Bismuth ferrite-barium titanate lead-free piezoelectric ceramic as well as preparation method and application thereof

A lead-free piezoelectric and barium titanate technology is applied in the field of preparation of bismuth ferrite-barium titanate lead-free piezoelectric ceramics, which can solve the problem that the performance of electronic equipment cannot be rapidly developed, the piezoelectric performance is not ideal, and the sintering temperature narrow interval, etc., to achieve the effect of high remanent polarization, favorable for industrial production and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

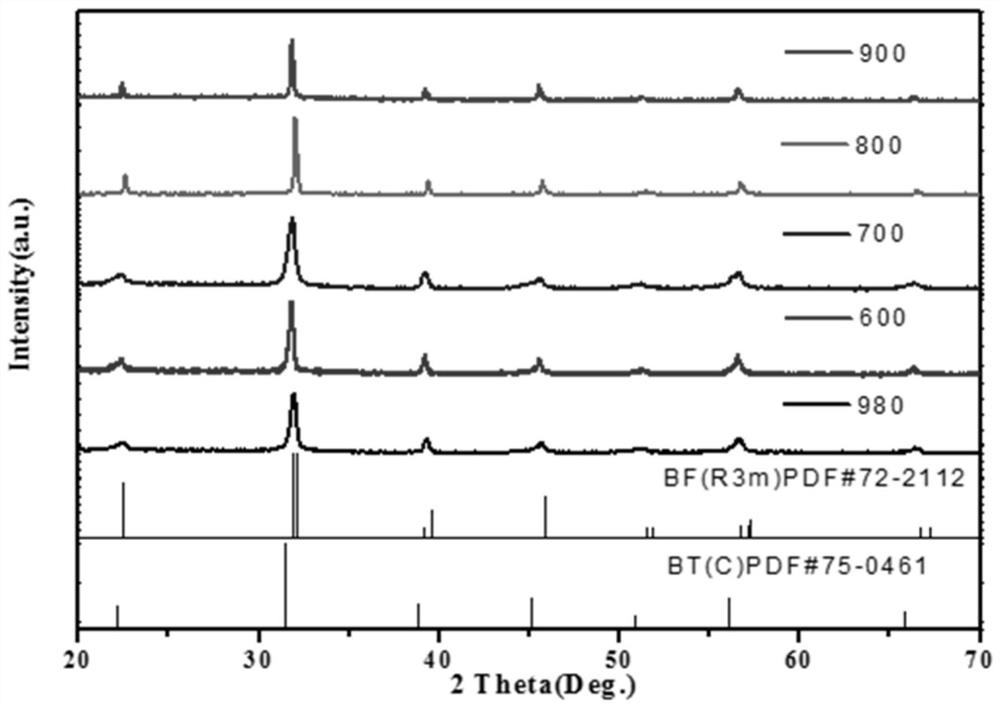

[0057] A preparation method of bismuth ferrite-barium titanate lead-free piezoelectric ceramics, the chemical formula of the bismuth ferrite-barium titanate is (1-x)Bi y FeO 3 -xBaTiO 3 , x and y are mole fractions, x takes a value of 0.3 to 0.4, and y takes a value of 0.6 to 1.2. The raw materials for preparing the bismuth ferrite-barium titanate include Bi 2 o 3 ﹑ Fe 2 o 3 ﹑BaCO 3 and TiO 2 , the preparation method comprises the steps of:

[0058] Bi 2 o 3 ﹑ Fe 2 o 3 ﹑BaCO 3 and TiO 2 React in an environment of 780°C to 850°C to prepare the precursor;

[0059] Performing granulation treatment, molding treatment, debinding treatment and sintering treatment on the precursor to prepare ceramics;

[0060] Annealing treatment, silver burning treatment, quenching treatment and polarization treatment are performed on the ceramics.

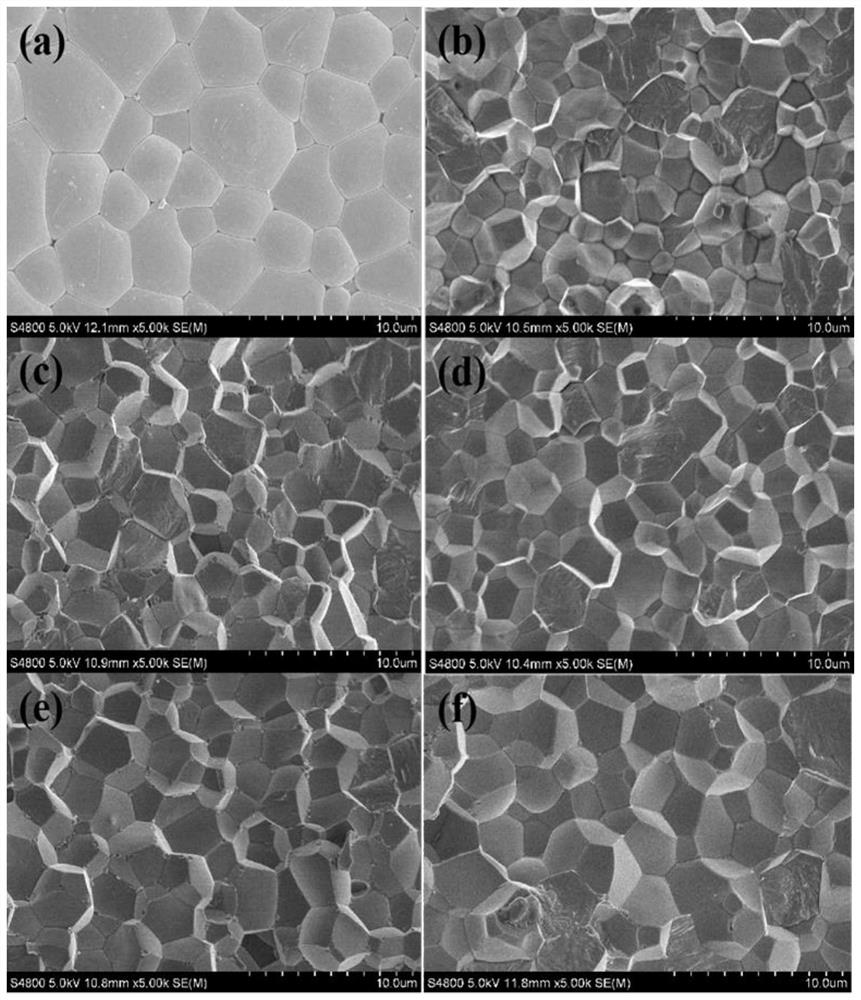

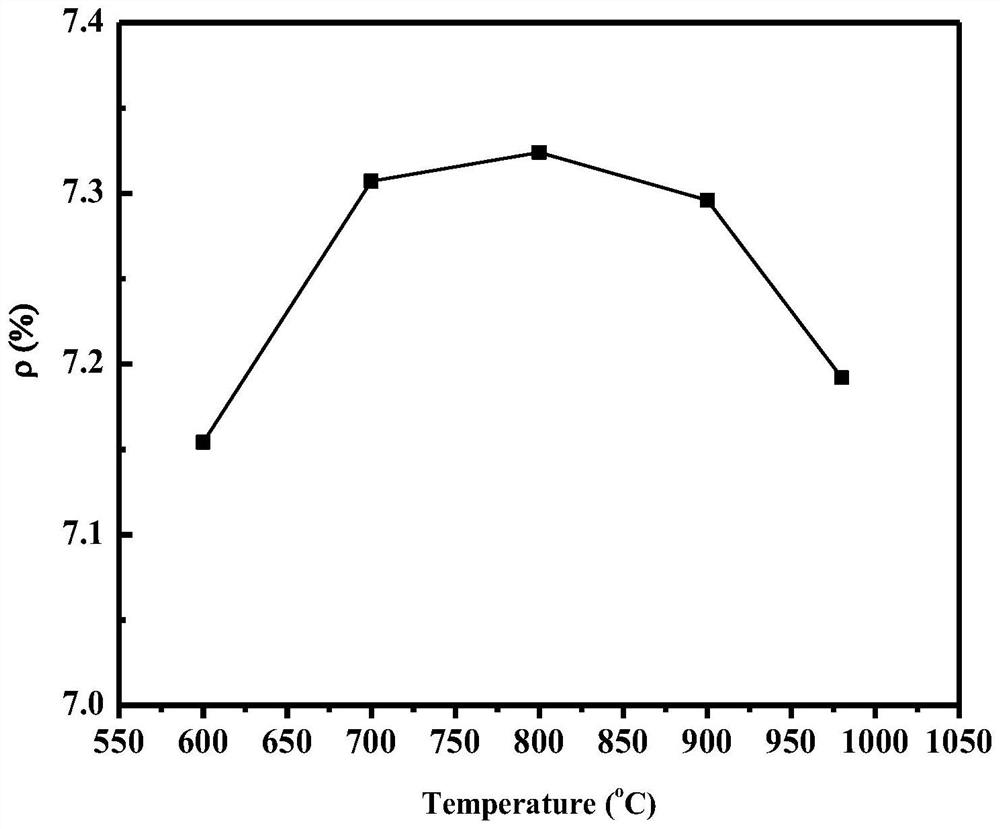

[0061] The microstructure, density and charge defect concentration of bismuth ferrite-barium titanate lead-free piezoelectric ceramics a...

Embodiment 1

[0098] This embodiment provides a bismuth ferrite-barium titanate lead-free piezoelectric ceramic and its preparation method. The preparation method is as follows:

[0099] (1) Calculation: according to the prepared (1-x)Bi y FeO 3 -xBaTiO 3 The stoichiometric ratio in the formula accurately calculates the Bi in the formula 2 o 3 ﹑ Fe 2 o 3 ﹑BaCO 3 and TiO 2 The quality of x=0.3, y=1.02 among the present embodiment;

[0100] (2) Weighing: according to the pre-calculated Bi 2 o 3 ﹑ Fe 2 o 3 ﹑BaCO 3 and TiO 2 The mass of the sample is weighed, and the weighing is accurate to the thousandth, and then the weighed raw materials are put into the ball mill jar in turn;

[0101] (3) The first ball mill: use absolute ethanol as the ball mill medium, mix agate beads with a diameter of 5mm and zirconia beads with a diameter of 2mm in a ratio of 1:4, wherein raw materials: ball mill beads: mass of absolute ethanol Ratio = 1:4:1. After pre-mixing the ball anhydrous ethanol ...

Embodiment 2

[0114] This embodiment provides a bismuth ferrite-barium titanate lead-free piezoelectric ceramic and its preparation method. The preparation method is as follows:

[0115] (1) Calculation: according to the prepared (1-x)Bi y FeO 3 -xBaTiO 3 The stoichiometric ratio in the formula accurately calculates the Bi in the formula 2 o 3 ﹑ Fe 2 o 3 ﹑BaCO 3 and TiO 2 The quality of x=0.3, y=1.02 among the present embodiment;

[0116] (2) Weighing: according to the pre-calculated Bi 2 o 3 ﹑ Fe 2 o 3 ﹑BaCO 3 and TiO 2 The mass of the sample is weighed, and the weighing is accurate to the thousandth, and then the weighed raw materials are put into the ball mill jar in turn;

[0117] (3) The first ball mill: use absolute ethanol as the ball mill medium, mix agate beads with a diameter of 5mm and zirconia beads with a diameter of 2mm in a ratio of 1:4, wherein raw materials: ball mill beads: mass of absolute ethanol Ratio = 1:4:1. After pre-mixing the ball anhydrous ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com