Two-dimensional coupled radio frequency piezoelectric resonator and preparation method thereof

A piezoelectric resonator, two-dimensional coupling technology, applied in electrical components, impedance networks, etc., can solve problems such as inability to manufacture multi-frequency devices, high requirements for piezoelectric film thickness uniformity, and complex implementation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

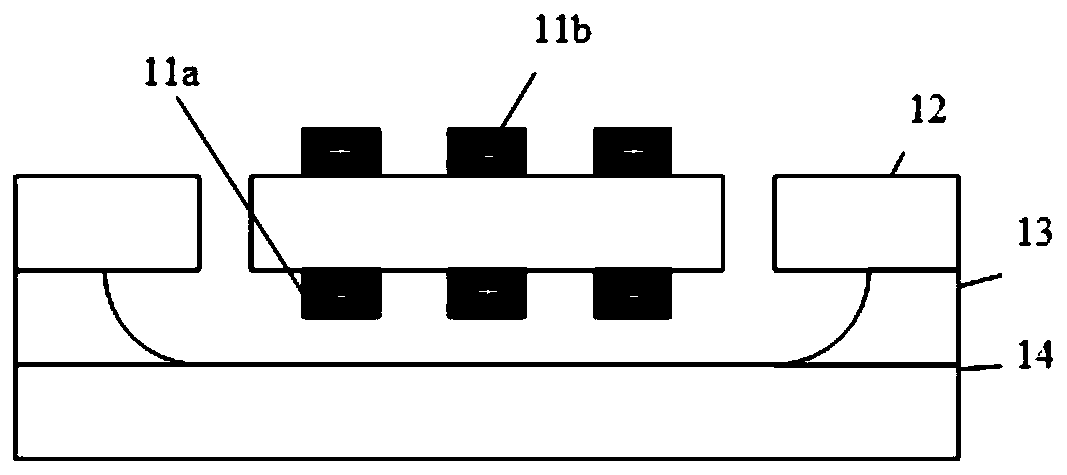

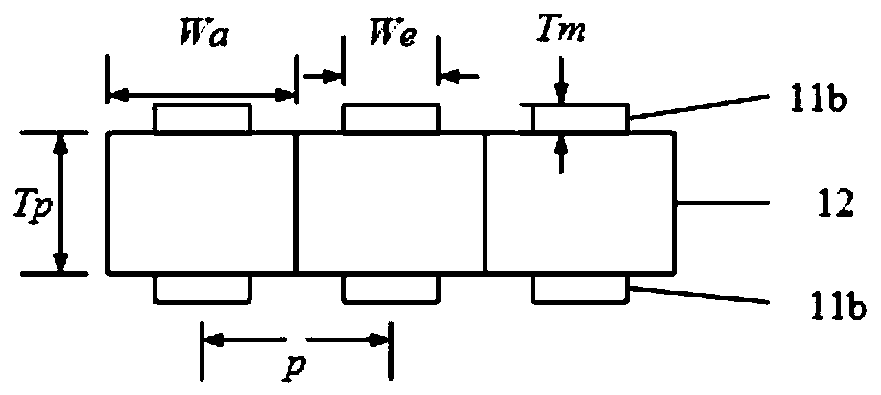

[0061] like Figure 1a As shown, a two-dimensionally coupled RF piezoelectric resonator provided in this embodiment includes a piezoelectric layer 12 for fixing interdigital electrodes, and the piezoelectric layer 12 is fixed on a sacrificial layer 13 or a silicon substrate 14 The interdigitated electrodes are used to drive the resonator to resonate. The upper and lower electrodes 11b and 11a of the interdigitated electrodes are respectively fixed on the upper and lower sides of the piezoelectric layer 12. The electrode is a resonant unit. In this embodiment, a resonant unit is provided on the piezoelectric layer 12. The resonant unit includes three pairs of finger electrodes 11. The resonant unit is connected to the peripheral piezoelectric layer 12 through a small anchor point. Among the interdigital electrodes on the same section, the directions of the first and third interdigital electrodes are opposite to those of the second interdigital electrodes, and the roots of the in...

Embodiment 2

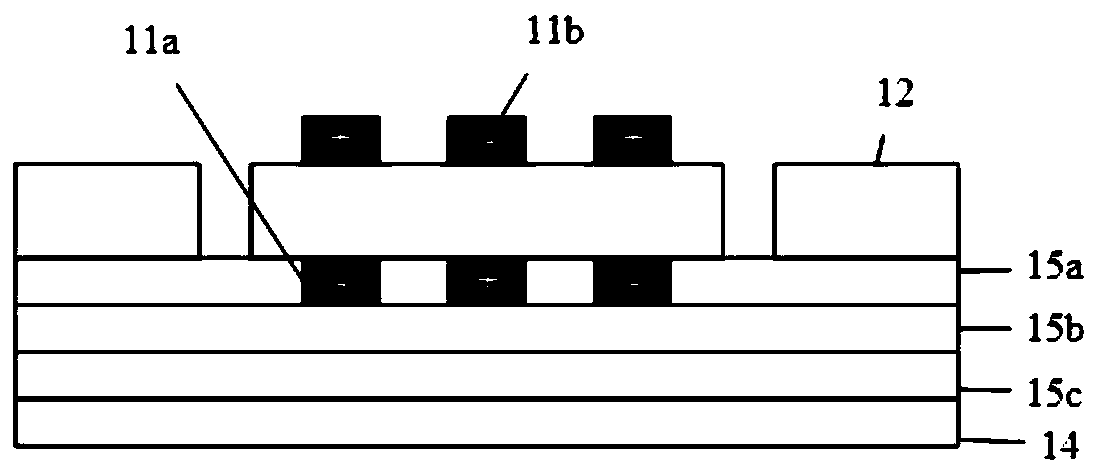

[0071] like Figure 1c As shown, the difference between this embodiment and Embodiment 1 is that the piezoelectric layer 12 and the silicon substrate are solid structures, and the two pass through three layers of acoustic reflection layers (the first acoustic reflection layer 15a, the second acoustic reflection layer 15a, respectively). The two acoustic reflective layers 15b and the third acoustic reflective layer 15c) are connected. The acoustic impedance of two adjacent acoustic reflective layers is very different, so that the sound wave is reflected, and the sound wave propagates in each layer for 1 / 2 cycle.

Embodiment 3

[0073] like Figure 2a , 2b As shown, the difference between this embodiment and Embodiment 1 is that the resonant unit includes five pairs of interdigitated electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com