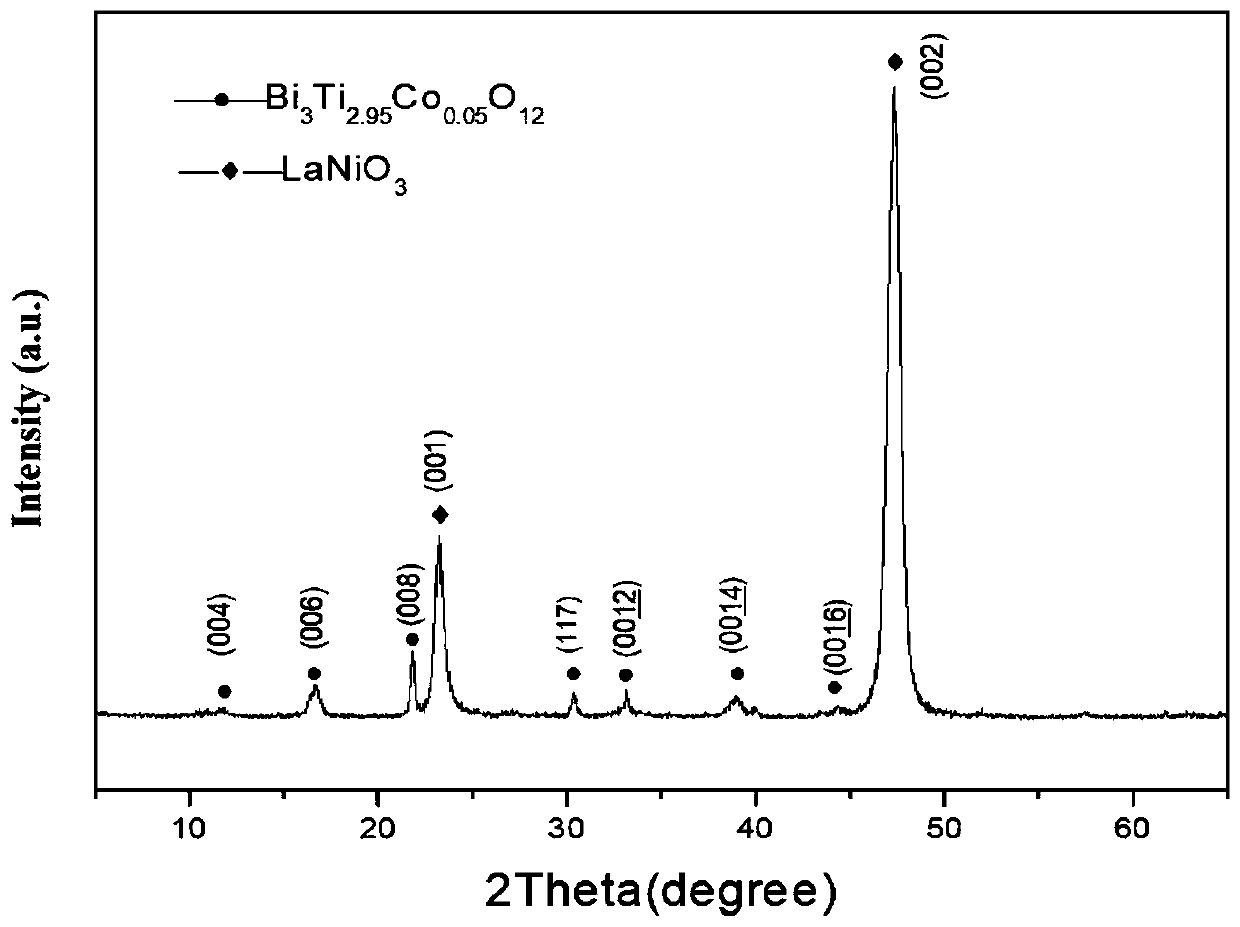

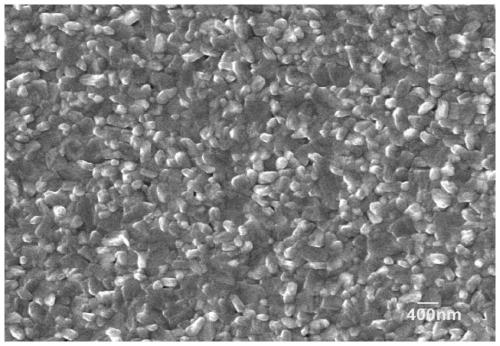

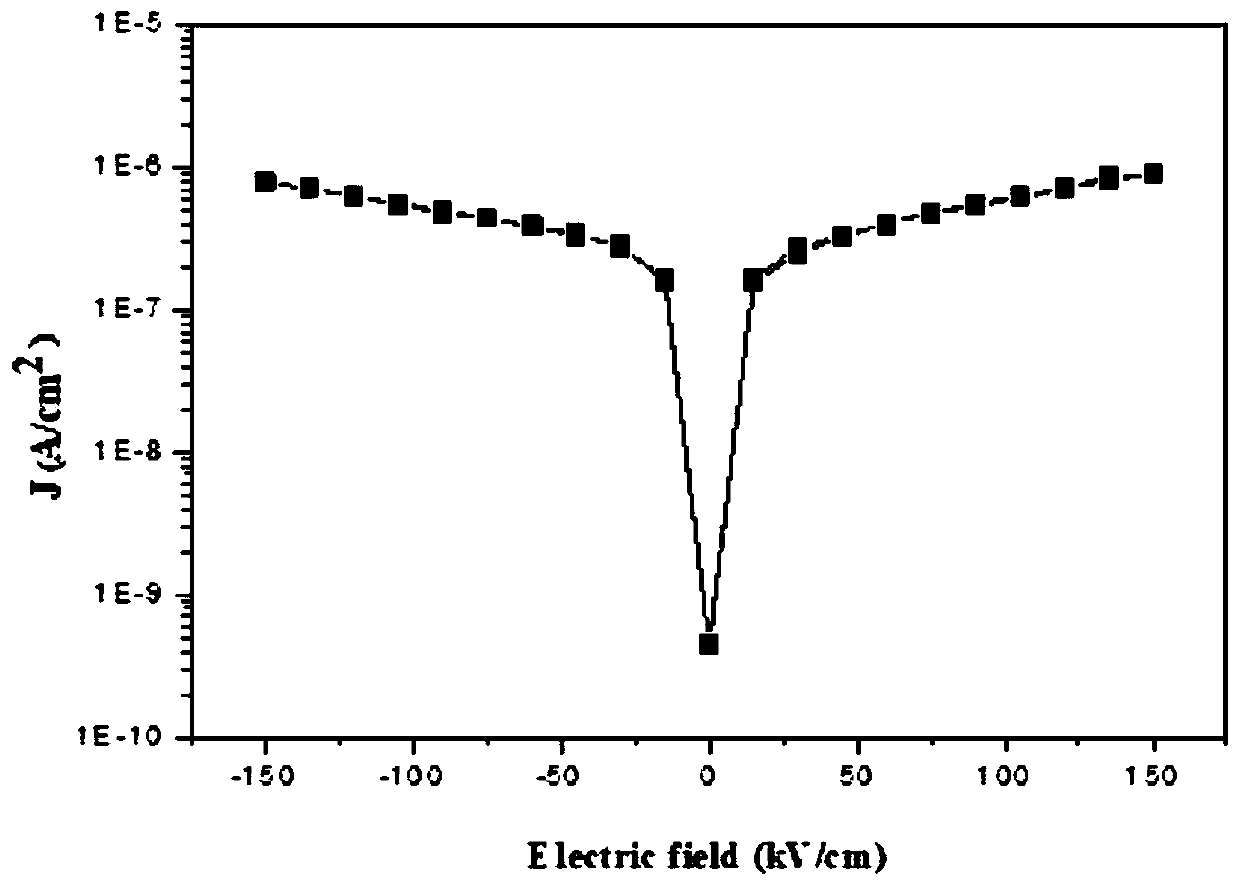

Bi4Ti2.95Co0.05O12 multiferroic film capable of realizing c-axis oriented growth on Si as substrate and preparation method of Bi4Ti2.95Co0.05O12 multiferroic film

A bi4ti2.95co0.05o12, oriented growth technology, applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc., can solve the problems of unsatisfactory film properties, large differences in lattice matching and thermal expansion coefficients, etc. Low cost of raw materials, high remanent polarization, and stable sol properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Growth of Bi in c-axis orientation on Si substrate 4 Ti 2.95 co 0.05 o 12 Multiferroic film, by weight percentage, includes the following components: Bi(NO 3 ) 2 ·5H 2 O7.63%, Co(NO 3 ) 2 ·6H 2 O0.1%, butyl titanate 3.5%, ethylene glycol methyl ether 80.4%, acetylacetone 8.37%.

Embodiment 2

[0046] Growth of Bi in c-axis orientation on Si substrate 4 Ti 2.95 co 0.05 o 12 Multiferroic film, by weight percentage, includes the following components: Bi(NO 3 ) 2 ·5H 2 O19.22%, Co(NO 3 ) 2 ·6H 2 O0.26%, butyl titanate 8.88%, ethylene glycol methyl ether 50.64%, acetylacetone 21%.

Embodiment 3

[0048] Growth of Bi in c-axis orientation on Si substrate 4 Ti 2.95 co 0.05 o 12 Multiferroic film, by weight percentage, includes the following components: Bi(NO 3 ) 2 ·5H 2 O12.93%, Co(NO 3 ) 2 ·6H 2 O0.18%, butyl titanate 5.69%, ethylene glycol methyl ether 66.55%, acetylacetone 14.65%.

[0049] The present invention prepares Bi 4 Ti 2.95 co 0.05 o 12 The multiferroic thin film specifically comprises the following steps:

[0050] Step 1: According to Bi(NO 3 ) 2 ·5H 2 O: ethylene glycol methyl ether = (0.75 ~ 3): molar ratio of 10, weigh a certain amount of Bi (NO 3 ) 2 ·5H 2 Add O and ethylene glycol methyl ether into the beaker, stir at room temperature for 10-30 minutes until completely dissolved, and form solution A;

[0051] According to Co(NO 3 ) 2 ·6H 2 O: ethylene glycol methyl ether = (9.125 × 10 -3 ~0.0365):10 molar ratio, weigh a certain amount of Co(NO 3 ) 2 ·6H 2 Add O and ethylene glycol methyl ether into the beaker, stir at room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com