Patents

Literature

225results about How to "High electromechanical coupling coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

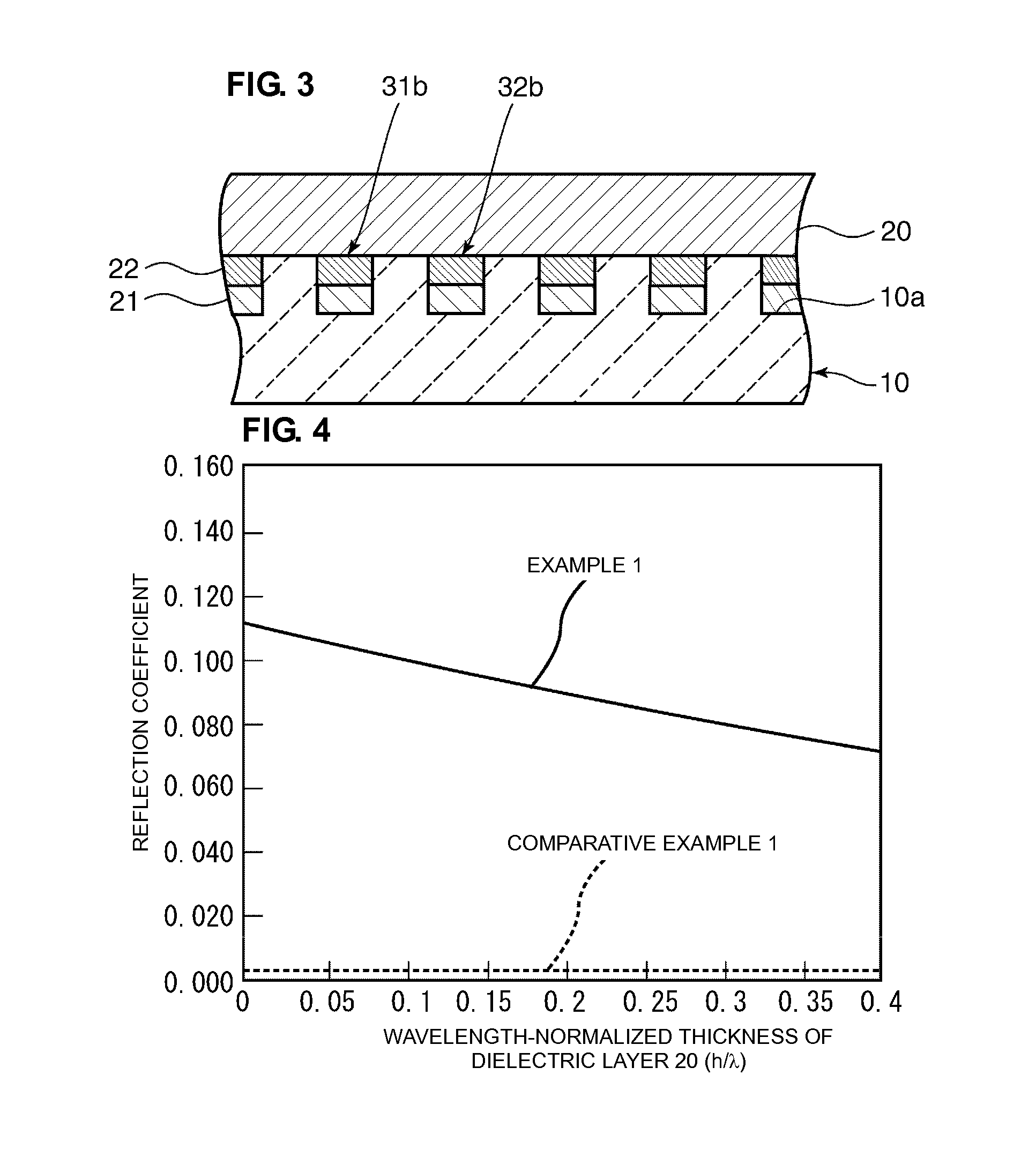

Boundary acoustic wave device

ActiveUS20090115287A1Efficiently vibrational energyLow boundary acoustic wave propagation lossImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectromechanical coupling coefficientAcoustic wave

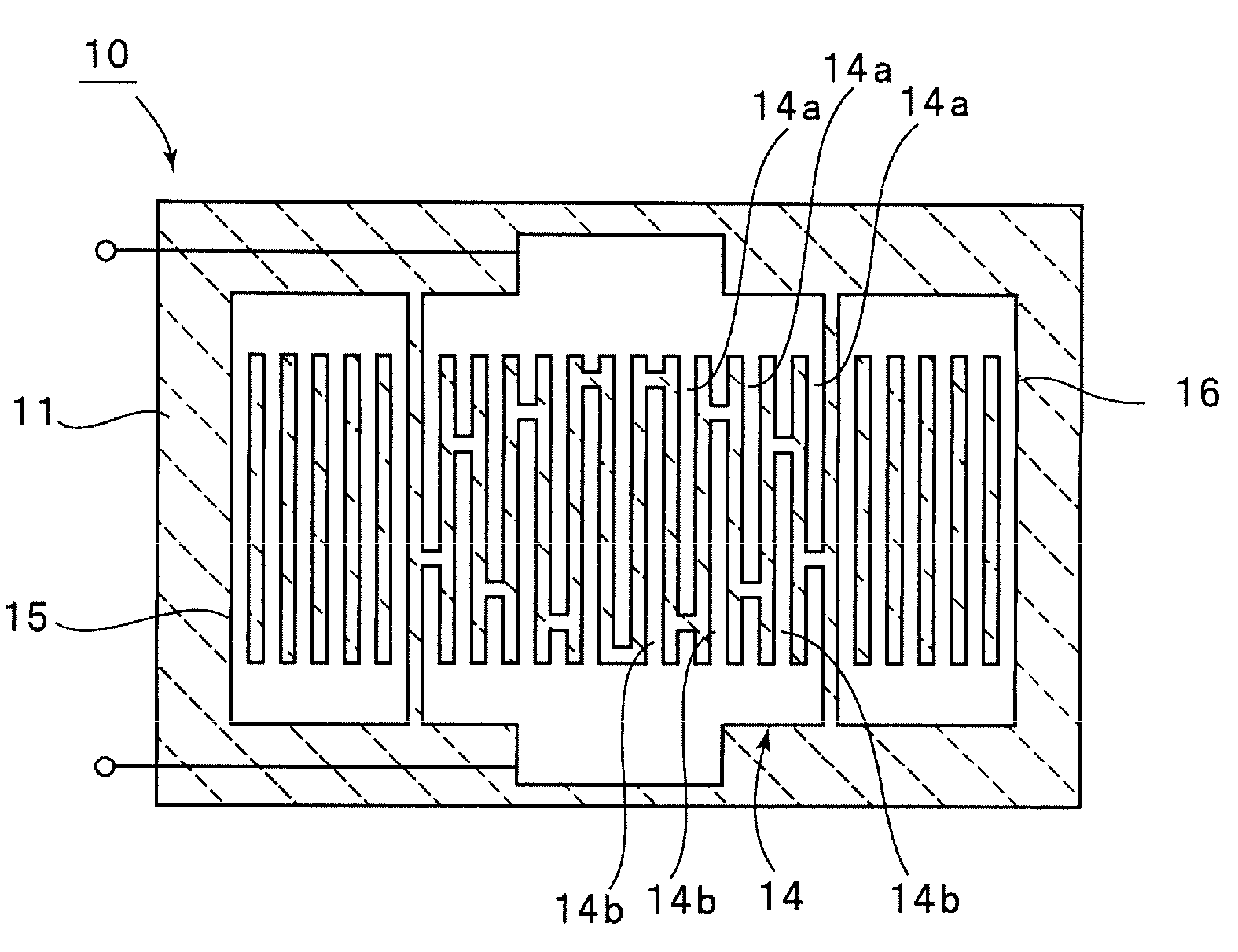

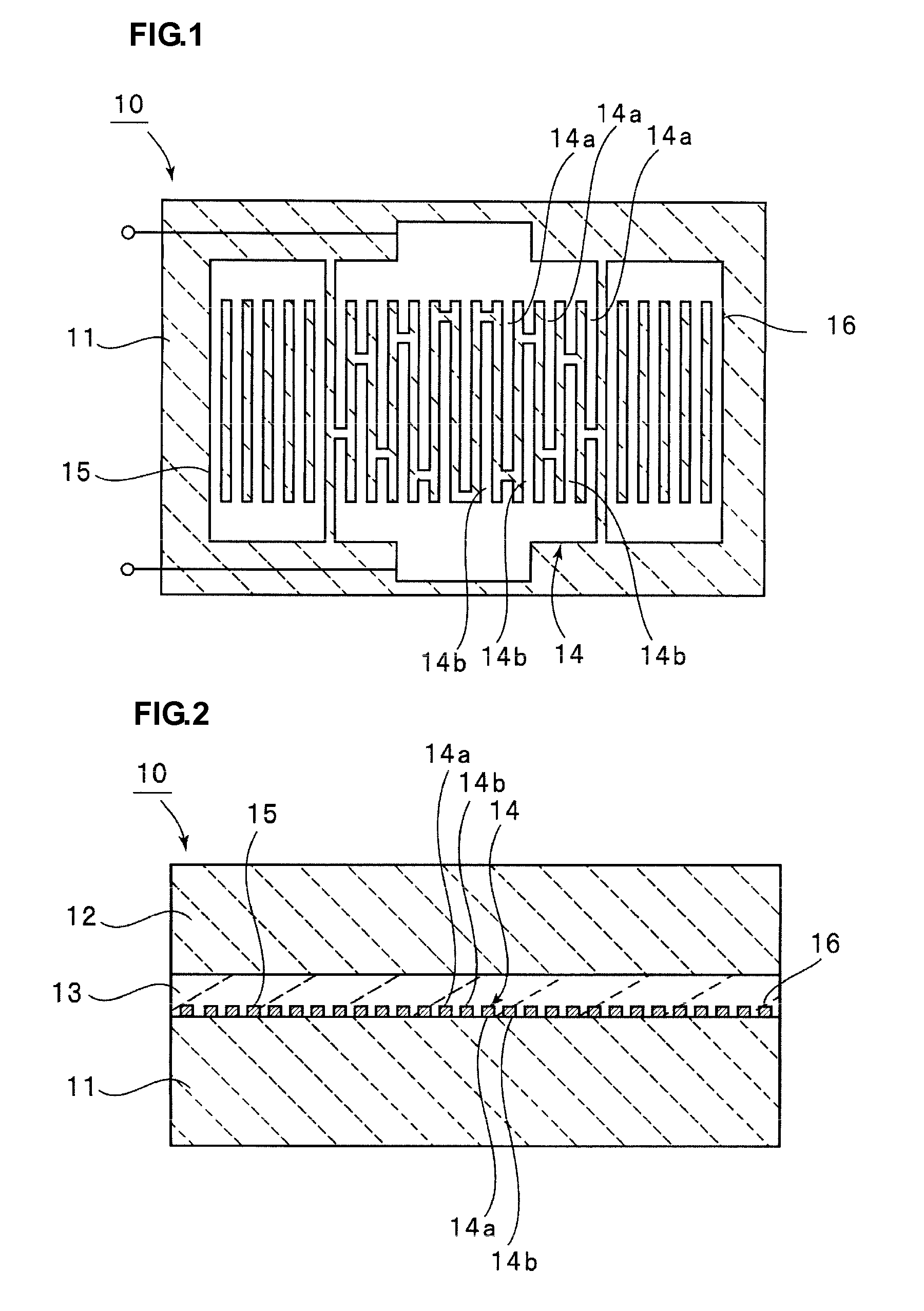

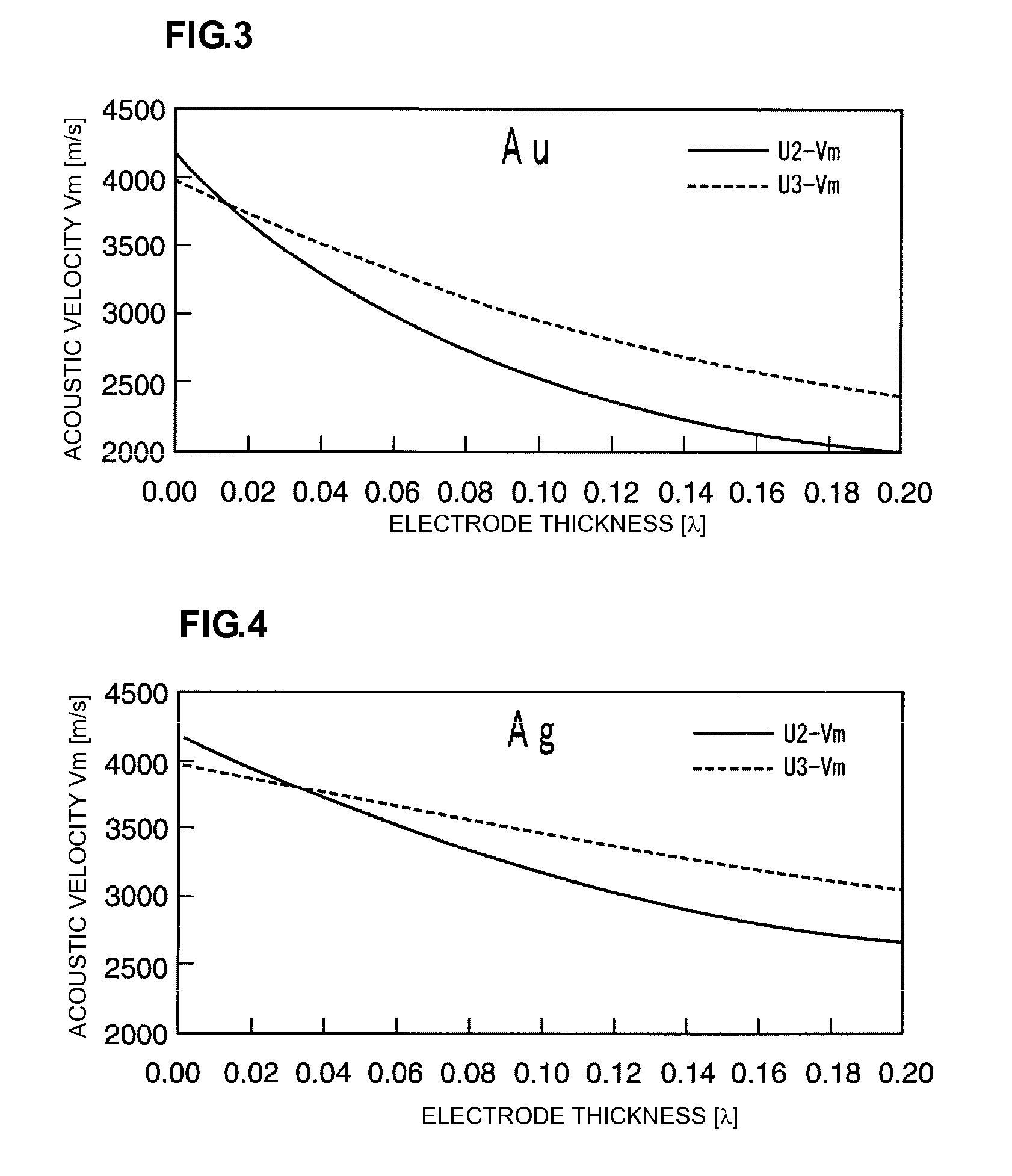

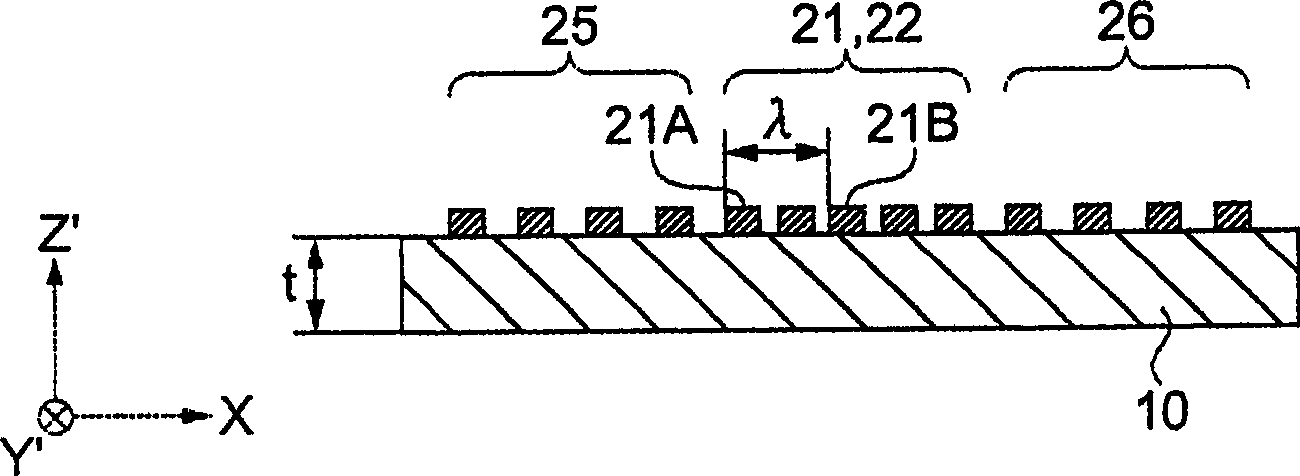

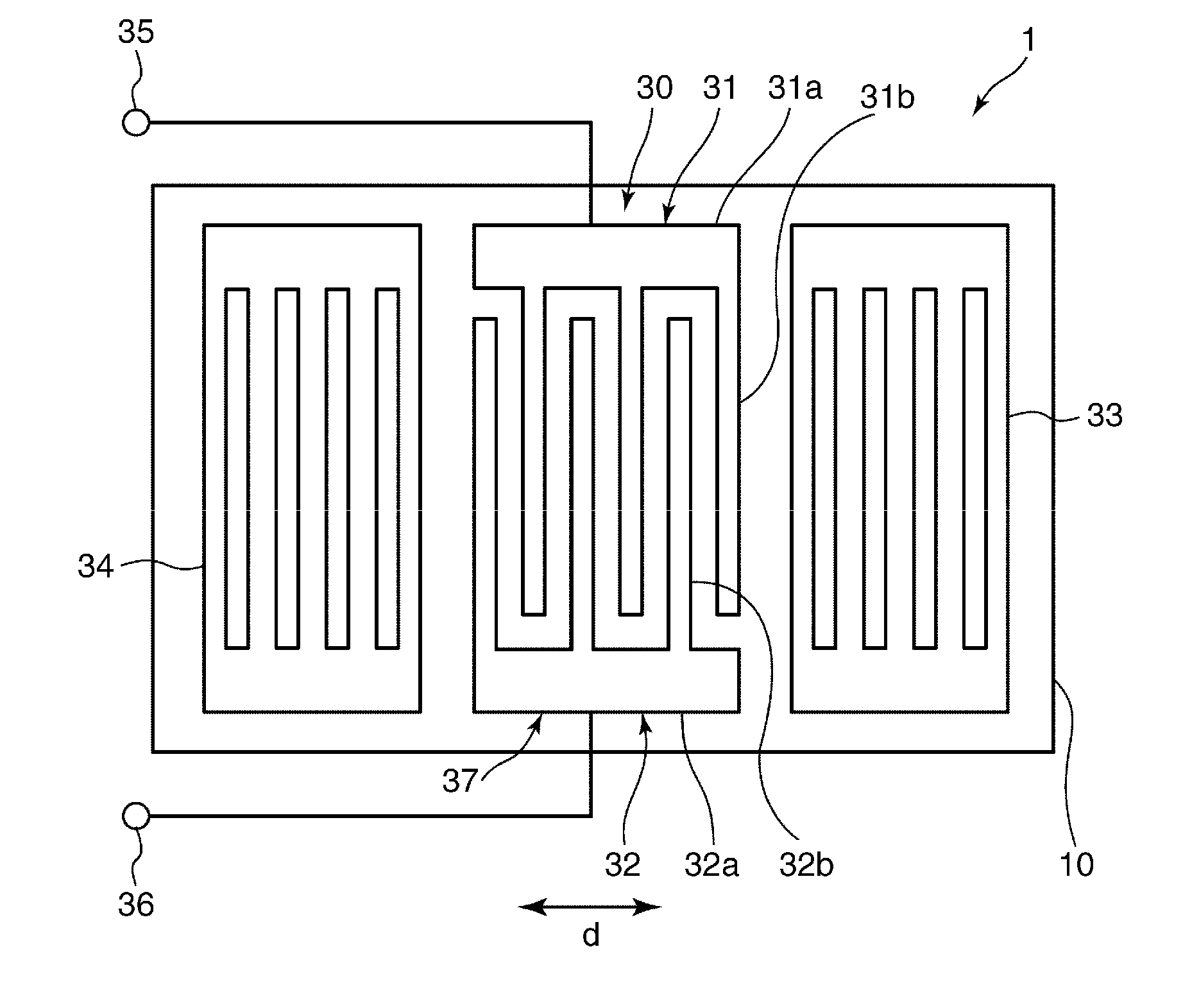

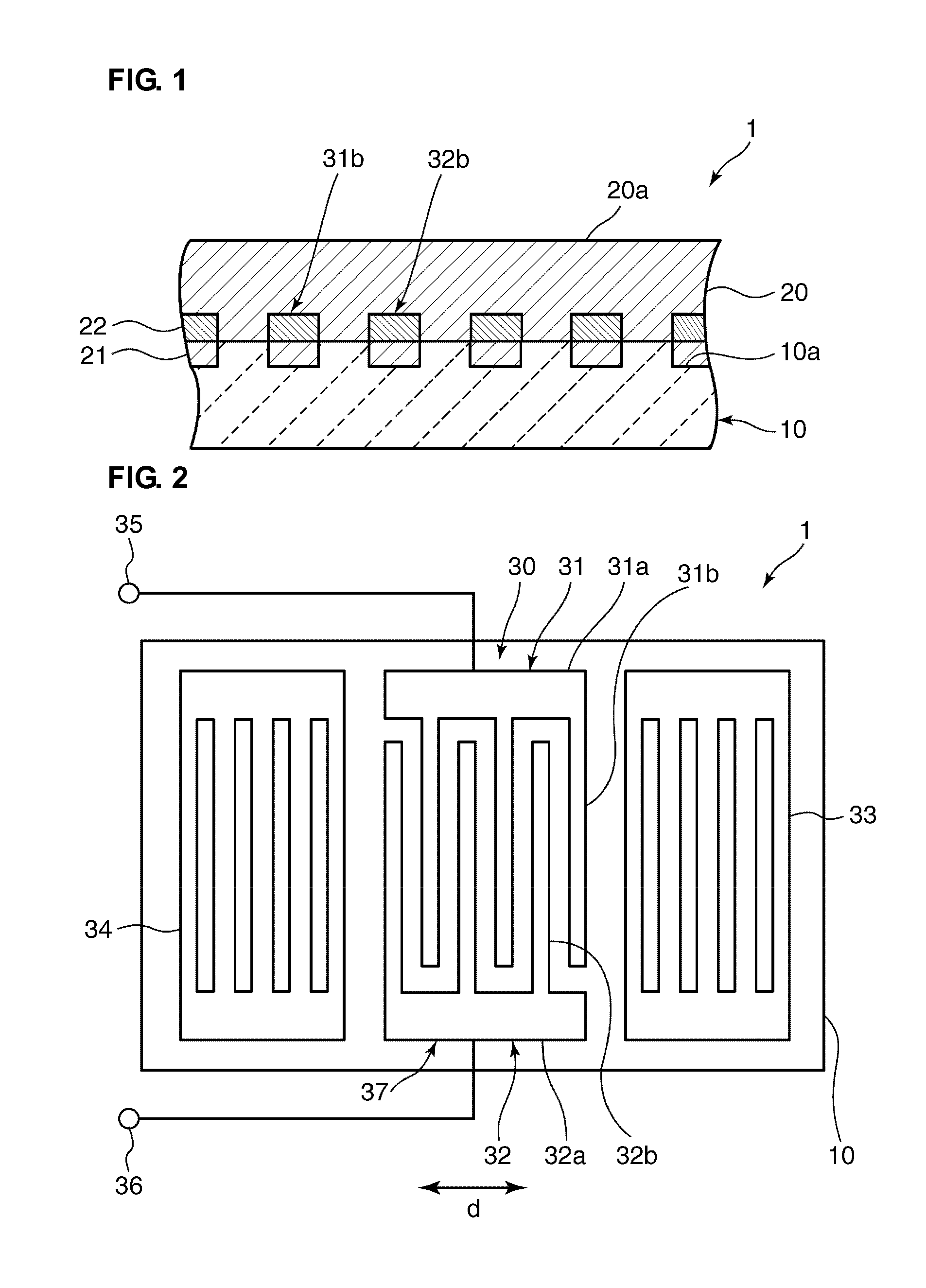

A boundary acoustic wave device efficiently traps the vibrational energy of boundary acoustic waves and exhibits a high electromechanical coupling coefficient, and is consequently not affected by higher-order modes. The boundary acoustic wave device includes a first medium having piezoelectric characteristics, a non-electroconductive second medium, and a third medium through which slow transverse waves propagate at a lower acoustic velocity than slow transverse waves propagating through the first and second media. The first medium, the third medium, and the second medium are stacked in that order. An IDT is disposed between the first medium and the third medium. The IDT includes a metal layer made of a metal having a density ρ in the range of about 3000 kg / m3 to about 21500 kg / m3. The IDT has electrode fingers arranged at a pitch of λ and has a thickness H1 satisfying the relationship 0.006λ≦H1≦0.2λ, and the third medium has a thickness H2 satisfying the relationship H1<H2≦0.7λ.

Owner:MURATA MFG CO LTD

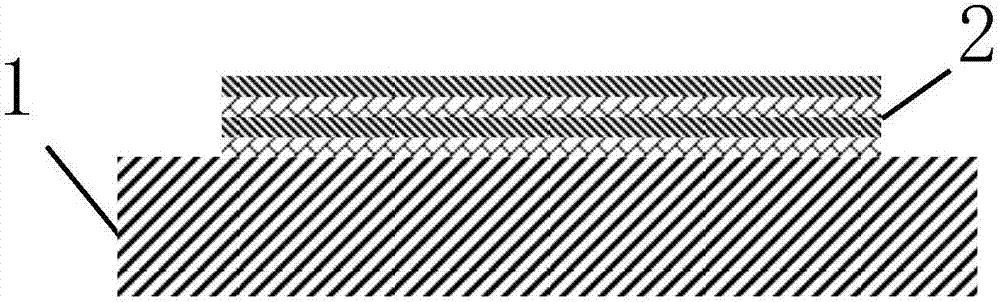

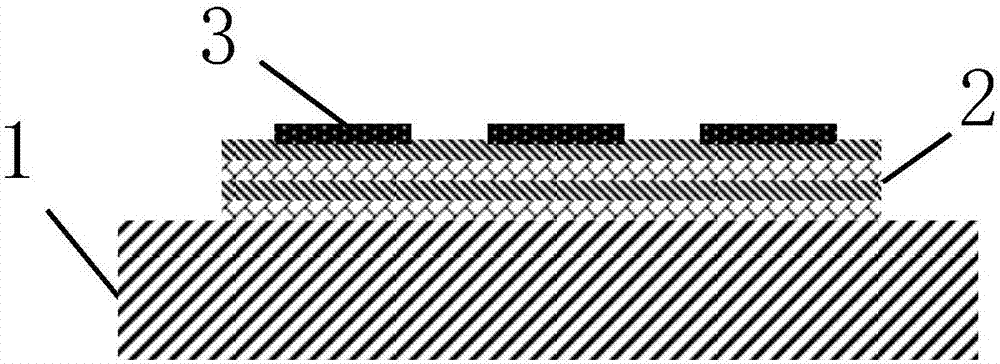

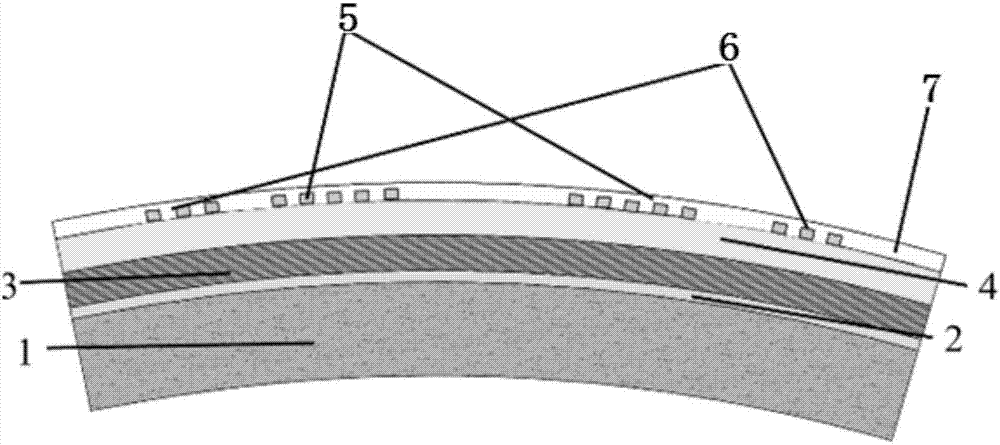

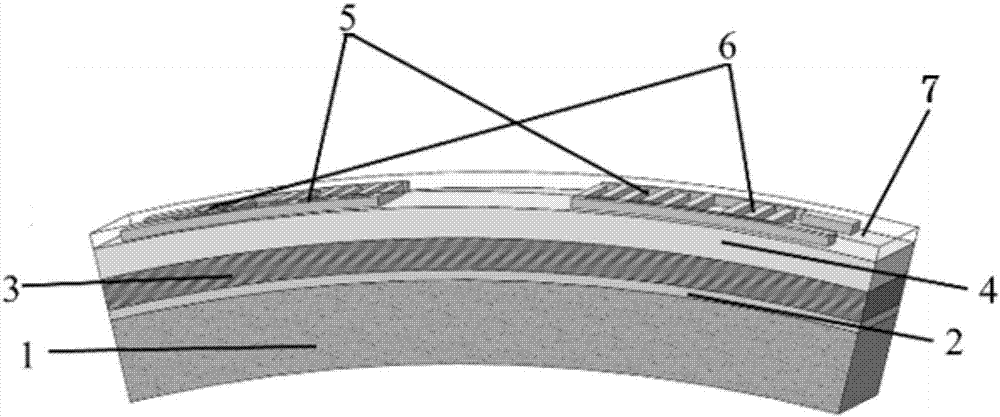

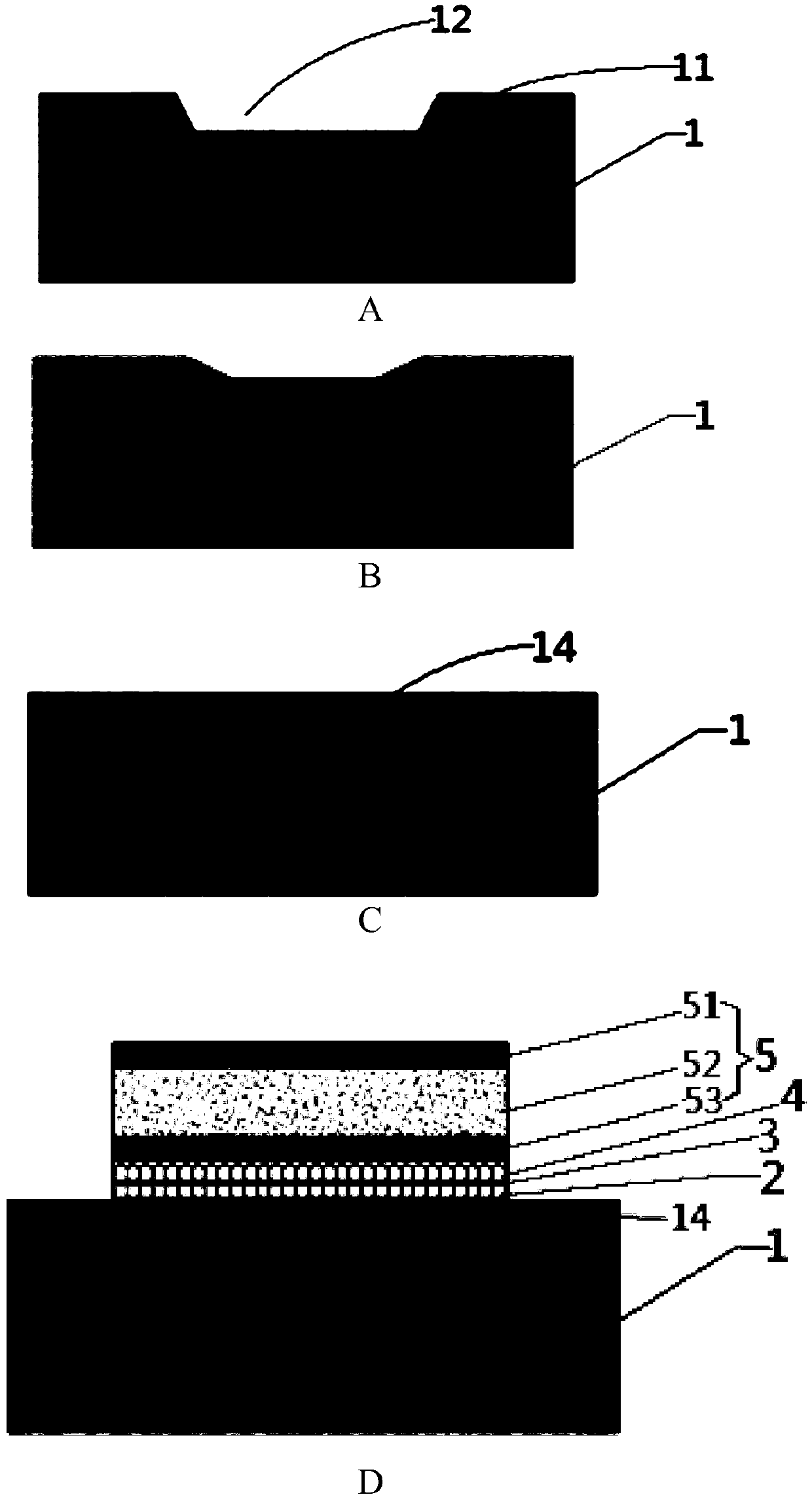

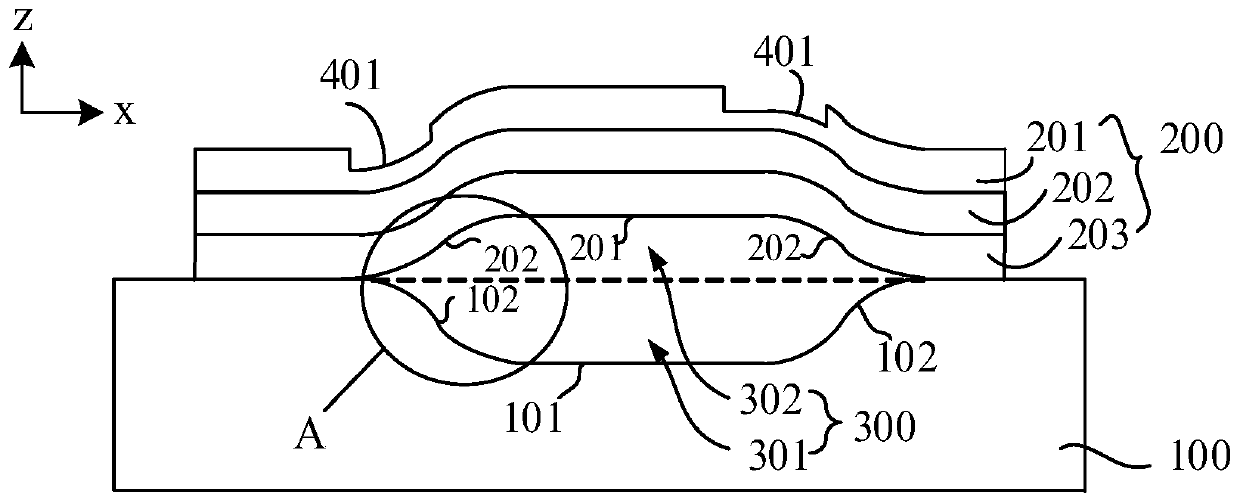

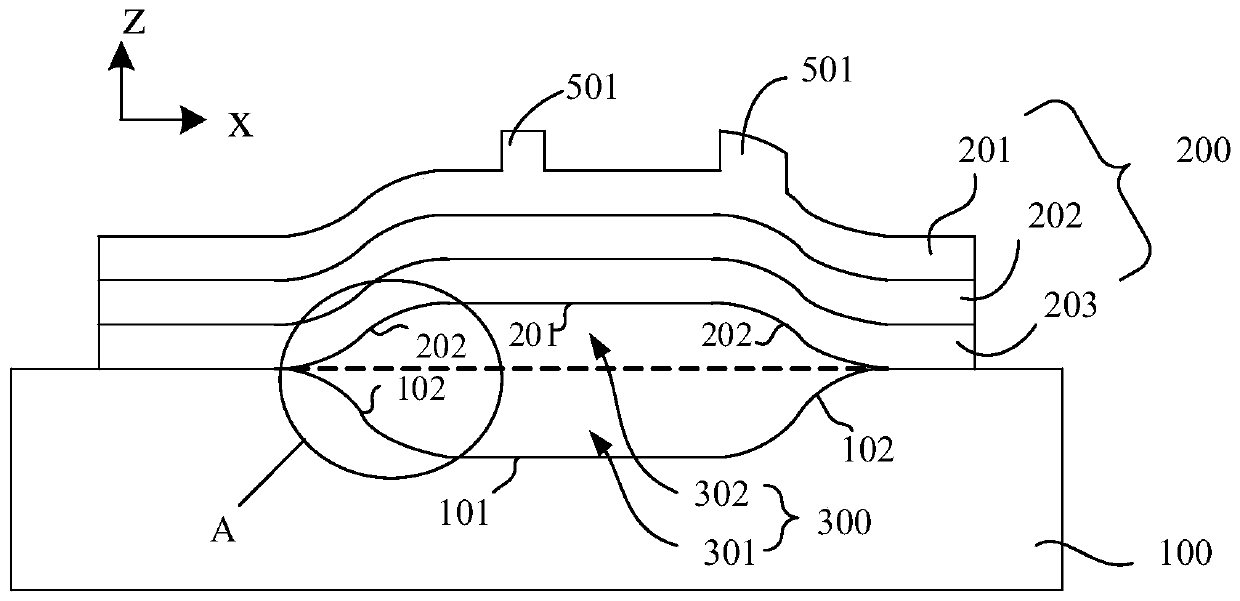

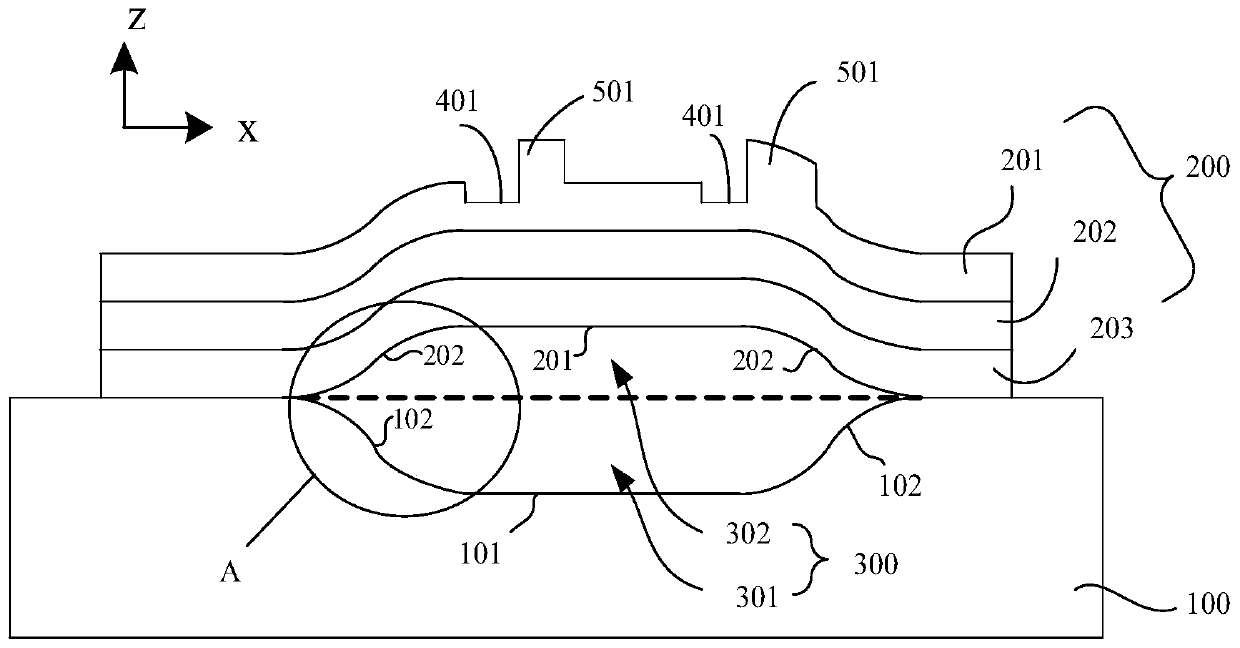

Bulk acoustic resonator based on mono-crystal piezoelectric film and preparation method thereof

ActiveCN107342748AImprove quality factor and electromechanical coupling coefficientHigh electromechanical coupling coefficientImpedence networksAcoustic reflectionData transmission

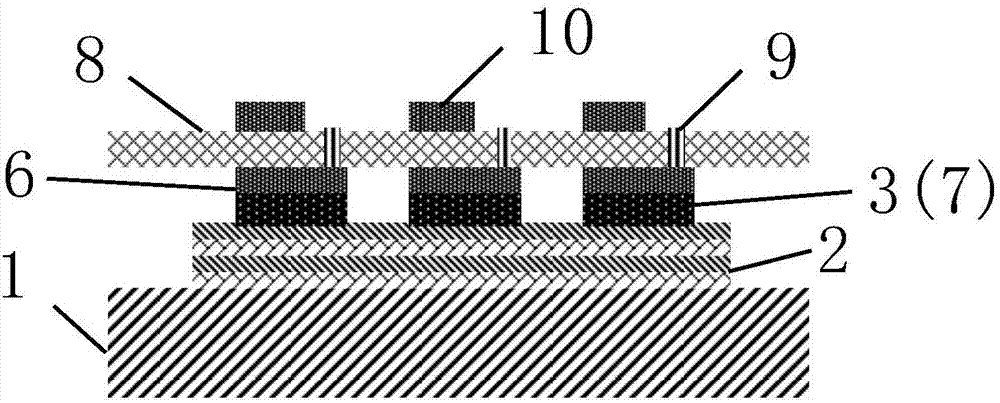

The invention discloses a bulk acoustic resonator based on a mono-crystal piezoelectric film. The bulk acoustic resonator includes a substrate, an acoustic reflection layer formed on the substrate, and a piezoelectric sandwich structure covering the acoustic reflection layer. The piezoelectric sandwich structure includes a lower electrode, a mono-crystal piezoelectric film, and an upper electrode. A metal film is deposited on the surface of the lower electrode and on the acoustic reflection layer, and a patterned bonding fulcrum is formed through a lithography process, and therefore, the piezoelectric sandwich structure and the acoustic reflection layer are bonded at low temperature. The mono-crystal piezoelectric film is obtained through crystal ion slicing, and the thickness of the film can be controlled by controlling the energy of ion implantation and the ion dose. The bulk acoustic resonator prepared in the invention has an electromechanical coupling coefficient above 44% and a quality factor above 2500, and can play an important role in the modern communication system featuring high-bandwidth and large-capacity data transmission.

Owner:ZHEJIANG UNIV

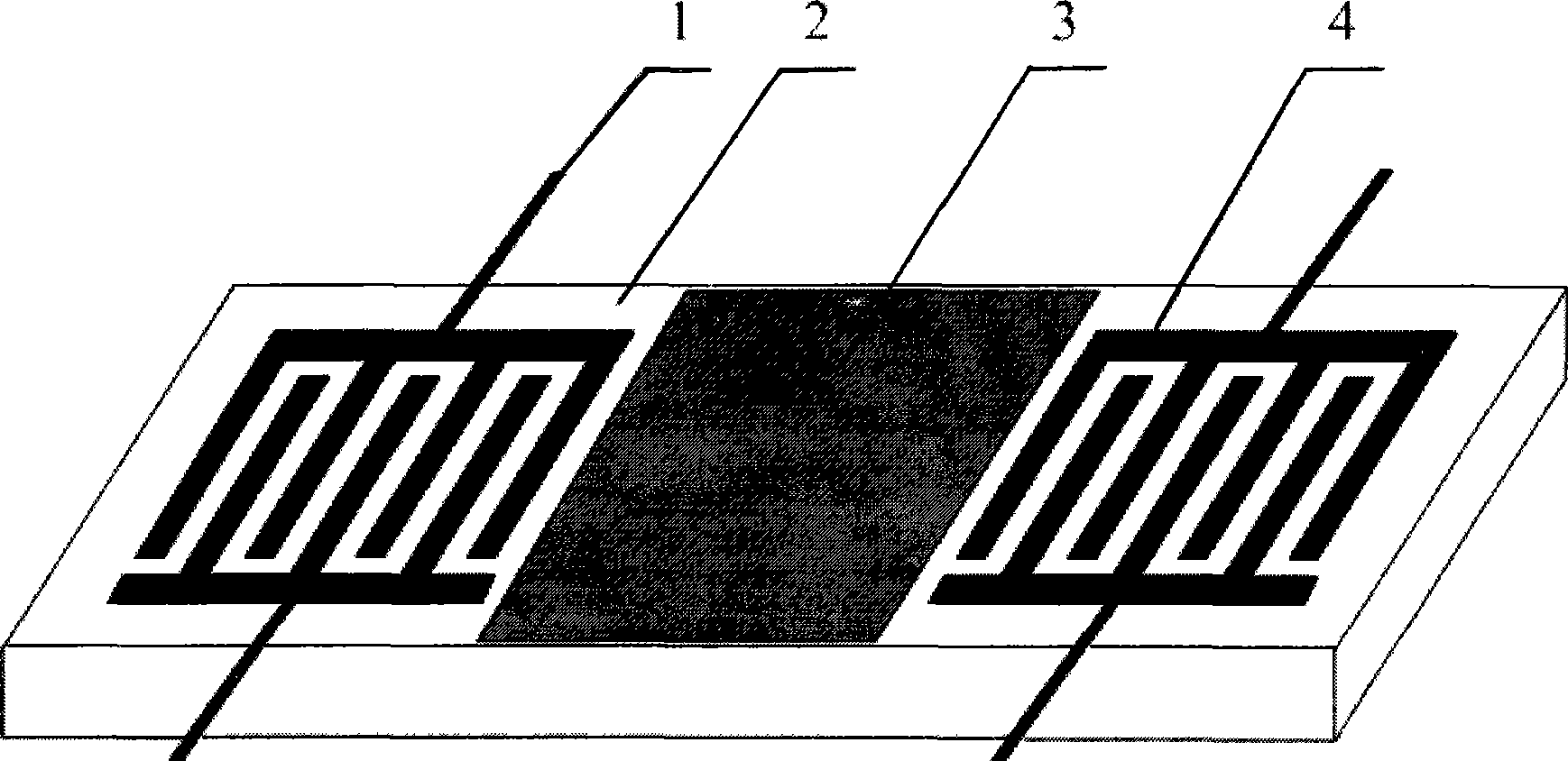

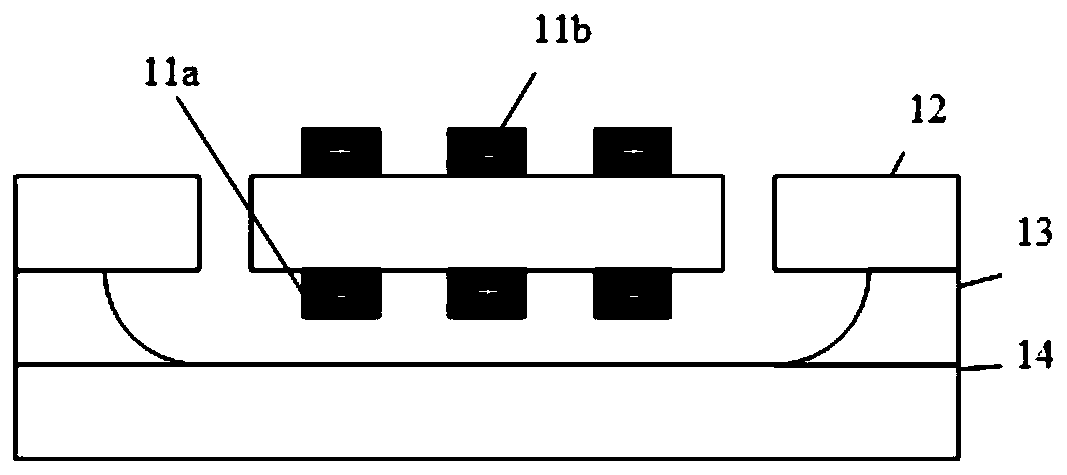

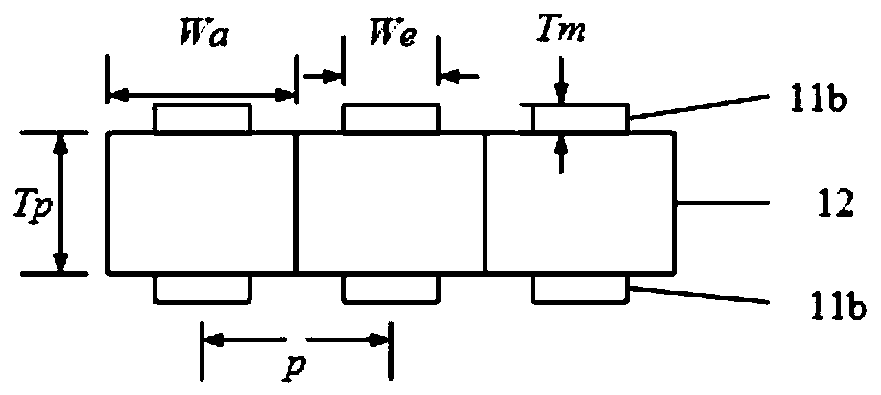

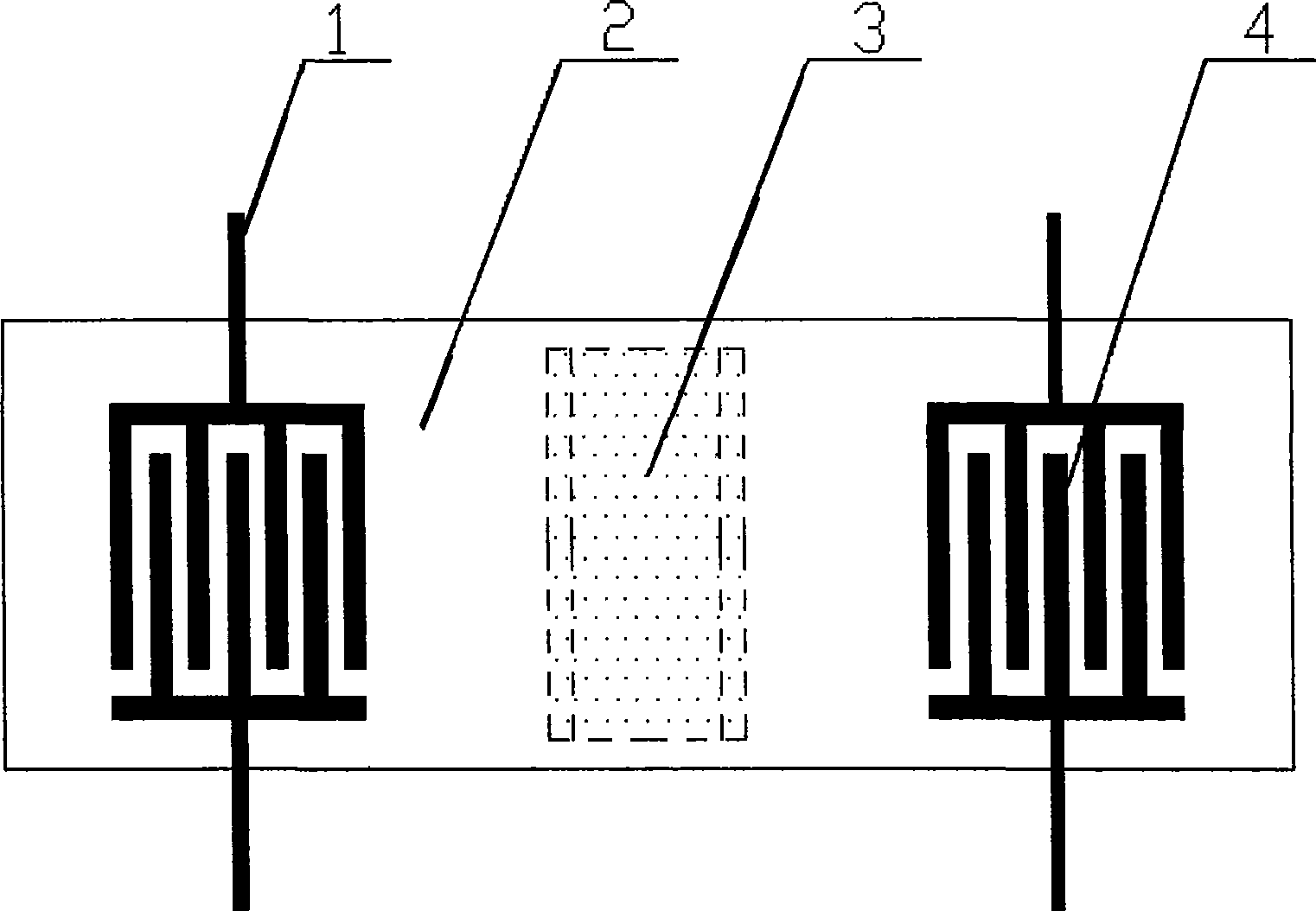

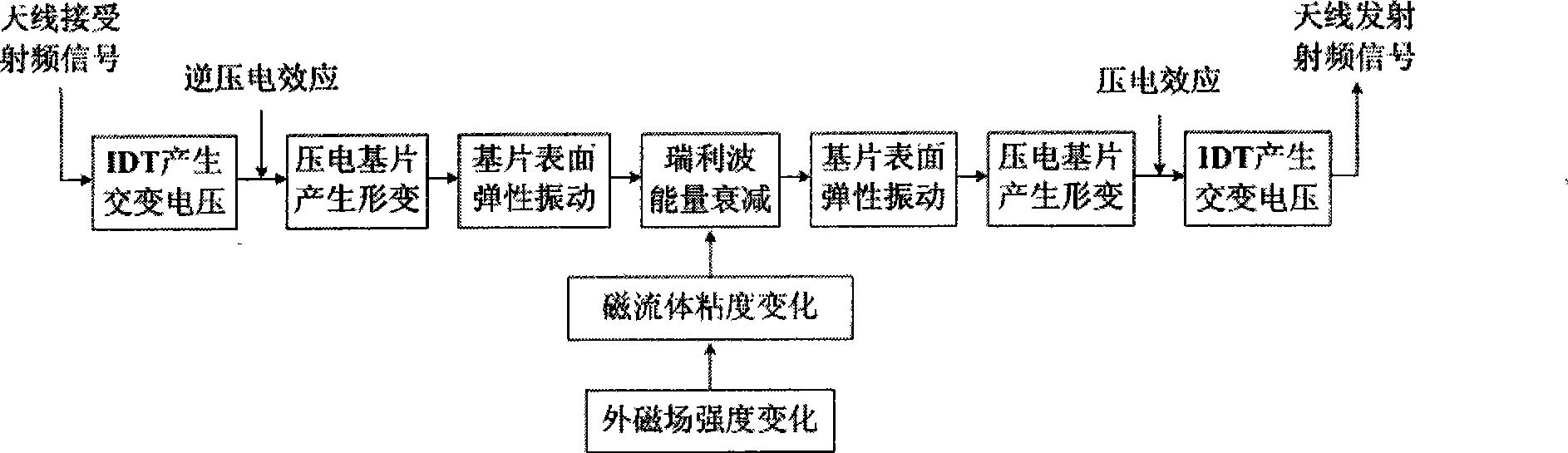

Thin film type structural magnetofluid-sonic surface wave integrated magnetic transducer

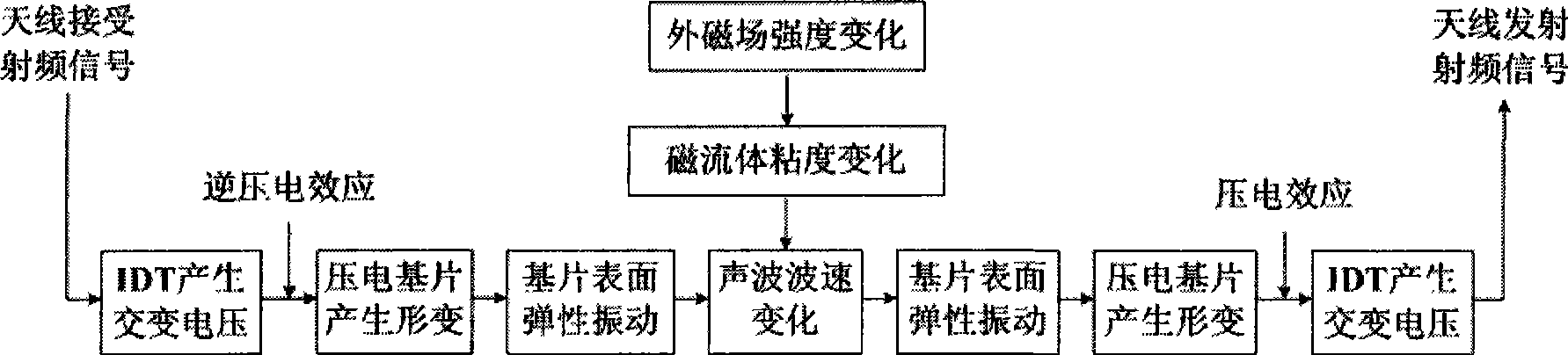

InactiveCN101504446AGood temperature characteristicsSmall propagation lossMagnitude/direction of magnetic fieldsMagnetic transducersMagnetic field magnitude

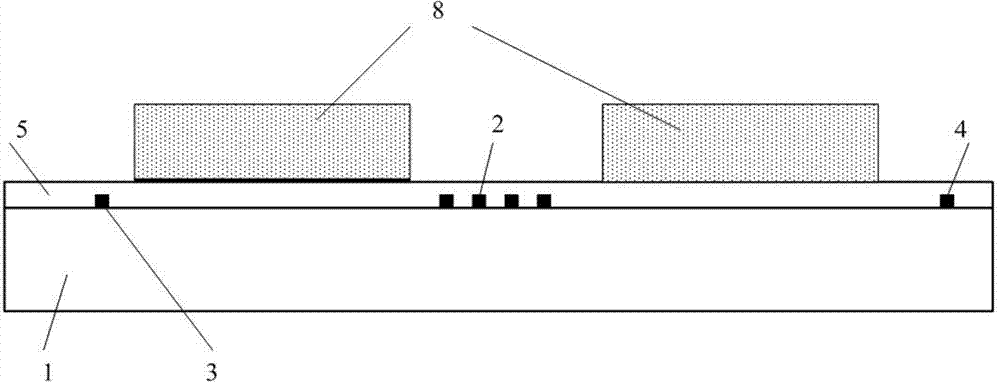

The invention discloses a sound surface wave integrated magnetic sensor for a magnetic fluid with a thin film structure, which comprises a piezoelectric substrate, two interdigital transducers (IDT), a magnetic fluid thin film and two sets of antennae for receiving and transmitting magnetic wave signals; the two interdigital transducers (IDT) are positioned at two ends of the substrate respectively; the magnetic fluid thin film is filled in a shallow groove between the two interdigital transducers on the surface of the sensor and encapsulates the groove; two sets of the antennae for receiving and transmitting the magnetic wave signals are connected to omnibus bars of the two IDTs respectively; the sensor can realize passive wireless high-precision real-time magnetic intensity measurement, and receive a radio frequency signal by the antennae, excite a horizontal shearing sound surface wave on the IDTs; the zero lagging response of the magnetic fluid on the change of an outer magnetic field instantaneously changes the delaying time of the sound surface wave delaying line, namely the viscosity change of the magnetic fluid changes the wave speed of the sound wave, converts the sound surface wave subjected to sound speed change into a magnetic wave by the IDTs and transmits the magnetic wave by the antennae. According to the corresponding relation of the delaying time and the magnetic filed intensity change, the magnetic filed change can be accurately measured.

Owner:SOUTH CHINA UNIV OF TECH

Bismuth sodium titanate based leadless piezoelectric ceramic and preparation technique thereof

InactiveCN101462875AImprove performanceHigh electromechanical coupling coefficientPiezoelectric/electrostrictive/magnetostrictive devicesAlkaline earth metalElectromechanical coupling coefficient

The invention discloses a sodium bismuth titanate based lead-free piezoelectric ceramic and a preparation process thereof. The general formula of the piezoelectric ceramic composition is (1-x)(Na0.5Bi0.5)1-aMaTiO3-xNaNbO3, wherein, x is the mol content of NaNbO3 in a ceramic system, a is the atom number of composite ions (Na0.5Bi0.5) which are replaced by M in (Na0.5Bi0.5)TiO3, x is not less than 0 but less than 0.3, a is more than 0 but less than 0.3, and M represents divalent alkaline earth metal elements Ba, Sr and Ca. As a secondary isostatic pressing forming method is adopted in the preparation process, the piezoelectric ceramic has the advantages of simple operation, high stability and low cost; and the method helps easily obtain high-density microcrystal ceramic materials, obviously improve the piezoelectric parameter and electromechanical coupling factor of the materials, and meet the practical requirement of the piezoelectric ceramic materials used in a micro-displacement actuator.

Owner:XIAN UNIV OF SCI & TECH

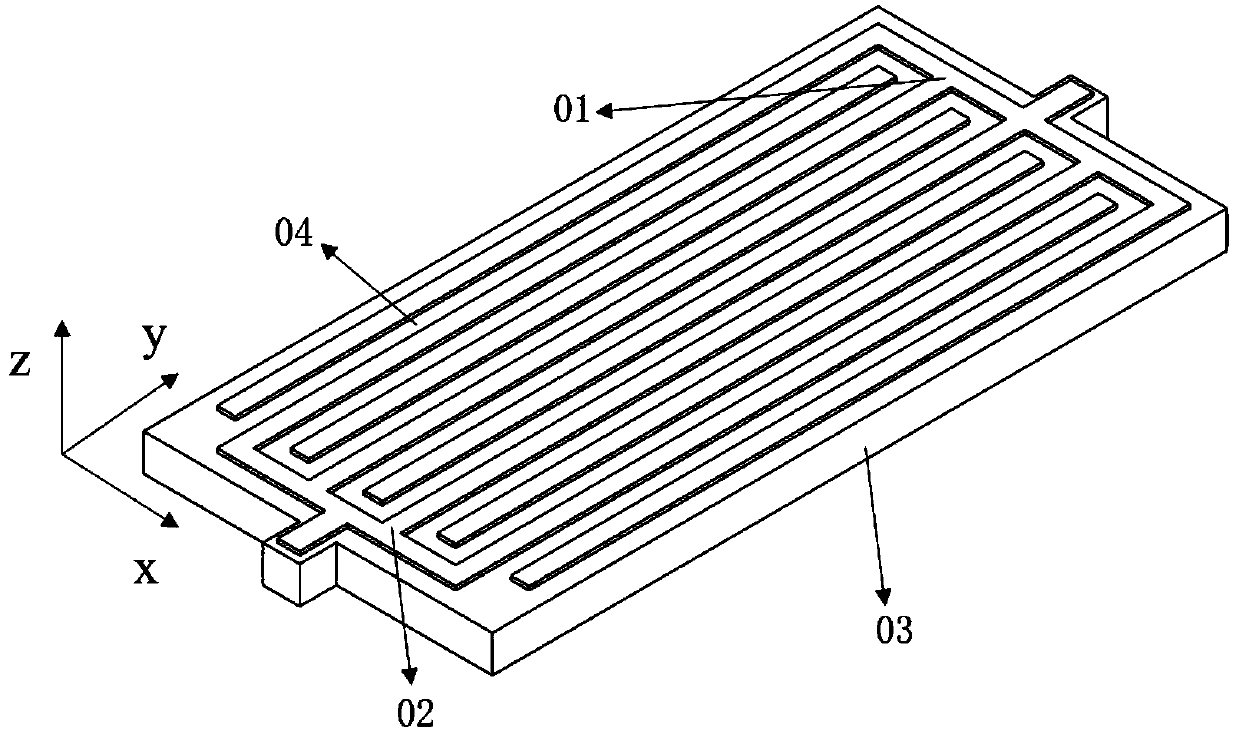

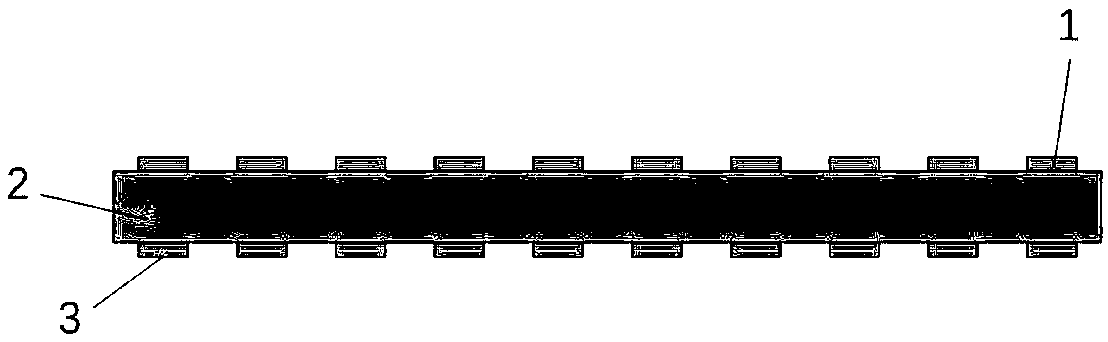

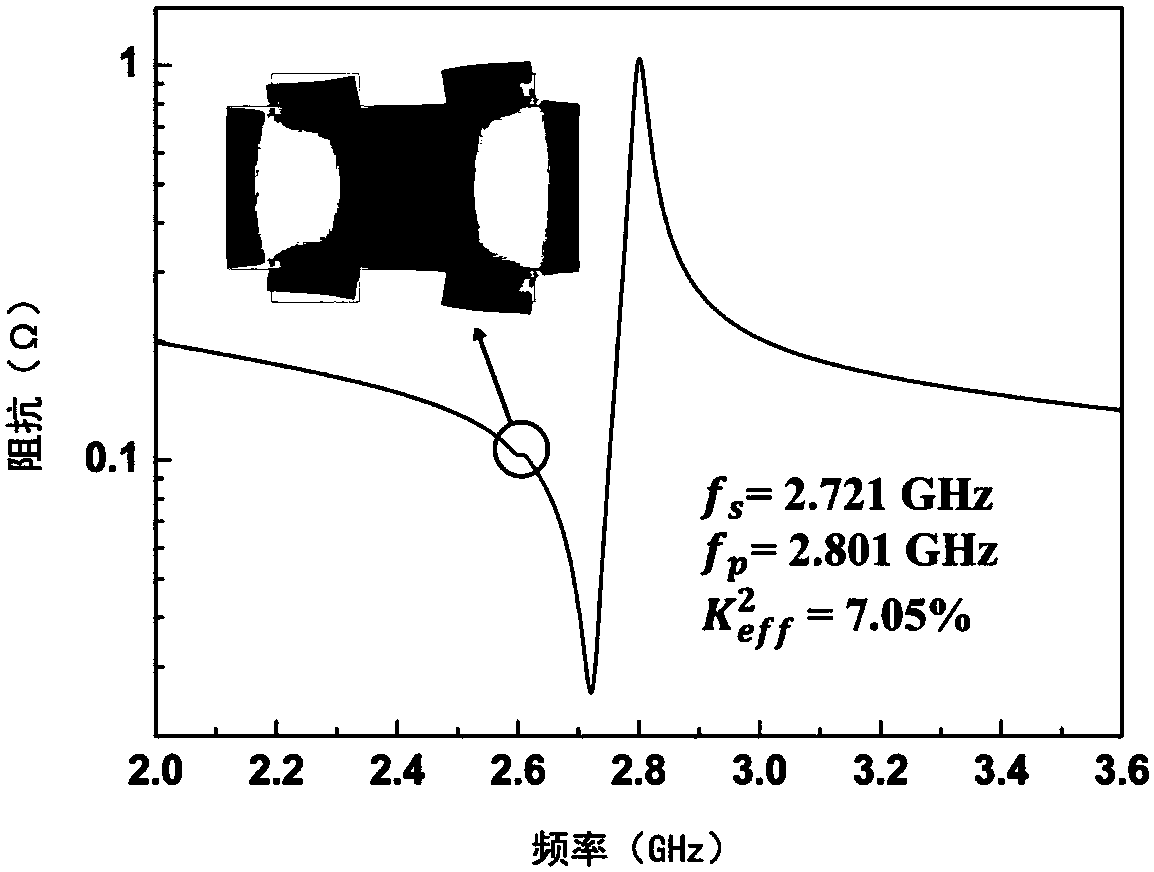

Two-dimensional coupled radio frequency piezoelectric resonator and preparation method thereof

PendingCN110166012AHigh electromechanical coupling coefficientImpedence networksElectromechanical coupling coefficientResonance

The invention discloses a two-dimensional coupled radio frequency piezoelectric resonator and a preparation method thereof. The radio frequency piezoelectric resonator comprises a piezoelectric layerused for fixing the interdigital electrode, and the piezoelectric layer is fixed on the silicon substrate. An upper electrode and a lower electrode of the interdigital electrode are respectively fixedon the upper side and the lower side of the piezoelectric layer, the interdigital electrode positioned on the continuous piezoelectric layer on the cross section is a resonance unit, and at least oneresonance unit is arranged on the piezoelectric layer. The preparation method comprises the following steps: growing a sacrificial layer on a silicon substrate, or directly taking the upper layer ofthe silicon substrate as the sacrificial layer; plating a lower electrode on the surface of the sacrificial layer; growing a piezoelectric layer on the surface of the lower electrode; aligning a lowerelectrode on the upper surface of the piezoelectric layer and plating an upper electrode; etching the resonant unit; and etching the sacrificial layer at the bottom of the lower electrode to form a cavity between the lower electrode of the piezoelectric layer and the silicon substrate below the lower electrode. Electromechanical coupling coefficient of the two-dimensional coupled radio frequencypiezoelectric resonator is increased to 7%-11%.

Owner:SHANGHAI TECH UNIV

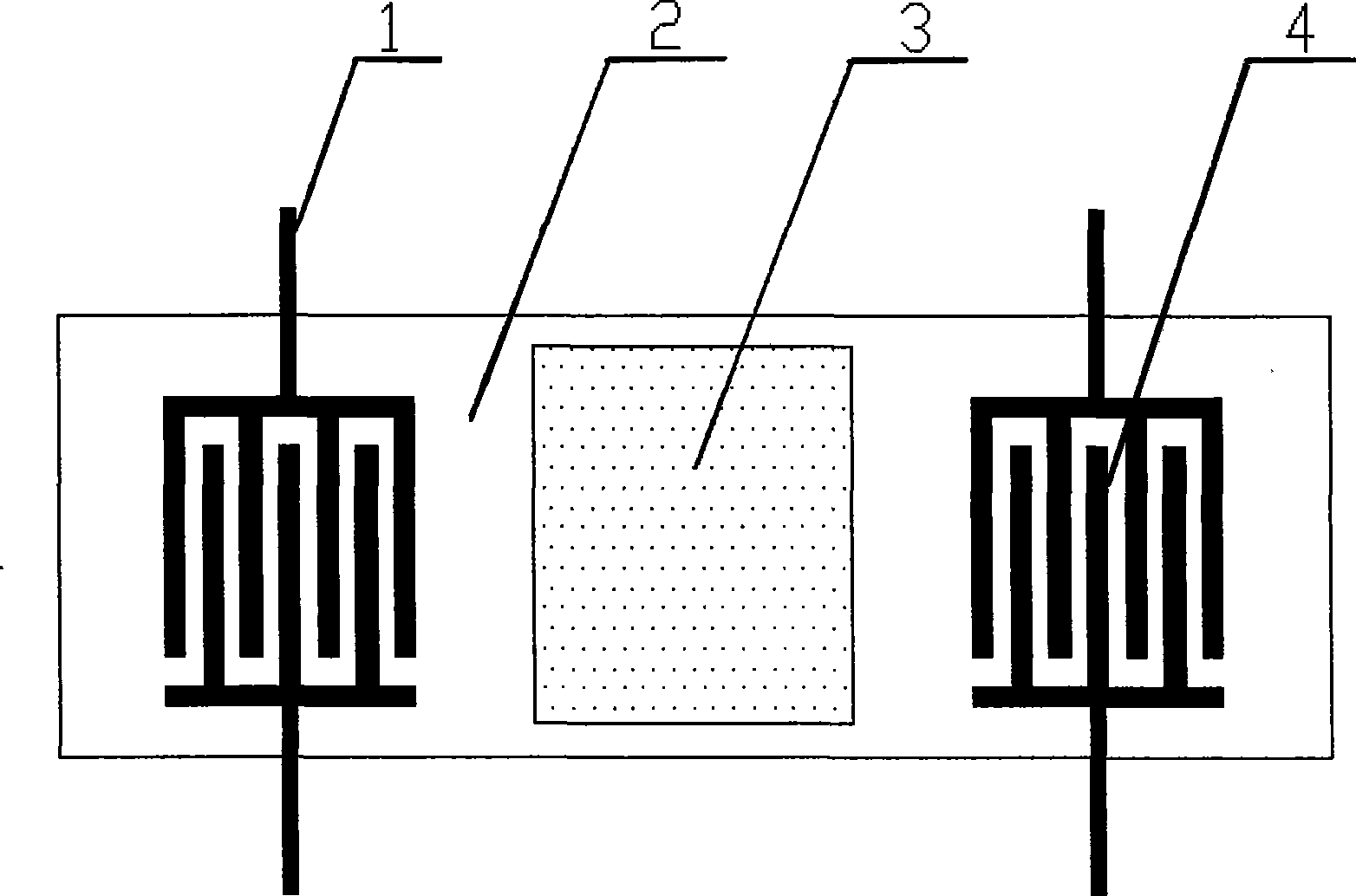

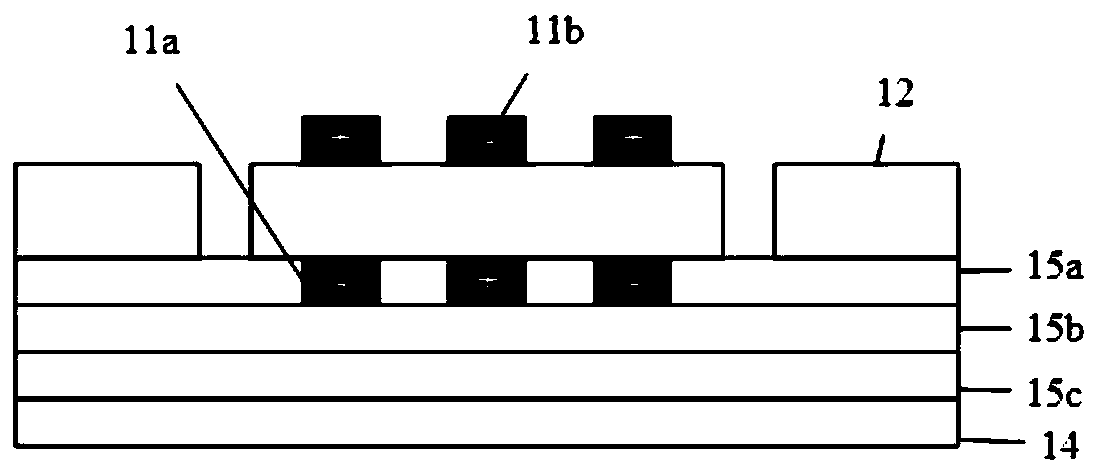

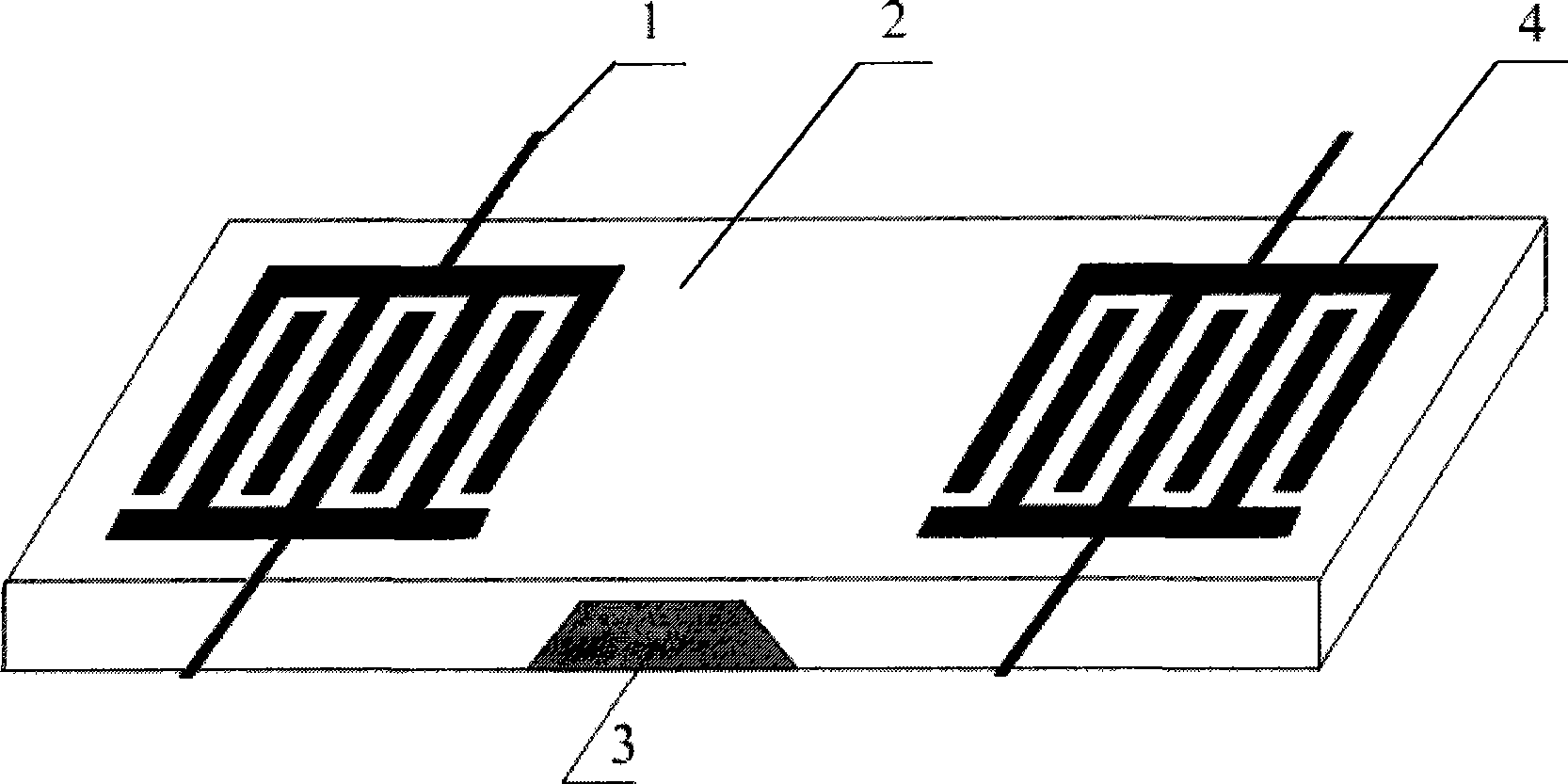

Back-trough type structural magnetofluid-sonic surface wave integrated magnetic transducer

InactiveCN101504445AGood temperature characteristicsSmall propagation lossMagnitude/direction of magnetic fieldsElectricityMagnetic transducers

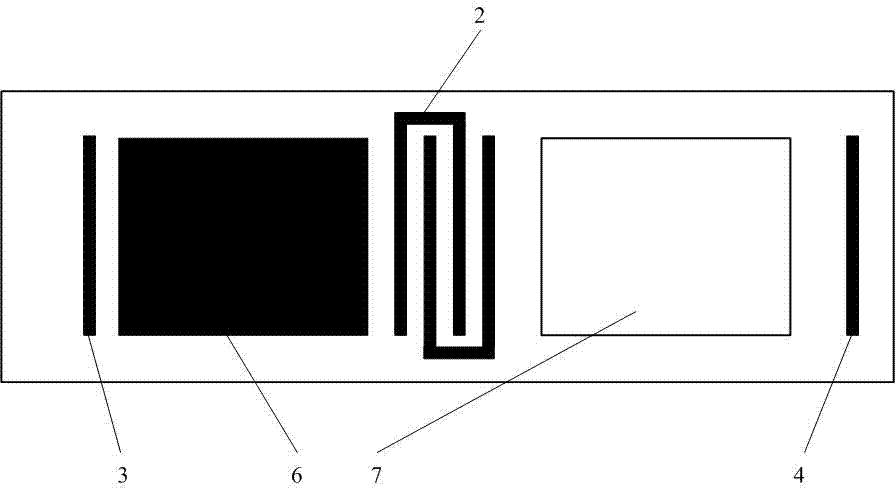

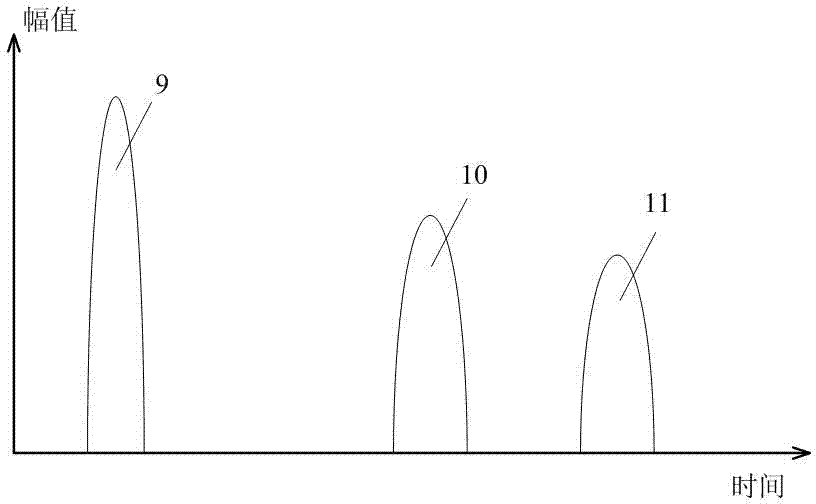

The invention discloses a sound surface wave integrated magnetic sensor for a magnetic fluid with a back groove type structure, which comprises a piezoelectric substrate, two interdigital transducers (IDT), a magnetic fluid groove and two sets of antennae for receiving and transmitting magnetic wave signals; the two interdigital transducers (IDT) are positioned at two ends of the surface of the substrate respectively; the magnetic fluid groove is arranged in the middle of the bottom of the piezoelectric substrate between the two interdigital transducers; the antennae for receiving and transmitting the magnetic wave signals are connected to omnibus bars of the two IDTs respectively; the sensor can realize passive wireless high-precision real-time magnetic intensity measurement, and receive a radio frequency signal by the antennae, excite a Rayleigh wave (RSAW) on the IDTs; the zero lagging response of the magnetic fluid on the change of an outer magnetic field instantaneously makes the energy of the Rayleigh wave attenuated, converts the attenuated Rayleigh wave into a magnetic wave by the IDTs and transmits the magnetic wave by the antennae. According to the corresponding relation of the changes of the frequency and the amplitude of the transmitted magnetic wave and the magnetic filed intensity change, the magnetic filed change can be accurately measured.

Owner:SOUTH CHINA UNIV OF TECH

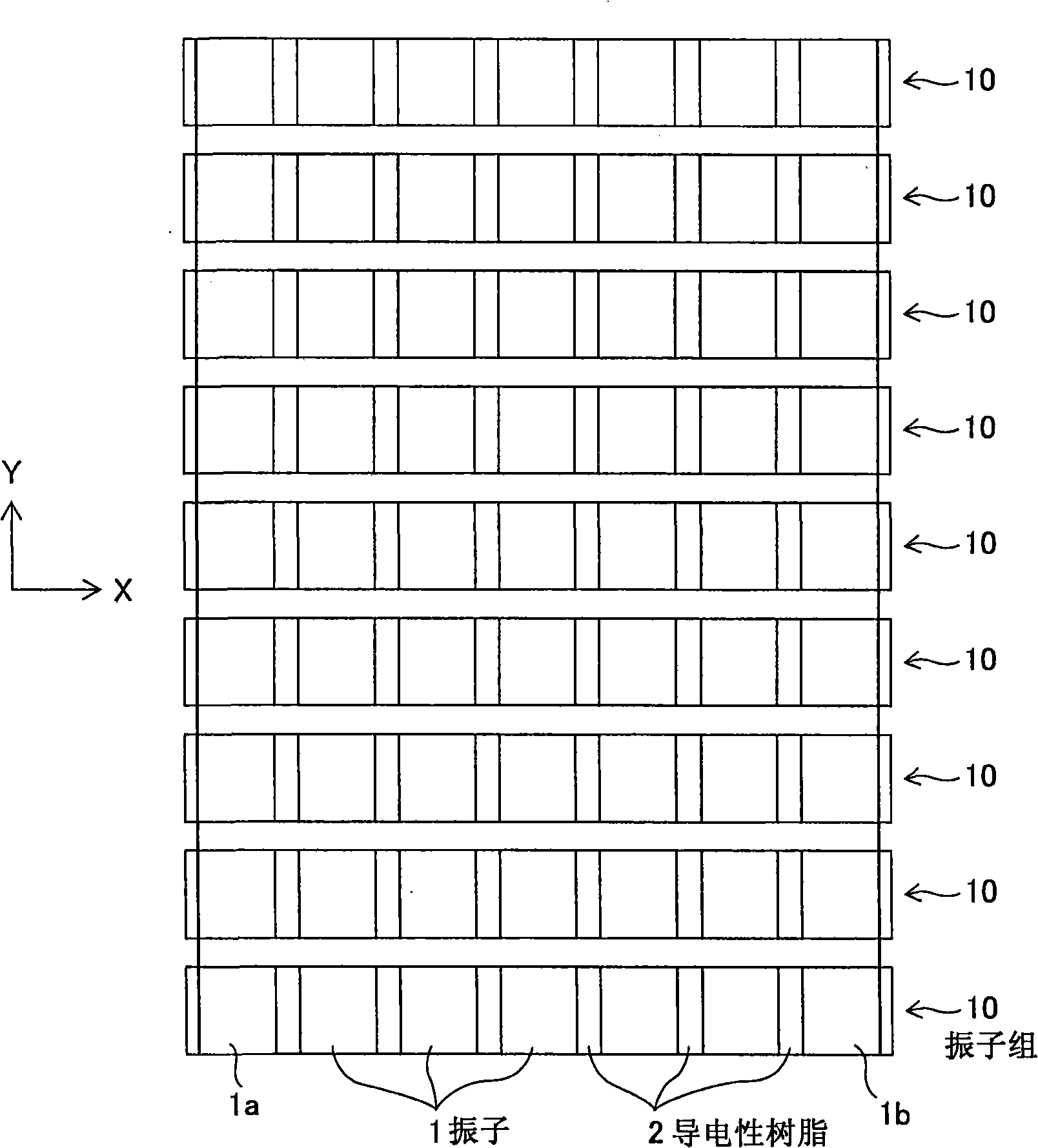

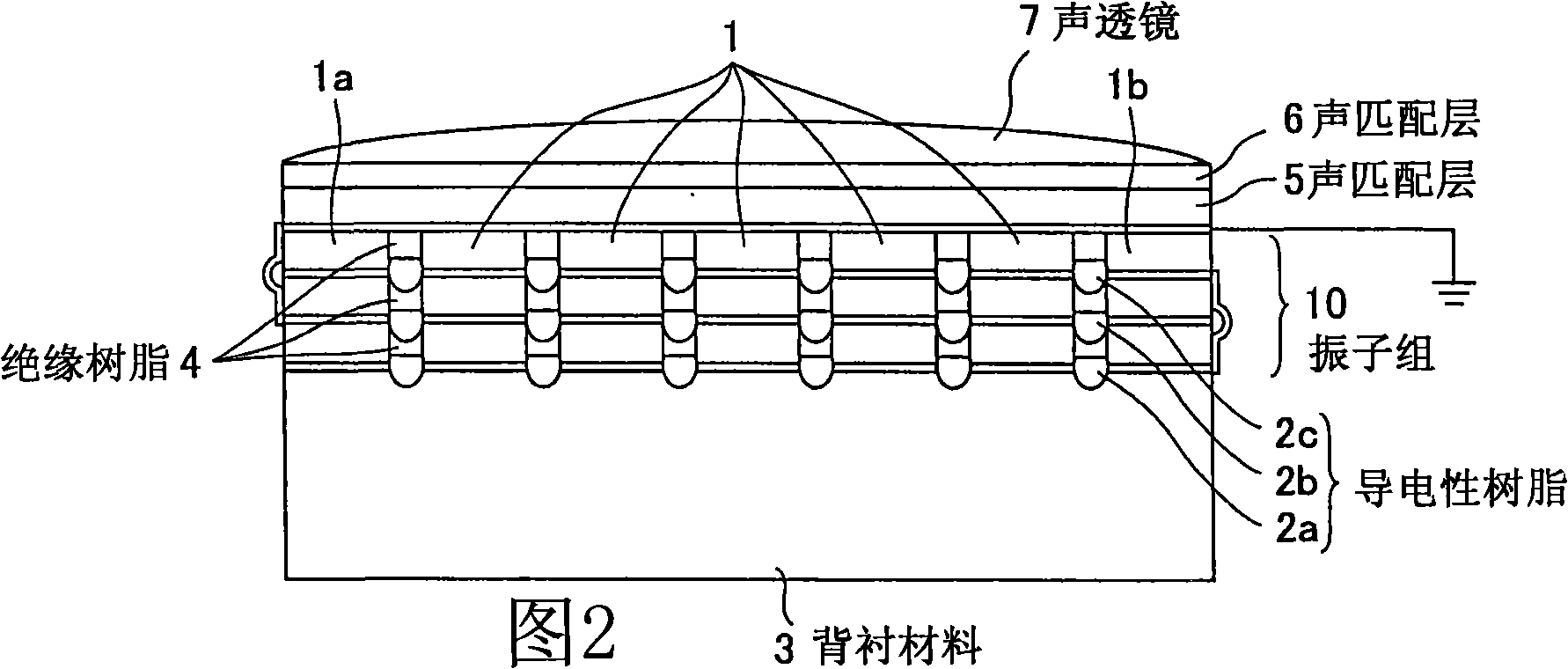

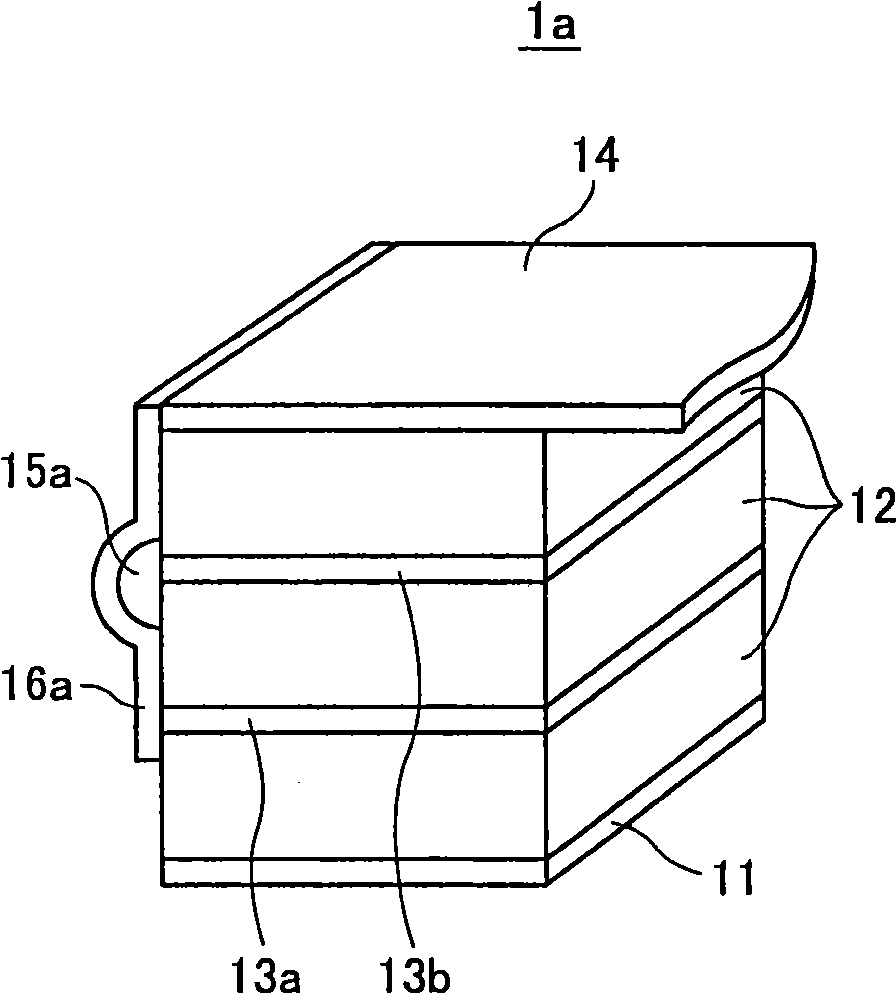

Ultrasonic probe and production method thereof

InactiveCN101278843AHigh sensitivityHigh electromechanical coupling coefficientUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesElectricityTransducer

An ultrasonic probe realizing a high sensitivity and a wide band thereof while miniaturizing a transducer and also taking into consideration a measure against generated heat. The ultrasonic probe includes: a backing material; a transducer array having a multi-layered structure in which a plurality of transducers are arranged in a first direction to compose a transducer group and a plurality of the transducer groups are arranged in a second direction different from the first direction; a first layer of conductive resin electrically connecting the first electrode layers of adjacent transducers with each other in each transducer group; a second layer of conductive resin electrically connecting the internal electrode layers of adjacent transducers with each other in each transducer group; and an insulating resin disposed in a predetermined region among the plurality of transducers in each transducer group.

Owner:FUJIFILM CORP

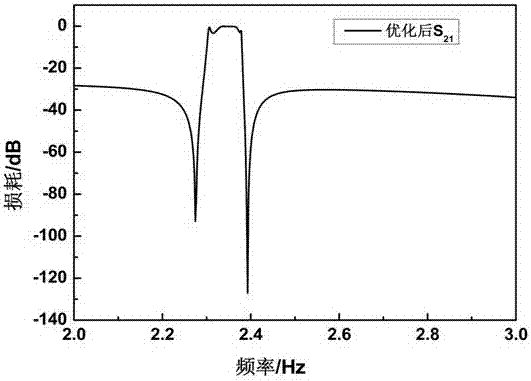

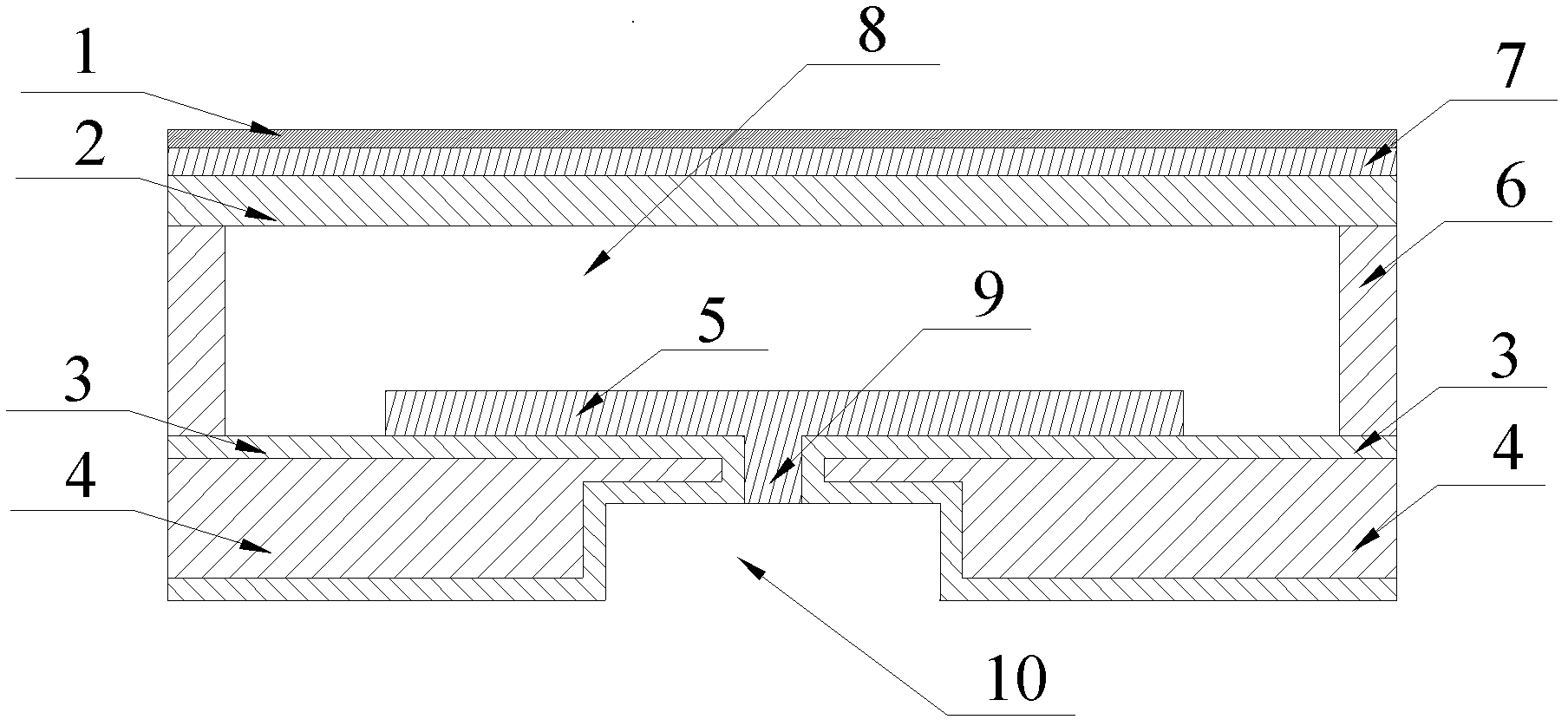

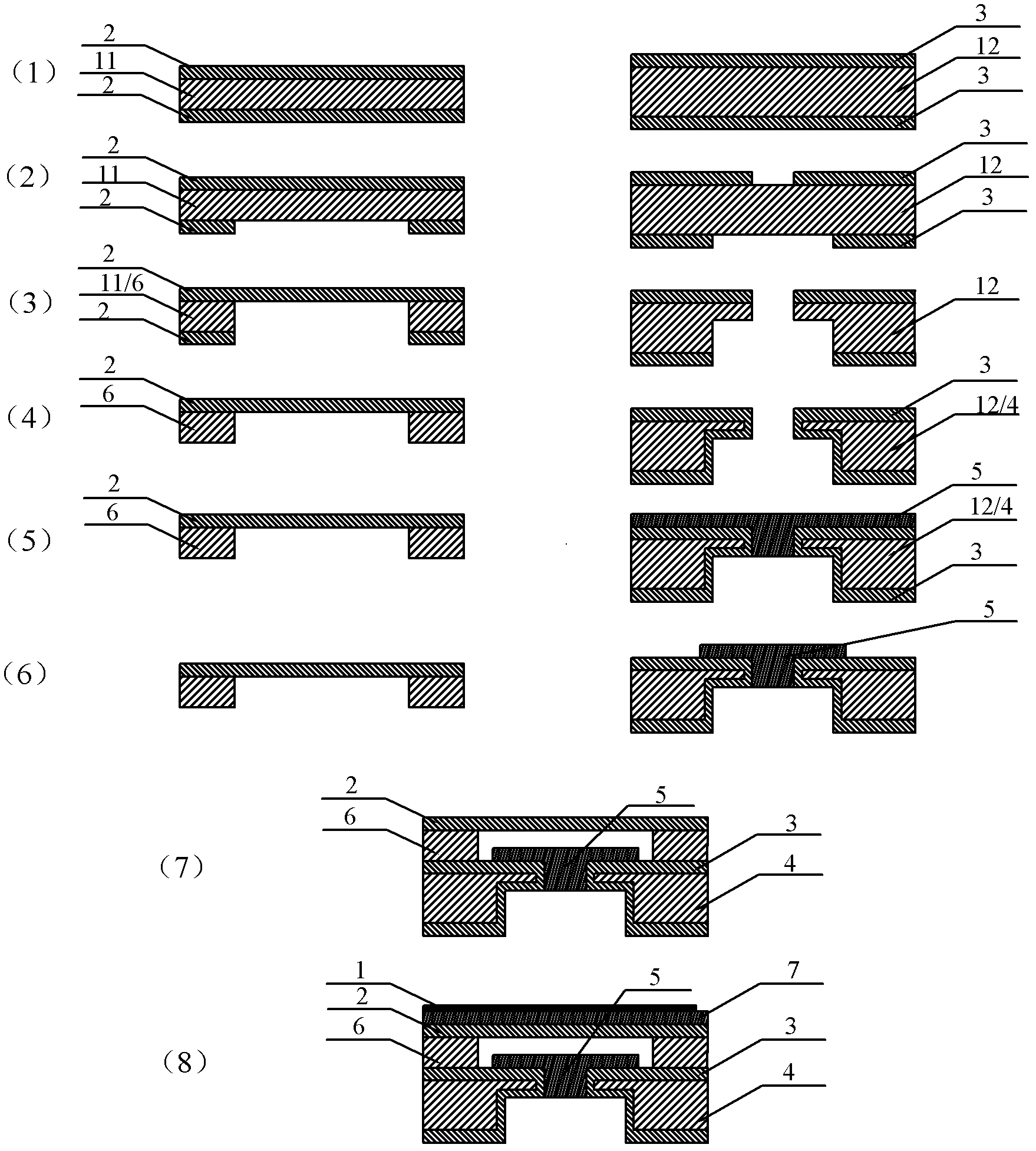

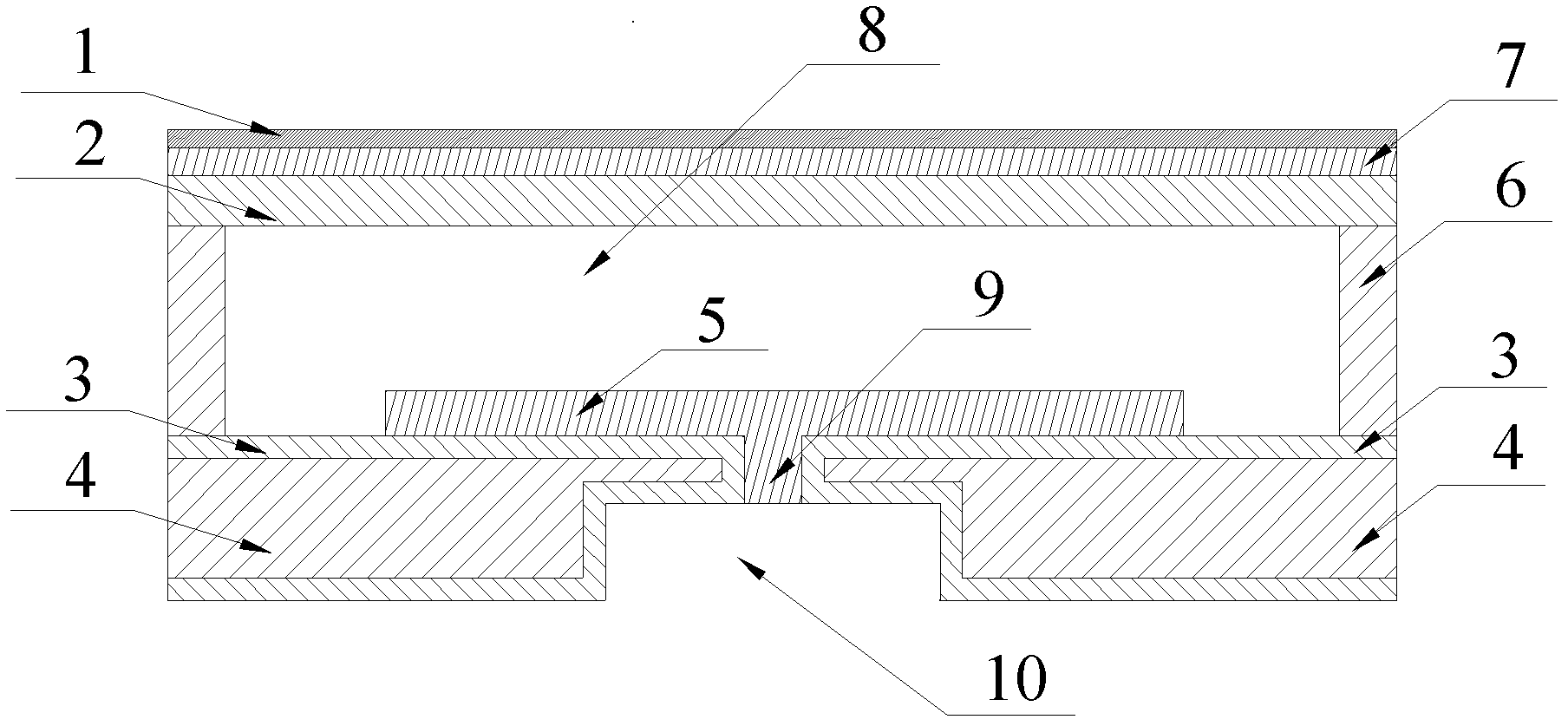

Design and preparation method for cavity type FBAR (thin-film bulk acoustic resonator) filter

ActiveCN107025321AHigh Q valueHigh electromechanical coupling coefficientCAD circuit designSpecial data processing applicationsThin-film bulk acoustic resonatorComposite film

The invention discloses a design and preparation method for a cavity type FBAR (thin-film bulk acoustic resonator) filter. The method comprises the following steps: an FBAR ladder filter based on a Mason model is simulated with ADS (Advanced Design System) software, and physical parameters of each film layer whose transmission performance meets index requirements for insertion loss and out-of-band rejection are obtained; a piezoelectric layer in corresponding thickness and a composite film layer of an electrode layer grow on a preparation substrate, a support substrate is taken additionally for forming cavities, the composite film layer is bonded with the support substrate, the original preparation substrate is stripped off, upper electrode layers with different thicknesses grow, and an electrode / piezoelectric layer / electrode / cavity composite structure is formed. Parameters of the upper electrode film layer on the FBAR filter designed and prepared with the method are controlled precisely, and the performance of the obtained filter is excellent; damage probably caused by introduction of a sacrificial layer and adoption of a chemical mechanical polishing method to a resonance structure in the traditional technology is avoided, and device loss is reduced.

Owner:广州市艾佛光通科技有限公司

CMUT (Capacitive Micromachined Ultrasonic Transducer)-based biochemical transducer and manufacturing method thereof

InactiveCN102520032AReduce thicknessReduce quality problemsMaterial electrochemical variablesElectrical field strengthCapacitive micromachined ultrasonic transducers

The invention provides a CMUT (Capacitive Micromachined Ultrasonic Transducer)-based biochemical transducer and a manufacturing method thereof. The CMUT-based biochemical transducer comprises a sensitivity identification material layer, an upper electrode, a silicon dioxide film, a silicon strut, a lower electrode, a silicon dioxide insulating layer and a silicon substrate in sequence from top to bottom. According to the biochemical transducer, the metal lower electrode is completely isolated from the silicon substrate, the method which takes the substrate as the lower electrode in the conventional CMUT based biochemical transducer is replaced, the power consumption is reduced, the electric field strength between the upper electrode and the lower electrode is greatly improved, and the electromechanical coupling capability is strengthened; the lower electrode is only positioned inside a cavity formed by the silicon dioxide film, the silicon strut and the silicon dioxide insulating layer, so that the lower side of the film is effectively vibrated rather than covering the whole silicon substrate, the parasitic capacitance is effectively reduced, the electromechanical conversion ratio is further increased, and the effective utilization rate of electric energy is improved.

Owner:XI AN JIAOTONG UNIV

Flexible magnetic field measurement device and manufacturing method

InactiveCN107576922ARealize measurementHigh electromechanical coupling coefficientMagnitude/direction of magnetic fieldsGratingMeasurement device

The invention discloses a flexible magnetic field measurement device and a manufacturing method and belongs to the magnetic sensor field. The device comprises a flexible substrate layer, a metal buffer layer, a magnetostrictive layer, a piezoelectric film layer and a protection layer which are sequentially laminated from down to up, wherein a side of the piezoelectric film layer corresponding to the protection layer is provided with an energy transducer layer embedded in the protection layer, and the energy transducer layer is a single-end or double-end resonance type structure composed of aninterdigital energy transducer and a reflecting grating. The measurement device is advantaged in that through utilizing the flexible substrate material, compared with a sensor prepared from a traditional rigidity substrate material, besides surface acoustic wave modes including common rayleigh waves and Love waves, a new wave mode, e.g., lamb waves can be further generated by the flexible magneticsensor, so bending property, high magnetic field sensitivity, integrated processing and low cost are realized, and the measurement device is suitable for miniaturization and intelligentization development of sensors, and the measurement device is applicable to magnetic field measurement and intelligent wearing fields.

Owner:CHONGQING UNIV

High-temperature-resistant piezoelectric ceramic and preparation method thereof

ActiveCN105622097AMeet needsLow voltage electric constantPiezoelectric/electrostrictive device manufacture/assemblyElectricityAlkaline earth metal

The invention relates to a high-temperature-resistant piezoelectric ceramic and a preparation method thereof. The structural general formula of the piezoelectric ceramic is Pb(Zr1 / 2Ti1 / 2)x(Ni1 / 3Nb2 / 3)y(Sb1 / 3Nb2 / 3)z(Mg1 / 3Nb2 / 3)1-x-y-zO3+wmo1%A, wherein x ranges from 0.85 to 0.97, y ranges from 0.01 to 0.10, z ranges from 0.01 to 0.05, w ranges from 0.05 to 2.0, and A is a modified element of alkali metal or alkaline-earth metal. The preparation method of the high-temperature-resistant piezoelectric ceramic comprises the following steps: pre-sintering; ball milling; drying; sieving; granulating, forming, punching, dumping and sintering; silver brushing, silver sintering and polarizing. The high-temperature-resistant piezoelectric ceramic provided by the invention solves the problems that existing piezoelectric ceramic is low in use temperature, and the electrical property cannot meet the requirements, can be used at the temperature of above 200 DEG C and has a high-voltage constant and a high-dielectric constant.

Owner:GUIZHOU ZHENHUA HONGYUN ELECTRONICS

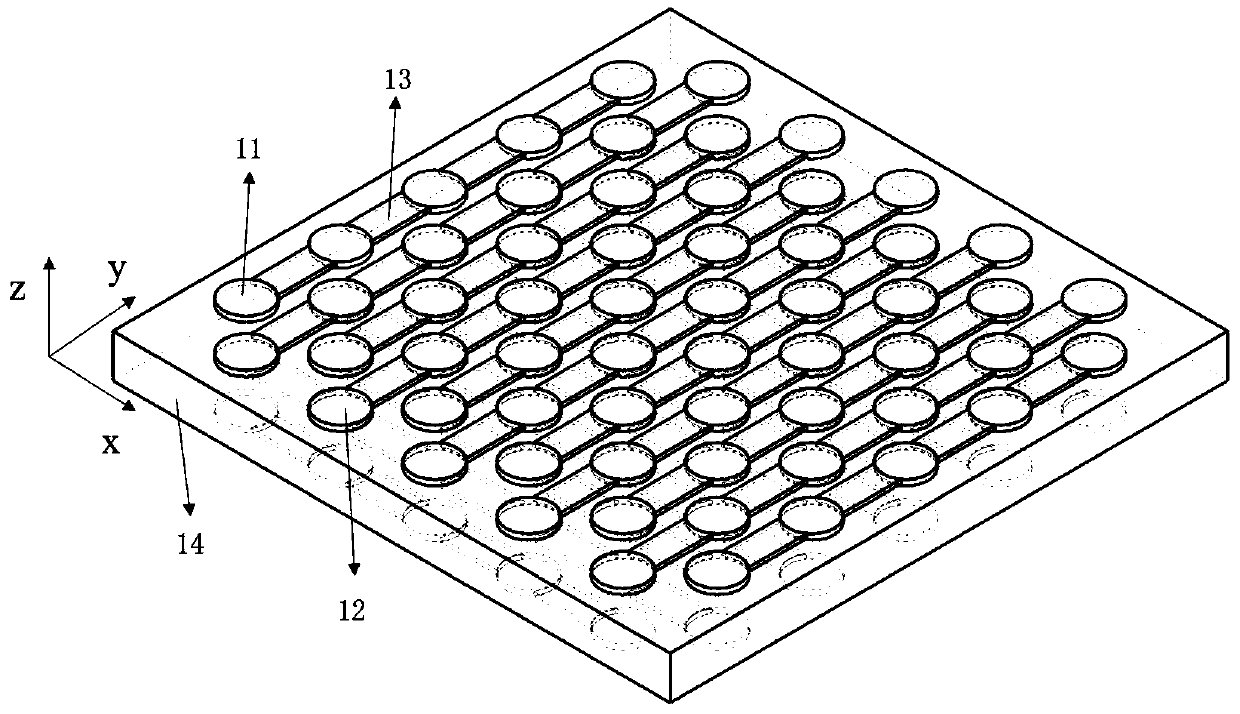

Two-dimensional Lamb wave resonator

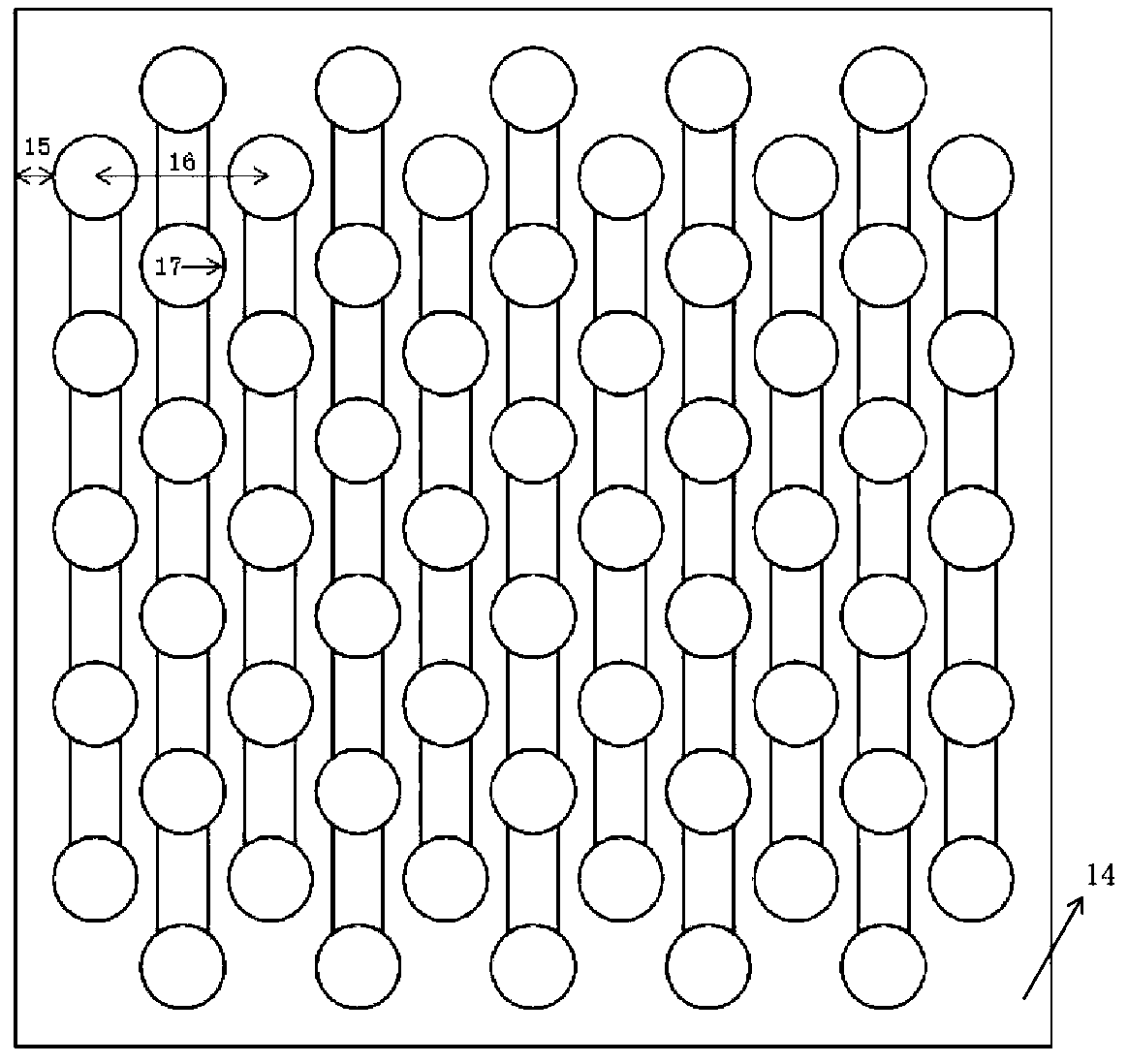

ActiveCN110113026AReduce adverse effectsEnhanced electrical responseImpedence networksElectromechanical coupling coefficientElectrode array

The invention belongs to the technical field of resonators and discloses a two-dimensional Lamb wave resonator which is characterized in that a first electrode array and a second electrode array are arranged on the upper surface and the lower surface of a piezoelectric layer, each of the first electrode array and the second electrode array comprises a plurality of positive electrode columns and first negative electrode columns which are arranged along a first direction and a second direction, and the positive electrode columns and the negative electrode columns are alternately arranged; the positive electrode columns comprise a plurality of positive electrodes, every two adjacent positive electrodes are connected through a bridge, the negative electrode columns comprise a plurality of negative electrodes, and every two adjacent negative electrodes are connected through a bridge; the first direction is perpendicular to the second direction; the orthographic projection of any one of thepositive electrodes in the first electrode array to the second electrode array covers one of the negative electrodes, and the orthographic projection of any one of the negative electrodes in the firstelectrode array to the second electrode array covers one of the positive electrodes. The two-dimensional Lamb wave resonator provided by the invention can improve the electromechanical coupling coefficient of the resonator and reduce the parasitic modes.

Owner:武汉敏声新技术有限公司

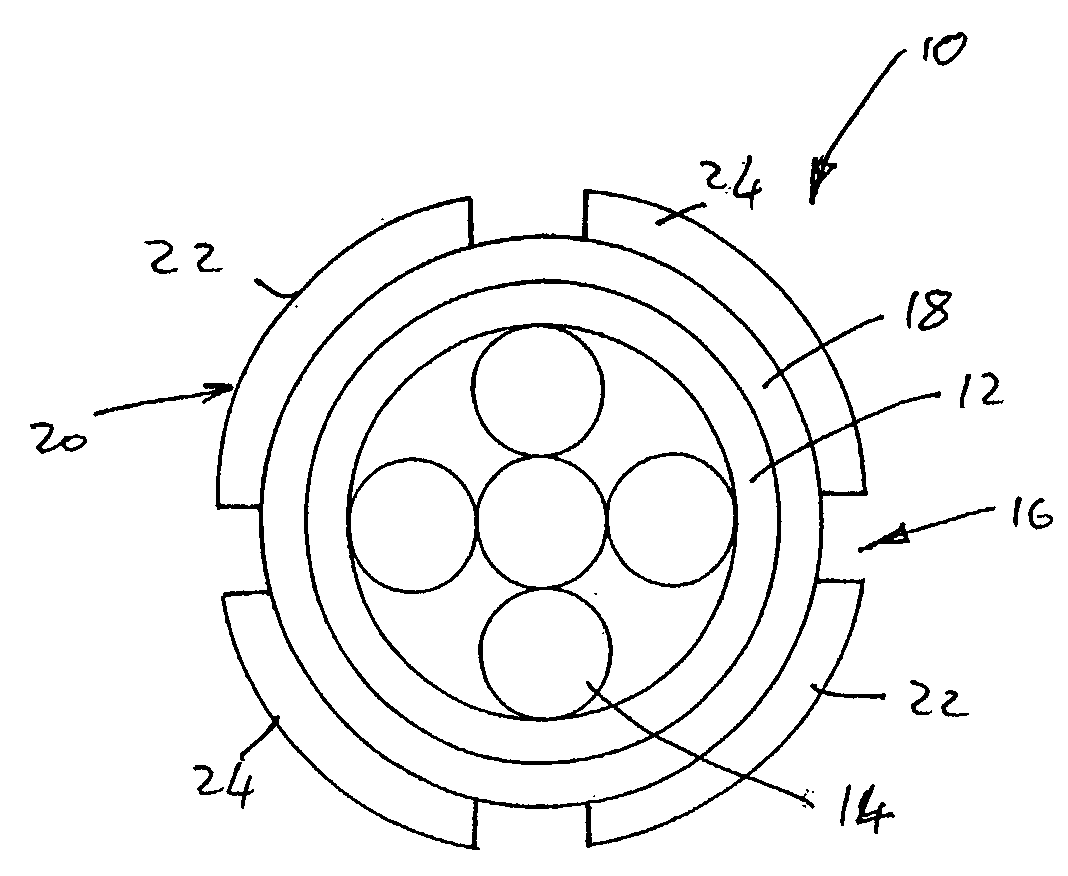

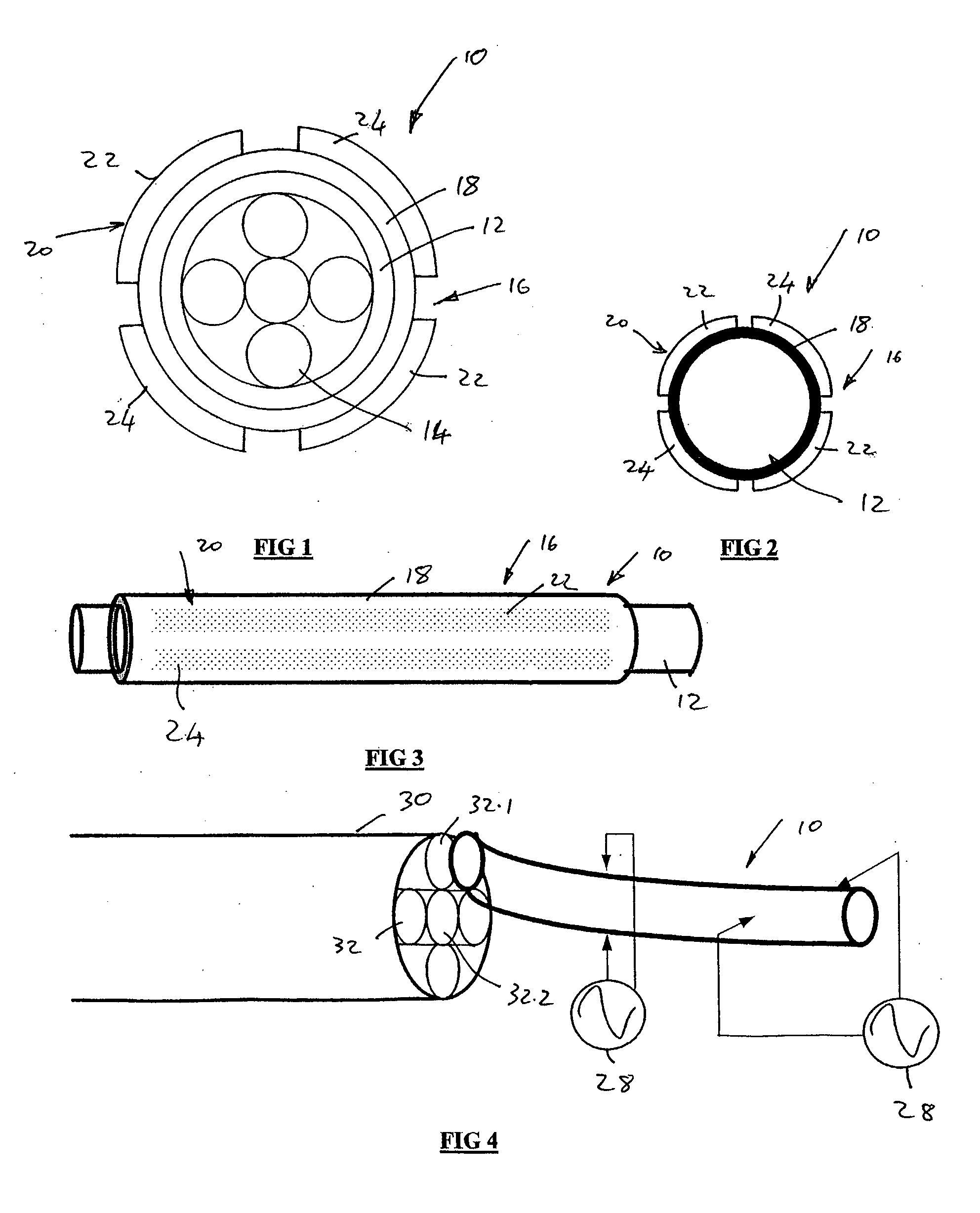

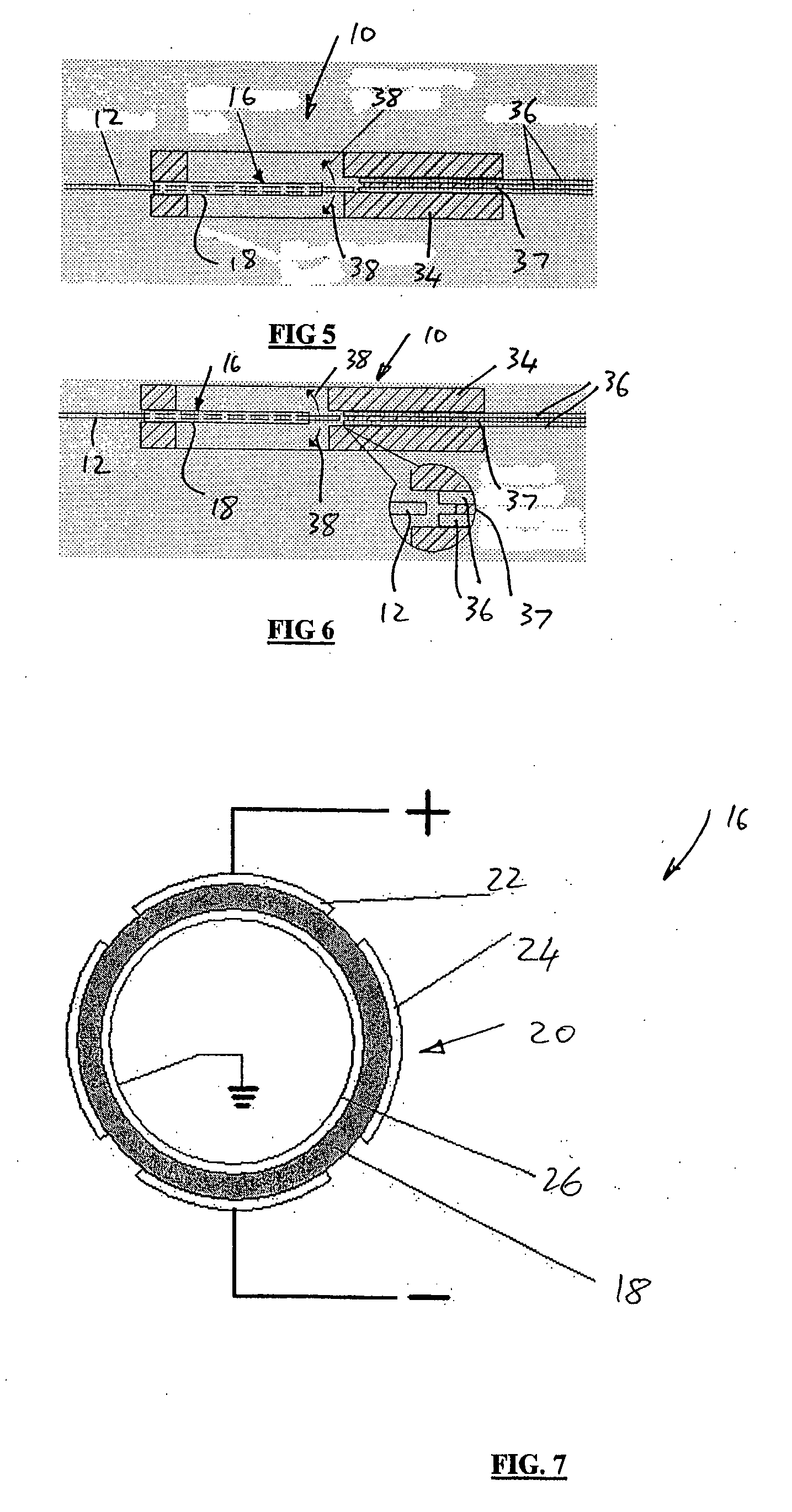

Optical Fibre Switch

InactiveUS20080131048A1High electromechanical coupling coefficientPiezoelectric/electrostriction/magnetostriction machinesCoupling light guidesMechanical energyTransducer

An optical fibre switch (10) includes an optical fibre conduit (12). A transducer (16) is carried on the conduit (12), the transducer (16) converting input energy of one form into mechanical energy so that the application of an external stimulus causes a change in condition of the transducer (16) which imparts that change in condition to the conduit (12). An input energy applying arrangement (20) is arranged on the transducer (16) for applying the external stimulus.

Owner:AUCKLAND UNISERVICES LTD

AlN/GaN/freestanding diamond structured surface acoustic wave (SAW) device and preparation method thereof

InactiveCN102185583AHigh crystallinityHigh Electromechanical Coupling CoefficientImpedence networksElectromechanical coupling coefficientCoupling

The invention discloses an AlN / GaN / freestanding diamond structured surface acoustic wave (SAW) device and a preparation method thereof. In the multi-layer film structure SAW device, a nano GaN middle layer preferably oriented by a high-quality C shaft is arranged between a freestanding diamond thick film substrate and an AlN thin film. In the AlN / GaN / freestanding diamond structured SAW device and the preparation method thereof, the nano GaN middle layer preferably oriented by the high-quality C shaft is deposited on the surface of the freestanding diamond thick film substrate at first, and the AlN thin film preferably oriented by the high-quality C shaft is deposited on the nano GaN middle layer then. The invention has the advantages that: by adoption of the nano GaN middle layer preferably oriented by the high-quality C shaft serving as a middle layer between the freestanding diamond and the AlN thin film, the flat, smooth, high crystallinity and high-quality AlN thin film preferably oriented by the high-quality C shaft can be obtained. The structure of the thin film meets the application requirements in the fields of high frequency, high mechanical coupling factor, low loss and high power SAW devices.

Owner:DALIAN UNIV OF TECH

Doped and modified lead zirconate-titanate piezoelectric ceramic and preparation method thereof

ActiveCN107986782ALower sintering temperatureHigh electromechanical coupling coefficientPiezoelectric/electrostrictive device manufacture/assemblyLead zirconate titanateElectromechanical coupling coefficient

The invention discloses a doped and modified lead zirconate-titanate piezoelectric ceramic and a preparation method thereof. The doped and modified lead zirconate-titanate piezoelectric ceramic is shown in a following chemical formula I, namely xPb(Mg1 / 3Nb2 / 3)O3-yPb(Ni1 / 3Nb2 / 3)O3-(1-x-y)Pb(Ti1 / 2Zr1 / 2)O3+lSrCO3+mZnO+nQ, wherein Q is at least selected from Li2CO3 (lithium carbonate), CuO (copper oxide), SiO2 (silicon dioxide), MnO2 (manganese dioxide), Bi2O3 (bismuth oxide) and La2O3 (lanthanum oxide); l, m and n are respectively the mass percentages of SrCO3 (strontium carbonate), ZnO (zinc oxide) and Q in the compound Pb(Mg1 / 3Nb2 / 3)O3-Pb(Ni1 / 3Nb2 / 3)O3-Pb(Ti1 / 2Zr1 / 2)O3; x is greater than or equal to 0.10 and is smaller than or equal to 0.70, y is greater than or equal to 0.08 and is smallerthan or equal to 0.38, l is greater than 0 and is smaller than or equal to 0.5, m is greater than 0 and is smaller than or equal to 0.50, and n is greater than or equal to 0 and is smaller than or equal to 0.5. The doped and modified lead zirconate-titanate piezoelectric ceramic has the excellent properties of low sintering temperature, high electromechanical coupling coefficient, high piezoelectric strain coefficient, small dielectric loss and the like.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

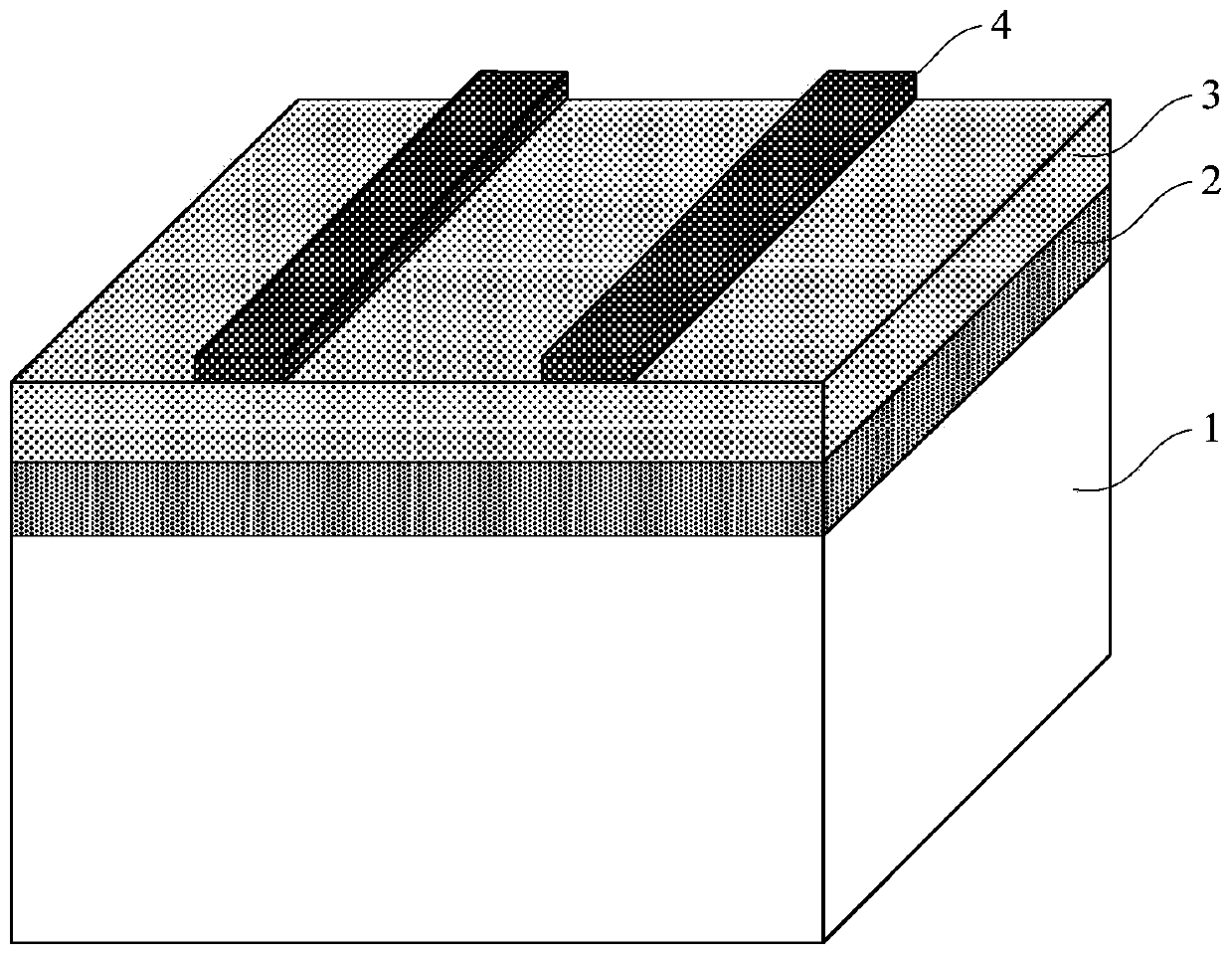

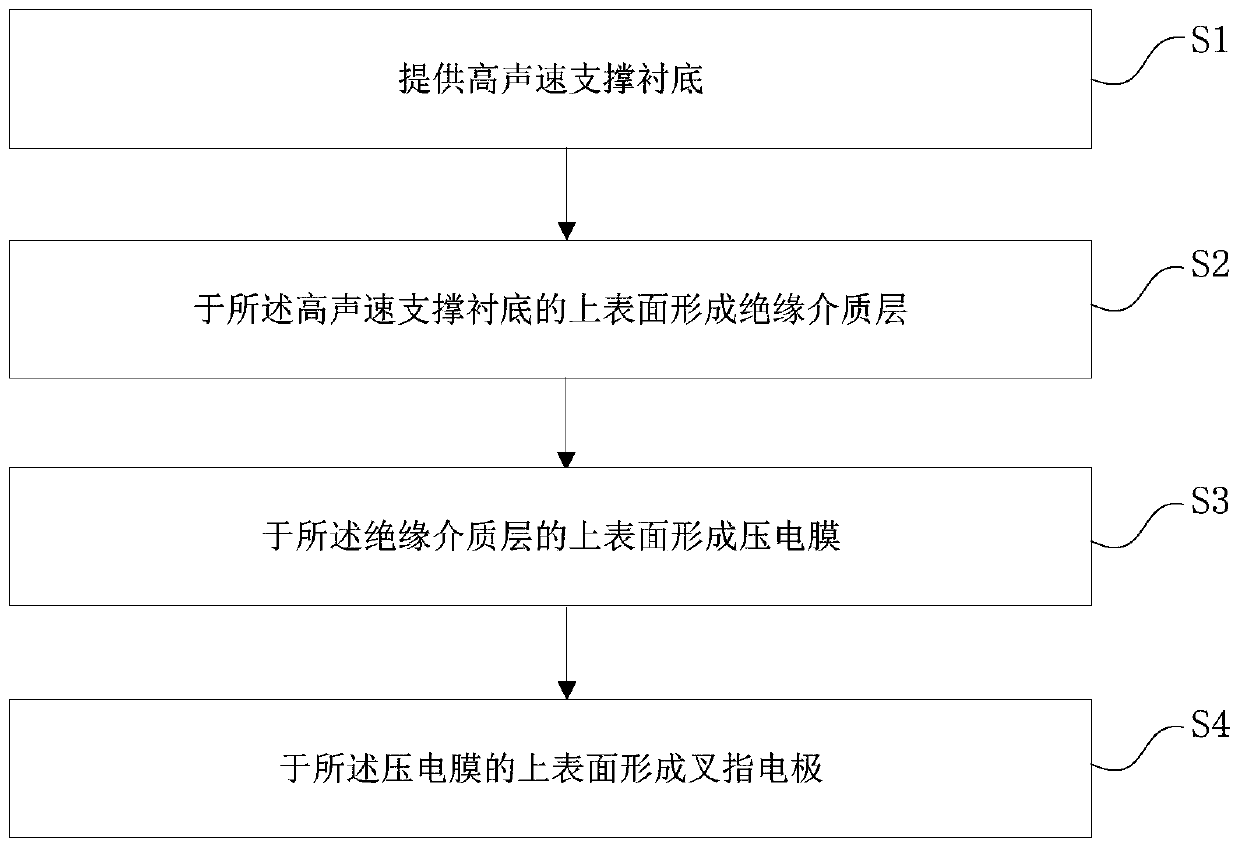

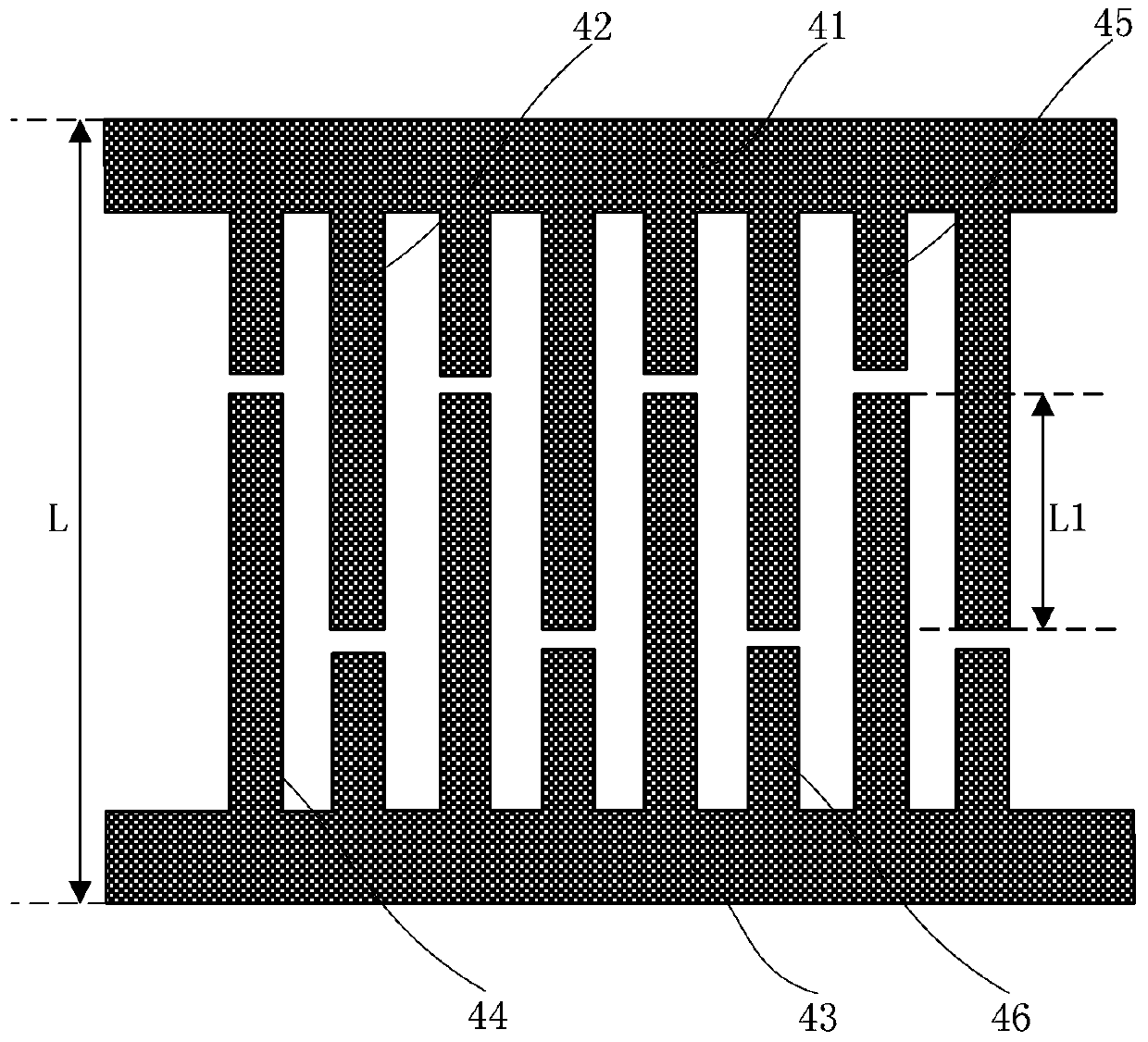

High-frequency acoustic wave resonator and preparation method thereof

ActiveCN111416590ARaise the resonant frequencyHigh electromechanical coupling coefficientImpedence networksHigh level techniquesElectromechanical coupling coefficientAcoustic wave

The invention provides a high-frequency acoustic wave resonator and a preparation method thereof. The high-frequency acoustic wave resonator comprises a high-acoustic-velocity support substrate, an insulating dielectric layer which is located on the upper surface of the high-sound-velocity supporting substrate, a piezoelectric film which is located on the upper surface of the insulating dielectriclayer, and an interdigital electrode which is located on the upper surface of the piezoelectric film. By arranging the high-sound-velocity supporting substrate below the piezoelectric film, the soundvelocity of target elastic waves excited and propagated in the piezoelectric film can be increased, propagation of the target elastic waves can be effectively restrained, and the resonant frequency of the high-frequency sound wave resonator is improved; the insulating dielectric layer is arranged between the piezoelectric film and the high-sound-velocity supporting substrate, the leakage of electric field energy in the piezoelectric film can be effectively reduced, and the electromechanical coupling coefficient of the high-frequency sound wave resonator can be enhanced; by selecting the appropriate insulating dielectric layer, temperature compensation can be carried out on the high-frequency acoustic wave resonator, temperature drift of the high-frequency acoustic wave resonator is reduced, and temperature stability of the high-frequency acoustic wave resonator is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

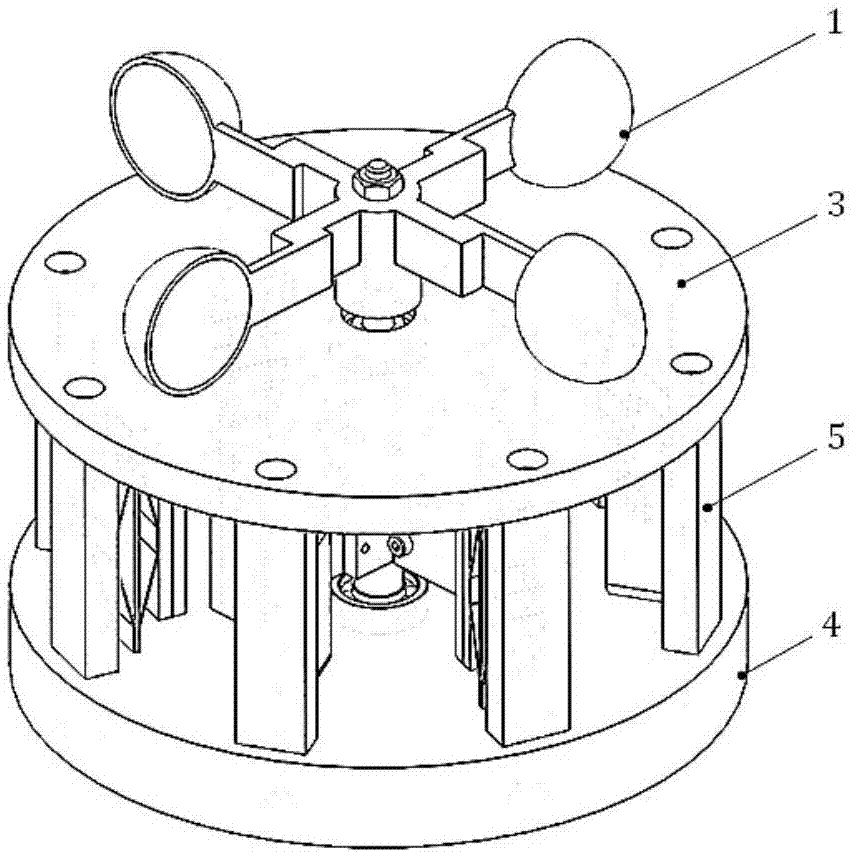

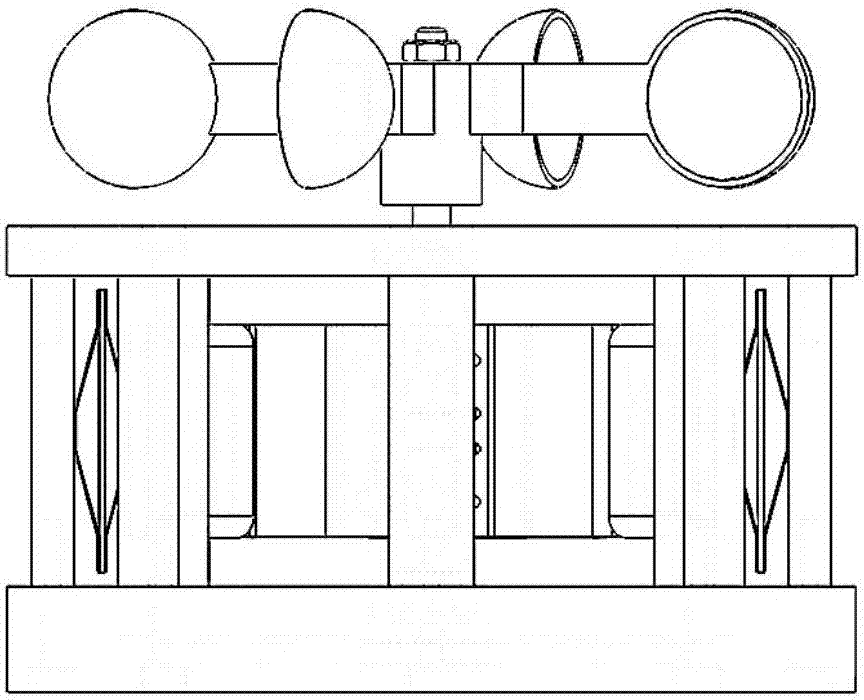

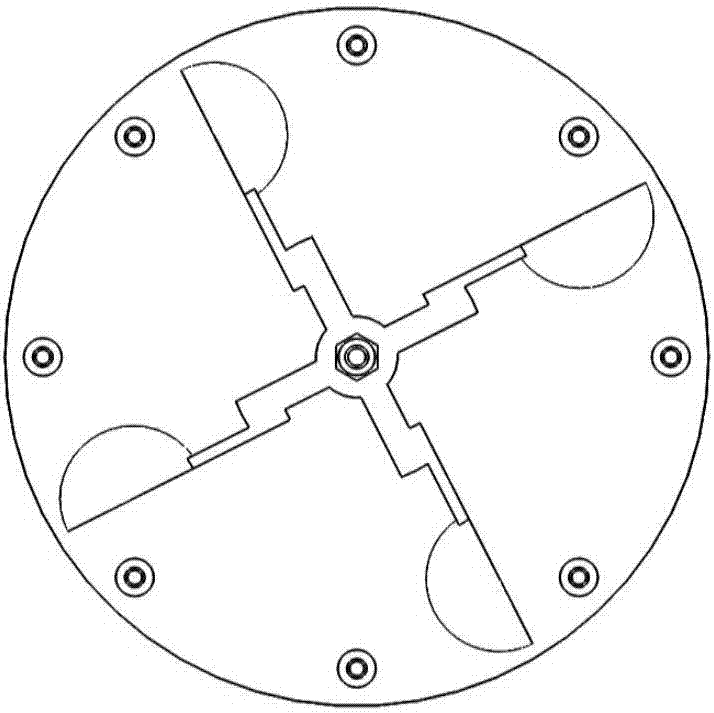

Wide-speed-domain magnetic force coupling piezoelectric wind energy collector

ActiveCN107453647AHigh electromechanical coupling coefficientIncrease energy densityPiezoelectric/electrostriction/magnetostriction machinesWind motor combinationsMagnetic tension forceElectromechanical coupling coefficient

Disclosed is a wide-speed-domain magnetic force coupling piezoelectric wind energy collector. The wide-speed-domain magnetic force coupling piezoelectric wind energy collector comprises a wind power rotary mechanism, a power generation apparatus and a rotor arranged in the power generation apparatus and connected with the wind power rotary mechanism, wherein the wind power rotary mechanism is rotationally arranged in the center of the power generation apparatus; a plurality of power generation units directly aligned to the rotor are arranged in the power generation apparatus; each power generation unit comprises a magnetic coupling piezoelectric power generation mechanism and a power generation coil; and the power generation coils and the magnetic coupling piezoelectric power generation mechanisms are arranged at intervals to be connected with the control unit separately. Through rotation, wind power is converted into periodical magnetic force to act on the magnetic coupling piezoelectric power generation mechanisms, so that a higher electromechanical coupling coefficient is realized, and energy density and reliability are improved; by virtue of designed multiple magnetic force coupling configuration, counteractive reluctance torque is overcome, so that the apparatus can perform effective operation even if at relatively low wind power; when the wind power is relatively high, an electromagnetic inductive power generation coil is switched on; and meanwhile, the magnetic coupling piezoelectric power generation mechanisms and the power generation coils are adopted for power generation, so that more energy can be harvested.

Owner:SHANGHAI JIAO TONG UNIV

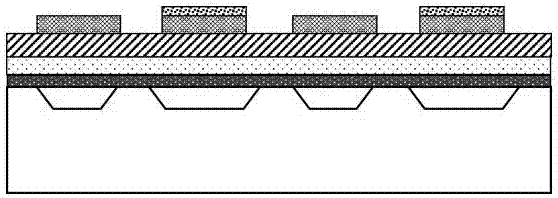

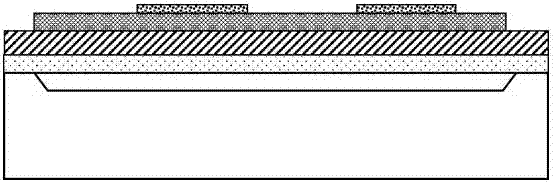

Radio frequency resonator structure

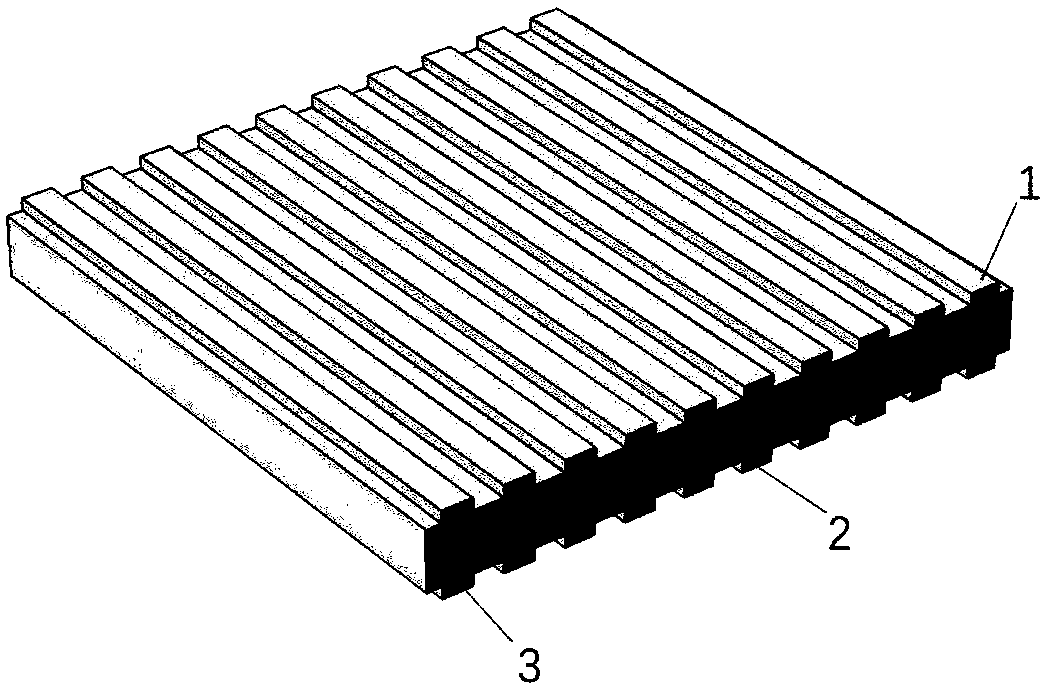

PendingCN108540105AEliminate parasitic patternsHigh electromechanical coupling coefficientImpedence networksElectromechanical coupling coefficientRadio frequency

A radio frequency resonator structure disclosed by the invention includes a piezoelectric layer, and a certain amount of top interdigital electrodes and bottom interdigital electrodes respectively configured on the upper and lower surfaces of the piezoelectric layer, wherein troughs along the length direction of the top interdigital electrodes are respectively disposed at the positions between adjacent top interdigital electrodes on the upper surface of the piezoelectric layer; and at the same time, troughs along the length direction of the bottom interdigital electrodes are respectively disposed at the positions between adjacent bottom interdigital electrodes on the lower surface of the piezoelectric layer. By disposing troughs along the length direction of the interdigital electrodes onthe piezoelectric layer between adjacent interdigital electrodes, the invention obviously eliminates the parasitic mode of the resonator and improves the electromechanical coupling factor of the resonator, and is easy to implement and low in implementation cost.

Owner:武汉敏声新技术有限公司

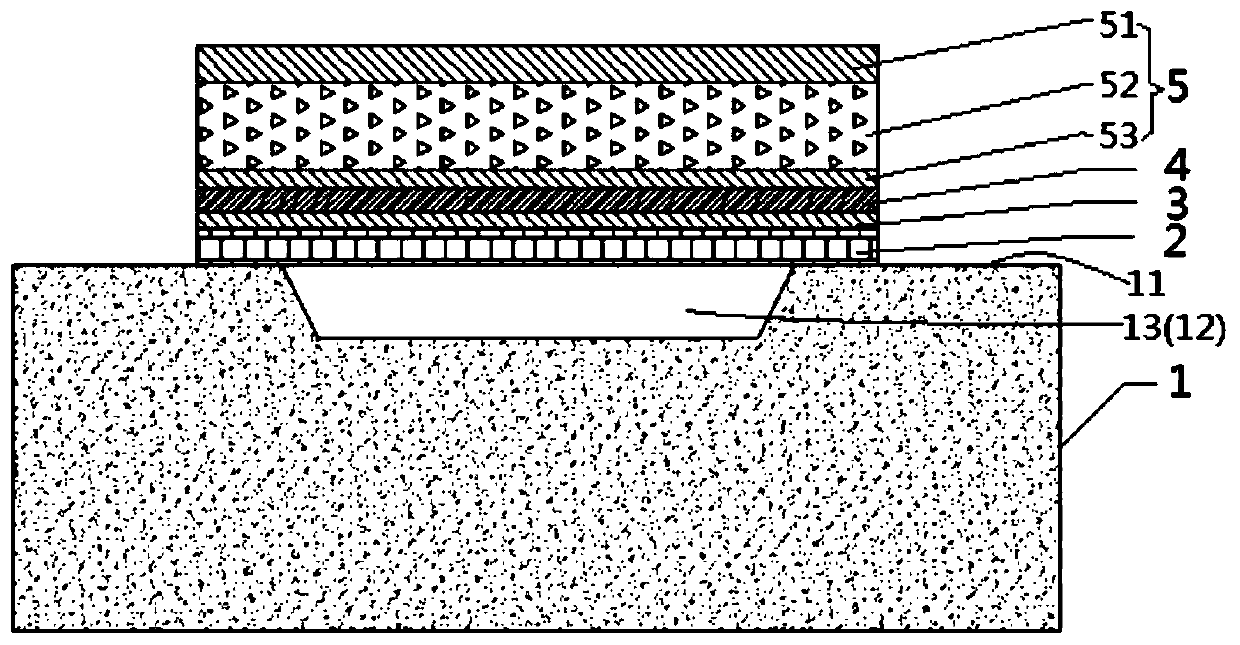

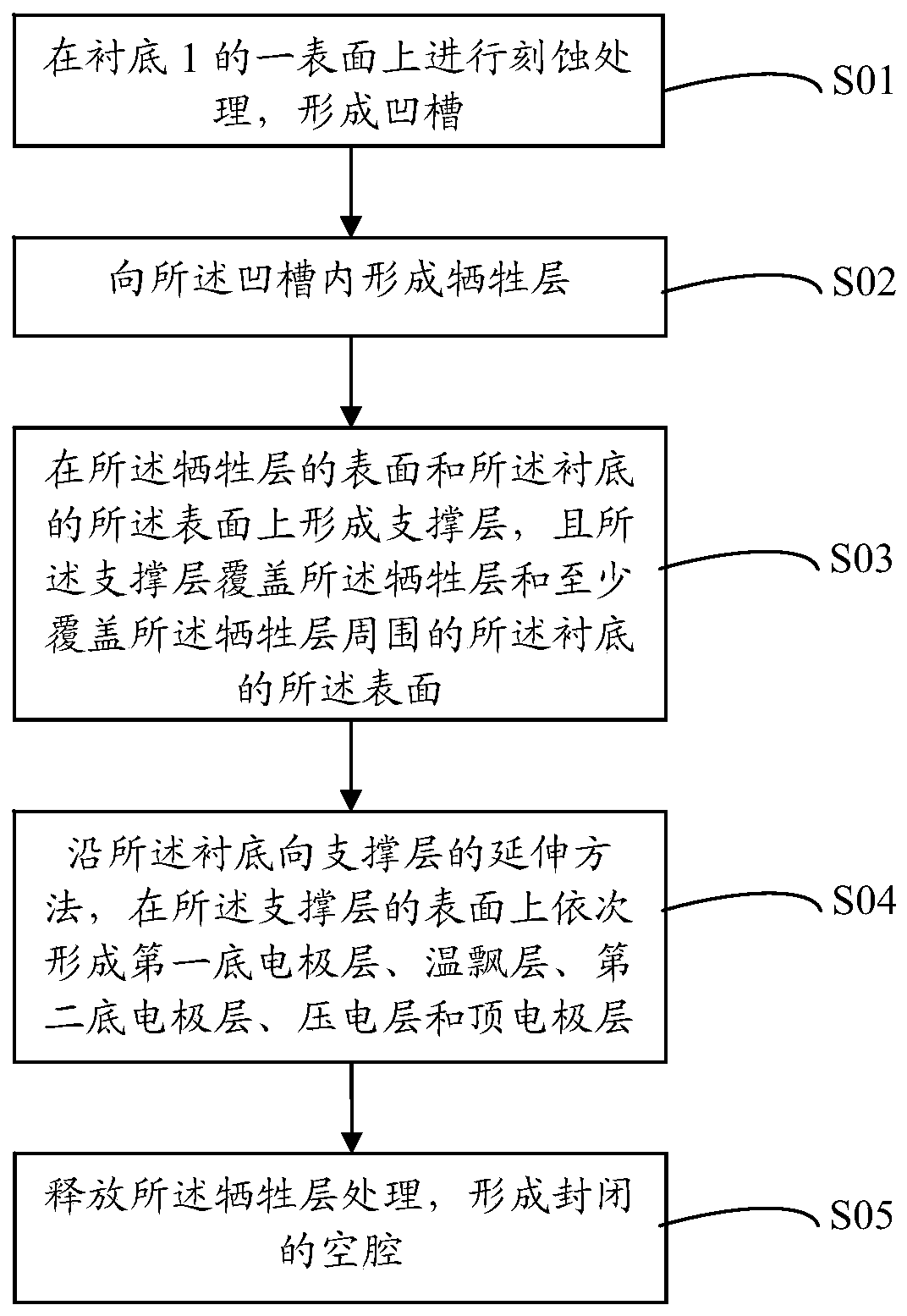

Film bulk acoustic wave resonator and a film bulk acoustic wave filter

PendingCN109756201AWen PiaoxiaoReduce lossImpedence networksThin-film bulk acoustic resonatorElectromechanical coupling coefficient

The invention discloses a film bulk acoustic wave resonator and a film bulk acoustic wave filter. The thin film bulk acoustic wave resonator comprises a silicon substrate, a support layer and a firstbottom electrode layer, a temperature drift layer and a sandwich piezoelectric stack structure, the supporting layer is combined on the surface, provided with the groove, of the substrate in a laminated manner; a closed cavity is defined by the supporting layer and the groove; wherein the first bottom electrode layer is laminated and combined on the surface, deviating from the substrate, of the supporting layer, the temperature drift layer is laminated and combined on the surface, deviating from the supporting layer, of the first bottom electrode, and the sandwich piezoelectric stack structureis laminated on the surface, deviating from the first bottom electrode layer, of the temperature drift layer. The film bulk acoustic wave filter comprises the film bulk acoustic wave resonator. The film bulk acoustic wave filter and the resonator are low in consumption, small in temperature coefficient, low in temperature drift, high in power bearing capacity, high in working frequency, high in electromechanical coupling coefficient, good in compatibility and good in Q value.

Owner:ZHEJIANG HUAYUAN MICRO ELECTRONICS TECH CO LTD +1

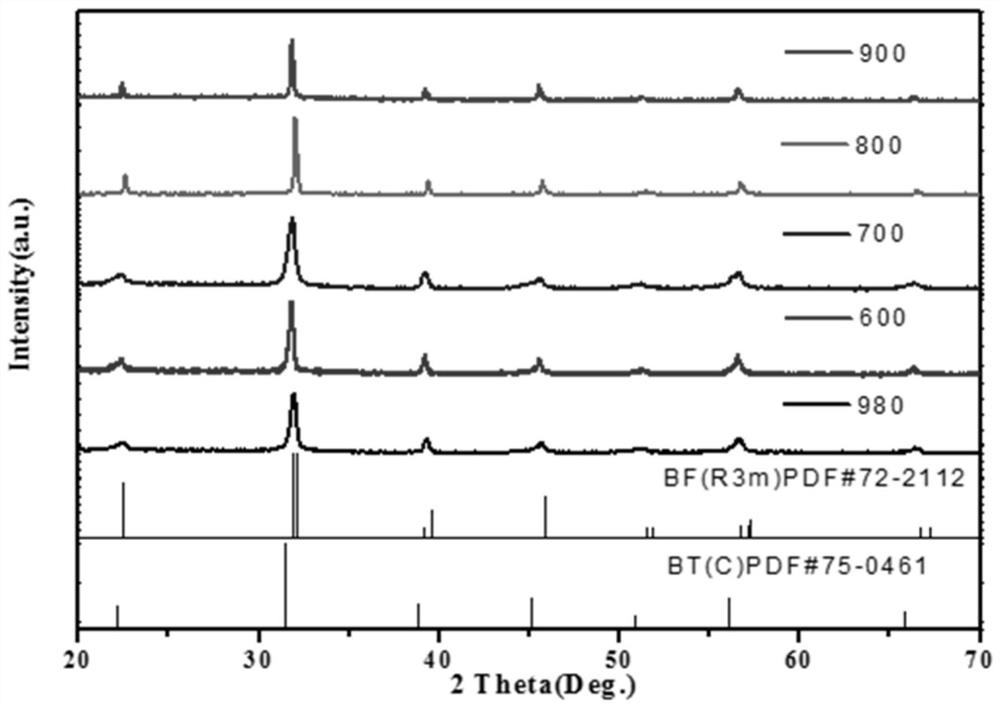

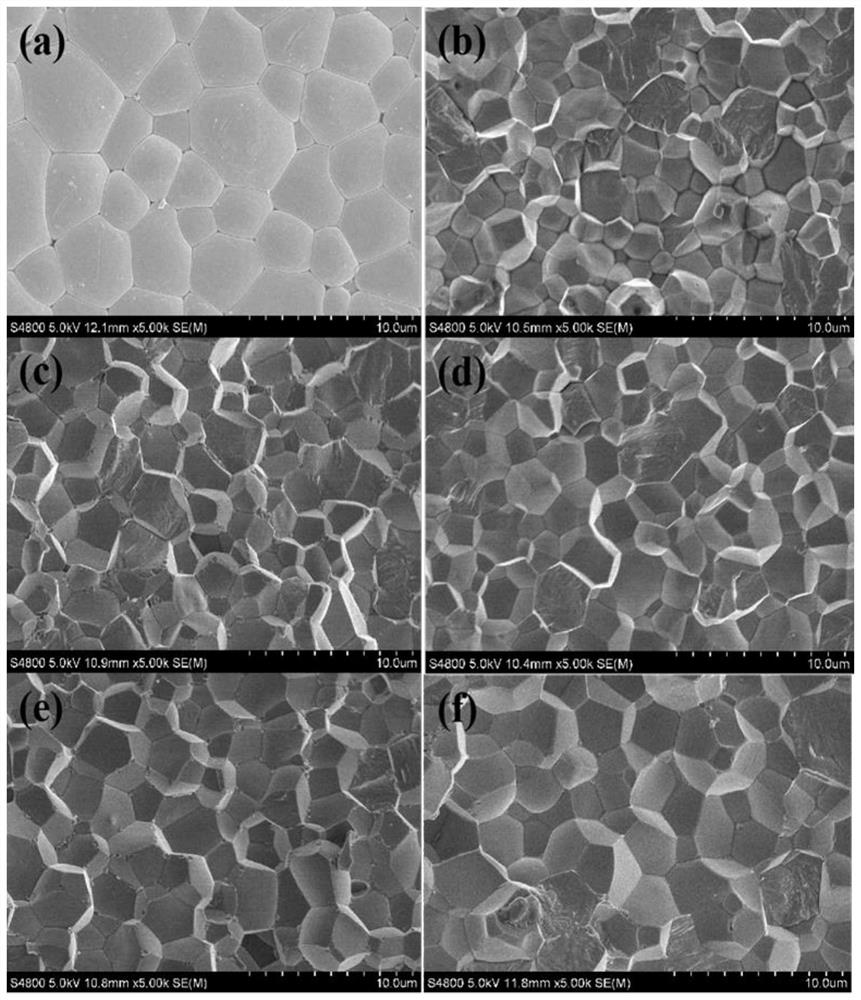

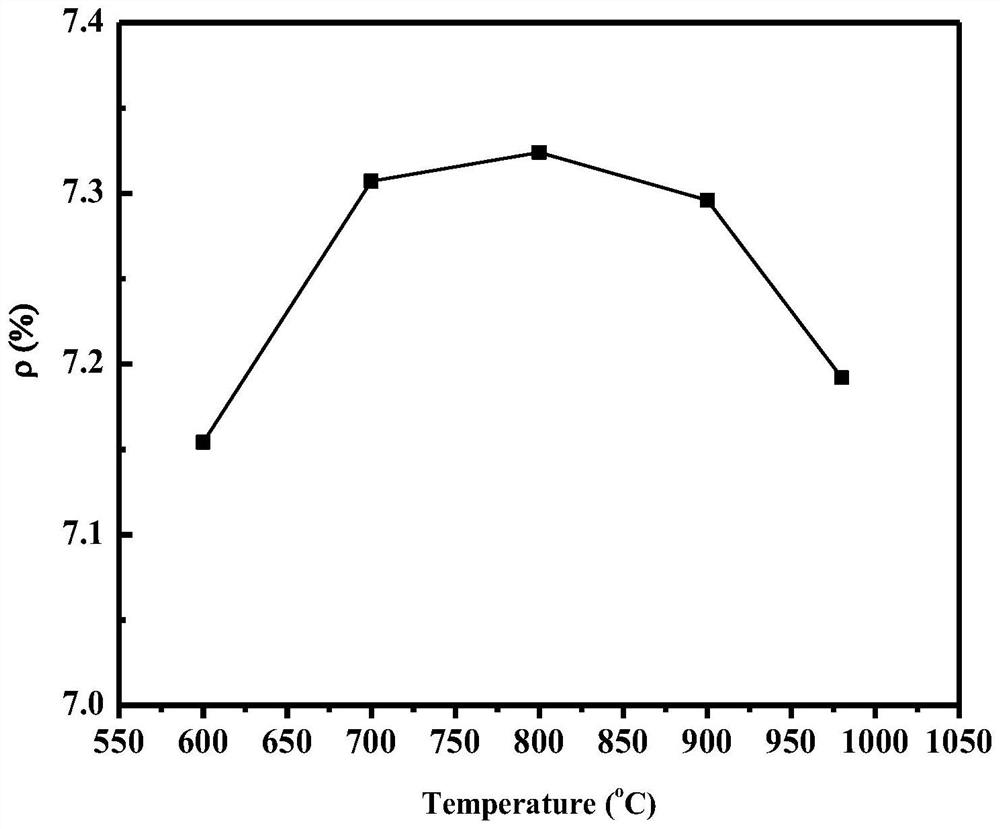

Bismuth ferrite-barium titanate lead-free piezoelectric ceramic as well as preparation method and application thereof

The invention relates to bismuth ferrite-barium titanate lead-free piezoelectric ceramic and an application thereof. The chemical formula of the bismuth ferrite-barium titanate is (1-x)BiyFeO3-xBaTiO3, x and y are mole fraction, x is 0.3-0.4, y is 0.6-1.2, the raw materials for preparing the bismuth ferrite-barium titanate comprise Bi2O3, Fe2O3, BaCO3 and TiO2, and the preparation method comprises the following steps: reacting Bi2O3, Fe2O3, BaCO3 and TiO2 at 780-850 DEG C to prepare a precursor; and performing granulation treatment, forming treatment, glue discharging treatment, sintering treatment, specific annealing treatment, silver firing treatment, quenching treatment and polarization treatment on the precursor. The microstructure, density and charge defect concentration of the ceramic are improved through annealing treatment, the ceramic generates lattice distortion in the high-temperature quenching process through quenching treatment after silver firing, and the piezoelectric property of the ceramic is cooperatively improved.

Owner:LANZHOU UNIVERSITY +1

Love wave device structure and detecting method for liquid multiparameter sensing

ActiveCN104768113AHigh electromechanical coupling coefficientStrong echo signalTransducer detailsFlow propertiesInterdigital transducerElectricity

The invention discloses a love wave device structure and detecting method for liquid multiparameter sensing. The love wave device structure comprises a piezoelectric substrate, a piezoelectric film, a first reflecting grating, a second reflecting grating, an interdigital transducer, a first liquid sensitive area and a second liquid sensitive area. The interdigital transducer is deposited at the middle portion of the piezoelectric substrate surface, the first reflecting grating (3) and the second reflecting grating (4) are deposited at the left side and the right side of the piezoelectric substrate surface respectively, the piezoelectric film is sputtered on the piezoelectric substrate surface, the first liquid sensitive area is arranged between the first reflecting grating and the interdigital transducer, and the second liquid sensitive area is arranged between the second reflecting grating and the interdigital transducer. The love wave device structure and detecting method for liquid multiparameter sensing has the advantages that parallel detection on liquid density, viscosity, dielectric constant and specific conductance is realized only with one love wave device, influence of liquid volumetric modulus of elasticity to a measuring result can be eliminated, and a passive wireless function is possessed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

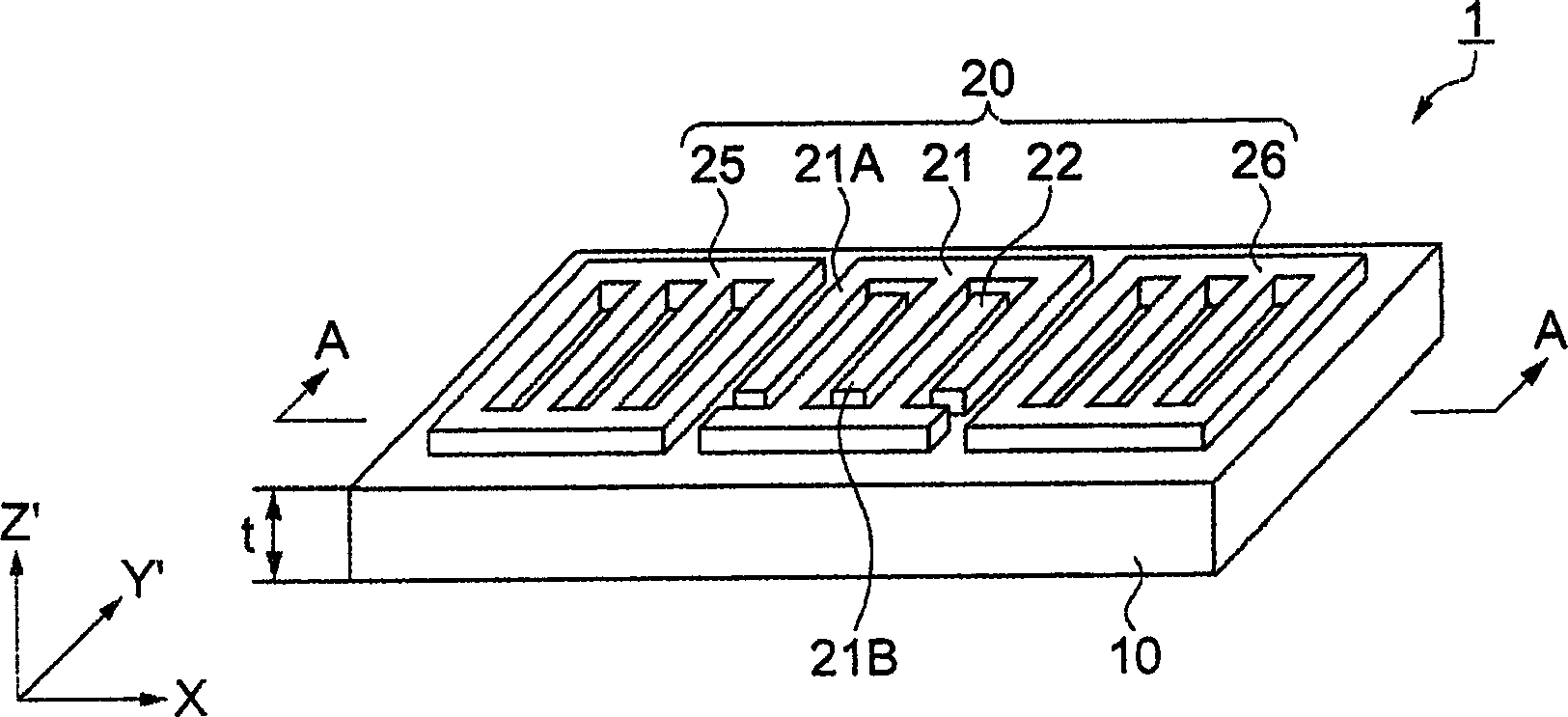

Lamb-wave high-frequency resonator

InactiveCN1801612AEasy to manufactureAchieve high frequencyImpedence networksPiezoelectric/electrostrictive device material selectionManufacturing cost reductionLength wave

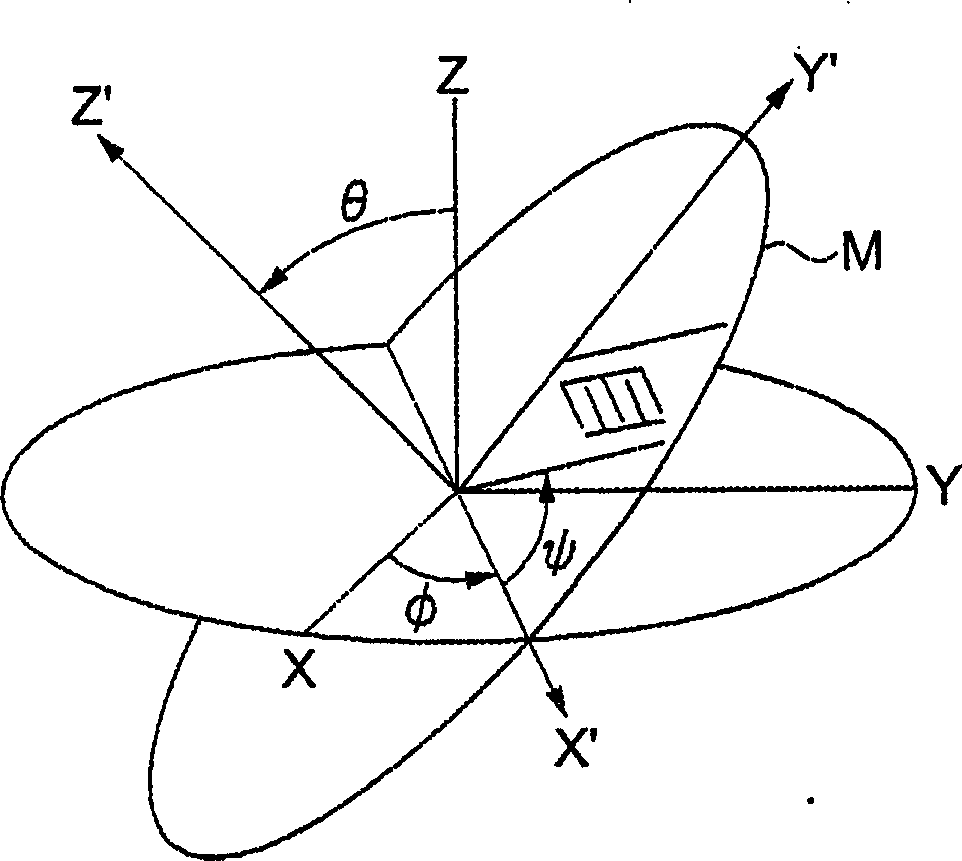

To provide a Lamb-wave high-frequency resonator which obtains high frequency waves, has excellent frequency temperature characteristics and can reduce its manufacturing cost.The Lamb-wave high-frequency resonator 1 includes an interdigital IDT electrode 20 for exciting a Lamb wave on one main surface of a quartz substrate 10, the IDT electrode 20 is formed such that the cut angle of the quartz substrate 10 and the direction of propagation of the Lamb wave are expressed in Euler angles (0, [theta], 0), relation between thickness t of the quartz substrate 10 and the wavelength [lambda] is set within a range to be expressed as 0 H03H 9 / 145 H03H 9 / 25 H01L 41 / 09 H01L 41 / 18 17 15 2 2006 / 1 / 6 1801612 2006 / 7 / 12 100477514 2009 / 4 / 8 2009 / 4 / 8 2009 / 4 / 8 Seiko Epson Corp. Japan Tanaka Satoru li hui 11127 San You Patent Agency No.201 Entrance 1, Building 13, the East of Jinmenli, Haidian District, Beijing 100088 Japan 2005 / 1 / 7 JP2005-002111 Japan 2005 / 10 / 5 JP2005-292126

Owner:SEIKO EPSON CORP

Elastic wave device

ActiveUS20110133600A1Reduced insertion lossHigh electromechanical coupling coefficientPiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectricityElectromechanical coupling coefficient

An elastic wave device has a low temperature coefficient of frequency (TCF), a low insertion loss, a high electromechanical coupling coefficient (k2), and an increased pitch of the electrode fingers. The elastic wave device includes a piezoelectric component, IDT electrodes, and a dielectric layer arranged to cover the IDT electrodes. The dielectric layer has a temperature coefficient of frequency, the sign of the temperature coefficient of frequency being opposite to that of the temperature coefficient of frequency of the piezoelectric component, or the sign of the temperature coefficient of frequency being the same as that of the temperature coefficient of frequency of the piezoelectric component, and the absolute value of the TCF being smaller than that of the temperature coefficient of frequency of the piezoelectric component. Electrode fingers of the IDT electrodes each include a first electrode layer and a second electrode layer. Each first electrode layer is located in a corresponding one of a plurality of grooves. Each second electrode layer is located above the top of a corresponding one of the grooves. The one-half power of the product of the cube of the mean density (ρa) and the mean stiffness (C44a) of the first electrode layer, i.e., (ρ3×C44)1 / 2 of the first electrode layer is larger than (ρ3×C44)1 / 2 of the second electrode layer.

Owner:MURATA MFG CO LTD

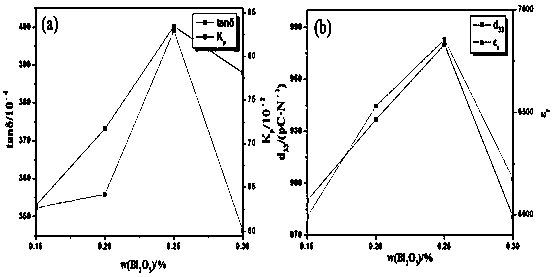

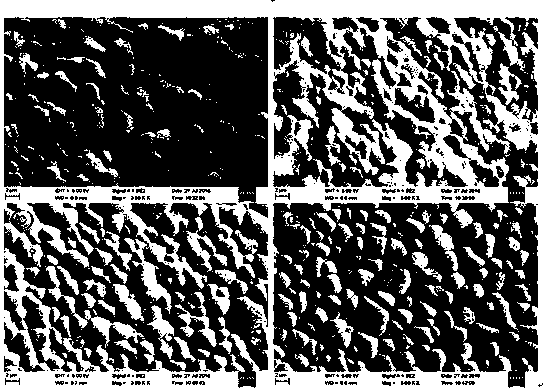

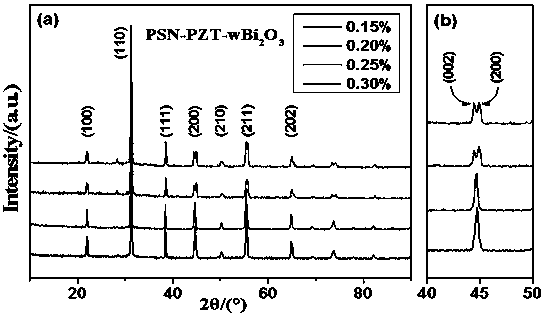

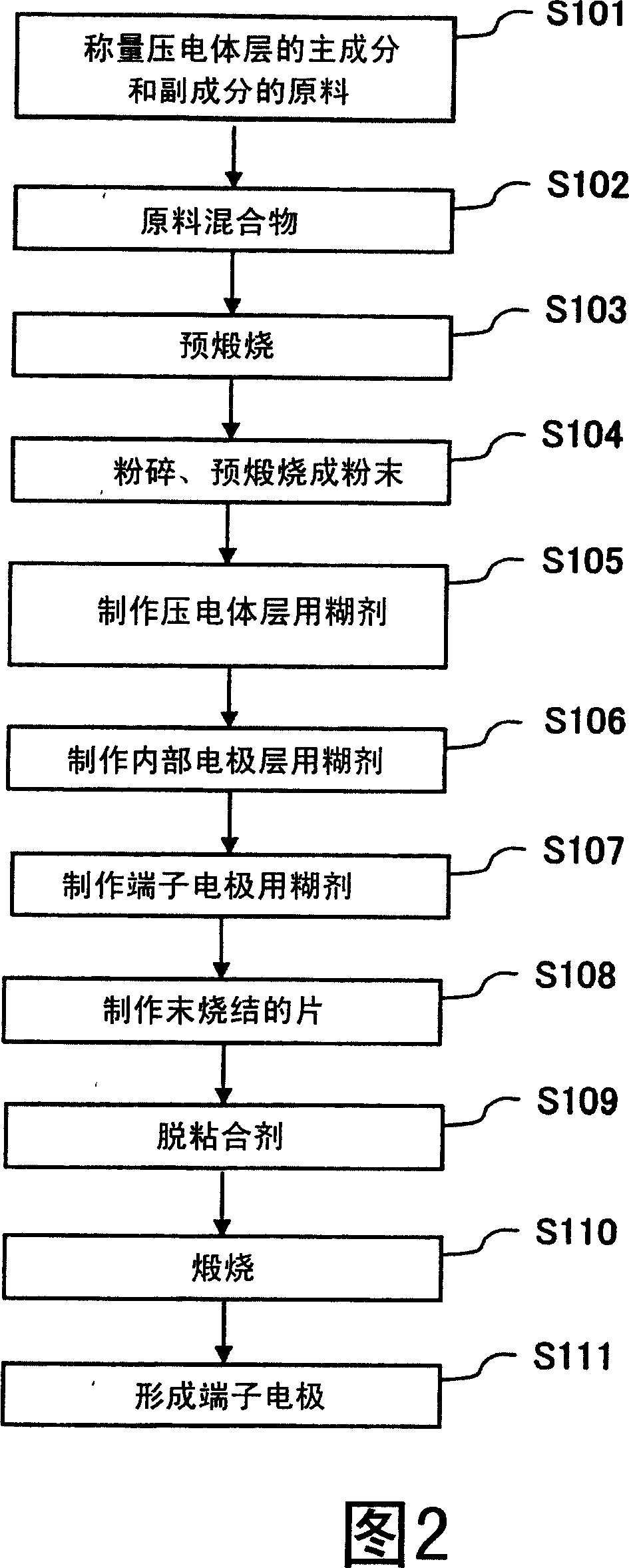

Ternary system PSN-PZT piezoelectric ceramic sheet and preparation method thereof

InactiveCN108275998AHigh dielectric constantHigh electromechanical coupling coefficientBurn treatmentElectromechanical coupling coefficient

The invention discloses a ternary system PSN-PZT piezoelectric ceramic sheet and a preparation method thereof, and belongs to piezoelectric ceramic sheets and preparation methods thereof. The formulastoichiometric general formula of the ternary system PSN-PZT piezoelectric ceramic sheet is: Pb<1-x-y>M<x>Z<y>(Sb<1 / 3>Nb<2 / 3>)<0.02>(Zr<1 / 2>Ti<1 / 2>)<0.98>+<z>wt%Bi2O3, wherein x=0-0.17, y=0-0.1, z=0-0.4, and M and Z are at least two of SrCO3, BaCO3 or CaCO3. The preparation method comprises the following steps: performing ball-milling on each raw material, then performing drying, pulverizing and sieving, performing pre-burning, then performing ball-milling again, and then performing drying, pulverizing and sieving again; mixing the obtained material with polyvinyl alcohol, performing granulation, and pressing the mixture into a blank; performing rubber discharging at 350-630 DEG C; then firing the rubber discharged blank into a ceramic sheet at 1200-1280 DEG C; and treating the surface ofthe ceramic sheet with silver, then performing silver burning treatment; and performing polarization treatment. The ternary system PSN-PZT piezoelectric ceramic sheet prepared by using the method andthe raw materials provided according to the formula stoichiometric general formula has the advantages of high dielectric constant and piezoelectric constant, large electromechanical coupling coefficient, suitable Curie temperature, etc.; and is suitable for preparing piezoelectric pump drive wafers and piezoelectric actuator wafers.

Owner:GUIZHOU ZHENHUA HONGYUN ELECTRONICS +1

Ceramic material and piezoelectric element using the same

InactiveCN1484624AHigh electromechanical coupling coefficientLow permittivityPiezoelectric/electrostrictive device material selectionDielectric loss factorElectromechanical coupling coefficient

Owner:DIESEL KIKI CO LTD

IDT/h-BN/c-BN/diamond multi-layer film structure surface acoustic wave device and its manufacture method

InactiveCN101060318ASmall difference in phase velocity VSmall velocity dispersionImpedence networksTemperature coefficientFilm structure

The disclosed IDT / h-BN / c-BN / diamond multilayer membrane structure SAW device comprises: from bottom to top, a nano-diamond membrane base prepared on mirror silicon, a nano c-BN membrane intermediate layer, a high-C-axis preferred orientated nano h-BN membrane, and an IDT. This invention can be used on condition of 2. 5GHz, high electromechanical coupling factor, smaller loss at 8w propagation, and low frequency temperature coefficient.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Bulk acoustic wave resonator and semiconductor device

PendingCN110868184AImprove the acoustic impedance ratioHigh Q valueImpedence networksDevice materialAcoustic wave

The invention relates to the technical field of semiconductors, and discloses a bulk acoustic wave resonator and a semiconductor device. The bulk acoustic wave resonator comprises a substrate; and a multi-layer structure which is formed on the substrate, wherein the multi-layer structure sequentially comprises a lower electrode layer, a doped piezoelectric layer and an upper electrode layer from bottom to top, a cavity is formed between the substrate and the multilayer structure, the electrode surface of at least one of the lower electrode layer and the upper electrode layer is provided with aconcave part extending towards the interior of the corresponding electrode layer and / or a convex part extending towards the exterior of the corresponding electrode layer, the doped piezoelectric layer includes a piezoelectric material doped with at least one rare earth element. According to the resonator, the cavity with the lower half cavity and the upper half cavity is arranged, the convex partand / or the concave part are / is arranged on the surface of the electrode layer, and the piezoelectric layer is doped with at least one rare earth element, so that a novel bulk acoustic wave resonatorstructure is formed, and the resonator has relatively good performance.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

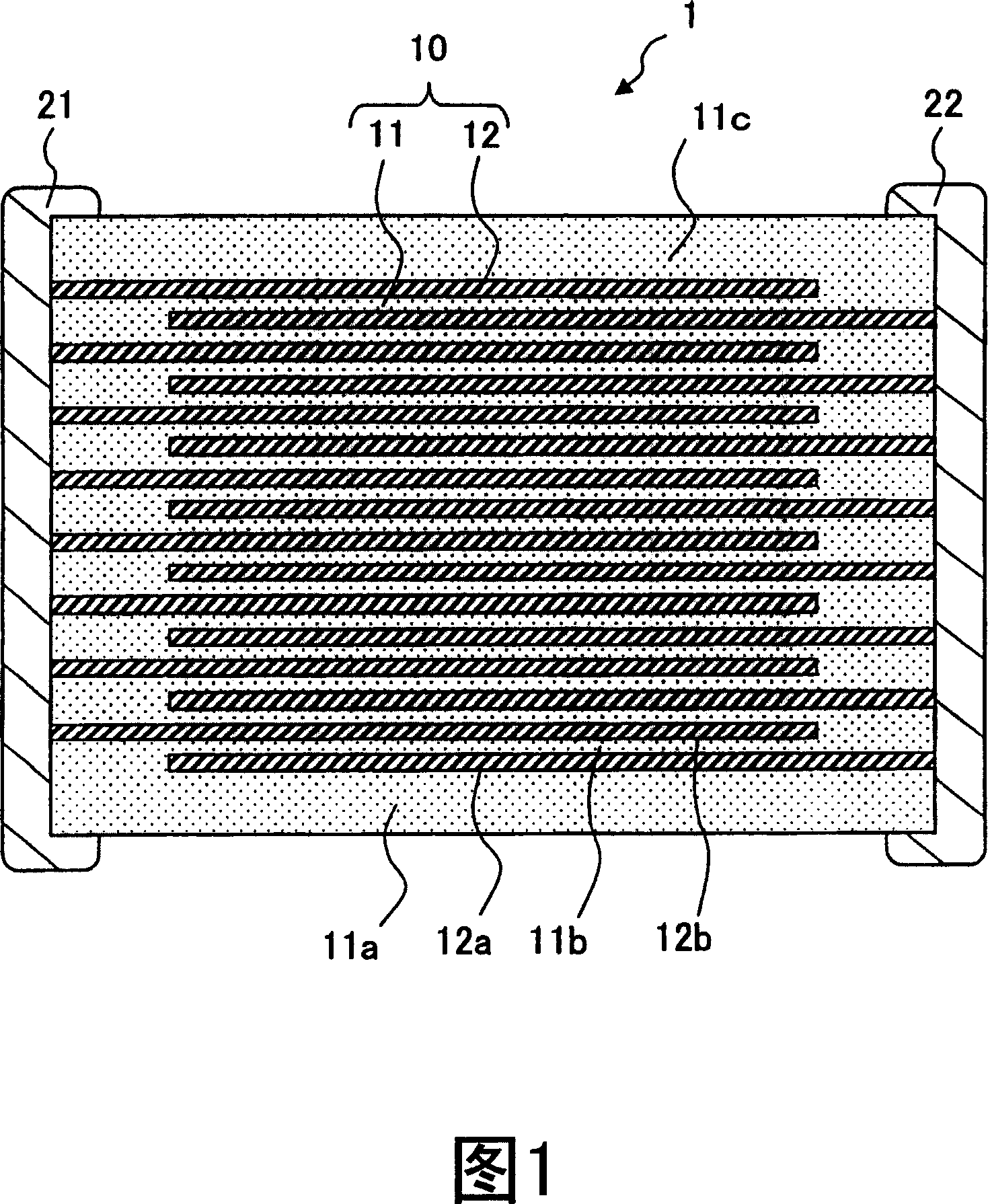

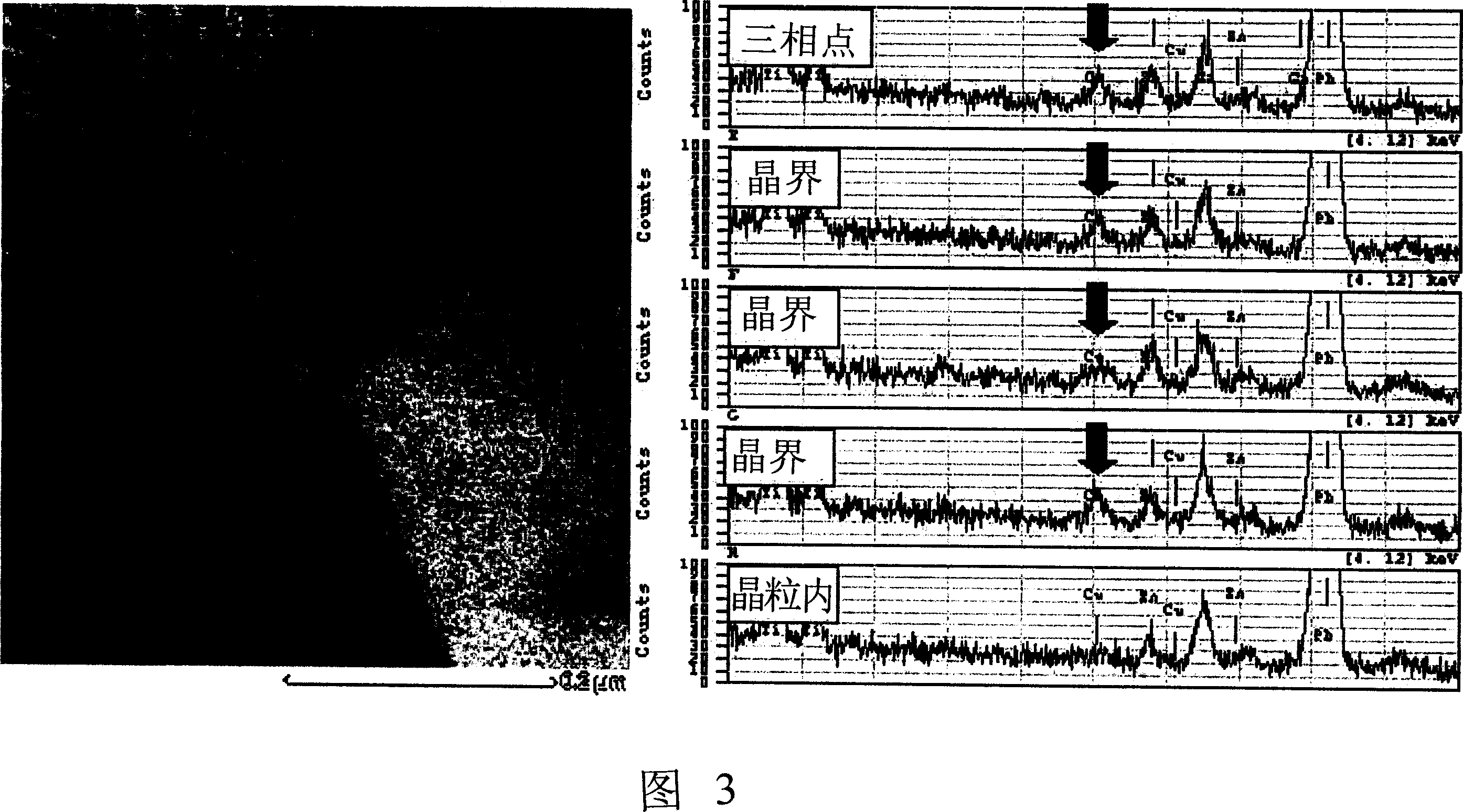

Piezoelectric ceramic composition and laminated piezoelectric element

ActiveCN1944335AHigh electromechanical coupling coefficientExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyFixed capacitor dielectricComposite oxideElectrode

For the purpose of preventing the degradation of the piezoelectric strain properties when Cu is used for internal electrodes, there is provided a piezoelectric ceramic composition including: a composite oxide, as a main constituent thereof, represented by (Pb a - b Me b ) [(Zn 1 / 3 Nb 2 / 3 ) x Ti y Zr z ]O 3 with the proviso that 0.96<=a<=1.03, 0<=b<=0.1, 0.05<=x<=0.15, 0.25<=y<=0.5, 0.35<=z<=0.6, and x + y + z = 1, and Me represents at least one selected from Sr, Ca and Ba; and at least one selected from Co, Mg, Ni, Cr and Ga as a first additive to the main constituent in a content of 0.5% by mass or less (not inclusive of 0) in terms of oxide, wherein an electrode made of Cu is to be disposed on the piezoelectric ceramic composition.

Owner:TDK CORPARATION

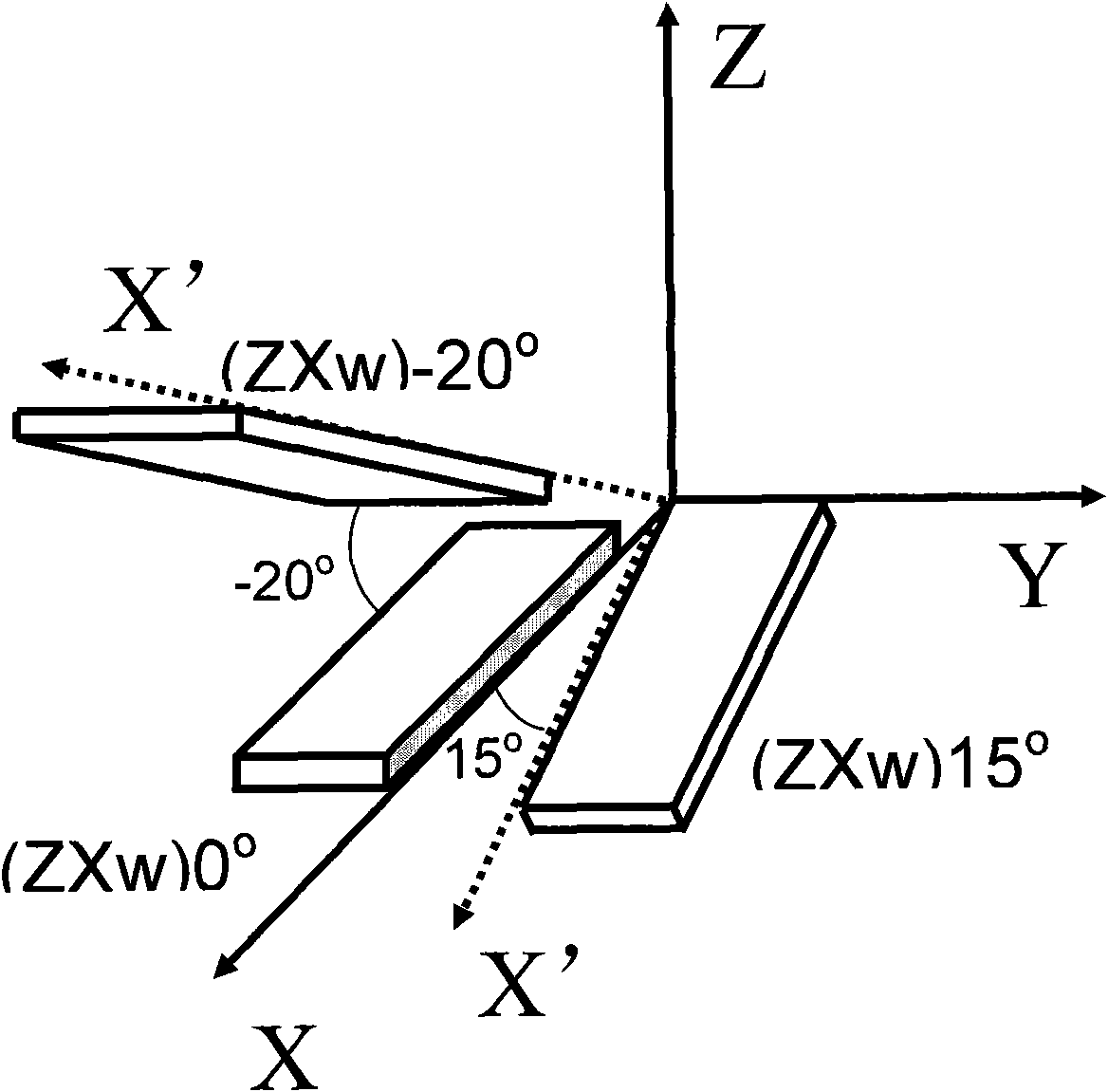

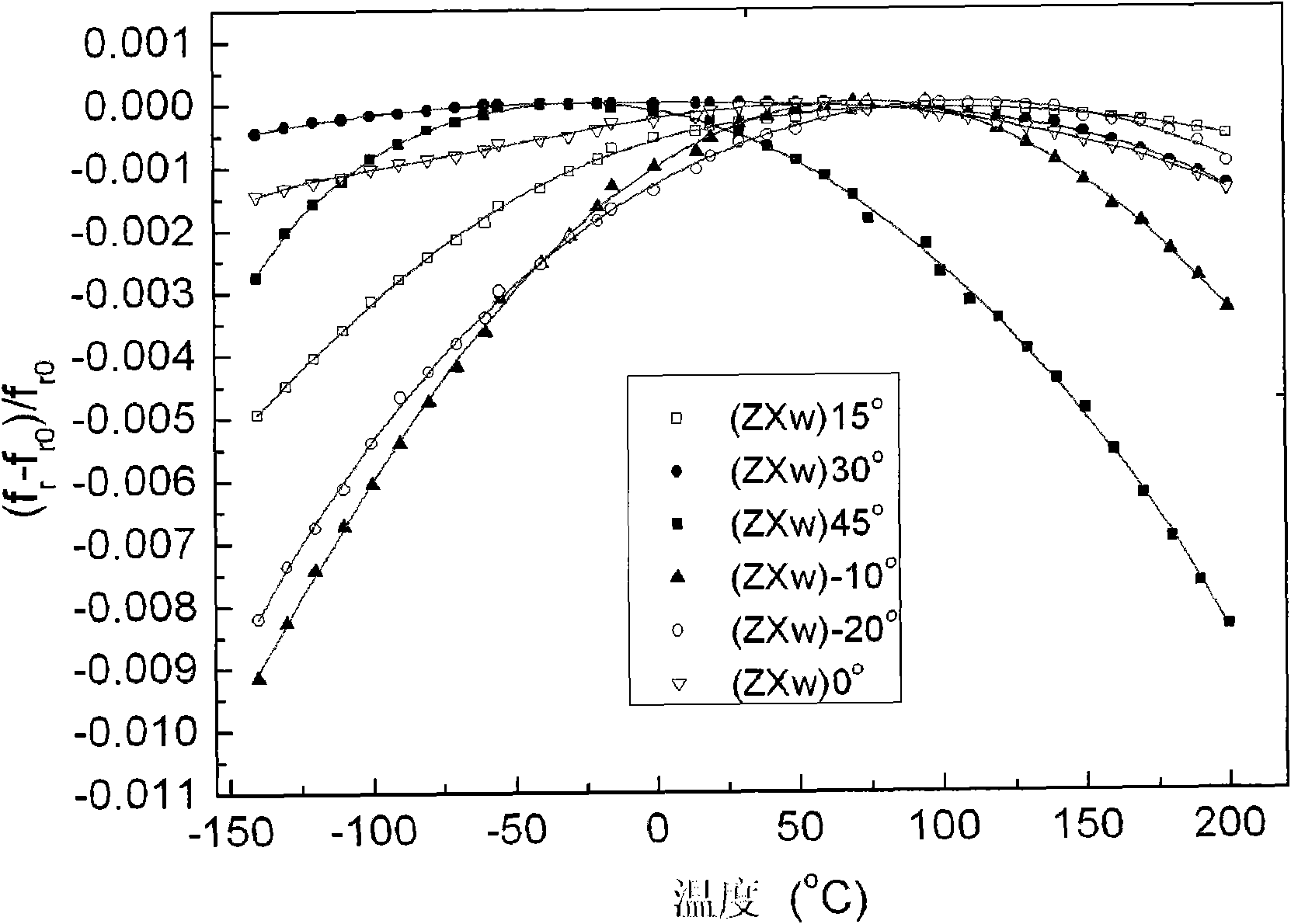

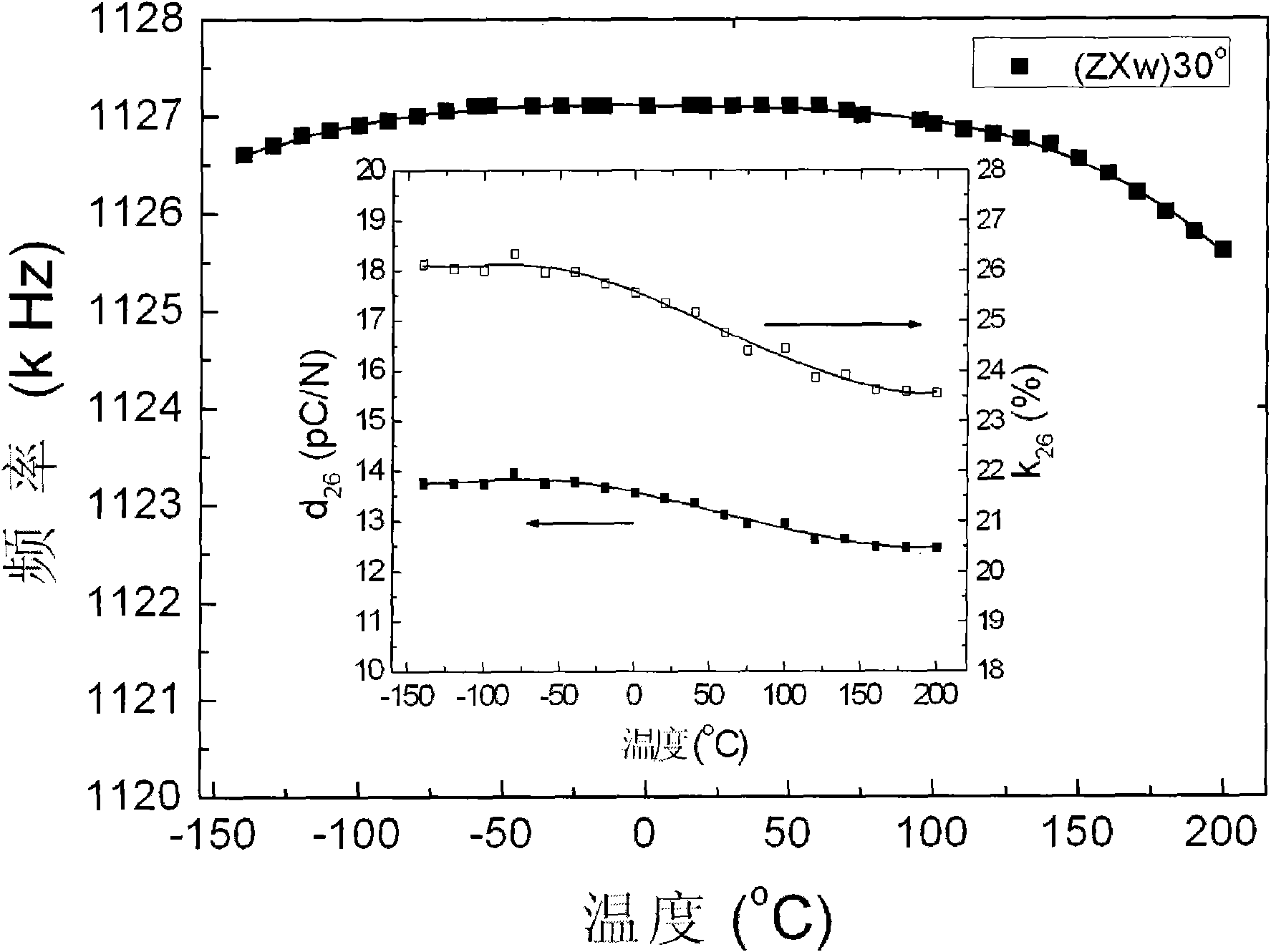

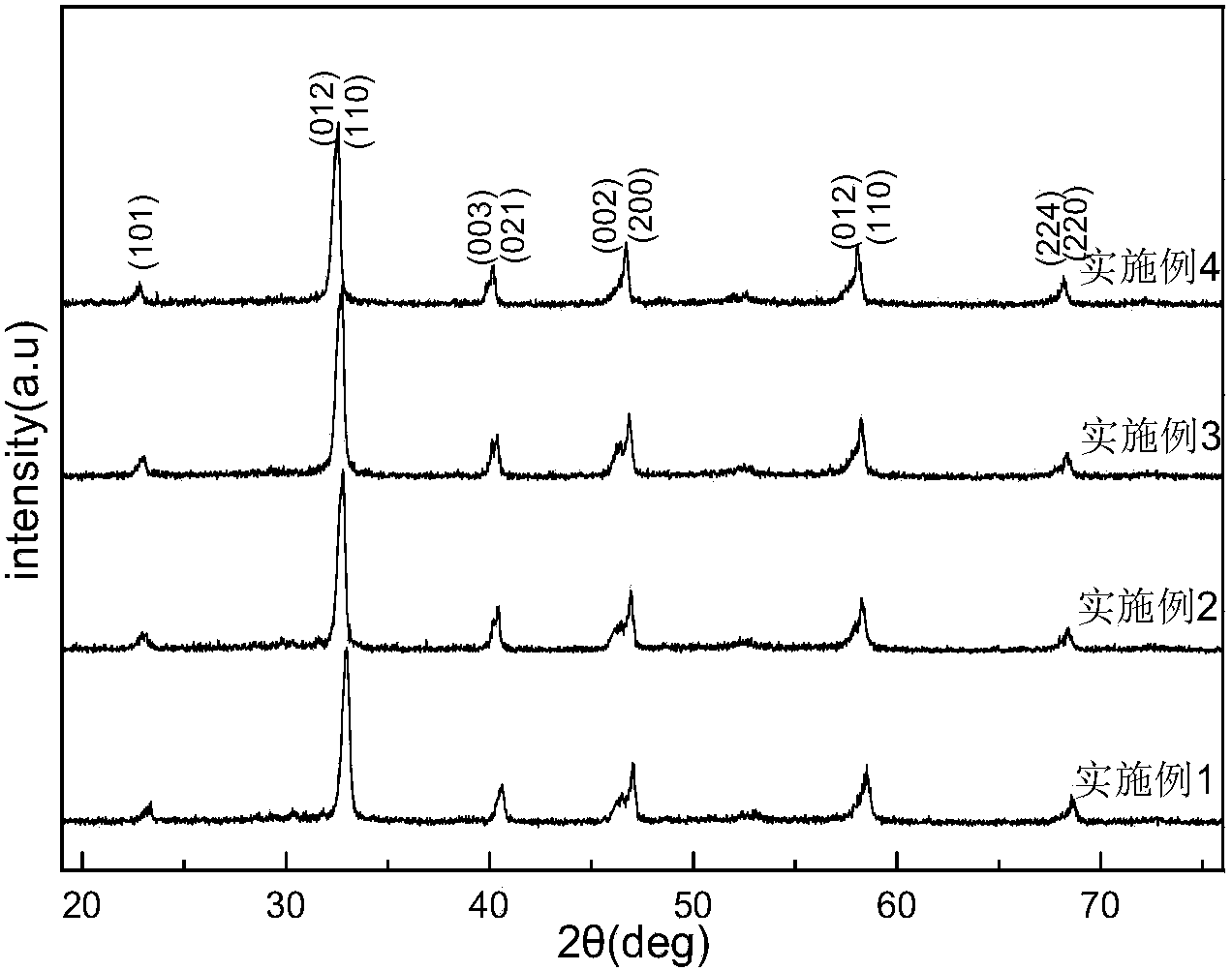

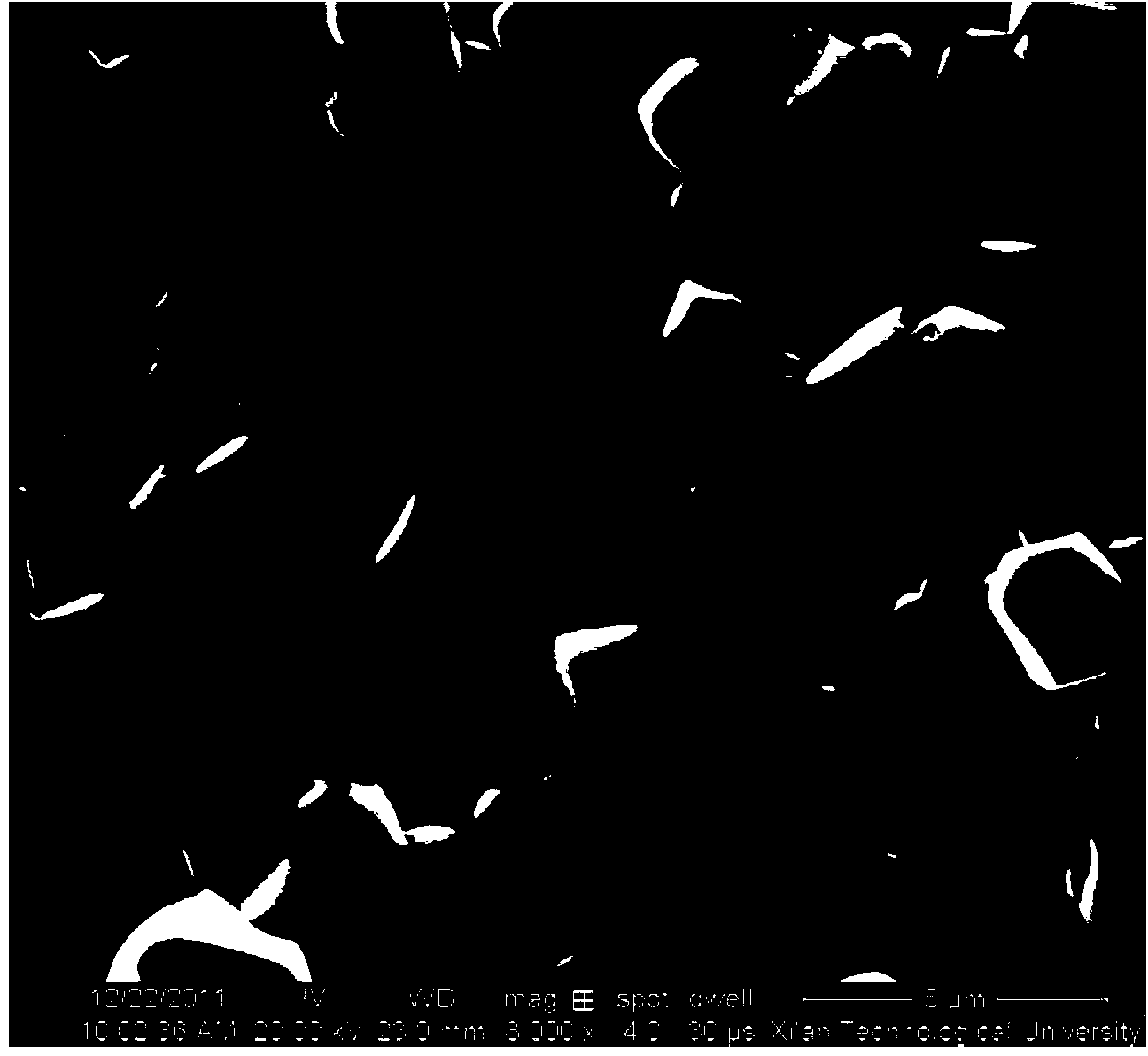

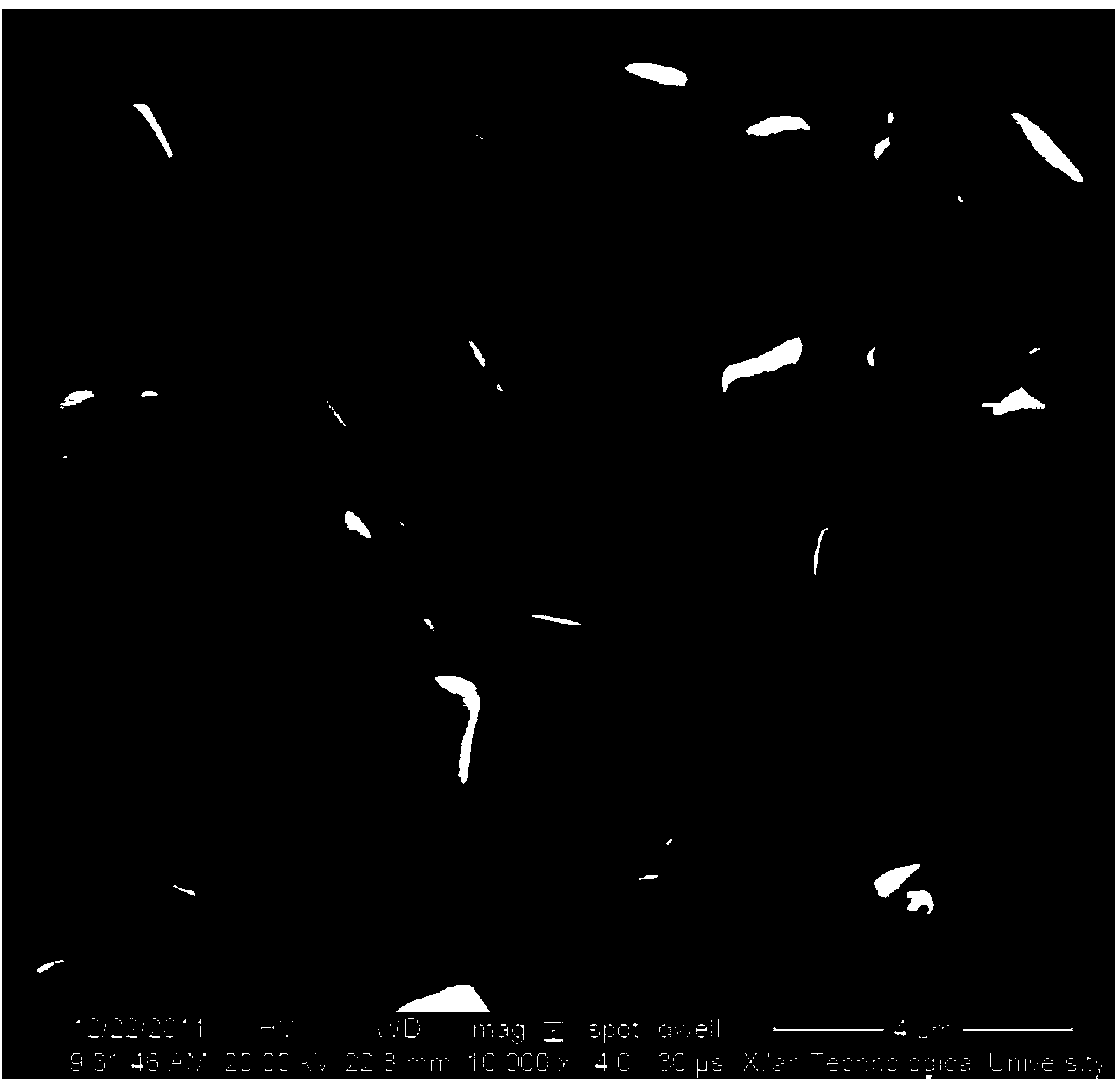

NdCa4O(BO3)3 crystal zero frequency temperature coefficient cut and application

ActiveCN101847975AImprove frequency temperature stabilityReduce mechanical wear and tearImpedence networksNarrow rangePlatinum

The invention relates to an NdCa4O(BO3)3 crystal zero frequency temperature coefficient cut and application. A crystal rotates with an alpha angle and is recorded as (ZXw) alpha, wherein alpha is no less than 20 degrees below zero and no more than 45 degrees; and the dimensional proportion of the cut is shown that thickness:width:length=1:(2-3):(6-10). Platinum electrode is plated on an NdCa4O(BO3)3 crystal cut in the width direction with the electrode thickness of 200-220nm; and by adopting a mode of width shearing vibration, the temperature stability of a crystal resonant frequency is controlled to be 0-25ppm / DEG C within a range from 140 DEG C below zero to 200 DEG C. The invention solves the problems of lower electromechanical coupling coefficient (smaller than 8 percent) of quartz crystals as well as stable crystal frequency and narrower range of crystals of lithium tantalate, lanthanum galium silicate single and the like and is suitable for manufacturing a frequency controller used in a wide temperature range.

Owner:山东本源晶体科技有限公司

Solid solution-modified sodium bismuth titanate leadless piezoelectric ceramics and preparation method thereof

ActiveCN103833354AExcellent piezoelectric propertiesHigh electromechanical coupling coefficientElectromechanical coupling coefficientTwo step

The invention provides solid solution-modified sodium bismuth titanate leadless piezoelectric ceramics and a preparation method thereof. The piezoelectric ceramics are represented by chemical composition general formula of (1-x)(0.74Na0.5Bi0.5TiO3-0.26SrTiO3)-xBa(Zr0.05Ti0.95)O3 or (1-y)(0.9Na0.5Bi0.5TiO3-0.1CaTiO3)-yBa(Zr0.05Ti0.95)O3, wherein 0.04<=x<=0.1 and 0.04<=y<=0.1. Solid solution of Ba(Zr0.05Ti0.95)O3 is realized at the morphotropic phase boundary of a 0.74Na0.5Bi0.5TiO3-0.26SrTiO3 and 0.9Na0.5Bi0.5TiO3-0.1CaTiO3 system, and high-density microcrystalline structure ceramics with uniform crystal grain size distribution are obtained by a two-step forming method and a self-bearing pressure sintering process. The piezoelectric property of the material is optimized by the morphotropic phase boundary composition characteristics and the solid solution modification method, and the piezoelectric constant d33 reaches 110-138 PC / N; the electromechanical coupling coefficient of the material is also increased obviously; the preparation process of the material is simple and stable, and the material is an optimal material for manufacturing low-power ultrasonic devices and energy transducers used in fields of gas sensors, industrial nondestructive test, and the like.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com