Patents

Literature

65results about How to "High speed of sound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

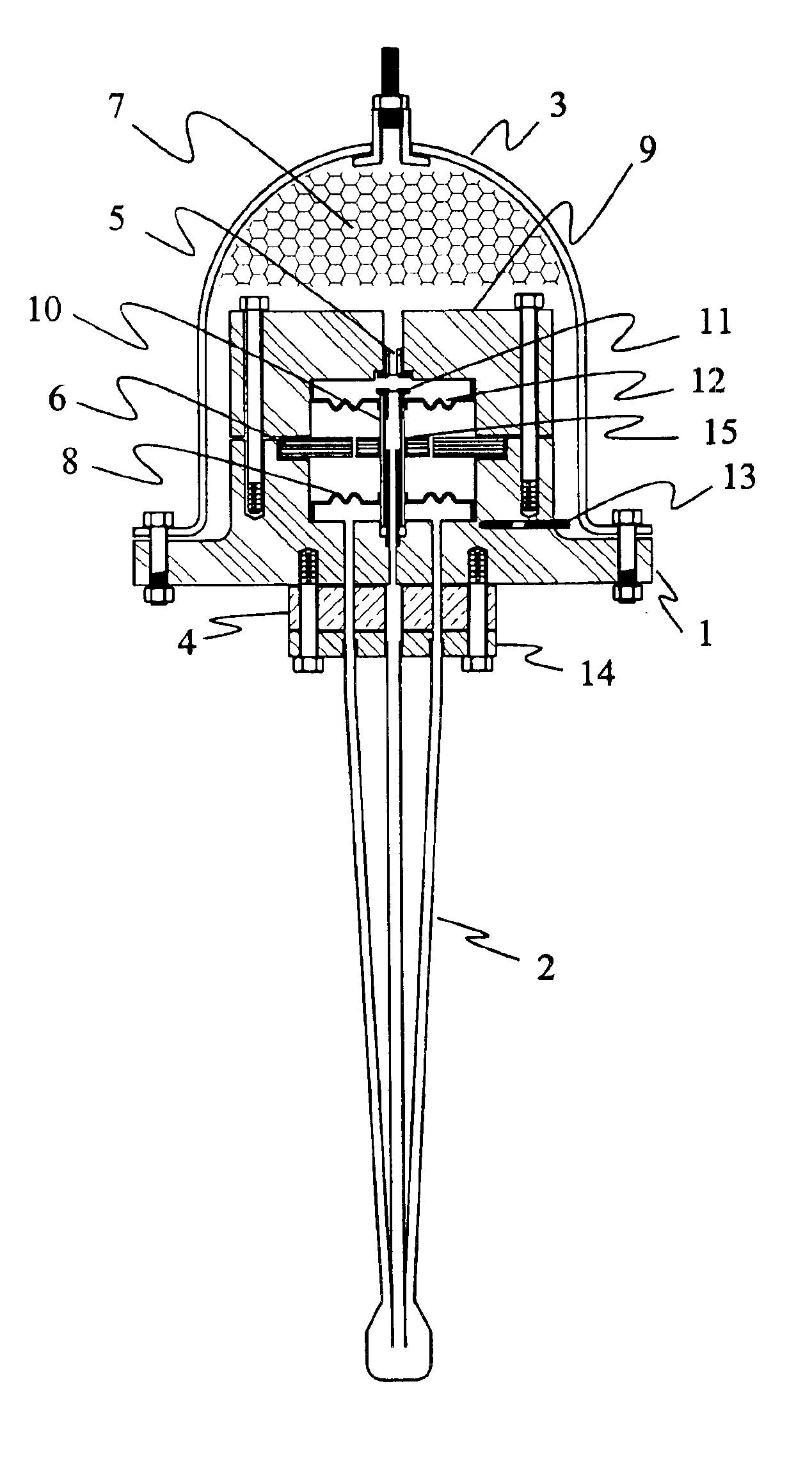

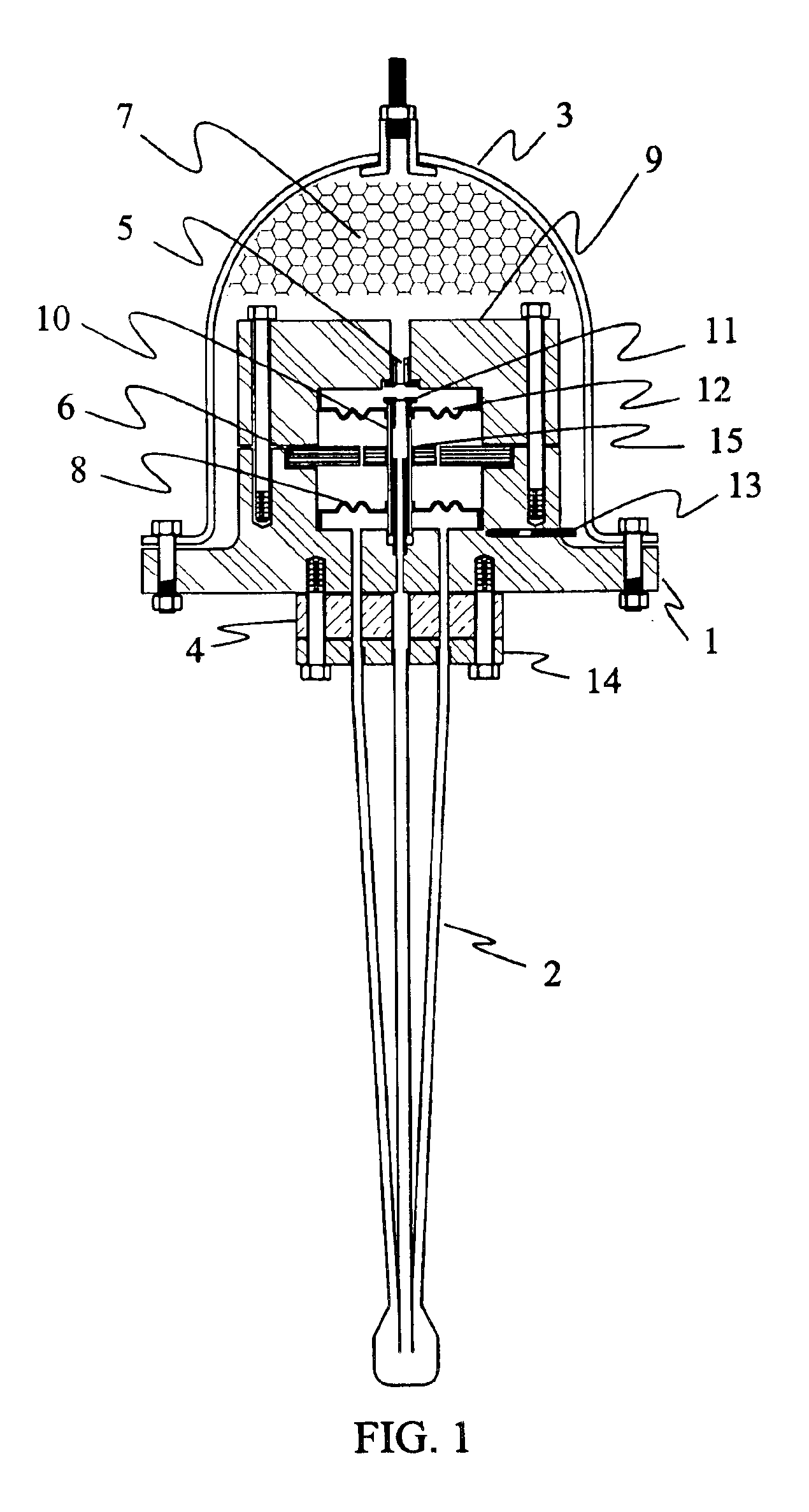

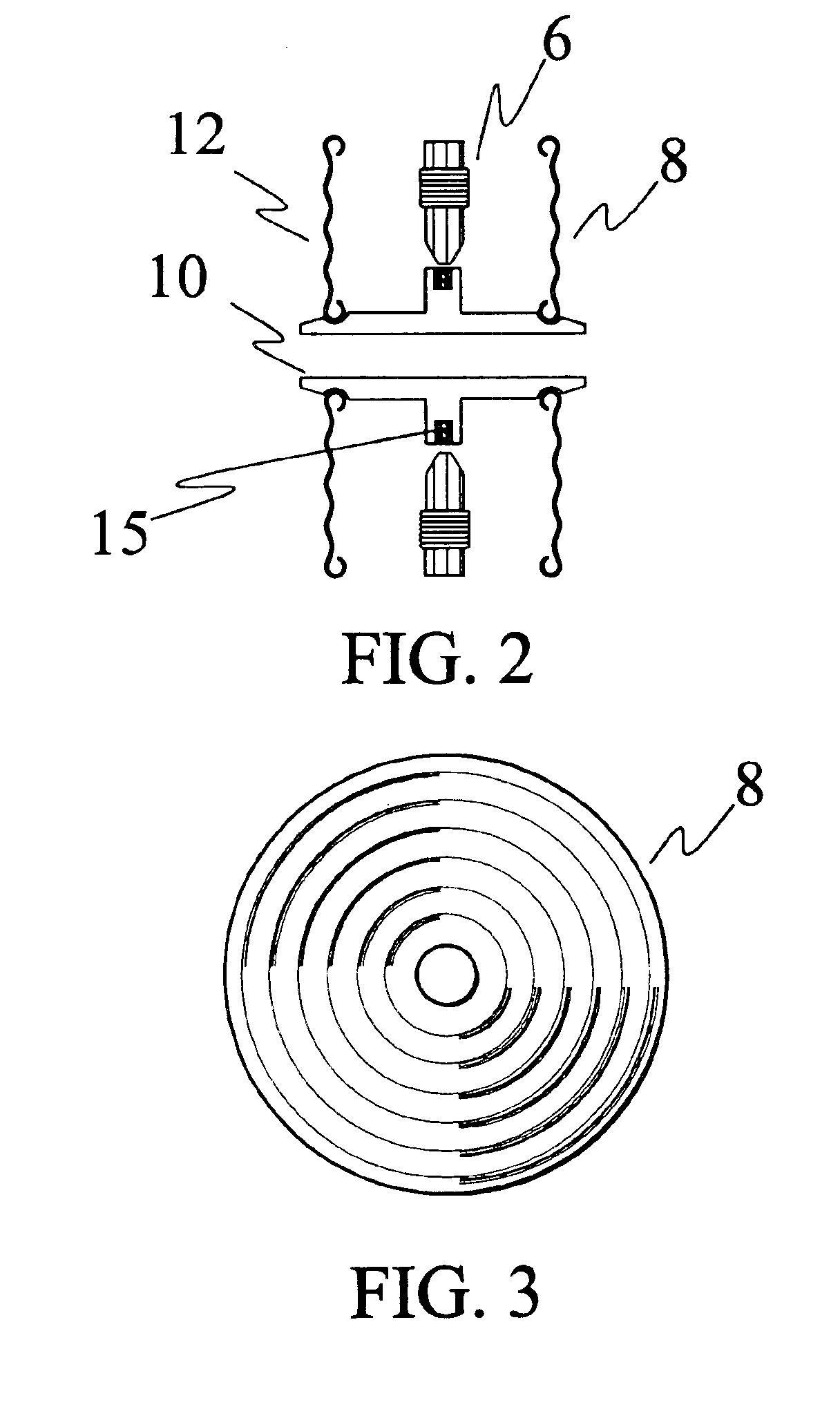

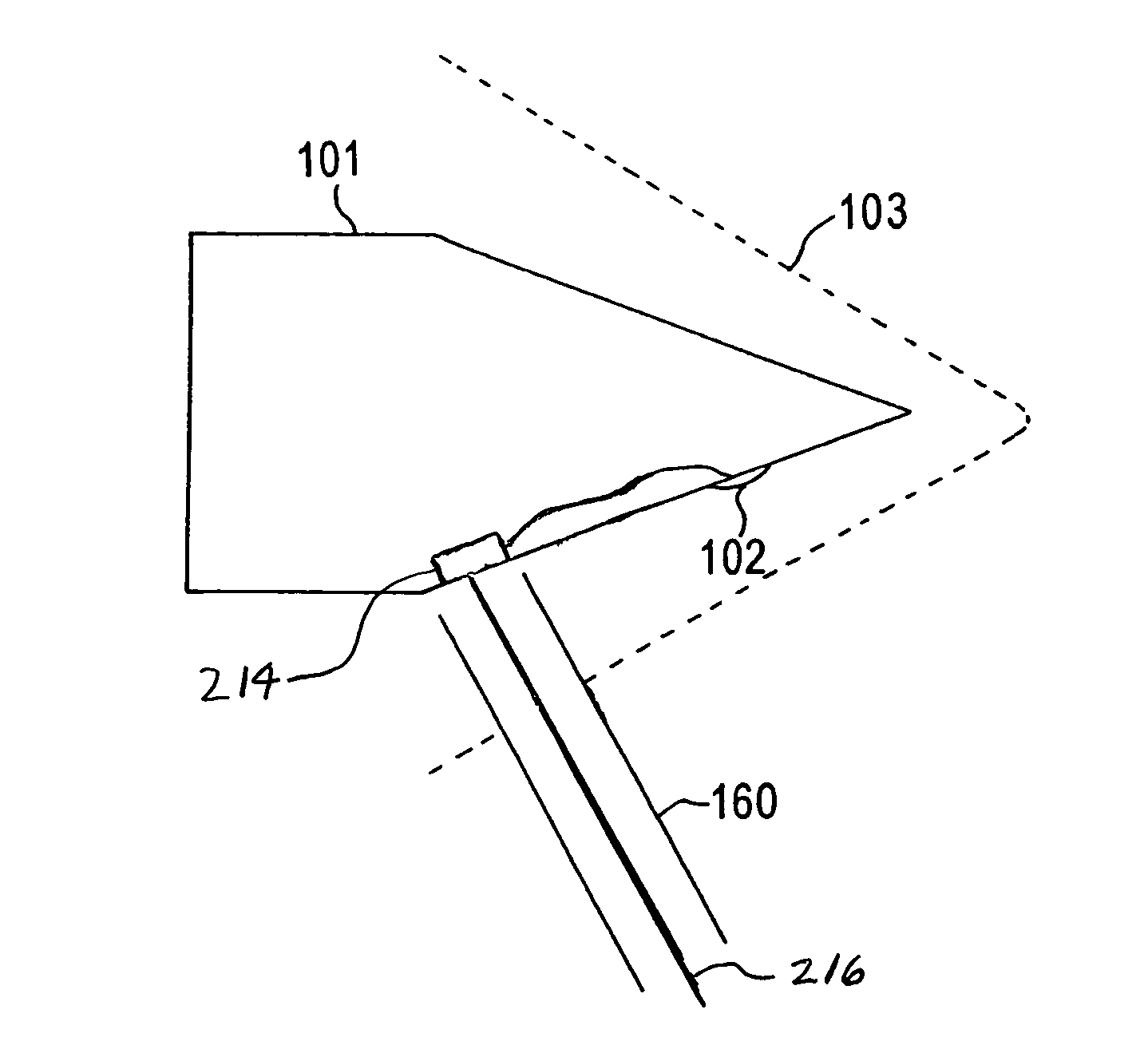

Thermoacoustic engine-generator

InactiveUS6910332B2Optimized areaLower impedancePiezoelectric/electrostriction/magnetostriction machinesStirling type enginesThermal energyWorking fluid

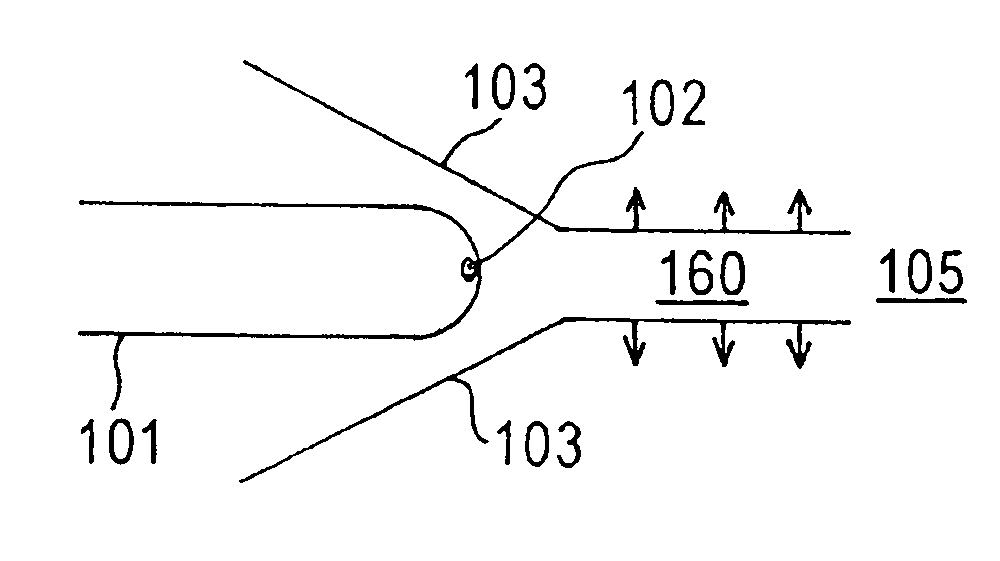

A thermoacoustic engine-generator that converts waste heat into electrical power. Thermal energy is converted to useful work via temperature-pressure amplification of periodic acoustic traveling waves in a compressible working fluid which cause the armature of a linear alternator to reciprocate and produce alternating current electrical energy. An external oscillator initiates reciprocating motion in the armature of a linear alternator. The armature is a combination fluid pump and fluid motor as well as the induction armature of a linear alternator. The pump end of the armature generates an acoustic traveling wave with each cycle of the armature. The traveling wave enters a waveguide-heat exchanger and is amplified in temperature, pressure and propagation velocity by thermal conduction of energy through the wall of the waveguide. The amplified traveling wave acts upon the opposite end of the armature, causing it to reciprocate within the magnetic field windings of the generator, and generate an electrical current as well as a new acoustic traveling wave. When the operating temperature gradient is attained across the hot and cold heat exchangers, the thermoacoustic engine-generator becomes acoustically resonant and self-regenerative, and will continue to operate as long as the thermal gradient is maintained. The theoretical conversion efficiency is dependent on the thermal gradient, and is 63% of Carnot.

Owner:FELLOWS RES GRP INC

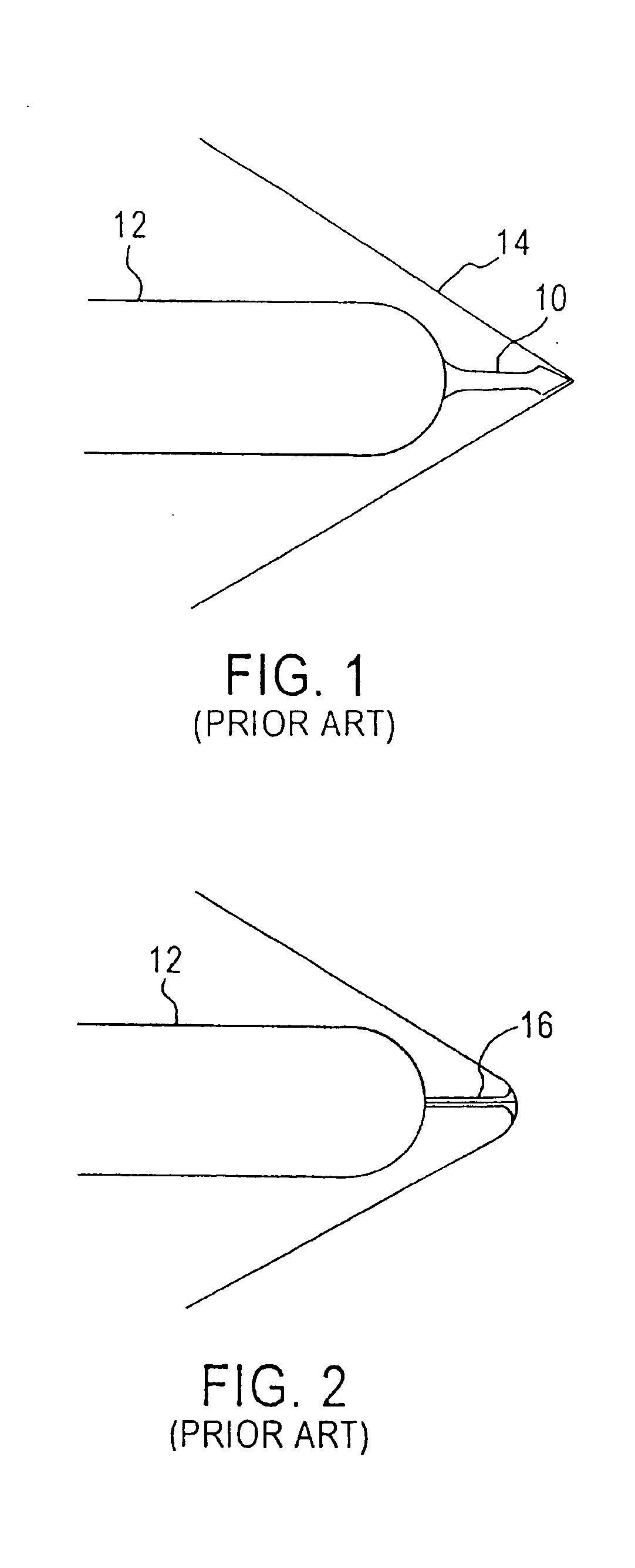

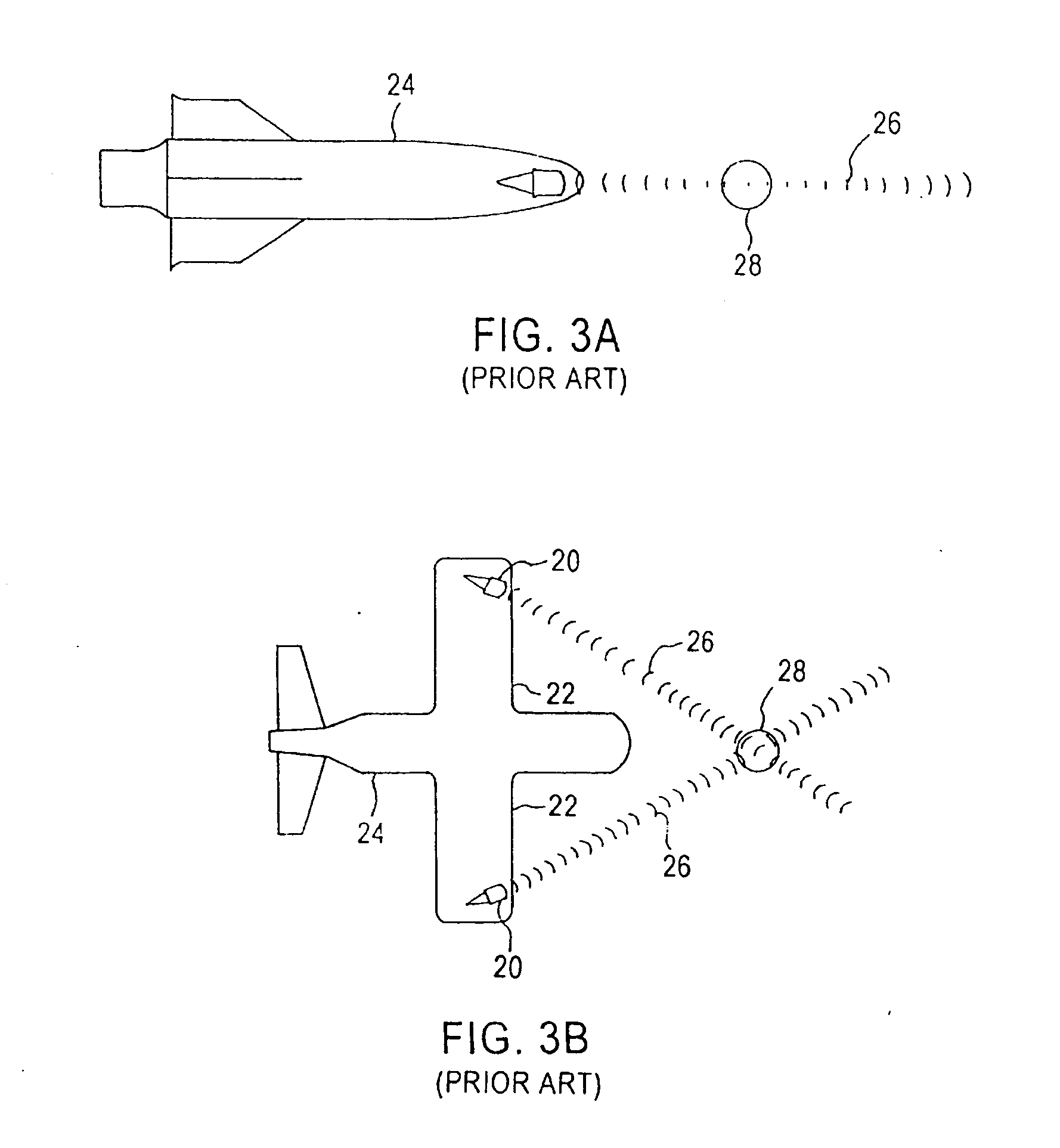

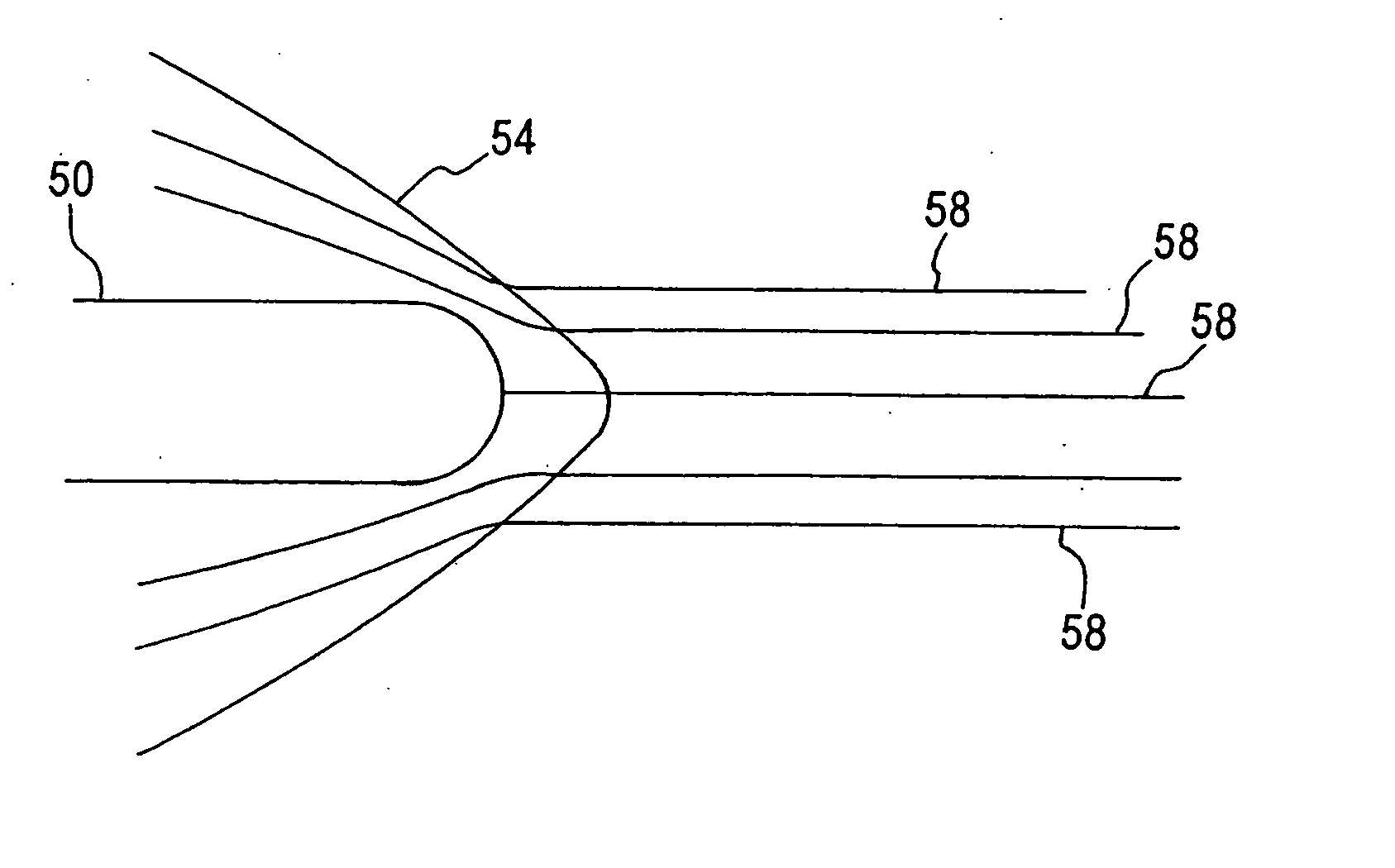

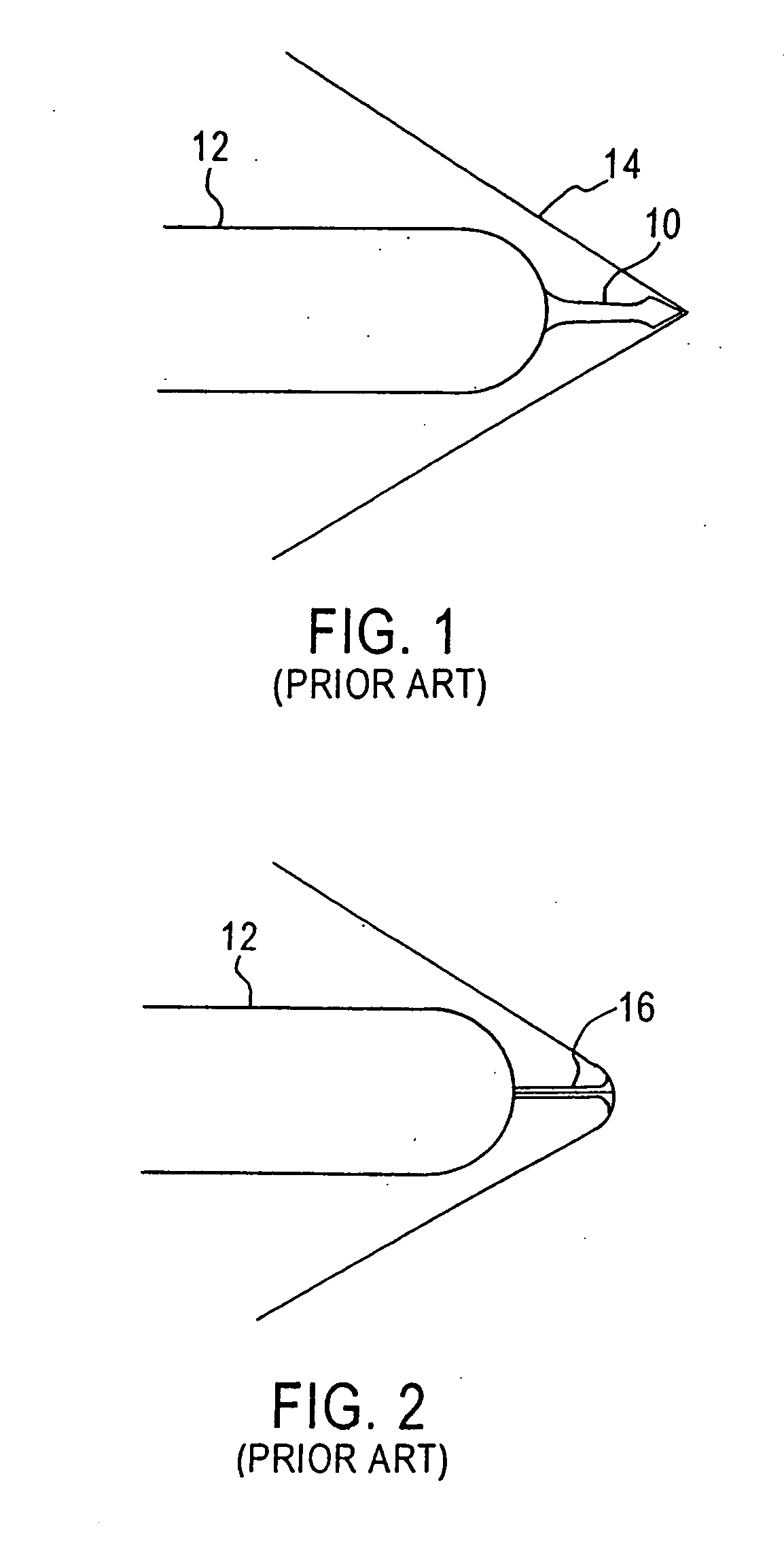

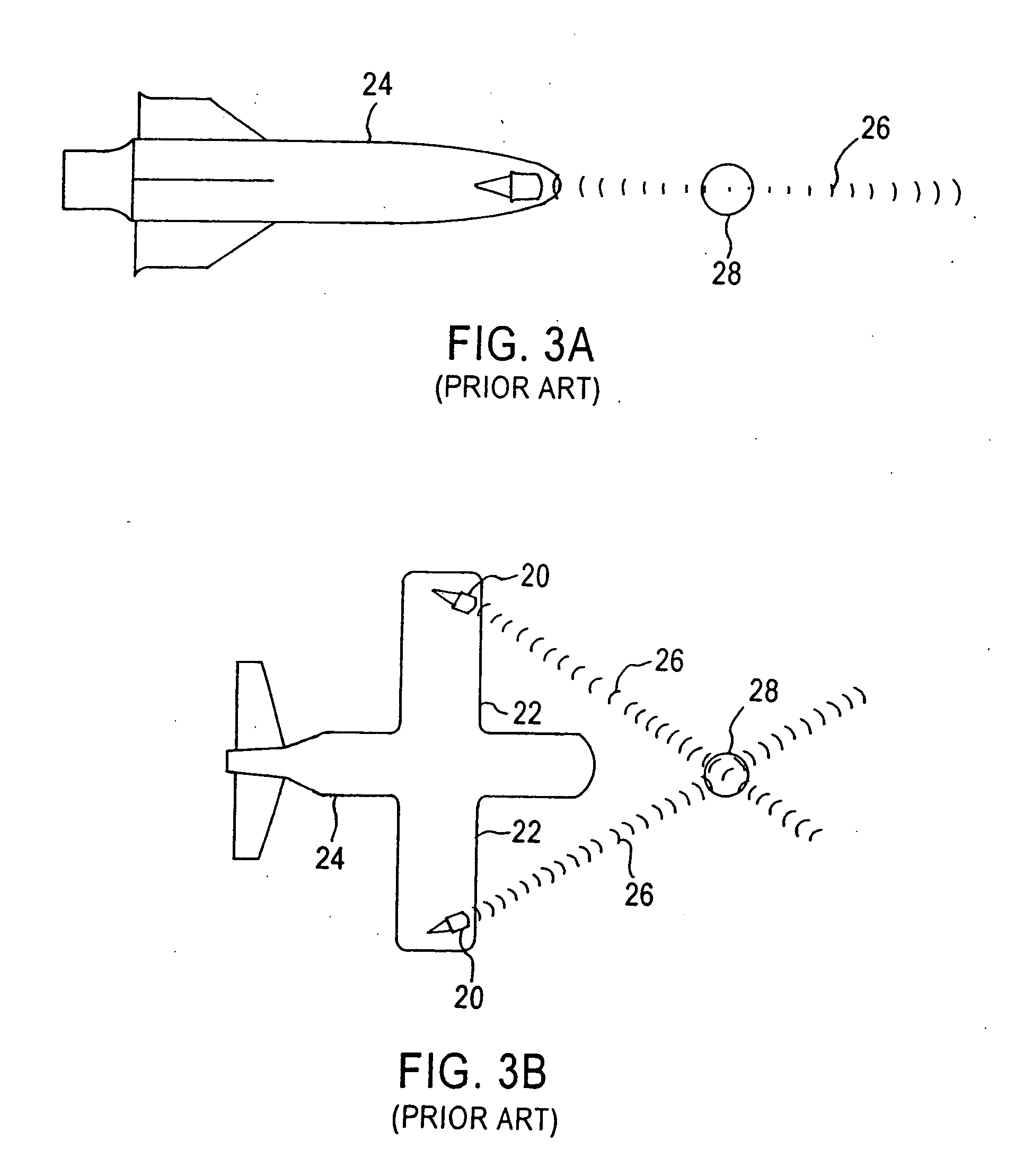

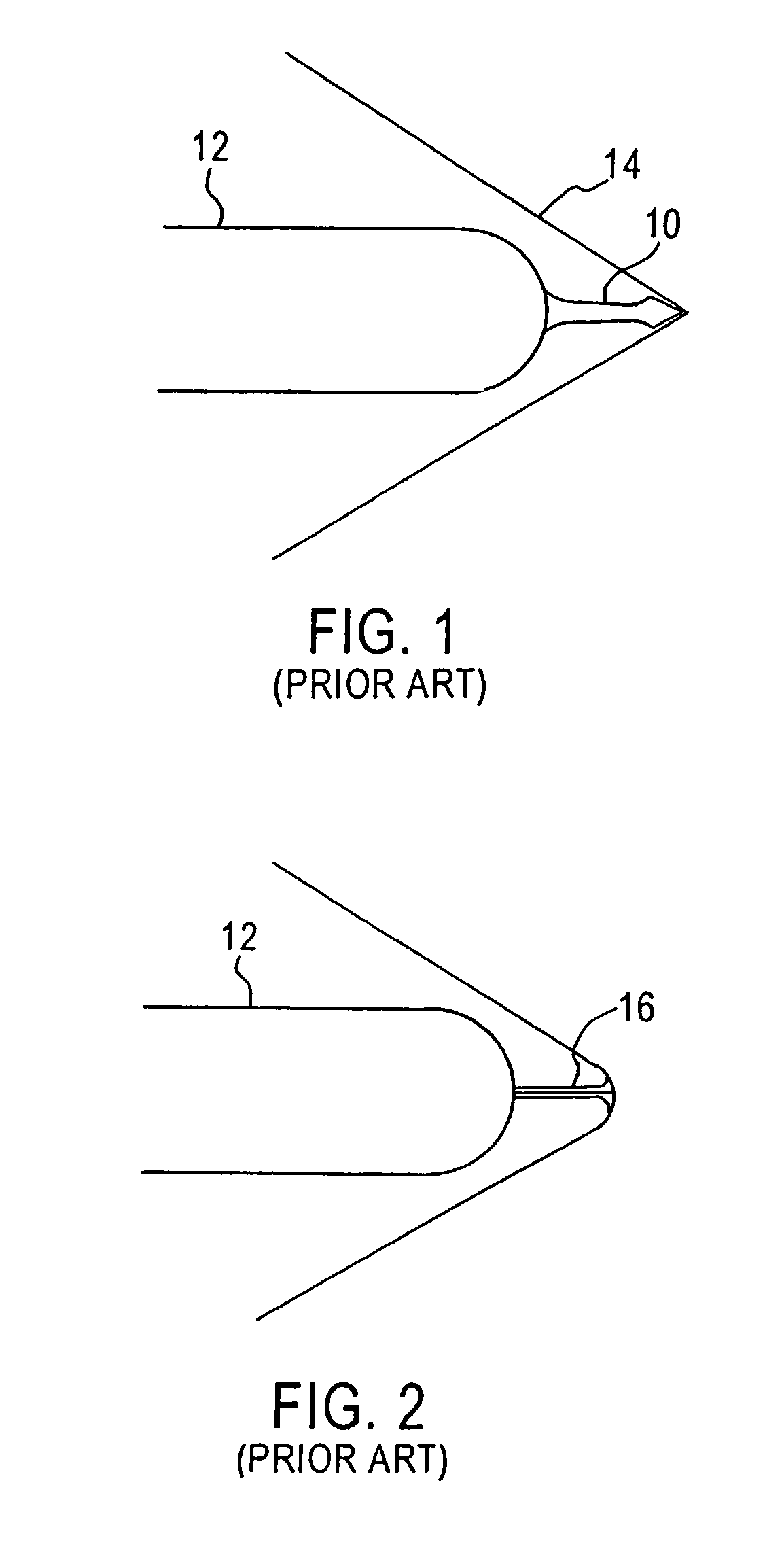

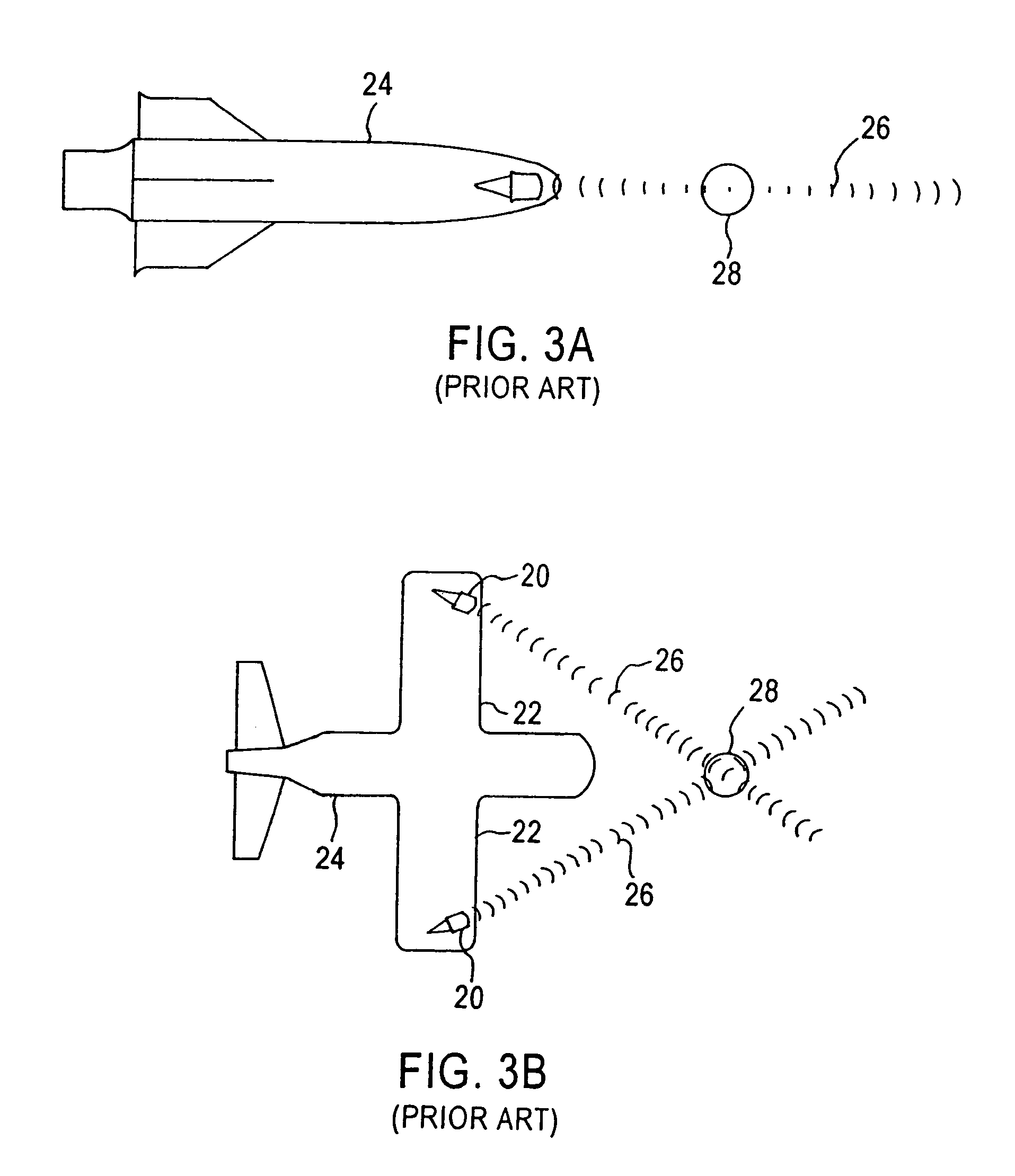

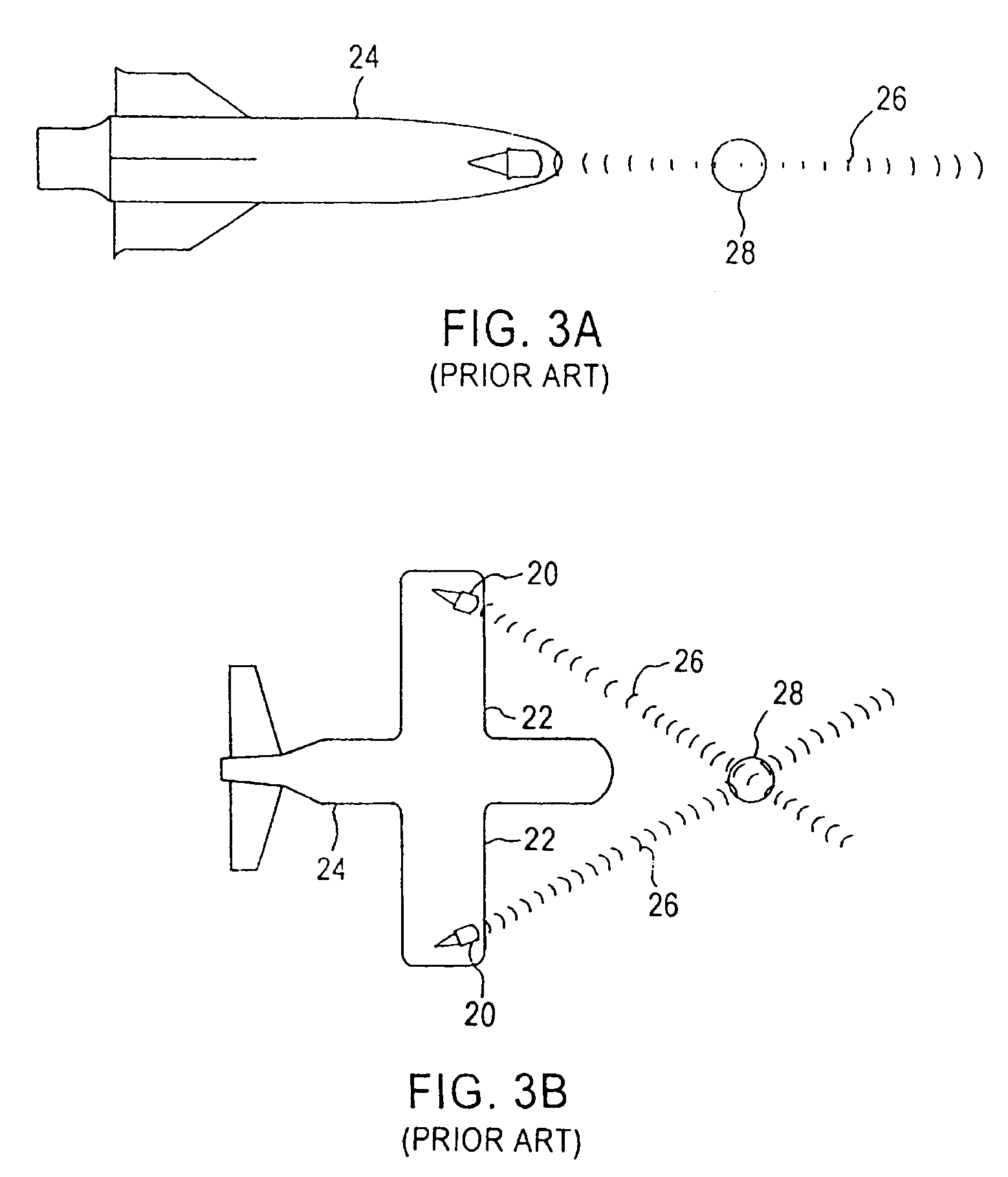

Shock wave modification method and system

InactiveUS20050061908A1Reduce pressureHigh speed of soundFluid dynamicsSystems for re-entry to earthElectric dischargeEngineering

A shock wave in a gas is modified by emitting energy to form an extended path in the gas; heating gas along the path to form a volume of heated gas expanding outwardly from the path; and directing a path. The volume of heated gas passes through the shock wave and modifies the shock wave. This eliminates or reduces a pressure difference between gas on opposite sides of the shock wave. Electromagnetic, microwaves and / or electric discharge can be used to heat the gas along the path. This application has uses in reducing the drag on a body passing through the gas, noise reduction, controlling amount of gas into a propulsion system, and steering a body through the gas. An apparatus is also disclosed.

Owner:KREMEYER KEVIN

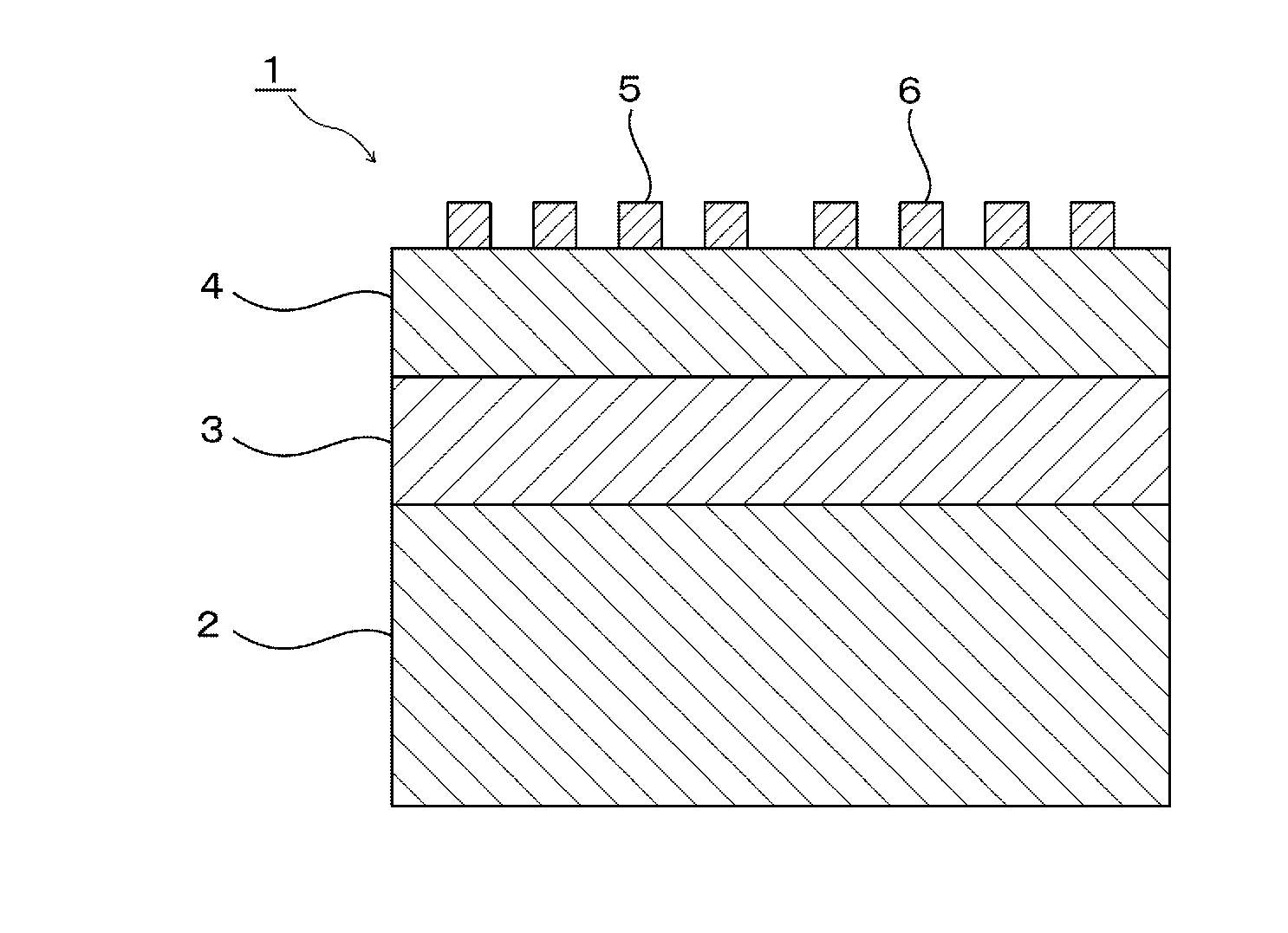

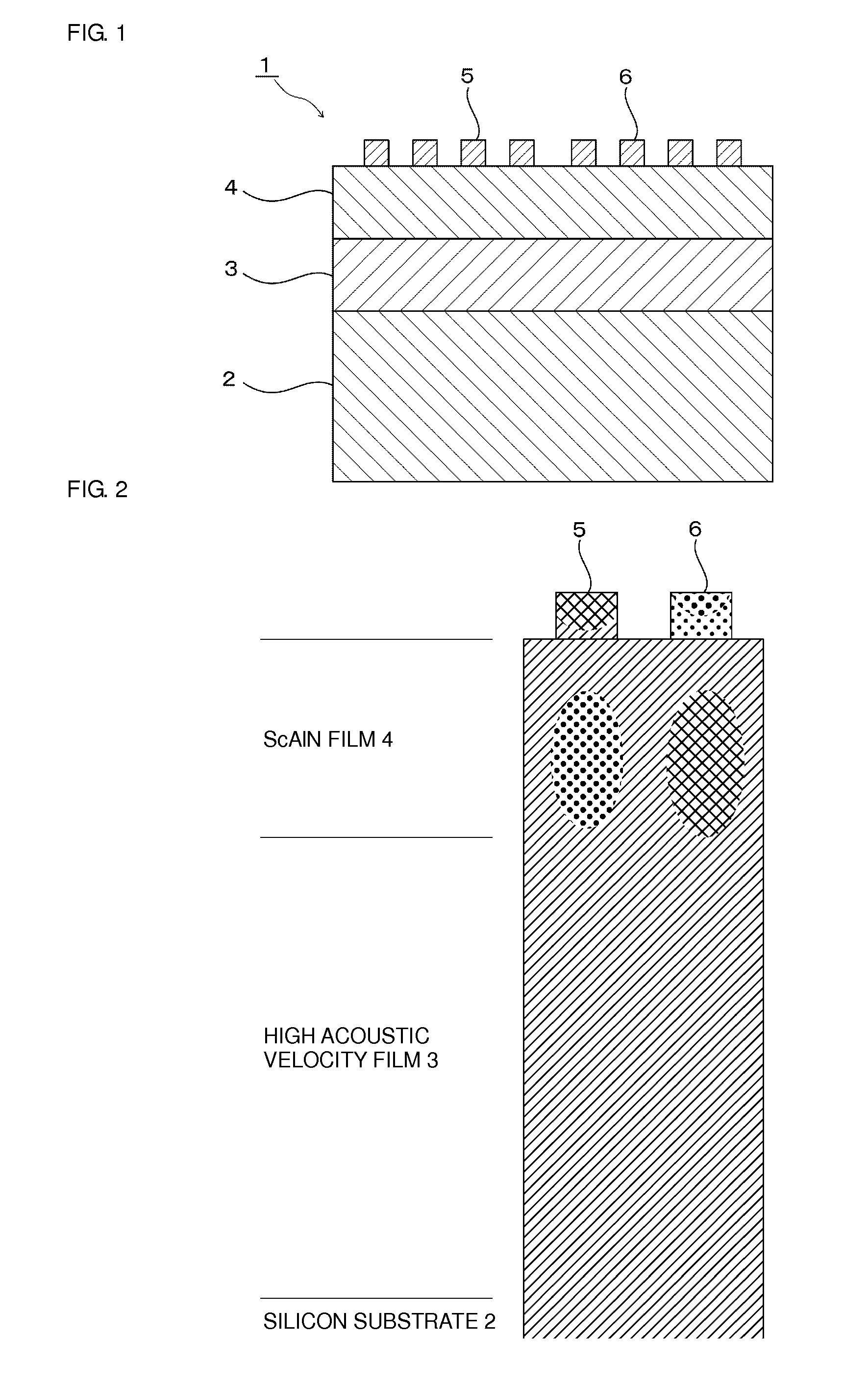

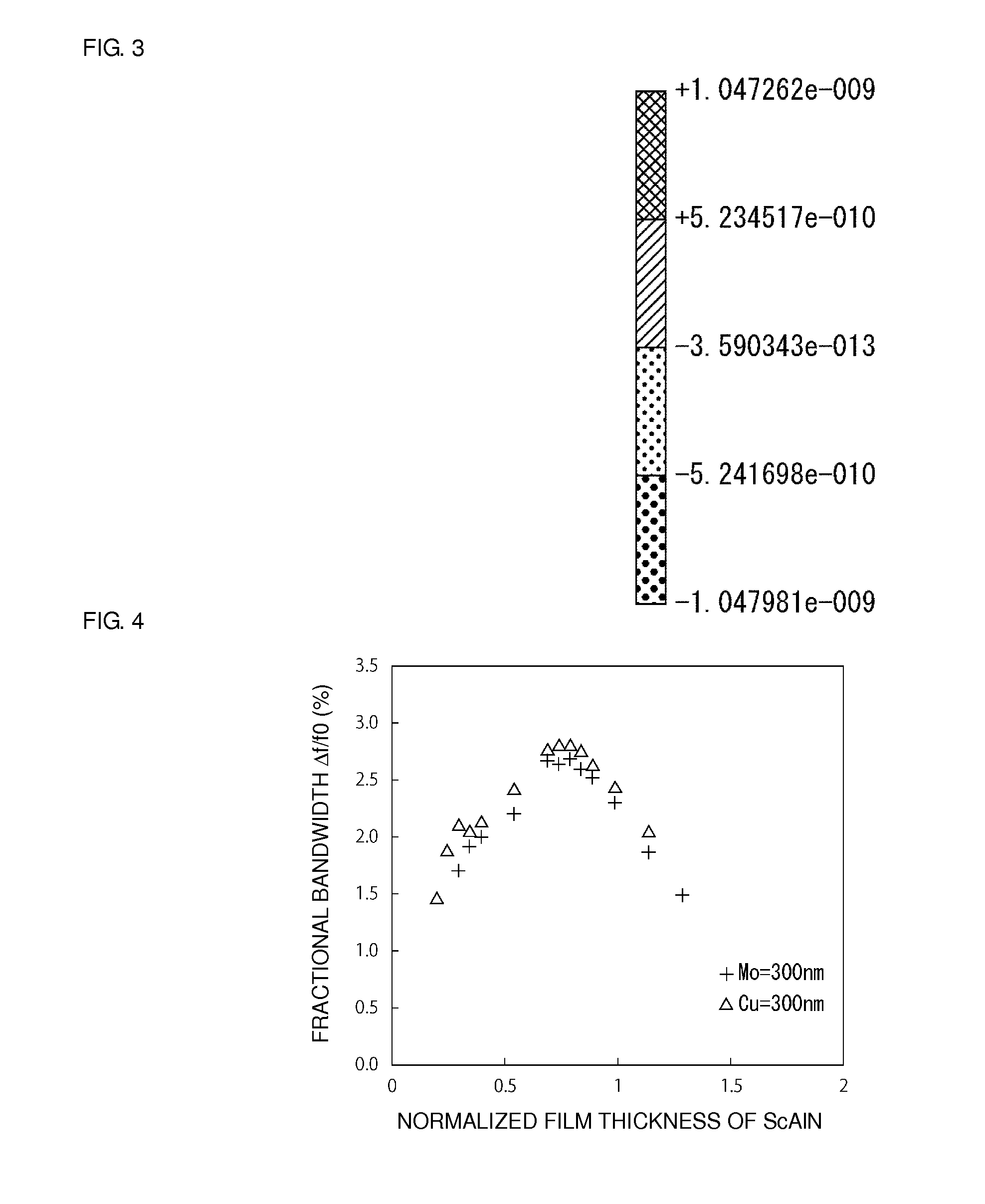

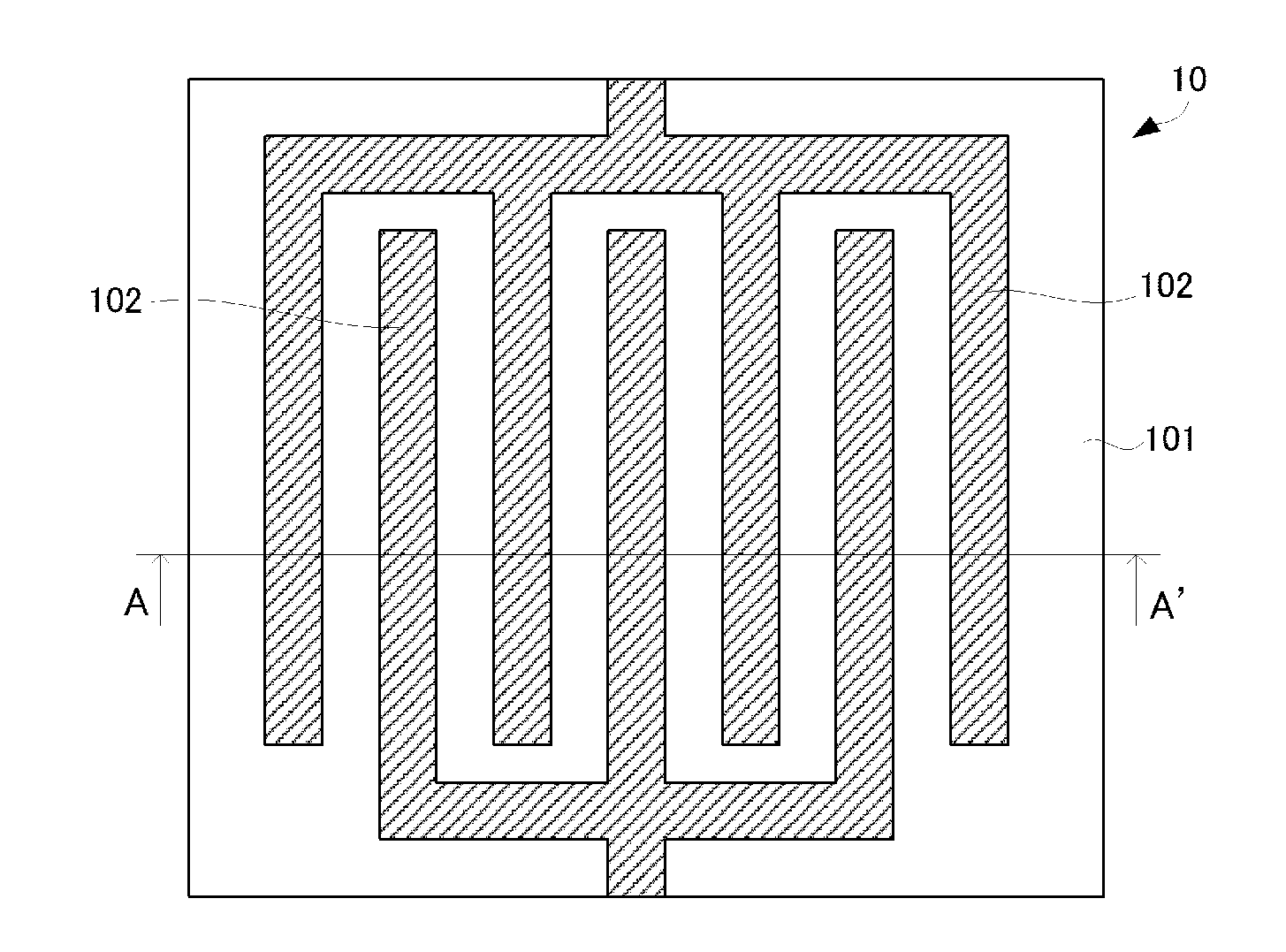

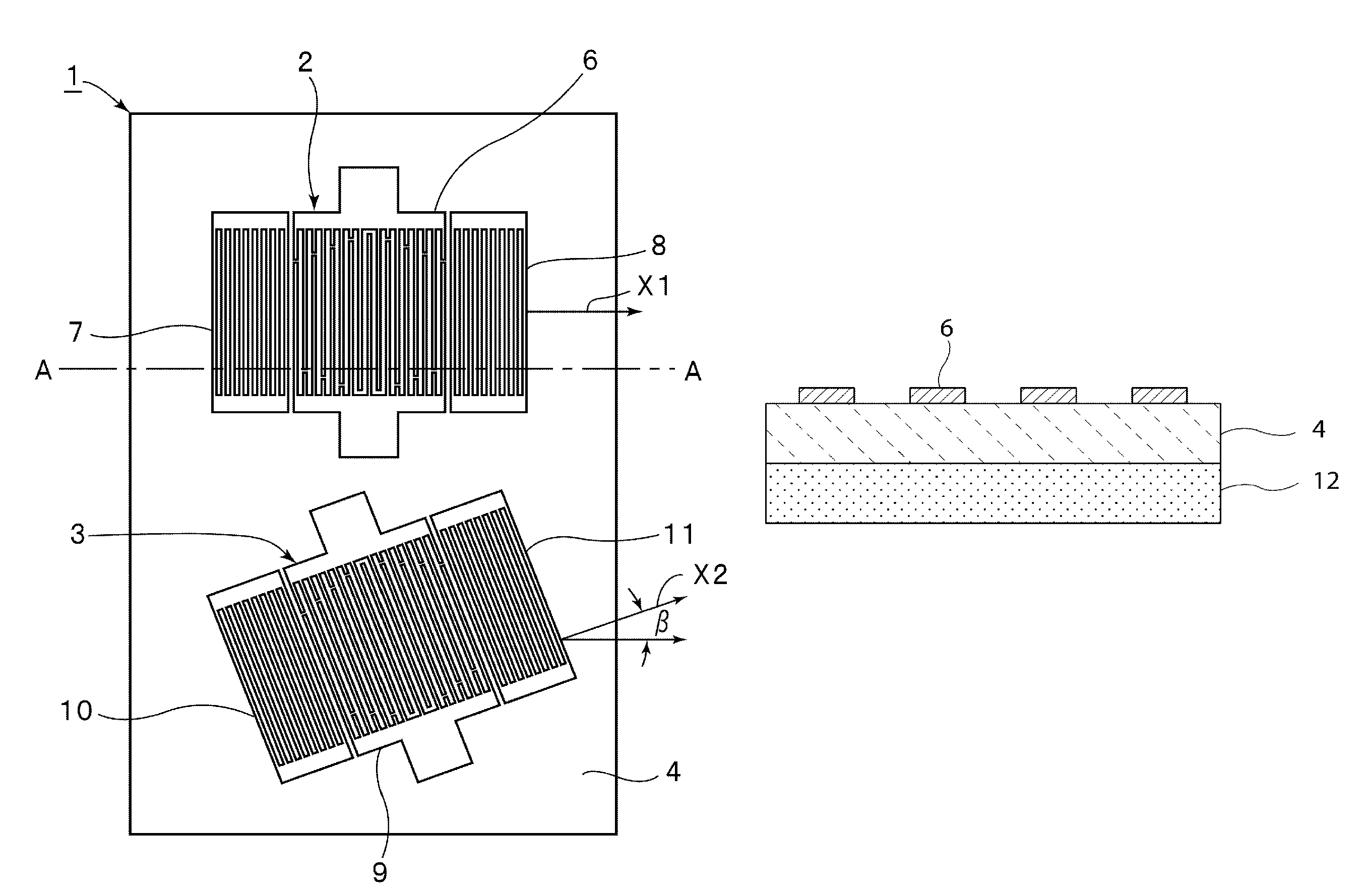

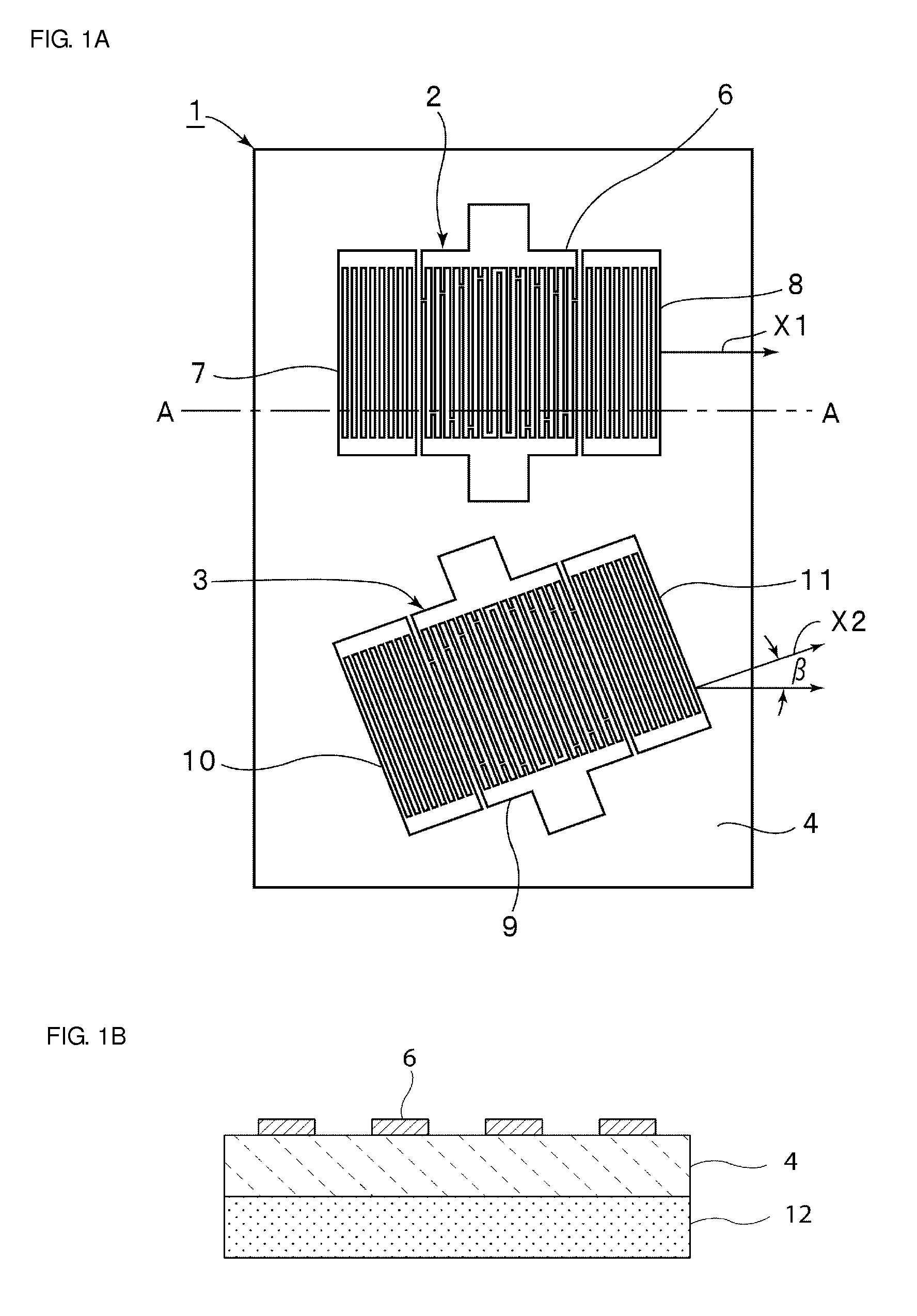

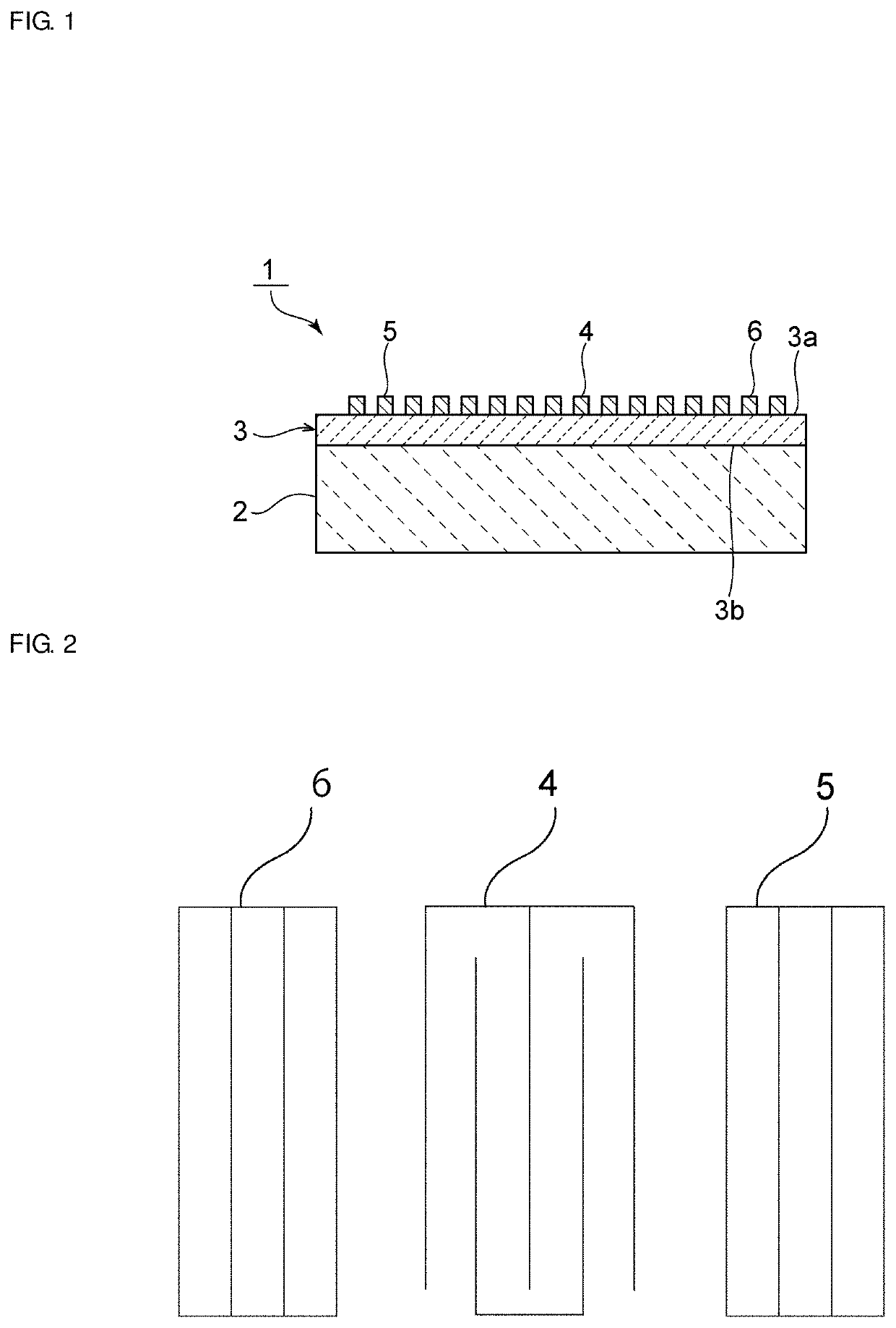

Surface acoustic wave device

ActiveUS20150069882A1Low priceLarger diameter design is achieved with easePiezoelectric/electrostriction/magnetostriction machinesImpedence networksSurface acoustic wave sensorSilicon

A surface acoustic wave device includes a high acoustic velocity film in which a transversal wave propagates at a higher acoustic velocity than in a ScAlN film laminated on a substrate made of silicon or glass. The ScAlN film is laminated on the high acoustic velocity film, and IDT electrodes are laminated on the ScAlN film.

Owner:MURATA MFG CO LTD

Shock wave modification method and system

ActiveUS20070040726A1Reduce pressureHigh speed of soundElectric discharge tubesMaterial analysis by optical meansEngineeringInformation transfer

A system for modifying a shock wave formed in a fluid by a body to modify effects of the shock wave on information transferred to or from the body. The system includes means for heating fluid along a path to form a volume of heated fluid expanding outwardly from the path, the path extending from the body and through the shock wave; means for transferring the information to or from the body; and means for timing the transferring of the information relative to the heating of the fluid along the path to modify certain effects of the shock wave on the information.

Owner:KREMEYER KEVIN

Shock wave modification method and system

InactiveUS7648100B2Low densityHigh speed of soundElectric discharge tubesMaterial analysis by optical meansShock waveEngineering

A system for modifying a shock wave formed in a fluid by a body to modify effects of the shock wave on information transferred to or from the body. The system includes an element for heating fluid along a path to form a volume of heated fluid expanding outwardly from the path, the path extending from the body and through the shock wave; mechanism for transferring the information to or from the body; and device for timing the transferring of the information relative to the heating of the fluid along the path to modify certain effects of the shock wave on the information.

Owner:KREMEYER KEVIN

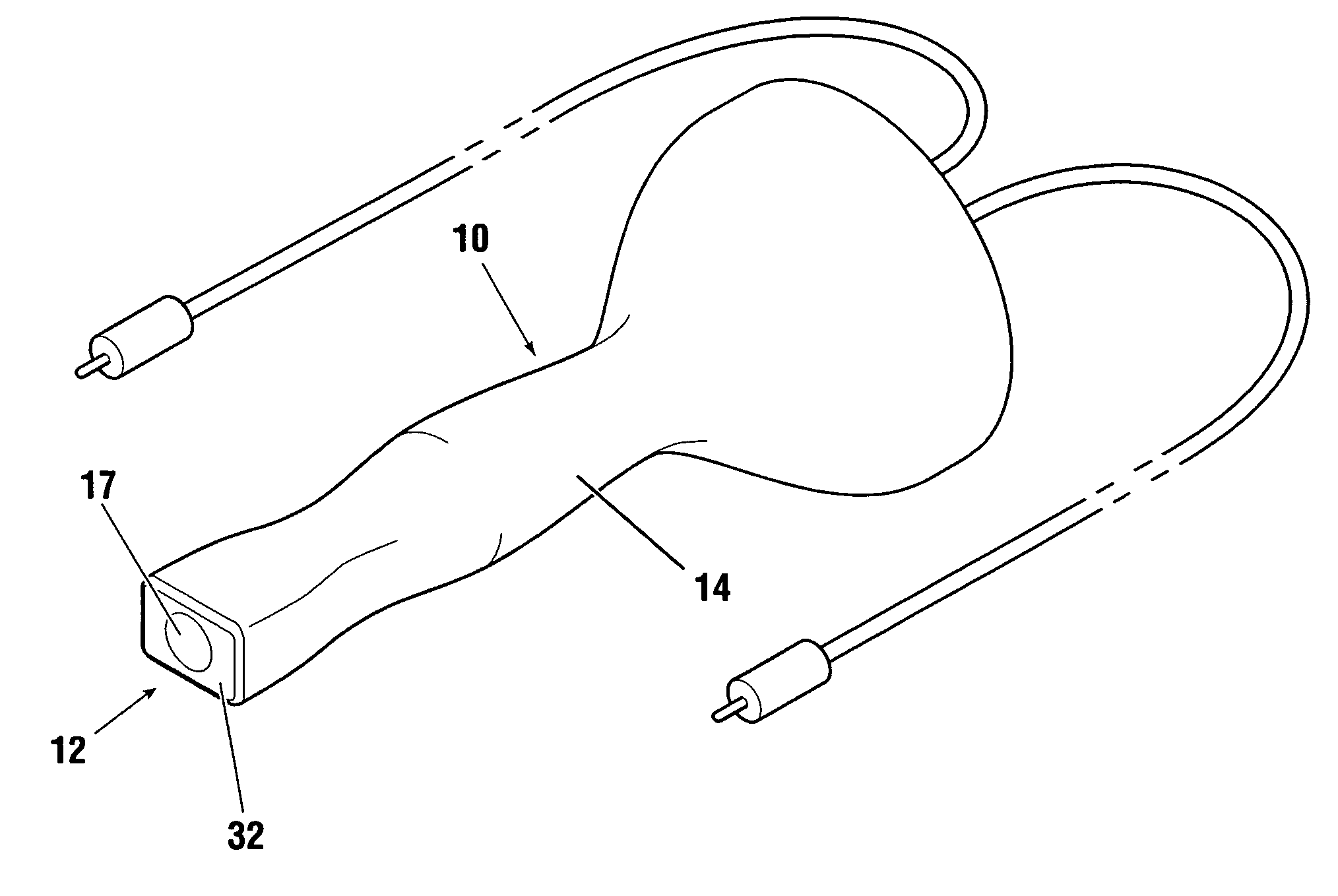

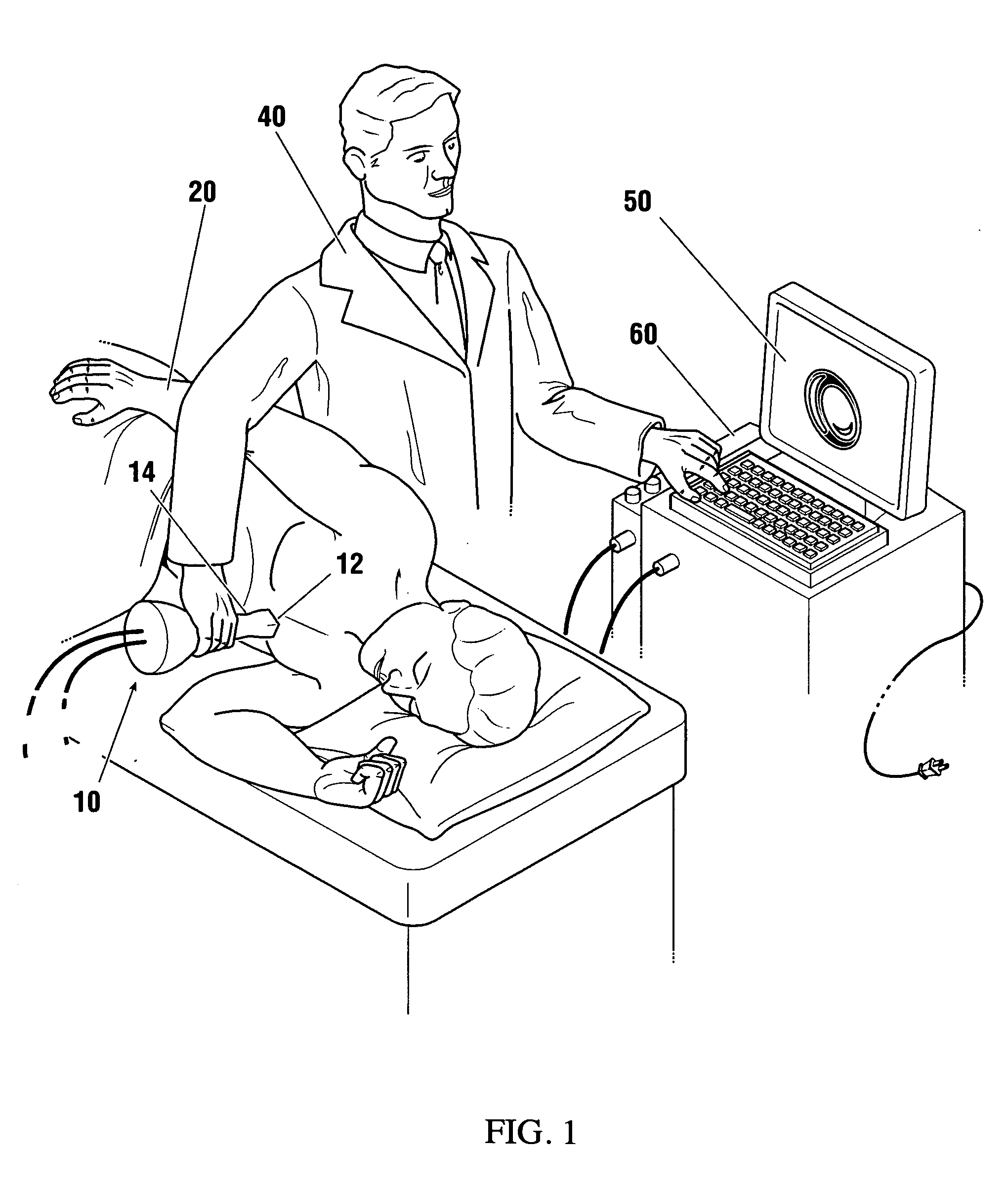

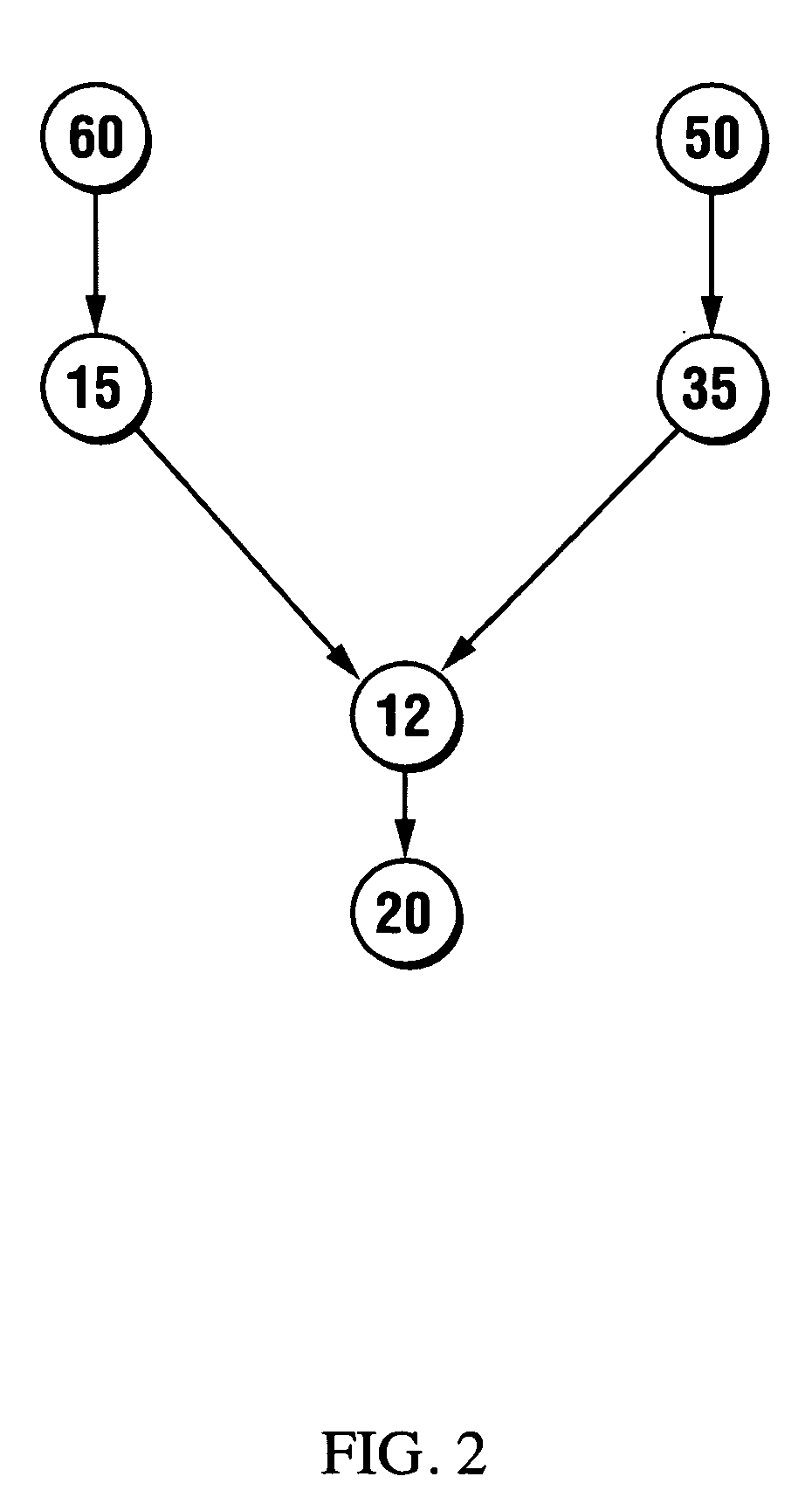

Hand-held imaging probe for treatment of states of low blood perfusion

InactiveUS20060025683A1Efficient seatingIncrease sound energyUltrasound therapyOrgan movement/changes detectionVascular obstructionBlood flow

A non-invasive hand-held treatment imaging probe for treatment of acute blood flow disturbances and states of low blood perfusion. The treatment imaging probe is operable to emit high intensity therapeutic mechanical acoustic waves while under ultrasonic imaging guidance. The probe has a substantially rigid application surface, sized to enable seating within a rib space of a patient (i.e. for cardiac applications), comprising the combination of an engagement face of an ultrasonic imaging transducer and an application end of a high powered therapeutic actuator operable in about the 1-500 kHz (and preferably 1-150 kHz) range. Treatment imaging probe can be used as an adjunct to thrombolytic therapy in the treatment of acute thrombotic vascular obstructions, such as in acute myocardial infarction, or alternatively to enhance localized delivery of angiogenic agents or other useful medications to targeted vascular regions.

Owner:AHOF BIOPHYSICAL SYST

Shock wave modification method and system

InactiveUS7121511B2Low densityHigh speed of soundSystems for re-entry to earthFluid dynamicsShock waveElectric discharge

A shock wave in a gas is modified by emitting energy to form an extended path in the gas; heating gas along the path to form a volume of heated gas expanding outwardly from the path; and directing a path. The volume of heated gas passes through the shock wave and modifies the shock wave. This eliminates or reduces a pressure difference between gas on opposite sides of the shock wave. Electromagnetic, microwaves and / or electric discharge can be used to heat the gas along the path. This application has uses in reducing the drag on a body passing through the gas, noise reduction, controlling amount of gas into a propulsion system, and steering a body through the gas. An apparatus is also disclosed.

Owner:KREMEYER KEVIN

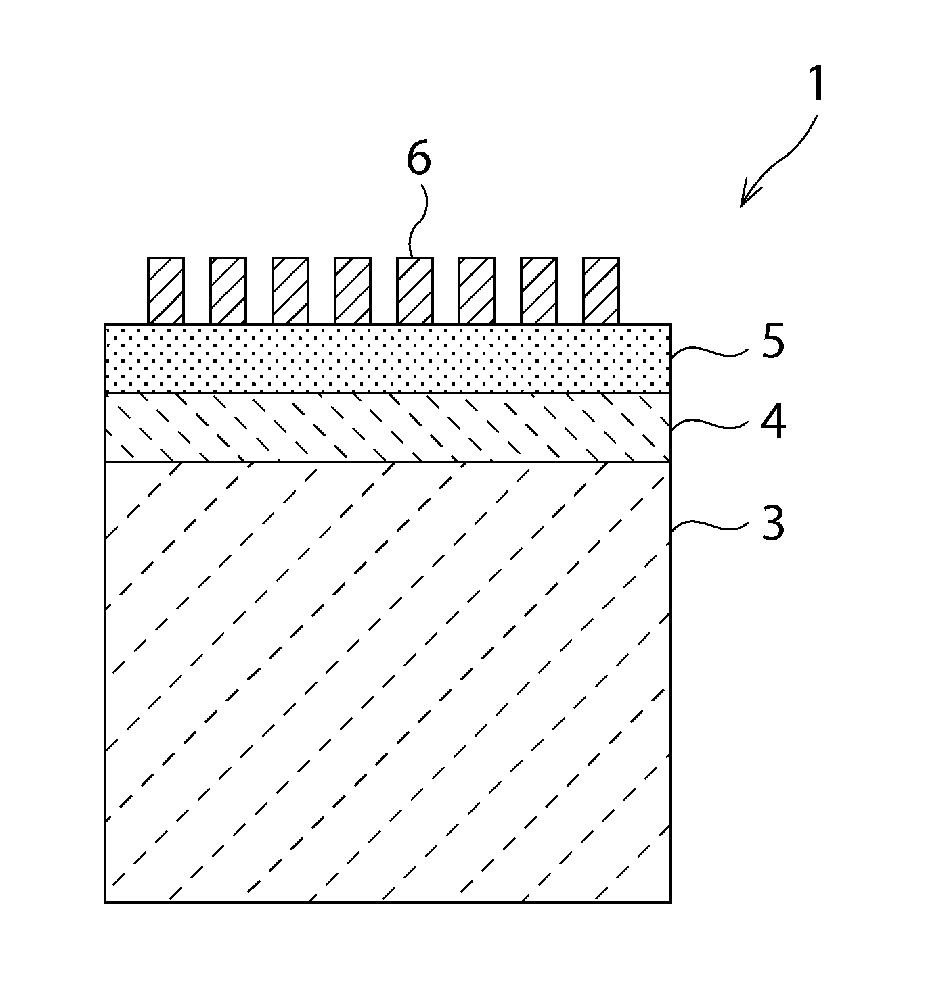

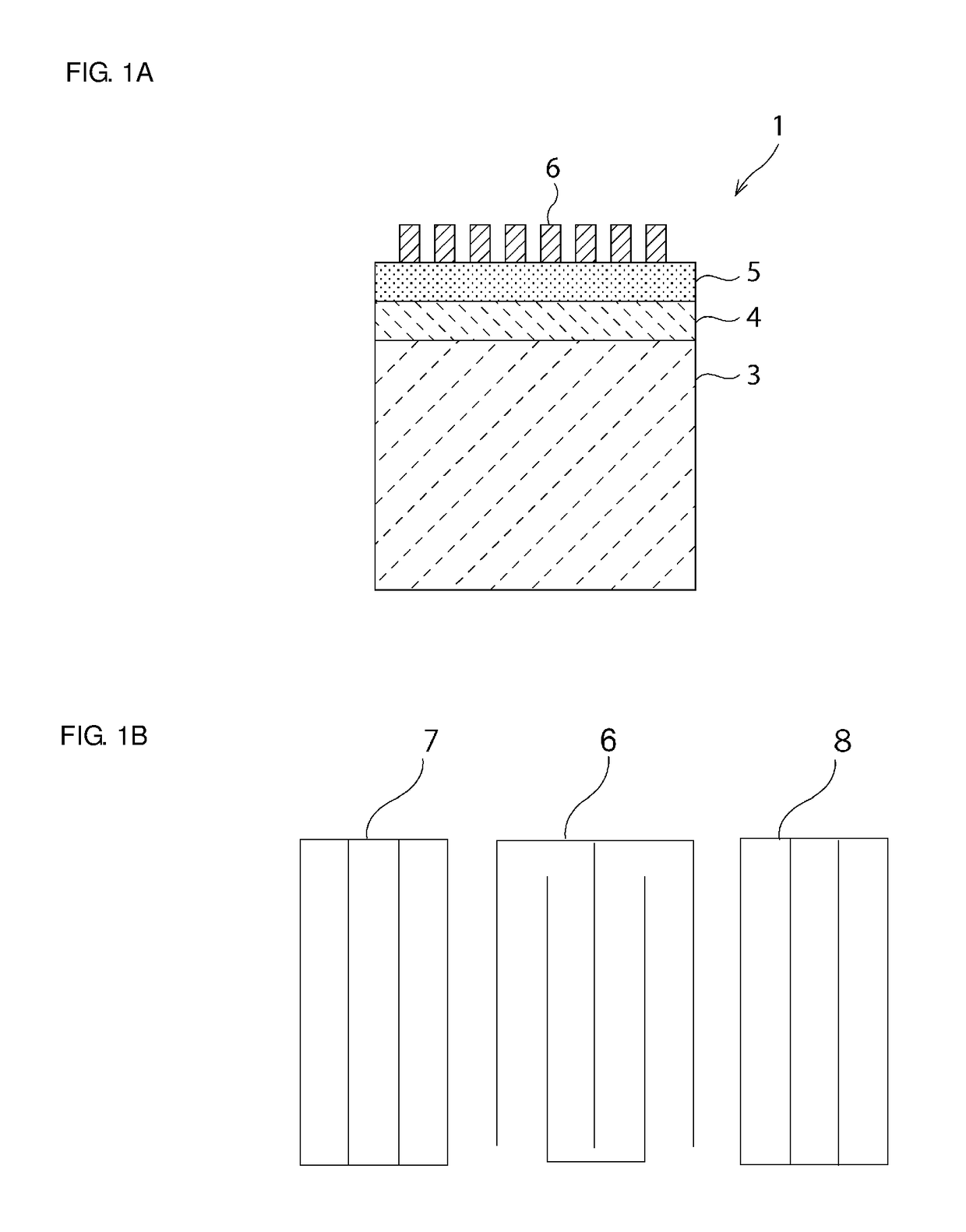

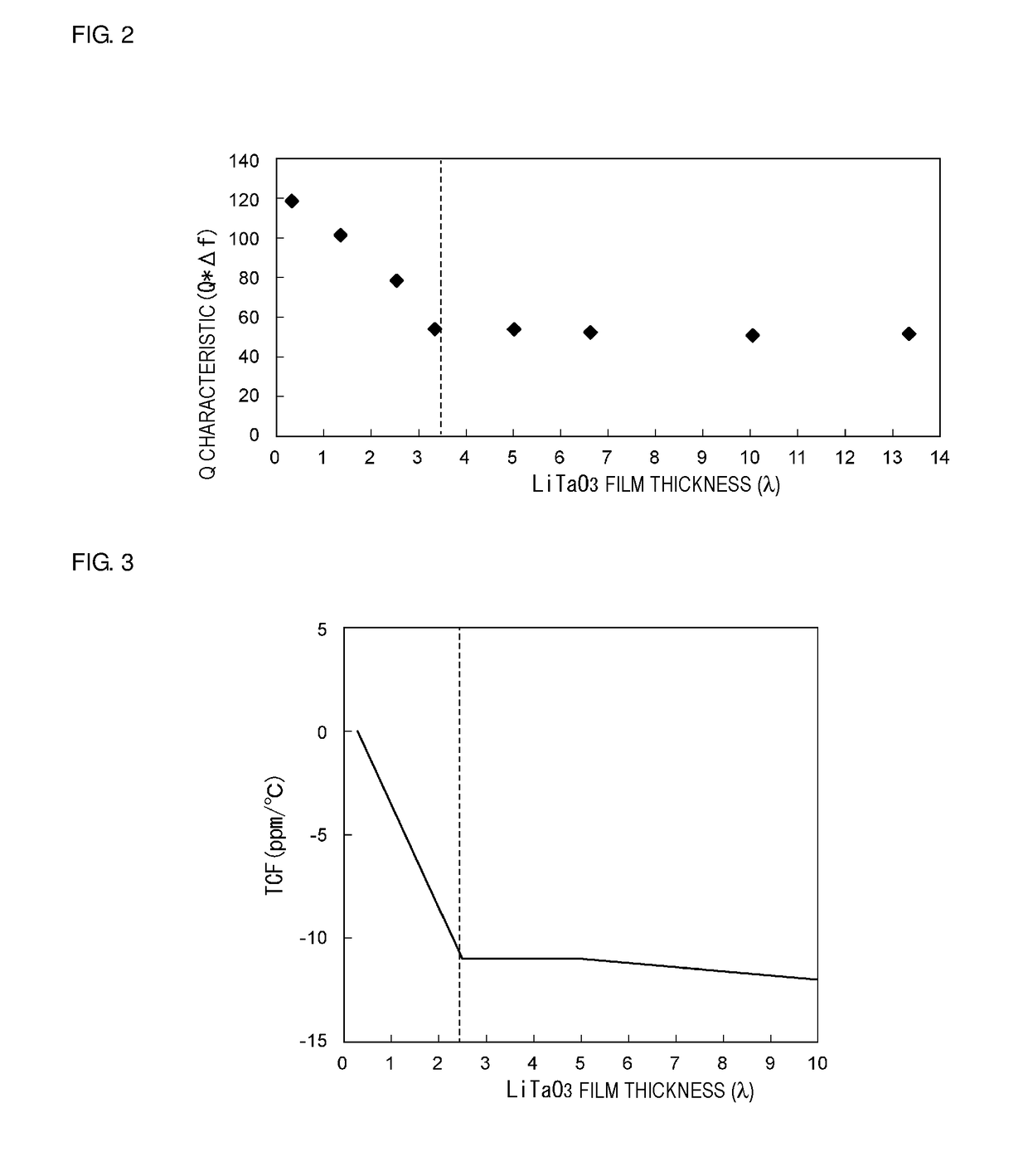

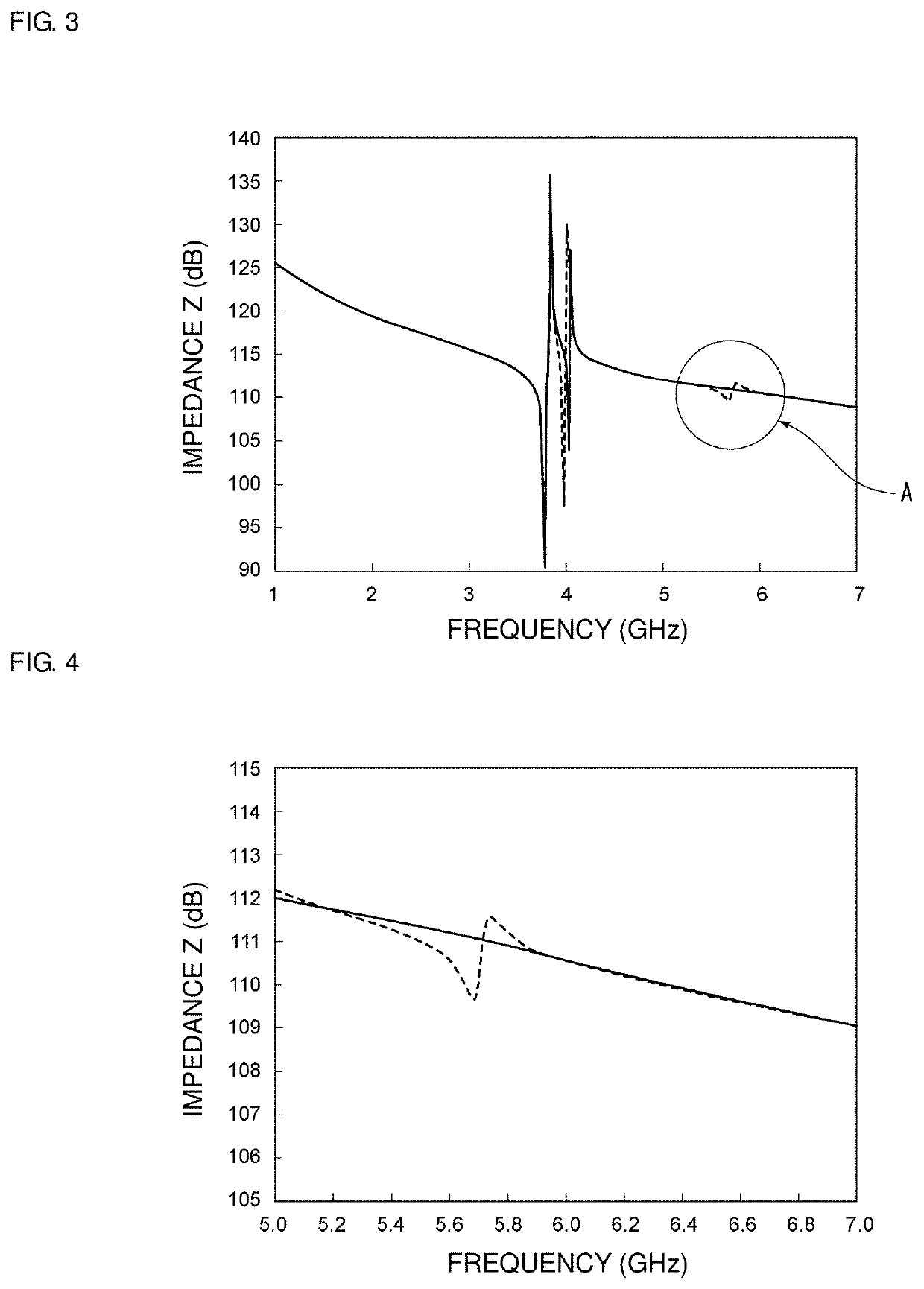

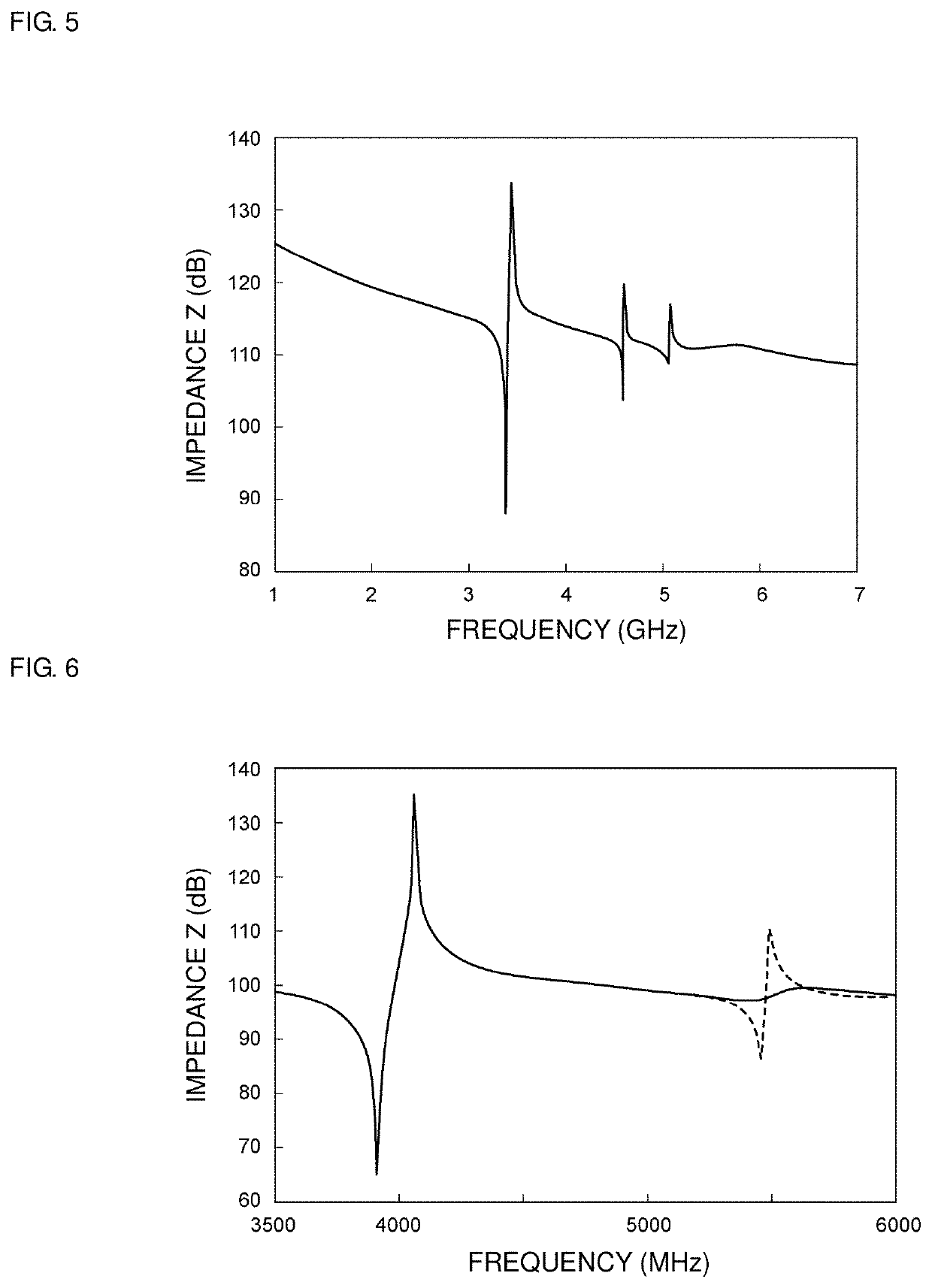

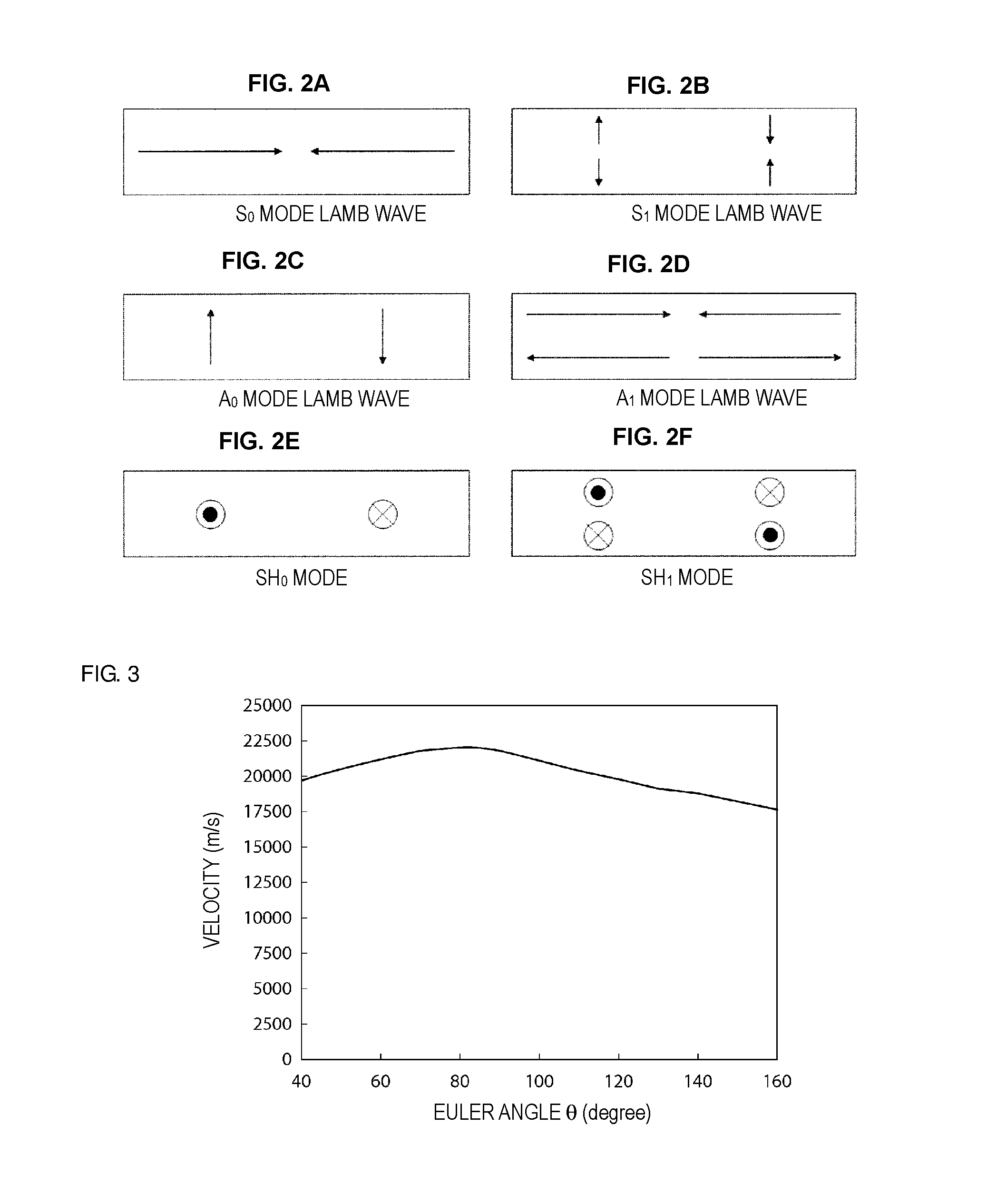

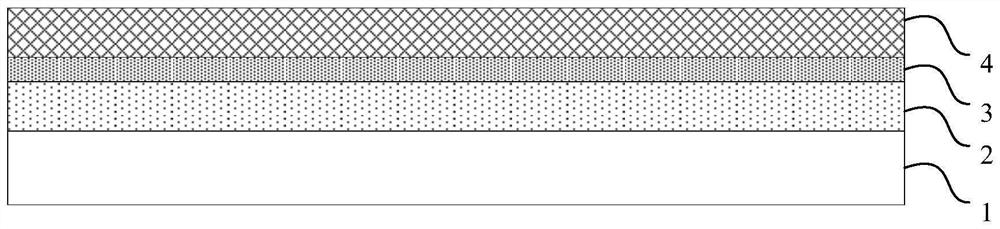

Acoustic wave device, high-frequency front end circuit, and communication device

An acoustic wave device includes a high acoustic velocity support substrate defining and functioning as a high acoustic velocity member, a low acoustic velocity film, a piezoelectric film, and an IDT electrode that are laminated in this order. When a wavelength of an acoustic wave determined by an electrode finger cycle of the IDT electrode is represented by λ, a film thickness of the piezoelectric film is about 1.5λ or more and about 3.5λ or less. The acoustic velocity of a bulk wave propagating in the high acoustic velocity support substrate is higher than the acoustic velocity of an acoustic wave propagating in the piezoelectric film. The acoustic velocity of a bulk wave propagating in the low acoustic velocity film is lower than the acoustic velocity of an acoustic wave propagating in the piezoelectric film.

Owner:MURATA MFG CO LTD

High-frequency high-performance acoustic surface wave device and preparation method thereof

InactiveCN108493325AHigh speed of soundImprove thermal stabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionSingle crystalCenter frequency

The invention discloses a high-frequency high-performance acoustic surface wave device and a preparation method thereof. The acoustic surface wave device comprises a silicon carbide monocrystal substrate, a piezoelectric thin film and an interdigital electrode which are stacked in sequence; the piezoelectric thin film is a lithium tantalate monocrystal thin film or a lithium niobate monocrystal thin film; and the silicon carbide monocrystal substrate is a 4H-SiC monocrystal substrate, a 6H-SiC monocrystal substrate, a 3C-SiC monocrystal substrate or a 3C-SiC epitaxial monocrystal substrate. The silicon carbide monocrystal substrate has relatively high sound velocity, excellent thermal stability and chemical stability and high heat conductivity; the lithium tantalate or lithium niobate piezoelectric monocrystal thin film is high in crystal quality, high in consistency and low in propagation loss; by adoption of the acoustic surface wave device with the interdigital electrode / lithium tantalate or lithium niobate monocrystal thin film / silicon carbide monocrystal substrate structural form, relatively high central frequency, high power tolerance and low temperature coefficient are achieved, so that the acoustic surface wave device has huge application prospect in the field of mobile communication.

Owner:TSINGHUA UNIV +1

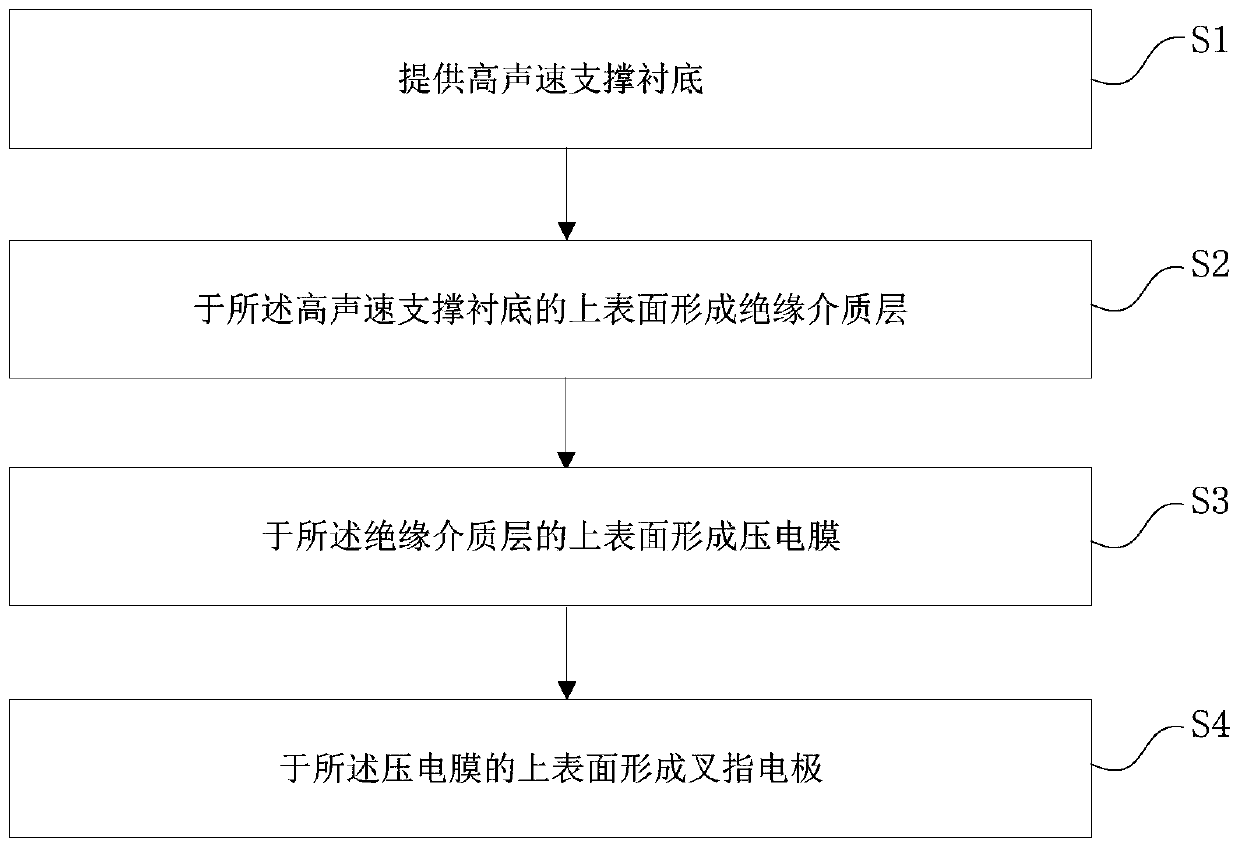

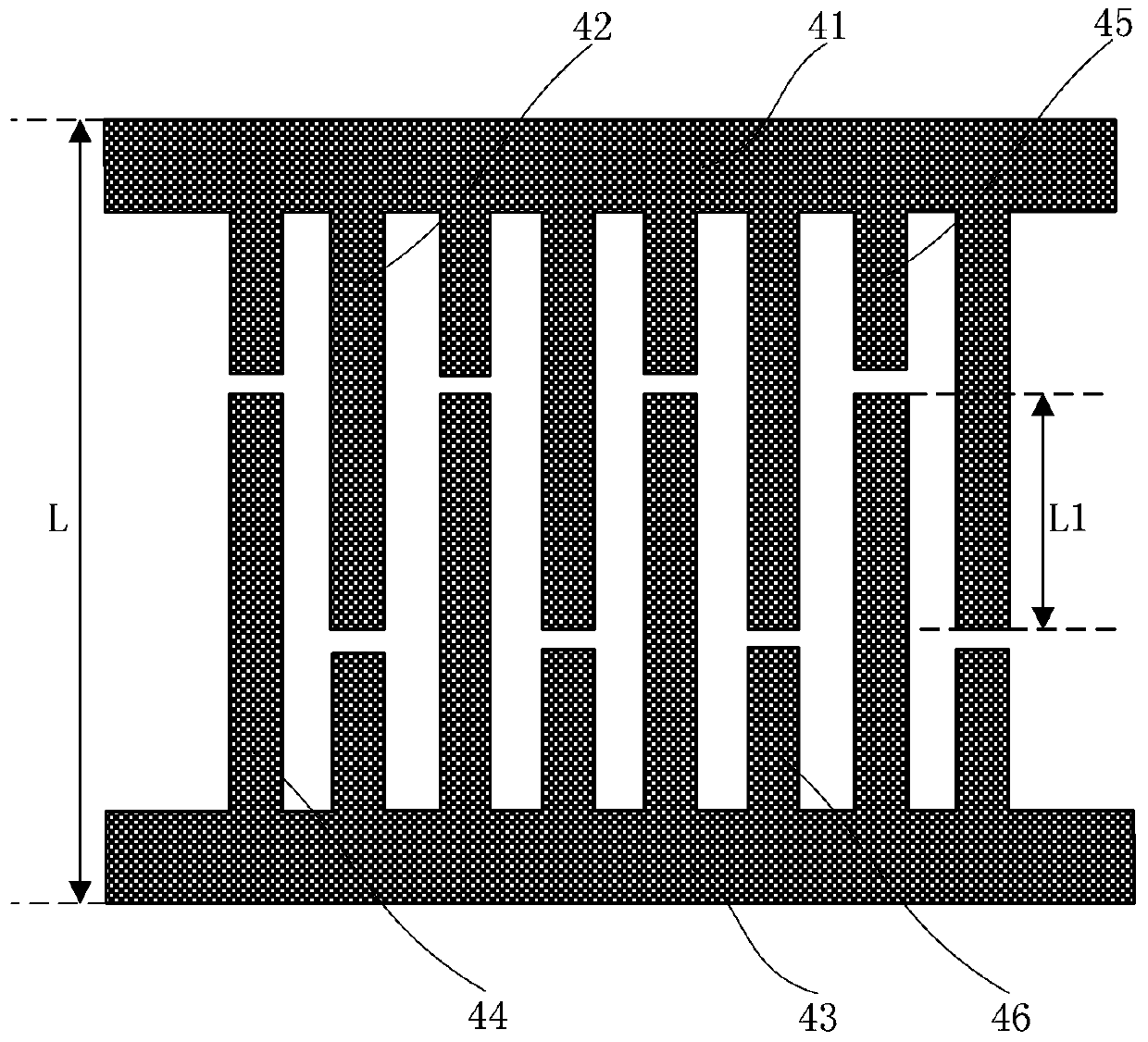

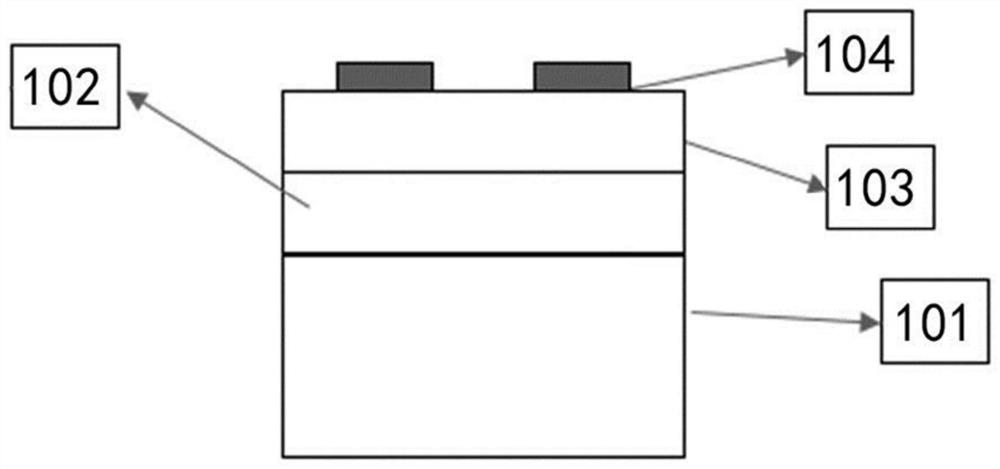

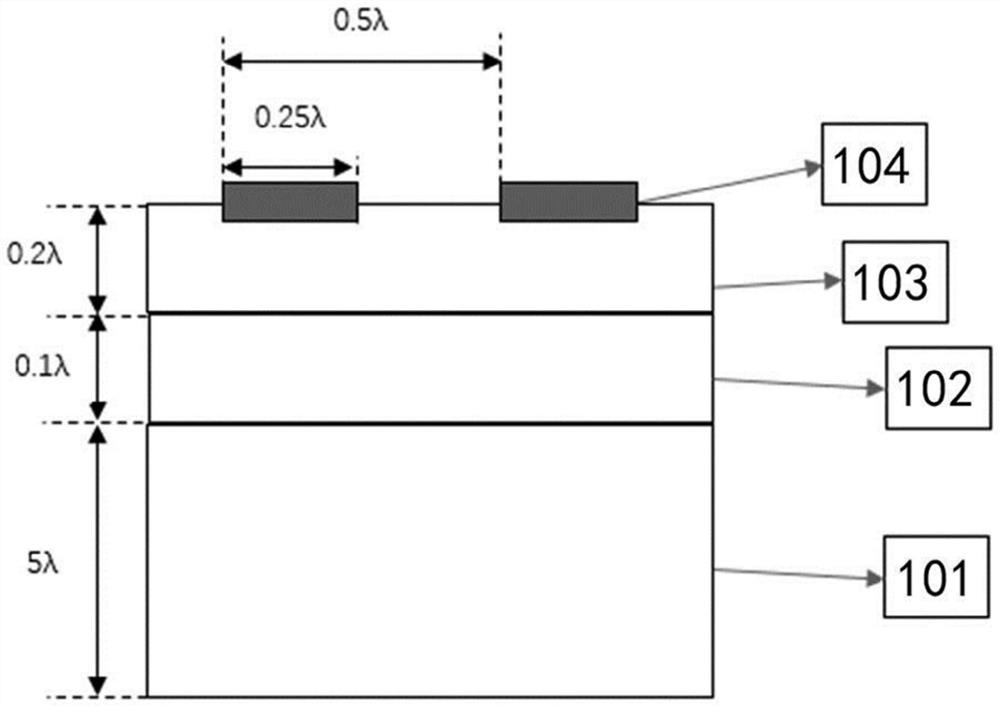

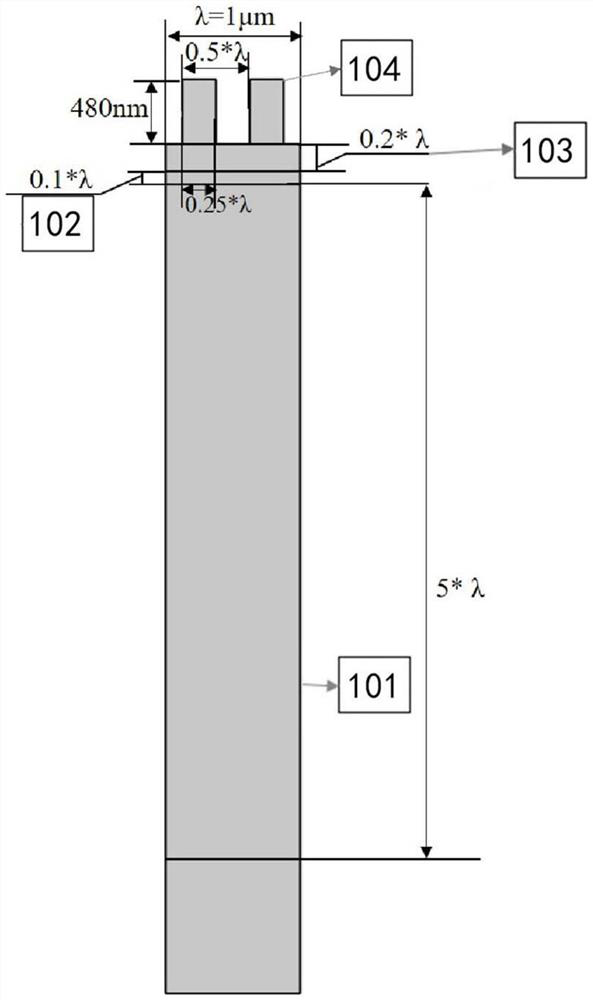

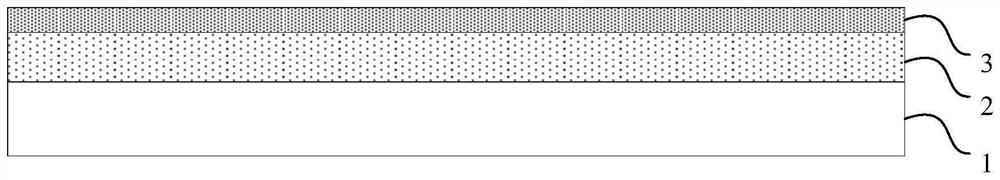

High-frequency acoustic wave resonator and preparation method thereof

ActiveCN111416590ARaise the resonant frequencyHigh electromechanical coupling coefficientImpedence networksHigh level techniquesElectromechanical coupling coefficientAcoustic wave

The invention provides a high-frequency acoustic wave resonator and a preparation method thereof. The high-frequency acoustic wave resonator comprises a high-acoustic-velocity support substrate, an insulating dielectric layer which is located on the upper surface of the high-sound-velocity supporting substrate, a piezoelectric film which is located on the upper surface of the insulating dielectriclayer, and an interdigital electrode which is located on the upper surface of the piezoelectric film. By arranging the high-sound-velocity supporting substrate below the piezoelectric film, the soundvelocity of target elastic waves excited and propagated in the piezoelectric film can be increased, propagation of the target elastic waves can be effectively restrained, and the resonant frequency of the high-frequency sound wave resonator is improved; the insulating dielectric layer is arranged between the piezoelectric film and the high-sound-velocity supporting substrate, the leakage of electric field energy in the piezoelectric film can be effectively reduced, and the electromechanical coupling coefficient of the high-frequency sound wave resonator can be enhanced; by selecting the appropriate insulating dielectric layer, temperature compensation can be carried out on the high-frequency acoustic wave resonator, temperature drift of the high-frequency acoustic wave resonator is reduced, and temperature stability of the high-frequency acoustic wave resonator is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

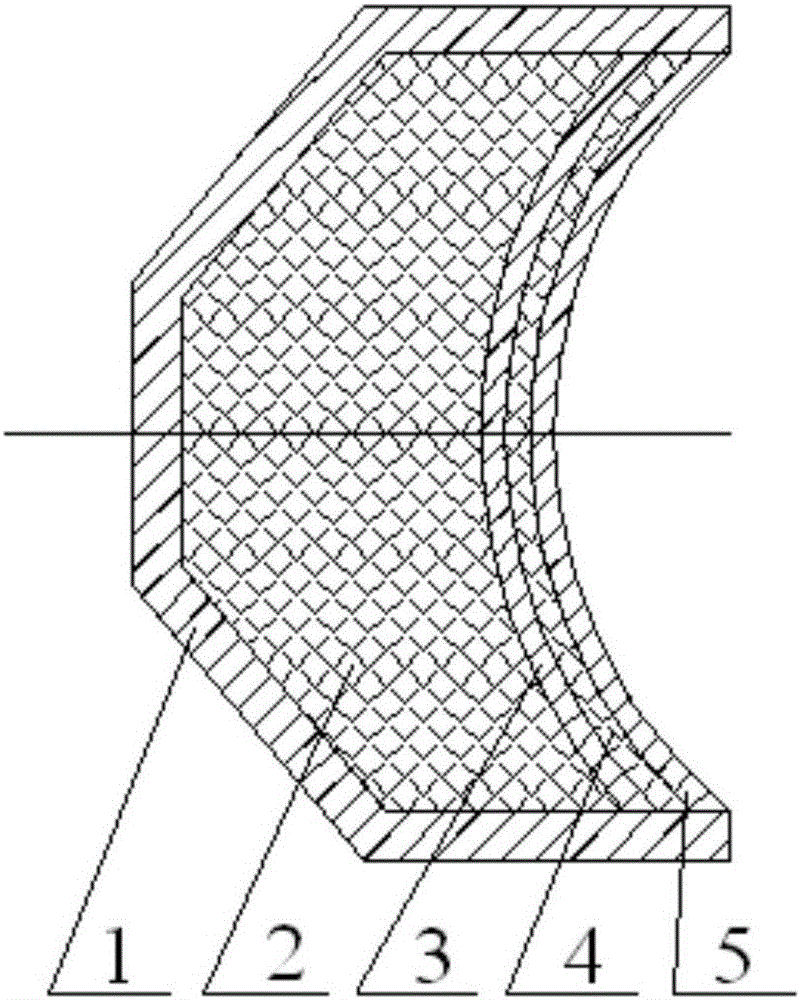

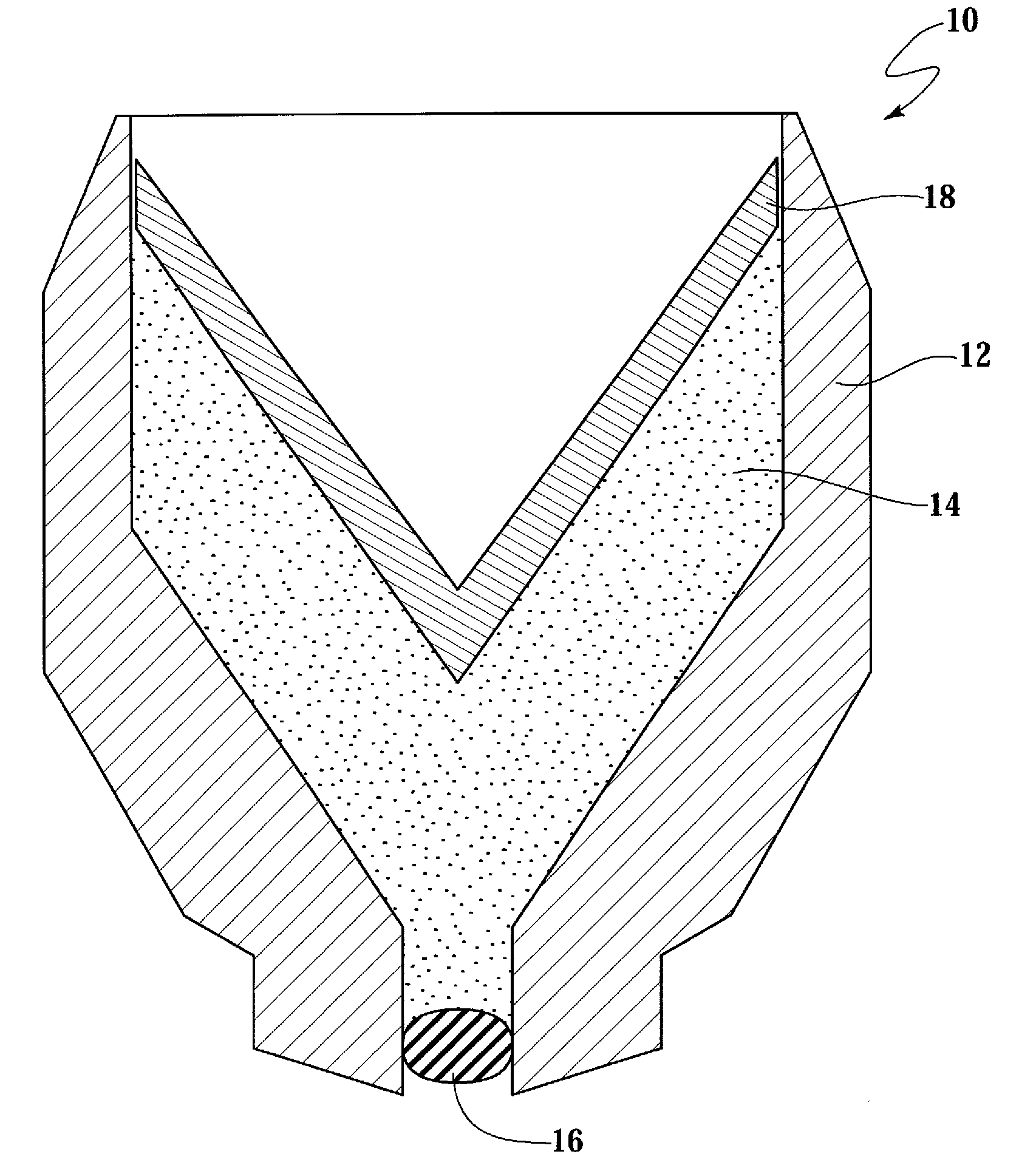

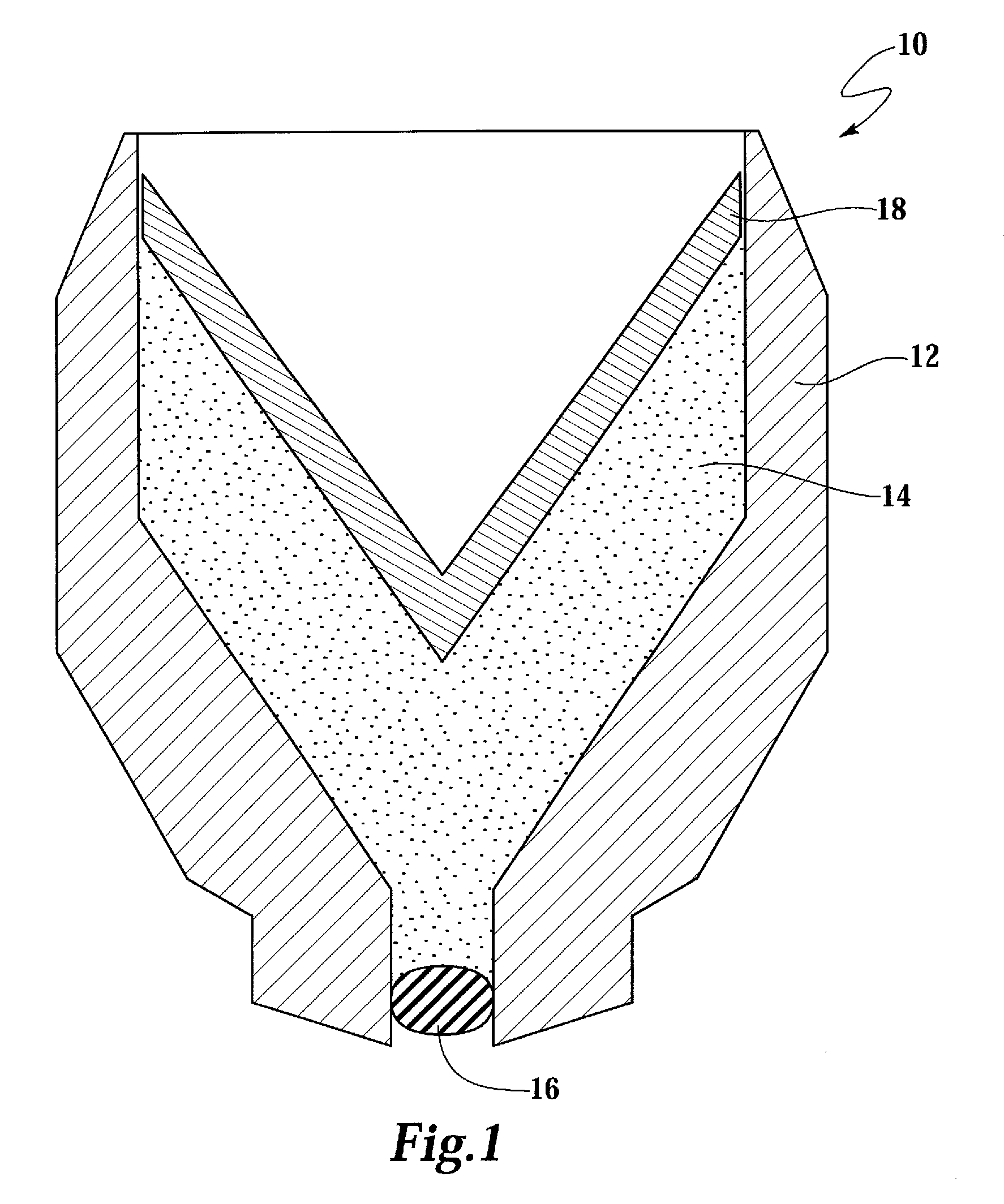

Shaped charge structure for active energy-containing composite shaped charge liner

The invention relates to a shaped charge structure for an active energy-containing composite shaped charge liner. The shaped charge structure comprises a shell, charge, a buffering shaped charge liner, the active energy-containing shaped charge liner and a penetration shaped charge liner, all of which are of axis symmetric structures. The shell is a combined structure of a circular truncated cone and a cylinder. One end of the cylinder structure is sealed through the circular truncated cone structure. The combined structure of the circular truncated cone and the cylinder is filled with the charge. The other end of the cylinder structure is sequentially provided with the buffering shaped charge liner, the active energy-containing shaped charge liner and the penetration shaped charge liner, and the buffering shaped charge liner, the active energy-containing shaped charge liner and the penetration shaped charge liner are used for sealing the charge into the shell. Each of the buffering shaped charge liner, the active energy-containing shaped charge liner and the penetration shaped charge liner is in a spherical segment shape, and the conical angle of the spherical segment ranges from 10 degrees to 175 degrees. The shaped charge structure has a perforating function and also has a detonation-like effect, and the detonation capability on ammunition, the ignition capability on fuel, the burning stifling actions on personnel and the transverse damaging effect on targets of the shaped charge structure are far stronger than those of an inert shaped charge liner.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

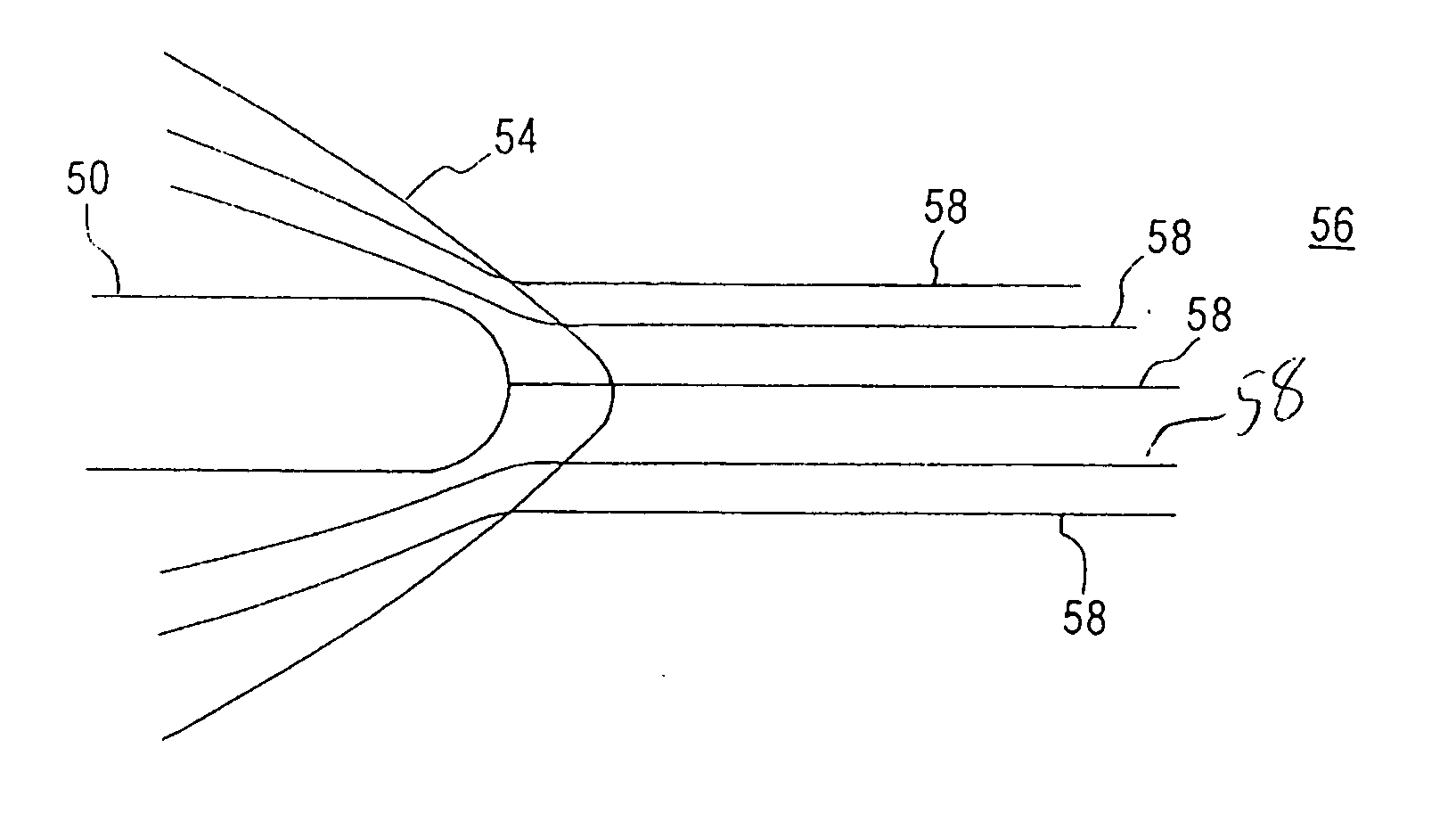

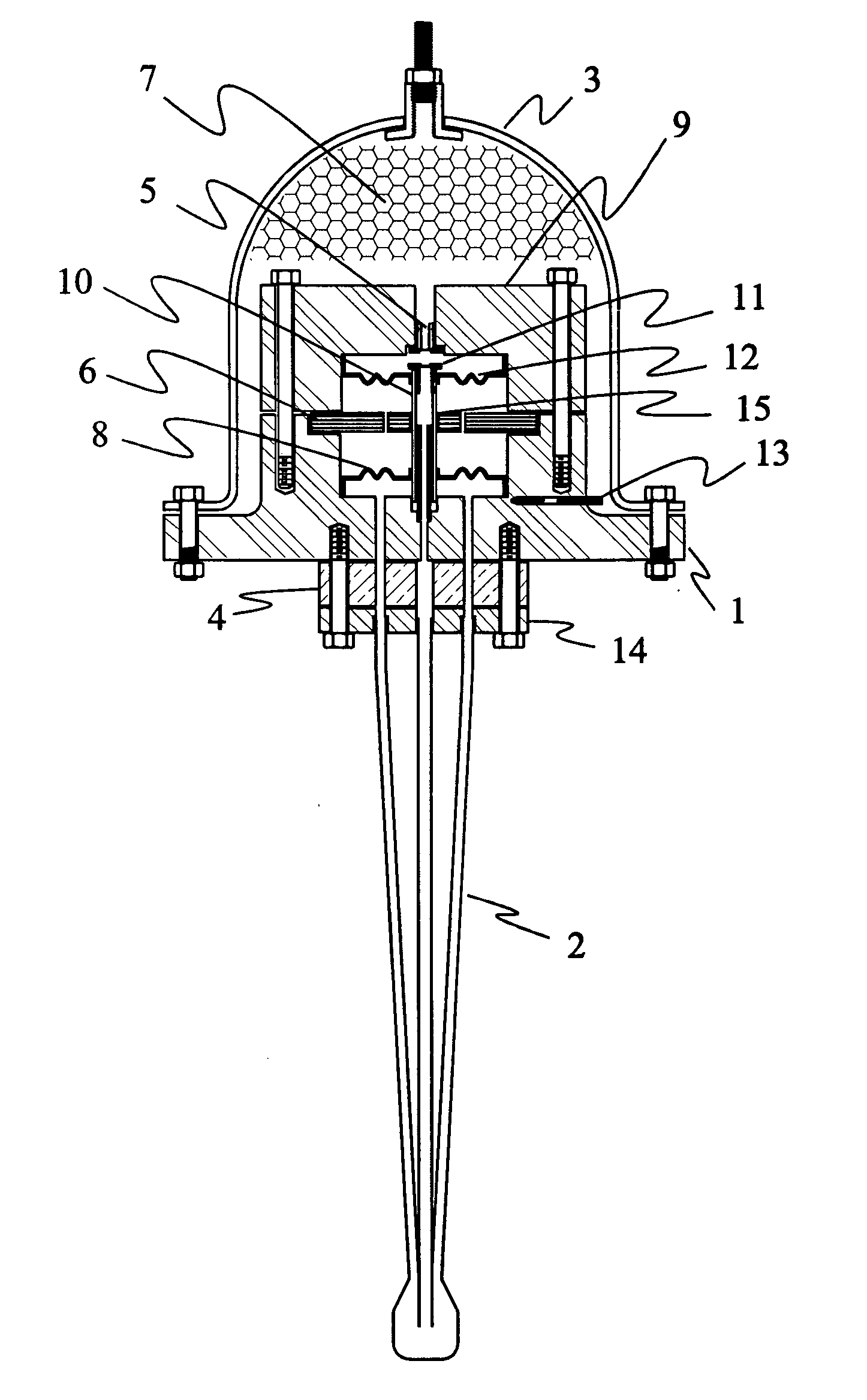

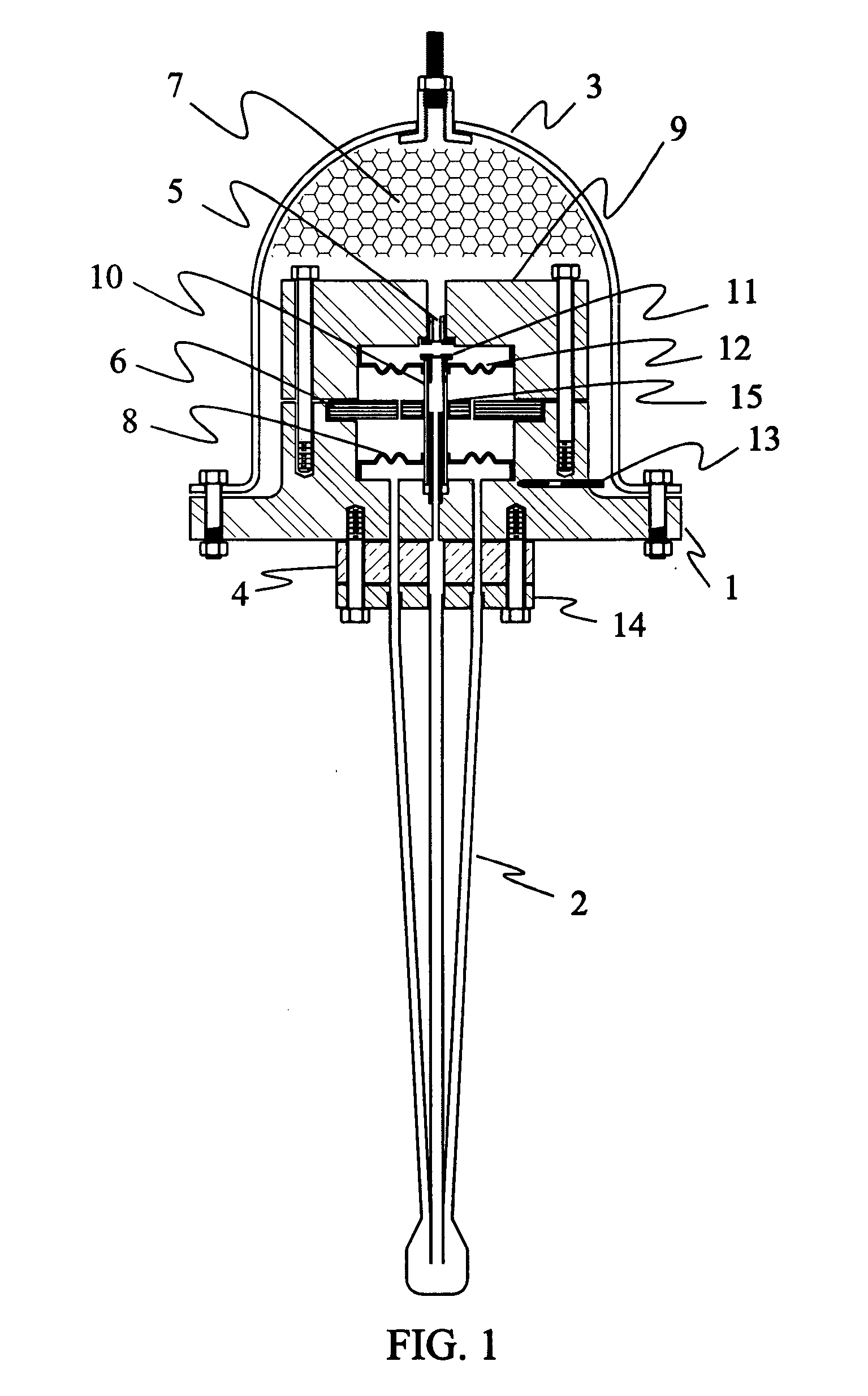

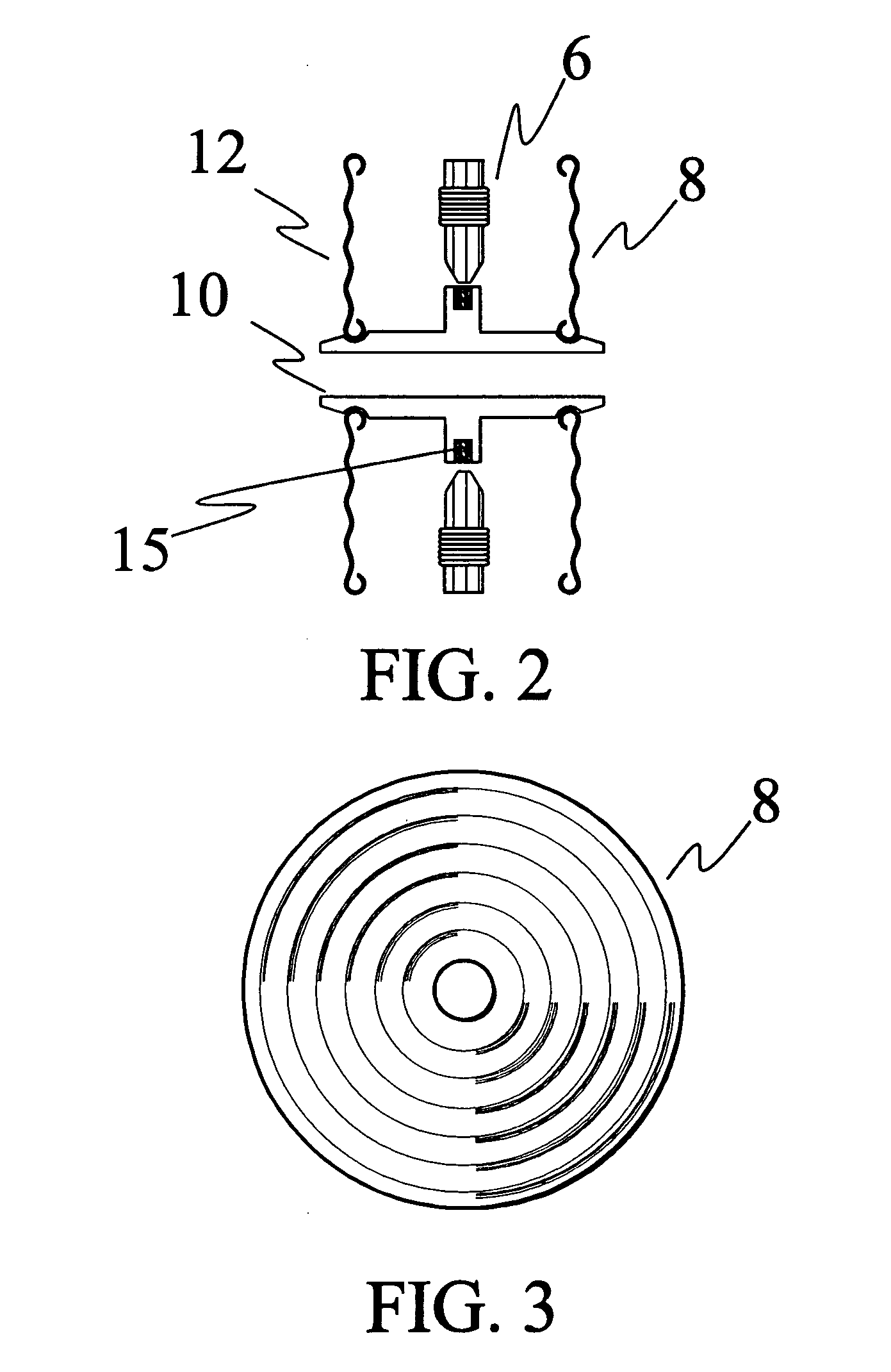

Thermoacoustic engine-generator

InactiveUS20050016171A1High speed of soundLess initial workStirling type enginesCompression machinesThermal energyWorking fluid

A thermoacoustic engine-generator that converts waste heat into electrical power. Thermal energy is converted to useful work via temperature-pressure amplification of periodic acoustic traveling waves in a compressible working fluid which cause the armature of a linear alternator to reciprocate and produce alternating current electrical energy. An external oscillator initiates reciprocating motion in the armature of a linear alternator. The armature is a combination fluid pump and fluid motor as well as the induction armature of a linear alternator. The pump end of the armature generates an acoustic traveling wave with each cycle of the armature. The traveling wave enters a waveguide-heat exchanger and is amplified in temperature, pressure and propagation velocity by thermal conduction of energy through the wall of the waveguide. The amplified traveling wave acts upon the opposite end of the armature, causing it to reciprocate within the magnetic field windings of the generator, and generate an electrical current as well as a new acoustic traveling wave. When the operating temperature gradient is attained across the hot and cold heat exchangers, the thermoacoustic engine-generator becomes acoustically resonant and self-regenerative, and will continue to operate as long as the thermal gradient is maintained. The theoretical conversion efficiency is dependent on the thermal gradient, and is 63% of Carnot.

Owner:FELLOWS RES GRP INC

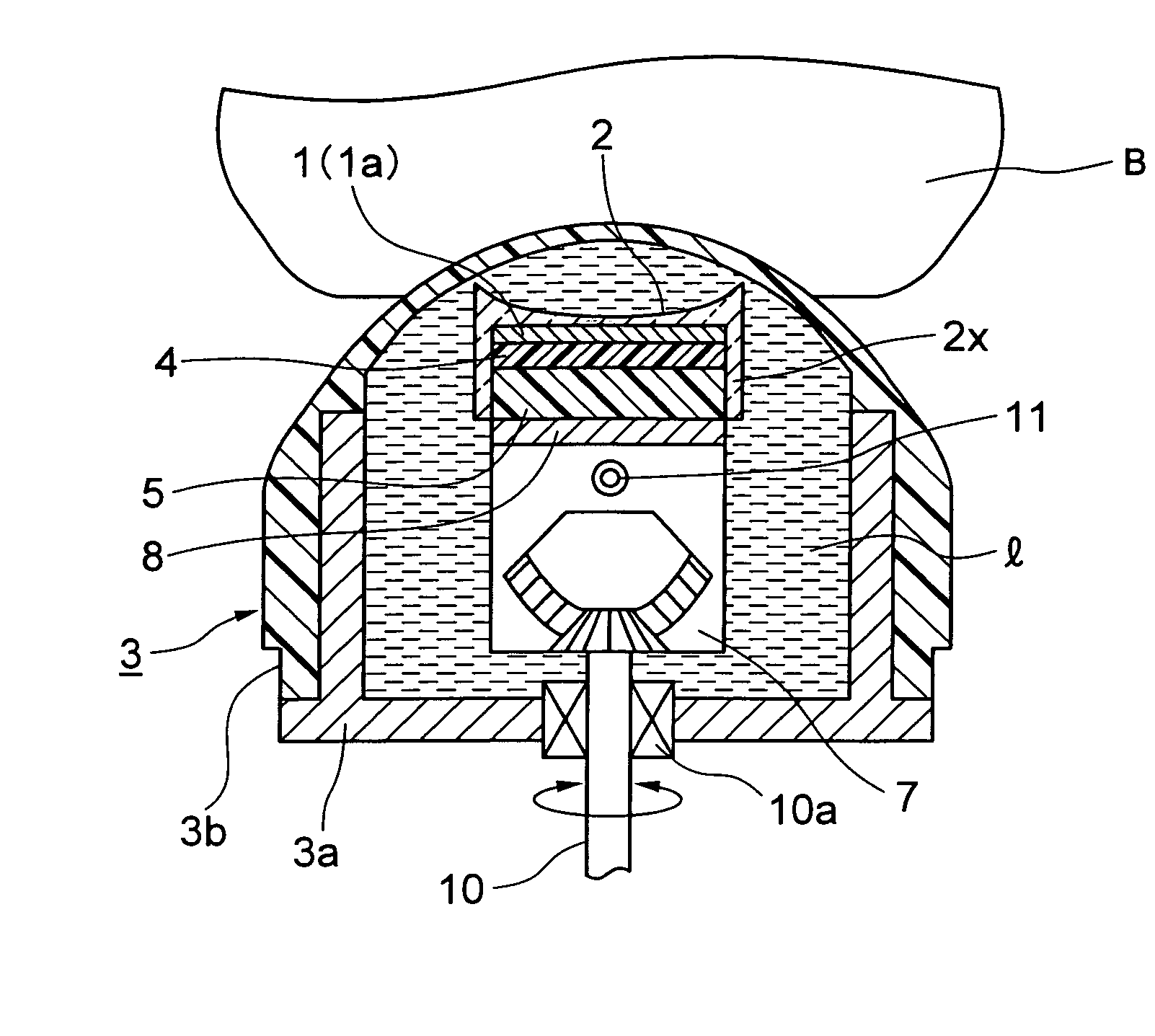

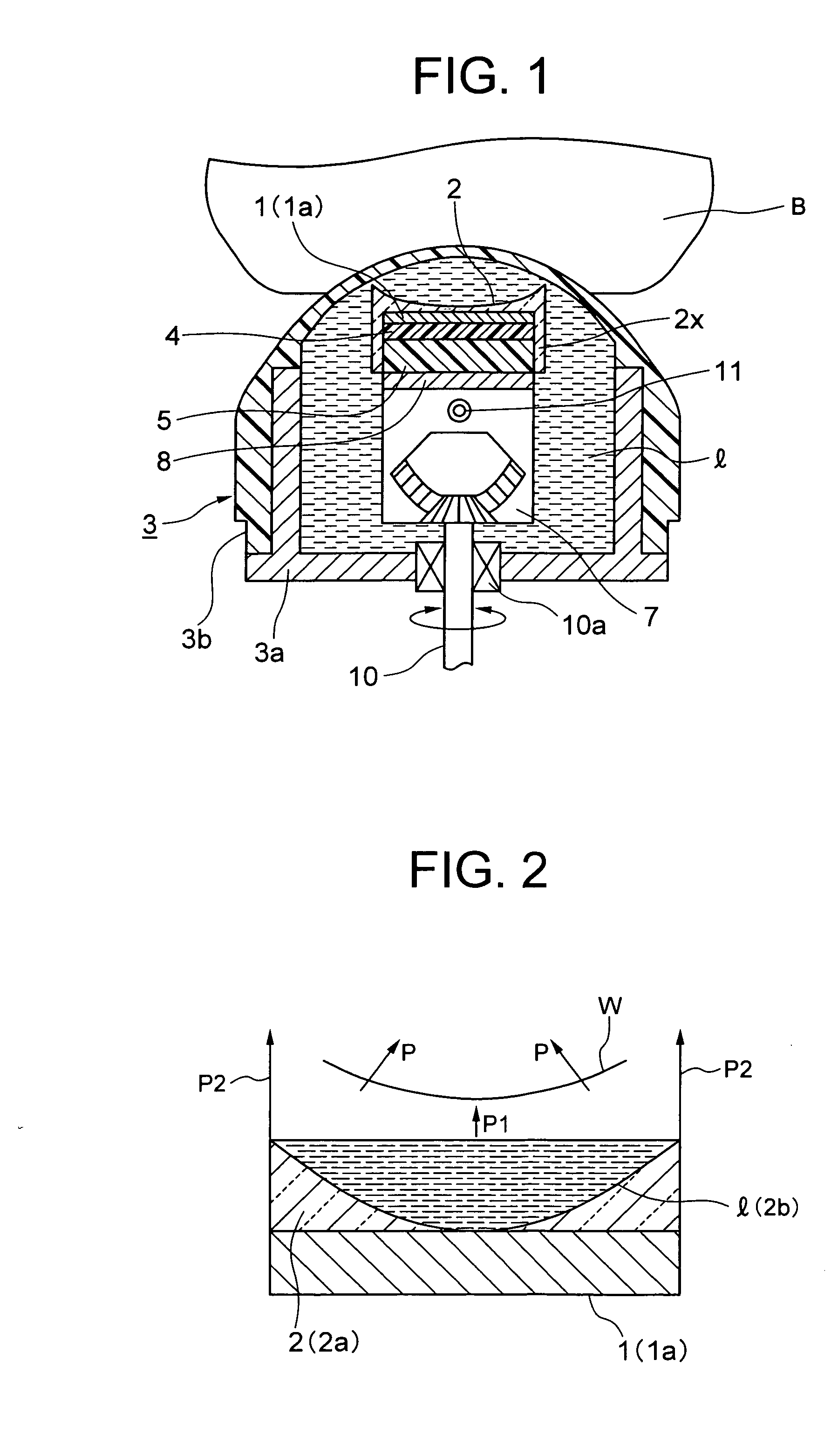

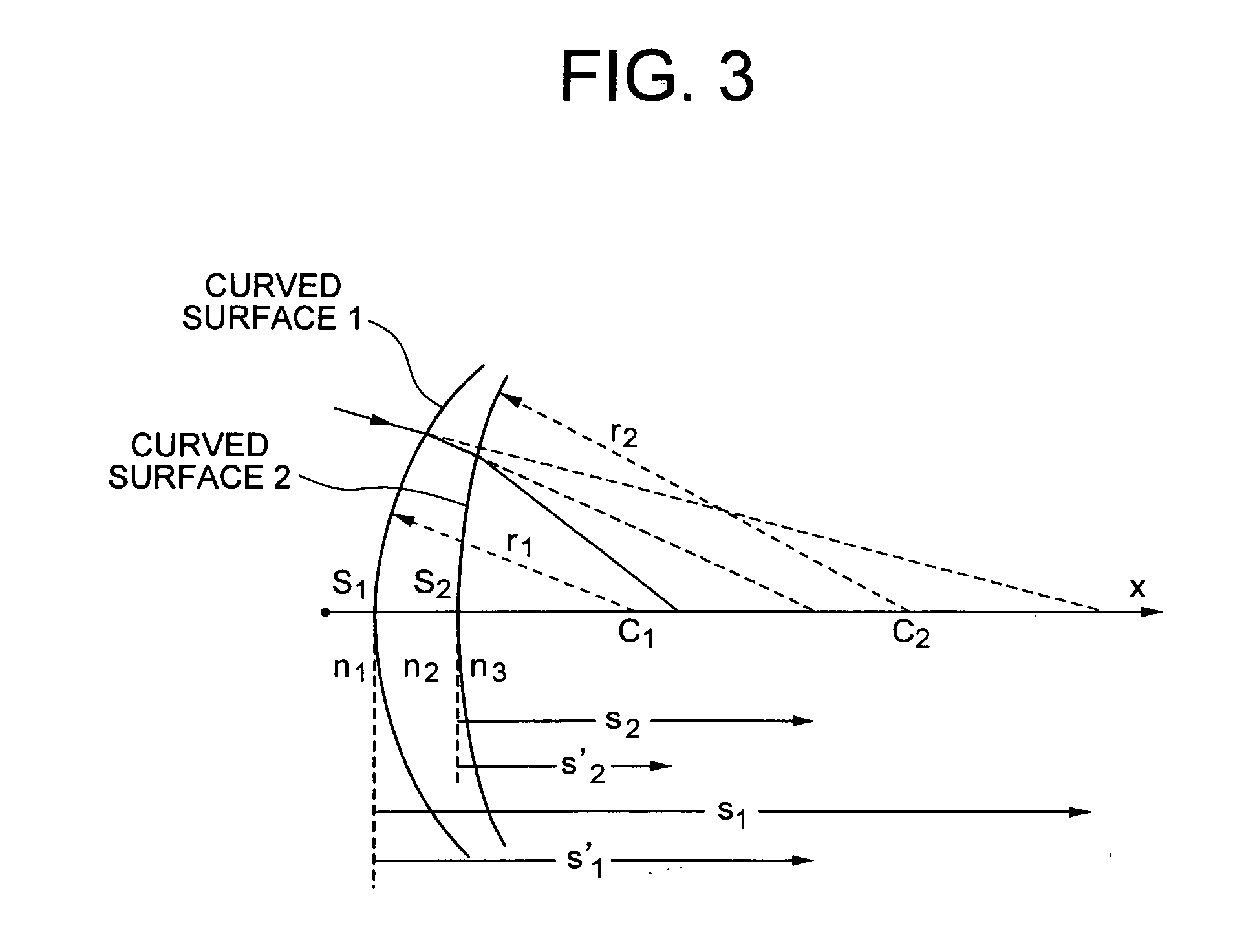

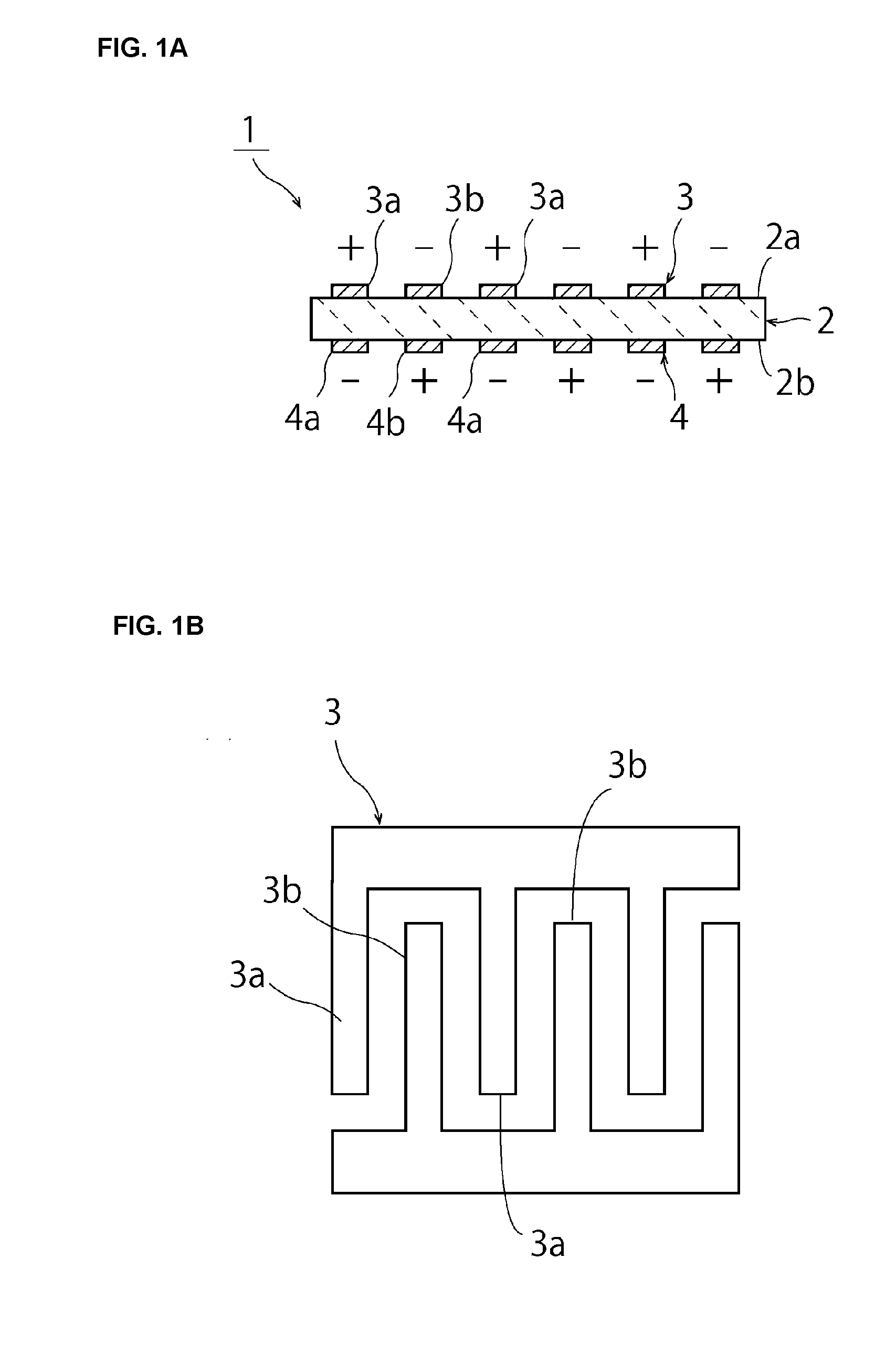

Minor axis motion type ultrasonic probe

ActiveUS20090299194A1Radius of curvature of the lens becomes greaterSuppress propagation lossUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringElectricityLiving body

The invention relates to a minor axis motion type ultrasonic probe with high sensitivity that suppresses propagation loss. The minor axis motion type ultrasonic probe of the invention comprises: a piezoelectric element group in which a plurality of piezoelectric elements are arranged in a line in a major axis direction of the piezoelectric element group; an acoustic lens that is provided on an ultrasonic wave transmitting / receiving surface side of the piezoelectric element group and that has a predetermined curvature in a minor axis direction of the piezoelectric element group; and a sealed container that houses the piezoelectric element group with the acoustic lens provided thereon and that is filled with a liquid serving as an ultrasonic wave medium, and the piezoelectric element group is moved in the minor axis direction and ultrasonic waves are transmitted and received to and from a living body, wherein the configuration is such that the acoustic lens is a concave lens formed from a material that has less propagation loss than a silicone resin and that has a greater acoustic velocity than a living body, and a relationship between acoustic velocity c1 of the concave lens, acoustic velocity c2 of the liquid, and acoustic velocity c3 of the living body is expressed as c1>c3>c2.

Owner:NIHON DEMPA KOGYO CO LTD

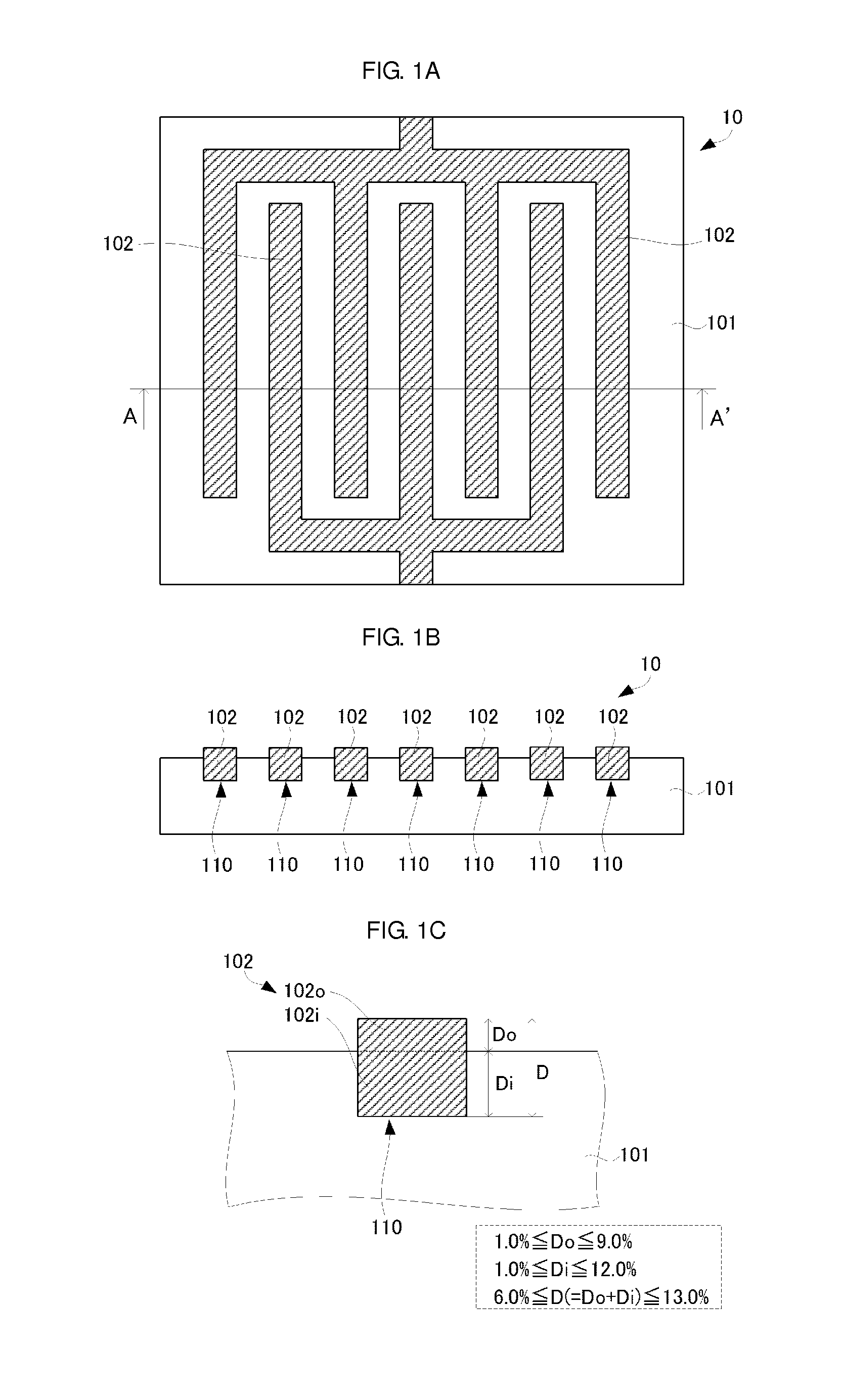

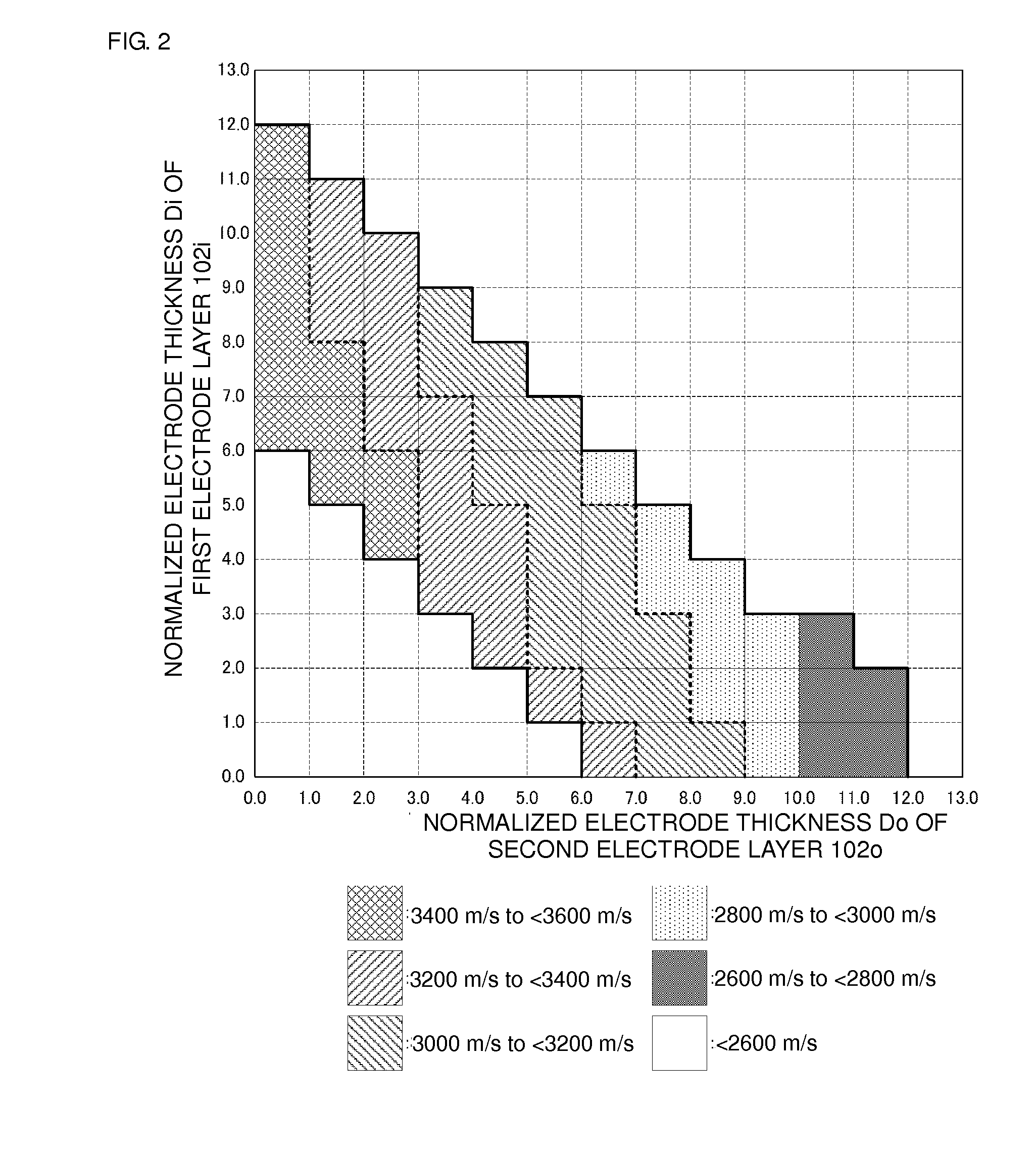

Surface acoustic wave device

ActiveUS20130300253A1Easy to manufactureImprove featuresImpedence networksPiezoelectric/electrostriction/magnetostriction machinesOptoelectronicsSurface acoustic wave sensor

A surface acoustic wave device includes a piezoelectric substrate made of lithium niobate and including grooves in a surface thereof. Each groove includes a finger of an IDT electrode made of copper. The IDT electrode includes a first electrode layer embedded in the grooves and a second electrode layer sticking out of the surface of the piezoelectric substrate. A normalized electrode thickness of the first electrode layer is about 1.0% to about 12.0% inclusive, and the normalized electrode thickness of the second electrode layer is about 1.0% to about 9.0% inclusive. The normalized electrode thickness of the entire IDT electrode is about 6.0% to about 13.0% inclusive.

Owner:MURATA MFG CO LTD

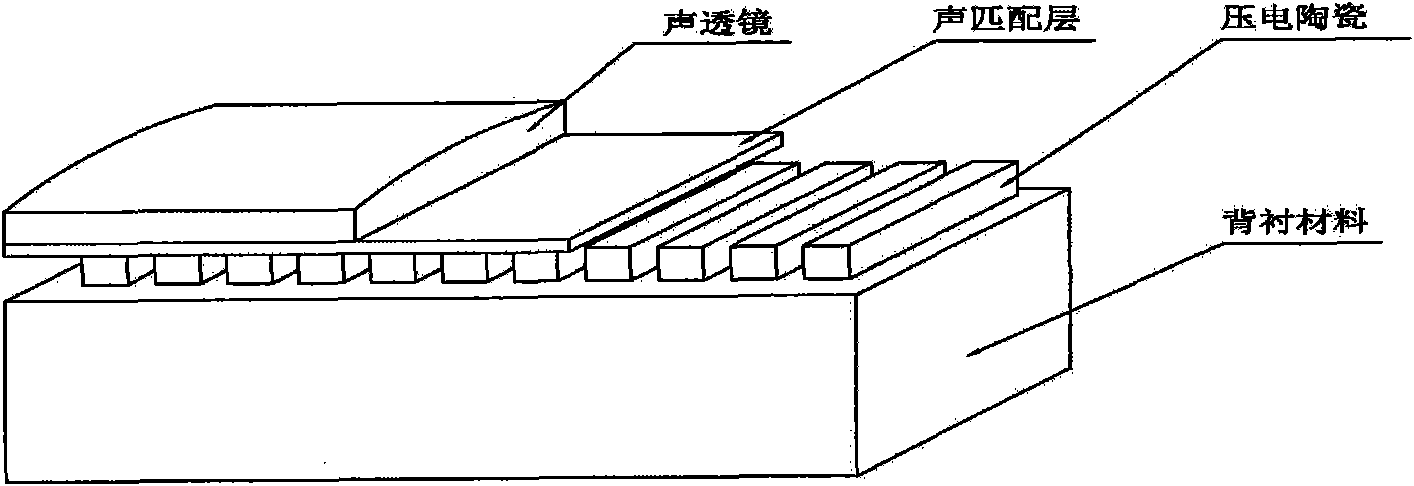

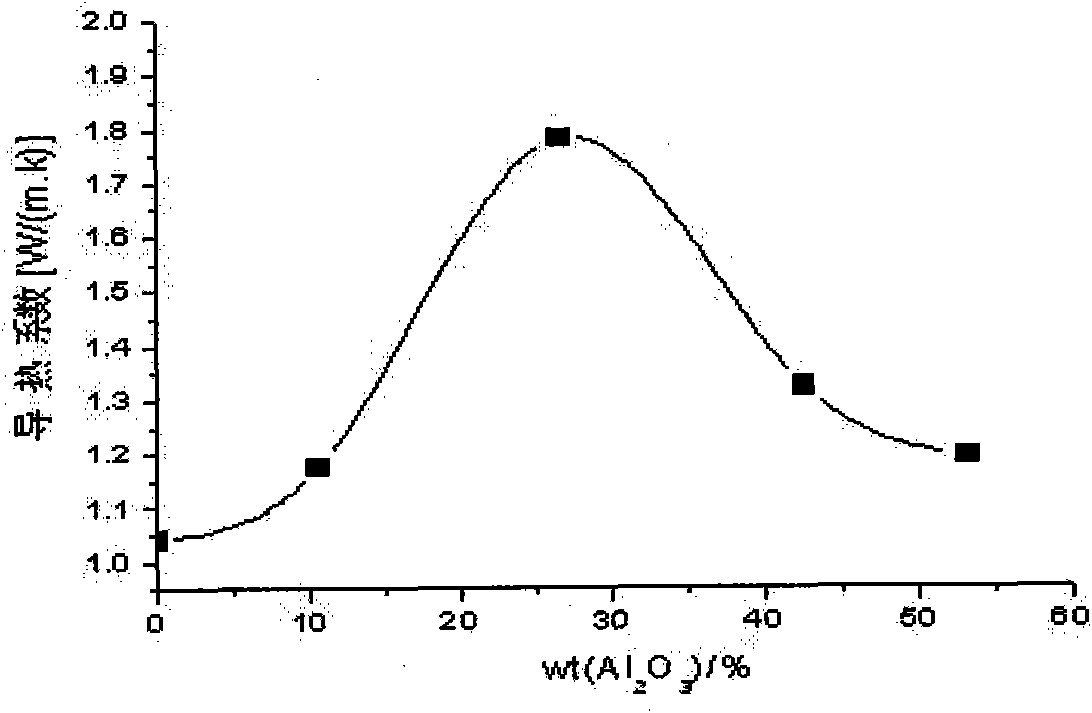

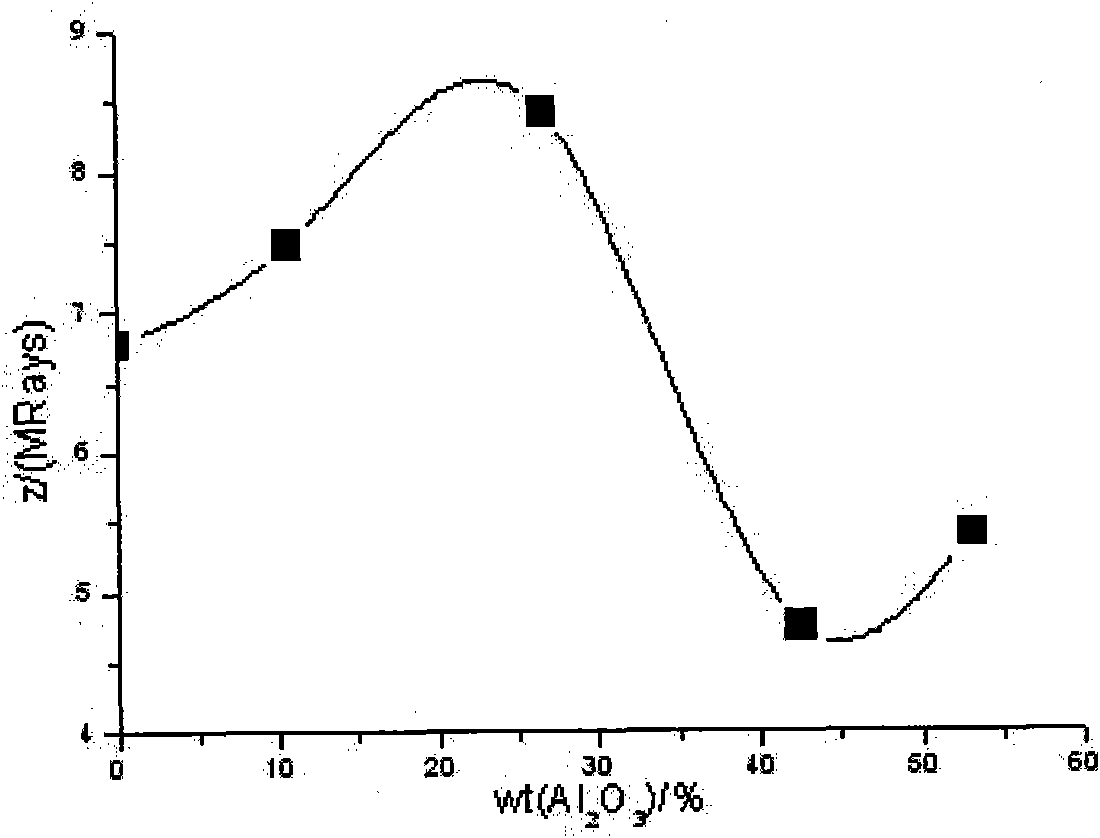

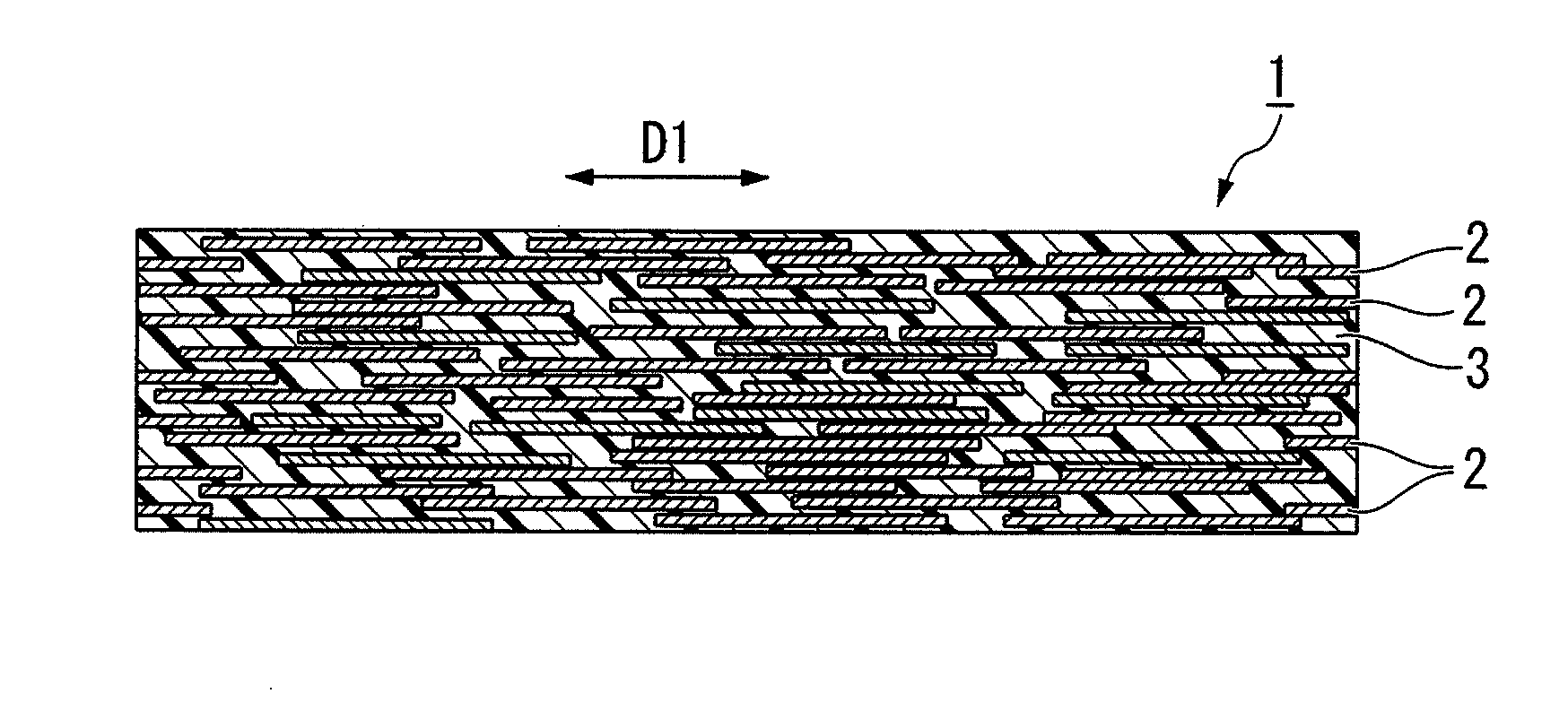

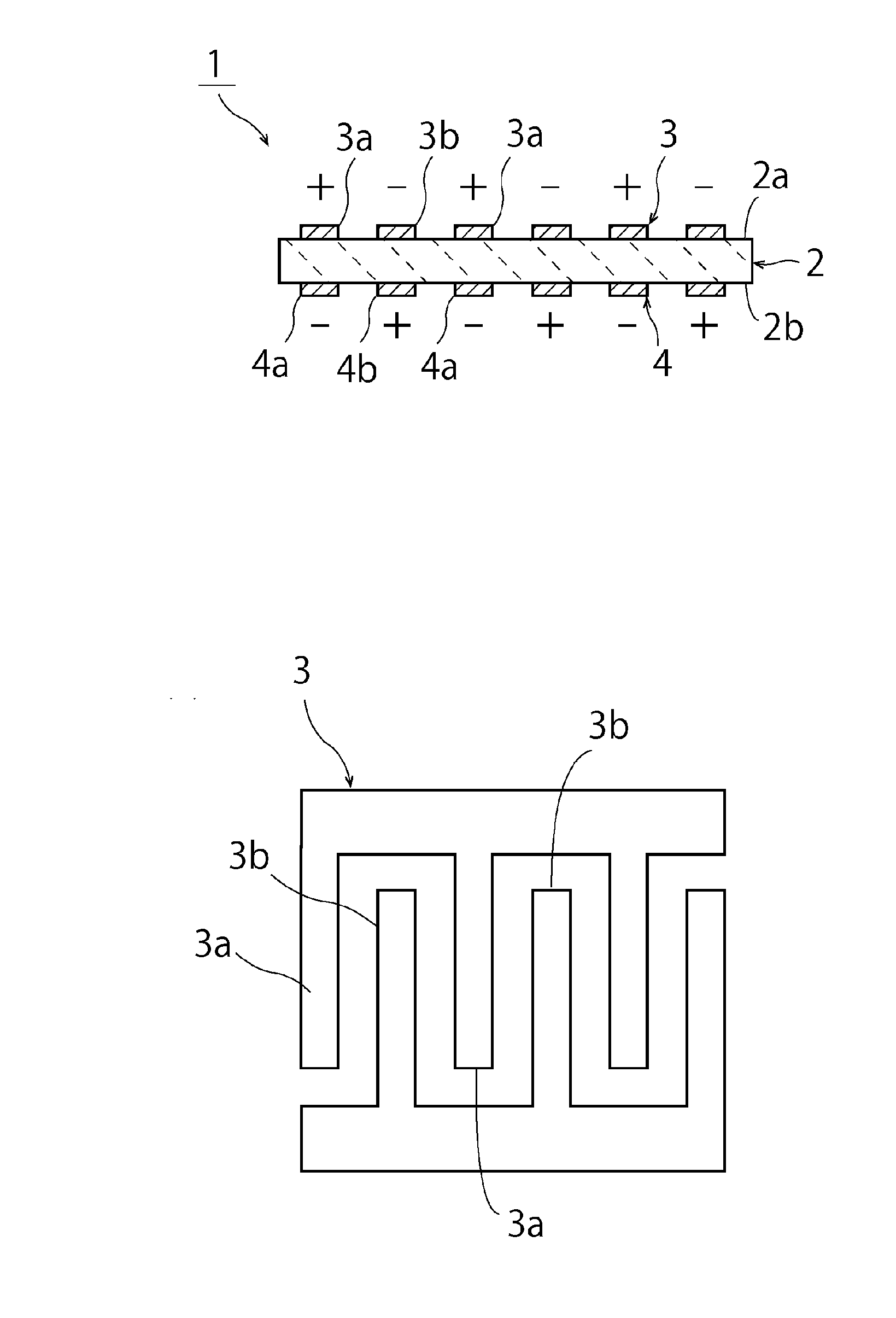

High heat conduction and high attenuation backing material for ultrasonic phased array probe and manufacturing method thereof

InactiveCN102338777AConvenient source of raw materialsLow priceMaterial analysis using sonic/ultrasonic/infrasonic wavesHeat-exchange elementsThermal conductivityImage resolution

A high heat conduction and high attenuation backing material for ultrasonic phased array probe is made from lutecium oxide, alumina, a tungsten compound material and an epoxy adhesive and is characterized in that the epoxy adhesive is prepared by mixing epoxy resin E-54 and triethanolamine; the tungsten compound material is prepared by mixing rubber and a tungsten powder; and the alumina accounts for 10.48-53.04wt% of the backing material. A manufacturing method of the backing material comprises the following steps of: (a) mixing the epoxy resin E-54, lutecium oxide, alumina and the tungsten compound material with stirring, wherein the epoxy resin E-54 accounts for 6.22% the total weight of the backing material and alumina accounts for 10.48-53.04wt% of the backing material; (b) adding triethanolamine which accounts for 0.95% the total weight of the backing material into the above composite particles with stirring; (c) putting the composite particles into a die, and extruding the composite particles into the required backing material by the use of a powder pressing machine; and (d) putting the pressed backing material into an air-blasting heating oven of 65 DEG C for heating-curing. The thermal conductivity of the backing material is 1.782W / (m.k), its specific acoustic impedance is 8.42*106Pa.s / m and its acoustic attenuation coefficient at 5MHz is 294.4dB / cm. The backing material has high thermal conductivity and high attenuation. In addition, the sensitivity and resolution of the phased array probe produced by the use of the backing material can satisfy the requirement for application.

Owner:广州多浦乐电子科技股份有限公司

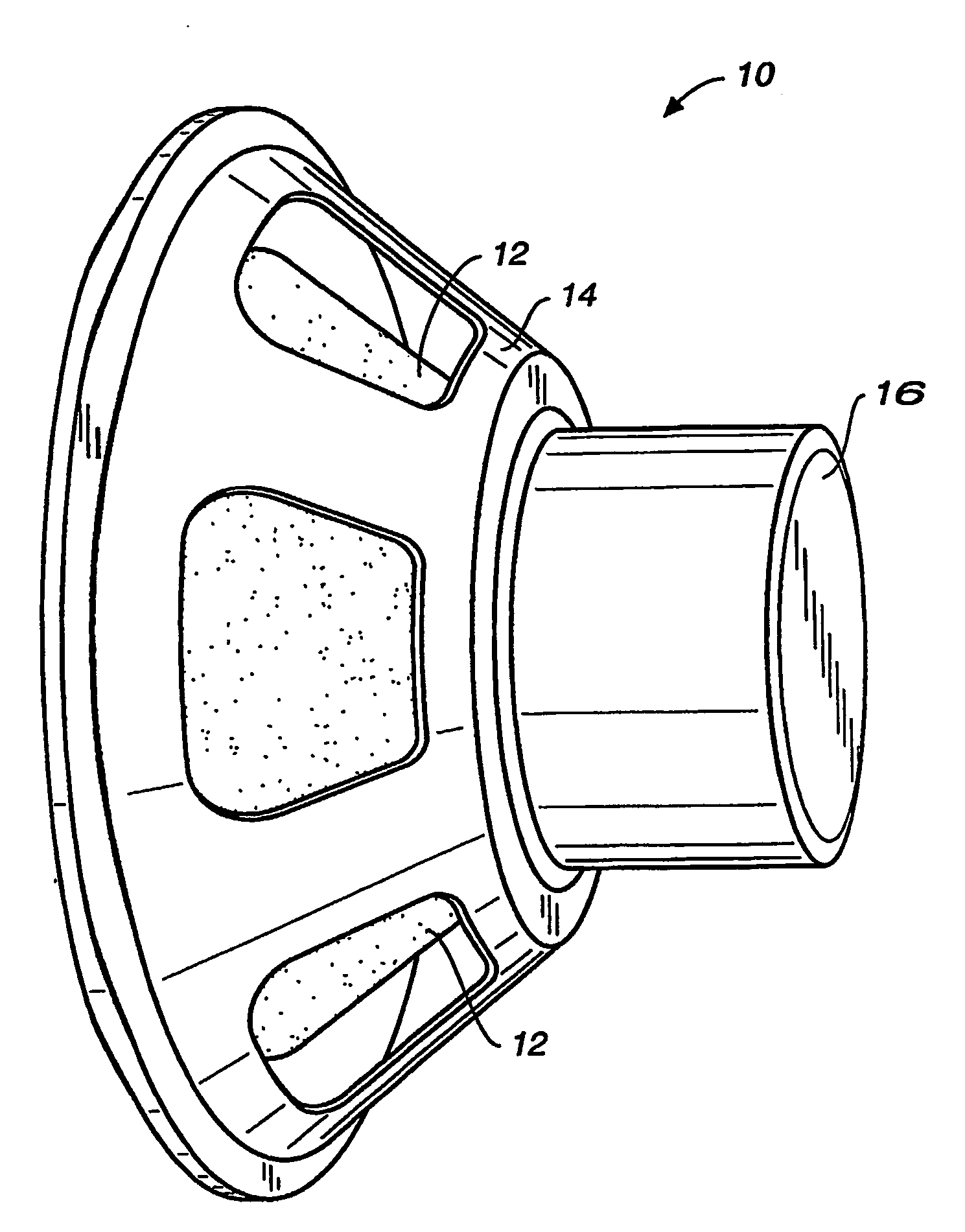

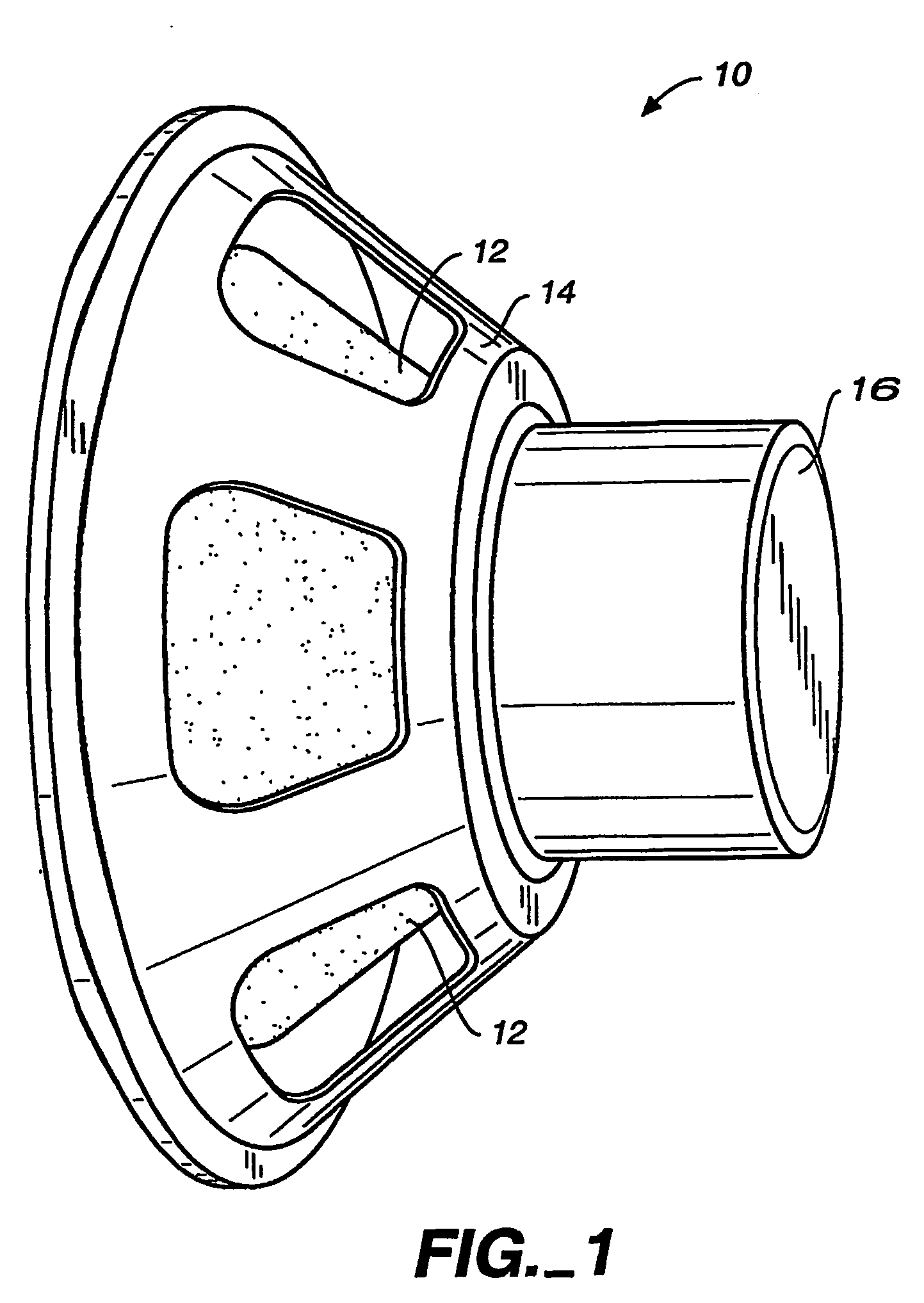

Audio speaker cone appartus and method of manufacture

InactiveUS20060013433A1Superior tone and sonic propertyIncreased durabilityFibre diaphragmsTransducer detailsCompound (substance)Engineering

The invention provides for the construction of cones (12) of audio speaker (10) from at least some quantity of hemp fiber, alone or with other materials and / or binding chemicals. The hemp composition may range from approximately 2% to approximately 100% hemp fiber. The invention composition may be mixed, molded, pressed, and placed into a frame (14) in a traditional manner of speaker cone structure.

Owner:HARRISON JOHNG

Surface acoustic wave device including a confinement layer

ActiveUS9276558B2Sufficiently small propagation lossHigh speed of soundImpedence networksSurface acoustic wave sensorElectrode

In a surface acoustic wave device, a plurality of surface acoustic wave elements include piezoelectric bodies having the same cut-angle. A propagation azimuth of a surface acoustic wave in at least one of surface acoustic wave elements is different from a propagation azimuth of a surface acoustic wave in at least another one of the surface acoustic wave elements. In each of the surface acoustic wave elements, a confinement layer configured to confine the surface acoustic wave inside the piezoelectric body is disposed on the piezoelectric body at the side opposite to the side where an electrode is located.

Owner:MURATA MFG CO LTD

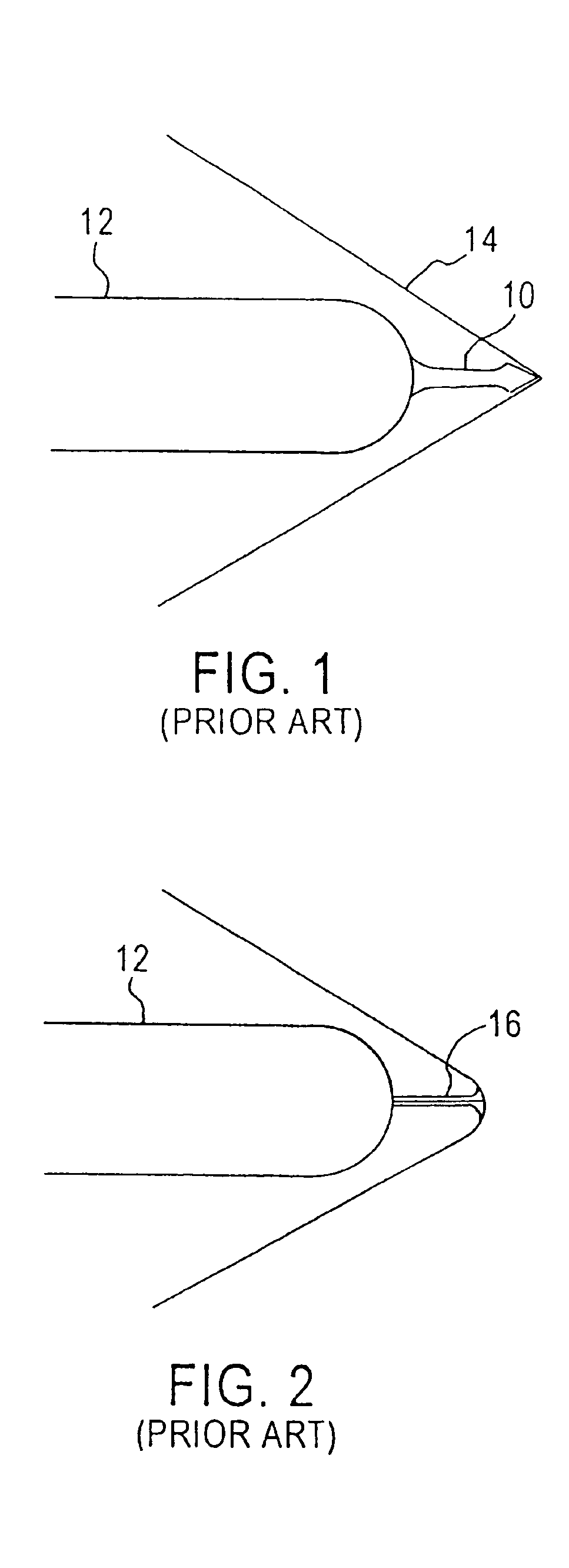

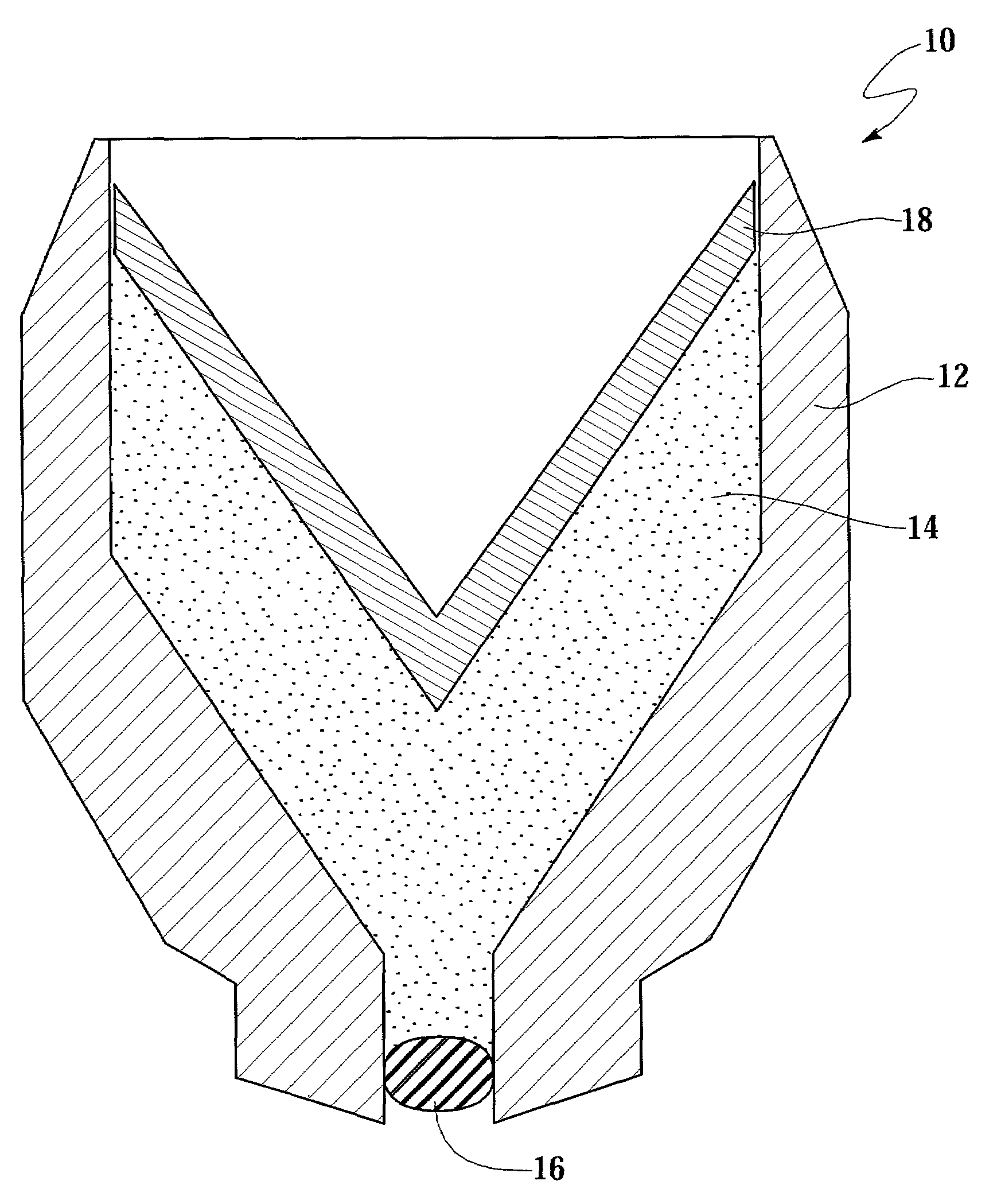

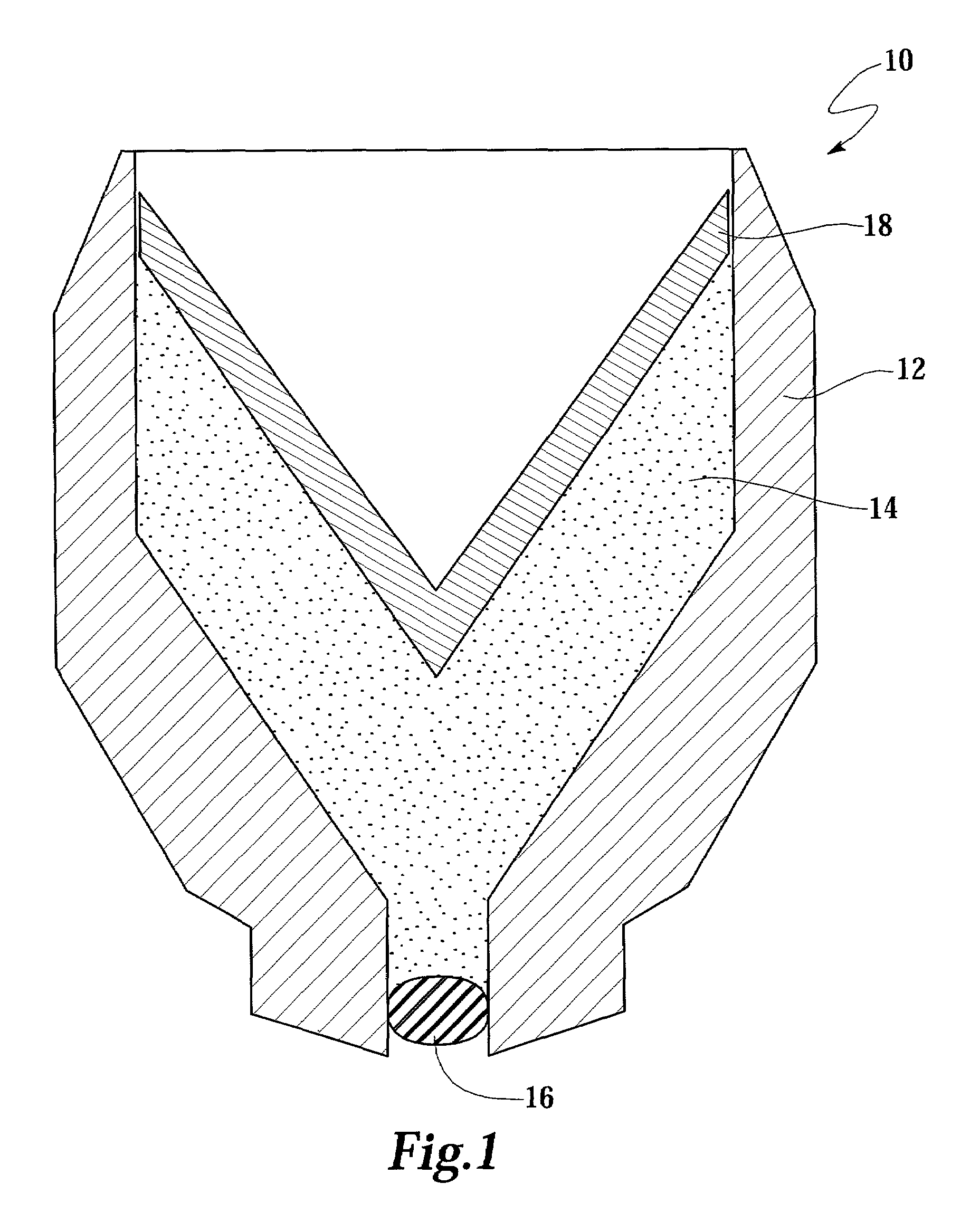

High performance powdered metal mixtures for shaped charge liners

InactiveUS7547345B2Decrease oxidationImprove depthAmmunition projectilesExplosive chargesTungstenPenetration depth

A liner (18) for a shaped charge (10) that utilizes a high performance powered metal mixture to achieve improved penetration depths during the perforation of a wellbore is disclosed. The high performance powdered metal mixture includes powdered tungsten and powdered metal binder. The powered metal binder may be selected from the group consisting of tantalum, molybdenum, lead, cooper and combination thereof. This mixture is compressively formed into a substantially conically shaped liner (18).

Owner:HALLIBURTON ENERGY SERVICES INC

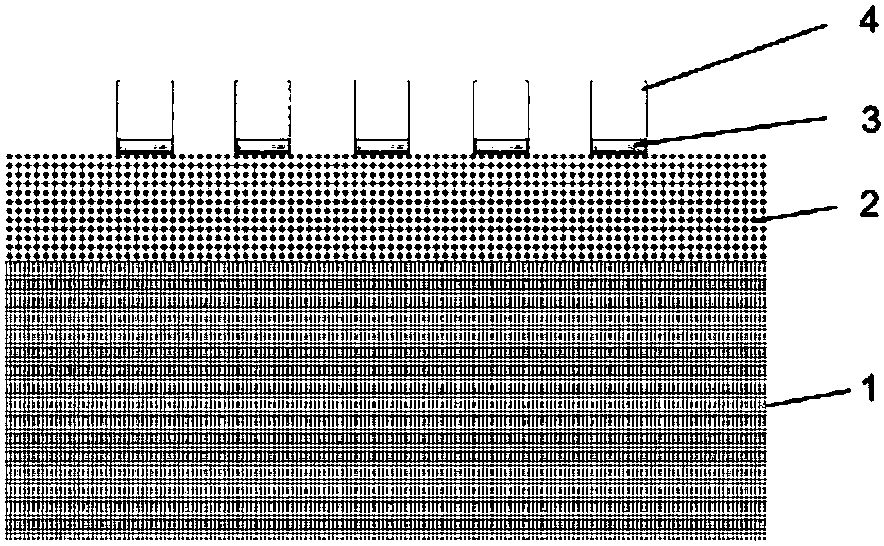

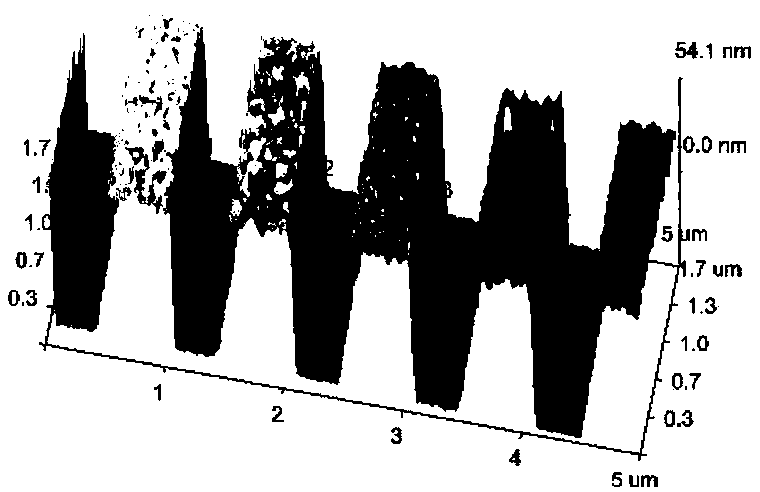

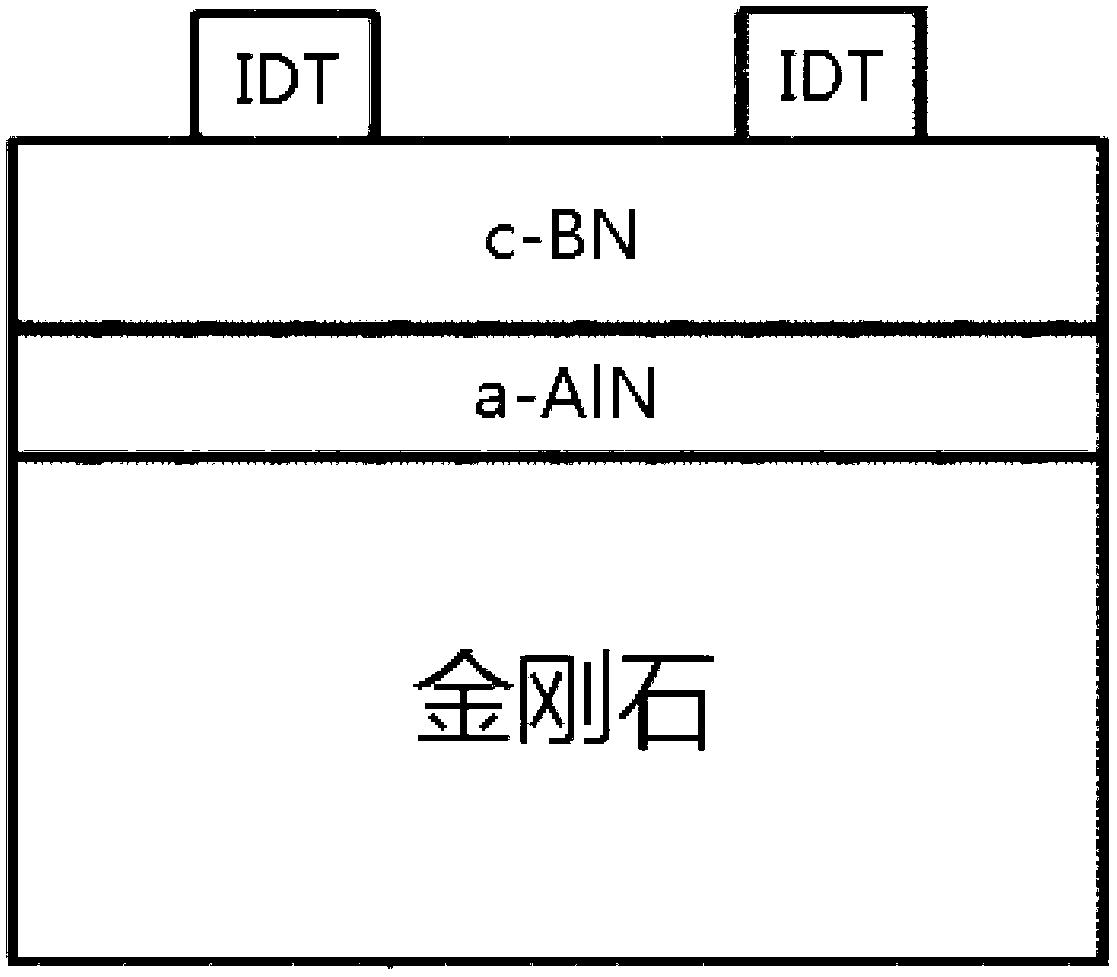

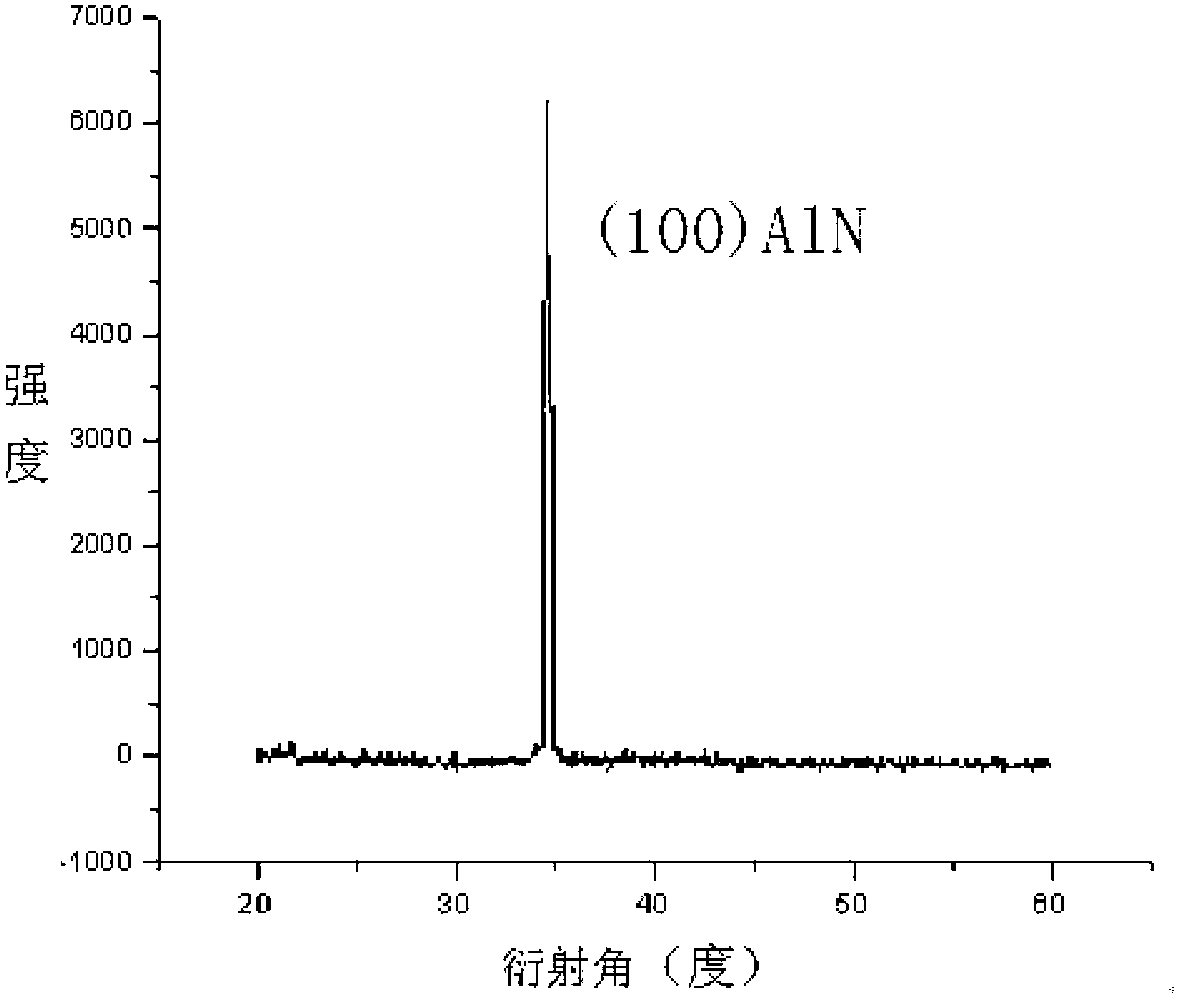

Surface acoustic wave device of multilayer film structure and preparation method thereof

InactiveCN103138702AHigh hardnessHigh speed of soundImpedence networksElectromechanical coupling coefficientMicrometer

A surface acoustic wave device of a multilayer film structure comprises a CVD diamond film, an a-AlN film of axle a preferred orientation, a c-BN film of axle c preferred orientation and an interdigital transducer (IDT) in a successive superposition mode to form a diamond-complex film structure, wherein the thickness of the CVD diamond film is 20-25 micrometers, the thickness of the a-AlN film is 300-500nm, the thickness of the c-BN film is 300-500nm, the thickness of the IDT is 100nm, and the IDT is an aluminium film. The surface acoustic wave device of the multilayer film structure has the advantages that hardness and sound velocity of the diamond are high, high sound velocity of the a-AlN can effectively relieve a sound velocity frequency dispersion effect caused by big difference of the sound velocity between the diamond and the c-BN and a high electromechanical coupling coefficient of the c-BN. The surface acoustic wave device of the multilayer film structure can be used for manufacturing surface acoustic wave (SAW) devices which are high in frequency, high in sound velocity, high in power and high in electromechanical coupling coefficients.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

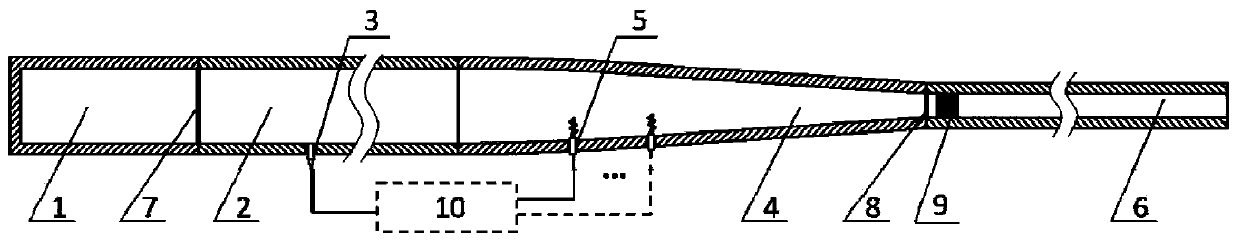

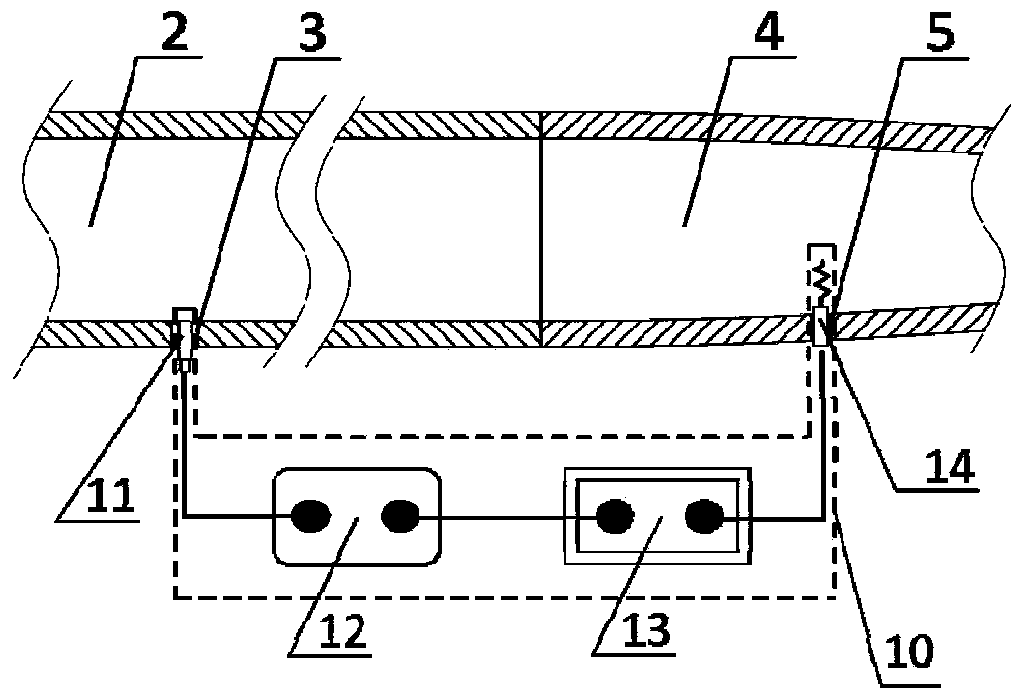

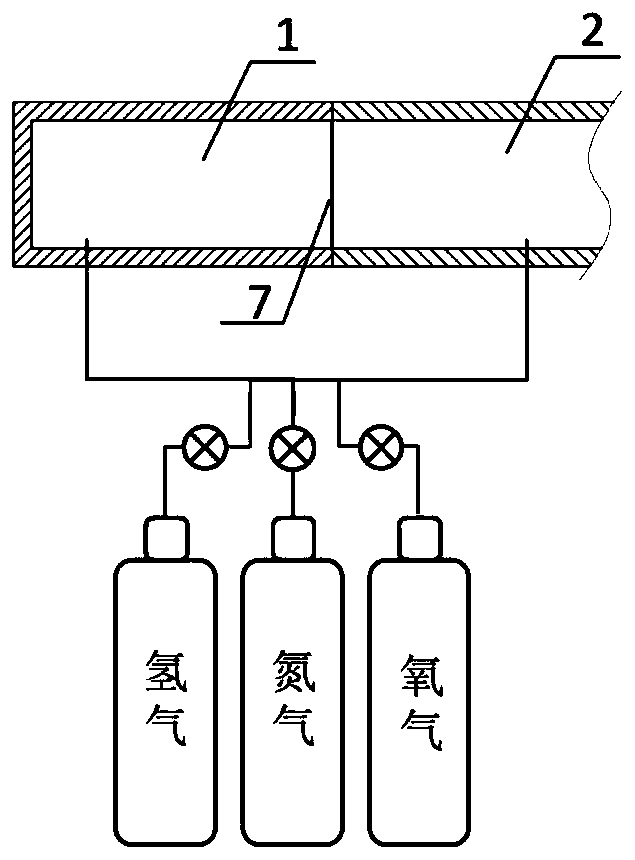

Composite ignition type combustion light gas gun

PendingCN110132053ASolve stressAddresses an issue that caused suboptimal launch performanceCompressed gas gunsShock waveDelayed pulse

The invention discloses a composite ignition type combustion light gas gun. The composite ignition type combustion light gas gun comprises a drive section, a driven section, a convergence section, anemitting tube and an ignition control system, wherein one end of the drive section is sealed, and the other end of the drive section is connected to the driven section, and a joint is clamped with a diaphragm; the tube body of the driven section is equipped with a pressure sensor; the front end of the convergence section is connected to the driven section, the rear end of the convergence section is connected to the emitting tube, and the joint of the rear end and the emitting tube is clamped with a diaphragm, and an igniter is mounted on a tube body; a shot is placed on a position, close to the diaphragm, in the emitting tube; and the ignition control system comprises a pressure sensor, a charge amplifier, a digital delay pulse generator. The light gas gun utilizes a composite ignition form, adopts mutual action between detonation waves induced by convergence shock wave reflection and detonation waves forcibly detonated by the igniter to generate intense shock waves, then, the intenseshock waves chase after the shot and are reflected, so that shot-bottom pressure is instantaneously increased, and a gas gun system with higher operation efficiency is developed with a lower price.

Owner:UNIV OF SCI & TECH OF CHINA

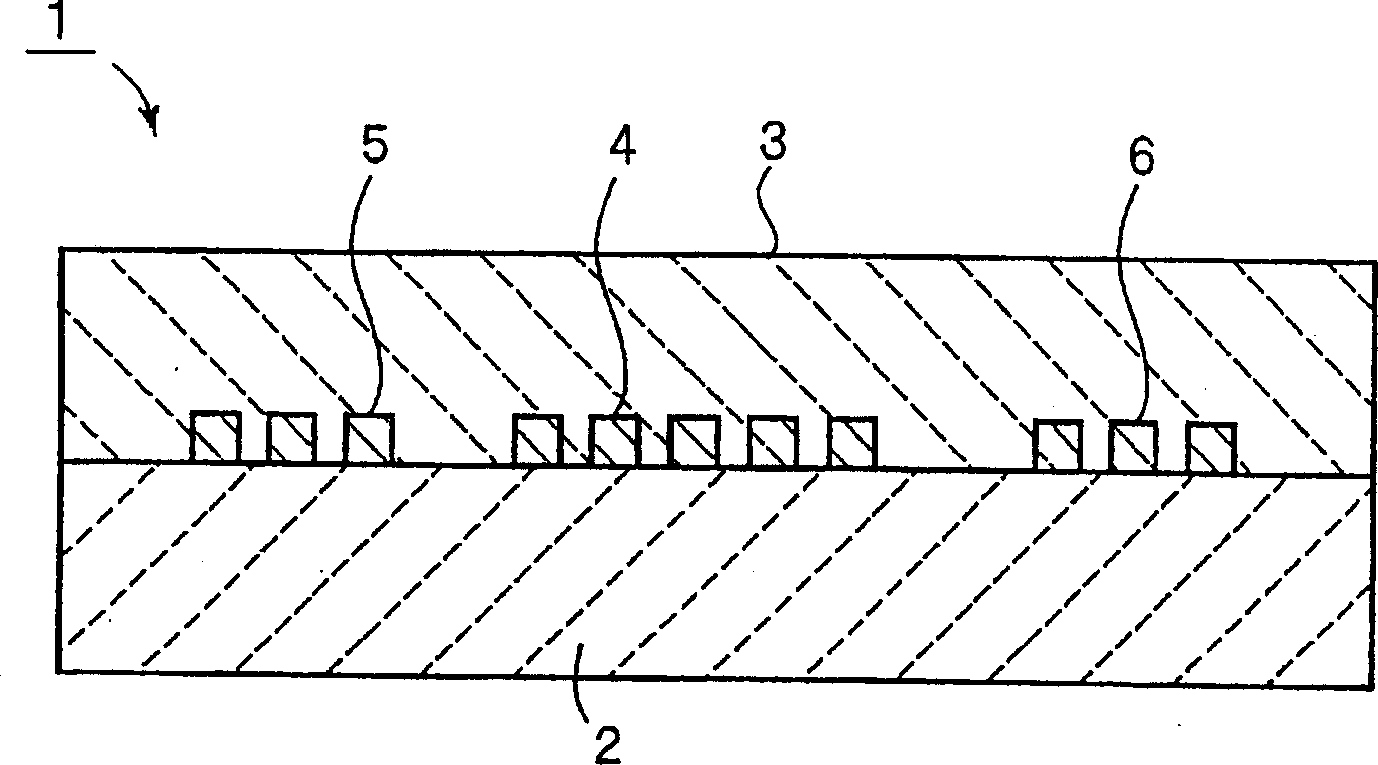

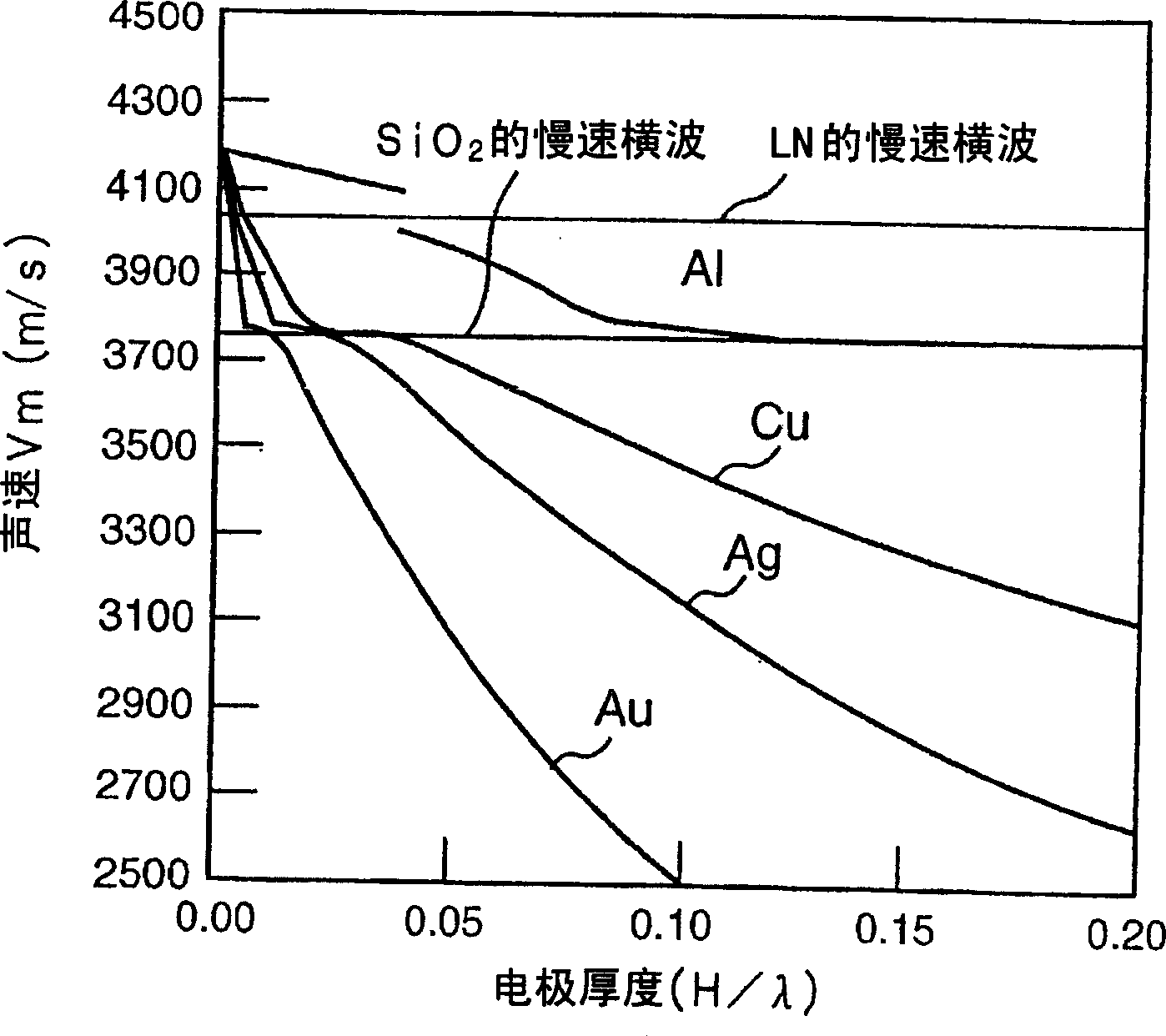

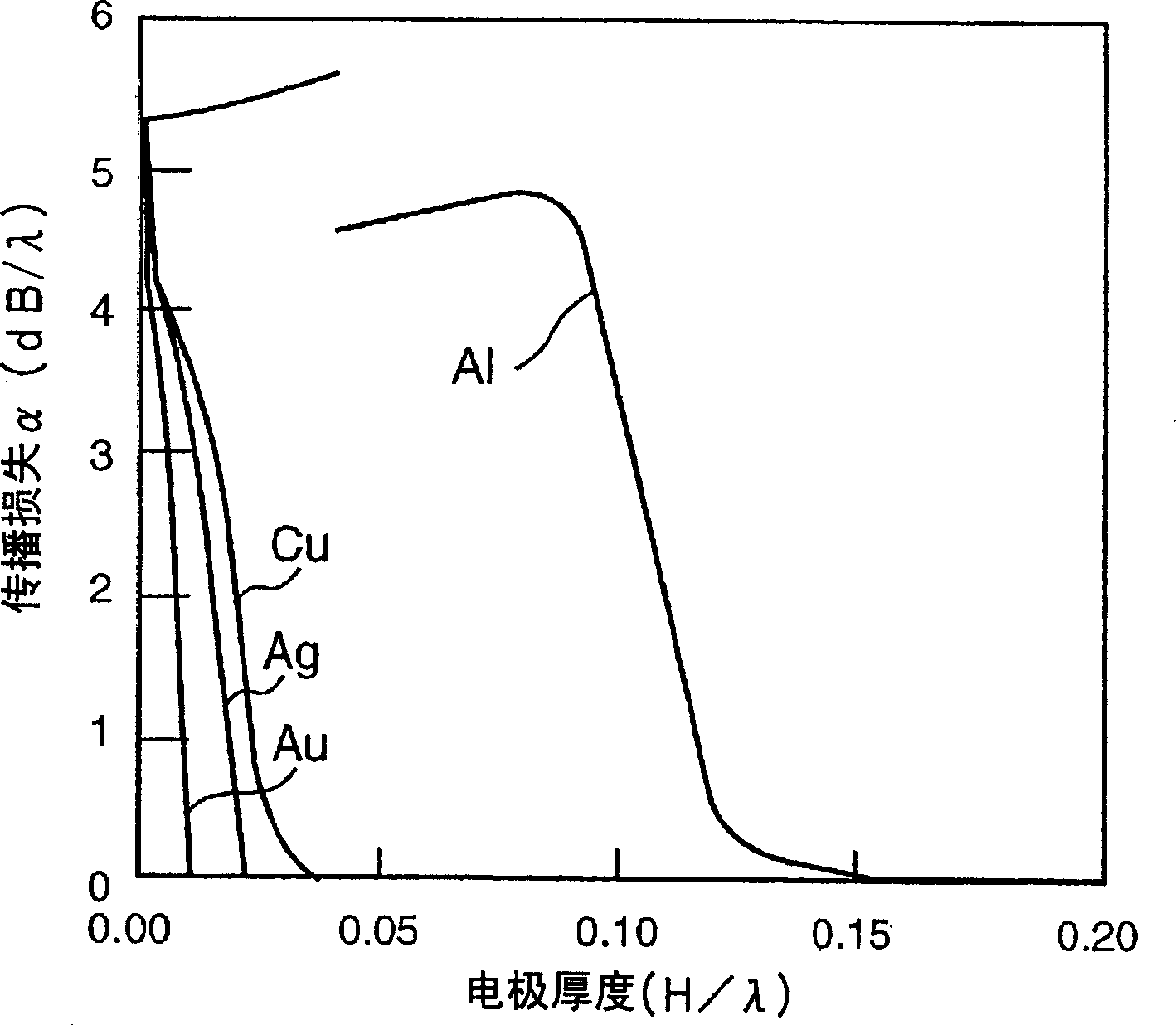

Elastic boundary wave device

ActiveCN1745516ALow speed of soundImprove electromechanical coefficientImpedence networksTemperature coefficientSpeed of sound

An elastic boundary wave device employing an SH type elastic boundary wave having a large electromechanical coupling coefficient, a low propagation loss, a small power flow angle, a temperature coefficient of frequency TCF in an appropriate range, and a simple structure which can be produced through a simple process. A dielectric is deposited on one side of a piezoelectric and an IDT and a reflector are arranged as electrodes on the boundary of the piezoelectric and the dielectric, wherein the thickness of the electrodes is set such that the sound velocity of the SH type elastic boundary wave becomes lower than the sound velocity of a slow transverse wave propagating through the dielectric and the sound velocity of a slow transverse wave propagating through the piezoelectric.

Owner:MURATA MFG CO LTD

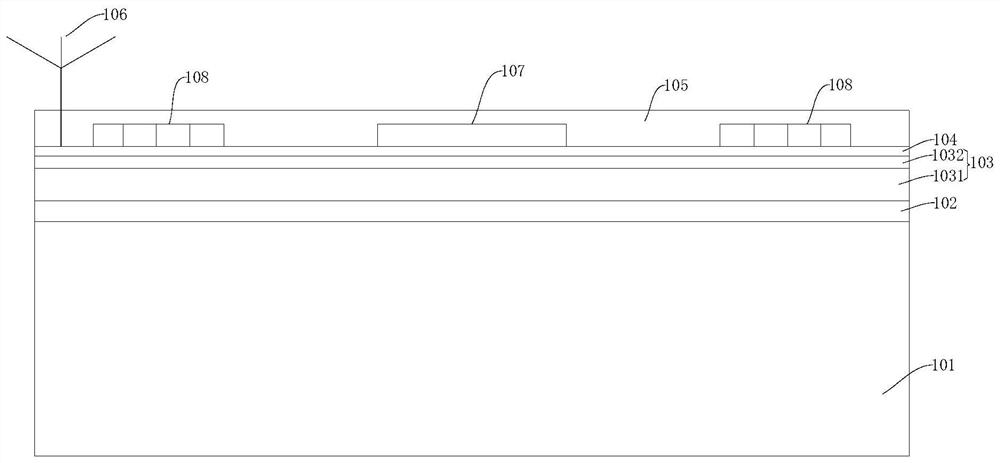

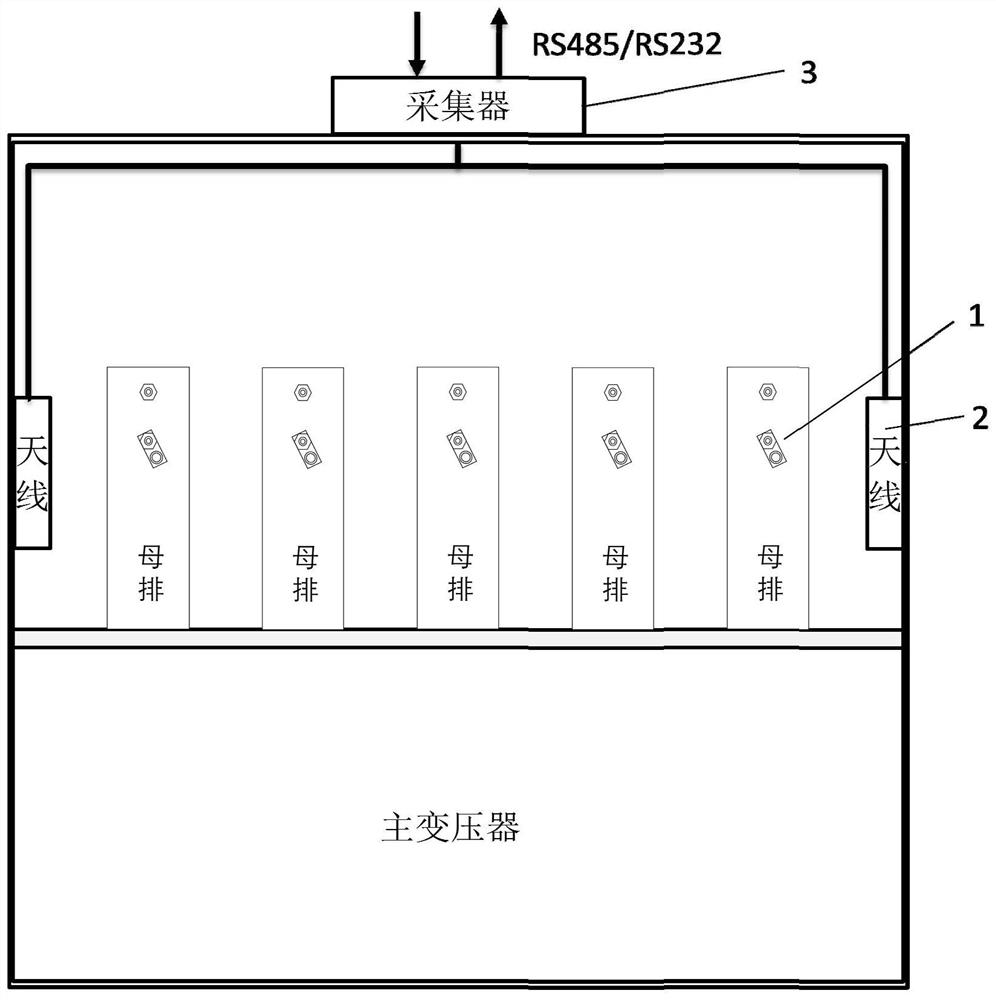

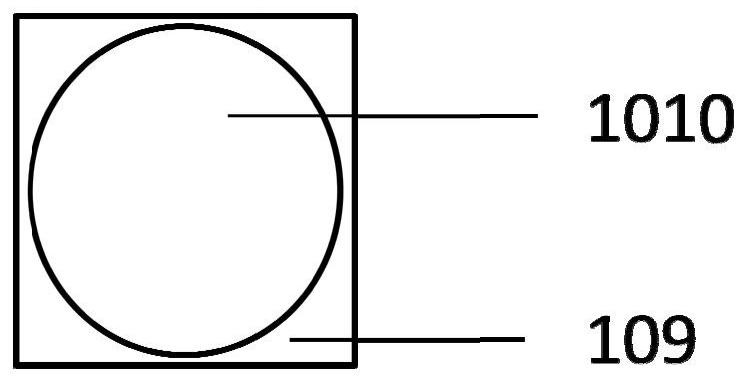

Wireless passive temperature sensing system for main transformer cabinet of electric locomotive

InactiveCN112179518ARealize online temperature monitoring functionAchieve readThermometer detailsThermometers using physical/chemical changesGratingTransformer

The invention discloses a wireless passive temperature sensing system for a main transformer cabinet of an electric locomotive. The wireless passive temperature sensing system comprises a surface acoustic wave temperature sensing unit, an antenna unit and an acquisition unit, the surface acoustic wave temperature sensing unit is mounted at a to-be-measured temperature in a main transformer cabinetof the electric locomotive, and is connected with the acquisition unit through the antenna unit; and the surface acoustic wave temperature sensing unit comprises a substrate, a piezoelectric substrate, an antenna module, an interdigital transducer and a reflecting grating. The piezoelectric substrate comprises a sound wave conduction substrate and a piezoelectric film positioned on the sound waveconduction substrate; the sound wave conduction substrate is located on the substrate, and the antenna module, the interdigital transducer and the reflecting grating are located on the piezoelectricfilm; and a sound absorption layer is laid on the surface of the piezoelectric film and used for absorbing bulk acoustic wave signals in the acoustic surface waves. The system has the advantages of high frequency, low time delay, high sound velocity, high reliability, high adaptability and the like.

Owner:ZHUZHOU NAT INNOVATION RAILWAY TECH CO LTD

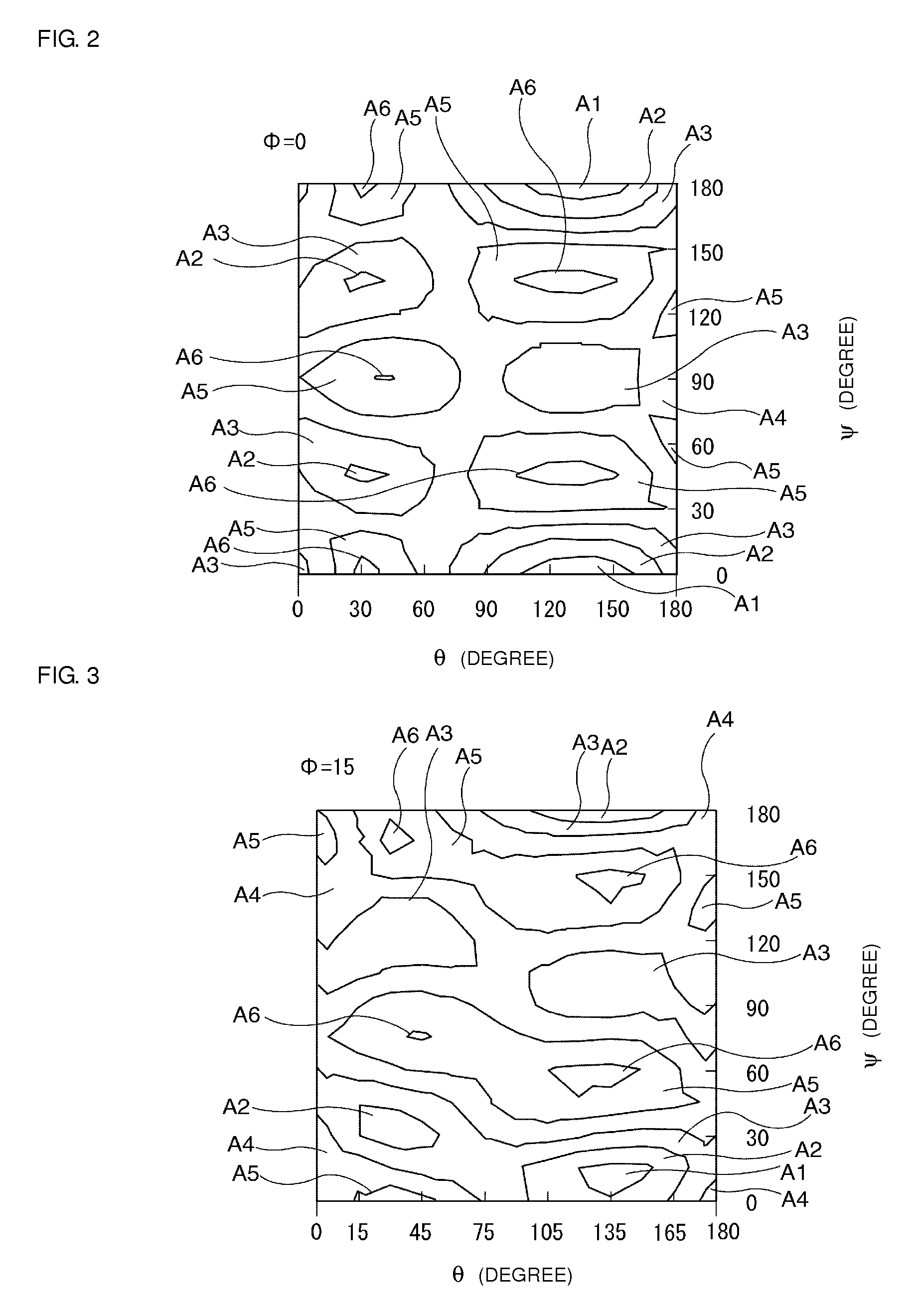

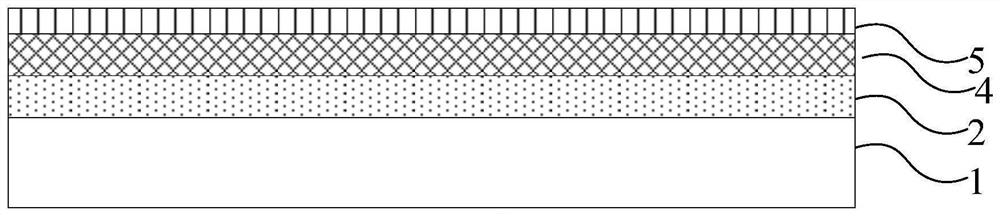

Acoustic wave device, high frequency front end circuit, and communication apparatus

ActiveUS20190393856A1High speed of soundEffectively preventedImpedence networksAcoustic waveEuler angles

An acoustic wave device includes a material layer which has Euler angles and an elastic constant at the Euler angles, a piezoelectric body which includes first and second principal surfaces opposing each other, is laminated directly or indirectly on the material layer so that the second principal surface is on the material layer side and has Euler angles, and whose elastic constant at the Euler angles, and an IDT electrode which is disposed on at least one of the first principal surface and the second principal surface of the piezoelectric body. At least one elastic constant among elastic constants C11 to C66 of the material layer not equal to 0 and at least one elastic constant among elastic constants C11 to C66 of the piezoelectric body not equal to 0 have opposite signs to each other.

Owner:MURATA MFG CO LTD

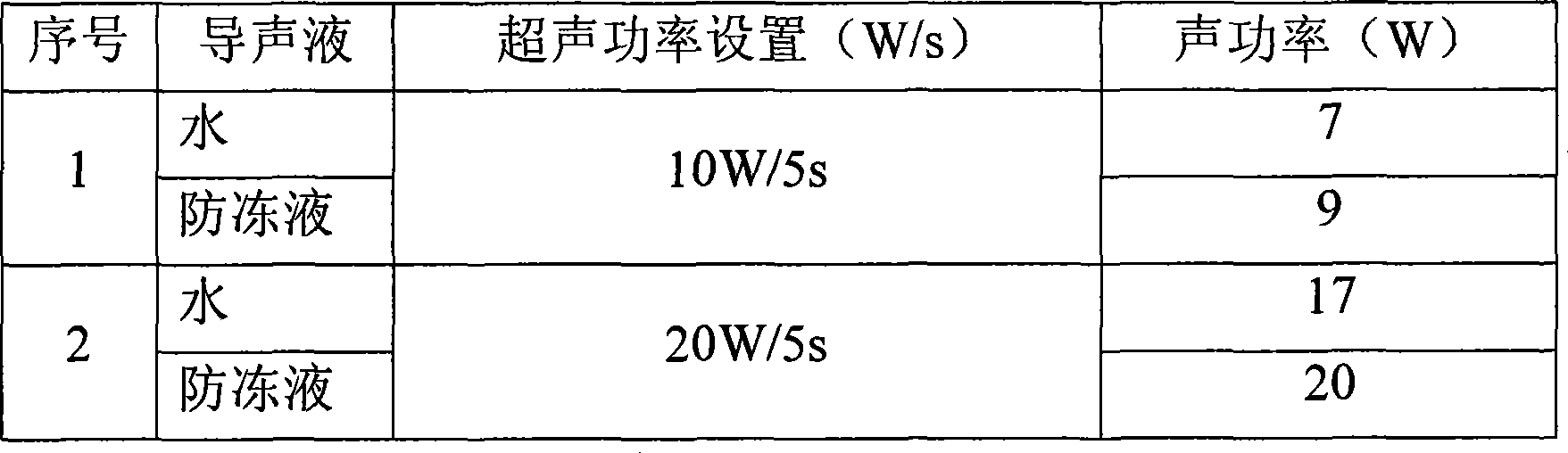

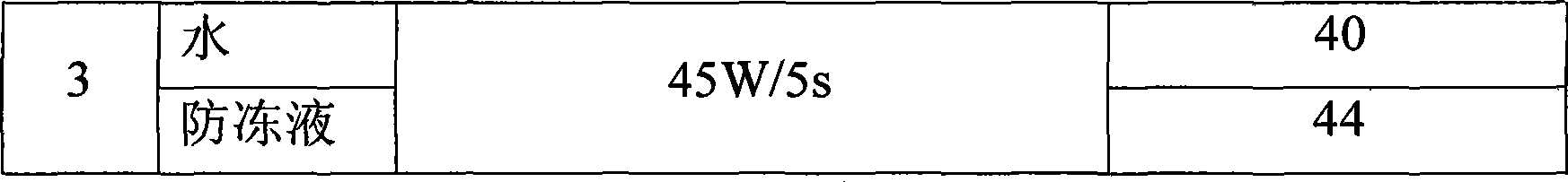

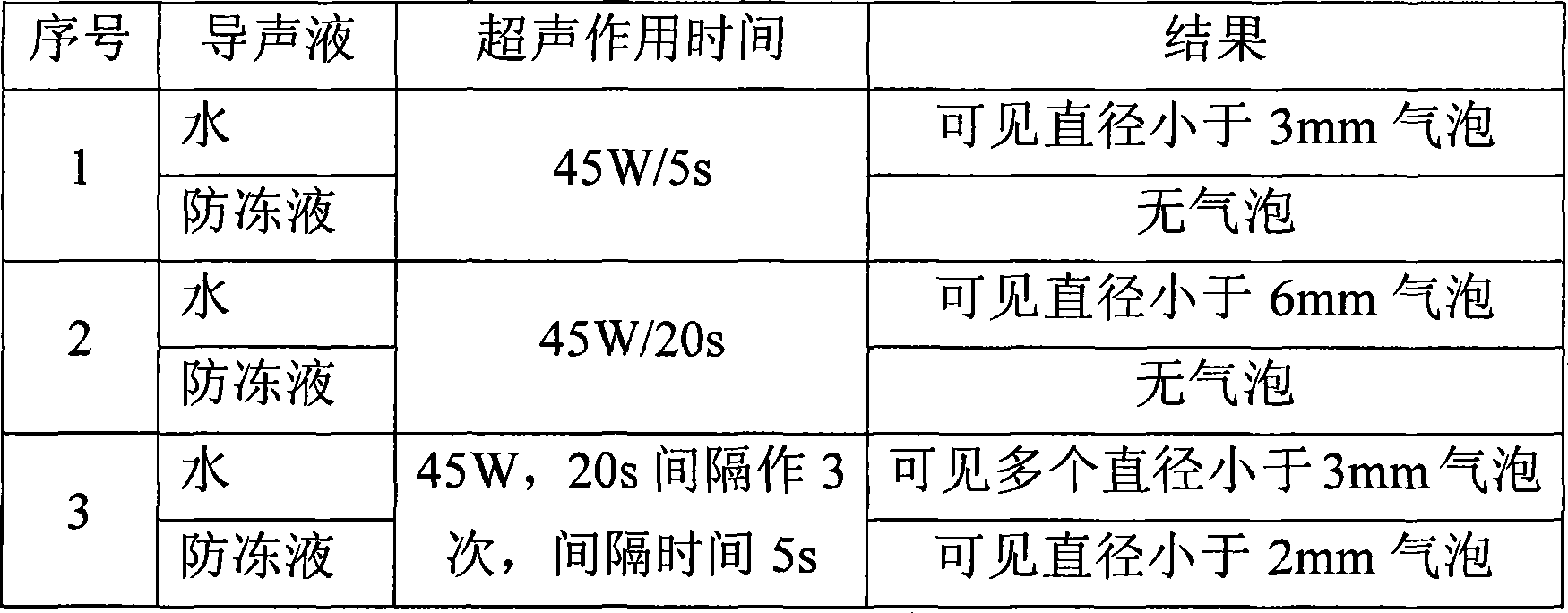

Novel use of anti-freezing fluid as sound guide liquid

InactiveCN101497783AExcellent sound conduction performanceEliminate generationUltrasound therapyHeat-exchange elementsUltrasound attenuationAnti freezing

The new application of antifreeze used as sound liquid relates to the new application of the antifreeze and aims at solving the problem that the prior sound liquid is easy to generate bubbles. The antifreeze is arranged between a sound wave emission point and a receiving point to be used as sound wave transmitting medium, especially to be used as sound wave transmitting medium in a sound shield on a curing head of a medical ultrasonic focusing therapy, thereby effectively reducing or eliminating the bubbles generated by the thermal effect, the mechanical effect and the cavitation effect of ultrasonic when the medical ultrasonic focusing therapy works, having the advantages of higher sound velocity and lower sound power attenuation, and being suitable for occasions applying the ultrasonic wave to use the antifreeze as the sound liquid.

Owner:绵阳索尼克电子有限责任公司

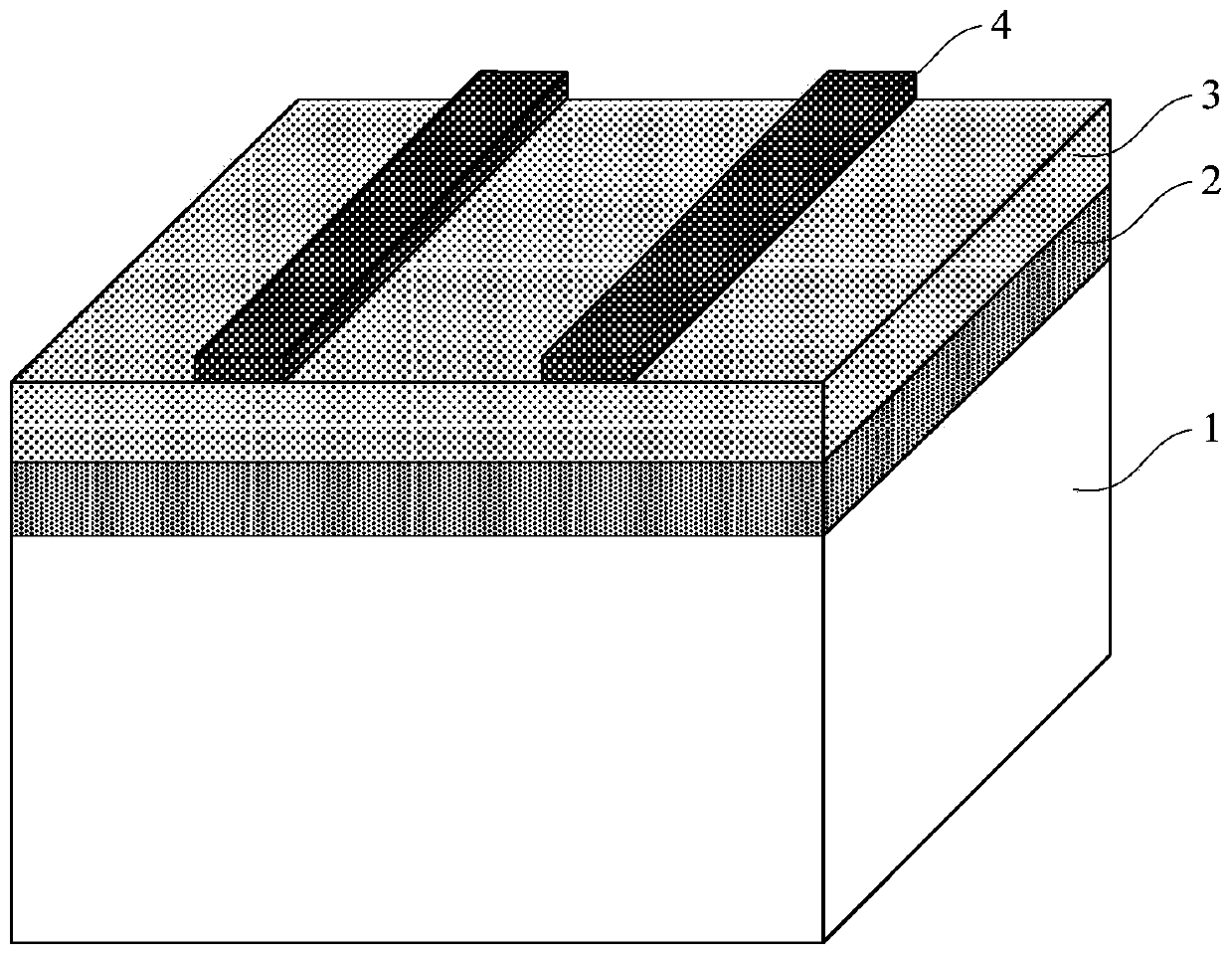

Lamb wave resonator with POI structure and manufacturing method of Lamb wave resonator

PendingCN112511128AHigh speed of soundHigh electromechanical coupling coefficientImpedence networksHigh bandwidthElectromechanical coupling coefficient

The invention provides a Lamb wave resonator with a POI structure and a manufacturing method of the Lamb wave resonator. The resonator includes at least one reflective layer including a high acousticvelocity substrate and a low acoustic velocity dielectric layer on the substrate, a piezoelectric layer bonded together with the dielectric layer on a side opposite the substrate, and an electrode onthe piezoelectric layer. The manufacturing method comprises the steps of providing a piezoelectric layer, and forming an IDT electrode on the piezoelectric layer; providing a substrate, and depositinga dielectric layer on the substrate; and performing low-temperature bonding on the dielectric layer and the piezoelectric layer. According to the invention, a Lamb wave S0 mode is excited, a high-frequency, high-bandwidth and low-insertion-loss Lamb wave resonator is realized, and the design requirements of high frequency, high electromechanical coupling coefficient, high Q value, low TCF value,no stray and the like are met at the same time.

Owner:GUANGDONG CANCHIP TECH CO LTD

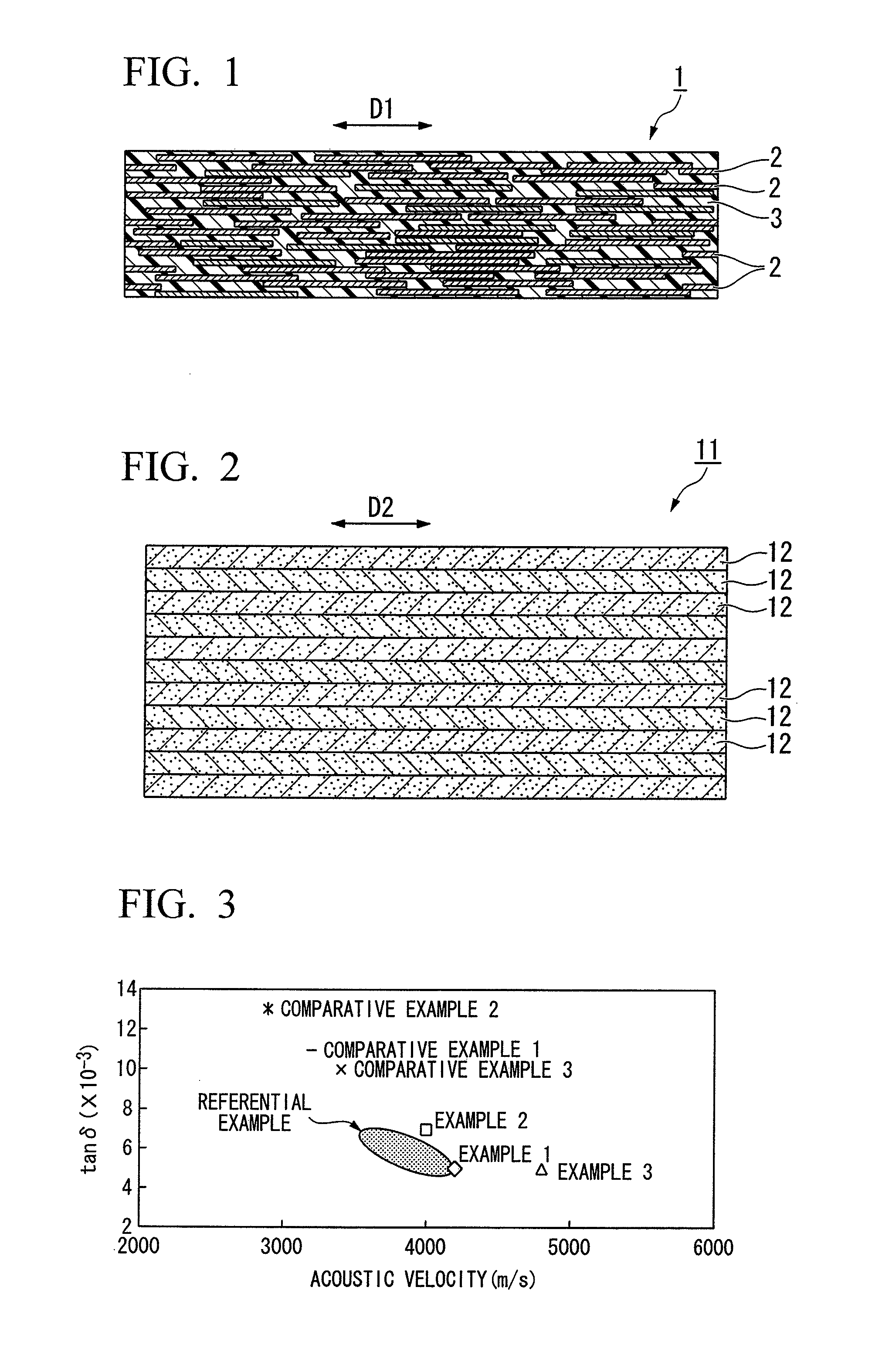

Acoustic timber for musical instrument

ActiveUS8217249B2Improve sound qualityReduce size changeWood working apparatusGlass/slag layered productsFiberEpoxy

An acoustic timber for use in an acoustic musical instrument is constituted of a plurality of woody members, such as woody fibers, woody veneers, blasted bamboo fibers, and defibrated bamboo fibers, whose fiber length is 50 mm or more. An epoxy resin is impregnated into the woody members with an impregnation factor of 5 weight-percent through 50 weight-percent. The woody members impregnated with the epoxy resin are joined together by way of heating and compressive molding so that the fibers thereof are uniformly aligned in the desired fiber-aligning direction.

Owner:YAMAHA CORP

Elastic wave device

ActiveUS20160352304A1Increase in acoustic velocityIncrease in fractional bandwidthImpedence networksVoltageHigher order mode

An elastic wave device includes a first IDT electrode on a first main surface of a LiNbO3 substrate, and a second IDT electrode on a second main surface thereof. The application of alternating voltages with reversed phases to each other to the first and second IDT electrodes excites plate waves in which SH waves in a high order mode predominate. The elastic wave device uses the plate waves in the high order mode in which the SH waves predominate.

Owner:MURATA MFG CO LTD

Composite substrate, composite film and preparation method thereof

ActiveCN112260660AEnhanced inhibitory effectImprove performanceImpedence networksComposite filmComposite substrate

The invention provides a composite substrate, a composite film and a preparation method and application of the composite substrate and the composite film. A trap enhancement layer is additionally arranged on one side of a trap layer near an interface of a trap layer insulating layer or an interface of a trap layer active layer; a trap enhancement layer insulating layer or a trap enhancement layeractive layer structure is formed, and doping atoms are doped in the trap enhancement layer, so compared with the trap layer, the trap enhancement layer has the advantages that the defect density is increased, the PSC inhibition effect is improved, the electric loss is reduced, and the sound velocity is improved; therefore, the sound velocity difference with the insulating layer / active layer is increased, the reflection effect of sound waves at the interface of the insulating layer trap enhancement layer or the interface of the active layer trap enhancement layer is enhanced, the sound wave leakage is reduced, the performance of the device is improved, and two performance improvement effects are realized through one-step process treatment.

Owner:JINAN JINGZHENG ELECTRONICS

High performance powdered metal mixtures for shaped charge liners

InactiveUS20100154670A1Reduce oxidationIncrease penetration depthExplosive chargesShaped chargeMaterial Perforation

Owner:HALLIBURTON ENERGY SERVICES INC

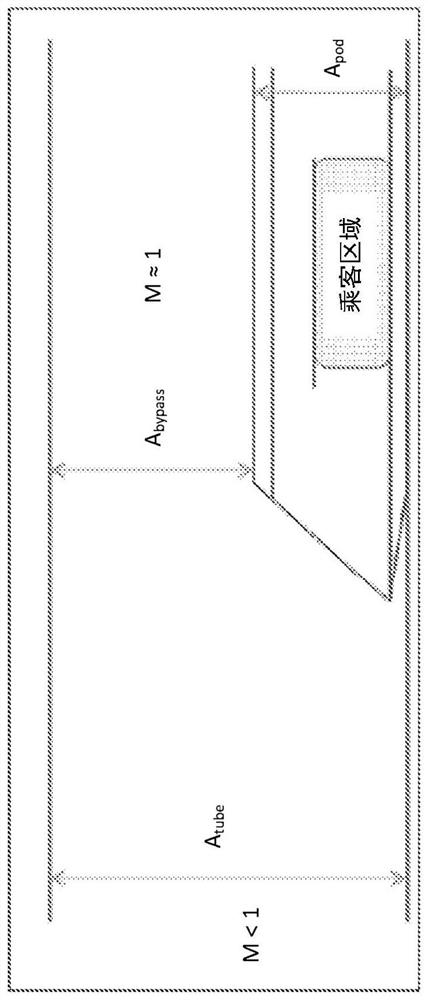

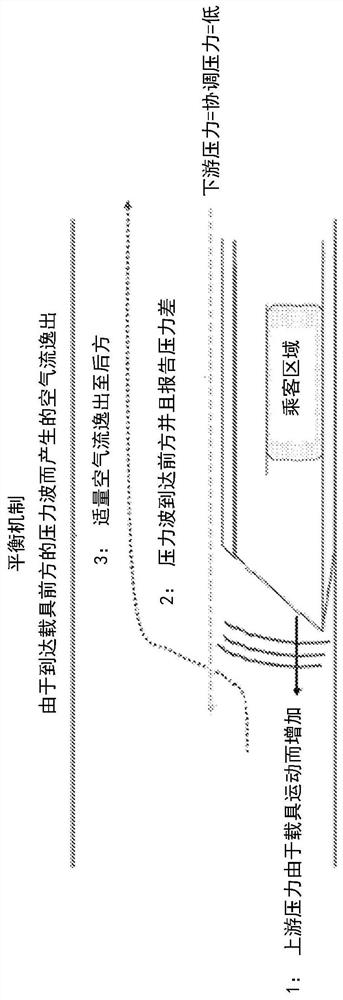

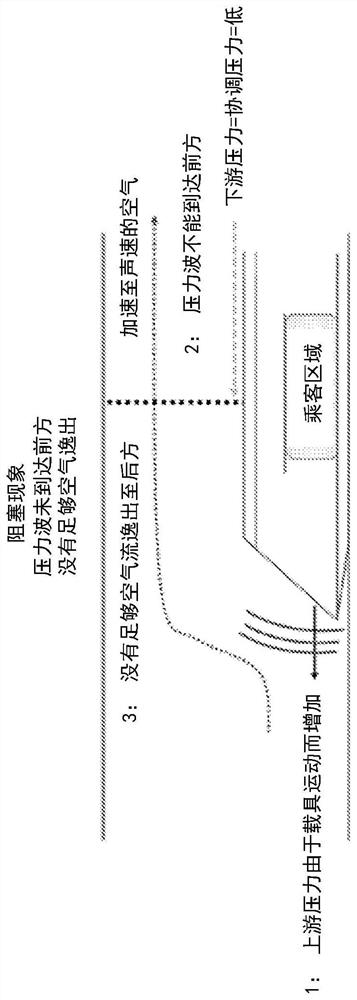

Tube transportation systems using a gaseous mixture of air and helium

PendingCN112638693ALow densityHigh speed of soundRailway tunnelsSliding/levitation railway systemsTransit systemPipeline transport

A tubular transportation system is disclosed for transporting one or more passengers or one or more cargos via a capsule along a predetermined route. The tubular transportation system has: (1) a plurality of substantially evacuated tubes arranged along the predetermined route, where each tube is maintained at a pressure that is below atmospheric pressure; and (2) means for maintaining within each tube in the plurality of substantially evacuated tubes, a gaseous composition comprising a mixture of a first percentage, x, of helium and a second percentage, (100-x), of air, and wherein the first percentage, x, of helium is picked based on a predetermined power value and a leak rate associated with the tube.

Owner:HYPERLOOP TRANSPORTATION TECHNOLOGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com