Design and preparation method for cavity type FBAR (thin-film bulk acoustic resonator) filter

A thin-film bulk acoustic wave and resonator technology, which is applied in CAD circuit design, instruments, calculations, etc., can solve the problems of inaccurate filter film parameters, difficult FBAR filters, and unguaranteed problems, and achieve quality and structural integrity. Simple and precise control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

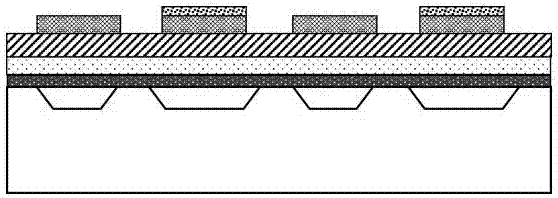

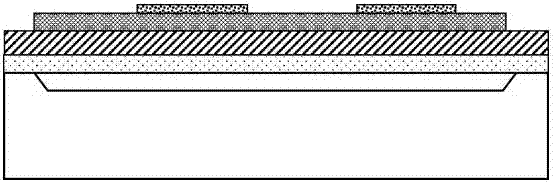

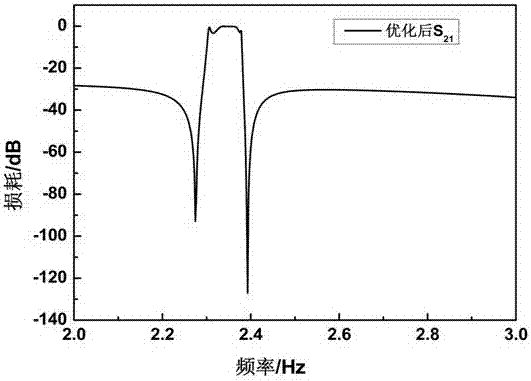

[0039] Such as figure 1 As shown, the design and manufacturing method of the cavity-type film bulk acoustic resonator filter in this embodiment includes the following steps.

[0040]1. Filter structure design. According to the Mason model, add the electronic components and connections corresponding to the FBAR filter in the ADS schematic diagram. The topology of the four-step ladder filter in this embodiment is two series FBARs and two parallel FBARs using T-type cascading. AlN and Mo are selected as the piezoelectric layer material and electrode material respectively, and are updated according to the physical parameters of the selected materials. Component parameter values in the schematic diagram:

[0041] The longitudinal wave sound velocity, characteristic acoustic impedance, electromechanical coupling coefficient, clamping permittivity, and attenuation factor of piezoelectric layer AlN are 11350 m / s and 3.70e7 kg / m, respectively 2 s, 6.0%, 9.50e-11 F / m, 800 dB / m;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com