Patents

Literature

67results about How to "High remnant polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

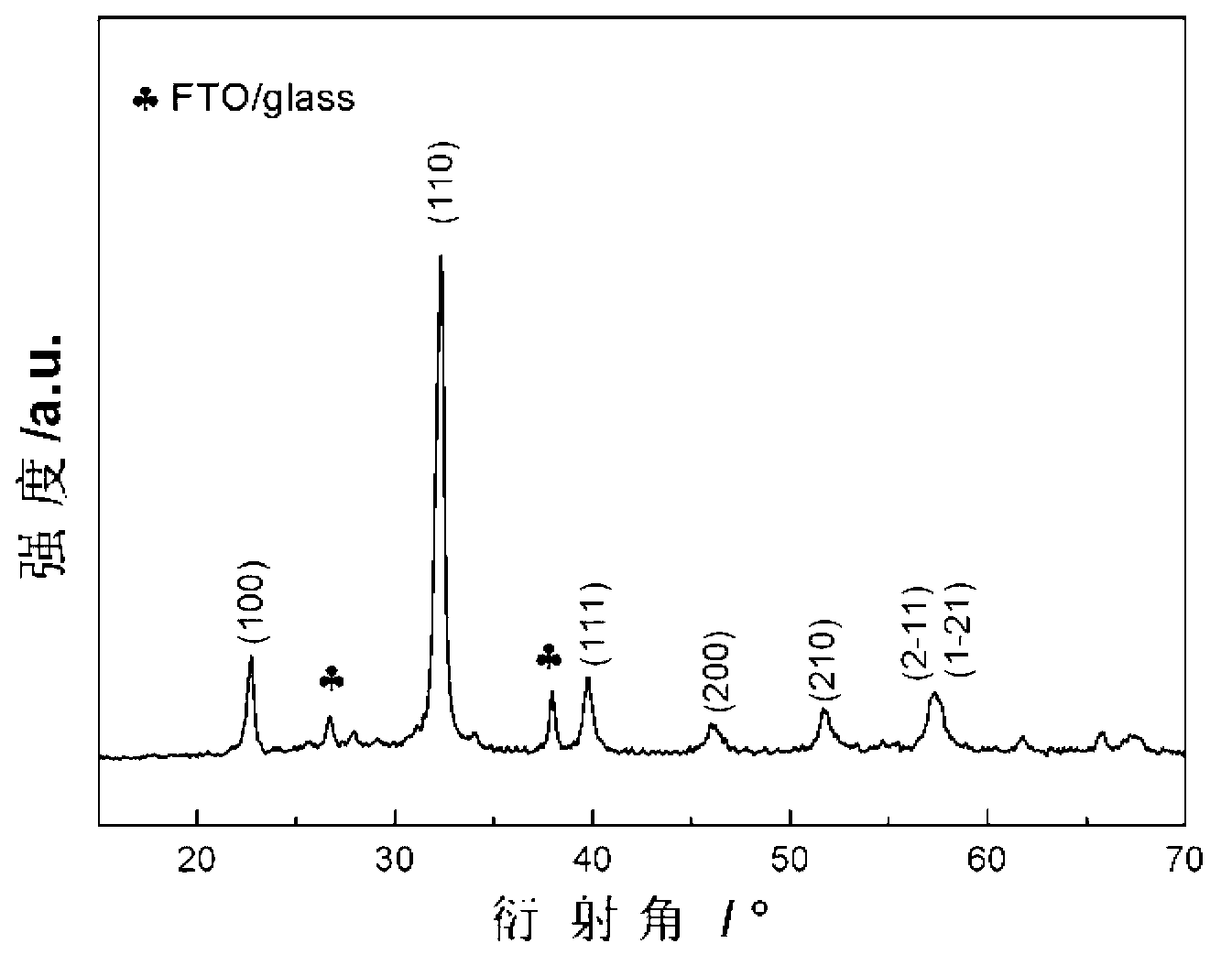

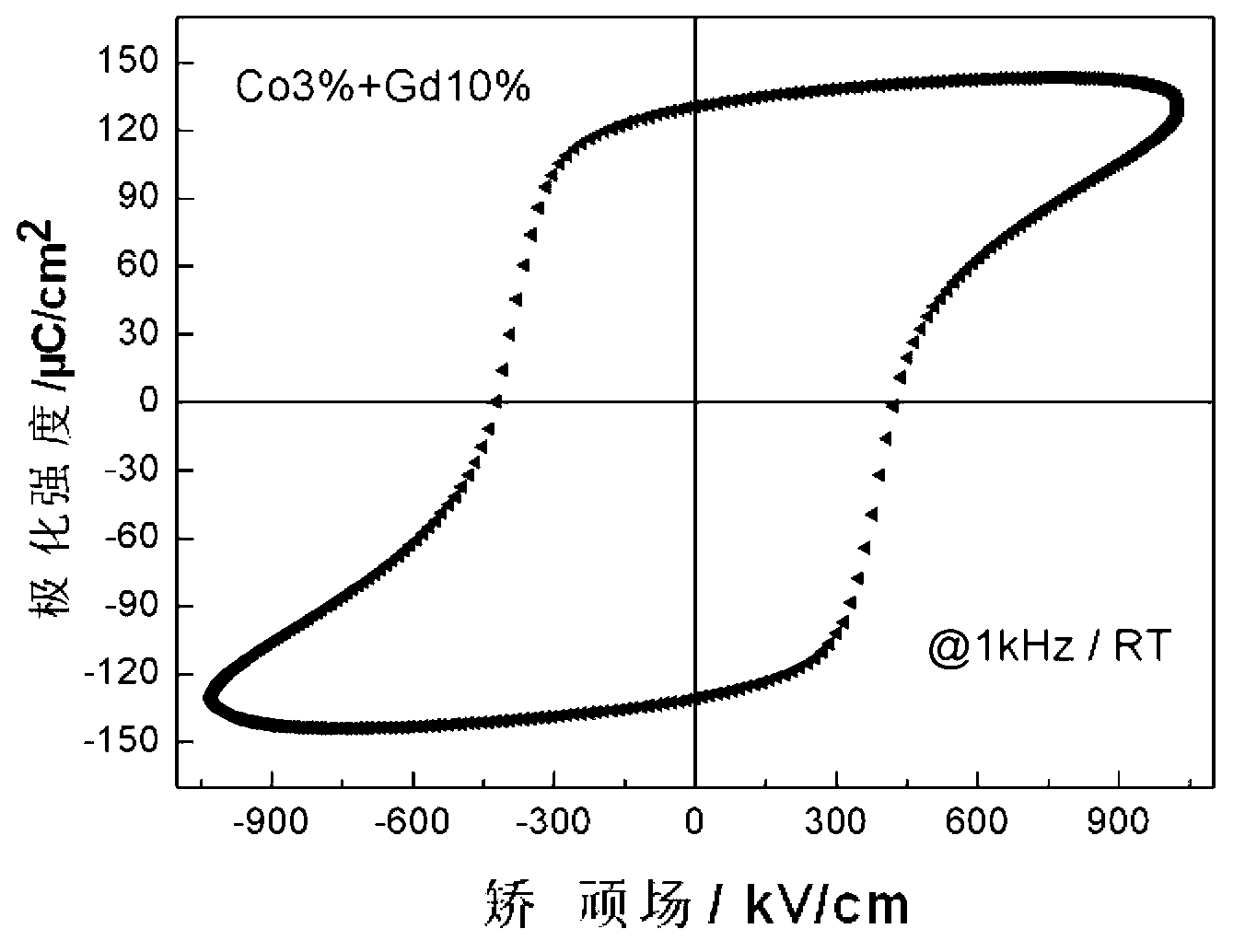

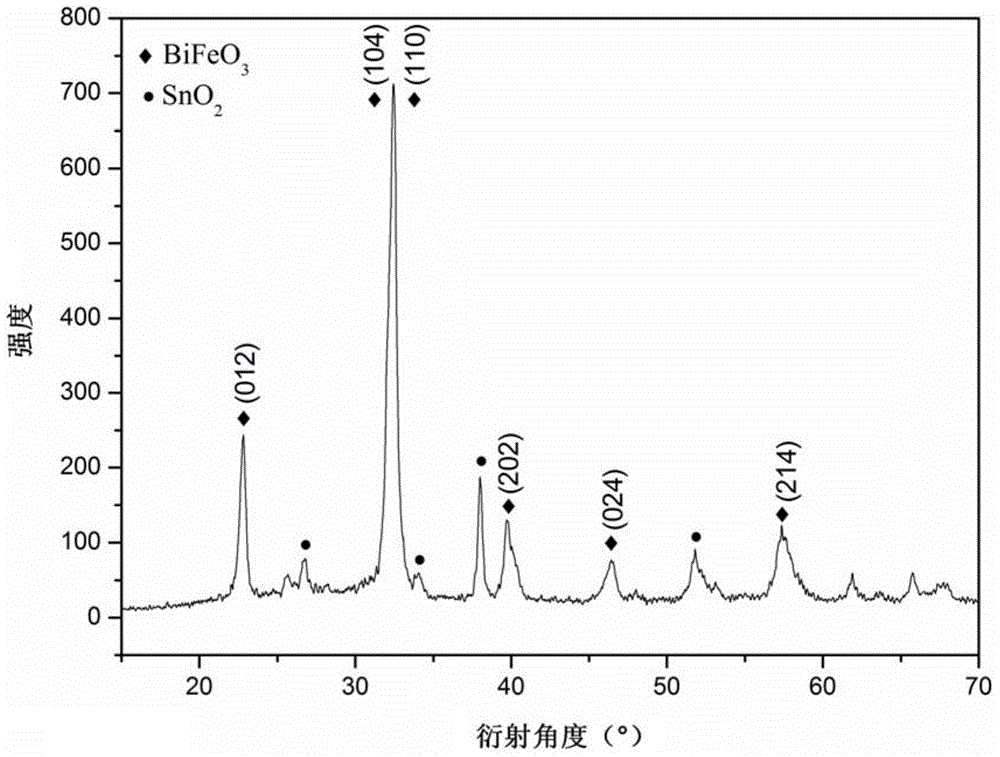

Method for preparing Gd and Co codoped high-remanent-polarization BiFeO3 thin film by sol-gel method

ActiveCN103073064AImprove multiferroic performanceImprove ferroelectric propertiesIron compoundsEthylene glycol monomethyl etherSol-gel

The invention provides a method for preparing a Gd and Co codoped high-remanent-polarization BiFeO3 thin film by a sol-gel method. The method comprises the steps that Bi(NO3)3*5H2O, Fe(NO3)3*9H2O, Gd(NO3)3*6H2O and Co(NO3)2*6H2O are dissolved in ethylene glycol monomethyl ether, and then heated and stirred in an 80 DEG C water bath for 1h; acetic anhydride is added and stirred for 1h; a BiFeO3 precursor solution is obtained and stands for 24h; an FTO (Fluorinedoped Tin Oxide) / glass substrate is subjected to spin coating with the BiFeO3 precursor solution for preparing a thin film; the thin film is subjected to rapid annealing at 550 DEG C, and then cooled to a room temperature; and spin coating and rapid annealing processes are repeated till the BiFeO3 thin film with the required thickness is prepared. The adopted sol-gel method does not require expensive equipment, and is suitable for preparing the thin film on a large surface and a surface with an irregular shape; in addition, chemical constituents are precise and controllable; the ferroelectric property of the prepared BiFeO3 thin film is improved under coaction of Gd and Co.

Owner:盐城市枯枝牡丹旅游开发投资有限公司

Ferroelectric-antiferroelectric phase transition leadless ferroelectric ceramic material, ceramic element and preparation method of ferroelectric ceramic material

InactiveCN104402429ALarge remanent polarizationHigh remnant polarizationChemical compositionPulse discharge

The invention relates to a ferroelectric-antiferroelectric phase transition leadless ferroelectric ceramic material, a ceramic element and a preparation method of the ferroelectric ceramic material. The chemical composition of the ferroelectric-antiferroelectric phase transition leadless ferroelectric ceramic material accords with the chemical general formula of (1-x)Bi0.5Na0.5TiO3-xBiAlO3, wherein 0.01<=x<=0.09. Through composition adjusting and technology improving, the obtained ceramic material has relatively large remanent polarization Pr, the ceramic has ferroelectric-antiferroelectric phase transition (FE-AFE) at a certain temperature, and has important value on practical application of the ceramic to instantaneous pulsed discharge or heat-electrical energy transition and other fields.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

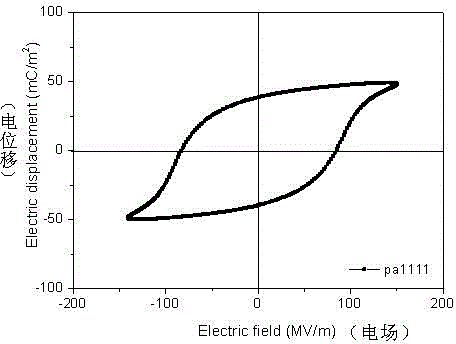

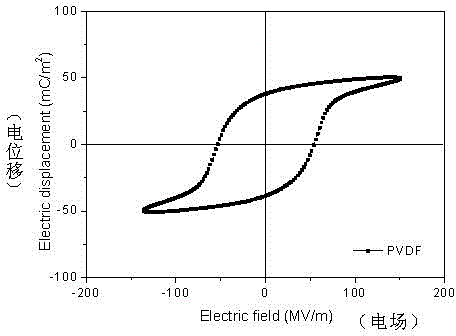

Nylon 1111/ polyvinylidene fluoride ferroelectric composite film and preparation method thereof

ActiveCN104629358AHigh remnant polarizationLow cost of industrializationMaterials preparationComposite film

The invention belongs to the field of high-polymer blending composite material preparation and discloses a nylon 1111 / polyvinylidene fluoride ferroelectric composite film and a preparation method thereof. The ferroelectric composite film disclosed by the invention is prepared by 20-80 parts of nylon 1111 and 80-20 parts of polyvinylidene fluoride. The preparation method comprises the following steps: firstly blending the nylon 1111 and polyvinylidene fluoride in melt mixing equipment, then hot-pressing the mixture by hot pressing equipment into a film, quenching the molten film and finally stretching by uniaxial tension of a stretching device to obtain the nylon 1111 / polyvinylidene fluoride ferroelectric composite film. The composite film prepared according to the invention exceeds a pure polyvinylidene fluoride film in remanent polarization strength. The preparation method disclosed by the invention has simple preparation process, industrially common equipment and easy operation. The ferroelectric composite film is low in cost, and is expected to be used for apparatus preparations in the fields of piezoelectric, pyroelectric and ferroelectric materials.

Owner:ZHENGZHOU UNIV

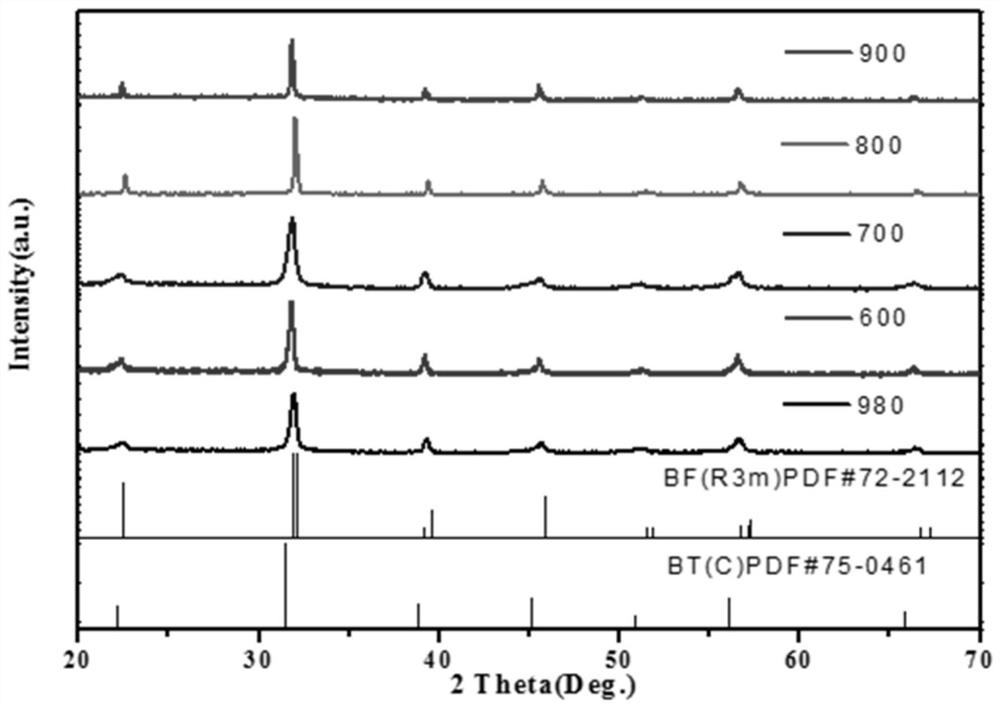

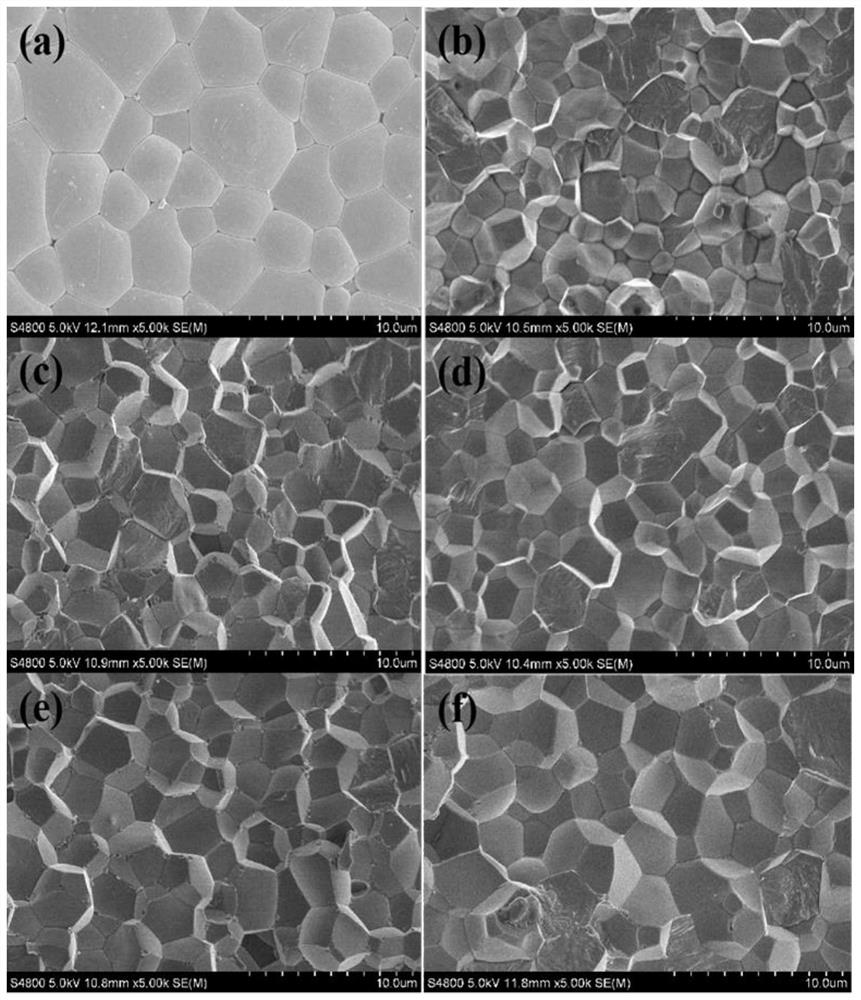

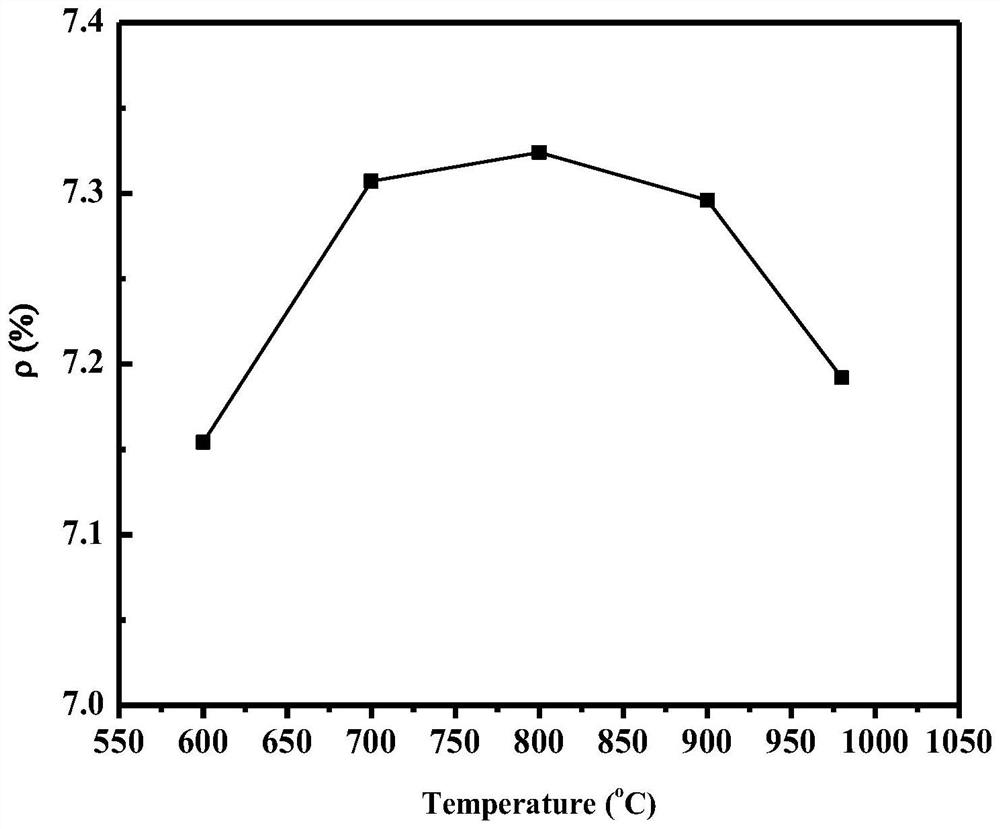

Bismuth ferrite-barium titanate lead-free piezoelectric ceramic as well as preparation method and application thereof

The invention relates to bismuth ferrite-barium titanate lead-free piezoelectric ceramic and an application thereof. The chemical formula of the bismuth ferrite-barium titanate is (1-x)BiyFeO3-xBaTiO3, x and y are mole fraction, x is 0.3-0.4, y is 0.6-1.2, the raw materials for preparing the bismuth ferrite-barium titanate comprise Bi2O3, Fe2O3, BaCO3 and TiO2, and the preparation method comprises the following steps: reacting Bi2O3, Fe2O3, BaCO3 and TiO2 at 780-850 DEG C to prepare a precursor; and performing granulation treatment, forming treatment, glue discharging treatment, sintering treatment, specific annealing treatment, silver firing treatment, quenching treatment and polarization treatment on the precursor. The microstructure, density and charge defect concentration of the ceramic are improved through annealing treatment, the ceramic generates lattice distortion in the high-temperature quenching process through quenching treatment after silver firing, and the piezoelectric property of the ceramic is cooperatively improved.

Owner:LANZHOU UNIVERSITY +1

Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and making method thereof

The invention provides a Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and a making method thereof. The method comprises the following steps: preparing a Bi0.9Er0.1Fe1-xCoxO3 precursor solution from bismuth nitrate, iron nitrate, cobalt nitrate and erbium nitrate, spin-coating a substrate with the Bi0.9Er0.1Fe1-xCoxO3 (x is 0.01-0.03) precursor solution, uniformly sizing, drying, and annealing to obtain the Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity. The method has the advantages of simple device requirements, easy reaching of experiment conditions, easy control of the doping amount, and great improvement of the ferromagnetism of a BiFeO3 film, and the Bi0.9Er0.1Fe1-xCoxO3 film made in the invention has the advantages of good uniformity, high magnetic intensity and high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

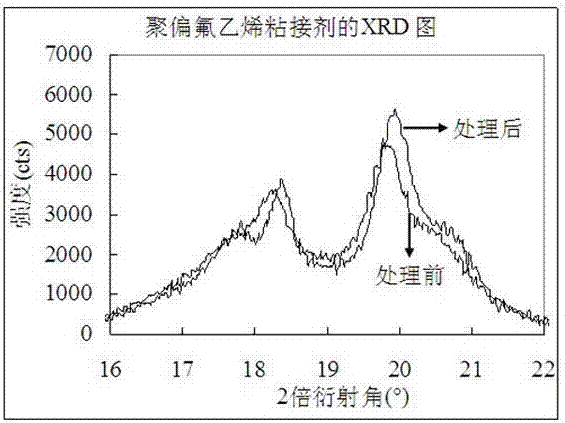

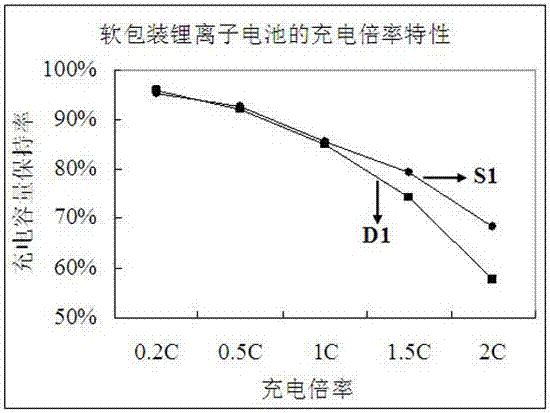

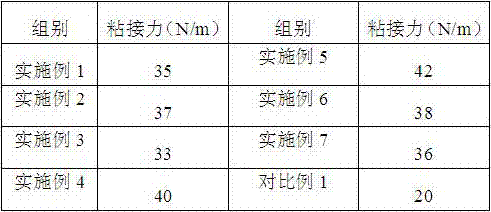

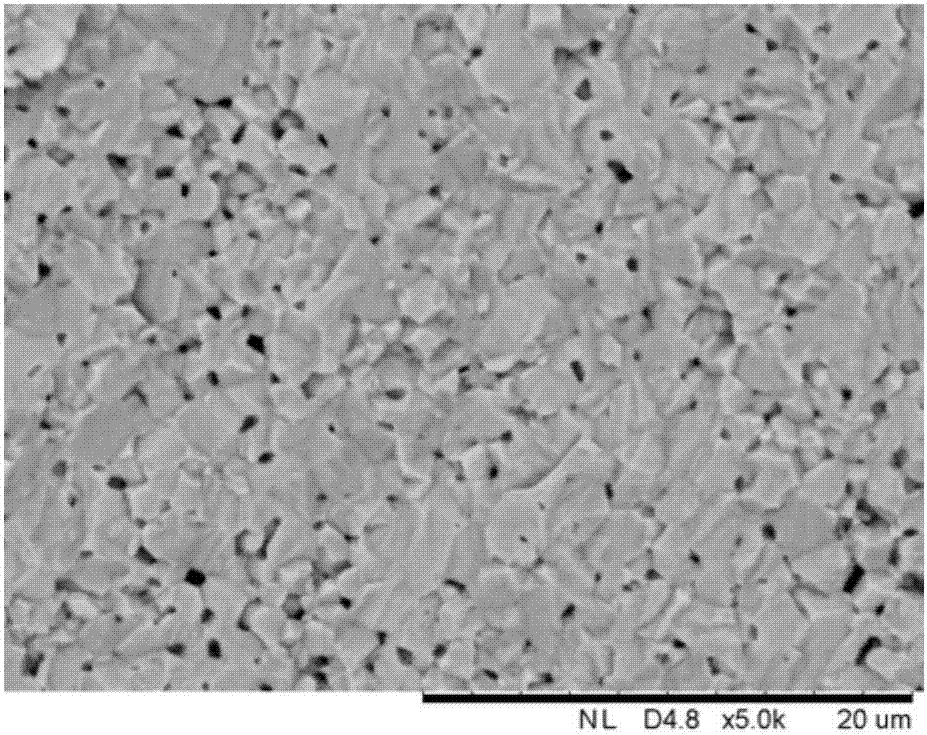

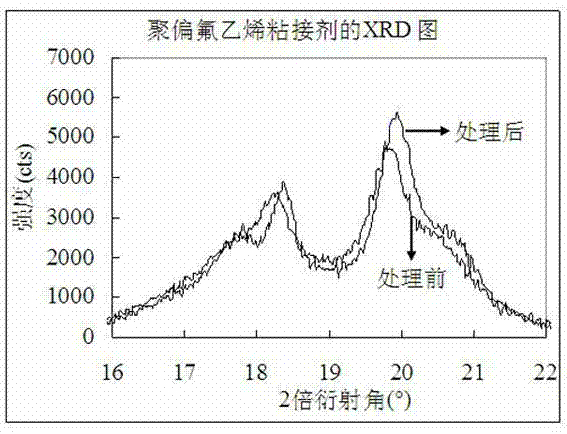

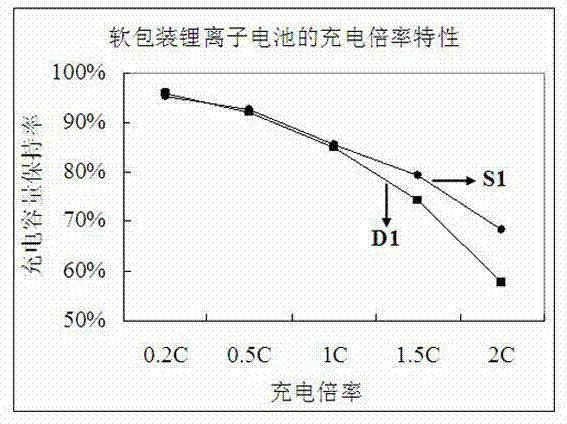

Method for producing flexible package lithium ion battery negative plates

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a method for producing flexible package lithium ion battery negative plates, wherein the method comprises the steps that: adding a carbon material, a polyvinylidene fluoride adhesive agent and a conductive agent into the solvent, mixing uniformly, and coating cathode slurry on the negative current collector so as to form anode diaphragms; placing the negative plates to be baked in a vacuum oven to bake, wherein the temperature of the oven is higher than the final melting temperature of polyvinylidene fluoride, so as to melt polyvinylidene fluoride adhesive agent completely into liquid; and cooling the negative plates to be cooled so as to complete the production of the negative plates. Compared with the prior art, the method causes crystle transformation of polyvinylidene fluoride, so that a monoclinal TGTG' molecular chain configuration is transferred into an orthogonal TTTT molecular chain configuration with high remanent polarization and higher bonding strength; and the bonding performance is improved, and thus enhancing the cycle performance of batteries, reducing the cyclic swelling of batteries, and improving the rate capability of batteries simultaneously.

Owner:DONGGUAN AMPEREX TECH

Potassium-sodium lithium niobate-base lead-free piezoelectric ceramic complex with good temperature stability

InactiveCN101935215AImprove ferroelectric propertiesHigh remnant polarizationPiezoelectric/electrostrictive/magnetostrictive devicesCurie temperatureLithium niobate

The invention discloses a potassium-sodium lithium niobate-base lead-free piezoelectric ceramic complex with good temperature stability, a preparation method and application thereof. The general formula of the complex is as follows: (1-x) (K0.5Na0.5)0.94Li0.06NbO3-xY, wherein, x is equal to 0-0.05 and Y is a perovskite structural component. The complex has the characteristics of good ferroelectricity, relatively higher remanent polarization, relatively higher piezoelectric property, high Curie temperature, low room-temperature dieiectric loss and good temperature stability, thus being applicable to devices such as a piezoelectric actuator, an energy converter, a sensor, a buzzer and the like.

Owner:LIAOCHENG UNIV

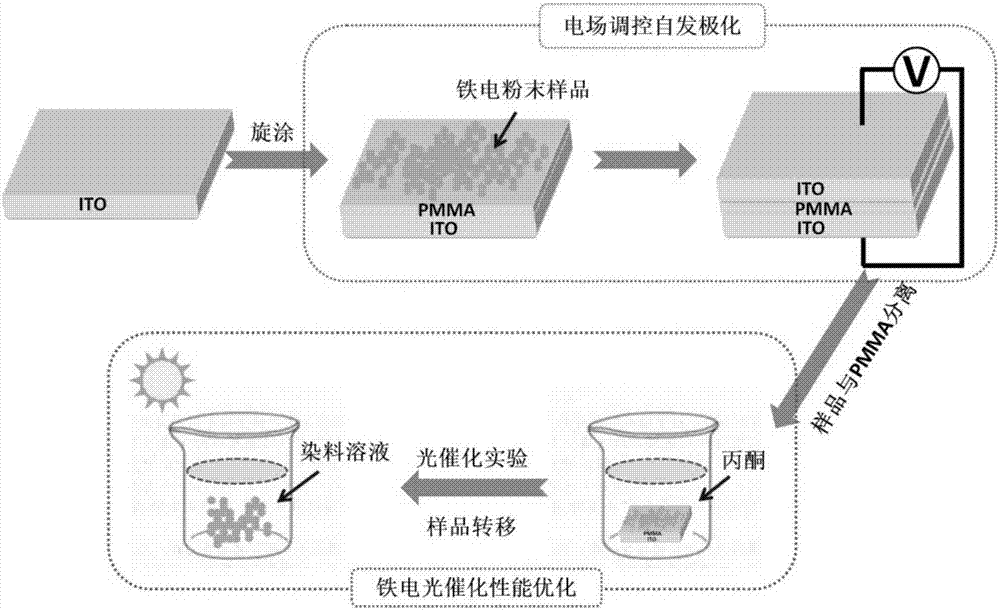

Method for enhancing photocatalysis performance of ferroelectric material through regulation and control of spontaneous polarization

ActiveCN107042105AImprove photocatalytic performanceGuaranteed decentralizationCatalyst carriersWater/sewage treatment by irradiationIntrinsic polarizationMolecular materials

The invention relates to a method for enhancing photocatalysis performance of a ferroelectric material through regulation and control of spontaneous polarization, an insulation film is prepared by employing soluble high-molecular material-loaded ferroelectric material powder, spontaneous polarization intensity of the ferroelectric material can be adjusted by an applied electric field, photo-induced electron and cavity are effectively separated under effect of intrinsic polarization field, life of a photon-generated carrier is prolonged, so that a purpose of enhancing photocatalysis performance of the material can be achieved. Compared with the prior art, the method provides the simple and effective approach for enhancing the photocatalysis performance of the ferroelectric material (especially the ferroelectric powder material).

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

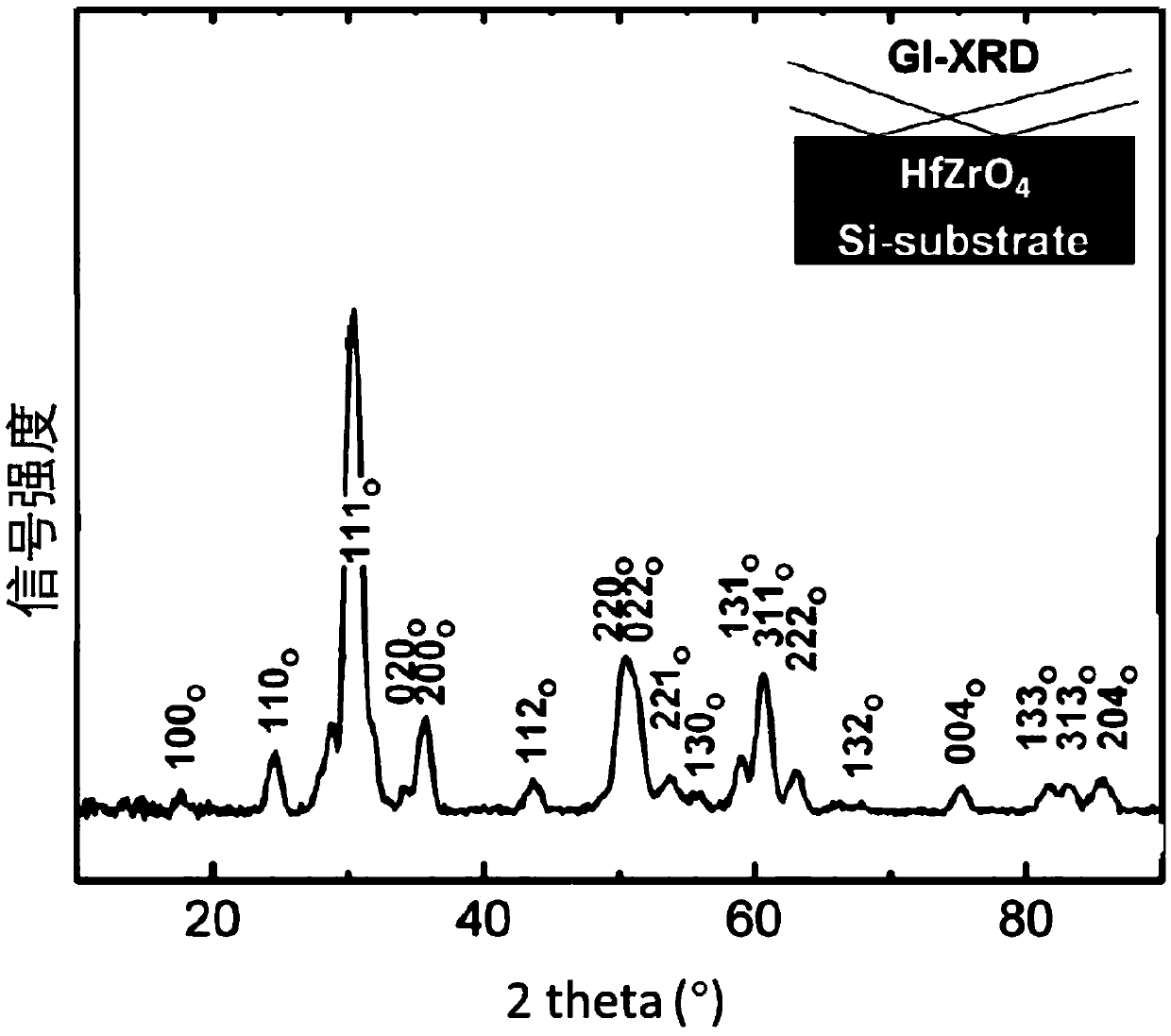

Preparation method of zirconium-doped hafnium oxide ferroelectric film, and product and application thereof

PendingCN109518163APrevent peelingGood repeatabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingHafniumDeposition process

The invention provides a preparation method of a zirconium-doped hafnium oxide ferroelectric film and a product and application thereof. The preparation method is characterized in that the preparationmethod comprises the HfO2 and ZrO2 alternate atomic layer deposition process; the mole ratio of effective Hf to effective Zr in a hafnium-containing precursor and a zirconium-containing precursor ofthe adjacent deposition processes is (40%-60%):(60%-40%). Through the preparation method, the technical problem that a doped HfO2 film with the good ferroelectric properties is hard to prepare can besolved, and the high-quality ferroelectric film with the application value can be grown easily and controllably.

Owner:合肥安德科铭半导体科技有限公司

Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film and preparation method thereof

The invention provides a Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film and a preparation method thereof. The preparation method comprises the following steps: preparing a Bi(1-x)RExFe0.96Co0.02Mn0.02O3 precursor solution from bismuth nitrate, ferric nitrate, cobalt nitrate, manganese acetate and nitric acid RE which serve as raw materials, wherein x is 0.06-0.12, and RE is La, Eu or Er; and coating the precursor solution on a substrate in a spinning manner, uniformly coating, baking and annealing to obtain the Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film. By adopting the method, requirement for equipment is simple, the experiment condition can be easily achieved, the doping amount can be easily controlled, and the ferroelectric performance of the film can be greatly improved, so that the prepared Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film has good uniformly, less current leakage and high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

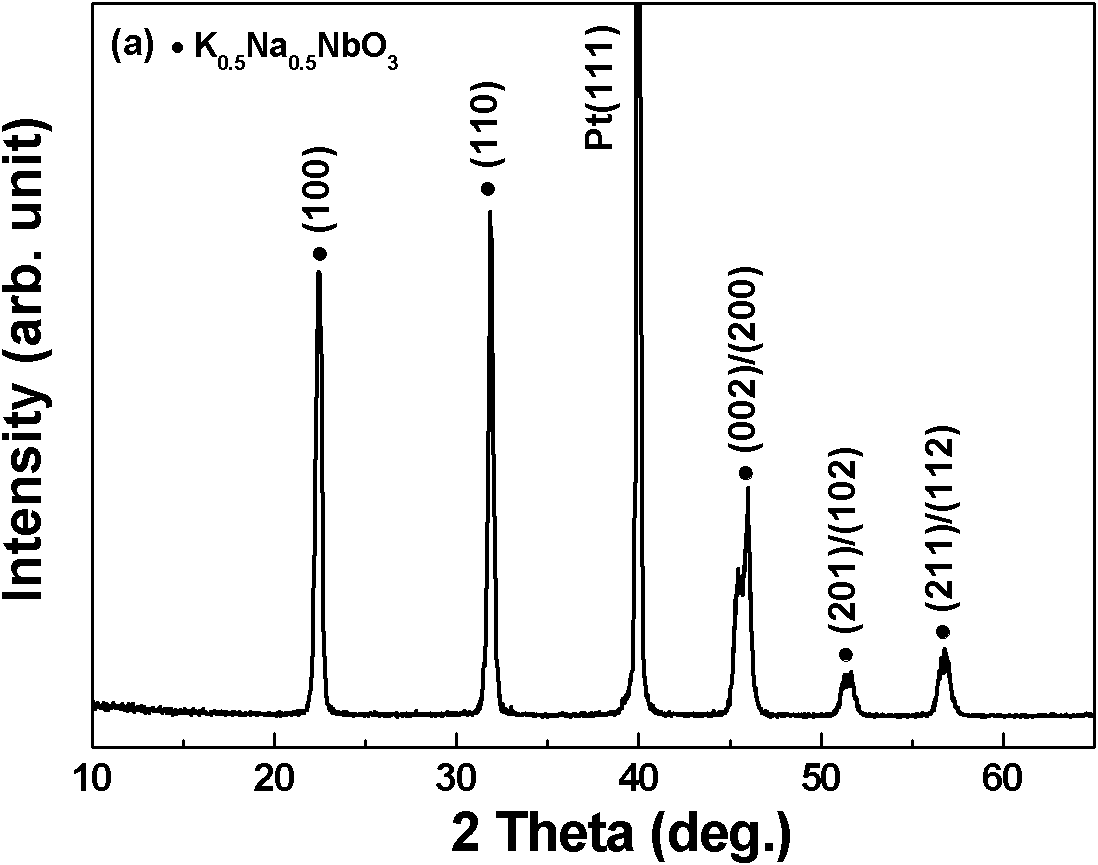

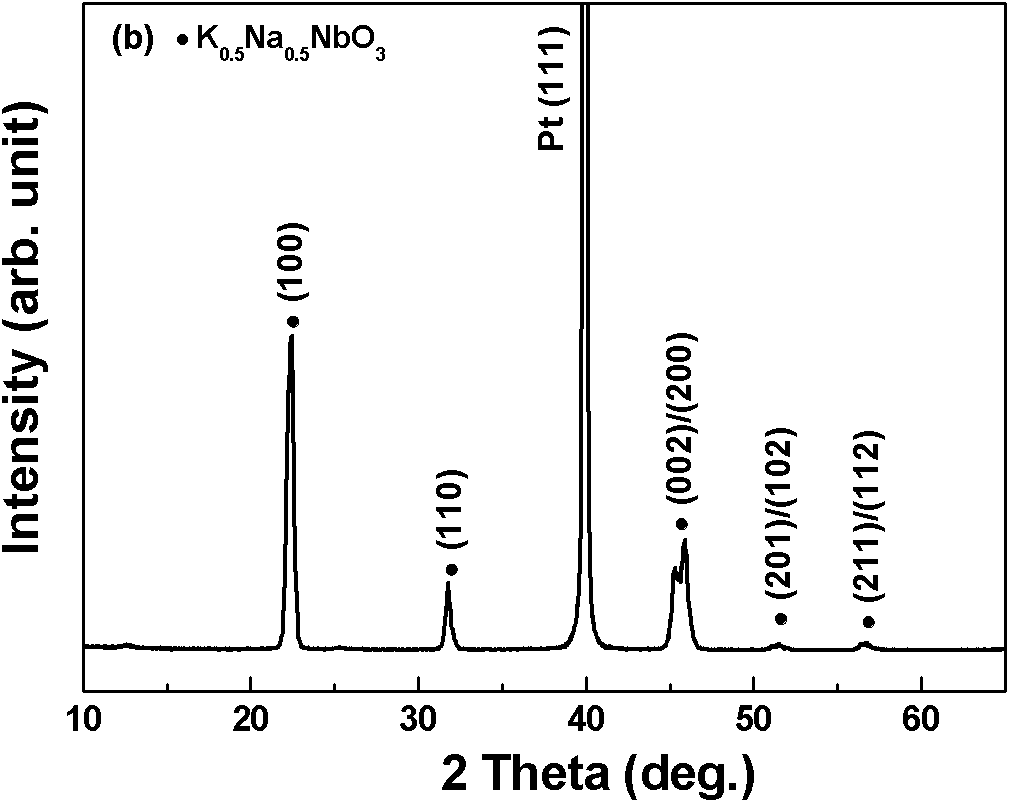

Preparation method of potassium-sodium niobate ceramic material with high remnant polarization strength

The invention discloses a preparation method of a potassium-sodium niobate ceramic material with high remnant polarization strength, and relates to a preparation method for improving the remnant polarization strength of K0.5Na0.5NbO3 ceramic. The invention aims to solve the technical problem that the existing lead-free K0.5Na0.5NbO3 ceramic is low in remnant polarization intensity. The method comprises the following steps: mixing dried potassium carbonate and sodium carbonate powder with niobium pentoxide powder and then carrying out wet ball milling; drying, putting the dried raw materials into a tubular furnace for presintering, then carrying out wet ball milling, putting the dried raw materials into a hot-pressing furnace in an oxygen atmosphere for high-temperature and high-pressure sintering, and putting ceramic slices obtained by hot-pressing sintering into the tubular furnace for oxygen annealing so as to obtain the K0.5Na0.5NbO3 ceramic with high remnant polarization strength.The remnant polarization intensity of the ceramic is 24-27 [mu] C / cm < 2 >, which is 1.6-2.7 times that of K0.5Na0.5NbO3 ceramic prepared by a traditional solid-phase method, and the ceramic can be used in the fields of electricity and electronics.

Owner:HARBIN INST OF TECH

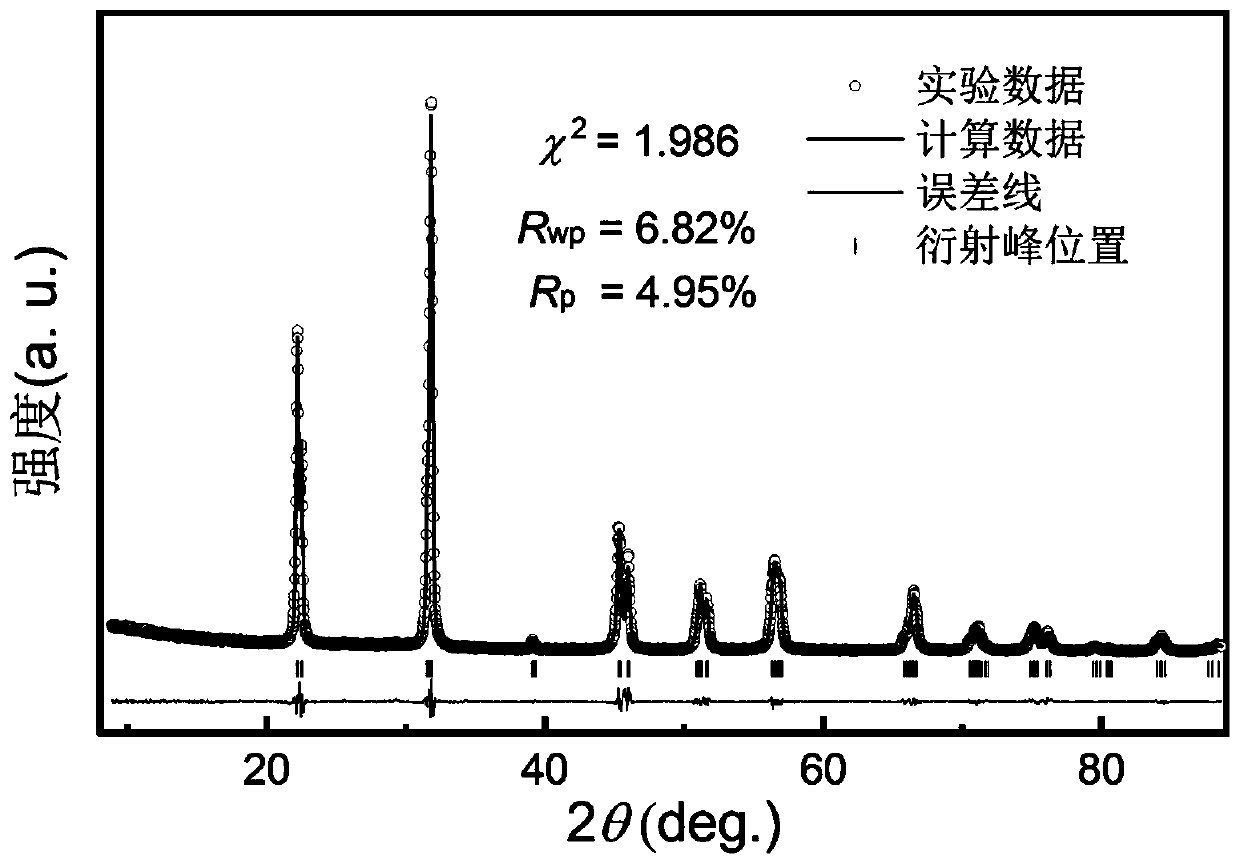

Method for preparing bismuth ferrite-barium titanate (BiFeO3-BaTiO3) ceramic through two-step sintering

The invention discloses a method for preparing bismuth ferrite-barium titanate (BiFeO3-BaTiO3) ceramic through two-step sintering, and belongs to the technical field of lead-free ceramic preparation. The preparation method comprises the following steps: calculating and weighing according to a chemical formula (1-x) Bi (1 + y) FeO3-xBaTiO3, ball-milling and mixing, drying, sieving, putting into an alumina crucible, and pre-sintering at 780-950 DEG C for 2-12 hours to obtain pre-sintered powder; carrying out secondary ball milling, drying at 70-120 DEG C, sieving dried powder, adding polyvinyl alcohol with the concentration of 2wt% into the sieved dried powder, carrying out grinding granulation, and putting the granulated powder into a mold for compression molding; placing the ceramic green body in a muffle furnace, heating to 300-440 DEG C, discharging glue for 2-4 hours, heating to 950-1060 DEG C, preserving heat for 1-10 minutes, cooling to 900-1060 DEG C, sintering for 4-12 hours, and cooling to room temperature along with the furnace to prepare the required ceramic. According to the two-step sintering method disclosed by the invention, by ingeniously controlling the two-step sintering temperature and the heat preservation time, an impure phase generation temperature interval in the bismuth ferrite-barium titanate ceramic can be avoided; the prepared ceramic is good in crystallinity, uniform in component, small in grain size, compact in structure, low in dielectric loss, high in insulativity, high in remanent polarization intensity and excellent in piezoelectric property and photovoltaic property.

Owner:UNIV OF SCI & TECH BEIJING

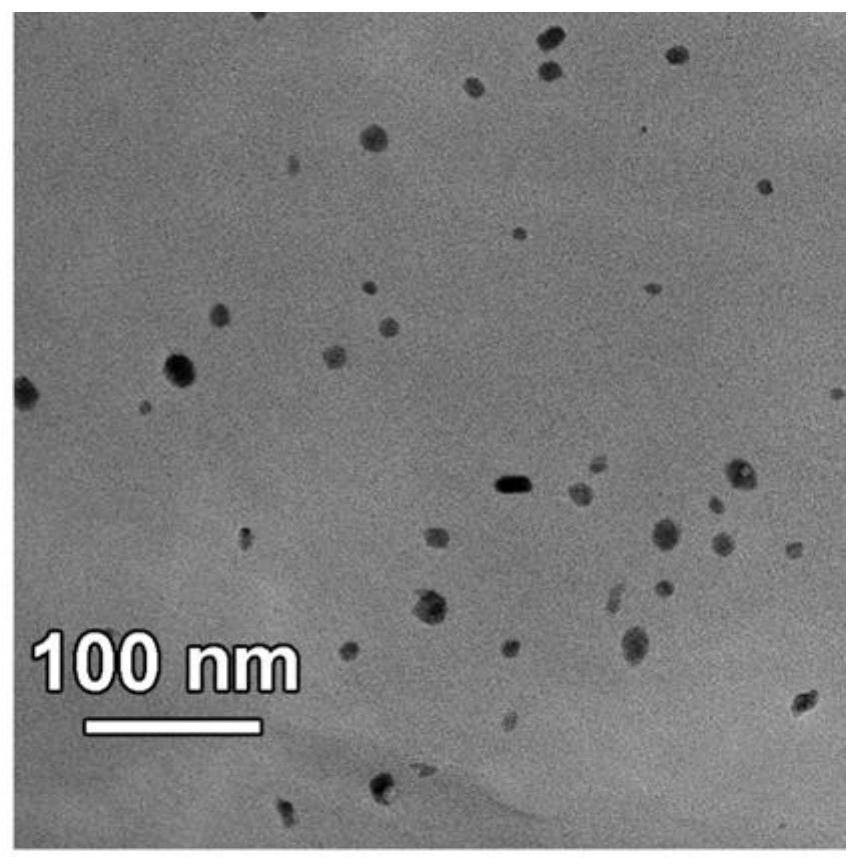

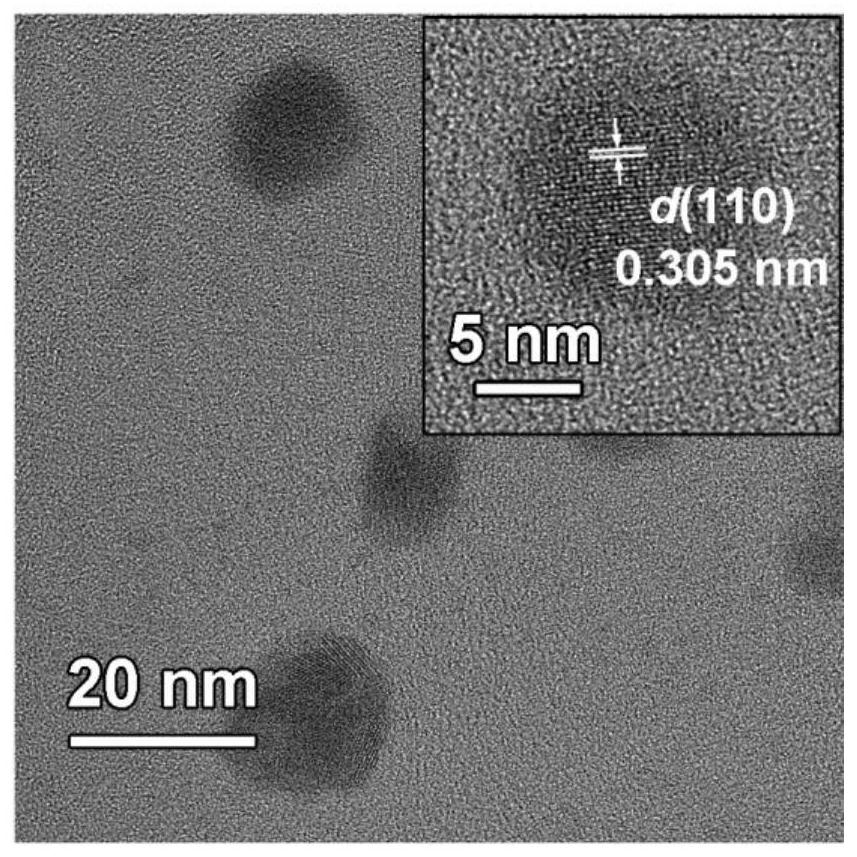

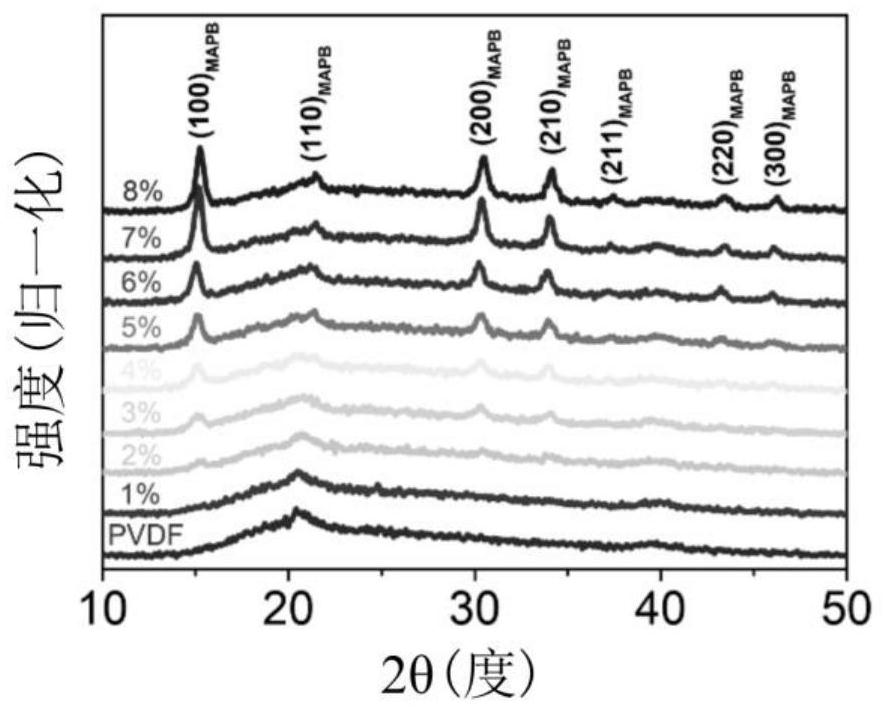

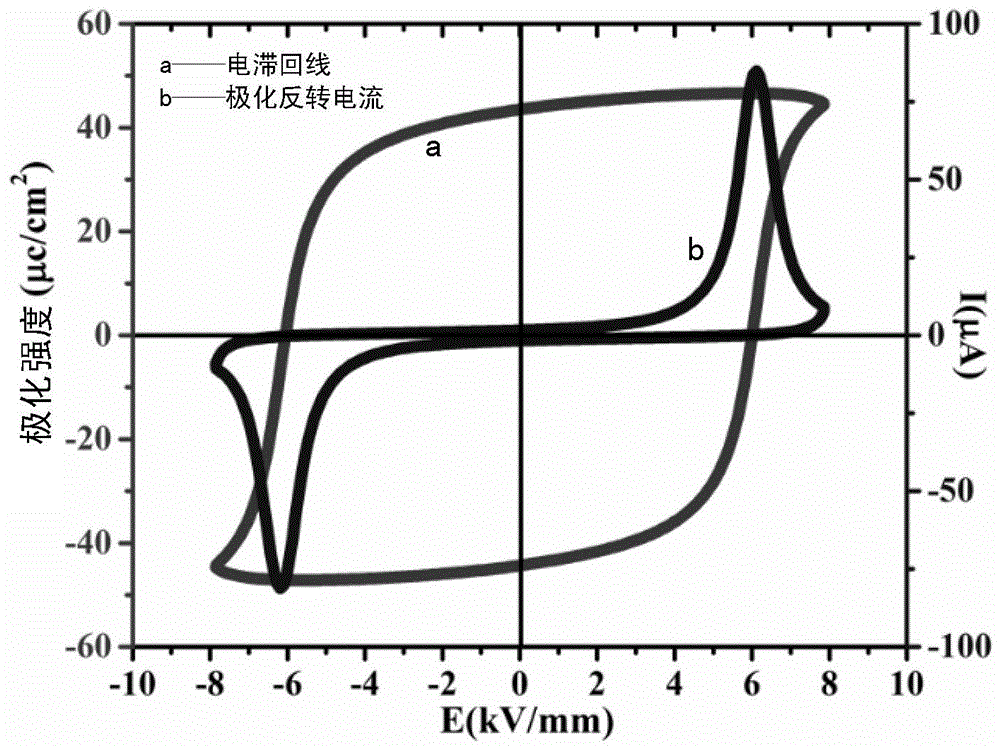

Photosensitive ferroelectric polymer composite film and preparation method thereof, and ferroelectric device or piezoelectric device using composite film

ActiveCN113801413ALuminous properties are stableGood ferroelectricityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionFiller particlePolymer chemistry

The invention relates to a photosensitive ferroelectric polymer composite film and a preparation method thereof, and a ferroelectric device or a piezoelectric device using the composite film. The composite film comprises an organic flexible polymer matrix and inorganic-organic hybrid perovskite filler particles, wherein the content of the filler particles relative to the total mass of the composite film is 1%-5% by mass, and the filler particles exist in the matrix in a monodisperse state.

Owner:BEIHANG UNIV

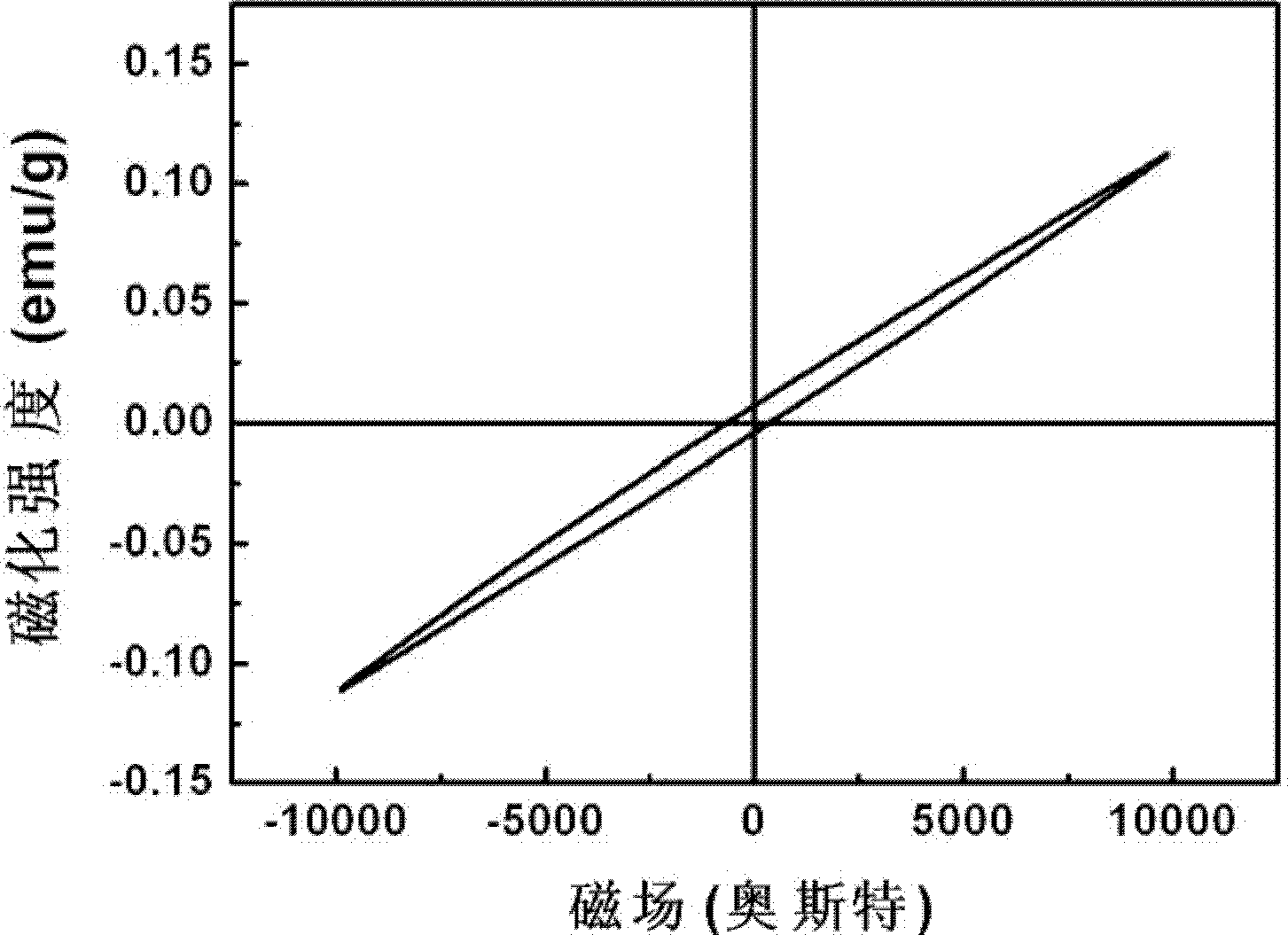

Novel room-temperature multi-ferroic ceramic with high polarization intensity and preparation method of novel room-temperature multi-ferroic ceramic

ActiveCN106242546AImprove ferromagnetic propertiesImprove ferroelectric propertiesChemical compositionRoom temperature

The invention relates to novel room-temperature multi-ferroic ceramic with high polarization intensity and a preparation method of the novel room-temperature multi-ferroic ceramic. The chemical composition of a room-temperature multi-ferroic ceramic material is 0.75 ((1-x)BiFeO<3>-xBiGaO<3>)-0.25Ba<0.85>Ca<0.15>Ti<0.90>Zr<0.10>O3 +yMnCO<3>, wherein x is greater than 0 and is smaller than or equal to 0.05, and y is smaller than or equal to 0.5wt%. By adjusting and controlling components, the novel room-temperature multi-ferroic ceramic material simultaneously having excellent ferromagnetism and excellent ferroelectricity is obtained, and has high remanent polarization intensity (22-44 [mu]C / cm<2>) and high ferromagnetism properties (0.09-0.27emu / g).

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

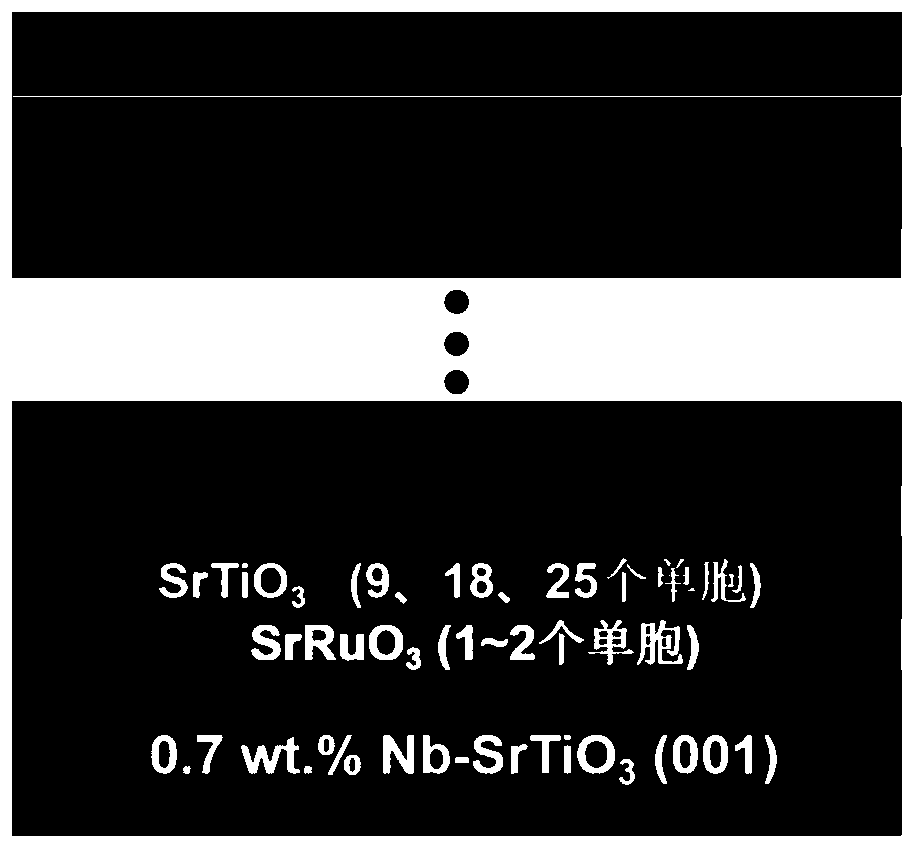

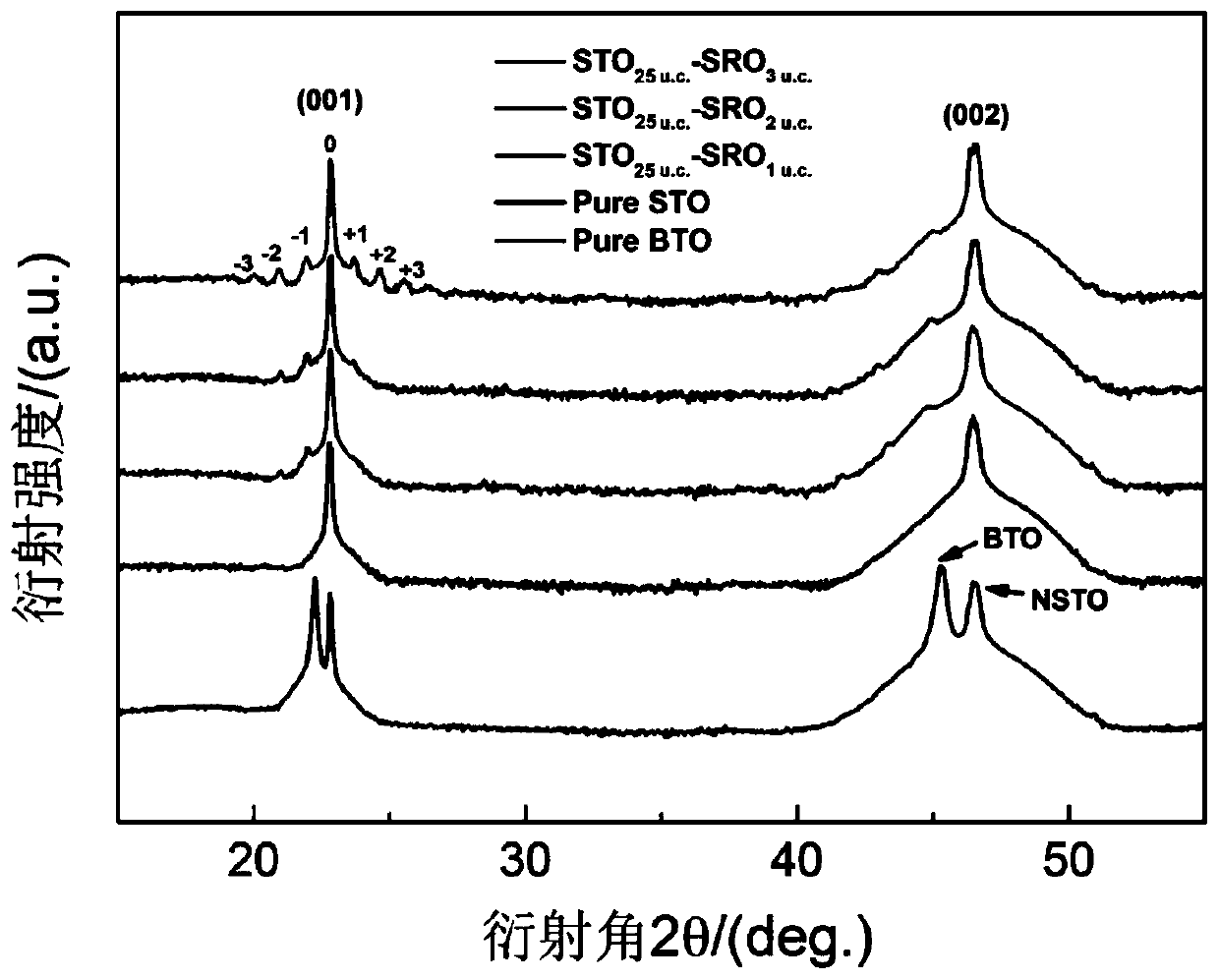

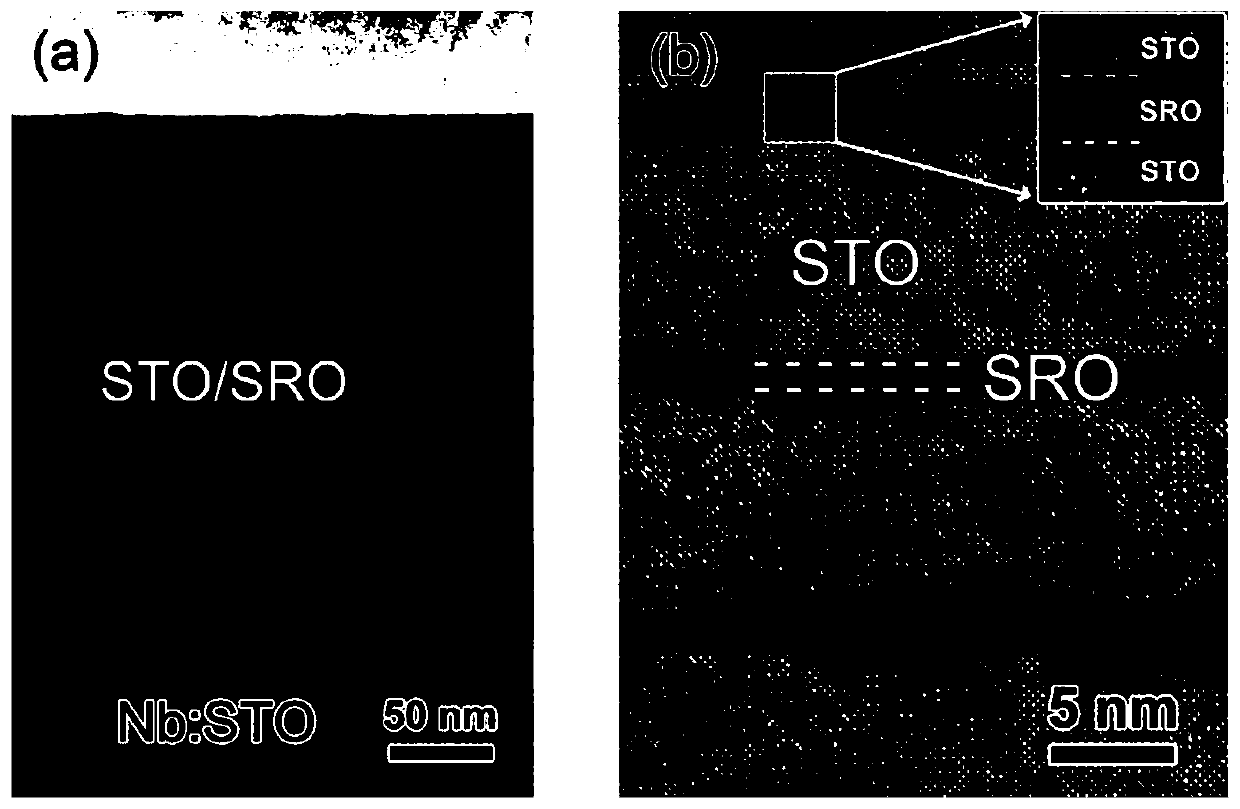

Strontium titanate/strontium ruthenate ferroelectric superlattice film material and preparation method thereof

PendingCN110643948AEffective regulation of ferroelectricityEffective regulation of dielectricVacuum evaporation coatingSputtering coatingLead zirconate titanateFerroelectric thin films

The invention aims to provide a strontium titanate / strontium ruthenate ferroelectric superlattice film material and a preparation method thereof. The material is composed of periodically grown quantumparaelectric insulator strontium titanate and metal conductive oxide strontium ruthenate. The strontium titanate / strontium ruthenate ferroelectric superlattice film material is a high-performance lead-free ferroelectric material, and the residual polarization strength of the high-performance lead-free ferroelectric material reaches 33.0 [mu]C / cm<2>, is 750% higher than that of a traditional lead-free ferroelectric material barium titanate film, and is as excellent as that of a lead zirconate titanate (Pb(ZrxTil-x)O3) lead-based ferroelectric film material that is commonly used at the present.According to the preparation method of the material, strontium ruthenate and strontium titanate are alternately grown on a single crystal substrate through a pulse laser deposition method, and the period thicknesses of a superlattice is accurately adjusted and controlled by controlling the time of laser ablation on different targets. The strontium titanate / strontium ruthenate ferroelectric superlattice film material can be used as the high-performance lead-free ferroelectric material to replace the Pb(ZrxTil-x)O3 lead-based ferroelectric film and has broad application prospects in integratedferroelectric devices such as ferroelectric memories, sensors and actuators.

Owner:SHENYANG POLYTECHNIC UNIV

BNT-BA-KNN leadless ferroelectric phase change ceramic and preparation method thereof

ActiveCN106957174AHigh remnant polarizationLarge Ferroelectric-Antiferroelectric Phase TransitionCeramicFerroelectric ceramics

The invention relates to BNT-BA-KNN leadless ferroelectric phase change ceramic and a preparation method thereof. The chemical constitution of the ferroelectric ceramic material is 0.97((1-x)Bi0.5Na0.5TiO3-xBiAlO3)-0.03K0.5Na0.5NbO3 where x is greater than or equal to 0.01 and less than or equal to 0.04. The ferroelectric ceramic material has ferroelectric-antiferroelectric two-phase coexistence at room temperature, and the remanent polarization strength of the ferroelectric ceramic material is within 33-38mu C / cm<2>. A BNT-BA-KNN tertiary ceramic prepared from the material has characteristics of relatively large remanent polarization strength and ferroelectric-antiferroelectric phase change, and thus the material has significant application values in the technical field of high-power pulse.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

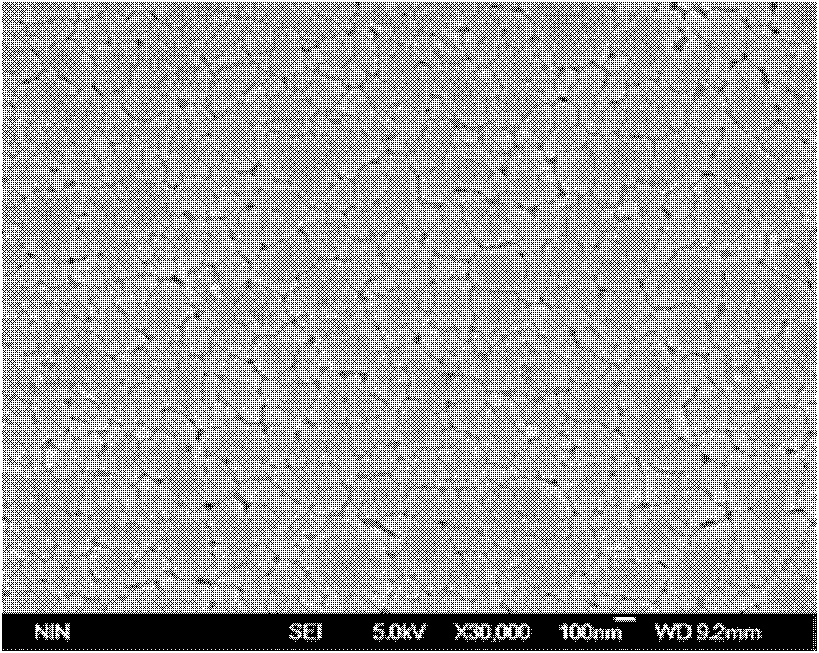

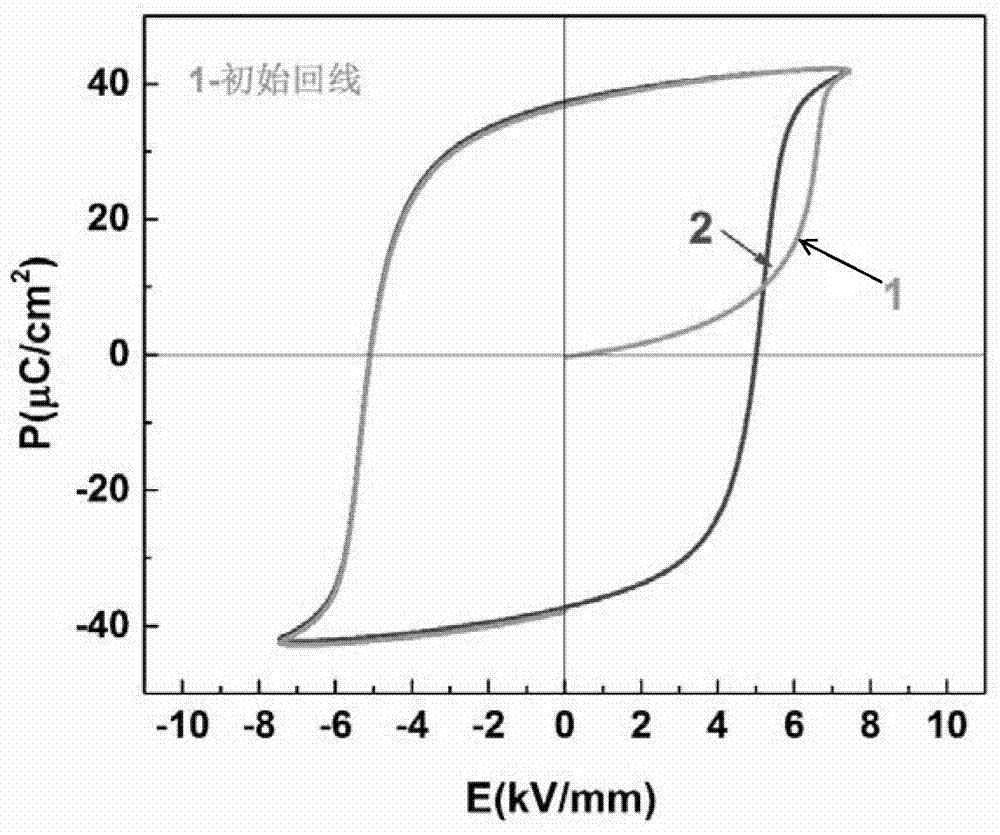

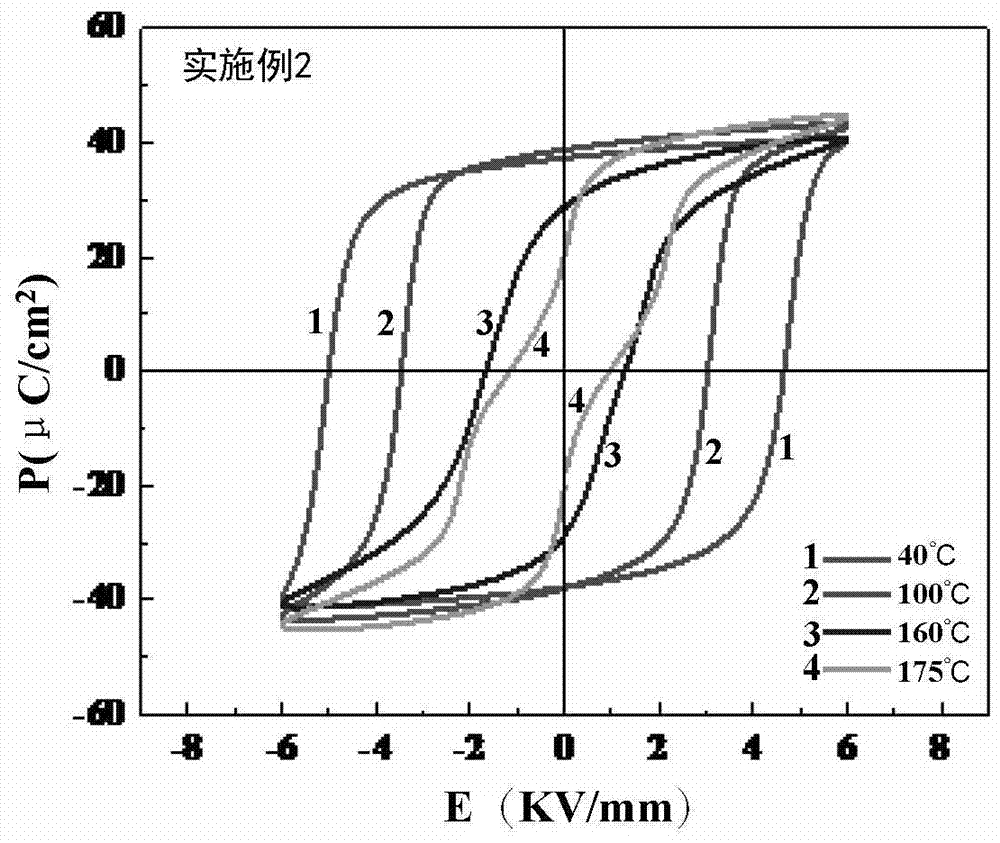

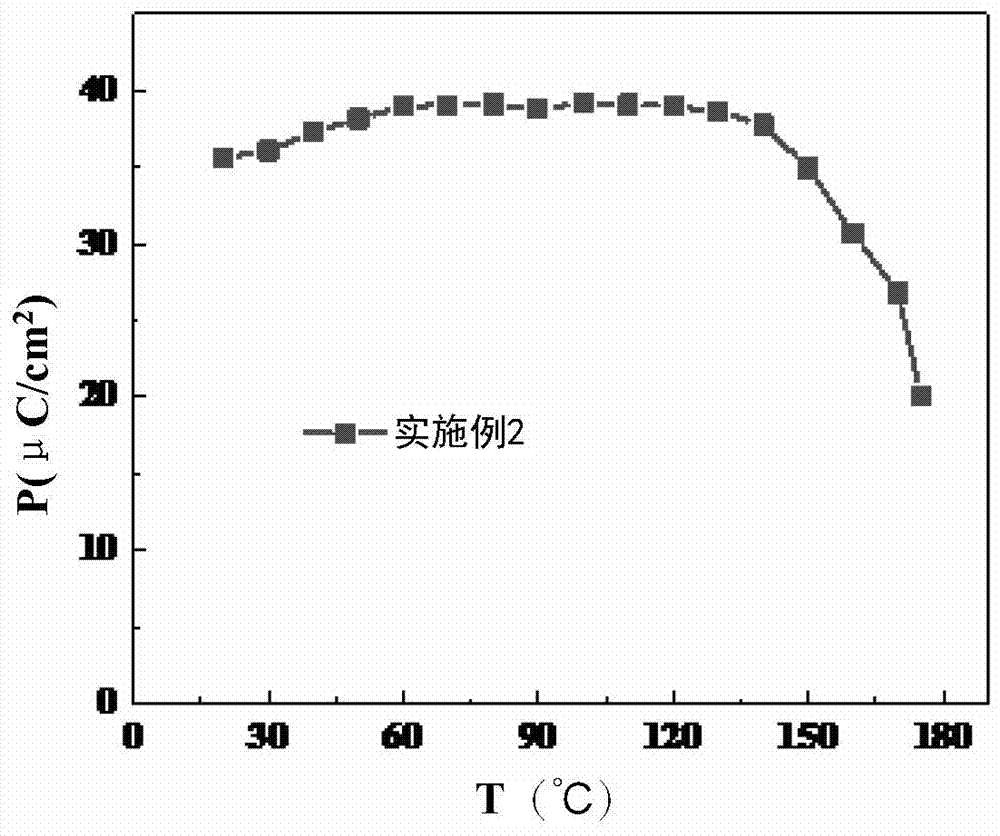

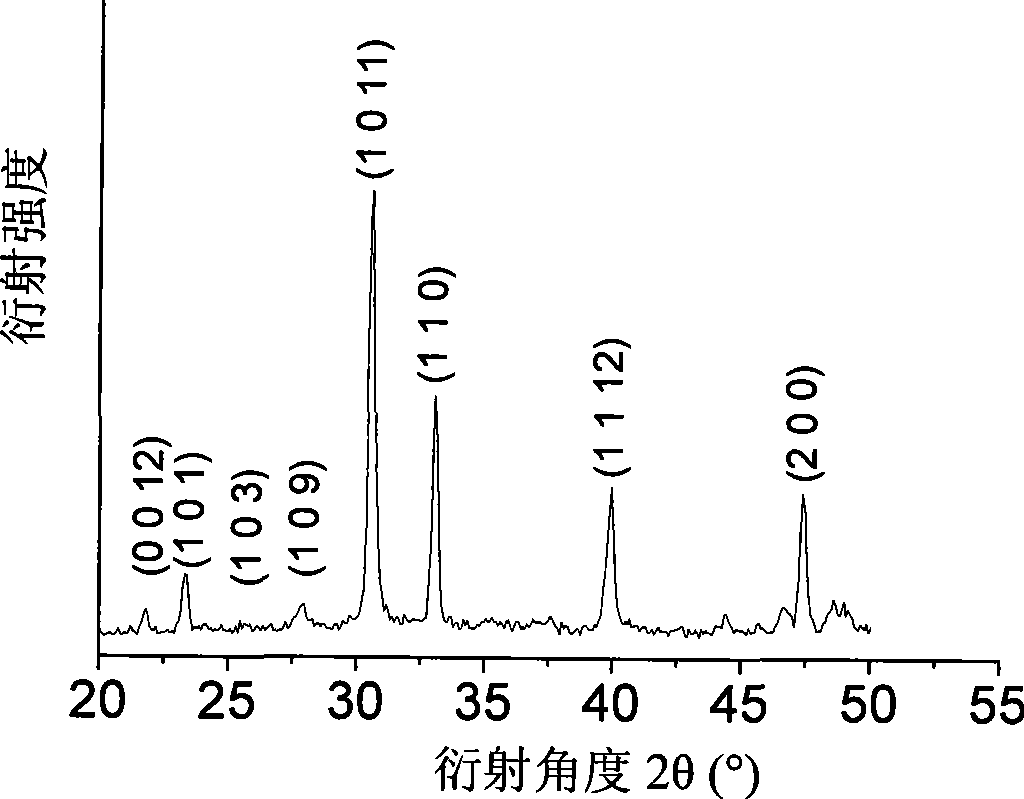

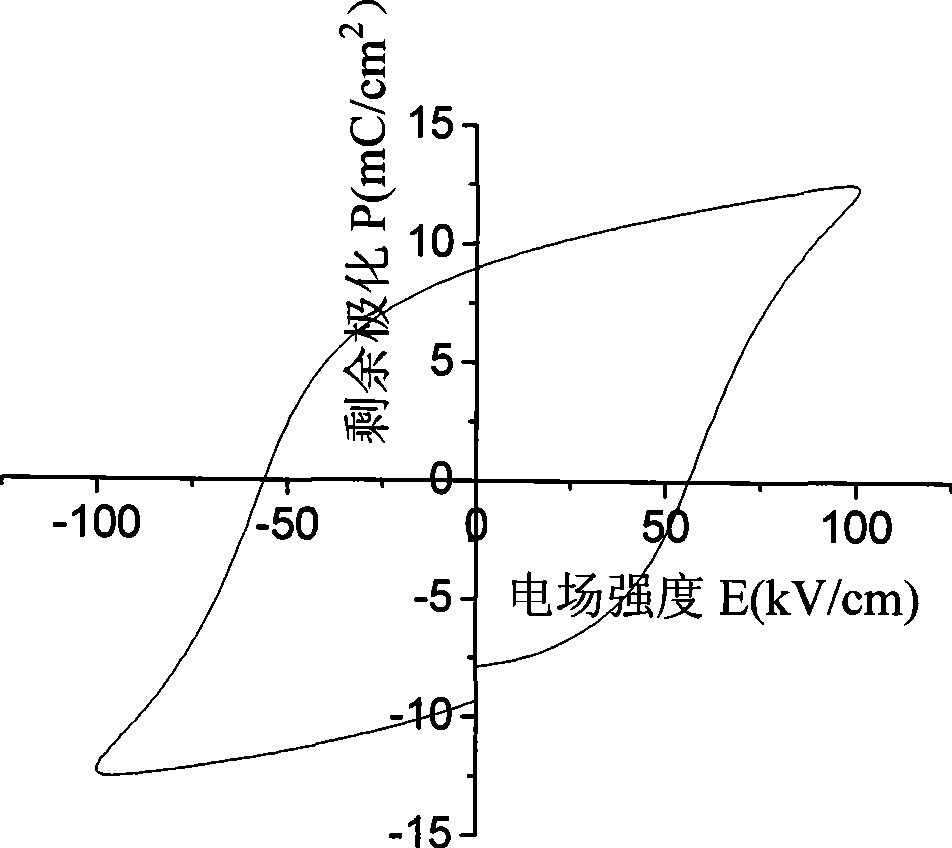

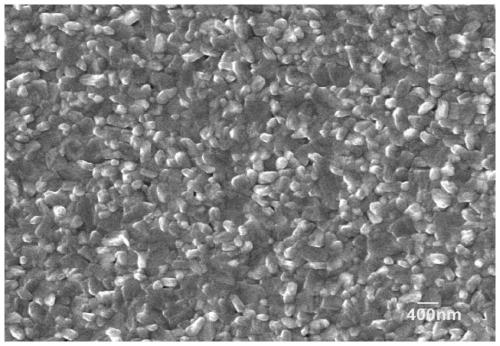

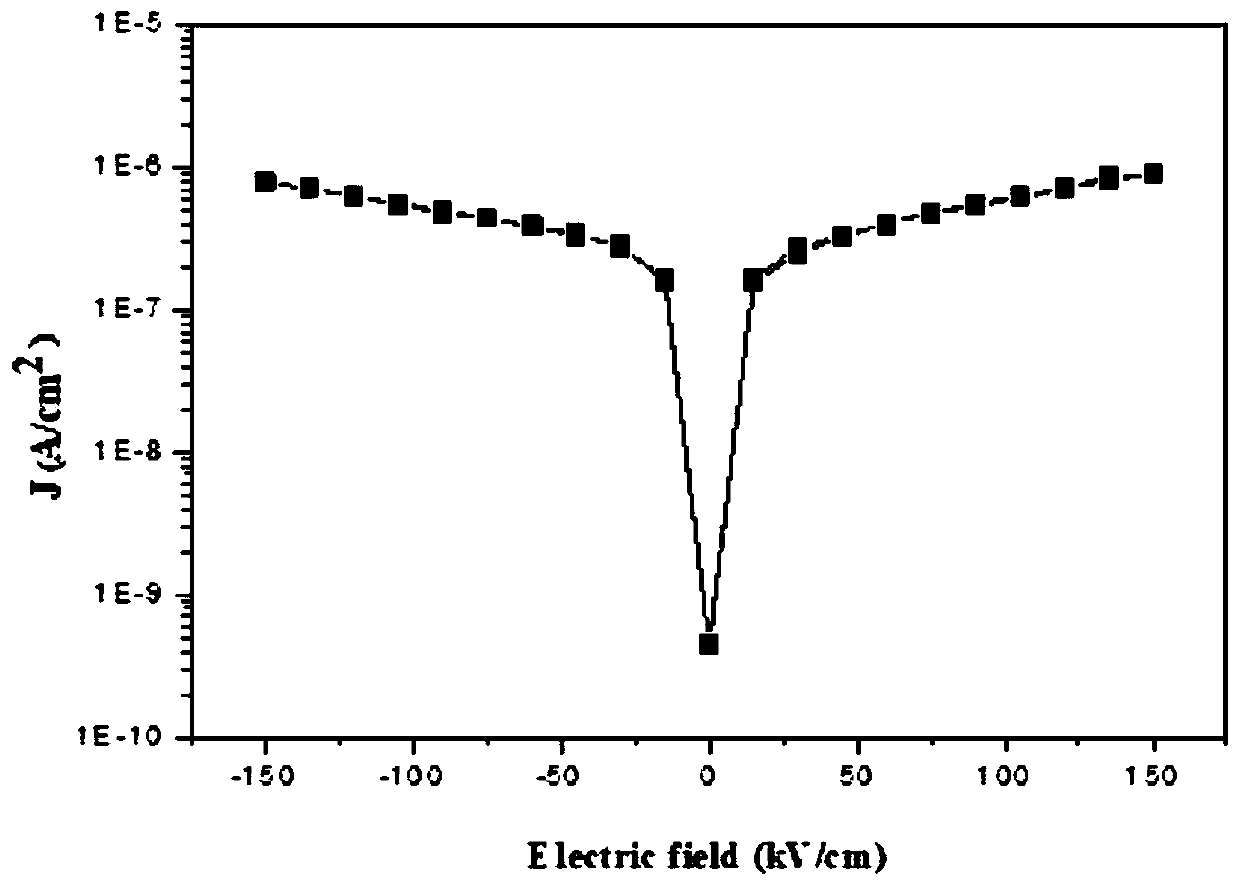

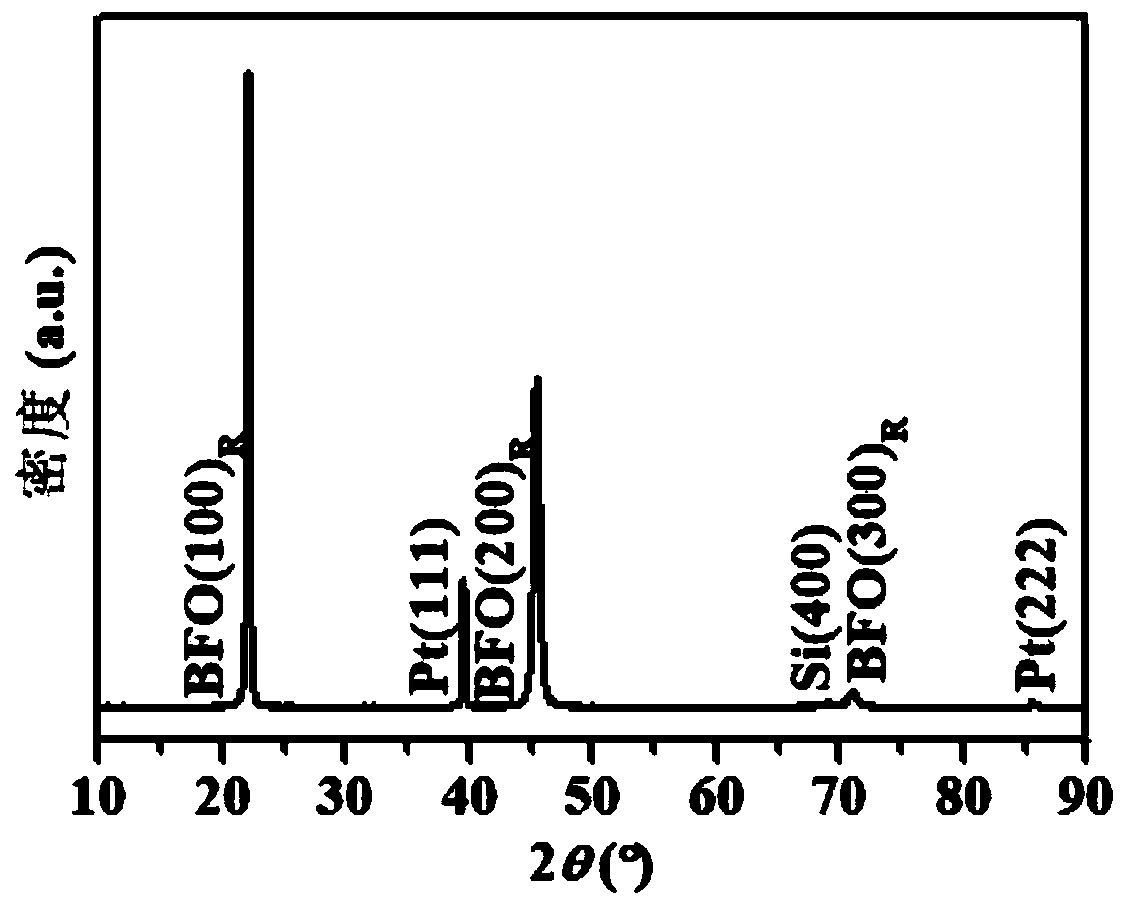

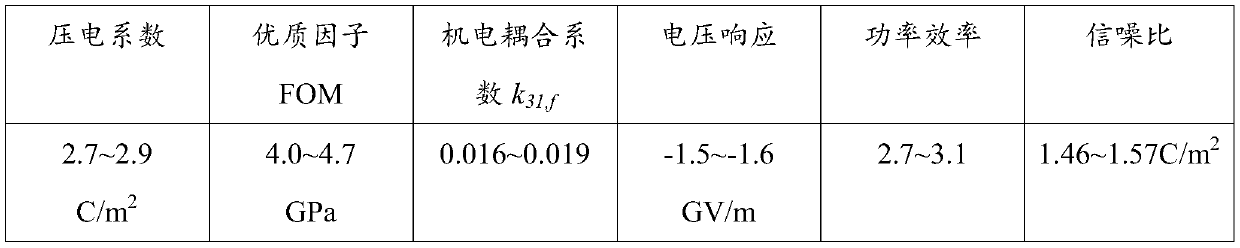

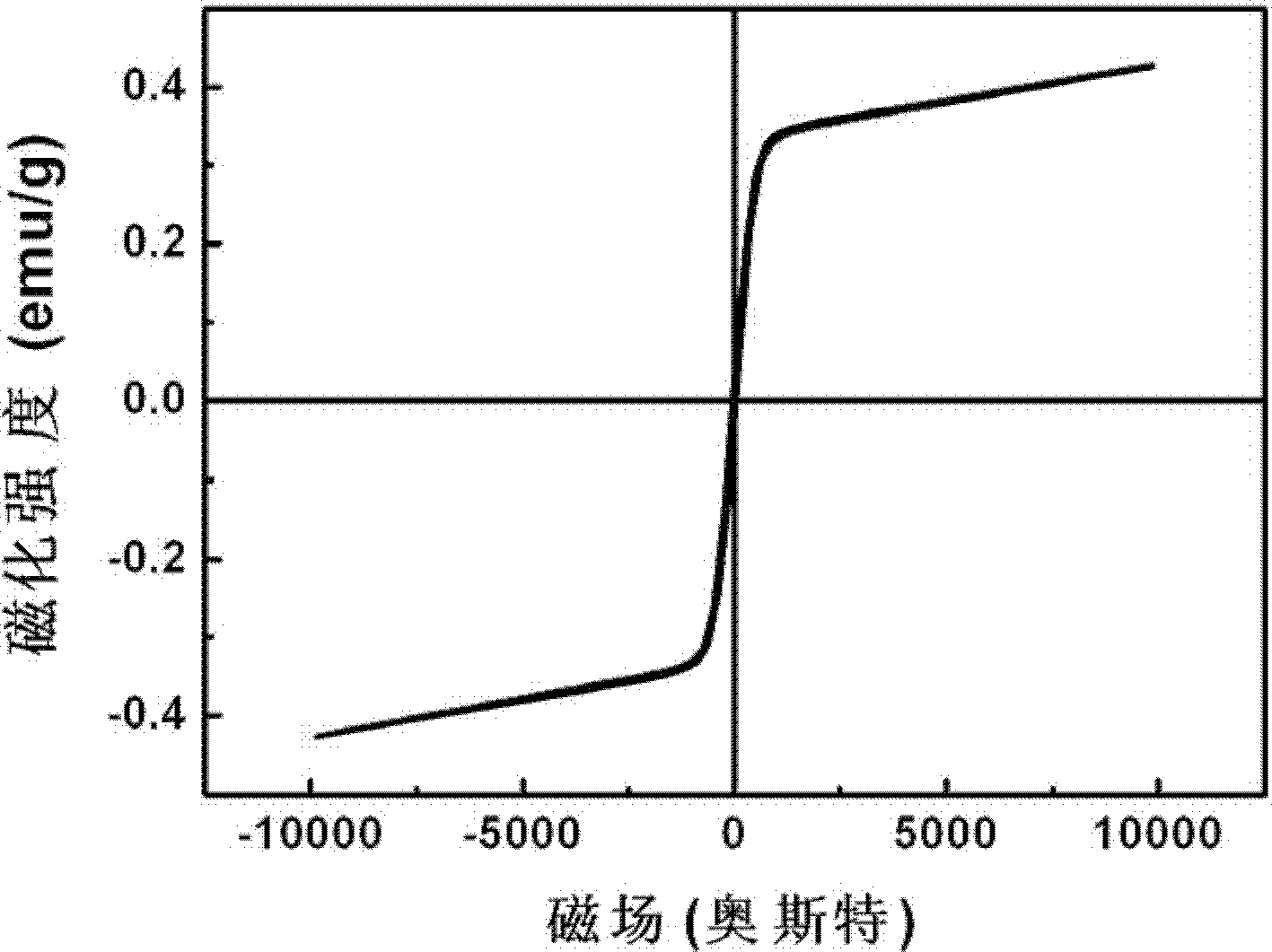

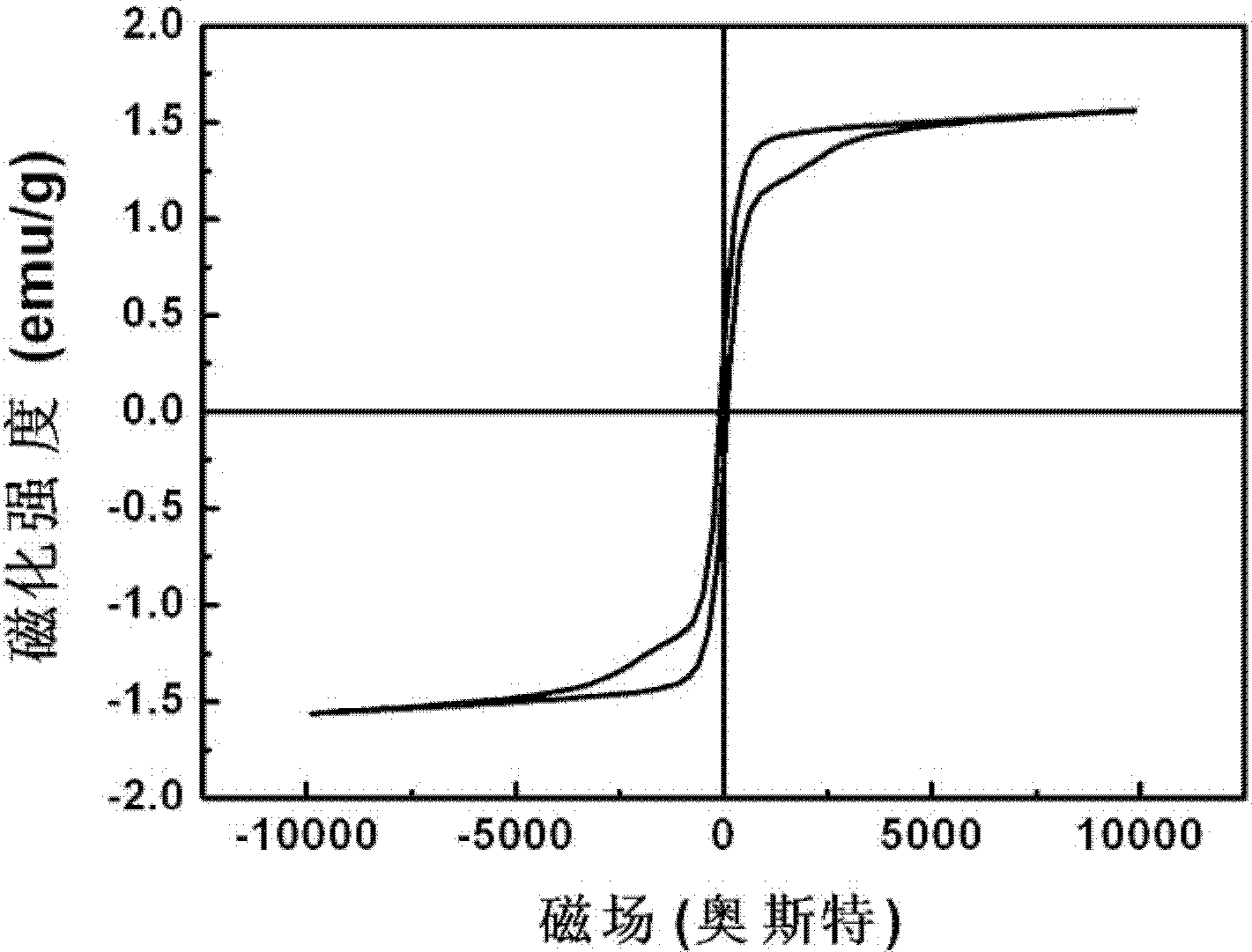

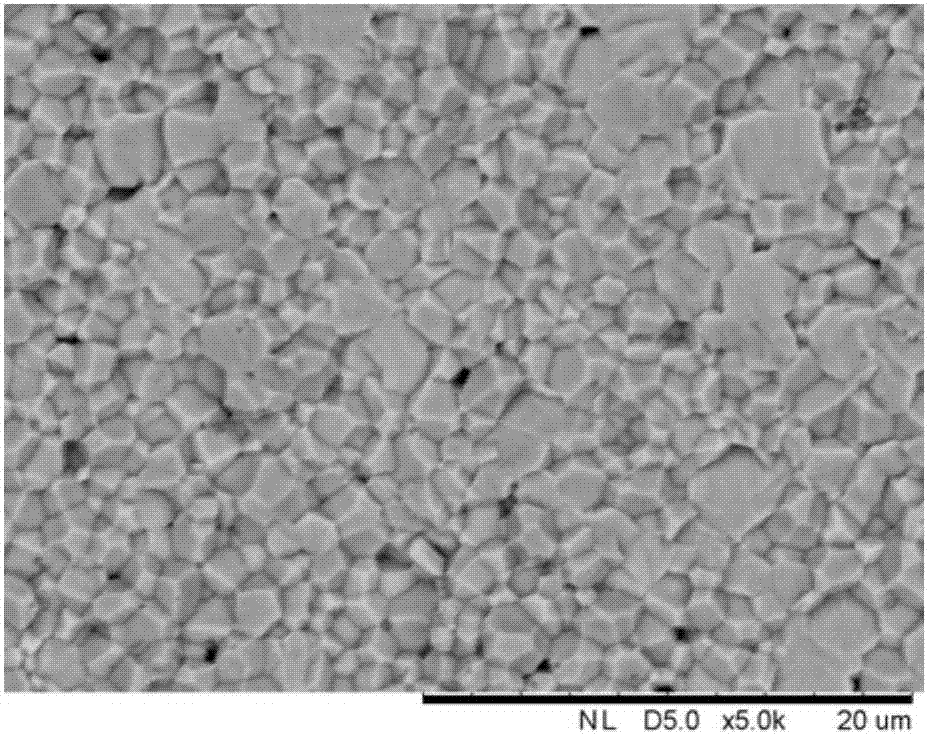

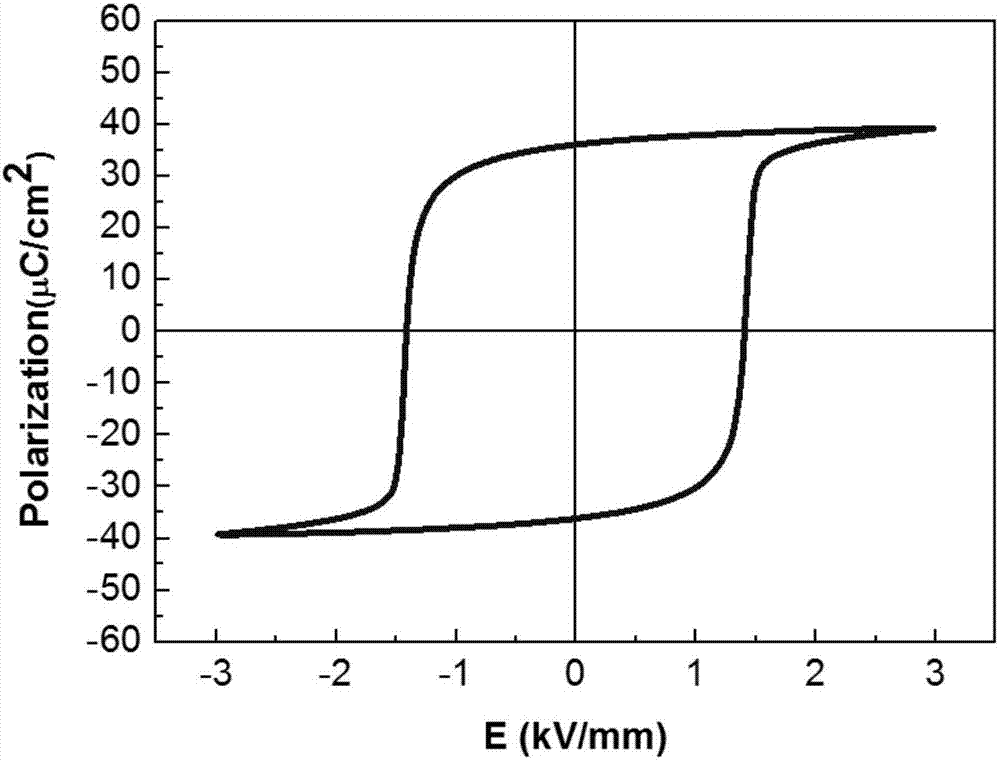

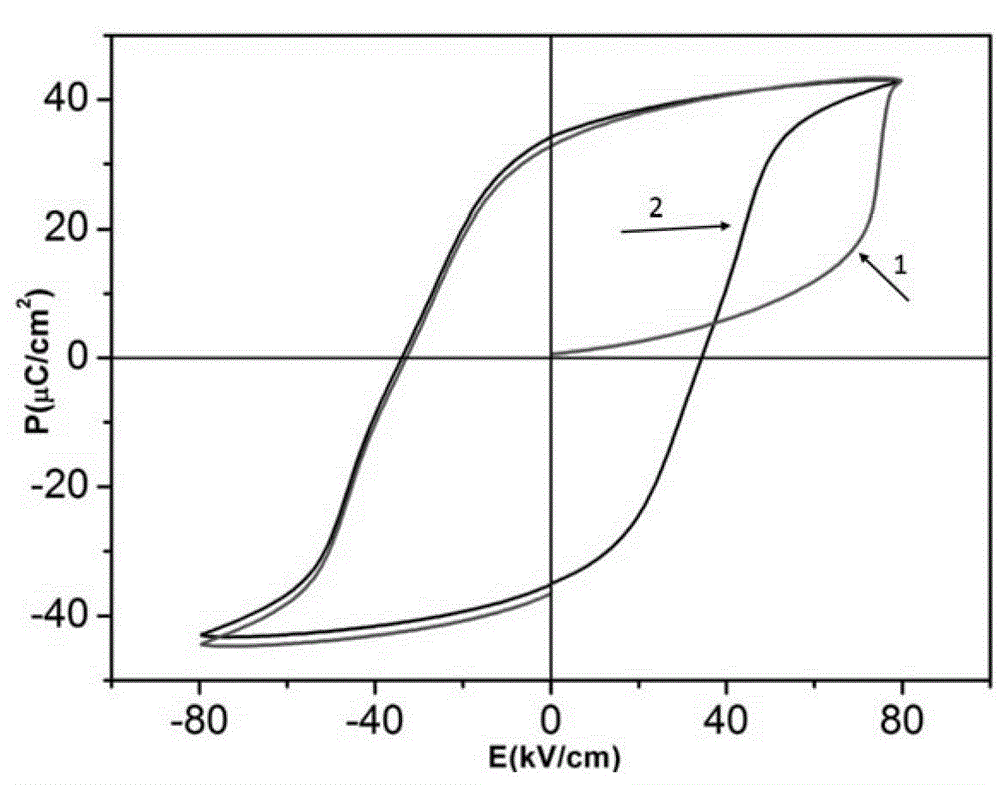

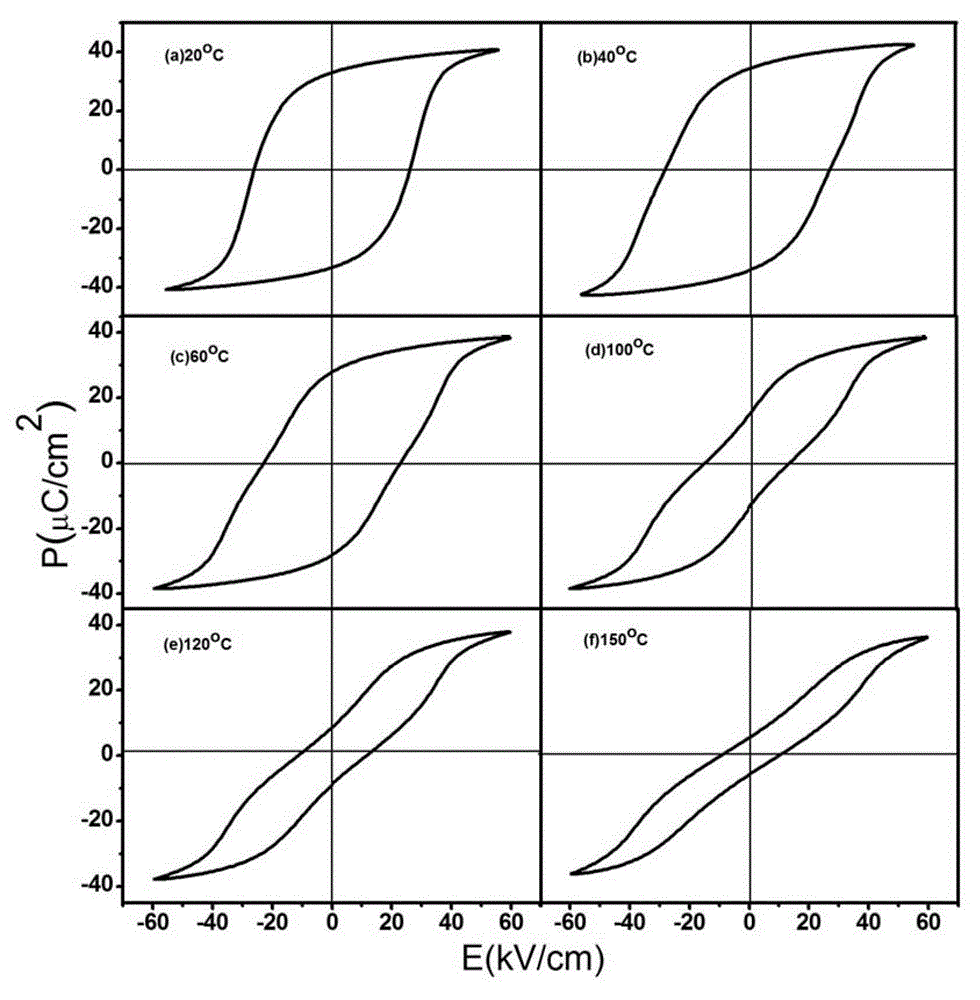

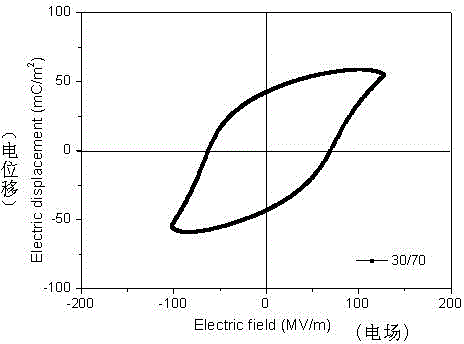

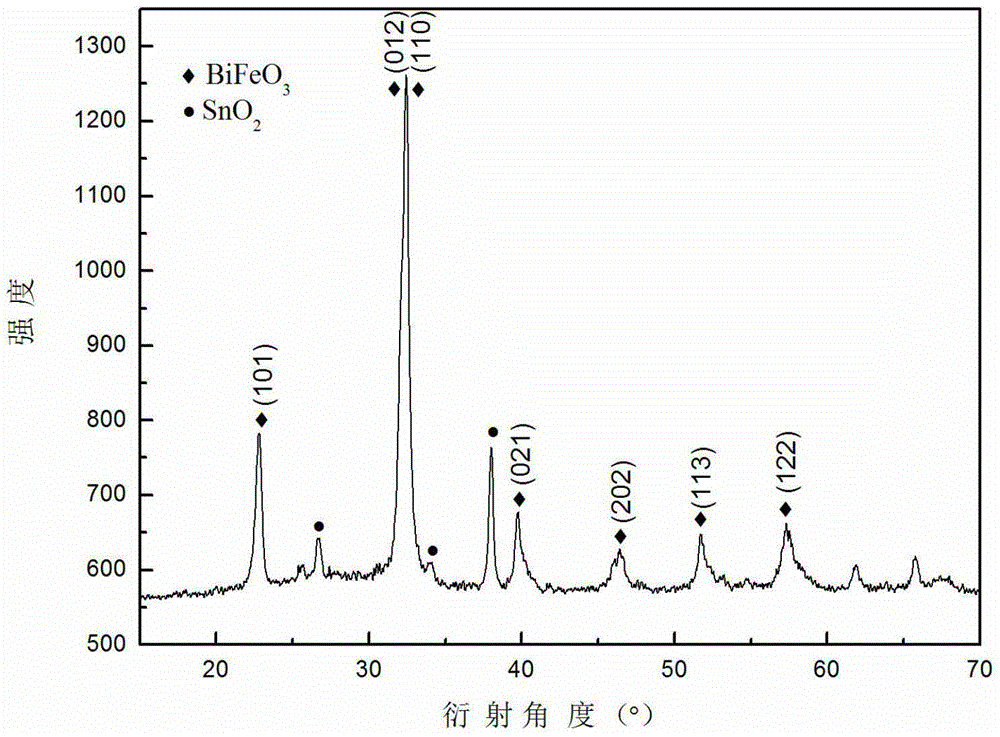

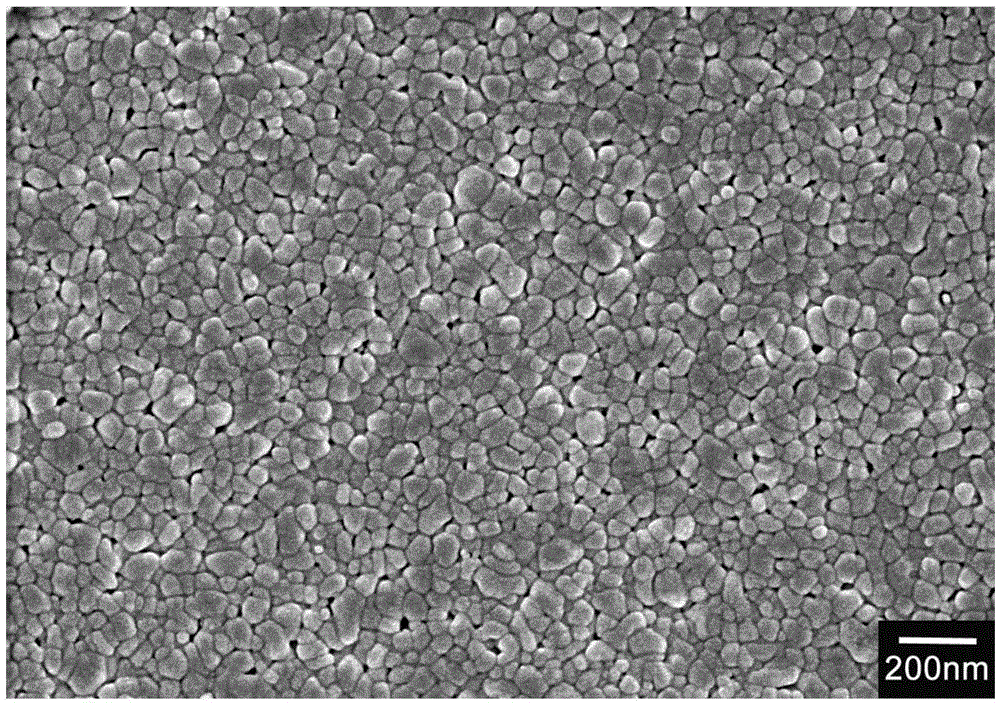

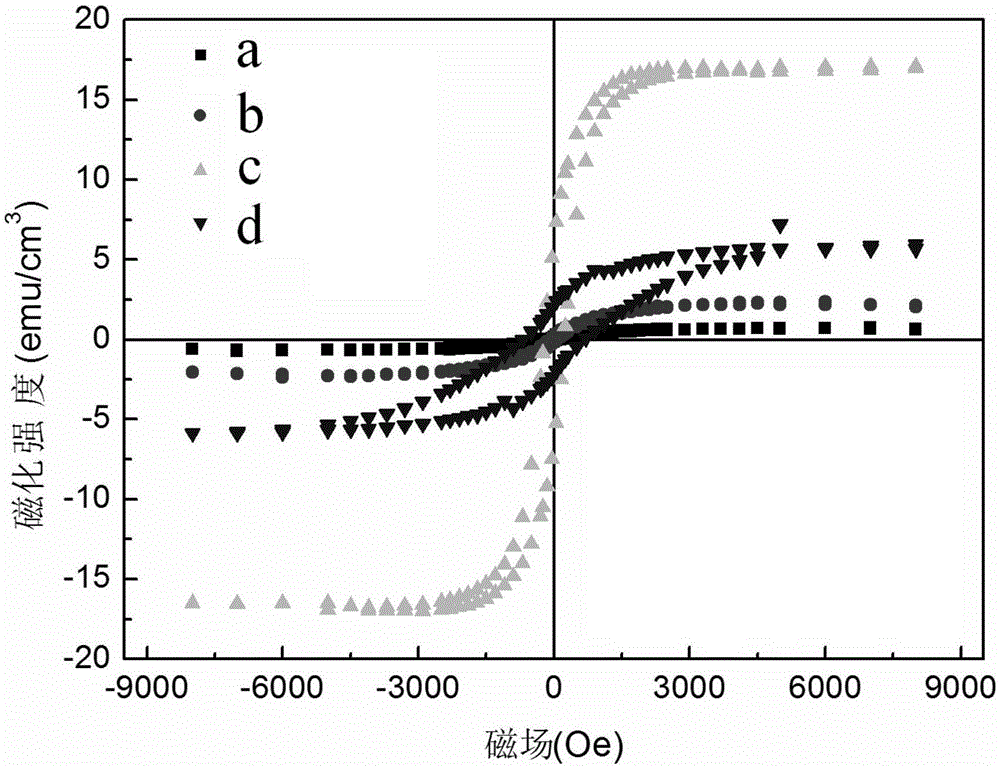

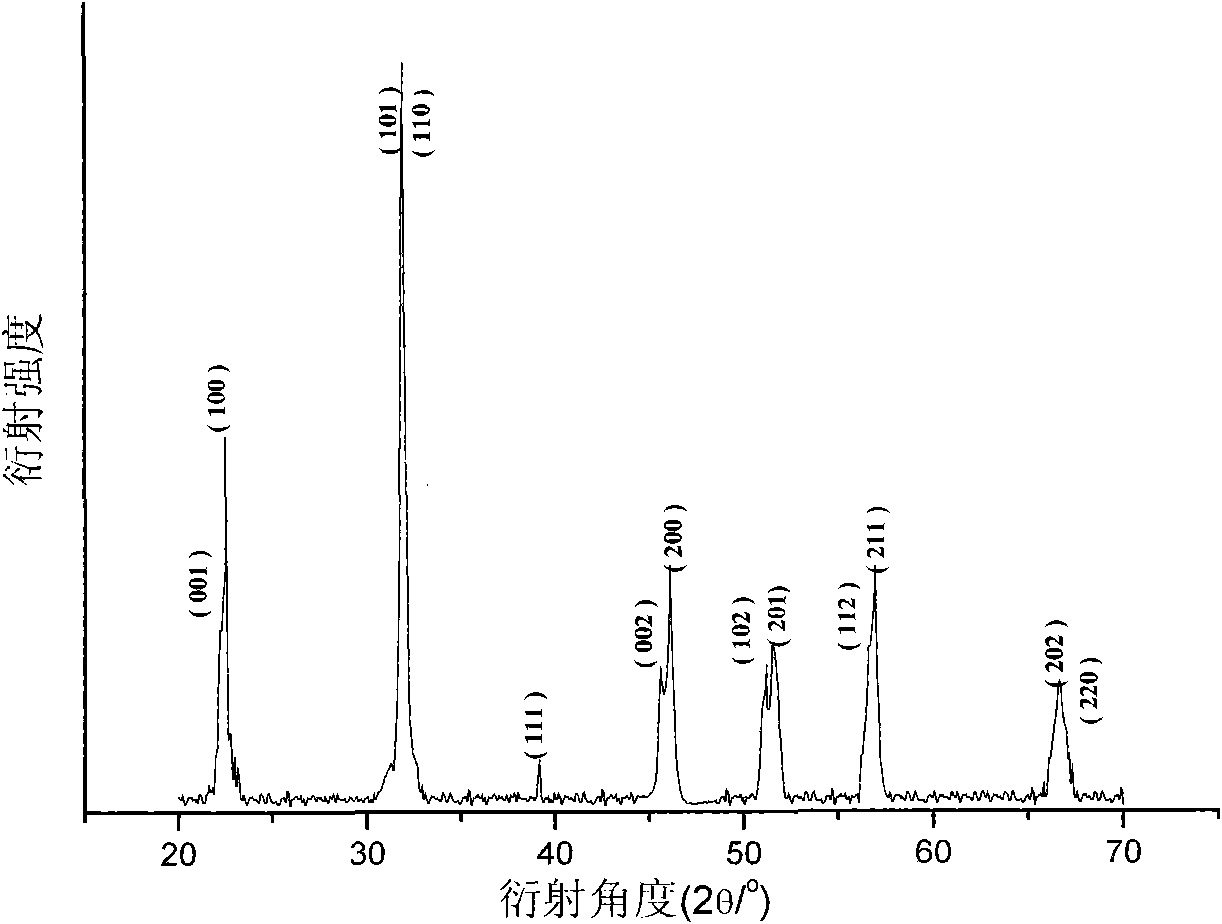

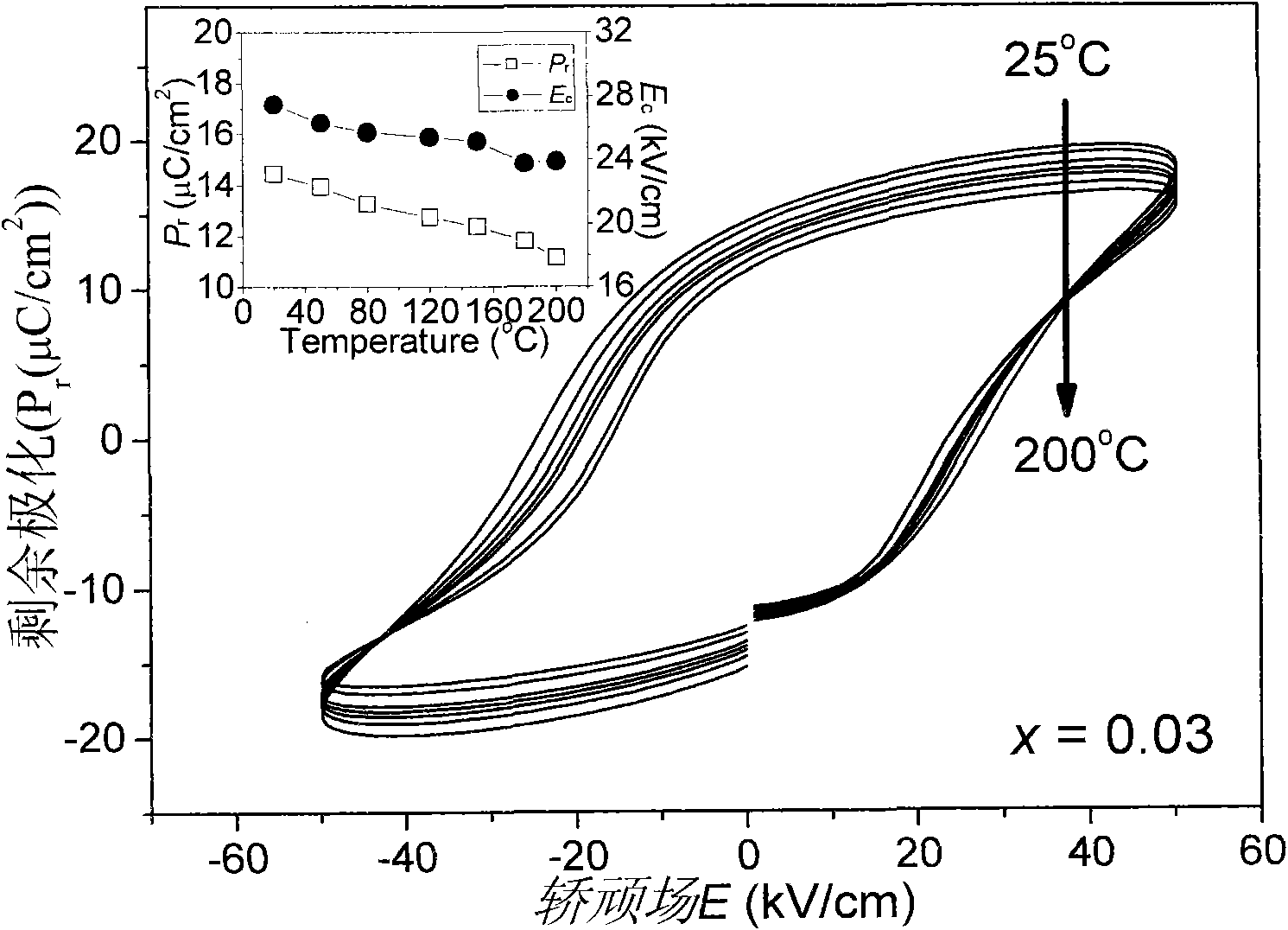

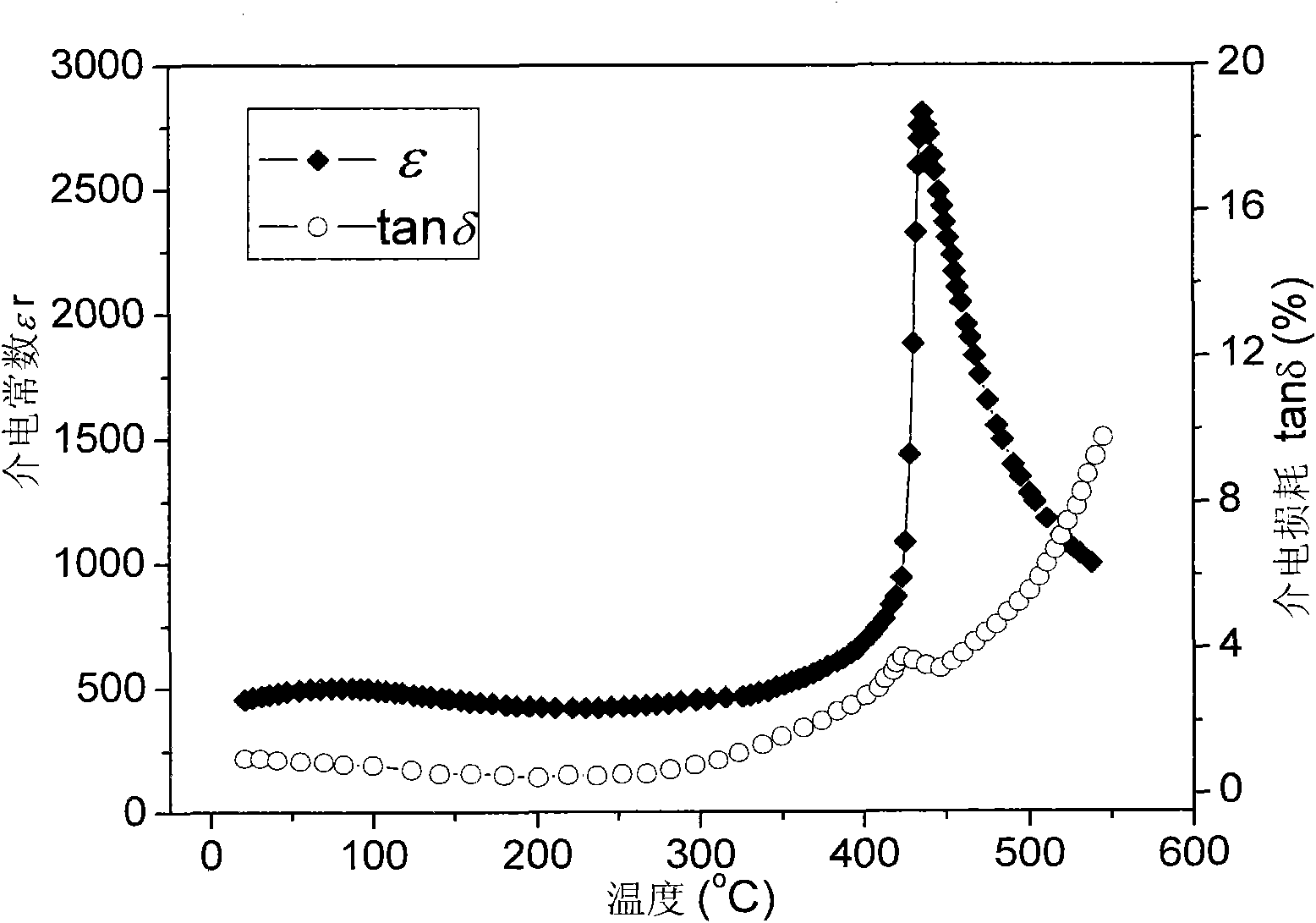

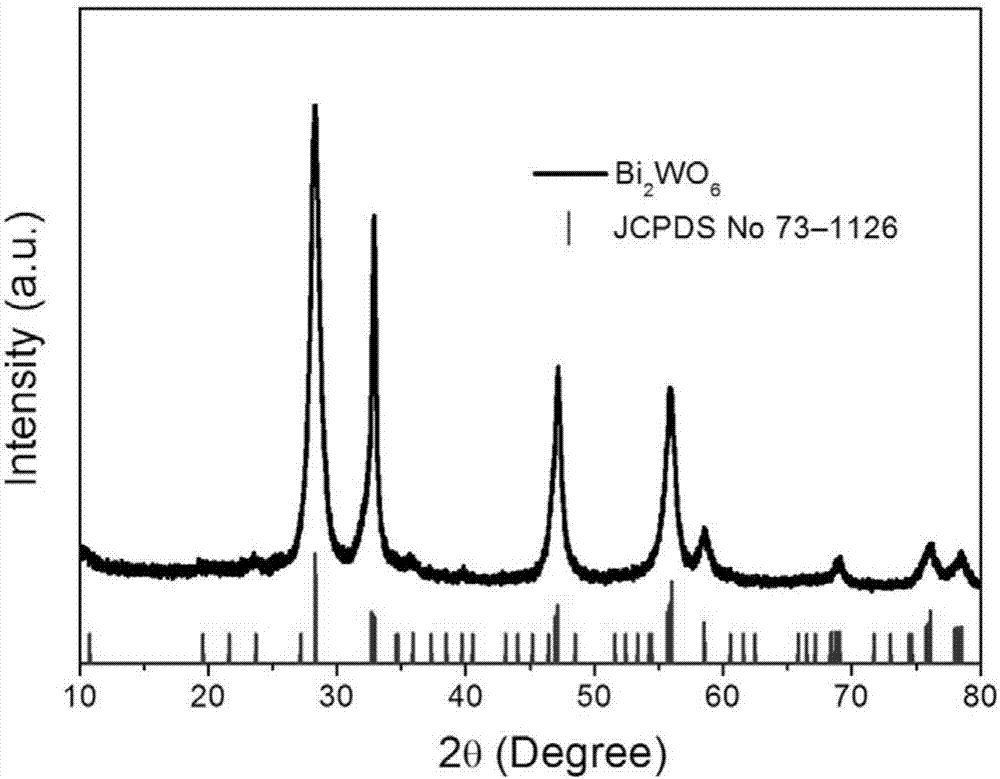

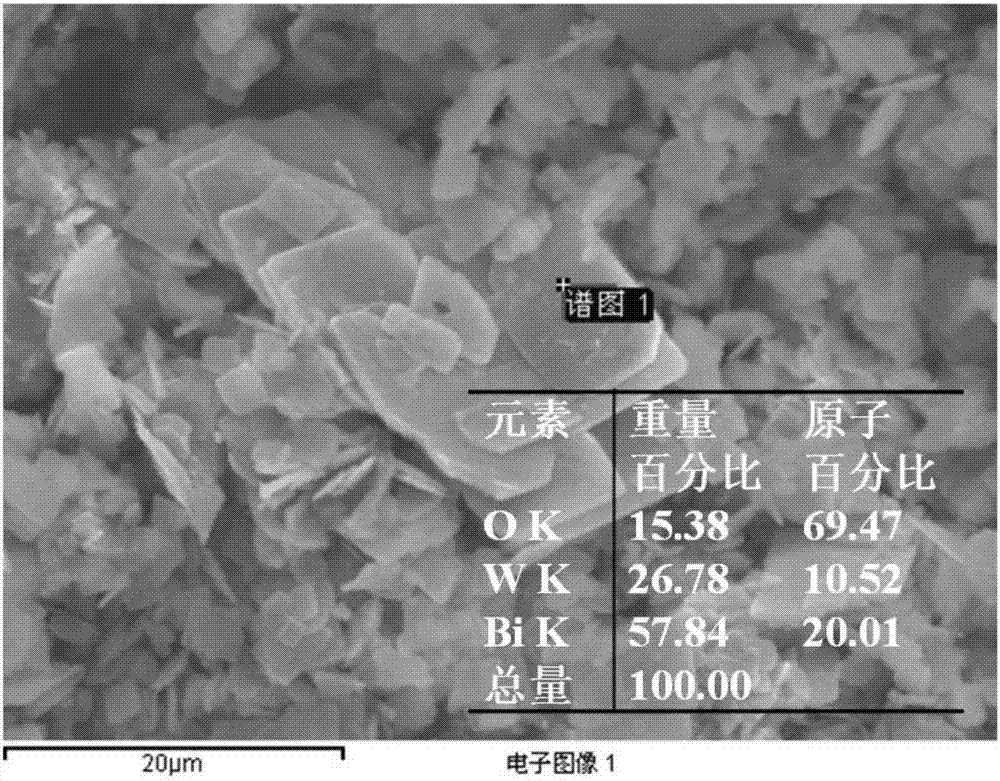

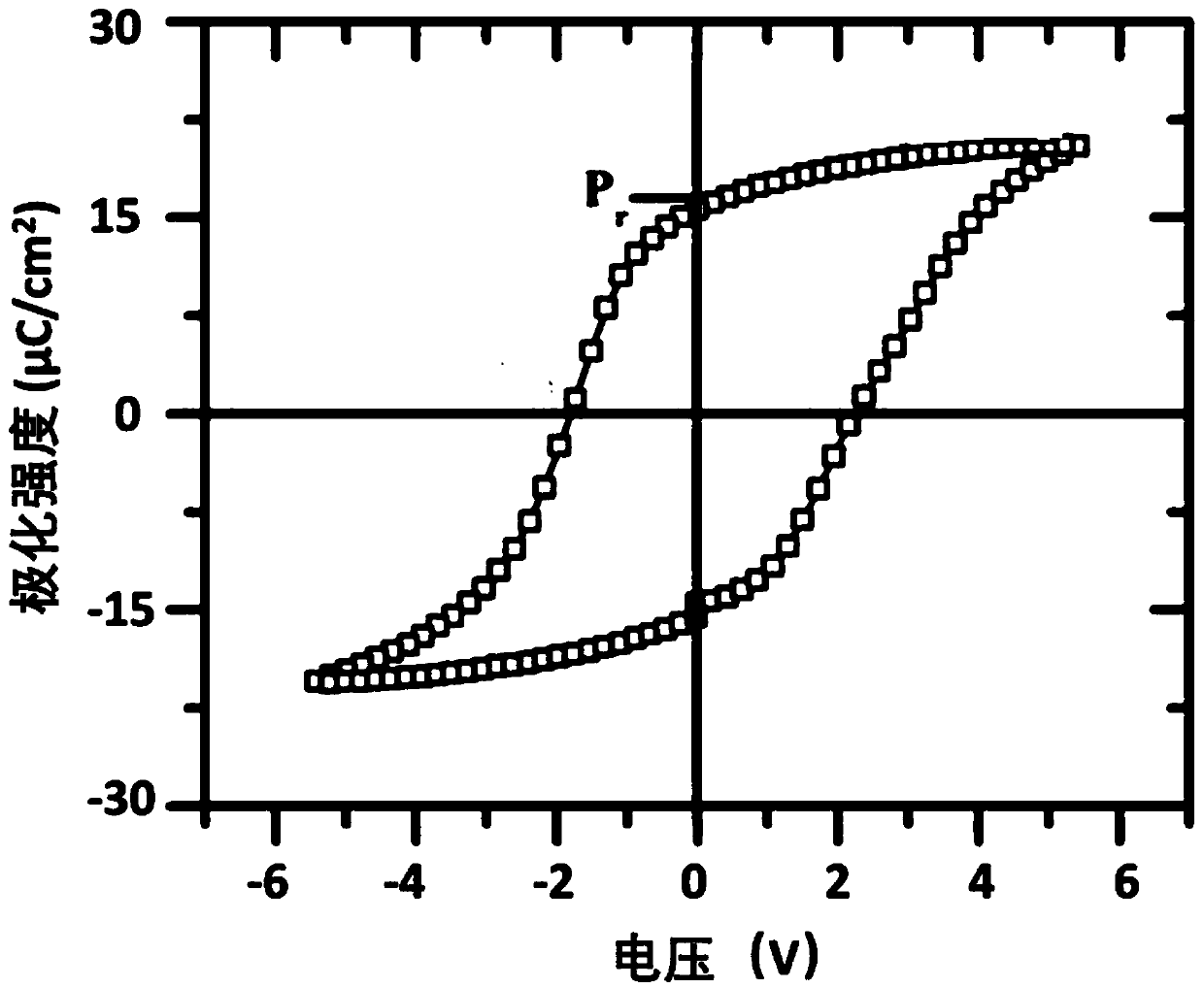

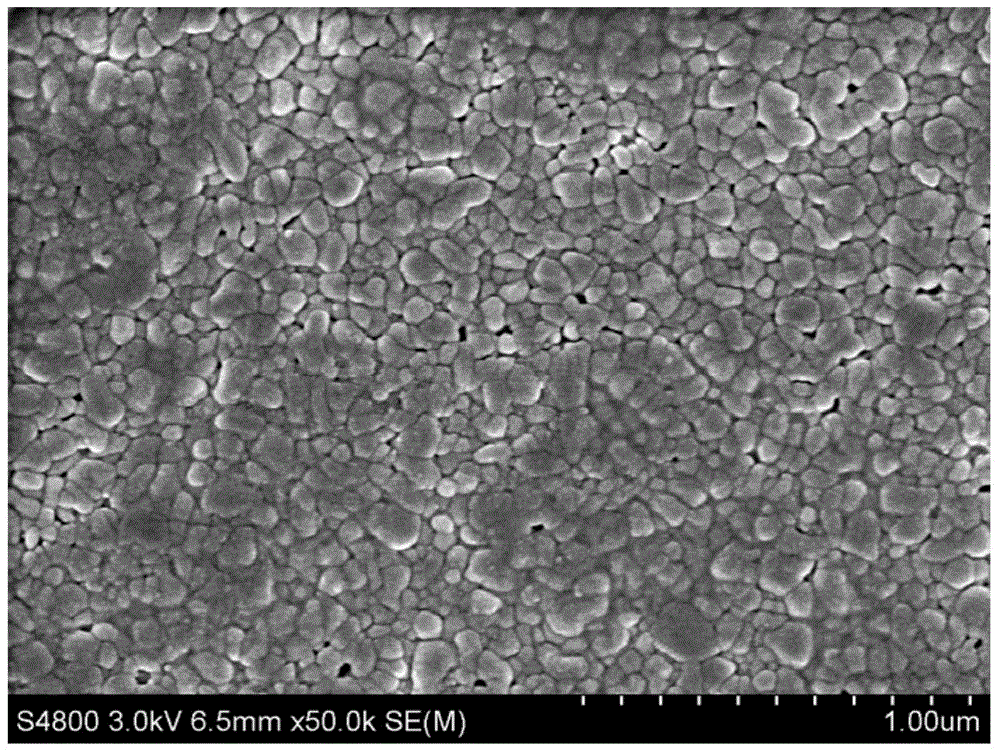

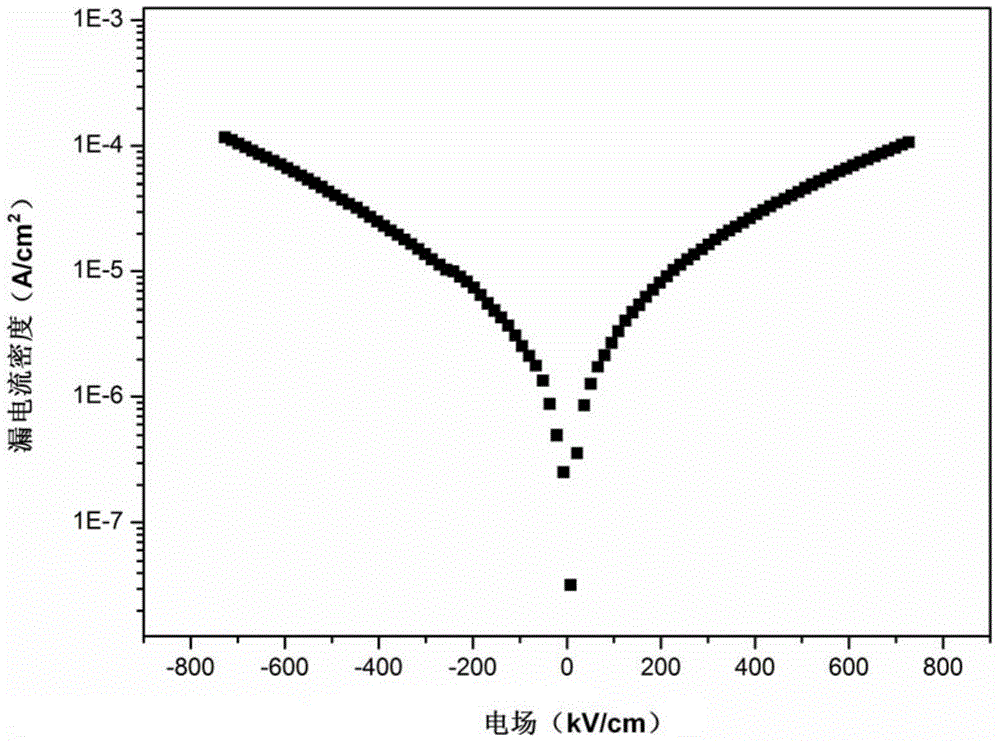

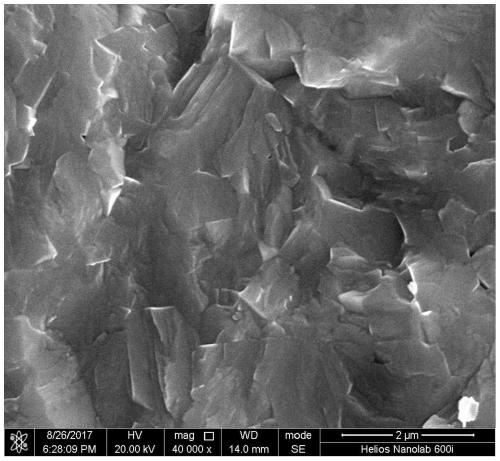

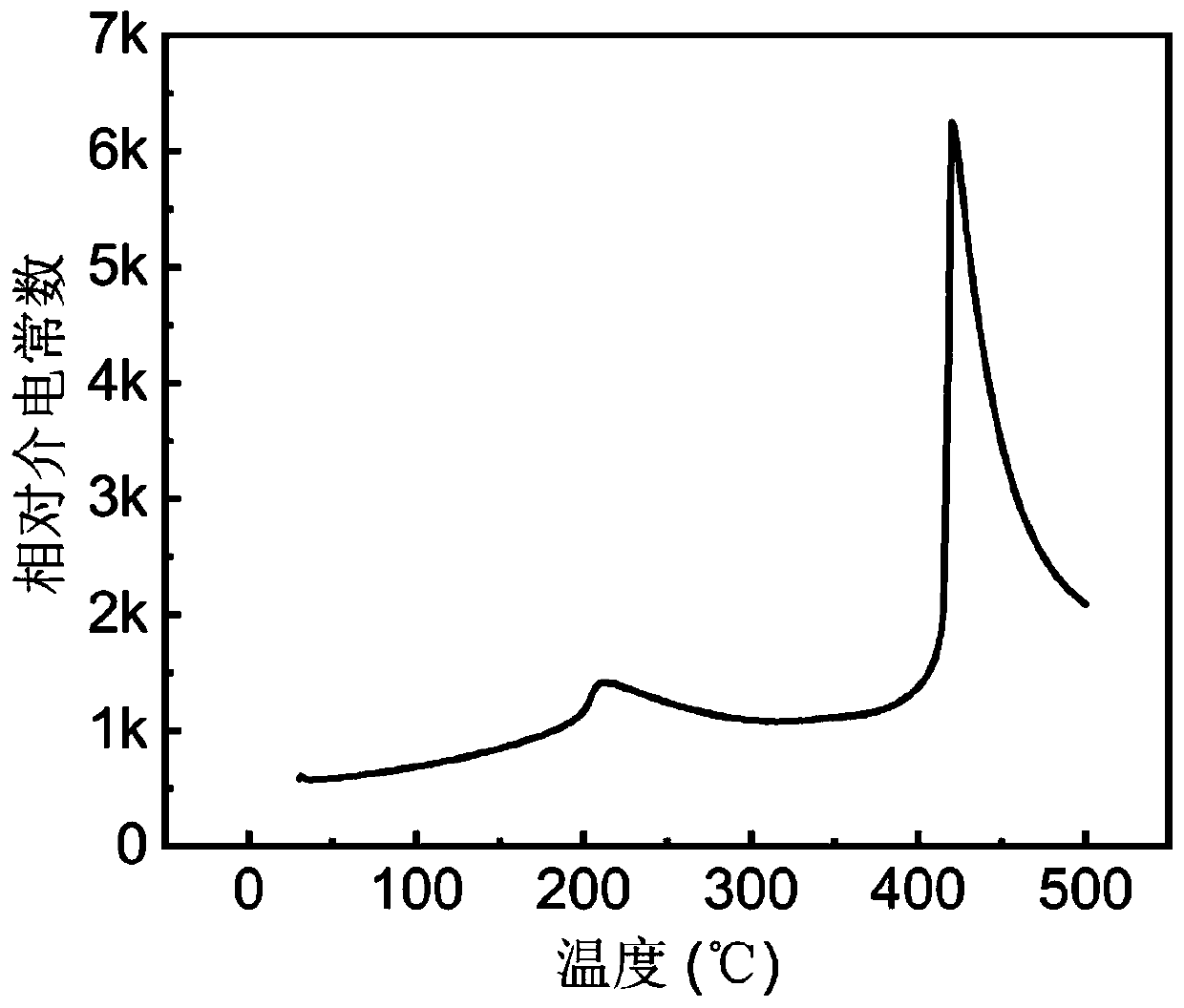

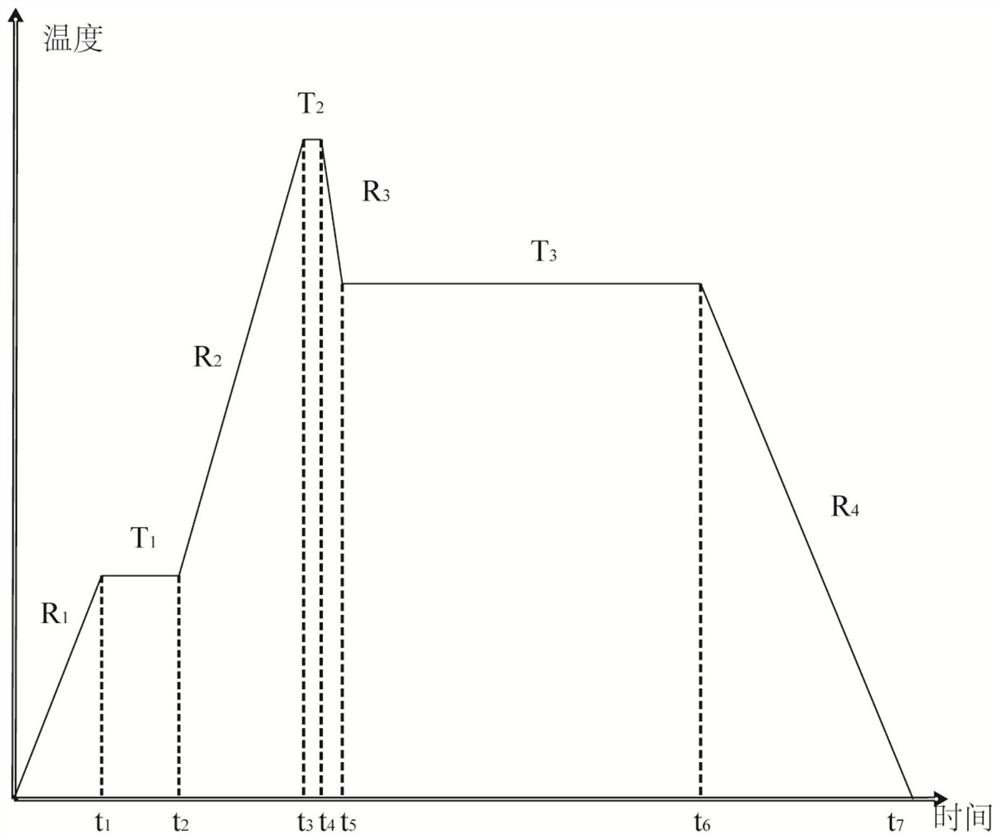

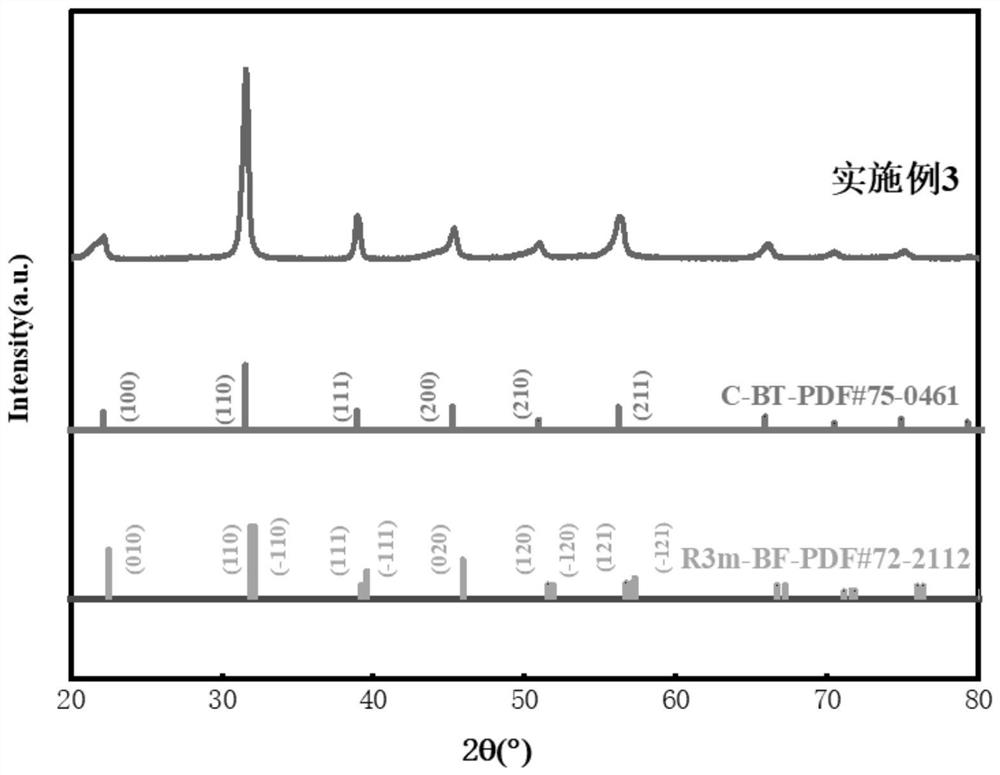

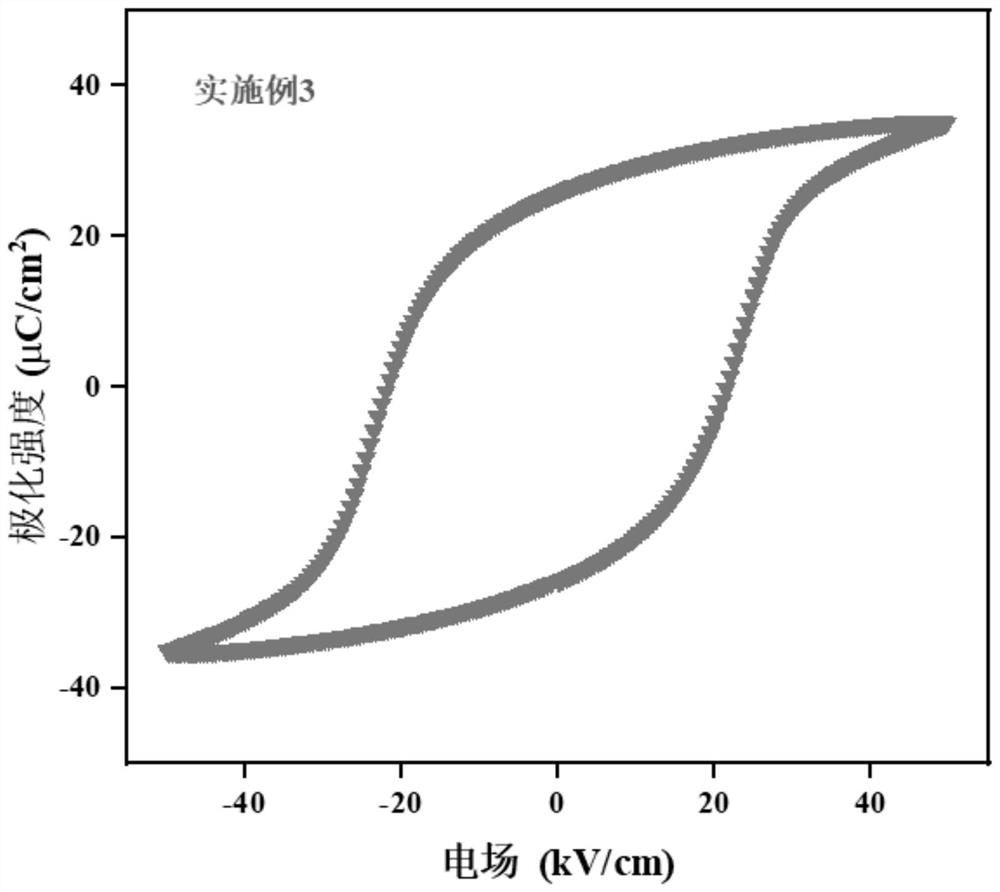

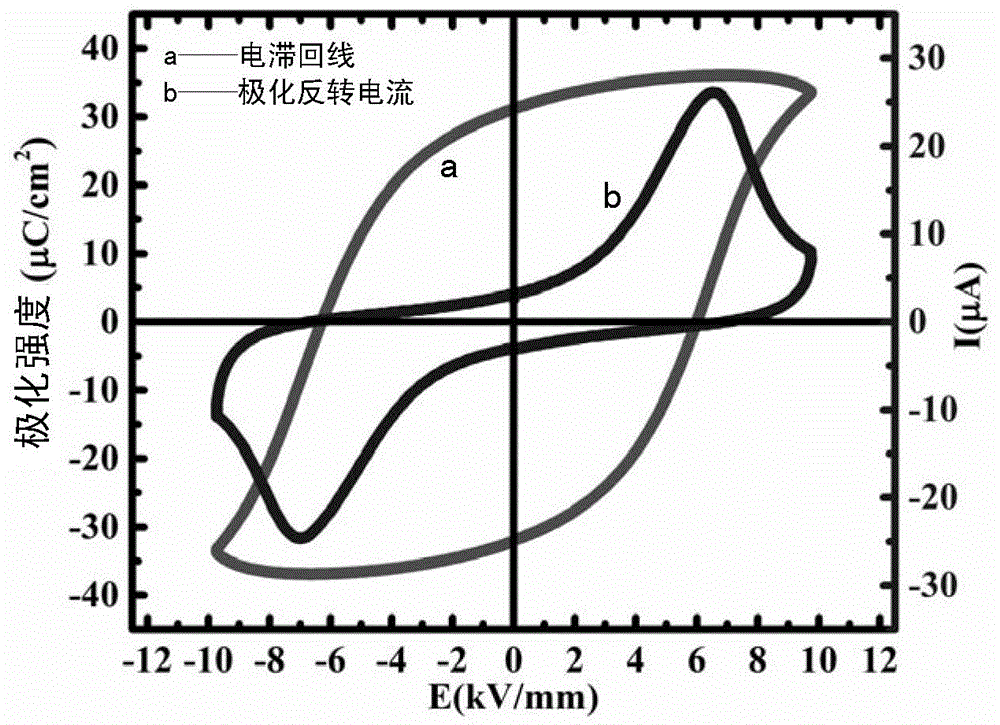

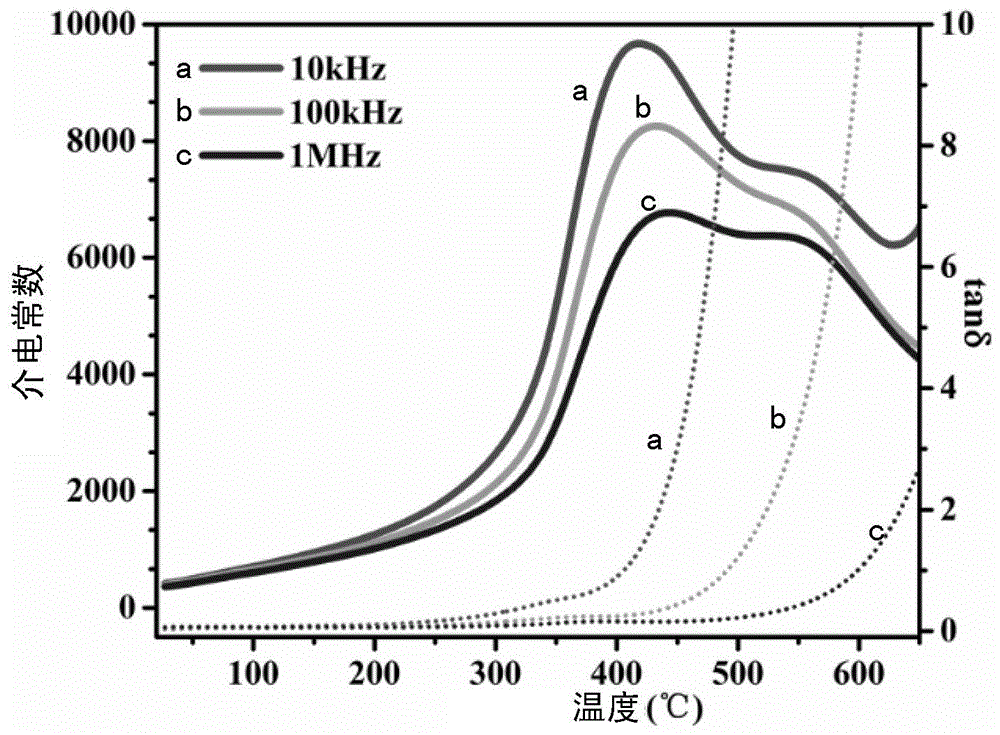

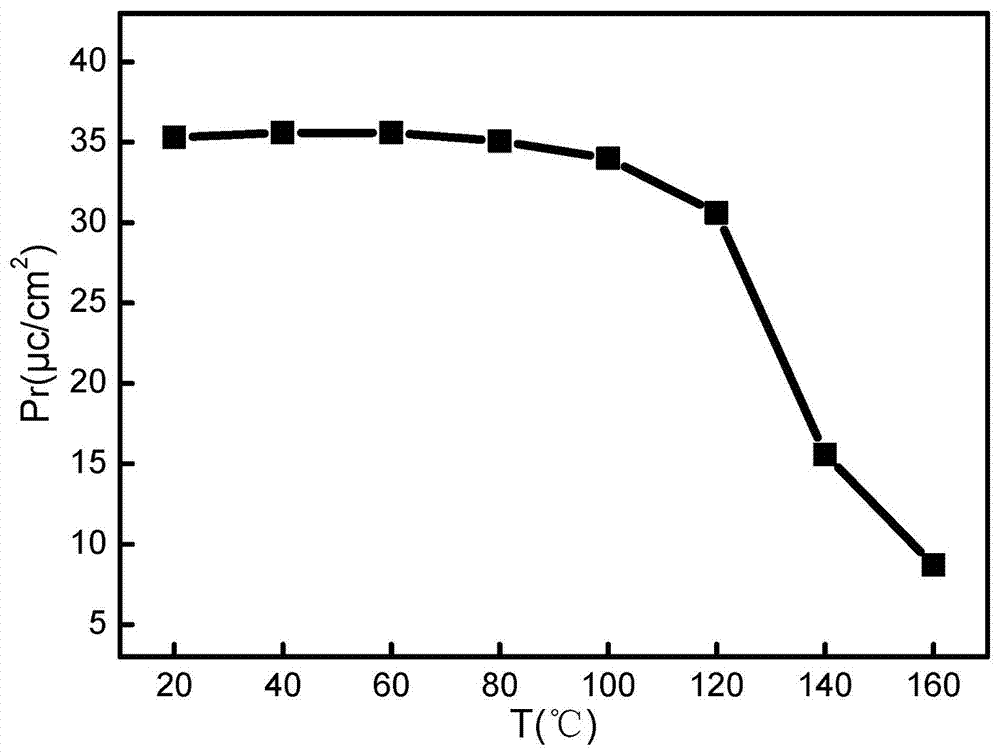

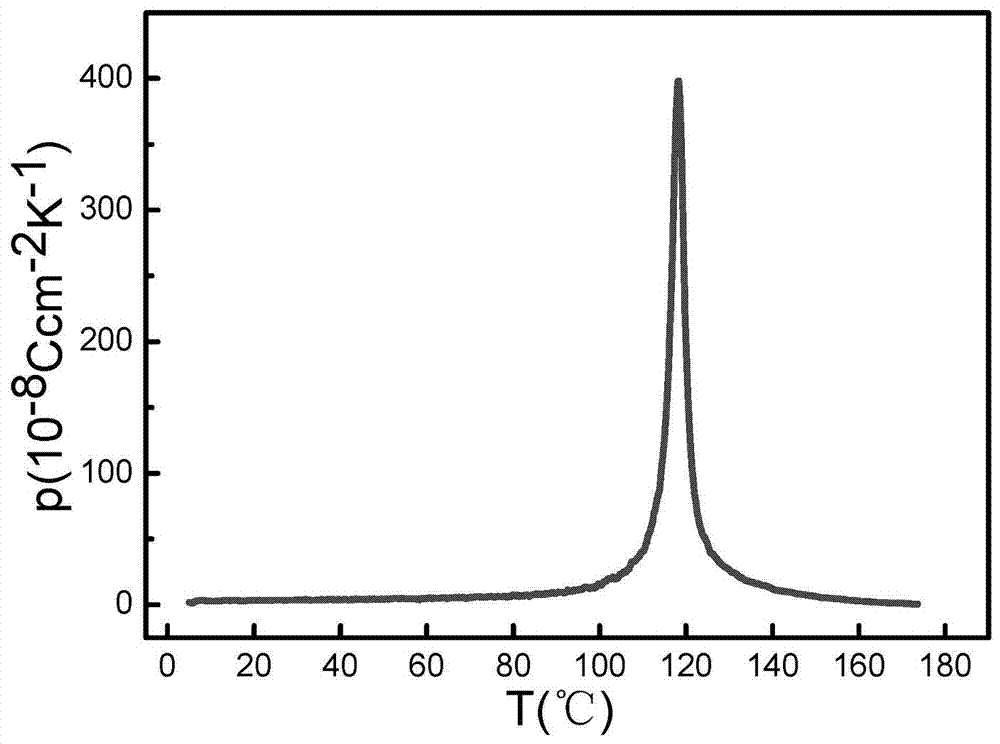

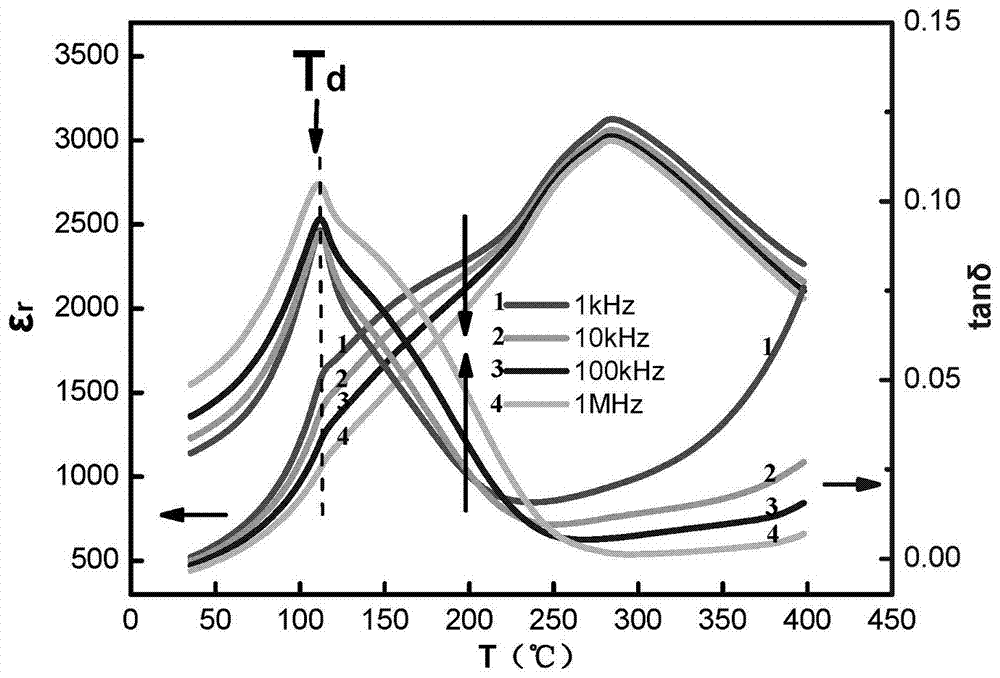

Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof

The invention provides a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and a preparation method thereof. The method comprises the following steps: preparing a Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 precursor solution from bismuth nitrate, praseodymium nitrate, hydrogen nitrate AE, ferric nitrate and manganous nitrate, wherein AE is Sr, Ca or Ba, and x=0.02-0.05; spinning the precursor solution on a substrate; and then spinning, drying and annealing, so as to obtain the Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film. The Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is simple in demands on equipment; the experiment condition is easy to achieve; the doping amount is easy to control; the ferroelectric property of the film can be greatly improved; and the prepared Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film is good in uniformity, low in leakage current, and low in coercive field, and has relatively high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

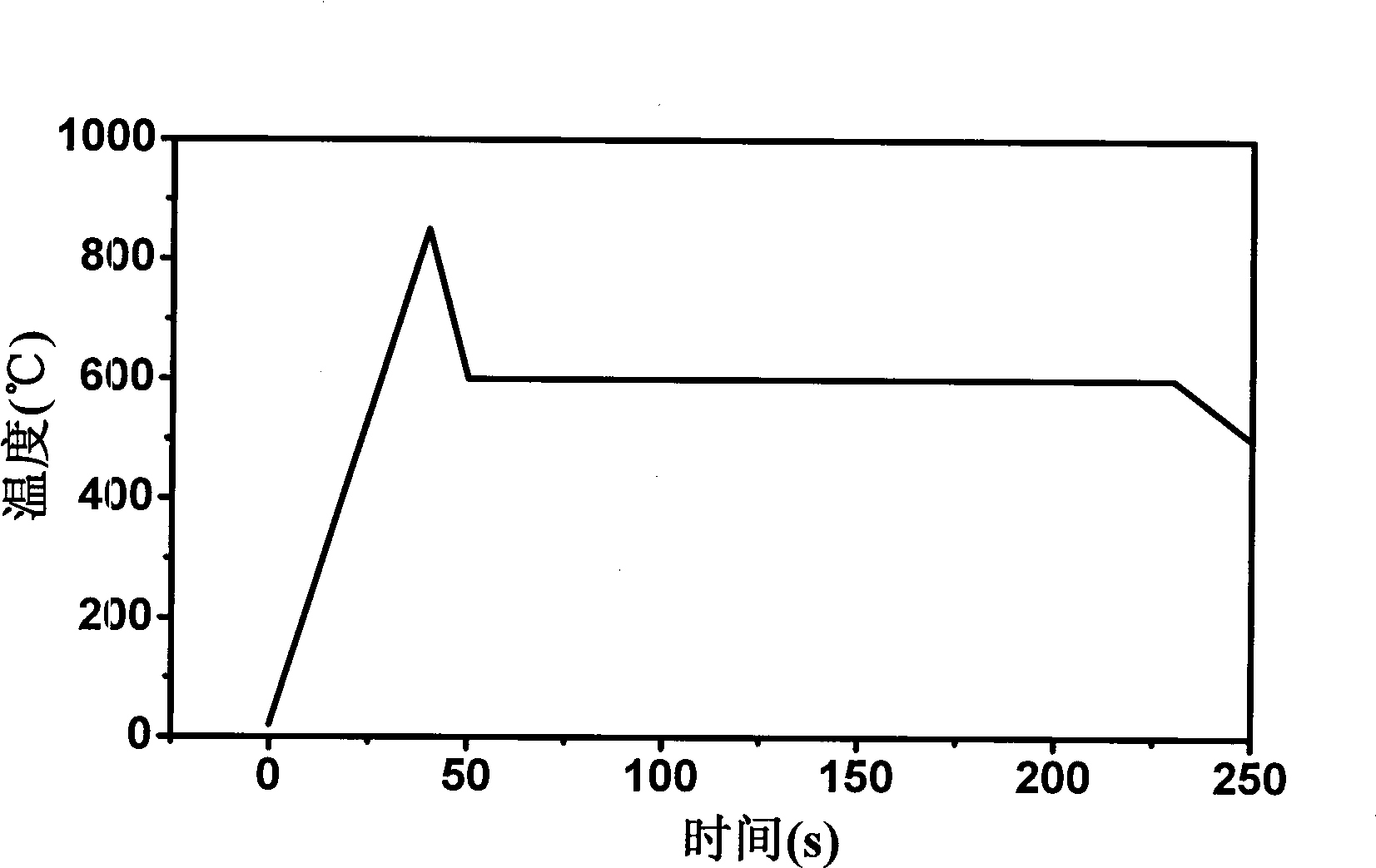

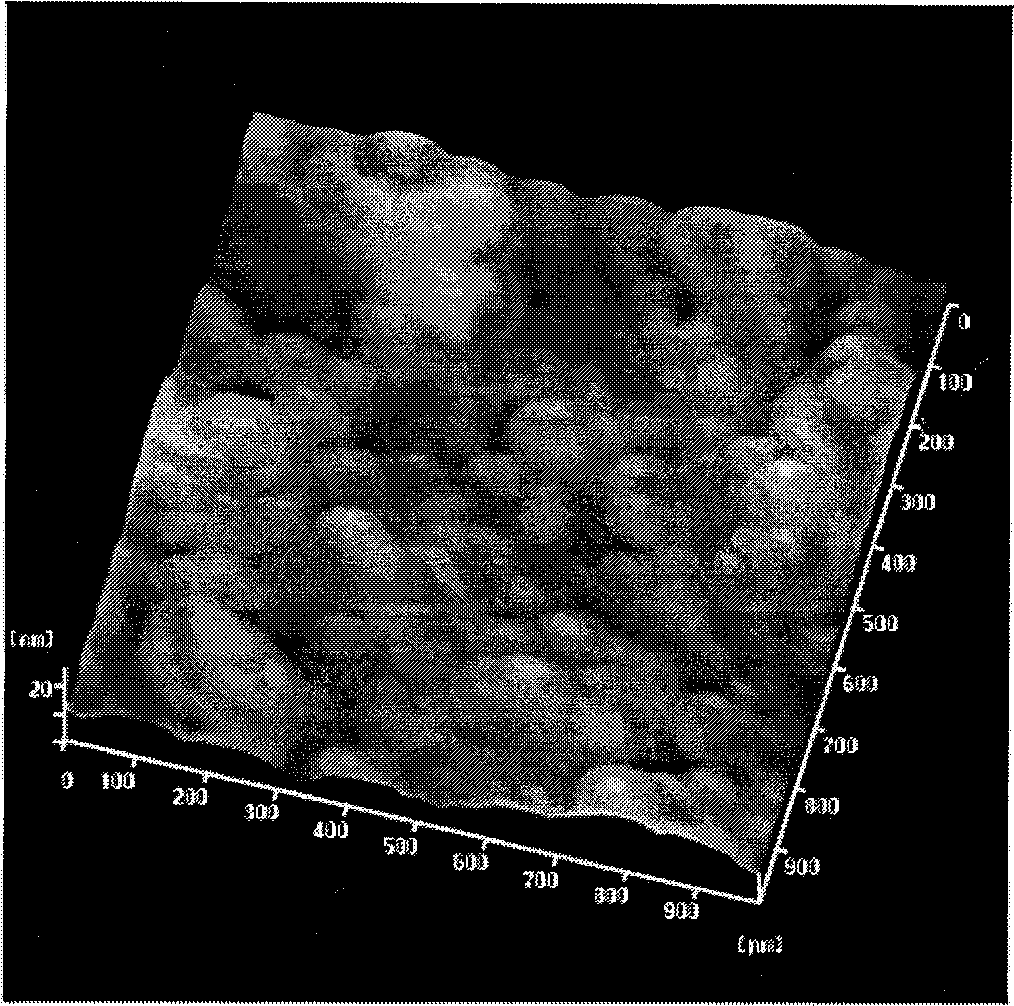

Method for the annealing preparation of tantalum scandium acid plumbum-based ferroelectric film by two step method

InactiveCN101532175AHigh purity perovskite phaseGood crystallization performancePiezoelectric/electrostrictive device manufacture/assemblyPolycrystalline material growthScandiumRms roughness

A method for the annealing preparation of a tantalum scandium acid plumbum-based ferroelectric film by a two step method is disclosed, comprising the technological steps of preparing a transition layer, preparing the tantalum scandium acid plumbum-based ferroelectric film and annealing the tantalum scandium acid plumbum-based ferroelectric film; annealing the tantalum scandium acid plumbum-based ferroelectric film comprises the steps of: putting the tantalum scandium acid plumbum-based ferroelectric film in an annealing furnace, heating up to 800-850 DEG C at a heating rate of 40 DEG C / s in an oxygen flow and then stopping heating up at once so that the tantalum scandium acid plumbum-based ferroelectric film is naturally cooled to 500-600 DEG C along with the furnace, preserving the heat for 3-5 minutes, and afterwards naturally cooling the ferroelectric film to room temperature along with the furnace. The tantalum scandium acid plumbum-based ferroelectric film prepared by the method has a perovskite phase purity capable of reaching 100%, good crystallization performance and low RMS roughness on the surface as well as also has the characteristic of high polarization intensity and high preferred orientation.

Owner:SICHUAN UNIV

Method for preparing potassium-sodiumniobate lead-free piezoelectric thick film

InactiveCN101817559AHigh purityImprove stabilityPiezoelectric/electrostrictive device manufacture/assemblyNiobium compoundsChemical solutionAlcohol

The invention relates to a method for preparing a ferroelectric / piezoelectric thick film in inorganic materials, and discloses a method for preparing a potassium-sodiumniobate (K0.5Na0.5NbO3, KNN) lead-free piezoelectric thick film on the basis of a modified chemical solution coating process. The method comprises the following steps of: (1) preparing niobium ethoxide from anhydrous niobium chloride and absolute ethyl alcohol at low cost; (2) preparing precursor solution of potassium-sodiumniobate from anhydrous sodium acetate, anhydrous potassium acetate and the niobium ethoxide by PVP modification and ion doping technique; and (3) performing repeated coating-thermal treatment to obtain the piezoelectric thick film which is compact, has no cracks and has the thickness between 0.8 and 5 mu m.

Owner:XI AN JIAOTONG UNIV

Manganese-doped BNT-BA lead-free ferroelectric ceramic material and preparation method thereof,

ActiveCN107488032AHigh remnant polarizationHigh depolarization temperatureChemical compositionCeramic

The present invention relates to a manganese-doped BNT-BA lead-free ferroelectric ceramic material and a preparation method thereof, wherein the chemical composition of the manganese-doped BNT-BA lead-free ferroelectric ceramic material is 0.96Bi0.5Na0.5(Ti1-xMnx)O3-0.04BiAlO3, and x is more than or equal to 0.1% and is less than or equal to 1.0%. According to the present invention, the prepared manganese-doped BNT-BA binary ceramic has excellent comprehensive electrical properties and is expected to be applied in the technical field of high-power pulses.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

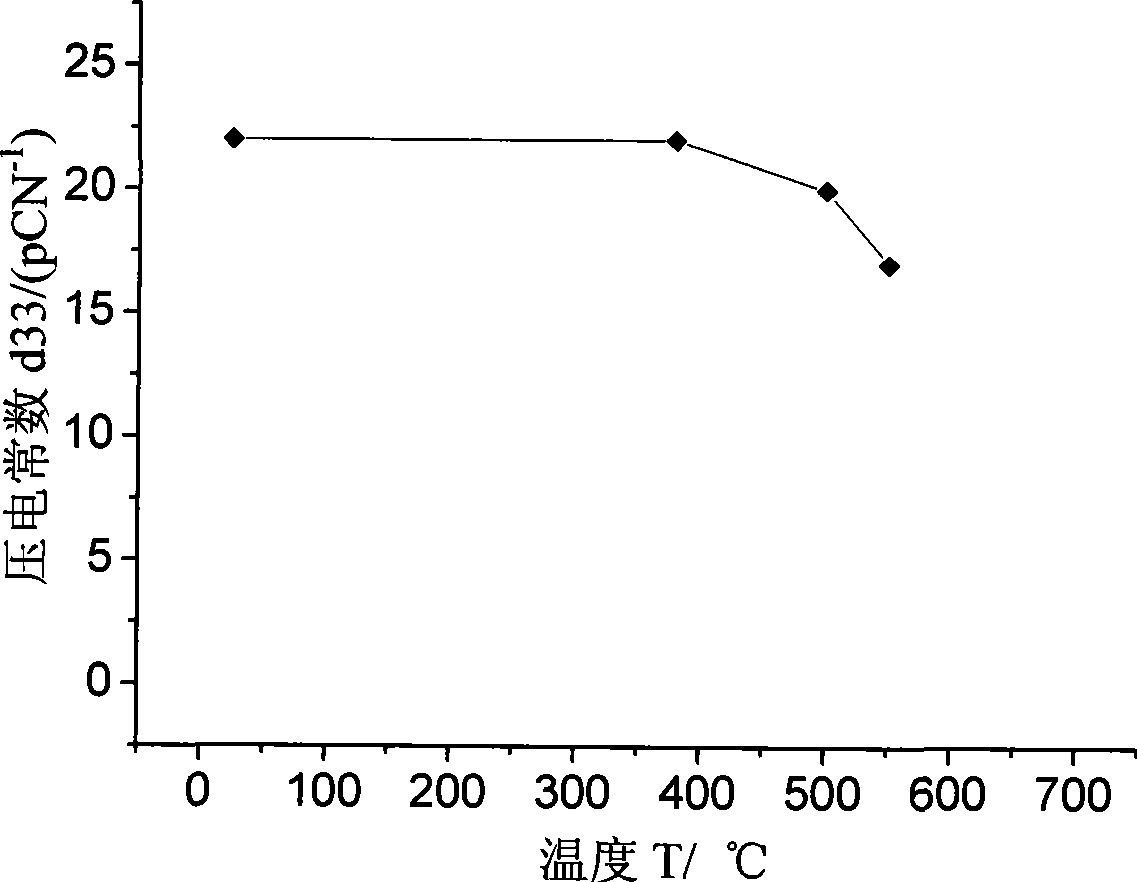

Piezoelectric ceramic complexes

InactiveCN101386532AImprove temperature stabilityDielectric constant - small temperature coefficientPiezoelectric/electrostrictive/magnetostrictive devicesDielectric lossTemperature coefficient

The invention relates to a ceramic composite with a bismuth layer structure with good comprehensive performance in high-temperature piezoelectricity, dielectric and so on. The chemical formula of the ceramic composite is (Sr2-xCax)1-yMyBi4Ti5O18, wherein M can be one or more of Mn, Ba, Ce, Pb and other elements; x is more than or equal to 0 and is less than or equal to 2, and y is more than or equal to 0 and is less than or equal to 1. The composite has good performance when x is equal to 1 and y is equal to 0, and the Curie temperature is more than or equal to 570 DEG C. At room temperature, piezoelectric constant d33 is more than or equal to 22pC.N<-1>; d33 is more than 17pC.N<-1> at a temperature of 550 DEG C, and 80 percent of the piezoelectric activity is still maintained. From room temperature to 550 DEG C, the dielectric loss of the composite in 100 kHz is less than or equal to 0.07, and the dielectric loss of the composite in 1MHz is less than or equal to 0.02, and the specific inductive capacity-temperature coefficient is small. The ceramic composite can fulfill the application in steel, chemical engineering, energy, aerospace engineering and other industrial fields.

Owner:LIAOCHENG UNIV

BT-KBT-NN (BaTiO3-K0.5Bi0.5TiO3-NaNbO3)-based high energy storage density ceramic and preparation method thereof

The invention discloses a BT-KBT-NN (BaTiO3-K0.5Bi0.5TiO3-NaNbO3)-based high energy storage density ceramic and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing BT presintering powder, KBT presintering powder and NN presintering powder; then, carrying out burdening on the BT presintering powder, the KBT presintering powder and the NN presintering powder according to a chemical formula (1-x)(0.92BaTiO[3]-0.08(K[0.5]Bi[0.5])TiO[3])-xNaNbO[3], wherein x is 0.02-0.08, and x is a mole percent; evenly mixing, drying, tabletting, and forming to obtain mixed tablets; then, sintering the mixed tablets to obtain the BT-KBT-NN-based high energy storage density ceramic.

Owner:SHAANXI UNIV OF SCI & TECH

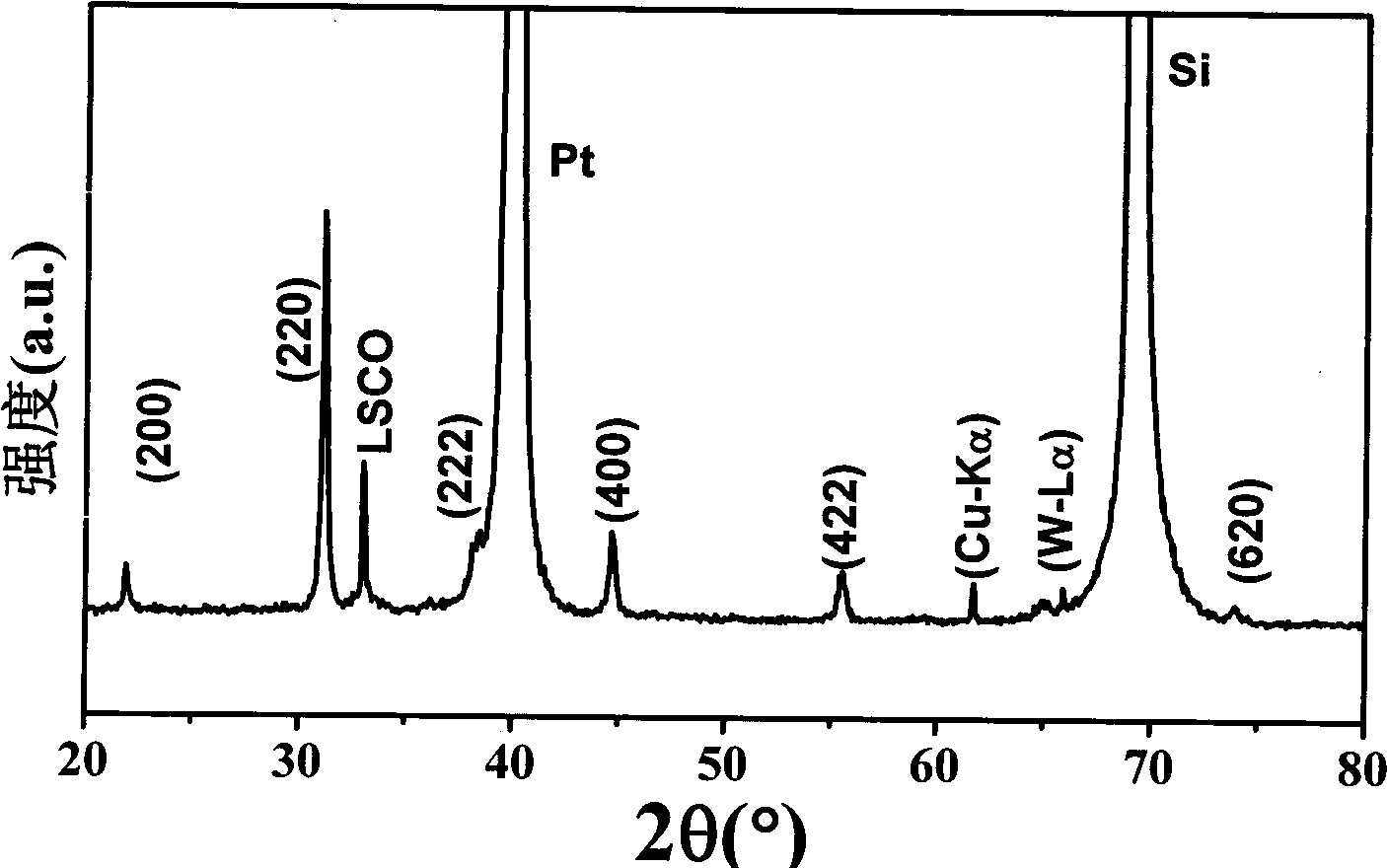

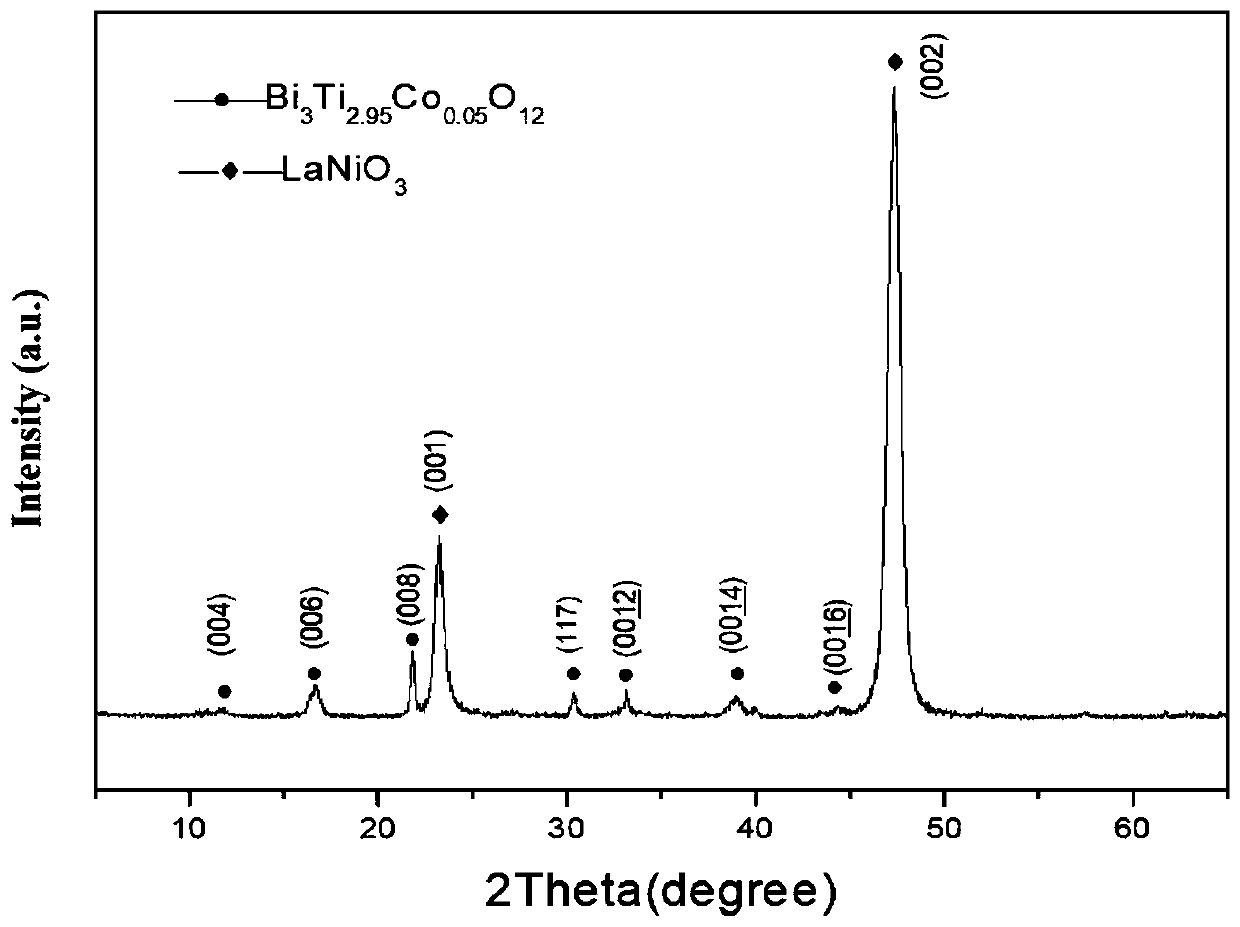

Bi4Ti2.95Co0.05O12 multiferroic film capable of realizing c-axis oriented growth on Si as substrate and preparation method of Bi4Ti2.95Co0.05O12 multiferroic film

A Bi4Ti2.95Co0.05O12 multiferroic film capable of realizing c-axis oriented growth on Si as a substrate is prepared from components as follows: Bi(NO3)2.5H2O, Co(NO3)2.6H2O, butyl titanate, ethylene glycol monomethyl ether and acetylacetone. The preparation method comprises the steps as follows: Bi4Ti2.95Co0.05O12 sol is used as a precursor, a Bi4Ti2.95Co0.05O12 gel film is prepared on the Si substrate taking c-axis oriented LaNiO3 as a buffer layer, then, drying and heat tretament are performed, and the Bi4Ti2.95Co0.05O12 multiferroic film with c-axis orientation is prepared. The Bi4Ti2.95Co0.05O12 multiferroic film has the characteristics that the film has excellent conductivity and can replace noble metals such as platinum and gold to be used as a bottom electrode for electric performance test of the Bi4Ti2.95Co0.05O12 film.

Owner:XIAN UNIV OF TECH

Bismuth ferrite film material, method for integrally preparing bismuth ferrite film on silicon substrate at low temperature and application

ActiveCN111525024AHigh polarizationHigh remanent polarizationVacuum evaporation coatingSputtering coatingSputteringPerovskite (structure)

The invention discloses a bismuth ferrite film material, a method for integrally preparing a bismuth ferrite film on a silicon substrate at a low temperature and application. The method comprises: under the condition of 300-400 DEG C, a bottom electrode, a buffer layer and a bismuth ferrite film being sequentially subjected to magnetron sputtering on the surface of a base body from bottom to top,reducing the temperature to the room temperature, a top electrode being subjected to magnetron sputtering on the surface of the bismuth ferrite film, and the buffer layer being made of conductive oxide which can be matched with bismuth ferrite lattices and is of a perovskite structure. The temperature for preparing the bismuth ferrite film material can be reduced to 450 DEG C or below, and the bismuth ferrite film material has high polarization strength.

Owner:欧阳俊

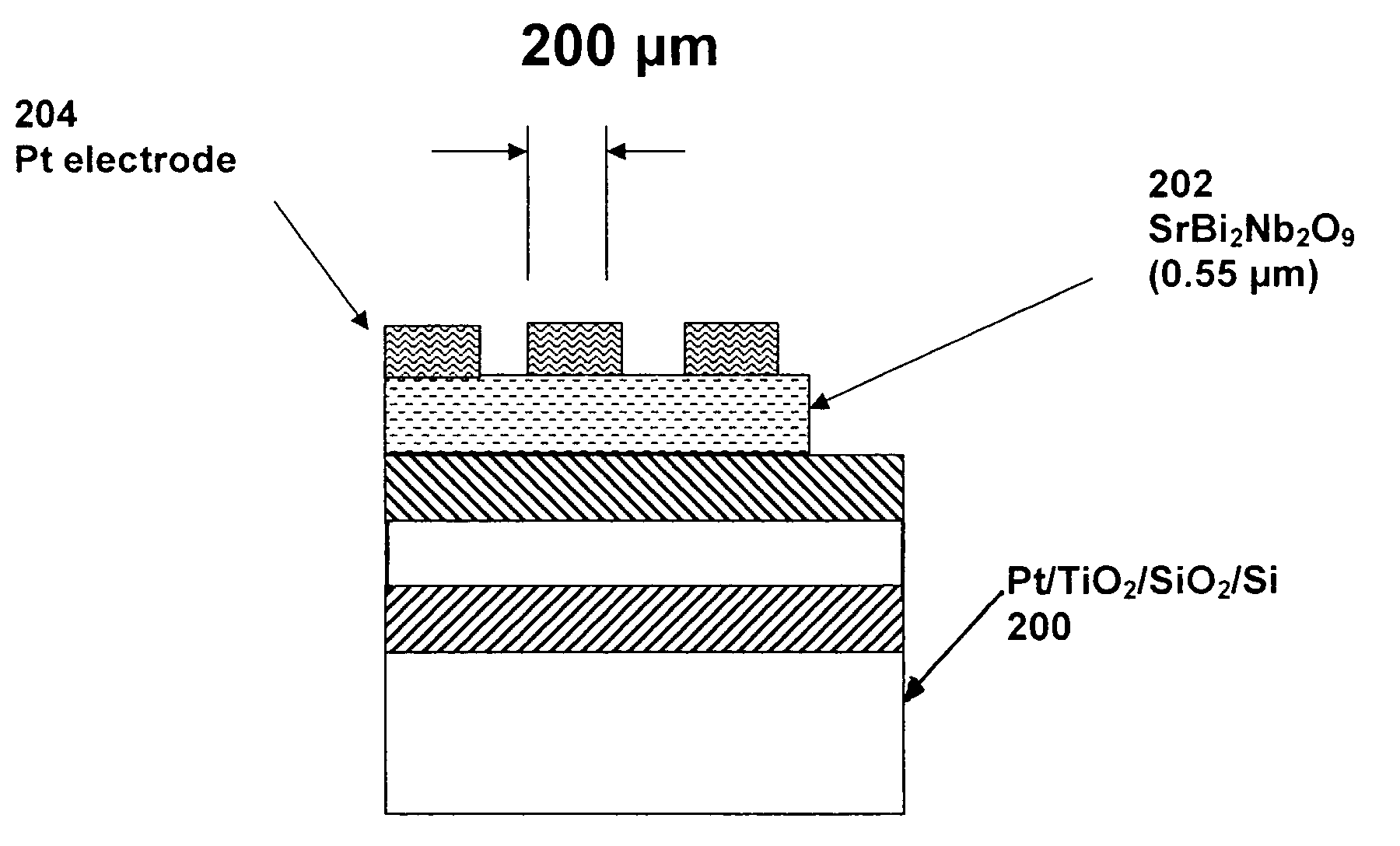

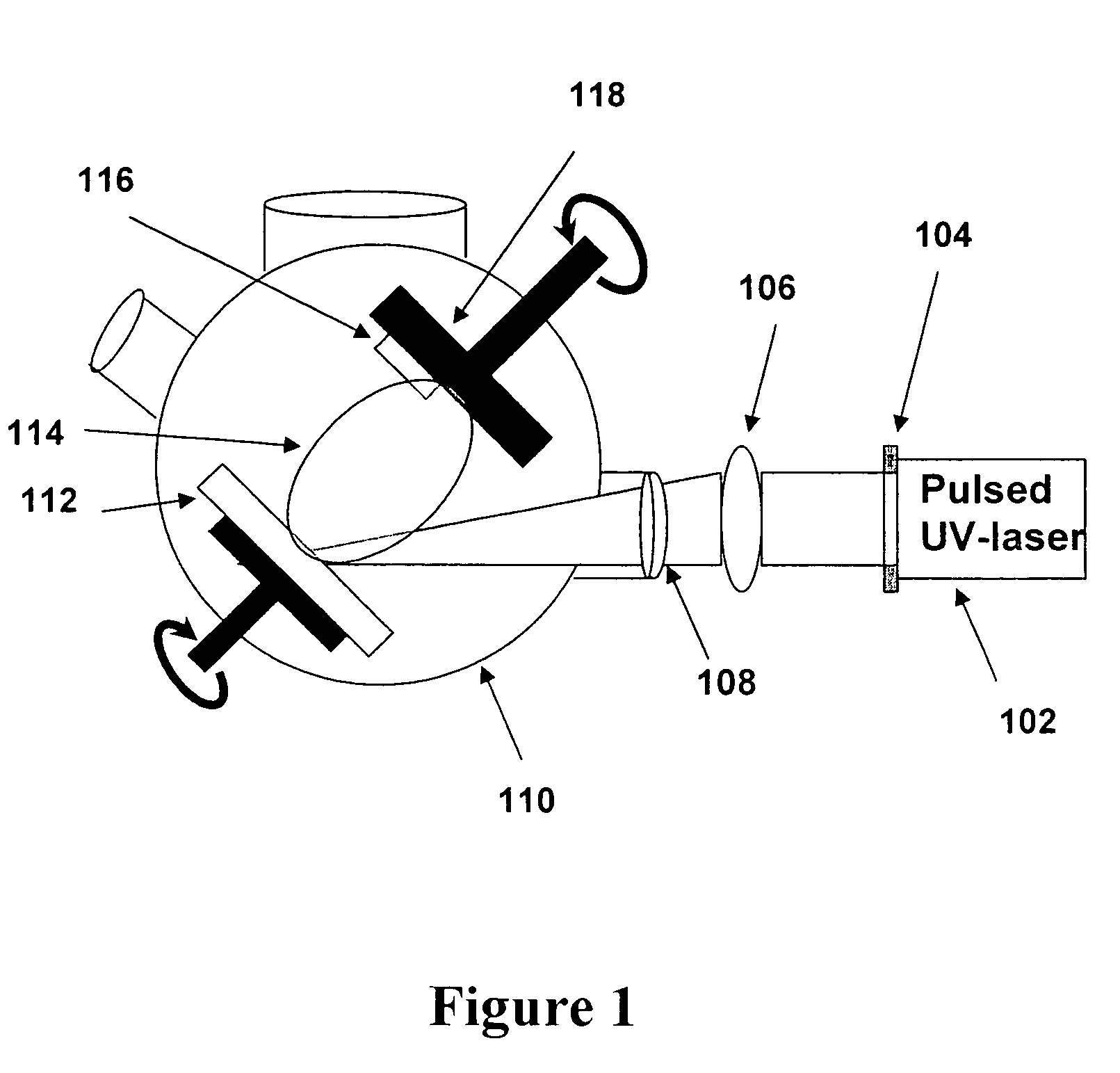

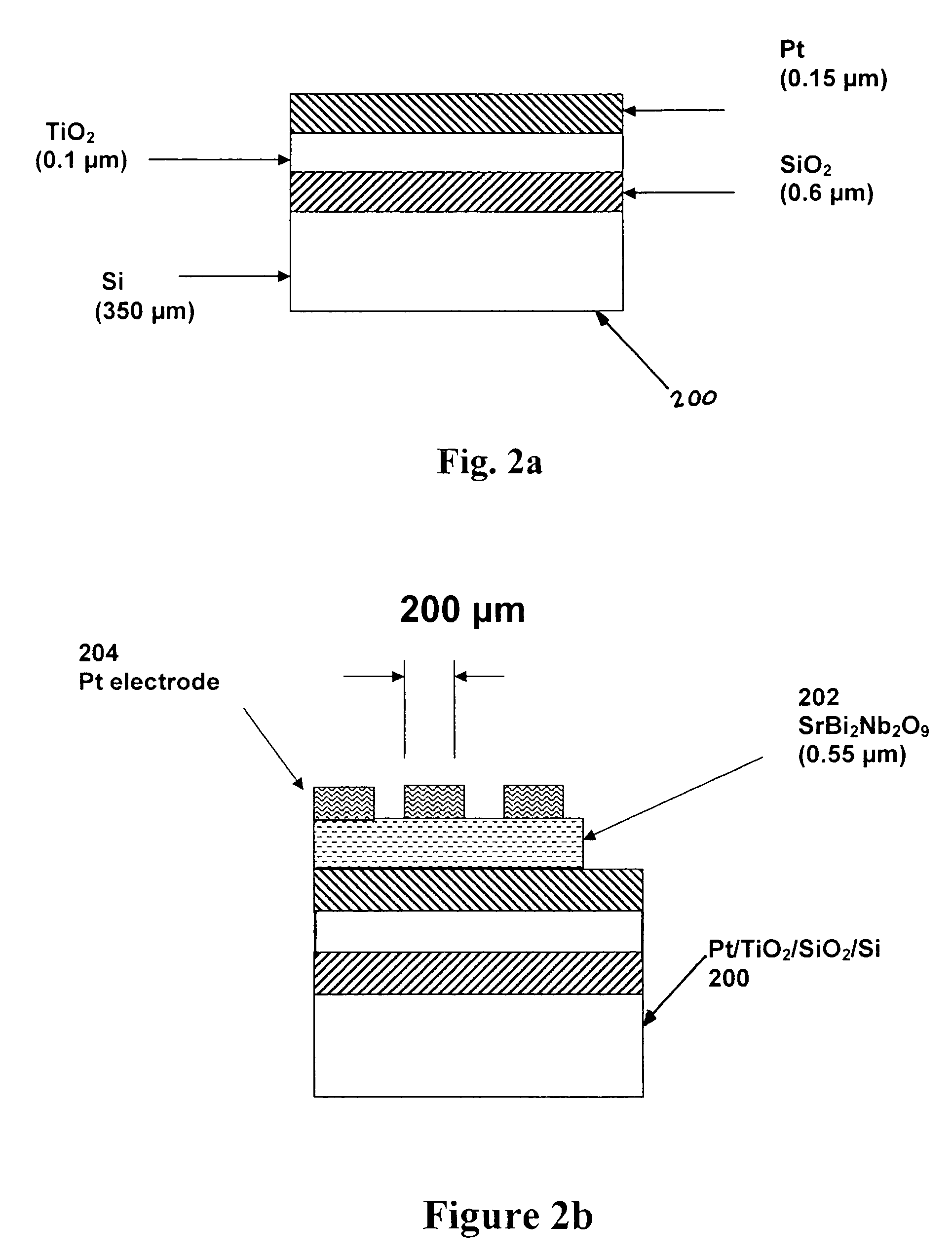

Giant remnant polarization in laser ablated SrBi2Nb2O9 thin films on Pt/TiO2/SiO2/Si substrates

ActiveUS7157144B1High remnant polarizationDielectric heatingElectric discharge heatingSwitching cycleElectric field

SrBi2Nb2O9 (SBN) thin films are deposited on Pt / TiO2 / SiO2 / Si substrates using off-axis pulsed laser deposition technique. Off-axis laser ablation avoids plasma damaging of the surface of SBN thin films and is favorable to grow films along the polarization axis (a–b plane). SBN thin films are grown at 350° C. substrate temperature, with 5 mm away from the plasma focus, and annealed at 750° C. for 1 hour in oxygen ambient. These SBN thin films exhibited giant remnant polarization (Pr) of 50 μC / cm2 with coercive field of 190 kV / cm. The fatigue endurance of these SBN thin films was measured at 400 kV / cm and showed minimal (<20%) polarization degradation of up to 1010 switching cycles. The leakage current density of SBN thin films was found to be about 2×107 up to an applied field of 100 kV / cm. The above-mentioned properties of off-axis deposited SBN thin films, makes it a good material for NVRAM devices.

Owner:PUERTO RICO UNIV OF

Preparation method of bismuth ferrite-based composite material with high ferromagnetic and ferroelectric properties

A preparation method of a bismuth ferrite-based composite material with high ferromagnetic and ferroelectric properties comprises the following steps: dissolving Bi(NO3)3.5H2O, Y(NO3)3.5H2O, and Fe(NO3)3.9H2O in glycol to obtain BiY2Fe5O12 sol; ball-milling La2O3, Bi2O3 and Fe2O3, oven-drying, sieving, briquetting, grinding the block-shaped sample, and sieving to obtain La0.1Bi0.9FeO3 powder; uniformly blending BiY2Fe5O12 sol with La0.1Bi0.9FeO3 powder to obtain a slurry, and processing the slurry by temperature preservation thermal treatment to obtain mixed powder; adding PVA adhesive into the mixed powder to obtain mixed powder of the composite material; compressing the mixed powder, heating to remove the PVA adhesive, and sintering to obtain the bismuth ferrite-based composite material. The magnetization intensity of the bismuth ferrite-based composite material is improved from 0.007emu / g to 4.5emu / g. The bismuth ferrite-based composite material can significantly improve the shape of electric hysteresis loop of bismuth ferrite ceramic, and improve remanent polarization from 0.6 muC / cm<2> to 1.2 muC / cm<2>.

Owner:SHAANXI UNIV OF SCI & TECH

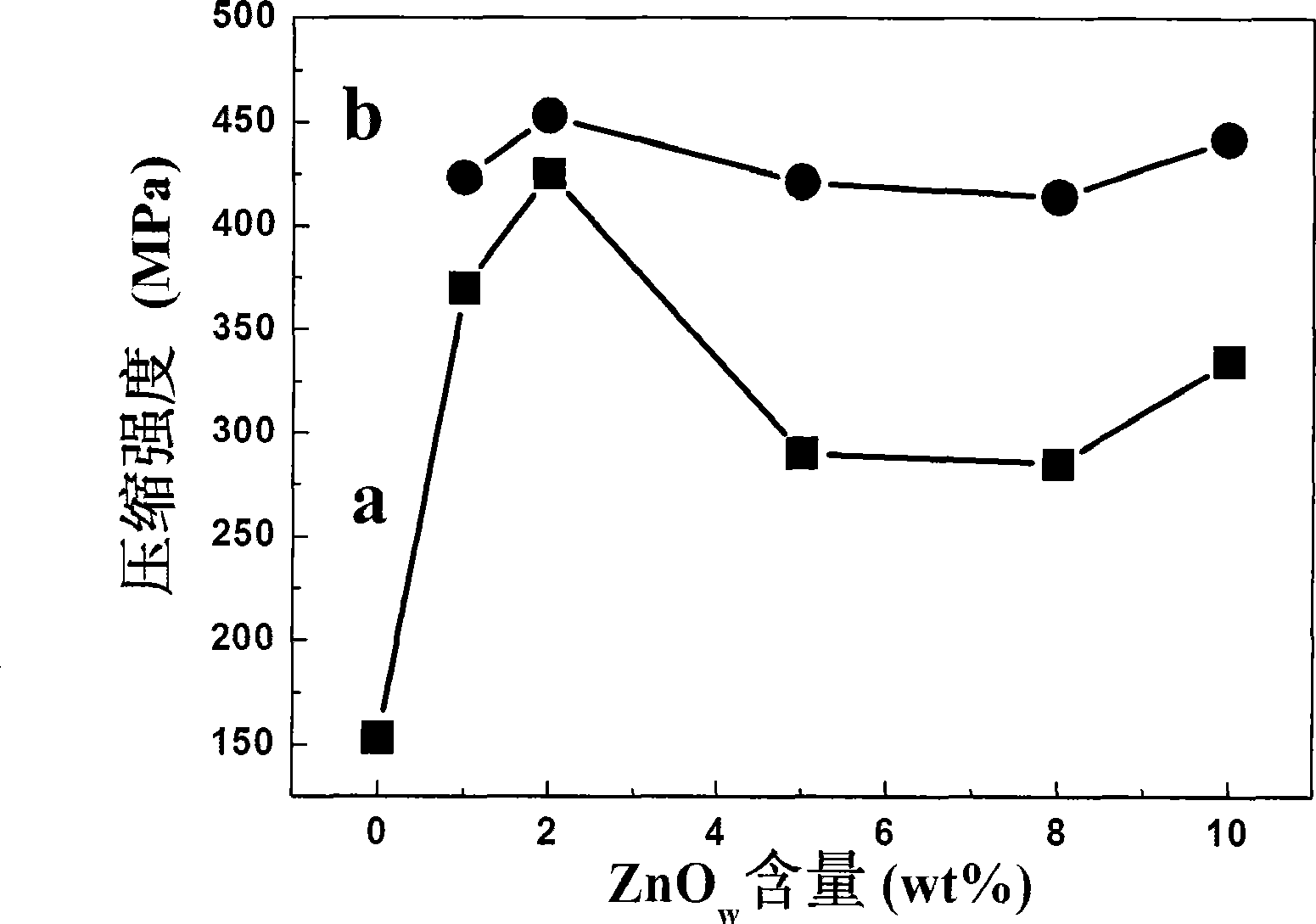

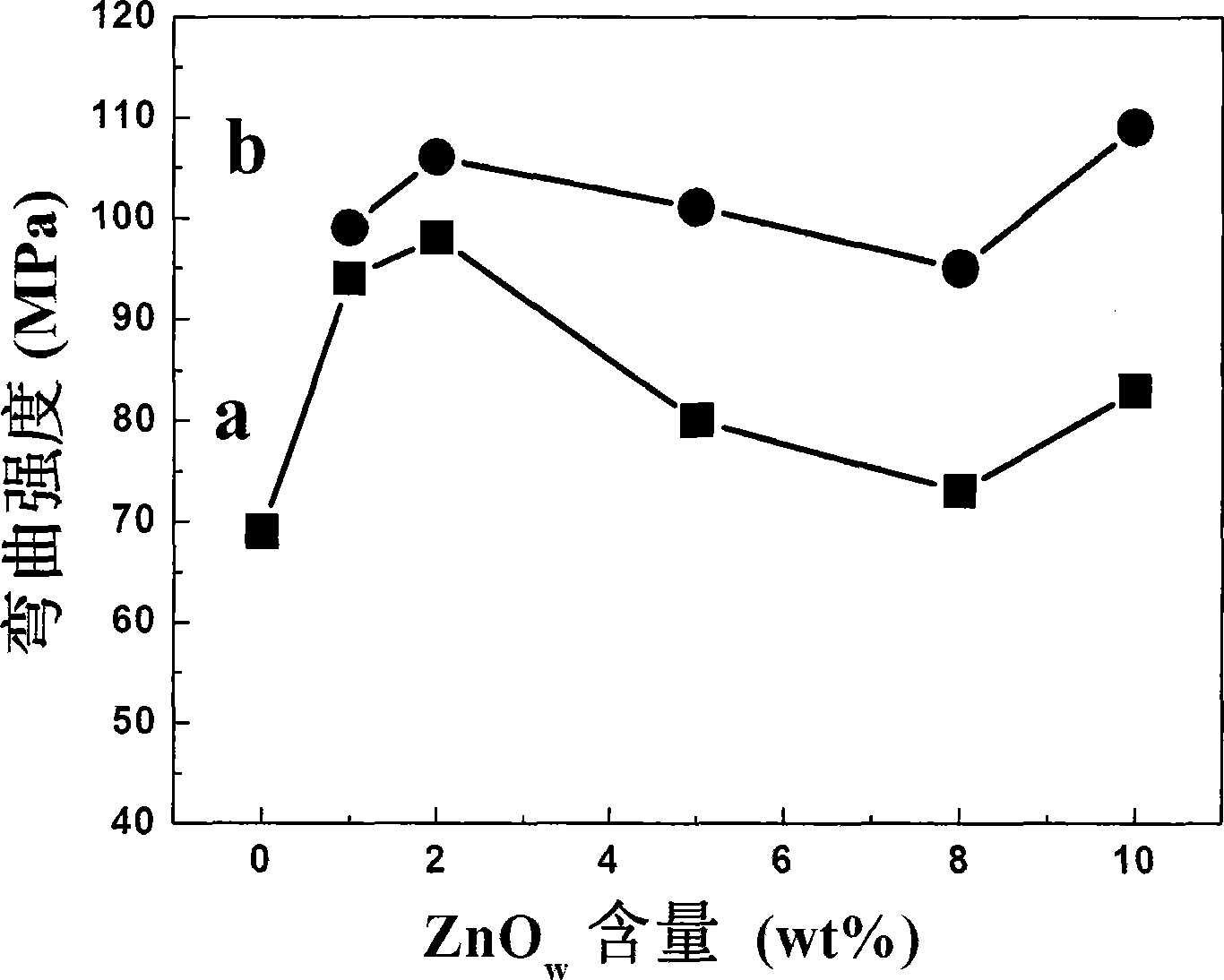

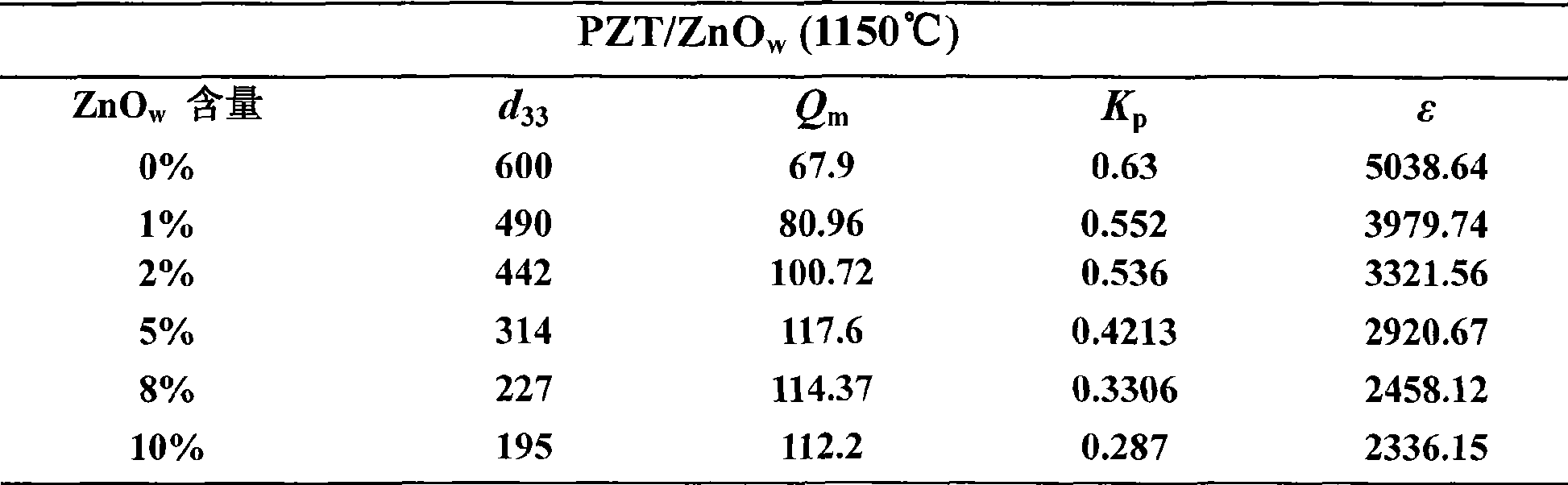

Sb2O3 doped ZnOw/PZT two-phase piezoelectric composite ceramic and preparation thereof

InactiveCN101475375ALower sintering temperatureImprove intrinsic brittlenessPiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateComposite ceramic

The invention relates to Sb2O3-doped ZnOw / PZT biphase piezoelectric composite ceramics and a preparation method thereof, and belongs to the field of inorganic non-metallic material science. The Sb2O3-doped ZnOw / PZT biphase piezoelectric composite ceramics comprise the following raw materials: Sb2O3 powder, nano ZnO crystal whiskers and plumbum zirconate titanate (PZT) ceramic powder. The preparation method comprises: uniformly mixing the ZnO crystal whiskers, the PZT powder and the Sb2O3 powder first, adding a polyvinyl alcohol solution in a system for ball milling and stirring, performing drying, crushing, fine grinding, sieving, and dry pressing and forming, preparing the composite ceramics through binder removal and sintering, and performing cutting processing and polarization aging. Compared with the prior ZnOw / PZT piezoelectric ceramics, the Sb2O3-doped ZnOw / PZT biphase piezoelectric composite ceramics greatly improve the prior piezoelectricity and strengthen the mechanical property, are novel biphase piezoelectric composite ceramics with wide application prospect, have simple preparation operation technique and low cost, and can meet the requirements of industrial promotion and application.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

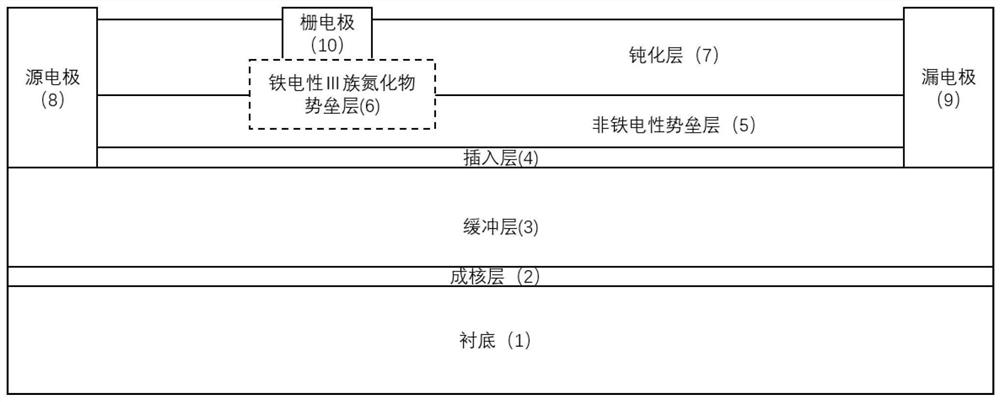

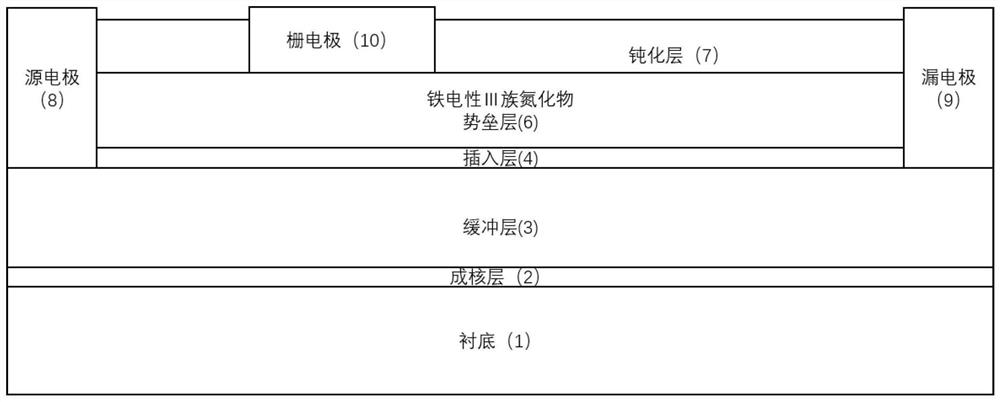

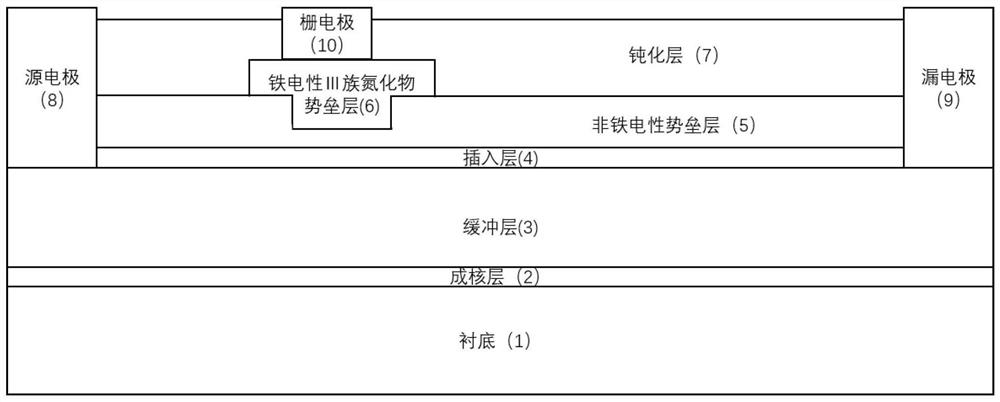

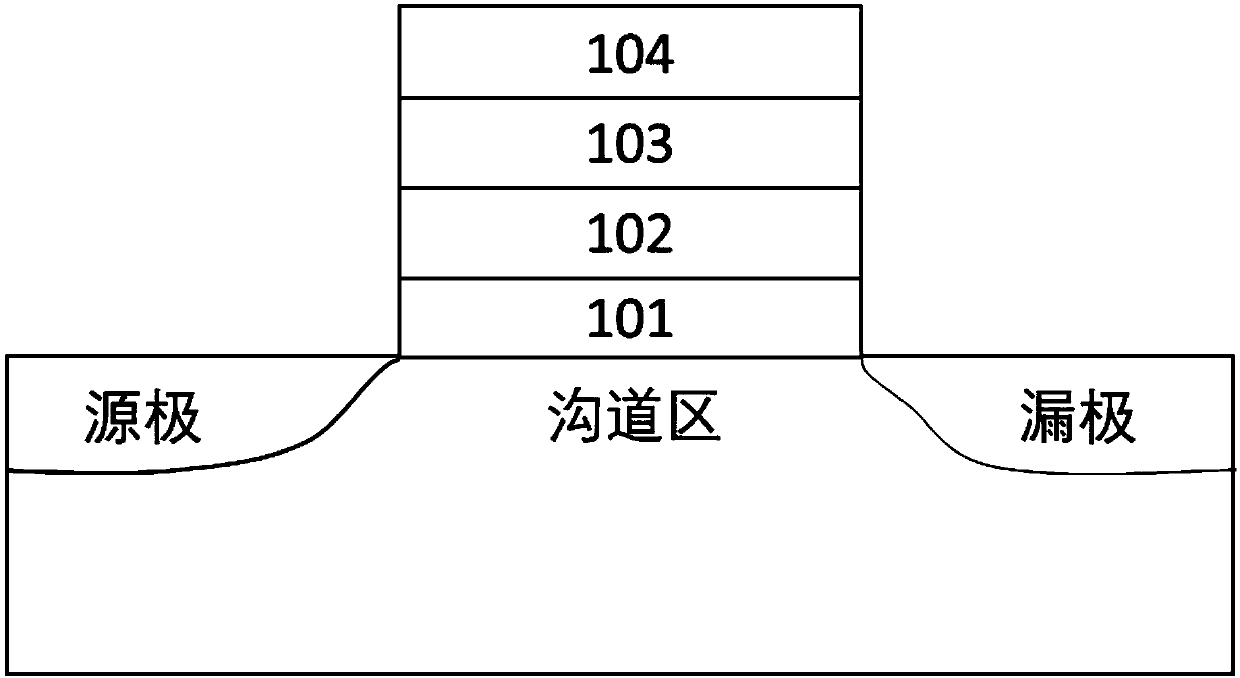

Enhanced high-electron-mobility transistor based on ferroelectric group III nitride polarization reversion

PendingCN113745332AGrowth process compatibleSmall lattice mismatchSemiconductor devicesPhysicsThin membrane

;An enhanced high-electron-mobility transistor based on ferroelectric III nitride polarization reversion comprises a substrate, a nucleating layer, a buffer layer, an insertion layer, a barrier layer and a passivation layer in sequence from bottom to top and the barrier layer comprises a non-ferroelectric barrier layer and a ferroelectric group III nitride barrier layer, and the ferroelectric group III nitride barrier layer is arranged between the non-ferroelectric barrier layer and the passivation layer. The buffer layer and the barrier layer form heterojunctions with different forbidden band widths, and the forbidden band width of the buffer layer is smaller than the forbidden band width of the barrier layer; two ends of the upper surface of the buffer layer are provided with a source electrode and a drain electrode; and a gate electrode is arranged on the ferroelectric III nitride barrier layer, and the gate electrode is nested in the passivation layer. The buffer layer and the barrier layer are made of III-V group semiconductor materials, the preparation processes of the buffer layer and the barrier layer are compatible, the film growth quality of each layer is high, and the interface characteristic between the films is good; and meanwhile, the ferroelectric hysteresis loop rectangularity of the group III nitride ferroelectric material is high, the remanent polarization intensity is high, the retention time of the closed and on states of the device is long, and the service reliability is higher.

Owner:DALIAN UNIV OF TECH

A kind of manufacturing method of flexible packaging lithium-ion battery negative plate

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a method for producing flexible package lithium ion battery negative plates, wherein the method comprises the steps that: adding a carbon material, a polyvinylidene fluoride adhesive agent and a conductive agent into the solvent, mixing uniformly, and coating cathode slurry on the negative current collector so as to form anode diaphragms; placing the negative plates to be baked in a vacuum oven to bake, wherein the temperature of the oven is higher than the final melting temperature of polyvinylidene fluoride, so as to melt polyvinylidene fluoride adhesive agent completely into liquid; and cooling the negative plates to be cooled so as to complete the production of the negative plates. Compared with the prior art, the method causes crystle transformation of polyvinylidene fluoride, so that a monoclinal TGTG' molecular chain configuration is transferred into an orthogonal TTTT molecular chain configuration with high remanent polarization and higher bonding strength; and the bonding performance is improved, and thus enhancing the cycle performance of batteries, reducing the cyclic swelling of batteries, and improving the rate capability of batteries simultaneously.

Owner:DONGGUAN AMPEREX TECH

Preparation method of low-temperature-sintered PZT95-5 piezoelectric ceramics

The invention relates to a ferroelectric ceramic material with high dielectric withstanding voltage, high remanent polarization, low loss and low sintering temperature, a preparation method of the ferroelectric ceramic material and a piezoelectric element prepared from the ferroelectric ceramic material. The ferroelectric ceramic material contains components as follows: Pb(1-x)Cdx(Zr0.965Ti0.035)O3(x=0-0.03)+1wt%Nb2O5+bwt%Li2CO3(PCZT95 / 5). The compact PCZT95 / 5 ferroelectric ceramic material with high dielectric withstanding voltage, high remanent polarization and low loss is prepared through addition of CdO and Li2CO3 and adjustment of proper Zr / Ti ratio under the condition of reducing the sintering temperature from 1350 DEG C to 1050 DEG C, the ferroelectric ceramic material is applicable to a multilayered PCZT95 / 5 thick-film device, the problem that mechanical strength and electric breakdown resistance of a monolithic PZT95 / 5 are not high after bonding currently is solved, and meanwhile, the ferroelectric ceramic material is greatly helpful for reliability and miniaturization of the device and has great application prospect in the aspects of industrial and national defense fields of explosive ferroelectric power supplies.

Owner:YANTAI BRANCH NO 52 INST OF CHINA NORTH IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

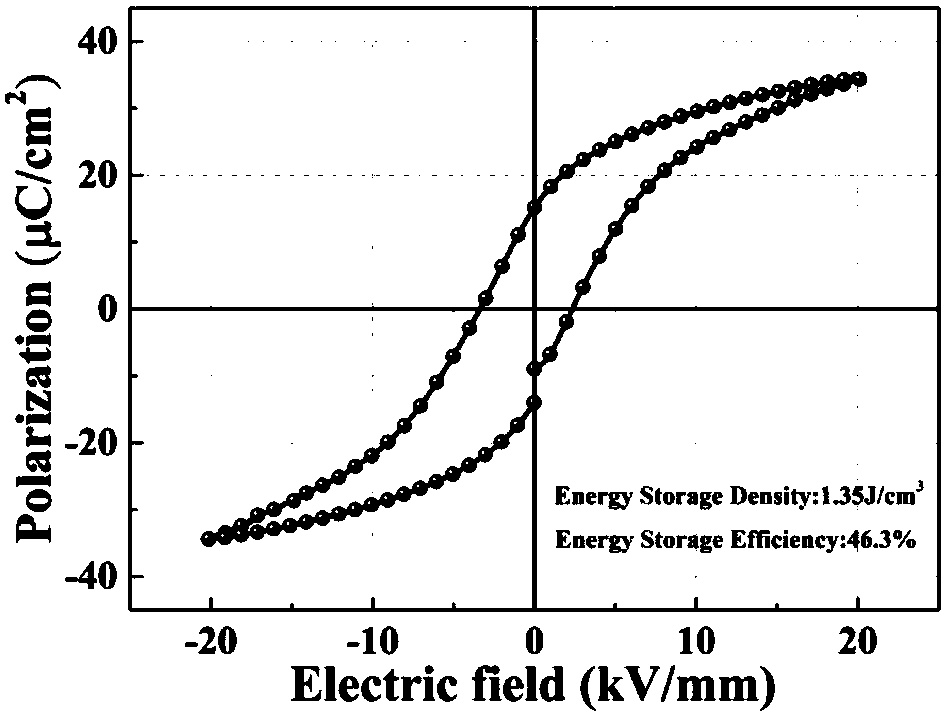

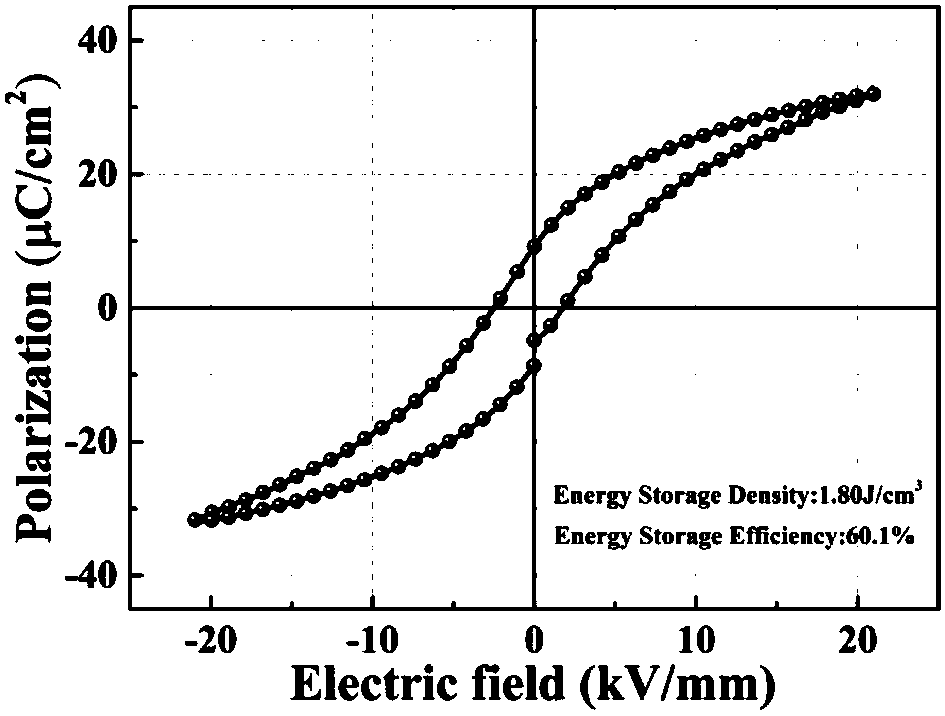

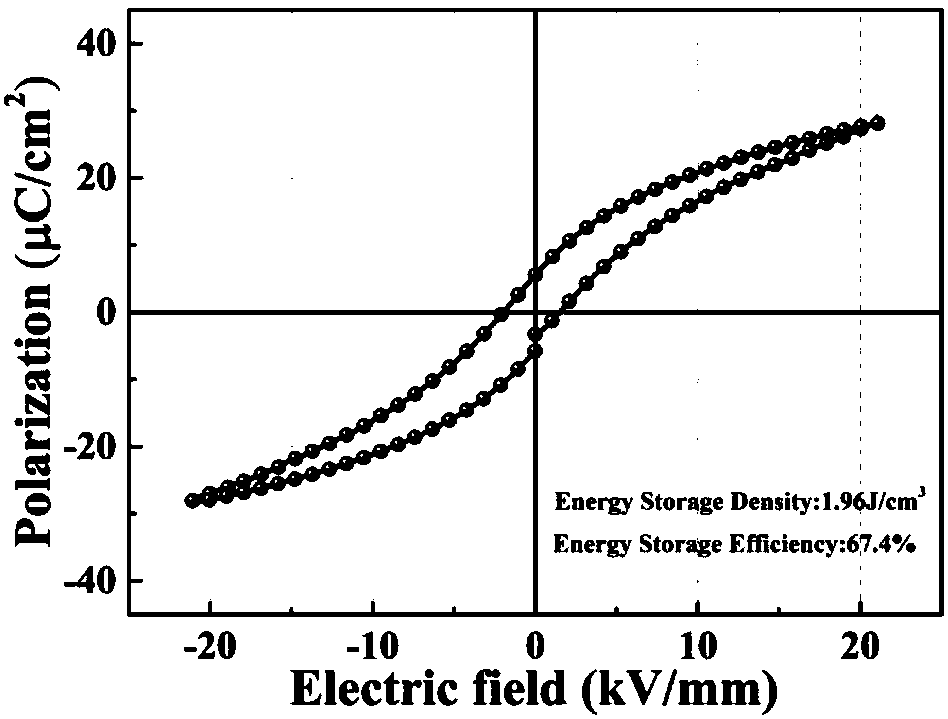

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000011.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000012.PNG)

![Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof Bi[0.85-x]Pr0.15AExFe0.97Mn0.03O3 ferroelectric film and preparation method thereof](https://images-eureka.patsnap.com/patent_img/d33c2ba5-ceec-44cc-a709-6bfddffa1e71/HDA0000631192430000021.PNG)