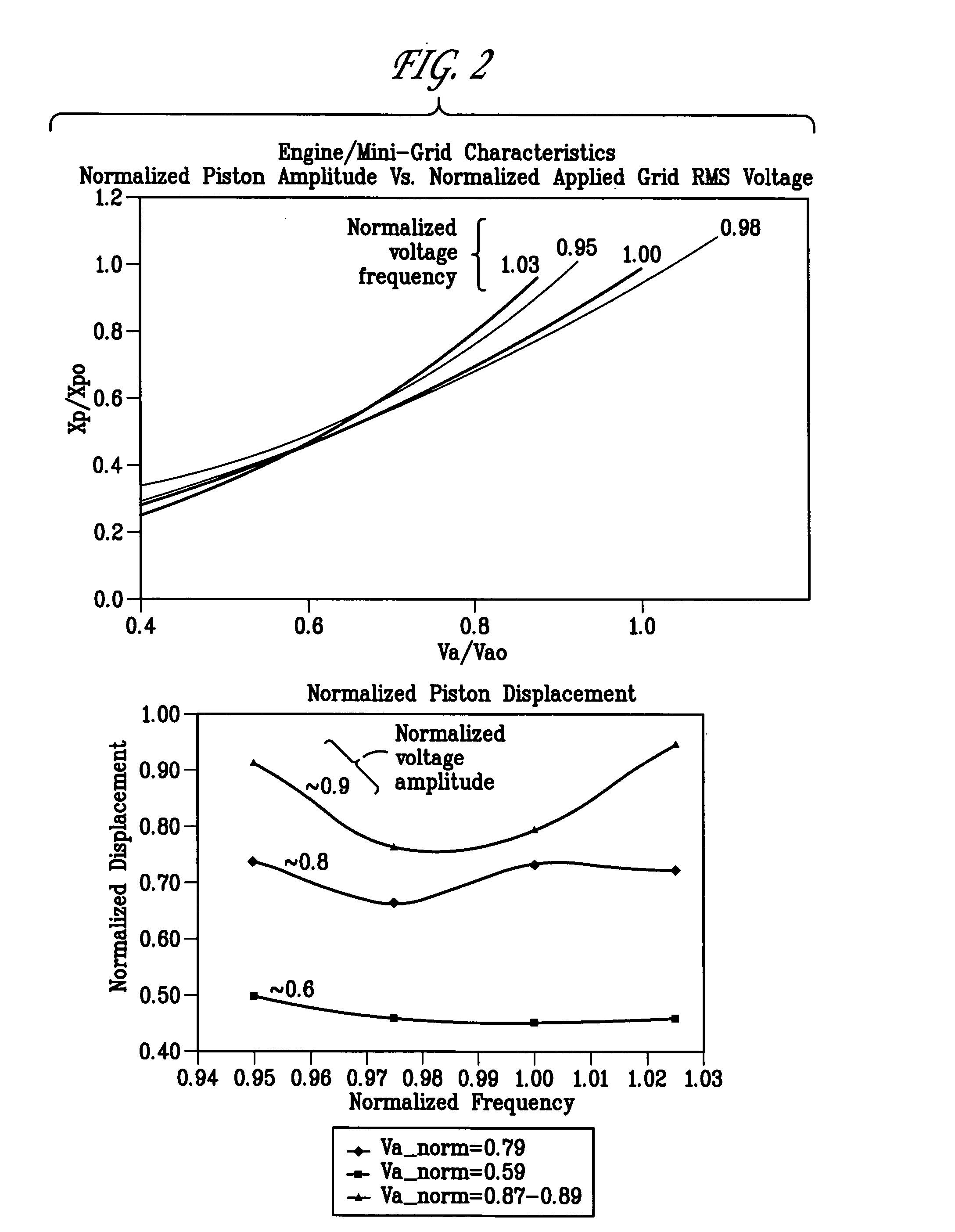

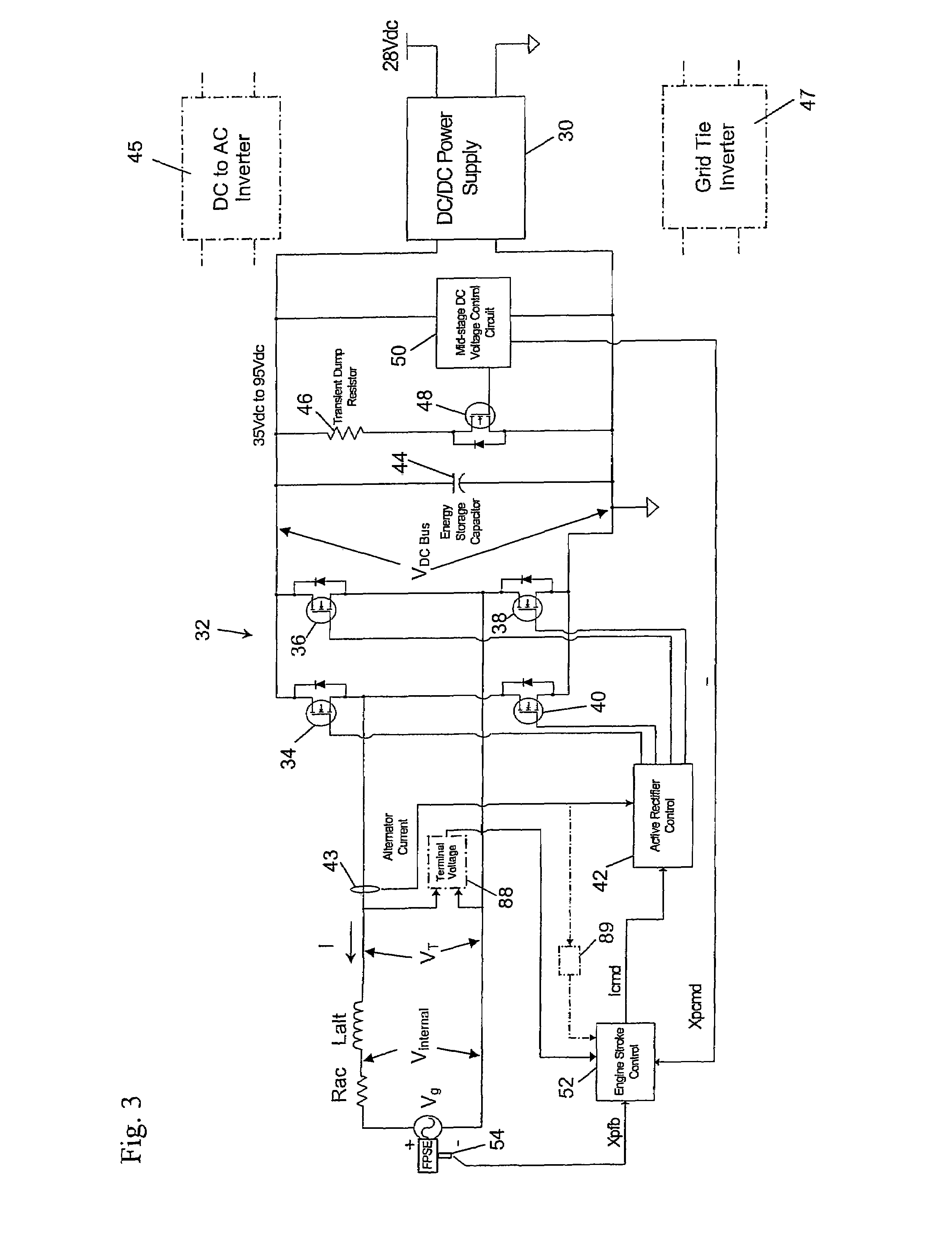

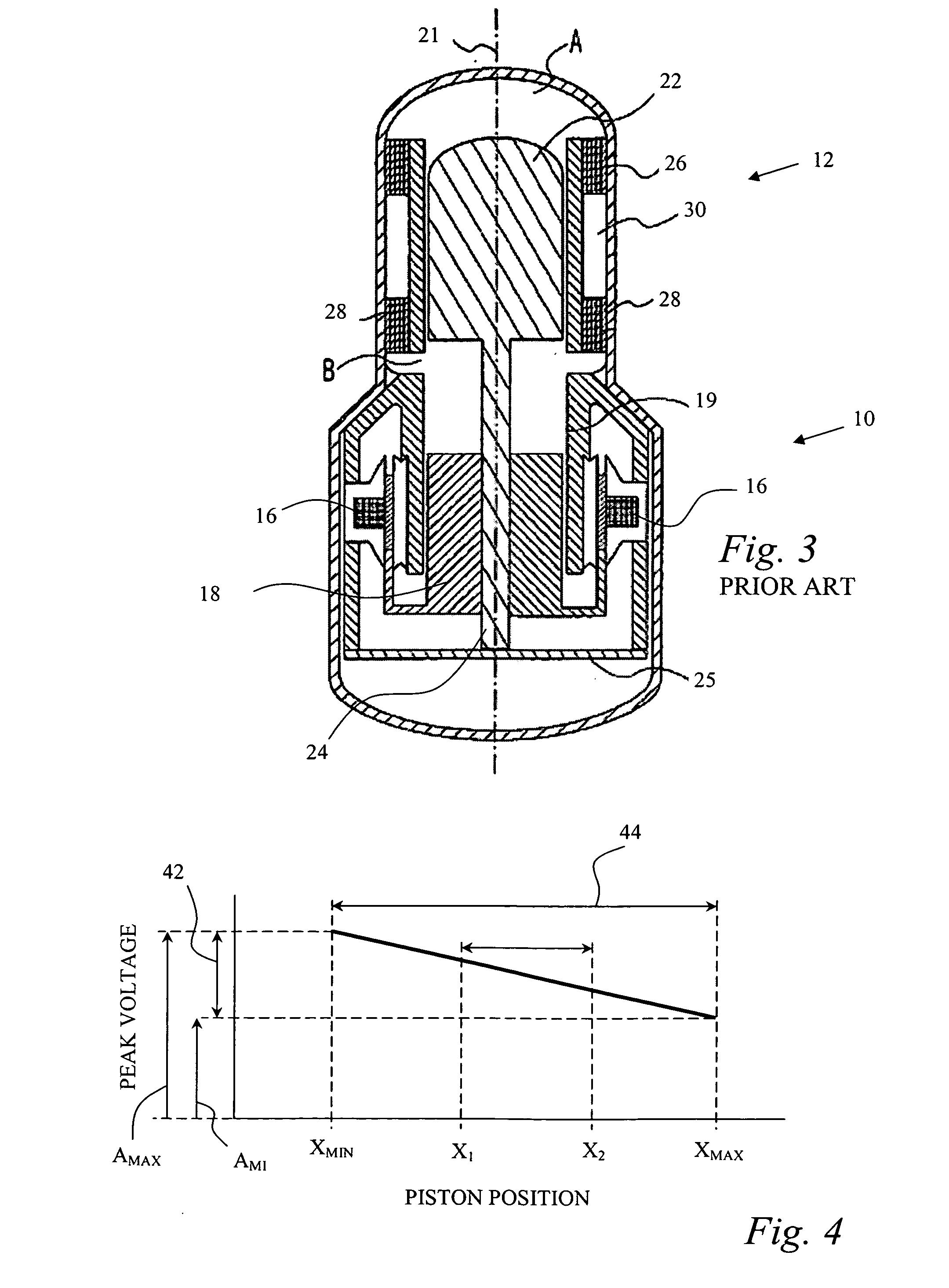

Free piston Stirling engine control

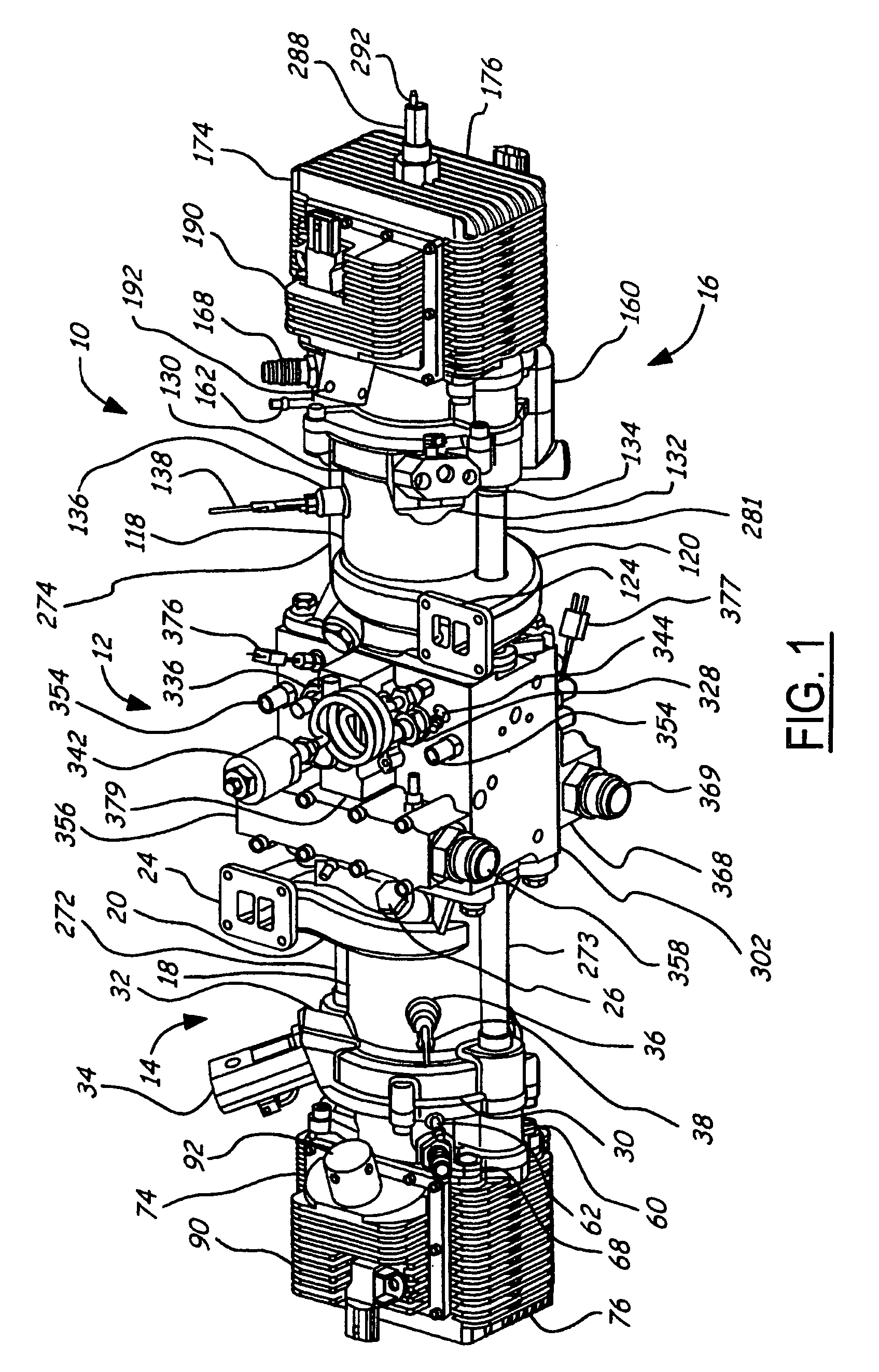

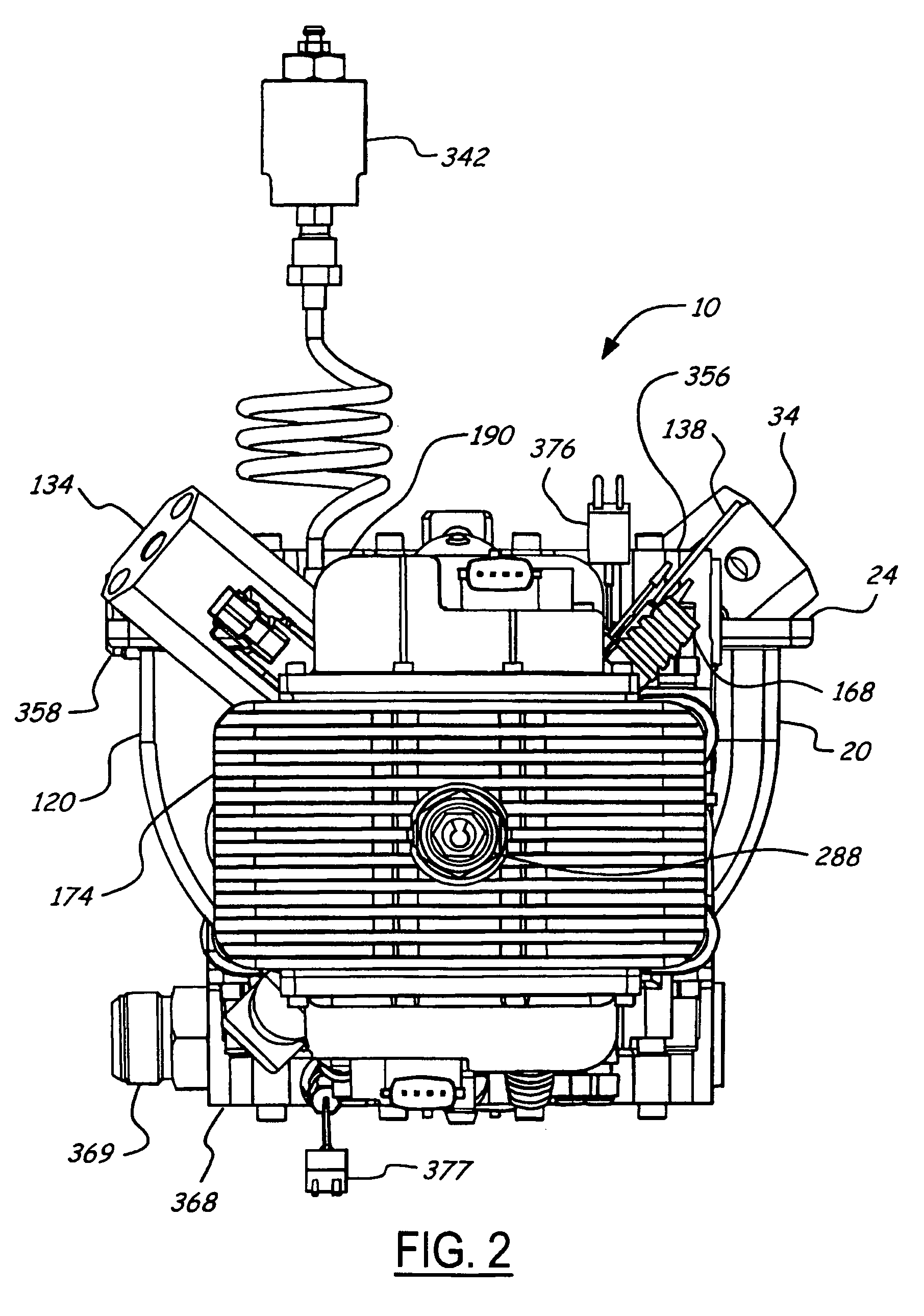

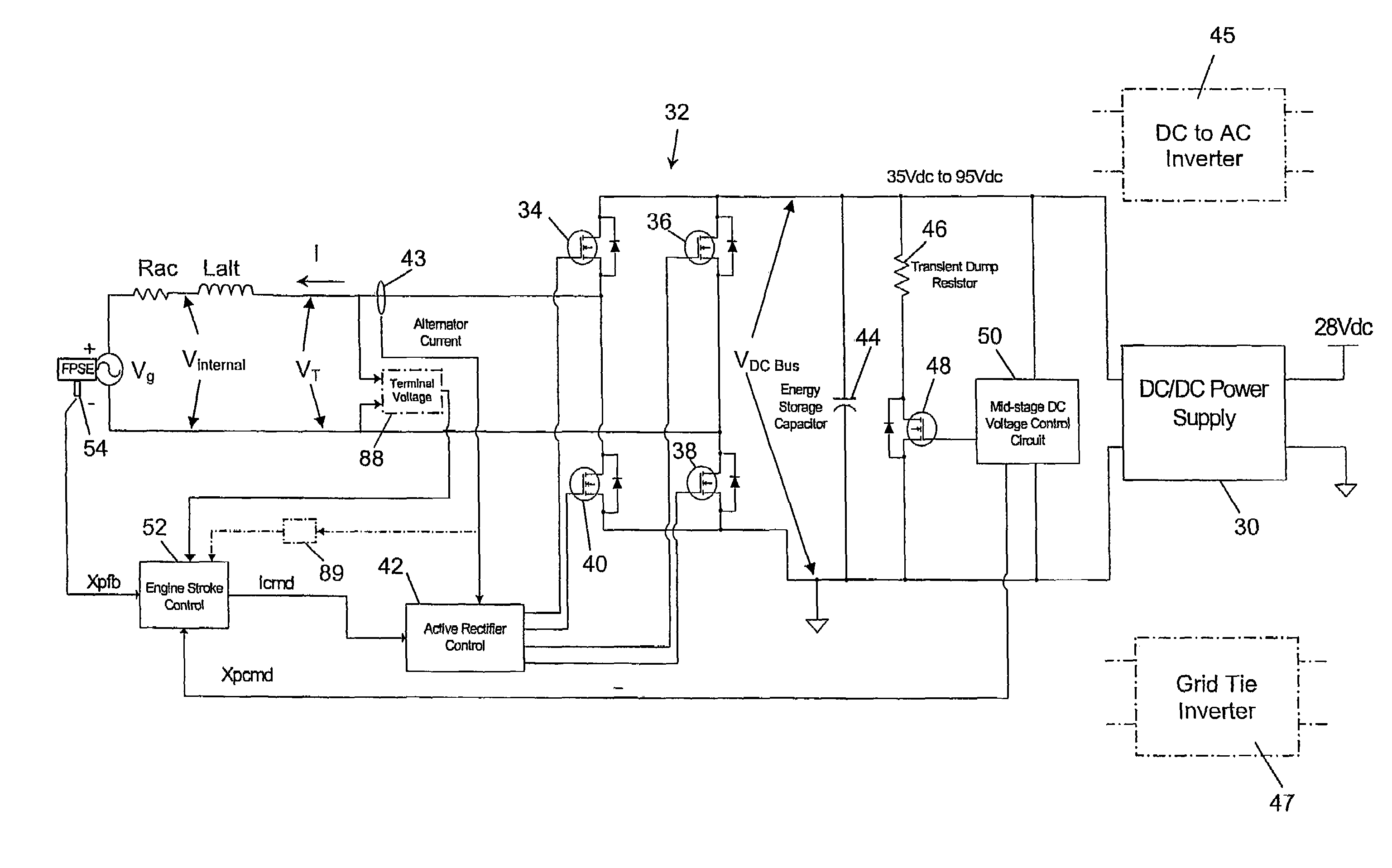

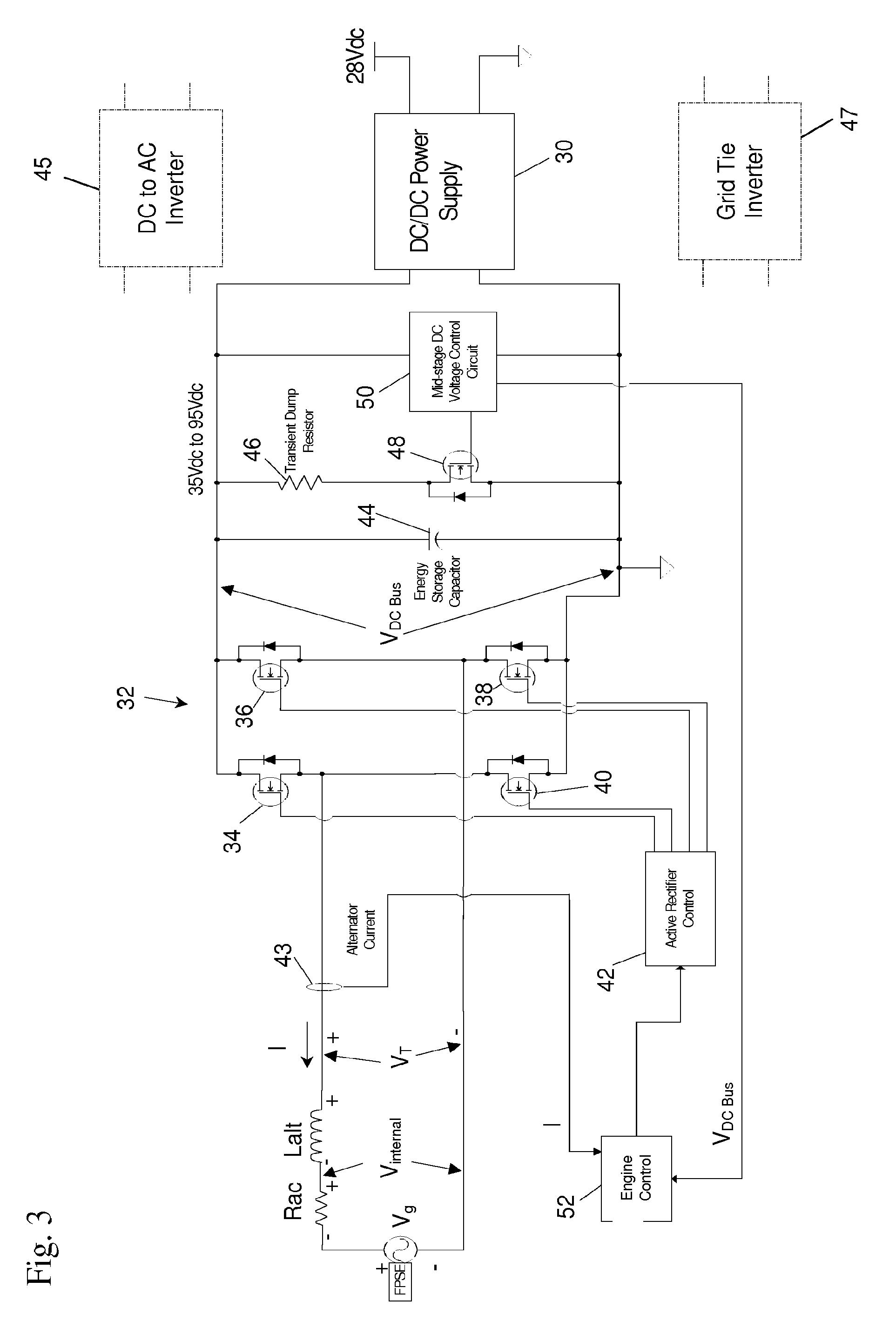

InactiveUS20050028520A1Large and heavy and expensiveAC motor controlEngine componentsVoltage amplitudeElectric power system

A control system for a Stirling engine including the use of a synchronous power converter (“SPC”) which is connected to the terminals of the alternator in a linear alternator / FPSE power system. According to the teachings of the present invention, the attached SPC is small and portable and further ensures that piston and displacer excursion within the system remain within design limits. The system and method are designed such that it is possible to adjust both the voltage amplitude and the waveform frequency at the terminals of the linear alternator. By controlling these operational aspects, both the speed and the range of travel associated with the piston and the displacer in the FPSE can be controlled.

Owner:TIAX LLC

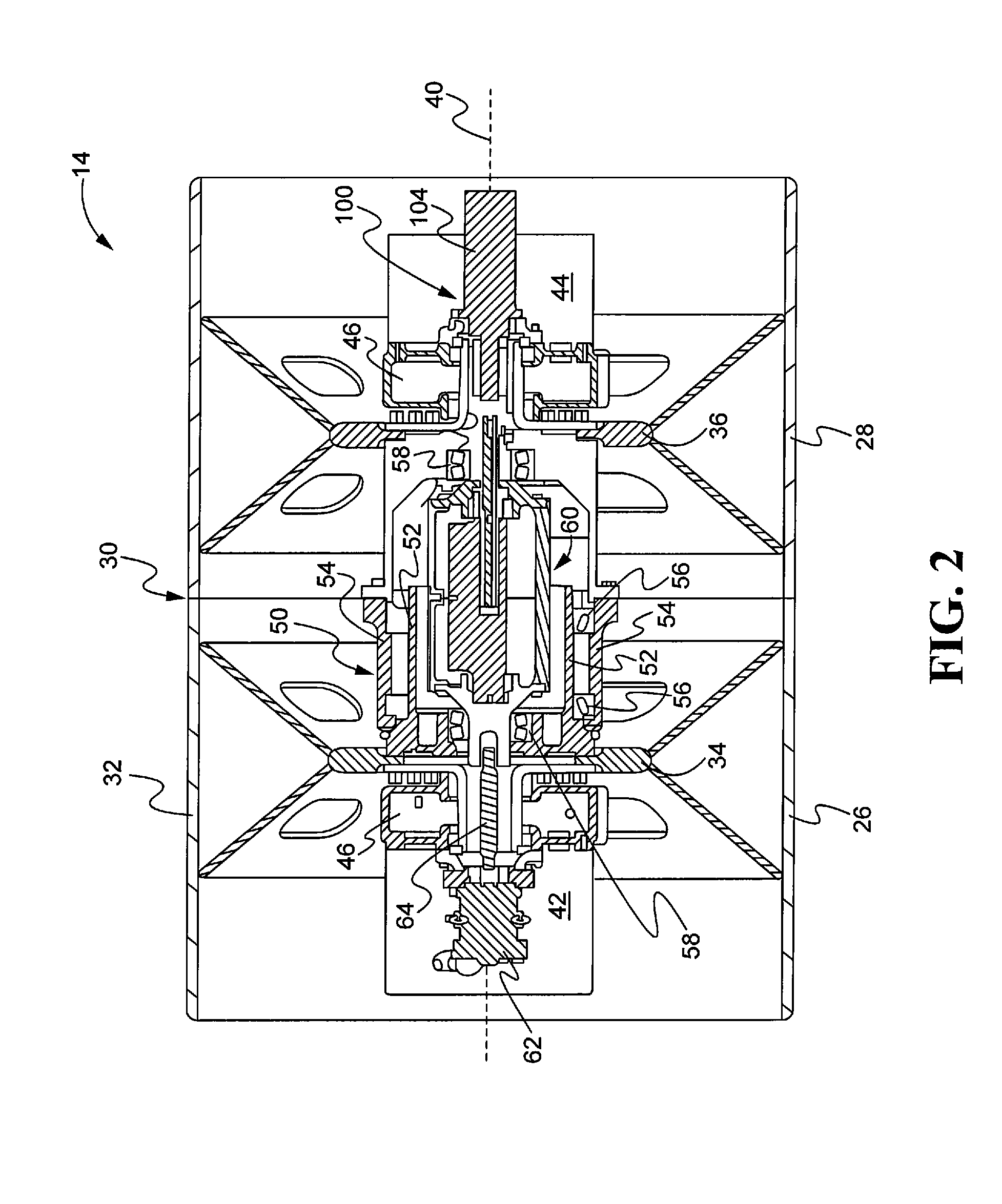

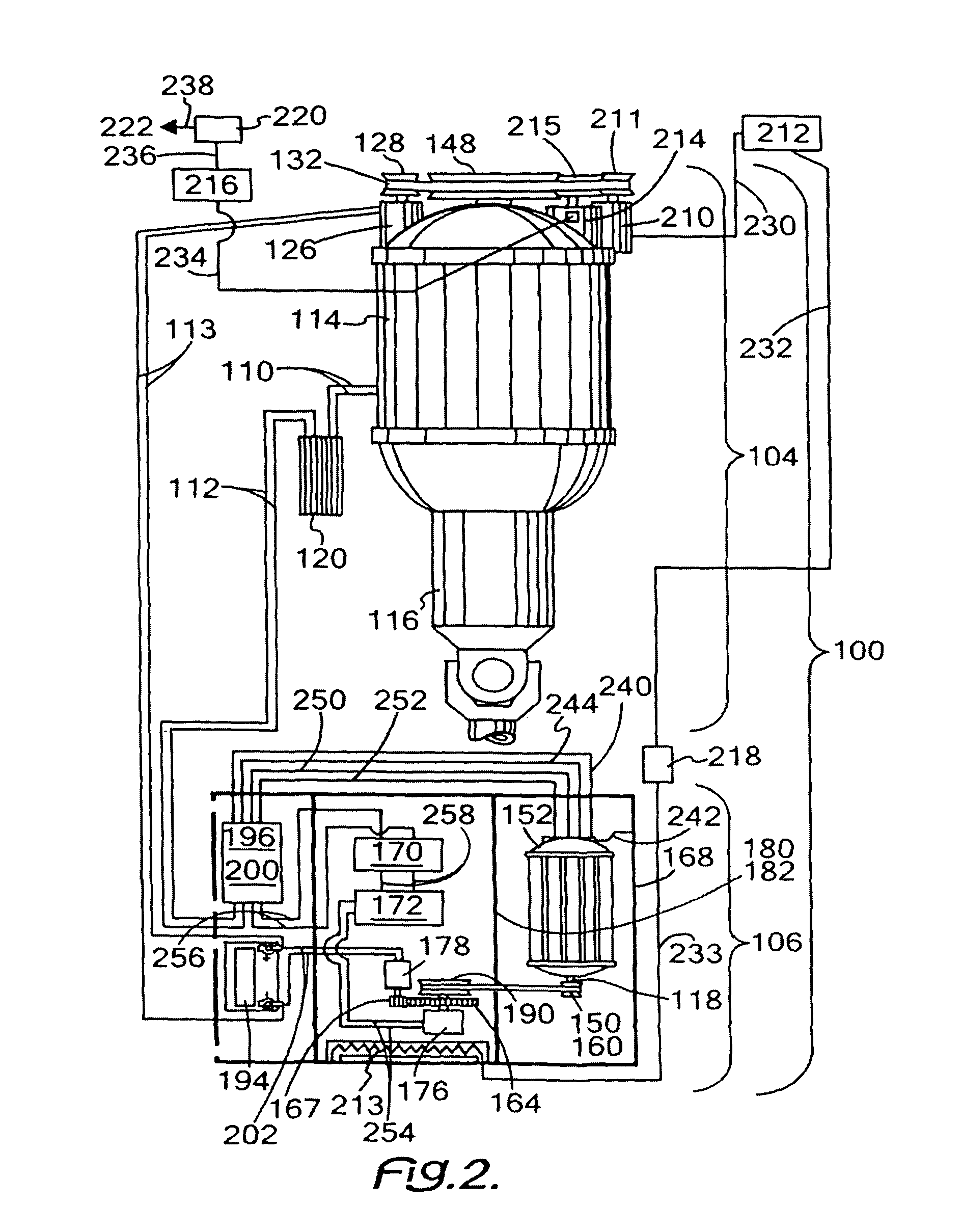

Double acting thermodynamically resonant free-piston multicylinder stirling system and method

Present implementations provide an approach that allows for a double-acting, multi-cylinder, thermodynamically resonant, alpha configuration free-piston Stirling system. The system includes overstroke preventers that control extent of piston travel to prevent undesirable consequences of piston travel beyond predetermined limits. The overstroke preventers involve controlled work extraction out of the system or controlled work input into the system. Implementations can also include duplex linear alternators, and / or frequency tuning systems, and / or vibration balancing configurations.

Owner:QNERGY

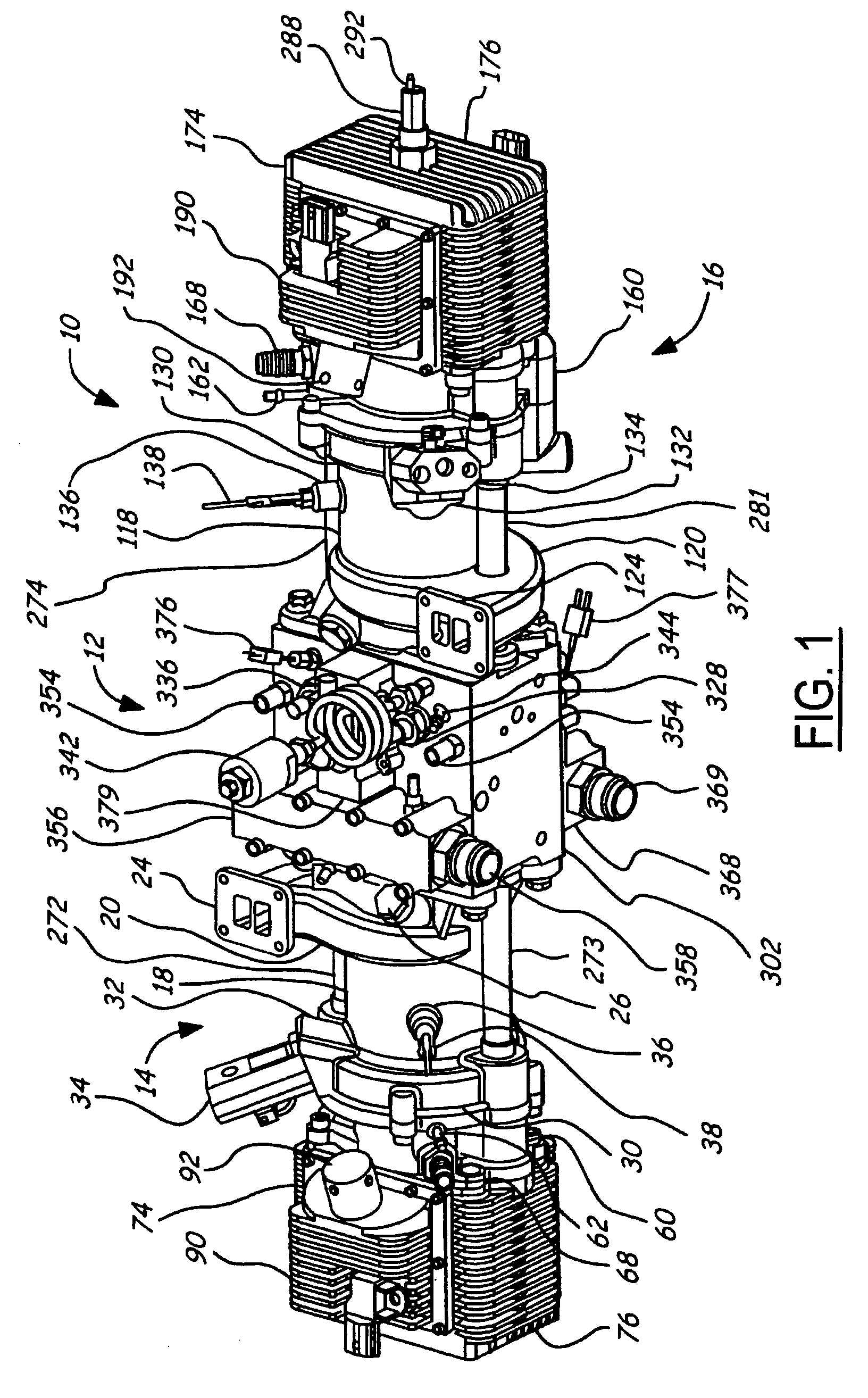

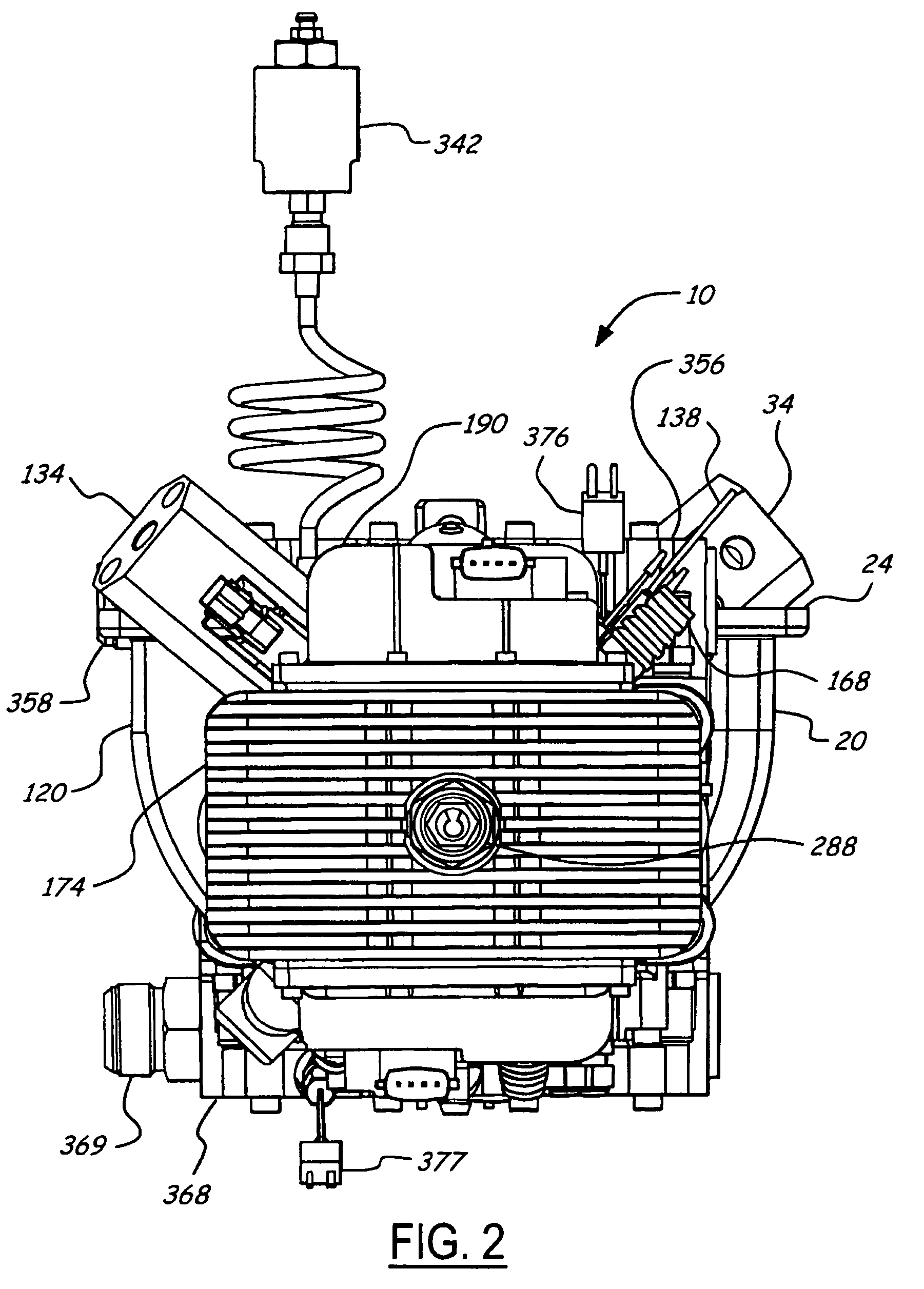

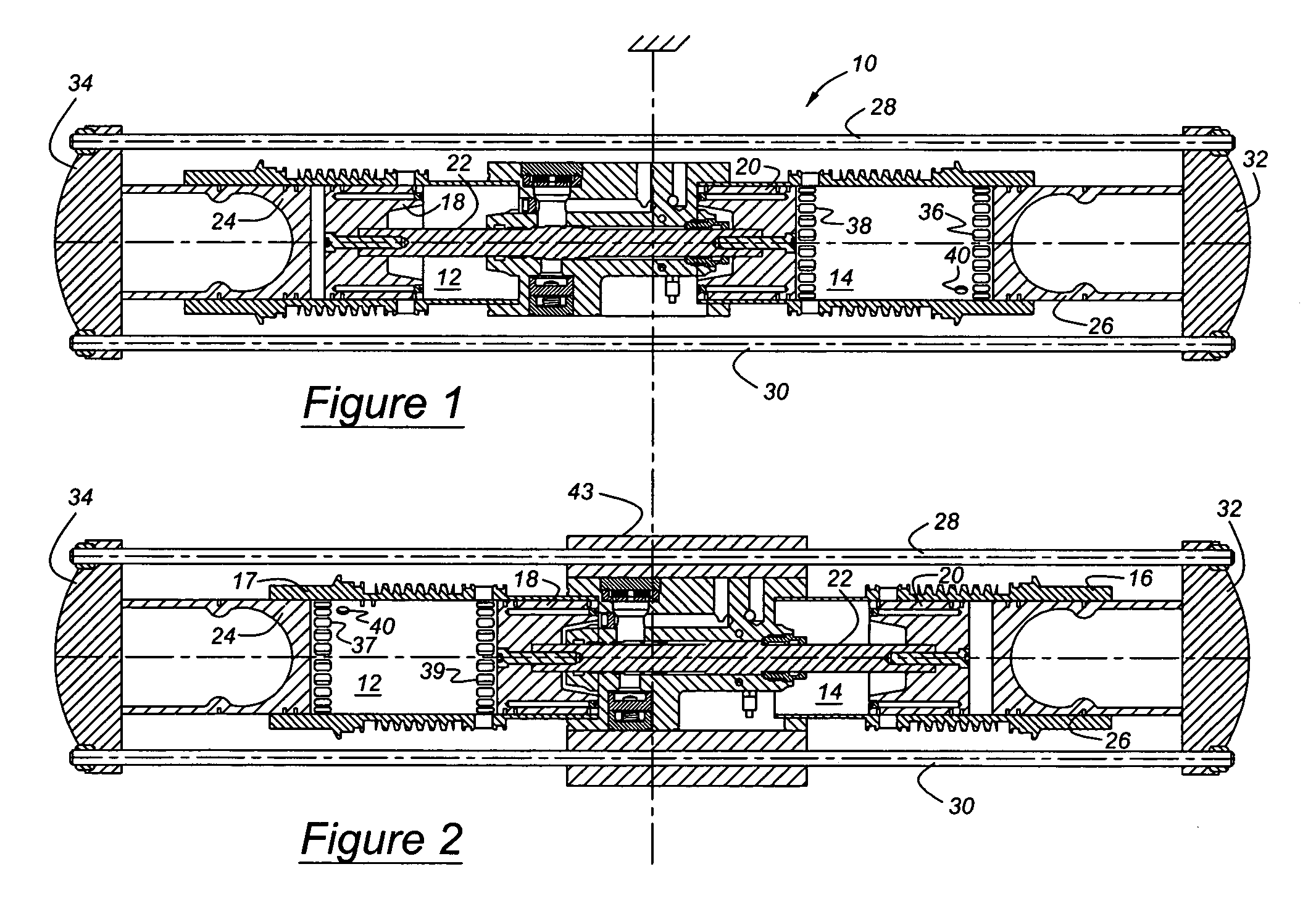

Piston guides for a free piston engine

InactiveUS20050284426A1Easy to changeConducive effective homogeneous chargeFree piston enginesFree-piston enginePump chamber

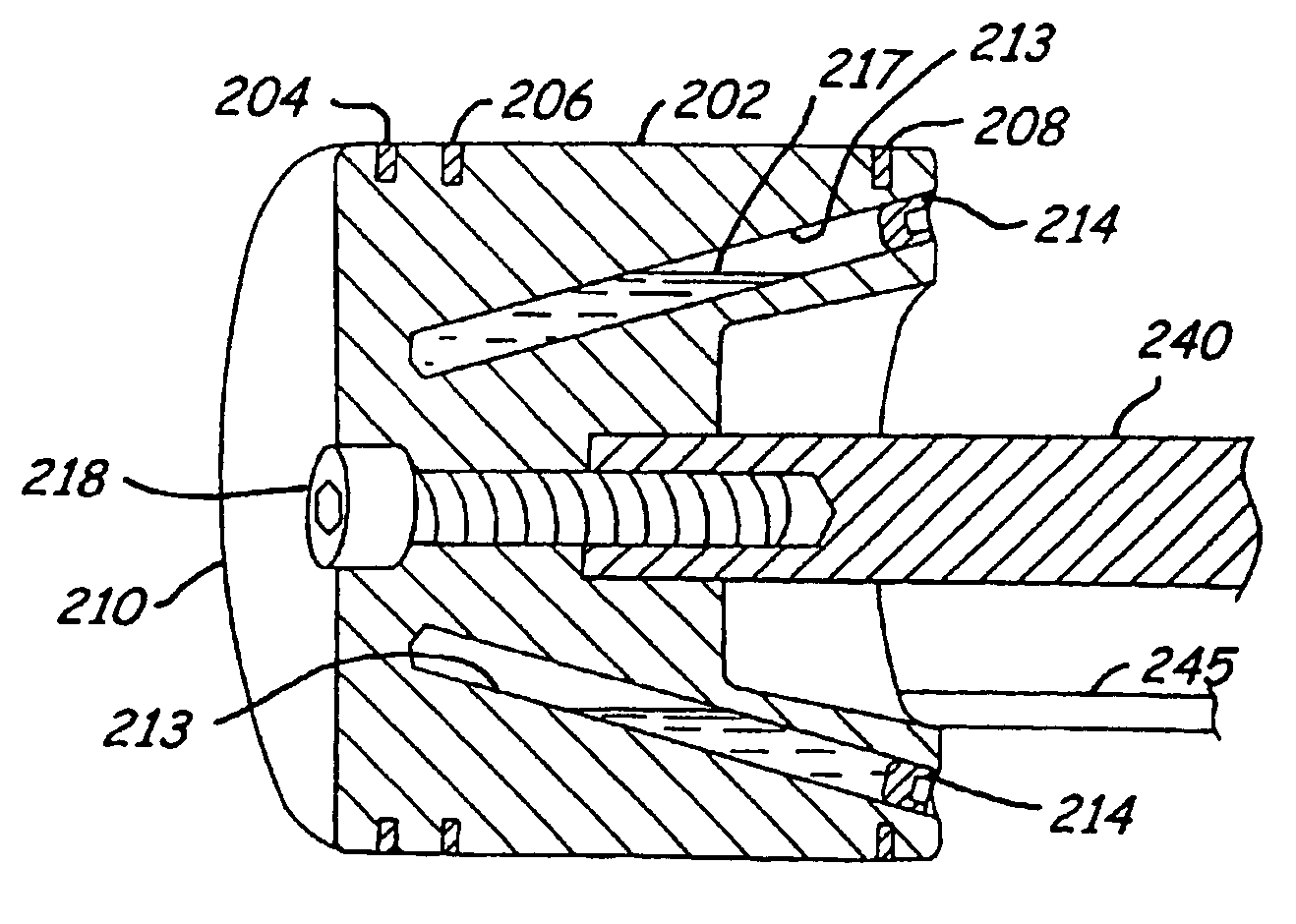

A free piston engine is configured with a pair of opposed engine cylinders located on opposite sides of a fluid pumping assembly. An inner piston assembly includes a pair of inner pistons, one each operatively located in a respective one of the engine cylinders, with a push rod connected between the inner pistons. The push rod extends through an inner pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. An outer piston assembly includes a pair of outer pistons, one each operatively located in a respective one of the engine cylinders, with at least one pull rod connected between the outer pistons. The pull rod extends through an outer pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. The movement of the inner and outer piston assemblies during engine operation will cause the fluid plungers to pump fluid from a low pressure container into a high pressure chamber as a means of storing the energy output from the engine. Alternatively, the piston assemblies may drive a linear alternator. Piston guide posts are fixed and guide the outer pistons as they reciprocate within the engine cylinders.

Owner:FORD GLOBAL TECH LLC

Piston guides for a free piston engine

InactiveUS7032548B2More balancedEfficient chargingFree piston enginesFree-piston engineReciprocating motion

A free piston engine is configured with a pair of opposed engine cylinders located on opposite sides of a fluid pumping assembly. An inner piston assembly includes a pair of inner pistons, one each operatively located in a respective one of the engine cylinders, with a push rod connected between the inner pistons. The push rod extends through an inner pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. An outer piston assembly includes a pair of outer pistons, one each operatively located in a respective one of the engine cylinders, with at least one pull rod connected between the outer pistons. The pull rod extends through an outer pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. The movement of the inner and outer piston assemblies during engine operation will cause the fluid plungers to pump fluid from a low pressure container into a high pressure chamber as a means of storing the energy output from the engine. Alternatively, the piston assemblies may drive a linear alternator. Piston guide posts are fixed and guide the outer pistons as they reciprocate within the engine cylinders.

Owner:FORD GLOBAL TECH LLC

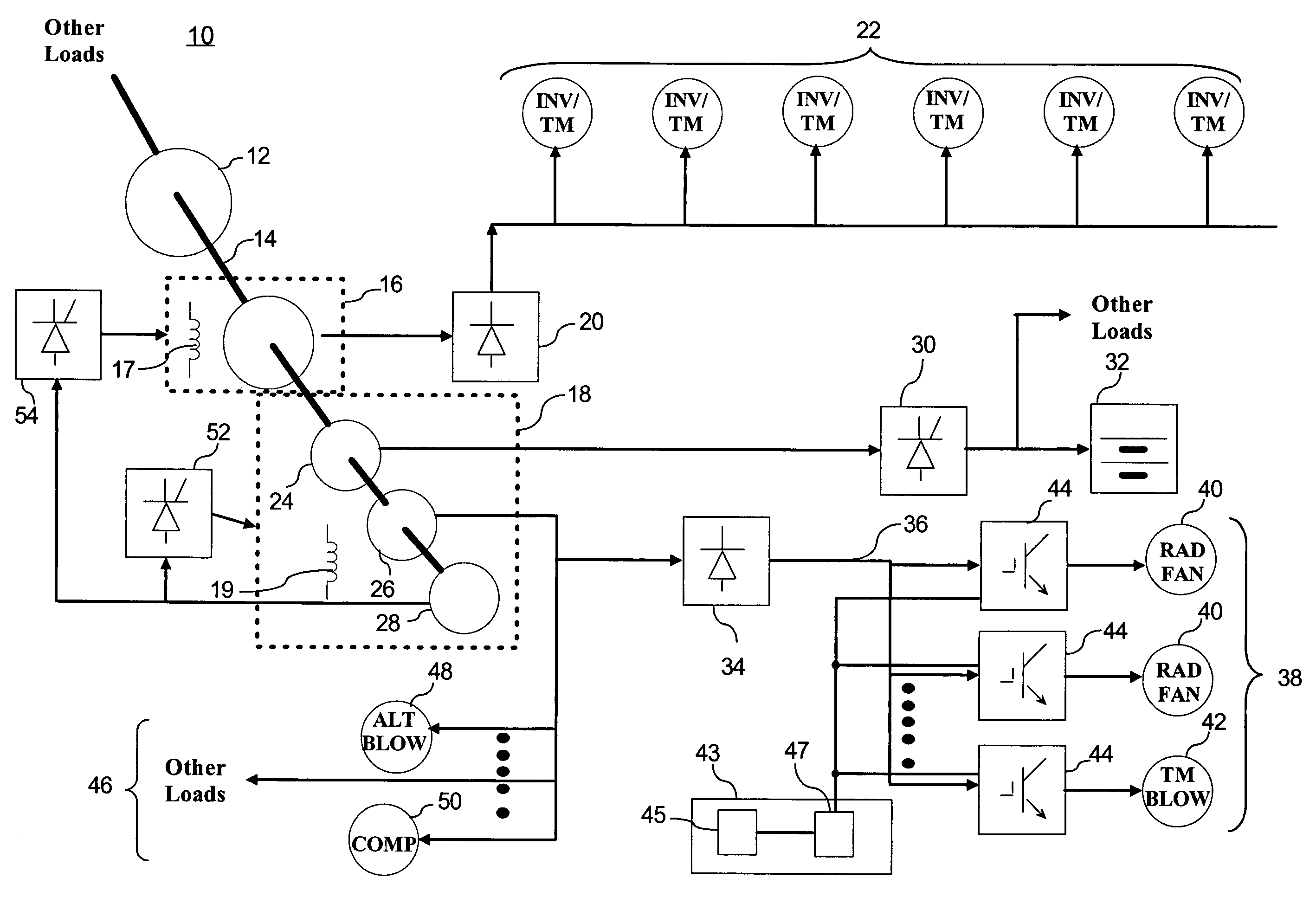

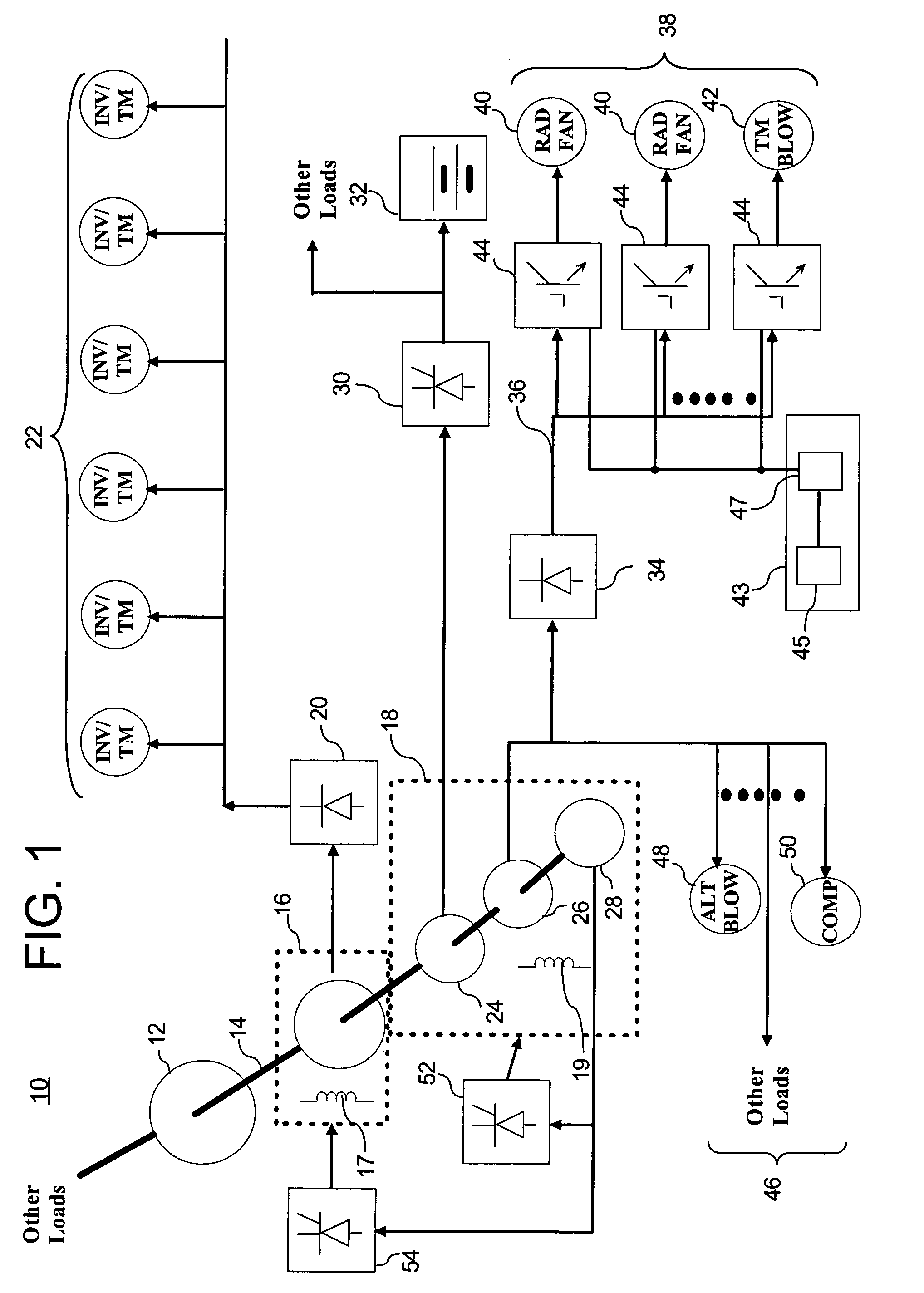

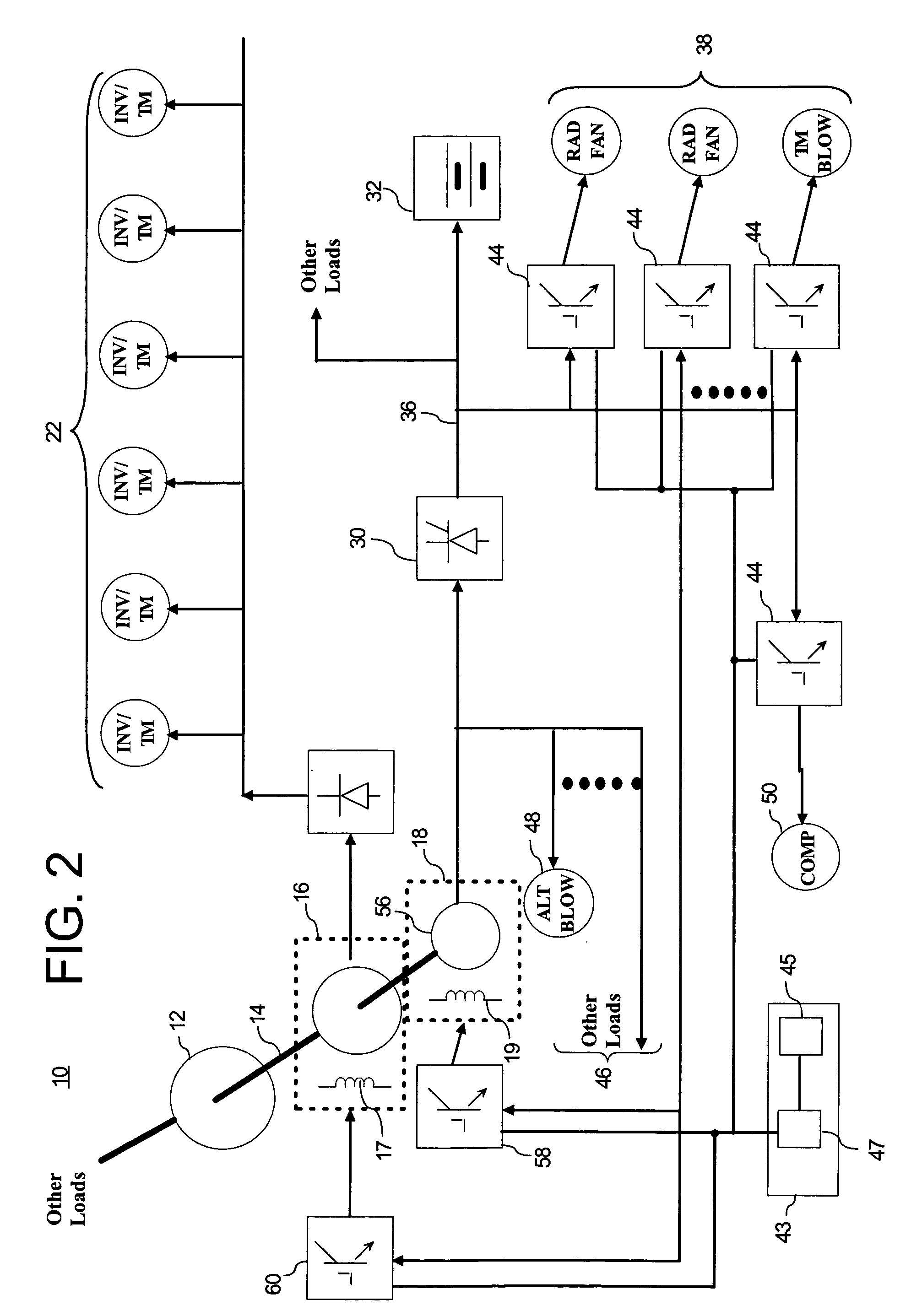

Locomotive auxiliary power system

ActiveUS7256513B2Electrical storage systemBatteries circuit arrangementsTransient modeLinear alternator

Owner:GE GLOBAL SOURCING LLC

Resonant stator balancing of free piston machine coupled to linear motor or alternator

ActiveUS8011183B2Vibration is reduced and minimized and eliminatedEliminate needMechanical energy handlingSafety/regulatory devicesReciprocating motionTransducer

Owner:GLOBAL COOLING

Sodium cooled pistons for a free piston engine

InactiveUS6904876B1Easy to changeConducive effective homogeneous chargeAir coolingPistonsFree-piston enginePump chamber

A free piston engine is configured with a pair of opposed engine cylinders located on opposite sides of a fluid pumping assembly. An inner piston assembly includes a pair of inner pistons, one each operatively located in a respective one of the engine cylinders, with a push rod connected between the inner pistons. The push rod extends through an inner pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. An outer piston assembly includes a pair of outer pistons, one each operatively located in a respective one of the engine cylinders, with at least one pull rod connected between the outer pistons. The pull rod extends through an outer pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. The movement of the inner and outer piston assemblies during engine operation will cause the fluid plungers to pump fluid from a low pressure container into a high pressure chamber as a means of storing the energy output from the engine. Alternatively, the piston assemblies may drive a linear alternator. At least one of the pistons includes one or more generally axially extending bores partially filled with a sodium compound. As the piston reciprocates, the sodium moves back and forth in each cooling bore, thereby better distributing heat in the piston.

Owner:FORD GLOBAL TECH LLC

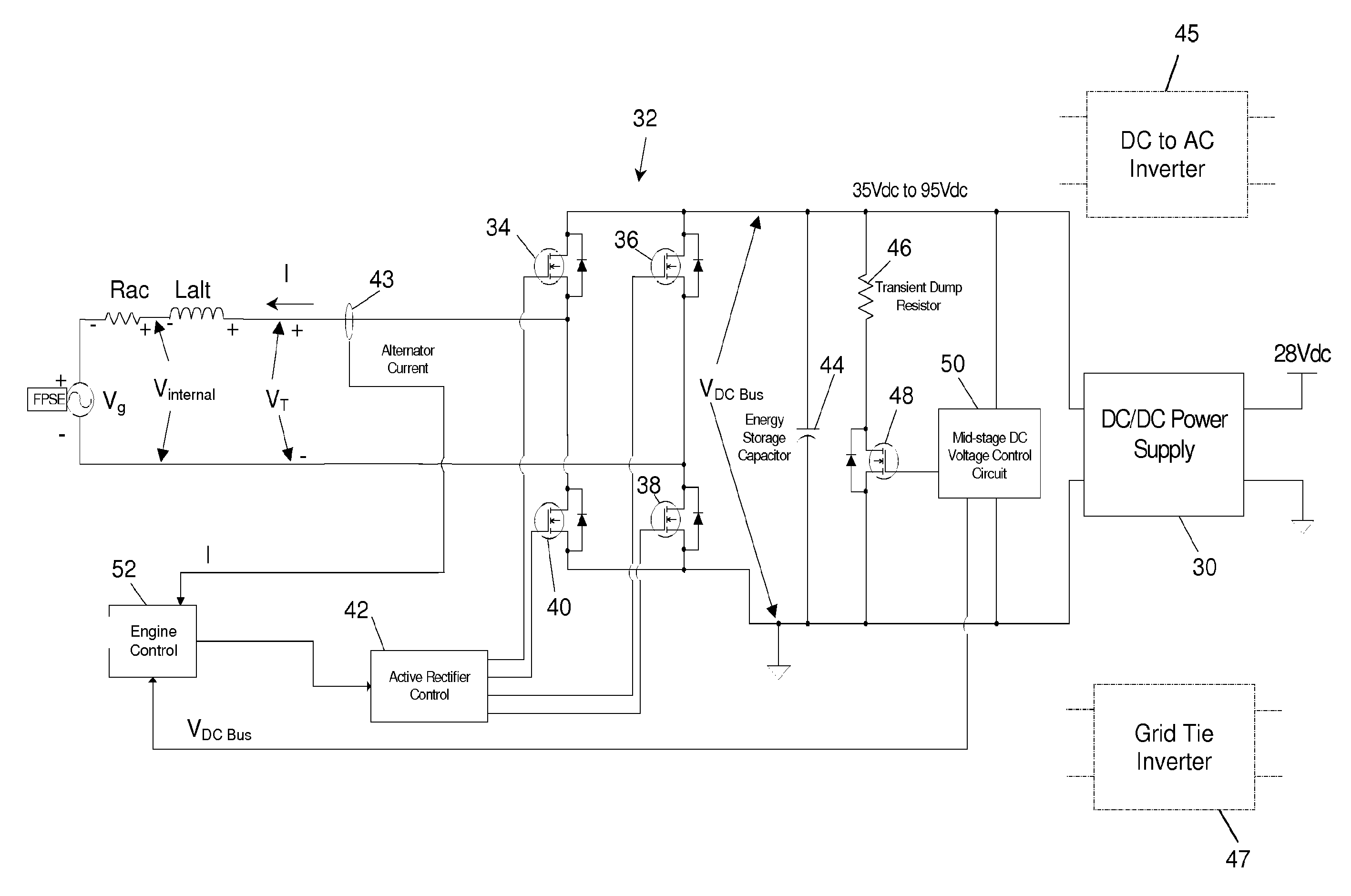

Electronic controller matching engine power to alternator power and maintaining engine frequency for a free-piston stirling engine driving a linear alternator

InactiveUS7453241B2AC motor controlConversion with intermediate conversion to dcElectronic controllerCurrent sensor

Owner:SUNPOWER

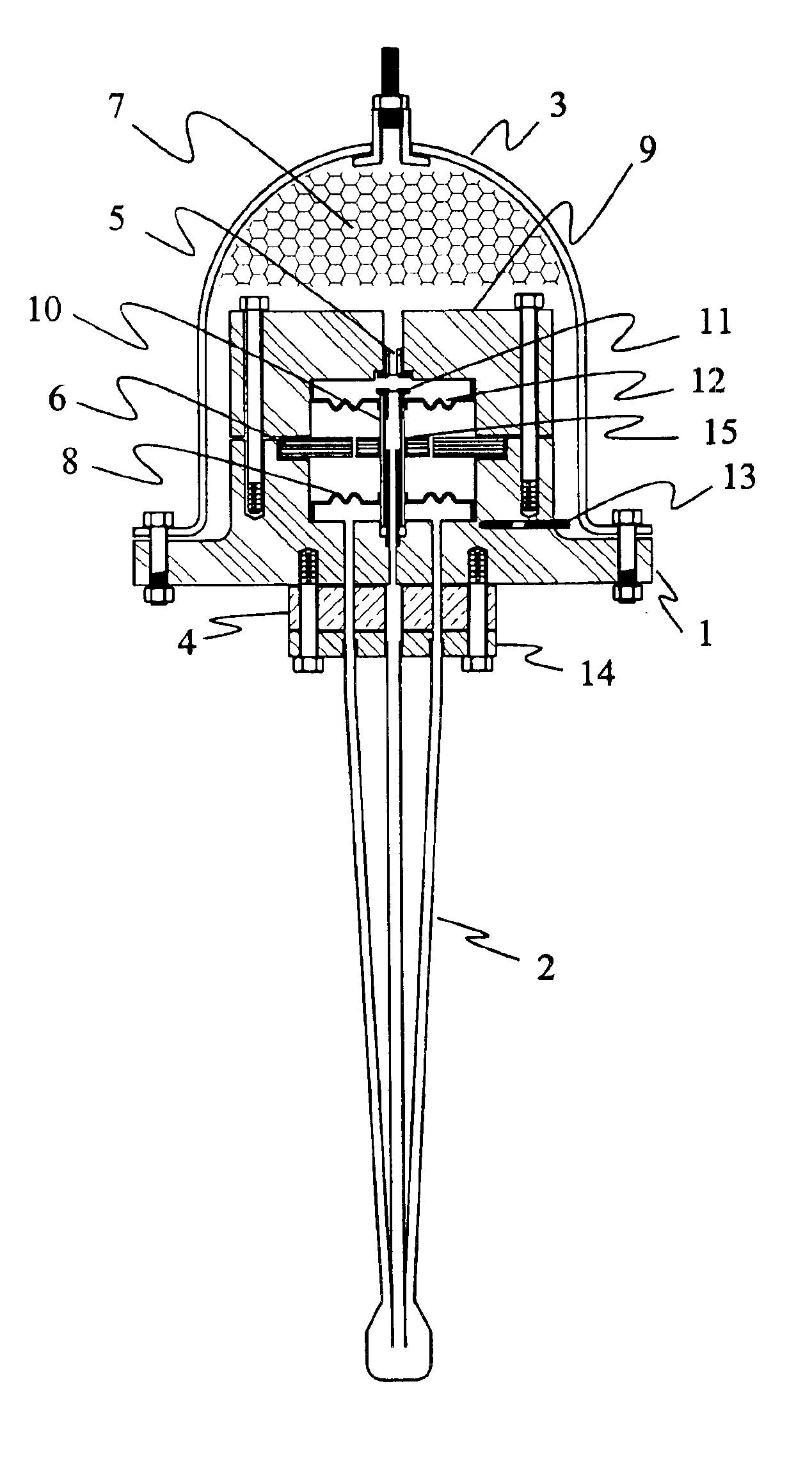

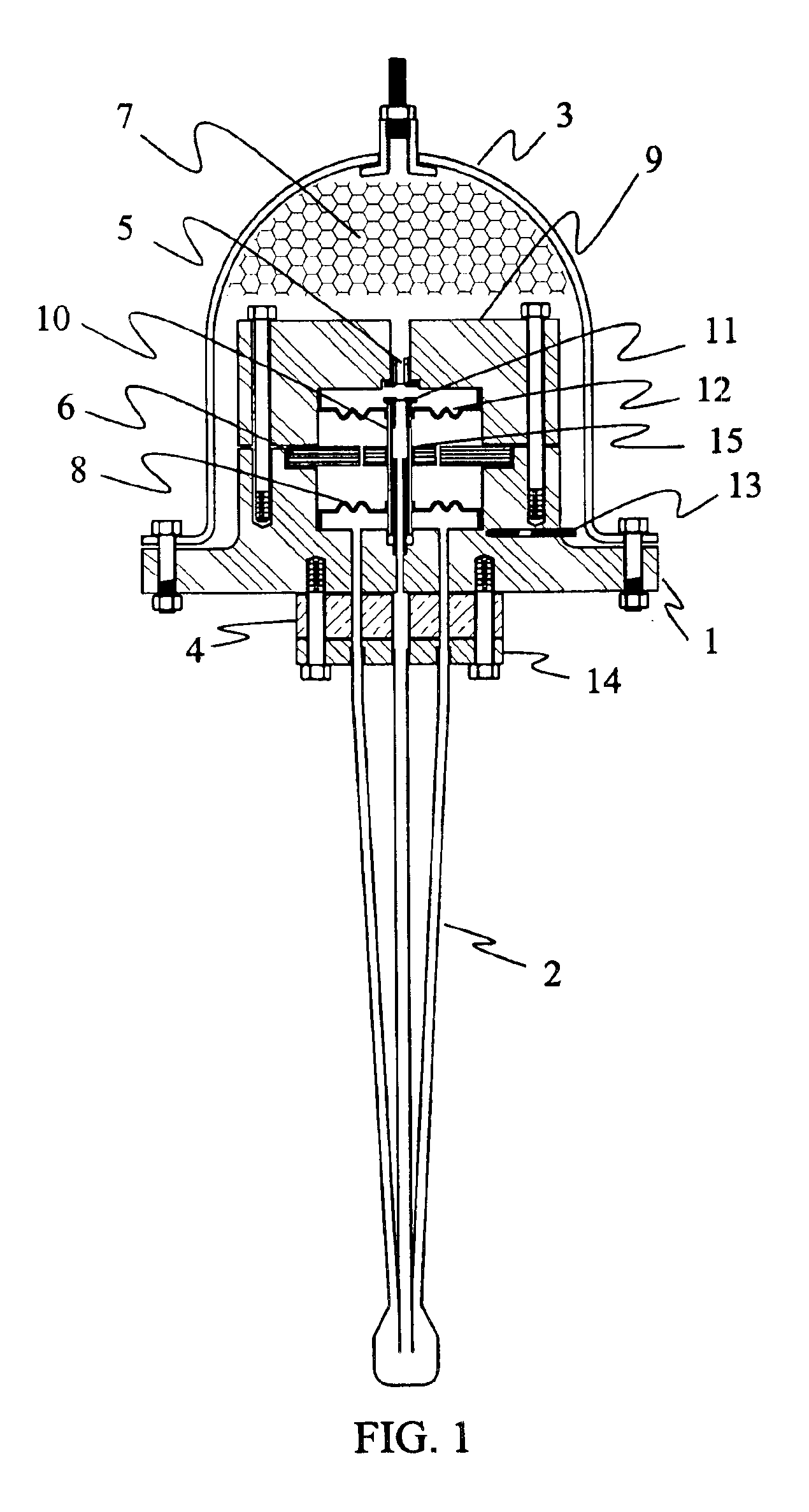

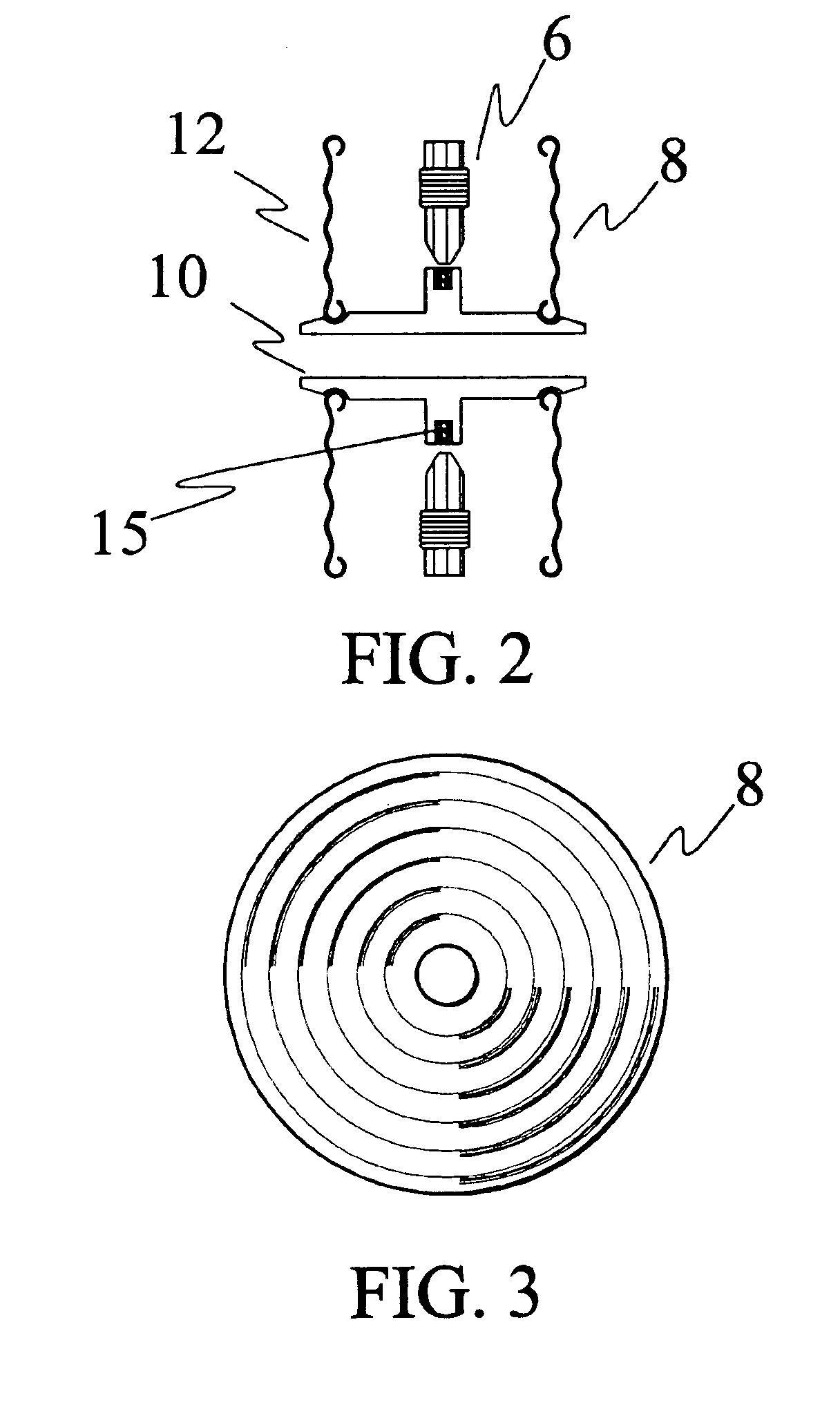

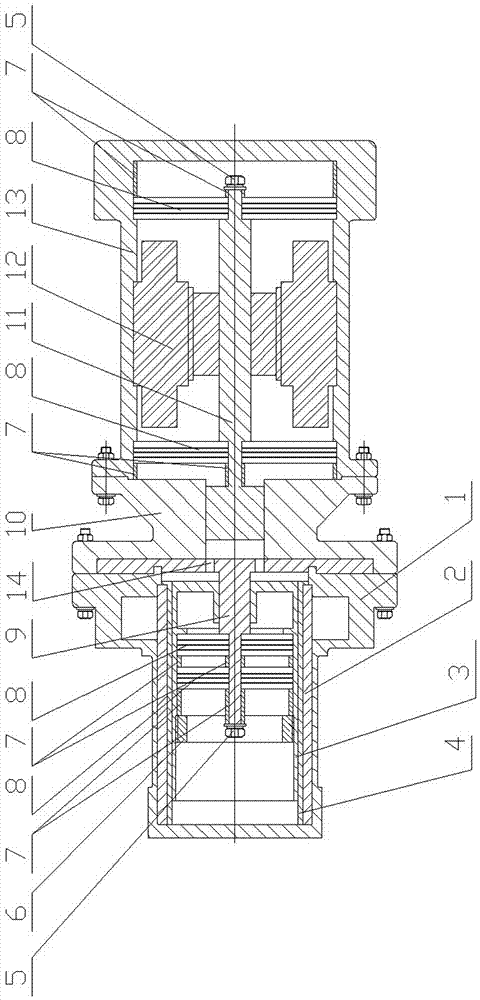

Clearance type sealing Stirling thermoelectric converter supported by adopting supporting flexible plate springs

ActiveCN102900561AAchieve long runLong-term wear-free operationHot gas positive displacement engine plantsConvertersEngineering

The invention relates to a clearance type sealing Stirling thermoelectric converter supported by adopting plate springs. The clearance type sealing Stirling thermoelectric converter comprises a hot cylinder, a compression cylinder and a linear alternating current generator which are fixedly connected through a flange, wherein the interior of the hot cylinder is sequentially sleeved with a heat exchanger and an expansion cylinder towards the center, and an expansion piston is arranged in the expansion cylinder; the expansion piston is sleeved on an expansion piston rod; and an inner cavity of the expansion piston is provided with a plurality of groups of supporting flexible plate springs which are respectively sleeved on limit pipes on the inner wall of the expansion piston and the expansion piston rod for positioning so as to ensure that clearance sealing structures are radially formed between the expansion cylinder and the expansion piston and the expansion piston and the expansion piston rod. According to the clearance type sealing Stirling thermoelectric converter, the non-contact type clearance sealing structures are realized by adopting the flexible plate spring supporting systems, and meanwhile, the rigidity requirement of a generator active cell oscillation system can be met, so that the structural characteristic of no abrasion after long-term running of moving components is realized so as to guarantee the long service life and the high rigidity of the Stirling generator.

Owner:中国航天科技集团公司第五研究院第五一0研究所

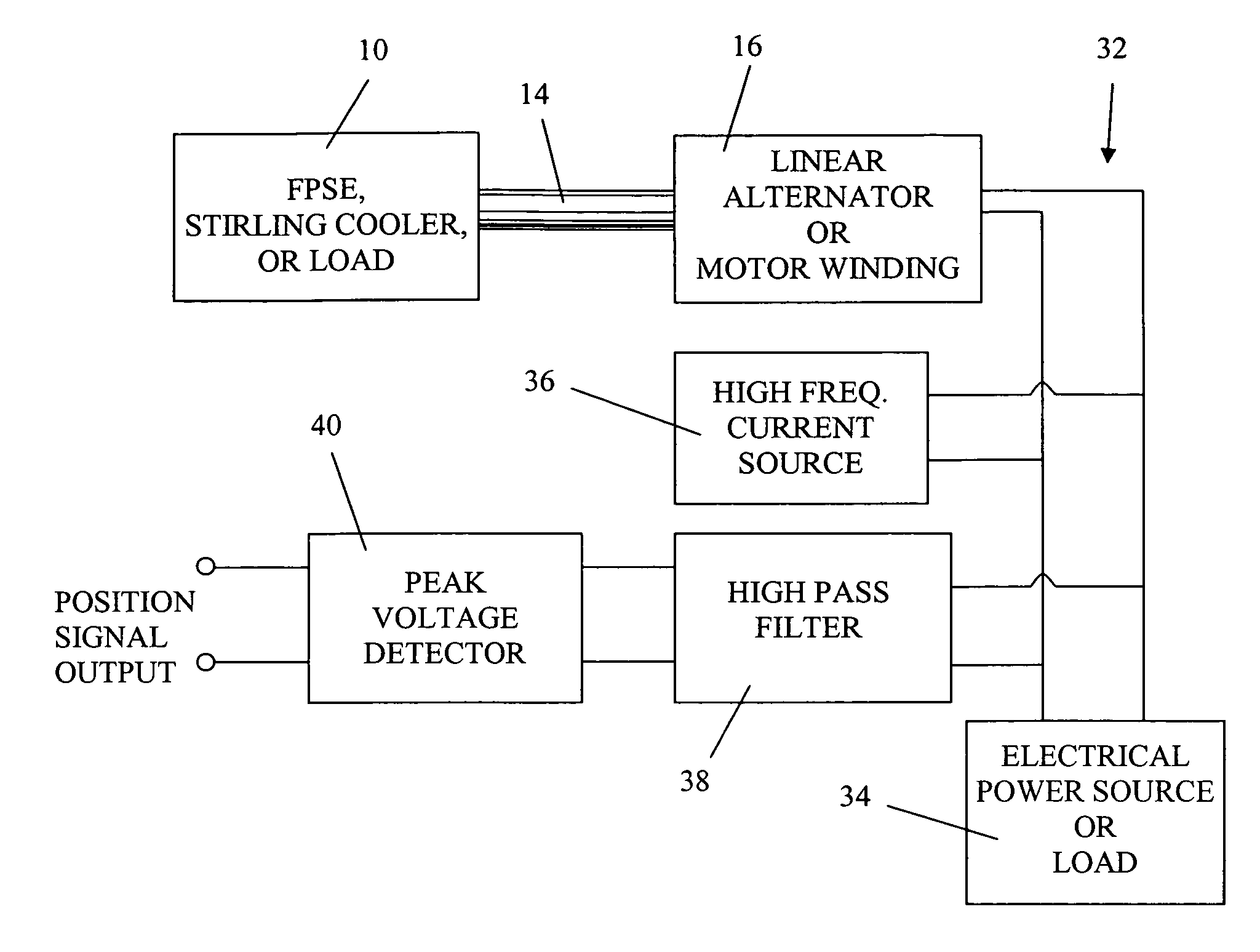

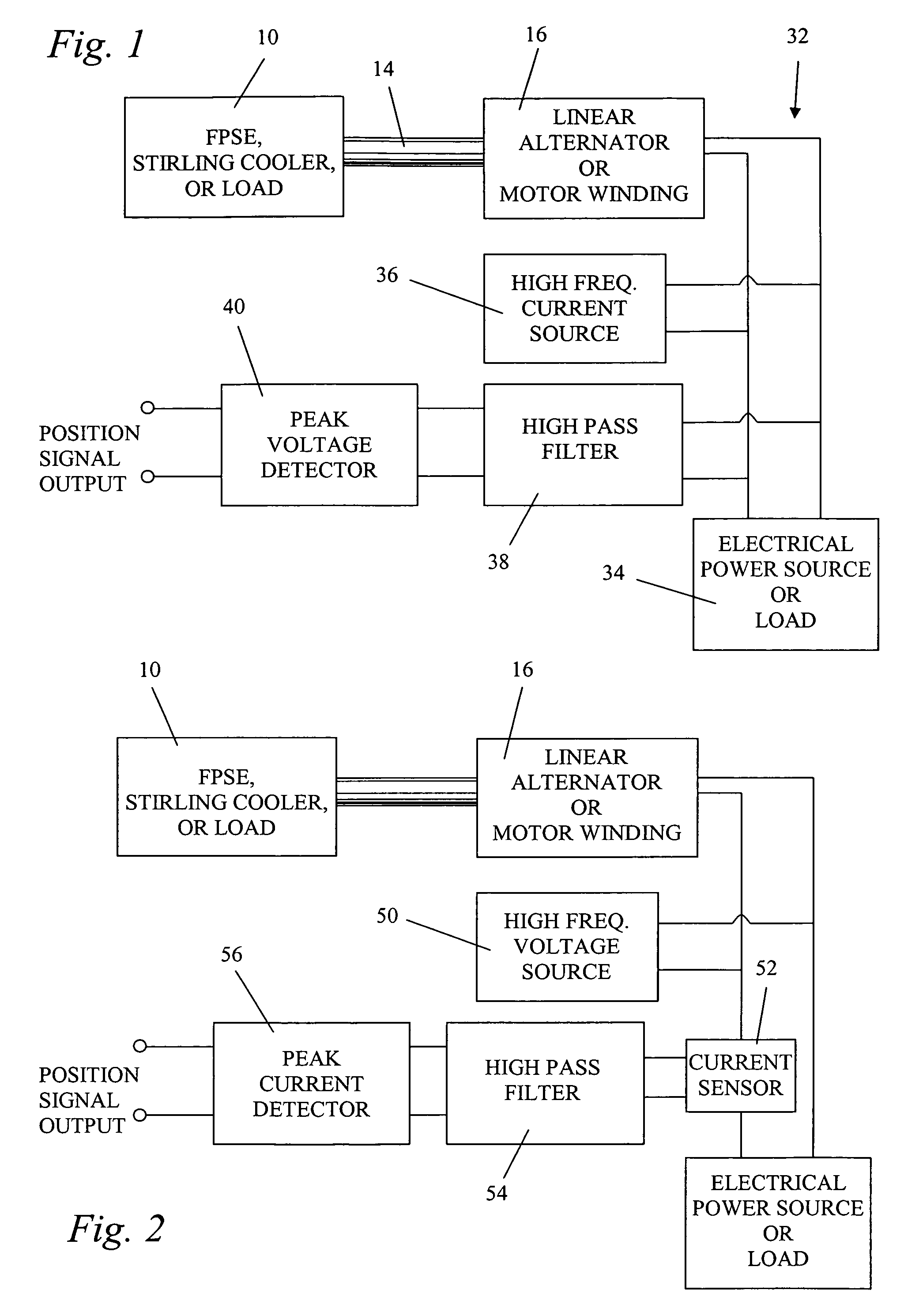

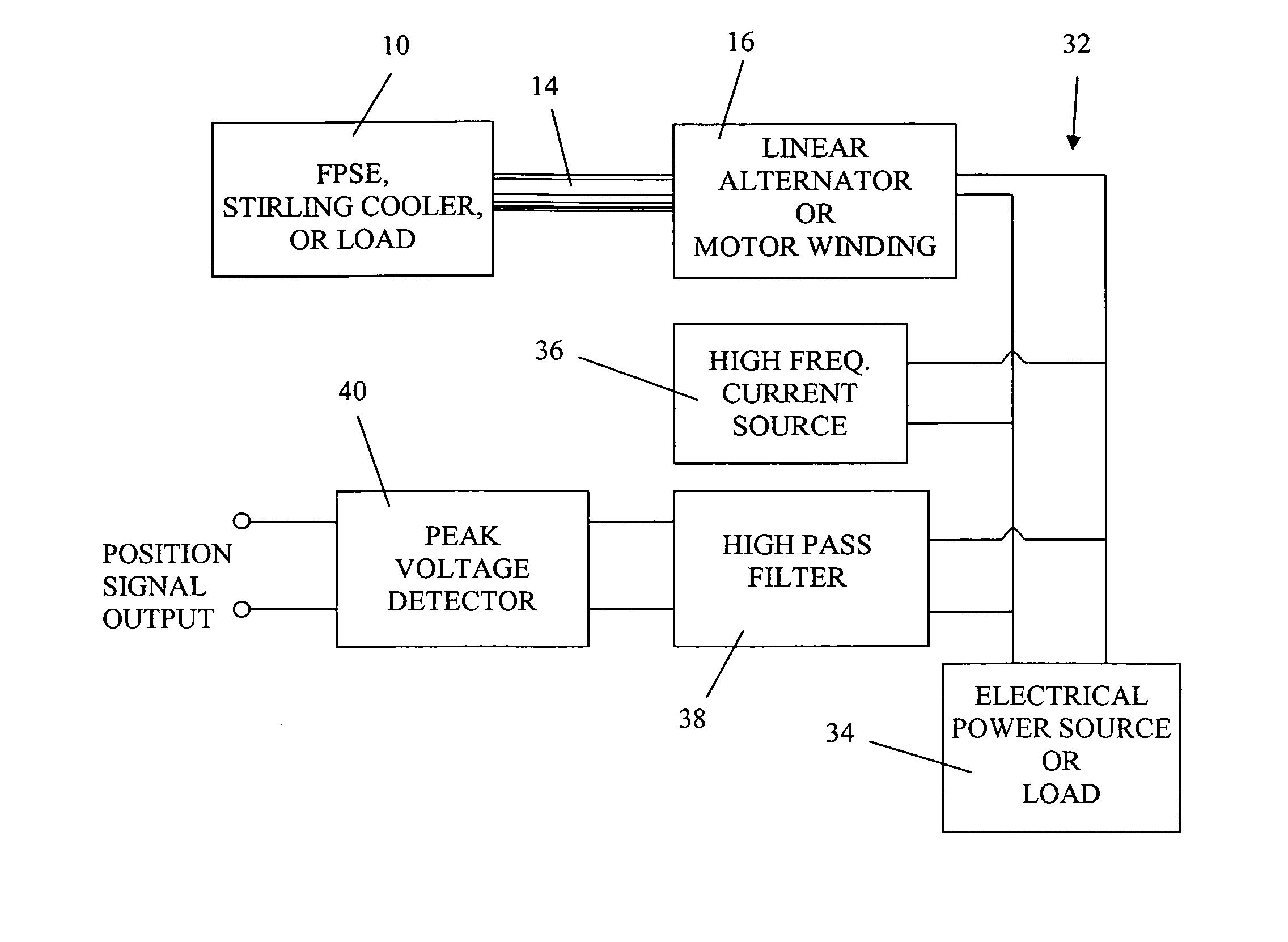

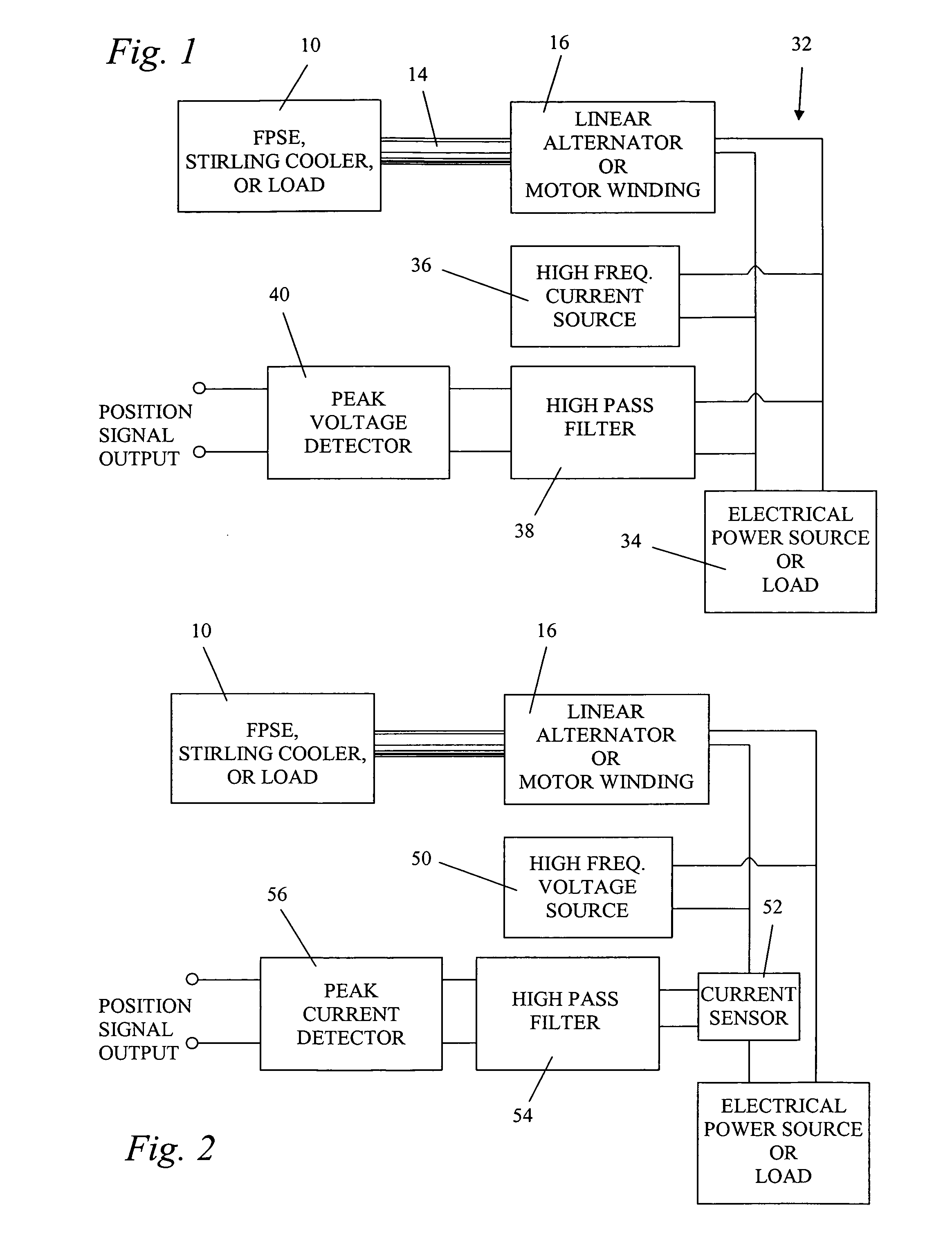

Detection of the instantaneous position of a linearly reciprocating member using high frequency injection

A piston position sensing circuit for sensing the instantaneous position of a piston of a free piston Stirling machine or a compressor mechanically connected to a reciprocating member of a linear electric motor or alternator. A source of a high frequency, alternating, electrical signal applies a high frequency signal to the winding circuit of the linear alternator or motor. A filter circuit is connected to the winding circuit and passes electrical signals at the frequency of the high frequency source and blocks signals at the operating frequency of reciprocation. A peak detector circuit is connected to the filter circuit and detects the peak of the filter circuit output signal to provide an instantaneous peak magnitude that is proportional to the instantaneous piston position.

Owner:SUNPOWER

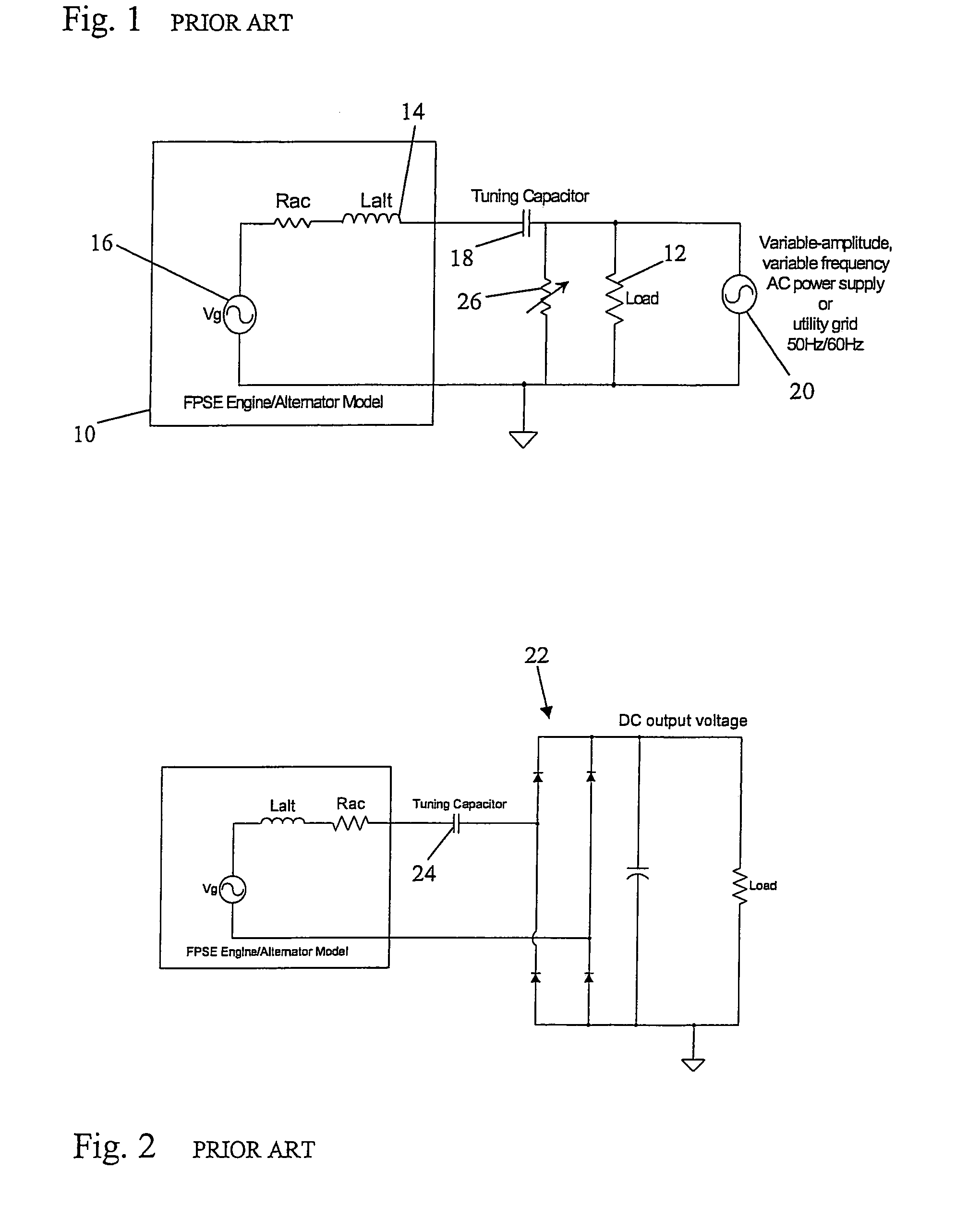

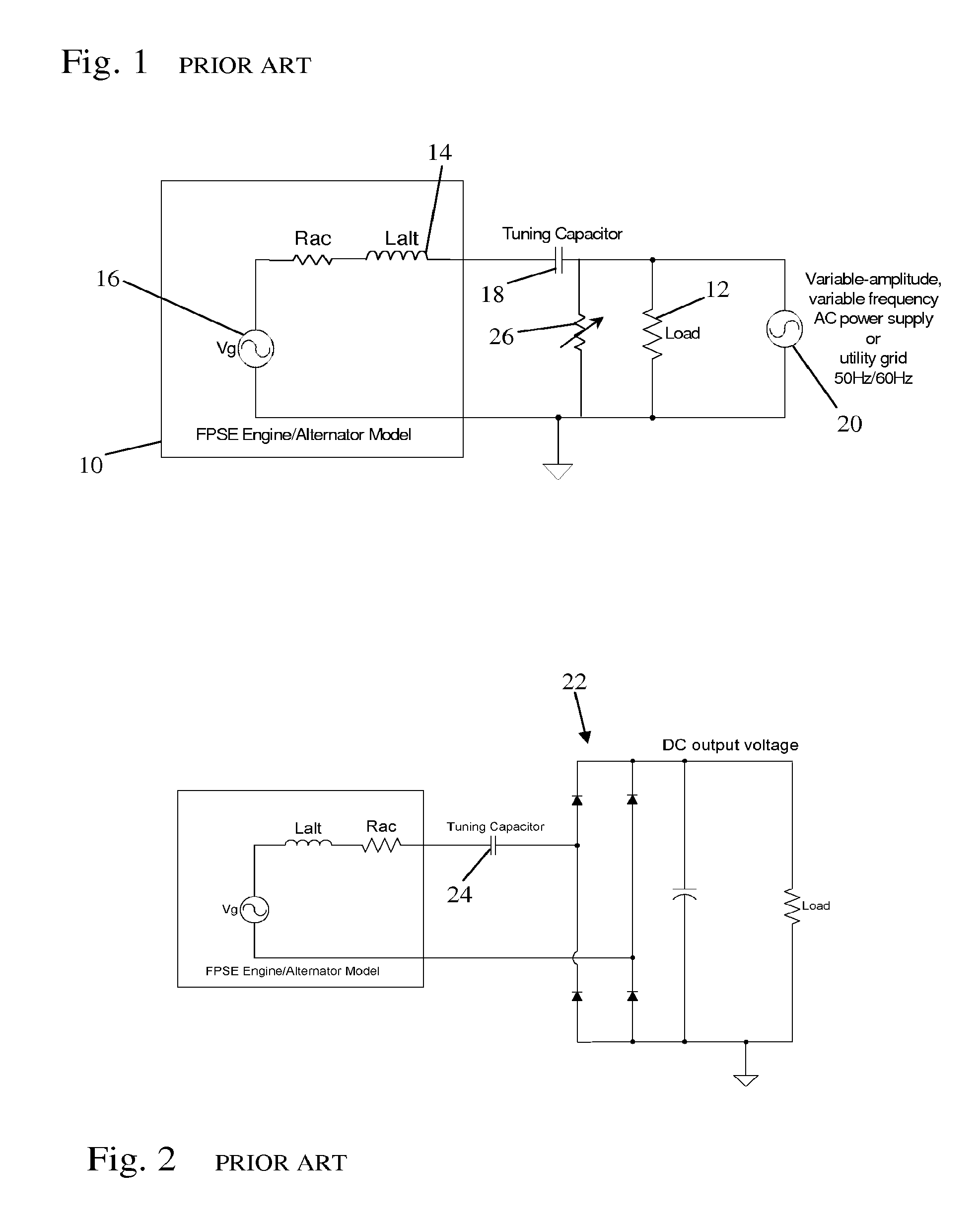

Controller computing a virtual tuning capacitor for controlling a free-piston stirling engine driving a linear alternator

InactiveUS7511459B2Electric motor controlEmergency protective circuit arrangementsControl systemLinear alternator

A feedback control circuit and method for a control system used to control an electrical power generating source that comprises a free piston Stirling engine driving a linear alternator. A switching mode rectifier connects the alternator winding to an output circuit that includes an electrical energy storage means and is controlled by a pulse width modulator that controls the rectifier switching duty cycle and phase. The control system controls the pulse width modulator. The improvement computes a voltage across a virtual tuning capacitor and uses the computed voltage to control the switching mode rectifier so that the switching mode rectifier is switched in a manner that makes the alternator circuit operate as if a tuning capacitor were actually present and so that the control system controls the piston of the Stirling engine to maintain balance of the mechanical power generated by the Stirling engine and the electrical power absorbed from the engine by the alternator.

Owner:SUNPOWER

Free piston stirling engine

A free piston Stirling engine, comprising a power piston fitted into a cylinder further includes: a support structure carrying moving magnets for a linear alternator; and a passive structure that at normal operating power and frequency produces a restoring force on the piston in the absence of contact with the cylinder. In one variation, the passive structure further comprises a mass suspended within the piston from at least one spring, such that the mass oscillates under influence of movement of the piston at normal operating power and frequency so as to produce the restoring force. In another variation, the passive structure further comprises: a magnet disposed outside the cylinder at a position and in an orientation to produce a field that opposes a field of a moving magnet carried by the support structure when the piston moves toward the magnet.

Owner:TIAX LLC

Thermoacoustic engine-generator

InactiveUS20050016171A1High speed of soundLess initial workStirling type enginesCompression machinesThermal energyWorking fluid

A thermoacoustic engine-generator that converts waste heat into electrical power. Thermal energy is converted to useful work via temperature-pressure amplification of periodic acoustic traveling waves in a compressible working fluid which cause the armature of a linear alternator to reciprocate and produce alternating current electrical energy. An external oscillator initiates reciprocating motion in the armature of a linear alternator. The armature is a combination fluid pump and fluid motor as well as the induction armature of a linear alternator. The pump end of the armature generates an acoustic traveling wave with each cycle of the armature. The traveling wave enters a waveguide-heat exchanger and is amplified in temperature, pressure and propagation velocity by thermal conduction of energy through the wall of the waveguide. The amplified traveling wave acts upon the opposite end of the armature, causing it to reciprocate within the magnetic field windings of the generator, and generate an electrical current as well as a new acoustic traveling wave. When the operating temperature gradient is attained across the hot and cold heat exchangers, the thermoacoustic engine-generator becomes acoustically resonant and self-regenerative, and will continue to operate as long as the thermal gradient is maintained. The theoretical conversion efficiency is dependent on the thermal gradient, and is 63% of Carnot.

Owner:FELLOWS RES GRP INC

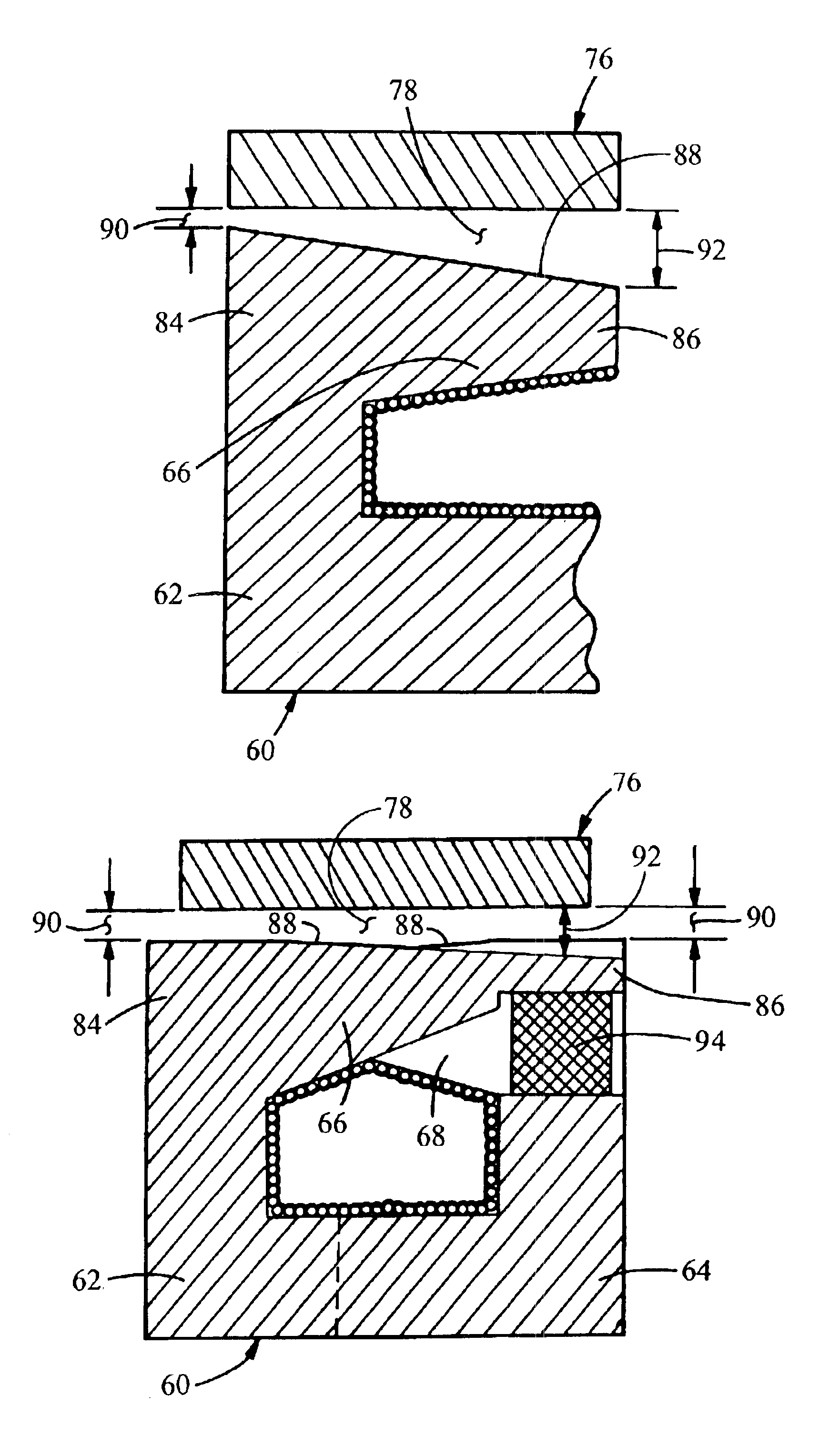

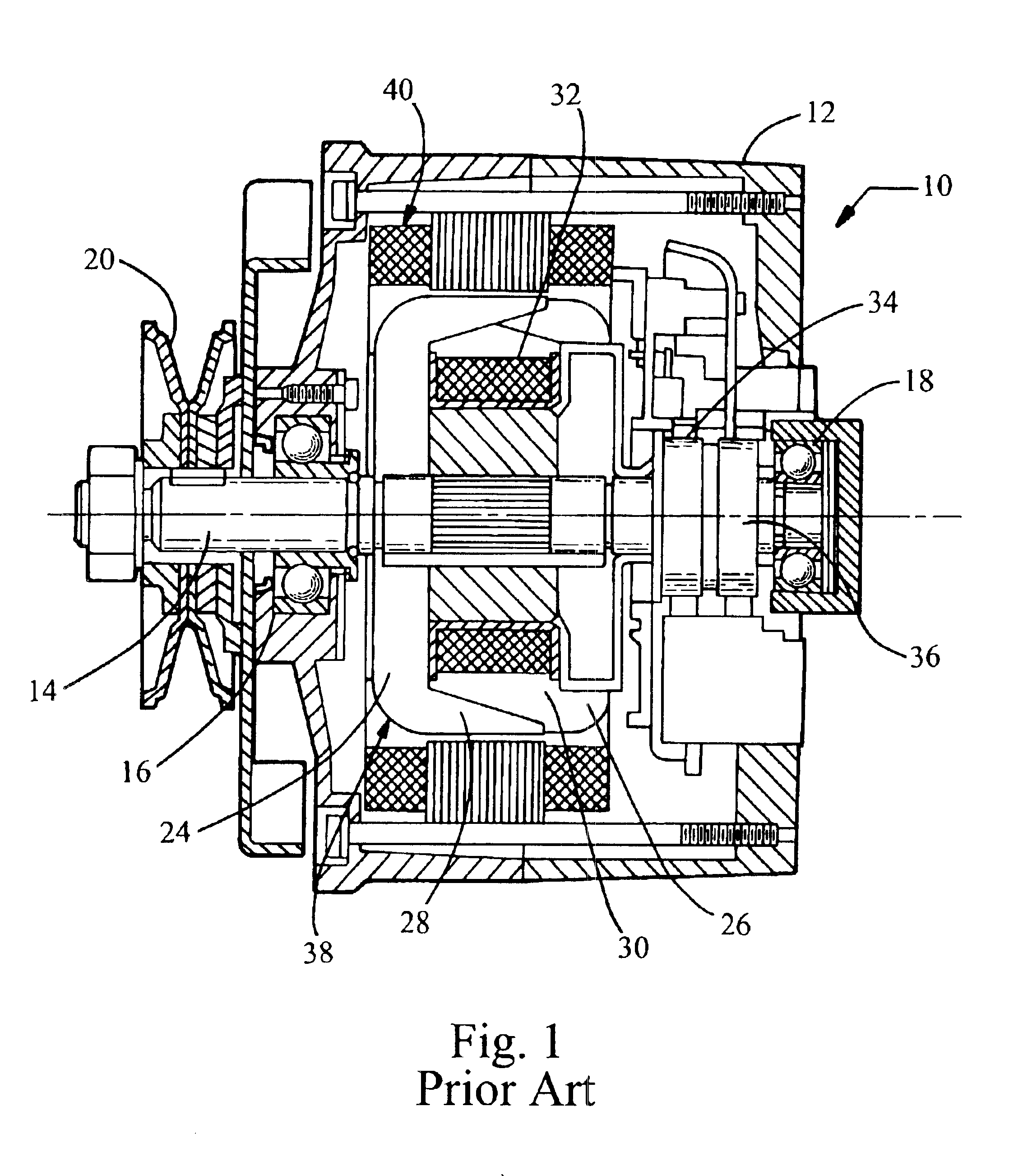

Claw-pole alternator with non-uniform air gap

An alternator of the present invention includes a housing, a stator assembly mounted stationary within the housing, and a rotor assembly mounted rotatably within the housing in functional engagement with the stator assembly. An air gap extends annularly around the alternator between the rotor assembly and the stator assembly. The rotor assembly has a first end and a second end, and the air gap has a non-uniform thickness that varies along the axial length of the rotor assembly between the first and second ends of the rotor assembly. This non-uniform thickness is designed to avoid interference between rotor outer surface and stator inner surface at high rotor spin speed, but minimize the averaged air gap thickness for high alternator performance.

Owner:VISTEON GLOBAL TECH INC

Apparatus for transferring linear loads

Apparatus for transferring a linear load through a high-speed rotating member includes a linear actuator containing an axially translatable cylinder rod. A mounting adapter fixed against axial and rotary movement is rigidly affixed to an actuator cylinder containing the cylinder rod. An elongate guide sleeve, fixed to the mounting adapter, extends axially from the adapter to accommodate an axially translatable thrust bearing affixed to one end of the cylinder rod. The guide sleeve contains a linear slot for accommodating a guide pin affixed to the thrust bearing housing, and transversely movable within the linear slot to prevent rotation of both bearing housing and cylinder rod components.

Owner:CATERPILLAR INC

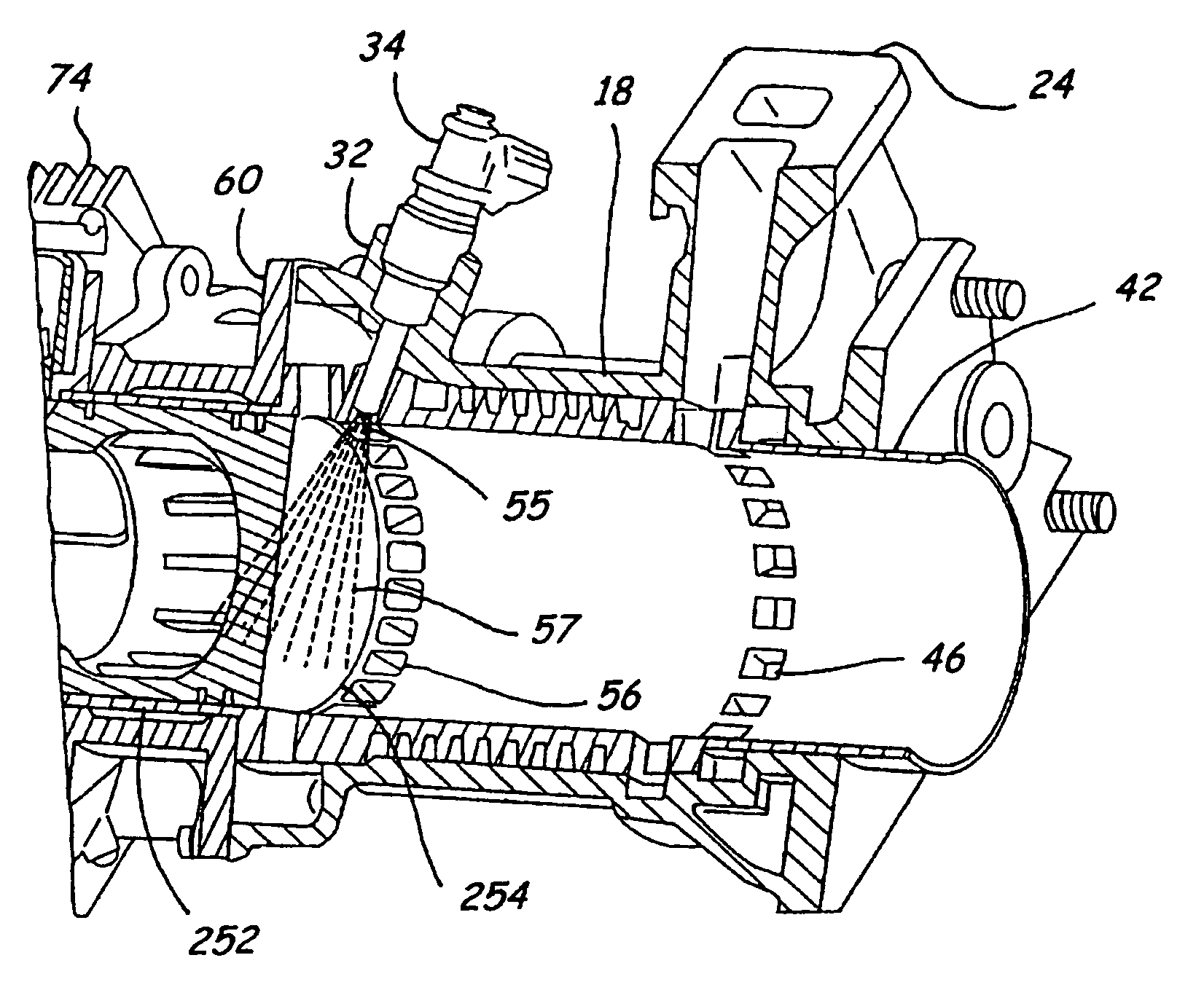

Fuel injection for a free piston engine

InactiveUS6959672B1Easy to changeConducive effective homogeneous chargeInternal combustion piston enginesLow pressure fuel injectionFree-piston engineCombustion

A free piston engine is configured with a pair of opposed engine cylinders located on opposite sides of a fluid pumping assembly. An inner piston assembly includes a pair of inner pistons, one each operatively located in a respective one of the engine cylinders, with a push rod connected between the inner pistons. The push rod extends through an inner pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. An outer piston assembly includes a pair of outer pistons, one each operatively located in a respective one of the engine cylinders, with at least one pull rod connected between the outer pistons. The pull rod extends through an outer pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. The movement of the inner and outer piston assemblies during engine operation will cause the fluid plungers to pump fluid from a low pressure container into a high pressure chamber as a means of storing the energy output from the engine. Alternatively, the piston assemblies may drive a linear alternator. Each fuel injector is located so that it injects directly into its cylinder near the intake ports, while also being covered during combustion events in order to avoid exposing the fuel injector to the harsh environment of combustion.

Owner:FORD GLOBAL TECH LLC

Piston lubrication for a free piston engine

InactiveUS6971341B1Easy to changeEasy to operateLubrication of auxillariesLubricant conduit arrangementsFree-piston enginePump chamber

Owner:FORD GLOBAL TECH LLC

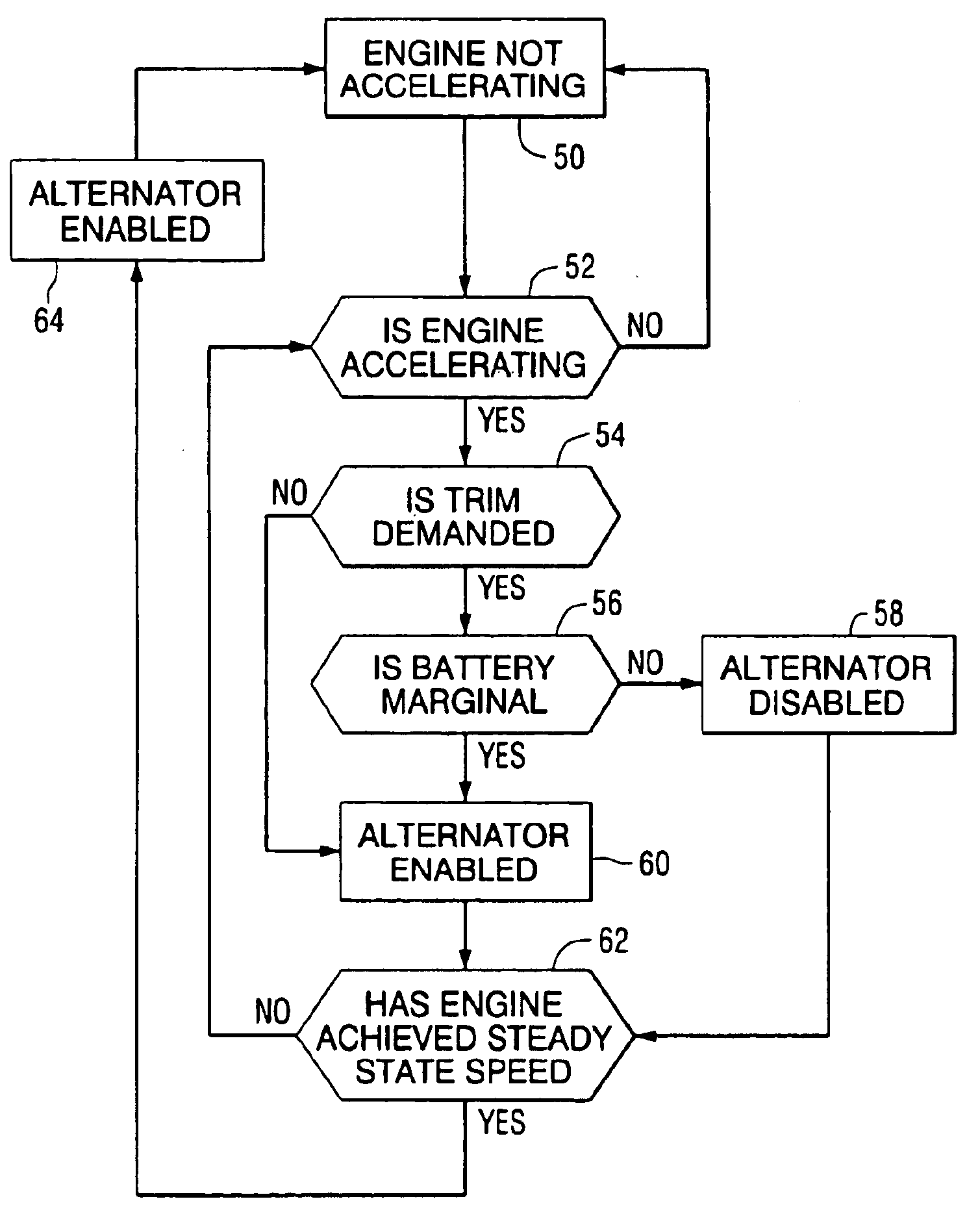

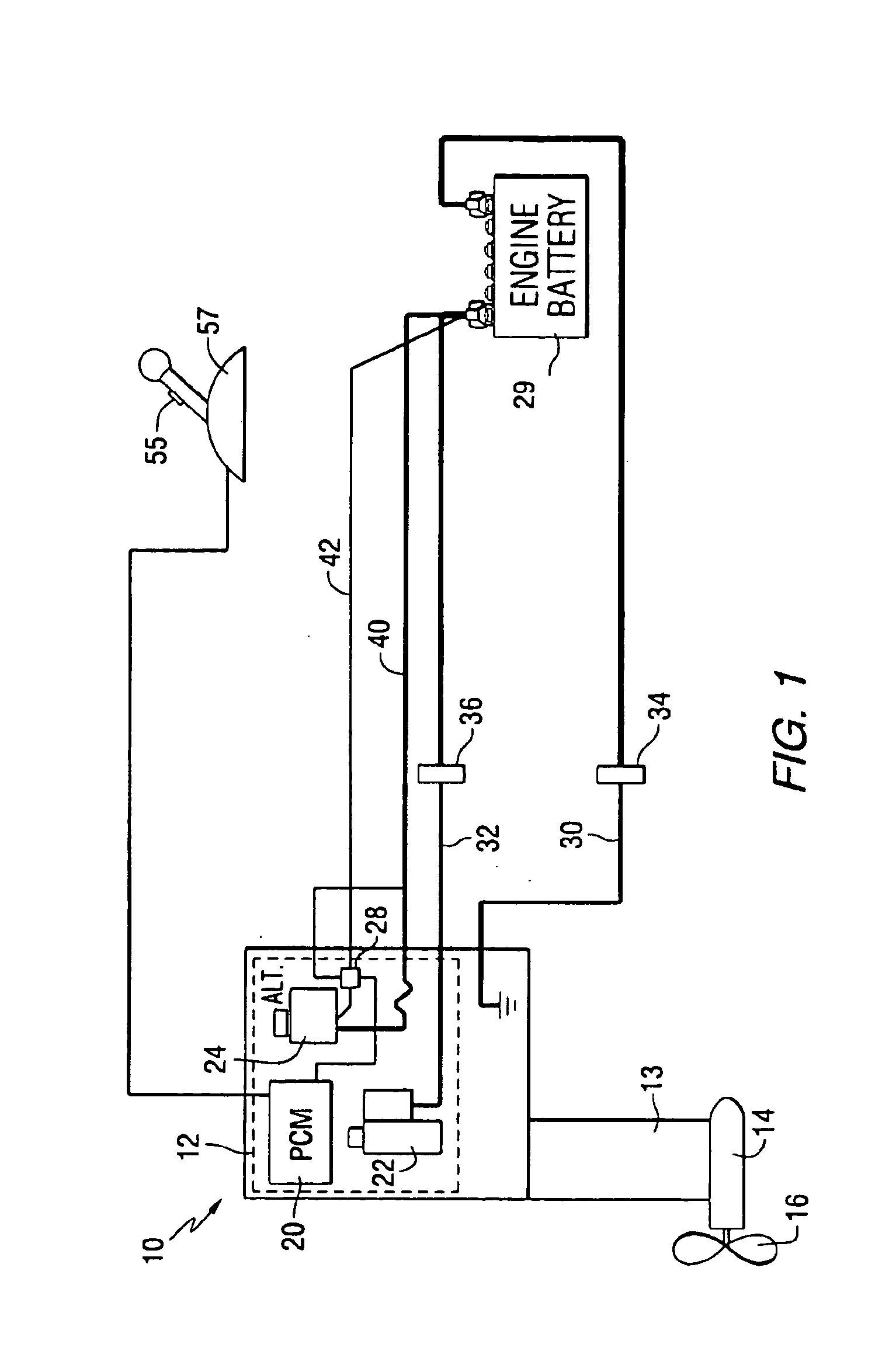

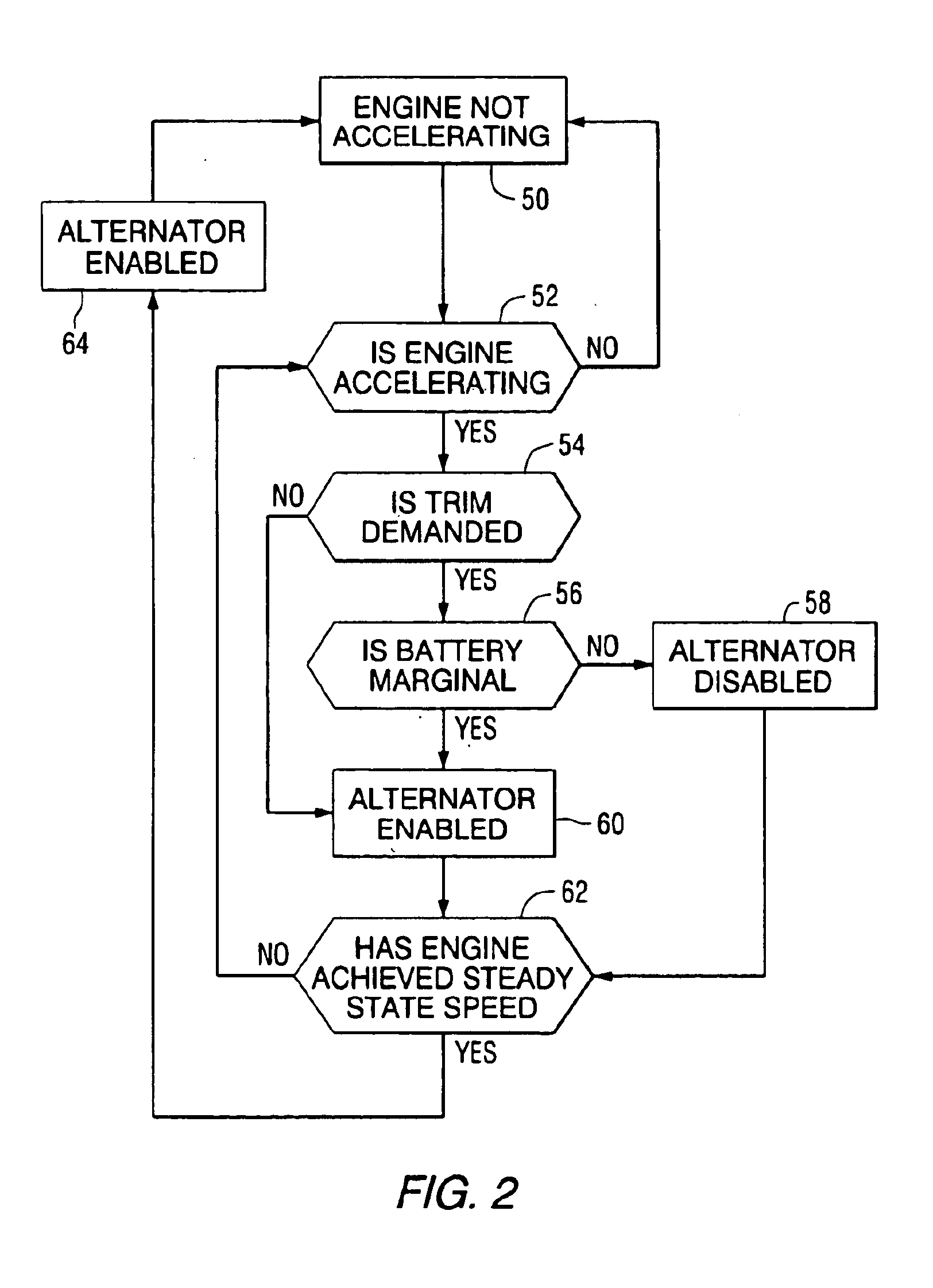

Method for deactivating a marine alternator during periods of high engine power requirements

A method is provided for controlling the operation of the alternator in such a way that during certain conditions, such as rapid acceleration of a marine vessel in combination with a trimming maneuver, the alternator of the marine propulsion system is deactivated so that it does not provide a mechanical load on the engine during the accelerating maneuvers. This allows the engine to provide more power to the propeller and achieve the desired operating speed commanded by the operator of a marine vessel.

Owner:BRUNSWICK CORPORATION

Electric vehicle

An electric vehicle having good range and power is achieved by providing a vehicle having a motor side assembly and a power side assembly. A battery starts or activates a starter. The battery is connected to a direct current motor to start off or begin the engine function by activating a rear alternator. The rear alternator has three phases by using three hot lines, one neutral line, and one ground line. One hot line and the neutral are connected or will go to a transformer to bring the voltage to the correct voltage. From the transformer, the feed goes to an inverter, so the alternating current voltage is changed to a direct current voltage. This structure will feed the direct current motor for a continuous feed.

Owner:LARKE HAROLD RAY

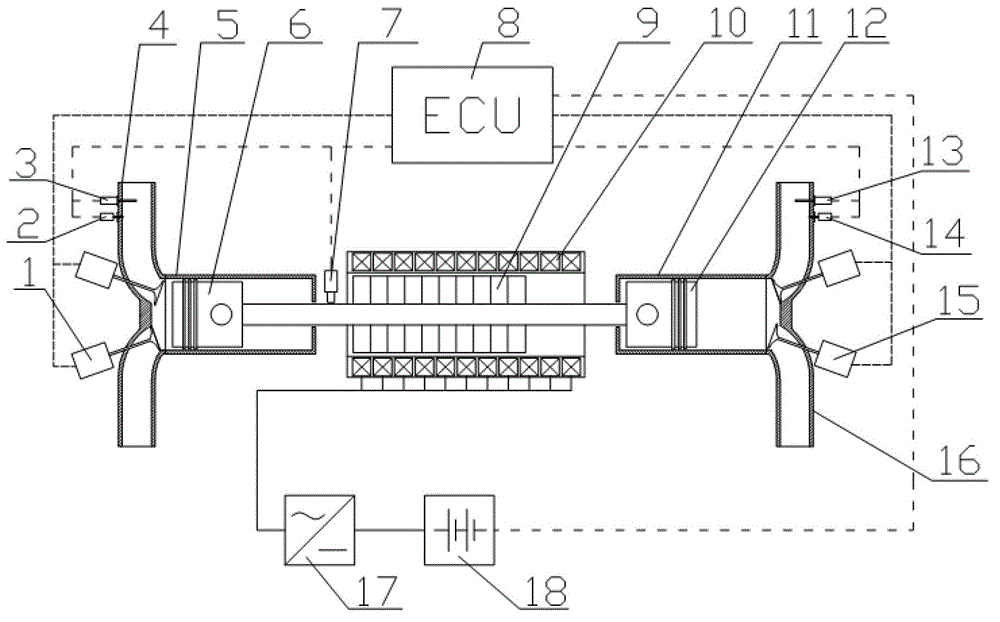

Free stroke piston expander generation device utilizing high pressure gas to output electric energy

InactiveCN103334795ACompact structureImprove balanceSafety/regulatory devicesDynamo-electric machinesHigh energyActive cell

The invention relates to a free stroke piston expander generation device utilizing high pressure gas to output electric energy. The device comprises a free stroke piston expander, a linear alternator, an ECU (electronic control unit), a rectifier and an electric energy storage device. According to the device, the high pressure gas is outputted to drive two pistons in the piston expander, so that the active cell in the linear alternator does reciprocating motion and cuts magnetic lines of force to directly output electric energy. Compared with the existing expander, the free stroke piston expander generation device has the advantages of compact structure, superior balance performance, adjustable expansion ratio, low abrasion frictional loss, higher energy exchange efficiency and the like, and achieves a wider application prospect.

Owner:BEIJING UNIV OF TECH

Compression pulse starting of a free piston internal combustion engine

InactiveUS20050257758A1Sufficient magnitudeIncrease kinetic energyStarters with fluid-driven auxillary enginesMuscle operated startersCombustion chamberActuator

A method for starting an engine uses an actuator, such as a hydraulic or pneumatic pump-motor or an electric linear alternator-starter to move the pistons to a position where the inlet ports are opened. This ensures that air is present in the cylinder in a space where fuel will be admitted and combustion will occur. This strategy compresses, with a minimum actuator capacity, such air to a state that the pressure and temperature satisfy the ignition requirements. The air stores kinetic energy of the moving pistons that partially form the air spring force of the opposite cylinder and partially from the actuator. Accumulation, cycle by cycle, of this stored energy accelerates the piston motion, increases the piston displacement, and increases the compression ratio. The cylinder pressure and temperature increas cycle by cycle until the fuel ignition conditions are satisfied. The actuator force is a periodic force preferably having a frequency that is the same or nearly the same as the natural frequency of the system that includes the inertia of the pistons and other masses reciprocating with the pistons and the variable spring, represented by the compressible air spring in the combustion chamber. When piston displacement reaches a sufficient magnitude, fuel is admitted to the air charge, preferably by injection. The actuator continues to increase piston displacement and the compression pressure of the air-fuel mixture in the cylinder until combustion of that mixture in the first cylinder occurs. Fuel is then admitted to the second cylinder while continuing cyclic displacement of the pistons, and combustion of the fuel-air mixture in the second cylinder occurs.

Owner:FORD GLOBAL TECH LLC

Detection of the instantaneous position of a linearly reciprocating member using high frequency injection

InactiveUS20080061770A1Magnetic property measurementsUsing electrical meansDetector circuitsEngineering

A piston position sensing circuit for sensing the instantaneous position of a piston of a free piston Stirling machine or a compressor mechanically connected to a reciprocating member of a linear electric motor or alternator. A source of a high frequency, alternating, electrical signal applies a high frequency signal to the winding circuit of the linear alternator or motor. A filter circuit is connected to the winding circuit and passes electrical signals at the frequency of the high frequency source and blocks signals at the operating frequency of reciprocation. A peak detector circuit is connected to the filter circuit and detects the peak of the filter circuit output signal to provide an instantaneous peak magnitude that is proportional to the instantaneous piston position.

Owner:SUNPOWER

Compression pulse starting of a free piston internal combustion engine

InactiveUS6971340B1Sufficient magnitudeIncrease kinetic energyStarters with fluid-driven auxillary enginesMuscle operated startersCombustion chamberEngineering

A method for starting an engine uses an actuator, such as a hydraulic or pneumatic pump-motor or an electric linear alternator-starter to move the pistons to a position where the inlet ports are opened. This ensures that air is present in the cylinder in a space where fuel will be admitted and combustion will occur. This strategy compresses, with a minimum actuator capacity, such air to a state that the pressure and temperature satisfy the ignition requirements. The air stores kinetic energy of the moving pistons that partially form the air spring force of the opposite cylinder and partially from the actuator. Accumulation, cycle by cycle, of this stored energy accelerates the piston motion, increases the piston displacement, and increases the compression ratio. The cylinder pressure and temperature increas cycle by cycle until the fuel ignition conditions are satisfied. The actuator force is a periodic force preferably having a frequency that is the same or nearly the same as the natural frequency of the system that includes the inertia of the pistons and other masses reciprocating with the pistons and the variable spring, represented by the compressible air spring in the combustion chamber. When piston displacement reaches a sufficient magnitude, fuel is admitted to the air charge, preferably by injection. The actuator continues to increase piston displacement and the compression pressure of the air-fuel mixture in the cylinder until combustion of that mixture in the first cylinder occurs. Fuel is then admitted to the second cylinder while continuing cyclic displacement of the pistons, and combustion of the fuel-air mixture in the second cylinder occurs.

Owner:FORD GLOBAL TECH LLC

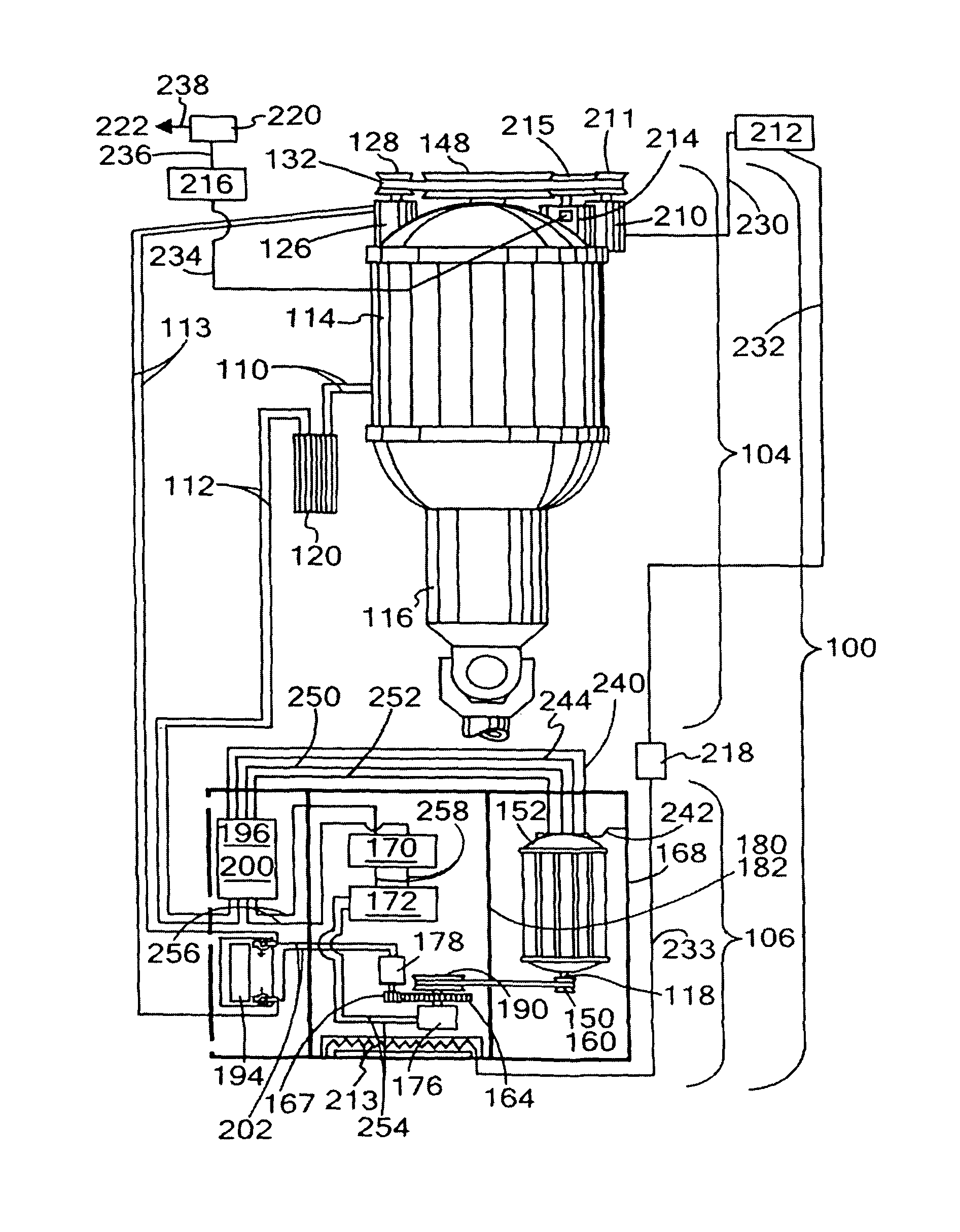

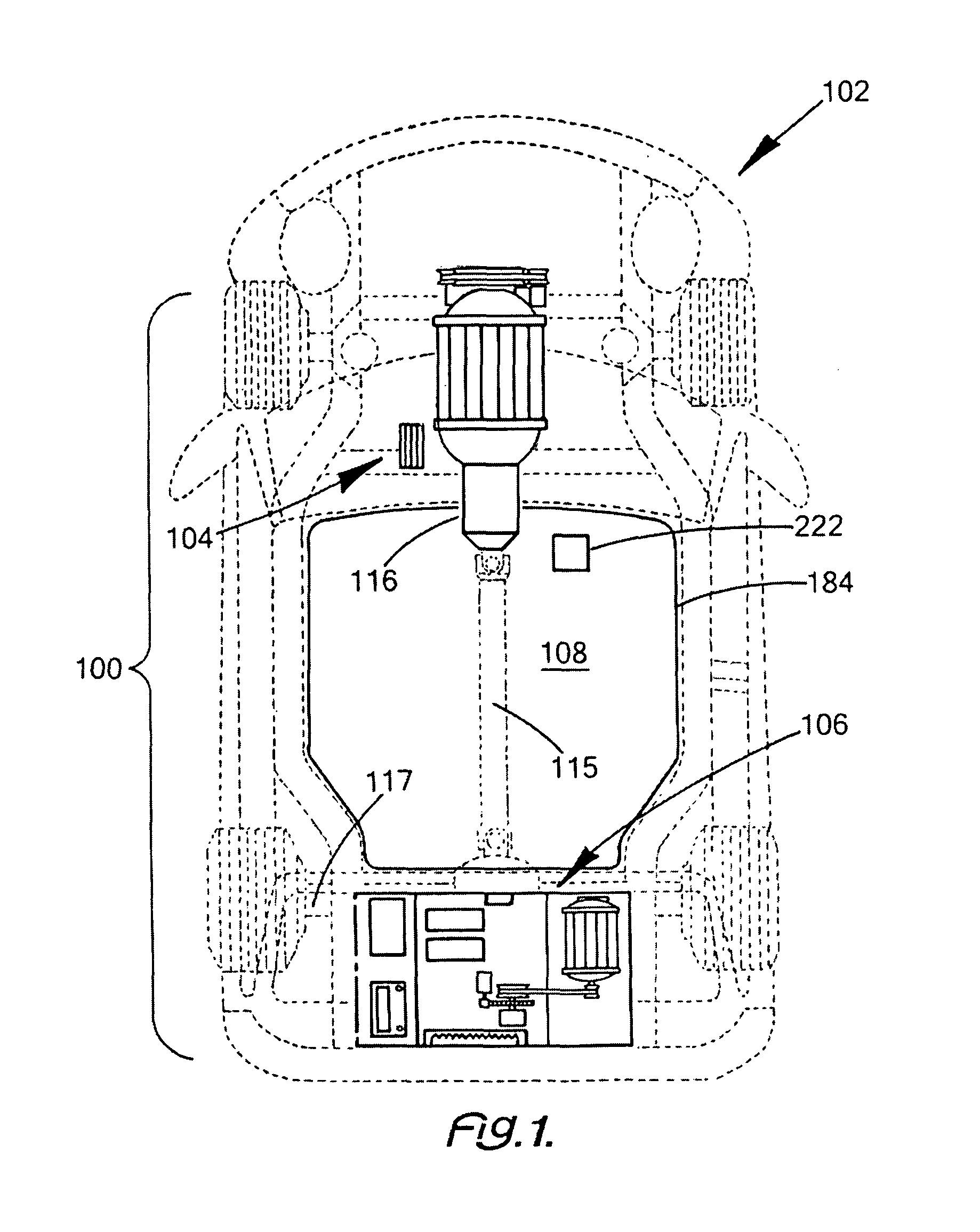

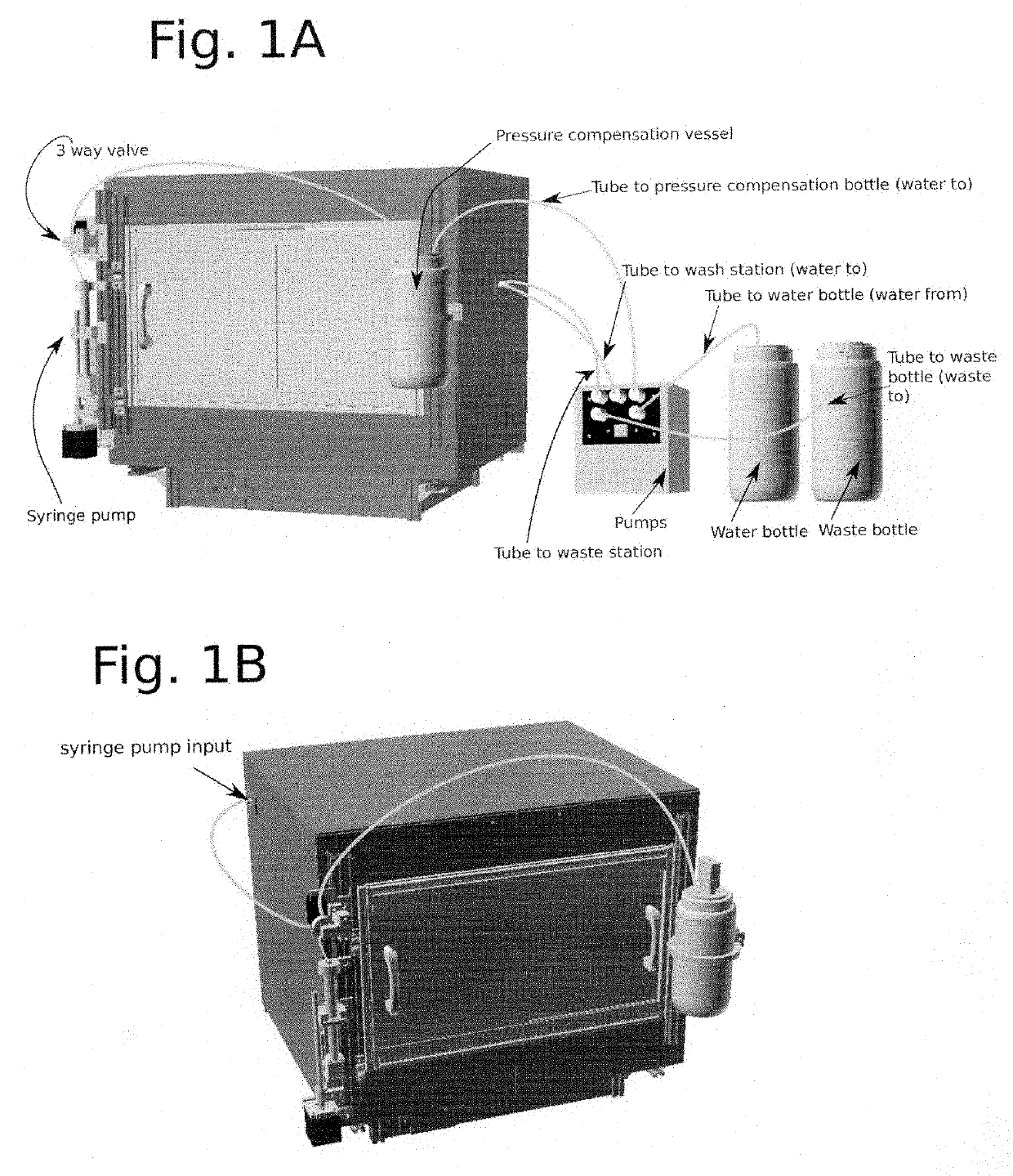

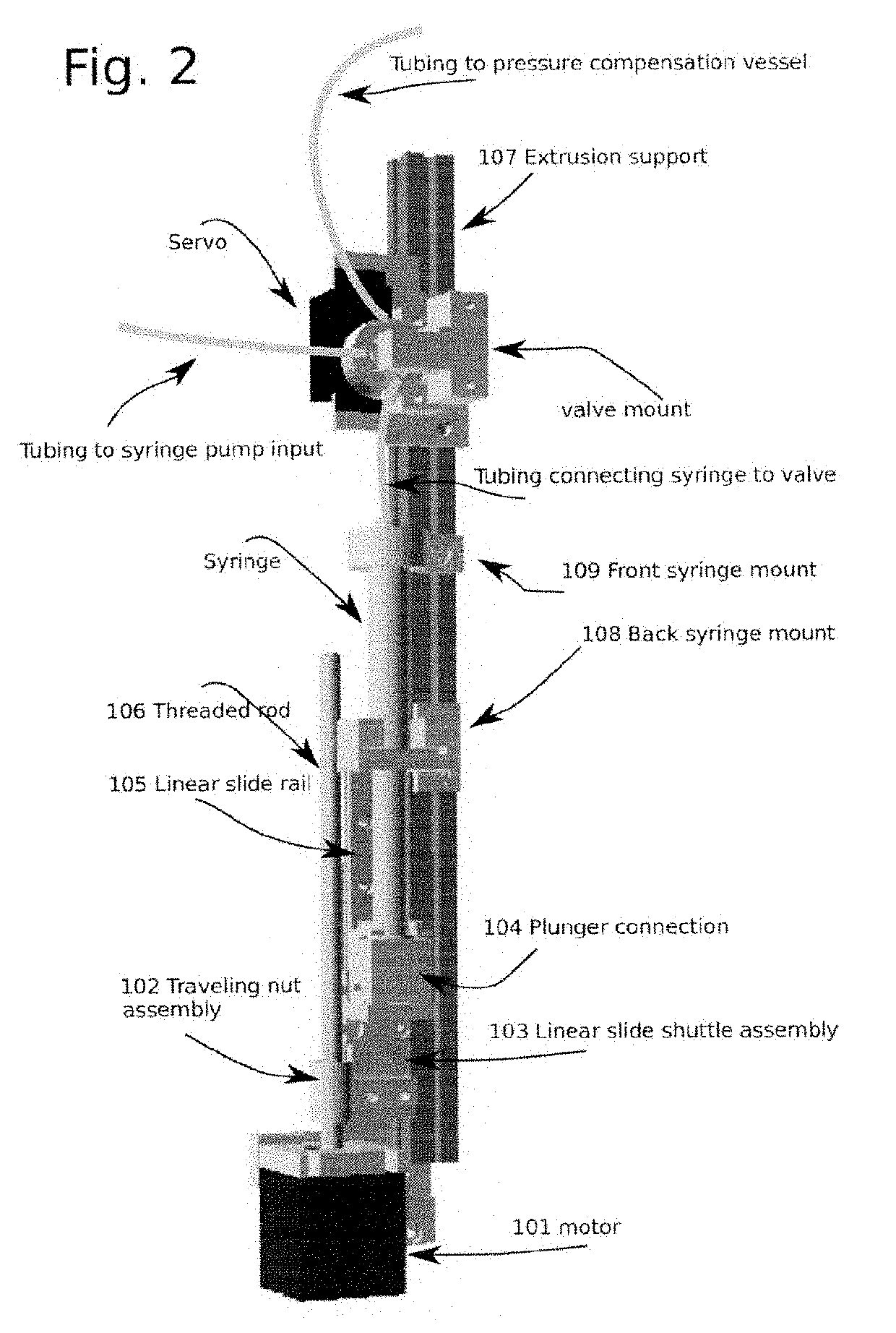

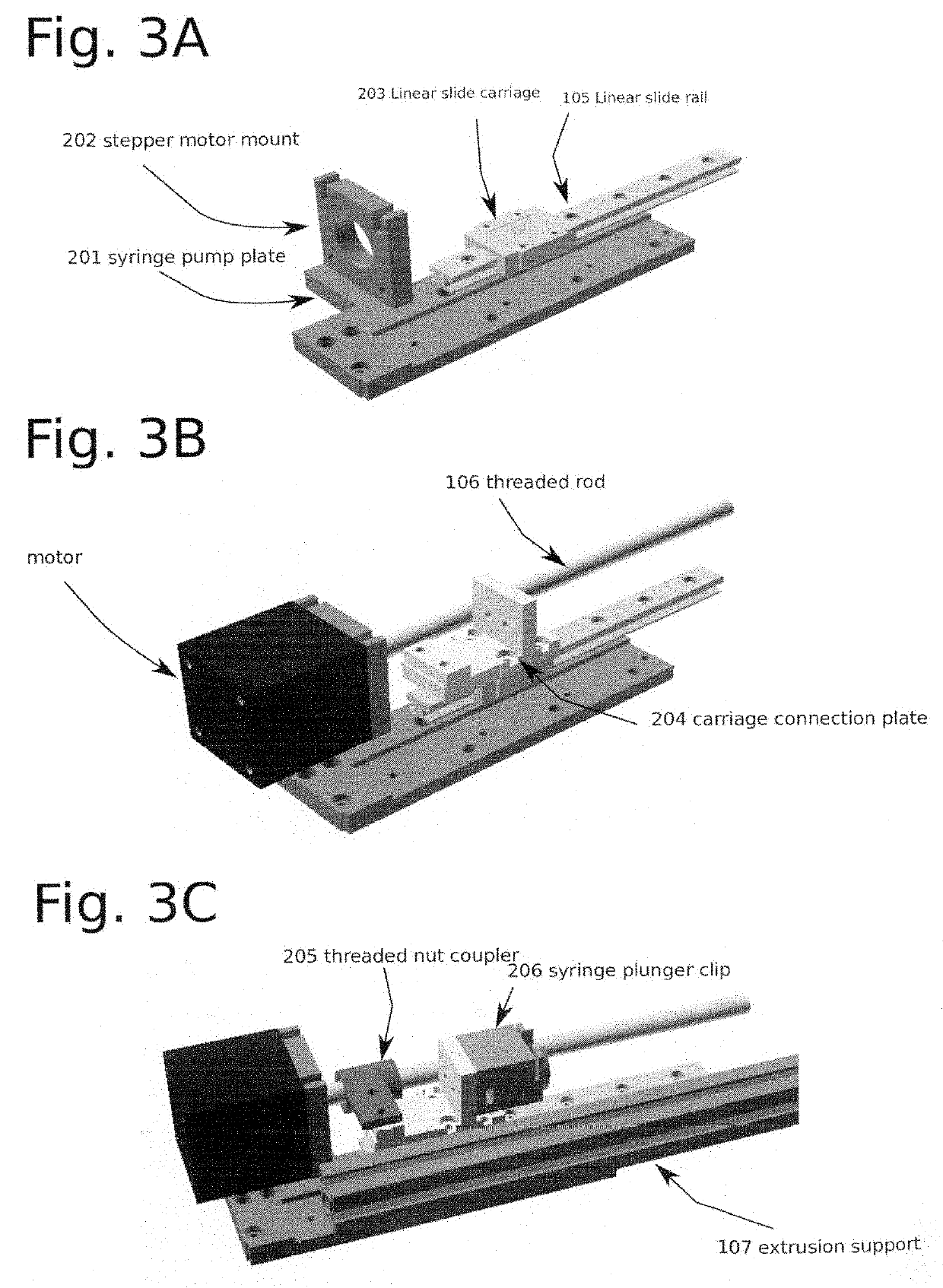

Bioprinter design and applications

InactiveUS20190210283A1Manufacturing driving meansBurette/pipette supportsSystems designFluorescence

Enclosed is a description of a high throughput 3D printing and imaging system that can be used for multiple laboratory purposes from bioassay fabrication to analysis. This compact system is designed to work with multiple microwell plates and slides. It also contains linear encoders for precise positional control in the XYZ direction. A syringe pump and 3 way select valve configuration and interrelated microfluidics are described and compact stepper motor driven linear actuators for moving tools on the gantry head is also explained. In addition, there is a visualization and sorting area for measuring droplets and for deflecting charged particles magnetized collection tubes. There is also an imaging module for quantifying fluorescence abundance and an analog signal triggered camera that can be synchronized with dispensers that can be used for synchronized imaging and data collection.

Owner:ROUSE RICHARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com