Surface acoustic wave device of multilayer film structure and preparation method thereof

A surface acoustic wave device and multi-layer film technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of restricting the frequency of SAW devices, high price, low phase velocity of surface acoustic waves, etc., and is conducive to large-scale promotion and application , The process conditions are convenient and easy to implement, and the effect of high electromechanical coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

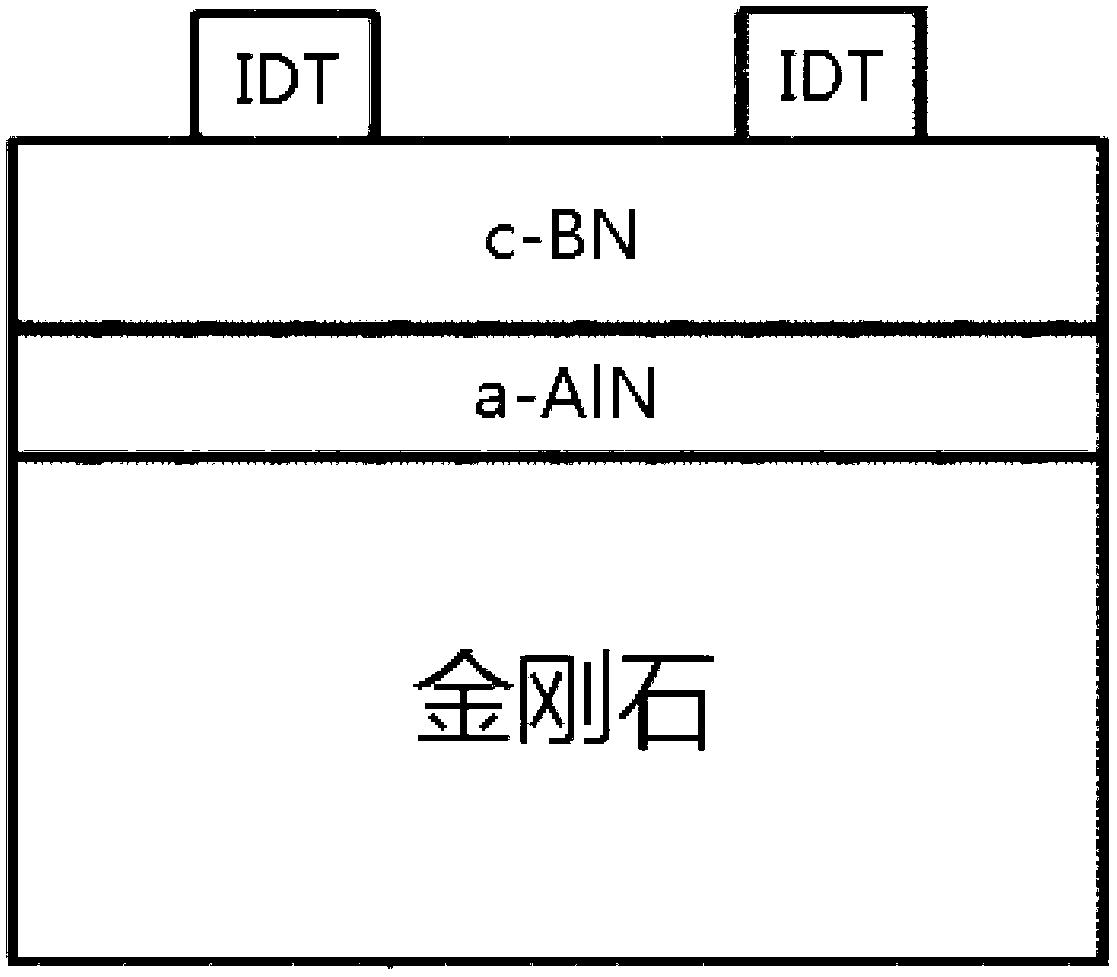

[0022] A surface acoustic wave device with a multilayer film structure, such as figure 1 As shown, the diamond is composed of CVD diamond film, a-axis preferentially oriented aluminum nitride (a-AlN) film, c-axis preferentially oriented boron nitride (c-BN) film and interdigital transducer (IDT). -Composite film structure, the thickness of described CVD diamond film is 20um, the thickness of a-AlN film is 300nm, the thickness of c-BN film is 400nm; Its preparation method comprises the following steps:

[0023] 1) Plasma treatment is performed on the surface of CVD diamond film to form a plasma-cleaned CVD diamond film surface. The specific method is: in the MOCVD deposition system, the surface of CVD diamond film is subjected to plasma treatment in a mixed gas atmosphere of nitrogen and argon , the nitrogen-argon volume flow ratio is 2:10, the filament voltage is 80V, the accelerating voltage is 100V, the temperature is 500°C, and the treatment time is 20min; this treatment ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com